Method of preparing crisp strawberry snacks using soaking pretreatment and vacuum microwave combined freeze drying

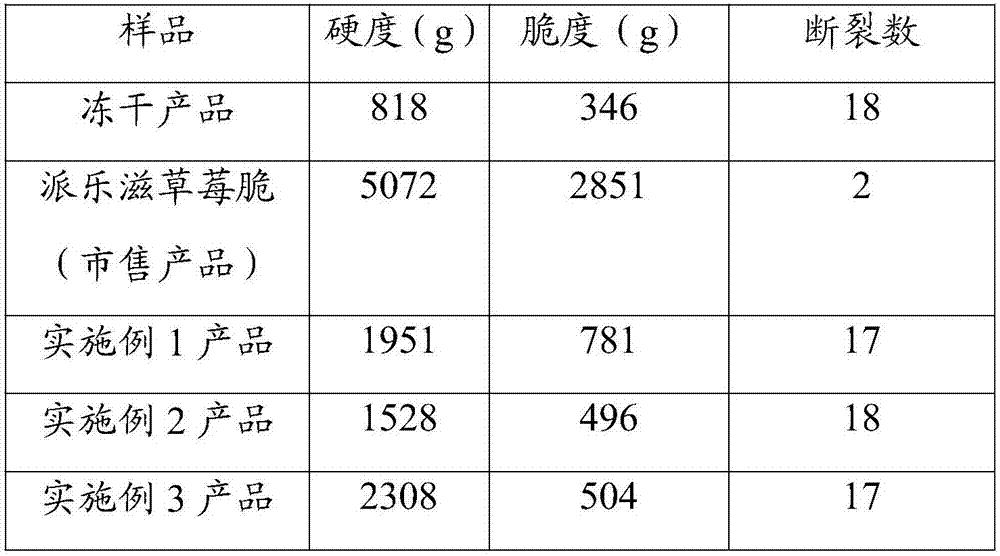

A technology of vacuum freeze-drying and vacuum microwave, which is applied in food drying, food freezing, food ultrasonic treatment, etc. It can solve the problems of not having general applicability, eating instant leisure products, and soft taste, so as to retain the nutritional content of the product and shorten the Effect of drying time, improving product hardness and brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of Strawberry Leisure Crisp by Dipping Pretreatment and Vacuum Microwave Combined Freeze-drying

[0035]1. Raw material screening, grading and cleaning: Fresh Zhangji strawberries (early and mid-harvest) picked in Tangshan Strawberry Garden, Jiangning District, Nanjing City, Jiangsu Province, are manually graded and screened according to the size of the fruit, and the larger fruit is selected for processing. Remove the stalks, rinse with salt water and drain;

[0036] 2. Ultrasonic vacuum impregnation: After cleaning and draining, the strawberries are impregnated in ultrasonic vacuum for 15 minutes in a mixed impregnation solution with a concentration of 8% white sugar, 6% maltodextrin and 6% calcium chloride, where the ultrasonic frequency is 80kHZ and the ultrasonic power It is 350W, and the sugar content of strawberries after dipping is 12Brix;

[0037] 3. Vacuum microwave pre-drying: After dipping and pre-treatment, strawberries are subjected ...

Embodiment 2

[0040] Example 2 Preparation of Strawberry Leisure Crisp by Dipping Pretreatment and Vacuum Microwave Combined Freeze-drying

[0041] 1. Raw material screening, grading and cleaning: Fresh Zhangji strawberries (late harvest) picked in Tangshan Strawberry Garden, Jiangning District, Nanjing City, Jiangsu Province, are manually graded and screened according to the size of the fruit, and the larger fruit is selected for processing, and the stems are removed , washed with salt water and drained;

[0042] 2. Ultrasonic vacuum impregnation: After washing and draining, the strawberries are impregnated in ultrasonic vacuum for 25 minutes in a mixed impregnation solution with a concentration of 6% white sugar, 8% maltodextrin and 10% calcium chloride, where the ultrasonic frequency is 60kHZ and the ultrasonic power It is 350W, and the sugar content of strawberries after dipping is 15Brix;

[0043] 3. Vacuum microwave pre-drying: after dipping and pre-treatment, strawberries are subjec...

Embodiment 3

[0046] Example 3 Preparation of Strawberry Leisure Crisp by Dipping Pretreatment and Vacuum Microwave Combined Freeze-drying

[0047] 1. Raw material screening, grading and cleaning: Fresh Zhangji strawberries picked in Tangshan Strawberry Garden, Jiangning District, Nanjing City, Jiangsu Province are manually graded and screened according to the size of the fruit, and non-commercial fruits with smaller fruit sizes are selected for processing. Drain after washing;

[0048] 2. Ultrasonic vacuum impregnation: After washing and draining, the strawberries are impregnated in ultrasonic vacuum for 30 minutes in a mixed impregnation solution with a concentration of 12% white sugar, 6% maltodextrin and 10% calcium chloride, where the ultrasonic frequency is 45kHZ and the ultrasonic power It is 350W, and the sugar content of strawberries after dipping is 13Brix;

[0049] 3. Vacuum microwave pre-drying: after dipping and pre-treatment, strawberries are subjected to high-power instantan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com