Halogen-free flame-retardant epoxy resin electronic pouring sealant

A technology of epoxy resin and potting glue, applied in the field of potting glue, can solve the problems of corrosiveness, toxicity, ozone layer destruction, etc., and achieve the effect of convenient operation and strong flame retardant ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

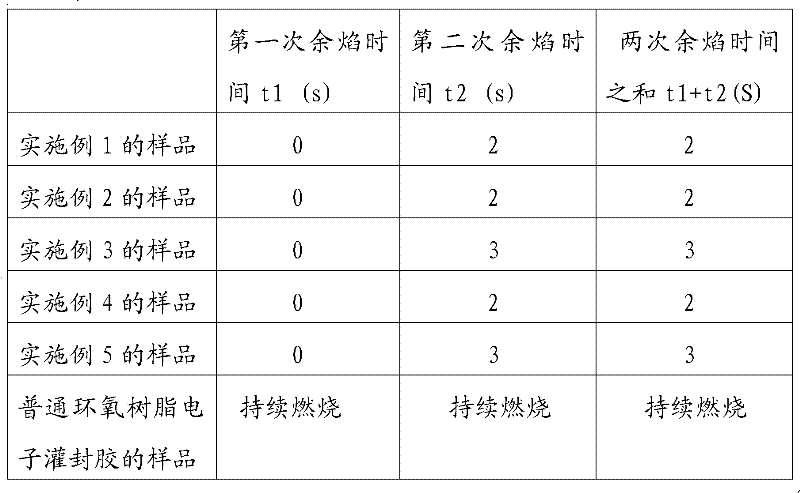

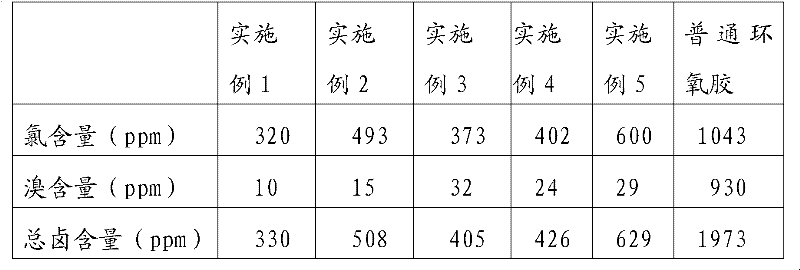

Examples

Embodiment 1

[0027] Bisphenol A type epoxy resin 828EL (from Hexion) 15 parts, bisphenol F type epoxy resin 830LVP (from Dainippon Ink) 15 parts, aluminum hydroxide 65 parts, CARDURA E-10 2 parts, Doher 601R2 1 part, 1 part of carboxyl-terminated liquid nitrile rubber, 0.1 part of KH560, 0.1 part of black paste (Degussa T4 carbon black and 828EL are mixed in proportion, and the specific weight ratio is 2:8), and stirred evenly at room temperature to obtain A Components: Polyetheramine D-400 and isophorone diamine are mixed in a weight ratio of 8:2 to form an amine curing agent. Mix component A and amine curing agent in a weight ratio of 100:13, stir evenly under vacuum at room temperature, pour the mixture into a mold and cure at 80°C for 4 hours, and measure the flame retardant grade of the cured product.

Embodiment 2

[0029] Bisphenol A type epoxy resin 828EL (produced by Hexion) 20 parts, bisphenol F type epoxy resin EP-4901E (produced by Japan Adidas) 15 parts, aluminum hydroxide 53 parts, CARDURA E-10 4.5 parts , 4.5 parts of Doher601R, 2.5 parts of carboxyl-terminated liquid nitrile rubber, 0.25 parts of KH560, 0.25 parts of black paste (Degussa T4 carbon black and 828EL are mixed in proportion, and the specific weight ratio is 2: 8), stir evenly at room temperature, Obtained component A; isophorone diamine constitutes an amine curing agent. Mix component A and amine curing agent at a weight ratio of 100:8.5, stir evenly under vacuum at room temperature, pour the mixture into a mold and cure at 80°C for 4 hours, and measure the flame retardancy of the cured product.

Embodiment 3

[0031] Bisphenol A type epoxy resin DER 331P (from Dow) 20 parts, bisphenol F type epoxy resin 830LVP (from Dainippon Ink) 20 parts, aluminum hydroxide 40 parts, CARDURA E-10 7 parts, Doher 7 parts of 601R, 5 parts of carboxyl-terminated liquid nitrile rubber, 0.5 parts of KH560, 0.5 parts of black paste (Degussa T4 carbon black and 828EL are mixed in proportion, the specific weight ratio is 2:8), and stirred evenly at room temperature to obtain A component; triethylenetetramine composition amine curing agent. Mix component A and amine curing agent in a weight ratio of 100:4, stir evenly under vacuum at room temperature, pour the mixture into a mold and cure at 25°C for 48 hours, and measure the flame retardant grade of the cured product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com