Patents

Literature

584 results about "Engineered wood" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Engineered wood, also called mass timber, composite wood, man-made wood, or manufactured board, includes a range of derivative wood products which are manufactured by binding or fixing the strands, particles, fibres, or veneers or boards of wood, together with adhesives, or other methods of fixation to form composite material. The panels vary in size but can range upwards of 64 by 8 feet (20m x 2.4m) and in the case of CLT can be of any thickness from a few inches to 16 inches or more. These products are engineered to precise design specifications which are tested to meet national or international standards. Engineered wood products are used in a variety of applications, from home construction to commercial buildings to industrial products. The products can be used for joists and beams that replace steel in many building projects. The term Mass Timber to describe this group of building materials was popularized by architect Michael Green (Michael Green Architecture), a prominent champion of engineered timber construction.

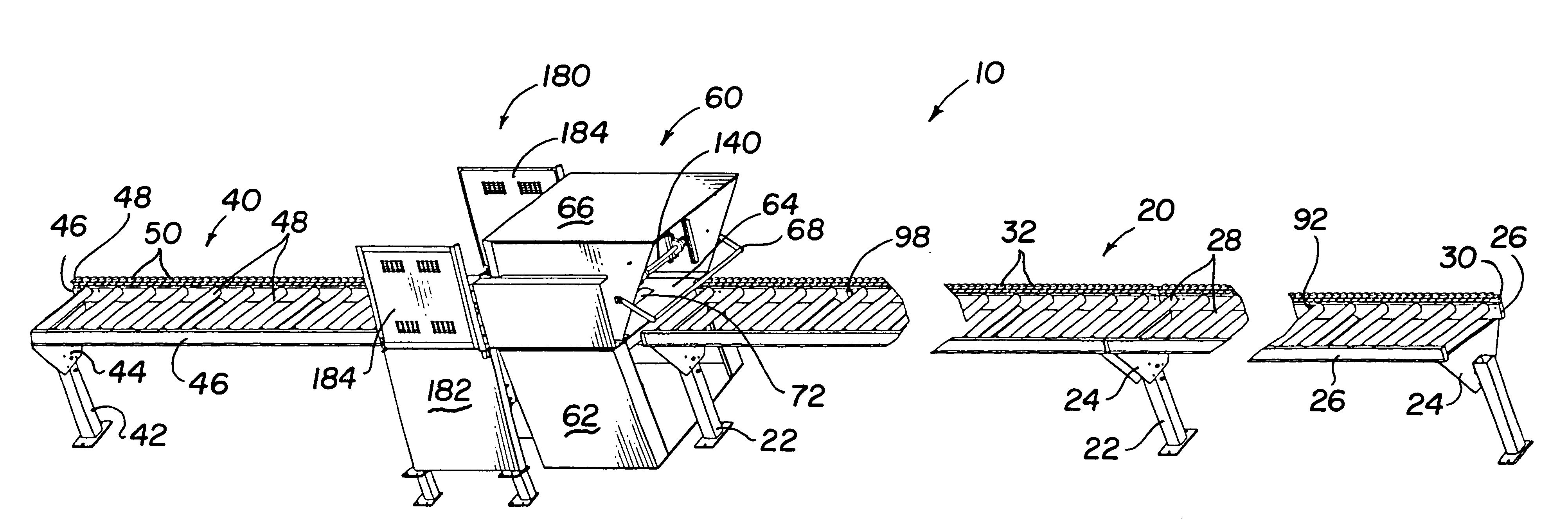

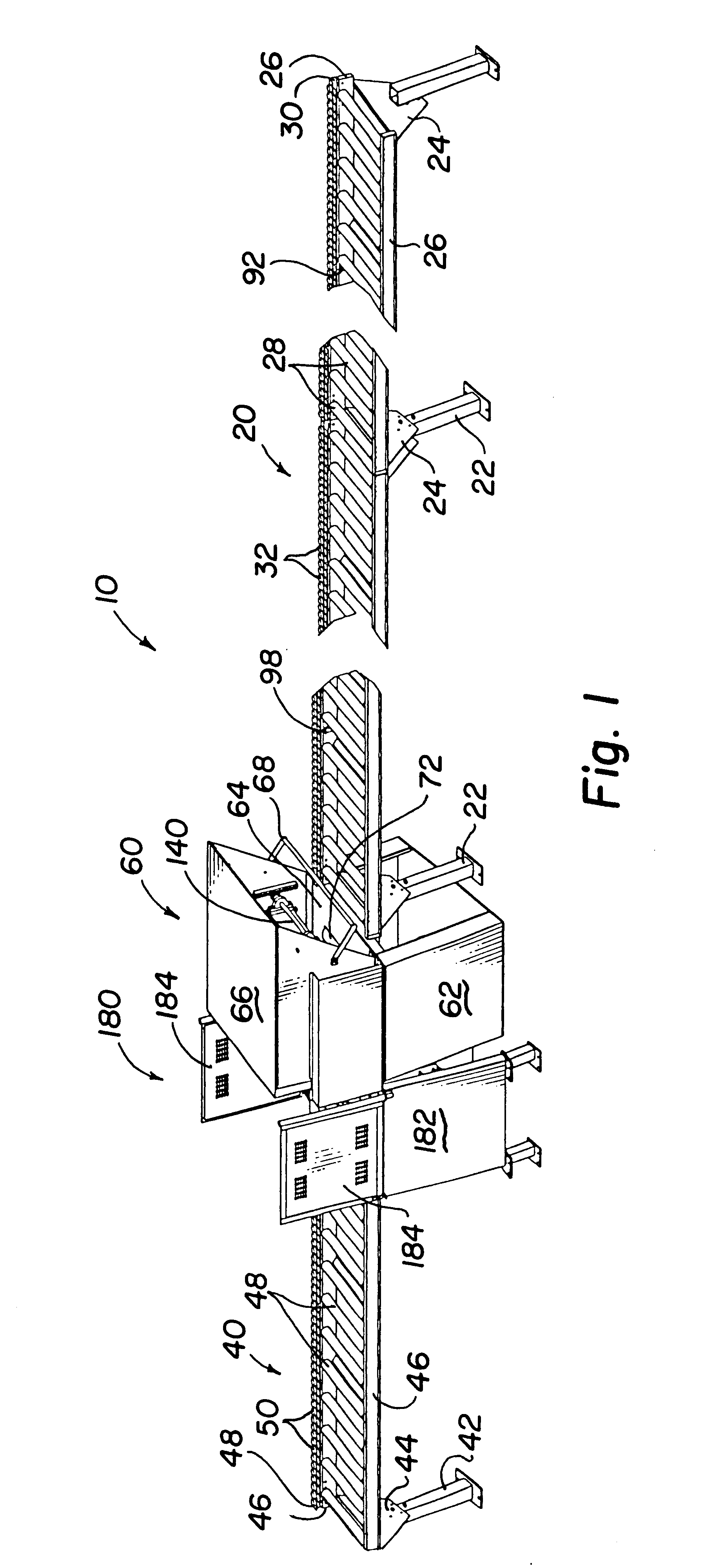

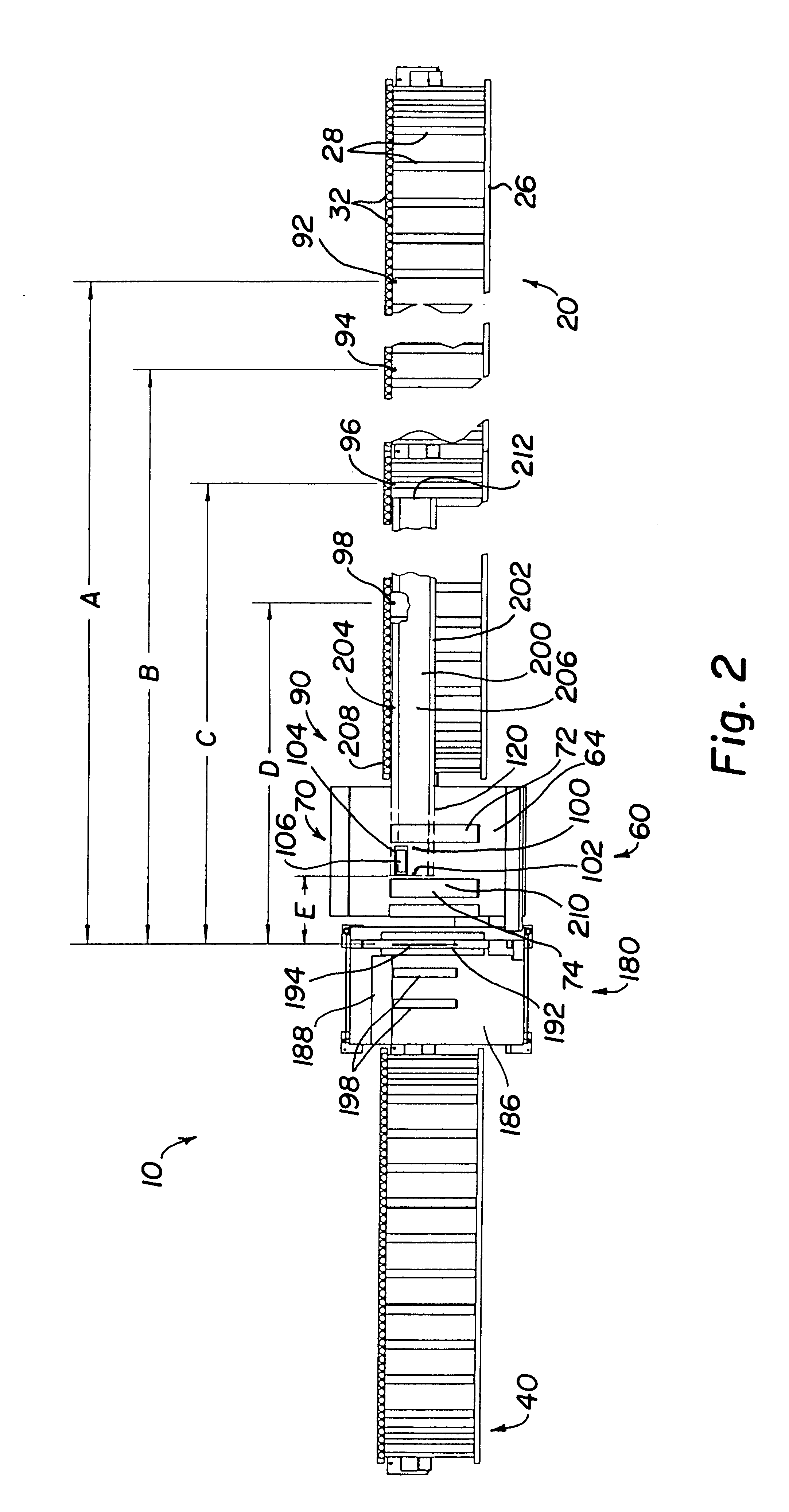

Engineered wood products cutting method and apparatus

InactiveUS6263773B1Automatic control devicesPrecision positioning equipmentEngineeringEngineered wood

The invention is a method and apparatus for processing an Engine Wood Product member. The member is moved to a home position in a driving unit and the length of the EWP member is automatically measured by moving the EWP member from the home position while engaging the EWP member with a measuring assembly including a measuring wheel having a smooth hard facing, the facing contacting the EWP member. The member is moved to a first cutting position and cut to a predetermined length. Activating one or more position sensor devices, at least one of the position sensor devices positioned such that the EWP member engages the position sensor device while the member is in the home position, the length of the member is determined as it is moved from the home position. Moving the EWP member is accomplished by clamping the EWP member between at least one driver roller and at least one pressure roller, each driver roller aligned with a corresponding pressure roller, and rotating the at least one driver roller to move the EWP member. First and second driver rollers may be spaced apart and positioned on opposite sides of the measuring wheel. An outfeed table and infeed table with angled rollers may further be employed.

Owner:ILLINOIS TOOL WORKS INC

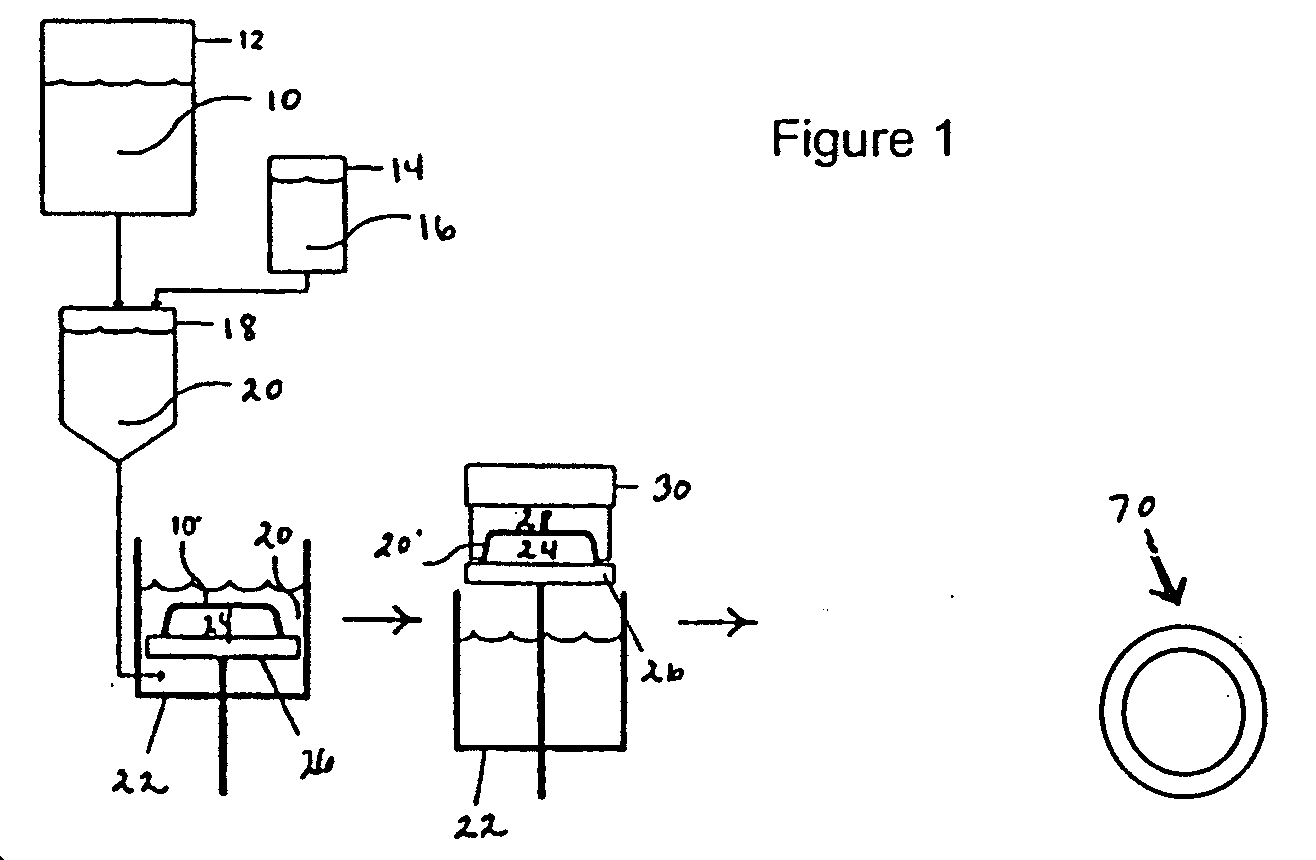

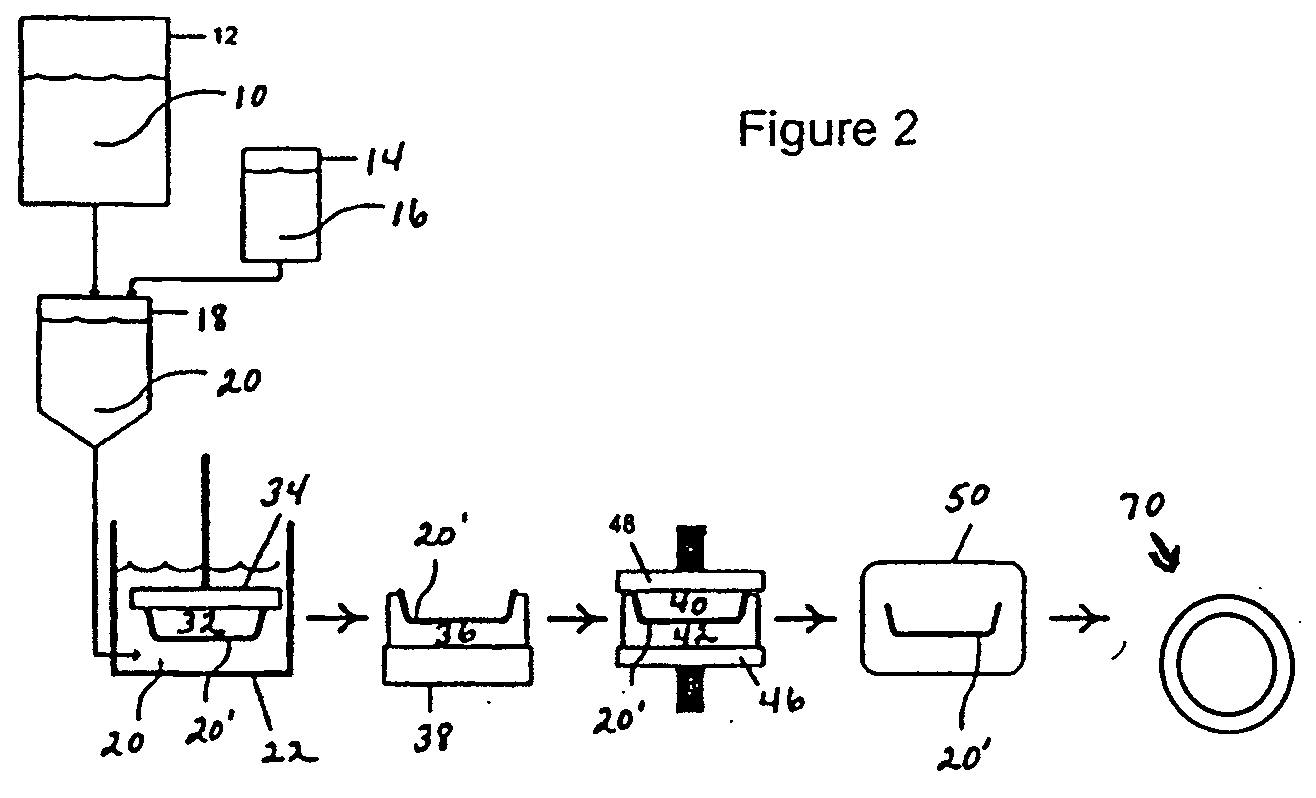

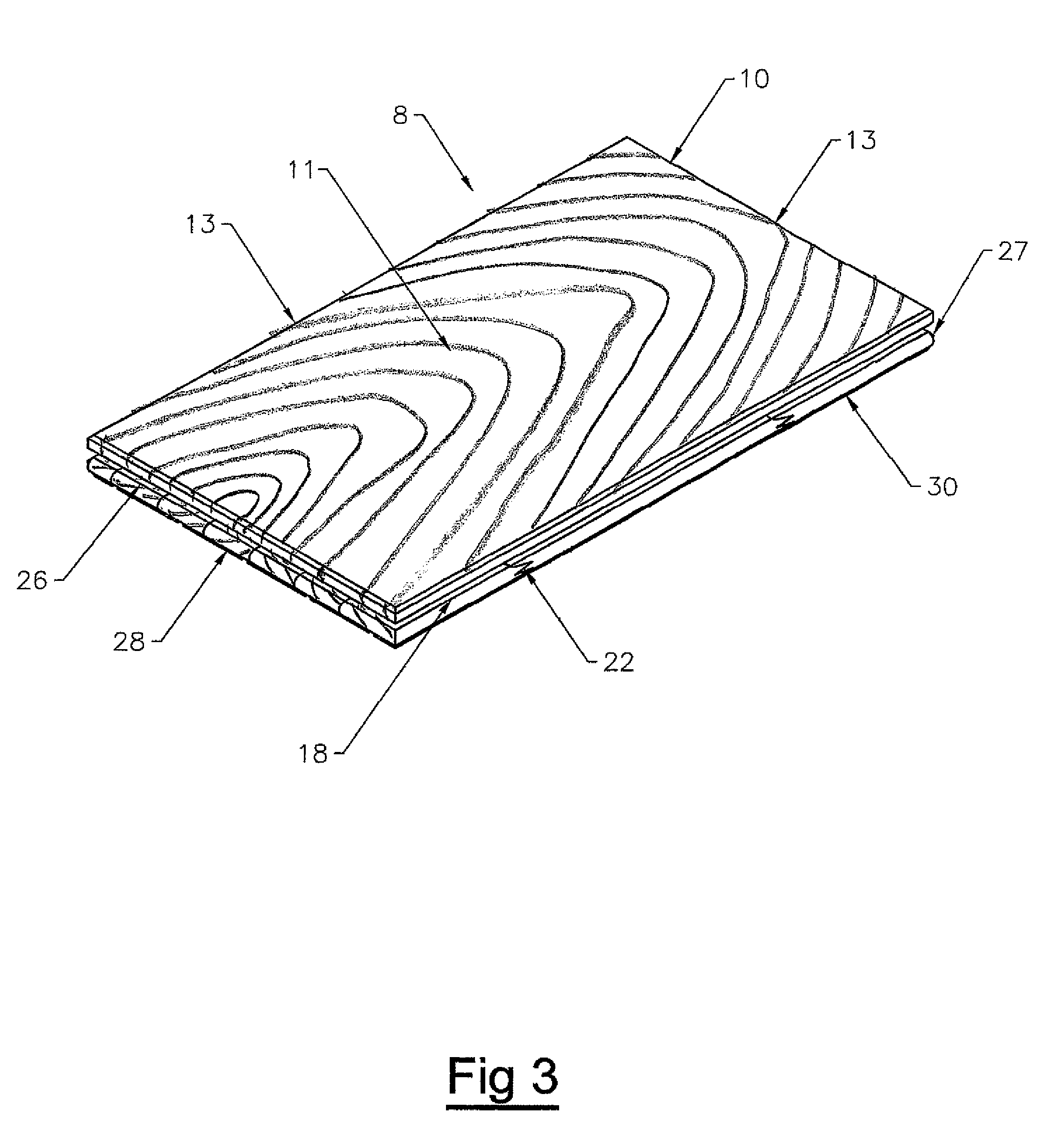

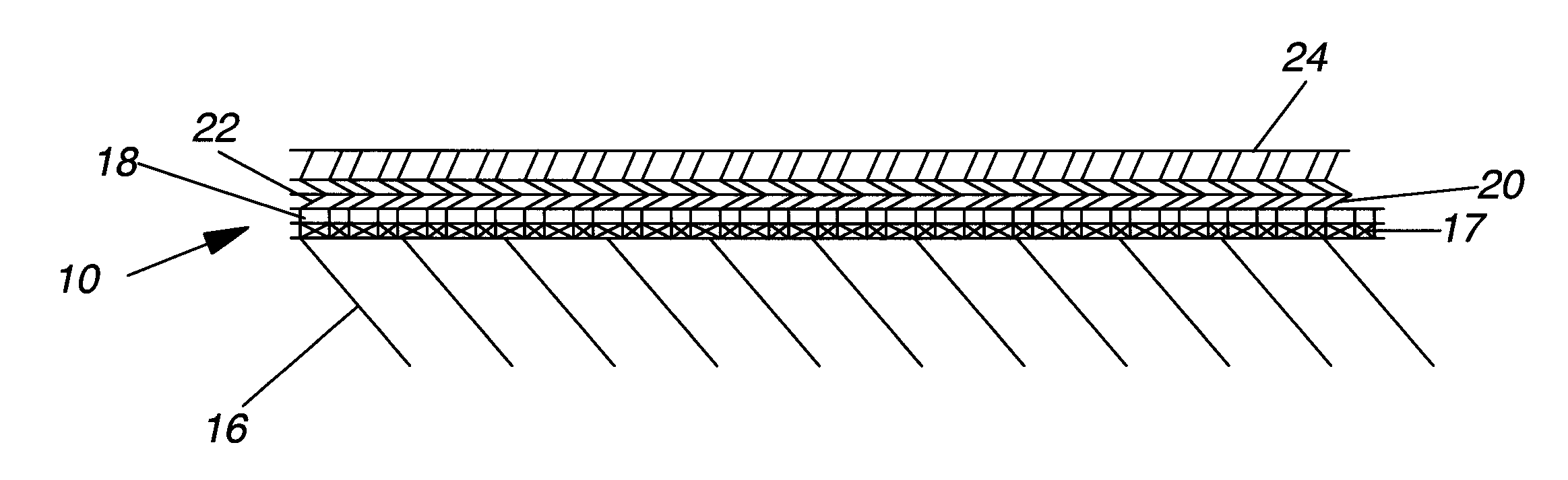

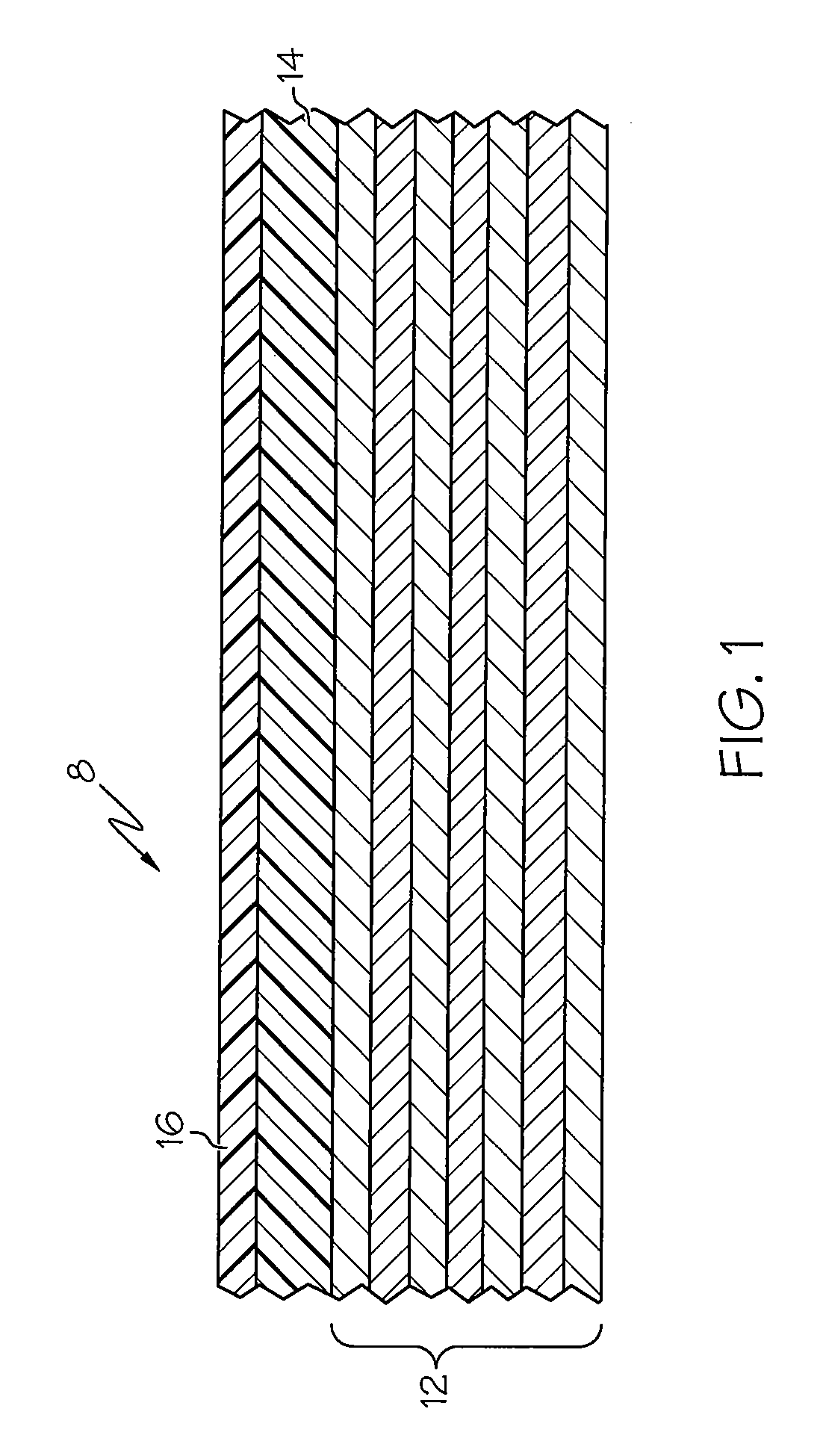

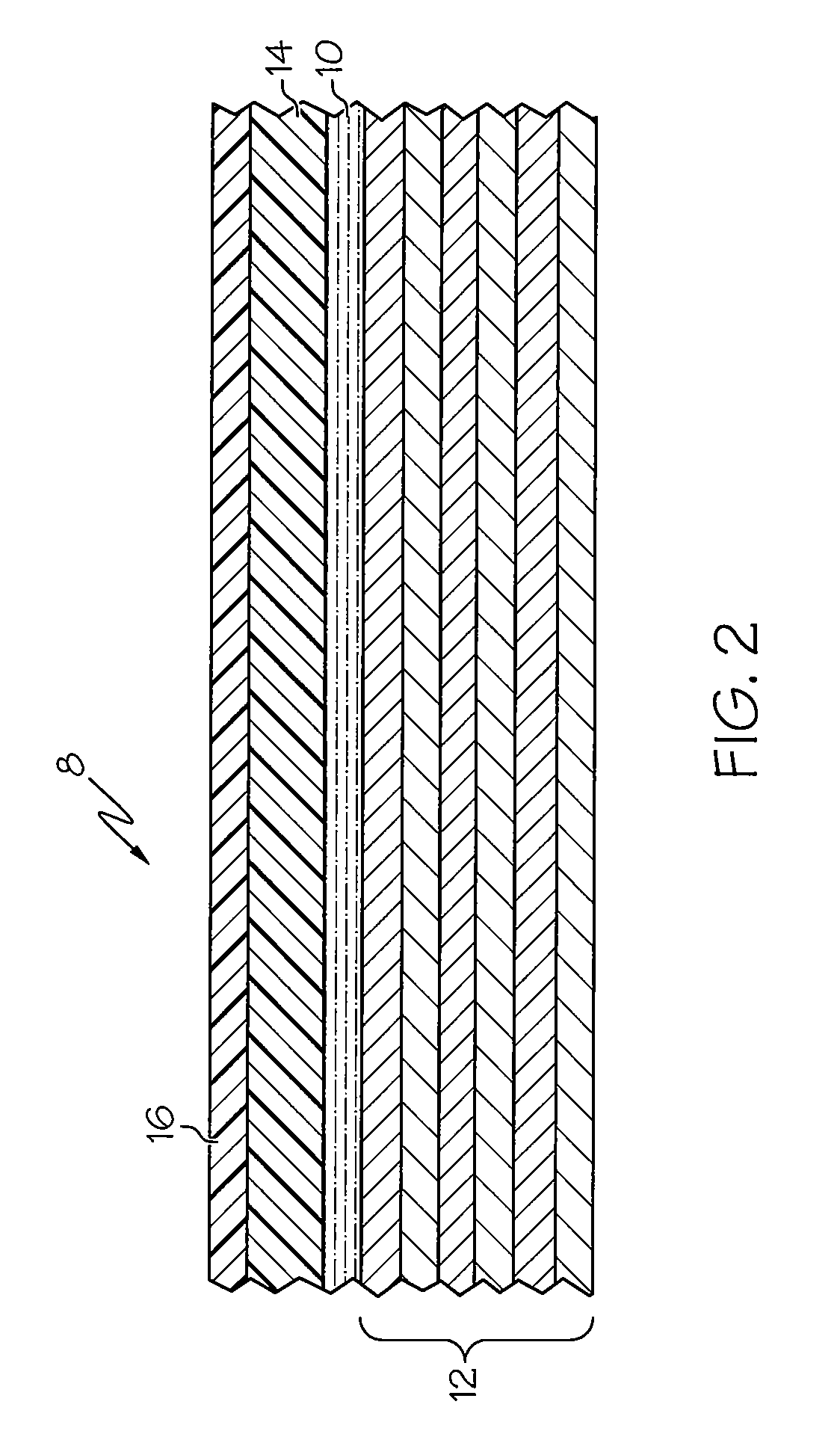

Engineered wood product

InactiveUS20100310893A1Lamination ancillary operationsSynthetic resin layered productsWood veneerCellulose fiber

Engineered wood products, methods of making the products, laminates including the products, and articles of manufacture which include the engineered products or composites, are disclosed. The products include wood and / or other cellulosic fibers, and can include non-cellulosic fibers, all or part of which can be derived from post-industrial and / or post-consumer materials. The products also include a binding agent, such as a latex dispersion, as well as hydrophobic materials, processing aids, colorants, and the like. The product can be in the form of a sheet, a three dimensional article or a plurality of laminated sheets, and can include one or more additional layers, such as top coat layers, reinforcing layers, cushioning layers, wood veneer layers, and / or additional product layers. The products can be used as flooring, and in construction, cabinetry, and the like.

Owner:SSI HOLDCO INC A DELAWARE +1

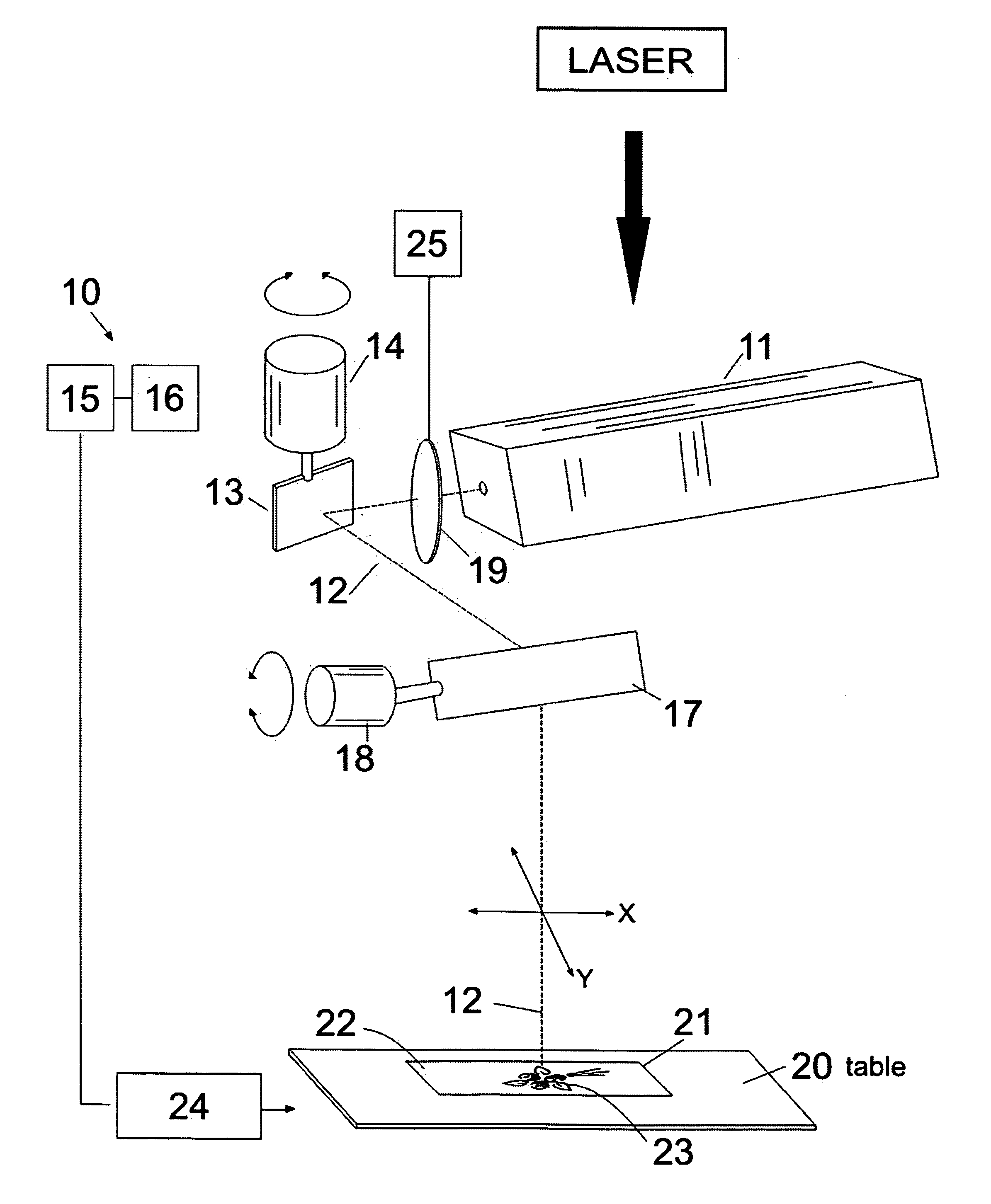

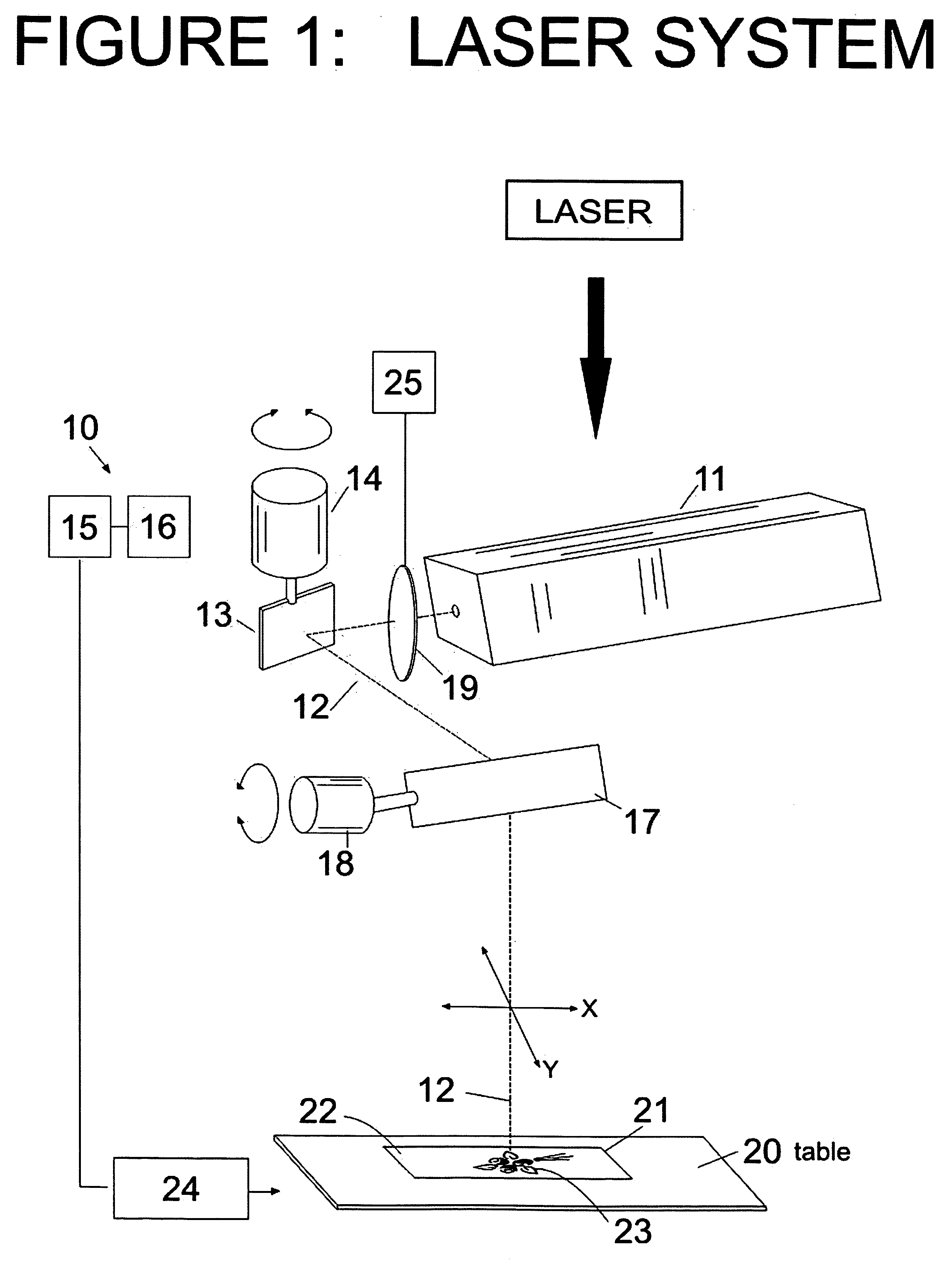

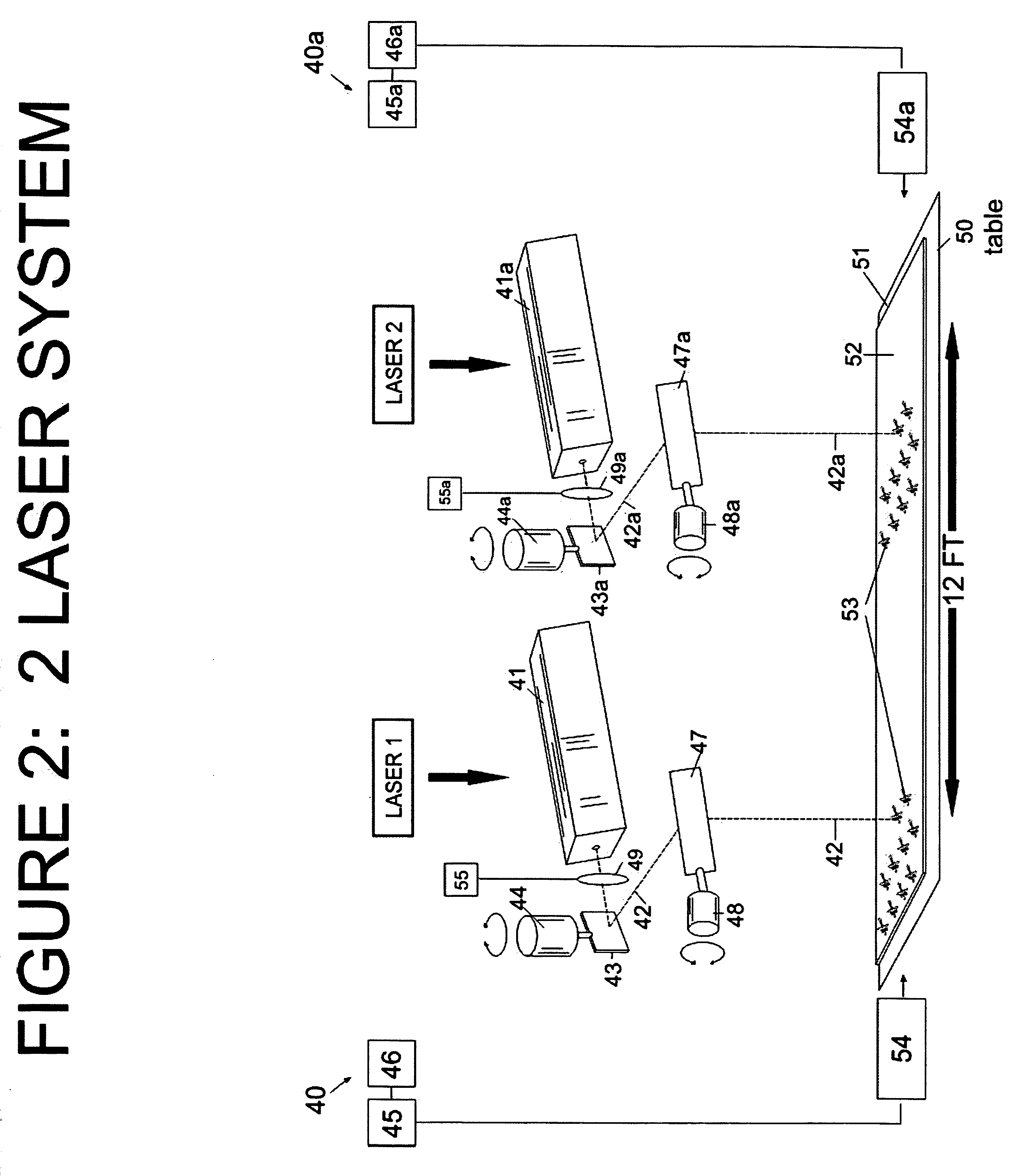

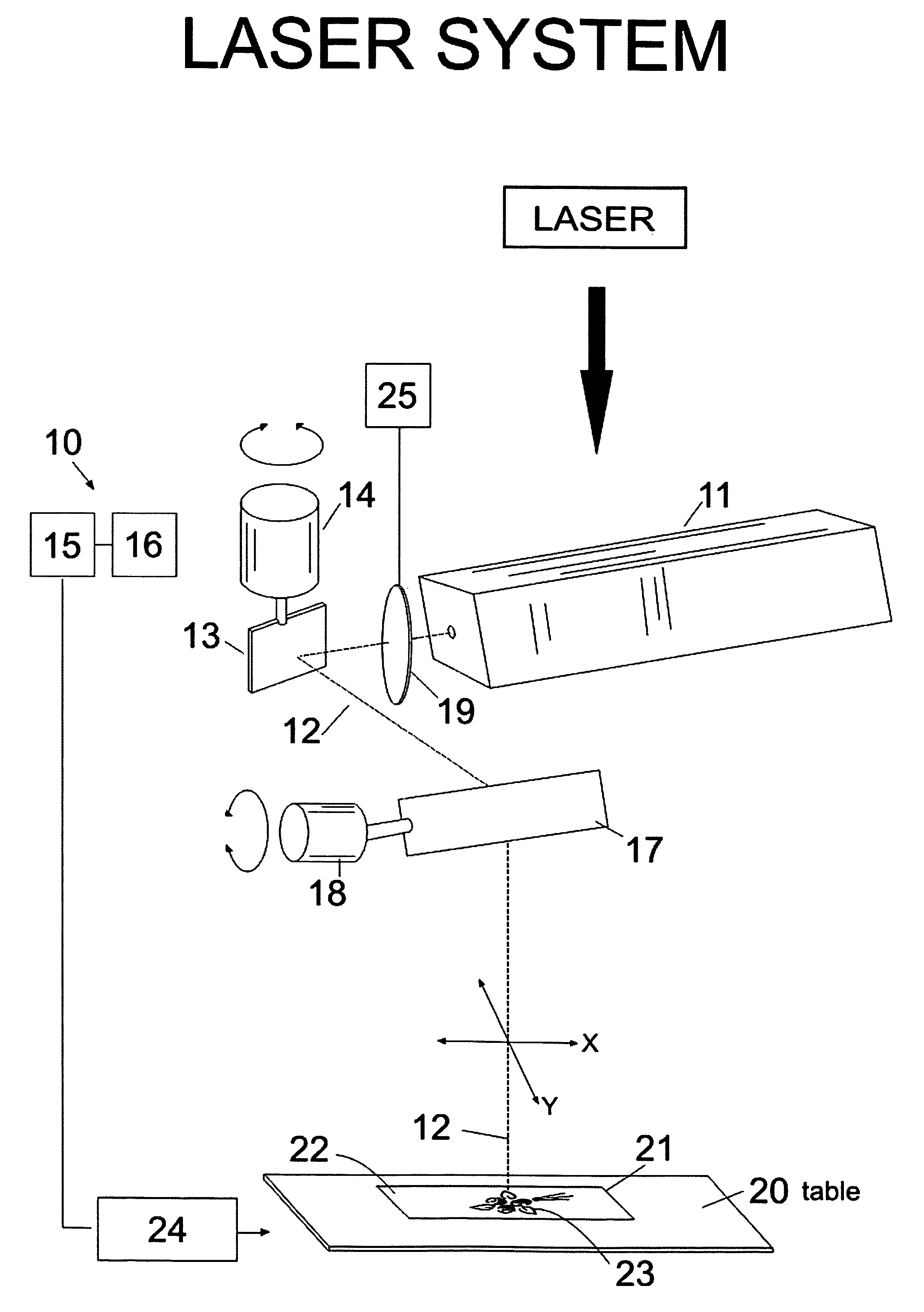

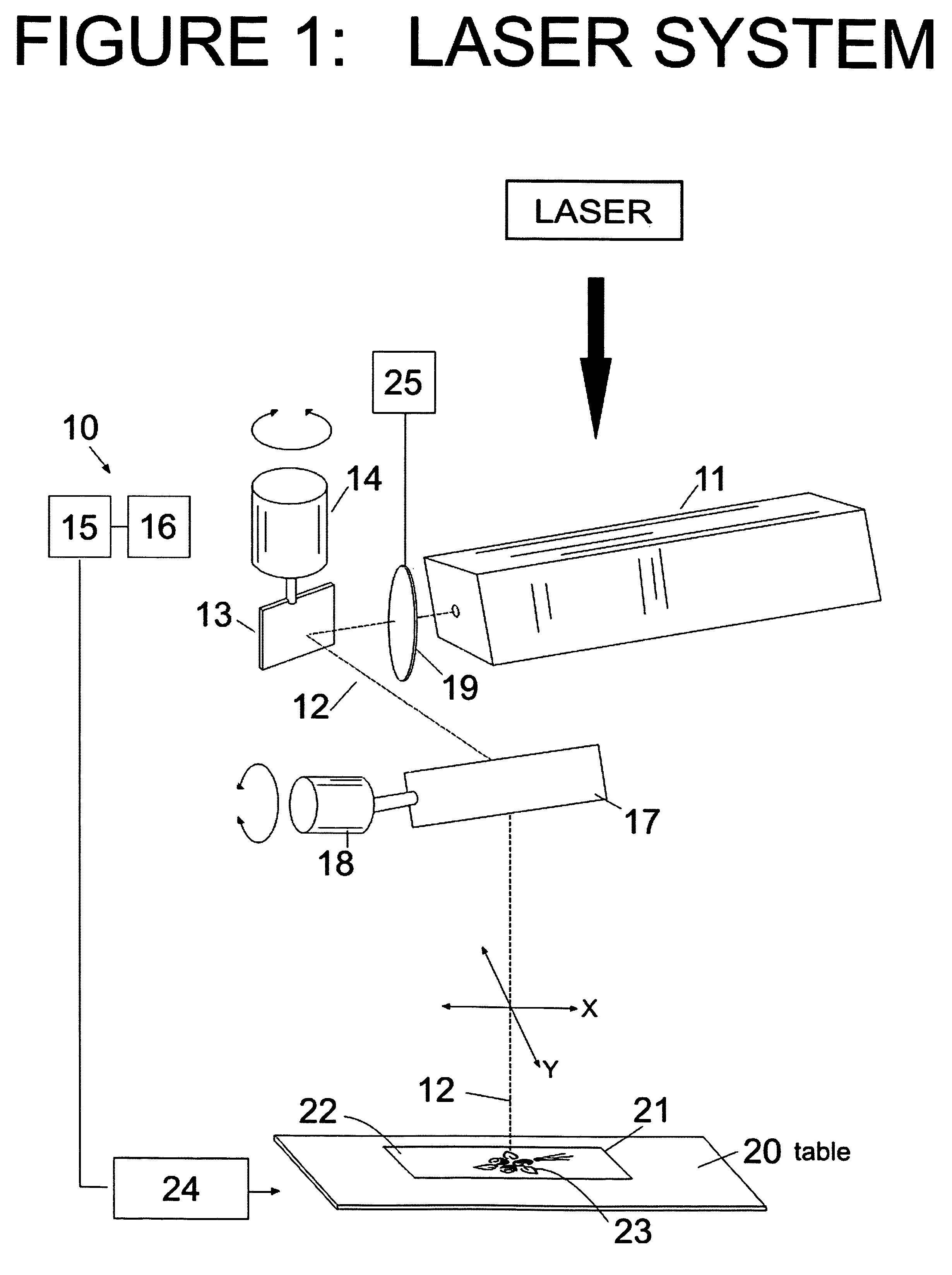

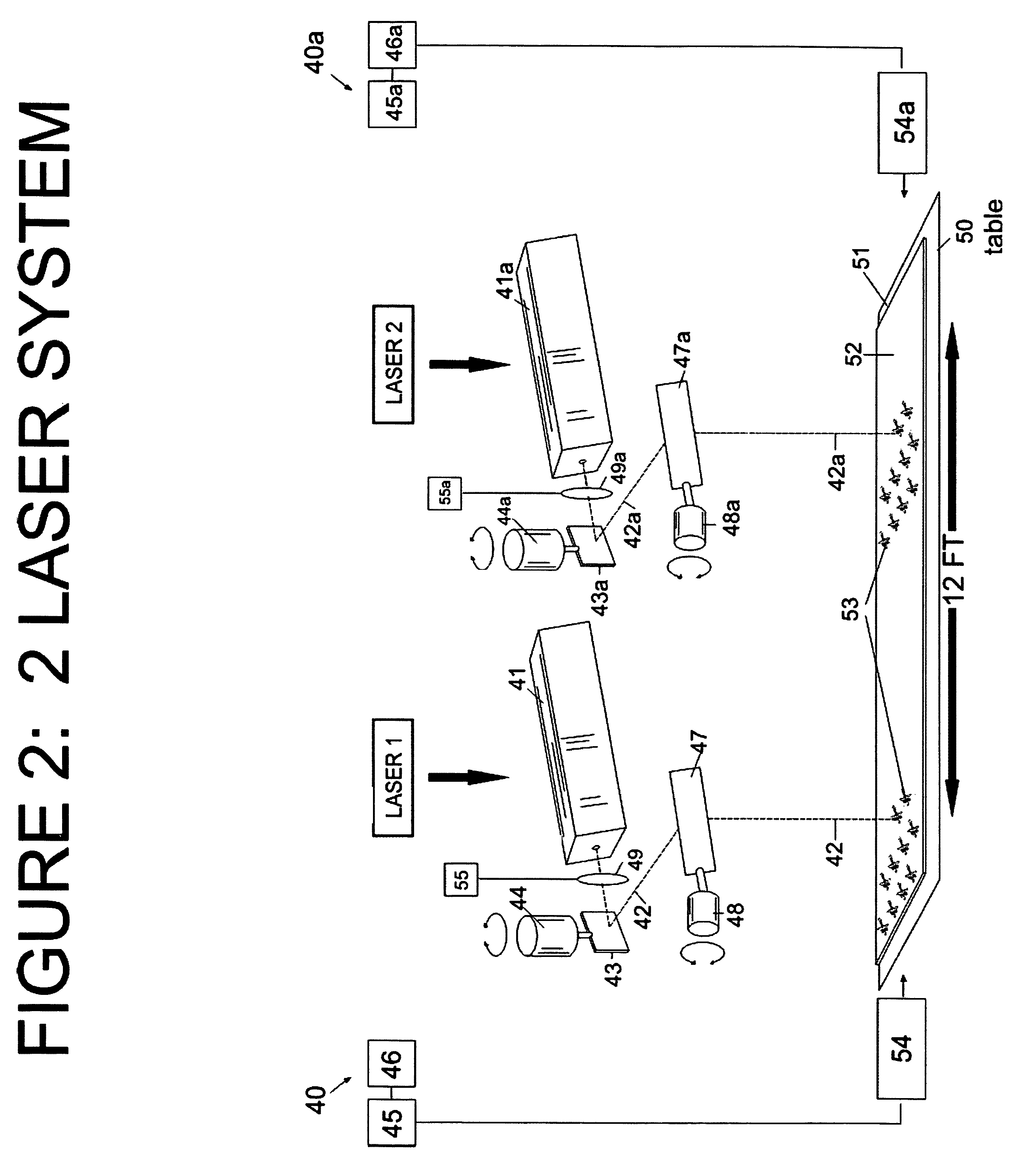

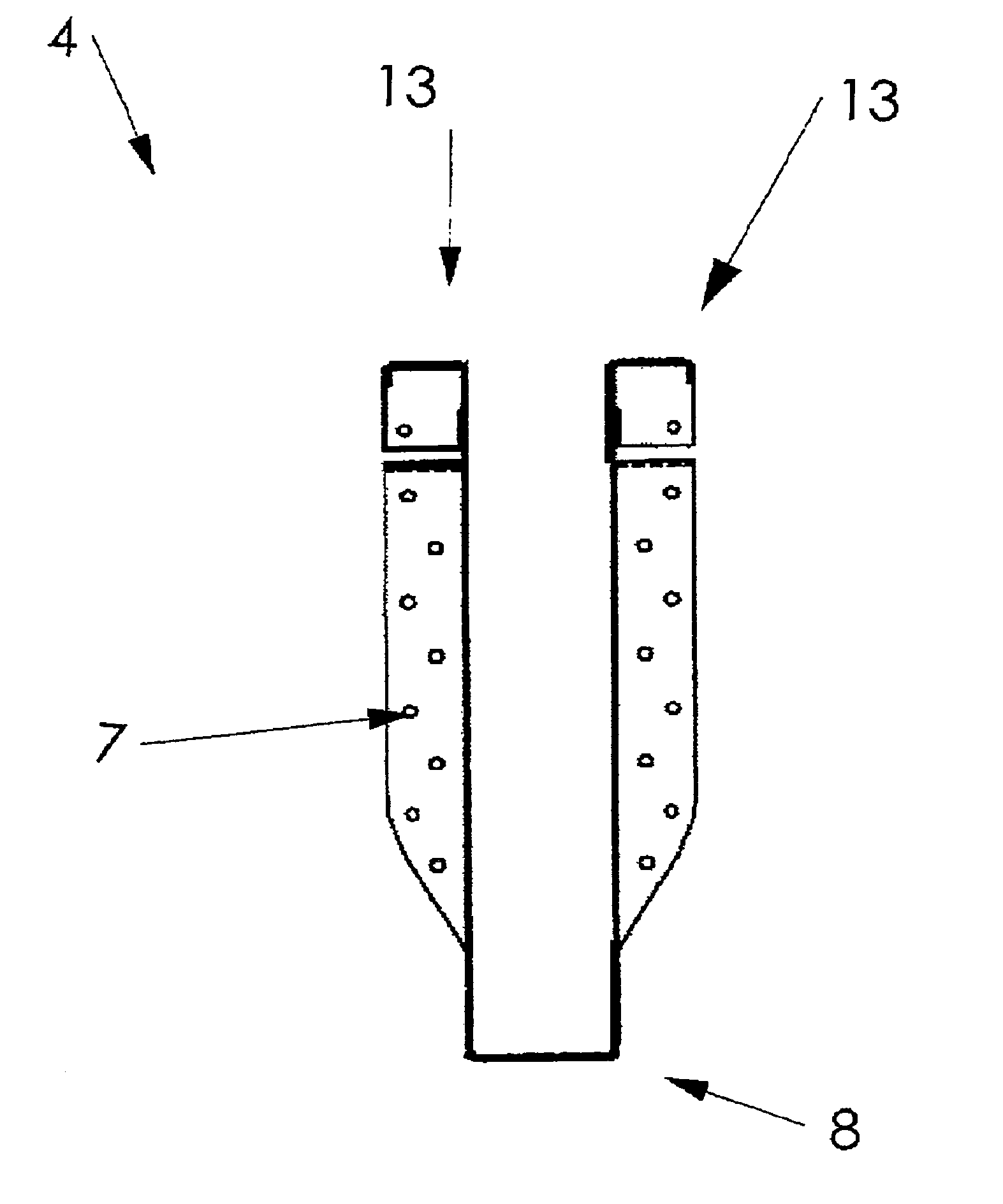

Engineered wood fiber product substrates and their formation by laser processing

InactiveUS20070108170A1Improve realismLow costNatural patternsDecorative surface effectsFiberLaser processing

A laser is used to a form information indicative of a pattern on a surface of a support piece formed from a compressed wood fiber product substrate. The pattern can be a wood grain. The field of the laser is increased, to allow lazing more of the material at once. According to an embodiment, the field is increased in a way that does not reduce the resolution of the lasing.

Owner:REVOLAZE LLC

Digitally printed surface covering

InactiveUS20050249929A1Finite shelf lifeAvoid necessityNatural patternsLayered productsEngineeringDigital printing

Owner:ARMSTRONG WORLD INDUSTRIES

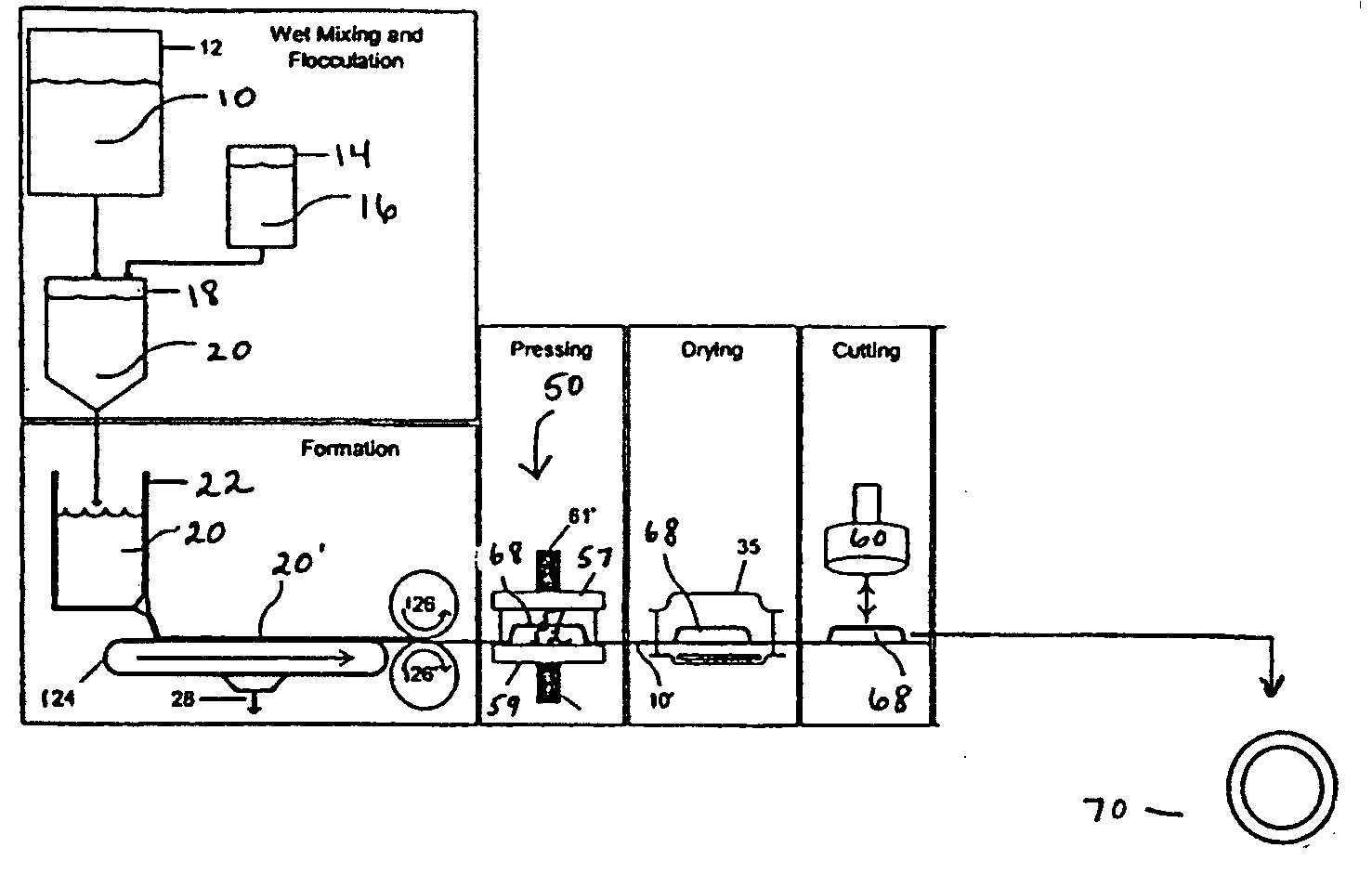

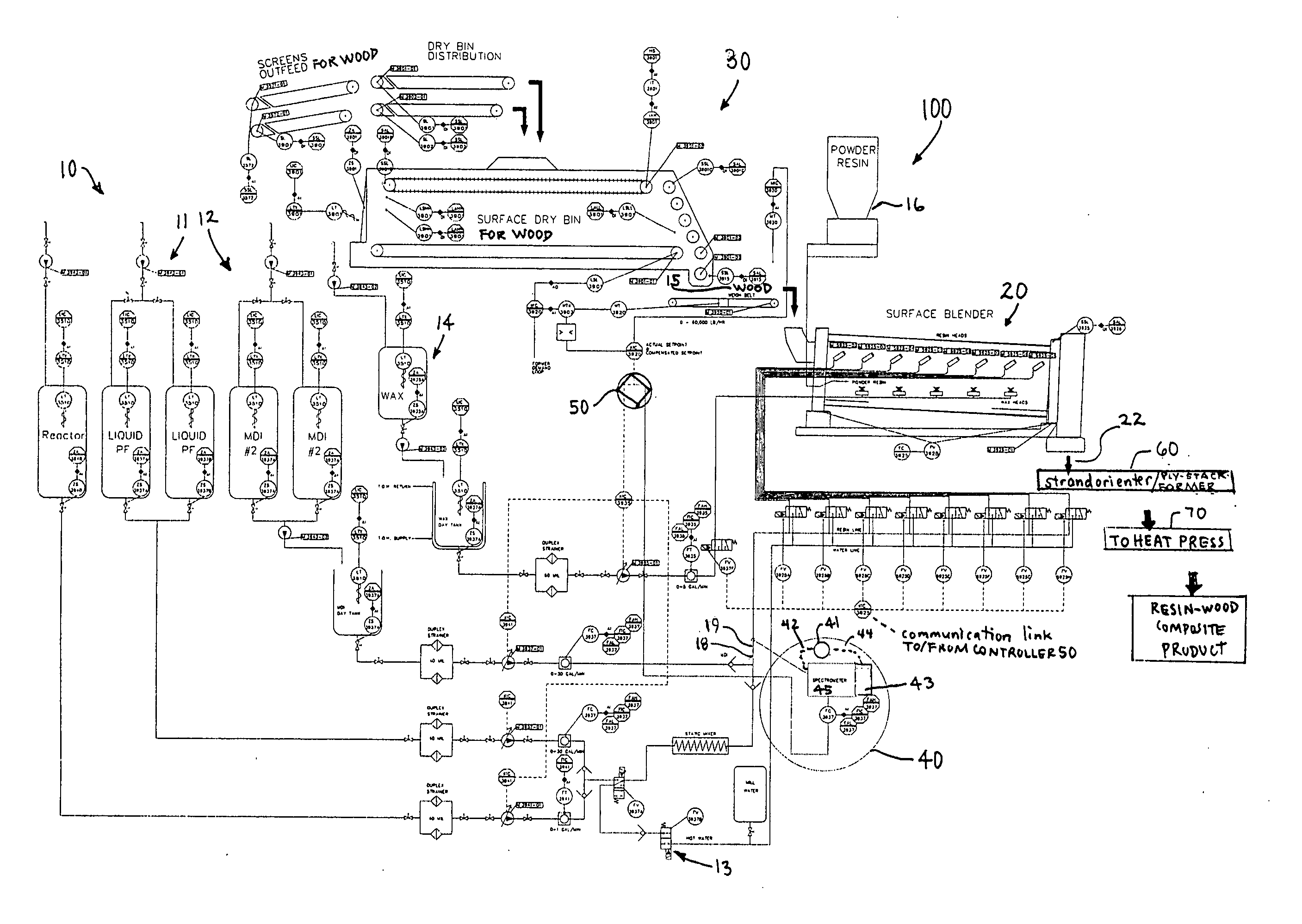

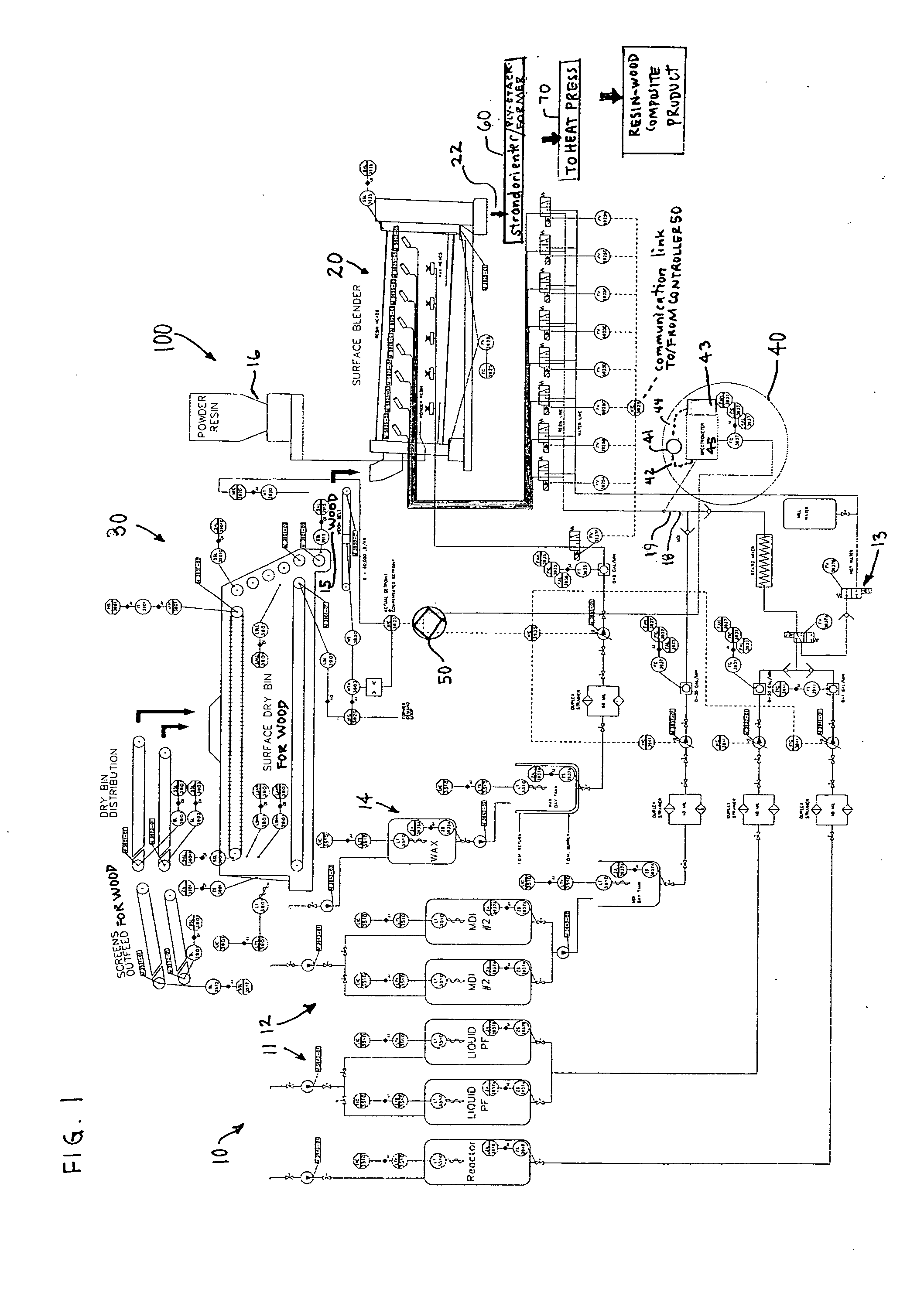

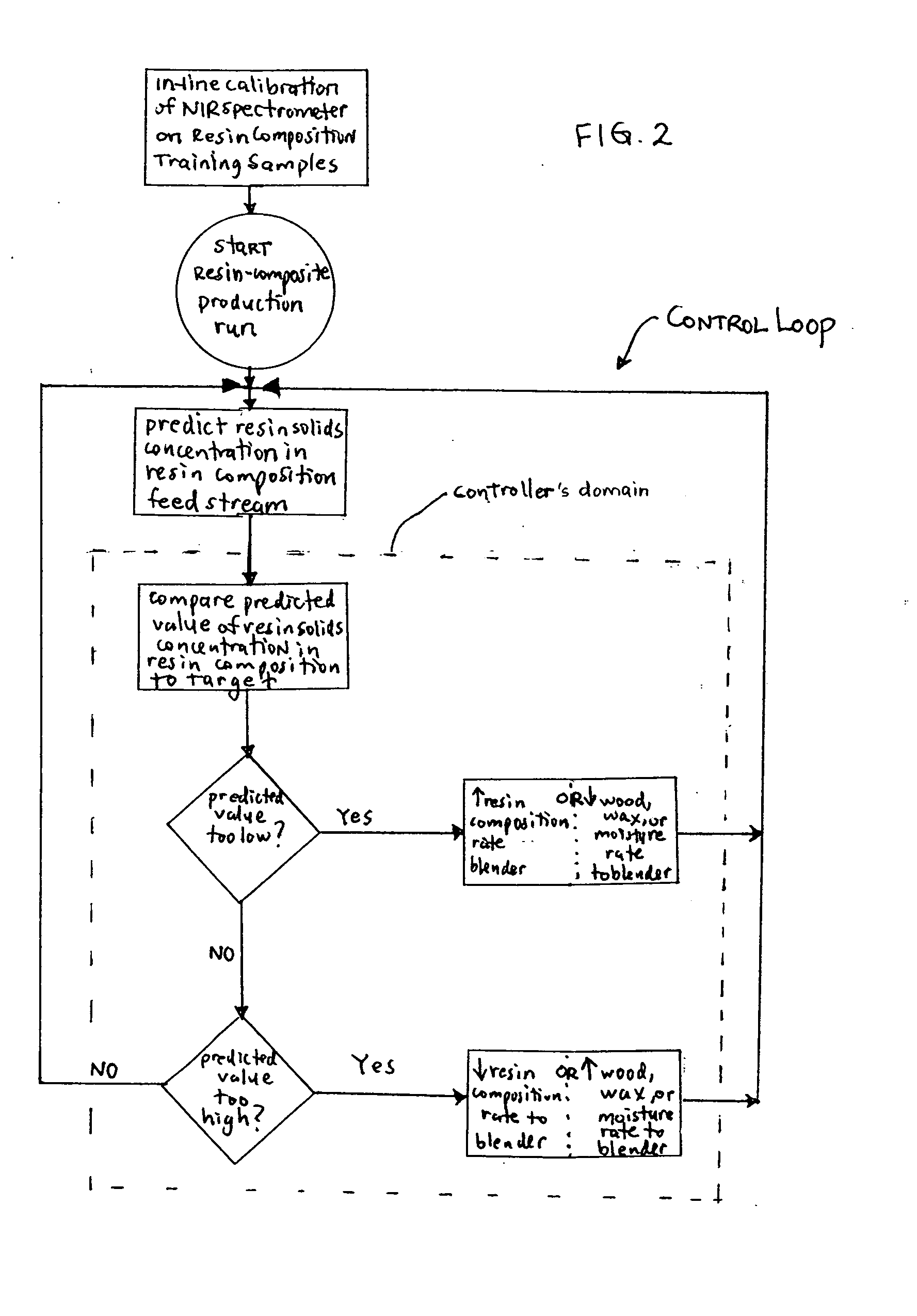

Method and system using NIR spectroscopy for in-line monitoring and controlling content in continuous production of engineered wood products

InactiveUS20070222100A1Efficient and early adjustmentMaintain consistencyPhotosensitive materialsAuxillary shaping apparatusAdditive ingredientSpectroscopy

Method and system using near infrared (NIR) spectroscopy for dynamically monitoring and controlling the proportion of resin solids or other additive solids in combination with other ingredients used in continuous production of resin-wood composite articles.

Owner:HUBER ENGINEERED WOODS

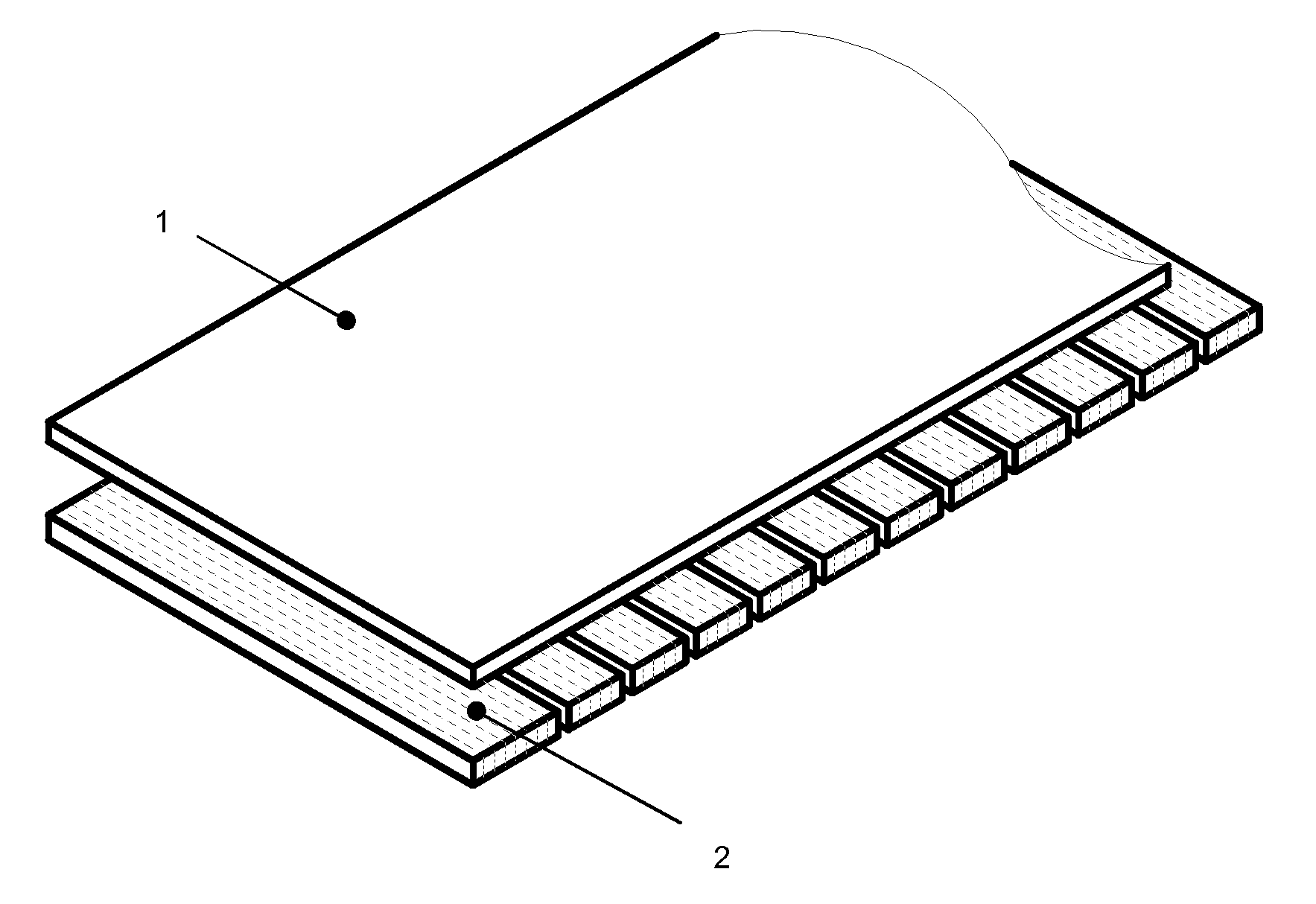

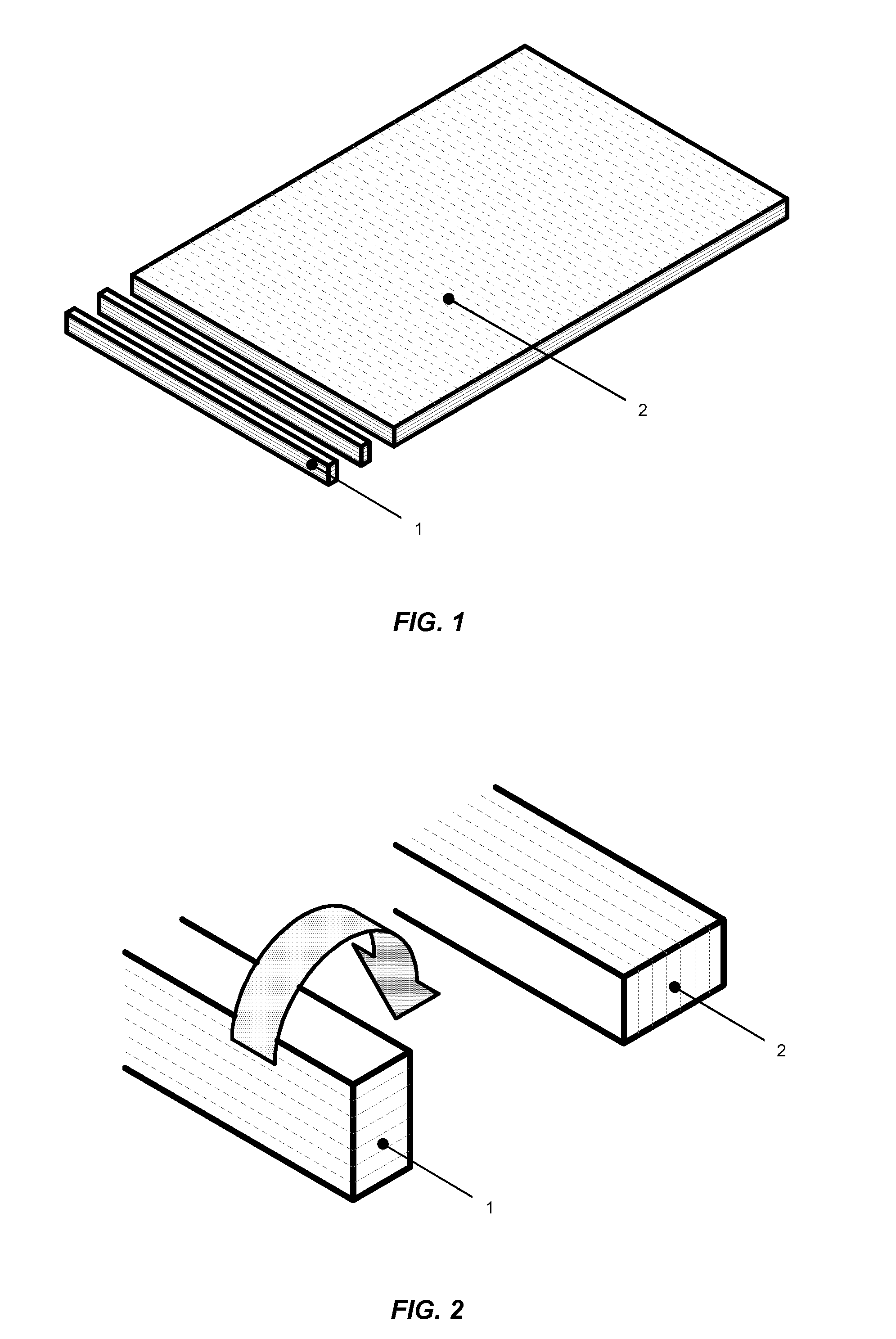

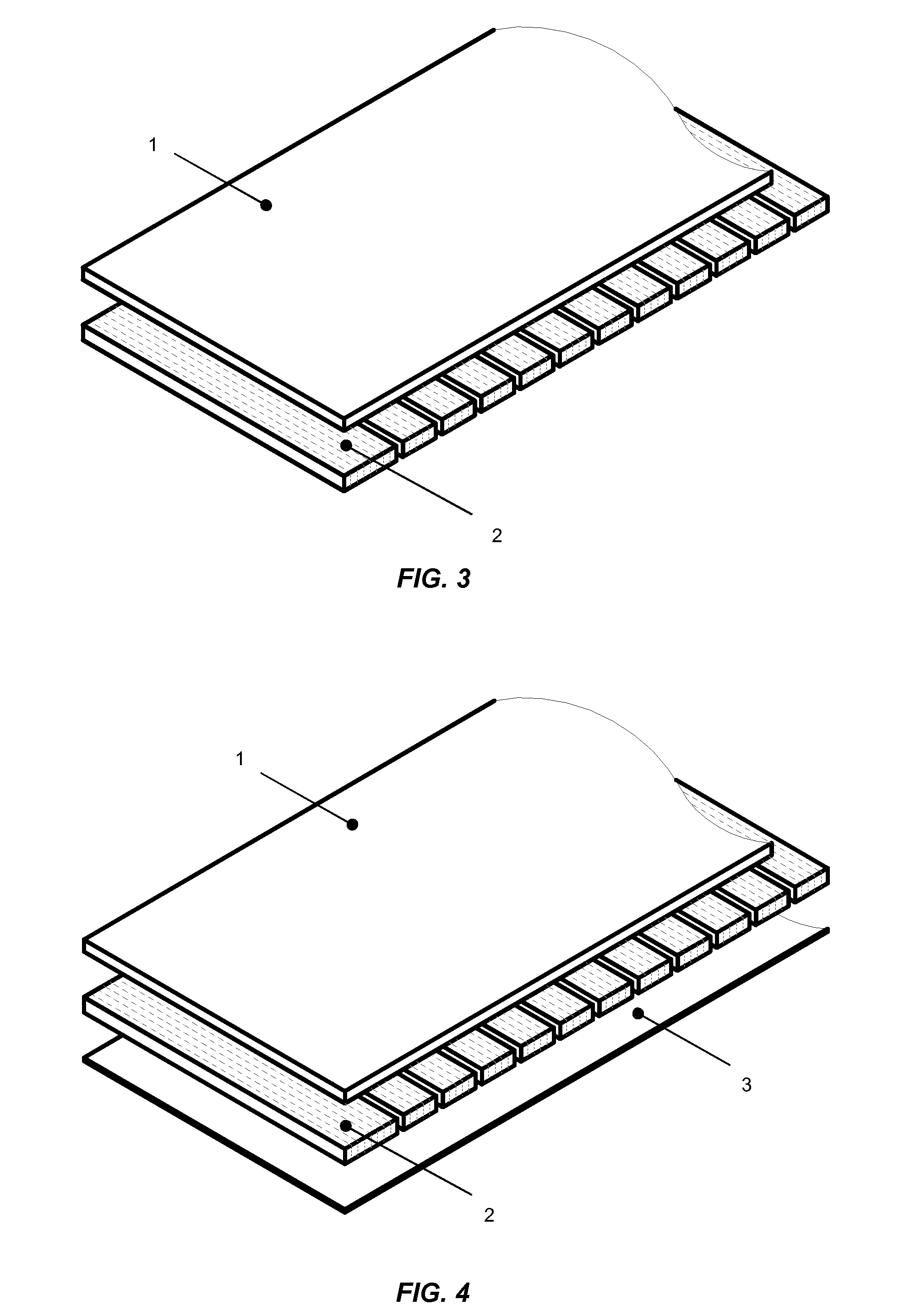

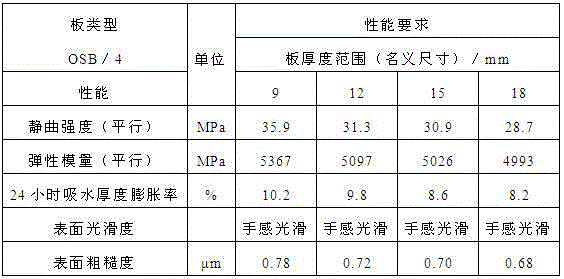

Burnishing surface wood oriented structure chipboard and manufacture method and use thereof

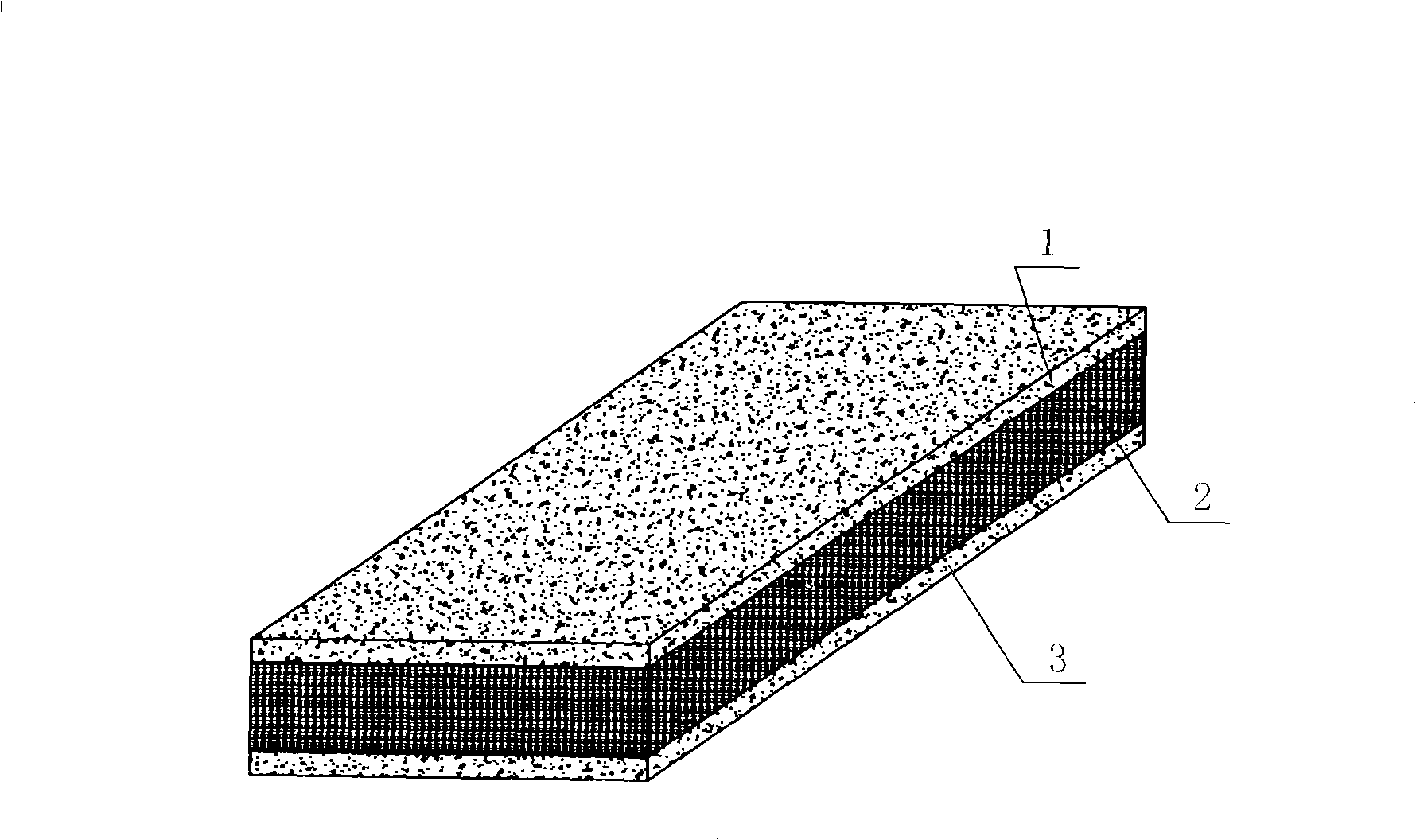

The invention provides a smooth surface wood oriented structure flakeboard and a preparation method used for the flakeboard, belonging to the technical field of artificial board, and more particularly relates to a modified wood oriented structure flakeboard and a preparation method of the flakeboard. The smooth surface wood oriented structure flakeboard of the invention is formed by the bonding of a surface layer, a core layer and a bottom layer; the core layer structure is the wood oriented structure flakeboard (OSB); the flakeboard is characterized in that the surface layer and the bottom layer are wood fine layers. The preparation method of the invention comprises the steps as follows: a wood slicing, grinding and fibre separation device is added at the front section of the preparation production line so as to manufacture and produce certain wood fine materials; the fine materials are dried, screened and chosen to carry out the sizing operation; subsequently, a paving machine is respectively arranged at the front section and the final section of the paving production line; a fine material layer is added at the surface layer and the bottom layer before the OSB is formed; subsequently, the hot extruding and plain plate disposals are carried out so as to prepare the flakeboard with smooth and flat surface.

Owner:云南永利发林业有限公司

Method For Preparing Functional Engineered Wood

ActiveUS20170239836A1Improve permeabilityWell mixedLiquid surface applicatorsPressure wood treatmentFire retardantEngineered wood

The present invention relates to furniture panels, and more particularly, to a method for preparing functional engineered wood. It includes the following steps: make veneer blanks by rotary cutting or splicing, and cut the veneer blanks into desired dimensions to obtain veneers A. Soak the veneers A in a ternary mixed solution of a biomass nanocellulose solubilizer, a fire retardant and an acid dye for toughening, fire retardation and dyeing to obtain veneers B. Add a formaldehyde decomposing powder into a modified MUF adhesive, mix them up, coat the veneers B with the mixture to obtain veneers C. Assemble and cold-press the veneers C to obtain flitches D, and saw the flitches D into desired patterns and dimensions to obtain finished products.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

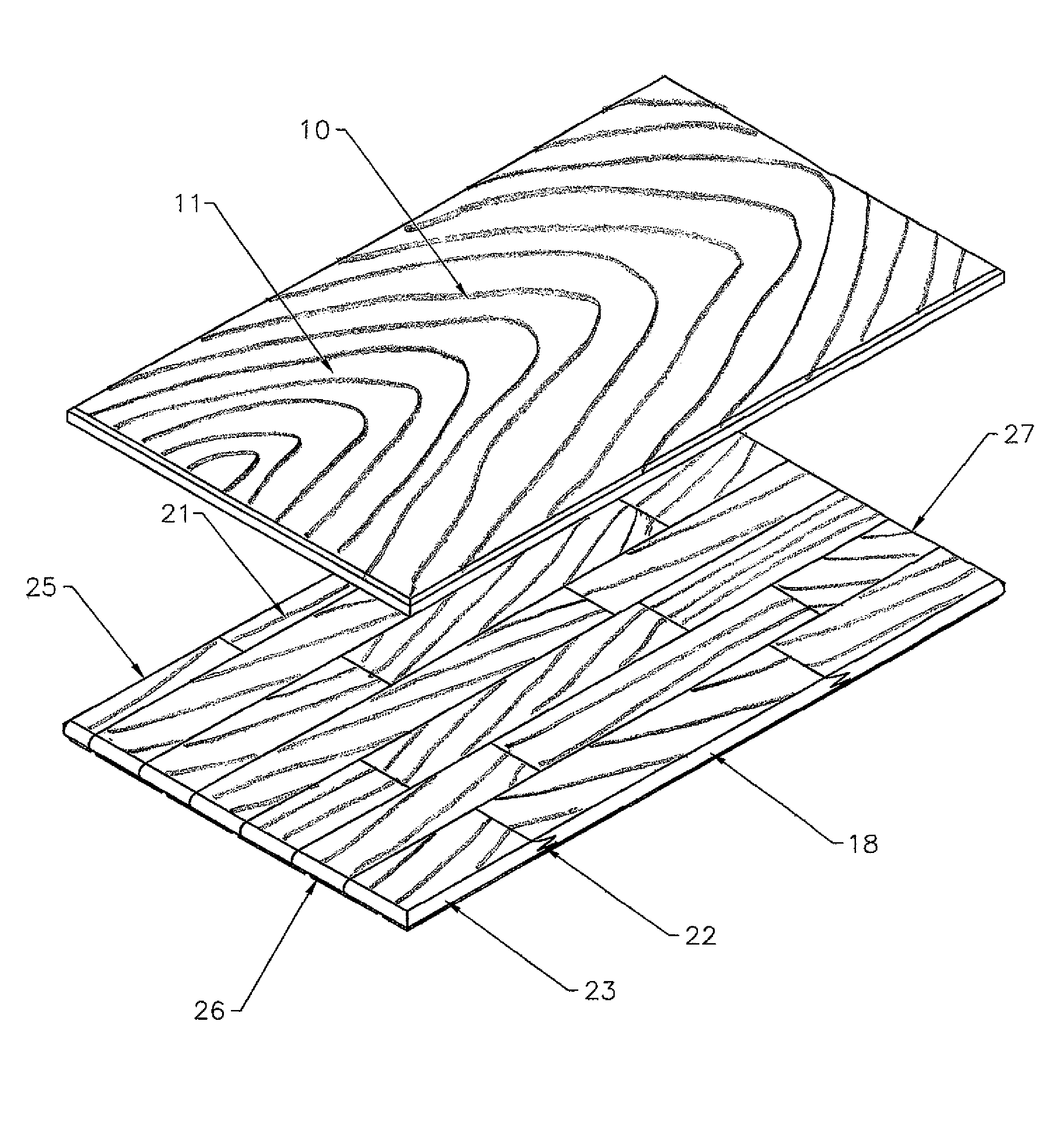

Engineered wood floor using core material with vertical glue-line position

ActiveUS20070292656A1Reduce and eliminate drawbackReduce and eliminate and problemLamination ancillary operationsLaminationEngineeringGlue line

Owner:TANJUNG KREASI PARQUET IND

Surface-decorated oriented strand board and preparation process thereof

ActiveCN104626292AHigh strengthGood dimensional stabilityLaminationLamination apparatusFiberParticle board

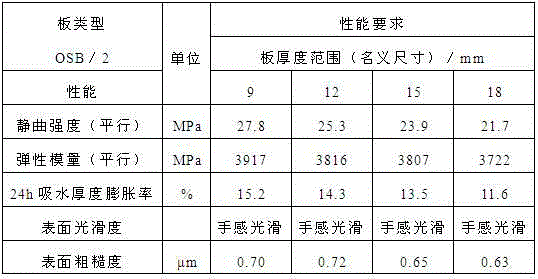

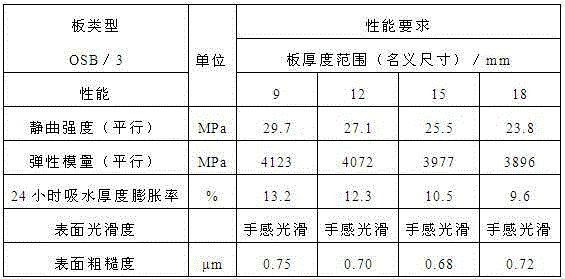

The invention relates to a surface-decorated oriented strand board and a preparation process of the surface-decorated oriented strand board. The surface-decorated oriented strand board comprises a core layer and a surface layer. Rotary cut veneer leftovers left in the plywood production process are selected as raw materials of the core layer. Sawdust, wood shavings, waste fibers and sanding powder produced in the production process of glued-laminated timber, core-boards, particle boards or medium-density fiberboards are selected as raw materials of the surface layer. The raw materials are subjected to drying, screening, gluing, laying, plate blank sawing and cutting and hot-pressing, and then the surface-decorated oriented strand board can be manufactured. The static bending strength of the oriented strand board in the parallel direction can reach 22-30 MPa, the elasticity modulus of the oriented strand board can reach 3500-4800 MPa, and the surface roughness of the oriented strand board is less than 0.8 micron. The surface-decorated oriented strand board can be directly processed into a decorative surface and can also be widely used for replacing artificial boards such as plywood, the core-boards, the particle boards and the medium-density fiberboards.

Owner:寿光市鲁丽木业股份有限公司

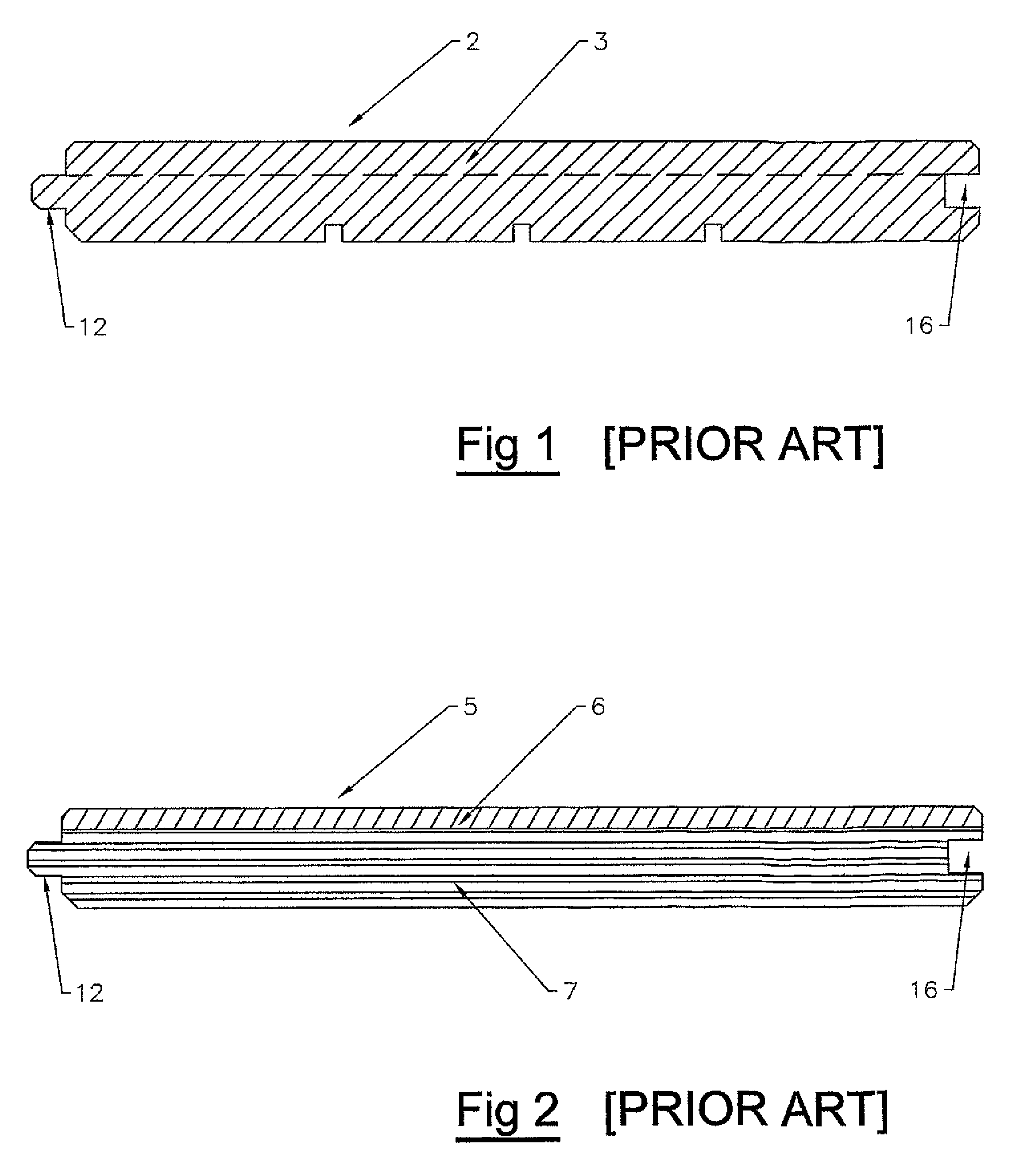

Hardwood Flooring System

InactiveUS20080184647A1Superior hydroscopic dimensional stabilityProvide durabilityConstruction materialStrutsSolid woodEngineering

An improved fabricated hardwood flooring product providing the advantage of a thick wood wear layer similar to a traditional ¾ inch solid wood floor with the dimensional stability characteristics of engineered wood floor products.

Owner:BEST WOODS

Engineered wood fiber product substrates and their formation by laser processing

InactiveUS8071912B2Improve realismLow costNatural patternsDecorative surface effectsFiberLaser processing

A laser is used to a form information indicative of a pattern on a surface of a support piece formed from a compressed wood fiber product substrate. The pattern can be a wood grain. The field of the laser is increased, to allow lazing more of the material at once. According to an embodiment, the field is increased in a way that does not reduce the resolution of the lasing.

Owner:REVOLAZE LLC

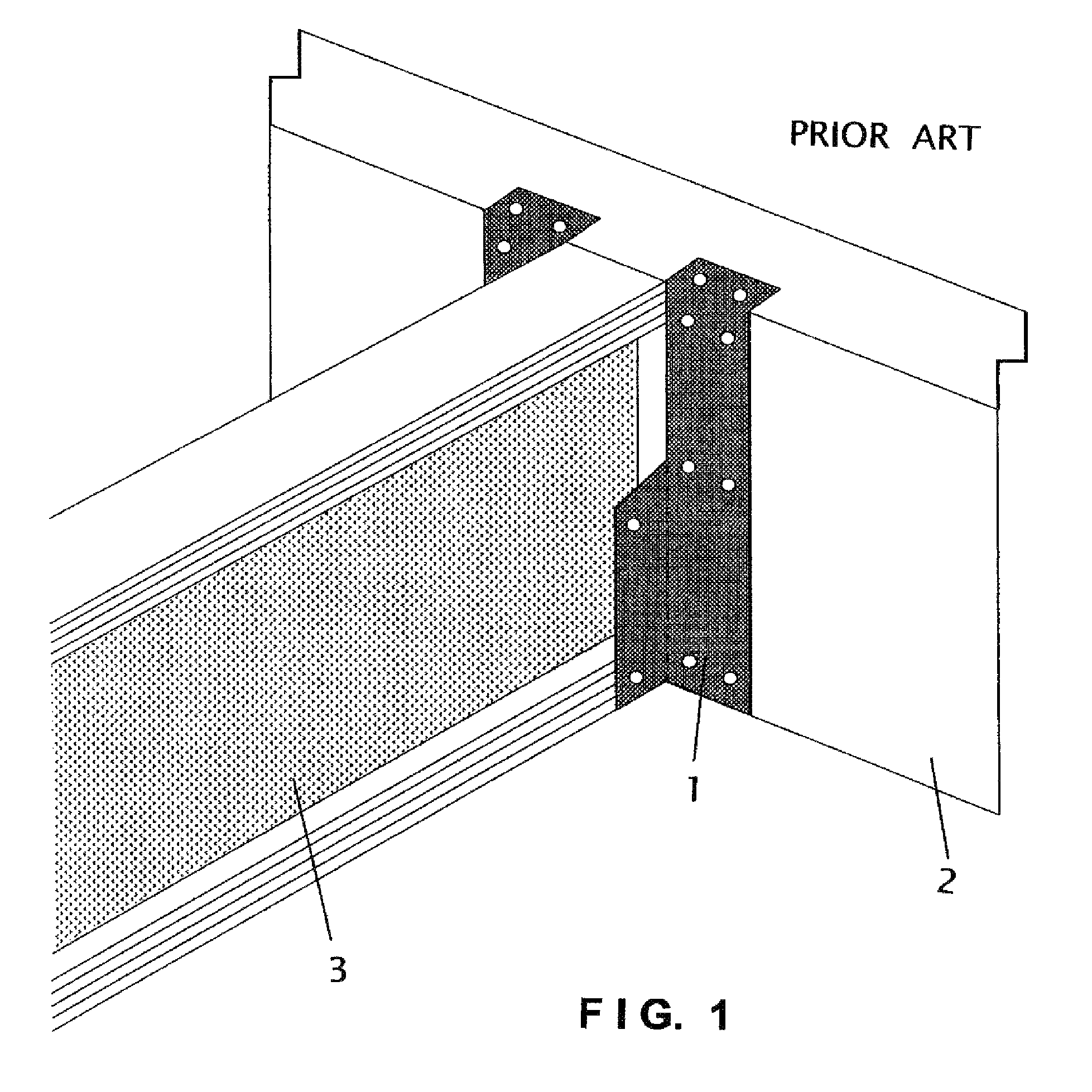

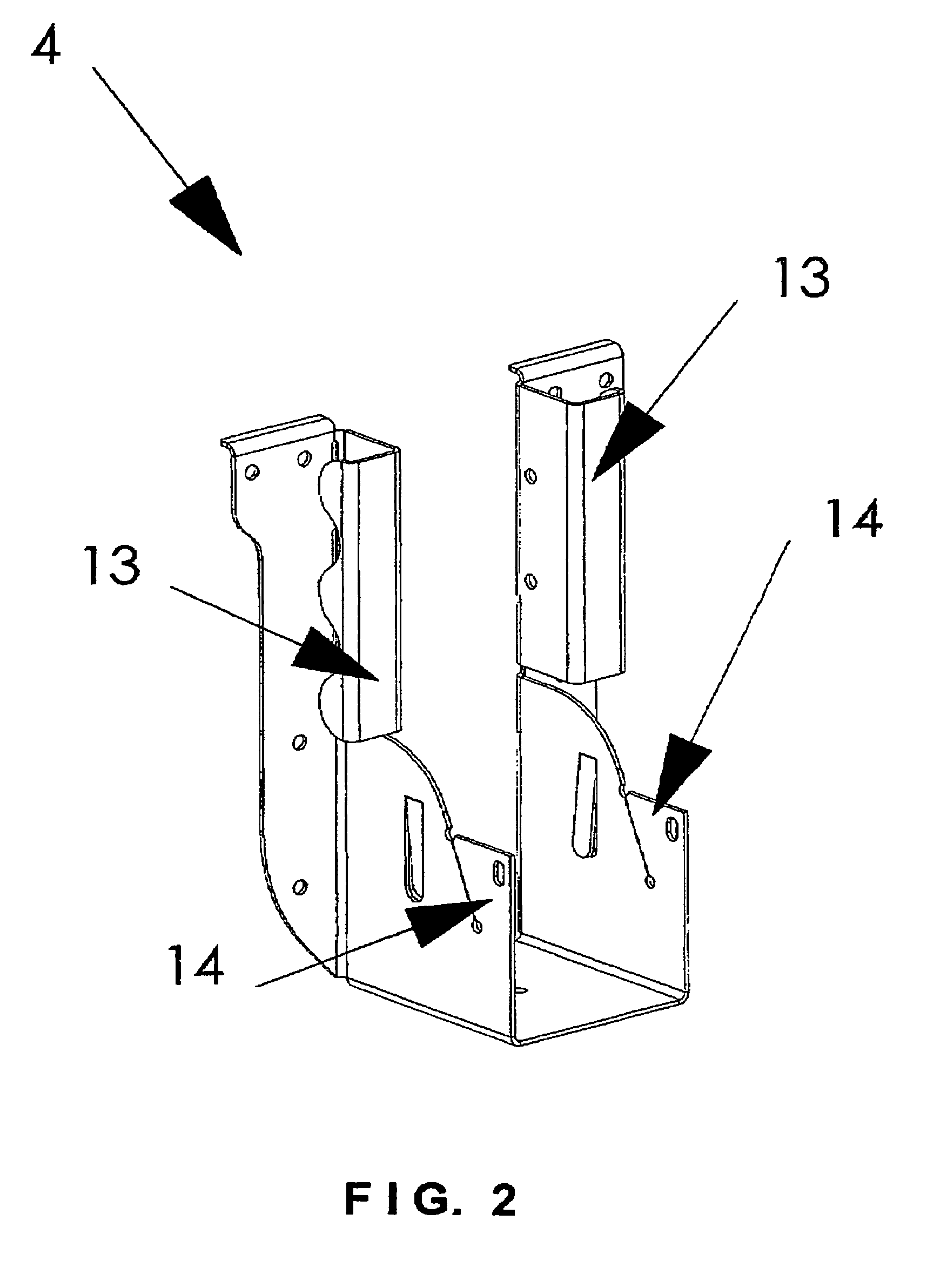

Method and system of framing components and hangers used in a structural interface

A system and method used in residential and commercial construction of floors, ceilings and roofs, where a beam and hanger together support a joist / rafter to which sheathing is applied. Hanger design features include bendable stiffeners that provide pinching structural support for opposing sides of an engineered wood I-joist web after the joist / rafter is seated into the bridge of the hanger, providing a superior structural interface connection, less material cost, and no contact between the hanger and sheathing which reduces unwanted noise in finished construction. Additional strengthening of the structural / load-bearing interface between the joist / rafter and beam may include selected horizontally-extending dato, groove, cut, or other detail formed in the support beams during their manufacture / milling and rearwardly-extending protections on the hanger configured to engage the detail.

Owner:ROBELL GLENN

Hardwood flooring system

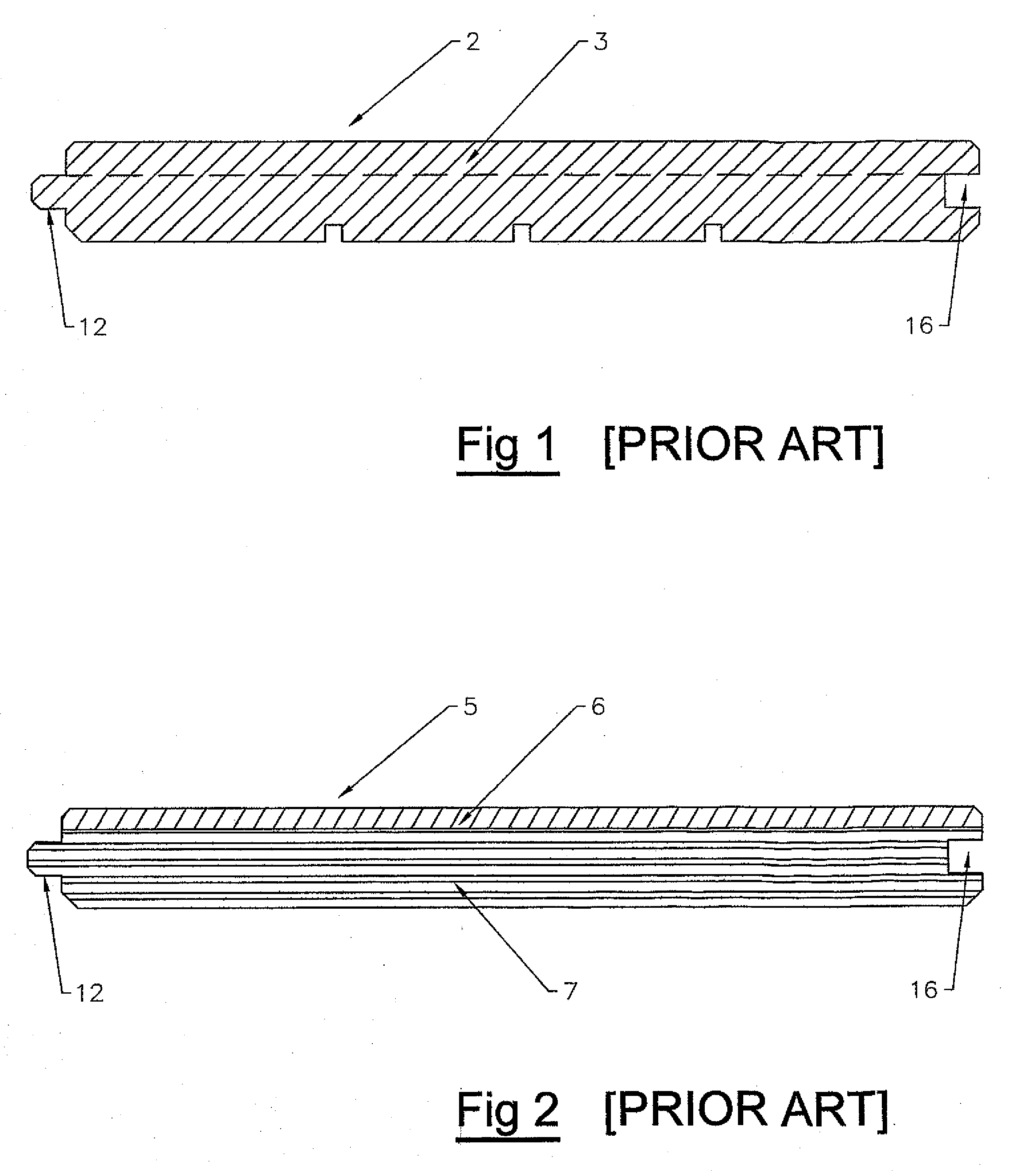

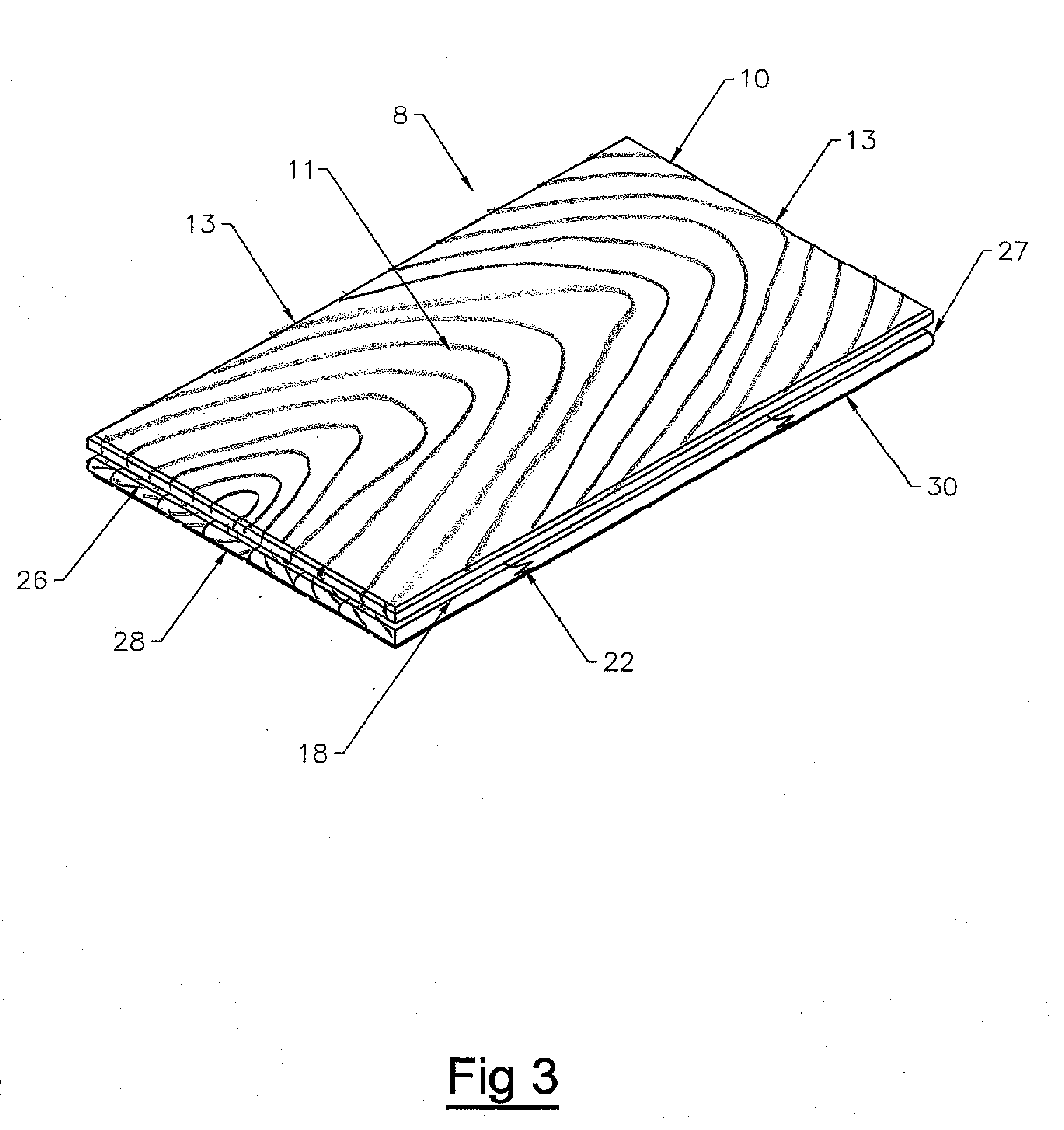

InactiveUS7665263B2Stable levelLong-term performance is often unsatisfactoryStrutsCovering/liningsSolid woodEngineering

An improved fabricated hardwood flooring product providing the advantage of a thick wood wear layer similar to a traditional ¾ inch solid wood floor with the dimensional stability characteristics of engineered wood floor products.

Owner:BEST WOODS

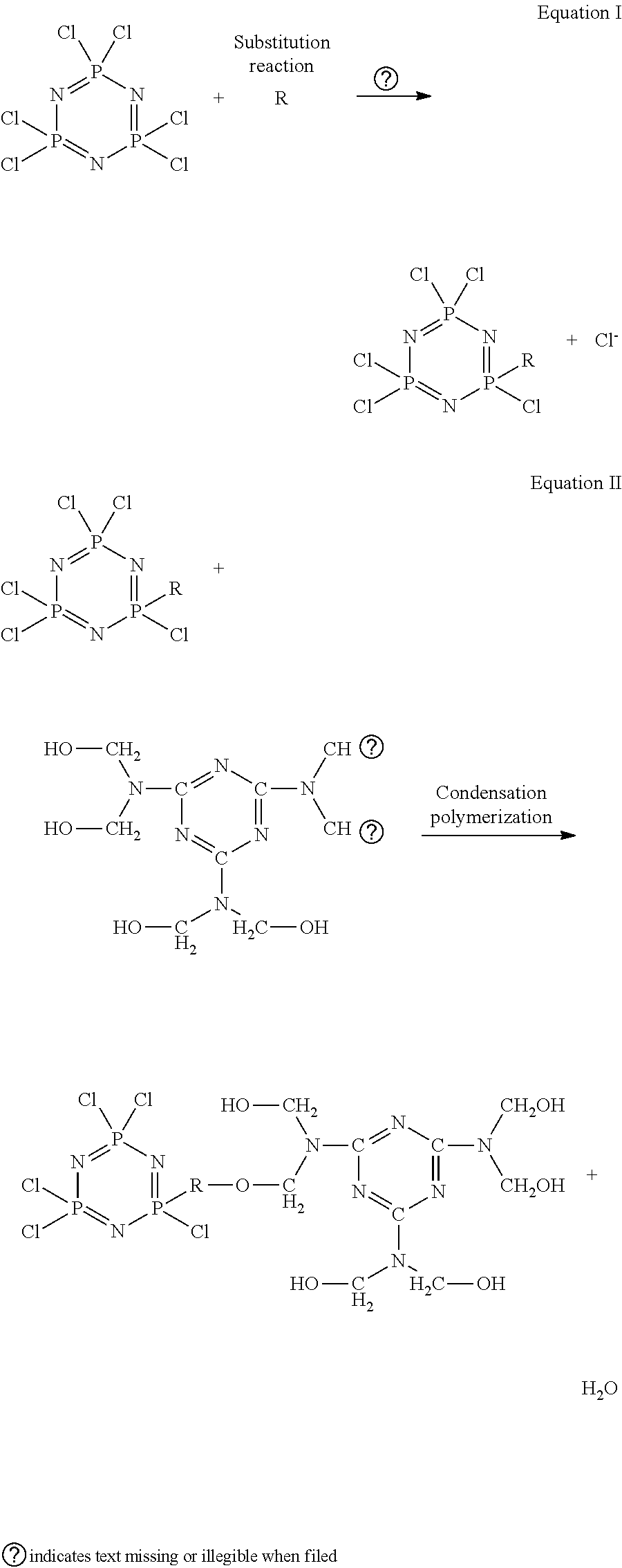

Lumber adhesive agent additives and preparation technique

InactiveCN101200624AReduce releaseGood for healthNon-macromolecular adhesive additivesAdhesiveMoisture

The present invention provides an additive for wood adhesive and a preparation technology thereof and is characterized in that the prescription and the weight percentage of the additive are 35 percent to 80 percent of material A filler, 15 percent to 60 percent of material B bulk agent, 0 percent to 10 percent of material C acidity-alkalinity regulator and 0 percent to 5 percent of material D formaldehyde absorbent; the preparation technology is that each prepared material with the moisture content less than 15 percent is crushed to the corresponding fineness, the material B is modified firstly, and then each prepared material is stirred completely and uniformly inside a mixer according to the percentage. The additive of the present invention can improves the sticking performance of a manmade board obviously, is fit for continuous mechanical production, ensures that the release quantity of free formaldehyde of the board is reduced, improves the indexes of waterproofing, anti-aging, anti-mildewing, etc. and reduces the production cost.

Owner:淮安市鹰翔新材料制造有限公司

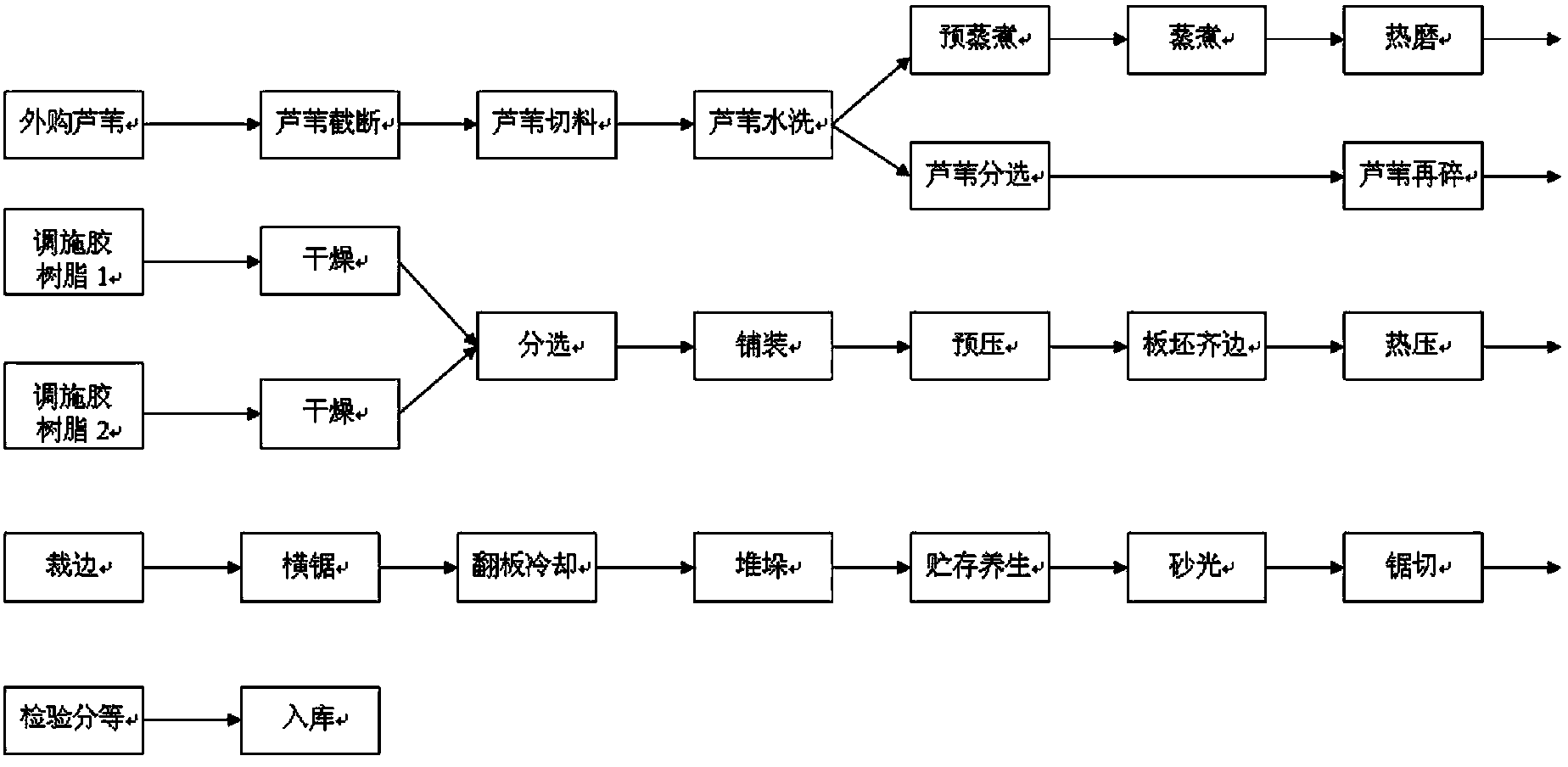

Preparation method for reed fiber particle board

ActiveCN104227819AReduce the effects of gluingReduce releaseLaminationLamination apparatusFiberWood shavings

The invention discloses a preparation method for reed fiber particle board. The preparation method comprises the following steps: cutting a reed raw material by using a circular sawing machine to prepare stem-shaped reeds with certain sizes; cutting the material by using a reed cutting machine, wherein one part of the cut material is cooked and softened to obtain the reed fibers, and the other part of the cut material crushed again to obtain fine reed shavings; respectively applying different resin adhesives to the reed fibers and the shavings, and drying, air-sorting and paving to form three-layer or multi-layer structural board blank; pre-pressing the three-layer or multi-layer structural board blank into a continuous flat-pressing hot press to press and produce the environment-friendly reed fiber particle board. The preparation method has the advantages that the influence of a wax layer on the surface of a reed on gluing performance is reduced to the greatest extent by graded pavement treatment; the production cost of the reed fiber particle board prepared by the process is moderate; both the physical and chemical properties of the reed fiber particle board meet related national standard requirements; the free formaldehyde release amount reaches the level-E1 standard requirement. According to the preparation method, reed resources of a wet land are fully utilized; the source of production raw materials of artificial boards is enlarged; the requirements on building resource-saving and environment-friendly society of China are met.

Owner:DONGYING ZHENGHE WOOD IND

Production method for damp-proof full-eucalyptus laminated wood veneer

ActiveCN103406951AStress reliefReduce water exposurePlywood pressesVeneer pressesWood veneerAdhesive

The invention provides a production method for a damp-proof full-eucalyptus laminated wood veneer. The artificial board is formed by high-temperature pressing and pasting of a base material and melamine impregnated paper, wherein the base material is formed by bonding a plurality of layers of eucalyptus veneers through adhesives. The production method comprises the steps of veneer sorting, gluing, cold pressing, hot pressing, stacking maintenance and pasting of the melamine impregnated paper. The production method is characterized in that three times of cold pressing and hot pressing and two times of thermostatic chamber standing maintenance and cooling maintenance processes are adopted, the cold pressing is performed at the room temperature and under the pressure of 0.8-1.0MPa, the hot pressing is performed under the pressure of 1.5-2.0MPa, the first hot pressing is performed at the temperature of 120-125DEG C, the second hot pressing is performed at the temperature of 115-120DEG C, and the third hot pressing is performed at the temperature of 125-130DEG C; the thermostatic chamber standing maintenance is performed at the temperature of 80-90DEG C for 4-6h; the cooling maintenance is cooled to the room temperature from the temperature of a thermostatic chamber through natural ventilation for 3-4h.

Owner:莫明鑫

A kind of attapulgite soil-based nano-wood flame retardant

ActiveCN102294718ANo costNo pollution in the processWood impregnation detailsSolid woodWood shavings

The invention discloses an attapulgite-based nano-scale wood fire retardant. A preparation method of the attapulgite-based nano-scale wood fire retardant comprises the following steps of weighing respectively raw materials by weight part, pouring an acid solution into attapulgite, carrying out stirring, supersonic treatment, standing and decantation of upper suspension at a normal temperature, washing solids by deionized water, wherein the solids are obtained by repeated centrifugation, drying attapulgite modified by an acid, grinding into powder, dividing the powder into two parts, preserving the two parts in a sealed environment, mixing water-soluble flame-retardant ingredients and one of the two parts, treating the other one of the two parts by an aluminate coupling agent aqueous solution with stirring at a normal temperature for 8 hours, mixing flame-retardant suspension and the attapulgite aqueous solution obtained by the previous step, and stirring the mixture for 20 minutes to obtain a attapulgite-based nano-scale wood fire retardant solution. Through vacuum pressurization, the attapulgite-based nano-scale wood fire retardant can be injected into solid wood, wood single boards, wooden fibers or wood shavings without changes of other production processes so that flame-retardant artificial boards or solid wood with efficient flame retardance are obtained.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

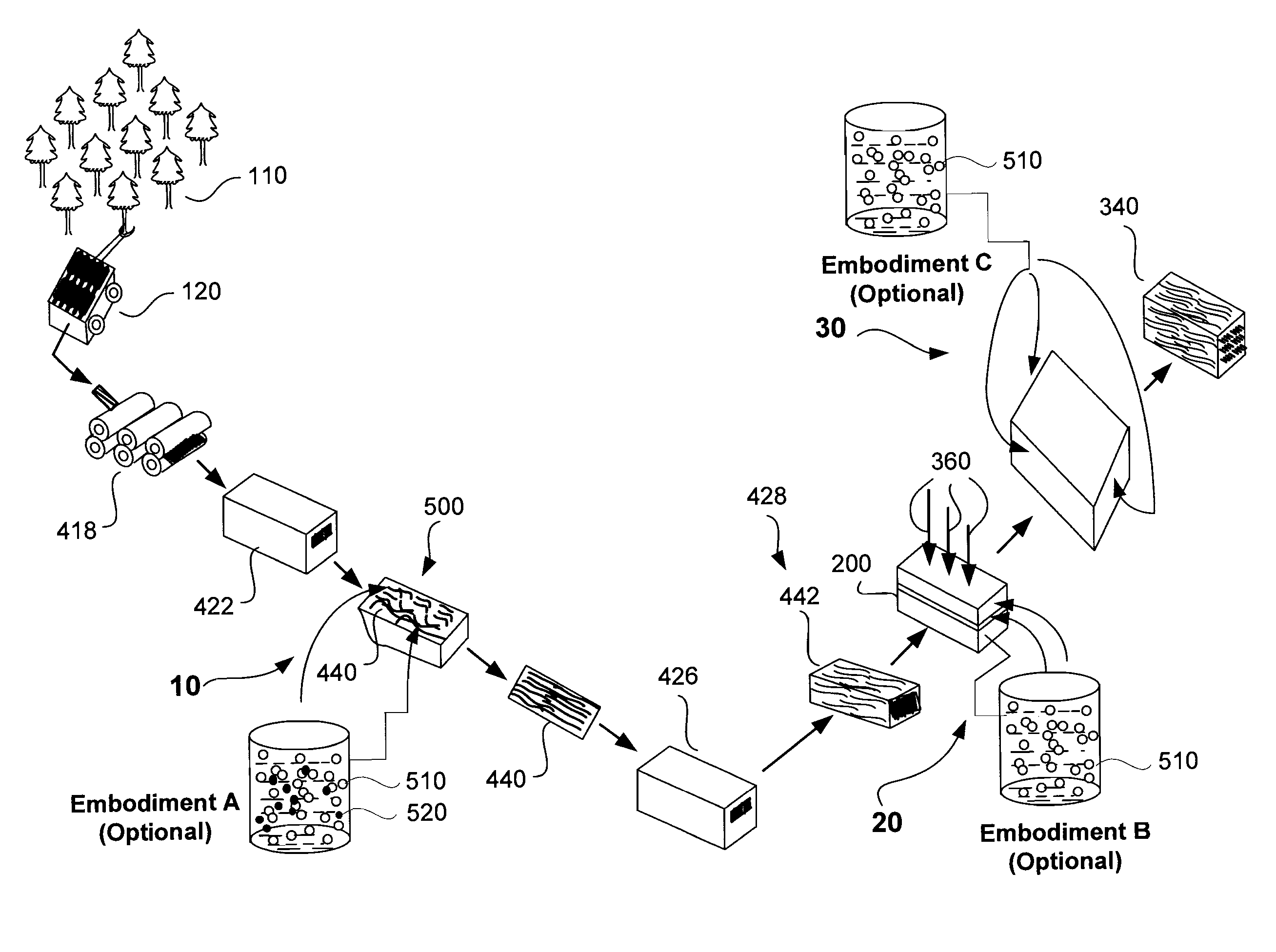

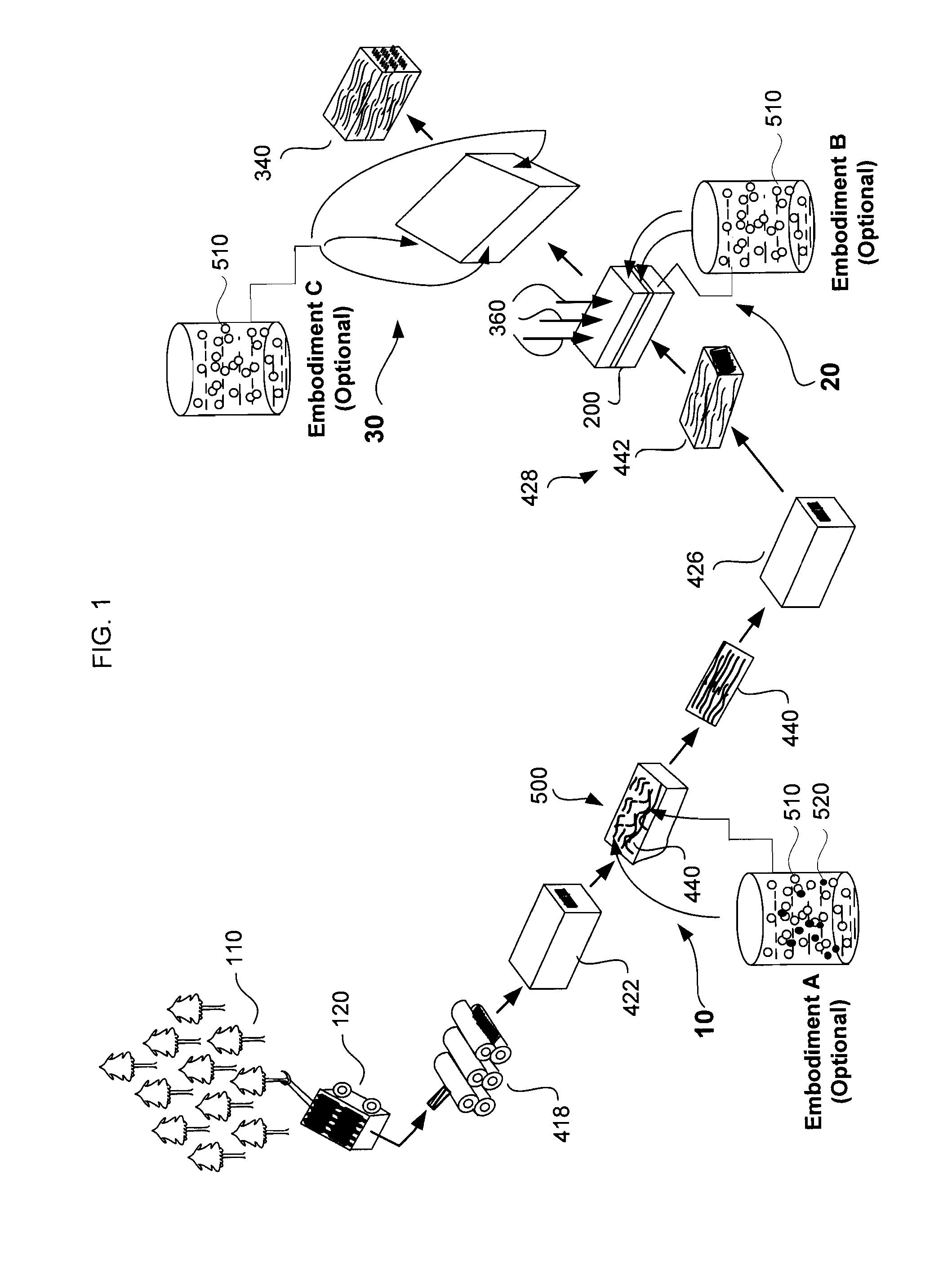

System and Method For The Preservative Treatment of Engineered Wood Products

ActiveUS20070122644A1Preserving stabilityGuaranteed preservation qualityWoven fabricsDomestic articlesWaxFungicide

Methods of making a wood enhancement agent treated engineered wood product. The wood enhancement agent includes at least one of a preservative, a water repellant, a fungicide, an insecticide, a stabilizing agent, wax, an ultra-violet light inhibitor, and combinations thereof, and may also include an antioxidant. The wood enhancement agent is incorporated into the engineered wood product during a billet making process or after forming the billet. The wood enhancement agent may be applied simultaneously with a bonding agent or at a later time, for example applied to a scrim log mat during a pre-press process or inside a steam press chamber. Alternatively, the wood enhancement agent may be applied to a warm billet after steam press, or to a reheated billet, by dipping, spraying, flood coating, diffusion, vacuum impregnation, pressure, or a combination thereof.

Owner:TIMTEK

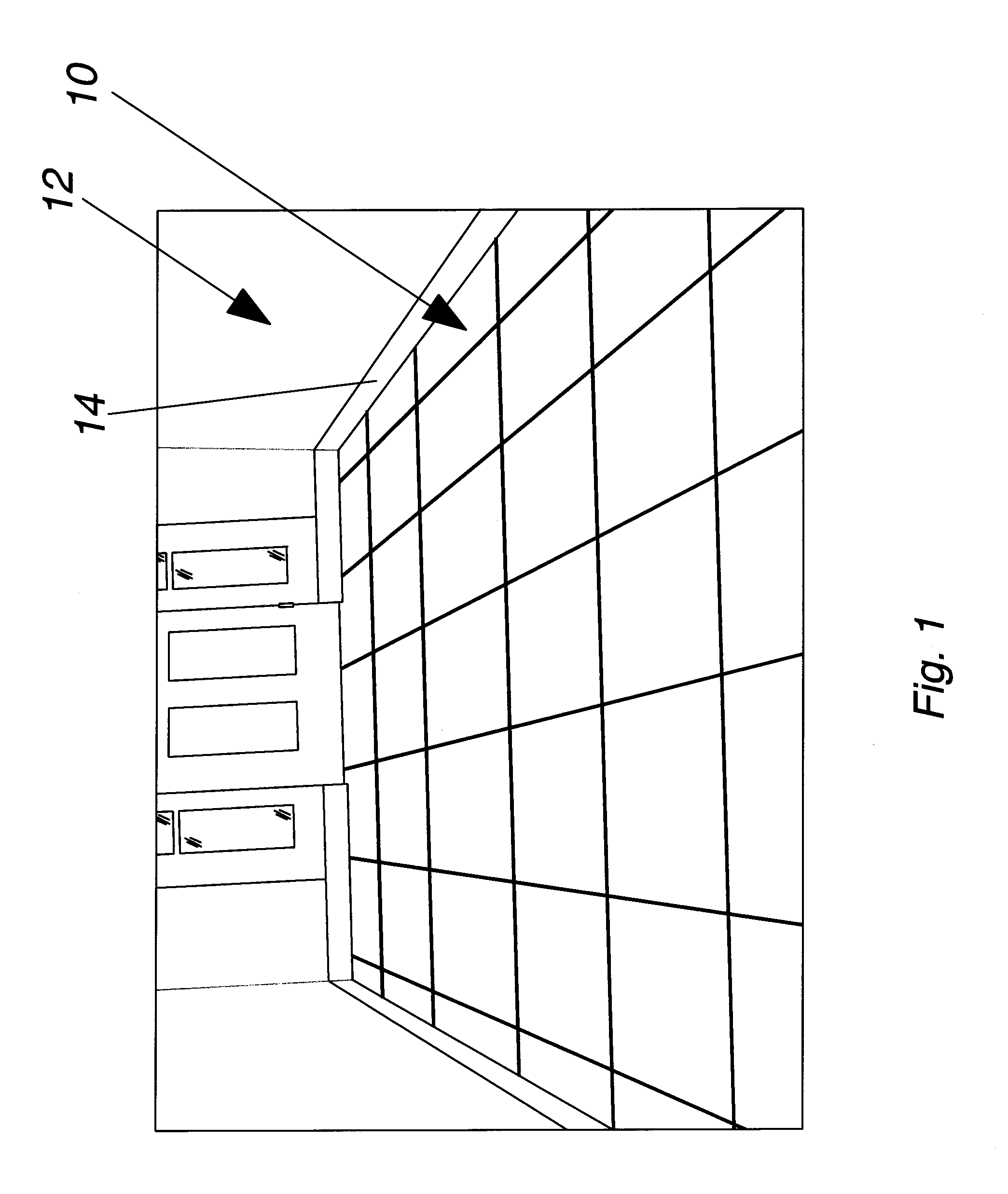

Decorative monolithic, functionally bonded composite surface overlayment system and application process

InactiveUS20130295346A1Raise the water levelMaximize overall degradationDecorative surface effectsCeramic layered productsArchitectural glassEngineering

The present invention describes a decorative surface covering comprising a plurality of component layers, structural and / or chemical, chemically bonded to the surface, together forming a unique single unit, monolithic decorative surface overlay, referred to generally herein as a functionally bonded system. The functionally bonded system is designed to be flexible, expandable, and functional, providing the same durability as pre-existing flooring or horizontal surfaces. While the individual components have various properties, the chemical bonding of one layer to an adjacent layer above and / or below provides for a unique surface covering that is decorative and functional. The functionally bonded system can be installed, retrofitted and bonded to a raw concrete floor foundation, countertops and other horizontal surfaces or to such surfaces having an existing ceramic tile, porcelain tile, concrete, VCT (Vinyl), asbestos (VAT) composite tile, hardwood floor, laminate or engineered wood floor, other synthetic or natural materials, or glass or architectural glass.

Owner:FINDEX COM

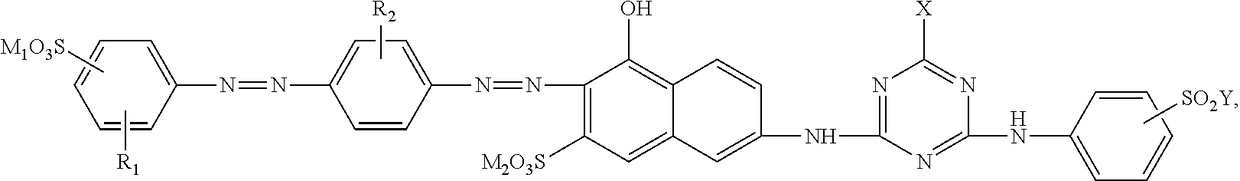

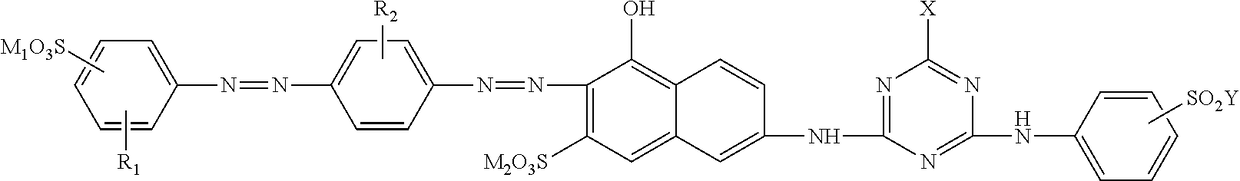

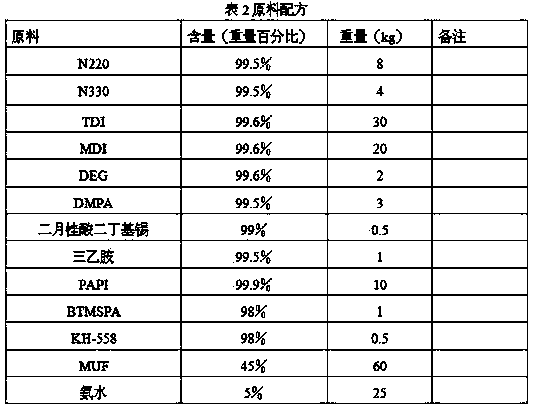

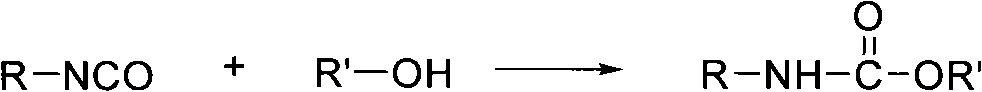

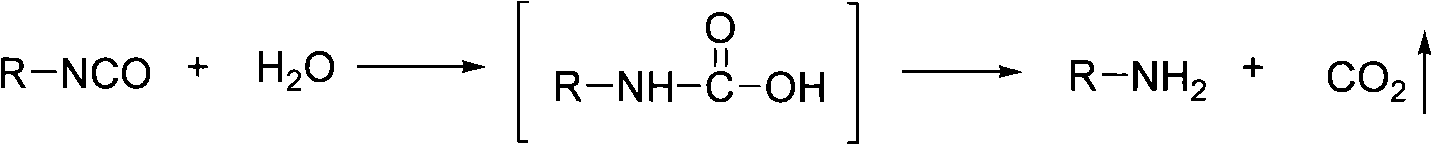

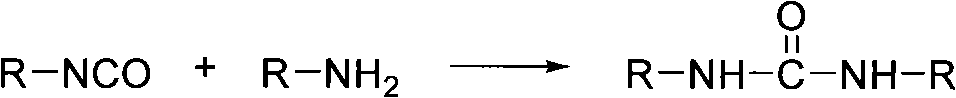

Plate alignment adhesive for surface plate lamination of engineered wood flooring and preparation method thereof

ActiveCN102086367AHigh strengthImprove water resistancePolyureas/polyurethane adhesivesFlooringAdhesivePolyvinyl alcohol

The invention relates to plate alignment adhesive for the surface plate lamination of the engineered wood flooring. The plate alignment adhesive contains main agent and curing agent, wherein the main agent consists of the following raw materials: polyvinyl alcohol, acrylic acid, butyl acrylate, hydroxyethyl acrylate, vinyl acetate, silane coupling agent, emulsifier, ammonium persulfate, deionizedwater and inorganic filler. The plate alignment adhesive of the invention has the advantages of high bonding strength, good water resistence, environmental friend, no solvent and no formaldehyde.

Owner:SHANGHAI JINQIANG ADHESIVE

Method for producing environment-friendly particle board through continuous hot pressing of total eucalypt wood leftover material

ActiveCN106363714ASolve insufficient resourcesSave raw materialsLaminationLamination apparatusNational standardParticle board

The invention discloses a method for producing an environment-friendly particle board through continuous hot pressing of a total eucalypt wood leftover material. The method comprises the procedures like chipping, flaking, drying, two-time screening (veneer removing and grit removing), sorting and polishing, mixing glue, hot press molding, aftertreatment, sanding and board selecting. According to the method, the eucalypt wood leftover material is fully utilized, and the wood waste is reduced; the produced particle board reaches the national standard and meets the GB / T4897-2015 requirement in Particle Board and the GB18570-2001 requirement in Indoor Decorating and Refurbishing Materials Limit of Formaldehyde Emission of Wood-based Panels and Finishing Products; melamine impregnated paper can be pasted on the surface of a produced panel; and the particle board is manufactured into high-end desk panels, wardrobe and cabinet panels, partitions, wood floors, ceilings, and other panels.

Owner:广西华晟木业有限公司

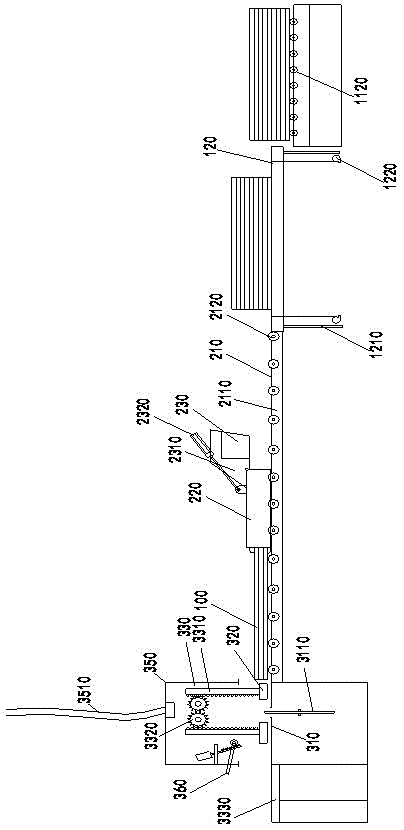

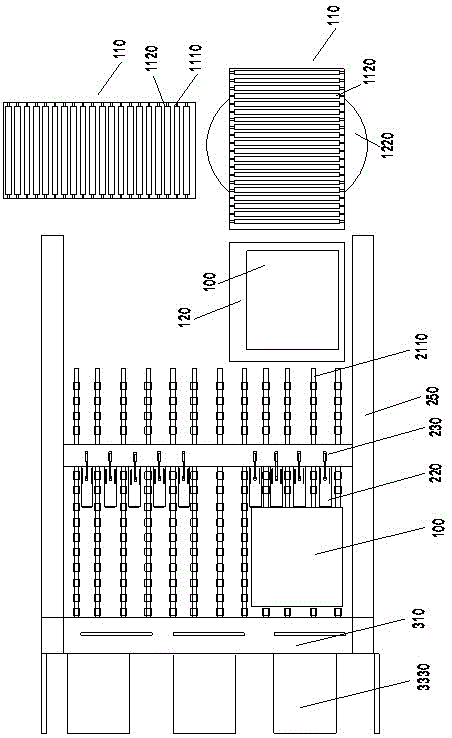

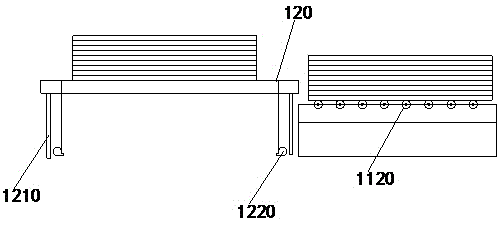

Automatic feeding and cutting process for artificial board

ActiveCN105583911ARealize pushStable recyclingFeeding devicesGripping devicesEngineeringMechanical engineering

The invention provides an automatic feeding and cutting process for an artificial board, comprising a feeding device, a pushing device and a cutting device, wherein the pushing device is arranged between the cutting device and the feeding device and comprises support rods arranged transversely and feeding mechanical arms arranged between adjacent support rods, a transverse moving rack is arranged above the support rods, the feeding mechanical arms are hinged to a fixed seat fixed on the transverse moving rack, a pulling arm cylinder is hinged to the fixed seat, and a telescopic rod of the pulling arm cylinder is hinged to the middle of the mechanical arm. The automatic feeding and cutting process is simple in structure, and the mechanical arms for pushing boards are provided, so that integrated conveying of the cut boards can be realized, and efficiency and safety are greatly improved. Pushing of boards can be well achieved by utilizing the structure of the feeding mechanical arms. Meanwhile, a clamping mechanism is designed to ensure stability in recovery and cutting of the board, and due to the arrangement of a feeding mechanism, working efficiency is greatly improved and manpower needed for conveying is greatly reduced.

Owner:FUTIAN FUZHOU ARTS & CRAFTS

Engineered Wood Composites Having Superior Strength and Stiffness

Disclosed is a process for making an engineered wood product comprising the following steps: (a) cutting a quantity of strands from wood lumber by use of a 3D stranding process, the strands having a length of about 6 inches to about 12 inches; and (b) forming the quantity of strands into an engineered wood product.

Owner:HUBER ENGINEERED WOODS

Wood panel with water vapor-permeable polyester layer

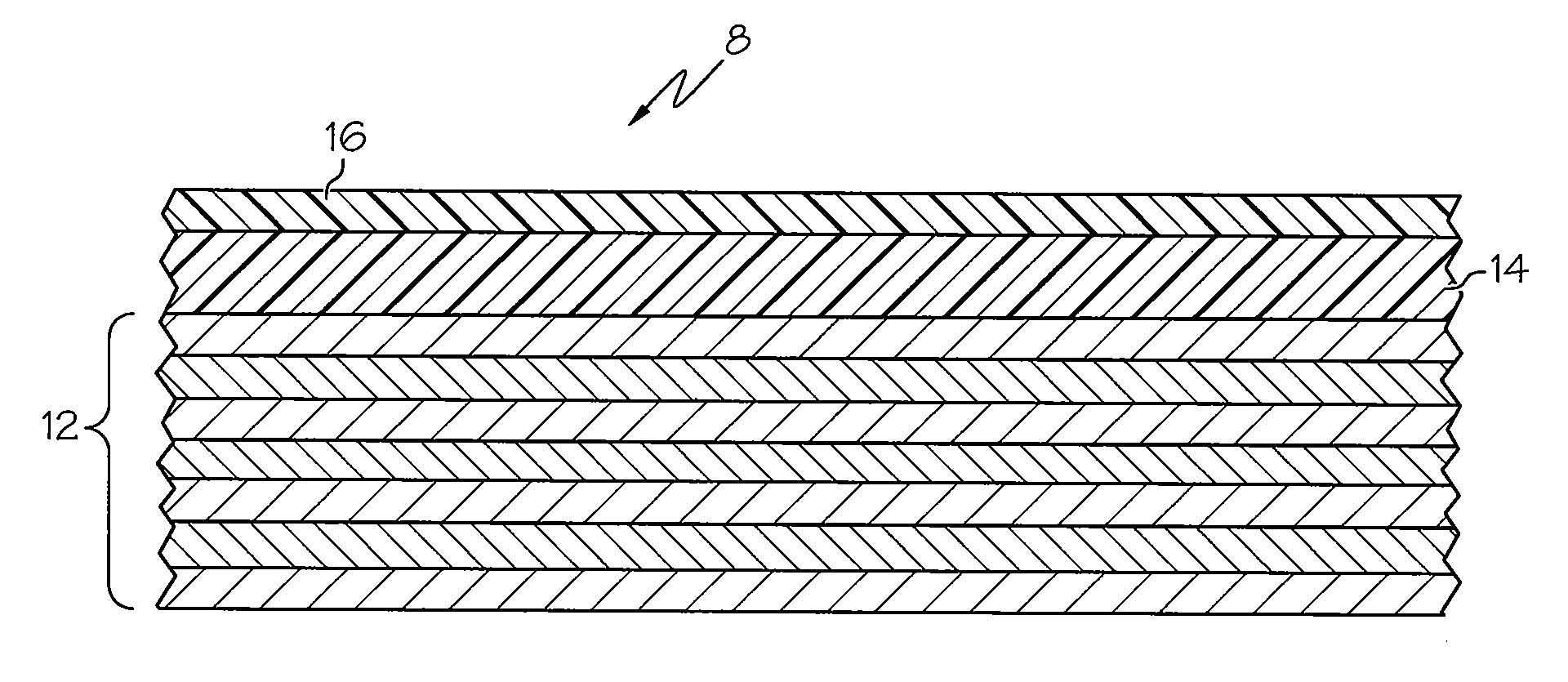

Disclosed is a panel comprising a nonwoven polyester water vapor-permeable layer having a moisture vapor transmission rate of less than 5 perms attached to an underlying engineered wood board.

Owner:HUBER ENGINEERED WOODS

Wood-plastic profiles and manufacturing method therefor

ActiveCN101181789APromote environmental protectionReduce releaseWood treatment detailsWood veneer joiningEnvironmental resistanceVolumetric Mass Density

The invention provides a wood-plastic sectional material that is synthesized by fast-growing wood veneer, corner offal of artificial boards that take the fast-growing wood as raw material and water-soluble phenol aldehyde resin adhesive and produced through production procedures of material selection-treatment-drying-gumming-gelatin-mould pressing-solidifying-post solidify. The density of the sectional material is 900-1300kg / m<3>, the hardness is 55-120MPa, the scale length is 500-5000mm, the width is 100-1300mm, the thickness is 15-200mm, 24-hour absorbing water thickness expansion rate is 0.6-3 percent and the formaldehyde release quantity is less than 1.5MG / L. The invention enhances the utilization of the fast-growing wood and the wood-plastic sectional material produced has high density and is a high quality material with the advantages of waterproof, heatproof, oil proof, age resistant, fungus resistant, chemical mediator resistant and better security, thereby being applicable to being used for making furniture, floor, decoration material, building moulding board, structure parts, motherboard of containers, track ties, and so on. The invention can also promote the utilization of the fast-growing wood and virtuous circle of the utilization of the wood, thereby having great environmental protection value.

Owner:SHANGHAI XINGJIA NUOHUA MATERIALS TECH

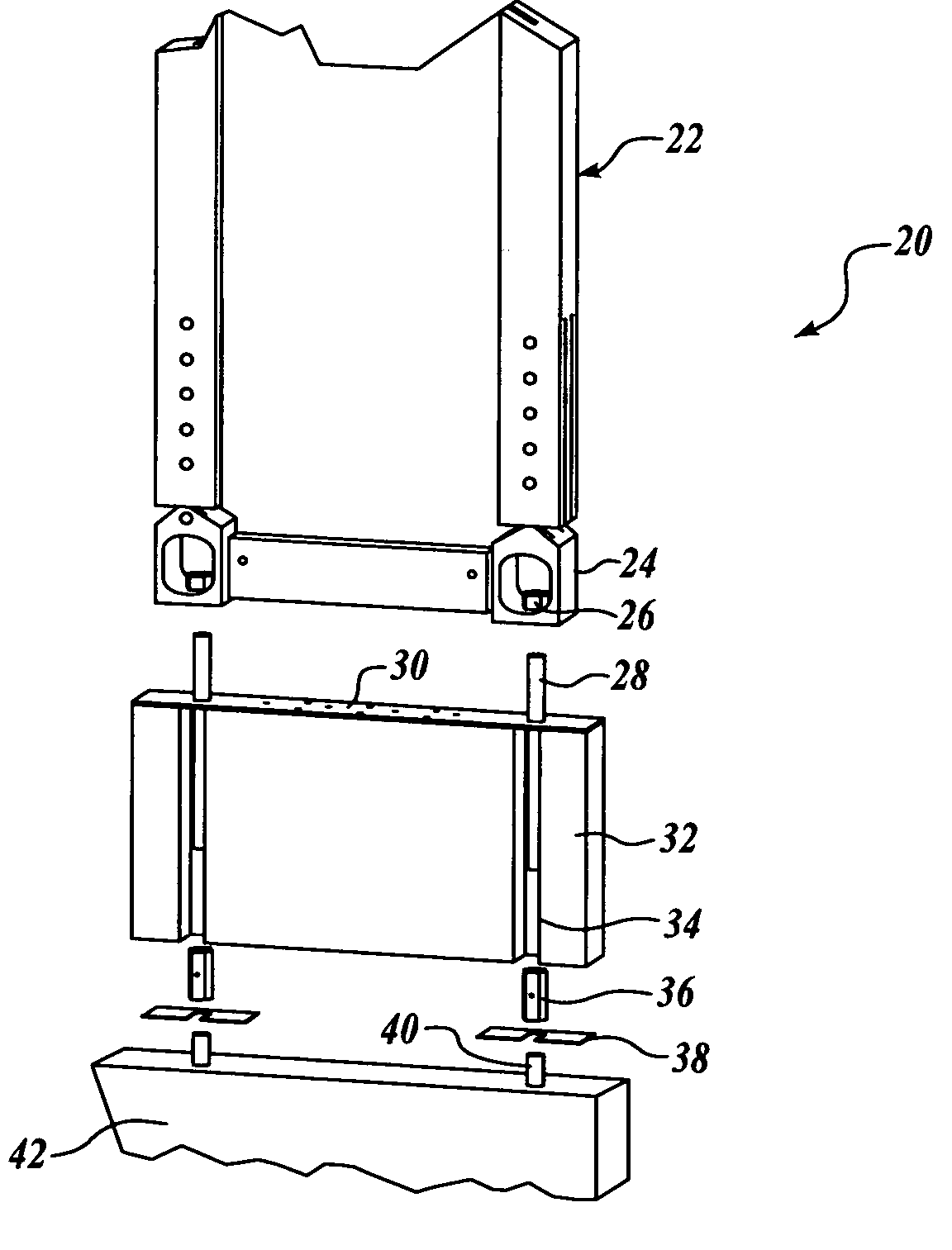

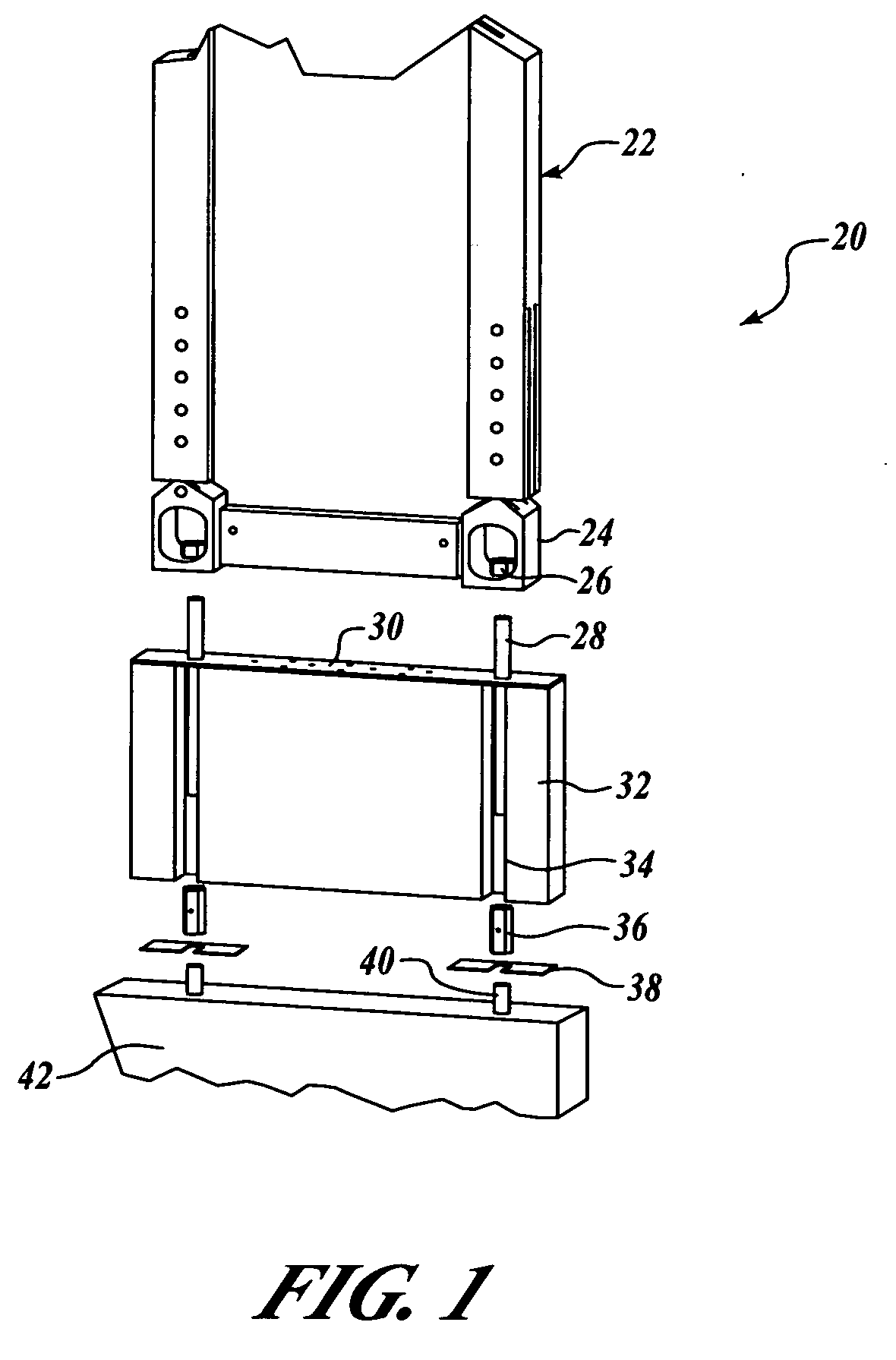

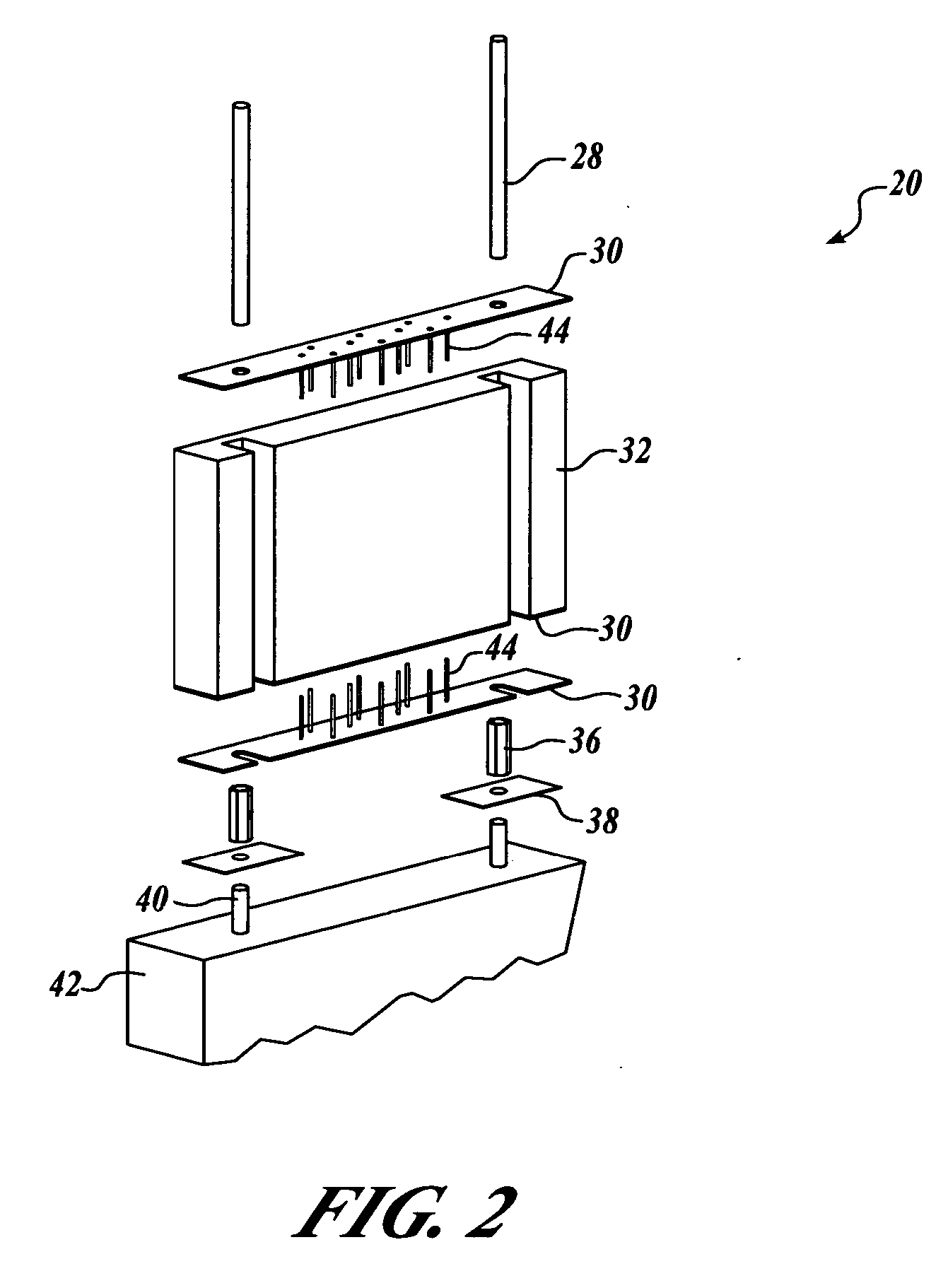

Shear wall attachment assembly and method of use

The present invention is a raised floor assembly efficiently connecting a pre-fabricated shear wall to a foundation in applications other than slab-on-grade. The raised floor assembly includes an engineered wood material block machined to accept a connecting rod therethrough. The raised floor assembly also includes a connecting rod that is configured to attach at one end to a pre-fabricated shear wall and is coupled at the other end to an anchor bolt. Additionally, a transfer plate may be positioned between the pre-fabricated shear wall and the top of the engineered wood material block. The transfer plate provides a bearing surface for the pre-fabricated shear wall and helps maintain connecting rod alignment. A transfer plate may also be provided underneath the engineered wood material block and above the foundation. Additionally, a variety of spacers may be provided between the bottom of the engineered wood material block and the foundation.

Owner:SIMPSON STRONG TIE

Wood veneer surfaced decorative laminate product and method of making same

InactiveUS20080268273A1Readily wetLow viscositySynthetic resin layered productsPretreated surfacesEngineeringMoisture resistance

A wood veneer surfaced laminate and method of making it are provided which produces a product having the appearance of a natural wood product, but with the toughness, moisture resistance, stain resistance, impact resistance, and abrasion resistance of melamine resin surfaced laminate products. The wood veneer surfaced laminate is made by providing a sheet of a natural or engineered wood veneer; impregnating the sheet with a first liquid curable resin such that said liquid resin substantially completely impregnates the sheet; coating a second liquid curable resin onto a surface of the sheet; laminating the sheet to a core while curing the resins to form a natural or engineered wood veneer surfaced laminate.

Owner:THE DILLER

Methods of conferring fire retardancy to wood and fire-retardant wood products

ActiveUS20150352744A1Radiation/waves wood treatmentVacuum evaporation coatingFire retardantEngineered wood

A process is provided for treating wood products including lumber, plywood and other engineered wood products comprising the steps of applying an aqueous fire-retardant impregnate and applying a coating to the surface of the wood product. In one embodiment, said process confers fire-retardant properties to the wood products sufficient to pass the extended burn test of ASTM E-84. The present invention also provides fire retardant wood products.

Owner:KOPPERS PERFORMANCE CHEM

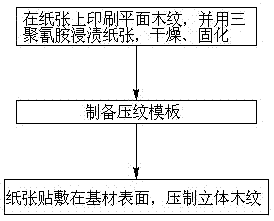

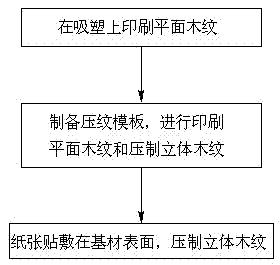

High-simulation three-dimensional wood-grain artificial board and production method thereof

InactiveCN103195224ACovering/liningsLamination ancillary operationsConvex structurePulp and paper industry

The invention discloses a production method for a high-simulation three-dimensional wood-grain artificial board. A concave-convex template synchronous with wood grain printing is used, so that base material embossments and printed wood grains have the same concave-convex structure, the three-dimensional effect of a finished product is synchronously combined with the wood grain printing effect, and the simulation degree of a finished board is highly unified with the grains and the three-dimensional effect of real wood.

Owner:叶建兵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com