Patents

Literature

417results about How to "Neat cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

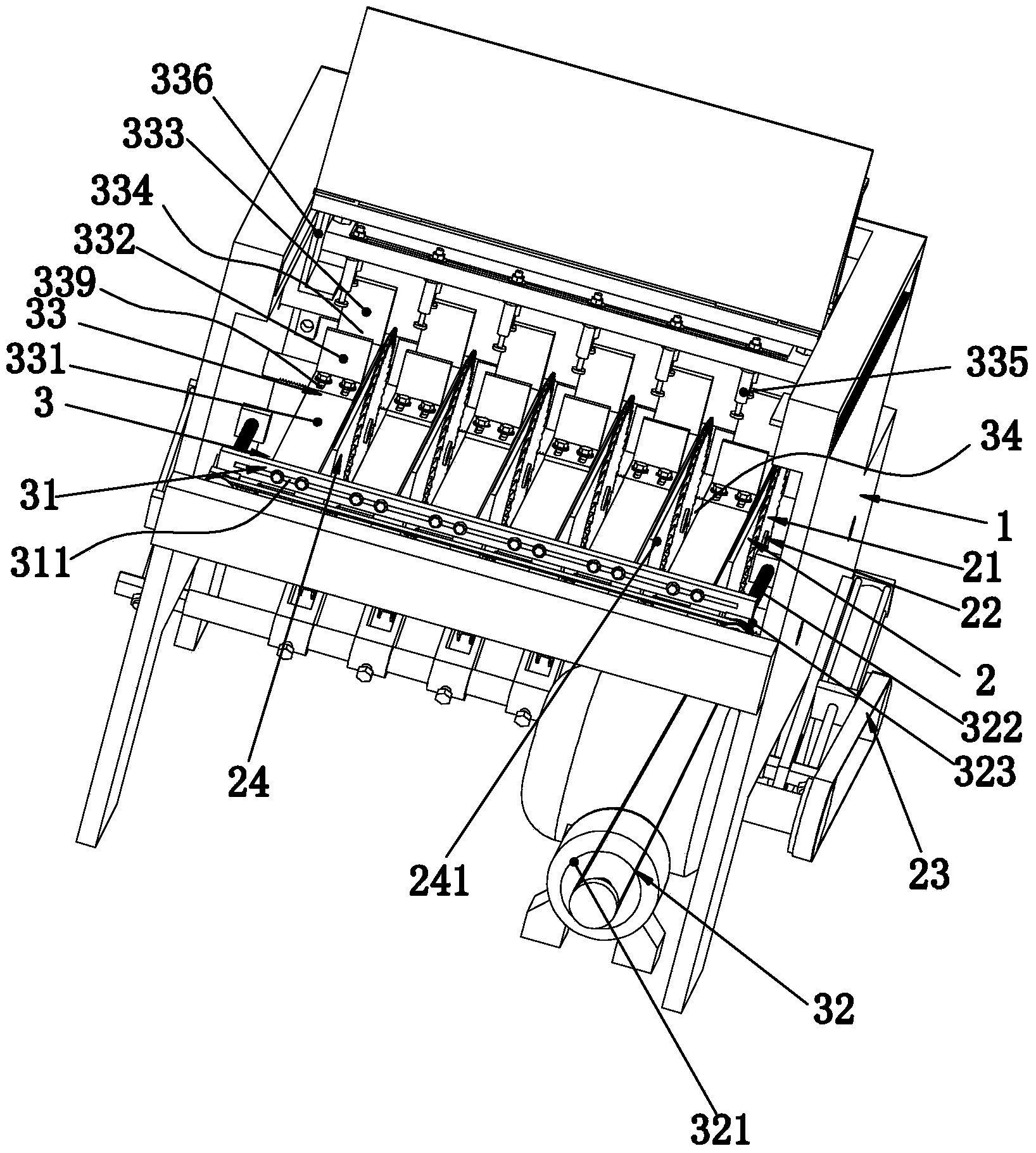

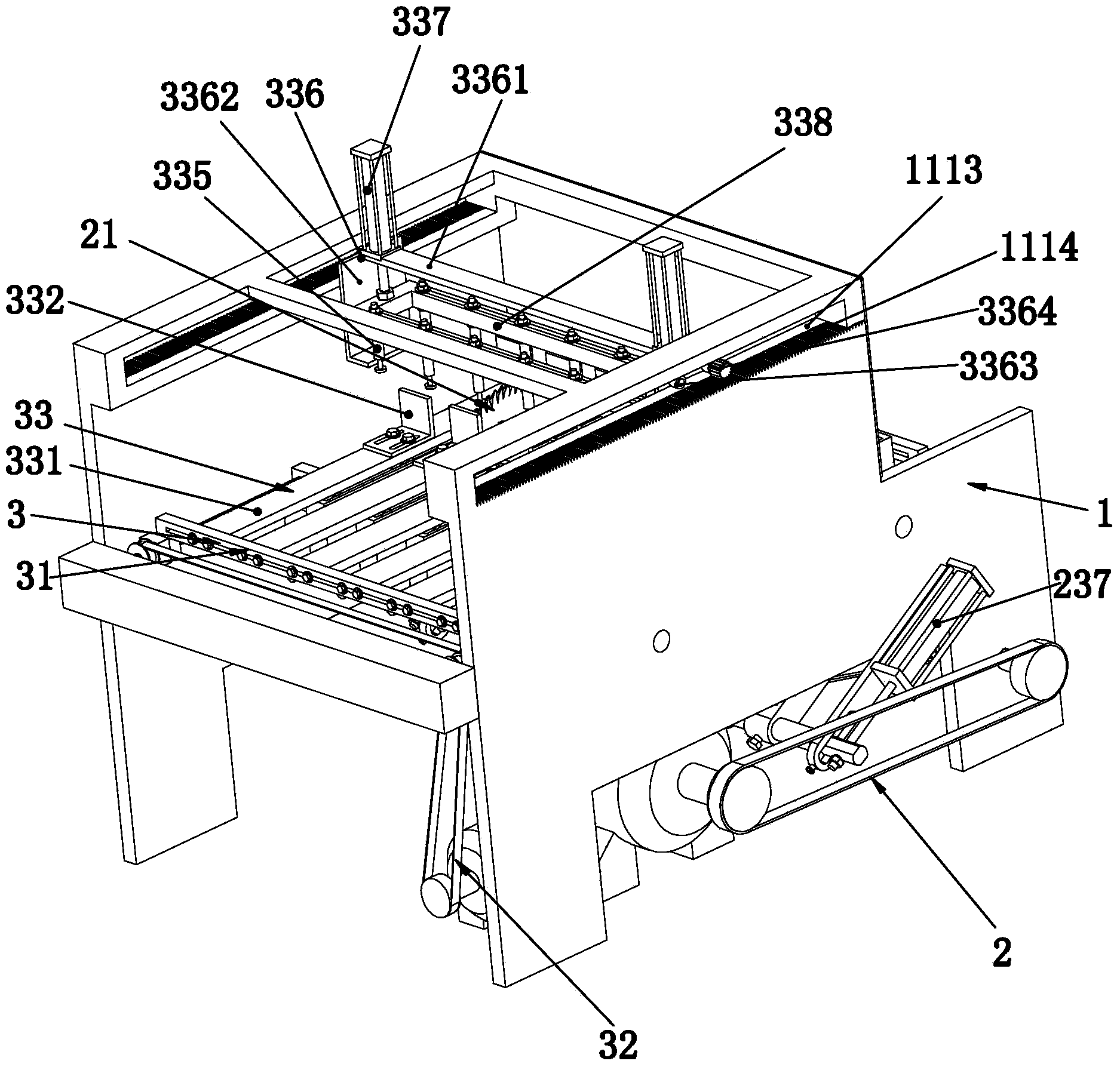

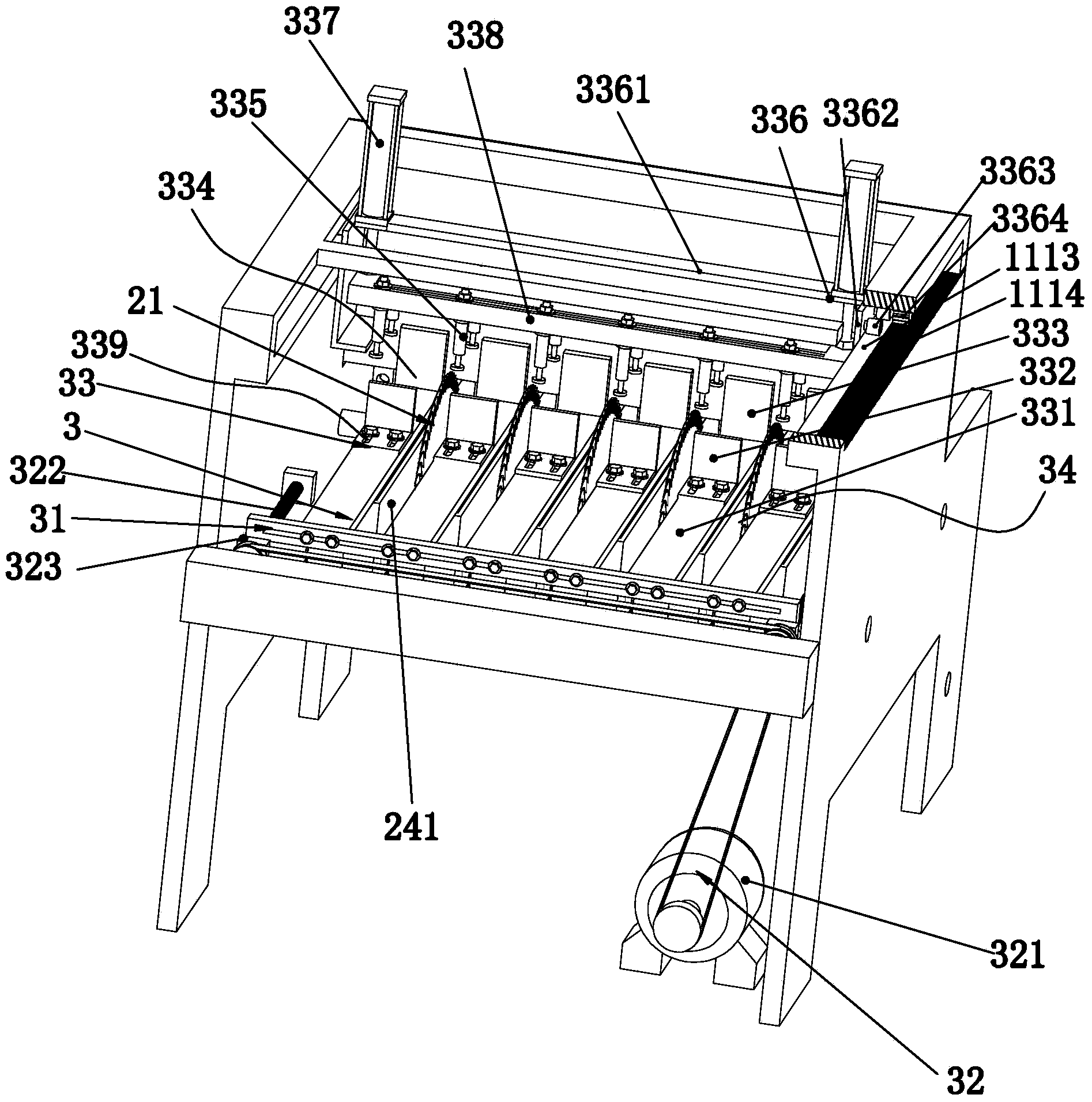

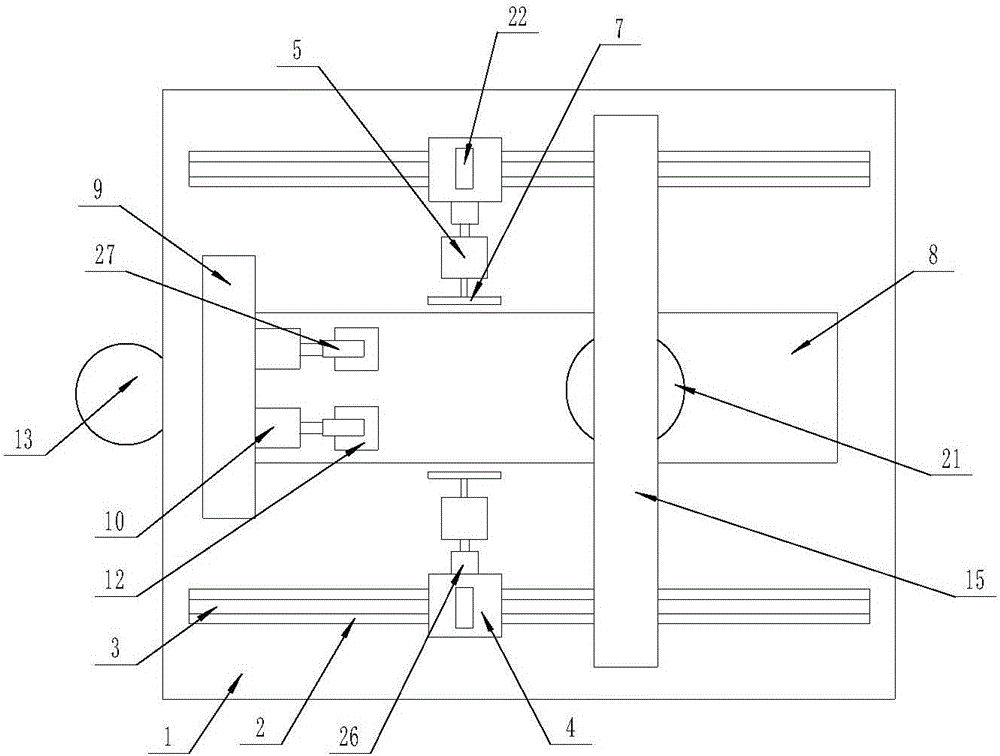

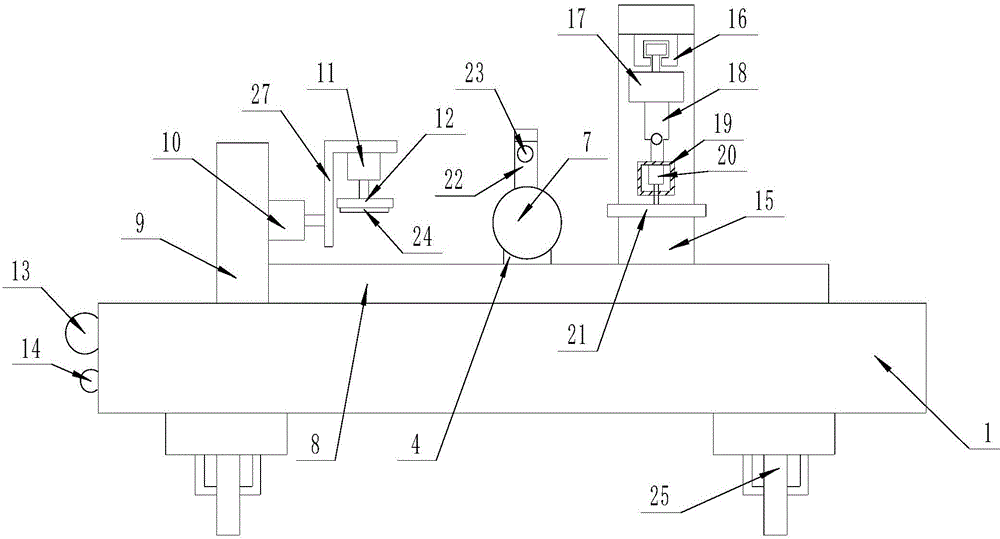

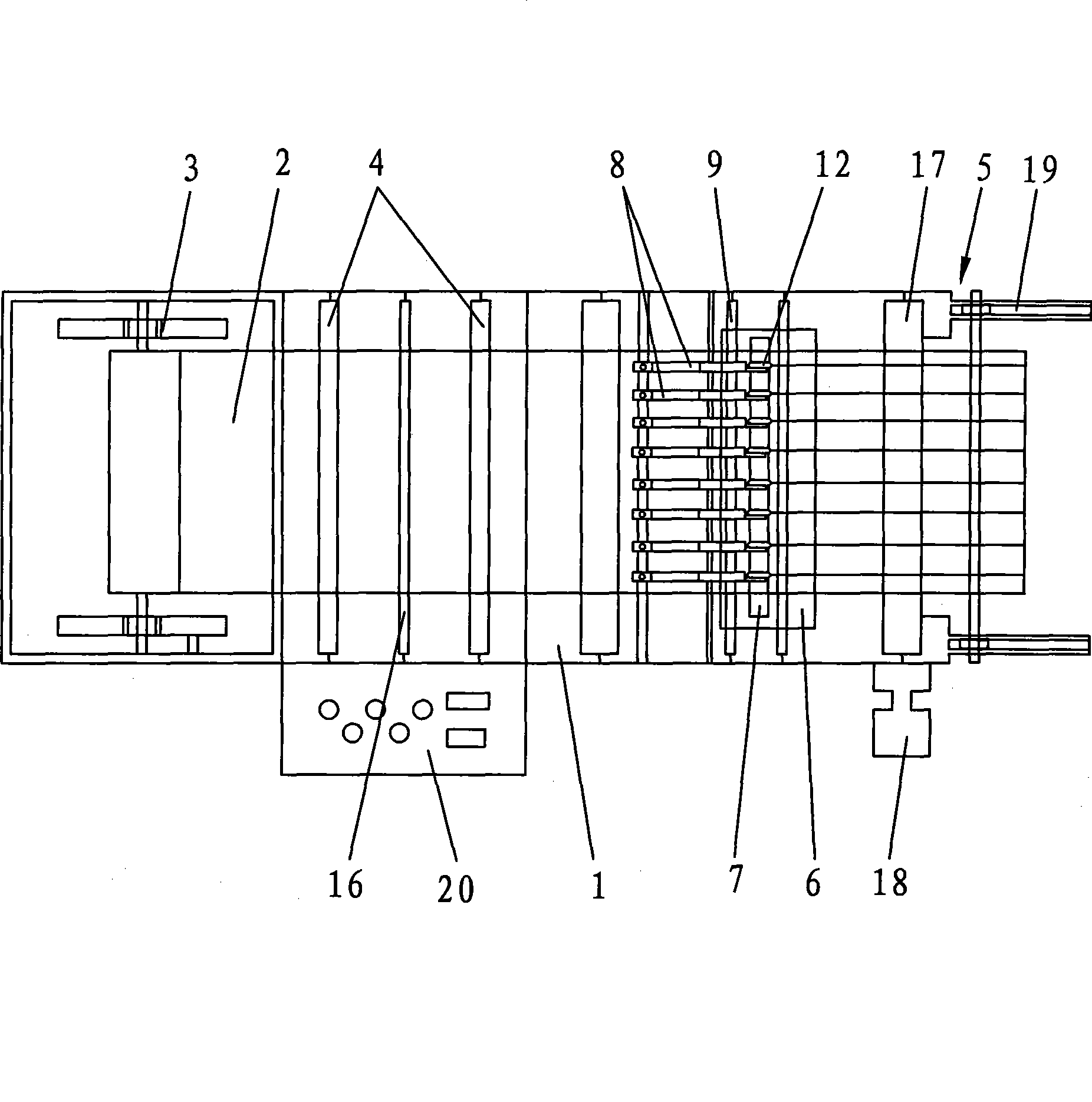

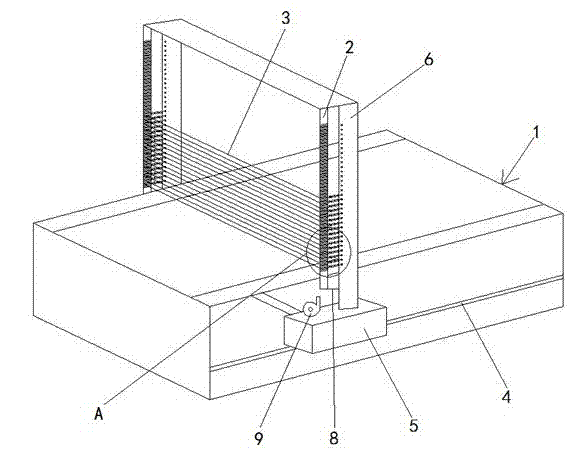

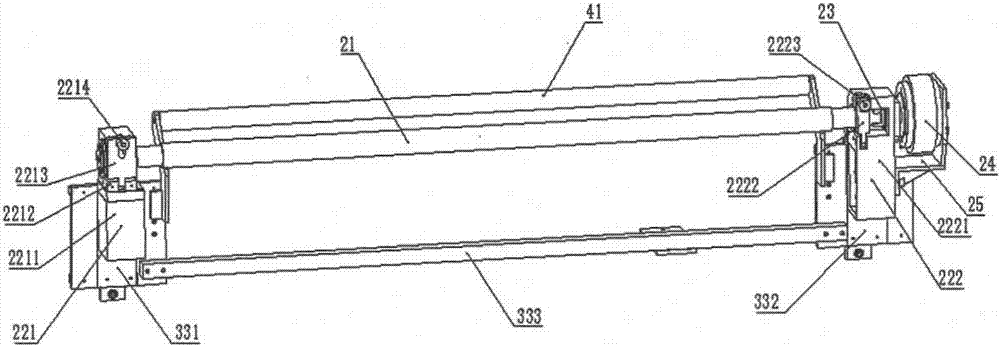

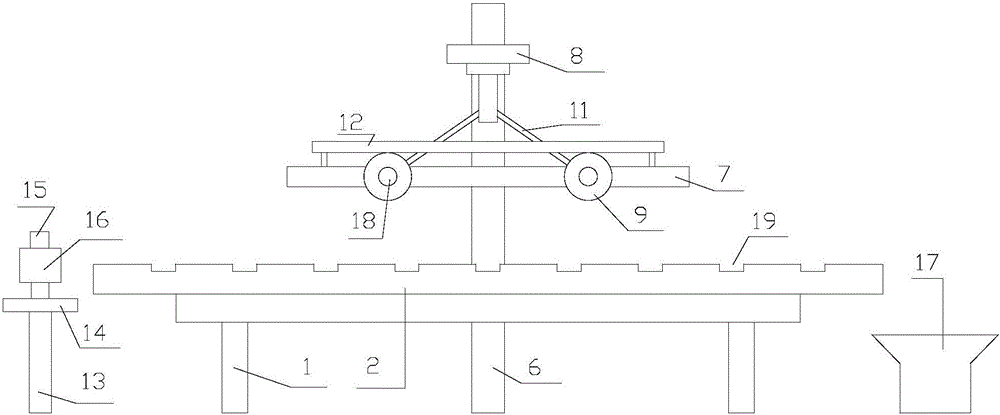

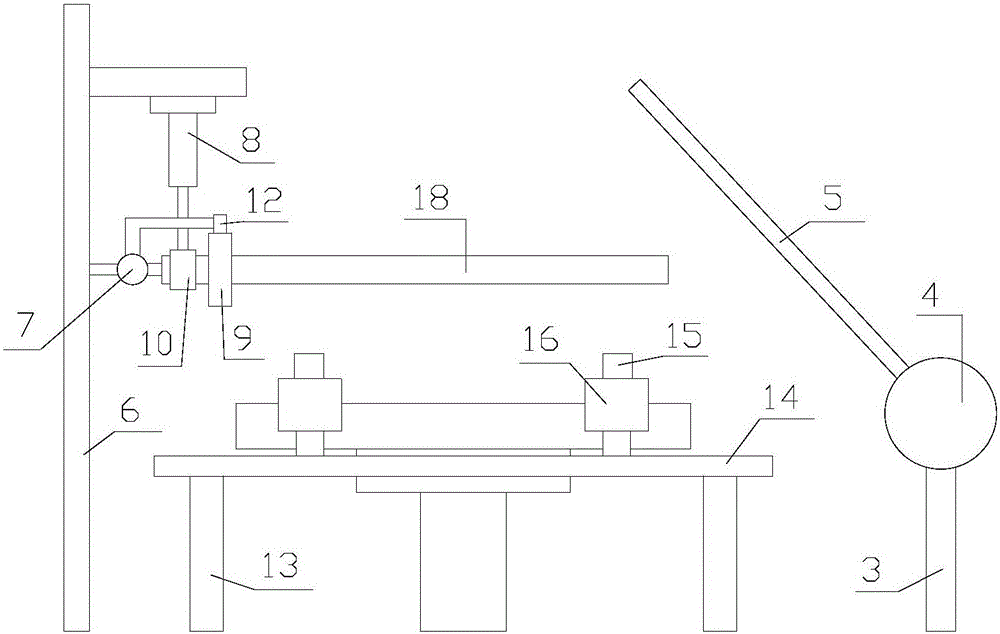

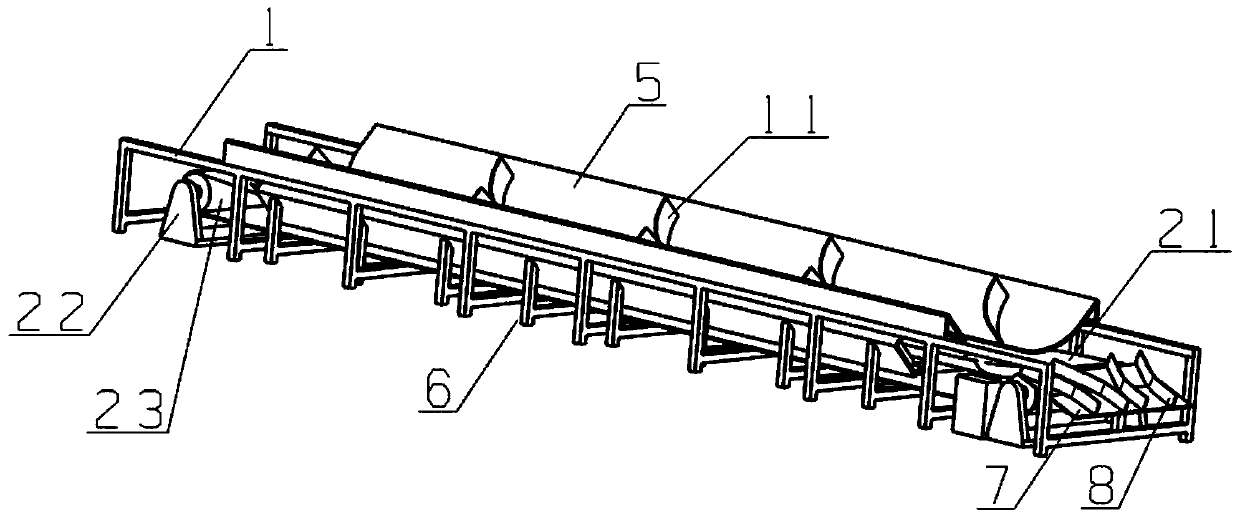

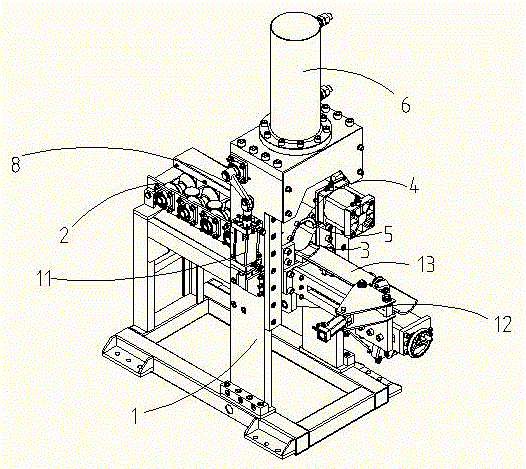

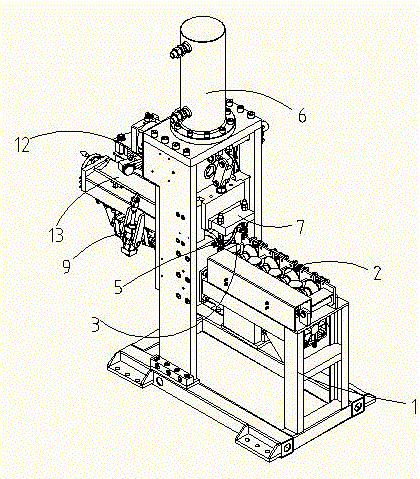

Safe type timber cutting machine with multiple cutting saw blades

The invention relates to a safe type timber cutting machine with multiple cutting saw blades. The safe type timber cutting machine comprises a machine base and a cutting device arranged on the machine base. The cutting device comprises a plurality of cutting saw blades, a saw blade mounting rotary shaft and saw blade driving mechanisms, wherein the cutting saw blades are coaxially assembled, and the spacing between the cutting saw blades can be adjusted, the saw blade mounting rotary shaft is used for allowing the cutting saw blades to be installed on, and the saw blade driving mechanisms drive the cutting saw blades to rotate and are in drive connection with the saw blade mounting rotary shaft. The machine base is further provided with an automatic feeding device. The automatic feeding device comprises a feeding rack and a feeding driving mechanism, wherein the feeding rack is arranged in a moving and sliding mode in the rotating and cutting direction of the cutting saw blades, and the feeding driving mechanism drives the feeding rack. A plurality of timber fixing platforms are arranged on the feeding rack, the number and the positions of the timber fixing platforms correspond to those of the cutting saw blades. The timber fixing platforms are coaxially arranged. Timber cutting passages for allowing the cutting saw blades to enter and cut timbers are formed between the adjacent timber fixing platforms in a spaced mode. The spacing between the adjacent timber fixing platforms can be adjusted. Compared with the prior art, the safe type timber cutting machine with the multiple cutting saw blades can automatically feed the timbers and is more convenient and safer to operate.

Owner:邹建静

Leftover material processing device

ActiveCN106166677AMaintain physical safetyEasy to operateOther manufacturing equipments/toolsElectricityElectric machinery

The invention discloses a leftover material processing device. The leftover material processing device comprises a working table, a set of sliding ways is formed in the upper surface of the working table, a sliding rail number one is arranged in each sliding way, an electric trolley number one is arranged on each sliding rail number one, a miniature air cylinder with the telescopic end in the horizontal direction is arranged on each electric trolley number one, the telescopic end of each miniature air cylinder is provided with an installing box, and a rotating motor with the rotating end in the horizontal direction is arranged in each installing box; a controller is arranged on one side face of the working table, a mains supply interface is formed below the controller and electrically connected with the controller, and the controller is electrically connected with the electric trolleys number one, the rotating motors, the telescopic air cylinders and miniature linear motors. The leftover material processing device has the advantages of being easy to operate, convenient to use, neat in cutting and suitable for small and medium-sized enterprises and practical, liberates manpower and protects body safety of operators.

Owner:JIANGSU LONGRUN IRRIGATION & DRAINAGE

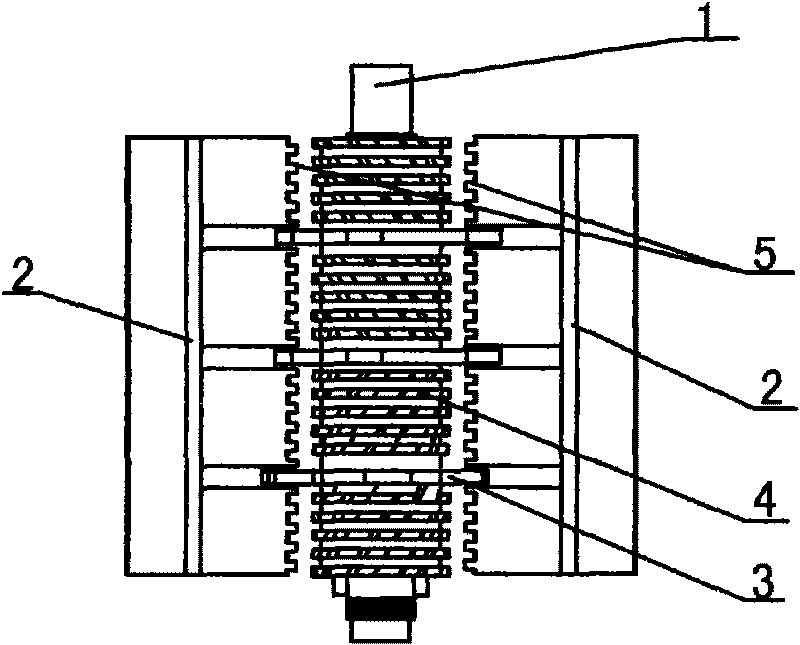

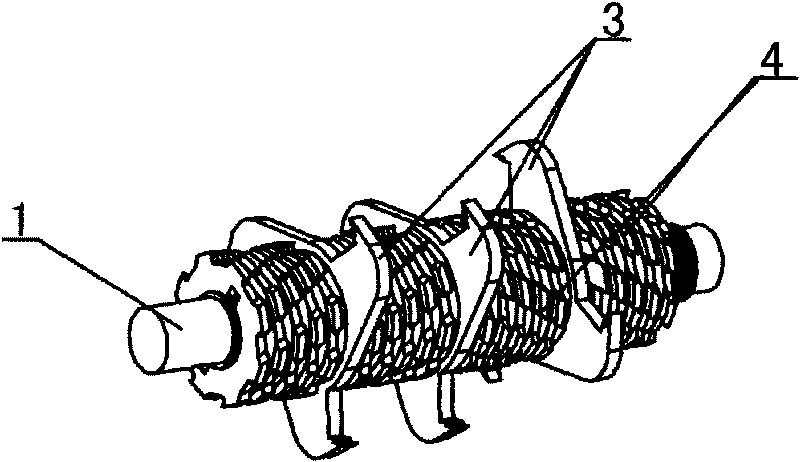

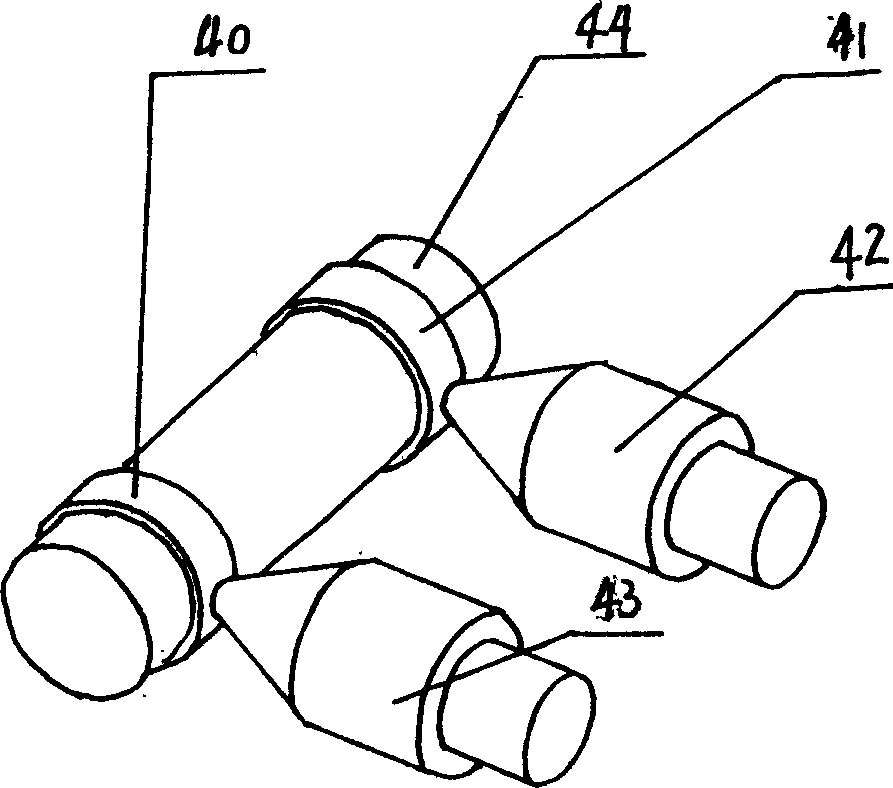

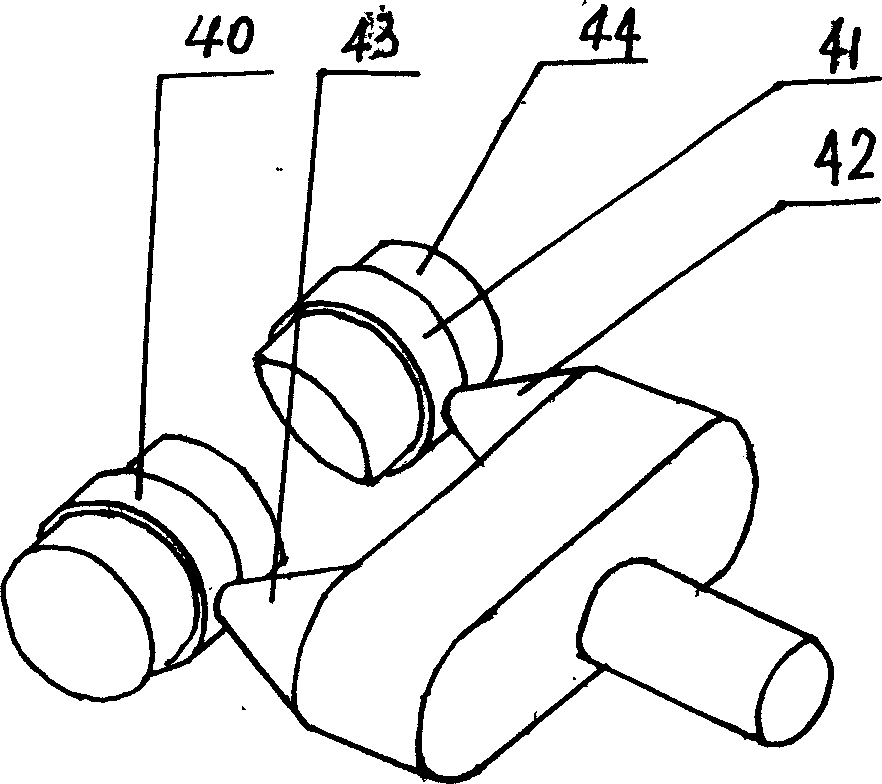

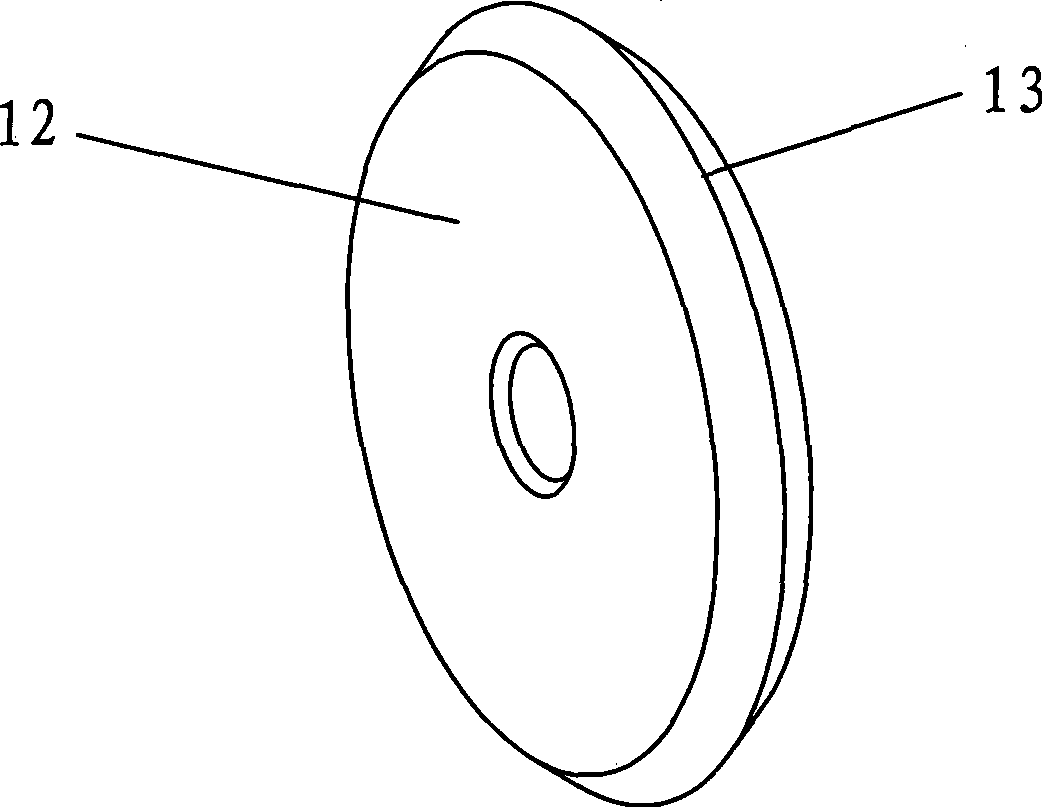

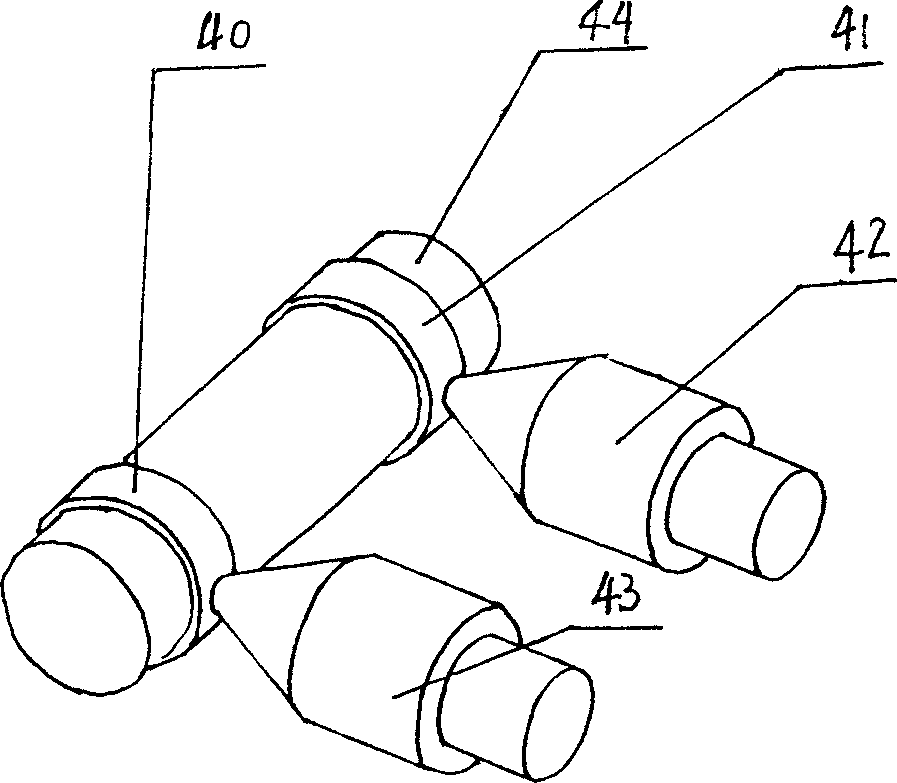

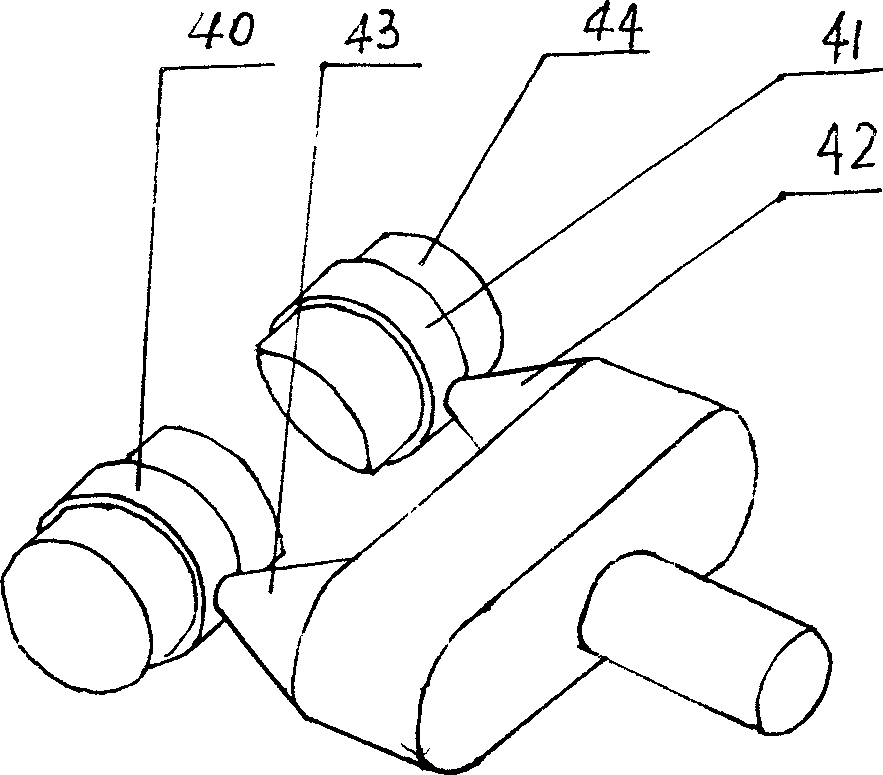

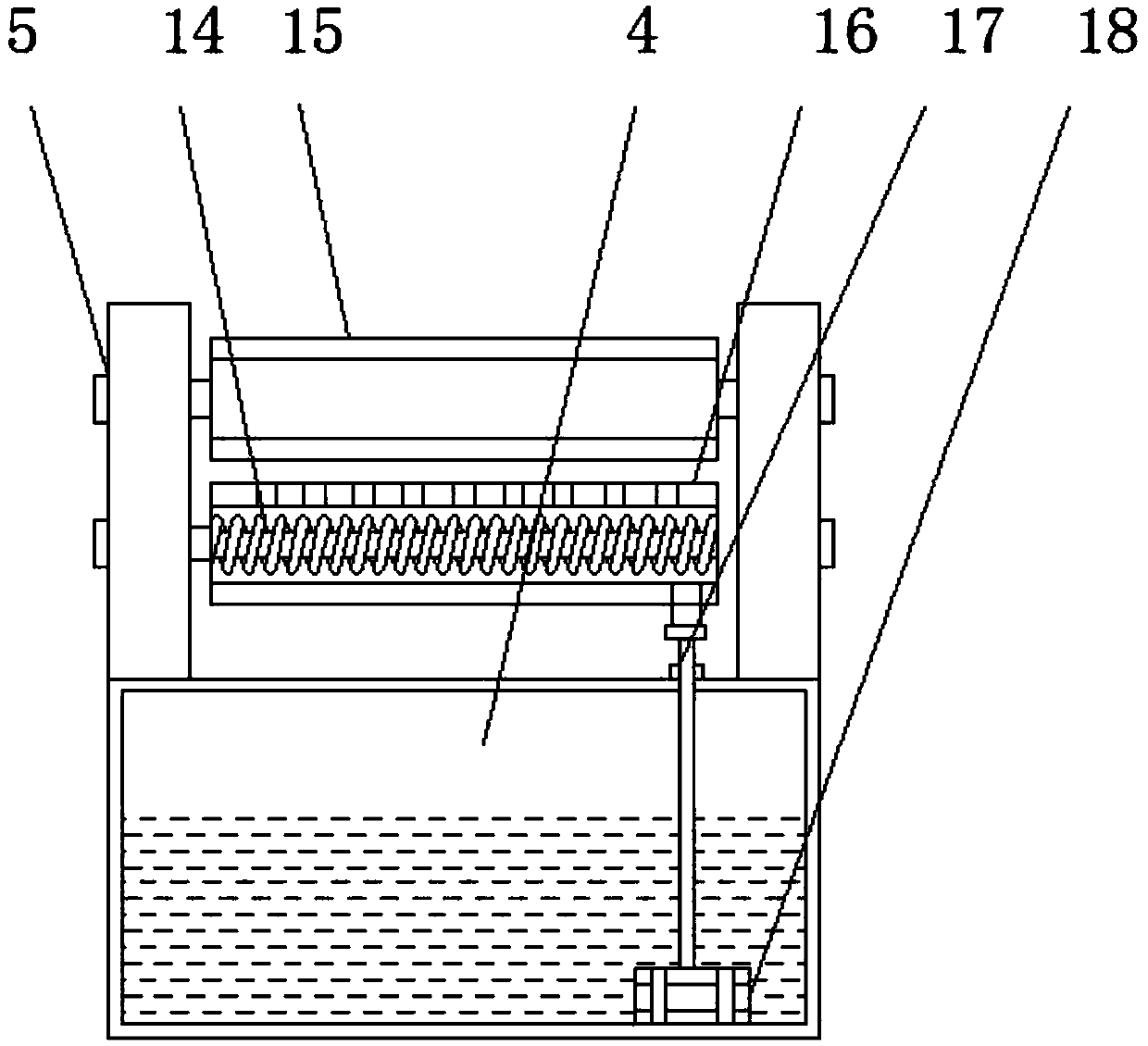

Crushing mechanism of plastic crusher

InactiveCN101722092AReduce generationEasy to install and maintainPlastic recyclingGrain treatmentsDrive shaftEngineering

The invention relates to a crushing mechanism of a plastic crusher, which comprises a transmission shaft, a fixed cutter and a movable cutter set, wherein the movable cutter set comprises a plurality of press cutters and circular cutters, the press cutters and the circular cutters are arranged on the transmission shaft through concentric shaft holes, and two sides of the movable cutter set are provided with a group of fixed cutters respectively; the movable cutter set comprises three press cutters and four circular cutters, wherein the press cutters form a three-leaf spiral structure and each press cutter is provided with three R-shaped press cutter edges, and a plurality of blades of the circular cutters are regularly arranged to form a spiral V-shaped structure and each circular cutter is provided with a plurality of R-shaped circular cutter edges; and a fixed cutter edge matched with the movable cutter part is formed inside the fixed cutter. The crushing mechanism of the plastic crusher has the advantages that through the R-shaped edges formed on the edges of the press cutters and the circular cutters respectively, the irregular cut materials are ensured, the production of dust is reduced, and the conventional complex structure is simplified; and meanwhile, the traditional screen is replaced by adopting the fixed cutter structure, so the assembly is convenient to mount and maintain.

Owner:黄国宏

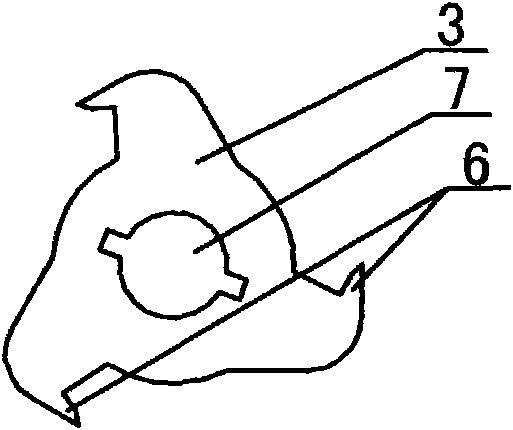

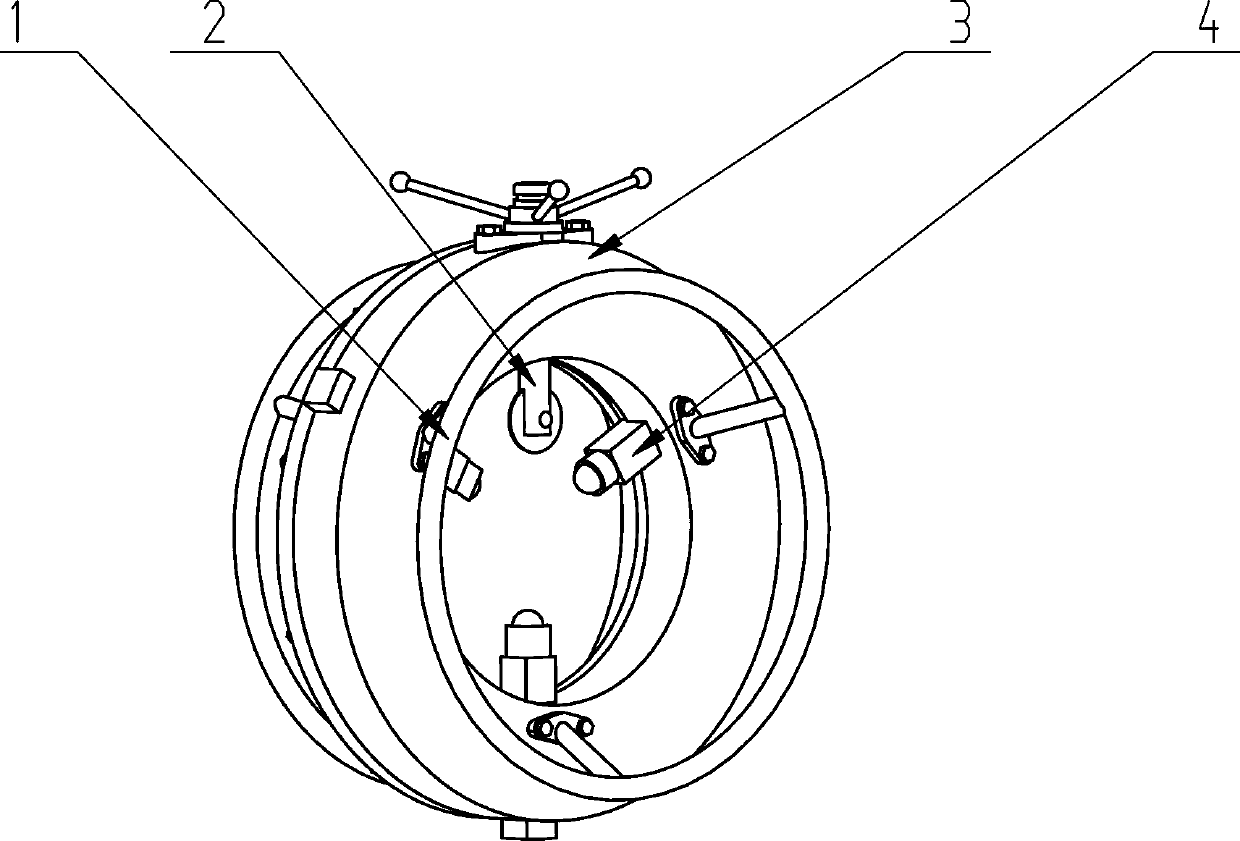

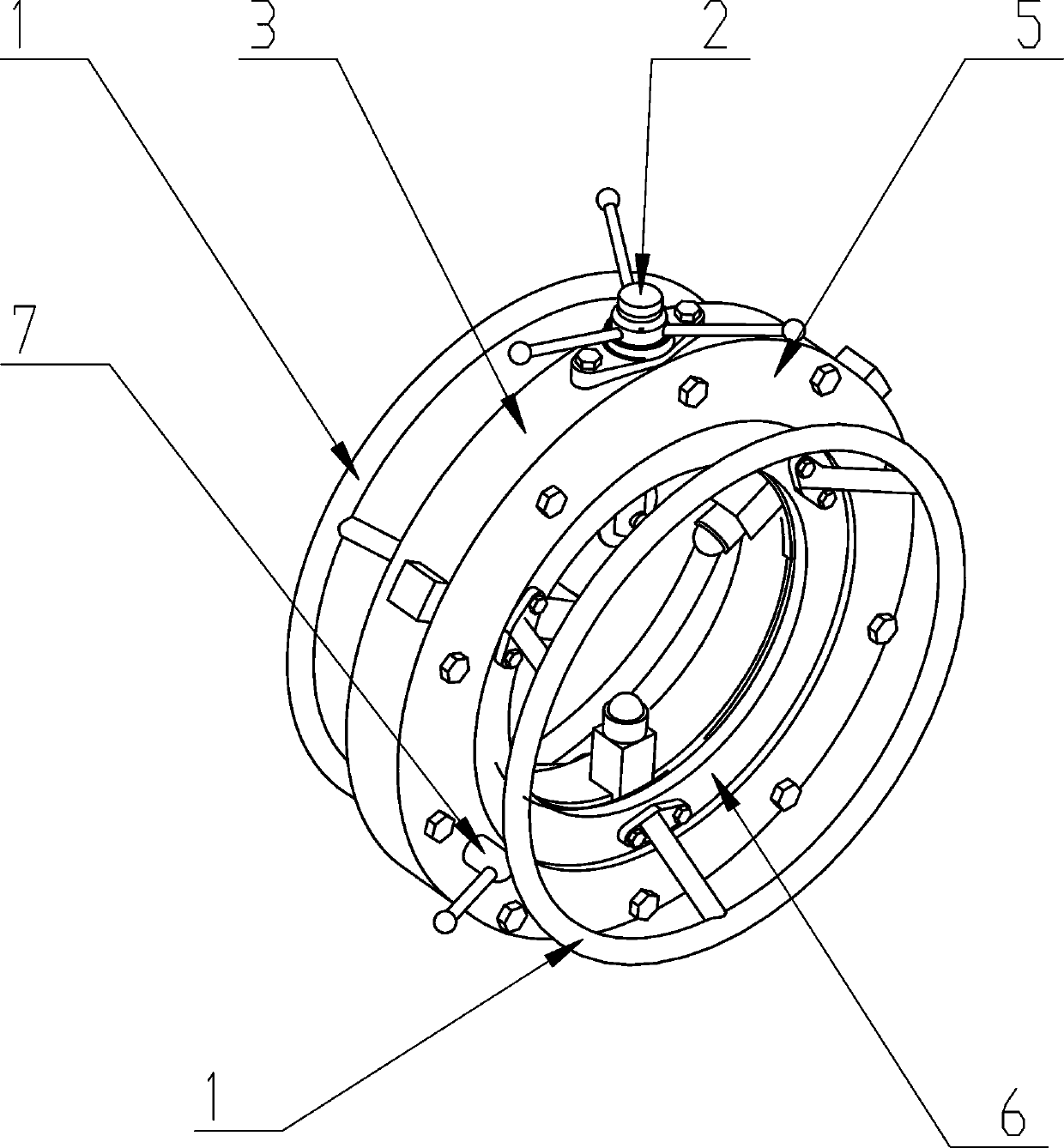

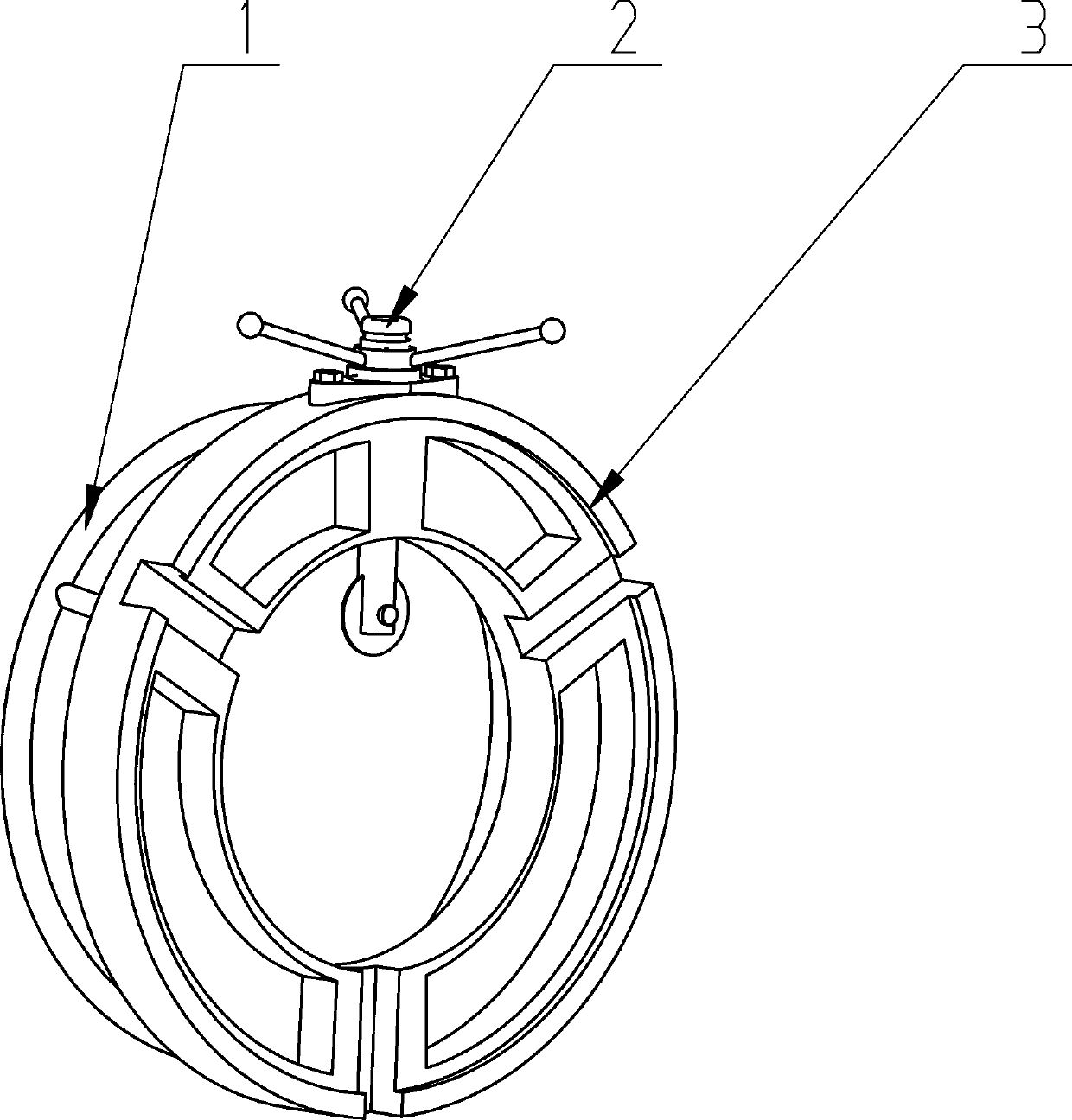

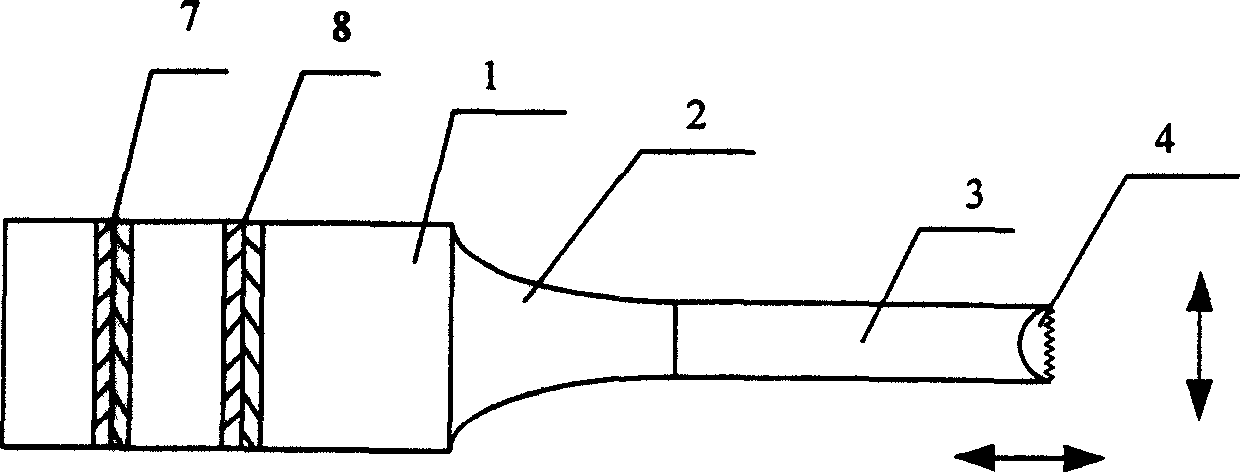

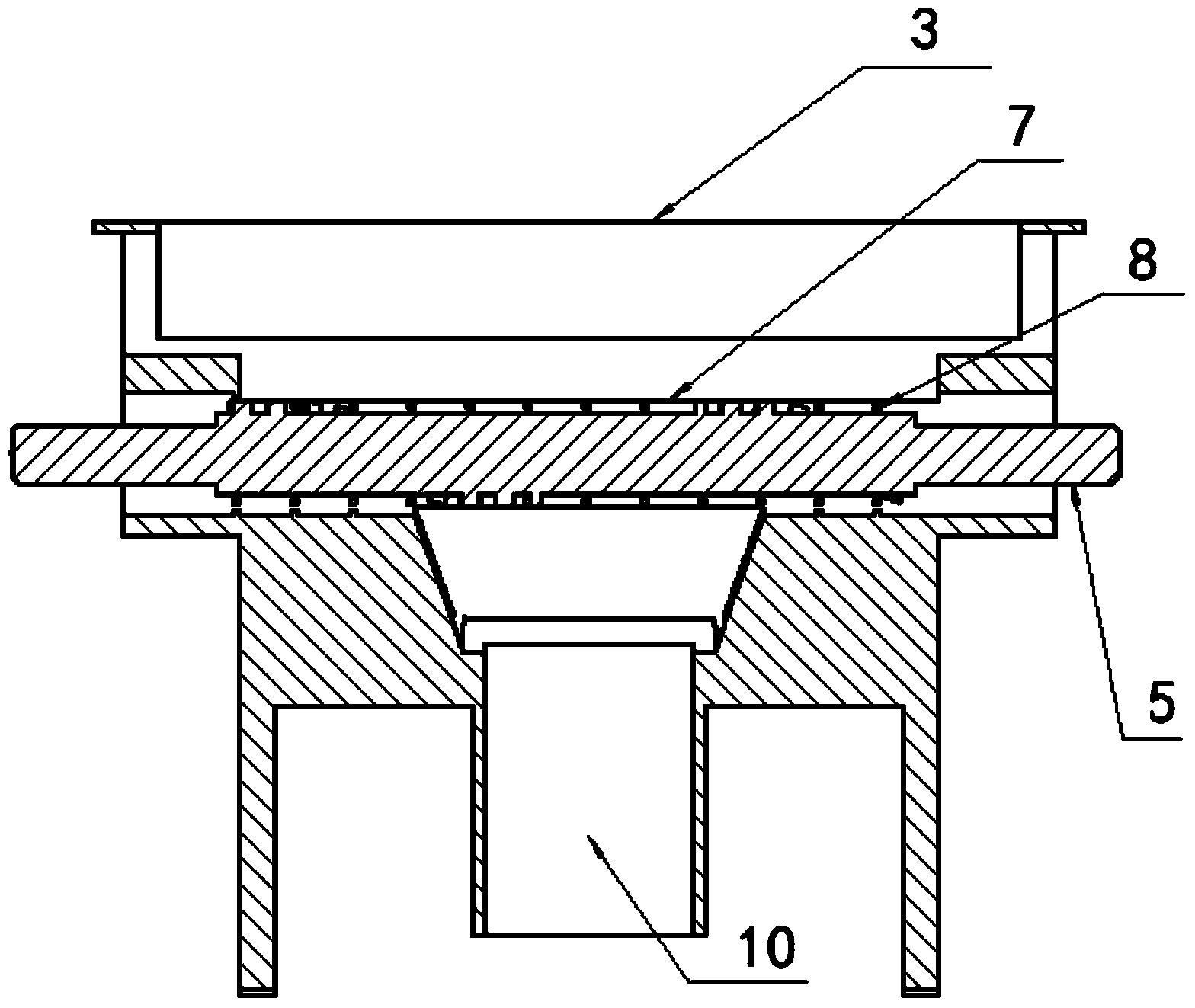

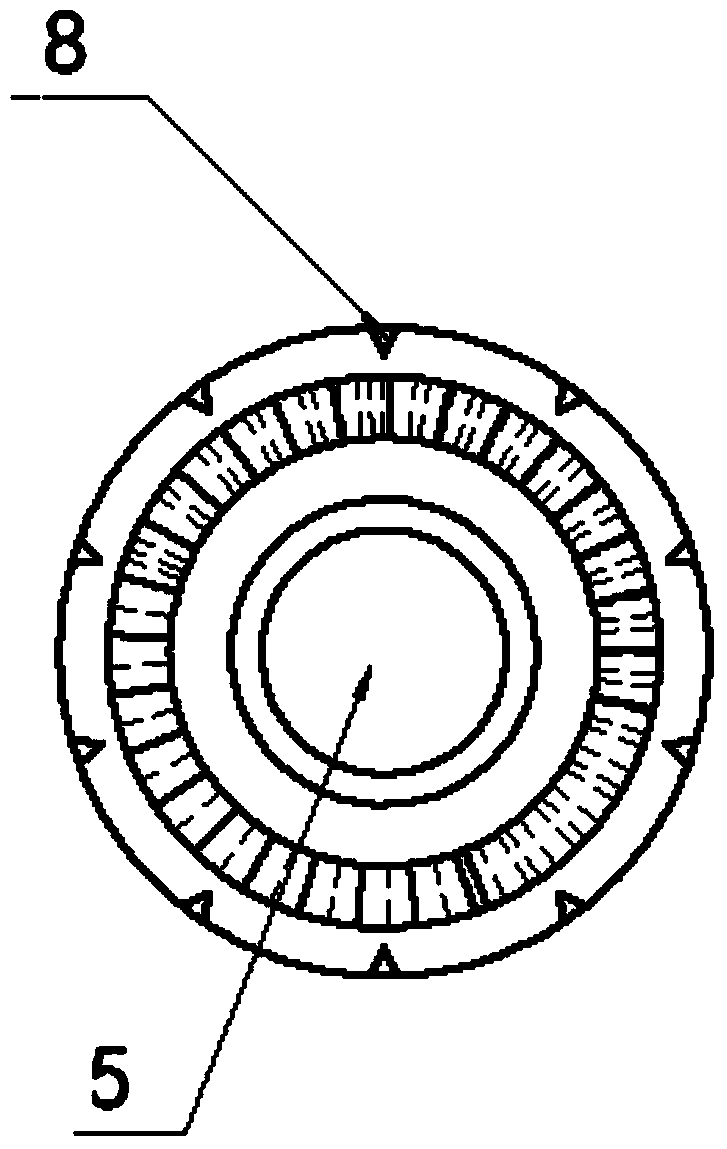

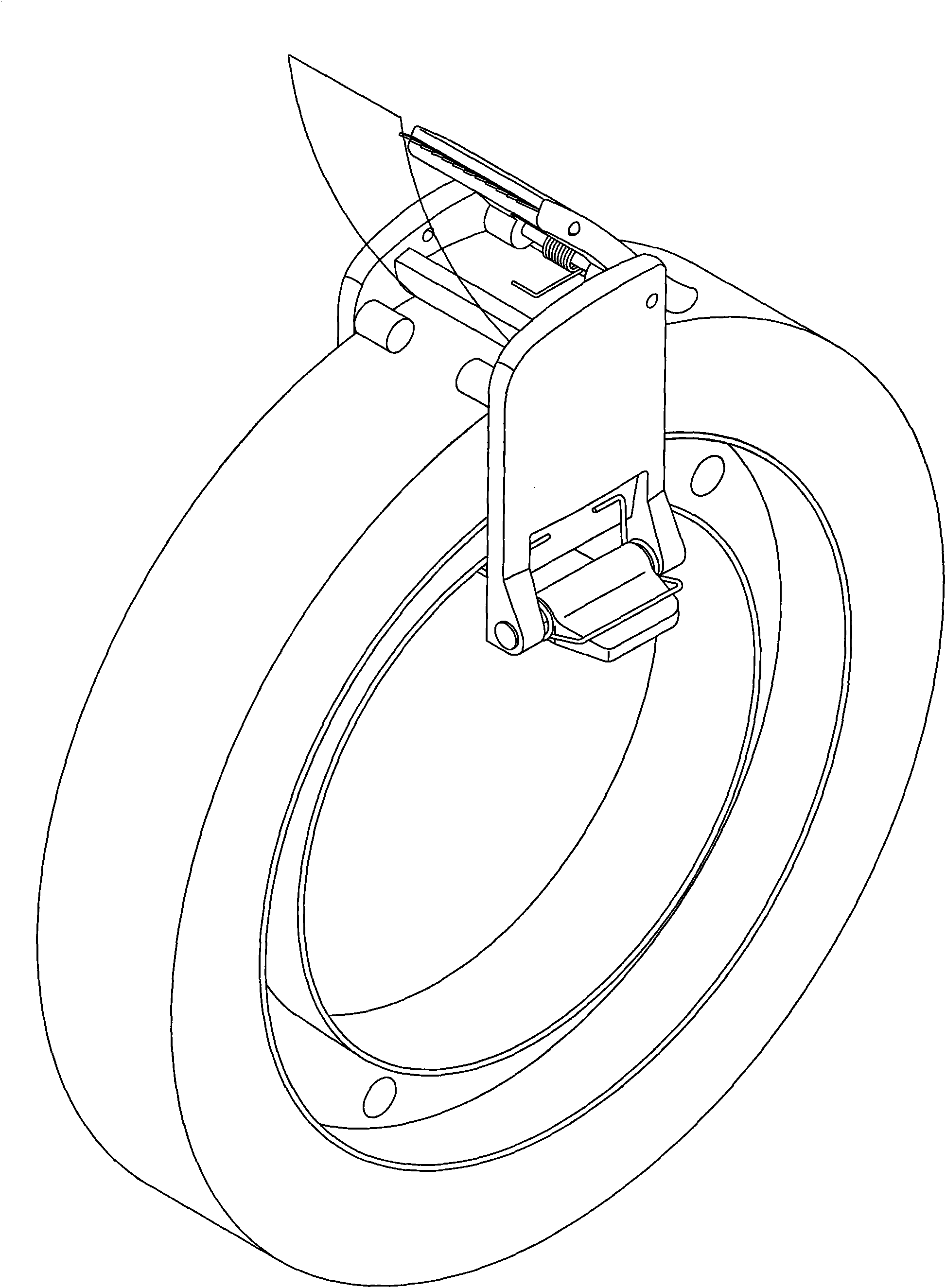

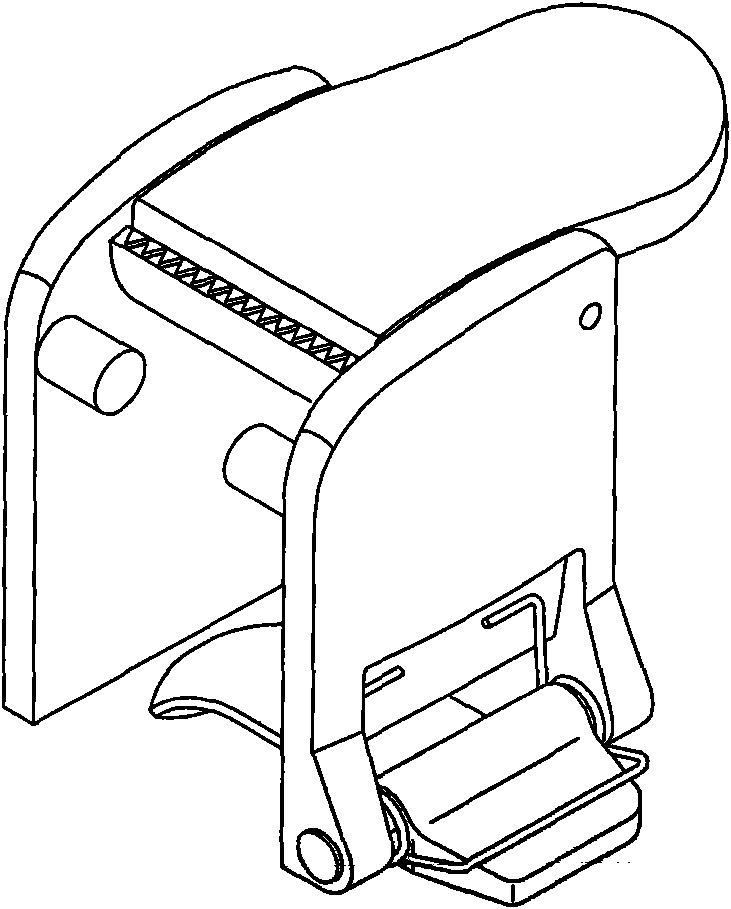

Multifunctional stripping tool for external insulation protection layer of high-voltage cable

ActiveCN111082369AEasy to operateLabor-saving operationApparatus for removing/armouring cablesInsulation layerStructural engineering

The invention discloses a multifunctional stripping tool for an outer insulating protective layer of a high-voltage cable. The multifunctional stripping tool is used for stripping the outer insulatingprotective layer of the high-voltage cable. The tool comprises a hand wheel assembly, a cutter assembly, a disc body, clamping jaw assemblies, a check ring, a wire disc and a locking handle. The handwheel assembly, the clamping jaw assemblies, the cutter assembly, the check ring and the wire disc are installed on the disc body, and the locking handle is installed on the check ring. The three clamping jaw assemblies have a self-centering function, and the cutter assembly can set the cutting thickness according to the thickness of a cut cable insulation layer. According to the high-voltage cable outer insulation stripping device, the high-voltage cable outer insulation can be stripped more conveniently, time and labor are saved, the stripping efficiency is improved, and hands are preventedfrom being scratched or the insulation layer of a cable core is prevented from being damaged due to insufficient experience of an operator.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +2

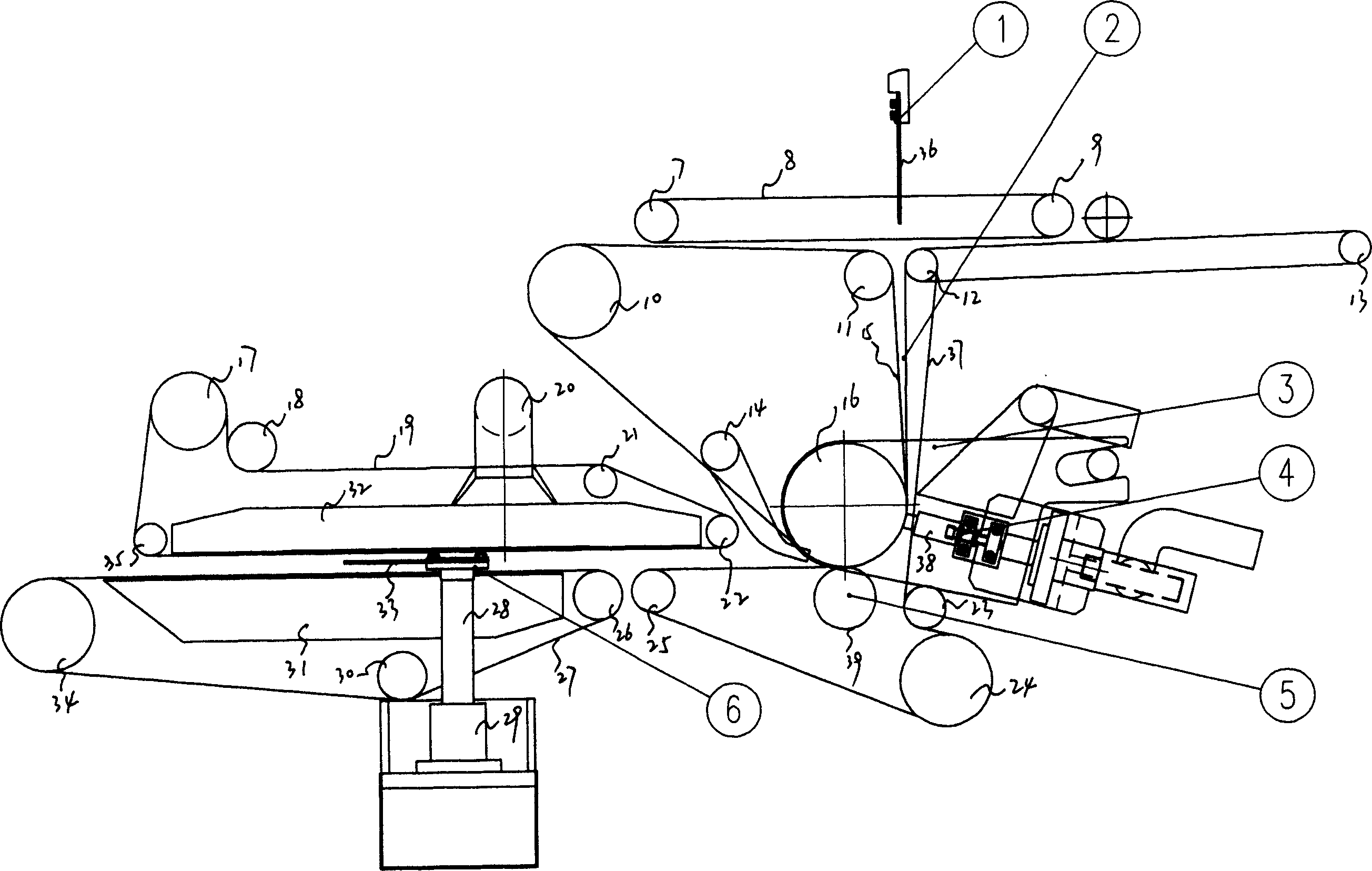

Infant and child training pants shaping derice and shaping method

A machine and method for forming the infantile training trousers are disclosed. An inserting plate can insert the training trousers in folding unit for symmetrically folding it. The two waist pieces of said training trousers are smoothed by a finishing unit. The pieces for waist and legs are welded by the patterning wheel or moulding roller and ultrasonic head in welding unit. The waist edge is cut by the trimming unit for making it neat. The left and right waist pieces are than curled by the edge curling unit.

Owner:ZHEJIANG ROBOT MACHINERY TECH

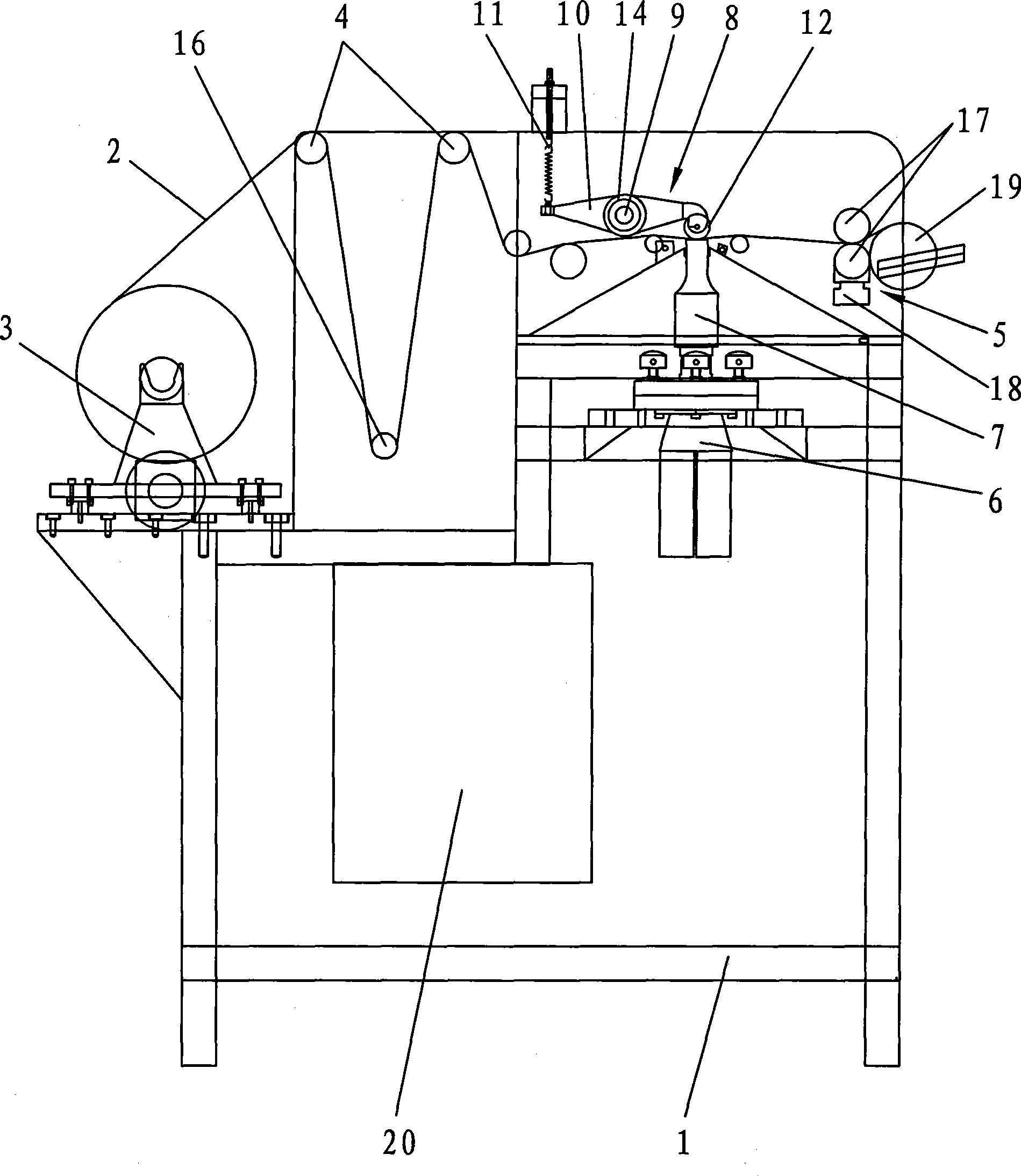

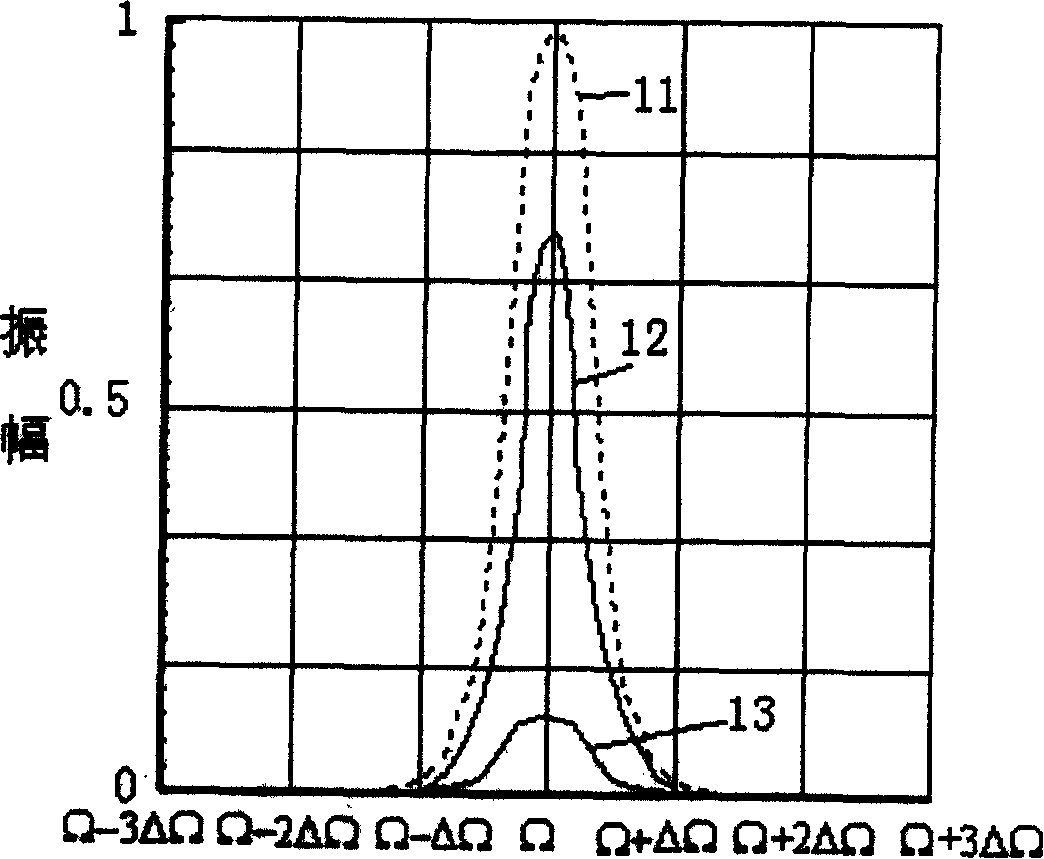

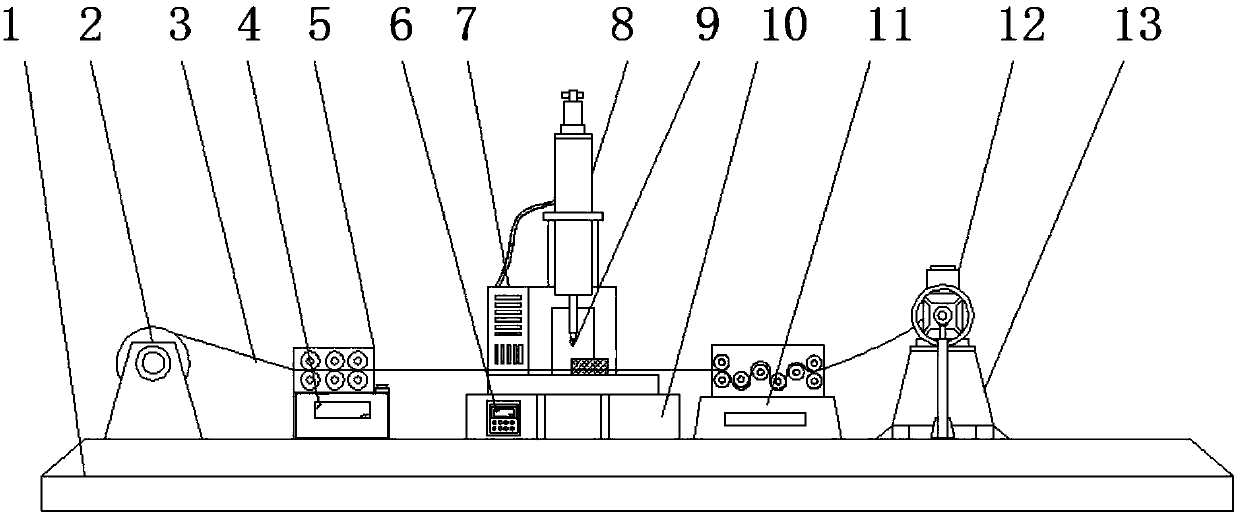

Ultrasonic slitter for clothes

ActiveCN101498096ATrimmed neatlyAesthetic TensileSevering textilesEngineeringHigh frequency vibration

The invention relates to a mercery ultrasonic slitter which belongs to the technical field of fabric shearing equipment. The mercery ultrasonic slitter comprises a slitter stand, wherein a substrate unreeling device, a feed roll, a slitter shearing mechanism and a substrate reeling device are arranged on the slitter stand, substrates pass through the feed roll and are sheared by the slitter shearing mechanism, and then the substrates are reeled by the substrate reeling device; the slitter shearing mechanism comprises an ultrasonic vibrator, a vibrator module and a cutter device, the vibrator module is arranged on the output end of the ultrasonic vibrator, the cutter device is matched with the vibrator module to cut the substrates, ultrasonic waves sent out by the ultrasonic vibrator cause the cutter device to generate high-frequency vibration and continuously collide with the vibrator module, then the substrates passing through the cutter device and the vibrator module are cut, the ultrasonic waves sent out by the ultrasonic vibrator also can heat cutter blades of the cutter device, the cutter blades of the cutter device have hot melt edge sealing effects as well as cut the substrates by high-frequency collision, thus the cutting edges of the cut fabric strips are tidy without fluffiness, the appearance is attractive, and the tensile resistance is high.

Owner:GUANGDONG SUOREC TECH

Cutting device for aluminum alloy tube with clamping rotation function

InactiveCN108856853AImprove cutting efficiencyNeat cutTube shearing machinesShearing machine accessoriesRotation functionBlock match

The invention provides a cutting device for an aluminum alloy tube with a clamping rotation function. The device comprises a bottom plate, a vertical plate is fixedly connected to the upper side of the right end of the bottom plate, a moving groove with an opening facing upward is formed in the bottom plate, the moving groove is internally provided with a moving block, a horizontal threaded through hole is formed in the moving block, the horizontal threaded through hole is internally in threaded connection with a horizontal threaded rod, the two ends of the horizontal threaded rod are rotatably connected with the two ends of the moving groove, the outer end of the horizontal threaded rod is fixedly connected a handle, a clamping rotation device is fixedly connected with the upper side of the moving block, and the outer side of the clamping rotation device is sleeved with the aluminum alloy tube; the upper side of the bottom plate is further provided with a supporting body. The device has the advantages that the moving block matched with the horizontal threaded rod moves to the right side in the moving groove, the right end of the aluminum alloy tube abuts the side wall of the vertical plate, each time lengths cut of the aluminum alloy tube are equal, it is not necessary to measure each time, and the cutting efficiency is effectively improved.

Owner:许媛

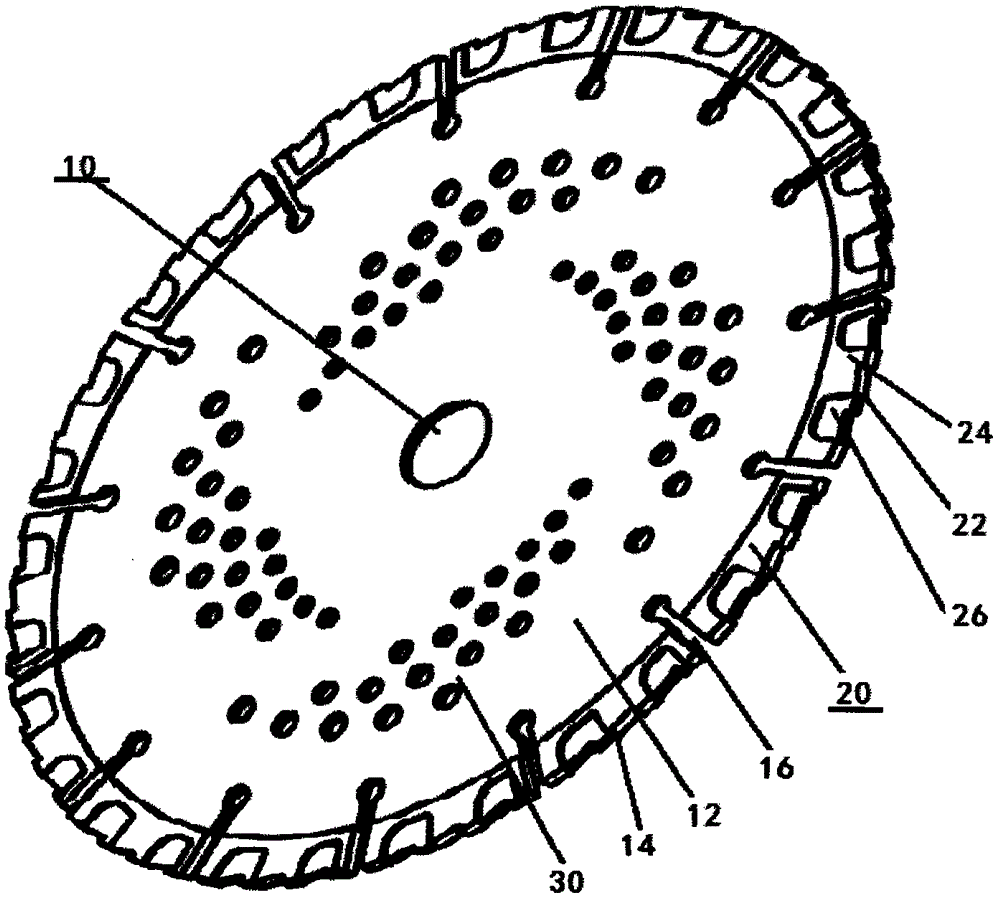

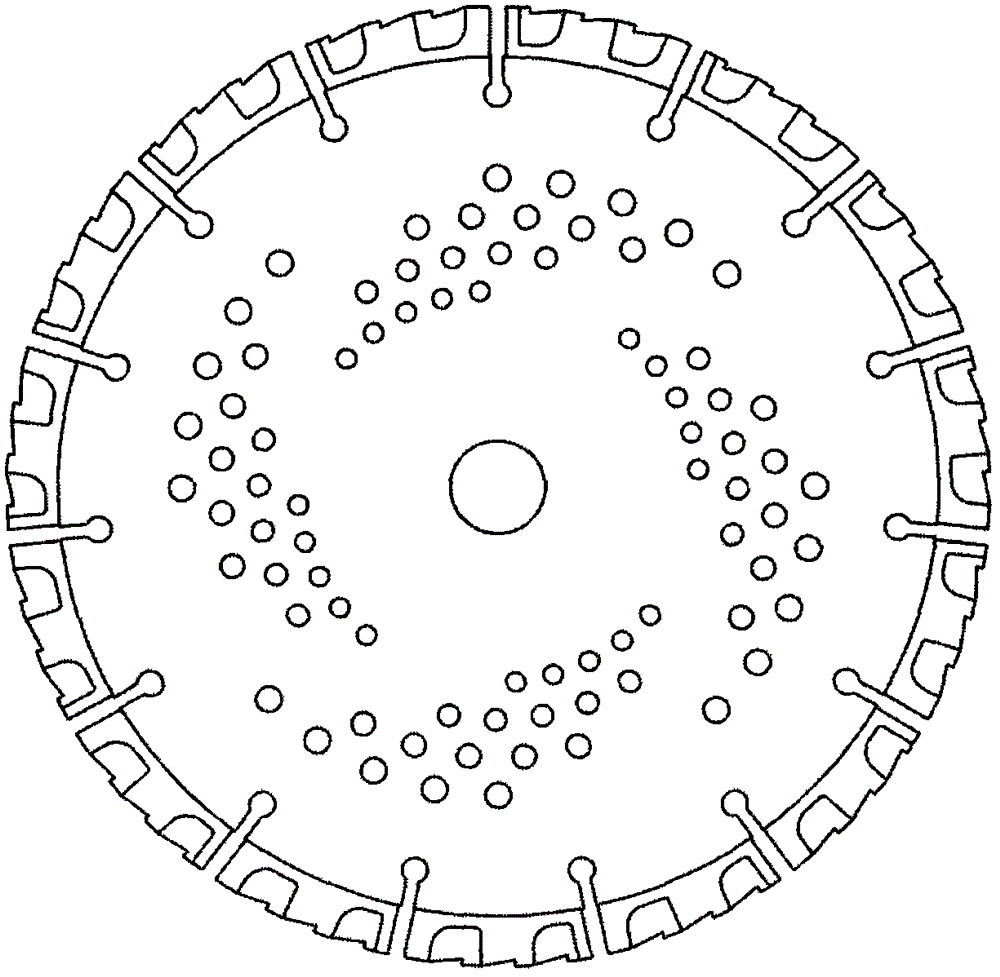

Saw-tooth double-faced concave U sharp type concrete laser welding cutting disk preparation method

ActiveCN104907942ANarrow kerfLess consumablesTransportation and packagingBonded abrasive wheelsBrickRebar

The invention relates to a saw-tooth double-faced concave U sharp type concrete laser welding cutting disk preparation method and belongs to the technical field of diamond machining tools. The preparation method is implemented through the following working procedures that a metallic bond and diamond are subjected to material preparation, granulation, cold pressing, hot pressed sintering, laser welding, first edge forming, polishing, painting, checking packaging storage in sequence. According to the saw-tooth double-faced concave U sharp type concrete laser welding cutting disk preparation method, a diamond tool bit is formed by the procedures that the metallic bond and diamond are subjected to the hot pressed sintering under vacuum conditions. By means of the saw-tooth double-faced concave U sharp type concrete laser welding cutting disk preparation method, the prepared cutting disk has the advantages that the cutting seam is narrow, the consumable items are less, the cutting deflection is small, the cut edge is neat, the cutting sharpness is good, and the cutting disk is particularly suitable for the cutting of hard materials including building materials, wall bodies, cement concrete, solidified concrete, reinforced concrete, hard concrete bricks, concrete piles and the like.

Owner:江苏华昌工具制造有限公司

Technical cubic foam block cutting machine

The invention discloses a technical cubic foam block cutting machine, which comprises a rack, electric heating poles and electric heating wires, wherein the electric heating poles are vertically arranged on two sides of the rack; the electric heating wires are fastened between the electric heating poles; two sides of the rack are provided with guide rails; the guide rails are provided with sliding seats which move along the guide rail direction; the electric heating poles are vertically fixed on the sliding seats; wire tightening poles are arranged near the electric heating poles in parallel; and the bottom of the electric heating poles is provided with a blower. The technical cubic foam block cutting machine can be operated only by one person, thereby being convenient and quick; the produced cubic foam block has the advantages of standard size and tidy notch; the cubic foam blocks with various sizes can be produced on batch so as to greatly improve the production efficiency; meanwhile, in the production process, the chance for workers to contact with the machine is small; and therefore the accident that an operator is scaled by the electric heating wires is greatly reduced.

Owner:JIANGSU ANYANG CULTURE CREATIVE IND PARK

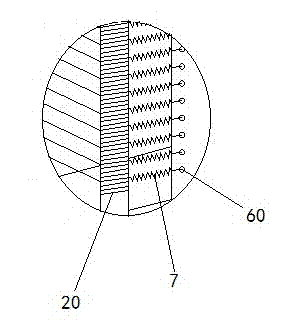

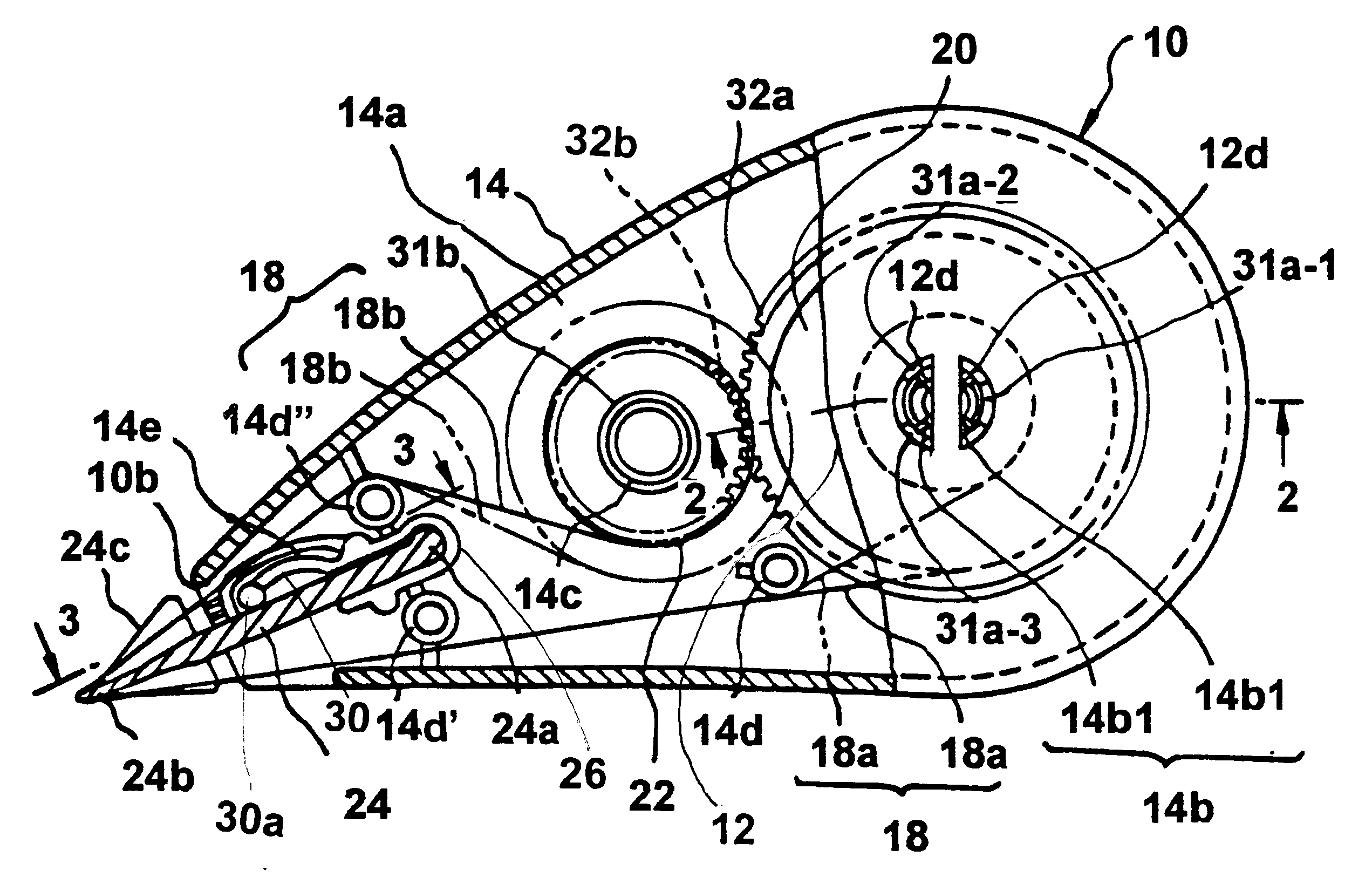

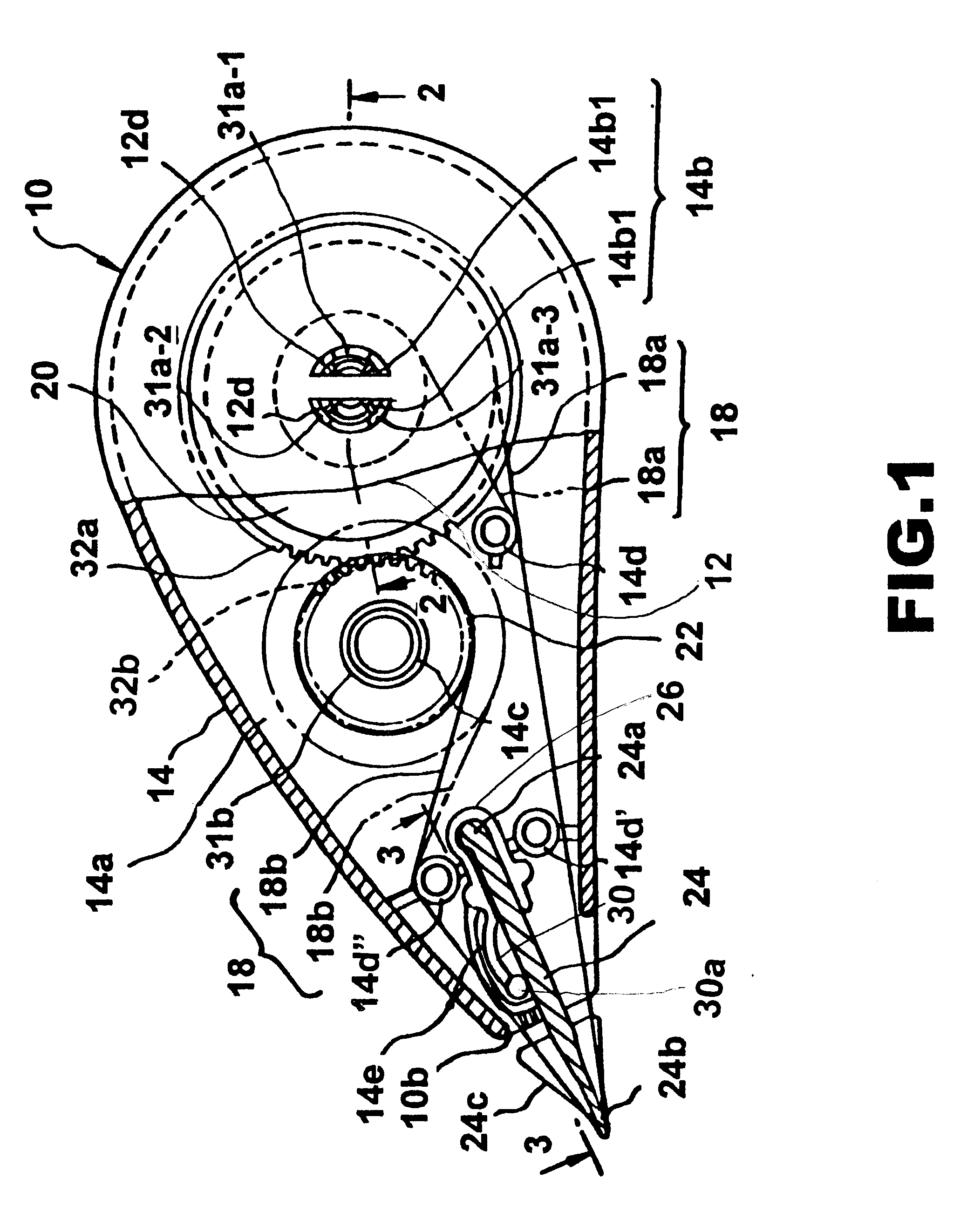

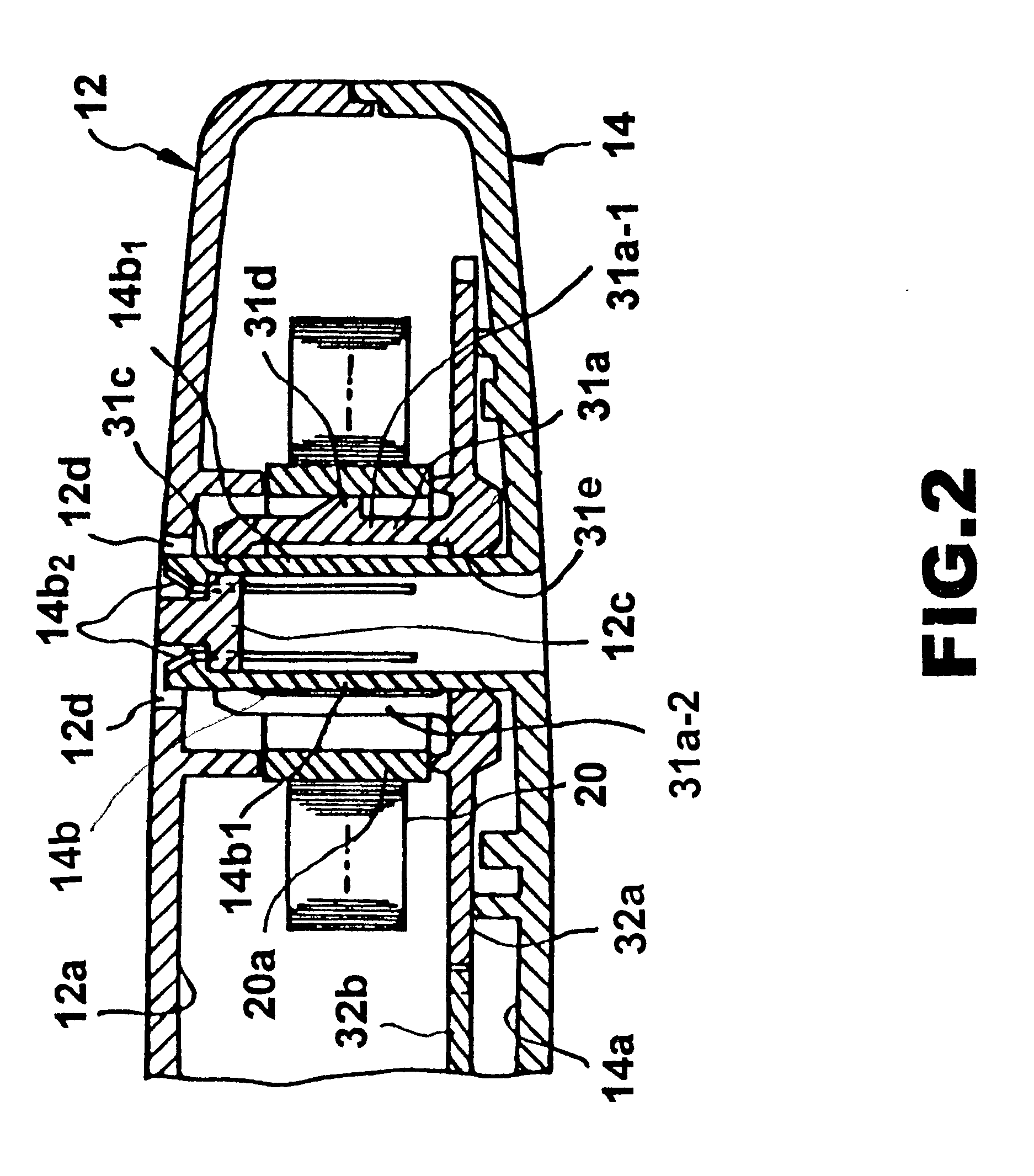

Coat transfer tool

InactiveUS6325130B1Neat cutSufficient forceLiquid surface applicatorsFilament handlingElectrical and Electronics engineeringEngineering

Owner:KOTOBUKI & CO LTD

Slitting cutting processing method for piece goods

The invention relates to a fabric slitting cutting processing method which belongs to the technical field of fabric shearing equipment. The processing method comprises the following steps: A. feeding fabric to the cutting edge of a cutter, B. tightening the fabric to stabilize the tensile force, C. driving the cutter to vibrate and heat by ultrasonic waves, D, using the vibrating and heating cutter to cut fabric with stable tensile force by high-frequency vibration, E. moving the fabric with respect to the cutter to be cut into fabric strips. The method uses the ultrasonic waves to drive the cutter to generate high-frequency vibration for cutting the fabric continuously, thus the effect of continuous cutting is achieved by the movement of the fabric with respect to the cutter. The ultrasonic waves also cause the cutter to be heated, the cutter has hot melt edge sealing effects as well as cuts the fabric, thus the cutting edges of the cut fabric strips are tidy without fluffiness, the appearance is attractive, and the tensile resistance is high.

Owner:GUANGDONG SUOREC TECH

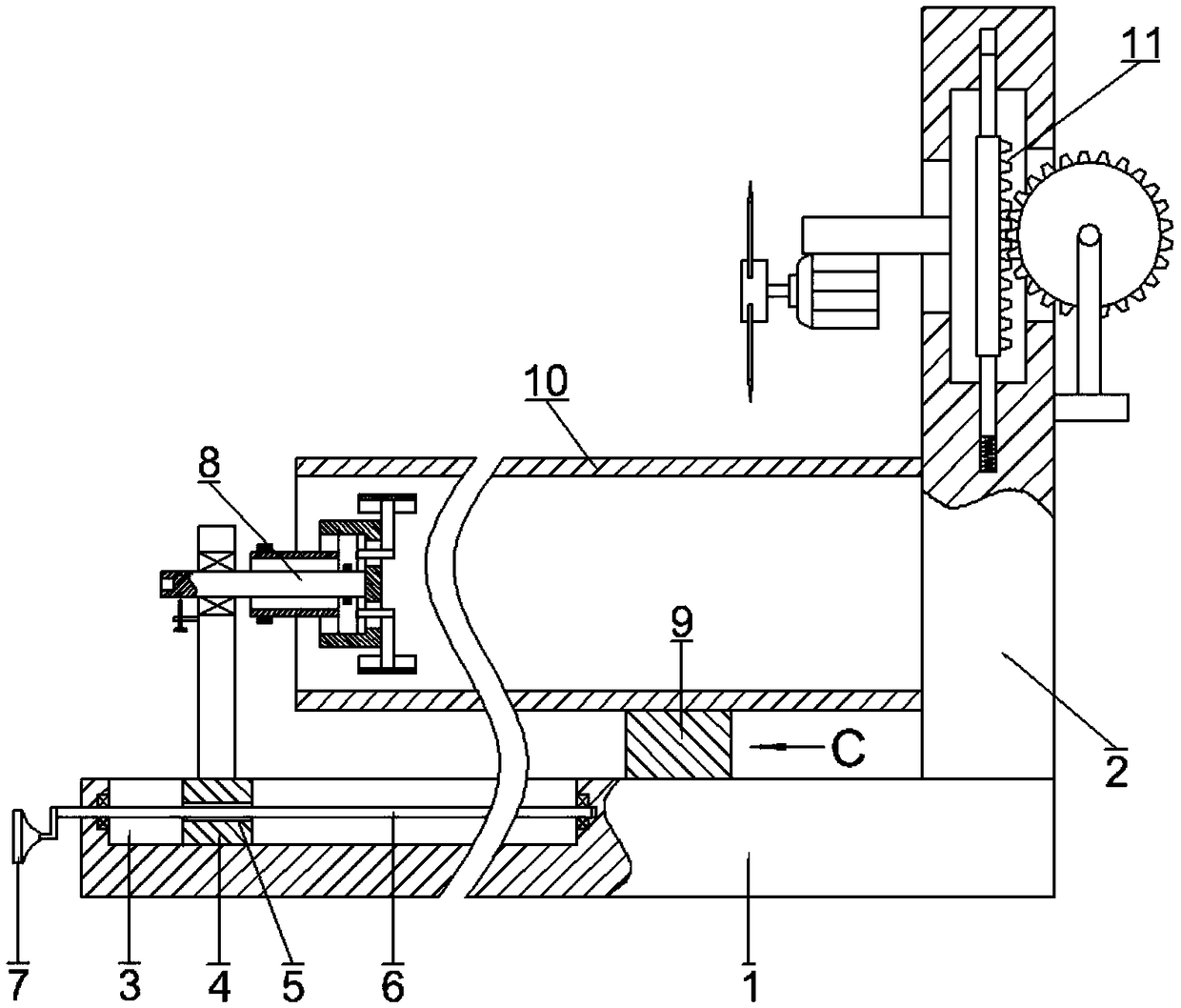

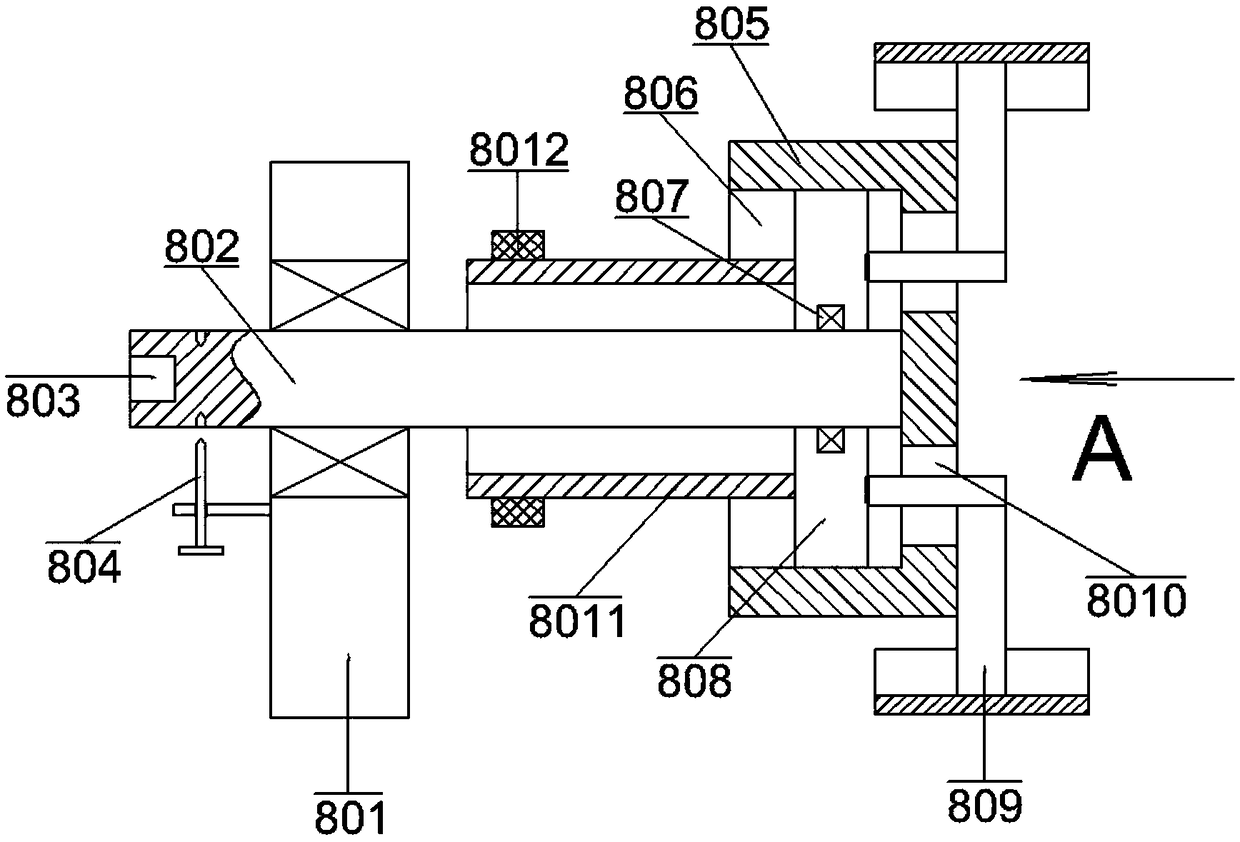

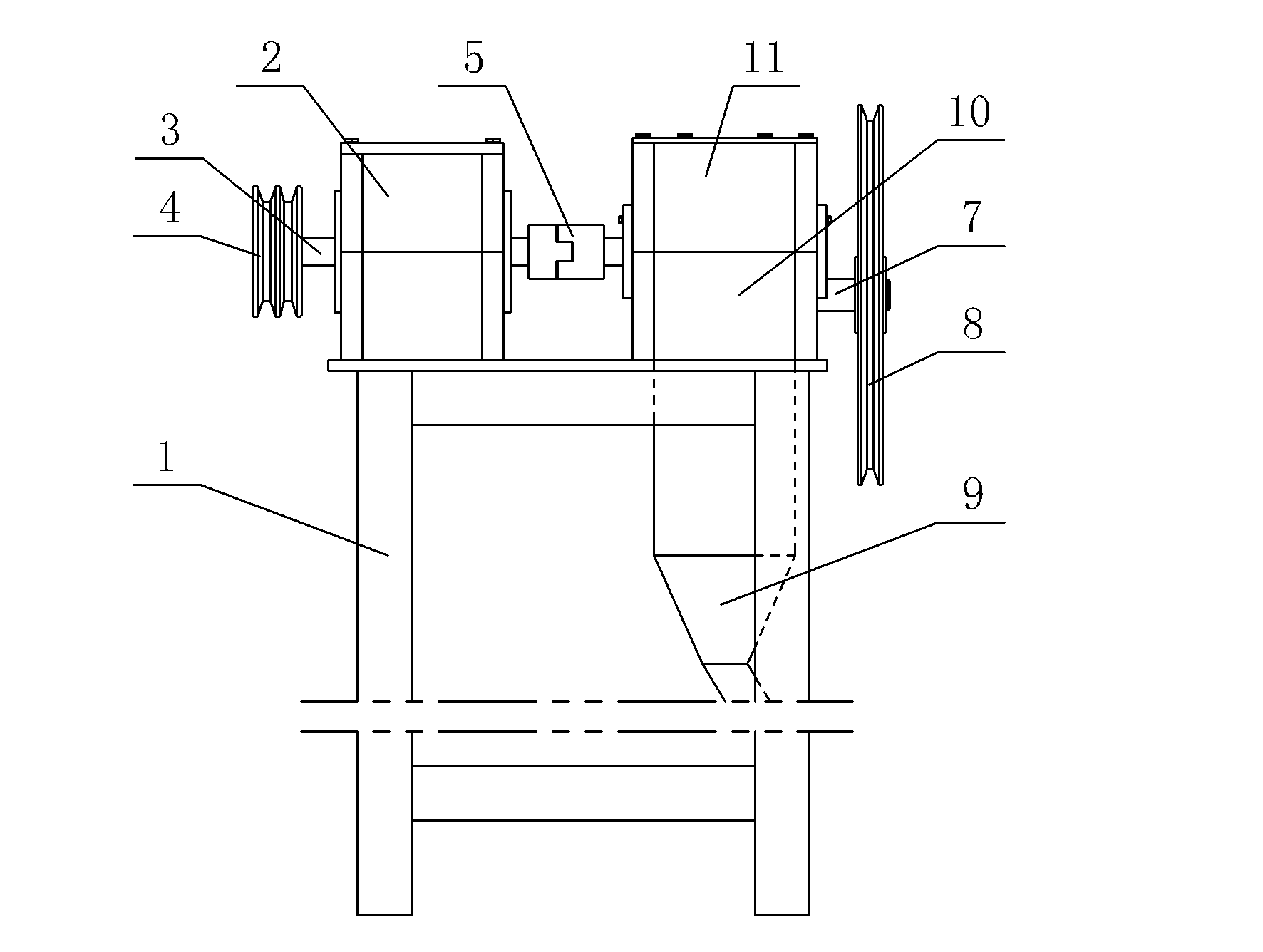

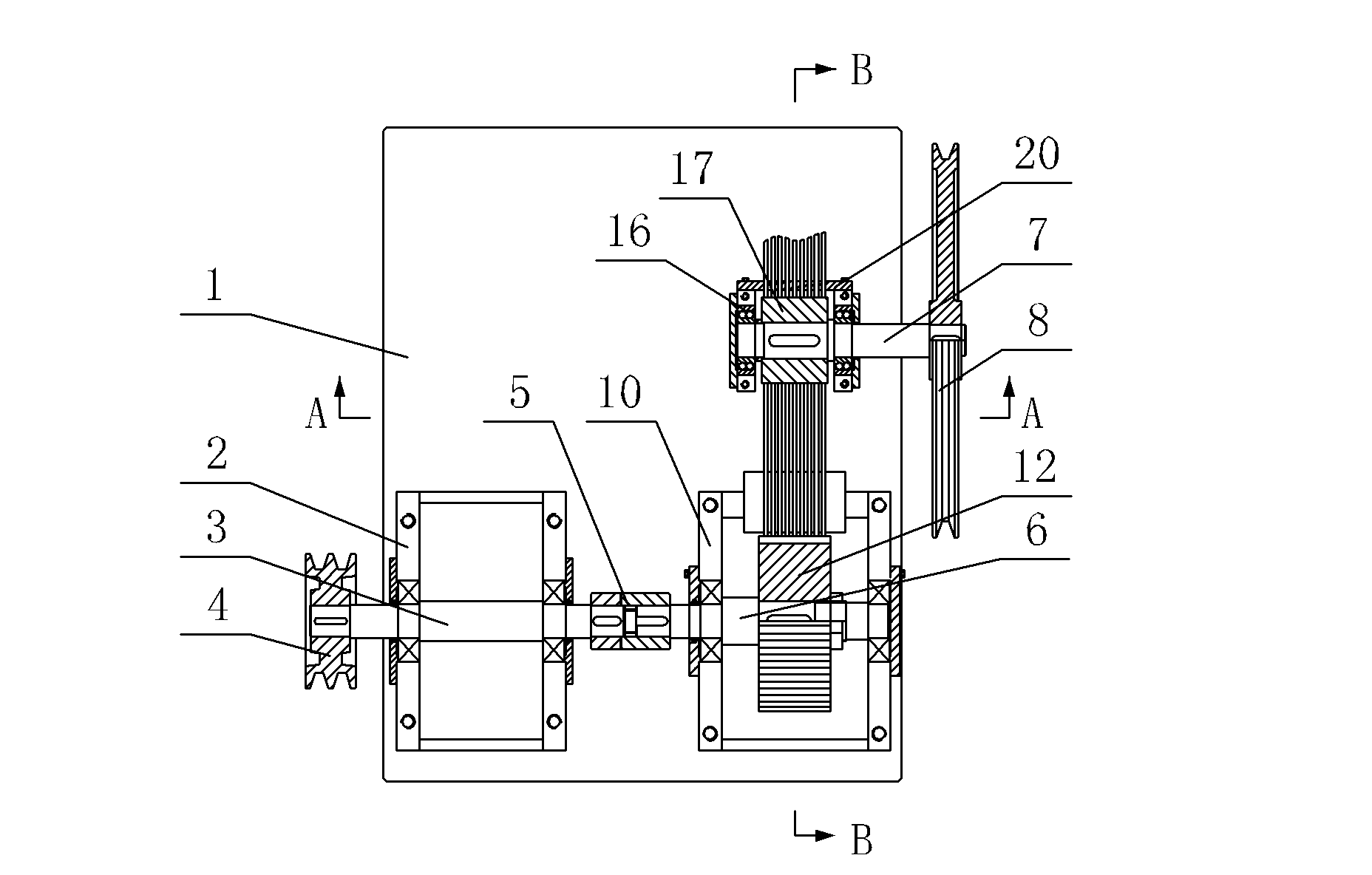

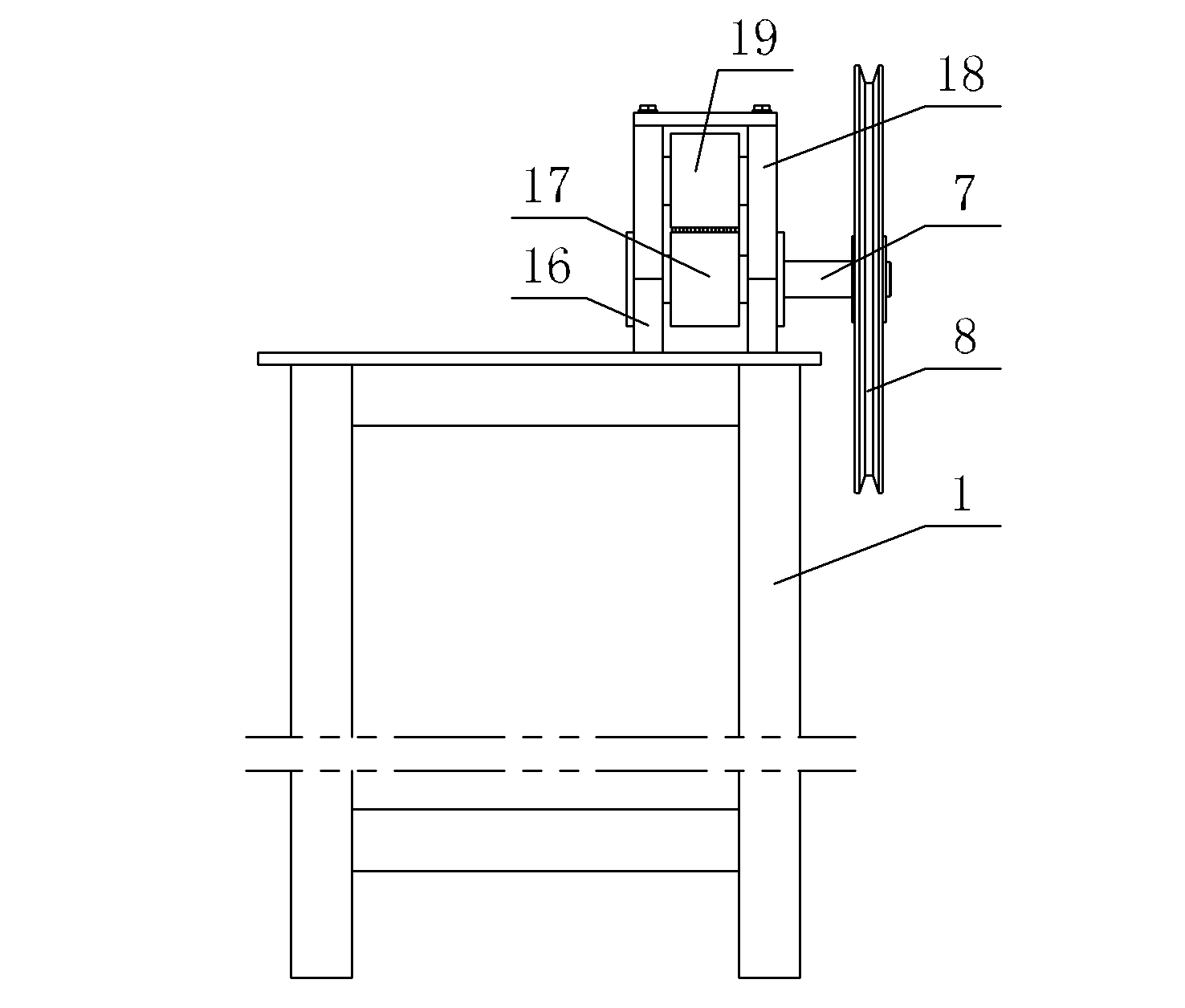

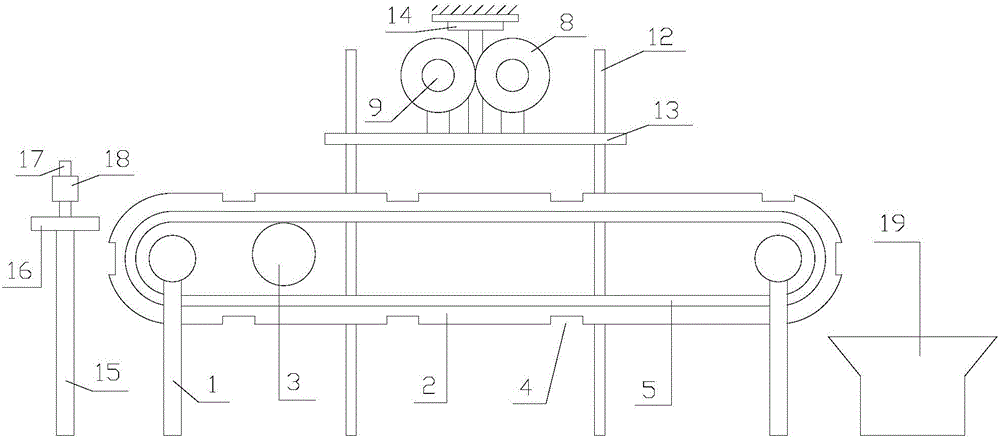

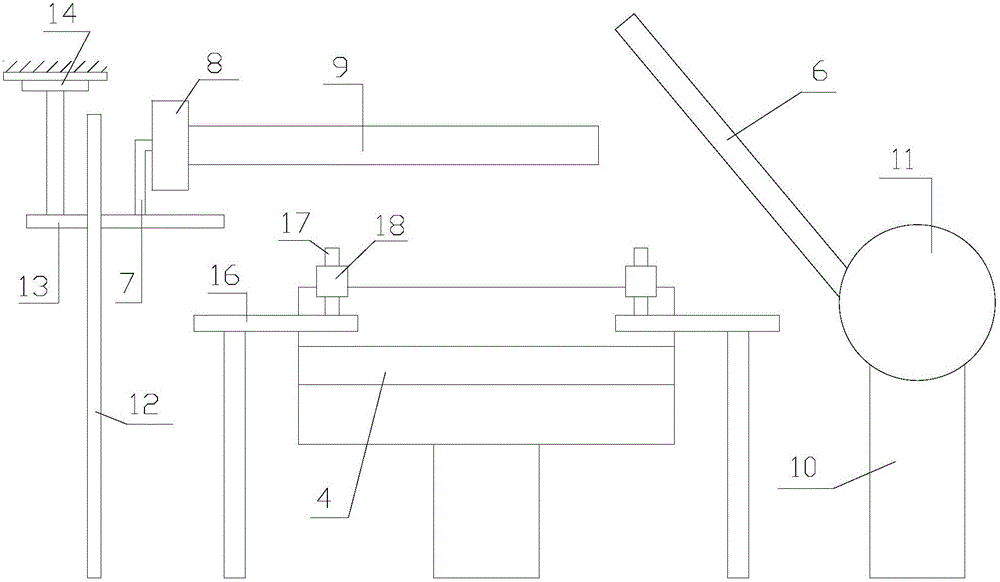

Ball cutter for steel wires

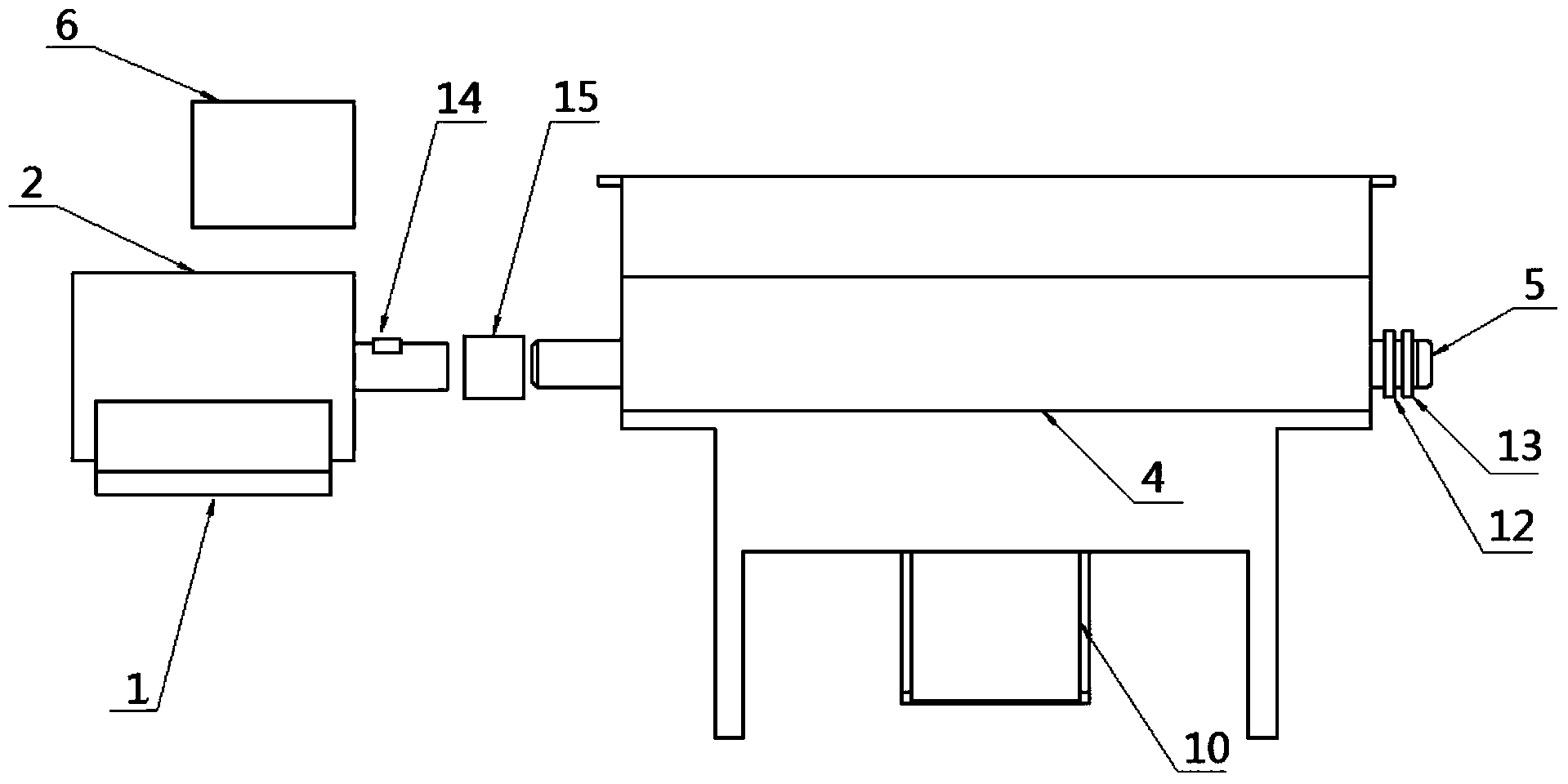

The invention relates to the field of steel wire shot granule forming, in particular to a ball cutter for steel wires. The ball cutter comprises a frame, wherein one end on the top of the frame is provided with a cutting input shaft through a bearing on a support box, while the other end is provided with a cutting device; a cutting pulley fixed connected to one end of the cutting input shaft is connected with a cutting motor through a belt, and the other end of the cutting input shaft is connected with a cutting shaft of the cutting device through a jaw clutch; the frame in front of a steel wire inlet of the cutting device is provided with a wire feeder; a wire feeding pulley on the outer end part of a wire feeding shaft of the wire feeder is connected with a frequency conversion motor through a belt; and the frame below the cutting device is provided with a steel shot collecting device corresponding to a steel shot outlet of the cutting device. The ball cutter is simple in structure, convenient to use, time-saving, labor-saving and high in efficiency; the length of steel shots can be convenient to adjust freely, the granularity is uniform and the quality is high; and the ball cutter is suitable for cutting high-hardness materials such as stainless steel wires, high carbon steel wires and the like.

Owner:山东开泰工业科技有限公司

Infant and child training pants shaping derice and shaping method

A machine and method for forming the infantile training trousers are disclosed. An inserting plate can insert the training trousers in folding unit for symmetrically folding it. The two waist pieces of said training trousers are smoothed by a finishing unit. The pieces for waist and legs are welded by the patterning wheel or moulding roller and ultrasonic head in welding unit. The waist edge is cut by the trimming unit for making it neat. The left and right waist pieces are than curled by the edge curling unit.

Owner:ZHEJIANG ROBOT MACHINERY TECH

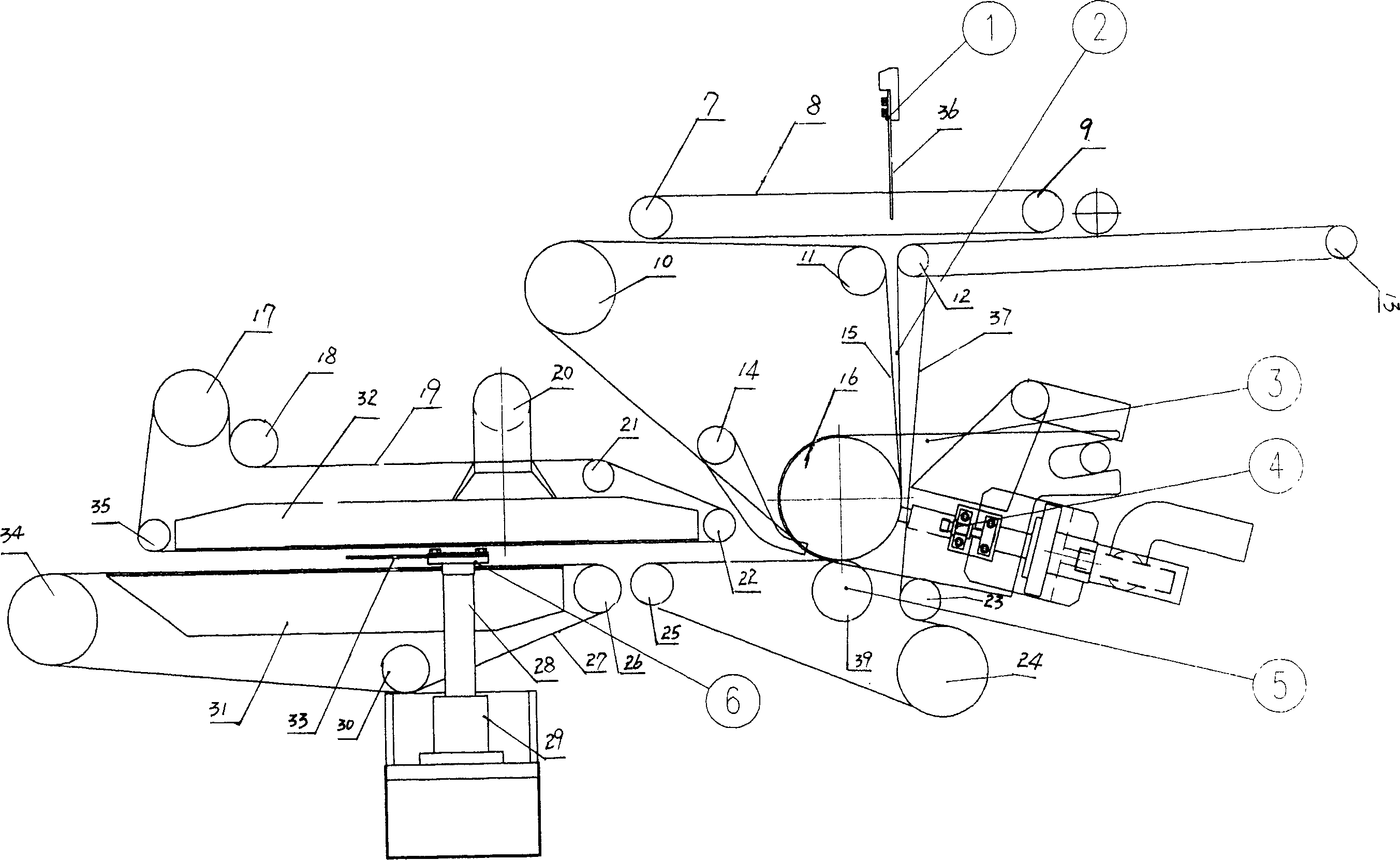

Slicing machine

InactiveCN107128732AChange manual cutting modeSolving automation problemsArticle deliveryWebs handlingEngineeringTension control

The invention relates to a slicing machine. The slicing machine is characterized in that the slicing machine comprises a rack, a depolarized part, a feeding part, a tension roller part, a traction roller part, a longitudinal knife part, a longitudinal knife transverse moving part, a transverse knife part and a control cabinet. A picture medium is spread out of a material roll, makes feeding conveying movement under the effect of a traction roller assembly, is longitudinally sliced when passing through the longitudinal knife part, continues moving and is transversely sliced when passing through the transverse knife part, and therefore picture partition slicing is completed. The depolarized part achieves the condition that the picture medium cannot skew during slicing operation. The slicing machine has the advantages that automatic slicing operation for the picture medium is achieved, and the slicing machine can also be applicable to slicing for picture media of large thicknesses. The problems of picture medium conveying skewing and tension control are solved, so that picture slicing is more orderly, and slicing quality is improved.

Owner:DONGHUA UNIV +1

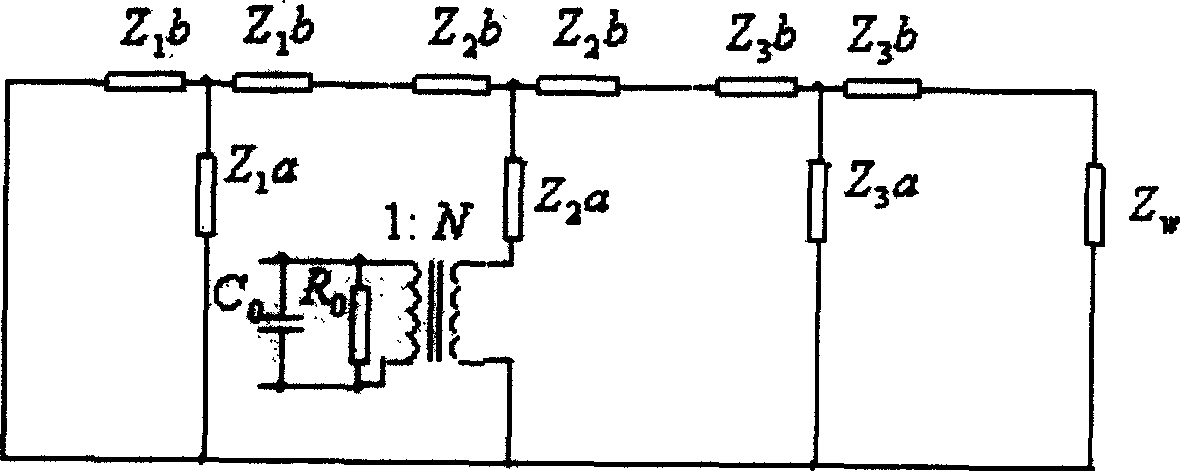

Supersonic skeleton cutting instrument

An ultrasonic bone cutting apparatus is composed of a host consisting of signal generator and powre amplifir, and a handle consisting of sequentially connected composite vibration transducers, ampletude changing rod and cutting tool. Said composite vibration transducer consists of a group of longitudinal polarized piezoelectric plates and a group of tangent polarized piezoelectric plates.

Owner:TSINGHUA UNIV

Slag cake crusher capable of dynamically adjusting speed and control method thereof

The invention provides a slag cake crusher capable of dynamically adjusting speed and a control method thereof. The slag cake crusher comprises a driving motor, a crushing chamber and a control system, wherein a feeding hole is formed at the upper end of the crushing chamber; a discharging hole is formed at the lower end of the crushing chamber; a crushing roller shaft is arranged inside the crushing chamber; the crushing roller shaft is connected with the driving motor through a coupler; spiral cutter teeth are welded on the surface of the crushing roller shaft; convex teeth are arranged on the inner wall of the crushing chamber; gaps are formed between the convex teeth and spiral cutter teeth; the control system comprises a power supply, a PLC (Programmable Logic Controller) controller, a man-machine interaction device, a frequency changer, a coder mounted on a shaft of the driving motor and a temperature senor mounted on the crushing roller shaft; the PLC controller comprises a speed controller and a temperature correction rotation speed controller. By improving the structure of the slag cake crusher and using a double closed-loop dynamic control adjustment method, the automatic control of crushing process and speed is achieved, the dynamic change of slag cake crushing load is automatically adapted, and the crushing force and crushing efficiency are maximized.

Owner:JIANGSU UNIV

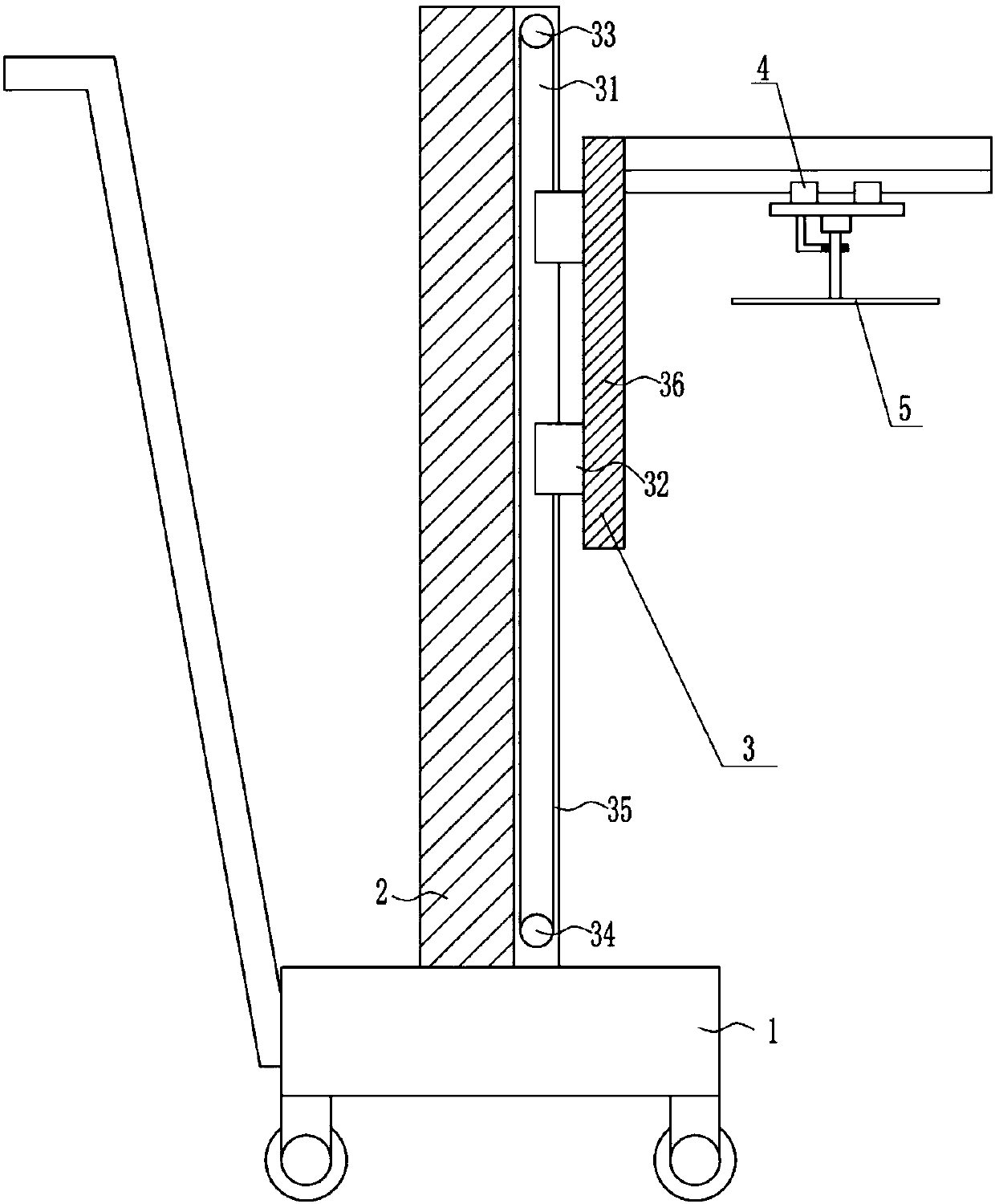

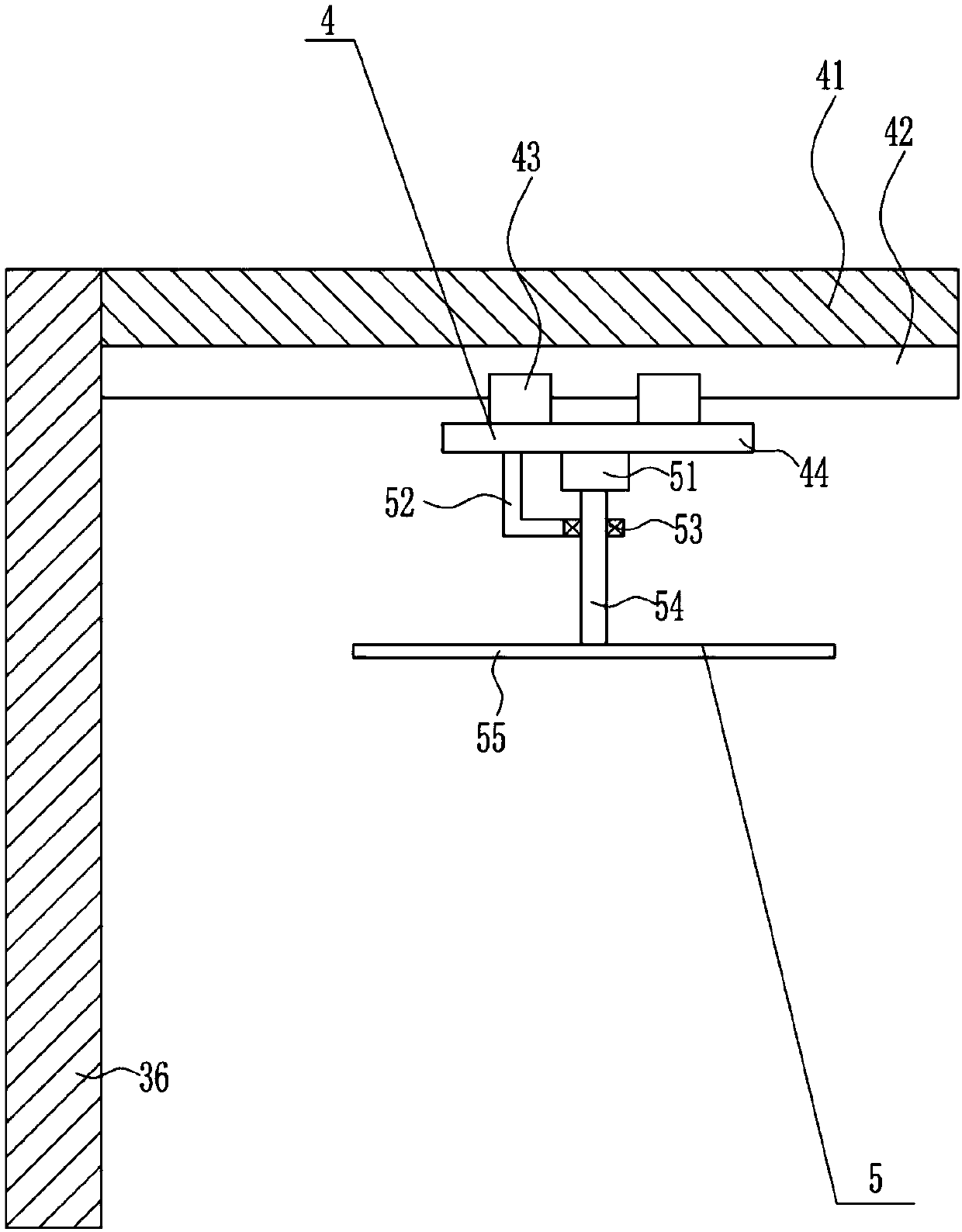

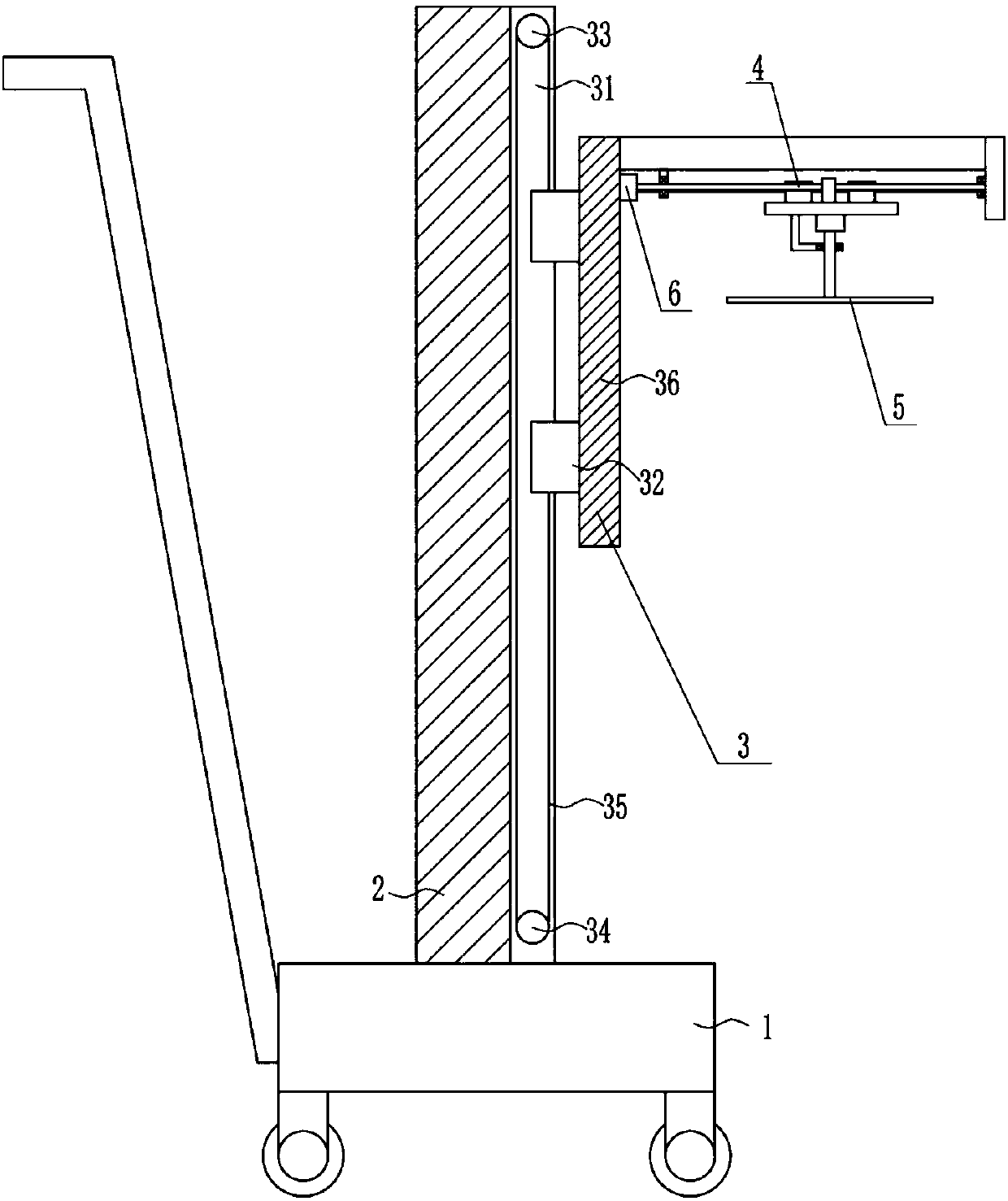

Plant rapid trimming equipment for garden

InactiveCN107711135ANeat cutShorten the timeCuttersMotor driven pruning sawsTime efficientEngineering

The invention relates to trimming equipment, in particular to plant rapid trimming equipment for a garden. The invention aims to provide the plant rapid trimming equipment for the garden, which has the following effects: time is saved, an operator is relaxed during manual trimming and the plants are trimmed tidily. In order to achieve the aim, the invention provides the plant rapid trimming equipment for the garden. The plant rapid trimming equipment for the garden comprises a trolley; a supporting plate is vertically arranged on the left of the top of a trolley plate of the trolley; a liftingdevice is arranged on the right side surface of the supporting plate; a left-and-right moving device is arranged on a lifting part of the lifting device; and a cutting device is arranged on a movingpart of the left-and-right moving device. The position of the cutting device is adjusted by the lifting device and the left-and-right moving device, and the plants are trimmed by the cutting device, so that the time is saved, the operator is relaxed during manual trimming and the plants are trimmed tidily.

Owner:郭昌磊

Device for continuously processing paperboard

ActiveCN105856300AHigh precisionImprove efficiencyMetal working apparatusArticle feedersPaperboardEngineering

The invention discloses a device for continuously processing a paperboard. The device comprises a base, a moving plate, a driving mechanism, a cutting mechanism and an assisting mechanism, wherein guide rails are arranged on the base, and the moving plate are movably mounted on the guide rails; the driving mechanism is used for driving the moving plate to move; the cutting mechanism comprises a driving unit, a mounting rack, a rotating wheel and a blade; the mounting rack is positioned at one side of the moving plate; the rotating wheel is rotatably mounted on the mounting rack, and the rotating center of the rotating wheel is parallel to the length directions of the guide rails; the first end of the blade is mounted on the rotating wheel; the plane of the blade is vertical to the length directions of the guide rails; the driving unit is used for driving the rotating wheel to rotate. The device has a good effect on paperboard cutting.

Owner:BENGBU ZHENHUA PACKING MACHINERY

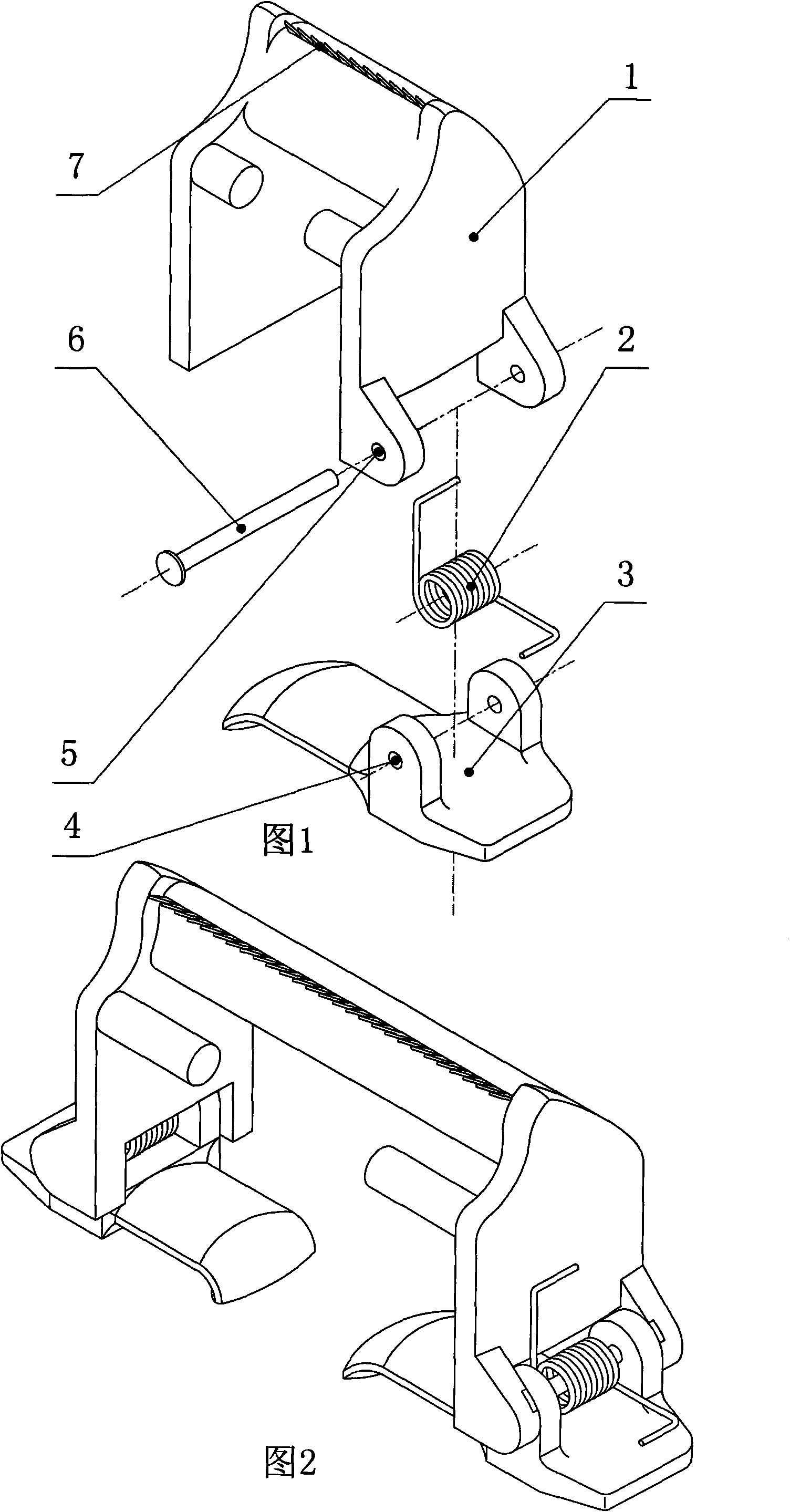

Portable tape cutter

The invention discloses a portable tape cutter. A technical scheme is that: the portable tape cutter is characterized by having a framework structure, wherein the top of the upper part of the framework is provided with a sawtooth cutting knife, while the lower part is provided with a torsion spring and a twist rod; and the torsion of the torsion spring rotates the twist rod to press a tape, and the cutter is prevented from sliding on the tape freely. When the cutter is used for the first time, one end of the twist rod is pressed, while the other end is opened in a rotating way; the cutter framework is clamped to two sides of the tape; the pressed twist rod is loosened and the torsion of the torsion spring rotates the twist rod to clamp the tape; the tape is pulled out and is back to the cutting knife, and when the tape with required length is pulled out, the tape is slightly pulled on the edge of the sawtooth cutting knife and is cut; the cut tape head falls to adhere to cylinders on two sides of the upper side of the framework, and the tape is convenient to pull out when used next time; and after the tape is used, a new tape is arranged to be continuously used.

Owner:孙凯

Trimming device for textile fabrics

InactiveCN107815847AEasy to collectAvoid flashSevering textilesTextile shapingWaste materialUltrasonic generator

The invention discloses a trimming device for textile fabrics. The device comprises a base plate, an ultrasonic generator, a cutting head and a steam ironing wheel; a roller is installed at one side of a top part of the base plate; textile fabrics are winded on the roller; a roll pedestal is installed on the other side of the top part of the base plate and a motor is fixed on one end of a top partof the roll pedestal; a fixed roll is fixed to an output end of the motor through a rotating shaft; one end, away from the motor, of the rotating shaft is connected with the other end of the top partof the roll pedestal; waste material cases are fixed at two ends of the middle position in the top part of the base plate; pedestals are fixed at two ends of the top part of the base plate between the waste material cases; a control panel is installed on one end of the pedestal; slideways are installed at the middle position of the top end of the pedestal and slide blocks are fixed in the slideways. The invention has the steam ironing wheel and the pressing wheel installed so that the device can be used for ironing the textile fabrics before trimming to facilitate subsequent cutting operations.

Owner:丽水遂智科技咨询有限公司

Chicken beancurd

The invention discloses a chicken deep processed food, in particular to an edible chicken beancurd for hot pot, oil frying, frying and the like. The components of edible chicken beancurd are followingraw material: 40-60g of fresh grade breast, 10-20g of chicken skin, 1-3g of egg white powder, 15-20g of ice water, 1.3-1.8g of common salt, 1-2g of white sugar, 0.3-0.5g of monosodium glutamate and 0.05g of five-spice powder; and the preparation method comprises the following steps: high-speed cutting and stirring, dishing, stewing, slitting, quick freezing and package. As the invention adopts ascientific process and an advanced formula, the produced products have pure white appearance which is similar to the conventional beancurd; and the edible chicken beancurd has order cutting blocks, soft and tender mouthfeel, good integrity after longtime boiling, good chewing feeling, incapability of oil frying, stir frying, boiling, rich nutrition, easy digestion and special flavor.

Owner:HENAN DAYONG INDUSTRIAL CO LTD

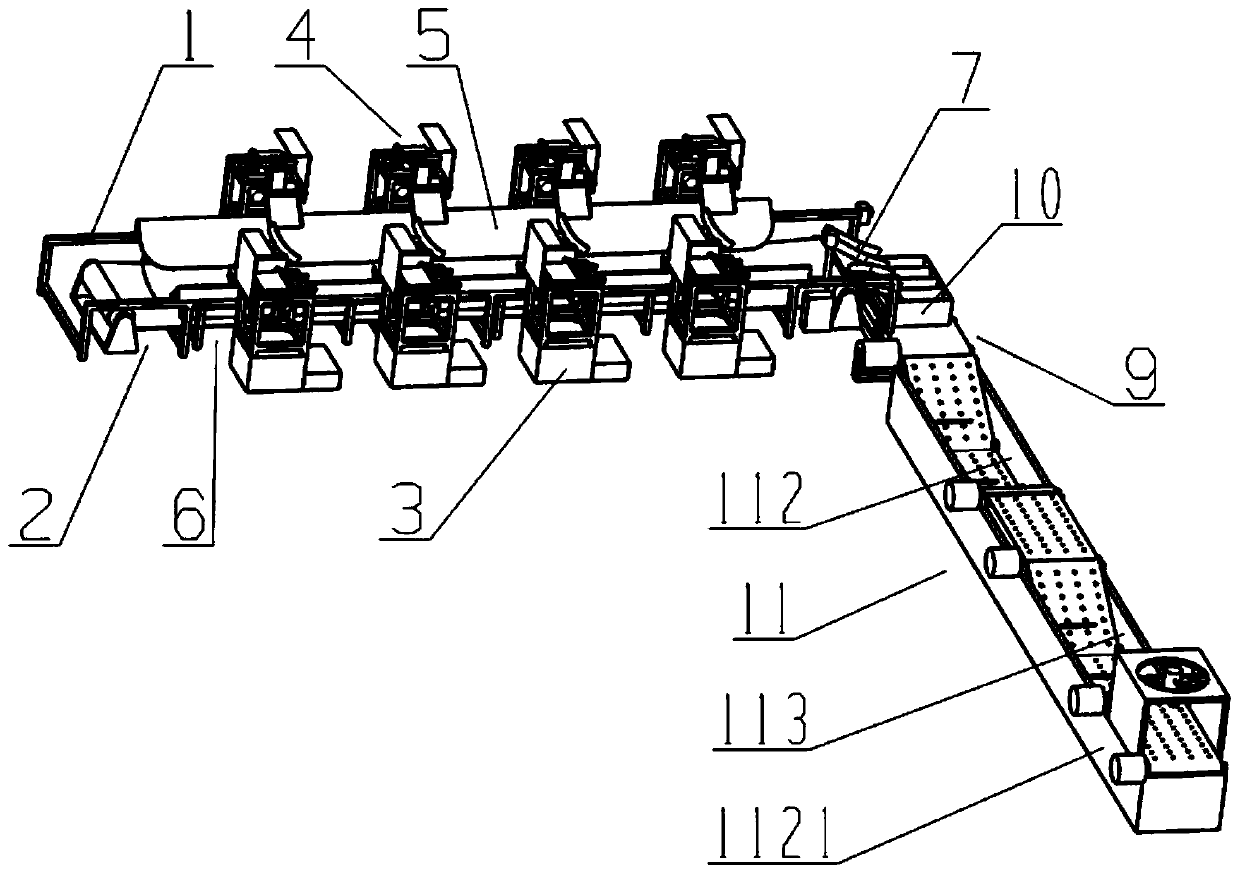

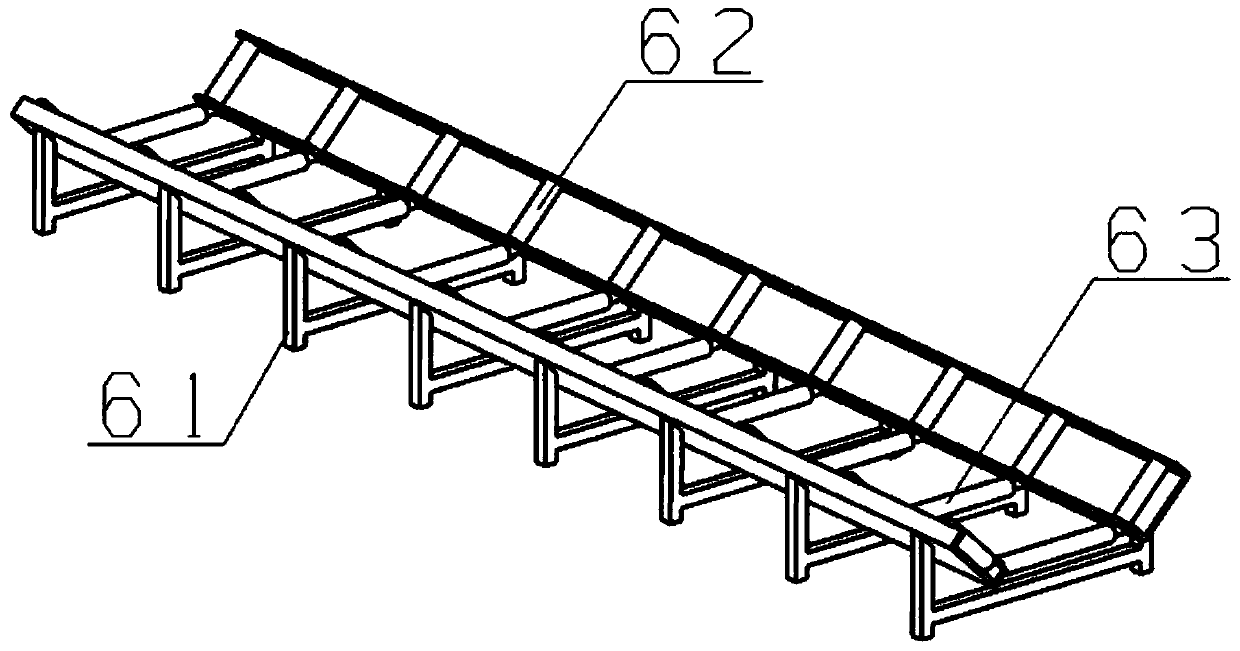

Healthy sugarcane seed stem production line

ActiveCN110583140ANeat cutImplement autoboxingDrying gas arrangementsMetal working apparatusProduction lineEngineering

The invention relates to the technical field of sugarcane planting, and particularly discloses a healthy sugarcane seed stem production line. The healthy sugarcane seed stem production line comprisesa first rack, a conveying device, seed cutting devices, side slip plates, a belt bending mechanism, a feeding plate, a vibrating device, a material box and a disinfecting and coating device. Accordingto the production line, through the seed cutting devices, sugarcane stalks can be orderly and quickly cut into sugarcane seed stems; when the sugarcane seed stems are conveyed by the conveying device, the side slip plates and the belt bending mechanism can place the sugarcane seed stems to be parallel to the conveying direction in orientation, and then boxing is facilitated; the feeding plate andthe vibrating device can achieve automatic boxing of the sugarcane seed stems, and the sugarcane seed stems can be orderly stacked in the material box; the disinfecting and coating device can automatically disinfect, coat and blow-dry the sugarcane seed stems, it is avoided that an operator is in direct contact with disinfecting liquid and coating liquid, the safety of the production operation environment is guaranteed, and the operation efficiency is also improved.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Paperboard cutting and processing equipment

ActiveCN105922331APrevent deviationGuarantee subsequent processing accuracyMetal working apparatusPaperboardEngineering

The invention discloses paperboard cutting and processing equipment. The equipment comprises a mounting frame, a conveyor belt, a rotary shaft, a first driving unit, a cutting part and a pressing and holding part. The conveyor belt is mounted on the mounting frame. The upper surface of the conveyor belt is provided with a plurality of accommodating grooves which are evenly distributed in the length direction of the conveyor belt. The length direction of the accommodating grooves is perpendicular to the length direction of the conveyor belt. The lower surface of the conveyor belt is provided with first gears which are distributed in the length direction of the conveyor belt. The rotary shaft is rotatably mounted on the mounting frame. One end of the rotary shaft is arranged in a space defined by the conveyor belt. The local peripheral surface of the rotary shaft is provided with second gears which are distributed in the circumferential direction of the rotary shaft. The second gears are engaged with the first gears. The first driving unit is used for driving the rotary shaft to rotate. The cutting part is used for cutting paperboards and comprises a second driving unit and a blade. The second driving unit is used for driving the blade to move close to the accommodating grooves or far from the accommodating grooves. The paperboard cutting and processing equipment is good in paperboard cutting effect.

Owner:BENGBU ZHENHUA PACKING MACHINERY

Processing method for quick-frozen fruit and vegetable slices

The invention discloses a processing method for quick-frozen fruit and vegetable slices. The processing method comprises the steps of raw material selection, cleaning, enzyme deactivation, slicing, quick freezing and packaging, wherein the enzyme deactivation is realized by a pulse magnetic field; the slicing is realized by high-pressure water cutting. According to the processing method, by the adoption of a non thermal treatment technology, the enzyme deactivation is realized by the pulse magnetic field, and the slicing is realized by high-pressure water cutting; therefore, the processed quick-frozen fruit and vegetable slices are higher in quality, and the processing efficiency is higher.

Owner:长沙星达知识产权服务有限公司

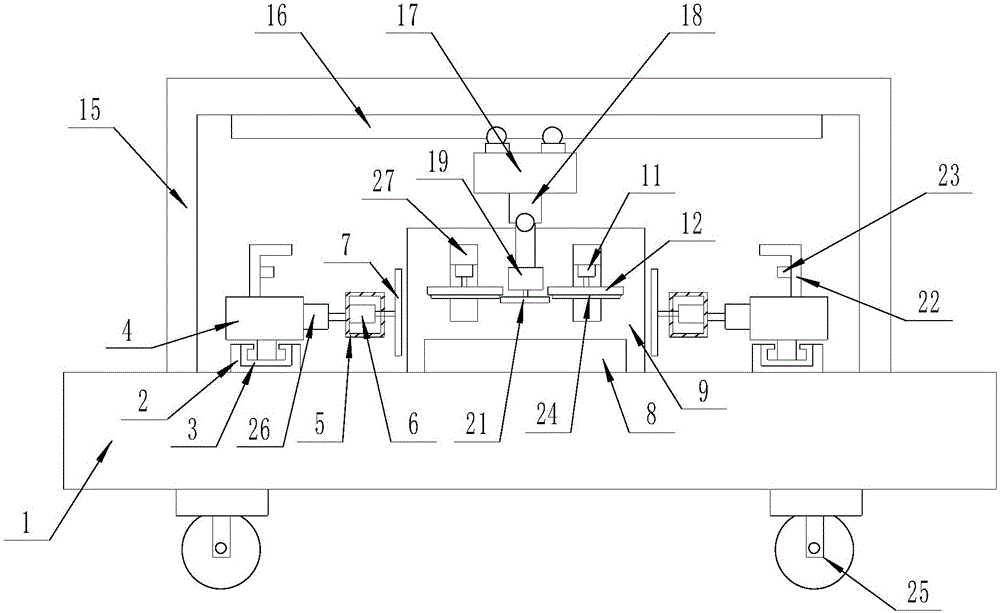

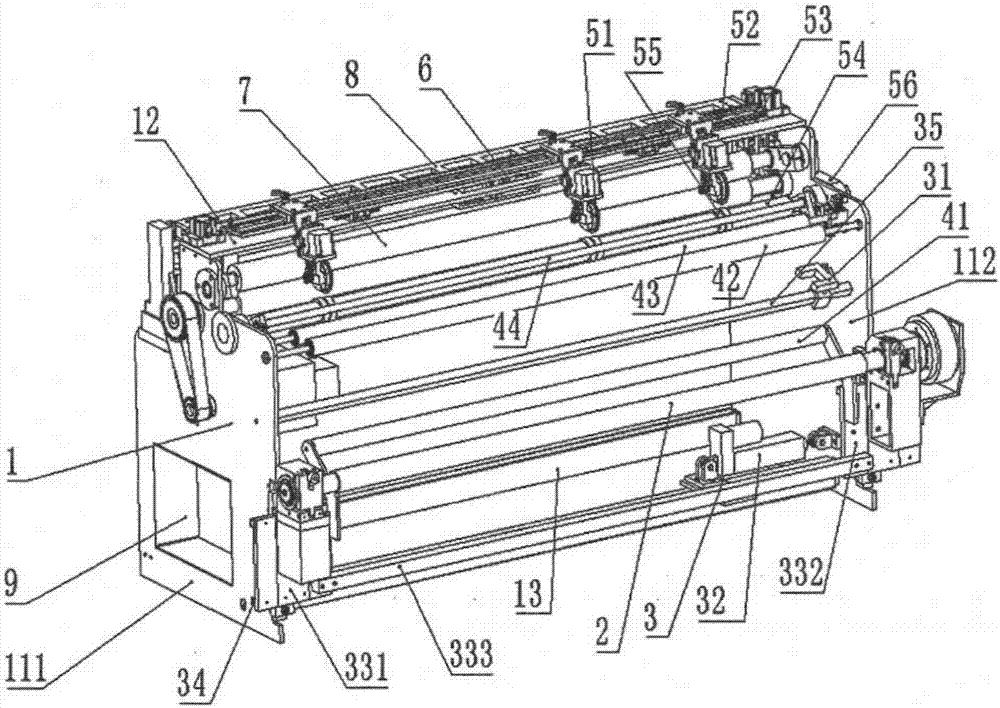

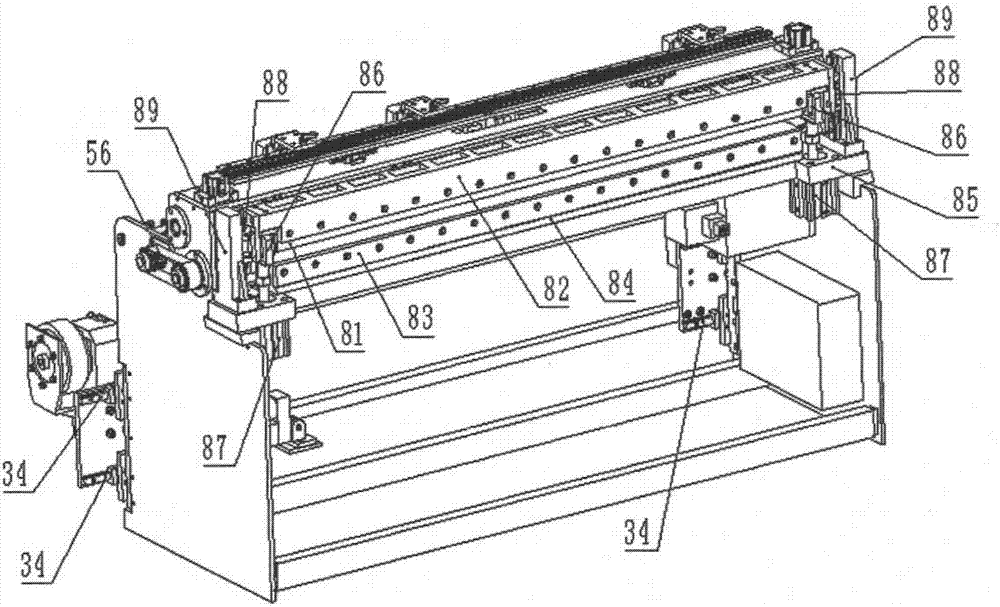

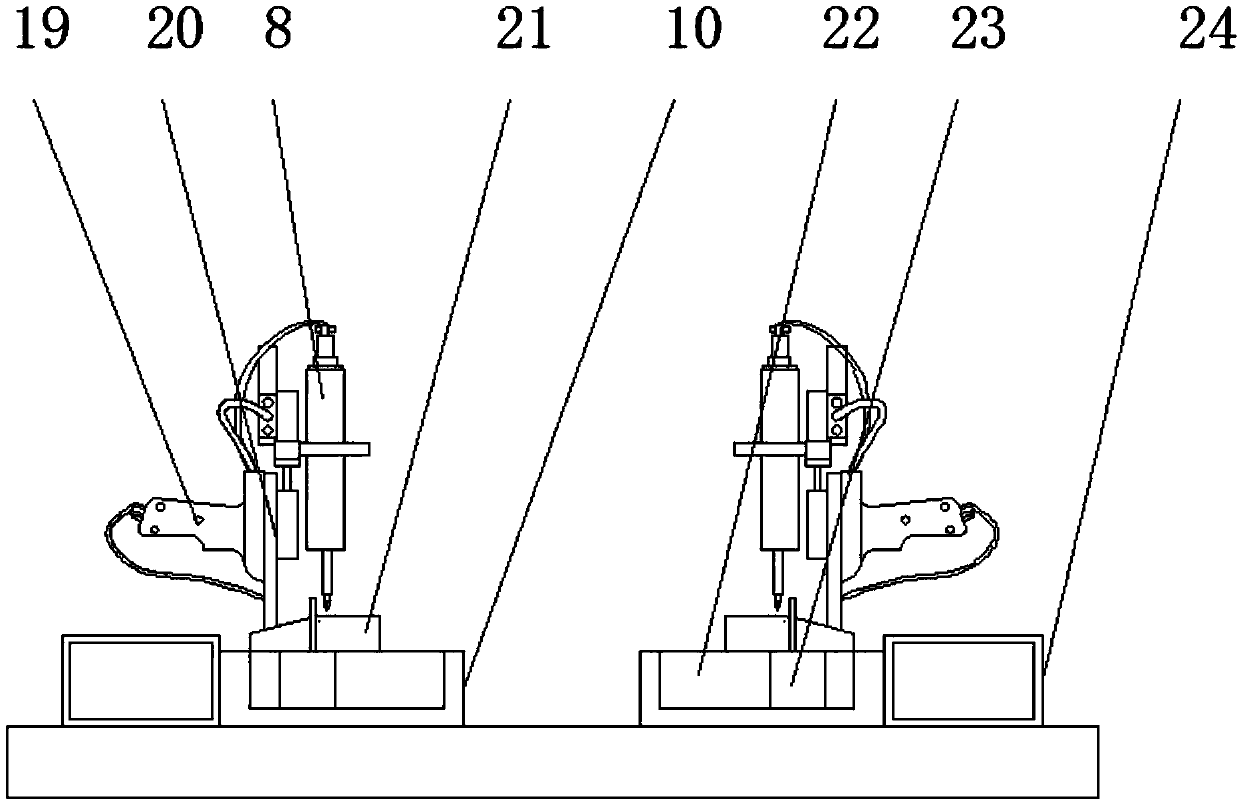

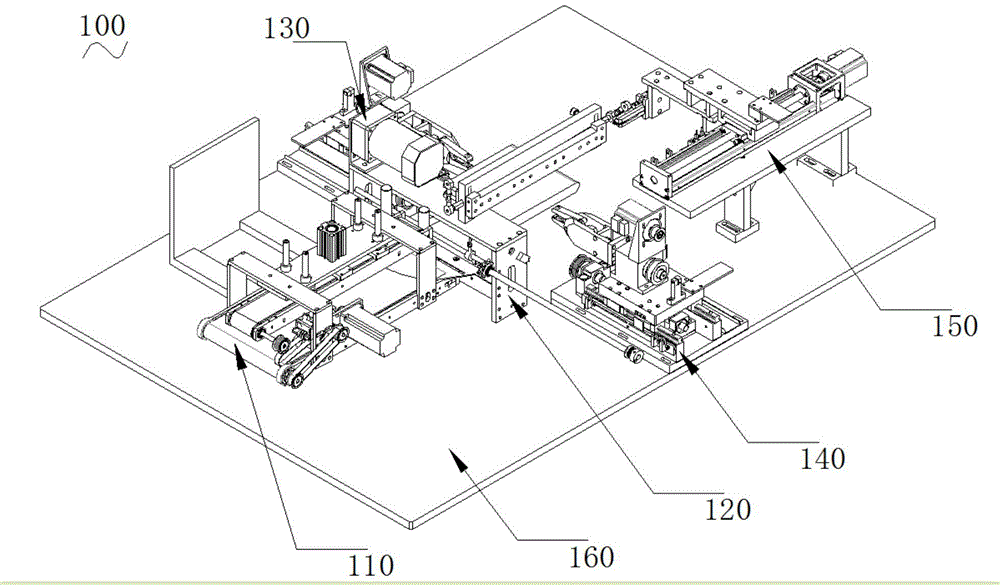

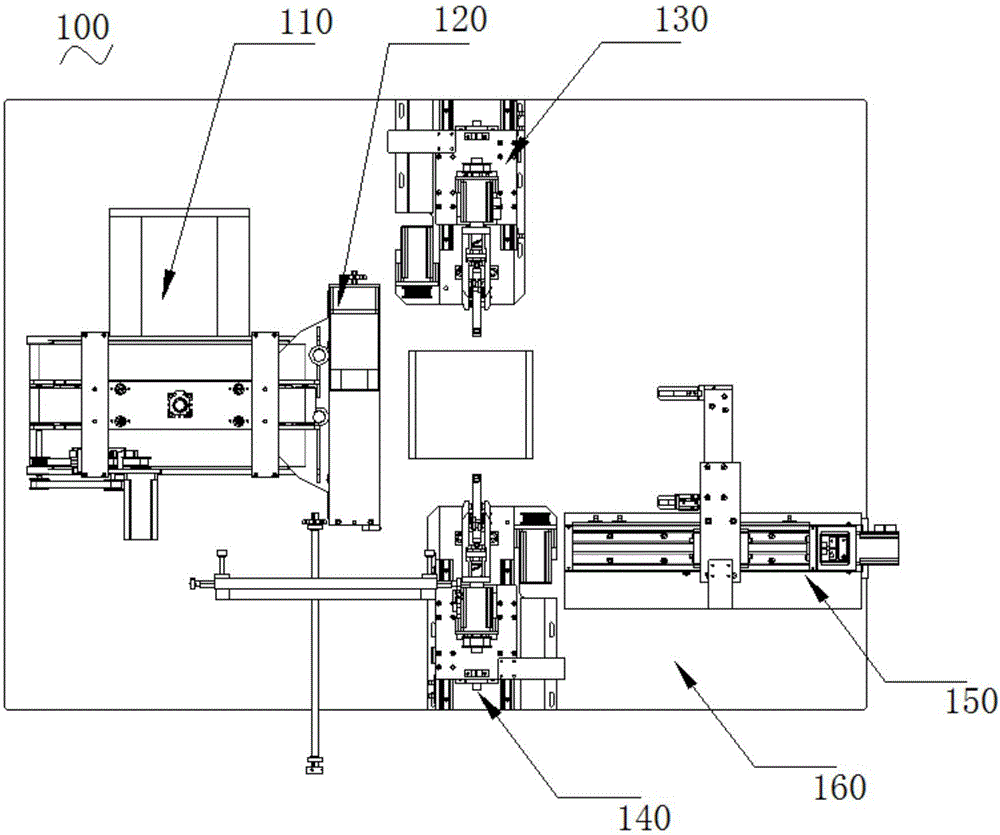

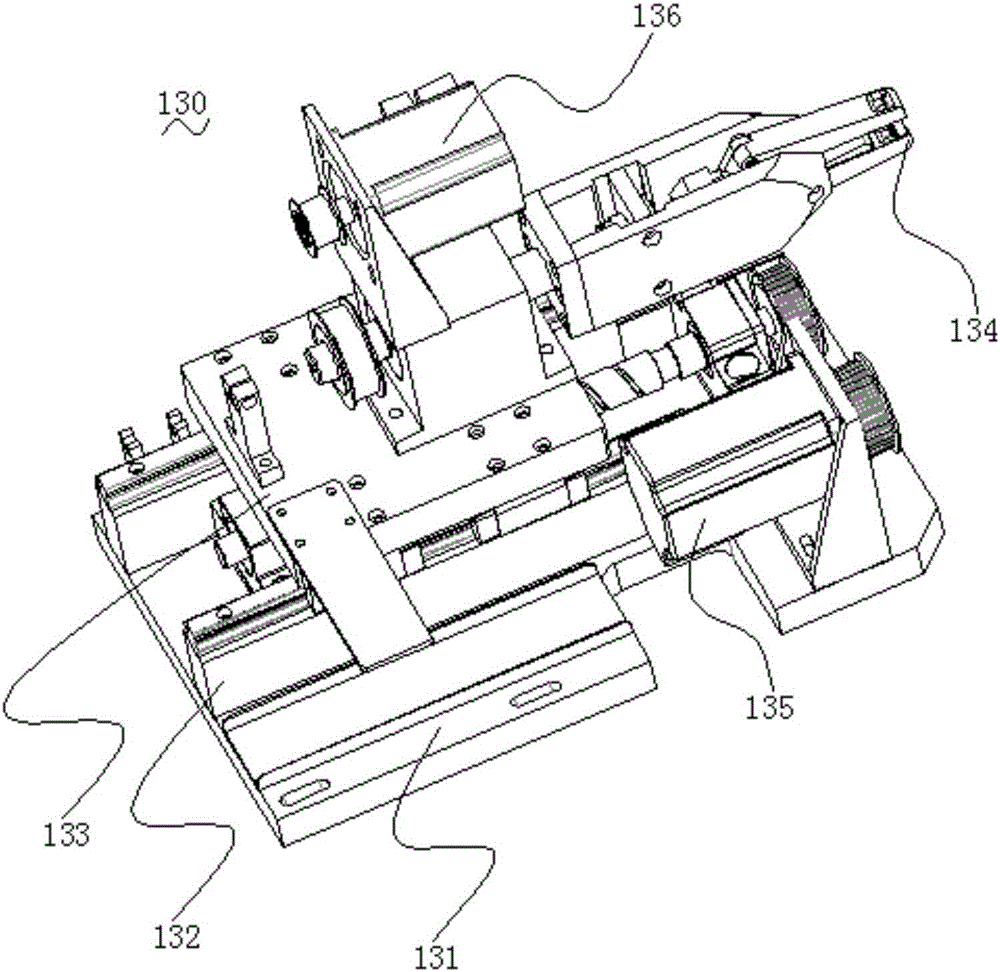

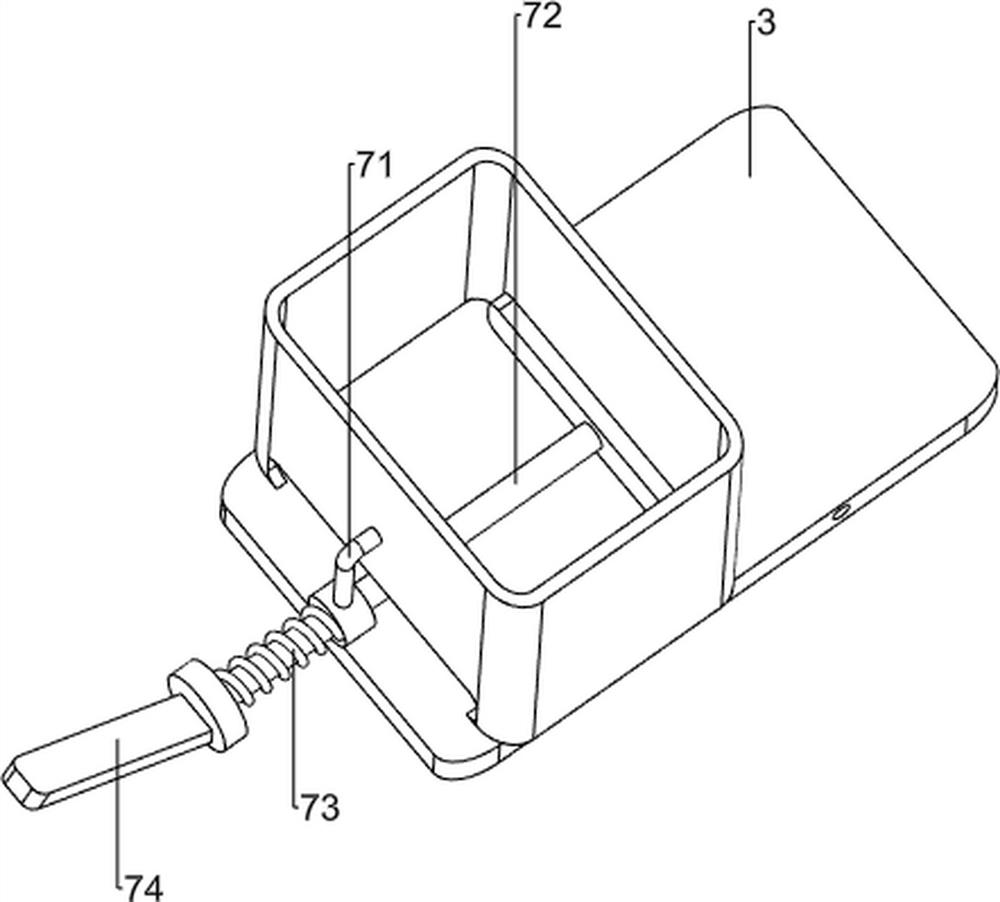

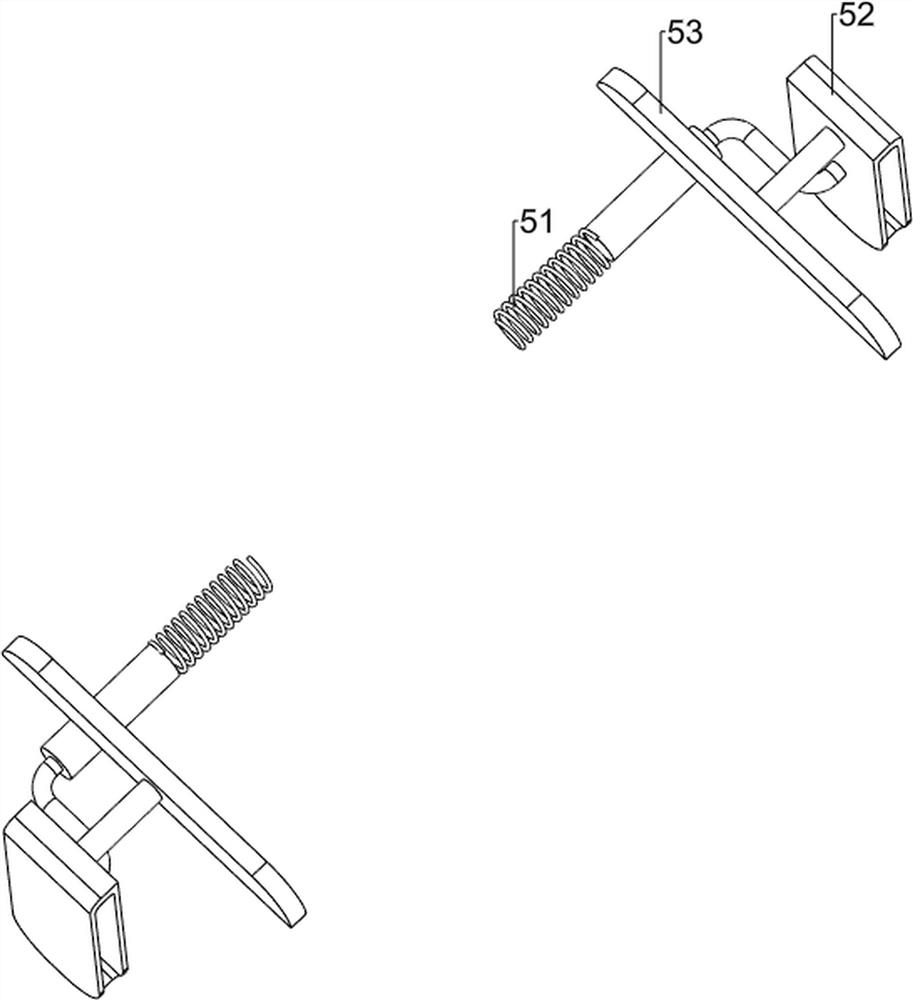

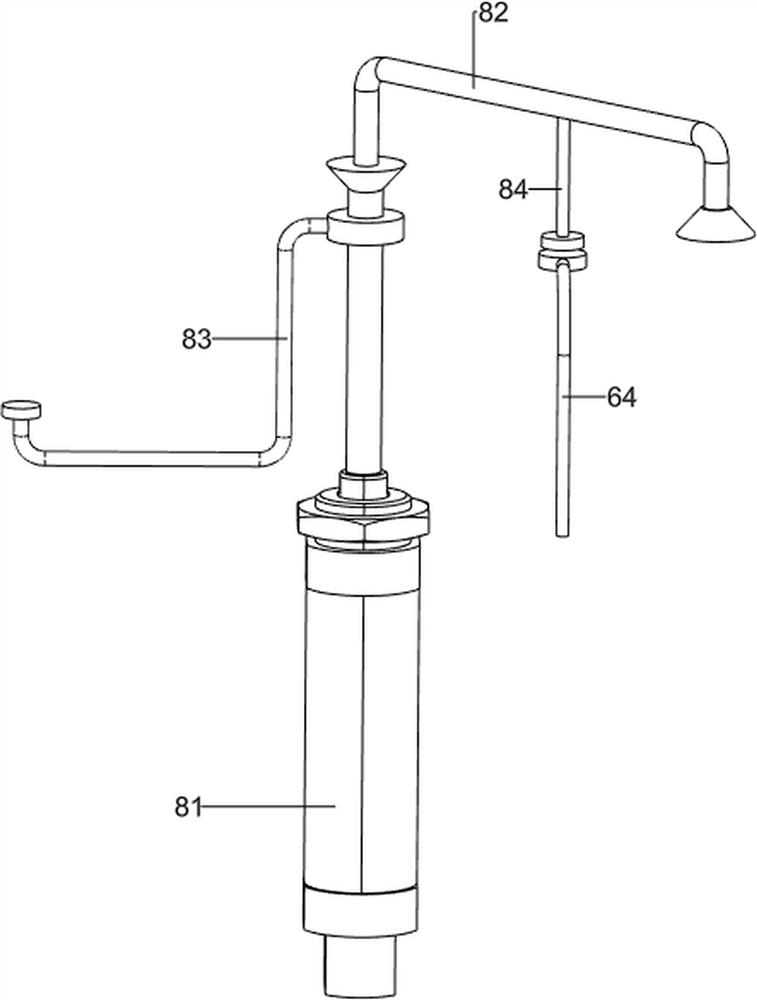

Winding device for battery cell winding lamination machine

ActiveCN105742720AEven by forceLamination effect is goodFinal product manufactureSecondary cellsEngineeringPole piece

The invention relates to the technical field of battery pole piece processing equipment, in particular to a winding device for a battery cell winding lamination machine. The winding device for the battery cell winding lamination machine comprises a sheet loading assembly, a sheet cutting assembly, a first winding assembly, a second winding assembly and a battery cell unloading assembly, wherein the sheet loading assembly is used for loading a diaphragm sheet; an anode piece and a cathode piece are pasted on two sides of the diaphragm sheet respectively; the sheet cutting assembly is used for cutting a diaphragm of the sheet; the first winding assembly and the second winding assembly are used for clamping the sheet and driving the sheet to rotate to wind the sheet into a battery cell; the battery cell unloading assembly is used for unloading the battery cell; the first winding assembly and the second winding assembly are symmetrically arranged at two sides of a connection line for the sheet loading assembly and the sheet cutting assembly; the first winding assembly and the second winding assembly are located at the rear part of the sheet cutting assembly; and the battery cell unloading assembly is located at the rear parts of the first winding assembly and the second winding assembly. The winding device for the battery cell winding lamination machine is simple in structure, high in work efficiency, stable to run and good in lamination effect.

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

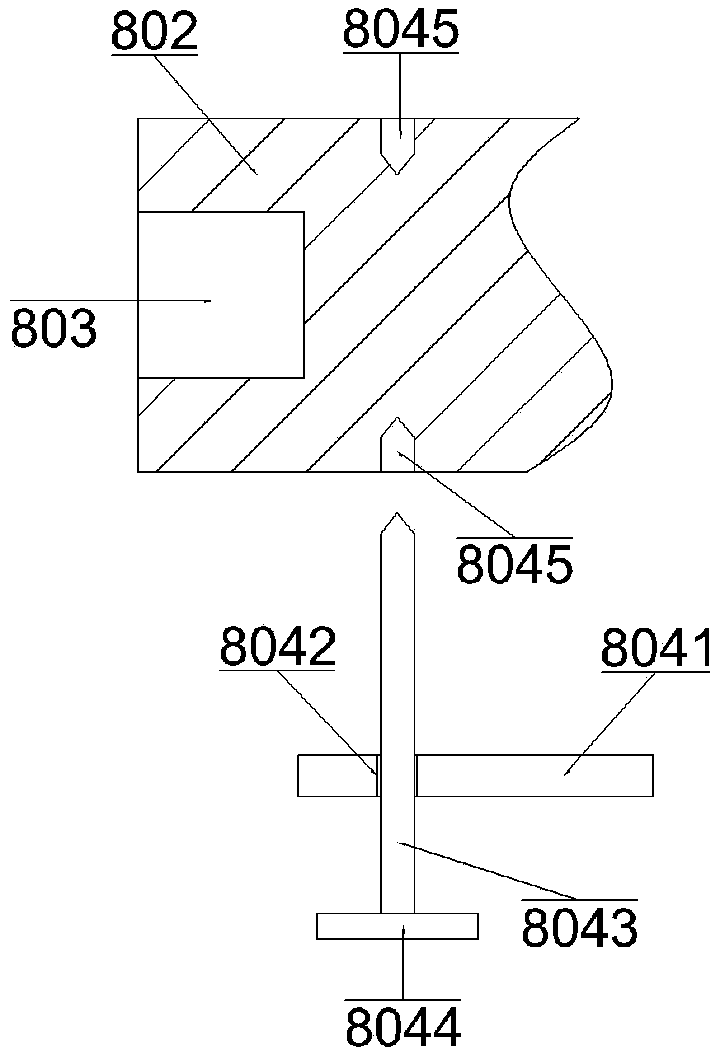

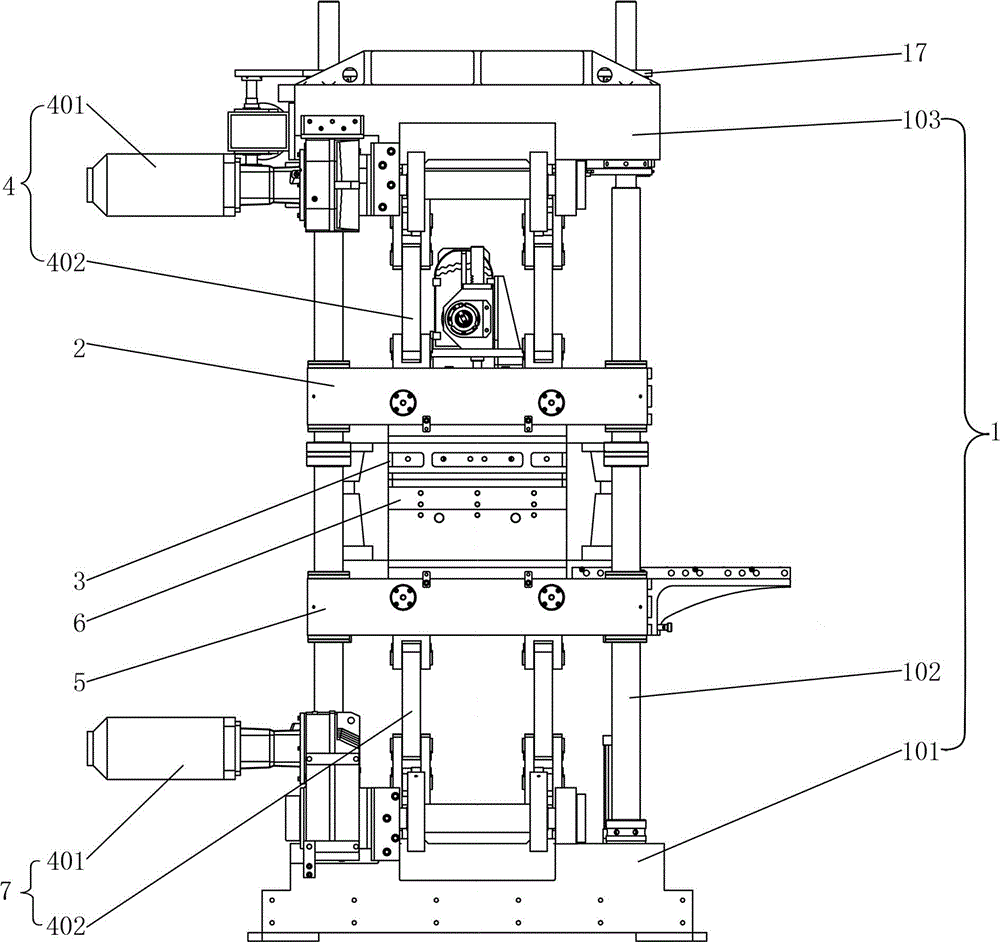

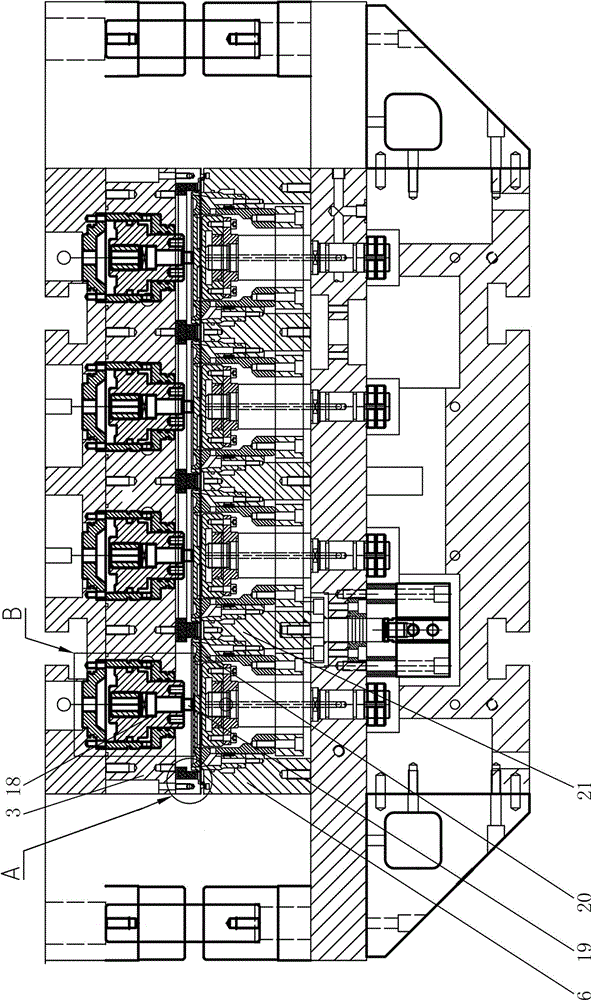

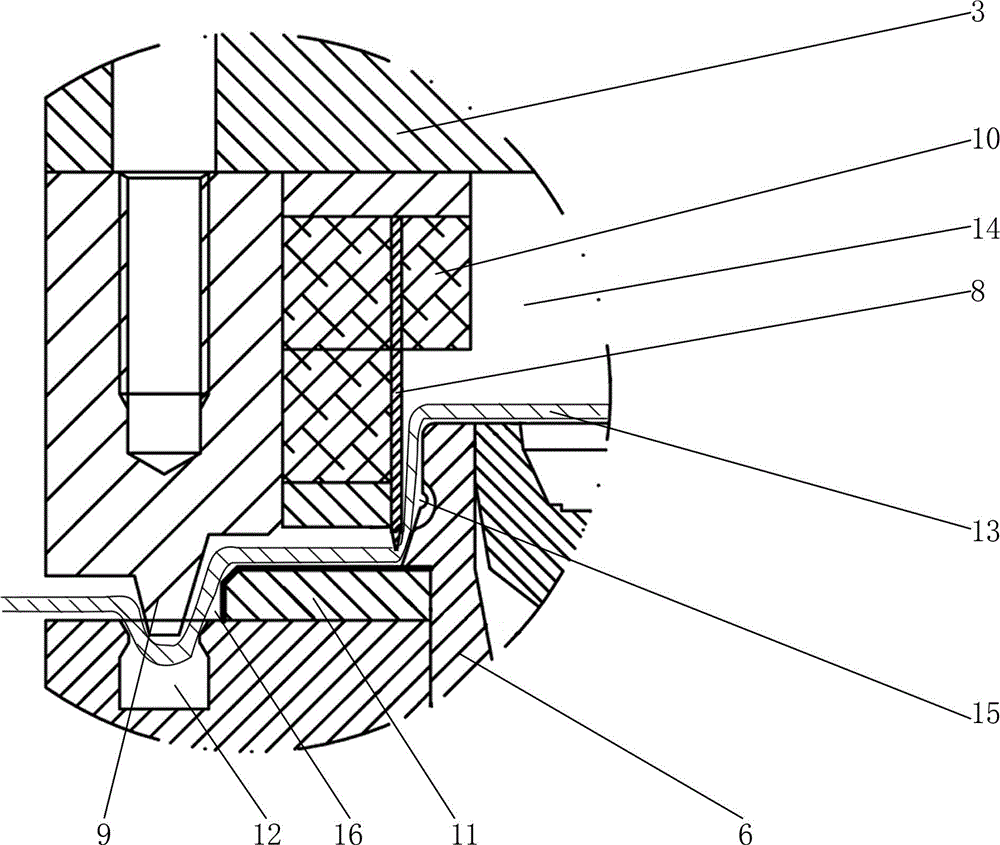

Die inner cutting forming device of forming machine

ActiveCN105252748ASolve the sealing problem of blister moldingSolve the sealing problemMolding machineAnnular cutter

The invention relates to a die inner cutting forming device of a forming machine. The die inner cutting forming device of the forming machine comprises a machine frame, an upper die platform, an upper die, an upper die platform driving mechanism, a lower die platform, a lower die and a lower die platform driving mechanism, wherein the upper die is provided with an annular laser cutter and an annular protruding strip, and the annular protruding strip is located on the outer side of the annular laser cutter; the lower die is provided with an annular cutter chop board and an annular groove which correspond to each other. During forming lifting control, the annular laser cutter does not cut off a plastic sheet but just tightly presses the plastic sheet to form sealing, so that the sealing during plastic uptake forming is achieved. The annular groove and the annular protruding strip form auxiliary sealing, so that the stability of plastic uptake forming is improved. The annular laser cutter is directly arranged on the upper die, the structure is simpler, the problems that as the annular laser cutter is too thin, the annular laser cutter is prone to being bent and cannot cut off the plastic sheet are solved, and the plastic sheet can be cut off more orderly and stably. After a product is formed, the product is cut on the forming device, the production efficiency is improved, and the manufacturing cost of the whole machine is lowered. Besides, the overall machine structure is simpler and more compact, and the occupied space is reduced.

Owner:广东金兴机械股份有限公司

Book ex-factory aligning and edge cutting equipment

The invention relates to edge cutting equipment, in particular to book ex-factory aligning and edge cutting equipment. The book ex-factory aligning and edge cutting equipment capable of clamping and fixing books in the edge cutting process is provided. The book ex-factory aligning and edge cutting equipment comprises a bottom plate, first supporting frames and a table, the first supporting frames are arranged in the middles of the two sides of the bottom plate, the table is arranged between the two first supporting frames, an edge cutting mechanism is arranged on the bottom plate, and an aligning mechanism is arranged on the table. By arranging the edge cutting mechanism and the aligning mechanism, people manually drive the edge cutting mechanism and the aligning mechanism to move, the aligning mechanism can fix and align books, and the effect of cutting edges in order is achieved; and through the arrangement of an alignment assisting mechanism and a pushing mechanism, people can conveniently push books out for cutting through the pushing mechanism, the alignment assisting mechanism can drive the alignment mechanism to automatically move, and the effect of reducing the workloads of people is achieved.

Owner:新疆恒远中汇彩印包装股份有限公司

Aluminum rod shearing machine

The invention discloses an aluminum rod shearing machine. The aluminum rod shearing machine comprises a rack, an aluminum rod conveying frame and an aluminum rod output frame, wherein the rack is fixedly provided with a fixed tool apron and a sliding frame; the sliding frame is provided with a movable tool apron; each of the fixed tool apron and the movable tool apron is provided with a pair of scissors; the sliding frame is driven by an oil cylinder to slide; an aluminum rod positioning seat is arranged at the output end of the aluminum rod conveying frame; the aluminum rod positioning seat is driven by a driving mechanism to do reciprocated up-down sliding relative to the rack; the aluminum rod output frame comprises an aluminum rod overturning frame with a circular-arc-shaped section; the aluminum rod overturning frame is rotatably connected with the rack and is driven by a first air cylinder to rotate; each pair of scissors is semi-annular; the aluminum rod positioning seat, the fixed tool apron and the movable tool apron are provided with arc-shaped surfaces adapted to the outer circumference of an aluminum rod; the aluminum rod is sheared through setting the semi-annular scissors and are orderly sheared, and cutting openings are flat; the aluminum rod is simultaneously positioned in upper and lower directions through the aluminum rod positioning seat and the aluminum rod overturning frame in a shearing process, so that the shearing effect is guaranteed.

Owner:JIANGYIN GIANSUN ALUMINUM PROFILE COMPLETE PLANT MFG

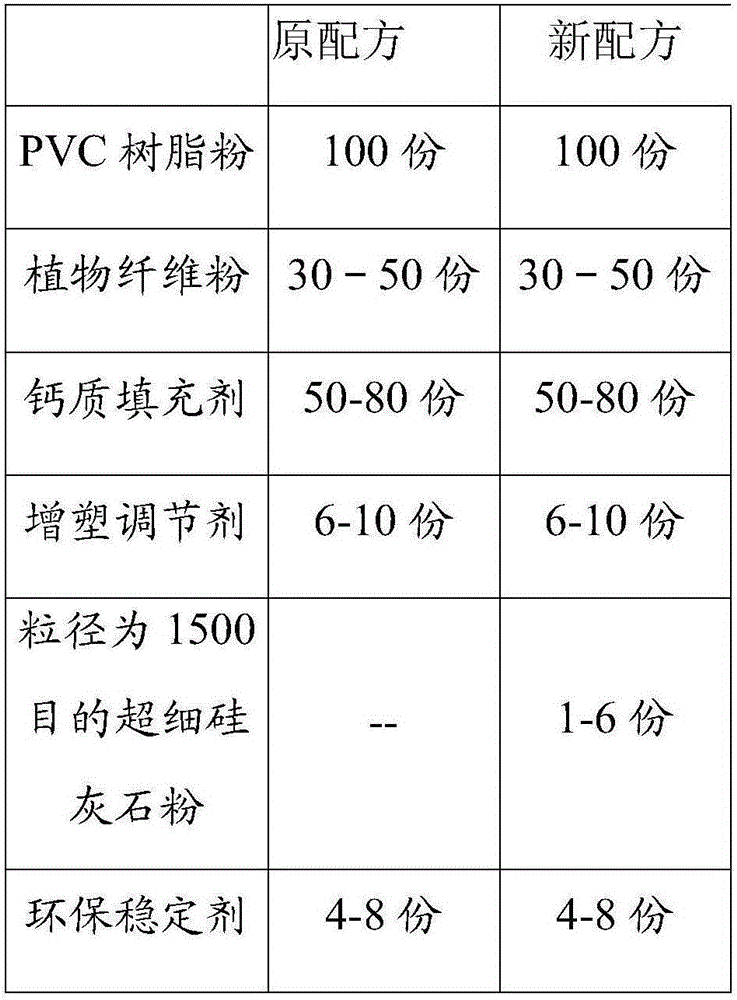

Wood-plastic plate and production process

The invention discloses a wood-plastic board, which is composed of raw materials in the following weight ratios: PVC resin powder: 100 parts; plant fiber powder: 25-60 parts; calcium filler: 40-90 parts; plasticizing regulator: 0.5 ‑5 parts; processing aid superfine wollastonite powder: 0.5‑5 parts; environmental stabilizer: 3‑9 parts; ACR processing aid: 3‑12 parts; foaming agent: 0.5‑4 parts; internal and external lubricants: 0.5-3.5 parts, the particle size of the superfine wollastonite powder is at least 1500 mesh, and the upper material is mixed, heated, shaped and cut. The invention also discloses a production process. It is environmentally friendly, low in cost, and the cut surface of the product is neat, dense and free of pores, and its hardness, strength, and nail holding force are higher than the national standard, which can meet the effects of various post-processing requirements of the product.

Owner:SHANDONG XIAGUANG INDAL

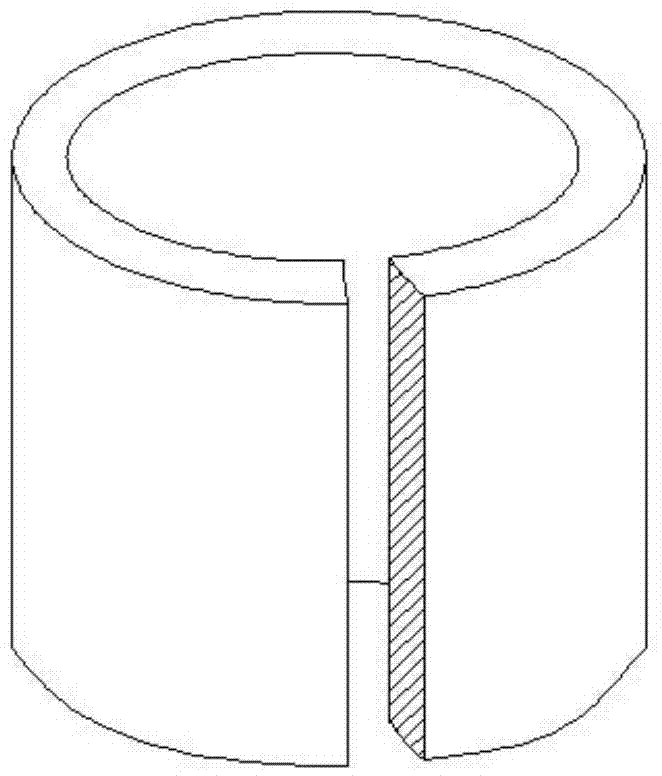

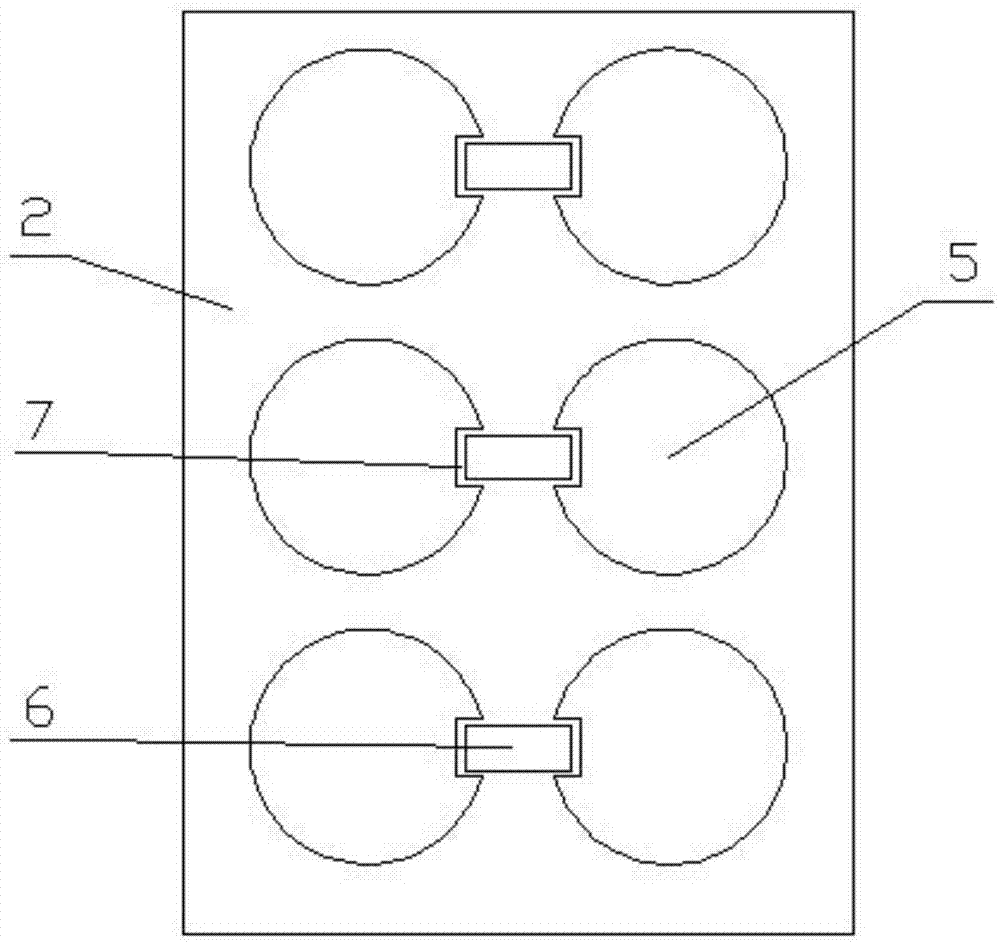

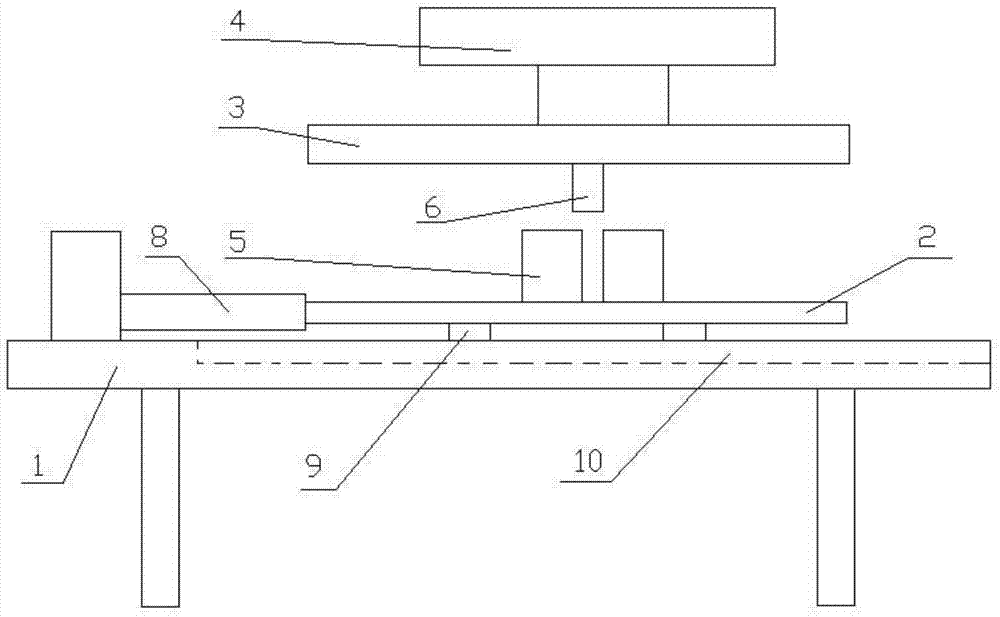

Device for clipping rubber rings

The invention discloses a device for clipping rubber rings, and relates to rubber rings. The device comprises a workbench, a base plate, a pressing plate, a driving device, a plurality of column bodies and a plurality of blades. The base plate is arranged on the surface of the workbench. The column bodies are arranged on the base plate. Each column body is provided with a groove in the axial direction. The length of the grooves is not smaller than the height of the rubber rings. The width of the grooves is not smaller than the thickness of the blades. The diameter of the column bodies is equal to the inner diameter of the rubber rings. The pressing plate is arranged above the base plate. The blades are installed at the bottom of the pressing plate. The blades are arranged above the grooves. The pressing plate is connected with the output end of the driving device. According to the device clipping the rubber rings, the rubber rings can be clipped at the same time, the speed is high, efficiency is high, labor intensity of workers is relieved, the clipping positions are in order and are attractive, the consistency is good, the structure is simple and practical, the cost is low, and operation is convenient.

Owner:ANHUI JINGHONG SEAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com