Nitrogen-containing resin, adhesive for environmentally friendly composite base copper-clad laminates and laminates

A technology of copper-clad laminates and nitrogen-containing resins, applied in epoxy resin adhesives, synthetic resin layered products, lamination, etc., can solve the problems of expensive adhesive materials and achieve good application prospects and market benefits , reduce material costs, and the effect of large market application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The present embodiment provides a nitrogen-containing resin, which is prepared through the following steps:

[0049] Add 26% melamine, 51% formaldehyde, 4.89% modified phenol and 0.045% catalyst to the reaction kettle in sequence, mix and stir for 5 minutes to obtain the mixed material, and measure the pH value of the mixed material;

[0050] When the pH value of the mixed material reaches 8 ≤ the pH value of the mixed material ≤ 9, in the reflux state, the temperature of the mixed material is raised to 95°C within 40 minutes, and the temperature is kept for 60 minutes;

[0051] Take a sample to measure the water number, the water number reaches 9mL, add 0.065% polymerization inhibitor to the mixed material, after stirring for 5 minutes, vacuumize to above 0.07MPa, after the temperature of the mixed material rises to 2°C, remove the vacuum, add 18% by mass The solvent methanol, obtains nitrogen-containing resin;

[0052] Wherein, modified phenol is cresol;

[0053] Th...

Embodiment 2

[0058] This example provides an adhesive for a composite-based flame-retardant copper-clad laminate, which is prepared by the following steps:

[0059] Add 12% of toluene, 6% of methanol, 3% of titanium dioxide, 5% of magnesium hydroxide, and 4% of polyphosphate in the reaction kettle, and mix and stir for about 30 minutes;

[0060] Then add 54% of nitrogen-containing resin, 12% of phosphorus-based epoxy resin, and 4% of non-halogen environmental protection epoxy resin in sequence, and stir and mix for about 60 minutes to obtain an adhesive;

[0061] Wherein, nitrogen-containing resin is the nitrogen-containing resin of embodiment 1;

[0062] Polyphosphate is T-903 polyphosphate flame retardant;

[0063] Phosphorous epoxy resin is GEBR577A70 high phosphorus epoxy resin;

[0064] Non-halogen environmental protection epoxy resin is GEBR580K70 resin;

Embodiment 3

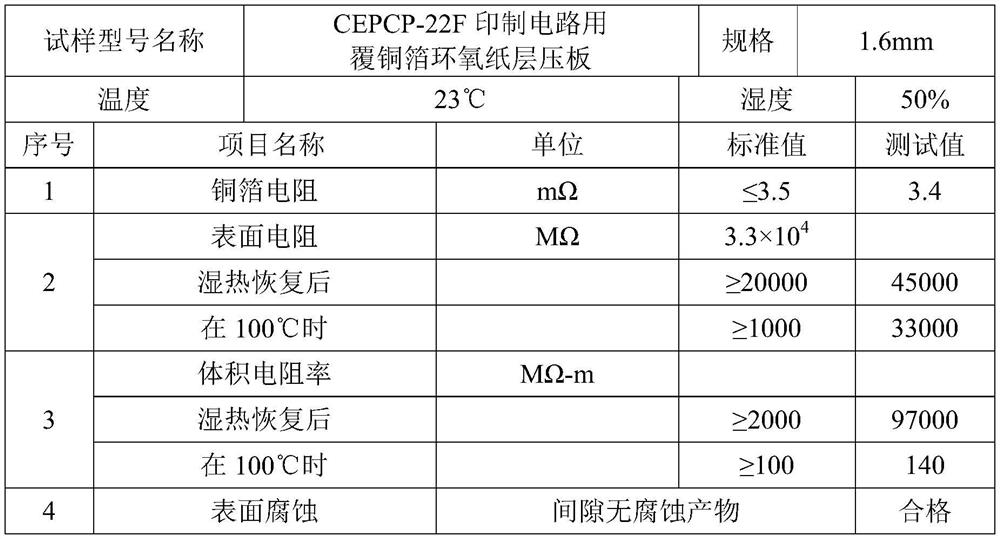

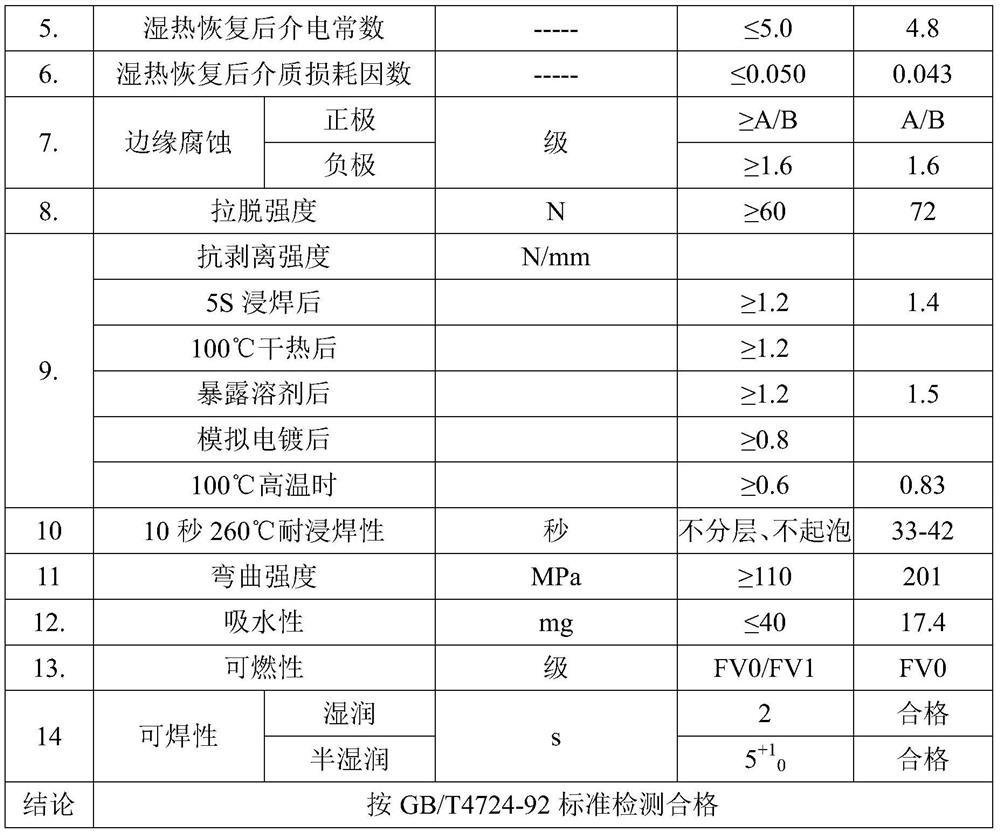

[0067] This embodiment provides a composite-based flame-retardant copper-clad laminate, which is prepared through the following steps:

[0068] Make adhesive content that is 55%, the sizing paper that soluble resin content is 80%, the sizing agent content is 57%, the sizing cloth that soluble resin content is 93%; Wherein, sizing agent is the glue of embodiment 2 Adhesive;

[0069] Compound the glued paper, glued cloth and copper foil, and press it for 90 minutes under the conditions of 16MPa and 163°C to obtain a composite base flame-retardant copper-clad laminate, which is a copper-clad ring for printed circuits of CEPCP-22F Oxygen paper laminate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com