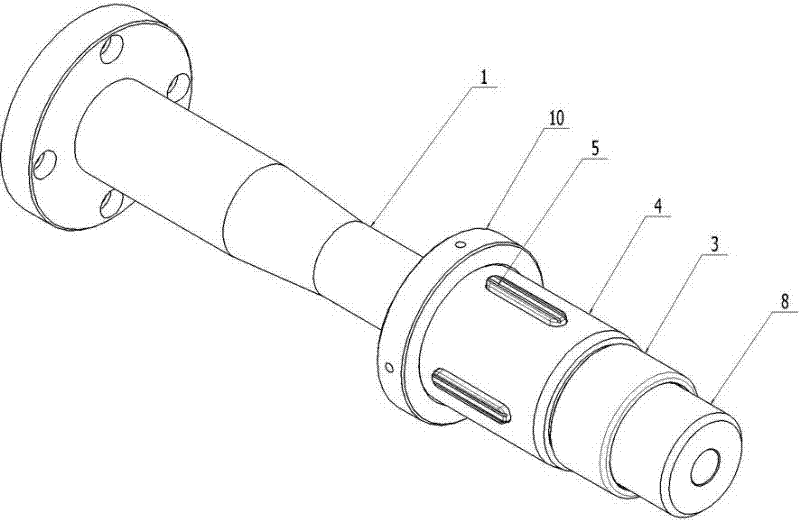

Wedge-block-type unwinding shaft used in production line of disposable hygienic products

A technology for sanitary products and production lines, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc. It can solve the problems of troublesome replacement of materials, inability to maintain constant tension, unstable unwinding, etc., to achieve convenient loading and unloading, and compact structure. Sophisticated, simple-looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

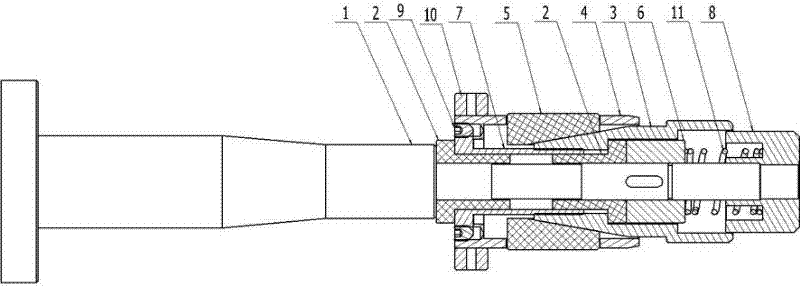

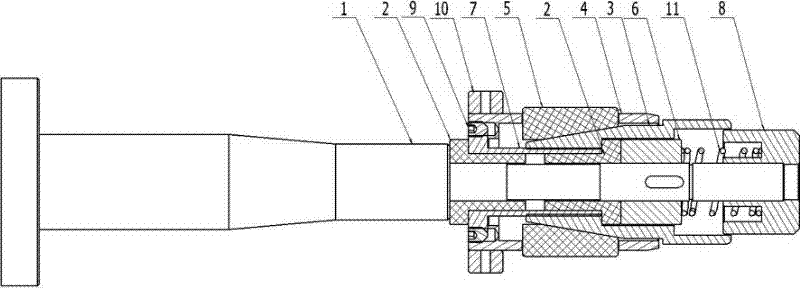

[0020] see figure 1 and figure 2 , the wedge-type unwinding material shaft used in the production line of disposable sanitary products includes a fixed shaft 1, which is a stepped shaft, and the end of the large-diameter section is a flange for fixed installation on the frame; The small-diameter section is successively fitted with a left guide sleeve 2A, a right guide sleeve 2B, a spacer 6 and a compression spring 11. The spacer 6 is installed on the fixed shaft 1 through a key, and the spacer 6 is connected with the fixed shaft 1 through a key and cannot be rotated. , but it can slide axially along the fixed shaft when the hand wheel 8 is screwed in and out. The end of the small-diameter section of the fixed shaft 1 is connected to the handwheel 8 through thread fit. The inner end of the handwheel 8 is provided with a ring groove. touch.

[0021] Both the left guide sleeve 2A and the right guide sleeve 2B are flange-shaped, and the material is nylon. The small diameter e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com