Integral paper frame structure, vertical type and horizontal type printers comprising same

An all-in-one, printer technology, applied to printing devices, printing, etc., can solve problems such as unfavorable installation and maintenance, difficulty in loading, and less movable space, so as to reduce the trouble of frequent paper replacement, facilitate installation and maintenance, and use The effect of convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

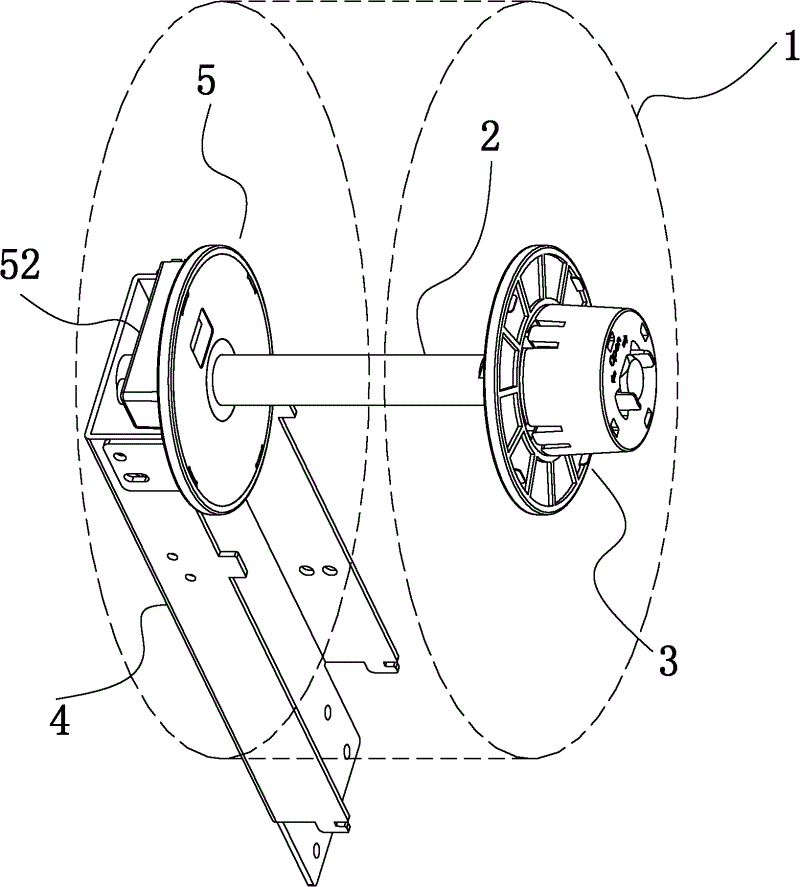

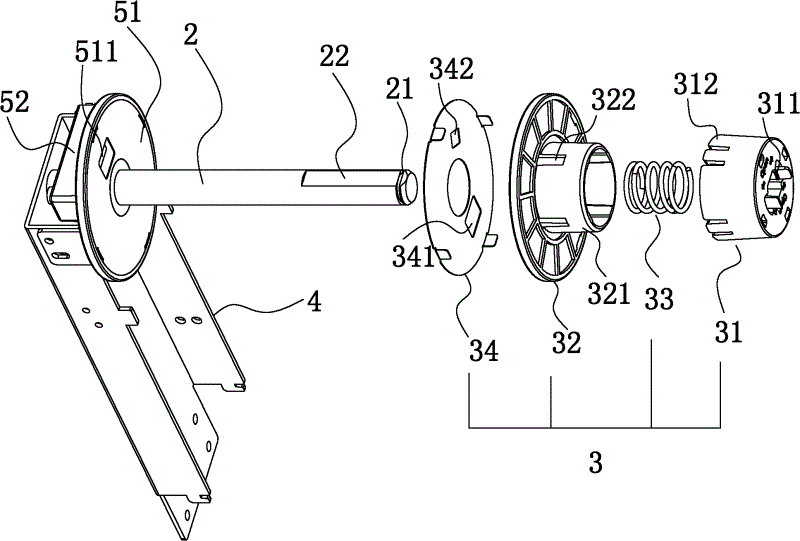

[0082] Embodiment of the integrated paper frame structure

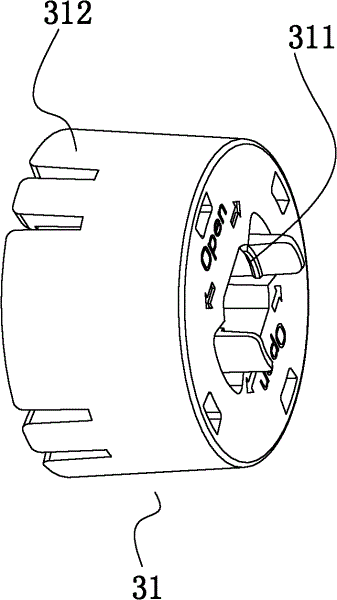

[0083] like Figure 1 to Figure 5 As shown, the integrated paper holder structure used in the receipt printer of the present invention includes a paper roll support shaft 2 for covering the paper roll 1, one end of the paper roll support shaft 2 is provided with a paper roll pretension mechanism 3, and the paper roll pretensioner Tightening mechanism 3 comprises the fixed part 31 that is fixedly connected with paper roll supporting shaft 2 ends and the pretensioning part 32 that is pressed on the side of paper roll 1, is provided with elastic part 33 between fixing part and pretensioning part (this embodiment elastic parts are springs). The pretensioning member 32 is axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com