Patents

Literature

48results about How to "Meet the performance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

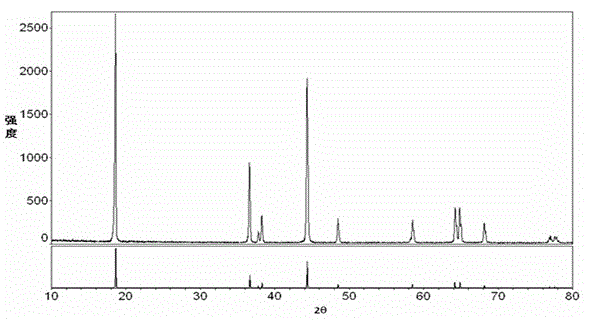

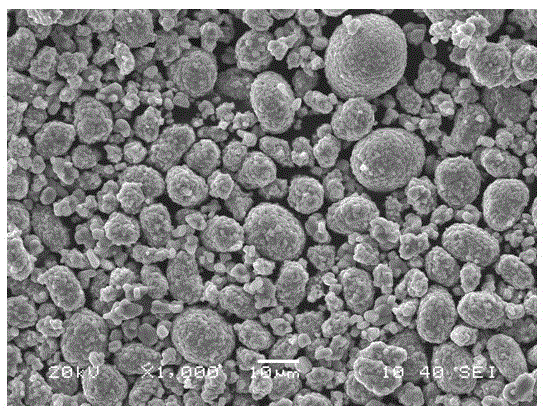

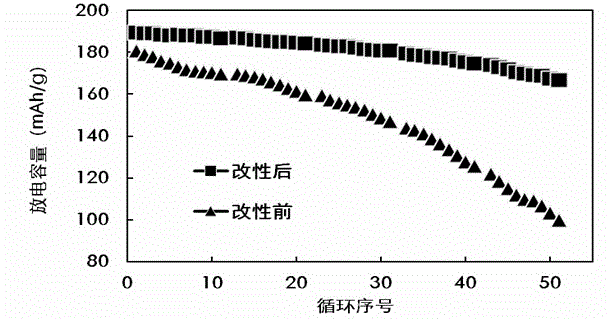

Positive electrode material of high-capacity dynamic-type nickel-rich lithium ion battery and preparation method thereof

ActiveCN103606671AStable structureImprove cycle performanceCell electrodesMaterials processingLithium-ion battery

The invention relates to a positive electrode material of a high-capacity dynamic-type nickel-rich lithium ion battery and a preparation method. The molecular formula of the positive electrode material of the high-capacity dynamic-type nickel-rich lithium ion battery is LiaNi1-x(MM')xO2.M''O, wherein a is equal to 0.9-1.2, x is more than or equal to 0 and less than or equal to 0.7, and M is at least one of Co, Mn and Al; M' is at least one of Co, Al, V, Mn, Zr, Mg, Ti, Cr, Zr, La, Ce, Pr, Nd, Nb, Mo, Y, Sr, Ba, B, Sr, Sn and Ta; M''O is a cladding layer, and M'' is Co and Al. The invention also relates to a preparation method for the positive electrode material of the high-capacity dynamic-type nickel-rich lithium ion battery. The material machining performance is excellent, the battery prepared by utilizing the material, the cycling performance and the high-voltage performance are excellent, the safety and stability in use can be realized, not only can the application performance requirement of a portable electronic device on the battery be met, but also the positive electrode material is applicable to the power battery.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

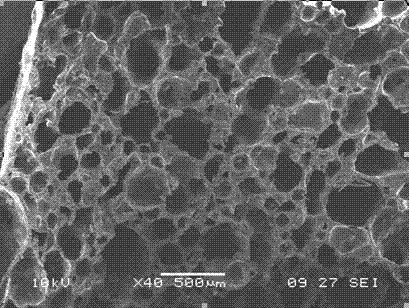

Ethylene propylene diene terpolymer sponge rubber and preparation method thereof

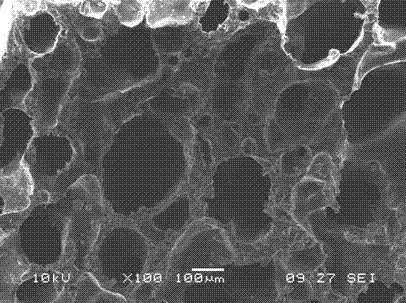

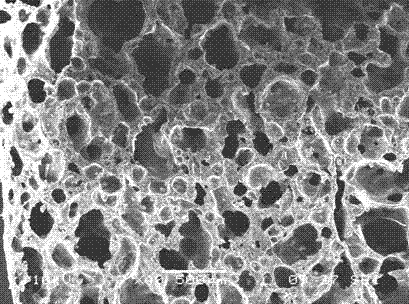

The invention provides an ethylene propylene diene terpolymer sponge rubber and a preparation method thereof, relating to a rubber and a preparation method thereof. The ethylene propylene diene terpolymer sponge rubber is prepared from ethylene propylene diene terpolymer, a foaming agent, a filling enhancer, a plasticizer, molecular sieve powder with a hygroscopic effect, a vulcanizing agent and a vulcanizing aid. The ethylene propylene diene terpolymer sponge rubber is characterized in that the molecular sieve powder is used for replacing traditional talc powder or calcium carbonate to be used as a filling agent, a foaming agent azobisformamide (AC) and a foaming agent 4,4'-oxy bis(benzenesulfonyl hydrazide) (OBSH) are combined and matched with an accelerant, and the decomposing rate of the foaming agent and the vulcanizing rate of the ethylene propylene diene terpolymer are matched, thus a microporous sponge rubber sealing product with a hygroscopic function is prepared under die pressing vulcanization conditions. The tensile strength, elongation percentage, stress at definite elongation, compression set and other indexes of the ethylene propylene diene terpolymer sponge rubber can meet the use performance requirements of sponge sealing strips; and at the same time, the sponge rubber has uniform foam pores, small density and hygroscopic function.

Owner:JINGDONG RUBBER

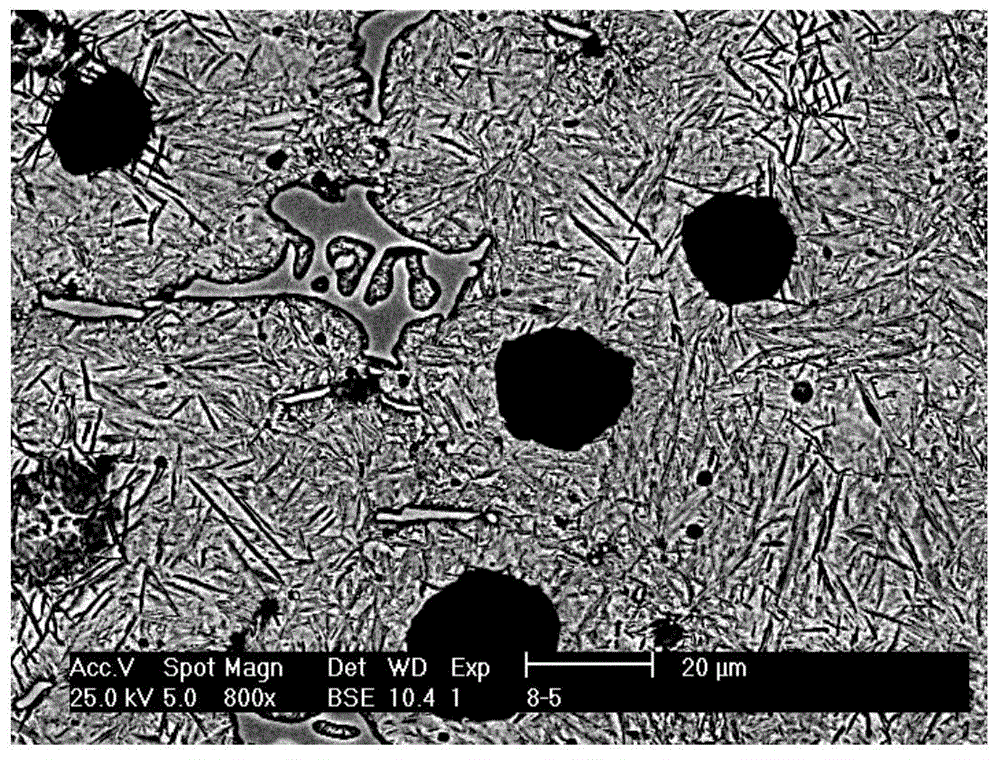

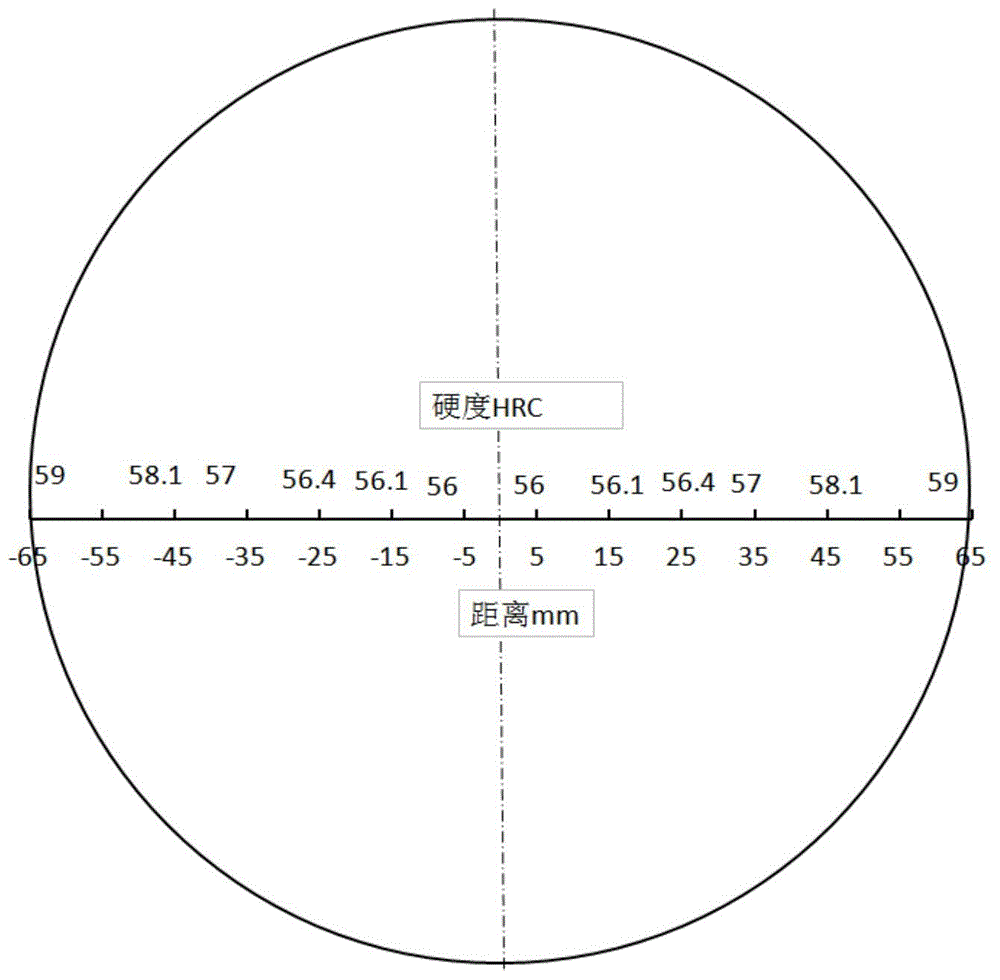

Ausferrite ductile cast iron grinding ball

ActiveCN104152792AHighlight substantive featuresImprove absorption rateGrain treatmentsAlloyDuctile iron

The invention discloses an Ausferrite ductile cast iron grinding ball, and relates to a spherulitic graphite-contained cast iron alloy. The Ausferrite ductile cast iron grinding ball comprises the following chemical elements in percentage by mass: 3.3-3.7% of C, 2.0-3.0% of Si, 1.0-2.5% of Mn, 0.7-3.0% of Cr, 0.1-1.0% of Mo, 0.1-1.0% of Cu, 0.04-0.08% of P, 0.01-0.020% of S, 0.03-0.05% of Mg, 0.02-0.04% of Ce, 0.03-0.07% of B, 0.06-0.12% of Ti, 0.03-0.2% of V, and the balance of Fe. The Ausferrite ductile cast iron grinding ball is prepared by the steps of preparation and smelting of raw materials, spheroidizing treatment, inoculation treatment and microalloying treatment, and isothermal quenching heat treatment. The Ausferrite ductile cast iron grinding ball overcomes the defects of low production efficiency and high consumption of electric energy of a ball mill due to easy surface stripping and crushing and shorter fatigue life of an existing grinding ball product in the service process.

Owner:HEBEI UNIV OF TECH

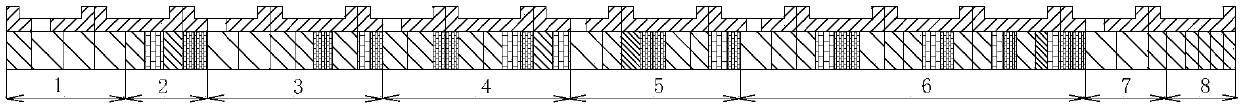

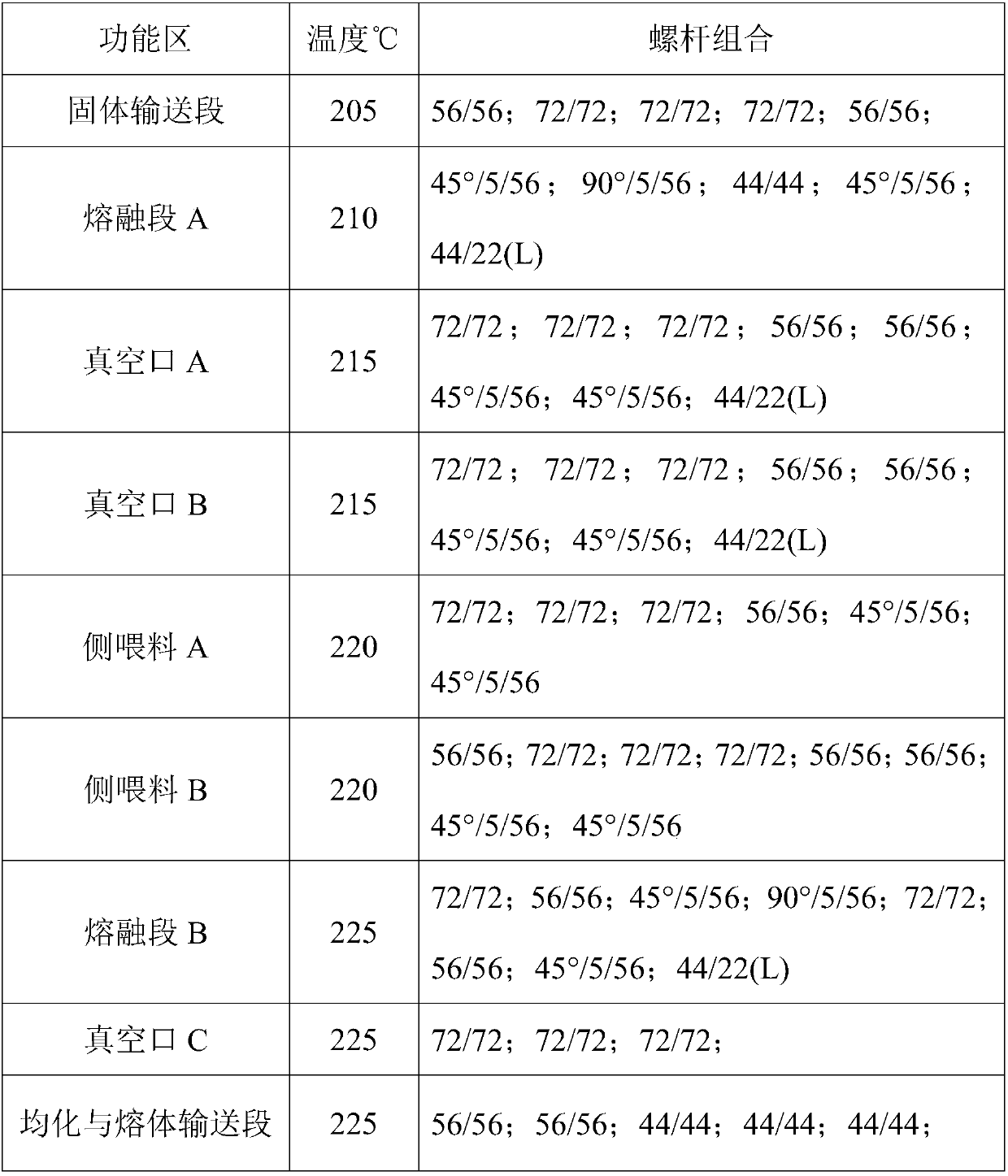

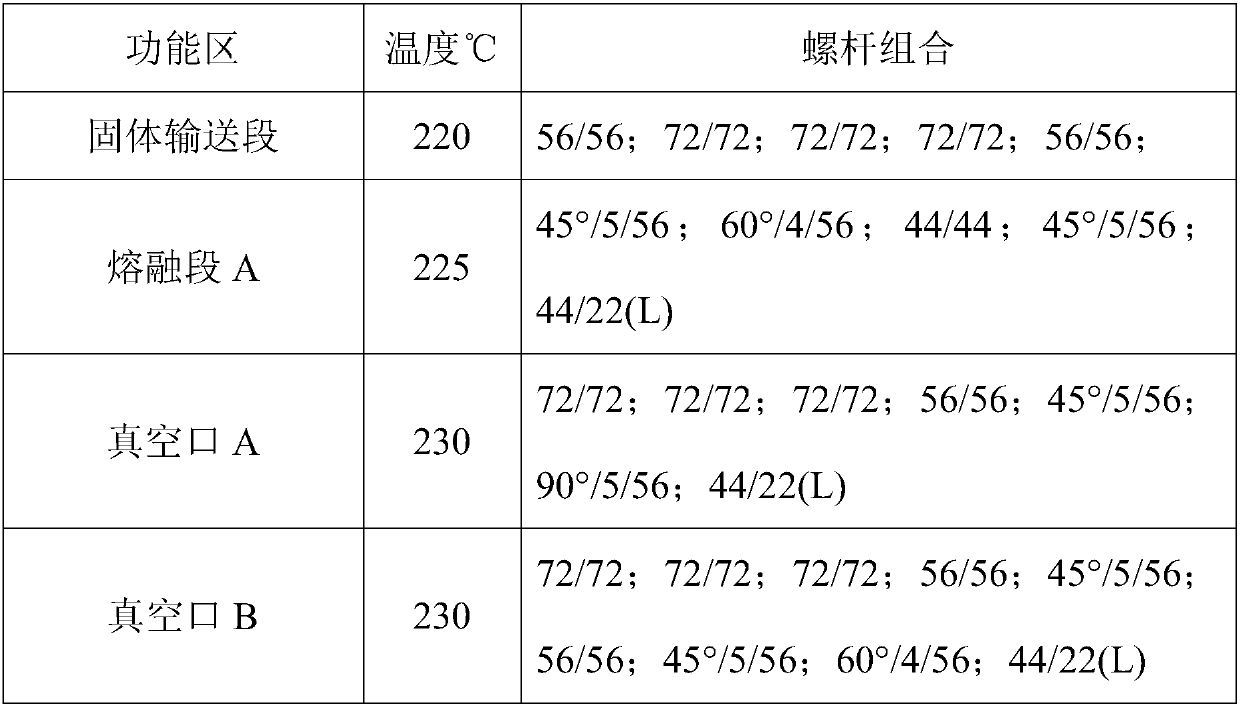

A kind of preparation method of fully biodegradable nanocomposite polyester plastic

The invention relates to a preparation method of a polysaccharide nanocrystalline composite polyester material. A preparation method of a biodegradable nanocomposite material, characterized in that it comprises the steps of: 1) selecting polysaccharide nanocrystals with a mass ratio of 1:1 to 30 according to the mass ratio of polypolysaccharide nanocrystals and polybutylene succinate (cellulose whiskers or starch nanocrystals), polybutylene succinate raw materials; 2) then adopt the method for solution blending or melt blending respectively, polysaccharide nanocrystals, polybutylene succinate Uniform compounding to obtain a solid mixture; 3) hot-pressing the solid mixture, drying the material, and preparing a polysaccharide nanocrystal modified polybutylene succinate bionano composite material product. The invention has many advantages such as low cost, non-toxic and harmless, environmental protection, complete biodegradability, simple process, etc. The prepared products can be processed into films, sheets, profiles, fibers and containers; they can be used in packaging, biological, medical, Engineering plastics and other material fields.

Owner:YANXIN WULONGXING PLASTICS HIGH TECH MATERIALS

Copper-base powder metallurgical brake pad material for sea-base wind turbine generator system and preparation process thereof

InactiveCN102002609AMeet the performance requirementsIncrease coefficient of frictionFriction liningFerrochromeSeawater

The invention provides a copper-base powder metallurgical brake pad material for a sea-base wind turbine generator system, which comprises the following components in percentage by weight: copper, FWCuZn30 brass, graphite, sea sand, silicon carbide, ferrochrome and tin. The preparation process of the brake pad material comprises the following five steps: blending materials, pressing blank, making support steel backing, pressurizing and sintering in sections, and machining for molding. In the invention, by adopting the seawater corrosion resistant brass as a material matrix and high-content nonmetal components the weight ratio of which is more than 30%, excellent corrosion resistance, high friction coefficient and high brake moment can be obtained, and the stability of friction coefficient is good; the obtained powder metallurgical brake pad material conforms to the service performance requirements for a high-speed shaft braking device of the sea-base high-power wind turbine generator system; the material has the advantages of rational component proportion, simple machining process, good corrosion resistance, high friction coefficient, good friction coefficient stability and high strength, and is suitable for industrialized production; and the copper-base powder metallurgical brake pad material can be taken as a high-speed shaft braking material for the sea-base high-power wind turbine generator system with the power of more than 3.5MW.

Owner:CENT SOUTH UNIV

Microwave heating body and method for manufacturing same

InactiveCN101786860AWon't happenMeet the performance requirementsMicrowave heatingClaywaresSoft claySilicic acid

The invention discloses a high temperature-resistance, safe and nontoxic microwave heating body and a method for manufacturing the same. The microwave heating body comprises a microwave active particle material and a bonding agent by which the microwave active particle material is bonded into a usable shape, wherein the microwave active particle material is silicon carbide, ferrite or a combination of the silicon carbide and the ferrite; and the bonding agent is a combination of fused quartz, talcpowder, spodumene, cordierite, mullite, feldspar, kaolin, soft clay and silicic acid. The preparation method comprises the following steps that: the raw materials are uniformly mixed and moulded; and a blank is dried and then sintered at the temperature of between 900 and 1,280 DEG C to form the microwave heating body. The microwave heating body does not burst when the microwave heating body is chilled from nearly 500 DEG C to room temperature, a good linear relationship is established between the microwave heating time and the surface temperature of the heating body, and the use performance requirements on cooking devices and industrial ovens are met.

Owner:陈潮通 +1

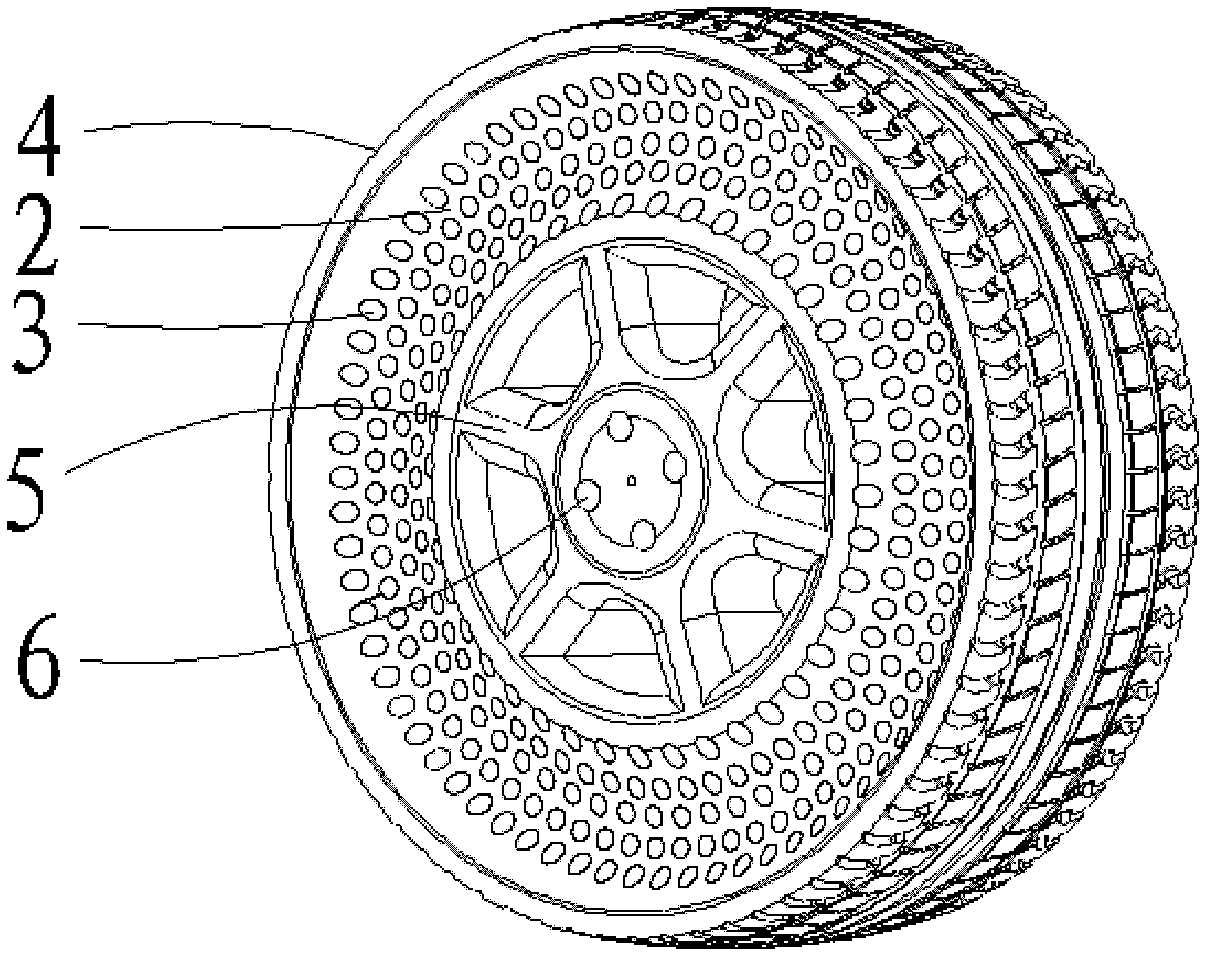

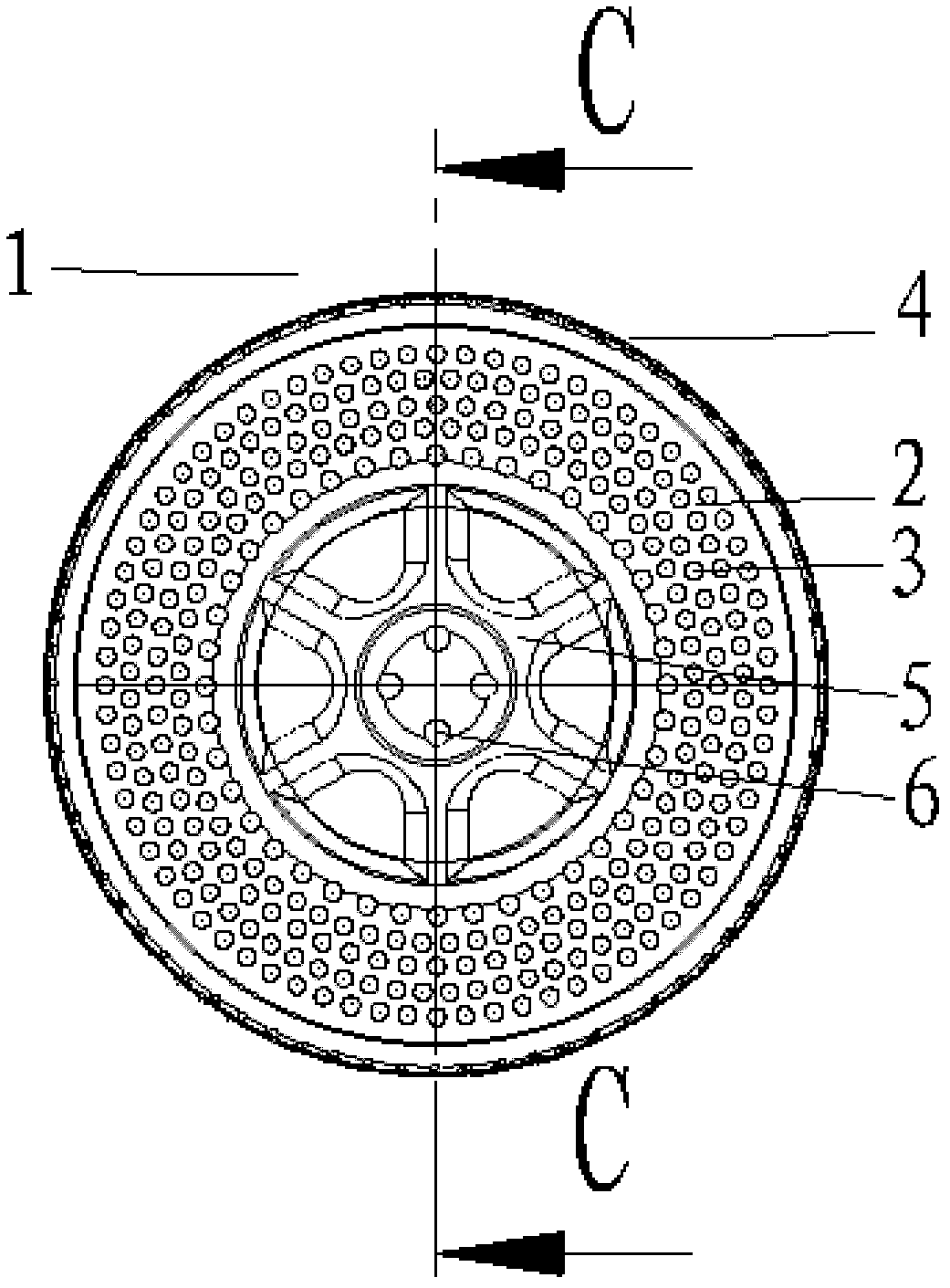

Non-pneumatic tire with rigid and flexible structure

InactiveCN102582365AStrong comfortSave raw materialsNon-inflatable tyresSpecial tyresMaximum diameterThermoplastic elastomer

The invention provides a non-pneumatic tire with a rigid and flexible structure. The non-pneumatic tire mainly comprises two parts, namely a tire tread and a casing structure, wherein the tread part is mainly made of a thermoplastic elastomer, and the casing structure always extends from an inner surface of the tread to the center of a rim along the radial direction, so that the rim and the casing are combined into a whole; and the whole part is made of tough and elastic engineering plastics, an inverted conical through hole is formed in the casing part in the axial direction, and the inverted conical through hole is structurally characterized in that: holes positioned on two sides of the tire have the maximum diameter and a hole in the middle of the tire has the minimum diameter. The non-pneumatic tire with the rigid and flexible structure has the advantages of other non-pneumatic tires and is endowed with excellent structural performance and safety performance. In addition, because the casing and the rim are made of thermoplastic polymer materials, the mass of the tire is greatly reduced, and the non-pneumatic tire has a great significance for energy conservation, emission reduction and oil consumption reduction.

Owner:BEIJING UNIV OF CHEM TECH

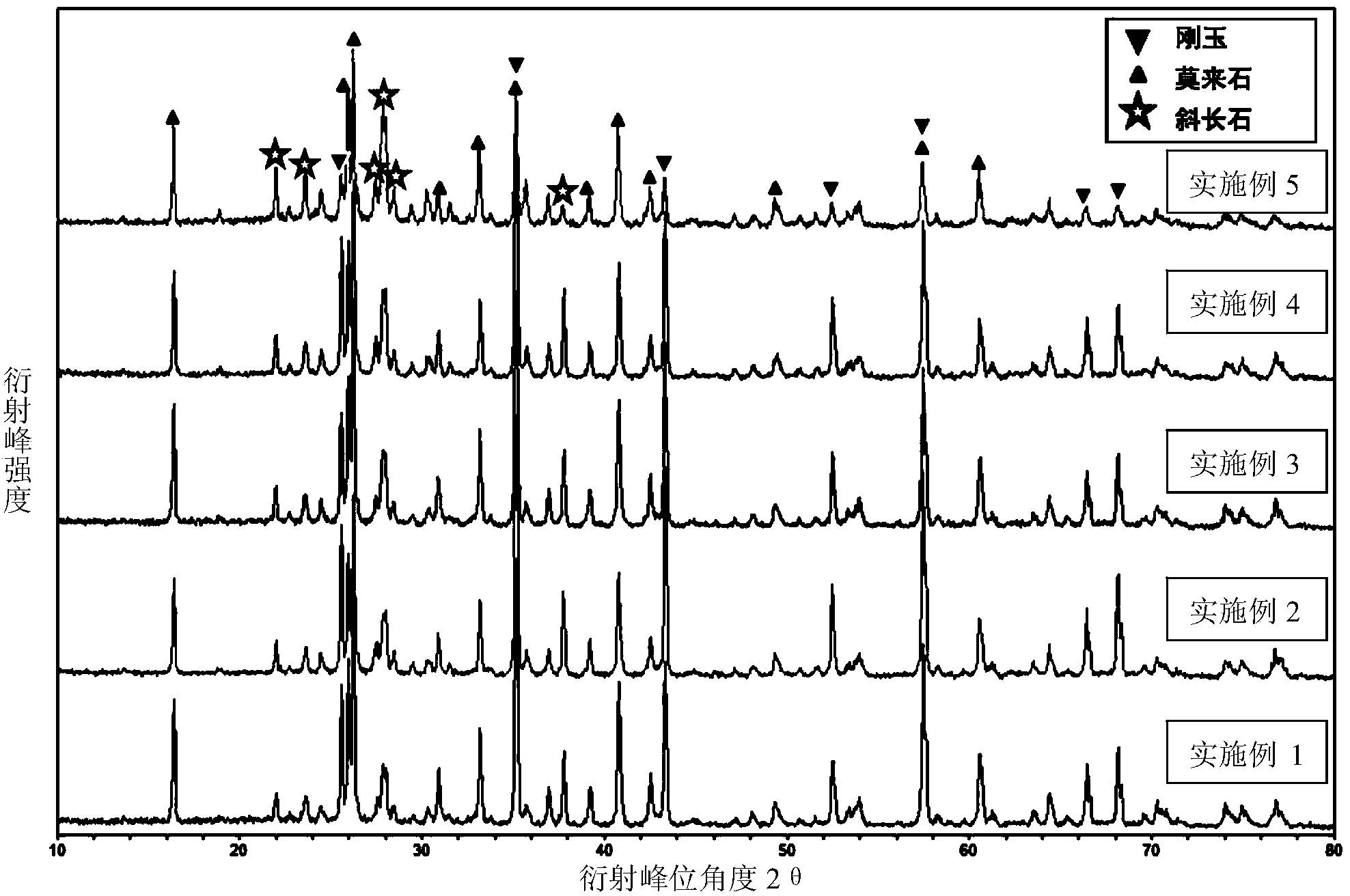

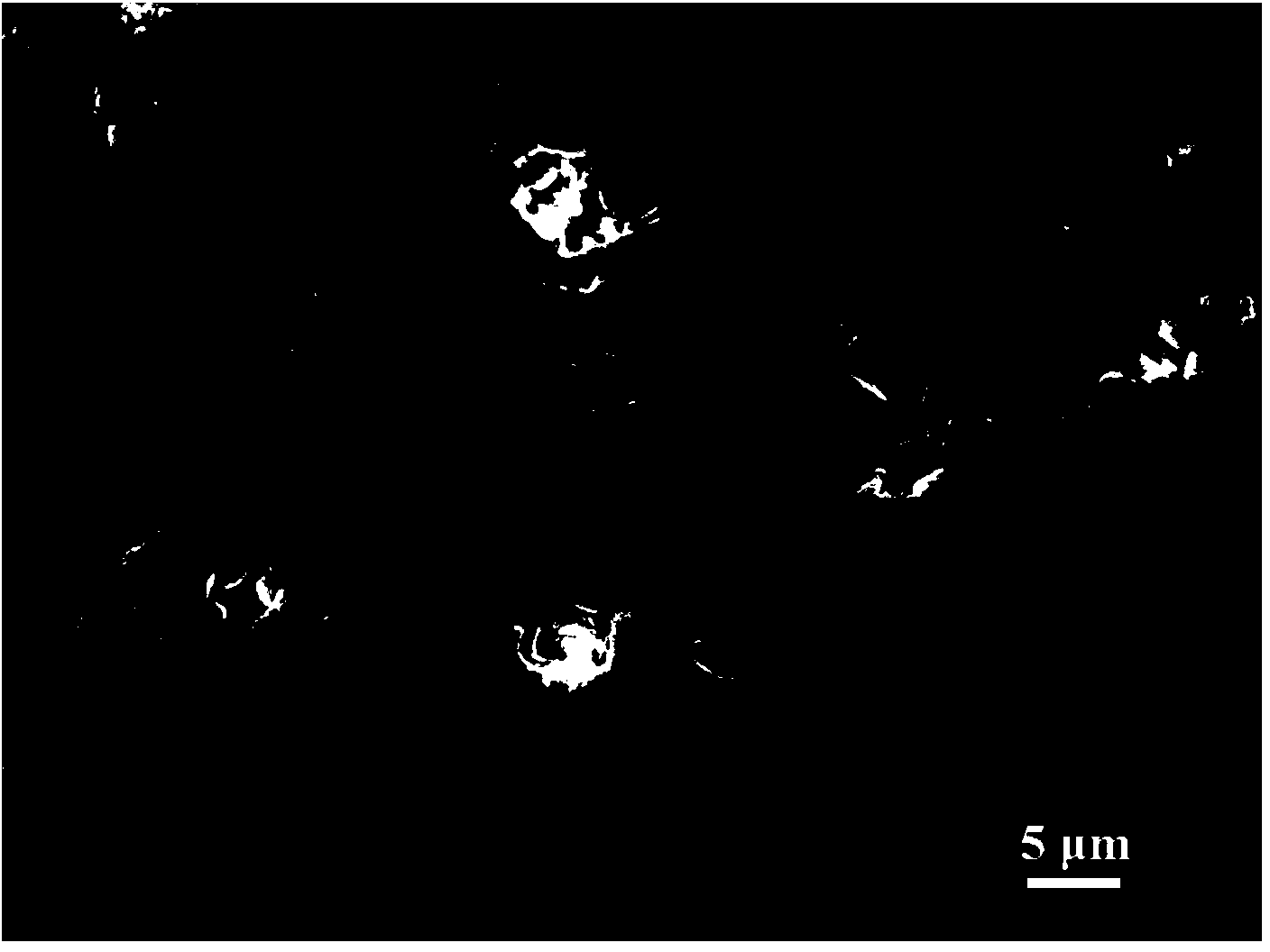

Preparation method of corundum-mullite complex phase ceramic material

InactiveCN103771841AMeet the performance requirementsReduce production energy consumptionResource utilizationMullite

The invention discloses a preparation method of a corundum-mullite complex phase ceramic material. The preparation method comprises the following steps: 1) uniformly mixing 1-25% by weight of coal ash, 0-5% by weight of calcium oxide, 0-10% by weight of albite and 60-99% by weight of bauxite to obtain a raw material, wherein the content of aluminum oxide in bauxite is 50-68% by weight; 2) uniformly mixing the raw materials in a ball mill and carrying out ball milling till the grain size of the raw material is less than 74 mu m to obtain mixed powder; 3) adding 1-3% by weight of water glass into the mixed powder to be uniformly stirred, aging for 1-2 hours, and forming and preforming on a press or a pelletizer to obtain a blank; and 4) heating the blank to 1350-1420 DEG C at a rate of 5-15 DEG C / min, insulating for 40-120 minutes and furnace cooling to obtain the corundum-mullite complex phase ceramic material. The bauxite used in the preparation method is a lower grade raw material, so that the production energy consumption and cost are lowered and the resource utilization rate is improved while the demand on the operational performance of the material is satisfied.

Owner:CNPC BOHAI DRILLING ENG

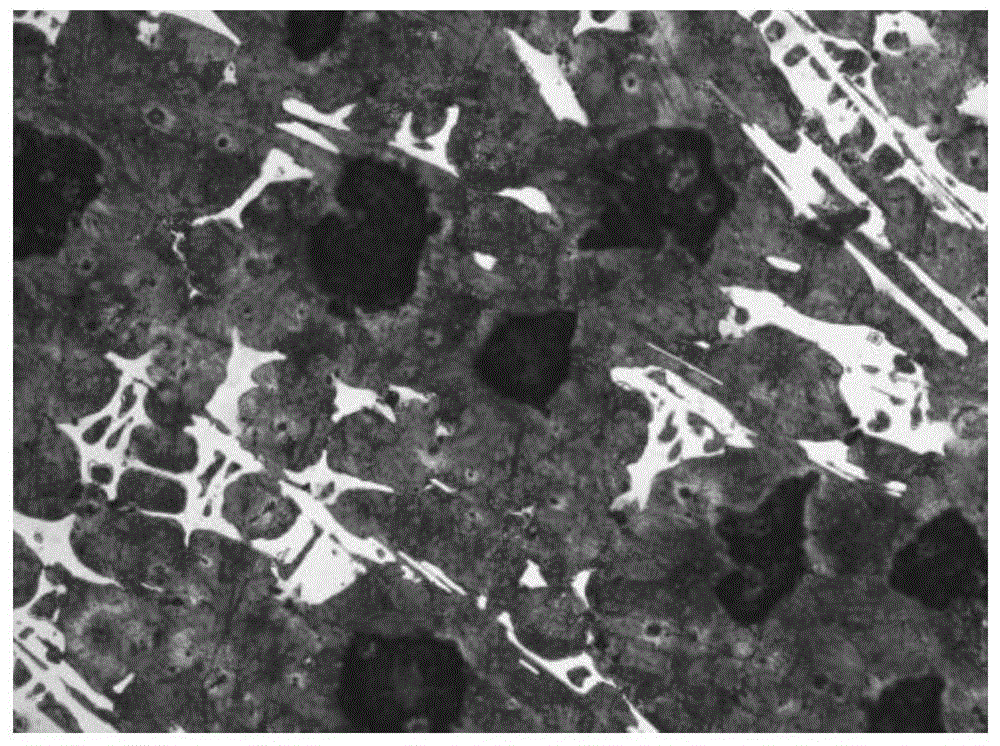

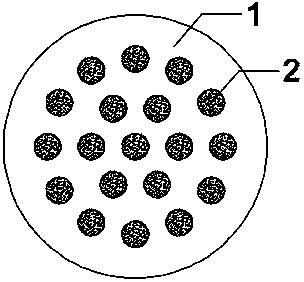

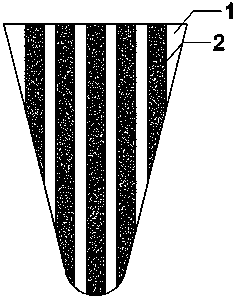

Ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head and manufacturing method thereof

ActiveCN108380850AFacilitate compounding processEfficient feedingBallastwayTransportation and packagingManufacturing technologyWear resistant

The invention discloses a ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head and a manufacturing method of the ceramic particle multi-scale reinforced metalbase composite wear-resistant raking tooth head, and belongs to the field of part manufacturing. According to the manufacturing method, ceramic particles and alloy powder are compacted and sintered tomanufacture rod-shaped composite materials, the rod-shaped composite materials are embedded into a metal base through the combination of the powder metallurgy technology and the embedment casting technology, and the purpose that the metal base covers the uniformly-distributed rod-shaped composite materials is achieved. The ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head solves the problems that an ordinary raking tooth is prone to being worn, and a homogeneous composite wear-resistant part is poor in toughness, brittle and low in impact resistance. Compared with overall metallurgical sintering, the manufacturing method has the advantages that by means of the technology of combination of powder metallurgy and embedment casting, the dimensionalaccuracy of parts is guaranteed, the requirements of specific parts for using performance are met, the assembling working procedure is omitted, the manufacturing technology is simplified to a certainextent, the part manufacturing cost is greatly reduced, the organization is compact, the metallurgical bonding is good, and the ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head can be applied to cleaning and screening vehicles for railway maintenance and parts of raking teeth of scraper loaders.

Owner:KUNMING UNIV OF SCI & TECH

Novel microcrystallite glass-ceramic composite brick and production method thereof

The invention discloses a novel microcrystallite glass-ceramic composite brick and a production method thereof. The production method comprises the following steps of: (1) preparing low-viscosity glass clinker and high-viscosity glass clinker; (2) preparing microcrystallite glass-ceramic composite brick blank powder for later use by the conventional method; (3) preparing a microcrystallite glass-ceramic composite brick substrate by using the obtained microcrystallite glass-ceramic composite brick blank powder for later use; (4) preparing the microcrystallite glass-ceramic composite brick; and (5) performing aftertreatment. The prepared microcrystallite glass-ceramic composite brick is low in firing temperature, and short in firing period; energy consumption can be reduced greatly, emission is reduced, and preparation cost is saved; the surface of the prepared microcrystallite glass-ceramic composite brick has a small amount of blowholes; and the prepared microcrystallite glass-ceramic composite brick is high in soil resistance, and abrasive resistance, and can fully meet the requirement of using performance.

Owner:HANGZHOU NABEL CERAMIC

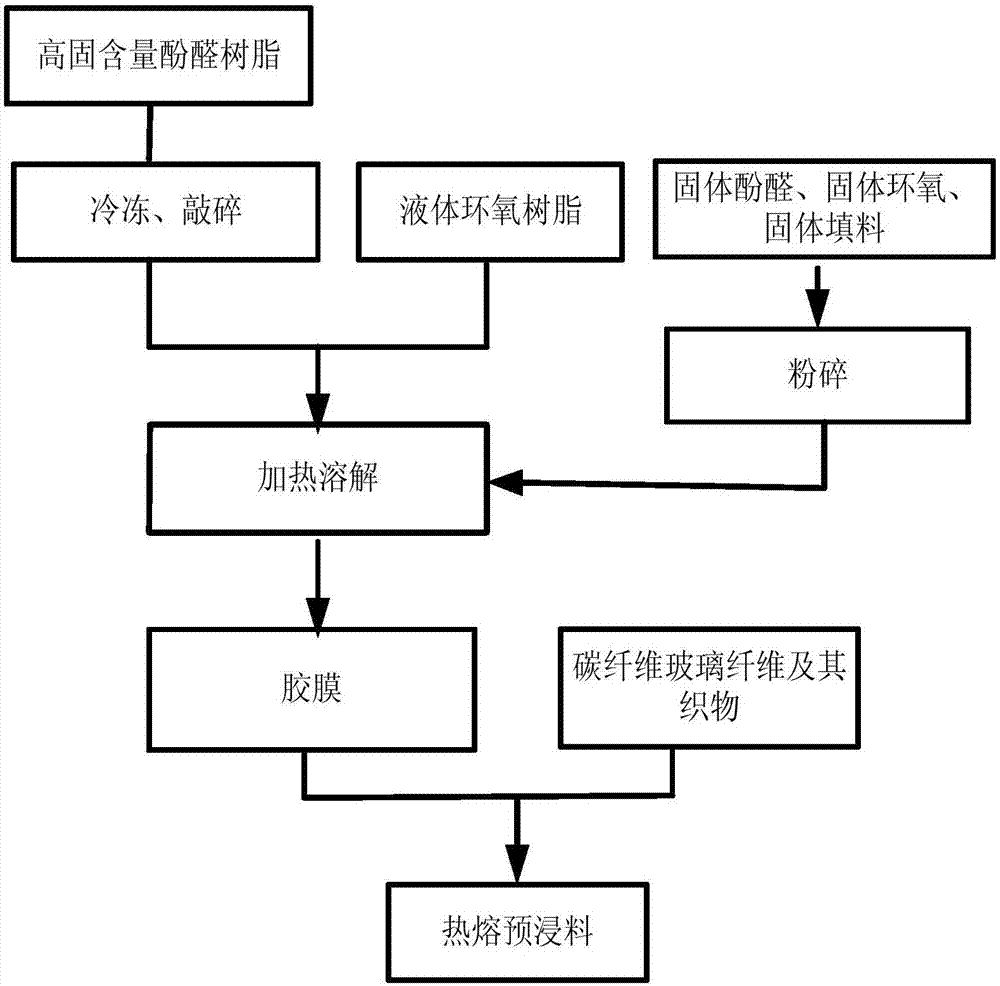

Preparation method of halogen-free, flame-retardant, low-smoke and low-toxin hot melt phenolic prepreg

The invention relates to a preparation method of halogen-free, flame-retardant, low-smoke and low-toxin hot melt phenolic prepreg. The solid content and the viscosity-temperature flow characteristic of phenolic resin are controlled with a reasonable synthesis process; solid phenolic resin and liquid epoxy resin are mixed uniformly according to formula design, and a resin system suitable for preparation of prepreg with a hot melt process is obtained; the gelation time of the resin is controlled to range from 140 s to 250 s, a hot melt resin adhesive film is prepared from the hot melt phenolic resin system, the coating temperature is controlled to range from 40 DEG C to 65 DEG C, the hot melt phenolic resin adhesive film and unidirectional fiber or fiber fabric are composited under heating and pressurizing conditions, and the hot melt prepreg is prepared. The hot prepreg with uniform texture and stable resin content can be obtained through resin synthesis, formula design and process design, and the hot melt prepreg and the composite have the characteristics of low smoke, no halogen, low smog toxin and flame retardancy and can meet requirements for use performance of interior trimming and structural composites for high-seed railways, aircrafts, steamships and other transportation tools.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

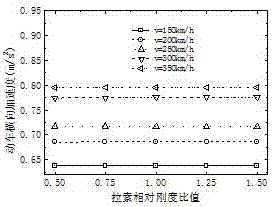

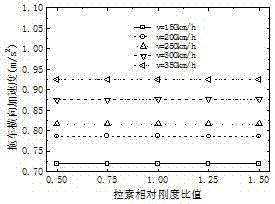

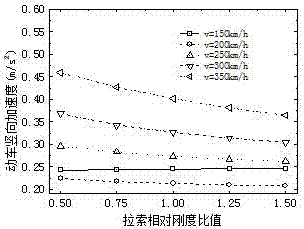

Method of controlling rigidity of long span cable-stayed bridge of railway through stay cable

InactiveCN107145664AStiffness controlEasy to meet stiffness requirementsGeometric CADDesign optimisation/simulationVehicle dynamicsCable stayed

The invention relates to the technical field of cable-stayed bridges and in particular relates to a method of controlling rigidity of a long span cable-stayed bridge of a railway through a stay cable. The method analyzes influence rules of the cable-stayed bridge on bridge dynamic characteristic, vehicle dynamic response and bridge dynamic response under different numerical values by establishing a long span cable-stayed bridge model of the railway and a bridge model by means of a dynamic analytical method, and performs judgment by taking an evaluating index system of a vehicle-bridge system as an index to obtain influence conditions on the integral rigidity of the bridge under different rigidity numerical values so as to further obtain a reasonable value range of the rigidity of the stay cable, thereby providing basis for valuing and designing the rigidity of the stay cable; the integral rigidity of the long span cable-stayed bridge of the railway is better controlled through the rigidity of the stay cable, so that the long span cable-stayed bridge of the railway achieves a breakthrough on the rigidity control technology; the technical problem is solved, so that the long span cable-stayed bridge of the railway is promoted, and a lot of engineering investment cost is saved.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Production method of microcrystalline glass-ceramic composite brick

ActiveCN104309215AImprove the decorative effectRaise the firing temperatureCeramic layered productsGlass/slag layered productsCeramic compositeBrick

The invention discloses a production method of a microcrystalline glass-ceramic composite brick. The production method comprises the following steps: (1) preparing a high-calcium raw material; (2) preparing a low-viscosity glass frit and a high-viscosity glass frit; (3) preparing powder of a green microcrystalline glass-ceramic composite brick through a conventional method; (4) preparing a microcrystalline glass-ceramic composite brick substrate from the powder of the green microcrystalline glass-ceramic composite brick prepared by the step (3) through a conventional method; (5) preparing a microcrystalline glass-ceramic composite brick; and (6) post-processing. The microcrystalline glass-ceramic composite brick prepared by the production method disclosed by the invention, through staggered distribution of crystallization regions and transparent and / or semitransparent regions, changes an original monotonous texture that has only crystallization patterns on the entire surface, and the brick is richer in pattern layering sense and better in decoration effect; the production method disclosed by the invention is lower in sintering temperature, shorter in sintering cycle, and capable of greatly reducing energy consumption, relieving emission and saving manufacturing cost; and the prepared composite brick has fewer surface pores, good anti-fouling performance and high wear resistance.

Owner:HANGZHOU NABEL CERAMIC

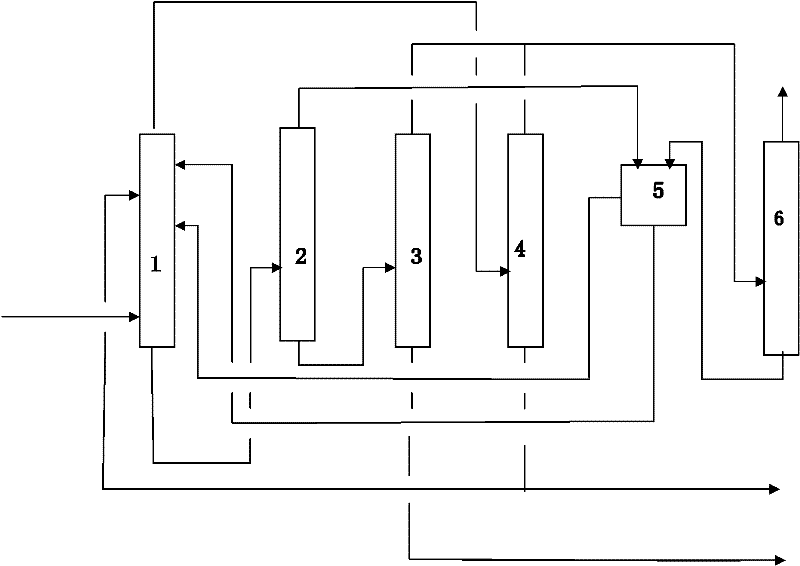

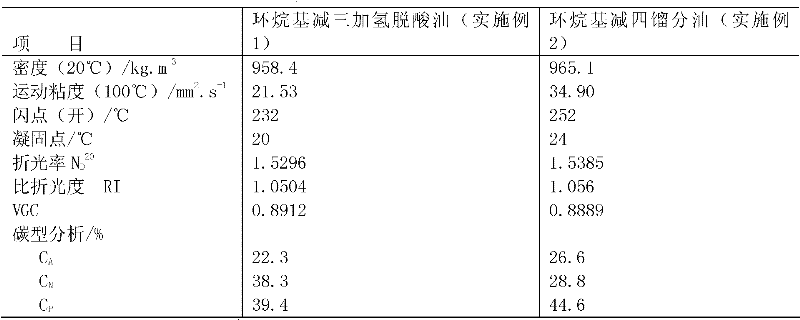

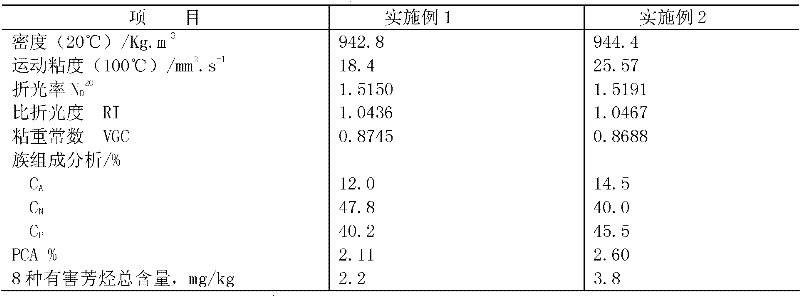

Solvent refining method and solvent refining equipment for producing environment-friendly rubber filling oil

ActiveCN102676213AIncrease contentImprove refining effectTreatment with plural serial refining stagesEvaporationPetrochemical

The invention belongs to the technical field of petrochemical engineering and discloses a method and equipment for producing environment-friendly rubber filling oil. The method includes: using solvent high in selectivity and appropriate in dissolving capacity as main solvent and auxiliary solvent; performing solvent refining in a counter-current extraction tower, enabling raw oil to enter the extraction tower from the lower portion thereof, enabling the main solvent to enter the extraction tower from the upper portion thereof, and enabling the auxiliary solvent to enter the extraction tower from a raw oil inlet to the lower portion of a main solvent inlet of the extraction tower; enabling part of raffinate oil or raffinate liquid to enter the extraction tower from the raw oil inlet to the lower portion of the main solvent inlet, refining under the combined action of the main solvent and the auxiliary solvent, subjecting extract at the bottom of the extraction tower to evaporation and steam stripping to recover solvent so that solvent extract oil is obtained, and subjecting raffinate liquid at the tower top to steam stripping to recover solvent so that raffinate oil, namely the environment-friendly rubber filling oil is obtained. By the aid of the method, lubricating oil distillate oil, hydrofined oil of the lubricating oil distillate oil or lubricating oil solvent extract oil can be used as raw oil to produce the environment-friendly rubber filling oil meeting requirements of environmental protection directive of European Union.

Owner:PETROCHINA CO LTD

Modified polyethylene and preparation method thereof

InactiveCN107841025AHigh tensile strengthImprove impact toughnessPlastic recyclingCross-linkMaterials science

The invention discloses modified polyethylene and a preparation method thereof, aiming at providing the modified polyethylene which is prepared from a polyethylene-based waste recycled material and has high tensile strength and good impact toughness. The modified polyethylene is prepared from the following components: 60 percent to 85 percent of the polyethylene-based waste recycled material, 0.01percent to 5 percent of a cross-linking agent, 0.1 percent to 0.5 percent of a stabilizer, 10 percent to 35 percent of an enhanced modifier, 0.1 percent to 1.5 percent of an antioxidant and 0.1 percent to 3 percent of a processing modifier; the sum of all the components is 100 percent.

Owner:GUANGDONG JUHANG INST FOR ADVANCED MATERIALS CO LTD +1

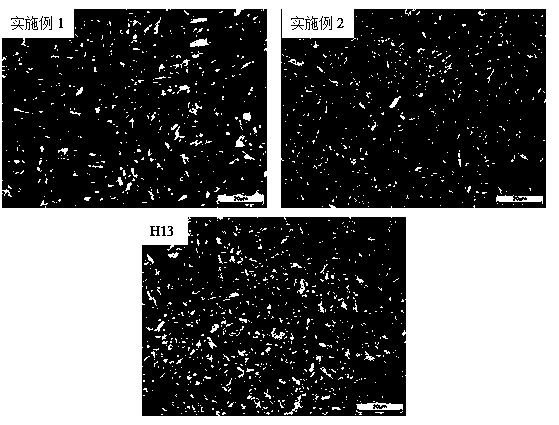

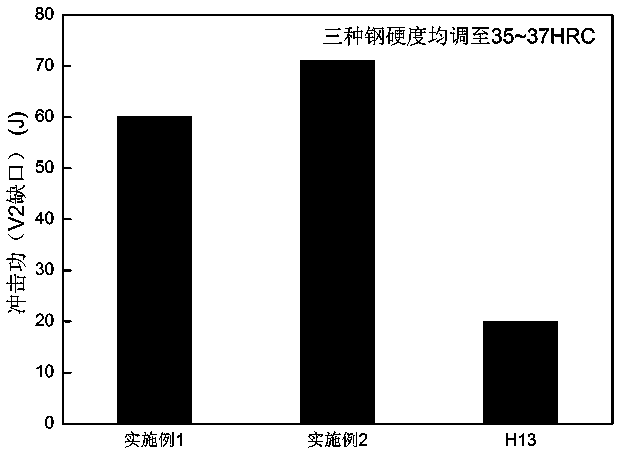

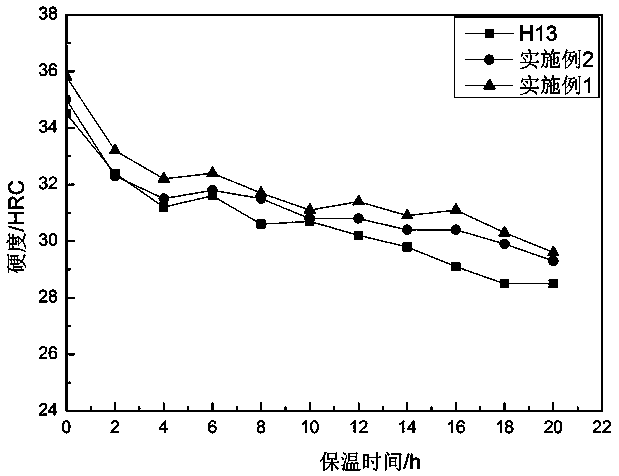

Economic type core rod alloy steel and preparation and heat treatment method thereof

The invention relates to an economic type core rod alloy steel and a preparation and heat treatment method thereof, belongs to the technical field of alloy steel manufacturing process, and is characterized in that the alloy steel comprises the following main alloy elements by mass percentage: 0.25-0.30% of C, 0.10-0.20% of Si, 1.51-1.62% of Mn, 3.60-4.10% of Cr, 0.20-0.30% of Mo, 0.20-0.40% of V, 0.03-0.05% of Nb, and the balance Fe. The alloy steel preparation process comprises the following steps: preparing materials, smelting, casting an electrode rod, and annealing; then carrying out electroslag remelting, and annealing; followed by carrying out multidirectional forging and direct water cooling; then carrying out two-section type annealing; and finally, carrying out quenching and tempering treatment. The properties of the alloy steel are equal to or exceed those of H13 steel under same conditions. The low-alloying-composition design thought of the alloy steel meets a transformation concept that current Chinese steel enterprises are in urgent need of energy saving, consumption reduction, cost reduction and benefit increase.

Owner:SHANGHAI UNIV +1

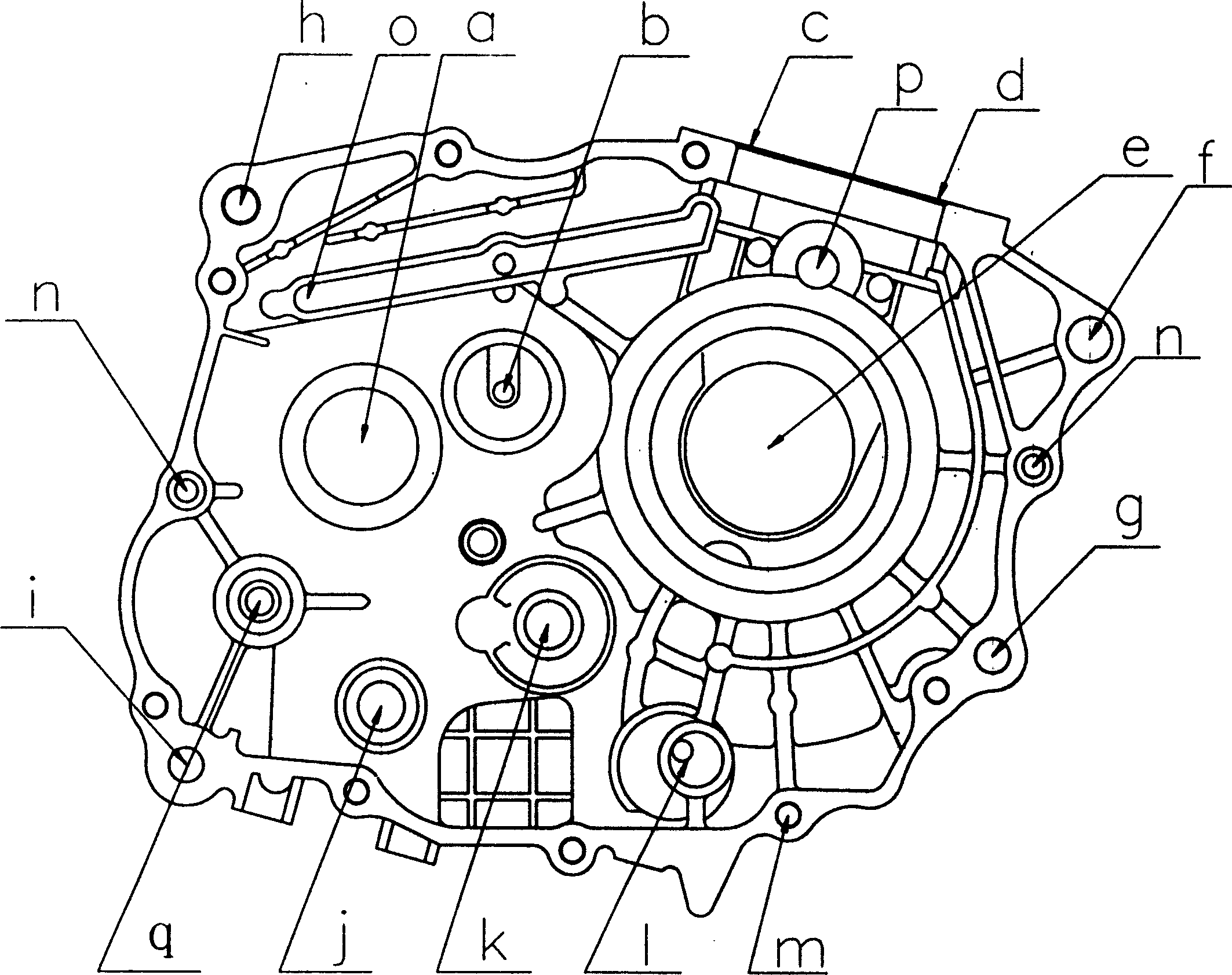

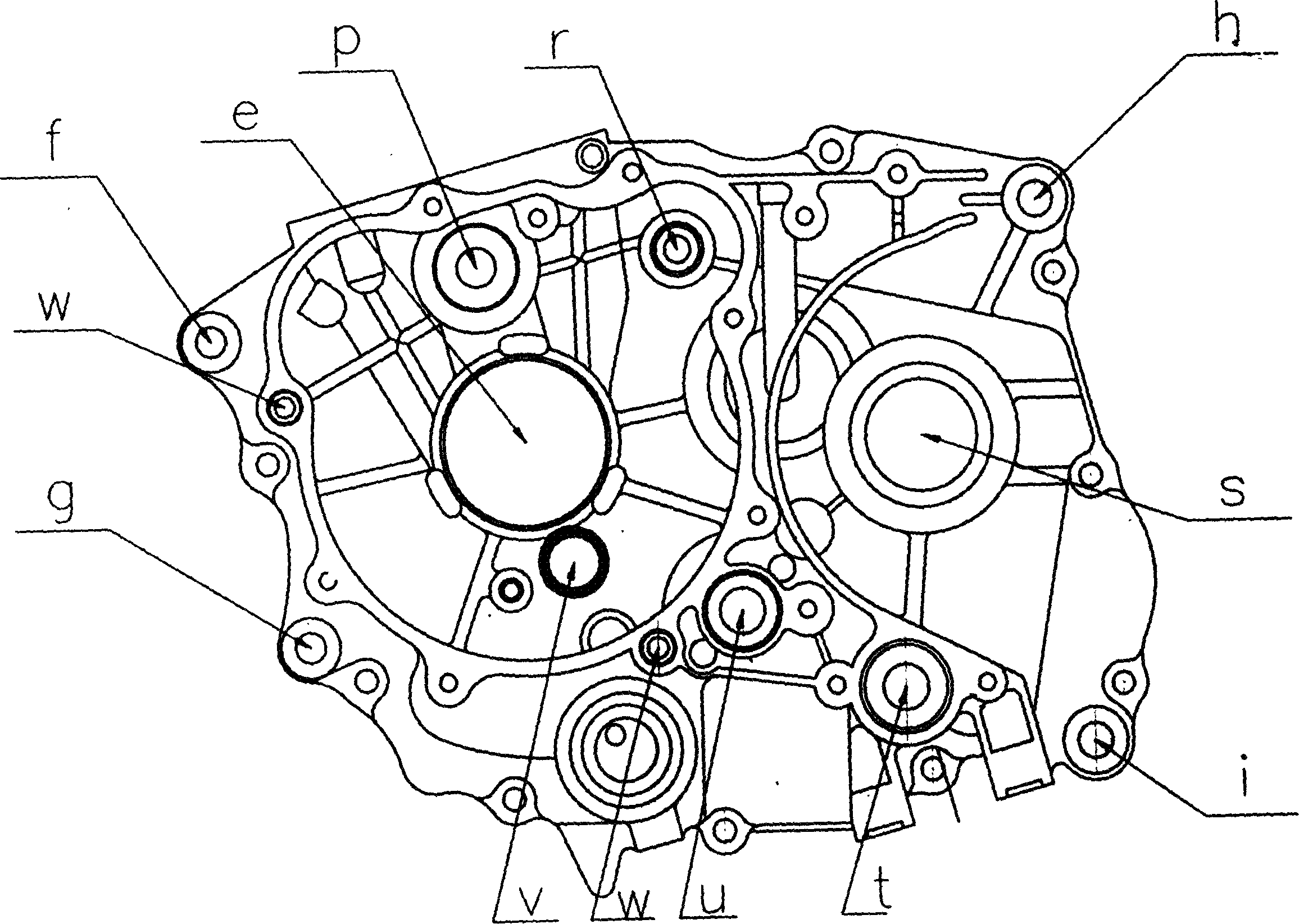

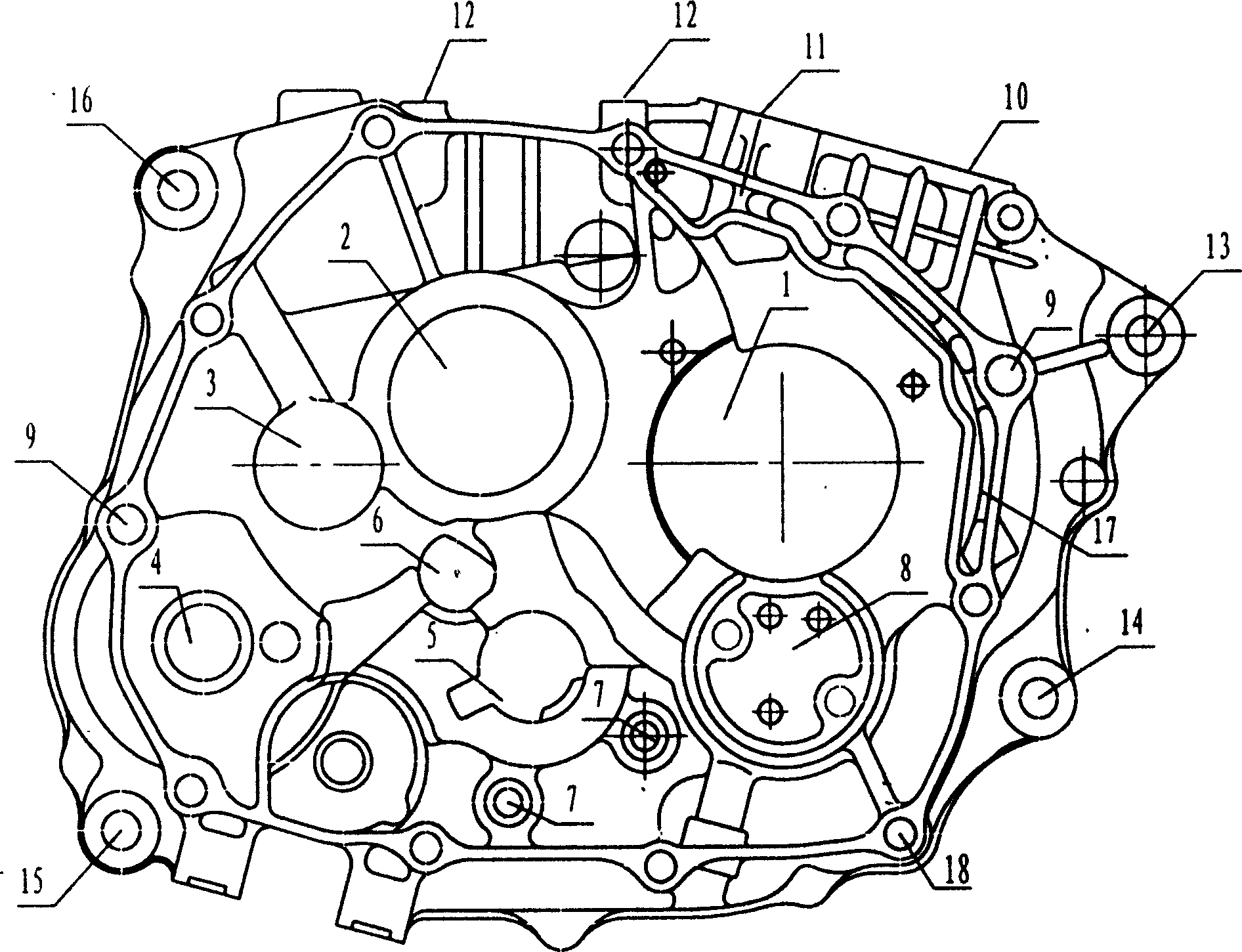

Reducing vibration type engine crankcase of motorcycle

InactiveCN1560460AImprove structural strengthIncrease cooling areaCasingsMachines/enginesCrankcaseEngineering

The invention belongs to combustion engine crank box, which is a crank box for the vibration damping motorcycle engine, made up of left crank box and the right crank box, the character lies in: the left and the right crank boxes use magnesium alloy to be cast and formed, the thickness of the box wall is 3.5-6mm, several reinforcing ribs with width of 3-5mm are arranged on the box surface and the cover. Compared to the gearing aluminum alloy crank box, when the structure intensity of the box is upgraded, the heat irradiating area is also increased, it can reduce the high temperature creep, the mechanical intensity of the magnesium alloy crank box in the high temperature environment is not affected; the experience to the same motorcycle LC125 testifies, the crank box of the invention caters all the demands of engine, and the weight is reduced, thus it can save 0.4l oil per hundred kilometers, the average heat vibration and noise only the 1 / 3 of the traditional crank box.

Owner:重庆镁业科技股份有限公司

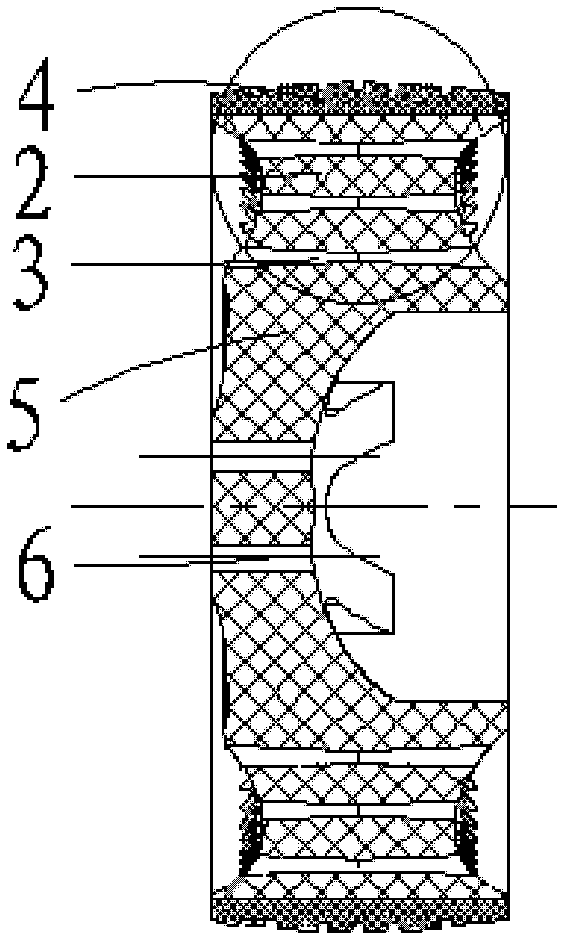

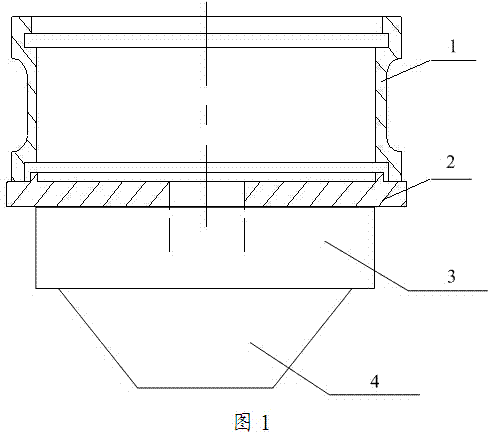

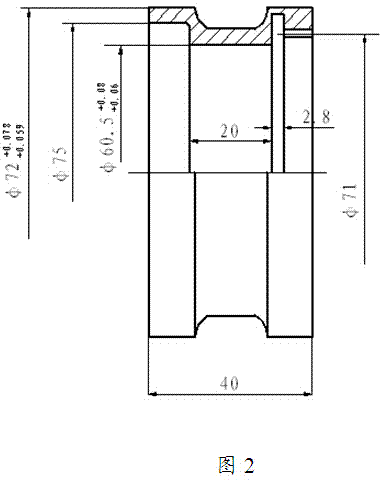

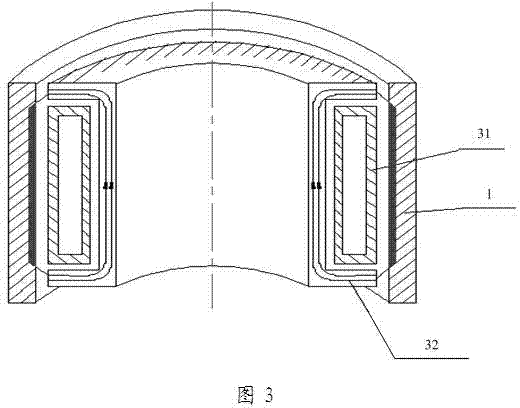

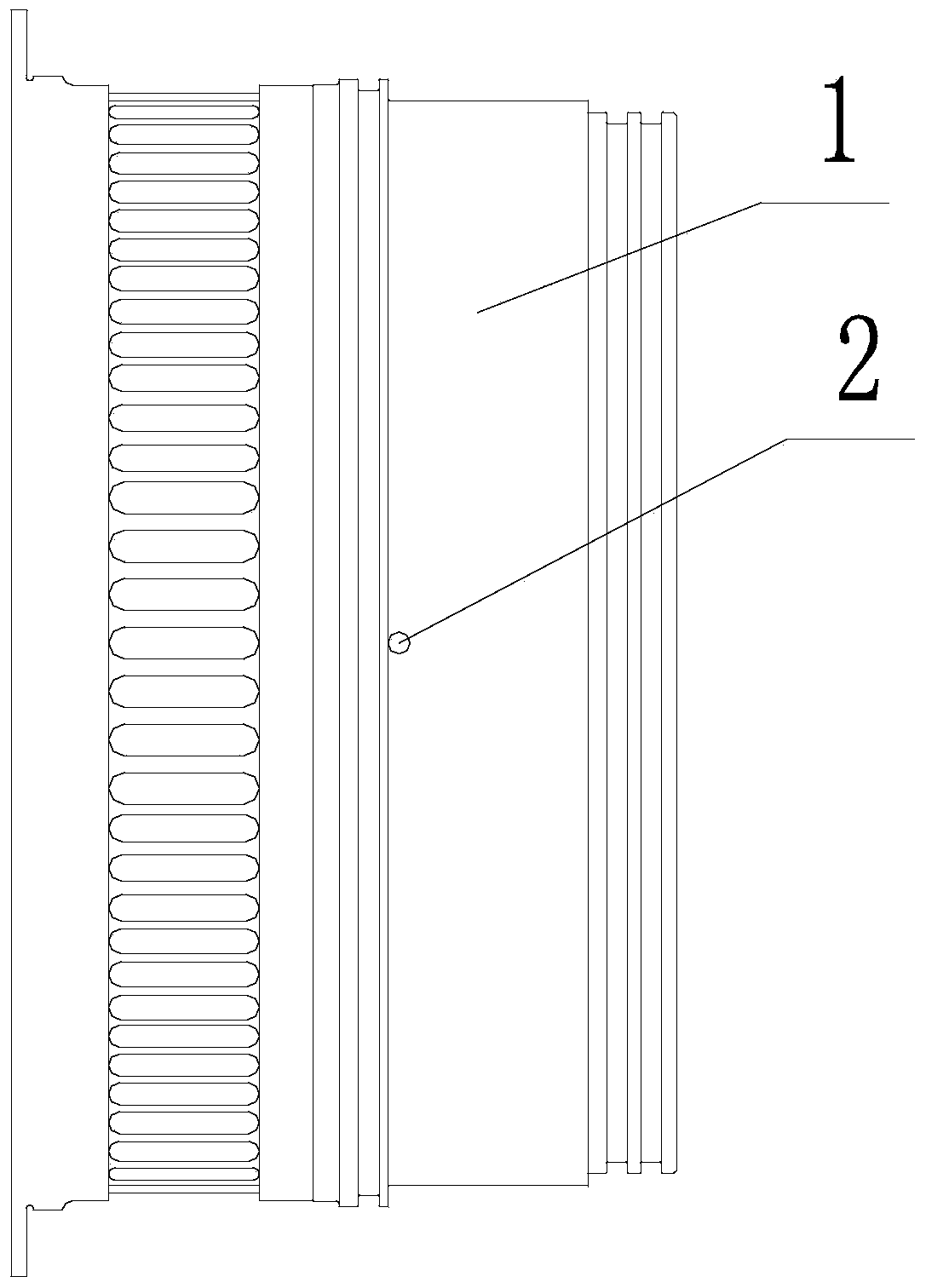

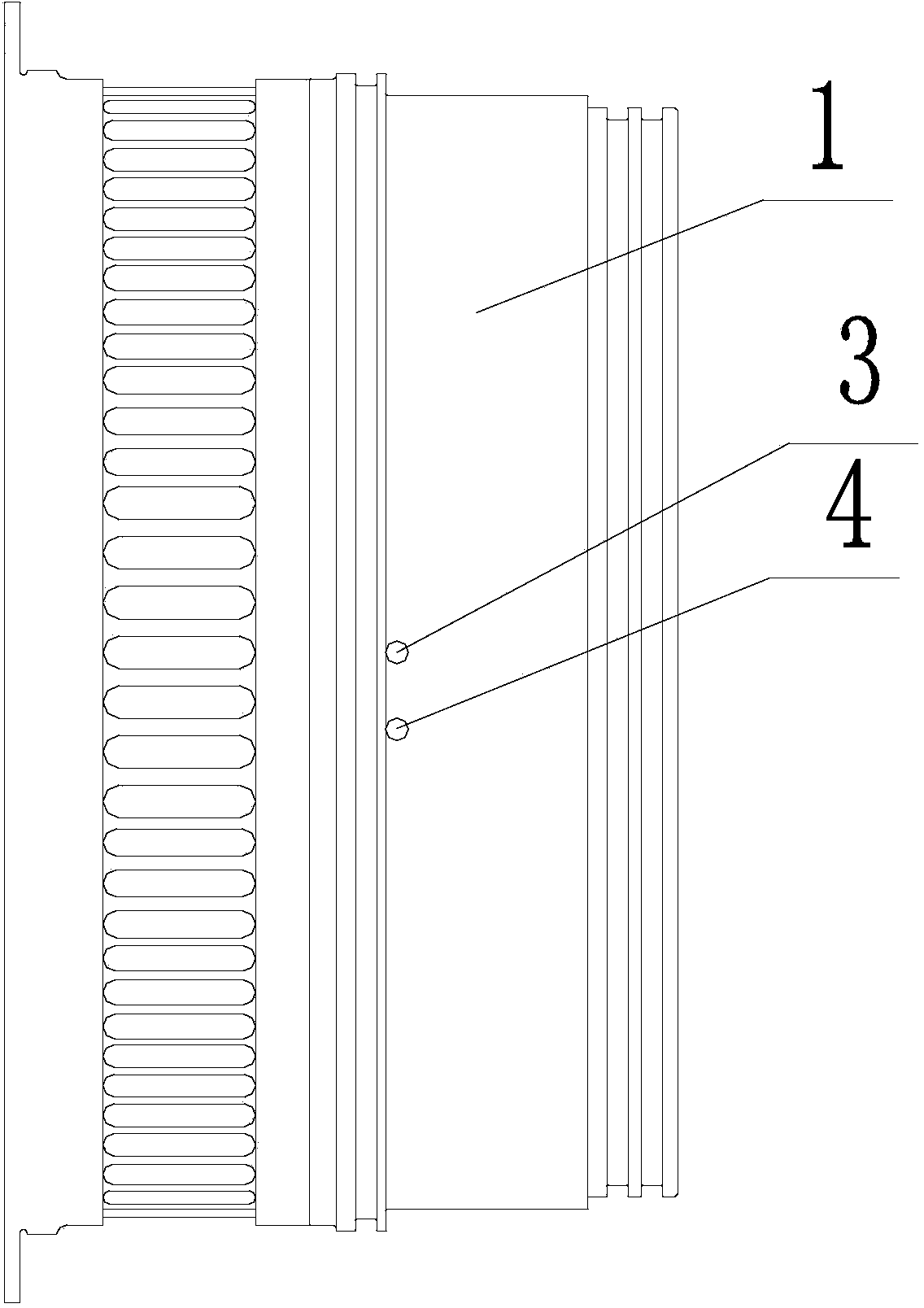

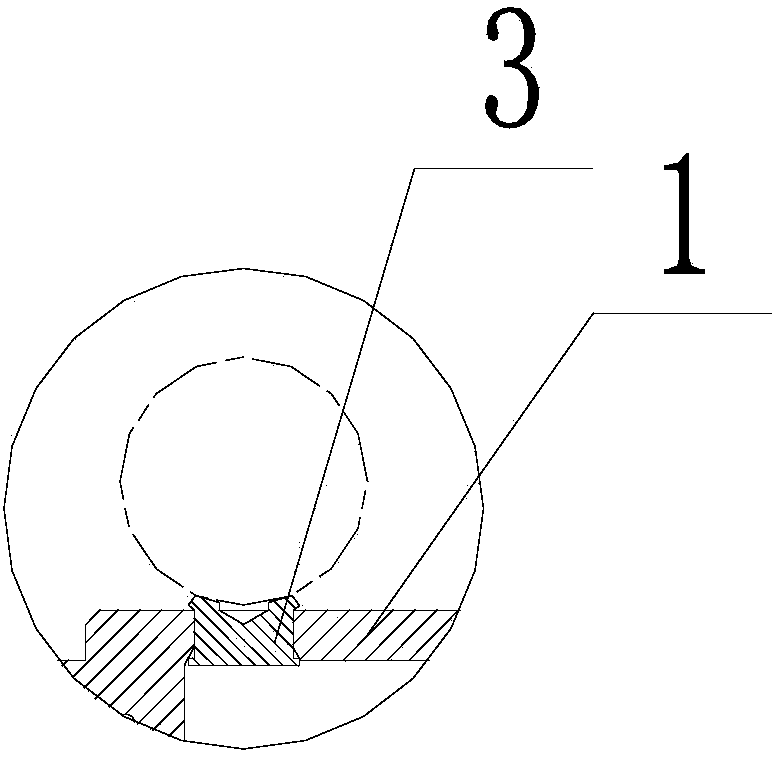

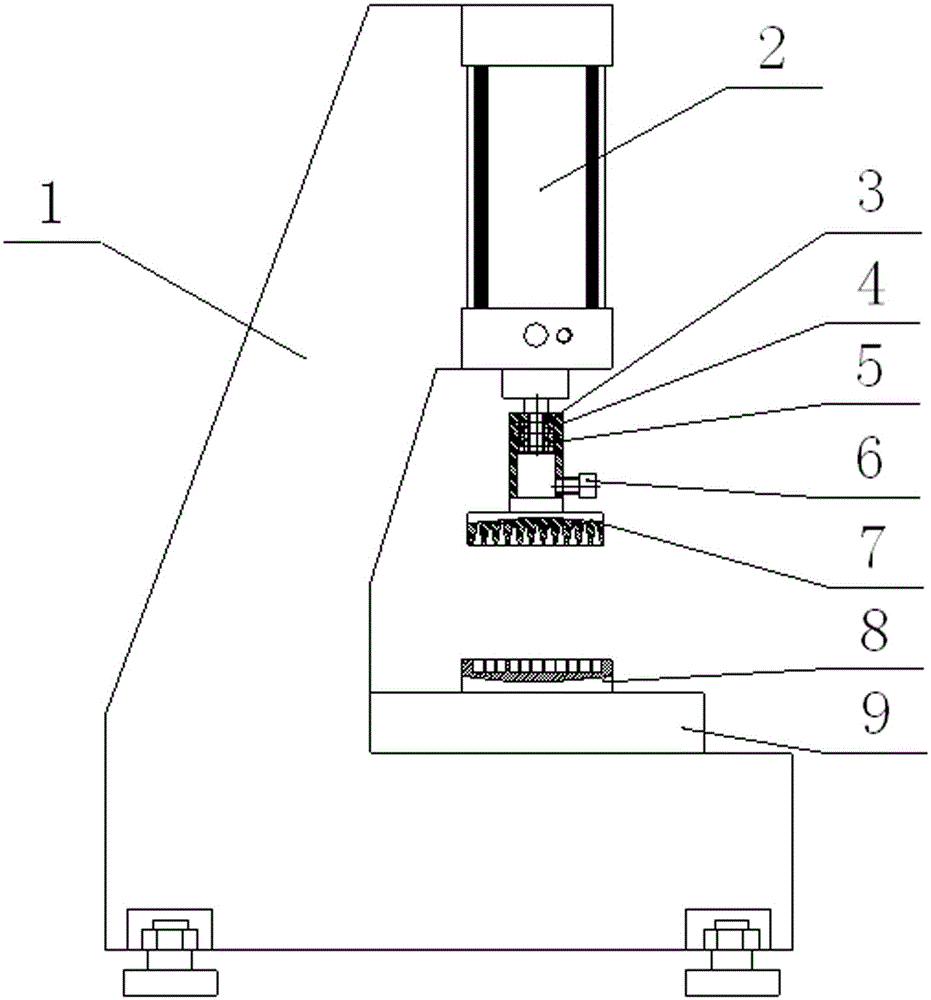

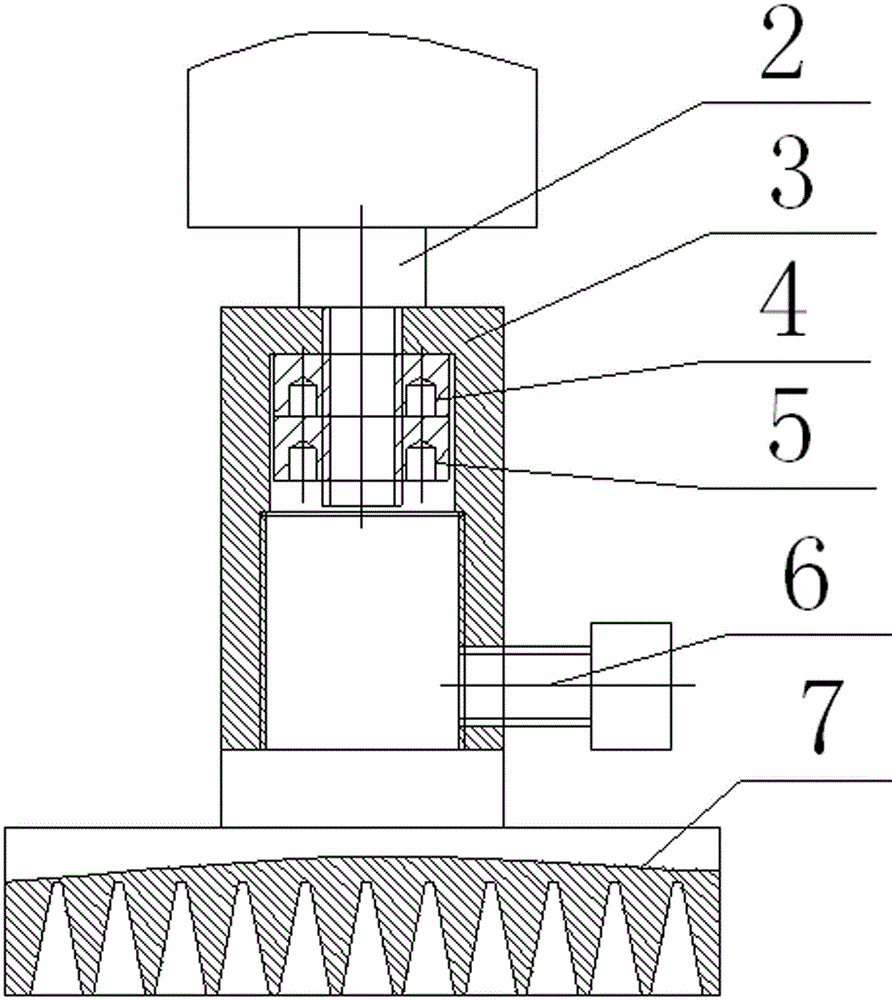

Equipment and method for induction hardening in inner-bore carburization treatment

InactiveCN104498867ASimple processingMeet the performance requirementsSolid state diffusion coatingIncreasing energy efficiencyQuenchingHardness

The invention discloses equipment and a method for induction hardening in inner-bore carburization treatment. The equipment mainly comprises an inner gear part, a locating tray, a heating sensor and a cooling device, wherein the heating sensor comprises an induction coil and a magnetizer; the inner gear part is arranged at the upper end of the locating tray; the locating tray is arranged at the upper end of the heating sensor; the heating sensor is arranged at the upper end of the cooling device; the cooling device is arranged at the bottom end of the equipment for the induction hardening in the inner-bore carburization treatment; the induction coil is arranged between the left and right sides of the heating sensor; the magnetizer is arranged outside the inner side of the induction coil. The method comprises the steps of carburization, cooling of a protective atmosphere, vacuum tempering, high-frequency induction hardening of inner bores, cold quenching and low-temperature tempering. The equipment disclosed by the invention can be used for realizing the performances of low hardness of the overall parts and high hardness of the inner bores, guaranteeing that the hardness of a non-carburized part is 22HRC to 26HRC and realizing the technical application requirements on low hardness of the non-carburized part and high hardness of carburizing surfaces of the inner bores of a 18Cr2Ni4WA material.

Owner:陕西长空齿轮有限责任公司

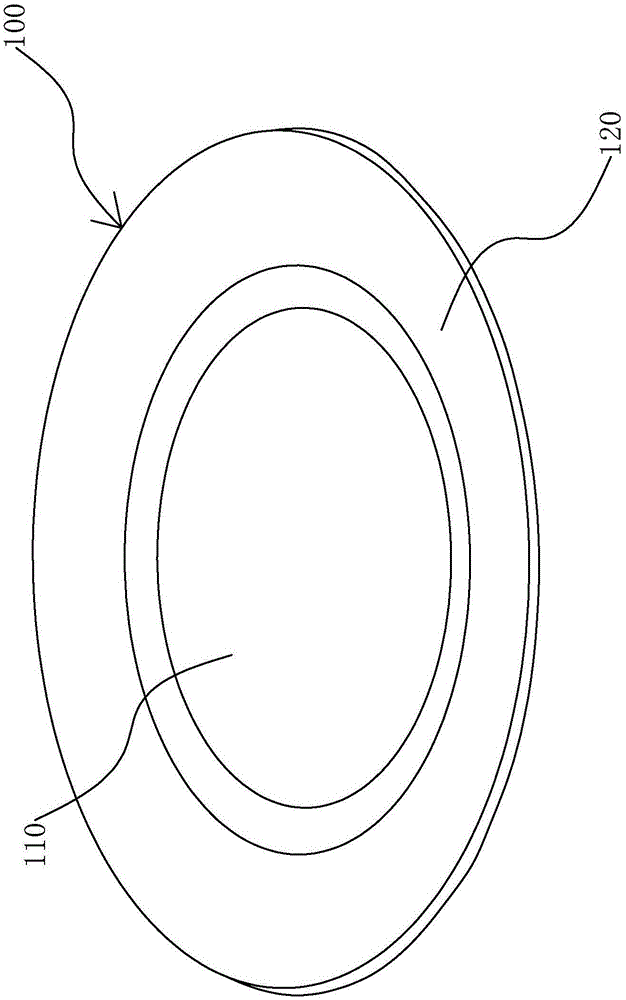

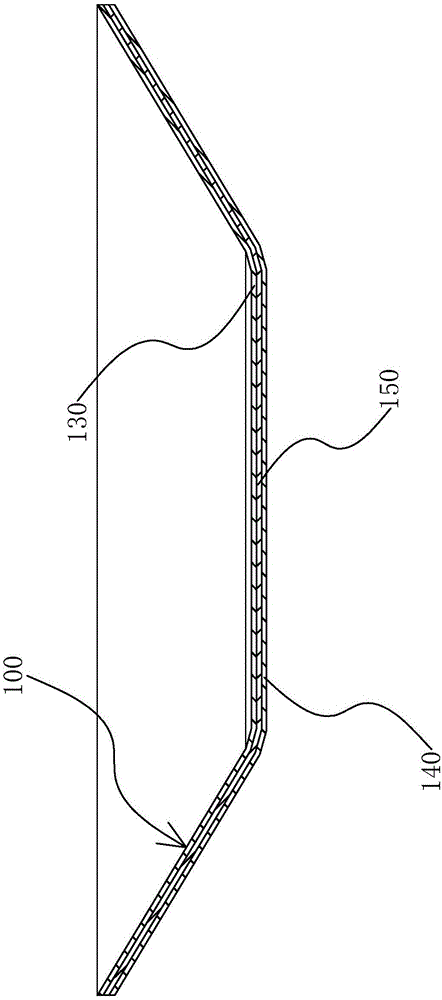

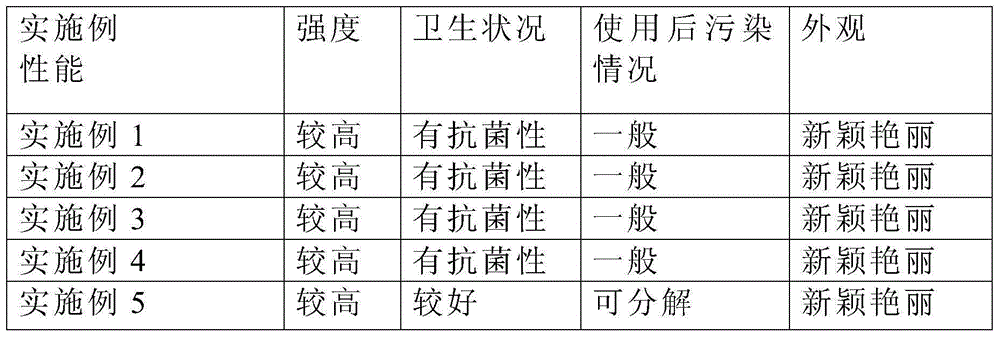

Double-color thin-wall plastic tableware and processing method thereof

ActiveCN105029984AImprove antibacterial propertiesStable anti-mildew effectSynthetic resin layered productsPlatesSurface layerPolystyrene

The invention relates to double-color thin-wall plastic tableware and a processing method thereof, and belongs to the technical field of tableware. The tableware comprises a body. The body comprises a round bottom in the middle and a conical flange extending to the periphery of the round bottom. The body is formed by multiple layers of sheets in a laminated mode and comprises an upper surface layer and a lower surface layer, the sheets are tightly attached to one another, the thickness of the sheets ranges from 0.2 mm to 0.7 mm, the sheets forming the upper surface layer and the lower surface layer have different colors, and the sheets are made of plastic, including polypropylene plastic (PP) and polystyrene plastic. Because the tableware is formed by the multiple layers of sheets of different colors in a combined mode, the tableware has high strength without becoming sunk easily, and is convenient to use and more novel and bright-colored in appearance; because the tableware is made of the polypropylene plastic (PP) or the polystyrene plastic with reasonable compatibility, on one hand, the long-lasting antibacterial and antifungal property and other properties of the cup are effectively guaranteed, and on the other hand, environmental pollution caused by disposable tableware can be reduced; because the tableware is processed through a plastic sucking moulding process with special parameters, the final properties of the tableware are improved.

Owner:宁波市森佰工贸有限公司

Antibacterial sweat-absorbing type feather quilt shell fabric processing method

InactiveCN107090714AImprove the effective adhesion rateExcellent antibacterial and sweat absorption functionBiochemical fibre treatmentYarnYarnFiber

The invention discloses an antibacterial sweat-absorbing type feather quilt shell fabric processing method and relates to the technical field of feather quilt processing. The processing method mainly comprises the following steps: (1) selectively oxidizing cotton fiber; (2) processing blended yarns; (3) dyeing blended yarns; (4) weaving shell fabric; (5) performing calendering pretreatment on the shell fabric; (6) calendering the shell fabric. According to the processing method, an antibacterial sweat-absorbing agent is added in a blended yarn dying process, the manufactured shell fabric has an excellent antibacterial sweat-absorbing function through the dyeing work procedure, and cost invest of additional work procedures is reduced; furthermore, an effective adhesive rate of the antibacterial sweat-absorbing agent is improved through binding force of dye on the fibers; by means of the calendering pretreatment on the shell fabric, moisture penetrability and downproofness of the shell fabric are improved under action of a calendering auxiliary agent.

Owner:ANHUI SANXIANG DOWN

Method for repairing corner of locating pin of bearing case

InactiveCN104384815AThere is no problem of welding deformationReduce processing difficultyStructural engineeringMachine tool

The invention provides a method for repairing a corner of a locating pin of a bearing case, belongs to the technical field of aero-engines, and relates to a repairing method of the bearing case. The method for repairing the corner of the locating pin of the bearing case, provided by the invention, has the advantages that the machining difficulty is low, the repairing cost is low, the repairing quality is reliable, and no welding deformation problem is generated. The method comprises the following steps of step 1, machining a hole blocking pin, and enabling the hole blocking pin to correspond to an original locating pin hole; step 2, pulling out an original locating pin of the bearing case, aligning the bearing case to a machine tool and fixing the bearing case, and machining a new locating pin hole after the bearing case is rotated in an angle by taking the original locating pin hole as the standard; step 3, installing the hole blocking pin in the original locating pin hole, and installing a new locating pin in the new locating pin hole.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

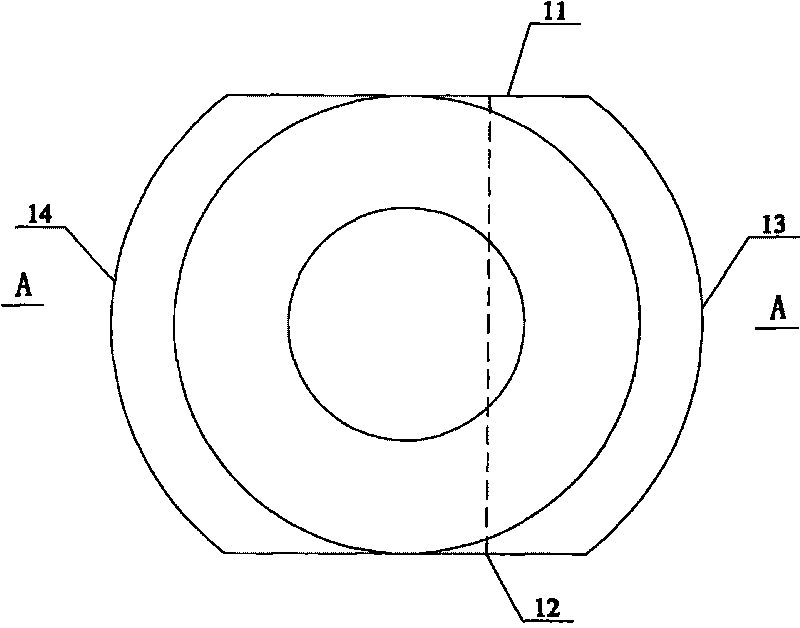

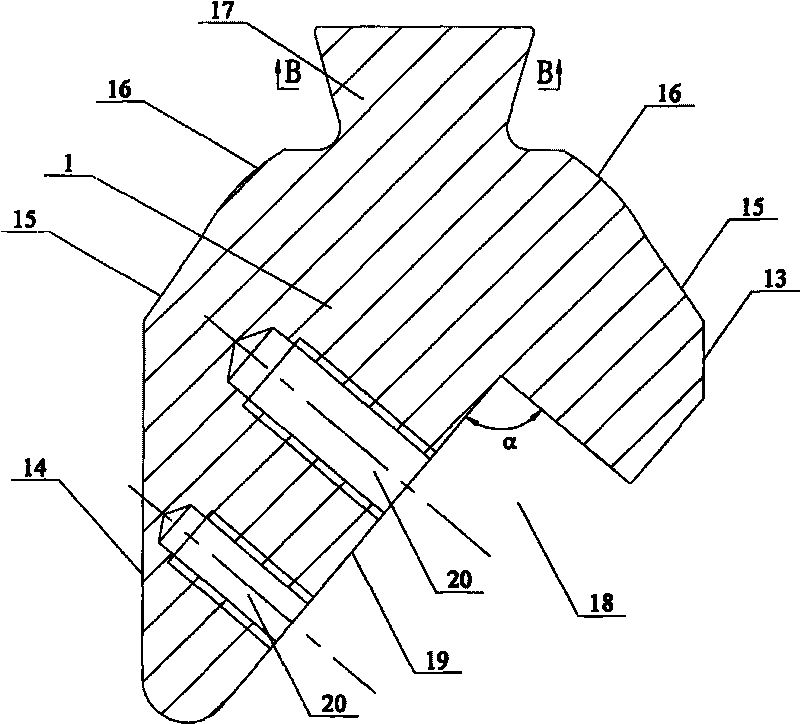

Magnesium alloy artificial limb connector and manufacturing method thereof

InactiveCN101721265AReduce processing costsMeet the performance requirementsArtificial legsCircular coneMaterials science

The invention discloses a magnesium alloy artificial limb connector and a manufacturing method thereof. The artificial limb connector is provided with a cylindrical main body, wherein the cylindrical main body is provided with two parallel lateral surfaces; the lower parts of the other two lateral surfaces of the cylindrical main body are cylindrical surfaces, the middle parts are big end down circular conical surfaces, and the upper parts are revolution surfaces similar to spherical surfaces; the upper surface of the cylindrical main body is provided with a big end up four-arris platform; the bottom surface of the cylindrical main body is provided with a triangular wedge-shaped groove; and the apex angle of the wedge-shaped groove is 90 degrees. In the manufacturing method, a formed turning tool is adopted to finish the appearance of a blank of the artificial limb connector by performing only one turning to greatly reduce the processing cost, and an aging treatment is performed to ensure that the magnesium alloy has the tensile strength of 280 to 300 MPa, the specific elongation of 12 to 14 and the Webster hardness of 13 to 14, so the magnesium artificial limb connector completely meets the requirements on service performance, and provides an effective guarantee for obtaining a portable and flexible artificial limb.

Owner:唐山亨利车料有限公司

Waste heat water toughening method and device for multi-mold assemblage casted high manganese steel casting

InactiveCN104894350AMeet the performance requirementsReduce process complexitySteel castingToughening

The invention discloses a waste heat water toughening method and device for a multi-mold assemblage casted high manganese steel casting, and belongs to the technical field of metal casting and heat treatment. The method has the beneficial effects that step connection of the water toughing method is in order, and it is ensured that after waste heat water toughening is carried out on the multi-mold assemblage casted high manganese steel casting, a single-austenite structure is obtained, so that the use performance requirement of the high manganese steel casting is met; in the waste heat water toughening process, the casting is not cracked; and compared with a conventional waste heat water toughening method, the technology complexity is reduced, the production efficiency is improved, and the production cost is reduced.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

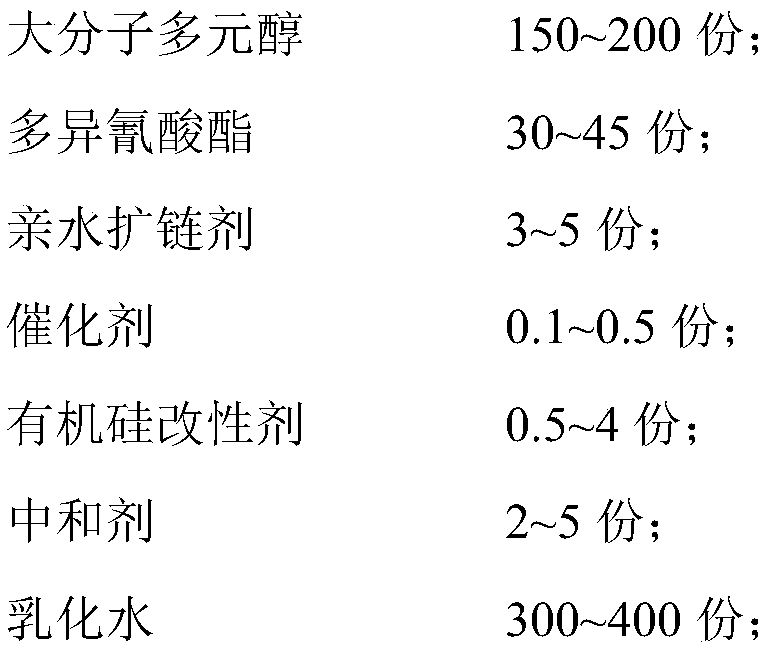

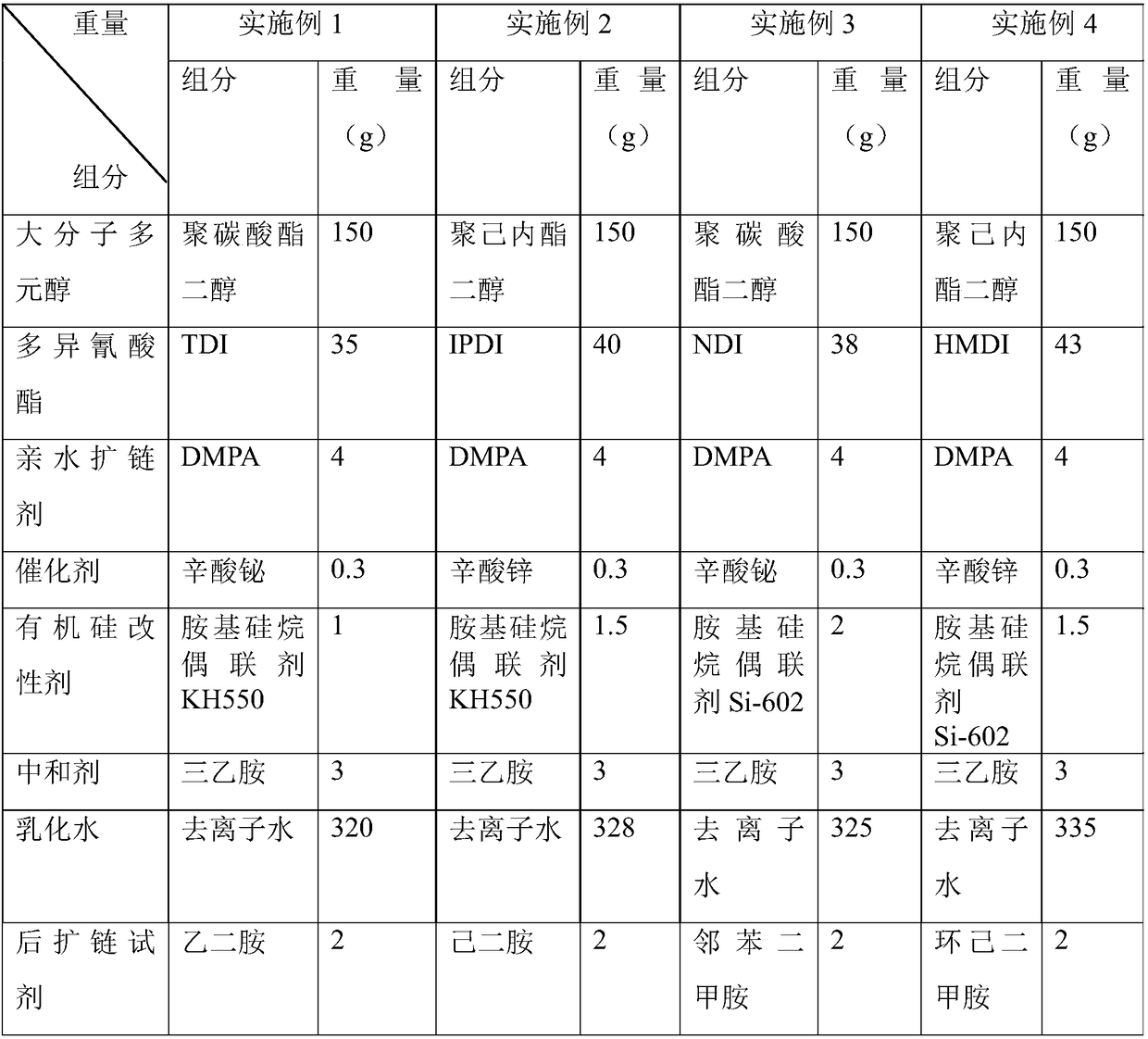

Waterborne polyurethane resin for sofa leather, preparation method and application of waterborne polyurethane resin

The invention provides waterborne polyurethane resin for sofa leather, and a preparation method and application of the waterborne polyurethane resin. The waterborne polyurethane resin comprises the following raw material components in parts by weight: 150-200 parts of macromolecular polyol, 30-45 parts of polyisocyanate, 3-5 parts of hydrophilic chain extender, 0.1-0.5 part of catalyst, 0.5-4 parts of organic silicon modifier, 2-5 parts of neutralizer, 300-400 parts of emulsification water, and 1-5 parts of post chain extender. The waterborne polyurethane resin prepared by the preparation method disclosed by the invention is friendly to environment and non-toxic, and can meet environmental protection requirements; furthermore, the prepared resin can fully satisfy use performance requirements of sofa leather, and has good flexibility and wear resistance; and at the same time, a one-step feeding method is adopted in the resin synthesis process, and human and material costs are greatly saved.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

Dyeing method for biological energy fiber knitted fabric

InactiveCN104988767AMeet the performance requirementsMeet performance requirementsDyeing processSodium carbonateBrilliant Red

The invention discloses a dyeing method for biological energy fiber knitted fabric. The method includes the following steps that firstly, dispersing brilliant red, a diffusion agent and acetic acid are added at a room temperature, and the temperature is raised to 90 DEG C and lasts for 60 min; secondly, reactive brilliant red, sodium sulphate, a leveling agent and soda ash are added at the temperature of 60 DEG C, washing is performed for 30 min, and the bath ratio is 1:35: thirdly, 20 g / L sodium carbonate is added at the temperature of 80 DEG C, color fixation is performed for 60 min, and the bath ratio is 1:35: fourthly, a 0.5 g / L detergent is added at the temperature of 90 DEG C, soaping is performed for 15 min, and the bath ratio is 1:20. The color fastness to washing, the color fastness to abrasion and the color fastness to perspiration of the biological energy fiber knitted fabric are all higher than the fourth level and the requirement for wearability is met.

Owner:ZHANGJIAGANG CITY HUAYANG KNITTING TEXTILE

Closing device of connector jack

InactiveCN105119123AMeet the performance requirementsEnsure concentricityLine/current collector detailsSet screwOperational performance

The present invention relates to a closing device of a connector jack, comprising a body, a pneumatic actuator, a fixing sleeve, set screws, a closing dish, a positioning fixture and a workbench. The workbench is arranged on the body, the pneumatic actuator correspondingly located above the workbench is connected with the body, and the fixing sleeve is connected with the pneumatic actuator; the closing dish is penetrated into and connected within the fixing sleeve, the set screws are penetrated into and connected with the side wall of the fixing sleeve and are configured to compress the closing dish located within the fixing sleeve, and a plurality of conical bores are uniformly distributed with respect to the set of the connector jacks at the lower end surface of the closing dish; and the positioning fixture is arranged on the workbench with respect to the closing dish. The closing device of the connector jack provided by the invention has advantages of convenient operation, high overall closing concentricity and high precision, and is able to effectively ensure the concentric performance and the plugging performance of the corresponding pins and satisfy the operational performance requirement of the electric connector.

Owner:TAIXING SPACE APPLIANCE

Air conditioner foil material

The invention belongs to the field of processing of aluminum products and particularly discloses an air conditioner foil material. The air conditioner foil material is obtained by mixing raw materials including iron, silicon, titanium, copper, magnesium, zinc and aluminum according to a certain weight proportion and continuously roll-casting the mixture. According to the air conditioner foil material, disclosed by the invention, batch production can be formed as product quality is steady; use amount of the air conditioner foil material under the condition of the same heat exchange area is reduced efficiently due to the moderate tensile strength and high specific elongation; cost of an air conditioner radiator can be decreased; and volume as well as weight of an air conditioner are reduced.

Owner:SHANDONG LOFTEN ALUMINUM FOIL

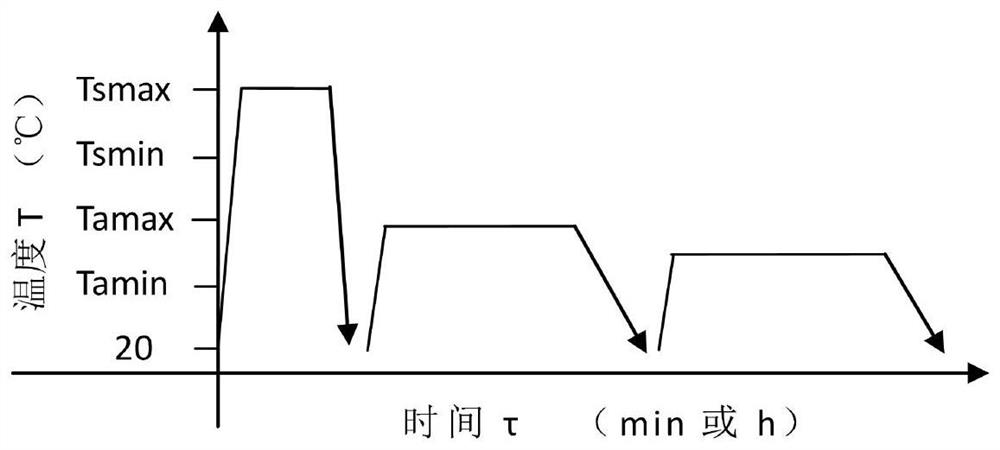

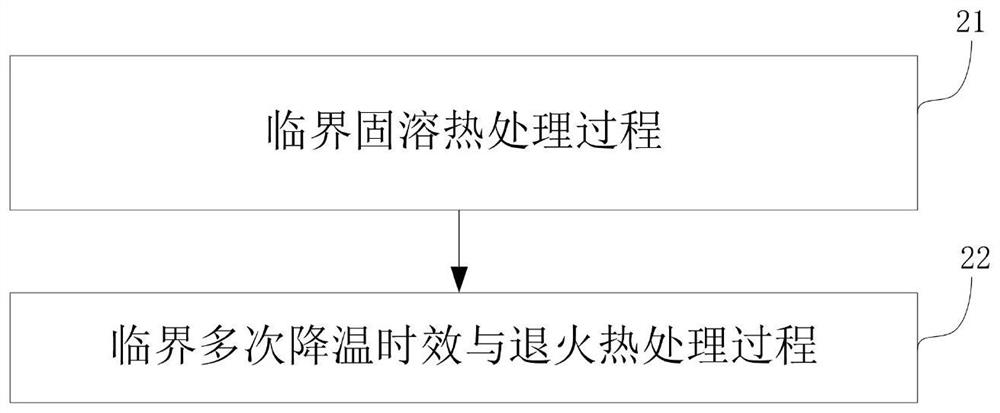

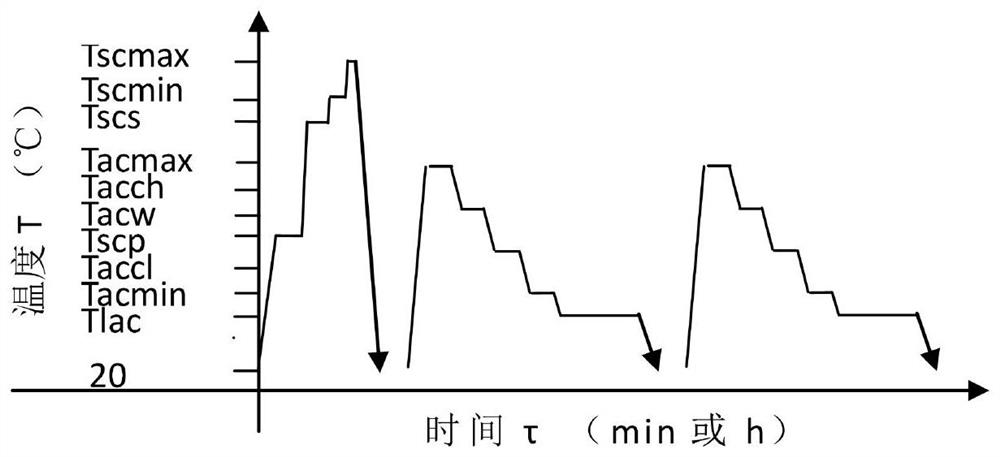

Critical solid solution and critical repeated cooling aging and annealing heat treatment method

The invention provides a critical solid solution and critical repeated cooling aging and annealing heat treatment method which comprises a critical solid solution heat treatment process and a critical repeated cooling aging and annealing heat treatment process. The scheme of the invention has technical feasibility, process adaptability, quality reliability, economic reasonability and use safety, can effectively enhance the advantages and avoid the disadvantages of a conventional mainstream heat treatment method of austenitic stainless steel, fundamentally solves the "one-long one-high four-poor five-low" special heat treatment technical difficult problems of "poor quality stability, low rate of qualified products, low hardness, low mechanical property, poor consistency, poor discoloration and rust corrosion resistance, long heating time, low efficiency, poor heating reliability of heat treatment equipment and low service life and high cost of a high-temperature component" of existing austenitic stainless steel heat treatment, and is particularly suitable for the technical field of heat working engineering such as smelting, steel rolling, forging, heat treatment and the like related to the austenitic stainless steel in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

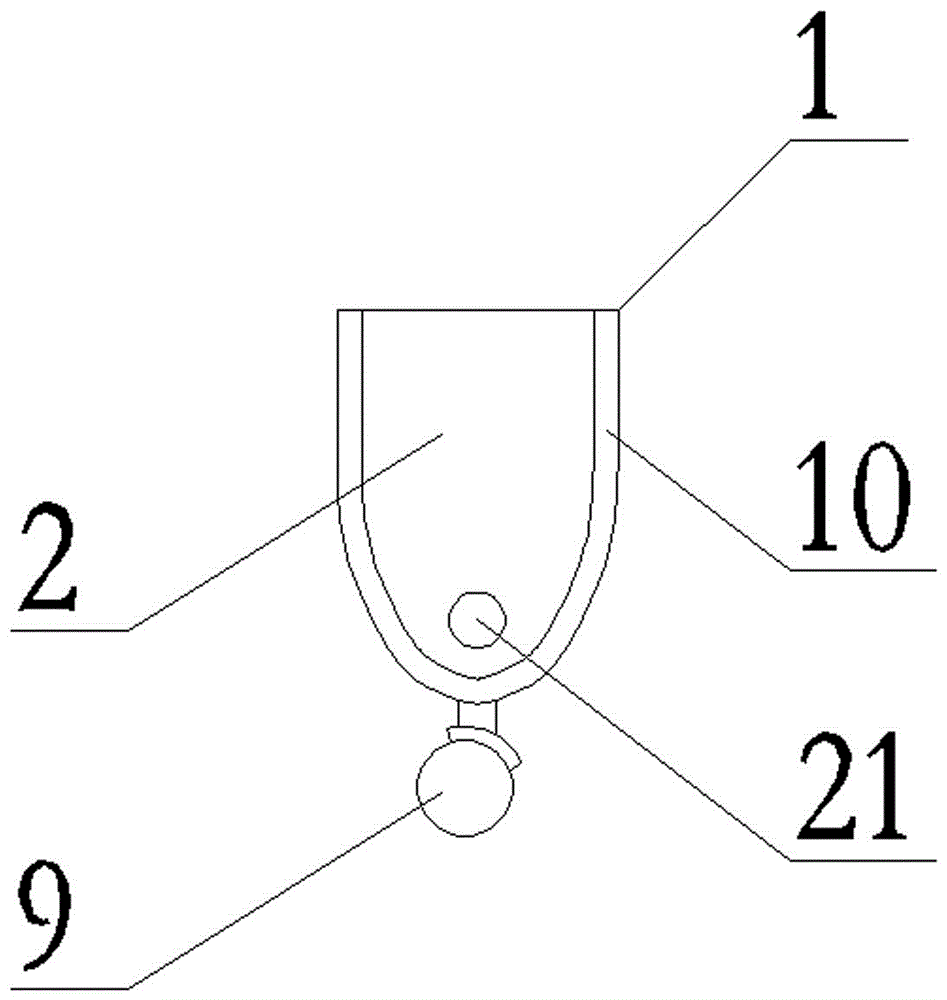

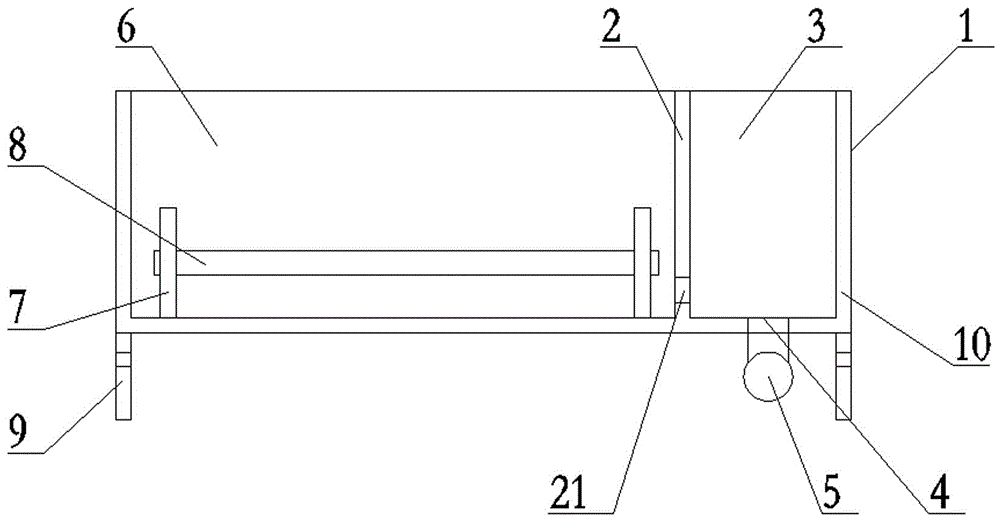

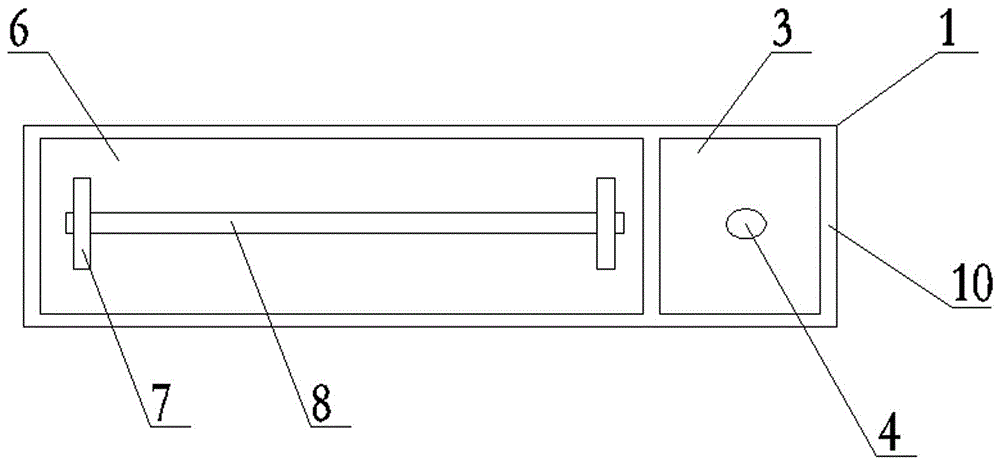

Teflon high-temperature cloth impregnating emulsion glue tank

ActiveCN105734878AAffect the dipping effectGuaranteed performanceTextile treatment containersTextile treatment machine arrangementsPolymer scienceEngineering

The invention relates to a Teflon high-temperature cloth impregnating emulsion glue tank which is characterized by comprising a tank body, wherein the bottom of a cross section of the tank body is circular-arc-shaped; a partition plate is arranged on one side of the tank body; the partition plate divides the tank body into a transit feed tank in one side and an emulsion impregnating tank in the other side; a through hole for communicating two sides is formed in the lower part of the partition plate; a support is arranged in the emulsion impregnating tank, and a feed roller is connected with the support in an overhanging and penetrating manner; a liquid outlet with a valve is formed in the bottom of the transit feed tank; the tank body is of a hollow structure with constant-temperature through water.

Owner:江苏斯凯氟复合材料有限公司

Preparation of low cost refractory metal material flow-off

InactiveCN101249565ASave resourcesMeet the performance requirementsRecycling and recovery technologiesPowder mixtureMetal

The invention discloses a manufacture method for a refractory metal flow port with low cost, which comprises the following steps of: ball-grinding refractory metal powder recovered from turning process to-60 to-200 meshes; purifying the powder; adding into eligible powder of the same trademark according to a certain weight percentage and mixing completely; and subjecting the powder mixture to powder metallurgic method such as pressing and sintering to obtain the refractory metal flow port. The refractory metal flow port meets the requirement for use performance and can improve the yield, reduce the production cost, save limited refractory metal resources and protect the natural environment. The process is simple and can save energy resources and reduce consumption.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com