Steel tube derusting device

A technology of steel pipes and mounting seats, which is applied in the direction of grinding drive devices, grinding machines, and parts of grinding machine tools. It can solve the problems of reducing economic benefits, high labor intensity, and affecting production, and achieves small size, convenient movement, and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now the present invention is further described in conjunction with description of drawings and embodiments:

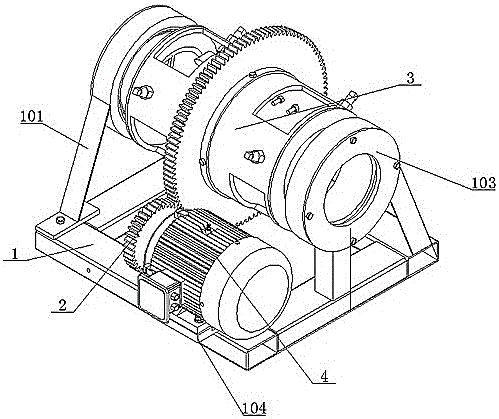

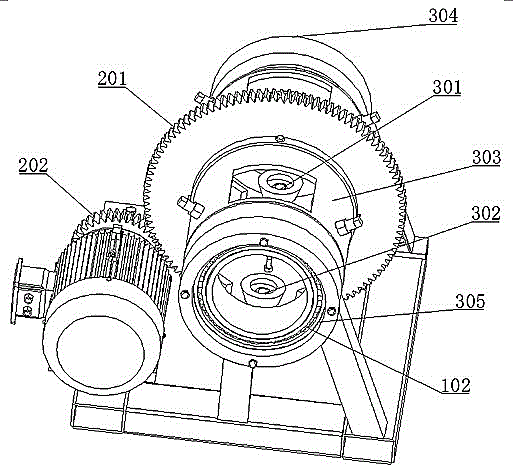

[0020] refer to figure 1 and figure 2 , steel pipe derusting device, comprising frame 1 and transmission mechanism 2 installed on frame 1, derusting mechanism 3 and motor 4, wherein: described frame 1 both sides are provided with detachable side frame 101, so Described side frame 101 is provided with fixed steel ring, and described derusting mechanism 3 is located between two fixed steel rings, and described derusting mechanism 3 comprises three hard brushes 301 and soft brush 302, cylinder 303, and described cylinder 303 Including a pipe inlet 304 and a pipe outlet 305, the hard brush 301 is arranged on the surface of the cylinder 303 and is close to the pipe inlet 304, the soft brush 302 is arranged on the surface of the cylinder 303 and is near the outlet 305, the rust removal The mechanism 3 is connected with the motor 4 through the transmission mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com