Preparation method of halogen-free, flame-retardant, low-smoke and low-toxin hot melt phenolic prepreg

A prepreg and toxic heat technology, which is applied in the field of composite material preparation and phenolic resin-based composite material preparation, can solve the problems of unsatisfactory application requirements, unstable resin content, and difficult control of defects, so as to improve the covering performance and process Sexuality, smoke toxicity is small, and the effect of volatile matter reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

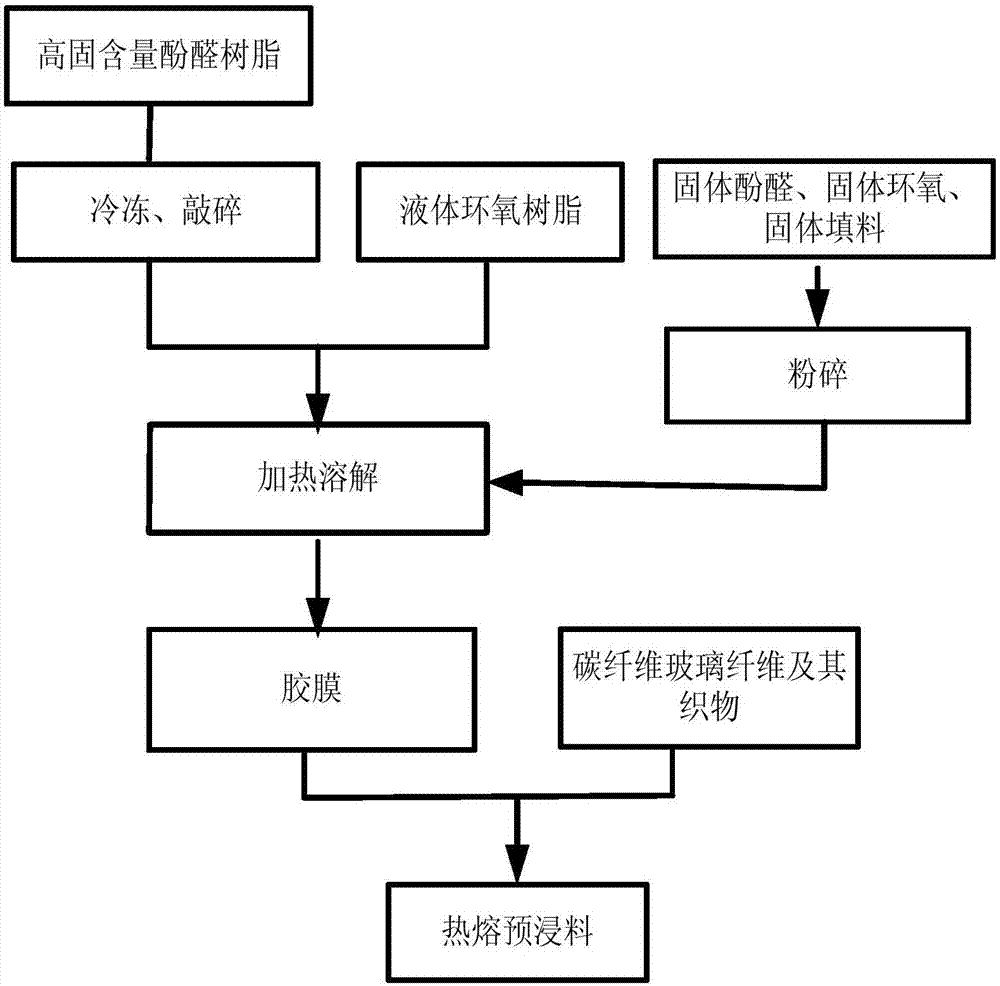

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the epoxy resin-based composite material with controllable toughness of the present invention comprises the following steps:

[0037] (1) Raw material preparation: the resin solid content of the high-solid content phenolic resin is ≥ 93%, and the viscosity of the phenolic resin is 5000-30000cp. Freeze the colloidal phenolic resin at -18~-10°C for ≥6 hours. After taking out the frozen phenolic resin, use physical methods to crush it quickly. Preferably, the solid content of the resin is 93% to 96%.

[0038] The solid thermosetting resin is pulverized at room temperature, and the solid thermosetting resin includes phenolic resin, benzoxazine resin or phosphorus-containing epoxy resin.

[0039] (2), add the crushed high-solid content phenolic resin matrix obtained in step (1) into a reaction kettle with a temperature control device, add low-viscosity, high-activity liquid epoxy resin at the same time, stir at a low speed, and stir at a temperatur...

Embodiment 1

[0054] The solid content of synthetic phenolic resin is 95%, and its gel time of testing is 230 seconds, confirms to comprise the matrix component of following mass percent content:

[0055] Phenolic resin 92%;

[0056] Solid phenolic resin 5%

[0057] Liquid Epoxy 3%

[0058] The reinforcing fiber is: T700 carbon fiber

[0059] Step (1), taking out the colloidal phenolic resin after being stored at -15°C for 10 hours, and crushing it. The solid phenolic resin was pulverized.

[0060] Step (2), put the phenolic resin and liquid epoxy resin into a temperature-controlled reactor and stir at a low speed, stir and melt at 60°C for 1.5 hours to obtain a transparent colloid.

[0061] Step (3), adding solid phenolic resin, stirring and mixing with the phenolic resin for 20 minutes under heating at 70° C. to obtain a finished resin.

[0062] Step (4), put the finished resin mixture into the coating machine, apply the film at 50-60°C, adjust the coating speed at 6m / min, and the sp...

Embodiment 2

[0068] The solid content of synthetic phenolic resin is 96%, and its gel time of test is 170 seconds, confirms to comprise the matrix component of following mass percentage content:

[0069] Phenolic resin 95%;

[0070] Solid phosphorus epoxy resin 3%

[0071] Liquid Epoxy 2%

[0072] The reinforcing fiber is: EW200 glass fiber cloth

[0073] Step (1), after storing the colloidal phenolic resin at -15°C for 24 hours, take it out and crush it. The solid phosphorus-containing epoxy resin was pulverized.

[0074] Step (2), put the phenolic resin and liquid epoxy resin into a temperature-controlled reactor and stir at a low speed, stir and melt at 70°C for 1 hour to obtain a transparent colloid.

[0075] Step (3), adding solid phosphorus-containing epoxy resin, stirring and mixing with phenolic resin for 30 minutes under heating at 80° C., to obtain a finished resin.

[0076] Step (4), put the finished resin mixture into the film coating machine, apply the film at 45-55°C, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com