Automatic feeding and cutting process for artificial board

A technology of automatic feeding and cutting process, applied in the direction of manufacturing tools, sawing components, sawing equipment, etc., can solve the problems of safety accidents, large manpower consumption, low efficiency, etc., to prevent displacement, improve efficiency and safety, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

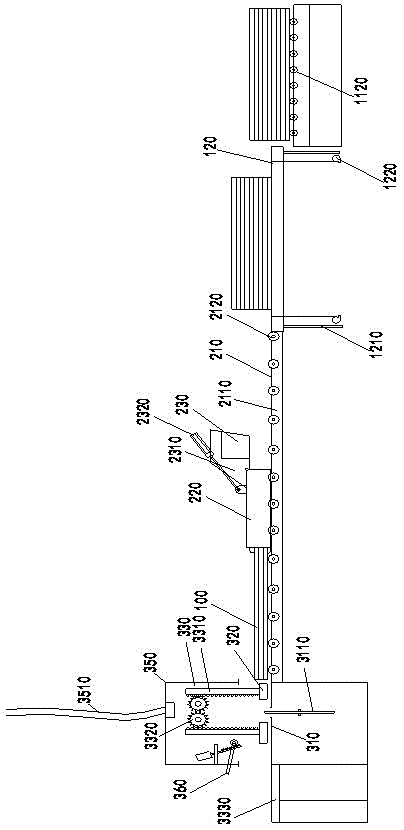

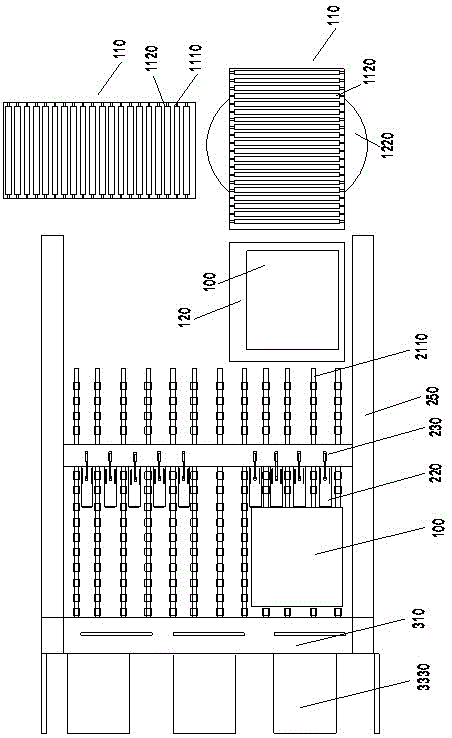

[0035] The following describes the overall device according to the processing process of the wood board material. In this embodiment, it mainly includes three parts: the feeding device, the pushing device and the cutting device.

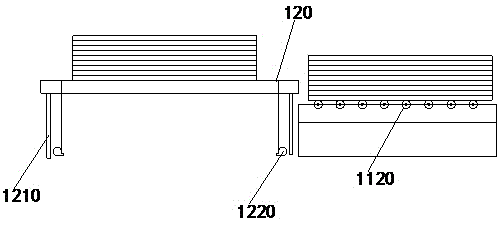

[0036] Such as Figure 1~2 As shown, an automatic feeding device for wood-based panel cutting includes one or more placing and conveying platforms 110 located on the front side of the cutting device. The placement roller 1120 is formed, and the two ends of the roller 1120 are hinged on the placement table 1110,

[0037] A lifting and placing platform 120 is provided beside the placing and conveying platform 110, and the lifting and placing platform 120 is set on the surrounding guide pillars and driven by a hoist.

[0038] Placement conveyor 110 can be designed and added according to the needs of the place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com