Patents

Literature

744results about "Pretreatment apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood treatment process

InactiveUS6274199B1High shear stabilityImprove permeabilityWood treatment detailsPretreated surfacesWater basedMolten state

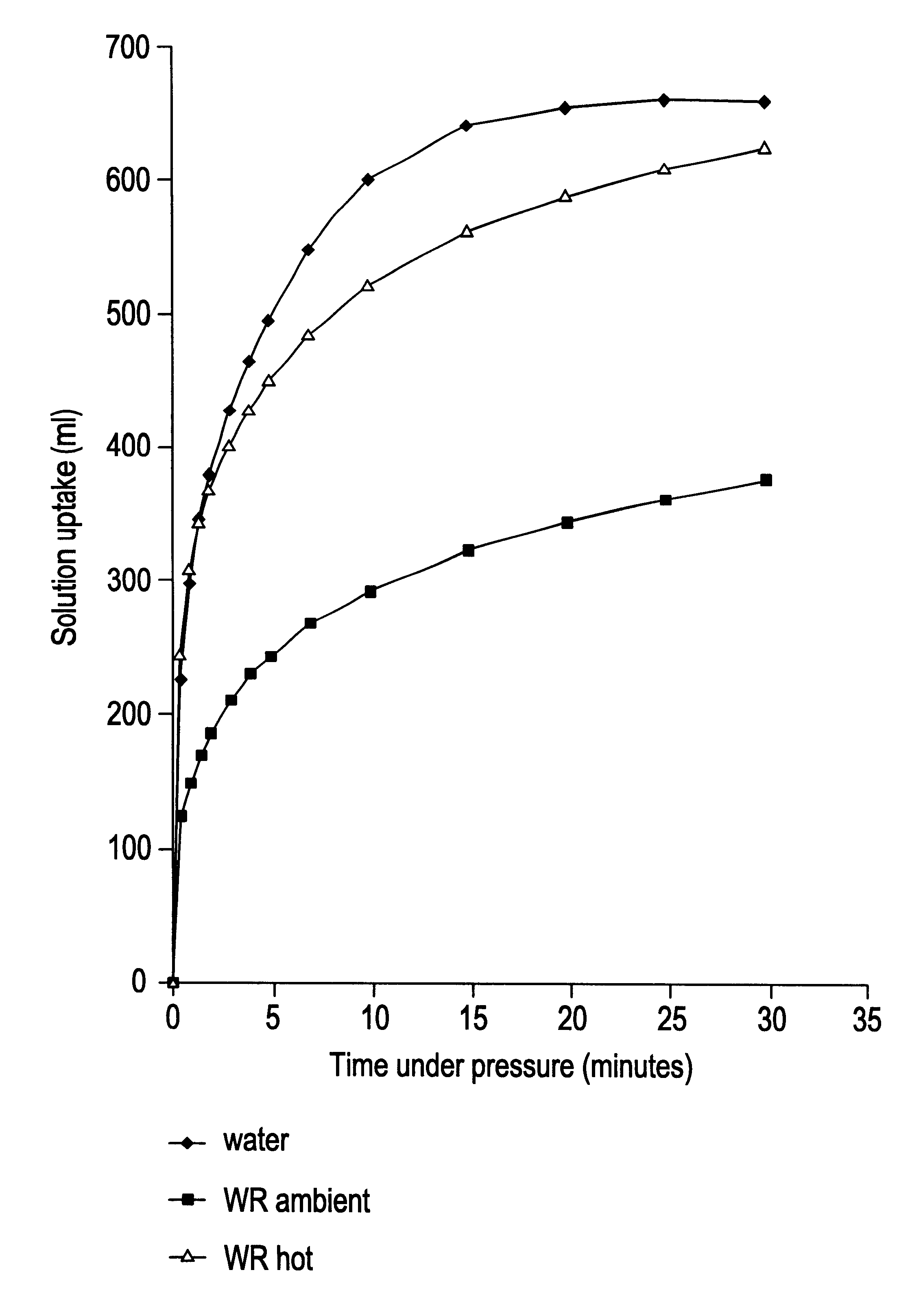

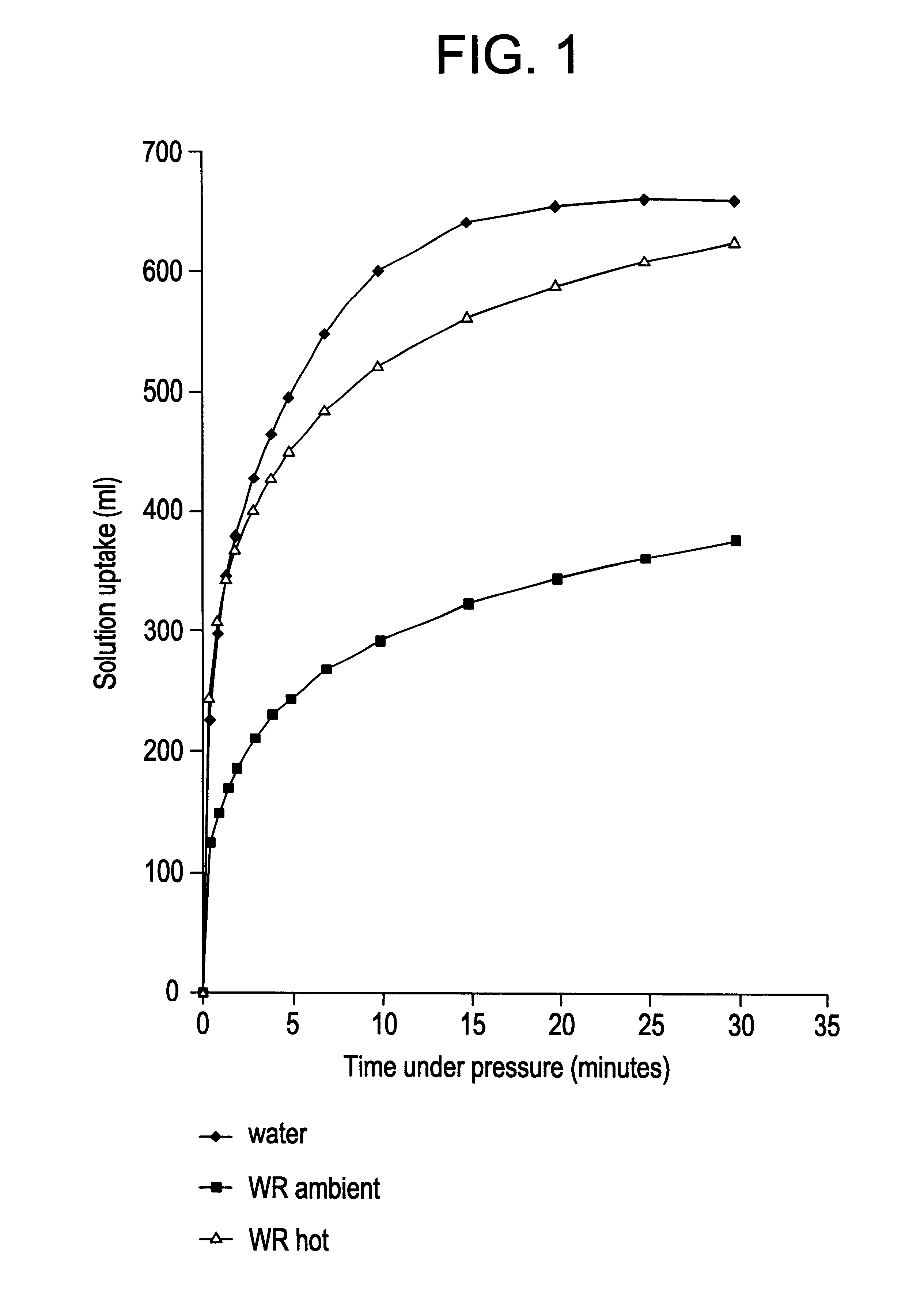

A process for treating a wood substrate with a water-based formulation containing a wax in order to confer water repellency to the substrate comprising the steps of:(a) placing the substrate in a treatment vessel and reducing the pressure in the vessel to remove air in the pores of the substrate;(b) contacting the substrate in the vessel, while reduced pressure is present in the vessel, with the formulation to allow the formulation to flow into said pores, said contacting being carried out at a temperature at or above that required to cause the wax to change into a molten state;(c) applying a positive pressure to the vessel to force the formulation into said pores; and(d) releasing the pressure in the vessel and removing the resultant wood substrate from the vessel.

Owner:VIANCE

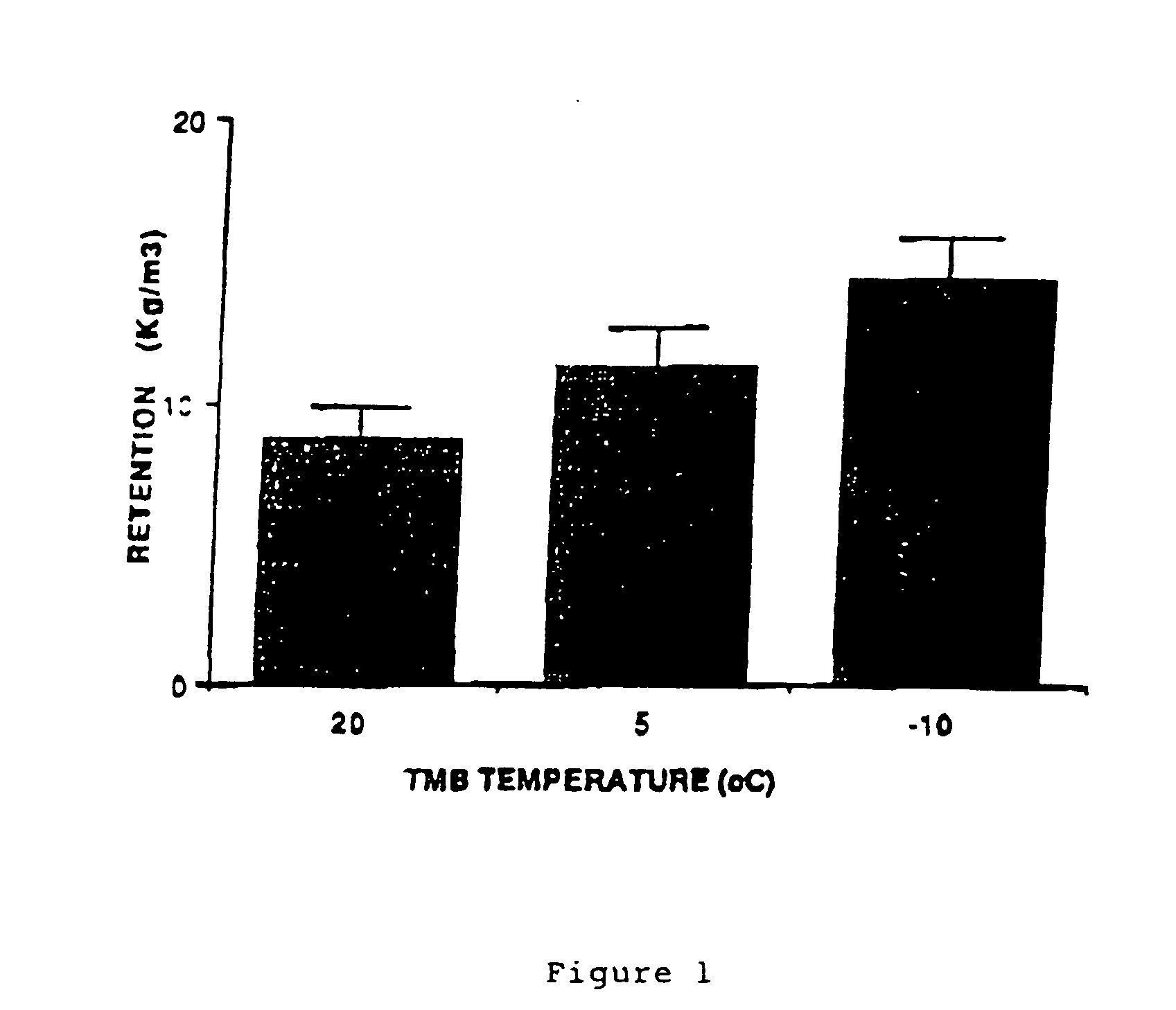

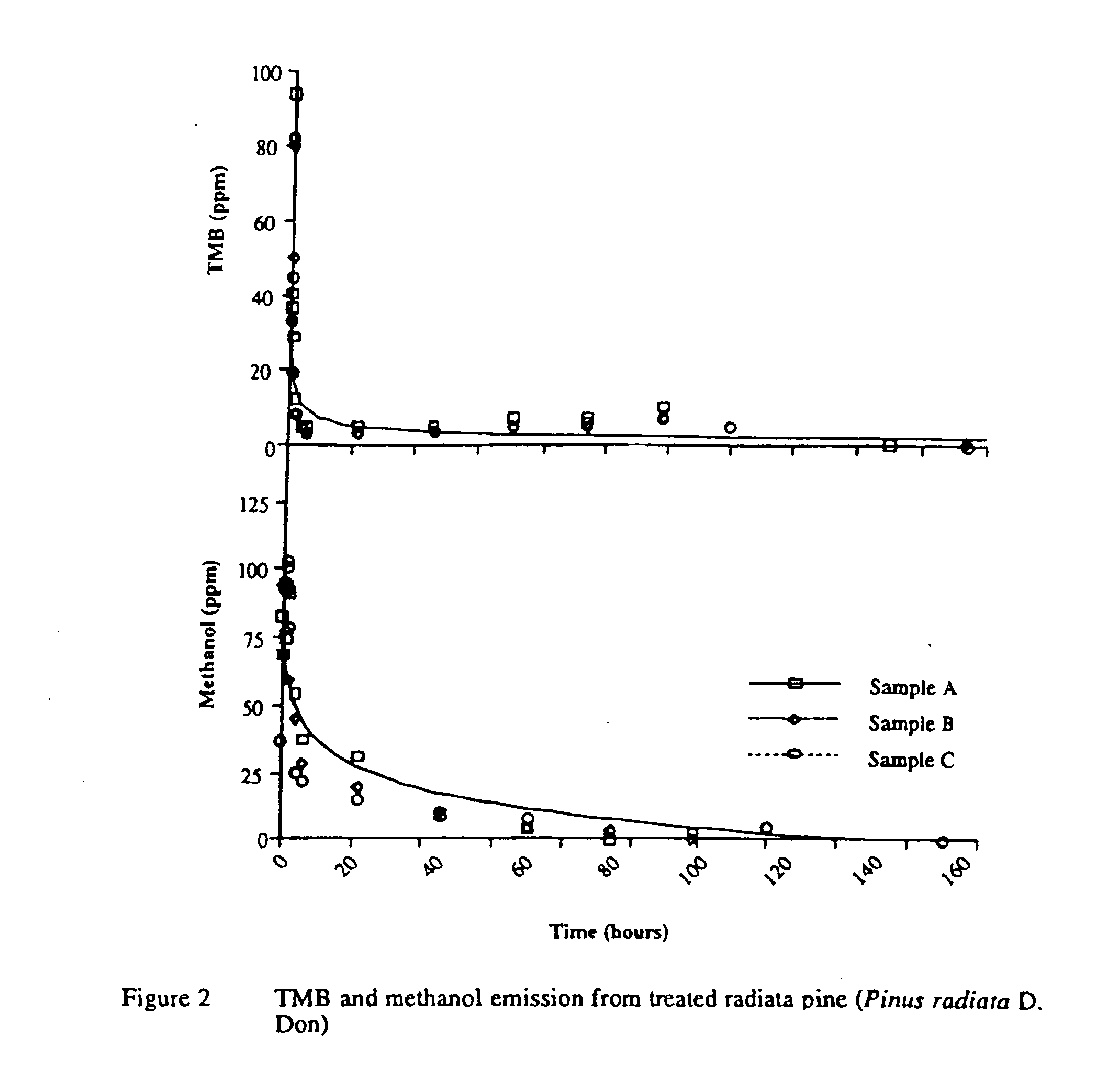

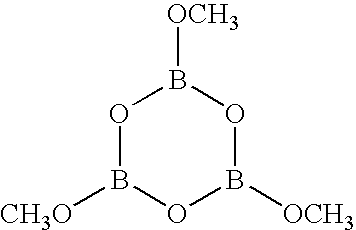

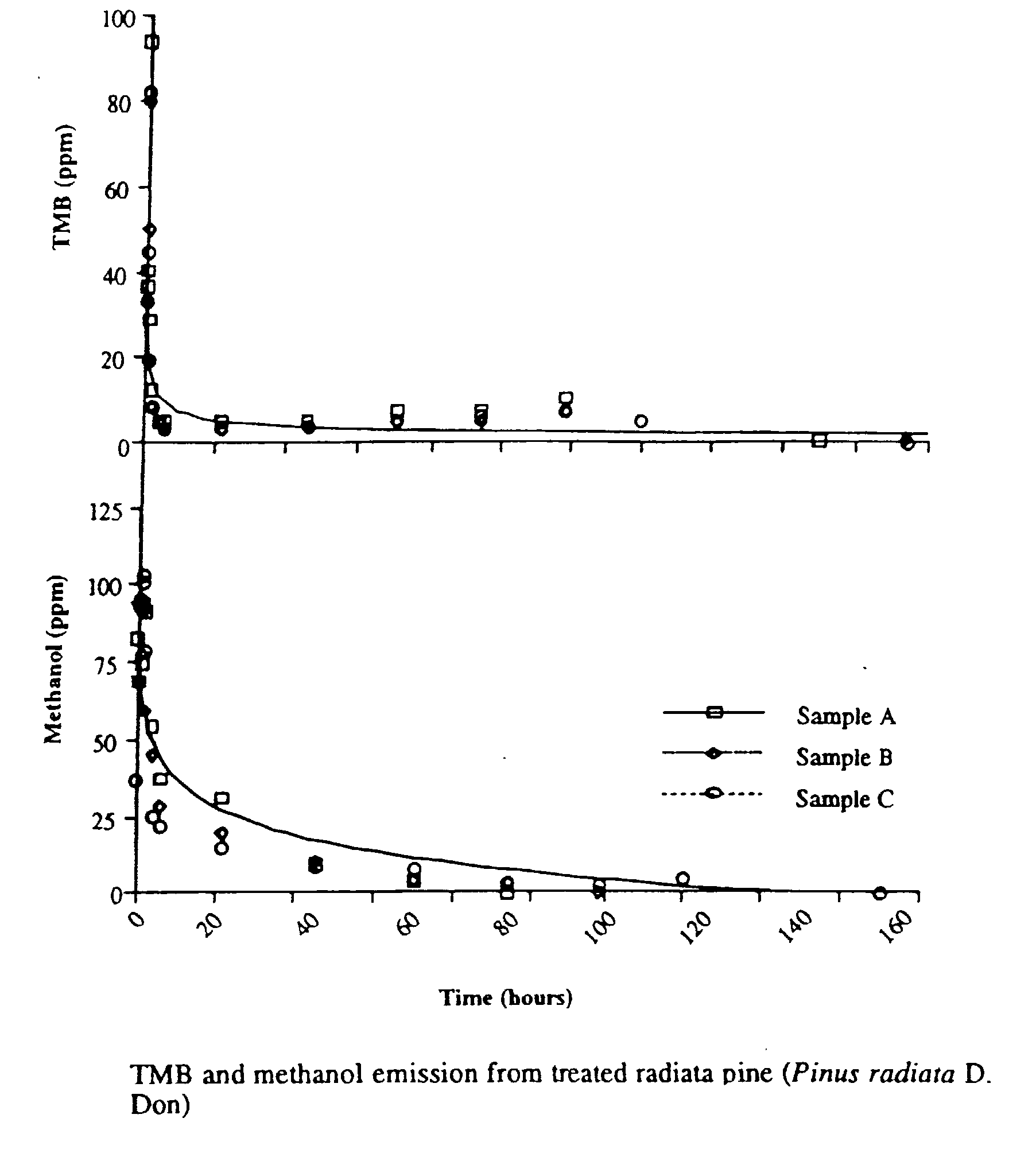

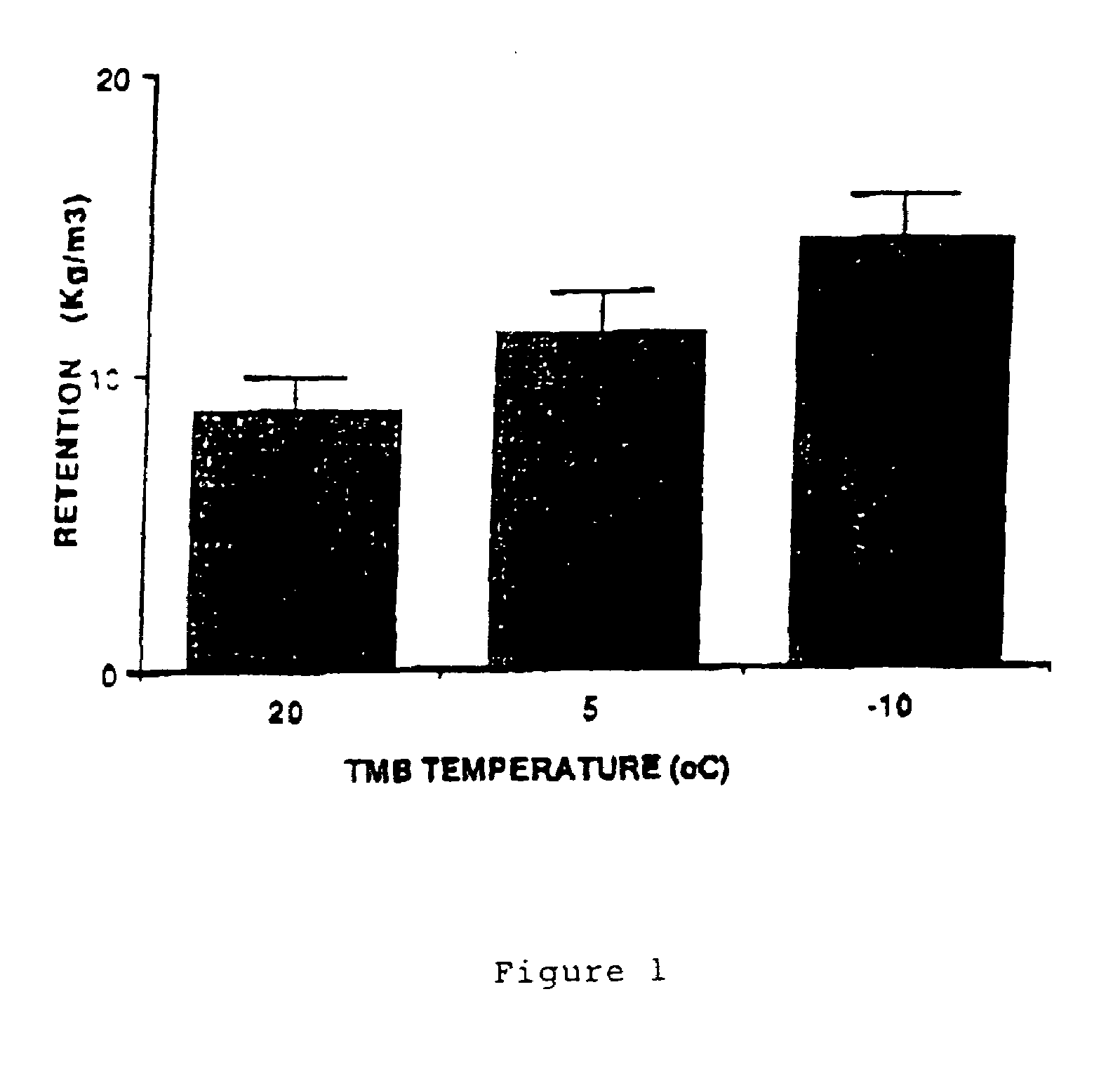

Boron-based wood preservatives and treatment of wood with boron-based preservatives

InactiveUS20050013939A1Safe handlingConvenient treatmentBiocideBoron compound active ingredientsAlcoholPreservative

A process for treating wood comprising applying to the surface of the wood a boron based preservative which reacts with moisture within the wood to form a boron compound and alcohol and subjecting the wood with the applied preservative to a substantially moisture-free and enclosed environment for a period sufficient for the applied preservative to be absorbed into the wood and to produce the boron compound on reaction with the moisture in the wood and for the alcohol by-product of the reaction to be adsorbed within the wood structure.

Owner:UNIVERSITY OF MELBOURNE

Method For Preparing Functional Engineered Wood

ActiveUS20170239836A1Improve permeabilityWell mixedLiquid surface applicatorsPressure wood treatmentFire retardantEngineered wood

The present invention relates to furniture panels, and more particularly, to a method for preparing functional engineered wood. It includes the following steps: make veneer blanks by rotary cutting or splicing, and cut the veneer blanks into desired dimensions to obtain veneers A. Soak the veneers A in a ternary mixed solution of a biomass nanocellulose solubilizer, a fire retardant and an acid dye for toughening, fire retardation and dyeing to obtain veneers B. Add a formaldehyde decomposing powder into a modified MUF adhesive, mix them up, coat the veneers B with the mixture to obtain veneers C. Assemble and cold-press the veneers C to obtain flitches D, and saw the flitches D into desired patterns and dimensions to obtain finished products.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

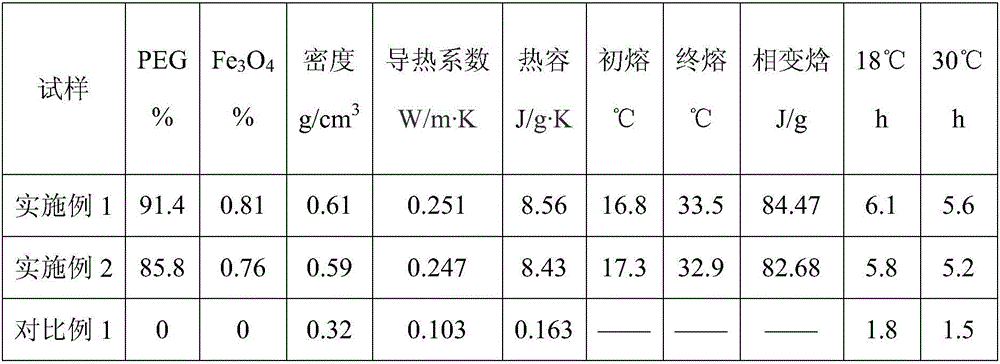

Phase-change energy storage heat-insulation solid wood and manufacturing method thereof

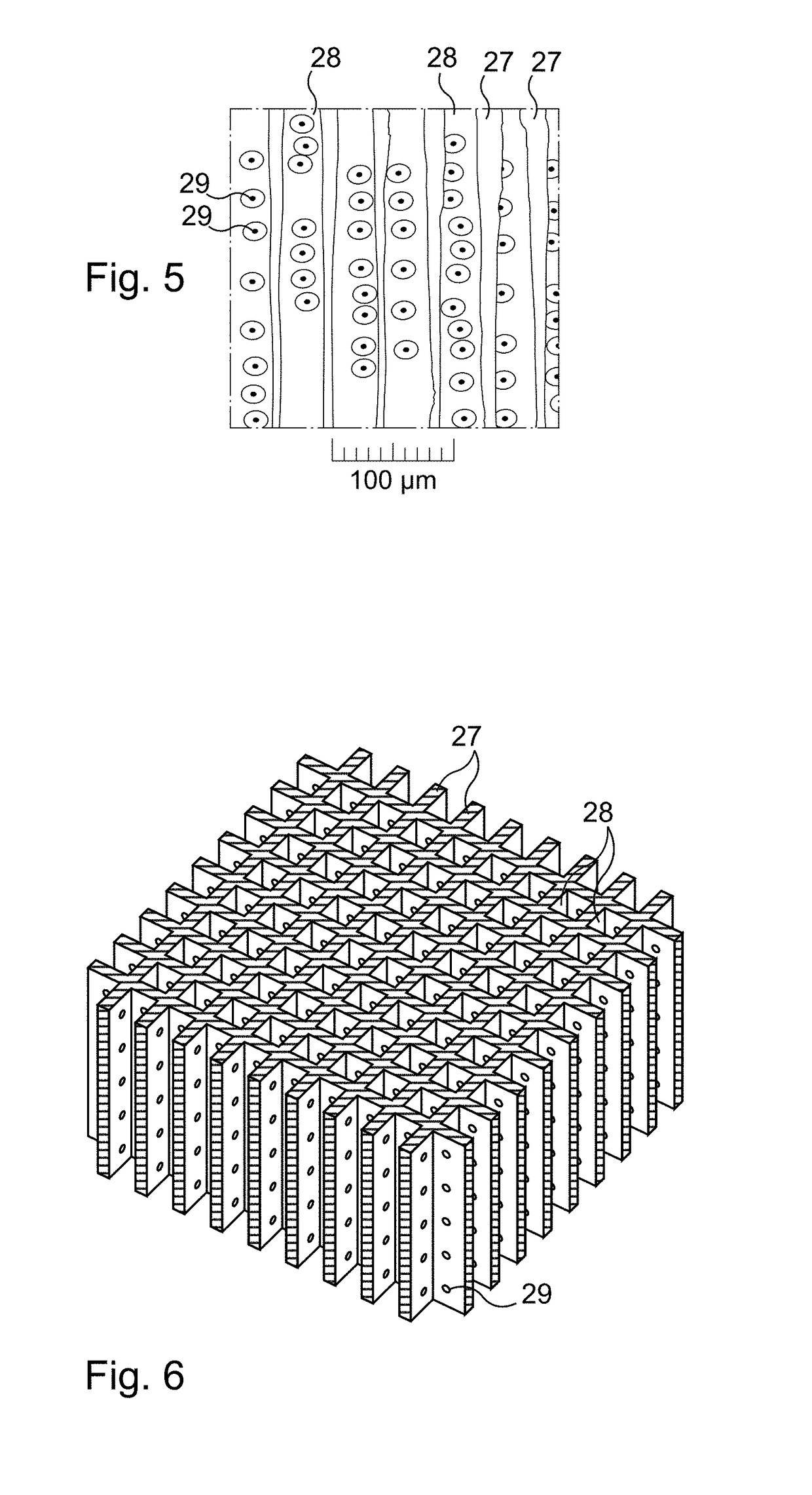

ActiveCN106625930ALow viscosityFacilitated Diffusion MigrationPressure wood treatmentWood treatment detailsSolid woodCell cavity

The invention provides phase-change energy storage heat-insulation solid wood. The wood comprises a solid wood component, wherein magnetic Fe3O4 nanoparticles are formed in a conduit and a cell cavity of the solid wood component through in-situ attached growth, and the conduit and the cell cavity are filled with composite phase-change energy storage materials of polyethylene glycol 600 and polyethylene glycol 800; and a protective coating is painted on the surface of the heat-insulation solid wood. The heat-insulation solid wood is capable of absorbing heat to withstand excessive rise of an indoor temperature during the day, releasing phase-change latent heat for thermal retention and cold dispelling during the night, and maintaining a human body within a comfort temperature range. The invention further provides a manufacturing method of the heat-insulation solid wood. The method comprises the steps of firstly processing the solid wood component according to the required dimension; carrying out degreasing and drying pretreatment on the solid wood component, forming the magnetic Fe3O4 nanoparticles in the solid wood component through in-situ attached growth and then impregnating and filling the composite phase-change energy storage material of the polyethylene glycol 600 and the polyethylene glycol 800; and finally carrying out sanding shaping and painting the protecting coating. According to the manufacturing method, the process is simple and the cost is low.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

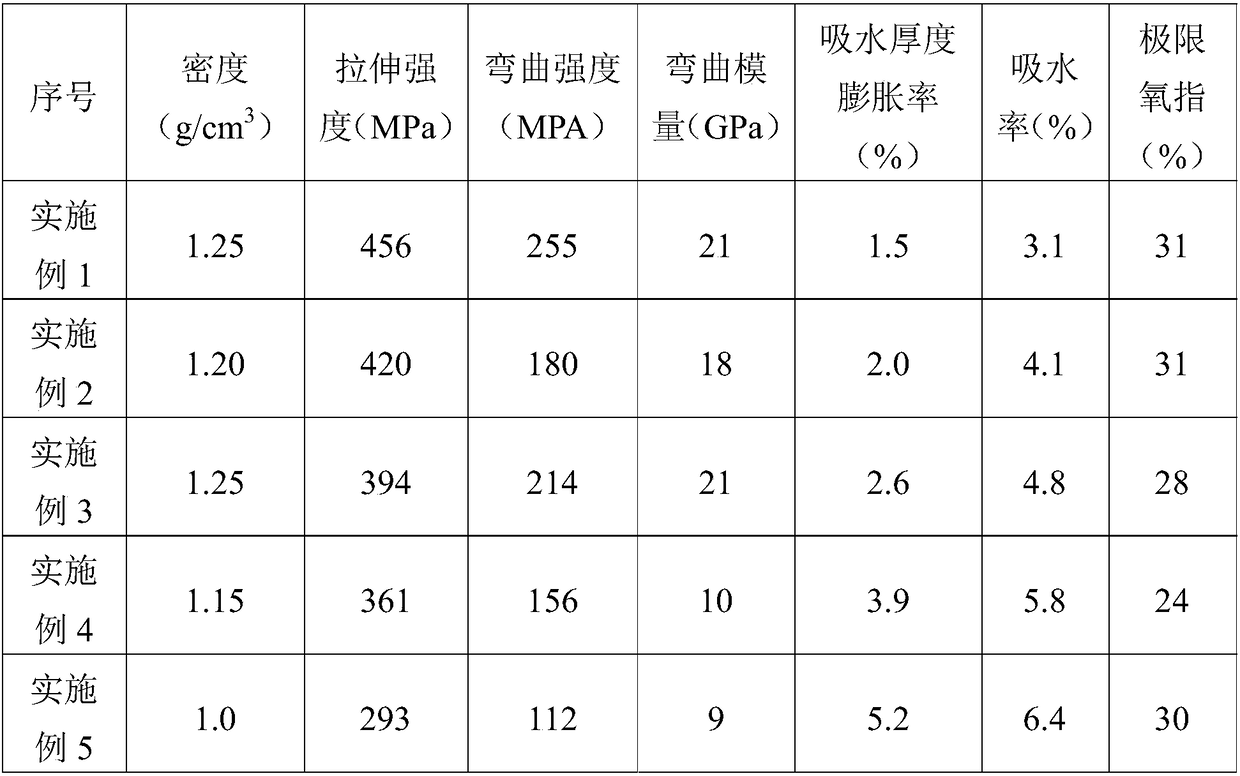

Preparation method for wood-bamboo reinforced resin composite material based on high-pressure densification

ActiveCN108772922AIncrease productivityPromote greenWood treatment detailsReed/straw treatmentStress concentrationHigh pressure

The invention relates to a preparation method for a wood-bamboo reinforced resin composite material based on high-pressure densification, and belongs to the field of composite materials and artificialboards. The preparation method for the wood-bamboo reinforced resin composite material based on the high-pressure densification comprises the steps that lignin and hemicellulose are partially removedfrom wood veneers, wood boards or bamboo sheets by a chemical reagent, the chemical reagent is removed by water, and the water is replaced by ethanol or acetone; the wood veneers, the wood boards orthe bamboo sheets with lignin and hemicelluloses removal are put into a mixed solution of a resin system or a resin solution and a flame retardant, a diluent and / or a toughening agent additive, or sequentially put into the resin system or the resin solution and the mixed solution of the additive, so that the resin and additive penetrate into cells and cell pores of the wood or the bamboo; and semi-finished products are assembled into blanks, and high-pressure densification and high-temperature curing are carried out to prepare the high-strength composite material. The preparation method for the wood-bamboo reinforced resin composite material based on the high-pressure densification overcomes the stress concentration problem caused by the pores and the like in an existing artificial board,and the prepared novel structural composite material has good mechanical properties and flame retardancy, so that the application of wood in the structural fields of airplanes, high-speed trains, buildings and the like are greatly promoted.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

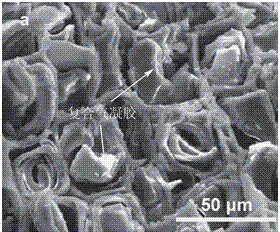

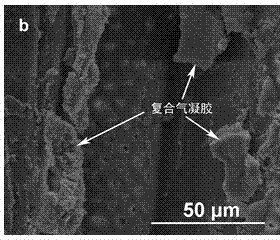

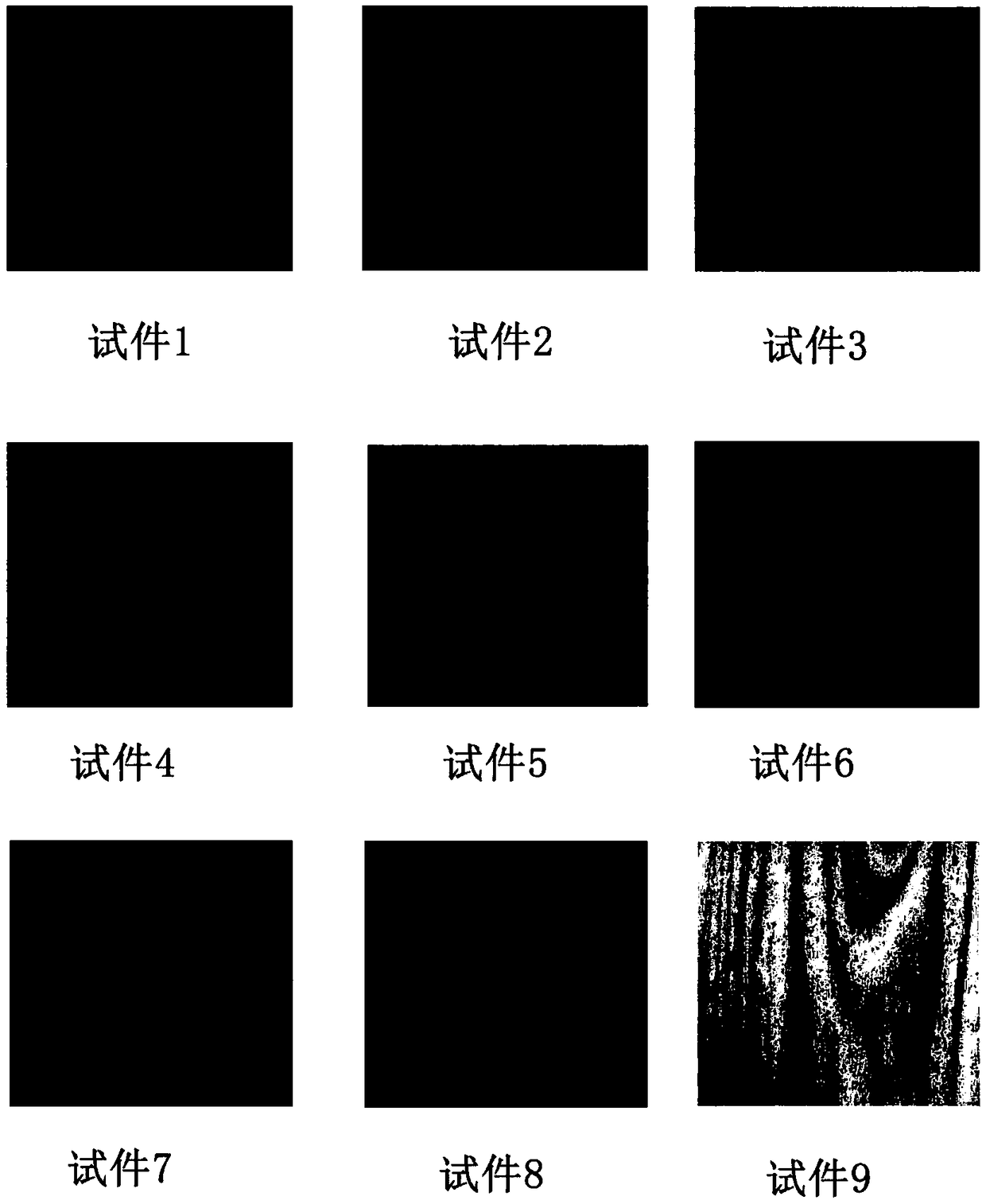

Ammonium polyphosphate/SiO2 composite aerogel flame-retardant reinforced timber and preparation method thereof

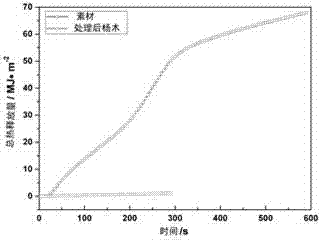

ActiveCN104760103AImprove permeabilityEvenly dispersedRadiation/waves wood treatmentWood treatment detailsSolid woodCorrosion prevention

The invention discloses an ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber which comprises a timber and an ammonium polyphosphate / SiO2 composite aerogel in timber pores. The invention also discloses a preparation method of the flame-retardant reinforced timber, which comprises the following steps: pretreating the timber with microwaves to form new flow channels in the timber, thereby enhancing the timber permeability; hydrolyzing the previously prepared ammonium polyphosphate and silicon source by pressure dipping treatment, and introducing the generated uniform sol solution into the timber; and carrying out condensation reaction and normal-pressure drying to generate the ammonium polyphosphate / SiO2 composite aerogel in the timber pore structure in situ. The ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber has favorable flame-retardant and smoke-inhibition functions, and can effectively prevent the flame retardant from loss. The composite aerogel in the timber pores has the effect of enhancing wear resistance and corrosion resistance. The method can be widely used in flame retardancy, reinforcement and corrosion resistance of the solid wood or composite wood, has the advantages of feasible technical process, cheap raw materials and favorable effect, and is worthy of popularization.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

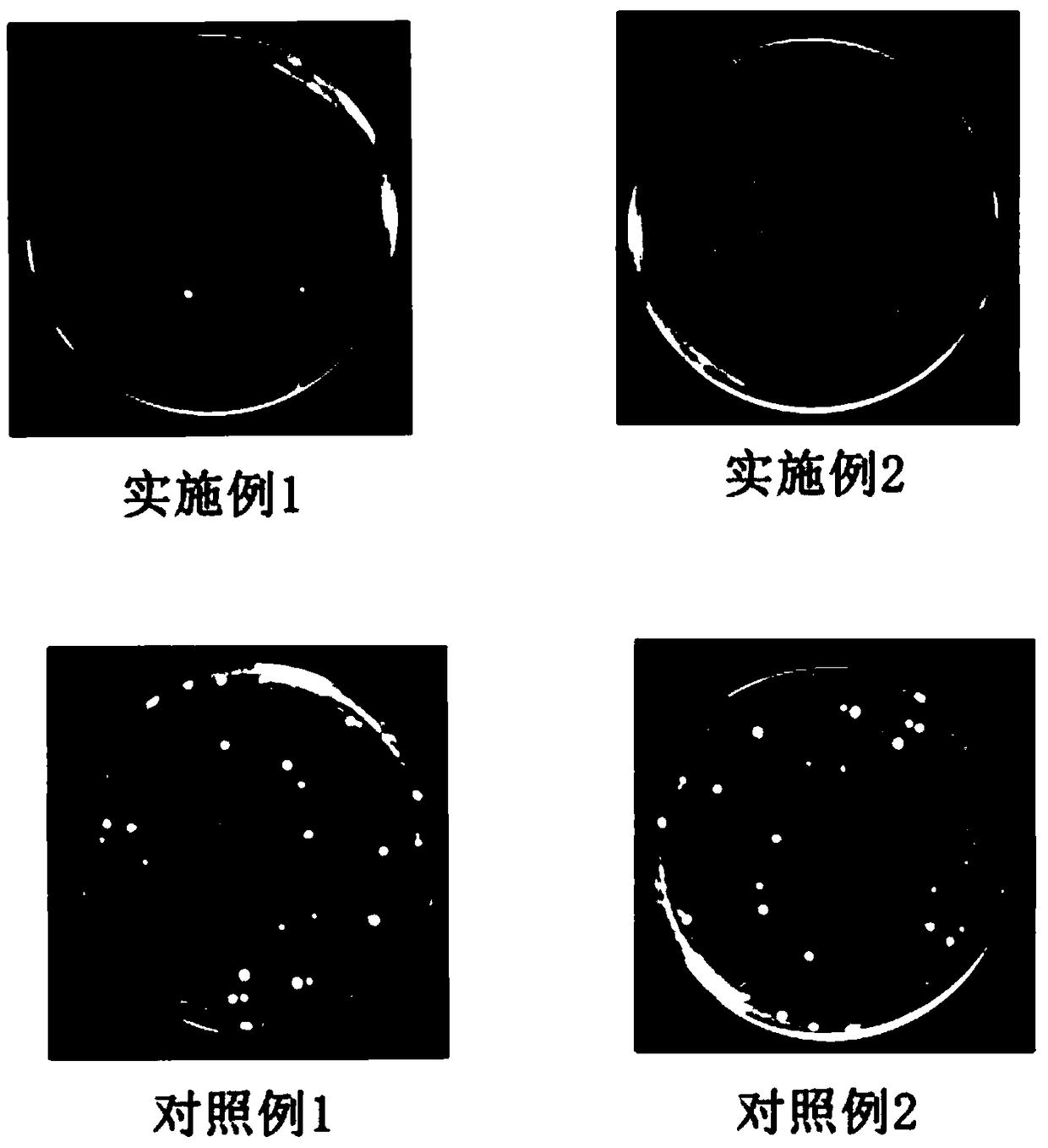

Method for improving mechanical stability of super-hydrophobic film on wood surface

ActiveCN105563577AHigh mechanical strengthEasy to operateWood treatment detailsPretreatment apparatusEpoxySilanes

The invention belongs to a method for improving mechanical stability of a super-hydrophobic film on a wood surface, which comprises the steps of: (1) coating the wood surface with a layer of transparent epoxy resin bottom layer to fill the concave structures on the wood surface so as to obtain a smooth surface; (2) preparing a silicon dioxide nanoparticle / epoxy resin / triethyloxy-1H,1H,2H,2H-heptadecyl fluoro decyl silane organic-inorganic composite coating solution; and (3) carrying out multiple immersion coating treatment on the wood provided with the epoxy resin bottom layer with the composite solution to obtain enough coating thickness, and heating for curing to obtain the super-hydrophobic wood. The wood treated by the method has the super-hydrophobic surface with high mechanical strength, and has good mechanical stability and durability. The method is used for solving the problems that the super-hydrophobic wood film layer prepared by the traditional method has poor stability and relatively short service life, is simple in operation, easy to realize and low in cost, can be used for scale production, and has good application prospects.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Archaizing distressing method for jujube wood

ActiveCN104589438AIncrease the sense of simplicityReduce harmWood treatment detailsPretreatment apparatusRelative humidityCorrosion

A related archaizing distressing method for jujube wood comprises the following steps: (1) cleaning wood surface and airing; (2) adding water into liquor cellar mud to prepare a liquor cellar mud solution with the weight ratio of 25%; (3) immersing the wood processed in the step (1) into the liquor cellar mud solution prepared in the step (20 for 30 min, taking out, and keeping warm at 22 DEG C for 5 h; (4) performing temperature-variation processing; (5) polishing, immersing and cleaning; and (6) processing wood processed in the step (5) at 42 DEG C at relative humidity of 78% for 10 h. the provided wood distressing method employs liquor cellar mud for processing, causes small corrosion to wood, and helps to increase delicate fragrance of wood, deepens black color of jujube wood and improve antique feeling. Also, by using a little amount of quicklime and performing sanding and temperature treatment, the jujube wood surface forms clear uniform textures and the antique color of jujube wood is further deepened.

Owner:安徽省阜南志峰工艺品有限公司

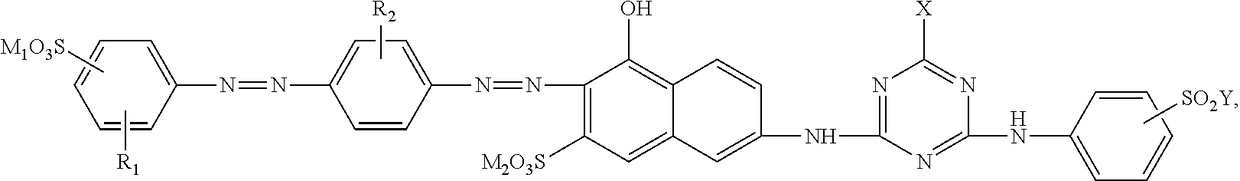

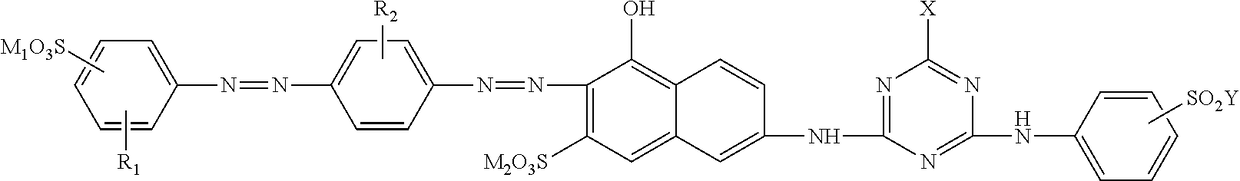

Method for increasing dyeing and fixation rate of reactive dye to wood

InactiveCN104493937AImprove color fixation effectHigh color fixing rateWood treatment detailsPretreatment apparatusSilicic acidOrganosolv

The invention discloses a method for increasing dyeing and fixation rate of a reactive dye to wood. The method for increasing the dyeing and fixation rate of the reactive dye to the wood comprises the following steps: respectively extracting to-be-dyed wood in hot water, NaOH solution and H2O2; after reactive dye liquor and anhydrous sodium sulphate are mixed, dyeing the extracted wood to obtain dyed wood; then carrying out fixation to the dyed wood by adopting an alkali silica sol fixing agent, wherein the alkali silica sol fixing agent is prepared by carrying out sol-gel reaction on ethyl orthosilicate, a silane coupling agent, ethanol, water and ammonia which are taken as raw materials; soaping with the fixed wood by adopting soap lotion, then washing with cold water, and drying, thus the dyed and fixed wood is obtained. The method for increasing the dyeing and fixation rate of the reactive dye to the wood has the advantages that a technology is simple, the dyeing and fixation rate of the reactive dye to the wood is high, and an alcohol organic solvent can be recycled, so that increase of difficulty for treating printing and dyeing wastewater caused by using a large number of salts is avoided, and the method for increasing the dyeing and fixation rate of the reactive dye to the wood is safe, energy-saving, economical and environment-friendly.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

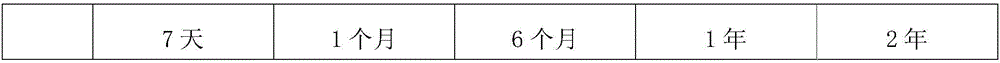

Mildew and worm preventive treatment method for wicker

InactiveCN106182271AHigh content of active ingredientsImprove mildew resistanceRadiation/waves wood treatmentPressure wood treatmentMedicineMildew

The invention discloses a wicker anti-mold and insect-proof treatment method, comprising the following steps: (1) raw material treatment, (2) air-drying treatment, (3) bacterial liquid treatment, (4) water steaming treatment, (5) drying treatment, (6) Anti-mold and insect-proof treatment, (7) Secondary drying treatment. The mildew-proof and insect-proof properties of the treated wicker in the invention are well improved, no mold and insect-eaten phenomena will occur within 12 years under normal use conditions, and the wicker has good moisture-proof, crack-proof and wear-resistant properties.

Owner:阜南县永盛工艺品有限公司

Process for treating wood

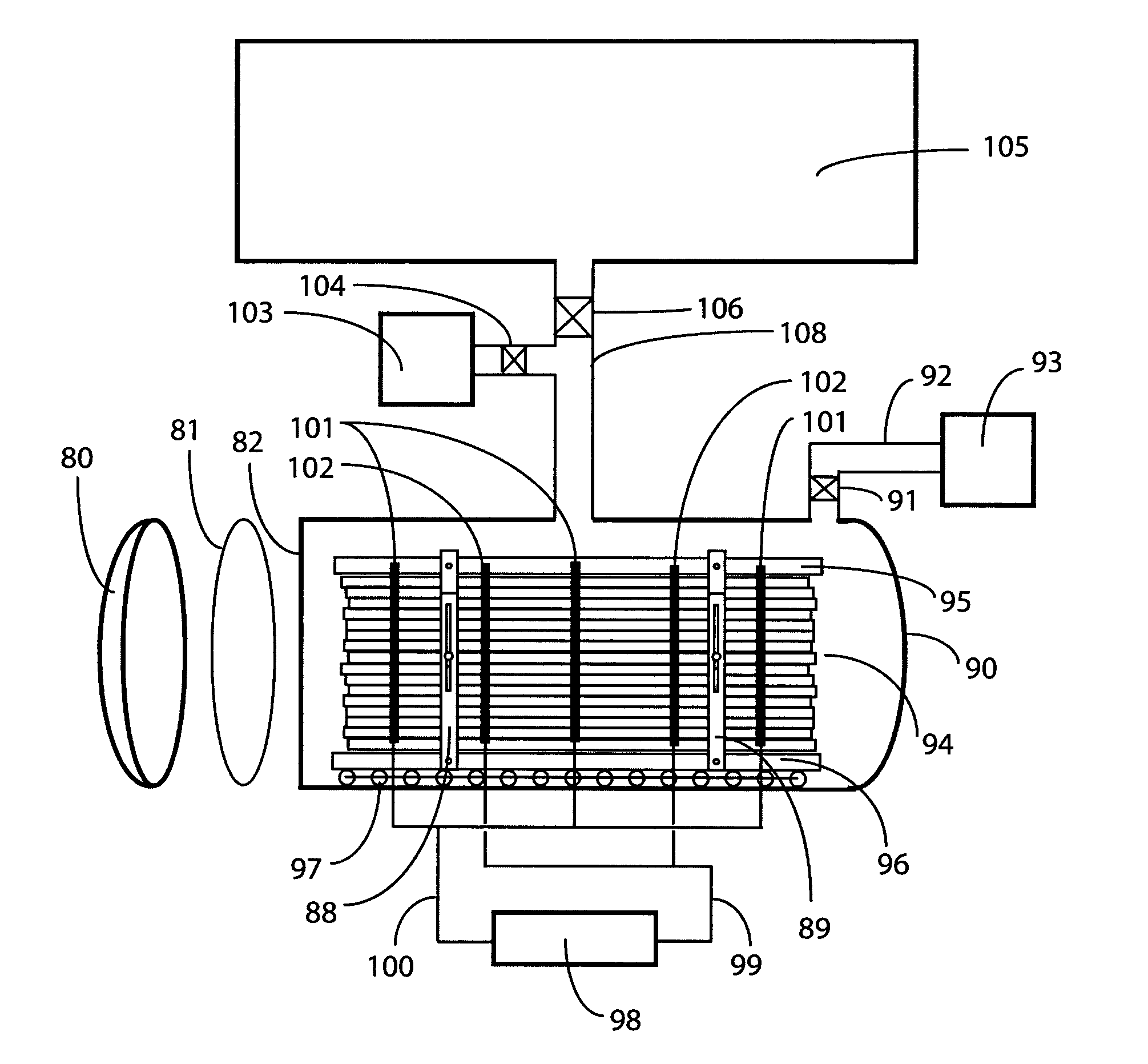

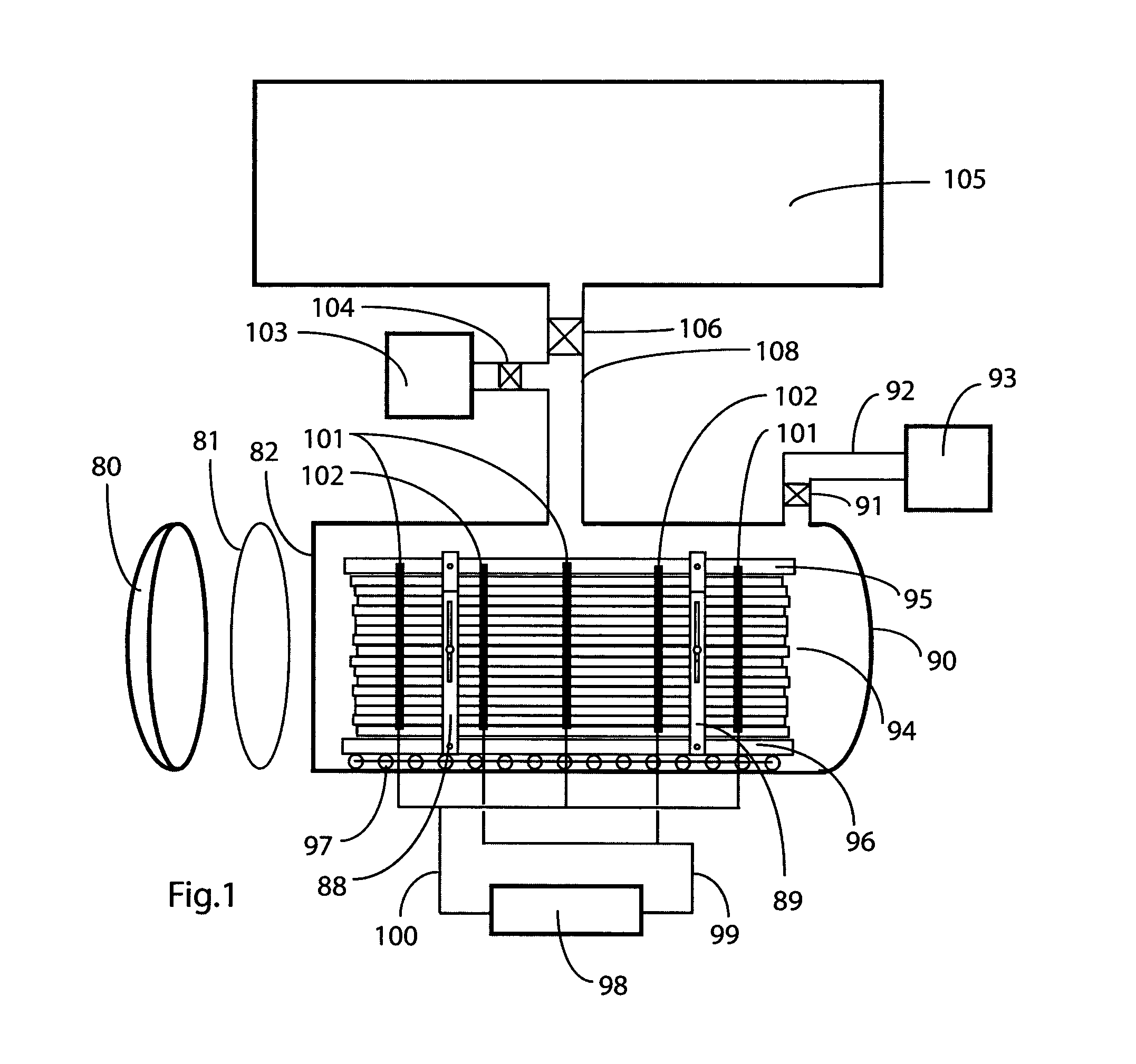

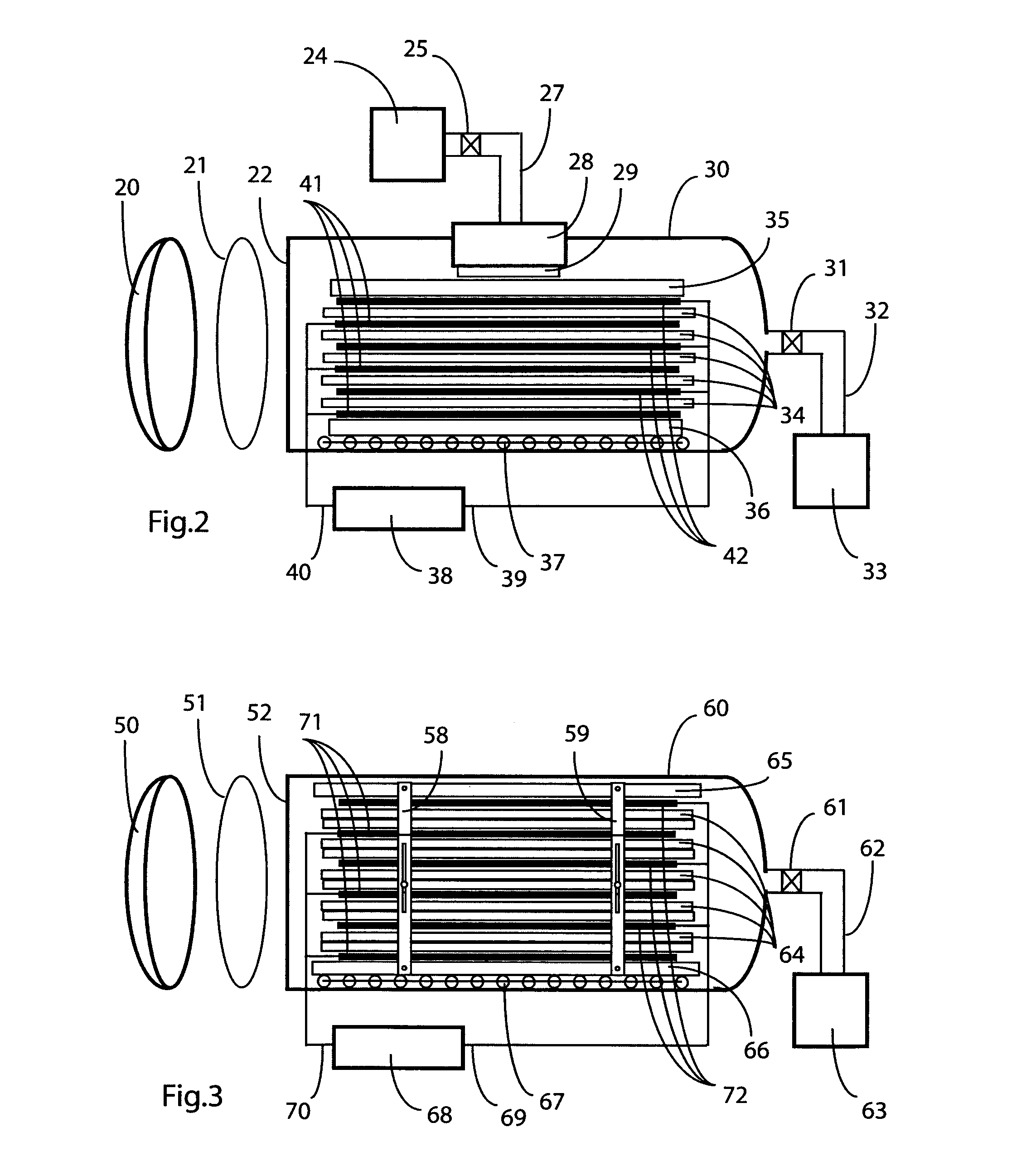

ActiveUS20110212273A1Shorten the timeImprove the heating effectDrying solid materials without heatPretreated surfacesEnvironmental engineeringElectromagnetic radiation

The proposed invention relates to a method for fluid treatment of wood comprising the steps of placing the wood in an airtight tank, evacuating the airtight tank to establish a vacuum environment for the wood, applying a fluid to the wood. Additionally, the method may further comprise the subsequent step of pressurizing the airtight tank to establish a pressurized environment for the wood. The method may further comprise the subsequent step of subjecting the wood to a subsequent heating, and / or the prior step of subjecting the wood to a prior heating by electromagnetic radiation through one or more electrodes.

Owner:GAIA WOOD PATENT

Anti-cracking method for woods

ActiveCN106426449ALipophilicImprove immersionWood treatment detailsPretreatment apparatusBatch operationPulp and paper industry

The invention relates to the technical field of wood processing, in particular to an anti-cracking method for woods. The anti-cracking method includes the steps: a, treating raw woods: firstly taking raw woods needing to prevent cracks, drying in the shade, and cutting the raw woods into plates; b, drying the plates: drying by the aid of a pressure reducing and drying method to obtain the dried plates; c, performing anti-cracking treatment: soaking the dried plates by the aid of wood anti-cracking agents, taking out and placing for 10-36h under the pressurized environments, moving the plates into a room, and drying in the shade; d, preparing wood finished products: preparing the wood finished products according to needs, painting the wood anti-cracking agents on the surfaces of the wood finished products for 1-5 times, and drying in the shade to obtain anti-cracking woods. The anti-cracking method has the advantages that the method is green and environmentally friendly, the treated woods are good in anti-cracking effect and durability, and cracking rate of the treated woods is reduced. The whole production process is controllable and nontoxic, and the anti-cracking method is applicable to batch operation of factories.

Owner:南通华尔利亚木业有限公司

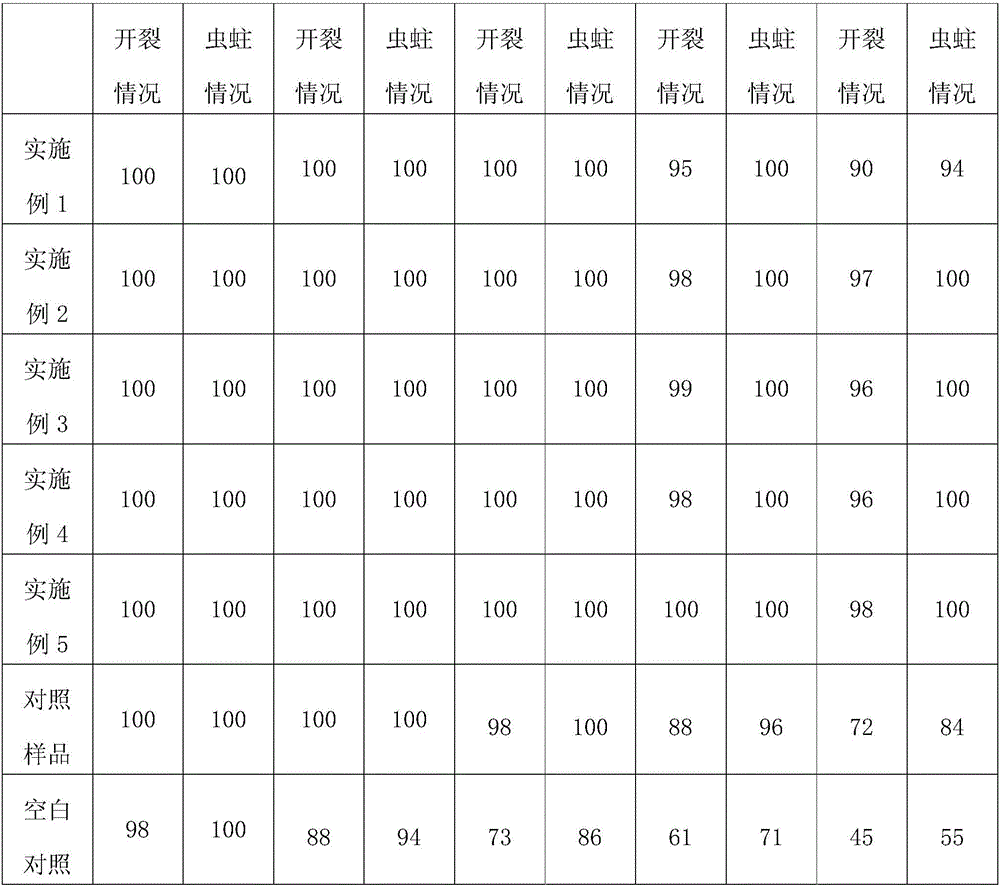

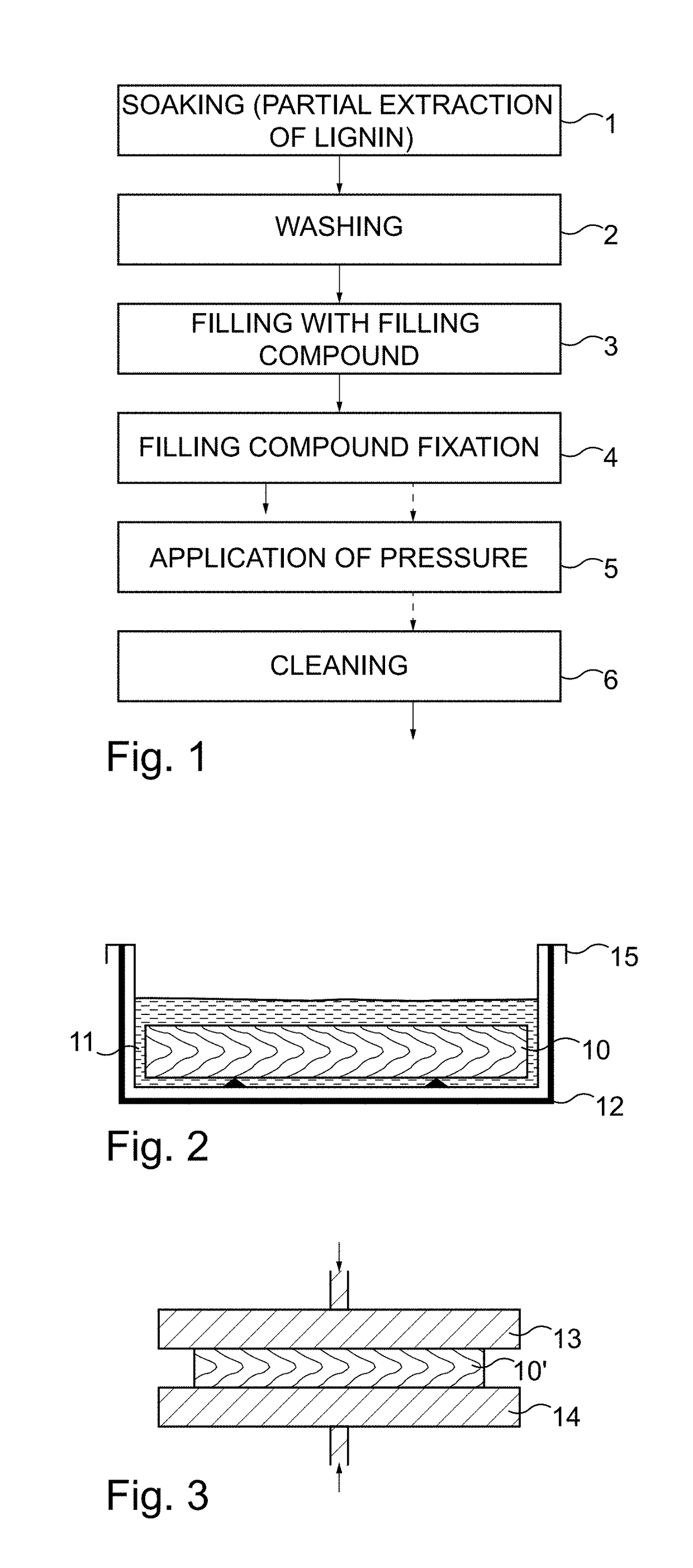

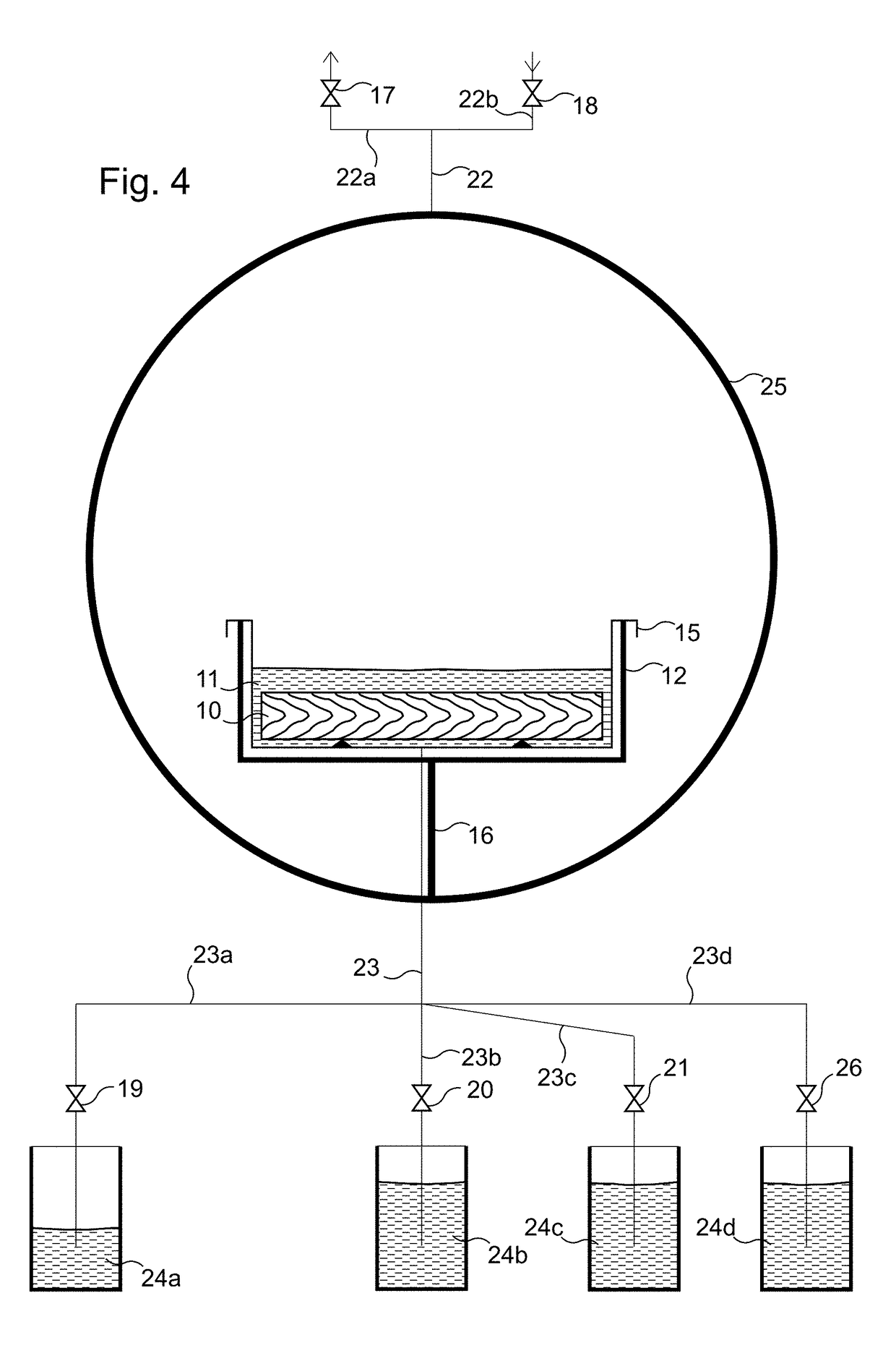

Process for partial delignification and filling of a lignocellulosic material, and composite material structure able to be obtained by this process

ActiveUS20180370071A1Improve organizationImprove compactnessPressure wood treatmentWood treatment detailsChemical compoundOrganic fluid

The invention relates to a process for treating a lignocellulosic material, preferably wood, comprising the following steps: (1) soaking of the material with organic fluid in order to dissolve at least 40% and at most 85%, in weight %, of the lignin of the material; (2) washing with organic fluid so as to discharge the dissolved lignin; (3) filling with a filling compound; and (4) finishing, so as to obtain a composite formed of a three-dimensional network of transformed filling compound incorporated into a cellulose and lignin network. The invention also relates to a composite structure able to be obtained in this way, and to any part comprising at least one such structure.

Owner:SAS WOODOO

Methods of conferring fire retardancy to wood and fire-retardant wood products

ActiveUS20150352744A1Radiation/waves wood treatmentVacuum evaporation coatingFire retardantEngineered wood

A process is provided for treating wood products including lumber, plywood and other engineered wood products comprising the steps of applying an aqueous fire-retardant impregnate and applying a coating to the surface of the wood product. In one embodiment, said process confers fire-retardant properties to the wood products sufficient to pass the extended burn test of ASTM E-84. The present invention also provides fire retardant wood products.

Owner:KOPPERS PERFORMANCE CHEM

Modification treatment method of salix integra for weaving

ActiveCN107088941AHigh hardnessHigh strengthWood treatment detailsPretreatment apparatusSolution treatmentHardness

The invention discloses a modification treatment method of salix integra for weaving, and belongs to the technical field of wickerwork processing. The method comprises the following steps of (1) salix integra pretreatment, (2) steam treatment, (3) acid-base solution treatment, (4) soaking modification treatment and (5) drying treatment. According to the method, salix integra branches are subjected to special modification treatment, the contents and compositions of inner material compositions are effectively adjusted, the flexibility of the salix integra branches is improved, the weaving yield is guaranteed, the hardness and strength of the salix integra can be recovered and improved in time after weaving, and the service life of a wickerwork product is prolonged. In addition, the salix integra branches treated through the method can be recycled again through high temperature softening treatment, and the problem that existing wickerwork products cannot be reused effectively is solved.

Owner:阜南佳利工艺品股份有限公司

Method for inducing wood discoloration by using chemical color-changing agent

ActiveCN109434993AImprove color saturationStrong sense of hierarchyWood treatment detailsThermal wood treatmentColor saturationColor changes

The invention discloses a method for inducing wood discoloration by using a chemical color-changing agent. The method comprises the following steps that firstly, a precursor substance solution is coated on the surface of wood, then the surface of the wood is coated with the color-changing agent after drying, and drying is carried out again to complete the color change of the wood to obtain a finished product. According to the method, the color saturation after chemical color change of the wood can be improved, so that the color of the wood is more easy to display after the wood is subjected tothe color change, the excellent permeability performance is achieved, the bonding strength of the wood color-changing layer is higher, the loss resistance is better, moreover, the displayed color isnatural and beautiful, the texture is clearer, the layering sense is stronger, and the color is richer.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Boron-based wood preservatives and treatment of wood with boron-based preservatives

InactiveUS20090110842A1Safe handlingElectric shock equipmentsWood treatment detailsAlcoholPreservative

A process for treating wood comprising applying to the surface of the wood a boron based preservative which reacts with moisture within the wood to form a boron compound and alcohol and subjecting the wood with the applied preservative to a substantially moisture-free and enclosed environment for a period sufficient for the applied preservative to be absorbed into the wood and to produce the boron compound on reaction with the moisture in the wood and for the alcohol by-product of the reaction to be adsorbed within the wood structure.

Owner:UNIVERSITY OF MELBOURNE

Softening method for osier wood

InactiveCN106272811AGood softening effectFeatures have little effectRadiation/waves wood treatmentWood treatment detailsMicrowaveEngineering

The invention discloses a softening method for osier wood, and belongs to the technical field of osier processing. The softening method specifically comprises the following steps of (1) pretreatment of osier; (2) steam explosion treatment; (3) immersing and drying treatment; (4) microwave treatment; and (5) drying and weaving. By adoption of the softening method for the osier wood, a remarkable softening effect on the osier wood is achieved, and the weaving time can be shortened by 30-50%; in addition, the softening method has little influence on the original characteristics of the osier wood, the cracking rate in softening treatment and the cracking rate in weaving processing are decreased by 15-20% and 20-30% correspondingly compared with existing methods; and the finally treated osier wood is good in strength and stability, excellent in corrosion resistance and worm prevention and not prone to being roughed when used, and better use value is achieved.

Owner:阜南县环宇柳木工艺制品有限公司

Preparation method of antibacterial mould-proof plywood for decoration

ActiveCN107351197AInhibit residual mold activityGood flexibilityRadiation/waves wood treatmentNon-macromolecular adhesive additivesCelluloseHuman health

The invention mainly relates to the technical field of machining of artificial boards, and discloses a preparation method of antibacterial mould-proof plywood for decoration. The preparation method comprises drying, dipping, freezing, gluing, hot pressing and arrangement; the method is simple, safe and nontoxic; the obtained plywood for decoration reaches the mould inhibition rate of 76.3%, and contains no poisonous chemical reagent; the human health is guaranteed in the preparation and use process of the plywood; a veneer is firstly dried at low temperature, so that the water content is lower than the water content of a conventional veneer, the activity of the mould remained in the veneer is inhibited, the moulding is inhibited, the absorption of treatment solution in later treatment process is promoted, and the production efficiency is improved; and the dried veneer is put in sodium selenite solution for ultrasonic dipping, so that the sodium selenite solution is fully infiltrated in the veneer to inhibit growth of infectious microbes, the binding force of lignin to cellulose is reduced, the softness of the veneer is improved, breakage is prevented, and the machining performance and the use performance of the plywood are improved.

Owner:徐州市嘉翔木业有限公司

Production technology for rattan-woven wood bottom vase

InactiveCN105904552AImprove corrosion resistanceImprove antioxidant capacityWood treatment detailsCane mechanical workingUltravioletOxidation resistant

The invention provides a production technology for a rattan-woven wood bottom vase. The production technology comprises the following steps that fresh willows are selected and processed into a circular or rectangular wood board, and then the wood board is immersed for 1-2 h through preservative liquid; freshly-cut rattan is naturally aired and dried, the interior of a pressure tank is pressurized through mixed gas of nitrogen and carbon dioxide, and the interior of the pressure tank continues to be pressurized to 0.15 MPa-0.2 MPa through hot steam; the processed wood board and the processed rattan are input into a drier to be dried, and the rattan is utilized for being woven on the wood board to form the vase; distilled water is sprayed to the vase for wetting, and drying is conducted again through the drier. According to the production technology, the corrosion resistance and oxidation resistance of the vase are greatly improved, planting soil can be placed in the vase and used for planting flowers, and the vase cannot be decomposed by humus bacteria. The vase manufactured through the production technology is particularly suitable for being used near the equator, and the vase can bear long-time and continuous high-temperature scorching in the open and resist the high-intensity ultraviolet irradiation.

Owner:FUNAN FANGLIU ARTS & CRAFTS CO LTD

Preparation method for high-strength antibacterial mould-proof bamboo plywood

InactiveCN105773740AImprove wettabilityImprove antibacterial propertiesElectric wood treatmentWood treatment detailsResin adhesiveUltimate tensile strength

The invention discloses a preparation method for high-strength antibacterial mould-proof bamboo plywood. The preparation method comprises the steps that a bamboo sheet is manufactured, specifically, the bamboo sheet is dried to be 8-15% in moisture content, and then the bamboo sheet is subjected to plasma processing to obtain a material A; the material A is added into an antibacterial agent to be soaked for 30-45 min, and then is dried to be 8-15% in moisture content to obtain a material B; the material B is soaked in a phenolic resin adhesive for 100s-120s, and then is dried to be 10-15% in moisture content to obtain a material C; the material C is assembled to obtain a work board; the work board is subjected to hot-pressing consolidation to obtain a substrate; and the substrate is aged to obtain the high-strength antibacterial mould-proof bamboo plywood. The preparation method for the high-strength antibacterial mould-proof bamboo plywood has the advantages of being simple in process, mild in condition and low in cost; and the obtain bamboo plywood is high in strength, good in corrosion resistance and excellent in antibacterial and mould-proof performance.

Owner:安徽福佳竹木日用品有限公司

Production and treatment process of solid wood furniture

InactiveCN106976142AImprove product qualityNo cracking deformationWood treatment detailsThermal wood treatmentSolid woodWax

The invention discloses a production and treatment process of solid wood furniture. The process comprises cutting, mildewproof treatment, wax boiling, finish polishing, painting assembly and aftertreatment; the cutting is to cut furniture logs into multiple assembly blocks according to the shape and the structure of the furniture; the mildewproof treatment is to treat assembly blanks by a mildewproof process and to dry to reach the water content of lower than 10%; the pressure planing and tenoning step is to use a pressure planing machine for polishing the dried blanks to produce mortise-tenon joint structures; the blanks are polished to become concentrates; after a primer is sprayed on the surfaces, the concentrates are cooled for drying; and the concentrates are assembled as a product. The process is reasonable; and the produced solid wood furniture is excellent in product quality, is not deformed by cracking, reinforces the mildewproof capacity, and is stable in performance and long in service life.

Owner:张强

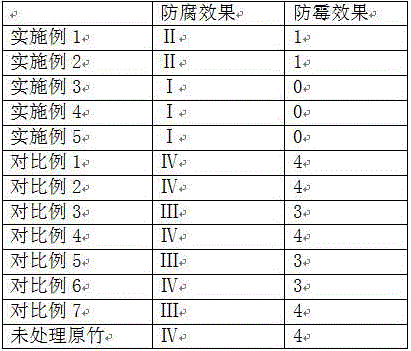

Antiseptic and mildewproof treatment technology for bamboo

ActiveCN106671234AIdeal Saturation Injection EffectExtended stayPressure wood treatmentWood treatment detailsVacuum pressureEngineering

The invention belongs to the field of bamboo treatment and relates to an antiseptic and mildewproof treatment technology. The technology comprises the following steps that (1), the fresh bamboo is dried to be with the water content of 12-15%; (2), the dried bamboo is put into a vacuum pressure tank, the vacuum degree of the vacuum pressure tank is controlled to be over 0.08 MPa, and the treatment time ranges from 35 min to 50 min; (3), a protective agent is added to the vacuum pressure tank; (4), a vacuum pump is closed, a pressure pump is started, the pressure is made to be in the range of 1.2-1.8 MPa, and treatment is conducted for 50-70 min under the condition of keeping the pressure; and (5), the pressure is relieved, and the protective agent is drained. According to the antiseptic and mildewproof treatment technology for the bamboo, for the characteristic of the bamboo, the technological processes of drying, high-pressure, vacuum, pressurization and vacuum are adopted, in combination with the protective agent special for the bamboo, the protective agent can be effectively permeated into the bamboo from bamboo inner rings (inner of the bamboo) with the high nutrient content and the low density, the ideal protective agent saturation injection effect is achieved, the protective agent stays in the bamboo for a long time and is not easy to drain, and the long-term protective effect can be played.

Owner:安吉竹境竹业科技有限公司

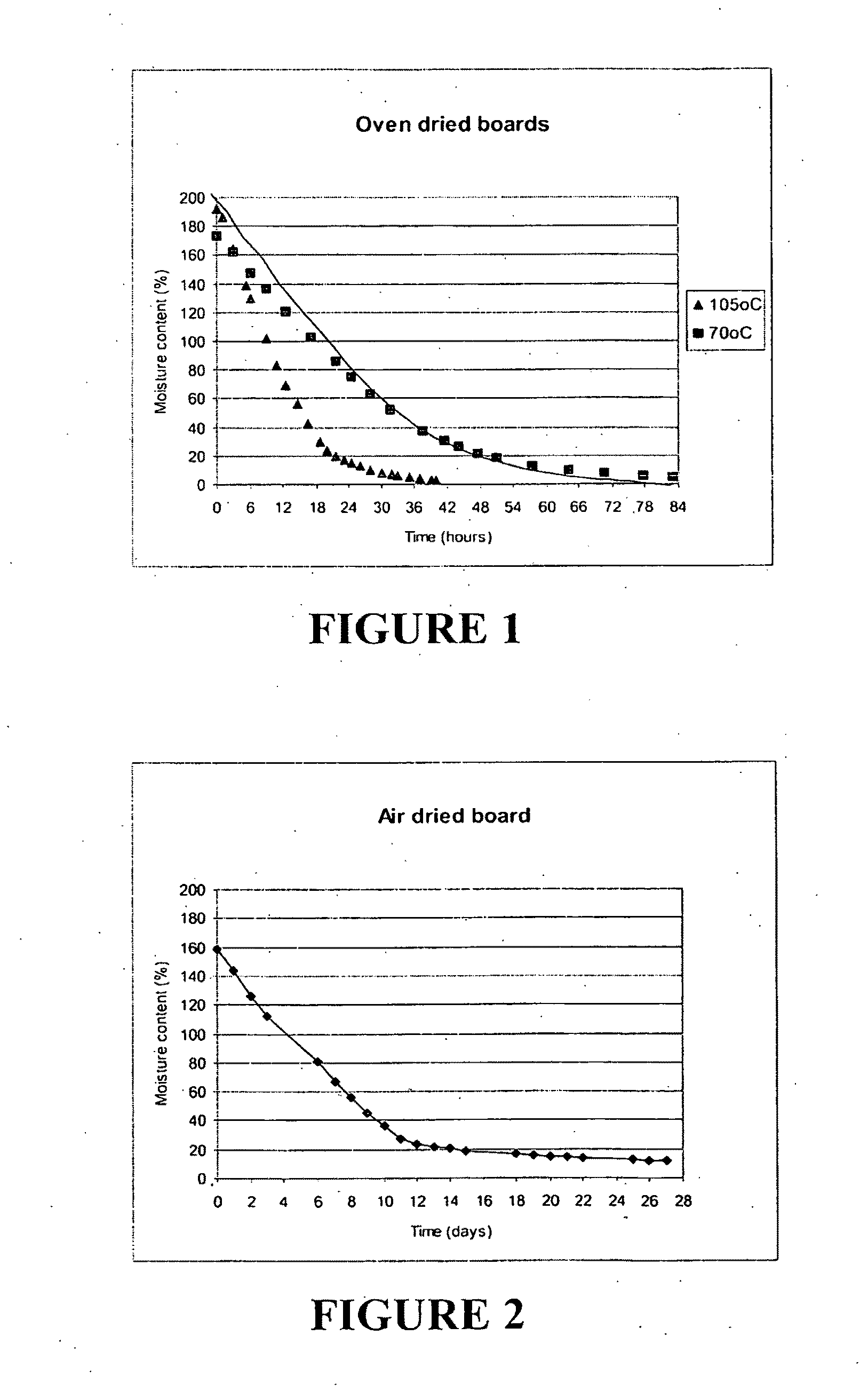

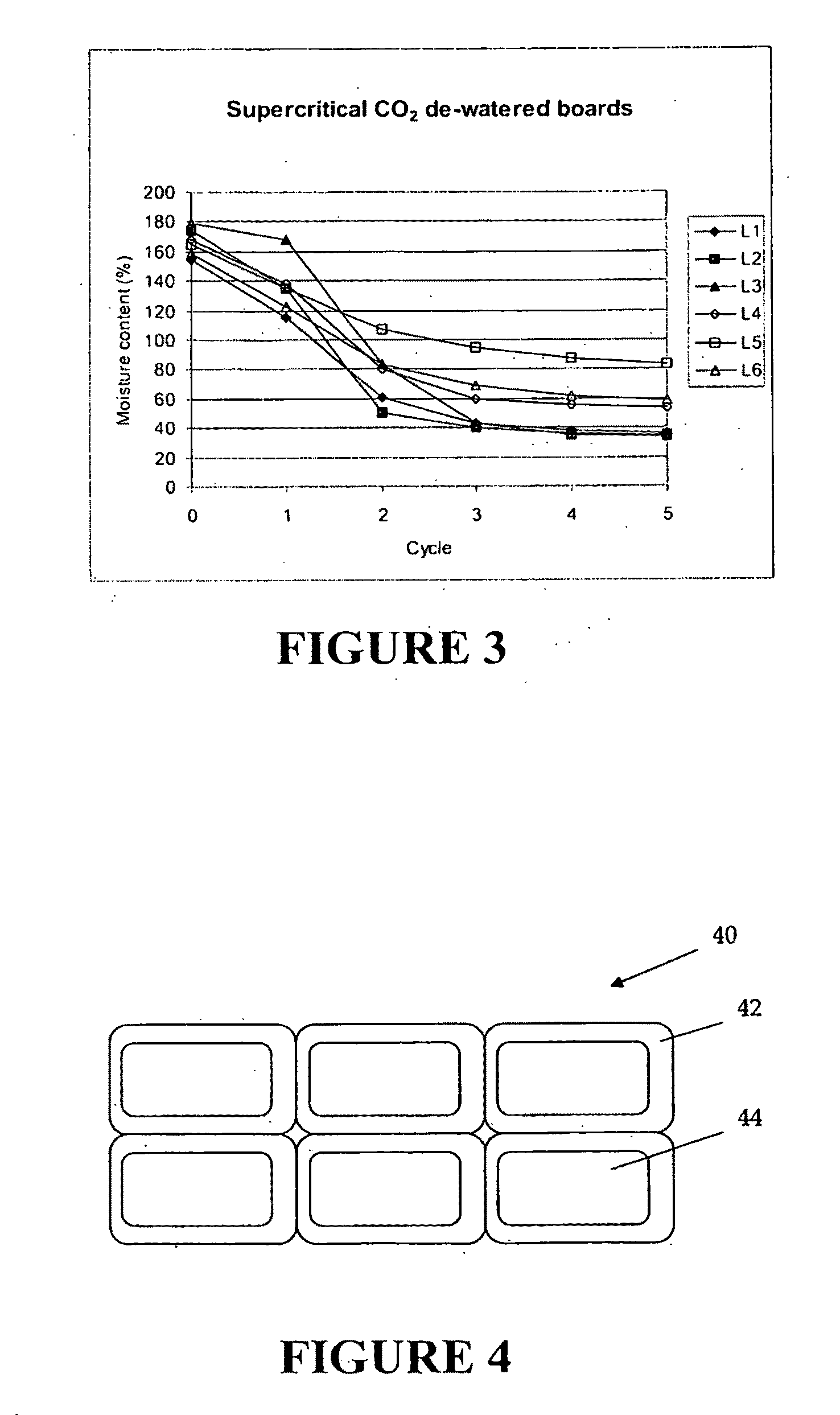

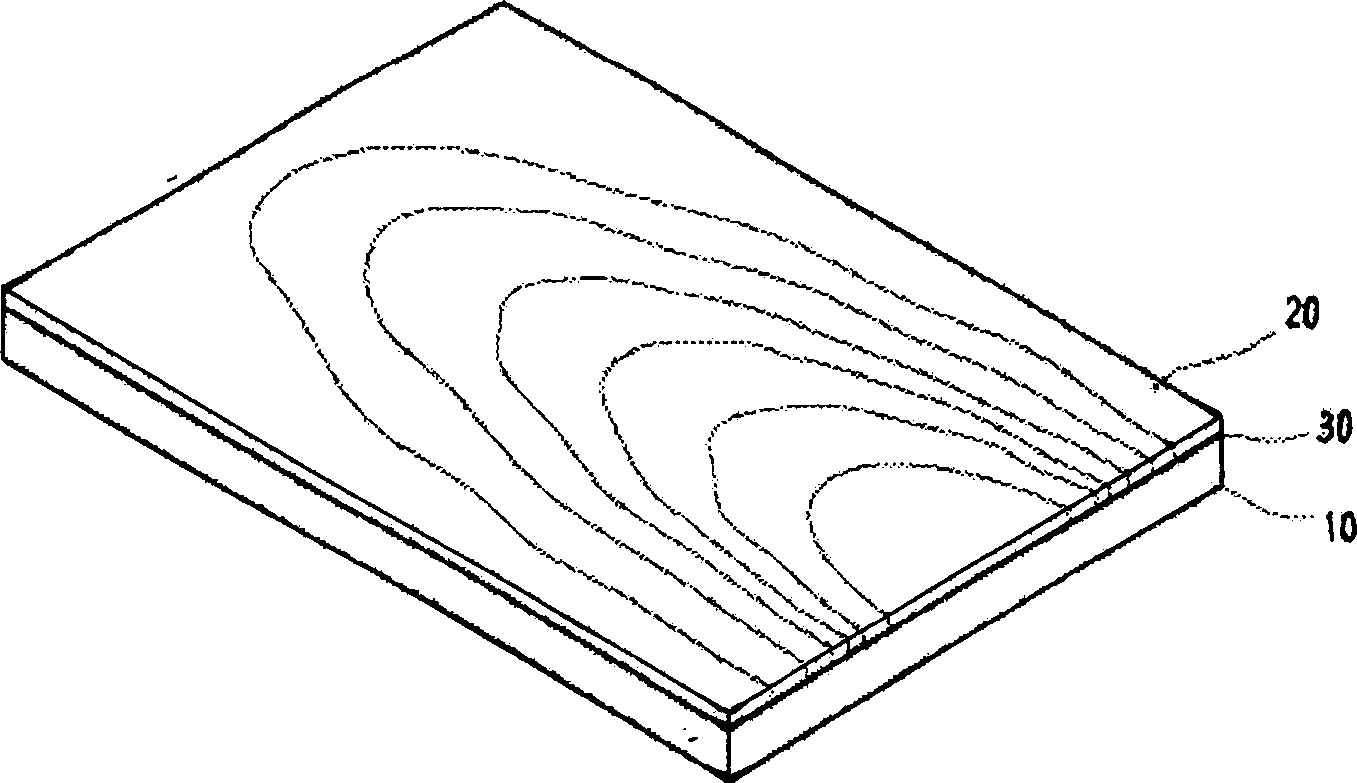

Wood drying

InactiveUS20100058607A1Increase biological durability durabilityExcellent physical durabilityDrying using combination processesPressure wood treatmentGreen woodCell wall

A process for removing water and solutes from the lumens of green wood, while leaving the cell walls throughout the wood uniformly fully swollen, comprises subjecting the green wood to supercritical carbon dioxide.

Owner:NEW ZEALAND FOREST RES INST

Manufacturing method of veneer adhibited on the top surface of floor board using chinese medicine

The invention provides a method for producing a veneer adhered to the top surface of a floor board by Chinese medicine, which comprises the following procedures: a procedure of respectively mixing szechwan lovage rhizome, lignum Santali, clove, mint, megnolia hypoleuca, muskiness, thin cinnamon bark, Chinese angelica, Chinese lizard-tail, beatamaria in catalan and oldenlandia by the weight ratio of less than 10 percent to produce a mixed herb, and putting the mixed herb with weight ratio of 20 percent to 40 percent and the water with weight ratio of 60 percent to 80 percent into a heating container to be fully heated to prepare the Chinese medicine liquid; a procedure of putting a veneer with thickness of 0.3 to 3mm and with certain width into a vacuum pot to be heated under temperature of 70 to 90 degrees; a procedure of pouring the Chinese medicine liquid into the heated vacuum pot and stewing the Chinese medicine liquid for one to four hours; a procedure of dehydrating and drying the stewed veneer taken out from the vacuum pot. The method has the advantages that the various components of the Chinese medicine are immersed on the veneer and the veneer is directly adhered to the indoor floor or the floor board on the wall, so that the floor board emits the smell of the Chinese medicines, which is good for the health of people.

Owner:WIN & WIN WOOD

Process for the acetylation of wood and acetylated wood

InactiveUS20150050483A1High degree of acetylationHigh degreeSynthetic resin layered productsWood treatment detailsAcetic acidSolid wood

The invention relates to a process for acetylation of wood having a density of above 400 kg / m3, particularly, of Southern Yellow Pine, and acetylated wood obtainable by this method. The described acetylation process allows the production of acetylated wood having higher acetylation levels, such as an acetyl content of at least 20% by weight. The acetylated wood has also a low residual acetic acid content, in particular, lower than 1% by weight. The invention is particularly useful for acetylation on industrial scale of pieces of solid wood, preferably, of wood beams.

Owner:TITAN WOOD LTD

Manufacturing method for impregnated wood and preparation method for impregnating resin

ActiveCN104526804AReduce polarityReduce acidityWood treatment detailsPretreatment apparatusMechanical propertyPolyresin

The invention provides a manufacturing method for impregnated wood and a preparation method for impregnating resin. The manufacturing method for the impregnated wood comprises the steps of primary drying, impregnating, secondary drying and hot and wet treatment. The mechanical property, the formaldehyde emission and the size stability of the impregnated wood manufactured through the method are obviously improved, and the impregnated wood can meet the using requirements of furniture and decoration such as cabinets, chests and doors and windows and wood floors. The preparation method for the impregnating resin comprises the steps of feeding, reacting and discharging, raw materials needed for preparing the resin are simple and easy to store, and under the condition that the water content of the wood is low, the resin can evenly impregnate the wood.

Owner:GUANGZHOU HOLIKE CREATIVE HOME FURNISHING

Preparation method of functional wood material with photocatalytic activity

ActiveCN107803900AWide variety of sourcesReduce manufacturing costRadiation/waves wood treatmentPhysical/chemical process catalystsProtonationUltraviolet lights

The invention provides a preparation method of a functional wood material with a photocatalytic degradation function. The preparation method solves the problems that a wood material is easily polluted, color change under ultraviolet light is large, and the catalyzing efficiency of photocatalytic degradation of organic dyestuff through a single catalyst is low. The preparation method comprises thesteps that first, surface activation is conducted on the wood material through a sodium hydroxide solution; g-C3N4 after being subjected to protonated treatment is loaded on the surface of the wood material through a vacuum impregnation method; and taking ammonium fluorotitanate and urea as raw materials, TiO2 is grown on the surface of the wood material which is loaded with the g-C3N4, and the functional wood material with the photocatalytic activity is obtained through the steps of heat preservation, cleaning and the like. The degradation rate of rhodamine B and a methylene blue solution with the mass concentration being 2 mg / L and under ultraviolet illumination within four hours can reach to 95% or above through the functional wood material, change in color difference of the surface ofthe wood material after being subjected to ultraviolet light aging can be effectively reduced, color stability of the surface of the wood material is greatly improved, and the preparation technology has the advantages that the technology is simple, operation is easy, the cost is low, and the environment-friendly effect is achieved.

Owner:NORTHEAST FORESTRY UNIVERSITY

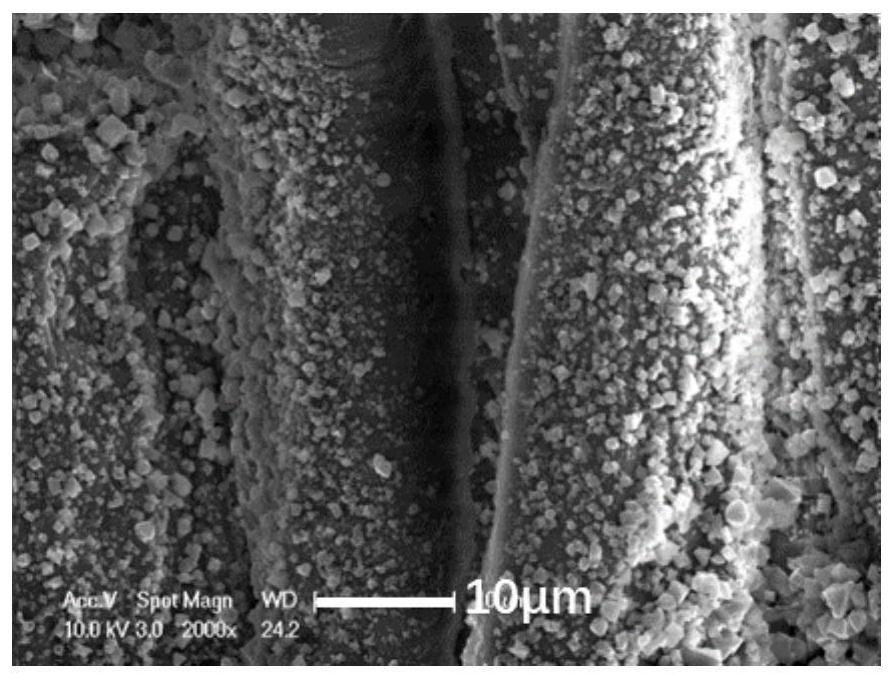

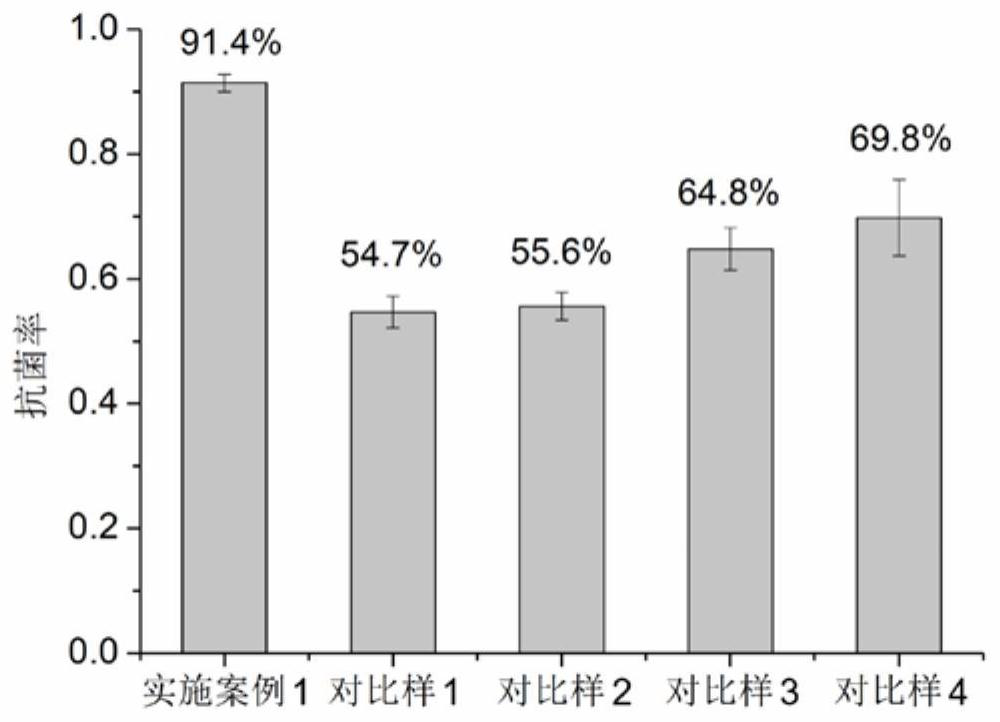

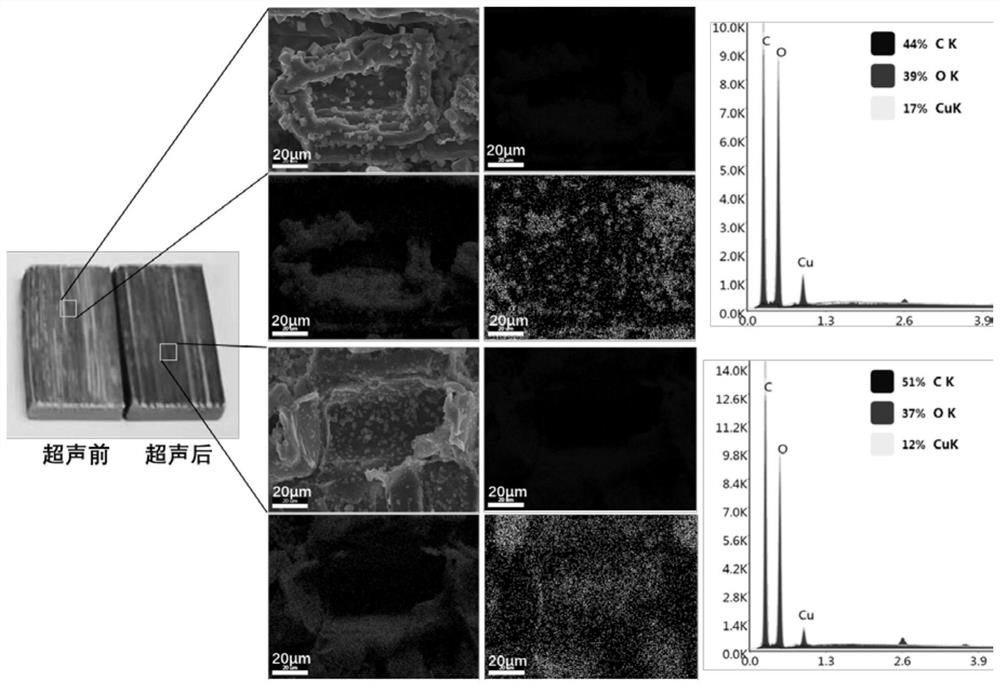

Metal organic framework/wood composite material, and preparation method and application thereof

ActiveCN112959446AUniform growthImprove structural stabilityOther chemical processesWood treatment detailsMetal-organic frameworkAnti bacteria

The invention provides a metal organic framework / wood composite material, and a preparation method and application thereof. A metal organic framework is uniformly distributed on the surface of a wood material after in-situ growth on the surface of the wood material. The composite material disclosed by the invention is formed by efficient and controllable growth of the metal organic framework material on the surface of the wood material in situ. The method comprises the following steps: firstly, carrying out delignification treatment on the surface of the wood material by using an acid and an alkali, then carrying out carboxylation treatment on the delignified wood material, and then soaking the wood material in a metal salt solution and an organic ligand solution in sequence to finally prepare the wood composite material with the metal organic framework uniformly grown on the surface of the wood material. The method is simple and effective, is suitable for various different metal organic frameworks, and is suitable for industrial production. Meanwhile, the metal organic framework / wood composite material prepared by the method has good structural stability and efficient antibacterial performance, and has potential application value in the aspects of drug loading, catalysis, gas adsorption and the like.

Owner:INT CENT FOR BAMBOO & RATTAN

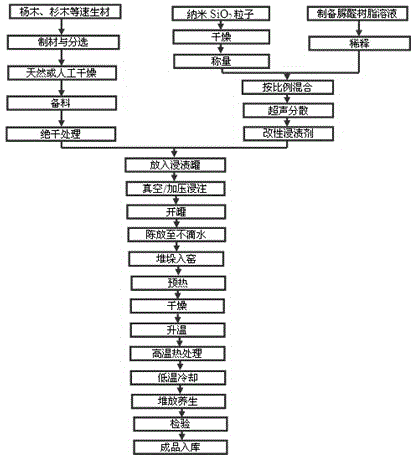

Modified fast growing wood impregnating agent and impregnation high-temperature integrated treatment method

InactiveCN105563578AThe modification effect is good in hardnessHigh hardnessPretreatment apparatusPressure impregnationHardnessAdditional values

The invention relates to a modified fast growing wood impregnating agent and impregnation high-temperature integrated treatment method. The method comprises the following steps: (1) preparing a modified urea-formaldehyde resin impregnating agent; (2) preparing the fast growing wood and treating at a preparation stage; (3) absolutely drying at a high temperature; (4) performing the impregnation and high-temperature integrated treatment; (5) aging, maintaining, inspecting and warehousing. The modified fast growing wood impregnating agent and impregnation high-temperature integrated treatment method has the advantages that: (1) a modified impregnating agent is made into a suspension by adding a nano material on the basis of the conventional urea-formaldehyde resin impregnating agent and ultrasonically stirring, the modification effect of the modified impregnating agent on the aspects such as hardness, abrasion resistance, size stability and the like is better than that of the conventional urea-formaldehyde resin impregnating agent, and the preparation process is simple, moderate in conditions and convenient to operate; (2) the physical and mechanical properties of the fast growing wood such as poplar and cedar can be well improved; the wide application of the fast growing wood can be realized, the consumption of top-grade wood can be reduced, the wood application range can be enlarged, the additional value and technical content of the fast growing wood can be increased, and the optimal application of poor wood can be realized.

Owner:GUANGDONG YIHUA TIMBER IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com