Ethylene propylene diene terpolymer sponge rubber and preparation method thereof

A technology of EPDM rubber and sponge rubber, which is applied in the field of EPDM sponge rubber and its preparation, to achieve the effect of uniform cells, low density, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

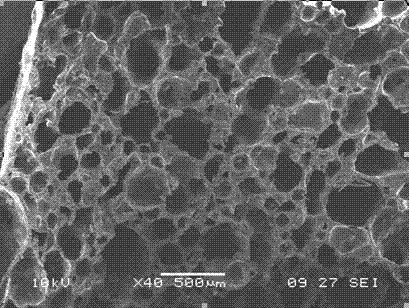

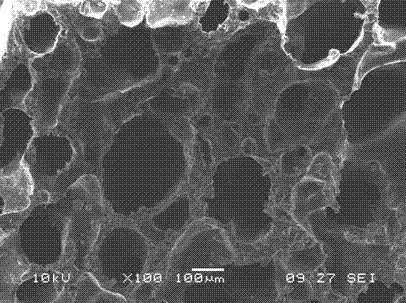

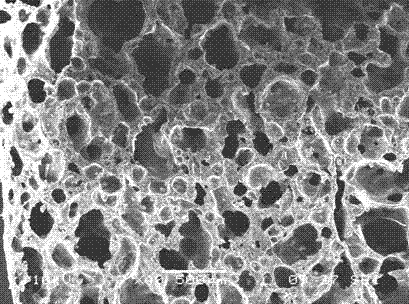

Image

Examples

Embodiment 1

[0030] The EPDM sponge rubber described in this embodiment is composed of an EPDM rubber matrix, a foaming agent, a filling reinforcing agent, related vulcanizing agents and vulcanization assistants. As the filling and reinforcing agent, molecular sieve powder is used instead of talc powder and active calcium as the filling and reinforcing system, and the porous structure of molecular sieve powder is used to distribute the cells of the sponge rubber evenly, and to make the sponge rubber product described in this embodiment have a hygroscopic function.

[0031] In this example, the vulcanization system is composed of sulfur, M, TMTD, PZ, BZ, and DPTT, the filler is composed of carbon black and molecular sieve, and the foaming system is composed of foaming agent OBSH. The specific formula is shown in Table 1.

[0032] Table 1

[0033] name Content / phr name Content / phr EPDM 100 TMTD 1 stearic acid 3 M 0.8 Calcium Oxide 5 PZ 0.5 Zinc...

Embodiment 2

[0040] In this example, the difference from Example 1 is that the content of the accelerator has changed, and the specific formula is shown in Table 2.

[0041] Table 2

[0042] name Content / phr name Content / phr EPDM 100 TMTD 0.5 stearic acid 3 M 0.8 Calcium Oxide 5 PZ 1 Zinc oxide 5 BZ 1.5 Si-69 2 DPTT 1 polyethylene glycol 5 EZ 0.5 solid paraffin 2 Blowing agent OBSH 6 Paraffin oil 65 Carbon black N550 20 sulfur 1.2 Molecular sieve powder 115 Antiaging agent 4010NA 1.5 Antiaging agent 2246 0.5

[0043] The performance test results of the EPDM sponge rubber obtained in this embodiment are shown in Table 16.

Embodiment 3

[0045] In this example, the difference from Example 1 is that the content of the accelerator has changed, and the specific formula is shown in Table 3.

[0046] table 3

[0047] name Content / phr name Content / phr EPDM 100 TMTD 1 stearic acid 3 M 0.8 Calcium Oxide 5 PZ 1 Zinc oxide 5 BZ 1.5 Si-69 2 DPTT 1 polyethylene glycol 5 EZ 1 solid paraffin 2 Blowing agent OBSH 6 Paraffin oil 65 Carbon black N550 20 sulfur 1.2 Molecular sieve powder 115 Antiaging agent 4010NA 1.5 Antiaging agent 2246 0.5

[0048] The performance test results of the EPDM sponge rubber obtained in this embodiment are shown in Table 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com