Patents

Literature

77 results about "Multicomponent systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multicomponent systems are the mixtures (the solutions) which consist of several pure (individual) substances (components). The initial amount each of the substances in the ν-component system may be represented in terms of the component masses m i (1 ≤ i ≤ ν).

Injectable depot compositions and it's process of preparation

InactiveUS20100015195A1Facilitated releaseSimplifying available daily dosage regimenPowder deliveryBiocideInjection siteActive agent

Novel injectable depot compositions are provided comprising at least one active agent(s) optionally with one or more pharmaceutically acceptable excipient(s) in the form of a multi-component system preferably comprising at least two components which when administered to a subject in need thereof forms an in situ gel depot or implant at the site of injection upon contact with body fluids. Also described are process for preparation of such compositions and method of using such compositions.

Owner:PANACEA BIOTEC

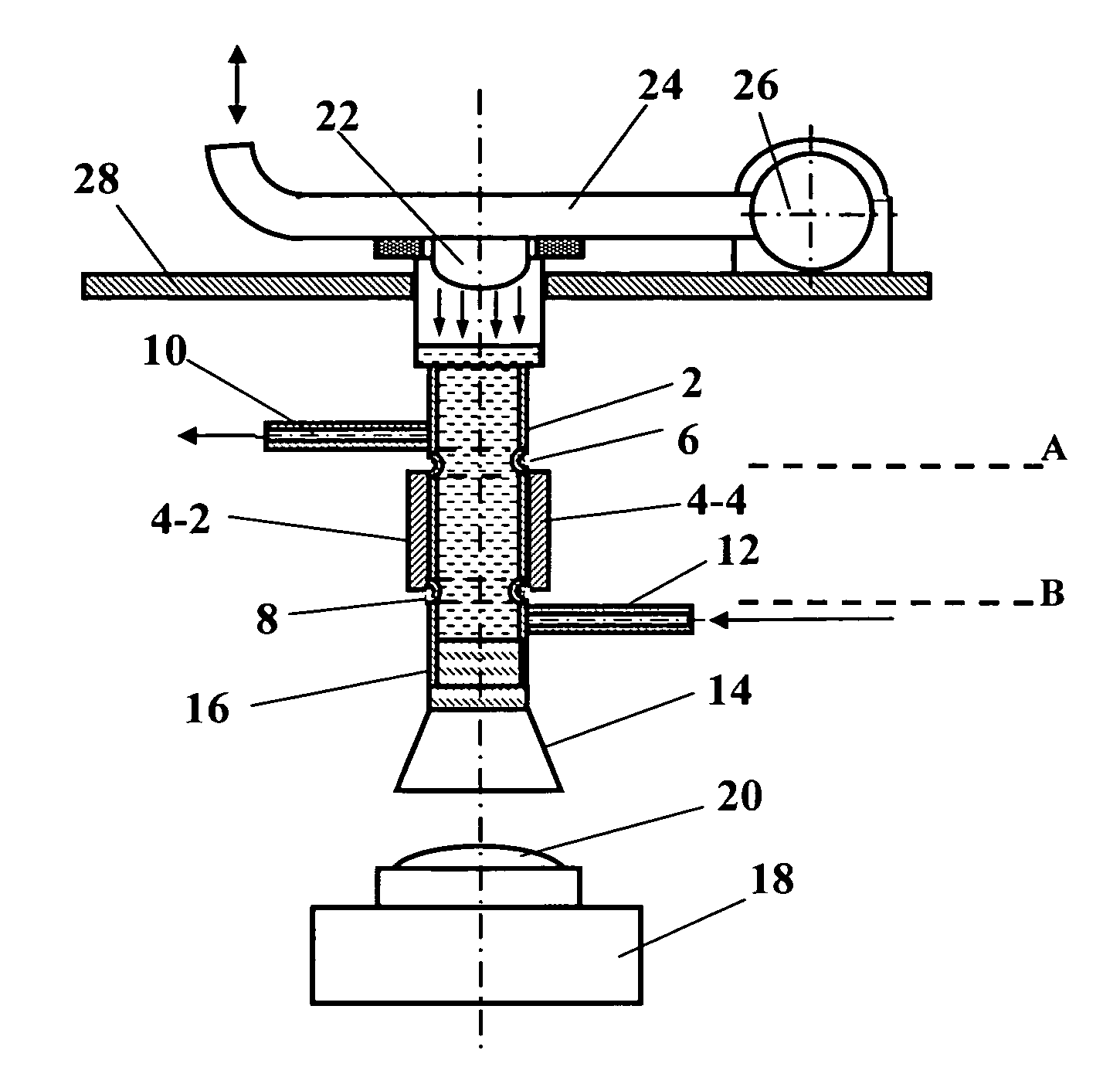

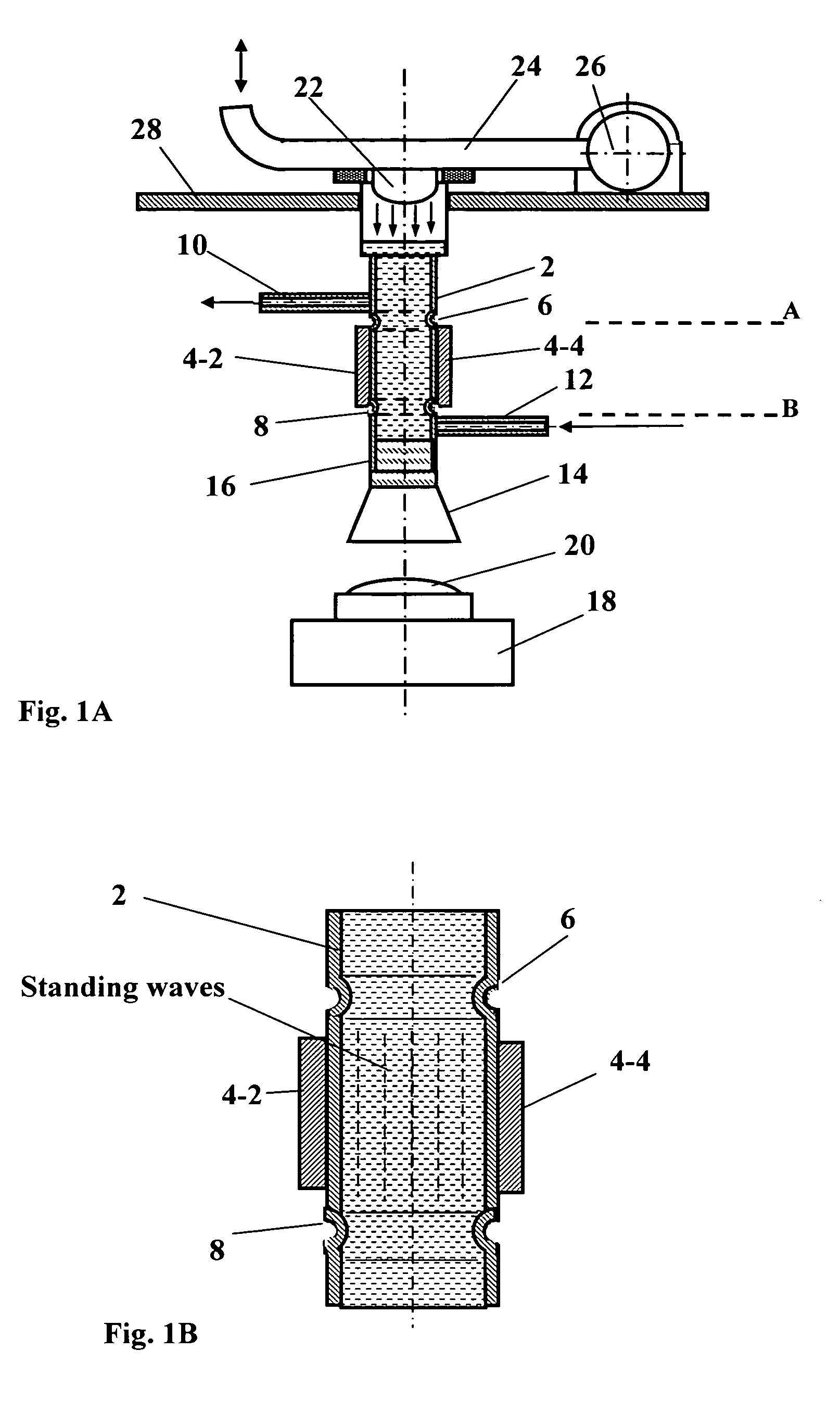

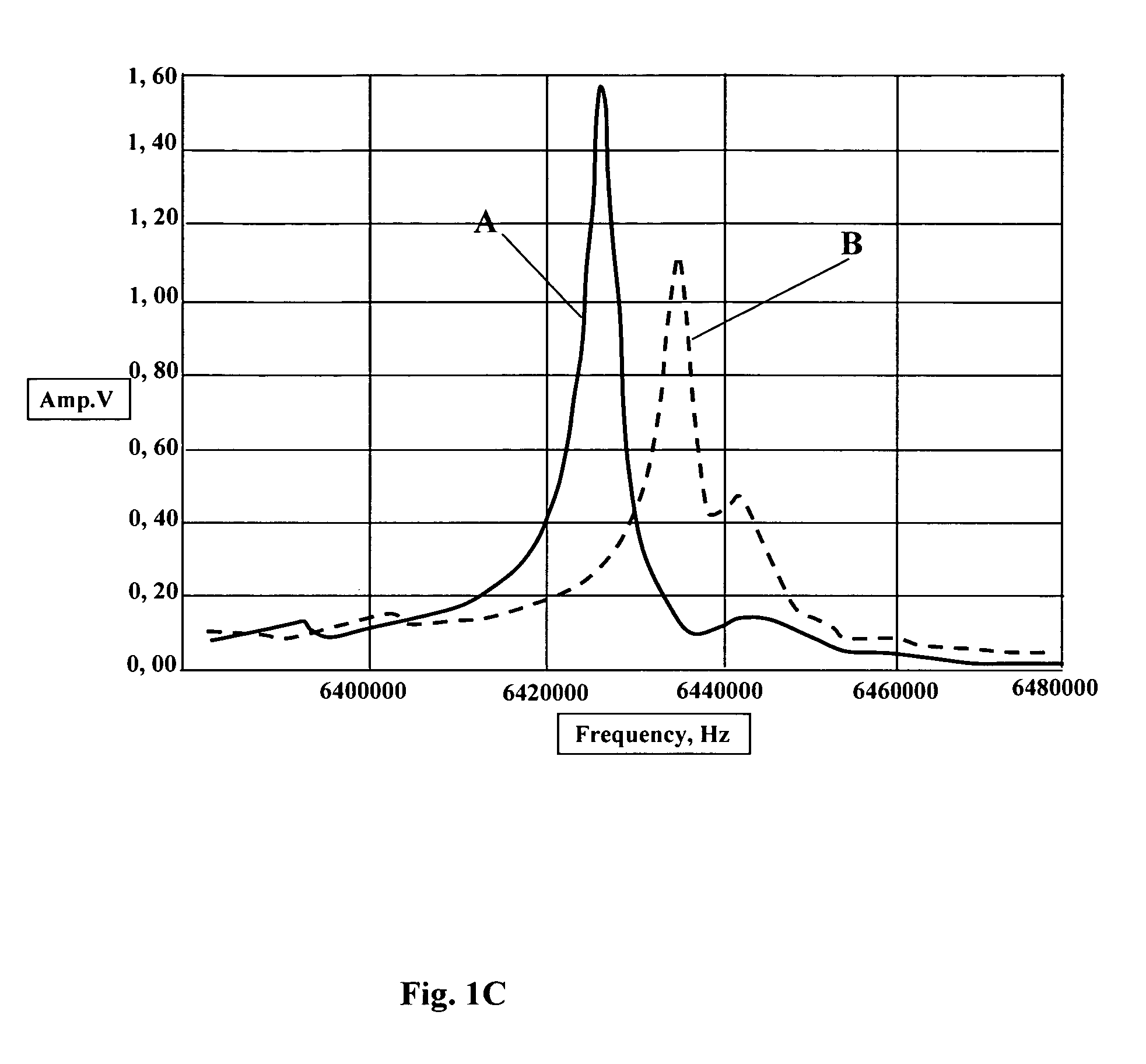

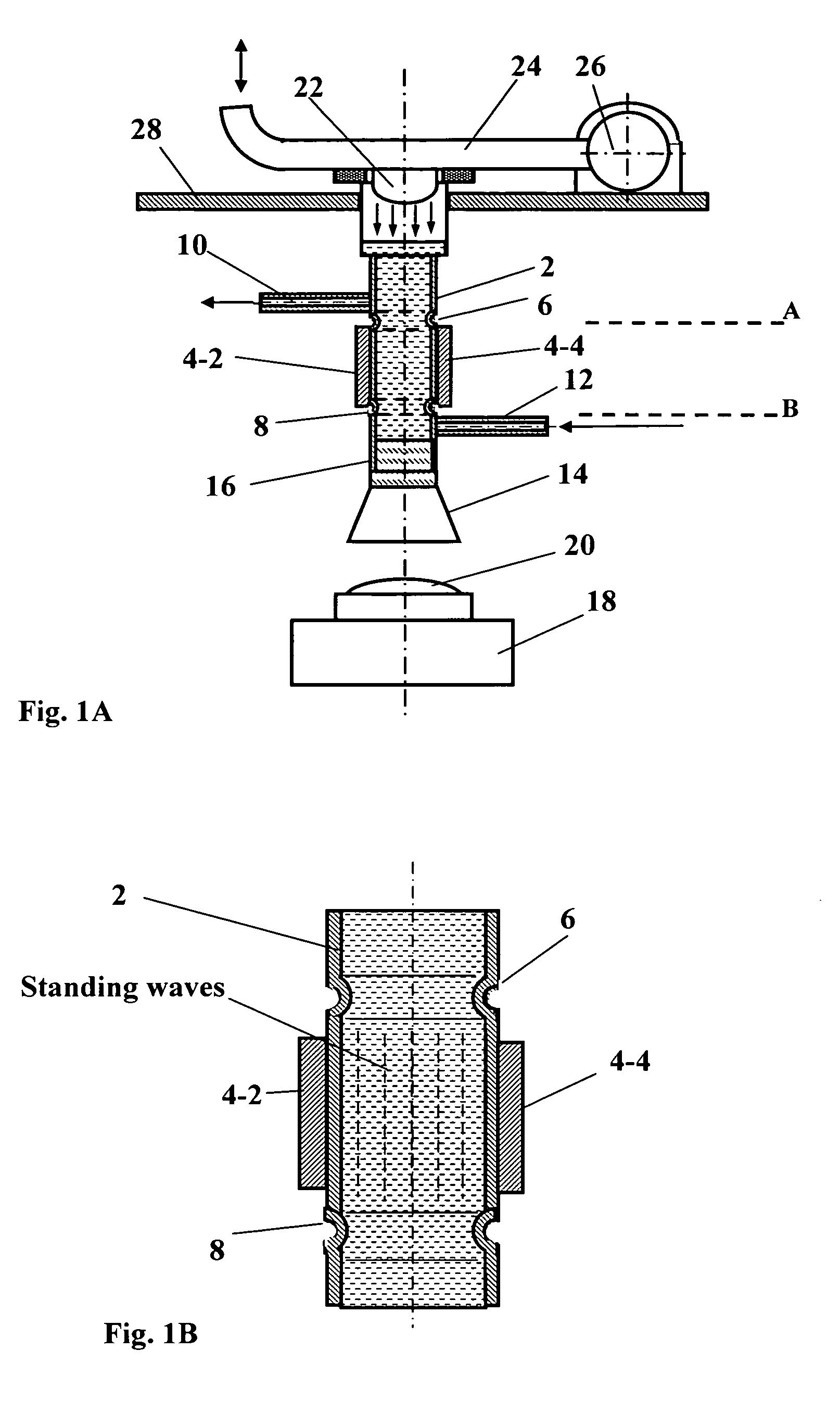

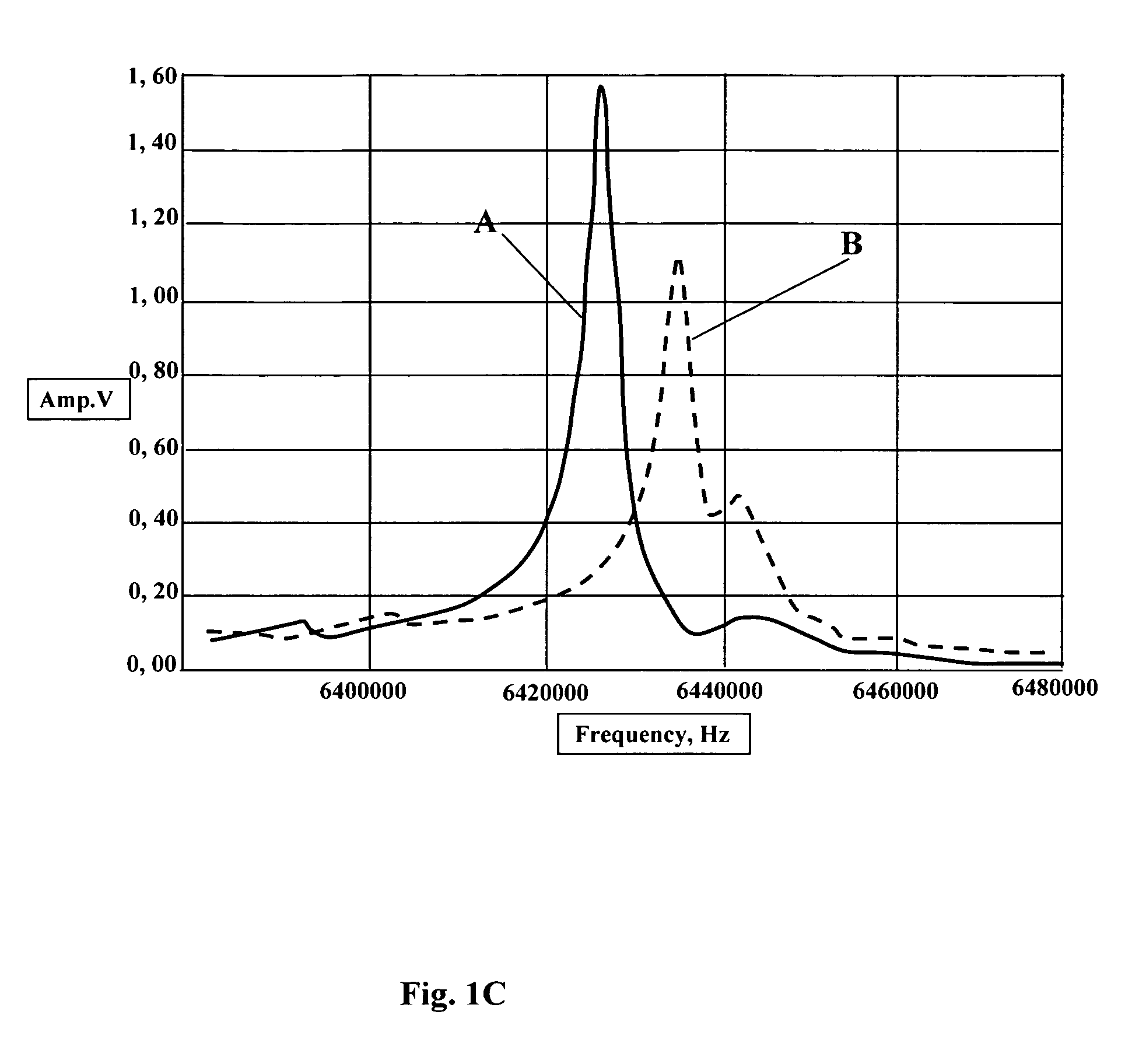

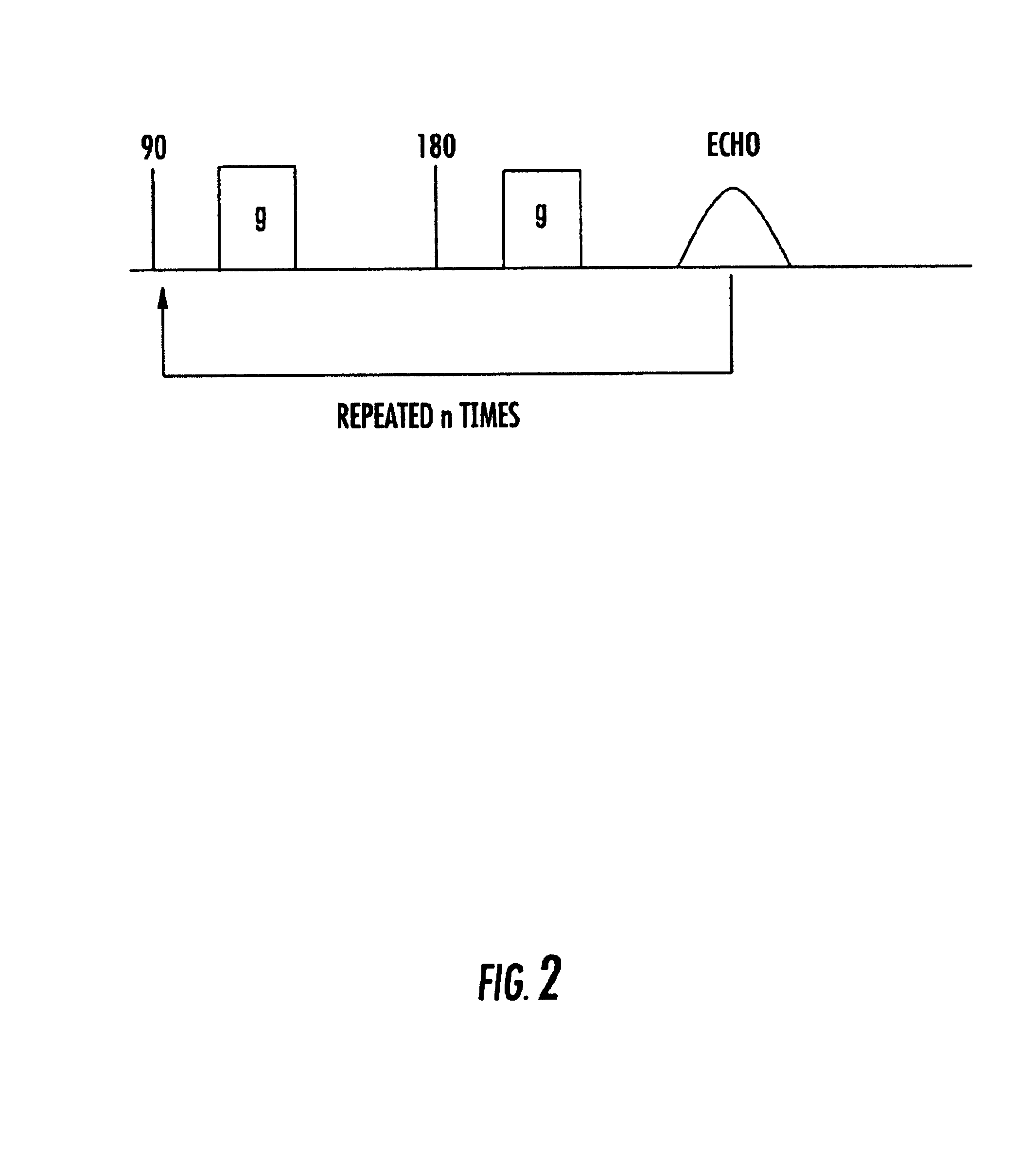

Method and apparatus for determination of the concentration of particles in multi-component fluid systems

InactiveUS20070119239A1Low temperature controlVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesFluid systemLarge particle

A method for determining the concentration of a large particle component in a multi-component system. The method requires first separating and concentrating the large particle component of the system by acoustic means and then measuring an acoustical parameter of the separated large particle component. The invention also provides for an apparatus for determining the concentration of large particles in a multi-component fluid system. The apparatus is comprised of an acoustic standing wave resonator, at least one acoustic standing wave generating source, electronic circuitry for actuating, controlling and processing the acoustic standing wave generating source and means for measuring at least one parameter of the multi-component system after the large particles have been concentrated and aggregated by the generated standing wave(s).

Owner:NANOALERT ISRAEL

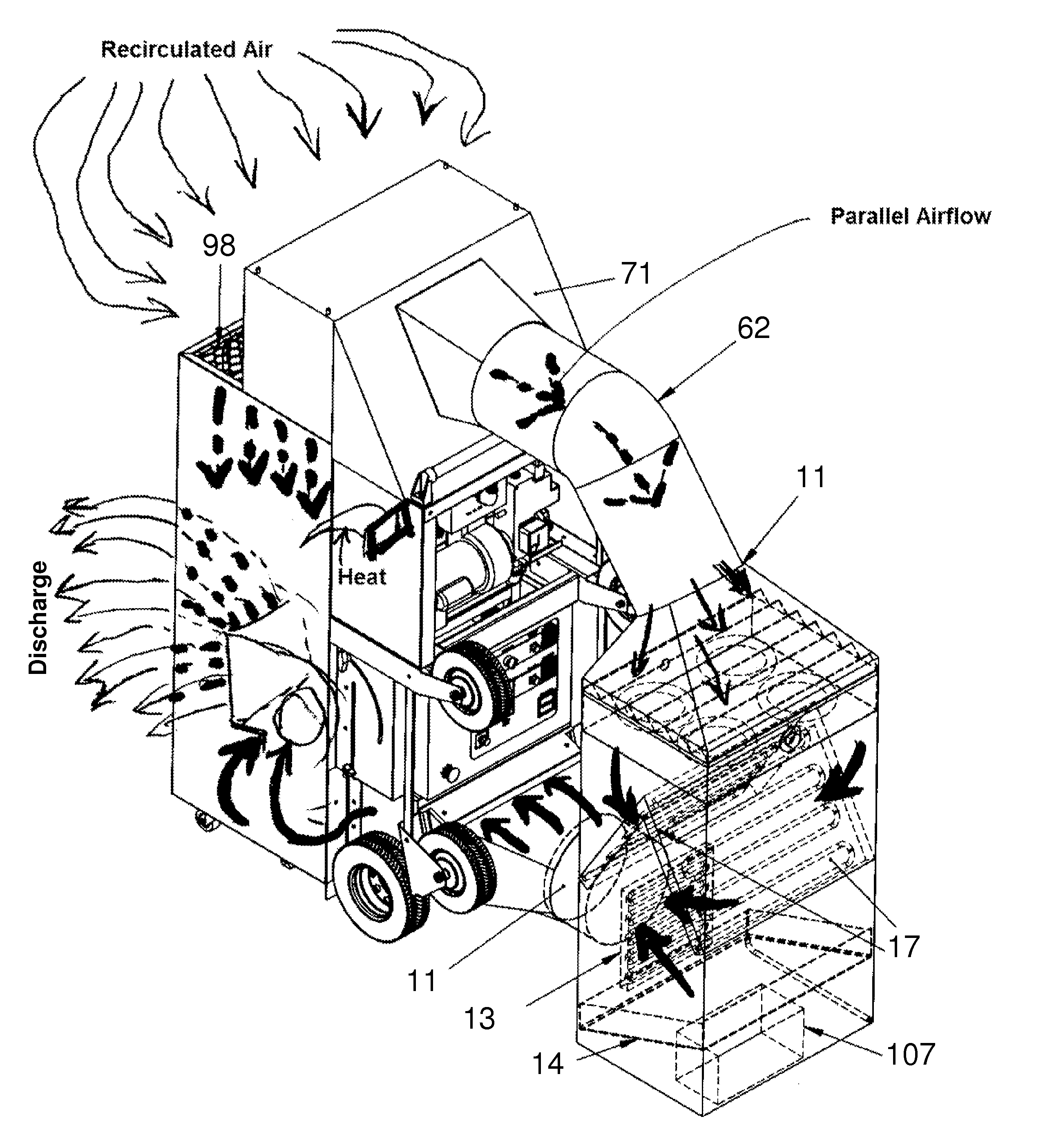

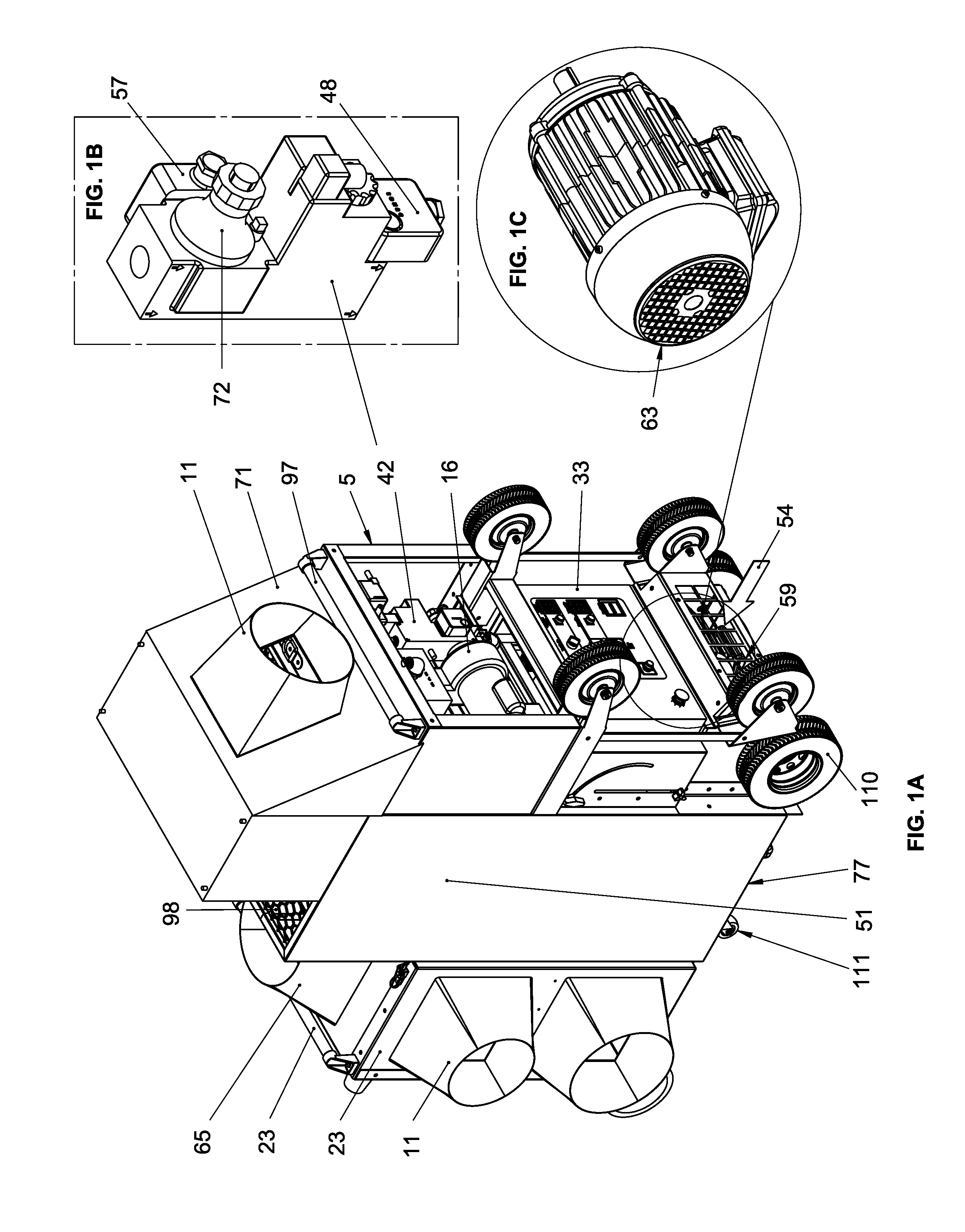

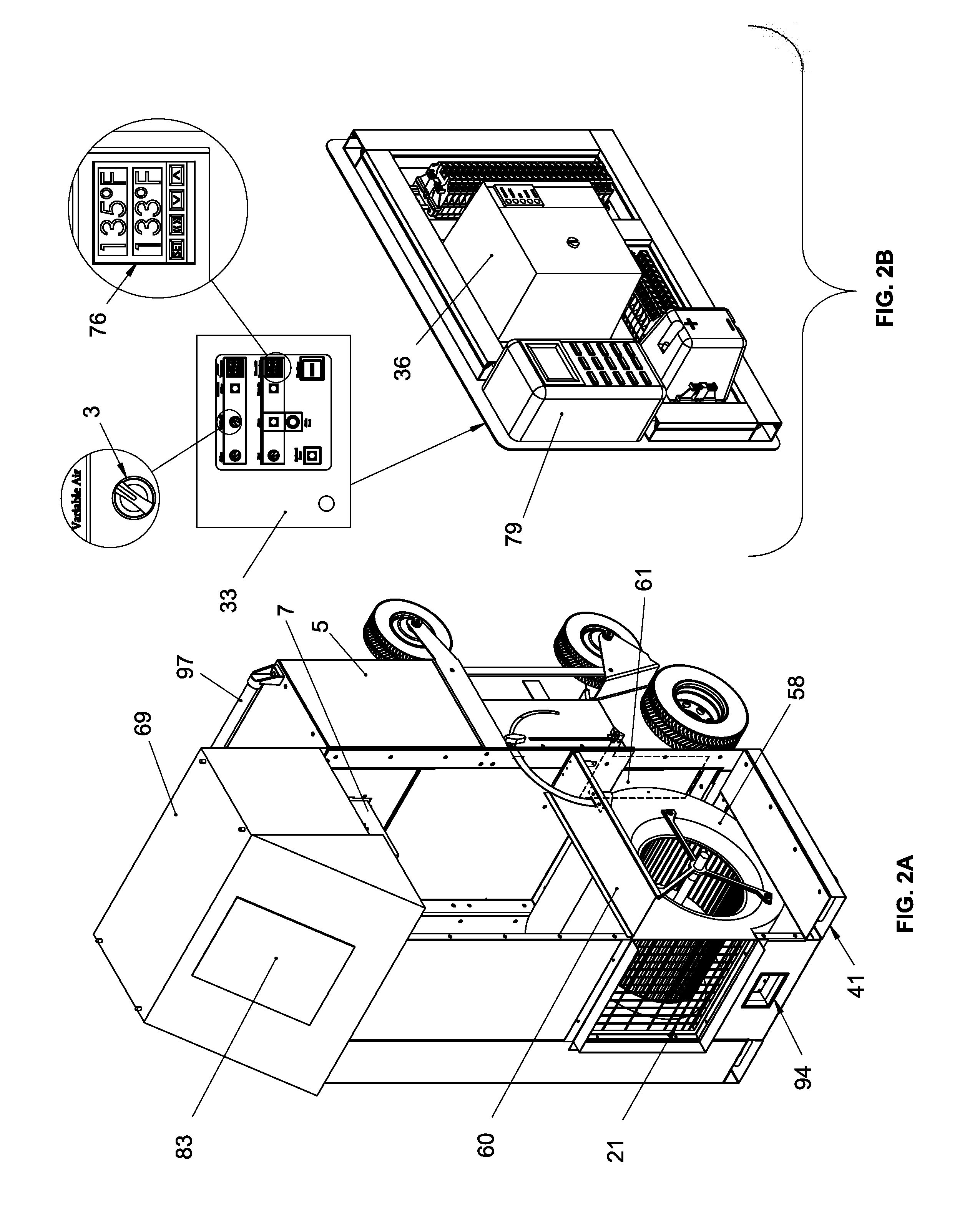

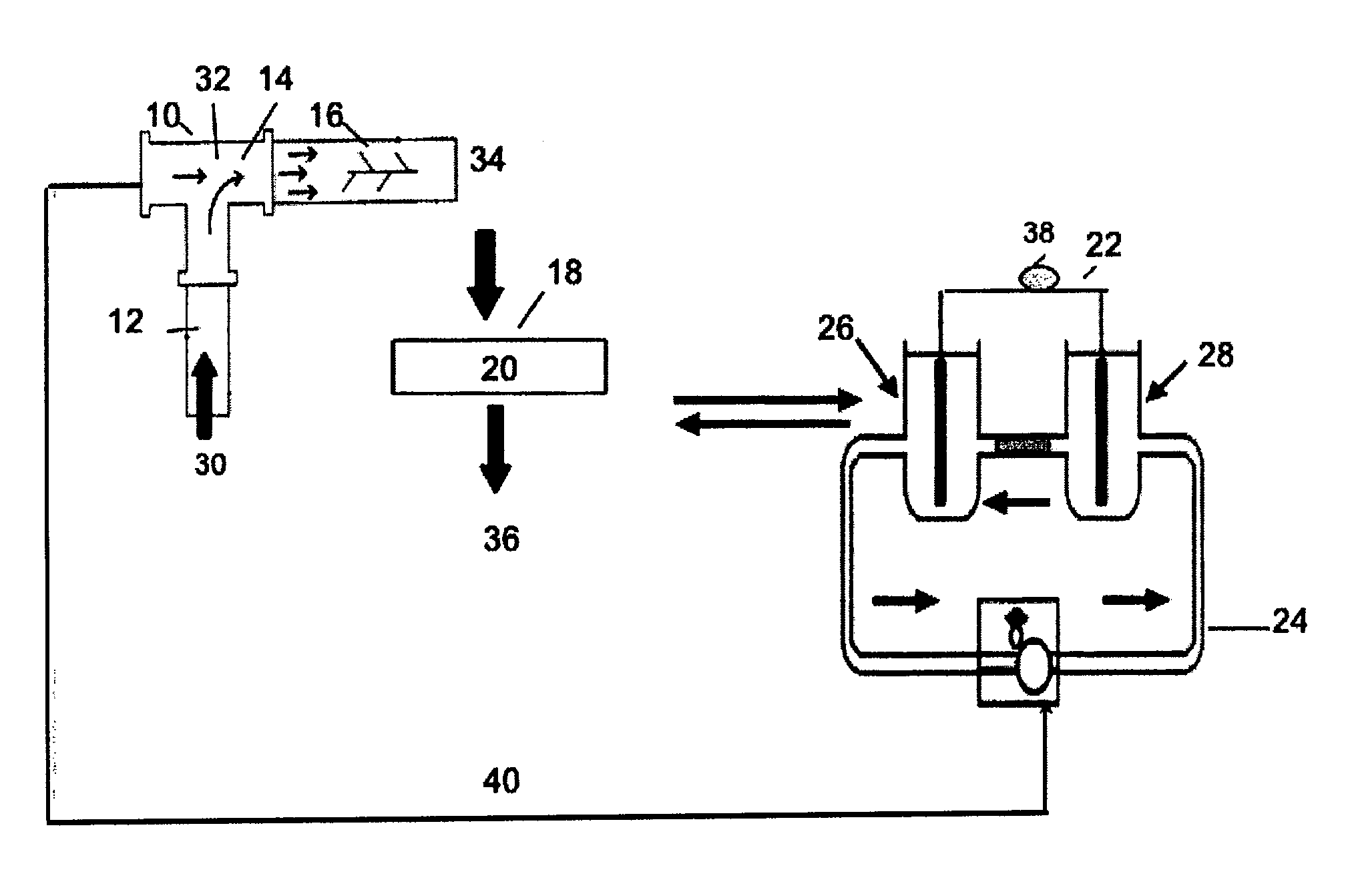

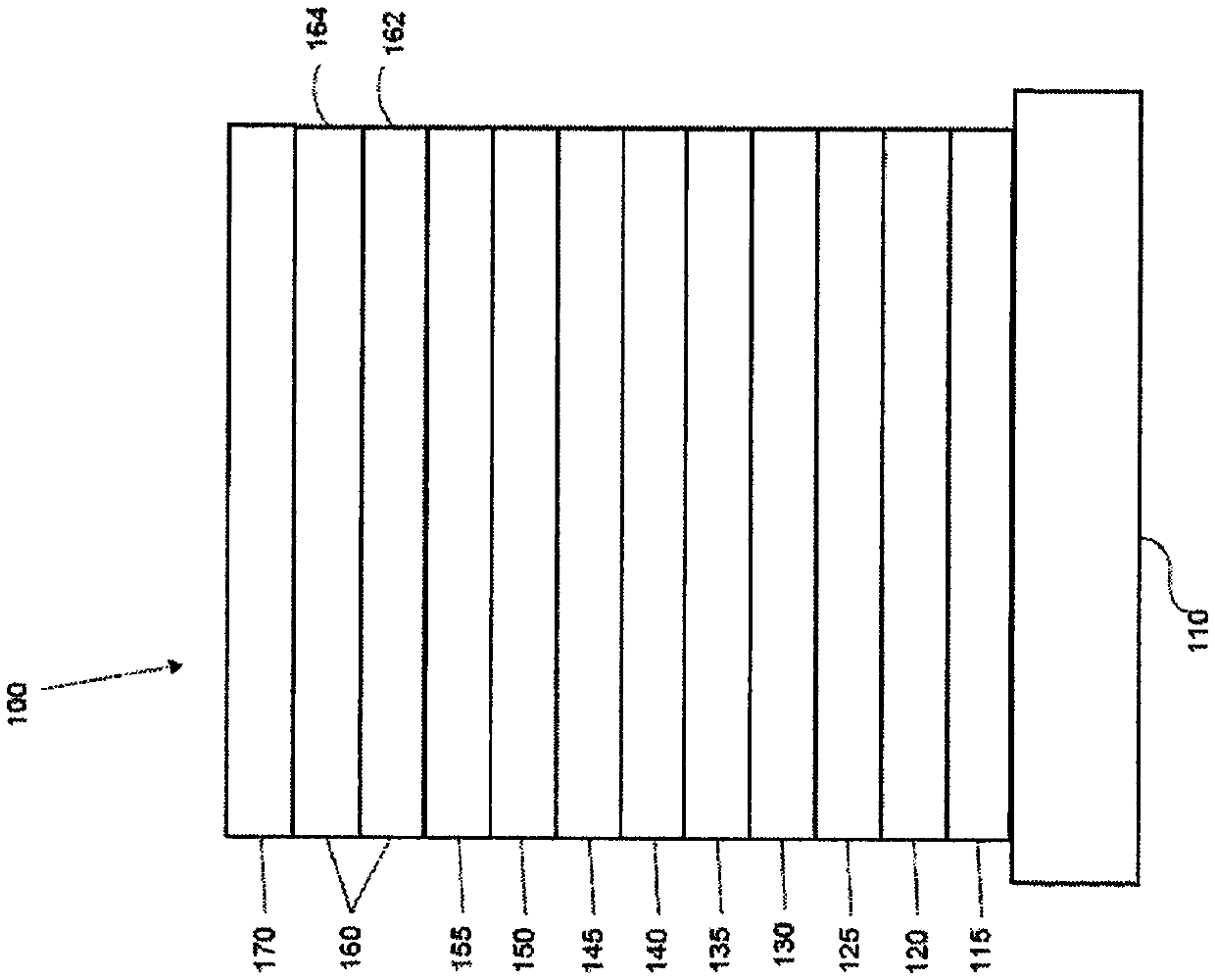

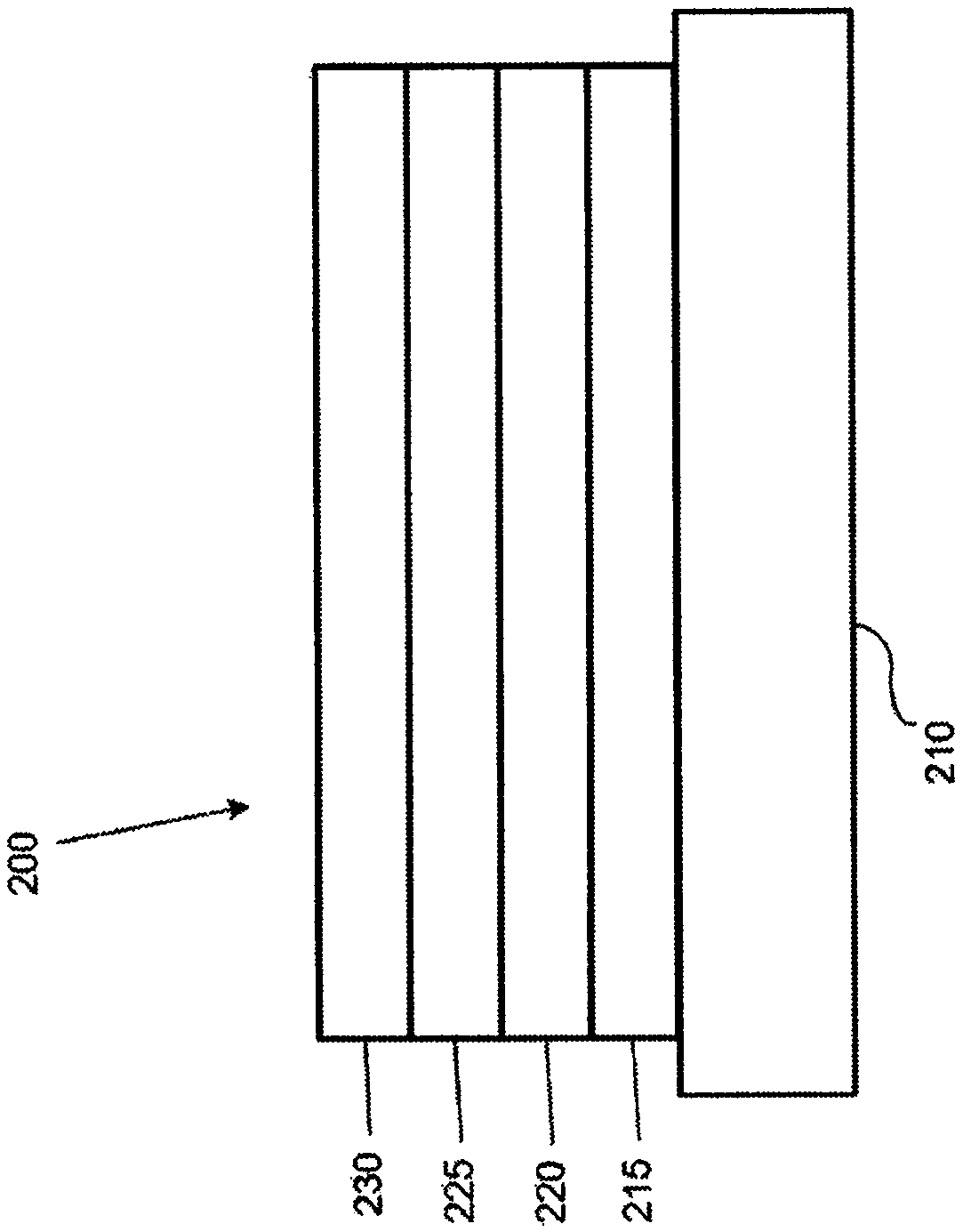

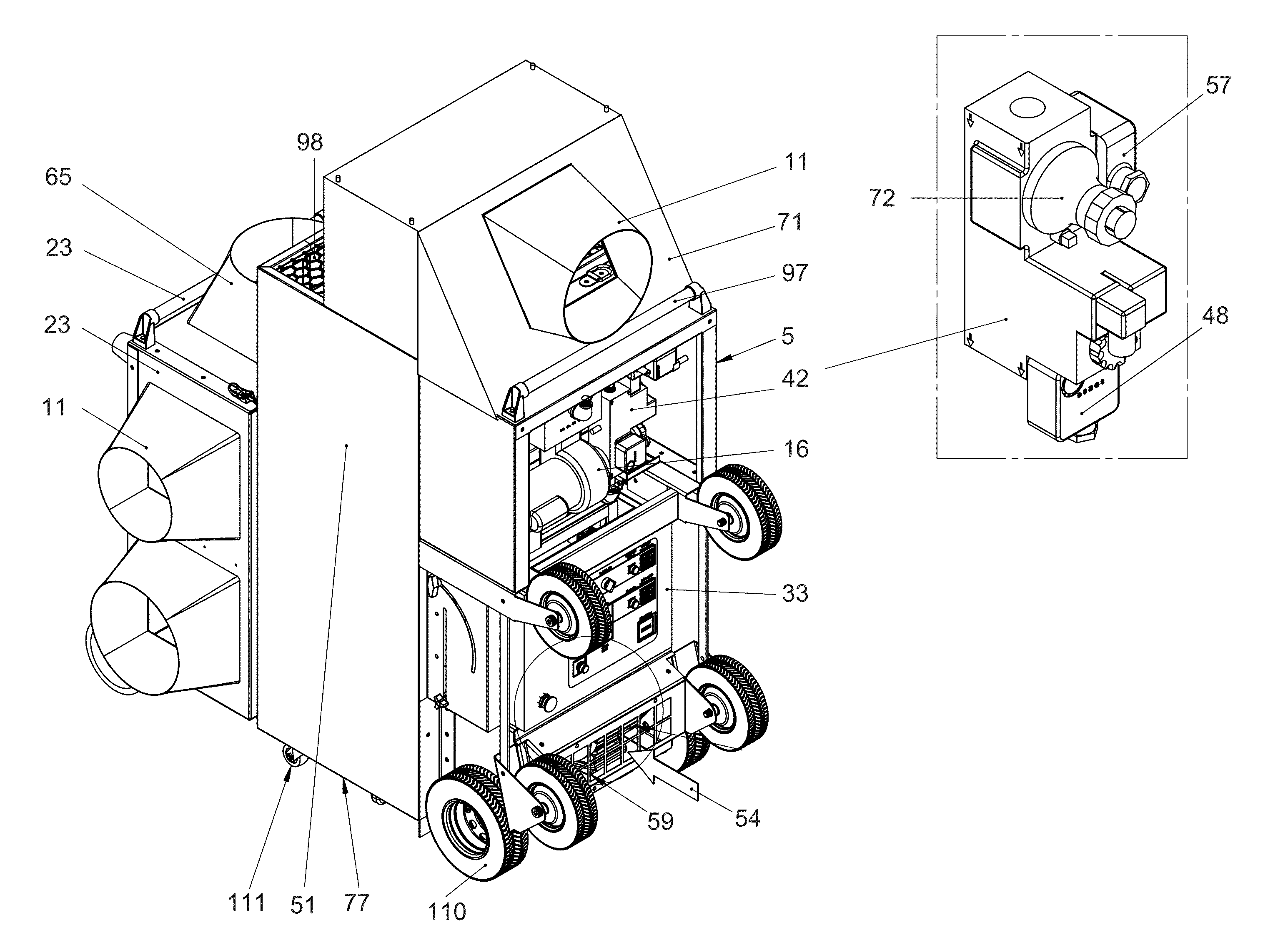

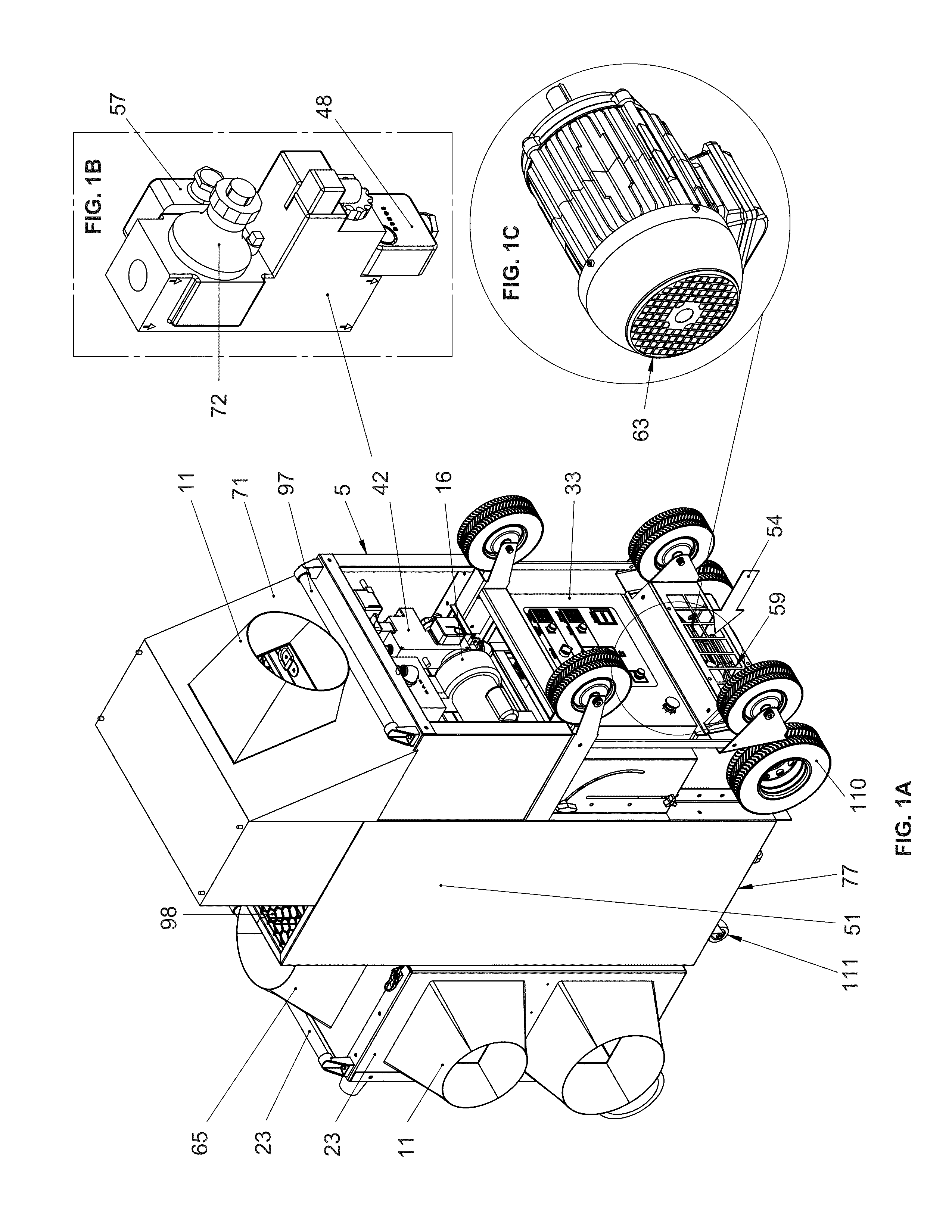

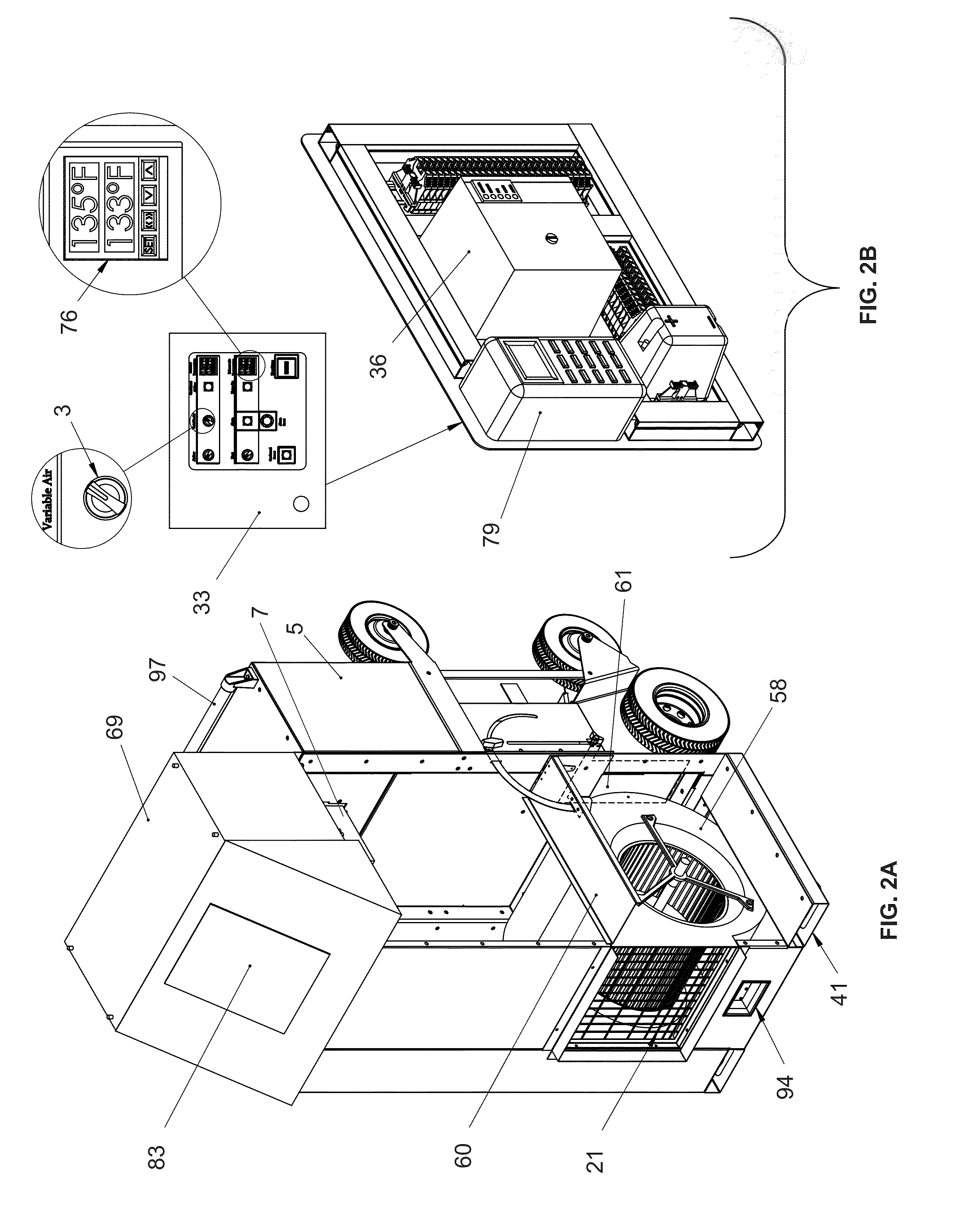

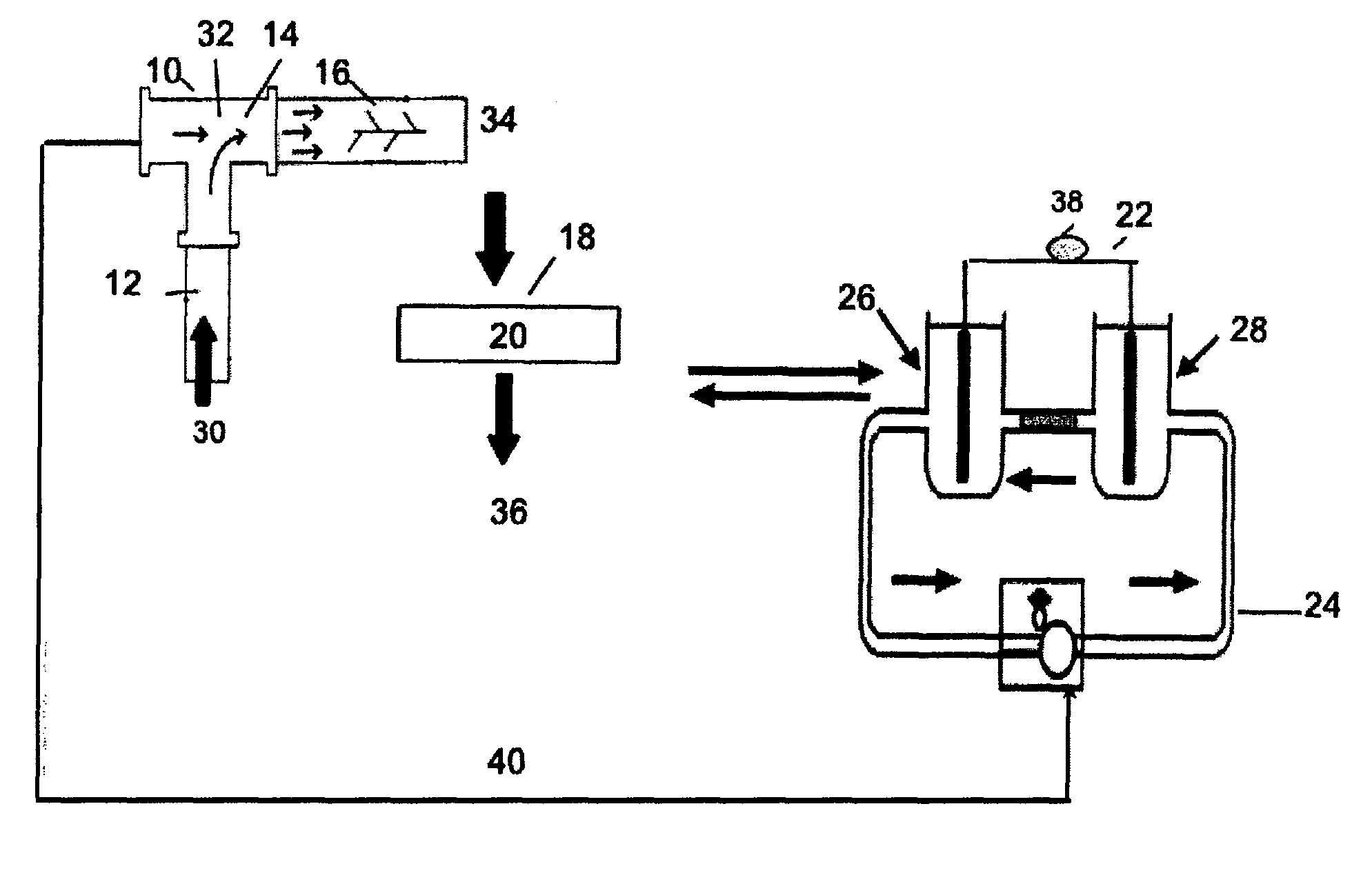

Multi-Component System for Treating Enclosed Environments

ActiveUS20150128483A1Eradicate smoke and water damageStructural damageHot-air central heatingDrying solid materials with heatComputer moduleEngineering

Described herein is a heating system where air is drawn into a system where hot gas is injected into it. The air is then discharged at a regulated temperature into an environment through ductwork to heat environments to elevated temperatures and employing functional modules to further condition the air to humidify, dehumidify, decontaminate with airborne free-radicals, and filtrate in both stationary and portable applications. The system is useful to eradicate pests, disease germs, bacteria, viruses, and mold. The system is also useful in water remediation and comfort heating. The system can be configured to create a parallel path to both heat and dehumidify the airflow blended and discharged at the operator-chosen set-point temperatures.

Owner:SUPPLIER SUPPORT INT

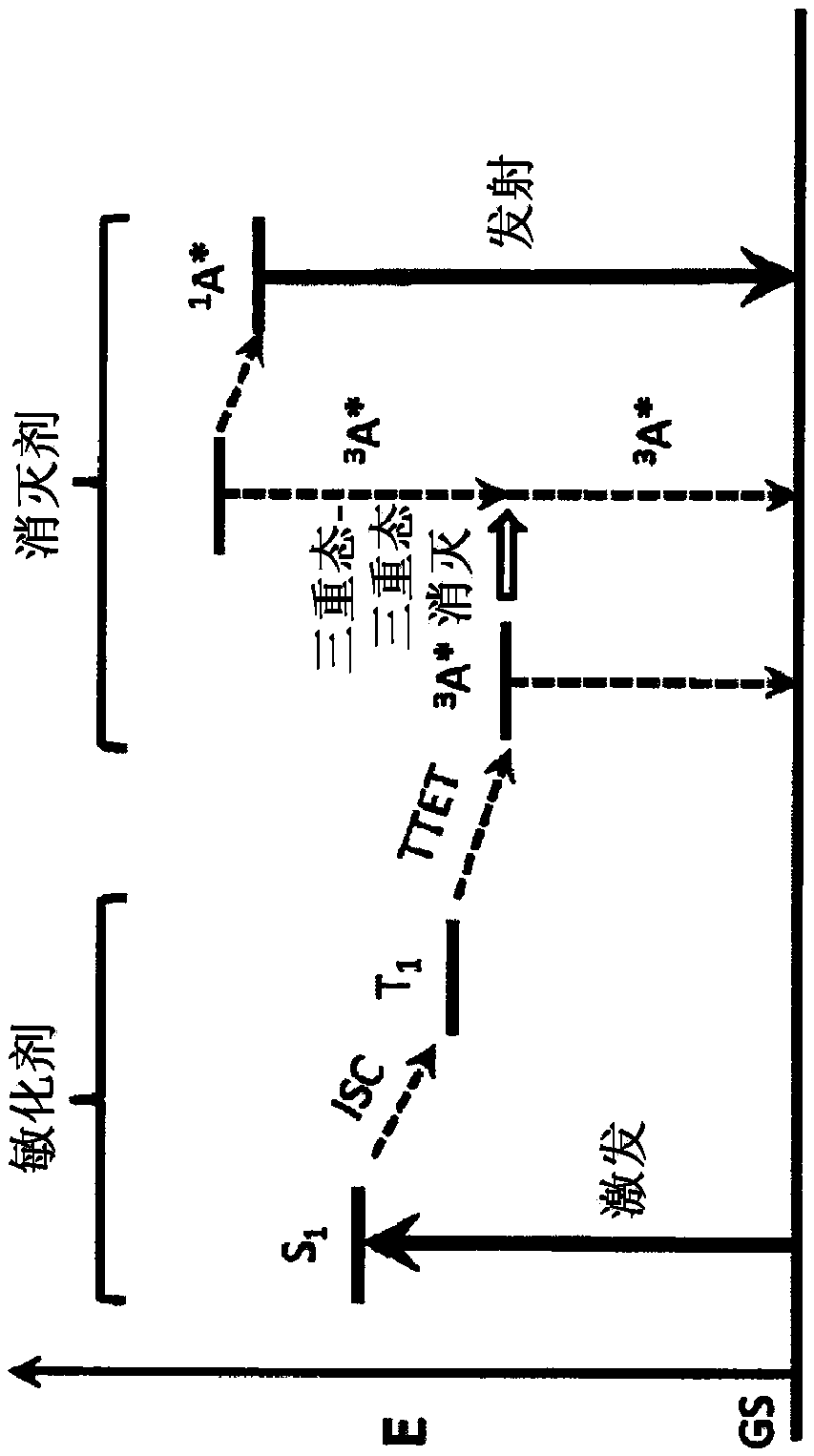

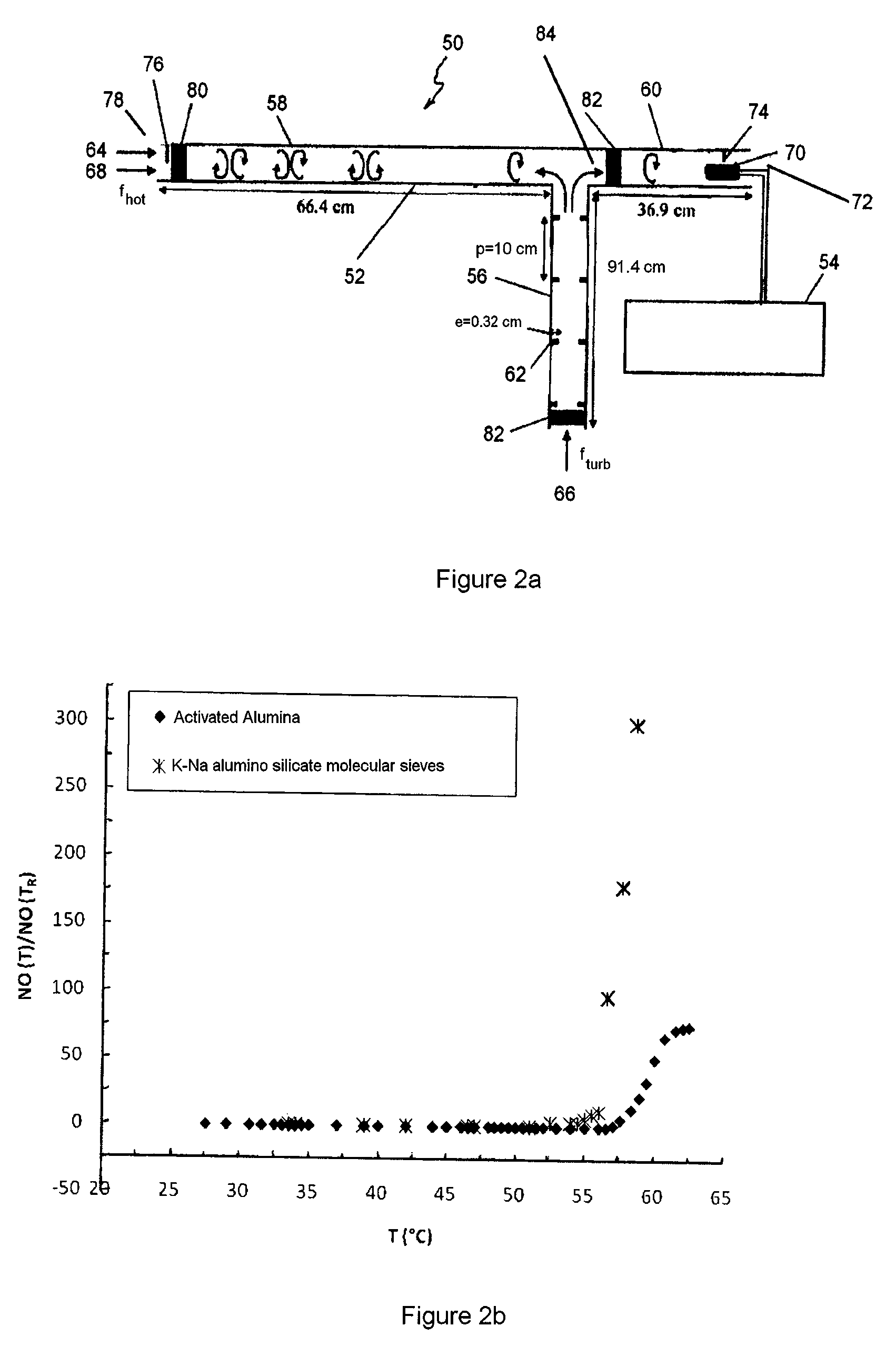

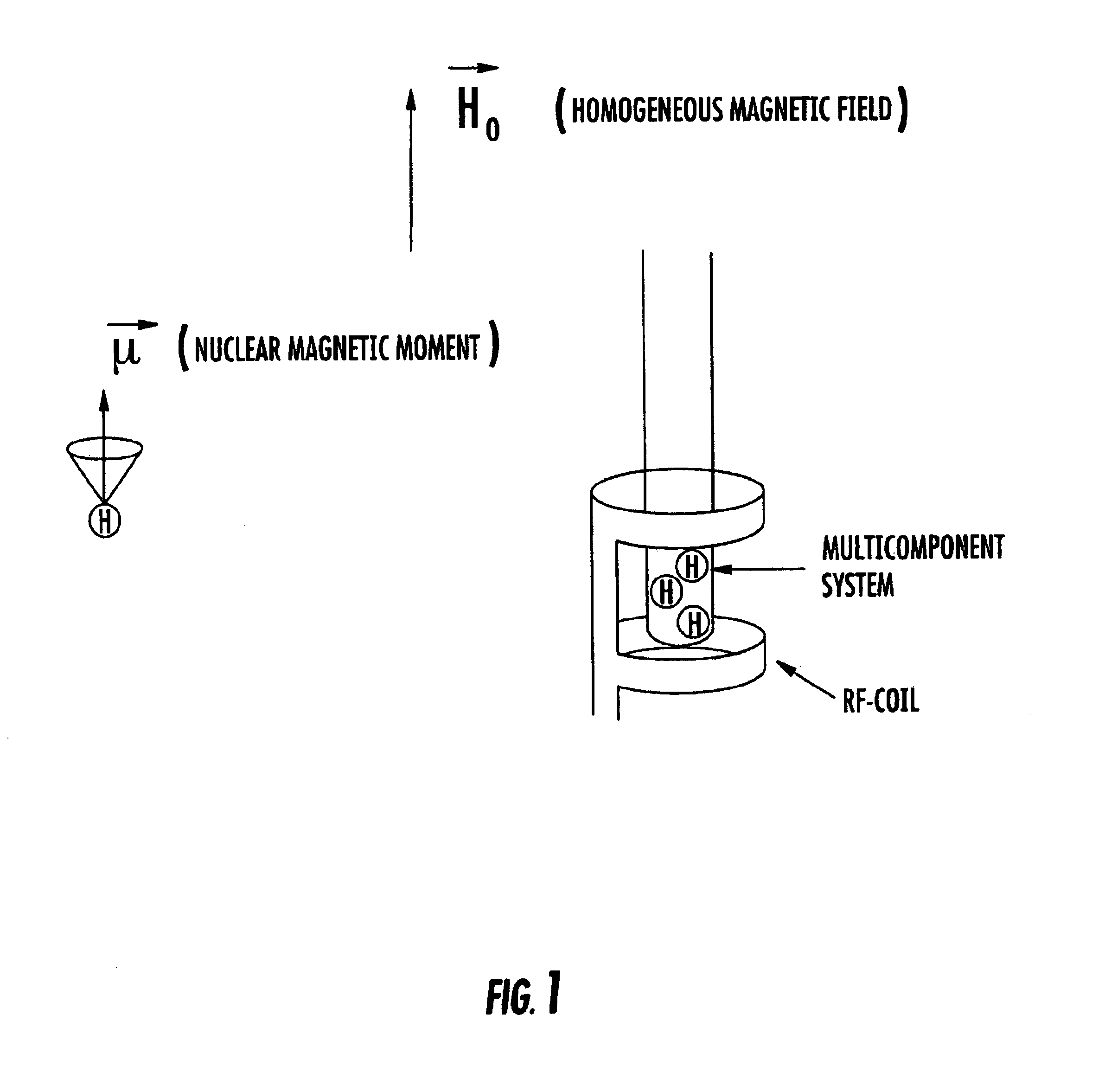

Novel compounds and uses in devices

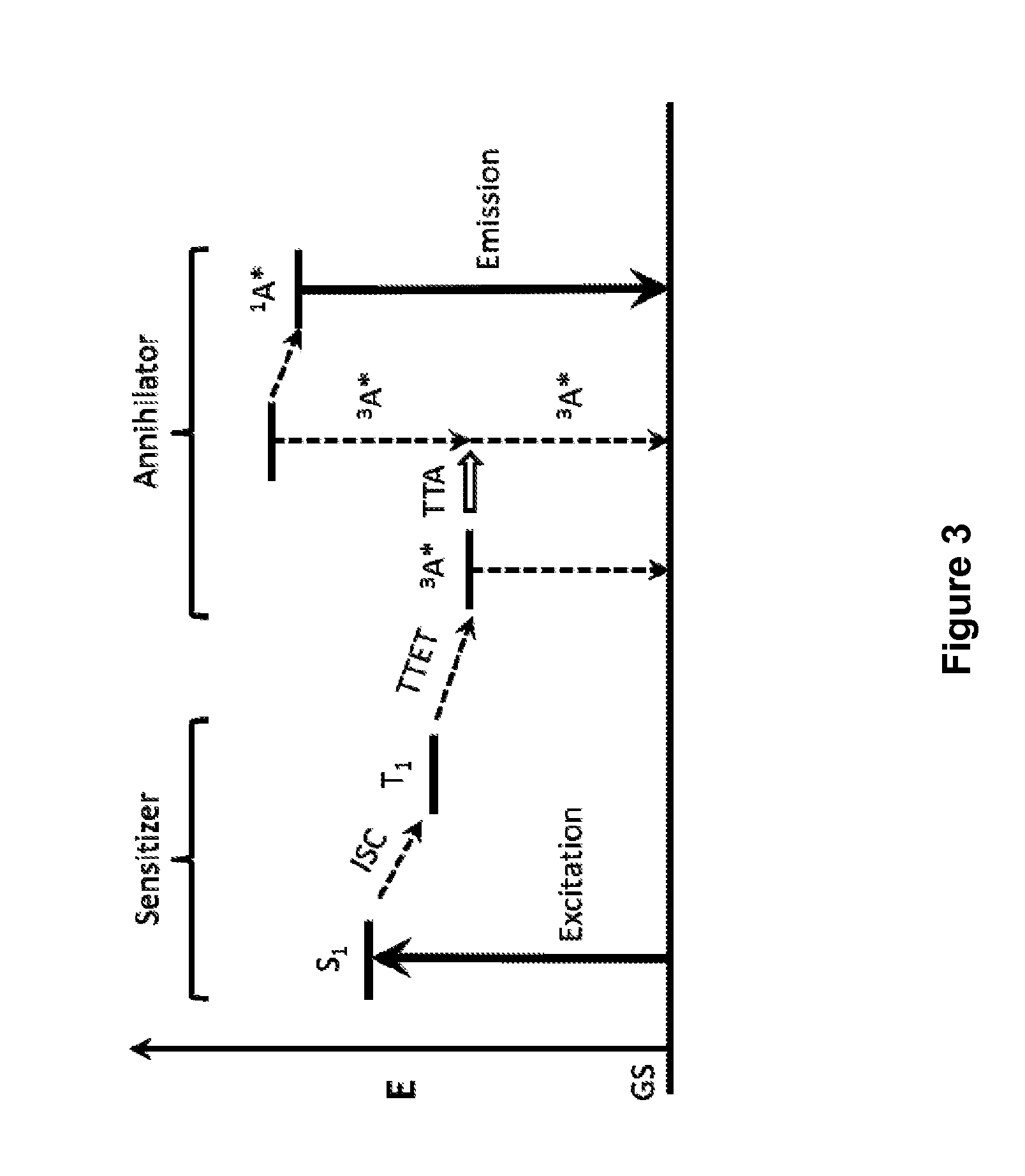

ActiveUS20160104847A1High triplet energyGroup 8/9/10/18 element organic compoundsSolid-state devicesUp conversionTriplet triplet annihilation

This invention discloses a novel multicomponent system or a single compound that is capable of performing triplet-triplet annihilation up conversion process. (TTA-UC) A solution or solid film that comprises this TTA-UC system or compound is provided. This system or compound can be used in an optical or optoelectronic device.

Owner:UNIVERSAL DISPLAY

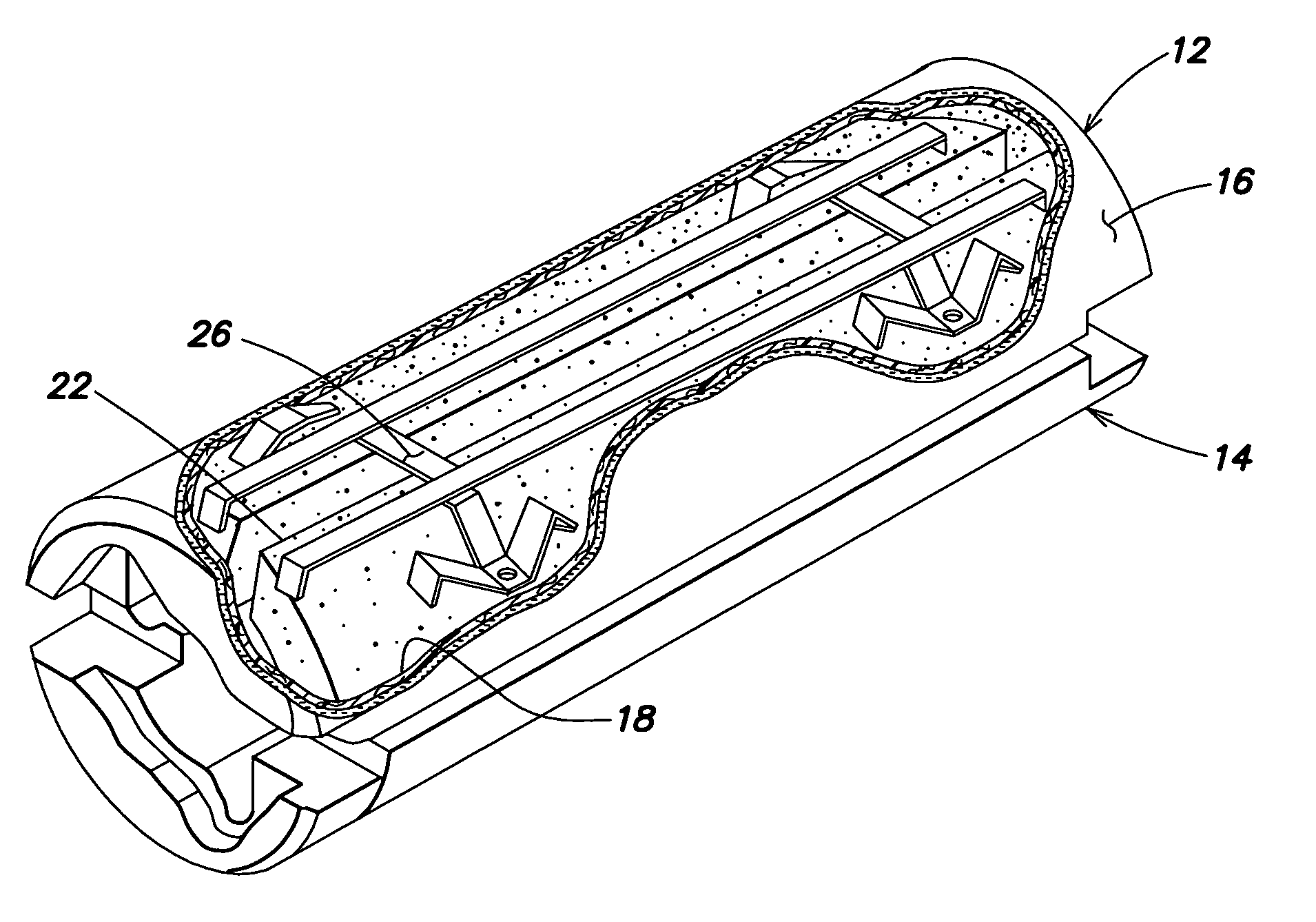

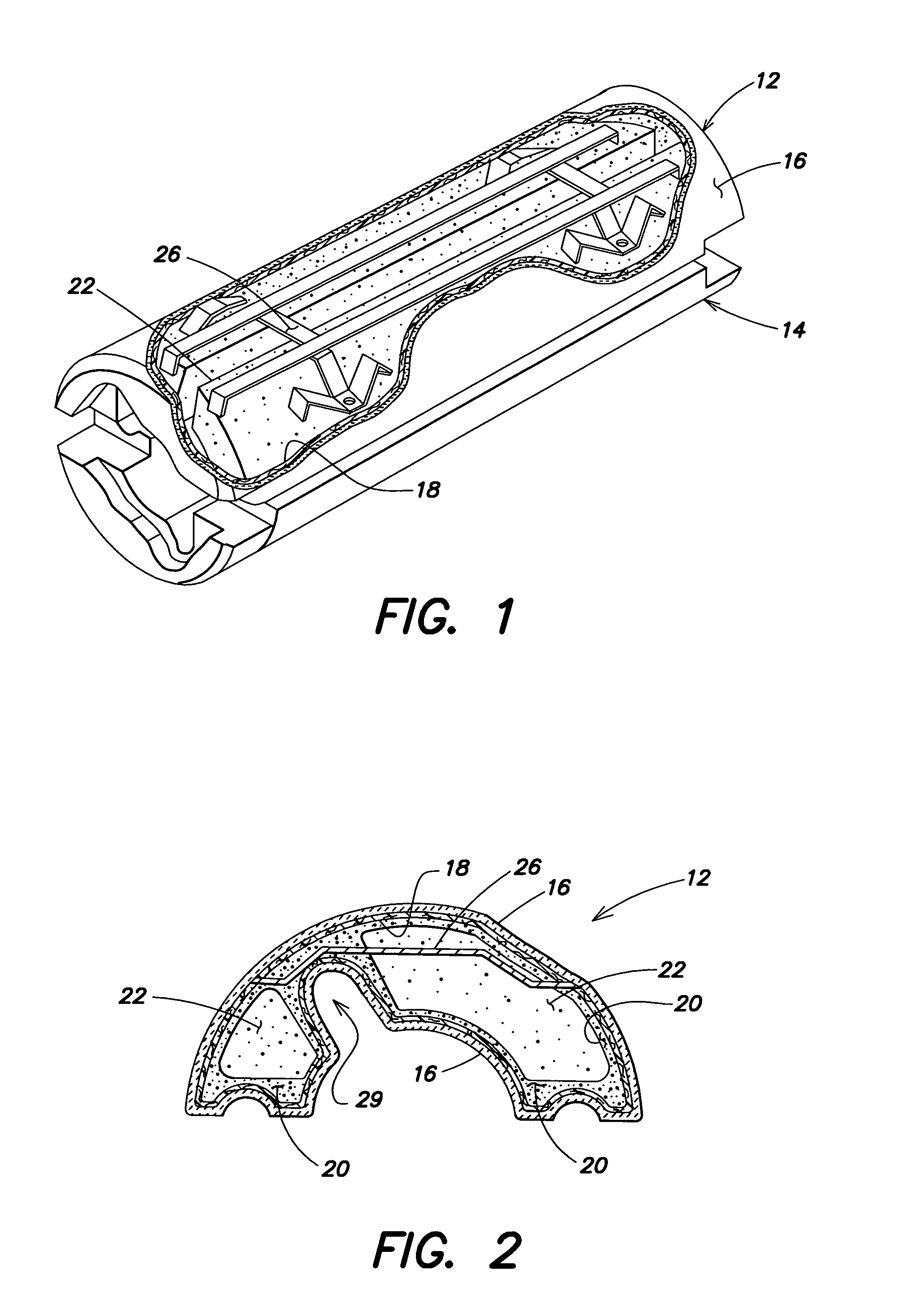

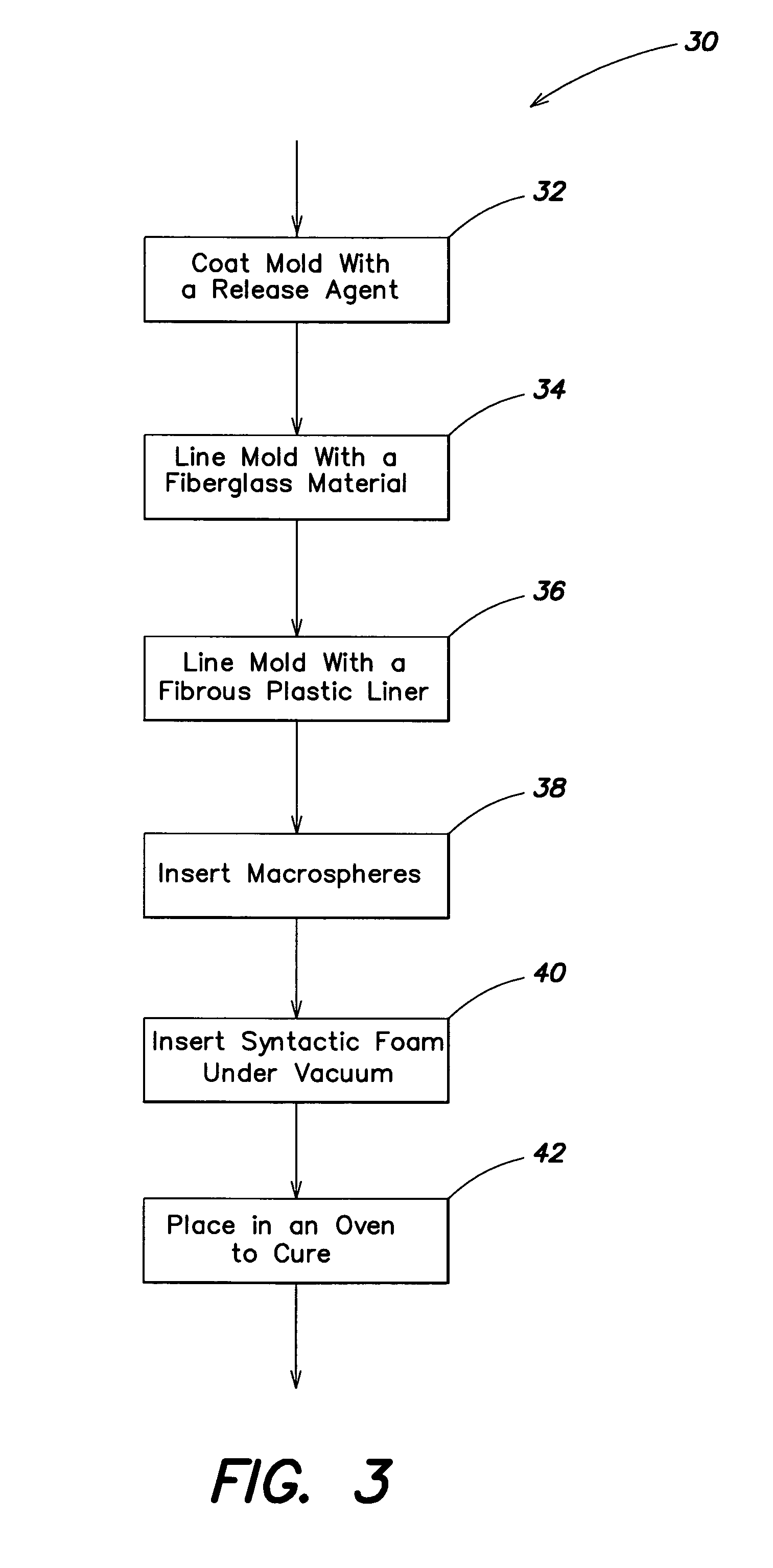

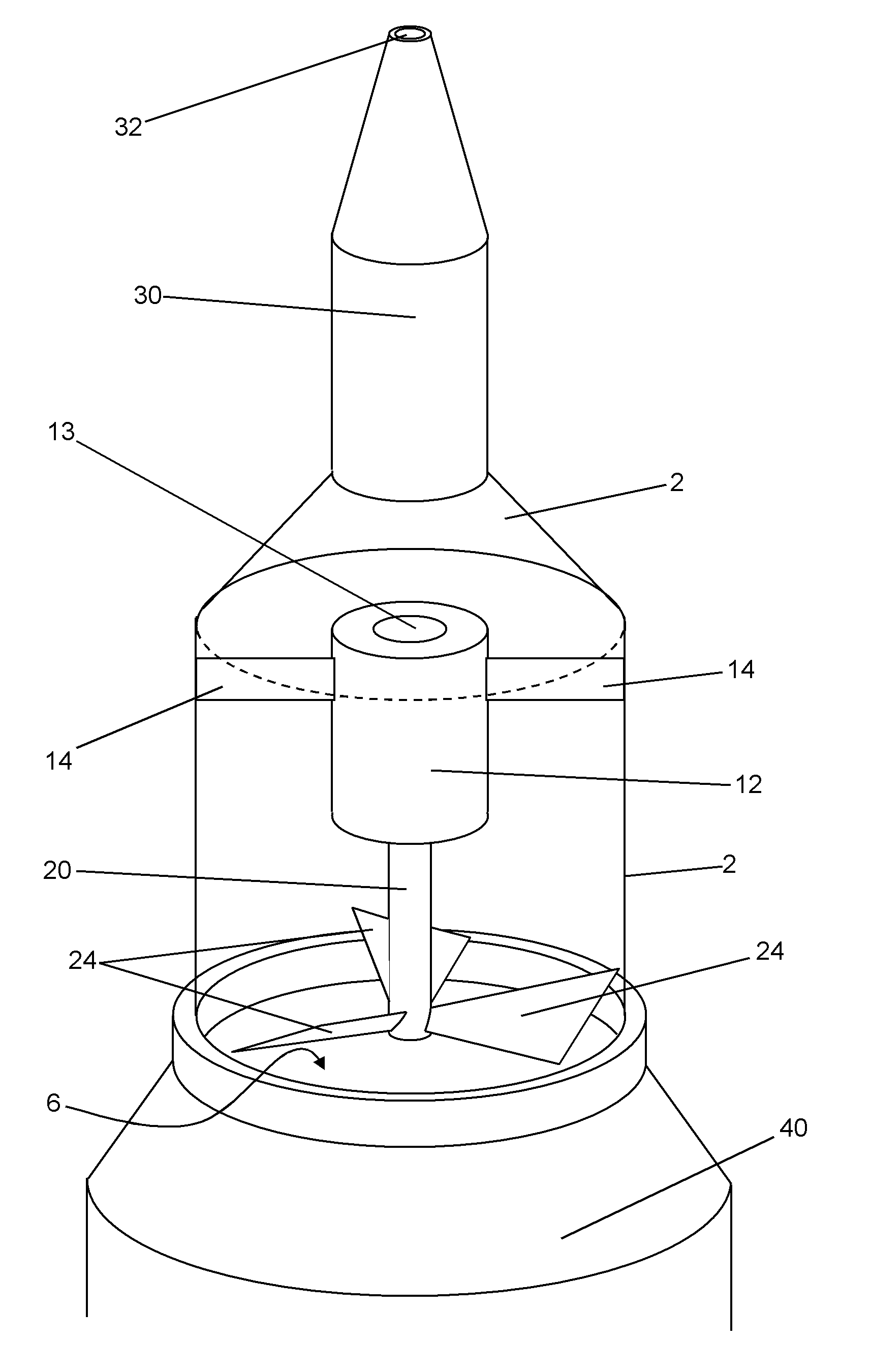

Rugged foam buoyancy modules and method of manufacture

InactiveUS7121767B1Increased durabilityImprove reinforcementDrilling rodsWaterborne vesselsFiberGlass fiber

A buoyancy module comprises a multi-layer outer protective shell that has an exterior surface and an interior surface. A first layer of foam buoyancy material is located adjacent to the interior surface. A second layer of foam buoyancy material that includes macrospheres and syntactic foam is surrounded by the first layer of foam buoyancy material. The multi-layer outer protective shell can include a layer of fiberglass backed by a fibrous plastic liner. In this embodiment, the layer of fiberglass provides the exterior surface of the multi-layer outer protective shell, while the fibrous plastic liner provides the interior surface of the protective shell. The second layer of foam buoyancy material can be a precast material. The precast material can include for example macrospheres and syntactic foam. The first layer of foam buoyancy material is preferably a stronger layer than the second layer of foam buoyancy material. Advantageously, the buoyancy module has a plurality of different layers, wherein the components of greatest strength and density are located on the outside. The multi-component system improves ruggedness of the buoyancy material, and provides increased reinforcement at locations subject to increased bending strengths, and provides a buoyancy module of longer life. In addition the buoyancy module may also include steel support members where bolting loads and other forces are brought to bear when parts are attached.

Owner:CUMING CORP

Graphics processing unit based discrete simulation computation method of multicomponent system

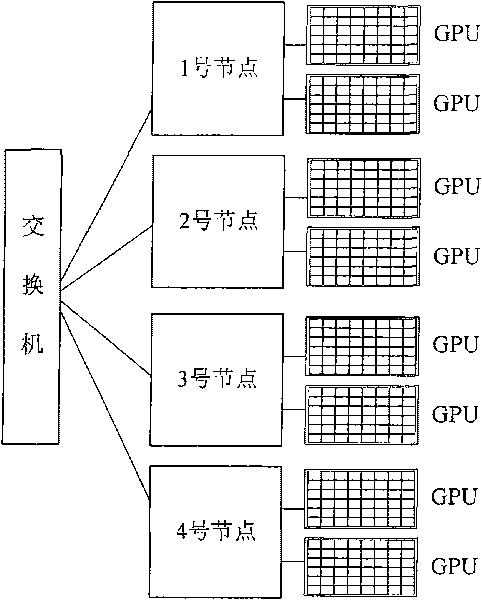

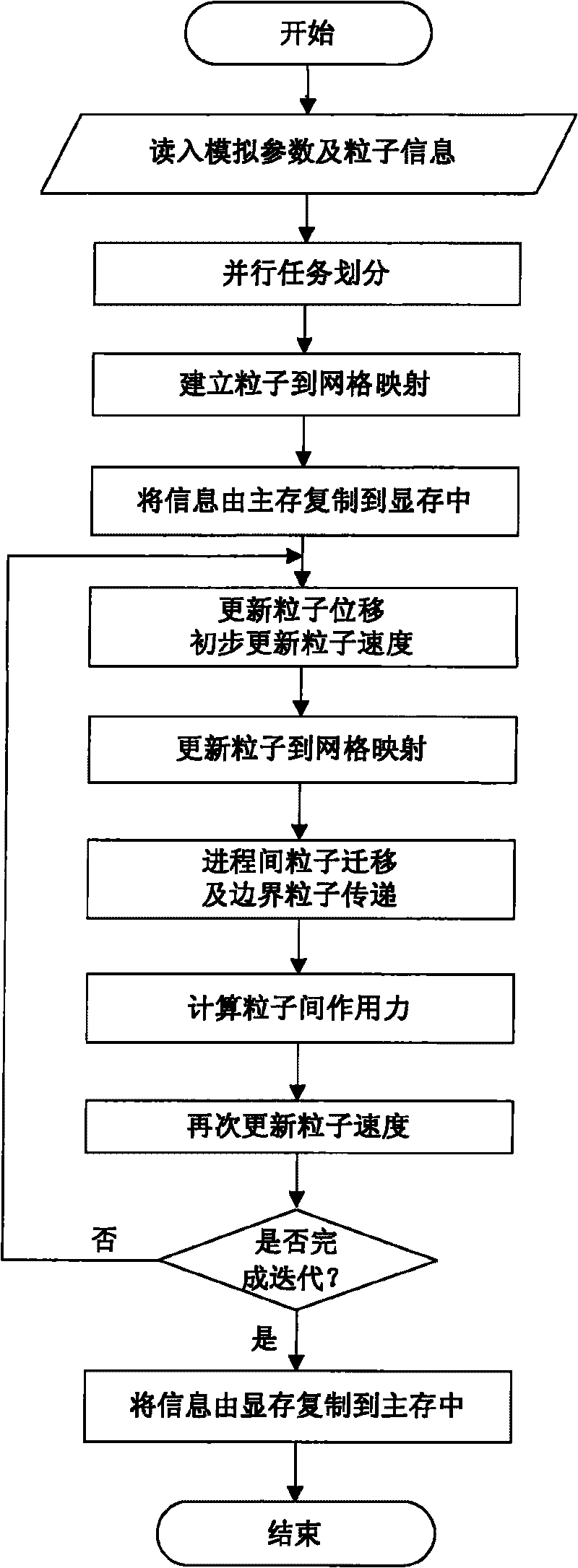

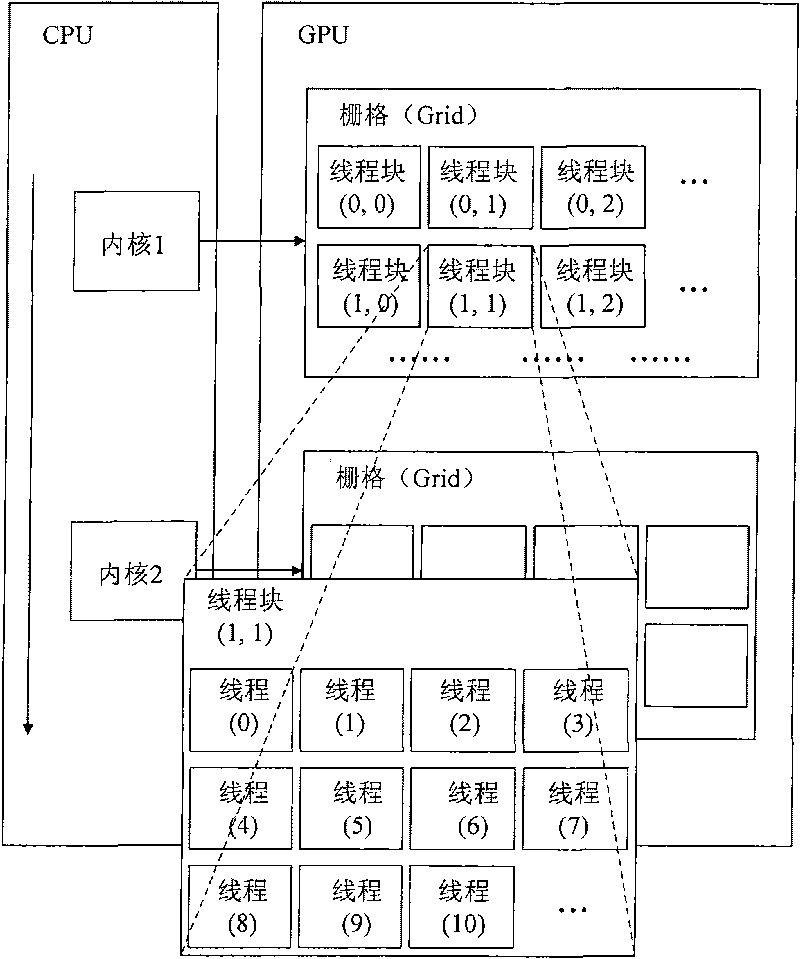

InactiveCN101727653ASolve inefficiencyImprove computing efficiencyImage data processing detailsGraphicsComputational science

The invention relates to a graphics processing unit based discrete simulation computation method of a multicomponent system, which is realized on a parallel computation system comprising multiple computation nodes, wherein the computation nodes are provided with graphics processing units (GPU). The discrete simulation computation method comprises the following steps of: decomposing the space of the multicomponent system to be simulated; establishing the mapping relationship between granules and grids inside the multicomponent system; (3) distributing the information of the granules to thread blocks inside the GPUs arranged on the multiple computation nodes, and storing the interaction potential parameters and the simulation setting information of the granules into internal storages of the GPUs; computing acting force born by the granules on the GPUs, and updating the speed and the positions of the granules according to the acting force; and before the simulation of the multicomponent system is completed, repeating executing steps completed in the GPUs till a simulated result is output from the parallel computation system after the simulation is completed. The invention solves the problem of low efficiency caused by selection when the GPUs compute multiple interaction potentials and greatly enhances the computation efficiency compared with a CPU.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

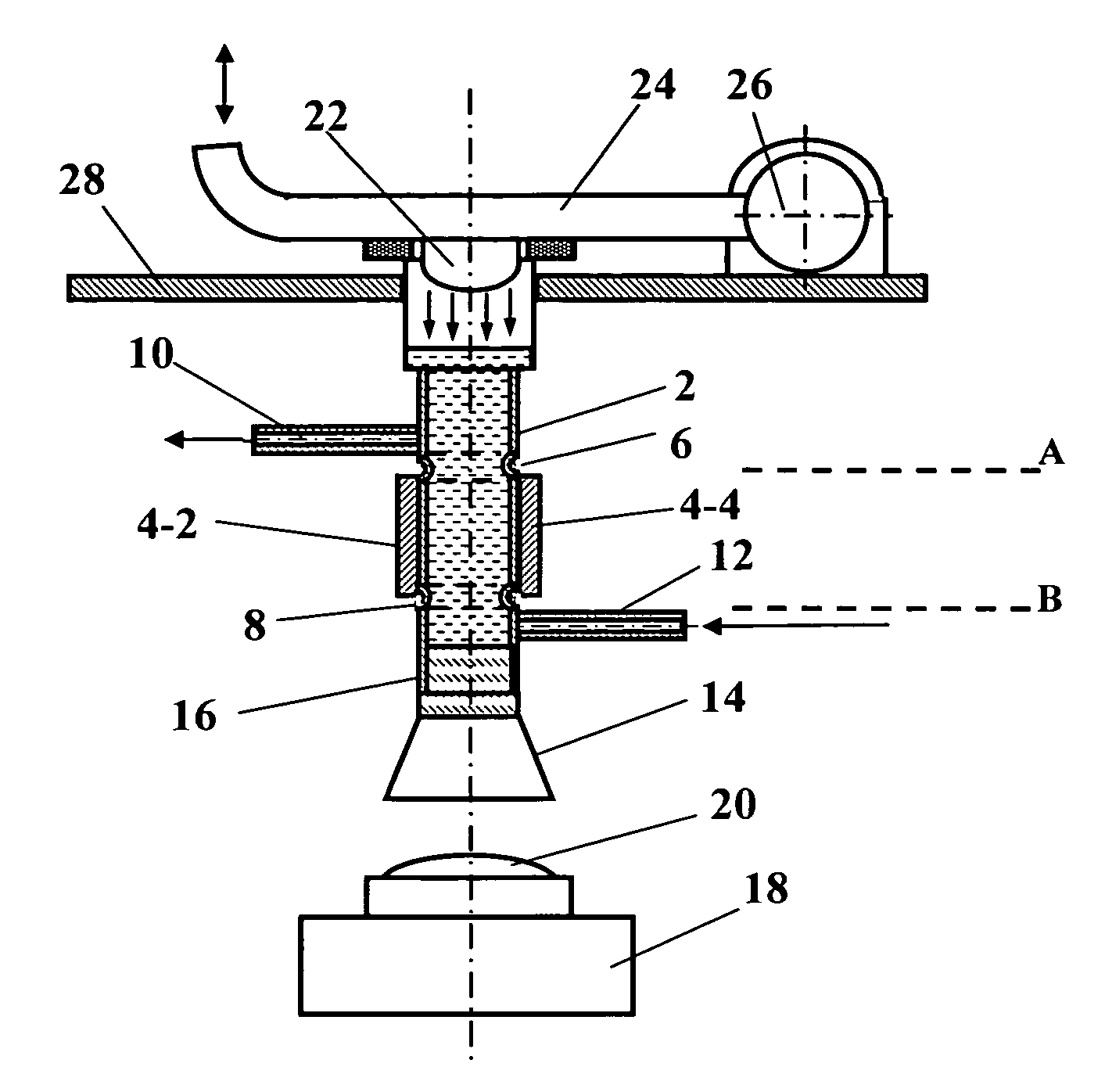

Method and apparatus for determination of the concentration of particles in multi-component fluid systems

InactiveUS7484414B2Low temperature controlVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesFluid systemLarge particle

A method for determining the concentration of a large particle component in a multi-component system. The method requires first separating and concentrating the large particle component of the system by acoustic means and then measuring an acoustical parameter of the separated large particle component. The invention also provides for an apparatus for determining the concentration of large particles in a multi-component fluid system. The apparatus is comprised of an acoustic standing wave resonator, at least one acoustic standing wave generating source, electronic circuitry for actuating, controlling and processing the acoustic standing wave generating source and means for measuring at least one parameter of the multi-component system after the large particles have been concentrated and aggregated by the generated standing wave(s).

Owner:NANOALERT ISRAEL

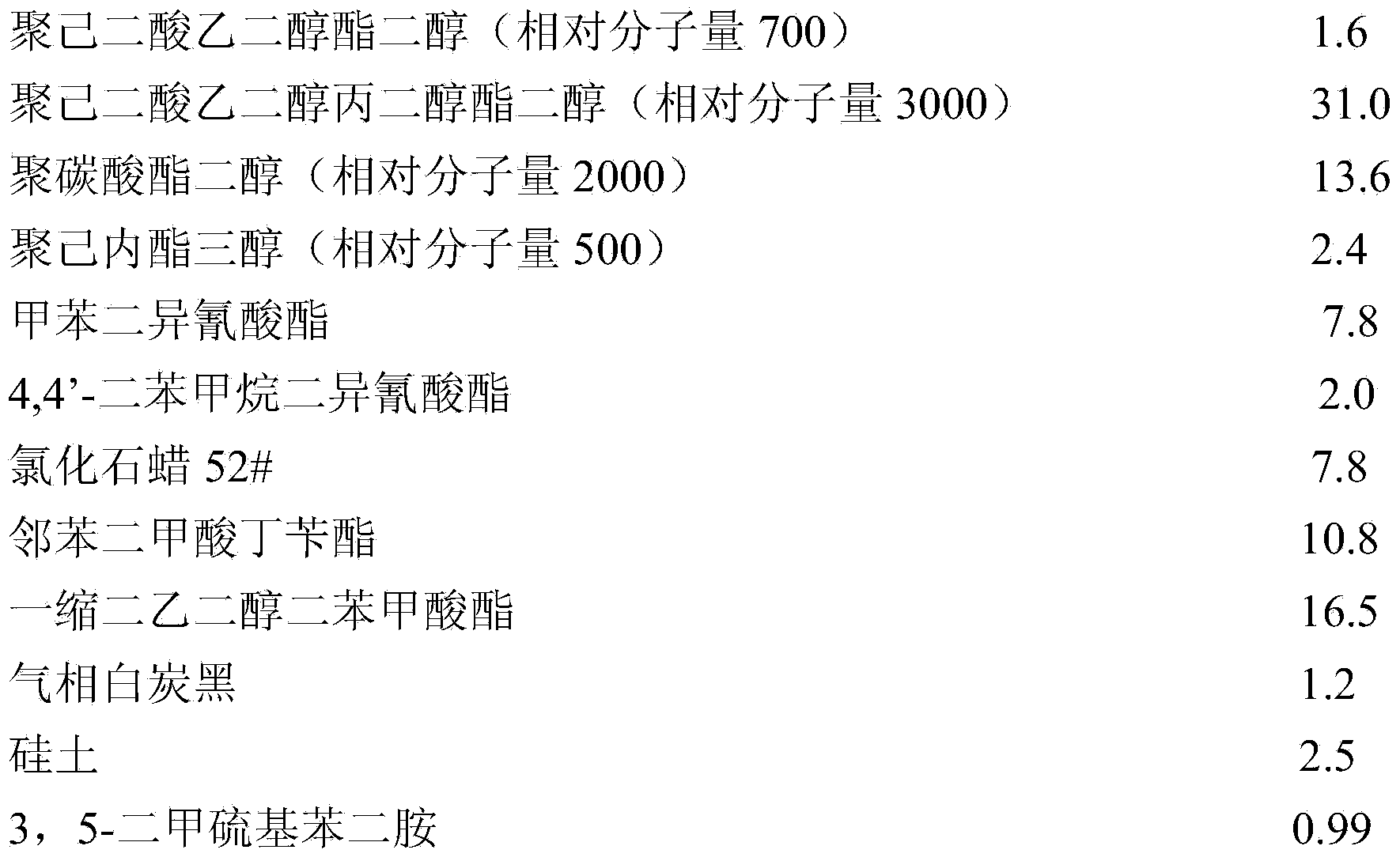

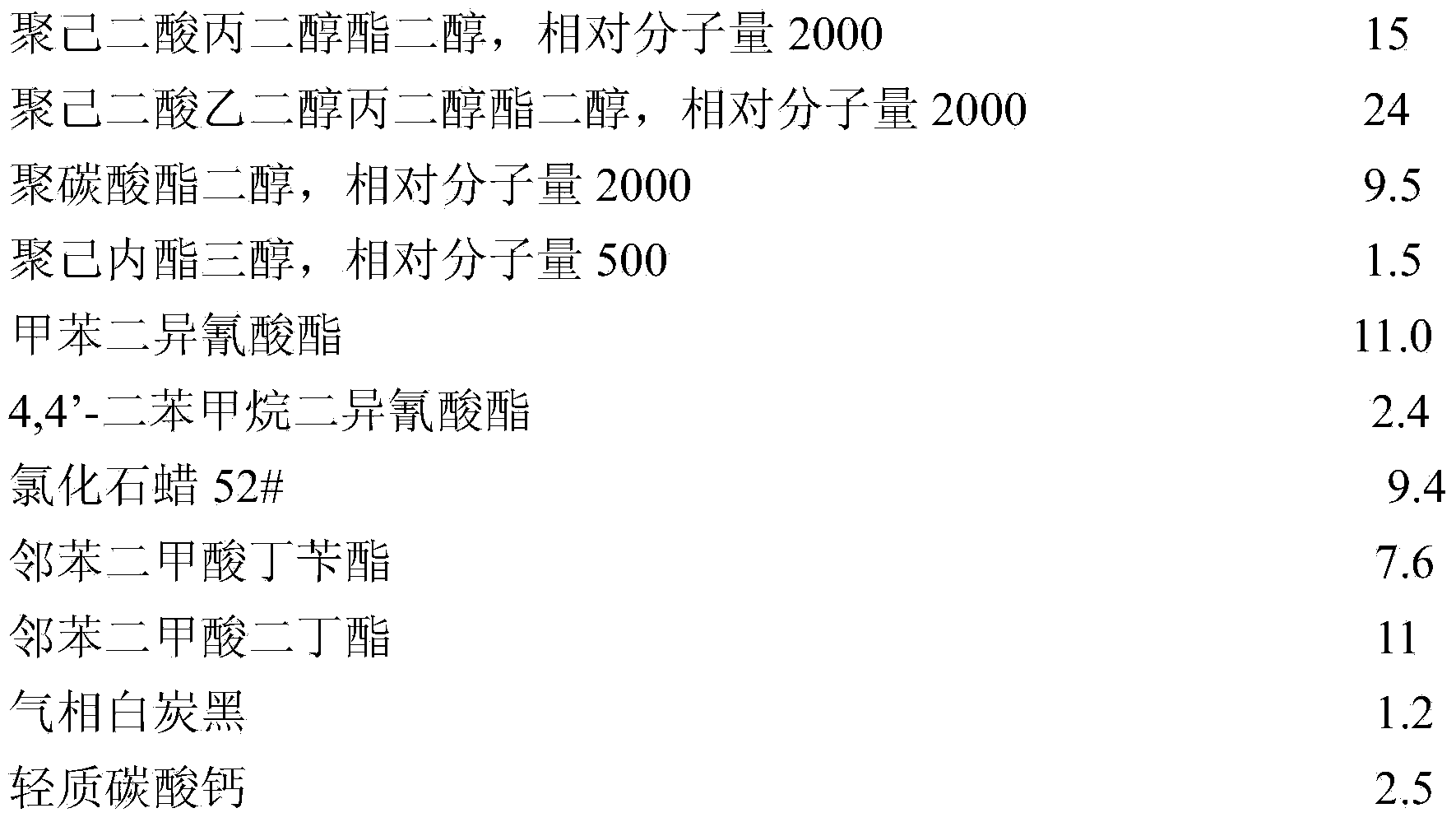

Solvent-resistance polyurethane rubber roller and manufacturing method and application thereof

The invention discloses a solvent-resistance polyurethane rubber roller and a manufacturing method and application thereof, and belongs to the field of rubber roller preparing. The solvent-resistance polyurethane rubber roller is achieved through combination of multicomponent systems and is formed by mixing and pouring a material component A, a material component B and a material component C, wherein the material component A comprises, by mass, 40%-60% of polyester polyol and 7%-20% of toluene disocynate, the material component B comprises, by mass, 2%-10% of 4-4'-diphenylmethane diisocyanate, 5%-40% of plasticizer and 1%-4% of filler, and the material component C comprises, by mass, 2.5%-8% of chain extender and 0.02%-0.05% of catalysts. The wear-resistance, solvent-resistance and mechanical properties of the solvent-resistance polyurethane rubber roller are obviously improved, and the solvent-resistance polyurethane rubber roller can be widely used in the fields of printing, coating and painting.

Owner:东莞华工佛塑新材料有限公司

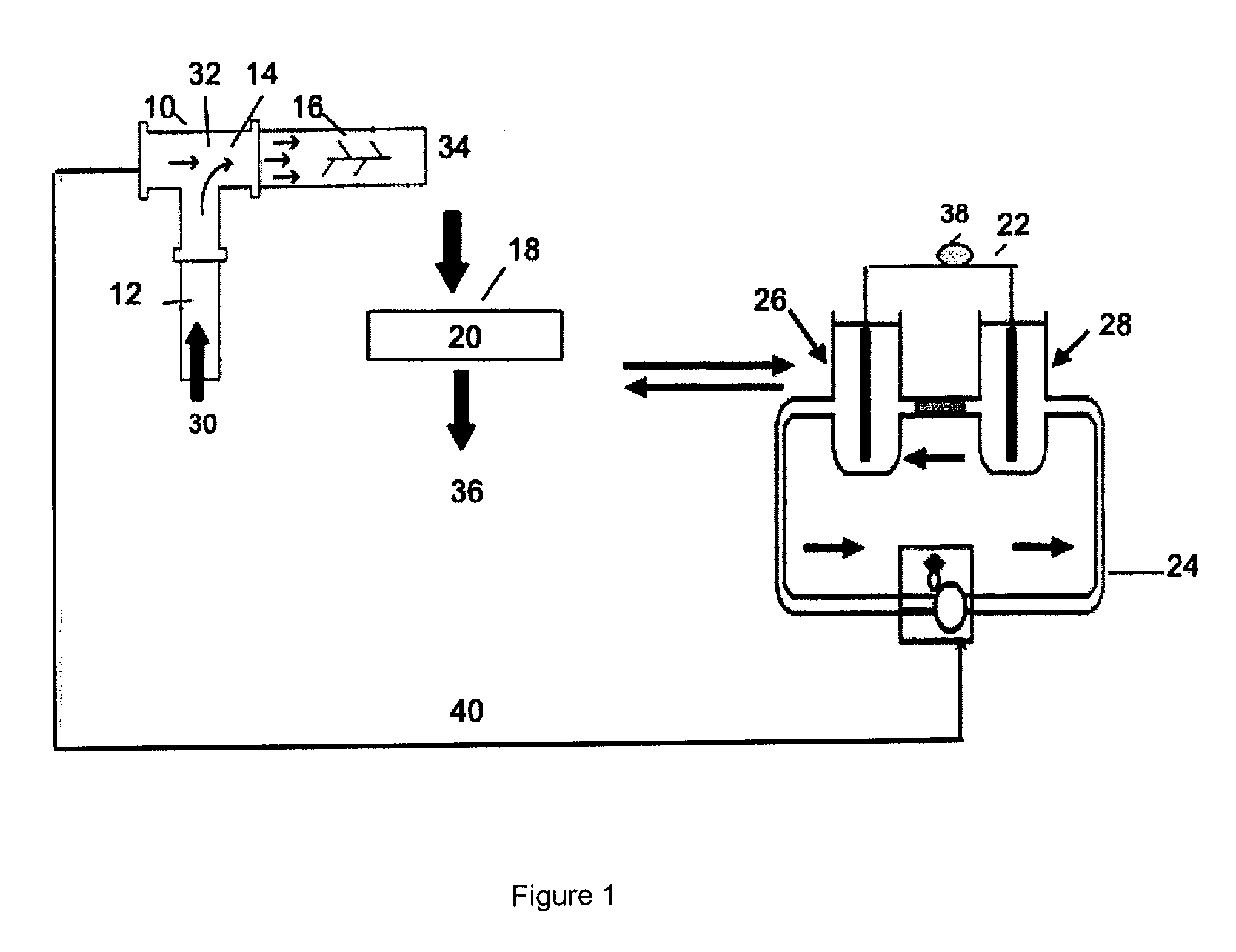

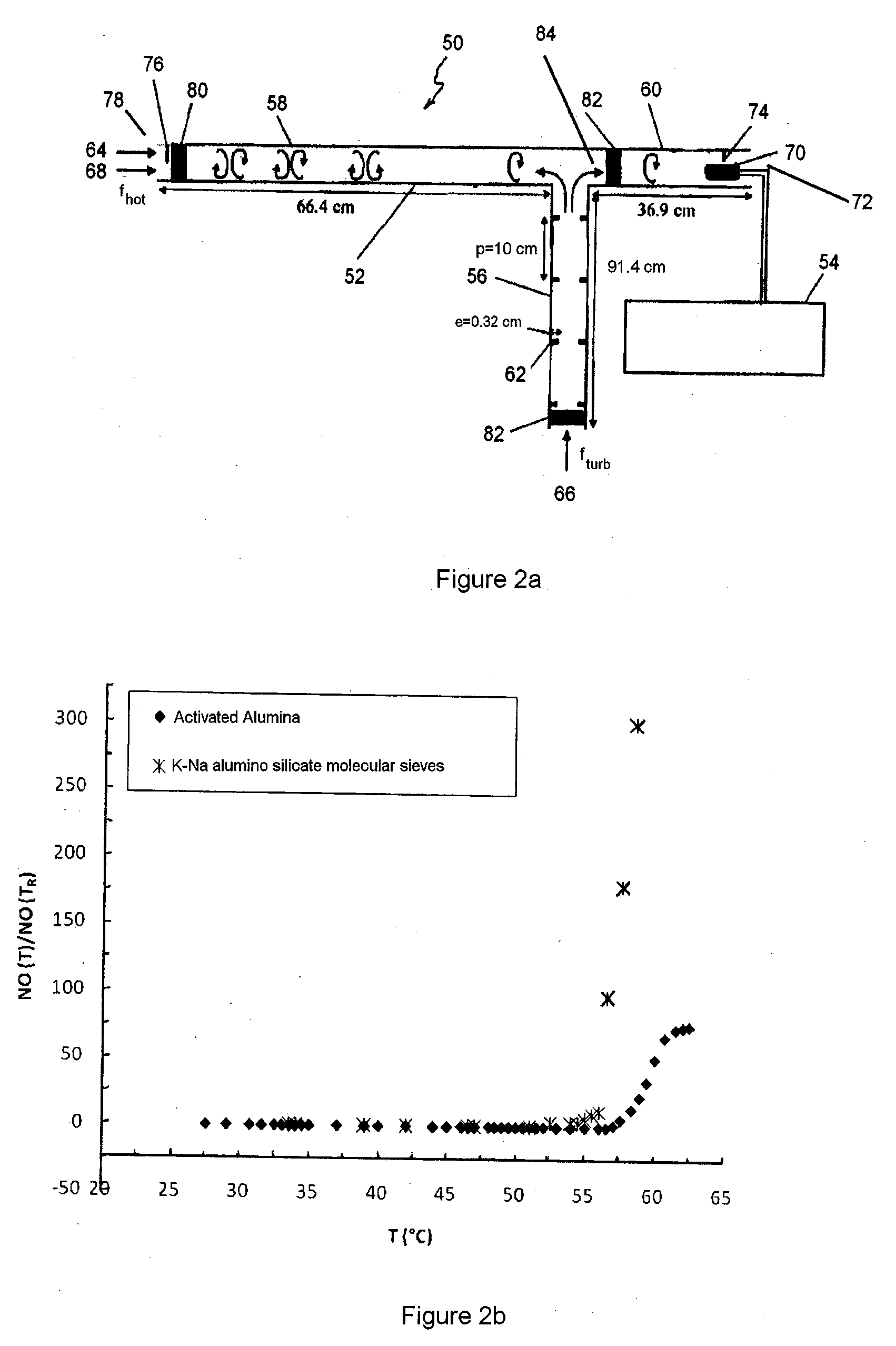

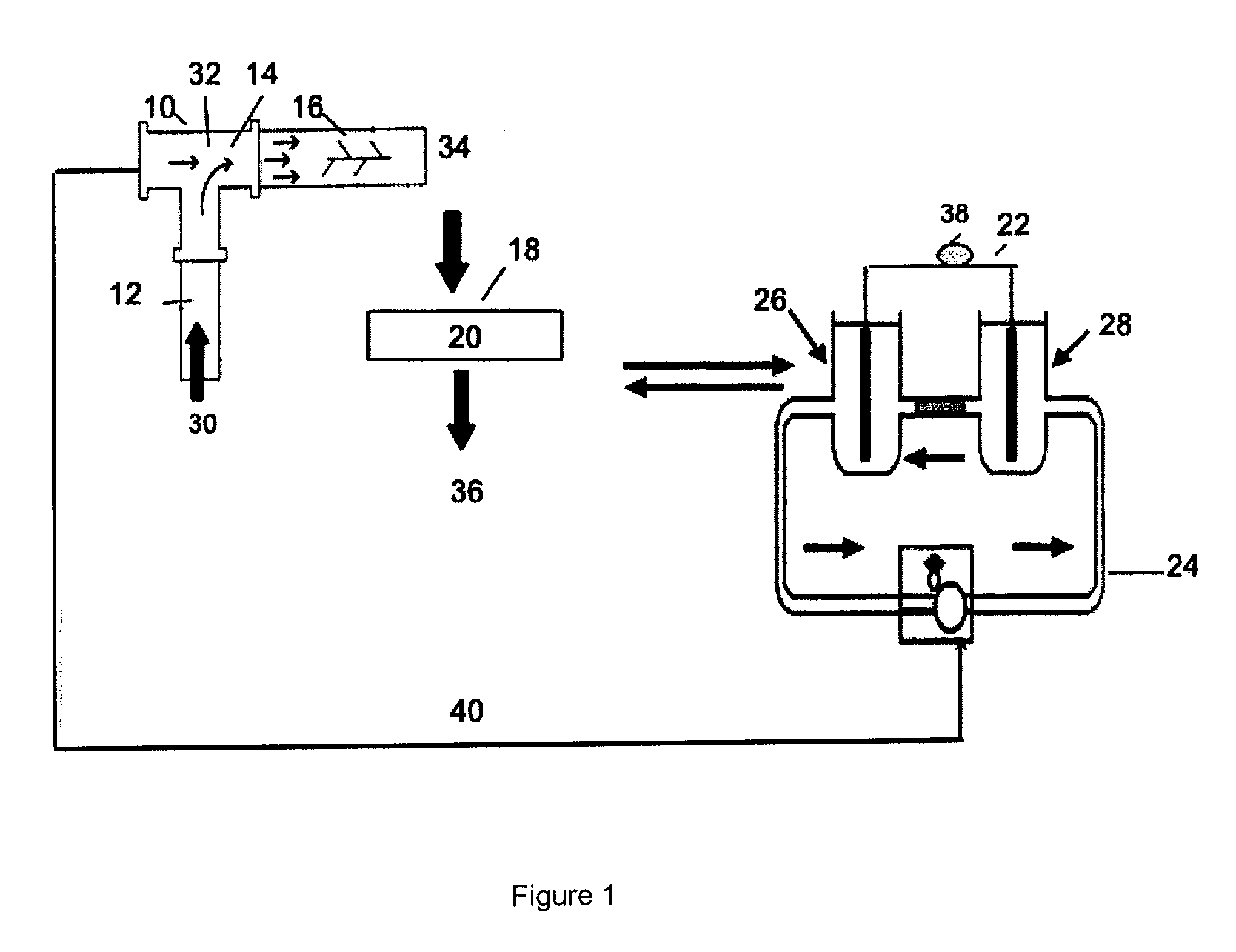

Method and System for Adsorbing Pollutants and/or Contaminants

ActiveUS20110158872A1Increasing contaminantIncreasing pollutant adsorptionCombination devicesNitrogen compoundsSorbentEngineering

The present invention relates to a method and a multi-component system for adsorbing contaminants and / or pollutants from a contaminated hot fluid by using a turbulent air stream, to adiabatically cool the temperature of the fluid, in association with one or more adsorbents. The system of the present invention can also be coupled to a recovery and recycling unit to recover and recycle the contaminant and / or pollutant and the adsorbent material.

Owner:ARIYA FAR PARISA A

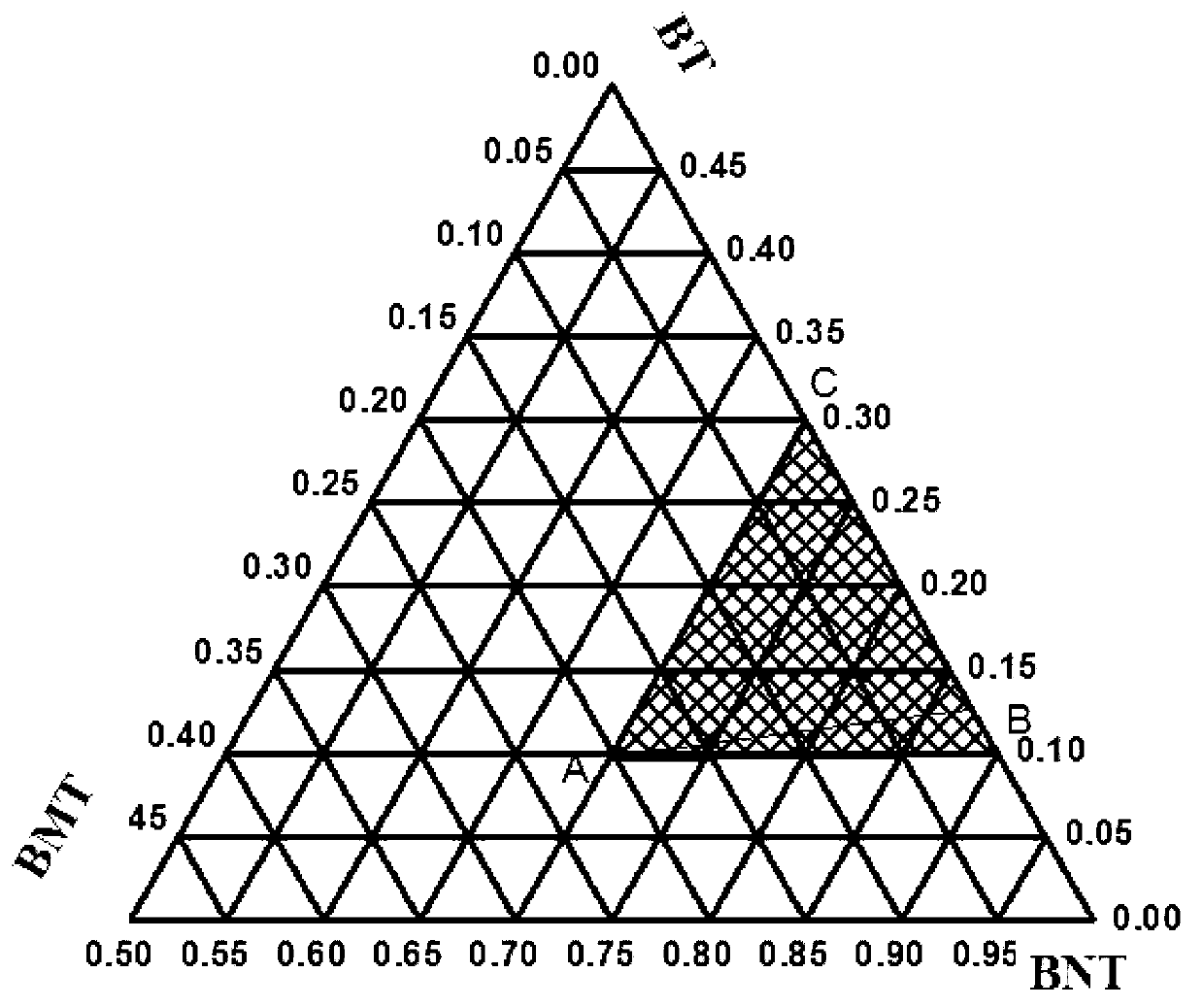

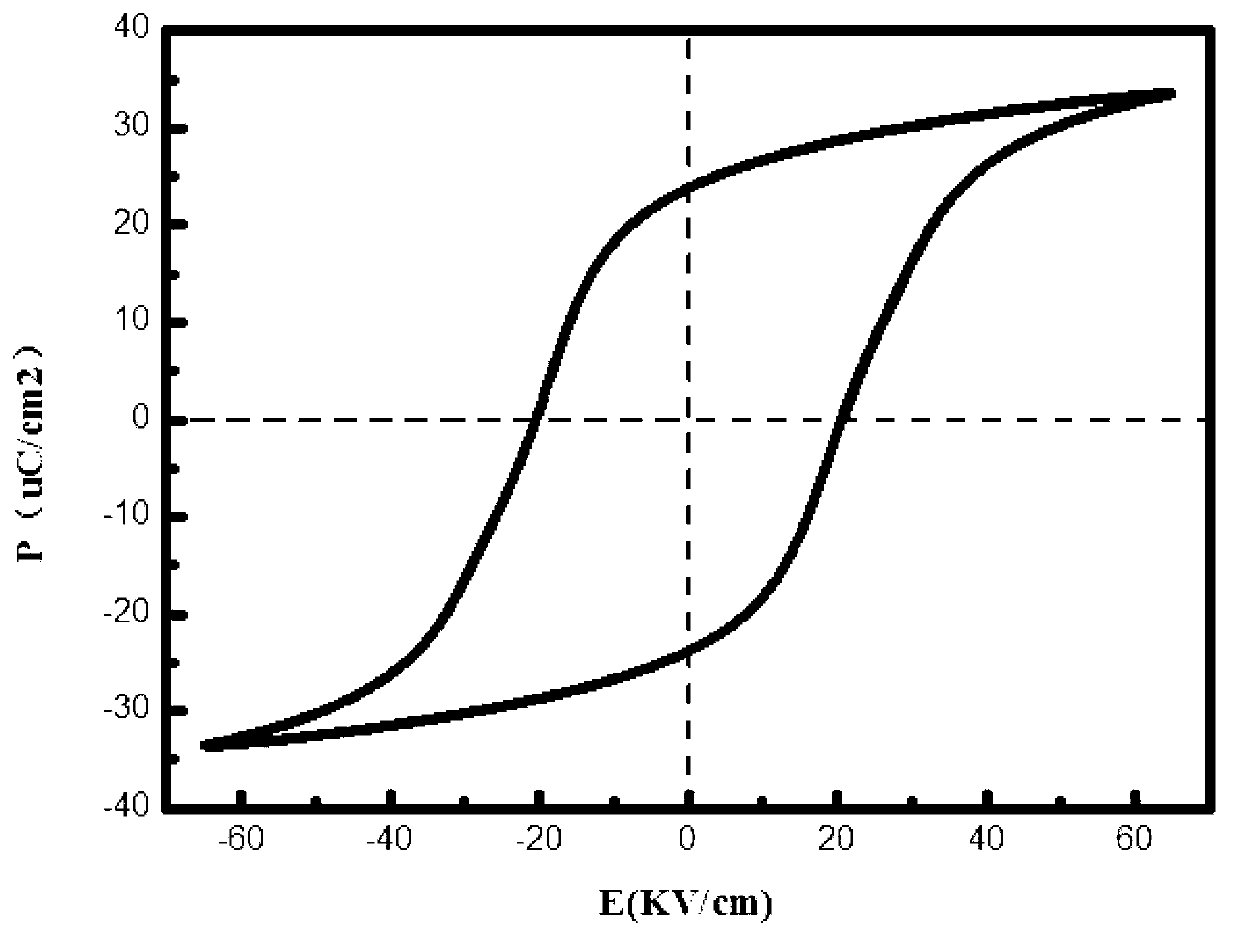

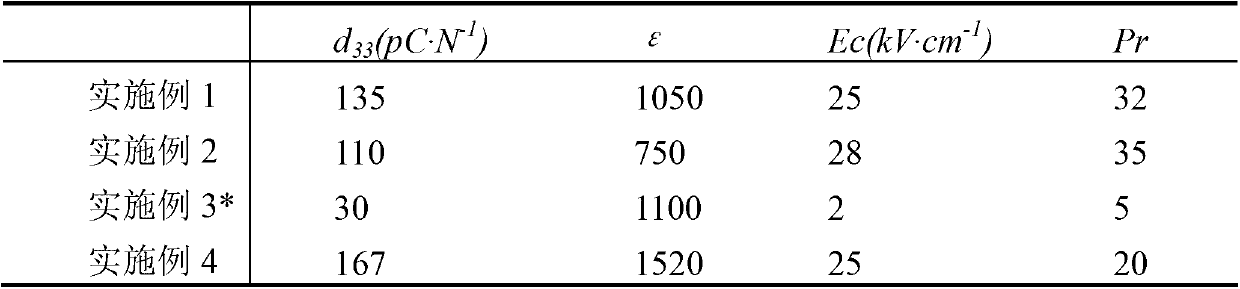

Bi0.5Na0.5TiO3-BaTiO3-BiMg0.5Ti0.5O3 lead-free piezoelectric ceramic material

The invention provides a Bi0.5Na0.5TiO3-BaTiO3-BiMg0.5Ti0.5O3 lead-free piezoelectric ceramic material, relates to a multicomponent system lead-free piezoelectric ceramic compound and belongs to the perovskite structure piezoelectric ceramic field. The composition provided by the invention can be expressed by a general formula of xBi0.5Na0.5TiO3-yBaTiO3-zBiMg0.5Ti0.5O3, wherein the numeric area of x, y and z is indicated by the shadow area of a ternary phase diagram (the area comprises the boundary line). The lead-free piezoelectric ceramic composition further contains oxide Bi2O3; and the content of oxide Bi2O3 is 1% of the content of Bi ions in the composition. The coercive field of the system changes with the three-component system components between 20kV / cm and 40 kV / cm; the piezoelectric coefficient d33 and the electromechanical coupling coefficient Kp are increased with the increase of the value of y in the polarizable component range; d33 is unequal from 100pC / N to 170 pC / N, while Kp is from 0.1 to 0.3. Besides, the depolarization temperature of the ceramics is slightly reduced between 80 DEG C and 120 DEG C with the increase of y.

Owner:BEIJING UNIV OF TECH

Novel compounds and uses in devices

ActiveCN105514288ASolid-state devicesSemiconductor/solid-state device manufacturingTriplet stateCombinatorial chemistry

Novel compounds and uses in devices are disclosed. The invention discloses a novel multicomponent system or a single compound that is capable of performing triplet-triplet annihilation up conversion process (TTA-UC). A solution or solid film that comprises the TTA-UC system or the compound is provided. The system or the compound can be used in an optical or optoelectronic device.

Owner:UNIVERSAL DISPLAY

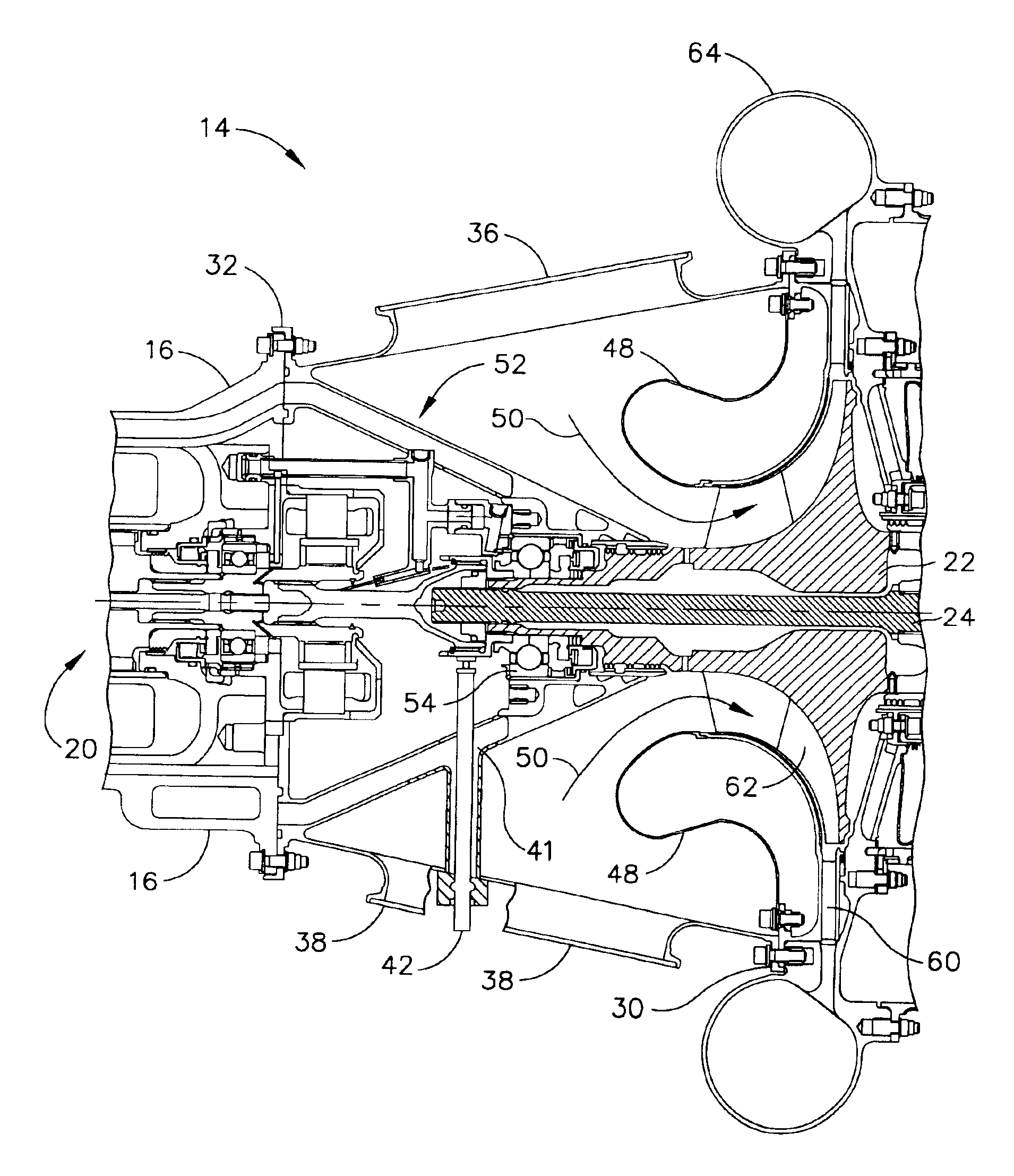

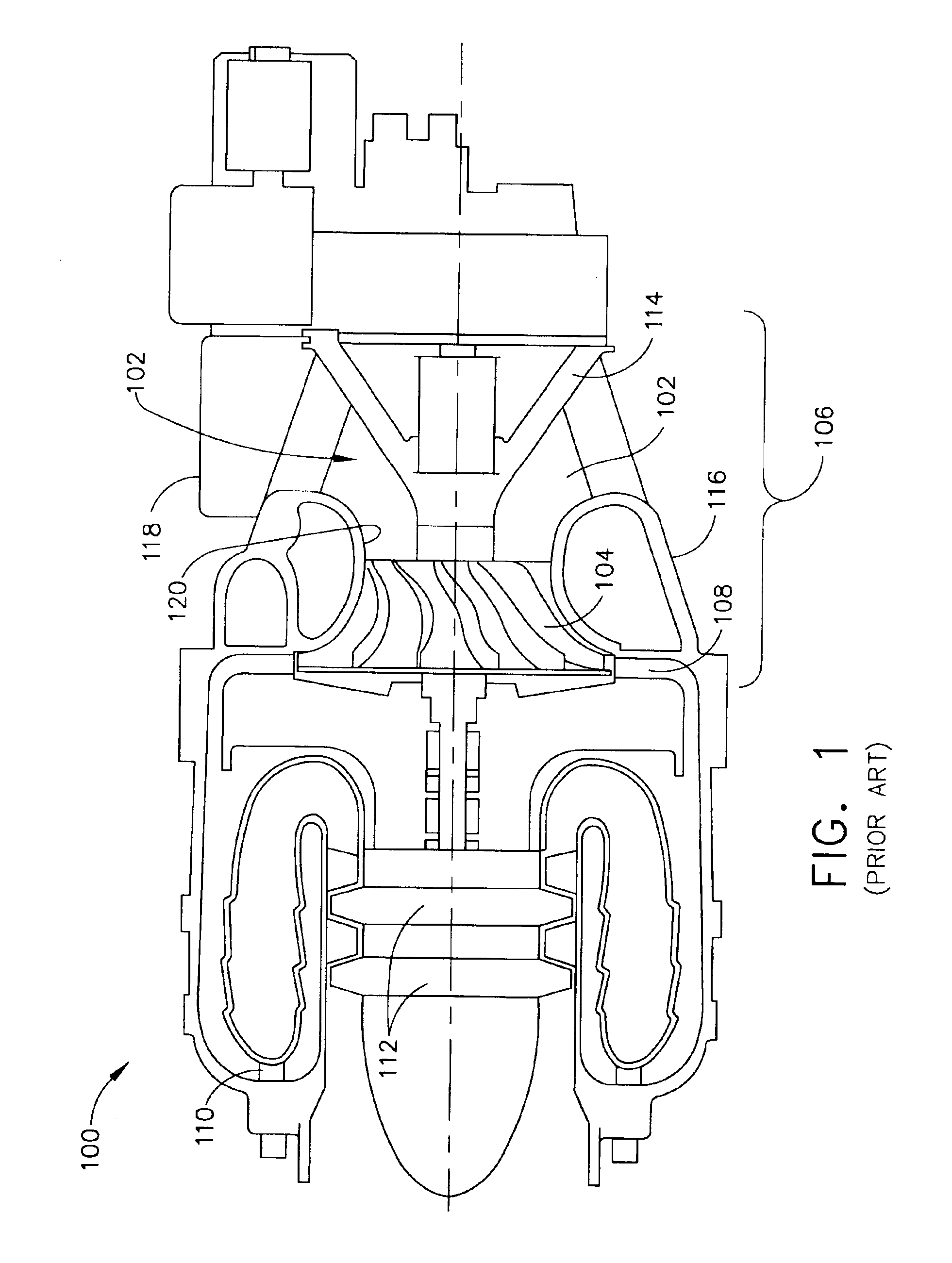

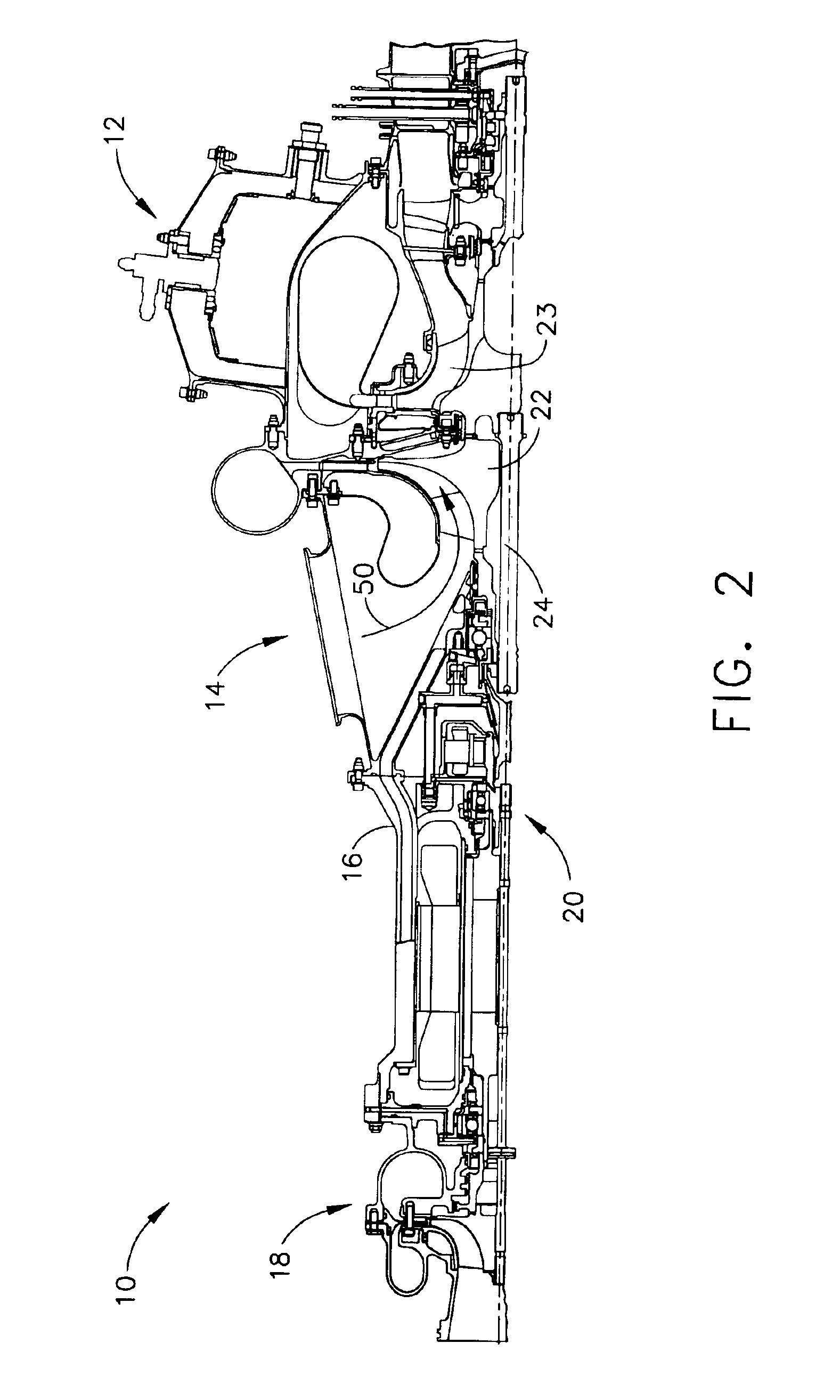

Integral compressor housing of gas turbine engines

A turbine engine compressor design utilizing multiple component integration, thereby reducing the number of required engine components. In conventional compressor designs, a multiple component system makes it difficult to predict the structural behaviors due to thermal and mechanical loading during transient conditions. The compressor design of the present invention has three main parts: a forward bearing housing, a bell-mouth (heat shield) and a coupled impeller shroud / diffuser. Such a design achieves the design objectives of the present invention, including reducing weight, reducing cost, minimizing tolerance build up and improving aerodynamic performance by utilizing multiple component integration for multiple modes of engine operation.

Owner:HONEYWELL INT INC

Dental temporary superstructures and materials for production thereof and corresponding methods

A dental material, a dental mixture or a dental multi-component system for making the material of or core for a temporary superstructure for a dental implant by polymerization hardening, consisting of one, two or a plurality of polymerizable (meth)acrylates, and optionally further constituents. The dental material, the dental mixture or the multi-component system is hardenable to a product, and the maximum compressive modulus is 420 MPa, and is used in therapeutic treatments for accelerating the osseointegration of dental implants, in particular according to the method of progressive bone loading. Also described are temporary superstructures and cores themselves, and a temporary dental prosthesis, a kit for making a plurality of temporary superstructures for a dental implant or a plurality of cores for temporary superstructures for a dental implant. A corresponding method of preparing a temporary superstructure or a core is also described.

Owner:VOCO

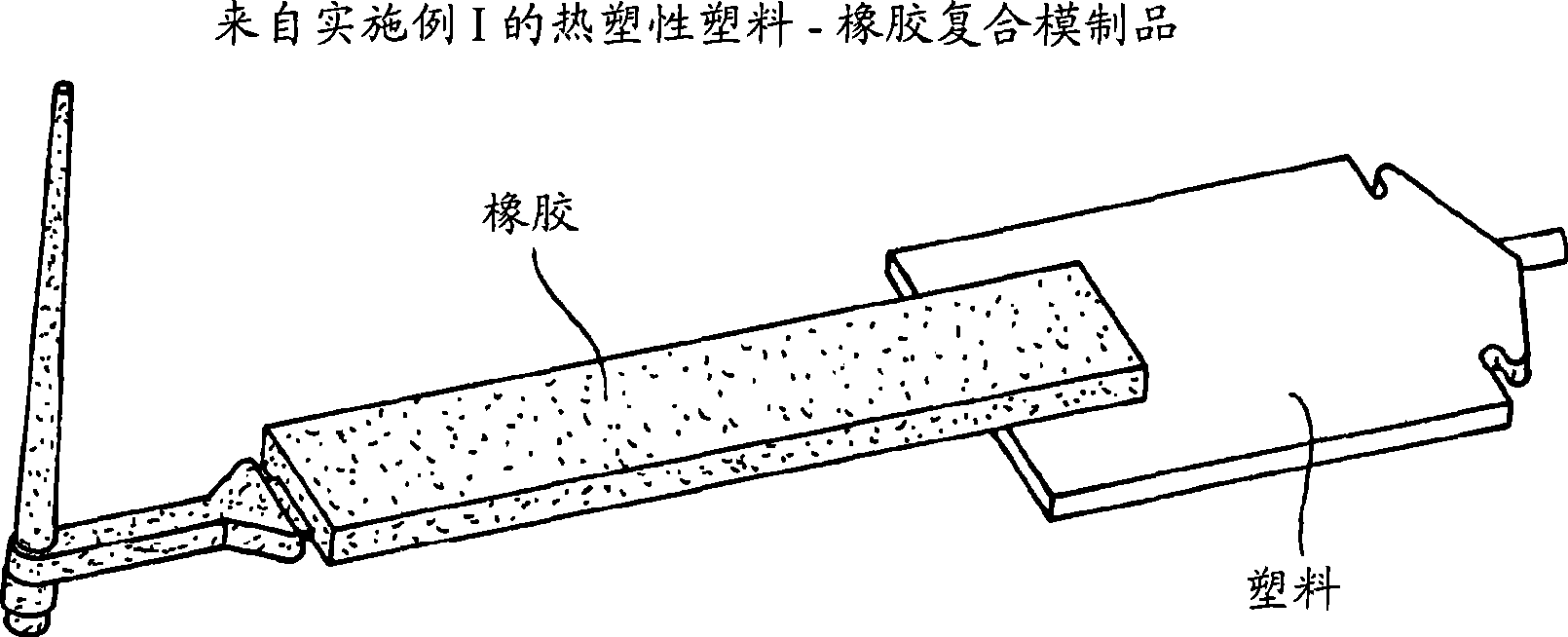

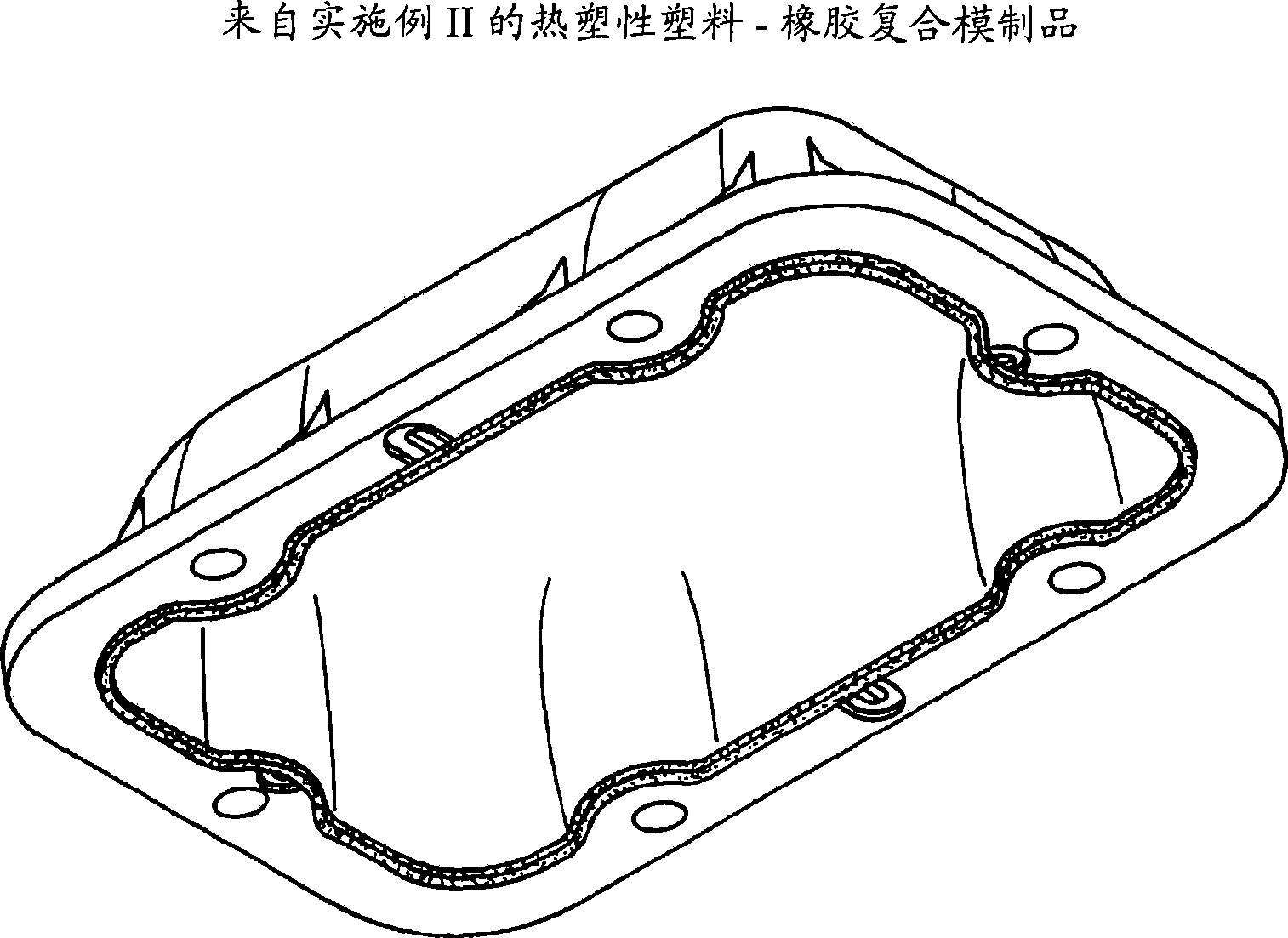

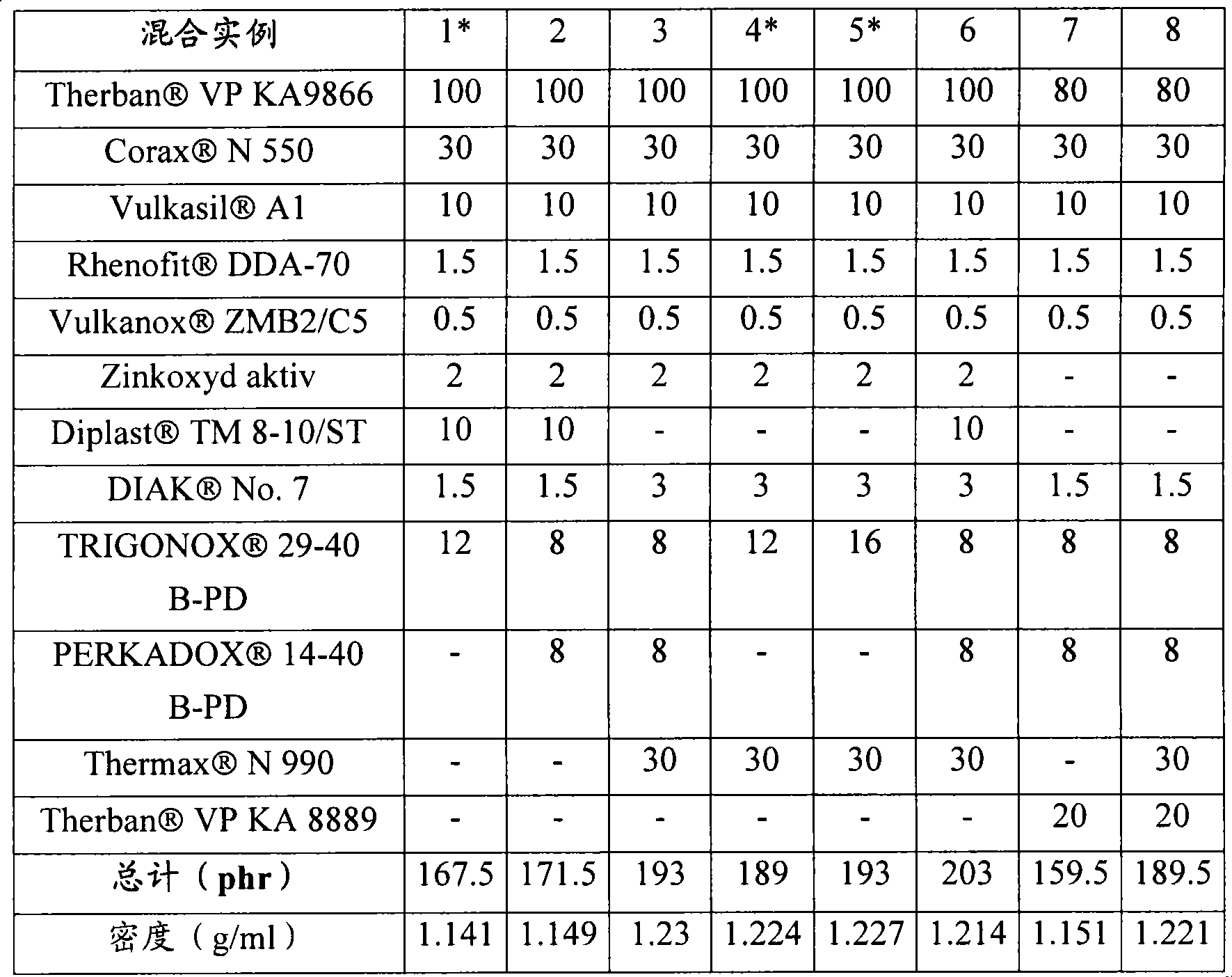

Novel rubber and thermoplastic multi-component systems rubber and thermoplastic composite moulded pieces made therefrom method for production and use thereof

A multi-component system made from a thermoplastic component and a rubber component containing at least two different peroxide cross-linking agents with particular decomposition temperatures and a method for production of rubber and thermoplastic composite moulded pieces using the multicomponent system and the rubber and thermoplastic composite moulded pieces obtained thus.

Owner:LANXESS DEUTDCHLAND GMBH

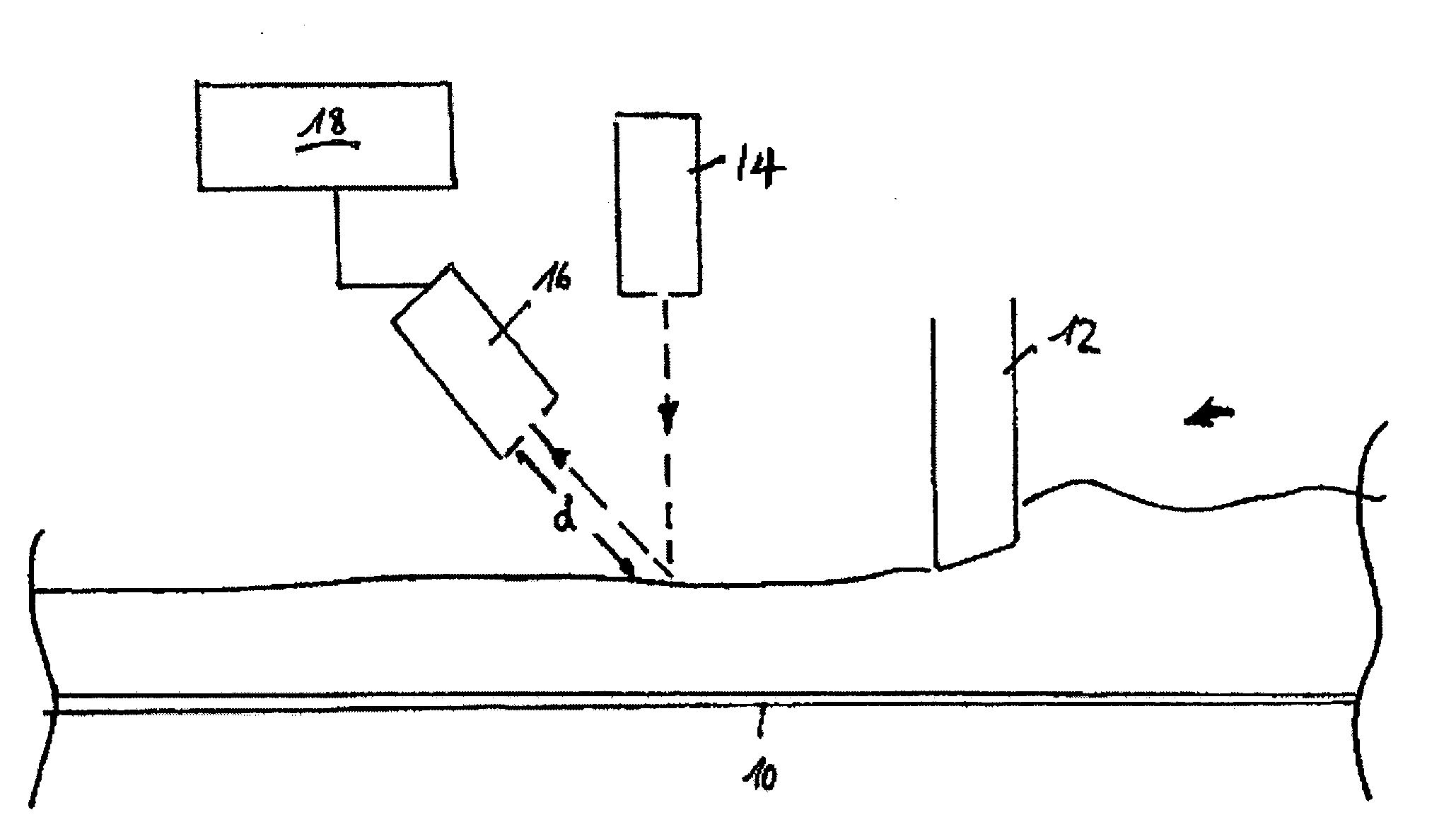

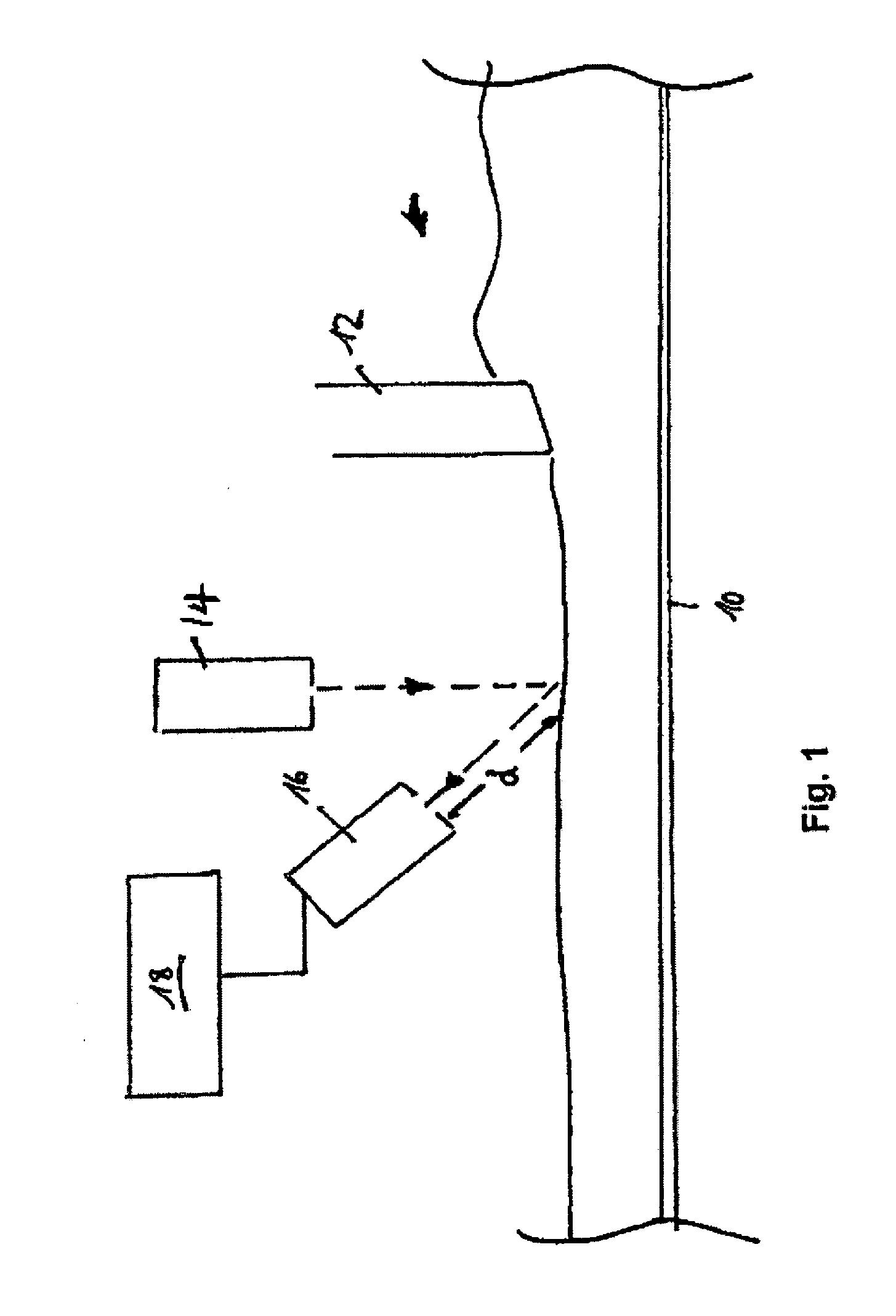

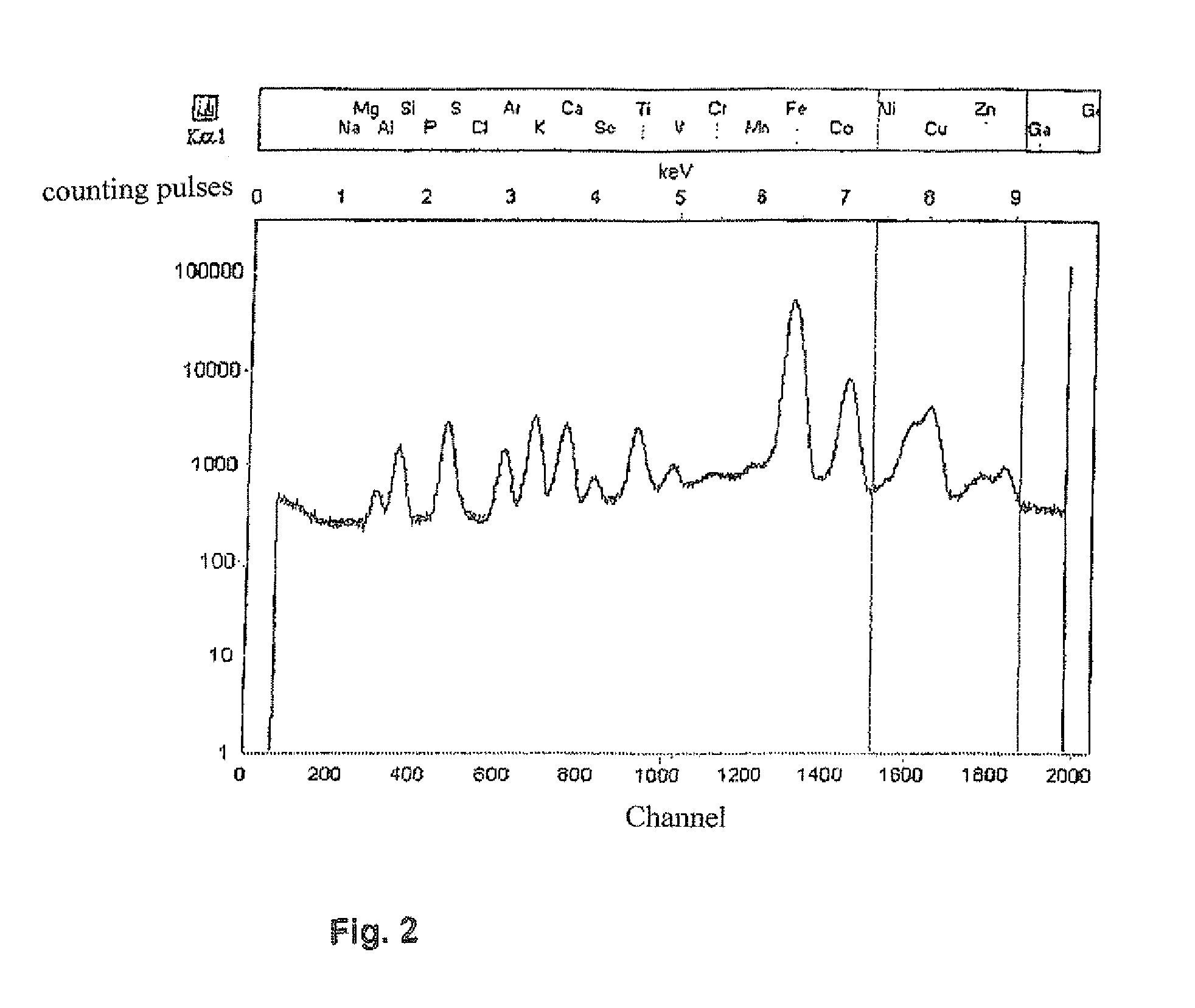

Process and device for the fast or on-line determination of the components of a two-component or multi-component system

InactiveUS7664225B2Precise and fast analysisReduce high voltageX-ray spectral distribution measurementMaterial analysis using radiation diffractionElemental compositionFluorescence

Owner:ELISABETH KATZ

Potassium-sodium niobate and sodium lithium bismuth titanate-system lead-free piezoelectric ceramic composition

InactiveCN102234195AExcellent piezoelectric propertiesImprove processing stabilityElectromechanical coupling coefficientDoped oxide

The invention provides potassium-sodium niobate and sodium lithium bismuth titanate-system lead-free piezoelectric ceramic, relating to a novel multicomponent-system lead-free piezoelectric ceramic composition, and belonging to the field of perovskite structures piezoelectric ceramic. The composition provided by the invention can be represented by a general formula of (1-z)(K1-xNax)NbO3-zBi0.5(Nal-yLiy)0.5TiO3, wherein x and y are both more than 0 and less than 1, and z is more than 0 and less than or equal to 0.06. The lead-free piezoelectric ceramic composition also can contain one or more oxides and has the general formula of (1-z)(K1-xNax)NbO3-zBi0.5(Nal-yLiy)0.5TiO3+aMalphaObeta (mol%), wherein the MalphaObeta is one or more doped oxides, the mole ratio of the content a to the main component (1-z)(K1-xNax)NbO3-zBi0.5(Nal-yLiy)0.5TiO3 is 0-3%, and M is an element which ranges from univalence to hexavalence and can form solid oxide with oxygen. The optimal piezoelectric constant d33 of the piezoelectric ceramic composition of the system can be more than 200pC / N, and the electromechanical coupling factors kp and kt can be more than 40%; the process is stable, and a traditional piezoelectric ceramic preparation technology and industrial raw materials are adopted to prepare the ceramic composition so that practicality is achieved.

Owner:SICHUAN NORMAL UNIVERSITY

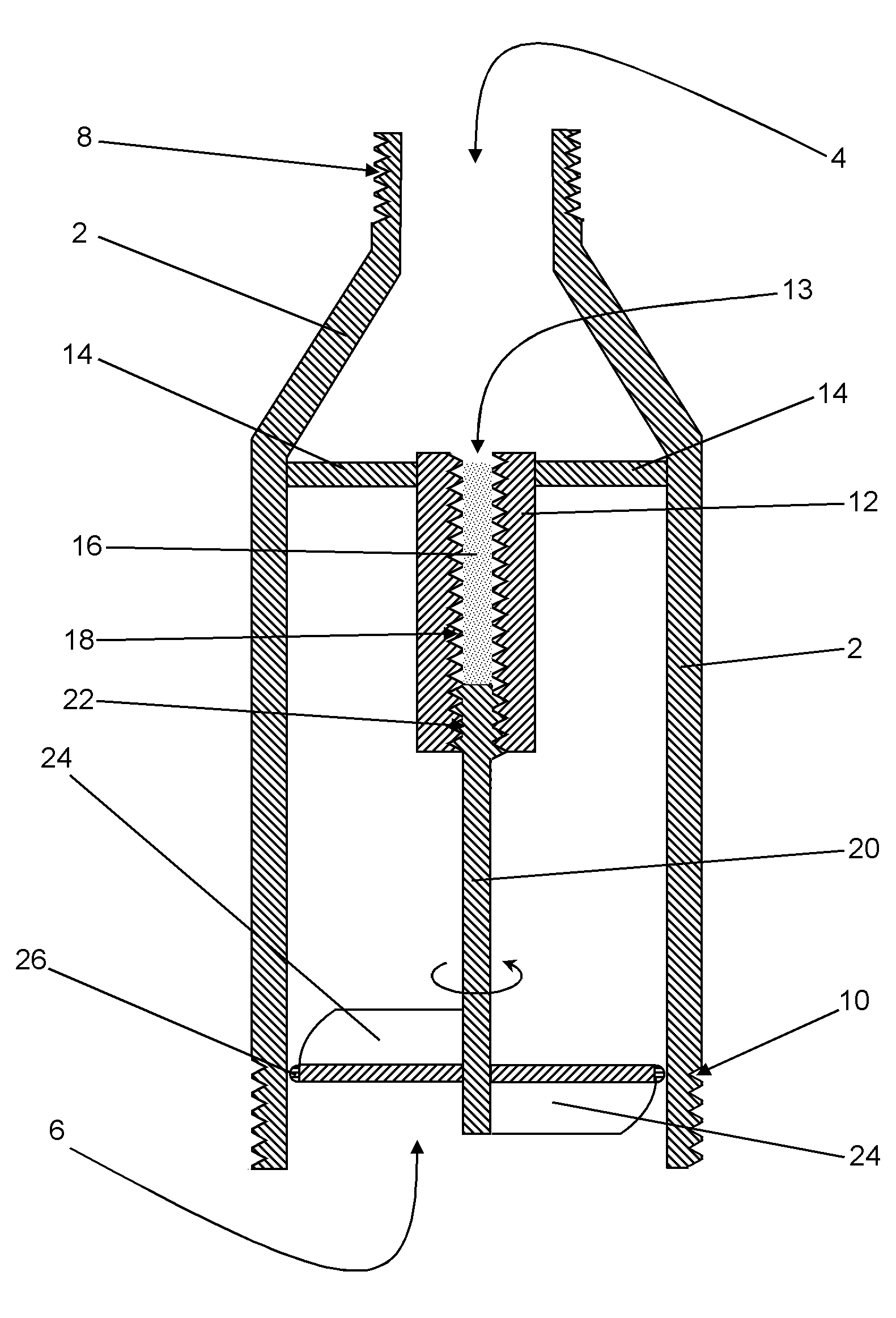

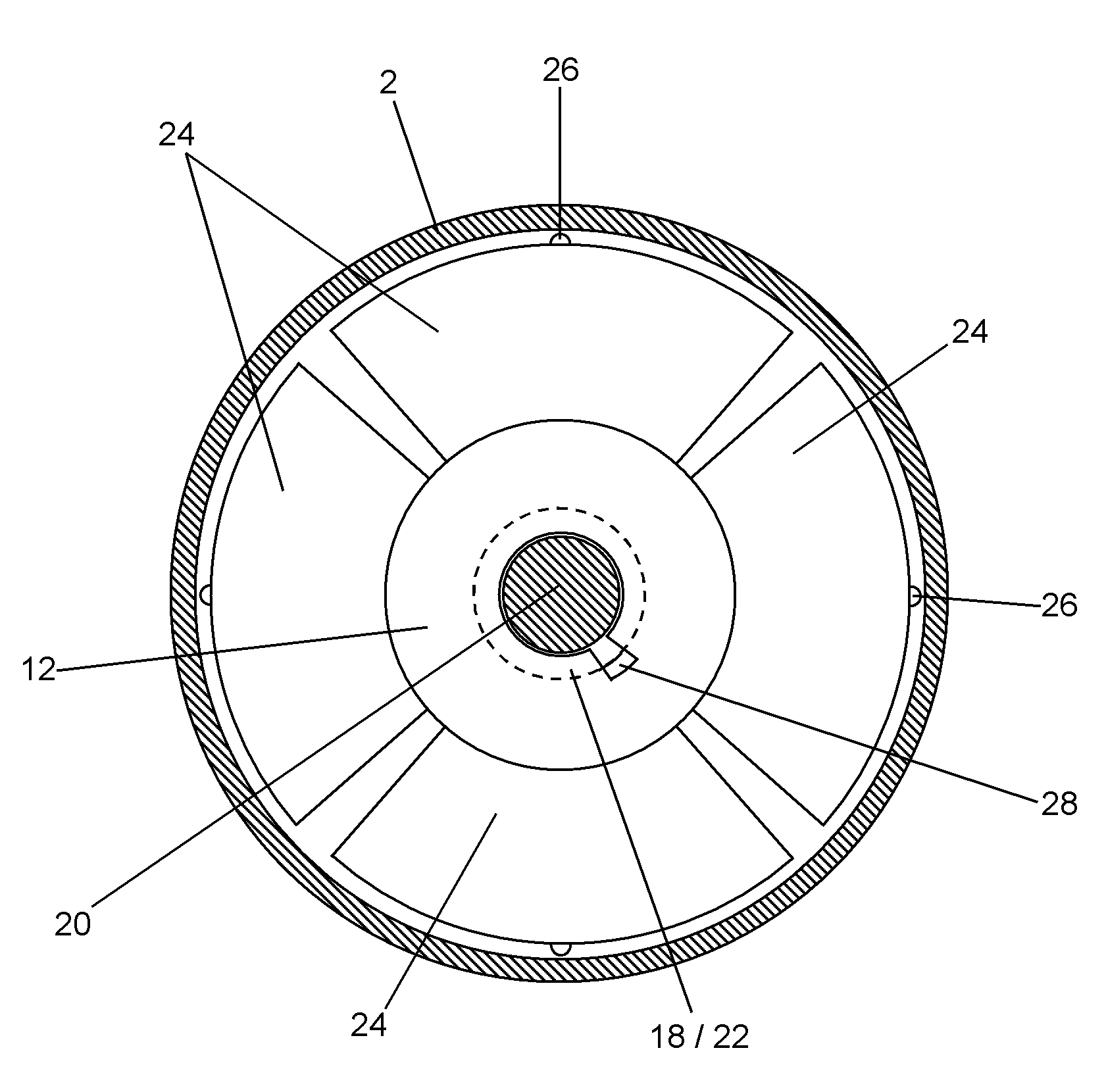

Mixing device for multi-component systems

InactiveCN103418263AWell mixedStable mixLiquid surface applicatorsFlow mixersEngineeringMechanical engineering

A mixing device produces a multi-component mixture, in particular for medical applications, and has at least one first component and one second component, whereby the first component is a pasty fluid mass, whereby the mixing device has a housing having at least one first opening and a hollow body, whereby the hollow body has an internal space that contains the second component, and the mixing device has a feed plunger for expelling the second component from the internal space of the hollow body, whereby the hollow body has a thread and the feed plunger has a counter-thread that engages the thread of the hollow body, and the mixing device has a propulsion element that is arranged inside the housing, whereby the propulsion element converts a flow of the first component through the housing into a rotary motion, whereby the rotary motion of the propulsion element screws the feed plunger into the internal space of the hollow body, and whereby the second component can thus be extruded from the hollow space into the fluid flow of the first component.

Owner:HERAEUS MEDICAL

Multi-component system for treating enclosed environments

ActiveUS9459022B2Eradicate smoke and water damageStructural damageHot-air central heatingDrying gas arrangementsRegulation temperatureDisease

Described herein is a heating system where air is drawn into a system where hot gas is injected into it. The air is then discharged at a regulated temperature into an environment through ductwork to heat environments to elevated temperatures and employing functional modules to further condition the air to humidify, dehumidify, decontaminate with airborne free-radicals, and filtrate in both stationary and portable applications. The system is useful to eradicate pests, disease germs, bacteria, viruses, and mold. The system is also useful in water remediation and comfort heating. The system can be configured to create a parallel path to both heat and dehumidify the airflow blended and discharged at the operator-chosen set-point temperatures.

Owner:SUPPLIER SUPPORT INT

Method and system for adsorbing pollutants and/or contaminants

ActiveUS8277767B2Improve efficiencyIncreasing contaminant or pollutant adsorptionCombination devicesNitrogen compoundsSorbentEngineering

The present invention relates to a method and a multi-component system for adsorbing contaminants and / or pollutants from a contaminated hot fluid by using a turbulent air stream, to adiabatically cool the temperature of the fluid, in association with one or more adsorbents. The system of the present invention can also be coupled to a recovery and recycling unit to recover and recycle the contaminant and / or pollutant and the adsorbent material.

Owner:ARIYA FAR PARISA A

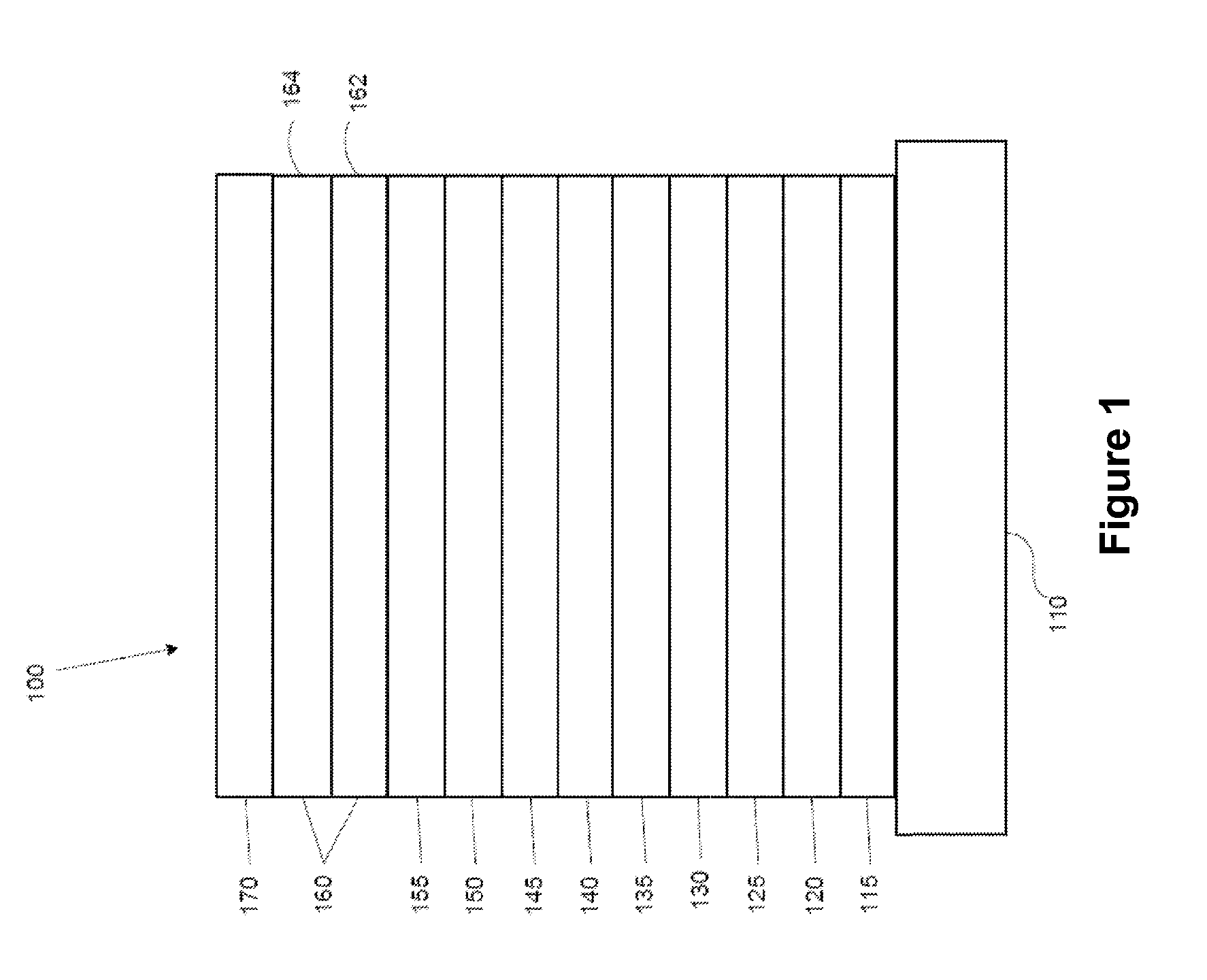

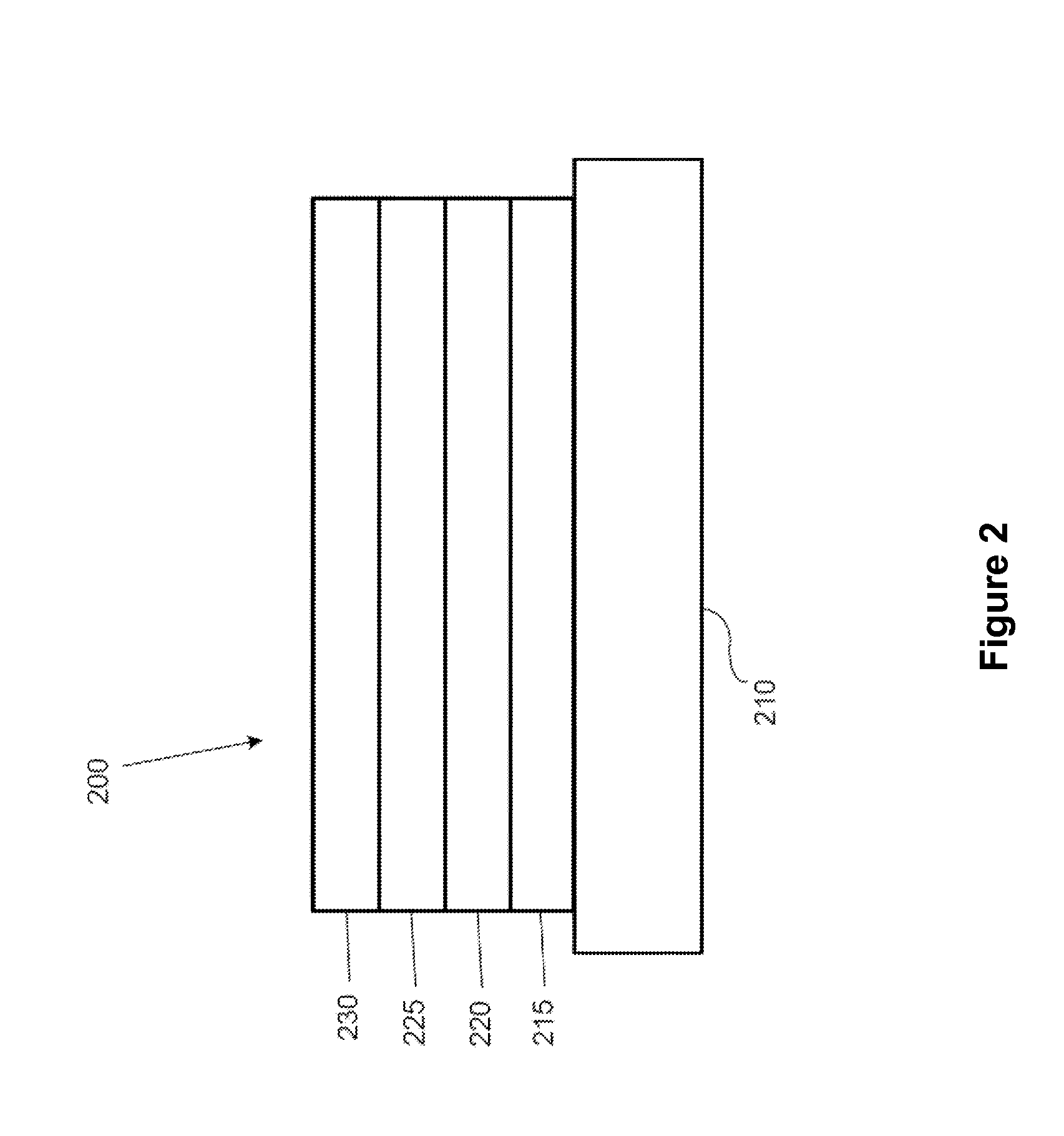

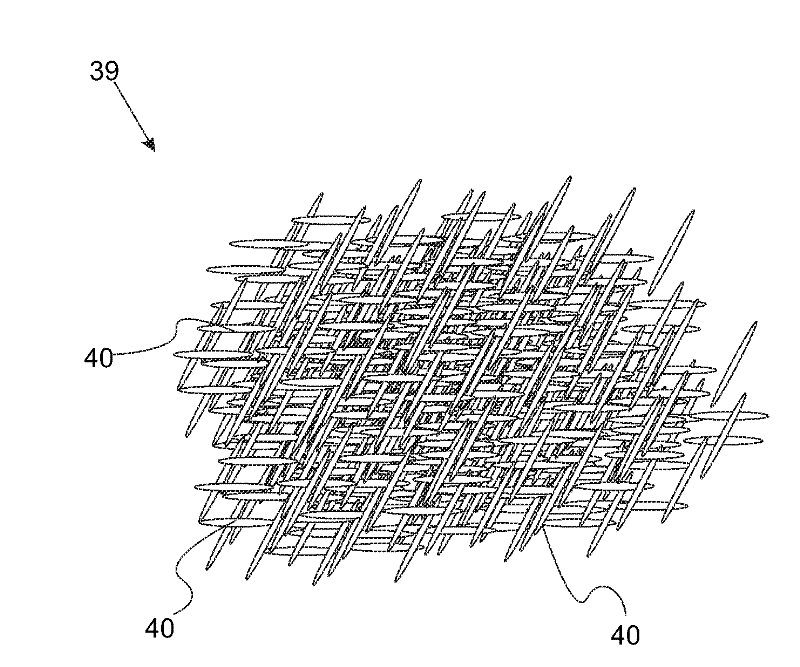

Battery separator

Resinous fibers of nanometer to micrometer width dimensions are drawn from a multi-component system by a melt extrusion process. The process includes a step of combining a fiber resin with a water-soluble carrier resin to form a resinous mixture. The resinous mixture is extruded to form an extruded resinous mixture, the extruded resinous mixture having strands of the fiber resin with the carrier resin. The extruded resinous mixture is then contacted with water to separate the strands of the fiber resin from the carrier resin. A fibrous sheet is then formed from the strands of fiber resin. The fibrous sheets are useful in filtration, as battery separators in Li ion batteries and as diffusion layers in fuel cells.

Owner:GM GLOBAL TECH OPERATIONS LLC

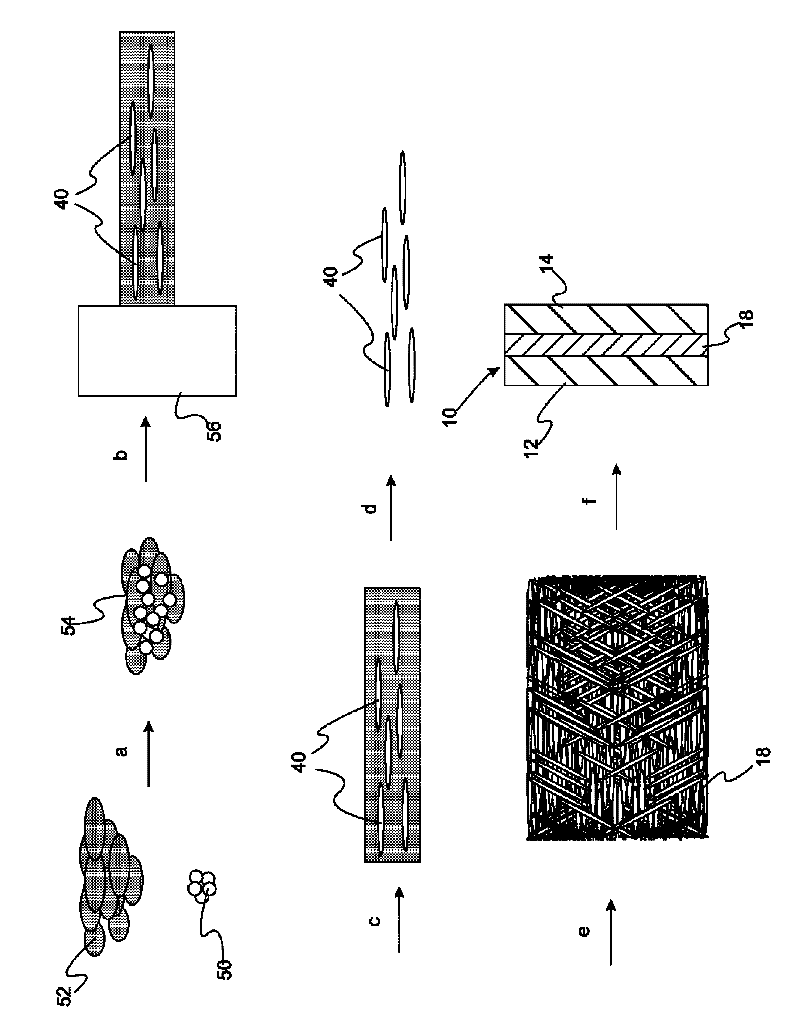

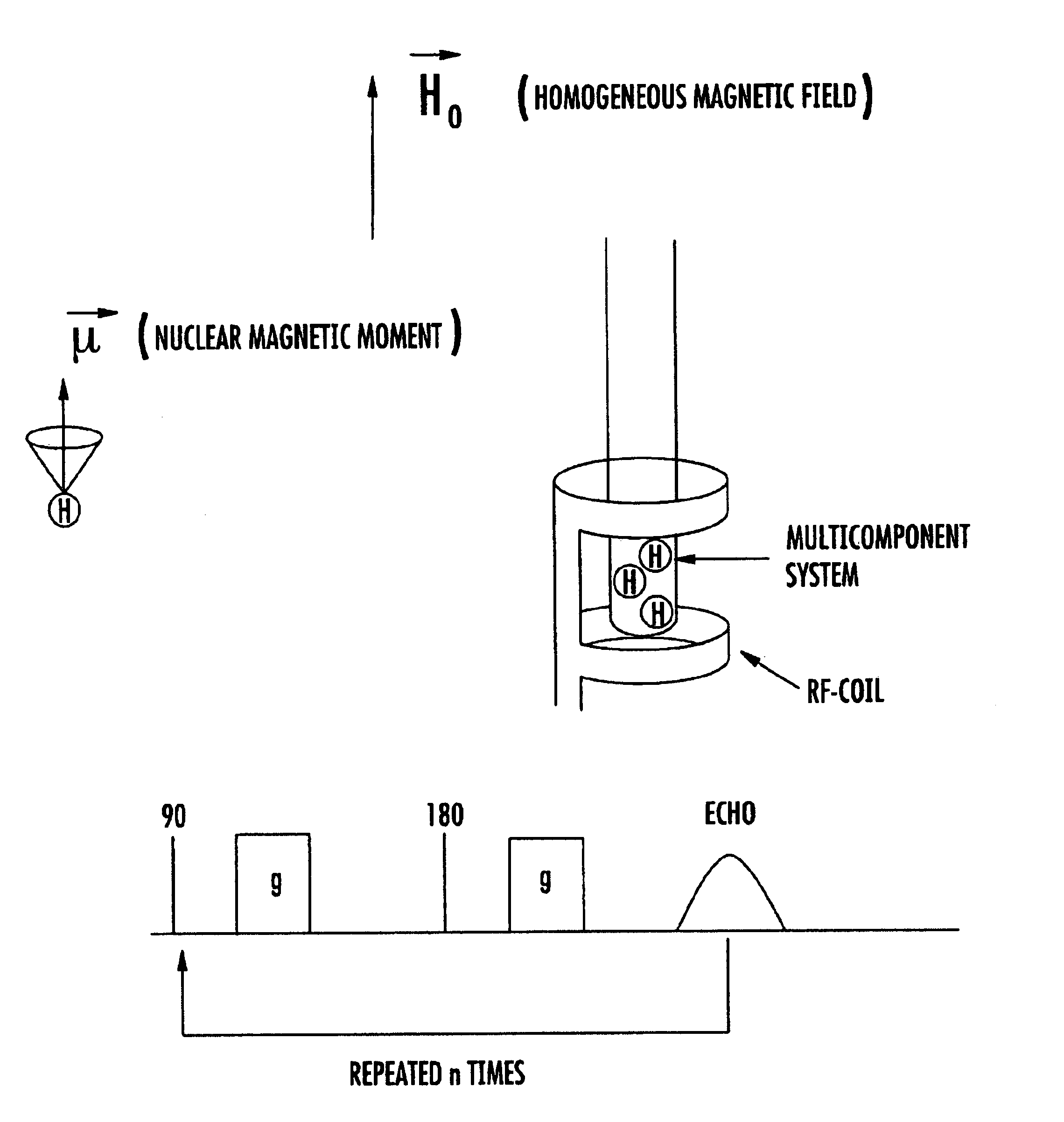

Method for measuring the content of fat/oil in multi component system

InactiveUS6946837B2Robust methodMeasurements using NMR spectroscopyElectric/magnetic detectionNMR - Nuclear magnetic resonanceIce cream

The invention is a method for determination of the content of fat in a multicomponent system. The method applies nuclear magnetic resonance (NMR) for the detemination of fat / oil in for example fillets of fish, olives, paint or ice cream.

Owner:SORLAND GEIR H

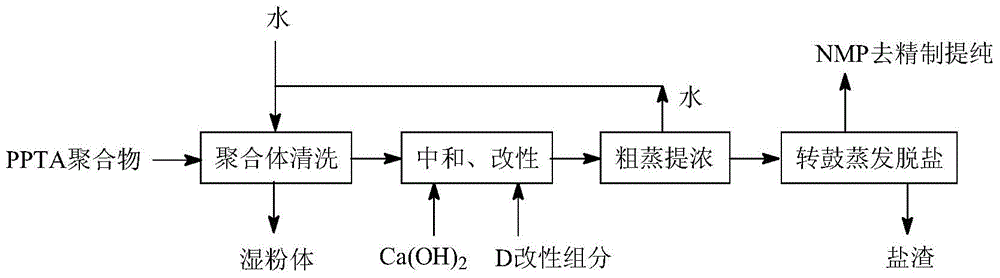

Method for reducing viscosity of residue on evaporation from distillation recovery of polymerization solvent NMP for producing PPTA

ActiveCN105330886AChange stickinessStable decompression multi-effect evaporation processDistillationSlag

The invention discloses a method for reducing viscosity of residue on evaporation from distillation recovery of a polymerization solvent NMP for producing PPTA. The method is as below: neutralizing a mixed mother liquor containing NMP with alkali, adding composite salt, and conducting coarse steaming and concentration to dryness to obtain pie-shaped residue, wherein the composite salt comprises sulfate and calcium salt; conducting rotary drum evaporative desalination on the pie-shaped residue after coarse steaming and concentration; and isolating salt slag and NMP for refining. The method improves the viscosity of a NMP-water-CaCl2 multicomponent system, reduces the adhesiveness of CaCl2 residue on evaporation in the wall, and avoids the formation of high-viscosity NMP-water-CaCl2 ternary complex adhered to the inner surface of the evaporator and tube wall of a heat exchanger in the evaporation recovery of NMP solvent, so that the multi-effect evaporation process for distillation recovery of NMP solvent can be conducted continuously, stably and efficiently.

Owner:SINOPEC YIZHENG CHEM FIBER +1

Total biodegradable film and preparation method

The present invention discloses a film which can be completely bio-degraded and its preparation method. Said film is made up by using (wt%) 5-20% of multicomponent system polymer, 60-80% of starch, 5-20% of plasticizer and 0.05-0.2% of defoaming agent and adopting the processes of mixing reaction, preplasticizing treatment, extruding granulation and blow-moulding to form film. Besides, sand invention also provides the concrete composition of every polymer of three polymers of the above-mentioned multicomponent system polymer.

Owner:湖北誉笛环保科技实业有限公司

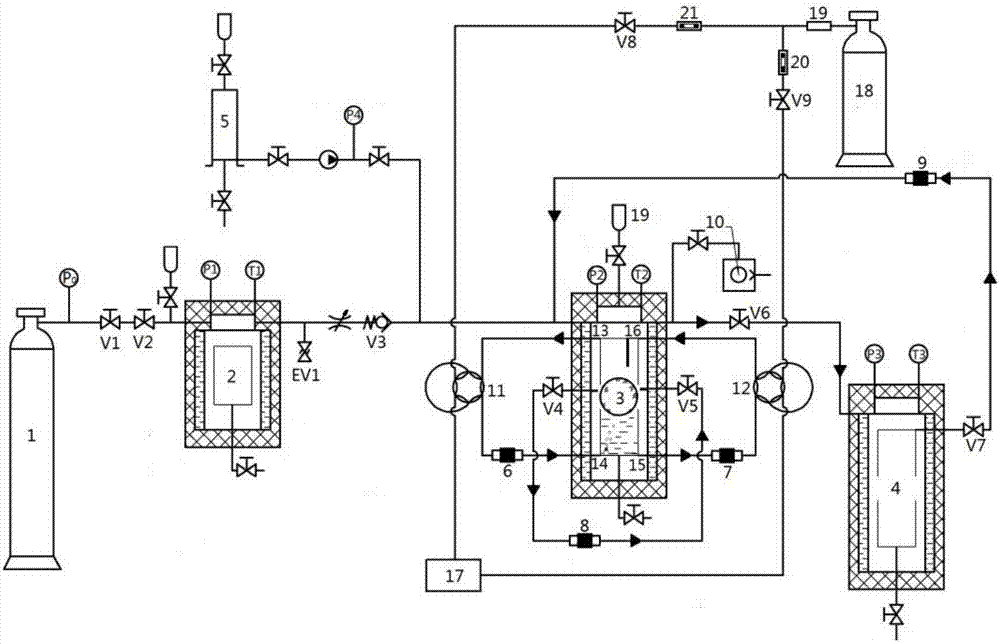

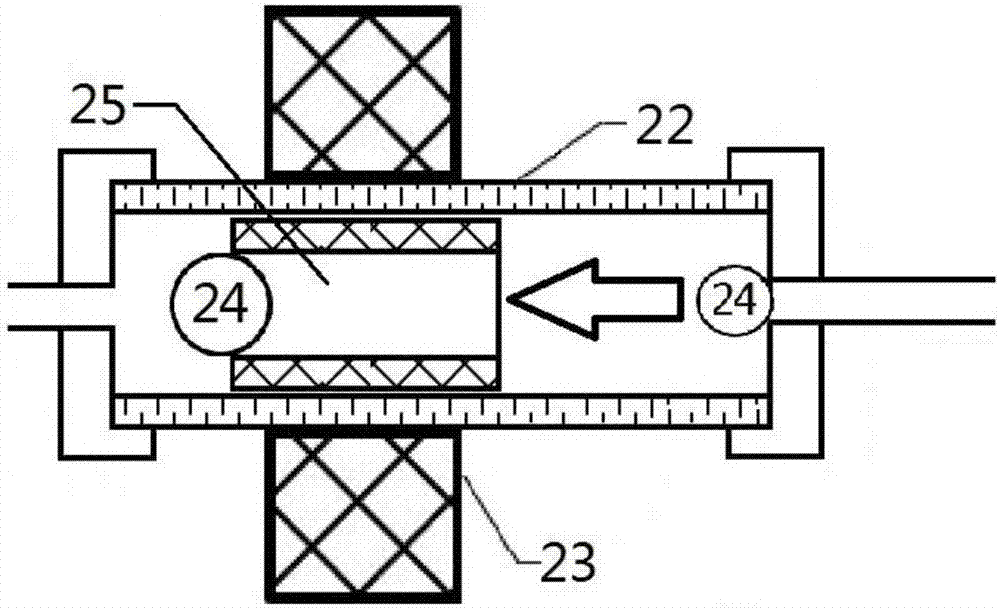

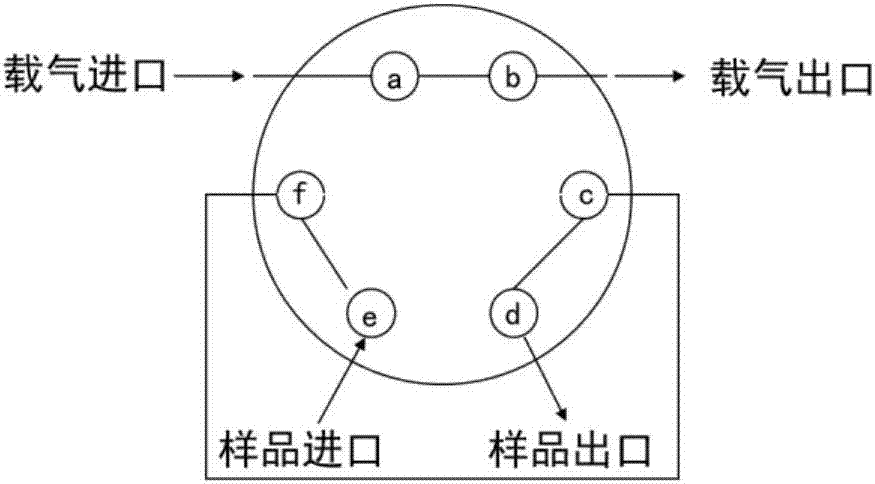

Continuous flowing type high temperature and high pressure experiment device

ActiveCN107202815AStable phase equilibriumDetermination is accurate and reliableInvestigating phase/state changeChemical reactionProcess engineering

The invention relates to a continuous flowing type high temperature and high pressure experiment device. The continuous flowing type high temperature and high pressure experiment device comprises an accumulator still, a three-cycle high pressure phase equilibrium still, a separation kettle, a solvent storage tank, a first zero leak pump, a second zero leak pump, a third zero leak pump, a fourth zero leak pump, a vacuum device, a first six-way transfer valve, a second six-way transfer valve and an online analysis system. The provided continuous flowing type high temperature and high pressure experiment device is suitable for the phase equilibrium of a multicomponent system, supercritical fluid extraction, and measurement of various experimental data in high temperature and high pressure chemical reactions, a phase equilibrium sample truly representing the state is acquired, the balance time is short, the balance composition, the balance temperature and the balance pressure are accurately measured, and the experiment operation is simple and convenient.

Owner:NANJING TECH UNIV

Method for preparing sulfoaluminate cement clinker by using five-component mineral phase system

The invention relates to a method for preparing sulfoaluminate cement clinker by using a five-component mineral phase system. The alite-sulphoaluminate cement clinker is prepared by using a CaO-SiO2-Al2O3-Fe2O3-SO3 multicomponent system under the condition of not adding fluorite. The method comprises the following steps: (1) achieving the conditions that the basicity factor [(CaO+MgO) / (SiO2+Al2O3)] is 1.42 and the aluminum and sulfur ratio Al2O3 / SO3 is 1.73; (2) uniformly mixing and tabletting 75-80% of limestones, 5-7% of sandstones, 1-2% of coal ash, 6-10% of low-grade bauxite and 5-8% of gypsum, putting in a high-temperature furnace and sintering; and (3) insulating at 950 DEG C in a low-temperature furnace for 30 minutes, directly transferring to a high-temperature furnace at 1450 DEG C, insulating for 40 minutes, cooling along with the furnace to 1300 DEG C, insulating for 40 minutes, and cooling to room temperature after taking for 30 minutes to room temperature so as to obtain the CaO-SiO2-Al2O3-Fe2O3-SO3 multicomponent system cement clinker with coexisting C3S and C4A3S. The cement clinker has the advantages of high early strength and no shrinkage of long-term strength.

Owner:BEIJING UNIV OF TECH

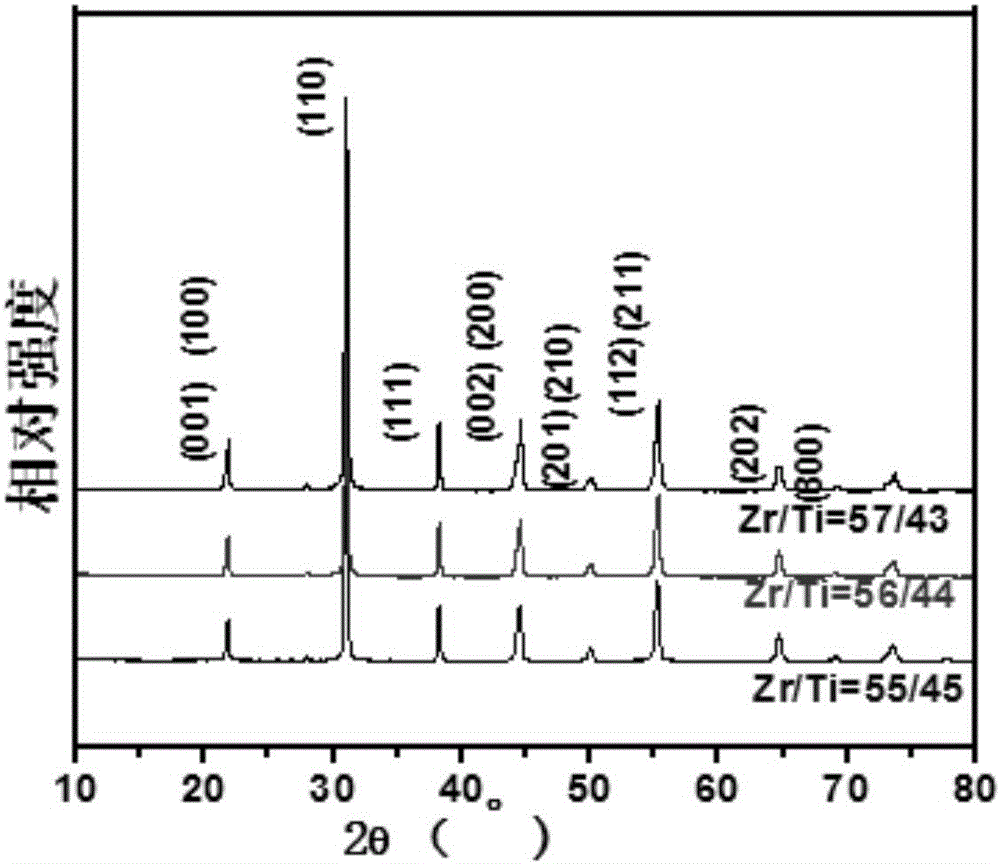

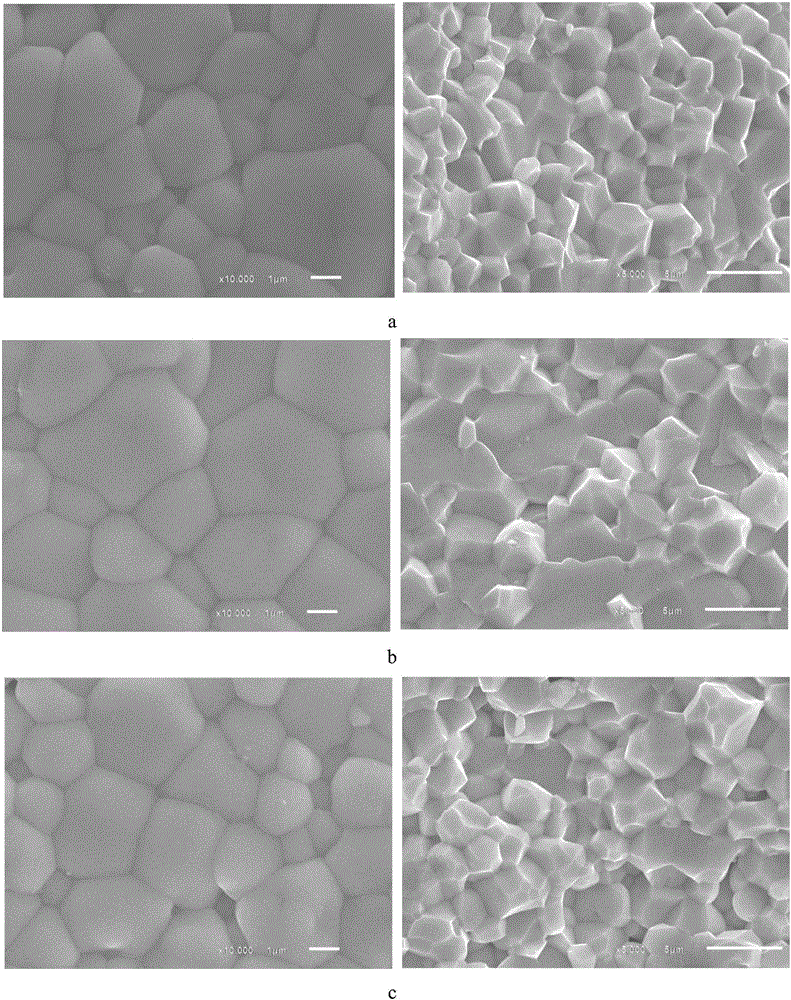

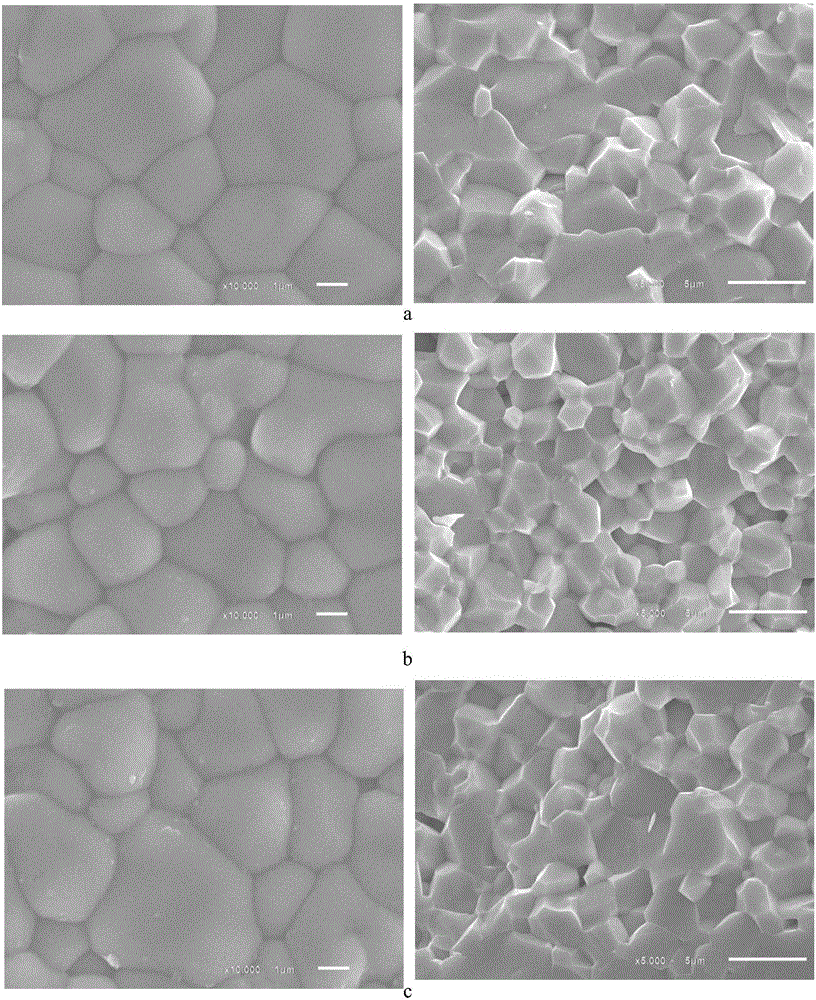

Multicomponent-system high-piezoelectric-activity piezoelectric ceramic material and preparation method therefor

ActiveCN106518070ALow melting pointImprove diffusion abilityMetallic materialsElectromechanical coupling

The invention relates to a multicomponent-system high-piezoelectric-activity piezoelectric ceramic material and a preparation method therefor and belongs to the technical field of nonmetallic materials. The composition of the material is represented by a general formula, i.e., xPb(Ni<1 / 3>Nb<2 / 3>)O<3-y>Pb(Zn<1 / 3>Sb<2 / 3>)O<3-z>Pb(Zn<1 / 3>Nb<2 / 3>)O3-(1-x-y-z)Pb<1-m-n>BamSrnTiAZr<1-A>O<3-p>WO3, wherein x is not smaller than 0.01 and not greater than 0.14, y is not smaller than 0.01 and not greater than 0.07, z is not smaller than 0.005 and not greater than 0.10, m is not smaller than 0.02 and not greater than 0.16, n is not smaller than 0.02 and not greater than 0.12, A is not smaller than 0.42 and not greater than 0.53, and p is not smaller than 0.002 and not greater than 0.015. The preparation method for the material comprises the steps of synthesizing ingredients, carrying out preburning, carrying out ball-milling, carrying out granulating, carrying out forming, carrying out degumming, carrying out embedded burning, carrying out silver roasting and carrying out polarization. The preparation method has the advantages of simple processing steps, good repeatability and high nondefective rate; and compared with properties of like piezoelectric materials reported in the literature, the properties, i.e., piezoelectric strain constant d33 and planar electromechanical coupling factor Kp of prepared ceramic samples are improved obviously, so that industrial large-scale production is facilitated.

Owner:CHANGZHOU UNIV

Total biodegradable film and preparation method

Owner:湖北誉笛环保科技实业有限公司

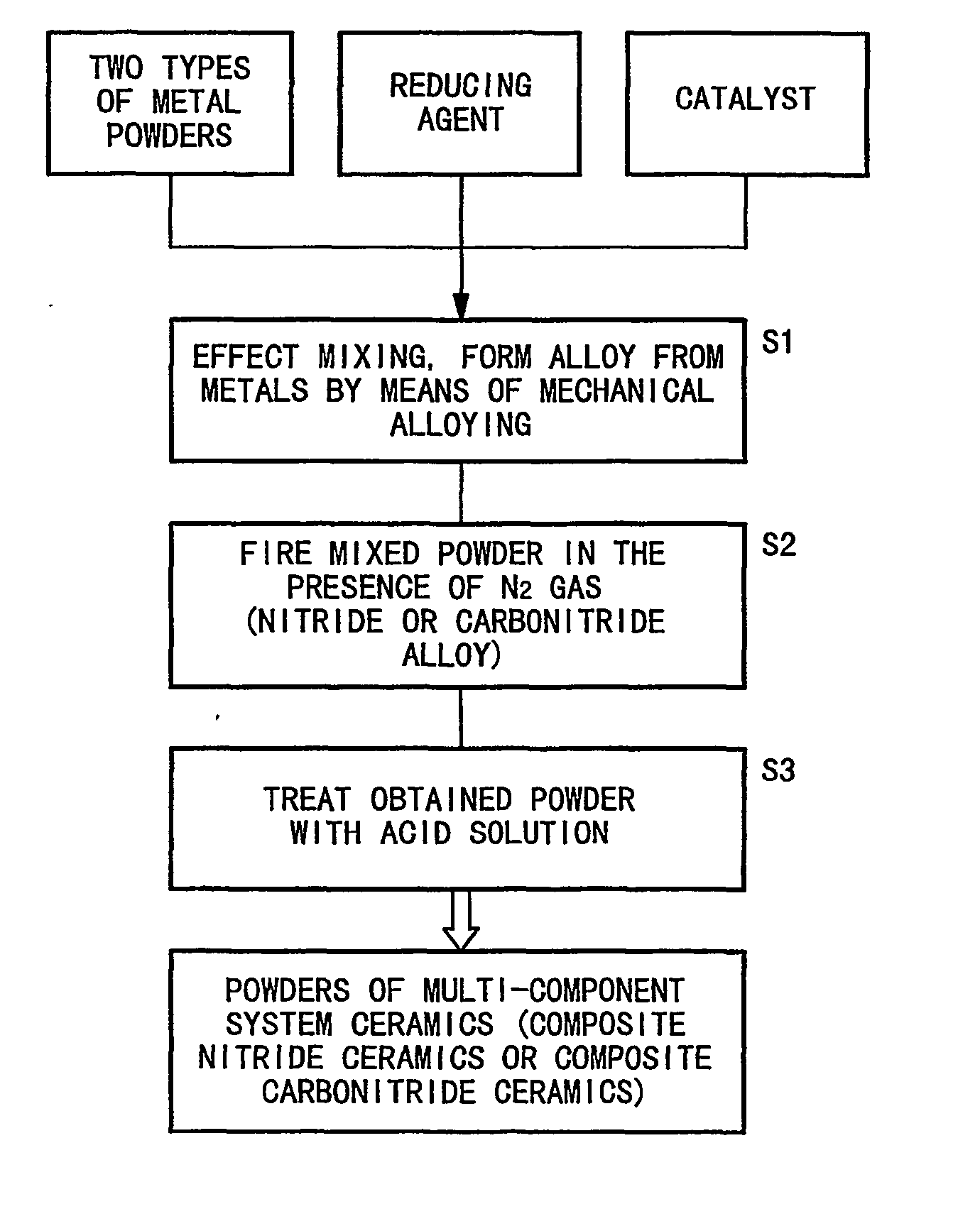

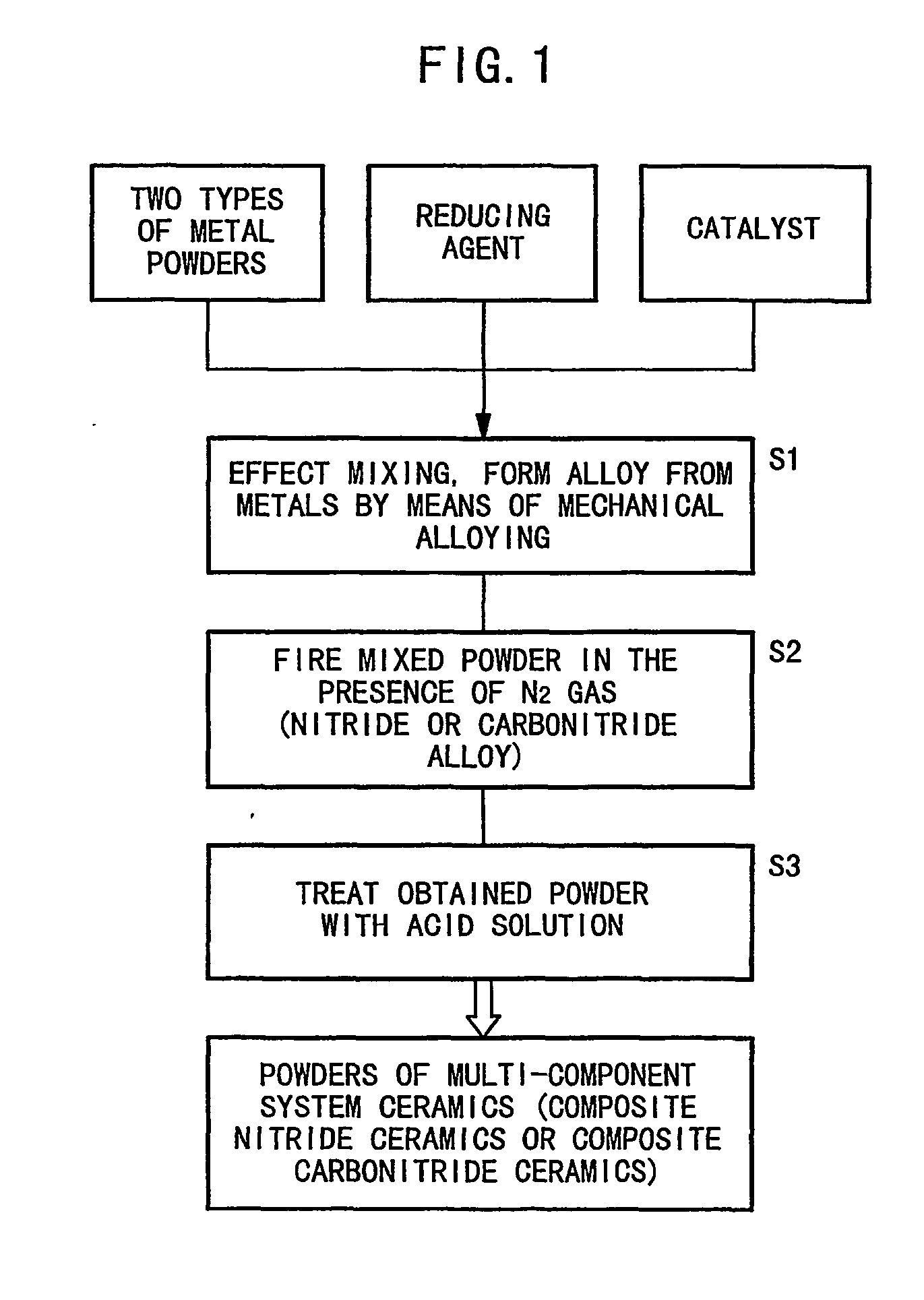

Composite material

A compact is obtained from a mixed powder of a multi-component system ceramics composed of constitutive elements of at least two metal elements selected from the group consisting of Ti, Al, V, Nb, Zr, Hf, Mo, Ta, Cr, and W, N, and optionally C; and Fe, Ni, Co, or an alloy composed of a constitutive element of at least one metal element of Fe, Ni, and Co. A composite material is prepared by sintering the compact.

Owner:HONDA MOTOR CO LTD

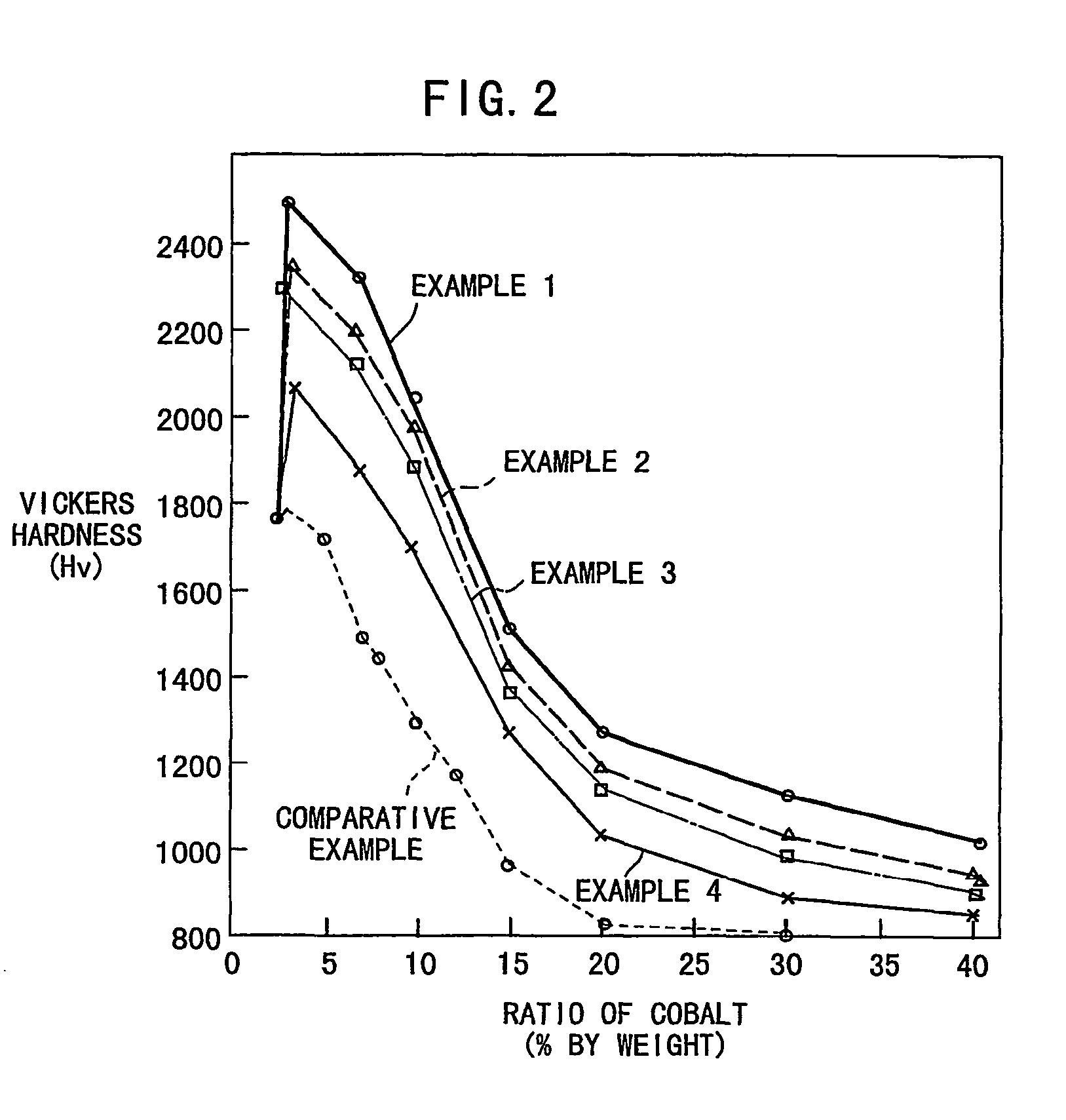

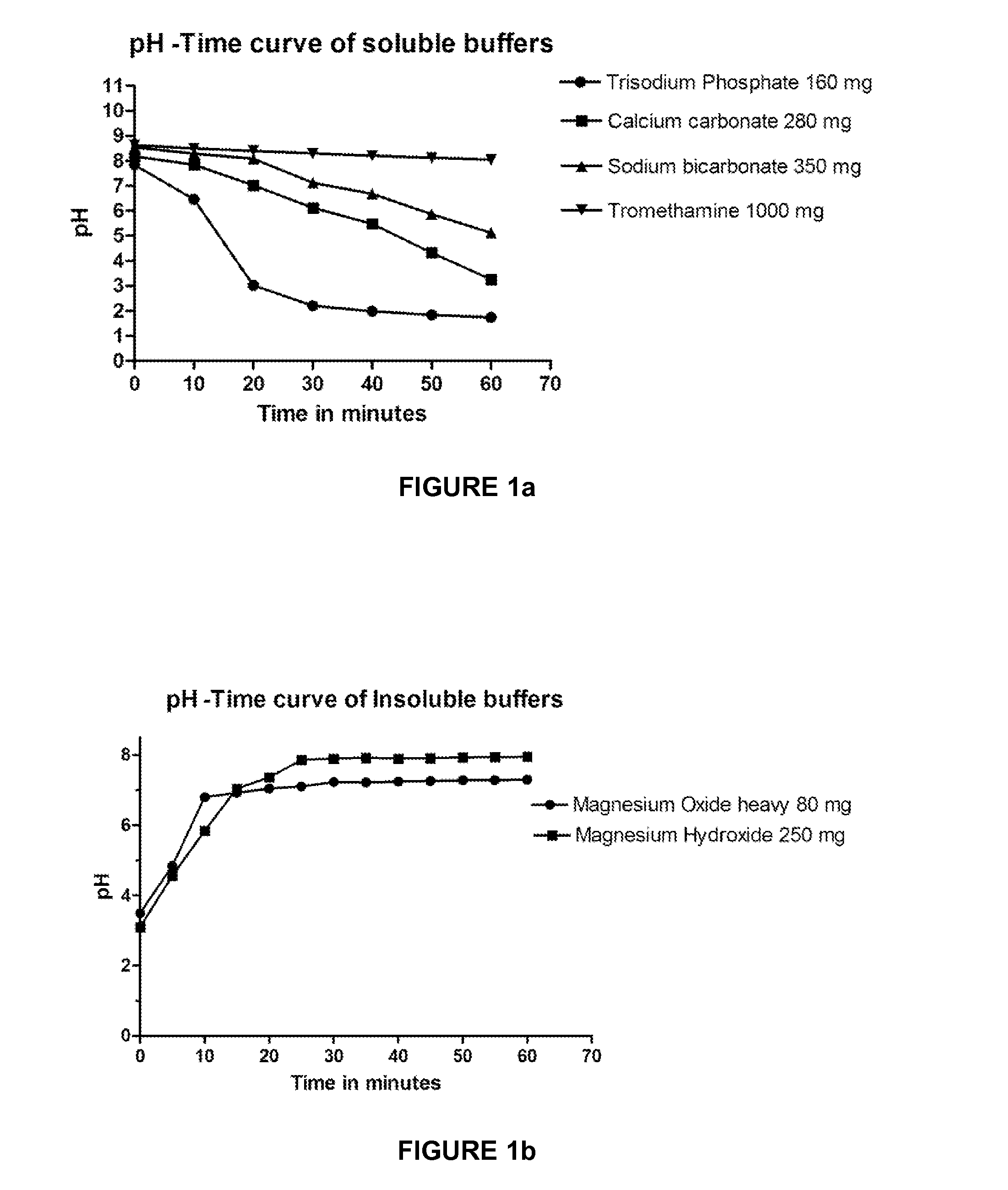

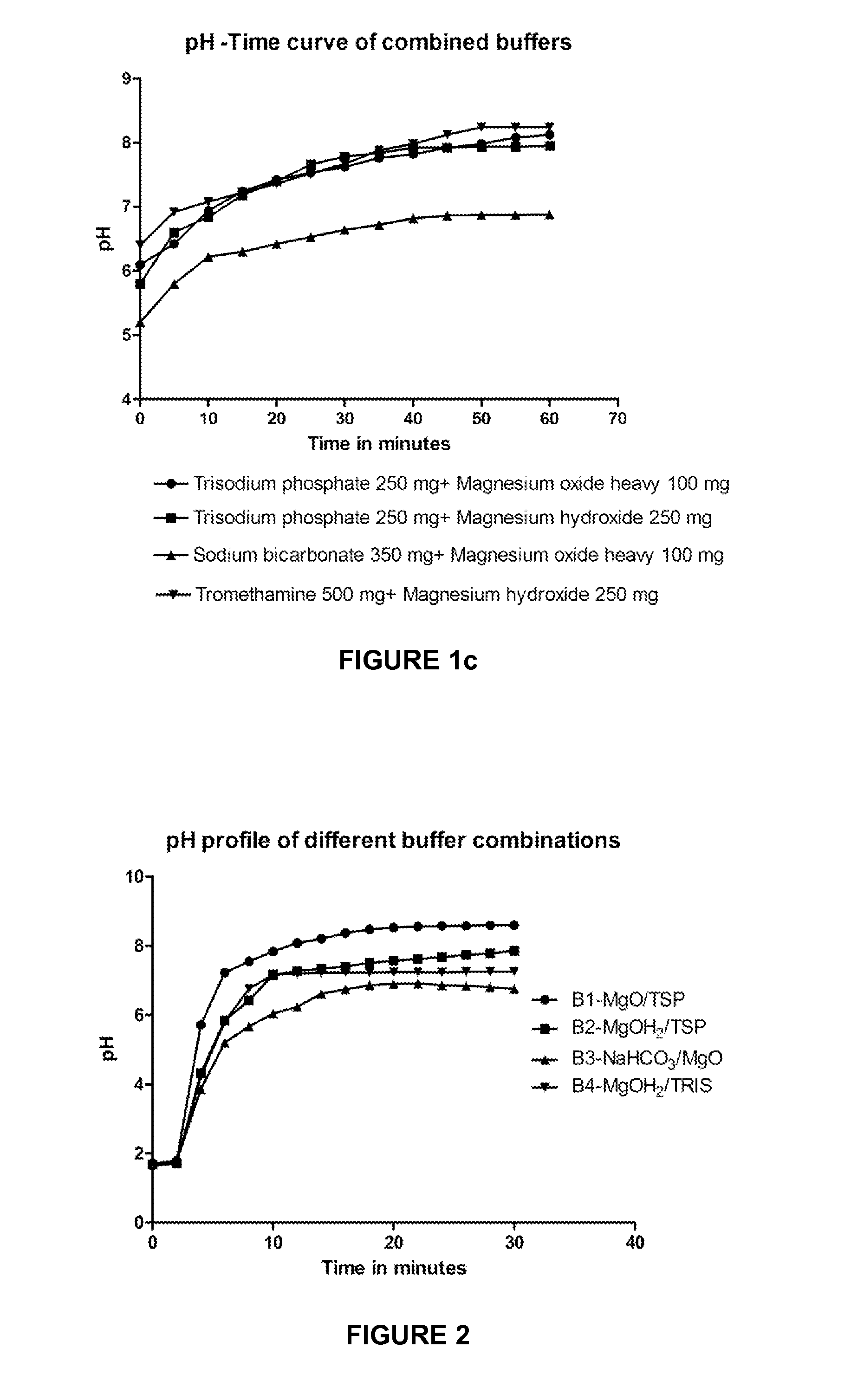

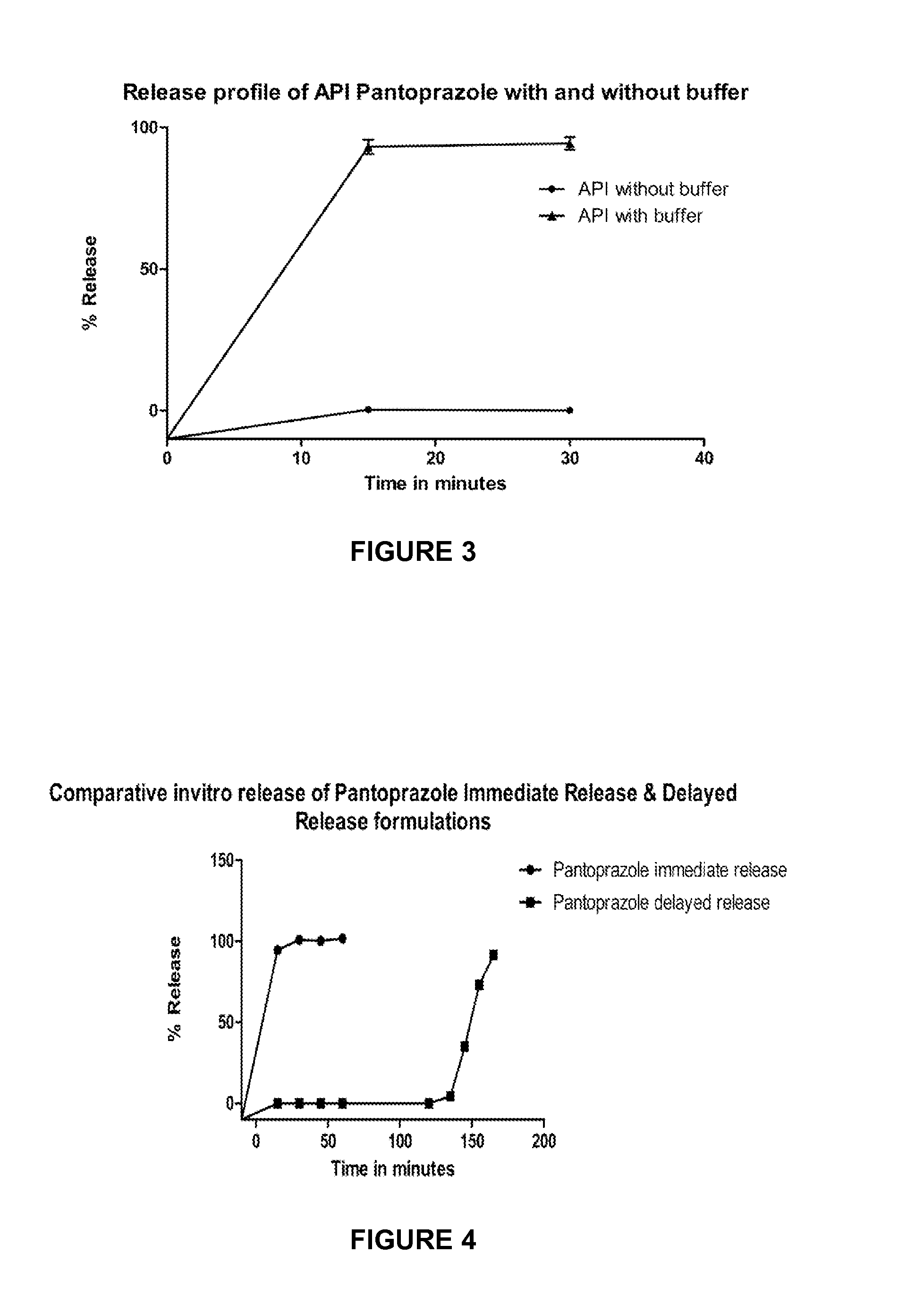

Immediate release compositions of acid labile drugs

InactiveUS20110171295A1High concentrationEliminate needBiocideDigestive systemMacro environmentWater insoluble

The present invention provides a method of creating a macro environment in the stomach for immediate release of acid labile compounds stable at alkaline or near alkaline pH comprising the step of administering a composition comprising acid labile compound stable at alkaline or near alkaline pH together with a water soluble buffer, a water insoluble buffer, a disintegrant and pharmaceutically acceptable excipients. The present invention also provides a pharmaceutical composition of a multi component system in which one component essentially contains an acid labile drug and the other component comprises a fast releasing buffer composition along with pharmaceutically acceptable excipients for oral administration and ingestion by a subject, and process for preparing the same.

Owner:SHAFEE MUNEERA MOHAMED +4

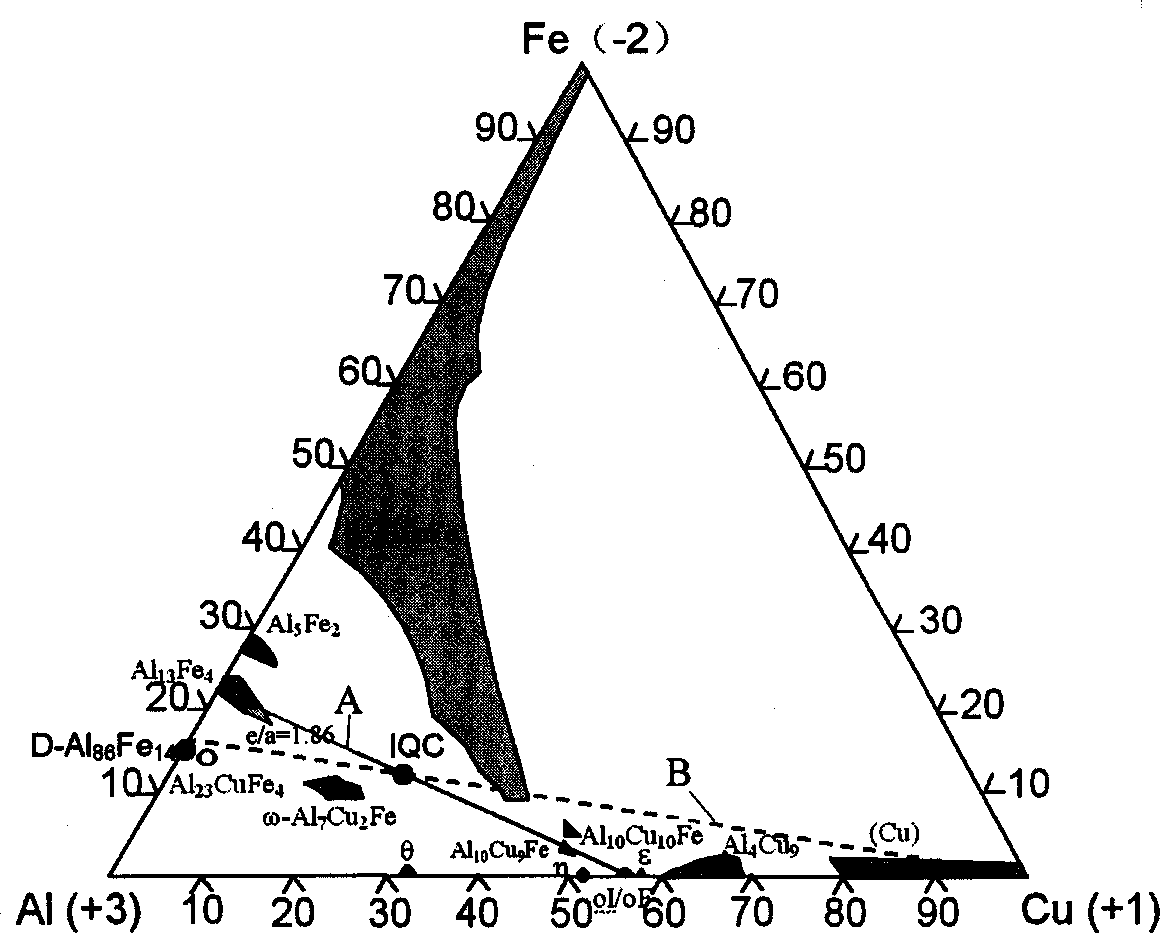

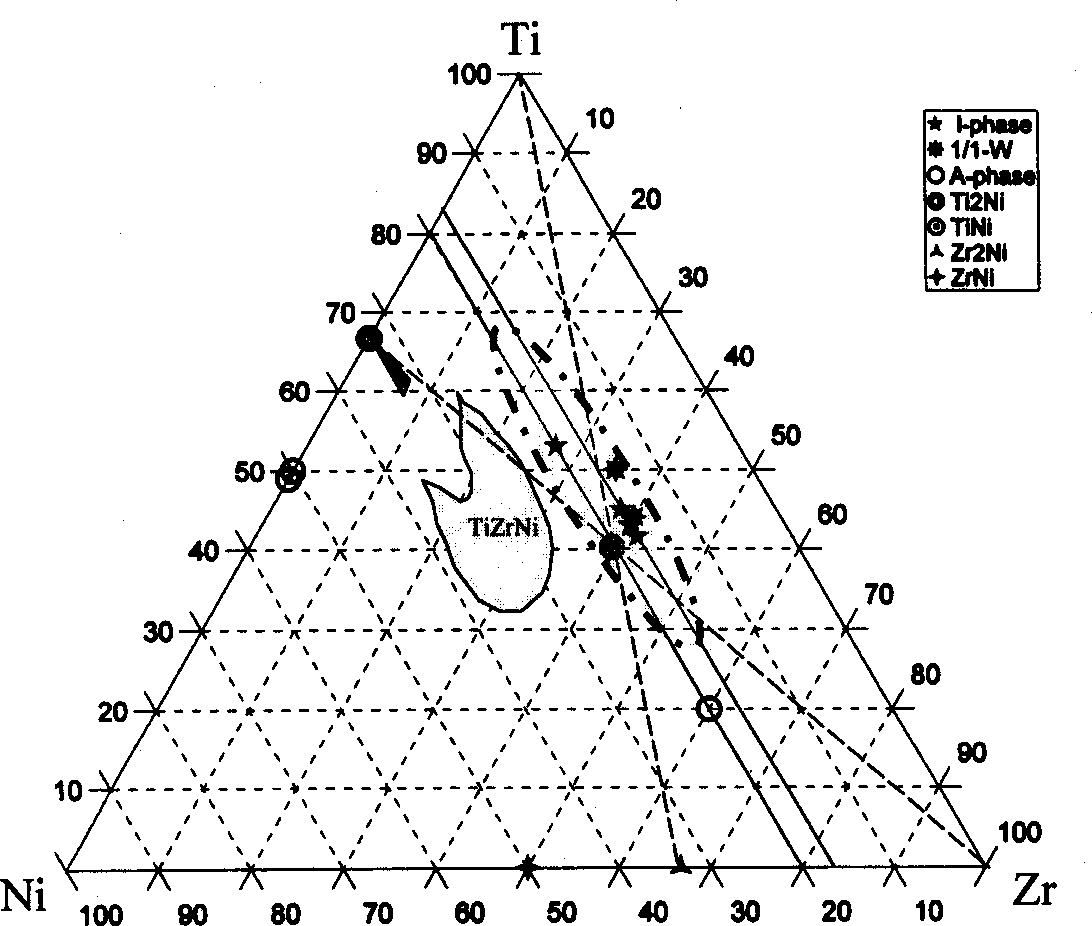

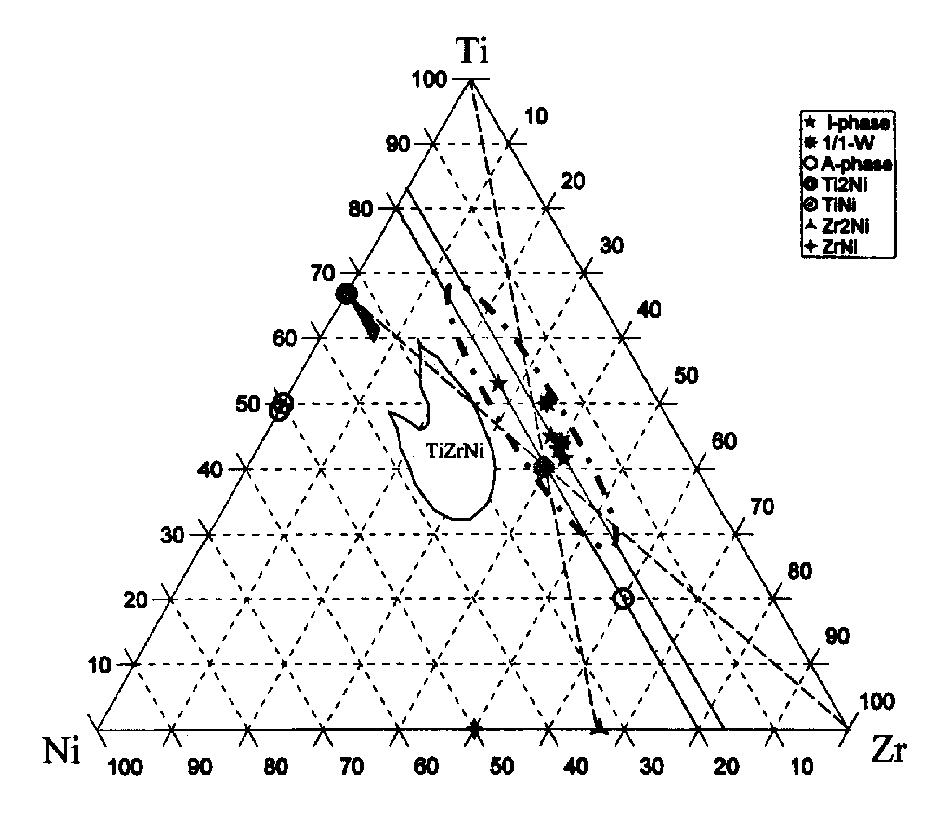

Zr TiNi quasi-crystal with compactness and high elastic deformation property and composition design method

The present invention relates to a ZrTiNi quasicrystal and its composition design method. When the multicomponent system quasicrystal composition is defined, firstly, the multicomponent system is decomposed into subgroup component system, then the quasicrystal component point of subgroup component system and third grou pcomponent are lined, and the cross-point of its with quasicrystal isoelectronic concentration line is the ideal composition of the multicomponent system quasicrystal. For example, it utilizes copper mould suction-moulding process to prepare compact Zr-Ti-Ni quasicrystal with high elastic deformation capability, its room-temp. compressive strength exceeds 1000 MPa, its elastic strain is up to 5.2%, electronic concentration range is 1.20-1.25 and its typical composition is Zr40Ti40Ni20.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com