Safe type timber cutting machine with multiple cutting saw blades

A wood cutting machine, safe technology, applied in the direction of circular saws, sawing equipment, wood processing equipment, etc., can solve the problems of dirty operators, unsafe operation, low degree of automation, etc., to achieve safe and reliable wood cutting process, The effect of safe and convenient operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

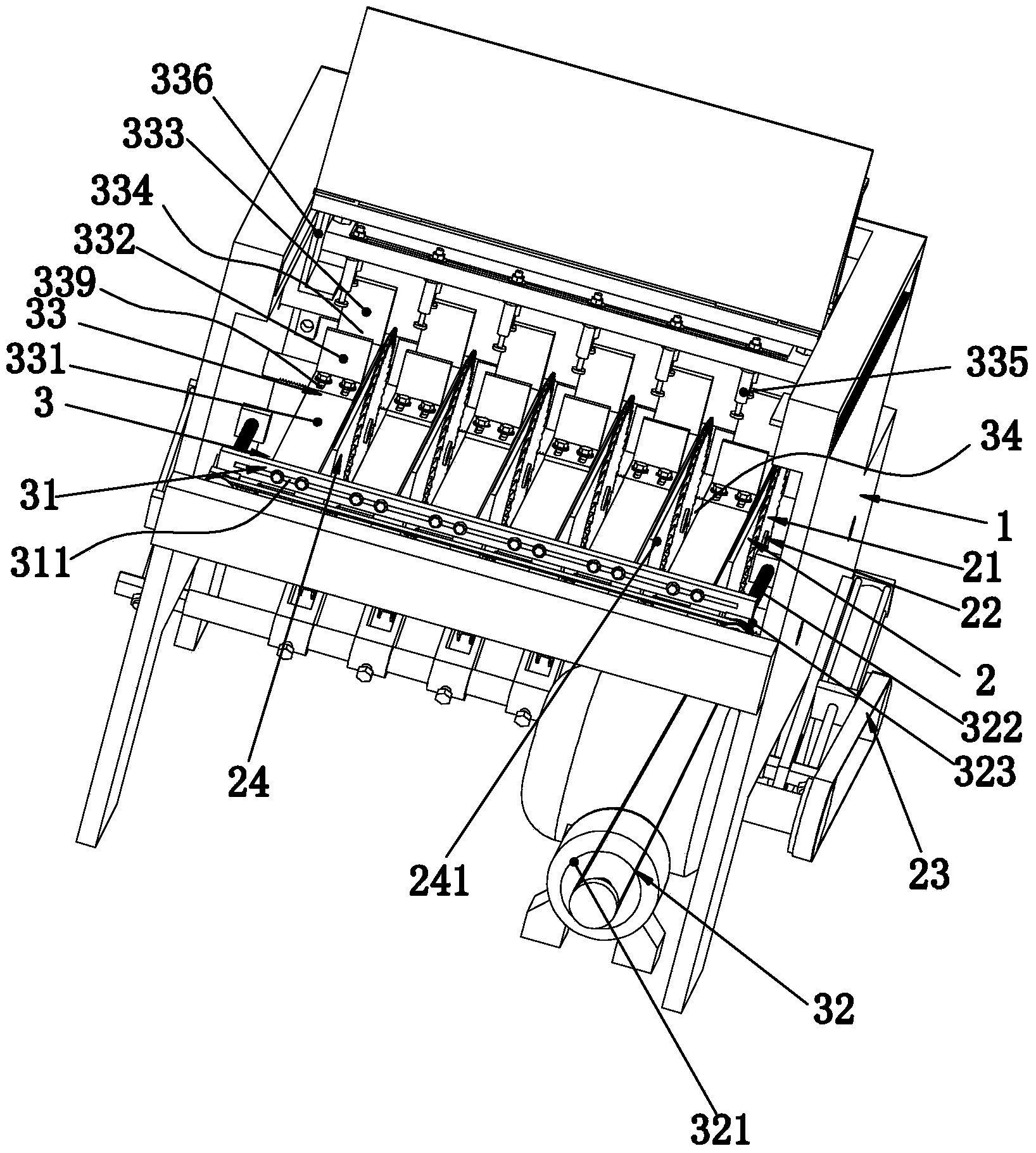

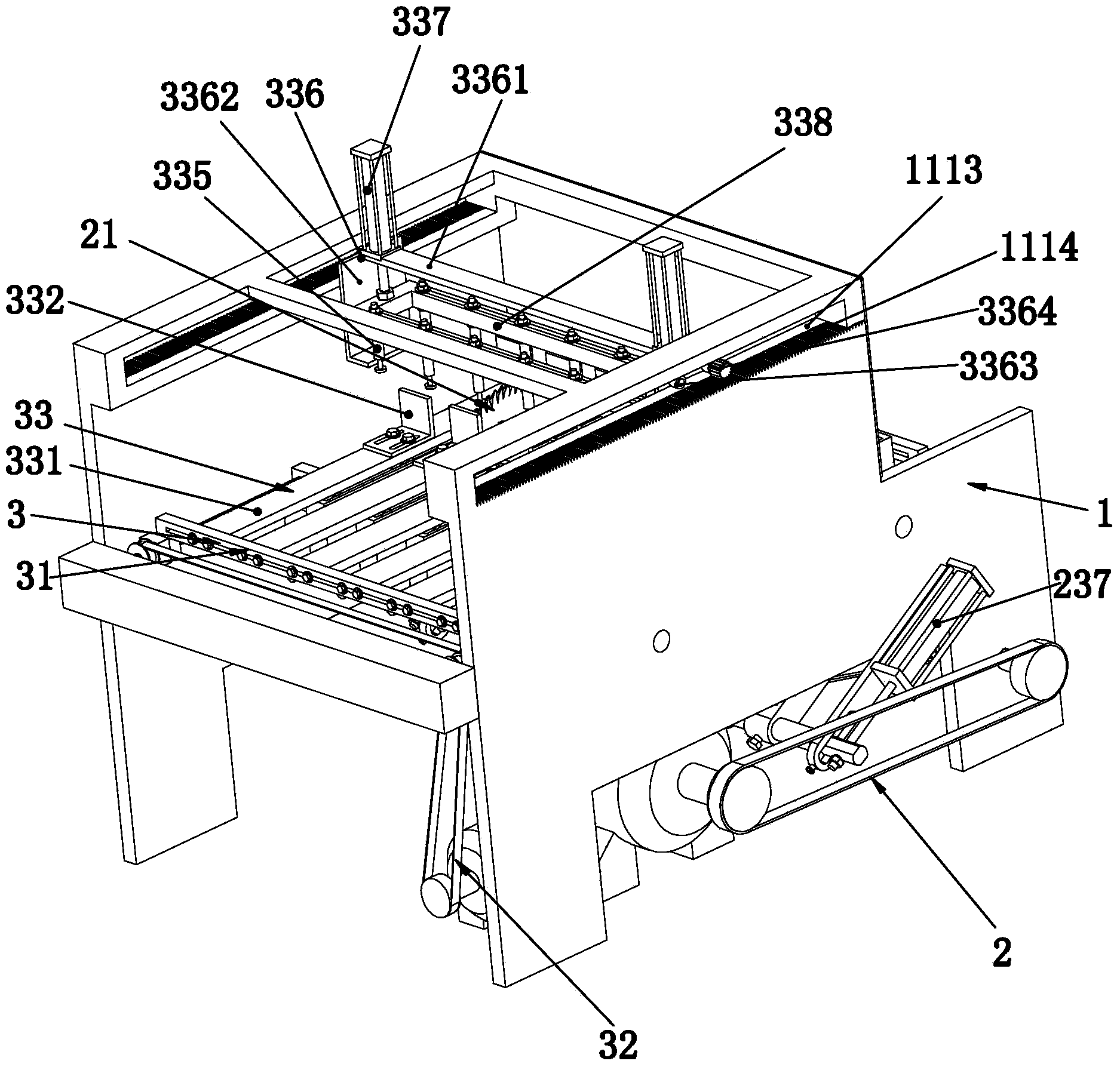

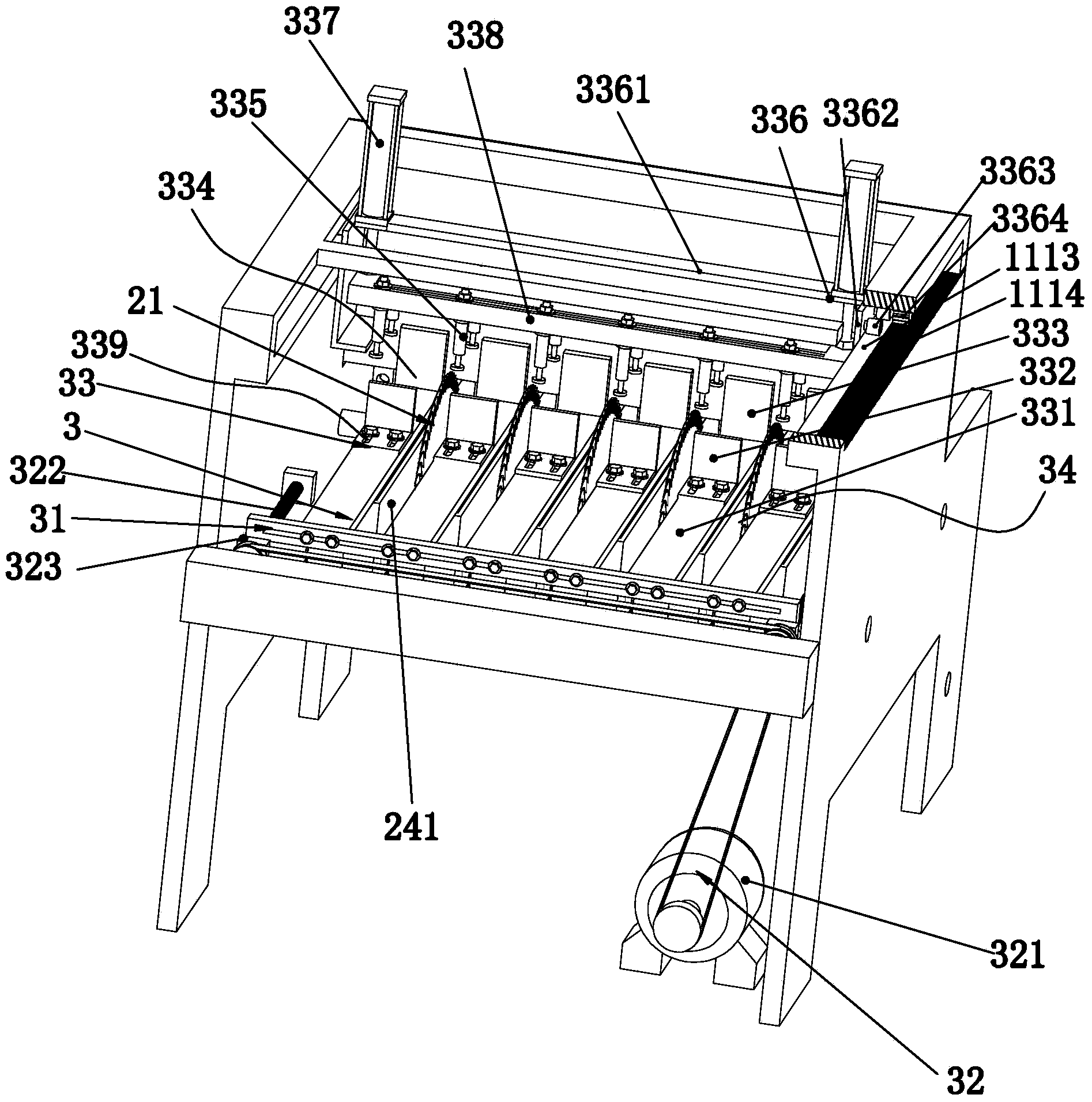

[0034] Such as Figures 1 to 8 As shown, the present invention discloses a safety type wood cutting machine with multiple cutting saw blades, which includes an organic base 1 and a cutting device 2 installed on the base 1 . The cutting device 1 includes a plurality of coaxially assembled, adjustable pitch cutting saw blades 21, a saw blade mounting shaft 22 for the cutting saw blades 21 to assemble, and a saw blade driving mechanism 23 for driving the cutting saw blades to rotate; The blade driving mechanism 23 is drivingly connected with the saw blade installation rotating shaft 22 . Also equipped with an automatic feeding device 3 on the base 1, the automatic feeding device 3 includes a feeding frame 31 that is slidably arranged along the cutting saw blade 21 rotating and cutting direction and a feeding drive mechanism 32 that drives the feeding frame 31. The frame 31 is provided with a number of wood fixing tables 33 adapted to the number and position of the cutting saw bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com