Structure and adjustment method of a horizontal electromagnetic control valve

A technology of an electromagnetic control valve and an adjustment method, applied in the field of power machinery, can solve the problems of unfavorable working reliability of high-pressure sealing parts of the electromagnetic control valve, affecting the convenience of adjustment of the electromagnetic control valve, inconvenient adjustment of the stroke of the control valve core, etc. The effect of small cross-section change, favorable adjustment and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

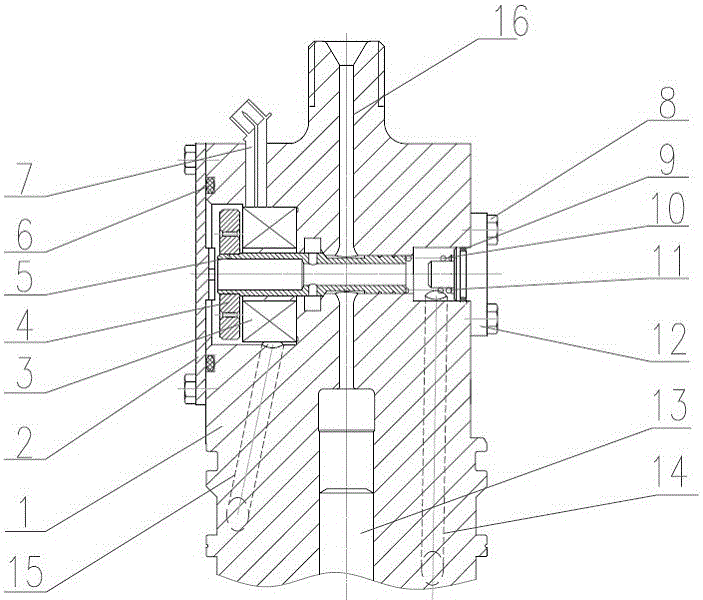

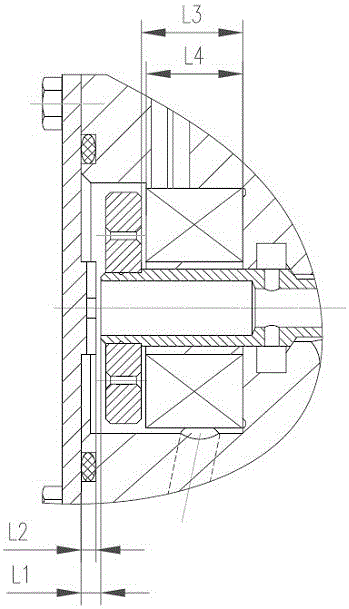

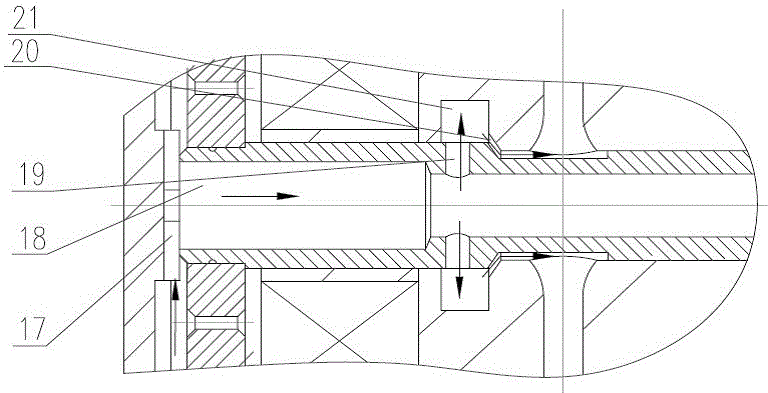

[0045] The working process of the present invention will be further described below in conjunction with the accompanying drawings.

[0046]A horizontal electromagnetic control valve structure, including a valve seat, a stroke adjustment block for adjusting the stroke of the control valve core, an electromagnet, an armature, a control valve core, an end face sealing ring, an electromagnet terminal, a compression screw, and a groove seal ring, return spring, adjusting gasket, spring seat, among them, the electromagnet is a circular or square structure; the armature is a circular or square structure matched with the electromagnet, and is provided with a hole to reduce resistance; The internal hollow structure connects the low-pressure oil chambers on both sides of the valve seat; the electromagnet coated with holding glue on the periphery is connected with the inner side of the valve seat by interference press fitting; Iron connection; the armature coated with retaining glue on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com