Magnetic pulse forming method for lining bimetal composite pipe

A bimetallic composite pipe and magnetic pulse forming technology, which is applied to the field of magnetic pulse forming processing of lined bimetallic composite pipes, can solve the problem that the bimetallic composite pipe cannot be formed into large-diameter tube blanks and other problems, and achieves easy processing energy and reduced processing energy. Friction effect, high processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

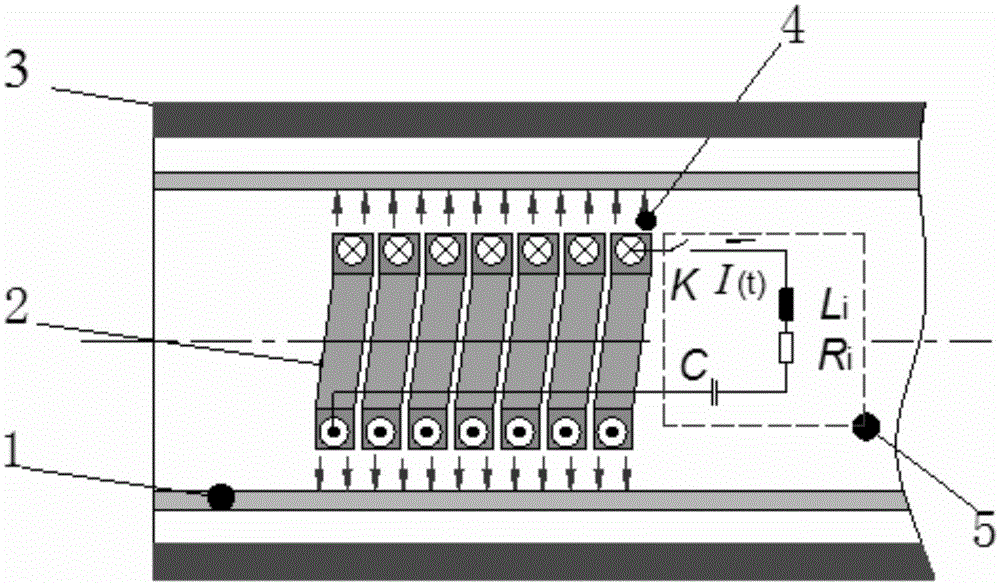

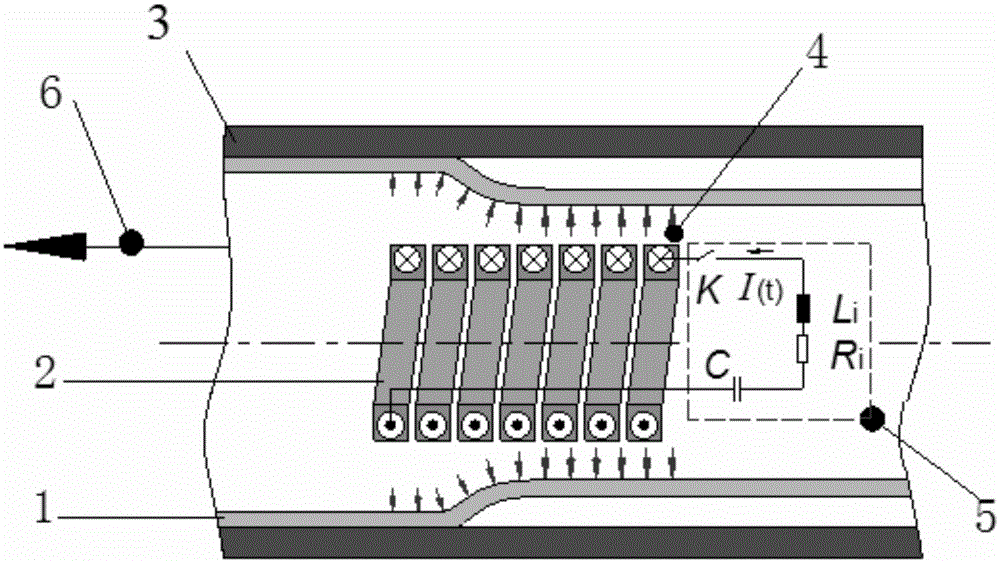

[0023] Specific implementation mode 1: A magnetic pulse forming processing method of a lined bimetallic composite pipe according to this implementation mode is carried out according to the following steps:

[0024] 1. Surface purification treatment of the composite tube billet: clean the inner surface of the composite outer tube and the outer surface of the composite inner tube with acetone to remove the pollutants on the inner surface of the outer tube to be composite and the outer surface of the inner tube to be composited , to obtain the cleaned outer pipe to be compounded and the cleaned inner liner to be compounded;

[0025] 2. Positioning and clamping of the composite tube blank: first use alcohol to wipe the inner surface of the cleaned outer tube to be composited and the outer surface of the cleaned inner tube to be composited, and then the outer tube to be composited and The lining pipe to be composited is placed concentrically, and the pipe wall gap between the outer...

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment differs from Embodiment 1 in that the outer pipe to be composited in step 1 is a carbon steel pipe. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the lining pipe to be compounded in Step 1 is an aluminum pipe. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com