Solvent-resistance polyurethane rubber roller and manufacturing method and application thereof

A polyurethane and solvent-resistant technology, which is applied in the field of solvent-resistant polyurethane rubber rollers and its preparation, can solve problems such as difficult to process smooth surfaces, large changes in hardness, and decreased mechanical properties, so as to improve the problem of rubber becoming brittle and surface grinding Excellent performance and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

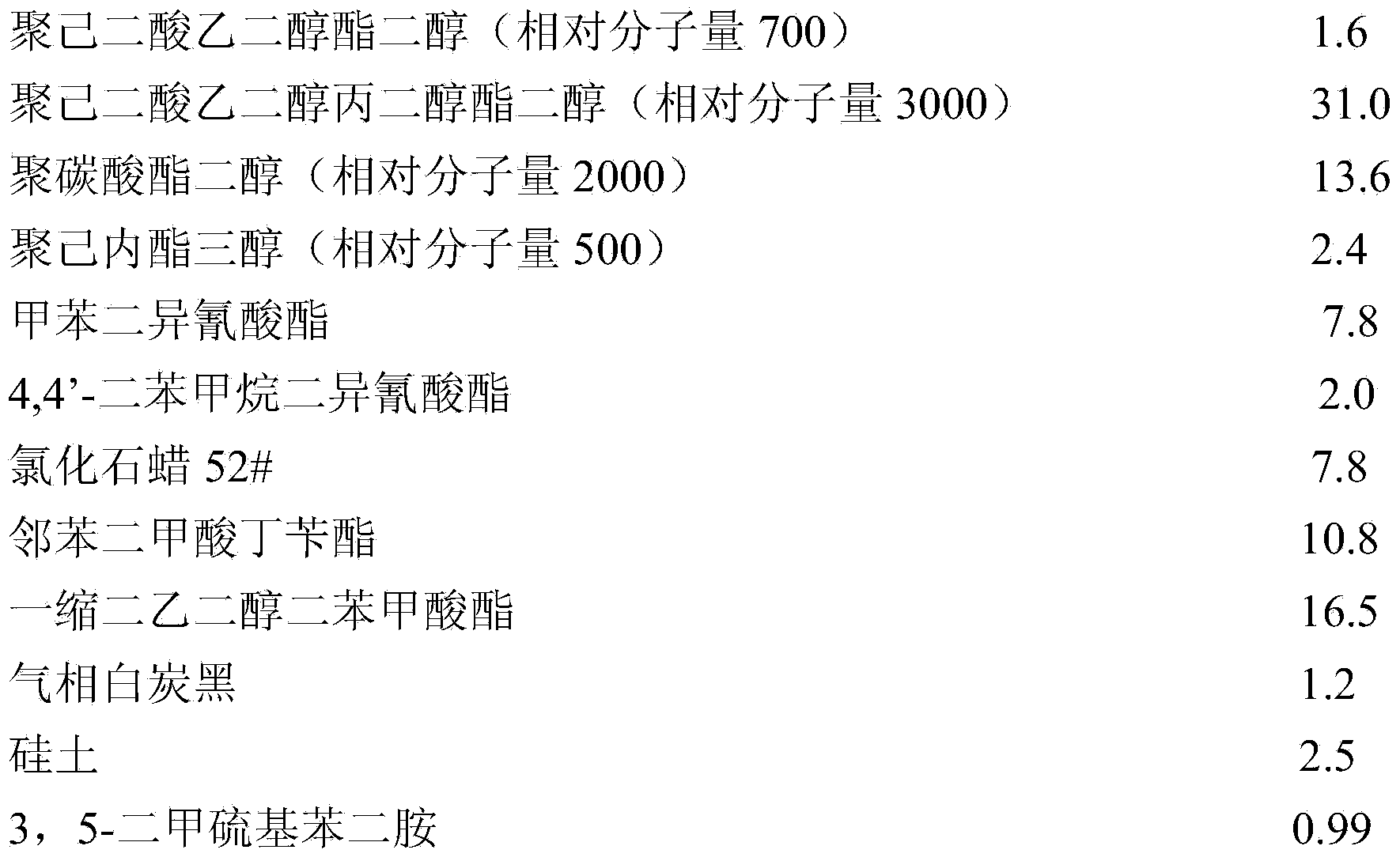

[0034] Get the following commercially available raw materials, and each of the following raw materials is expressed in mass percentage (%):

[0035]

[0036]

[0037] The preparation method is:

[0038] Step 1: Stir polyethylene adipate diol, polyethylene adipate propylene glycol ester diol, polycarbonate diol, and polycaprolactone triol together and heat to 120°C, then vacuum dehydrate for 2 ~3 hours until the moisture content is lower than 0.05%; then cool down to 60°C, add toluene diisocyanate and react at 65°C for 2 hours, then raise the temperature to 85°C for 1 hour to obtain component A.

[0039] Step 2: Stir and mix chlorinated paraffin, butyl benzyl phthalate and diethylene glycol dibenzoate evenly; add fumed silica and silica to disperse at high speed for 30 minutes, heat to 120°C, Vacuum dehydration for 2 to 4 hours until the moisture content is lower than 0.05%; then cool down to 80°C, add 4,4'-diphenylmethane diisocyanate and stir for 30 minutes to obtain c...

Embodiment 2

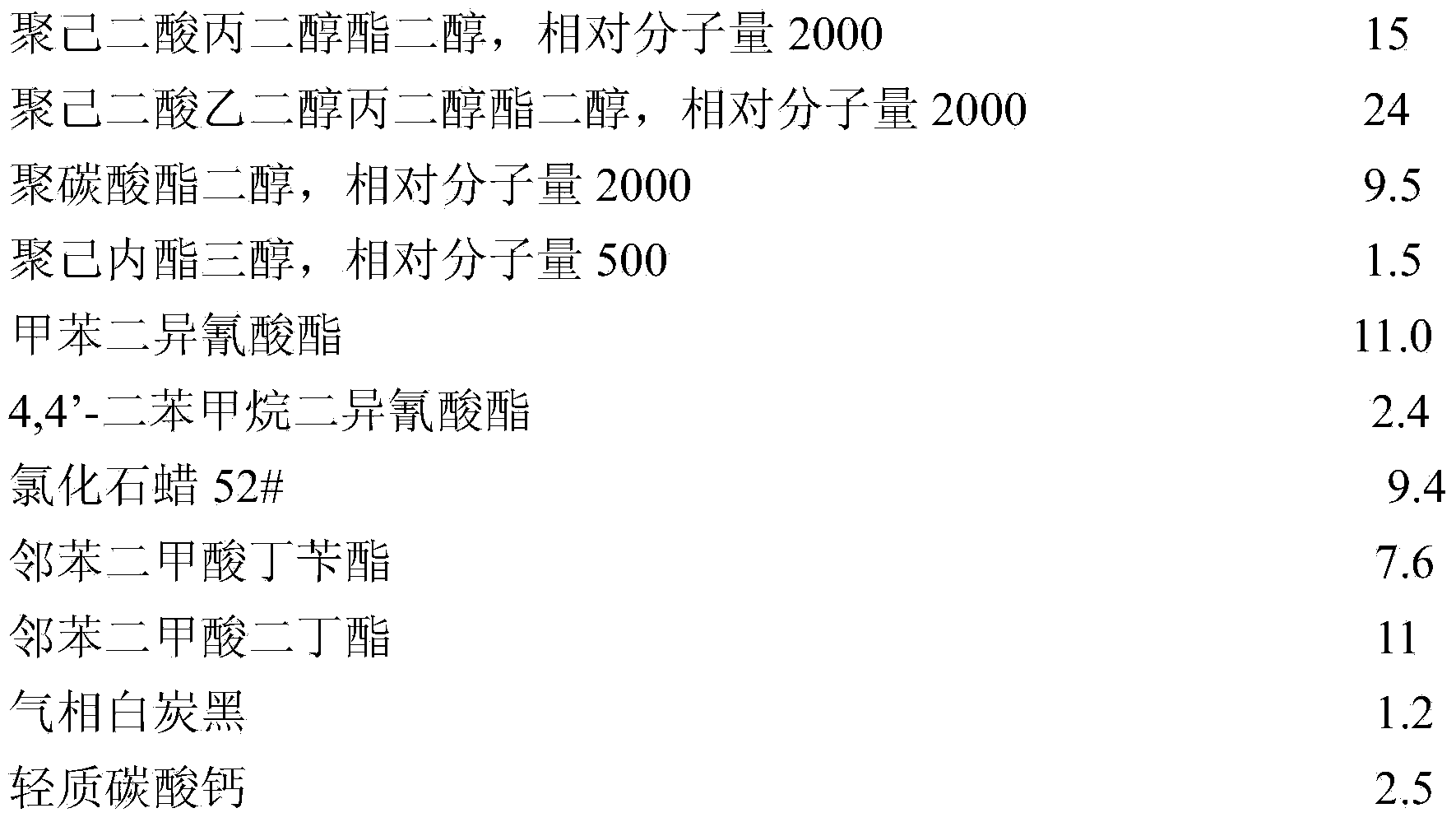

[0044] Get the following commercially available raw materials, and each of the following raw materials is expressed in mass percentage (%):

[0045]

[0046]

[0047] via the following method:

[0048] Step 1: Stir and heat polytrimethylene adipate diol, polyethylene adipate propylene glycol triol, polycarbonate diol, and polycaprolactone triol together to 120°C, vacuum dehydration for 2 to 3 hours until the moisture content is lower than 0.05%; then cool down to 60°C, add toluene diisocyanate to react at 63°C for 2 hours, then raise the temperature to 83°C for 1 hour to obtain component A.

[0049] Step 2: Stir and mix chlorinated paraffin, butyl benzyl phthalate and dibutyl phthalate evenly; add fumed silica and light calcium carbonate to disperse at high speed for 30 minutes, heat to 120°C, and vacuum dehydrate 2 to 4 hours, until the moisture content is lower than 0.05%; then cool down to 80°C, add 4,4'-diphenylmethane diisocyanate and stir for 30 minutes to obtain ...

Embodiment 3

[0054]Get the following commercially available raw materials, and each of the following raw materials is expressed in mass percentage (%):

[0055]

[0056]

[0057] Through the same method as in Example 2, the required solvent-resistant polyurethane rubber roller product can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com