Patents

Literature

570results about How to "Not easy to settle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-viscosity and high-heat conduction epoxy resin electronic potting adhesive

InactiveCN101974302AImprove thermal conductivityRapid heat buildupNon-macromolecular adhesive additivesOther chemical processesEpoxyAdhesive

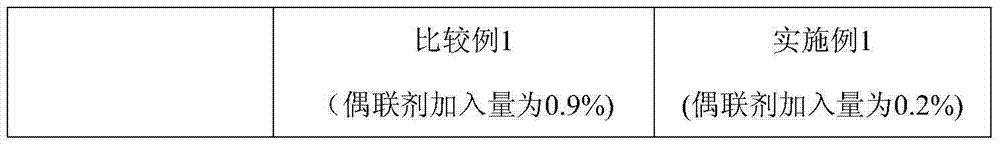

The invention relates to a low-viscosity and high-heat conduction epoxy resin electronic potting adhesive which is formed by mixing a component A with an amine curing agent according to the weight ratio of 100:5-12, wherein the component A comprises the following raw materials in weight ratio: 70-85 parts of spherical alumina powder, 10-20 parts of epoxy resin, 2-4 parts of active thinner, 2.5-5 parts of toughening agent and 0.1-0.5 parts of coupling agent. The invention has the advantages that the spherical alumina of the potting adhesive has higher filling amount compared with non-spherical alumina, the viscosity is less affected, the fluidity is favorable and the construction is convenient; the potting adhesive has good dispersibility and is difficult to sedimentate; a condensate has high heat conductivity and can quickly dissipate accumulated heat of heating parts and components; a high-filling filler can reduce a thermal expansion coefficient and a volumetric shrinkage rate and is very suitable for potting parts and components; and the price is cheaper compared with boron nitride and aluminum nitride, and the cost is low.

Owner:YANTAI DARBOND TECH

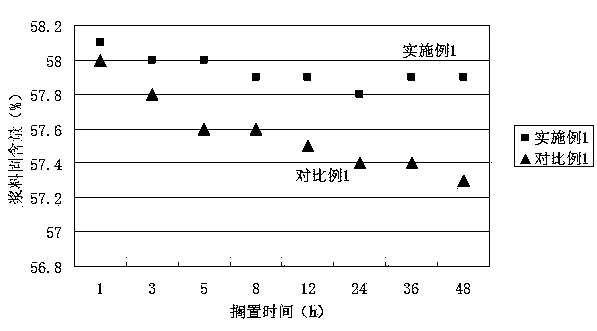

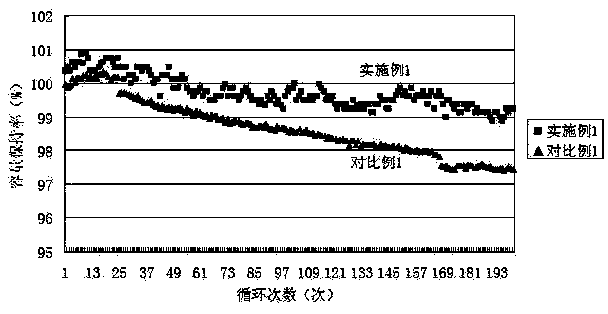

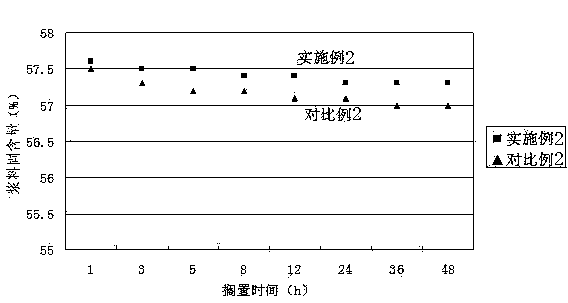

Lithium ion battery aqueous anode slurry and preparation method thereof

ActiveCN103579579AReduce pollutionGood capacityCell electrodesSecondary cellsAdhesiveCarbon nanotube

The invention discloses a lithium ion battery aqueous anode slurry consisting of the following components in percentage by weight: 40-50% of anode active material, 1-10% of carbon nanotube, 0-5% of conductive agent, 1-3% of aqueous adhesive and 40-50% of de-ionized water. Furthermore, the invention discloses a preparation method of the lithium ion battery aqueous anode slurry, and the preparation method mainly comprises the following steps: (1) preparing a premix liquid; (2) preparing a conductive adhesive liquid; (3) dispersing for the first time; (4) dispersing for the second time; (5) defoaming and standing. The preparation method is simple in processing step, strong in feasibility and suitable for mass industrial production; the prepared lithium ion battery is excellent in both capacity and circulating performance, and can be used for effectively solving the problems of an existing aqueous anode slurry preparation method which has difficulty in uniformly dispersing the conductive agent, the anode active material and other solid materials and is high in possibility of aggregation, relatively poor in consistency of the prepared aqueous anode slurry, not high in stability and easy to settle.

Owner:WANXIANG 123 CO LTD

Conductive graphite cream and preparation method thereof

ActiveCN102618107AReduce carbon additionDoes not affect conductivityCellulose coatingsConjugated diene hydrocarbon coatingsConductive polymerGraphite

The invention discloses conductive graphite cream and a preparation method thereof, which solve the technical problem of improving dispersibility of graphite cream. The conductive graphite cream comprises materials including, in weight percent, 10-30% of conductive graphite, 1-30% of matrix resin, 0.1-5% of conductive polymer auxiliaries, 0.1-5% of dispersing auxiliaries and the balance solvents. The preparation method includes the steps: adding the conductive polymer auxiliaries into the solvents to obtain solution 1; adding the matrix resin into the solvents to obtain solution 2; adding the conductive graphite into the solution 2; adding the dispersing auxiliaries into the solution 2 for ball-milling; adding the solution 1 into solution 3; and performing ultrasonic oscillation, high-pressure dispersion and stirring to obtain the conductive graphite cream. Compared with the prior art, the conductive graphite cream and the preparation method have the advantages that nano carbon materials are added, ball-milling, ultrasonic oscillation and high-pressure dispersion are performed for assisting so that the conductive graphite cream is uniformly dispersed, and the preparation method is simple and low-cost.

Owner:BTR NEW MATERIAL GRP CO LTD

Anti-corrosion antistatic coating made of waterborne acrylate grafted epoxy resin and preparation method thereof

ActiveCN103173087ANovel structureImprove conductivityAnti-corrosive paintsElectrically-conductive paintsEpoxyEmulsion

The invention discloses an anti-corrosion antistatic coating made of waterborne acrylate grafted epoxy resin and a preparation method thereof and relates to the technical field of production of a coating. According to the invention, carbon nano tube is selected as an antistatic additive; and a film forming matter is waterborne acrylate grafted epoxy resin emulsion. The characteristics of the acrylate resin and epoxy resin can be effectively integrated into a whole; the prepared anti-corrosion antistatic coating is good in storage stability, good in construction property, fast to dry after being coated, smooth in dried film, and excellent in mechanical behavior, antistatic property, acid resistance, alkali resistance, salt water resistance and the like.

Owner:扬州市伊丽特高分子材料科技有限公司

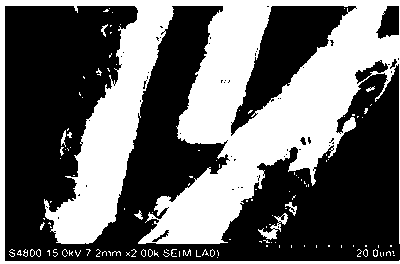

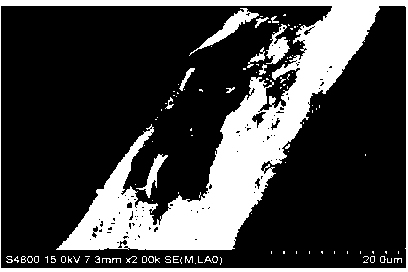

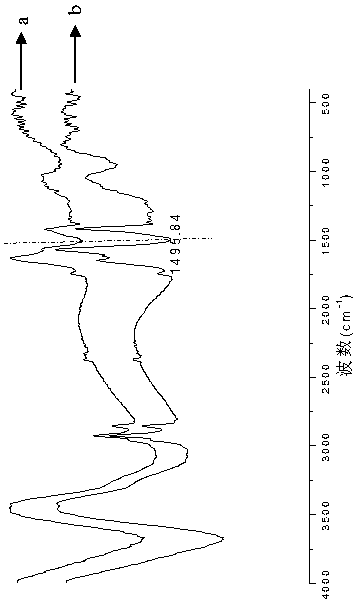

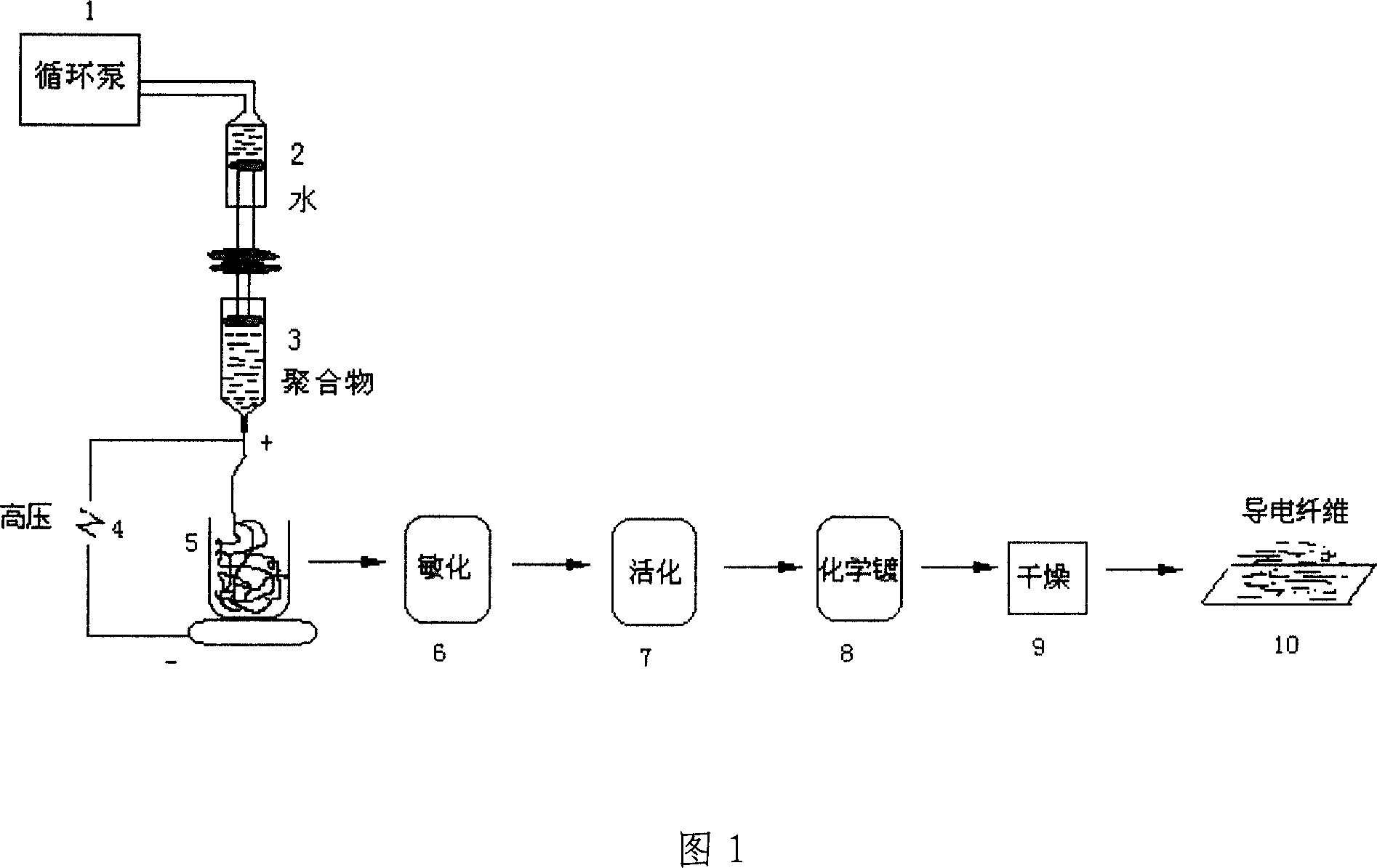

Method for preparing super fine light conductive fibre

The process of preparing super fine light conductive fiber includes the following steps: electrically spinning polymer to form super fine light polymer fiber; and 2. chemically plating the super fine light polymer fiber. The prepared super fine light conductive fiber has the features diameter smaller than 1 micron, length smaller than 50 microns, density smaller than 2 g / cu cm and high conductivity. It may be used as the conductive filler for conducting adhesive in circuit board and electrode in the electronic industry, and the conducting adhesive has excellent conductivity and high stability.

Owner:XIANGTAN UNIV

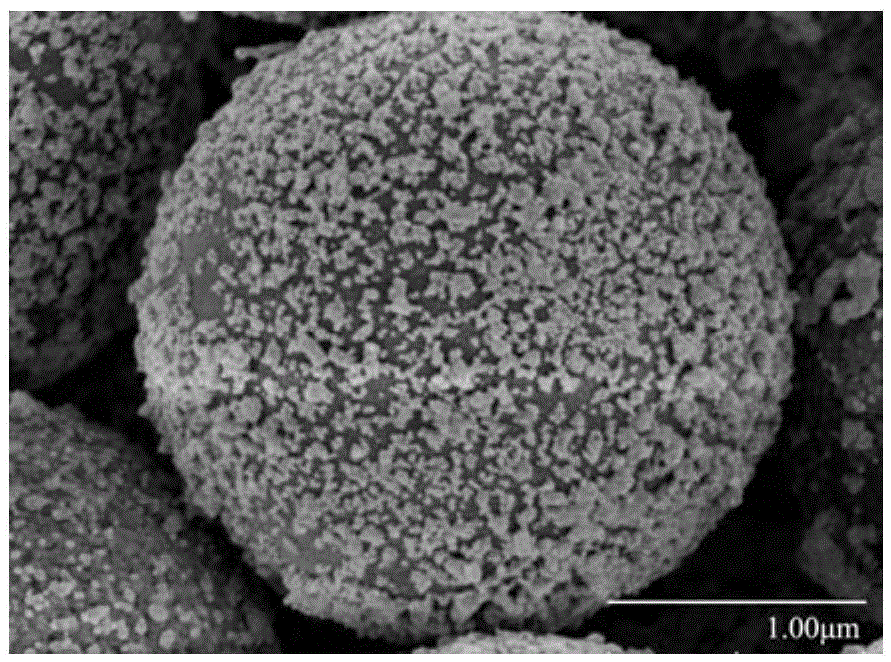

Method for preparing low-toxicity marine antifouling paint by applying Cu2O submicrospheres

InactiveCN101531841ALow densityEvenly dispersedRubber derivative coatingsAntifouling/underwater paintsMicrosphereSolvent

The invention discloses a method for preparing a low-toxicity marine antifouling paint by applying Cu2O hollow submicrospheres, and belongs to the fields of preparation and application of inorganic functional materials and marine antifouling paints. The method applies the Cu2O hollow submicrospheres singly or the Cu2O hollow submicrospheres embedded with a nontoxic organic antifouling composition as an antifouling composition to prepare the low-toxicity marine antifouling paint; and the antifouling composition, resin base stock, pigment (filler), and solvent are added to a ball mill for grinding to prepare the marine antifouling paint, wherein the antifouling composition consists of the Cu2O hollow submicrospheres with adjustable grain diameter (150-500nm), hollow structures and porous surfaces or the Cu2O hollow submicrospheres embedded with other antifouling compositions. The method has the characteristics that the Cu2O grain diameter reaches nano / micron grade, and grains in the paint are distributed uniformly; and the special appearance of the hollow structures and the porous surfaces can be used for embedding and slowly releasing other nontoxic organic antifouling compositions, reduces Cu2O dosage and has the function of cooperative antifouling so as to prolong the antifouling term, strengthen the antifouling effect and reduce the emission pollution.

Owner:JIANGNAN UNIV

Water-based transparent super-amphiphobic nano-paint and preparation method and application thereof

The invention relates to water-based transparent super-amphiphobic nano-paint and a preparation method and application thereof. Under the room temperature condition, hydrophilic silica nanoparticles and tetraethoxysilane or carbon tetrachloride serve as raw materials to synthesize oily nanoparticles with the concentration of 1-10 mg / mL; the oily nanoparticles and fluorocarbon resin are compounded according to the volume ratio of 1:1, a rotary evaporator is utilized for rotary evaporation for 30-60 min under the condition of a water bath at the temperature of 60-90 DEG C, and high-solid-content oily nano-paint concentrated liquor with the concentration of 20-40 mg / mL is obtained; water and surfactant are added, and the water-based transparent nano-paint with the super-amphiphobic surface is obtained. The prepared paint is soluble in water, the preparation process is simple, and the paint is suitable for large-area spraying, is high in adaptability to a base material and transparency, good in protective performance, environmentally friendly and capable of improving the working environment, and saves energy.

Owner:SOUTHEAST UNIV

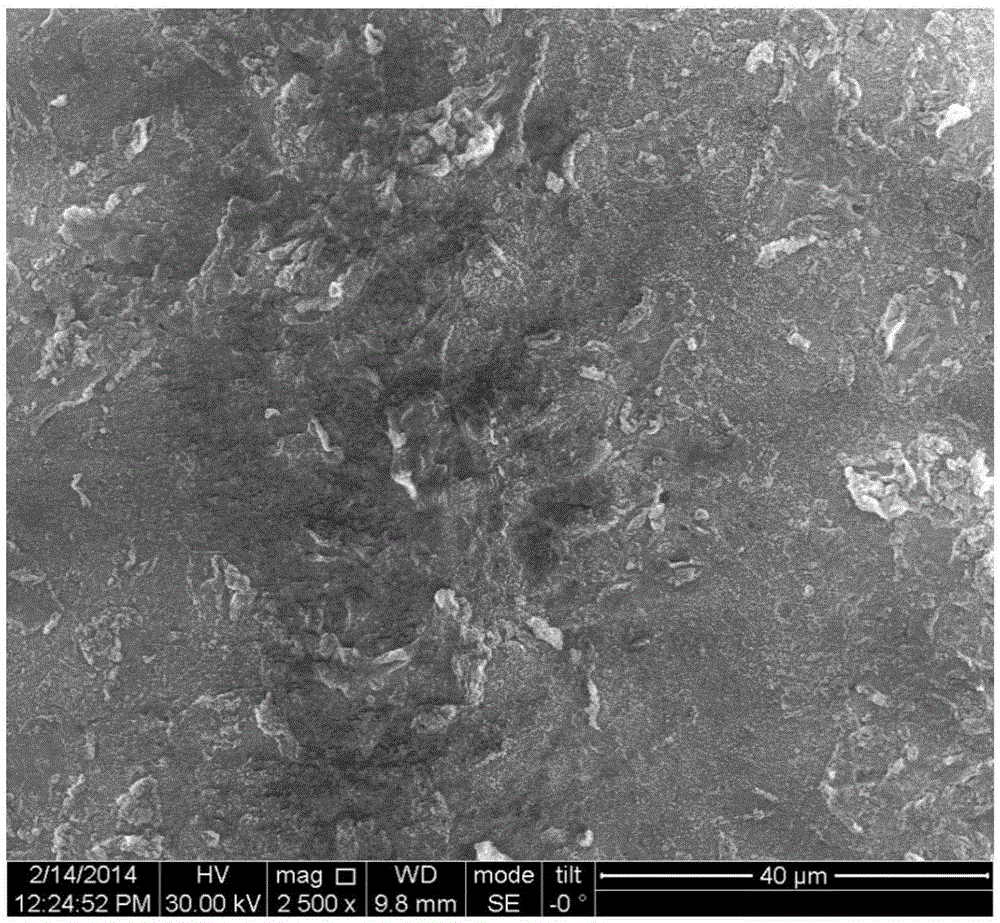

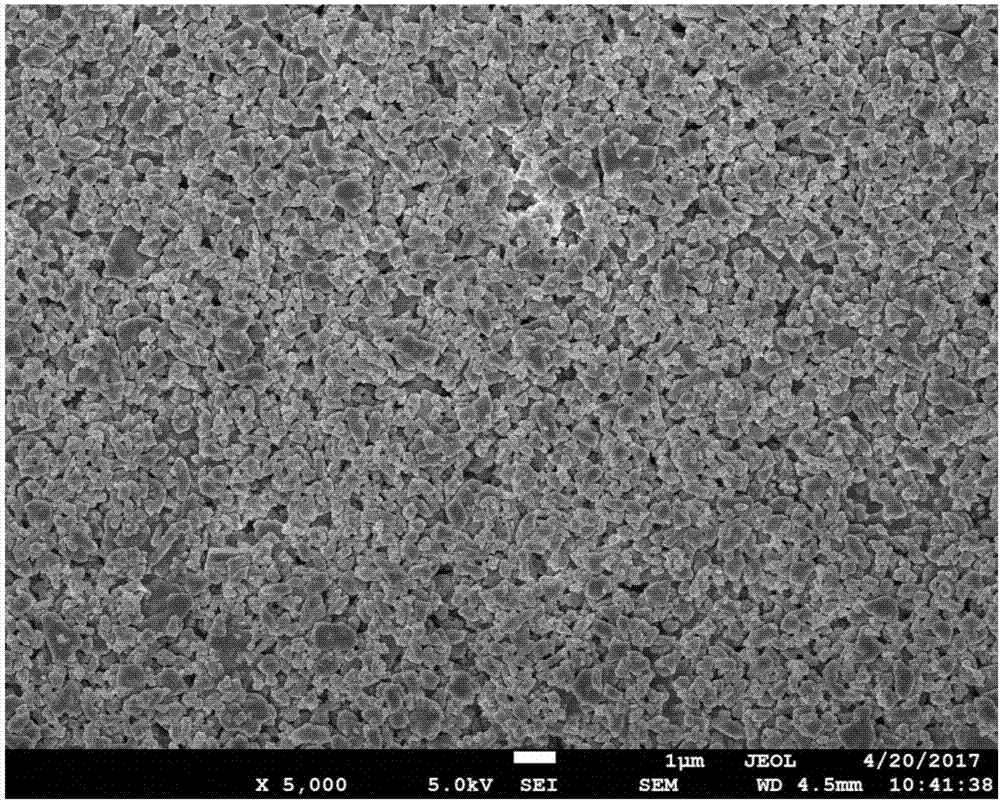

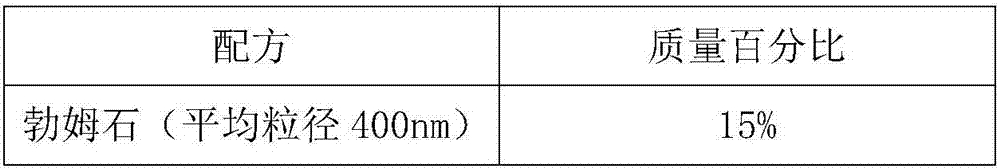

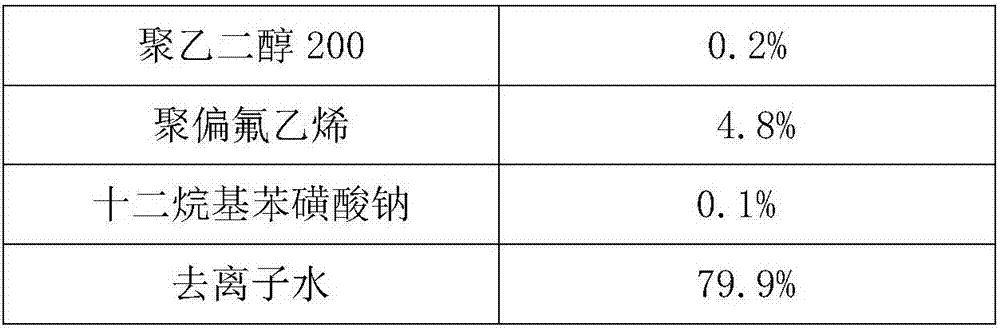

Waterborne ceramic slurry for lithium ion battery and preparation method of composite separator from waterborne ceramic slurry

InactiveCN107403898ASlurry stabilizationNot easy to settleCell component detailsCeramic compositeHeat resistance

The invention provides waterborne ceramic slurry for a lithium ion battery and a preparation method of a composite separator from the waterborne ceramic slurry. The waterborne ceramic slurry is prepared from inorganic powder, an adhesive, a dispersant, an aid and deionized water. The invention further provides a preparation method of the waterborne ceramic composite separator. Compared with oily ceramic coated lithium ion battery separators, the composite separator has good wettability, heat resistance and adhesion performance, a coating contains inorganic powder with uniform particle sizes, the safety performance of the battery is effectively improved, and the composite separator cannot cause pollution to the environment and has a good application prospect.

Owner:VONTRON MEMBRANE TECH CO LTD

Magneto-rheological fluid with good settling agglomeration resistance

InactiveCN103215113AGood resistance to sedimentation and agglomerationImprove stabilityLubricant compositionWater basedAntioxidant

The invention relates to magneto-rheological fluid with good settling agglomeration resistance. The magneto-rheological fluid comprises the following ingredients in parts by weight according to 100 volume parts: 125-225 parts of ferromagnetic particles, 30-85 parts of carrier fluid, 0.2-5 parts of xanthan gum, and 0-12.5 parts of additives, wherein the additives are a thixotropic agent, a dispersing agent, an antioxidant and a lubricant when the carrier fluid is water-based; and when the carrier fluid is oil-based, the additives are a thixotropic agent, a dispersing agent, and a lubricant. The magneto-rheological fluid is good in stability within a larger temperature range (minus 18 DEG C-130 DEG C), difficult to settle, and also keeps the original performances, namely high shearing stress and good friction property.

Owner:CHONGQING MATERIALS RES INST

Scratch-resistant outdoor powder paint

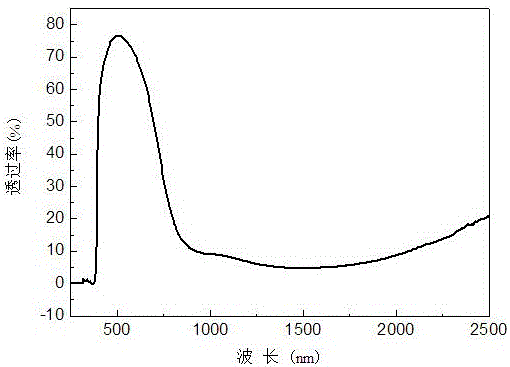

ActiveCN106366892AImprove shielding effectHigh visible light transmittancePolyurea/polyurethane coatingsPowdery paintsArchitectural glassWater based

The invention discloses a scratch-resistant outdoor powder paint which is composed of the following raw materials in parts by weight: 5-8 parts of modified sericite, 10 parts of silicon dioxide, 8-15 parts of modified nano tin tungsten oxide, 5 parts of barium sulfate, 7 parts of titanium dioxide, 1-3 parts of dispersing aid, 1-3 parts of leveling agent, 0.05-1 part of defoaming agent, 1 part of polytetrafluoroethylene wax, 30 parts of water-based polyurethane resin and 30 parts of organic silicon resin. The paint is suitable for heat insulation on the surfaces of building glass, vehicle glass and cement, can shield ultraviolet and infrared light, and has the advantages of favorable heat-insulating property, favorable scratch resistance, stable coating performance and simple preparation technique.

Owner:广东捷宇粉体涂料有限公司

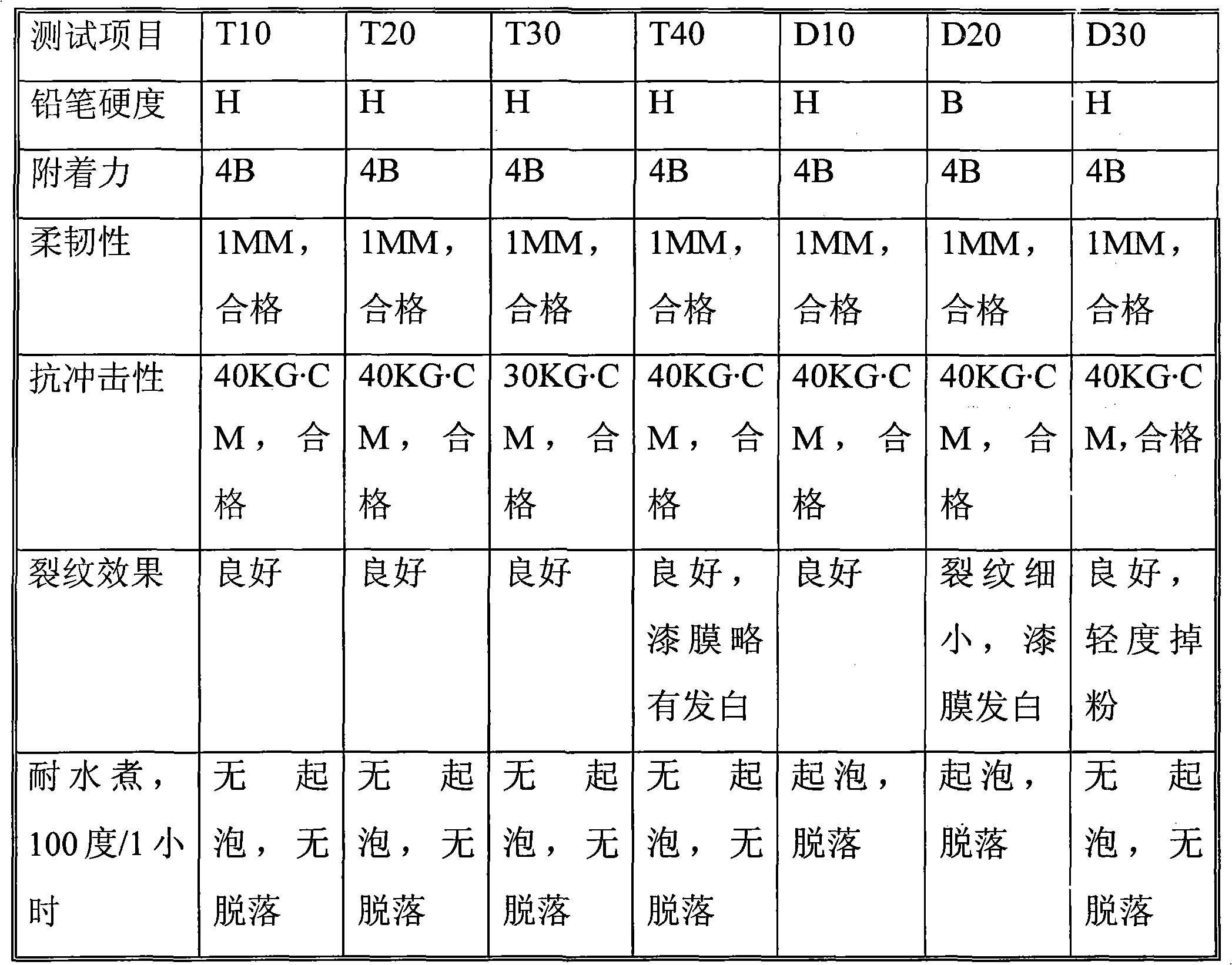

Crackle paint and preparation method thereof

InactiveCN102031049ANo need to worry about unusable problemsSave the supporting processCoatingsAcrylic resinTG - Triglyceride

The invention provides a crackle paint, comprising thermoplastic acrylic resin, crack agent and solvent, wherein the temperature of Tg (triglyceride) of the thermoplastic acrylic resin is 70-80 DEG C, and the crack agent is mica powder with the average particle size of 2000-3000 meshes. The invention also provides a preparation method of the crackle paint, comprising the steps of adding the thermoplastic acrylic resin, crack agent and solvent into a container, mixing and stirring. The invention has the advantages of simple steps when using the crackle paint provided by the invention and smallpossibility of picking of the crackle paint layer after being sprayed.

Owner:BYD CO LTD

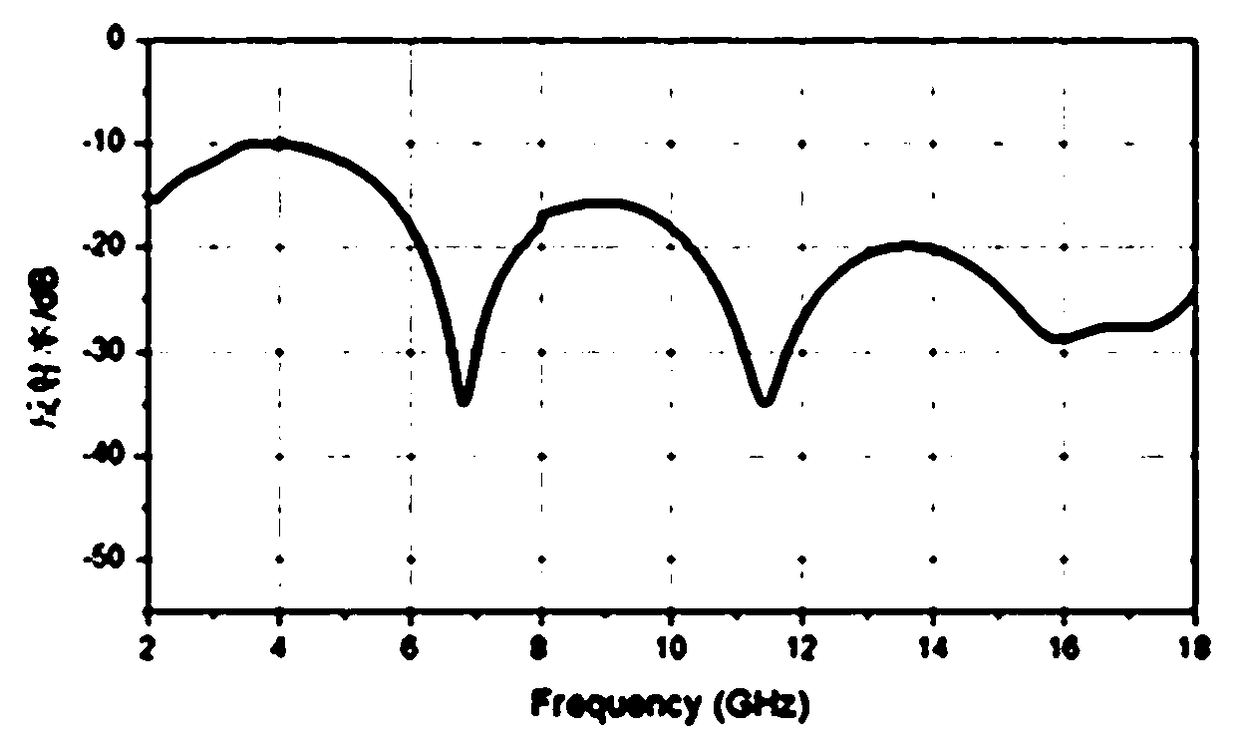

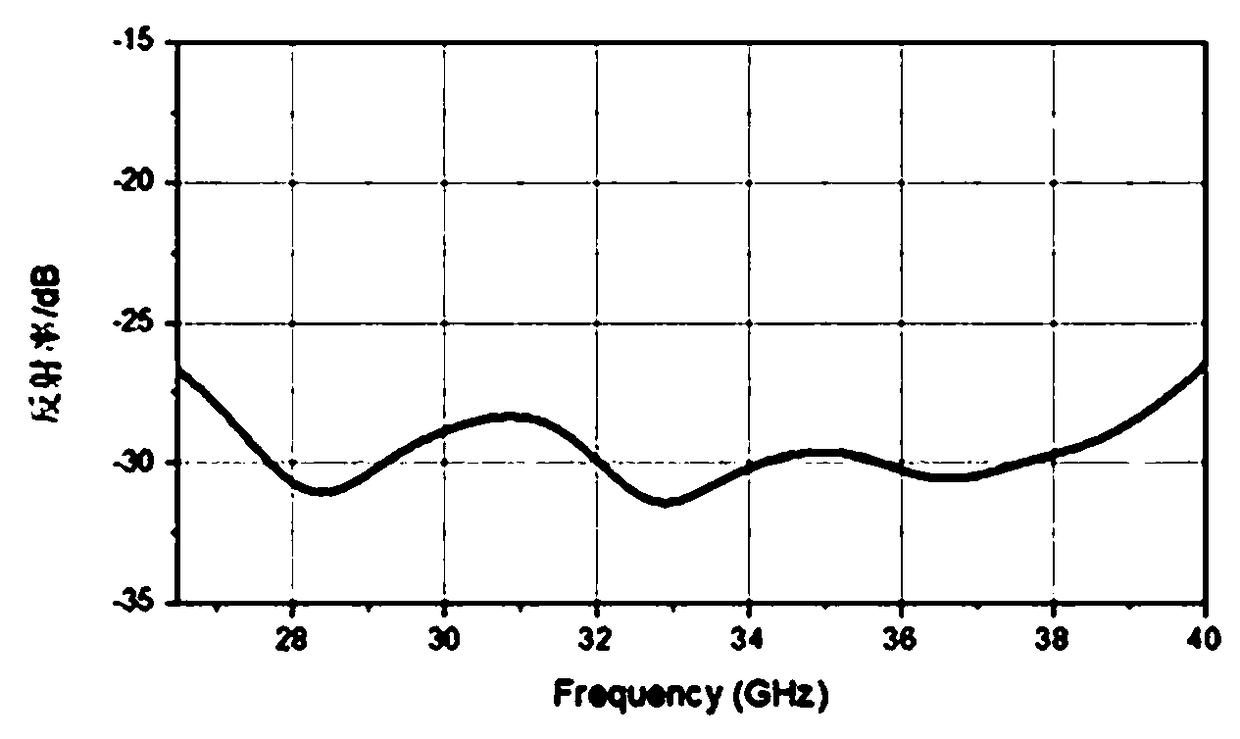

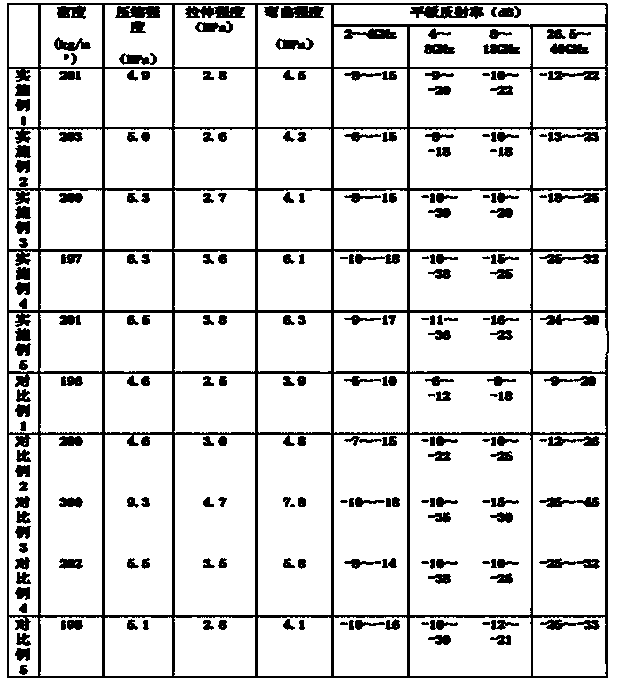

Preparation method for polymethacrylimide composite foam conductive wave-absorbing material

The invention specifically relates to a preparation method for a polymethacrylimide composite foam conductive wave-absorbing material, belonging to the field of preparation of novel materials. The preparation method comprises the following steps: weighing (meth)acrylic acid, (meth)acrylonitrile, a third monomer, a functionalized wave-absorbing agent, a dispersing agent, an anti-settling agent, aninitiator, a nucleating agent, a polymerization inhibitor, a cerium-containing foaming material and a cross-linking agent, adding the weighed substances into a reaction vessel, and performing a polymerization reaction to prepare an expandable polymethacrylimide resin particle; and then mixing the expandable polymethacrylimide resin particle with a binder, an auxiliary agent, the functionalized wave-absorbing agent and a fibrous substance, and carrying out preheating and foaming to obtain the polymethacrylimide composite foam conductive wave-absorbing material. The material of the invention hasgood wave-absorbing properties, heat resistance and mechanical properties, can be used for preparing special-shaped parts, and can avoid defects such as complicated process and wasting of materials during mechanical processing of materials for acquisition of complicated shapes.

Owner:CASHEM ADVANCED MATERIALS HI TECH CO LTD ZHEJIANG

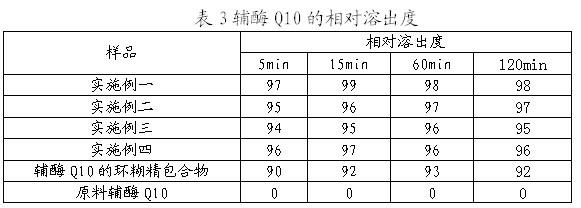

Water-soluble coenzyme Q10 combination and preparation method thereof

InactiveCN101940564AEasy to getImprove solubilityEther/acetal active ingredientsMacromolecular non-active ingredientsFructoseCarrageenan

The invention relates to a coenzyme Q10 combination and a preparation method thereof and provides a water-soluble coenzyme Q10 combination, which contains the following raw materials in parts by weight: 5-15 parts of coenzyme Q10, 10-120 parts of water-soluble carrier and 0.5-40 parts of emulsifier; the water-soluble carrier is one or more of maltodextrin, CMC, purity gum, soluble starch, lactose, fructose, sorbierite, mannite, Arabic gum, carrageenan, microcrystalline cellulose and sodium carboxymethyl starch; and the emulsifier is non-ionic surfactant. The invention also provides the preparation method of the water-soluble coenzyme Q10 combination. Fat-soluble coenzyme Q10, the water-soluble carrier and the amphoteric emulsifier are mixed and prepared into the water-soluble coenzyme Q10 combination, and the method synthesizes the advantages of an inclusion technique and a solid dispersion technique and solves the problems that the fat-soluble coenzyme Q10 is difficult to dissolve in water and has low bioavailability, and a number of experiments prove that the water-soluble coenzyme Q10 combination has good water solubility, fast dissolution rate, good stability and high content of effective substances.

Owner:杭州华东医药集团康润制药有限公司

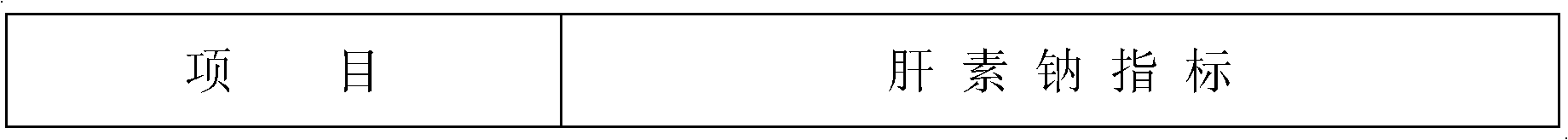

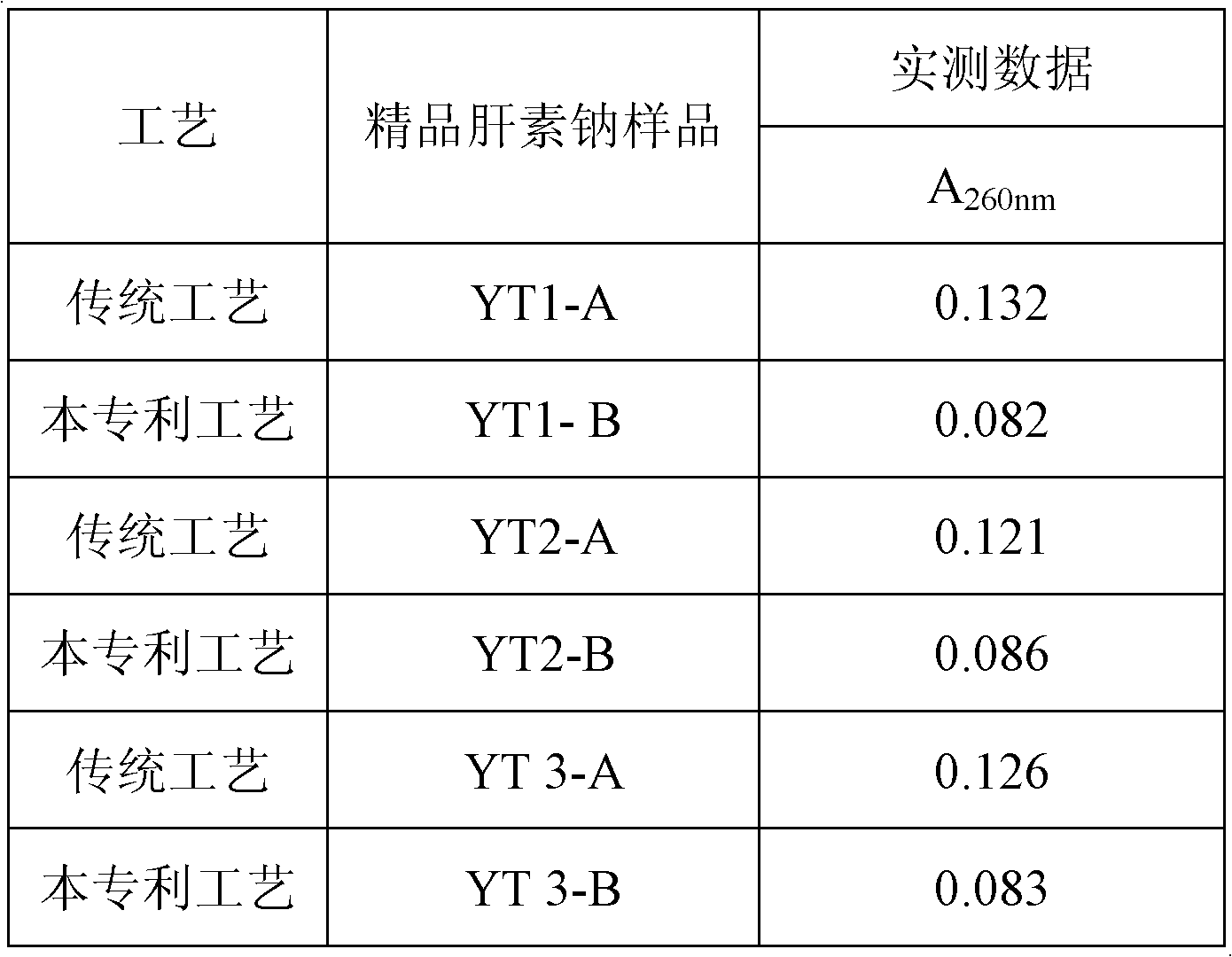

Crude heparin sodium purification technology

The invention relates to a heparin sodium purification technology. The crude heparin sodium purification technology sequentially comprises the following steps: 1, dissolving crude heparin sodium in a sodium chloride solution, and adding an alkaline protease for enzymatic hydrolysis; 2, inactivating, adding diatomite, carrying out high speed centrifugation, and removing insoluble impurities; 3, adding polysilicate, carrying out high speed centrifugation, and removing insoluble impurities; 4, adding alcohol for precipitating, and removing supernatant alcohol; 5, dissolving in the sodium chloride solution, adding hydrogen peroxide for oxidizing, carrying out high speed centrifugation after oxidation, and removing insoluble impurities; 6, adding alcohol for precipitating, and removing supernatant alcohol; and 7, filtering, and carrying out vacuum lyophilizing to obtain refined heparin sodium. The crude heparin sodium purification technology has the advantages of low content of proteins in the refined heparin sodium, and high yield of the refined heparin sodium.

Owner:PUJIANG CAREX BIOTECH

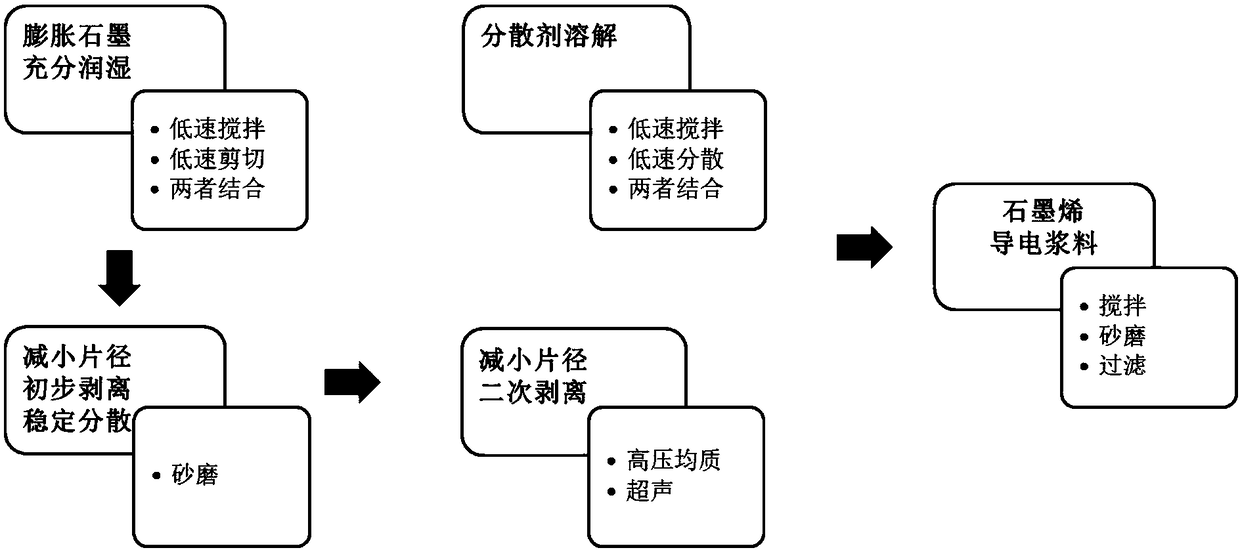

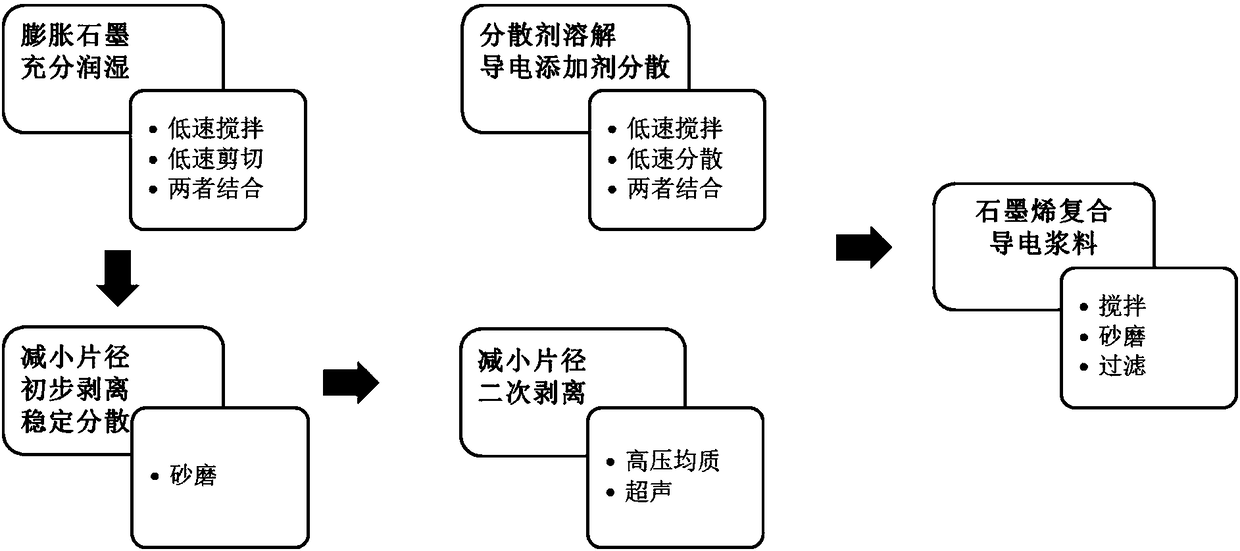

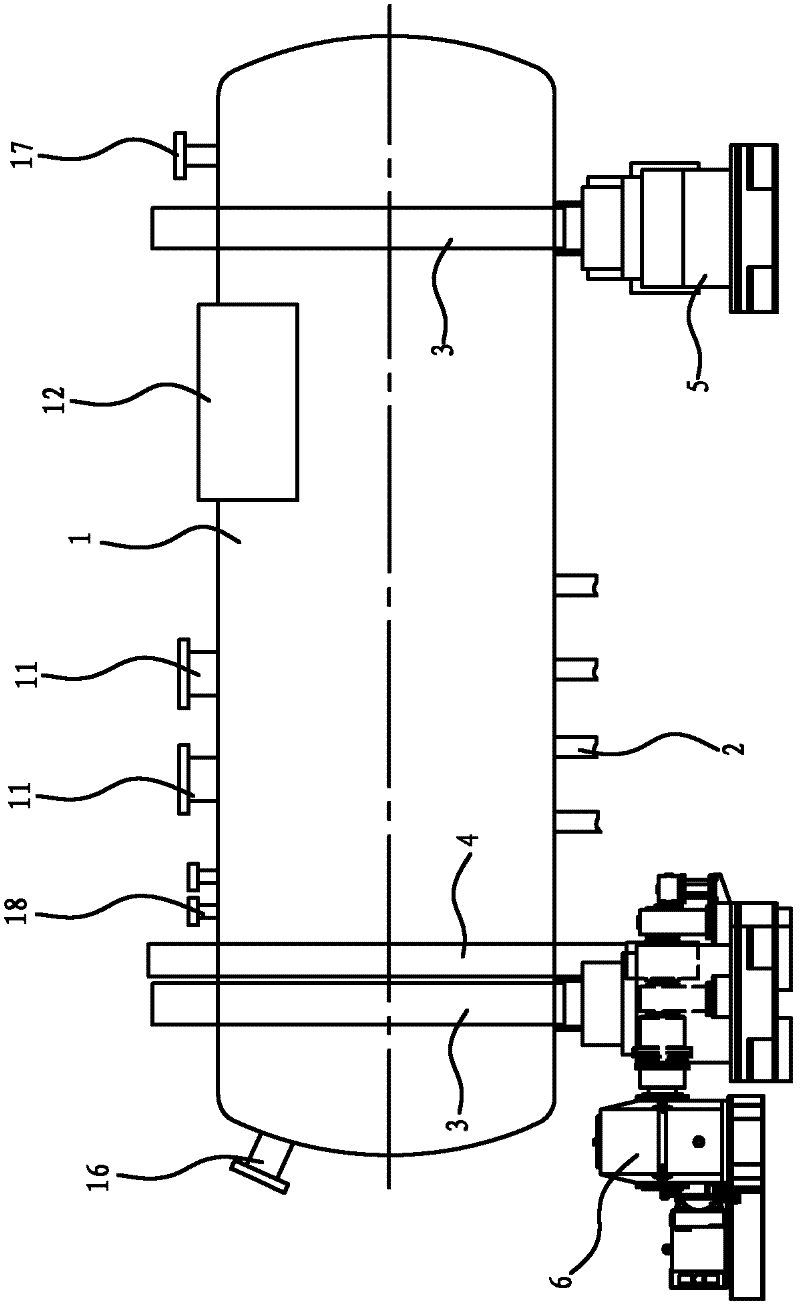

Method and device for massively producing graphene conductive slurry and prepared graphene conductive slurry

ActiveCN108630338AExcellent physical and chemical propertiesEvenly dispersedNon-conductive material with dispersed conductive materialCable/conductor manufactureHigh concentrationGraphite

The invention provides a method and a device for massively producing a graphene conductive slurry and a prepared graphene conductive slurry. The method comprises the following steps of a) mixing graphite and a solvent, carrying out at least one low-speed mixing processing or / and low-speed shearing processing and acquiring a graphite dispersion liquid; b) carrying out at least one sanding processing on the graphite dispersion liquid and acquiring a preliminary stripped graphene dispersion liquid; c) carrying out at least one high pressure homogenization processing or / and ultrasonic processing on the preliminary stripped graphene dispersion liquid, and acquiring a single layer or a small layer of graphene dispersion liquid; d) dissolving a dispersing agent in a solvent to obtain a dispersantsolution; and e) mixing the single layer or the small layer of graphene dispersion liquid and the dispersant solution, carrying out at least one sanding processing, and acquiring the graphene conductive slurry. By using the method, under the condition of environmental protection, the stable and uniformly-dispersed graphene conductive slurry with a high concentration is acquired. And the device issuitable for the continuous automatic production of the high-concentration and high-stability graphene conductive slurry.

Owner:北京地泽科技有限公司

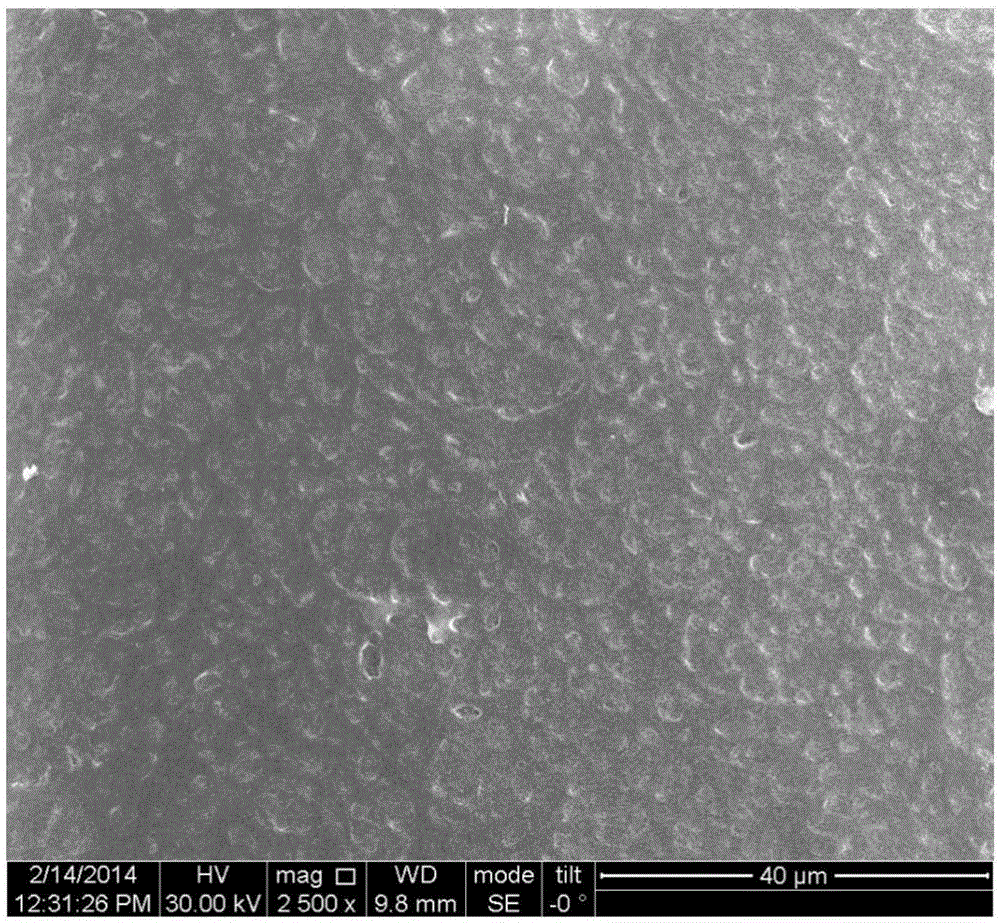

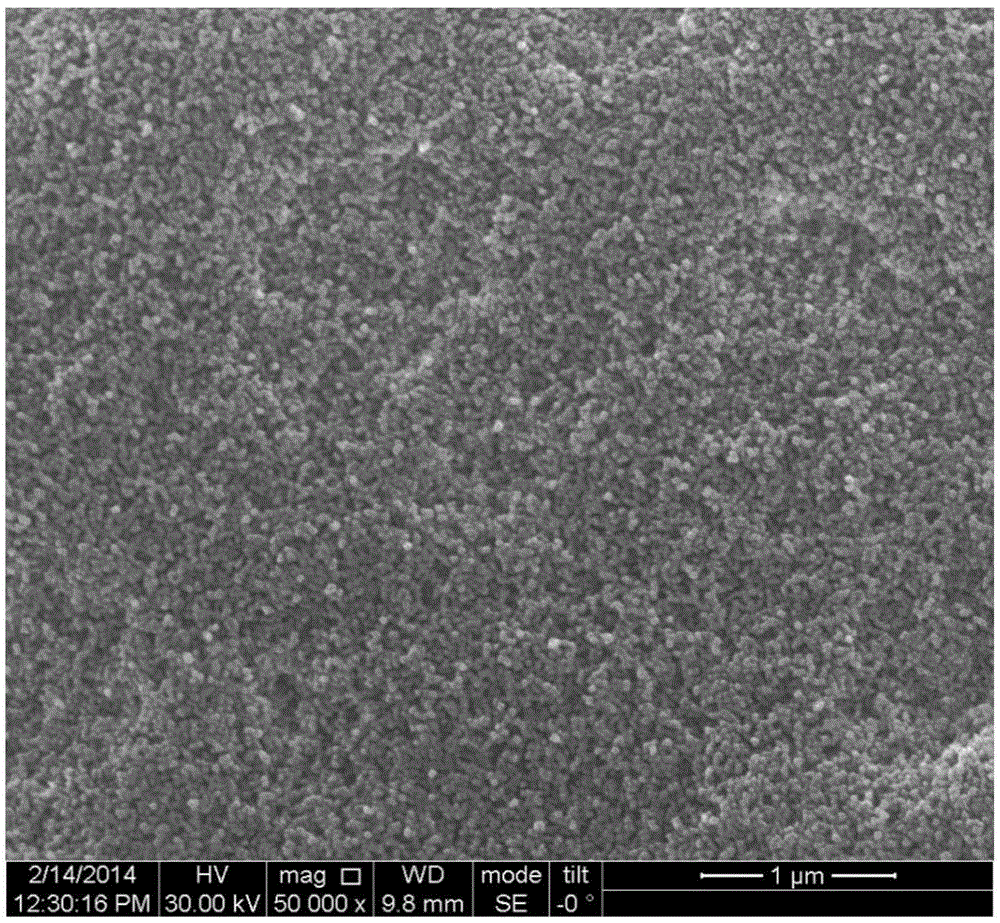

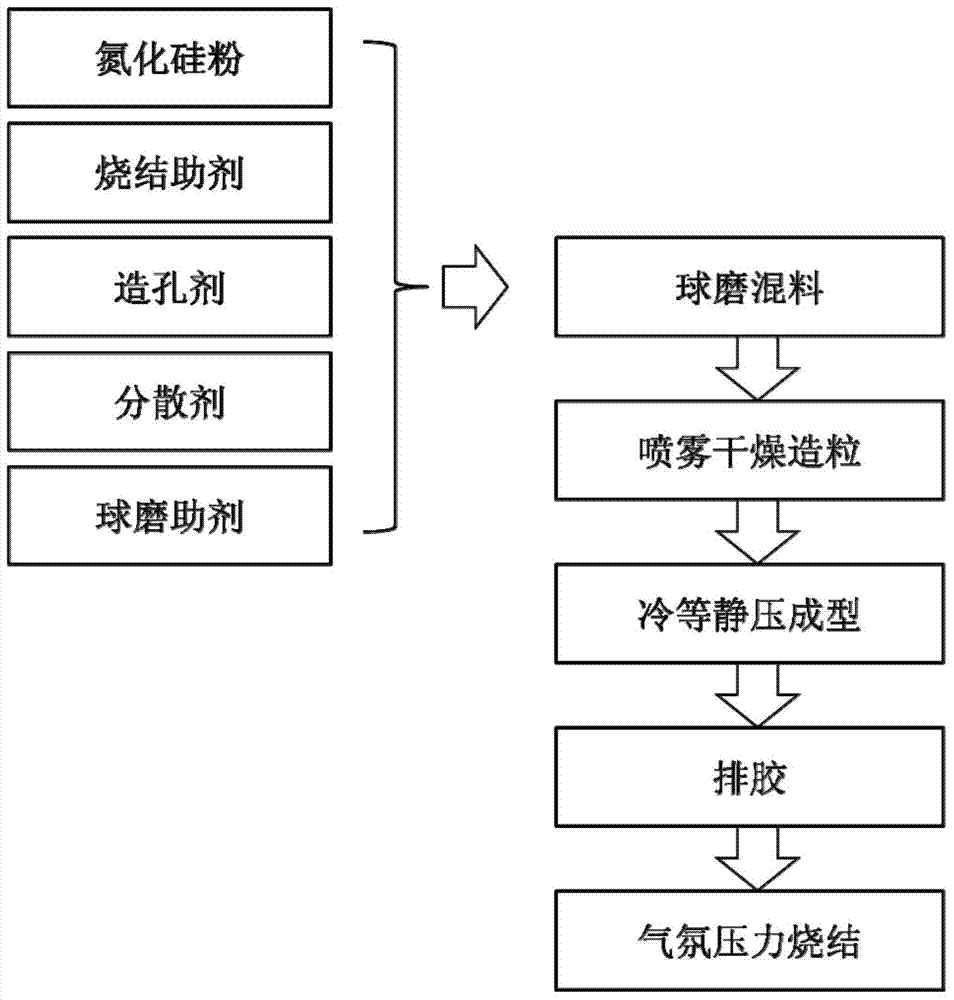

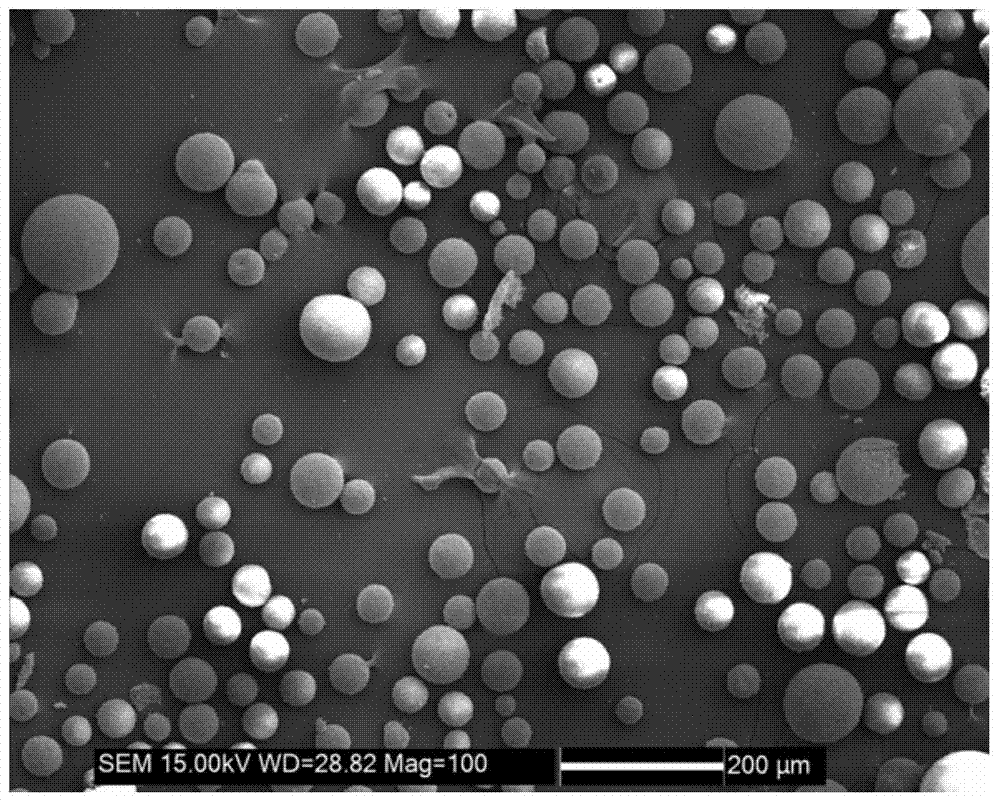

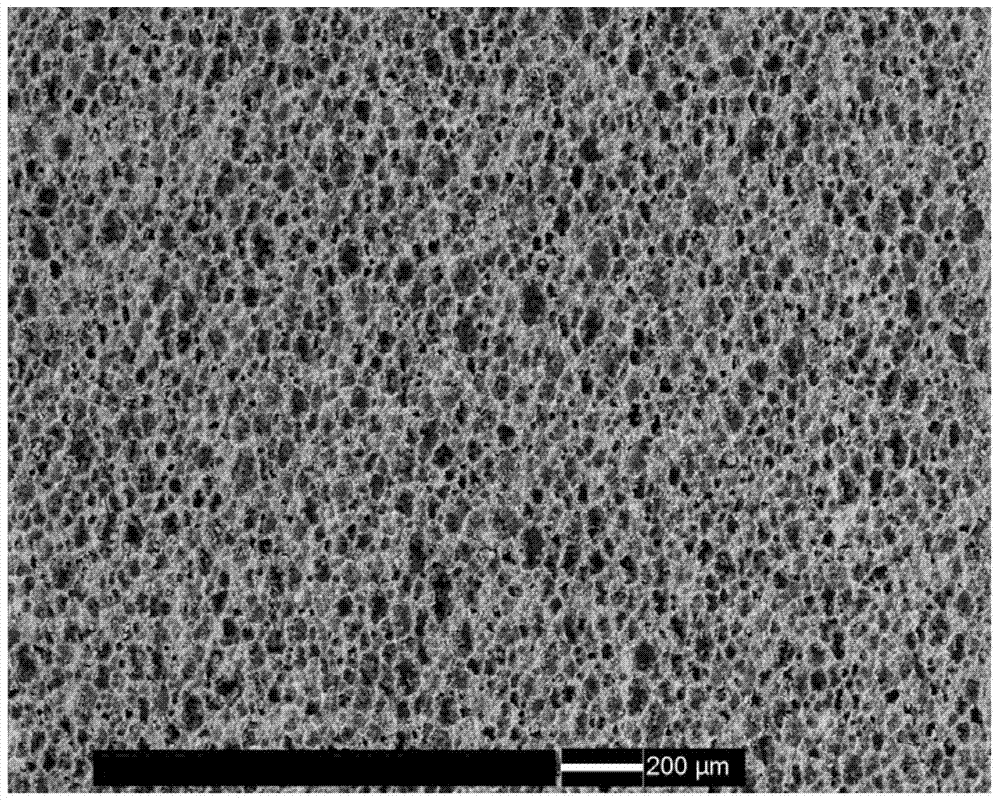

Preparation method of porous silicon nitride ceramic material with spherical pore structure

The invention relates to a preparation method of a porous silicon nitride ceramic material with a spherical pore structure. The method comprises the following steps: uniformly mixing silicon nitride powder with a mono-dispersed polymethyl methacrylate (PMMA) spherical pore forming agent to prepare a stable slurry, preparing microsphere powder (the silicon nitride powder and / the spherical pore forming agent are uniformly dispersed in the above microspheres) with good fluidity and regular shape through a spray drying process, carrying out a direct cold isostatic pressing technology on the microsphere powder to prepare a blank with uniform density, carrying out an optimized batching technology to completely remove the pore forming agent and other organic matters, and sintering in nitrogen pressure atmosphere to obtain the complete non-crack porous silicon nitride ceramic material. The porous silicon nitride ceramic material prepared through the method has the advantages of uniform space distribution, uniform size spherical pores, high bending strength and small discreteness.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Far infrared bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556275AImprove antibacterial propertiesSignificant far infrared health functionArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceFar infrared

The invention discloses provides a far infrared bamboo charcoal viscose fiber and a preparation method thereof, in order to make up for the blank of the conventional far infrared bamboo charcoal viscose fiber and solve the problem of poor spinnability of the bamboo charcoal viscose fiber. The far infrared bamboo charcoal viscose fiber is characterized in that the fiber comprises 1-10 percent by weight of far infrared ceramic powder and 0.1-10 percent by weight of bamboo charcoal, wherein the far infrared emissivity is greater than 80 percent, the ammonia absorption rate is greater than or equal to 50 percent, the permeability is greater than or equal to 500 mm / s, and the color fastness to washing is class 4-5. The far infrared bamboo charcoal viscose fiber has a heat insulation effect; the radiated far infrared also has the health-care functions of activating cell tissues and promoting the blood circulation.

Owner:YIBIN HIEST FIBER +1

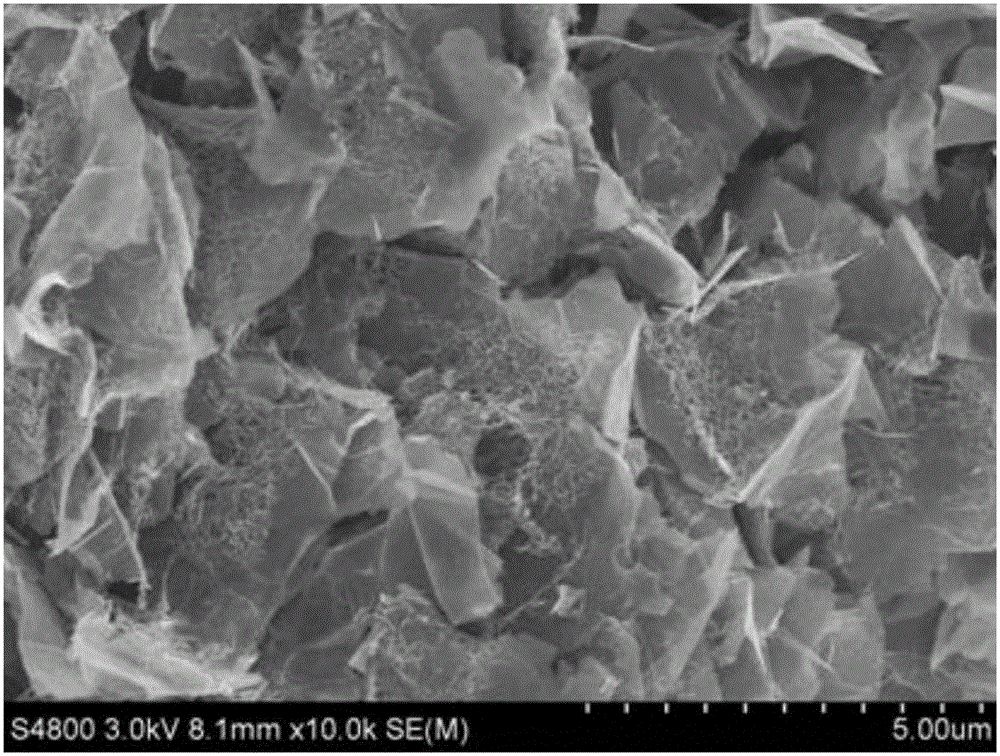

Preparation method of lithium ion battery anode slurry

The invention relates to a preparation method of lithium ion battery anode slurry. The method comprises the following steps: a. weighing anode slurry, an active material, a conductive agent, a thickener, a binder, a solvent and a surfactant in the lithium ion battery anode slurry ratio; b. mixing the thickener with the solvent in the raw materials, adding the conductive agent to the mixed solventafter full stirring, and continuing stirring the mixture uniformly; c, adding the surfactant to the mixture of step b, performing stirring, adding the active material in three batches, and fully stirring the mixture again for 1. 5 h to obtain slurry a with uniform appearance; d, adding the binder to the slurry a, and adjusting the viscosity of the slurry with the solvent in the stirring process toobtain the lithium ion battery anode slurry. With adoption of a step-by-step wet mixing process, the anode slurry is dispersed evenly, the conductive agent SP and the active material form a mutuallydispersed interlocking microstructure, stability is good, settling is not likely to occur, and peel strength of a prepared pole piece is significantly improved compared with that of a pole piece prepared with the traditional process.

Owner:天臣新能源研究南京有限公司

Water plugging agent for carbonatite and preparation method and using method thereof

InactiveCN101712863AHigh densityLow densityDrilling compositionSealing/packingHigh densityVolumetric Mass Density

The invention provides a water plugging agent for carbonatite and a preparation method and a using method thereof. The water plugging agent consists of the following raw materials in part by weight: 5 to 14 parts of cement, 4 to 8 parts of quartz, 0.1 to 0.5 part of cement flocculating agent, 4 to 11 parts of density lightening admixture, 1 to 2 parts of grid structure agent and 72 to 74 parts of water. The water plugging agent has high bonding strength and low density, and is suitable for high-temperature and high-mineralization carbonatite oil wells so as to solve the problem that the water plugging agent in the prior art is not suitable for the high-temperature and high-mineralization environment, has poor bonding strength and high density, and cannot effectively control water or improve the oil recovery ratio.

Owner:北京德美高科科技股份有限公司

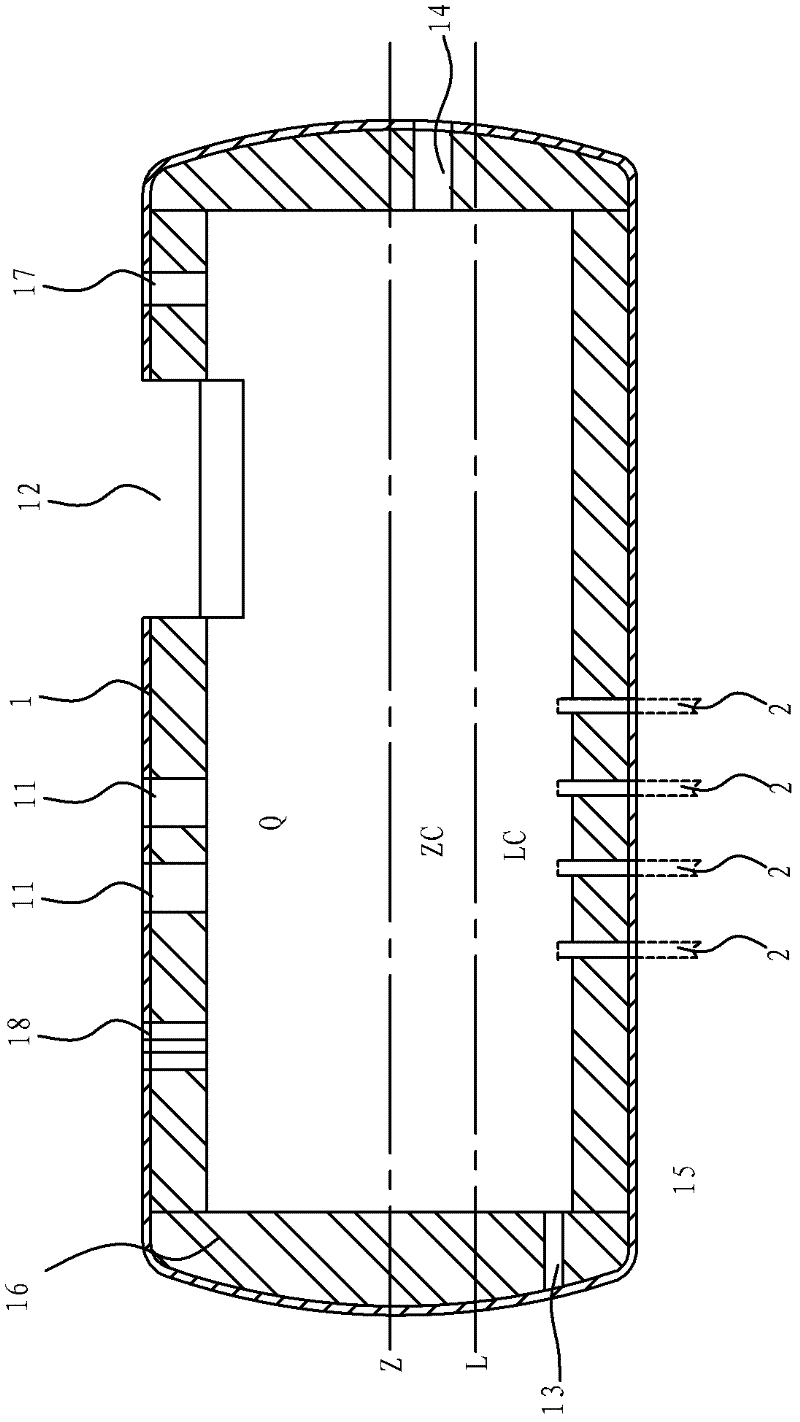

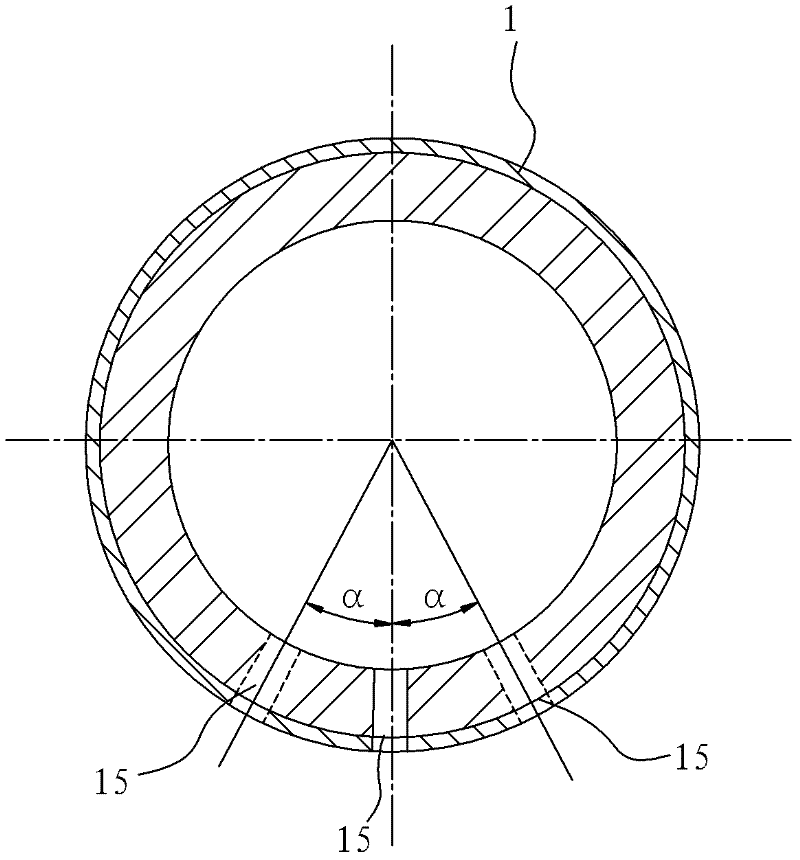

Oxygen-enriched bottom-blown matte smelting furnace and oxygen-enriched bottom-blown matte smelting technology

InactiveCN102230091ASimplify smelting operationsLow costRotary drum furnacesCrucible furnacesSlagSulfide

The invention provides an oxygen-enriched bottom-blown matte smelting furnace and an oxygen-enriched bottom-blown matte smelting technology. The oxygen-enriched bottom-blown matte smelting furnace comprises a furnace body and oxygen guns. The furnace body is equipped with a furnace chamber therein, feed inlets, a flue gas outlet, a sulfonium outlet, a slag hole and oxygen gun jacks formed on furnace body bottom; and the oxygen guns are inserted into the oxygen gun jacks to blow oxygen-enriched gas into a sulfonium layer in the furnace chamber. According to an embodiment of the oxygen-enriched bottom-blown matte smelting furnace and the oxygen-enriched bottom-blown matte smelting technology of the invention, granulation of materials is not required, so as to simplify smelting operations and reduce costs. Most oxygen is reacted with sulfides in the sulfonium layer, and little oxygen, company with a reacted gas, enters to a slag layer from the sulfonium layer; a content of magnetic iron generated in the slag is small, and viscosity of the slag is lowered, so that a separating layer is not likely to form, and sulfonium in the slag is easy to be precipitated. Therefore, a high iron slag type can be adopted to lower flux rate and slag rate, and reduce loss of metal in the slag. Meanwhile, foam slag is not likely to generate to ensure good security, and mushroom head is easy to form on an upper end of the oxygen gun to protect the oxygen gun for a long life.

Owner:CHINA ENFI ENGINEERING CORPORATION

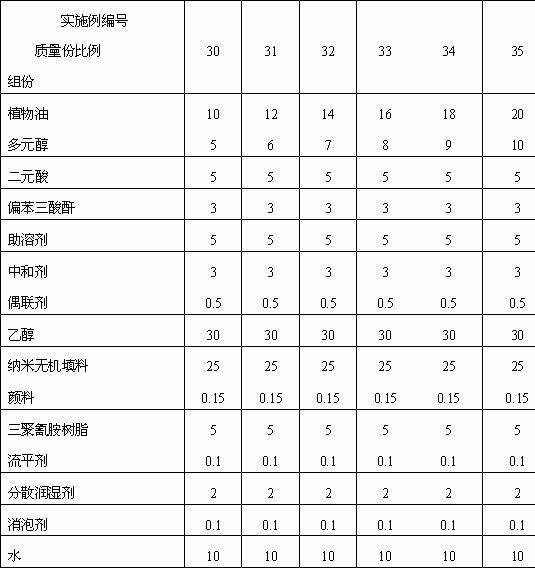

Preparation method of H-grade water-solubility silicon steel sheet paint

ActiveCN102304319AImprove the state of the interfaceNot easy to settlePolyester coatingsSolventSolubility

The invention discloses a preparation method of a H-grade water-solubility silicon steel sheet paint, which comprises the following steps of: taking raw materials such as 10-20 parts of plant oil, 5-10 parts of polyatomic alcohol, 5 parts of binary acid, 3 parts of trimellitic anhydride, 5 parts of cosolvent, 3 parts of neutralizer, 0.5 part of coupling agent, 30 parts of alcohol, 25 parts of nanometer inorganic packing, 0.15 part of pigment, 5 parts of melamine resin, 0.1 part of flatting agent, 2 parts of dispersing moistening agent, 0.1 part of deforming agent and 10 parts of water according to a weight ratio, and preparing an environmental-friendly product with good combination properties for large generators through the synthesis of alkyd resins, the coupling treatment of the nanometer inorganic packing, the mixing and dispersion of materials such as the inorganic substances and the like in a paint, the grinding of the paint vehicle and the like. The preparation method has the advantages of solving the problems of sedimentation, aggregation and blocking of powder in paint liquid under the condition of high content of inorganic powder, obviously increasing the storage stability of the paint liquid and the hardness of a paint film, effectively reducing the discharge of poisonous and harmful gases in the production process and reducing the harm to the health of human bodies.

Owner:四川东材绝缘技术有限公司

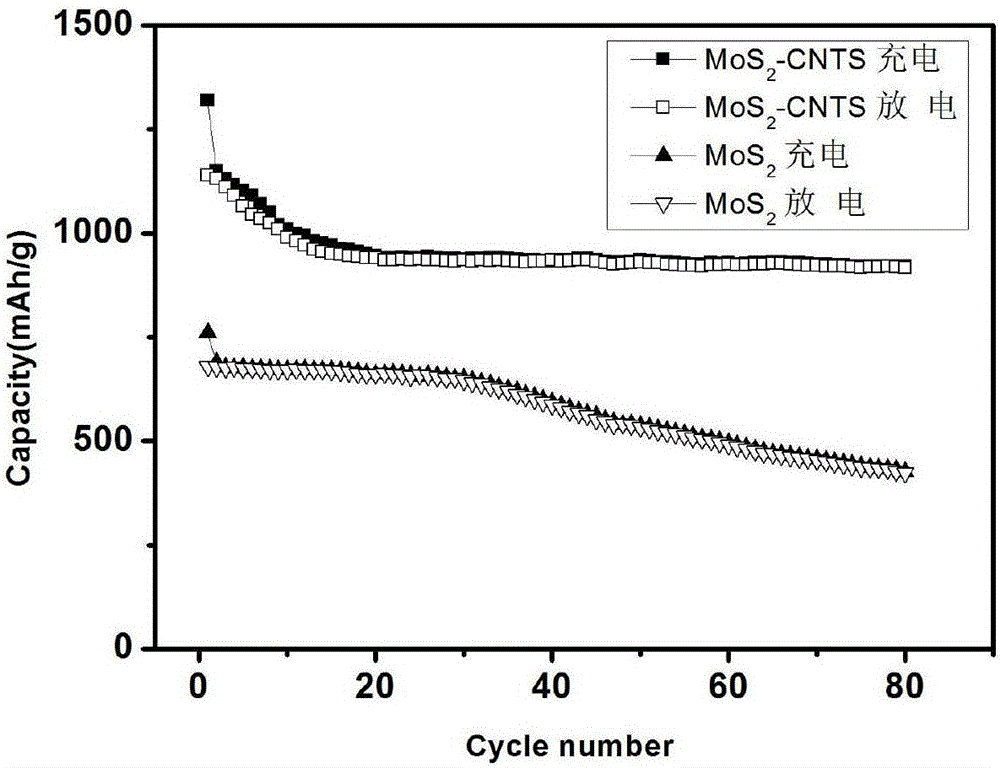

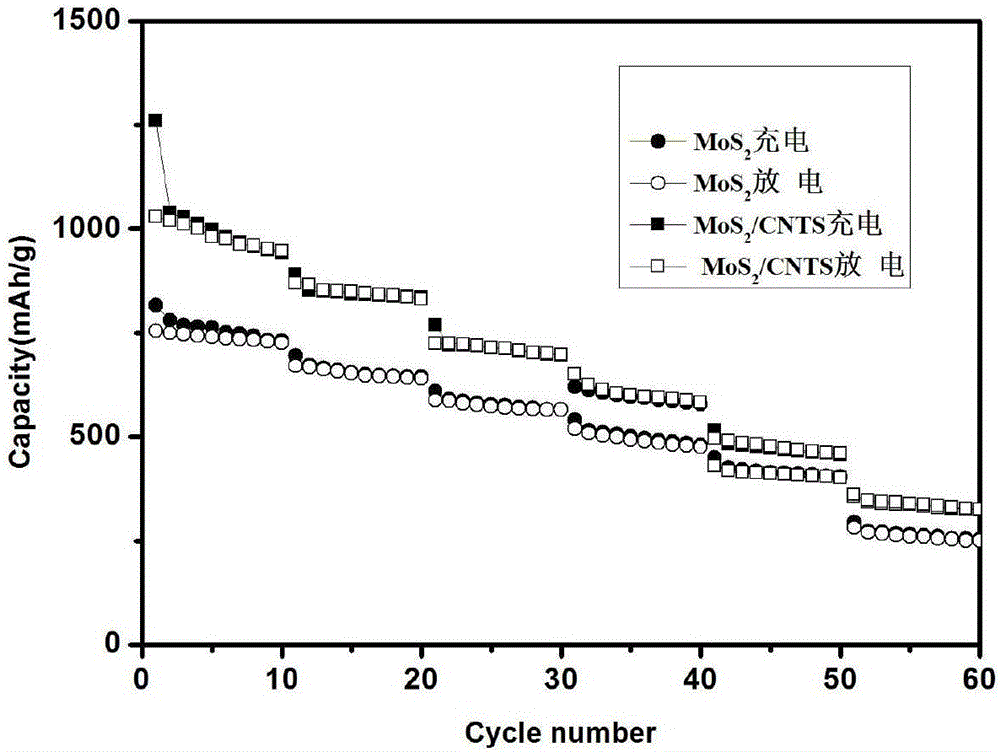

Lithium-ion-battery multiwalled carbon nanotube/ molybdenum disulfide combination electrode and preparation method

ActiveCN106711413AHigh electrochemical lithium storage specific capacityPromote circulationCell electrodesSecondary cellsHigh rateLithium-ion battery

The invention provides a lithium-ion-battery multiwalled carbon nanotube / molybdenum disulfide combination electrode and a preparation method. According to the preparation method, multiwalled carbon nanotube, soluble molybdate and L-cysteine are adopted as materials, glucose and triton X-100 are used as additives, dispersion uniformity of MoS2 on the surface of the carbon nanotube is improved, and through an in-situ hydrothermal reduction method, a combination electrode material of MoS2 and the multiwalled carbon nanotube is synthesized. The material has high electrochemical storage lithium specific capacity, excellent cycle performance and a high-rate feature. Meanwhile, the synthetic method has the advantages of being moderate in reaction condition, simple in process, high in yield and good in repeatability.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

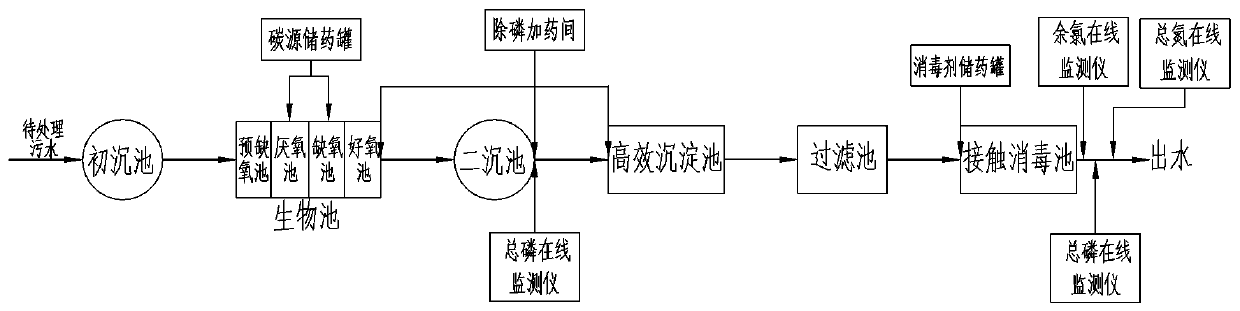

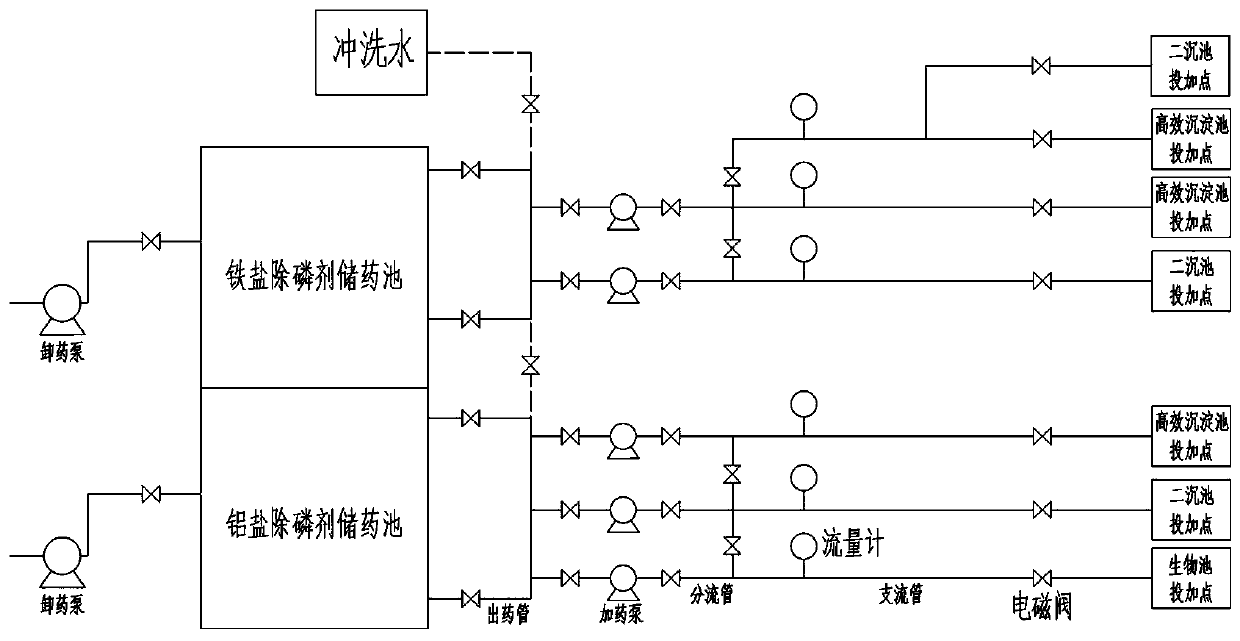

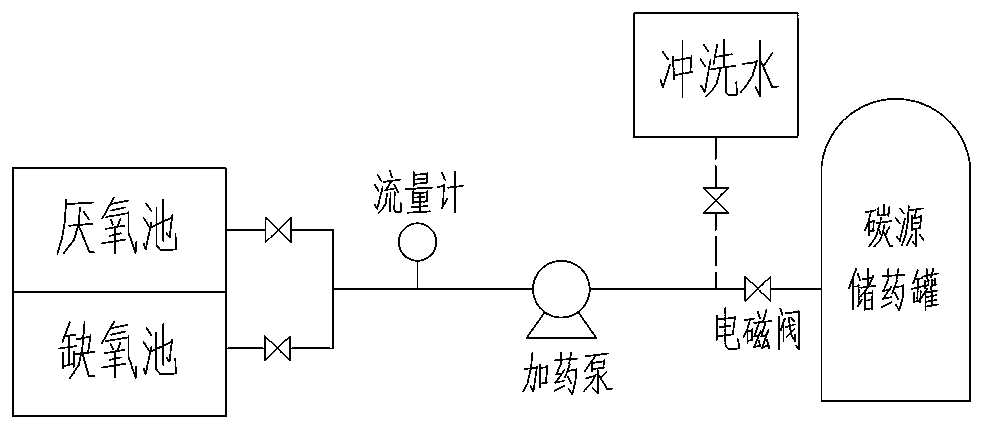

Accurate chemical dosing system and chemical dosing method for sewage treatment

PendingCN108017235APrecise adjustment of dosageIncrease carbon sourceWater treatment parameter controlWater treatment compoundsDisinfectantMedicine

The invention discloses an accurate chemical dosing system and a chemical dosing method for sewage treatment. The system comprises a treatment tank group, a phosphorus removing agent feeding assembly,a carbon source feeding assembly, a disinfectant feeding assembly and a control assembly. The method comprises the following steps: adjusting the feeding of an aluminum salt phosphorus removing agent, a ferric salt phosphorus removing agent and a carbon source according to a monitoring value of water outlet total phosphorus; adjusting the feeding of the carbon source according to a monitoring value of water outlet total nitrogen; adjusting the feeding of a disinfectant according to a monitoring value of water outlet residual chlorine. The system disclosed by the invention has the advantage ofhigh automation degree, the chemical phosphorus removing agent can be fed according to water outlet on-line TP (Total Phosphorus), the water outlet stability is improved, and the problem of standardreaching lag of chemical dosing and water outlet quality is solved to a maximum extent, so that the system is more stable and safer; meanwhile, frequency of a chemical dosing pump can be adjusted according to a feeding ratio so as to control a chemical dosing amount, and therefore, a using amount of a medicament is reduced to a maximum extent, so that chemical dosing phosphorus removal, denitrification and sterilization are more scientific, and the sewage treatment cost is also reduced.

Owner:中原环保股份有限公司

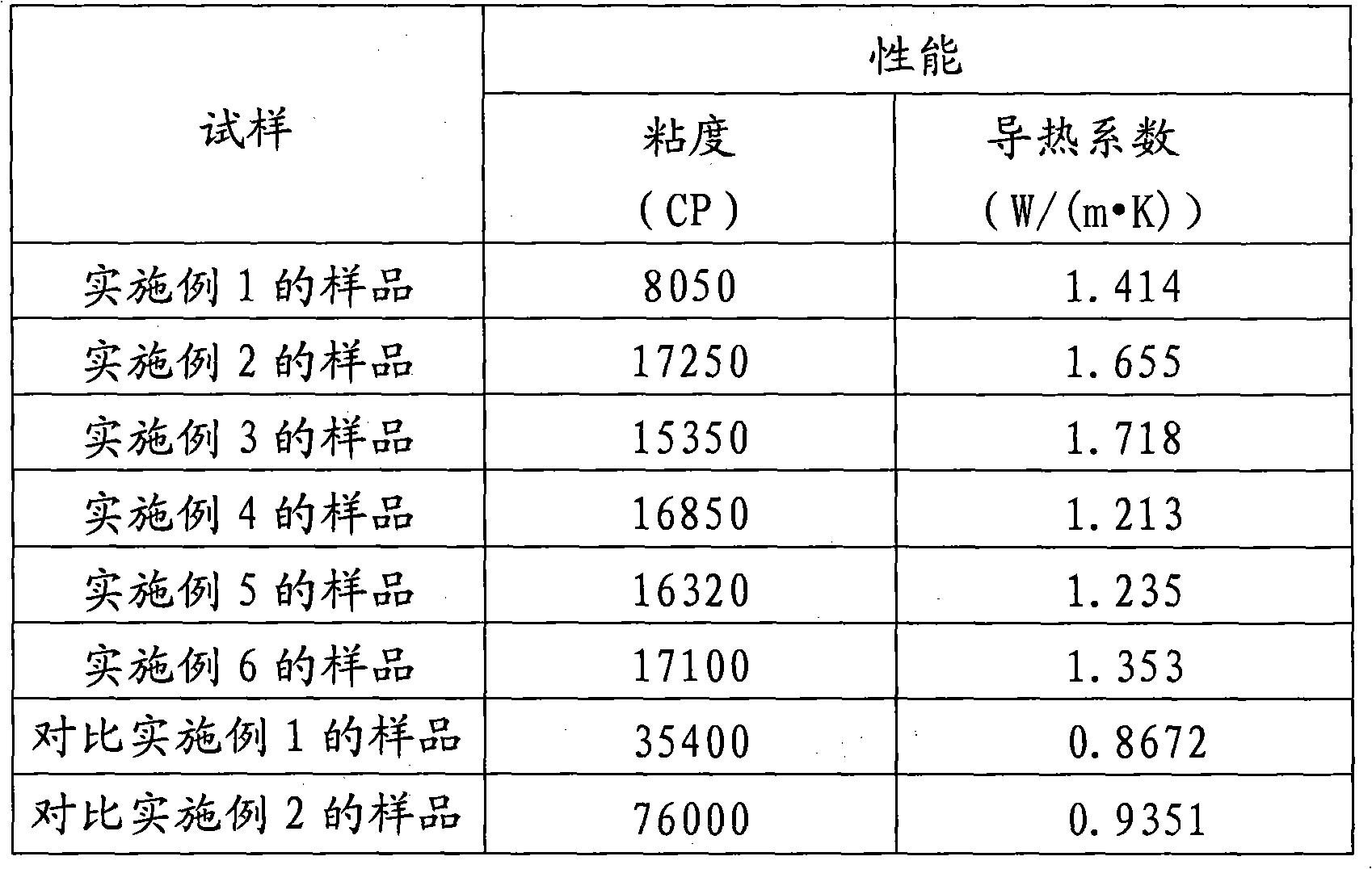

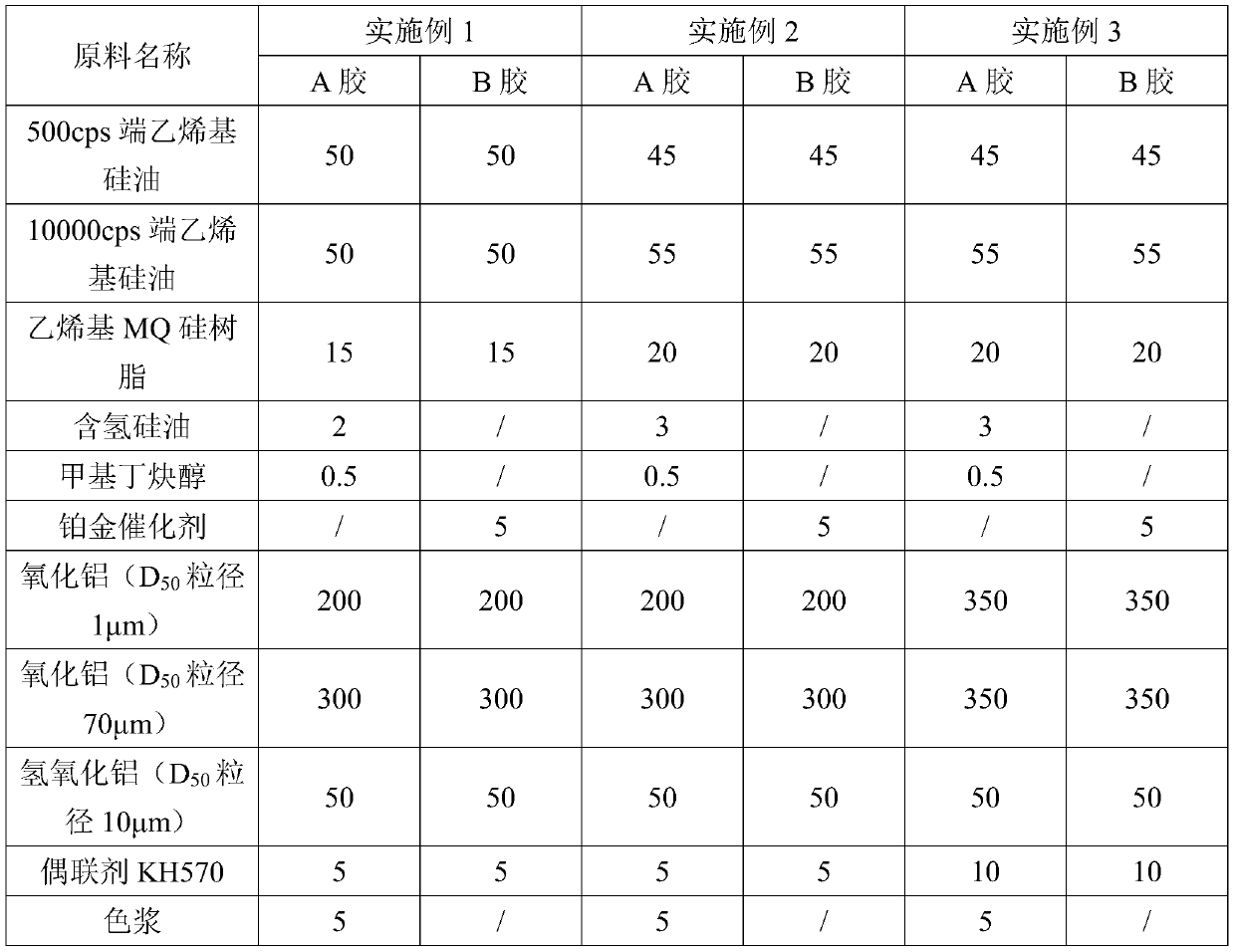

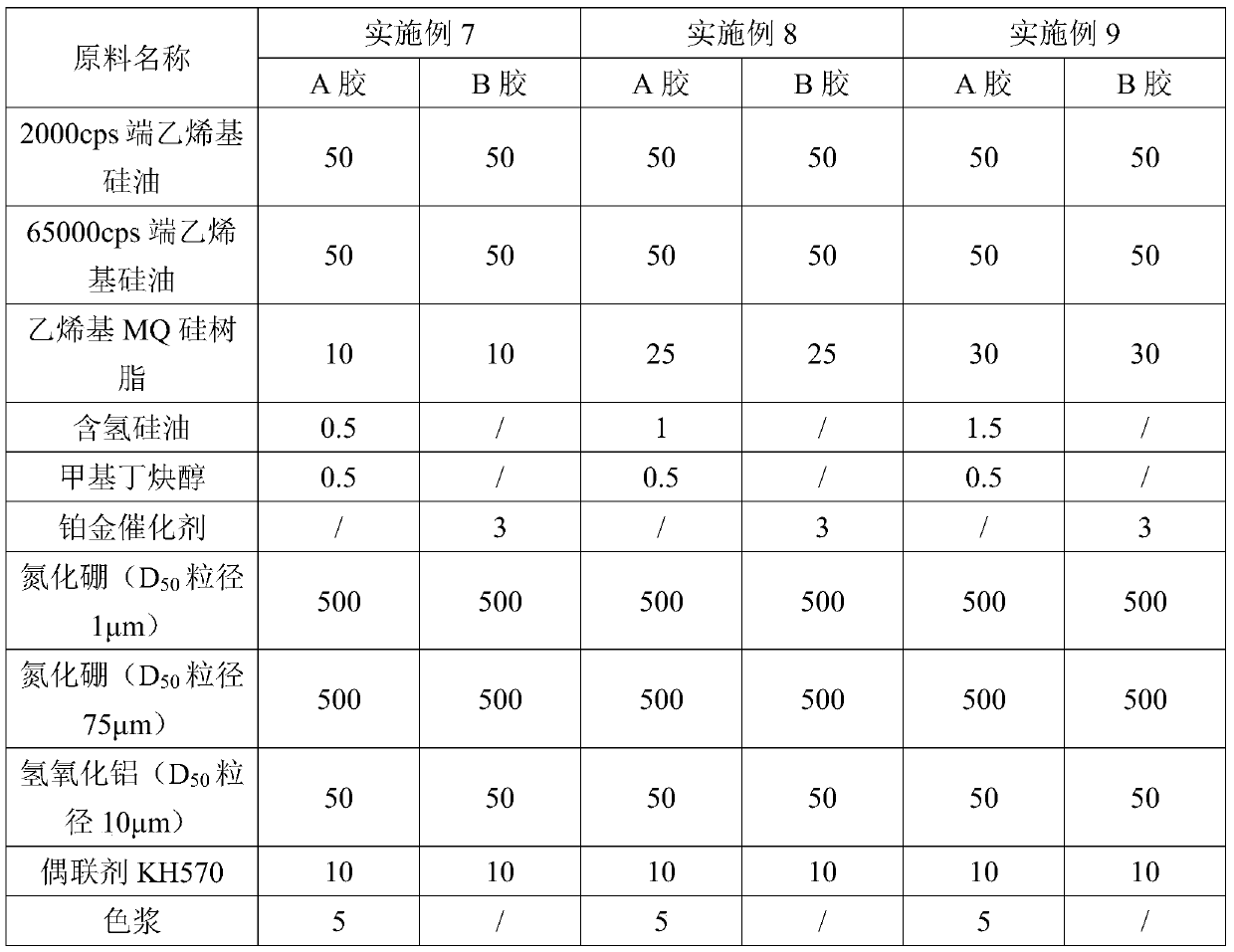

Heat-conducting silica gel as well as preparation method and application thereof

InactiveCN111004510ANot easy to settleHigh thermal conductivityHeat-exchange elementsSilicone resinPolymer chemistry

The invention provides heat-conducting silica gel as well as a preparation method and application thereof. The heat-conducting silica gel comprises an adhesive A and an adhesive B according to a massratio of (0.5-1.5): 1; wherein the adhesive A comprises the following components in parts by weight: 100 parts of vinyl silicone oil, 10-30 parts of vinyl MQ silicone resin, 0.5-5 parts of hydrogen-containing silicone oil, 0.1-2 parts of an inhibitor, 300-1500 parts of a heat-conducting filler and 1-10 parts of a coupling agent; the adhesive B is prepared from 100 parts of vinyl silicone oil, 10 to 30 parts of vinyl MQ silicon resin, 1 to 20 parts of a catalyst, 300 to 1500 parts of a heat-conducting filler and 1 to 10 parts of a coupling agent; and the vinyl silicone oil is prepared from vinyl silicone oil with the viscosity of 1 to 2000 cps and vinyl silicone oil with the viscosity of 5000 to 65000cps. The heat-conducting silica gel provided by the invention has good storage stability, and a cured product of the heat-conducting silica gel has relatively high strength and toughness and is easy to integrally peel off.

Owner:CYBRID TECHNOLOGIES INC

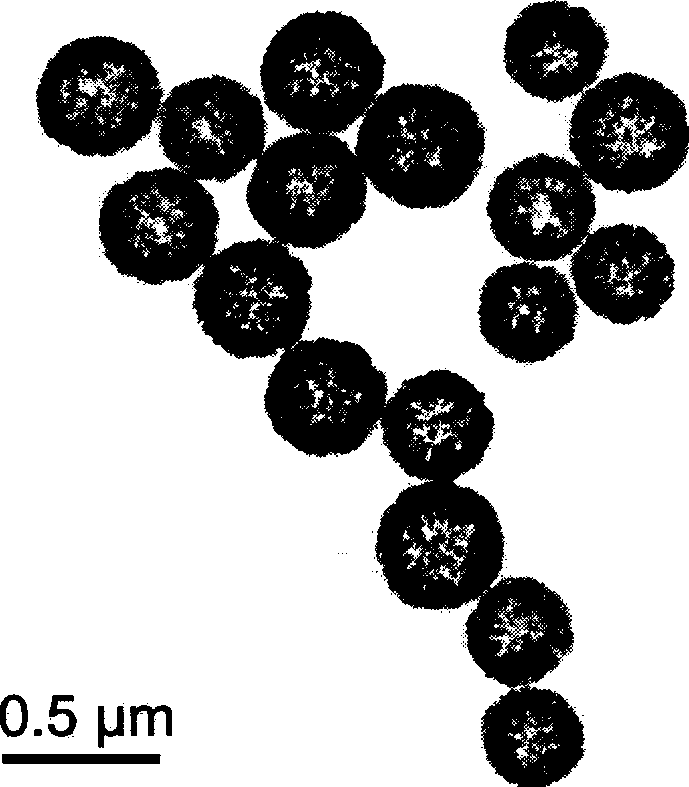

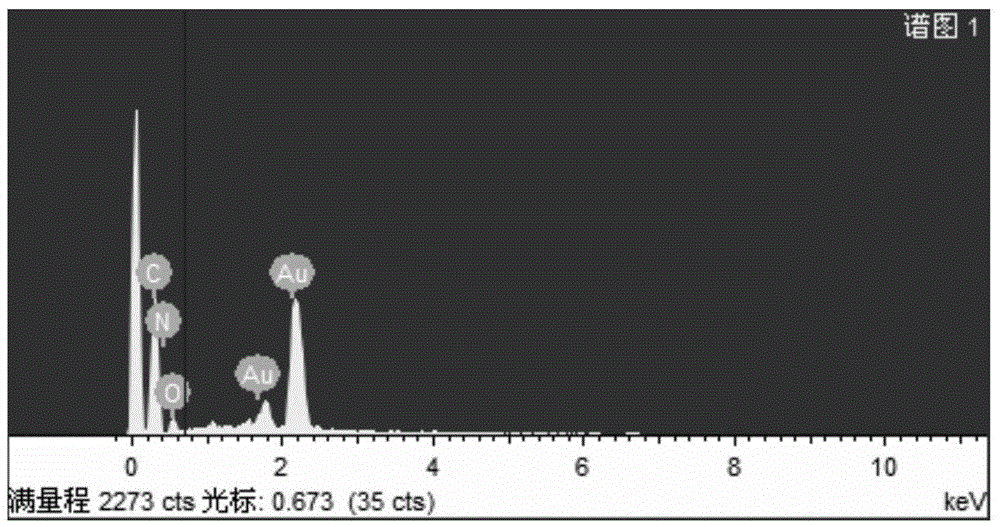

Preparation method of micron polymer-based composite conductive gold balls

ActiveCN105478752AGood lookingAvoid multi-step preprocessingTransportation and packagingMetal-working apparatusGold ballChemical plating

The present invention relates to a preparation method of micron polymer-based composite conductive gold balls. The method comprises: dispersing polymer microparticles in water; then adding stabilizing agent; stirring to obtain polymer microparticle dispersion liquid; then adding an amino-modified reagent; mechanically stirring and reacting to obtain amino-modified polymer microparticles; ultrasonically dispersing in water; adding carboxylic acid-modified gold sol; magnetically stirring, washing, centrifuging and drying to obtain polymer microparticles overlapped with nanoparticles on the surface; ultrasonically dispersing in a cyanide-free gold growth solution; under a condition of 40-80 DEG C, ultrasonically or mechanically stirring and reacting, washing, centrifuging and drying to obtain the product. The preparation method in the present invention is environmentally friendly and is simple and convenient to operate, avoids the heavy and complicated pre-treatment process in the traditional chemical plating and solves the problems of interference of impurity ions such as tin and palladium and toxicity of chemical plating solution such as cyanide.

Owner:DONGHUA UNIV

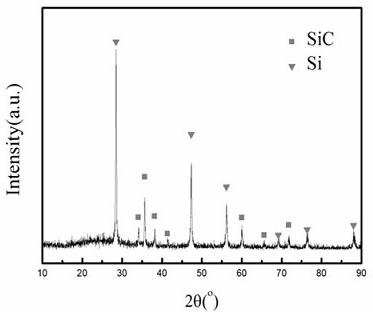

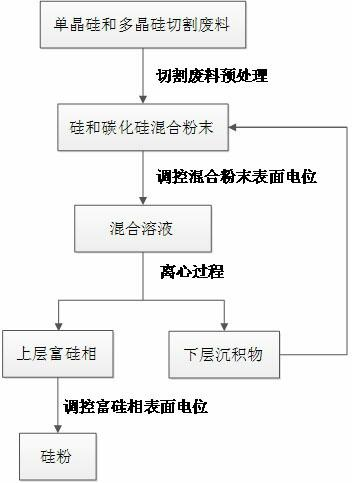

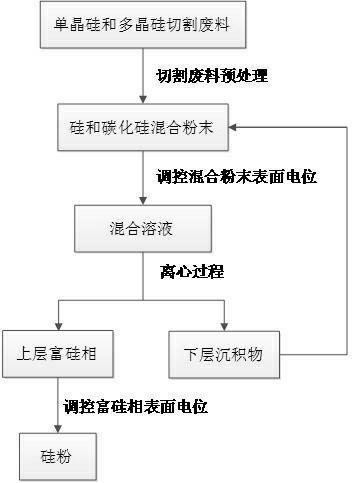

Method for recovering silicon powder from monocrystalline and polycrystalline silicon cutting wastes by utilizing potential adjustment centrifugal process

InactiveCN102659112ASimple processStable process parametersSilicon carbideSilicon compoundsCarbide siliconSilica fume

The invention discloses a method for recovering a silicon powder from monocrystalline and polycrystalline silicon cutting wastes by utilizing a potential adjustment centrifugal process. The method comprises the following steps of: firstly, performing pretreatment on the cutting wastes to remove a polyethylene glycol solution; drying to obtain a mixed powder of silicon and silicon carbide; adding water to the mixed powder and stirring; regulating a pH value to 6-9 by acid and base; performing centrifugal separation for a plurality of times, and then, adding the acid to an isolated upper layer suspension to regulate the pH value to 1-3 so as to enable a silicon powder aggregate to grow up; and performing standing settling for 30min or centrifugal settling for 5min to collect the silicon powder, wherein the purity of the silicon powder can reach more than 80 percent.

Owner:UNIV OF SCI & TECH BEIJING

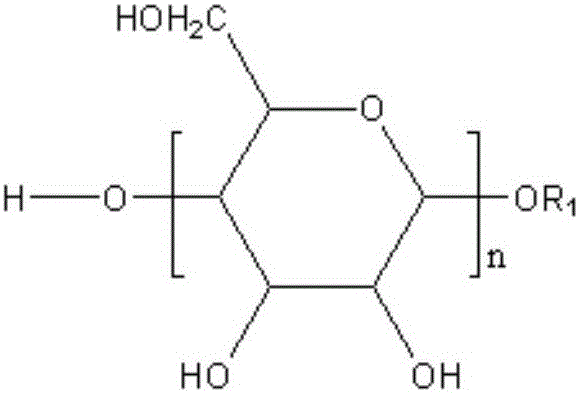

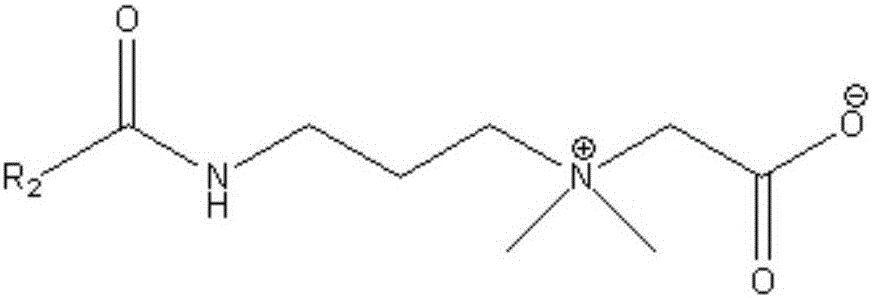

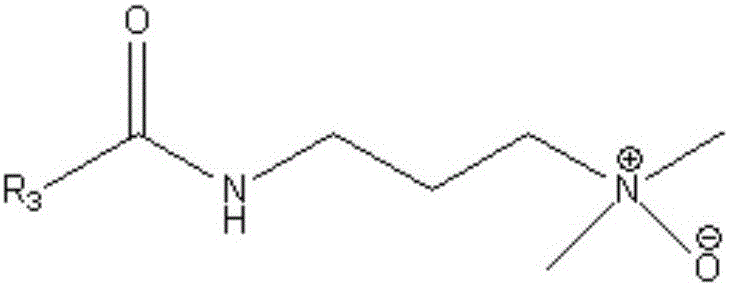

Kitchen wet-tissue immersion liquid as well as preparation method and application thereof

ActiveCN106148030APrevents wet wipe contents from settlingImprove stabilityCationic surface-active compoundsOrganic detergent compounding agentsChemistryOxide

The invention relates to kitchen wet-tissue immersion liquid as well as a preparation method and application thereof. The kitchen wet-tissue immersion liquid is prepared from the following raw material components in percentage by mass: 0.01-0.2% of a rheology control agent, 1-10% of a surfactant composition, 0-1.5% of a fungicidal preservative, 0-5% of a chelating agent, 0-0.1% of an antifoaming agent, 0-0.2% of essence and the balance of water, wherein the rheology control agent is an acrylate crosslinking copolymer with molecular weight of 1.0*10<8>-1.0*10<10> Daltons; the surfactant composition is a mixture composed of alkyl glycoside, alkyl amidopropyl betaine and alkenamides propylamine oxide according to a mass ratio of (10-1):(5-1):1. According to the kitchen wet-tissue immersion liquid disclosed by the invention, the problem that content of the wet-tissue is easy to settle is solved, the product stability is improved, and the immersion liquid is efficient in decontamination, safe and mild and has good application prospect.

Owner:广州超威生物科技有限公司

Preparation method of titanate-modified nano cerium oxide/polyurethane composite paint

ActiveCN103589311AGuaranteed decentralizationGuarantee stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsPhysical chemistryCorrosion resistant

Owner:STATE GRID CORP OF CHINA +2

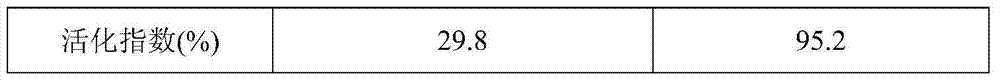

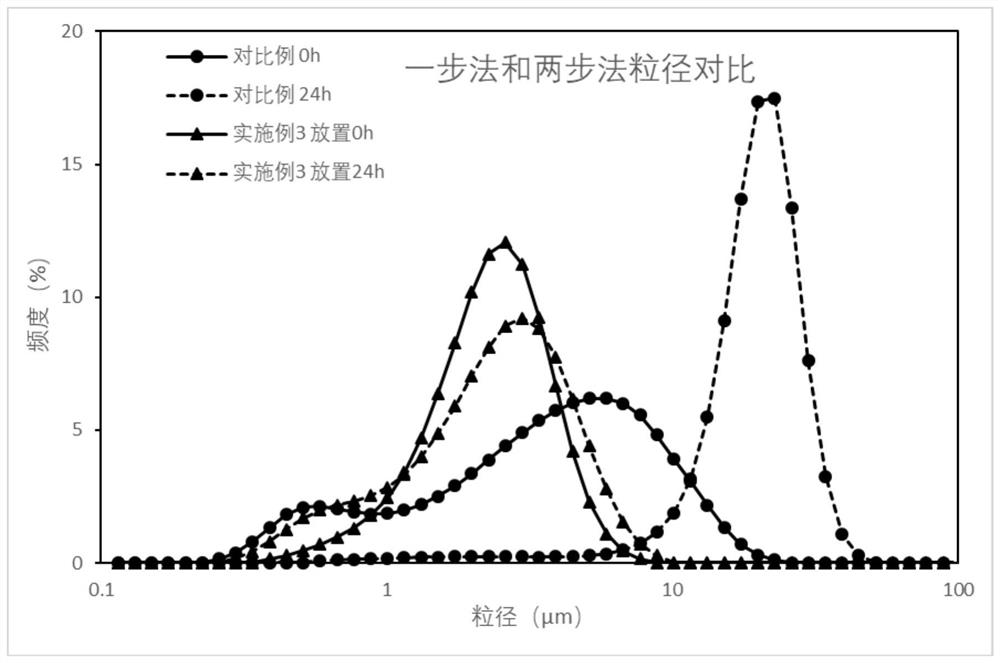

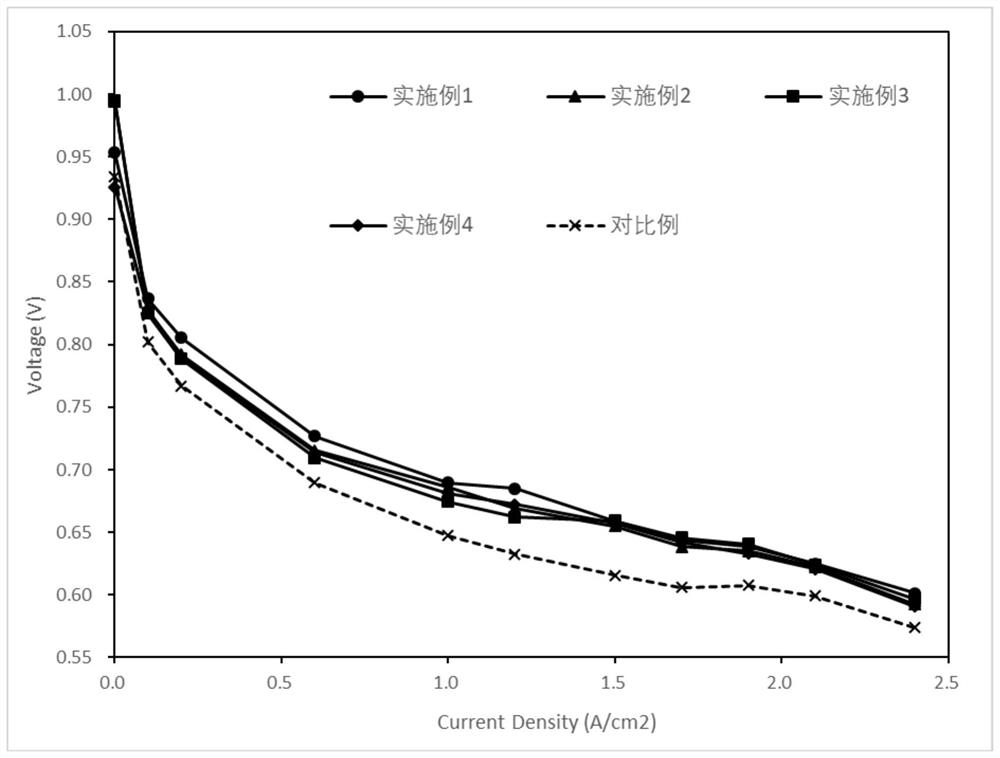

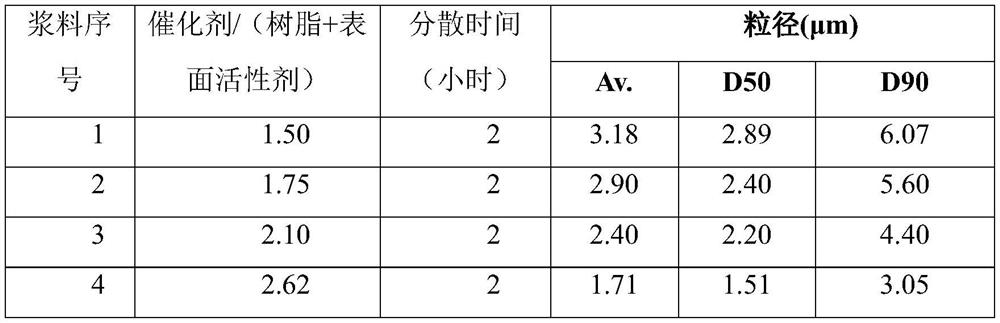

Method for preparing high-stability fuel cell catalyst coating slurry

The invention relates to the field of fuel cells, in particular to a method for preparing high-stability fuel cell catalyst coating slurry. The method for preparing the high-stability fuel cell catalyst coating slurry comprises at least two mixing and dispersing steps: mixing and dispersing a catalyst, perfluorosulfonic acid resin and a solvent in the first mixing and dispersing step to obtain a first-stage mixed dispersion liquid; and mixing and dispersing the previous-stage mixed dispersion liquid and newly added perfluorosulfonic acid resin in other mixing and dispersing steps; wherein a surfactant is added in at least one mixing and dispersing step for mixing and dispersing. The catalyst in the catalyst slurry prepared by the method has good dispersion stability, is not easy to settle,and has good performance when being applied to a membrane electrode.

Owner:SINOHYKEY TECH CO LTD

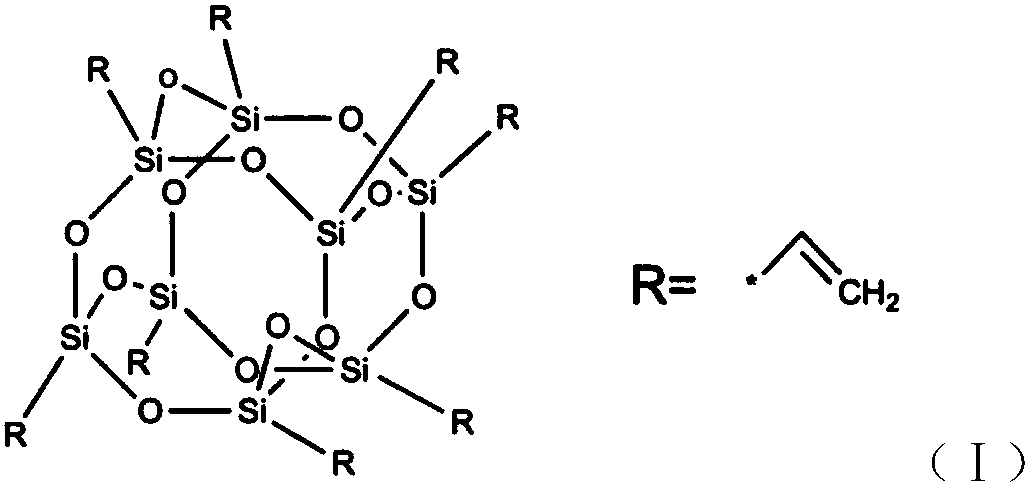

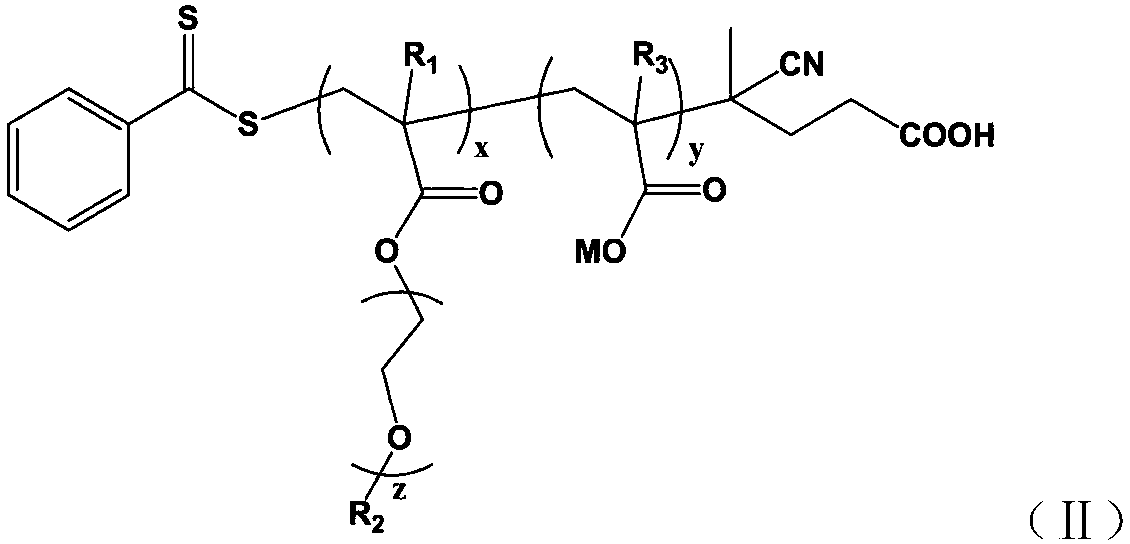

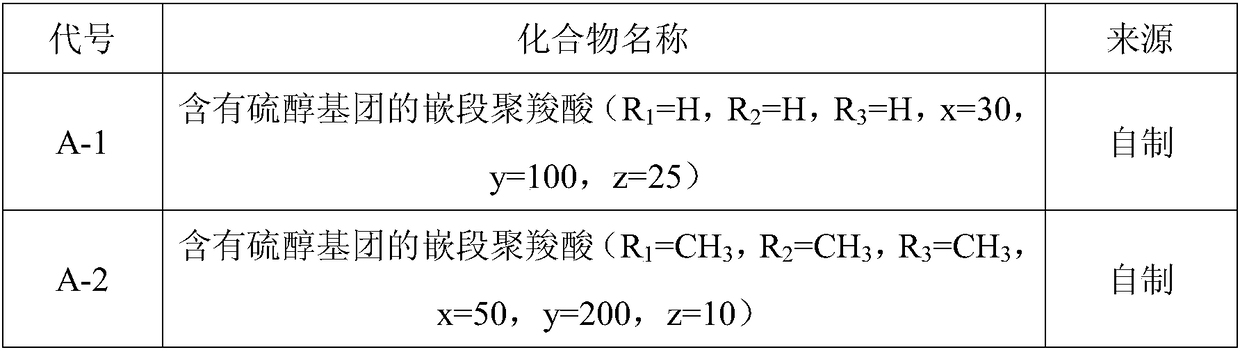

Preparation method and applications of composite super-early strength admixture

The invention discloses a composite super-early strength admixture preparation method, which comprises: dissolving octavinyl POSS and a block polycarboxylic acid A containing a thiol group in a tetrahydrofuran solvent, carrying out a thiol-alkenyl click chemistry reaction under the action of a catalyst, and carrying out rotary evaporation to remove the tetrahydrofuran solvent after completing thereaction so as to obtain a POSS-based star block polycarboxylic acid water-reducing agent; and at a temperature of 20-40 DEG C, simultaneously adding a soluble calcium salt B aqueous solution and a soluble silicate C aqueous solution into the POSS-based star block polycarboxylic acid water-reducing agent in a dropwise manner at a uniform speed, and carrying out thermal insulation for 2-5 h after completing the adding so as to obtain the composite super-early strength admixture. According to the present invention, the POSS core inorganic nanometer structure material in the composite super-earlystrength admixture can achieve the compounding of the polycarboxylic acid water-reducing agent and the nanometer material, such that the dispersion efficiency of the inorganic nanometer structure material is high, the inorganic particles are stable and do not easily settle, the early strength is easily increased, and the transportation cost can be reduced.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com