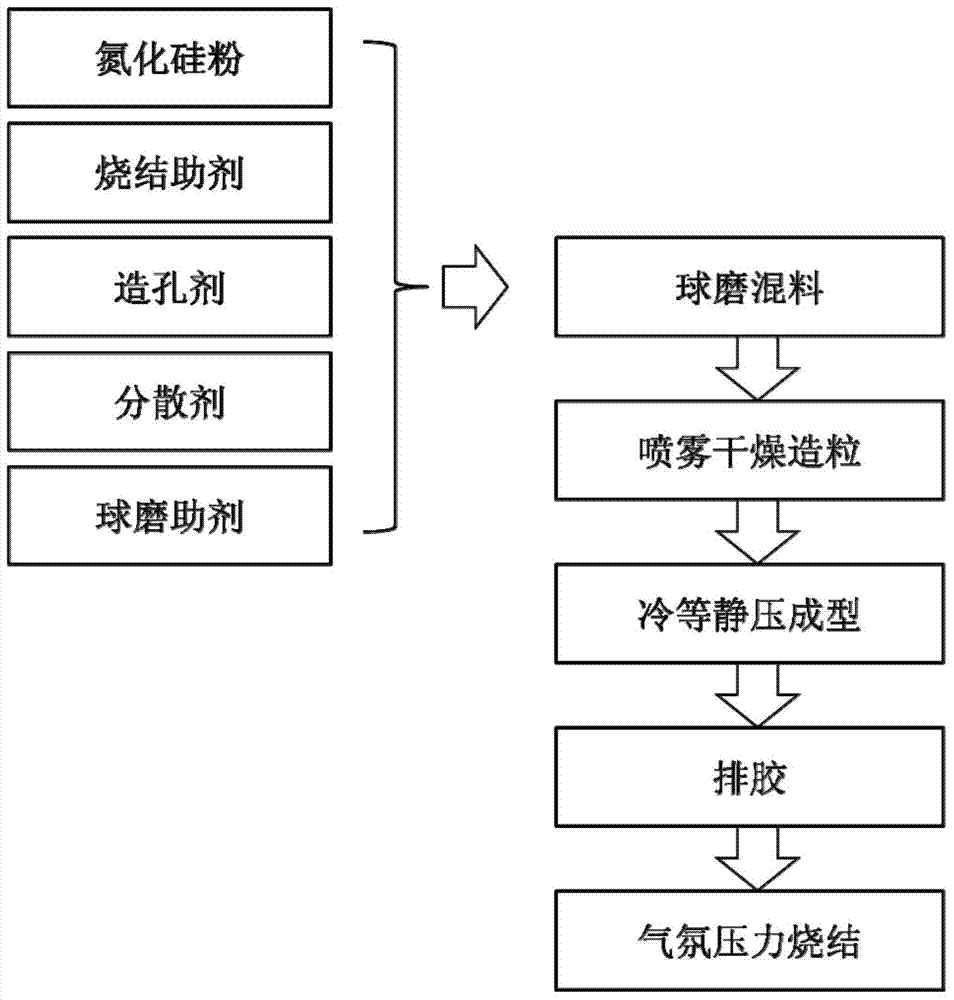

Preparation method of porous silicon nitride ceramic material with spherical pore structure

A technology of silicon nitride ceramics and pore structure, which is applied to ceramic products, household appliances, and other household appliances, etc., can solve the problems affecting the stability of material mechanical properties, difficult to control the size of hollow balls, and little potential for engineering applications, etc., to achieve The effect of uniform size, high bending strength and small proportion of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the water-based slurry adopts roller ball milling, and the ball milling time is 12-48 hours.

[0042] Step (2), adding a binder and a water-based defoamer to the water-based slurry in sequence, mixing them uniformly, and ball-milling again, and the ball-milling time is 0.2-2 hours. The binder is polyvinyl alcohol PVA aqueous solution, the mass concentration of the PVA aqueous solution is 5-30%, and the mass of the added PVA aqueous solution is 0.5-5% of the mass of the silicon nitride powder. The mass of the added water-based defoamer is 0.02-0.2% of the mass of the water-based slurry.

[0043] Step (3), spray drying the water-based slurry obtained in step (2), and slowly stirring the water-based slurry while spray-drying, the stirring speed is 10-60r / min;

[0044] Step (4), putting the powder obtained by spray drying into a mold for cold isostatic pressing; the pressure during the cold isostatic pressing is 200-700 MPa, and the holding time i...

Embodiment 1

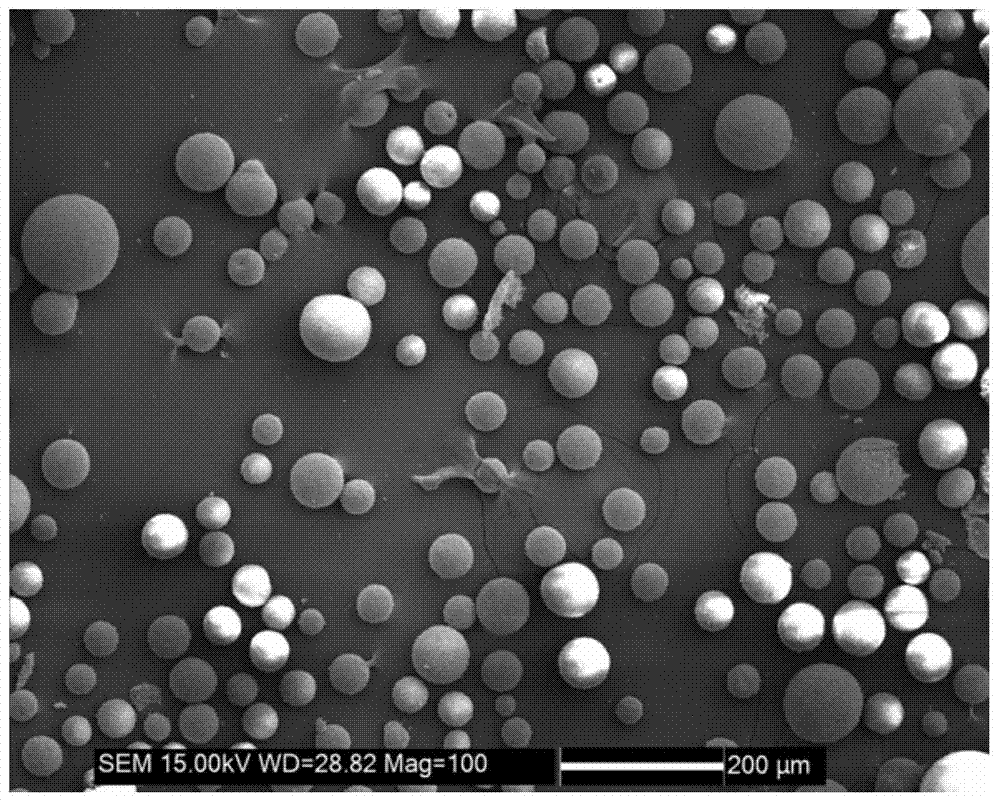

[0057] Weigh 20Kg silicon nitride powder, 100gY 2 o 3 , 200Al 2 o 3 , 400gSiO2 2 , 100gMgO, 9.4Kg PMMA microspheres with a diameter of 20μm, 200g polyethylene glycol-4000, 200g BYK2012, and add 30Kg deionized water, after roller ball milling for 18 hours, add 200g of pre-configured 30wt% PVA aqueous solution and stir evenly, then add water-based 50g of defoaming agent, continue ball milling for 1h, then move the slurry into the mixing tank, take out the slurry and spray dry while stirring at a speed of 30r / min, put the obtained powder into a special mold, and perform cold isostatic pressing, The pressure is 300MPa, and the pressure is maintained for 30 minutes to obtain a conical green body with a height of 1200mm and an outer diameter of 500mm. The density of the green body is uniform, and the fluctuation range is ±0.01g / cm 3 within.

[0058] Such as figure 2 Shown is the morphology of the silicon nitride powder mixed with the pore-forming agent in Example 1 of the pr...

Embodiment 2

[0062] Weigh 20Kg silicon nitride powder, 150gY 2 o 3 , 300Al 2 o 3 , 200gSiO2 2 , 200gMgO, 8.5Kg PMMA microspheres with a diameter of 5μm, 220g polyethylene glycol-4000, 180g BYK2012, and add 29Kg deionized water, and add 300g of pre-configured 20wt% PVA aqueous solution after roller milling for 20h, stir evenly, and then add water-based 40g of defoaming agent, continue ball milling for 0.5h, then move the slurry into the mixing tank, stir at a speed of 35r / min while extracting the slurry for spray drying, put the obtained powder into a special mold, and carry out cold isostatic pressing , the pressure is 200MPa, and the pressure is maintained for 35min to obtain a conical green body with a height of 1000mm and an outer diameter of 550mm. The density of the green body is uniform, and the fluctuation range is ±0.01g / cm 3 within.

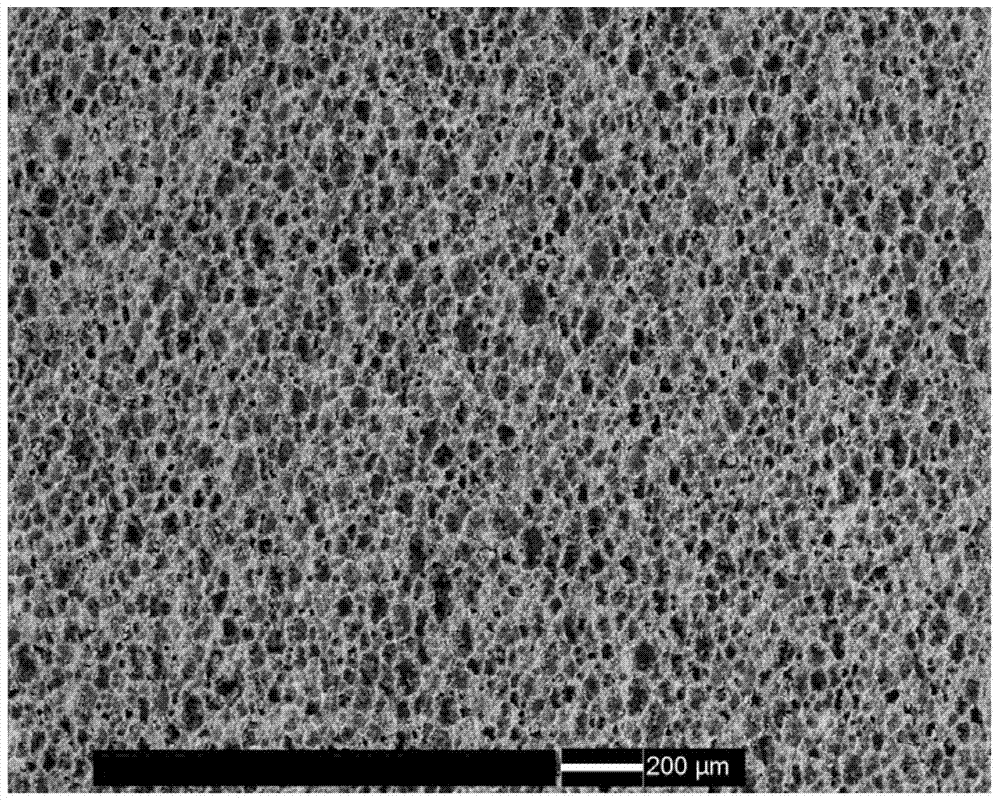

[0063] Such as Figure 5 , Image 6 Shown is the morphology of the silicon nitride powder mixed with the pore-forming agent in Example 2 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com