Rock shearing seepage coupling true triaxial test system

A test system, true triaxial technology, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, instruments, etc., can solve the problem of no open loading device structure, test box structure seepage loading system structure, no measurement test There are no problems such as the installation of crack-like cracks, no introduction of measuring parts, etc., to achieve the effect of reducing end friction effect and corner effect, uniform triaxial stress state, and high protection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

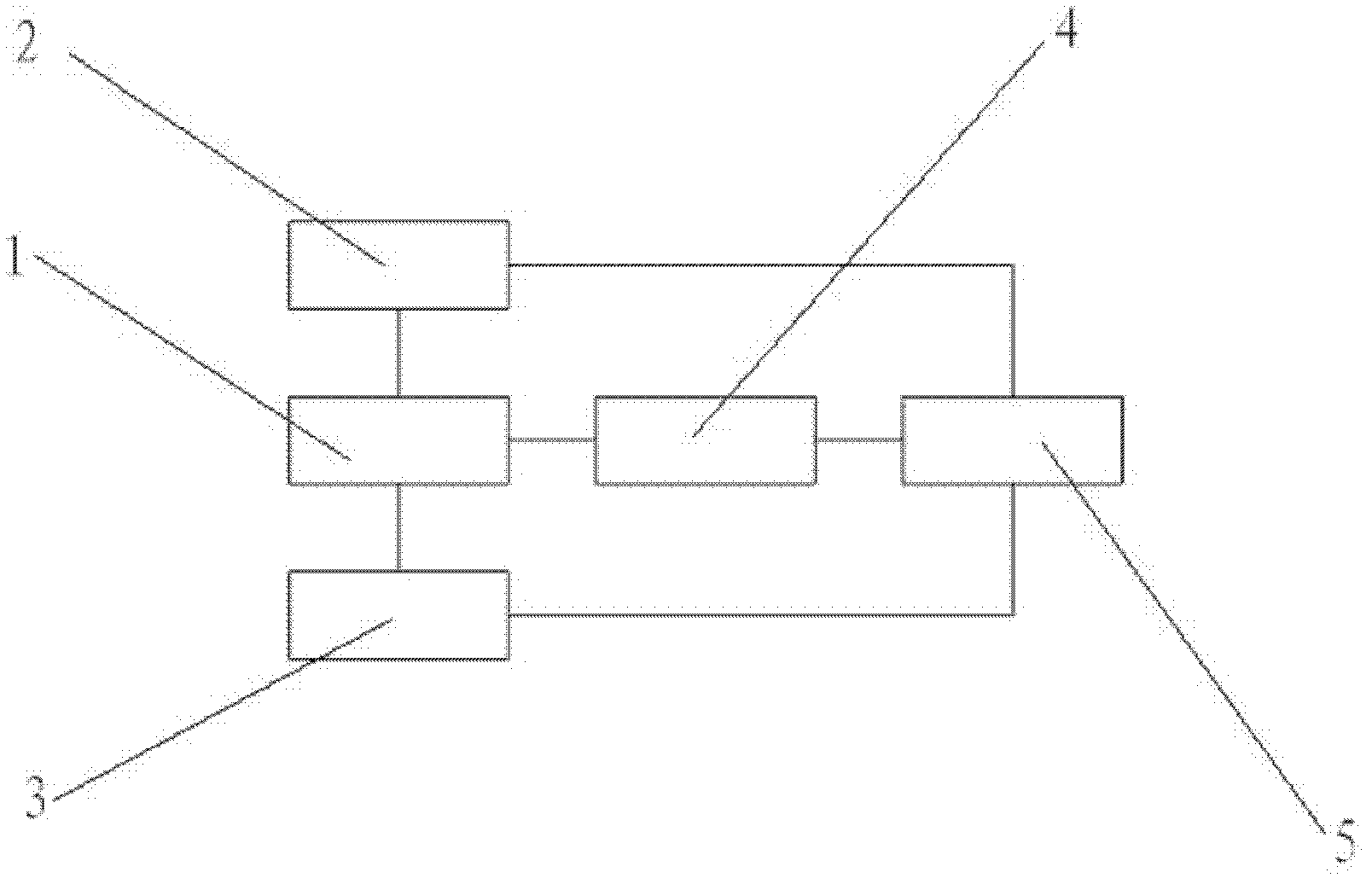

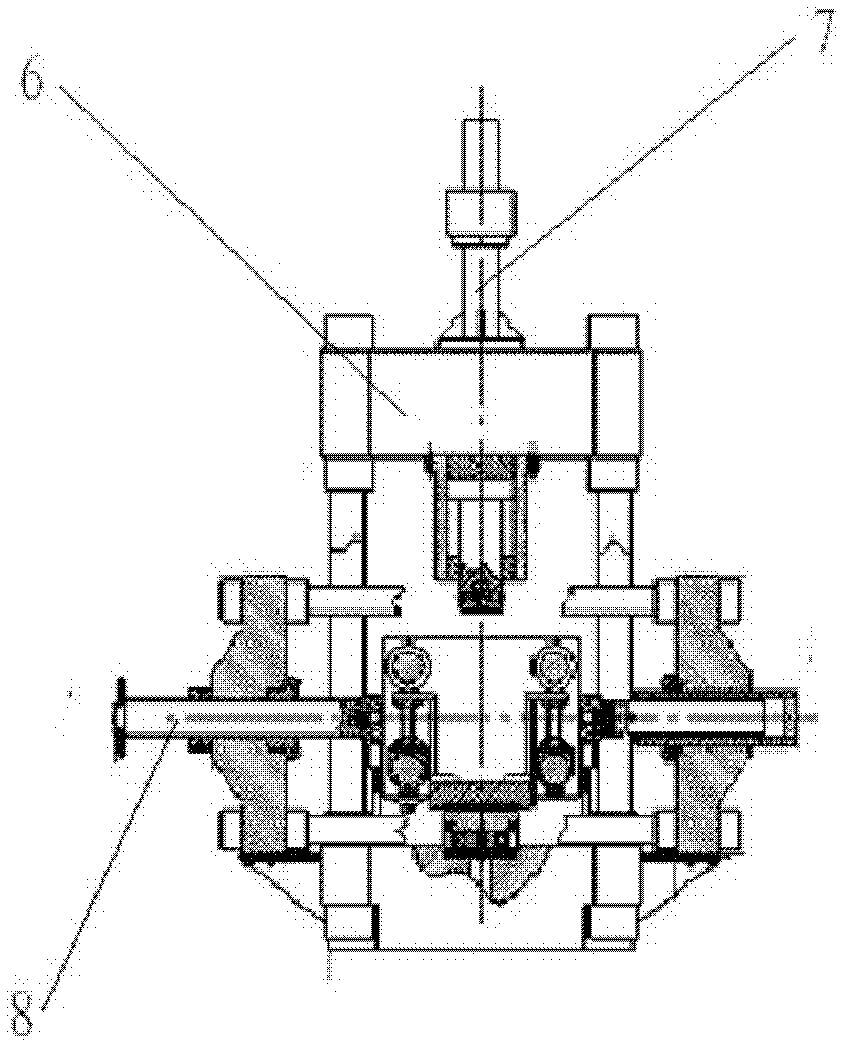

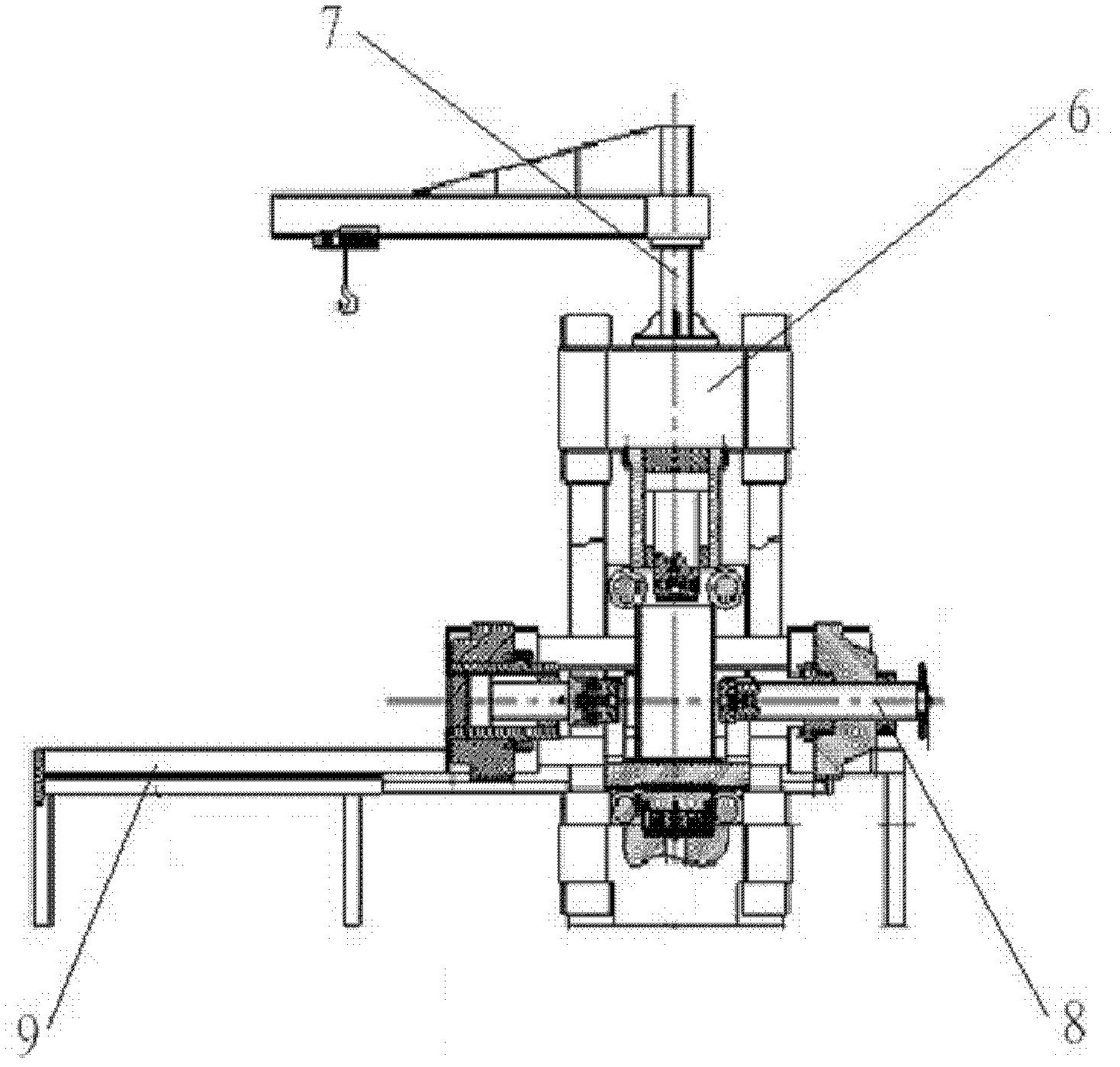

[0021] Referring to the accompanying drawings, a rock shear-seepage coupled true triaxial test system includes a loading assembly, a test box, a seepage assembly, a detection assembly, and a control assembly;

[0022] The loading assembly includes a frame, an axial loading device, a lateral loading device, and a transverse shearing loading device. The test box is arranged in the frame and connected with the axial The loading device, lateral loading device, and transverse shearing loading device can apply force to the test box respectively, and the application directions of the above three loading devices are perpendicular to each other; each loading device has an independent loading cylinder, force sensor, pressure first class. The frame adopts the form of frame structure, two side loading oil cylinders are horizontally and vertically fixed on the pressure column, and the force sensor is installed on the piston. The axial loading mechanism includes a loading cylinder, a force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com