Adjustable automobile parts paint spraying device

An auto parts and adjustable technology, applied in the direction of spraying device, etc., can solve the problems of dead corners of painting, uneven distribution of paint surface on the surface of auto parts, affecting the overall quality of parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

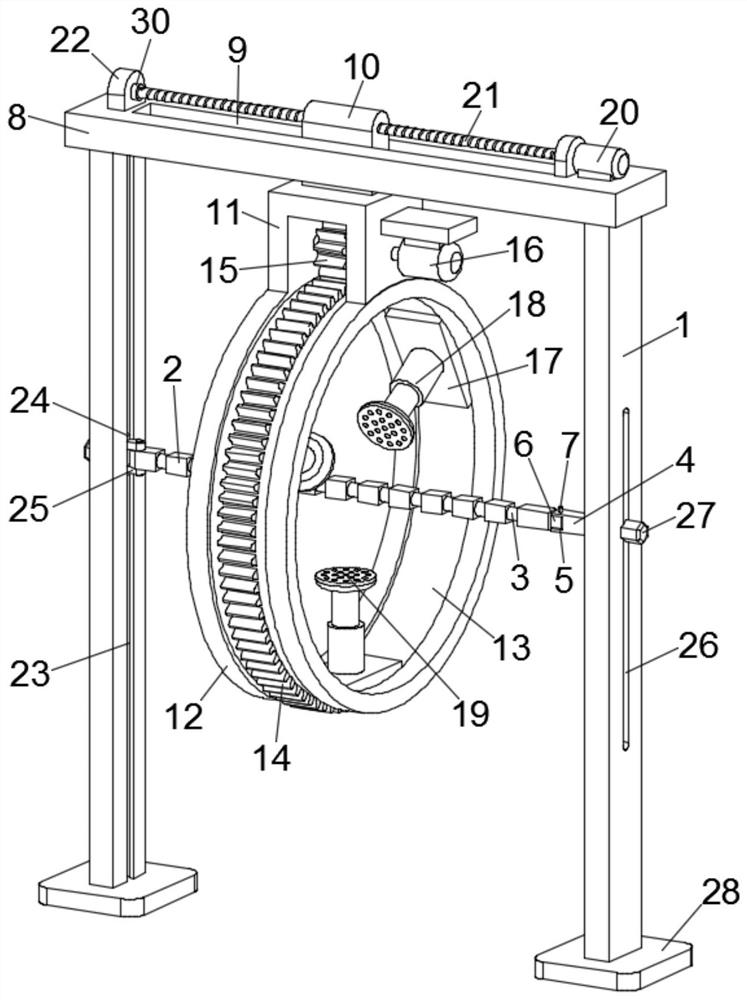

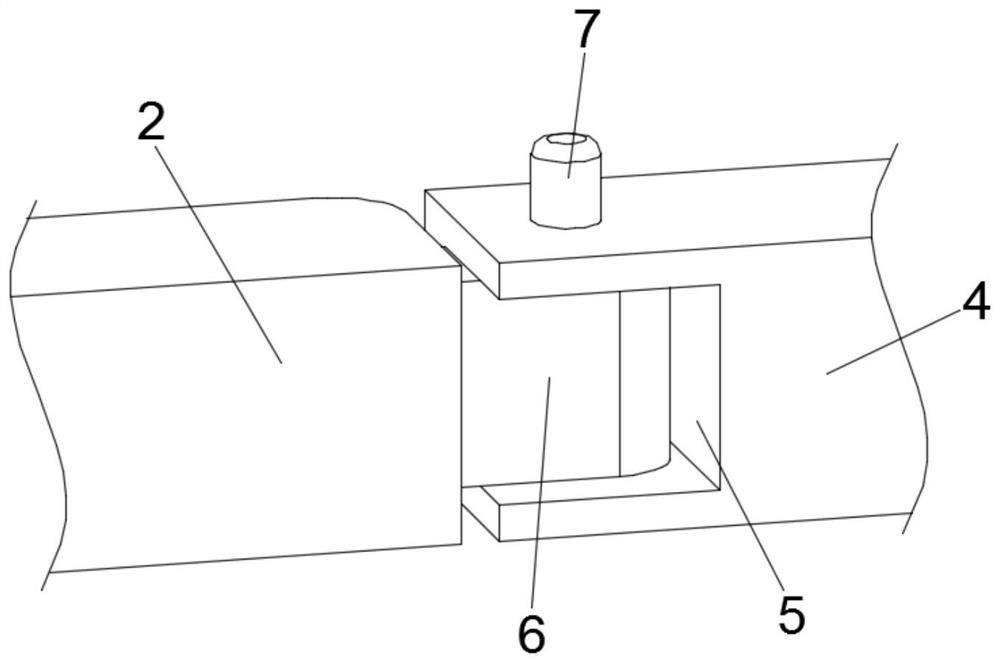

[0027] see figure 1 , an adjustable auto parts painting device, including a support frame 1, the number of the support frame 1 is two and symmetrically distributed, a base 28 is installed on the bottom of the support frame 1, and the support frame 1 on one side is horizontally rotated and installed There are hanging rods 2, on which the hanging rods 2 are equidistantly distributed with a number of hanging grooves 3 for hanging auto parts, and on the other side support frame 1, lock blocks 4 are fixed, and the hanging rods 2 and the locking blocks 4 A locking assembly is provided between them; a top plate 8 is fixed on the upper end of the support frame 1, and a through groove 9 is opened on the top plate 8, and a translation block 10 is slidably embedded in the through groove 9, and the bottom of the translation block 10 Installed with a rotary paint spraying mechanism;

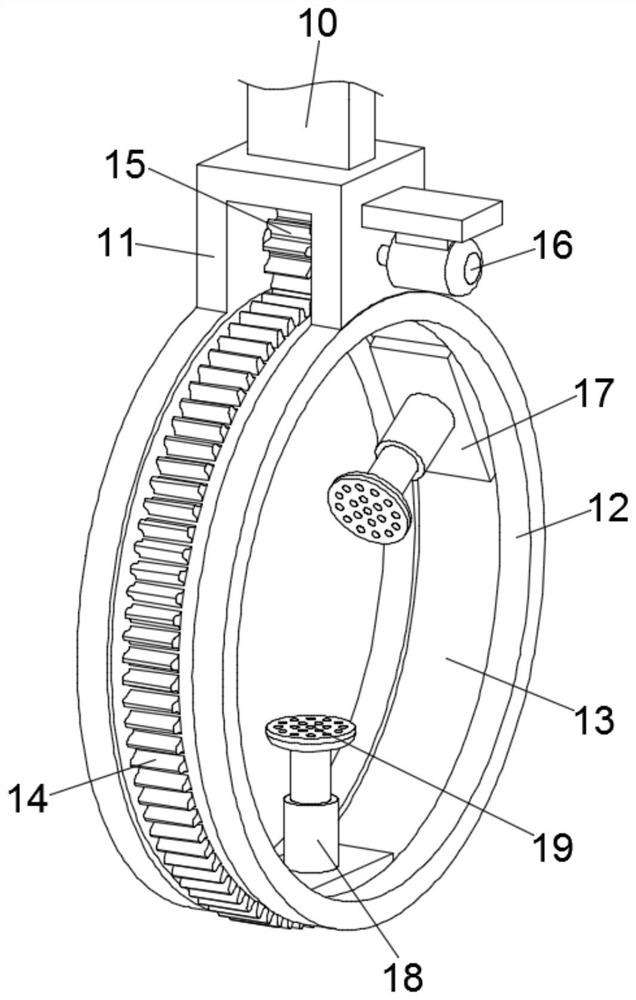

[0028] see figure 2 , the rotary painting mechanism includes a connecting seat 11, a fixed collar 12 an...

Embodiment 2

[0038]In order to facilitate the hanging of auto parts, this embodiment has been further improved on the basis of Embodiment 1. The improvement is: there are vertically provided chutes 23 in the support frames 1 on both sides, and sliding clamps are installed in the chute 23. There is a slider 24, the hanging rod 2 is rotatably connected with the slider 24 on one side through the hinge seat 25, the lock block 4 is fixedly installed in the slider 24 on the other side, and an adjustment slot is also opened on the support frame 1 on both sides 26, the slider 24 is equipped with a fastening knob 27 that runs through the adjustment groove 26; when it is necessary to hang auto parts, unscrew the fastening knobs 27 on both sides, so that the slider 24 slides down the chute 23, thereby lowering the hanging rod The height of 2 is convenient to the operation of the upper part, and the upper part is completed, and then the hanging rod 2 is slid to the central axis of the rotating ring 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com