Patents

Literature

38results about How to "Low mixing viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

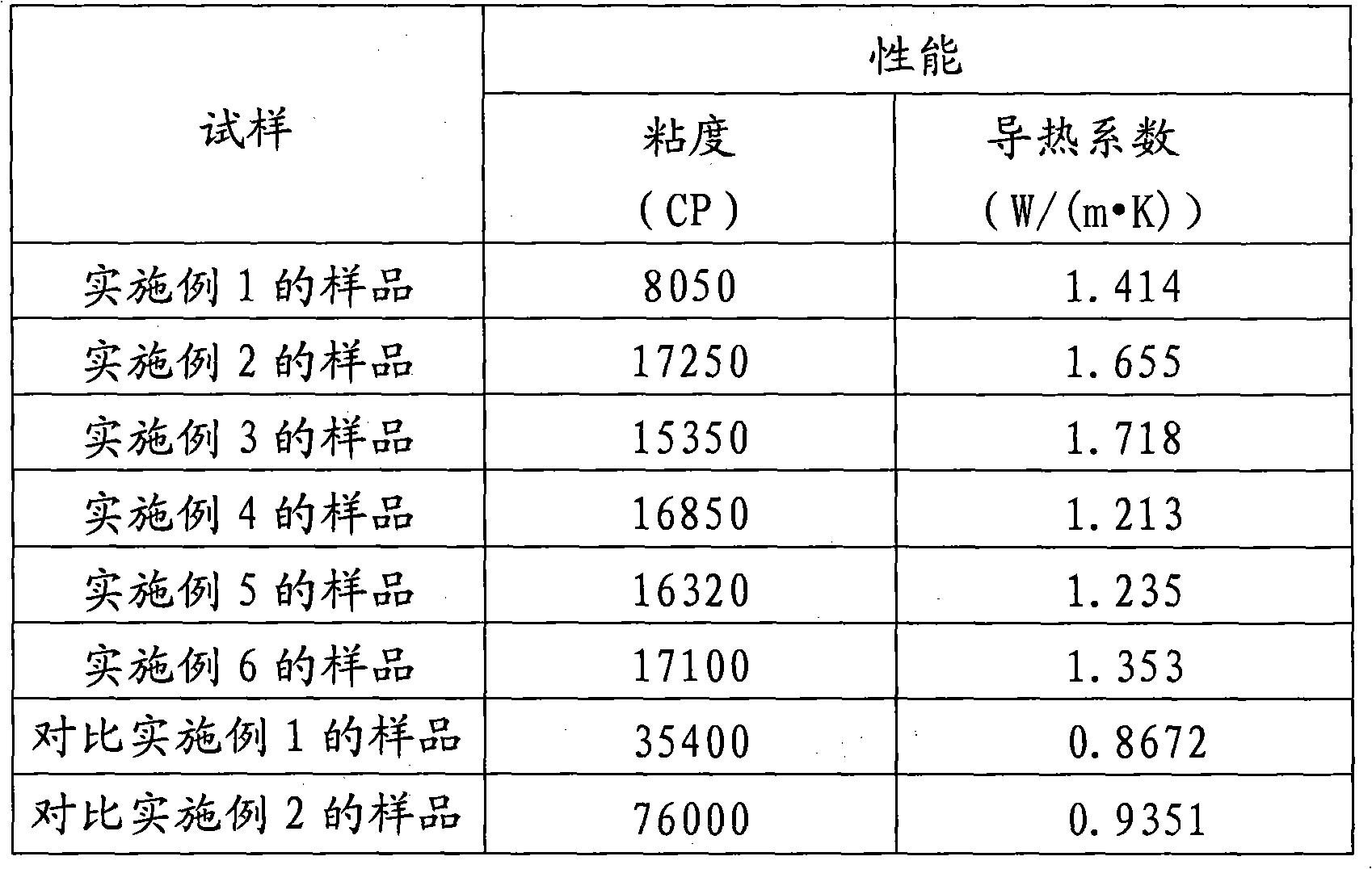

Low-viscosity and high-heat conduction epoxy resin electronic potting adhesive

InactiveCN101974302AImprove thermal conductivityRapid heat buildupNon-macromolecular adhesive additivesOther chemical processesEpoxyAdhesive

The invention relates to a low-viscosity and high-heat conduction epoxy resin electronic potting adhesive which is formed by mixing a component A with an amine curing agent according to the weight ratio of 100:5-12, wherein the component A comprises the following raw materials in weight ratio: 70-85 parts of spherical alumina powder, 10-20 parts of epoxy resin, 2-4 parts of active thinner, 2.5-5 parts of toughening agent and 0.1-0.5 parts of coupling agent. The invention has the advantages that the spherical alumina of the potting adhesive has higher filling amount compared with non-spherical alumina, the viscosity is less affected, the fluidity is favorable and the construction is convenient; the potting adhesive has good dispersibility and is difficult to sedimentate; a condensate has high heat conductivity and can quickly dissipate accumulated heat of heating parts and components; a high-filling filler can reduce a thermal expansion coefficient and a volumetric shrinkage rate and is very suitable for potting parts and components; and the price is cheaper compared with boron nitride and aluminum nitride, and the cost is low.

Owner:YANTAI DARBOND TECH

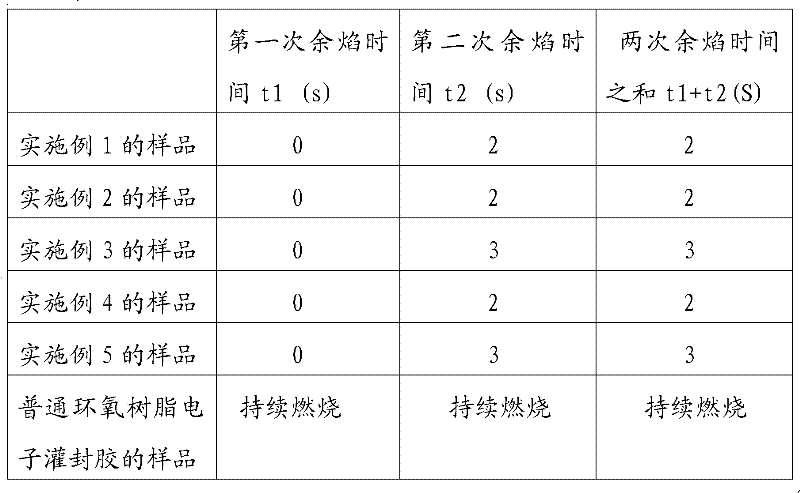

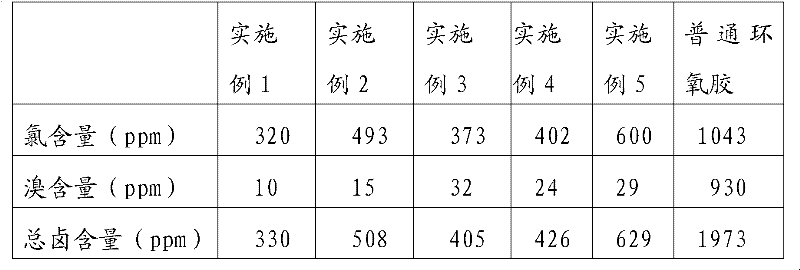

Halogen-free flame-retardant epoxy resin electronic pouring sealant

InactiveCN102516914ASatisfy Halogen Free RequirementsImprove flame retardant performanceNon-macromolecular adhesive additivesOther chemical processesEpoxyHalogen

The invention relates to a halogen-free flame-retardant epoxy resin electronic pouring sealant which is formed by mixing an A component and an amine curing agent according to the weight ratio of 100:4-13, wherein the A component comprises the following raw materials in parts by weight: 30-40 parts of halogen-free epoxy resin, 40-65 parts of flame-retardant fillers, 2-7 parts of halogen-free active diluting agents, 2-7 parts of halogen-free liquid flame retardants, 1-5 parts of toughening agents, 0.1-0.5 part of coupling agent and 0.1-0.5 part of pigment. The invention has the beneficial effects that the pouring sealant is free from halogen and satisfies the halogen-free requirements; the flame retardance is independent of a halogen-added flame retardant, so that the environment friendliness is achieved; the fame retardant ability is strong and can achieve the grade UL94-V0; and with the adoption of a double-component system, not only can the room-temperature curing be achieved, but also the thermal curing can be achieved, so that the operation is covneneint.

Owner:YANTAI DARBOND TECH

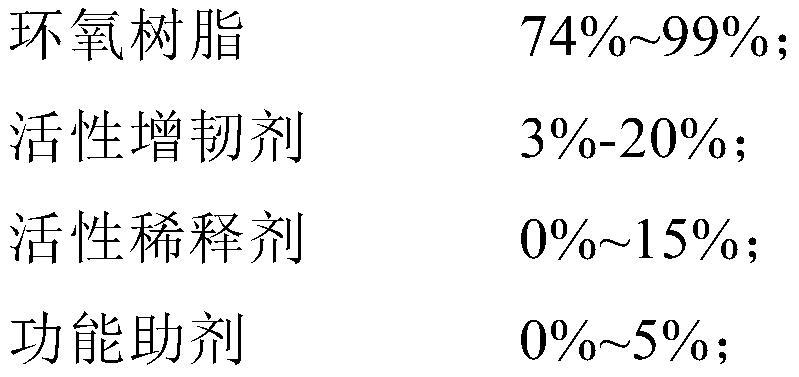

Epoxy-based pouring sealant for end capping of PVDF ultrafiltration membrane assembly and preparation method of epoxy-based pouring sealant

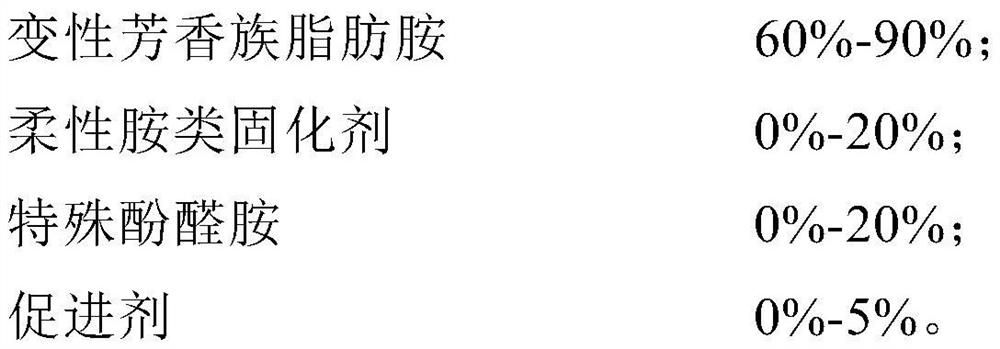

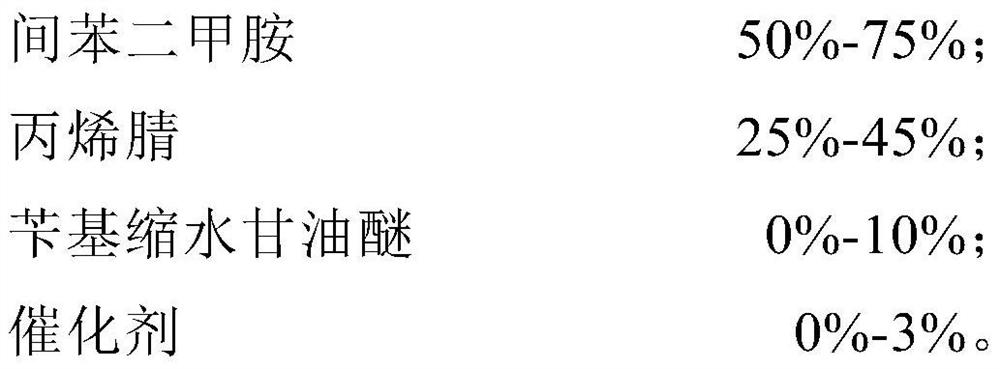

ActiveCN106753131AAbandon the corrosion discoloration effectCorrosion discoloration effect eliminationMacromolecular adhesive additivesEpoxy resin adhesivesFatty amineSewage treatment

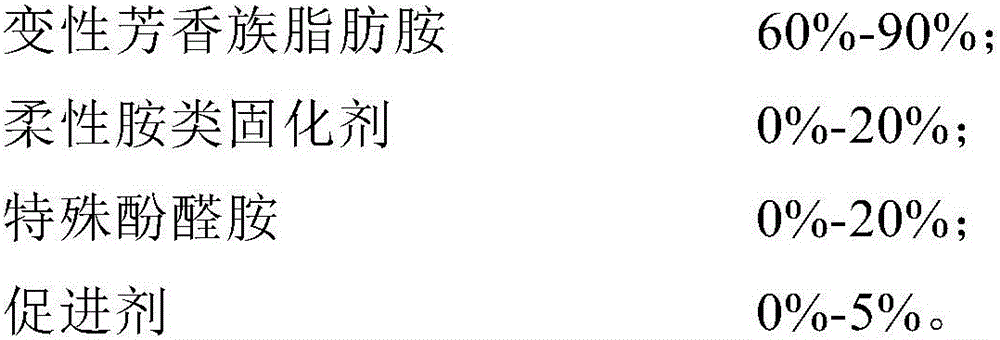

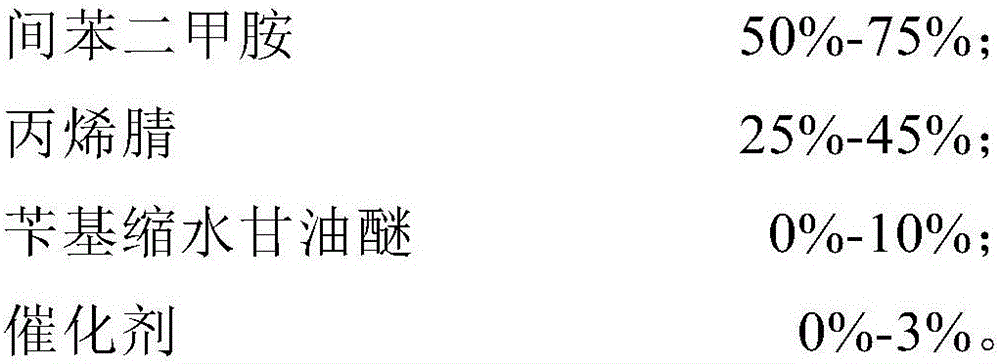

The invention discloses an epoxy-based pouring sealant for end capping of a PVDF ultrafiltration membrane assembly and a preparation method of the epoxy-based pouring sealant. The epoxy-based pouring sealant comprises a component A and a component B. The component A is prepared from epoxy resin, an active flexibilizer, an active diluent and a functional assistant. The component B is prepared from degenerative aromatic fatty amine, a flexible amine curing agent, special phenolic aldehyde amine and an accelerant. Degenerative aromatic fatty amine is degenerated based on m-xylylenediamine. Epoxy glue has high toughness, certain flexibility is achieved for the root of membrane silk of the ultrafiltration membrane assembly, and therefore the silk breakage problem is relieved; corrosion of the epoxy glue to the PVDF membrane silk is eliminated, the reddish brown blackening phenomenon of the membrane silk of the ultrafiltration membrane assembly is eliminated, and the membrane silk is kept intact. The requirements of the end capping process of ultrafiltration membrane assemblies of multiple types can be met, adhesion is excellent after end-capping curing is completed, chemical medium resistance is good, the durable ultrafiltration membrane assembly can be prepared, and the ultrafiltration membrane assembly is suitable for being applied to the field of industrial sewage treatment of wide occasions.

Owner:康达新材料(集团)股份有限公司

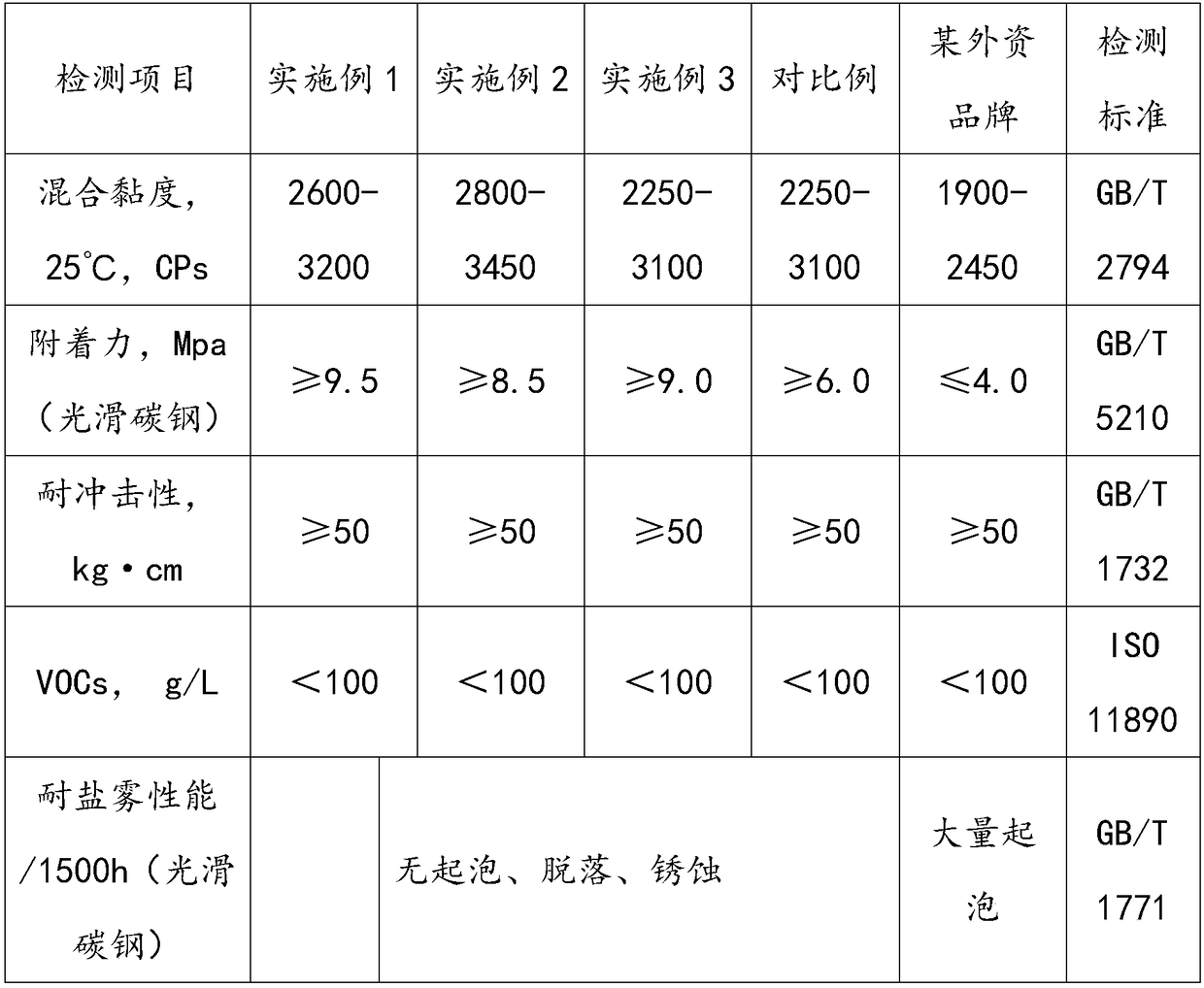

Epoxy anticorrosion primer for smooth metal surface and preparation method thereof

ActiveCN106318131AImprove permeabilityGood adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyTO-18

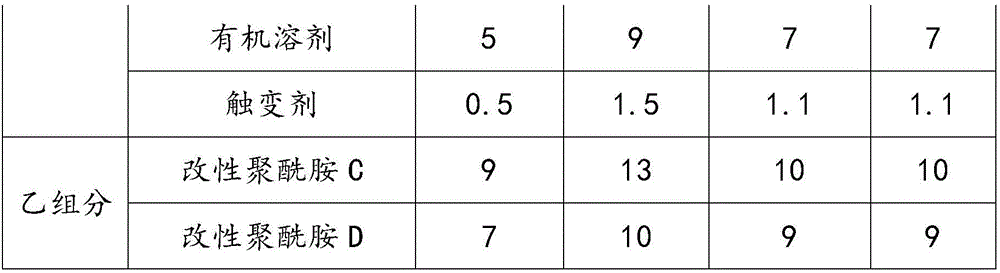

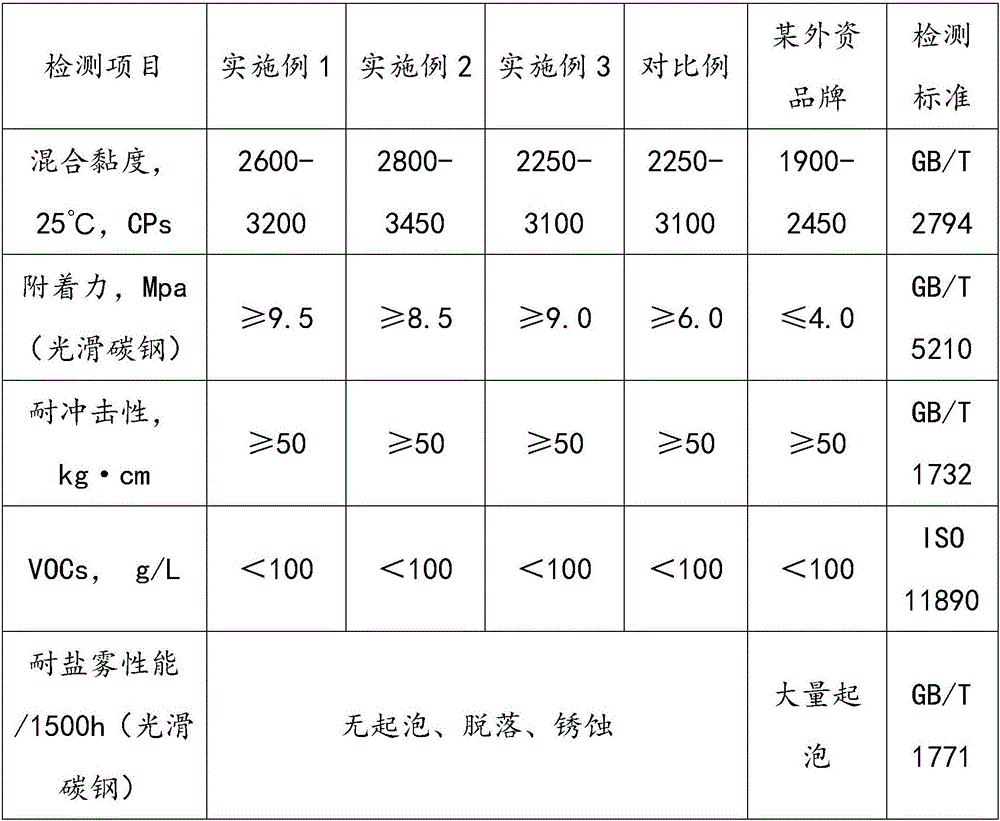

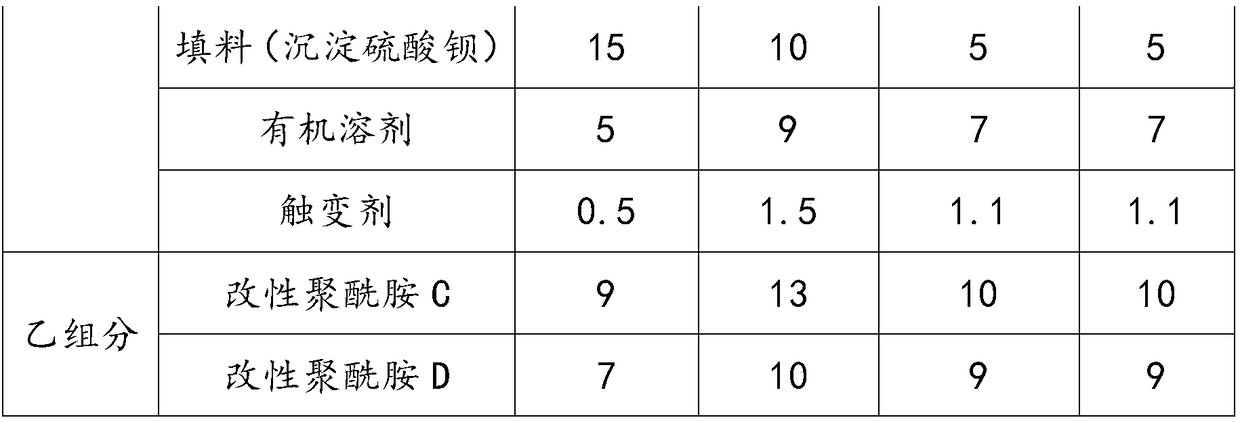

The invention relates to an epoxy primer and particularly relates to an epoxy anticorrosion primer for a smooth metal surface and a preparation method thereof. The epoxy anticorrosion primer is prepared from a component A including 6 to 13 parts of epoxy resin A, 8 to 18 parts of epoxy resin B, 0.3 to 1.0 part of a de-foaming agent, 0.4 to 1.0 part of an aminosilane coupling agent, 0.6 to 1.5 parts of a wetting dispersant, 15 to 25 parts of anti-rust paint, 20 to 35 parts of packing, 0.5 to 1.5 parts of a thixotropic agent and 5 to 9 parts of an organic solvent; and a component B including 9 to 13 parts of epoxy modified polyamide C and 7 to 10 parts of epoxy modified polyamide D. Compared with the prior art, the epoxy anticorrosion primer for the smooth metal surface, provided by the invention, adopts the aminosilane coupling agent to modify the epoxy resin, and a modified polyamide curing agent is reasonably compounded and a solvent system is reasonably optimized, thus solving the problem that the adhesive force of an anticorrosion coating on the smooth surface is poor.

Owner:XIAMEN SUNRUI SHIP COATING

Epoxy resin pouring sealant, preparation method thereof, and novel electric driven motor

ActiveCN111040698AEnhanced Service Life RequirementsLow mixing viscosityNon-macromolecular adhesive additivesManufacturing dynamo-electric machinesPolymer scienceFirming agent

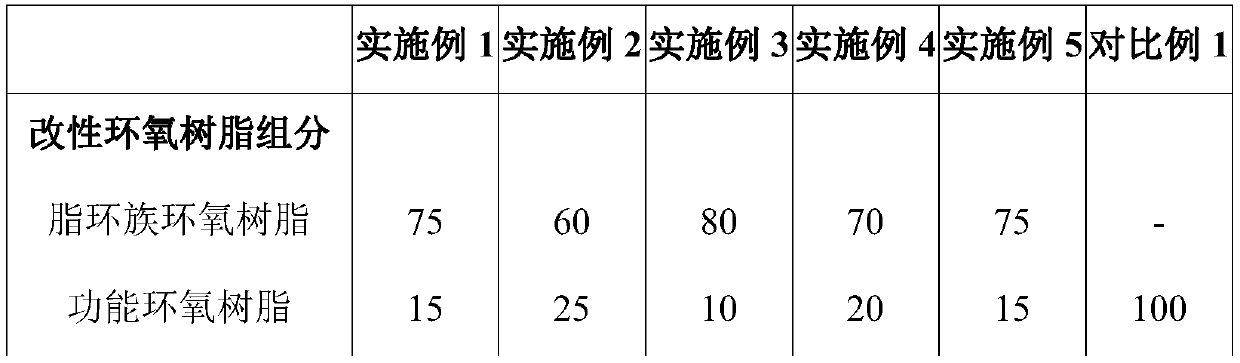

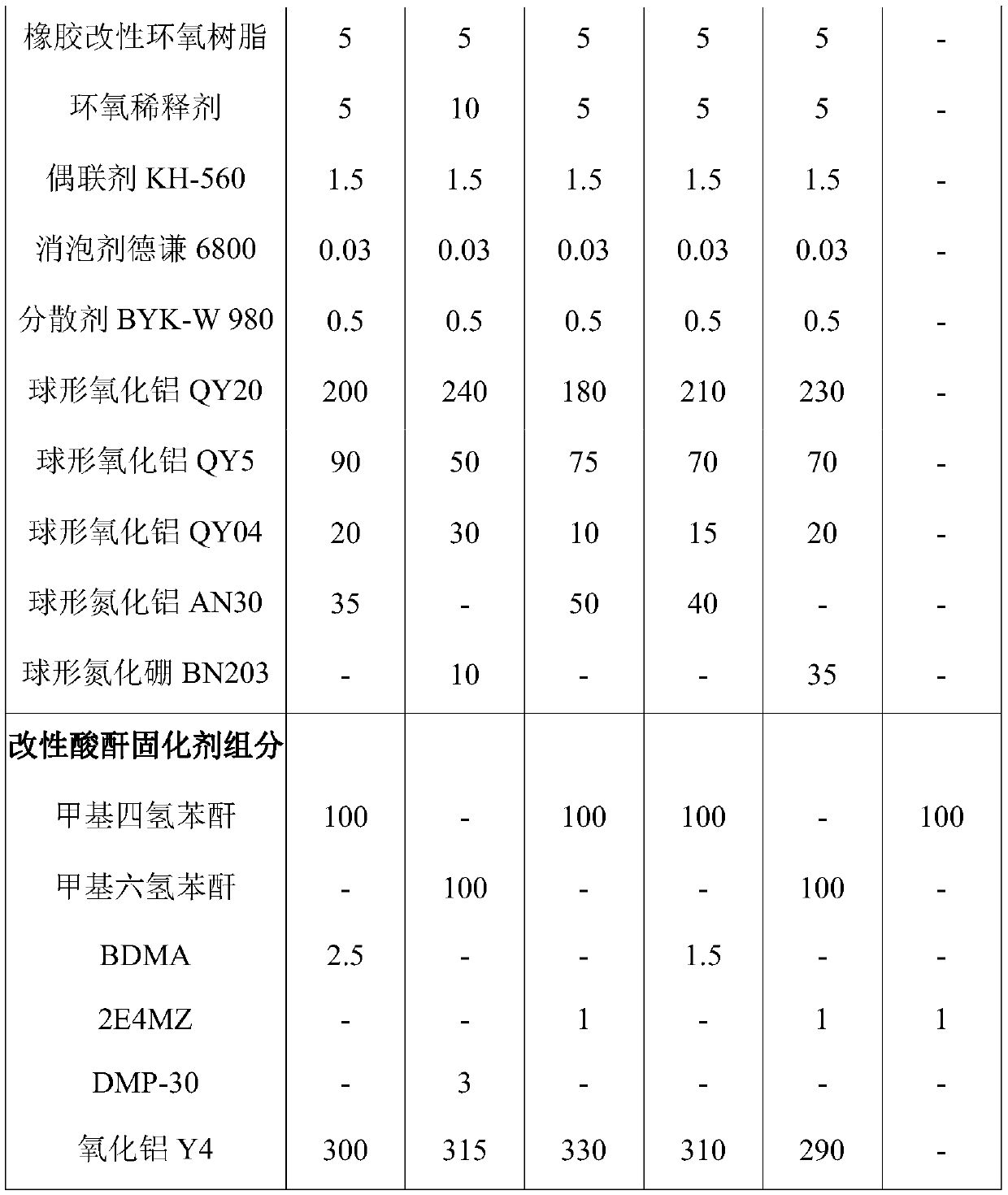

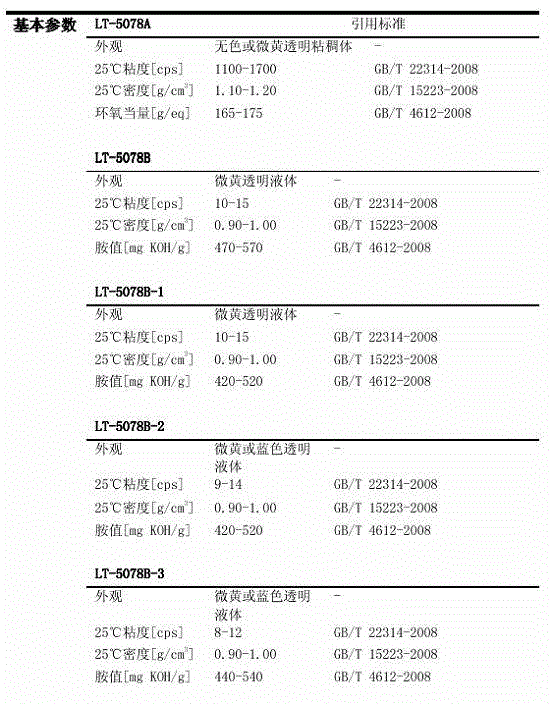

The invention discloses an epoxy resin pouring sealant. The epoxy resin pouring sealant comprises modified epoxy resin and a modified anhydride curing agent according to a mass ratio of 100:(48-71); the modified epoxy resin is prepared from, by mass, 90-95 parts of epoxy resin, 5-10 parts of an epoxy diluent, 1.5 parts of a coupling agent, 0.03 part of a defoaming agent, 0.5 part of a dispersing agent and 315-355 parts of a heat-conducting filler; and the modified anhydride curing agent is prepared from, by mass, 100 parts of anhydride, 1-3 parts of a curing accelerator and 290-330 parts of afiller. The invention further provides a preparation method of the epoxy resin pouring sealant, and also provides a novel electric driven motor prepared from the epoxy resin pouring sealant. The heatresistance and heat conductivity of the epoxy resin pouring sealant are improved.

Owner:镇江利德尔复合材料有限公司

Vacuum flow guide epoxy resin composition for wind turbine blade

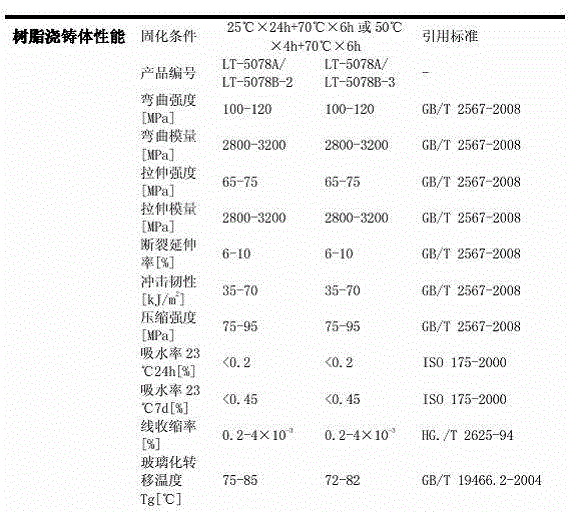

The invention relates to a wind turbine blade and in particular relates to an epoxy resin composition for the wind turbine blade. The vacuum flow guide epoxy resin composition for the wind turbine blade comprises a component A and a component B, wherein the component A comprises 45-65wt% of bisphenol-A epoxy resin 128, 5-15wt% of bisphenol-F epoxy resin 170, 15-25wt% of low-viscosity bisphenol-A epoxy resin 332 and 10-20wt% of epoxy diluent BDGE; the component B comprises 50-70wt% of polyether amine curing agent D230 and 30-50wt% of isophorone diamine (IPDA). The composition is obtained after mixing the component A with the component B according to a proportion of parts by weight, namely 100 to (29-31). The composition has the effects of reducing the viscosity of epoxy resin and improving the processability of epoxy resin on the premise of ensuring various physical and chemical properties of cured resin, especially the mechanical properties.

Owner:WELLS ADVANCED MATERIALS SHANGHAI

Bis-secondary amine containing siloxane groups and preparation method and application of bis-secondary amine

ActiveCN110760047AExcellent heat and oxygen aging resistanceSlow curingGroup 4/14 element organic compoundsPolyurea/polyurethane coatingsPrepolymerChemistry

The invention discloses bis-secondary amine containing siloxane groups and a preparation method and application of the bis-secondary amine. The bis-secondary amine containing the siloxane groups is obtained by Michael addition reaction of one or more bis-primary amines and siloxane containing unsaturated double bonds. A B component of spray polyurea is prepared by mixing the bis-secondary amine and an auxiliary agent, an isocyanate prepolymer generated by reaction of polyether polyol and isocyanate is taken as a component A, and the component A and the component B are mixed and sprayed according to the volume ratio of the components A and B of 1 : 1 to obtain a polyurea material. Two active hydrogens of the bis-secondary amine can react with the isocyanate to generate linear polyurea, andthe siloxane groups can be hydrolyzed to generate Si-O-Si cross-linking points, so that the cross-linking speed of the amine and the isocyanate is reduced and the mechanical properties of the polyureamaterial are improved.

Owner:WANHUA CHEM GRP CO LTD

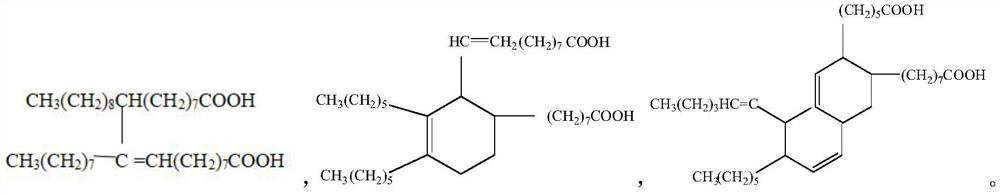

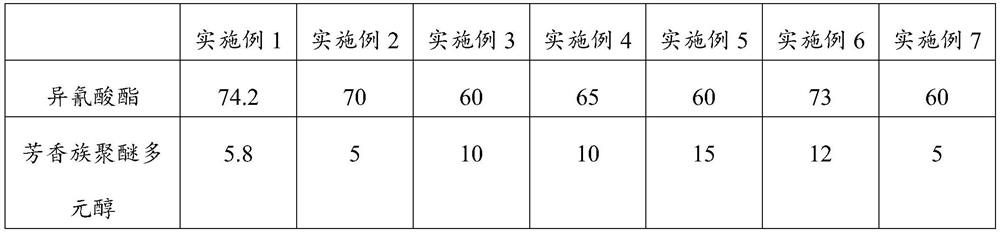

Two-component polyurethane adhesive and preparation method thereof

ActiveCN112724913AGood acid and alkali resistanceImprove hydrolysis resistanceNon-macromolecular adhesive additivesGeneral water supply conservationAdhesive cementPolymer science

The invention provides a two-component polyurethane adhesive and a preparation method thereof. The two-component polyurethane adhesive is composed of a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 65 parts to 85 parts of vegetable oil polyol, 5 parts to 20 parts of polymer polyol, 5 parts to 12 parts of small molecular polyol, 0.3 part to 1.3 parts of a defoaming agent, 0.01 part to 0.5 part of a wetting agent, 0.3 part to 3 parts of a water removal agent and 0.1 part to 1.5 parts of a rheological agent; and the component B comprises a polyurethane prepolymer, and the structure of the polyurethane prepolymer has a rigid benzene ring and a side group protection structure. Compared with the prior art, the acid and alkali resistance and hydrolysis resistance are good, and a foundation is provided for use under the strong corrosion condition; the mixed viscosity is small, so that the adhesive has good flowability and wettability, and subsequent use is facilitated; the strength and the toughness are considered, so that the adhesive has good post-processing performance; and the adhesive has high bonding shear strength with ABS and PVC, and has favorable bonding performance.

Owner:湖北南北车新材料有限公司 +1

Casting epoxy resin composition for part repair

The invention relates to a casting epoxy resin composition for part repair, aims at achieving the technical purpose that the requirements of rapid curing at room temperature and excellent properties can be met simultaneously, and belongs to technical field of high-molecular polymers. The composition is characterized in that a preparation method of the composition comprises the steps that 1, preheated bisphenol A type epoxy resin, toughening type epoxy resin and a diluent are added into a reaction kettle in sequence, the temperature inside a stirring tank is maintained to be 50-70 DEG C, a defoamer is added, stirring and defoaming are conducted simultaneously, and a resin mixture is obtained; 2, aliphatic amine is added into another reaction kettle, stirring is started, the temperature inside a tank is maintained to be about 25-40 DEG C, alicyclic amine and an amine type accelerator are added in sequence, mixing and stirring are conducted continuously for 15-30 min, and a curing agent mixture is obtained; 3, the resin mixture and the curing agent mixture are mixed to be uniform according to the ratio of 100:(15-17), and the epoxy resin composition for part repair is obtained. The comprehensive performance of the product is excellent, and the composition has low viscosity and rapid curing speed and can meet curing requirements in different temperature environments.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

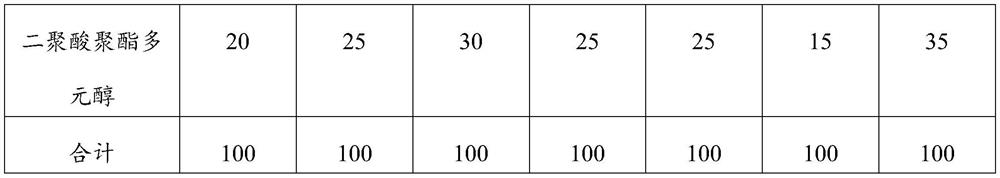

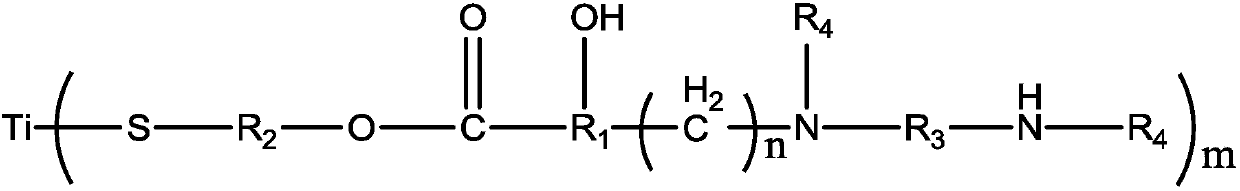

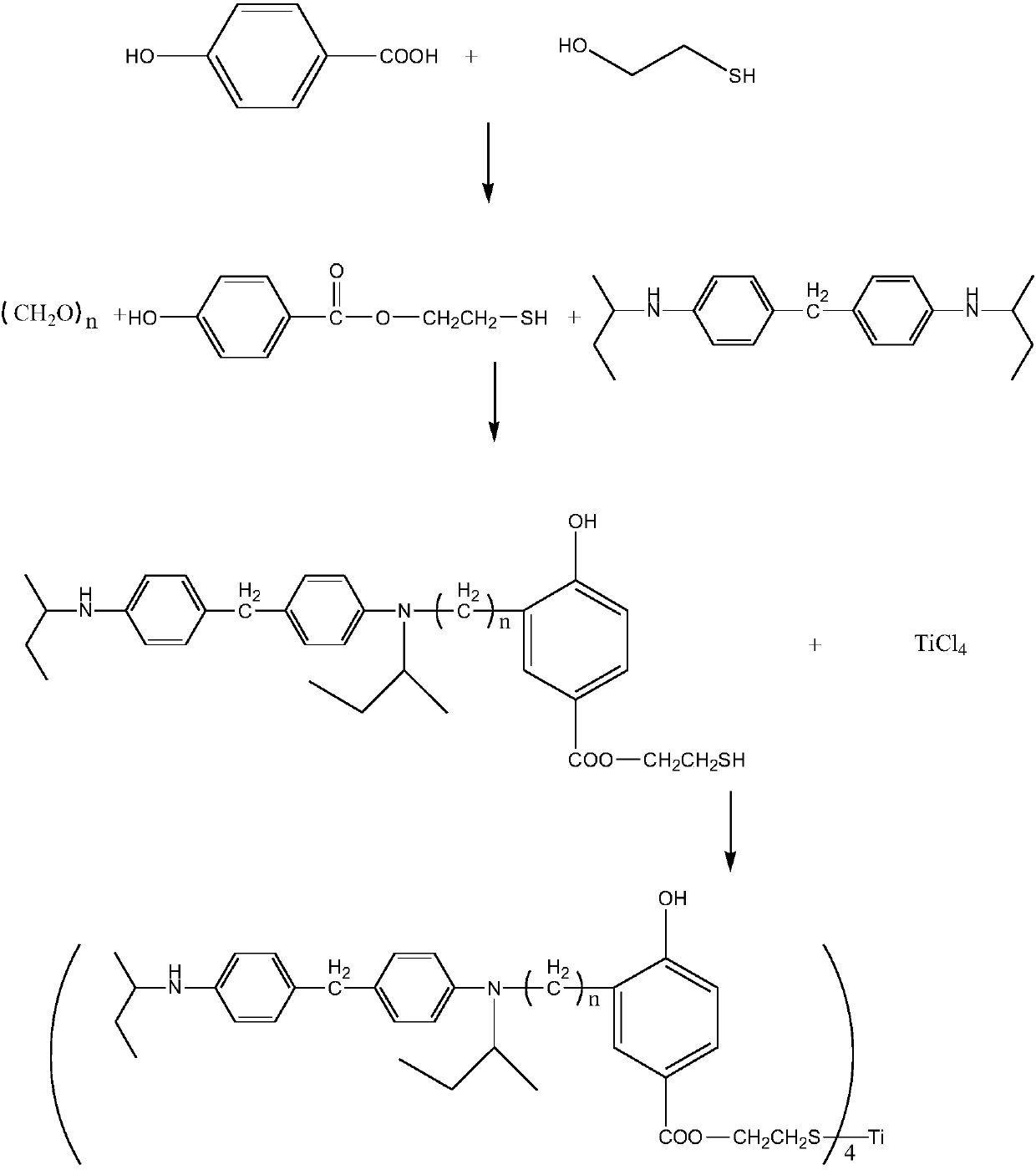

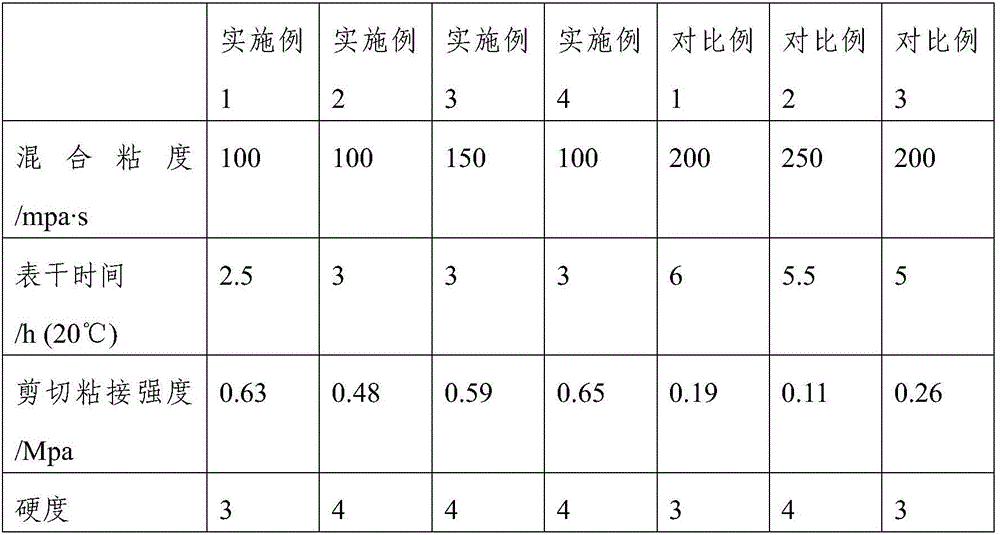

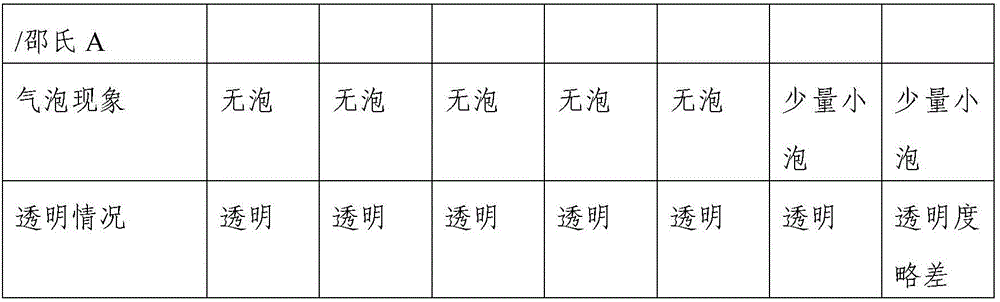

Epoxy curing agent, and preparation method and application thereof

ActiveCN107722241AImprove adhesionSolve the smellTitanium organic compoundsEpoxy resin coatingsBenzeneThiol

The invention discloses an epoxy curing agent for concrete refinishing paint, and a preparation method and application of the epoxy curing agent. The preparation method of the epoxy curing agent includes 1), allowing a carboxylic phenolic compound to react with a mercaptan compound to obtain a sulfhydryl phenolic compound; 2), under the action of an acid catalyst, evenly mixing an amine compound,the sulfhydryl phenolic compound and an aldehyde compound to react to obtain sulfhydryl-terminated phenolic aldehyde amine; 3), injecting nitrogen into a mixture of a titanium dichloride compound andbenzene, slowly adding the sulfhydryl-terminated phenolic aldehyde amine after the pH value of a reaction system reaches 9-10, and performing distillation after reaction to obtain the epoxy curing agent. The epoxy curing agent has the advantages that the epoxy curing agent can be mixed with epoxy resin to prepare an epoxy resin composition for the concrete refinishing paint; sulfydryl, tertiary amine and phenolic hydroxyl in the molecular structure of the curing agent have synergistic promotion effect, and accordingly, the epoxy curing agent can cure the epoxy resin below minus 25 DEG C and has high adhesion to concrete materials.

Owner:WANHUA CHEM GRP CO LTD

Sealing method for direct-insert type light-emitting diode (LED) lamp

The invention discloses a sealing method for a direct-insert type light-emitting diode (LED) lamp. The sealing method comprises the following steps: firstly, setting the heights of a mold strip and a sticking point, and selecting a diffusant and a coloring agent; secondly, heating epoxy resin A, mixing the epoxy resin with epoxy resin B at a certain ratio, adding the diffusant and the coloring agent, stirring the diffusant and the coloring agent, and carrying out vacuum-pumping treatment on stirred mixed glue; thirdly, fixing the bound LED bracket on a loading rack; fourthly, adjusting the glue-pouring quantity, the glue-extruding speed, the sticking time and the sticking distance; and finally starting a pouring machine and carrying out sealing treatment on the bound LED bracket. The epoxy resin A is heated and then is mixed with the epoxy resin B at the certain ratio, so that the mixing viscosity is reduced; the diffusant and the coloring agent are added and stirred, so that the problem of yellow discoloration of the baked LED lamp is avoided by controlling the mixing ratio and the mixing time; and the quality and the yield of the LED lamp are improved, so as to improve the cost performance of an LED display screen.

Owner:苏州市英富美欣科技有限公司

Ultralow-hardness polyurethane pouring sealant and preparation and application thereof

ActiveCN105907353AAddress process complexitySolve viscosityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyolPlasticizer

The invention relates to an ultralow-hardness polyurethane pouring sealant and a preparation method and application thereof. The polyurethane pouring sealant is composed of a component A and a component B, wherein the component A is prepared from, by weight, 90-100 parts of Polypolyol, 0.1-1 part of compound type anti-yellowing agent, 0.1-2 parts of catalyst, 0.1-1 part of defoaming agent, 0.1-5 parts of coupling agent and 0-10 parts of plasticizer, the component B is prepared from, by weight, 30-40 parts of polyisocyanate and 60-70 parts of plasticizer. The pouring sealant can be suitable for automatic pouring of handwork, is short in curing time at room temperature, and has the advantages of being transparent, few in bubble, high in insulativity, high in adhesion to metal and the like after being cured.

Owner:BEIJING POLYSTAR HITECH CO LTD

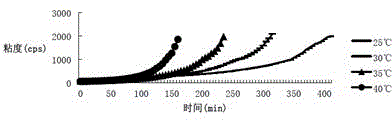

Vacuum infusion epoxy resin for carbon fiber

The invention relates to wind driven generator blades, vessels, yachts, automobile bodies and the like, in particular to vacuum infusion epoxy resin used for carbon fiber and applied to the production and manufacture process. The vacuum infusion epoxy resin comprises a resin component and a curing agent component, wherein the resin component comprises 50%-70% of a bisphenol A epoxy resin 127, 15%-30% of a bisphenol F epoxy resin 170 and 5%-15% of an epoxy diluent BDGE; the curing agent component comprises 40%-70% of a polyether amine curing agent D230, 20%-30% of diaminocyclohexane DCH 99 and 10%-20% of 2-methyl-diaminopentane Dytek A; and the resin component and the curing agent component are mixed in the proportion of 100:30 to form composition. The vacuum infusion epoxy resin for carbon fiber has low blending viscosity, the infiltration of carbon fiber is good, the operation pot life is flexible, appropriate adjustment can be performed according to different curing agents, the quality of blade and automobile body products is improved greatly, and the production efficiency can be increased.

Owner:WELLS ADVANCED MATERIALS SHANGHAI

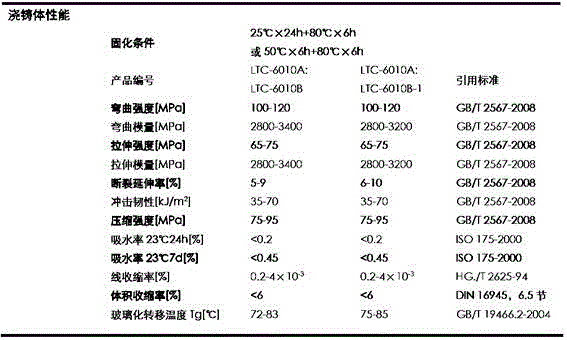

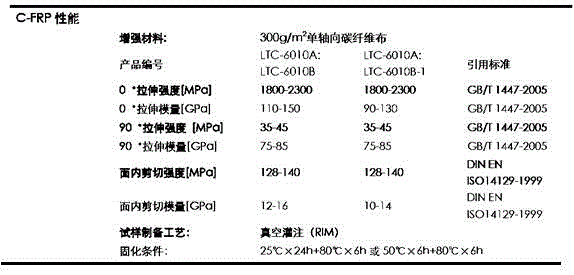

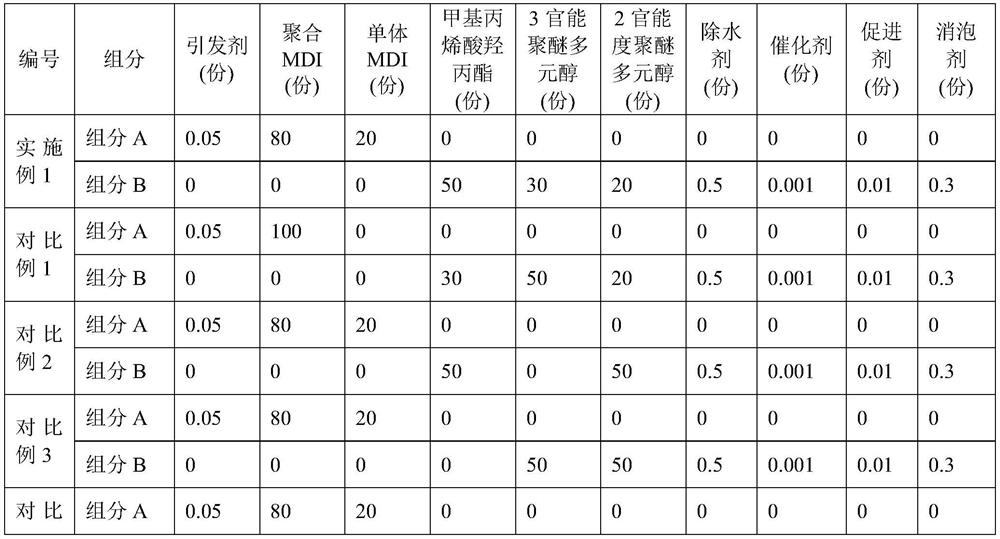

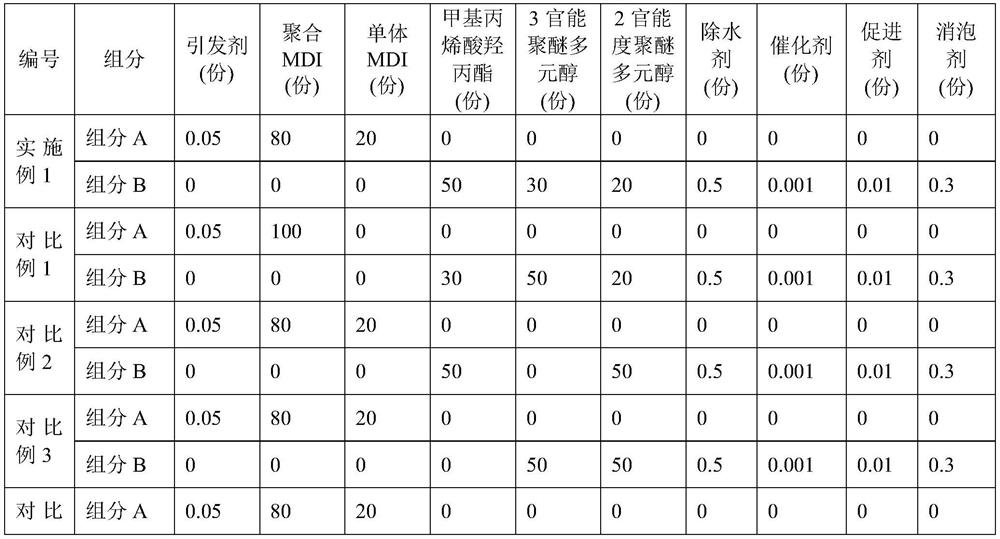

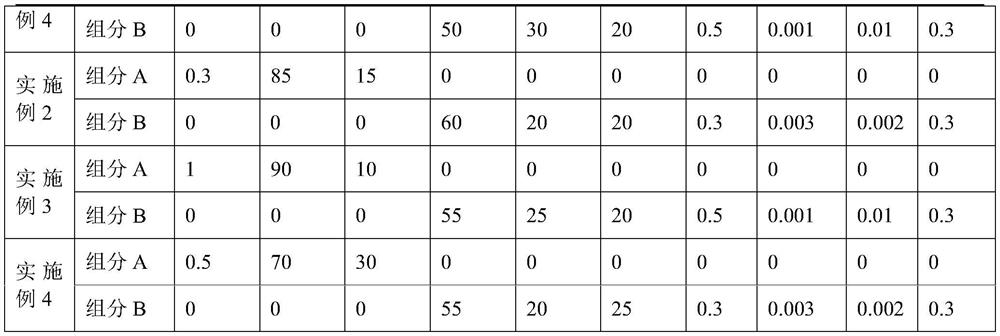

Perfusion polyurethane resin for wind power blade and preparation method thereof

The invention relates to perfusion polyurethane resin for a wind power blade and a preparation method thereof, and belongs to the field of composite materials of a wind power technology. The pouring polyurethane resin for the wind power blade comprises a component A and a component B which are respectively packaged and mixed during use; the component A comprises polymerized isocyanate, an isocyanate monomer and an initiator; the component B comprises polyether polyol with the functionality of 2, polyether polyol with the functionality of 3, a water removal agent, an active diluent, a defoaming agent, a polyurethane delay catalyst and an accelerant. The perfusion polyurethane resin is a two-component polyurethane system, the mixed polyurethane system has the advantages of low mixing viscosity, long gelation time, high mechanical strength and low moisture sensitivity, and a composite material product prepared from the polyurethane has the advantages of no bubble and excellent FRP (Fiber Reinforced Plastic) performance, and completely meets the requirements of wind turbine blade manufacturing. The preparation method is simple, the raw material cost is low, no bubble, whitening and other defects are generated in the filling process, and the perfusion polyurethane resin can be widely applied to preparation of various large-scale wind power blade composite materials.

Owner:四川东树新材料有限公司

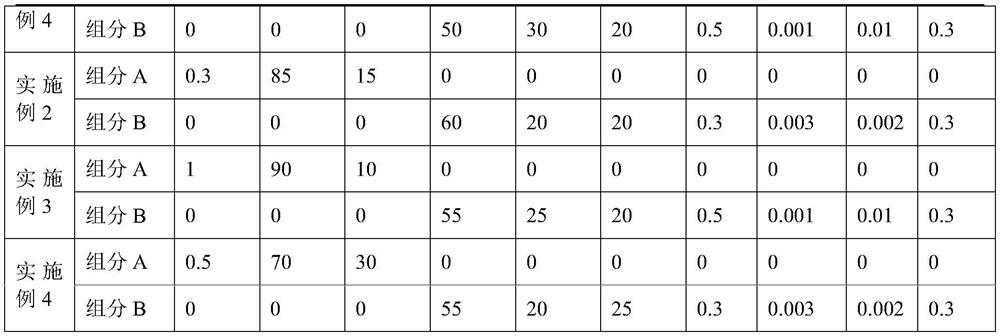

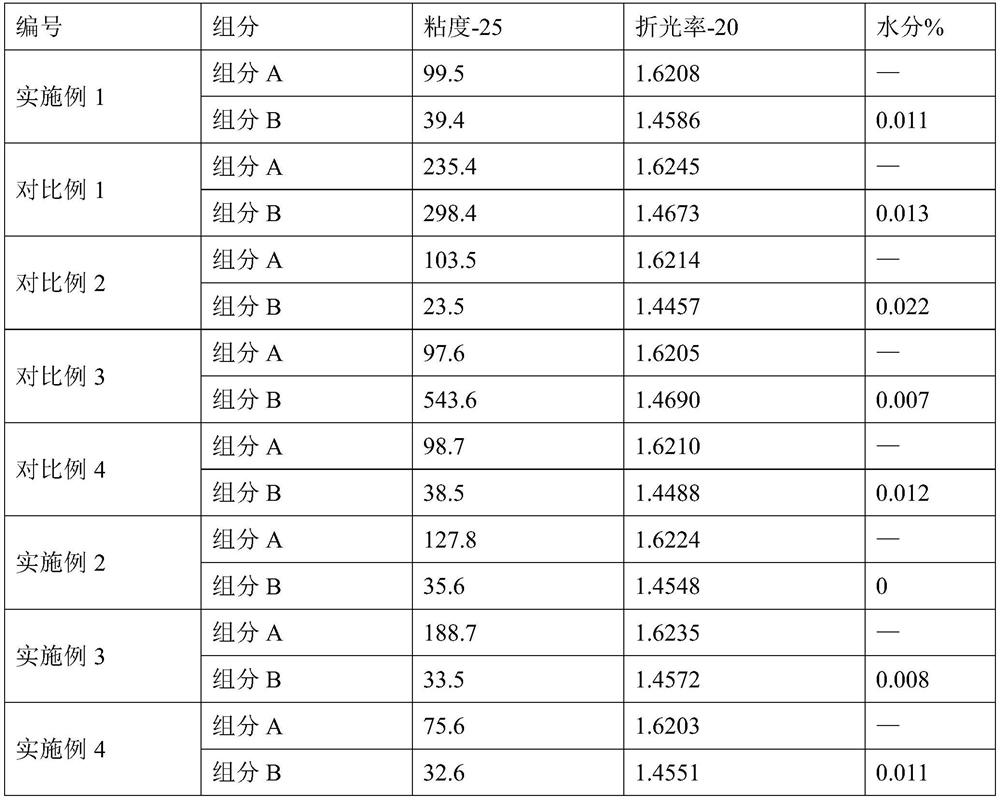

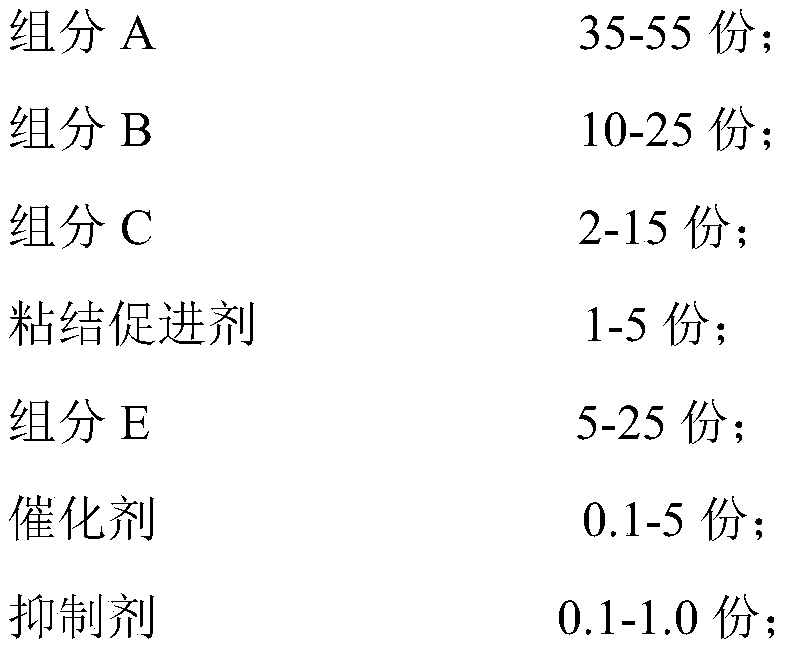

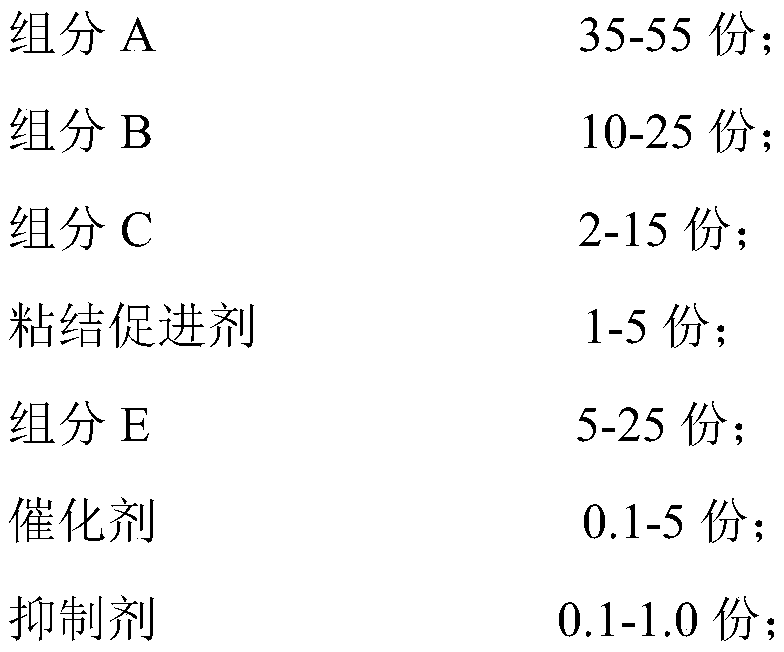

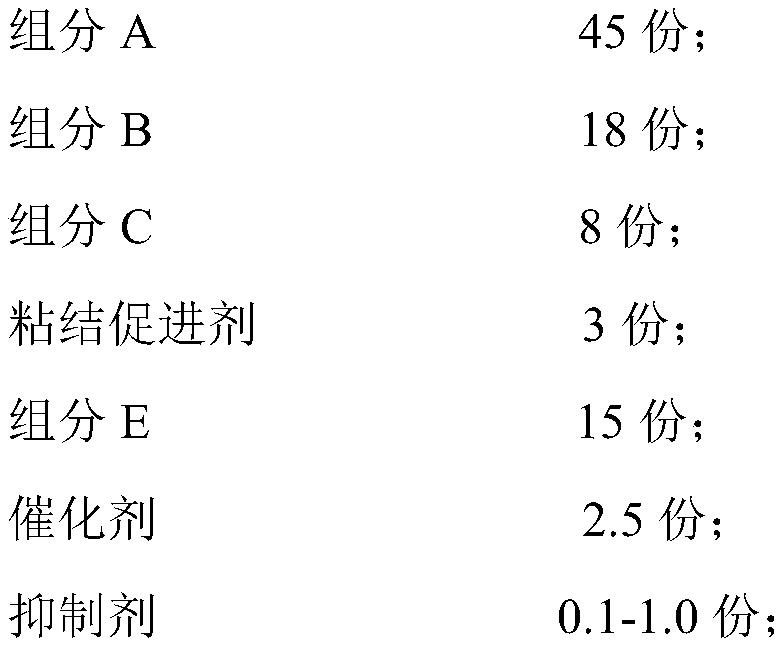

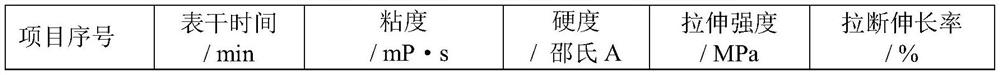

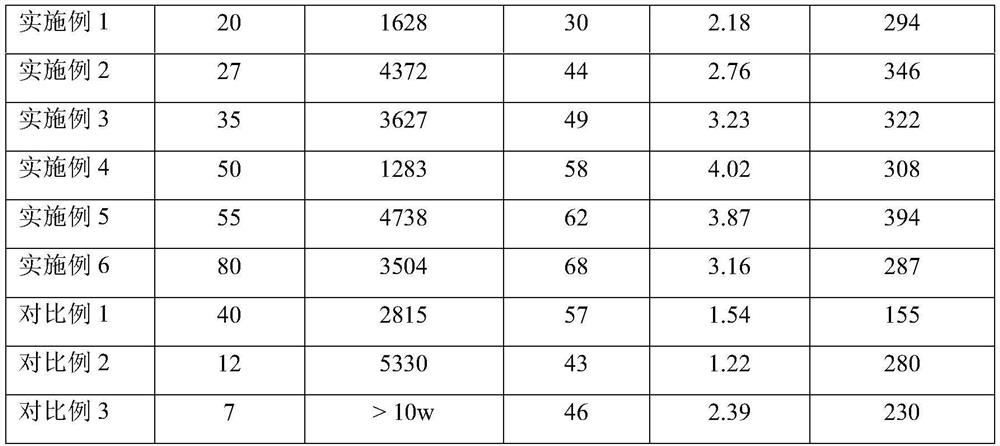

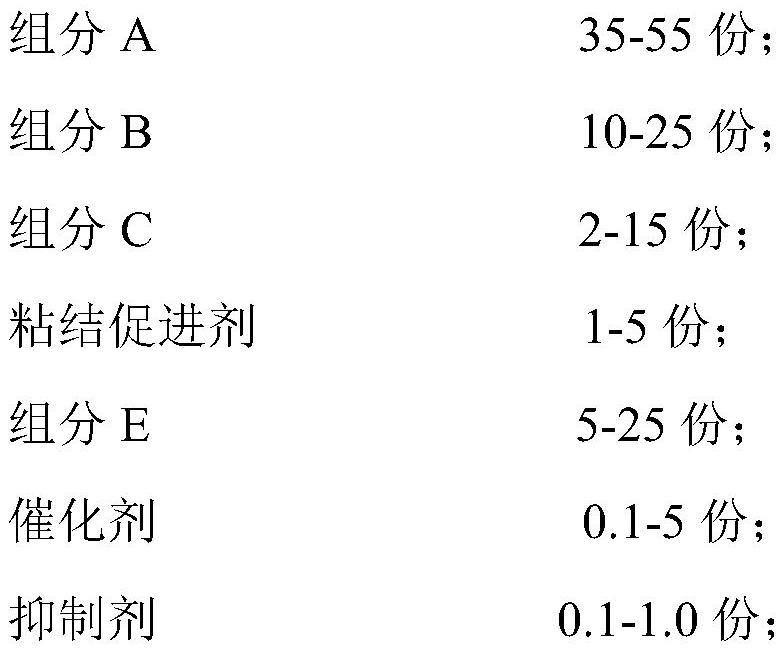

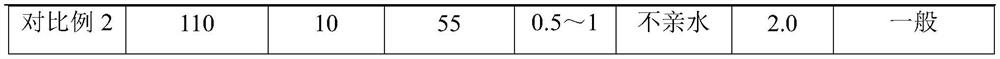

Transparent silica gel for liquid crystal display fitting

The invention relates to a transparent silica gel for liquid crystal display fitting. A raw material formula comprises 35-55 parts of component A, 10-25 parts of component B, 2-15 parts of component C, 5 parts of bonding accelerant, 5-25 parts of component E, 0.1-5 parts of catalyst and 0.1-1.0 part of inhibitor; the component A is vinyl-terminated polysiloxane conforming to general formula (1); the component B is allyloxy-terminated polypropylene oxide conforming to general formula (2); the component C is vinyl MQ silicon resin; ratio of M to Q is at 0.8-1.5; the component E is hydrogen-endedpolysiloxane conforming to general formula (3). The transparent silica gel for liquid crystal display fitting prepared according to the invention has the advantages of low viscosity, short defoamingtime, quick curing molding and moderate hardness.

Owner:铜陵桐力光电有限公司

Formula for low free nanometer wear-resistant polyurethane

The invention brings forward a formula for low free nanometer wear-resistant polyurethane. The formula comprises, by weight, 100 parts of a low free PU performed polymer, 12 to 12.5 parts of MOCA and 3 to 5 parts of montmorillonite. With the formula provided by the invention, polyurethane has a small viscosity after mixing, good fluidity in processing and a small compressive deformation value, and a rebound value of a product is great.

Owner:江苏泰东环保工程有限公司

Low-viscosity and high-strength transparent dealcoholized organosilicon sealant and production method thereof

PendingCN114196372AHigh mechanical strengthMaintain viscosityMacromolecular adhesive additivesEndcappingPolymer science

The invention discloses a transparent dealcoholized organosilicon sealant with low viscosity and high strength, which is characterized by comprising the following components in parts by weight: 100 parts of alkoxy-terminated polydimethylsiloxane; 5 to 50 parts of methoxy modified silicon resin; 5-50 parts of methyl MQ silicone resin; 3-10 parts of a cross-linking agent; 0.5-3 parts of a coupling agent; 0.5-3 parts of a compound catalyst; the invention also discloses a production method of the transparent dealcoholized organosilicon sealant with low viscosity and high strength. The low-viscosity and high-strength transparent dealcoholized organosilicon sealant has the advantages of high mechanical strength and low viscosity, and can be widely applied to the fields of electronic appliances, high-end medical equipment, automobile industry and the like; the production method disclosed by the invention is simple to operate, good in reproducibility and small in dust.

Owner:GUANGZHOU BAIYUN CHEM IND +1

A kind of ultra-low hardness polyurethane potting glue and its preparation and application

ActiveCN105907353BHigh mixing viscosityLow mixing viscosityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyolPlasticizer

Owner:BEIJING POLYSTAR HITECH CO LTD

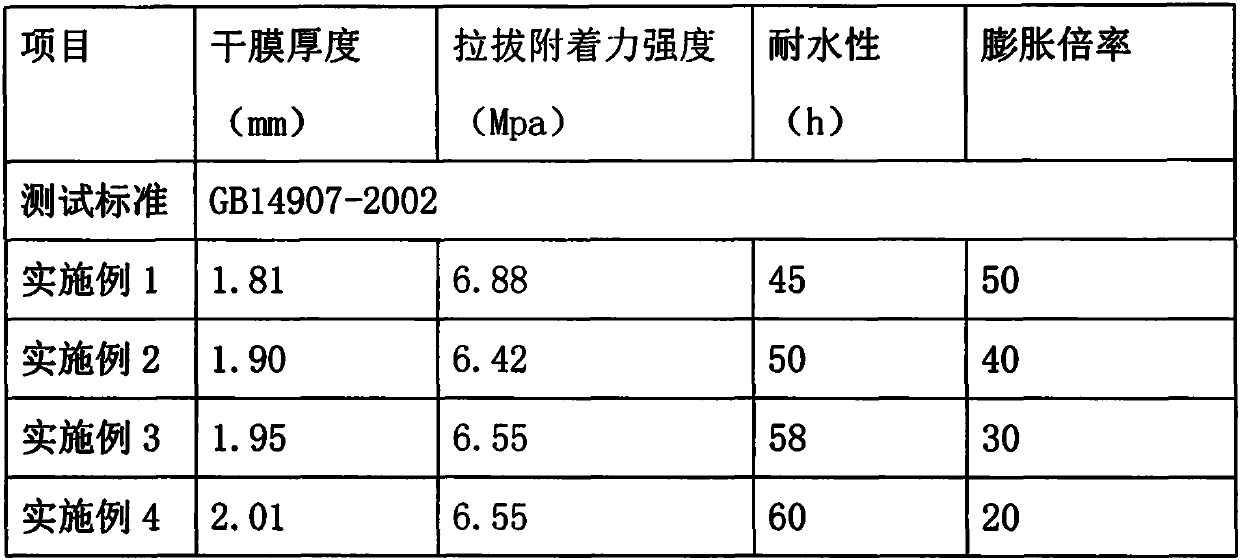

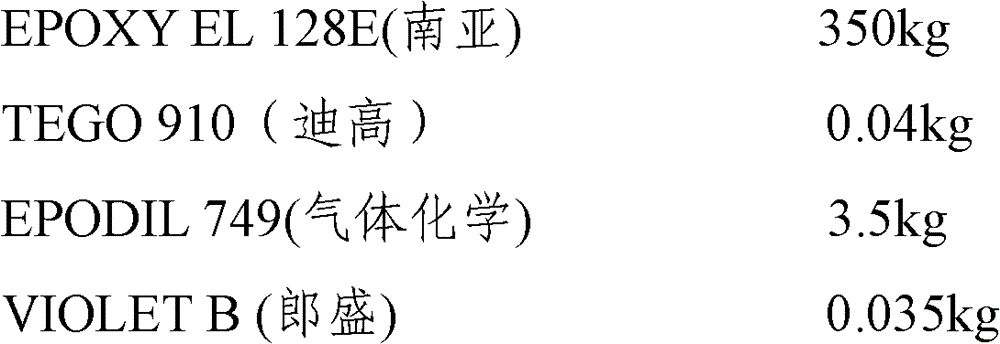

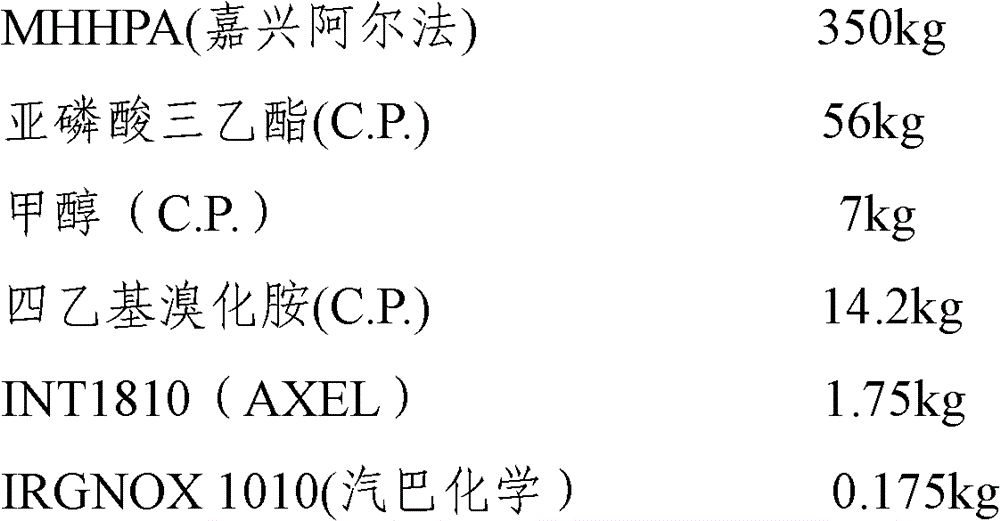

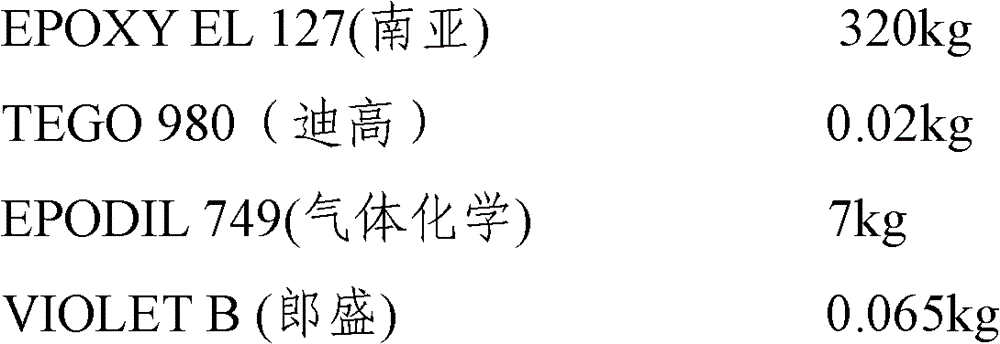

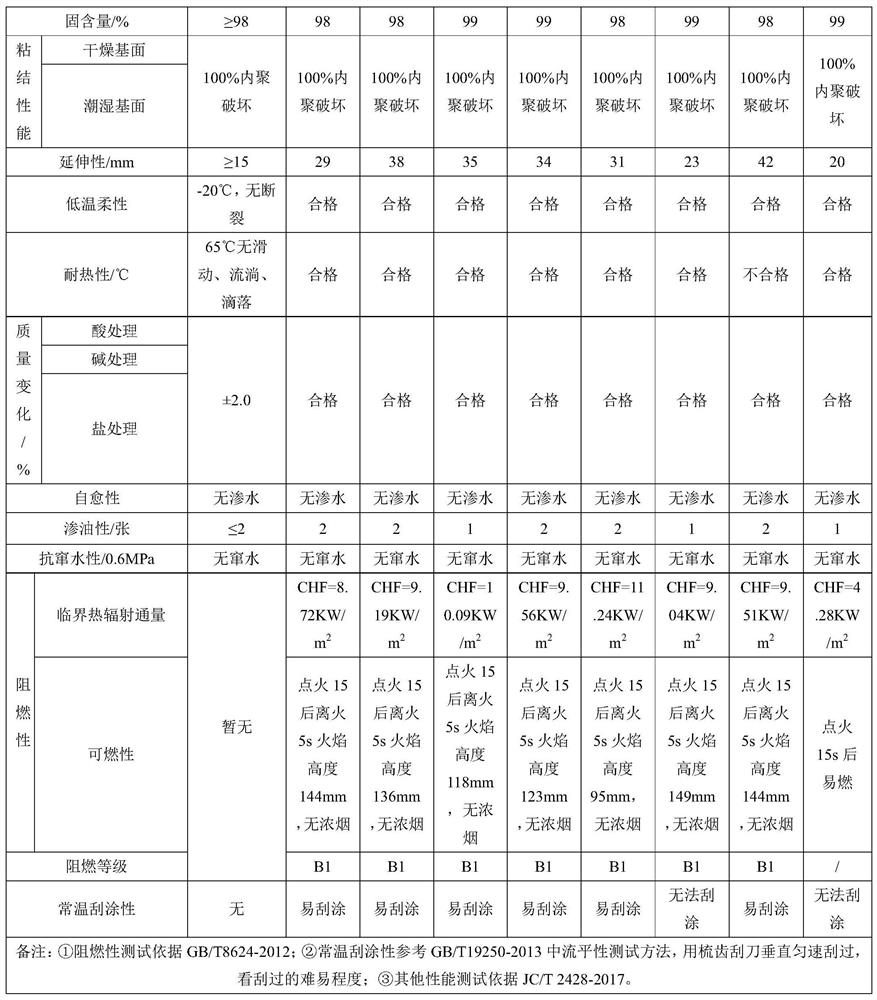

Novel rail vehicle fireproof coating

PendingCN111253791ALow mixing viscosityEasy constructionFireproof paintsEpoxy resin coatingsFiberGlass fiber

The invention belongs to the technical field of fireproof coatings, and discloses a novel rail vehicle fireproof coating which is a double-component coating and is formed by mixing a resin A componentand a curing agent B component, wherein the resin A component comprises 25-50 parts of acrylic acid modified epoxy resin, 15-35 parts of a flame retardant, 2-15 parts of a reinforcing agent and 0.1-2parts of a thickening aid; the curing agent B component comprises 5-20 parts of a modified amine curing agent, 2-15 parts of a foaming agent, 0-2 parts of glass fibers, 0-2 parts of carbon fibers and0-2 parts of ceramic fibers; in conclusion, the double-component fireproof coating disclosed by the invention has the advantages that the solid content is 100%, and any solvent and curing acceleratorare not required to be added, so that the double-component fireproof coating has good environmental protection property; meanwhile, the coating is low in mixing viscosity and has the advantage of being easy to construct; besides, the curing agent in the coating adopts a modified amine curing agent, so that the curing agent does not contain volatile micromolecular amine and tertiary amine catalysts, and the problem of strong odor of the curing agent is effectively avoided.

Owner:江苏庞捷实业发展有限公司

A kind of transparent silicone gel for laminating liquid crystal screen

A transparent silicone gel for bonding liquid crystal screens. The raw material formula includes 35-55 parts of component A; 10-25 parts of component B; 15 parts of component C2; 5 parts of adhesion promoter; 5-25 parts of component E; 0.1-5 parts of the catalyst; 0.1-1.0 parts of the inhibitor; the component A is a vinyl-terminated polysiloxane conforming to the general formula (1): the component B is a vinyl-terminated polysiloxane conforming to the general formula (2) Propoxy polypropylene oxide: the component C is a vinyl MQ silicone resin, and the M:Q ratio is 0.8-1.5; the component E is a terminal hydrogen polysiloxane conforming to the general formula (3). The transparent silicone gel for bonding liquid crystal screens prepared by the invention has the advantages of low viscosity, short defoaming time, fast curing and molding, and moderate hardness.

Owner:铜陵桐力光电有限公司

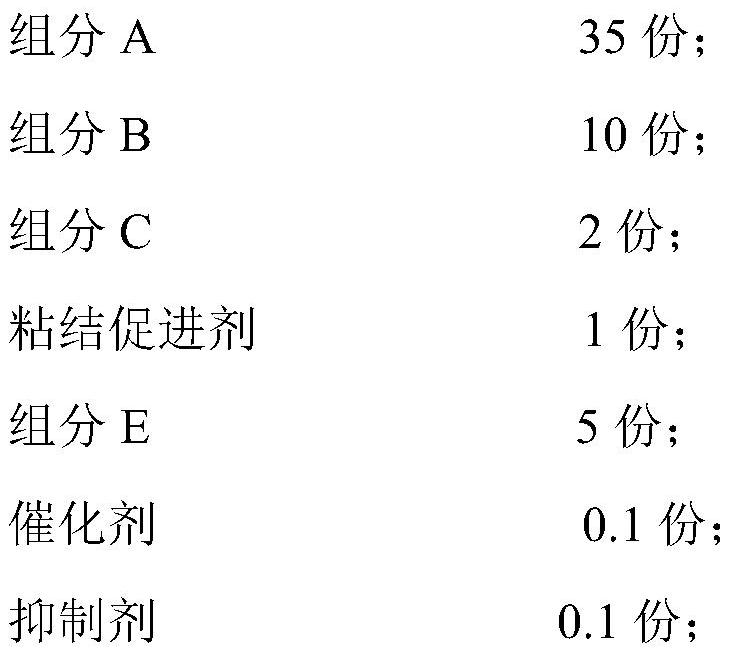

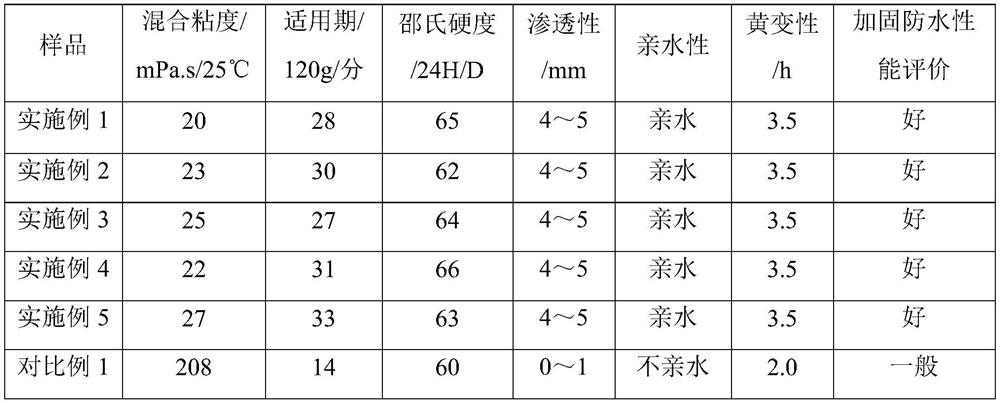

A kind of low-viscosity and high-permeability building concrete reinforcement and plugging epoxy waterproof material and preparation method thereof

The invention discloses a low-viscosity and high-permeability building concrete reinforcement plugging epoxy waterproof material, which includes A component and B component. The raw materials of A component include: 45-51% bisphenol A type epoxy resin, 18-32% Reactive diluent, 10-15% flexible modifier, 3-6% coupling agent and 6-12% auxiliary; B component raw materials include: 20-28% alicyclic amine curing agent, 36-41% modified Alicyclic amine curing agent, 20-30% polyetheramine curing agent and 10-15% auxiliary agent. The epoxy waterproof material of the present invention is environmentally friendly, has low viscosity, strong permeability, good aging resistance, can be cured at low temperature and normal temperature, has a moderate application period, is convenient for construction, and can easily penetrate into the small cracks and capillary pores of building concrete. After curing, it will form a consolidated body with concrete to strengthen and strengthen, and the formed consolidated body has a stable structure, good waterproof and impervious effects.

Owner:HUNAN SHENLI IND

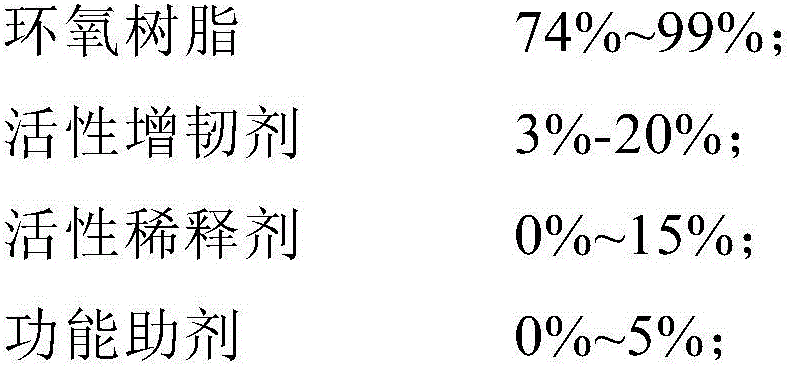

A kind of epoxy-based potting glue for PVDF ultrafiltration membrane module end sealing and preparation method thereof

ActiveCN106753131BAbandon the corrosion discoloration effectCorrosion discoloration effect eliminationMacromolecular adhesive additivesEpoxy resin adhesivesEndcappingPolymer science

The invention discloses an epoxy-based pouring sealant for end capping of a PVDF ultrafiltration membrane assembly and a preparation method of the epoxy-based pouring sealant. The epoxy-based pouring sealant comprises a component A and a component B. The component A is prepared from epoxy resin, an active flexibilizer, an active diluent and a functional assistant. The component B is prepared from degenerative aromatic fatty amine, a flexible amine curing agent, special phenolic aldehyde amine and an accelerant. Degenerative aromatic fatty amine is degenerated based on m-xylylenediamine. Epoxy glue has high toughness, certain flexibility is achieved for the root of membrane silk of the ultrafiltration membrane assembly, and therefore the silk breakage problem is relieved; corrosion of the epoxy glue to the PVDF membrane silk is eliminated, the reddish brown blackening phenomenon of the membrane silk of the ultrafiltration membrane assembly is eliminated, and the membrane silk is kept intact. The requirements of the end capping process of ultrafiltration membrane assemblies of multiple types can be met, adhesion is excellent after end-capping curing is completed, chemical medium resistance is good, the durable ultrafiltration membrane assembly can be prepared, and the ultrafiltration membrane assembly is suitable for being applied to the field of industrial sewage treatment of wide occasions.

Owner:康达新材料(集团)股份有限公司

Pouring polyurethane resin for wind power blades and preparation method thereof

The invention relates to pouring polyurethane resin for wind power blades and a preparation method thereof, and belongs to the field of wind power technology composite materials. The perfusion polyurethane resin for wind power blades of the present invention includes component A and component B which are packaged separately and mixed when used; said component A includes polymerized isocyanate, isocyanate monomer and initiator; said component B includes 2 functional Polyether polyols, trifunctional polyether polyols, water scavengers, reactive diluents, defoamers, polyurethane delayed catalysts and accelerators. The invention is a two-component polyurethane system. The mixed polyurethane system has the advantages of low mixing viscosity, long gel time, high mechanical strength and low moisture sensitivity. The composite material product prepared by the polyurethane has no bubbles and excellent FRP performance , fully meet the requirements of wind turbine blade manufacturing. Moreover, the preparation method is simple, the raw material cost is low, and defects such as bubbles and whitening do not occur during the pouring process, and can be widely used in the preparation of various large-scale wind power blade composite materials.

Owner:四川东树新材料有限公司

A kind of bis-secondary amine containing siloxane group and its preparation method and application

ActiveCN110760047BExcellent heat and oxygen aging resistanceSlow curingGroup 4/14 element organic compoundsPolyurea/polyurethane coatingsPolymer sciencePolyol

The invention discloses a bis-secondary amine containing siloxane group and its preparation method and application. The bis-secondary amine containing siloxane group is composed of one or more than one dibasic primary amine and containing Siloxanes with unsaturated double bonds are obtained by Michael addition. The B component of the spray polyurea is prepared by mixing the bis-secondary amine and its additives, and the isocyanate prepolymer generated by the reaction of polyether polyol and isocyanate is used as the A component, and the volume ratio of A\B components is 1 : 1 mixed and sprayed to obtain polyurea material. The two active hydrogens of the bis-secondary amine can react with isocyanate to form linear polyurea, while the siloxane group can be hydrolyzed to form Si‑O‑Si crosslinking points, which reduces the crosslinking speed of amine and isocyanate and improves the polyurea The mechanical properties of the material.

Owner:WANHUA CHEM GRP CO LTD

A kind of resin composition and preparation method thereof

Owner:成都市冠宇复合材料制品有限公司

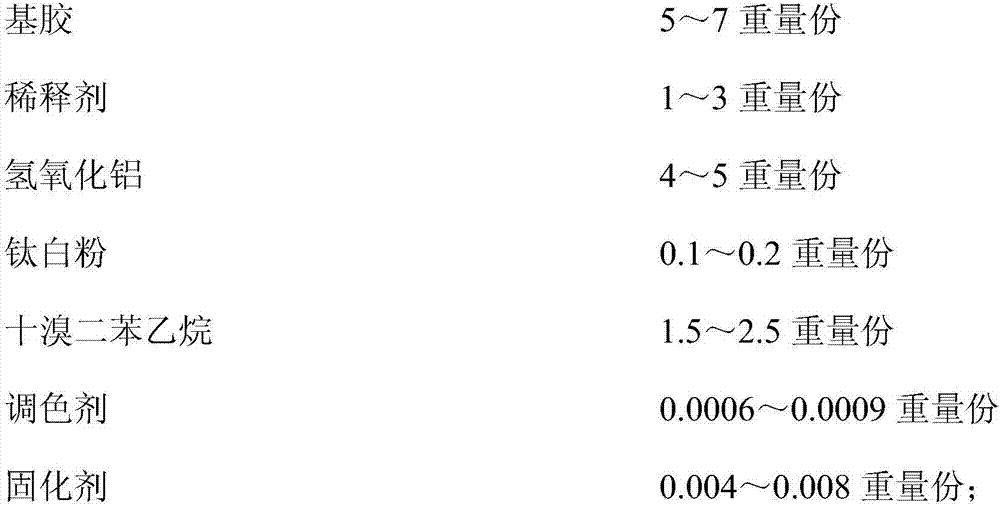

Low-viscosity flame-retardant casting glue and preparation method thereof

InactiveCN107474788AImprove flame retardant performanceLow viscosityNon-macromolecular adhesive additivesAluminium hydroxideThermal stability

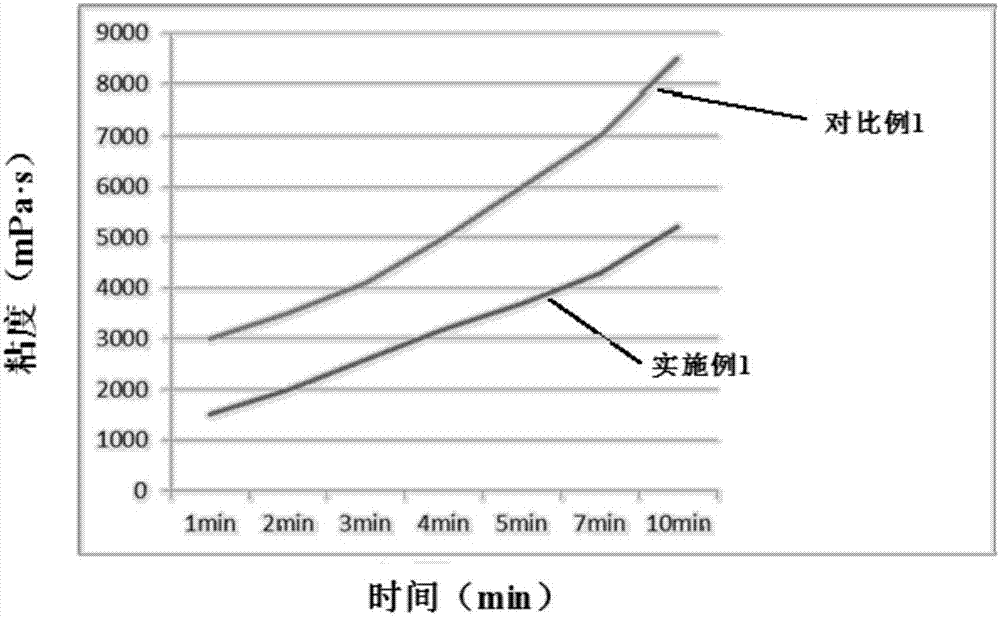

The invention provides low-viscosity flame-retardant casting glue and a preparation method thereof. The casting glue mainly comprises an A agent and a B agent. The A agent can improve flame retardance of a product through aluminium hydroxide and decabromodiphenylethane, which have a synergic effect on improving flame retardance of the product. Moreover, decabromodiphenylethane can further improve thermal stability and ultraviolet resistance of the product on the basis of aluminium hydroxide. The A agent has low leachability during storage. Through application of low-viscosity base glue, the entire viscosity of the A agent is greatly reduced. Through cooperation of the A agent with B agent during a using process, it is ensured that the product has better leveling property and low mixing viscosity, which is beneficial for bubble discharge and smooth appearance during stirring, mixing and use. Through cooperation of the components, the flame-retardant casting glue has excellent comprehensive performance. The preparation method is simple and easy to realize, and is suitable for industrial production.

Owner:CSI SOLAR POWER GROUP CO LTD +1

A kind of epoxy anticorrosion primer for smooth metal surface and preparation method thereof

ActiveCN106318131BImprove permeabilityGood adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyFoaming agent

The invention relates to an epoxy primer and particularly relates to an epoxy anticorrosion primer for a smooth metal surface and a preparation method thereof. The epoxy anticorrosion primer is prepared from a component A including 6 to 13 parts of epoxy resin A, 8 to 18 parts of epoxy resin B, 0.3 to 1.0 part of a de-foaming agent, 0.4 to 1.0 part of an aminosilane coupling agent, 0.6 to 1.5 parts of a wetting dispersant, 15 to 25 parts of anti-rust paint, 20 to 35 parts of packing, 0.5 to 1.5 parts of a thixotropic agent and 5 to 9 parts of an organic solvent; and a component B including 9 to 13 parts of epoxy modified polyamide C and 7 to 10 parts of epoxy modified polyamide D. Compared with the prior art, the epoxy anticorrosion primer for the smooth metal surface, provided by the invention, adopts the aminosilane coupling agent to modify the epoxy resin, and a modified polyamide curing agent is reasonably compounded and a solvent system is reasonably optimized, thus solving the problem that the adhesive force of an anticorrosion coating on the smooth surface is poor.

Owner:XIAMEN SUNRUI SHIP COATING

Light emitting diode (LED) epoxy encapsulation adhesive

InactiveCN102181253BImprove performanceIncrease brightnessNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyWeather resistance

The invention relates to light emitting diode (LED) epoxy encapsulation adhesive and a preparation method thereof. Aiming at the defects that the epoxy resin has poor weather resistance and is aged and yellowed under the irradiation of ultraviolet, an ultraviolet absorbent is added into the conventional LED epoxy encapsulation adhesive. The ultraviolet absorbent can absorb the light with wavelength of about 290 to 400 nanometers; and by chemical redox reaction, color molecules are finally decomposed and faded, and ultraviolet resistant effect is achieved. The LED encapsulation adhesive prepared by the method overcomes the defect that the common epoxy encapsulation adhesive cannot be used for long time under the environment of ultraviolet or high temperature; and in addition, because the yellowing resistance of the adhesive is promoted, the baking temperature and the baking time in the product encapsulation process can be improved when the adhesive is used, and the mechanical property of a product is greatly improved.

Owner:SUZHOU BANGCEN TECH

A low-free nanometer wear-resistant polyurethane formula

The invention brings forward a formula for low free nanometer wear-resistant polyurethane. The formula comprises, by weight, 100 parts of a low free PU performed polymer, 12 to 12.5 parts of MOCA and 3 to 5 parts of montmorillonite. With the formula provided by the invention, polyurethane has a small viscosity after mixing, good fluidity in processing and a small compressive deformation value, and a rebound value of a product is great.

Owner:江苏泰东环保工程有限公司

A non-curing rubber asphalt waterproof coating that can be applied at room temperature to prevent flames and suppress smoke

ActiveCN111117487BGood modification effectReduce pollutionFireproof paintsOther rubber coatingsWaste rubberEnvironmental engineering

The invention provides a non-curing rubber asphalt waterproof coating capable of flame retardancy and smoke suppression that can be applied at normal temperature. The raw materials include asphalt, softening oil, activator, waste rubber powder, modifier, liquid flame retardant and synergist. The preparation process is as follows: Mix and stir the mixed asphalt and softened oil evenly, heat up and dehydrate, add an activator, stir and develop fully, add waste rubber powder, after the development is complete, continue to add modifiers to dissolve, add liquid flame retardants to reduce viscosity And flame retardant synergist, discharge after cooling down. The present invention adopts the sol method, uses the liquid flame retardant as the liquid filler to reduce the viscosity and soften the rubber modifier, and also acts as the main flame retardant to achieve the flame retardant effect. The asphalt is also modified in multiple steps. Through the desulfurization of the activator, the S-S bond / S-C bond of the network macromolecular segment in the waste rubber powder is oxidized and broken, and a large number of small molecular segments are produced. The suspension is dispersed in asphalt and forms a stable semi-solid continuous phase system through a gel film. This process can reduce the shear rate and energy consumption in the production process, so as to realize normal temperature construction, flame retardancy and smoke suppression, effectively reduce construction energy consumption and environmental pollution, and fully recycle and reuse "polymer waste" such as waste rubber powder. Conducive to building a resource-friendly society.

Owner:山东雨中情防水材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com