Patents

Literature

1091results about How to "Quick loading and unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

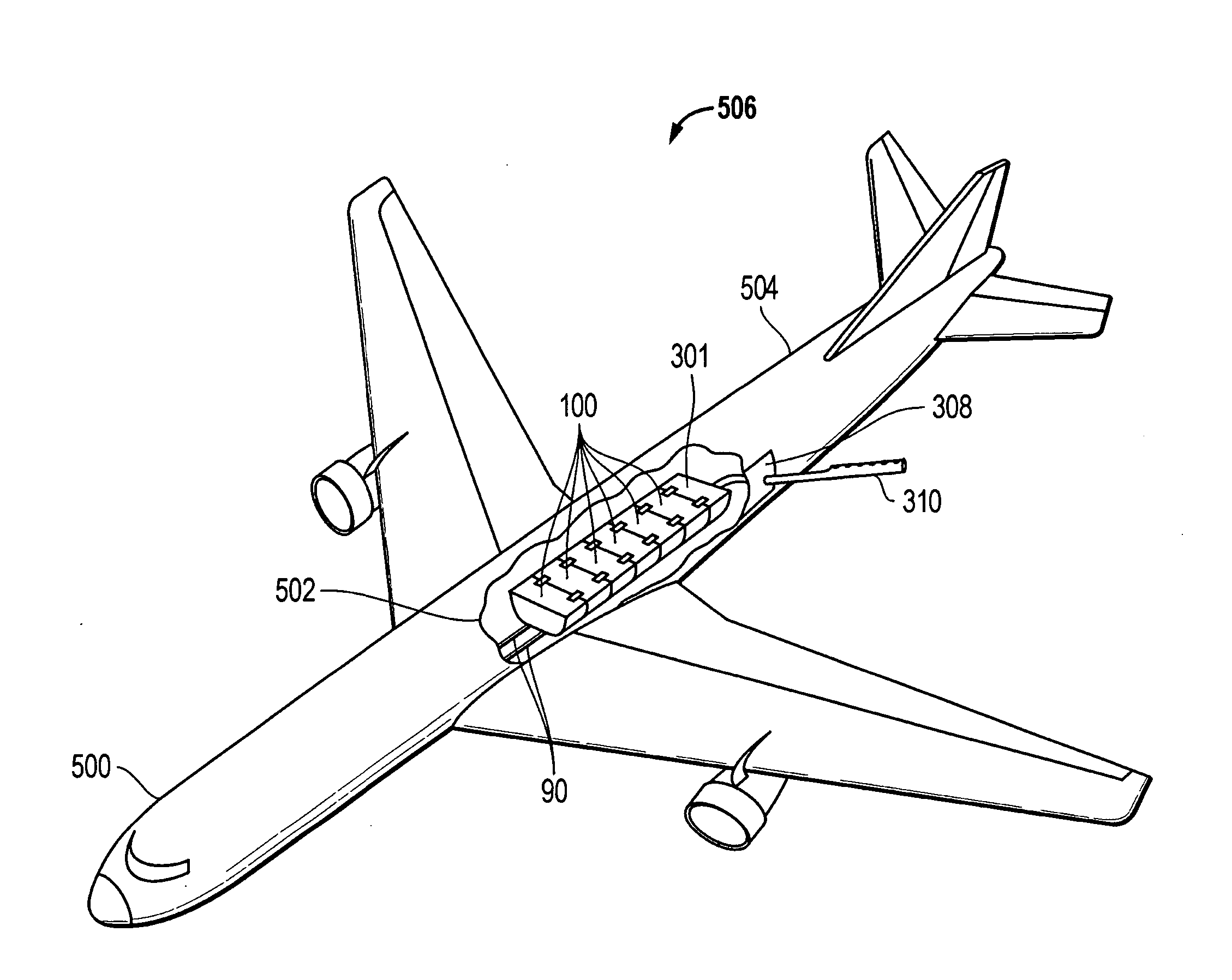

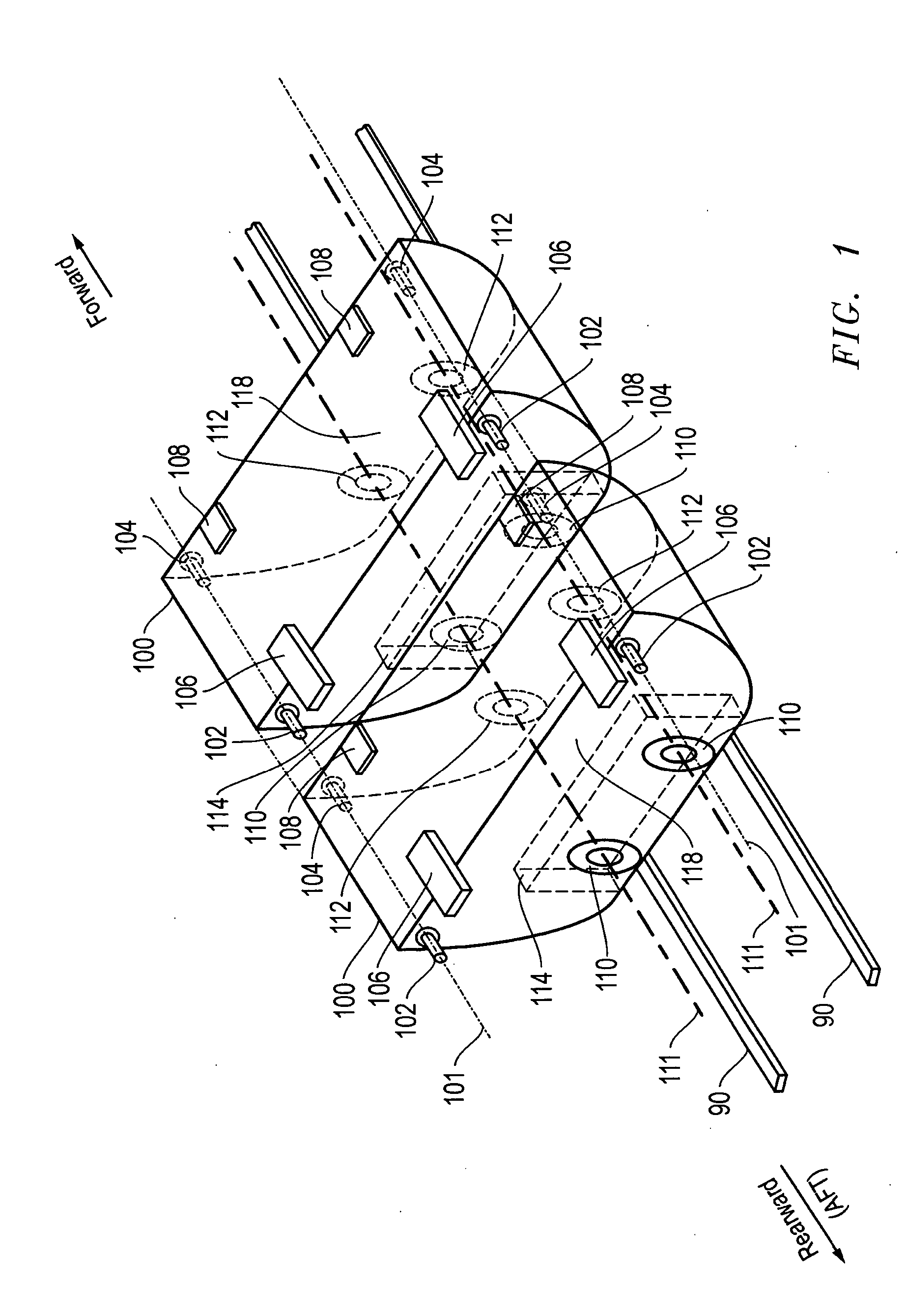

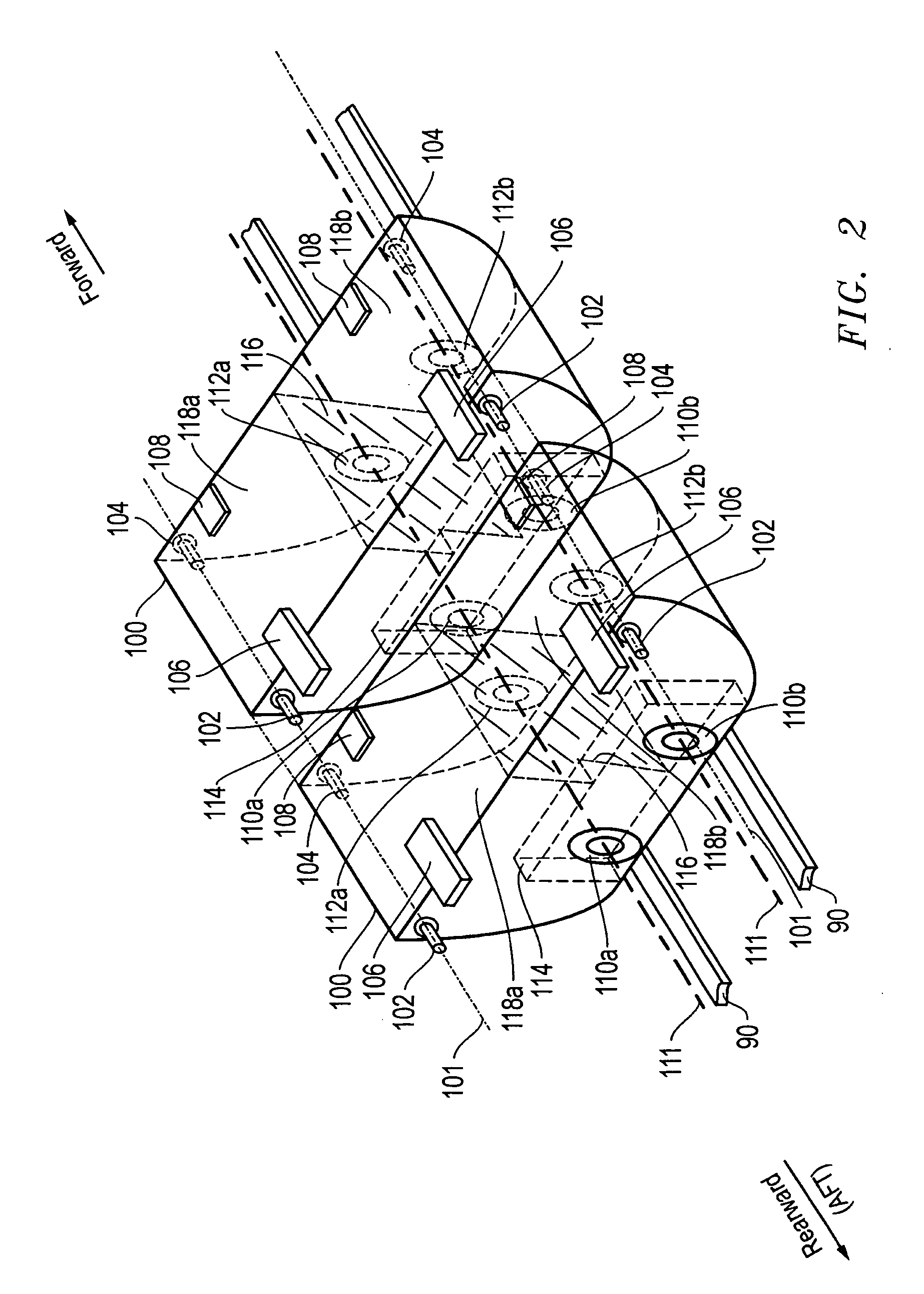

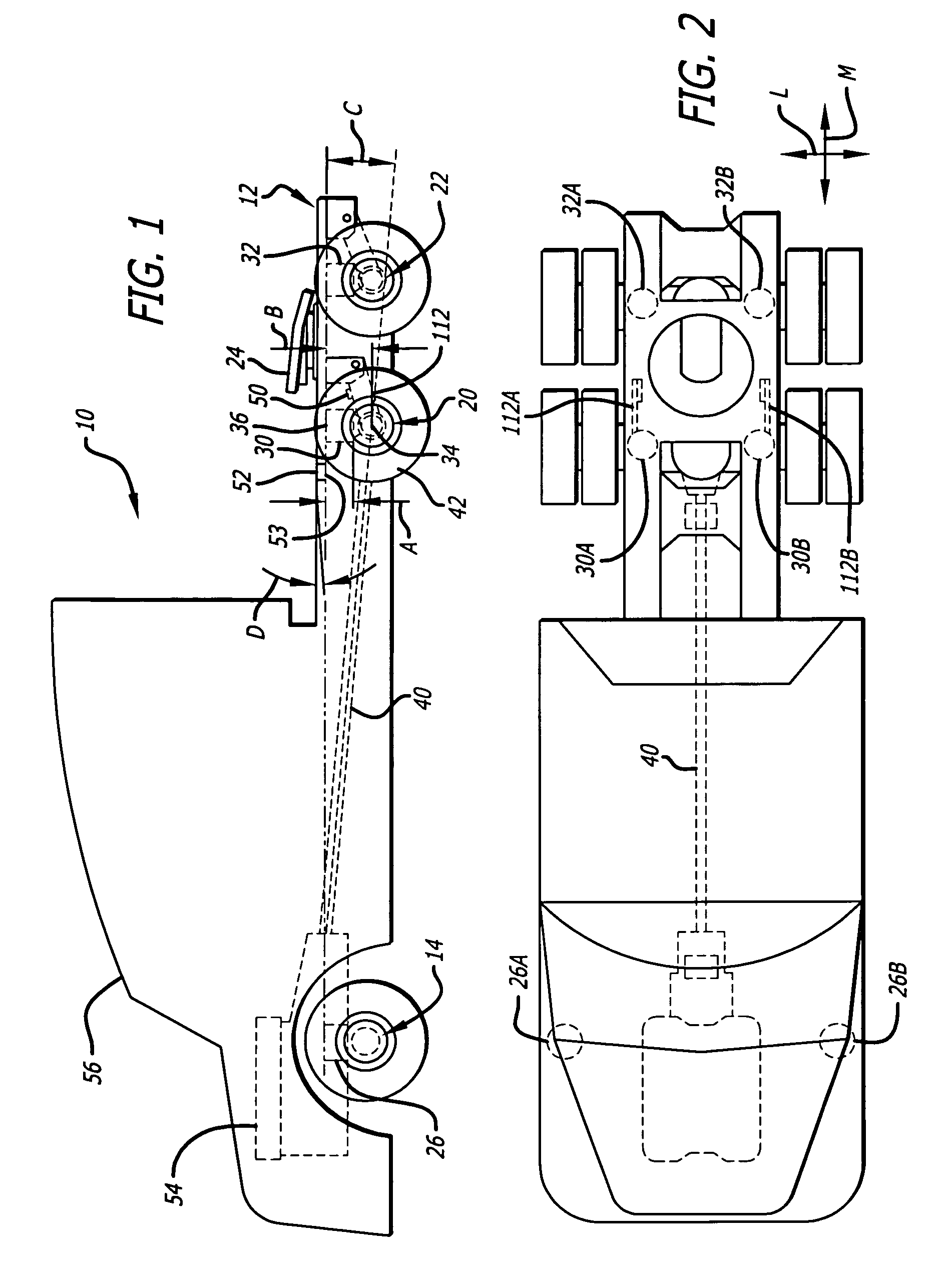

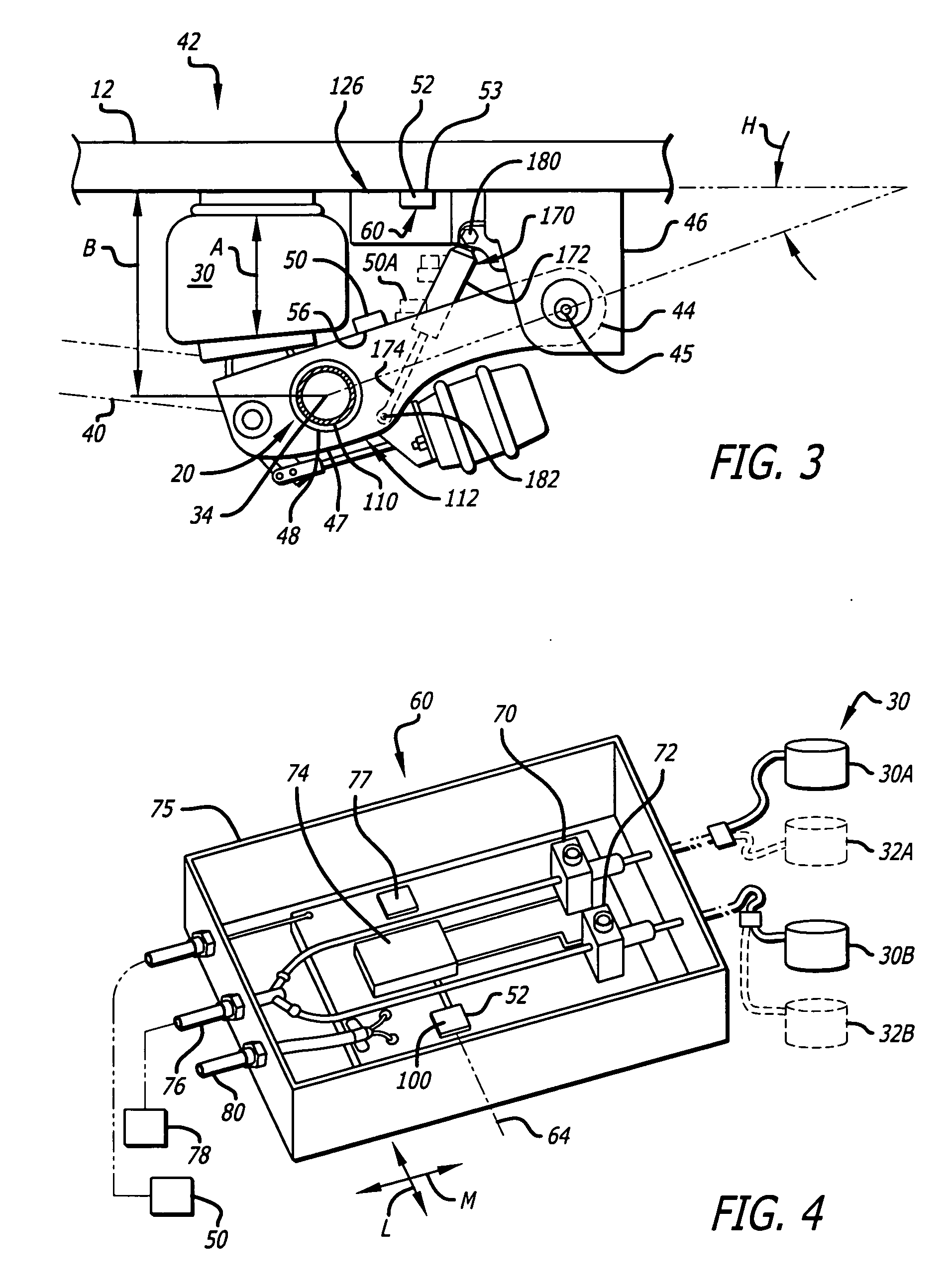

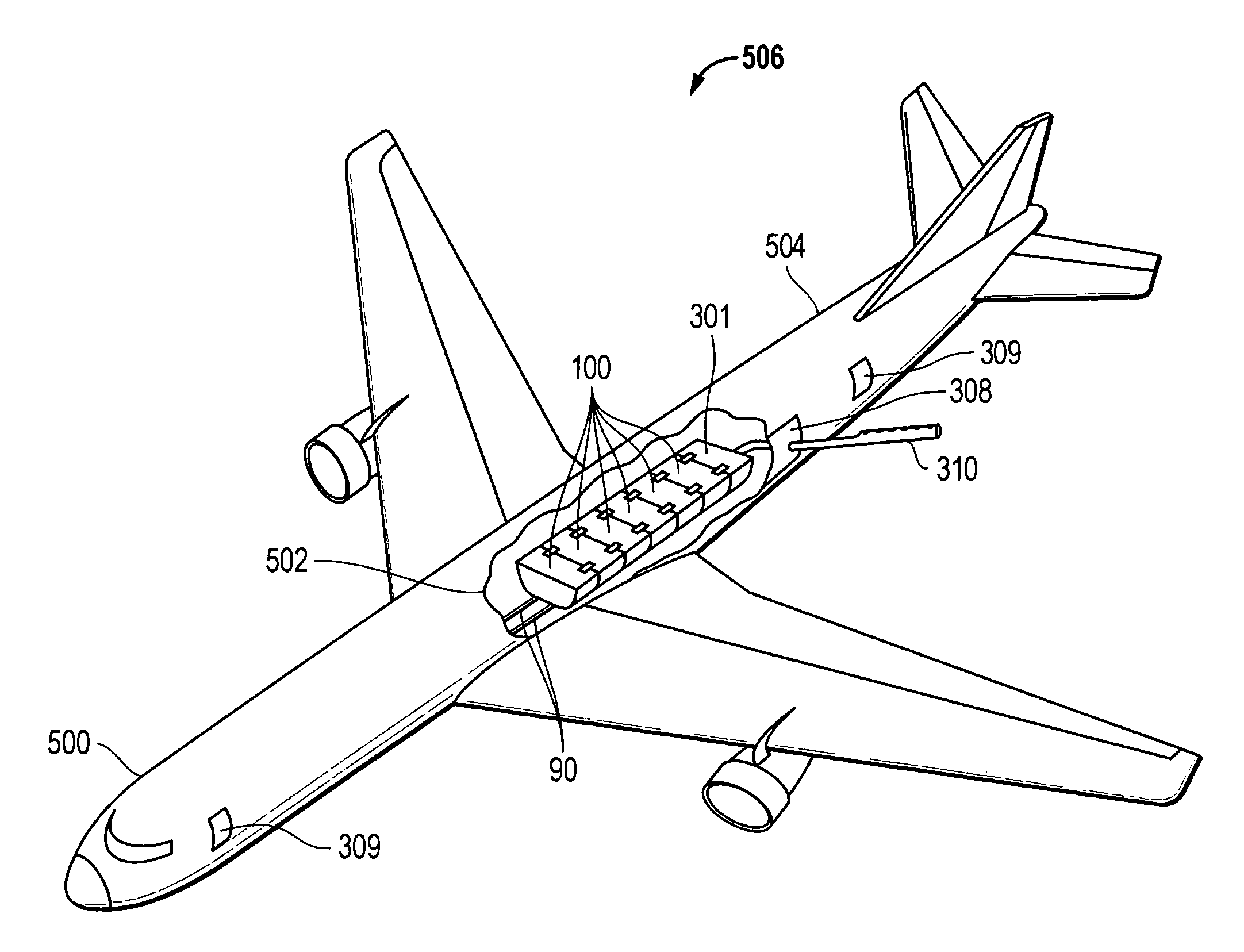

Systems and methods for aerial dispersion of materials

InactiveUS20050072880A1Improve lifting performanceQuick assemblyFire rescueFreight handlingFlight vehicleFirefighting

Aerial dispersion systems that may be employed to allow rapid and temporary conversion of aircraft for aerial dispersion purposes, such as aerial fire-fighting. The aerial dispersion systems may be implemented using modular components that may be configured for compatibility with conventional cargo loading and unloading systems of modern aircraft, including side-loading cargo systems of wide body passenger and cargo aircraft having high lift capacities. The aerial dispersion systems may be rapidly installed in a large fleet of high capacity aircraft in response to a wildfire or other rapidly-developing emergency such as an oil spill, chemical or biological contamination incident, building or refinery fire, etc. After use, the aircraft of the fleet may be rapidly de-modified and returned to original condition. The aerial dispersion systems may be operated with a fleet of aircraft in a coordinated manner, for example, as part of an aerial firefighting formation having multiple aircraft sharing information and / or common control.

Owner:L 3 INTEGRATED SYST +1

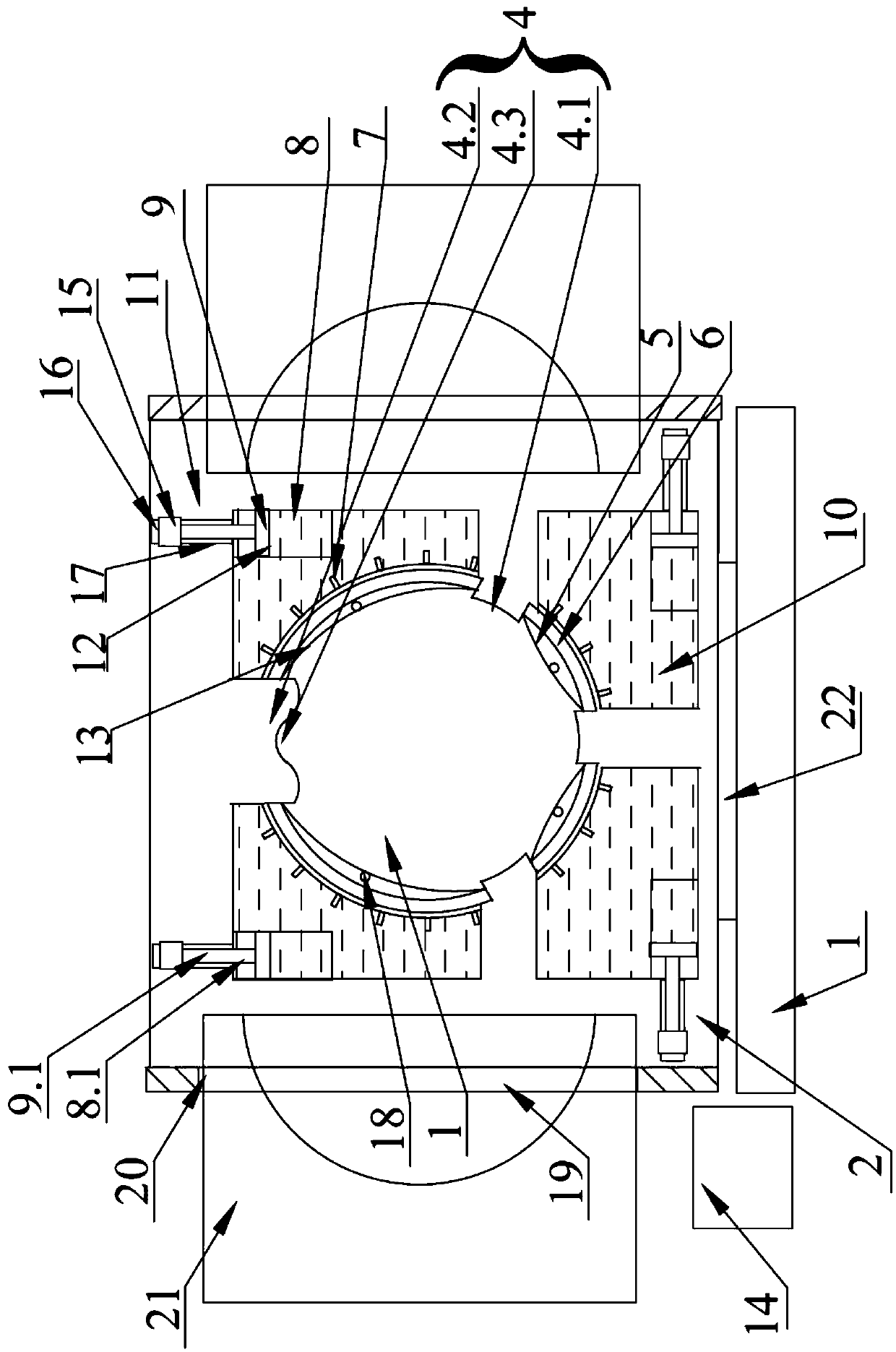

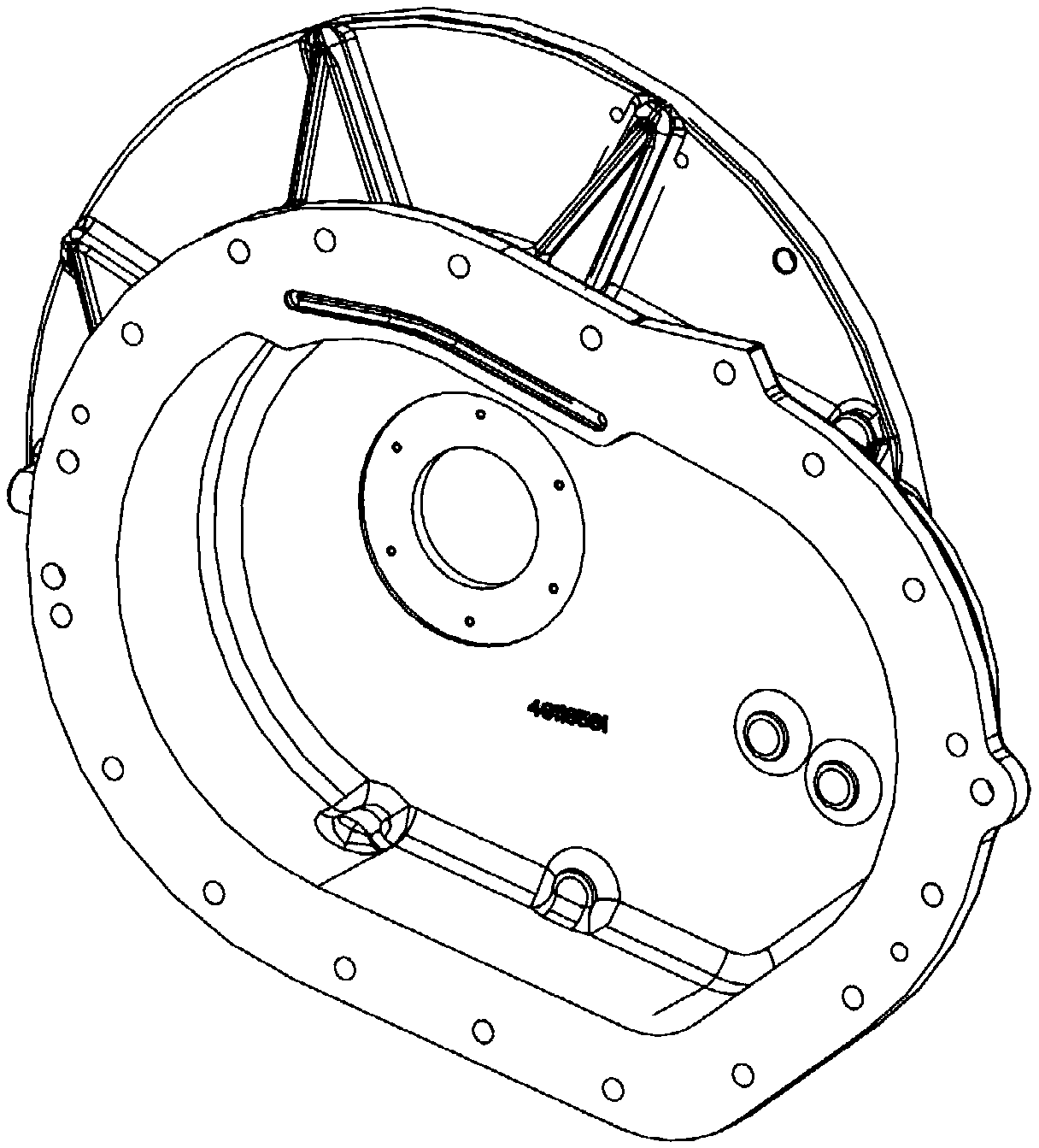

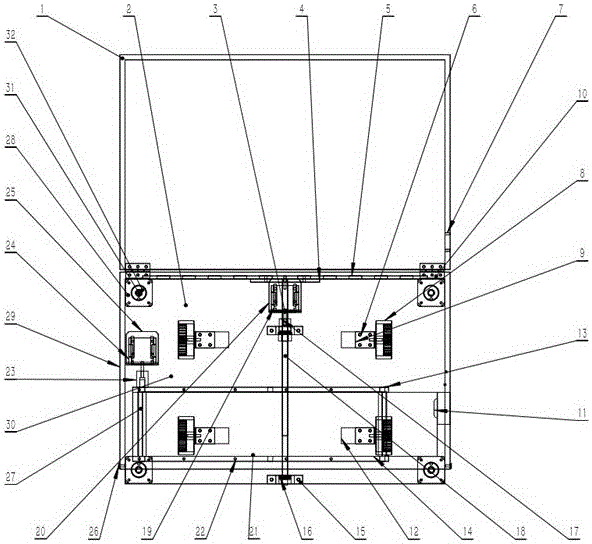

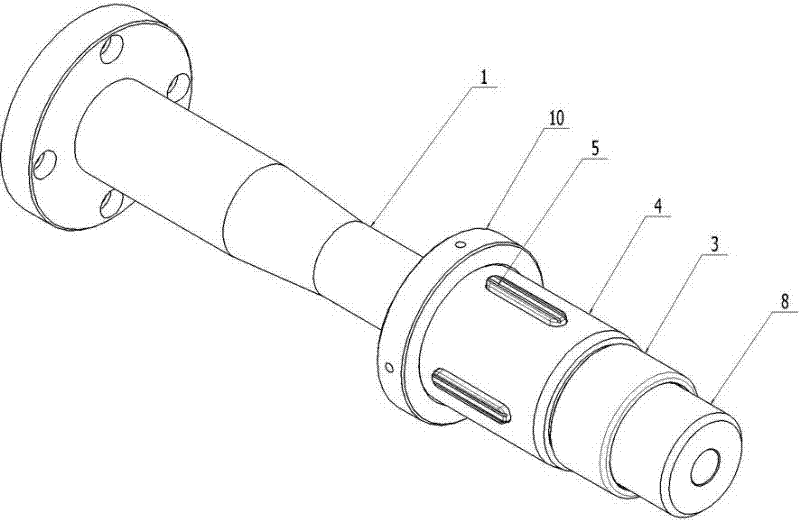

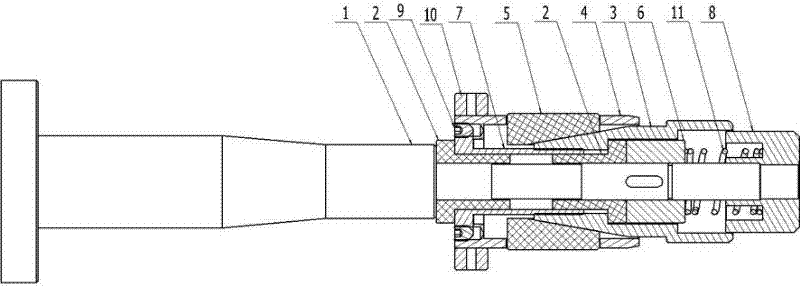

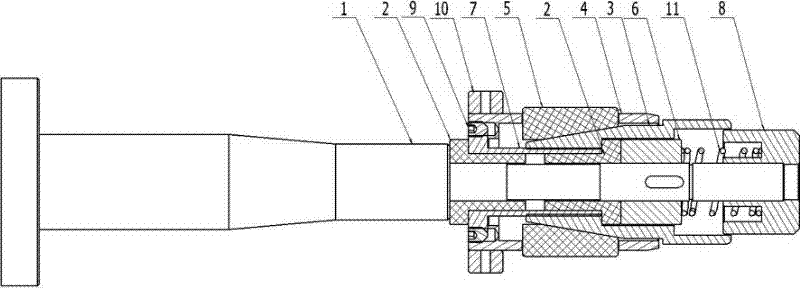

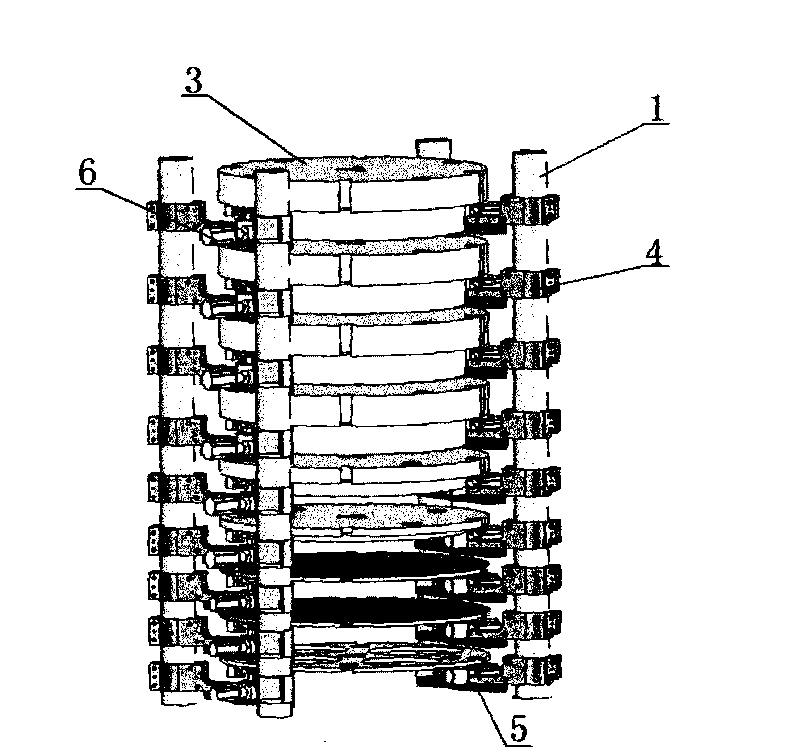

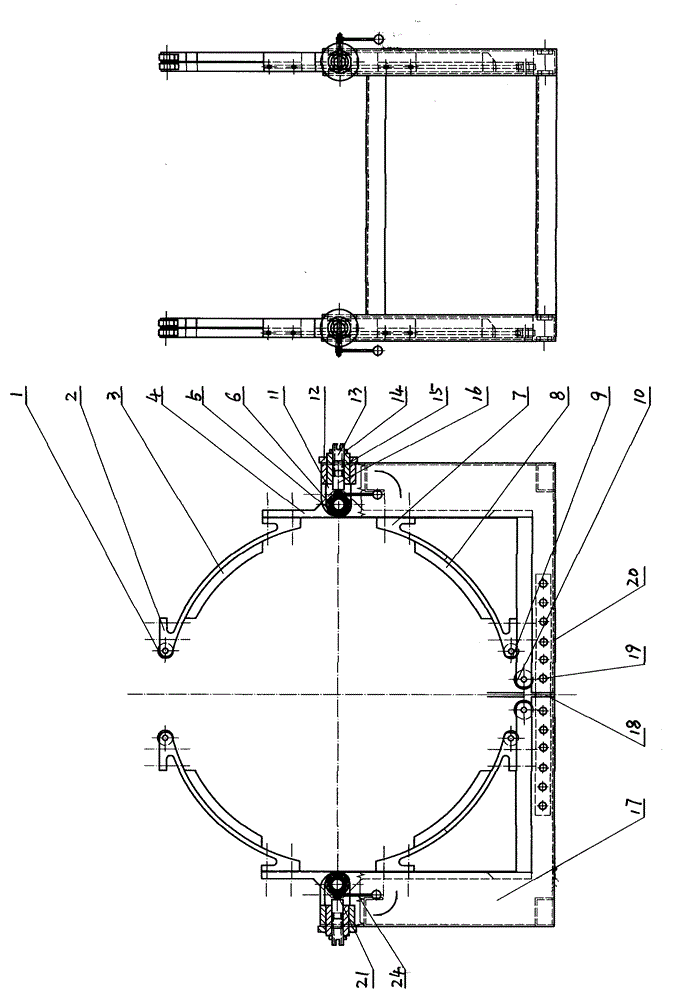

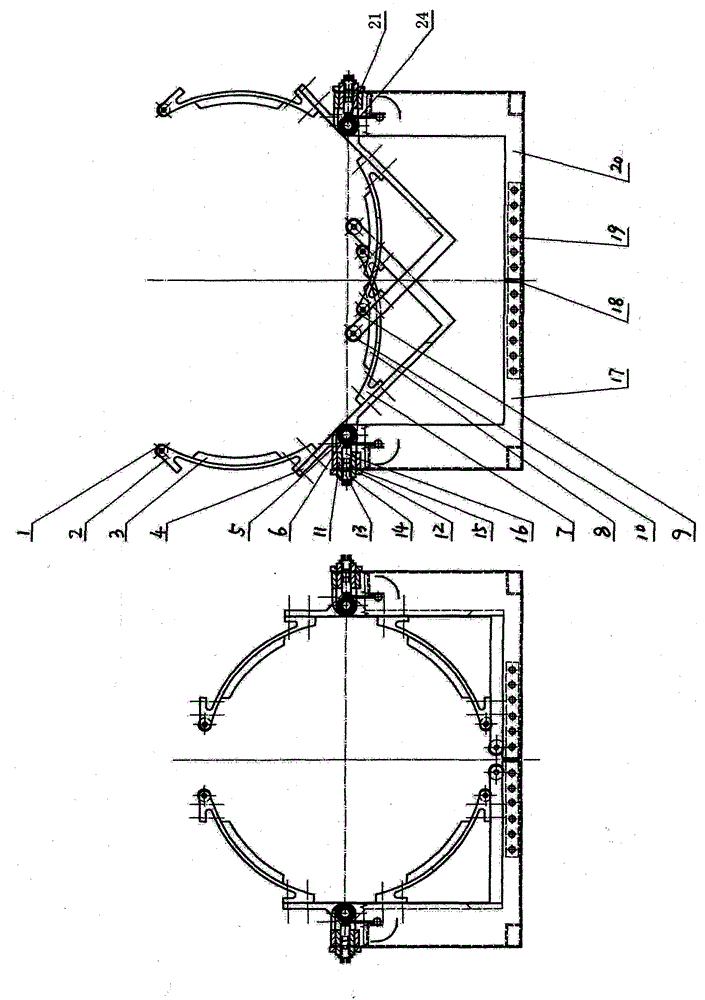

Electrorheological fluid clamping tool for light and low-noise gearbox

ActiveCN109623454AShorten the timeOverall small sizePositioning apparatusMetal-working holdersLow noiseEngineering

The invention discloses an electrorheological fluid clamping tool for a light and low-noise gearbox. The electrorheological fluid clamping tool is used for positioning and clamping the end face of thegearbox in the machining process, the tool comprises a base, the base is provided with a workpiece bearing plate perpendicular to the base, a through hole used for mounting and demounting the workpiece is formed in the middle of the workpiece bearing plate, protruding positioning blocks are arranged on the inner wall of the through hole, flexible fluid bag storing grooves are formed in the positions, between the positioning blocks, of the inner wall of the through hole, flexible fluid bags are arranged in the storing grooves and connected with a cylinder body through guiding pipes, the cylinder body is internally provided with a piston, the space, at one end of the piston, inside the cylinder body, the guiding pipes and the flexible fluid bags constitute an accommodating chamber for electrorheological fluid jointly, the other end of the piston is connected with a piston driving mechanism, positive electrodes and negative electrodes are arranged at one end of the piston and the inner walls of the flexible fluid bags correspondingly, and the positive electrodes and the negative electrodes are connected with a controller. The electrorheological fluid clamping tool is simple in structure, convenient to use and good in workpiece clamping effect, clamping force in all directions of the workpiece is uniform and firm, and the workpiece can be quickly mounted and demounted.

Owner:江阴市惠尔信精密装备股份有限公司

Electronic control of vehicle air suspension

InactiveUS20060267296A1Prolong lifeReduce the amount requiredSpringsResilient suspensionsMotion detectorVehicle frame

A system is provided for use on large vehicles of the type wherein the vehicle frame is supported on vehicle axle assemblies through air bags, and each air bag has a lower end coupled to the lower end of an arm such as a swing arm whose upper end is pivotally mounted on the frame. The height of the air bag is sensed by a pair of tilt sensors, sensing tilt of its location with respect to gravity, and the difference in tilt indicates air bag height. The output of the tilt sensors may be filtered, and a motion detector allows rapid filling or dumping of air bags independent of filtering of tilt sensor signals. Control of the vehicle air suspension can also be based upon inputs from one or more air bag pressure sensors.

Owner:BARKSDALE

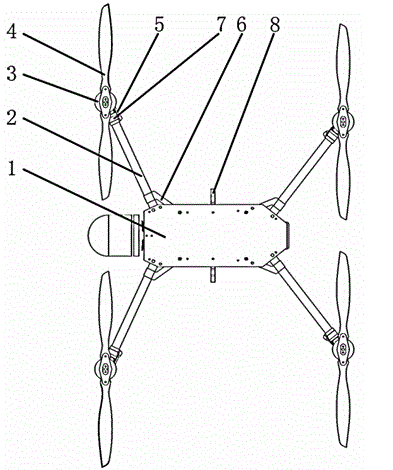

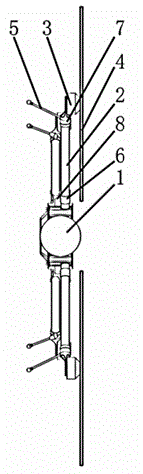

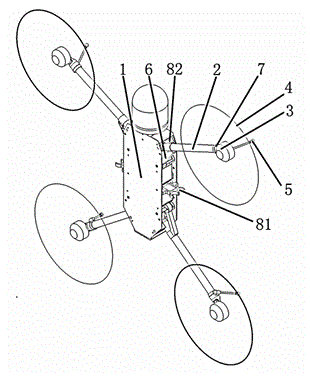

Transversely staggered four-rotor aircraft

The invention discloses a transversely staggered four-rotor aircraft mainly comprising a fuselage, supporting arms, a motor, rotors and a landing gear. Each two supporting arms among four supporting arms are distributed on both sides of the fuselage; the two supporting arms on the same side are installed up and down in a staggered manner; one end of each supporting arm is connected with the fuselage through a hinge mechanism, and a supporting seat is installed on the other end of the supporting arm; a motor is fixedly installed above the supporting seat; the rotors are installed on the rotating shaft of the motor; the landing gear is further installed below the supporting seat. When the aircraft works, the supporting arms and the landing gear are unfolded, and the positions of the supporting arms are kept by locking mechanisms, so that normal flight can be implemented; in a non-working state, the landing gear is folded, the supporting arms are folded transversely in a staggered manner, and the positions of the supporting arms are kept by the locking mechanisms, so that the volume is reduced for convenient carrying and transporting.

Owner:葛讯

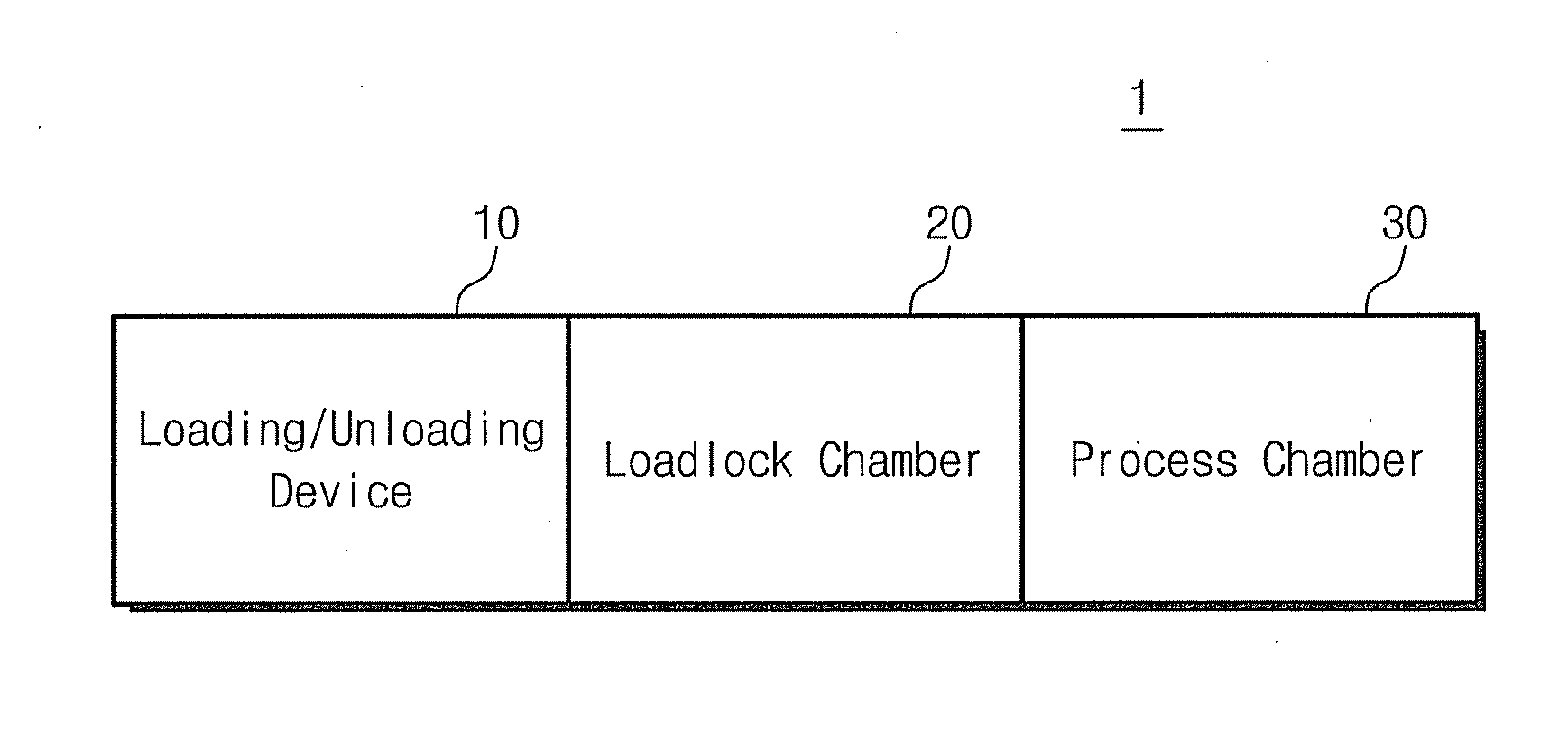

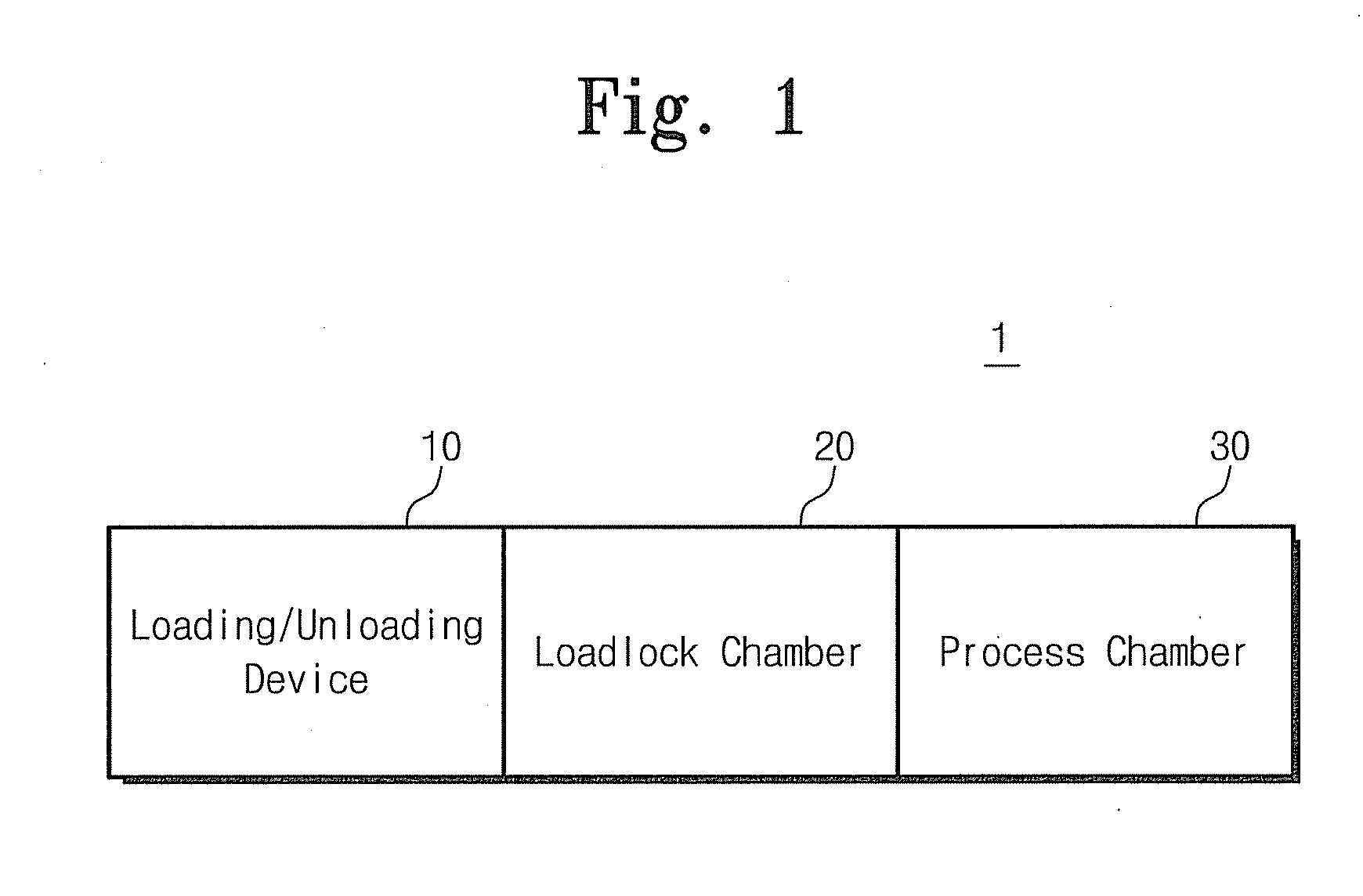

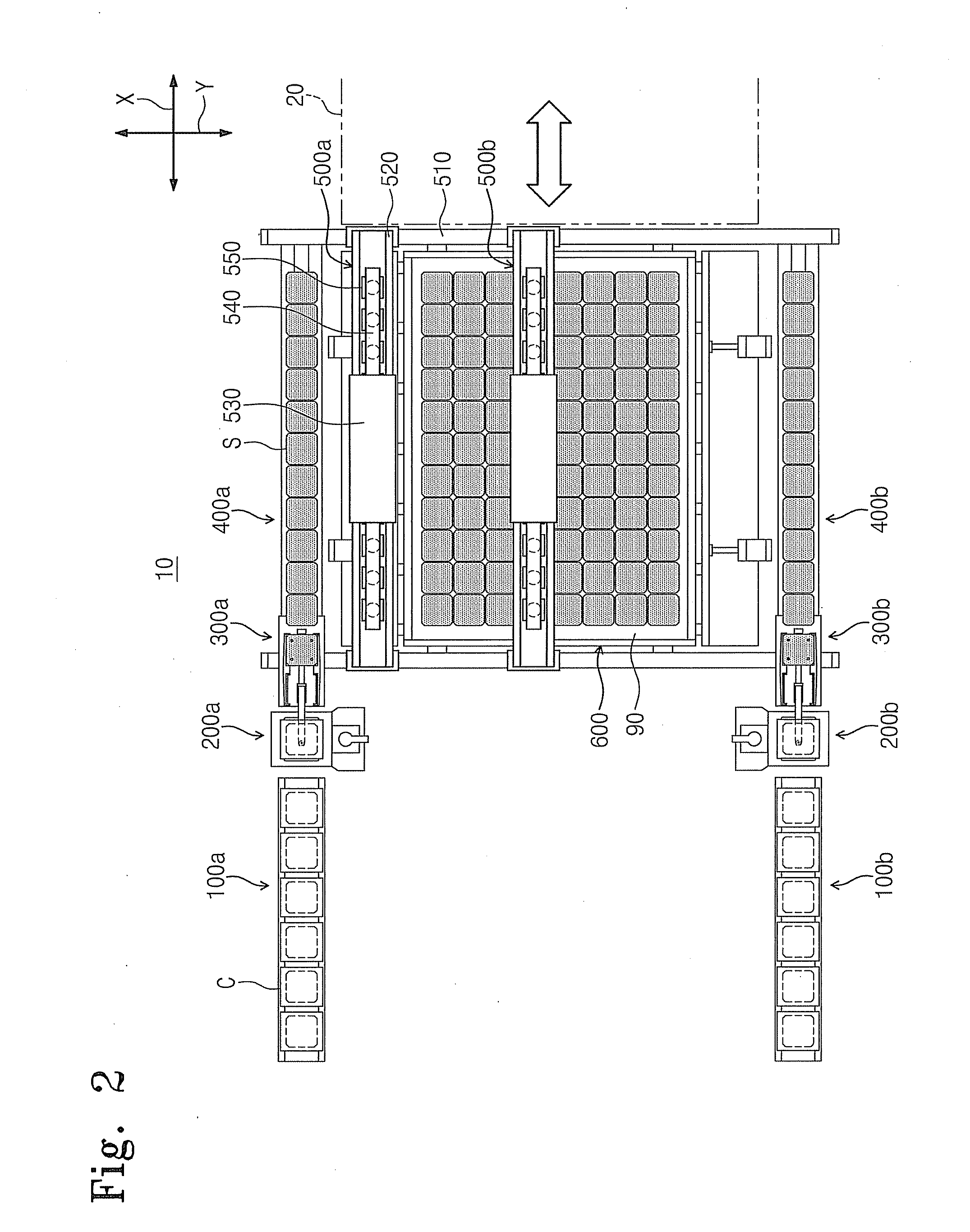

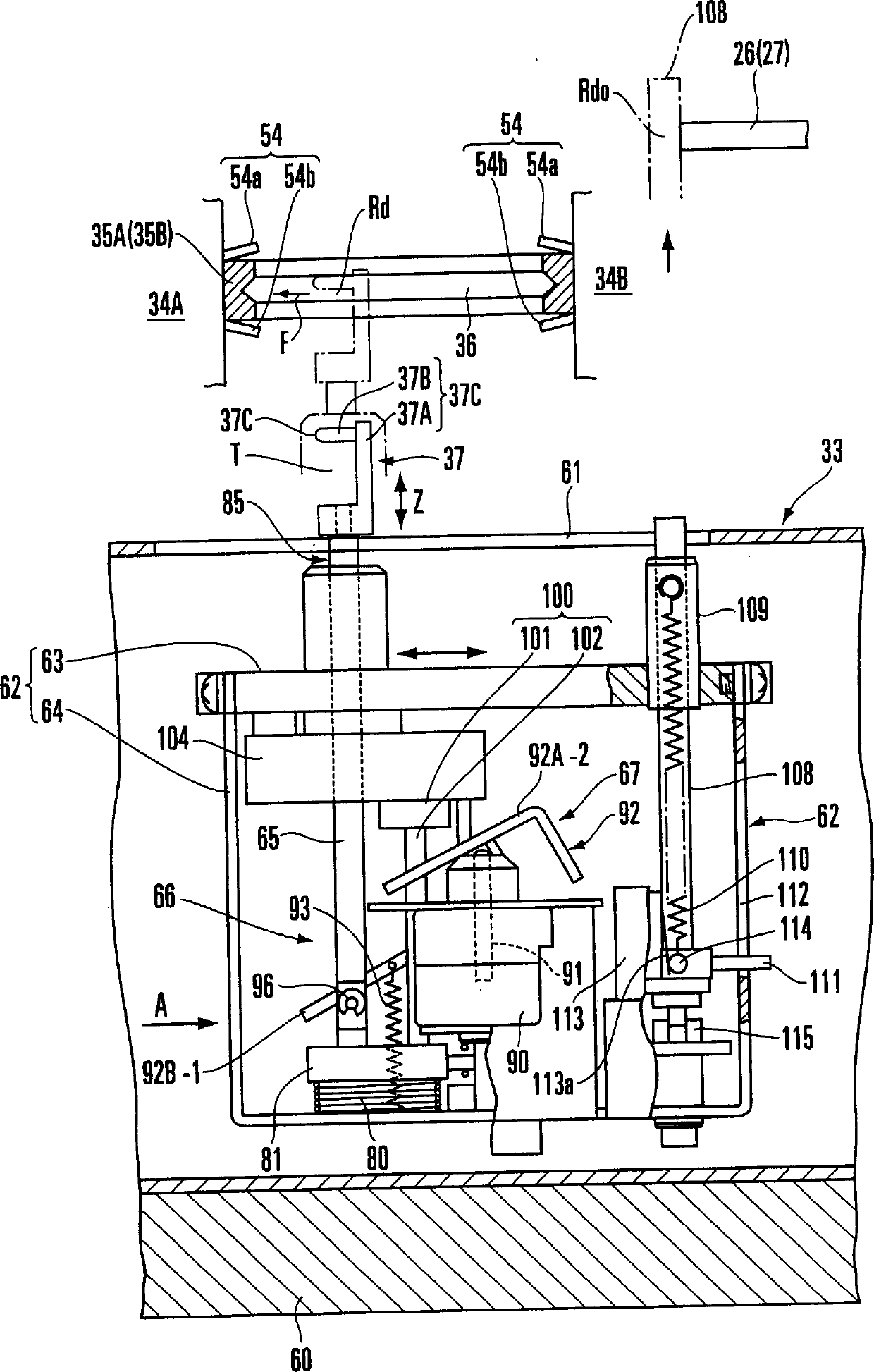

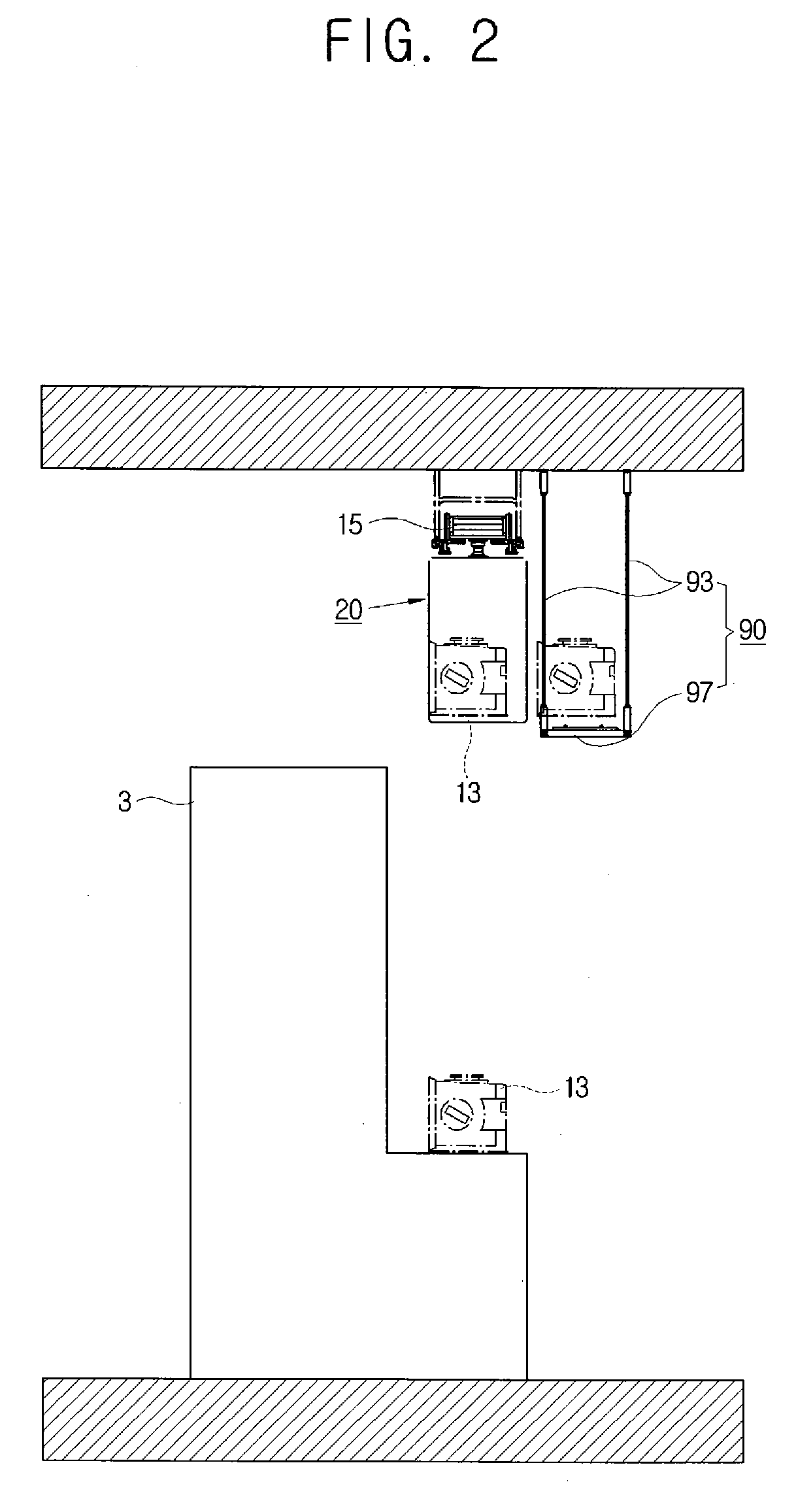

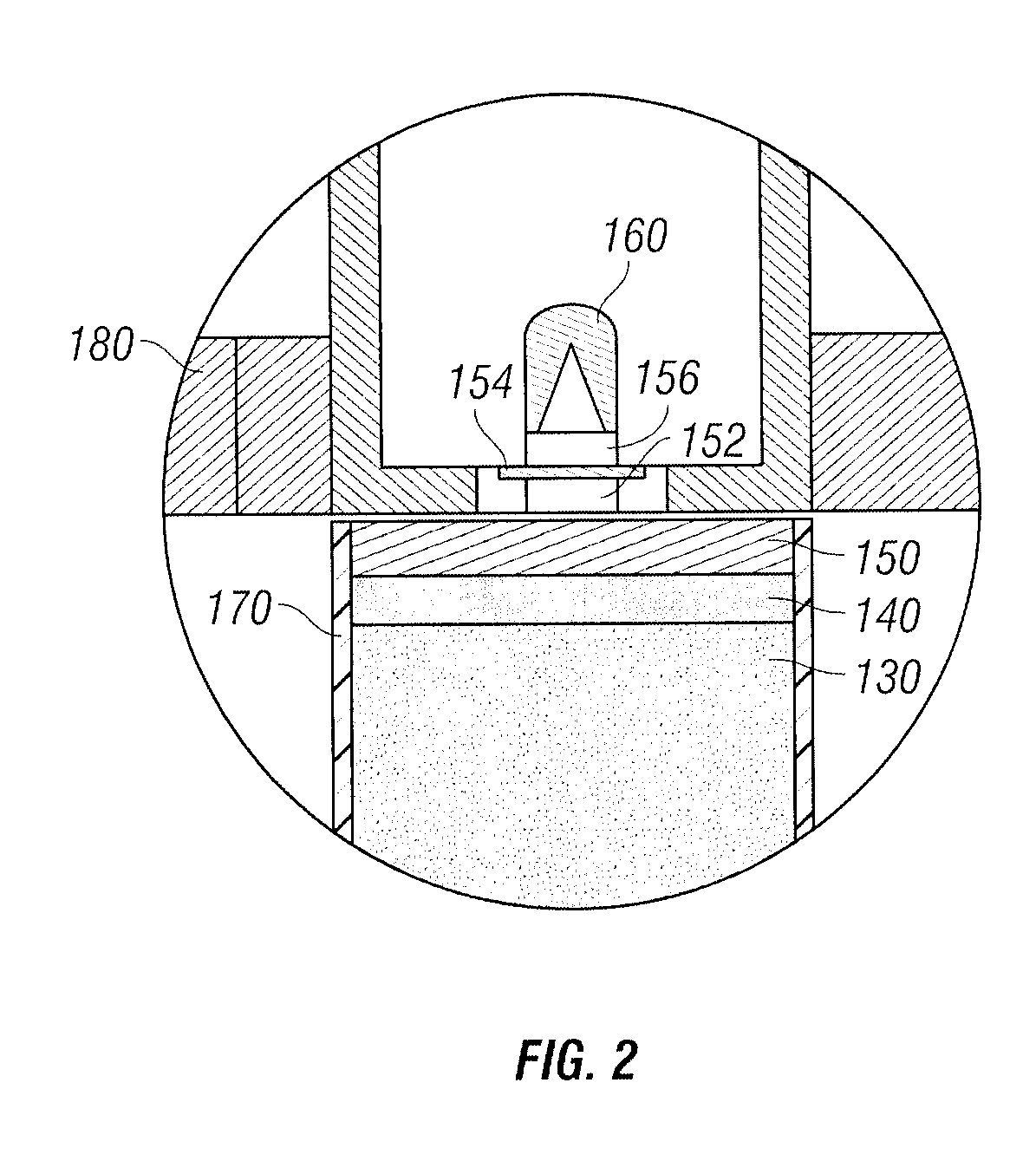

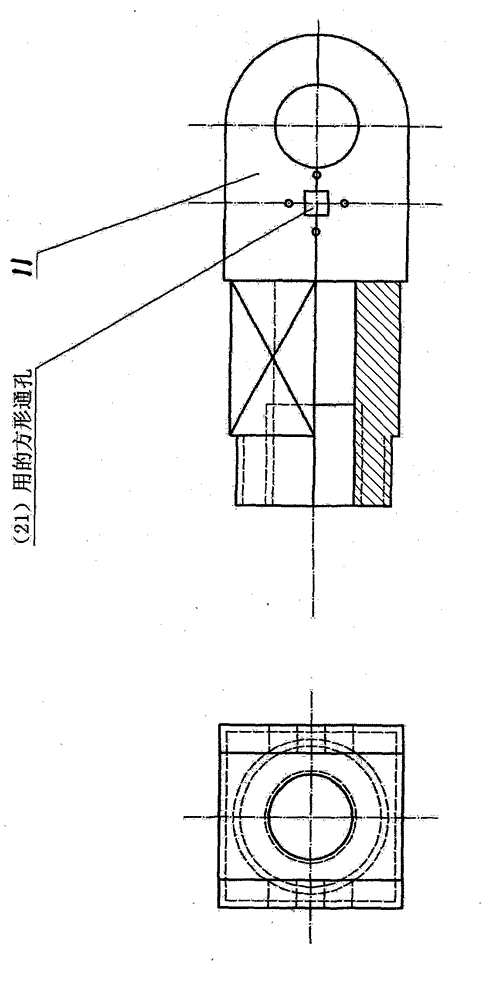

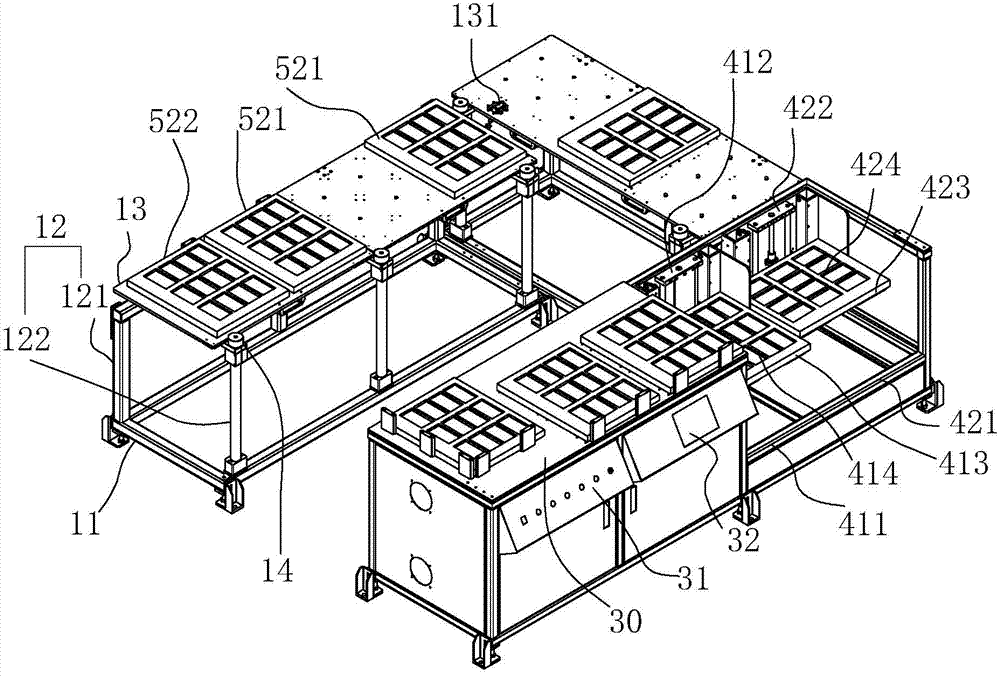

Substrate Processing Apparatus And Method For Loading And Unloading Substrates

ActiveUS20110313565A1Quick unloadingQuick loading and unloadingFinal product manufactureDigital data processing detailsEngineeringSolar cell

Provided is a substrate processing apparatus for loading substrates such as solar cell substrates on a tray in substrate processing equipment for processing a large number of substrates. The substrate processing apparatus includes: a tray carrying unit configured to receive and carry a tray; a substrate loading conveyor unit on which substrates to be loaded on a tray are arranged in a line; a substrate unloading conveyor unit on which substrates unloaded from a tray are arranged in a line; a first substrate carrying robot configured to pick up substrates from the substrate loading conveyor unit and carry the substrates to a tray placed on the tray carrying unit; and a second substrate carrying robot configured to pick up substrates from a tray placed on the tray carrying unit and carry the substrates to the substrate unloading conveyor unit.

Owner:SEMES CO LTD

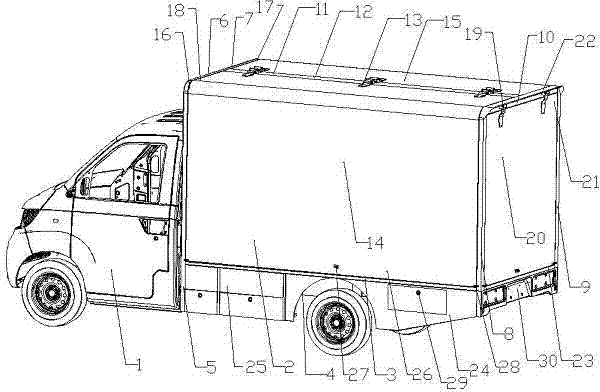

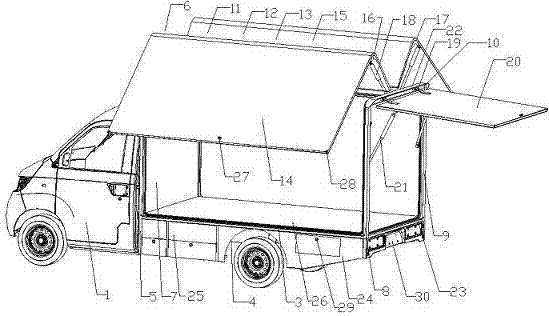

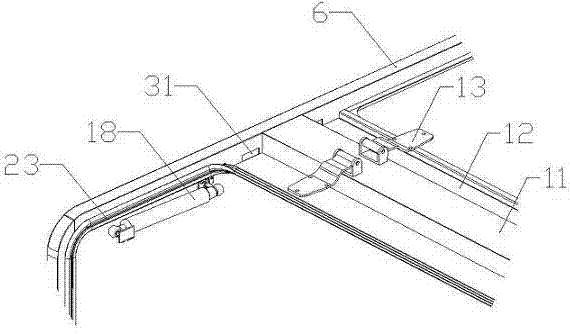

Multifunctional wingspan truck and truck carriage

InactiveCN102351014AQuick loading and unloadingGood effectWorkshop/display transportationLoading-carrying vehicle superstructuresGas springWingspan

The invention relates to a truck carriage which is characterized in that: the truck carriage is a wingspan carriage (2), wherein one or more of a left door (14), a right door (15) and a back door (20) of the wingspan carriage (2) is / are opened in a wingspan manner under the action of a gas spring. In the invention, as the wingspan carriage is adopted, the left, right and back doors of the carriage can be opened completely, and goods in the carriage almost can be completely shown to people; and moreover, the left and right doors can protect people from sunlight and rain after being opened, so that the goods can be loaded / unloaded conveniently and quickly and people can move conveniently. Moreover, storage boxes of various specifications are additionally arranged on the side skirt below a carriage floor, thus the storage space is expanded without changing the carriage capacity. The effect is better due to the adoption of an inner sealing mode; and the truck carriage can prevent rain and dust more effectively and is suitable for the transportation of more goods with high performance requirements.

Owner:CHERY AUTOMOBILE CO LTD

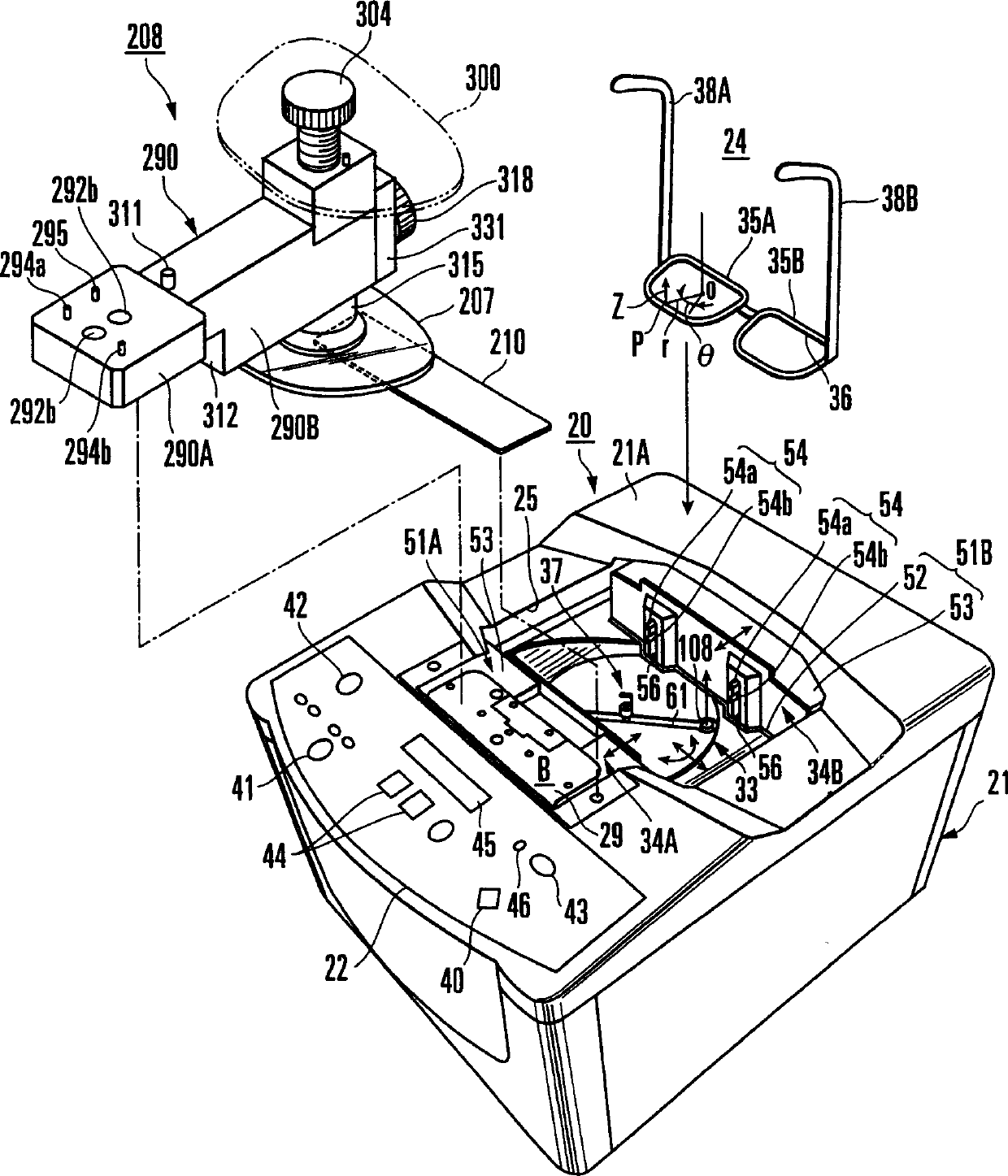

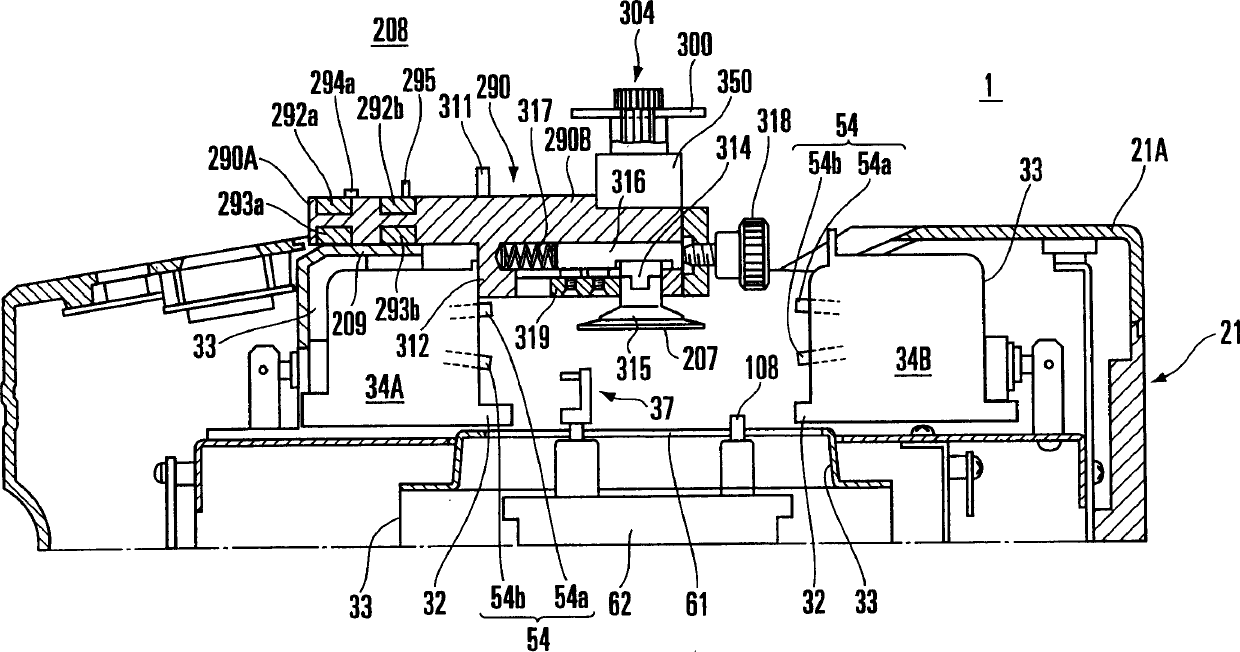

Picture frame type detector

InactiveCN1460834AWon't fall offReliable withdrawal toEdge grinding machinesMechanical counters/curvatures measurementsThree dimensional measurementBalance spring

A spectacle frame shape measuring apparatus includes a measurement element holding mechanism. The measurement element holding mechanism holds a measurement element in a substantially loadless state along a frame groove formed in the inner circumferential surface of a rim of a spectacle frame. The measurement element holding mechanism includes a rod, balance spring, and evacuating mechanism. The rod is vertically movable and has an upper end portion on which the measurement element is mounted. The balance spring pushes the rod upward to hold the measurement element at a loading position during shape measurement. The evacuating mechanism regularly evacuates the measurement element to an evacuation position, thereby performing three-dimensional measurement of a rim shape. A spectacle frame shape measuring apparatus holder is also disclosed.

Owner:HOYA CORP

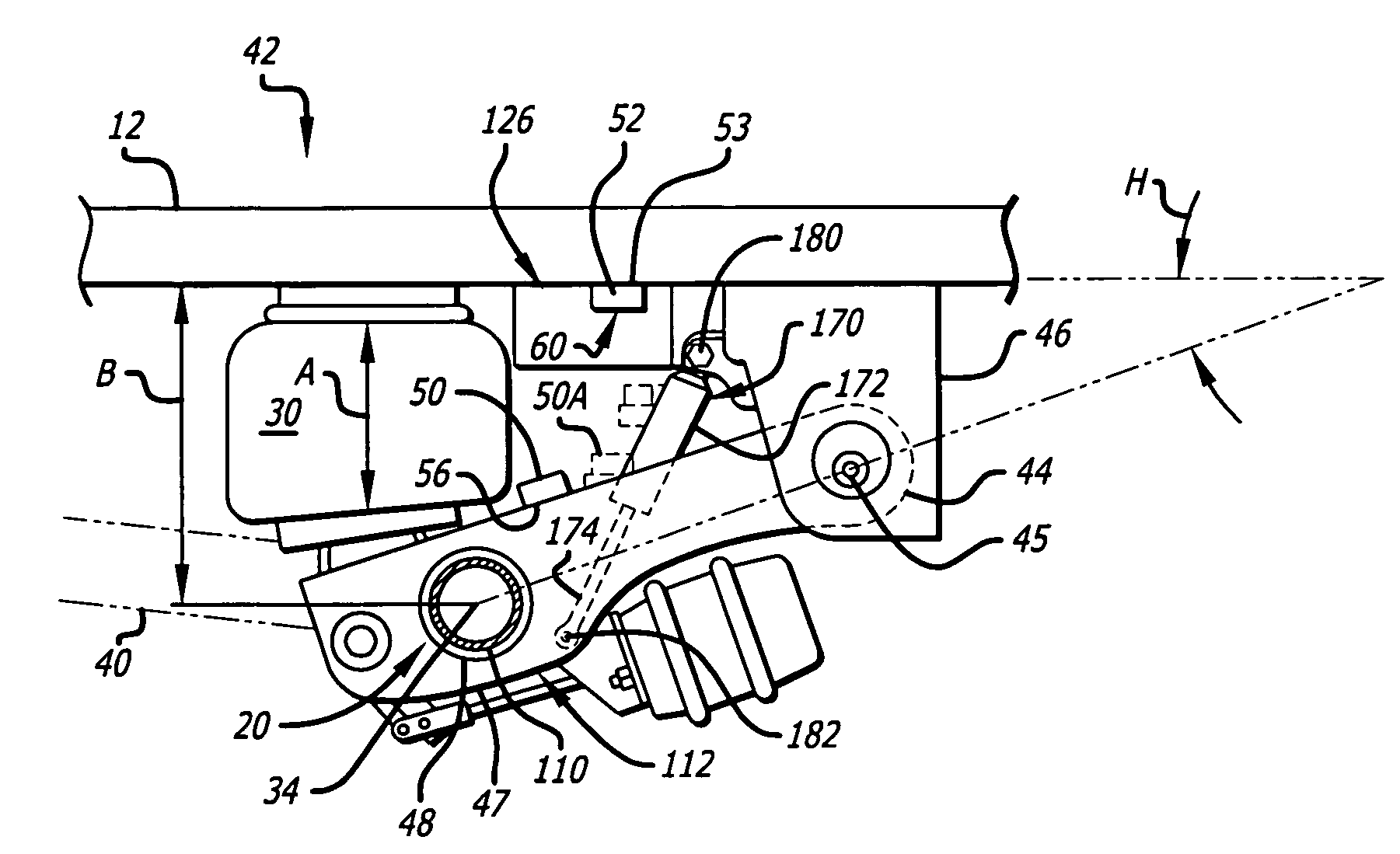

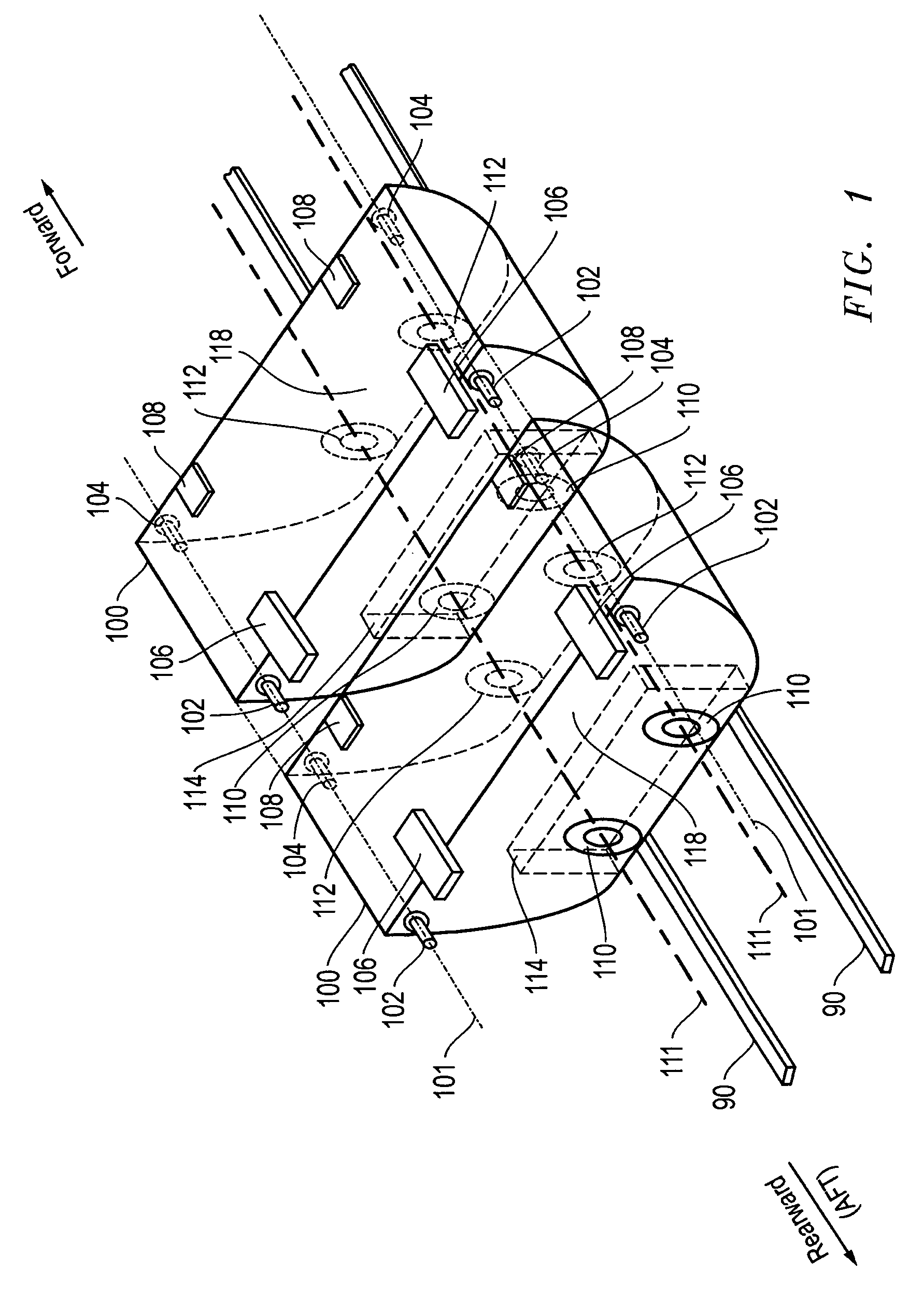

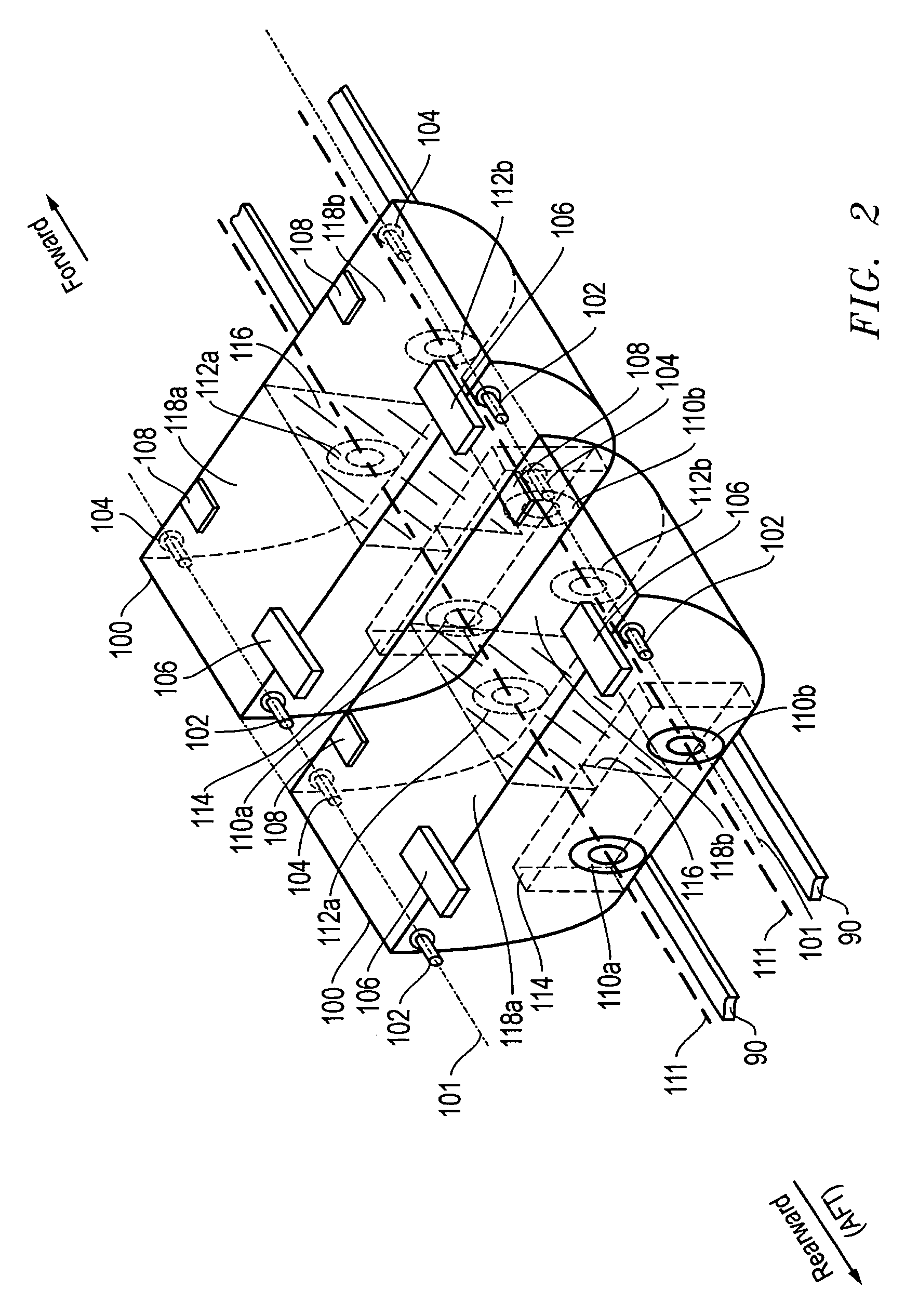

Systems and methods for aerial dispersion of materials

InactiveUS7284727B2Rapid and temporary conversionImprove lifting performanceFire rescueFreight handlingFlight vehicleFirefighting

Aerial dispersion systems that may be employed to allow rapid and temporary conversion of aircraft for aerial dispersion purposes, such as aerial fire-fighting. The aerial dispersion systems may be implemented using modular components that may be configured for compatibility with conventional cargo loading and unloading systems of modern aircraft, including side-loading cargo systems of wide body passenger and cargo aircraft having high lift capacities. The aerial dispersion systems may be rapidly installed in a large fleet of high capacity aircraft in response to a wildfire or other rapidly-developing emergency such as an oil spill, chemical or biological contamination incident, building or refinery fire, etc. After use, the aircraft of the fleet may be rapidly de-modified and returned to original condition. The aerial dispersion systems may be operated with a fleet of aircraft in a coordinated manner, for example, as part of an aerial firefighting formation having multiple aircraft sharing information and / or common control.

Owner:L 3 INTEGRATED SYST +1

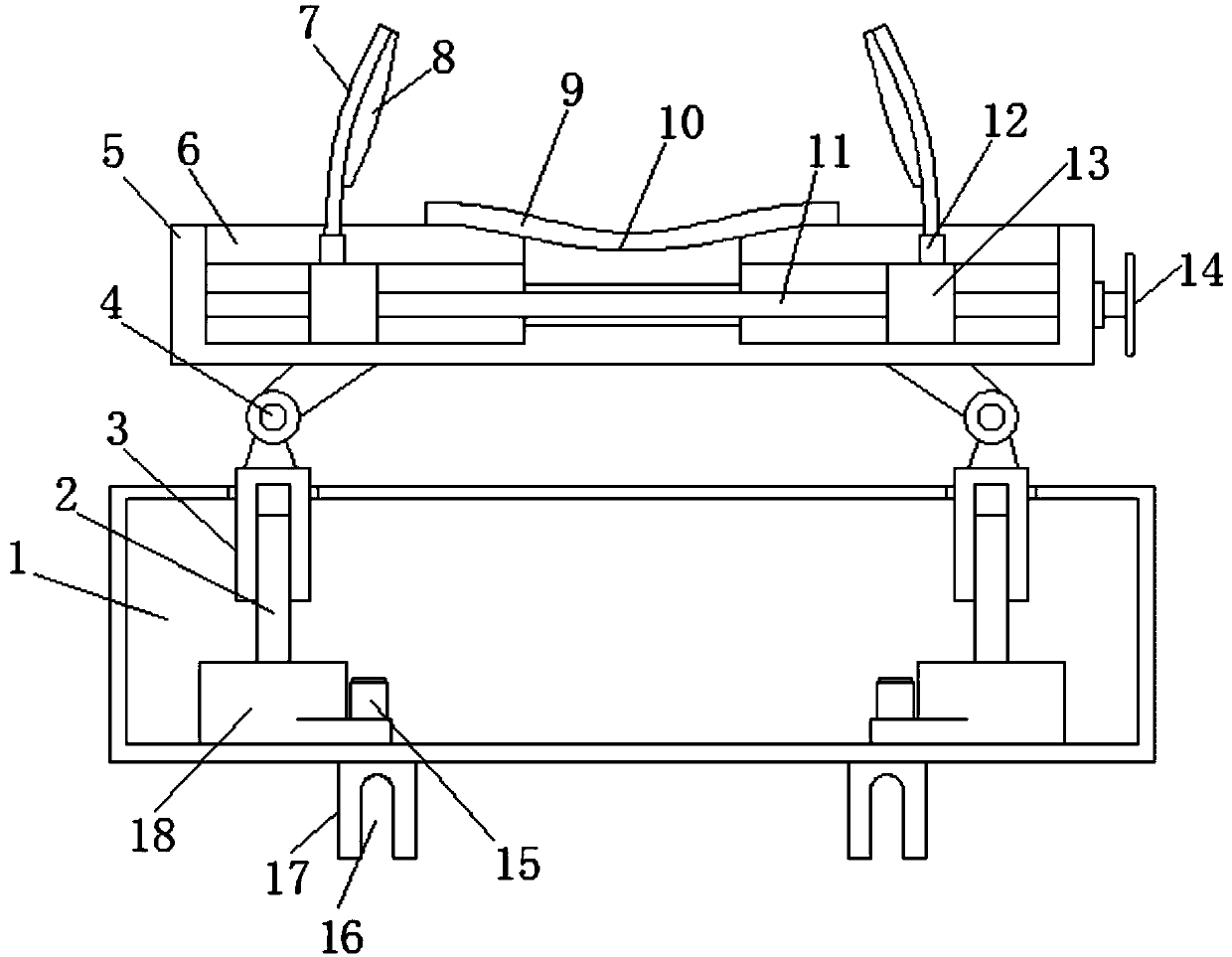

Neurosurgery clinical nursing head fixing device

InactiveCN109646123AStable structureGuaranteed uptimeOperating tablesNursing bedsFixed-functionRotation function

The invention discloses a neurosurgery clinical nursing head fixing device. The device comprises a chassis, a gearbox is arranged in the chassis, an adjusting threaded rod is arranged on the upper endof the gearbox, a threaded sleeve is arranged on the upper end of the adjusting threaded rod, the upper end of the threaded sleeve is connected with a hinged frame, the hinged frame is connected to the lower end surface of a pillow seat, limit sliding grooves are formed in the left and right sides of the inside of the pillow seat, the limit sliding grooves are provided with a rotating threaded rod and a threaded sliding block, the upper end of the threaded sliding block is provided with a connecting block, the upper end of the connecting block is provided with a fixing plate, the fixing plateis a curved plate, and the inner side surface of the fixing plate is provided with a sponge pad. The device is stable in structure, stable in operation, convenient to adjust, convenient to use and quick in loading and unloading, is capable of achieving a head fixing function for clinical nursing of neurosurgery, can be applied to the head fixing of different patients, has wide applicability, canachieve the lifting adjustment function, can achieve the rotation function, provides convenience for the operation of a surgery and the nursing function, and satisfies the current use requirements.

Owner:孙永霞

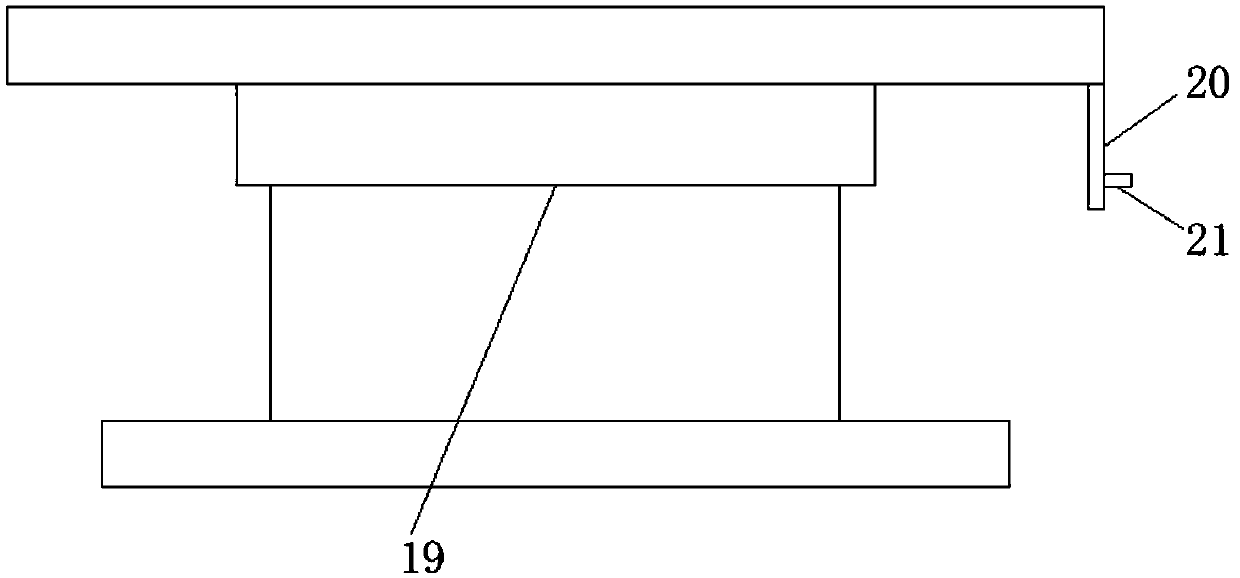

Express carrying truck bed convenient for loading and unloading as well as automatic code scanning

InactiveCN105774624ALarge working spaceQuick loading and unloadingVehicle with endless chains/beltsTransportation itemsTruckAutomatic control

The invention discloses an express carrying truck bed convenient for loading and unloading as well as automatic code scanning. The express carrying truck bed consists of a truck bed body, a vehicle-mounted transportation mechanism, a telescopic type conveying mechanism, a control mechanism, a code scanner, a side door, side door connection members and side door supporting members, wherein upper and lower two bearing plates are arranged in the truck bed body, and the space in the truck bed can be reasonably adjusted according to carried cargoes; the side door of the truck bed can be opened and is provided with the supporting members; the telescopic type conveying mechanism is arranged on the outer edge of the side door and protrudes out of the side door of the truck bed; a pushing plate in the truck bed body can push a cargo onto the telescopic type conveying mechanism under the driving of an automatic control stepping motor transmission mechanism; the code scanner is arranged on the telescopic type conveying mechanism and is used for automatically scanning the cargo conveyed to identify and store cargo information. The express carrying truck bed realizes automatic control over express cargo loading and unloading processes, so that the cargo conveying, sorting and code scanning efficiency is greatly improved, the labor intensity of cargo loading and unloading during express transportation is effectively relieved, and the safety is improved.

Owner:XIANGTAN UNIV

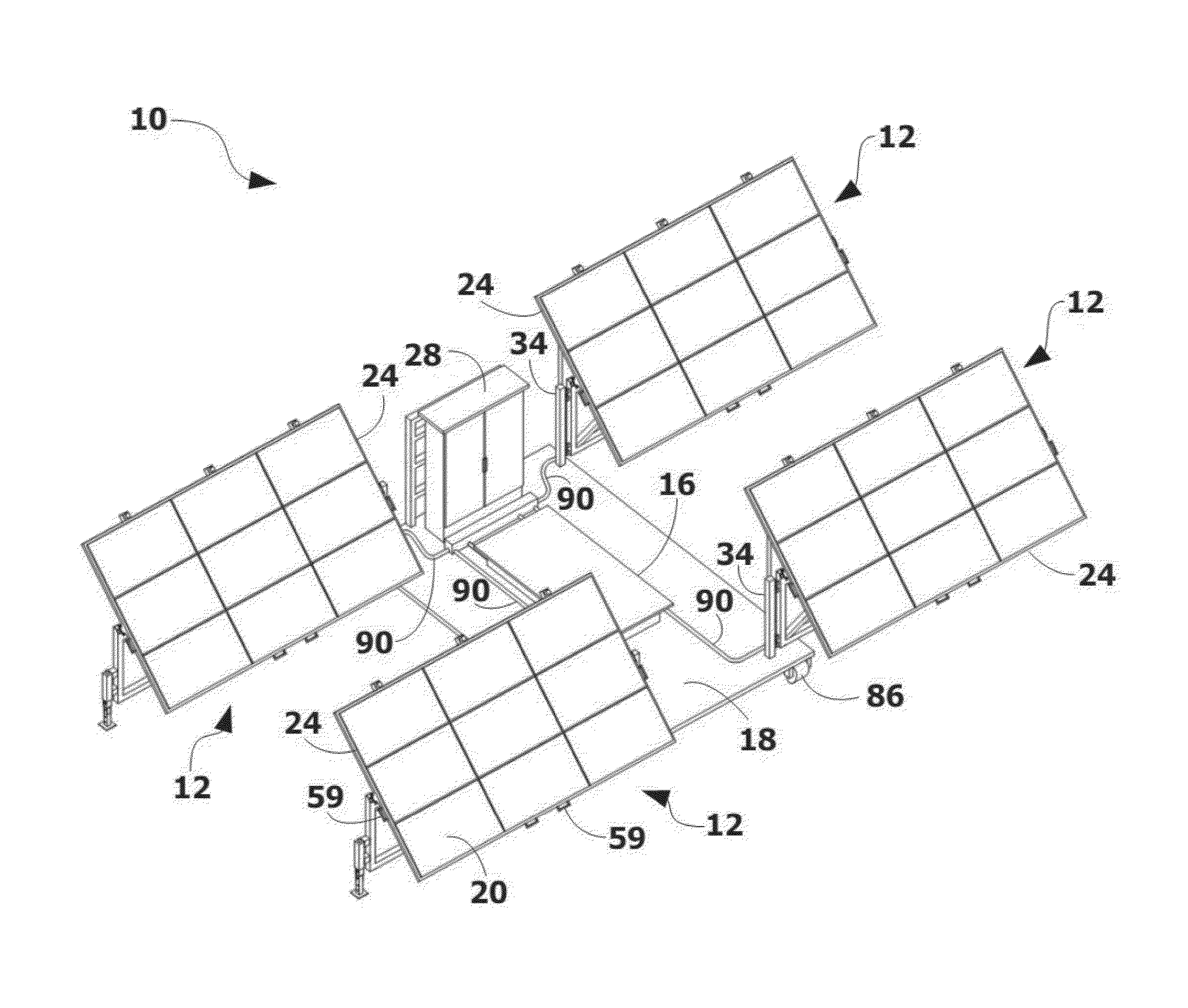

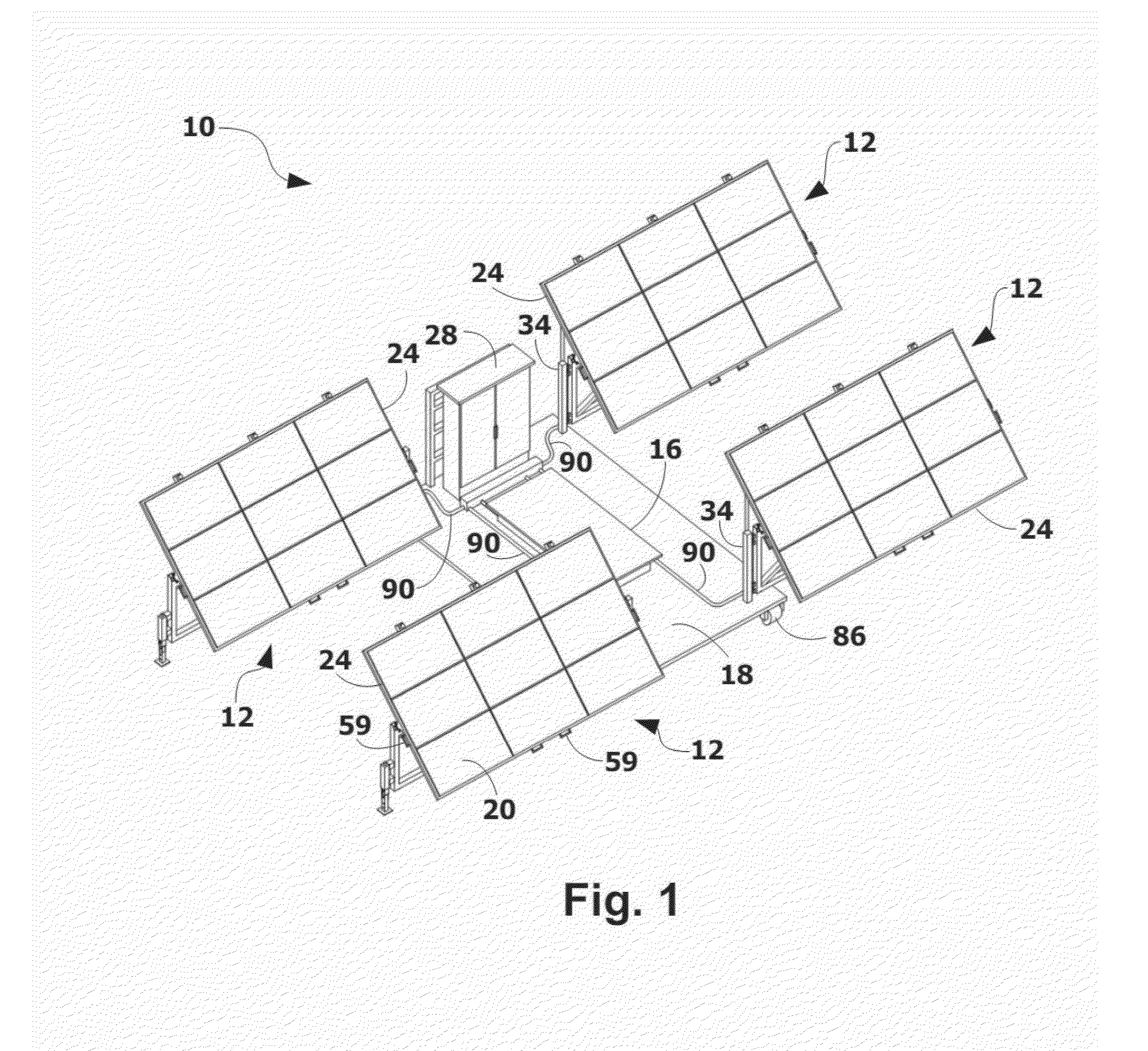

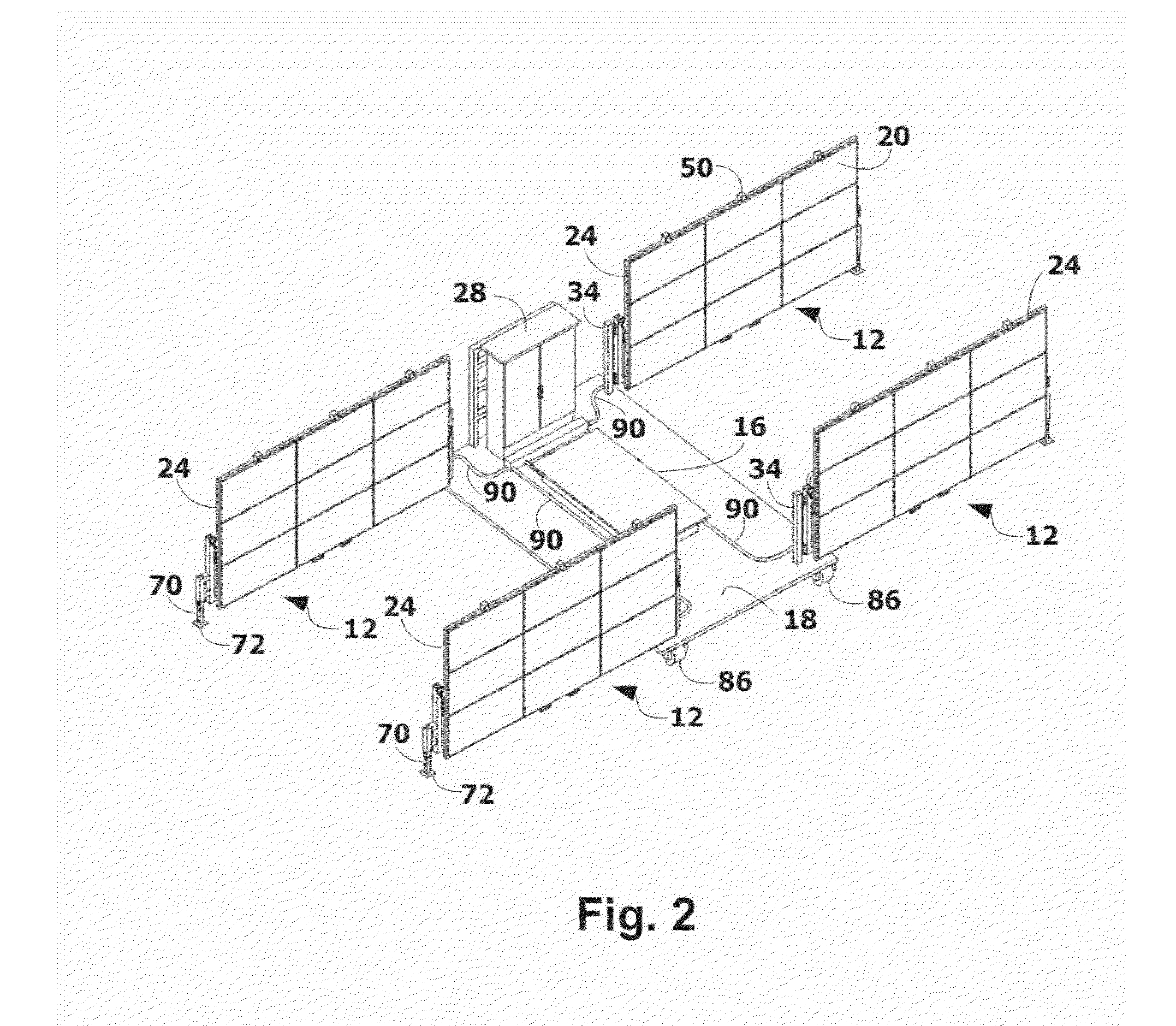

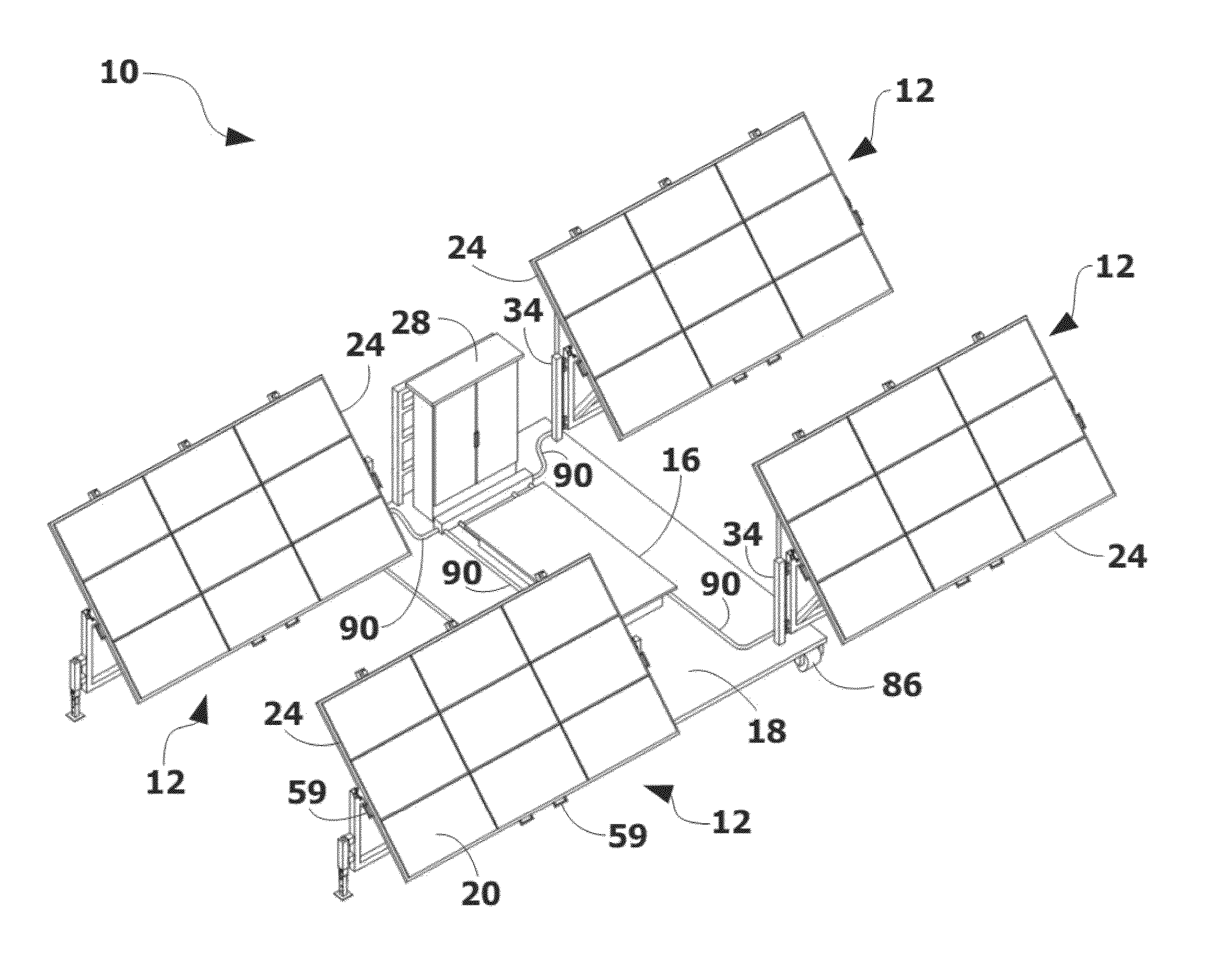

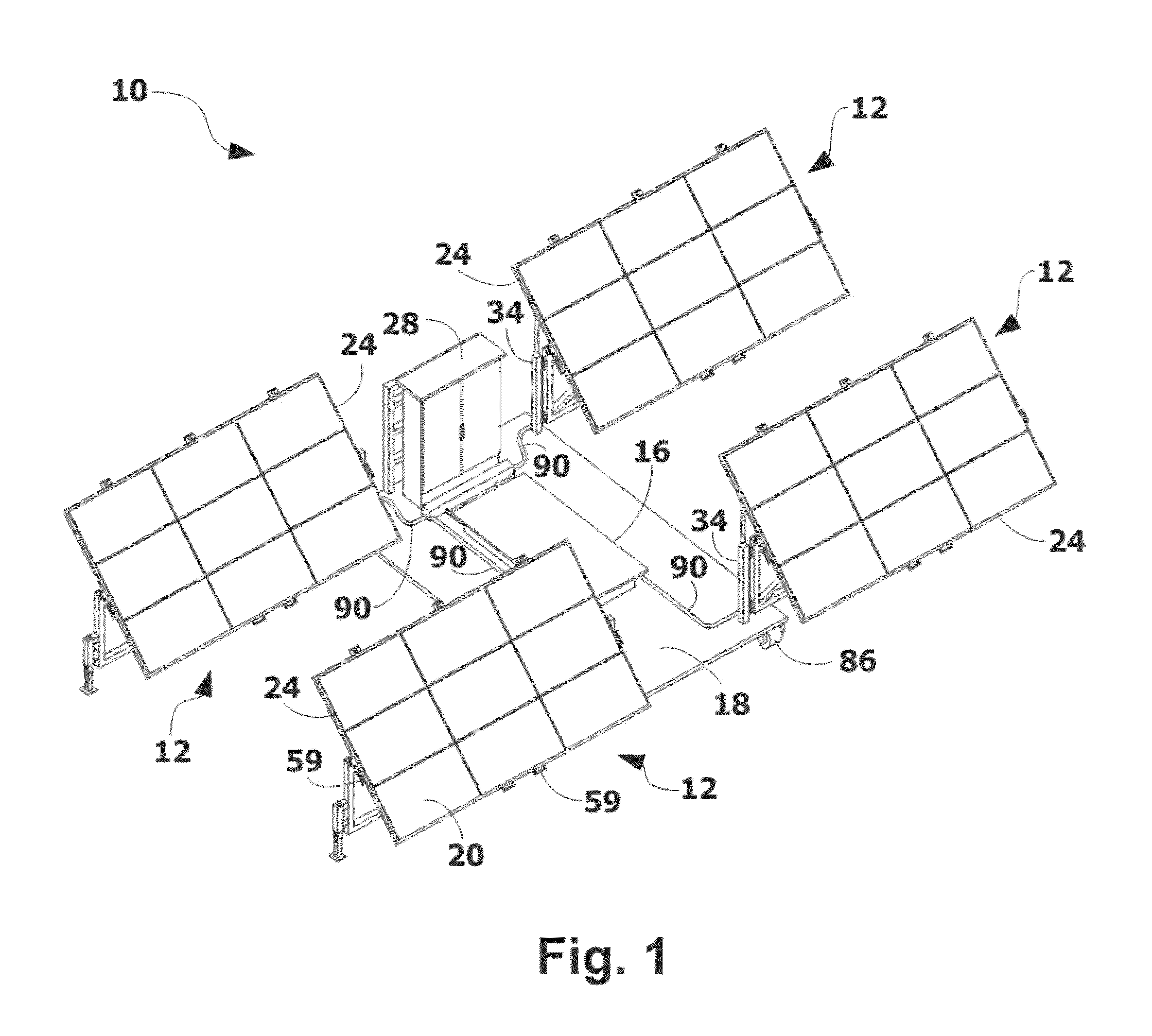

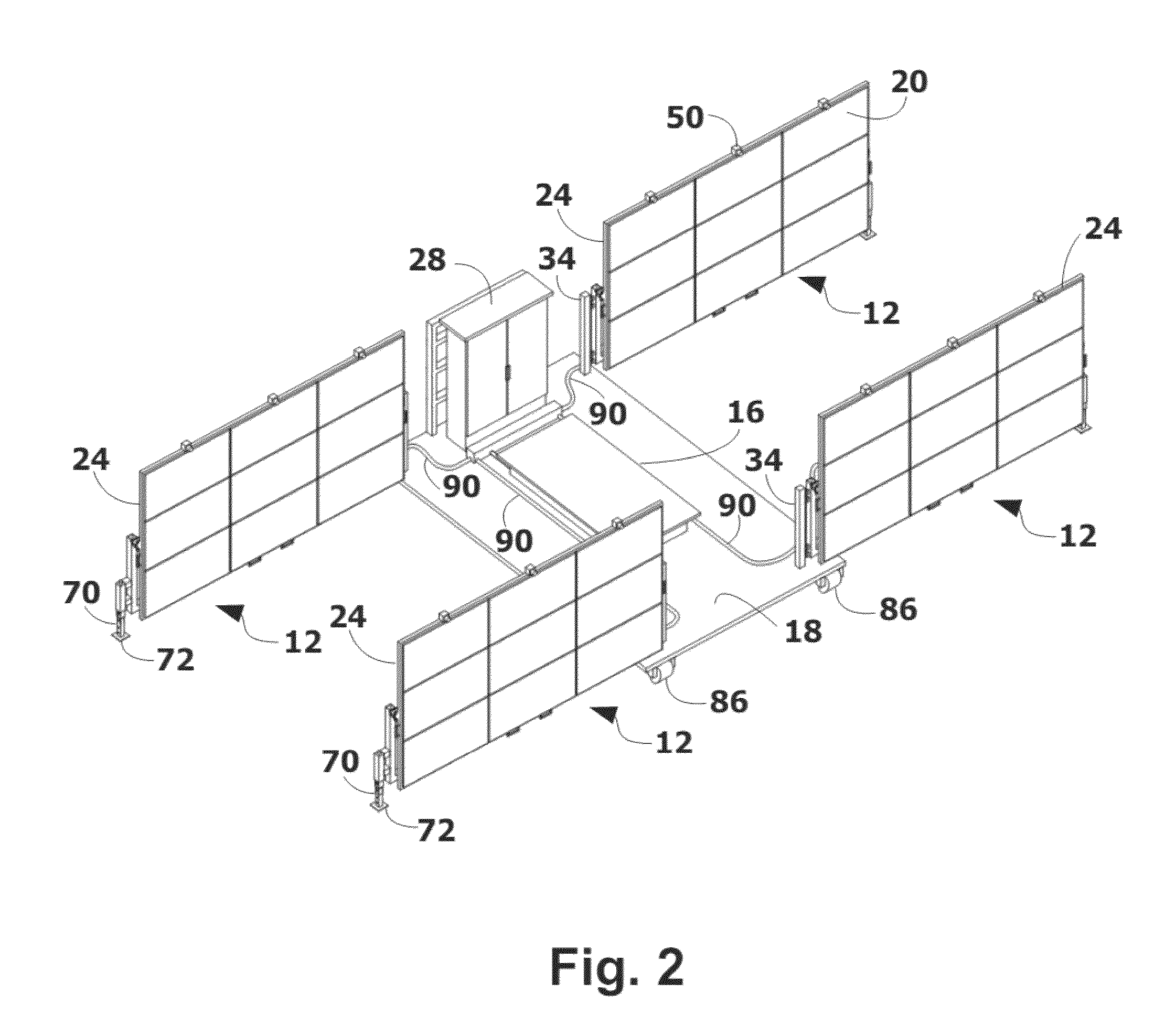

Portable power system

ActiveUS20140020731A1Quick unloadingQuick loading and unloadingPhotovoltaic supportsSolar heating energyElectric power systemPortable power

A portable self-sustained power system including, a transportable platform, a plurality of solar array racking structures. The system includes a plurality of solar panels securely mounted upon said solar array racking structures thereby supporting the solar panels to form a plurality of planar solar arrays. The system further includes a plurality of hinge posts, each respectively connected near the corners of said transportable platform. The system further includes a plurality of solar array support frames, each of the solar array support frame vertically hinged to respective hinge posts, wherein the respective solar array support frame is capable of rotating at various angles around the vertical axis of the respective hinge post. The system further includes a plurality of horizontal hinges; each horizontal hinge rotatably interconnected between the solar arrays and the plurality support frames respectively, each respective hinge capable of rotatably positioning the respective solar array at various angles.

Owner:LEVI OFIR +3

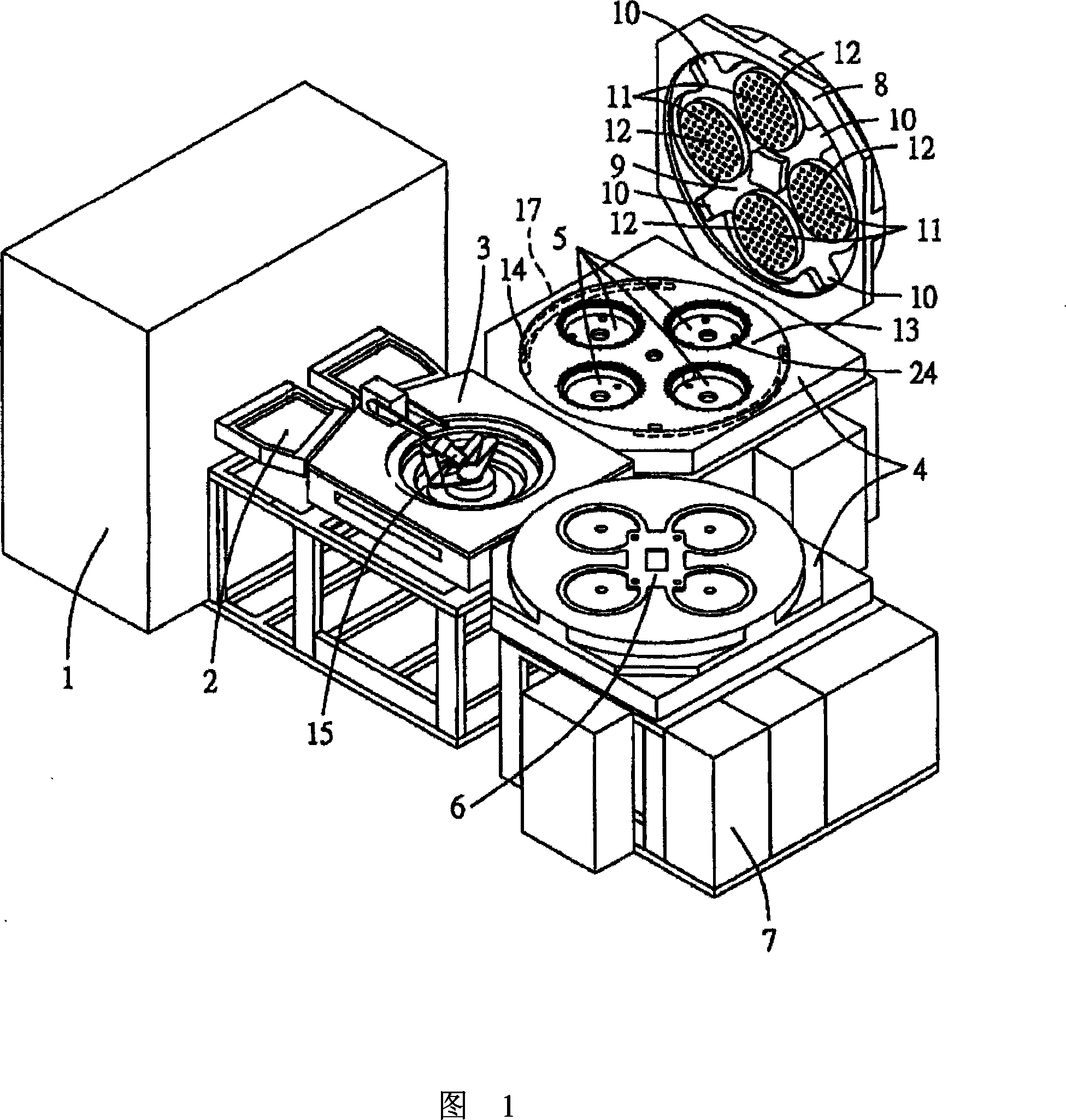

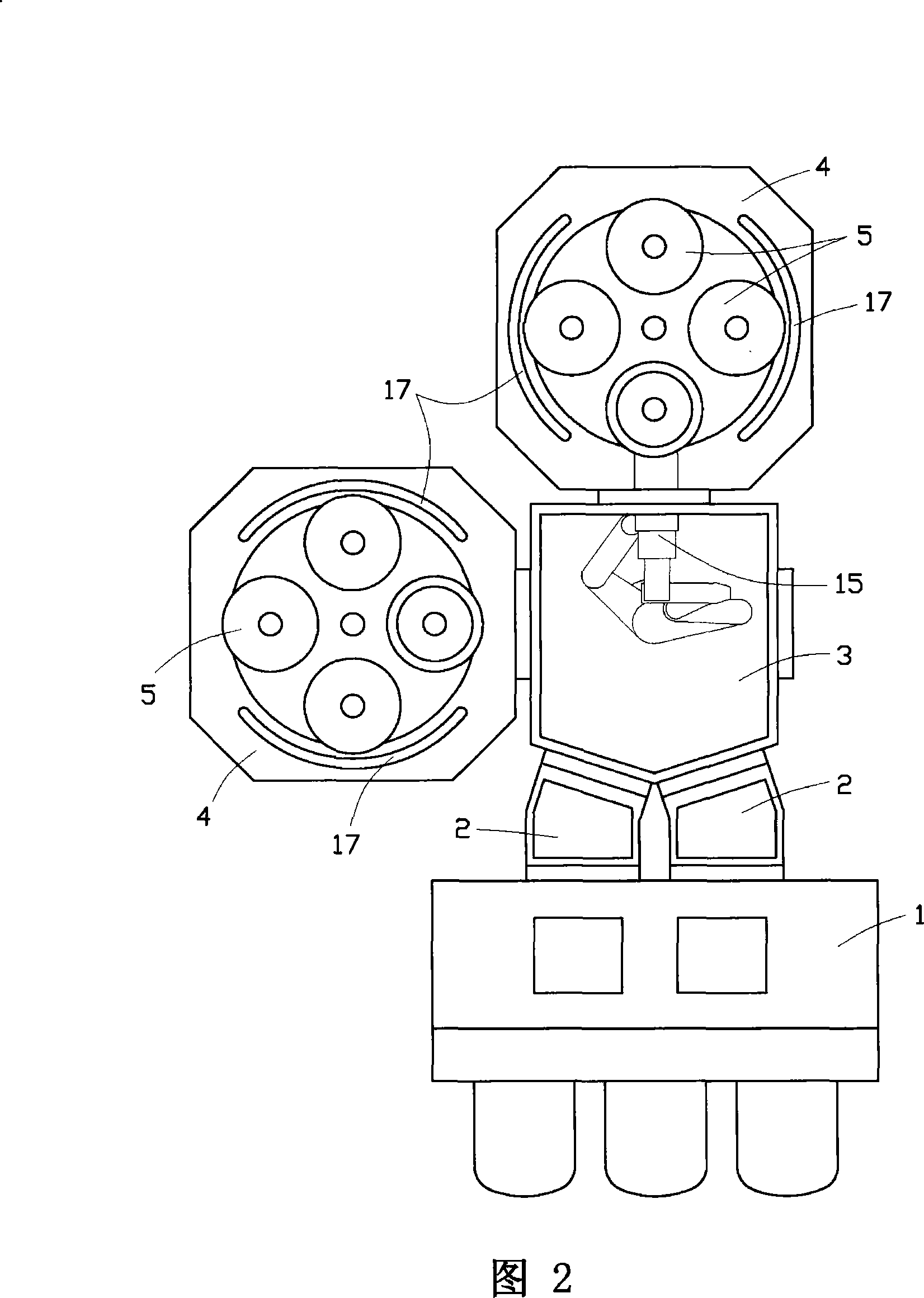

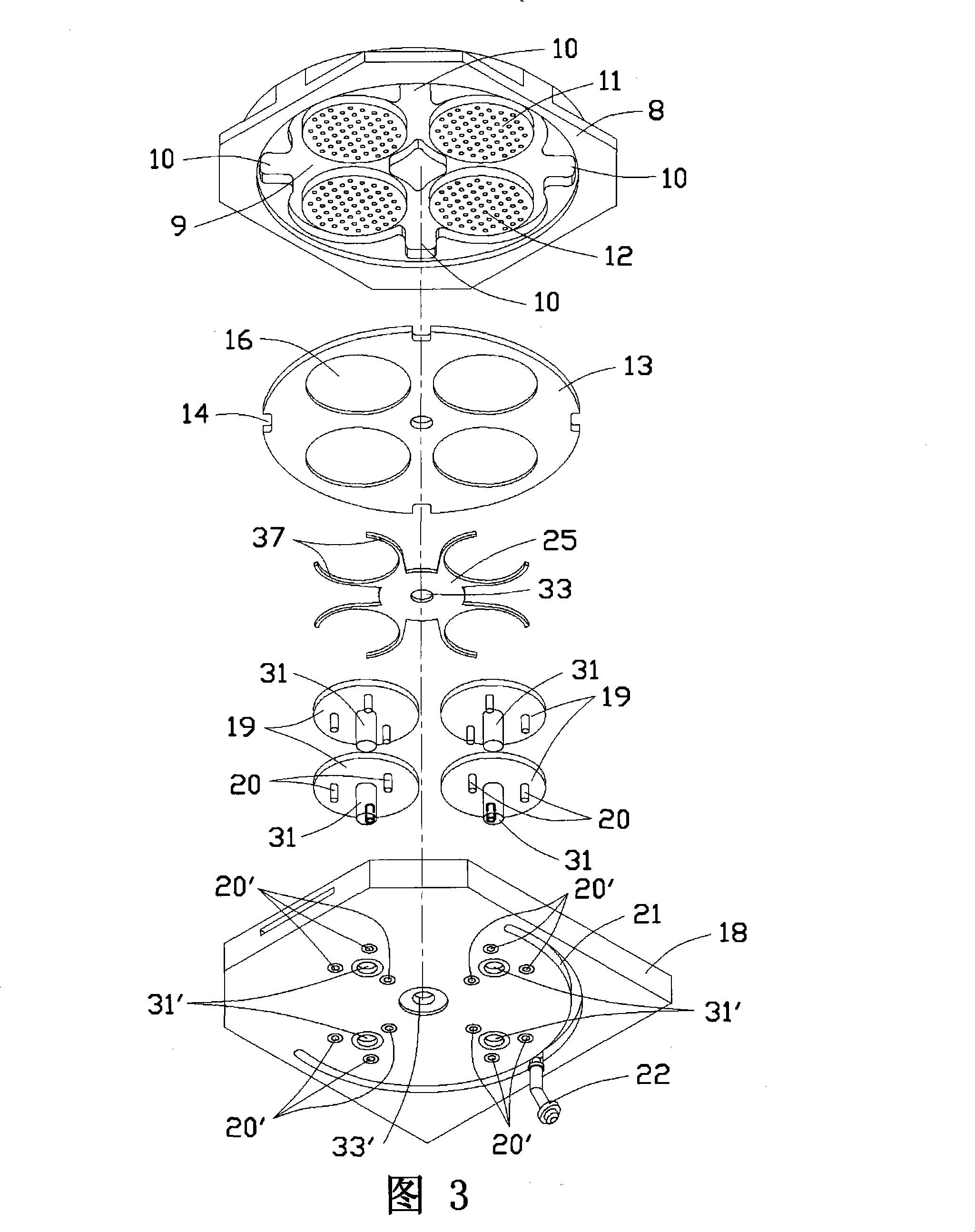

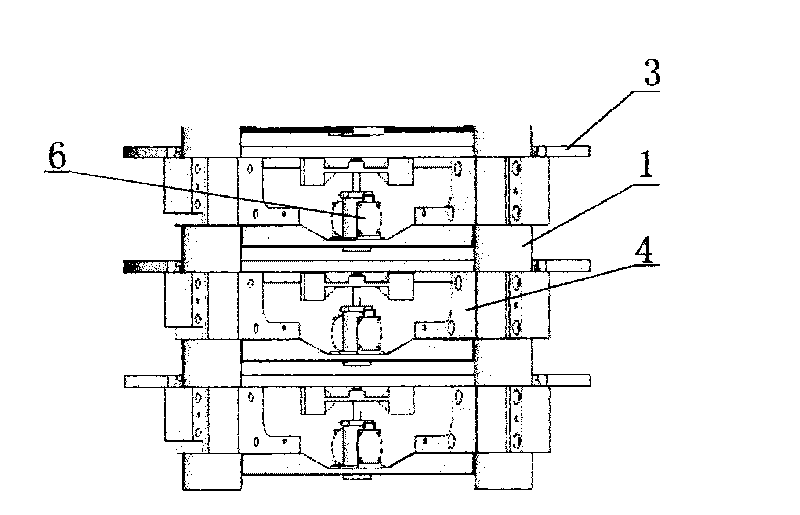

Semiconductor technology processing system and processing method thereof

ActiveCN101174556AQuick loading and unloadingImprove uniformitySemiconductor/solid-state device manufacturingSpecial designEngineering

The invention relates to a semiconductor craft processing system, which comprises a vacuum lock, a transfer chamber, a processing cavity chamber or a plurality of processing cavity chambers; wherein, the transfer chamber is positioned between the vacuum lock and the processing cavity chamber, the processing cavity chamber can be arranged around the transfer chamber; a transfer device is arranged in the transfer chamber. The invention can adjust the position only through the movement of the transfer device, but the vacuum lock or the processing cavity chamber is not required in the vertical direction, the assembly and disassembly or the exchange motion of a craft piece can be accomplished, thereby the craft piece can be assemble, disassemble and exchanged rapidly and low-costly, and the production capacity is improved. The invention also discloses a processing cavity chamber of an intake and exhaust system which adopts a special design to lead a reaction gas curtain barrier to be formed between each processing platform in the processing cavity chamber, the homogeneity between each processing platform can be promoted, and the interference of the reaction gases between the different processing platforms is avoided.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

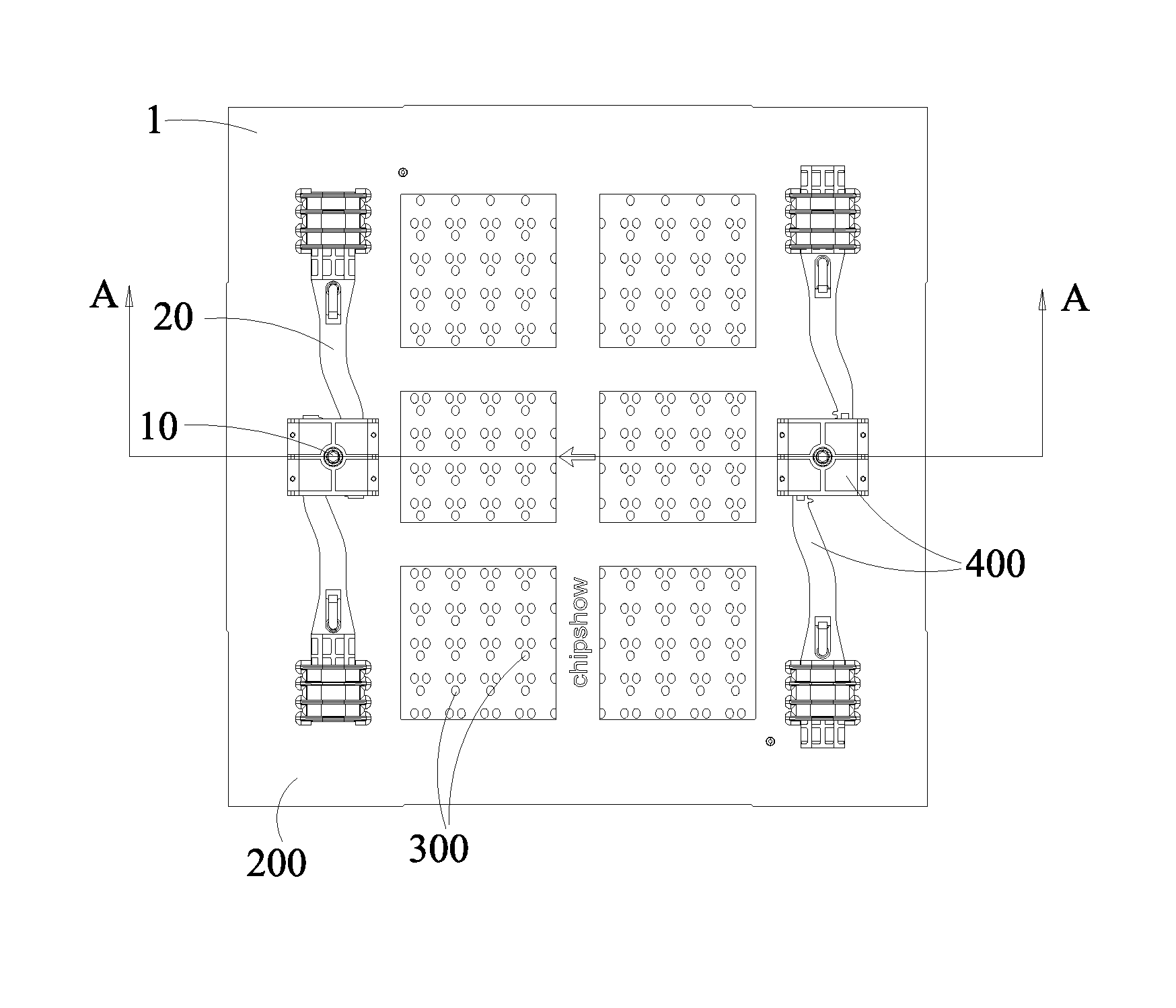

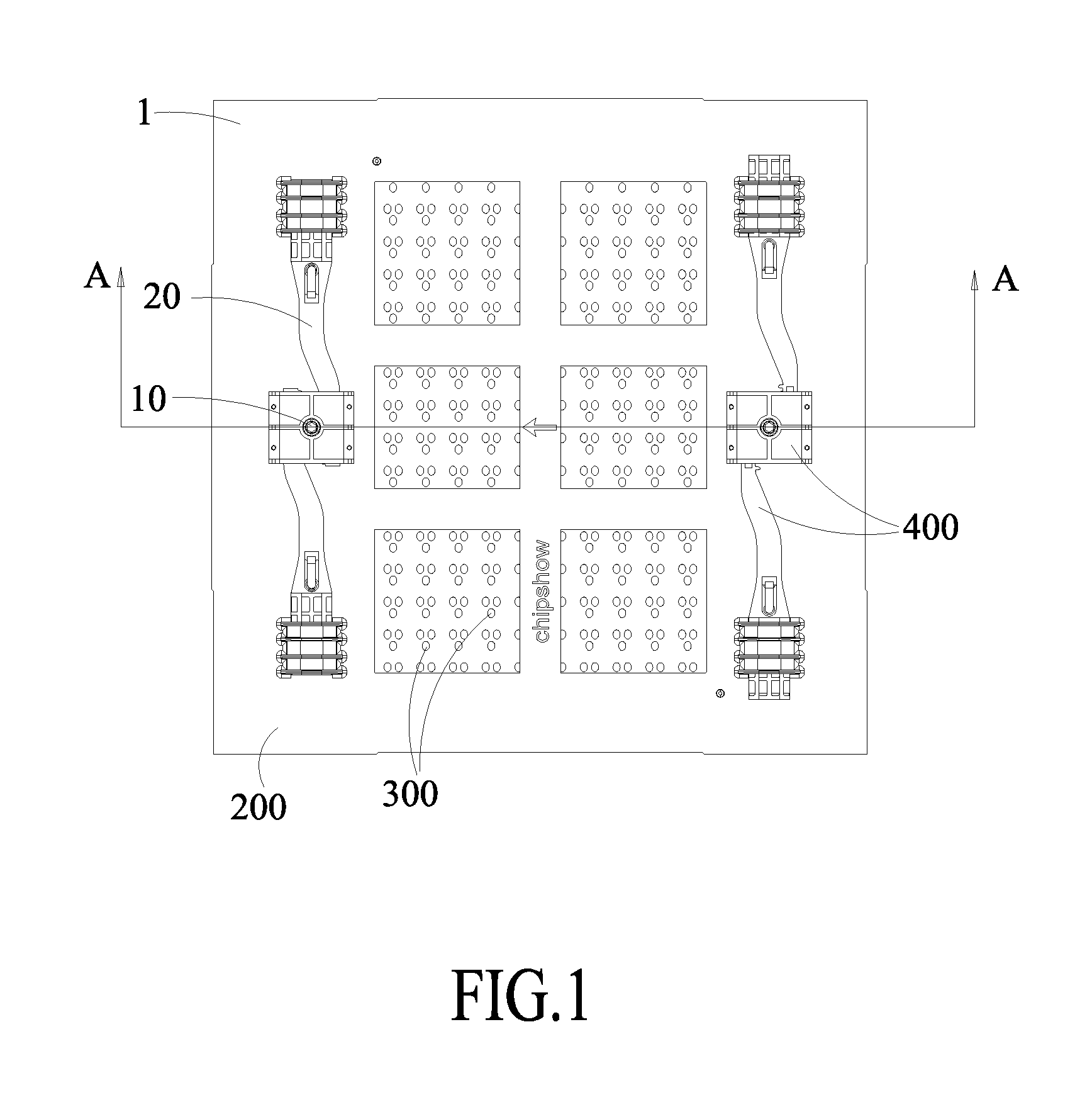

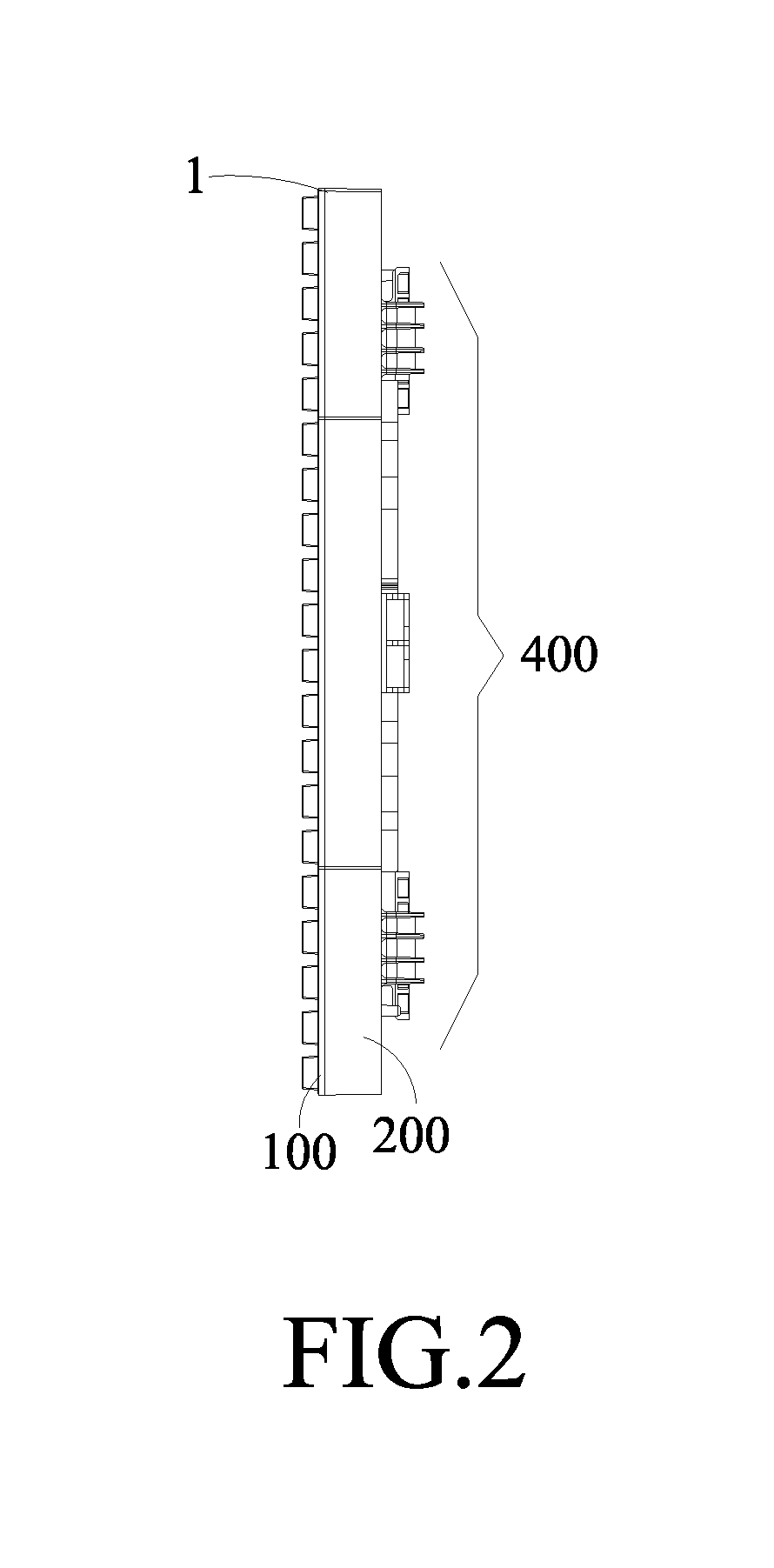

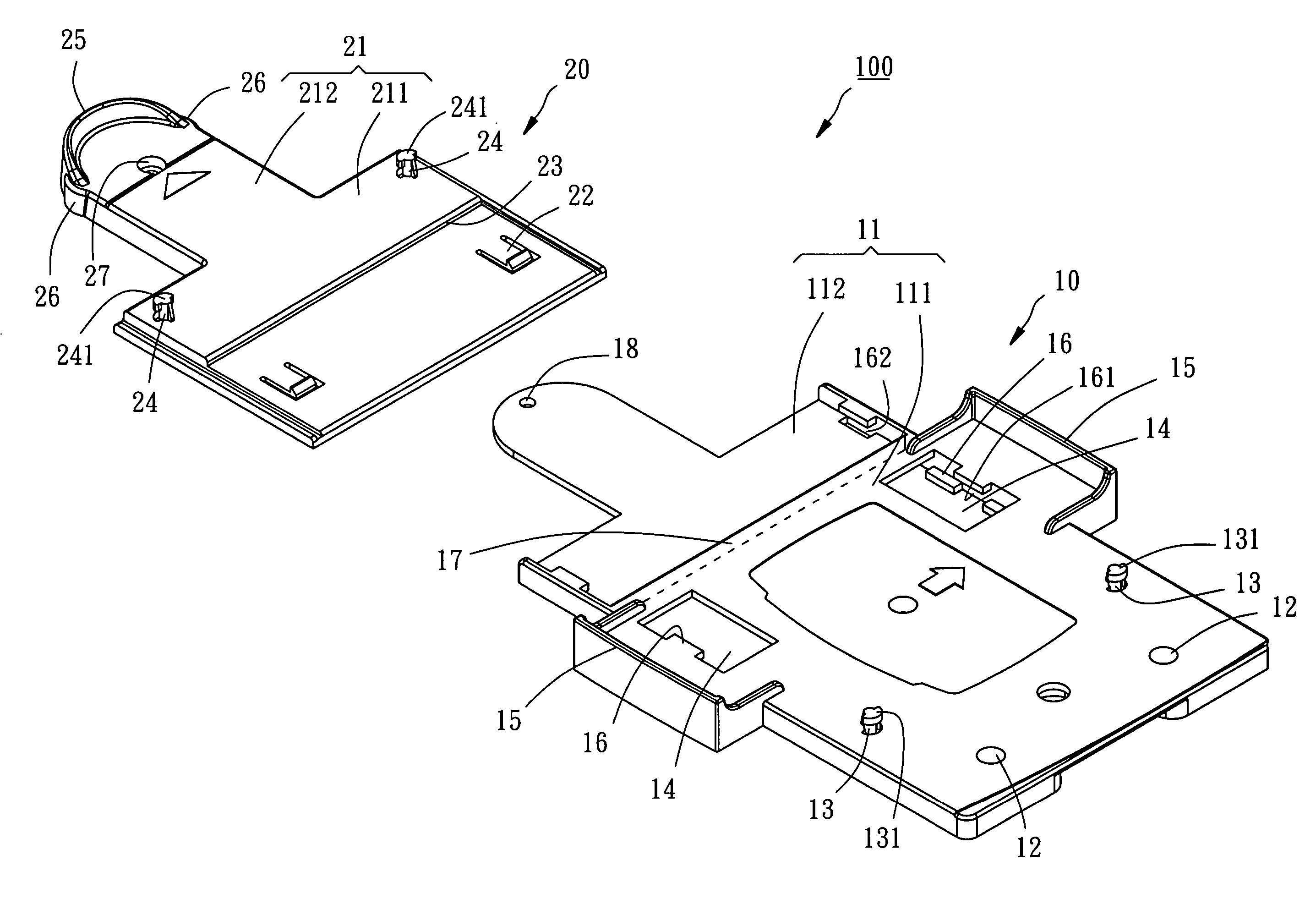

LED display module with quick mounting-dismounting structure

ActiveUS9234652B2Convenient assemblingMeet convenient maintenanceLight fasteningsIdentification meansLED displayEngineering

A LED display module with a quick mounting-Dismounting structure comprising: a mask; a bottom shell; and an LED lamp board; the LED display module further comprises a quick mounting-dismounting unit, wherein the quick mounting-dismounting unit is adapted to be provided the LED display module to fixed to the frame of display screen or removed from the frame of display screen quickly.

Owner:SHENZHEN CHIP OPTECH

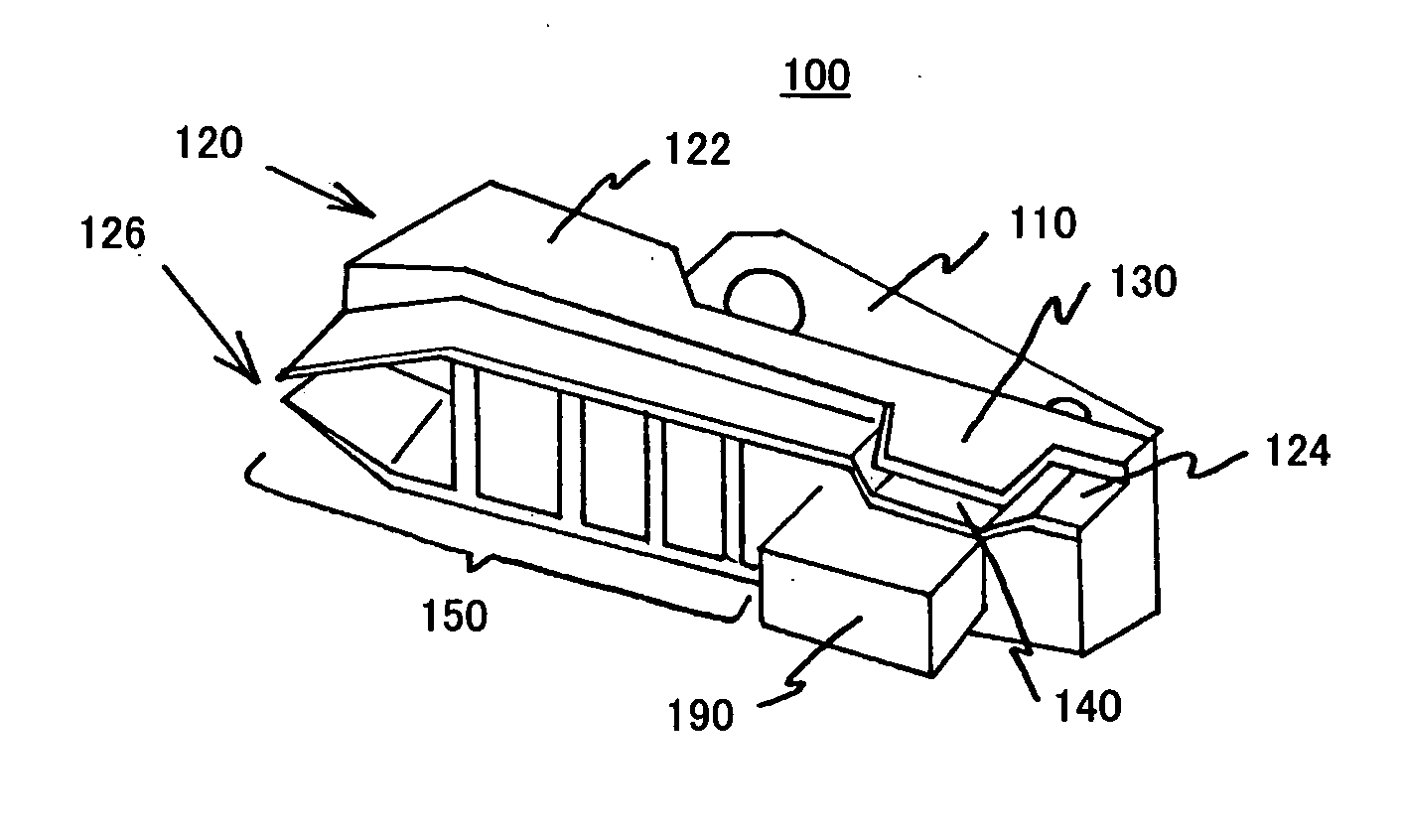

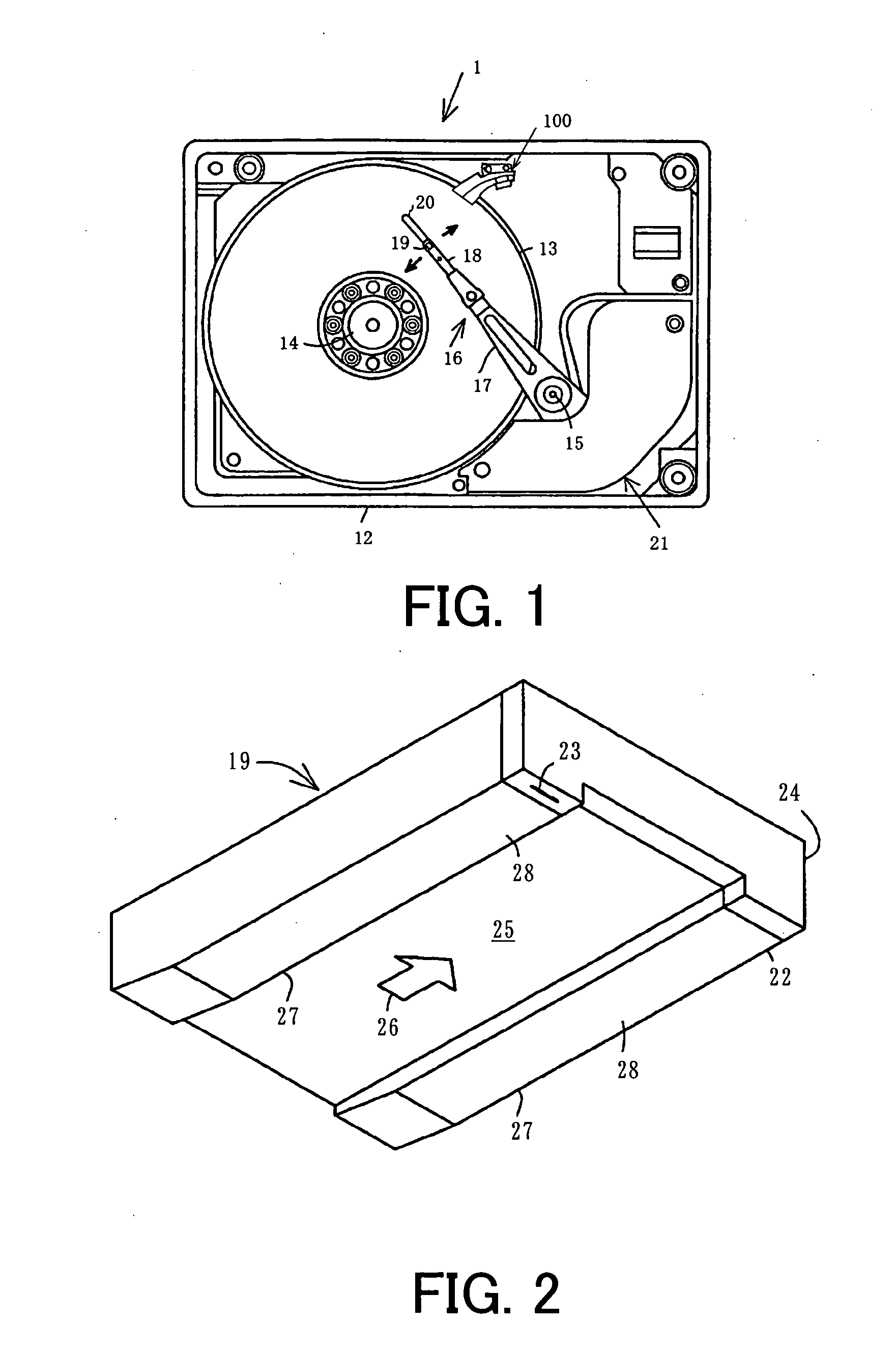

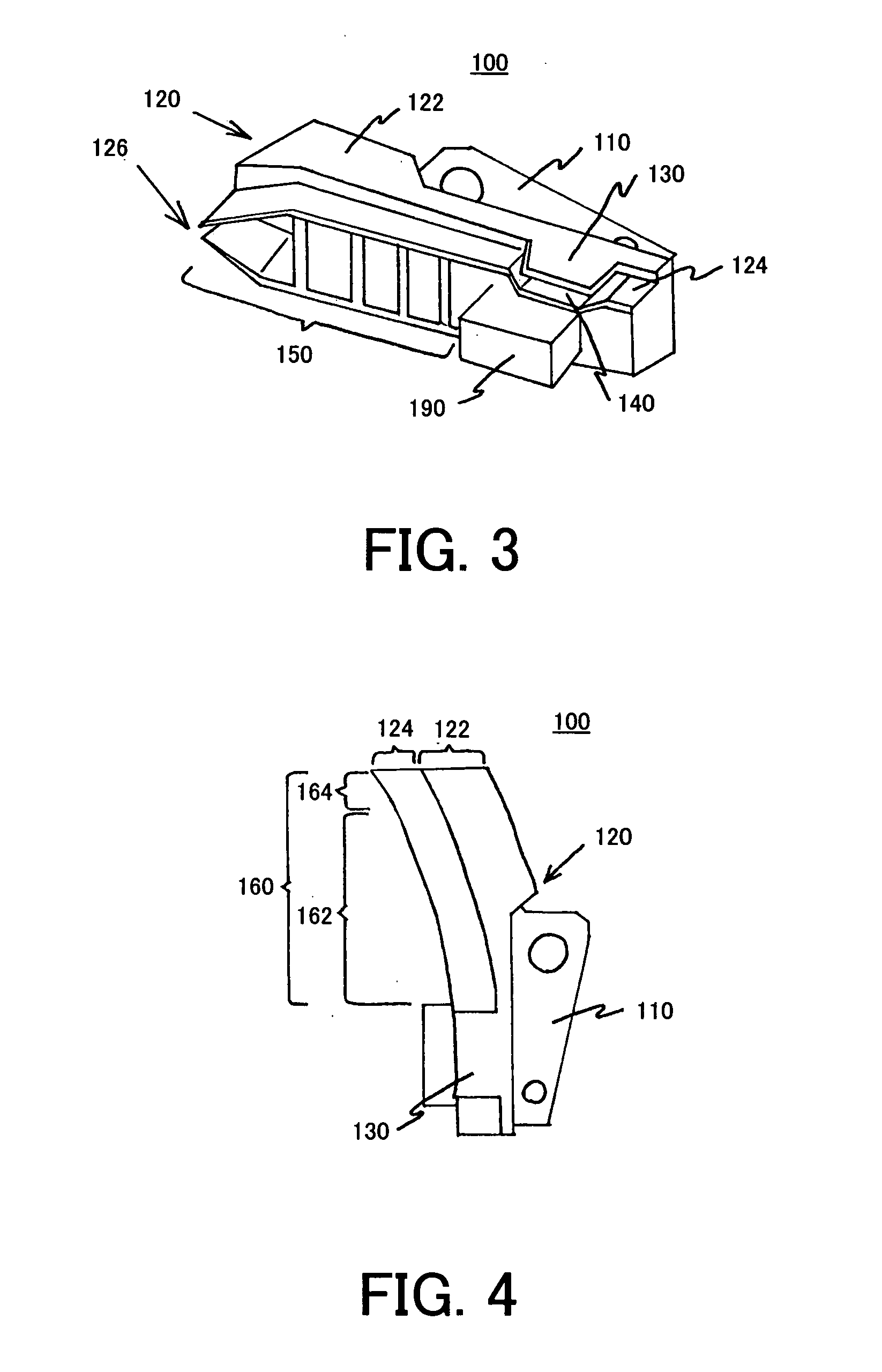

Ramp loading unit and drive having the same

InactiveUS20060268462A1Avoid damageWide effective recording areaDisposition/mounting of recording headsRecord information storageEngineeringMechanical engineering

A ramp loading unit includes a holding part that holds, outside a recording medium, a lift tab connected to a suspension that supports a head used to record information in or reproduce the information from the recording medium, and a sliding part to which the lift tab elastically contacts in loading the head onto the recording medium and in unloading the head from the recording medium, wherein the sliding part includes an inclined part that projects at least partially above the recording medium, inclines relative to a surface of the recording medium, and partially changes an inclination angle of the inclined part.

Owner:KK TOSHIBA

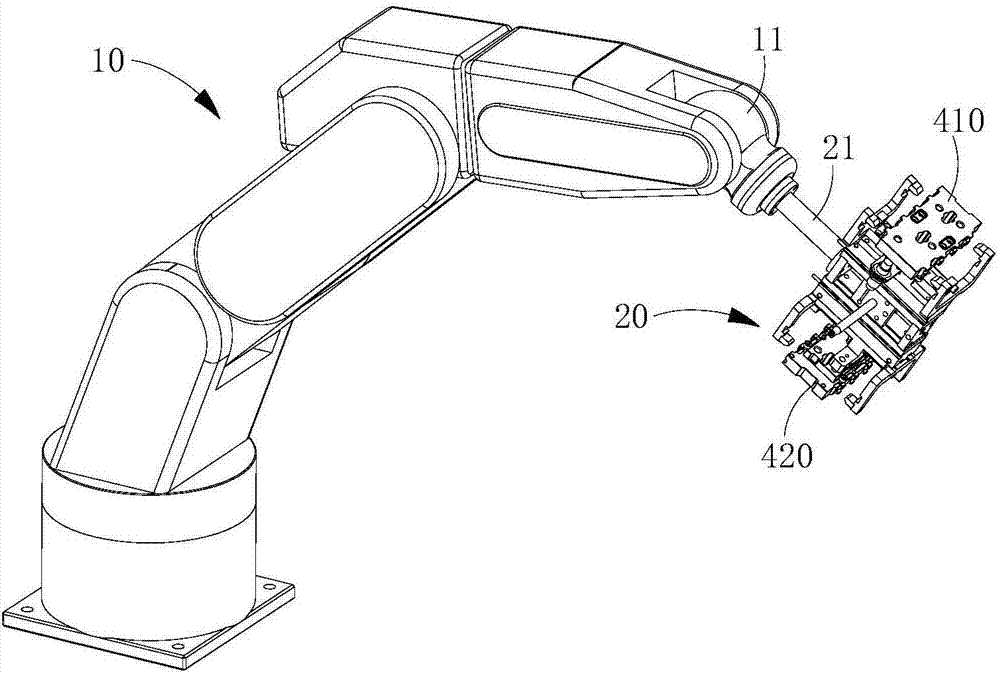

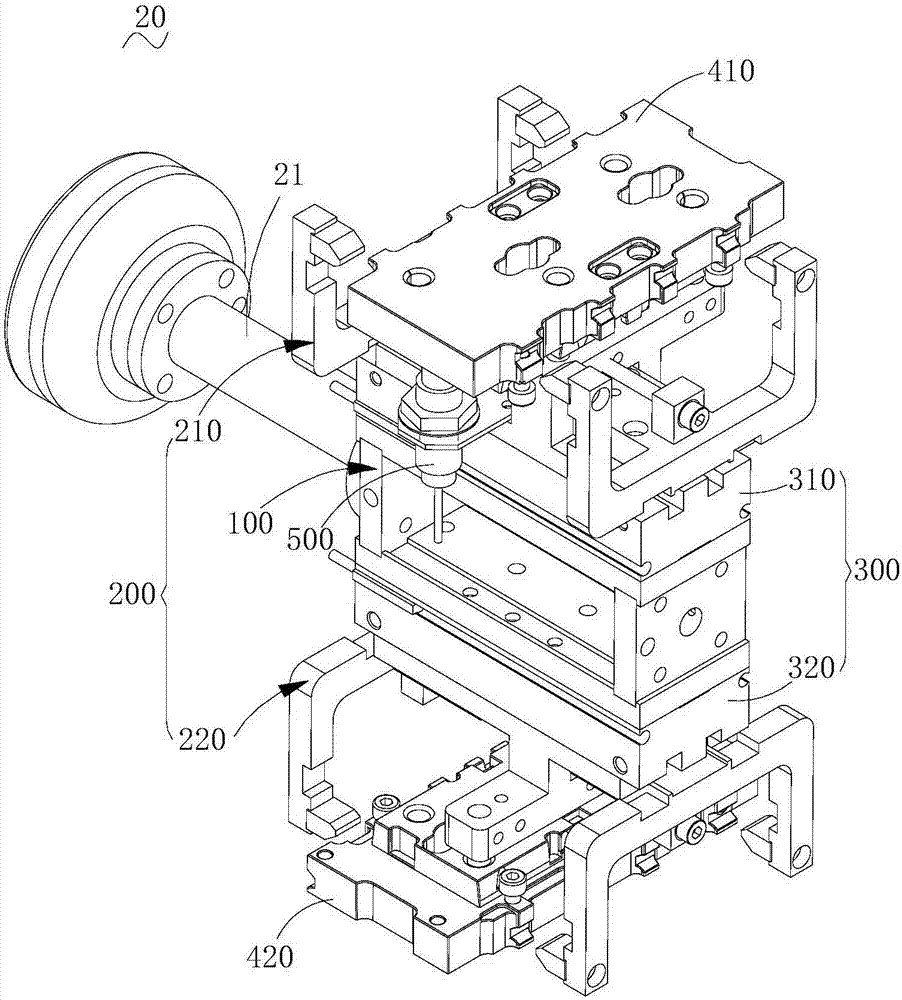

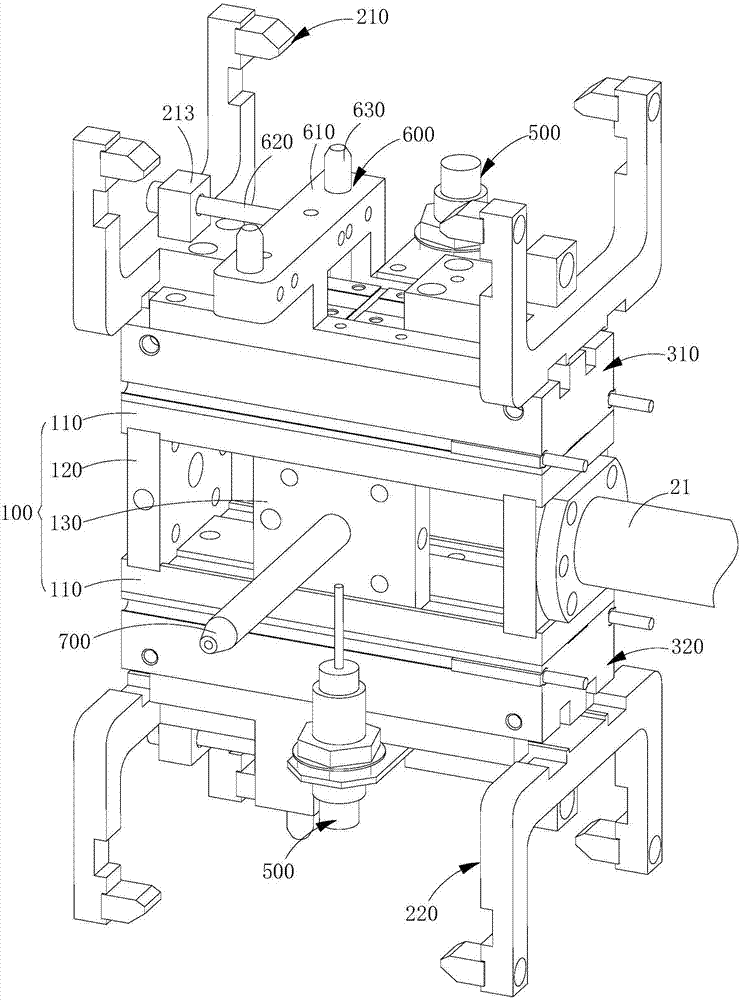

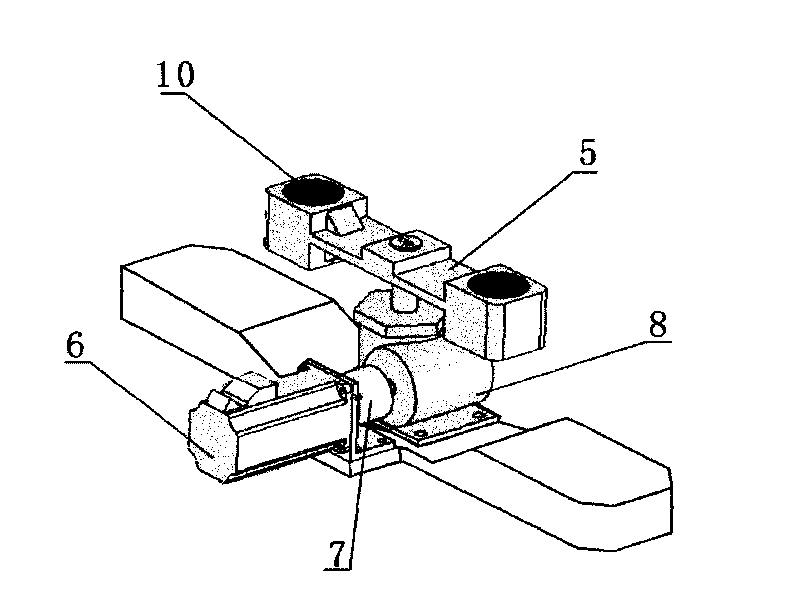

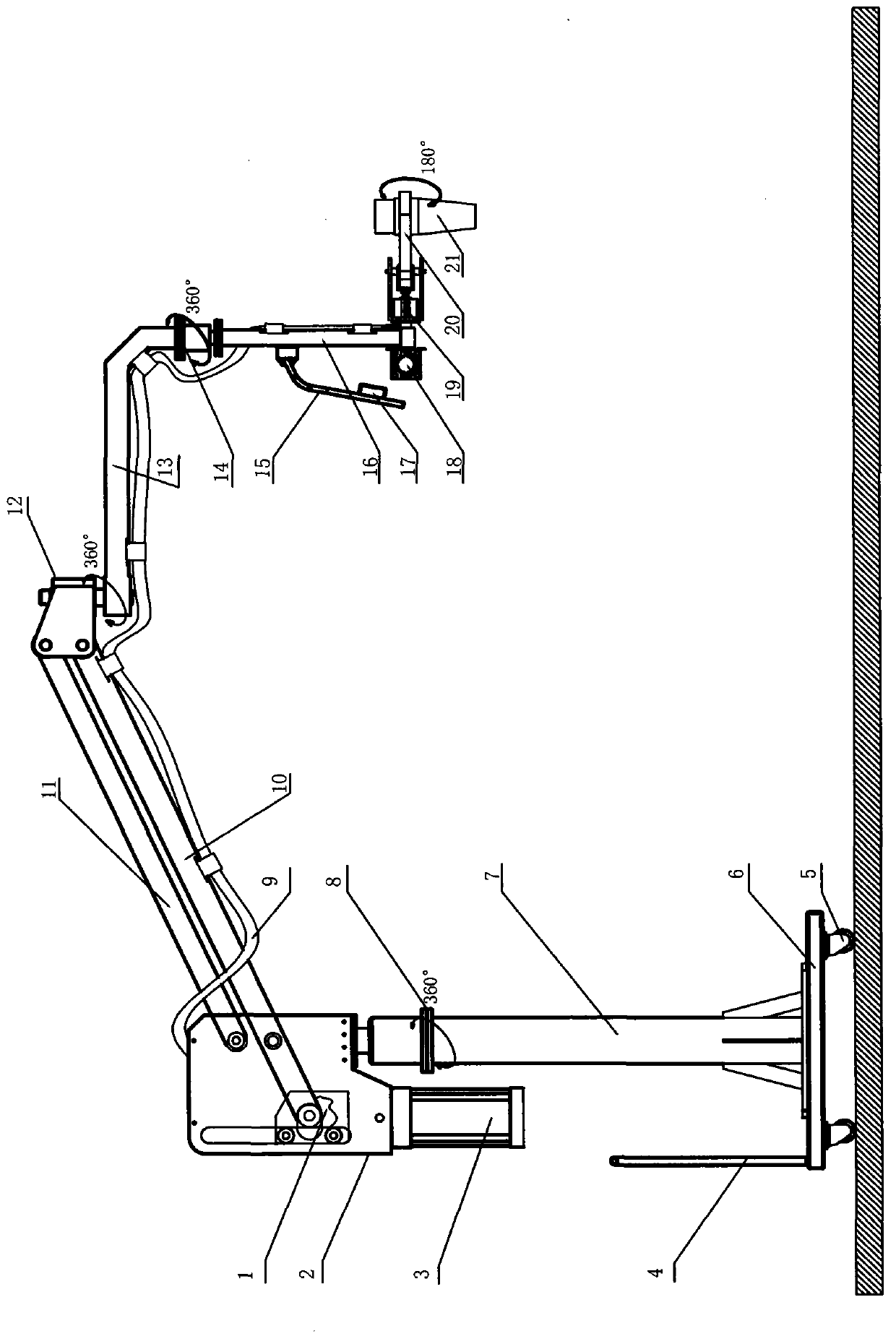

Manipulator

InactiveCN107150248AQuick loading and unloadingHigh degree of automationGripping headsMetal working apparatusManipulatorMachine tool

The invention relates to a manipulator, comprising: a fixed seat; two claws, symmetrically arranged on the opposite side walls of the fixed seat, and one of the two claws is used for grabbing from a jig The workpiece to the machine tool, and the other jaw is used to grab the workpiece processed on the machine tool and place it on the fixture or the external workpiece collection place; the driving mechanism is arranged on the fixed seat and connected with the two jaws to Drive the opening and closing of the two claws. The above-mentioned manipulator is equipped with two jaws, one jaw is used for loading and the other jaw is used for unloading, which can be used for fast loading and unloading in actual processing. high.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD

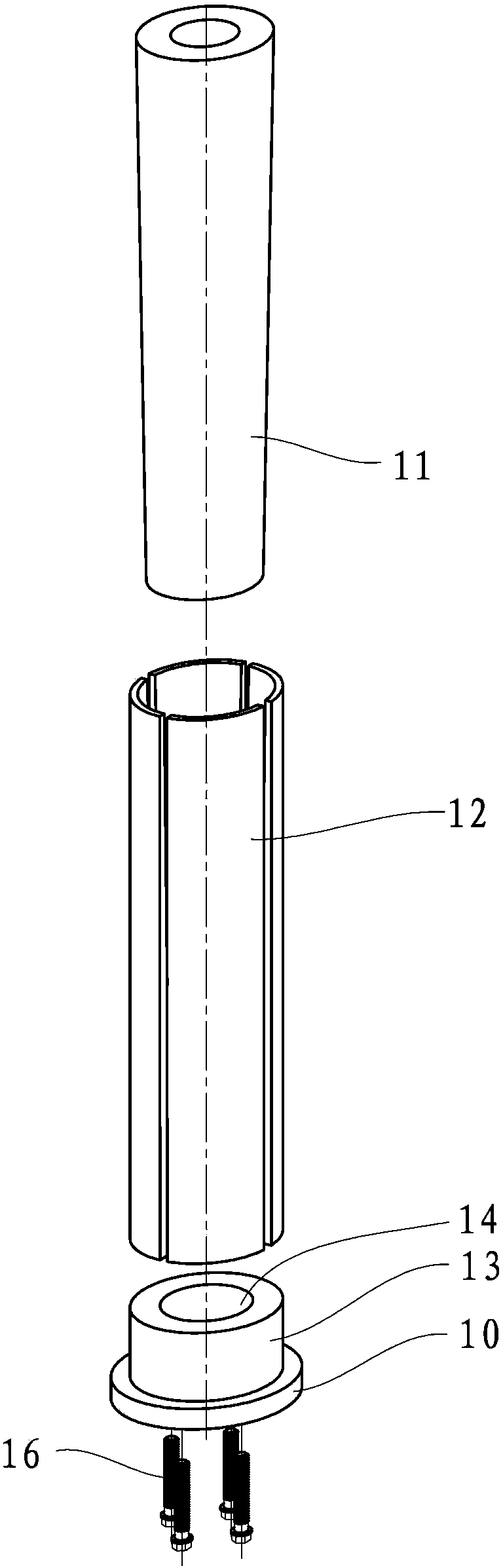

Wedge-block-type unwinding shaft used in production line of disposable hygienic products

The invention relates to a wedge-block-type unwinding shaft used in a production line of disposable hygienic products. In the invention, a fixed shaft is a stepped shaft, a small-diameter section of the fixed shaft is sequentially sheathed with two guide sleeves, a spacer bush and a compression spring, and an end part of the small-diameter section of the fixed shaft is in threaded connection witha hand wheel; one end of the compression spring is positioned in a circular groove of the hand wheel, and the other end of the compression spring is in contact with an end face of the spacer bush; locking sleeves are sheathed on small-diameter sections of the two guide sleeves, sleeves are sheathed outside the locking sleeves, four axial expansion pin grooves are uniformly distributed on each sleeve, and each expansion pin groove is internally equipped with an expansion pin; each expansion pin is in the shape of a wedge block, and an oblique plane of each expansion pin corresponds to each locking sleeve; and a taper sleeve is inserted between the locking sleeve and the sleeve which are positioned at one end adjacent to the spacer bush, a conical tube is arranged at one side of the taper sleeve, a cylindrical tube is arranged at the other side of the taper sleeve, and the conical surface of the conical tube of the taper sleeve is in contact with the oblique planes of the four expansionpins in a fit manner. The wedge-block-type unwinding shaft has the advantages of compact and delicate structure and reasonable design, and is convenient in use; unwinding resistance can be controlledby adjusting the hand wheel; and material coils can be fixed, assembled and disassembled quickly through the expansion pins.

Owner:ANQING HENG CHANG MACHINERY

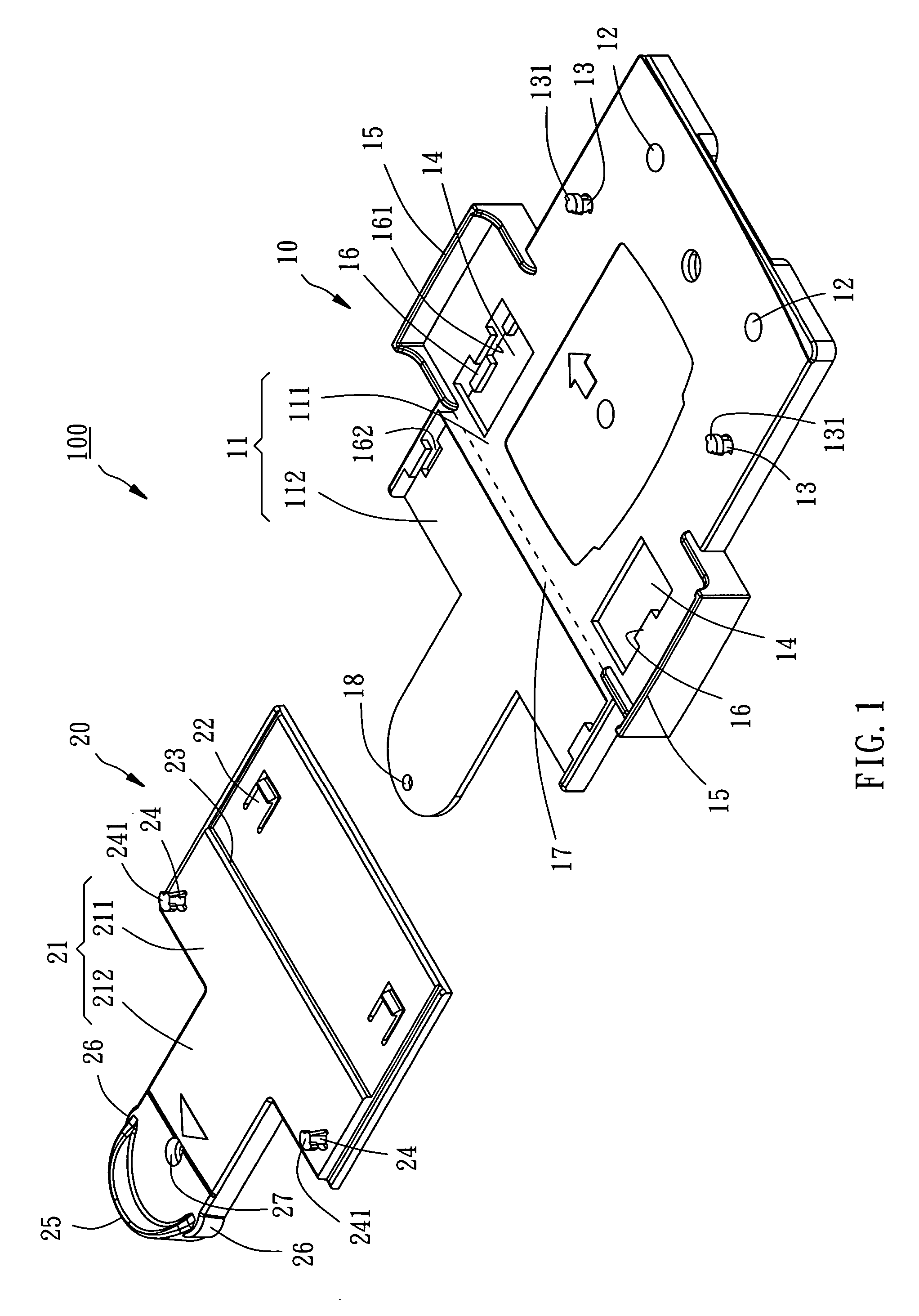

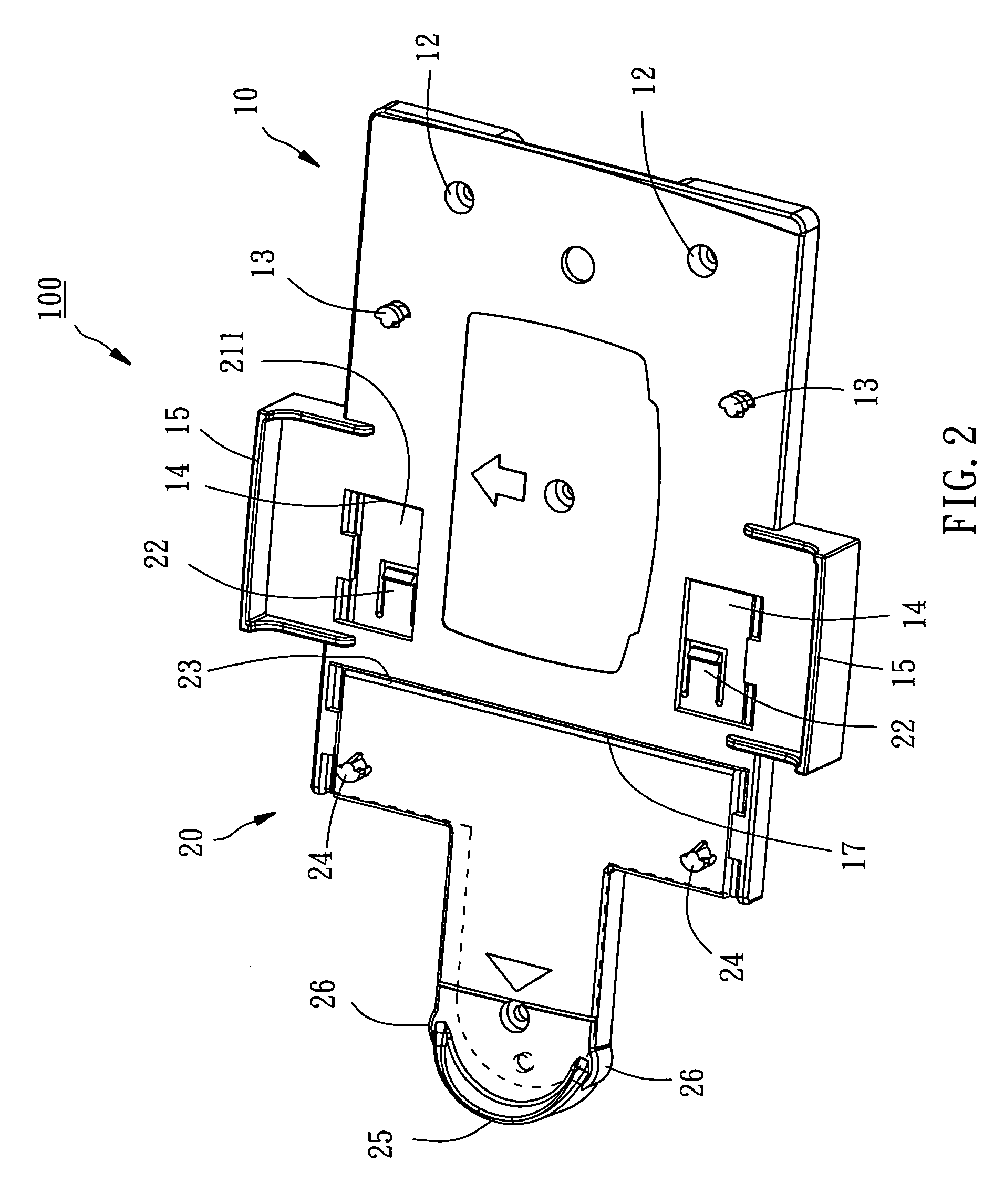

Electronic device holder

InactiveUS20070018067A1Quick unloadingQuick loading and unloadingCasings/cabinets/drawers detailsStands/trestlesEngineeringMechanical engineering

Owner:ASKEY COMP

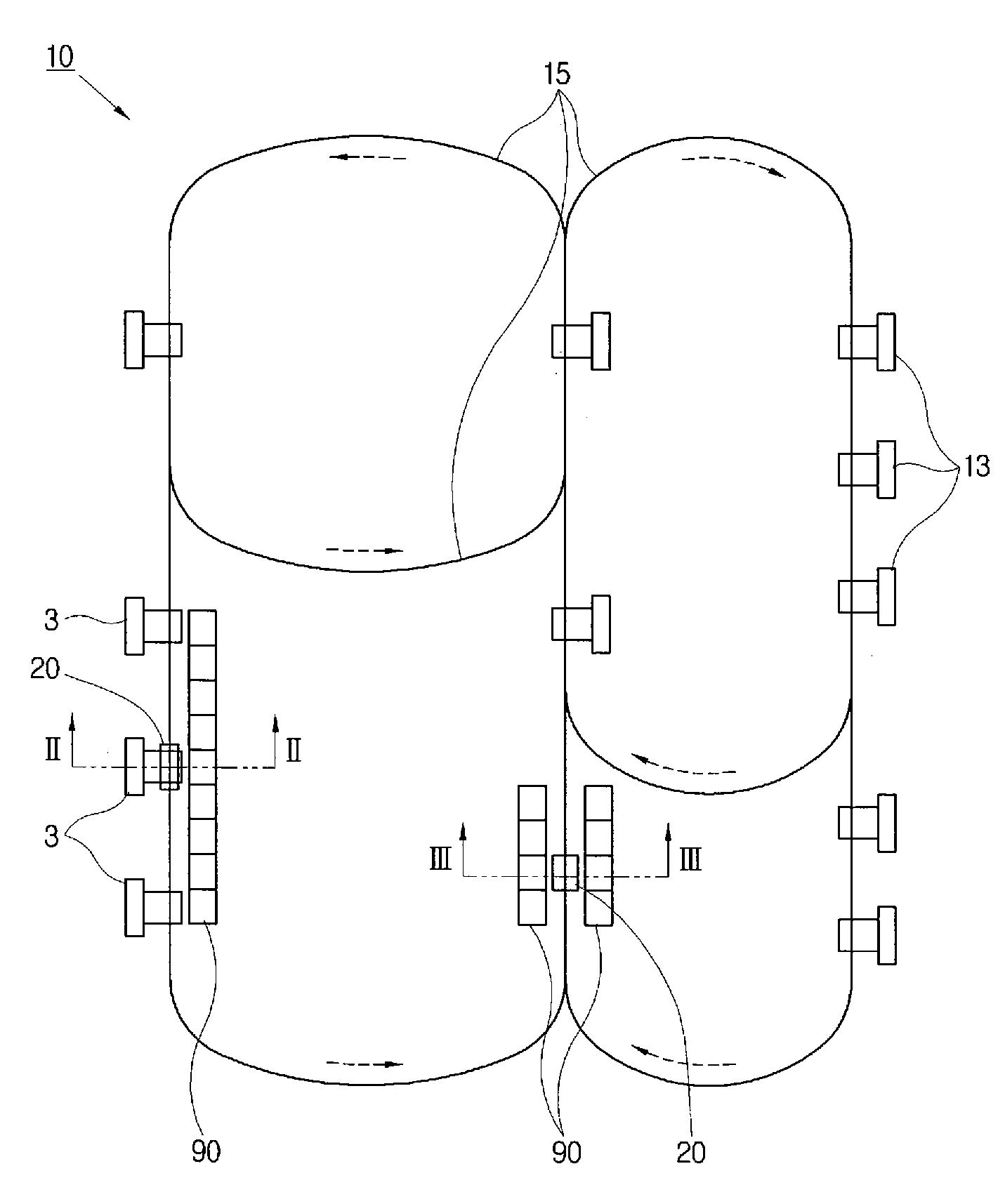

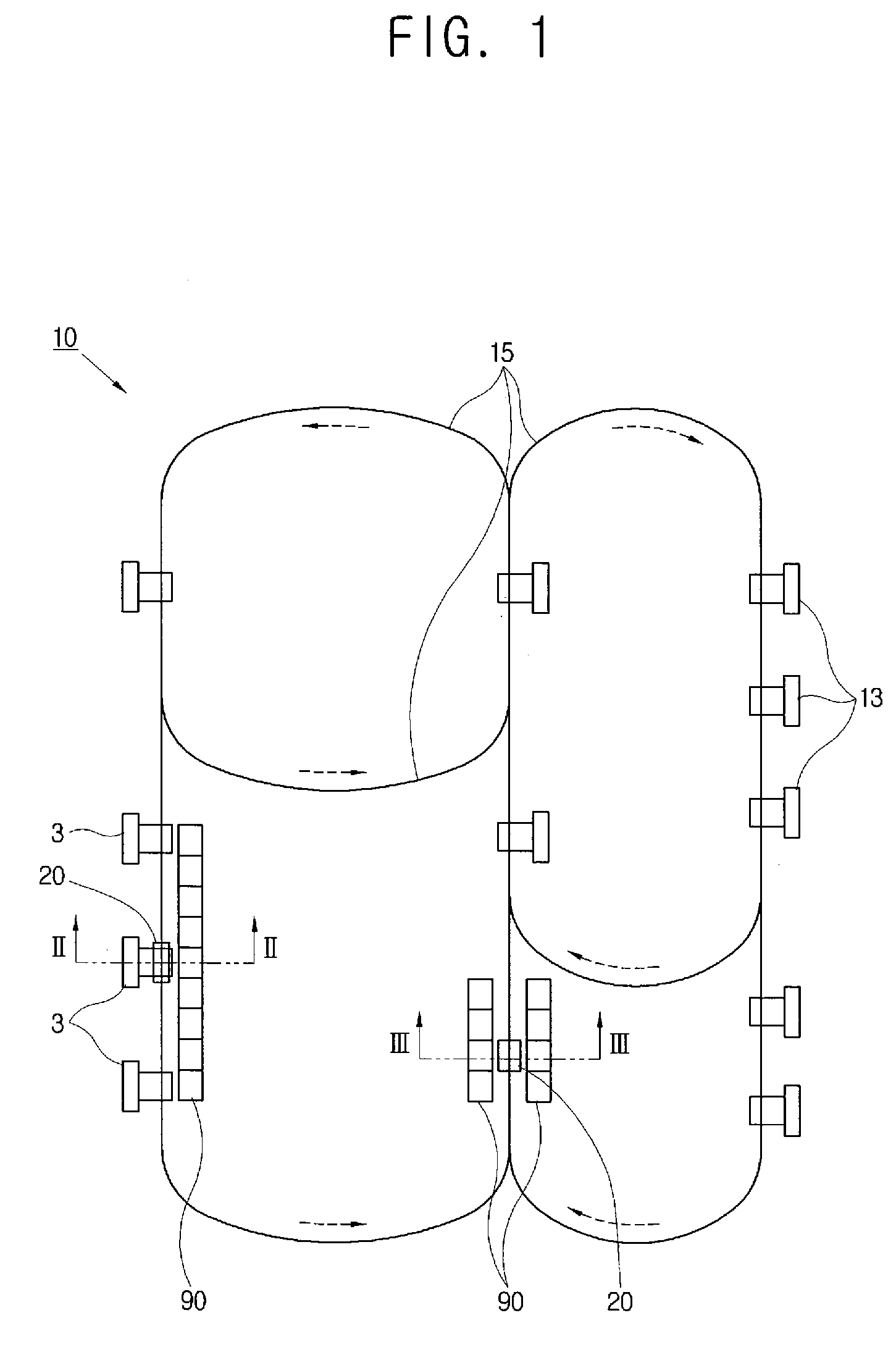

Transferring system

InactiveUS20070224026A1Quick loading and unloadingSemiconductor/solid-state device manufacturingCable carsTransfer systemEngineering

A transferring system to travel along a rail to transfer and load and / or unload a workpiece include a transferring apparatus provided with a main body unit to travel along the rail, a sliding unit coupled to the main body unit to relatively move between a transferring position and a storing position with respect to the main body unit, and a hoist unit coupled to the sliding unit to move upward and downward the workpiece, and one or more buffering apparatus disposed beside a traveling path of the transferring apparatus to support the workpiece in the storing position, and provided with a supporting part to support the sliding unit when the sliding unit moves between the transferring position and the storing position.

Owner:SAMSUNG ELECTRONICS CO LTD

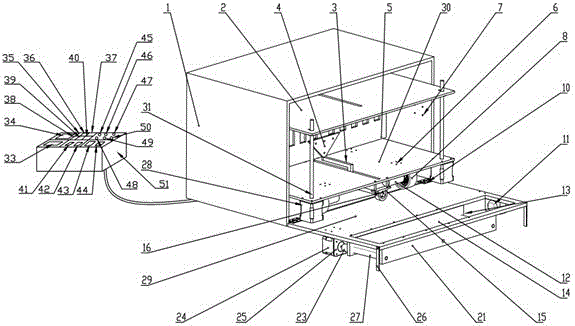

Independent weight adding force standard machine and independent weight adding method

InactiveCN101706344AQuick loading and unloadingStable loading and unloadingWeighing apparatus testing/calibrationForce/torque/work measurement apparatus calibration/testingReduction driveControl engineering

The invention discloses an independent weight adding force standard machine and an independent weight adding method, which belong to the technical fields of quality standard and measurement. The independent weight adding force standard machine comprises a main stand and a weight hanger, nine weights and nine groups of motion mechanisms are longitudinally arranged layer by layer in the main stand, and each group of motion mechanism comprises two pairs of supporting corners, a pair of brackets, a pair of servo motors, a pair of speed reducers and a pair of worm gear pairs; each servo motor is sequentially connected with each speed reducer, each worm gear pair and each bracket, a pair of force sensors is arranged on each bracket, and a weight is placed on each pair of brackets. In the independent weight adding method, each servo motor drives the brackets and the weights placed at the upper surfaces to move up and down through each speed reducer and each worm gear pair. The weights are rapidly and steadily added and unloaded, thereby realizing the maximum loading series and enlarging the use measuring range of the detected sensor; the control method and processes are simple, and the energy saving effect is remarkable.

Owner:SILKWORM COCOON RES GROUP CHINESE INST OF TEST TECH

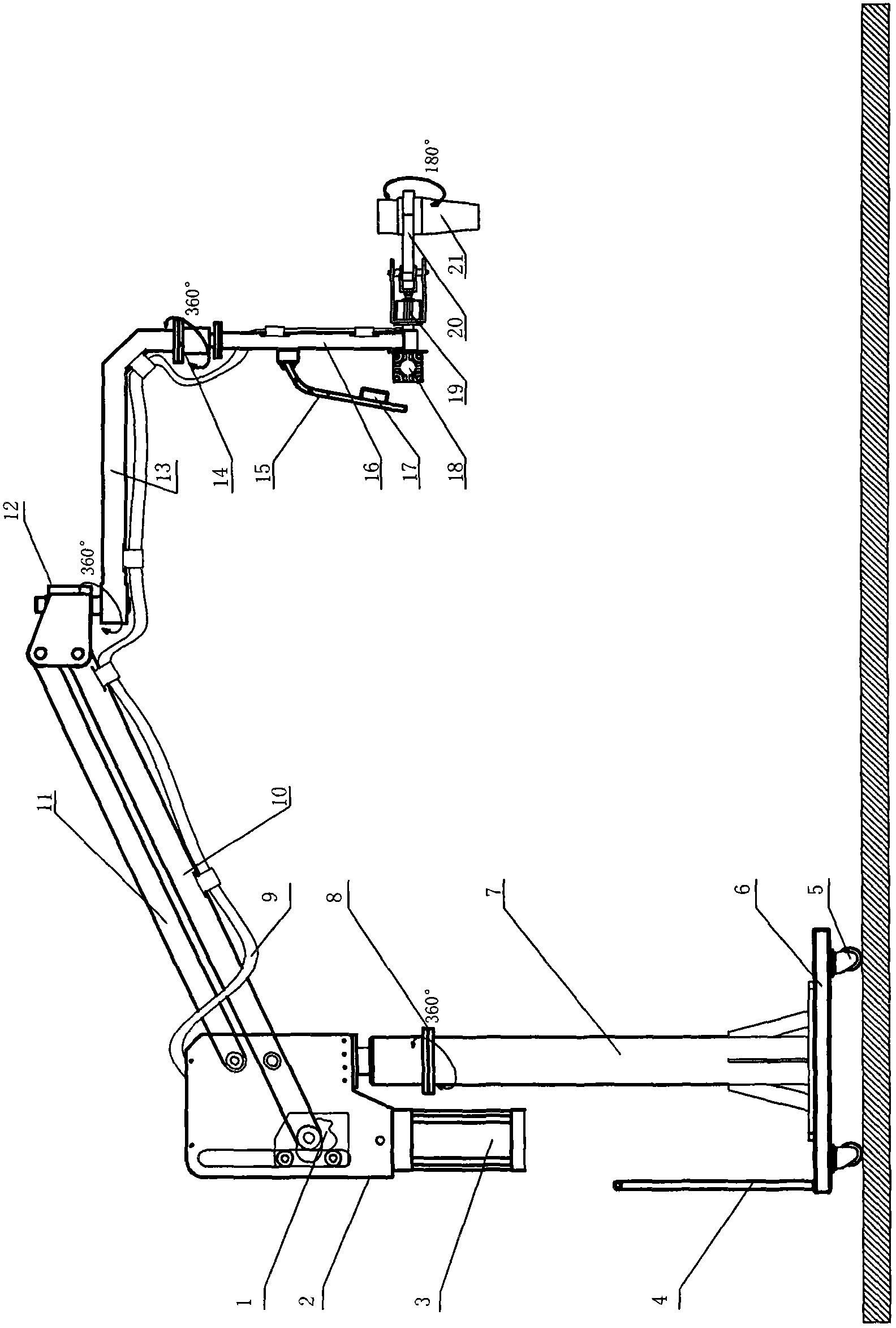

Mobile constant-pressure control boosting manipulator

InactiveCN103448051AIncrease flexibilityWide versatilityGripping headsAtmospheric pressureControl valves

The invention belongs to a manipulator in machinery and transport industries, and relates to a mobile constant-pressure control boosting manipulator. The mobile constant-pressure control boosting manipulator is designed by combination of computerized control, air pressure control and mechanical principles, an air pressure control valve is controlled by the aid of a computerized technical program to enable the manipulator to quickly grip workpieces, transfer, load and unload, different command parameters are set in a computer, and when certain action is needed, only corresponding command parameters are required to be input to enable a certain part of the manipulator to operate and command the manipulator to complete tasks. Air pressure outputted by air cylinders can be kept in balance, air pressure impact and rebound are reduced, and performance, safety and reliability of machines are improved. A mobile device is further arranged, and accordingly mobile operation can be realized. Due to the unique gripping jaw design, the manipulator is suitable for gripping and holding workpieces of different shapes, materials and weights; parts, for arranging gripping jaws, of a clamping cylinder can be provided with electromagnet attraction plates, and the workpieces are attracted by dependence on attractive force of electromagnets. Due to the design in multiple degrees of freedom, the manipulator is high in flexibility and wide in versatility, and working efficiency is improved.

Owner:盐城市昱博汽车零部件有限公司

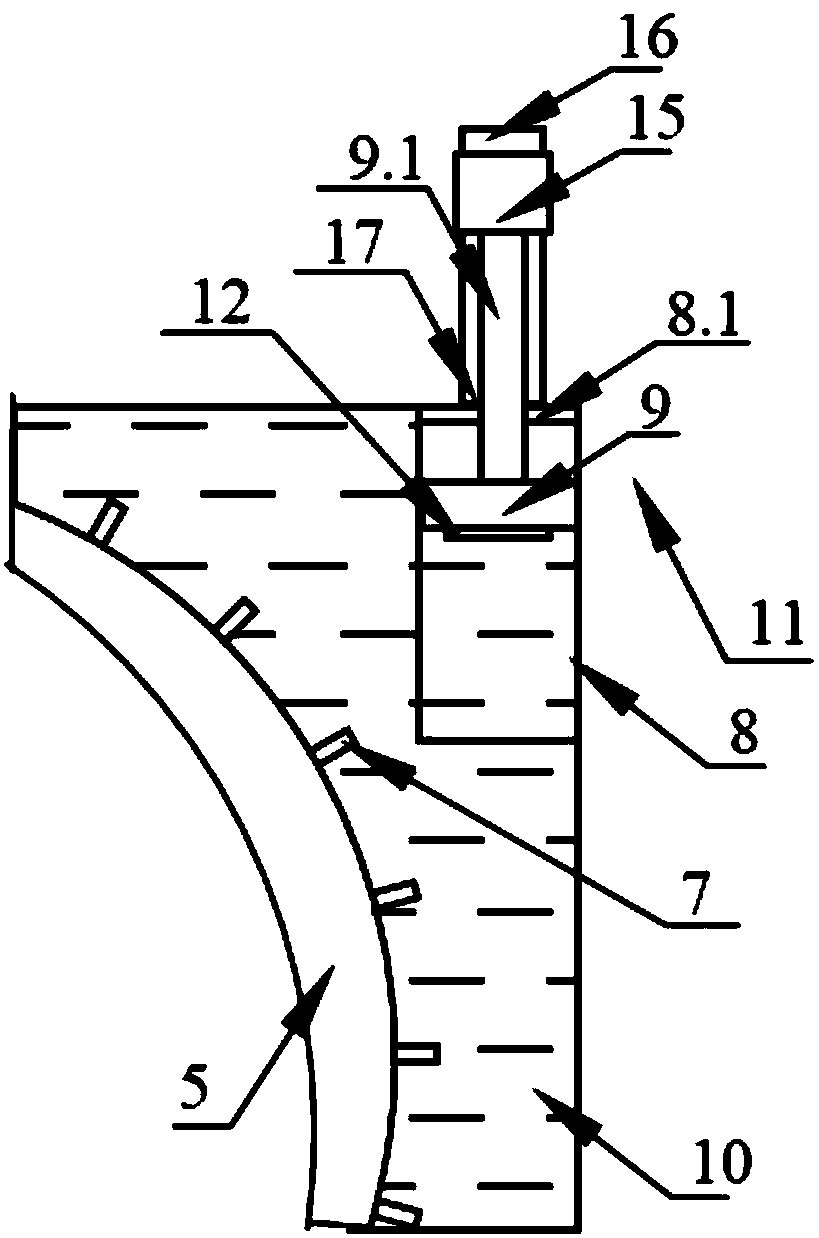

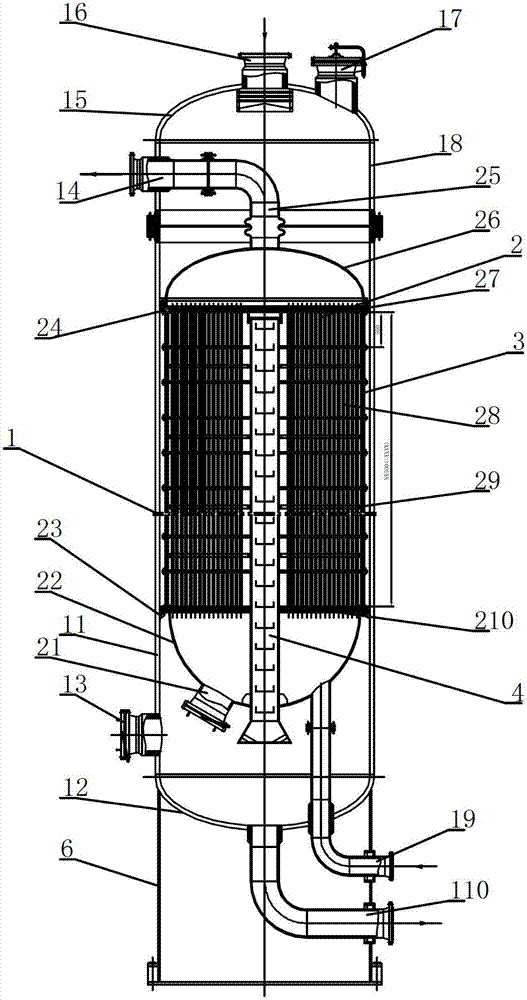

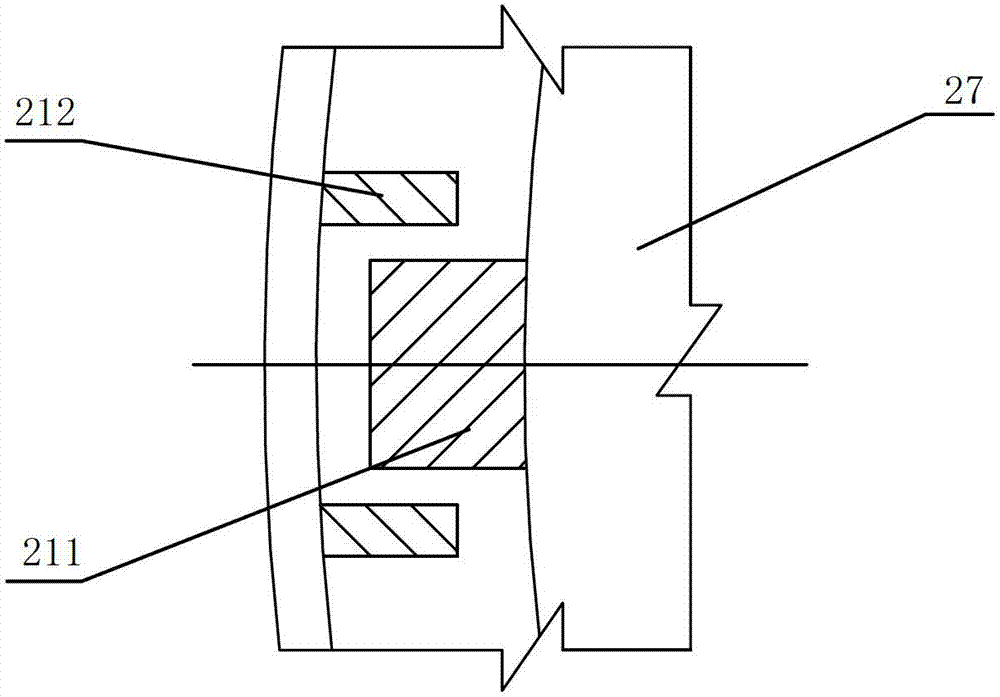

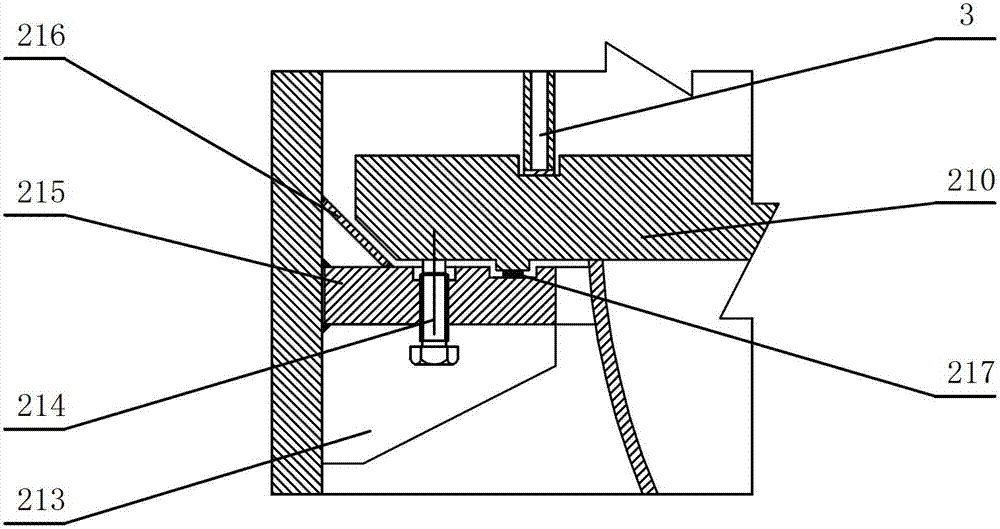

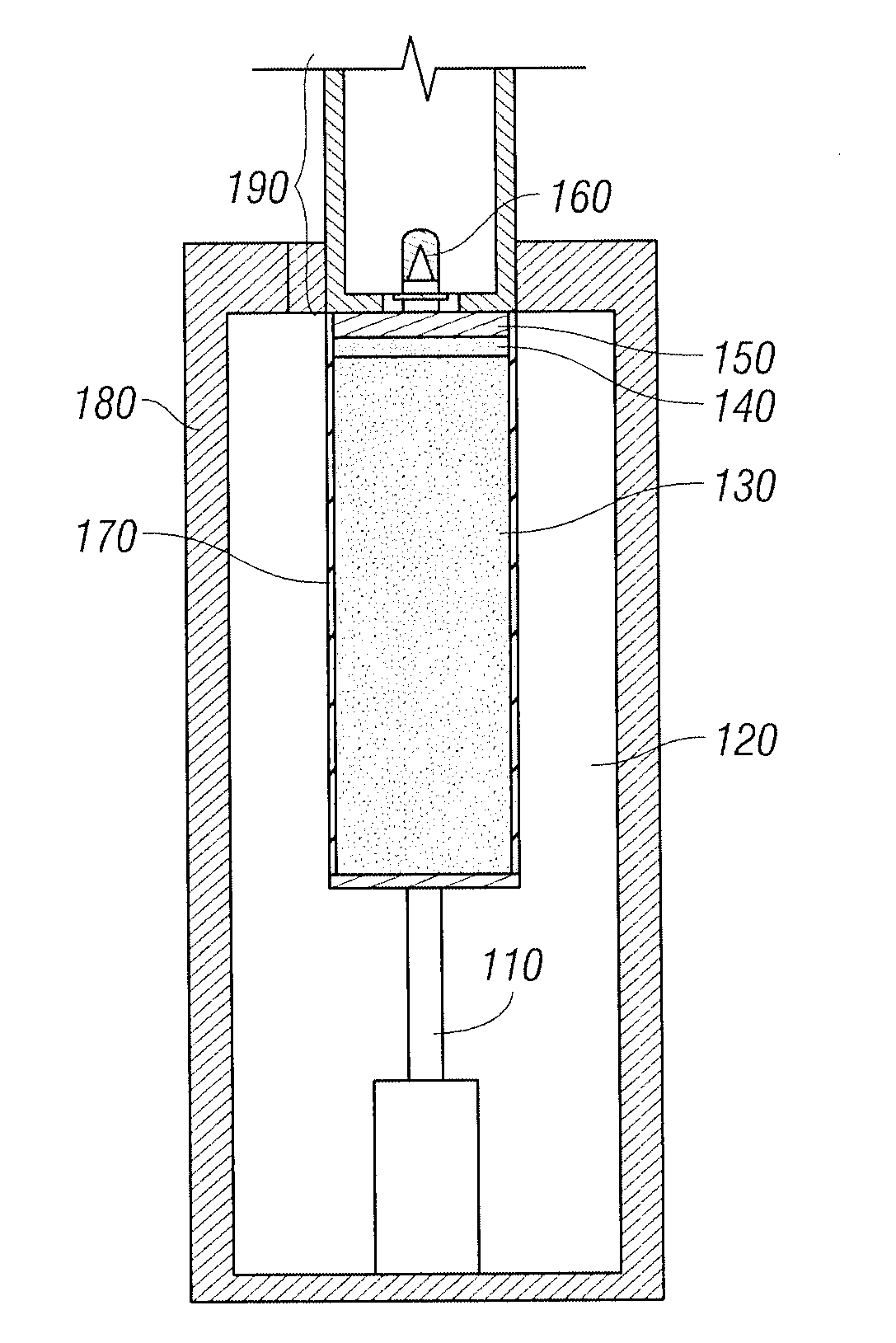

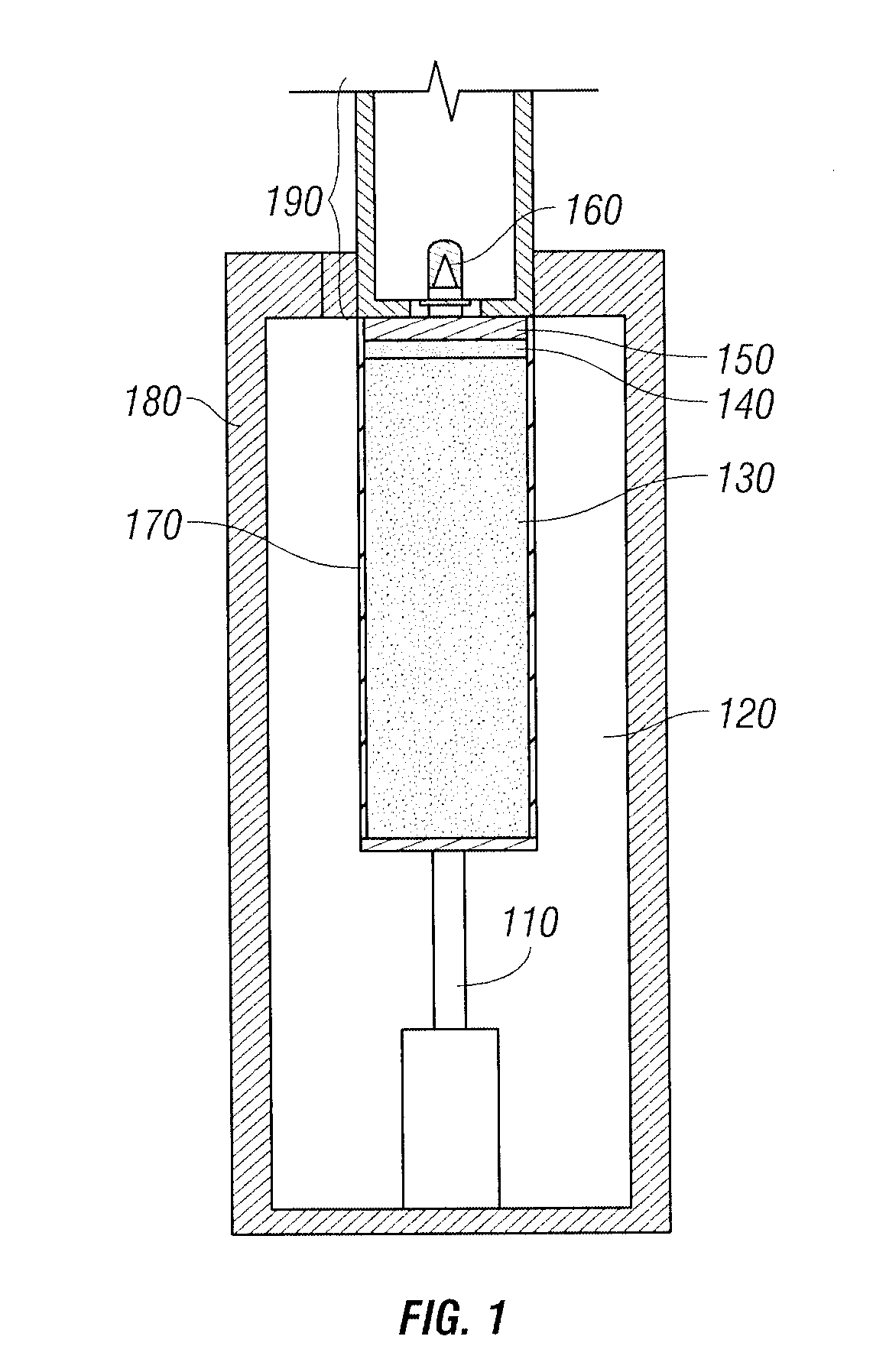

CO (carbon monoxide) full-radial isothermal converting furnace

ActiveCN102886229ASimple structureLess investmentHydrogenChemical/physical processesSystem pressureProduct gas

The invention relates to a CO (carbon monoxide) full-radial isothermal converting furnace comprising a furnace body, a heat-exchanging pipe bundle and a gas collector and being characterized in that the furnace body comprises a first segment of furnace body at the upper part and a second segment of furnace body at the lower part, which are detachably connected, a gas distributor is arranged in the second segment of furnace body; the upper end and the lower end of the gas distributor are respectively connected with an upper pipe plate and a lower pipe plate; an upper seal is arranged above the upper pipe plate while a lower seal is arranged below the lower pipe plate; and the heat-exchanging pipe bundle is arranged in the gas distributor. Compared with the prior art, the CO full-radial isothermal converting furnace provided by the invention has the advantage that a series of problems such as long process, multiple reaction stages, high system pressure reduction, high equipment investment, likely-occurred temperature exceeding of the converting furnace, short catalyst life, and the like in a high water-gas ratio CO conversion technique in the prior art are solved.

Owner:CHINA PETROCHEMICAL CORP +2

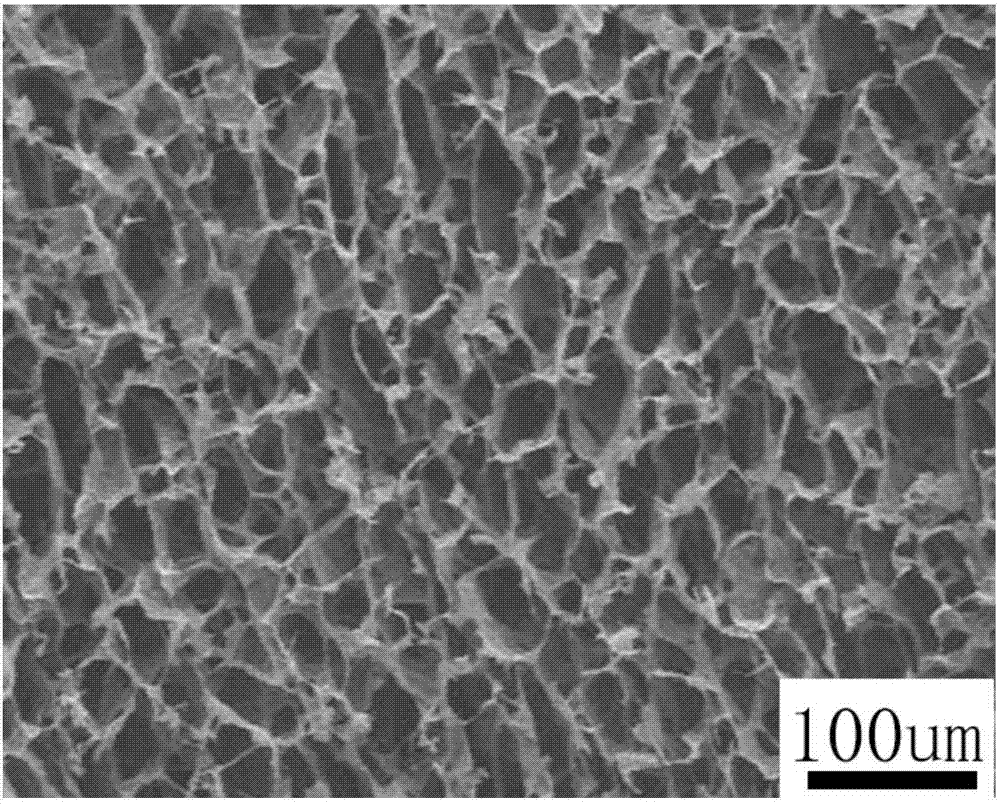

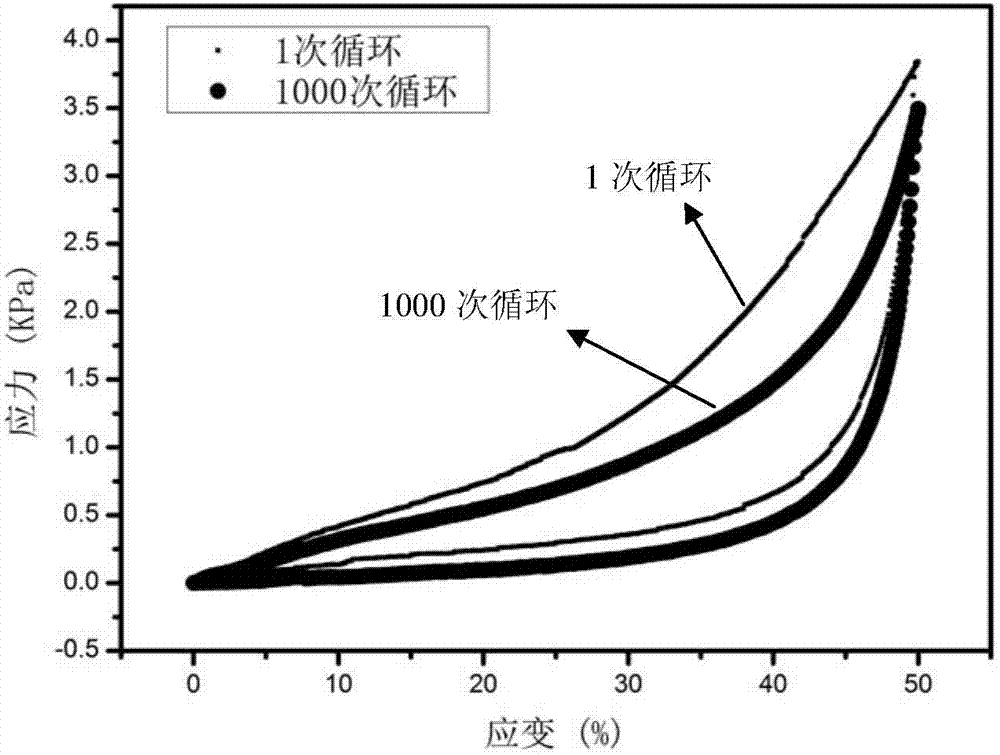

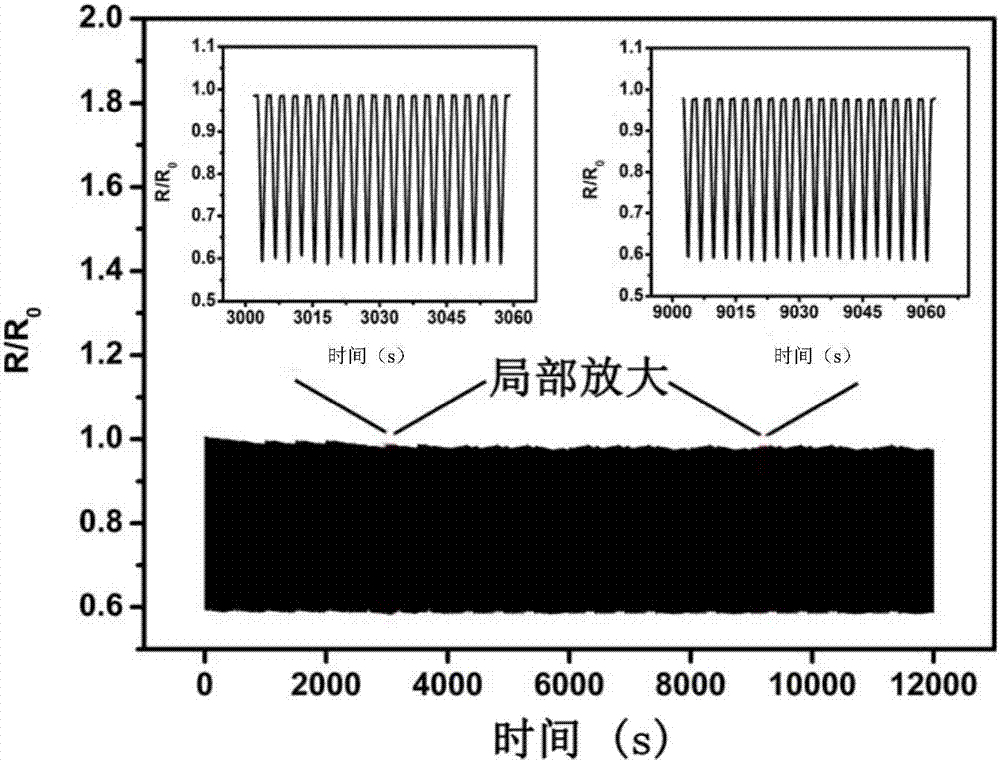

High-elasticity graphene composite deformation sensing material and preparation and application method thereof

InactiveCN107141514AReliable Resistance ResponseRegular resistance responseElectrical resistance and conductanceStress conditions

The invention belongs to the technical field of deformation sensing materials and discloses a high-elasticity graphene composite deformation sensing material and a preparation and application method thereof. The preparation method of the high-elasticity graphene composite deformation sensing material comprises (1) dispersing graphene oxide in water to obtain graphene oxide dispersing agent; (2) stirring cellulose derivatives inside the graphene oxide dispersing agent, performing standing and freeze-drying processes to obtain graphene oxide / cellulose aerogel; (3) reducing the graphene oxide / cellulose aerogel through reducing agent, and then performing thermal drying to obtain the high-elasticity graphene composite deformation sensing material. The preparation method of the high-elasticity graphene composite deformation sensing material is simple, efficient, green and environmentally friendly; the prepared high-elasticity graphene composite deformation sensing material is high in stable sensing performance and can achieve more than 4000 times of repeated and rapid loading and unloading under 70% stress conditions and recover within 1 second, thereby being good in elastic property; during deformation, the high-elasticity graphene composite deformation sensing material obtains stable, reliable and regular electrical resistance response. The high-elasticity graphene composite deformation sensing material is applied to the field of deformation sensing.

Owner:SOUTH CHINA UNIV OF TECH

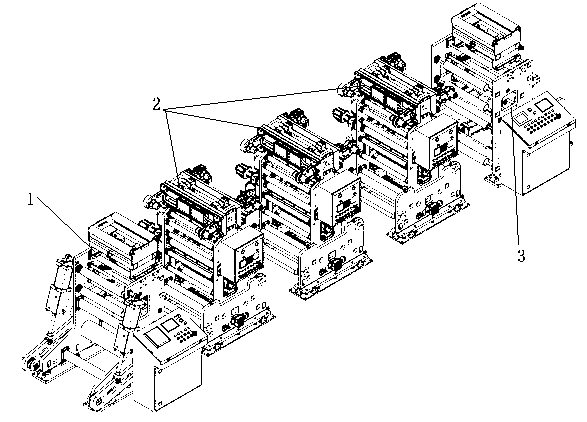

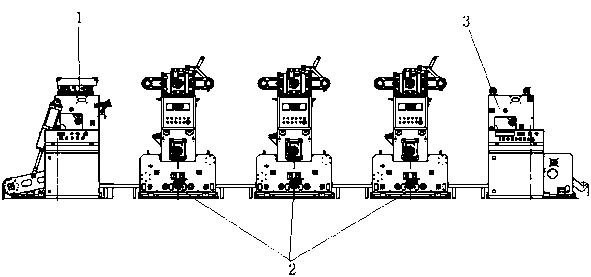

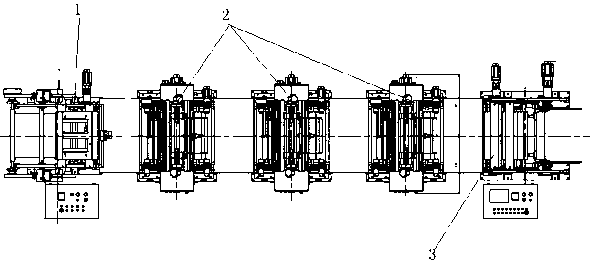

Modular wide hot stamping machine

The invention aims at providing a modular wide hot stamping machine and belongs to the field of printing equipment. According to the hot stamping machine, modular design is adopted, mechanical devices corresponding to different technologies are designed and integrated to be different modules with independent functions; a tipping paper unwinding unit and a tipping paper traction unit are integrated into an unwinding module; a film winding unit, a film unwinding unit, a film traction unit, an automatic registration unit and a gold stamping unit are integrated into a gold stamping module; and a tipping paper winding unit serves as a winding module. The units can be increased or decreased as required to change the existing combination mode in a technology application, mono-color or multicolor gold stamping can be switched quickly on the same gold stamping device, requirements for diversification, scientification, standardization, large scale and short product refresh cycles in the modern gold stamping industry are satisfied, the machine structure is exquisite and compact, accurate technique indicators and energy-saving and consumption-reducing indicators are achieved, and control performances and product quality are streamlined.

Owner:YUNNAN YUXI TIPPING PAPER FACTORY

Method for the development and quality control of flow-optimized shaped charges

ActiveUS20090217739A1Rapid turnaround testingQuick and efficient progressExplosive chargesAmmunition testingShaped chargeDesign engineer

An improved test setup facility, referred to as a “Quick Development Cell” (QDC), which allows for rapid turnaround testing with valuable feedback to a design engineer. Because the QDC allows for quick and efficient testing at a sufficient frequency, QDC tests are compatible with production quality control. In addition to fostering improvement of the API's Section 2 type tests using stressed natural rock for benchmark experiments, the QDC tests allow for progress to be made towards the development of a flow-optimized shape charge and superior well performance.

Owner:WELLS FARGO BANK NAT ASSOC +1

Portable power system

ActiveUS9287822B2Quick loading and unloadingPhotovoltaic supportsSolar heating energyElectric power systemPortable power

Owner:LEVI OFIR +3

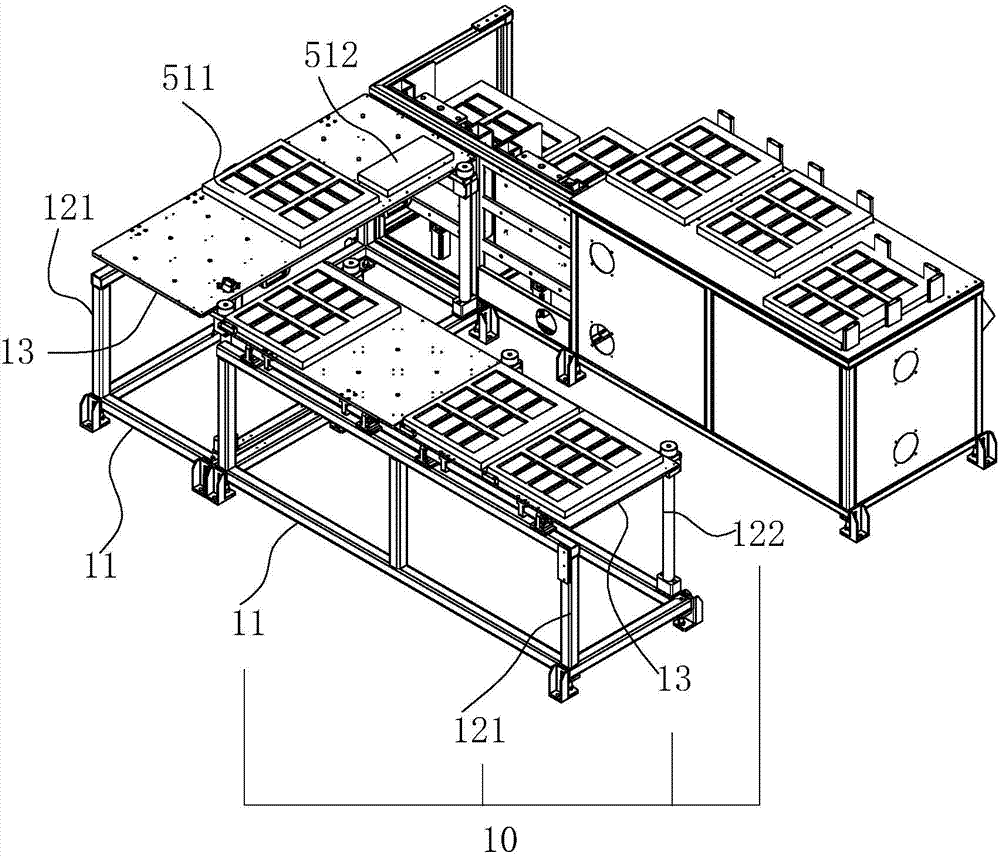

Automatic gravity gripper

ActiveCN104058182AStrong interchangeabilityFast loading and unloadingExternal framesEngineeringMechanical engineering

The invention relates to a gripper for transportation and storage. The gripper consists of a gripper seat assembly, a square shaft assembly, groove-shaped movable gripping head assemblies and a spine lock assembly, wherein the gripper seat assembly looks like a square with a half capable of being separated and combined, and the gripper seat assembly is fastened integrally through screws and adjusting connecting plates; the square shaft assembly is fastened on square holes for square shafts of the gripper seat assembly through fastening nuts; each groove-shaped movable gripping head assembly looks like a bow, the left and right groove-shaped movable gripping head assemblies can be matched to form a sleeved ring which can be opened and closed, and the groove-shaped movable gripping head assemblies are mounted in hinge pin holes in front ends of the square shafts through hinge pins and can be freely opened at 45 degrees-135 degrees; the spine lock assembly penetrates through round spine lock assembly through holes above the front side of the gripper seat assembly and is fastened on the square shafts through screws. The automatic gravity gripper is generally applicable to transportation and storage, and parts are high in interchangeability and can be produced in batches in a standard manner (the automatic gravity gripper can also be assembled on a liftable trolley and is quick, convenient and safe in object transportation, loading and unloading).

Owner:江苏北华微电子科技有限公司

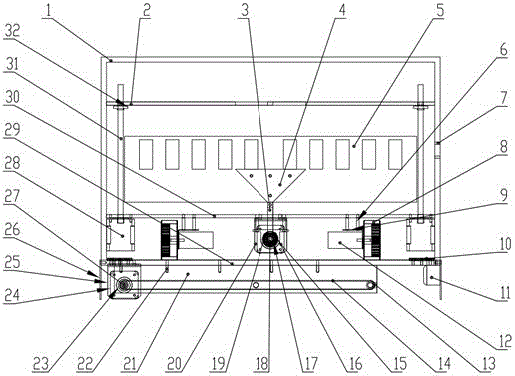

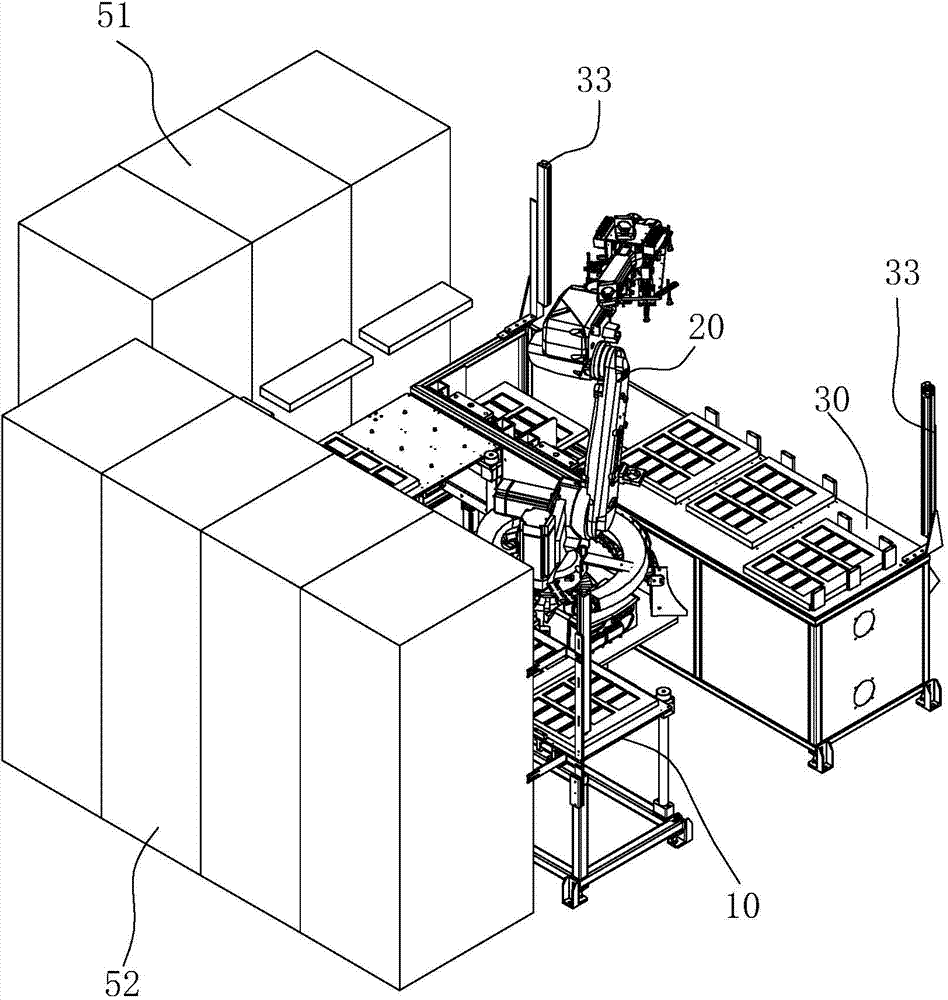

Turnover platform plate and robot feeding and discharging system for PCBA (Printed Circuit Board Assembly) test

ActiveCN104501849AImprove work efficiencyImprove maintenance efficiencyMeasurement apparatus componentsPrinted circuit boardElectric cables

The invention discloses a turnover platform plate and a robot feeding and discharging system for a PCBA (Printed Circuit Board Assembly) test. The turnover platform plate comprises a rectangular base, supports and a bearing plate, wherein the supports are arranged at two sides of the base, and the bearing plate is arranged at the upper ends of the supports; the supports comprise hinging supports which are provided with hinges and detachable supports which are provided with movable check blocks; one side edge of the bearing plate is connected with the hinging supports in a hinging way, and the other side edge of the bearing plate is supported on the movable check blocks on the detachable supports; the bearing plate downwards rotates to the inner side edges of the hinging supports when the movable check blocks rotate to the outside. According to the turnover platform plate disclosed by the invention, the bearing plate can be put down during maintenance, thus a maintainer can enter for maintenance operation, and the maintenance efficiency is greatly increased. The robot feeding and discharging system disclosed by the invention adopts a robot for feeding and discharging, thus quick feeding and discharging can be realized, and the working efficiency of a PCBA test device can be increased. The robot adopts a flexible body fixing device, so that an air pipe and an electric cable can be movably fixed on a rotating arm, the robot is flexible and little space is occupied.

Owner:SHENZHEN RAPOO TECH

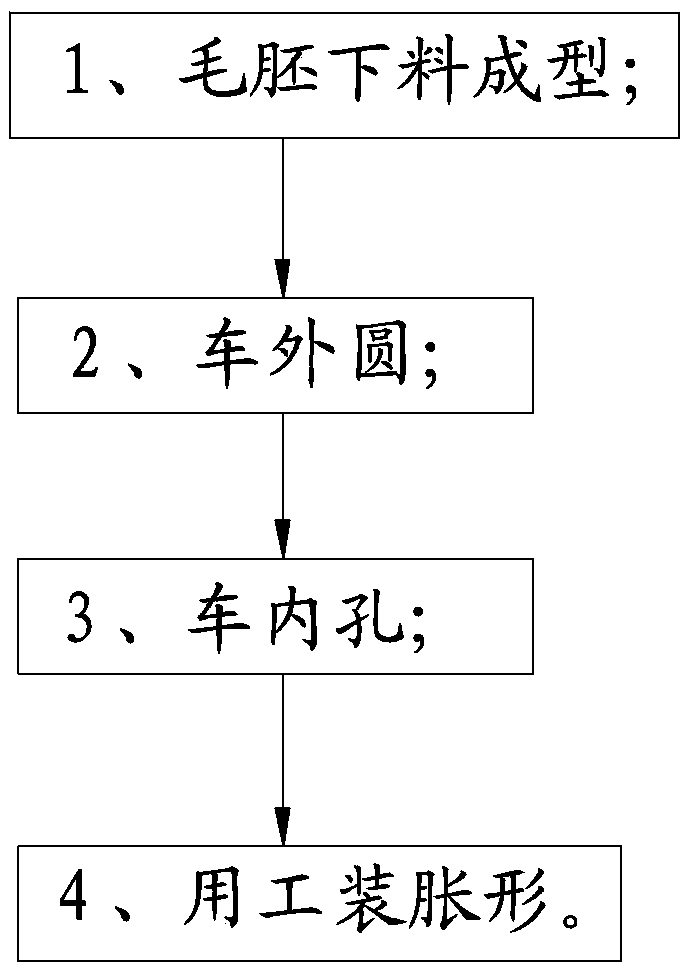

Cabin processing method and bulging tooling used in same

The invention relates to the technical field of aerospace industries, in particular to an aircraft cabin processing method and a bulging tooling used in the same. The method comprises the following steps: 1, blank blanking; 2, machining an excircle; 3, machining an inner hole, wherein the size of the machined inner hole is smaller than that of a nominal size; 4, using a tooling to perform bulging up to meet a required size. According to the method, the machining and the bulging processing are adopted, so that the precision requirements on the machining are greatly reduced, the production efficiency is improved, the consistency and the qualification rate of finished products are greatly improved, the manufacturing cost is relatively reduced, the cost is greatly reduced, and the economic efficiency is improved.

Owner:北京新航钛空天技术有限公司

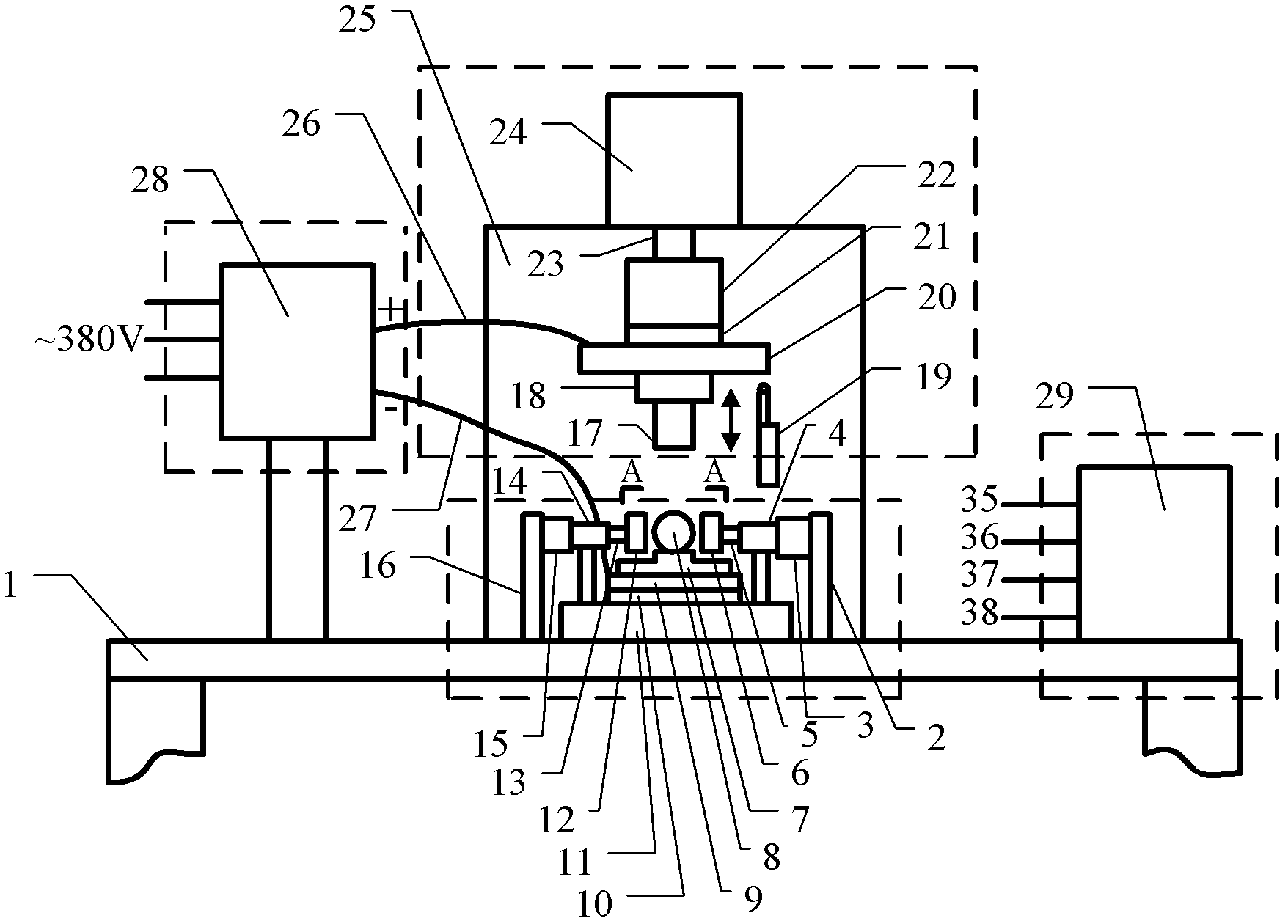

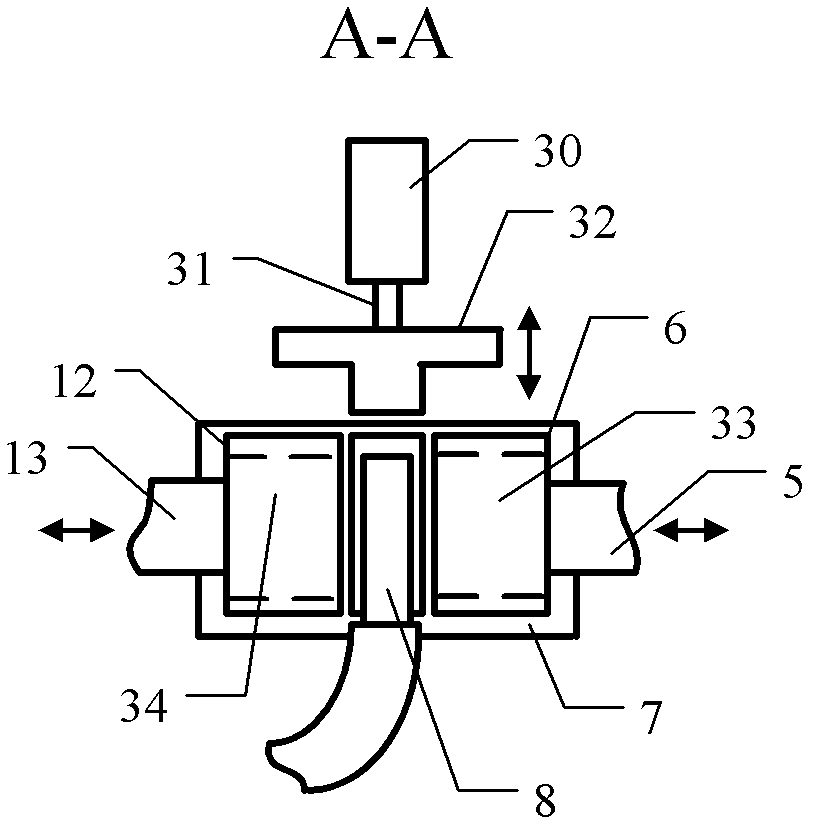

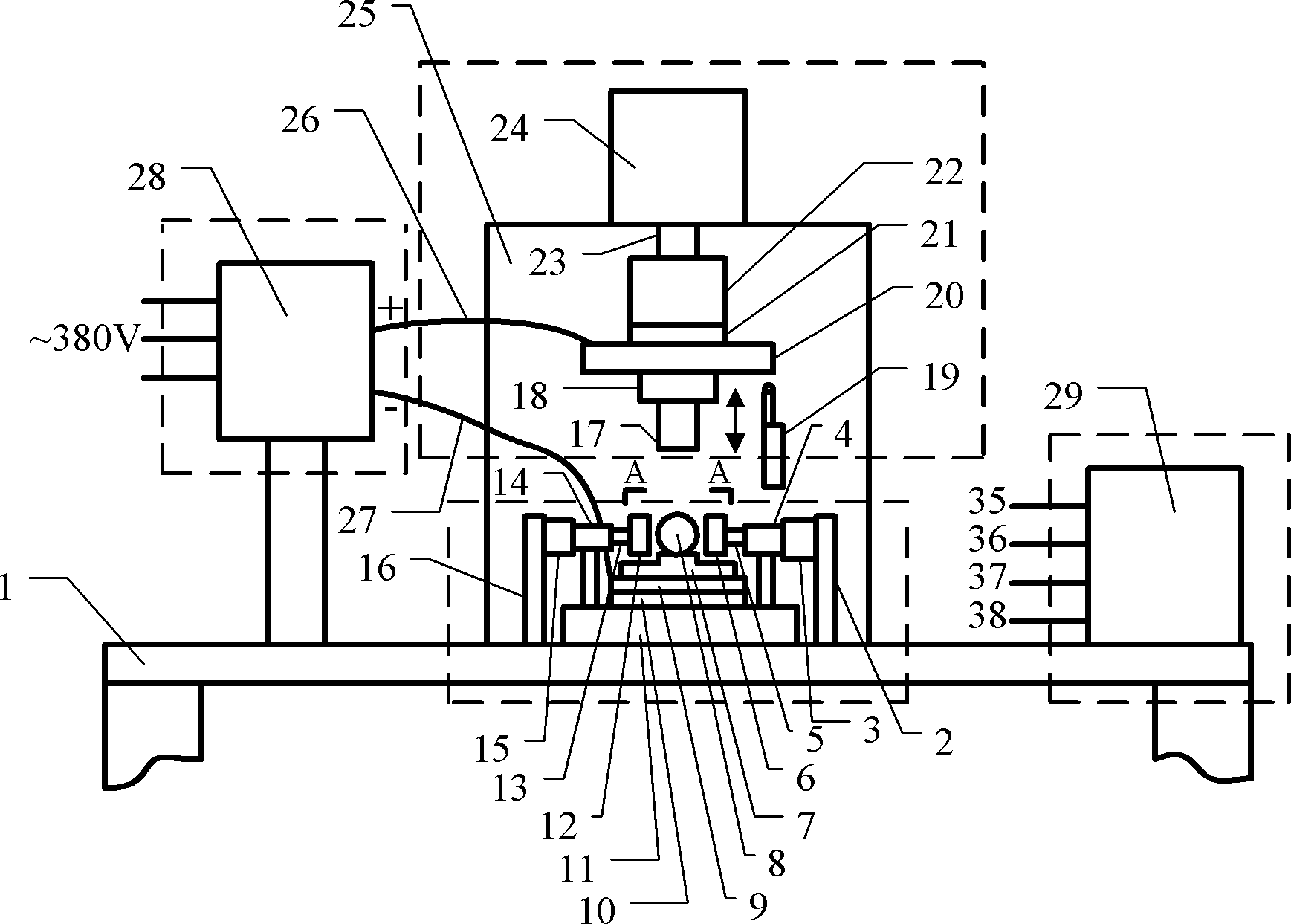

Multi-wire copper harness end forming device and forming method thereof

InactiveCN102528258AQuick loading and unloadingLoad Stability ControlWelding/cutting auxillary devicesWelding electric supplyElectrical resistance and conductancePower flow

The invention discloses a multi-wire copper harness end forming device and a method for forming a multi-wire copper harness end by the aid of the multi-wire copper harness end forming device, which are used for solving the technical problem that connection quality of a multi-wire copper hardness and a conducting copper plate is poor by an existing resistance welding method. The technical scheme includes that the device comprises a worktable (1), a power source (28), a controller (29), a forming fixture and a pressurizing mechanism, high-precision forming of the multi-wire copper harness end is realized under the effect of pressure, two sides of the forming fixture are made of high-temperature-resistant ceramic insulating materials, heating current which is precisely controlled uniquely flows through the multi-wire copper harness end assuredly, a stopping mechanism and a copper hardness end positioning mechanism which are disposed on two sides of the forming fixture adopt an electronic-controlled pneumatic closing mode, a copper harness can be quickly assembled and disassembled, the device is provided with a mum-grade high-precision displacement sensor, and a method for controlling conduction time by the aid of deformation displacement quantity is adopted and matches with the forming fixture, so that stably control of high-precision dimension when the multi-wire copper harness end is formed is realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Constant pressure control assisted manipulator

InactiveCN104227696AIncrease flexibilityWide versatilityProgramme-controlled manipulatorGripping headsSuction forceEngineering

The invention belongs to a manipulator used in the machinery and carrying industry and relates to a constant pressure control assisted manipulator, which is designed by combination of computerized control, pressure control and theory of machines and mechanisms. A pressure control valve is controlled via a computer technological program, the manipulator is allowed to quick hold, transmit and handle a workpiece, different command parameters are set in a computer, a certain action is executed just after a corresponding command parameter is input, the certain part of the manipulator is allowed to operate, and the manipulator is commanded to finish a task. A cylinder can be kept outputting balanced pressure, pressure impact and bounce are decreased, and the performance of a machine and safety and reliability thereof are improved. A travelling device allows mobile operations. A unique claw design allows the manipulator to adaptively hold the workpieces different in shape material and weight. An electromagnetic sucker can be mounted at the position, where a claw is mounted, of a clamping cylinder, and workpieces are picked via magnetic attraction of an electromagnet. A multi-DOF (degree of freedom) design allows better flexible and universality for the manipulator, and work efficiency is improved.

Owner:盐城市昱博汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com