Patents

Literature

1313results about How to "Improves sealing reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

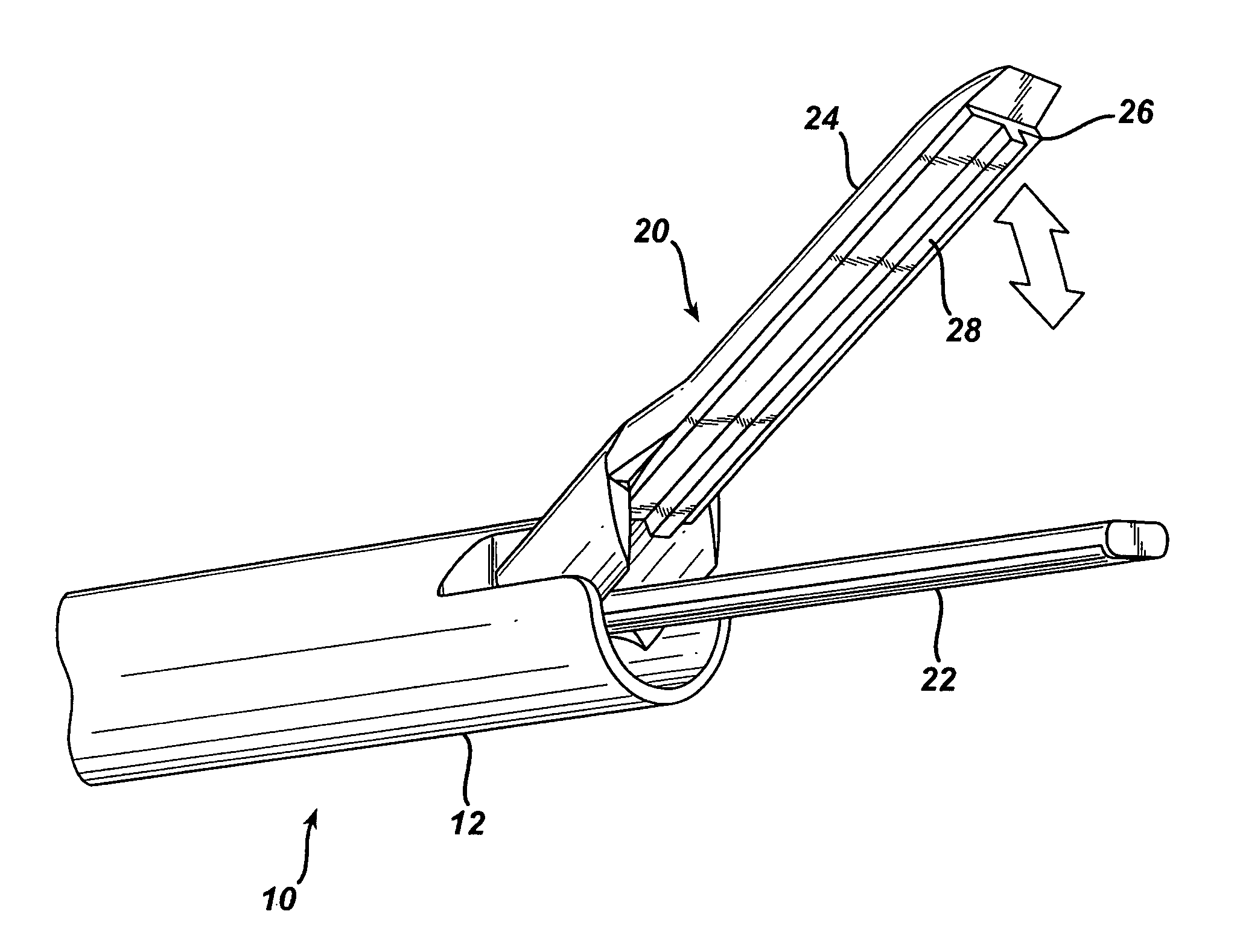

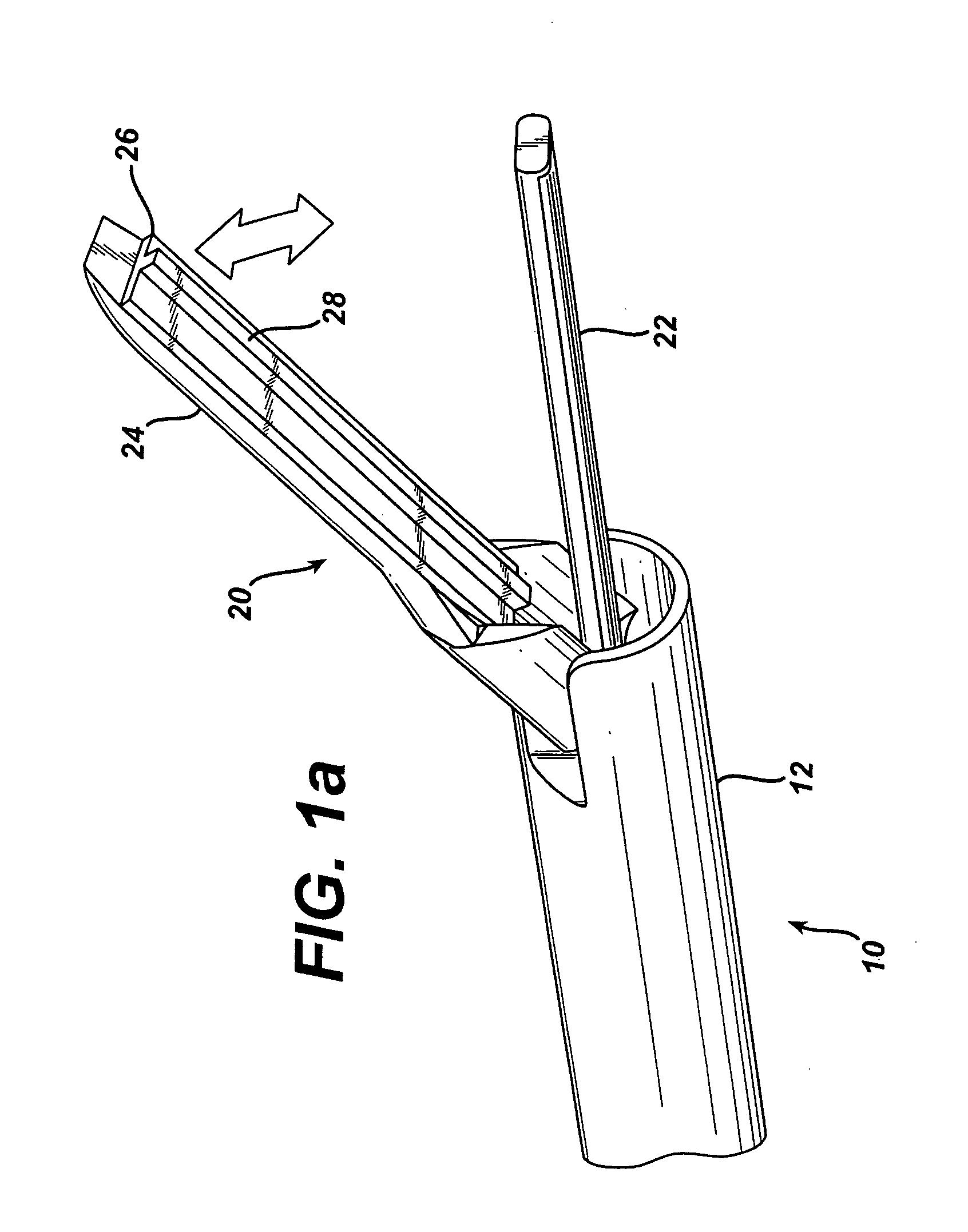

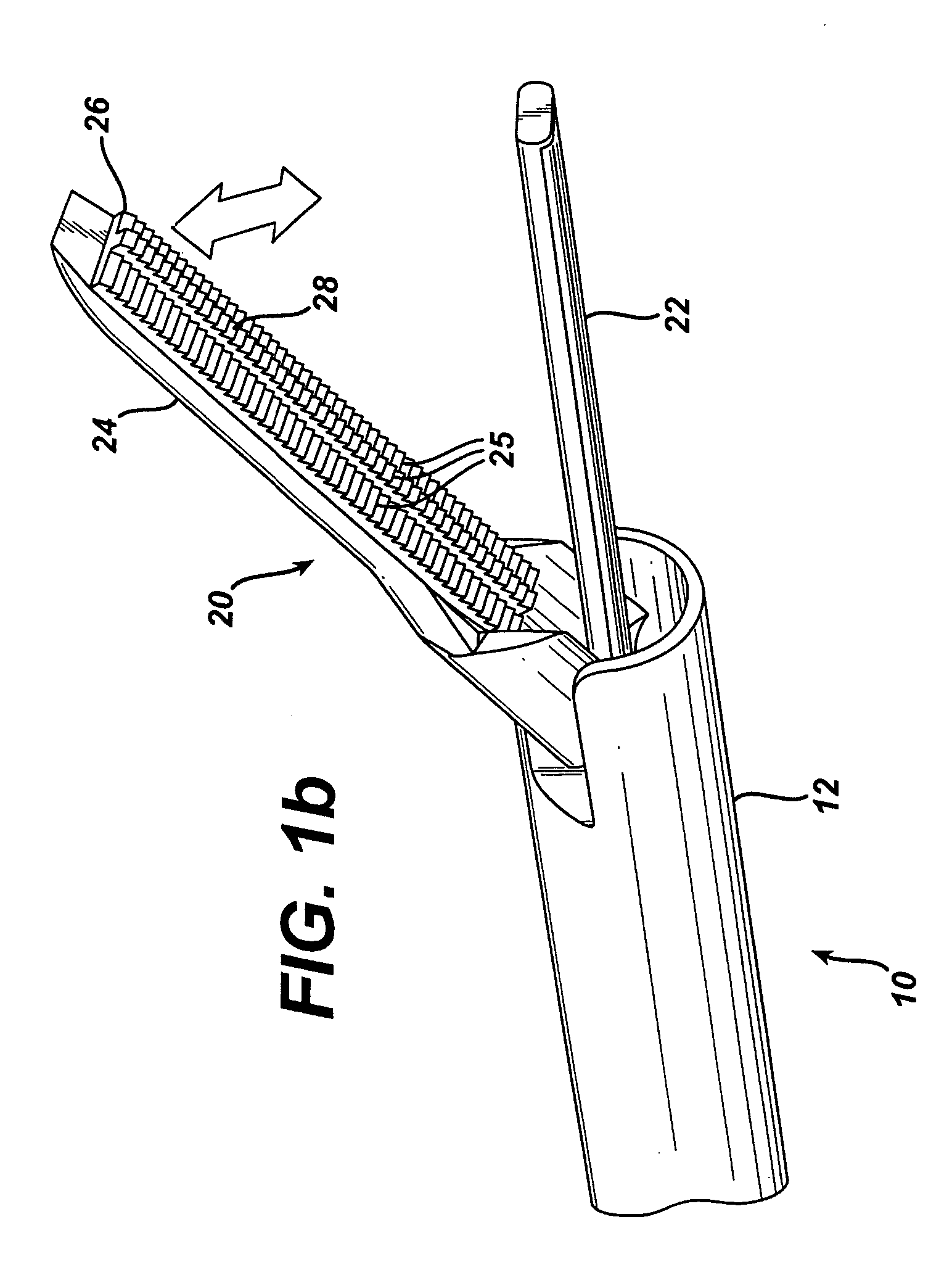

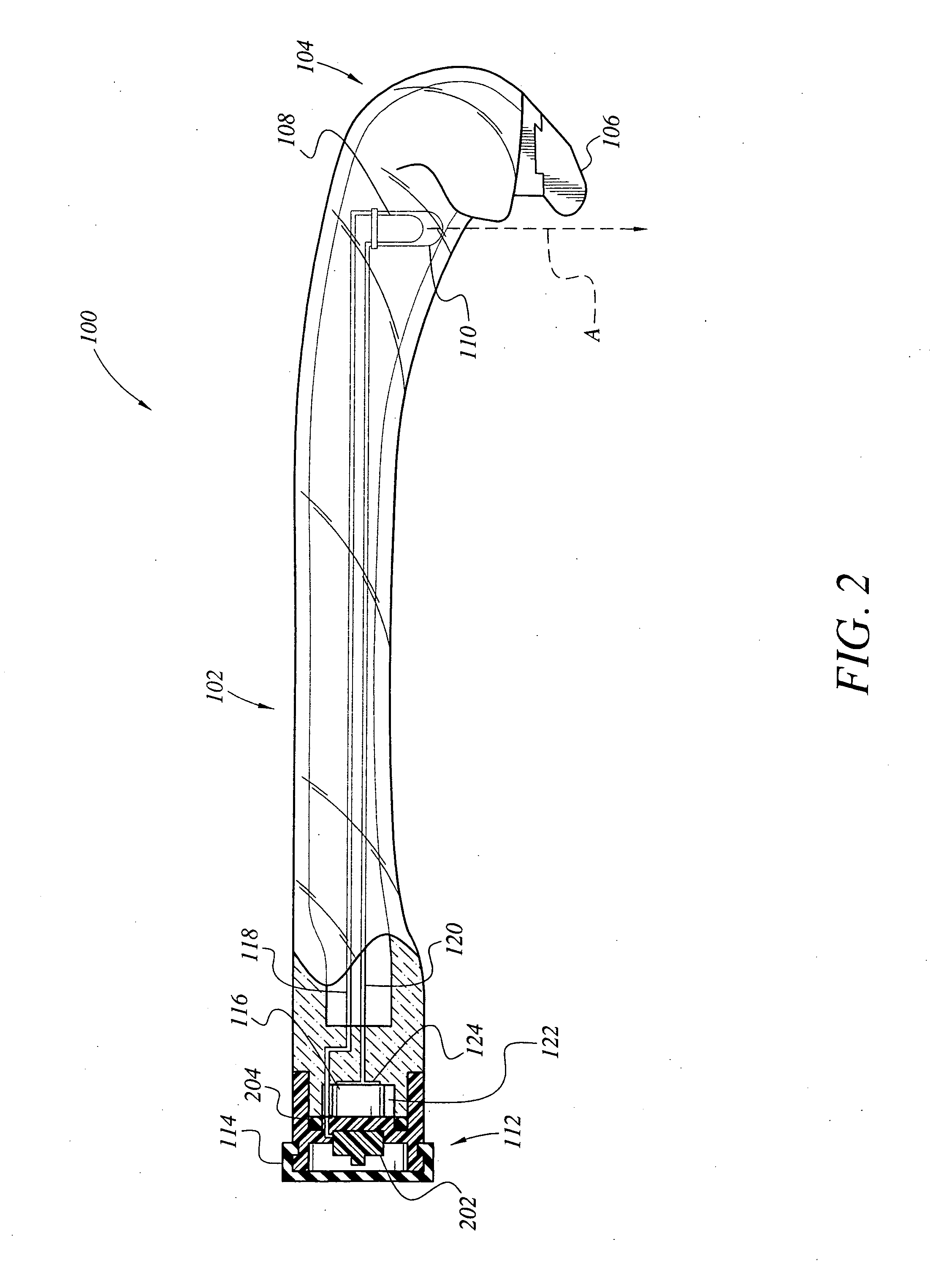

Ultrasonic clamp coagulator apparatus having an improved clamping end-effector

InactiveUS20060030848A1Reduce coagulationReduce the amount of controlPhysical therapySurgical instrument detailsSurgical ClampsActuator

An ultrasonic surgical clamp coagulator apparatus is configured to effect cutting, coagulation and clamping of tissue by cooperation of a clamping mechanism of the apparatus with an associated ultrasonic end-effector. The clamping mechanism includes a pivotal clamp arm, which cooperates with the end-effector for gripping tissue. The clamp arm is provided with a clamp tissue pad that has at least one raised portion to achieve the desired cutting and coagulation effect on the tissue.

Owner:CRAIG H WAYNE +7

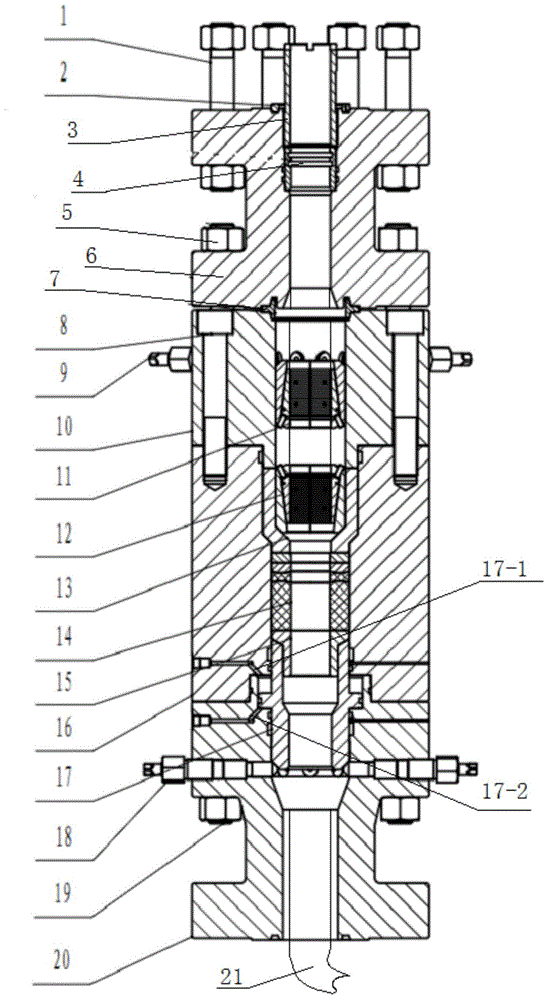

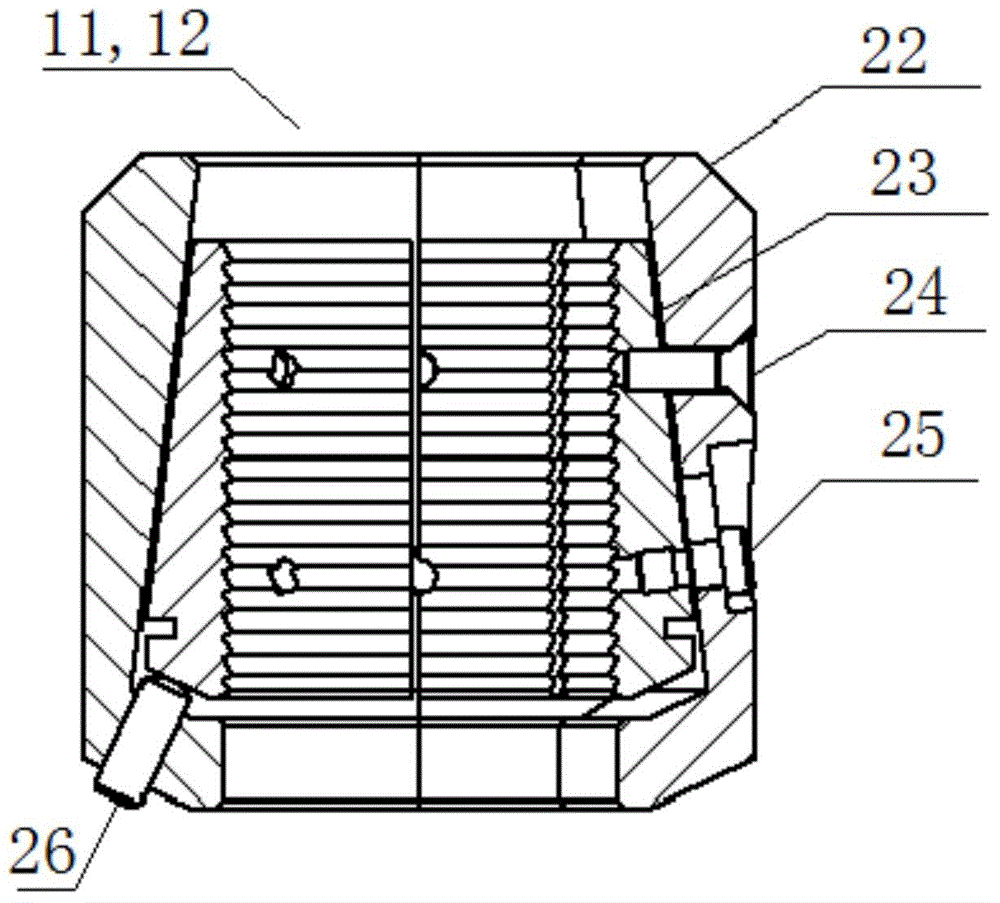

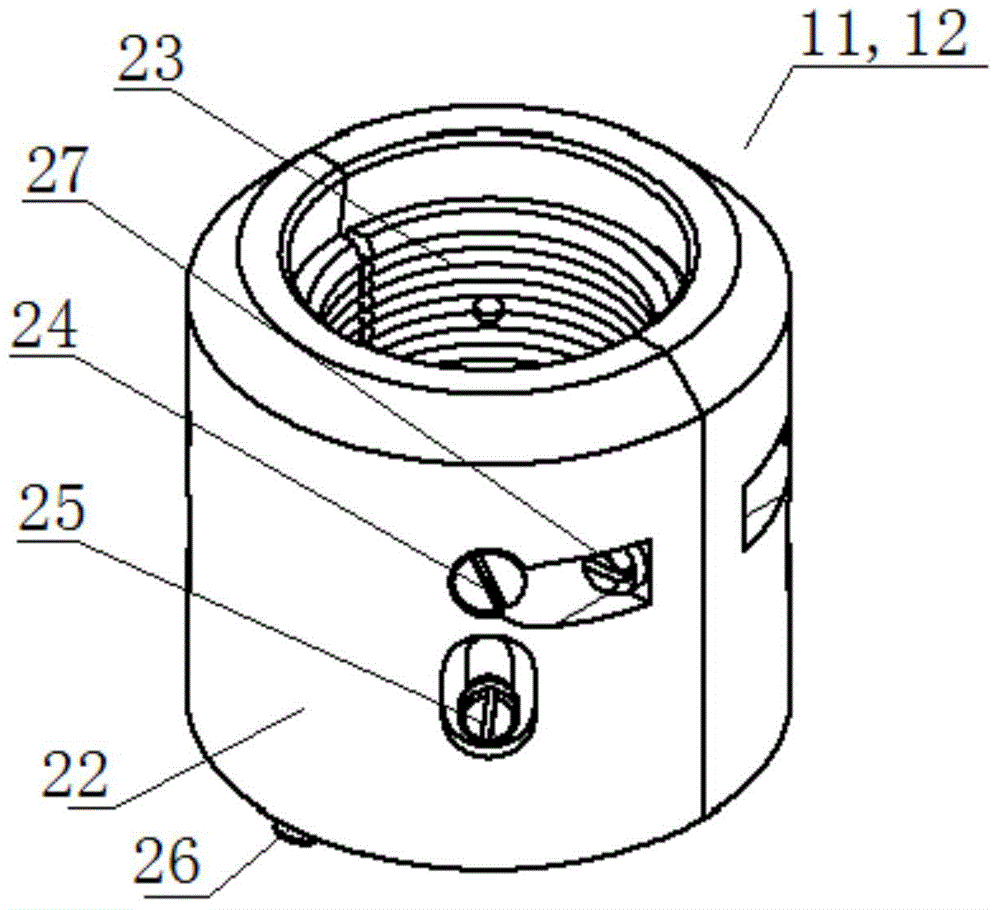

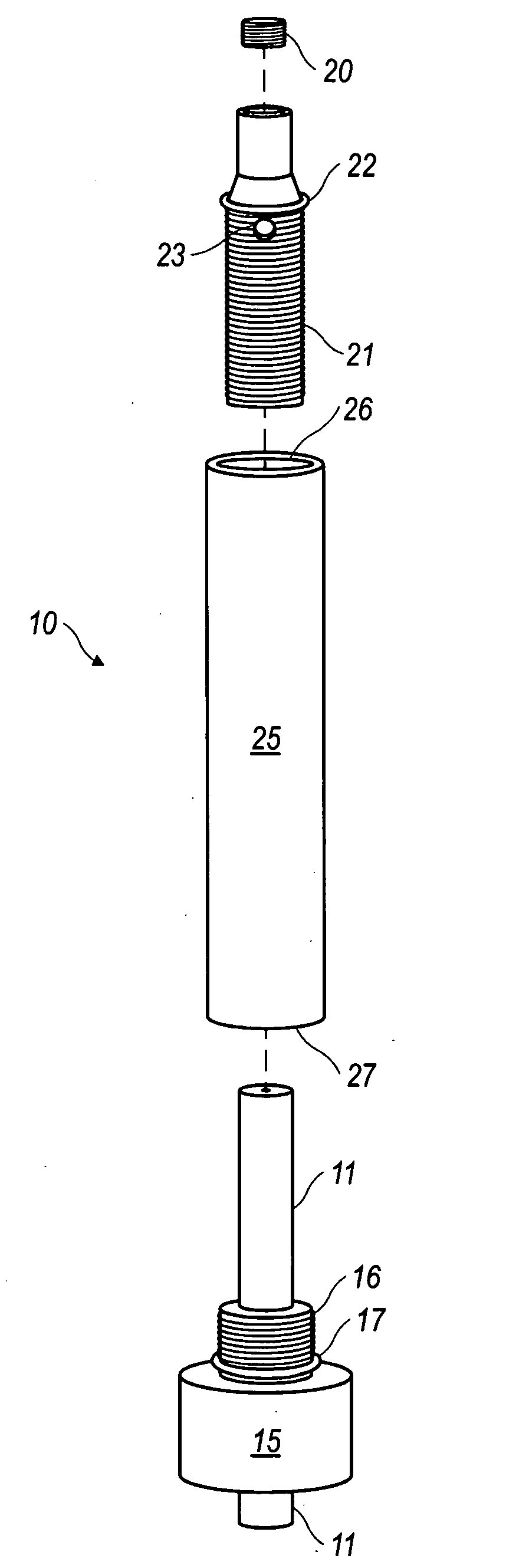

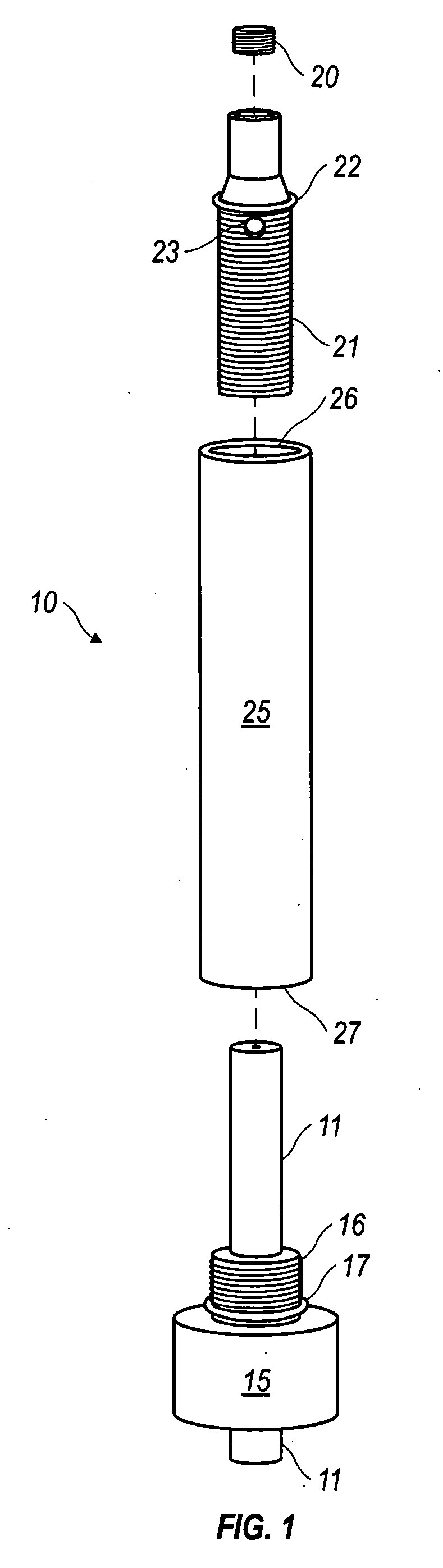

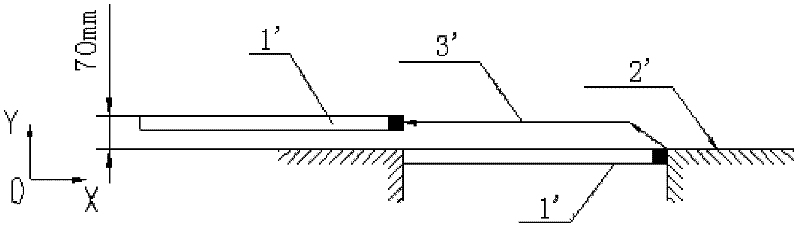

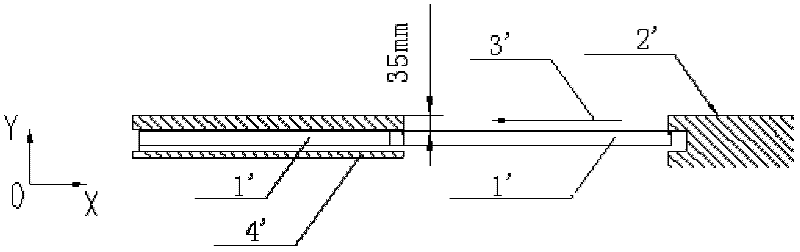

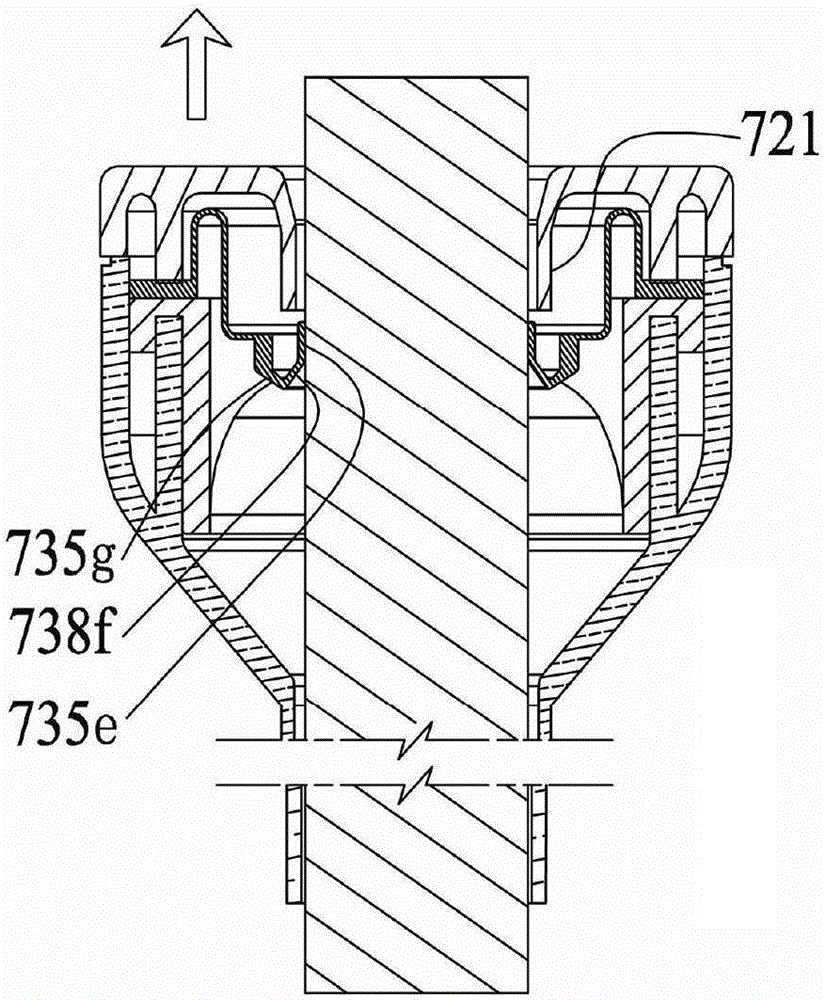

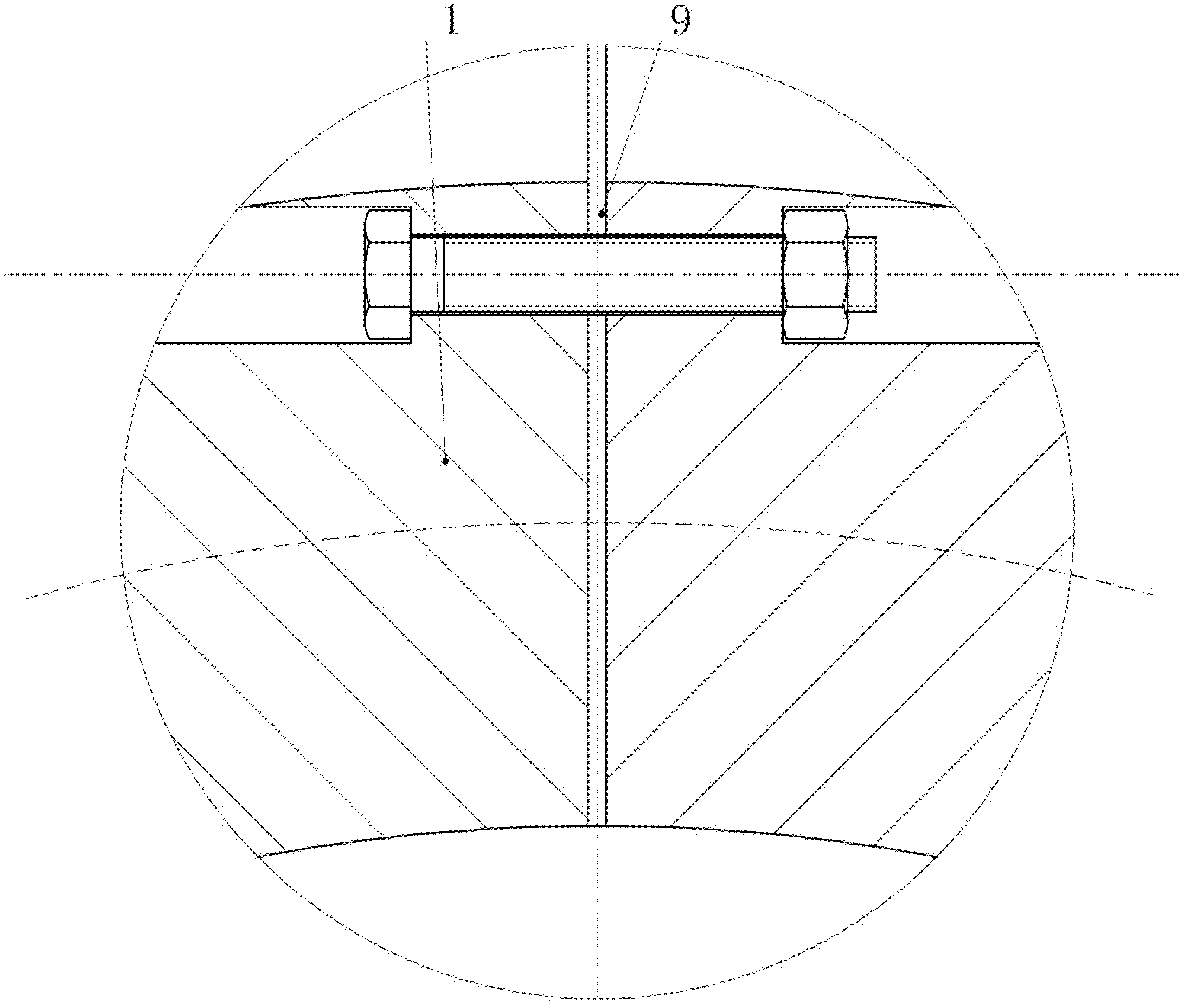

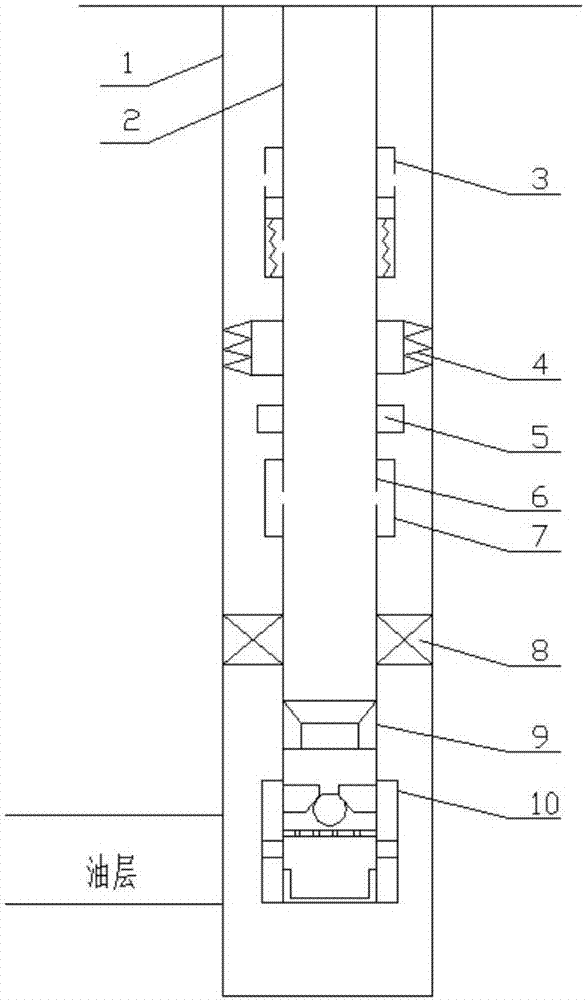

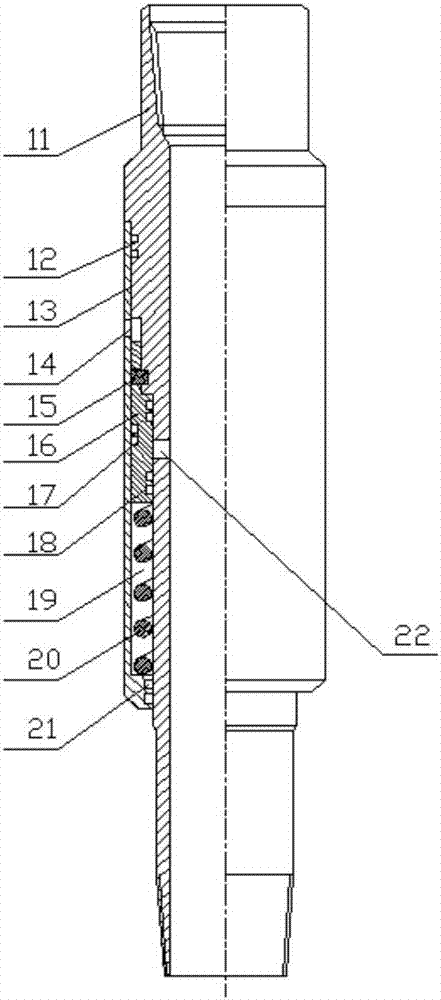

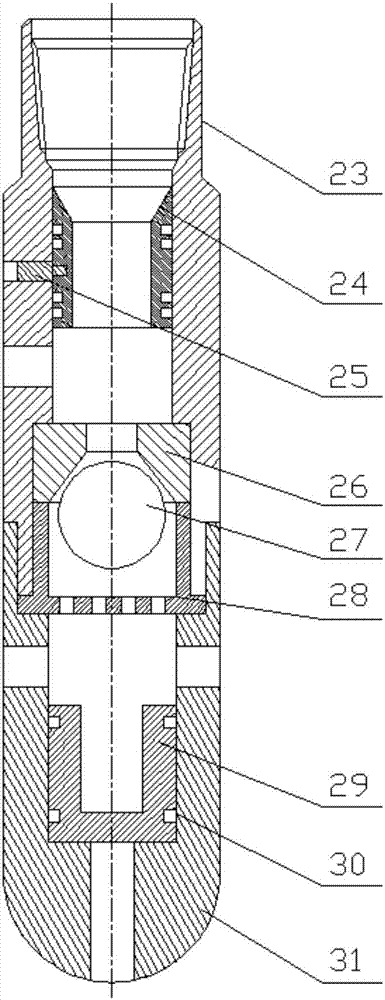

Continuous oil pipe hanger for velocity tubular column

ActiveCN104358536AGuaranteed sealing performanceFix the leakBorehole/well accessoriesCoiled tubingEngineering

The invention relates to a continuous oil pipe hanger for a velocity tubular column. The continuous oil pipe hanger comprises a continuous oil pipe, an I-shaped flange, an upper slip assembly, a lower slip assembly, an upper shell, a middle shell and a lower shell, wherein vertically penetrating central holes are formed in the upper shell, the middle shell and the lower shell; the I-shaped flange is fixedly arranged at the top of the upper shell; the continuous oil pipe passes through the I-shaped flange and the central holes of the upper shell, the middle shell and the lower shell in turn; the upper slip assembly is clamped on an inner wall of the central hole of the upper shell; the lower slip assembly is located in the central hole of the middle shell; a connecting pipe sealing set is fixedly arranged on an inner wall of the central hole of the middle shell and the lower side of a hanging supporting sleeve; at least one pair of driving pistons is arranged on the inner walls of the central holes of the middle shell and the lower shell and under the connecting pipe sealing set; an upper oil port and a lower oil port respectively communicated with the driving pistons are arranged on the side walls of the middle shell and the lower shell. The continuous oil pipe hanger has the beneficial effect of capability of hanging the continuous oil pipe.

Owner:JEREH ENERGY SERVICES

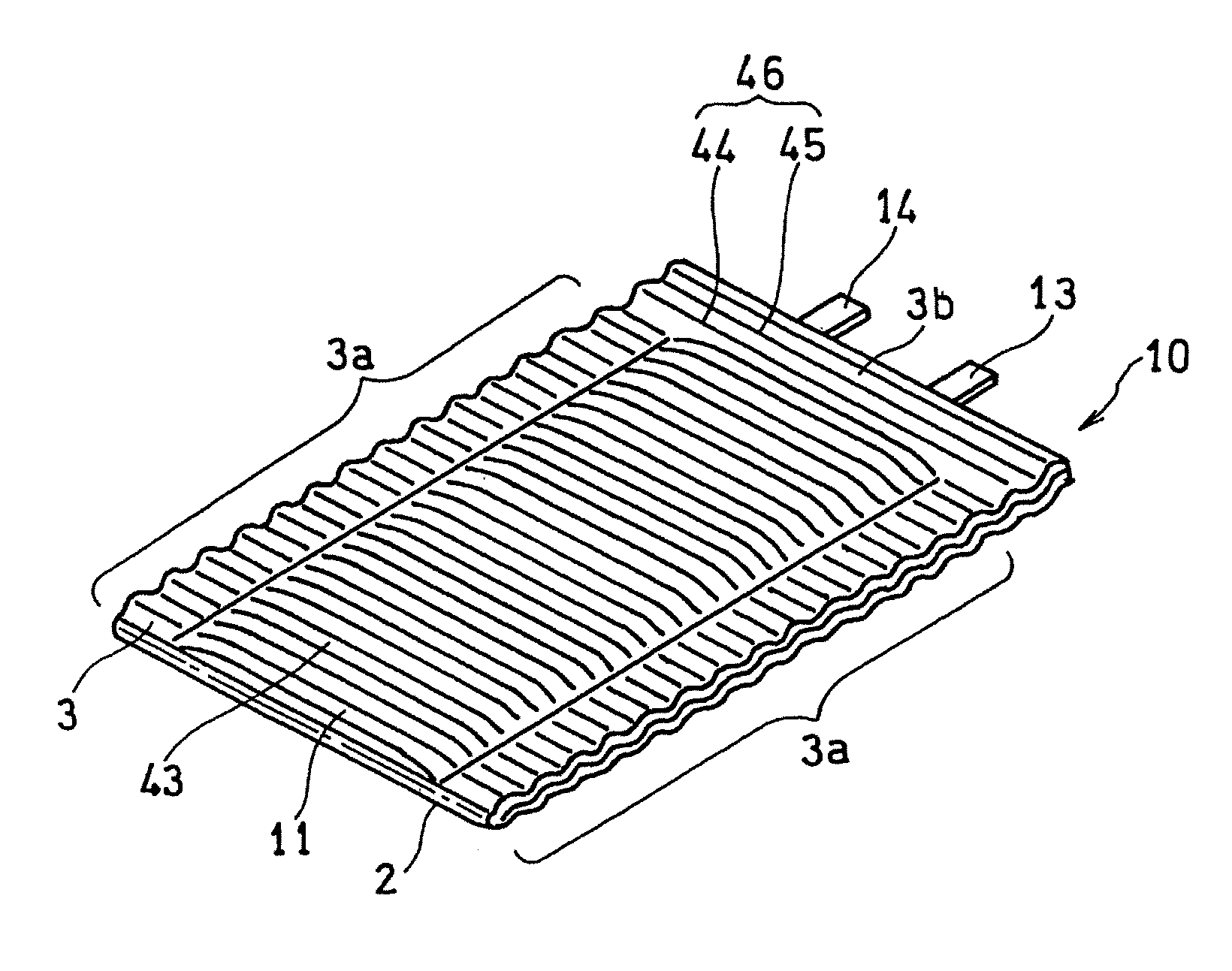

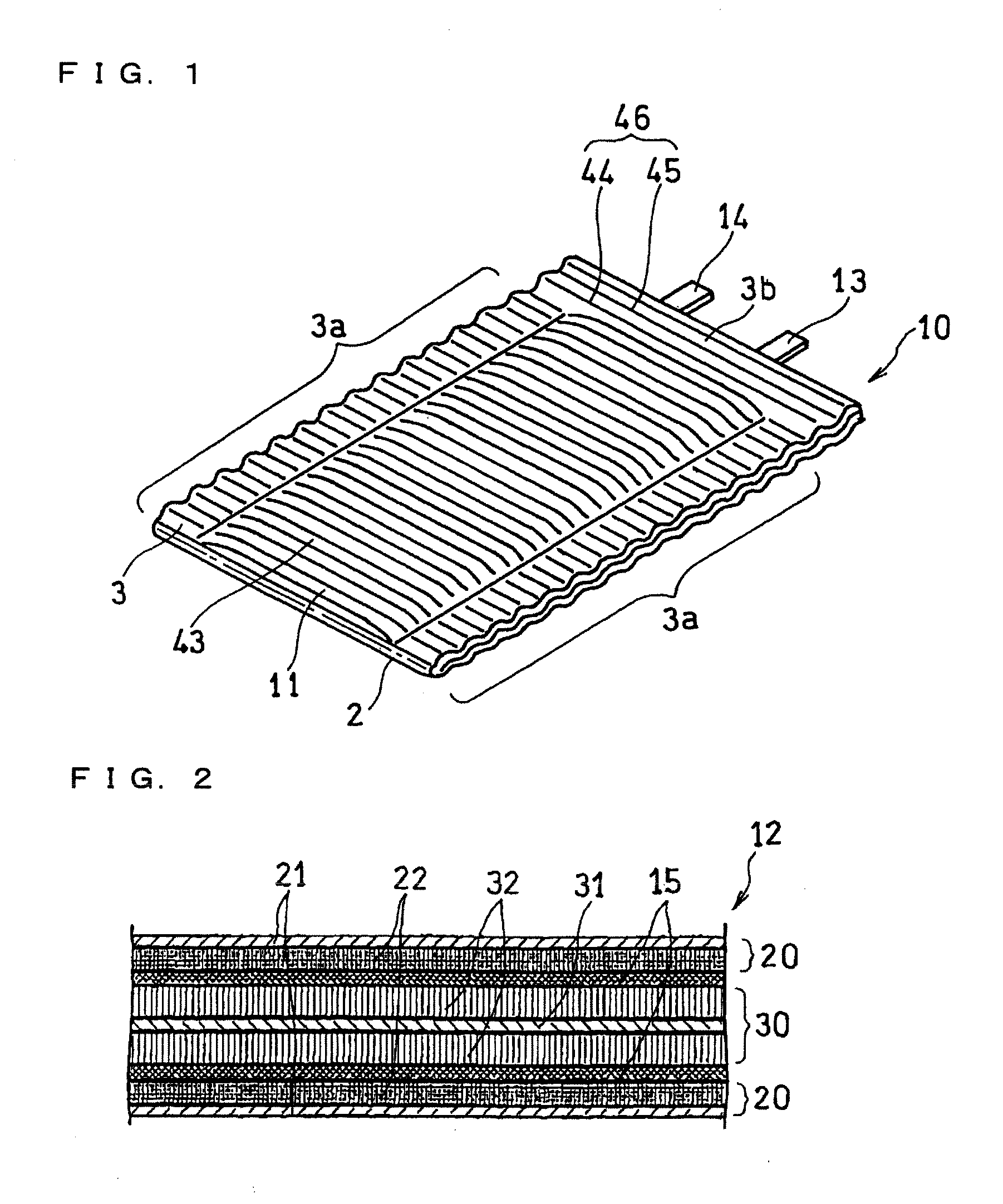

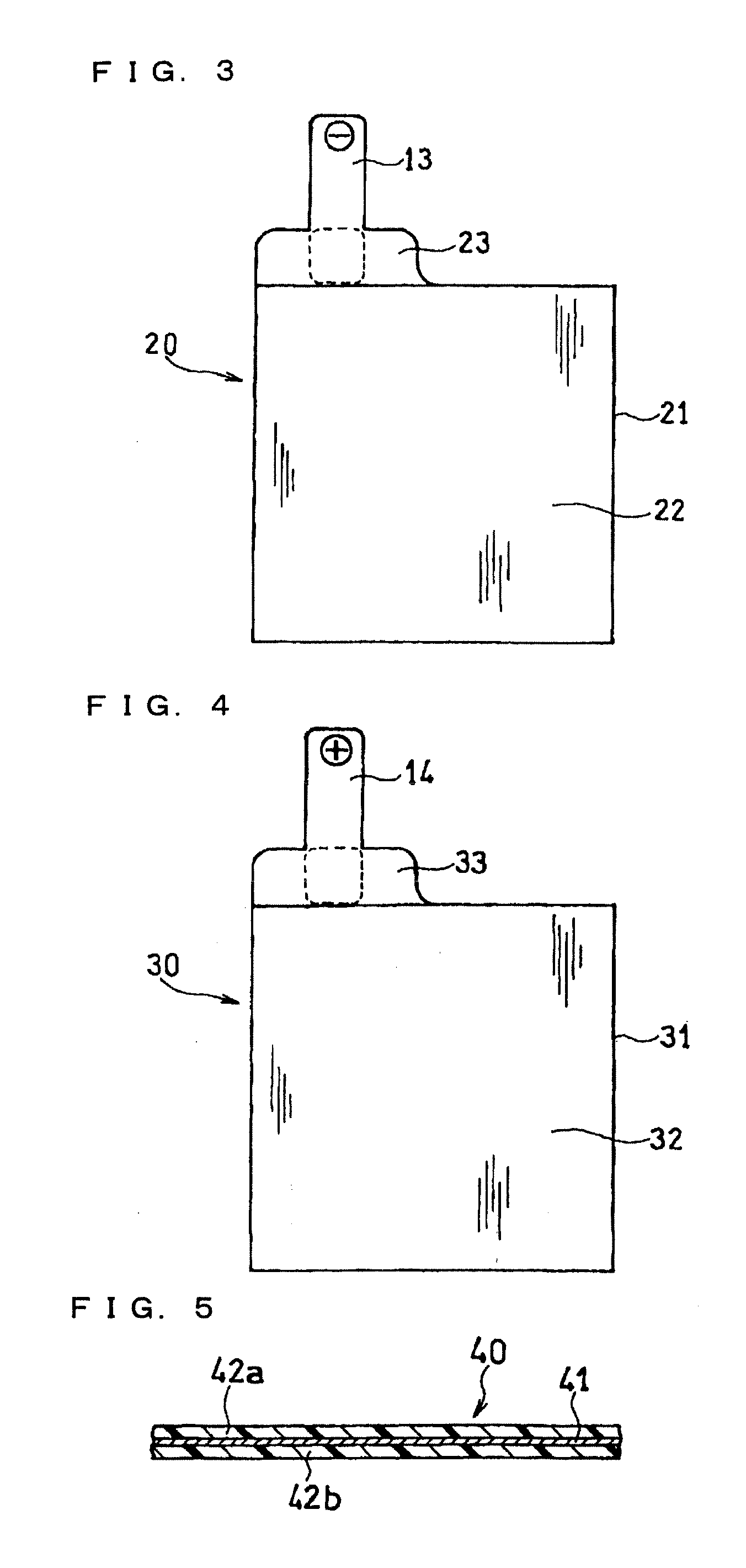

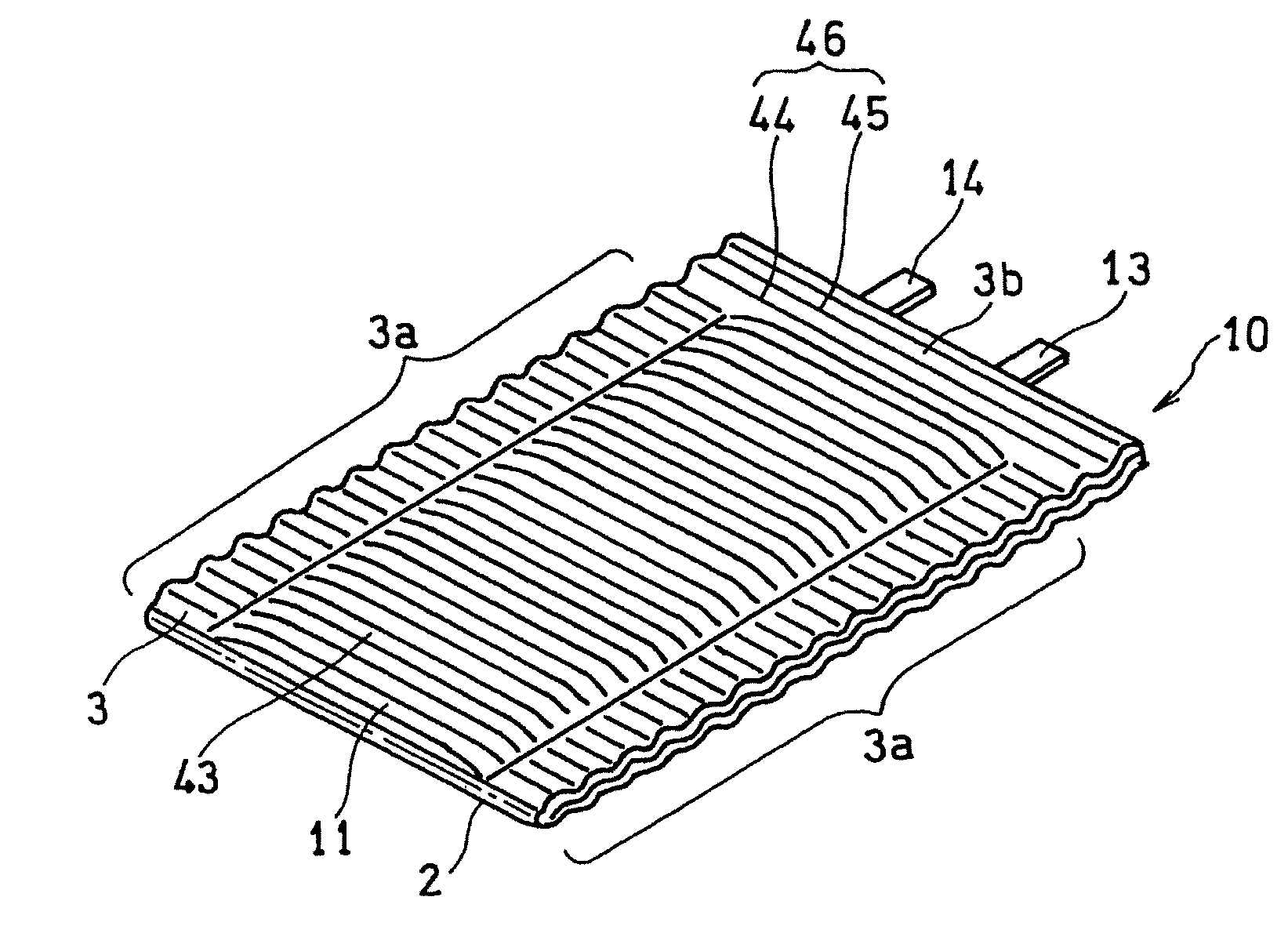

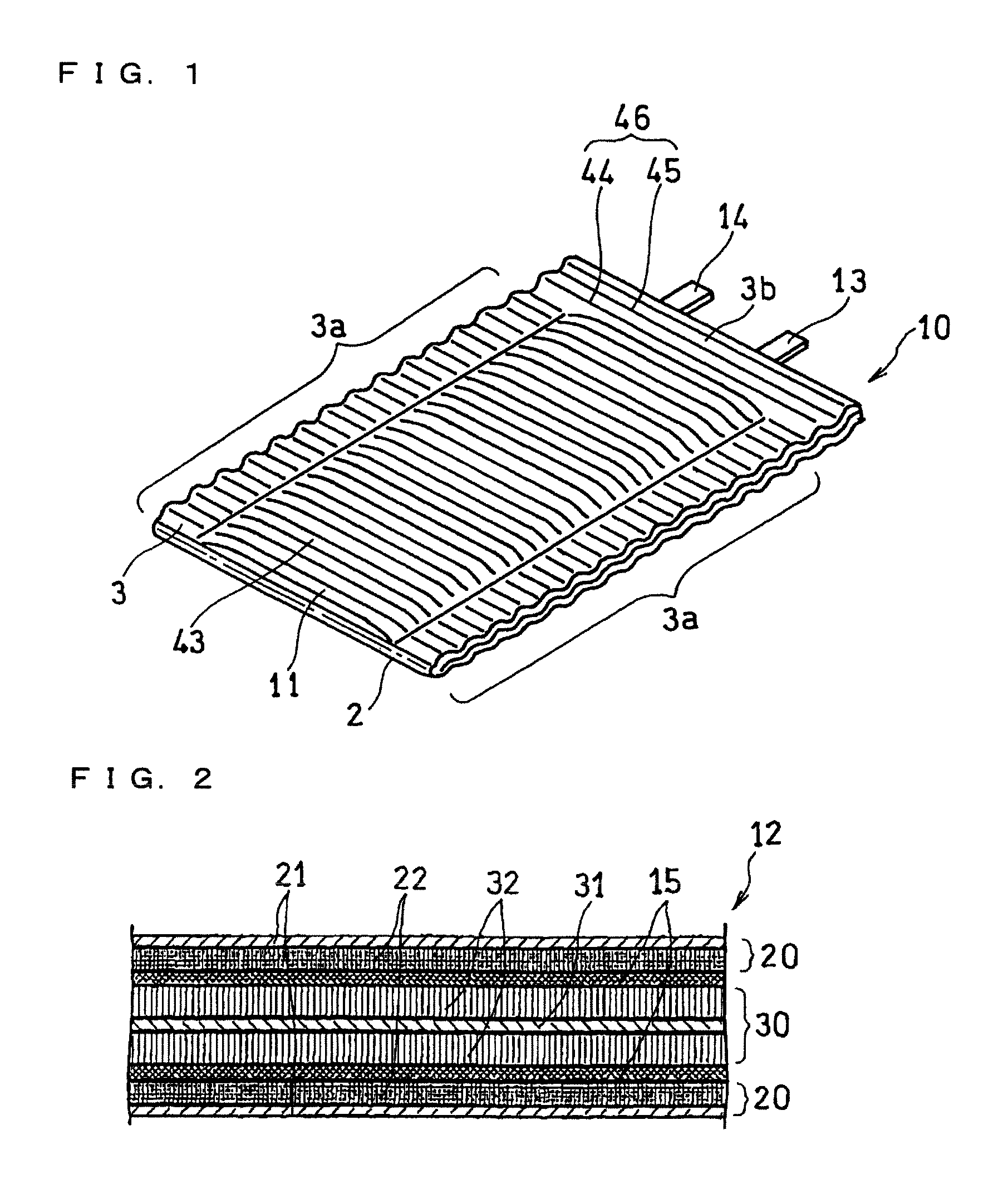

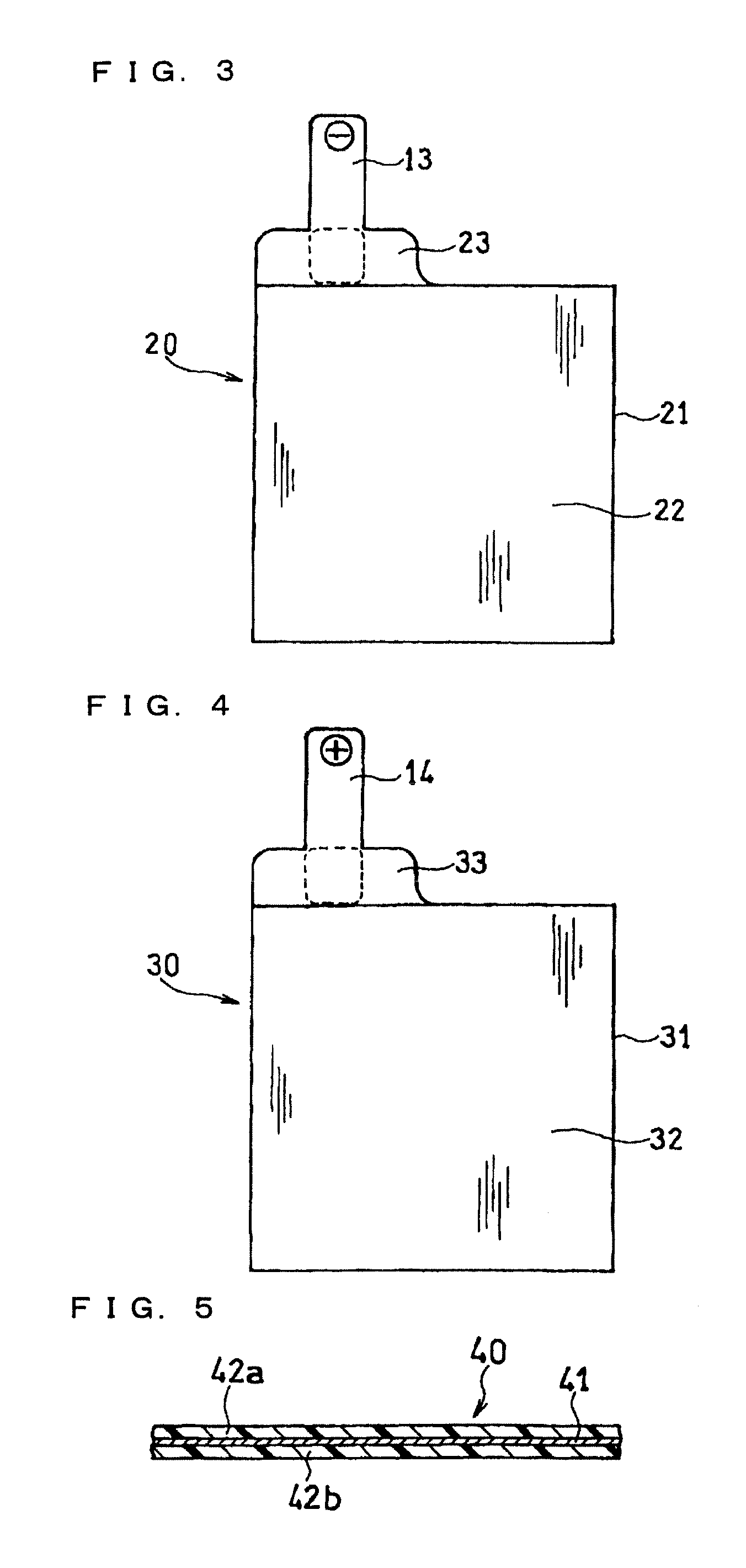

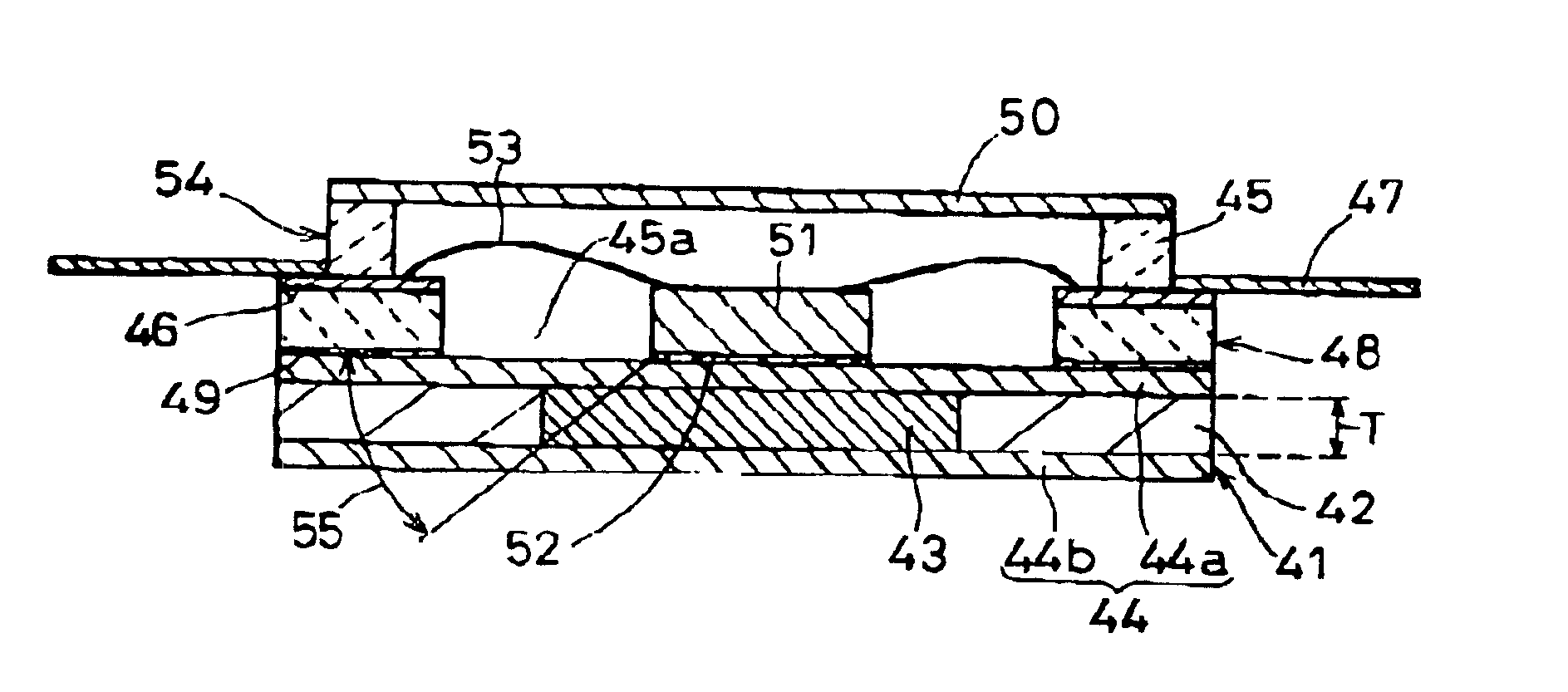

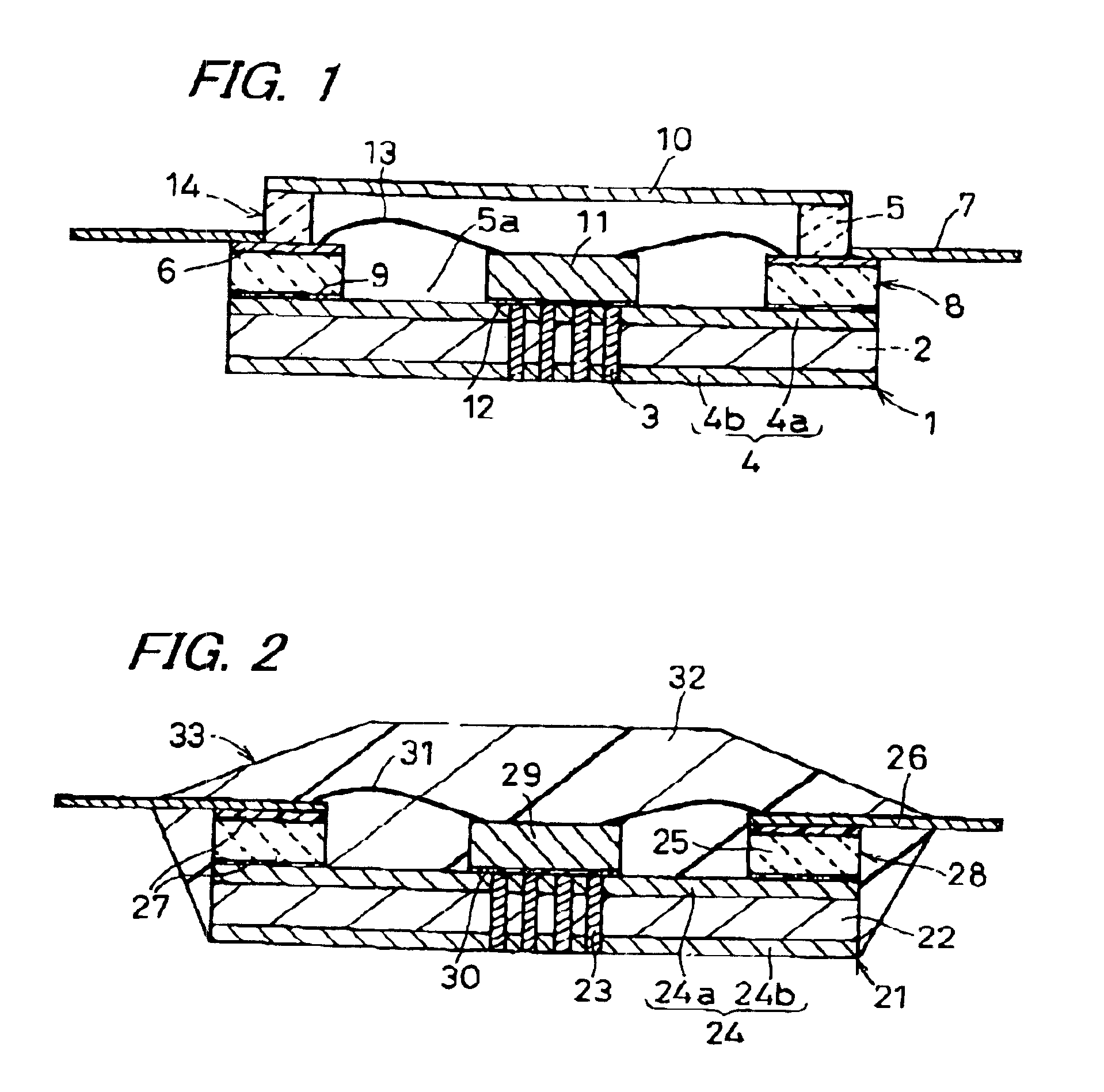

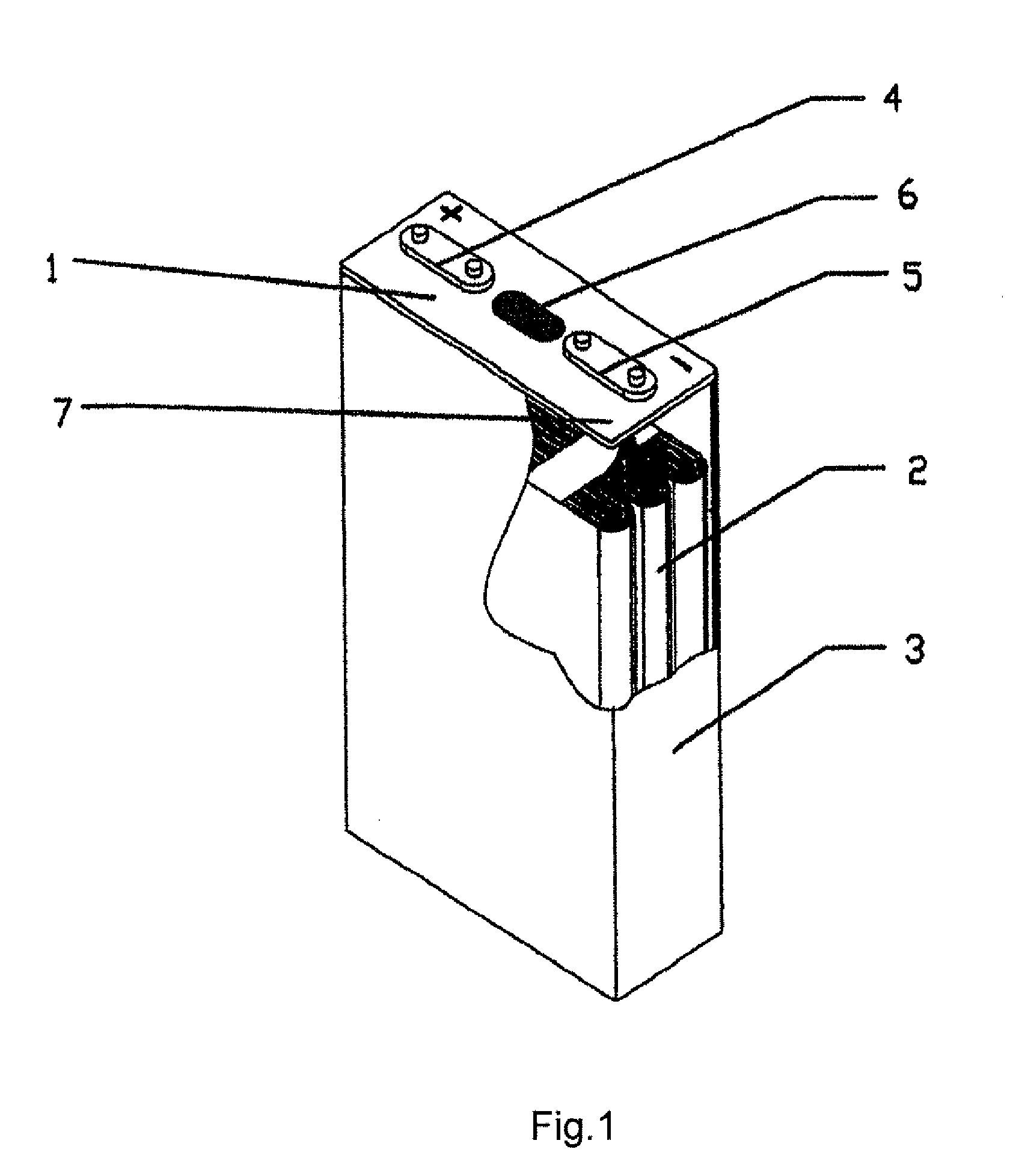

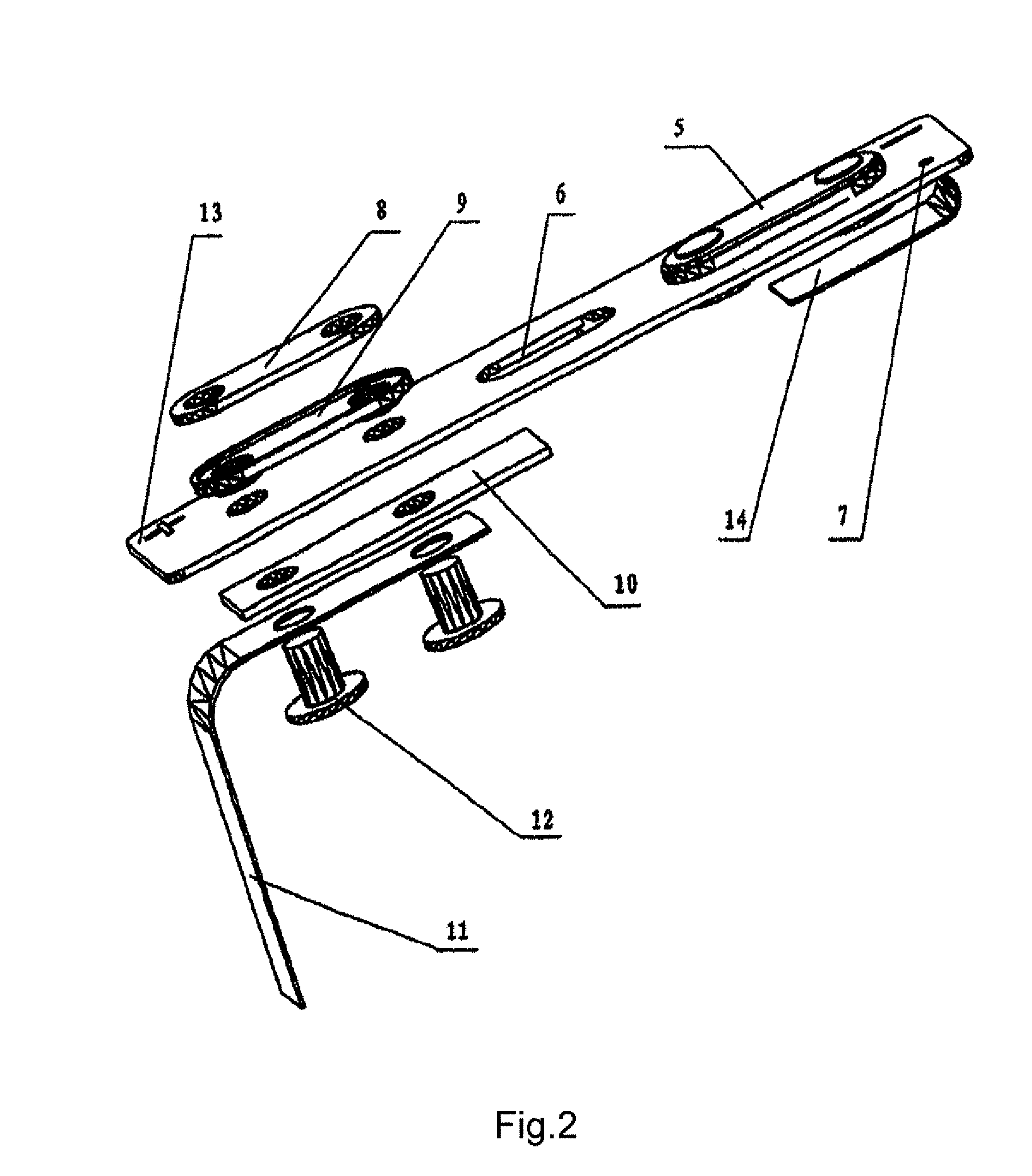

Flexible battery and method for producing the same

InactiveUS20130101884A1Impart high flexibilityImproves sealing reliabilityFinal product manufactureSmall-sized cells cases/jacketsEngineeringFlexible battery

Disclosed is a flexible battery including a sheet-like electrode group, an electrolyte, and a housing with flexibility enclosing the electrode group and electrolyte. The housing includes a film material folded into two in which the electrode group is inserted. The film material has two facing portions respectively facing two principal surfaces of the electrode group, a fold line which is between the two facing portions and along which the film material is folded, and two bonding margins respectively set around the two facing portions. The two bonding margins are bonded to each other into a bonded portion. At least the two facing portions of the film material are formed in a corrugated shape having a plurality of ridge and valley lines arranged in parallel to each other. The ridge lines in one of the two facing portions are overlapped with the valley lines in the other. The fold line is parallel to the ridge and valley lines.

Owner:PANASONIC CORP

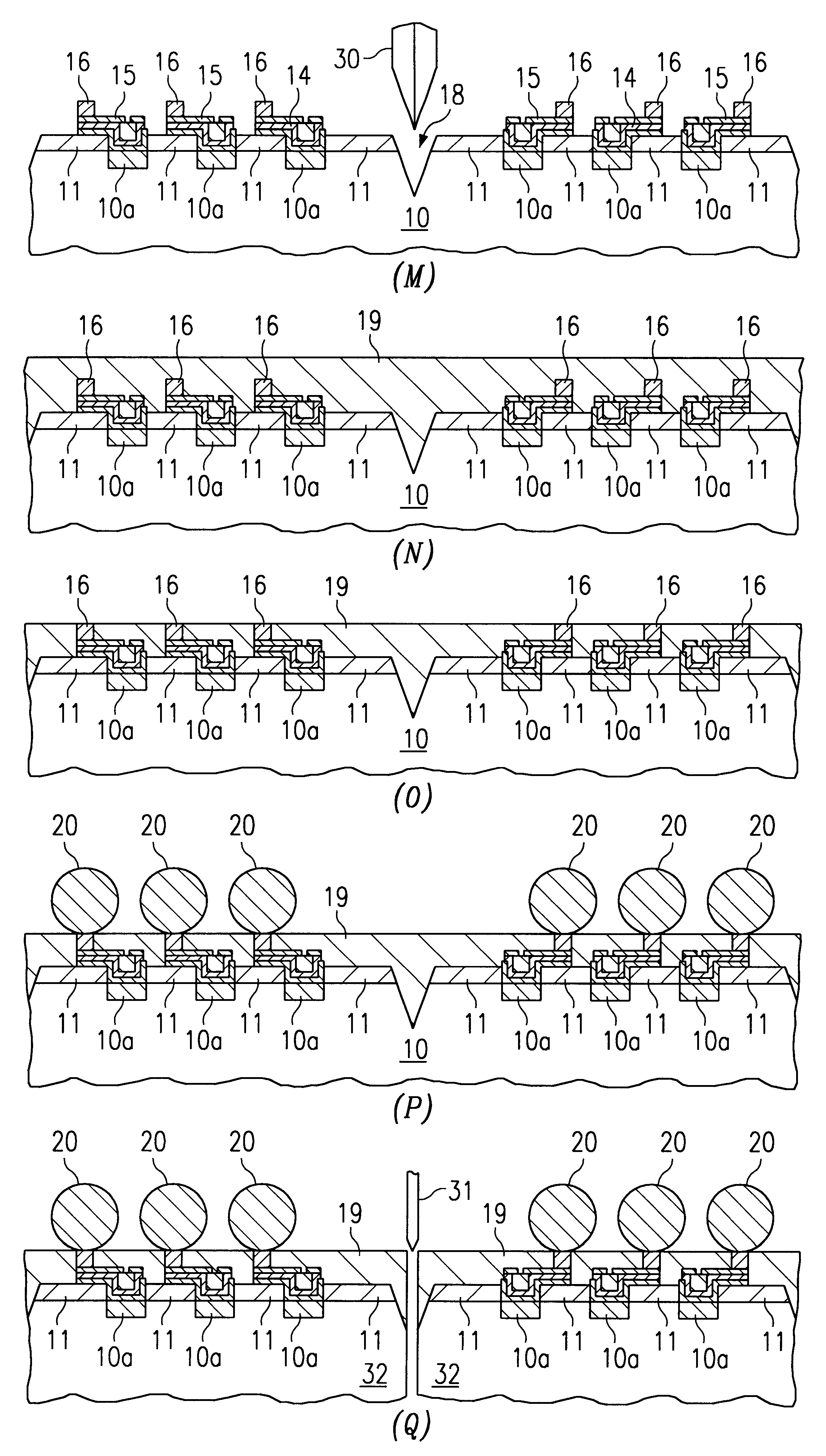

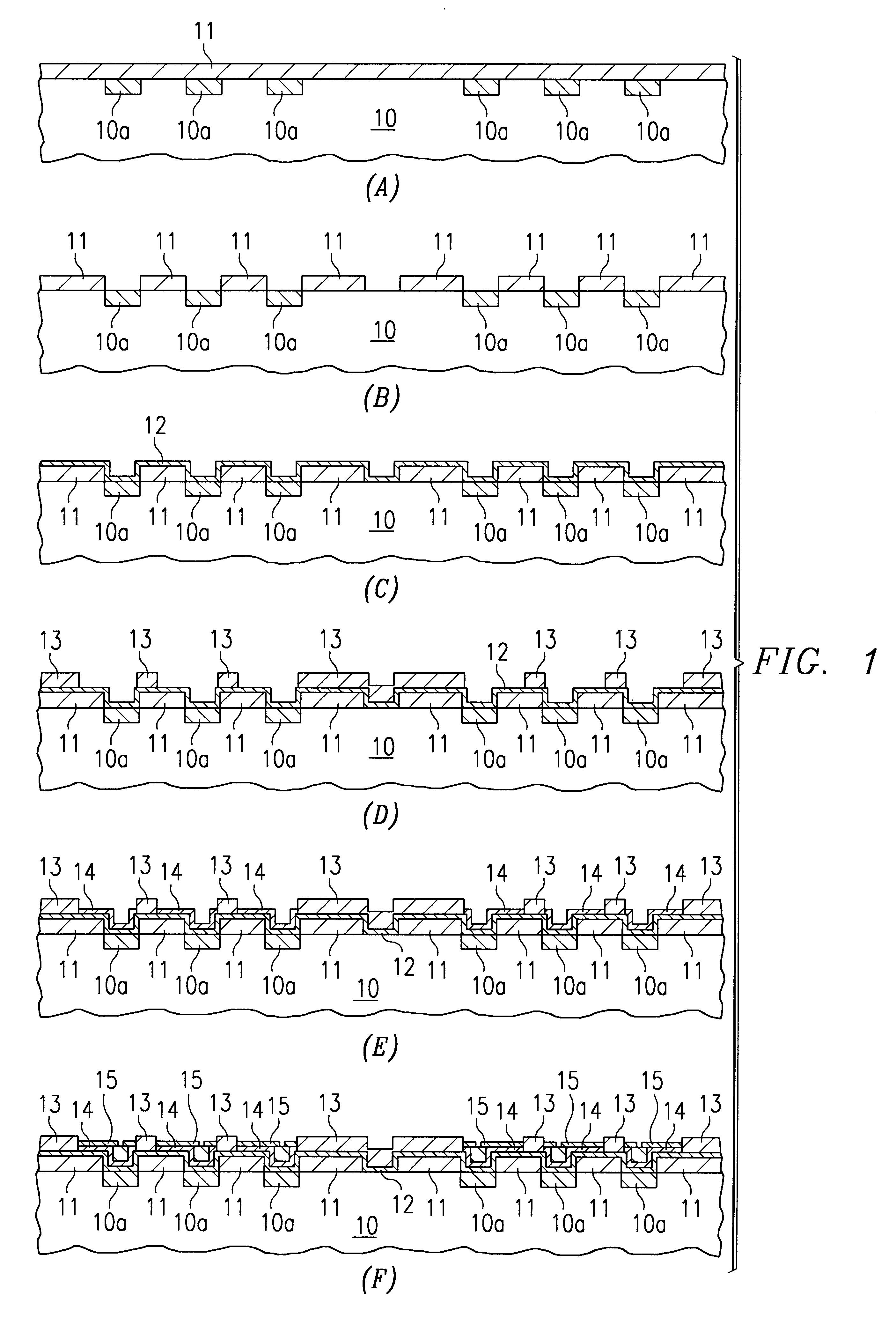

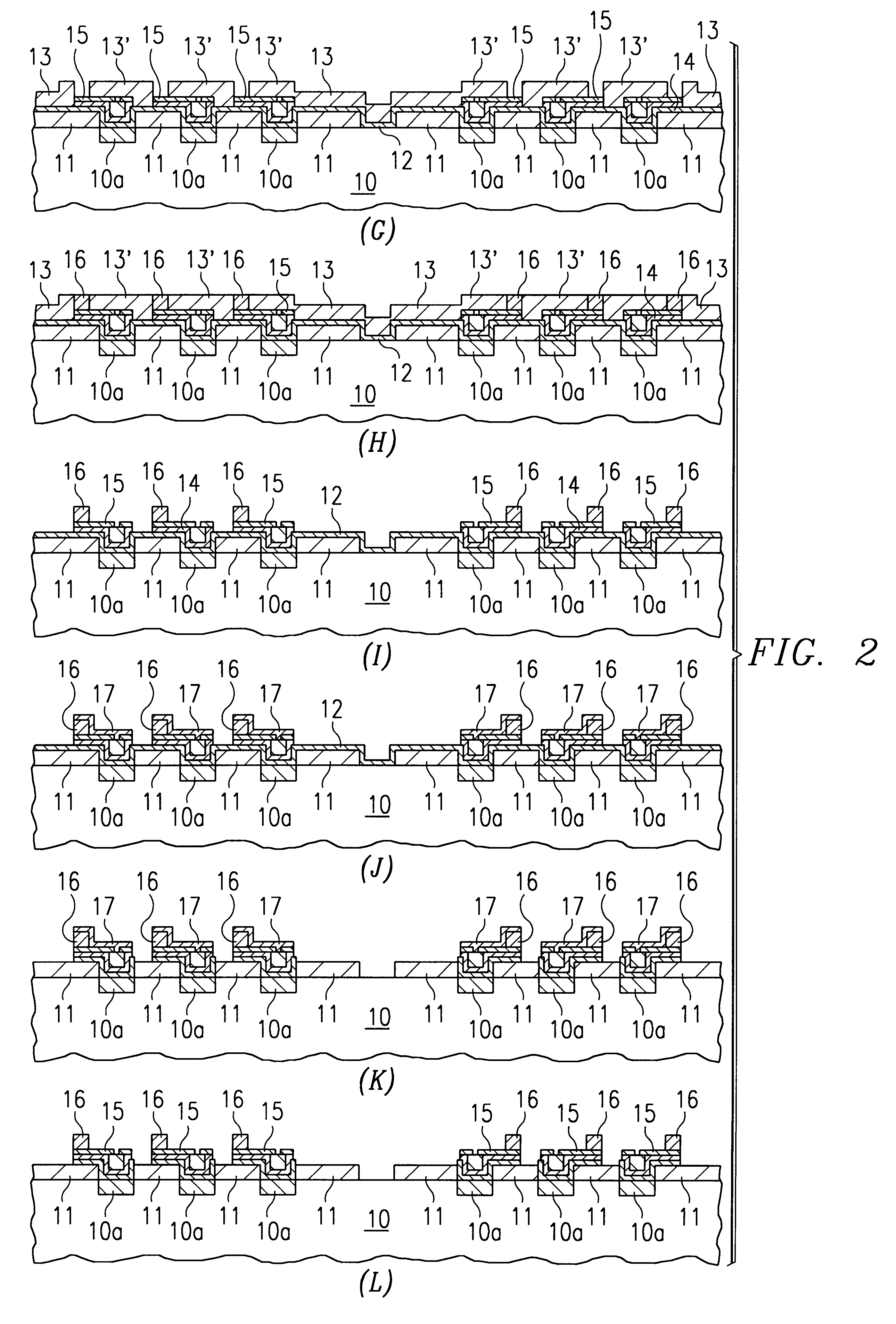

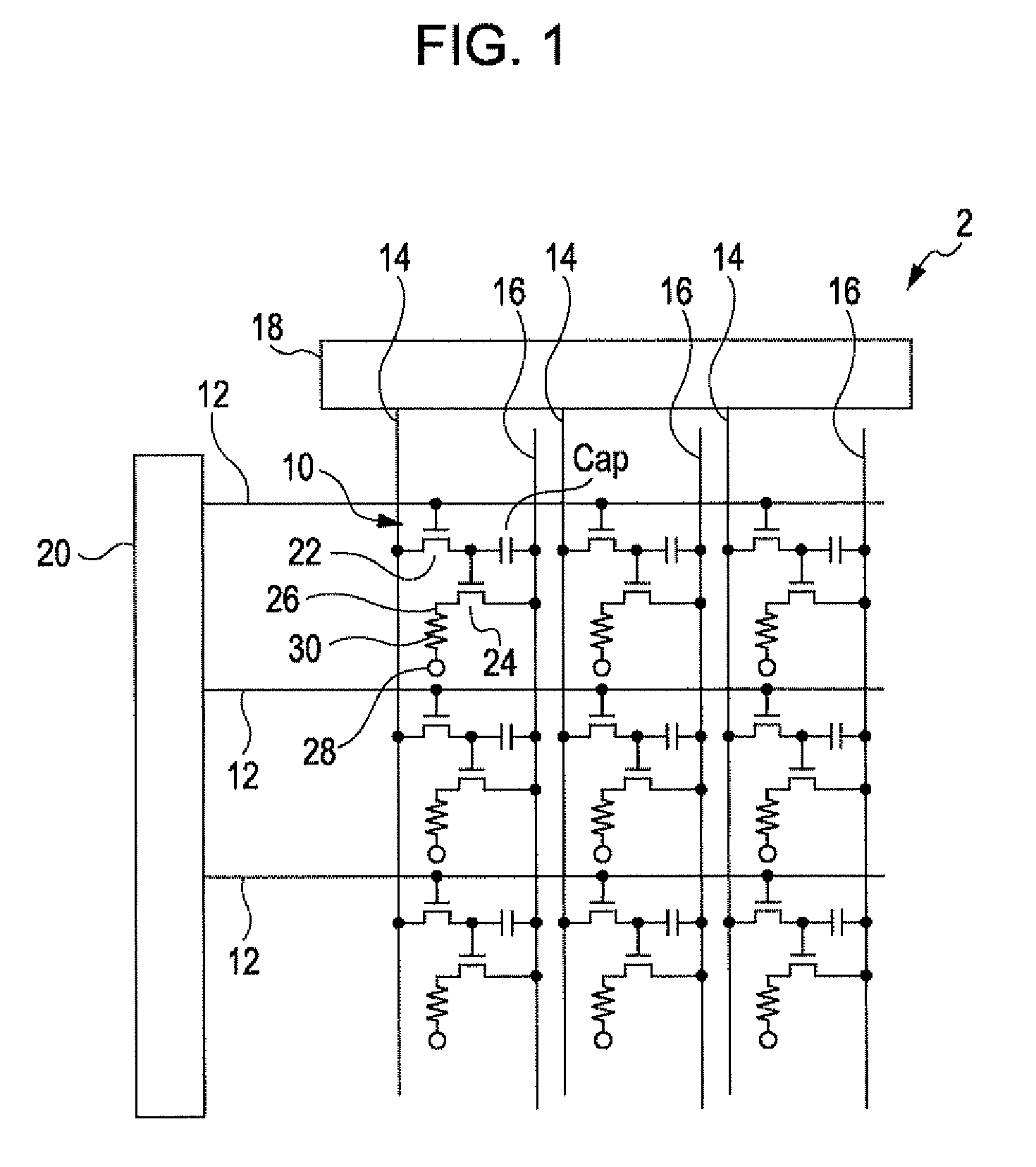

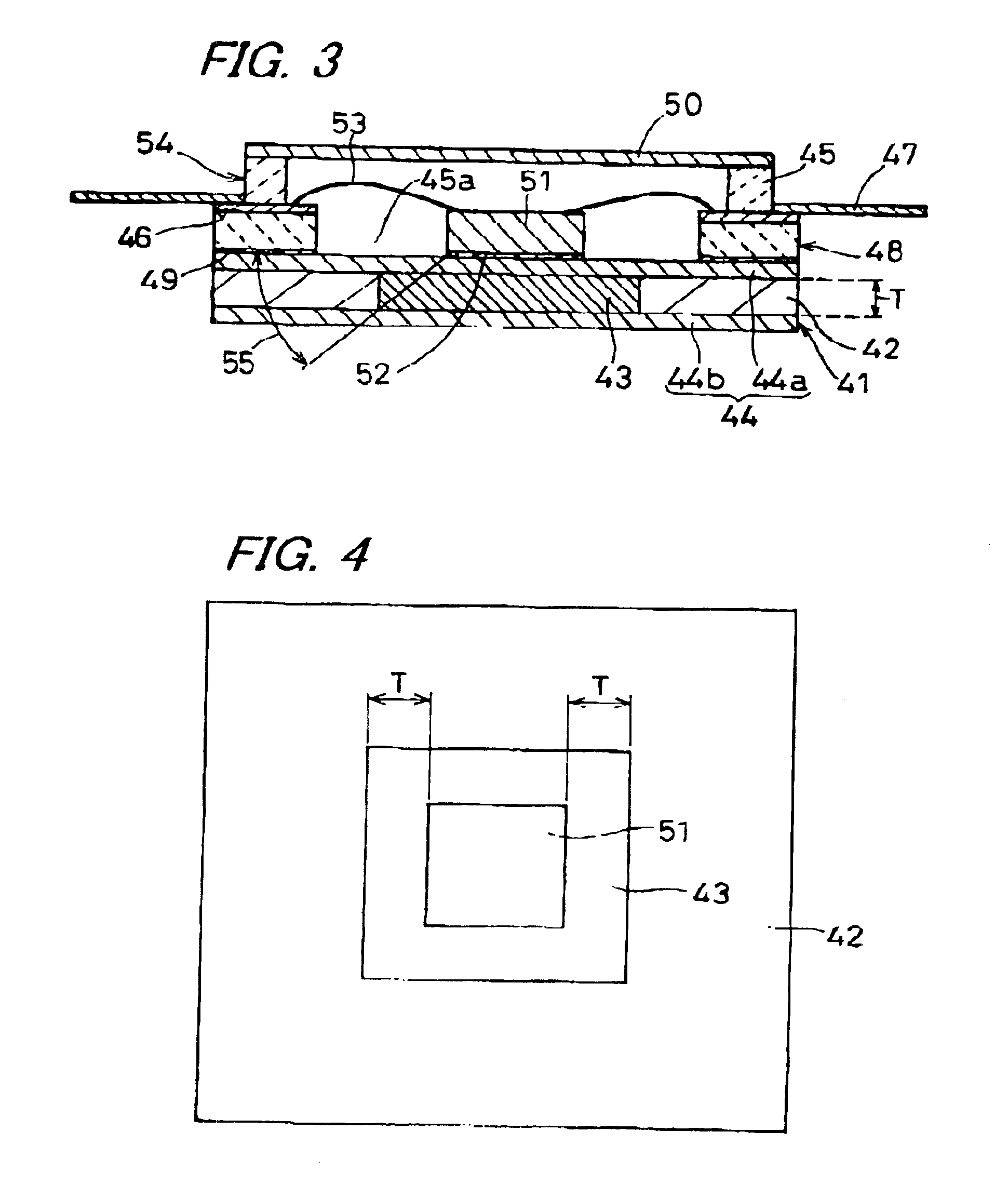

Method for manufacturing a semiconductor device

InactiveUS6482730B1Improves resin sealing reliabilityImprove accuracySemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor device

A method to improve the resin sealing reliability in the manufacturing of a wafer-level CSP. The method for manufacturing a semiconductor device of the present invention includes a process that forms wiring 14 and conductive supports 16, which electrically connect electrode pads 10a and corresponding external terminals, on a wafer 10 on which semiconductor elements are formed. In subsequent processes, a groove 18 (preferably V shaped) is formed in the surface of the above-mentioned wafer along the boundary lines of the respective semiconductor elements. Next, the end surfaces of the above-mentioned conductive supports 16 are exposed, and the above-mentioned wafer surface is covered with a resin 19 so that external terminals 20 are arranged on the end surfaces of the conductive supports. In the final process, along the boundary lines of the above-mentioned semiconductor elements, packaged semiconductor devices 32 are obtained by dicing the above-mentioned wafer.

Owner:TEXAS INSTR INC

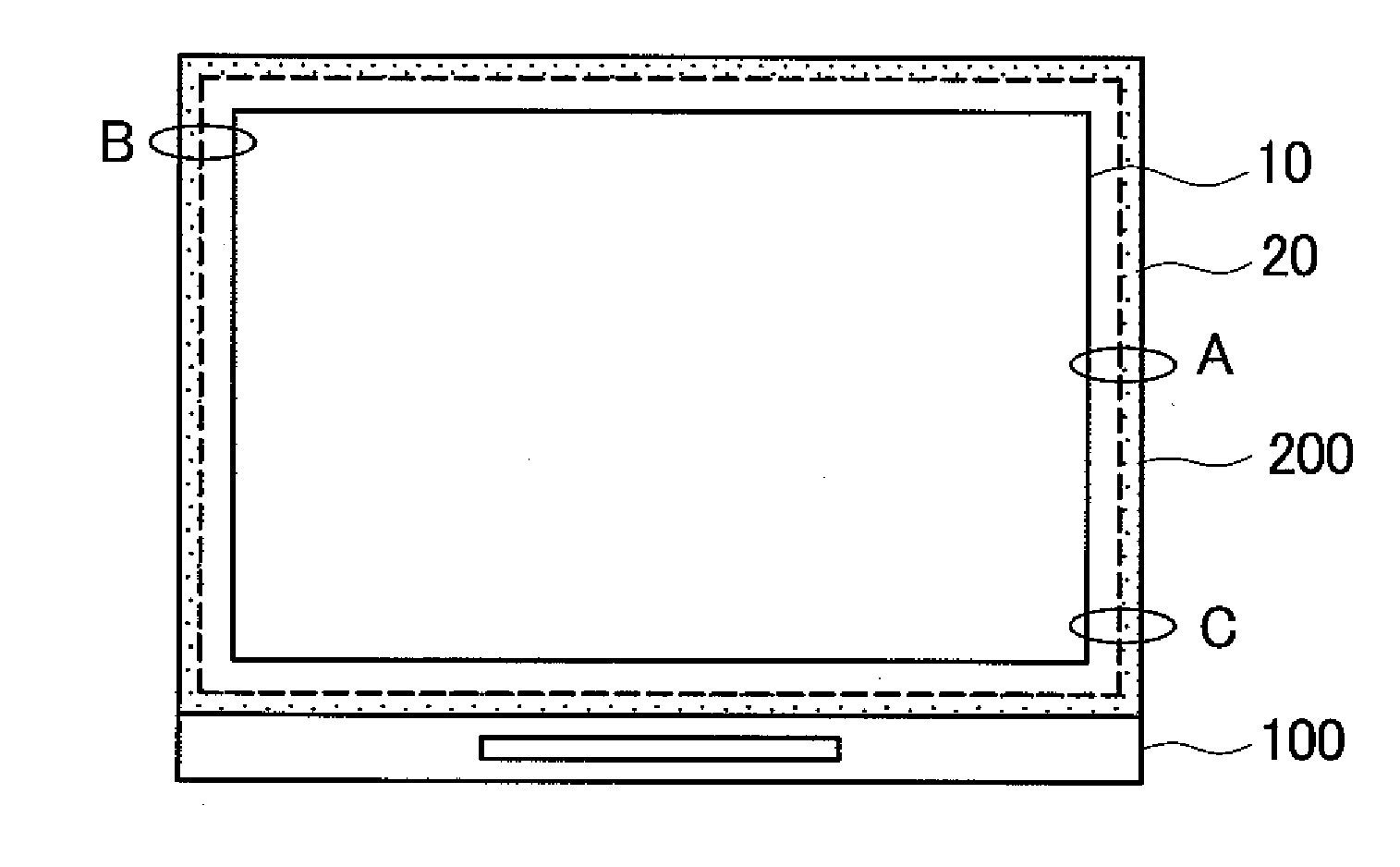

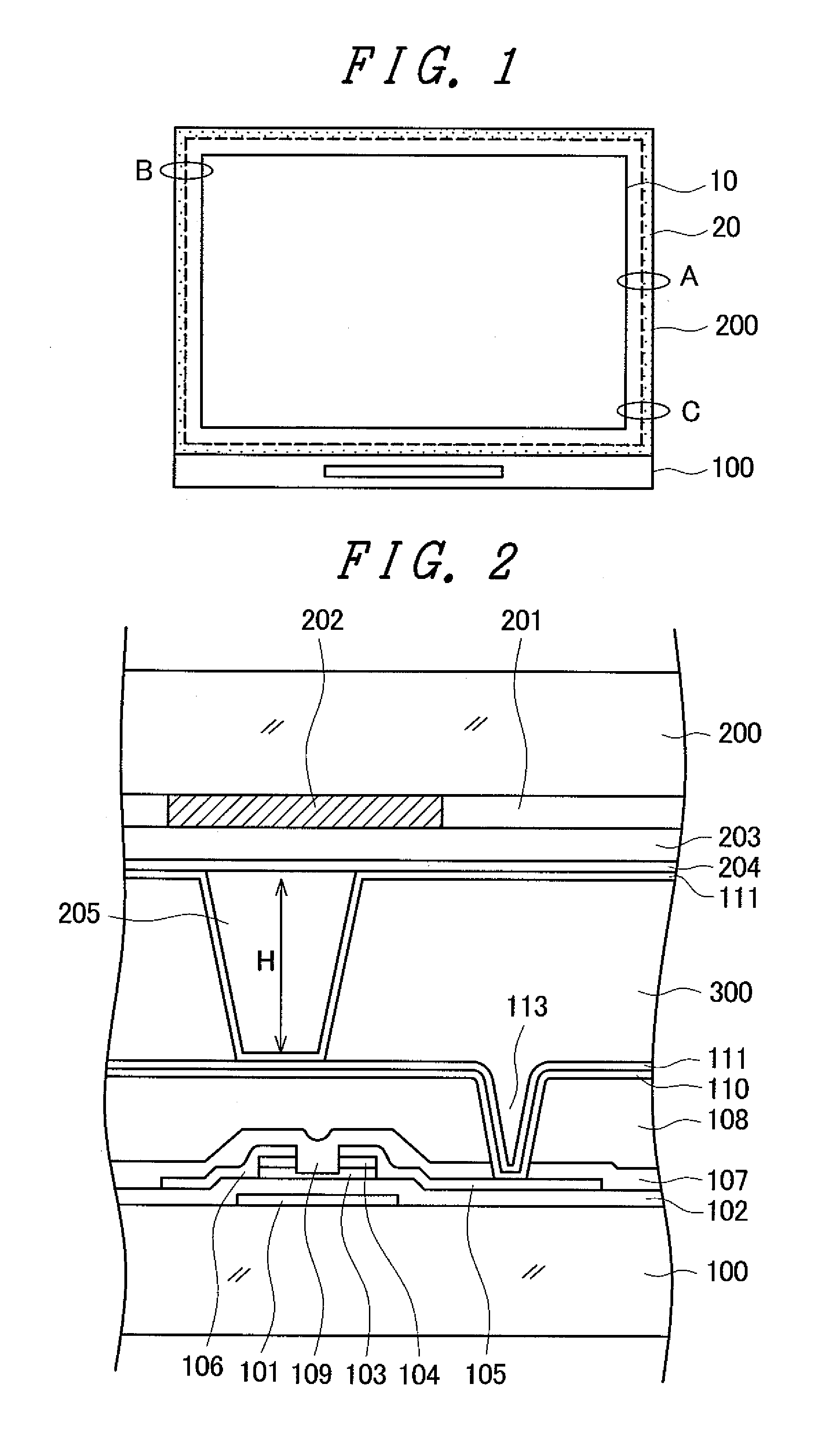

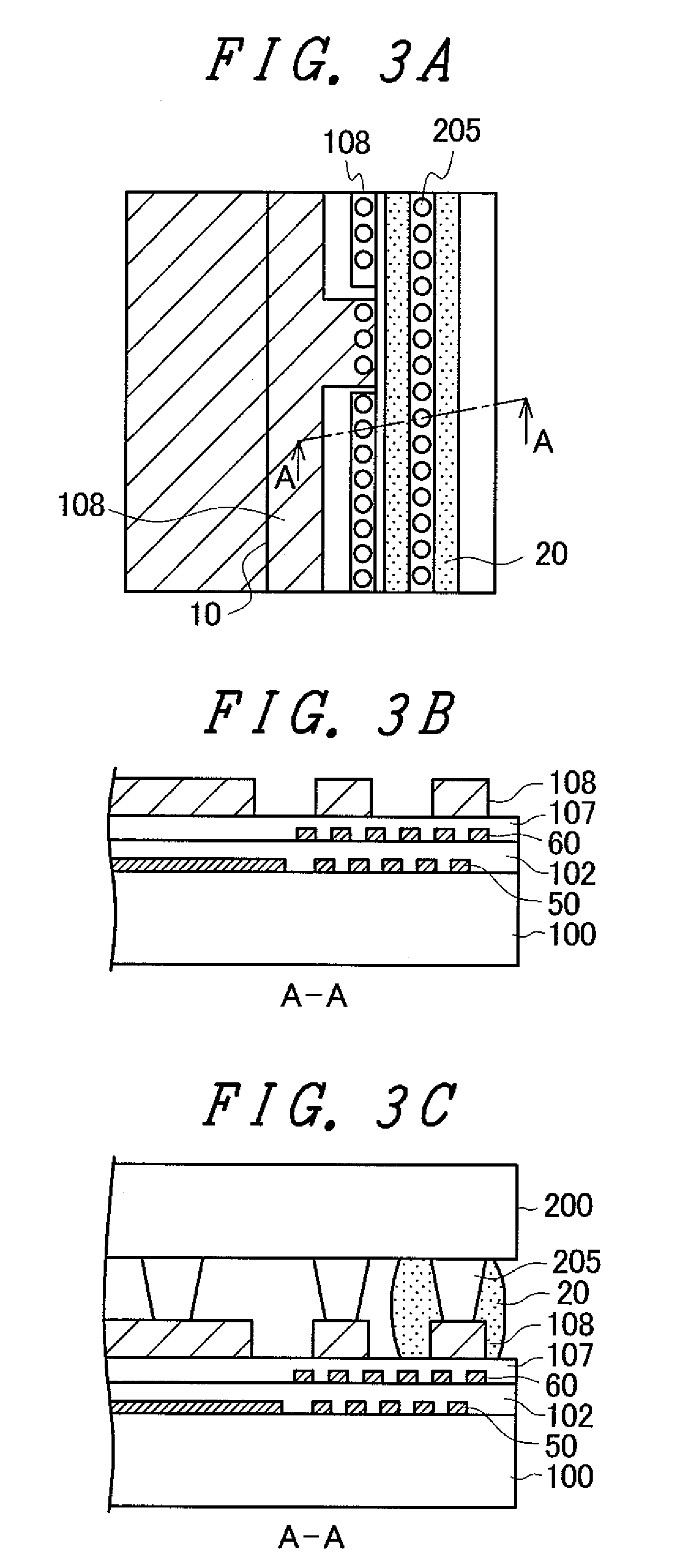

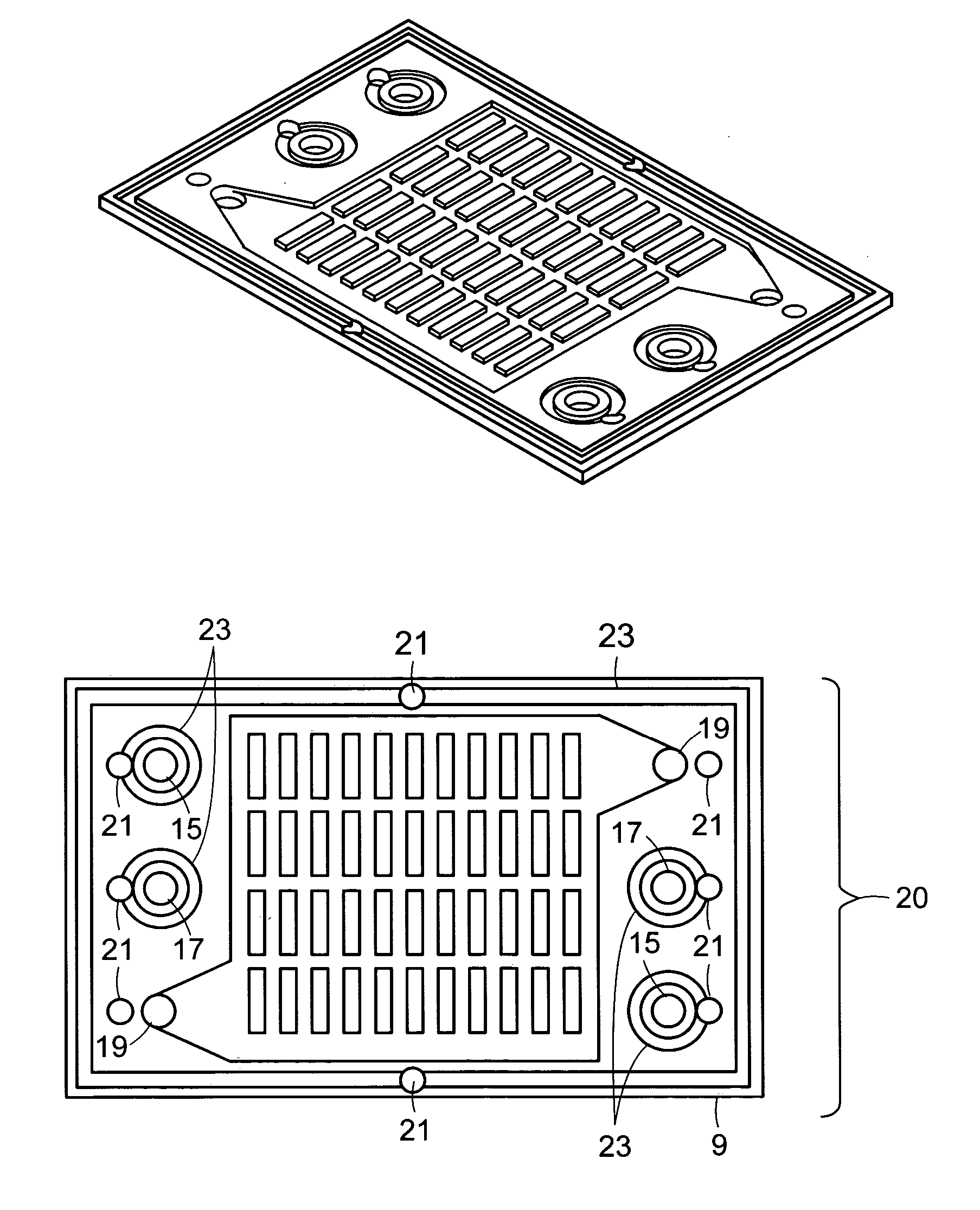

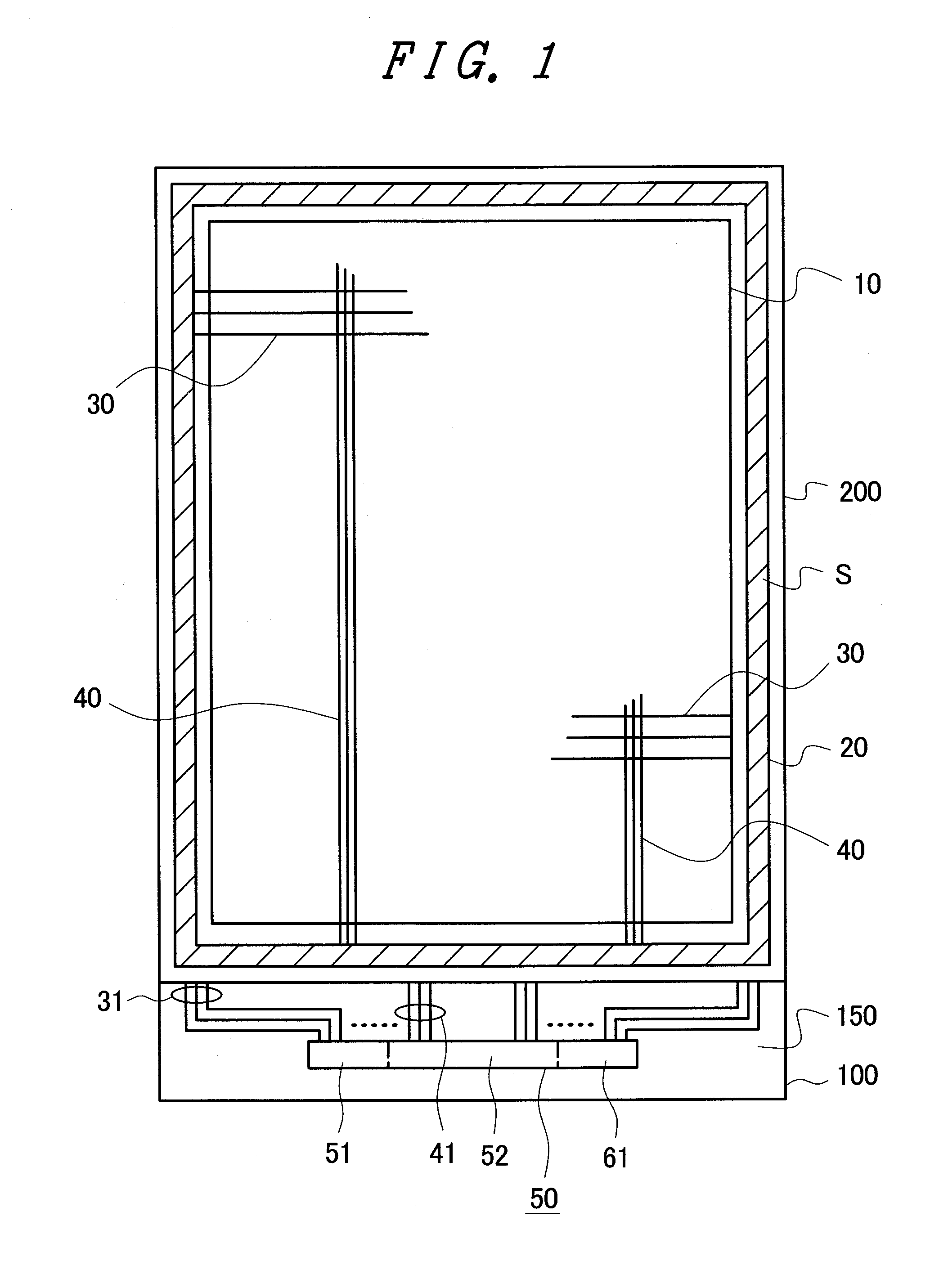

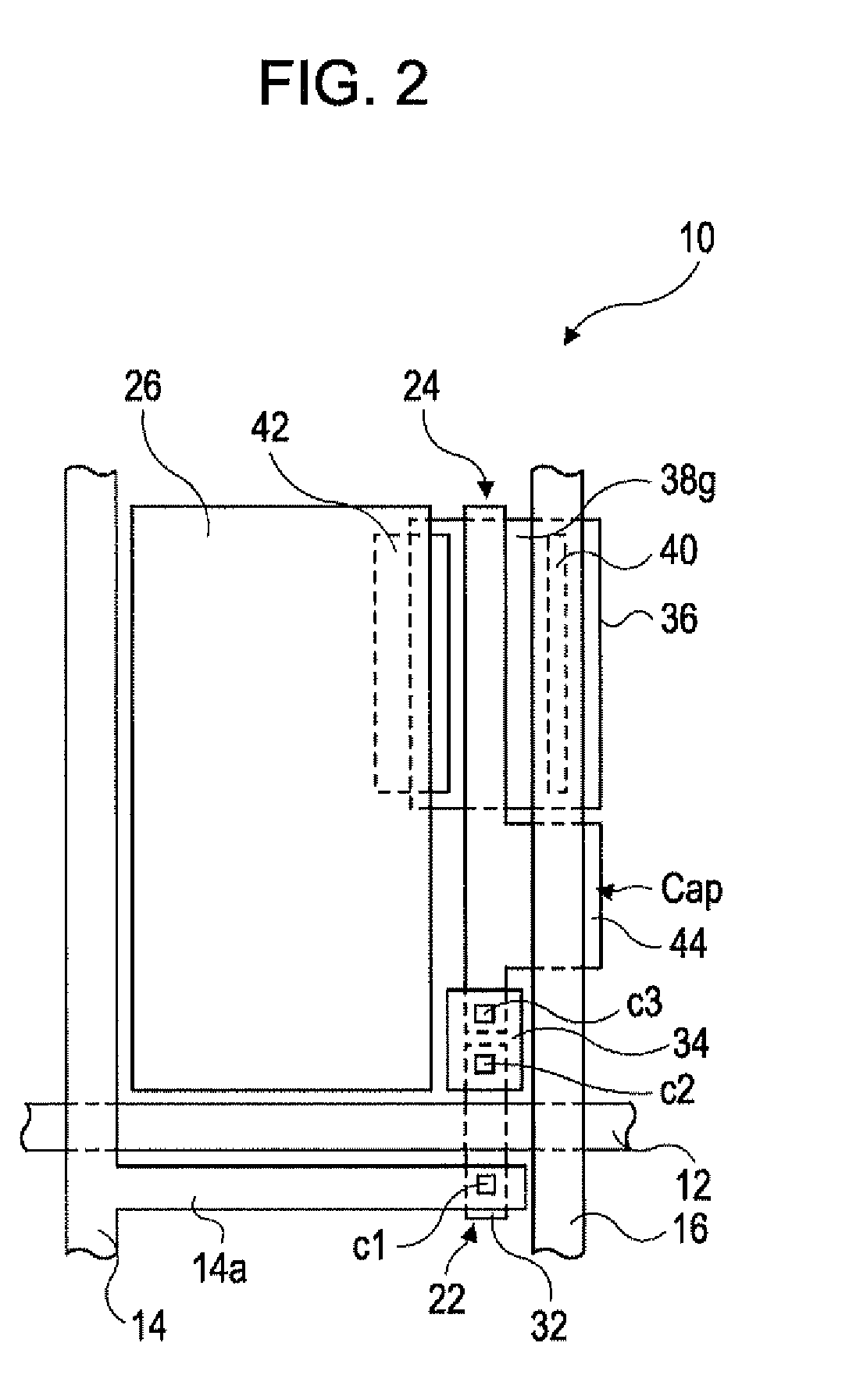

Liquid crystal display device

ActiveUS20100149477A1Reliability be ensureImprove reliabilityNon-linear opticsLiquid-crystal displayEngineering

In a seal portion of a liquid crystal display device, column spacers are formed on a counter substrate side, organic passivation films are formed so as to face the column spacers on a TFT substrate side, and the gap between the TFT substrate and the counter substrate is controlled by the column spacers and the organic passivation films. A sealing material covers the column spacers and the organic passivation films and is in contact with an inorganic film formed on the TFT substrate on the TFT substrate side. Therefore, the adhesive force of the sealing material is improved to ensure the reliability of the seal portion.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

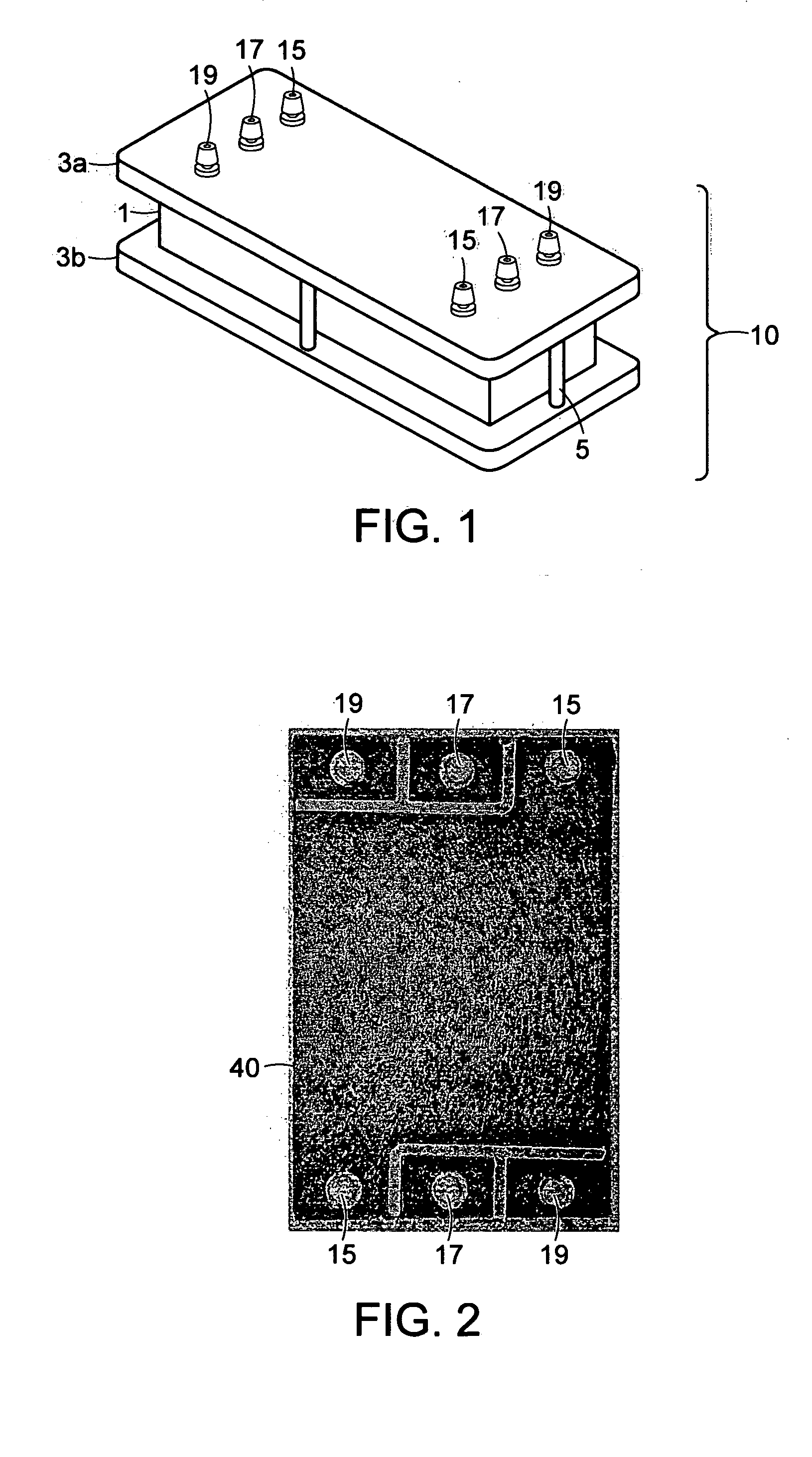

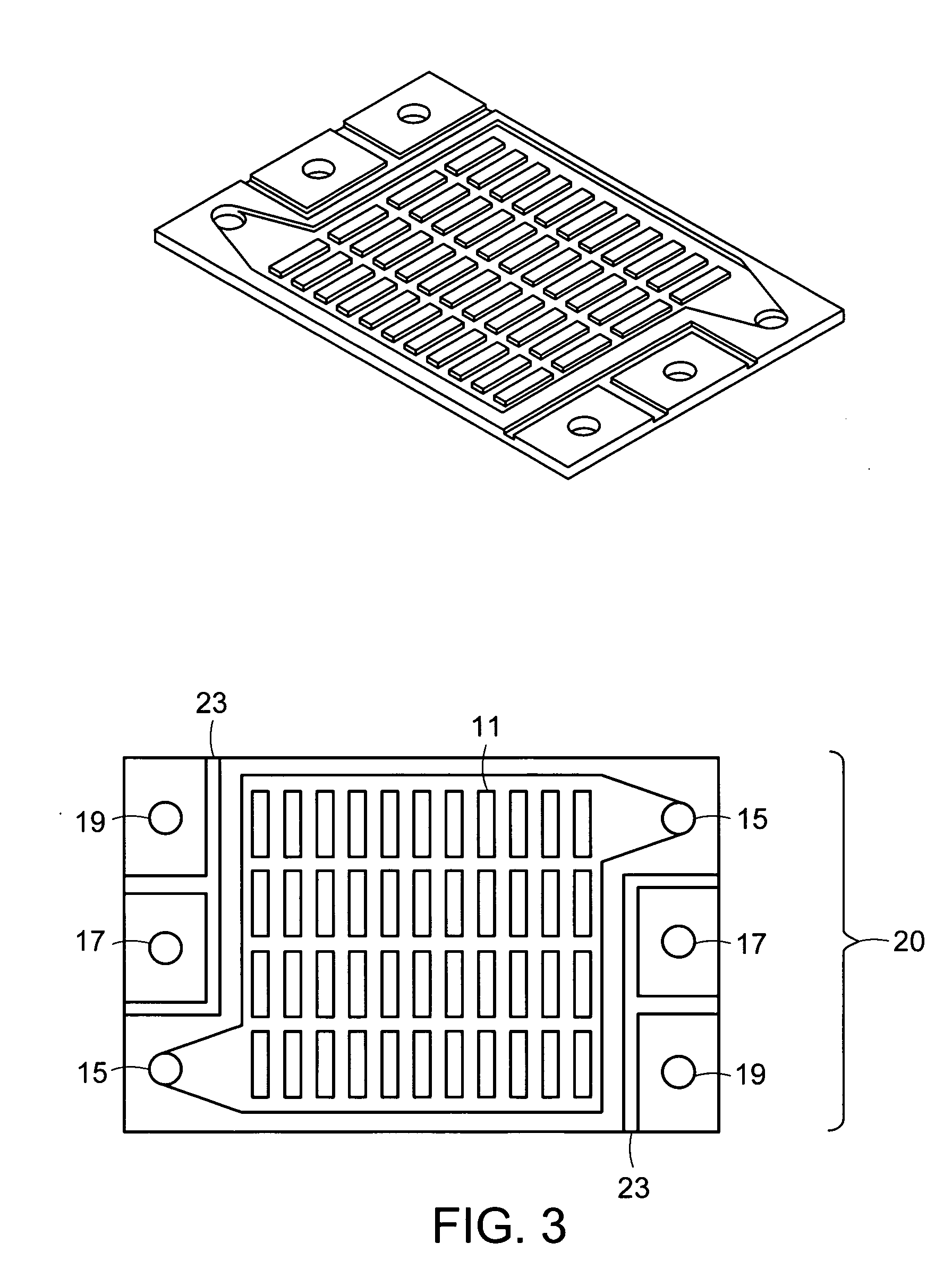

Membrane based electrochemical cell stacks

ActiveUS20050244703A1Eliminate needImprove the ease of assemblyFuel cell heat exchangeReactant parameters controlFuel cellsDesign improvement

The present invention provides membrane cassettes and stacks thereof which are suitable for a use in a variety of electrochemical applications. The invention further provides membrane cassettes which comprise one or more bipolar plates which have one or two reactant or coolant flow fields consisting of at least one groove in opposing surfaces of the bipolar plate. In certain preferred embodiments, the invention provides cassettes and stacks which are suitable for use in fuel cell applications. Particularly preferred embodiments of the invention include design improvements which enhance the performance and reliability of certain components of the fuel cell stack.

Owner:SILICON VALLEY BANK

Flexible battery and method for producing the same

InactiveUS8785030B2Impart high flexibilityImproves sealing reliabilityFinal product manufactureSmall-sized cells cases/jacketsEngineeringFilm material

Disclosed is a flexible battery including a sheet-like electrode group, an electrolyte, and a housing with flexibility enclosing the electrode group and electrolyte. The housing includes a film material folded into two in which the electrode group is inserted. The film material has two facing portions respectively facing two principal surfaces of the electrode group, a fold line which is between the two facing portions and along which the film material is folded, and two bonding margins respectively set around the two facing portions. The two bonding margins are bonded to each other into a bonded portion. At least the two facing portions of the film material are formed in a corrugated shape having a plurality of ridge and valley lines arranged in parallel to each other. The ridge lines in one of the two facing portions are overlapped with the valley lines in the other. The fold line is parallel to the ridge and valley lines.

Owner:PANASONIC CORP

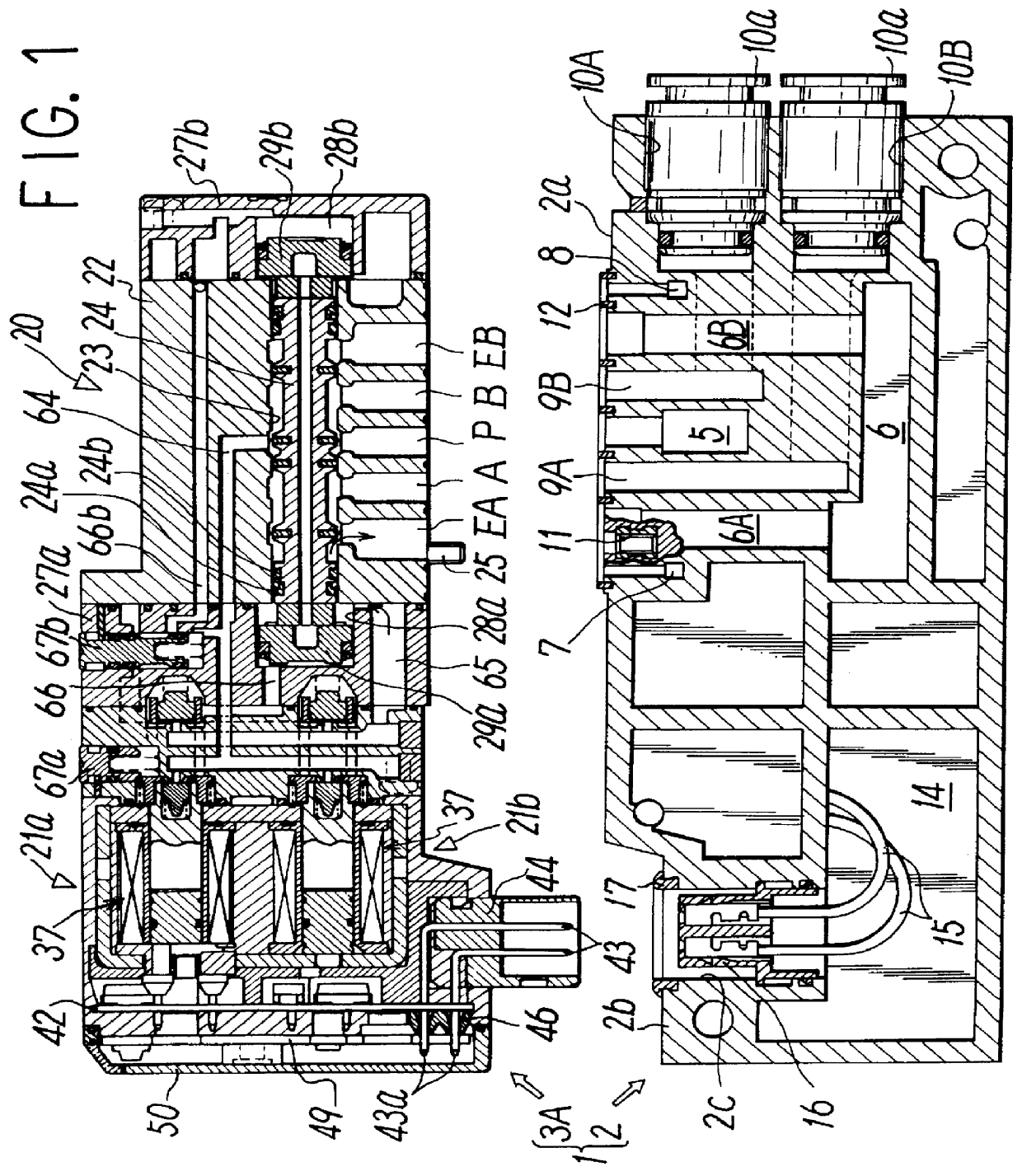

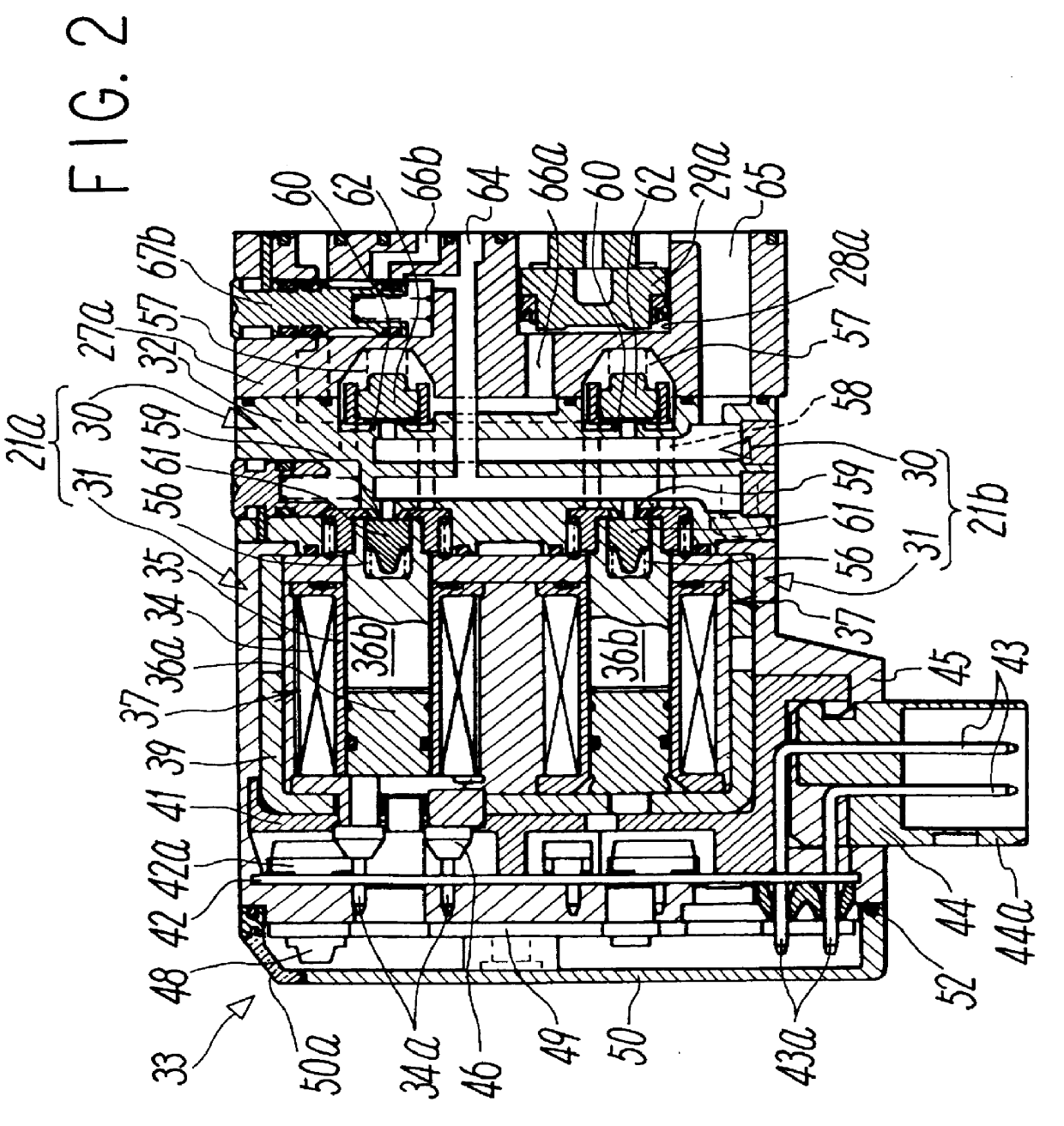

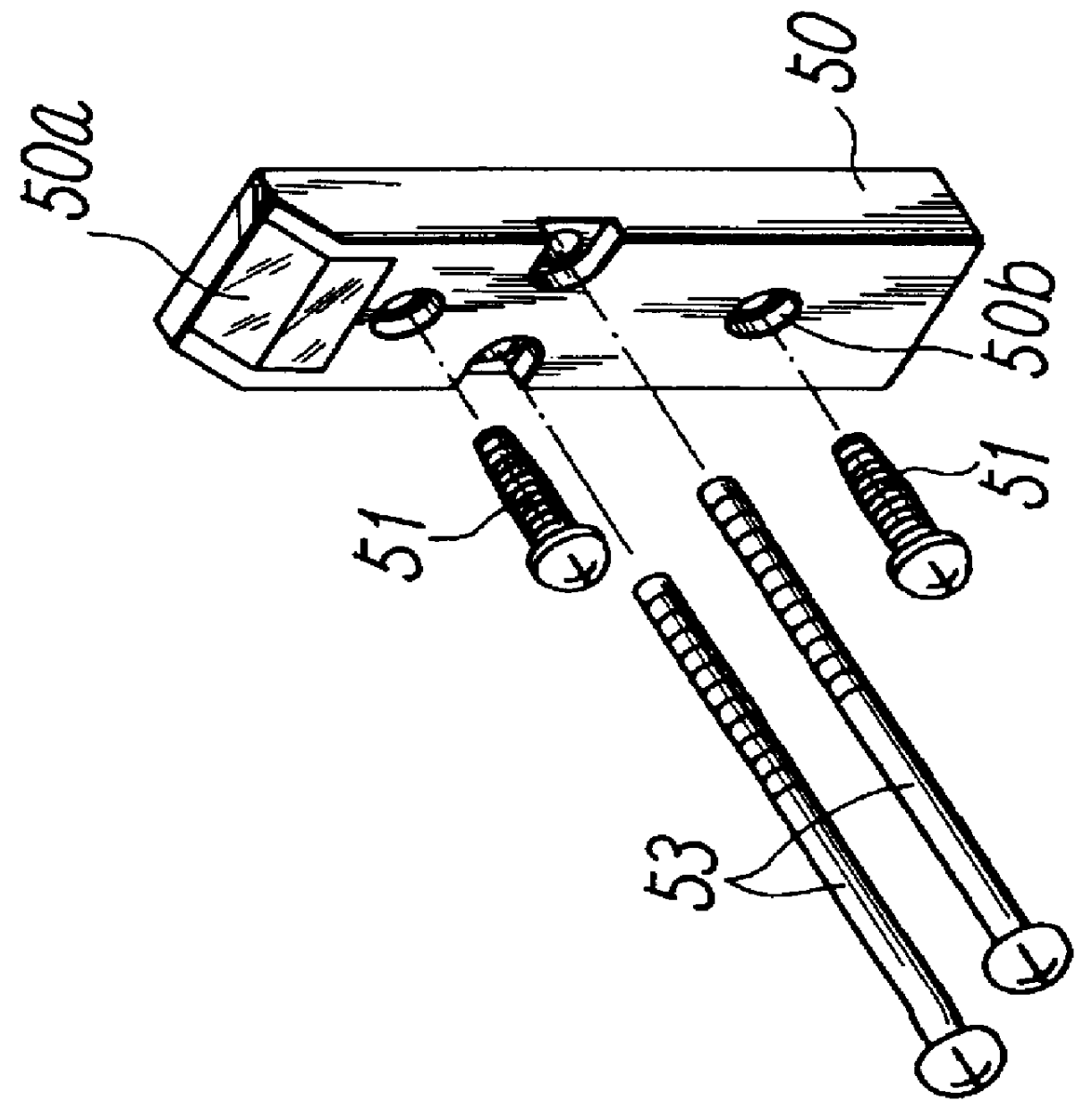

Sealed transfer valve assembly

InactiveUS6109298AImprove insulation performanceImprove sealingOperating means/releasing devices for valvesElectrical apparatusEngineeringSynthetic resin

A sealing article 17 is provided in the opening edge of a depression 2c provided in a manifold 2 to connect a supply connector 16 and a receiving connector 44 in an air-tight manner. A solenoid section 33, in which a solenoid 31 in each of pilot valve 21a and 21b and a receiving connector 44 that supplies power to connector 31 are sealed into a synthetic resin 45, is provided in a transfer valve 3A. Solenoid section 33 has a lamp circuit board 49 mounted on its outer surface to receive power from receiving connector 44, and includes power supply indicator lamps 48; and a cover 50, covering the whole of lamp circuit board 49, mounted to form an air-tight seal on its outer surface via a gasket 52.

Owner:SMC CORP

Enhanced reliability sealing system

InactiveUS20060249914A1Provides redundancyImprove the dilution effectEngine sealsDependabilityLubricant

An enhanced reliability sealing system is disclosed herein. The sealing system has multiple sealing elements for entrapping a lubricating agent capable of reducing or eliminating properties of a processing medium that could damage or compromise operation of the sealing system.

Owner:DULIN ROBERT D

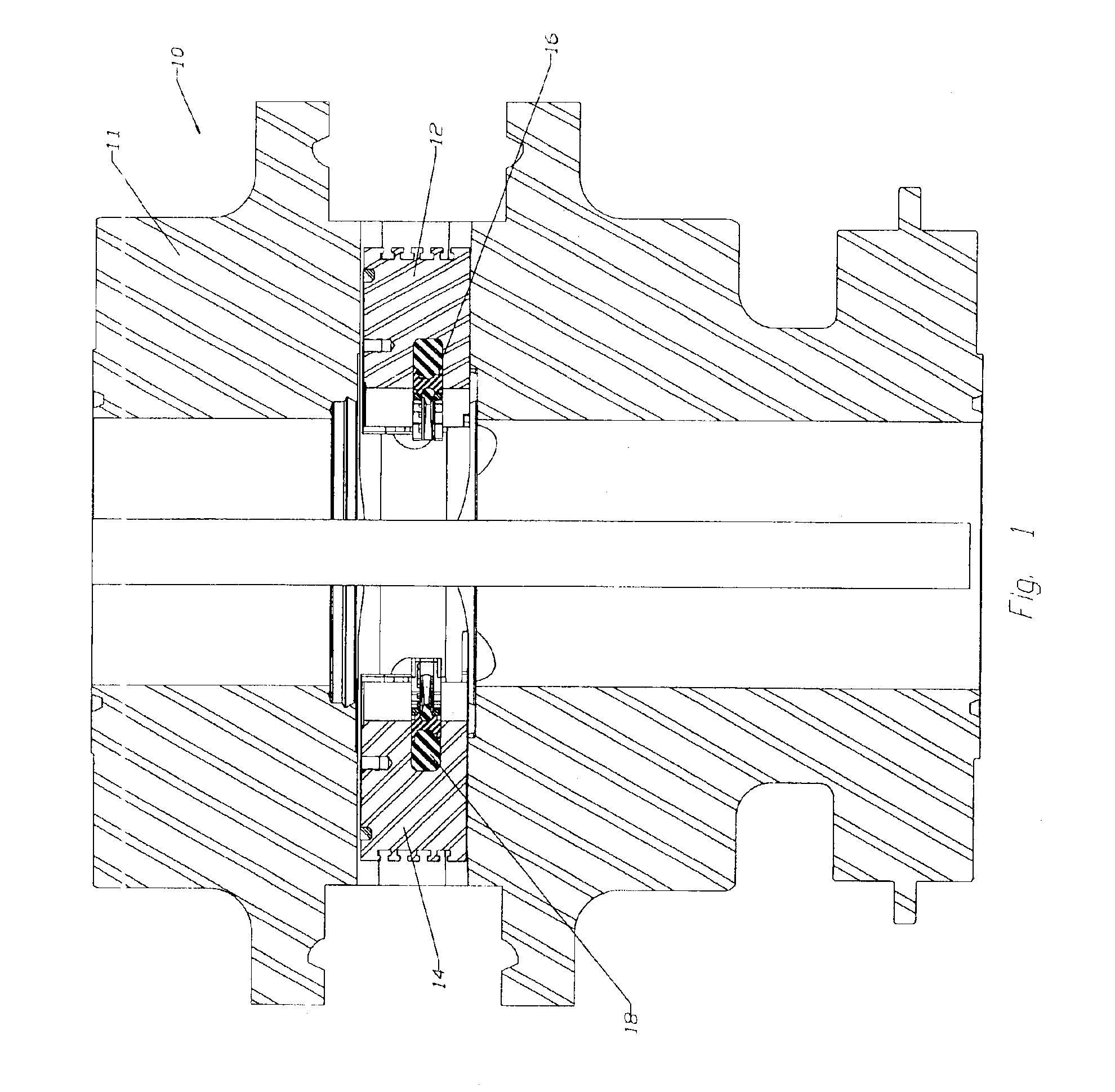

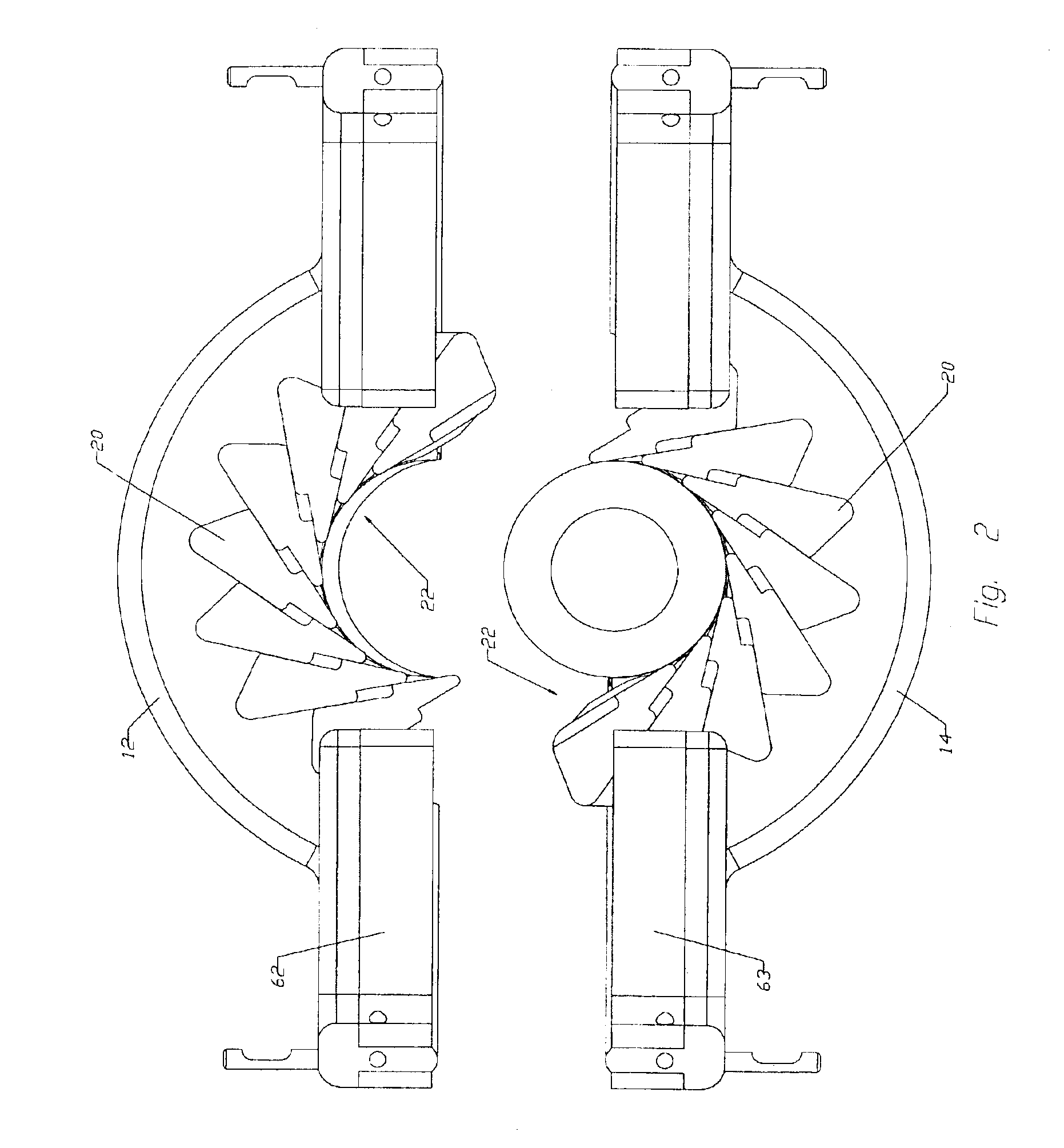

BOP assembly with metal inserts

InactiveUS6857634B2Improve reliabilityReduced diameter requirementsSleeve/socket jointsDrilling rodsElastomerEngineering

A blowout preventer assembly 10 includes opposed rams 12, 14, each including a rubber or elastomer sealing assembly 16, 18, with a plurality of inserts 20 forming an array 22 of metal inserts within each sealing assembly. Each insert has an upper body 24, a lower body 26, and a rib 50. Each upper and lower body includes a trailing face 36, a radially outward opposite face 38 and a leading face 40. An antiextrusion ledge 46 minimizes the extrusion gap between the OD of a tubular in the BOP and the leading face of the metal inserts in the array.

Owner:VARCO SHAFFER

Rock shearing seepage coupling true triaxial test system

InactiveCN102607950AReduce the effects of frictionReduce corner effectsMaterial strength using tensile/compressive forcesTriaxial shear testFriction effect

The invention relates to a rock shearing seepage coupling true triaxial test system, which comprises a loading assembly, a test box, a seepage assembly, a detection assembly and a control assembly. The whole system is high in rigid, safe and reliable in high-pressure water injection and sealability, good in sealing reliability, high in loading stability and protection strength and capable of effectively reducing the end-part friction effect and the corner effect and realizing the uniform triaxial stress state as far as possible; a loading test device and a mainshaft loading mechanism are designed in a split manner, and safe high-pressure water injection is achieved; a safety valve and a pressure-stabilizing control device are arranged on a water outlet; and the rock shearing seepage coupling true triaxial test system is stable to control.

Owner:SHANDONG UNIV OF SCI & TECH

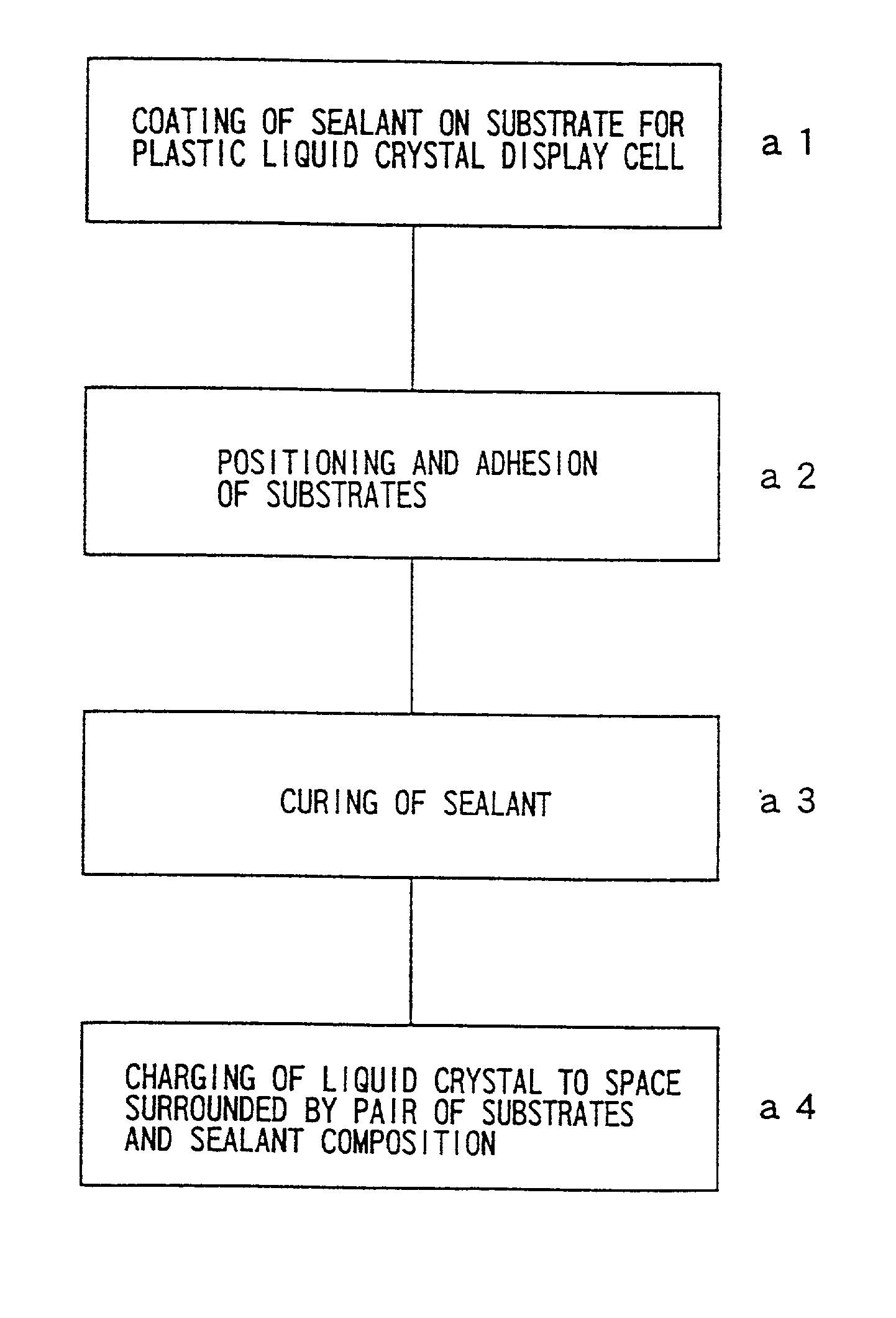

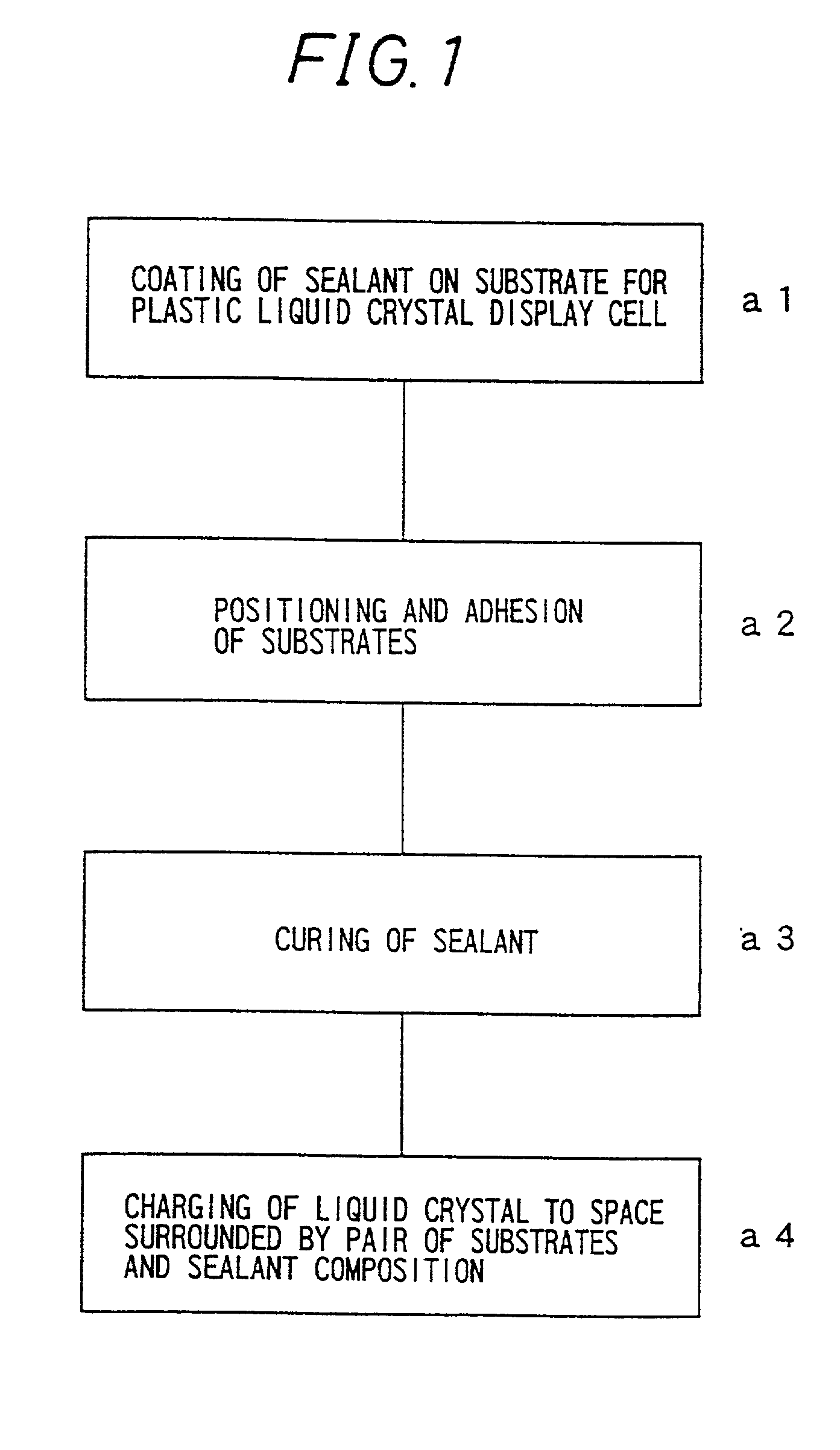

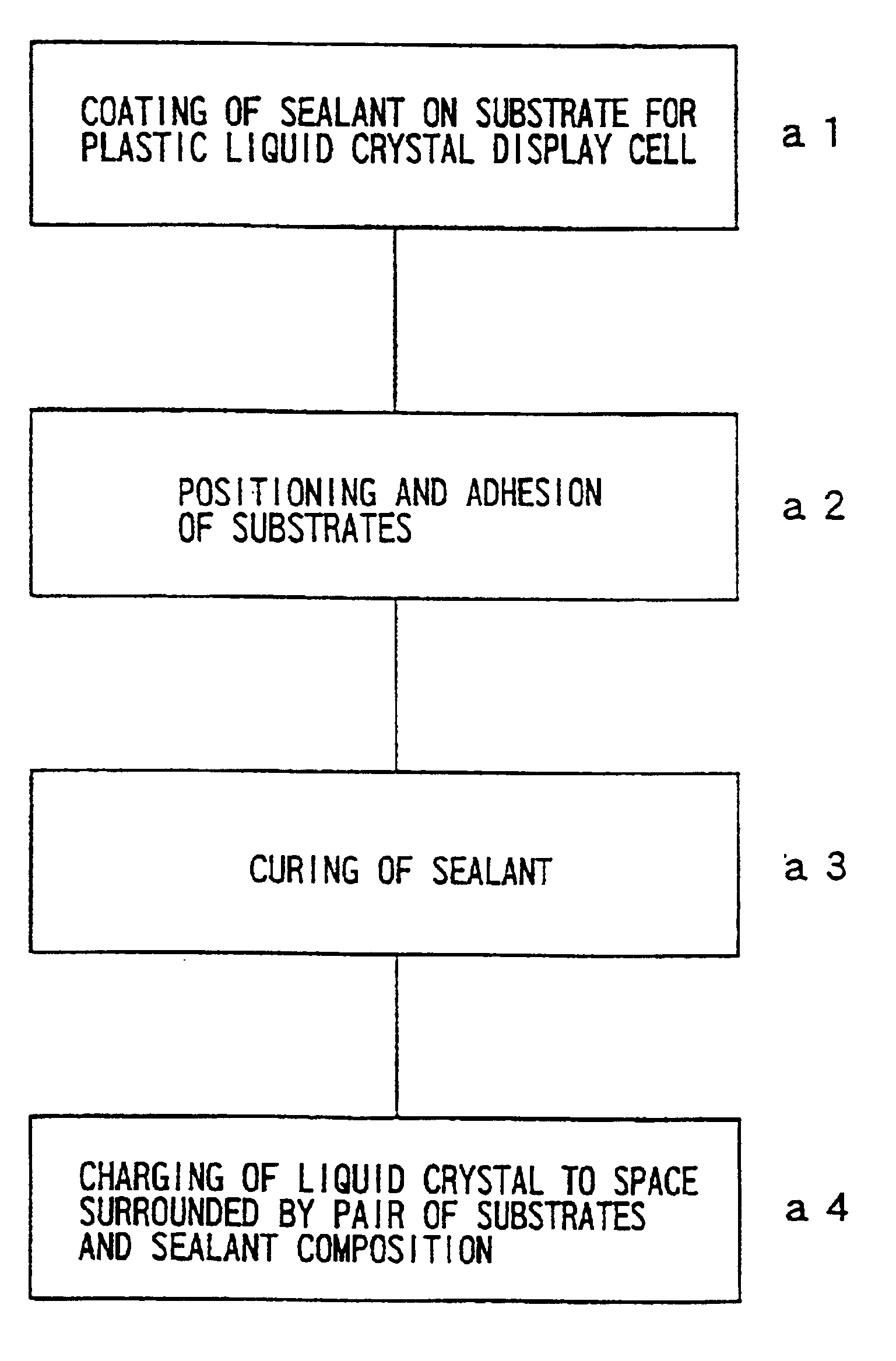

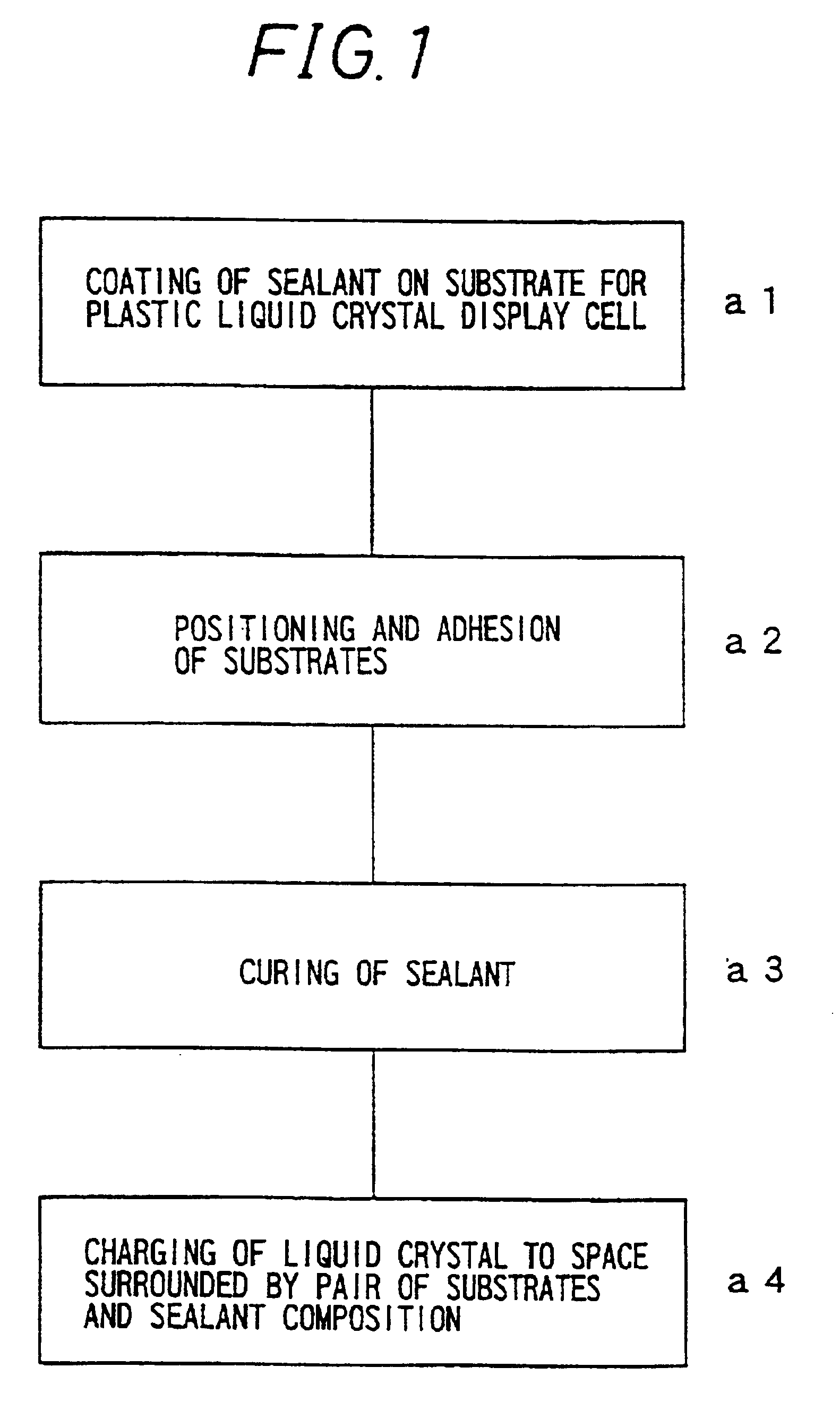

Sealing material for plastic liquid crystal display cells

InactiveUS20020176046A1Improves sealing reliabilityLiquid crystal compositionsEpoxy resin adhesivesEpoxySealant

An object of the invention is to provide a sealant composition for a plastic liquid crystal display cell that is capable of being applied to a sheet heat press adhesion method and of producing a plastic liquid crystal display cell having high reliability under a high temperature and high humidity environment. A two-component sealant composition for a plastic liquid crystal display cell of the invention contains the following components (1) to (6): (1) from 15 to 84% by weight of a liquid epoxy resin having from 1.7 to 6 in weight average of epoxy groups in one molecule and an ionic conductivity of an aqueous solution obtained by extraction separation by contact mixing with 10 times by weight of pure water at from 40 to 80° C. of 2 mS / m or less, (2A) from 10 to 50% by weight of a curing agent containing one or a mixture of two or more selected from (2A-1) a tetrafunctional mercapto compound or (2A-2) a modified polymercapto derivative, having an ionic conductivity of an aqueous solution obtained by extraction separation by contact mixing with 10 times by weight of pure water at from 40 to 80° C. of 0.6 mS / m or less, (3) from 0.01 to 15% by weight of a curing accelerator, (4) from 5 to 50% by weight of an inorganic filler, (5) from 0.1 to 5% by weight of a silane coupling agent, and (6) from 1 to 25% by weight of rubbery polymer fine particles having a softening temperature of 0° C. or less and an average particle diameter of primary particles of from 0.01 to 5 mum.

Owner:MITSUI CHEM INC

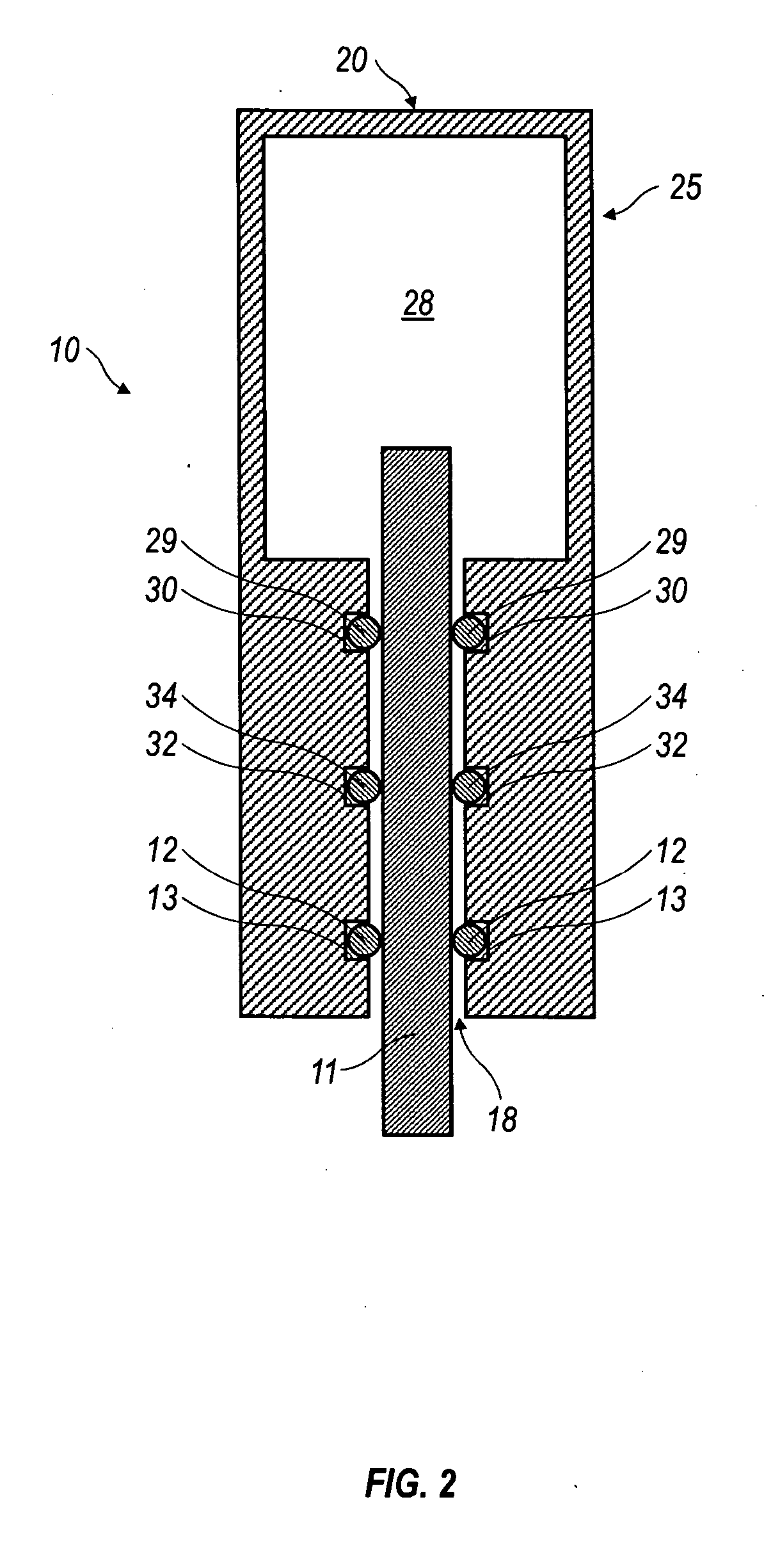

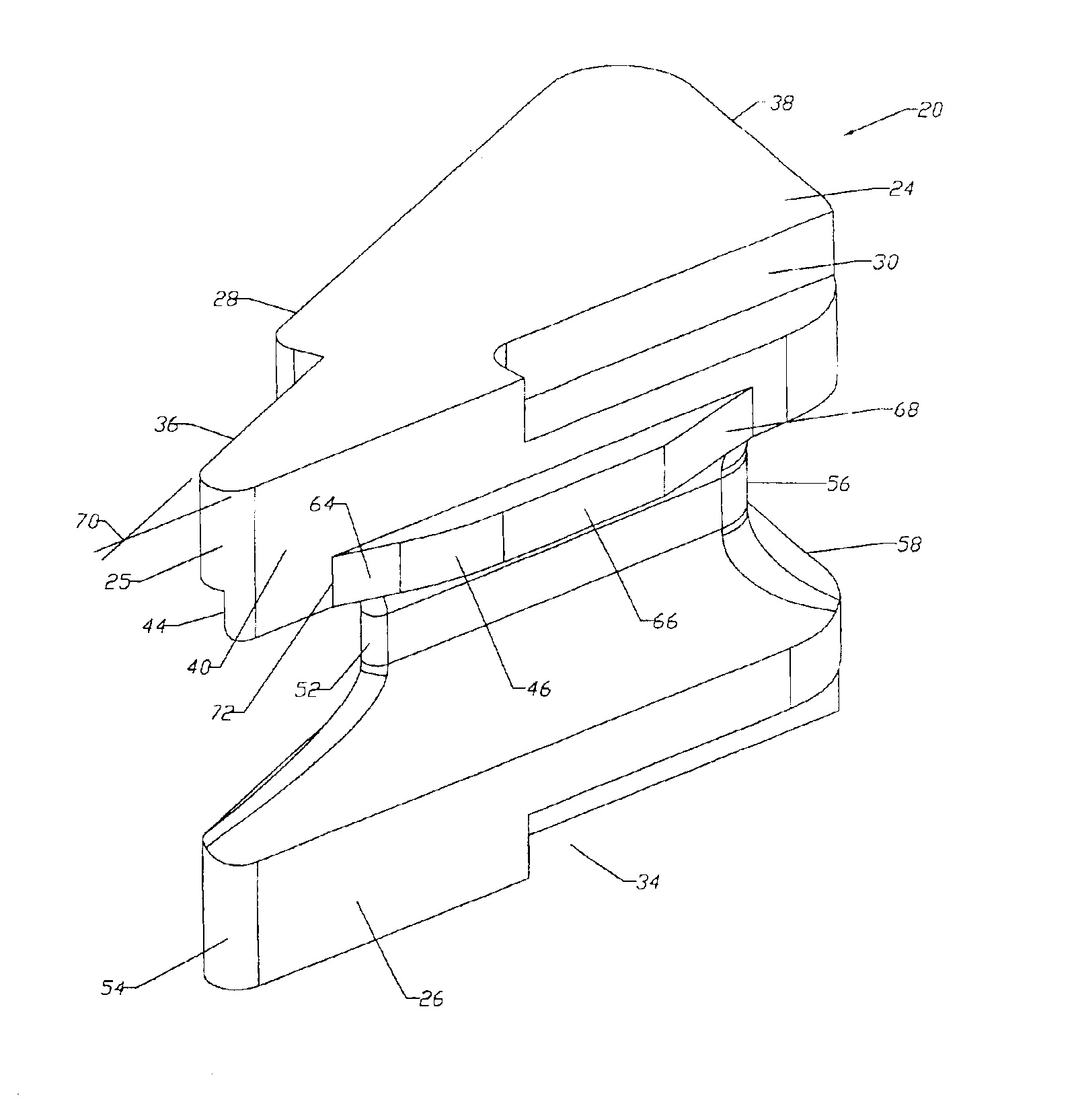

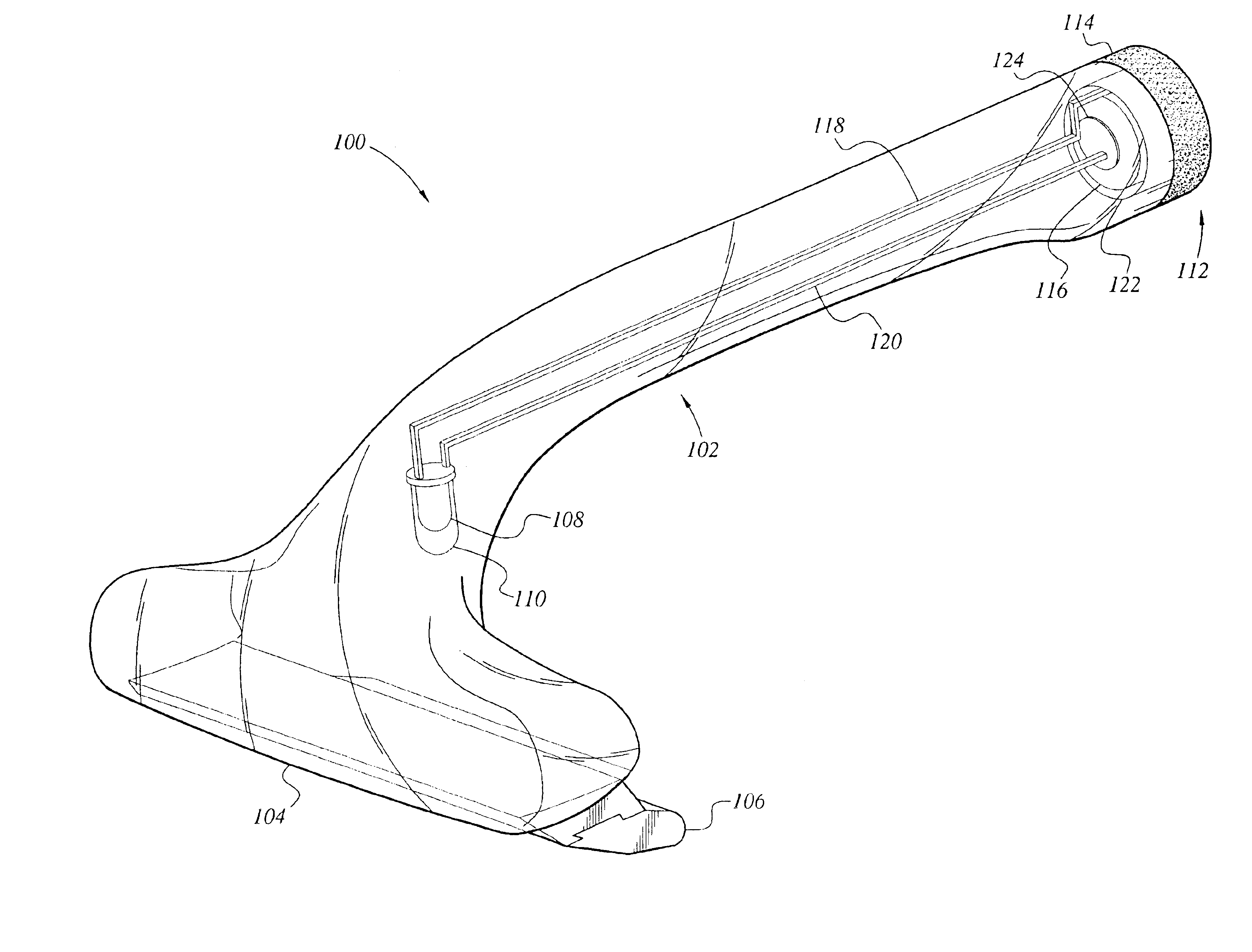

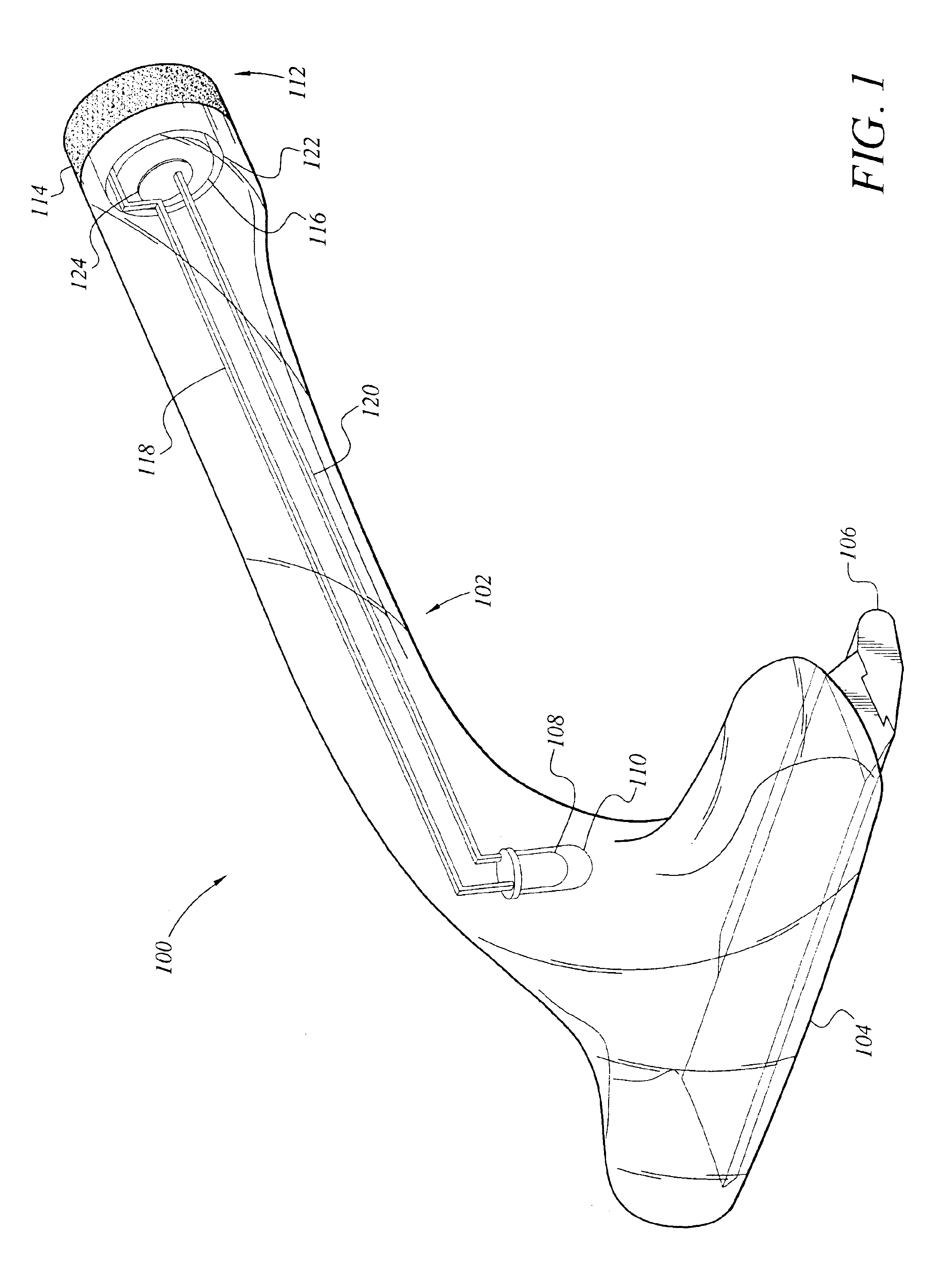

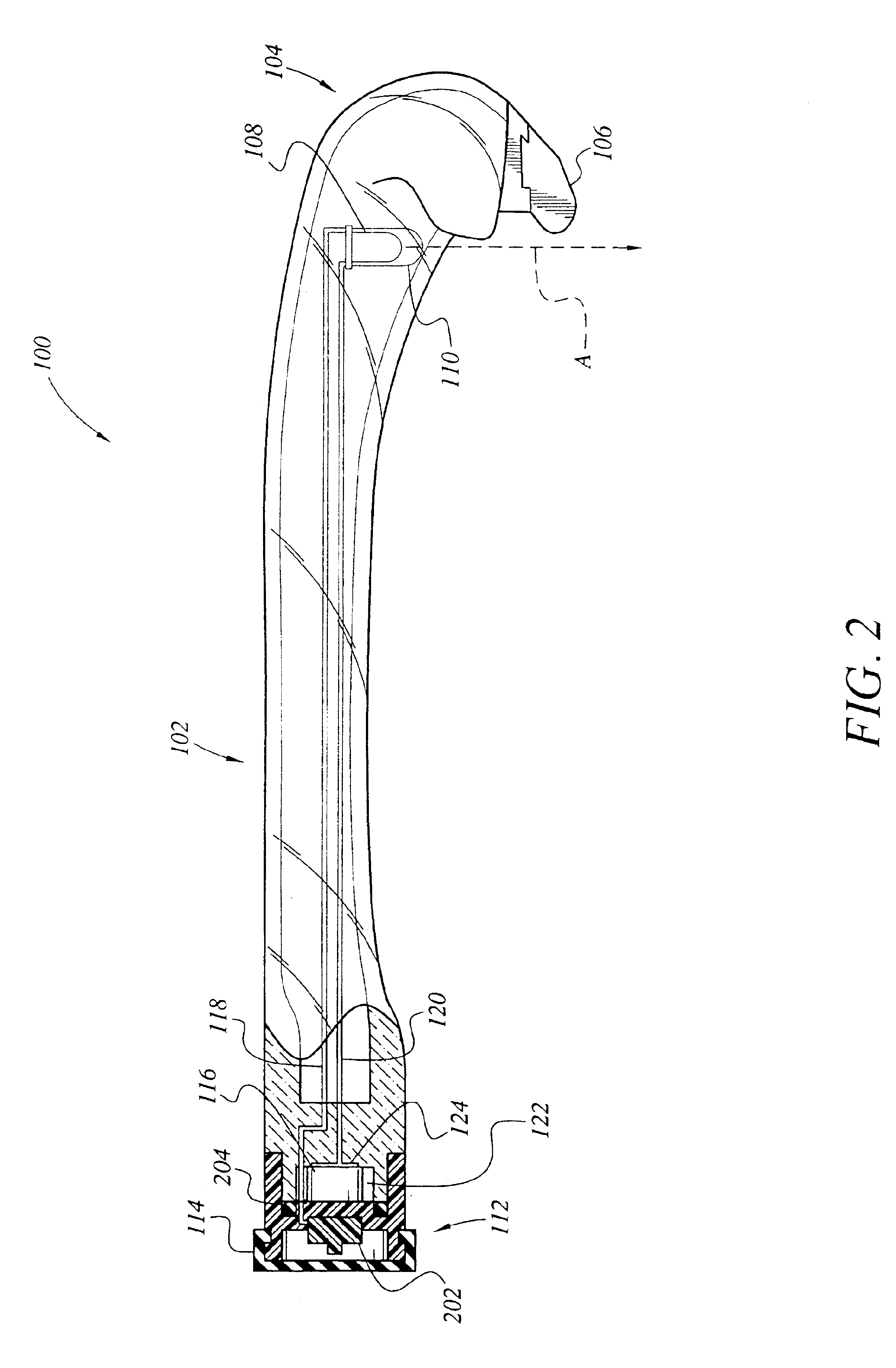

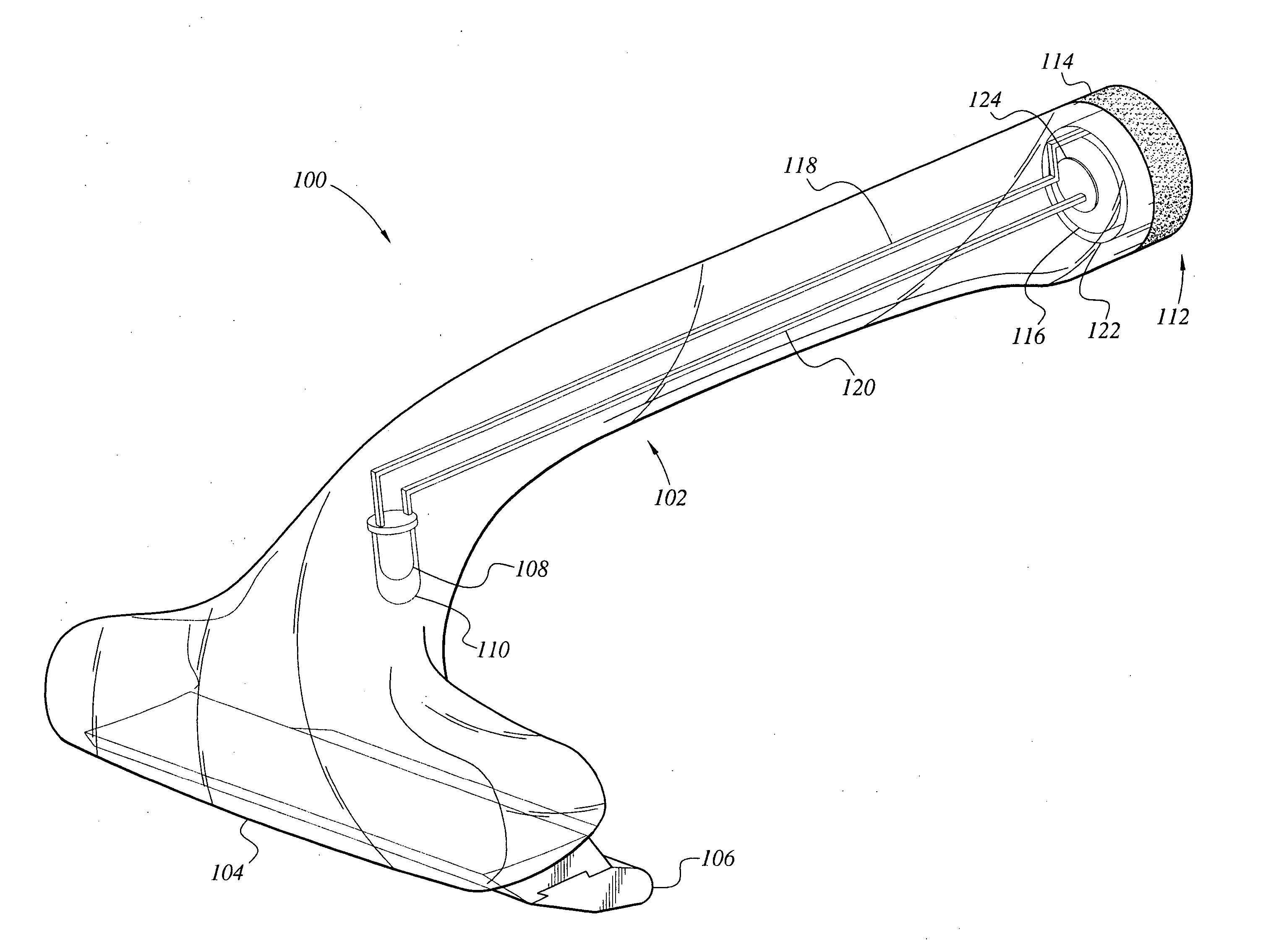

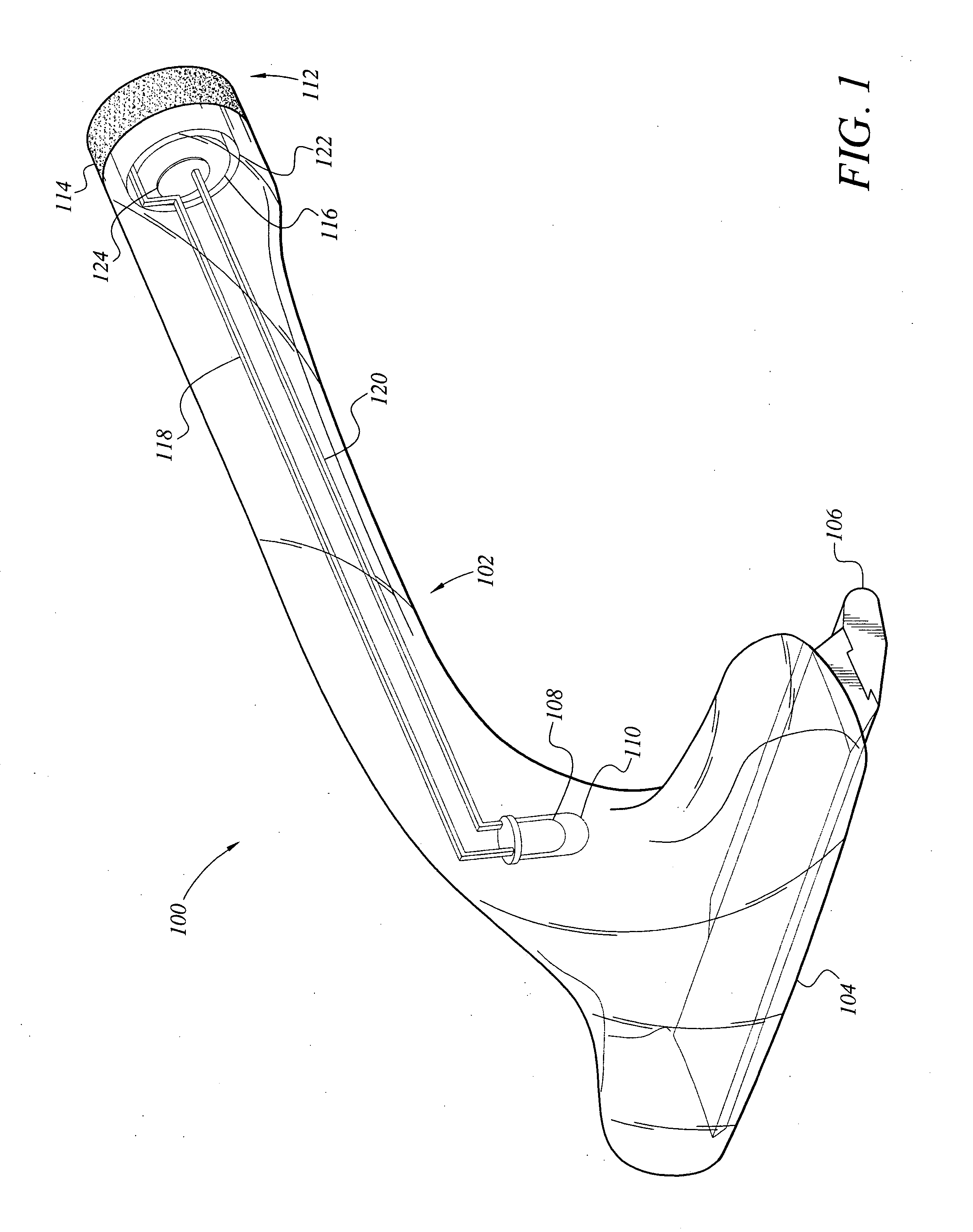

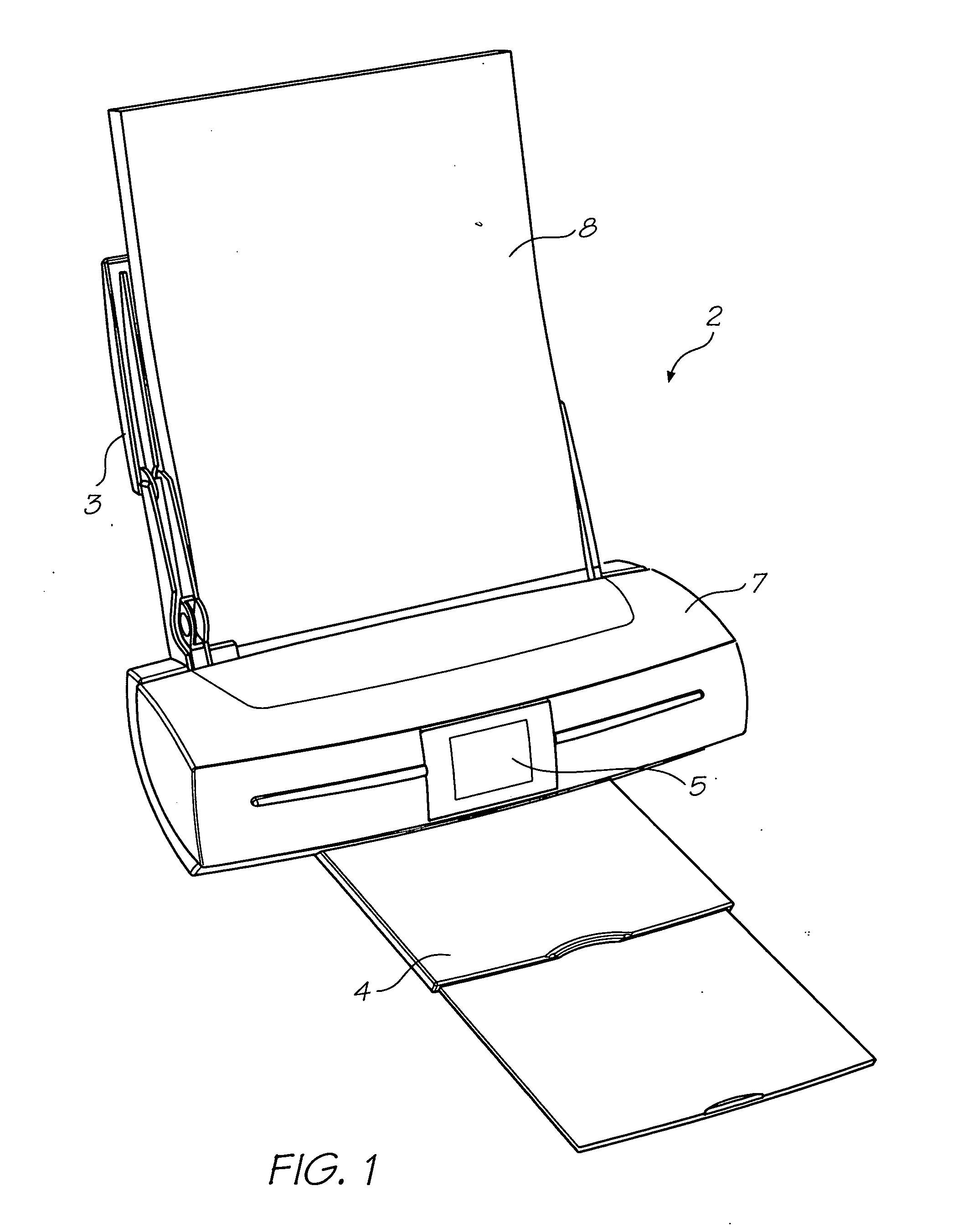

Illuminated safety razor

InactiveUS6915576B2Improves sealing reliabilityPortable power-driven toolsMetal working apparatusRazor stropEngineering

Owner:BRZEZINSKI LISA M

Illuminated safety razor

InactiveUS20050034307A1Improves sealing reliabilityPortable power-driven toolsMetal working apparatusEffect lightHigh intensity

The illuminated safety razor has a substantially transparent handle and a razor head adapted to hold a razor blade cartridge. A high-intensity LED disposed in the razor head illuminates the area to be shaved. The LED may be molded within the razor head in various orientations dependent upon the contour of the razor head and the desired lighting effect. The handle open at the rear end, is adapted to receive at least one battery. A threaded end cap engages the opening, abutting the battery and contains a micro-pushbutton switch. Depressing a waterproof diaphragm covering the rear of the end cap toggles the switch, supplying a voltage to the LED, thereby illuminating the razor and the area to be shaved.

Owner:BRZEZINSKI LISA M

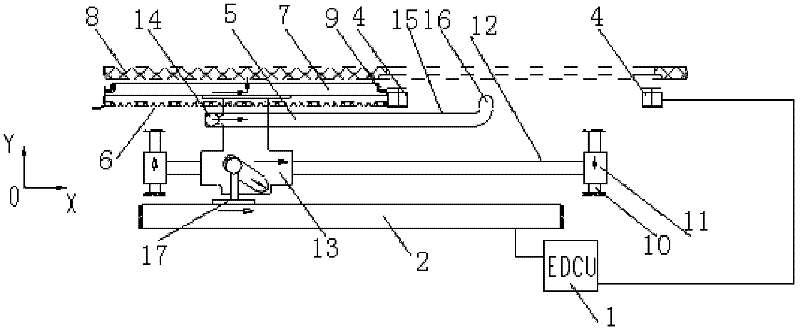

Built-in plug door device for rail vehicle

ActiveCN102303618AAvoid disadvantagesLimit sheddingPower-operated mechanismDoor arrangementEngineeringMechanical engineering

The invention discloses a built-in plug door device for a rail vehicle. The device comprises a control mechanism, a driving mechanism, a bearing mechanism, a compaction mechanism, a guide chute and a door leaf; the bearing mechanism comprises a guide post, two sleeves, a connecting rod, a sliding block and a guide wheel; and the control mechanism is respectively connected with the driving mechanism and the compaction mechanism. The advantages of an outward swing plug door and a built-in side sliding door are combined in the built-in plug door device, and the problem of smooth appearance of the built-in side sliding door is solved by plug movement; the outer side of the body is smoother, the influence of high-speed running pressure wave on the door leaf is reduced, and high-speed running noise is reduced; the body is 140 millimeters wider than the body using the outward swing plug door; and when the plug process of the door leaf is finished, the door leaf is compacted on the body, and the possibility that the door leaf drops outwards is totally limited, so safety and sealing reliability are improved.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

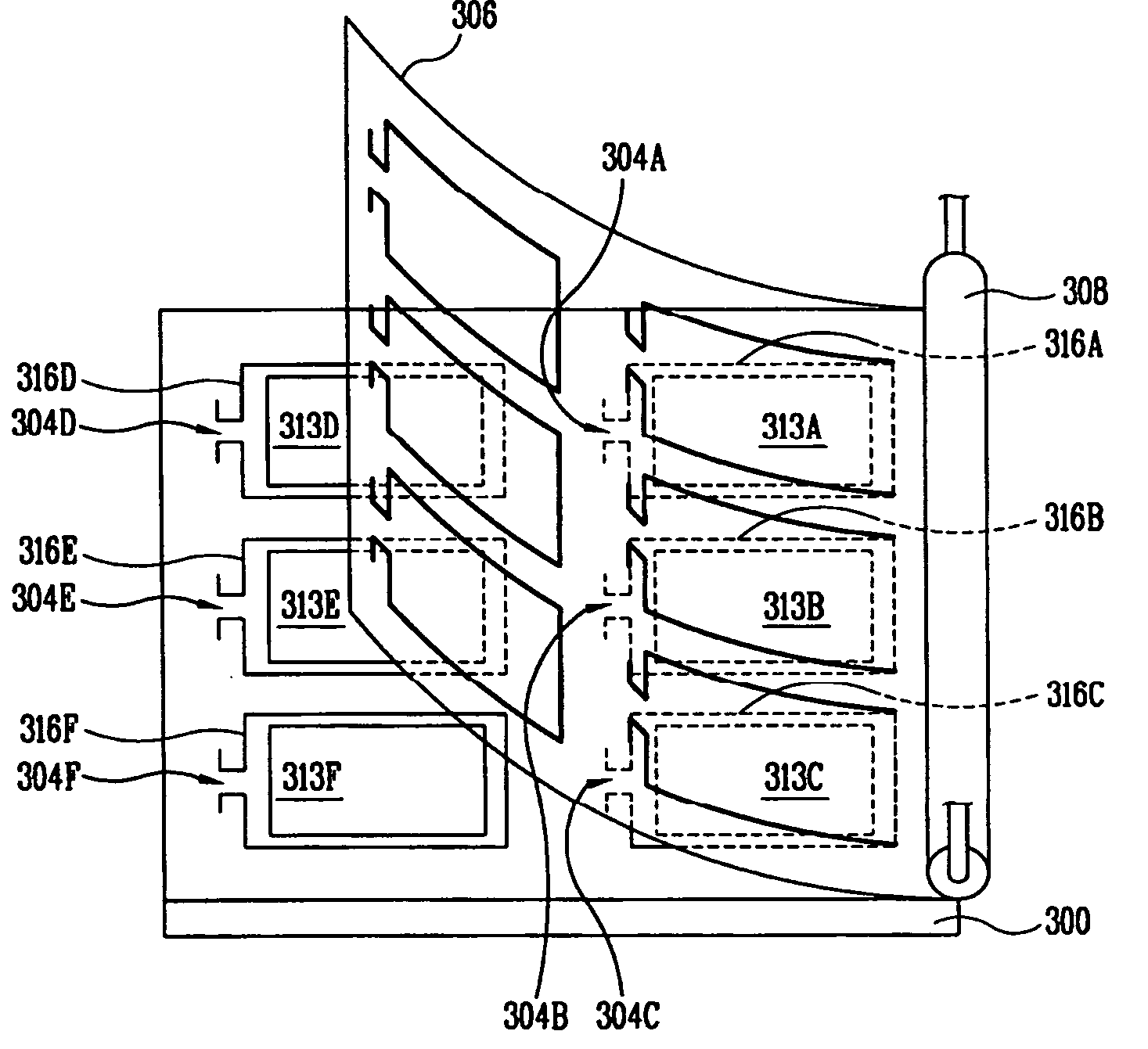

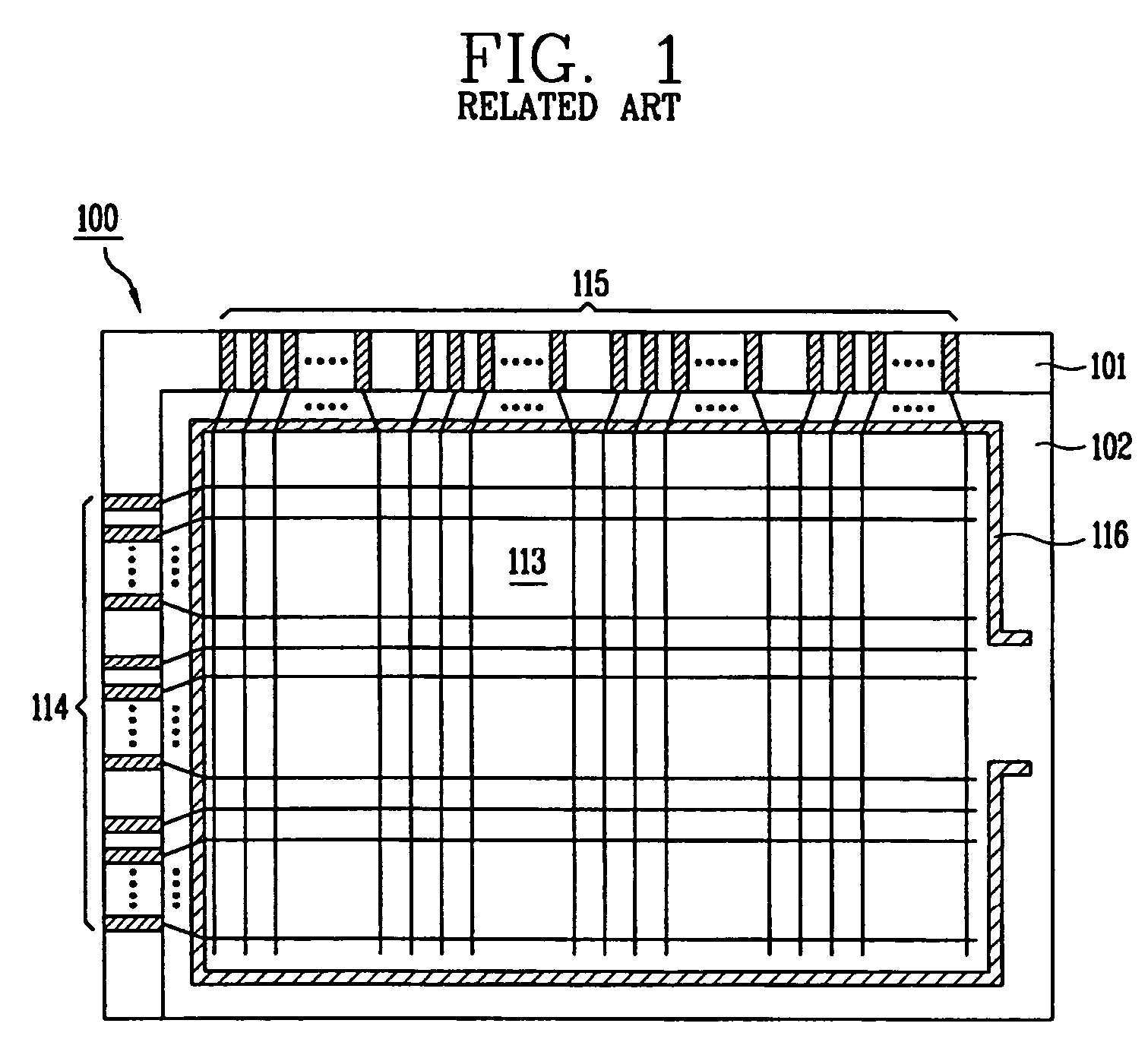

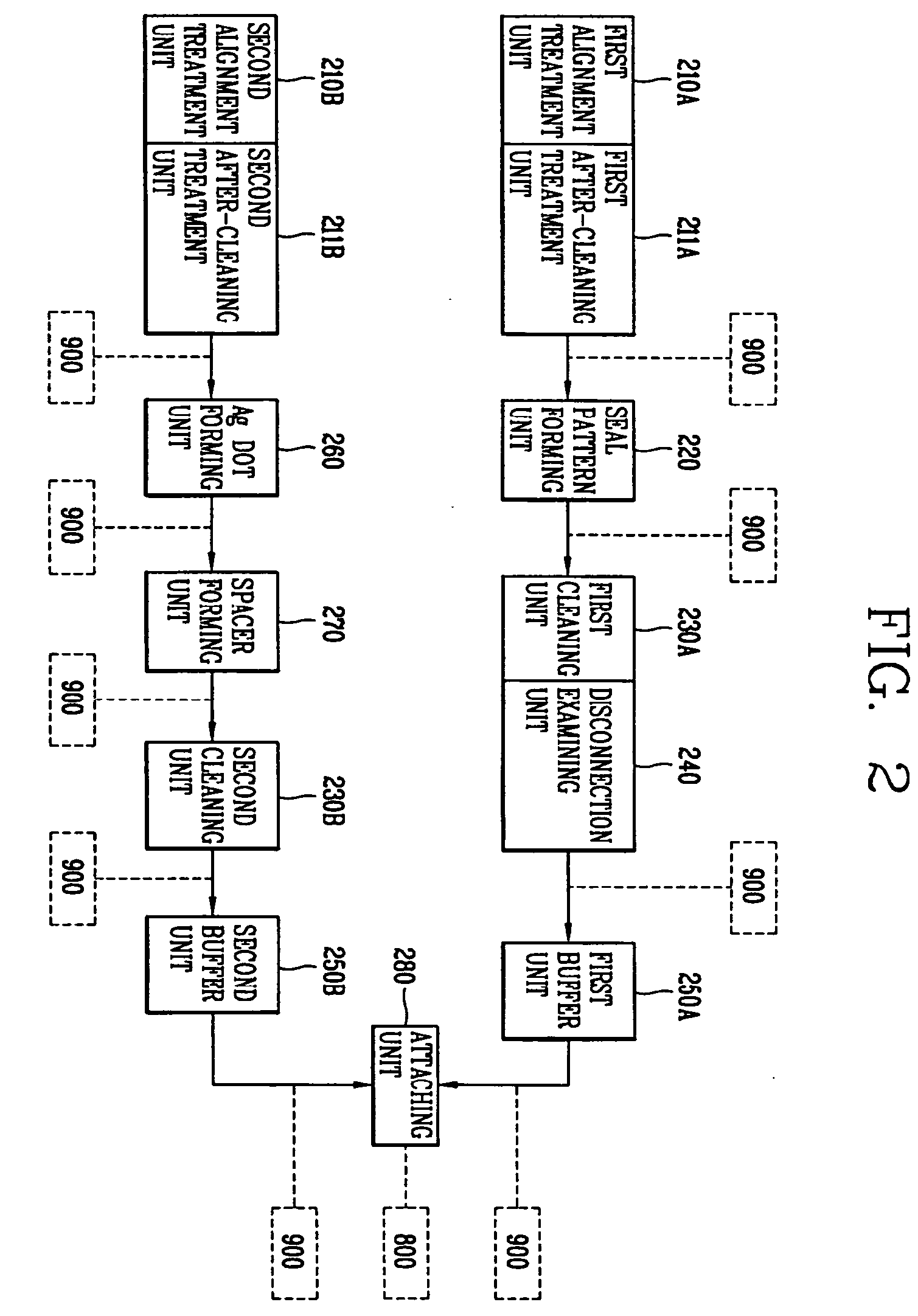

Apparatus and method for fabricating liquid crystal display

ActiveUS20050126679A1Improves sealing reliabilityShorten the timeLiquid surface applicatorsLamination ancillary operationsLiquid-crystal displayEngineering

Owner:LG DISPLAY CO LTD

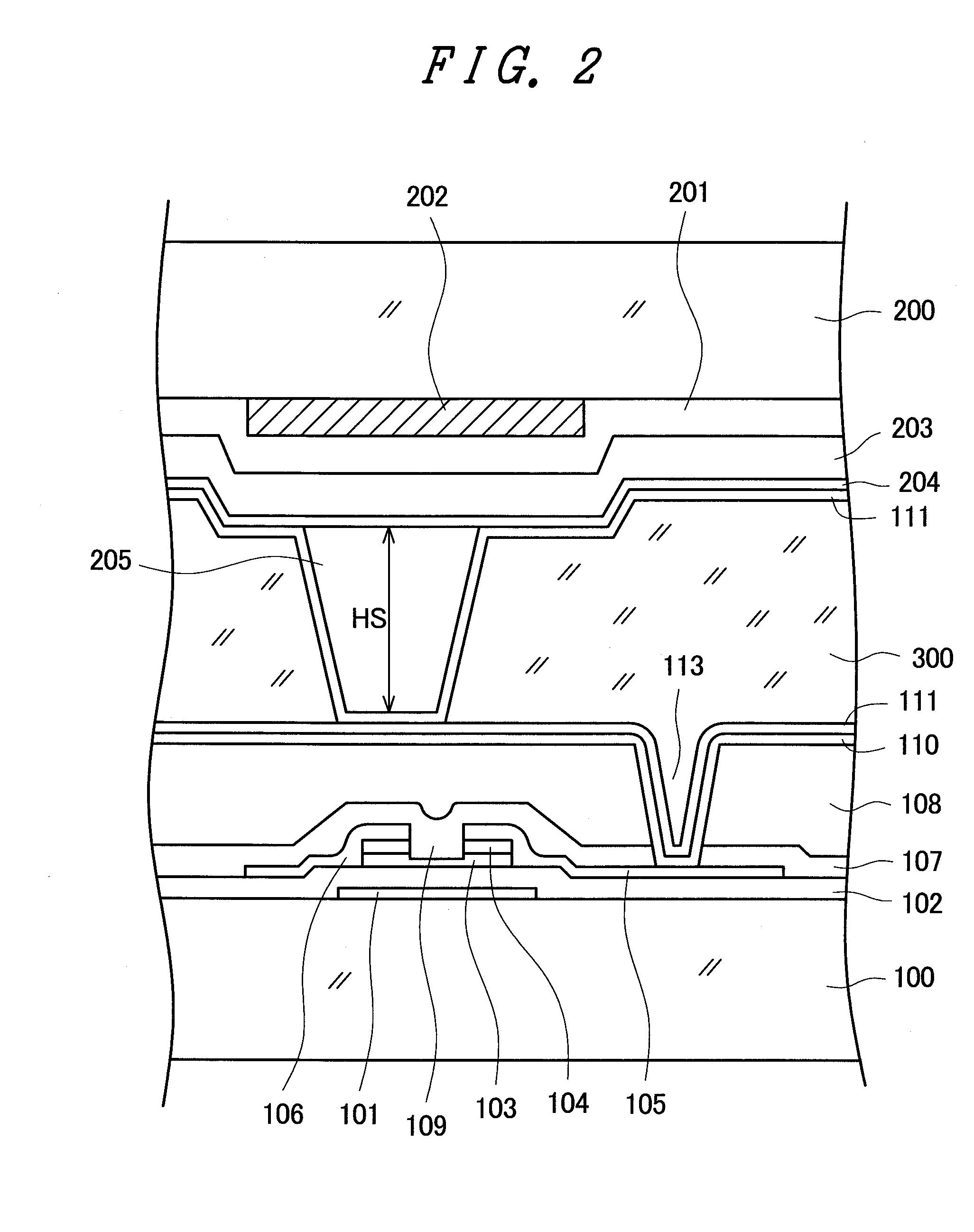

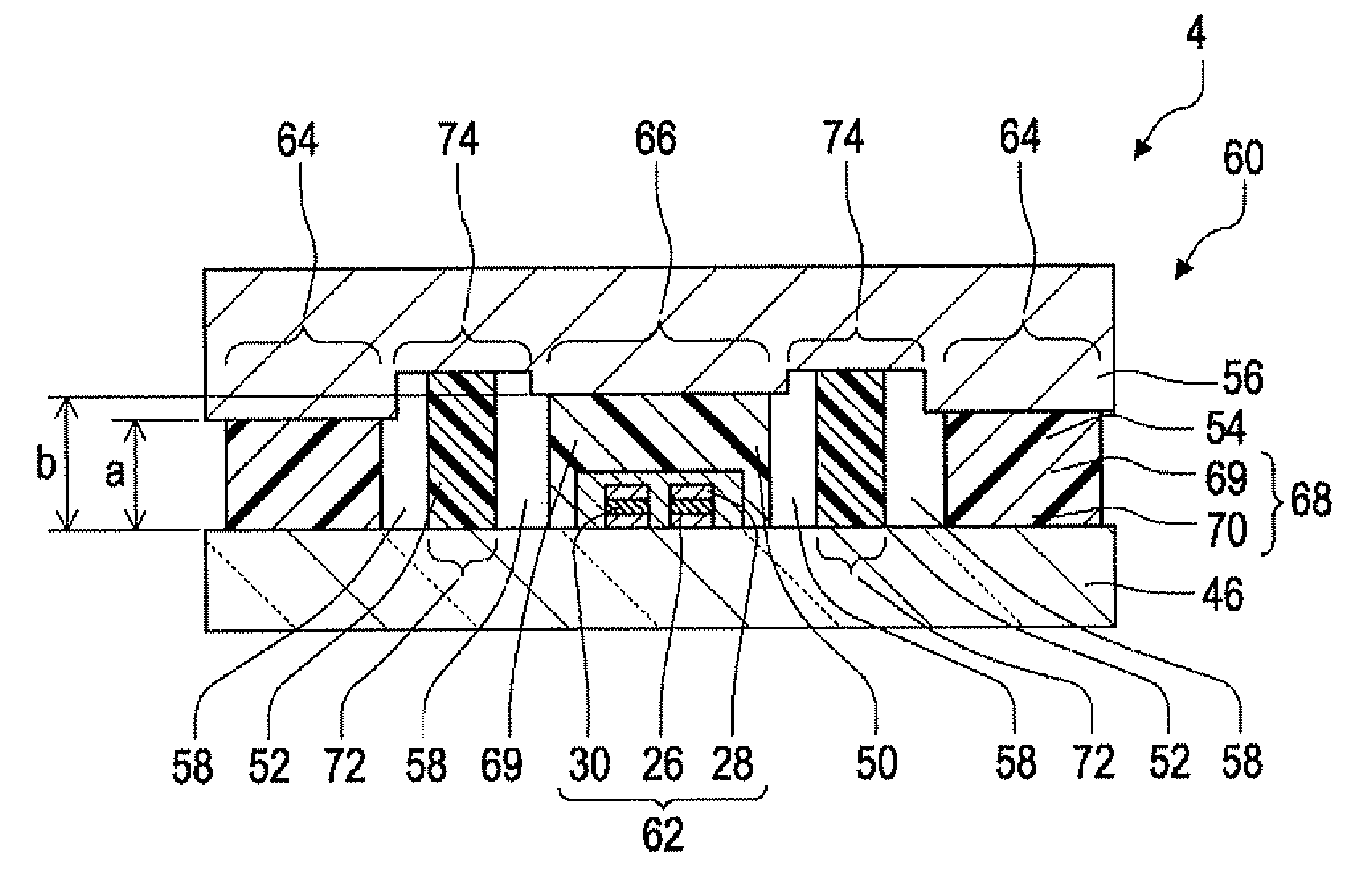

Liquid crystal display device

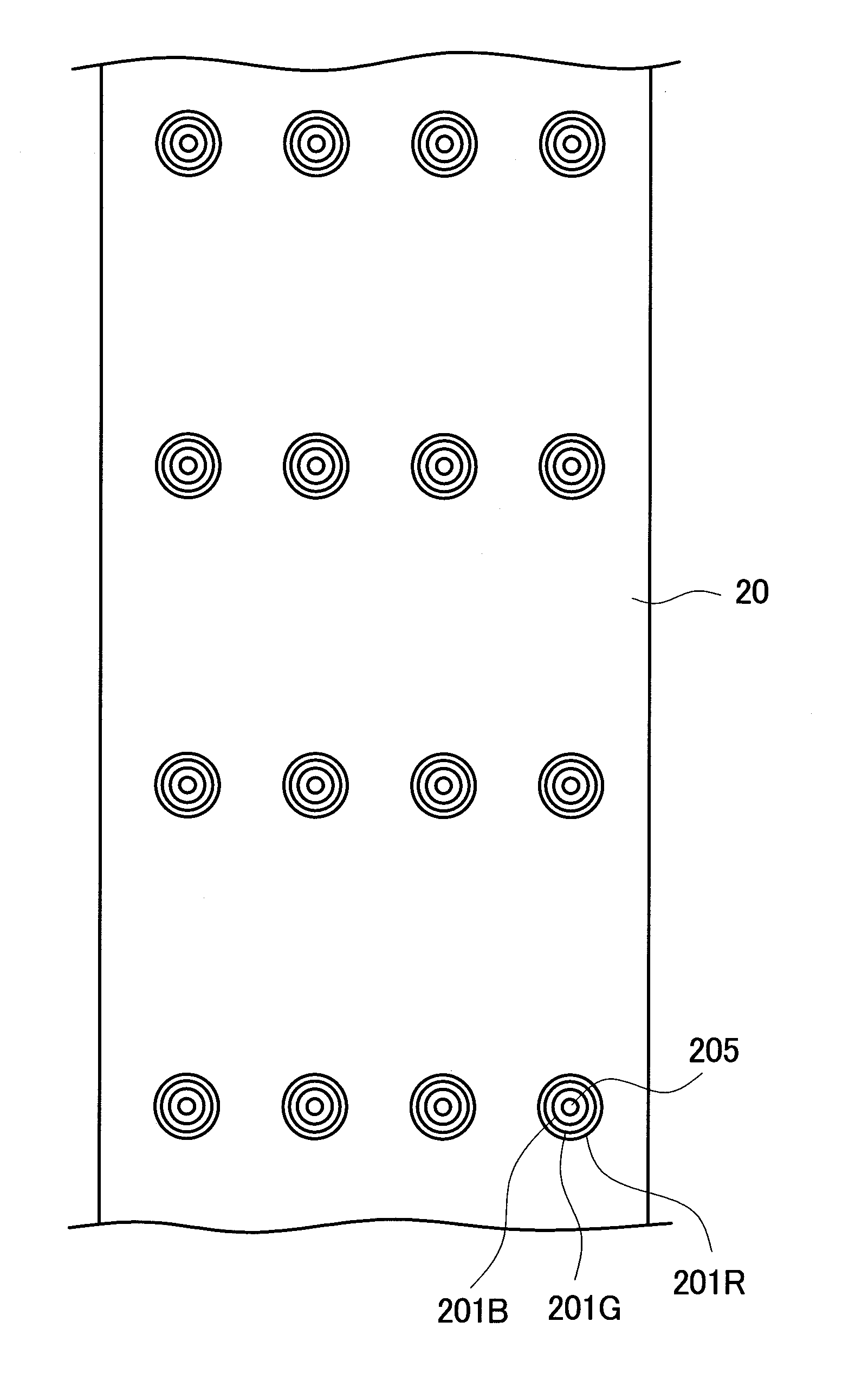

ActiveUS20110007251A1Improves sealing reliabilityGeneration of air bubble is preventedNon-linear opticsLiquid-crystal displayEngineering

In a liquid crystal display device in which liquid crystal is sealed by a one drop fill method, the gap between a TFT substrate and a counter substrate is defined by a columnar spacer in a display region, and the gap between them is defined by a columnar spacer also in a seal portion. In the display region, one layer of a color filter is formed below the columnar spacer. In the seal portion, two layers of island-shaped color filters are formed. With this configuration, the gap between the TFT substrate and the counter substrate can be maintained equal between the display region and the seal portion. Even when the process for forming the columnar spacer varies, it is possible to eliminate a change in difference between the gap between the TFT substrate and the counter substrate in the display region and the gap in the seal portion.

Owner:JAPAN DISPLAY INC +1

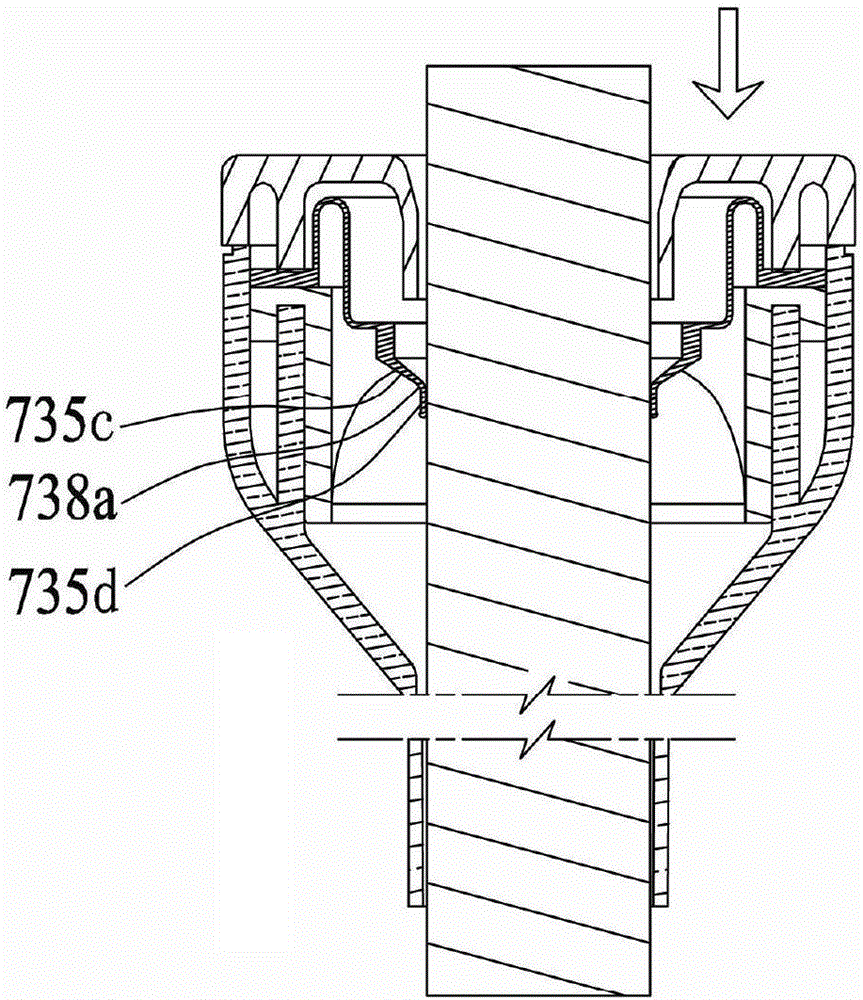

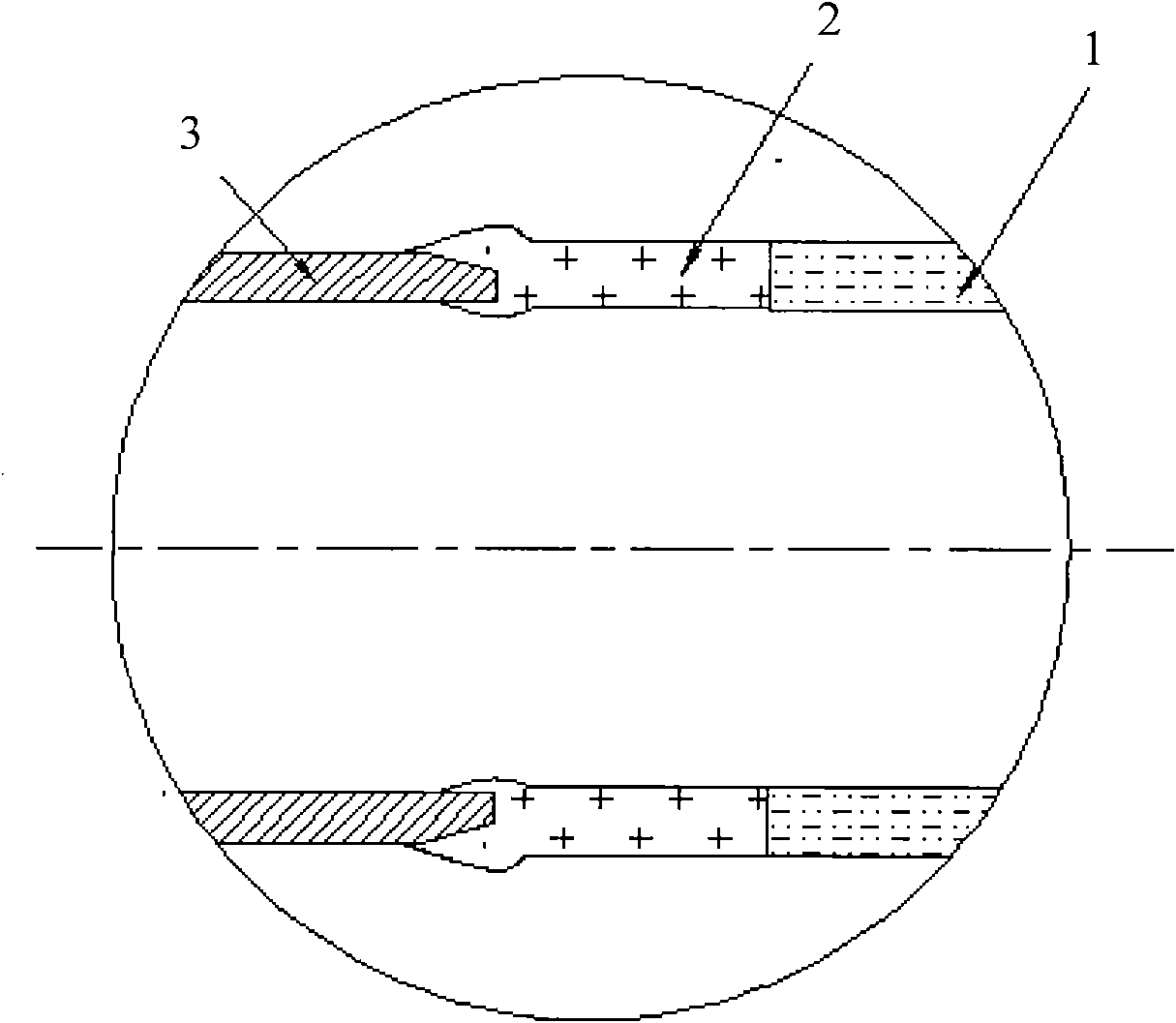

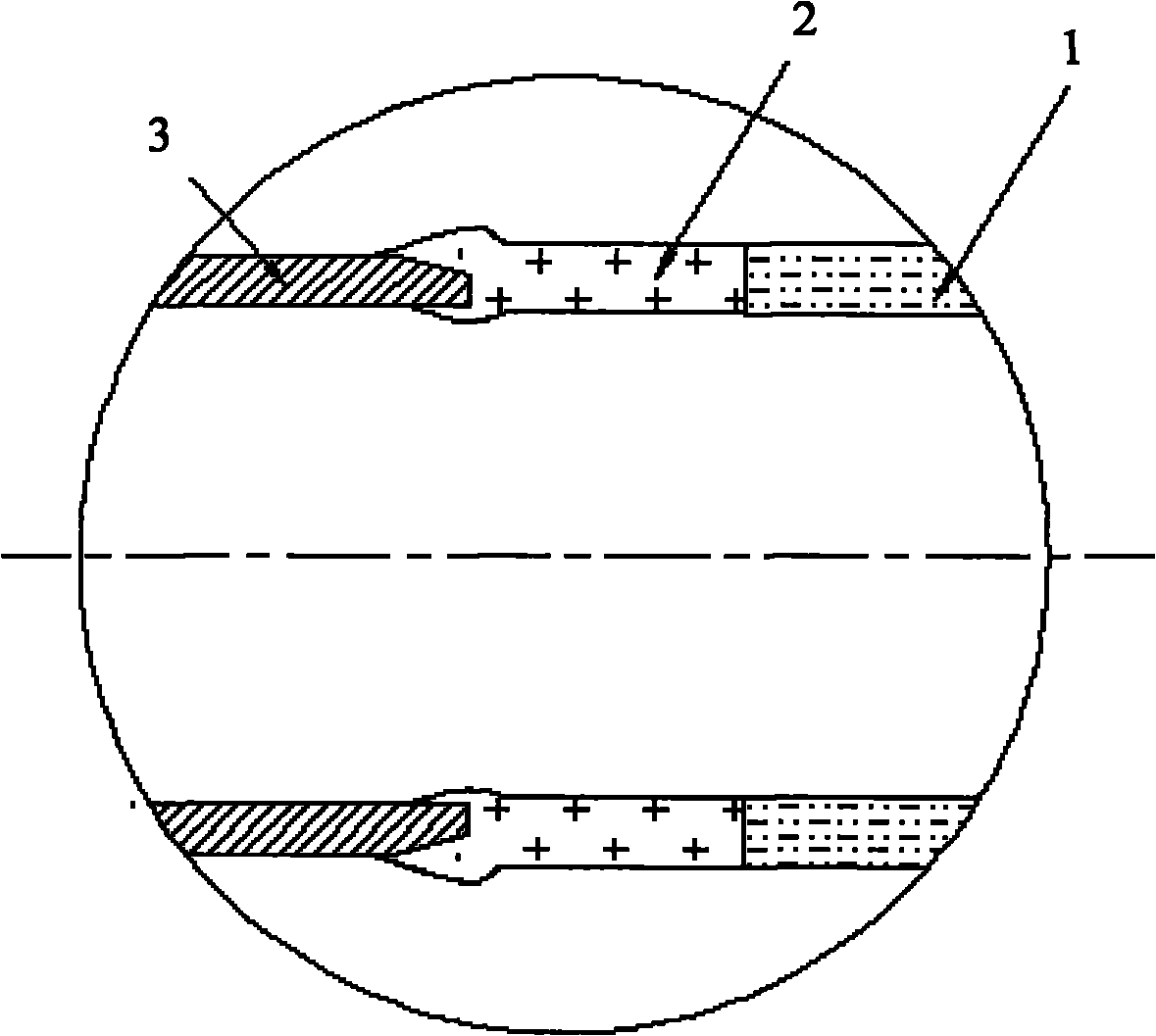

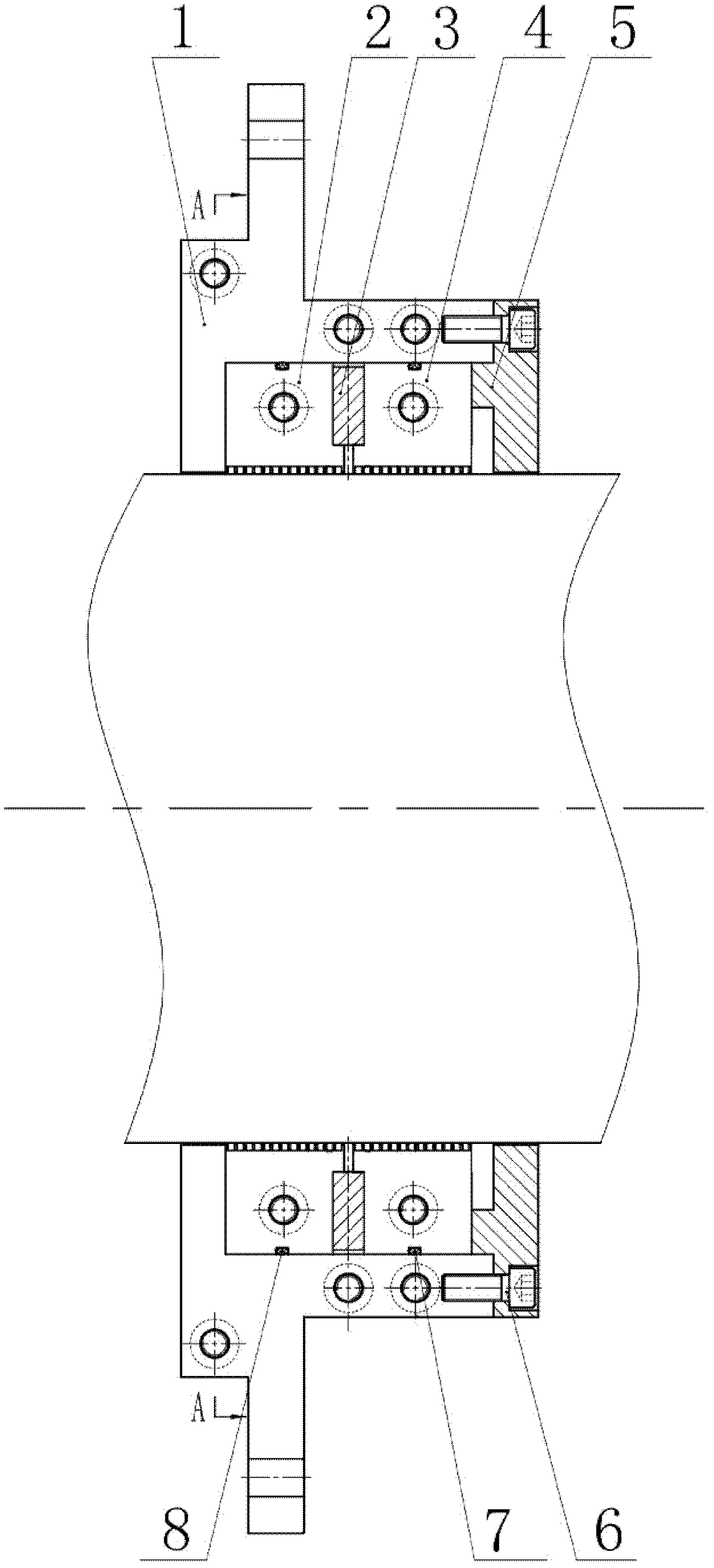

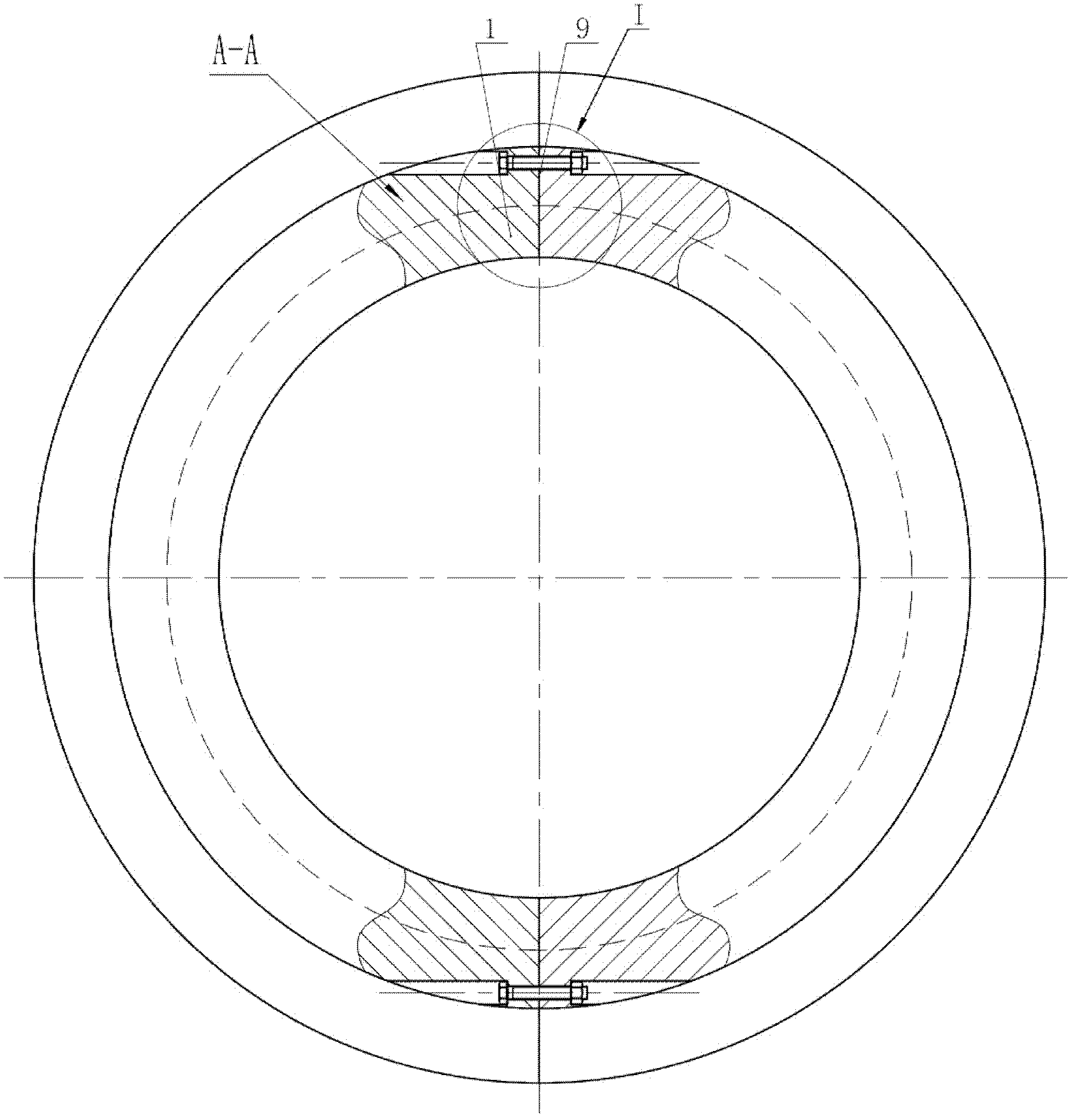

Multidimensional-fold-containing puncture outfit sealing membrane

ActiveCN105997204AImprove sealingReduce frictional resistanceCannulasSurgical needlesFriction forceMembrane configuration

The invention relates to a multidimensional-fold-containing puncture outfit sealing membrane which comprises a near-end opening and a far-end hole as well as a sealing wall extending from the far-end hole to the near-end opening, wherein the sealing wall is provided with a near-end surface and a far-end surface; the far-end hole is formed by a sealing lip and is used for accommodating an inserted instrument and forming an air seal. In a sealing lip close region, the sealing wall is simultaneously provided with a plurality of transverse folds transversely and outwards extending from the sealing lip and tangent folds uniformly distributed around the sealing lip; due to the fold type sealing wall, the annular perimeter of the sealing lip close region can be increased, and the general deformation caused by the application of a large-diameter instrument can be reduced favorably, so that the friction force is reduced, and the sealing reliability is improved.

Owner:5R MED TECH CHENGDU CO LTD

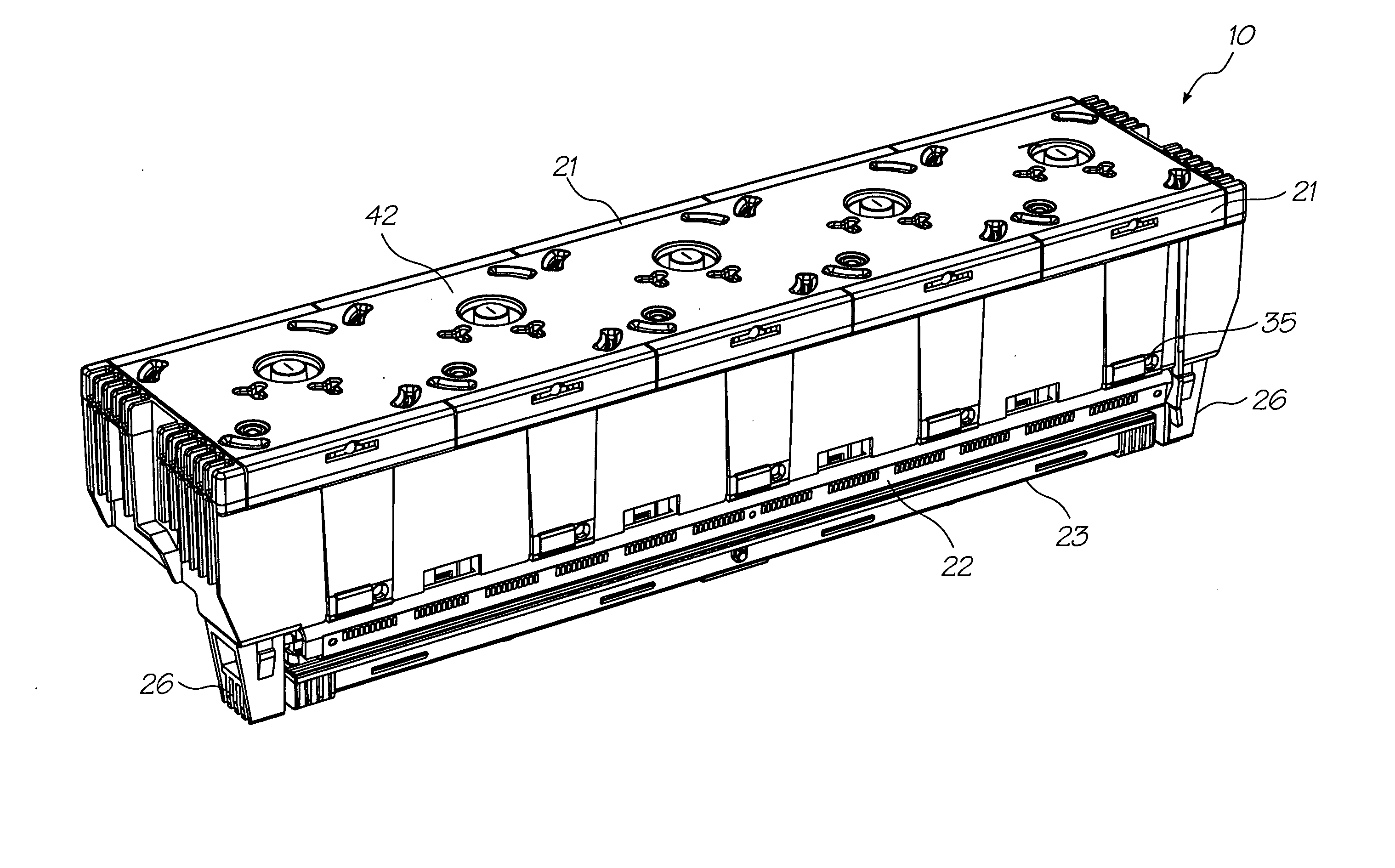

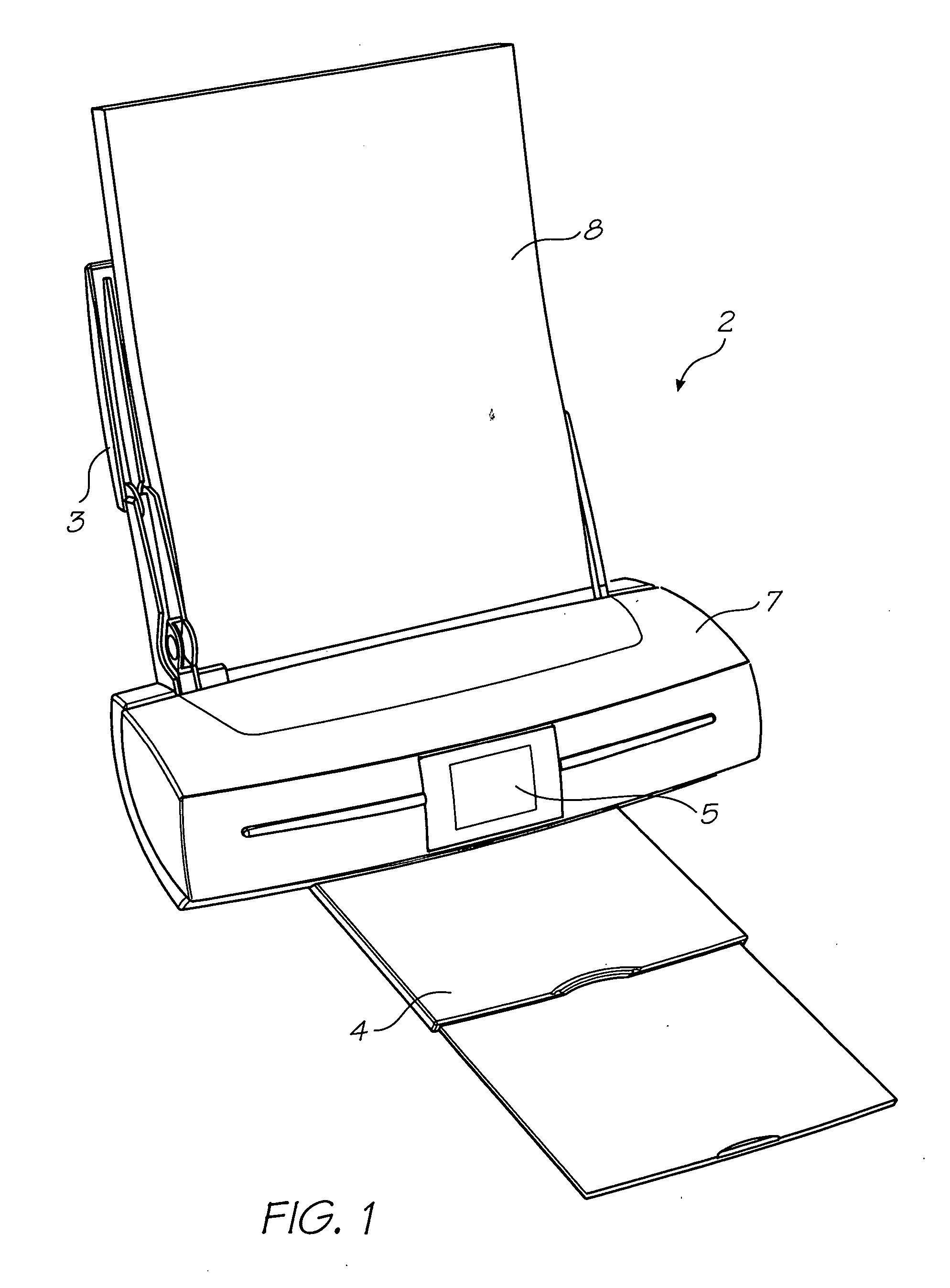

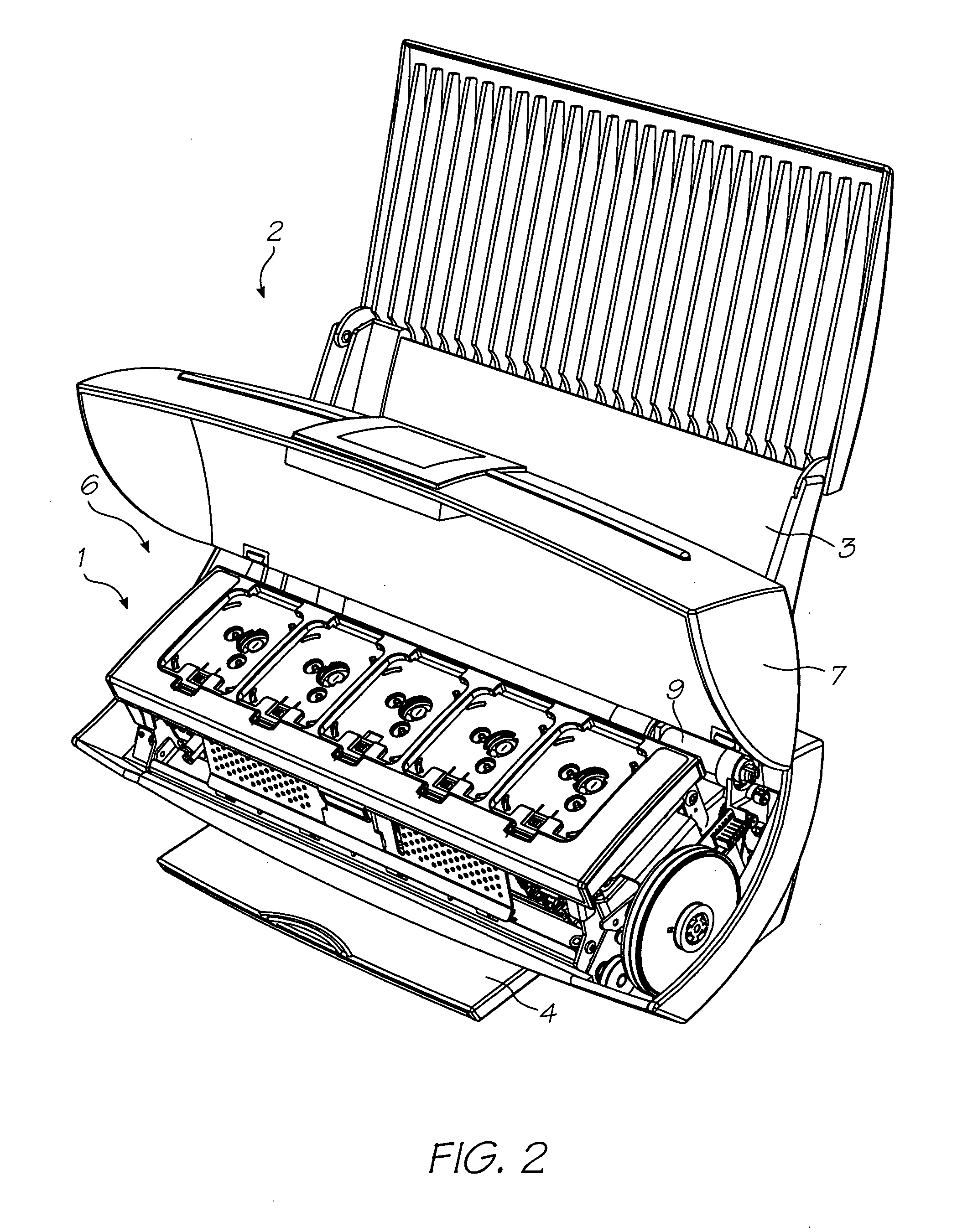

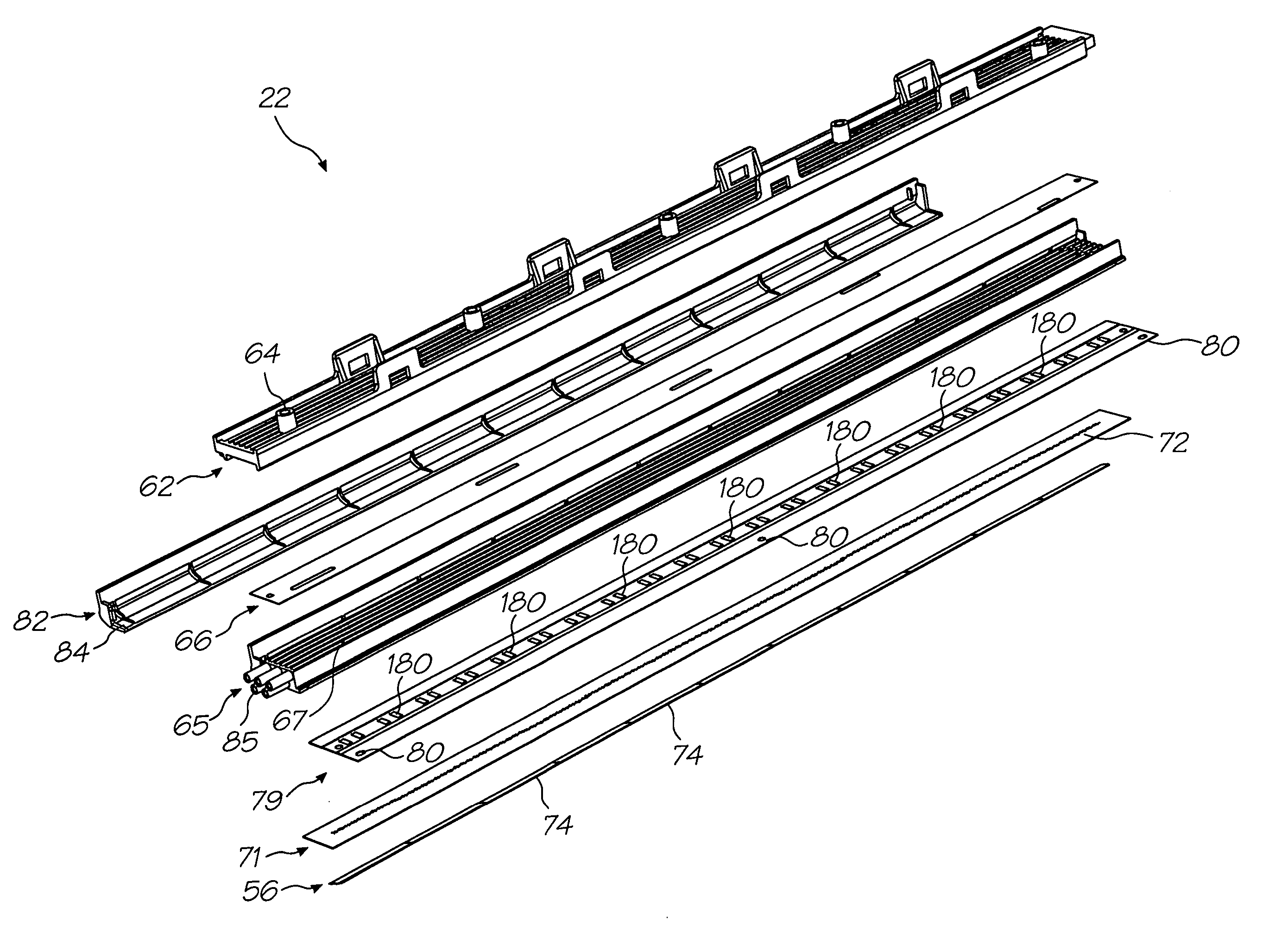

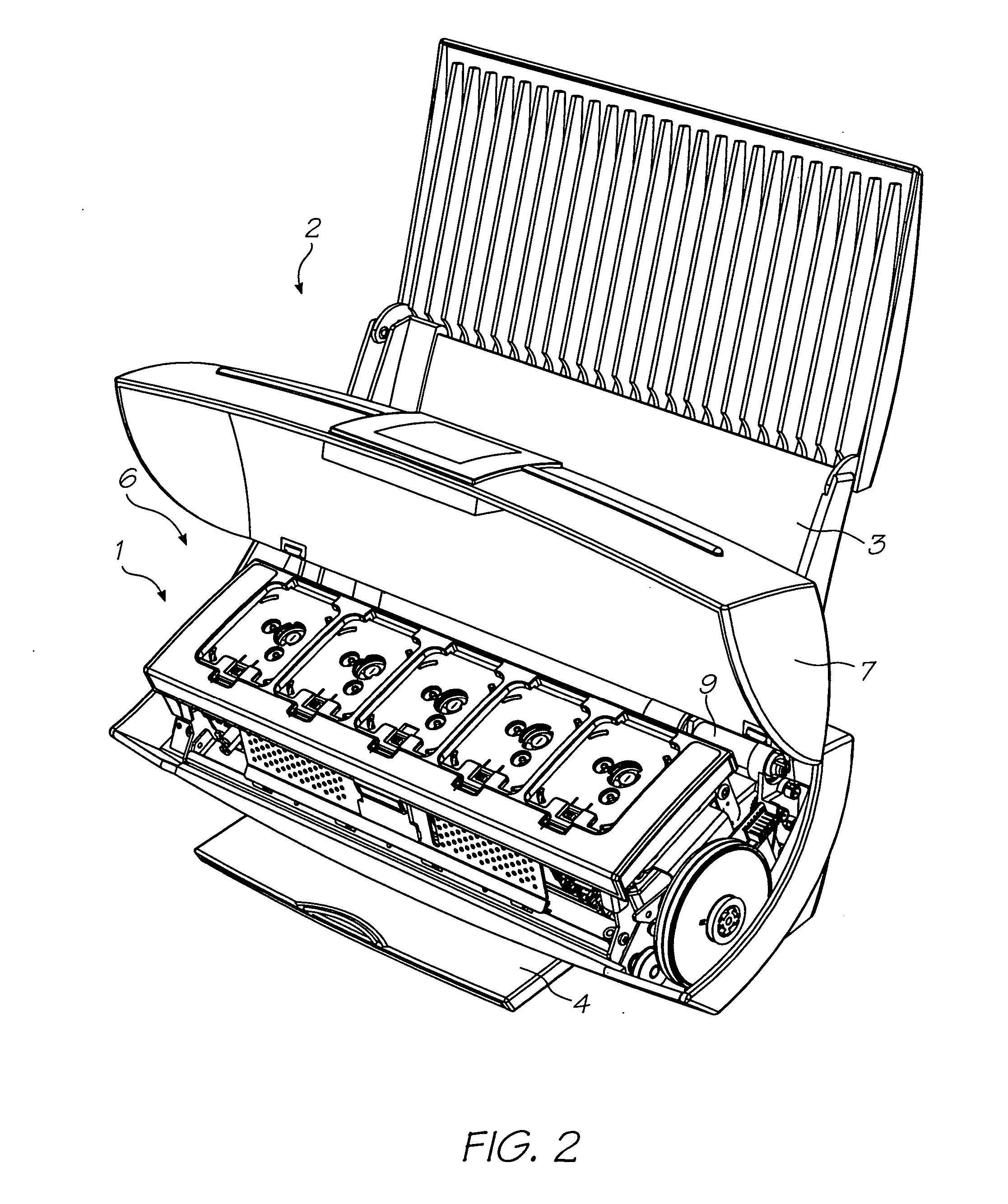

Inkjet printhead with integrated circuit mounted on polymer sealing film

InactiveUS20050156985A1Avoiding inadvertent ink leakageNegative pressure is createdInking apparatusPower drive mechanismsEtchingInk printer

A printhead for an inkjet printer, the printhead comprising: a printhead integrated circuit formed on a wafer substrate using lithographically masked etching and deposition techniques; an integrated circuit support structure for mounting in the printer adjacent a media feed path; and, a polymer sealing film between the integrated circuit support structure and the printhead integrated circuit for fixing the printhead integrated circuit to the integrated circuit support structure.

Owner:SILVERBROOK RES PTY LTD +1

Sealing material for plastic liquid crystal display cells including two-component epoxy resin composition

InactiveUS6913798B2Improves sealing reliabilityDisplay stableLiquid crystal compositionsLayered productsEpoxyLiquid-crystal display

A sealant composition for a plastic liquid crystal display cell is composed of a two-component epoxy resin composition of a base resin liquid and a curing agent liquid, wherein the base resin is a liquid epoxy resin having from 1.7 to 6 in weight average of epoxy groups in one molecule and an ionic conductivity of 2 mS / m or less; and the curing agent has an ionic conductivity of 0.6 mS / m or less. The sealant composition facilitates the fabrication of plastic liquid crystal displays having enhanced durability and sealant properties, particularly in high temperature and high humidity environments.

Owner:MITSUI CHEM INC

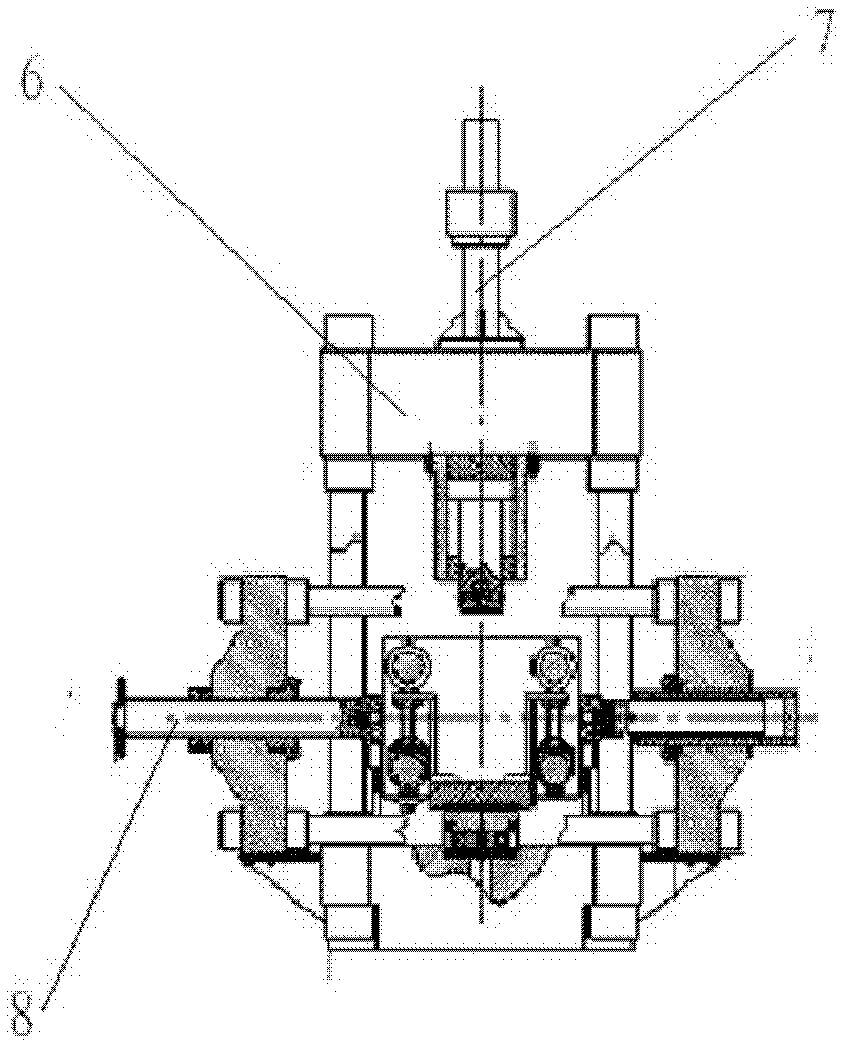

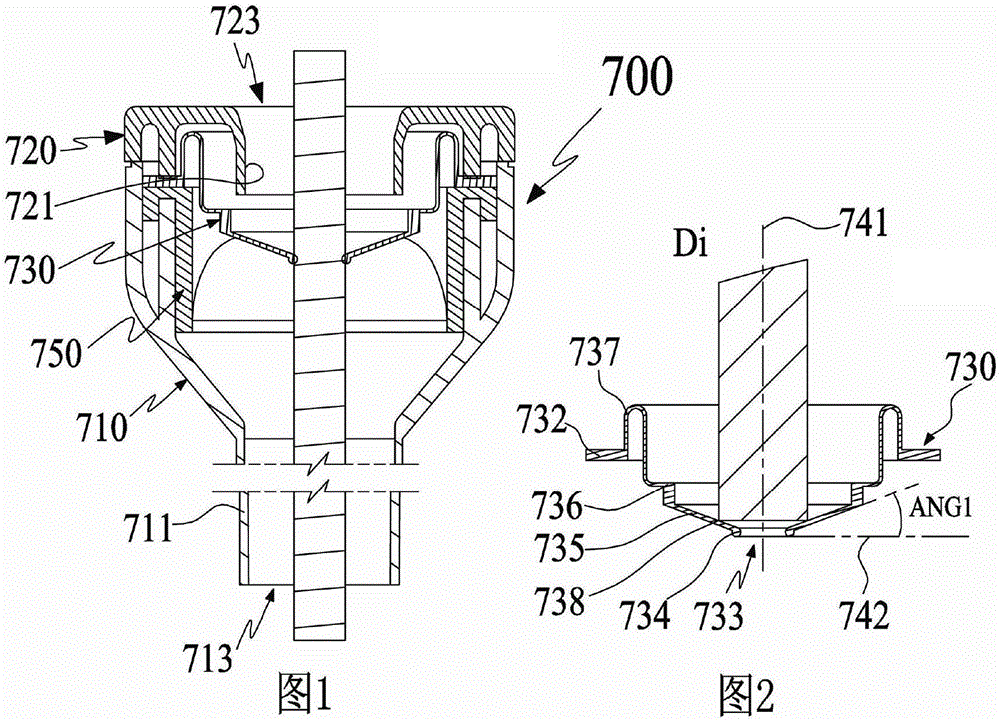

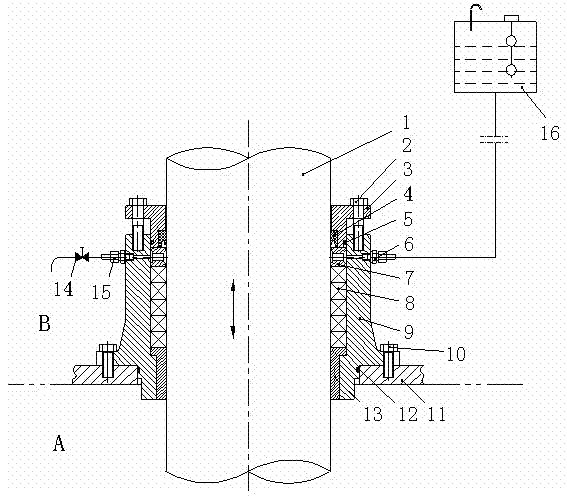

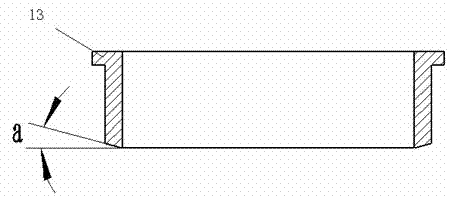

Movable sealing device for telescopic full-revolving rudder paddle

ActiveCN102359599AAlleviate harsh environmentExtended service lifeEngine sealsLubrication elementsEngineeringMechanical engineering

The invention relates to a seawater-proof movable sealing device of ocean engineering equipment, in particular to a movable sealing device for a telescopic full-revolving rudder paddle, which is used on an ocean engineering boat and an ocean platform. The sealing performance of the telescopic full-revolving rudder paddle is ensured through four measures of a guide sleeve guide and filth clearing protection measure, a packing sealing measure, a lip-type sealing ring sealing measure and a lubrication and leakage check measure, through the efficient lubrication and the leakage check measure, the movable sealing device of the telescopic full-revolving rudder paddle is in an efficient controllable state in seawater, the work safety of the sealing device is improved, and the service life of the telescopic full-revolving rudder paddle is prolonged by more than 50 percent.

Owner:WUHAN MARINE MACHINERY PLANT

Organic electroluminescent apparatus

InactiveUS20090261719A1Increase load weightImproves sealing reliabilityDischarge tube luminescnet screensLamp detailsOrganic electroluminescenceDrying Agents

An organic electroluminescent apparatus includes a first substrate and a second substrate facing each other, a first sealing portion that seals the first and second substrates so as to form a closed space between the first and second substrates, an organic light-emitting element that is disposed on the first substrate in the closed space and includes an organic light-emitting layer mainly composed of an organic light-emitting material, a second sealing portion that is disposed on the organic light-emitting element and seals the organic light-emitting element, and a drying agent film that is formed in a region surrounded by the first and second sealing portions and is mainly composed of a drying agent.

Owner:SEIKO EPSON CORP

Heat releasing member, package for accommodating semiconductor element and semiconductor device

InactiveUS6921971B2Dissipate heat generatedImproves sealing reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDevice material

Owner:KYOCERA CORP

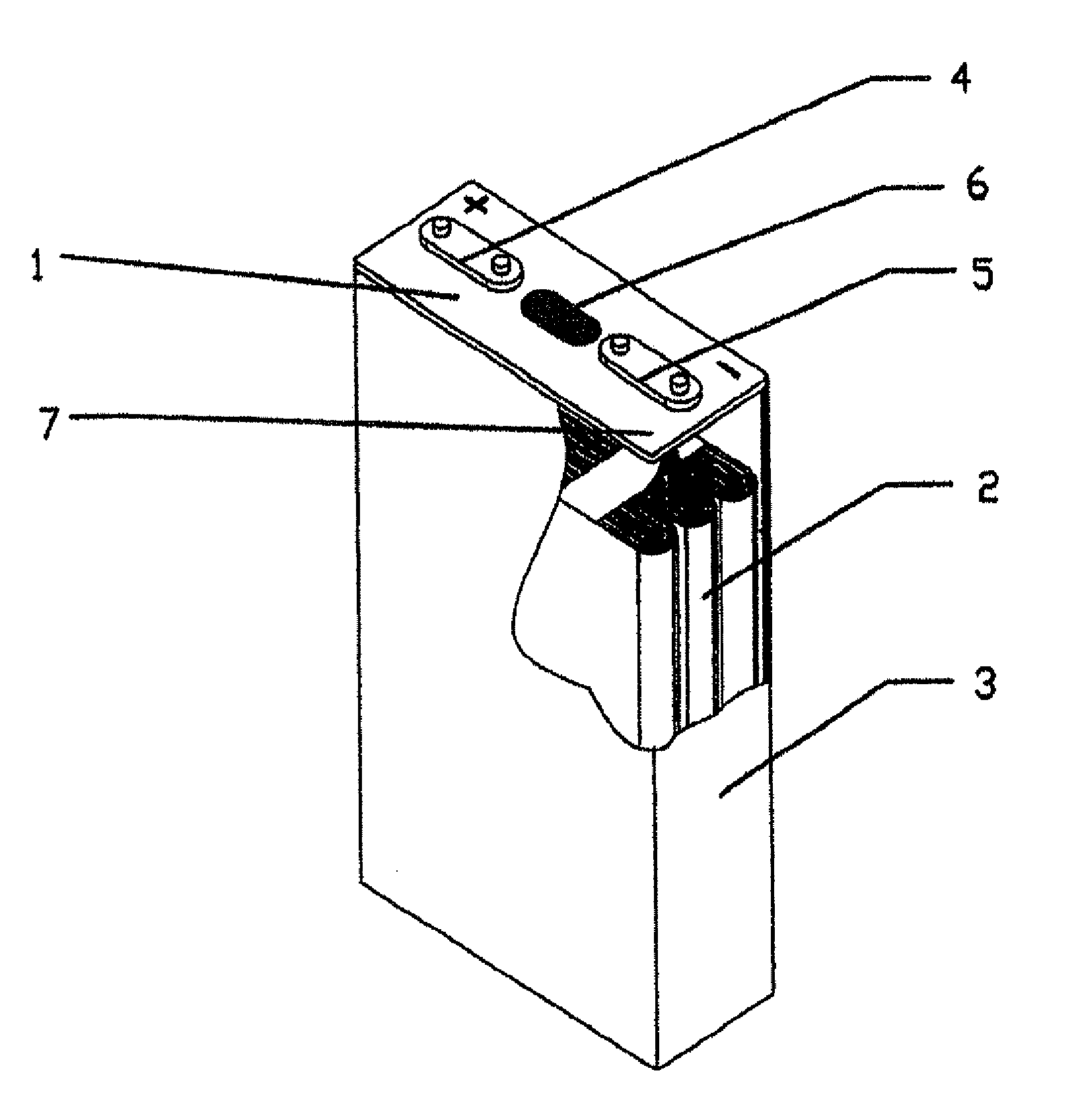

High Capacity Lithium Ion Secondary Battery with Metal Case

InactiveUS20080213657A1Improve battery safetyImprove securityFinal product manufactureSmall-sized cells cases/jacketsLithiumMetallic enclosure

The present invention relates to a high capacity lithium ion secondary battery with metal casing, characterized in that each of the positive terminal or negative terminal includes respectively an upper backing plate, an upper insulator and a lower insulator. The upper backing plate and upper insulator are long-circular piece, two or more rivets pass through the concentric holes on the upper arm of a positive or negative electrode tab, the lower insulator, a sealing cover, the upper insulator and the upper backing plate respectively and rivet them as a whole. The lower arm of the positive electrode tab or negative electrode tab is connected to the corresponding positive or negative electrode tab on a battery core body, and the battery core body is comprised of two or more winded cores in parallel connection. The battery is provided with the advantages and effects of good sealing performance, good electrochemistry property, and simple manufacturing process, as well as high security of a pile comprised of plurality of such individual batteries. As a result the useless space in height of battery is reduced and the volumetric specific energy of the same is enhanced.

Owner:CITIC GUOAN MENGGULI NEW ENERGY TECH

Inkjet printhead with apertured sealing film

ActiveUS20050156988A1Avoiding inadvertent ink leakageNegative pressure is createdInking apparatusPower drive mechanismsInk printerEngineering

A printhead for an inkjet printer, the printhead comprising: a printhead integrated circuit having an array of ink ejection nozzles formed on a substrate; a plurality of ink feed conduits for establishing fluid communication with at least one ink storage compartment; and, a polymer sealing film between the ink feed conduits and the printhead integrated circuits, the polymer film having an array of apertures such that the ejection nozzles are in fluid communication with the ink feed conduits; wherein, the polymer sealing film is more than 25 microns thick.

Owner:SILVERBROOK RES PTY LTD +1

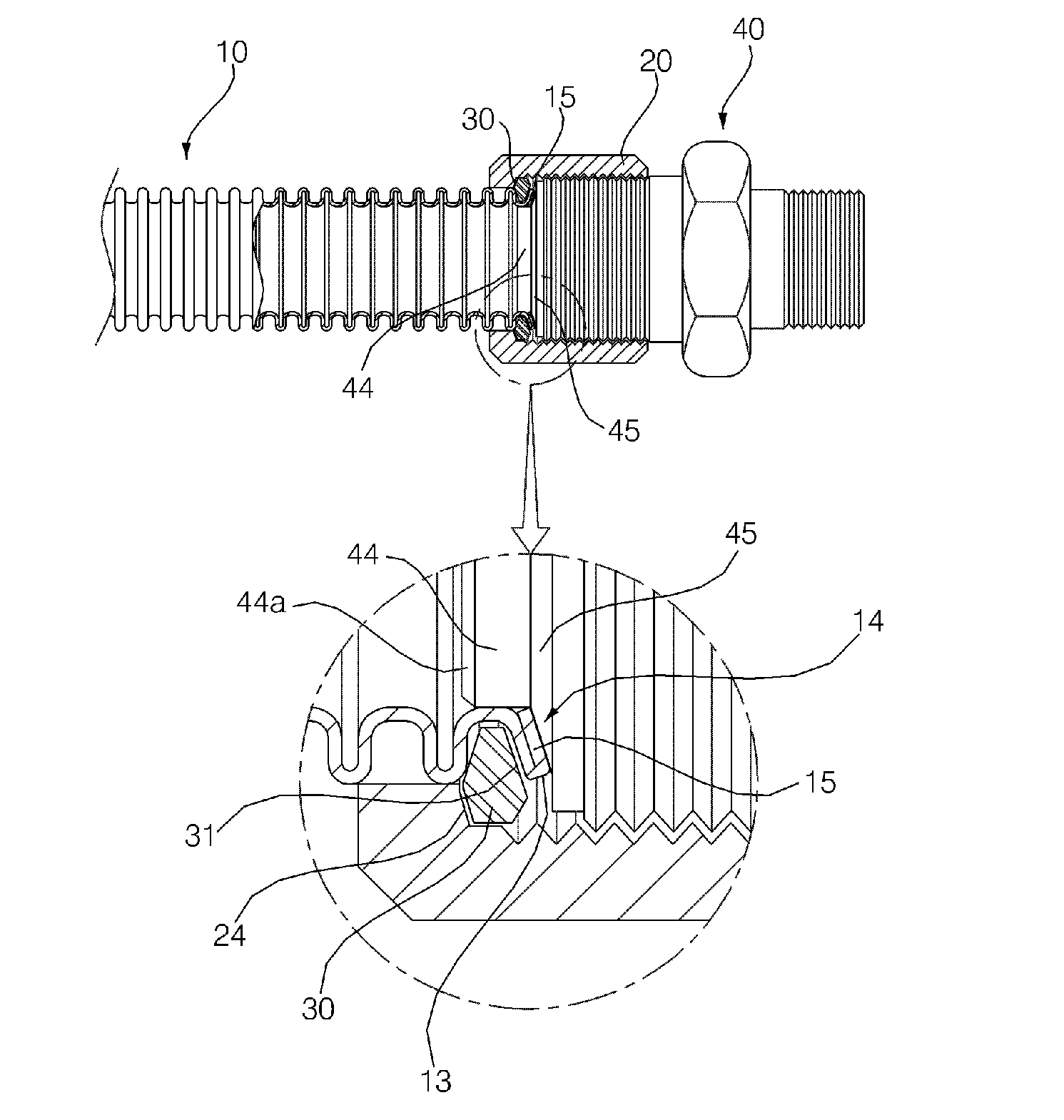

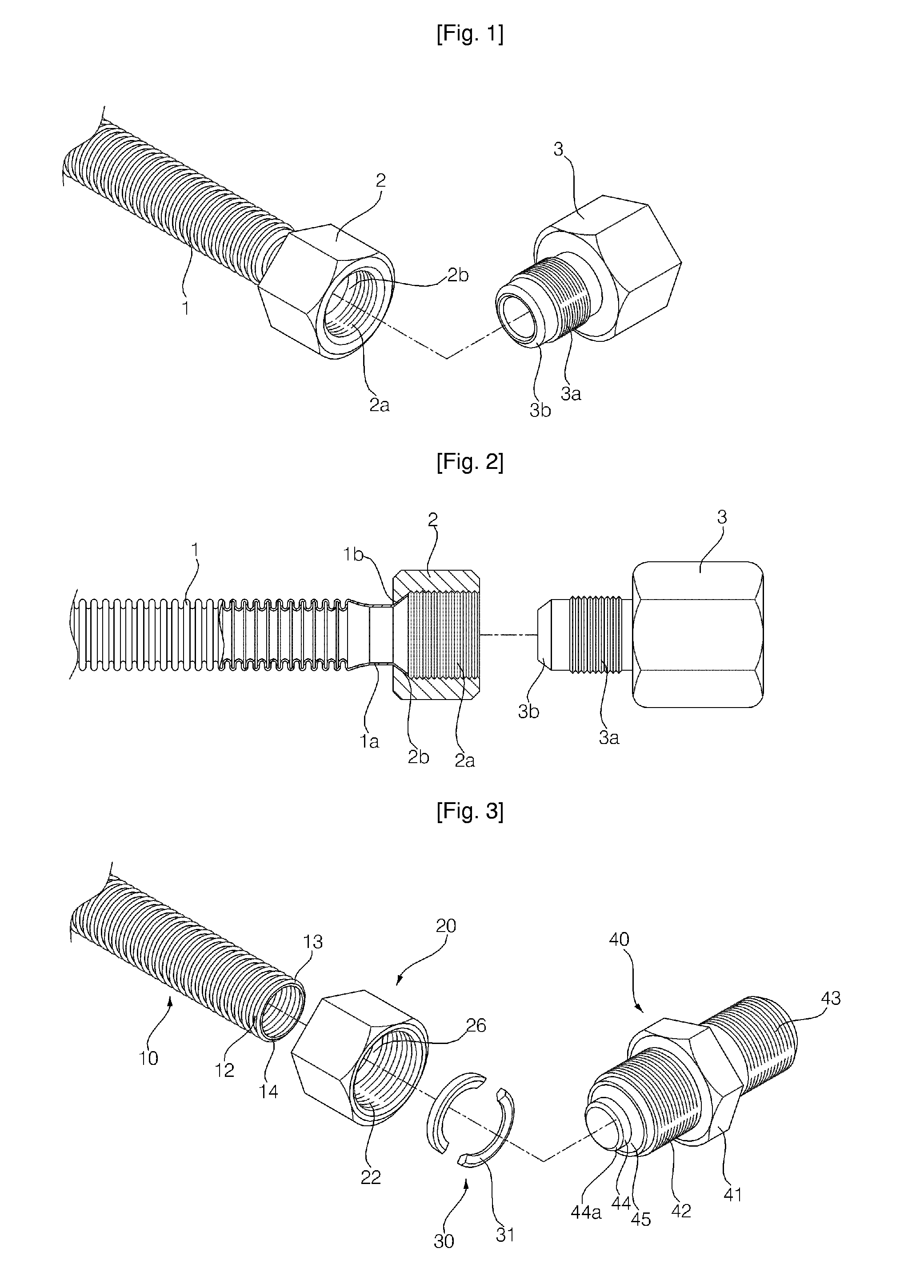

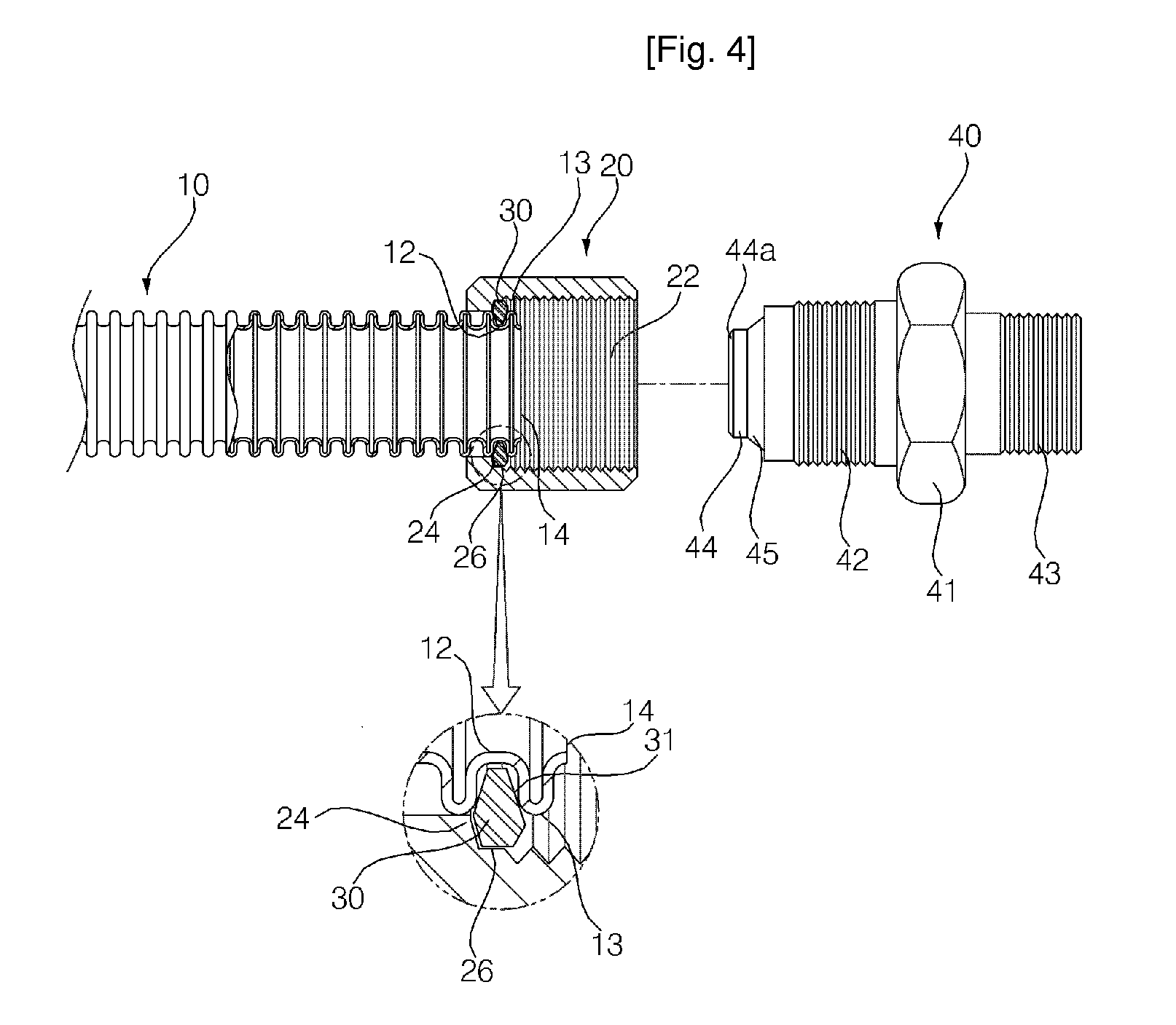

Connector of Flexible Pipe

InactiveUS20080036207A1Cost savingIncrease reliabilitySleeve/socket jointsJoints with sealing surfacesMachining processScrew thread

A connector of flexible pipe according to the present invention includes a flexible pipe; a fastening nut in which the flexible pipe is inserted; a latching ring having an inner portion received in a valley section of the flexible pipe and an outer portion extruded outward from a thread section of the flexible pipe for preventing the fastening nut from separating from the flexible pipe; and a socket tube screw combined with the fastening nut for pressurizing and transforming an end portion of the flexible pipe toward the latching ring. Accordingly, the coupler structure of the flexible pipe is conveniently achieved as well as the flexible pipe can be coupled easily by cutting in a desired length, and since there is no need to perform the process for machining the coupling portion, a cost for coupling the members is saved.

Owner:DONG A FLEXIBLE METAL TUBES CO LTD

Sealing connection method of metal and glass of novel medium-high temperature solar energy heat collection pipe

The invention discloses a sealing connection method of metal and glass of a novel medium-high temperature solar energy heat collection pipe, which relates to a method for matched sealing connection of two materials: the metal of kovar alloy and the glass of neutral borosilicate glass with the similar thermal expansion coefficients. The invention provides a novel method for manufacturing the metal glass medium-high temperature solar energy heat collection pipe. In the method, the difference of the thermal expansion coefficient of the kovar alloy and the thermal expansion coefficient of the neutral borosilicate glass is in a range between 5 percent and 10 percent, the difference of the thermal expansion coefficient of the transition section glass and the thermal expansion coefficient of the neutral borosilicate glass is in a range between 5 and 10 percent, the sealing connection temperature of the neutral borosilicate glass and the transition section glass is between 600 and 1000 DEG C, the heating temperature of the sealing connection region of the kovar alloy and the transition section glass is between 600 and 1200 DEG C, the length of the sealing connection opening is between 3 and 8 mm, and the whole sealing connection section of the neutral borosilicate glass, the transition section glass and the kovar alloy after the sealing connection carries out the annealing processing at the annealing temperature between 450 and 600 DEG C for 10 to 60 minutes.

Owner:北京天瑞星光热技术有限公司

Sealing method for split type magnetic liquid sealing device

InactiveCN102537366AIntegrity guaranteedGuaranteed sealing performanceEngine sealsMagnetic liquidsSealant

A sealing method for split type magnetic liquid sealing device belongs to the field of mechanical engineering sealing, and solves the problems that as the present large-diameter magnetic liquid rotation sealing device applies sealant at the jointed surface of a two-flap structure, the redundant sealant is extruded out after installation and remains on pole teeth at the inner circles of pole shoes, and uneven application influences the sealing performance at the same time. The sealing method is realized as follows: a stainless steel sheet is heated and kept at a temperature between 300 DEG C and 35 DEG C; the stainless steel sheet is stuck into a clearance between a sealing shaft and the pole teeth of the pole shoes; the stainless steel starts from a point at the jointed clearance between two half-pole shoes, and moves along the circumferences of the half-pole shoes to return the start point, so that the sealant extruded from the jointed surfaces of the pole shoes is vaporized; the thickness of the stainless steel sheet is smaller than the clearance between the sealing shaft and the pole teeth of the pole shoes, so as to enable the stainless steel sheet to stick into the clearance; a medical injector is used for sucking magnetic liquid at the jointed clearance between the two half-casings of the split type magnetic liquid sealing device, and the injector starts from a point at the jointed clearance, and continuously injects the magnetic liquid along the circumferences till returning the start point.

Owner:BEIJING JIAOTONG UNIV

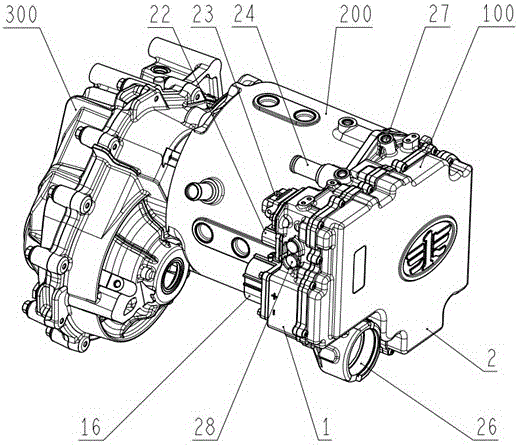

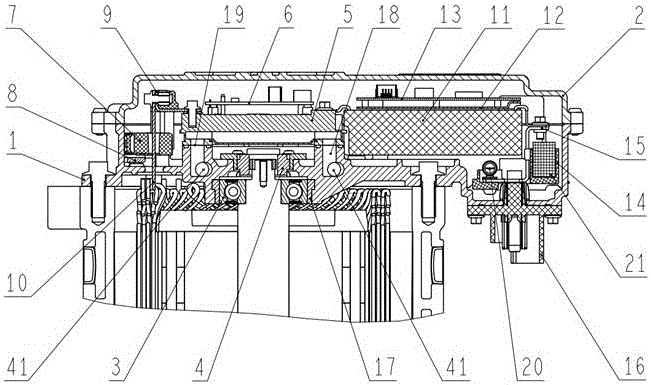

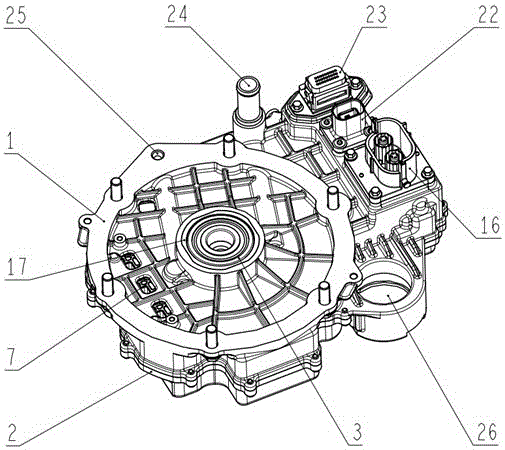

Inverter integrated into motor

PendingCN106655647AImprove power densityCompact structureAssociation with control/drive circuitsMechanical energy handlingPower inverterCapacitance

The invention relates to an inverter integrated into a motor. The inverter is characterized in that the inverter is integrated into the rear side of the motor; the bearing of a reducer output shaft is arranged on the inverter; a wire connector, a DC busbar, and a Y capacitor are arranged below a DC bus capacitor; the wire connector is installed on a main box; an air conditioner fuse is fixed to the embedded nuts of the wire connector; one end of the air conditioner fuse is connected with the negative extension end of the DC busbar; the other end of the air conditioner fuse is connected with the negative wire harness of an air conditioner connector; the DC busbar is electrically connected with the terminal of a DC connector and is connected with one end of the air conditioner fuse and the positive wire harness of the air conditioner connector at the wire connector. The inverter can be well integrated with the motor and the reducer, and the entire integrated device occupies small space as much as possible. Further, the inverter is compact in structure, low in cost, high in power density, and simple and reliable in cooling design.

Owner:CHINA FIRST AUTOMOBILE

Long-acting CO2 gas-injecting pipe column and operation method thereof

The invention discloses a long-acting CO2 gas-injecting pipe column and an operation method thereof. The long-acting CO2 gas-injecting column comprises an upper pipe column and a lower pipe column. The upper pipe column comprises an oil pipe which is arranged in a sleeve pipe in a sleeving mode. The oil pipe is provided with a circulating well-washing sliding sleeve, a hydraulic anchor, a ring-hanging device and a sealing inserting pipe in sequence from top to bottom. The lower pipe column comprises a sealing drum and a packer which are arranged on the oil pipe in sequence. The bottom of the lower pipe column is provided with a setting ball base and a double-grade check valve. The lower pipe column is fixed to the inner wall of the sleeve pipe through an anchor tile of the packer. Closing during water injecting can be achieved through the circulating well-washing sliding sleeve, and opening during backwashing can be achieved. According to the long-acting CO2 gas-injecting pipe column, the structure is simple, packing can be more reliable through the permanent packer, a down-hole well-closing function can be achieved through the multi-functional setting ball base, and down-hole well-closing can be more reliable through the double-grade check valve; through the circulating well-washing sliding sleeve and under the condition without moving pipe columns, the sliding sleeve can be started only through annular pressing, the operation of replacing annular protecting fluid can be conducted, the operation is more convenient and easy, and the cost is saved; and through the ring-hanging device, corrosion situations of pipe columns can further be monitored.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com