Patents

Literature

505results about How to "Good paint effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PC/ABS alloy modified engineering plastic dedicated for laptop casings and production method thereof

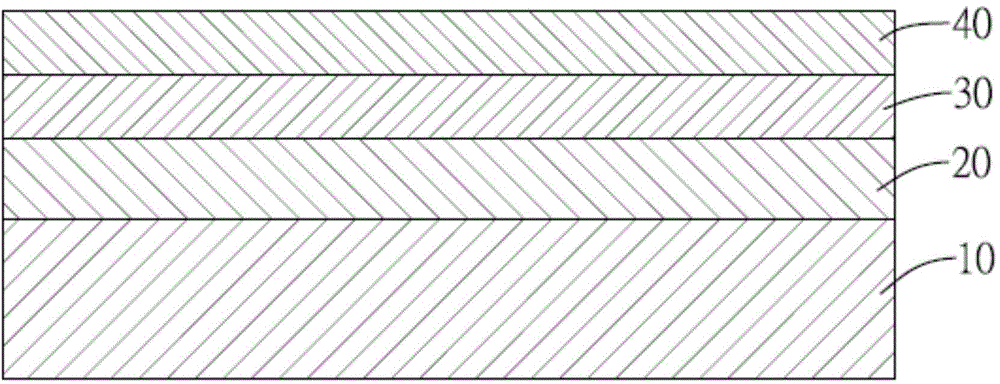

The invention discloses a PC / ABS alloy modified engineering plastic dedicated for laptop casings. The plastic comprises the following components in percentage by weight: 22% to 65% of polycarbonate, 1% to 10% of compatilizer, 22% to 65% of acrylonitrile-butadiene-styrene, 5% to 40% of mineral filling material, 0.3% to 1% of antioxidant, 3% to 20% of halogen-free fire retardant, 0.5% to 2% of dispersed lubricant, and 3% to 20% of flexibilizer. The invention also discloses a production method of the PC / ABS alloy modified engineering plastic dedicated for laptop casings. The PC / ABS alloy modified engineering plastic dedicated for laptop casings has the advantages of capability of being recycled and utilized, multi-choice of color and outer layer treatment, stable size, good heat radiation property, and high cost performance. The production method has the advantages of simple operation and suitability for mass production.

Owner:东莞市卡帝德塑化科技有限公司

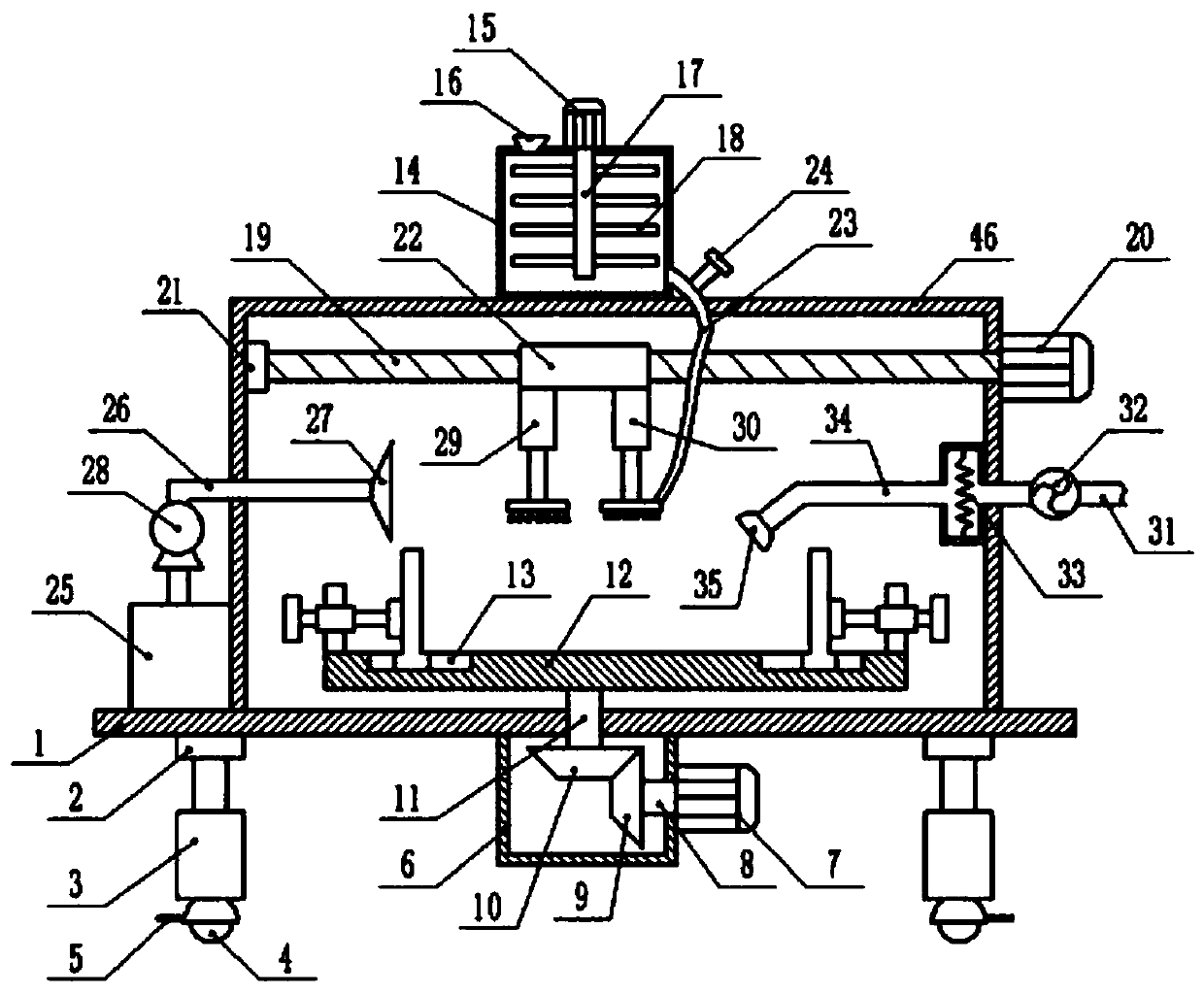

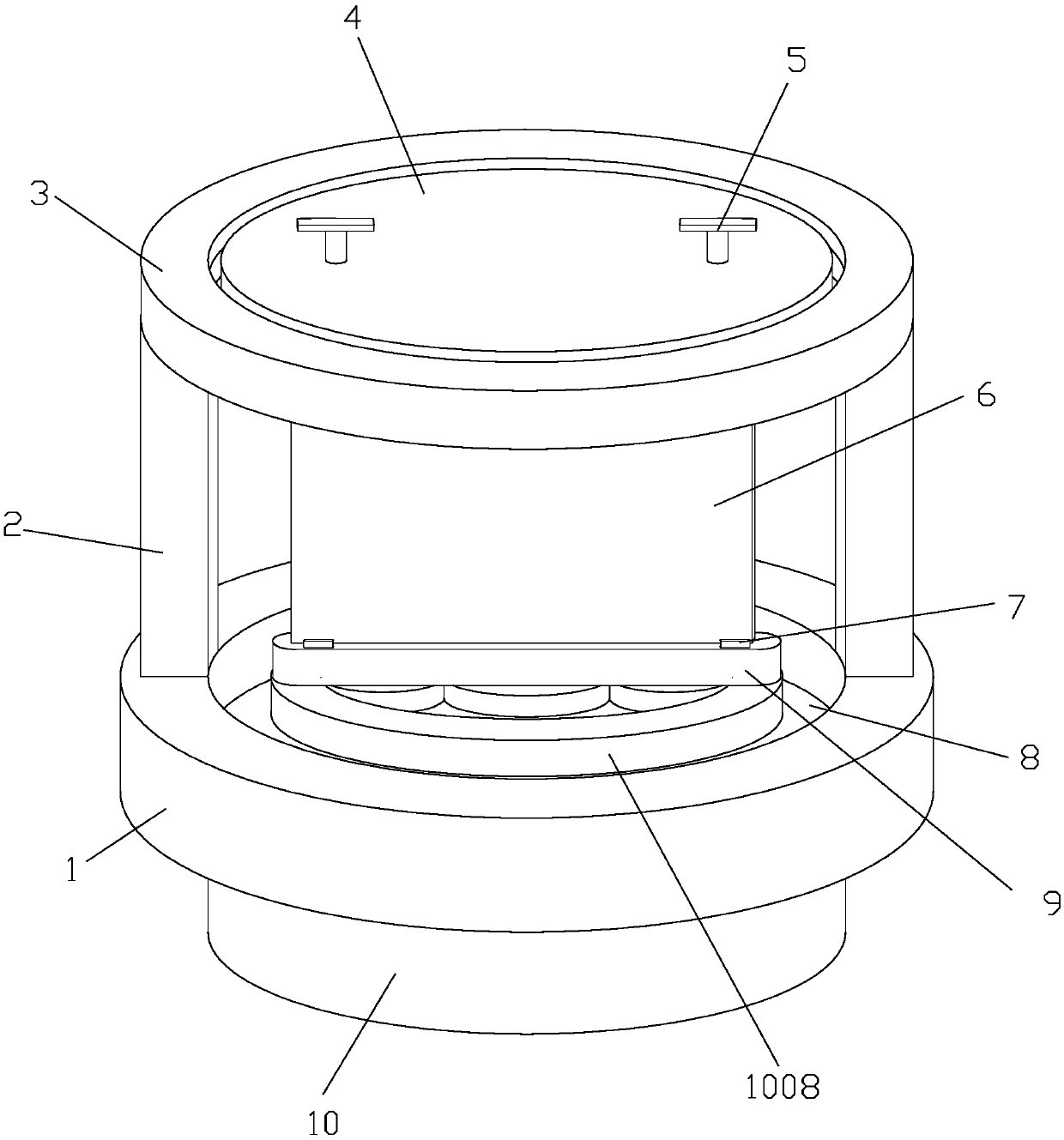

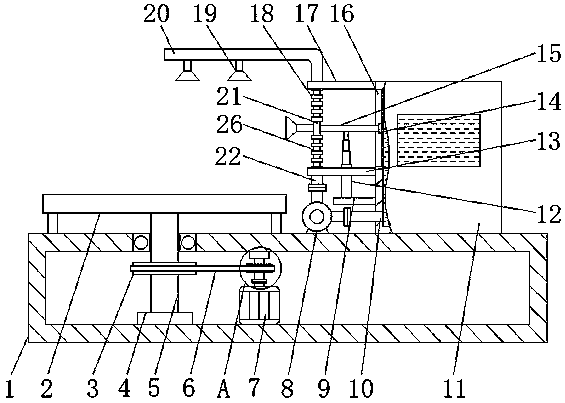

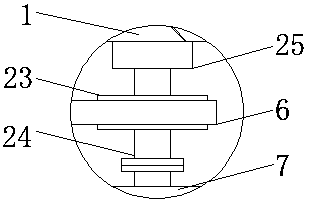

Automatic paint spraying device for metal castings

PendingCN107214035AEasy to installEasy to unloadLiquid surface applicatorsLiquid spraying apparatusPiston rodSpray painting

The invention discloses an automatic paint spraying device for metal castings. The automatic paint spraying device comprises a paint spraying barrel with an opening in the top end. Support columns are correspondingly mounted on the four corners of the bottom end of the paint spraying barrel. An air cylinder vertically arranged is fixedly arranged on the side wall of the bottom end of the paint spraying barrel through bolts. A movable plate is welded to a piston rod of the air cylinder. The movable plate is located on the inner wall of the bottom end of the paint spraying barrel. The top end of the movable plate is rotationally connected with a mounting plate horizontally arranged. A first electric motor is embedded into the movable plate. An output shaft of the first electric motor is connected with a gear. The gear is located on one side of the mounting plate. Tooth mouths distributed in an array manner are mounted on the side walls of the periphery of the mounting plate. The tooth mouths are engaged with the gear. A fixing ring is slidably connected into the paint spraying barrel. An annular air outlet pipe and a liquid spraying pipe are mounted on the inner wall of the fixing ring. The air outlet pipe is located above the liquid spraying pipe. By the adoption of the automatic paint spraying device, the multi-angle paint spraying of the metal castings can be achieved, the paint spraying effect is good, the quick mounting and discharging of the metal castings are achieved, and the air pollution is reduced.

Owner:JIANGSU SUGAO FLUID MACHINERY

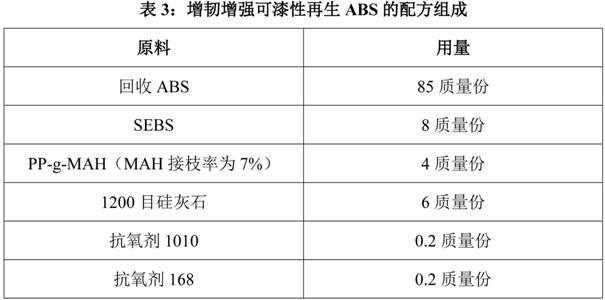

Toughening and reinforcing paintable reclaimed ABS (Acrylonitrile-Butadiene-Styrene) and preparation method thereof

The invention discloses a toughening and reinforcing paintable reclaimed ABS (Acrylonitrile-Butadiene-Styrene) which consists of the following raw materials in part by weight: 60-90 parts of recycled ABS, 5-20 parts of toughening agent, 1-6 parts of compatilizer, 1-15 parts of filler and 0.1-1 part of antioxidant. The reclaimed ABS aggregates provided by the invention have excellent mechanical property and painting property.

Owner:广东金柏新材料科技股份有限公司

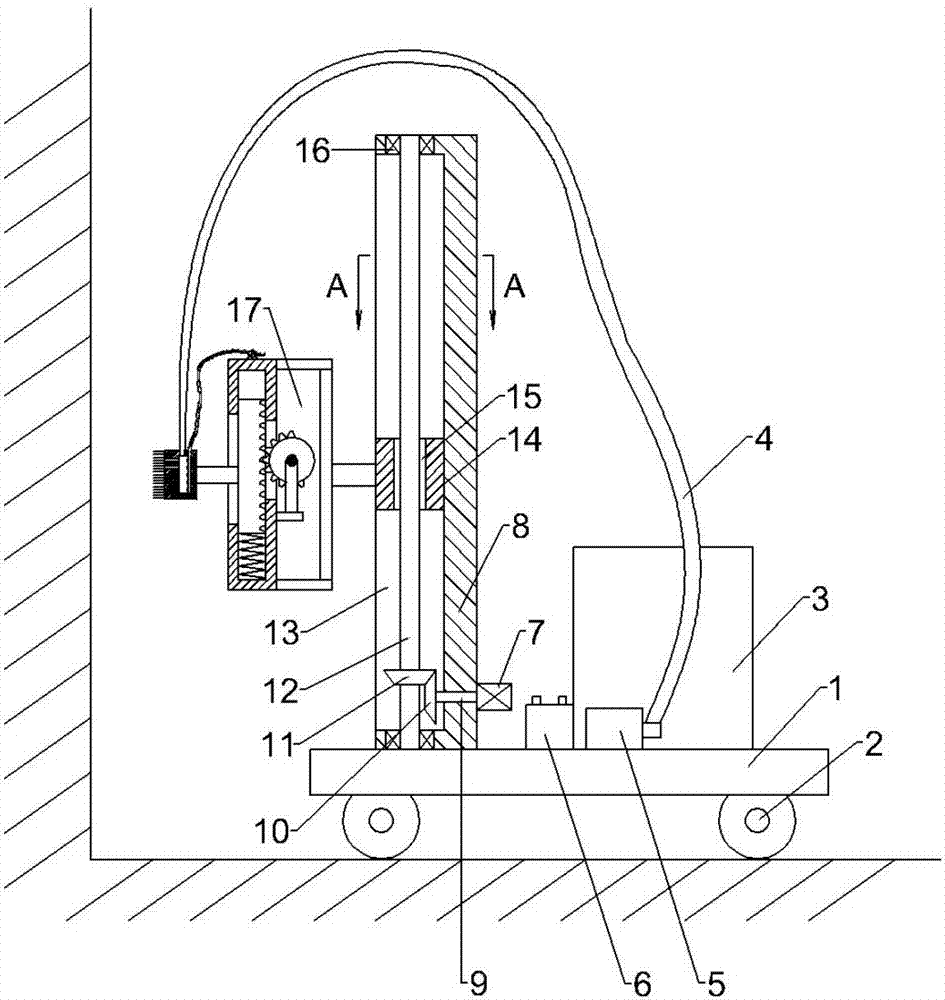

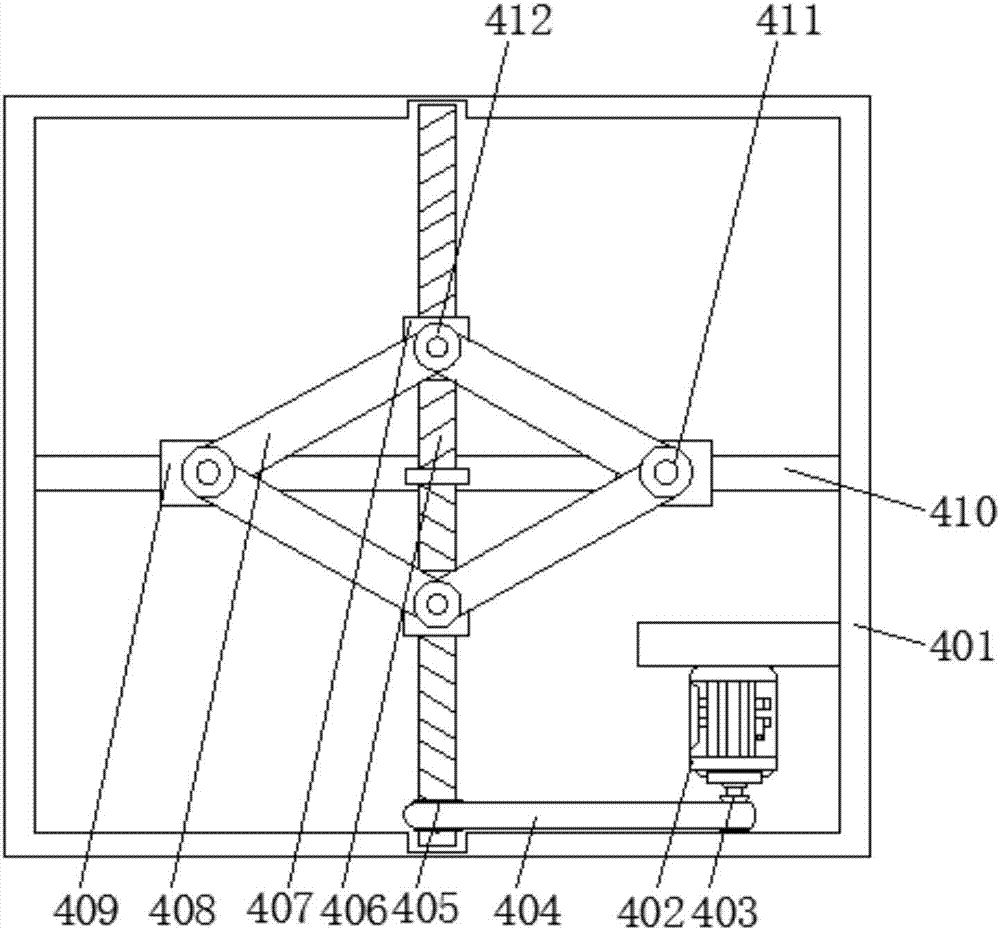

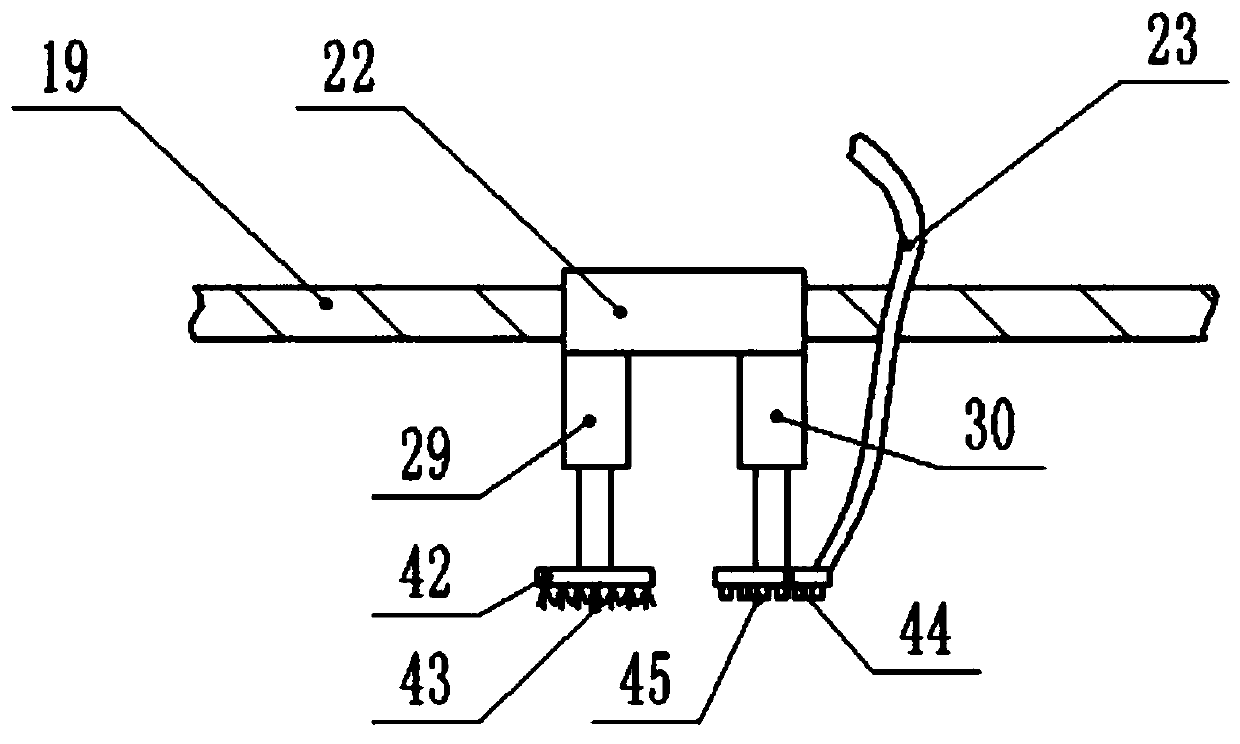

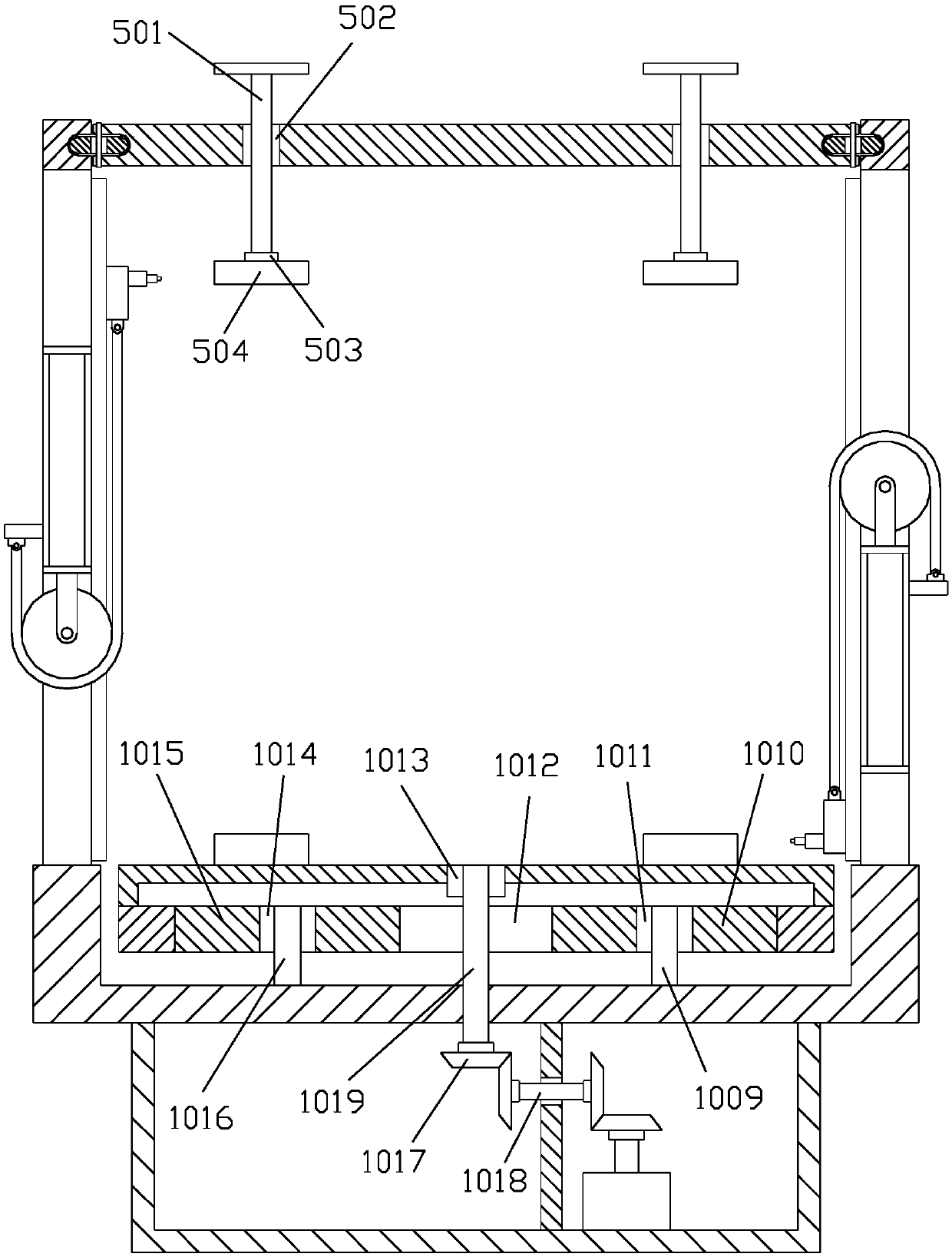

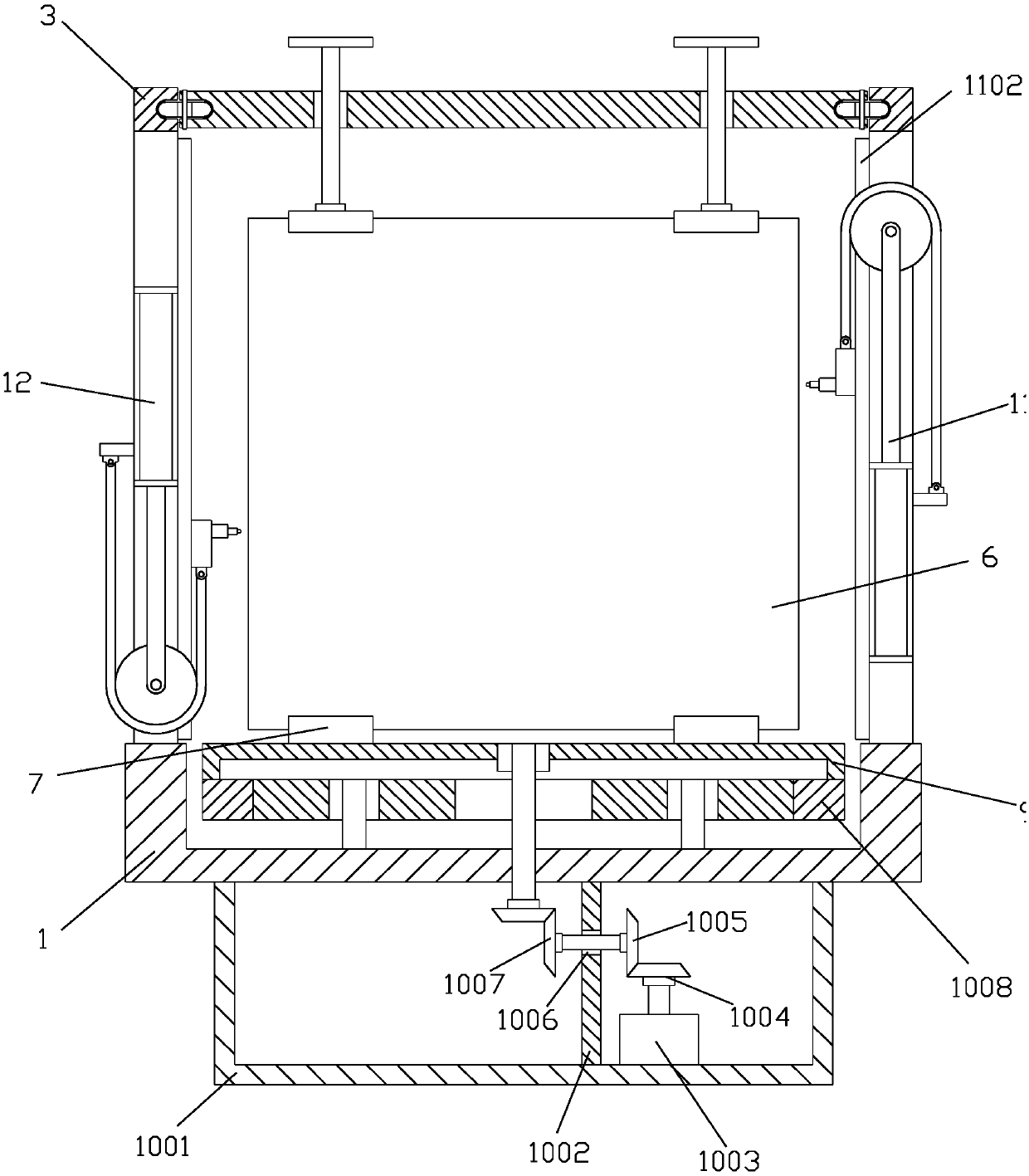

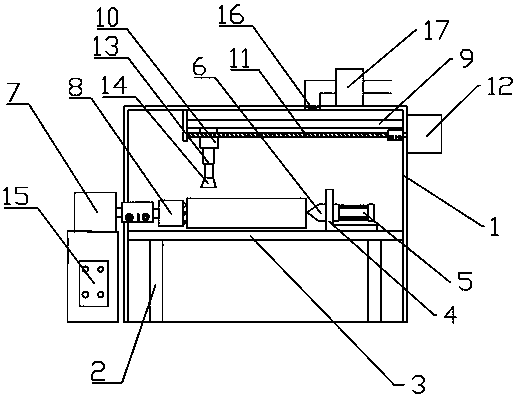

Building construction wall plastering equipment with reciprocating plastering function

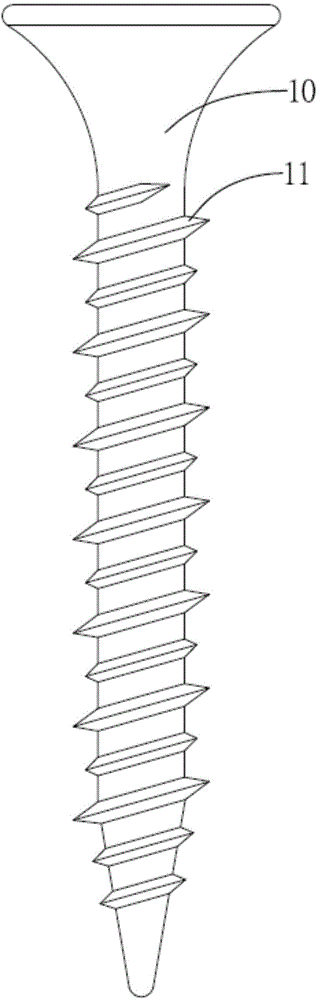

InactiveCN107035116ARealize up and down repeated movementApply evenlyBuilding constructionsArchitectural engineeringThreaded rod

A wall painting equipment for building construction with a reciprocating painting function, including a base plate, four rollers are fixedly connected to the lower side of the base plate, a support column is fixedly connected to the upper side of the base plate, and an opening is opened on the support column to move toward the left. groove, a moving block is arranged in the moving groove, and a vertical threaded through hole is provided on the moving block, and a threaded rod is connected to the internal thread of the vertical threaded through hole, and the two ends of the threaded rod are connected to the support column in rotation, and the lower part of the threaded rod A first bevel gear is fixedly connected, a second bevel gear meshes on the right side of the first bevel gear, and a first rotating shaft is fixedly connected to the right end of the second bevel gear, and the first rotating shaft extends rightward through the support column, and the first rotating shaft The right end of the right end is connected with the first motor output end fixedly arranged on the side wall of the support column. The invention has the advantages of reasonable structural design and good painting effect, effectively liberates manpower, ensures the painting effect, improves the painting efficiency, and has wide application value.

Owner:六安市我罗生工业设计有限公司

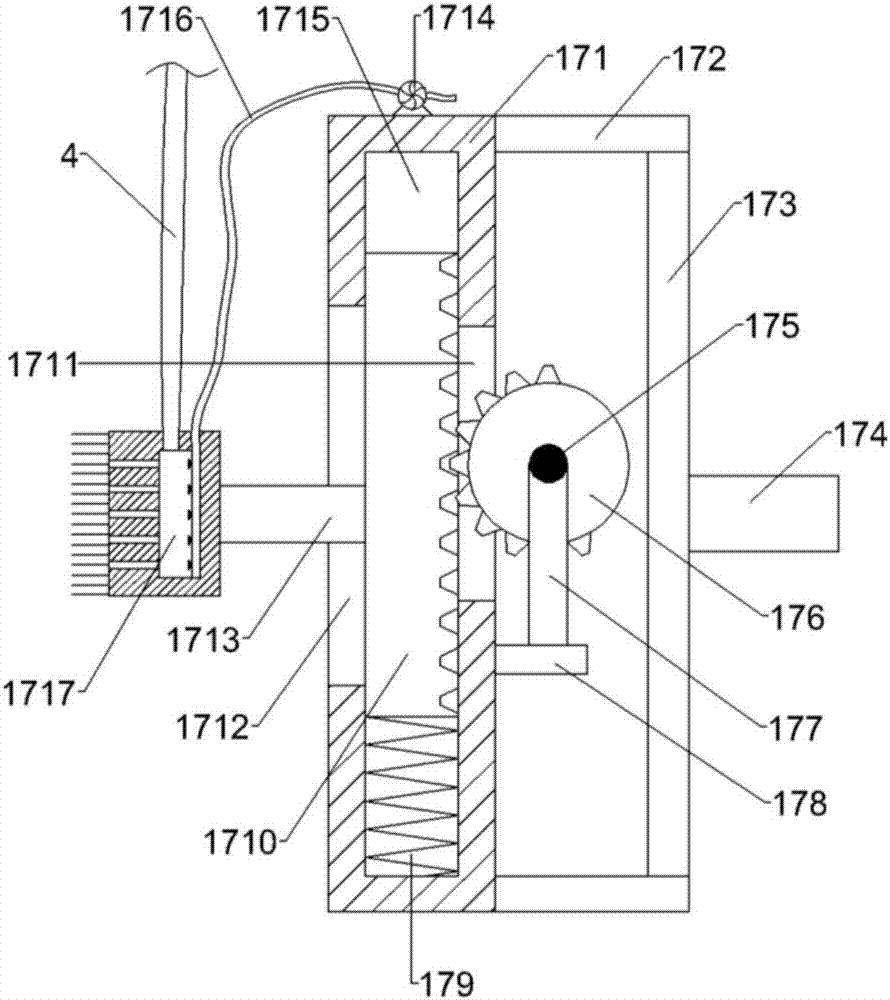

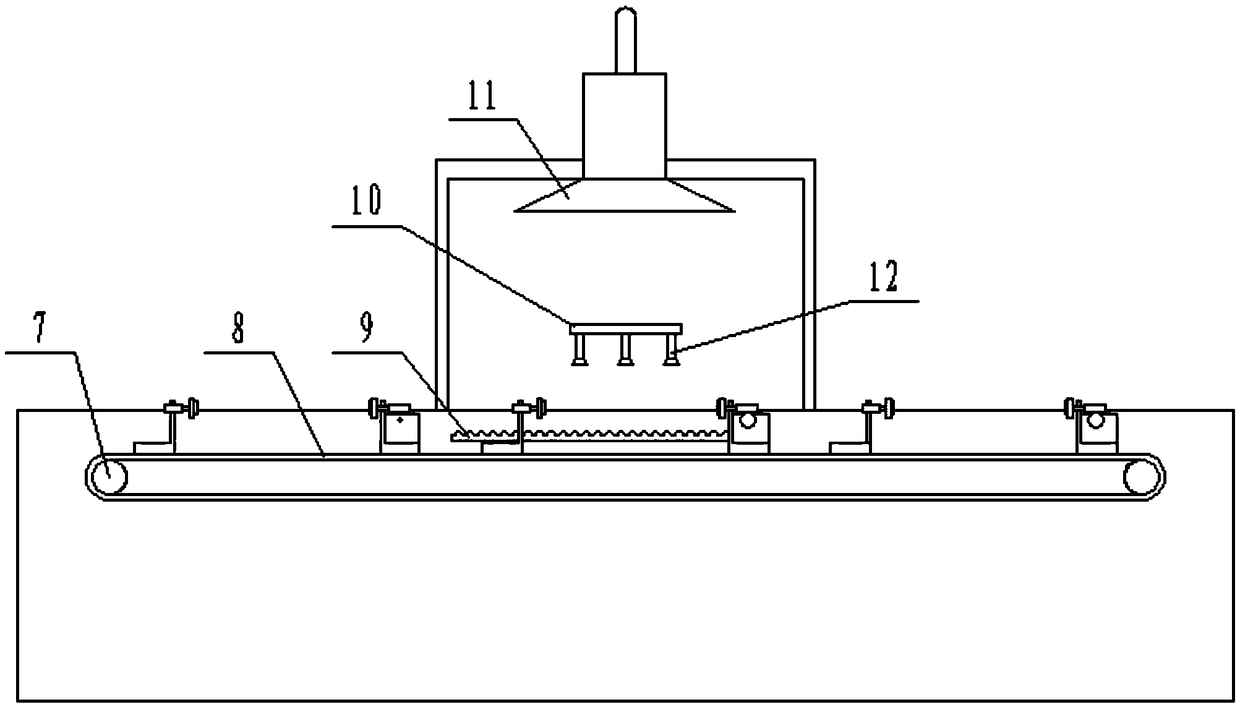

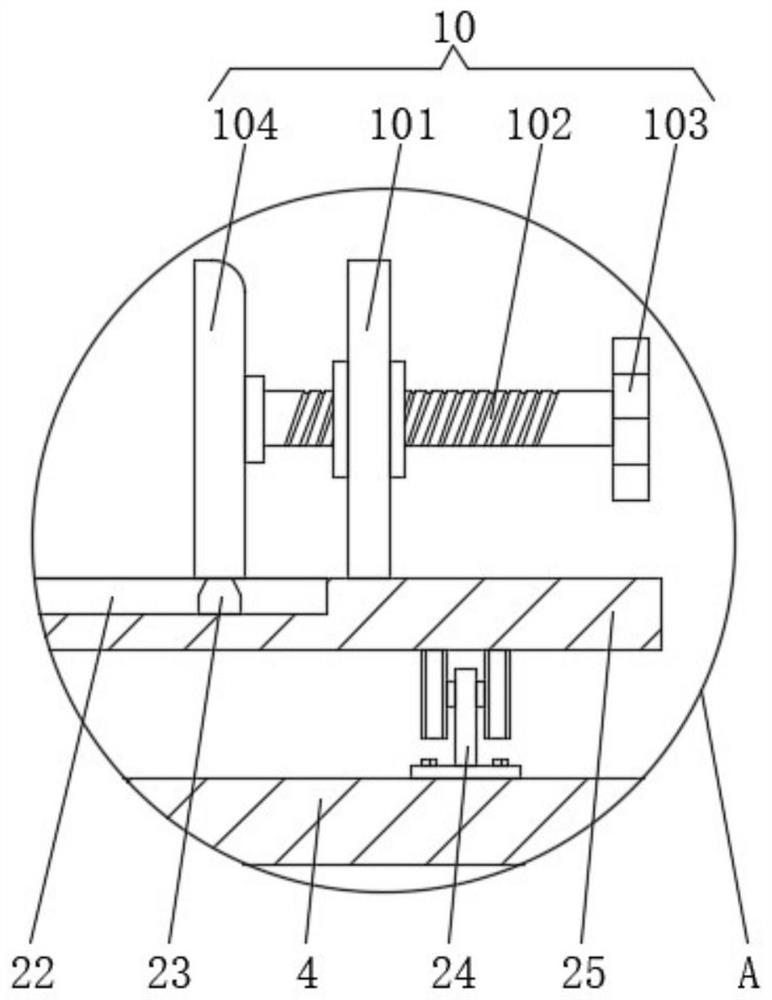

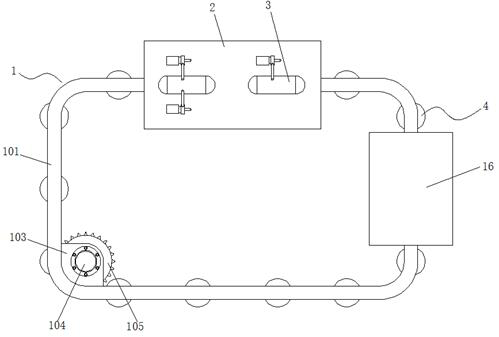

Environment-friendly building pipe paint spraying device

ActiveCN108654877ARealize automatic deliveryRealize automatic paintingSpraying apparatusEngineeringExhaust pipe

The invention discloses an environment-friendly building pipe paint spraying device. The environment-friendly building pipe paint spraying device comprises a rack, a conveying motor is arranged on oneside of the rack, a toothed bar is arranged on one side of the inner wall of the rack, a conveying roller is arranged in the rack, the conveying roller is fixedly connected with the conveying motor,a conveying belt is arranged on the outer side of the conveying roller, a clamping mechanism is arranged on the surface of the conveying belt, a box body is arranged at the upper end of the rack, an air suction pump is arranged at the upper end of the box body, the air suction pump communicates with the box body, the exhaust end of the air suction pump is provided with an exhaust pipe connected with a water box, a bearing plate is arranged in the box body, and a nozzle is arranged at the bottom of the bearing plate. The device has the beneficial effects that automatic conveying and automatic paint spraying of pipes can be achieved, the paint spraying effect is good, the efficiency is high, in the paint spraying process, paint mist generated by paint spraying can be absorbed, and the phenomenon that due to paint mist drifting, the health of an operator is affected is avoided.

Owner:杨智萍

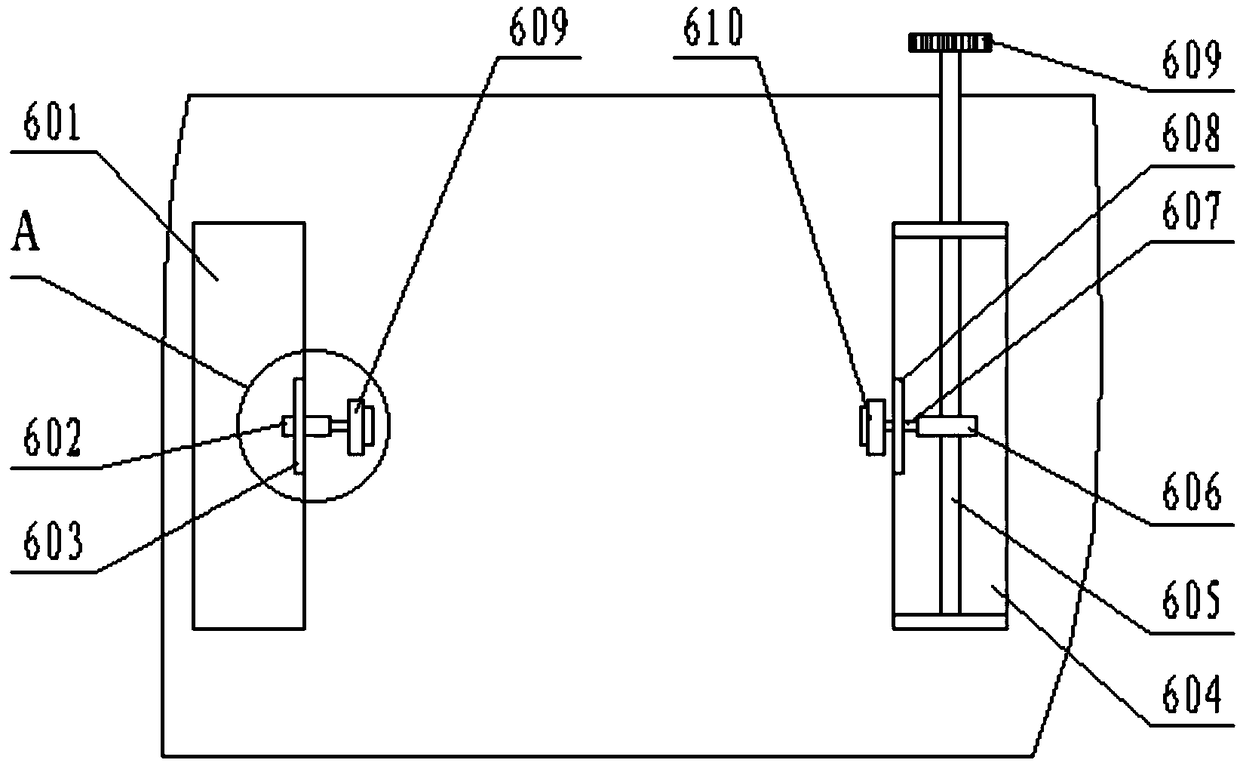

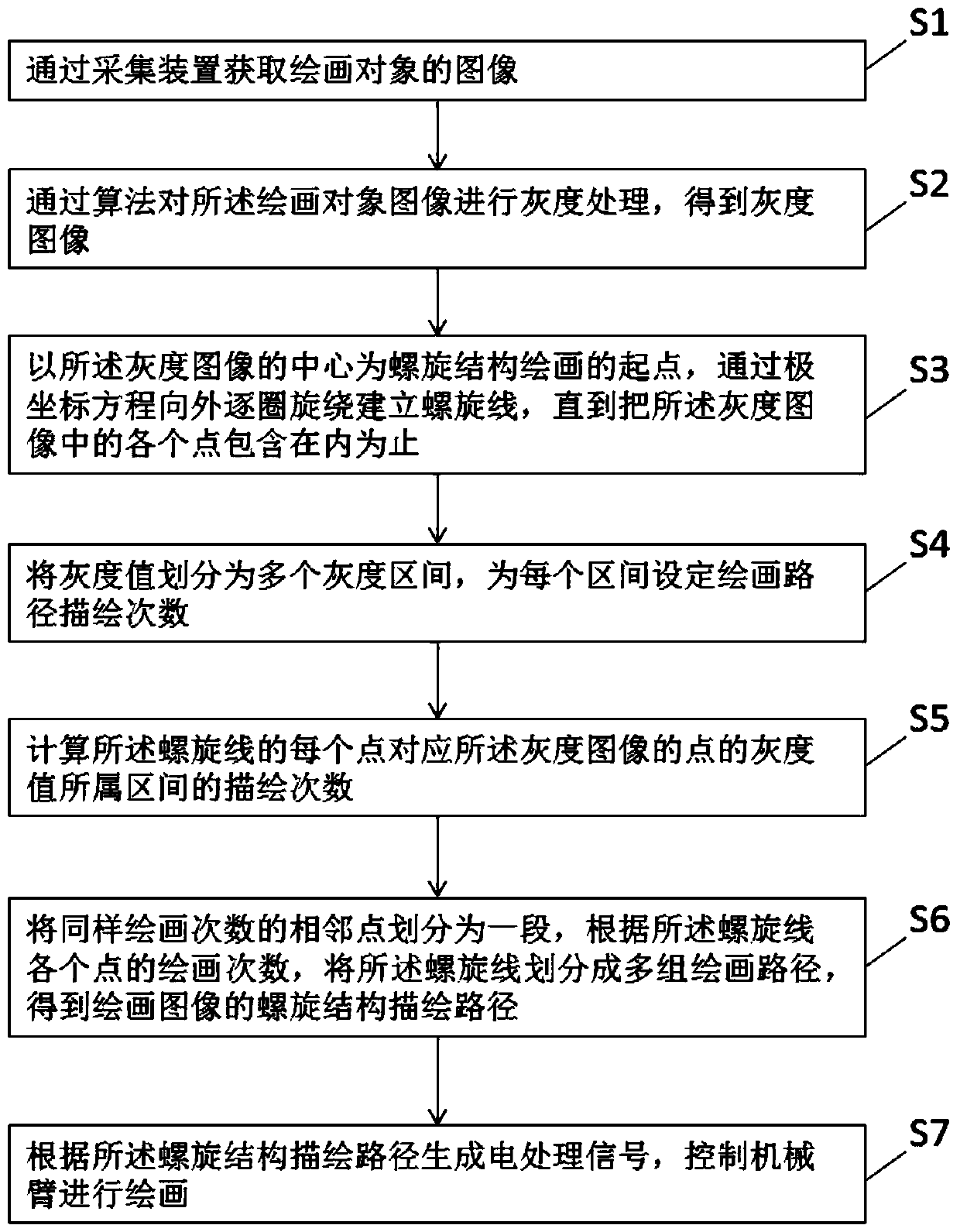

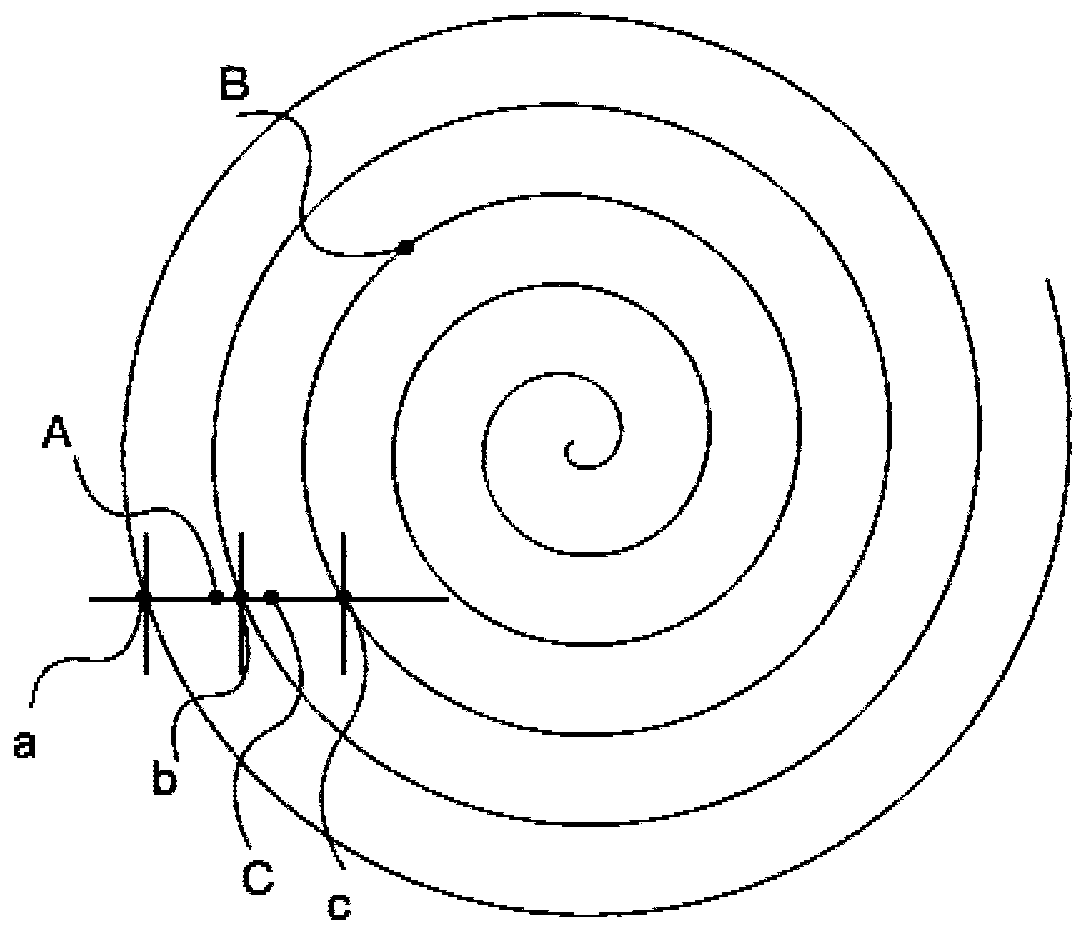

Intelligent sketch drawing method and device, storage medium and terminal equipment

ActiveCN109993810ASolve the technical problem of directly recognizing image lines for paintingImprove realismTexturing/coloringManufacturing computing systemsTerminal equipmentPath generation

The invention discloses an intelligent sketch drawing method. The method comprises the steps that S1, acquiring an image of a drawing object through an acquisition device; S2, performing gray processing on the drawing object image through an algorithm to obtain a gray image; S3, taking the center of the gray level image as a starting point of a spiral structure drawing, and establishing a spiral line outwards circle by circle through a polar coordinate equation until each point in the gray level image is contained in the spiral line; S4, dividing the gray value into a plurality of gray intervals, and setting drawing path description times for each interval; S5, calculating the description frequency of the interval to which the gray value of the point of the gray image corresponding to eachpoint of the spiral line belongs; S6, dividing adjacent points with the same number of times of drawing into a section, and dividing the spiral line into a plurality of groups of drawing paths according to the number of times of drawing of each point of the spiral line to obtain a spiral structure description path of the drawn image; and S7, generating an electric processing signal according to the spiral structure description path, and controlling the mechanical arm to draw.

Owner:GUANGDONG INTELL VISION TECH CO LTD

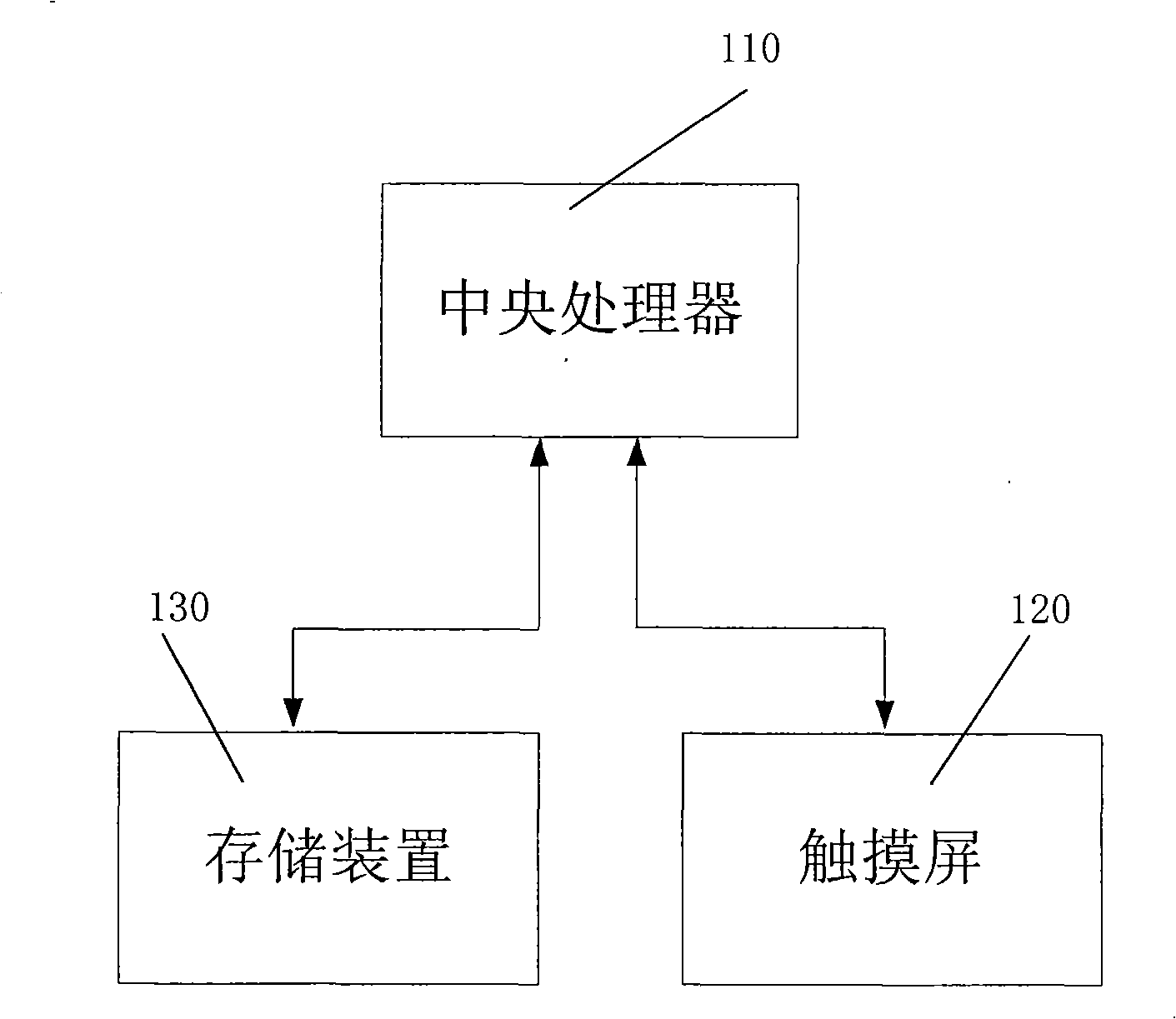

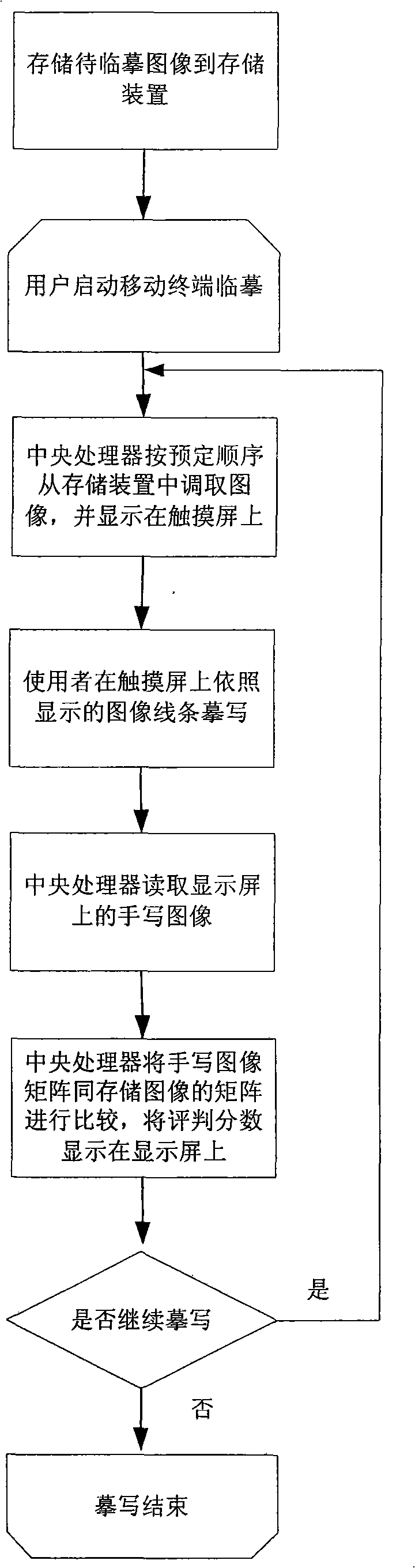

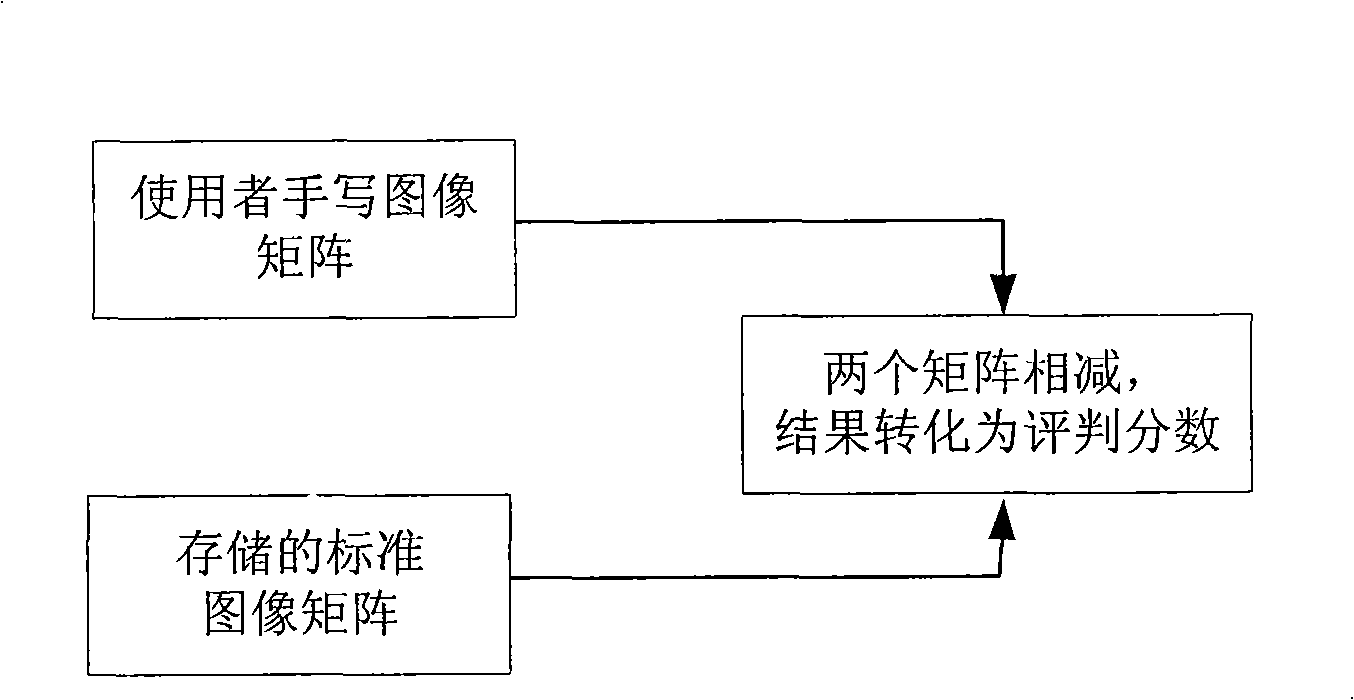

A facsimile mobile terminal device and its realization method

InactiveCN101262663AEasy to writeGood paint effectRadio/inductive link selection arrangementsTelephone set constructionsTerminal equipmentTouchscreen

The invention discloses a replicable mobile terminal device which comprises a central processing unit, a touch screen and a storage device. The realizing method of the replicable mobile terminal device comprises the following steps that an image to be replicated is stored at a storage device in advance, the central processing unit of the mobile terminal device obtains the image from the storage device according to a preset sequence and displays the image at the touch screen; a user replicates the image at the touch screen according to the lines of the image, and the central processing unit reads the replicated image and compares the replicated image with the image to be replicated to judge the consistency thereof. The replicable mobile terminal device and the realizing method thereof provided by the invention are convenient for the users to practice writing and drawing abilities at will with the mobile terminal device.

Owner:赵志新

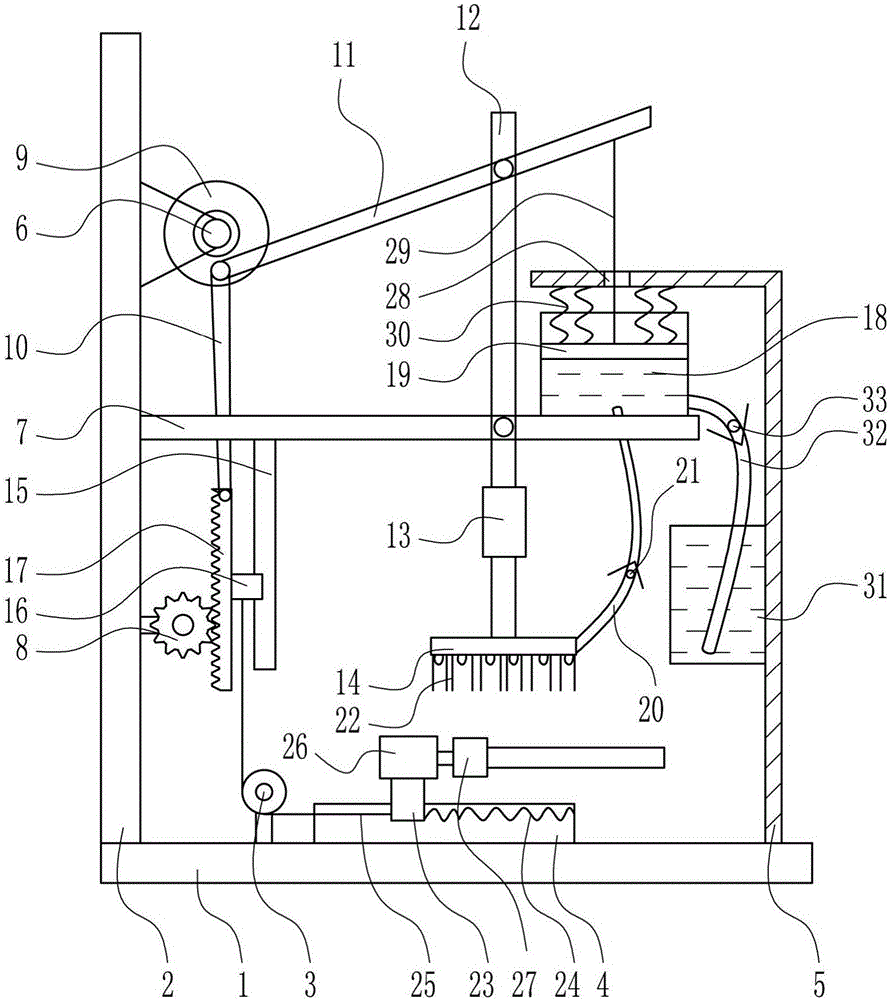

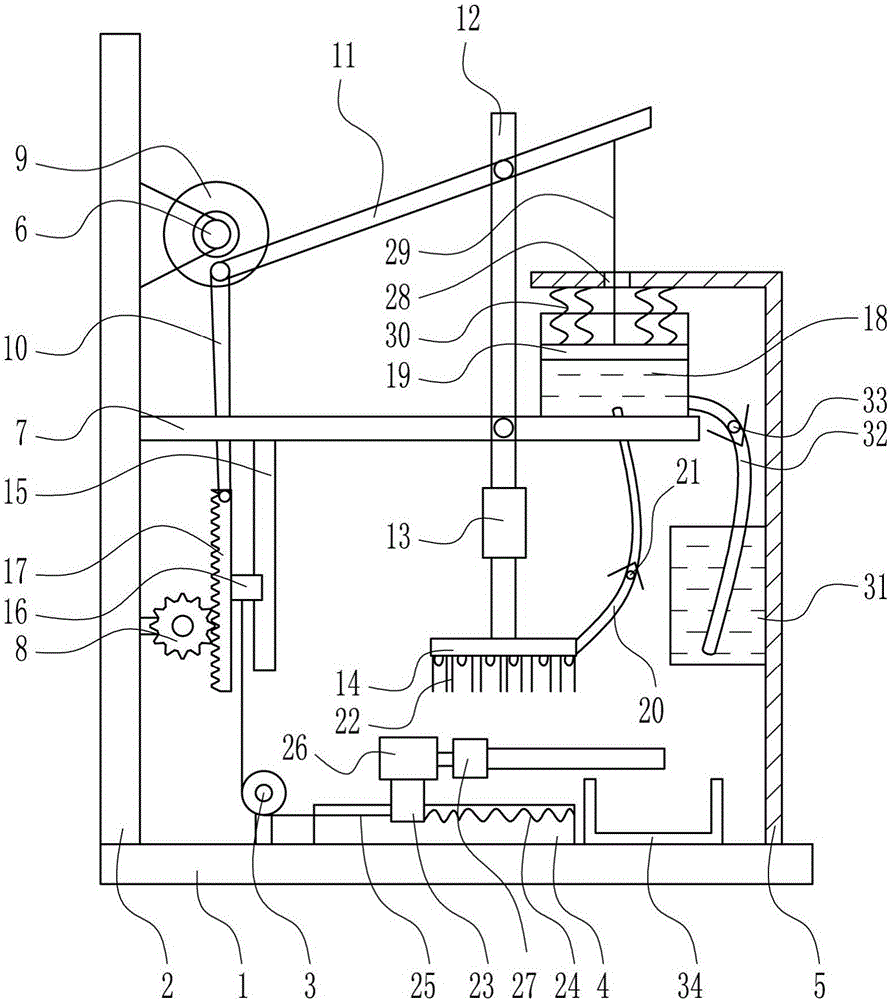

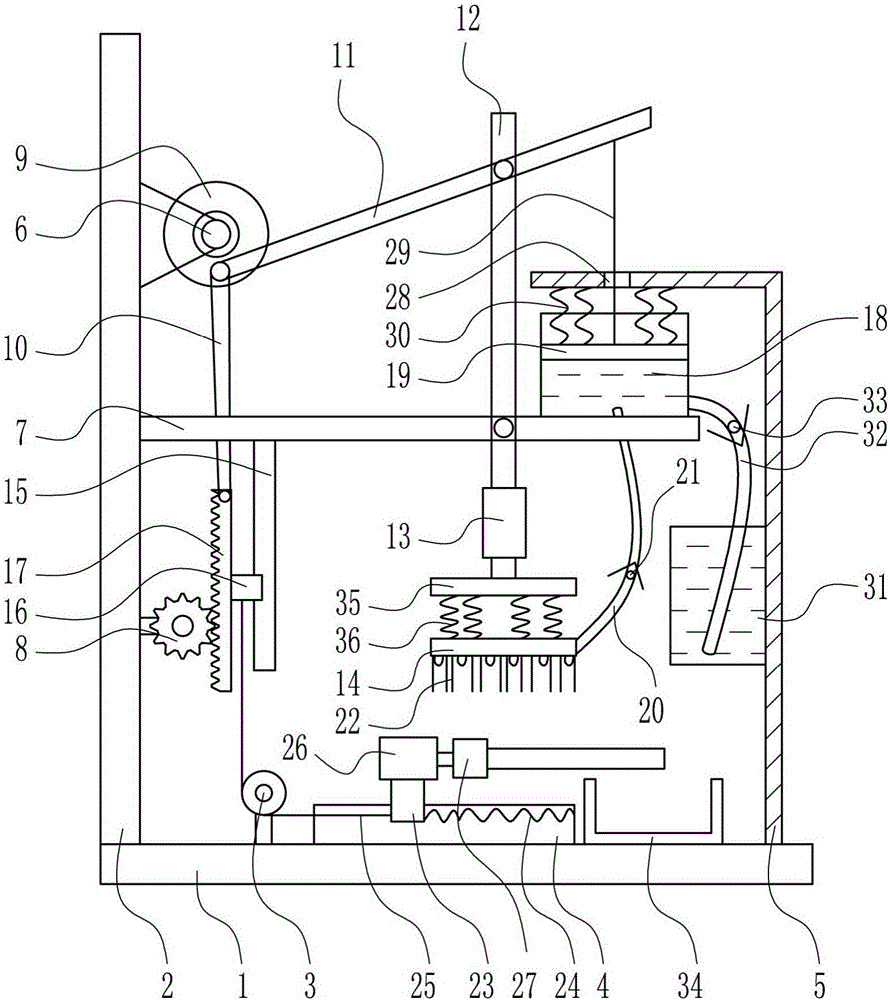

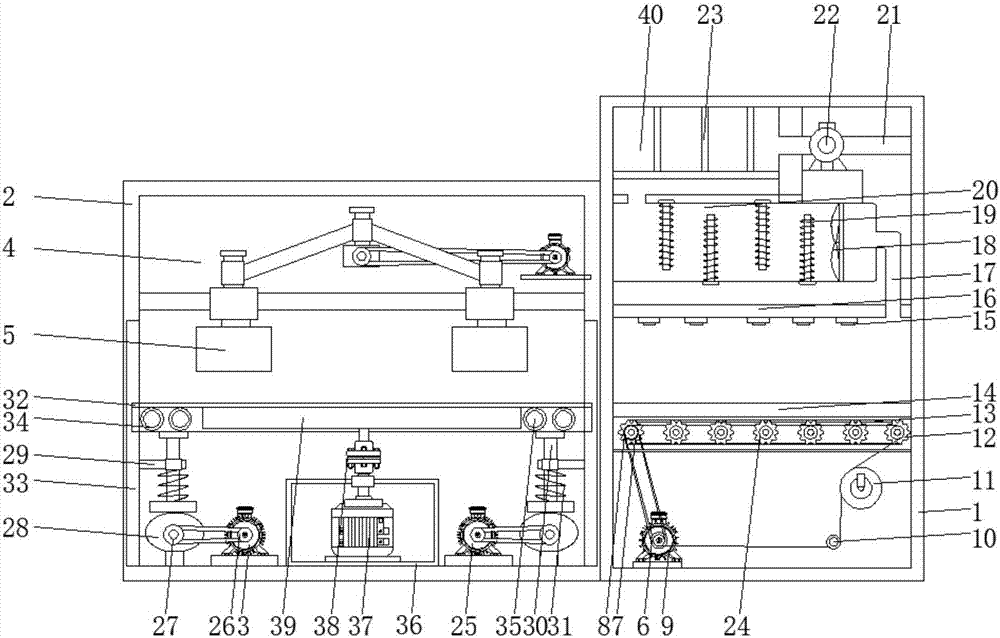

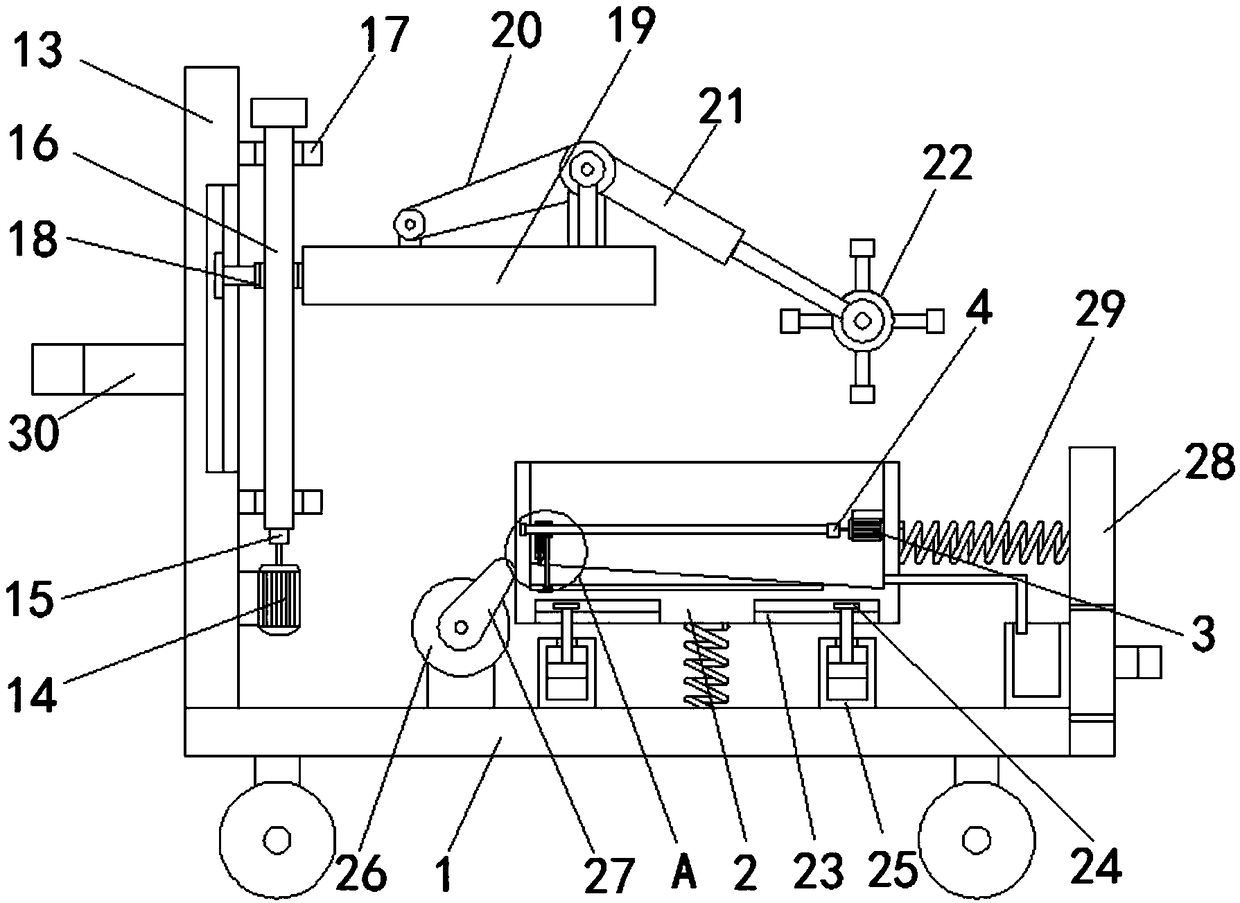

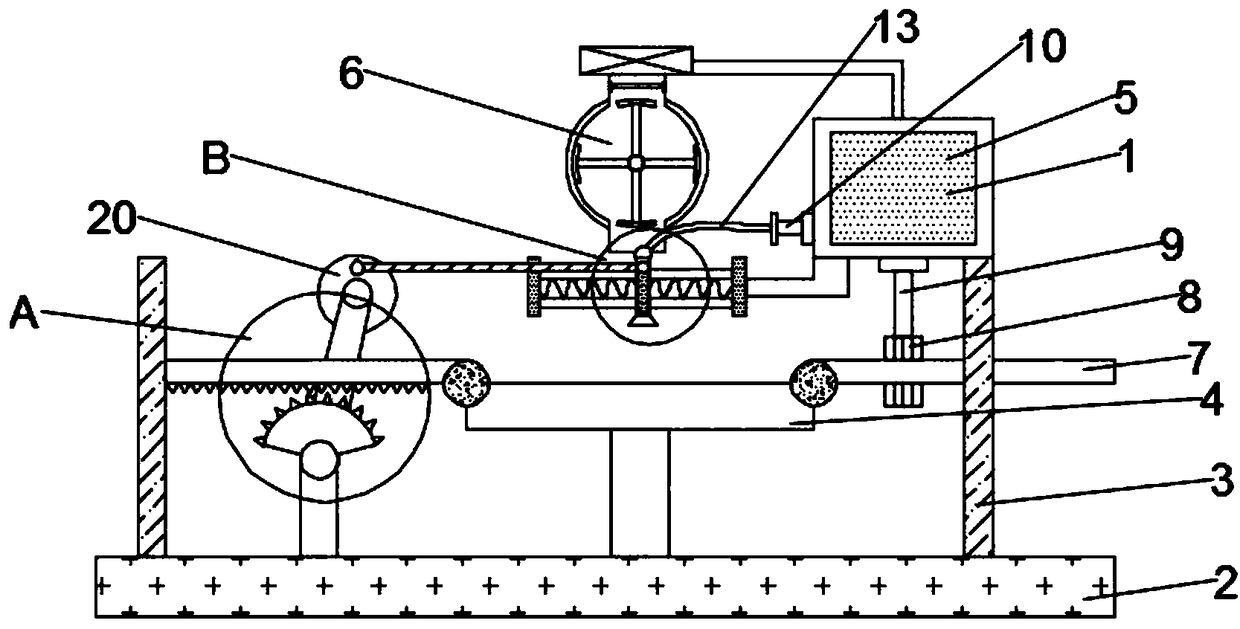

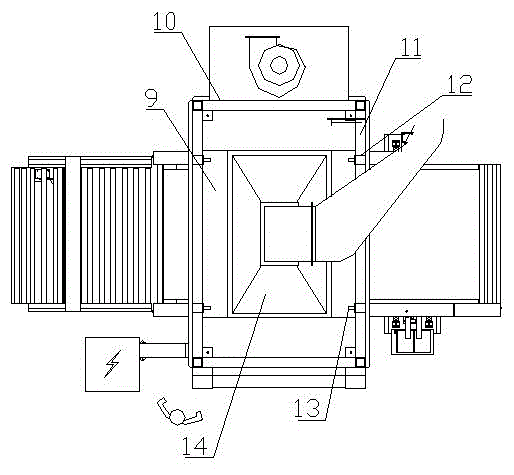

Efficient iron pipe paint-spraying device for hardware

ActiveCN106140552AEvenly paintedGood paint effectLiquid surface applicatorsCoatingsPistonEngineering

The invention relates to an iron pipe paint-spraying device, in particular to an efficient iron pipe paint-spraying device for hardware. By the adoption of the efficient iron pipe paint-spraying device for hardware, the technical purposes of good paint spraying effect, high paint spraying efficiency and simple operation are achieved. For achieving the technical purposes, the efficient iron pipe paint-spraying device for hardware comprises a base plate, a left side plate, a pulley, a first sliding rail, a 7-shaped support, a first motor, a storage plate, a gear, a disc, a first connecting rod, a second connecting rod, a second connecting rod, a supporting rod, an air cylinder, a paint spraying head, a second sliding rail, a compression cylinder, a piston, a first hose, a first one-way valve, a brush, a first sliding block, a first spring and the like. The left side plate, the pulley, the first sliding rail and the 7-shaped support are arranged at the top of the base plate in sequence from left to right. According to the efficient iron pipe paint-spraying device for hardware, a transverse plate and a third spring are utilized, so that the bush and an iron pipe are kept being in contact all the time, and the good paint spraying effect and high paint spraying efficiency are achieved.

Owner:江苏德祐精密钢管有限公司

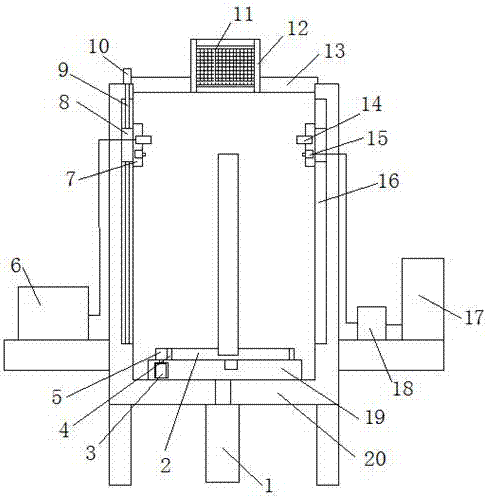

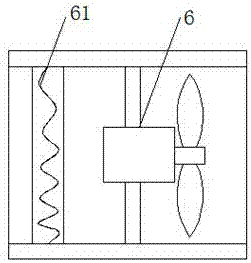

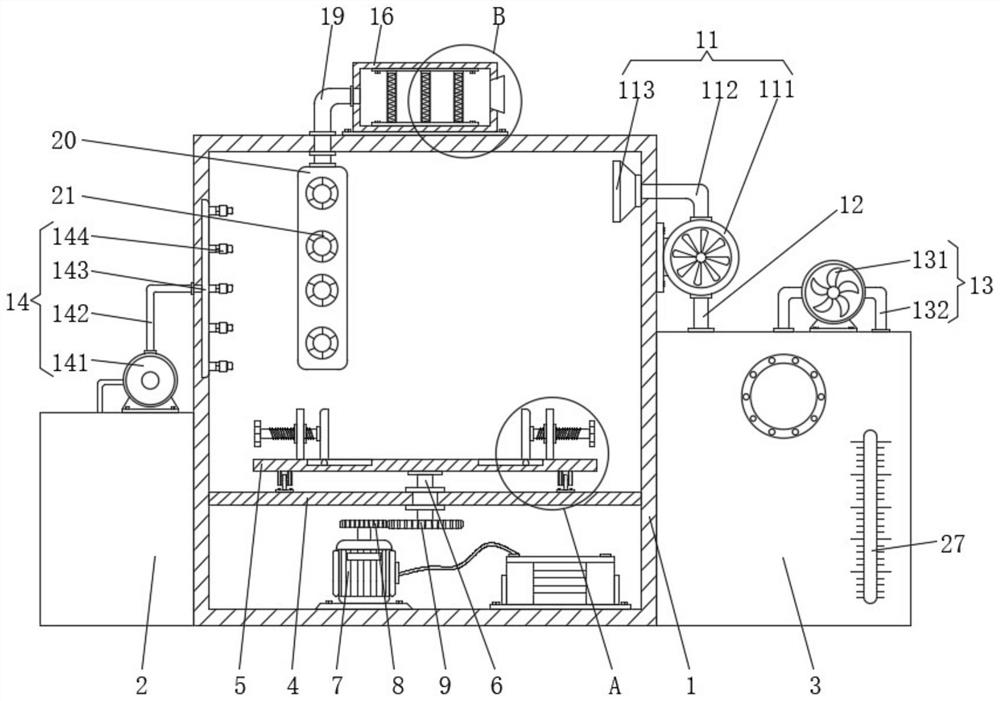

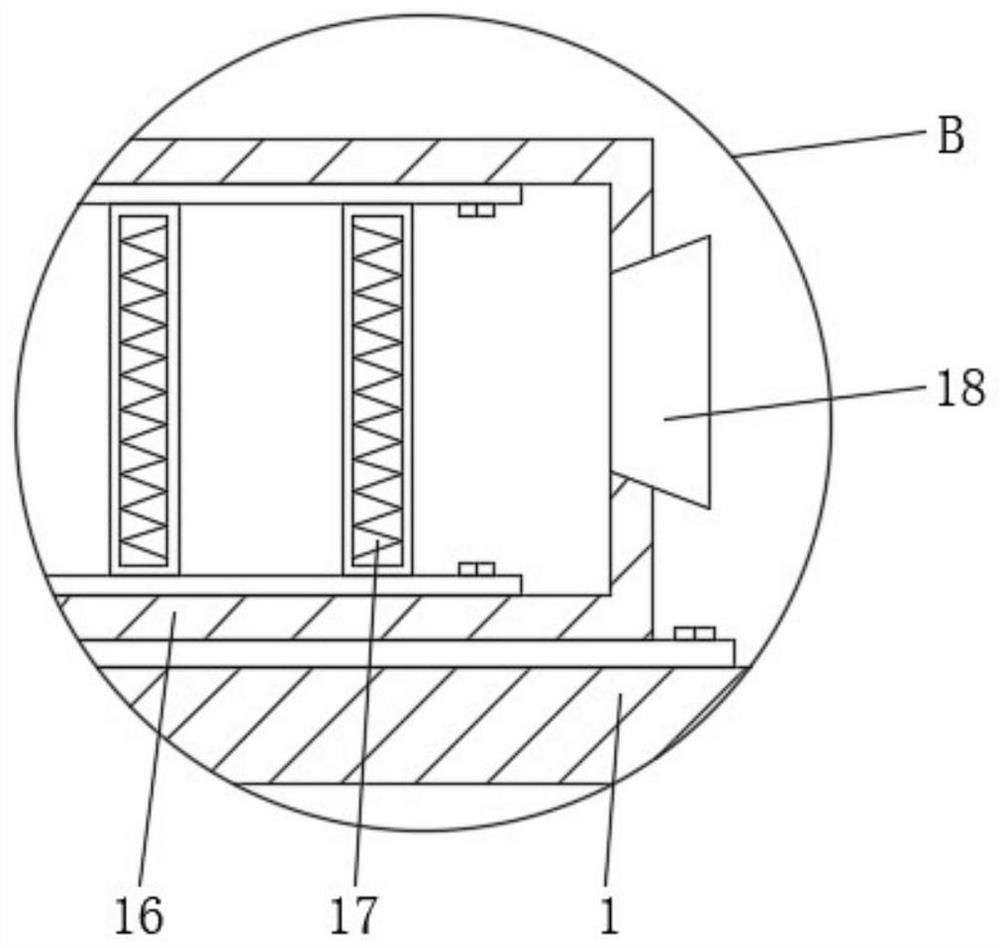

Paint spraying system and method for environment-friendly furniture production

InactiveCN112387442AAvoid pollutionImprove quality and efficiencyPretreated surfacesLiquid spraying apparatusThermodynamicsProcess engineering

The invention relates to the technical field of paint spraying devices, and particularly relates to a paint spraying system and method for environment-friendly furniture production. The paint sprayingsystem comprises a paint spraying box, a paint box and a treatment box, wherein the paint box and the treatment box are located on the two sides of the paint spraying box correspondingly; a partitionplate is connected to an inner cavity of the paint spraying box in a bolted mode; a mounting plate is arranged at the top of the partition plate; a rotating shaft is connected to the bottom of the mounting plate in a bolted mode; and the rotating shaft penetrates through the bottom of the partition plate. The paint spraying system has the advantages that the paint spraying effect is good, the paint spraying uniformity can be guaranteed, waste gas generated by paint spraying can be absorbed, air pollution is prevented, meanwhile, the paint solidification time can be effectively shortened, andthen the furniture production quality and the production efficiency can be improved; and the problems that a paint spraying device used for furniture production at present is poor in paint spraying effect, uneven paint spraying on the surface of furniture is prone to being caused, the waste gas generated by paint spraying cannot be absorbed and treated, and therefore air pollution can be caused, and the body health of workers is affected are solved.

Owner:章 忠

Solvent-resistance polyurethane rubber roller and manufacturing method and application thereof

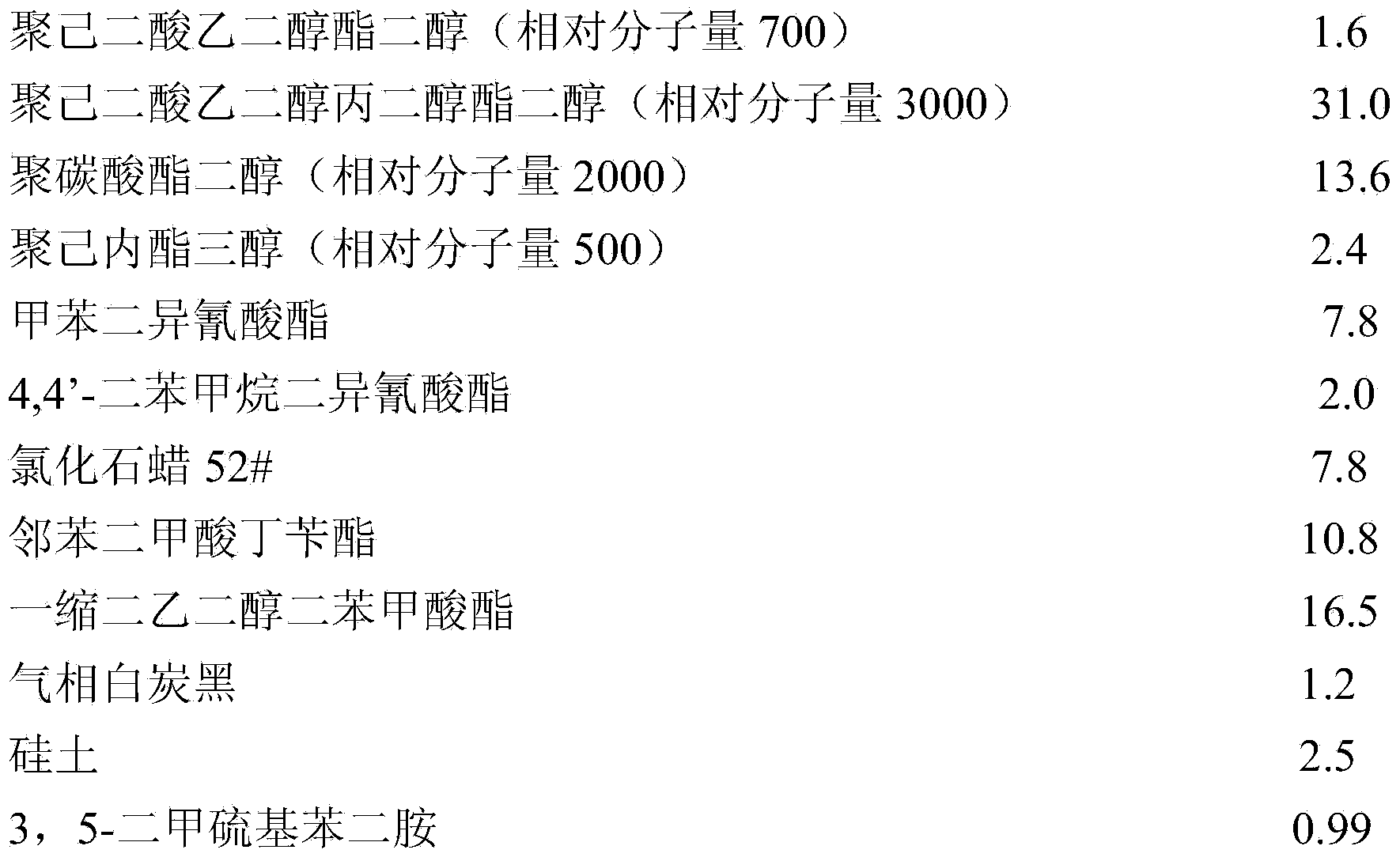

The invention discloses a solvent-resistance polyurethane rubber roller and a manufacturing method and application thereof, and belongs to the field of rubber roller preparing. The solvent-resistance polyurethane rubber roller is achieved through combination of multicomponent systems and is formed by mixing and pouring a material component A, a material component B and a material component C, wherein the material component A comprises, by mass, 40%-60% of polyester polyol and 7%-20% of toluene disocynate, the material component B comprises, by mass, 2%-10% of 4-4'-diphenylmethane diisocyanate, 5%-40% of plasticizer and 1%-4% of filler, and the material component C comprises, by mass, 2.5%-8% of chain extender and 0.02%-0.05% of catalysts. The wear-resistance, solvent-resistance and mechanical properties of the solvent-resistance polyurethane rubber roller are obviously improved, and the solvent-resistance polyurethane rubber roller can be widely used in the fields of printing, coating and painting.

Owner:东莞华工佛塑新材料有限公司

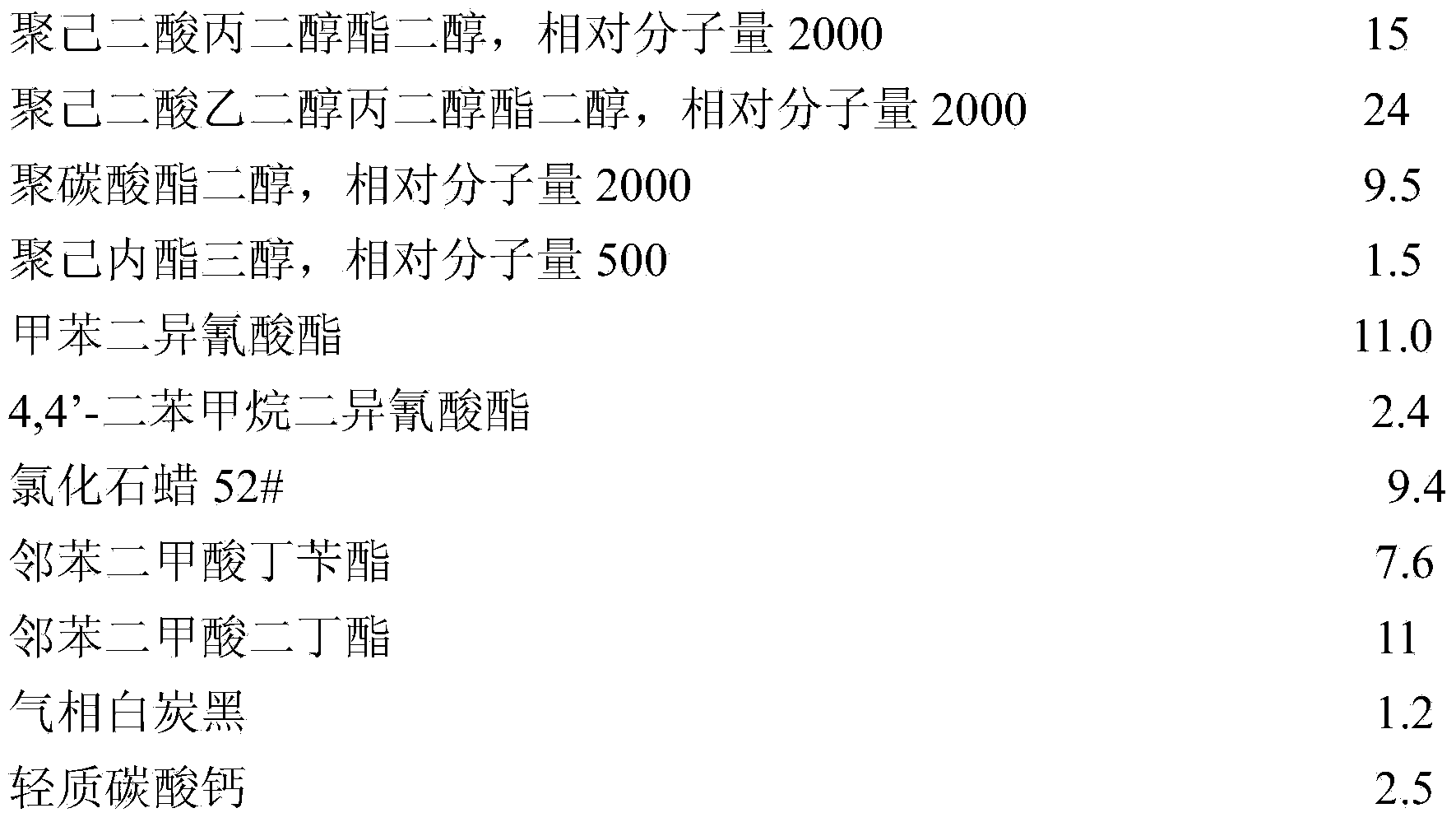

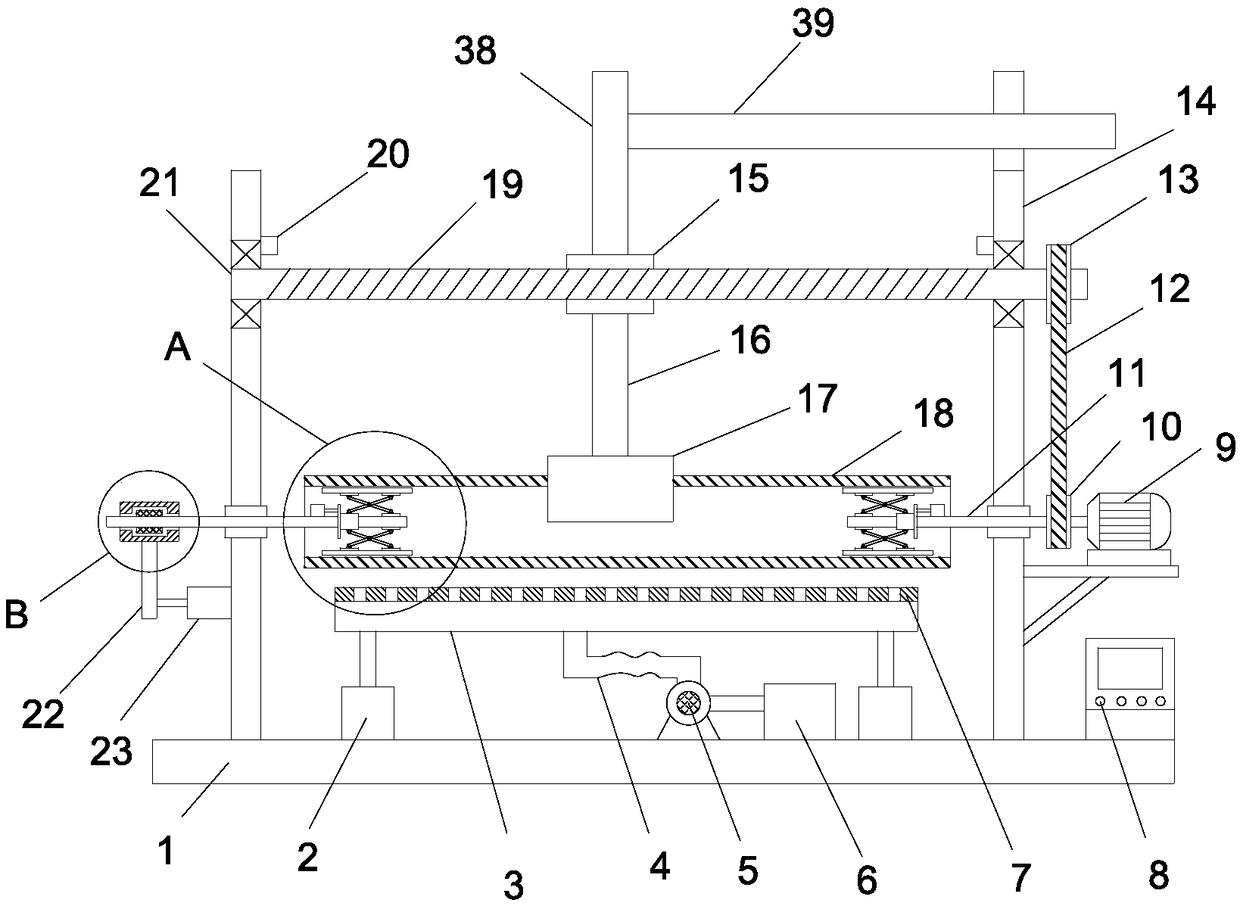

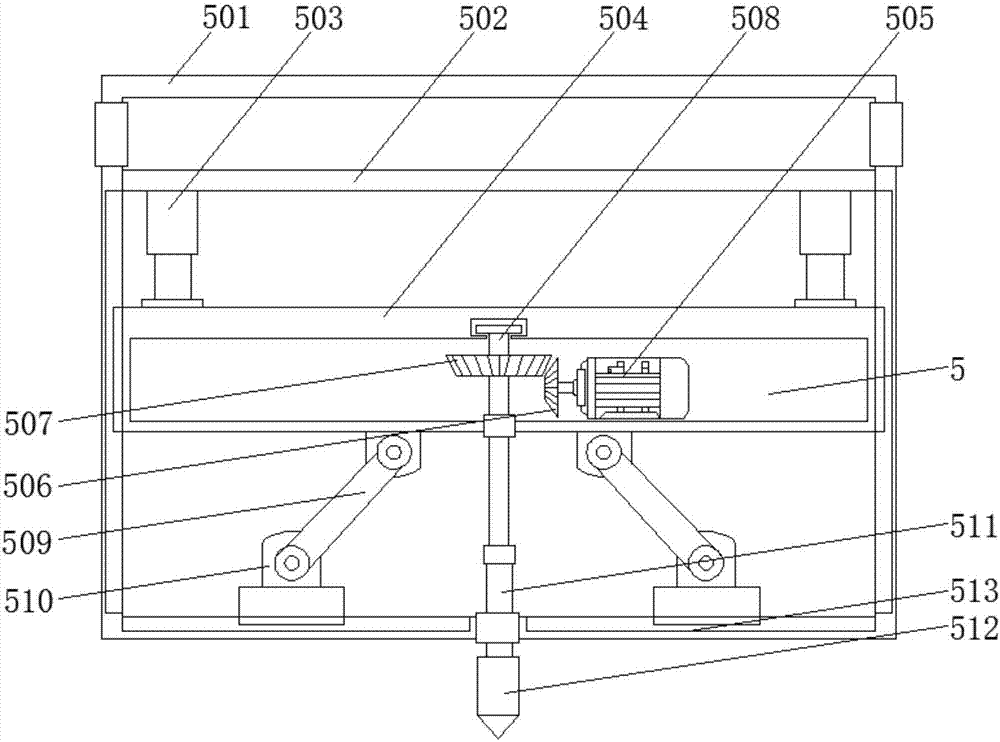

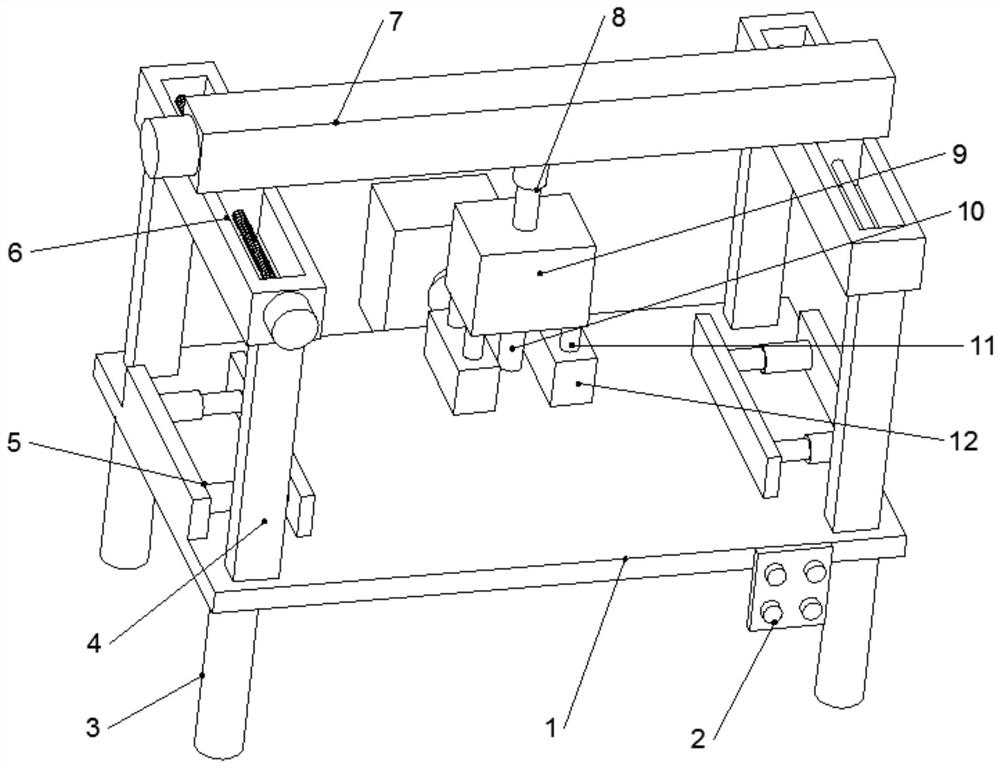

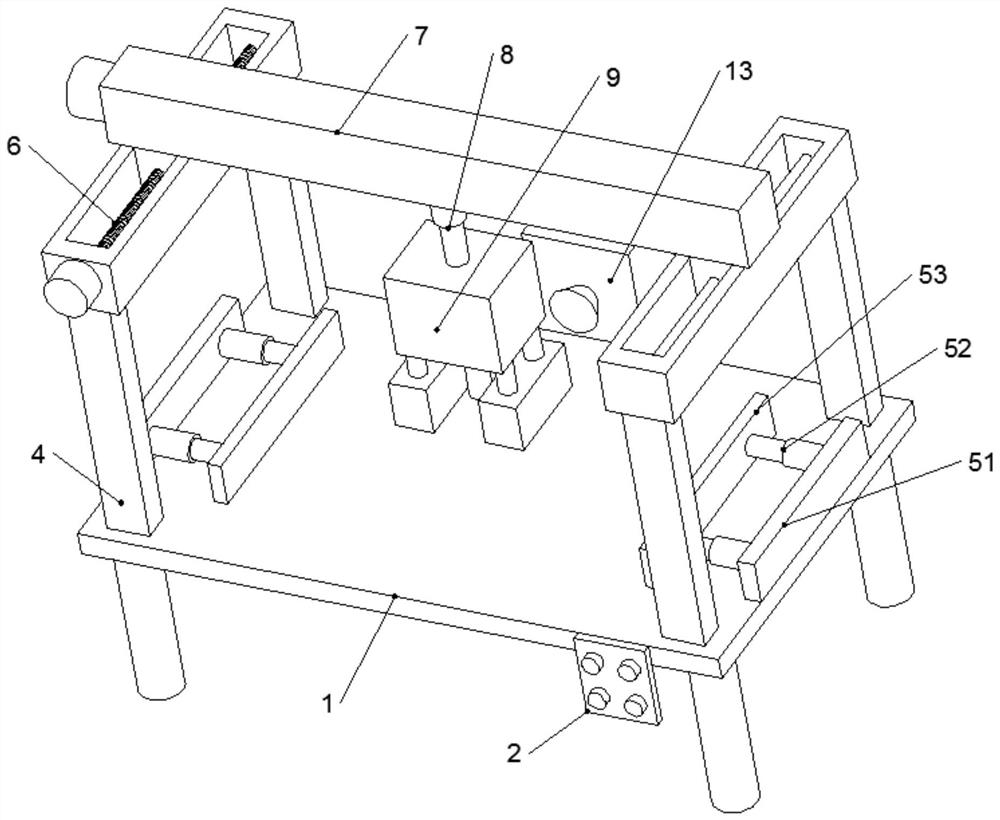

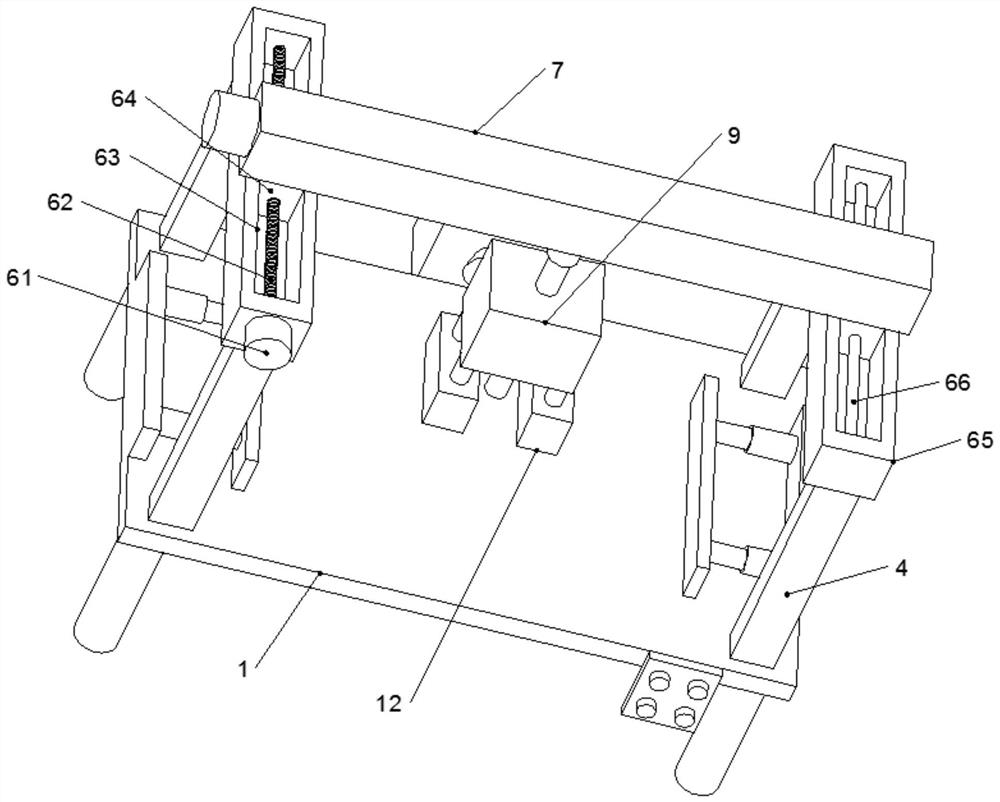

Paint spraying device for surface of large-diameter chemical pipeline

PendingCN108296067AEasy to fixGood paint effectSpraying apparatusPretreated surfacesDrive shaftSpray nozzle

The invention discloses a paint spraying device for a surface of a large-diameter chemical pipeline. The paint spraying device for the surface of the large-diameter chemical pipeline comprises a bottom plate; a left vertical plate and a right vertical plate are fixedly mounted on the bottom plate in a vertical welding manner; cross bridgings are arranged at the two sides of sliding sleeve barrelsand fixing plates; electric telescoping rods connected with the sliding sleeve barrels are arranged on a driven rotary shaft or a driving shaft; an output shaft of a positive and negative rotation motor is fixedly connected with the driving shaft in an axial manner and a driving pulley is arranged on the driving shaft; a threaded sleeve barrel is arranged on a threaded rod in a sleeving manner bythreaded connection; a paint spraying shield plate is of a half-arc-plate-shaped structure and a plurality of spray nozzles are uniformly arranged at the inner side of the paint spraying shield platealong the cambered surface; a cavity which communicates with the spray nozzles are arranged in the paint spraying shield plate. The device is strong in adjustability and adaptable to fixing function of steel pipes of different internal diameter; the steel pipe can rotate itself and the spray nozzles can move back and forth along the steel pipe and spray paint on the surface of the steel pipe at the same time, so that the paint spraying effect of the steel pipe can be better, the paint can uniformly attach on the surface of the steel pipe and the waste of the paint can be avoided.

Owner:ZHENGZHOU UNIV

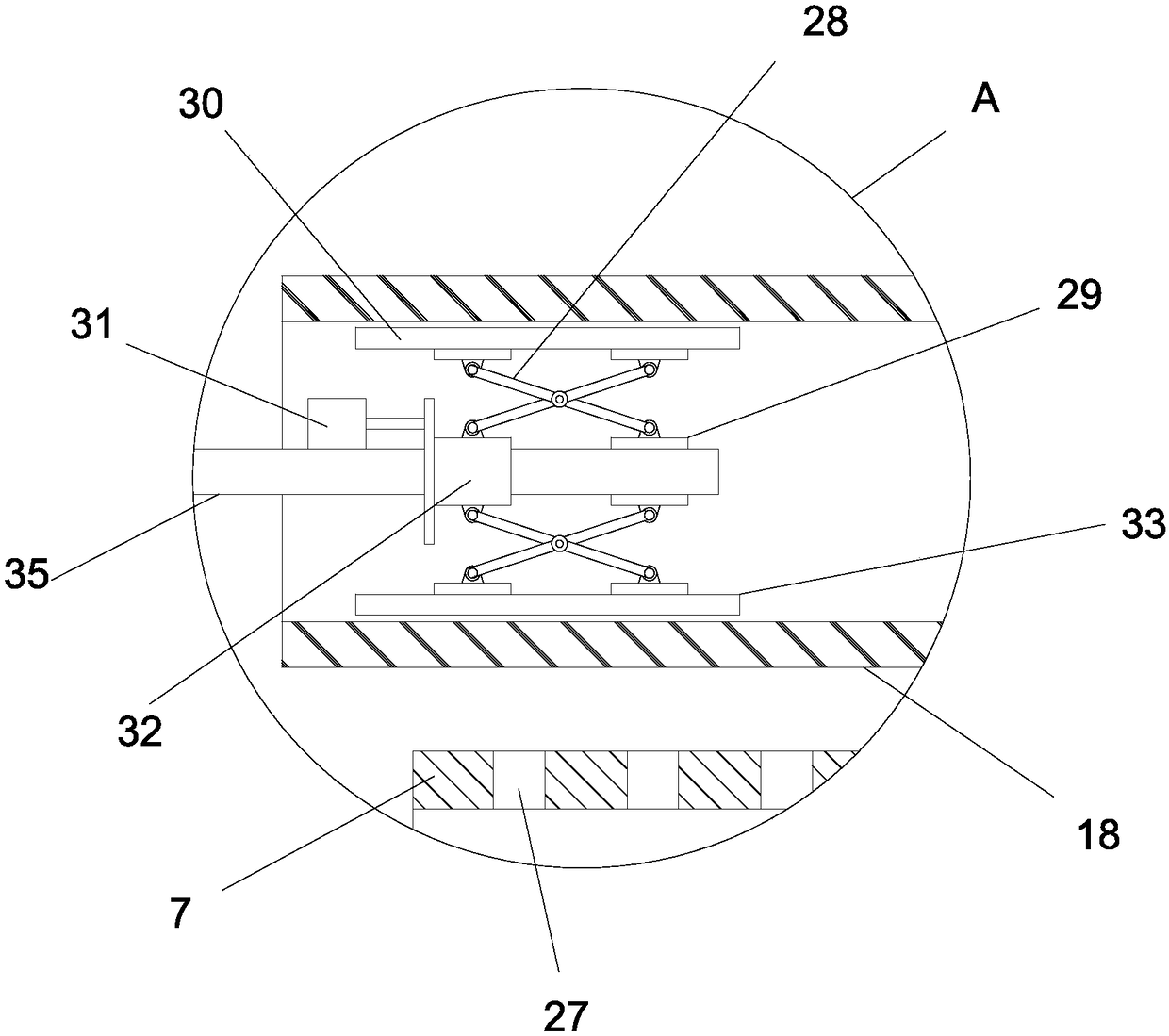

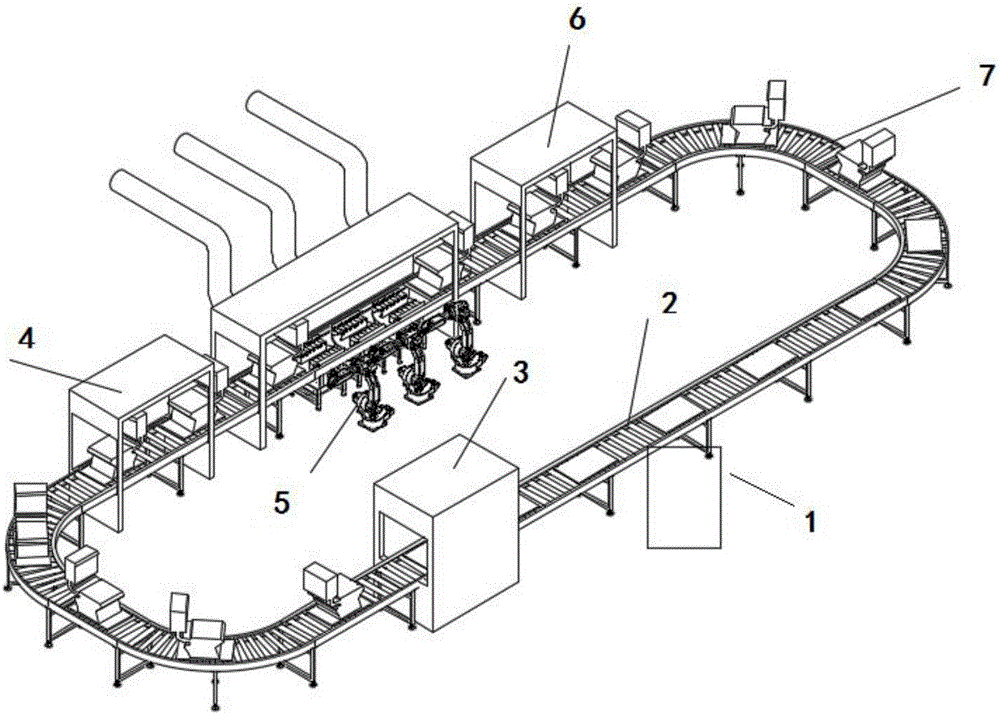

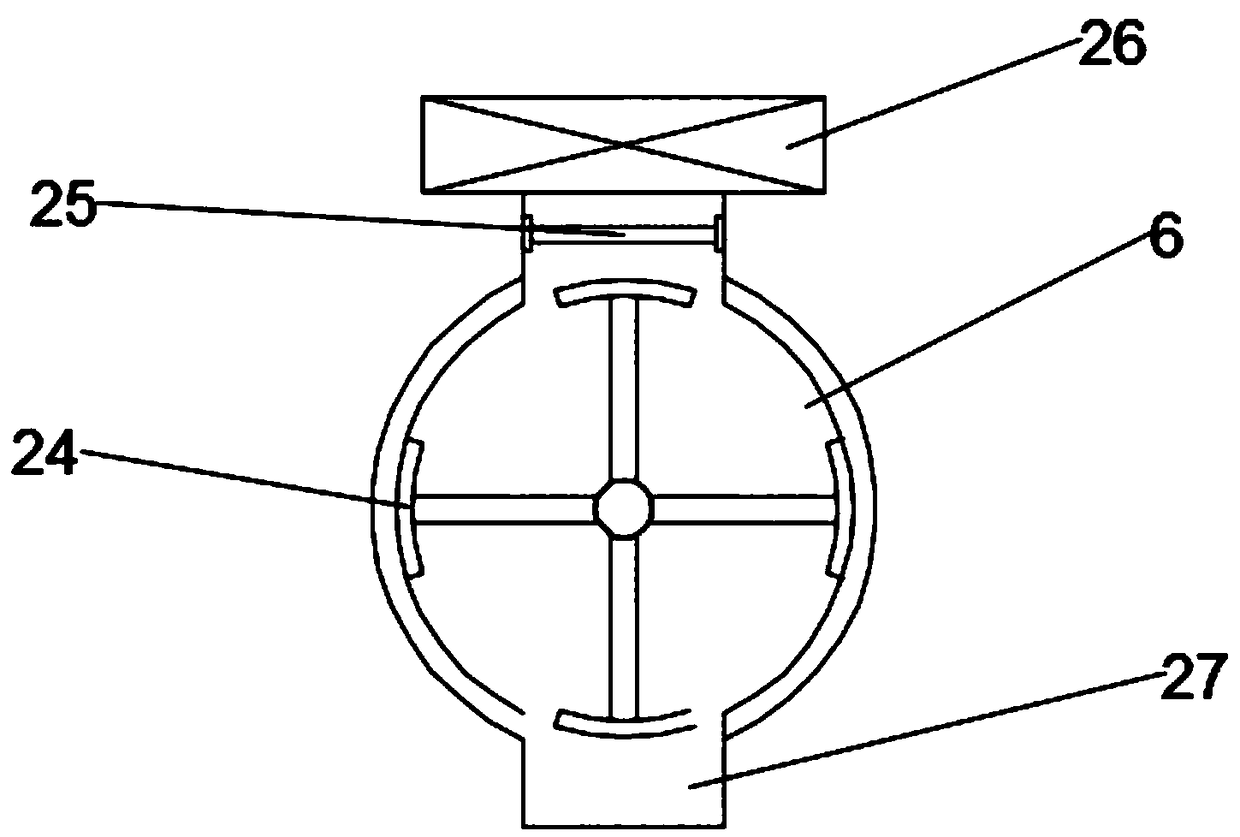

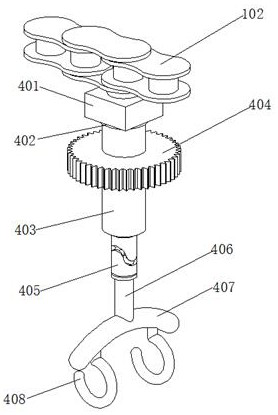

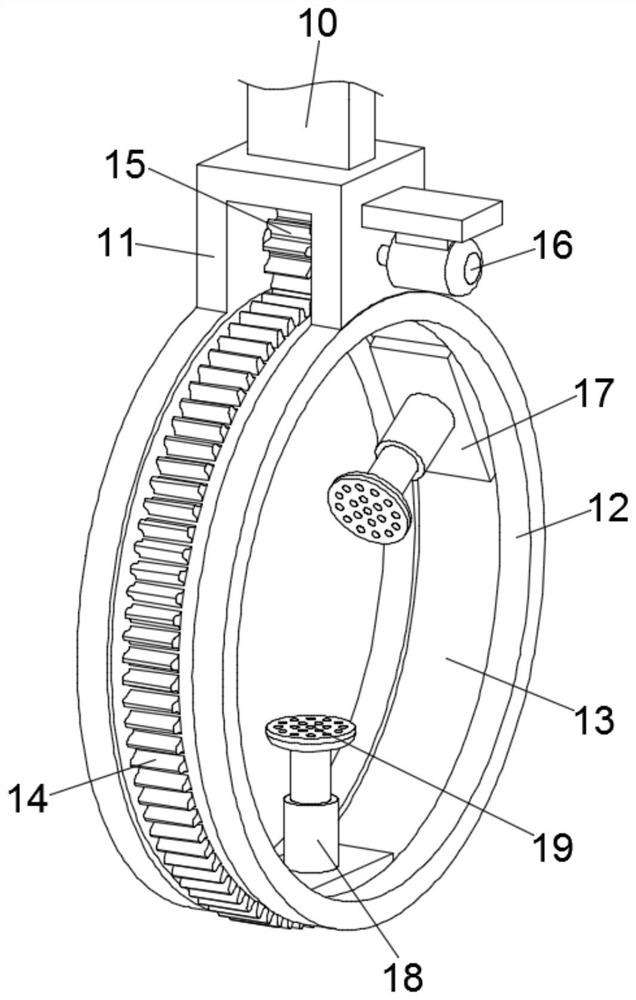

Automatic paint spraying device for bearing

ActiveCN106563601ASimple structureIngenious designSpraying apparatusPretreated surfacesRounded RectangleReducer

The invention provides an automatic paint spraying device for a bearing. The automatic paint spraying device for the bearing comprises a rounded rectangle roller way conveying line, a feeding area, a sprinkling device, a blow-drying device, a robot paint spraying device, a drying device and a discharging area. The automatic paint spraying device for the bearing has the advantages that the structure is simple, and the design is ingenious; labor resources are greatly saved through cooperative work of three steering arms, a steering mechanism, a stepping motor and a speed reducer, intelligent paint spraying can be conducted, and paint spraying is uniform; paint can be sprayed at multiple angles; the bearing is conveyed to the rounded rectangle roller way conveying line through a bearing lifter, through a series work of feeding, water sprinkling, blow-drying, paint spraying and drying, the surface of the bearing is quite smooth and clean, and the paint spraying effect is quite good.

Owner:嘉善蓝欣涂料有限公司

Method of laser digital coloured drawing

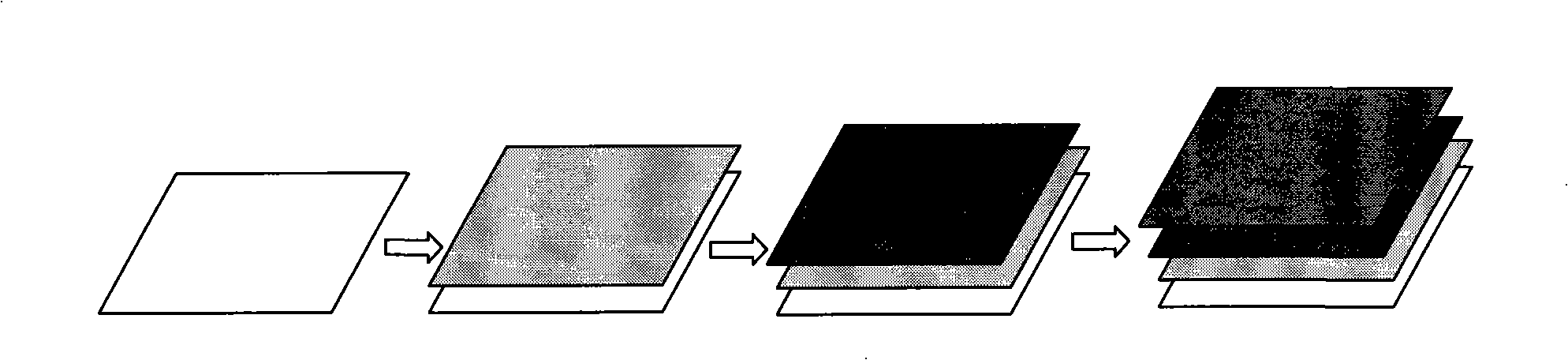

ActiveCN101279555AComplete and accurate transferIncrease flexibilityThermographyInformation layerGraphics

The invention discloses a method for laser digital colored drawing, which comprises: (1) a heat transfer printing film including an information layer is attached to the surface of the material going through the colored drawing; (2) the relative position of an optical head and the material going through the colored drawing is adjusted so as to ensure that the irradiating position of the laser beam to target the position of drawing pixels, (3) the laser beam is ensured to perform the instant heating to causes the information layer of the heat transfer printing film on the surface of the material to be melted and dropped off so as to be attached on the material going through the colored drawing; (4) according to position data of the predetermined image pixels, the step (2) and the step (3) are executed once again until the drawing of the information layer is completed; (5) the heat transfer printing film including another information layer is replaced, the step (1) and the step (4) are repeated until the drawing of all of the information layers is completed, namely the required laser digital colored drawing is realized. The method has the advantages of flexible control, high image precision, good colored drawing effect, more particularly, the capability of drawing the optical variable images with metal texture, etc., and is suitable for the application of digital laser colored drawing in the industries of digital printing, anti-counterfeiting and textile.

Owner:JIANGSU WEIGE NEW MATERIAL SCI & TECH

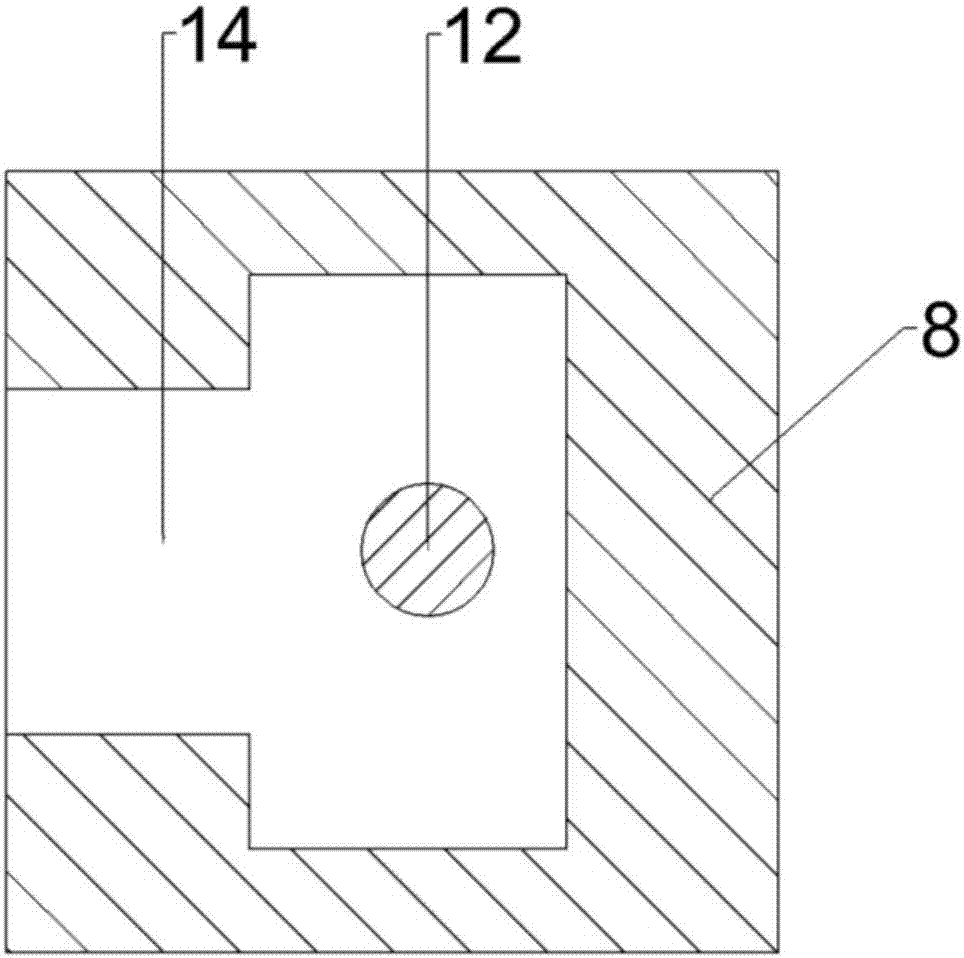

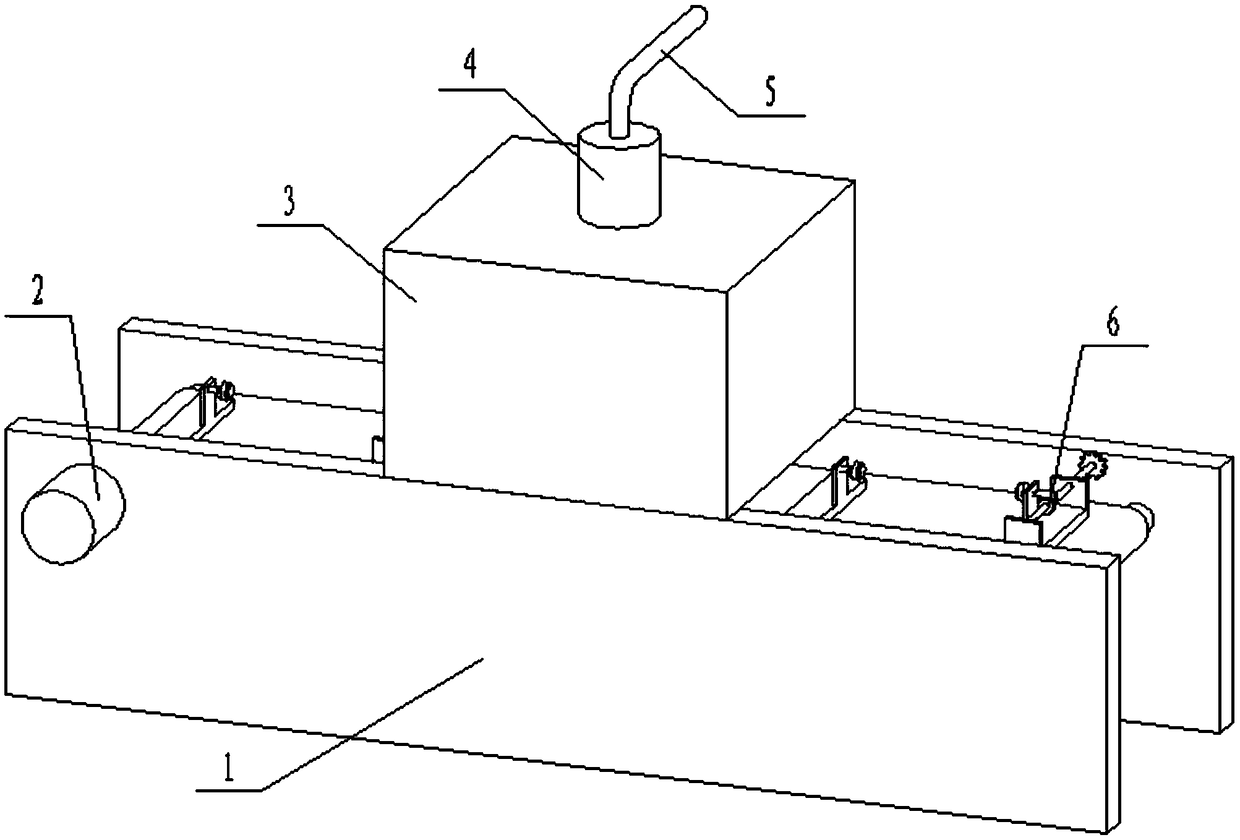

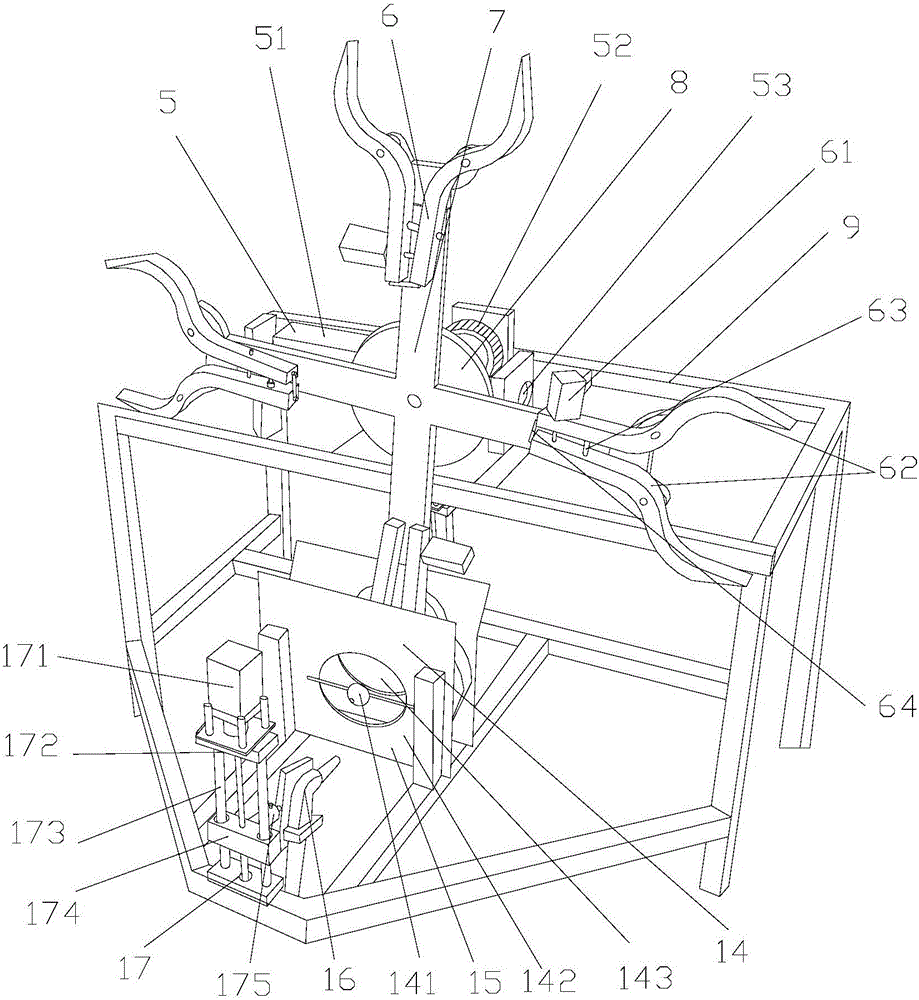

Bamboo plank slotting, paint spraying and automatic conveying device

InactiveCN107538580AGood paint effectImprove work efficiencyPretreated surfacesWood mortising machinesLacquerAir pump

The invention discloses a bamboo plank slotting, paint spraying and automatic conveying device and relates to the technical field of conveying equipment. The bamboo plank slotting, paint spraying andautomatic conveying device comprises a paint spraying box. The left side of the paint spraying box is provided with a slotting box. The top of an inner cavity of the paint spraying box is fixedly connected with an air inlet pipe. The end, far away from the inner wall of the paint spraying box, of the air inlet pipe communicates with an air pump. The air pump communicates with an air inlet chamberthrough an air outlet pipe. The inner wall of the air inlet chamber is fixedly connected with a dryer. The air inlet chamber communicates with a heating chamber through an air pipe. One side of the top of the outer wall of the heating chamber is fixedly connected with the air pump through an air pump installation platform. By means of the bamboo plank slotting, paint spraying and automatic conveying device, the effects that while pain spraying is carried out, hot air is enough to dry a bamboo plank, the paint spraying effect can be better, a conveying belt on the bottom can achieve automatic discharging after paint spraying is completed, the labor amount of working is reduced, height adjusting and direction slotting are carried out on the bamboo plank, and it is guaranteed that slotting cannot be limited to the size of the bamboo plank are achieved.

Owner:湖州创通输送设备有限公司

Painting device with cleaning function

The invention relates to the technical field of decoration equipment, and discloses a painting device with a cleaning function. The painting device includes a bottom plate, the right side of the uppersurface of the bottom plate is provided with a paint box, and the bottom of the inner wall of the right side of the paint box is fixedly provided with a cleaning motor; an output shaft of the cleaning motor is fixedly connected with a threaded rod through a first coupling, the left end of the threaded rod and the interior of the left side of the paint box is rotatably connected, and a thread of the left end of the threaded rod is connected with a threaded pipe; and the left side of the bottom surface of the threaded pipe is fixedly connected with a piston cylinder. According to the painting device with the cleaning function, the cleaning of the paint box is more convenient, next painting cannot be affected by residual paint, and paint in the paint box can be evenly shook in case of deposition of the paint; the paint can always maintain an even condition, a bad paint effect due to uneven paint can be prevented, and the height of a painting device can be changed; and the angle of the painting device can be further changed, so that the entire device can be more convenient to paint, and the effect of painting is better.

Owner:JIAXING NIYA OPTOELECTRONICS CO LTD

Mould-proof and anti-corrosion treatment device and method for wooden furniture materials

InactiveCN111804486AAchieve full paintingHealth effectsGas treatmentDispersed particle filtrationWorkbenchMaterials science

The invention discloses a mould-proof and anti-corrosion treatment device and method for wooden furniture materials. The mould-proof and anti-corrosion treatment device comprises a worktable, whereina supporting rod is connected to the top of the worktable, a longitudinal moving assembly is arranged at the top end of the supporting rod, a transverse moving assembly is connected to the longitudinal moving assembly, a first electric telescopic rod is connected to the transverse moving assembly, a paint box is connected to the first electric telescopic rod, a painting head is connected to the bottom of the paint box, an even-coating assembly is connected to the bottom of the paint box, a fixing assembly is arranged at the top of the worktable, and an odor absorption assembly is arranged on the rear side of the worktable. The paint box and the painting head are driven by the longitudinal moving assembly to move longitudinally, the paint box and the painting head are driven by the transverse moving assembly to move transversely, the overall painting of the furniture materials can be achieved, the painting efficiency is high, during painting, the paint on the furniture materials is evenly coated by the even-coating assembly, the painting effect is good, meanwhile the generated paint odor is adsorbed by the odor absorption assembly, and the influence of the paint odor on the health of the staff is avoided.

Owner:黄石市中维木业有限公司

Automatic tire paint spraying and drying system

ActiveCN104984855AGood for scrollingRealize repetitive processingSpraying apparatusPretreated surfacesEngineeringDelivery system

The invention provides an automatic tire paint spraying and drying system which comprises a rack, a feeding system arranged on the rack, a conveying system arranged on the rack and matched with the feeding system for use, a paint spraying system arranged on the rack and matched with the conveying system for use, and a drying system arranged on the rack and matched with the conveying system for use. The automatic tire paint spraying and drying system can automatically feed and convey a tire and carry out paint spraying treatment on the tire, and can automatically dry the tire after the tire is sprayed with paint; no manual transport is required in tire conveying, paint spraying and drying processes; and the automatic tire paint spraying and drying system is low in labor intensity, high in working efficiency, good in spraying effect, low in production cost and good in drying effect.

Owner:JIAXING YAJIE METAL & PLASTIC WARE

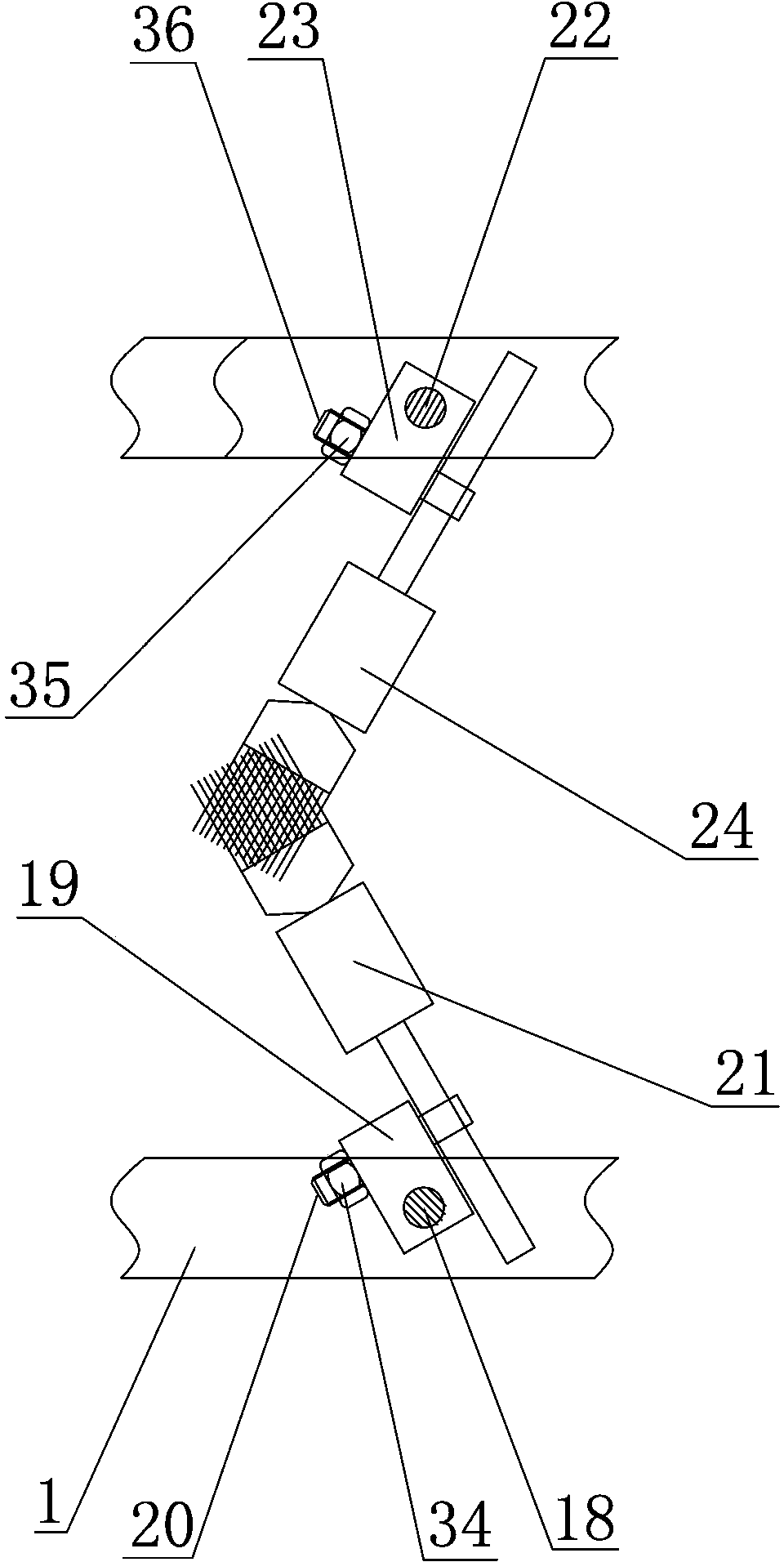

Spraying mechanism for mechanical equipment

InactiveCN110743744AEasy to useGood paint effectPretreated surfacesDirt cleaningBristleElectric machinery

The invention discloses a spraying mechanism for mechanical equipment, and relates to the field of mechanical equipment. The spraying mechanism comprises a base, a first motor, a second rotating shaft, a second motor, a second threaded sleeve, a dust suction hood, a fan, clamping plates and a supporting frame. Four mounting seats are uniformly distributed on the lower portion of the base, and a lifting device is mounted on the lower portion of each mounting seat. The spraying mechanism is provided with first hydraulic rods and bristles, so that the surface of the mechanical equipment can be cleaned, and the paint spraying effect is better. A dust collector and a dust suction box are arranged so that dust generated by cleaning can be collected. A heater and the fan are arranged so that thesprayed mechanical equipment can be dried. A stirring rod is arranged so that paint in a paint box can be continuously stirred, and the paint spraying effect is better. The lifting devices are arranged so that the height of a paint spraying device can be adjusted continuously according to different needs, and operation personnel are conveniently use the paint spraying device. An auxiliary lightingeffect is achieved through an illuminating lamp, and the practicability of the device is improved.

Owner:湖北中琛窑炉设备有限公司

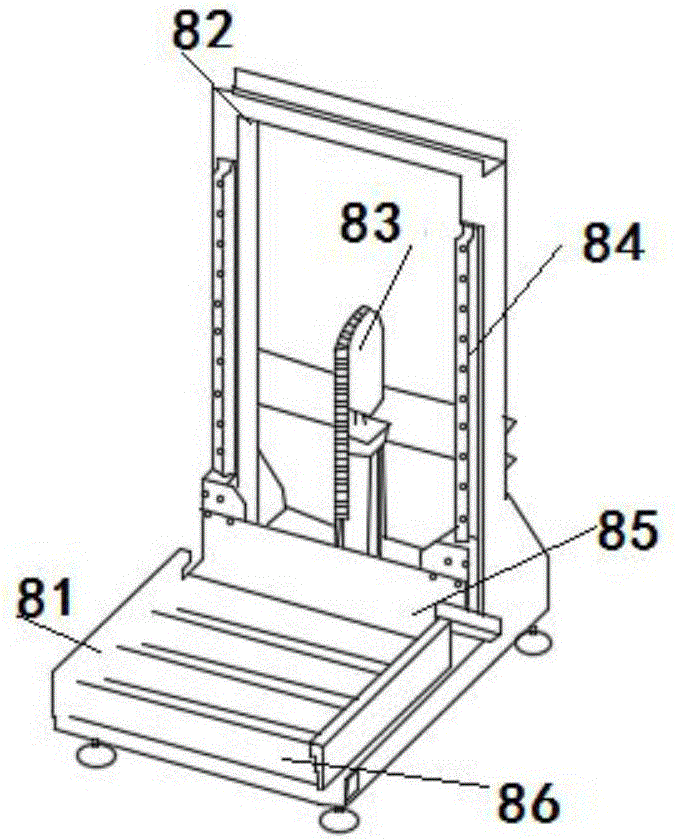

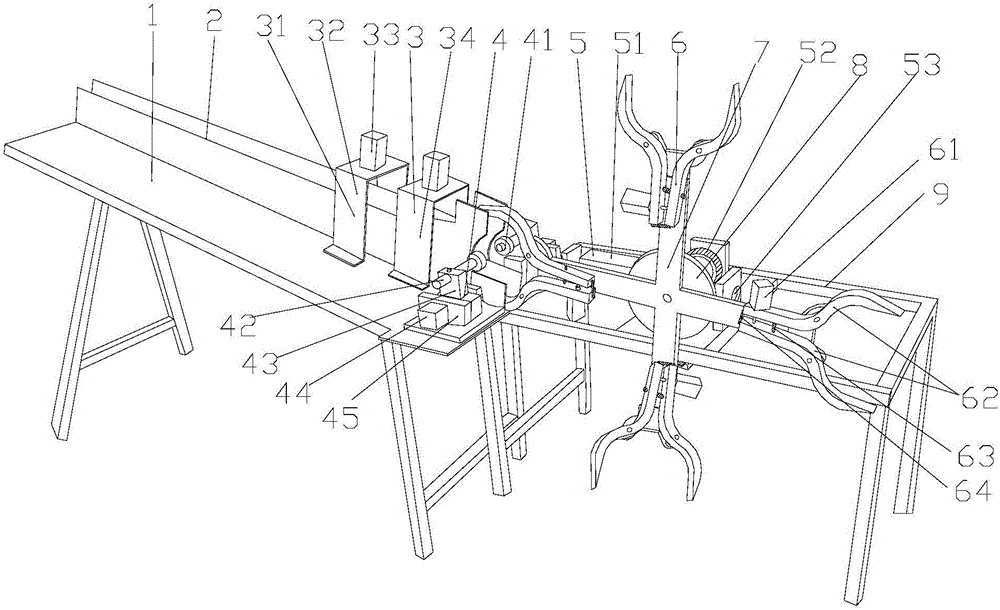

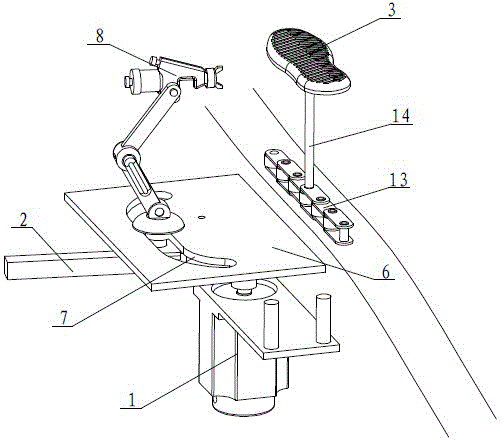

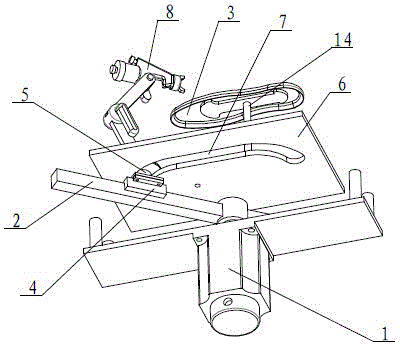

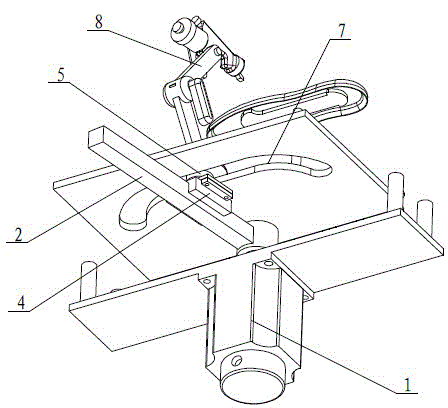

Fully automatic shoe sole paint spraying machine

ActiveCN103948216AReduce in quantityAvoid compromising qualityShoemaking devicesElectric machineryRelative motion

The invention relates to a fully automatic shoe sole paint spraying machine, which mainly solves the problems that during the paint spraying of the existing other automatic paint spraying flow line equipment, shoe sole workpieces need multi-position rotation, a plurality of spray guns are needed, and the technical problems of work procedure complexity, high consumption, troublesome color change spray gun washing, high cost and poor stability exist. The fully automatic shoe sole paint spraying machine has the advantages that in the workpiece conveying process according to the fully automatic paint spraying flow line spraying principle, a spray gun completes the work in two steps along the periphery of the shoe sole. The fully automatic shoe sole paint spraying machine comprises the spray gun, a motor, a linear guide rail, a sliding element, a moving element and a guide plate, wherein the motor drives the linear guide rail to rotate along the rotating center, the sliding element is glidingly and movably matched with the linear guide rail, the spraying gun is fixedly connected with the sliding element, the outer periphery of a support rod is provided with a rolling element doing relative movement to the peripheral direction of the support rod, and the rolling element is in rolling matching with the guide rail groove. The spray gun of the fully automatic shoe sole paint spraying machine adopts a fully automatic rotating spraying mode, so the spraying quality influence due to the shoe sole rotating falling can be avoided, and the fully automatic shoe sole paint spraying machine has the advantages that the work procedures are simple, the cost is low, the spraying quality is high, and the stability is good.

Owner:WENZHOU OUHAI LOUQIAO RUIBANG MACHINERY

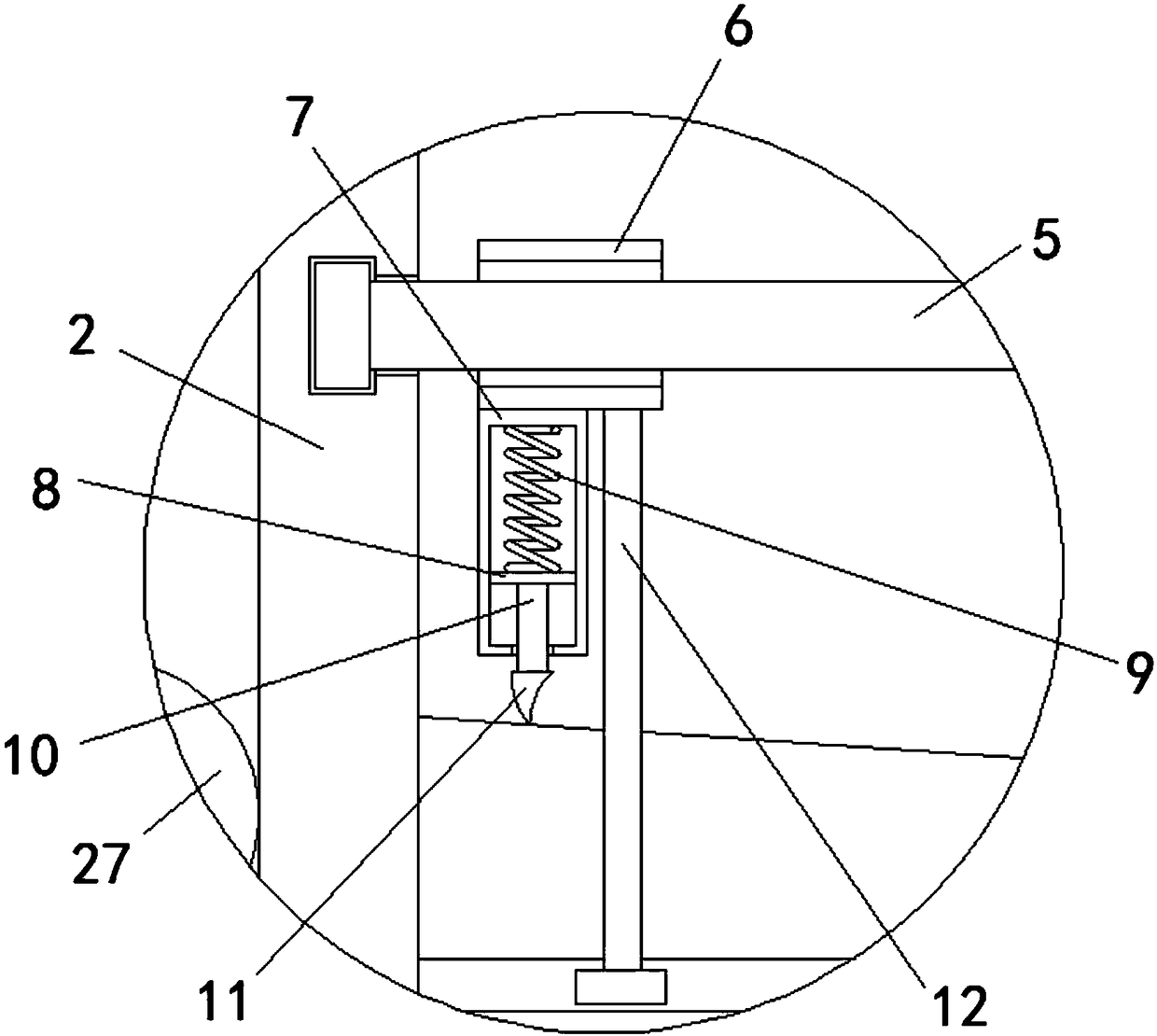

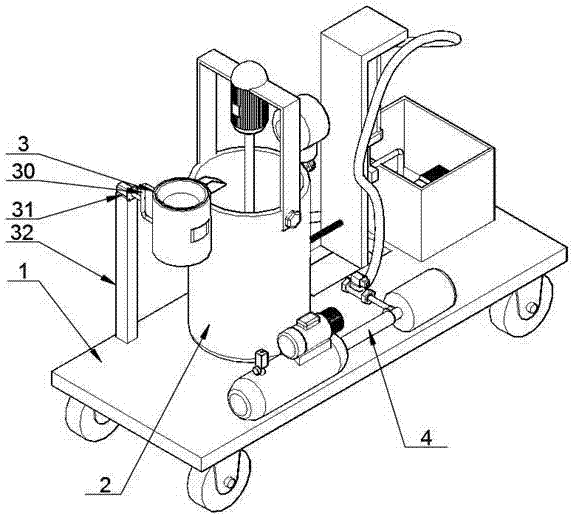

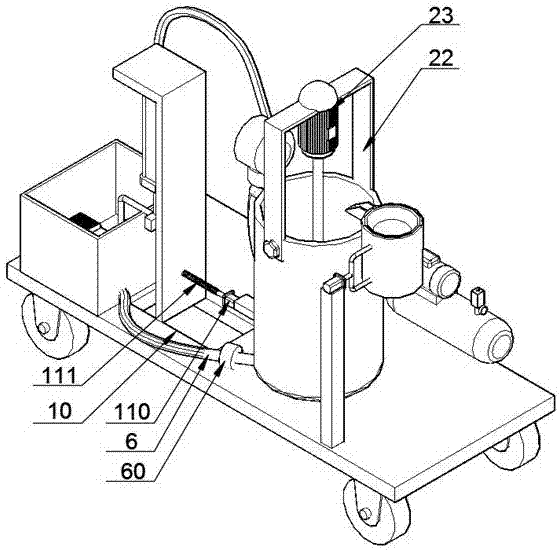

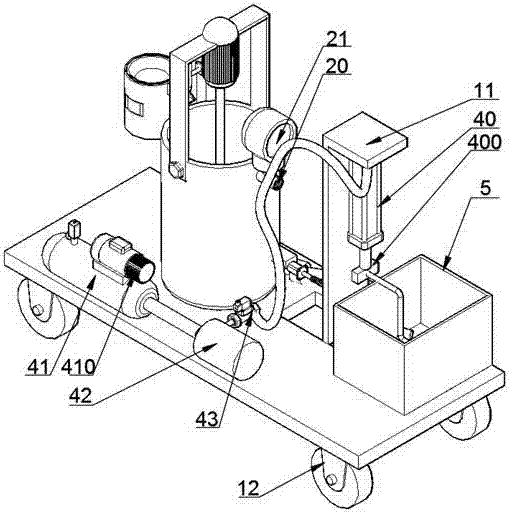

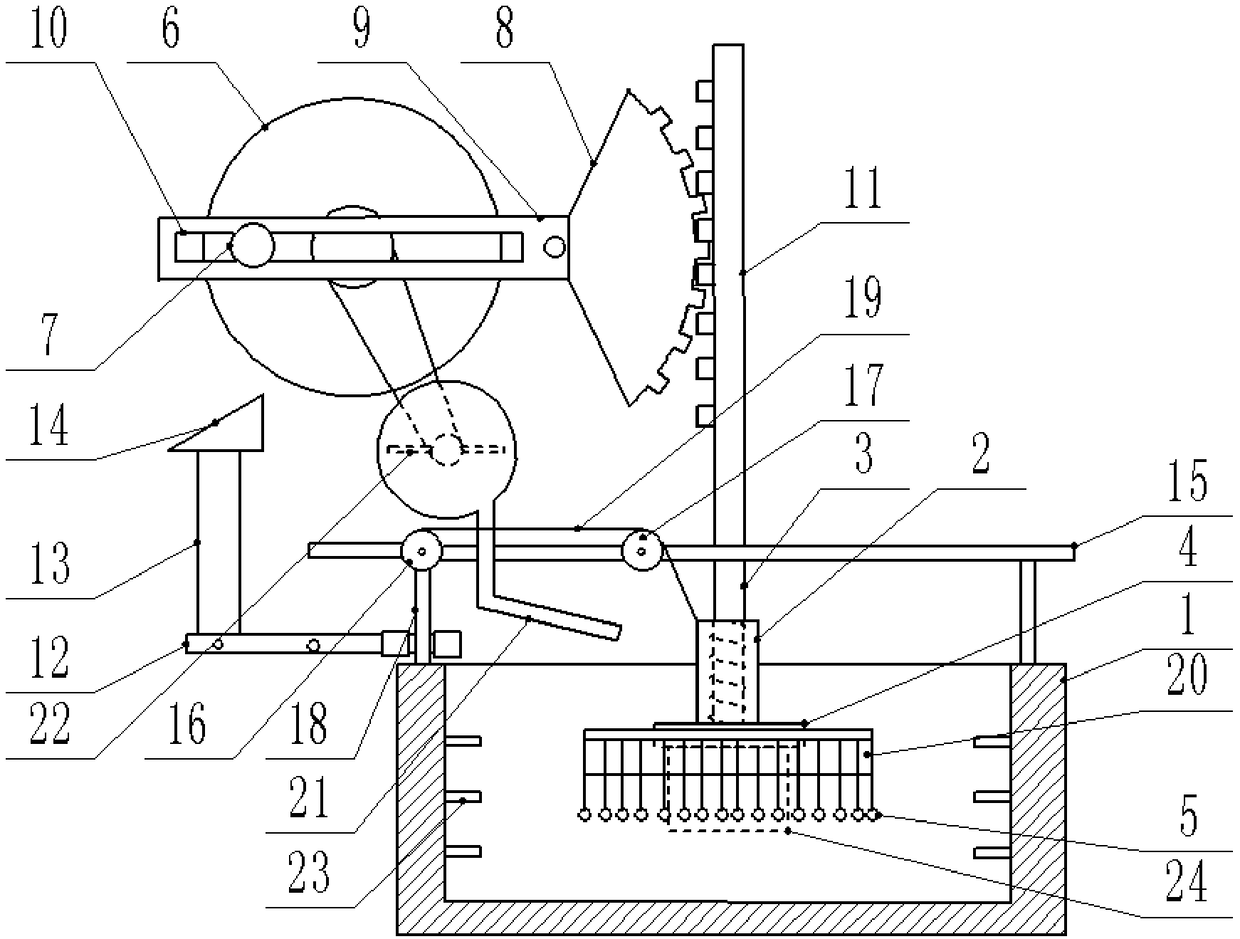

High-speed lime slurry agitator for house building coating

InactiveCN107349835APrecise ingredientsSave human effortRotary stirring mixersTransportation and packagingPistonHouse building

The invention relates to the technical field of construction machinery, in particular to a high-speed lime slurry agitator for house building coating. The high-speed lime slurry agitator comprises a rack, wherein a stirring bucket is arranged on the rack, a feeding cylinder is arranged on one side of the stirring bucket, a batching hopper is arranged on the feeding cylinder, a weighing sensor is arranged at the bottom of the batching hopper, a roll-over stand is arranged on the side face of the feeding cylinder, a second servo motor is arranged on one side of the roll-over stand, a second servo motor is fixed to the rack through a motor fixing base, an output shaft of the second servo motor is fixedly connected with the roll-over stand, a material storing pond is also arranged on the rack and is communicated with the stirring bucket through a discharging pipe, and added materials can reach the best proportional value by metering water flow and lime weight so that the agitator can agitate the best lime slurry. a wall face is automatically painted through piston motions of an air cylinder piston rod, labor is saved, painting is uniform, so that a wall face painting effect is greatly improved, and the working efficiency is greatly improved.

Owner:朱文连

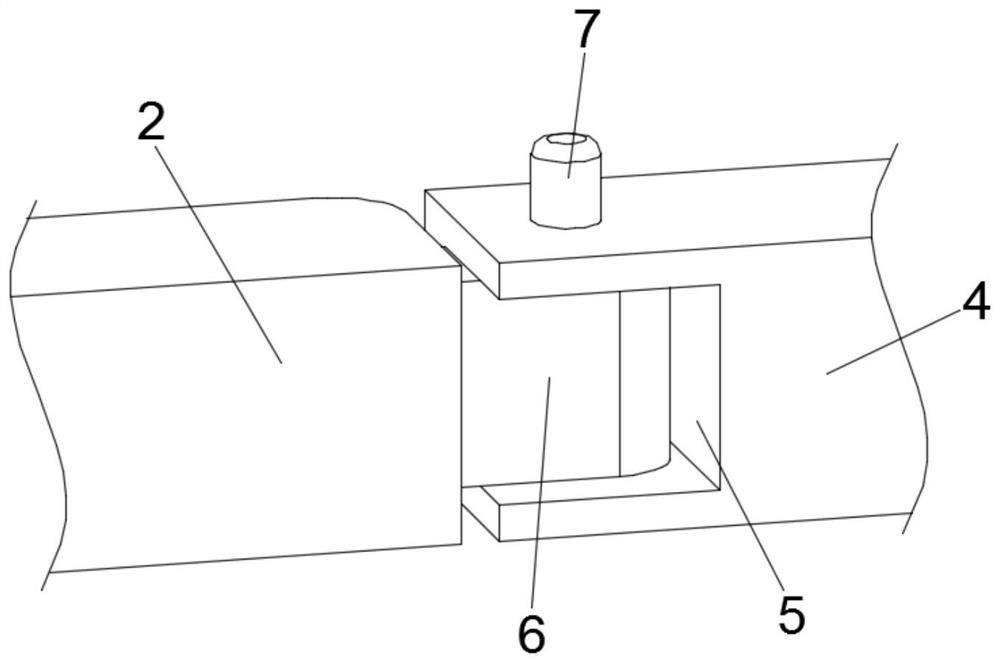

Device for processing gearbox parts

ActiveCN108554715AEasy to operateRealize automatic full paintingLiquid surface applicatorsCoatingsGear wheelReciprocating motion

The invention relates to the field of production and processing of gears and discloses a device for processing gearbox parts. The device comprises a paint tank; a vertically arranged screw rod pair isarranged in the paint tank; the screw rod pair is rotatably connected with the tank wall of the paint tank; the lower end of the screw rod pair is connected with a fixing disk for fixing a gear; theround side part of the fixing disk is connected with a plurality of lifting ropes which are distributed uniformly; the lifting ropes are connected with lifting balls; screw rods matched with the screwrod pair penetrate through the screw rod pair; and the screw rods are connected with a reciprocating motion mechanism for controlling the screw rods to do straight reciprocating motions. The device can realize comprehensive and automatic painting of the gear and does not need hands to turn over.

Owner:重庆市大足区川江金属制品厂

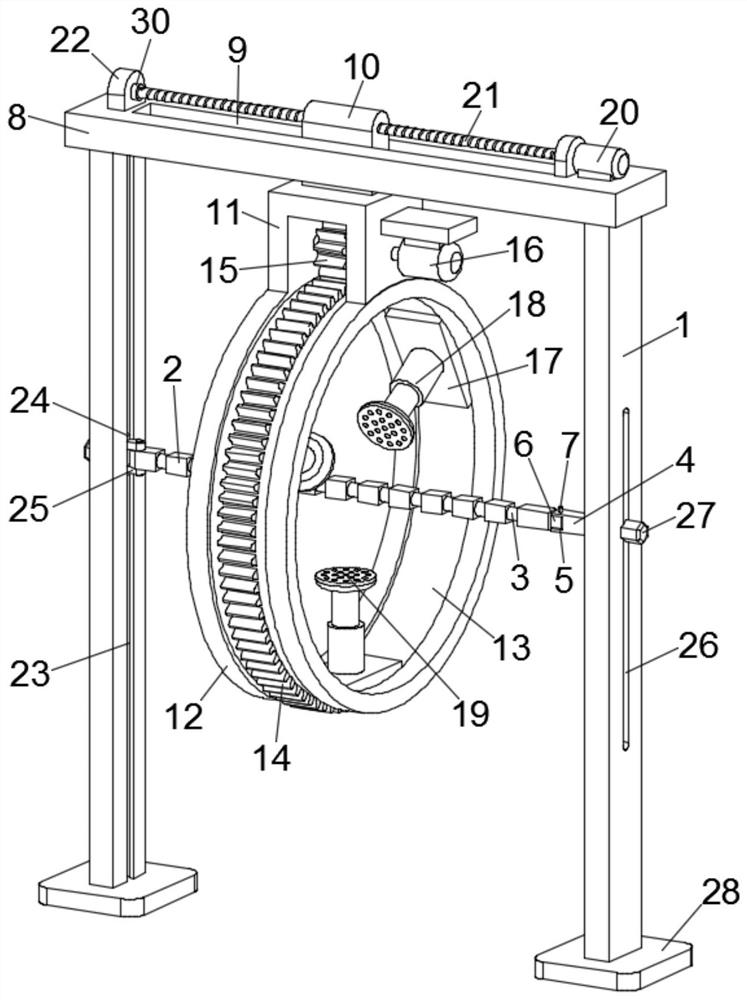

Rotary wood door frame paint spraying apparatus

The invention discloses a rotary wood door frame paint spraying apparatus. The rotary wood door frame paint spraying apparatus structurally comprises a worktable, supporting columns, an upper fixed seat, a rotating disc, a clamping device, a wood door, a limiting block, a groove, a transverse plate, a rotating device, a right paint spraying mechanism, a left paint spraying mechanism, a first semi-circular inner groove, a second semi-circular inner groove, a rolling wheel and a first rotating shaft. The supporting columns are arranged vertically in symmetry. According to the rotary wood door frame paint spraying apparatus disclosed by the invention, the wood door is fixed between the limiting block and a fixer, a gear ring drives the wood door to rotate, and the paint spraying mechanisms onthe supporting columns on two sides reciprocate up and down, and nozzles on the paint spraying mechanisms spray paint to the wood door all around. The paint spraying mode is simple. The rotary wood door frame paint spraying apparatus sprays paint to every position of the wood door uniformly, and is ideal in paint spraying effect.

Owner:南通市崇川广源彩印厂

Wood surface treatment equipment for producing furniture

InactiveCN108745748AAchieving turbulent mixingAchieving cutting and mixingSpray boothsSurface finishingWood machining

The invention discloses wood surface treatment equipment for producing furniture. The wood surface treatment equipment comprises a machine body, a base, supporting stand columns, a paint stirring boxand a heating device, wherein the base is horizontally arranged at the bottom of the machine body, the two supporting stand columns are symmetrically welded on the upper surface of the base, the paintstirring box is fixedly welded at the upper end of the supporting stand column on the right side, the heating device is arranged in the middle of the upper portion of the machine body, a wood placingtable is correspondingly arranged below the heating device, and the wood placing table is fixedly arranged in the middle of the upper surface of the base and is characterized in that a first rack iswelded to the right section of the wood placing table, and a pressurizing pump is welded to the bottom of the left side wall of the paint stirring box. According to the wood surface treatment equipment for producing the furniture, pain spraying treatment can be rapidly carried out on the wood surface, the paint spraying effect is good, the paint surface is uniform, and the thickness is consistent;and the paint surface after paint spraying can be quickly dried, and then the quality of the furniture after wood processing is guaranteed.

Owner:清远市简居科技有限公司

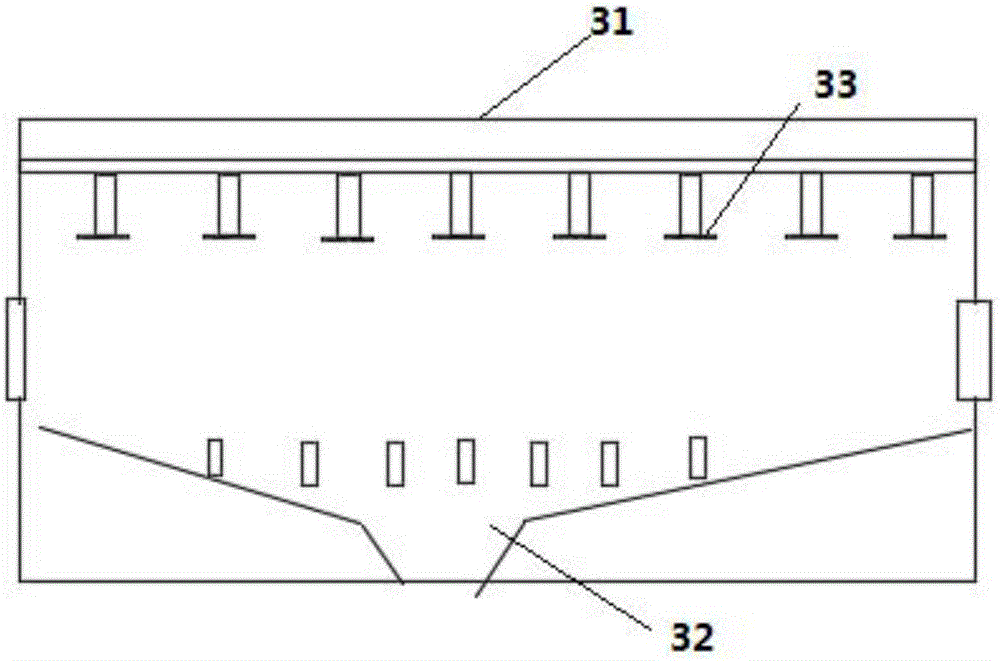

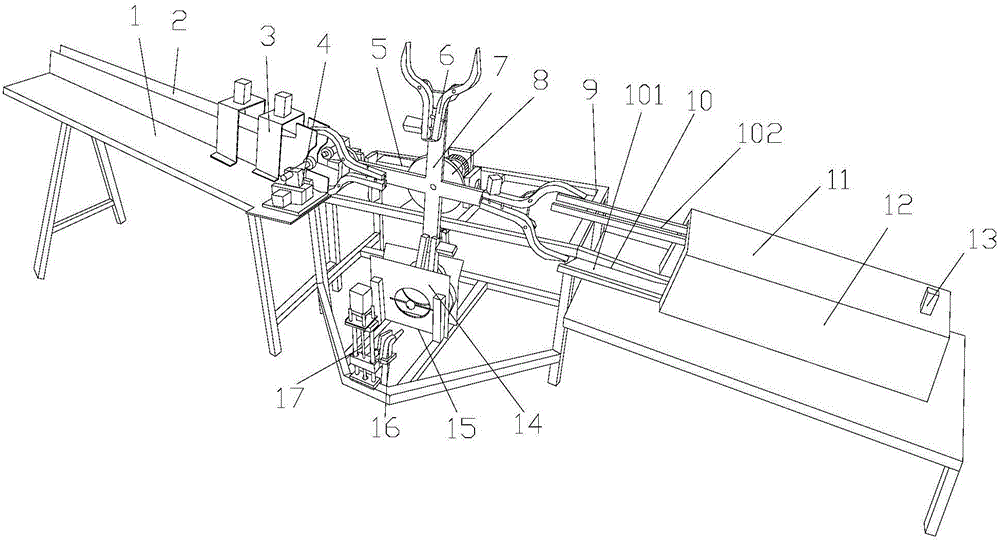

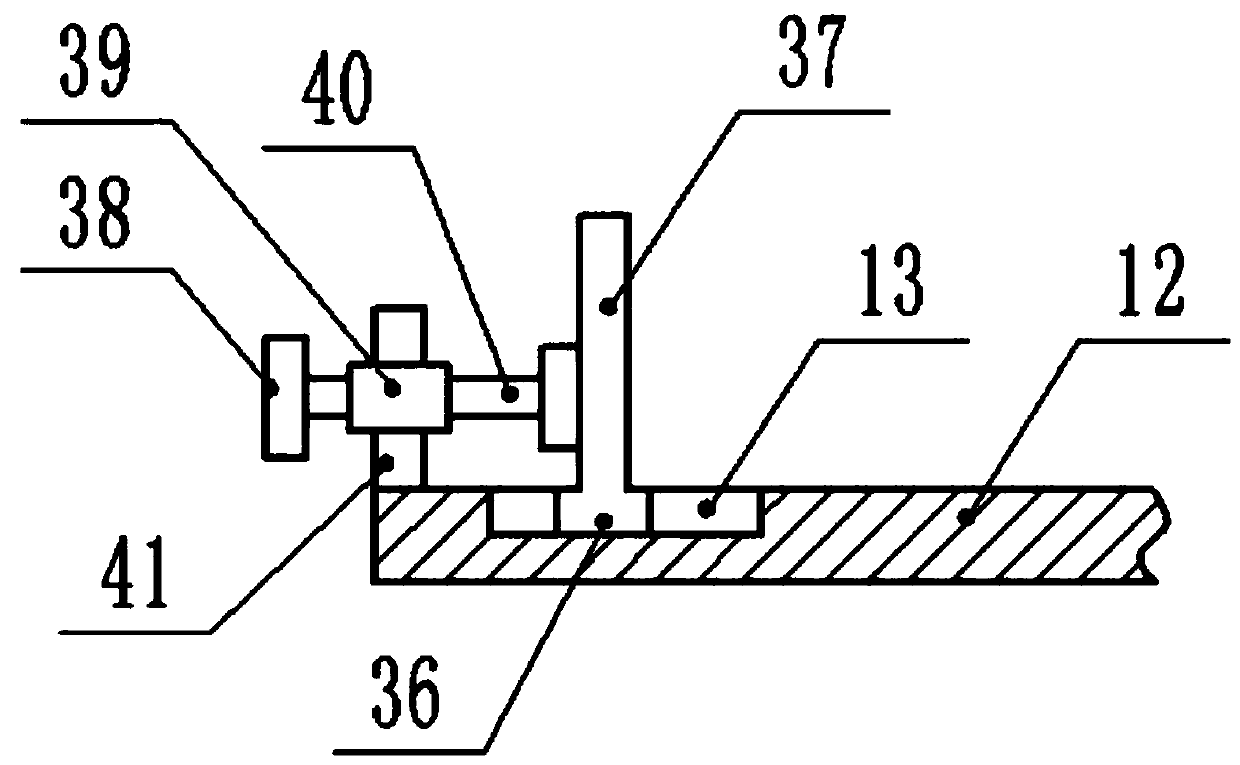

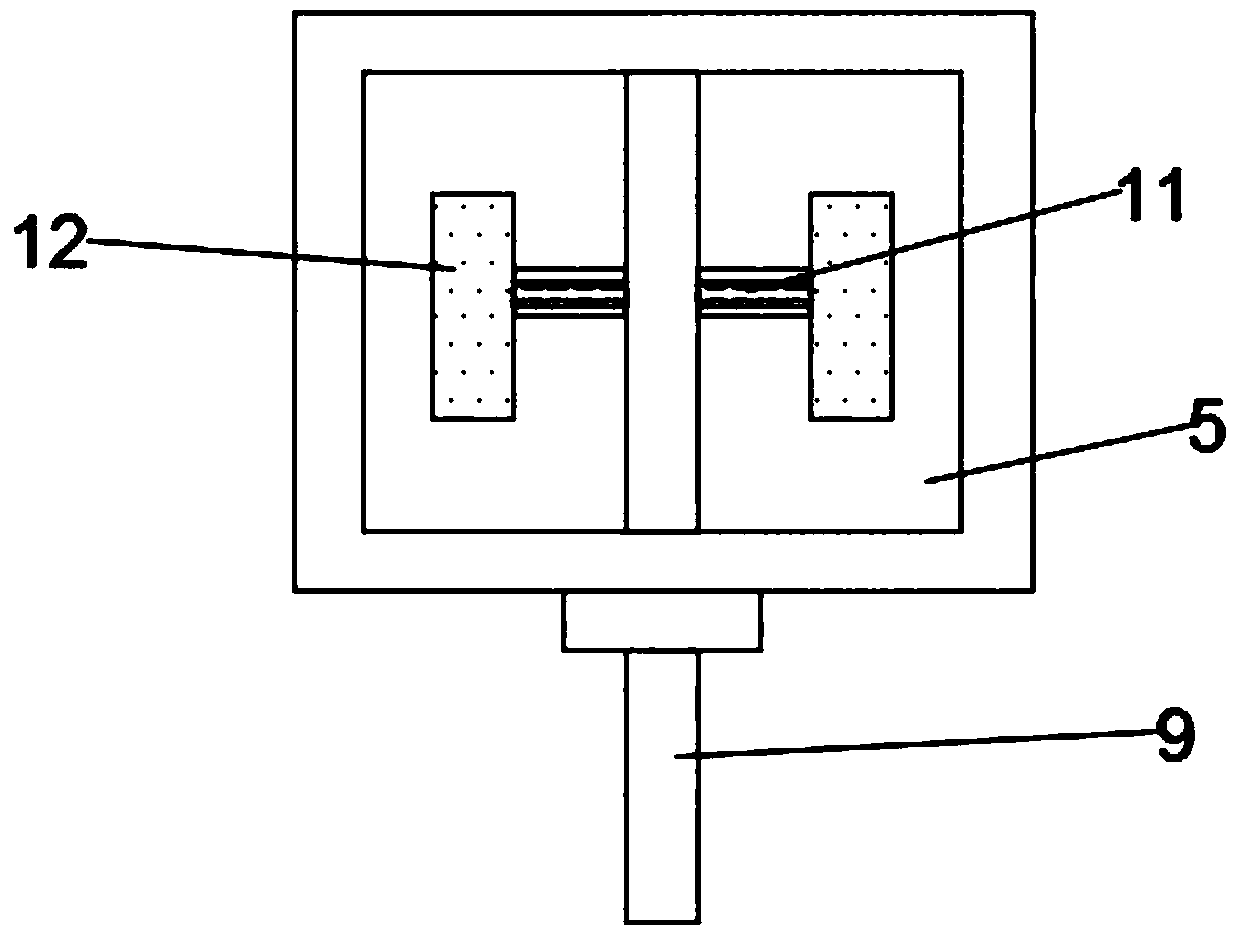

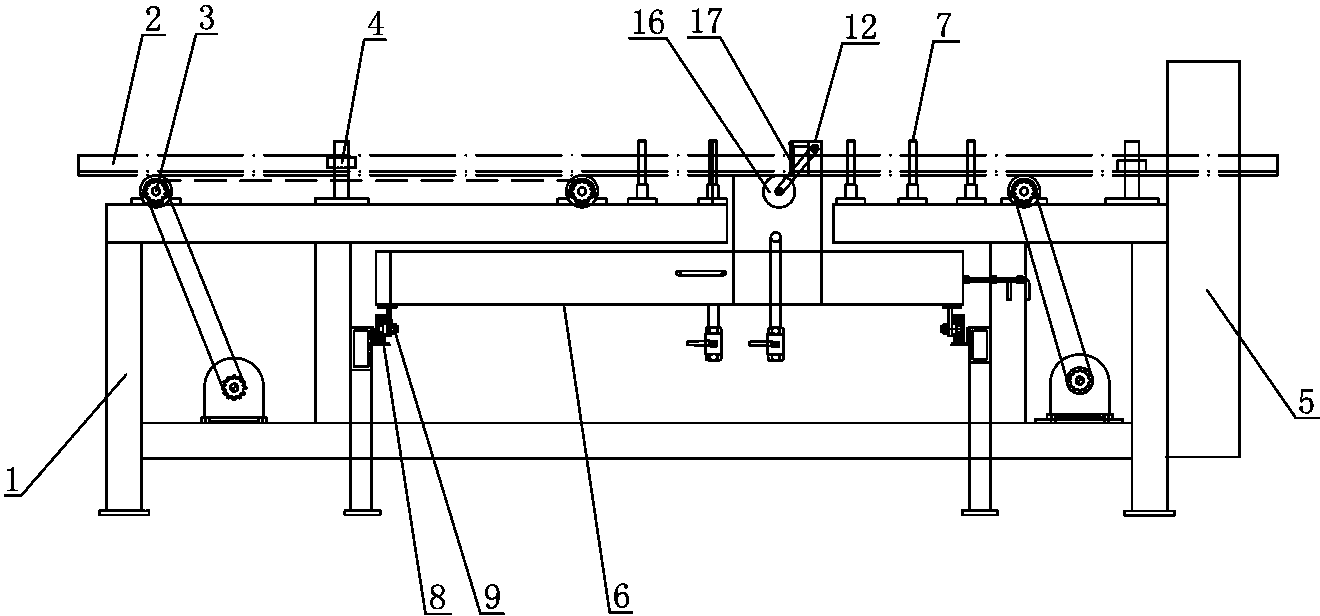

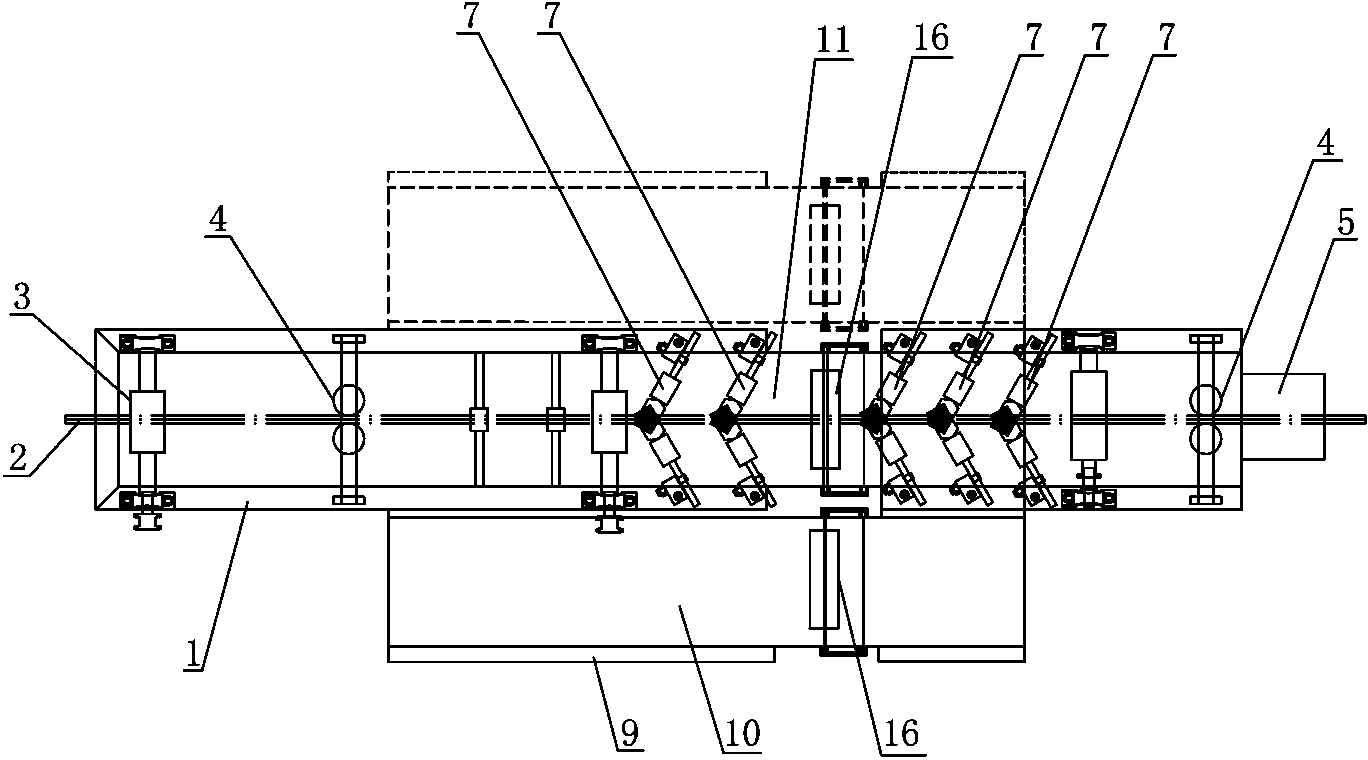

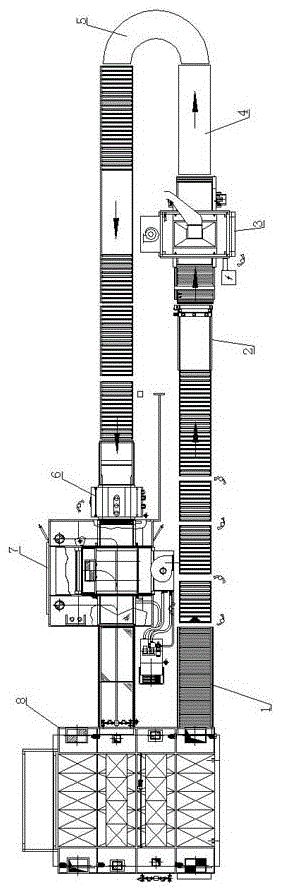

Automatic elevator guide rail painting line

ActiveCN104368496AImprove painting efficiencyGood paint effectLiquid surface applicatorsSpraying apparatusBrush deviceEngineering

The invention discloses an automatic elevator guide rail painting line. The automatic elevator guide rail painting line comprises conveying rollers and centering guide mechanisms which are both arranged in a rack; a paint spraying mechanism and a paint brushing device are orderly arranged in the rack in the conveying direction of the elevator guide rail; the paint brushing device comprises a bottom surface paint rolling mechanism and a surface paint brushing mechanism; the bottom surface paint rolling mechanism is so structured that a horizontal and longitudinal moving rail is arranged at the bottom of the rack, a longitudinal moving support is arranged on the horizontal and longitudinal moving rail, at least two paint tanks are formed in the longitudinal moving support, mounting supports are arranged on the two sides of each paint tank, respectively, a first rotating shaft is supported between every two mounting supports, connecting rods are arranged on the shaft bodies on the two sides of the first rotating shaft, respectively, a second rotating shaft is supported between every two connecting rods, a paint brushing roller is mounted on the second rotating shaft, the lower part of each paint brushing roller is soaked in the paint in the corresponding paint tank, each connecting rod is connected with the mounting supports by use of elastic return elements, the paint brushing rollers always have the trend of clinging to the bottom surface of an elevator guide rail fixing arm upwards under the action of the elastic force of the elastic return elements. The automatic elevator guide rail painting line has the advantage of high paint brushing efficiency.

Owner:张家港市张运机械制造有限公司

Special integrated production device for furniture parts

ActiveCN105057150AReduce transfer stepsSuitable for mechanized productionLiquid surface applicatorsCoatingsEngineeringMechanical engineering

A special integrated production device for furniture parts comprises a machine frame and a feeding rack arranged on the machine frame. One end of the feeding rack is a feeding end, the other end of the feeding rack is a discharging end, and a first automatic dust removal device, a embellishing device, a drying device, a paint spraying device and an airing bin are arranged on the feeding rack sequentially from the feeding end to the discharging end at intervals. The embellishing device and the paint spraying device each comprises a paint spraying chamber with a paint spraying platform and two groups of spraying guns arranged in the paint spraying chamber, wherein each group comprises two spraying guns, a conveying belt is laid horizontally on the paint spraying platform, a transverse sliding rail is arranged above a feeding end and a discharging end of the conveying belt, and a movable seat is installed on the transverse sliding rail. The two spraying guns in each group are installed on the same movable seat and are arranged in the mode of inclining downwards towards the two outer sides of the corresponding paint spraying platform. The transverse sliding rails and the movable seats are arranged, uniform paint spraying on the furniture parts is realized through transverse and reciprocating swinging of the spraying guns. The special integrated production device is suitable for embellishing and paint spraying of various furniture parts, and improves the production and quality.

Owner:LIANYUNGANG MOBO HOUSEHOLD

Paint spraying device for wooden pole

PendingCN108262192AImprove work efficiencyReduce manufacturing costSpray boothsHydraulic cylinderEngineering

The invention discloses a paint spraying device for a wooden pole. The paint spraying device comprises a box body with a front panel capable of being opened, a clamping device is arranged at the lowerpart in the box body, and a paint spraying device body is arranged at the upper part in the box body; the clamping device comprises supporting frames with a guide rail fixed to the upper ends, the guide rail is connected to a mounting base in a sliding mode, and the mounting base is fixedly provided with a hydraulic cylinder with the output end connected to a first ejector rod; the paint sprayingdevice body comprises a rotary motor, an output shaft of the rotary motor is connected to a second ejector rod, and multiple conical protrusions are symmetrically formed on the front end surface of the second ejector rod; the paint spraying device body also comprises a sliding rail, a sliding seat is connected to the sliding rail in a sliding mode, and a screw rod connected to a servo motor is inserted into an inner cavity of the sliding seat, an electric lifting rod is fixed on the lower surface of the sliding seat, and the lower end of the electric lifting rod is fixedly provided with a paint spraying head; and the hydraulic cylinder, the rotary motor, the servo motor and the electric lifting rod are connected to a control box. According to the paint spraying device, automatic paint spraying is adopted, so that the working efficiency is improved, and production cost is reduced; a closed paint spraying environment is adopted, so that discharge of harmful substances is reduced; and the height of the paint spraying head can be adjusted according to the size of the actual wooden pole, so that the paint spraying effect is better.

Owner:湖州泰信环保科技有限公司

Paint spraying device for production of high-low pressure switchgear

InactiveCN108543642ASpray evenlyGood paint effectLiquid spraying apparatusSwitchgearSwitchgearStorage tank

The invention discloses a paint spraying device for production of a high-low pressure switchgear. The paint spraying device includes a base, a paint storage tank is fixedly connected to the right sideof the top of the base, a pump body is fixedly connected to the position, on the left side of the paint storage tank, on the right side of the top of the base, a first bearing seat is fixedly connected to the left side of the bottom of the inner cavity of the base, and a rotating shaft is arranged at the top of the first bearing seat. Through the cooperation use of a support plate, an electric push rod, a first limiting plate, a sliding block, a connecting rod, a sliding groove, a second limiting plate, an upper telescopic pipe, a first liquid spraying pipe, a liquid draining pipe and a lowertelescopic pipe, the high-low pressure switchgear can be sprayed up and down uniformly, so that the paint spraying effect of a paint spraying device is better, and the problem that the spraying effect of the paint spraying device is poor due the fact that during use, the paint spraying device cannot adjust the position of paint spraying so that the paint spraying device can only spray paint on afixed position is solved.

Owner:许昌市长江高压计量设备有限公司

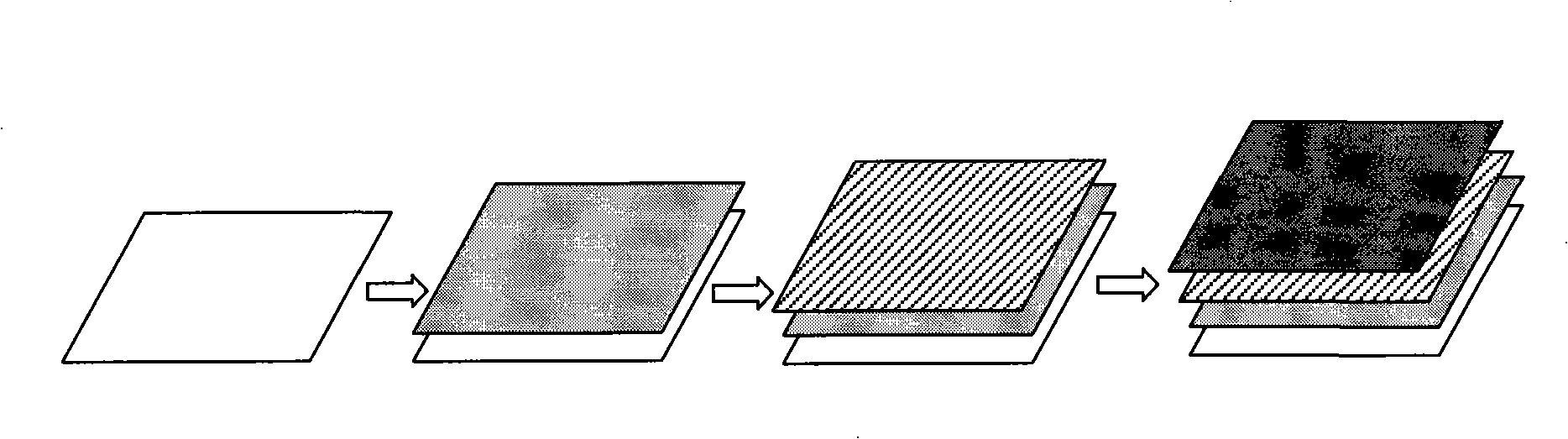

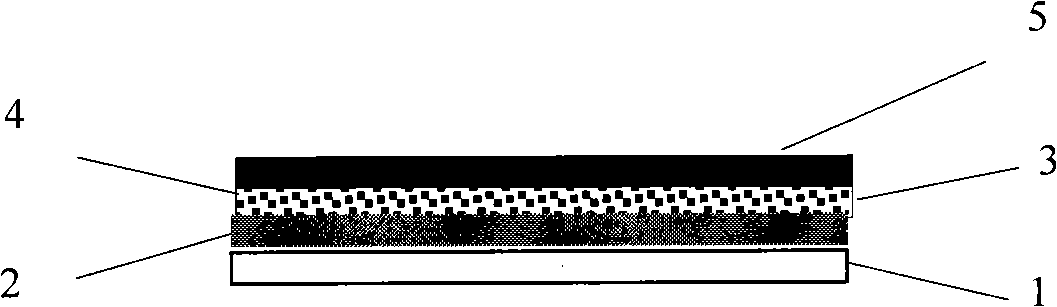

Nano surface treatment agent and treatment method thereof covering surface of metal materials

ActiveCN105018917AHigh Environmental Safety StandardNo pungent solvent odorSuperimposed coating processTectorial membraneChemical Linkage

The invention provides a nano surface treatment agent and a treatment method thereof covering surfaces of metal materials. The method comprises the following steps: 1) remove the oil and impurities from the surface of the material; 2) the nano-coated surface treatment agent to the surface to form a protective film by chemical bonding of the nano surface treatment agent to the surface of the material, wherein the nano surface nano treatment agent is a solution formed by mixing at least one alkoxide, water and an alkaline compound phase, and through a catalytic condensation reaction of alkoxide and water by the alkaline compound phase, the nano-surface treatment agent has a high flash fire point, and the surface treatment agent, and further, containing resins, additives and wax. The present invention will nanometer surface treatment agent chemically bonded to the surface of the material to increase the adhesion of a protective film on the surface of the material, and at the same time achieve the anti-corrosion and wear-resistant effect.

Owner:NANMAT TECH

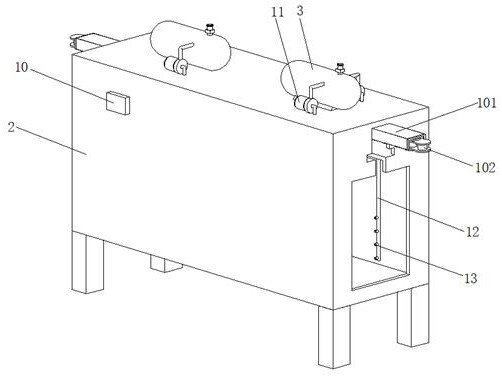

Wicker basket assembly line type efficient paint spraying equipment

ActiveCN112024238AImprove painting efficiencyGood paint effectLiquid spraying apparatusSpray boothsAssembly lineIndustrial engineering

The invention relates to the technical field of artware processing equipment, in particular to wicker basket assembly line type efficient paint spraying equipment. The wicker basket assembly line typeefficient paint spraying equipment comprises a closed type suspension conveying chain, a paint spraying box and a paint tank. The closed type suspension conveying chain penetrates an inlet and an outlet. The closed type suspension conveying chain is connected with a plurality of wicker basket paint spraying hanging pieces. A partition plate is arranged at the upper end in the paint spraying box and divides the interior of the paint spraying box into a paint spraying cavity and a drive cavity. A first fold line sliding groove is formed in the upper surface of the part, close to the inlet of the paint spraying box, of the partition plate. A first rack drive mechanism is arranged above the first fold line sliding groove. A second fold line sliding groove is formed in the upper surface of thepart, close to the outlet of the paint spraying box, of the partition plate. A second rack drive mechanism is arranged above the second fold line sliding groove. The paint spraying equipment is highin paint spraying efficiency and excellent in paint spraying effect, the waste of paint spraying raw materials is reduced to a certain degree, and the paint spraying comprehensive capability of the paint spraying equipment on wicker baskets is more excellent.

Owner:安徽三和工艺品有限公司

Adjustable automobile parts paint spraying device

InactiveCN111822185AImplement batch jobsImprove painting efficiencySpraying apparatusSupport planeSpray painting

The invention discloses an adjustable automobile parts paint spraying device. The device comprises two supporting frames which are symmetrically distributed, a hanging rod is horizontally and rotationally installed on the supporting frame on one side, a plurality of hanging grooves are evenly distributed in the hanging rod at equal intervals, a locking piece is fixed to the supporting frame on theother side, and a locking assembly is arranged between the hanging rod and the locking piece; a top plate is fixed to the upper end of the supporting frame, a through groove is formed in the top plate, a translation block is embedded in the through groove in a sliding mode, and a rotary paint spraying mechanism is installed at the bottom of a translation block; and a translation mechanism for driving the translation block to move horizontally is further arranged on the top plate. Batch operation can be achieved, paint spraying efficiency is improved, and workpiece feeding and discharging areconvenient and fast; multiple sets of paint spraying assemblies arranged in the circumferential direction are used for conducting 360-degree rotary spraying on the automobile parts on the hanging rod2, all-dimensional paint spraying is achieved, paint spraying is free of dead space, spraying coverage is uniform, the paint spraying effect is good, the operation efficiency is high, and consistencyis good.

Owner:秦春红

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com