Patents

Literature

631results about How to "Simple appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

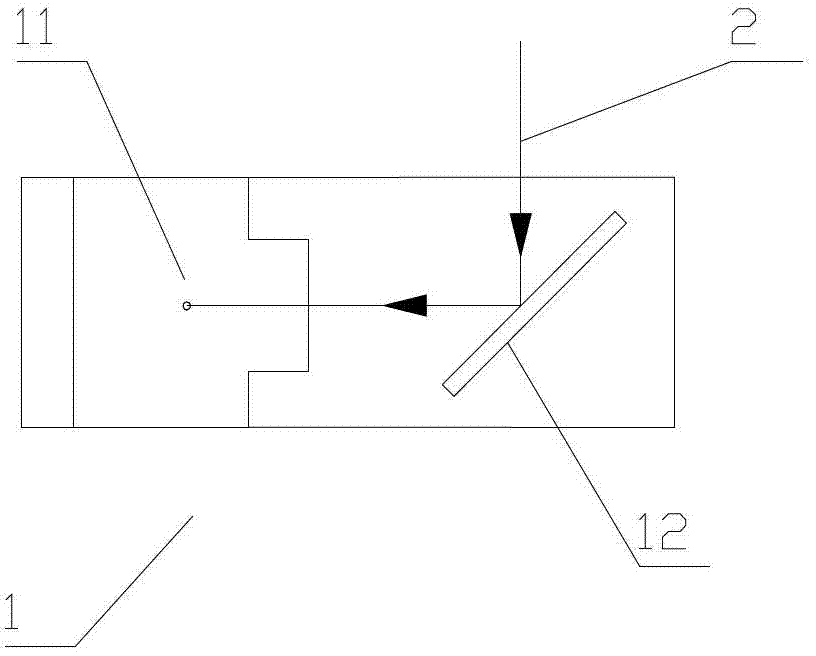

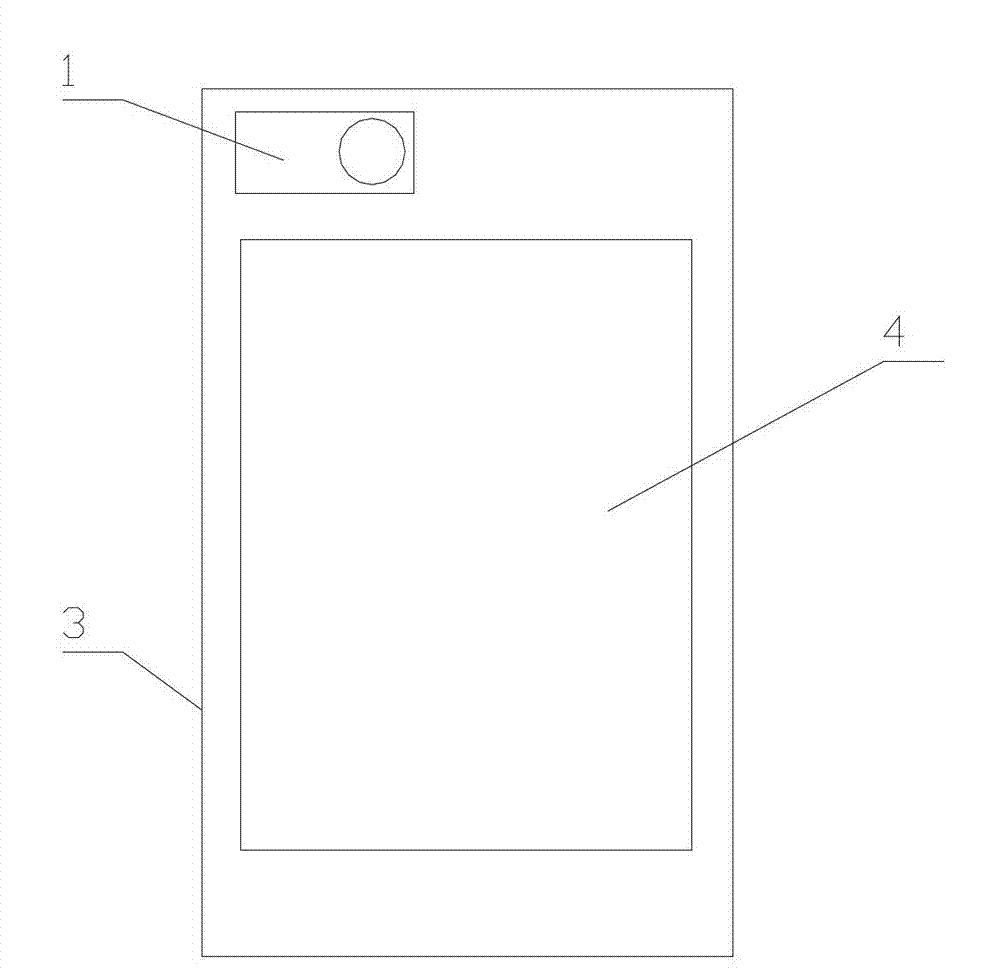

Camera structure and mobile phone provided with same

InactiveCN103200356AReduce in quantityCompact structureTelevision system detailsColor television detailsCamera lensPersonal computer

The invention discloses a camera structure. The camera structure comprises a camera and a lens arranged in front of a camera lens of the camera. The invention further discloses a mobile phone. The mobile phone comprises the camera structure. Light can enter the camera structure from two sides, and the camera structure and components, such as the mobile phone and a tablet personal computer, provided with the camera structure are integrated. The mobile phone provided with the camera structure is simple in structure, a pixel of a front-facing camera and a pixel of a rear camera are identical, shooting effect is improved, and the mobile phone is convenient to use.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

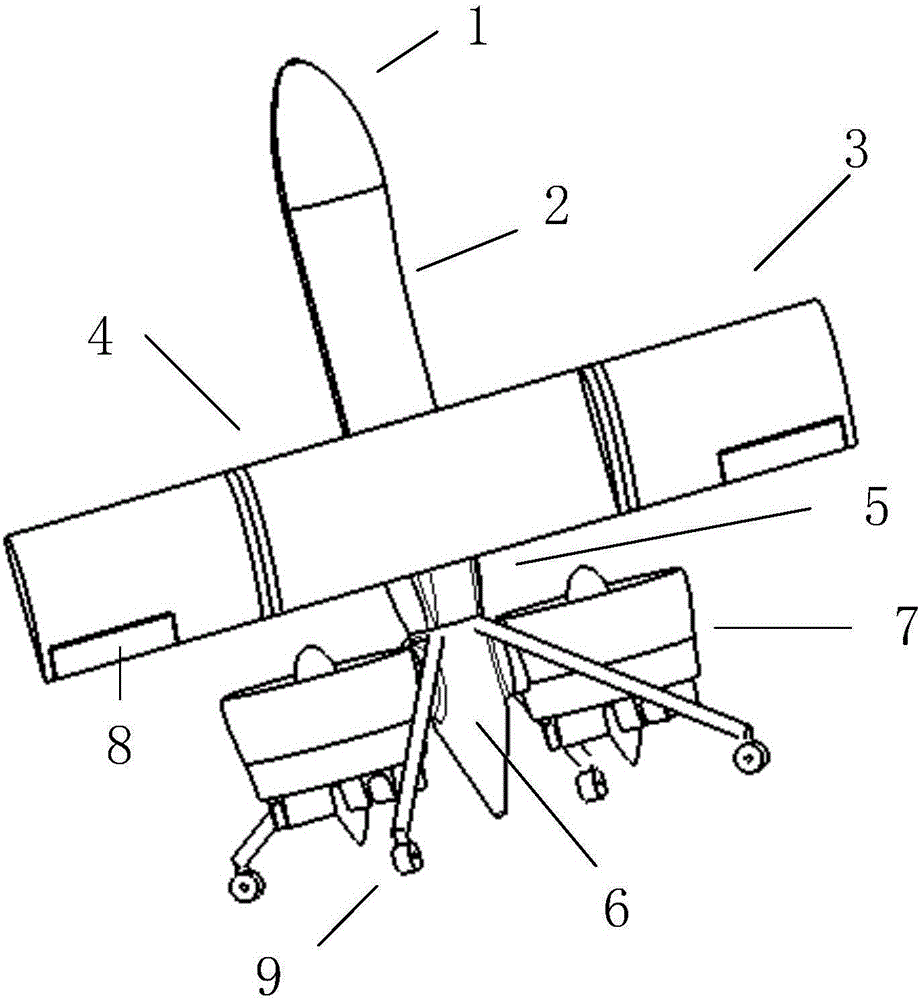

Vertical takeoff and landing unmanned aerial vehicle with foldable fixed wings based on dual-duct fan power system

ActiveCN107176286AImprove aerodynamic performanceBarrier formationPropellersRemote controlled aircraftLow speedTrailing edge

The invention discloses a vertical takeoff and landing unmanned aerial vehicle with foldable fixed wings based on a dual-duct fan power system. A dual-duct fan power system which is horizontally arranged at the tail of the body of the unmanned aerial vehicle in a tail-driving arrangement is adopted, so that lifting force for vertical takeoff and landing and thrust for horizontal flying are provided for an aircraft; a control surface which is arranged at the exit of each duct in a deflected manner is used for providing vector thrust, so that quick attitude change is realized; wings adopt a folding wing configuration, when the aircraft vertically takes off and lands / flies at a low speed, the wings are folded to decrease the frontal area of cross wind, and when the aircraft flies horizontally, the wings are unfolded to obtain large lifting force; and combined optimization of ducts and the wings is adopted, the wings are arranged in a specific duct air flow region, the duct suction generates a Coanda effect at a wing edge, so that the properties of the wings are improved. Multi-mold flight tasks such as vertical takeoff and landing, high-speed cruise, and the like of the aircraft are realized; the vertical takeoff and landing aircraft is high in aerodynamic efficiency during hanging in the air / flying at a low speed; and the vertical takeoff and landing unmanned aerial vehicle is high in anti-disturbance capacity during takeoff and landing / hanging in the air. The vertical takeoff and landing unmanned aerial vehicle is low in energy consumption, small in noise and high in safe reliability.

Owner:SOUTH CHINA UNIV OF TECH

Vegetable-flavored rhizome pickled vegetables and preparation method thereof

ActiveCN103584031AReduce consumptionRetain nutrientsFood ingredient functionsFood preparationSalty tasteFood flavor

The invention belongs to the field of pickled food processing, and in particular discloses vegetable-flavored rhizome pickled vegetables and a preparation method of the vegetable-flavored rhizome pickled vegetables. The preparation method of the vegetable-flavored rhizome pickled vegetables is characterized in that the preparation method comprises the following steps: taking rhizome vegetables as raw materials such as red carrot, white radish, carrot, kohlrabi, mustard tuber, Chinese artichoke, fresh ginger, allium chinensis, rutabaga, horseradish, Alpinia japonica, common beet, Jerusalem artichoke, sweet potato, taro, potato, Chinese yam, burdock and Platycodon grandiflorum; airing the raw materials, blending with a flavored curing material, pickling, tidying the vegetables, packaging and sterilizing. The flavored curing material is prepared by mixing and blending vinasse for making red wine, a salt agent, a sweetening agent, a sour agent, a tasty agent and a natural flavoring agent. The flavored curing material is mixed with the aired vegetable blocks, strips or pieces to be pickled. The vegetable-flavored rhizome pickled vegetables not only retain the special feature and nutrients of the original vegetables, but also increase flavor and nutrition of the natural flavoring agent through the pickling process, and enrich food constitutions on the table. The method is suitable for industrial volume production, low in price, beneficial to consumption of wage-earning class, and capable of achieving good market prospect.

Owner:徐州绿之野生物食品有限公司

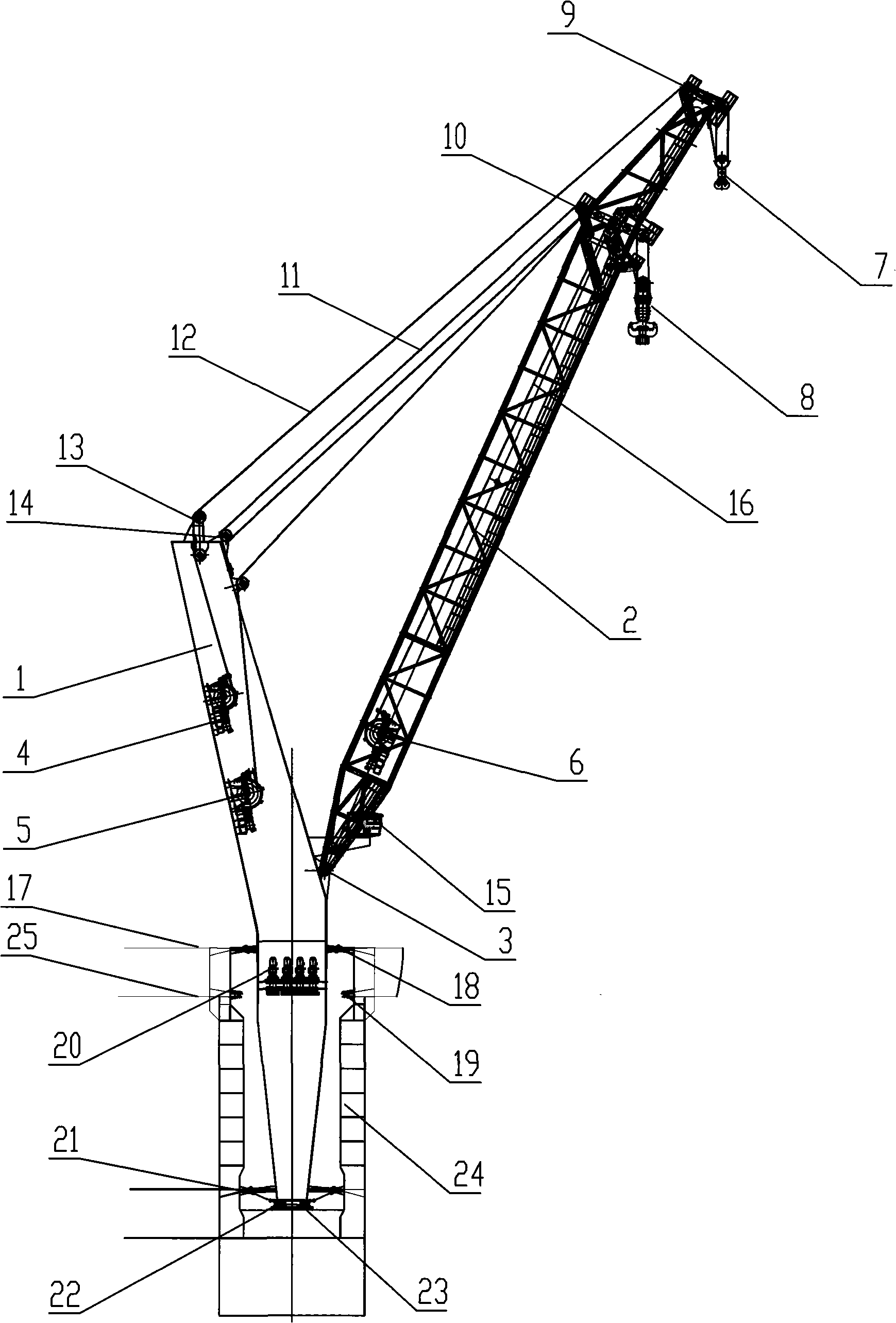

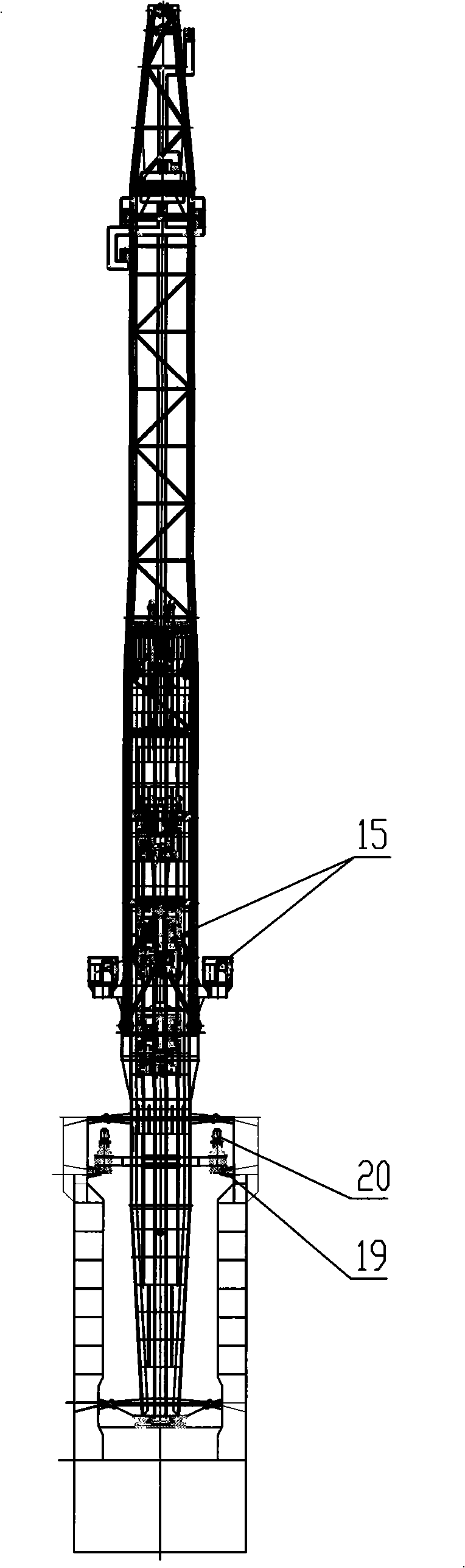

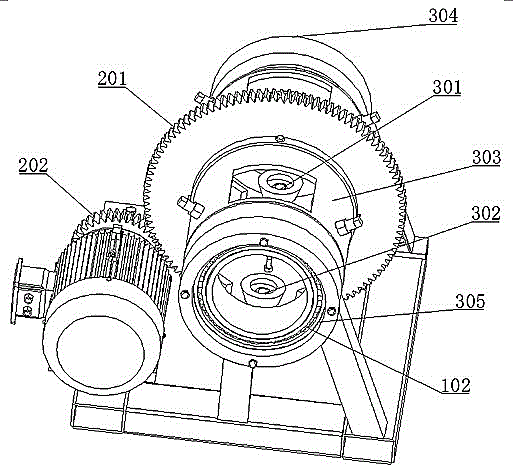

Large-scale full-turning offshore platform crane

ActiveCN101343021ASmall sizeSolve the problem of occupying a large deck areaCargo handling apparatusPassenger handling apparatusGyrationThrust bearing

The invention provides a large full-gyration offshore platform crane which relates to the lifting machinery and comprises a rotary column, an arm support, a main lifting winch, an auxiliary lifting winch, an arm support variable-breadth winch, a gyration bearing drive mechanism, a main hanger hook, an auxiliary hanger hook and a driver cab. The arm support is connected with the middle part of the rotary column through a hinge point mounted on the root of the arm support; the lower half part of the rotary column is arranged under a main deck and connected with a semi-diving platform through the gyration bearing drive mechanism. The gyration bearing mechanism is composed of an upper radial bearing, a lower radial bearing, a peg-tooth, a three-in-one decelerator, a centripetal thrust bearing and a rubber support; the upper radial bearing and the lower radial bearing are respectively mounted on the middle and the lower parts of the rotary column. The centripetal thrust bearing and the rubber bearing are sequentially mounted on the bottom part of the rotary column; the peg-tooth mounted on the lower deck is meshed with the three-in-one decelerator mounted on the corresponding position of the rotary column. The large full-gyration offshore platform crane has the advantages of novel, compact and practical structure, high efficiency and being a large full-gyration offshore platform crane with economical and practical properties.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

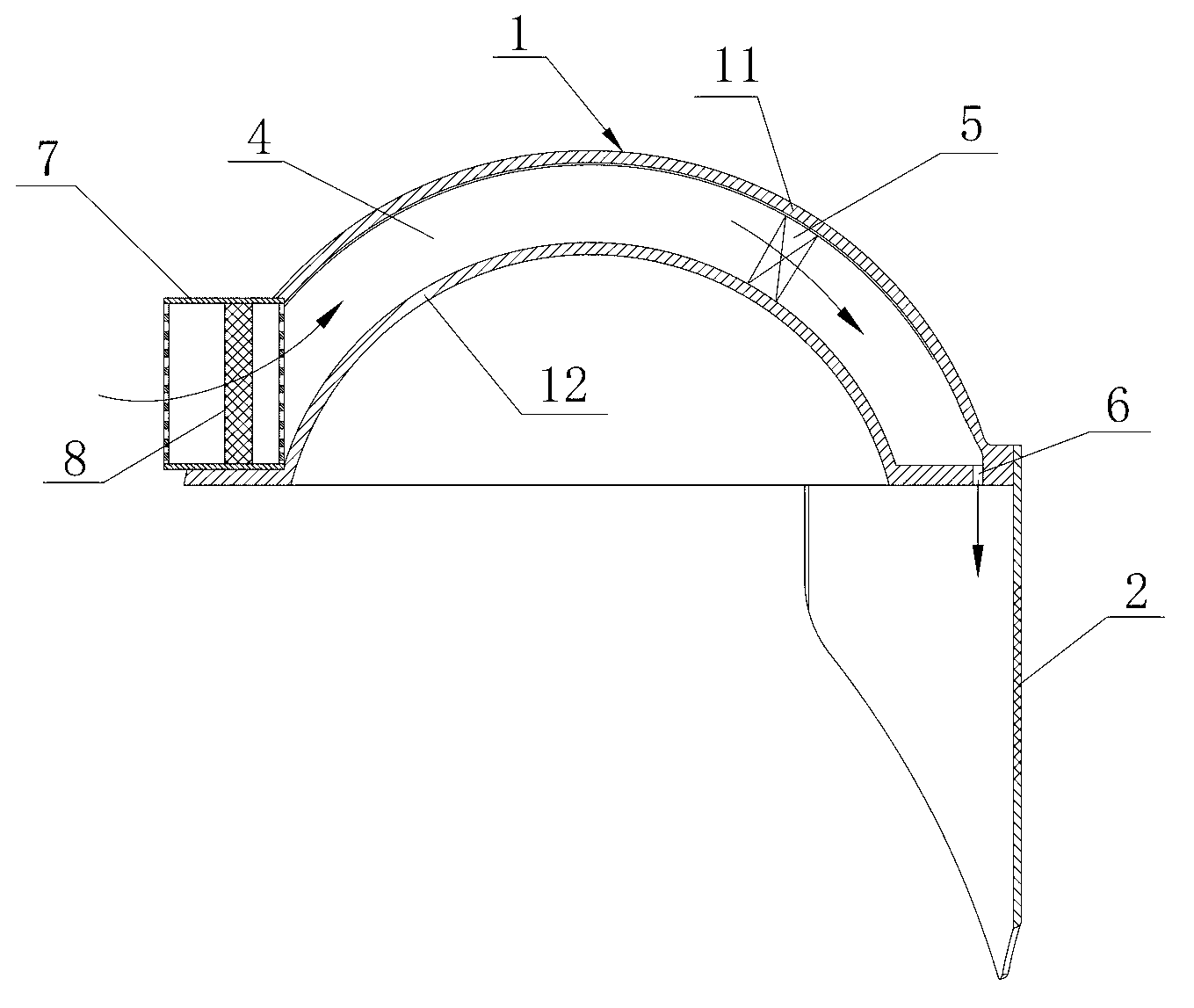

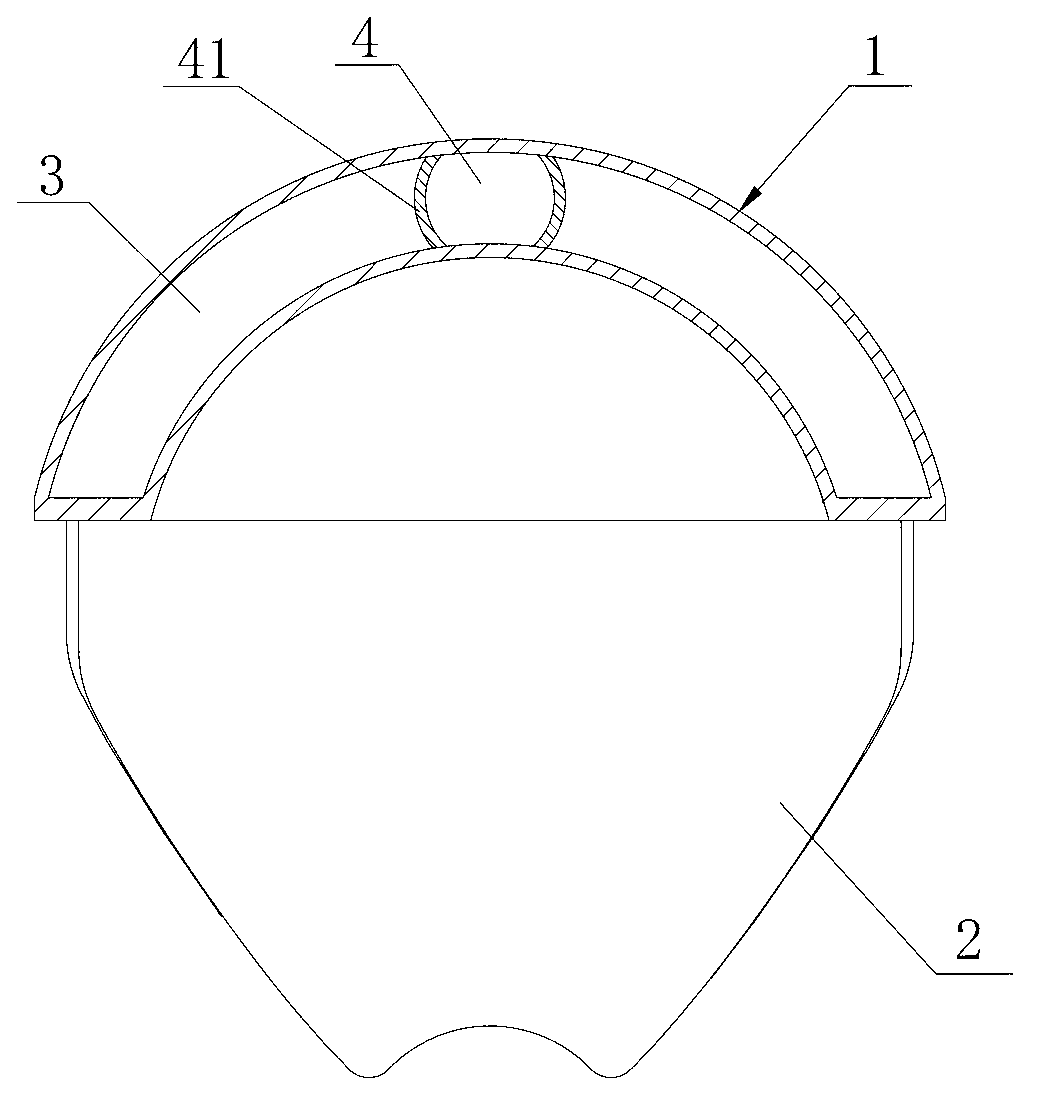

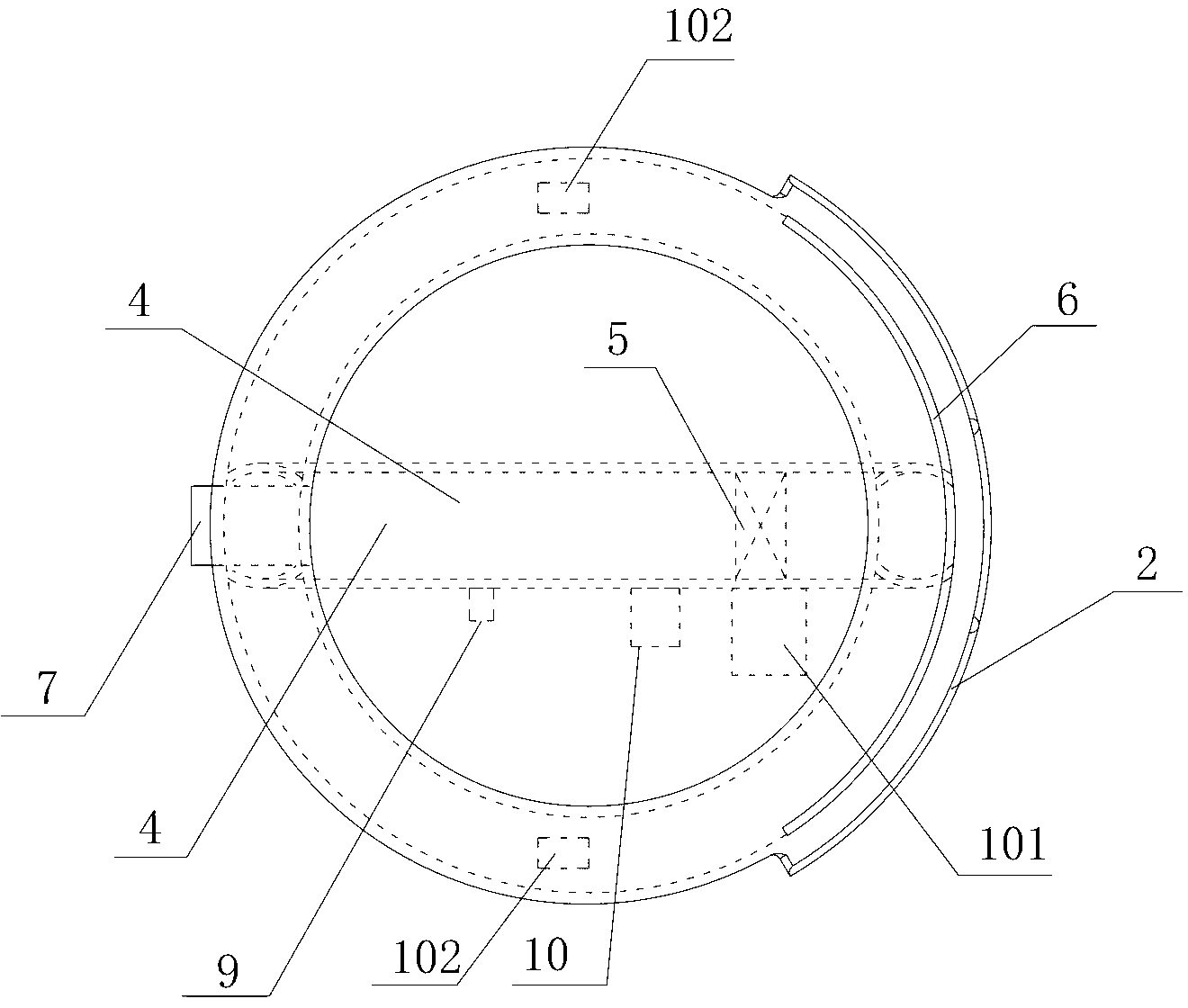

Semi-open type positive-pressure air supplying and purifying helmet shield

ActiveCN103223214ASimple appearanceEasy to useBreathing masksFire rescueExternal connectionSemi open

The invention discloses a semi-open type positive-pressure air supplying and purifying helmet shield which comprises a helmet, a shield, a power unit, an air filtering device and an air pressure and voltage alarm device as well as a static pressure box, wherein the shield is arranged in front of the helmet; a shield body extends downward to cover outside a human face; a gap is formed between the shield and the human face; the power unit comprises a fan and a power supply; the static pressure box, the power unit and the air filtering device are the arranged in the helmet; two ends of the static pressure box are an air inlet end and an air outlet end respectively; a blow-off nozzle facing downward is arranged at the front edge of the helmet; the fan in the power unit and the air filtering device are arranged in middle of the static pressure box and at the air inlet end respectively; and the air filtering device is a filter with a filter element made of an electret air filtering material. The helmet shield has functions of preventing dust, waste gas and bacterial virus, no other external connection pipeline device is required to be carried, the structure is simple, a user can conveniently wear the helmet shield and breathe smoothly and comfortably with the helmet shield.

Owner:JINAN UNIVERSITY

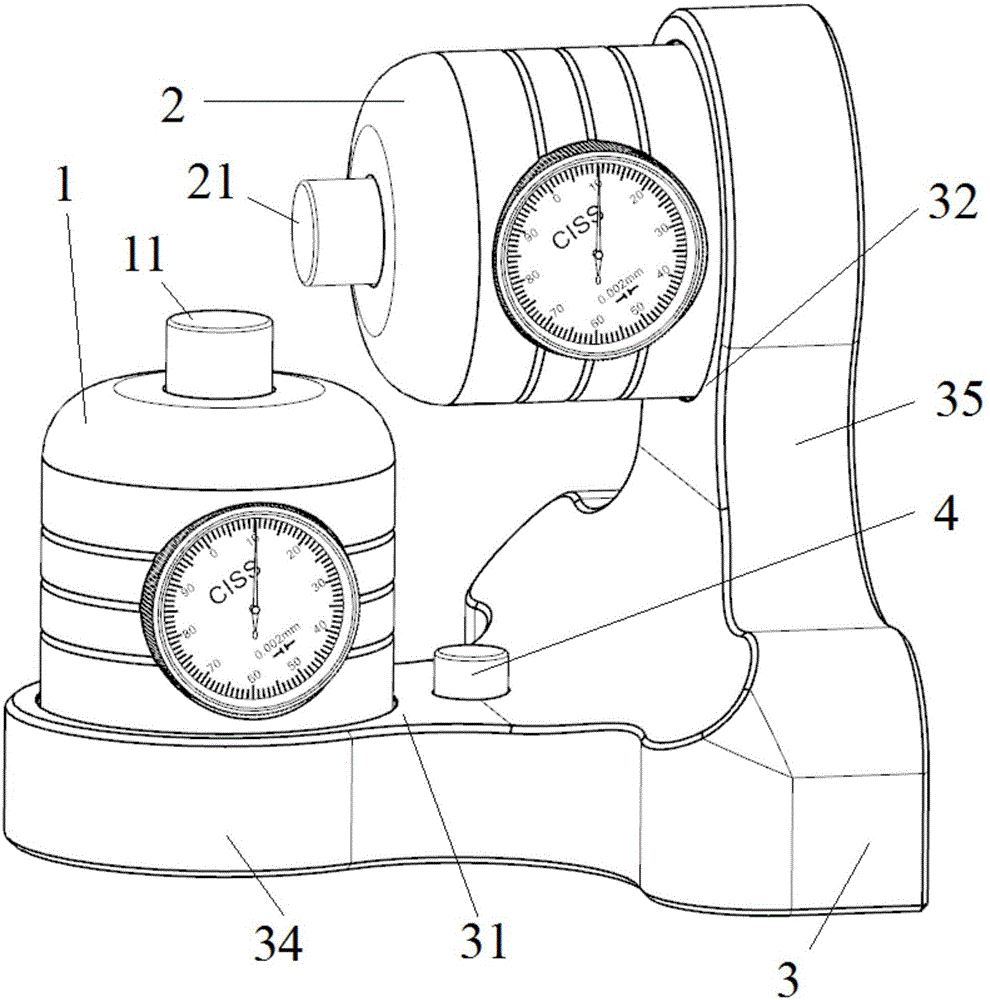

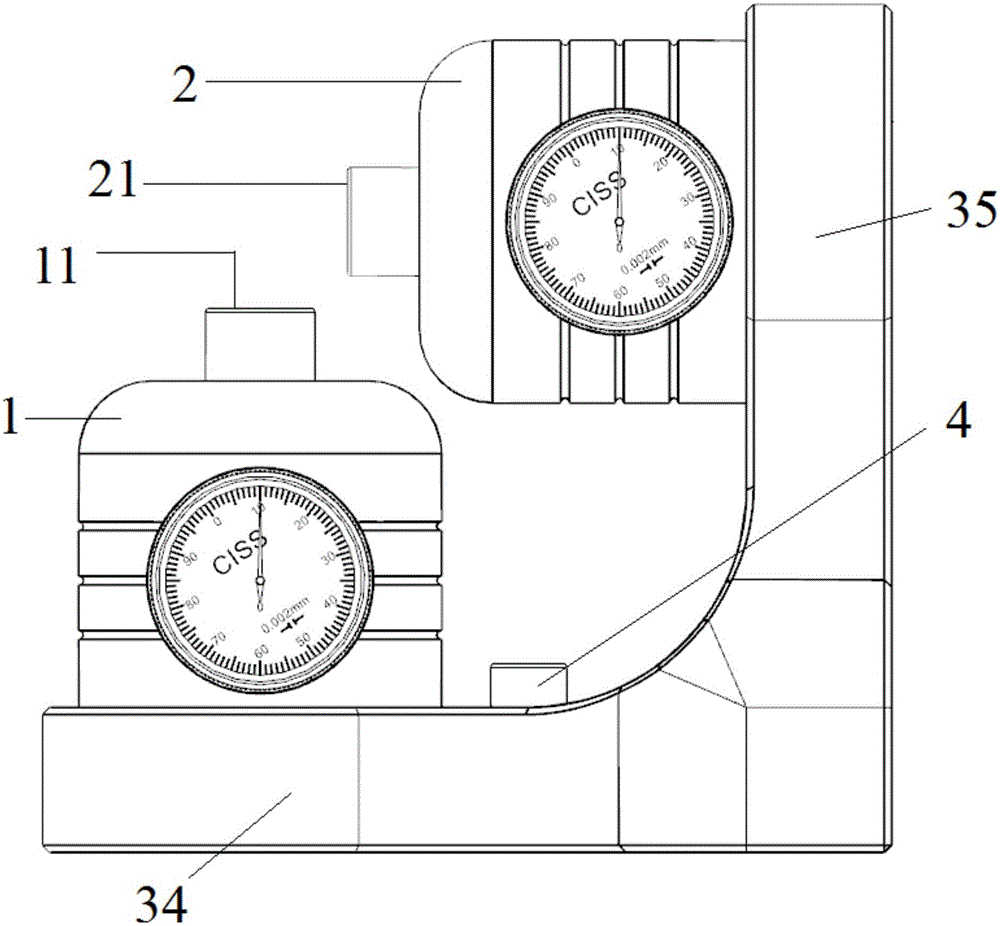

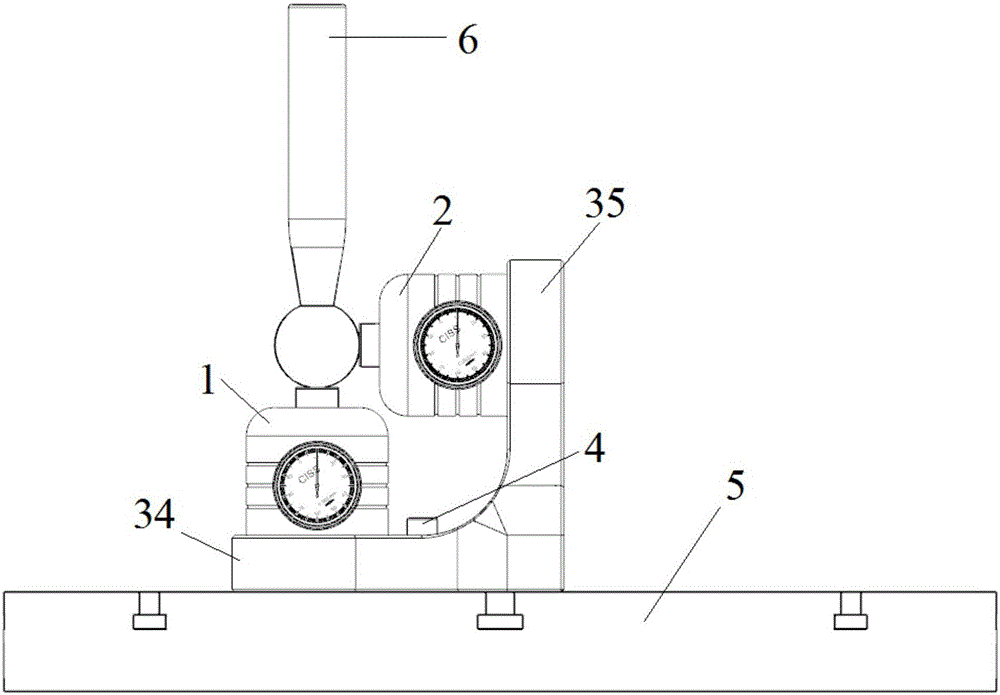

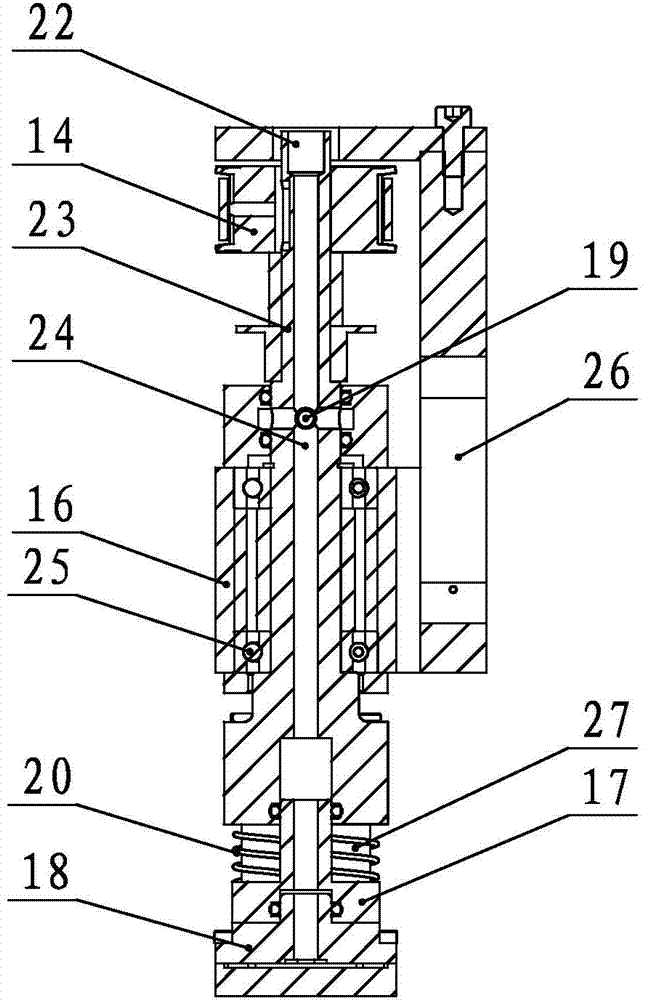

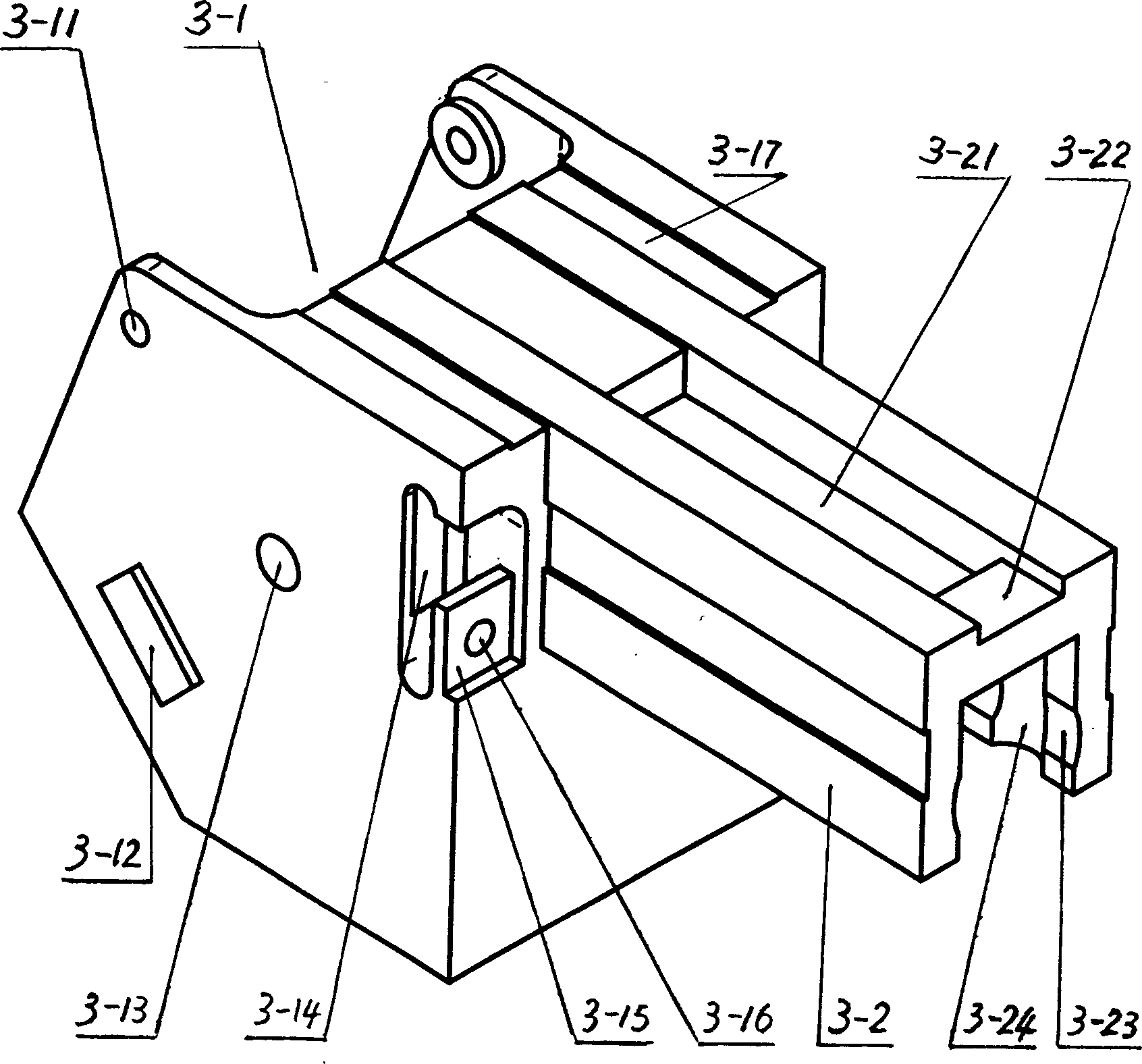

Five-axis linkage machine tool RTCP dynamic precision calibrating apparatus and calibrating method thereof

ActiveCN105043190AEasy to operateImprove calibration accuracyMechanical measuring arrangementsGeometric errorEngineering

The invention discloses a five-axis linkage machine tool RTCP dynamic precision calibrating apparatus and a calibrating method thereof. The apparatus comprises a support, and a first face contact type dial gauge and a second face contact type dial gauge both arranged on the support. The central axes of the two face contact type dial gauges are perpendicular to each other and located in the same plane. The apparatus satisfies the following formula: d1=d2<=r-3mm. d1 is the distance between the measuring end face of the first face contact type dial gauge to the vertically intersecting point of the central axes of the two face contact type dial gauges. d2 is the distance between the measuring end face of the second face contact type dial gauge to the vertically intersecting point of the central axes of the two face contact type dial gauges. r is the bulb radius of a bulb test rod for calibration. By using the two face contact type dial gauges arranged on the support, the apparatus prevents complex equation solving processes, conventional dial gauge calculating errors and measuring geometric errors, and complex operations during a conventional calibration method using process. The calibration efficiency and the calibration precision are thus greatly improved. The invention further discloses a calibrating method for the five-axis linkage machine tool RTCP dynamic precision calibrating apparatus.

Owner:中工科安科技有限公司

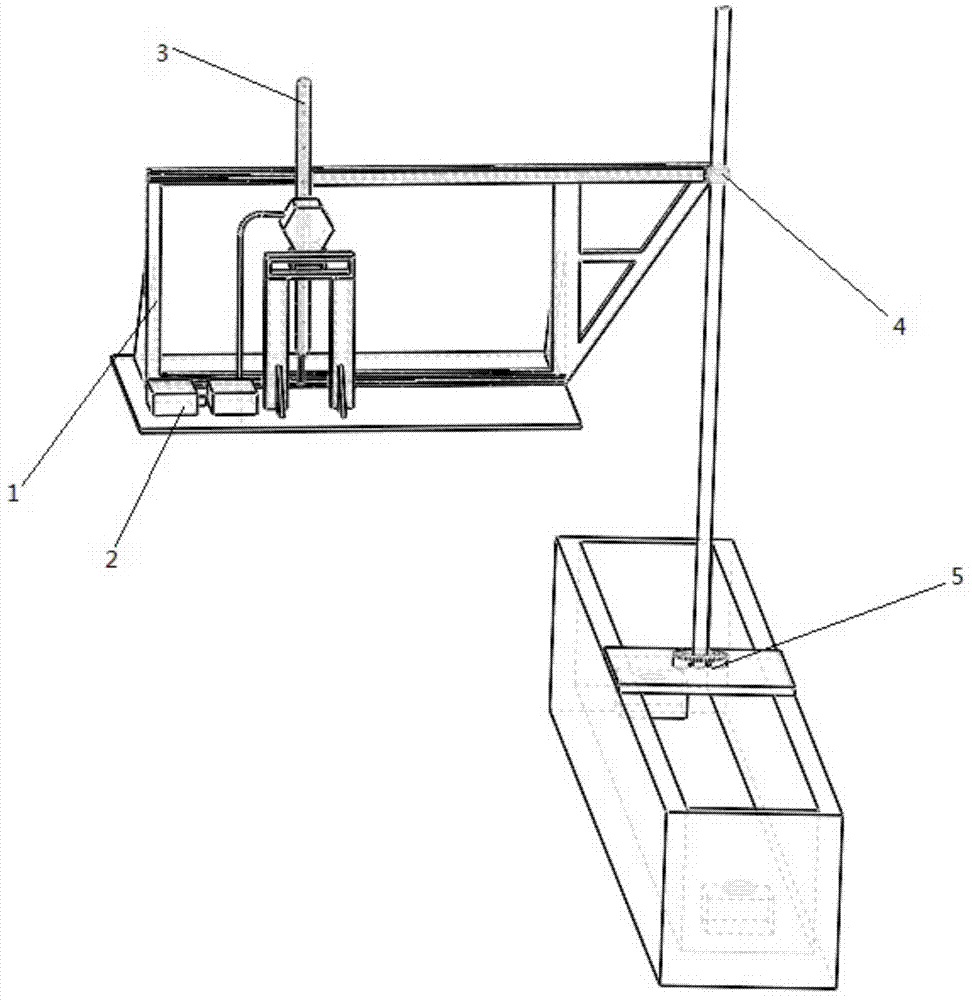

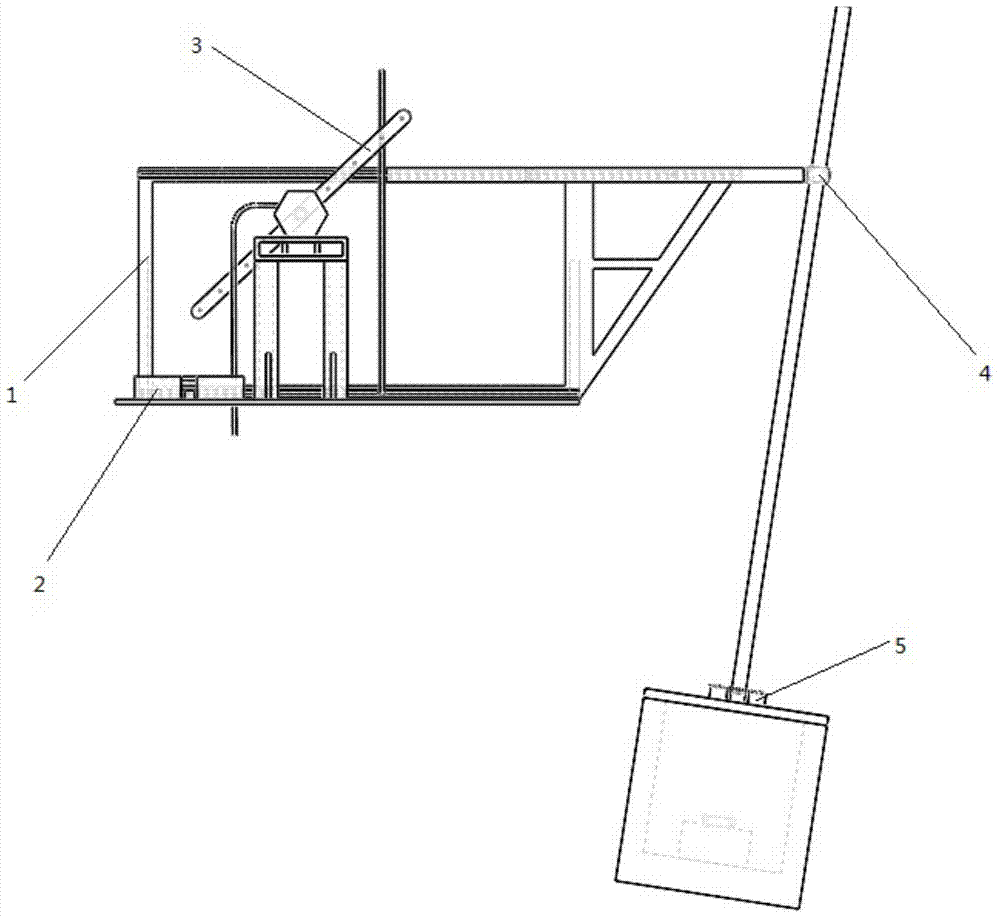

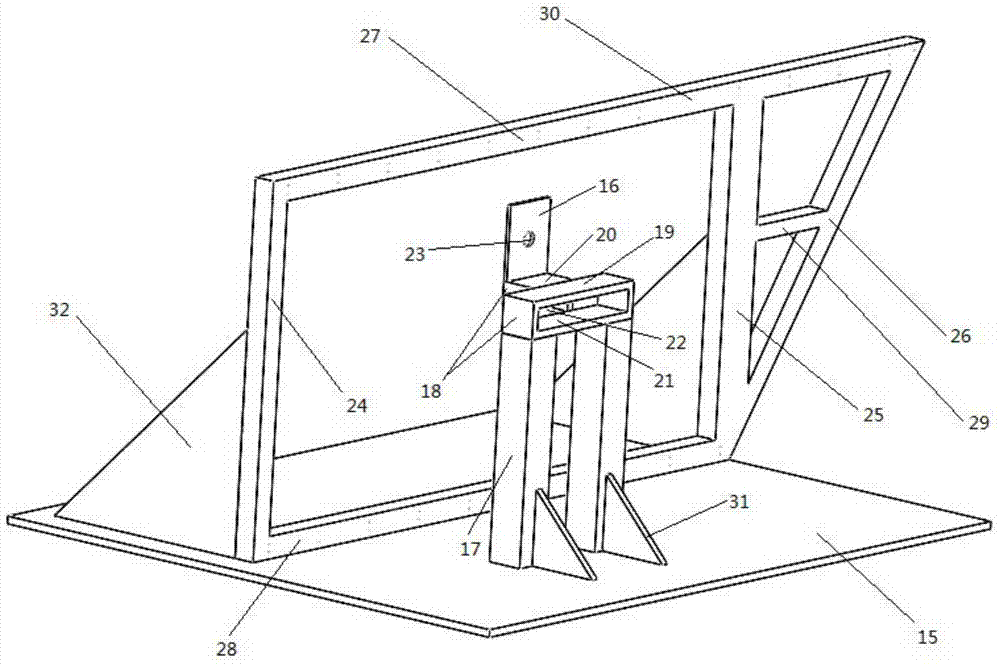

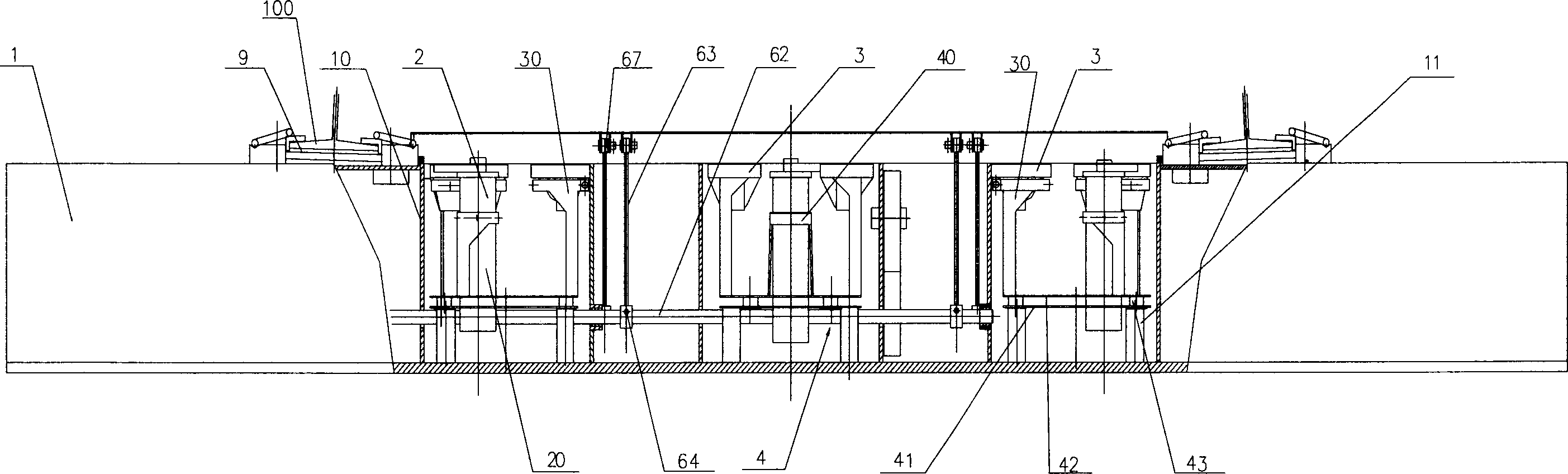

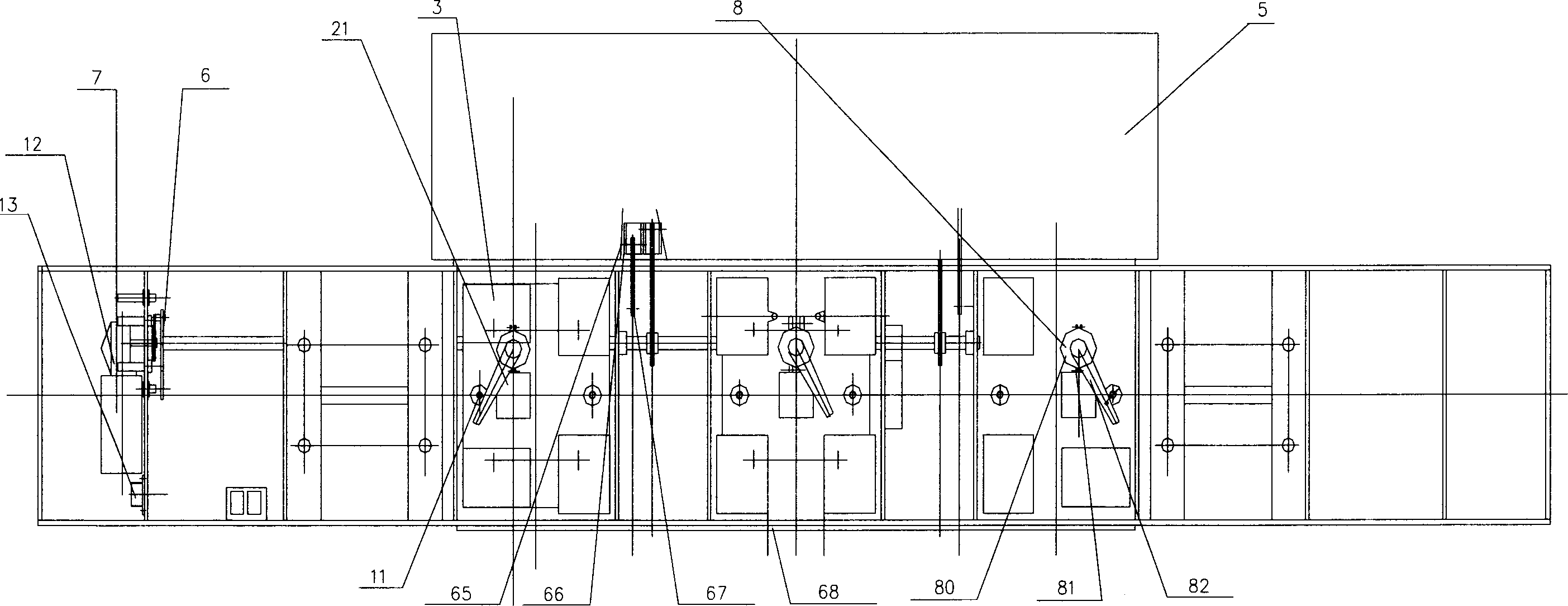

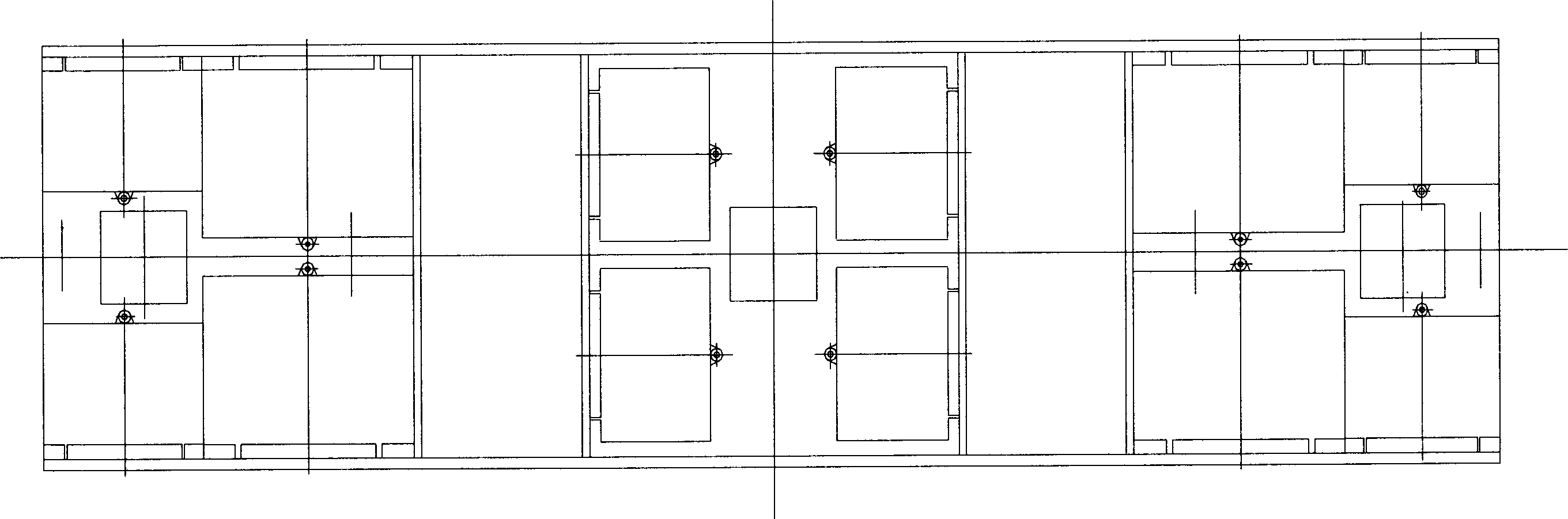

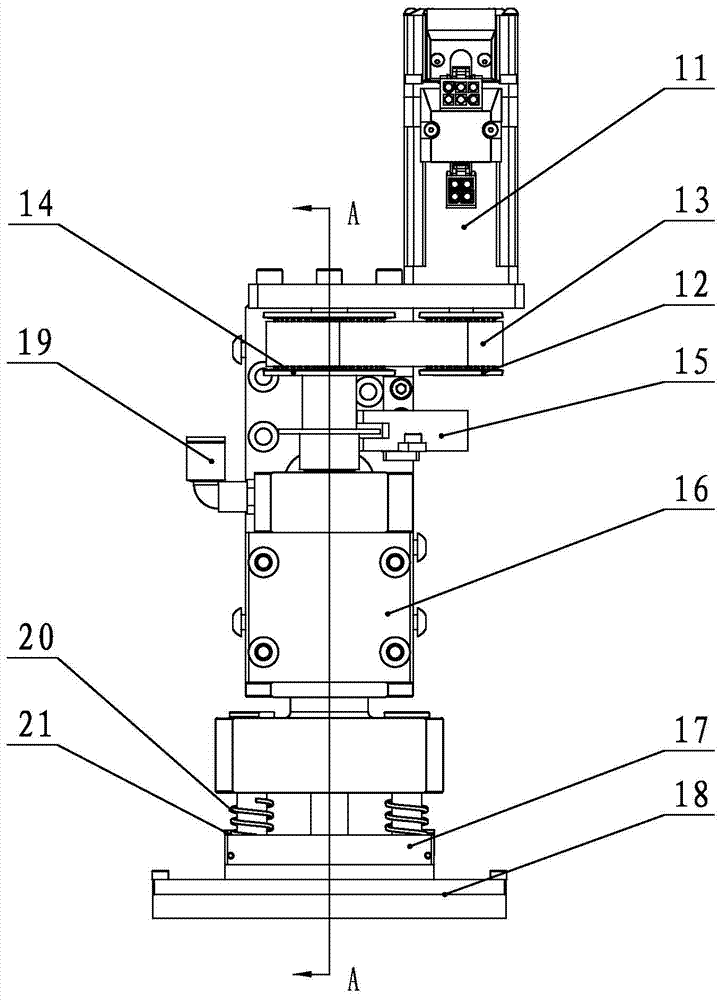

Forced ship model rolling experiment device

ActiveCN104123866AWith specialized functionsStrong Experimental ReliabilityEducational modelsData acquisitionBlock match

The invention provides a forced ship model rolling experiment device which comprises a fixing device, a control and drive device and a data acquisition device. The fixing device comprises a base plate and a frame installed on the base plate and further comprises a crank guide rail moving device and a connection rod driving device. The crank guide rail moving device comprises a horizontal guide rail I, a horizontal guide rail II, a slide block I, a slide block II, vertical guide rails fixedly connected with the two slide blocks, vertical slide blocks matched with the vertical guide rails and cranks connected with the vertical slide blocks, wherein the horizontal guide rail I and the horizontal guide rail II are installed on linear guide rail supports, the slide block I and the slide block II are matched with the horizontal guide rail I and the horizontal guide rail II, and the middle positions of the cranks are connected with the control and drive device. The connection rod driving device comprises a push rod and a connection rod, wherein one end of the push rod is connected with the slide block I, the other end of the push rod is connected with the connection rod, and the lower end of the connection rod is connected with the data acquisition device. The forced ship model rolling experiment device is simple in structure, convenient to operate and easy to process and manufacture and used for experimental study of ship rolling hydraulic performance.

Owner:HARBIN ENG UNIV

Auto seat cushion with heating and pressure sensing functions

InactiveCN102941817AImprove toughnessExtended service lifeSeat heating/ventillating devicesBelt control systemsElectrical resistance and conductanceInter layer

The invention provides an auto seat cushion with heating and pressure sensing functions and adopts the technical points that the auto seat cushion with the heating and pressure sensing functions comprises a pressure sensor arranged on a seat cushion and is characterized in that the pressure sensor comprises plastic film layers which are arranged in a corresponding manner; an aluminium foil layer conducting circuit and a carbon paste conducting layer are printed on each plastic film layer in sequence; each carbon paste conducting layer comprises a sensing circuit and a heater circuit; the plastic film layers printed with printed circuits are bonded together through a middle layer to form a composite structure; a plurality of sensing units capable of measuring the load on the automobile seat repeatedly are arranged in the composite structure; the tail end of the pressure sensor is connected with a plastic seal block; a core board is arranged in the plastic seal block and used for processing the resistance value signals of all the sensing units in a classified manner; and the core board is connected with an electric control center of a safe air bag of the whole automobile. The auto seat cushion with the heating and pressure sensing functions has the advantages of being simple and convenient to mount, having a concise appearance, and controlling the popup amount of the air bag to remind passengers of tying the safety belts well.

Owner:BRILLIANCE AUTO +1

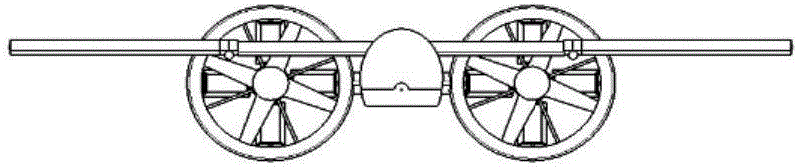

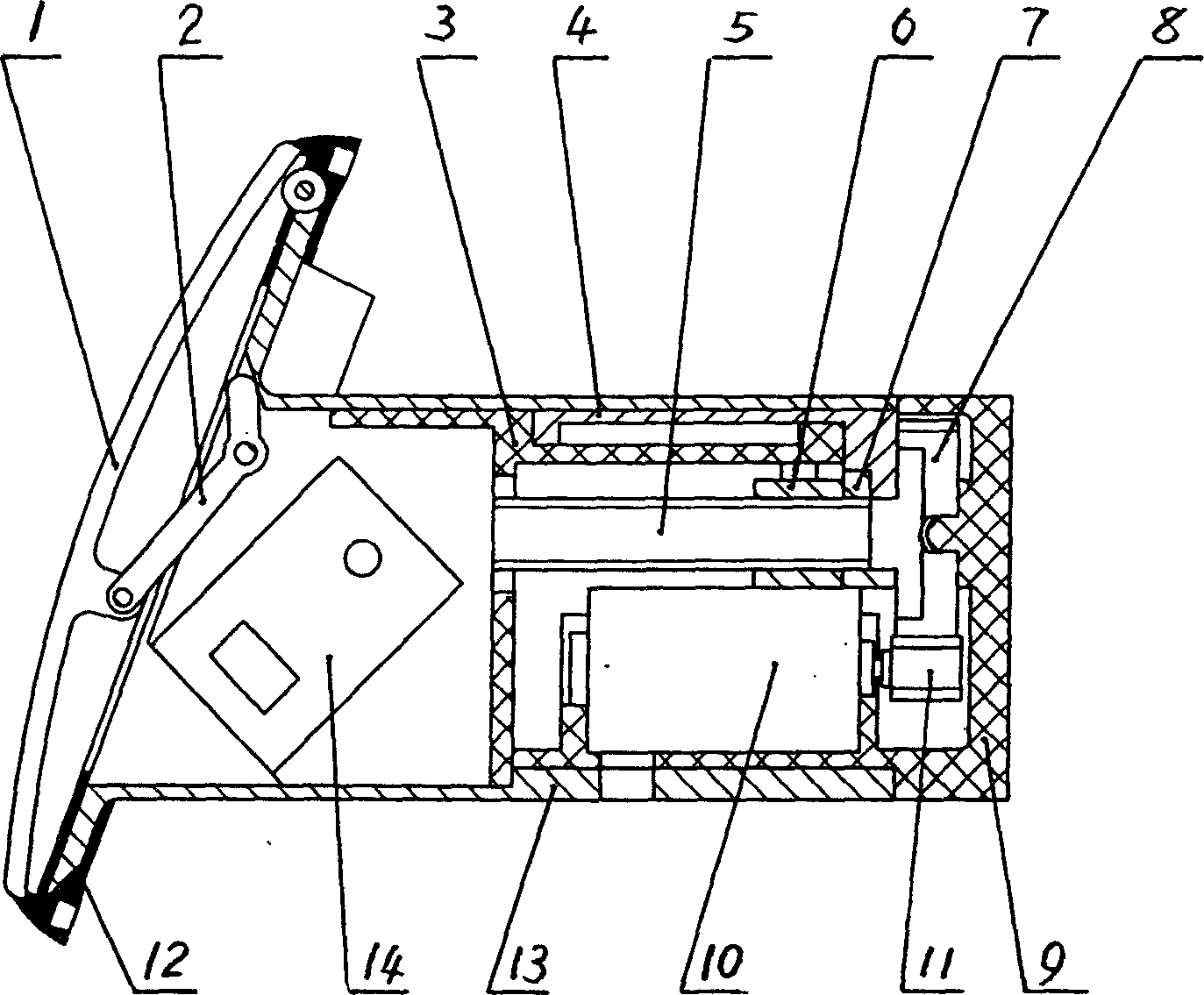

Dynamic fault detection device for bed timber type vehicle

InactiveCN1562686ANovel structureSimple appearanceRailway vehicle testingRailway auxillary equipmentCcd cameraWooden box

A sleeper-type dynamic failure detector for train features that multipole sets of CCD camera and lighting unit, vibration damper, protecting gate, cleaning unit, drive unit, insulating unit, electric unit and connecting lines are installed in a sleeper-type wooden box under rails for automatically taking the images of hook buffer, pneumatic brake, chassis, steering unit and the both sides of carriage, and the taken images are transmitted to detection center for analysis.

Owner:RUIWEI CENTURY SOFTWARE TECH DEV BEIJING

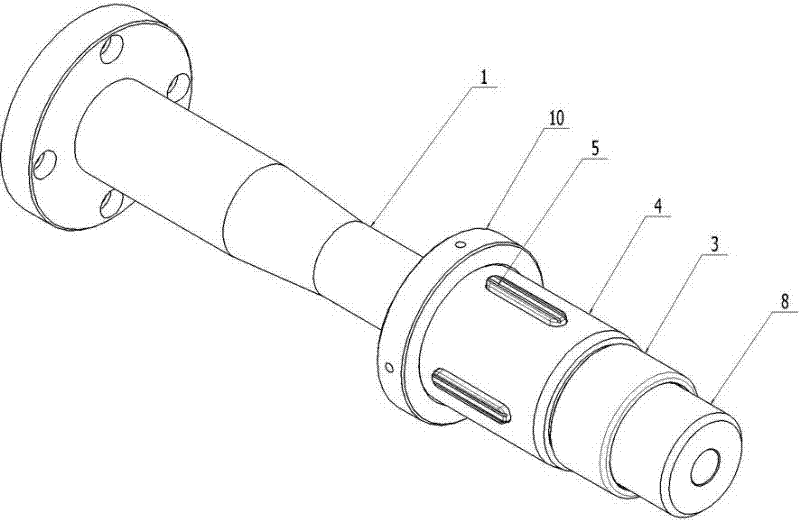

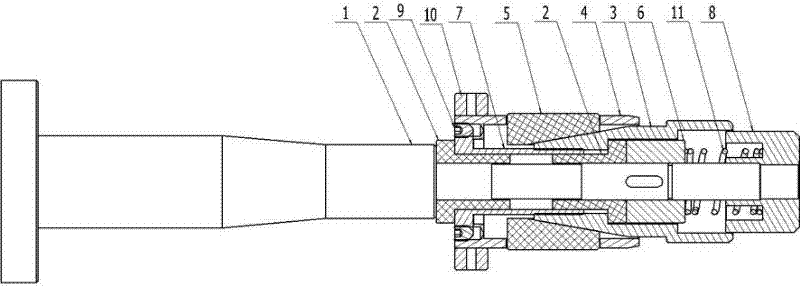

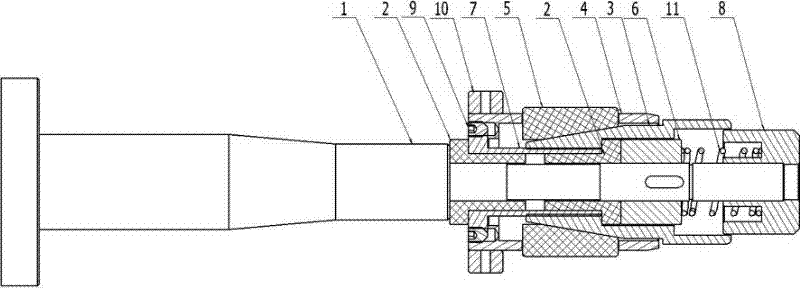

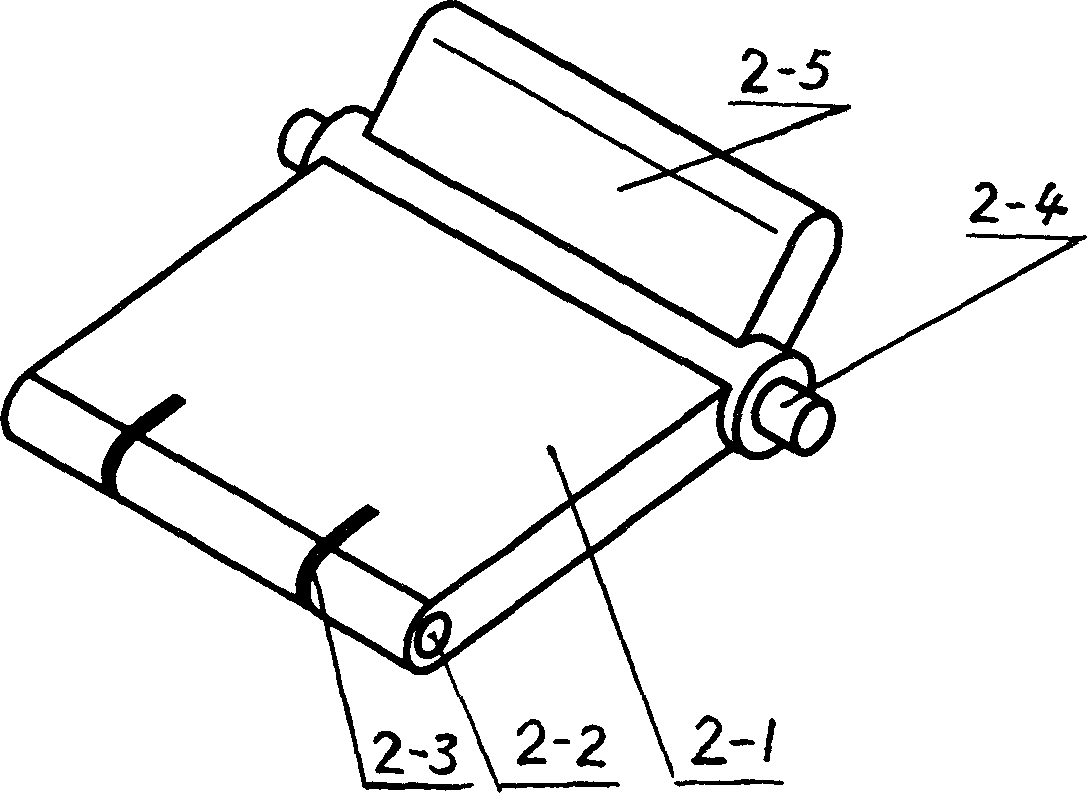

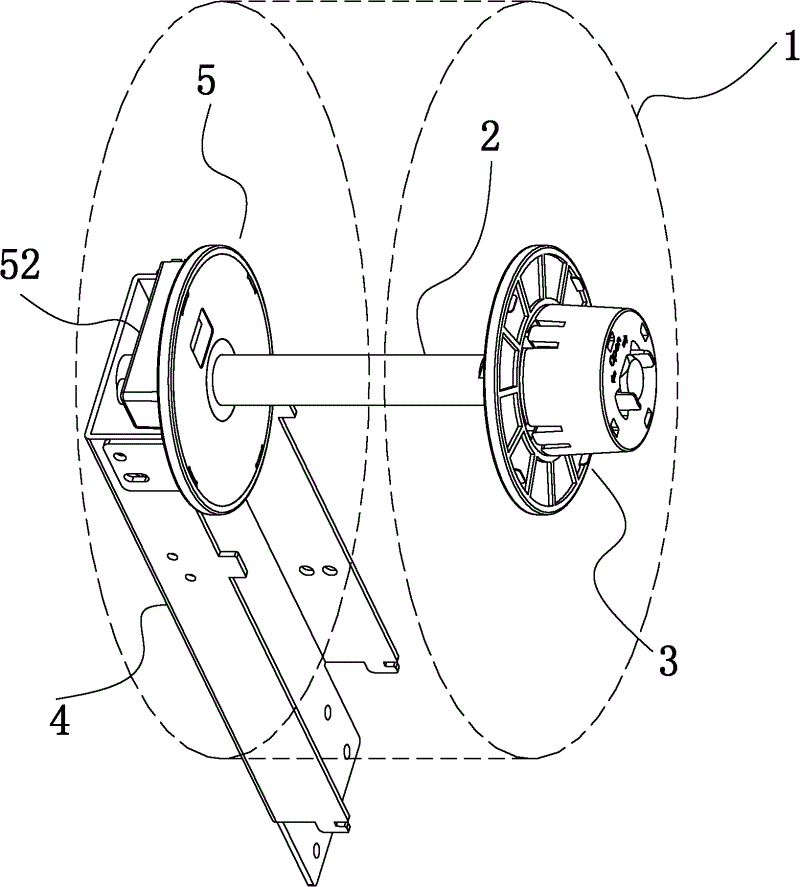

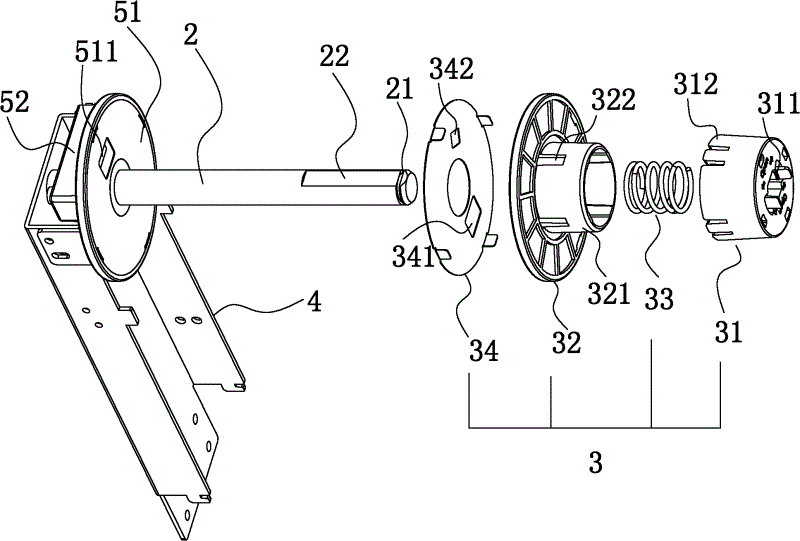

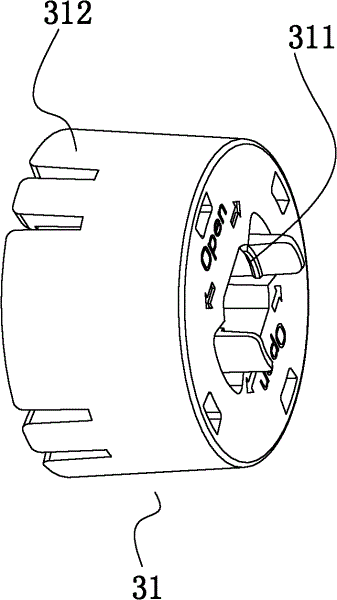

Wedge-block-type unwinding shaft used in production line of disposable hygienic products

The invention relates to a wedge-block-type unwinding shaft used in a production line of disposable hygienic products. In the invention, a fixed shaft is a stepped shaft, a small-diameter section of the fixed shaft is sequentially sheathed with two guide sleeves, a spacer bush and a compression spring, and an end part of the small-diameter section of the fixed shaft is in threaded connection witha hand wheel; one end of the compression spring is positioned in a circular groove of the hand wheel, and the other end of the compression spring is in contact with an end face of the spacer bush; locking sleeves are sheathed on small-diameter sections of the two guide sleeves, sleeves are sheathed outside the locking sleeves, four axial expansion pin grooves are uniformly distributed on each sleeve, and each expansion pin groove is internally equipped with an expansion pin; each expansion pin is in the shape of a wedge block, and an oblique plane of each expansion pin corresponds to each locking sleeve; and a taper sleeve is inserted between the locking sleeve and the sleeve which are positioned at one end adjacent to the spacer bush, a conical tube is arranged at one side of the taper sleeve, a cylindrical tube is arranged at the other side of the taper sleeve, and the conical surface of the conical tube of the taper sleeve is in contact with the oblique planes of the four expansionpins in a fit manner. The wedge-block-type unwinding shaft has the advantages of compact and delicate structure and reasonable design, and is convenient in use; unwinding resistance can be controlledby adjusting the hand wheel; and material coils can be fixed, assembled and disassembled quickly through the expansion pins.

Owner:ANQING HENG CHANG MACHINERY

Rotatable label sucking head for labeler

The invention discloses a rotatable label sucking head for a labeler. The rotatable label sucking head comprises a rotating motor, a small synchronous wheel driven by the rotating motor, a large synchronous wheel connected to the small synchronous wheel via a synchronous belt, a rotating shaft driven by the large synchronous wheel, and a sucker connected to one end of the rotating shaft. The rotating shaft has a hollow structure of a through hole; one end of the through hole of the rotating shaft is provided with a vacuum suction nozzle; and the other end of the through hole of the rotating shaft is provided with the sucker. A sucker mounting plate sleeves one end, connected to the sucker, of the rotating shaft; the sucker is arranged on the sucker mounting plate via a hook; one end of the hook is arranged on the sucker mounting plate through the rotating shaft; and the other end of the hook is locked in a slot formed in the sucker via a bended hook. The rotatable label sucking head in the invention can rotate through 360 degrees; the sucker is convenient to change and has a buffering function; and the sucker can prevent a labeled product against damage due to pressing while the product is labeled.

Owner:博宸睿(苏州)智能科技有限公司

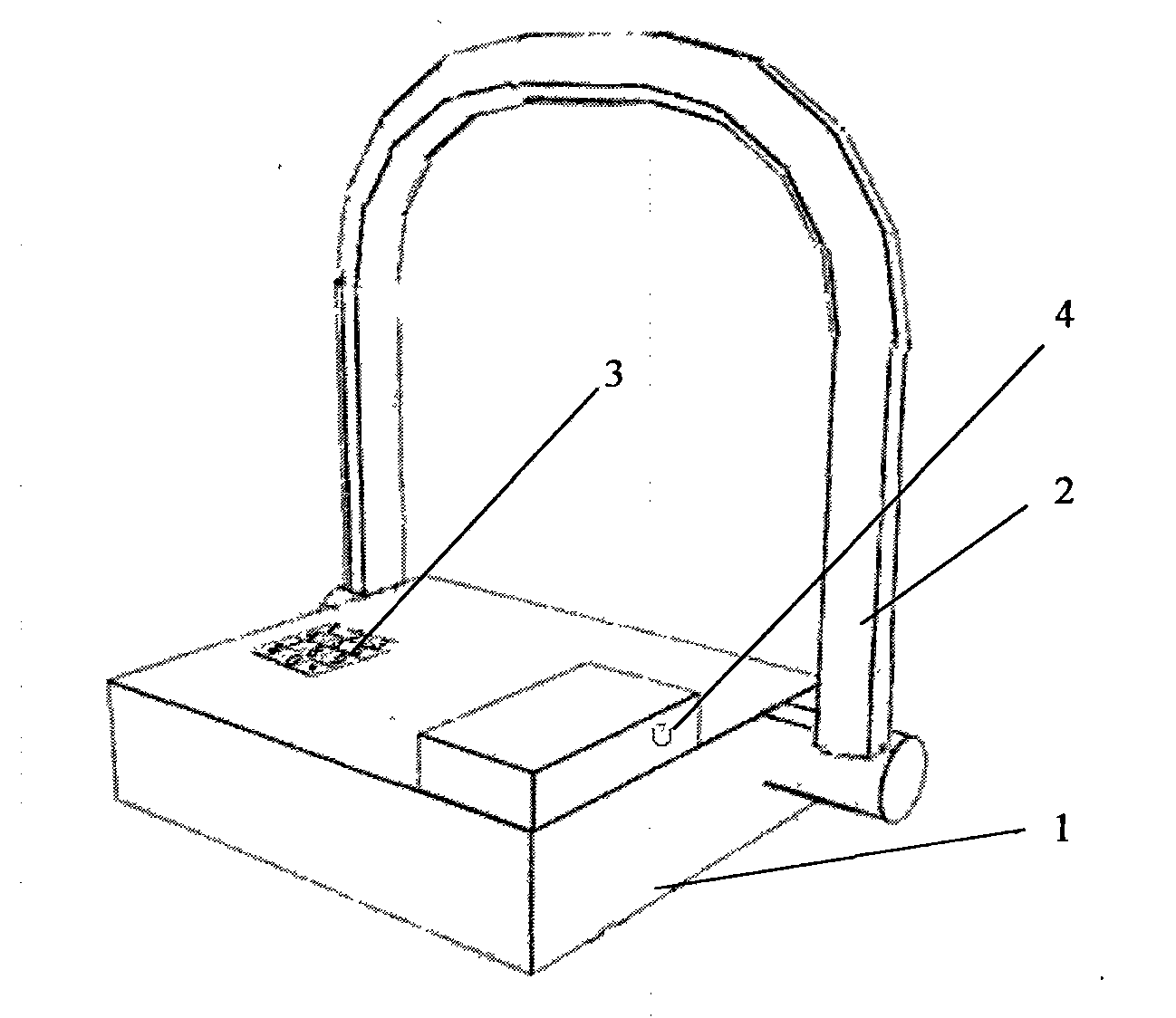

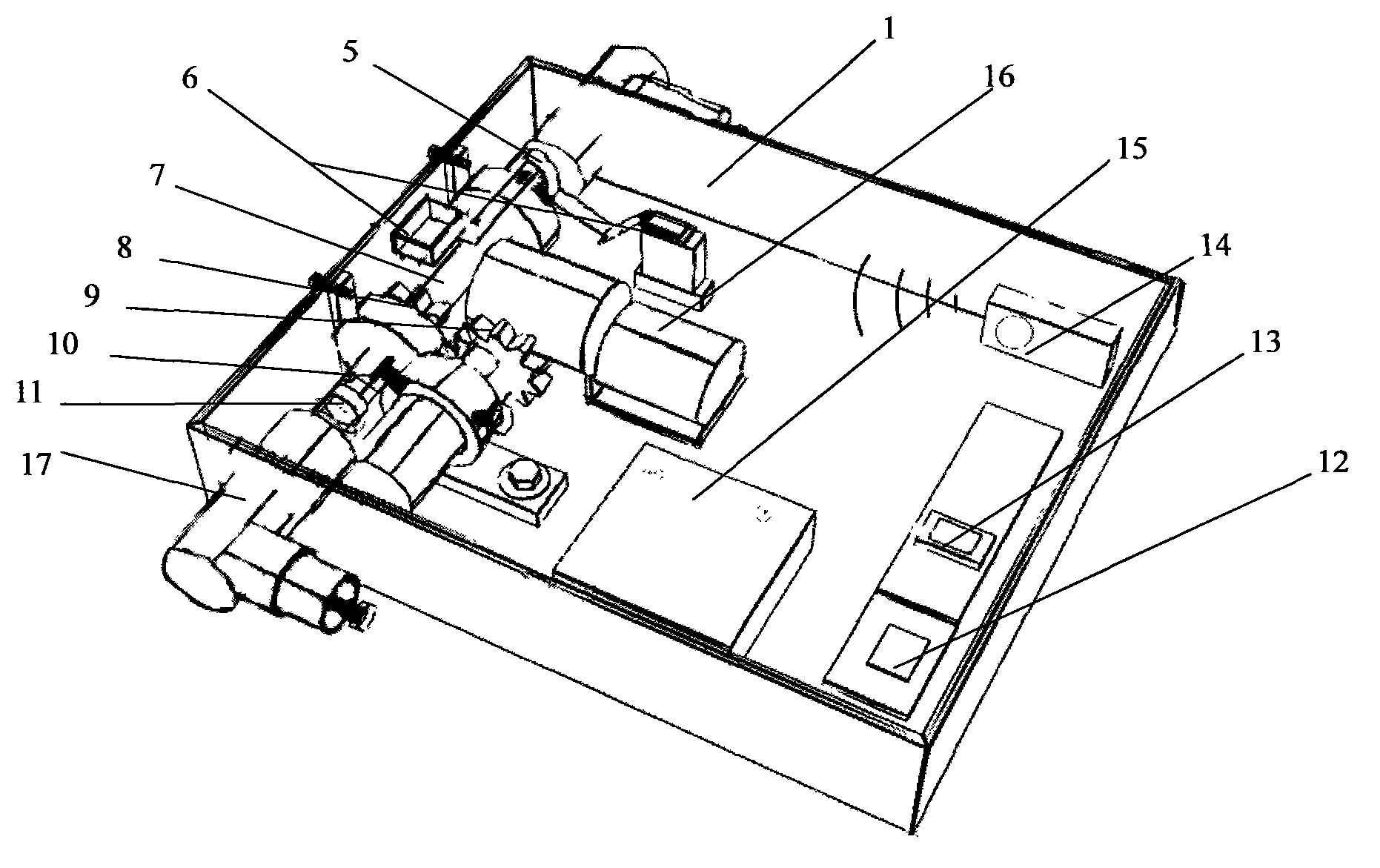

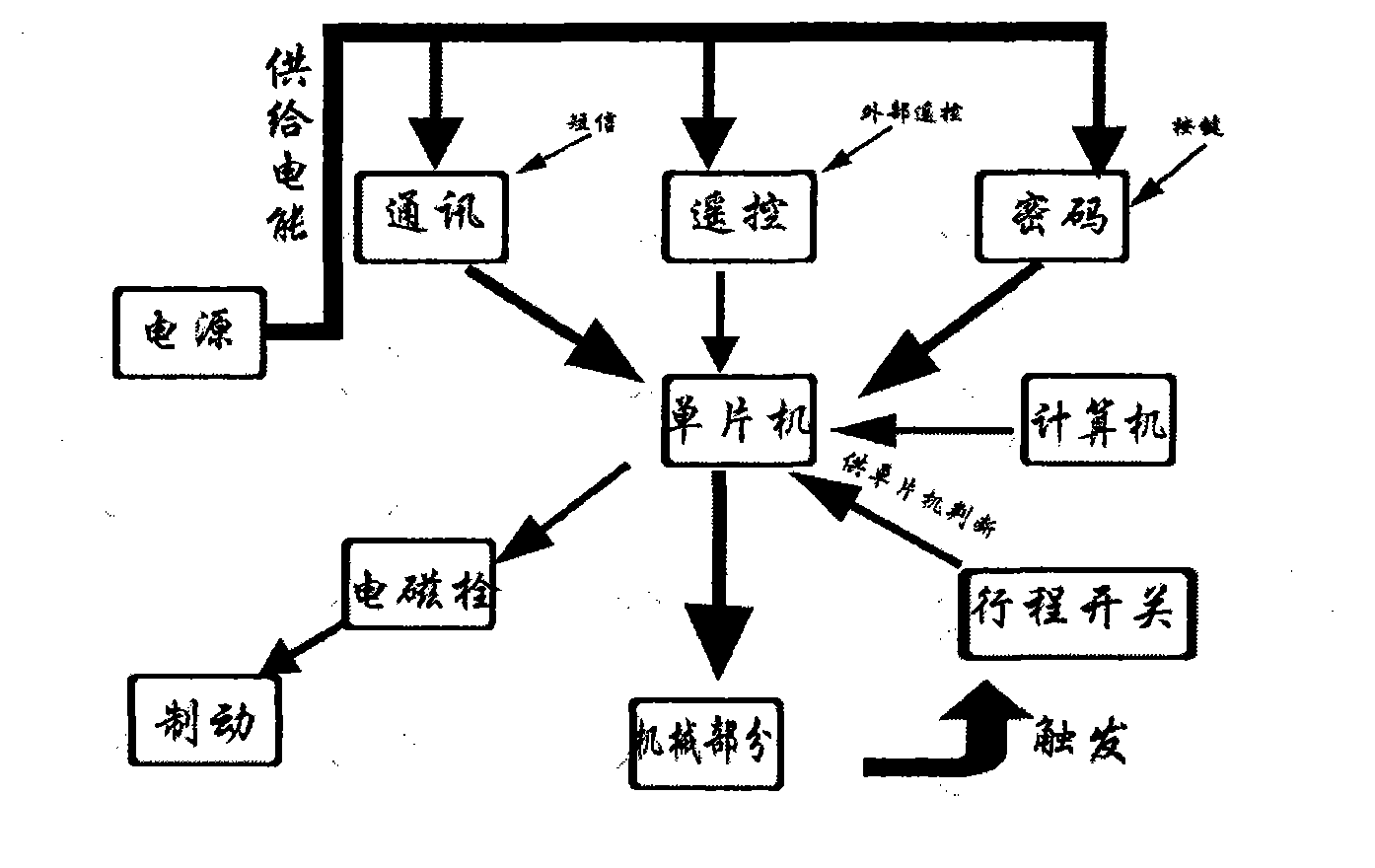

Intelligent remote control management system of private parking spaces

The invention relates to an intelligent remote control management system of private parking spaces. The intelligent remote control management system mainly consists of a control device and a parking space lock device, wherein the control device consists of a password press key, a remote controller, a mobile phone and a computer, the parking space lock device mainly consists of a liftable U-shaped rod , an outer box body, a mechanical driving module, a circuit control module and an information receiving module, and the ascending and descending of the U-shaped rod are controlled mainly through adopting four modes for reaching the functions of parking space unlocking and locking management, wherein any one control device can send signals to the system for controlling the ascending and descending of the U-shaped rod of a parking space lock, and an infrared receiving module arranged in the device receives remote controller signals; an MC55 communication module is utilized for receiving short message signals of the mobile phone; a single chip microcomputer is utilized for recognizing the password press key to give out signals; the remote computer can recognize whether the parking spaces are in an vacant state or not, and the parking space information is collected and synthetically analyzed, so the omnibearing intelligent management on the parking spaces is realized. The parking space device adopts the fully sealed design, and has the unique functions such as burglary prevention, anti-collision warning and falling through resistance. The performance of the whole system is stable, the operation is simple, the cost is low, the technological content is high, the compatibility is high, and the intelligent remote control management system is applicable to middle-low-end residential districts of ordinary users, and can meet requirements of large-scale parking lots and high-grade residential districts for realizing intelligent property management.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

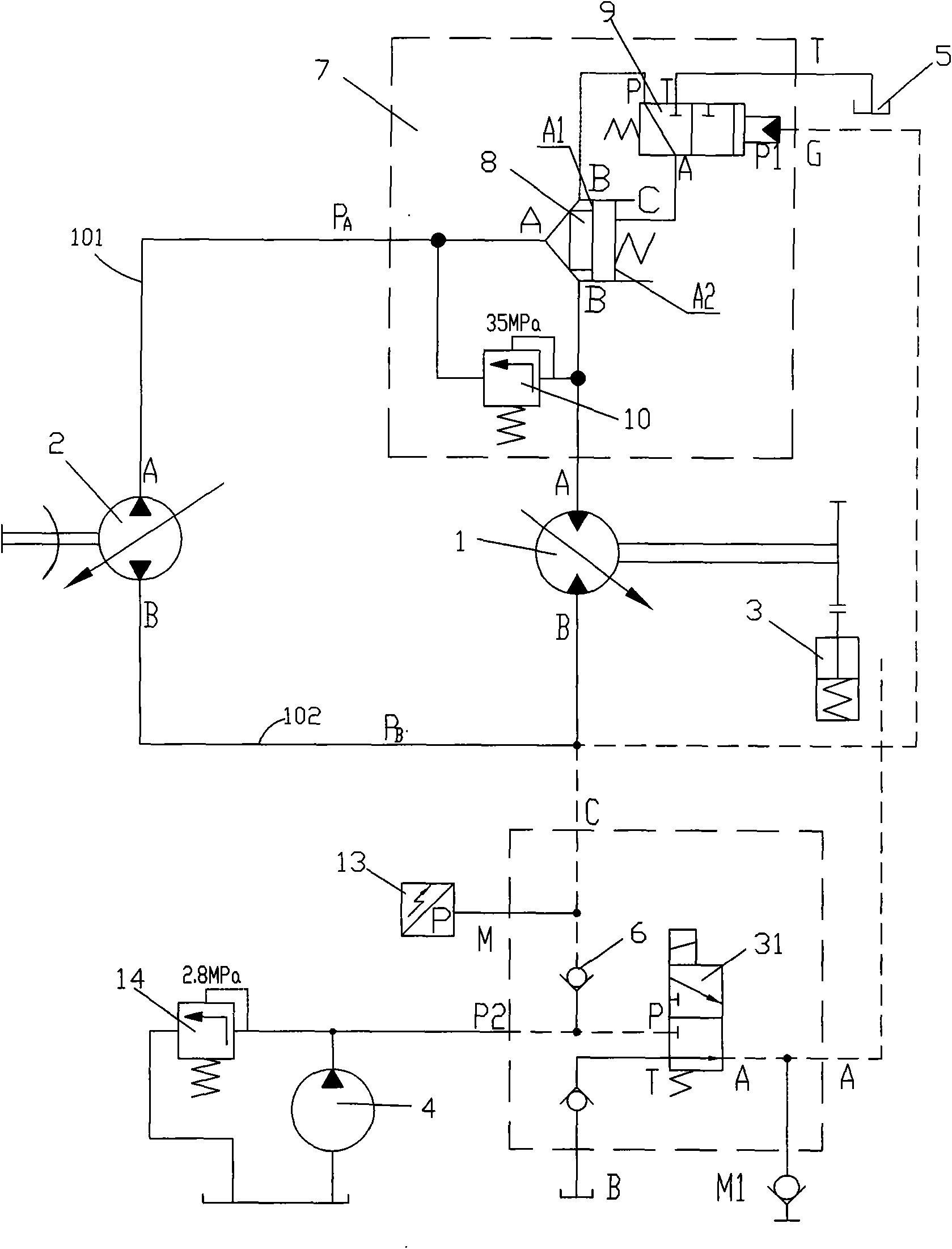

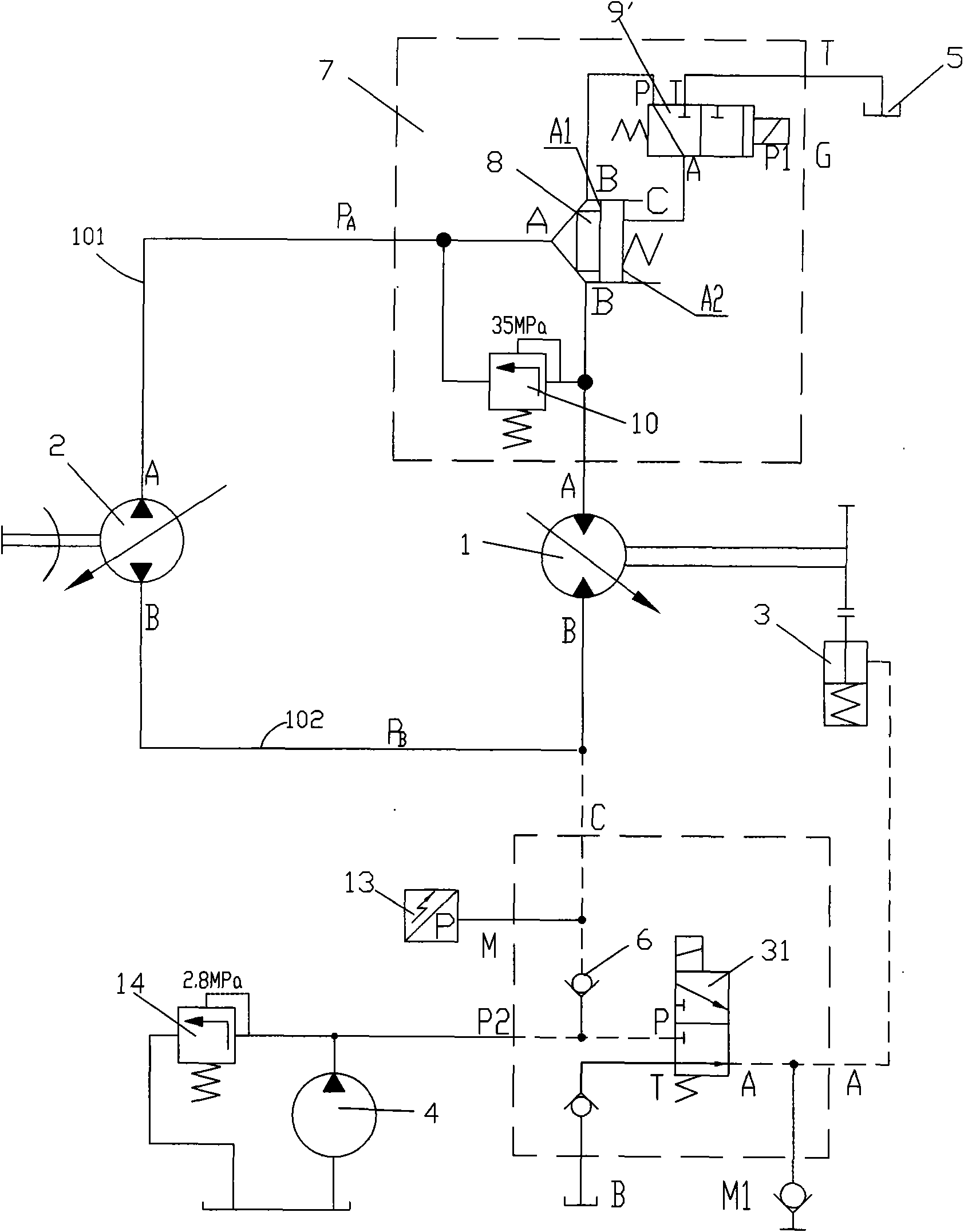

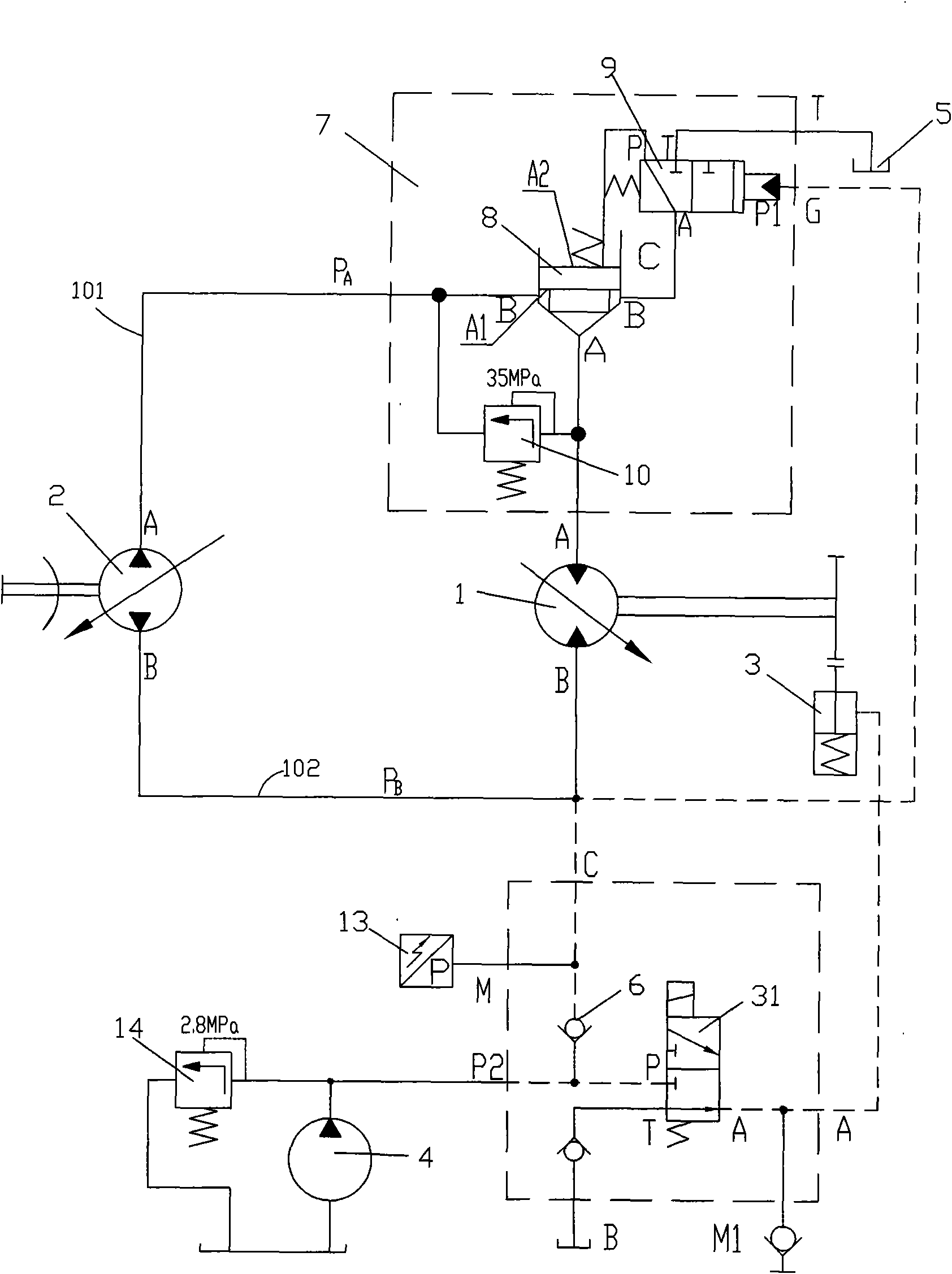

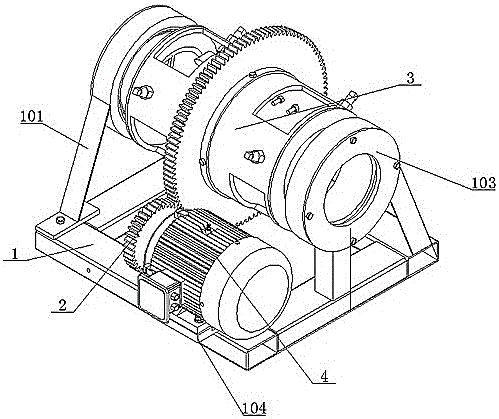

Hoist motor closed type hydraulic system for preventing pipelines from bursting and control method thereof

ActiveCN101537984AQuick responseAvoid safety accidentsFluid-pressure actuator safetyWinding mechanismsFuel tankEngineering

The invention provides a hoist motor closed type hydraulic system for preventing pipelines from bursting, comprising a hoist motor, a rising oilway and a descending oilway thereof, and a closed type pump serially arranged in the oilways thereof; a brake and a braking electromagnetic valve are connected; the oilways of the hoist motor is connected with the oil supplementing oilways and oil supplementing pumps, oil sump tank and oil sump oilways of the braking electromagnetic valve; a pipeline bursting prevention device comprises a two-way cartridge inserted valve and a reversing valve; the two-way cartridge inserted valve is arranged in the oilway between the hoist motor and the closed type pump, the two ports: B-port and A-port are respectively corresponding to the oilway between the hoist motor and the closed type pump; the reversing valve is respectively connected with B-port and C-port by the pipelines, G-port of the reversing valve is connected with the descending oilway of the hoist motor, and T-port is connected with the oil sump tank. In the invention, the starting of the hydraulic control reversing valve is controlled by the pressure of the closed type system oil supplementing oilways, and a security overflow valve is arranged in the oil sump oilways for preventing the pressure of the rising port of the hoist motor from being too high to protect the hoist motor.

Owner:ZHEJIANG SANY EQUIP

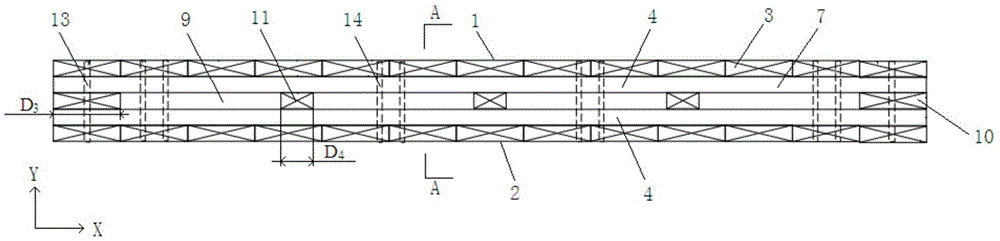

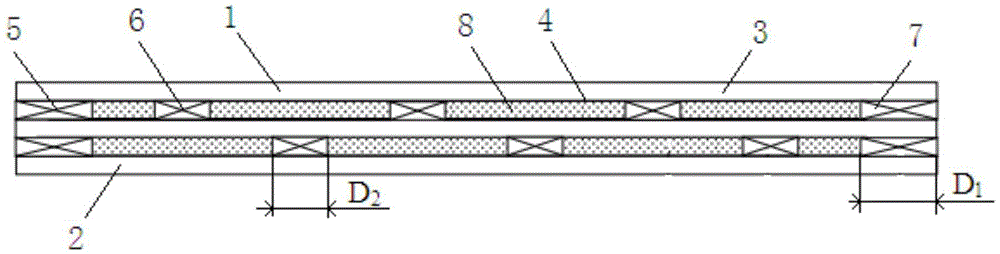

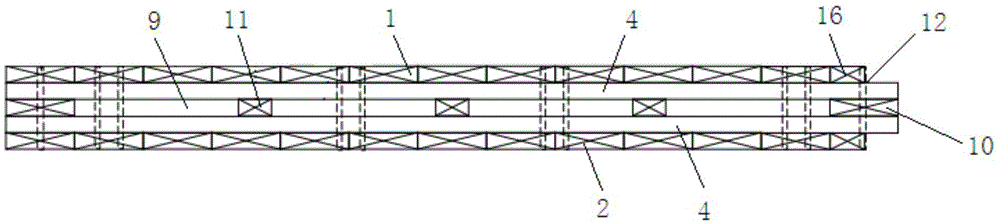

Hollow cross-ply laminated building block bearing plate

ActiveCN105544757AImprove mechanical performanceQuality improvementHeat proofingSound proofingInsulation layerPulp and paper industry

The invention relates to a hollow cross-ply laminated building block bearing plate which comprises an inner layer plate body and an outer layer plate body. At least two heat preservation or sound insulation layers are arranged in a first cavity formed between the inner layer plate body and the outer layer plate body. Each heat preservation or sound insulation layer comprises first wood boards arranged at the two ends of the first cavity, and second wood boards arranged in a cavity between the two first wood boards at intervals, cavities formed between every two second wood boards and between the first wood boards and the second wood boards are filled with non-bearing heat preservation boards or non-bearing sound insulation materials, a second cavity is formed between every two heat preservation or sound insulation layers, and third wood boards are arranged at the two ends of each second cavity respectively. The hollow design is adopted, and the heat preservation or sound insulation layers are embedded in plate bodies, so that good heat preservation performance or sound insulation performance is achieved, and heat preservation protection or sound insulation treatment does not need to be carried out outside the plate bodies any more; the boards in the plate bodies are distributed in a cross-ply mode, so that the plate bodies have good stress performance and are light and good in economic effect, the manufacturing cost is reduced, and environment pollution is effectively avoided.

Owner:张延年

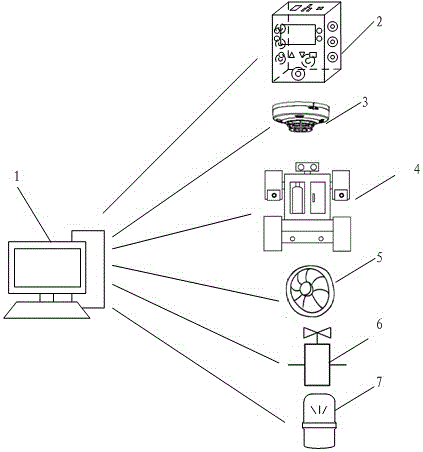

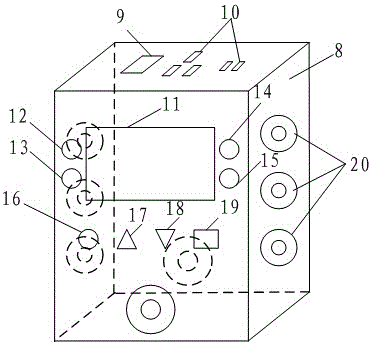

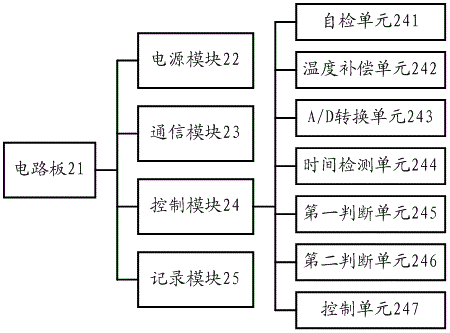

Combustible gas detection system

PendingCN106408886ASimple appearancePromote circulationFire rescueAlarmsFault indicatorFire detector

The present invention discloses a combustible gas detection system, comprising a background controller, a combustible gas detector, a fire detector, a fire extinguishing robot, an exhaust fan, a solenoid valve and an alarm device. The combustible gas detector comprises an explosion-proof shell, a charging interface, a power jack and a display screen; a power indicator light, a fault indicator light, a high report indicator light and a low report indicator light located at both sides of the display screen; an on / off key, an increase key, a decrease key and a query key at the bottom of the display screen; detection parts symmetrically disposed on the explosion-proof shell; a circuit board fixed inside the explosion-proof shell; and a power supply module, a communication module, a control module and a recording module on the circuit board. The control module comprises a self-test unit, a temperature compensation unit, an A / D conversion unit, a time detection unit, a first judgment unit, a second judgment unit and a control unit. With simplified keys, the combustible gas detection system is convenient to operate and is able to detect combustible gas and also deal with harsh conditions, thereby achieving high practicability.

Owner:SHANGHAI TENSUN TRANSMART

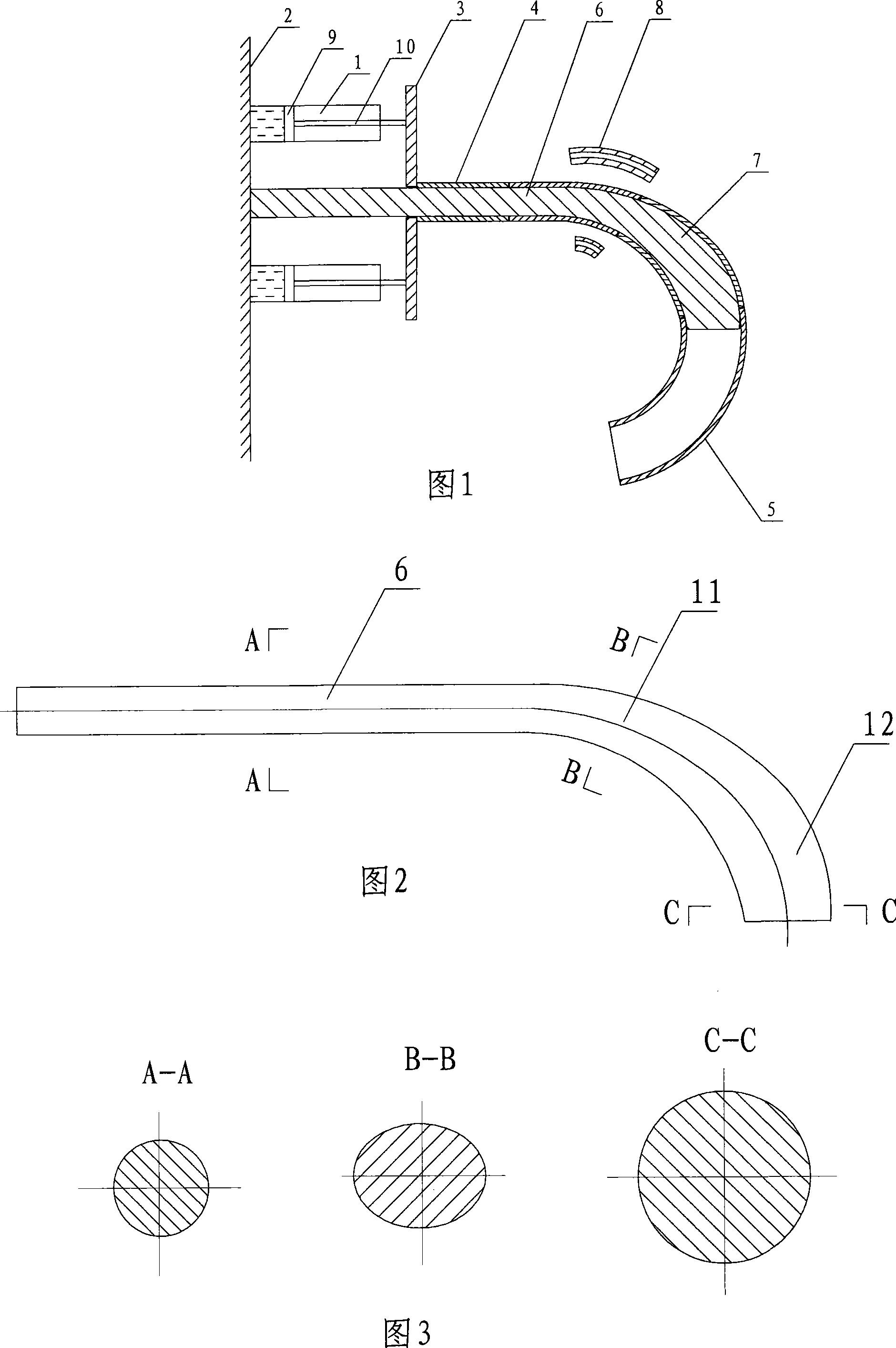

Technique and device for push-making angle fitting by intermediate frequency induction heating

The invention discloses a process of intermediate frequency induction heating propelling elbows and a device of the process. The process comprises coating at least one section of tube blank on a core rod from the terminal end of the core rod, fixing the terminal end of the core rod on the fixing end of the core rod, adopting hydraulic pressure to propel the tube blank through a propelling plate, heating the tube blank which is propelled on a horn core joint portion through a heater of the intermediate frequency inductions, thermal-deformating the tube blank which is propelled through a deforming section of the horn core joint, and squeezing a needing shaped elbow through a shaping section. The device of the process comprises a propelling oil cylinder, a fixing end of the core rod, the propelling plate, the core rod, the horn core joint, the heater of the intermediate frequency inductions, a piston and a connecting rod, wherein the core rod and the horn core joint are welded together into a horn core bar, the horn core joint is composed of a deforming section and a shaping section, a transverse section of the shaping section takes a positive round shape, the transverse section of the deforming section takes a oval shape, a circle center of the positive round shape and a central point of the oral shape are located on a central arc line of the horn core bar, both a long axle of the oral shape and a short axle of the oral shape are vertical to the central arc line of the horn core bar, the long axle of the oral shape is also vertical to a plane, and the central arc line of the horn core bar is located on the plane.

Owner:NINGBO LIANTONG EQUIP MFG

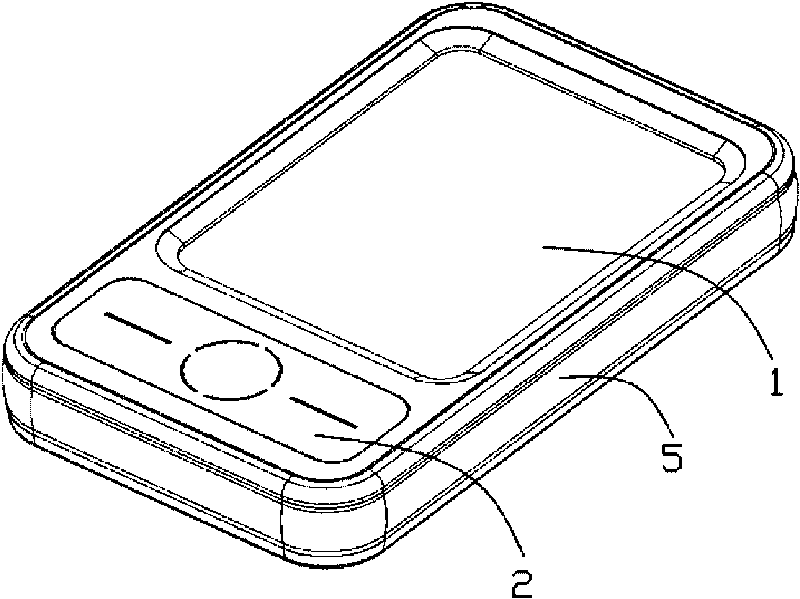

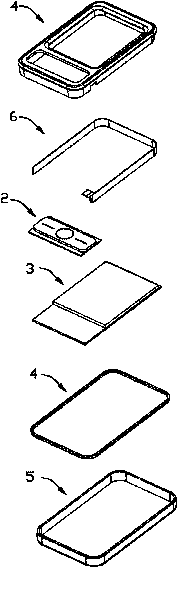

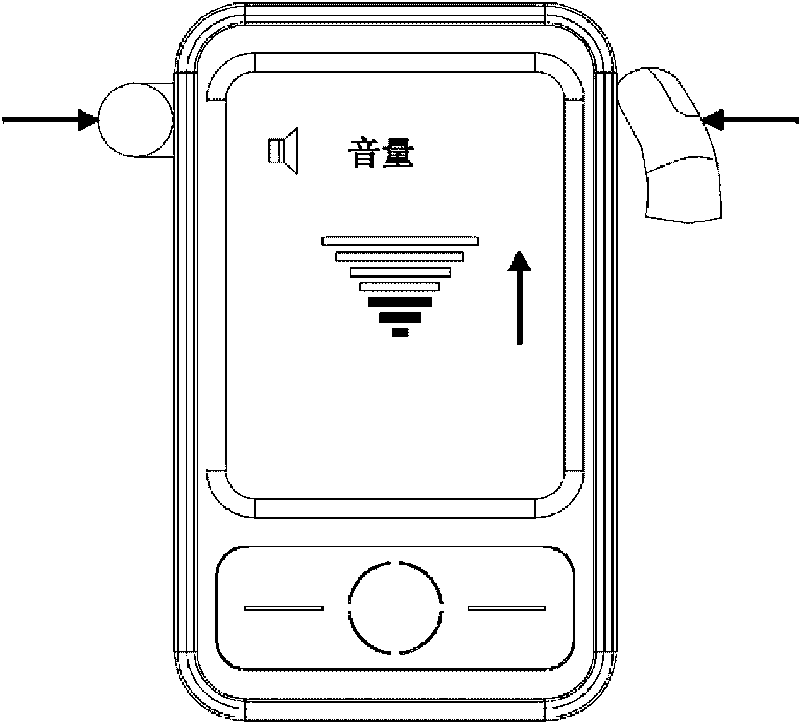

Handheld device with pressure induction control characteristic

InactiveCN101753680AReduce in quantitySimple appearanceFluid pressure measurement using ohmic-resistance variationForce measurementEngineeringInput device

The invention relates to a handheld device with pressure induction control characteristic, which at least comprises an output device, a controller and an input device; the controller analyses and judges a current signal generated and converted by the input device and transmits an instruction, and the instruction is output by the output device by other ways, wherein the input device comprises a variable resistance layer which is arranged at the side part of the handheld device, and the resistance characteristic of the handheld device is changed along the change of the applying pressure.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

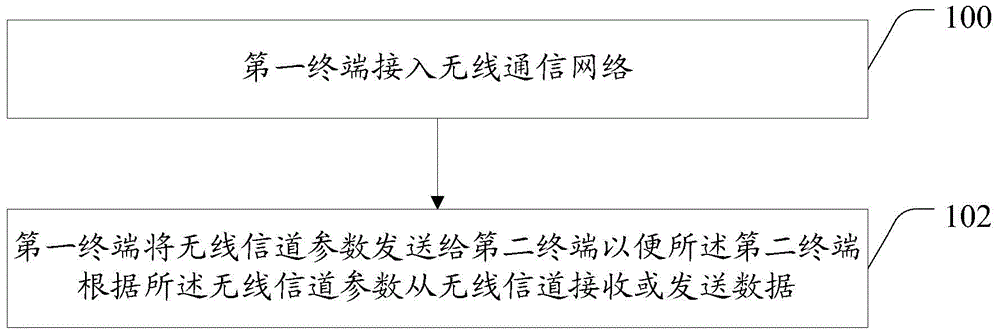

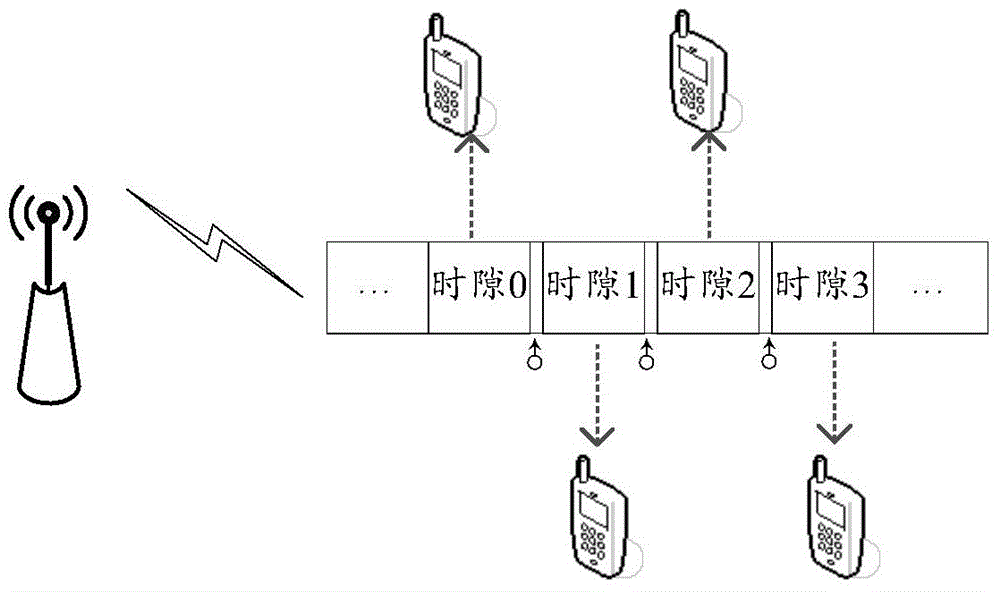

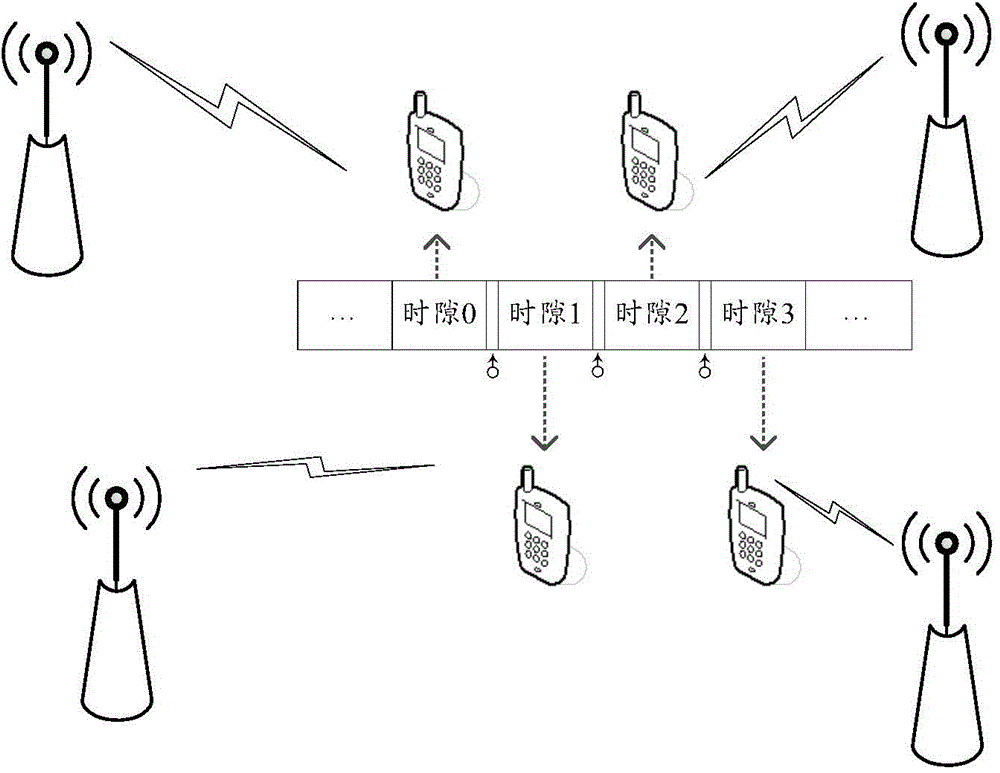

Method, corresponding device and system for cooperative processing of wireless data

InactiveCN104581834AReduce resource scheduling overheadImprove PRB utilizationNetwork traffic/resource managementAssess restrictionChannel parameterResource block

Disclosed in an embodiment of the present invention is a method for cooperative processing of wireless data, and also disclosed are a device, system and terminal interconnection device for cooperative processing of wireless data, the method comprising: a first terminal accessing a wireless communication network sends downlink wireless channel parameters to a second terminal, such that the second terminal receives data according to the downlink wireless channel parameters (including carrier frequency, a timeslot number and a modulation mode); or the first terminal sends uplink wireless channel parameters(including carrier frequency, a timeslot number and a modulation mode) to the second terminal, such that the second terminal sends data according to the uplink wireless channel parameters. The innovative terminal networking of the present invention enables multiple terminals to share the same wireless channel for receiving / sending data; in some scenarios, for example, in the scenario where multiple terminals in close proximity download the same data from a base station simultaneously, the invention can then reduce costs of resource scheduling and power consumption, and improve utilization of a physical resource block.

Owner:HUAWEI TECH CO LTD

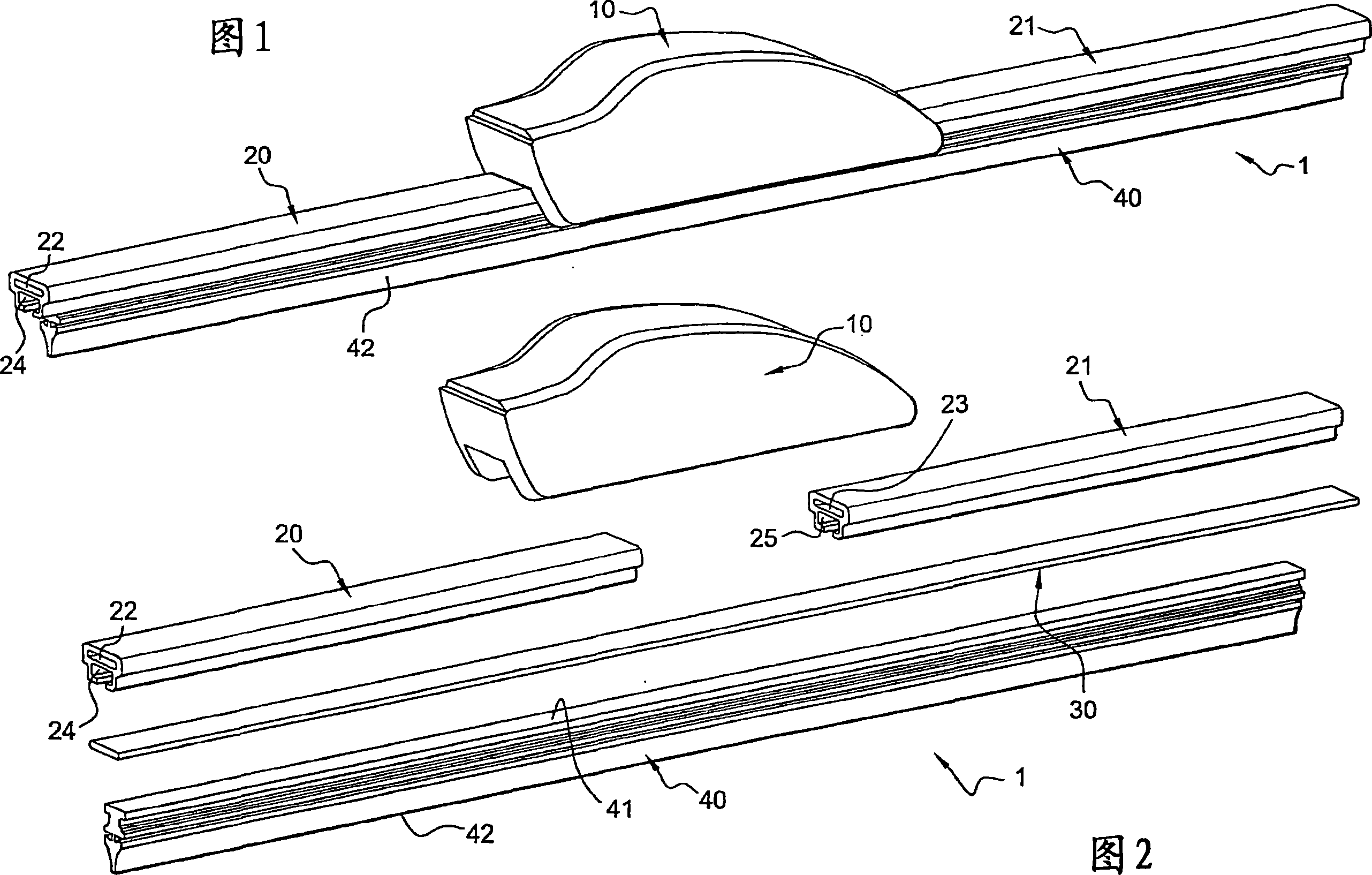

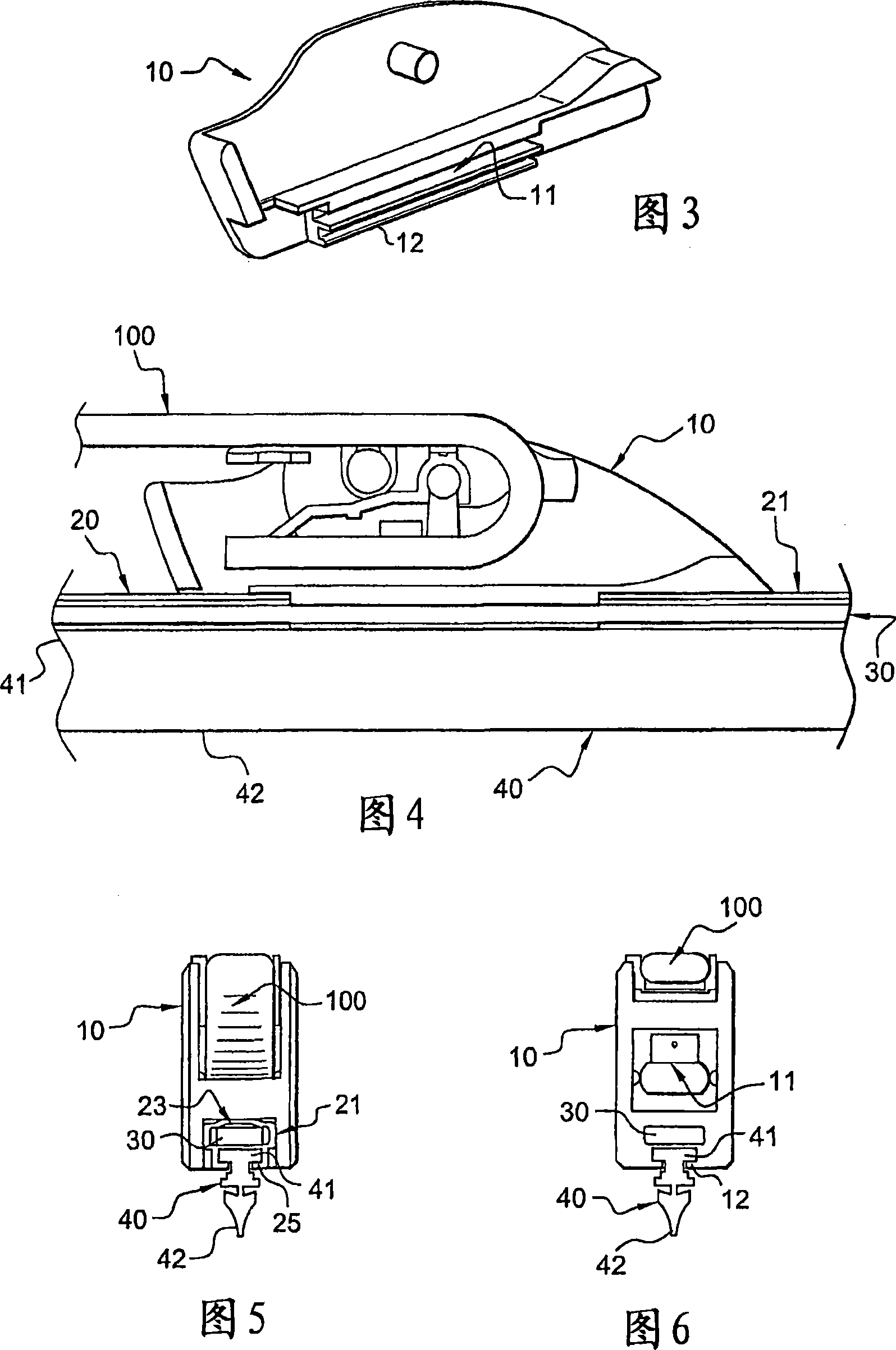

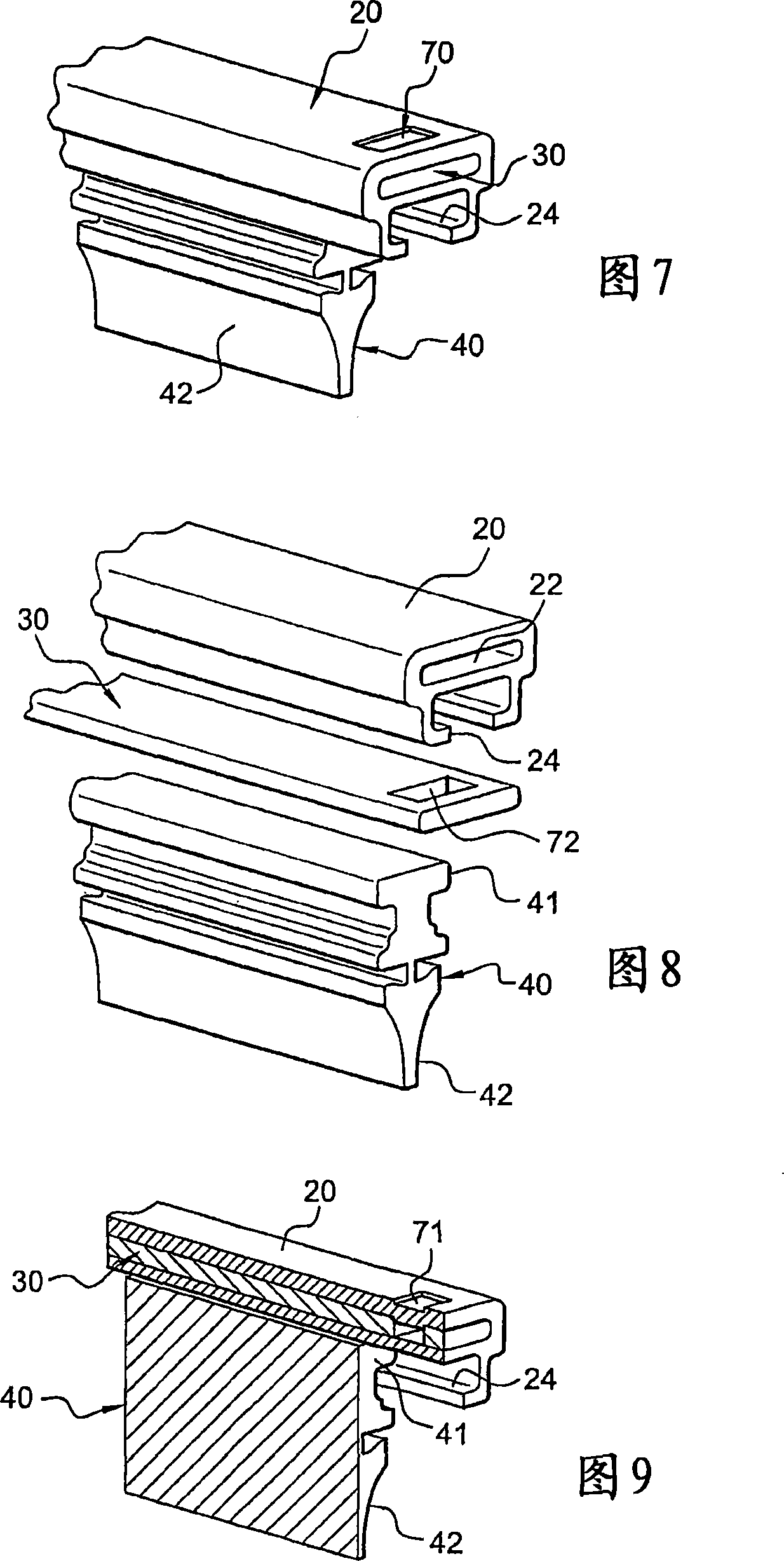

Flat wiper blade, in particular for motor vehicles

The invention relates to a flat wiper (1), in particular for a motor vehicle windscreen wiper device, wherein said flat wiper (1) comprises a connecting element (10) which connects the flat wiper (1) and is provided with a housing and a rail embodied therein, two mounting members (20, 21) provided with a housing (22, 23) and a rail (24, 25) arranged therein and connected to a housing (11) and the rail (12) of the connecting element (10), respectively, an elastically deformable vertebra (30) placeable inside the housings (11, 22, 23) of the connecting element (10) and of each mounting element (20, 21) and a wiping blade (40) which comprises a heel (41) nested inside the rails (12, 24, 25) of the connecting element (10) and of each mounting element.

Owner:VALEO SYST DESSUYAGE

Gel electrolyte film of lithium battery and preparation method of gel electrolyte film

InactiveCN102170021ASolve the problem of mechanical strengthIncrease fluid retentionFinal product manufactureElectrolyte accumulators manufactureFiltrationPhysical chemistry

The invention relates to a gel electrolyte film of a lithium battery and a preparation method of the gel electrolyte film. The preparation method comprises the following steps of: making bacterial cellulose neutral; producing bacterial cellulose pulp by beating and dispersion; and performing suction-filtration, dehydration and electrolyte soaking to obtain the gel electrolyte film. The gel electrolyte film of the lithium battery provided by the invention has good ion conductivity and mechanical strength and effectively solves the problem of poor mechanical strength of the gel electrolyte film. By the preparation method of the gel electrolyte film, the thickness of the gel electrolyte film is reduced by means of beating and suction filtration, the surface smoothness of the gel electrolyte film of the lithium battery is improved, fibre distribution is more uniform, arrangement is dense, physical property is relatively strong, an application range is expanded, a preparation process is simple, and industrial production is easy to carry out.

Owner:海南椰国热带水果食品加工有限公司 +1

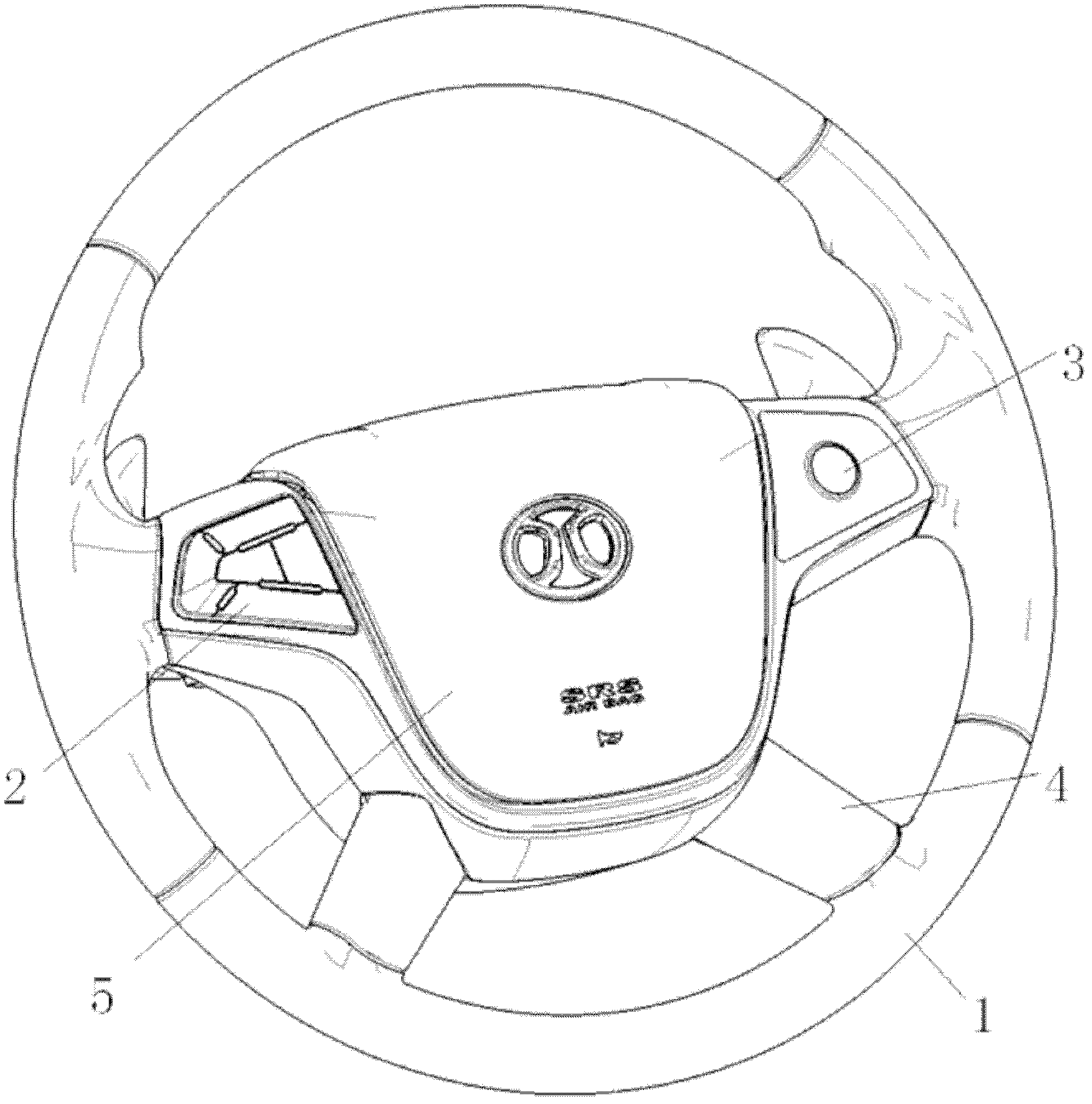

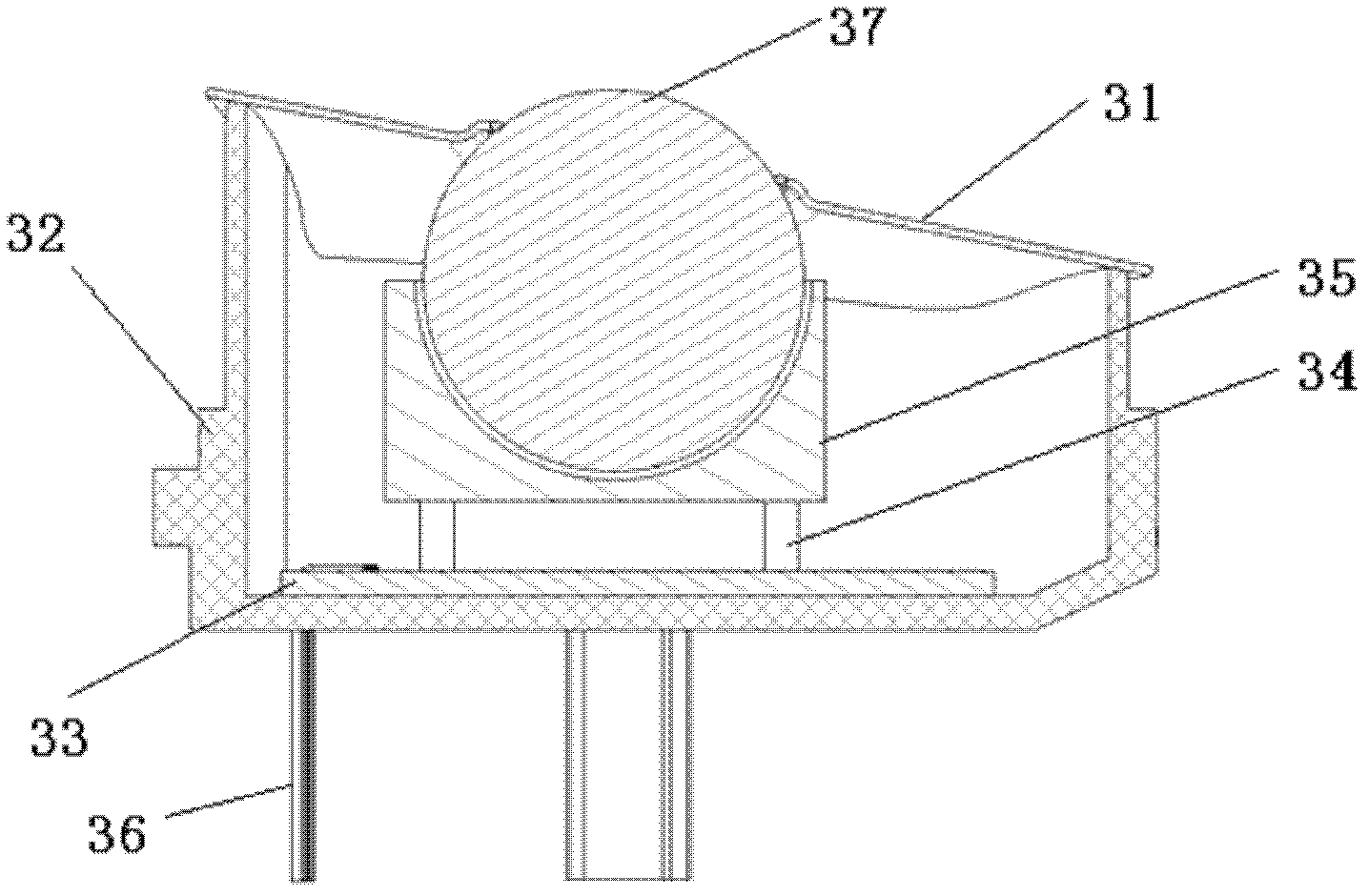

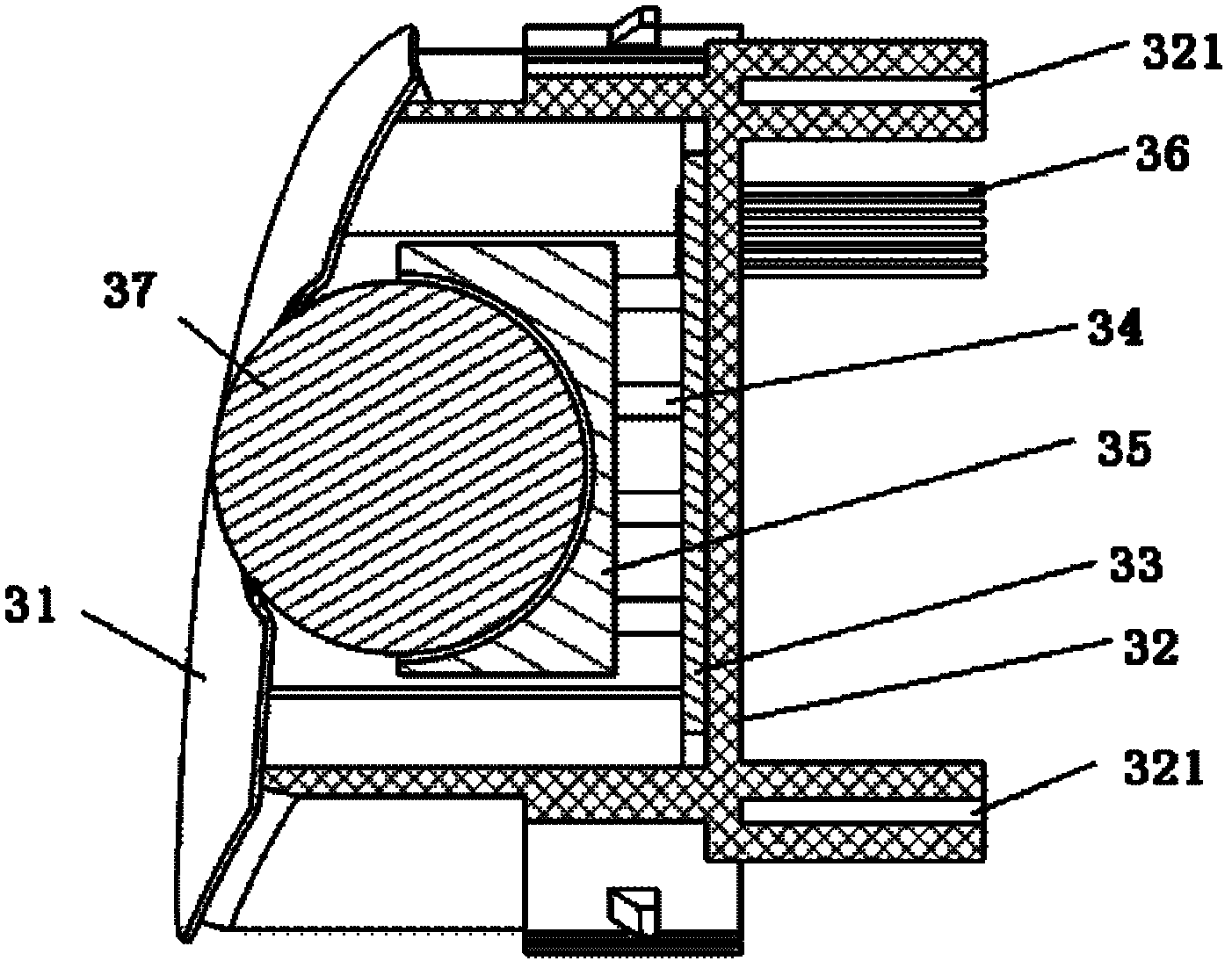

Steering wheel integrating trackball devices

ActiveCN102530049AEasy to operateEnsure safetyHand wheelsInput/output processes for data processingSteering wheelEngineering

The invention provides a steering wheel integrating a trackball devices, which comprises a wheel hub, a wheel rim and a plurality of wheel spokes, wherein the wheel spokes are connected with the wheel hub and the wheel rim, and two of the wheel spokes are provided with the trackball devices for controlling an interface of a display screen inside a vehicle. The trackball devices are used for operating a multimedia interface or a navigation interface displayed on the display screen and capable of moving positions of selected points on the multimedia interface or the navigation interface, the positions of the selected points can be determined by pressing trackballs, and a function option menu can be displayed on the display screen by pressing the trackballs for a long time, so that the steering wheel integrating the trackball devices is convenient and safe.

Owner:BAIC MOTOR CORP LTD

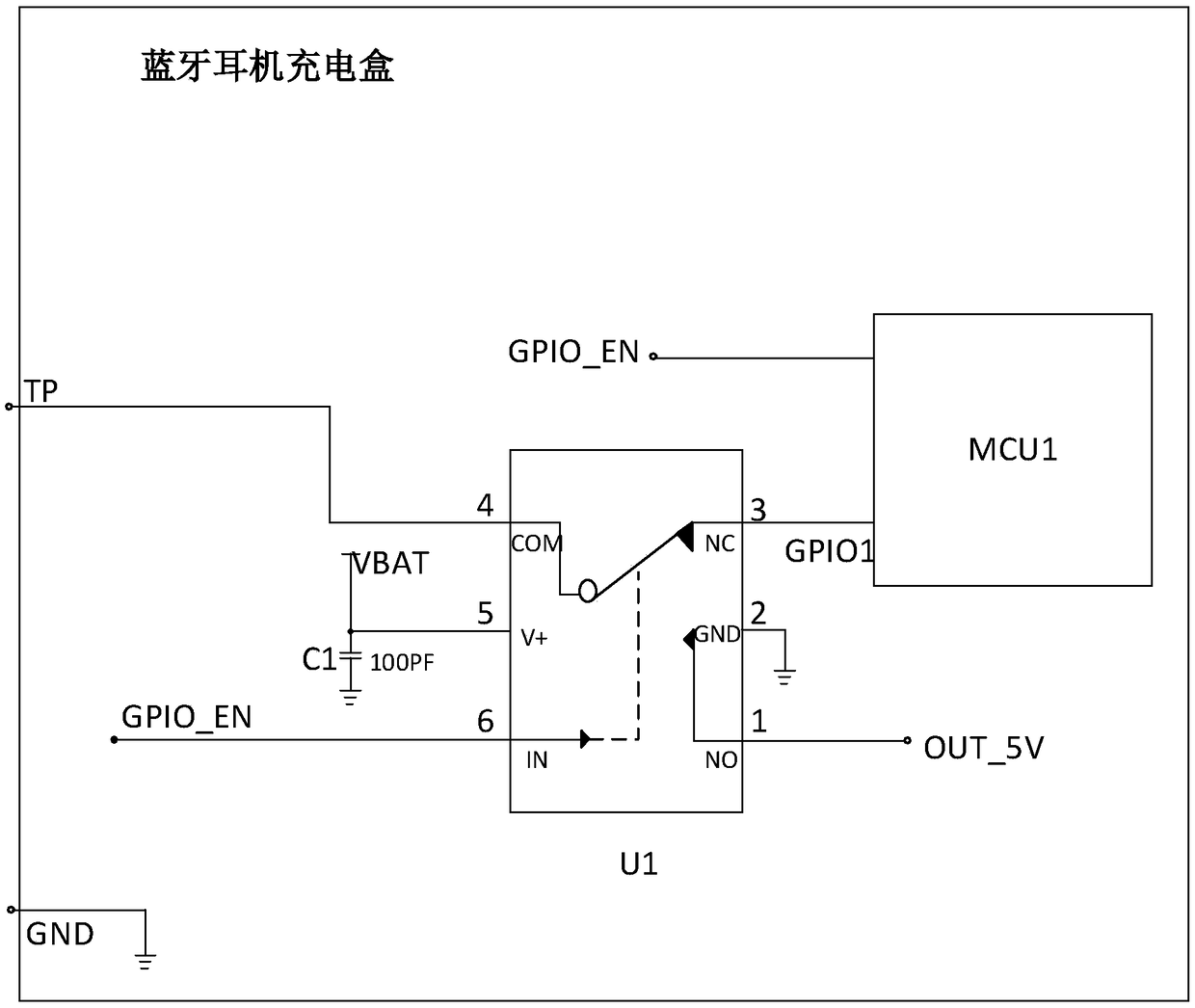

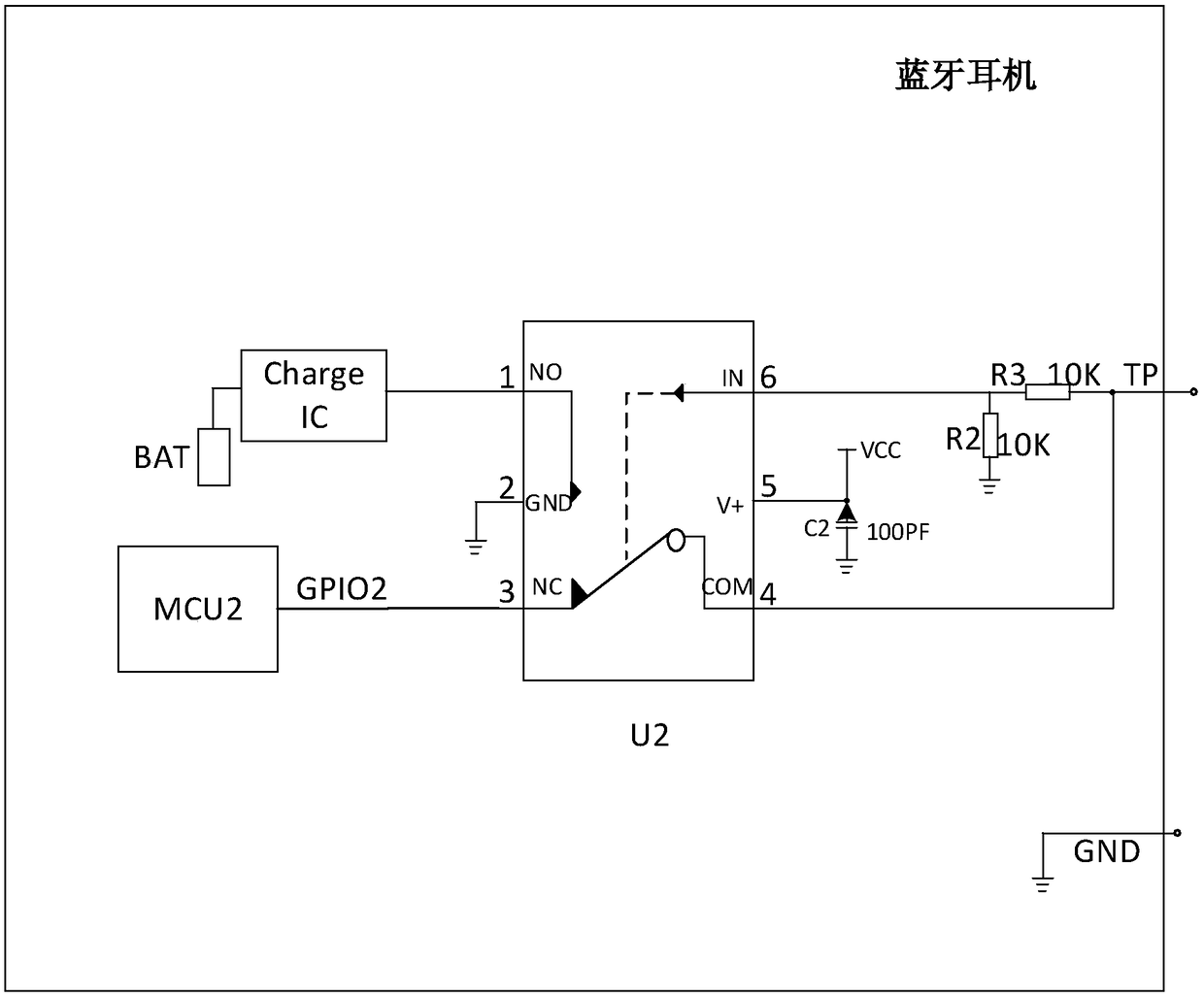

Bluetooth headset charging box and bluetooth headset

InactiveCN109495807AReduce the difficulty of structural designImprove stabilityBatteries circuit arrangementsEarpiece/earphone attachmentsMicrocontrollerEngineering

Embodiments of the present application disclose a bluetooth headset charging box and a bluetooth headset. The charging box comprises a first contact terminal and a second contact terminal. The secondcontact terminal is a ground terminal. The first contact terminal is connected to a common terminal of a first control chip. The control terminal of the first control chip is connected with an enableterminal of a controller chip of the charging box, and is used for controlling the common terminal to be connected with the normal-close terminal or connected with the normal-open terminal through theenable terminal of the microcontroller of the charging box. The normal-close terminal is connected to a signal terminal of the controller chip of the charging box. The normal-open terminal is connected to an output terminal of a charging power supply. By implementing the technical solution provided by the present application, the contact terminals of the bluetooth headset charging box and the bluetooth headset can be simplified into two, thereby reducing the difficulty of structural design of the headset, improving the stability of the headset in the charging box, and making the appearance ofthe headset more compact.

Owner:CHONGQING HUIYE IOT TECH CO LTD

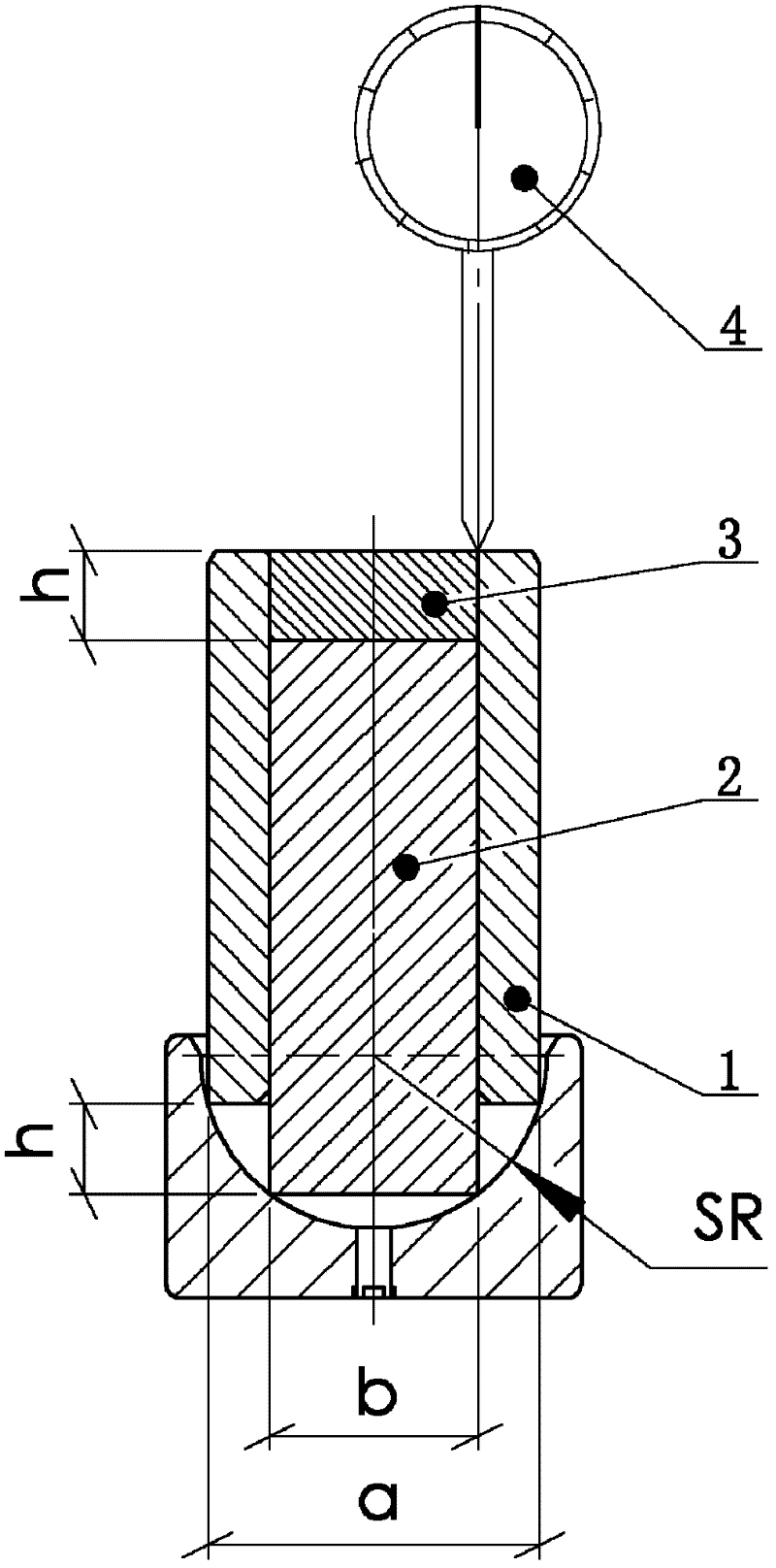

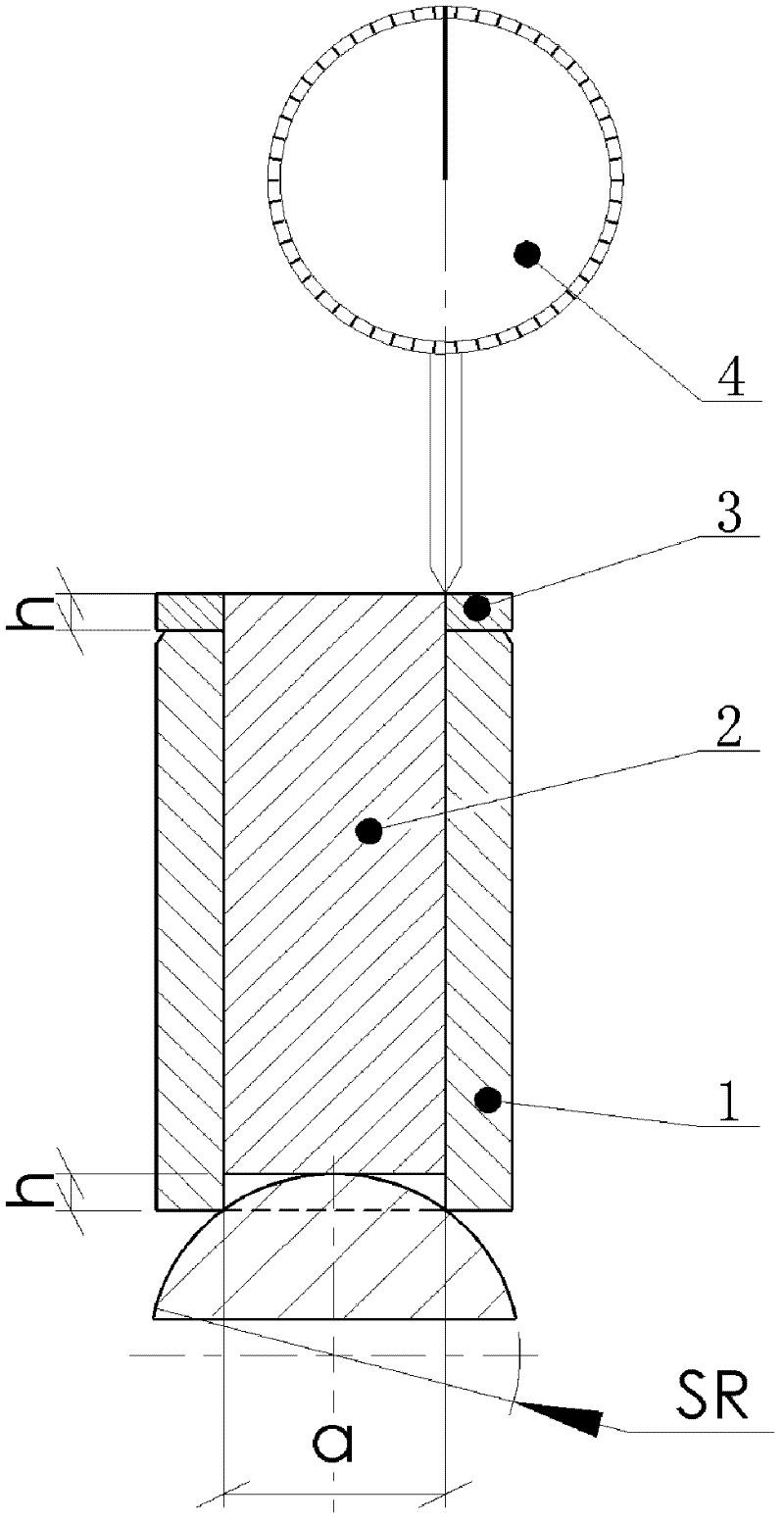

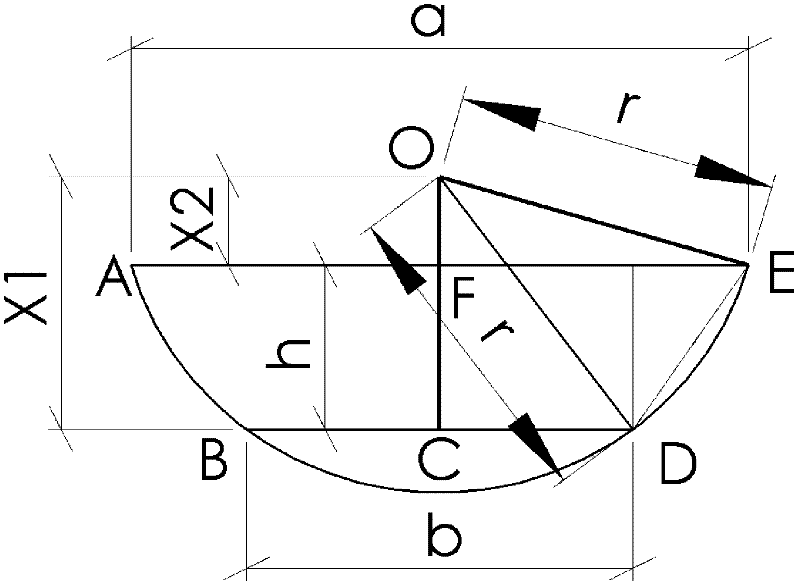

Device for measuring radius of spherical crown and measuring method thereof

InactiveCN102445137AEasy to manufactureSimple appearanceMechanical counters/curvatures measurementsOptics

The invention discloses a device for measuring radius of a spherical crown and a measuring method thereof. The device comprises an outer measuring rod (1), an inner measuring rod (2), a dial indicator (4) and a standard block (3), wherein the inner measuring rod (2) is arranged inside the outer measuring rod (1), and contacts with the surface of the measured spherical crown by a measuring rod outer circle or an inner hole; and the standard block (4) is added by the dial indicator (4) to read out the end surface fall of two measuring rods; and then the radius of the measured workpiece is calculated. The device has a very simple structure, convenience in use and high measuring precision.

Owner:FENY

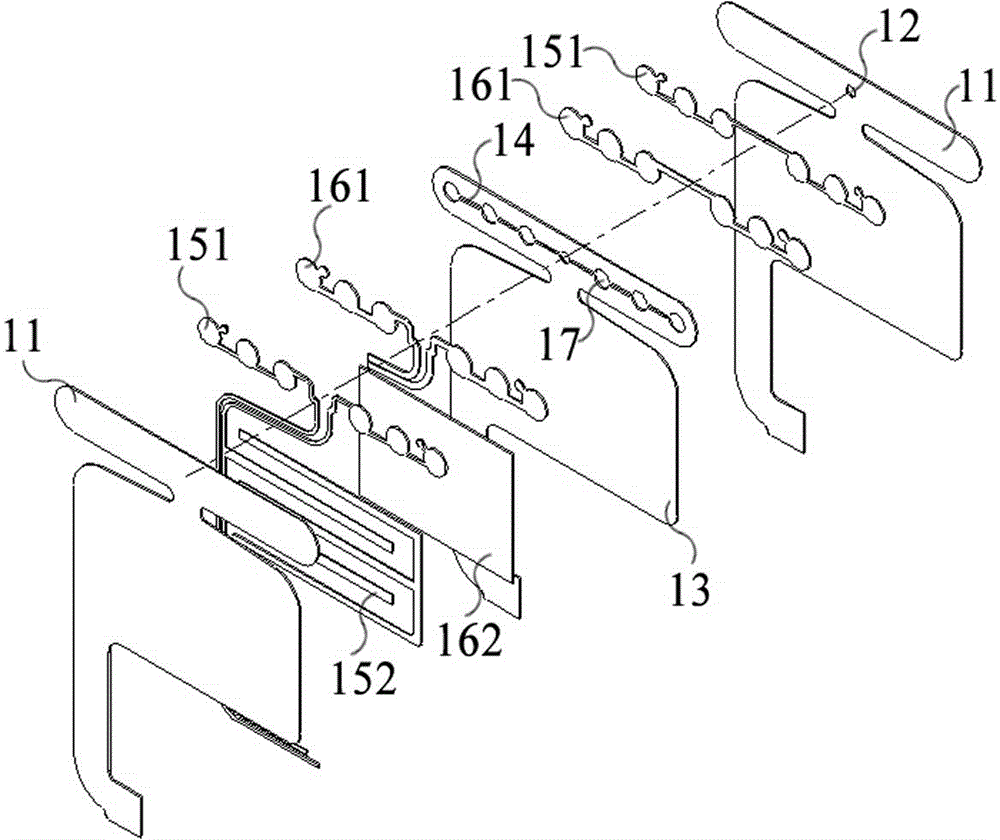

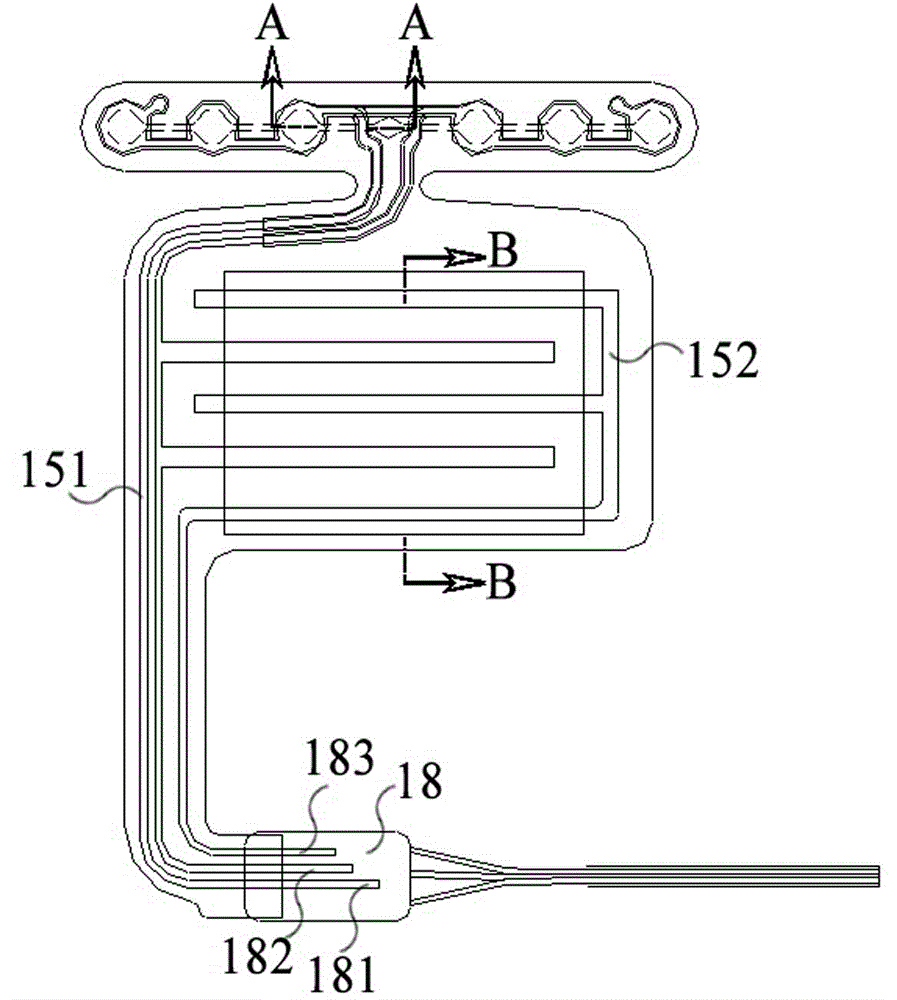

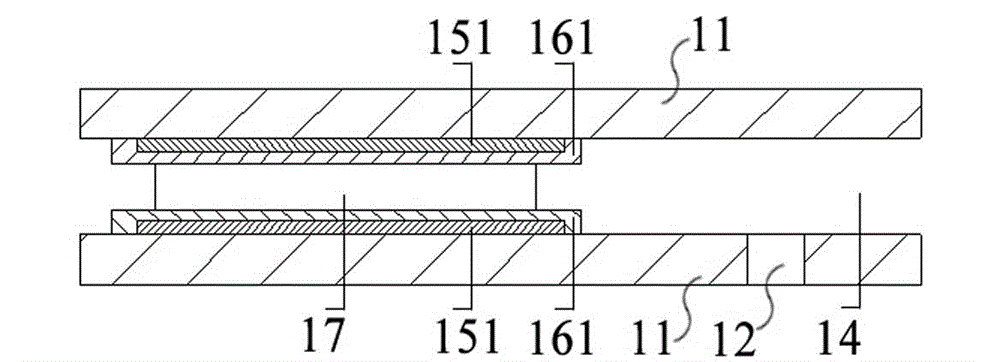

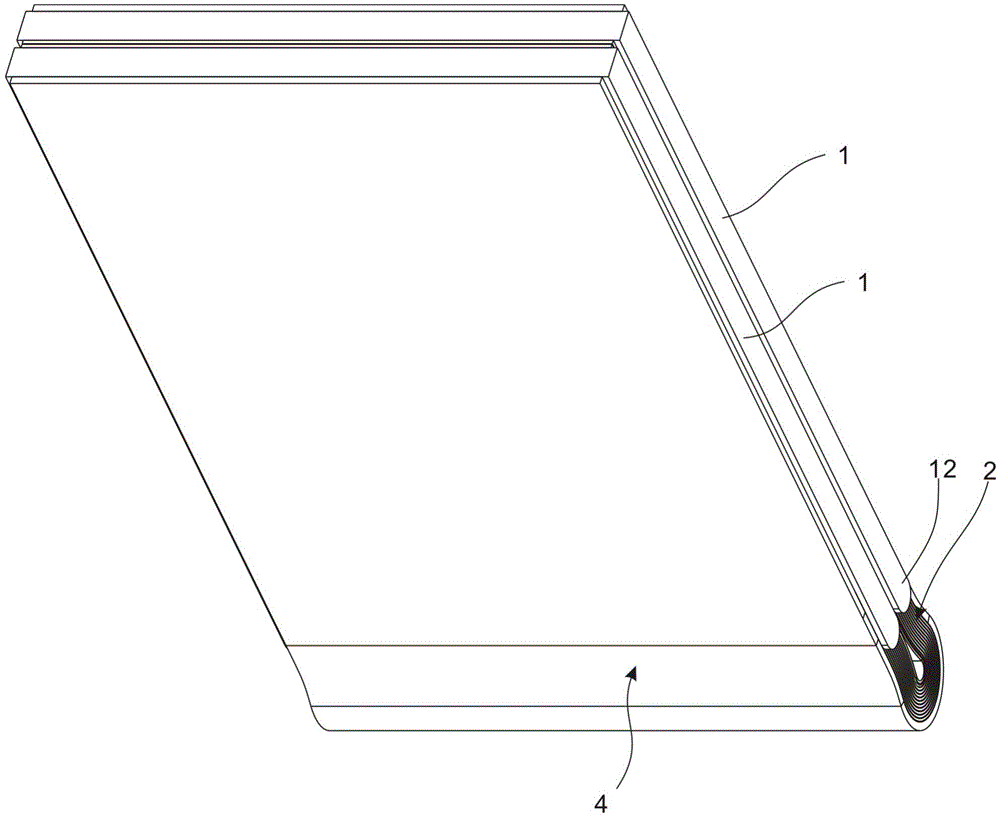

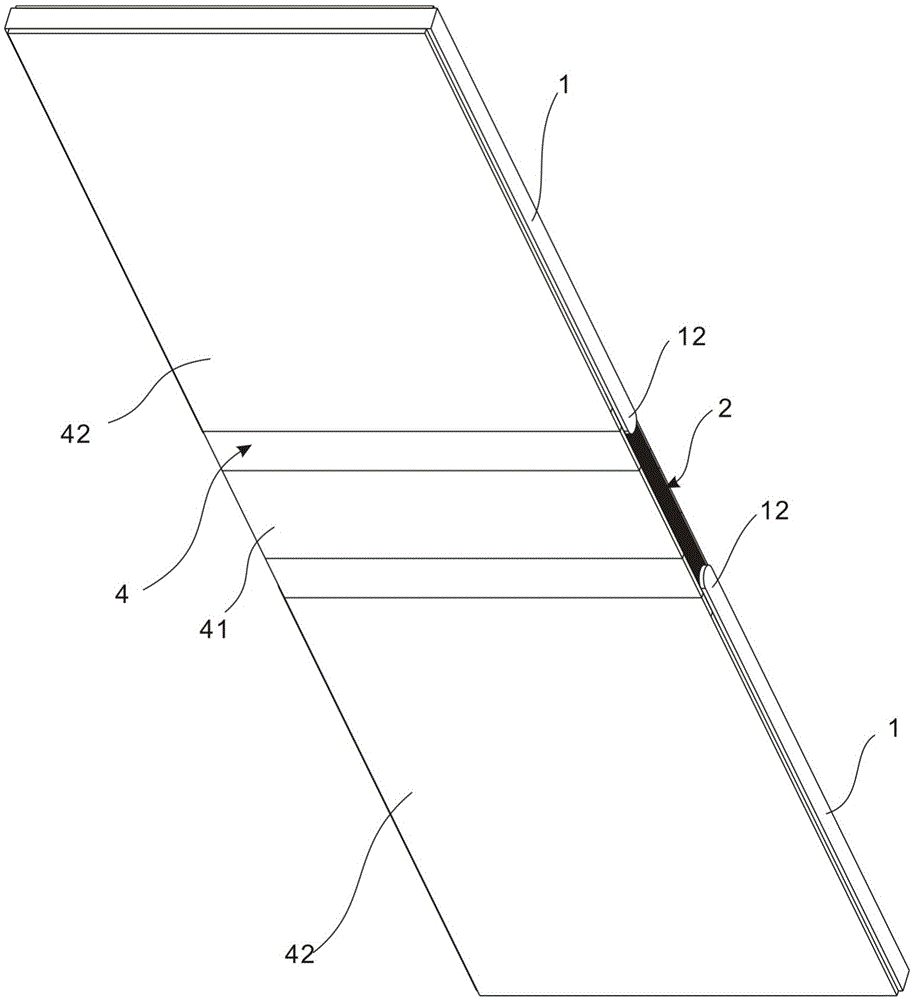

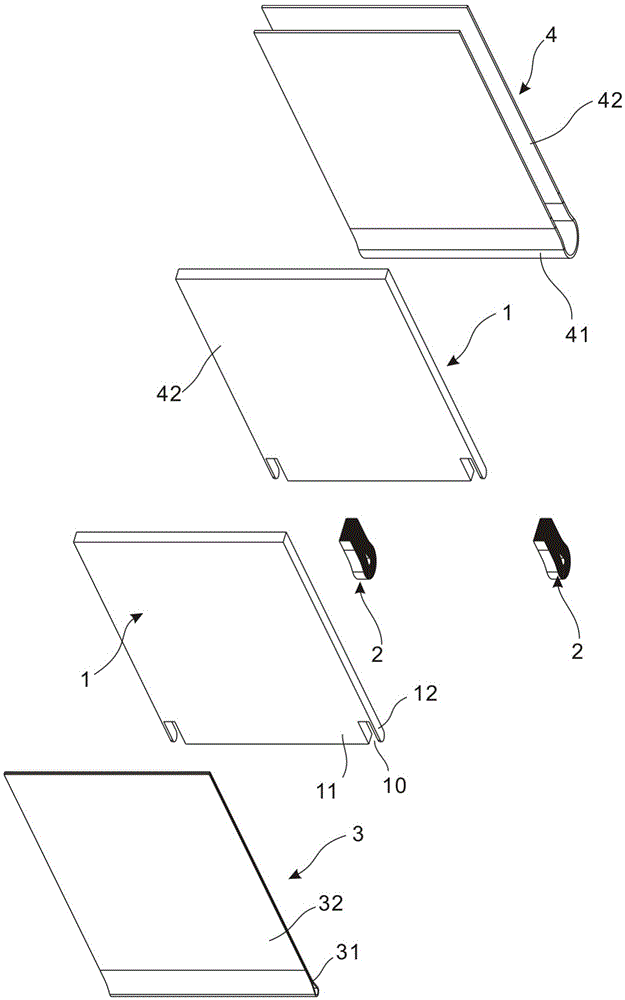

Foldable terminal

ActiveCN105430132ASimple appearanceSliding normallyTelephone set constructionsBend radiusMechanical engineering

The invention discloses a foldable terminal. The foldable terminal includes two main bodies, folding assemblies and a flexible screen; the folding assemblies are connected between the two main bodies; two folding assemblies are adopted and are respectively arranged at two sides at the width direction of the main bodies; one end of the main body is provided with a protruding portion and two slide lugs; slide grooves are formed between the slide lugs and the protruding portion; two ends of the folding assembly are accommodated in the slide grooves; the folding assembly induces a plurality of flexible connecting sheets; the connecting sheets are strip-shaped; the plurality of connecting sheets are stacked; and the flexible screen is arranged on the two main bodies. When the folding terminal is unfolded or folded, the bending radiuses of the connecting sheets at the inner side and outer side of a folded structure are different, and a certain displacement change is produced between the end portions of the plurality of connecting sheets, and the whole folding assembly will not be wrinkled in a folding process, and the displacement change of the end portions is limited in the slide grooves; the slide lugs are sheltered at the outer sides of the end portions of the folding assemblies, so that the slide lugs will not be affected by external interference, and normal slide of the slide lugs can be ensured, at the same time, the shape of the foldable terminal is simple.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Pick-up head actuating unit for reversion

The invention provides a kind of astern running camera executing device, which is made up of front cover, link, frame, keeper, screw stem, nut, connecting bracket, a big gear, base, direct current engine, small gear, rubber ring, shell and camera; the frame is a main component, the other parts are connected with frame, the frame is embedded in the shell, and it can be moved parallel in the shell. The device structure is light and handy; the appearance is compact, which can be set in the back tank cover of the car. When astern running, the executing device can extend the camera in the car, it is convenient and safe.

Owner:SHANGHAI HUGONG AUTO ELECTRIC

Steel tube derusting device

InactiveCN105817983ARealize no dead angle rust removalClean and even rust removalGrinding carriagesGrinding drivesElectric machinerySteel tube

The invention discloses a steel tube derusting device. The steel tube derusting device comprises a rack as well as a transmission mechanism, a derusting mechanism and a motor, which are mounted on the rack, wherein detachable type side frameworks are arranged at the two sides of the rack; the side frameworks are provided with fixed steel rings; the derusting mechanism is arranged between the two fixed steel rings; the derusting mechanism comprises at least two hard brushes, a soft brush and a roller, wherein the roller comprises a tube inlet and a tube outlet; the hard brushes are arranged on the surface of the roller, and are close to the tube inlet; the soft brush is arranged on the surface of the roller and is close to the tube outlet; and the derusting mechanism is connected with a motor through a transmission mechanism. The steel tube derusting device is clean and uniform in derusting effect, is concise in appearance, is small in size, is small in weight, and is convenient to move.

Owner:GUANGZHOU KOLLER REFRIGERATION EQUIP

Integral paper frame structure, vertical type and horizontal type printers comprising same

InactiveCN102616010AEasy to assemble and disassembleEasy to useOther printing apparatusPulp and paper industry

Owner:深圳市润信达科技有限公司

Mothproof and fireproof plasterboard with glass fiber surface and manufacturing method thereof

The invention discloses a mothproof and fireproof plasterboard with glass fiber surface and a manufacturing method thereof. The plasterboard comprises an intermediate basal layer composed of gypsum plaster; the outside of the intermediate basal layer is coated by glass fiber net to form a glass fiber surface; the contents of the components are respectively arranged through parts by weight in batching: 1000 parts of hemihydrate gypsum powder; 30-35 parts of adhesive; 20-45 parts of glass fiber; 75-90 parts of glass fiber mesh and 730-850 parts of water; the plasterboard of the invention features in improving strength of board material, strengthening ornament effect and easy application of basal layer paint; what is more, the plasterboard is effectively mothproof and more fireproof than the thistle board, belongs to A-level incombustible material and has better water resistance, thus being widely applied in fields such as architecture and decoration.

Owner:SHANDONG BAIER BUILDING MATERIAL CO LTD

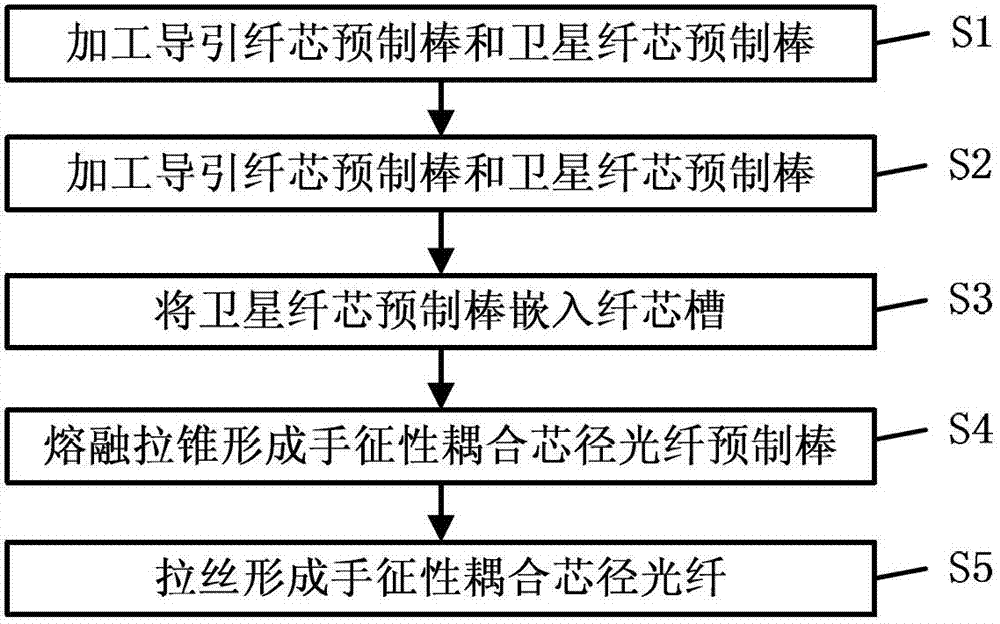

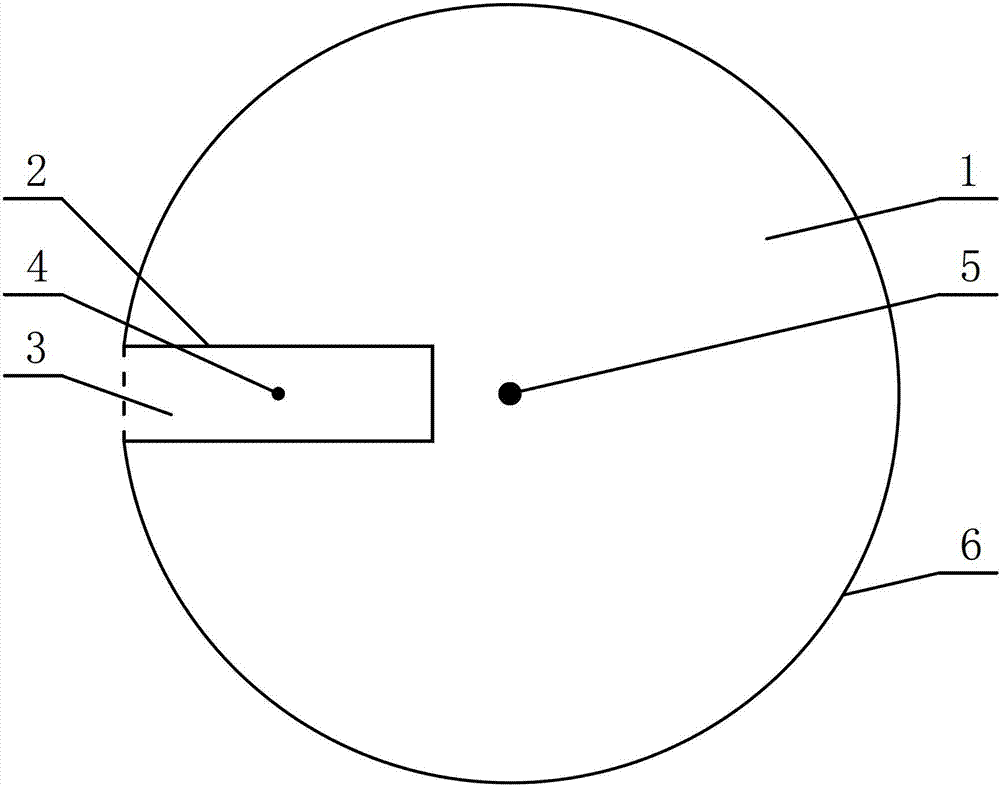

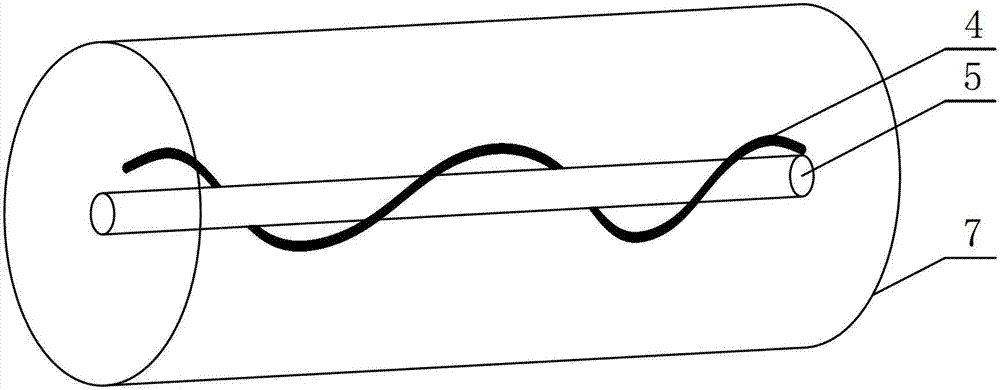

Chirality coupling core diameter optical fiber and manufacturing method thereof

ActiveCN103204629ALow manufacturing costReduce manufacturing difficultyGlass making apparatusMulticore optical fibreOptoelectronicsFiber

The invention discloses a chirality coupling core diameter optical fiber and a manufacturing method thereof and relates to the field of optical fiber laser transmission and amplification. The manufacturing method comprises the following steps of: processing a guide fiber core preform semifinished product and a satellite fiber core preform semifinished product to form a satellite fiber core preform and a guide fiber core preform; embedding the satellite fiber core preform into a fiber core slot; carrying out fused biconical taper at the top of the guide fiber core preform to form a chirality coupling core diameter optical fiber preform; and carrying out melting and wire drawing on the chirality coupling core diameter optical fiber preform to form a chirality coupling core diameter optical fiber. Output optical beam quality of the chirality coupling core diameter optical fiber is less than 1.1, fundamental mode loss is less than 0.5dB / m, and high-order mode loss is more than 100dB / m. The chirality coupling core diameter optical fiber manufactured by the invention is good in optical property and reliability, low in manufacturing difficulty and applicable to mass production.

Owner:FENGHUO COMM SCI & TECH CO LTD

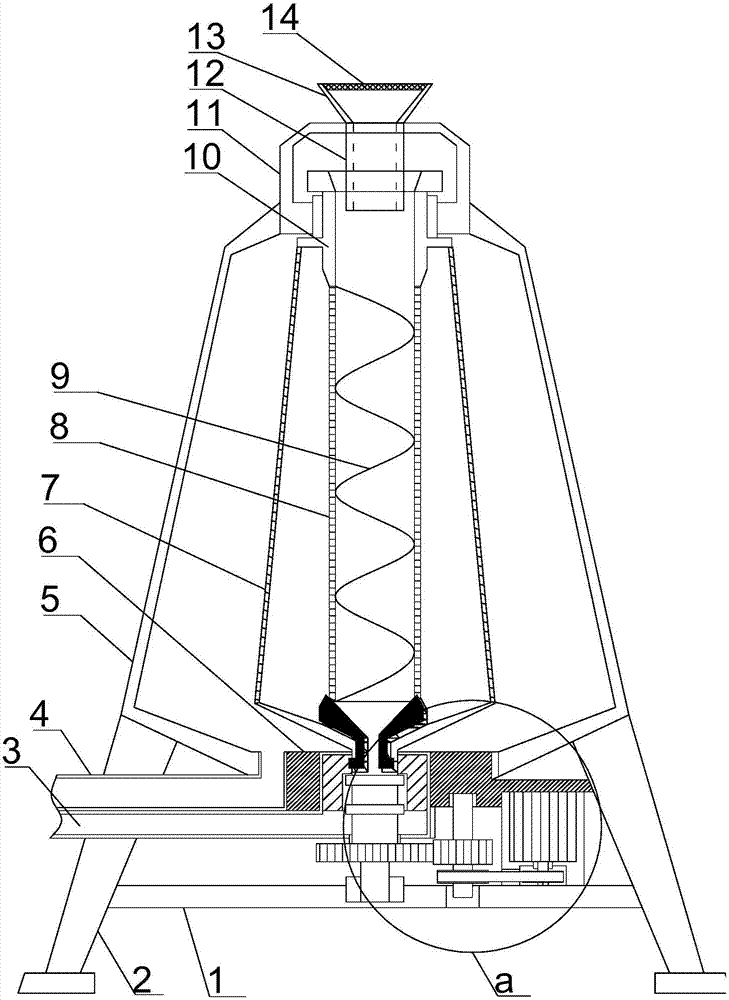

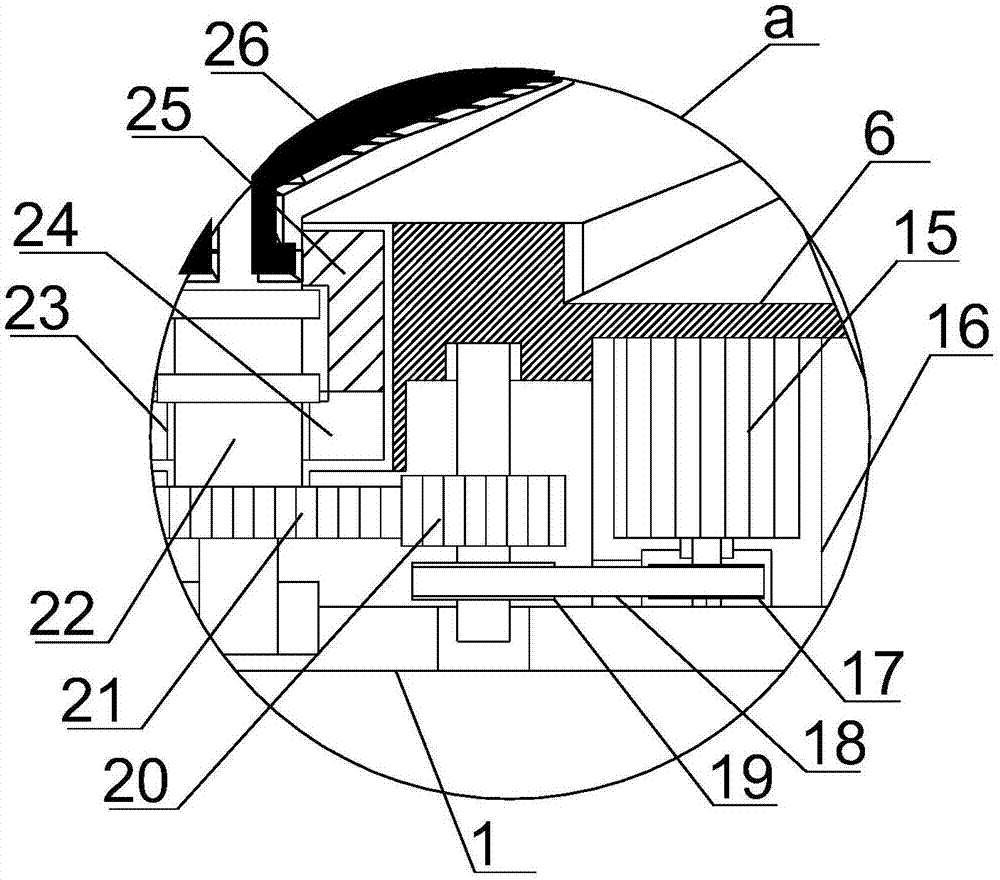

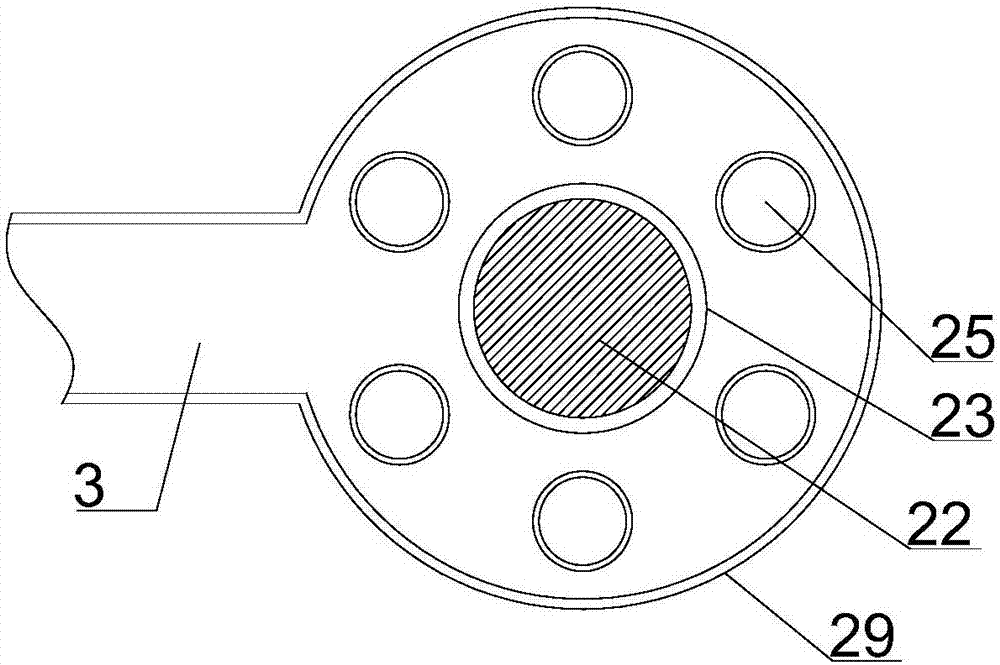

Spiral separation type sewage treatment plant

InactiveCN107376466ANovel structureSimple appearanceWater/sewage treatment by centrifugal separationTreatment involving filtrationTreatment effectSewage treatment

The invention discloses a spiral separation type sewage treatment device, which comprises a support installation module, a water inlet separation module and a centrifugal transmission module. The lower end of the cylinder is provided with supporting columns obliquely and symmetrically at the left and right ends, and a transmission support installation plate is horizontally arranged between the lower half of the support columns on the left and right sides. The water inlet separation module is arranged on the support installation cylinder, and the water inlet separation The module includes a feed protection cover arranged on the upper end of the support installation cylinder, a centrifugal filter cartridge is vertically arranged at the lower end of the feed protection cover in conjunction with the support installation cylinder, and a limited rotation feed ring is arranged on the upper end of the centrifugal filter cylinder in conjunction with the feed protection cover. The invention has the advantages of novel structure, simple appearance, stable transmission, centrifugal filtration instead of traditional sedimentation filtration, high separation efficiency and good treatment effect.

Owner:丁蒙蒙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com