Preparation method and applications of composite super-early strength admixture

A composite and admixture technology, applied in the field of concrete admixtures, can solve the problems of reducing the early mechanical properties of concrete, negative concrete durability, and failing to achieve the expected improvement of early strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

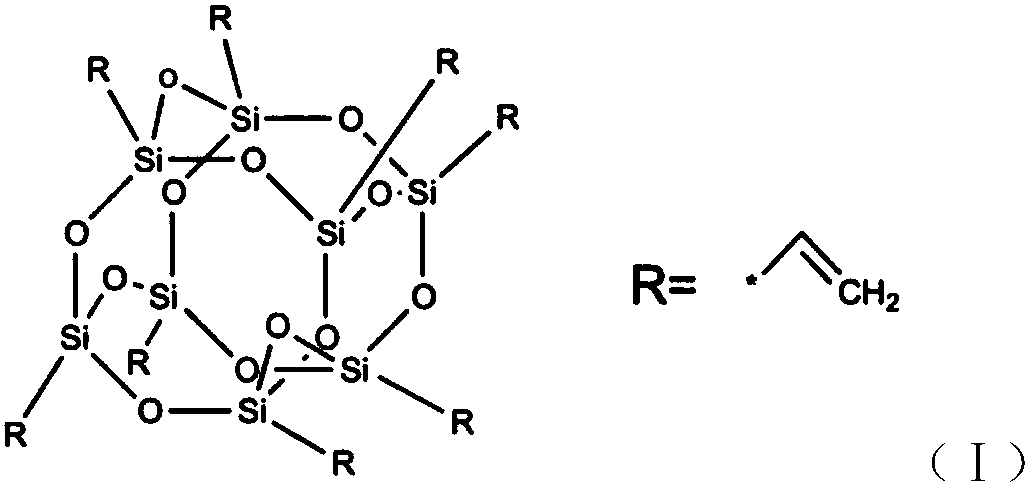

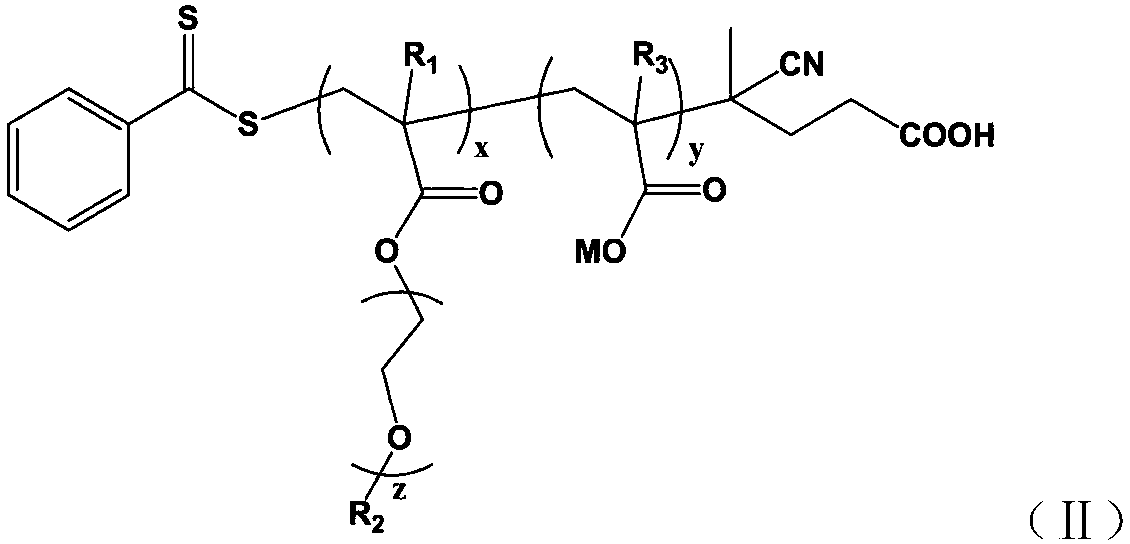

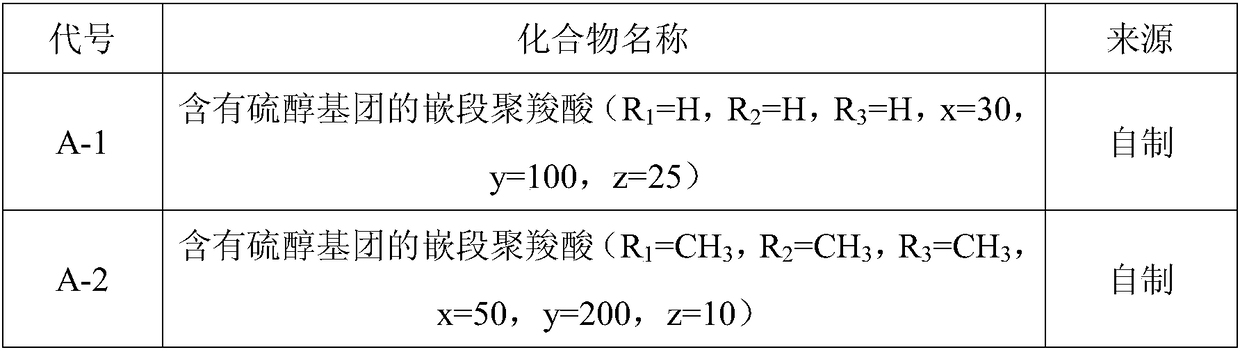

[0031] Weigh 0.317g octavinyl POSS, 160.8g block polycarboxylic acid A-1 containing thiol group and place in a round bottom flask, dissolve it with 300mL tetrahydrofuran, then add 0.162g dimethylphenylphosphine, Magnetic stirring was used to make it dissolve, and after nitrogen reflux for 30 minutes, 0.321 g of n-hexylamine was added, nitrogen reflux was continued for 30 minutes, and reaction was sealed at 35° C. for 12 hours. After the reaction, the tetrahydrofuran solvent was removed by rotary evaporation to obtain POSS-based star-shaped block polycarboxylic acid. Dissolve 148.5g of the above synthesized sample in 250g of water, keep stirring, and raise the temperature to 20°C, dissolve 98.5g of B-1 in 145g of water as the addition solution B, and dissolve 147.8g of C-1 in 210g of water as the addition solution C. At the same time, start to drop solution B and solution C at a constant speed. The dropping time is 2 hours.

Embodiment 2

[0033]Weigh 0.317g octavinyl POSS, 145.6g block polycarboxylic acid A-2 containing thiol group and place in a round bottom flask, dissolve it with 300mL tetrahydrofuran, then add 0.212g dimethylphenylphosphine, Magnetic stirring was used to dissolve it. After nitrogen reflux for 30 minutes, 0..433 g of n-hexylamine was added, nitrogen reflux was continued for 30 minutes, and reaction was sealed at 45°C for 18 hours. After the reaction, the tetrahydrofuran solvent was removed by rotary evaporation to obtain POSS-based star-shaped block polycarboxylic acid. Dissolve 101.7g of the above synthesized sample in 300g of water, keep stirring, and raise the temperature to 40°C, dissolve 147.7g of B-1 in 200g of water as the drop solution B, and dissolve 98.5g of C-2 in 150g of water as the drop solution Solution C, start to drop solution B and solution C at a constant speed at the same time, the dropping time is 8 hours, keep warm for 5 hours after dropping, cool down and discharge, an...

Embodiment 3

[0035] Weigh 0.317g octavinyl POSS, 152.0g block polycarboxylic acid A-3 containing thiol group and place in a round bottom flask, dissolve it with 300mL tetrahydrofuran, then add 0.304g dimethylphenylphosphine, Magnetic stirring was used to dissolve it, and after nitrogen reflux for 30 minutes, 0.609 g of n-hexylamine was added, nitrogen reflux was continued for 30 minutes, and reaction was sealed at 50°C for 24 hours. After the reaction, the tetrahydrofuran solvent was removed by rotary evaporation to obtain POSS-based star-shaped block polycarboxylic acid. Dissolve 82.5g of the above synthesized sample in 350g of water, keep stirring, and raise the temperature to 30°C, dissolve 50.7g of B-1 in 220g of water as dropwise solution B, and dissolve 53.5g of C-1 in 240g of water as dropwise Solution C, start to drop solution B and solution C at a uniform speed at the same time, the dropping time is 10h, keep warm for 3h after dropping, cool down and discharge, and the compound su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com