Patents

Literature

962results about How to "Improve crispness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick preparation method for pickled vegetable containing biodiasmin

InactiveCN103120294AImprove production efficiencyIncrease productivityFood preparationVegetable processingSalt content

The invention provides a quick preparation method for a pickled vegetable containing biodiasmin. The quick preparation method comprises the following steps of: preparing biodiasmin liquor, preparing pickled vegetable fermentation liquor, preparing a seasoning fermentation liquor, pre-treating and preparing a finished pickled vegetable containing biodiasmin. According to the quick preparation method disclosed by the invention, the pickled vegetable fermentation liquor is independently prepared according to the conventional pickled vegetable production way, and the pickled vegetable fermentation liquor is treated by seasoning to form seasoning fermentation liquor; osmotic dehydration and the brittleness-keeping treatment are carried out on the fresh vegetable to obtain a semi-finished product; and the semi-finished product is pickled by the seasoning fermentation liquor, and the seasoning fermentation liquor is quickened up to permeate into the vegetable through the vacuum treatment to obtain the delicious finished pickled vegetable. The pickled vegetable is prepared by the preparation method disclosed by the invention is low in salt content, short in production time, high in calcium content and biodiasmin content and beneficial to the body health of a user; and moreover, the automation degree of the pickled vegetable processing is improved.

Owner:HEFEI UNIV

Method for producing instant pleurotus eryngii chips

The invention relates to a method for producing instant pleurotus eryngii chips, and belongs to the technical field of the deep processing of agricultural products. The main pleurotus eryngii chip production process comprises: performing pretreatment such as conventional selection, washing, precise segmenting, blanching, enzyme killing, cooling and the like on pleurotus eryngii, and performing ultrasonic auxiliary dipping, hot-air drying, vacuum frying and dewatering, centrifugal deoiling, seasoning and packaging. In the method, due to the adoption of a new process of combining the ultrasonic auxiliary dipping, the hot-air drying, the vacuum frying and dewatering, the dipping efficiency is improved, the moisture content of pleurotus eryngii pieces is reduced due to hot-air predrying, and the vacuum frying time is shortened greatly; and products of the pleurotus eryngii chips have the characteristics of high puffing rate, low oil content, excellent sensory quality and the like. In the method, the pleurotus eryngii is not processed by conventional freezing, so the production period of the finished products is shortened greatly, the production cost is saved, and a feasible new path is provided for the deep processing of the pleurotus eryngii.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

Process for preparing glass fiber composite type silicon dioxide aerogel insulation quilt

The invention discloses a process for preparing a glass fiber composite type silicon dioxide aerogel insulation quilt. The process mainly comprises the following steps: absorbing a silicon dioxide aerogel liquid till being saturated by using a glass fiber quilt, gelling under specific conditions, and drying supercutical fluid CO2 to form a reinforced aerogel material. The glass fiber composite type silicon dioxide aerogel insulation quilt prepared by using the process is excellent in heat preservation property, mechanical property and fireproof and waterproof property, and is convenient to construct. By adopting the process, a solvent replacement step is avoided, the operation is simple and easy, the operation process is controllable, and continuous production can be achieved.

Owner:GUIZHOU AEROSPACE WUJIANG MACHINERY & ELECTRICITYEQUIP

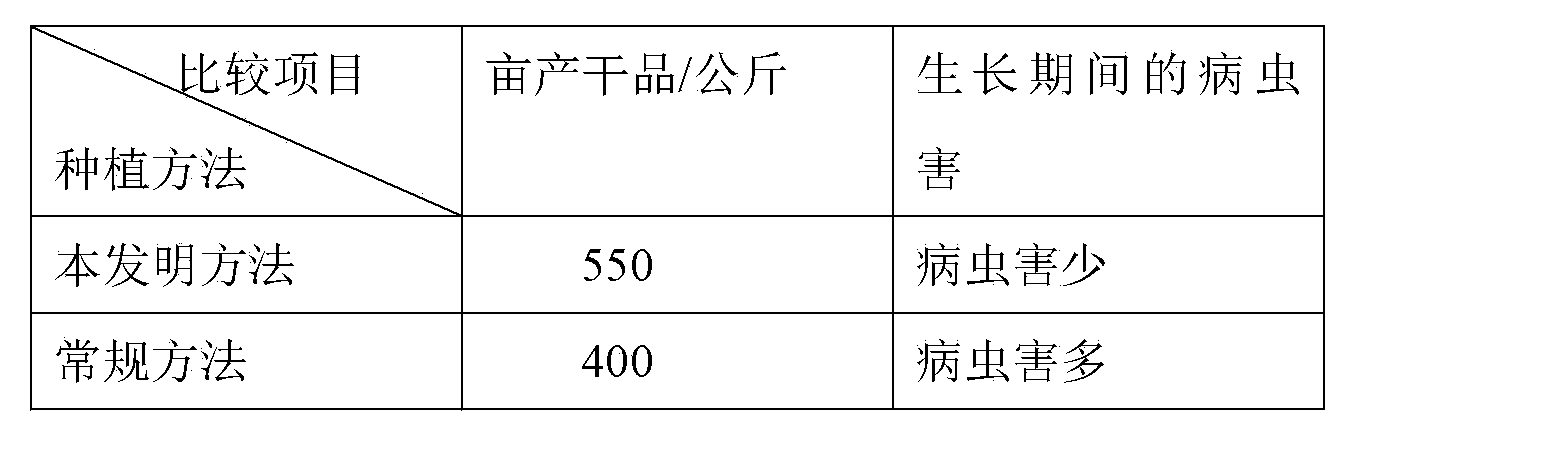

Method for planting Chinese angelica

InactiveCN103430723AImprove compactionImprove crispnessSoil lifting machinesHorticultureHydrogenSoil conditioner

The invention discloses a method for planting Chinese angelica. The method comprises the steps of seedbed finishing, seeding, land preparation of a large field, transplantation, field management, disease and pest prevention and harvesting and processing. A seeding matrix is paved on a seedbed field, and a soil conditioner is added into the soil of a transplantation field, so that the potential of hydrogen of the soil is improved, and the fertilizer quantity is increased. The Chinese angelica planted by using the method is high in mu yield, high in quality and small in disease and pest damage.

Owner:王运海

Manufacturing method for spiced beef

The invention discloses a manufacturing method for spiced beef. The manufacturing method is characterized by comprising the following steps of: cleaning and slicing, sliced beef is frozen in a freezer at a temperature of 15 DEG C below zero-18 DEG C below zero for 20-24 hours, pickling, light-stewing, primarily stewing in soy sauce, secondarily stewing in soy sauce, deep frying, slicing, mixing with stuff, packing, vacuum sealing and sterilizing. The beef mixed with stuff oil is packed and sealed on a vacuum sealing machine, after being placed in a sterilizing device for sterilization at a temperature of 121 DEG C for 20 minutes, the spiced beef is cooled into a normal temperature and then is encased.

Owner:NANCHONG GUOJIANGLONG FOOD

Multi-component dough

InactiveUS20050025862A1Not and lose palatabilityImprove crispnessConfectionerySweetmeatsMechanical engineeringEngineering

Owner:SCHWANS GLOBAL SUPPLY CHAIN

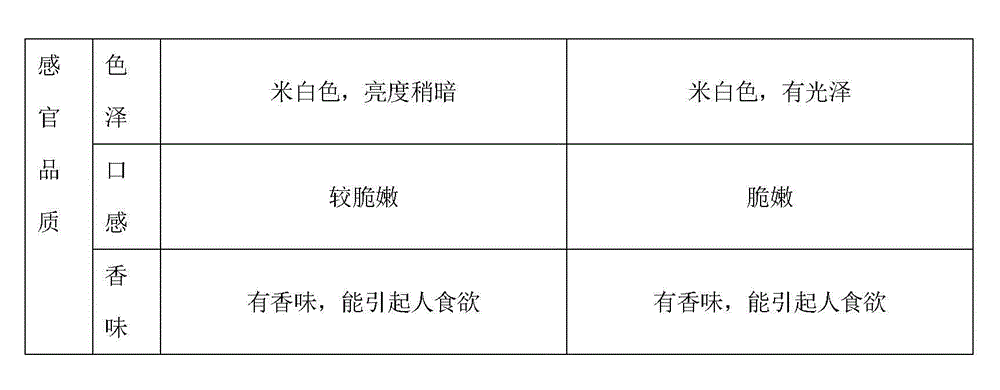

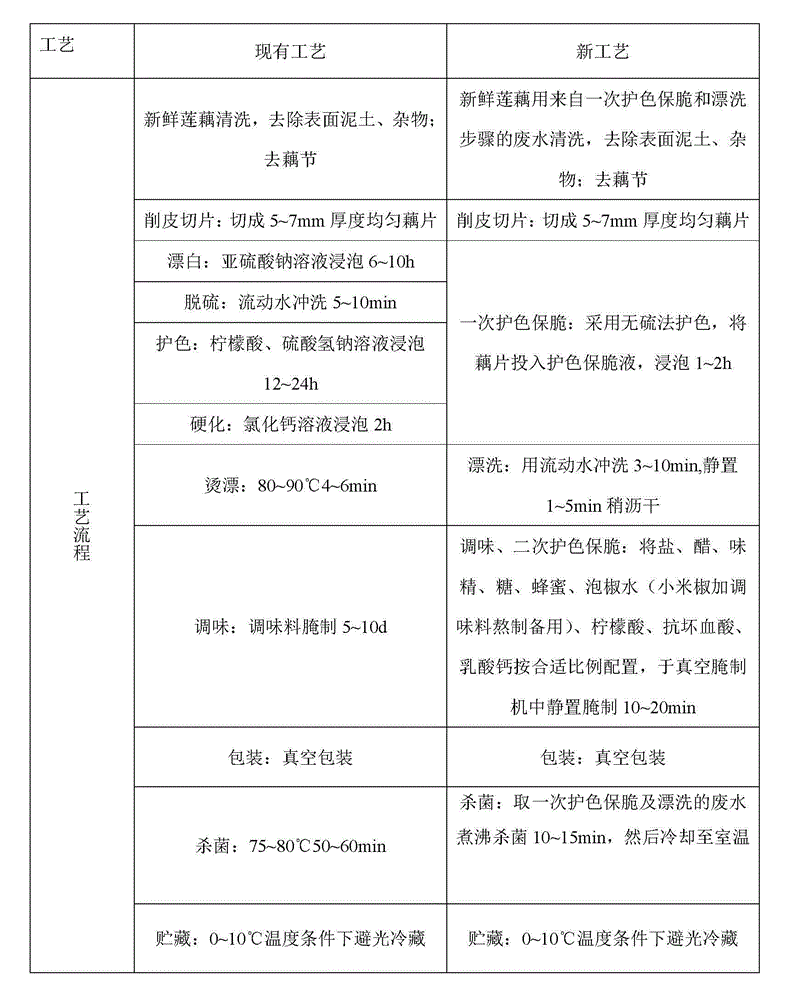

Processing method of instant seasoning lotus root

The invention discloses a processing method of an instant seasoning lotus root, which comprises the steps that a fresh lotus root is cleaned, peeled, sliced, then subjected to primary color protection and crisp keeping, rinsed, seasoned, subjected to secondary color protection and crisp keeping, seasoned, packaged and sterilized at a high temperature, and the instant seasoning lotus root is obtained. The processing method is simple and efficient; the color protection and crisp keeping are conducted simultaneously in the primary color protection and crisp keeping step; the secondary color protection and crisp keeping step is merged into the seasoning step, so that the time is saved and the effect is good. As a vacuum curing method is adopted, the curing time is saved; the appearance of an obtained lotus root sheet is creamy white; and the lotus root sheet has luster and a delicious and crisp taste. Compared with the prior art, the delicious and crisp taste is improved, and the lustrousness is better.

Owner:ZHEJIANG SHANSHUILANG FOOD

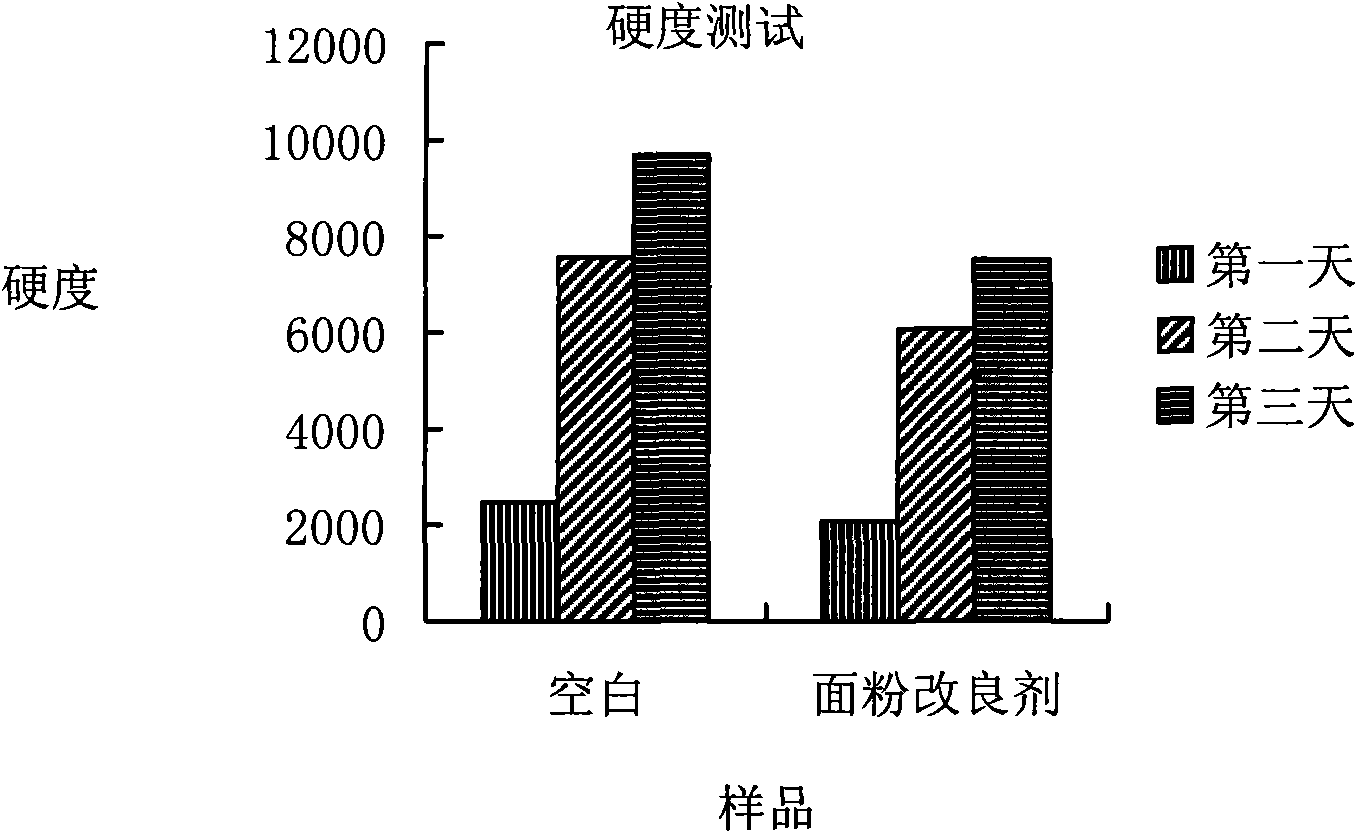

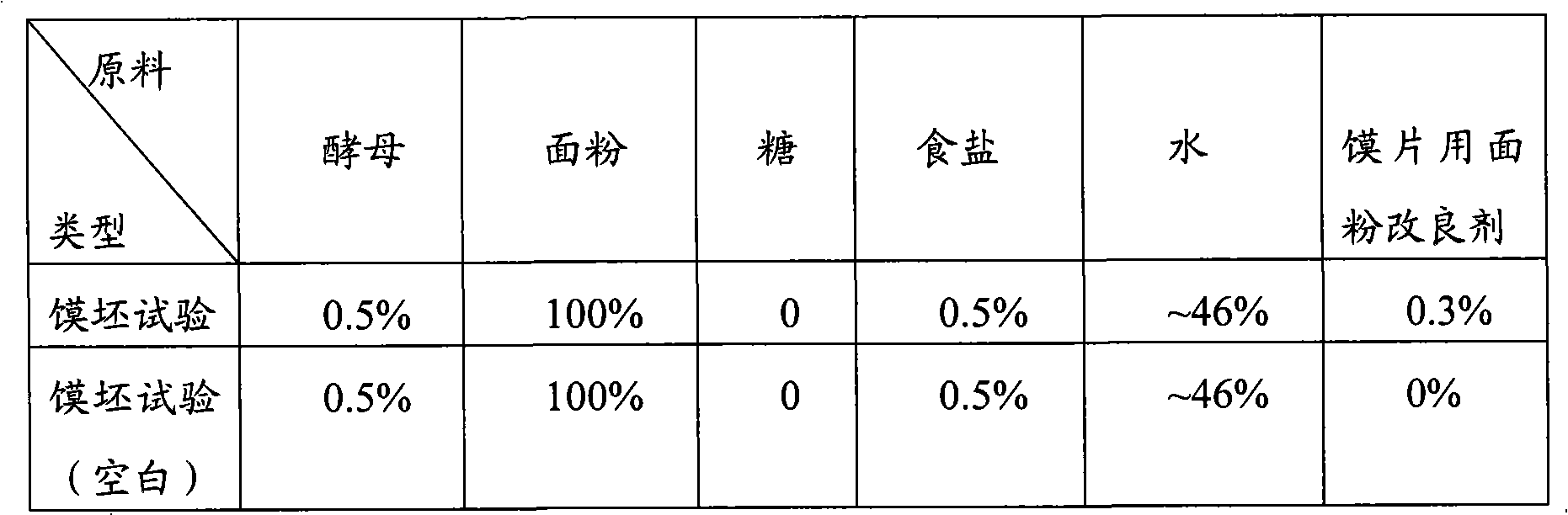

Steamed bread slice making flour modifier and use thereof

InactiveCN101664048AIncrease specific volumeImprove organizational structurePre-baking dough treatmentFood productsSteamed bread

The invention relates to a flour modifier and use thereof, in particular to a steamed bread slice making flour modifier and use thereof. The flour modifier comprises an enzyme preparation, an oxidant,an emulsifier, a swelling agent, a phosphate and starch, can be used for making wheaten food product such as steamed bread and steamed bread slices, improve the structure of steamed bread slices, make the hole in the steamed bread slices more uniform, provide the steamed bread slices with good appearance and improve the crisp degree and yield of the steamed bread slices.

Owner:ANGELYEAST CO LTD

Method for processing allium chinense

InactiveCN102511758AImprove crispnessEasy to solveClimate change adaptationFood preparationSaline waterFood safety

The invention discloses a method for processing allium chinense. The method for processing the allium chinense comprises the following steps of: (1) cleaning; (2) adding salt and pickling for 25 to 45 days to obtain salty allium chinense, wherein the saline concentration is 10 to 20 baume degrees; (3) cutting, removing two heads and maintain the middle part; (4) soaking in saturated saline for 6 to 8 days; (5) desalting until the salinity is reduced to 2 to 3 baume degrees; (6) precooking in hot water at the temperature of 80 DEG C for 1 minute; (7) preparing soup of different flavors; and (8) subpackaging and sterilizing. Compared with the traditional method for pickling the allium chinense, the method for processing the allium chinense has the advantages that harmful substances such as alum, sulfur dioxide and the like are not used, food safety is guaranteed, and crisp mouthfeel and flavor of the pickled allium chinense are maintained.

Owner:JIANGXI QIMENTANG VEGETABLE FOOD

Low-salt pickled fermented Allium chinense and processing method thereof

InactiveCN101926446ARich flavorPreserve the crispnessFood preparationAcetic acidSodium metabisulfite

The invention relates to a low-salt pickled fermented Allium chinense and a processing method thereof. The pickled fermented Allium chinense is prepared by the steps of: taking a fresh Allium chinense; removing fibrous roots and washing; adding table salt, drinking water, glacial acetic acid, citric acid and sodium metabisulfite to carry out primary fermentation for 10 to 12 days; taking the fermented Allium chinense; adding the table salt, the drinking water, the glacial acetic acid and the citric acid to carry out secondary fermentation for 30 to 60 days; proportionally mixing the fermented Allium chinense in the second time with soup; then adding dried red pepper rings; and sterilizing and cooling. The product of the invention has stable quality and low content of sulfur dioxide with preferable preservation of color, brittleness and nutritious elements of the Allium chinense, and has longer shelf life.

Owner:CHANGSHA TANTANXIANG FLAVORING FOOD +1

Subnanometer enhanced and toughened transparent master batch and preparation method thereof

The invention discloses a subnanometer enhanced and toughened transparent master batch and a preparation method thereof. The subnanometer enhanced and toughened transparent master batch comprises the following components in percentage by weight: 70-85 percent of subnanometer powder, 1-5 percent of dispersing agent, 0.3-1 percent of lubricating agent, 1-3 percent of coupling agent, 0.3-0.5 percent of thermal stabilizing agent, 0.1-0.5 percent of antioxidant and 10-25 percent of carrier resin. The preparation method comprises the following steps of: putting the subnanometer powder into a high speed mixer, selecting a high gear for stirring and heating, adding the coupling agent and treating for three minutes, then adding other raw materials, discharging and cooling after the raw materials are evenly stirred and mixed by the high speed mixer, then crushing, and extruding and pelleting through an extruding and pelleting device. The invention solves the problem that the mechanical performance of a plastic film is reduced after the common master batch is used in the prior art, in particular the problem that the light transmittance and the transparency are reduced; the mechanical performance of a film product is improved at the same time of reducing the cost; meanwhile, the invention achieves the purposes of enhancing and toughening and can be used in the fields of foods and medicines.

Owner:宁波益可达新材料有限公司

Process for preparing fragrant and crisp bamboo shoots

InactiveCN102008056AFragrant tasteImprove crispnessClimate change adaptationFood preparationFiberMonosodium glutamate

The invention belongs to the field of food processing, and relates to a process for preparing fragrant and crisp bamboo shoots. The preparation process comprises the following steps of: removing bamboo shells; boiling for removing green; squeezing and fermenting: performing natural fermentation for over 1 month in a squeezing state till the discharge of white pulp is stopped; taking out and airing or drying; slicing: slicing along the fiber direction; cleaning and soaking; digesting for the second time; cleaning and drying; and sterilizing in vacuum and packing. Specifically, the preparation process for the fragrant and crisp bamboo shoots comprises the following steps of: heating 8 to 12 parts of chili oil to 150 DEG C, putting 0.1 to 0.3 part of capsanthin into the chili oil, pouring 0.2 to 0.4 part of ginger, 0.2 to 0.4 part of garlic, 0.05 to 0.12 part of white pepper powder and 0.05 to 0.15 part of fennel into the chili oil and the capsanthin after 50 to 70 seconds, frying the mixture for 50 to 70 seconds, putting 100 parts of dried bamboo shoot slices into the mixture for frying, putting 2 to 3 parts of edible salt, 0.5 to 1.2 parts of monosodium glutamate and 0.5 to 0.8 part of chili extract during frying, frying uniformly, taking out the fried bamboo shoots from the pot after 15 to 25 minutes, and performing vacuum sterilization and packing. The semi-finished product prepared by the process is crisp, lightly fragrant and delicious, namely the fragrant and crisp bamboo shoots are fragrant, crisp, delicious and hot.

Owner:LICHUAN NATURAL SPECIALTY FOOD

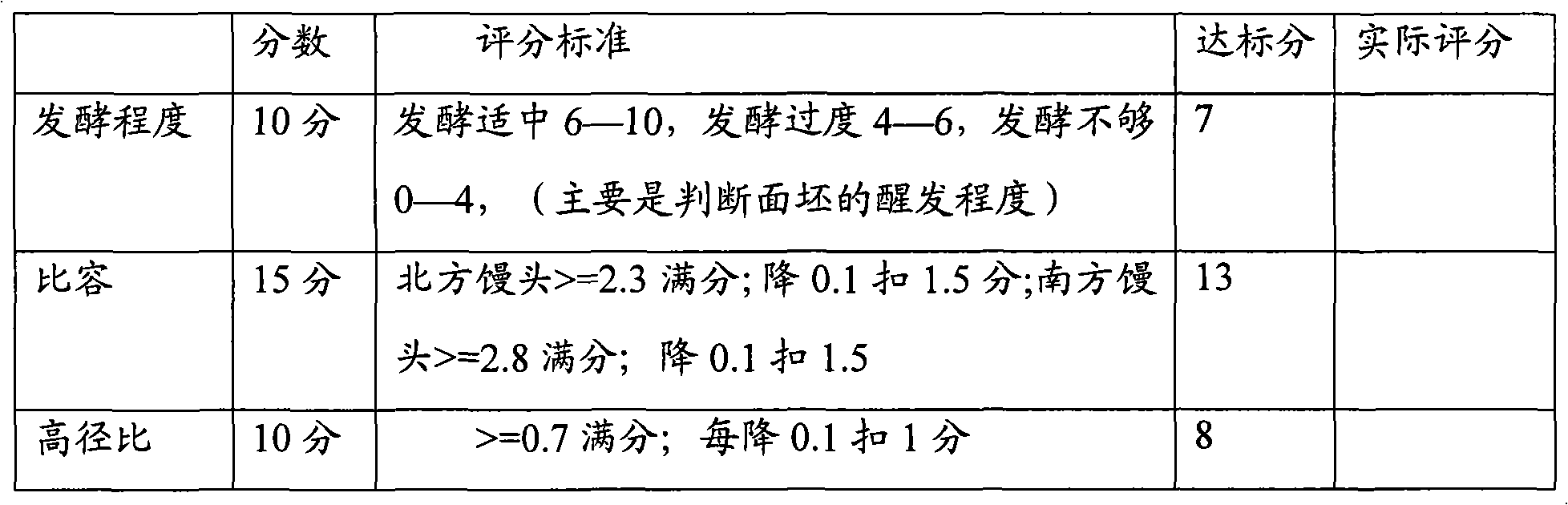

Super micronization method for botanical medicinal, product obtained thereby and use thereof

InactiveCN1994331AAvoid damageIncreased enzymolysis ratePowder deliveryPlant ingredientsEnzymeMicronization

The invention relates to a method for making stem drug containing xylon and cellulose into ultra micro powder, wherein said method comprises that: mechanically breaking; exploding via steam, treating at low temperature, breaking via airflow, enzyme hydrolyzing via microbe enzyme and extracting and separating. The invention also provides relative product and its application for preparing drug, transferring drug element, etc.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Crispy-skin peanuts and processing method thereof

InactiveCN101972010AGood crispiness and mouthfeelExtended shelf lifeFood preparationSodium bicarbonateMonosodium glutamate

The invention relates to crispy-skin peanuts and a processing method thereof. The invention is characterized in that the crispy-skin peanuts are prepared by using peanuts as raw materials and starch, flour, white granulated sugar, malt syrup, plant oil, salt, monosodium glutamate, sodium bicarbonate and water as ingredients and by selecting, coating, molding, baking, mixing, cooling and packaging, wherein the ingredients comprise 30 to 36 weight parts of starch, 30 to 36 weight parts of flour, 10 to 12 weight parts of white granulated sugar, 6 to 8 weight parts of malt syrup, 2 to 3 weight parts of salt, 1.5 to 2.5 weight part of monosodium glutamate, 0.6 to 1 weight part of plant oil, 0.4 to 0.6 weight part of sodium bicarbonate and a proper amount of water. The crispy-skin peanut prepared through automatic production equipment has the advantages of proper crisp degree, excellent mouthfeel and long quality guarantee period, and the processing method simultaneously has the advantages of reasonability and practicality, good effect, simplicity of operation and contribution to wide popularization.

Owner:CHACHA FOOD CO LTD

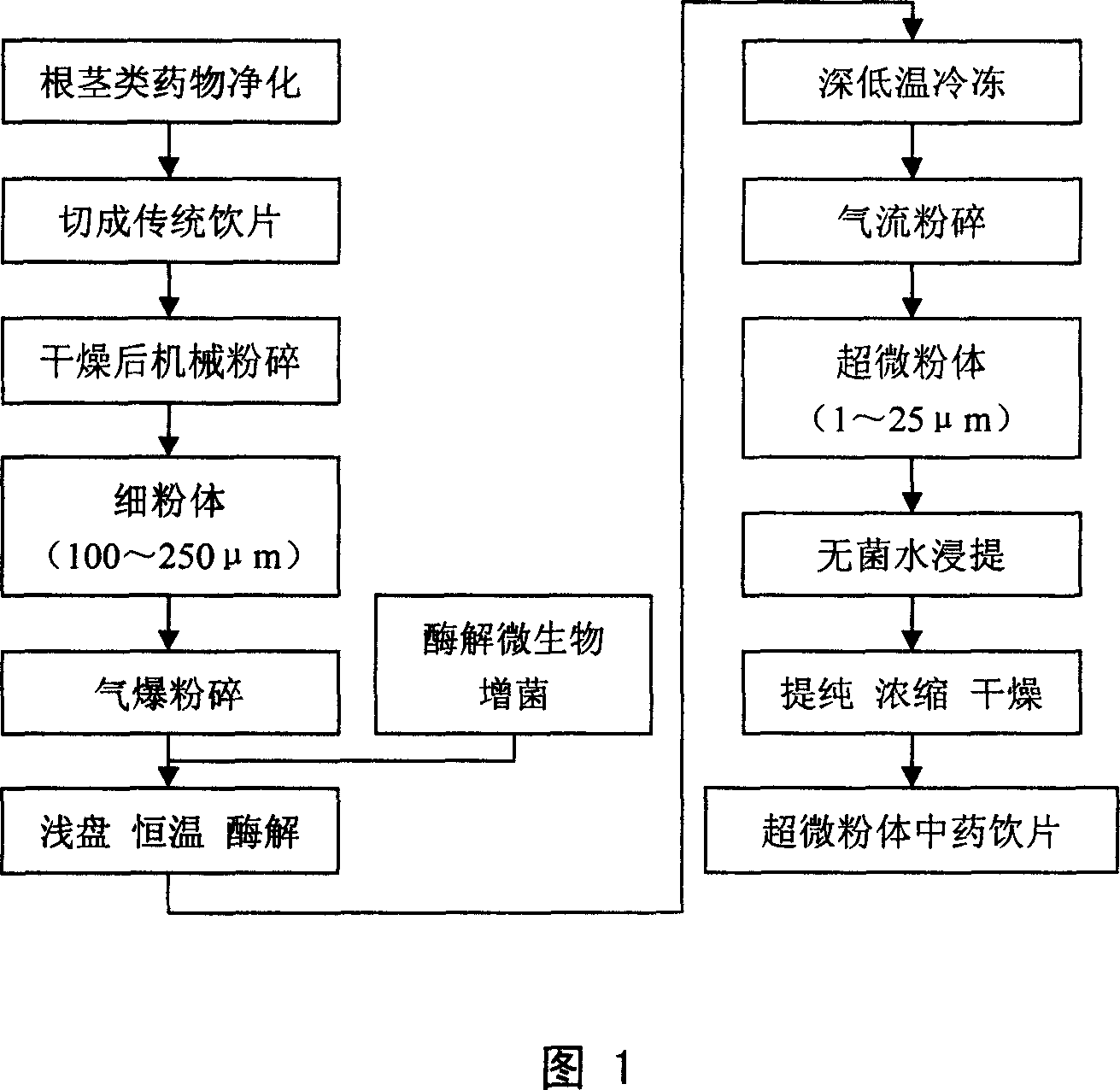

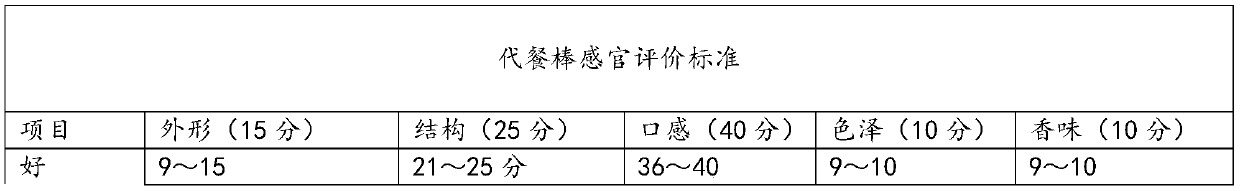

Low-GI meal replacement rod for diabetes patients and preparation method and applications thereof

InactiveCN109527396AIncrease satietyReduce hungerSugar food ingredientsFood ingredient functionsMeal replacementWater soluble

The invention provides a low-GI meal replacement rod for diabetes patients and a preparation method and applications thereof. The low-GI meal replacement rod is mainly prepared from following raw materials: dietary fibers, proteins, sugar alcohols, cereal grains, oil, and optional condiments; wherein dietary fibers comprise water soluble dietary fibers and insoluble dietary fibers. The main raw materials are all low-GI materials, at the same time, soluble and insoluble dietary fibers are added, through scientific blending, the meal replacement rod has a characteristic of low GI (glycemic index), and moreover, raw materials that are rich in dietary fibers such as chia seeds, oatmeal, quinoa, konjak, and the like, are added to effectively reduce the increasing of GI after meals. The low-GI raw material and raw materials rich in dietary fibers cooperate with each other, the satiety is enhanced, the hungry feeling is reduced, and the blood glucose fluctuation is reduced.

Owner:玛士撒拉(上海)医疗科技有限公司

Making method of vacuum-pickled vegetables

The invention discloses a making method of vacuum-pickled vegetables. The method needs the following raw materials in parts by weight: 50-70 parts of salt, 0.2-0.4 part of sodium dehydroacetate, 5-7 parts of acetic acid, 1-3 parts of lactic acid, 0.1-0.3 part of sodium pyrosulfite, 0.2-0.3 part of EDTA (Ethylene Diamine Tetraacetic Acid) disodium and 900-1100 parts of water. The method disclosed by the invention has the advantages that no wastewater or waste gas is discharged in the production process, so that environmental pollution does not occur; and the formula material water can be used for further seasoning after being processed, so that the material consumption is reduced to half of the material consumption of a traditional pickling method and the cost is saved. The pickled product is safe, sanitary and free from nutritional ingredient loss and has the advantages of good mouthfeel, good crispness, long shelf life, low salinity, convenient storage, small floor area, high product yield and the like.

Owner:闫庆忠

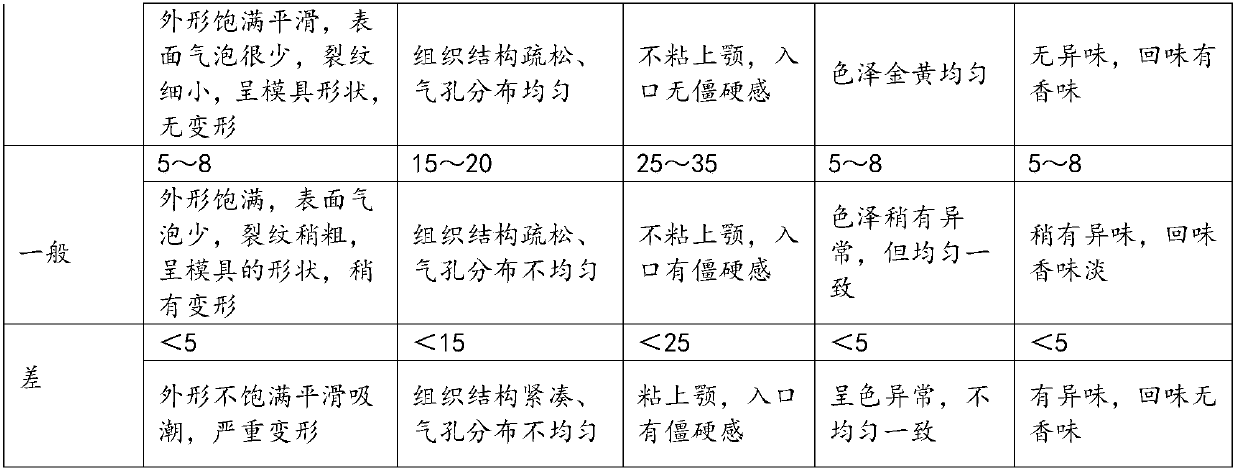

Material for producing disposable tableware or industrial goods tray and production method thereof

InactiveCN101624794AReduce pollutionLow costWater-repelling agents additionPaper/cardboardContaminationMaterials science

The invention discloses a material for producing disposable tableware or industrial goods trays and a production method thereof. The material comprises the following components in parts by weight: 60-80 parts of mechanical straw pulp, 20-40 parts of chemical wood pulp or straw pulp, 2-6 parts of modified starch, 1-5 parts of waterproof agent and 0.1-1 part of oil-proofing agent. The production method comprises the following steps: uniformly mixing the components and adding water into the mixture for stirring into uniform pulp to obtain the material; adding the material to a mold and draining excess water for producing prefabricated products; putting the prefabricated products and the mold to an external mold which is heated to 170-180 DGE C by steam in advance, and closing the two molds for pressing the prefabricated products into various shapes of disposable tableware or industrial goods trays. The material mainly contains the mechanical straw pulp and has the advantages of little chemical substance contamination and low production cost. The disposable tableware or industrial goods trays produced by the material have the advantages of sanitation, low cost, favorable crispness and the like.

Owner:山东蓝沃环保餐具有限公司

Formula of auxiliary materials for preparing dry chili bean sauce by lactobacillus fermentation and preparing method of products

ActiveCN102318803AAchieve rapid reproductionIntensify the fermentation processFood preparationWater contentFood products

The invention relates to a formula of auxiliary materials for preparing dry chili bean sauce by lactobacillus fermentation and a preparing method of the dry chili bean sauce products, belonging to the field of biological technology and food. The formula of auxiliary materials comprises the following raw materials in the terms of the washed and soaked absorbing-water dry chili base raw material with water content of 65-80% as the additive amount (G / G) of weight basis: 5.00-12.50% of edible salt and 0.50-1.50% of bean sauce type Paolemei lactobacillus preparation. The method for preparing the dry chili bean sauce fermented by lactobacillus comprises the following steps of: washing, soaking and smashing dry chili, then adding the edible salt and a bean sauce type Paolemei lactobacillus preparation into the chili base to be uniformly stirred, putting into a vessel for fermentation treating to obtain lactobacillus fermented dry chili base, and finally adding sweet beans to obtain the bean sauce product. According to the formula of auxiliary materials in the invention, the traditional natural basking fermentation can be adopted, and the heat-insulation fermentation can also be selected,so that the fermentation and mature time is obviously shortened. The dry chili bean sauce has better color, aroma and taste, higher freshness and good stability.

Owner:SICHUAN GAOFUJI FOOD

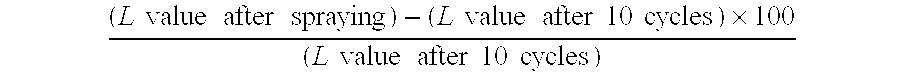

Fabric color restoration composition, article, and method

InactiveUS20090178212A1Good flexibilityReduce and eliminate needGrip property fibresDyeing processStatic friction coefficientMaximum level

The present invention relates to a stable, preferably well dispersed, more preferably translucent, and even more preferably clear, aqueous fabric color-restoring composition, fabric color-restoring methods, and articles of manufacture that use such fabric color-restoring composition. The fabric color-restoring composition comprises an effective amount of a silicone polymer fabric color-restoring agent, typically the minimum levels of fabric color-storing agent included in the composition are at least about 1.75%, preferably at least about 2.0%, more preferably at least about 2.5%, even more preferably at least about 3.0% and typically maximum levels of fabric color-restoring agent are less than about 10.0%, preferably less than about 7.0%, particularly in the range of about 3.0% to about 6.0%; and optionally, but preferably, an effective amount to increase the coefficient of static friction, of a static friction-increasing agent.

Owner:THE PROCTER & GAMBLE COMPANY

Puffed lentinus edodes free from sulfur peculiar smell, and production technology of puffed lentinus edodes

InactiveCN103504284AShorten the timeImprove yieldFood preservationFood shapingNutritionNutritional composition

The invention relates to puffed lentinus edodes free from a sulfur peculiar smell, and a production technology of the puffed lentinus edodes, and discloses the puffed lentinus edodes and a production method thereof. The sulfur peculiar smell is removed from the lentinus edodes; the technology is simple; the obtained lentinus edodes is low in contractility; the time required by rewatering soaking is short; and a nutrition preservation rate is high. The puffed lentinus edodes is prepared by a pretreatment, predrying, peanut oil leaching and varying temperature differential pressure puffing and drying method. In a leaching process, the time is short, a finished product rate is high, and nutritional ingredients of the lentinus edodes are preserved to the greatest extent; in a puffing process, moisture in a tissue of the lentinus edodes is instantly vaporized and dissipated, so that a raw material expands intracellularly or intercellularly to form a uniform honeycomb structure, and the puffed lentinus edodes has good crisp property, can be rapidly molten in a mouth after eaten, and is good in taste and easy to digest; and in addition, the uniform and porous texture allows the puffed lentinus edodes to absorb water easily, and the puffed lentinus edodes has good rewatering property.

Owner:食品行业生产力促进中心

A preparation method for high-fiber recombinant asparagus chips

The present invention discloses a preparation method for high-fiber recombinant asparagus chips, and belongs to the deep processing field of fruits and vegetables. The asparagus chips use discarded scraps of old stems and old roots from asparagus production enterprises as raw materials, and are prepared by the following steps: pre-treating the raw materials, blanching the materials in hot water, preserving color, conducting beating, mixing the materials with adjuvant materials, cooking the mixture for a short time, placing the mixture on plates, drying the mixture under vacuum by two section-type microwave to a moisture content of 10% -15%, drying the mixture by short- and medium-wave infrared method under vacuum to a moisture content below 5%, and packaging the mixture to obtain the end products. The dietary fiber content of the asparagus chips is 8.35% - 10.27%, and every 100g of the chips contains flavonoids 12.73-16.86 mg, polysaccharide 9.34-11.28 mg. The preservation rate of chlorophyll is 70% to 75% after processing, and the chip breaking force is 1123-1443 g. The preparation method provides a novel method for taking full advantage of asparagus scraps, and the microwave vacuum drying and the short- and medium-wave infrared vacuum drying have advantages of quick drying, low temperature and higher nutrient retention rate, etc. The asparagus chips are high in cellulose content, rich in flavonoids, polysaccharide and other active substances, crispy and delicious in taste and high in nutritional value. Therefore, the asparagus chips are leisure crisps for people of all ages.

Owner:JIANGNAN UNIV +1

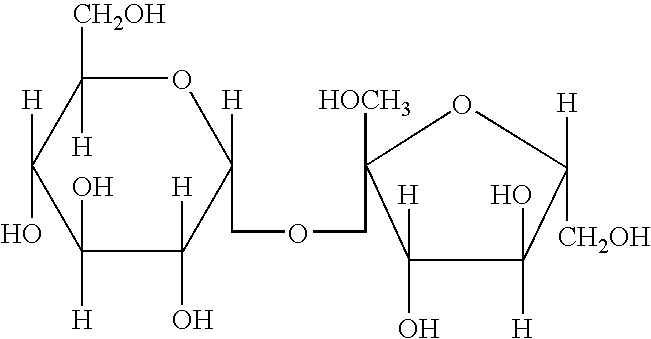

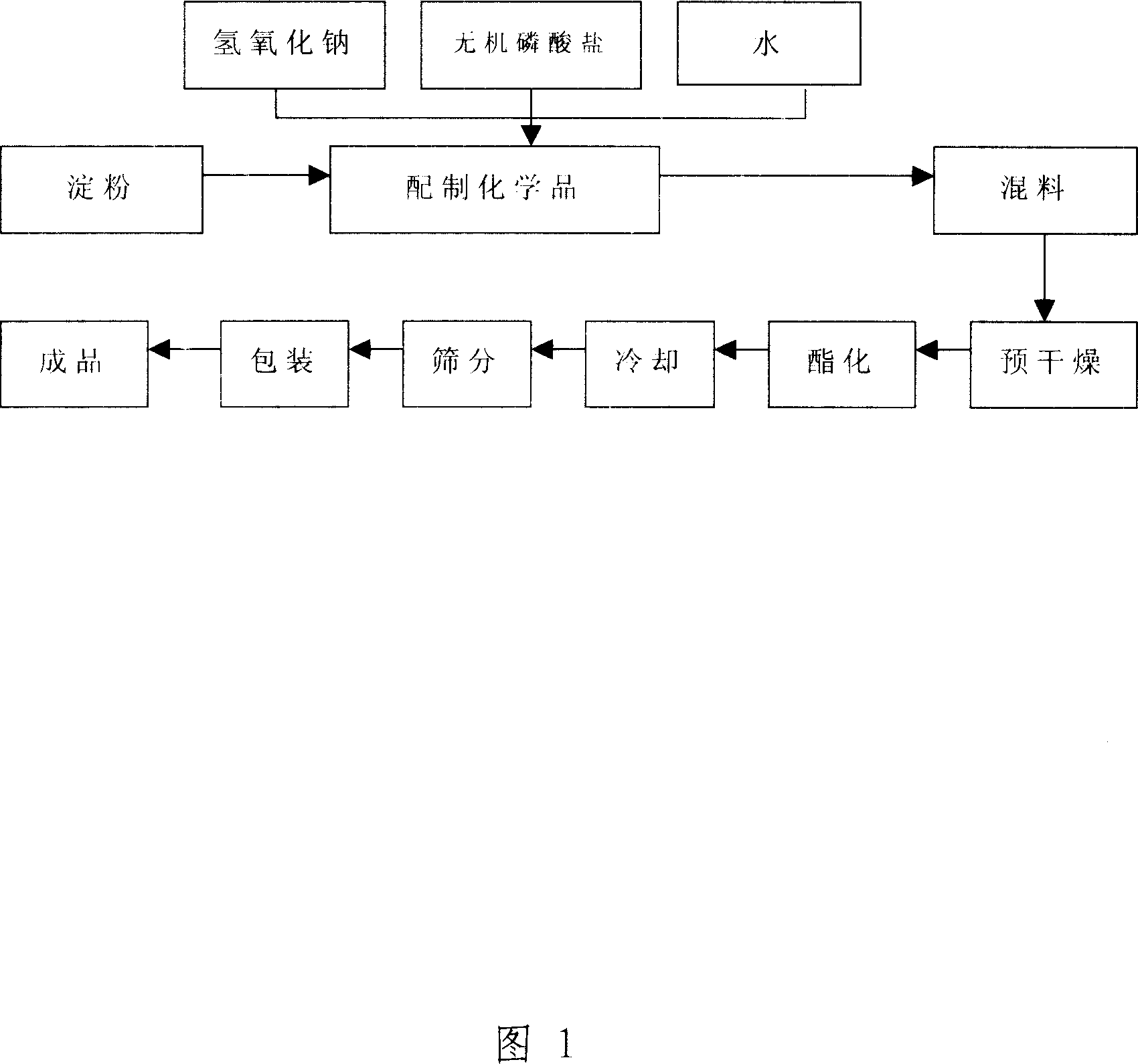

Method of preparing starch phosphate

InactiveCN101033262AThe production process is simple and applicableImprove reaction efficiencyInorganic phosphateStarch paste

This invention relates to a modified starch preparation method, specifically a phosphate starch, which takes starch, urea, inorganic phosphate as raw materials in the double-cones rotary dryer, and conducts seven process steps of preparing chemicals, mixing, pre-drying, esterification, cooling, sieving, packaging to prepare the finished product, which is light yellow to yellow powder particle, and the viscosity peak is from 1000 to 6000BU. When the mass concentration is 6% for starch paste, it can gelatinize at the temperature lower than 66deg.C till cold water.

Owner:四平帝达变性淀粉有限公司

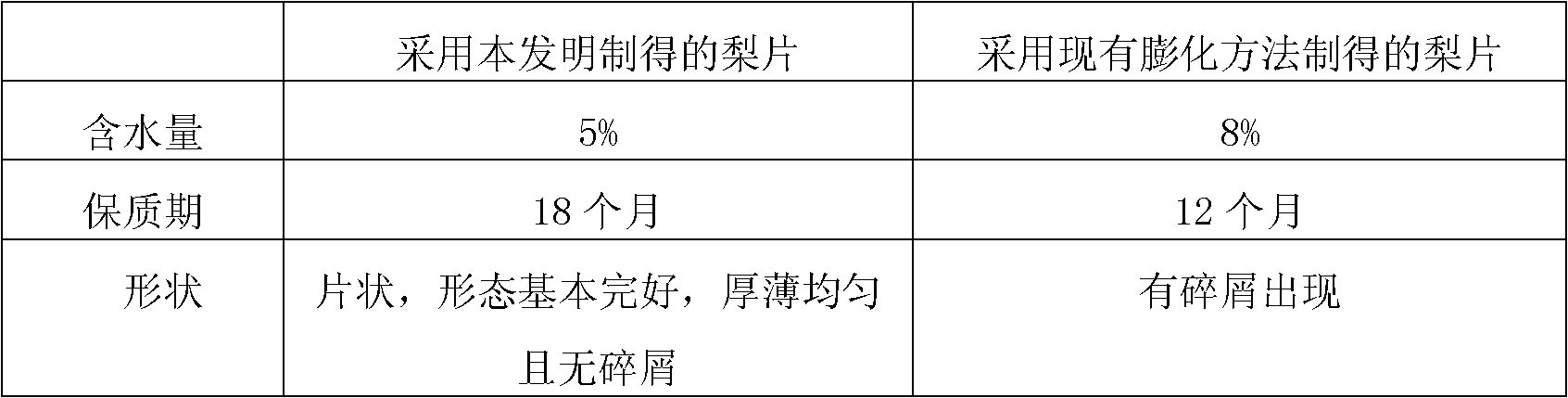

Production method of crispy pear slices

InactiveCN102349631AAvoid shrinkage, deformation or even distortionGuaranteed crispnessFood preparationChemistryMoisture

The invention relates to a production method of crispy pear slices. The method comprises the following steps of pear slicing, color protection, blanching, freezing, differential-pressure puffing, drying, moisture removal and cooling, wherein the moisture removal is performed after the puffing and drying; in the moisture removal, the filtered air is absorbed into a puffing tank, and the vacuum degree in the puffing tank is gradually reduced; and water in the puffed pear slices is dispersed into the puffing tank to form steam, so that the water in the pear slices can be further dispersed out. Therefore, the phenomenon of shrinking deformation or even distortion of the pear slices is avoided, the crispy degree of the pear slices is ensured, and the original color, flavor and vitamin content of fresh pears are maintained.

Owner:JINAN INST OF FRUIT PRODS CHINA GENERAL SUPPLY & MARKETING COOP

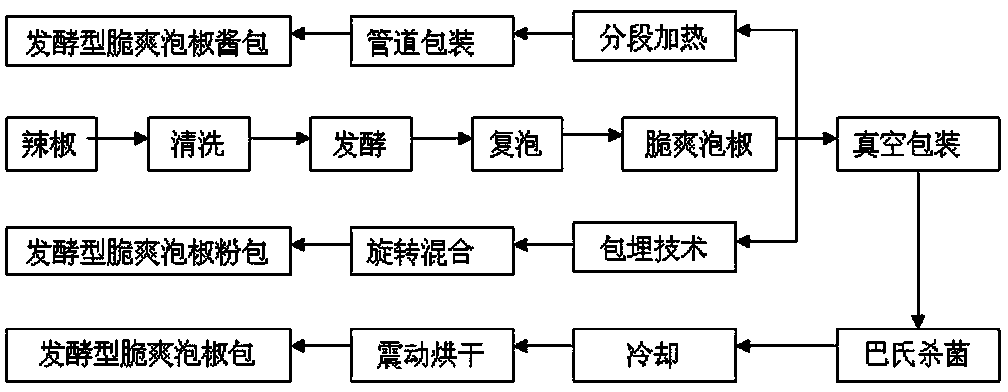

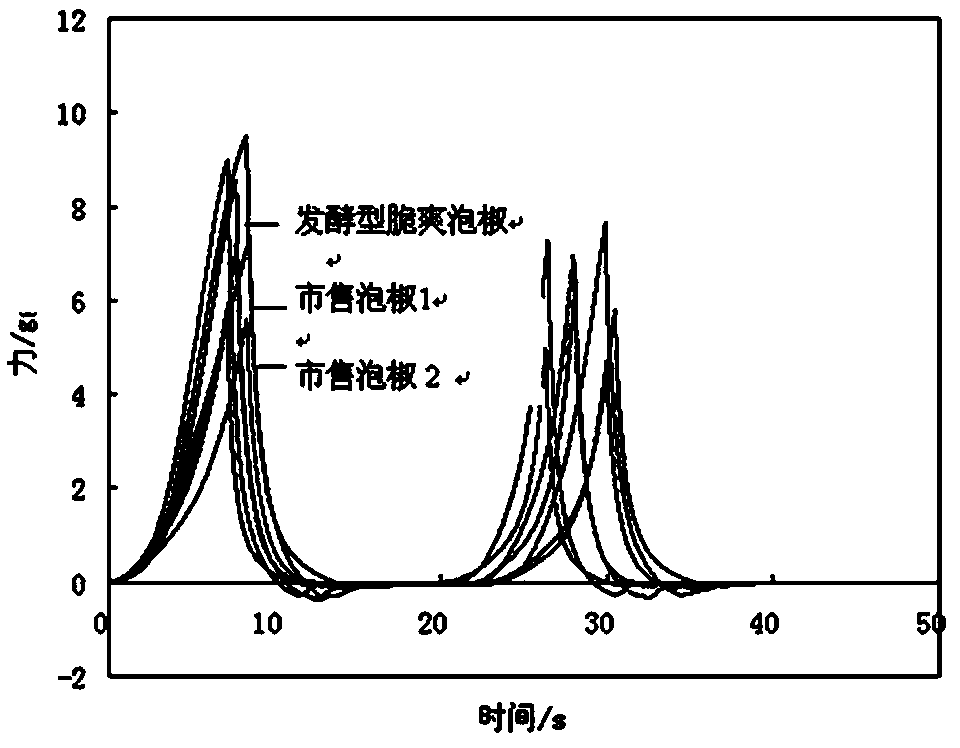

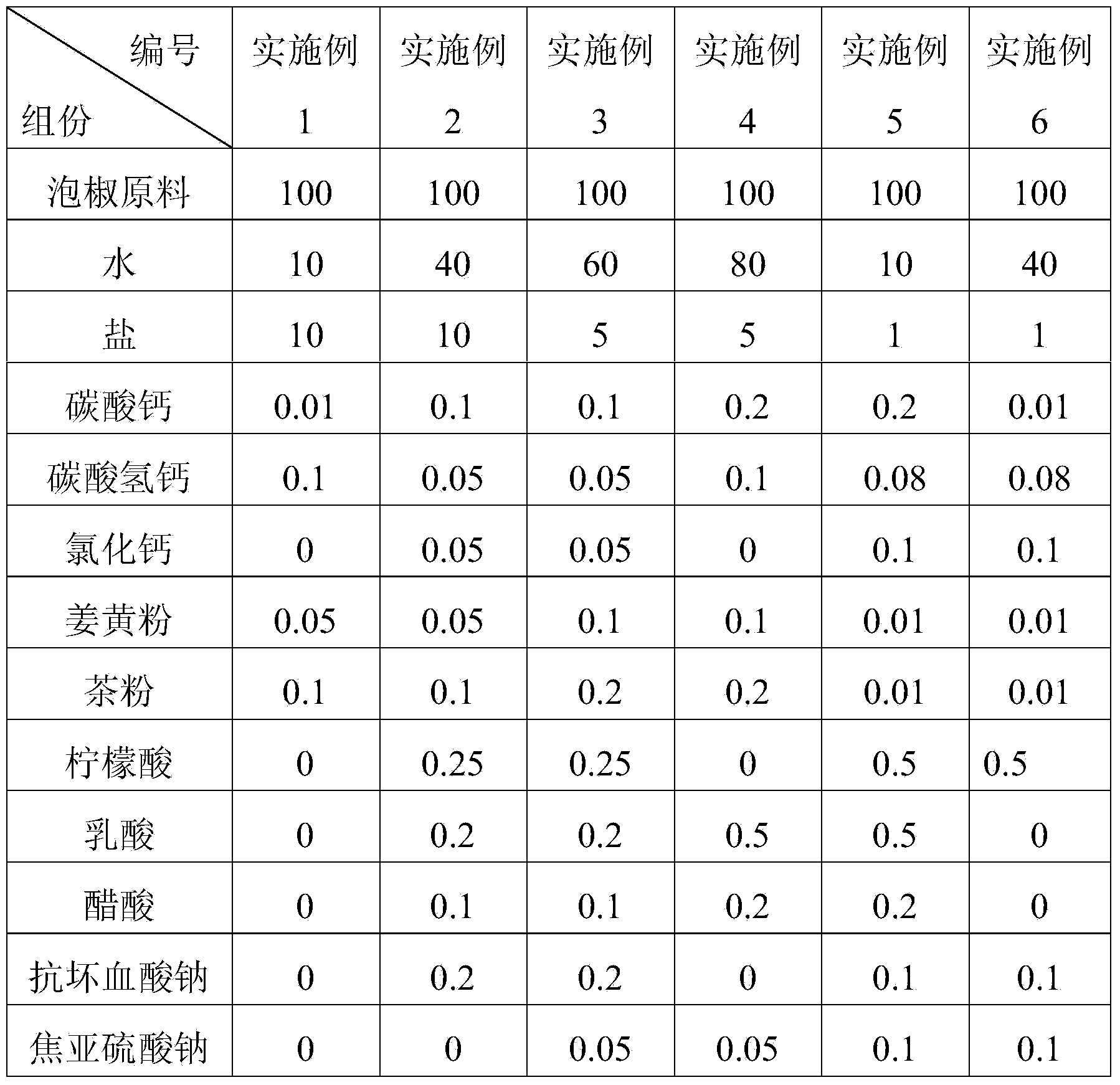

Fermentative crispy pickled pepper and application of fermentative crispy pickled pepper in seasoning packet of instant noodles

ActiveCN103907871APlay a role in color protectionImprove crispnessClimate change adaptationFood preparationBiotechnologyAntioxidant

The invention discloses a fermentative crispy pickled pepper and an application of the fermentative crispy pickled pepper in a seasoning packet of instant noodles. The fermentative crispy pickled pepper is prepared by the steps of with a fresh pepper as a raw material, fermenting the fresh pepper by virtue of brine rich in lactic acid bacteria, and adding a crisp-keeping agent compounded by alkaline calcium salt and citric acid and a composite antioxidant compounded by tea powder, curcuma powder, sodium ascorbate and the citric acid; with the fresh pepper, the crisp-keeping agent and the composite antioxidant act as the raw materials, directly carrying out vacuum packaging, pasteuring, air drying and cooling to prepare the fermentative crispy pickled pepper. With the adoption of the fermentative crispy pickled pepper, the fermentative crispy pickled pepper is prepared by virtue of a segmented temperature controlling heating technology; flavor compounds of the fermentative crispy pickled pepper can be completely kept by using an embedding and granulation technology, and a fermentative crispy pickled pepper powder packet is prepared; the preparation method is simple and is safe to operate; in addition, in the fermentative crispy pickled pepper seasoning packet of the instant noodles, the pepper is brilliant yellow, is good incrisp feeling, is good in fermentation fragrance and taste, is unique in flavor when being applied in the seasoning packet of the instant noodles, is good in taste and is longer in shelf life.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

Combined processing method for processing crisp peas by using dry peas

ActiveCN102488149AHigh degree of puffingImprove crispnessFood preparationNutrient contentOil content

The invention discloses a combined processing method for processing crisp peas by using dry peas, and belongs to the technical field of fruit and vegetable food processing. The dry peas are taken as raw materials and the leisure crisp peas are prepared by the following steps of: cleaning, soaking and selecting peas; blanching, protecting color, steeping, draining, freezing, performing negative-pressure microwave spouted drying, frying in vacuum, removing oil in vacuum, seasoning, cooling and packaging, and storing finished products. The dry peas are puffed at low temperature, the processing range is wide, the crispness of the products is improved by a pre-freezing method, and the vacuum frying technology has the characteristics that the original color and shape and nutrients of the peas are maintained, the oil content is low, the frying time is short, the fried fat is not easy to oxidize, the shelf life of the products is long and the like. The products are crispy, delicious, aromatic, not greasy, convenient and sanitary, and are a leisure food suitable for young and old.

Owner:JIANGNAN UNIV

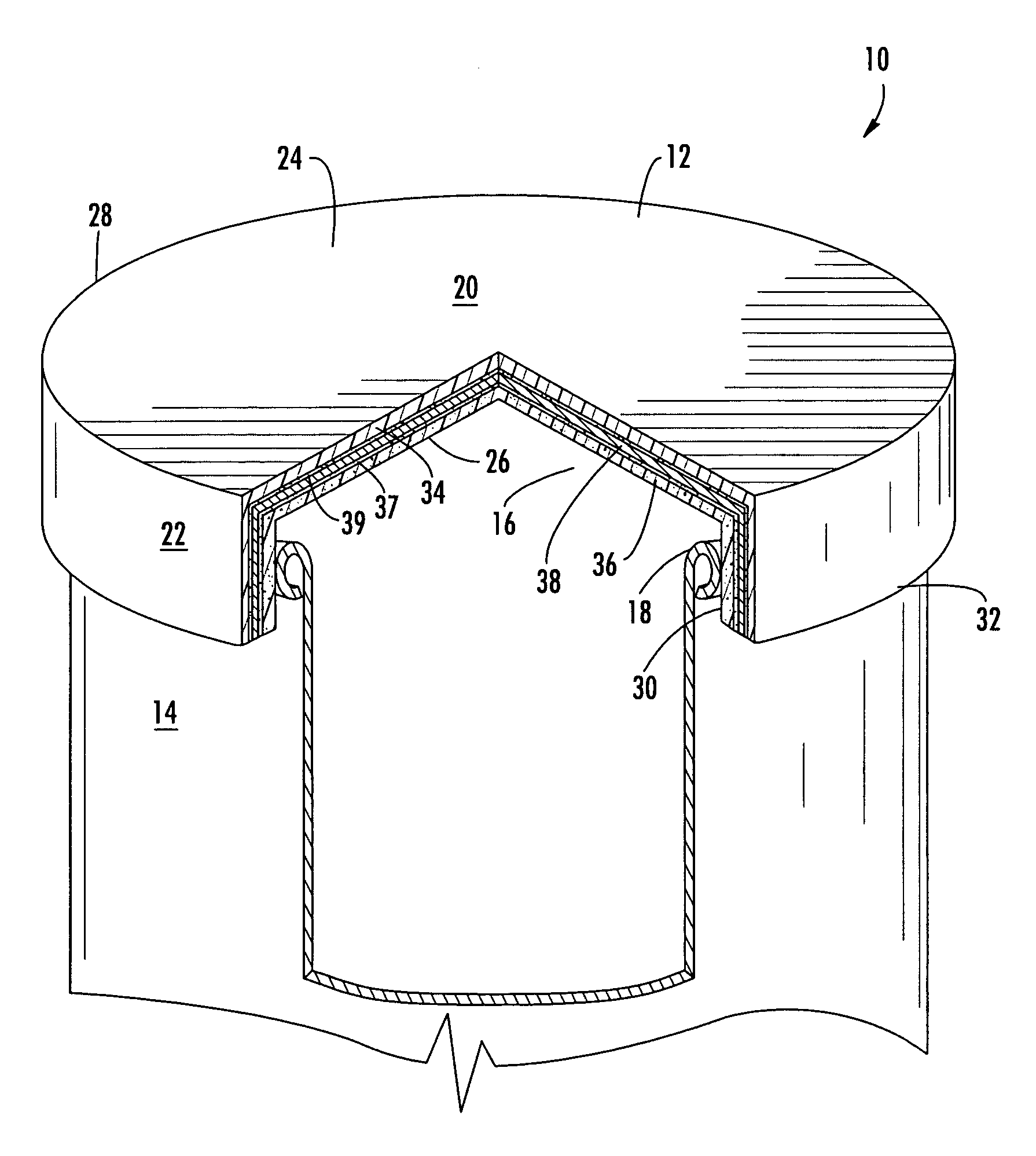

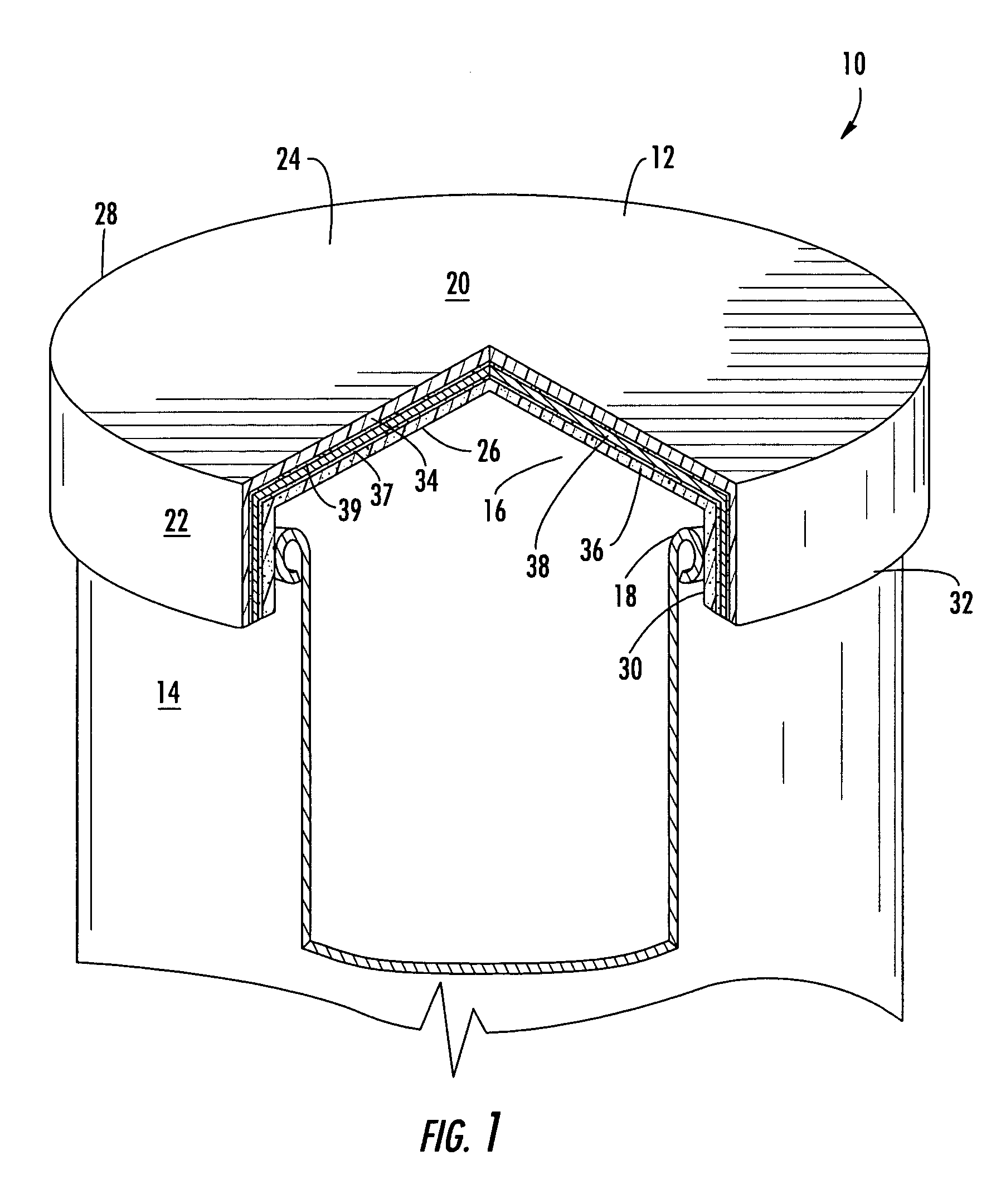

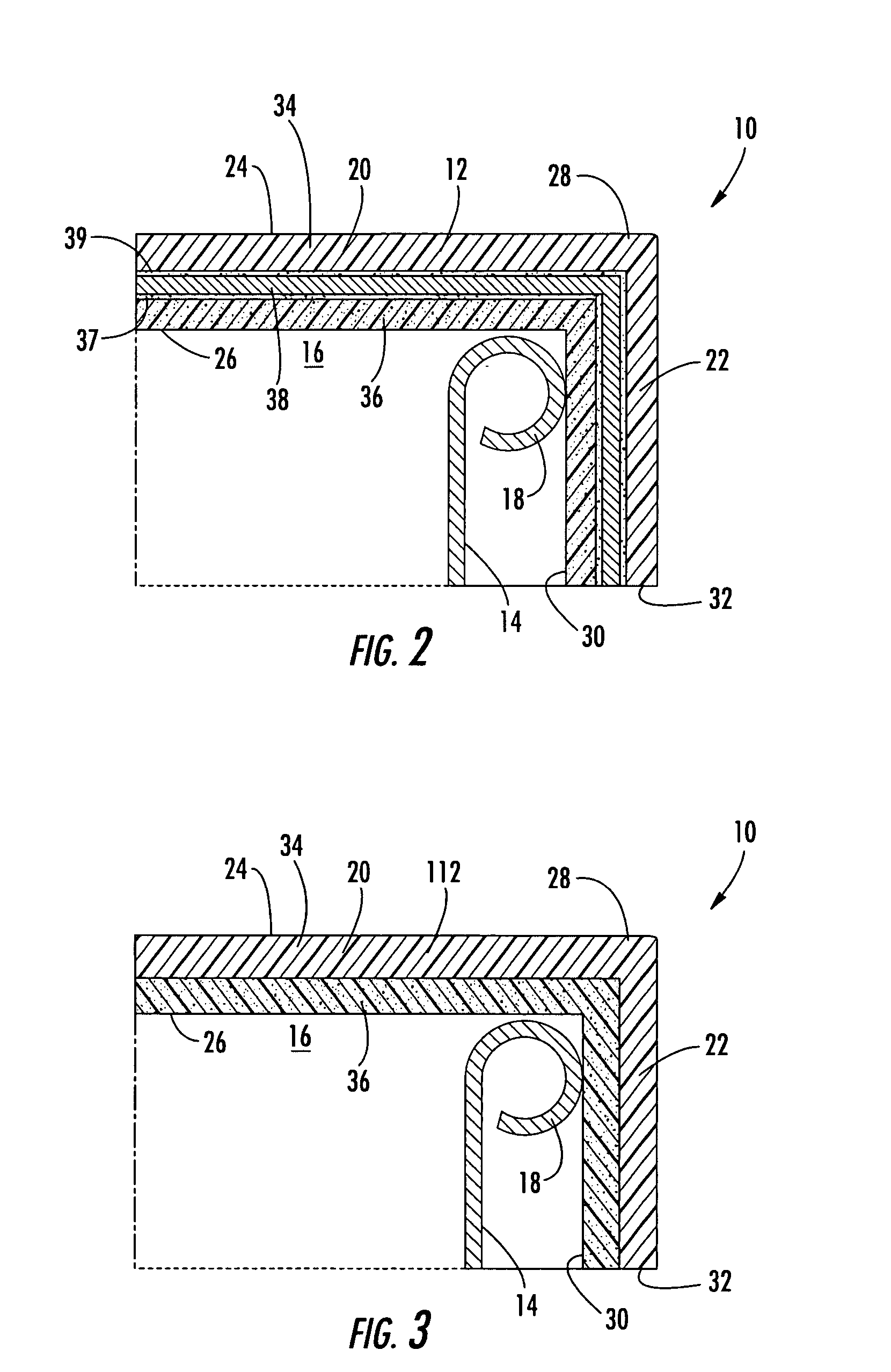

Container overcap with drying agent layer

InactiveUS7185780B2Reduce moistureImprove crispnessClosures with oxygen absorbersCapsDesiccantAdhesive

There is provided an overcap for a resealable container that includes a drying agent layer. The drying agent layer is included in a top portion of the overcap and is positioned below a top layer of the top portion such that the drying agent layer is exposed to the interior of the container. The overcap may be formed from a multilayered coextruded sheet having a top layer of polymer material and a drying agent layer mixed with a polymer material. The multilayered coextruded sheet may also include a barrier layer, a polymer layer, and / or additional drying agent layers. Alternatively, the drying agent layer may be joined to the overcap by an injection molding process or by an adhesive. The drying agent layer is exposed to moisture in the interior of the container such that the drying agent layer is operable to absorb moisture from the air that enters the interior of the container during the opening and resealing of the container.

Owner:SONOCO DEV INC

Flavored low-fat white mushroom crisp chip and preparation method thereof

InactiveCN103689552AImprove processing qualityGood colorFood freezingFood thermal treatmentMushroomFat content

The invention belongs to the technical field of food processing and specifically relates to a flavored low-fat white mushroom crisp chip and a preparation method thereof. The flavored low-fat white mushroom crisp chip comprises the following materials in parts by weight: 1000 parts of white mushrooms, 5-10 parts of konjac glucomannan, 10-80 parts of chitosan, 10-60 parts of salt, 60-200 parts of isolated soybean protein and 40-200 parts of a nutrition balancing agent. The preparation method comprises the following steps: pre-treating the white mushrooms, preparing impregnation liquid, carrying out vacuum soaking and ultrasonic coating, carrying out quick-freezing and slicing, carrying out vacuum frying and dehydrating, removing oil, and packaging. The prepared flavored low-fat white mushroom crisp chip has the advantages of being low in fat content, uniform in color, crisp in mouthfeel, full in nutrition, complete in product shape and almost free of fractures.

Owner:SHANDONG INST OF COMMERCE & TECH

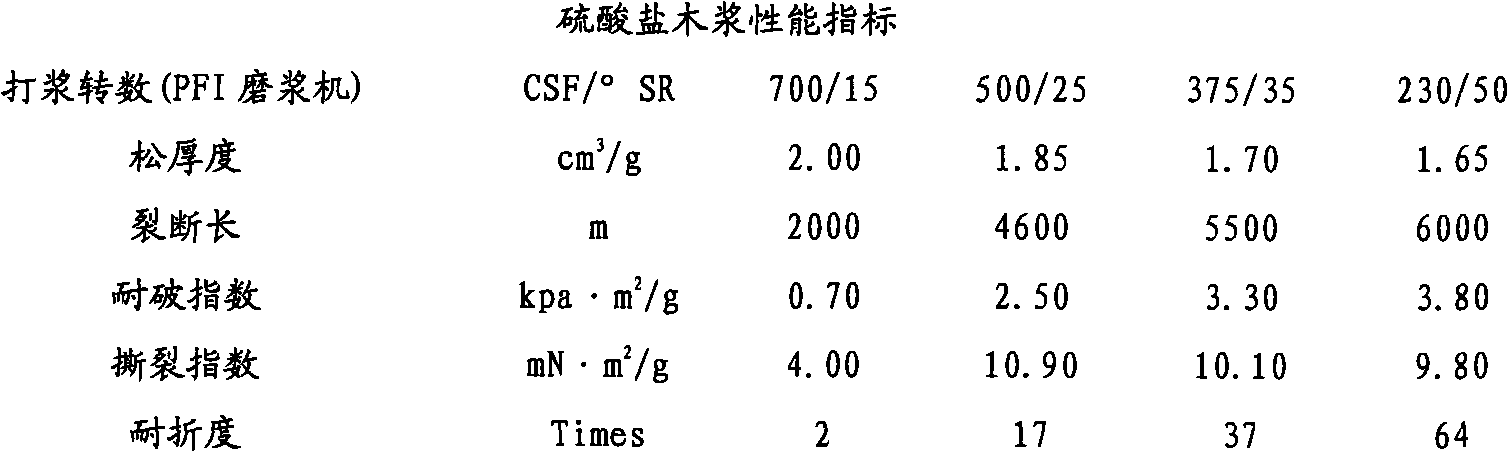

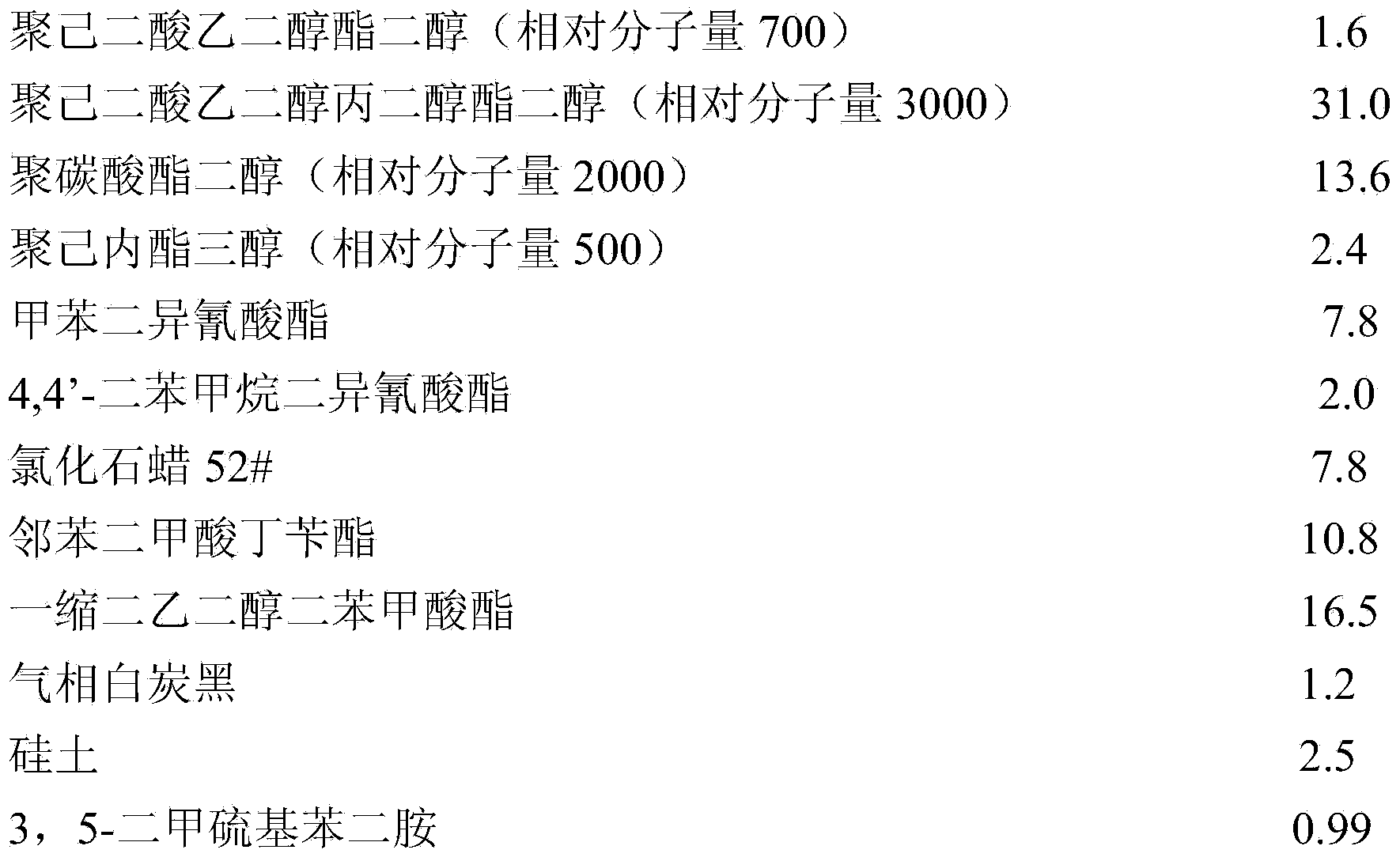

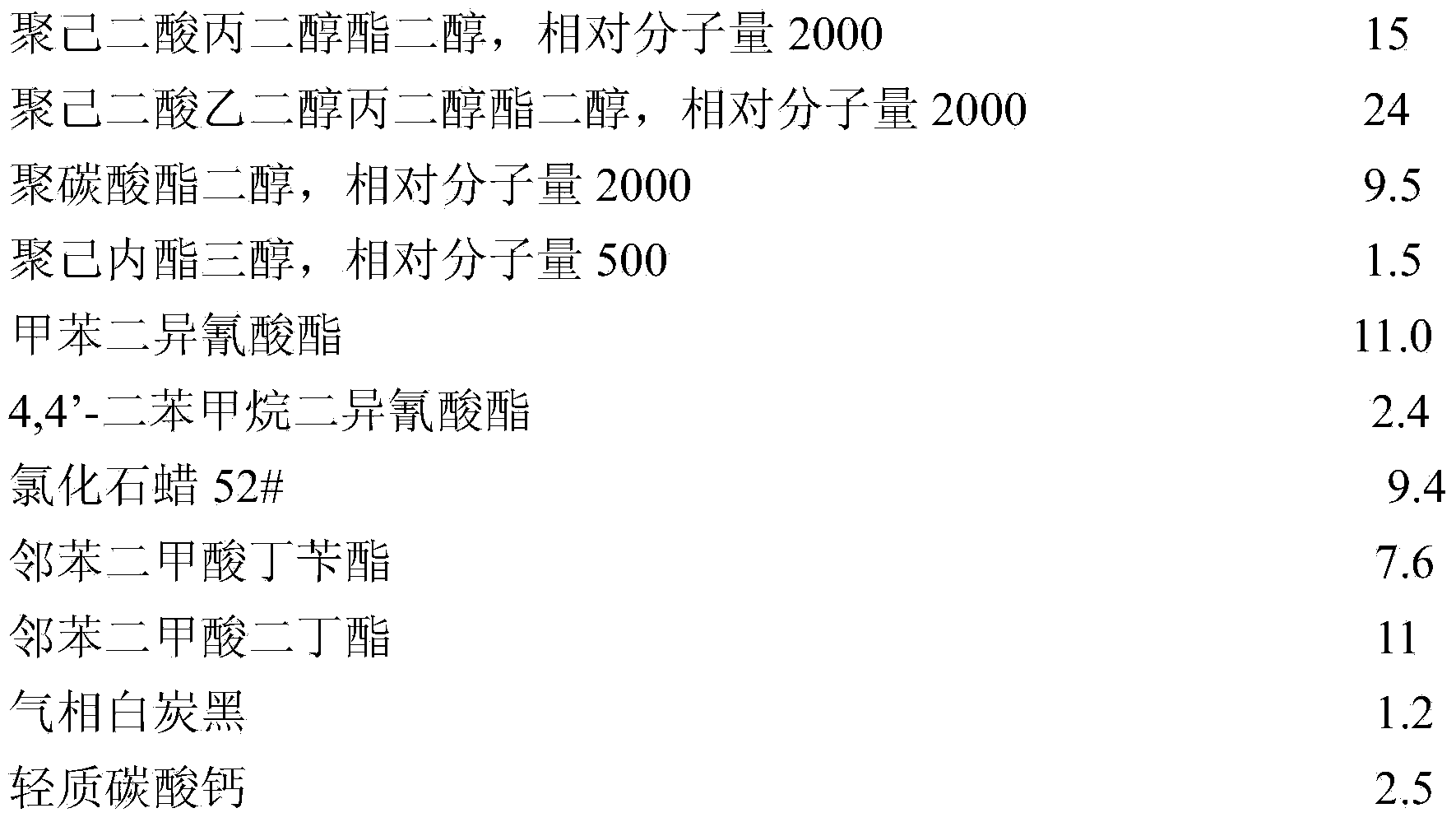

Solvent-resistance polyurethane rubber roller and manufacturing method and application thereof

The invention discloses a solvent-resistance polyurethane rubber roller and a manufacturing method and application thereof, and belongs to the field of rubber roller preparing. The solvent-resistance polyurethane rubber roller is achieved through combination of multicomponent systems and is formed by mixing and pouring a material component A, a material component B and a material component C, wherein the material component A comprises, by mass, 40%-60% of polyester polyol and 7%-20% of toluene disocynate, the material component B comprises, by mass, 2%-10% of 4-4'-diphenylmethane diisocyanate, 5%-40% of plasticizer and 1%-4% of filler, and the material component C comprises, by mass, 2.5%-8% of chain extender and 0.02%-0.05% of catalysts. The wear-resistance, solvent-resistance and mechanical properties of the solvent-resistance polyurethane rubber roller are obviously improved, and the solvent-resistance polyurethane rubber roller can be widely used in the fields of printing, coating and painting.

Owner:东莞华工佛塑新材料有限公司

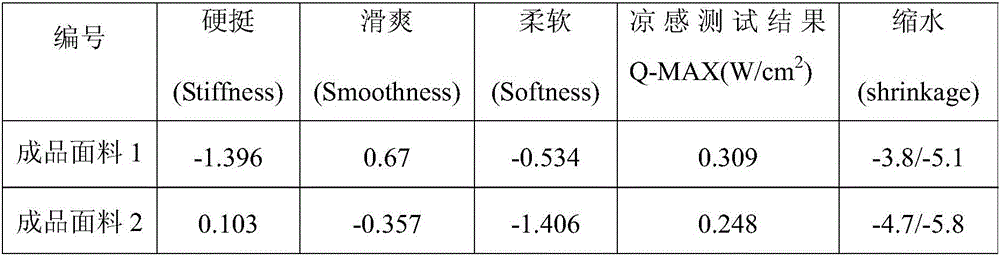

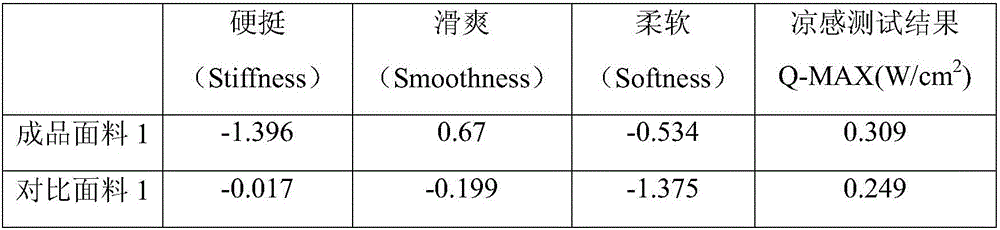

Knitted fabric containing cotton and having silky luster, handfeel and cool feeling and manufacturing method thereof

ActiveCN105734963ACompact structureNo blemishes on the clothWeft knittingBiochemical treatment with enzymes/microorganismsWoolDyeing

The invention provides knitted fabric containing cotton and having silky luster, handfeel and cool feeling and a manufacturing method thereof.The method includes the following steps that yarn is woven into gray fabric with a circular knitting machine, wherein the needle number of the circular knitting machine is 18-40, the yarn count is 20-80 S / 1, length 50 C of the yarn is 90-200 mm, and the gram weight of the gray fabric is 60-240 g / m<2>.The tissue structure of the gray fabric includes tabby, half cardigan, knitted cotton, rib, looped pile and ball wool or jacquard weave; open width alkali mercerizing, boiling-off, enzyme washing, dyeing, drying, soft stabilized finishing and preshrinking are conducted to finally obtain the knitted fabric containing cotton and having silky luster, handfeel and cool feeling.The knitted fabric containing cotton and having silky luster, handfeel and cool feeling has the advantages of being smooth, stiff, good in drapability, resistant to crease and small in shrinking amount and integrates smoothness, stiffness and crease resistance.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

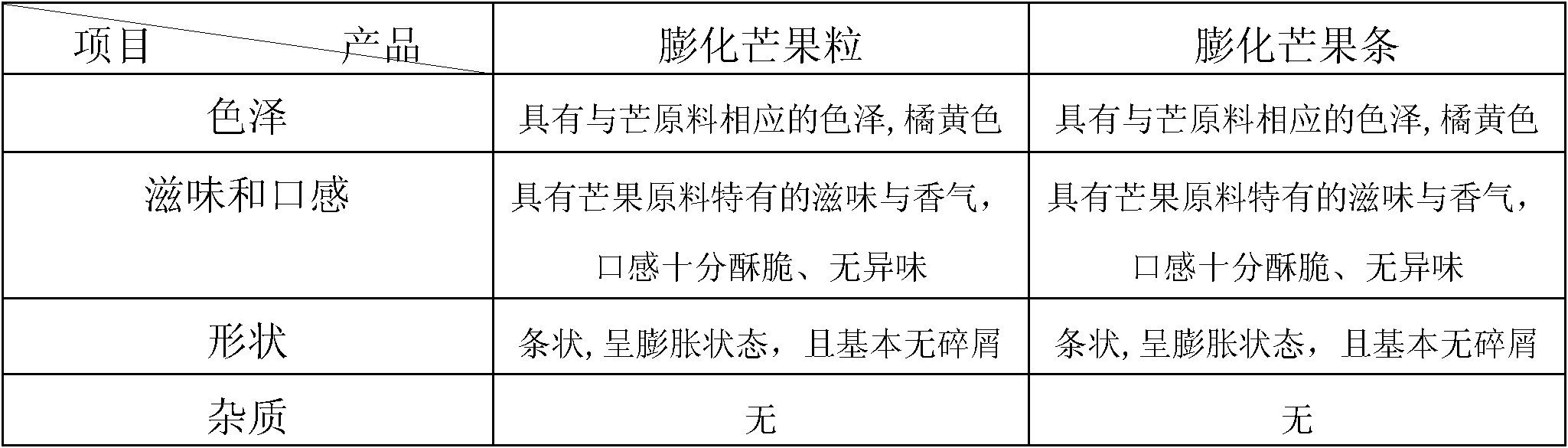

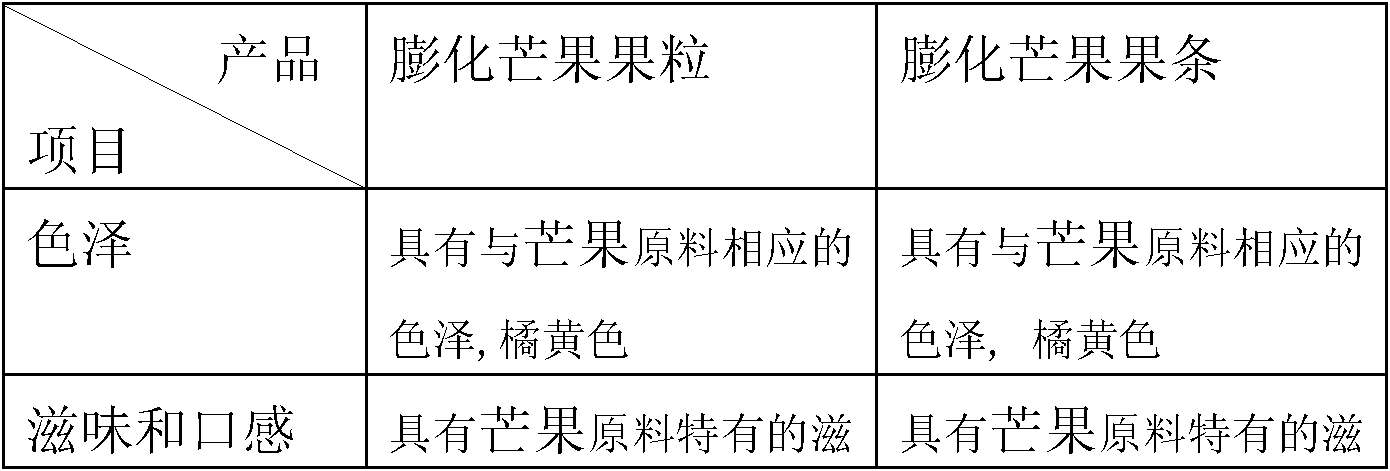

Puffed mango and preparation method thereof

The invention discloses a puffed mango and a preparation method thereof. The method comprises the following steps of putting the pulps of mango into a puffing tank; then carrying out variable-temperature and pressure-difference puffing on the pulps of mango; and the process of the variable-temperature and pressure-difference puffing comprises the following steps: 1) raising the temperature in thepuffing tank to 70-90 DEG C, raising the pressure in the puffing tank to a pressure 0.1-0.3 MPa higher than the atmospheric pressure outside the puffing tank, and keeping the temperature and the pressure, so that the surface temperature of a mango is consistent with the temperature in the puffing tank; 2) reducing the pressure in the puffing tank to a vacuum state, and reducing the temperature to60-80 DEG C under vacuum, then keeping the pressure and the temperature under vacuum, so that the moisture content of the pulps of mango is 3-5%; and 3) reducing the temperature in the puffing tank to 10-30 DEG C, and keeping the temperature 30-60 minutes under vacuum so as to obtain the puffed mango. The method is a new technique for processing vegetable slices; and by using the method disclosedby the invention, the nutrient compositions and flavors of raw materials can be kept furthest, no additive is used in the process of processing, and the defect that fried products contain a small amount of oils is avoided.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com