Welding manipulator

A technology for welding manipulators and welding torches, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. It can solve the problems of leaf spring processing operations that cannot adapt to different specifications and models, and the adjustment and positioning of solder joints are not flexible enough. Concise and durable, improve production efficiency, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

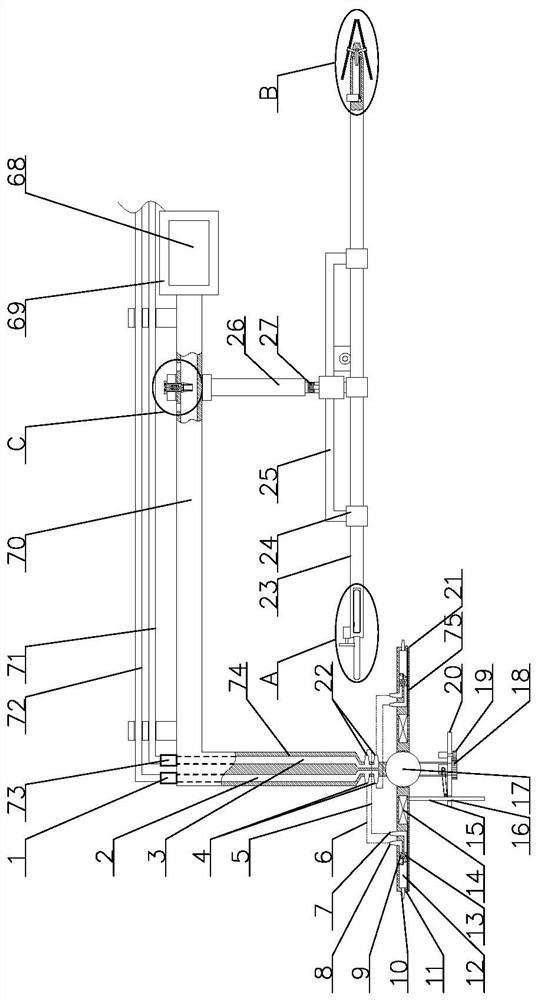

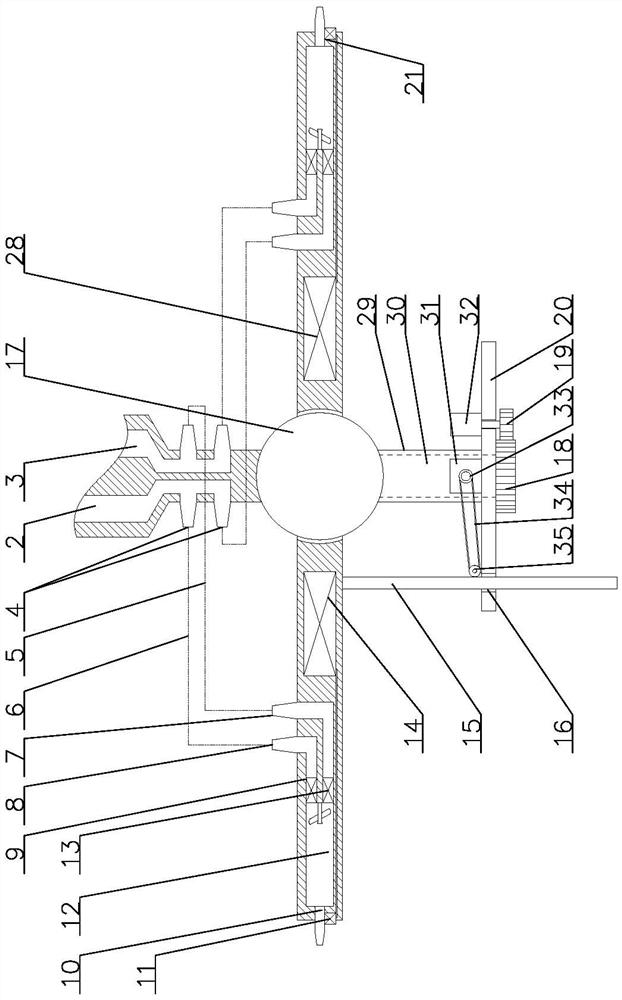

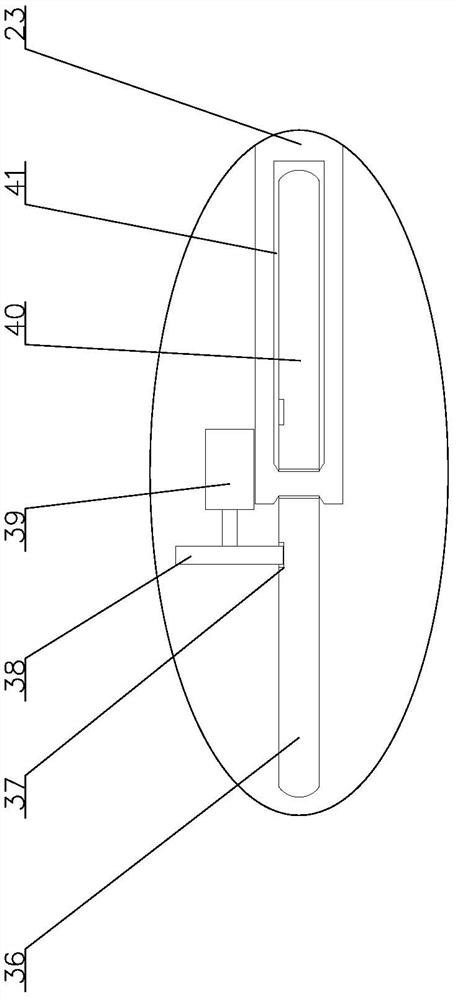

[0029] Such as figure 1 As shown, a welding manipulator according to the present invention includes a mounting arm, a universal ball head and a welding torch mounting plate, the mounting arm includes a cross arm and a vertical arm, the front end of the cross arm is vertically connected to the upper end of the vertical arm, The rear end of the cross arm is connected with a sliding collar, and the sliding collar is set on the slide rail and can move along the slide rail; a universal ball head is installed at the lower end of the vertical arm, and a mounting hole is opened in the middle of the welding torch mounting plate. A ball-sliding sleeve is arranged in the mounting hole, and the welding torch mounting plate is set on the universal ball head through the ball-sliding sleeve. The left and right ends of the welding torch mounting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com