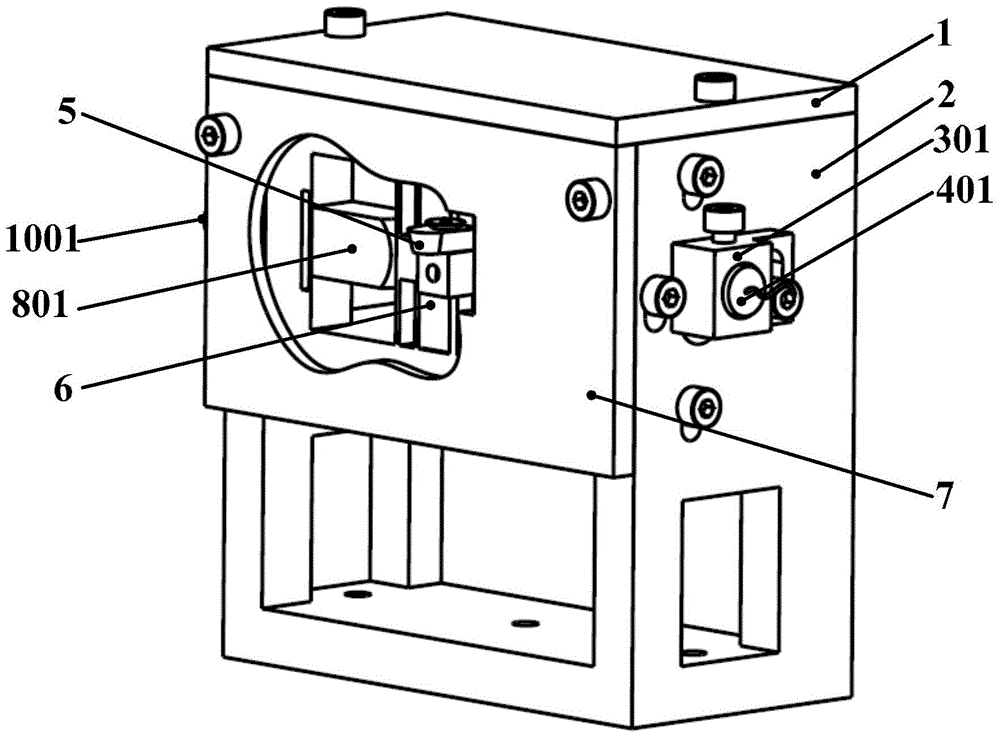

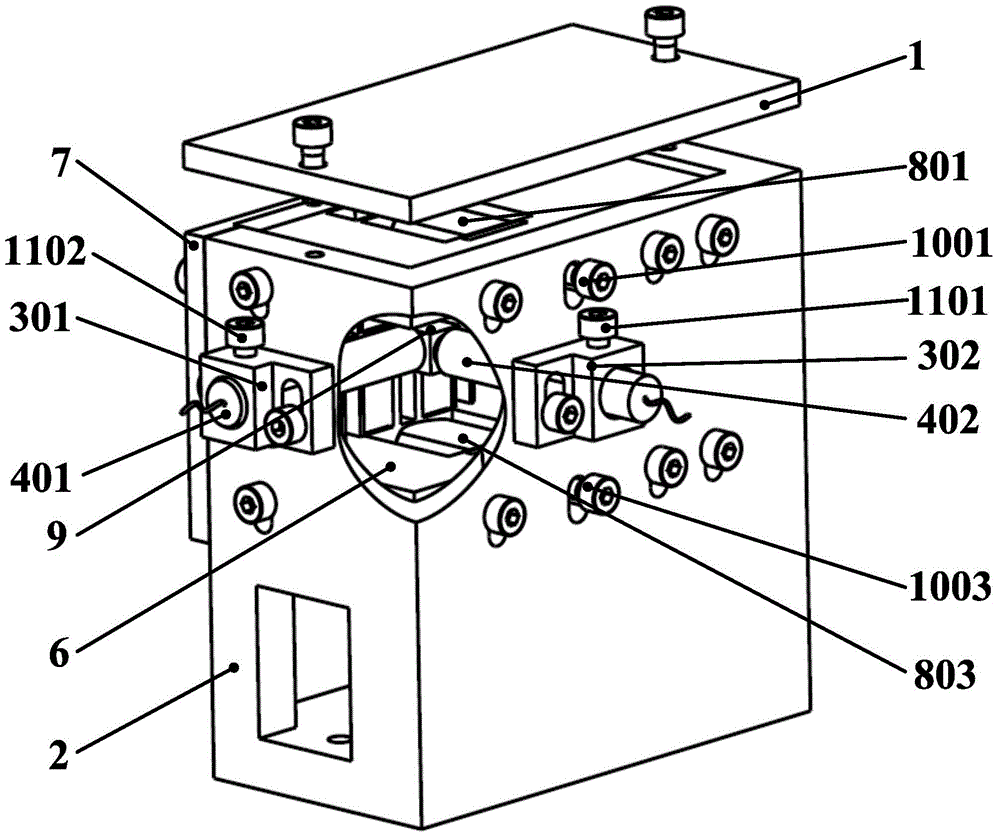

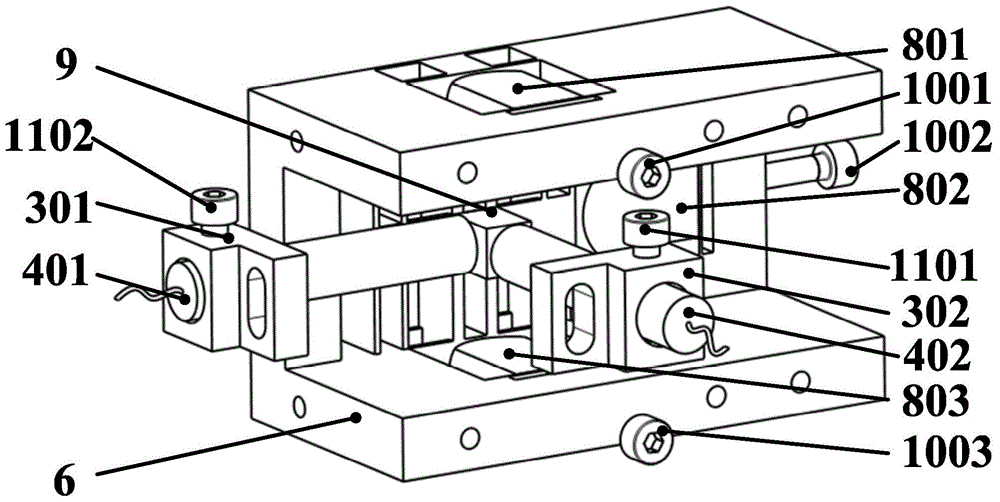

Quick cutter servo device with two decoupled shafts

A servo device and decoupling technology, applied in the field of optical curved surface parts and ultra-precision parts machining, can solve the problems of restricting application, unable to obtain decoupling motion, etc., to improve processing efficiency, reduce inertial mass, and increase working bandwidth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The diamond tool 5 is fixedly connected to the tool seat on the flexible hinge base 6 through fixing screws, and the flexible hinge base 6 is fixedly connected to the U-shaped groove on the base 2 through a set of fixing bolts. A cover plate 1 is installed above the base, and the base A front baffle 7 is installed on the front end of the X-axis piezoelectric stack 801, and the two ends of the X-axis piezoelectric stack 801 are respectively connected to the flexible hinge base 6 and the X-axis driving end 606. The X-axis piezoelectric stack 801 is connected to the The flexible hinge substrate is connected, and the Z-axis piezoelectric stack 1 802 and the Z-axis piezoelectric stack 2 803 are respectively connected with the flexible hinge substrate 6 and the Z-axis driving end 607, and are connected with the pre-tightening bolt 2 1002 and the pre-tightening bolt respectively. Three 1003 is connected with the flexible hinge substrate; the displacement detection block 9 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com