Patents

Literature

32results about How to "Preload achieved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

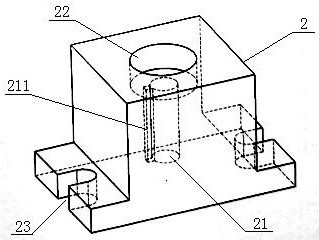

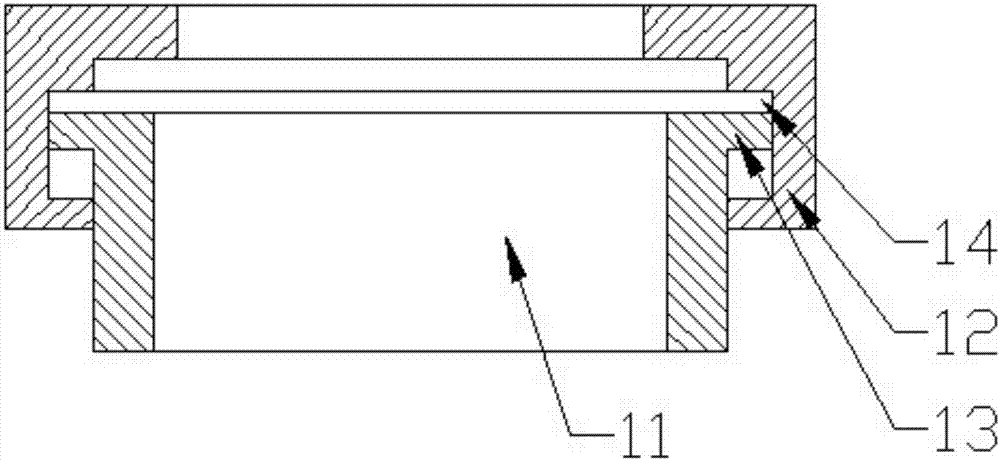

Integral paper frame structure, vertical type and horizontal type printers comprising same

InactiveCN102616010AEasy to assemble and disassembleEasy to useOther printing apparatusPulp and paper industry

Owner:深圳市润信达科技有限公司

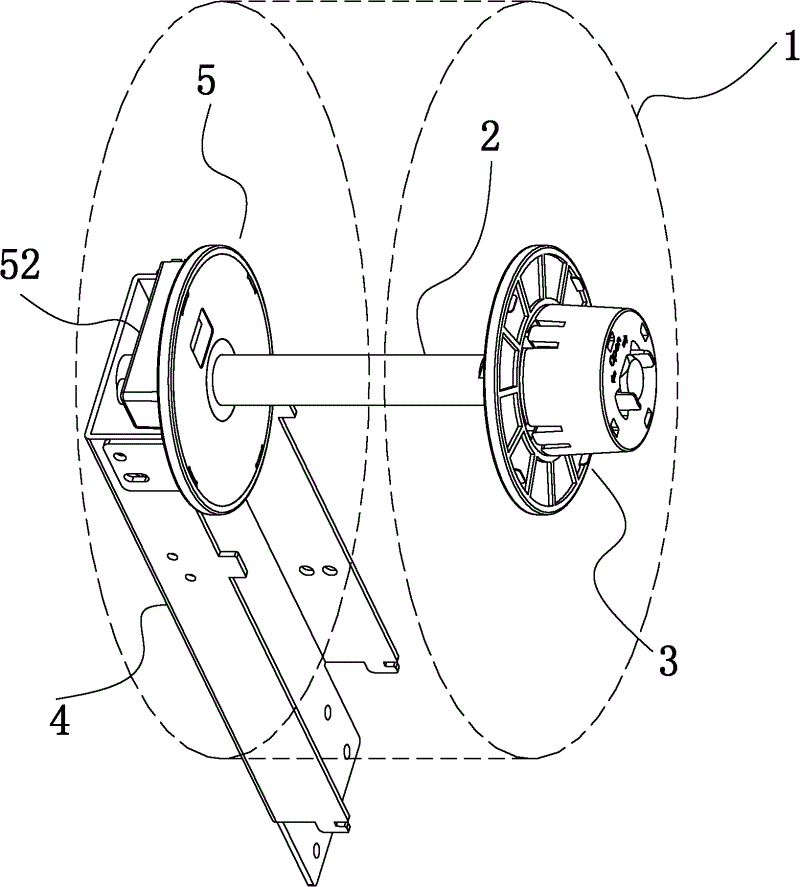

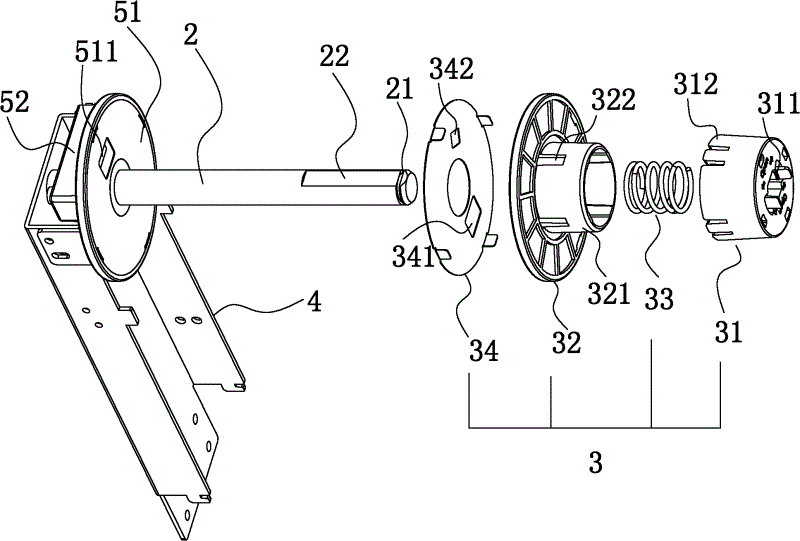

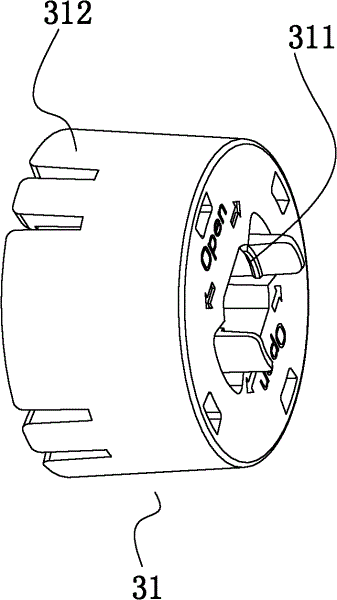

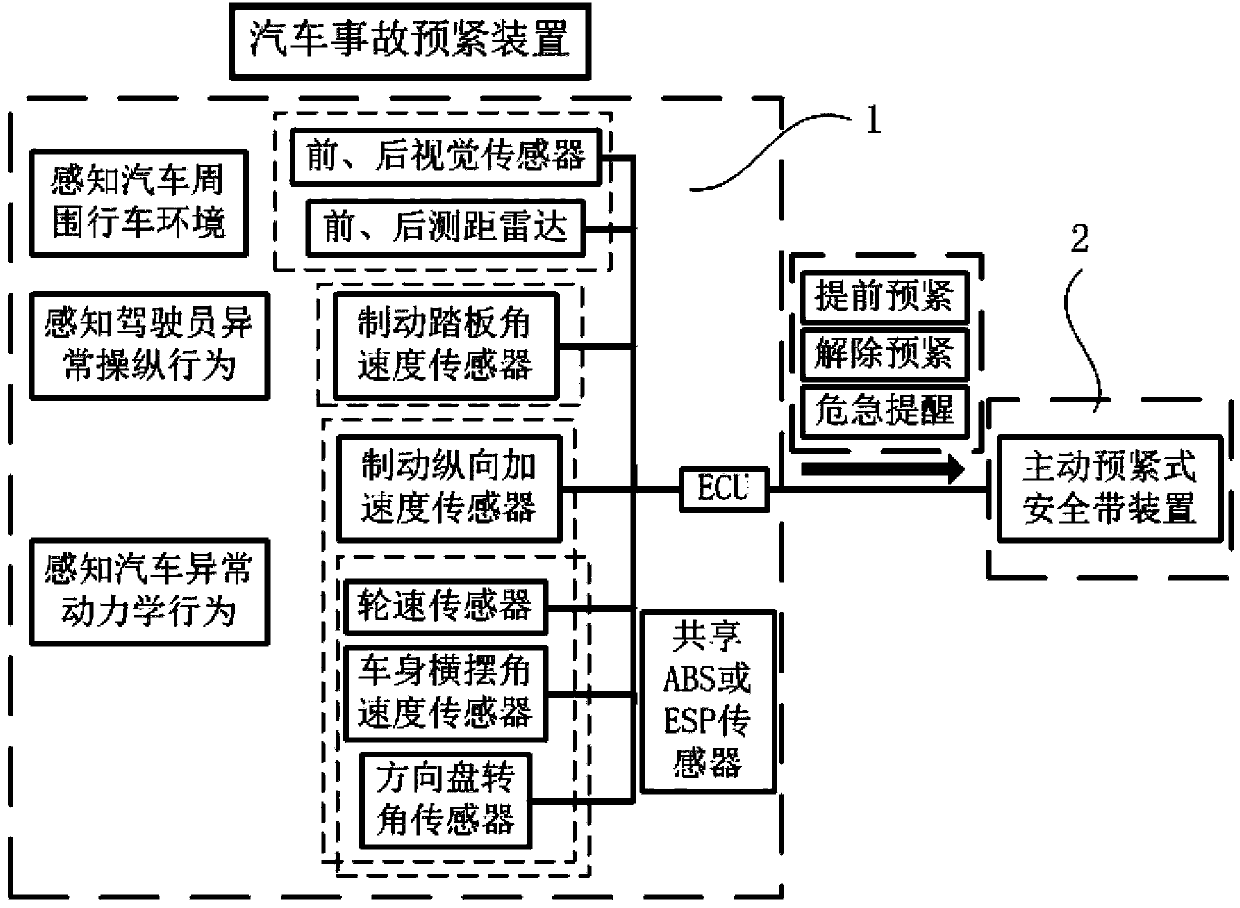

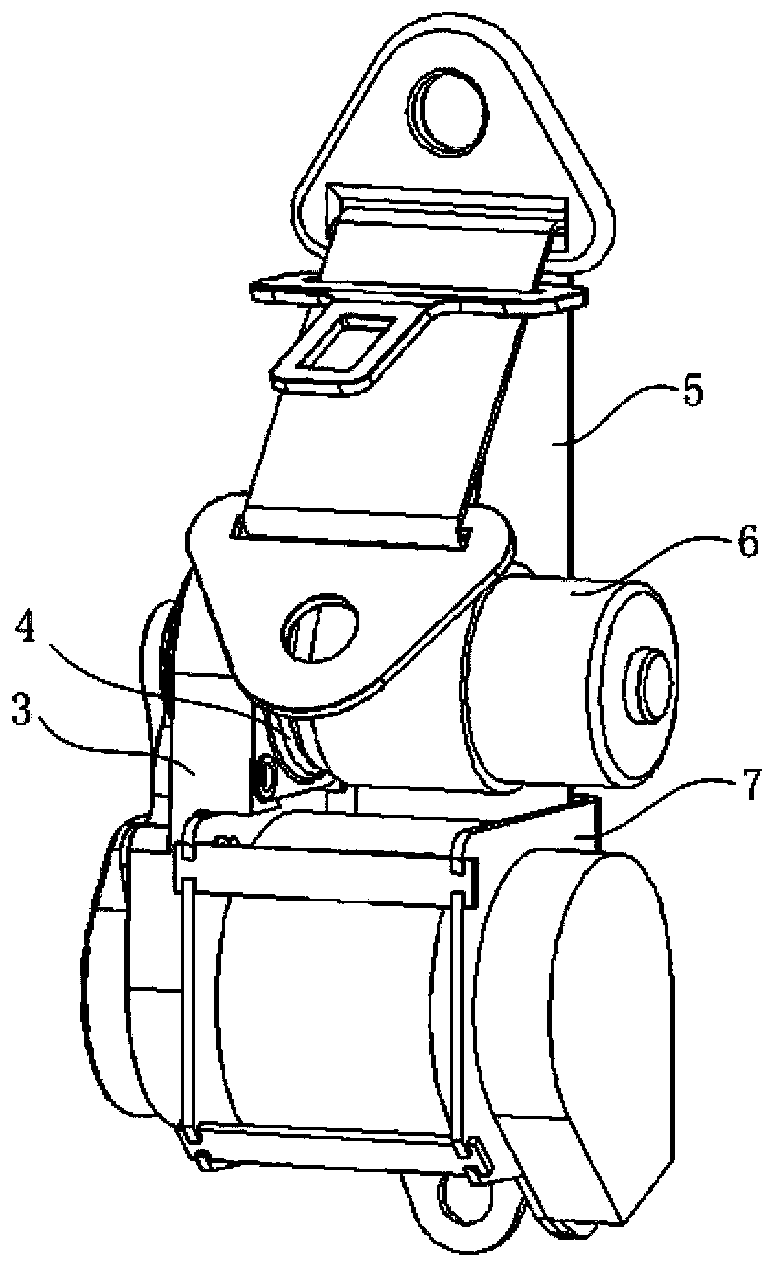

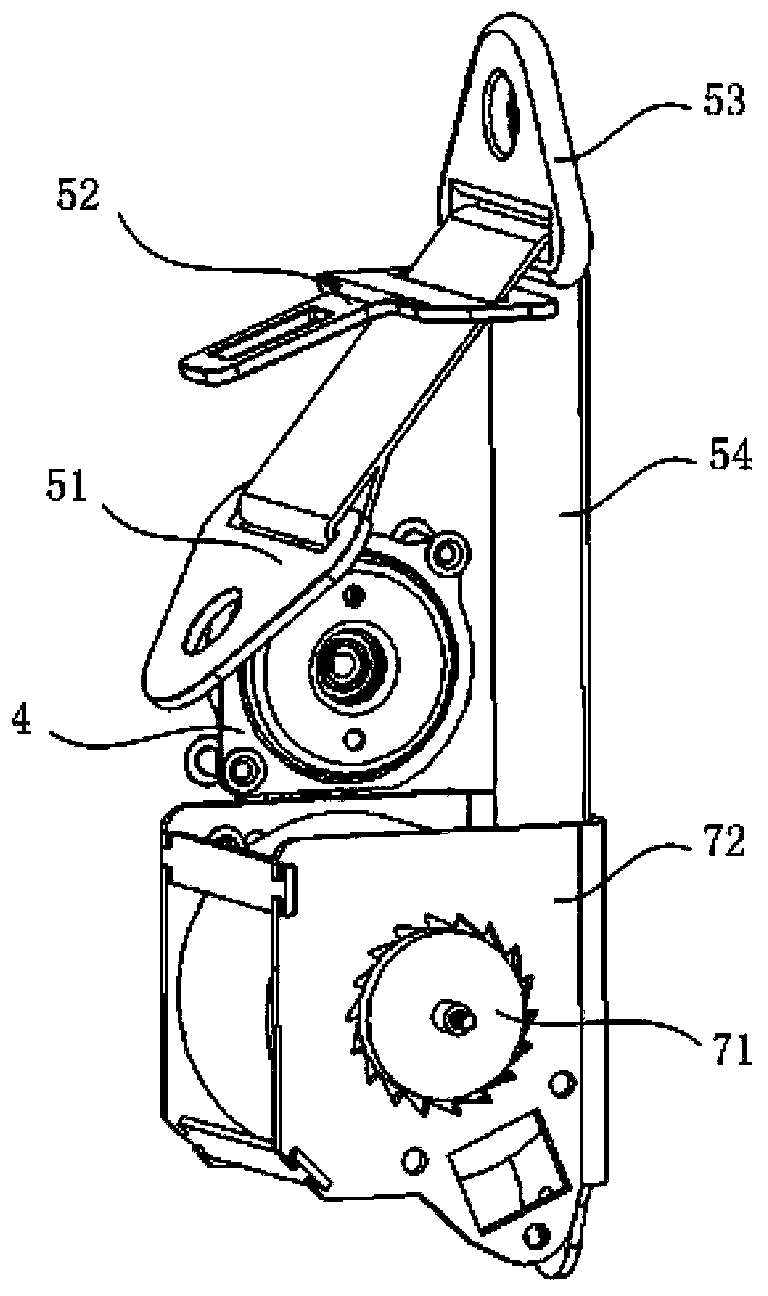

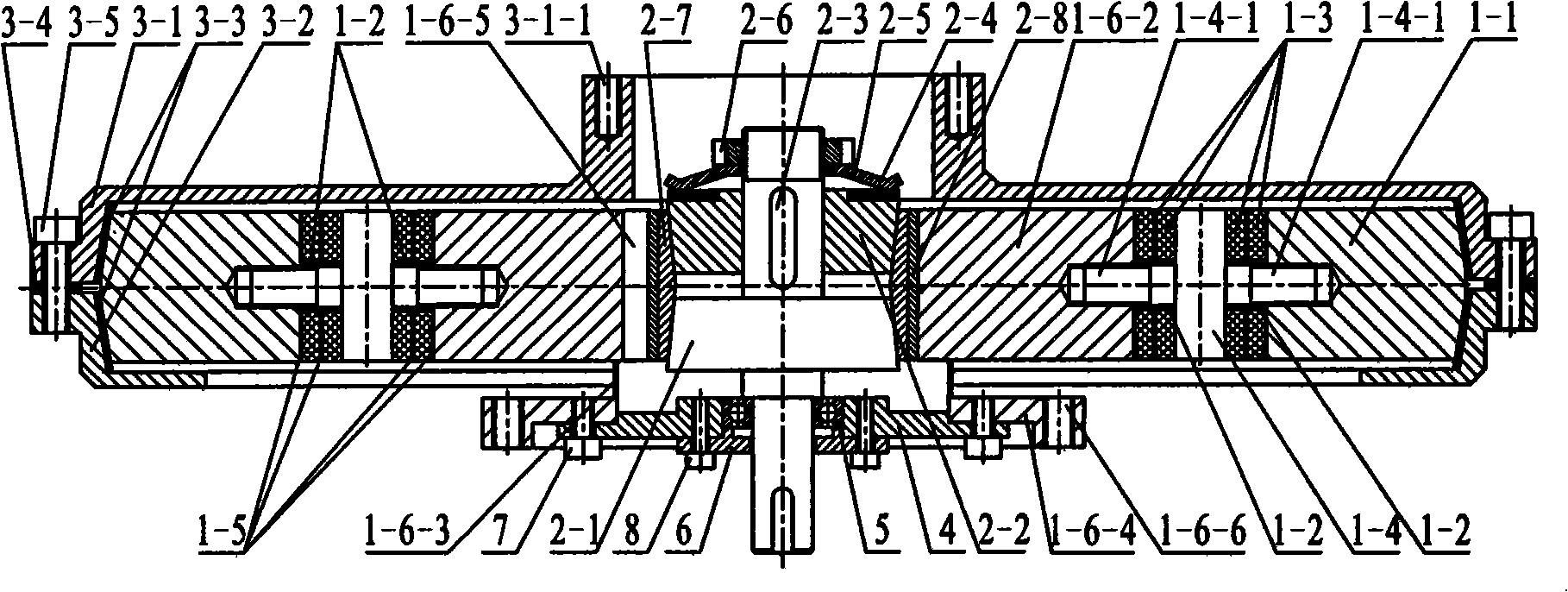

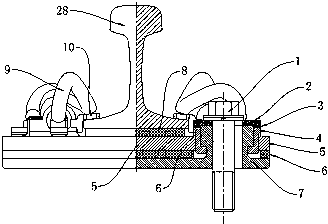

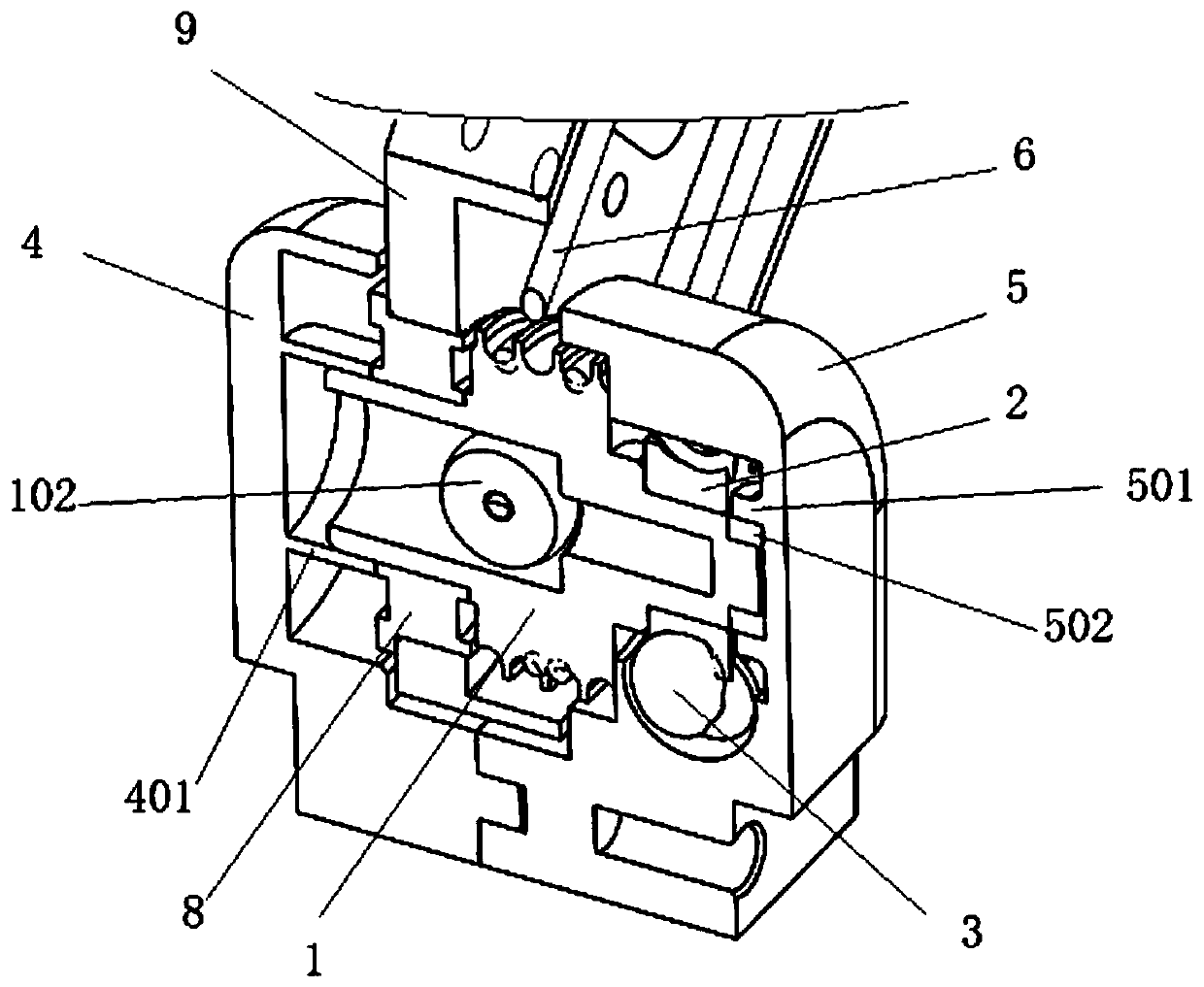

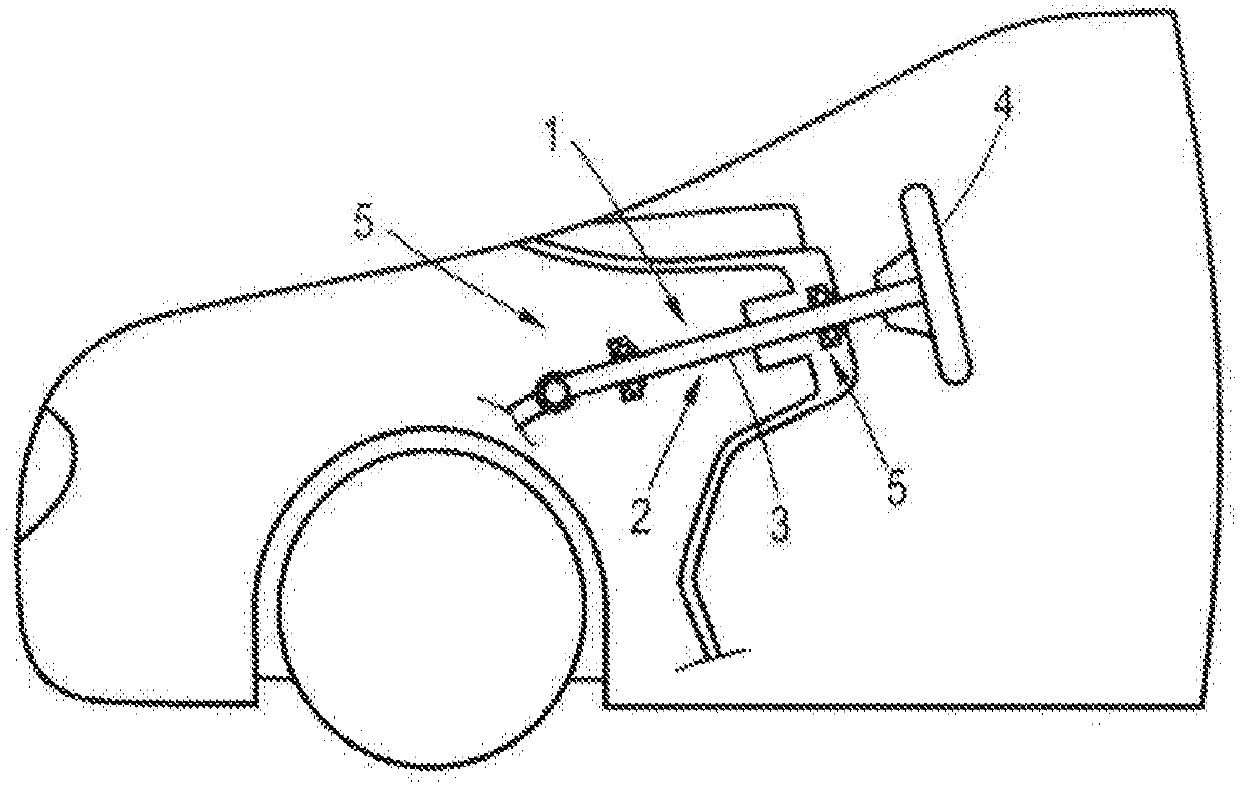

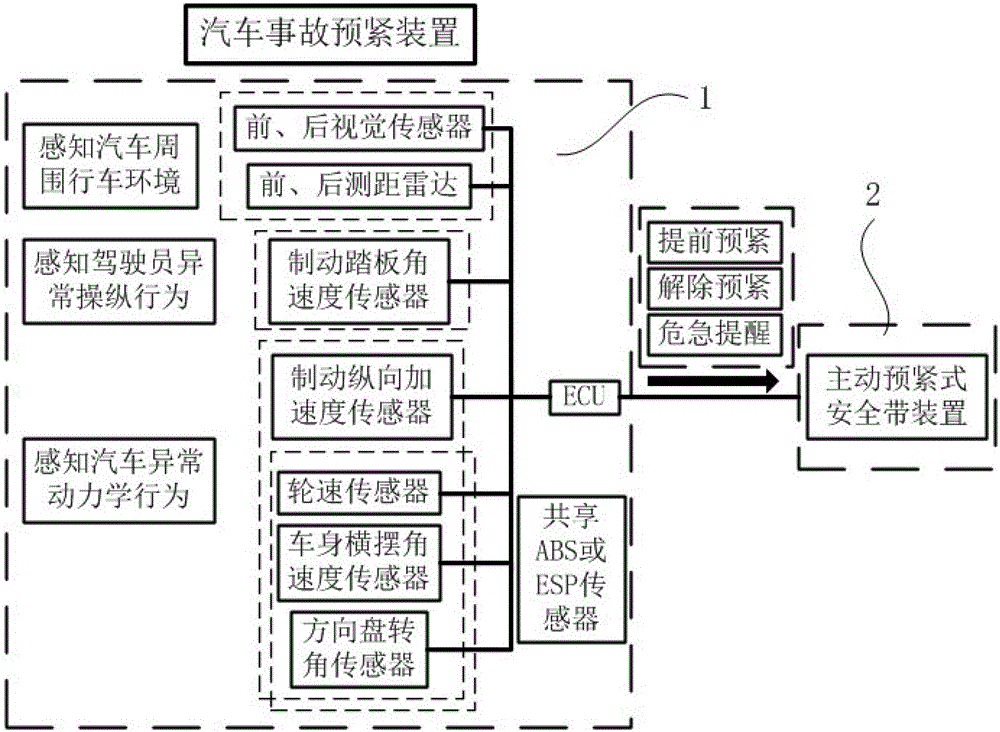

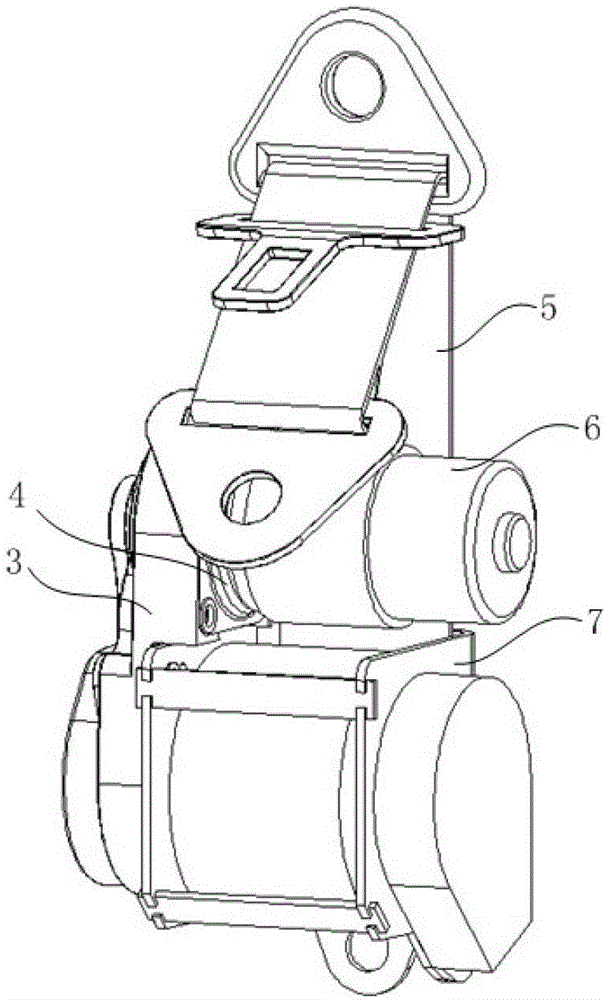

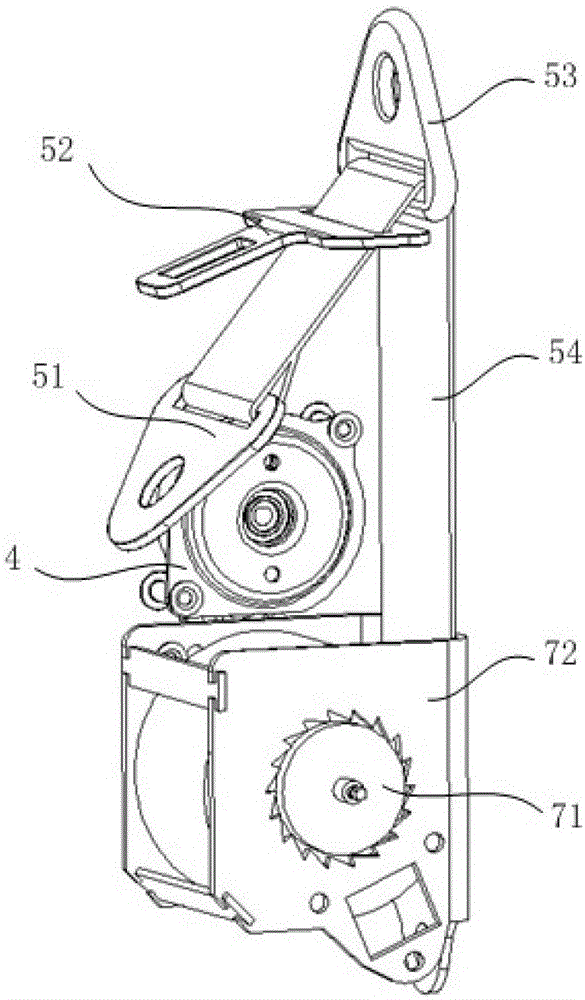

Active pre-fastening safety belt device

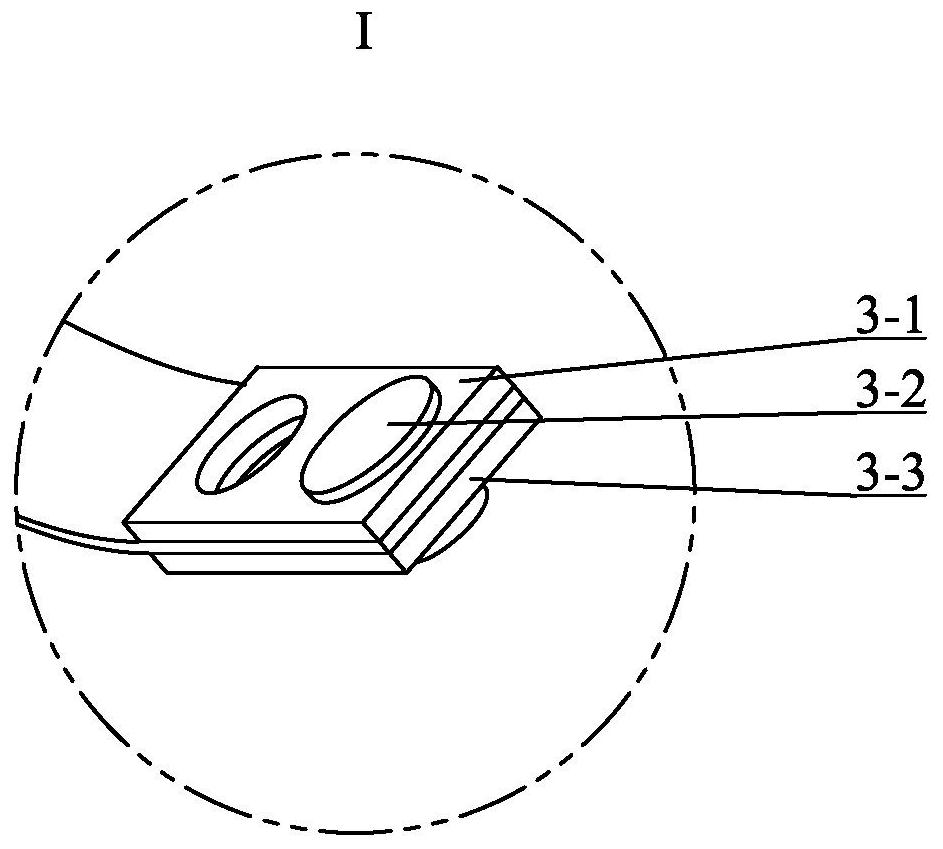

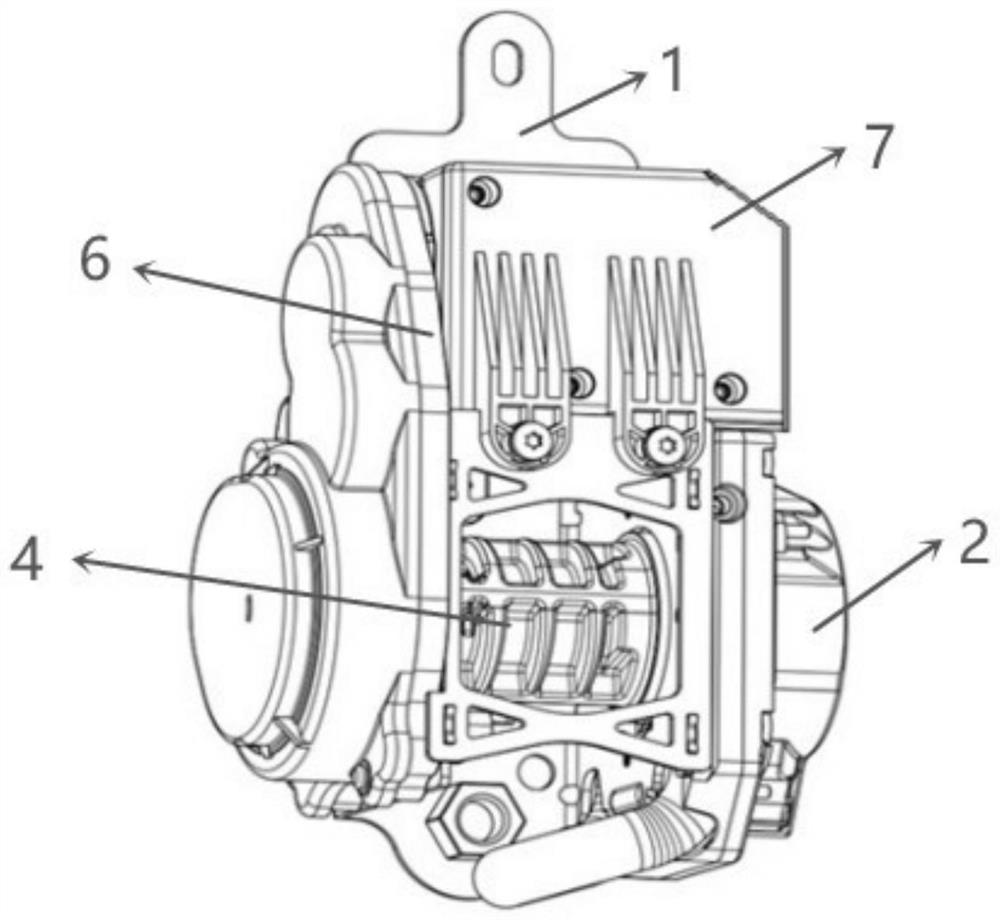

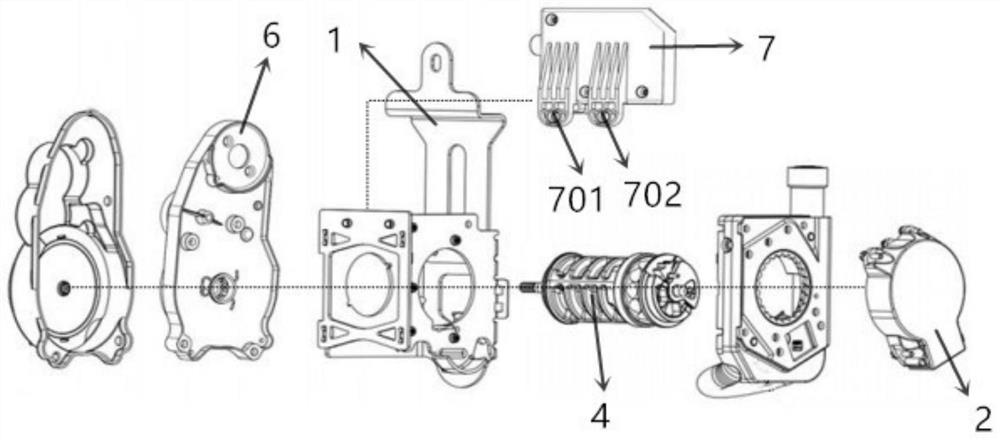

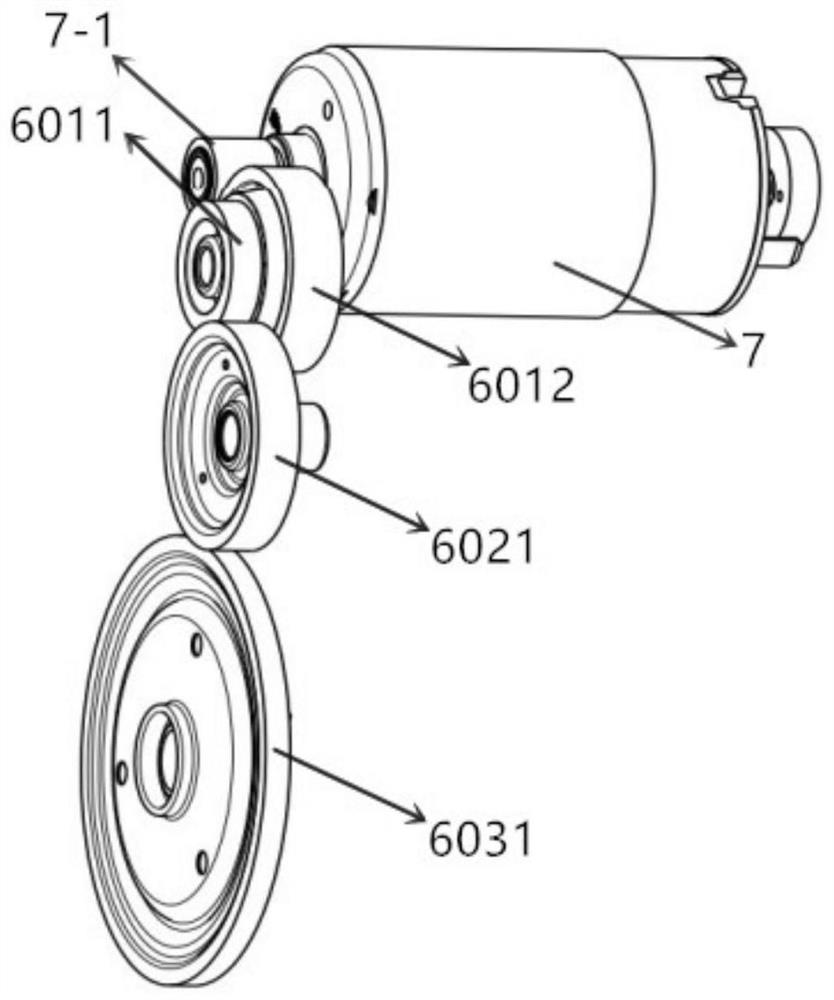

ActiveCN103386943APreload achievedAdd control functionBelt retractorsPedestrian/occupant safety arrangementActive safetyControl signal

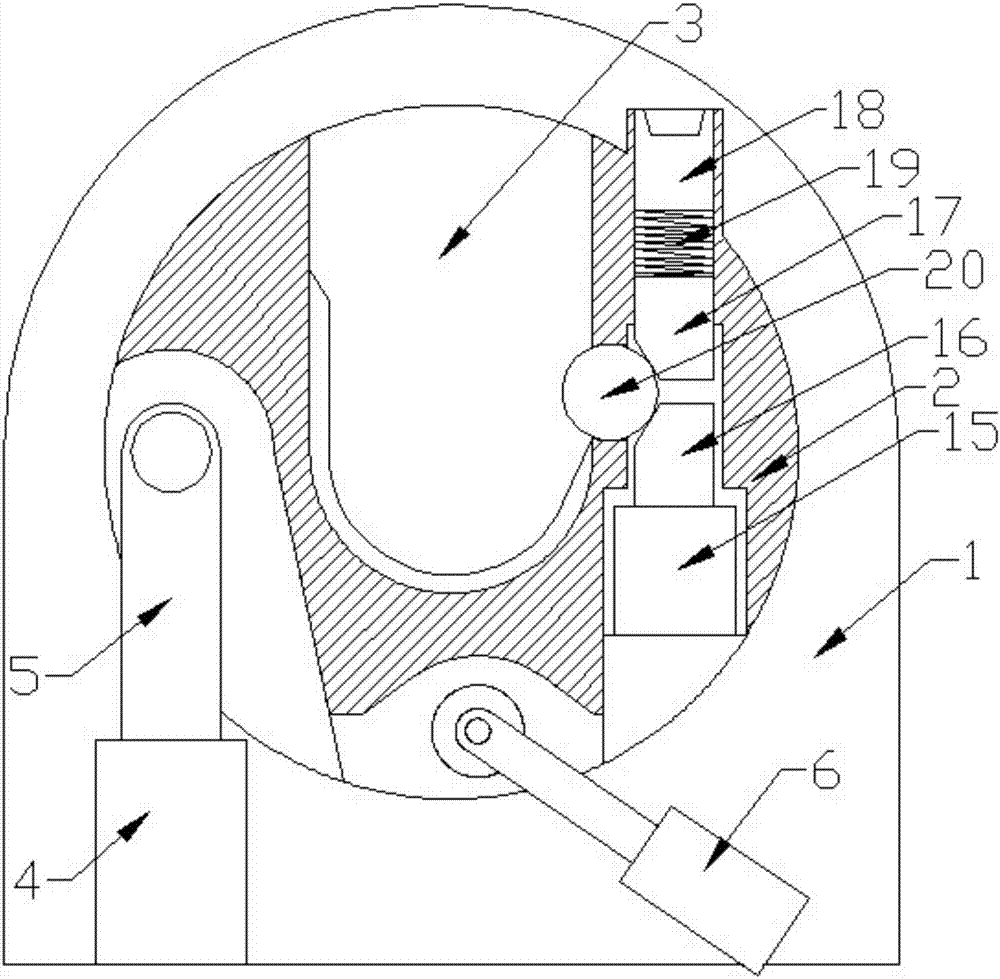

The invention discloses an active pre-fastening safety belt device, and belongs to the technical field of passenger injury protection in vehicle collision accidents. The safety belt device comprises a direct current motor, a transmission system, a coiler and a braid external part; the direct current motor is connected with the transmission system for responding a control signal of an accident pre-fastening device to work; an output shaft of the direct current motor is connected with a planetary gear train of the transmission system; the planetary gear train transmits power to the outer gear of an isolator by a middle idle gear; the isolator is designed into a ratchet structure; a safe coupling sleeve is mounted between the ratchet and a spindle of the coiler so as to transmit the power to the coiler; and one end of the frame of the coiler is provided with an emergency locking device which is sensitive to the placing angle of the safety belt and the pulling-out acceleration of a braid, thus realizing the emergency locking of the active safety belt. The pre-fastening of the safety belt can be finished before an accident occurs, and eliminates the wearing gap of the safety braid, so the restraining performance of the safety belt on a passenger is increased in the collision accident, and the collision injury of the passenger can be obviously reduced.

Owner:湖南立中科技股份有限公司

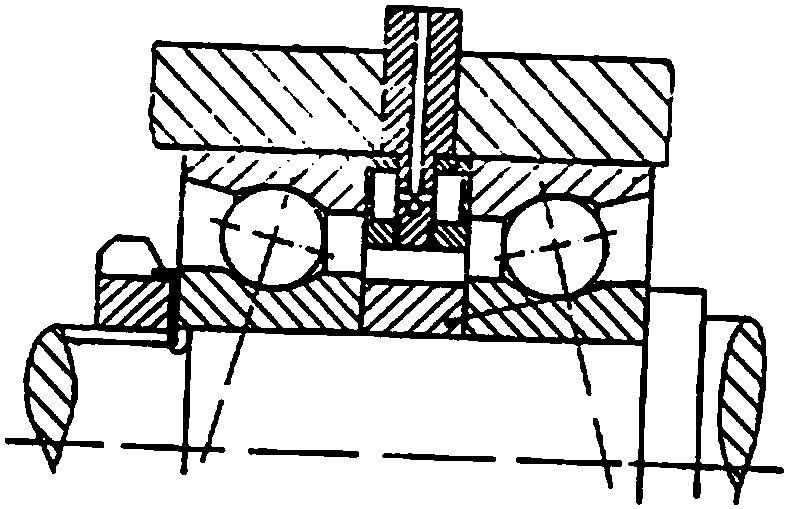

Quick cutter servo device with two decoupled shafts

InactiveCN104084829AReduce inertial massImprove working bandwidthFeeding apparatusGlass severing apparatusHinge anglePiezoelectric actuators

The invention relates to a quick cutter servo device with two decoupled shafts, and belongs to the technical field of cutting machining of optical curved surface parts and ultraprecise parts. A diamond cutter is fixedly connected with a cutter seat on a flexible hinge base body through a fixing screw, and the two ends of an X-axis piezoelectric stack are connected with the flexible hinge base body and an X-axis driving end respectively. The X-axis piezoelectric stack is connected with the flexible hinge base body through a first pre-tightening bolt, and a first Z-axis piezoelectric stack and a second Z-axis piezoelectric stack are connected with the flexible hinge base body and a Z-axis piezoelectric stack respectively. A displacement detection block is mounted behind the cutter seat on the flexible hinge base body, and the displacement detection block is fixedly connected with the flexible hinge base body through a fixing screw. The quick cutter servo device with the two decoupled shafts has the advantages that the structure is novel, the mode that a piezoelectric actuator is in parallel connection with a flexible mechanism is used, the inertia mass of the movement part of a flexible hinge mechanism is reduced, the operation bandwidth of an FTS device can be better increased, and the machining efficiency of the FTS device is improved.

Owner:JILIN UNIV

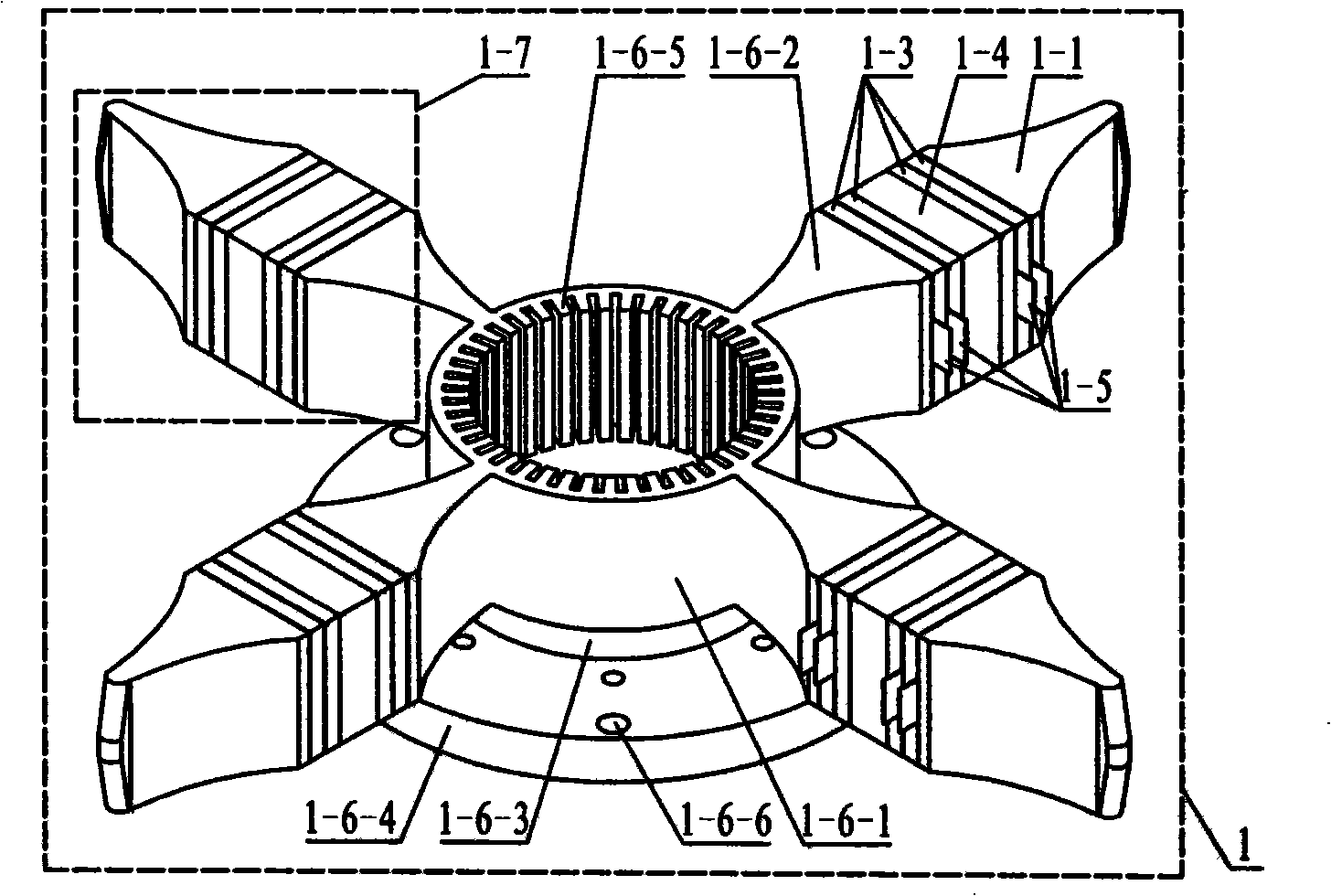

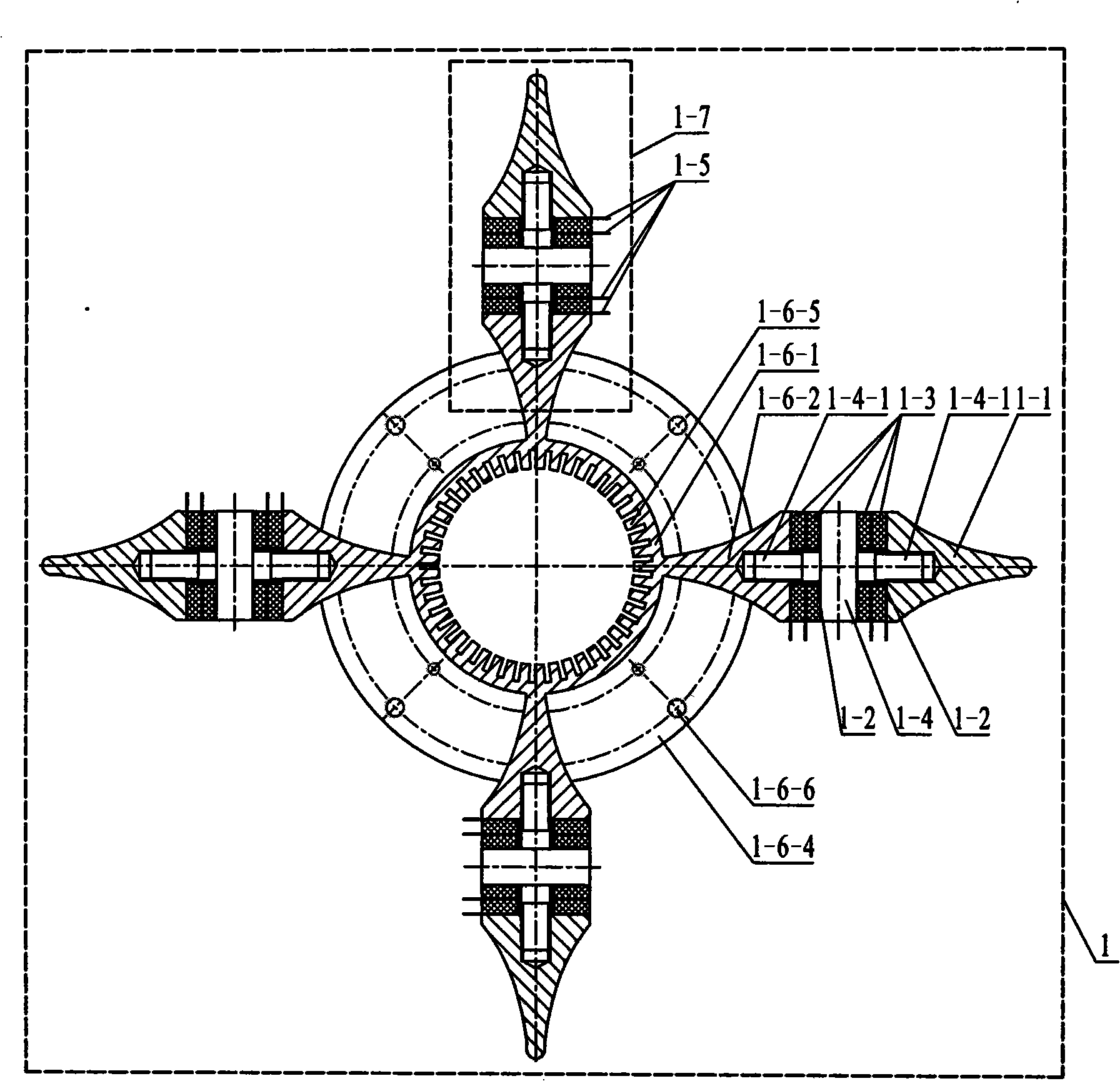

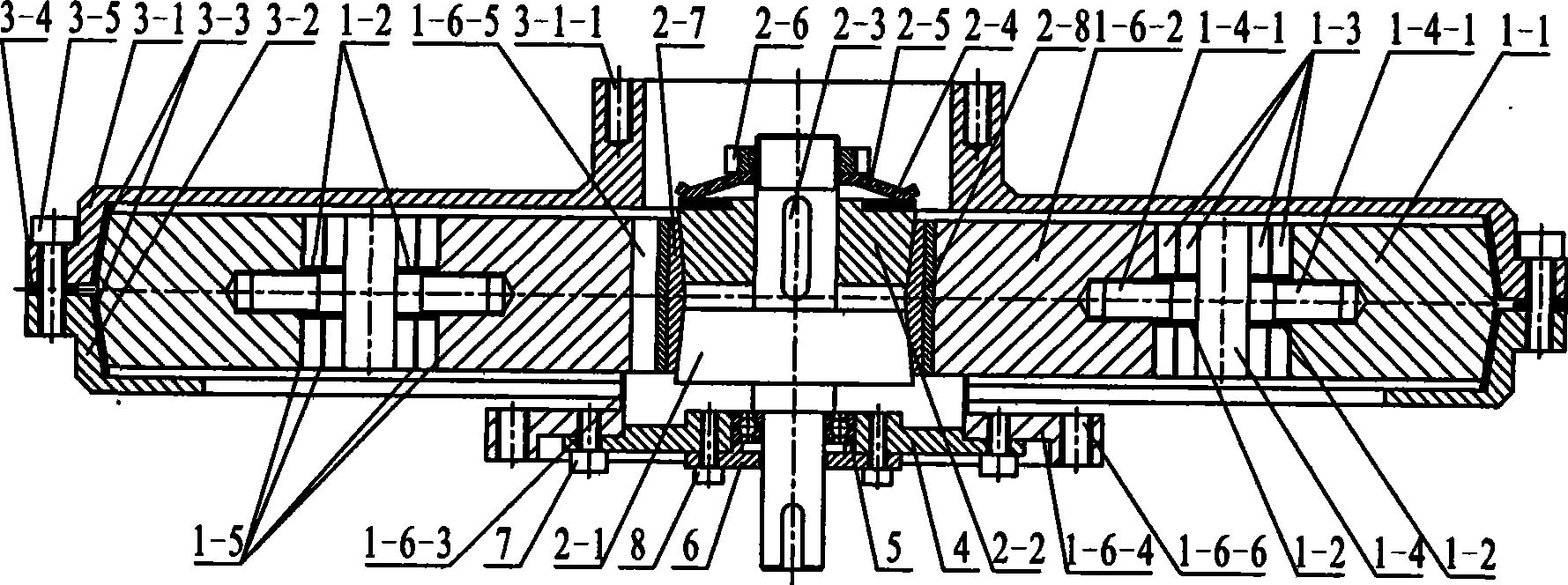

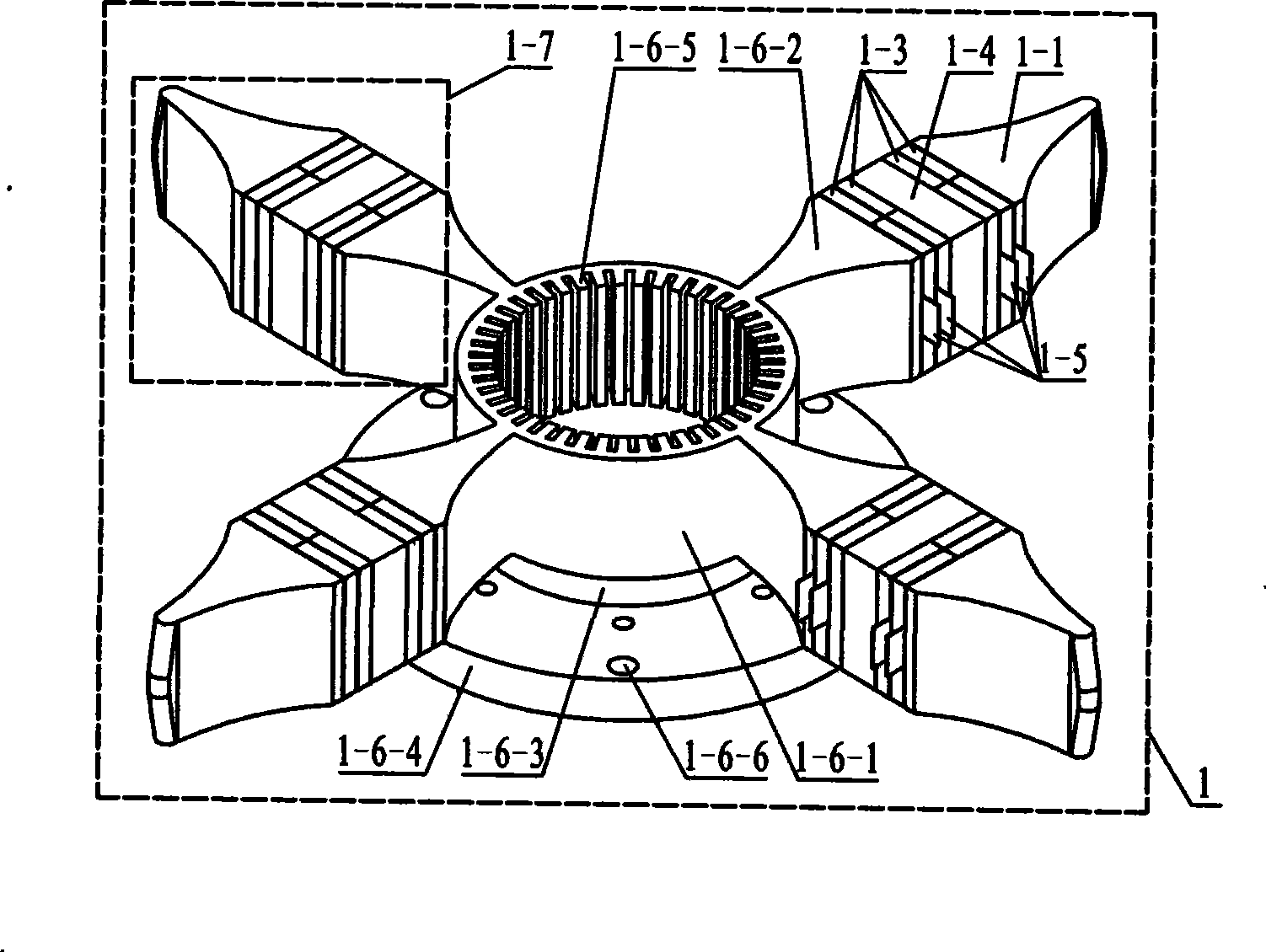

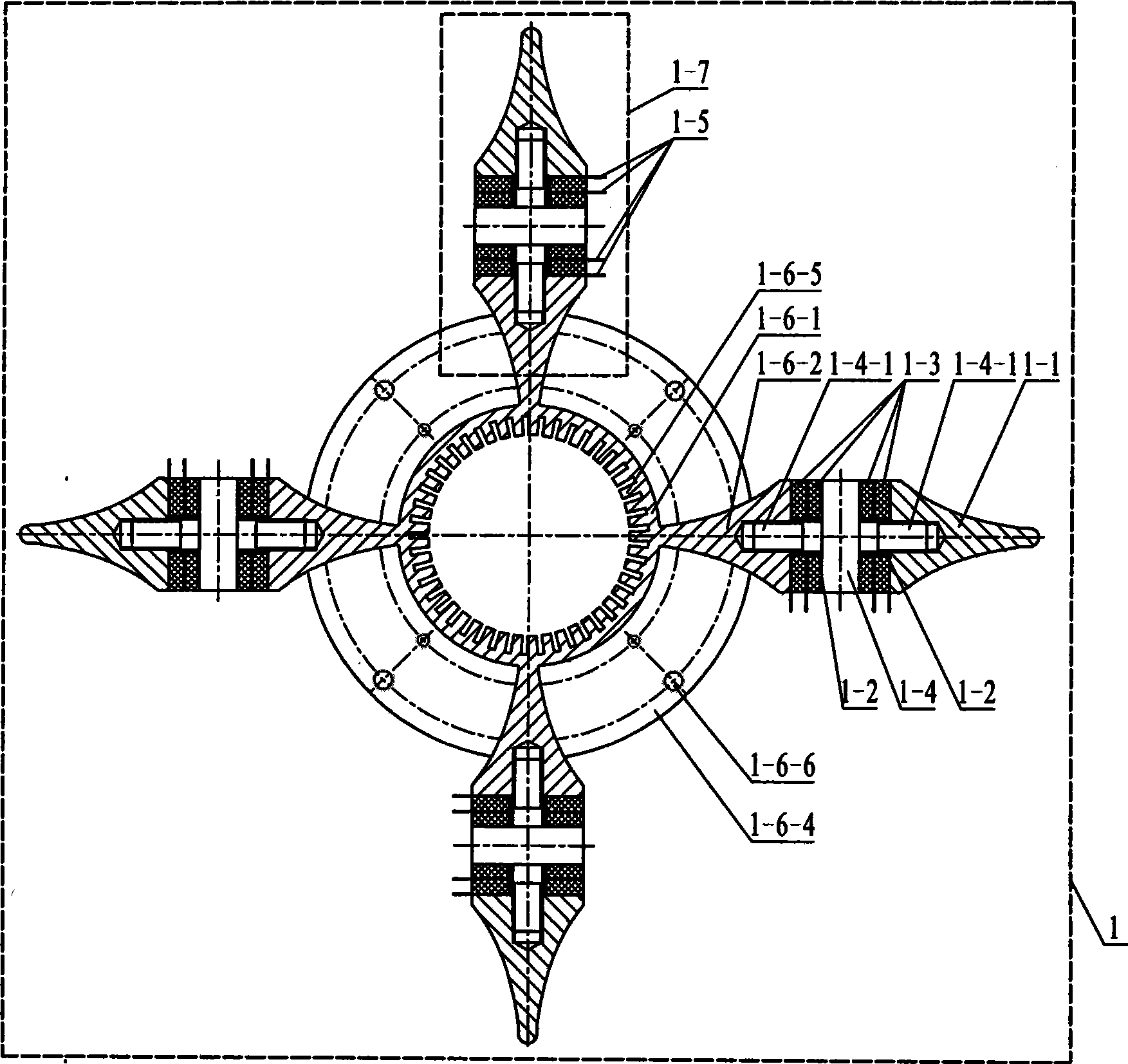

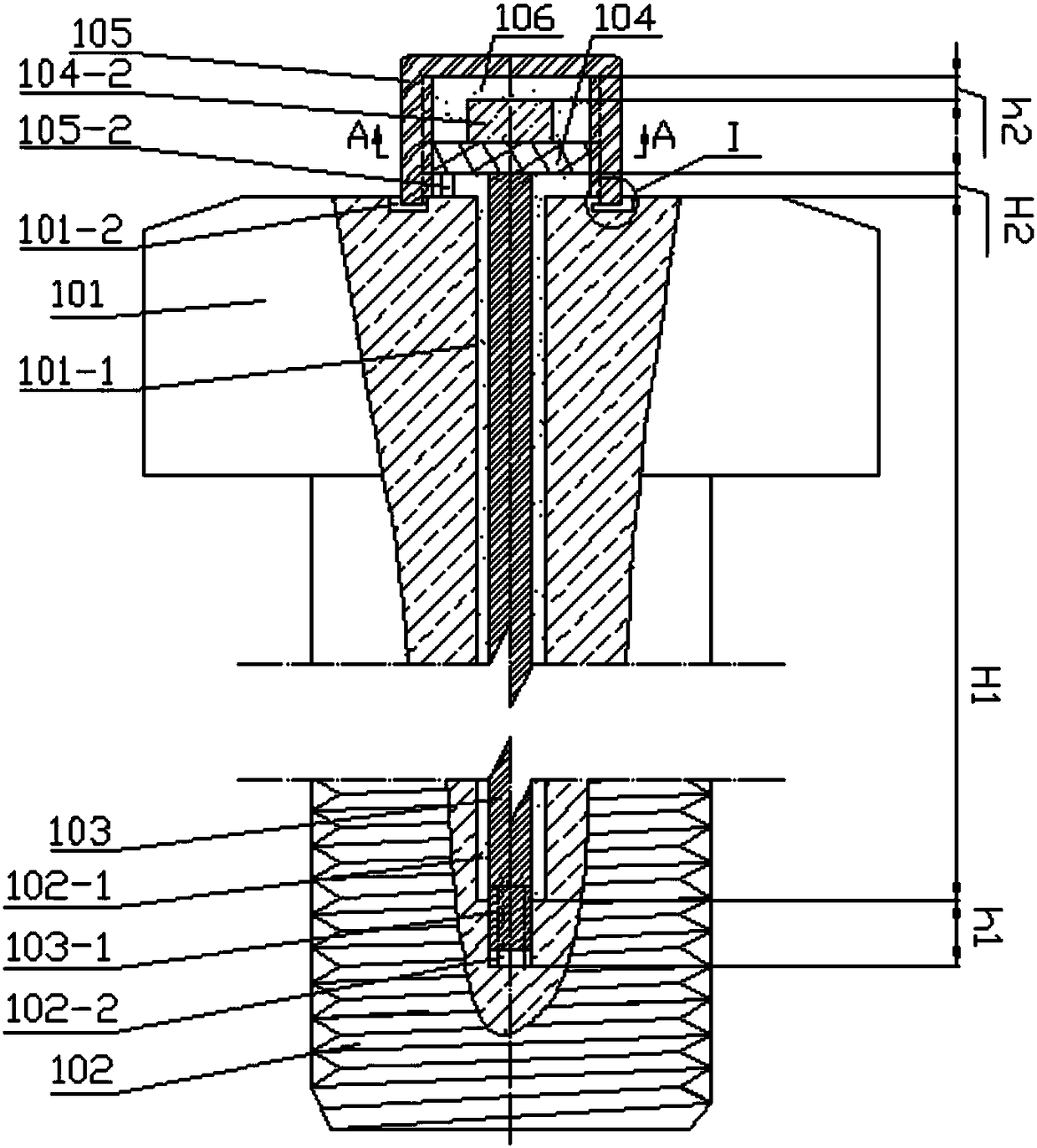

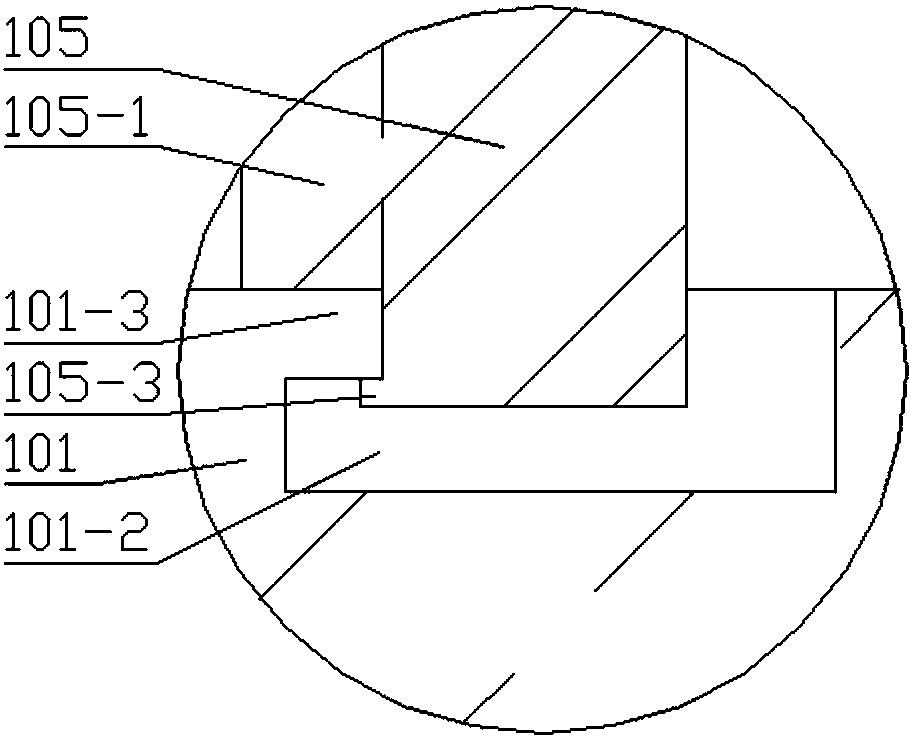

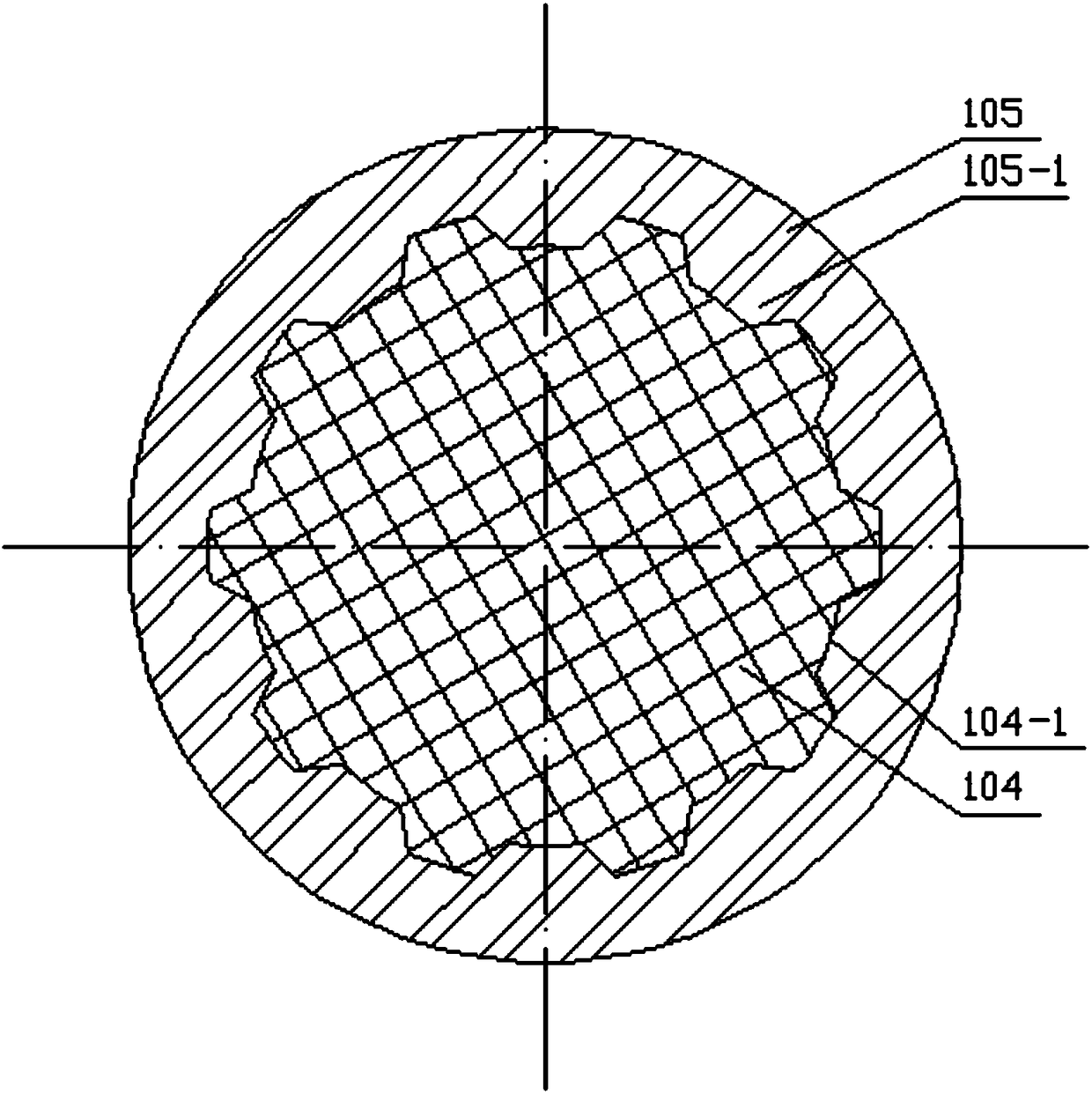

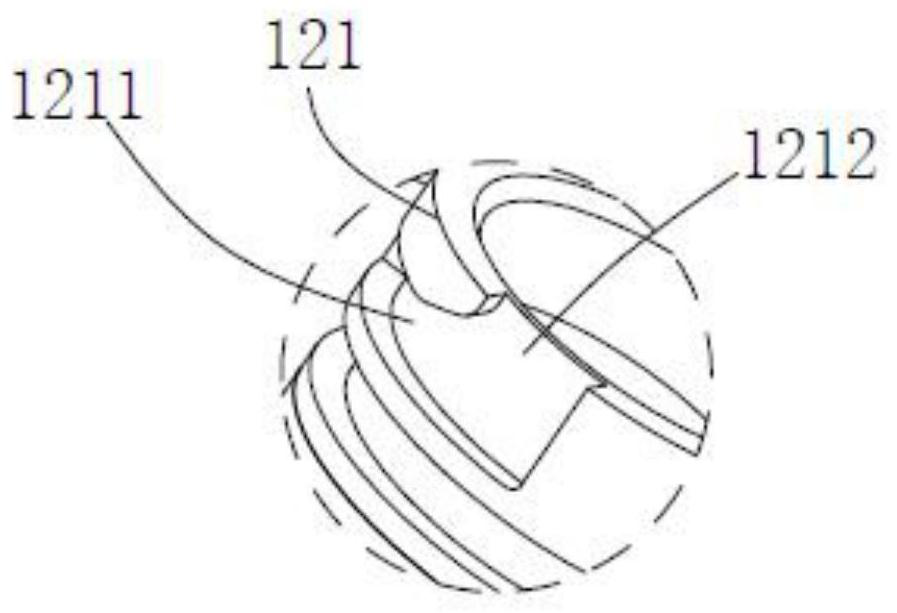

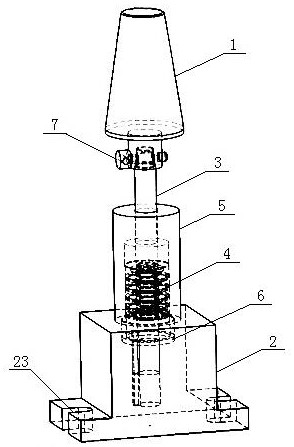

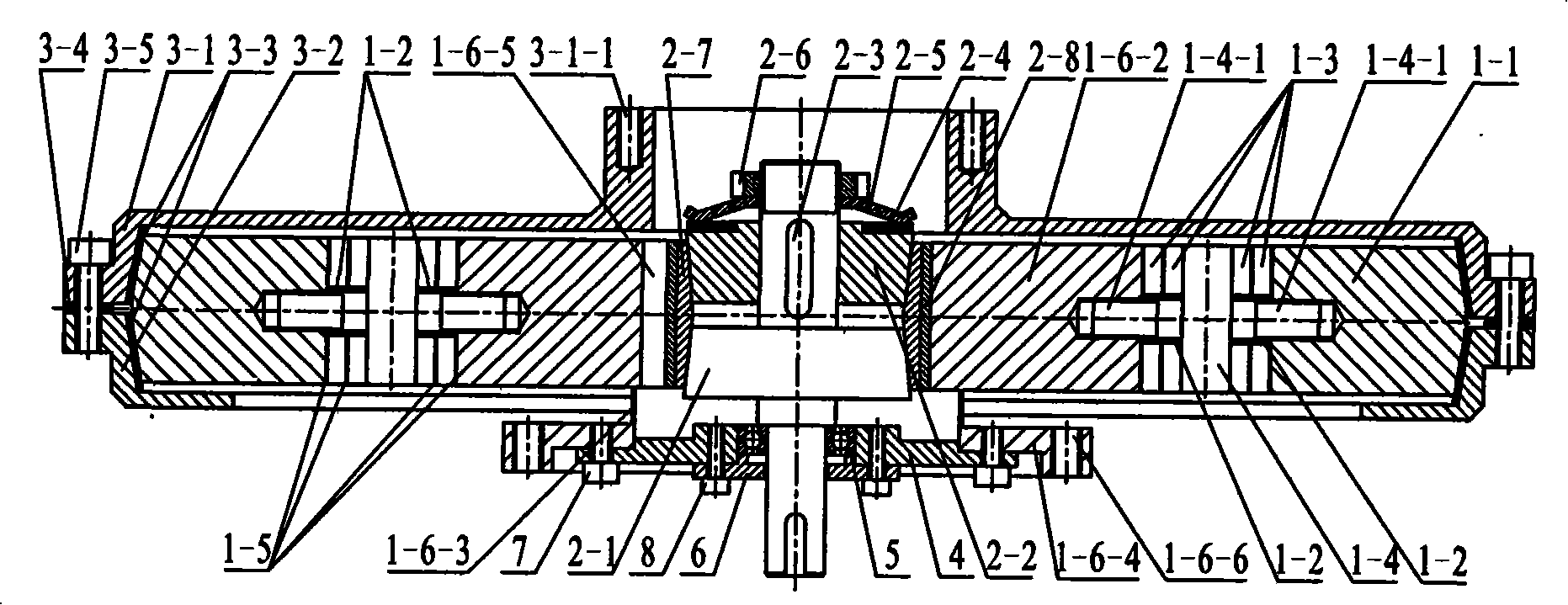

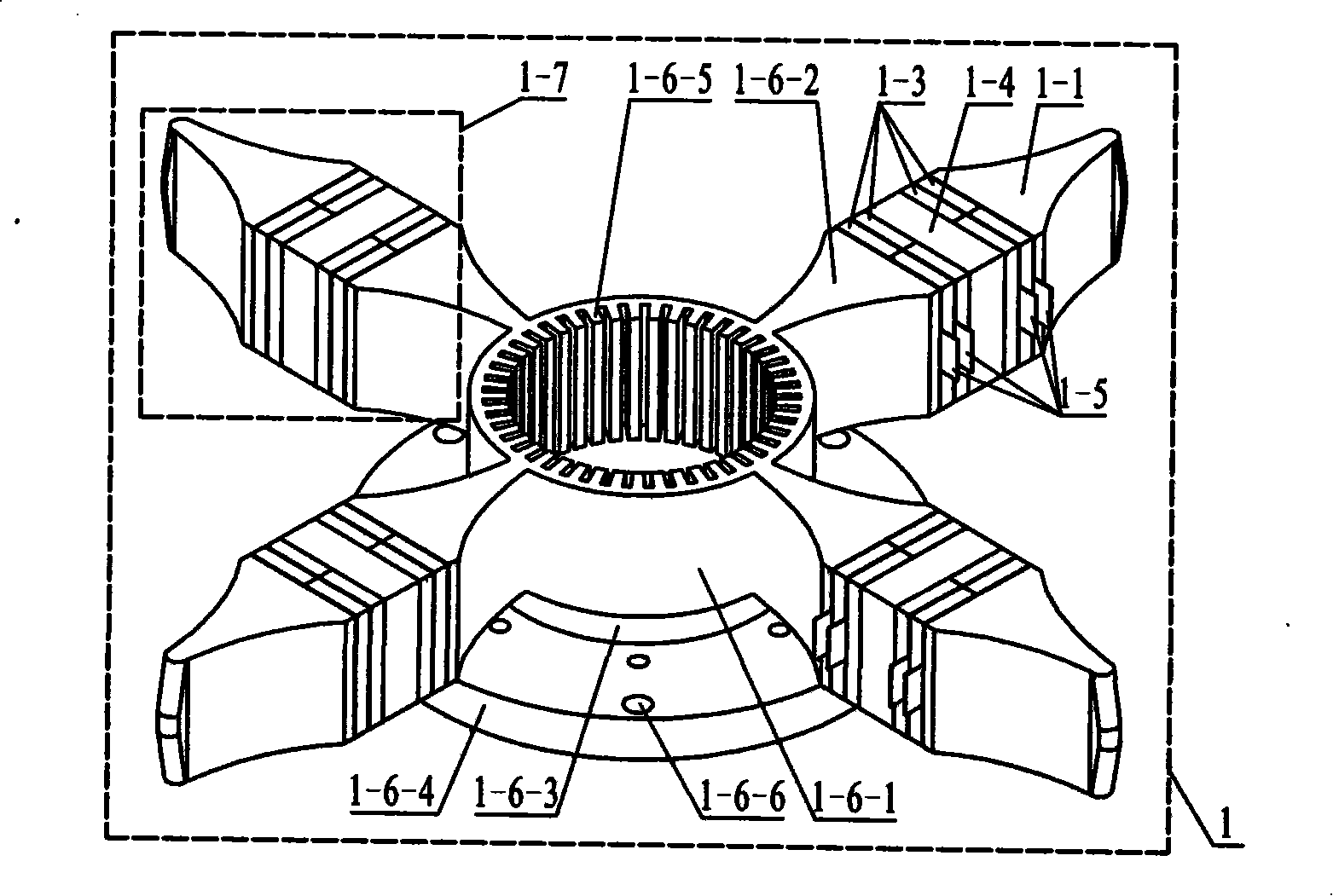

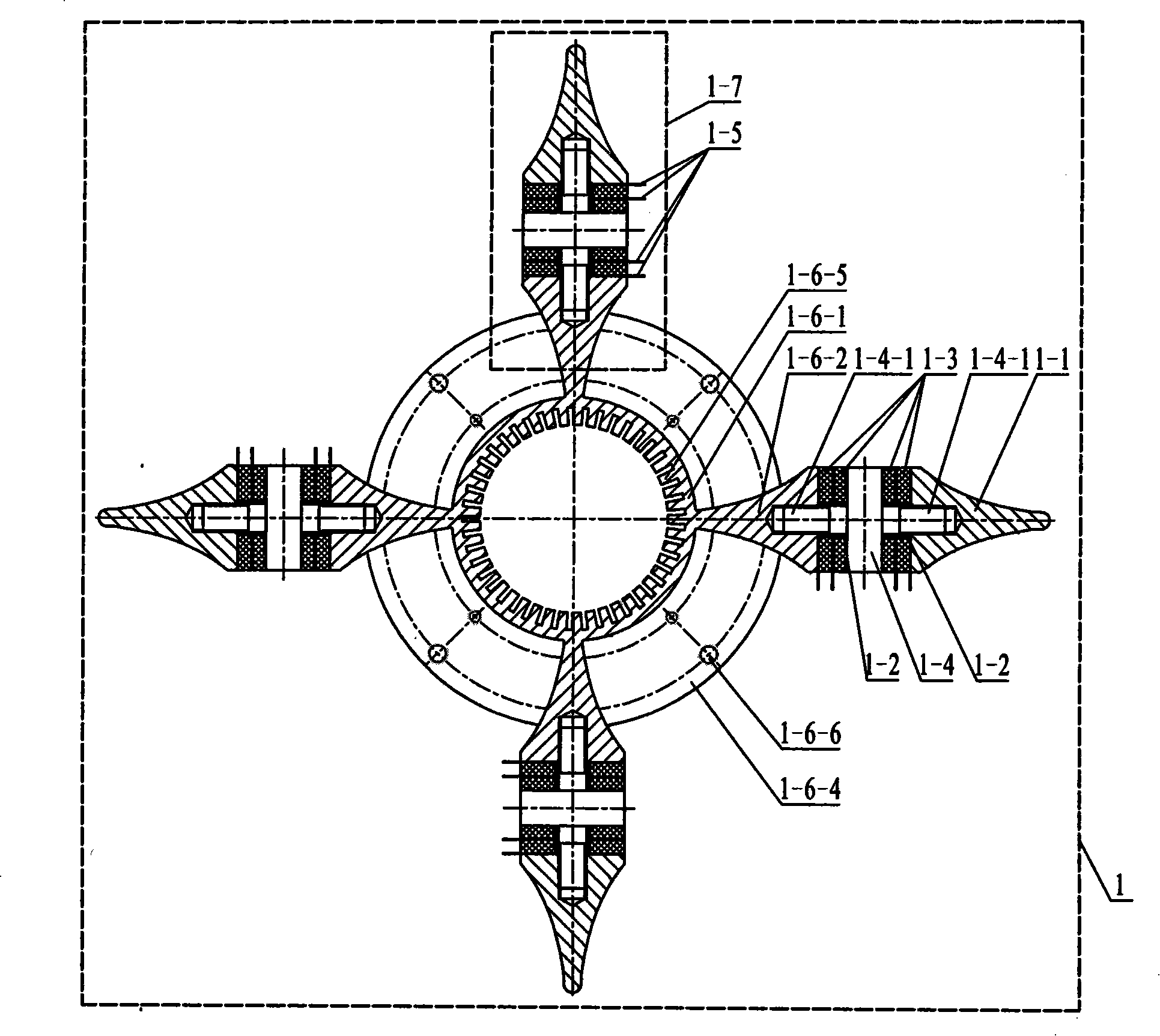

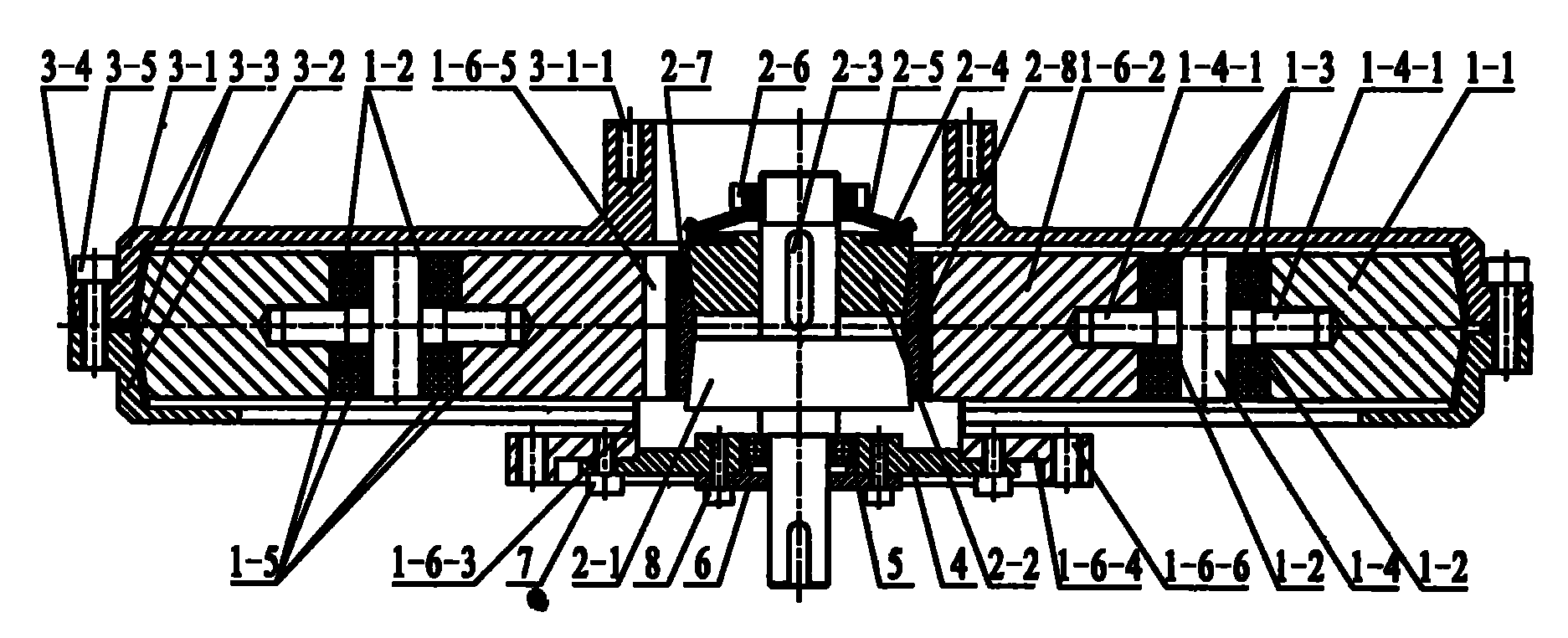

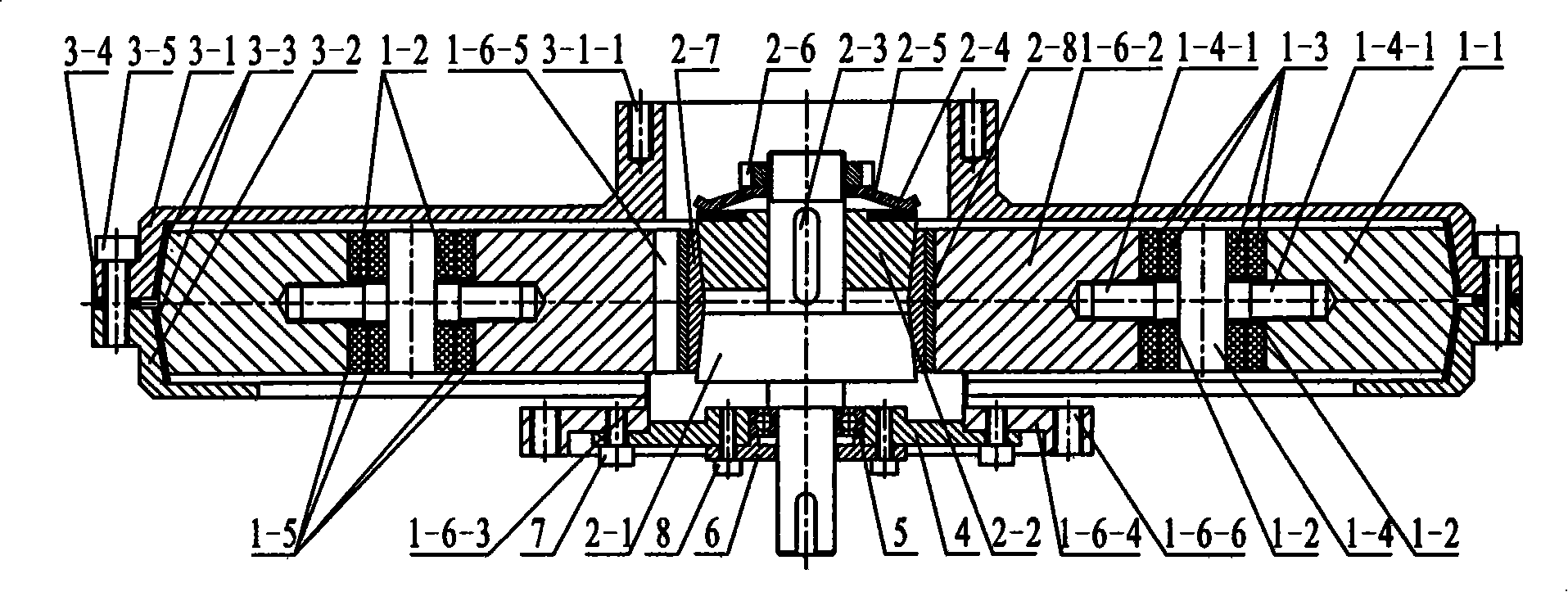

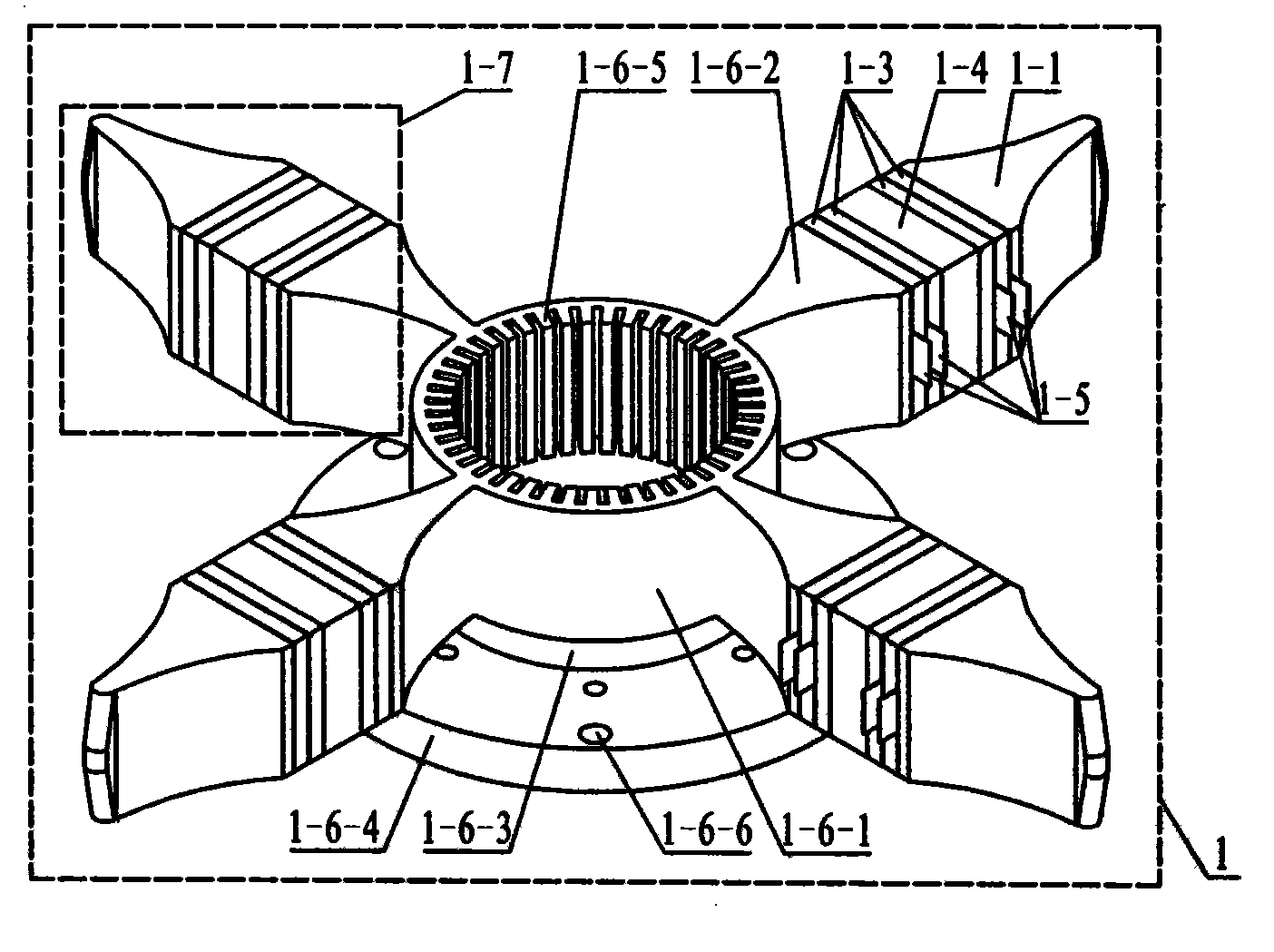

Longitudinal-shaking sandwich energy converter type cylinder type birotor ultrasonic motor

InactiveCN101304223AStrong process controllabilityReduce adverse effectsPiezoelectric/electrostriction/magnetostriction machinesTransducerLongitudinal vibration

The invention discloses a longitudinal vibration sandwiched transducer type cylindrical dual-rotor ultrasonic motor, which relates to the technical field of an ultrasonic motor and aims at solving the problems that the mechanical output capacity is restricted and a single stator can only realize single moving output existing in present ultrasonic motor. The longitudinal vibration sandwiched transducer type cylindrical dual-rotor ultrasonic motor of the invention comprises a stator component, a medial rotor component, an outer rotor component, a bearing base, a bearing and a bearing pretension cover. The inner surface of a cylinder is manufactured with continuous comb-shaped driving gears; a medial rotor with a shaft and a medial rotor without the shaft are cone-shaped, the thin ends of the medial rotor with the shaft and the medial rotor without the shaft are respectively inserted from the lower part of a stator cylinder and the upper part of the stator cylinder; an outer rotor with the shaft and an outer rotor without the shaft are respectively arranged on the upper part of the stator component and the lower part of the stator component; the lateral surfaces that the outer rotor with the shaft and the outer rotor without the shaft are contacted with the back end cover of the stator are respectively fixed with wear-resistance lining rings; the medial rotor with the shaft is rotatablely connected with the bearing base by the bearing. The longitudinal vibration sandwiched transducer type cylindrical dual-rotor ultrasonic motor of the invention can be applied to the ultrasonic motor manufacturing field.

Owner:HARBIN INST OF TECH

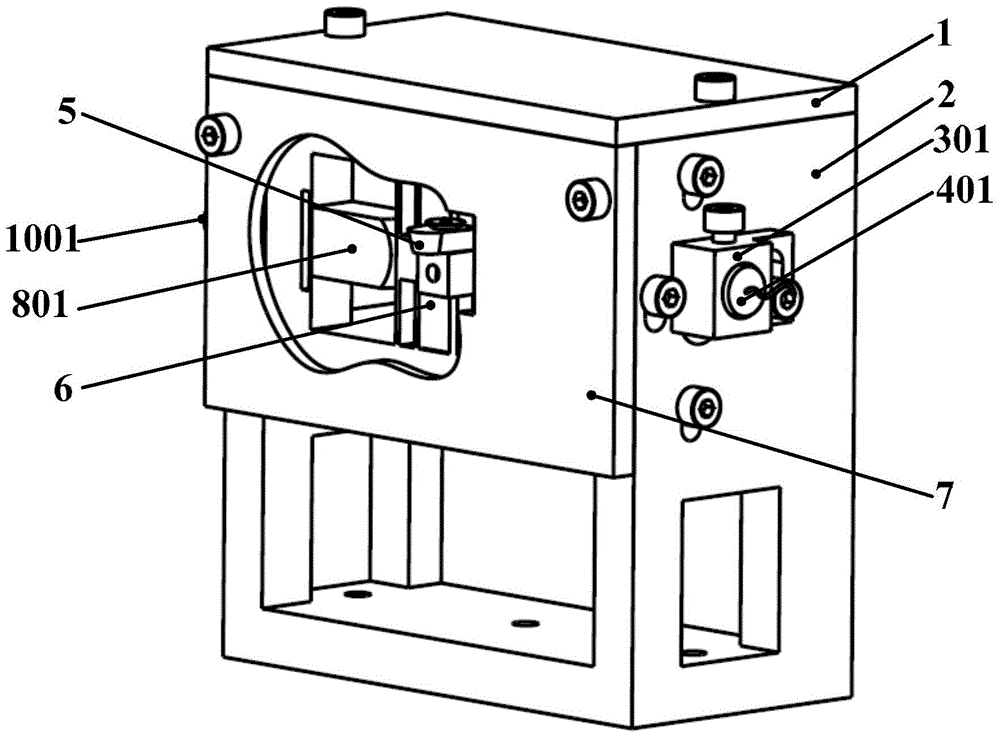

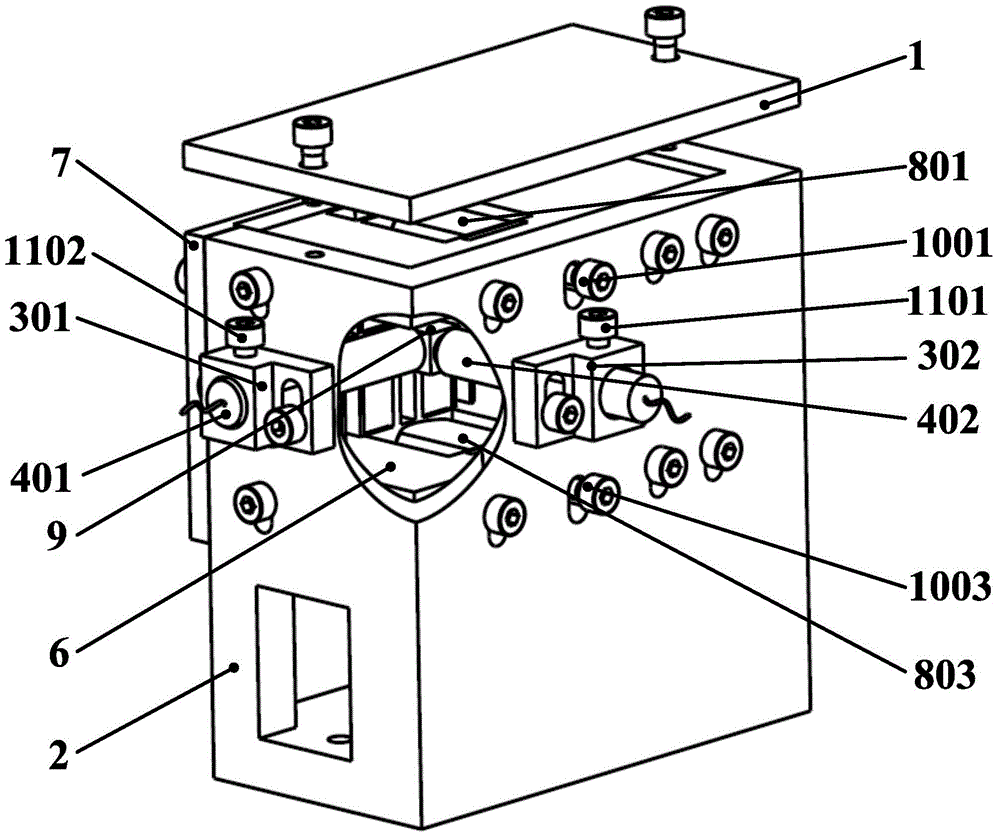

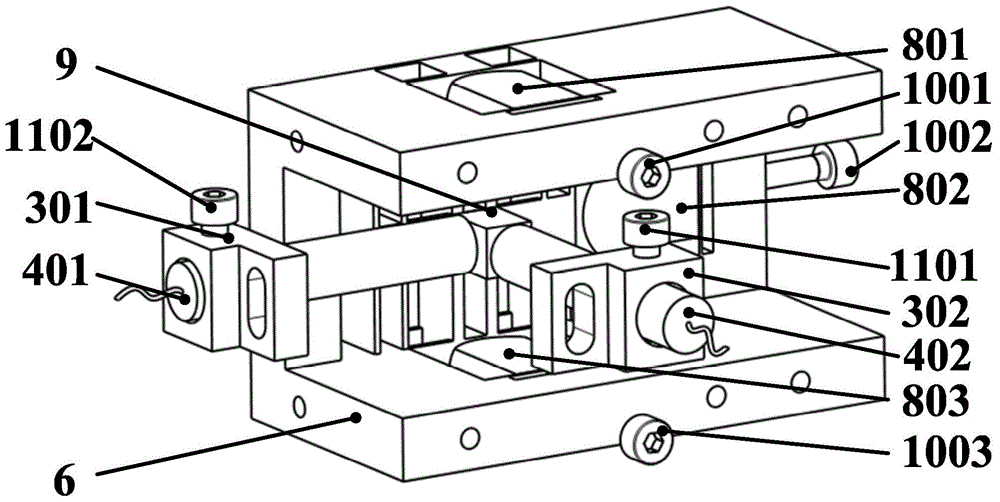

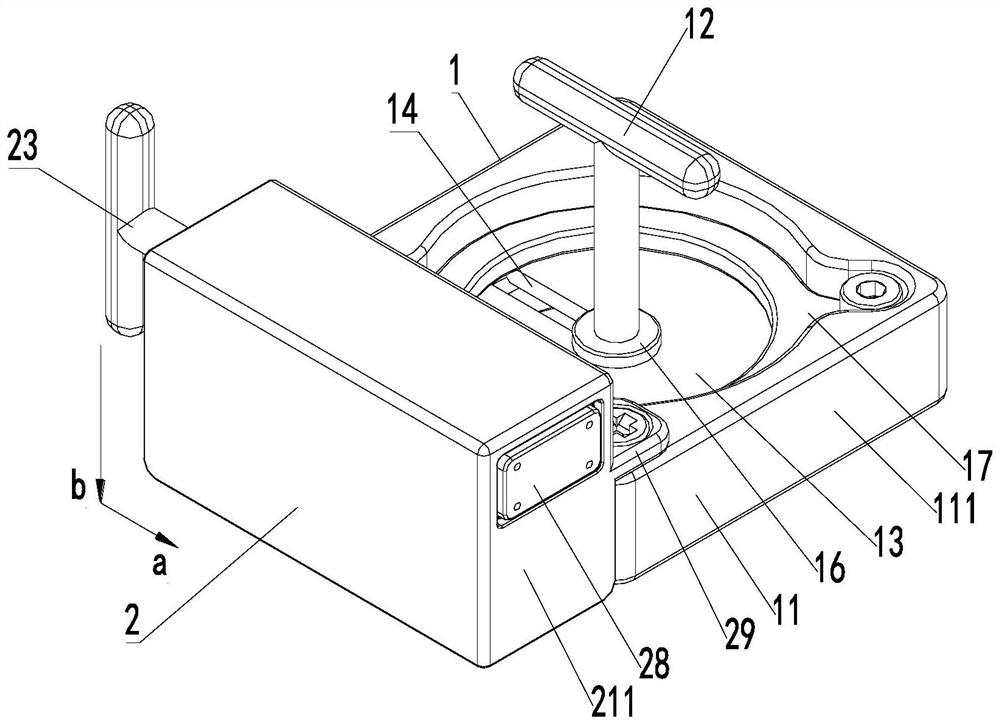

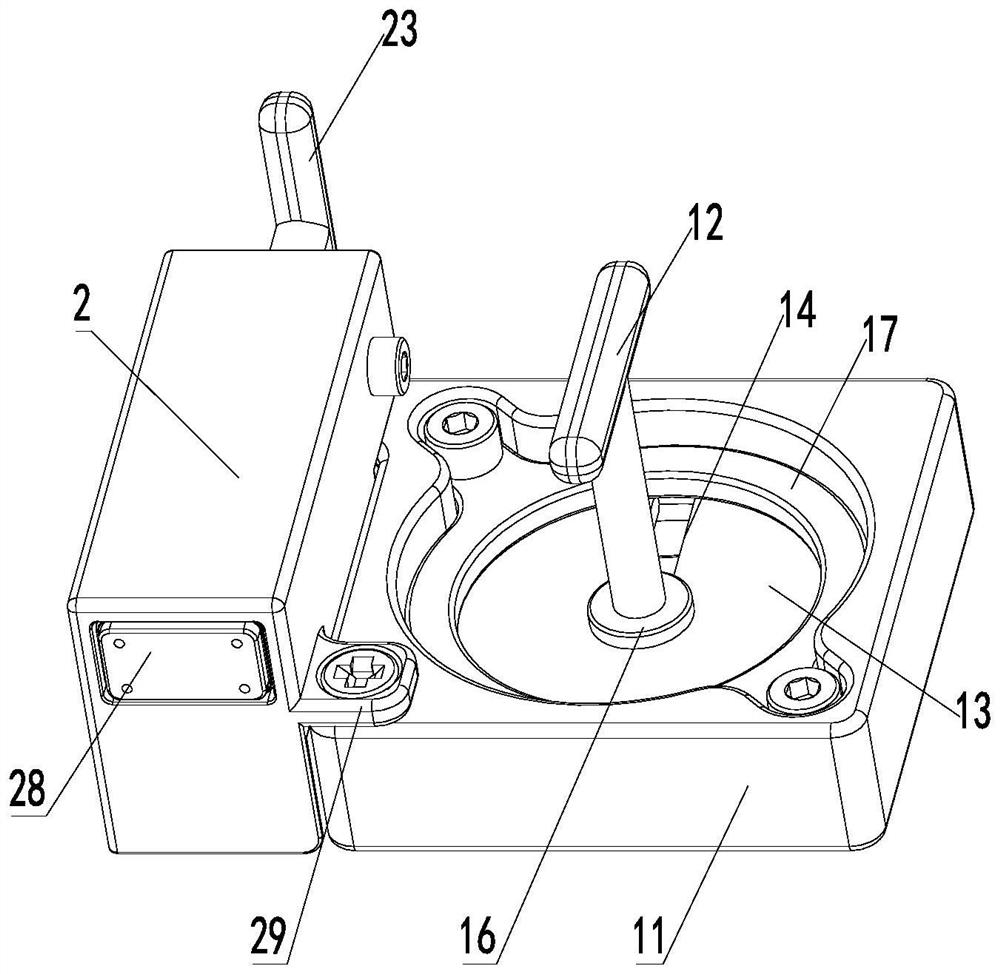

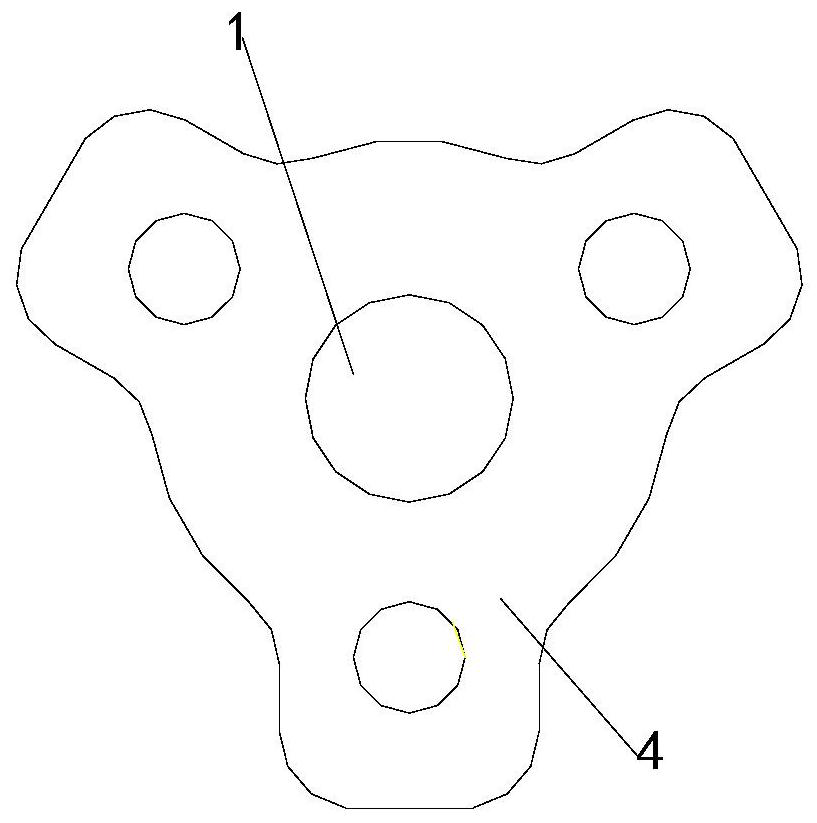

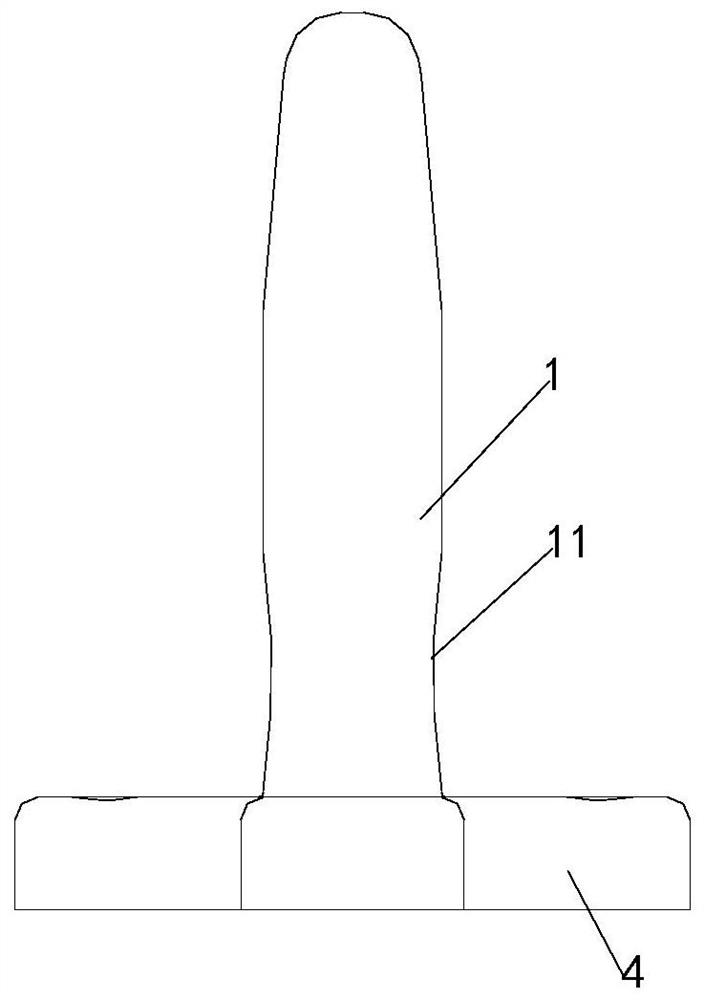

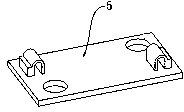

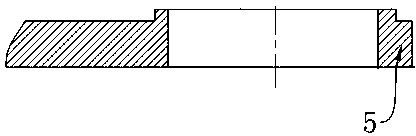

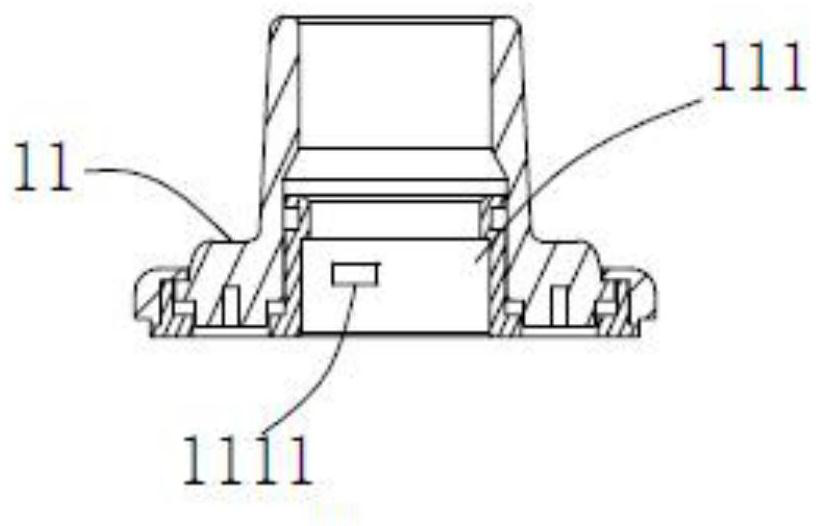

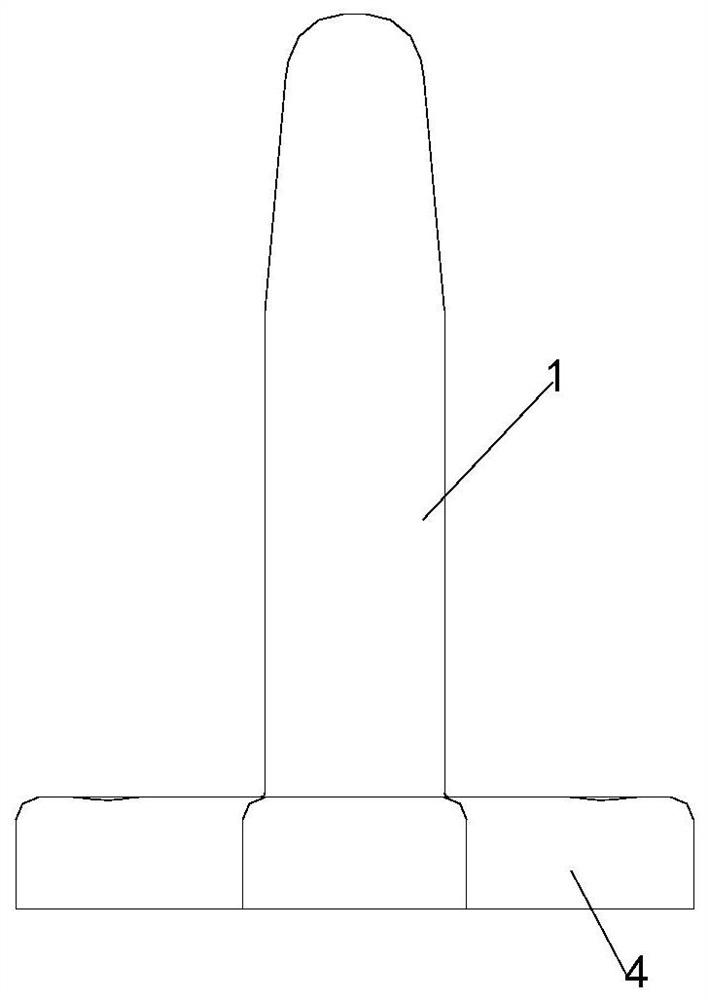

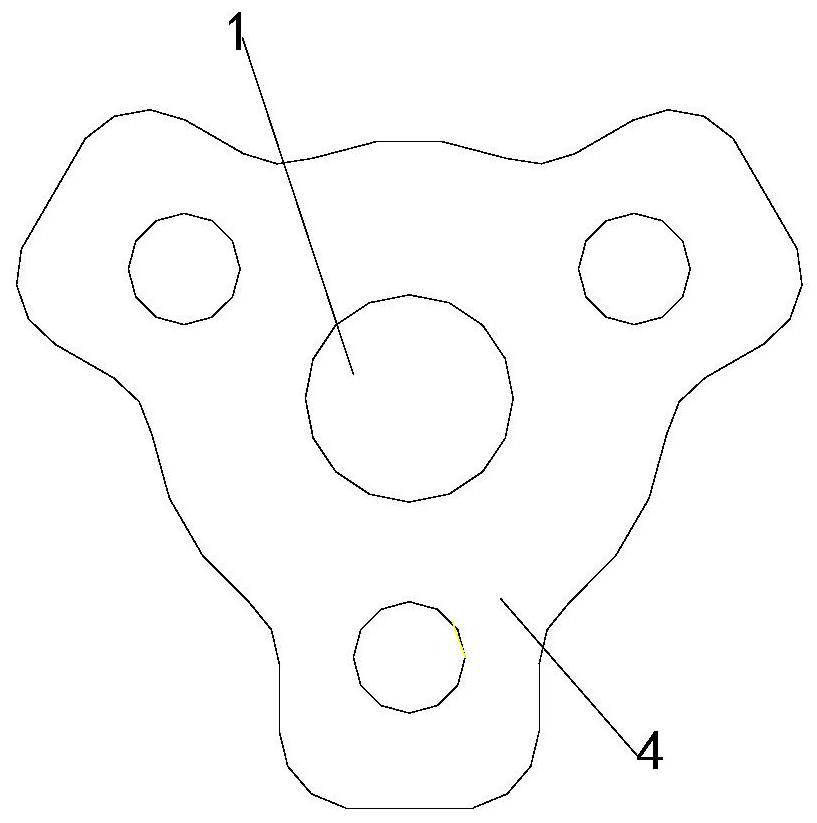

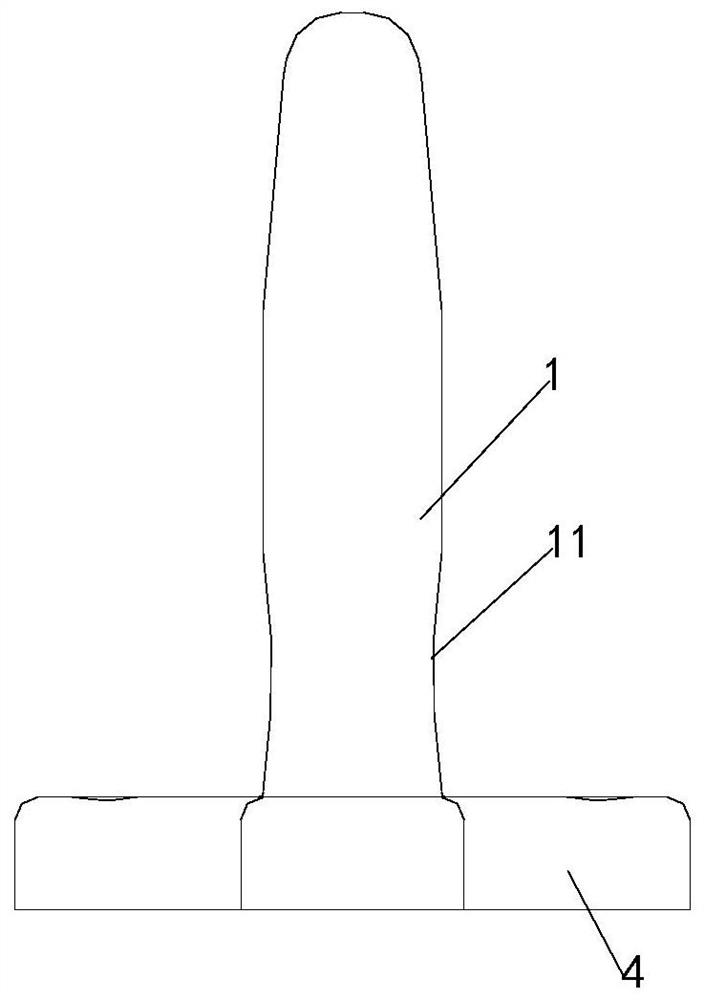

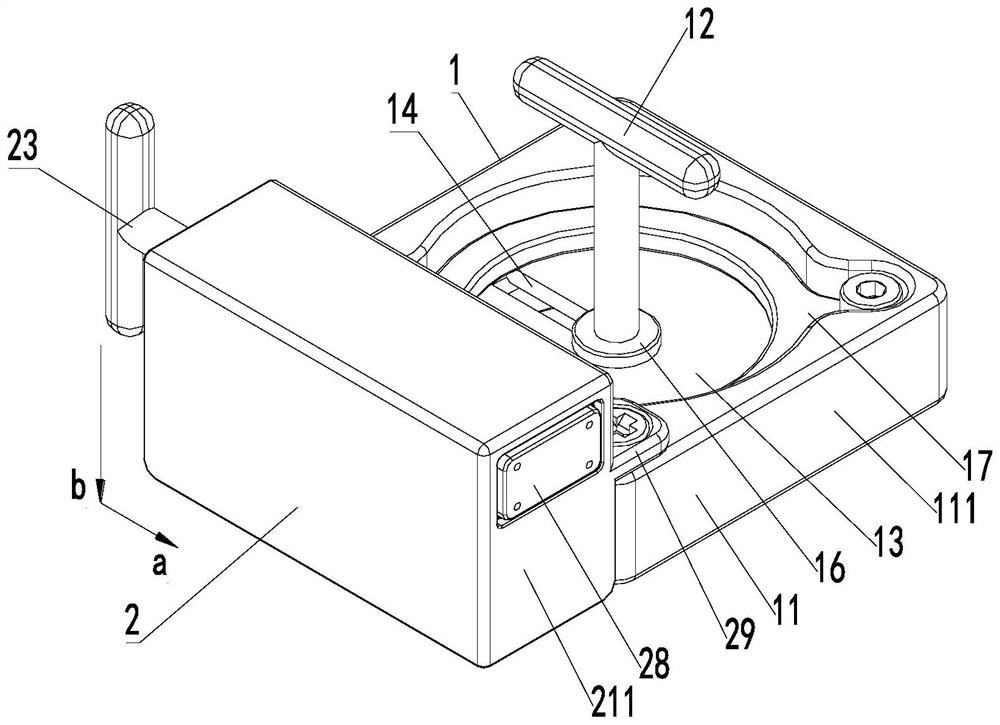

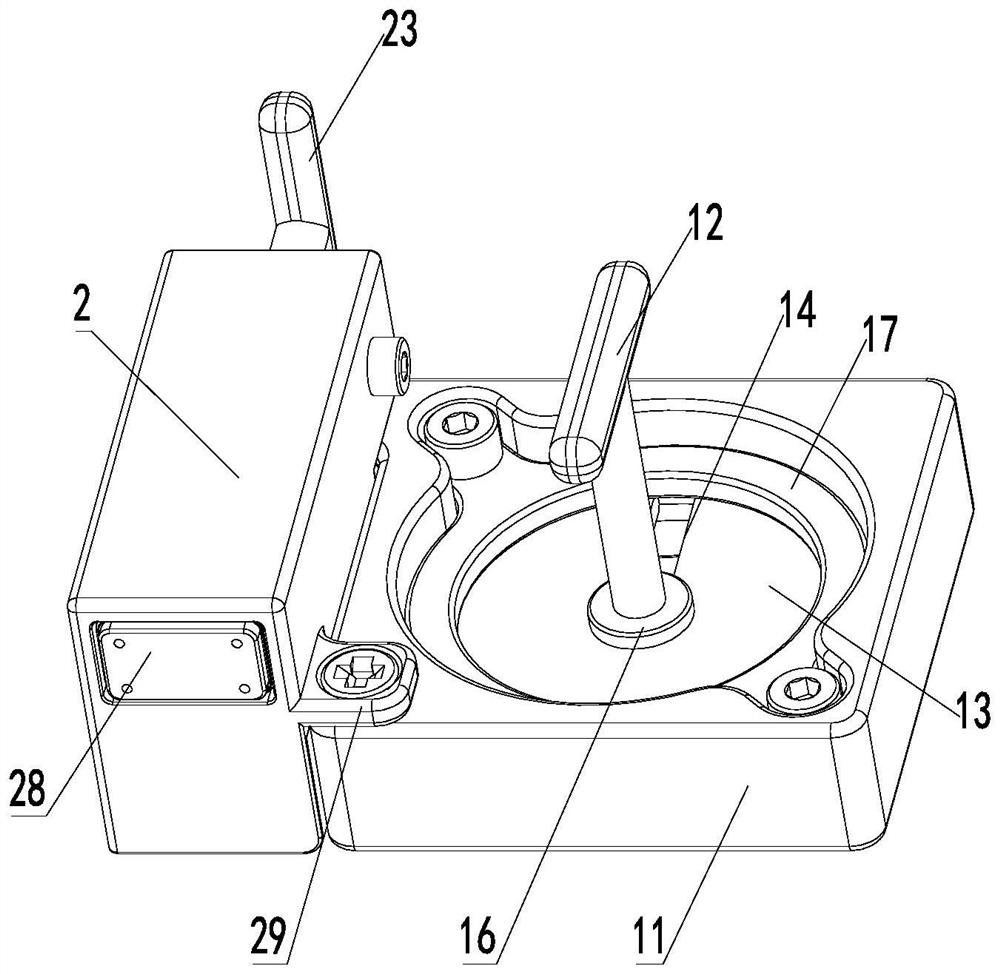

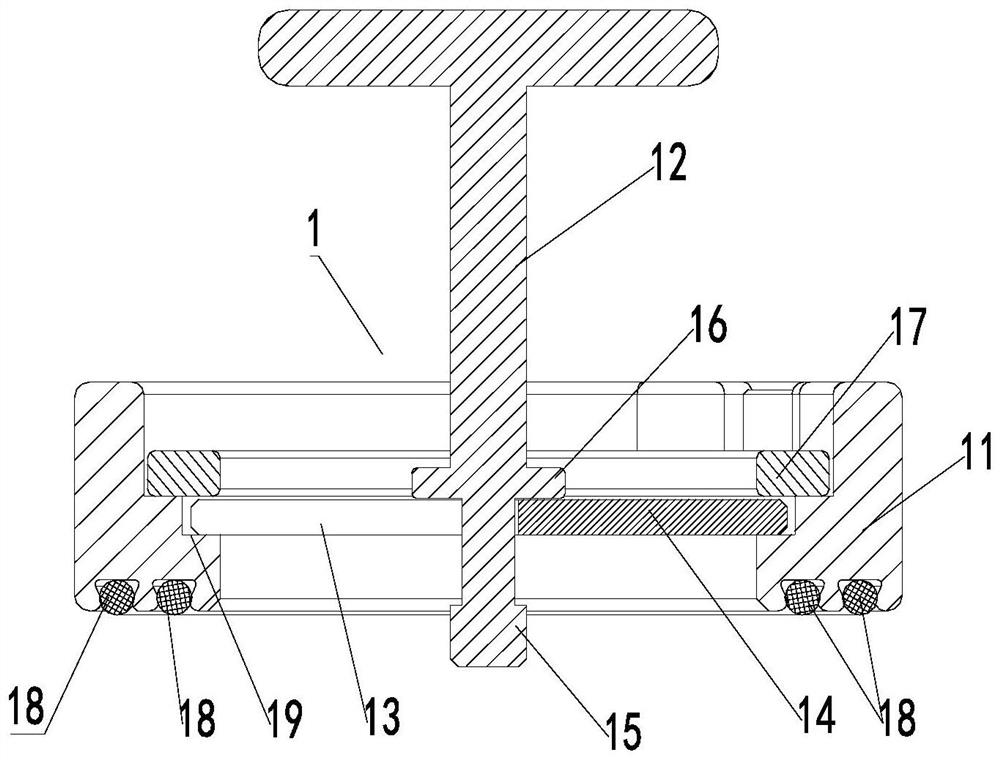

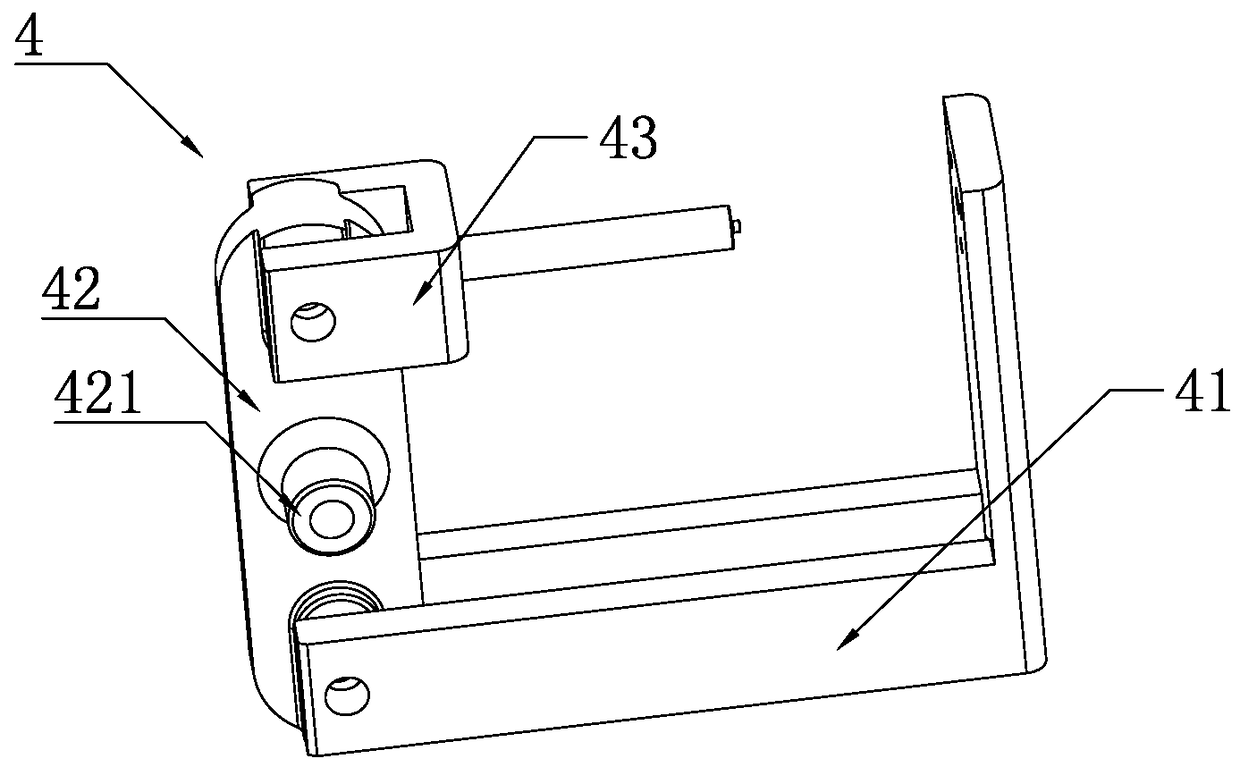

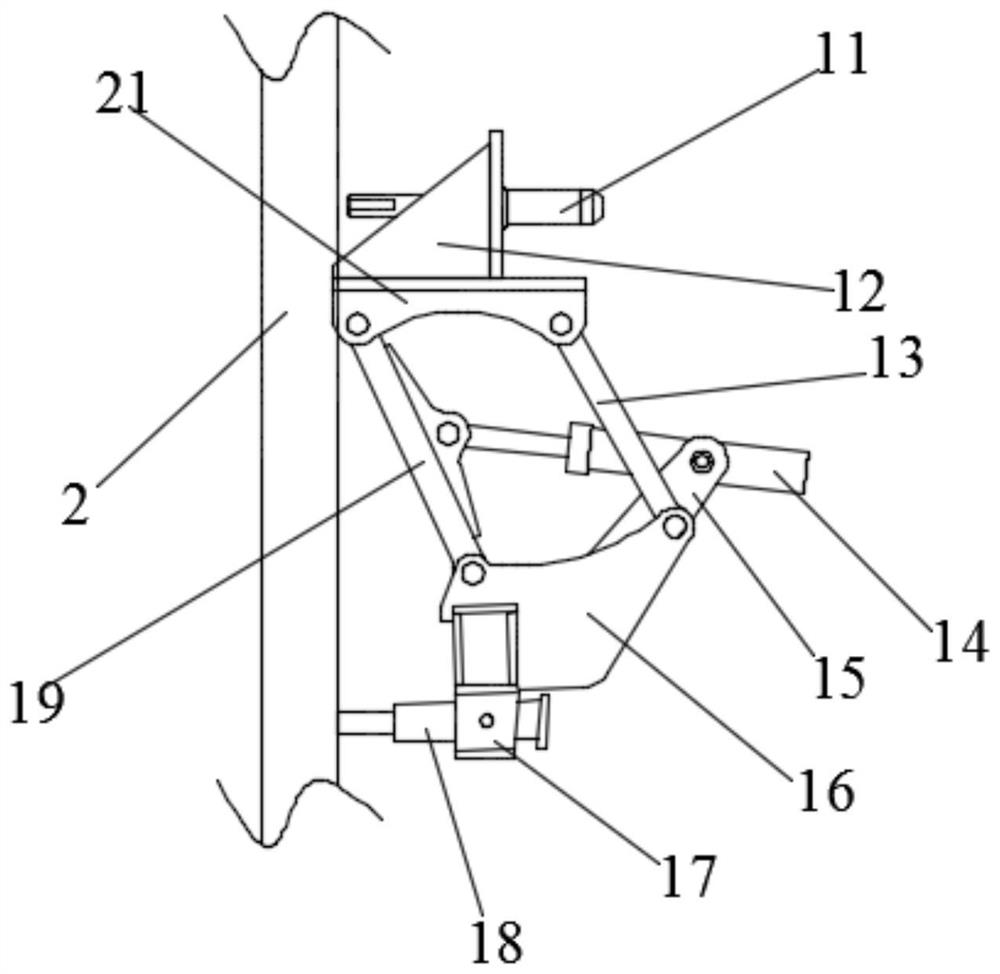

Push rod pressing device, positioning assembly and positioning device

ActiveCN113844680APreload achievedAchieve positioningCosmonautic vehiclesCosmonautic partsStructural engineeringFriction force

The invention relates to a push rod pressing device, a positioning assembly and a positioning device. The push rod pressing device comprises a workbench movable restraining base and a restraining head, the restraining head is installed on the workbench movable restraining base, and the restraining direction of the restraining head and the installation direction of the workbench movable restraining base are arranged at an angle; the workbench movable restraining base comprises a restraining base main support, a screwing handle and a movable check block, an assembling through hole is formed in the restraining base main support, the movable check block can be embedded in the assembling through hole of the restraining base main support in the mode of rotating in the circumferential direction of the assembling through hole, and a handle sliding groove is formed in the movable check block in the radial direction; and the screwing handle is installed in the handle sliding groove and can slide along the handle sliding groove. The workbench movable restraining base and the restraining head which are arranged at an angle are adopted, the restraining head is fixed to the proper position of the workbench through the workbench movable restraining base, a pre-tightening force is provided for load equipment, and then the load equipment is restrained and fixed through a friction force generated by the restraining head and the load equipment.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

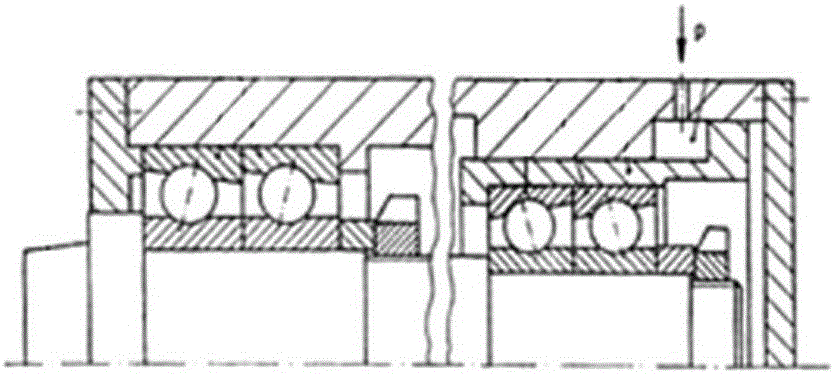

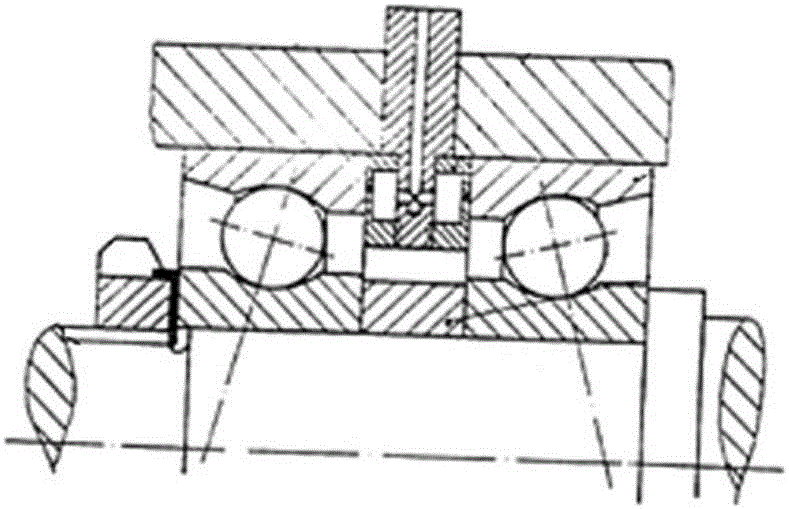

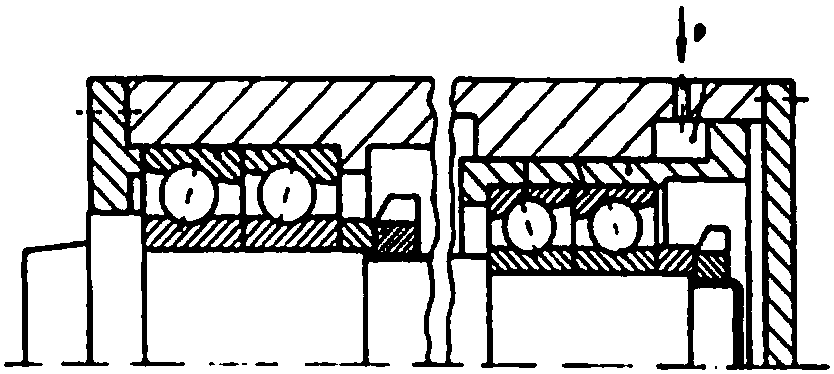

Machine tool spindle system provided with pretightening force adjusting device

The invention provides a machine tool spindle system provided with a pretightening force adjusting device. The machine tool spindle system comprises a spindle, a first ball bearing and a second ball bearing which sheath the spindle at intervals, an inner spacer bush, a cooling jacket, a piston element and a pressure measuring element, wherein the inner spacer bush sheathes the spindle and is arranged between the first ball bearing and the second ball bearing, and the two ends of the inner spacer bush respectively prop against the inner ring of the first ball bearing and the inner ring of the second ball bearing; the cooling jacket surrounds the spindle and is in respectively fit with the outer ring of the first ball bearing and the outer ring of the second ball bearing; the piston element is arranged on the cooling jacket and used for pushing the outer ring of the first ball bearing to move axially; and the pressure measuring element is arranged on the cooling jacket and used for acquiring a load born by the outer ring of the second ball bearing. The machine tool spindle system provided by the invention has the advantages that other spindle parts and structures do not need to be changed and the machine tool spindle system can be applicable to any bearing configuration way.

Owner:SHENJI GRP KUNMING MACHINE TOOL

Longitudinal-shaking sandwich energy converter type cylinder shape dual rotor ultrasonic motor

InactiveCN101388623AStrong process controllabilityReduce adverse effectsPiezoelectric/electrostriction/magnetostriction machinesTransducerEngineering

The invention relates to a bending vibration sandwich transducer type cylindrical double rotor ultrasonic motor which relates to the technical field of piezoelectric ultrasonic motors. The ultrasonic motor solves the problem in an existing ultrasonic motor that the mechanical output ability is restricted and a single stator only can realize single movement output. The bending vibration sandwich transducer type cylindrical double rotor ultrasonic motor of the invention comprises a stator component, an inside rotor component, an outside rotor component, a bearing block, a bearing and a bearing pre-tightening end cap, wherein continuous comb-shaped driving gears are manufactured on the inner surface of a cylinder, an inside rotor with a shaft and an inside rotor without the shaft are truncated cone-shaped, thin ends of the inside rotor with the shaft and the inside rotor without the shaft are respectively inserted on and under the cylinder, an outside rotor with the shaft and an outside rotor without the shaft are respectively installed on and under the stator component, wear resistance bush rings are respectively fixed on the side surfaces of the outside rotor with the shaft and the outside rotor without the shaft, which are contacted with a stator rear end cap, and the inside rotor with the shaft is connected with the bearing block in a rotary mode through the bearing. The bending vibration sandwich transducer type cylindrical double rotor ultrasonic motor can be applied in the manufacture field of ultrasonic motors.

Owner:HARBIN INST OF TECH

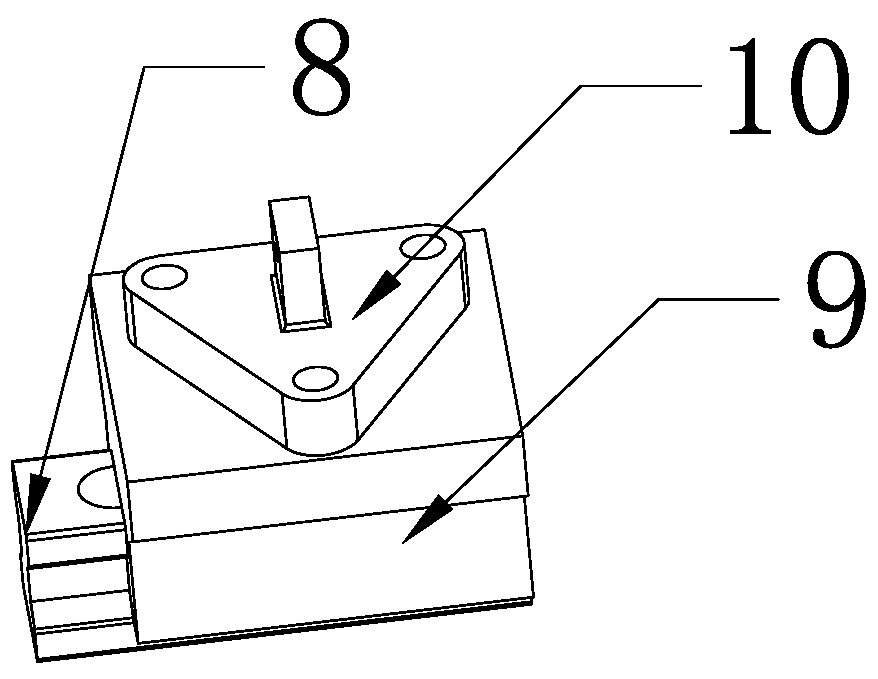

Anti-drift apparatus of device in microgravity environment and device

ActiveCN113236644AAchieve positioningImplementation orientationSnap-action fastenersBoltsMechanical engineeringPhysics

The invention relates to an anti-drift apparatus of a device in a microgravity environment and the device. The anti-drift apparatus comprises an anti-drift assembly and a guide positioning assembly; the anti-drift assembly comprises a locking pin and an anti-drift guide sleeve; the anti-drift guide sleeve is provided with a locking through hole; the locking pin can be inserted into the locking through hole in an axial movement manner; the guide positioning assembly includes a guide sleeve and a guide pin, a guide through hole is formed in the guide sleeve, and the guide pin can be inserted into the guide through hole in an axial movement mode; and the height of the guide pin is greater than that of the locking pin. According to the invention, the anti-drift assembly and the guide positioning assembly are combined for use, so that the positioning, guide and anti-drift functions are achieved; coarse positioning of the device is implemented through the guide positioning assembly, and at the moment, the device can rotate with the axis of the guide pin as the axis, or can horizontally move in the axial direction of the guide pin. The guide pin guides the device to be further installed with the anti-drift assembly (the height of the guide pin is greater than that of the locking pin), and at the moment, fine positioning is finished by the anti-drift guide sleeve on the device and the locking pin.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

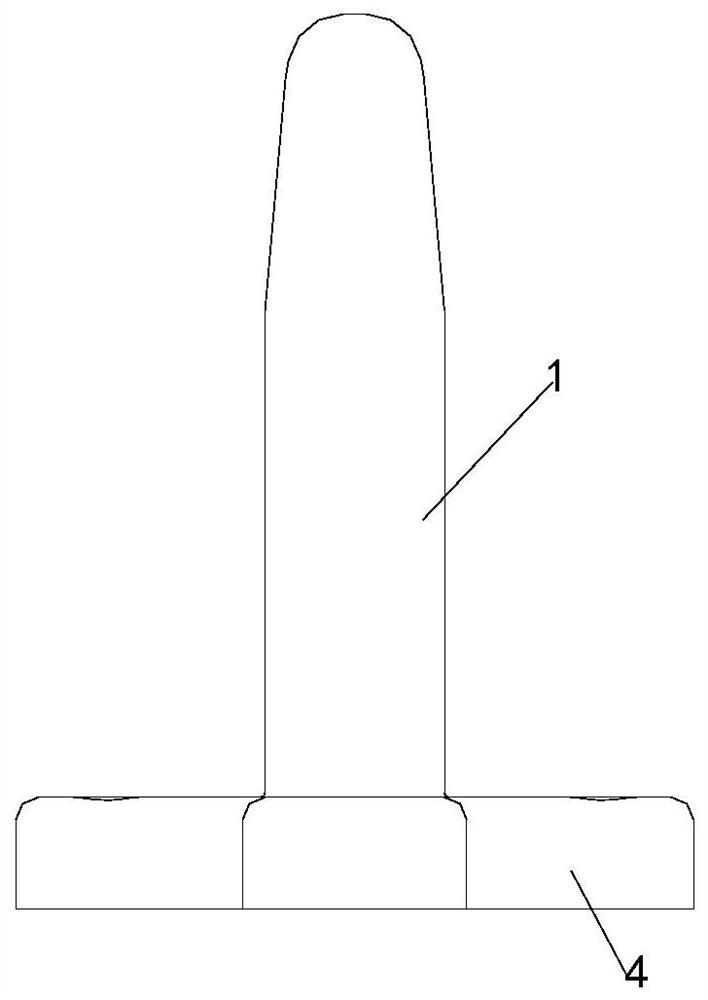

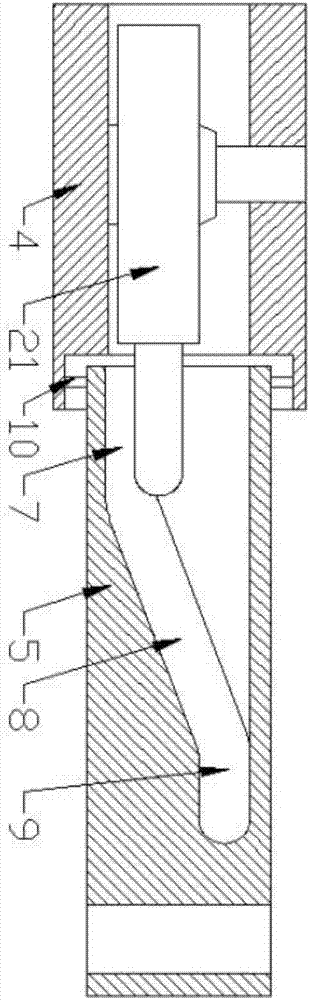

Precise pre-tightening bolt

PendingCN108571504APrecise preloadImprove durabilityScrewsMechanical measuring arrangementsHeight increasedEngineering

The invention provides a precise pre-tightening bolt. The precise pre-tightening bolt comprises a head, a screw, a mandrel and an indication wheel, wherein a through hole is formed in the end surfaceof the head, a blind hole is formed in one end of the screw, the end, where the blind hole is formed, of the screw is fixed with the head, and the though hole is coaxial with the blind hole; the mandrel is located in the through hole and the blind hole, one end of the mandrel is arranged at the bottom of the blind hole, the other end of the mandrel penetrates through the through hole and is fixedwith the indication wheel, and the distance between the indication wheel and the end surface of the head is the height increase distance of the blind hole after the precise pre-tightening bolt is mounted and reaches required pre-tightening force. The precise pre-tightening bolt has the advantages that the precise pre-tightening bolt can solve the problems that the pre-tightening force errors are large during pre-tightening mounting, pre-tightening is inconvenient and whether bolt pre-tightening is loose or not cannot be judged.

Owner:SHANGHAI WINNER ENG

An adjustable pretightening force double-layer shock-absorbing fastener system

The invention belongs to the field of urban mass transit, and discloses an adjustable pre-tightening force double-layer vibration attenuation buckle system. According to the adjustable pre-tightening force double-layer vibration attenuation buckle system disclosed by the invention, pre-tightening force inter-locking on a bottom plate elastic insulating pad (6) is formed in a gap between an upper bottom plate (5) and a lower bottom plate (7); the adjustable range of the pre-tightening force is 0.1-30KN; an adjusting method comprises the following steps: adjusting the locking height of a bottom plate connecting sleeve (4), or setting a pre-tightening force adjusting gasket I (3a) between the upper end surface of a baffle side (12) and a locking cover plate (2), or setting a pre-tightening force adjusting gasket II (3b) between the lower end surface of the baffle side (12) and the upper end surface of the upper bottom plate (5), or increasing the thickness of the baffle side (12). By adopting the system, the problem that the pre-tightening force is reduced as the double-layer vibration attenuation buckle system is worn in the application process or even crack occurs between the elastic insulating pads of the bottom plates and the upper and lower bottom plates are avoided, and the train security is ensured.

Owner:洛阳双瑞橡塑科技有限公司

Pre-tensioning device and pre-tensioning method for steel belts

The invention provides a pre-tensioning device and pre-tensioning method for steel belts, and relates to the technical field of robots. The invention aims to solve the problems that a current robot steel belt pre-tensioning device is not compact in structure, larger in volume, and not suitable for multi-layer steel belt pre-tensioning. The pre-tensioning device includes a steel belt pulley A, a steel belt pulley B, a steel belt component, a first fastening bolt and a second fastening bolt; and one end of the steel belt component is fixedly connected to the outer circumferential side wall of the steel belt pulley A through the first fastening bolt, and the other end of the steel belt component is fixedly connected to the outer circumferential side wall of the steel belt pulley B through thesecond fastening bolt. The pre-tensioning method comprises the following steps: pre-processing, assembling of the steel belt component, fixing of the steel belt component, and pre-tensioning of the steel belt component. The device and method provided by the invention are used for medical robots and industrial robots.

Owner:杭州唯精医疗机器人有限公司

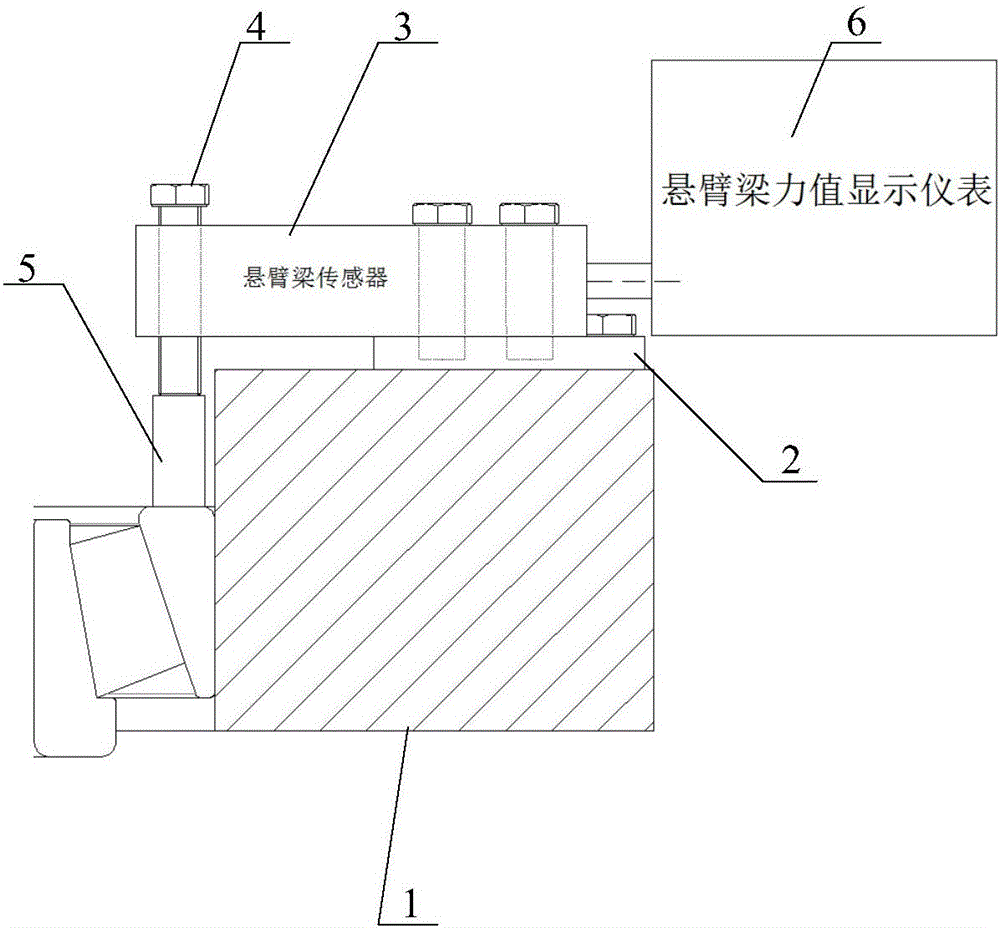

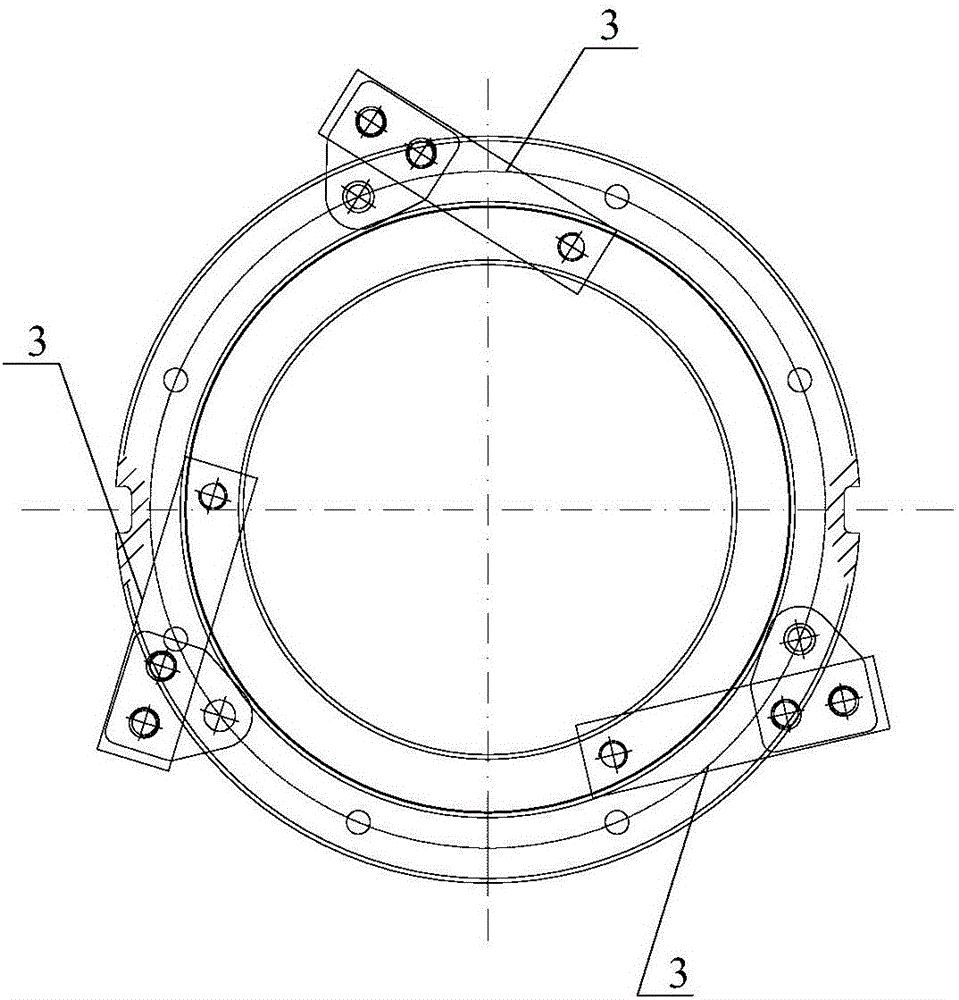

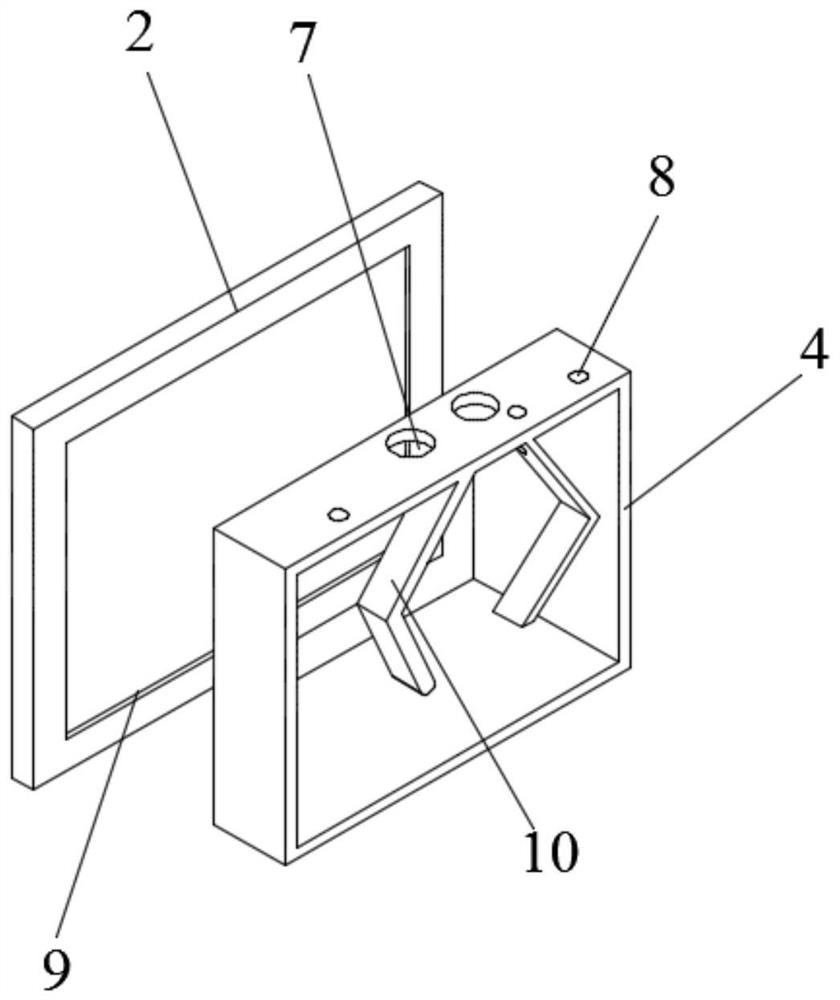

Bearing assembly and pre-tightening device of bearing

The invention discloses a pre-tightening device of a bearing. The pre-tightening device comprises pre-tightening assemblies and a cantilever beam force value display instrument. Each pre-tightening assembly comprises a cantilever beam sensor with one suspended end. An adjusting piece is mounted at the suspended end of each cantilever beam sensor and abuts against one end of an ejection block, and the other end of the ejection block is attached to the bearing for pre-tightening. The pressure applied to the ejection block can be adjusted by means of adjustment of the adjusting pieces. The cantilever beam force value display instrument is in signal connection with the cantilever beam sensors and is used for displaying the force values of the cantilever beam sensors. The force needed for bearing pre-tightening is set, adjustment of the force, applied to the ejection block, of the adjusting pieces is stopped when the cantilever beam force value display instrument achieves the force value, and therefore the bearing is pre-tightened, and detection accuracy is improved through the structure via sensor detection. The invention further discloses a bearing assembly with the pre-tightening device of the bearing.

Owner:WORLD TRANSMISSION TECH TIANJIN SHARE LTD

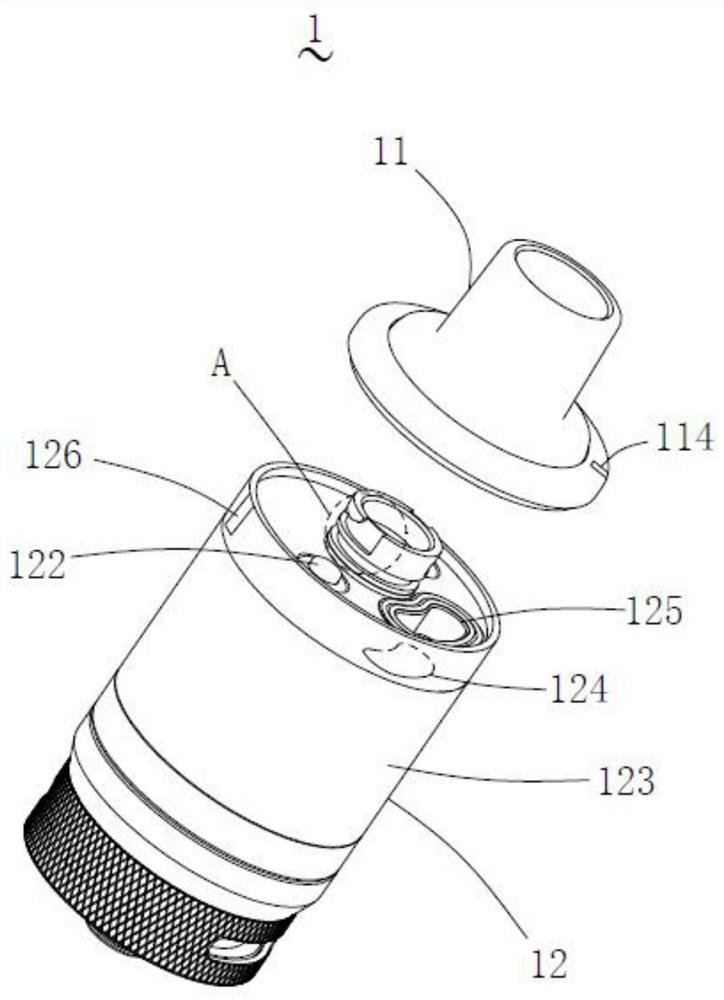

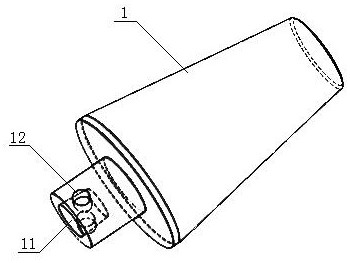

Atomizer capable of being prevented from being opened by mistake, atomizer fixing method and aerosol generating device

The invention relates to the field of aerosol generating devices, and particularly discloses an atomizer capable of preventing mistaken opening, an atomizer fixing method and an aerosol generating device. A suction nozzle and an atomization assembly are arranged, insertion is conducted through a positioning cylinder and a connecting column, a limiting block is arranged in a groove through an opening, so the limiting block abuts against the side face of the groove. In combination with reverse pre-tightening force applied to the suction nozzle by the first elastic piece, pre-tightening of the current position of the suction nozzle is achieved, positioning operation is completed, the positioning stability of the suction nozzle is improved, and the risk that an oil filling port is exposed dueto the fact that a young child opens the suction nozzle accidentally is avoided.

Owner:SHENZHEN JIYOU TECH CO LTD

Numerical control equipment spindle inner cone grinding device and grinding method of grinding device

The invention relates to the technical field of machining, and discloses a numerical control equipment spindle inner cone grinding device and a grinding method thereof. The numerical control equipment spindle inner cone grinding device comprises a grinding cutter handle and a fixing base, the grinding cutter handle is installed on the fixing base through a supporting connecting shaft, an installation key is arranged at the bottom end of the supporting connecting shaft, and a fixing hole is formed in the fixing base; and the inner side wall of the fixing hole is provided with a key groove used for limiting the installation key, the bottom end of the supporting connecting shaft is inserted into the fixing hole, the installation key is located in the key groove, the fixing base is further provided with a groove, the groove and the fixing hole are coaxial, the groove is communicated with the fixing hole, and the supporting connecting shaft is sleeved with a pre-tightening spring. One end of the pre-tightening spring acts on the bottom face of the groove, and the other end of the pre-tightening spring acts on a supporting shoulder extending out of the supporting connecting shaft in the radial direction. A spindle rotates to enable a spindle inner cone to be matched with a grinding cone so as to achieve grinding, and therefore the precision of the inner cone and the cutter installing matching precision are guaranteed.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

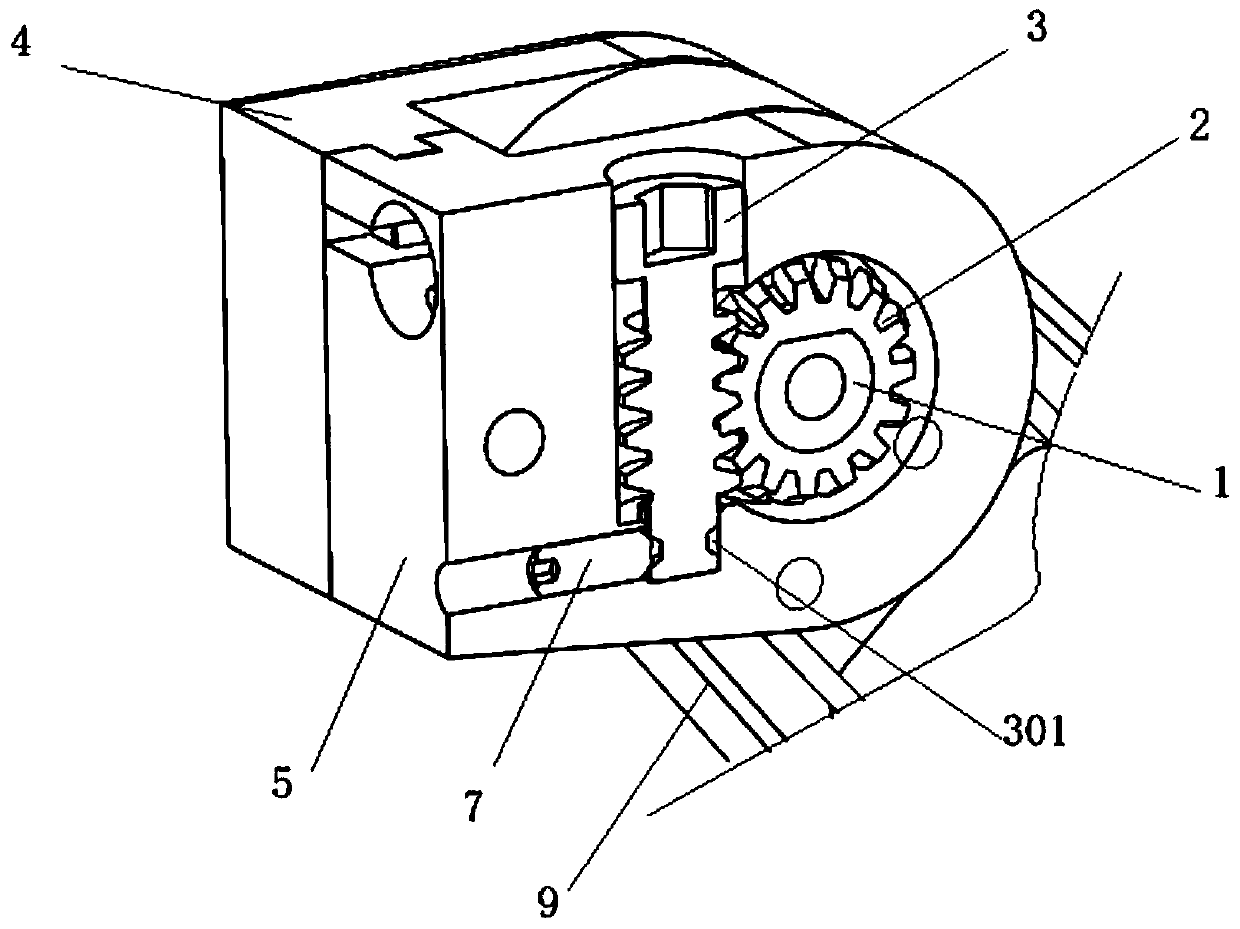

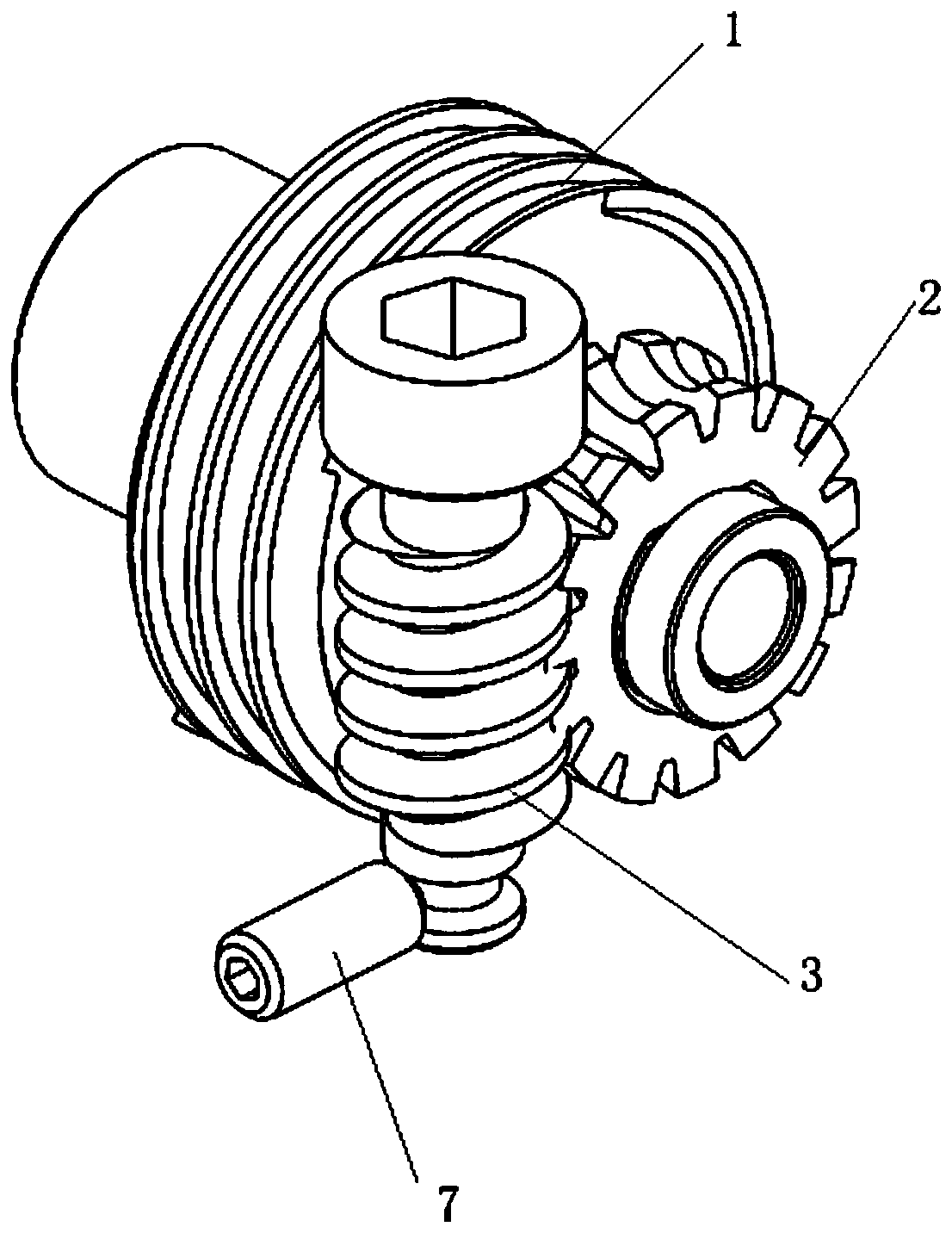

Pre-tightening, anti-loosening and balancing device for spiral rotating shaft

PendingCN111043267AImproved unilateral support designIncrease preload designGearingSet screwRotational axis

The invention relates to a pre-tightening, anti-loosening and balancing device for a spiral rotating shaft. The device comprises the spiral rotating shaft, a worm gear, a worm, a first rotating shaftseat body and a second rotating shaft seat body, wherein a spiral groove is formed in the middle of the spiral rotating shaft, a steel wire is wound on the spiral groove, an innermost end of the steelwire penetrates into the spiral rotating shaft and is fixed on a steel ball, a cylindrical shaft is arranged at one end of the spiral rotating shaft, a platform is arranged on the other end, a worm wheel with a platform inner hole is arranged on the platform shaft in a sleeving mode, the worm is arranged on the outer side of the worm gear and assembled in a worm mounting hole in the second rotating shaft seat body, an annular groove is formed at a tail end of the worm, a screw mounting hole is formed in the position, right opposite to the annular groove, of the second rotating shaft seat body, and a set screw is assembled in the screw mounting hole. The device has the advantages that pre-tightening design is added in a transmission mechanism of a steel wire rope through the spiral rotating shaft, so the steel wire rope is pre-tightened, the locking design of the tail end position of the worm is added, and a phenomenon that the steel wire rope is loosened due to self-rotation of the spiral rotating shaft caused by worm and gear matching loosening is prevented.

Owner:SUZHOU JODELL ROBOTICS CO LTD

An anti-floating device and equipment for equipment in a microgravity environment

ActiveCN113236644BAchieve positioningImprove efficiency during maintenance and replacementSnap-action fastenersBoltsMicro gravityControl theory

The invention relates to an anti-drifting device and equipment for equipment in a microgravity environment. The anti-drifting device includes an anti-drifting component and a guiding and positioning component. The anti-drifting component includes a locking pin and an anti-drifting guide sleeve. Tight through hole, the locking pin can be axially moved and inserted in the locking through hole; the guide positioning assembly includes a guide sleeve and a guide pin, the guide sleeve is provided with a guide through hole, and the guide pin can move axially Inserted in the guide through hole; the height of the guide pin is greater than that of the locking pin. The anti-floating component and the guiding and positioning component of the present invention are used in a complete set to realize the functions of positioning, guiding and anti-floating. The axial direction of the pin shaft is translated. The guide pin guides the equipment to continue to cooperate with the anti-floating component (the height of the guide pin is greater than the height of the locking pin). At this time, the anti-floating guide sleeve on the equipment and the locking pin complete the precise positioning.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

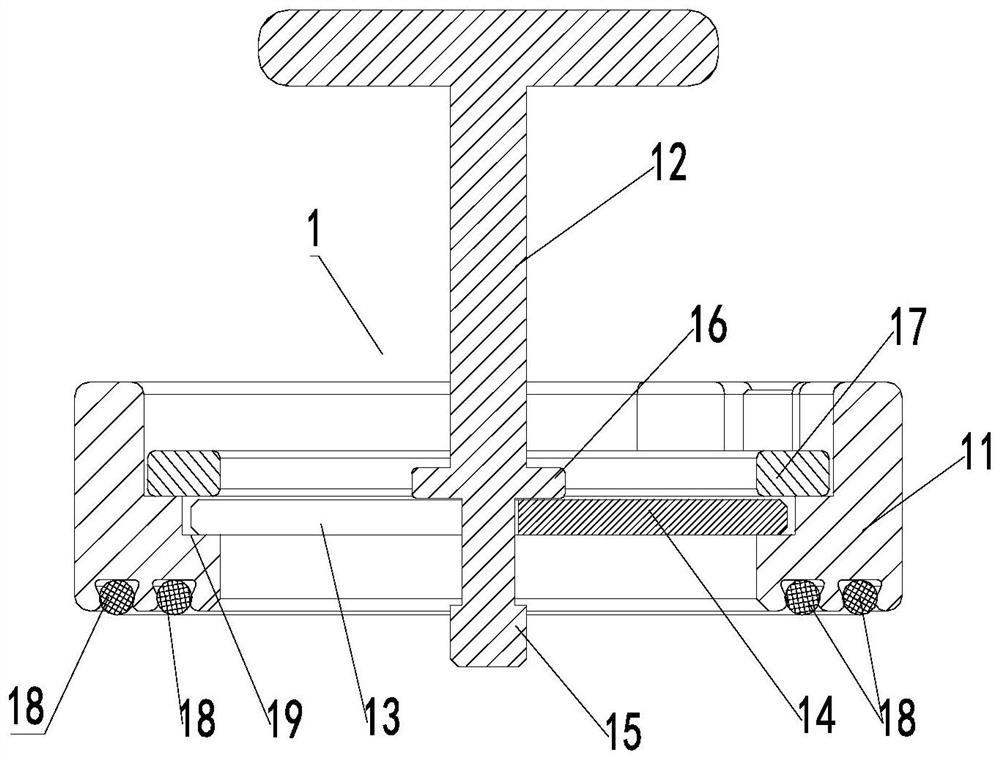

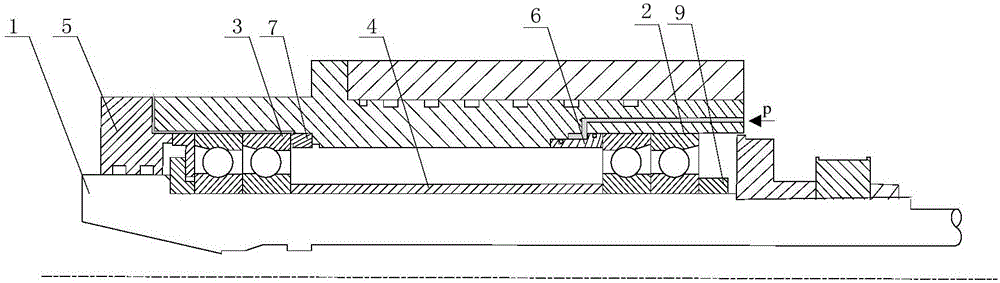

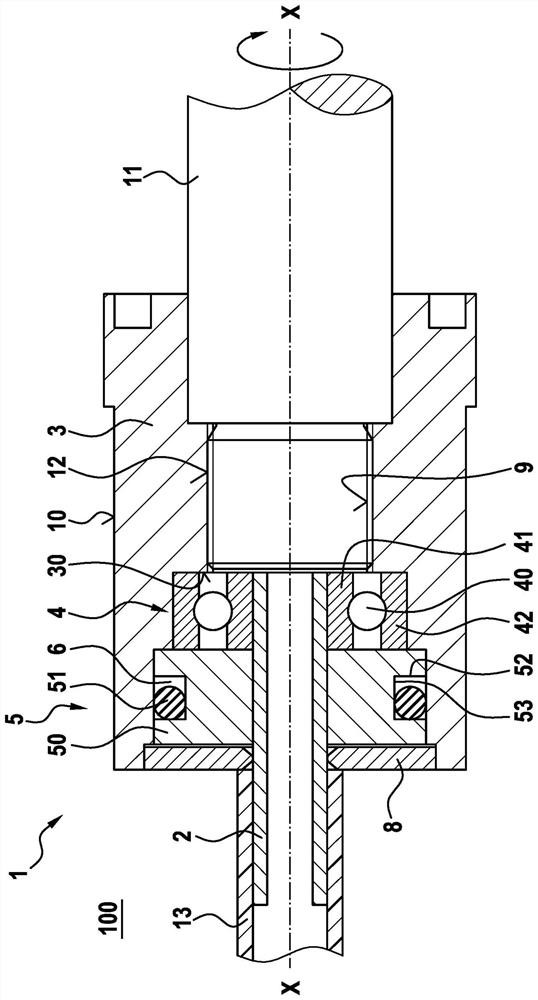

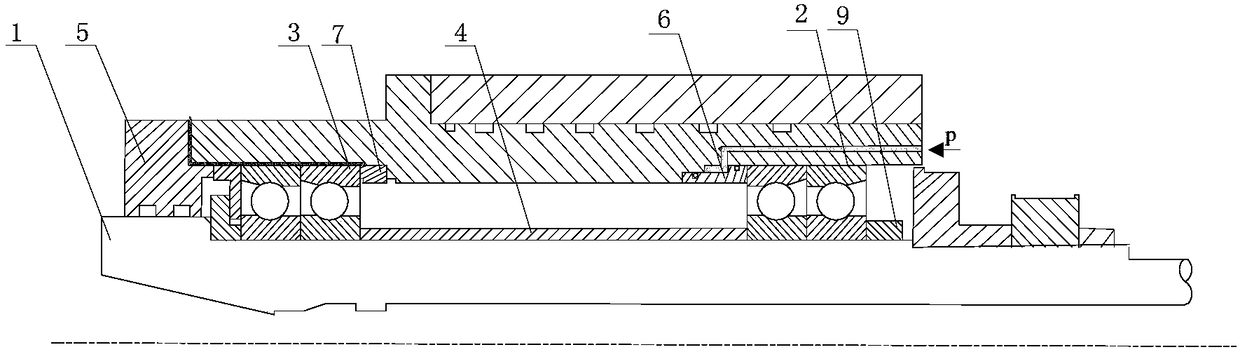

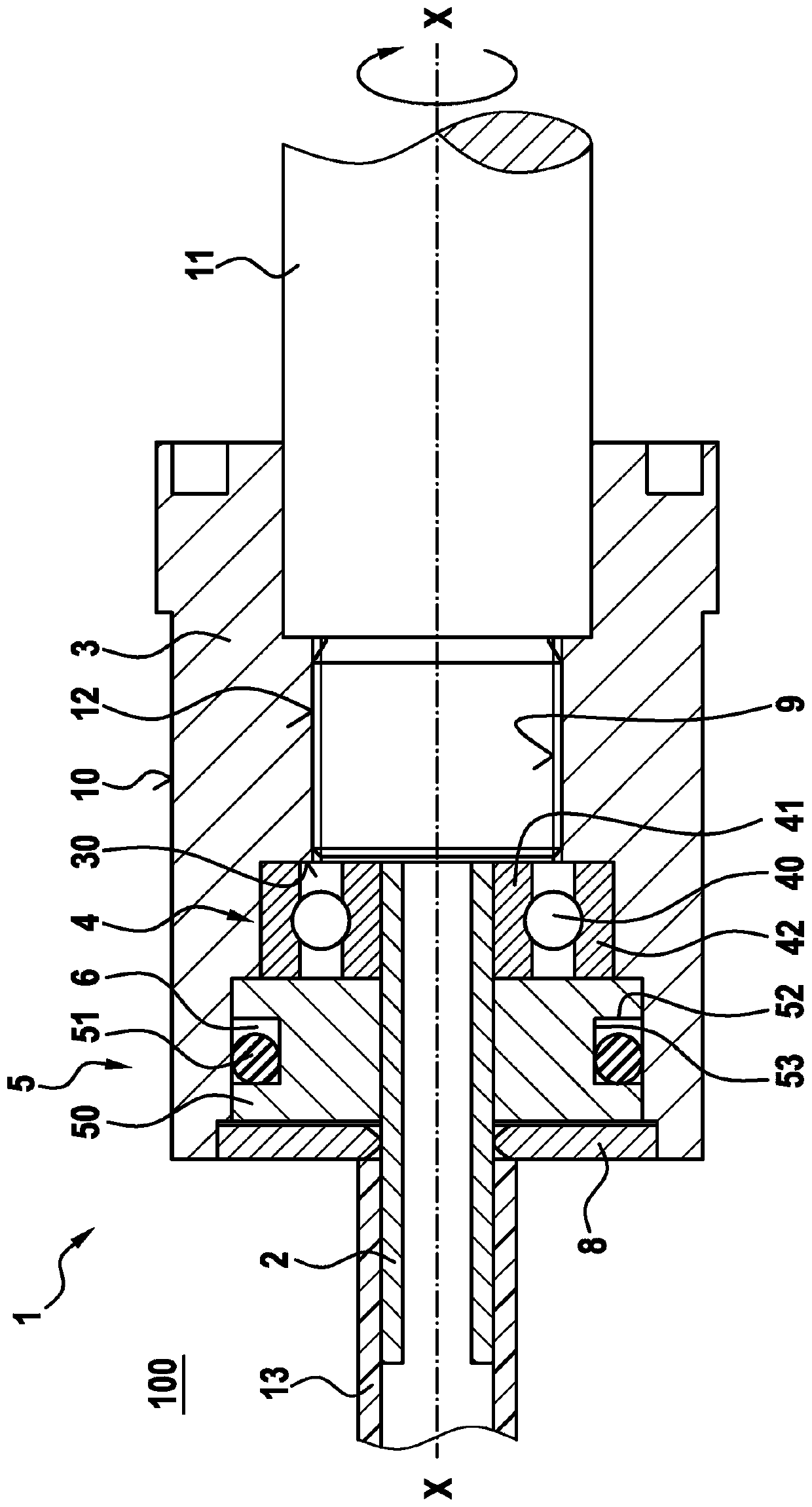

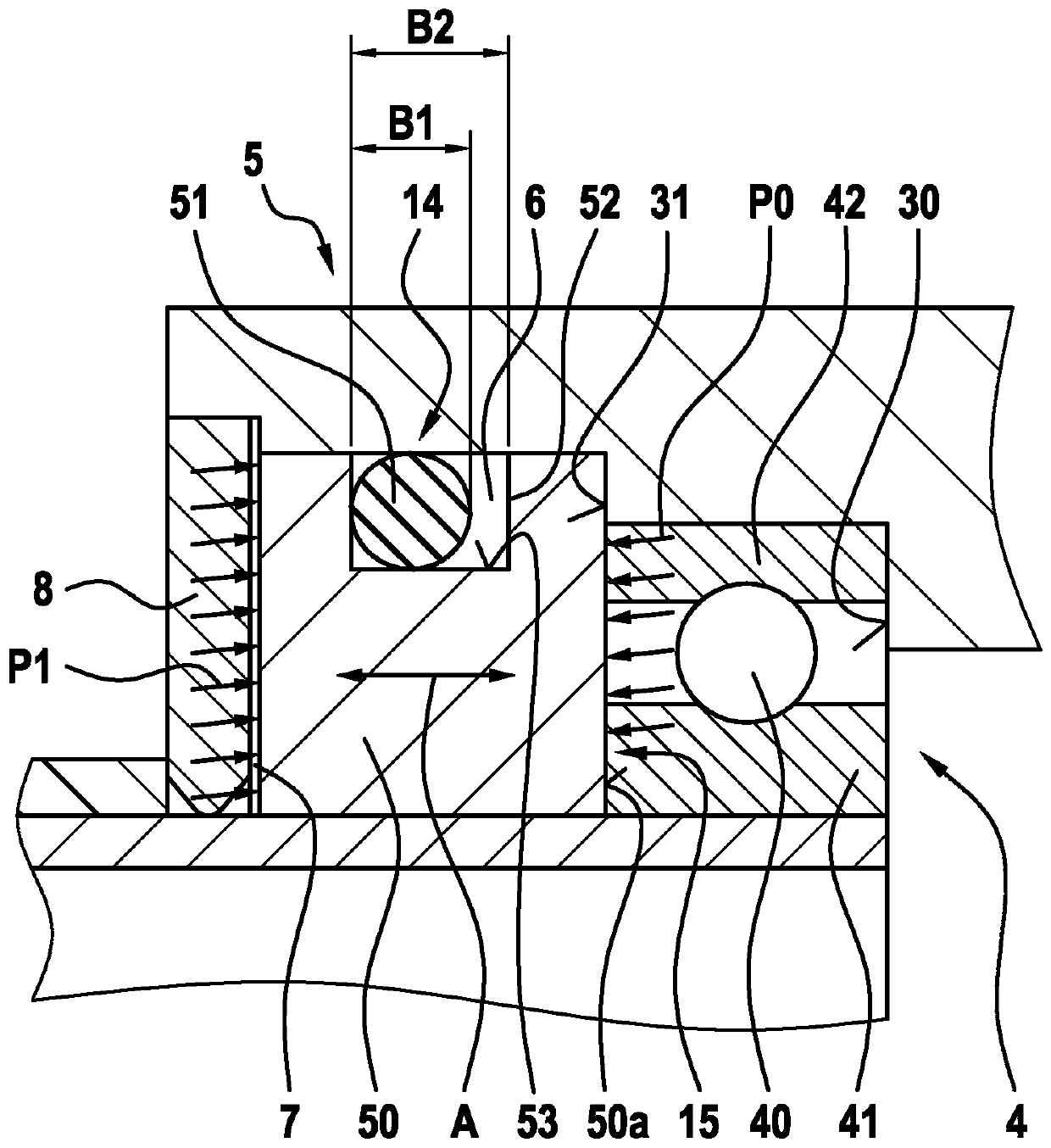

Rotary induction and crankshaft assembly

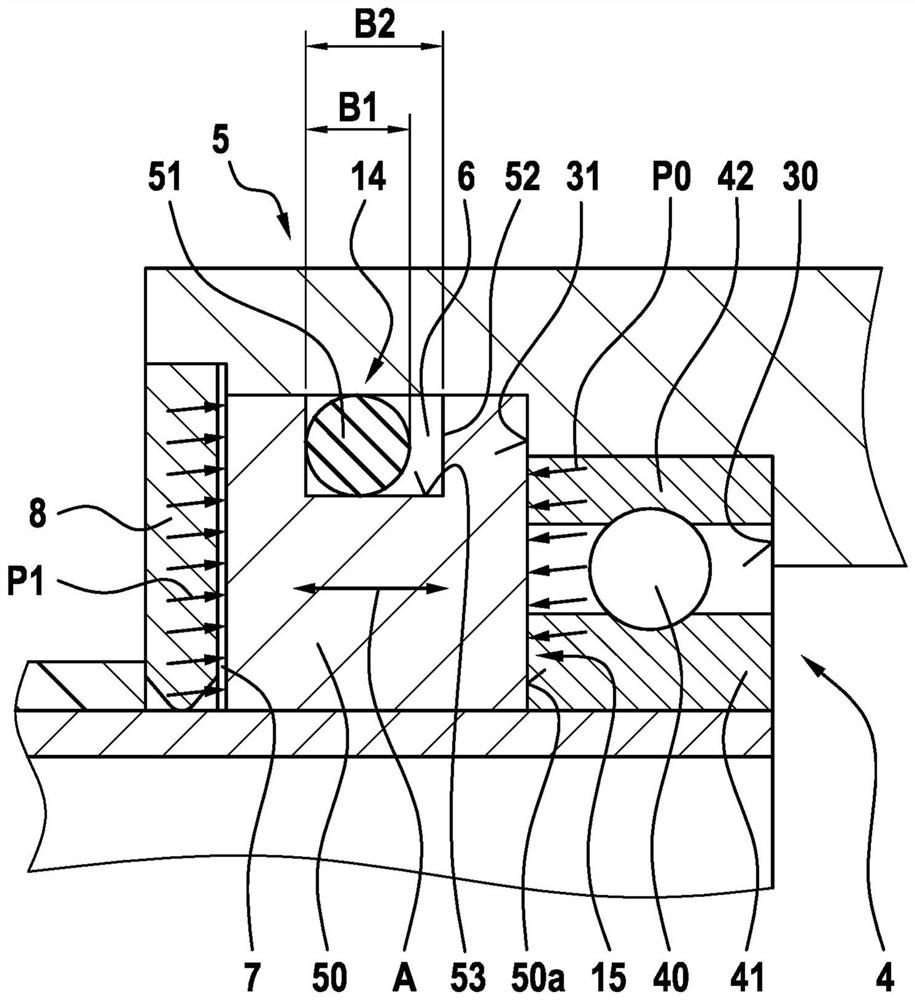

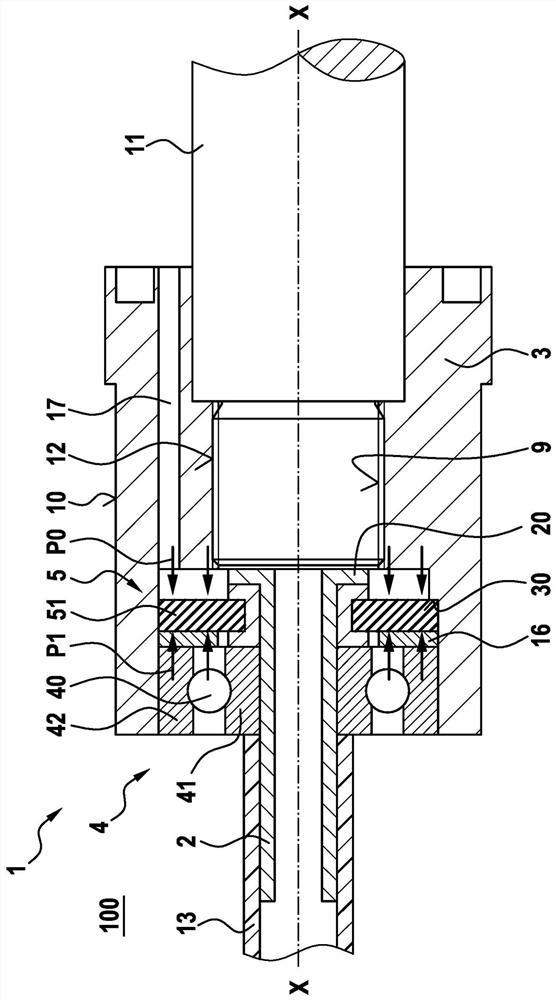

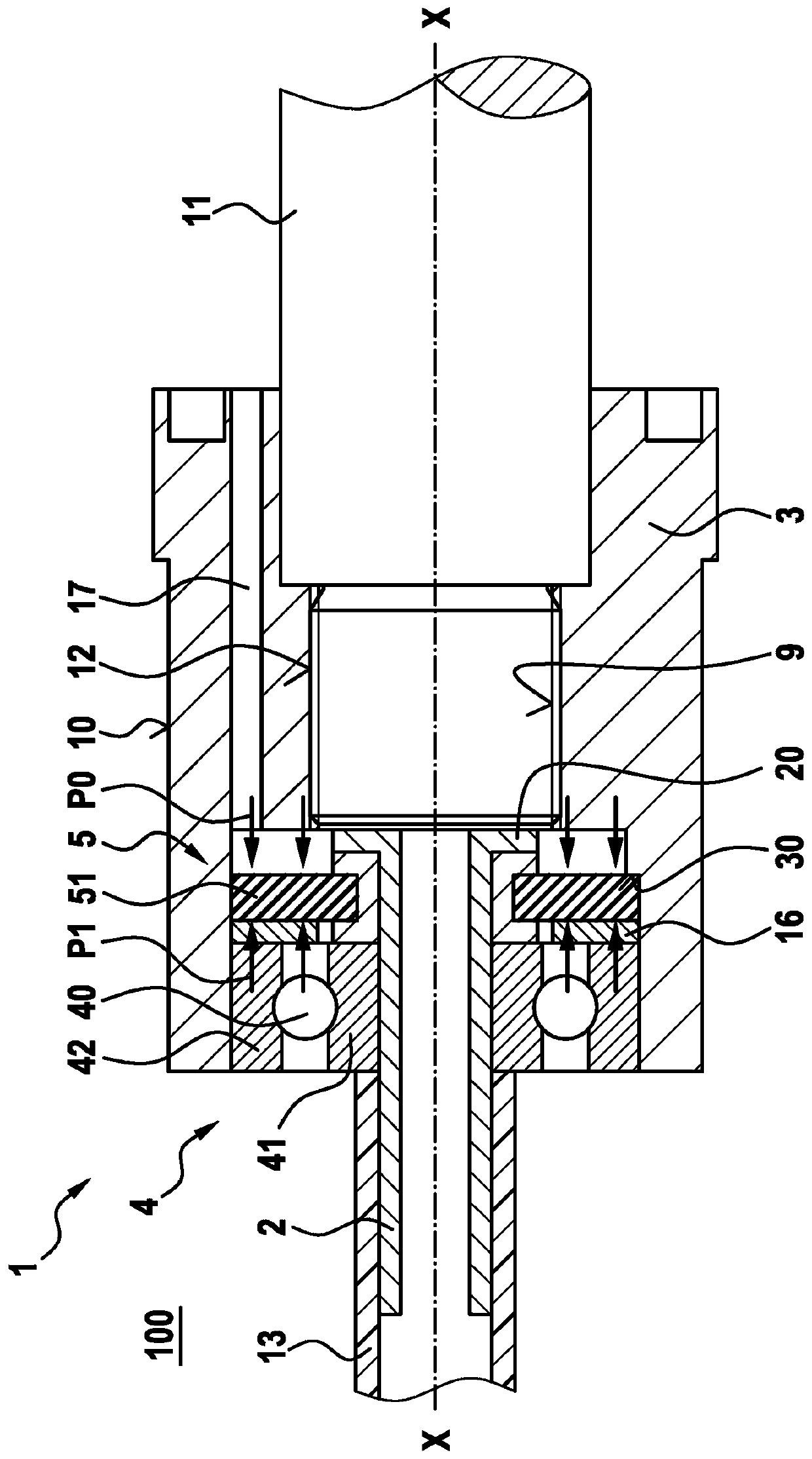

ActiveCN110268184BPreload achievedSmall space requirementEngine sealsBall bearingsElastomerMechanical engineering

The invention relates to a rotary lead-in comprising a stationary member (2), a rotating member (3), exactly one bearing (4) supporting said rotating member (3) on said stationary member (2), and a seal assembly (5) with a carbon ring (50) and an elastomer ring (51), wherein the carbon ring (50) is movably arranged in the axial direction (X‑X) between the rotating member (3) and the stationary member (2), and wherein the seal assembly has a first sealing area (14) on an elastomeric ring and a second sealing area on a carbon ring (50) Sealing area (15).

Owner:ROBERT BOSCH GMBH

Oil drilling pipe boosting power tongs

InactiveCN106978980ARealize push downRealize rotary driveDrilling rodsDrilling casingsAbove groundEngineering

The invention relates to a power tong for oil drill rods, which includes a driving tong body and a base, wherein the driving tong body is rotationally connected to the base through a rotating disc, and an opening for clamping a drill pipe is arranged on the driving tong body. A clamping mechanism for clamping the drill pipe is provided on the inner wall of the opening; a push cylinder is also provided between the drive tong body and the base; a push groove is arranged inside the push rod, and the push groove includes a guide part, a pressing part and a push part, Wherein the bottom surface of the pressing part is inclined to the surface of the base, the pressing part is connected between the guiding part and the pushing part, and the height of the pushing part relative to the base is higher than the height of the ground of the guiding part; The end of the seat is slidingly connected with the end of the push rod, and a push cylinder is installed inside the cylinder fixed seat; a return cylinder is also rotatably connected on the base, and the cylinder rod of the return cylinder is rotatably connected to the drive clamp body.

Owner:YANCHENG JINRUI PETROLEUM MACHINERY CO LTD

Longitudinal-shaking sandwich energy converter type cylinder shape dual rotor ultrasonic motor

InactiveCN101388623BStrong process controllabilityReduce adverse effectsPiezoelectric/electrostriction/magnetostriction machinesElectric machineEngineering

Owner:HARBIN INST OF TECH

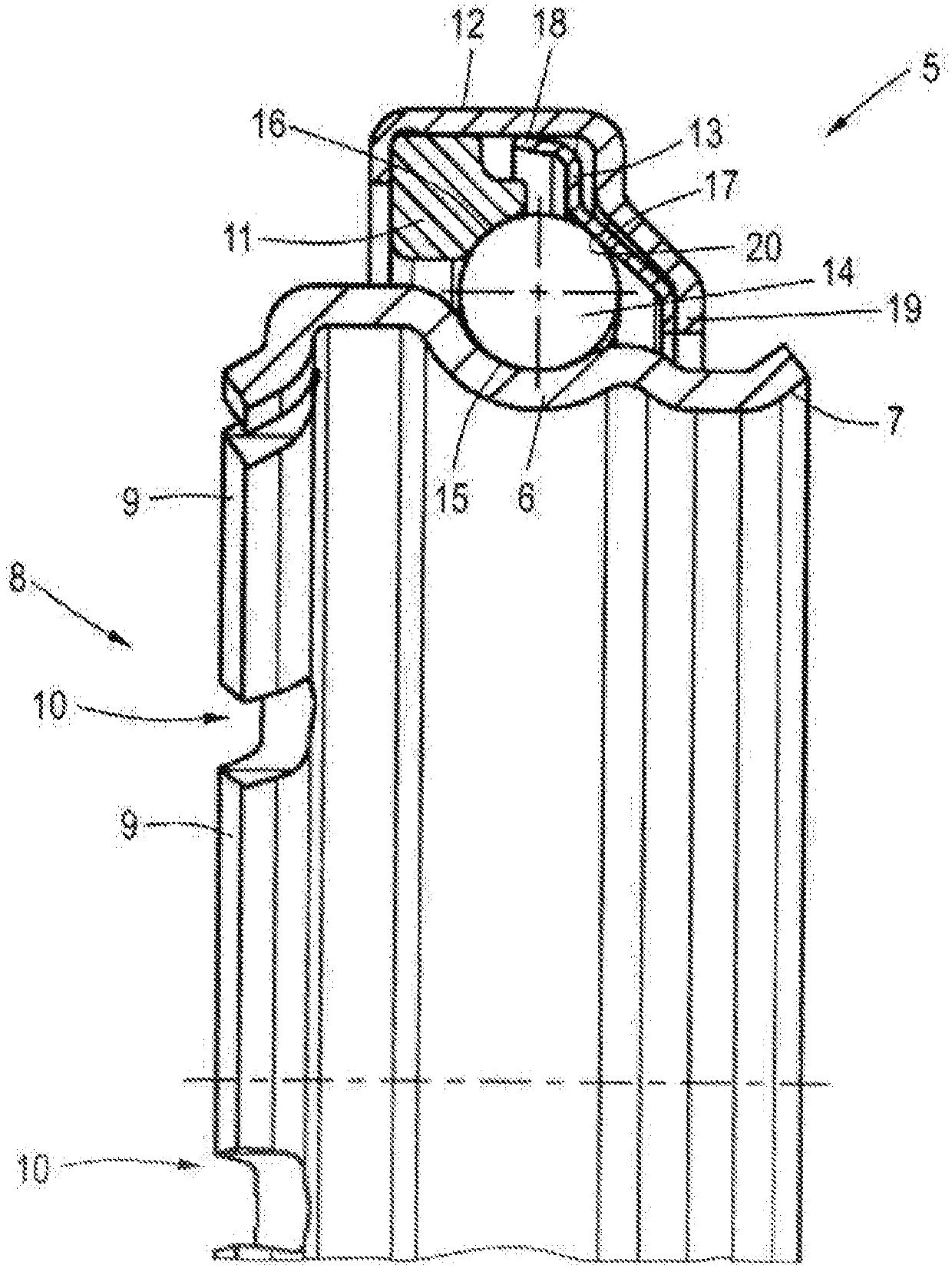

Steering column bearing for supporting a steering column of a motor vehicle

InactiveCN105765250BLow costReduce frictional torqueBall bearingsBearing componentsSteering columnControl theory

A steering bearing for bearing a steering column of a motor vehicle, including an inner ring and an outer ring having respective raceways on which balls roll, the outer ring being enclosed by a sleeve in which a spring ring is arranged. The spring ring tensions the balls against the respective raceways and the balls roll on said spring ring.

Owner:SCHAEFFLER TECH AG & CO KG

Longitudinal-shaking sandwich energy converter type cylinder type birotor ultrasonic motor

InactiveCN101304223BStrong process controllabilityReduce adverse effectsPiezoelectric/electrostriction/magnetostriction machinesTransducerLongitudinal vibration

The invention discloses a longitudinal vibration sandwiched transducer type cylindrical dual-rotor ultrasonic motor, which relates to the technical field of an ultrasonic motor and aims at solving the problems that the mechanical output capacity is restricted and a single stator can only realize single moving output existing in present ultrasonic motor. The longitudinal vibration sandwiched transducer type cylindrical dual-rotor ultrasonic motor of the invention comprises a stator component, a medial rotor component, an outer rotor component, a bearing base, a bearing and a bearing pretensioncover. The inner surface of a cylinder is manufactured with continuous comb-shaped driving gears; a medial rotor with a shaft and a medial rotor without the shaft are cone-shaped, the thin ends of the medial rotor with the shaft and the medial rotor without the shaft are respectively inserted from the lower part of a stator cylinder and the upper part of the stator cylinder; an outer rotor with the shaft and an outer rotor without the shaft are respectively arranged on the upper part of the stator component and the lower part of the stator component; the lateral surfaces that the outer rotor with the shaft and the outer rotor without the shaft are contacted with the back end cover of the stator are respectively fixed with wear-resistance lining rings; the medial rotor with the shaft is rotatablely connected with the bearing base by the bearing. The longitudinal vibration sandwiched transducer type cylindrical dual-rotor ultrasonic motor of the invention can be applied to the ultrasonic motor manufacturing field.

Owner:HARBIN INST OF TECH

Machine tool spindle system with preload adjustment device

The invention provides a machine tool spindle system provided with a pretightening force adjusting device. The machine tool spindle system comprises a spindle, a first ball bearing and a second ball bearing which sheath the spindle at intervals, an inner spacer bush, a cooling jacket, a piston element and a pressure measuring element, wherein the inner spacer bush sheathes the spindle and is arranged between the first ball bearing and the second ball bearing, and the two ends of the inner spacer bush respectively prop against the inner ring of the first ball bearing and the inner ring of the second ball bearing; the cooling jacket surrounds the spindle and is in respectively fit with the outer ring of the first ball bearing and the outer ring of the second ball bearing; the piston element is arranged on the cooling jacket and used for pushing the outer ring of the first ball bearing to move axially; and the pressure measuring element is arranged on the cooling jacket and used for acquiring a load born by the outer ring of the second ball bearing. The machine tool spindle system provided by the invention has the advantages that other spindle parts and structures do not need to be changed and the machine tool spindle system can be applicable to any bearing configuration way.

Owner:SHENJI GRP KUNMING MACHINE TOOL

A push rod pressing device, positioning assembly and positioning device

ActiveCN113844680BPreload achievedAchieve positioningCosmonautic vehiclesCosmonautic partsStructural engineeringWorkbench

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

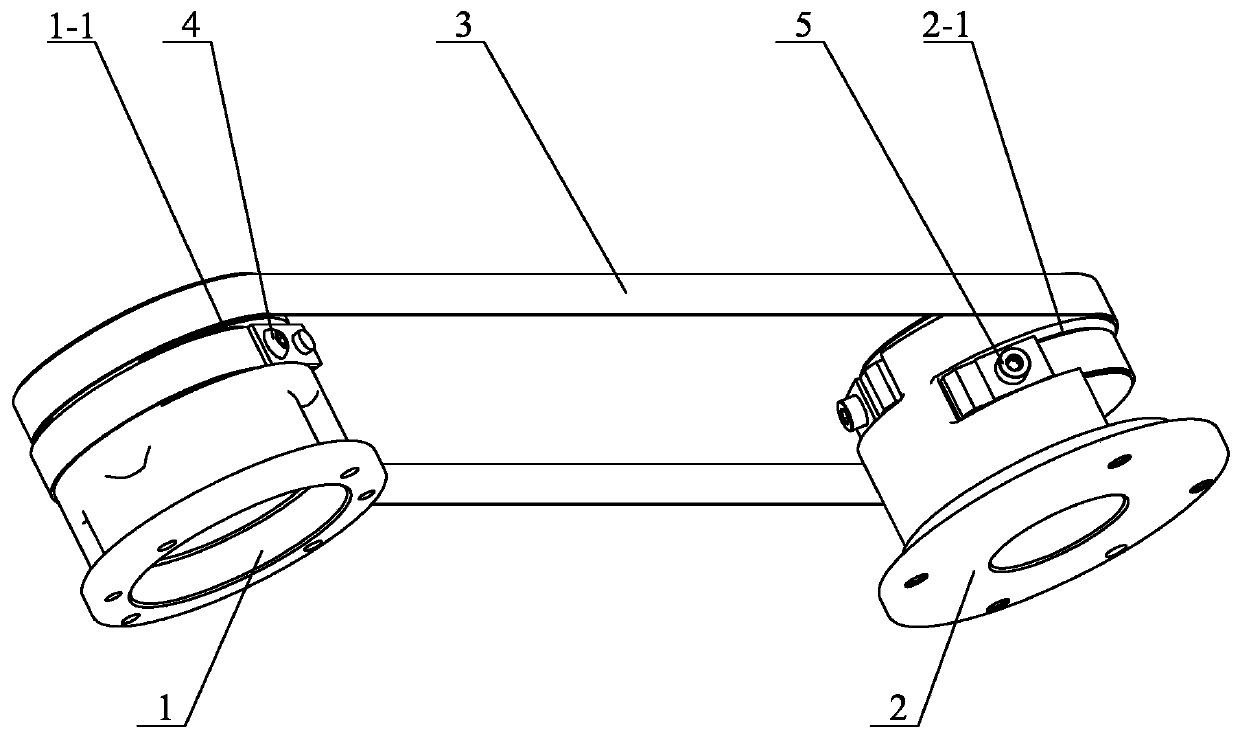

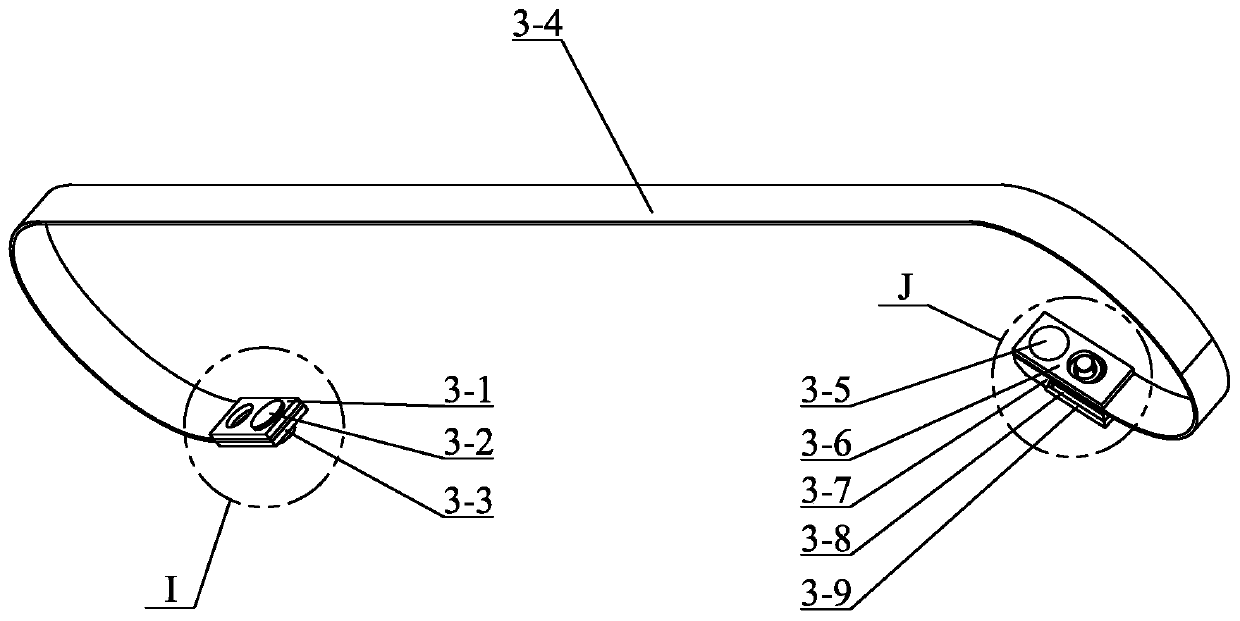

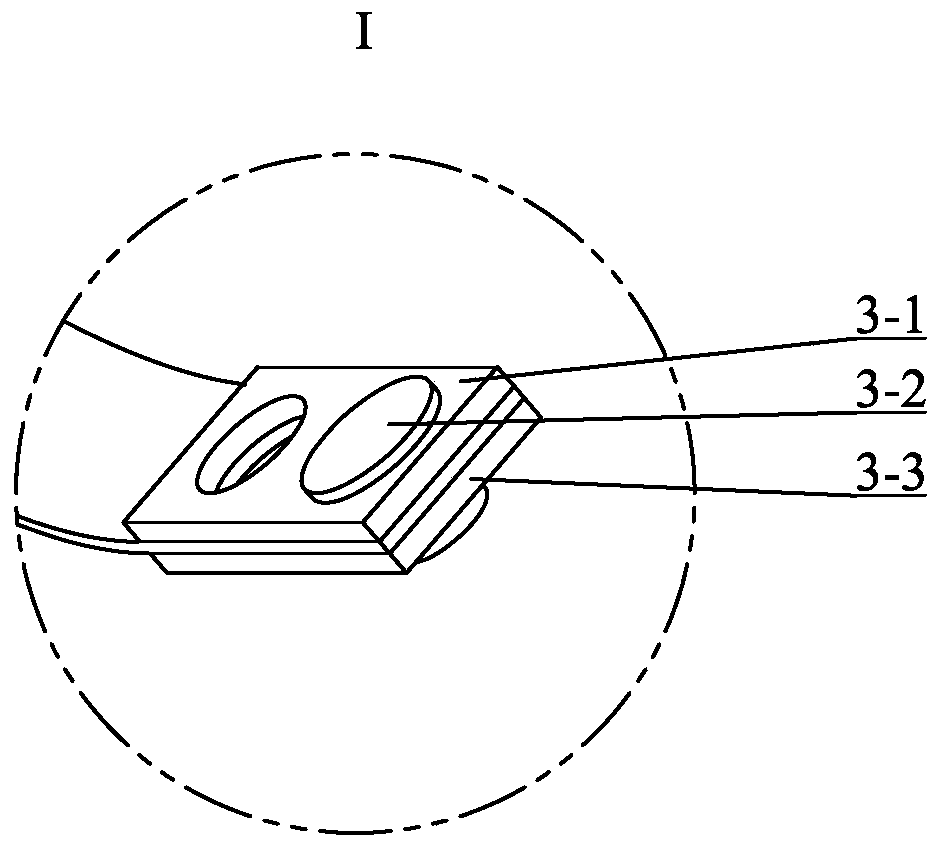

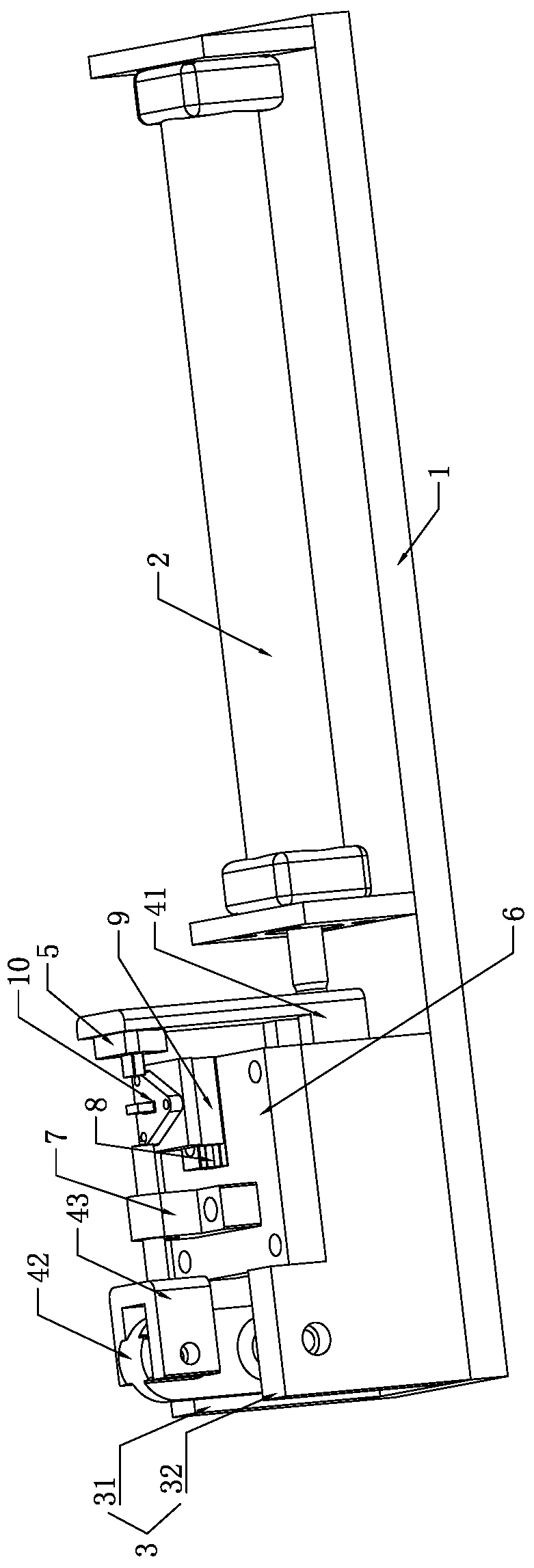

Shearing-type piezoelectric sensor module pre-loading device

ActiveCN108775910APreload achievedAccurately adjust the pressing forceMeasurement apparatus componentsElectricityProduction line

The present invention discloses a shearing-type piezoelectric sensor module pre-loading device. The device comprises a pedestal, a power device, a support, a drive connection rod device, a pressing block with a hole and a workbench; the support is formed by a front support and a rear support; the drive connection rod device is formed by an L-shaped connection rod, a turning arm and a push rod; thepressing block with the hole is installed at the top portion of a vertical rod of the L-shaped connection rod corresponding to the push rod; the workbench is formed by the fixing plate, a flange slide block and a linear guide rail, the flange slide block is fixed on the fixing plate, the linear guide rail can be arranged at the flange slide block through free movement in a horizontal direction, apiezoelectric sensor module to be pre-loaded is arranged on the flange slide block to allow the piezoelectric sensor module to be located between the pressing block with the hole and the push rod. The device is convenient to operate, and simple and practical, can improve the production efficiency and is suitable for assembling production lines of various shearing piezoelectric sensors.

Owner:XIAMEN NIELL ELECTRONICS

Rotary leadthrough and crankshaft assembly

ActiveCN110268184APreload achievedSmall space requirementEngine sealsBall bearingsEngineeringCrankshaft

The invention relates to a rotary leadthrough, comprising a stationary component (2), a rotating component (3), exactly one bearing (4), which supports the rotating bearing (3) on the stationary component (2), and a seal assembly (5) having a carbon ring (50) and an elastomer ring (51), wherein the carbon ring (50) is arranged between the rotating component (3) and the stationary component (2) such that the carbon ring can move in the axial direction (X-X), and wherein the seal assembly (5) has a first sealing region (14) on the elastomer ring and a second sealing region (15) on the carbon ring.

Owner:ROBERT BOSCH GMBH

Active pretensioner seat belt device

ActiveCN103386943BPreload achievedAdd control functionBelt retractorsPedestrian/occupant safety arrangementActive safetyControl signal

Owner:湖南立中科技股份有限公司

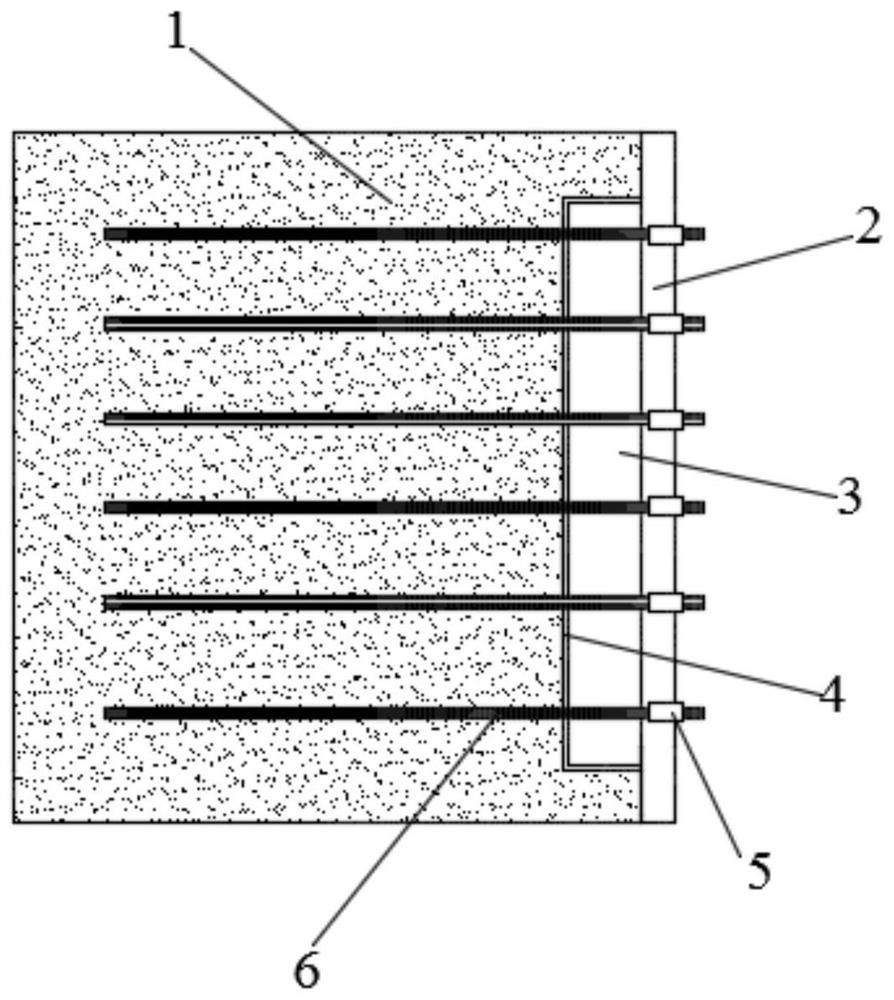

Geotechnical engineering foundation pit anti-collapse stable supporting structure

ActiveCN113957905AAvoid reliabilityAvoid uniformityExcavationsBulkheads/pilesCollapsed cavityArchitectural engineering

The invention discloses a geotechnical engineering foundation pit anti-collapse stable supporting structure. A supporting anchor rod of the geotechnical engineering foundation pit anti-collapse stable supporting structure sequentially penetrates through a supporting outer steel plate and supporting channel steel and then extends into the wall of a foundation pit, and a pre-tightening fixing head is arranged between the supporting anchor rod and the supporting outer steel plate. The pre-tightening fixing head can apply a pre-tightening force to the supporting anchor rod, so that the pre-tightening fixing head can be firstly used for pre-tightening a certain pre-tightening force, then an expanding agent is arranged in a concave cavity, the pre-tightening force of the supporting anchor rod is further increased through expansion of the expanding agent, and the pre-tightening force of anchoring is effectively improved. Meanwhile, damage to the pre-tightening fixing head or an anchor rod head caused by pre-tightening only through a pre-tightening tool is avoided, the pre-tightening force can be effectively improved, the pre-tightening effect is guaranteed, the supporting capacity is improved, and the loosening problem is prevented. According to the geotechnical engineering foundation pit anti-collapse stable supporting structure, the supporting channel steel and the outer supporting steel plate are adopted for supporting at the same time, and the supporting effect and stability are effectively improved.

Owner:ANHUI SCI & TECH UNIV

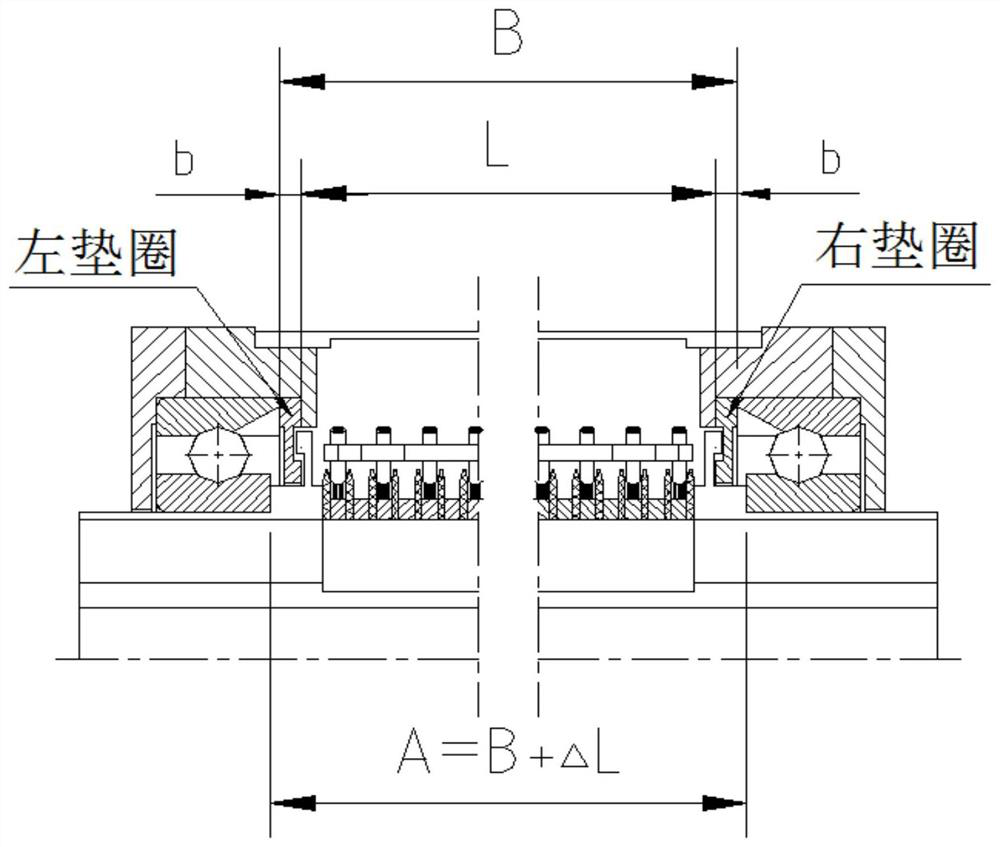

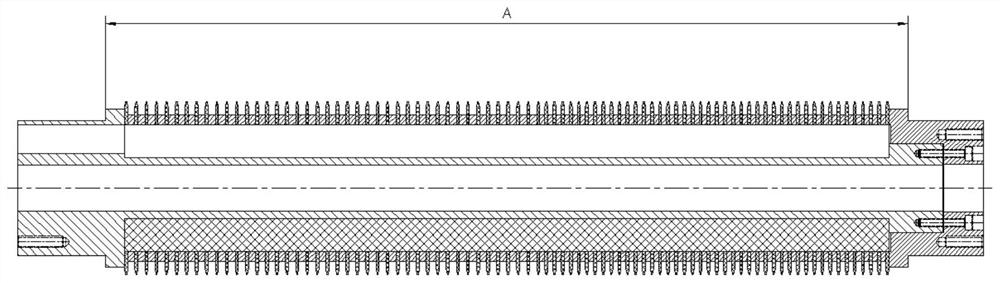

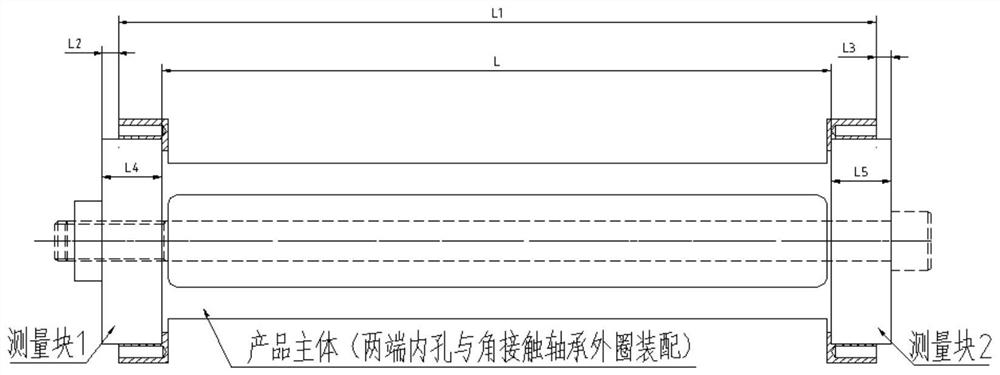

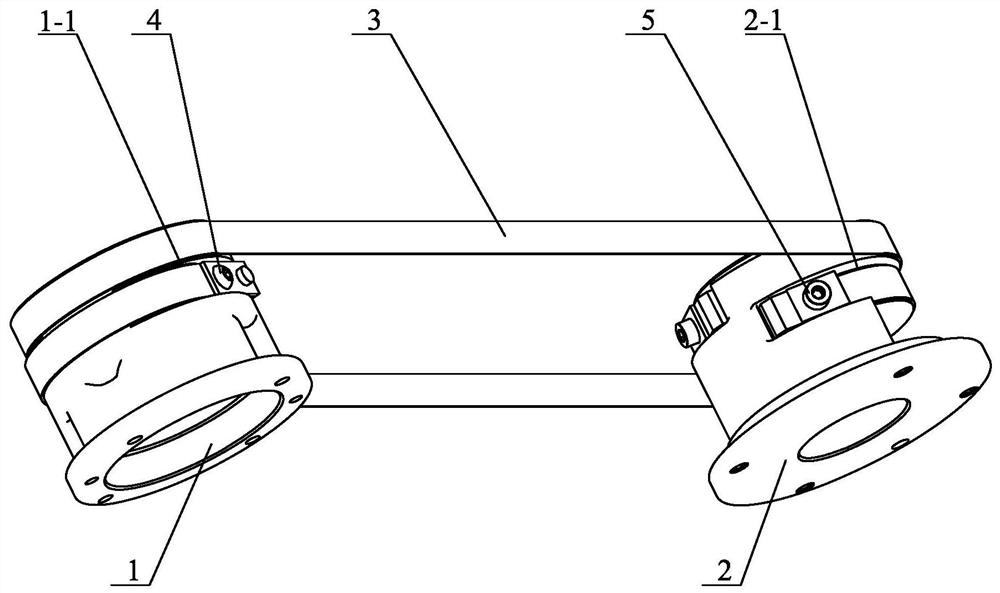

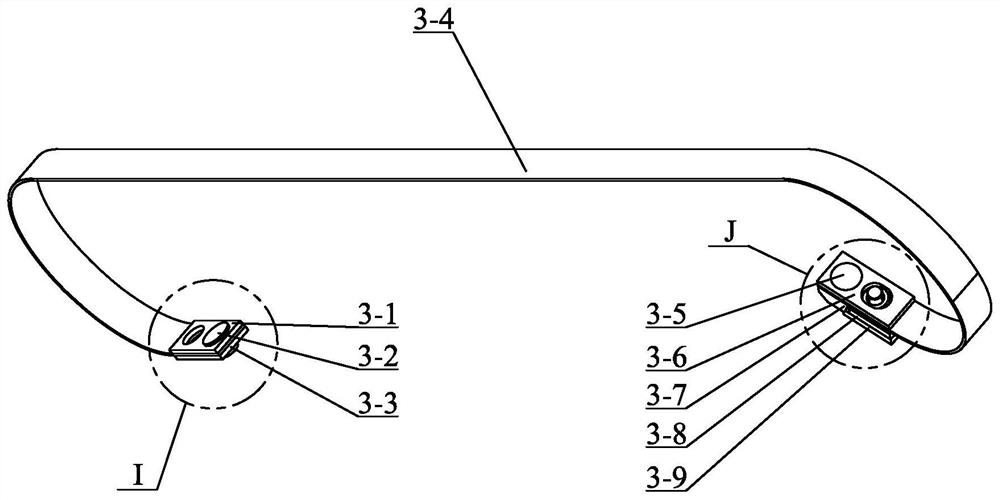

Angular contact bearing pre-tightening method

ActiveCN112879444APrecise relative movementGuaranteed preloadBearing unit rigid supportStructural engineeringDistance measurement

The invention relates to the technical field of bearing pre-tightening, in particular to an angular contact bearing pre-tightening method. The method comprises the following steps that the length of a bearing inner ring mounting position is measured; the left side end of an angular contact bearing is provided with a first measuring block, and the right side end of the angular contact bearing is provided with a second measuring block; the thickness of the first measuring block and the thickness of the second measuring block are measured through a measuring instrument; the first measuring block and the second measuring block are installed in a mounting bearing outer ring part main body, so that the mounting end face is tightly attached to the main body mounting bearing end face; the high-precision measuring instrument is used for measuring the distance between the opposite end faces of the first measuring block and the second measuring block, the distance between the outer side end face of the first measuring block and the left side end face of the main body as well as the distance between the outer side end face of the second measuring block and the right side end face of the main body; the distance L between the two end faces of the mounting bearing outer ring part main body is calculated; and the thickness of a gasket is calculated through the value L. By adoption of the method, the accurate size of the angular contact bearing adjusting gasket is obtained by arranging the measuring blocks, and it is guaranteed that the pre-tightening force of the angular contact bearing is achieved.

Owner:杭州全盛机电科技有限公司

A kind of steel belt pretensioning method

ActiveCN110878813BReduce volumeCompact structureProgramme-controlled manipulatorDriving beltsIndustrial roboticsMedical robotics

A steel belt pretensioning method relates to the technical field of robots. The invention aims to solve the problems that the existing robot steel strip pretensioning device is not compact in structure, large in size and unsuitable for multilayer steel strip pretensioning. The pretensioning device includes a steel belt pulley A, a steel belt pulley B, a steel belt assembly, a first fastening bolt and a second fastening bolt, and one end of the steel belt assembly is fixed on the outer surface of the steel belt pulley A through the first fastening bolt. On the peripheral side wall, the other end of the steel belt assembly is fixed on the outer peripheral side wall of the steel belt pulley B through the second fastening bolt. Pre-tightening method: pre-processing; assembling steel belt components; fixing steel belt components; pre-tightening steel belt components. The present invention is used in medical robots, industrial robots and the like.

Owner:杭州唯精医疗机器人有限公司

Safety belt retractor

A safety belt retractor is provided with a pre-tightening motor controlled by an electric control unit and a speed reducing mechanism connected between the pre-tightening motor and a reel unit. The speed reducing mechanism comprises a steering limiting mechanism which enables the pre-tightening motor to transmit forward rotation of the pre-tightening motor to the reel unit. The reel unit comprises a force limiting rod, the output end of the speed reducing mechanism is connected with the first end of the force limiting rod, and the reel unit obtains forward rotation torque transmitted by the speed reducing mechanism through the force limiting rod, so that pre-tightening of the retractor is achieved.

Owner:ZHEJIANG SONGYUAN AUTOMOTIVE SAFETY SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com