Patents

Literature

488 results about "Feeding drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

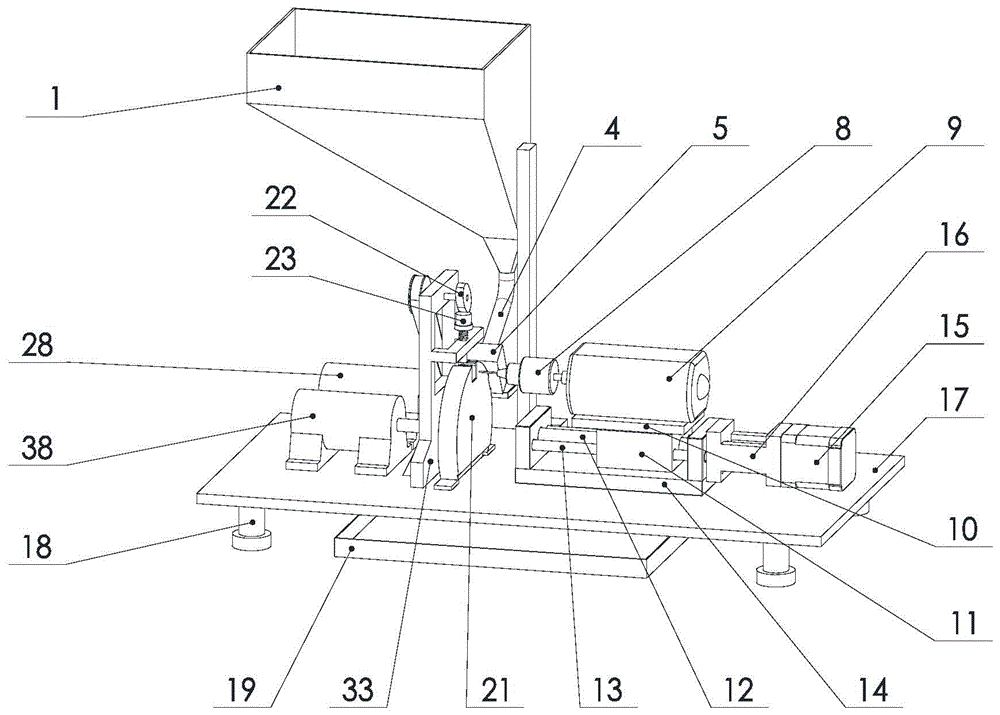

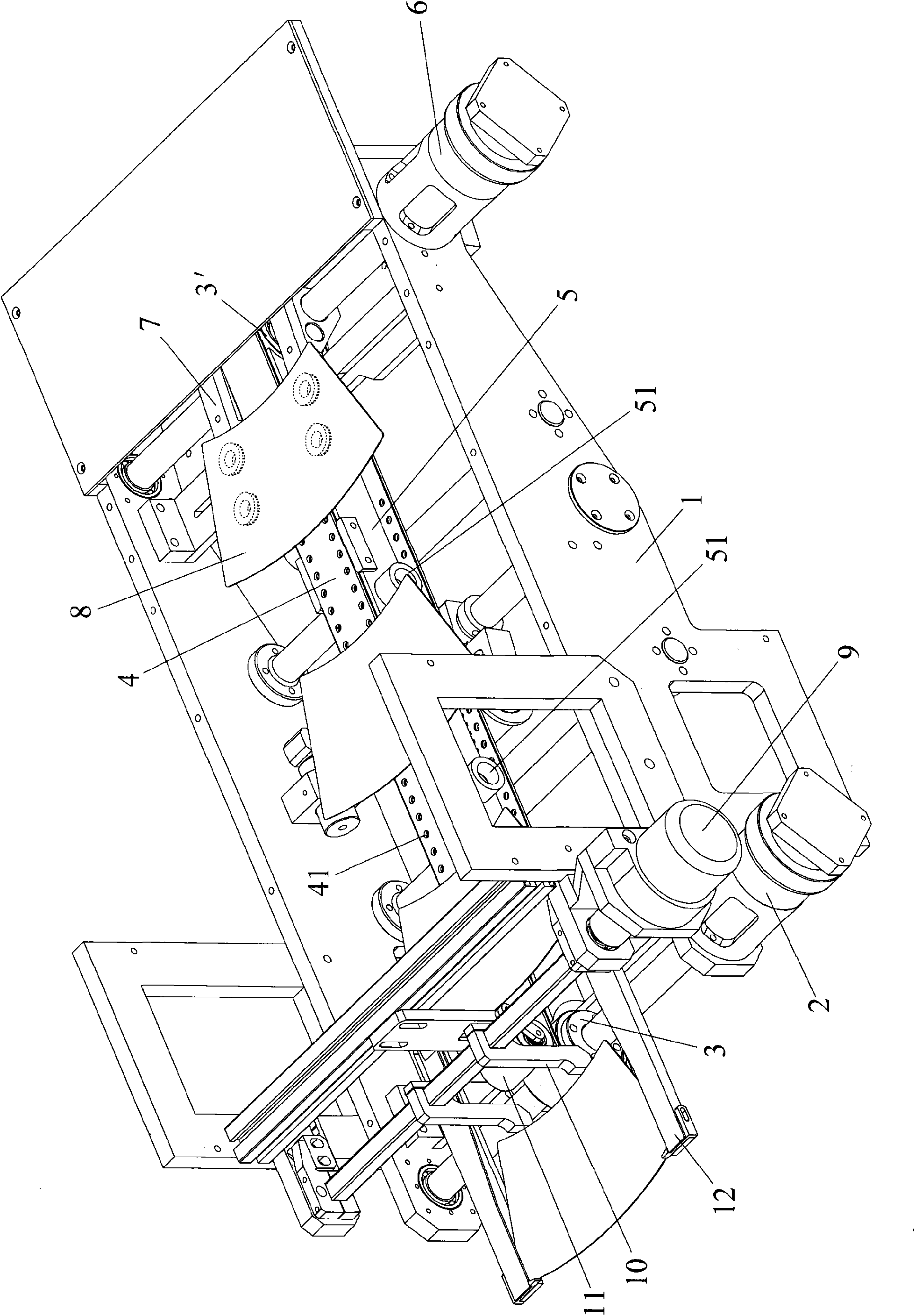

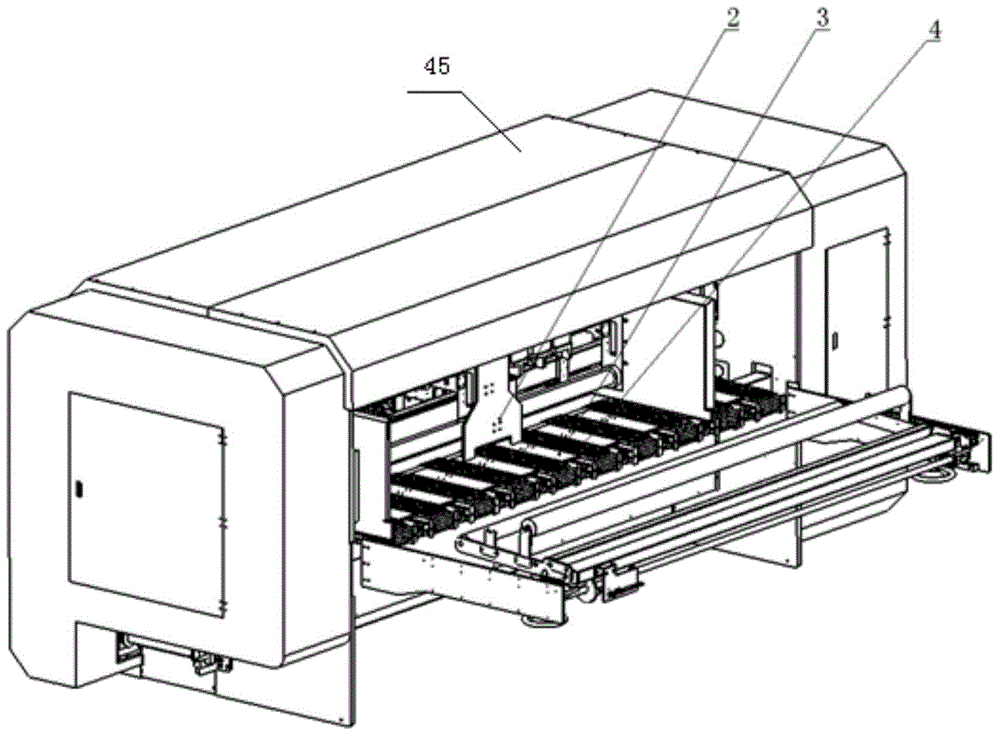

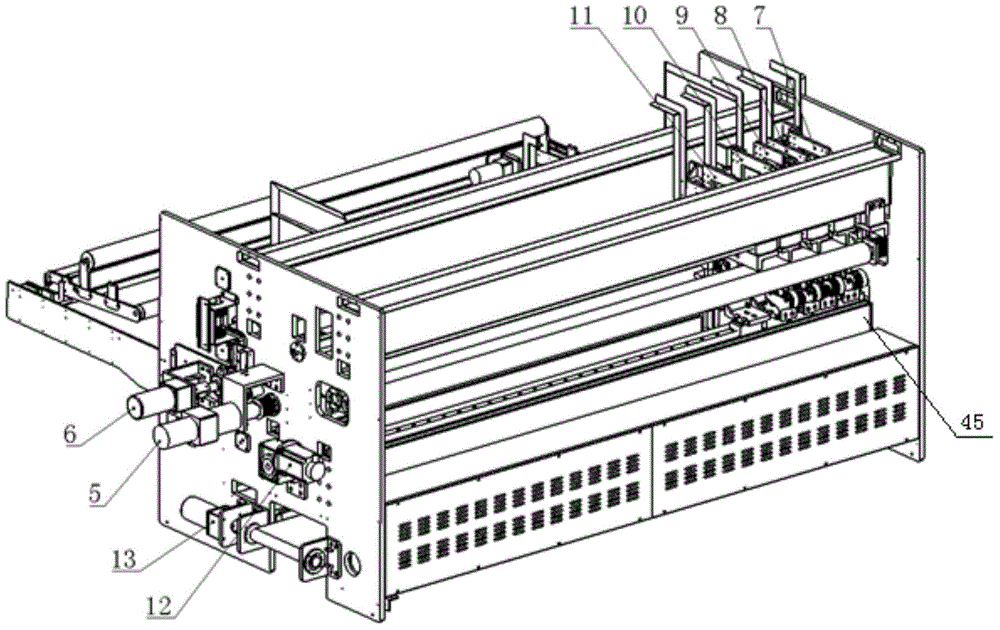

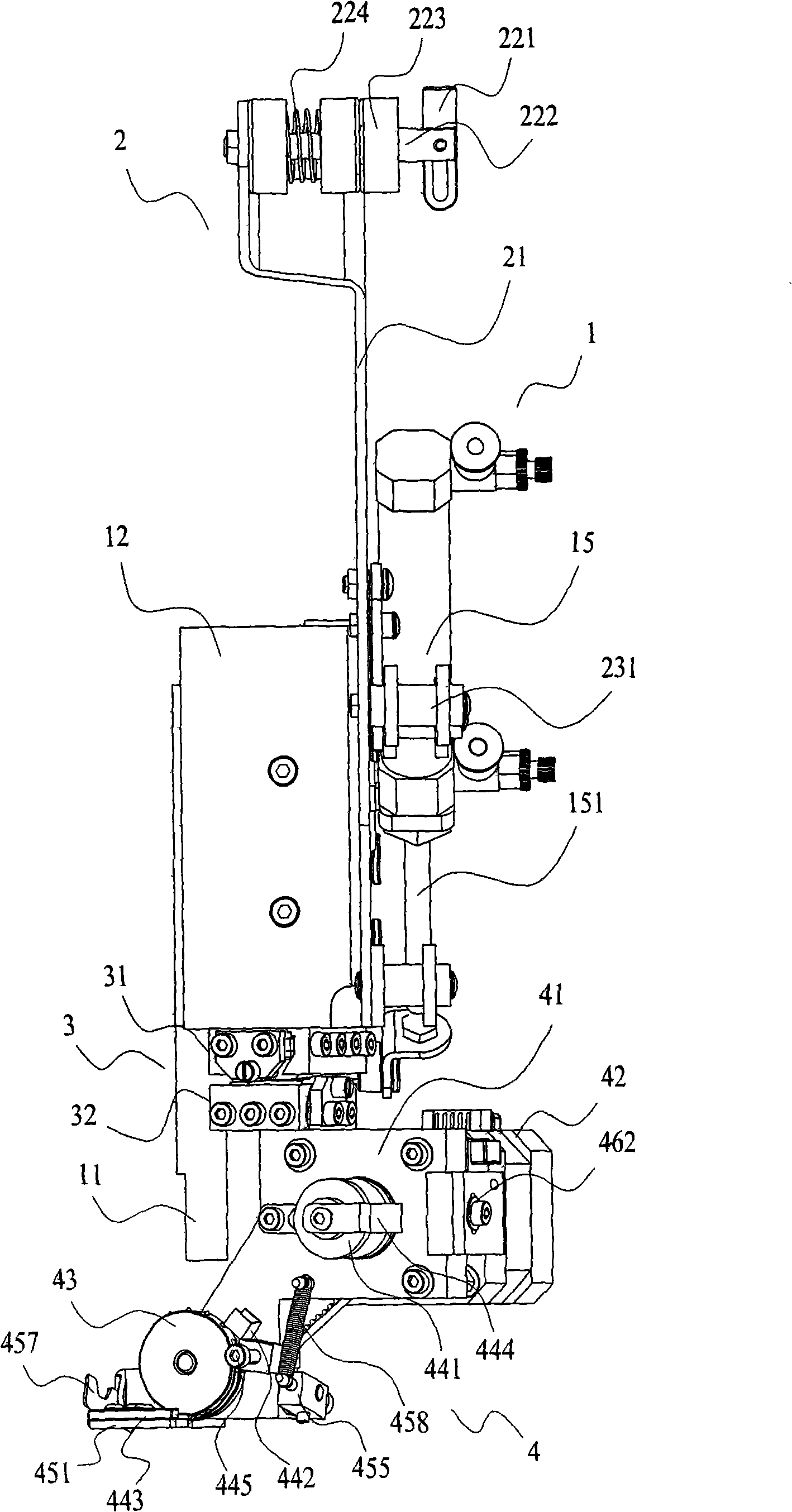

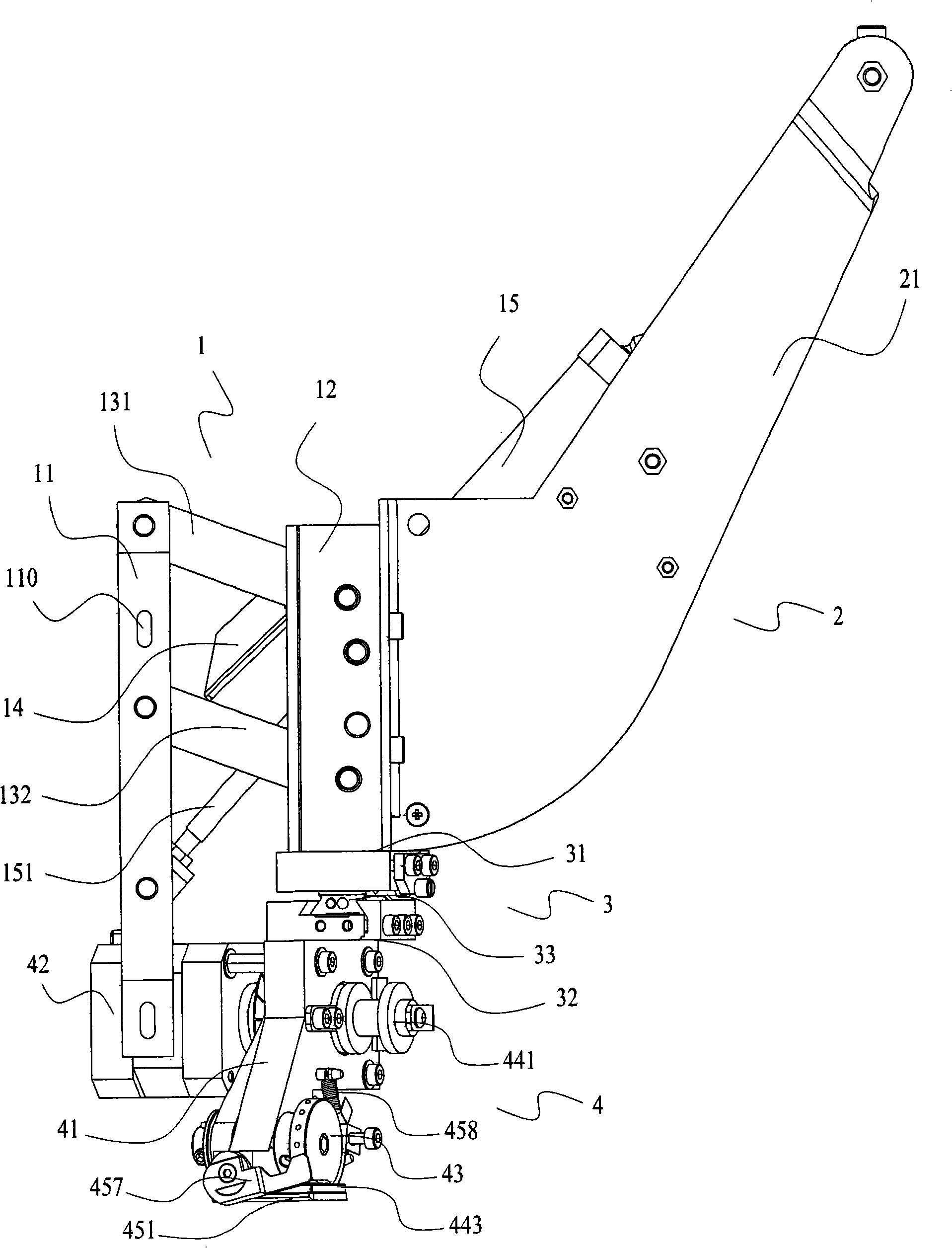

Full automatic pipe cutting machine

InactiveCN102179562AHigh degree of automationImprove cutting efficiencyTube shearing machinesShearing machine accessoriesEngineeringLength measurement

The invention discloses a full automatic pipe cutting machine. The pipe cutting machine comprises a feeding drive part, a cutting drive part, a pipe clamping part, a cutting part, an unloading part and a cutting measurement part which are sequentially arranged on an operating platform, wherein the feeding drive part conveys pipes to the cutting part by a driving wheel and a rolling wheel, then the pipes are cut off by a cutting tool driven by the cutting drive part; the driving wheel of the pipe cutting machine is driven by a stepping motor, and the lengths of the cut pipes can be accurately detected and controlled according to the electrical signals of stepping quantity of the stepping motor and the data of radius of the driving wheel; and in addition, the operating platform is also provided with an infrared distance measurement sensor, and the length accuracy of the cut pipe is jointly ensured by the electrical distance measurement signals and the movement detection signals of the stepping motor. By adopting the clamping feeding structure, the automatic cutting structure, the automatic clamping structure, the automatic unloading structure and the automatic cut pipe-length measurement and control mechanism, the degree of automation of the pipe cutting machine is improved.

Owner:中臻工业有限公司

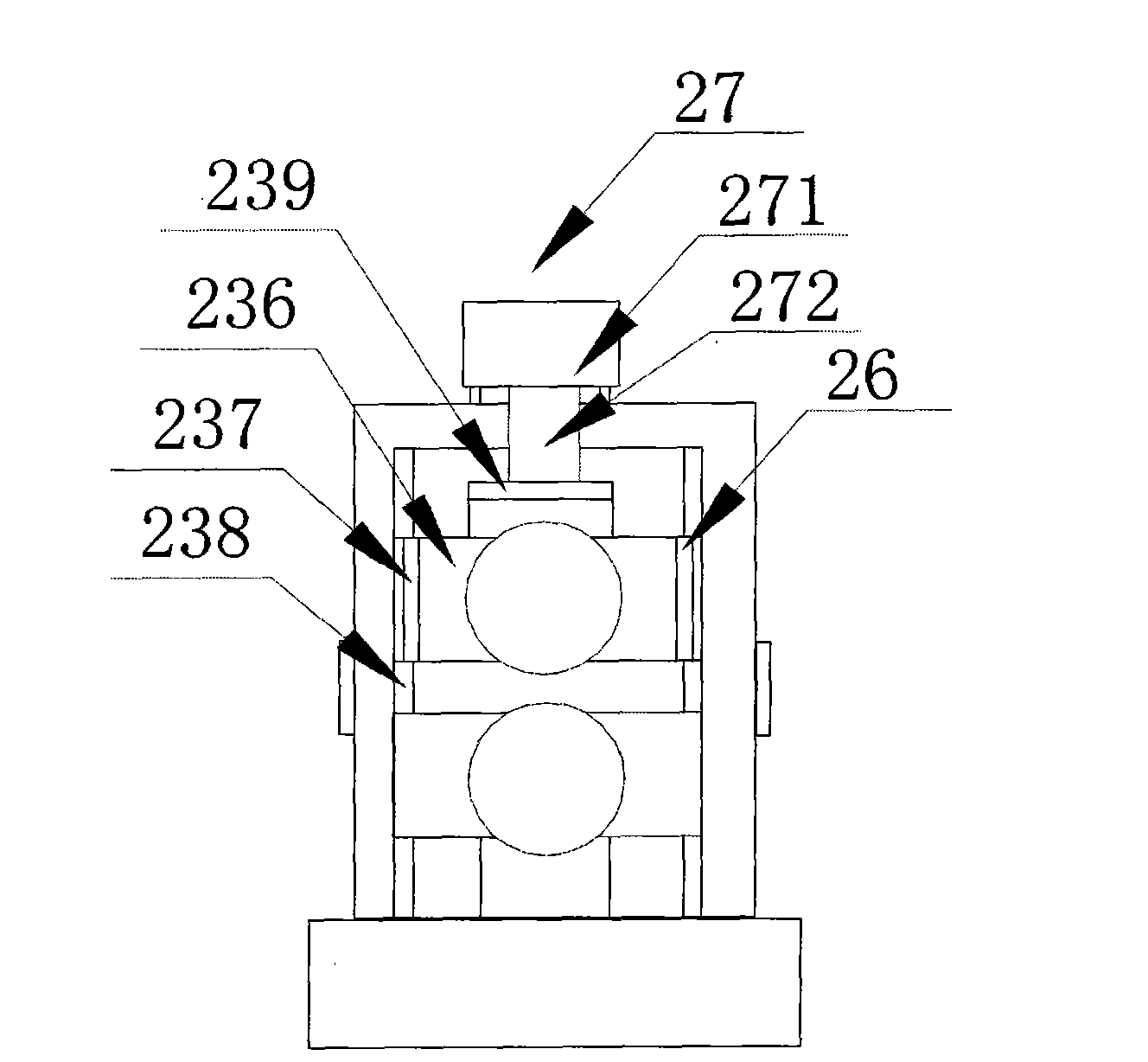

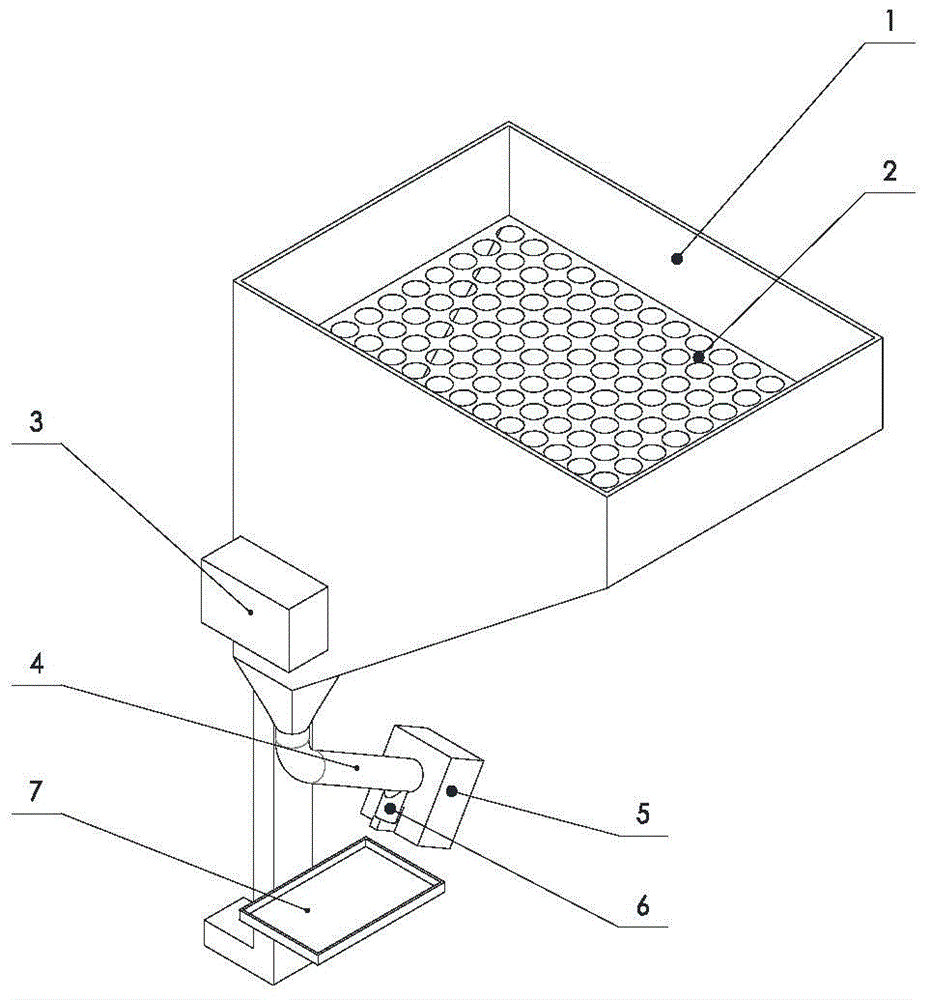

Automatic pearl drilling device

InactiveCN104441269AImprove drilling efficiencyReduce manufacturing costSievingScreeningReciprocating motionEngineering

An automatic pearl drilling device is provided with a rack and a discharging mechanism. The rack is provided with a hopper, a clamping mechanism, a drilling mechanism and a feeding mechanism. The feeding mechanism comprises a guide pipe, a guide piece and a feeding piece connected with the guide pipe and the feeding station, wherein the guide piece enables a single pearl to move from the feeding station to the drilling station and the discharging station in sequence. The feeding piece only allows one pearl to enter the feeding station every time. The drilling station aligns at the drilling mechanism, the discharging station is communicated with the discharging mechanism, and the guide pipe is inclined downwards. The clamping mechanism aligns at the drilling station and compresses pearls towards a guide plate. The drilling mechanism comprises a drill bit, a drilling motor for driving the drill bit to rotate, a feeding motor and a feeding drive mechanism, and the feeding motor and the feeding drive mechanism are used for enabling the drill bit to be fed towards pearls and enabling the drill bit and the drilling motor to move back and forth continuously. The automatic pearl drilling device has the advantages that pearls are positioned stably in the drilling process, and requirements for equipment manufacturing and installation accuracy are low.

Owner:ZHEJIANG UNIV

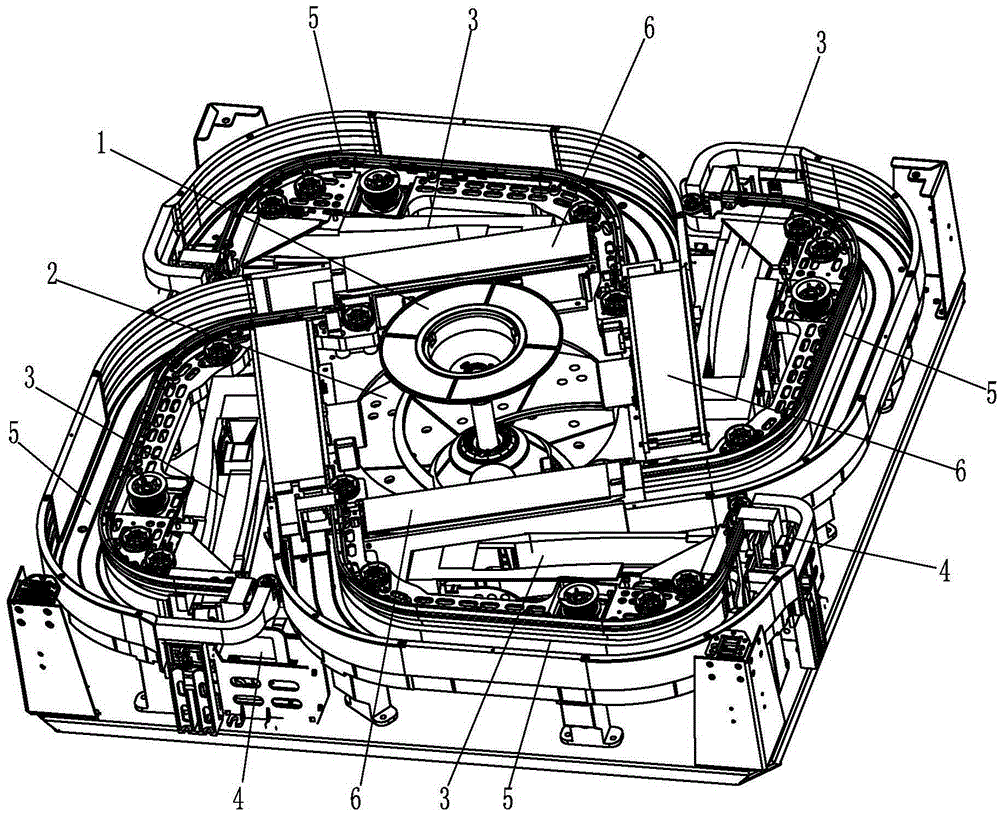

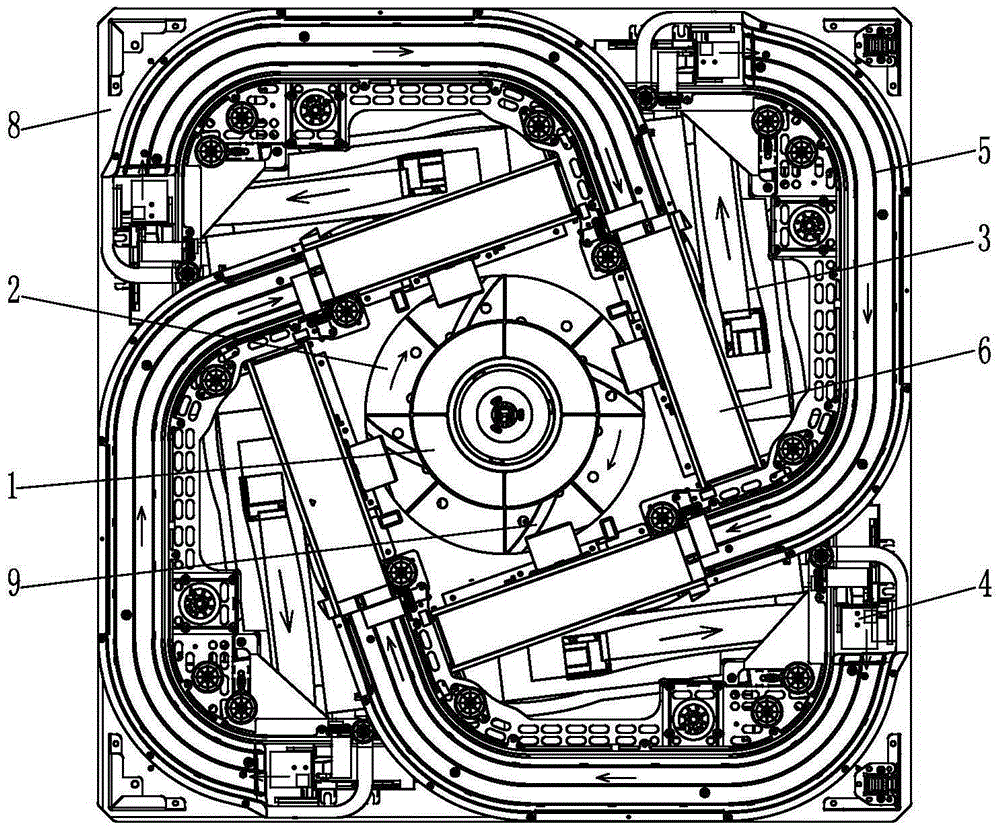

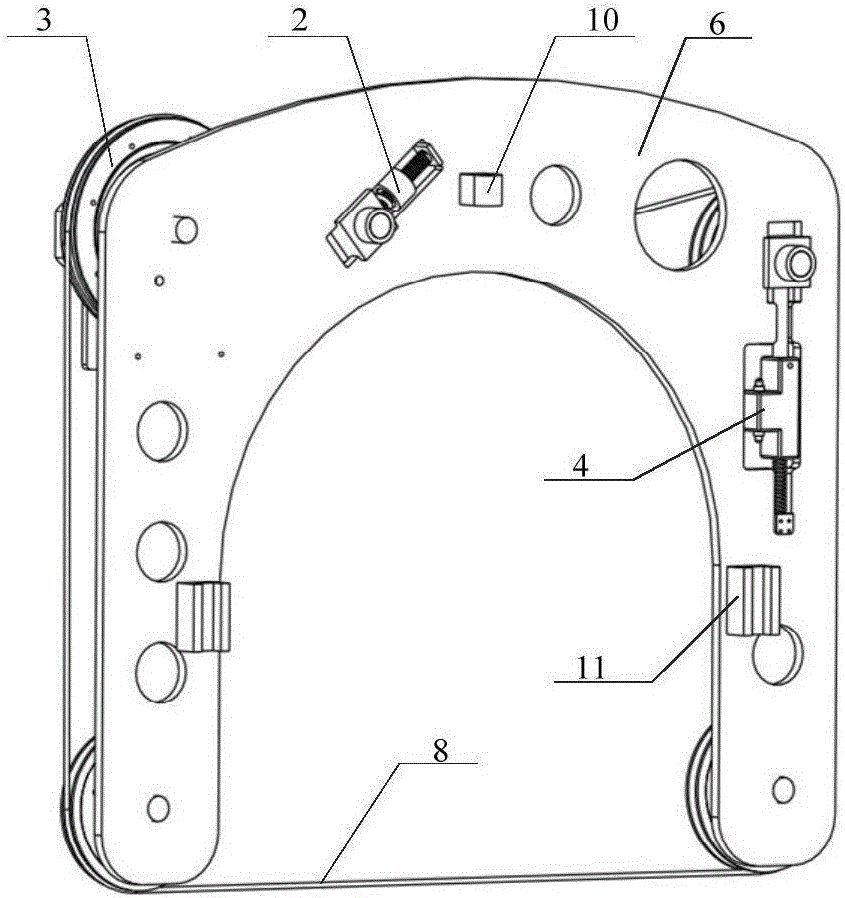

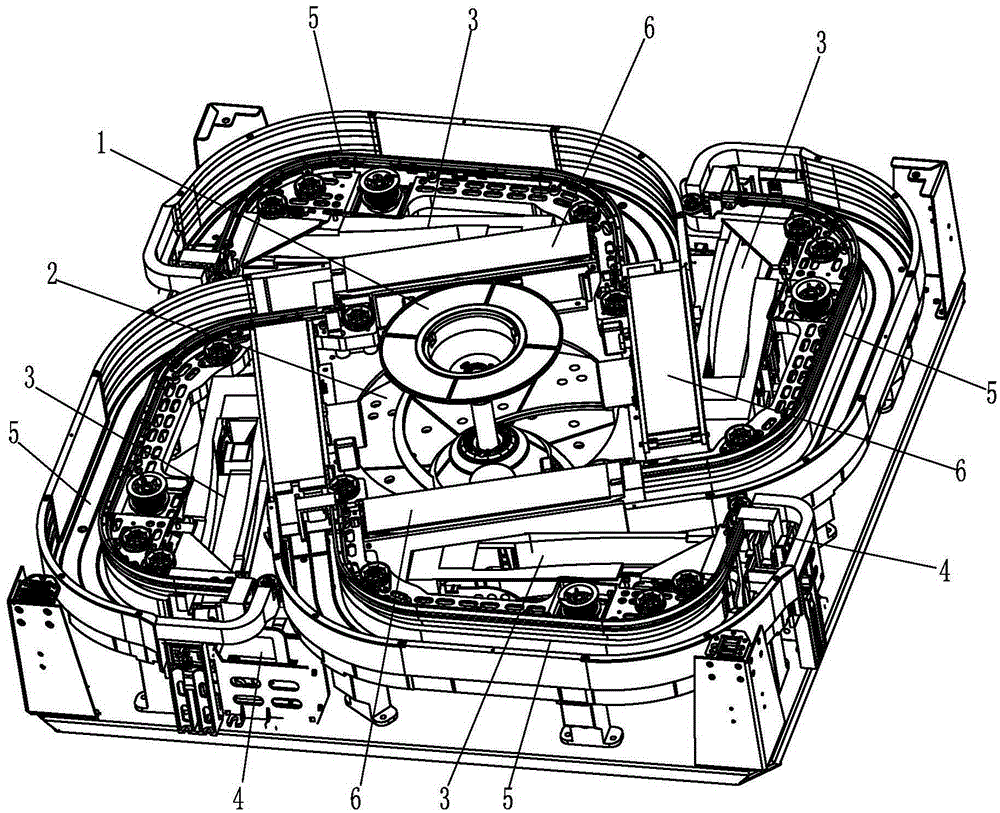

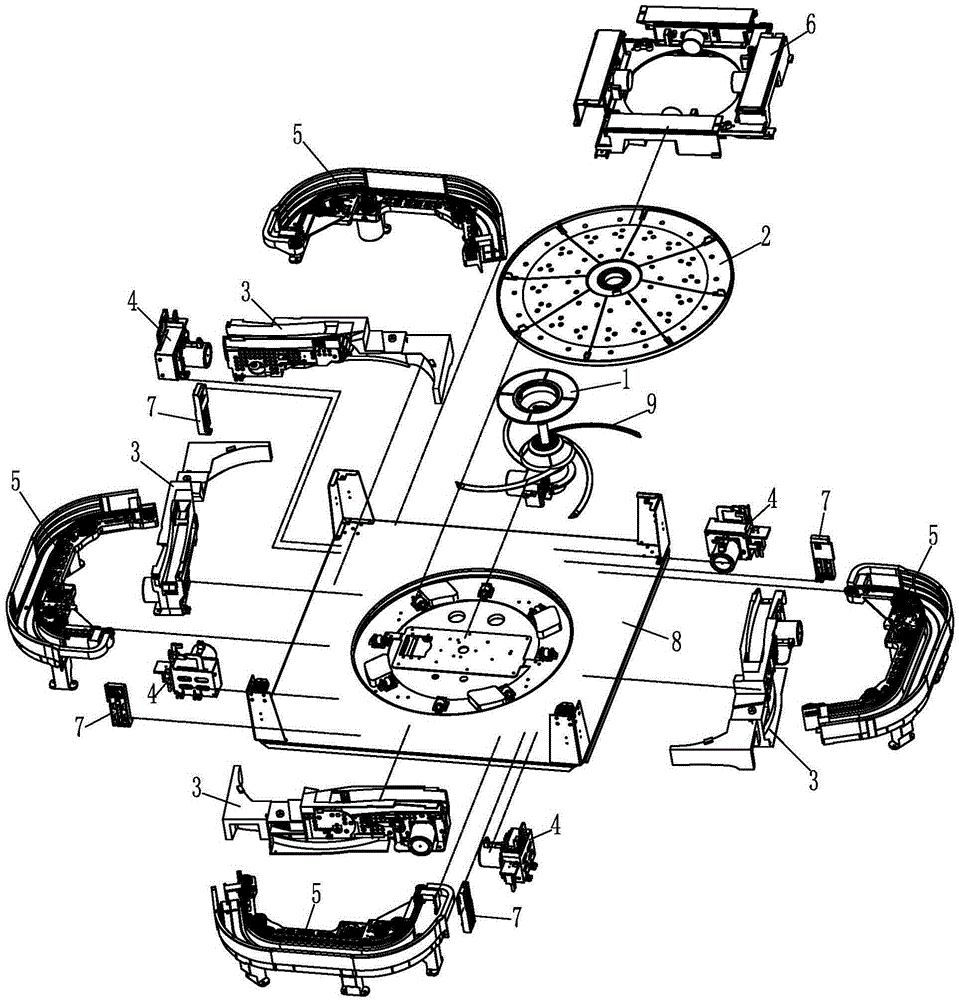

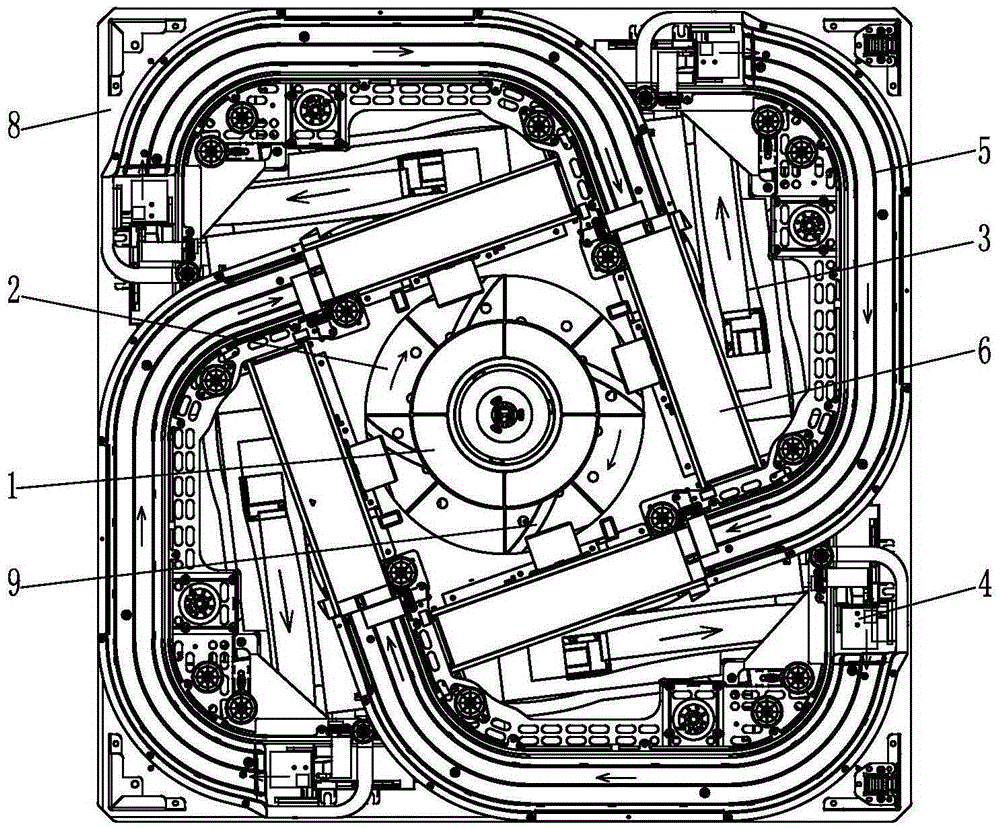

Mahjong machine and slope tile discarding device thereof

ActiveCN105381604AExtended service lifeImprove running stabilityIndoor gamesRolling resistanceFeeding drive

The invention discloses a mahjong machine and a slope tile discarding device thereof. Four integrated supports are connected end to end to form the square slope tile discarding device, and each integrated support is provided with a tile feeding part and a tile lifting part; each tile feeding part comprises a U-shaped tile storage groove which is integrally formed with the corresponding integrated support, wherein the tile storage groove is provided with a tile feeding guide rail, a tile feeding push head and a tile feeding drive mechanism; each tile feeding drive mechanism comprises a tile feeding motor, a drive winding wheel and a steel wire rope, multiple rolling needle grooves are formed in the tile feeding guide rails, rolling needles are embedded into the rolling needle grooves, the portions, in the tile storage grooves, of the steel wire ropes make rolling contact with the rolling needles, and gaps are maintained between the portions, in the tile storage grooves, of the steel wire ropes and the side walls of the tile feeding guide rails and / or the tile storage grooves. According to the mahjong machine and the slope tile discarding device thereof, the tile feeding support, provided with the large-arc-shaped tile storage part, of one party and the tile lifting part of the other adjacent party are both installed on the same integrated support, the four integrated supports are connected end to end to form the square slope tile discarding device, assembly is convenient, and the production efficiency is improved; sliding friction of the steel wire ropes is replaced by rolling friction, and therefore the service life and operation stability of the machine are improved.

Owner:ZHEJIANG CHAOSHENG ELECTROMECHANICAL TECH CO LTD

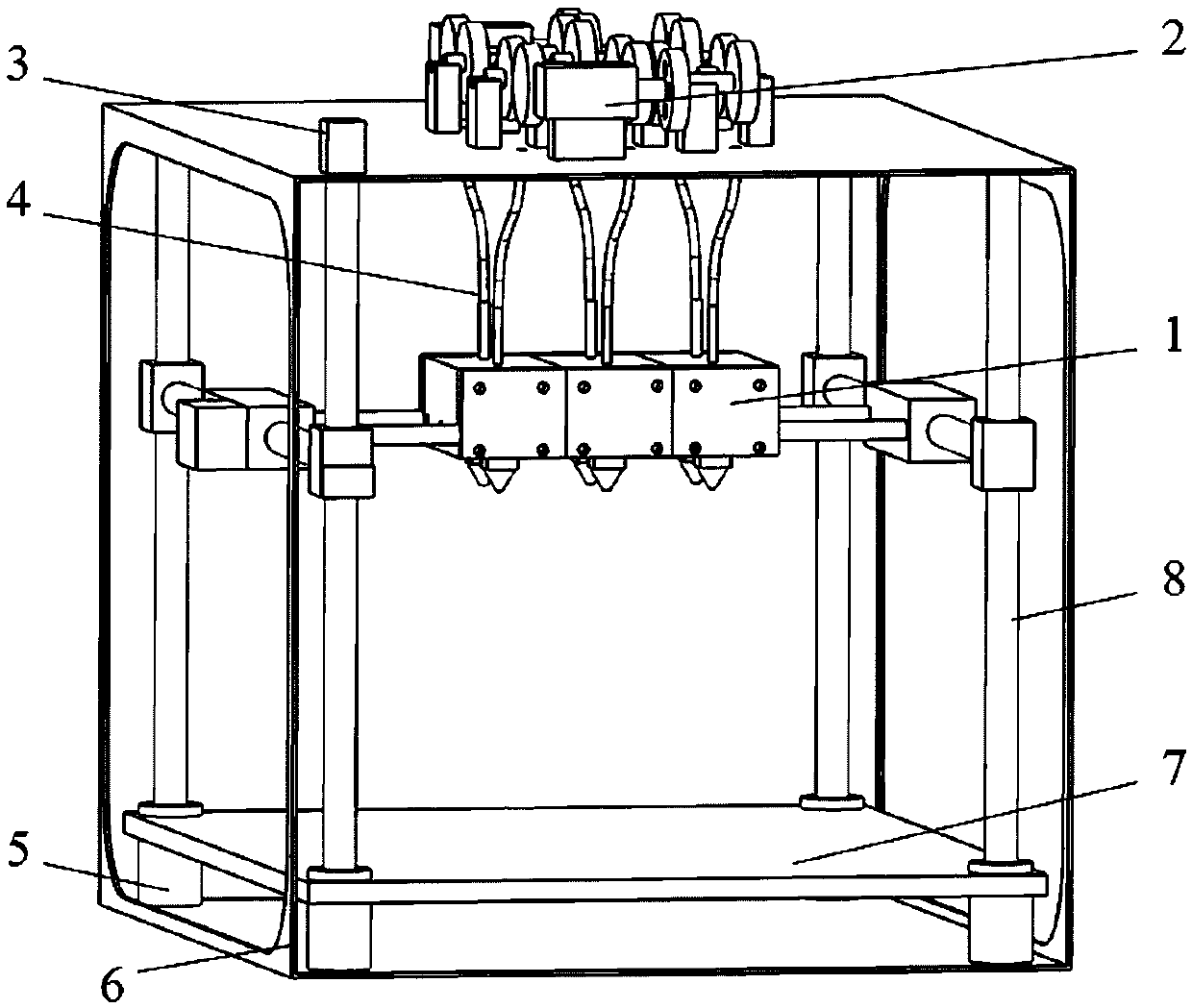

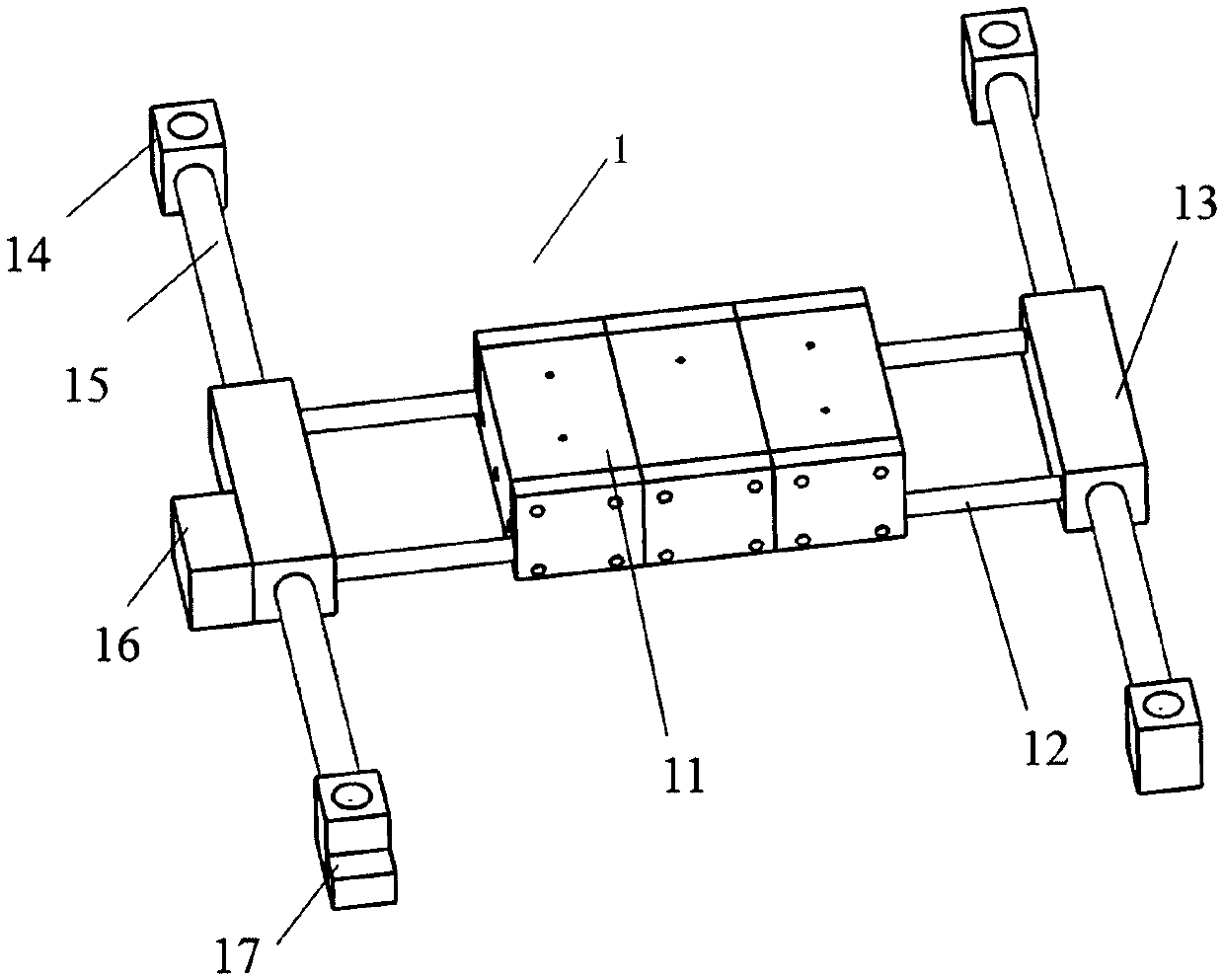

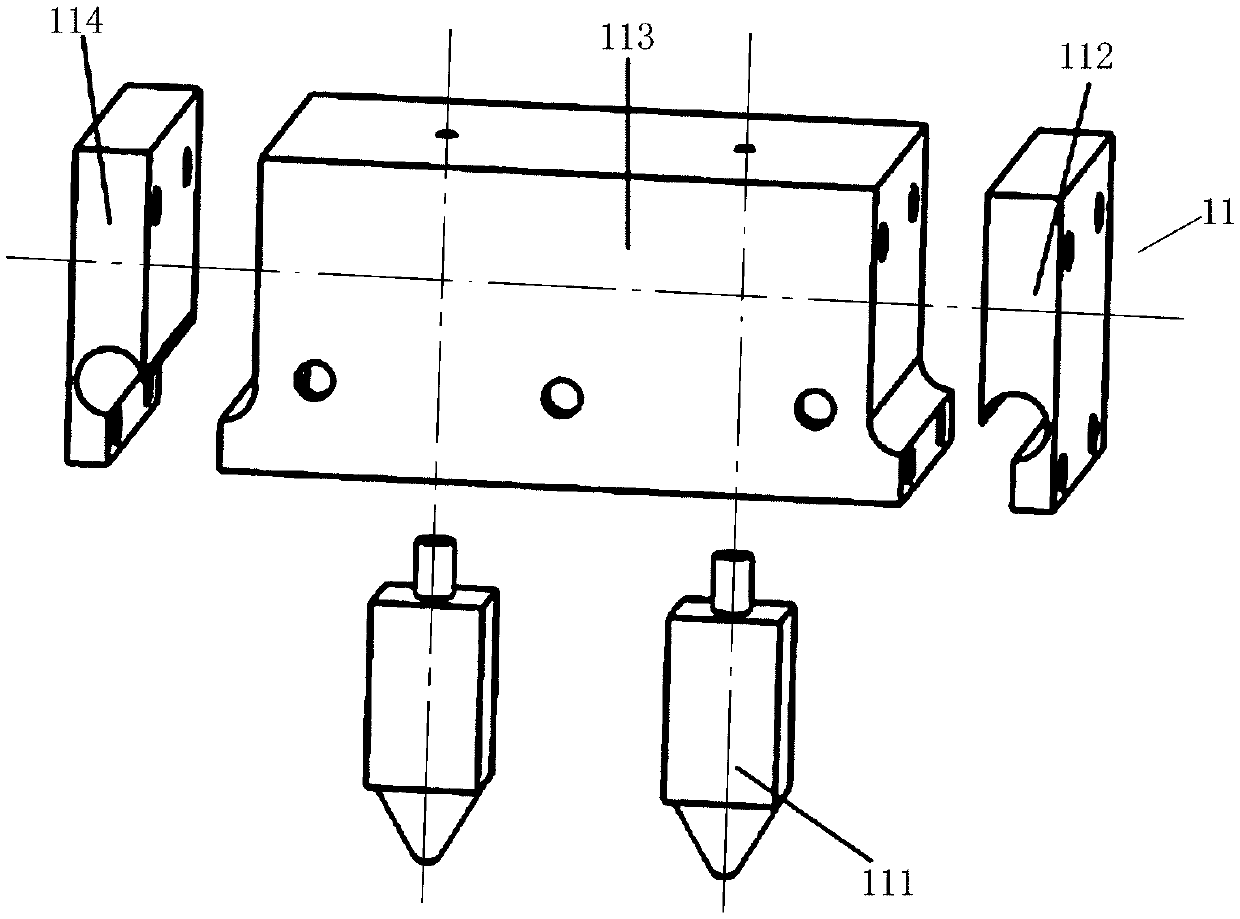

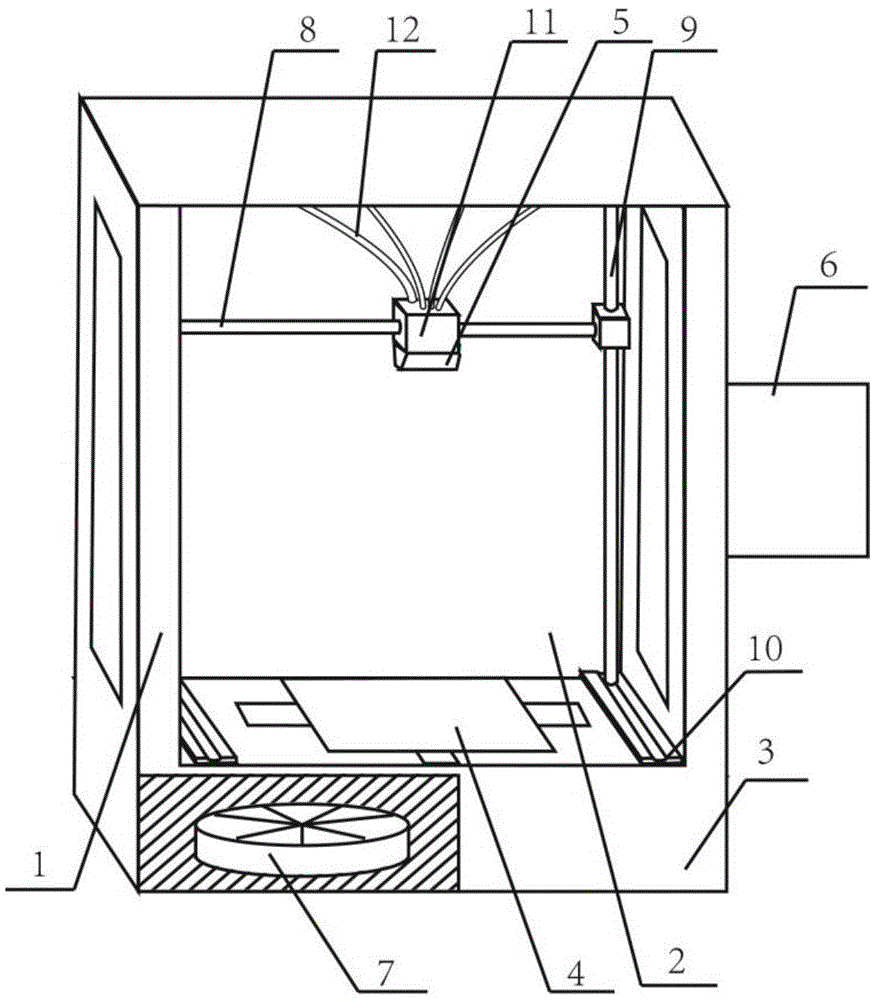

Array-type forming 3D printing system

ActiveCN105500714AImprove printing efficiencyAchieve multi-color printingAdditive manufacturing apparatusFeed driveGear wheel

Owner:WUXI VOCATIONAL & TECHN COLLEGE

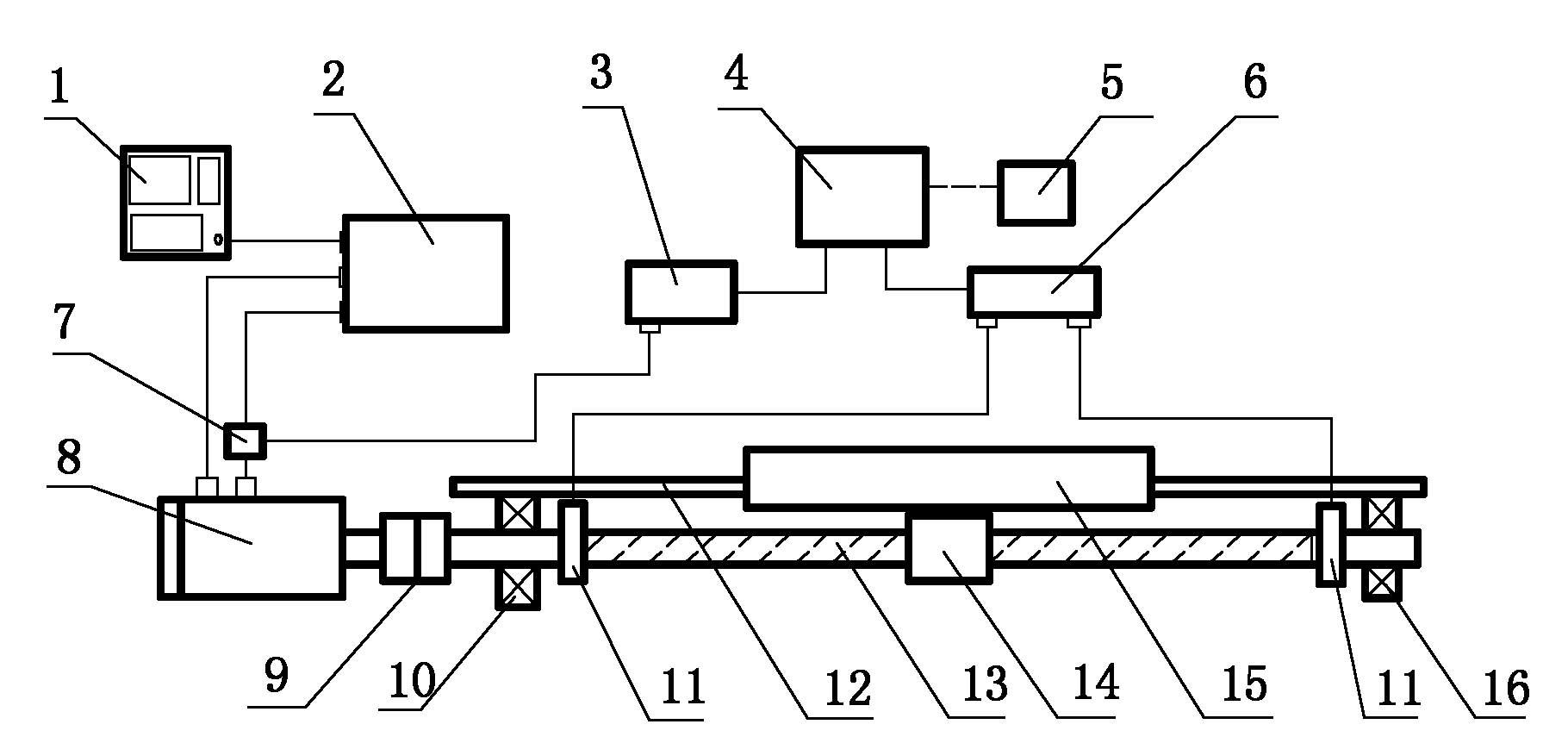

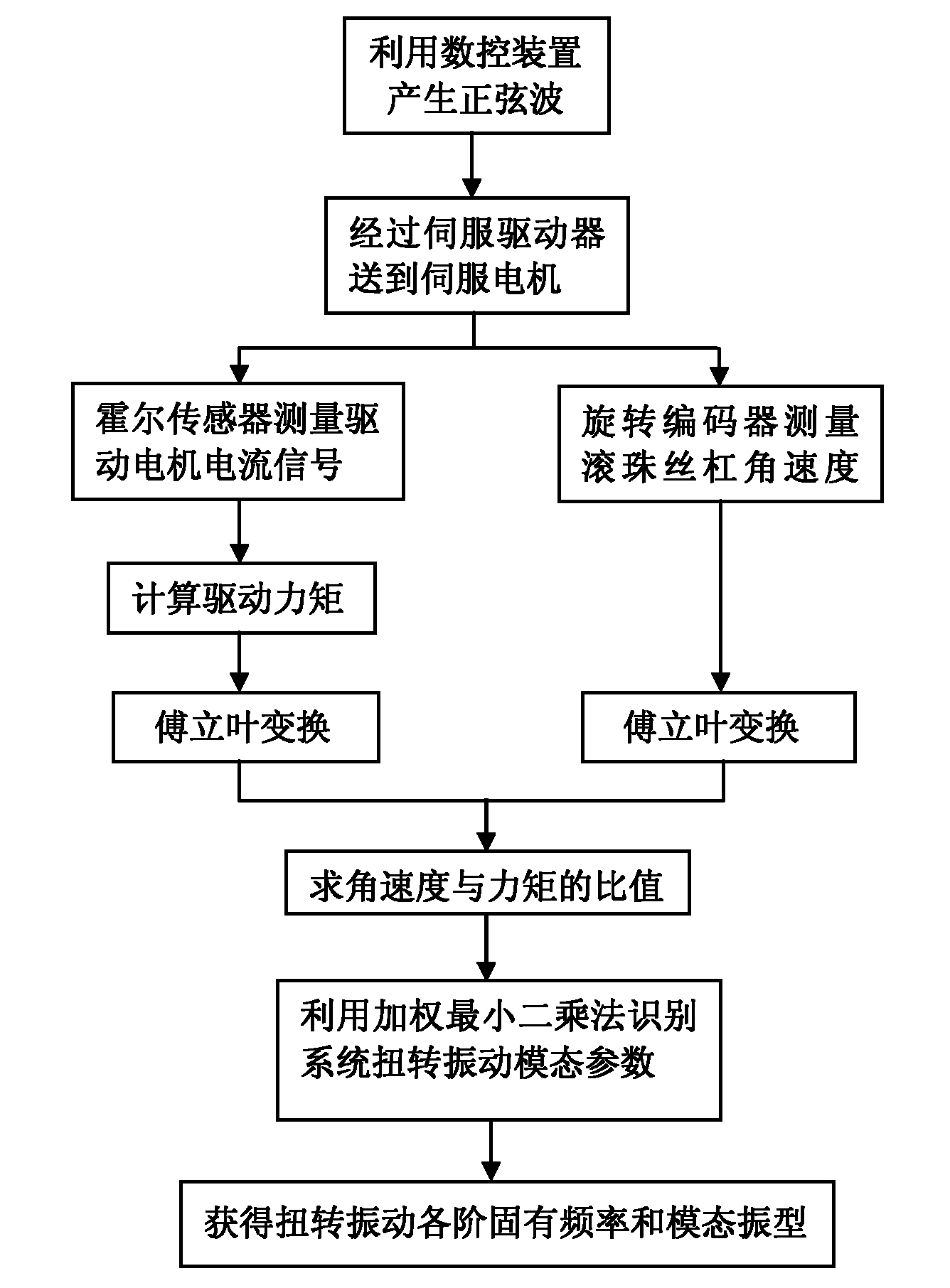

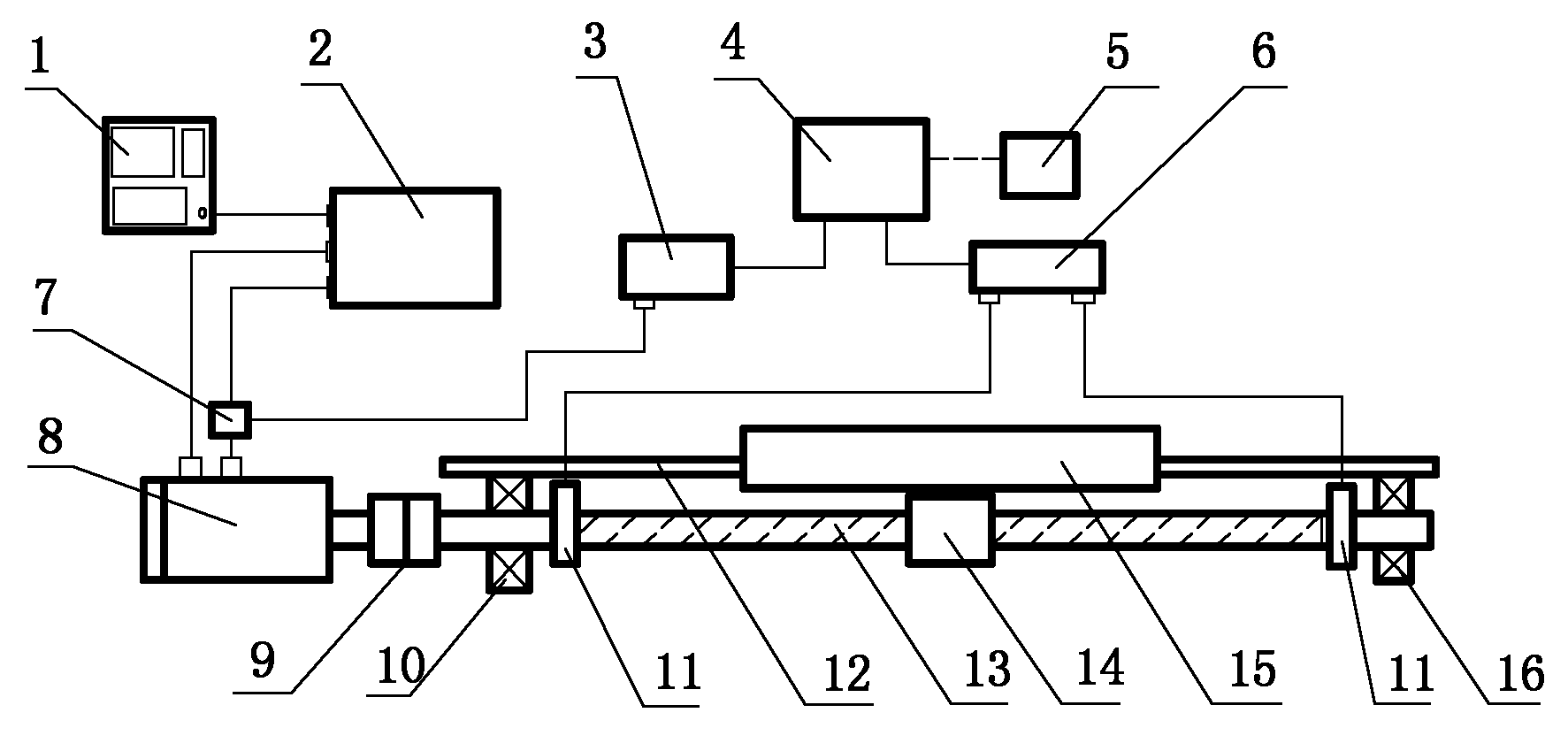

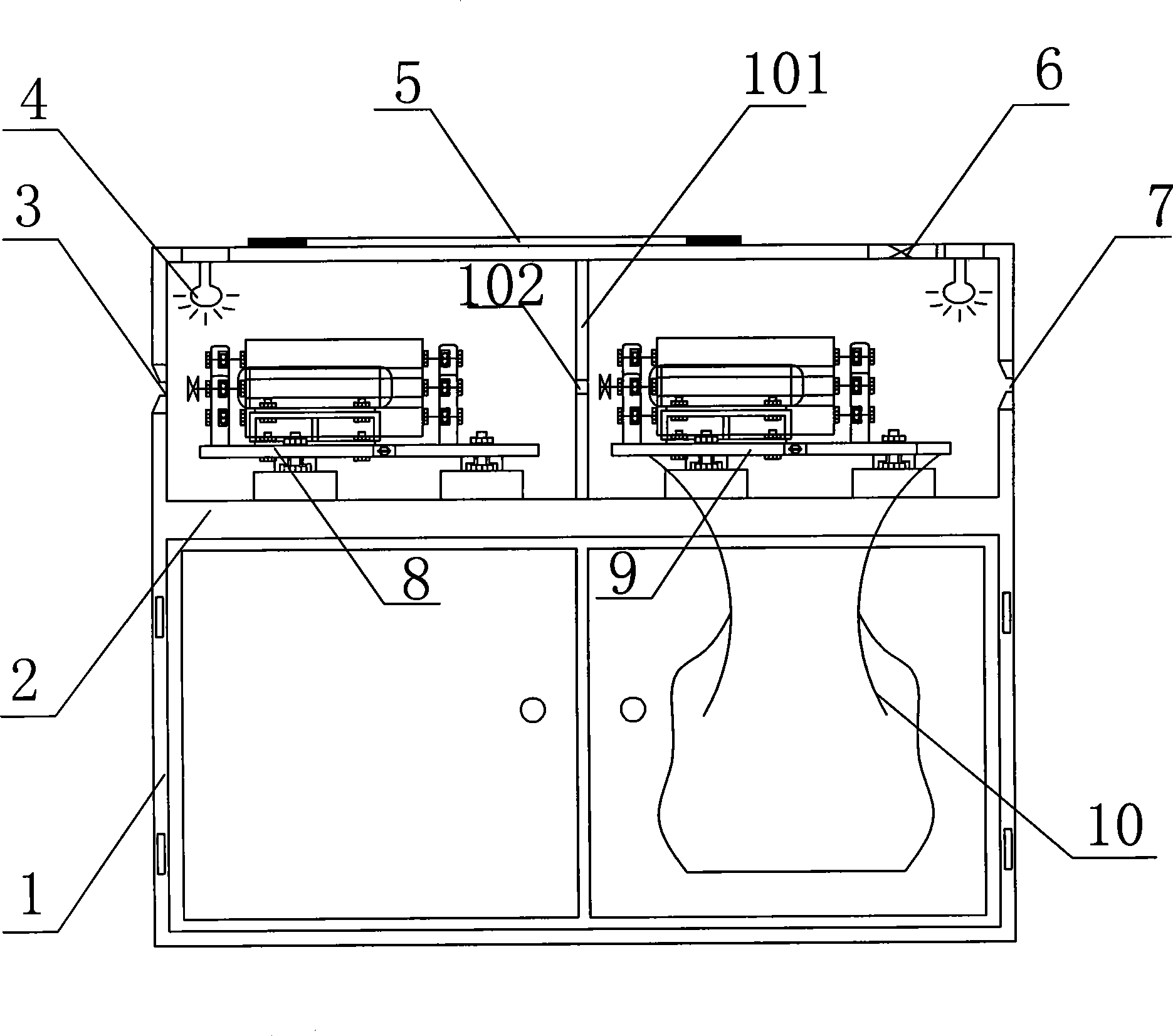

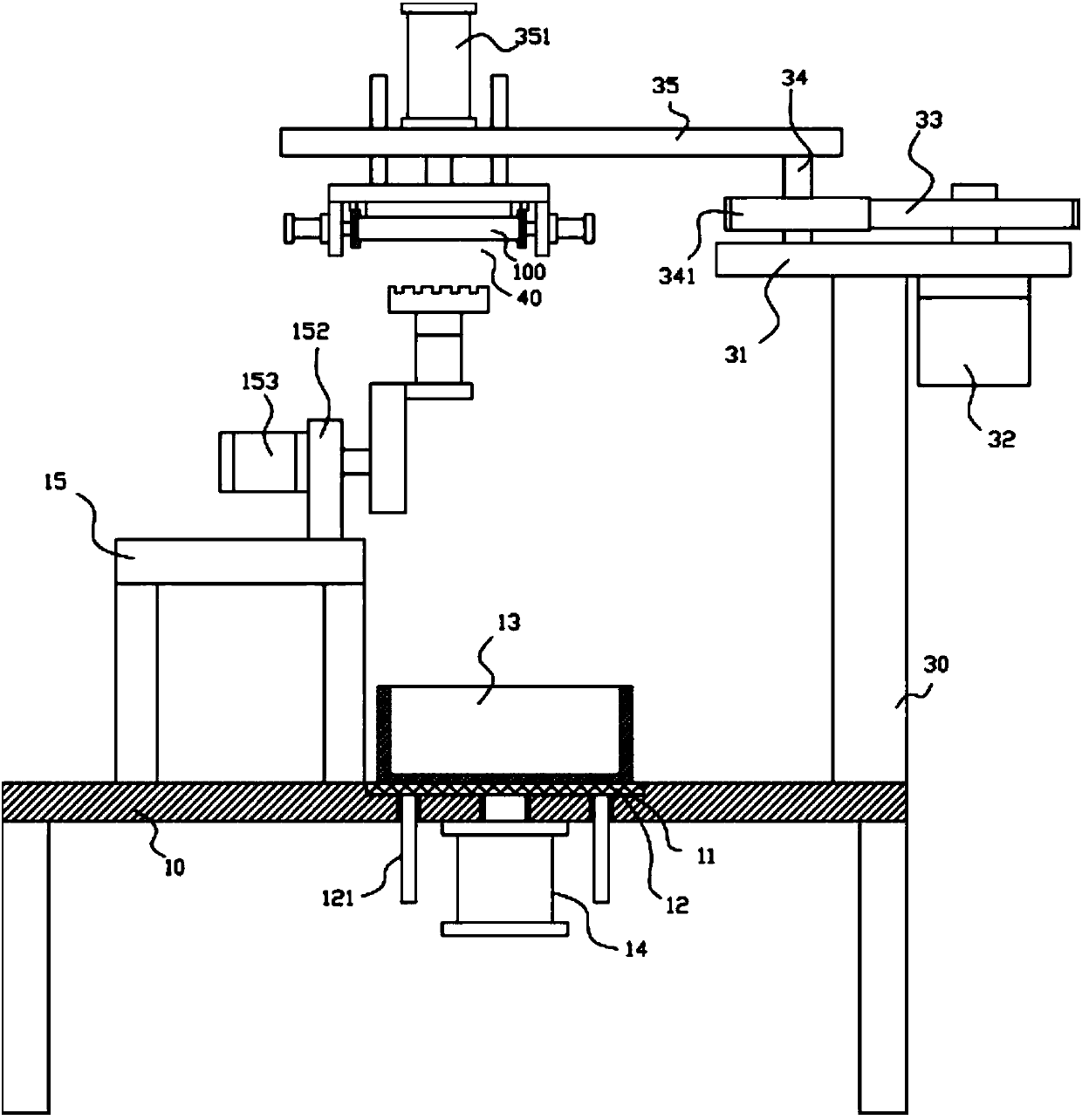

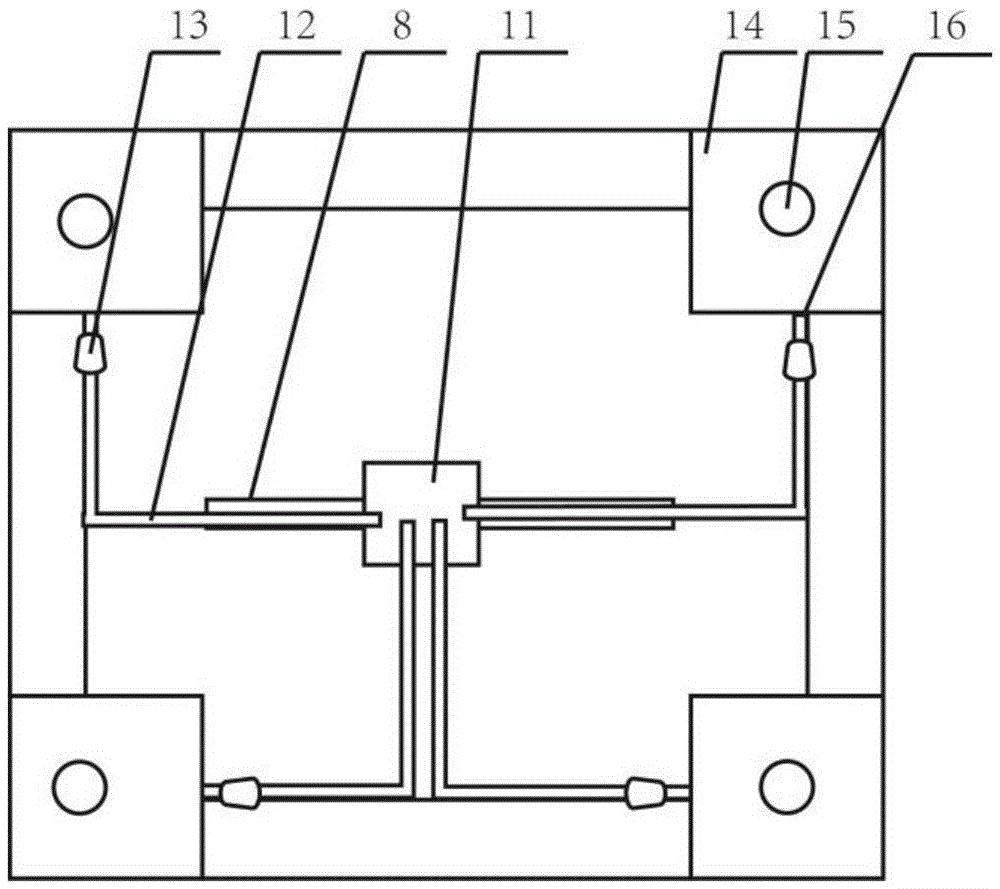

Measurement device and measurement method of torsional vibration modal of numerical control machine

InactiveCN102156033AAccurate and fast measurementVibration testingNumerical controlVibration amplitude

The invention discloses a measurement device and a measurement method of a torsional vibration modal of a numerical control machine. The measurement device comprises a Hall sensor, a data acquisition card, a high-resolution rotary encoder, a counter, a parametric recognition module and a computer. The measurement method comprises the following steps: generating a series of sinusoidal waves with the same vibration amplitude and the same variable frequency by utilizing a numerical control device; measuring the current signal of a servo motor to obtain the drive torque of the servo motor; measuring the rotational angular velocity of a screw rod through the high-precision rotary encoder; respectively carrying out Fourier transform on a sampled angle velocity signal and the motor torque, and solving the specific value of the sampled angle velocity signal to the motor torque; solving a transfer function between all measuring points on the motor torque and the screw rod; and identifying the torsional vibration modal parameter of a motor rotor-screw rod system by utilizing a weighted least squares method to obtain inherent frequency and a modal shape of each order of torsional vibration. By the measurement device and the measurement method, the torsional vibration modal of a ball screw feeding drive mechanism of the numerical control machine can be rapidly and accurately measured, andthe torsional dynamical characteristics are analyzed; the measurement device and the measurement method provide the scientific basis for the design of the ball-screw feeding drive mechanism and the vibration control, and are applied to the measurement of the torsional vibration modal of the numerical control machine.

Owner:WUHAN UNIV OF TECH

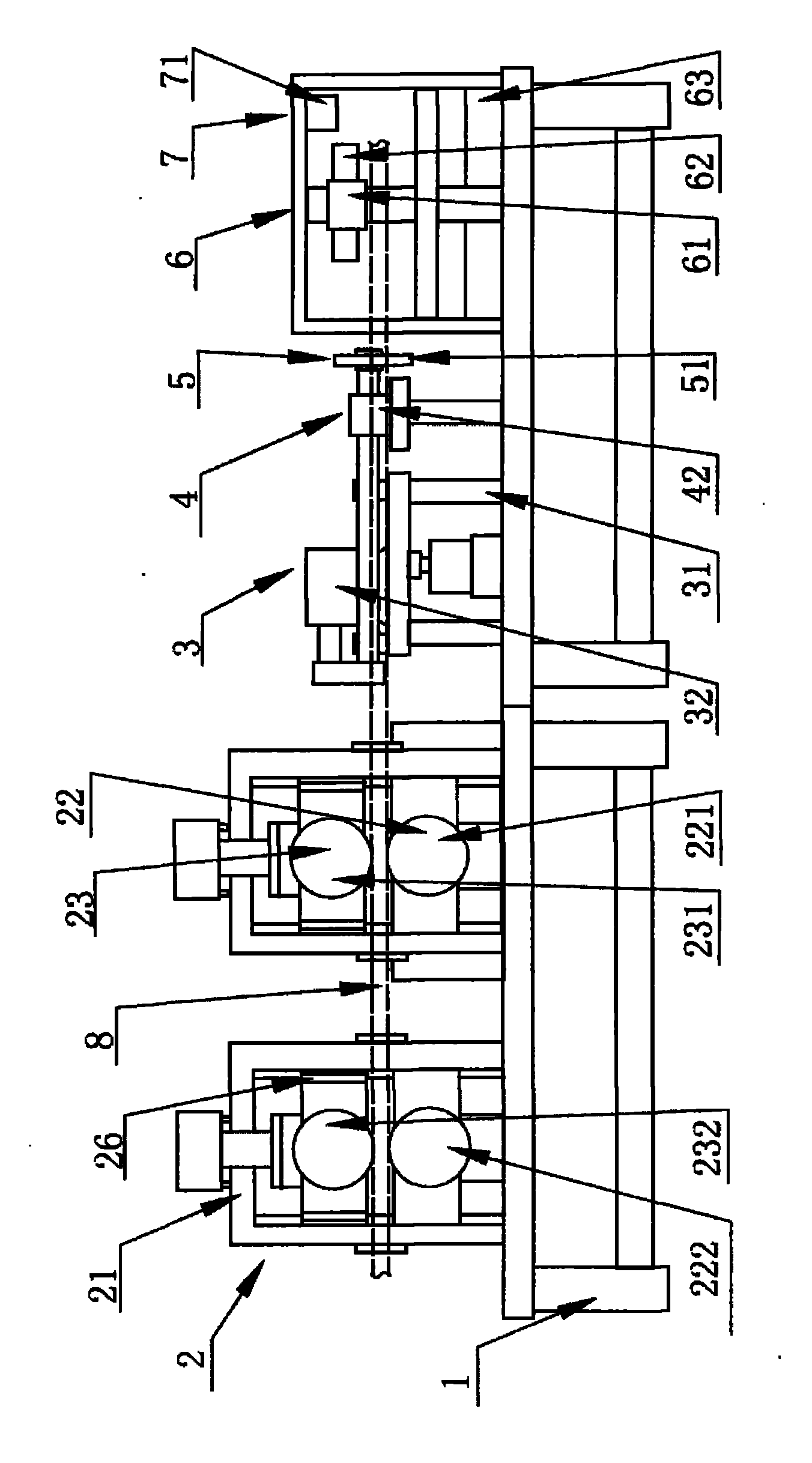

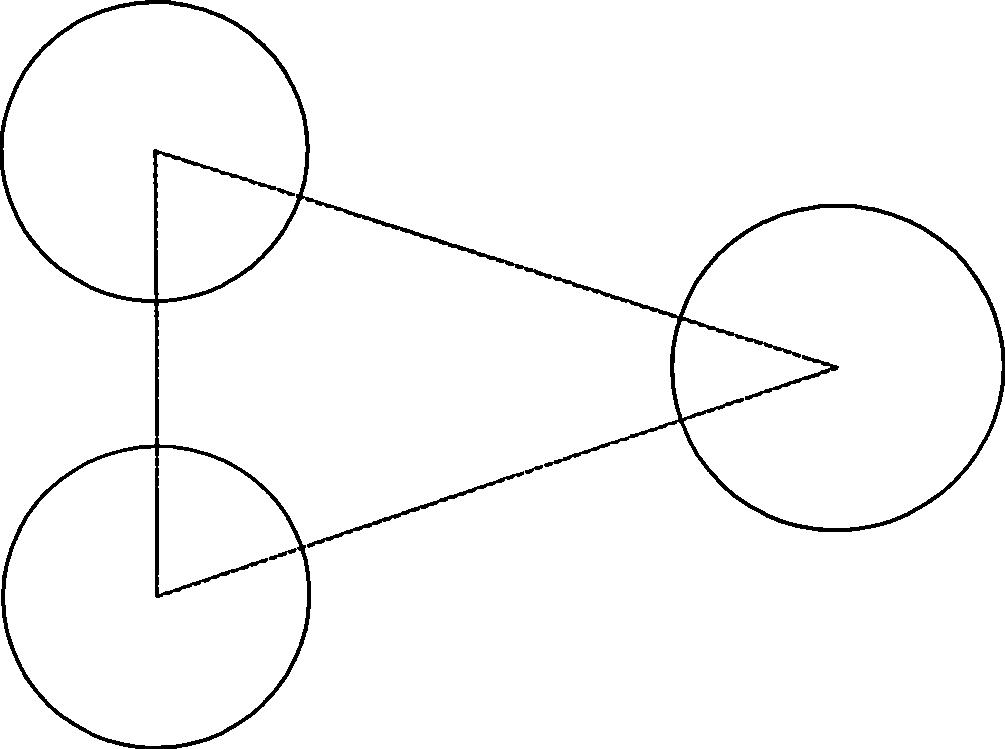

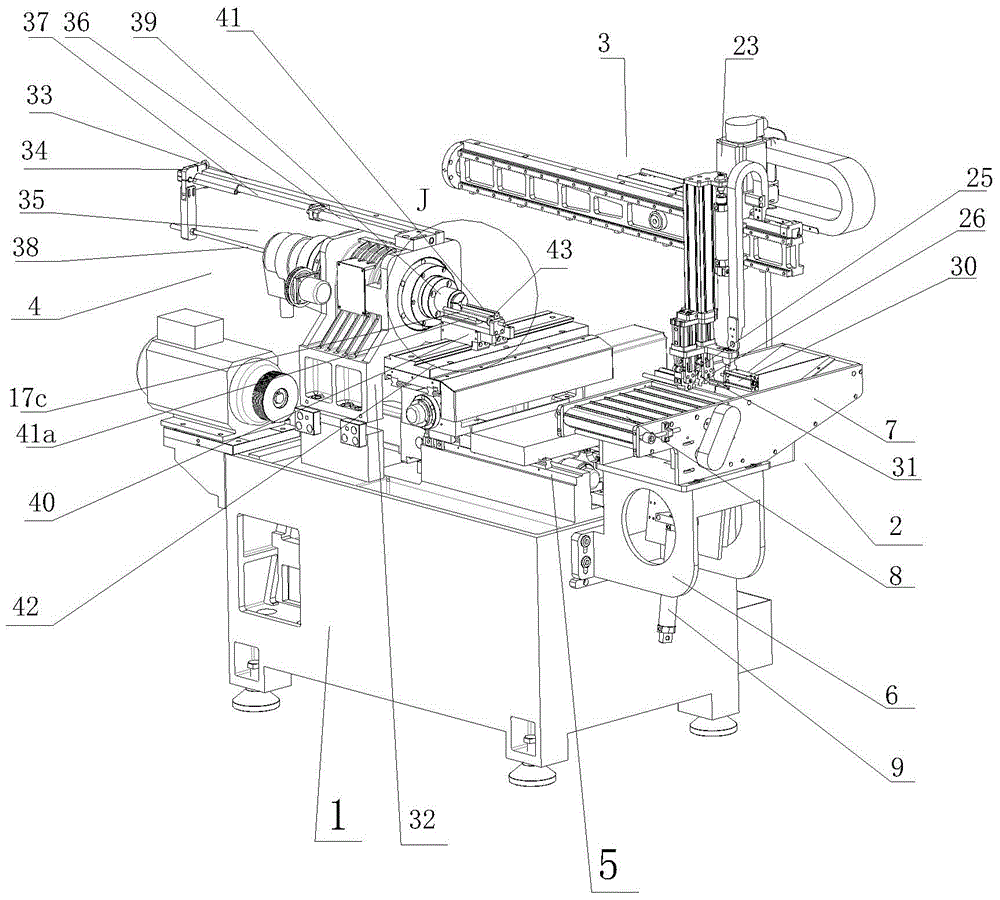

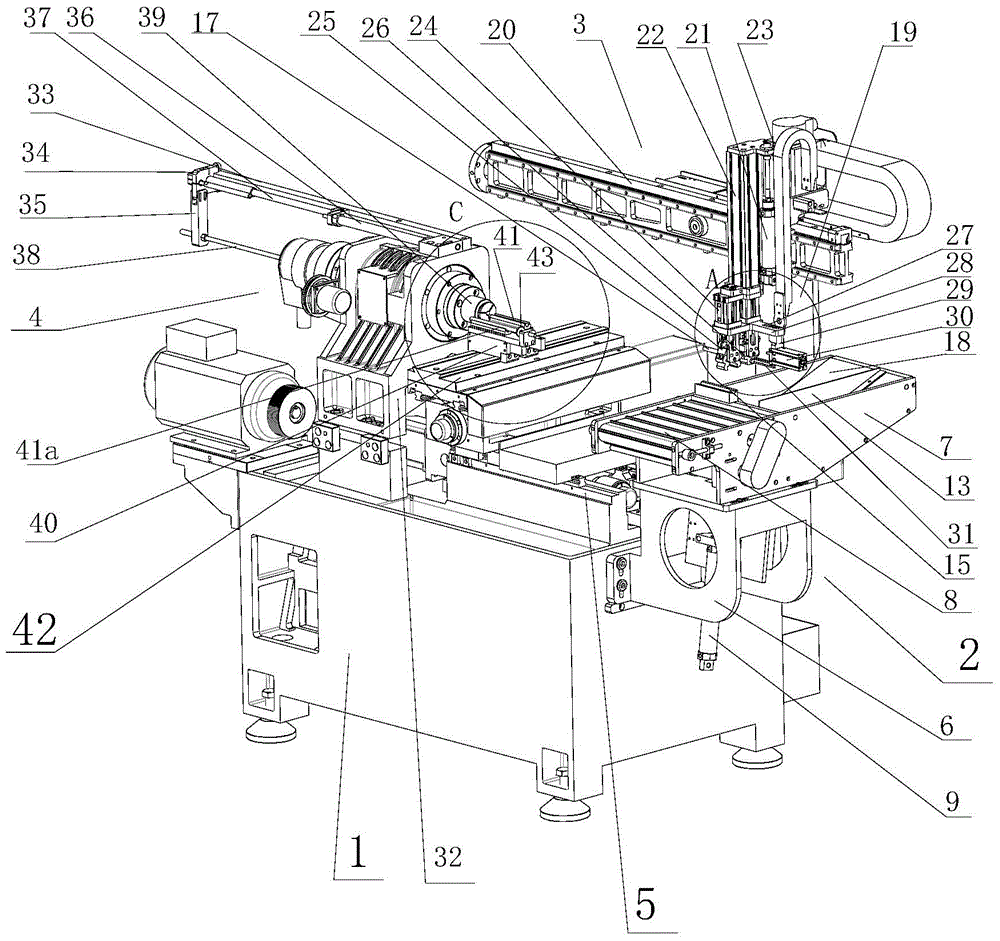

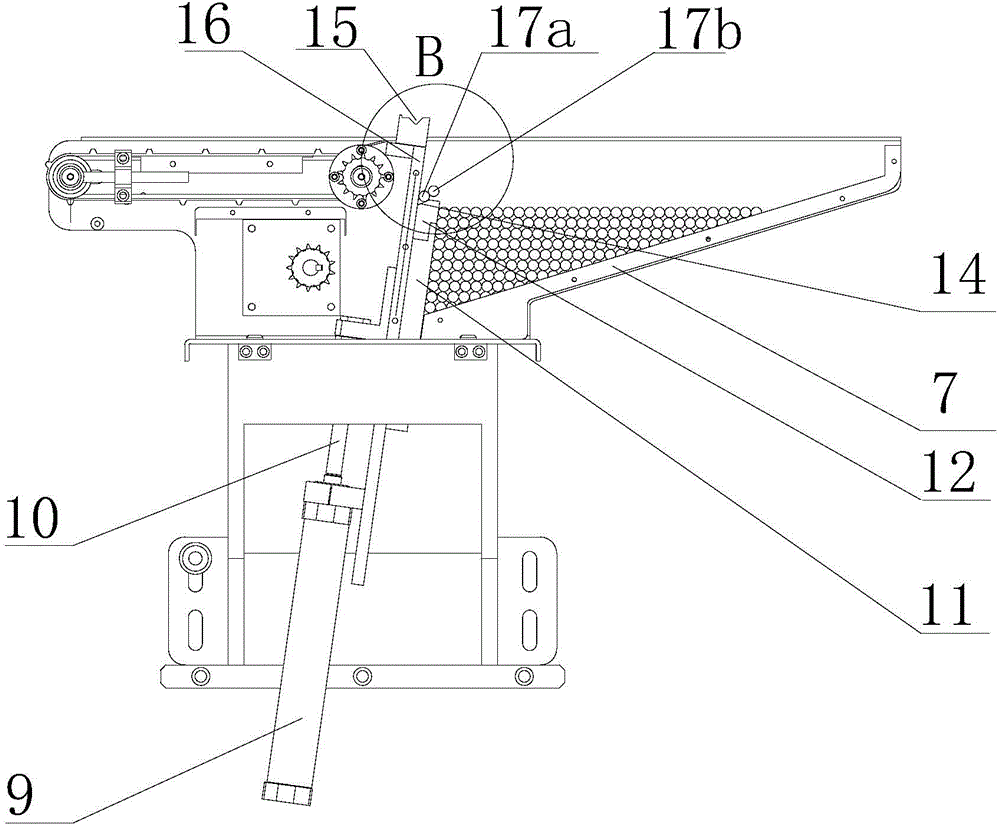

Core-rod grinding device

InactiveCN101417404AReasonable structureHigh degree of automationRevolution surface grinding machinesDrive wheelFeed drive

The invention discloses a core rod grinder, comprising a rod feeding platform and a rod grinding platform; wherein, the rod feeding platform is provided with two rod feeding driven wheels and driving wheels which are levelly arranged up and down, and the rod feeding driving wheels are connected with a rod feeding motor belt and provided with rotational screw threads on the surfaces and a rod feeding cross section consisting of the rod feeding driven wheels and driving wheels is an inverted isosceles triangle; the rod grinding platform is provided with two rod grinding driven wheels and driving wheels which are levelly arranged up and down, and the rod grinding driving wheels are connected with the rod feeding motor belt, and the rod grinding driven wheels and driving wheels are roller-typed grinding wheels and a rod grinding cross section consisting of the rod grinding driven wheels and driving wheels is an inverted isosceles triangle; and the rod feeding cross section is parallel with the rod grinding cross section and the center of the cross sections are on the same line. The invention is high in automation degree and stable in product quality, greatly reduces the labor intensity and eliminates most potential safety hazards; and after an outer cover is added, the working conditions are closed, and much of the dust is collected, thus ensuring the good health of workers and environmental sanitation.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ZHENGZHOU POWER SUPPLY +2

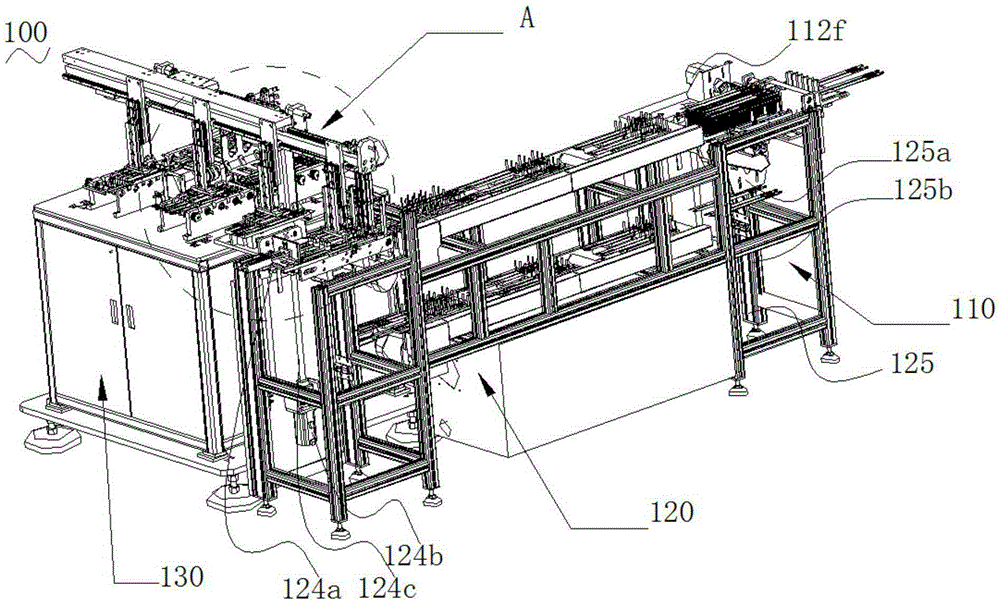

Ironing and interlining system

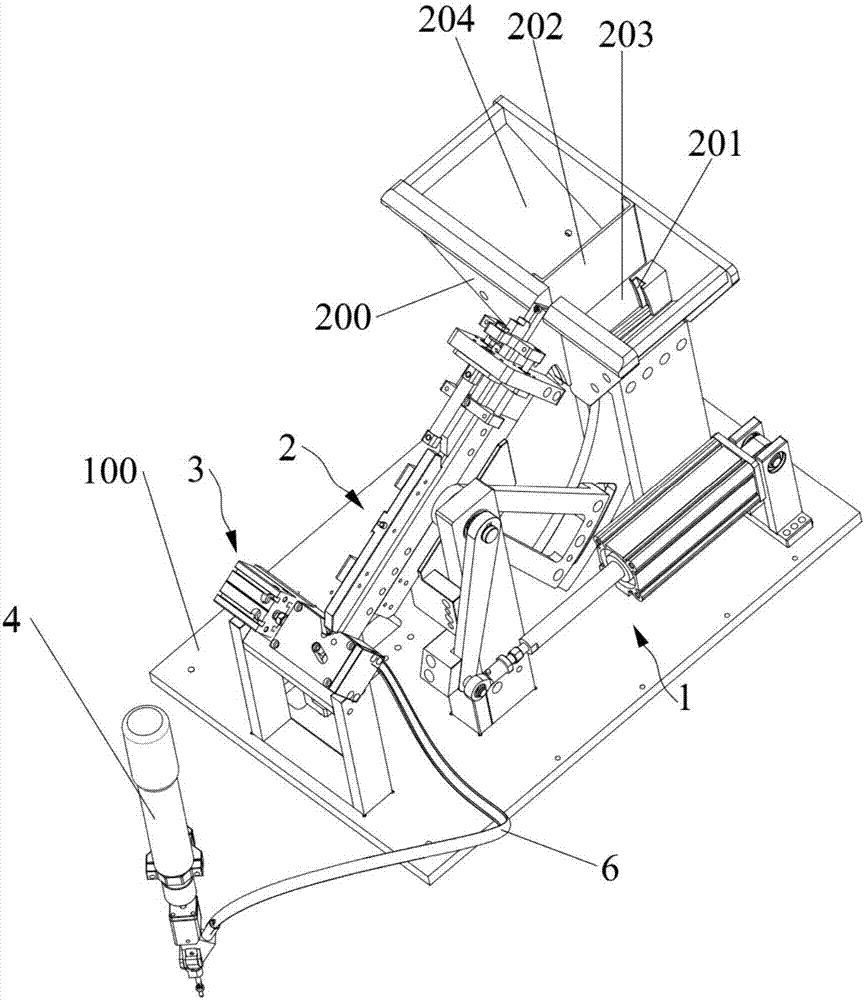

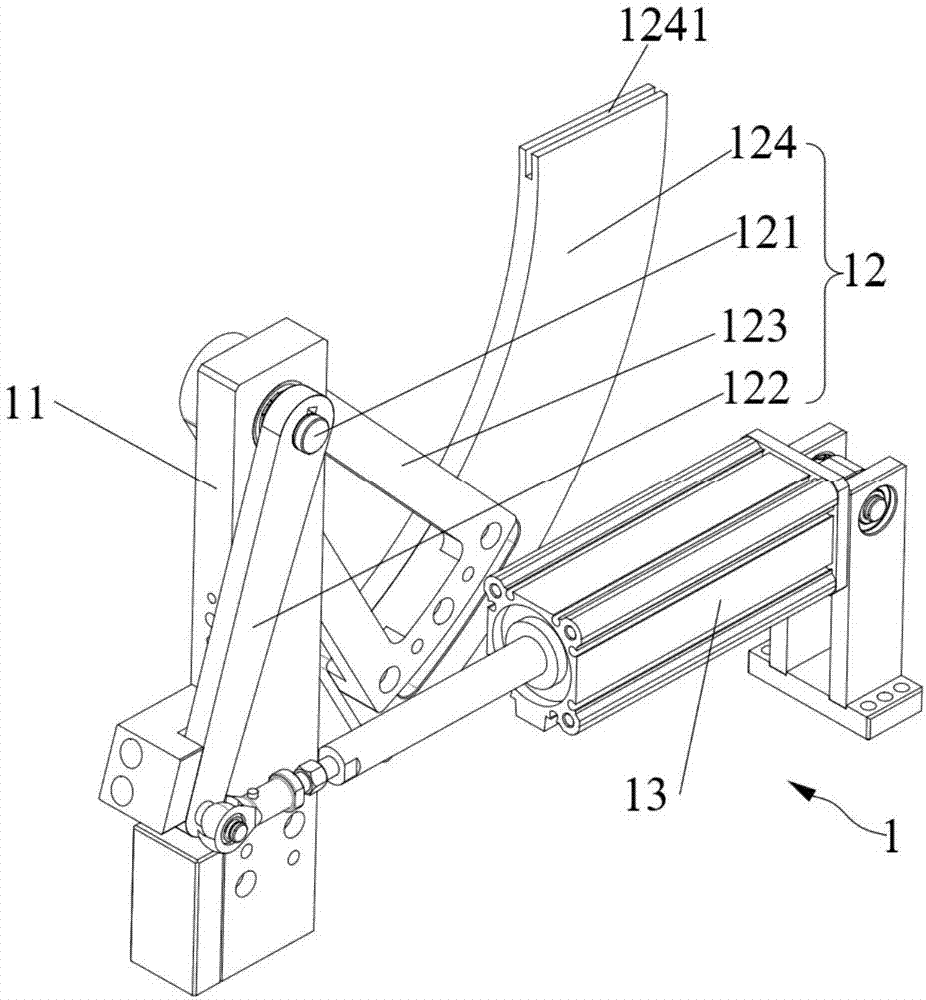

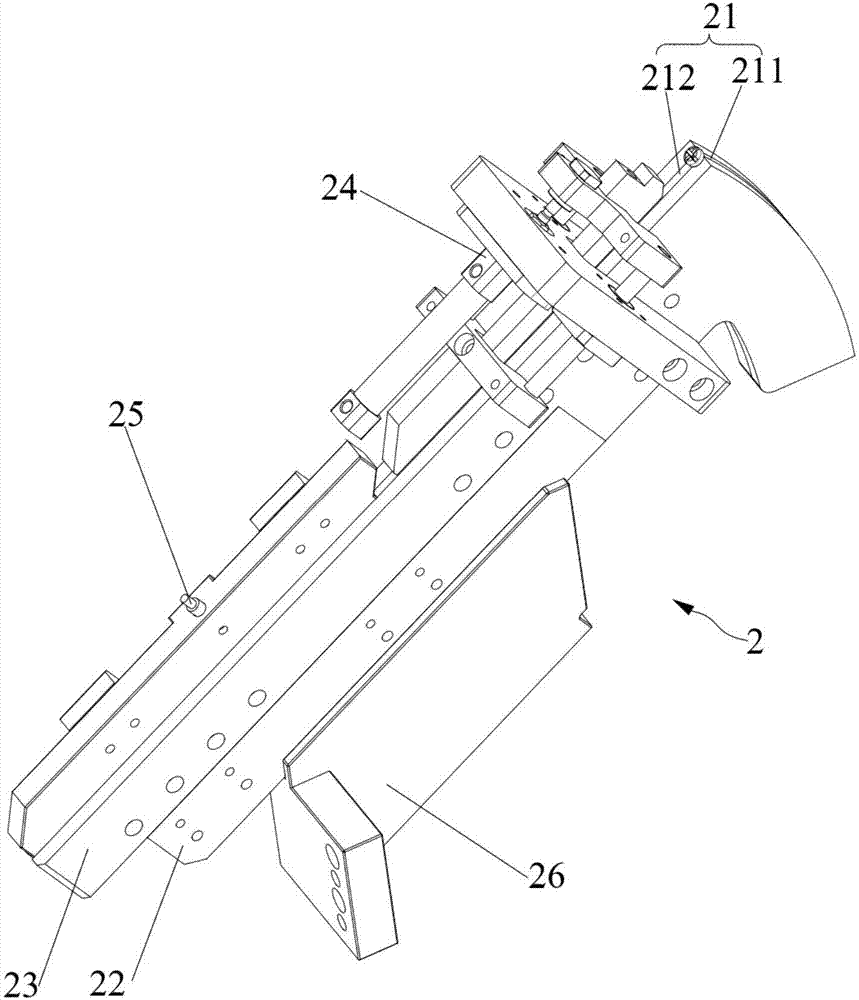

ActiveCN106087277ARealize automatic reclaimingRealize automatic feedingSewing-machine elementsClothes making applicancesInterliningFeed drive

The invention discloses an ironing and interlining system which comprises a machine, a feeding device, a taking device and an ironing and interlining device. A conveying surface is arranged on the machine, and can be used for holding interlining ribbons. The feeding device is provided with a support, a feeding plate, feeding drive components and a positioning blowpipe, the support is connected to the machine, the feeding drive component is arranged on the machine and connected to the feeding plate to drive the feeding plate to move, the feeding plate is used for overlap placement of multiple cut-parts, the feeding plate is provided with fixing air suction holes, and the positioning blowpipe is arranged on the support and located above the feeding plate. The taking device is arranged on the machine and used for getting the cut-parts from the feeding plate and moving the cut-parts to the interlining ribbons located on the conveying surface. The ironing and interlining device is arranged on the machine and used for ironing and interlining the interlining ribbons and the cut-parts. The ironing and interlining system is timesaving, laborsaving and high in ironing and interlining efficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Hardware plate oil immersion device with automatic moving and feeding structure

InactiveCN107716210ANo need for manual applicationHigh degree of automationLiquid surface applicatorsCoatingsRotational axisElectric machine

The invention discloses a hardware plate oil immersion device with an automatic moving and feeding structure. The device comprises a rack. A vertical supporting plate is fixedly arranged on the top face of one side of a top plate of the rack, a main supporting column is fixedly arranged on the other side of the top plate of the rack, an upper main plate is fixedly arranged at the top end of the main supporting column, a feeding rotating motor is fixedly arranged on the bottom face of the right side of the upper main plate, an output shaft of the feeding rotating motor penetrates through the upper main plate and is fixedly provided with a feeding driving gear, a rotating shaft is hinged to the left side of the upper main plate, a feeding transmission gear is fixedly arranged in the middle of the rotating shaft, the feeding transmission gear is meshed with the feeding driving gear, a feeding plate is fixedly arranged at the top end of the rotating shaft, and a stretchable cylinder is fixedly arranged on the top face of the left end of the feeding plate. A plate to be machined can be automatically moved to a permanent magnet and attached to the permanent magnet, the grabbed plate to be machined can be automatically rotated, an oil drum can be lifted, and the plate to be machined is immersed into the oil drum, so that no artificial smearing is needed, and the device is high in automatic degree, good in effect and high in efficiency.

Owner:FOSHAN RUIPUDA OPTOELECTRONICS TECH CO LTD

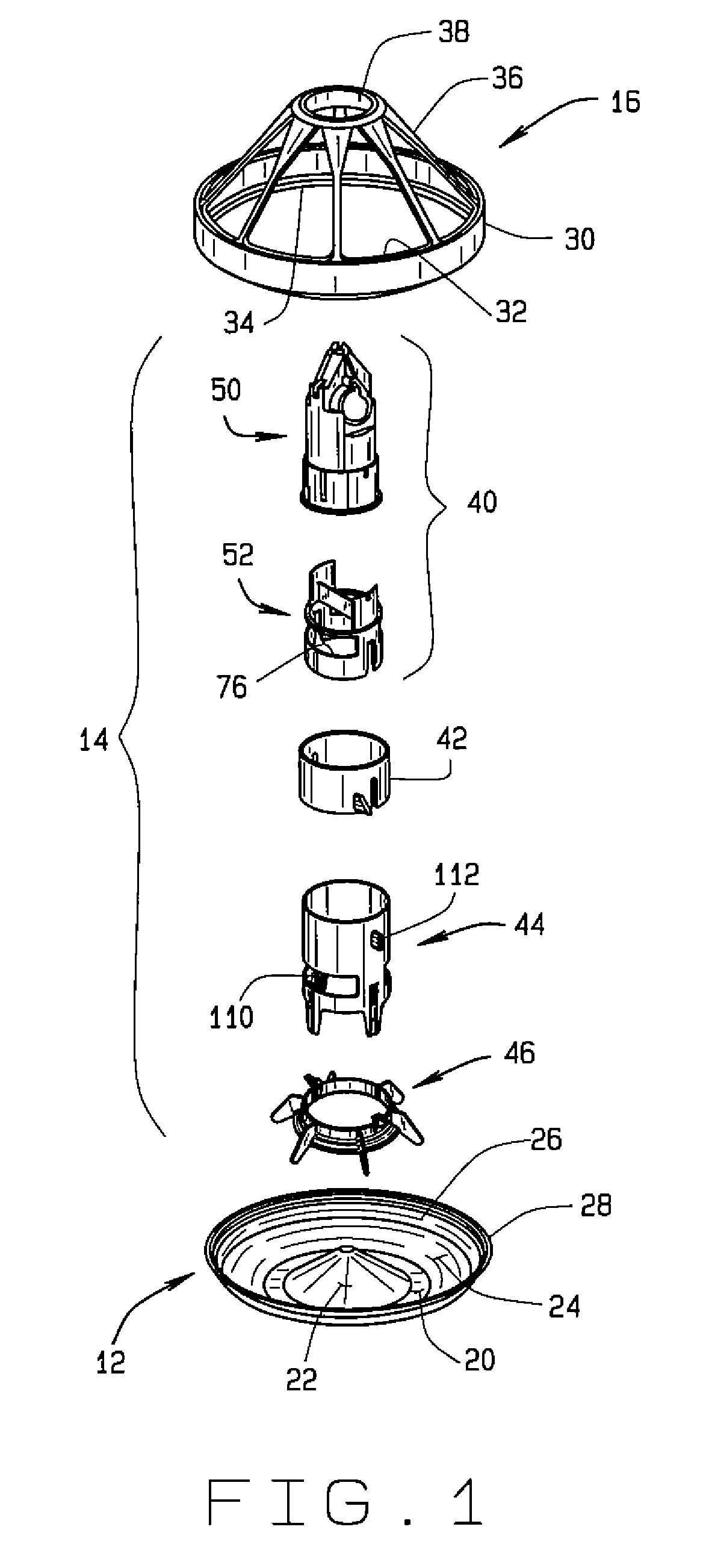

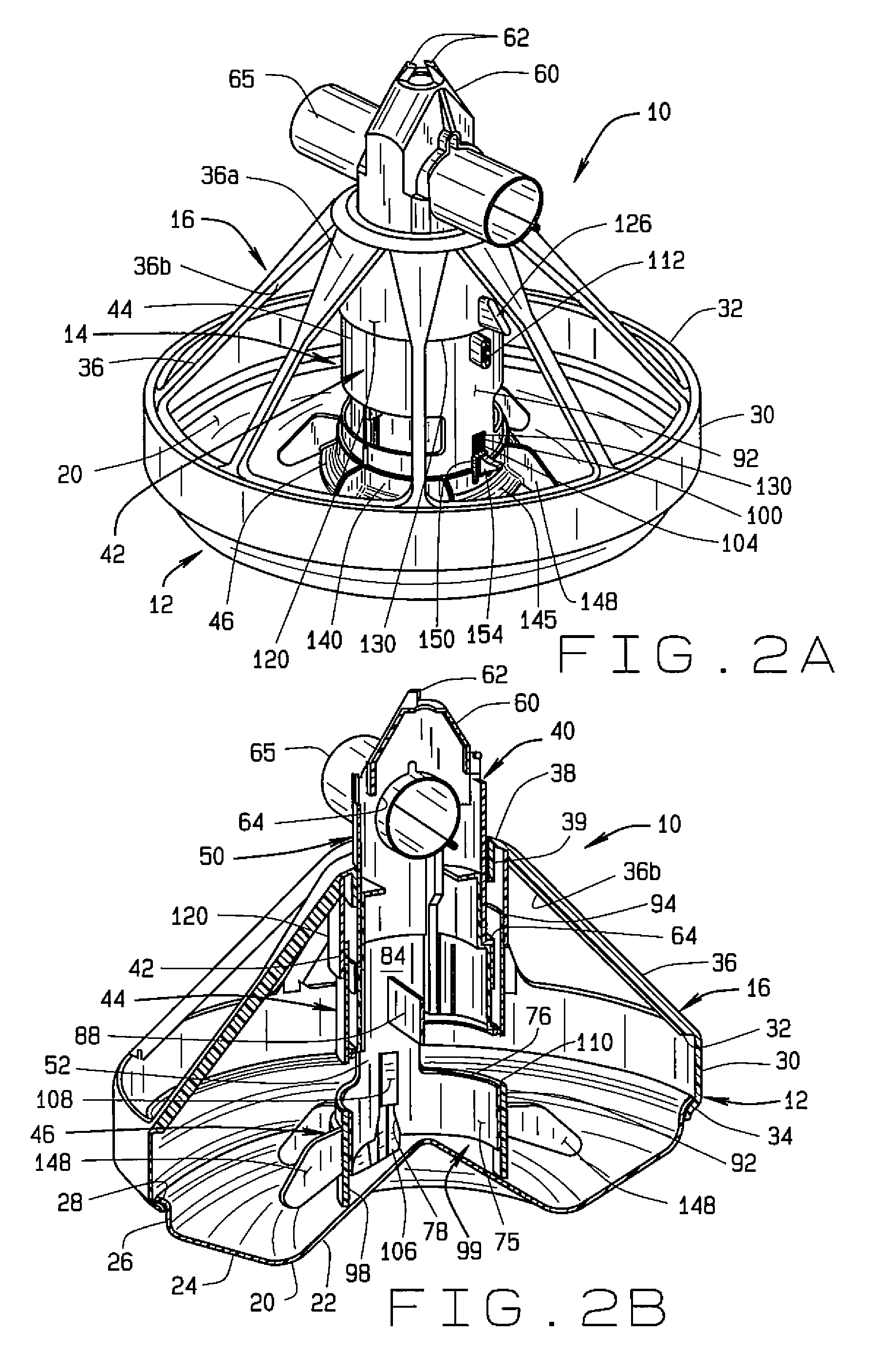

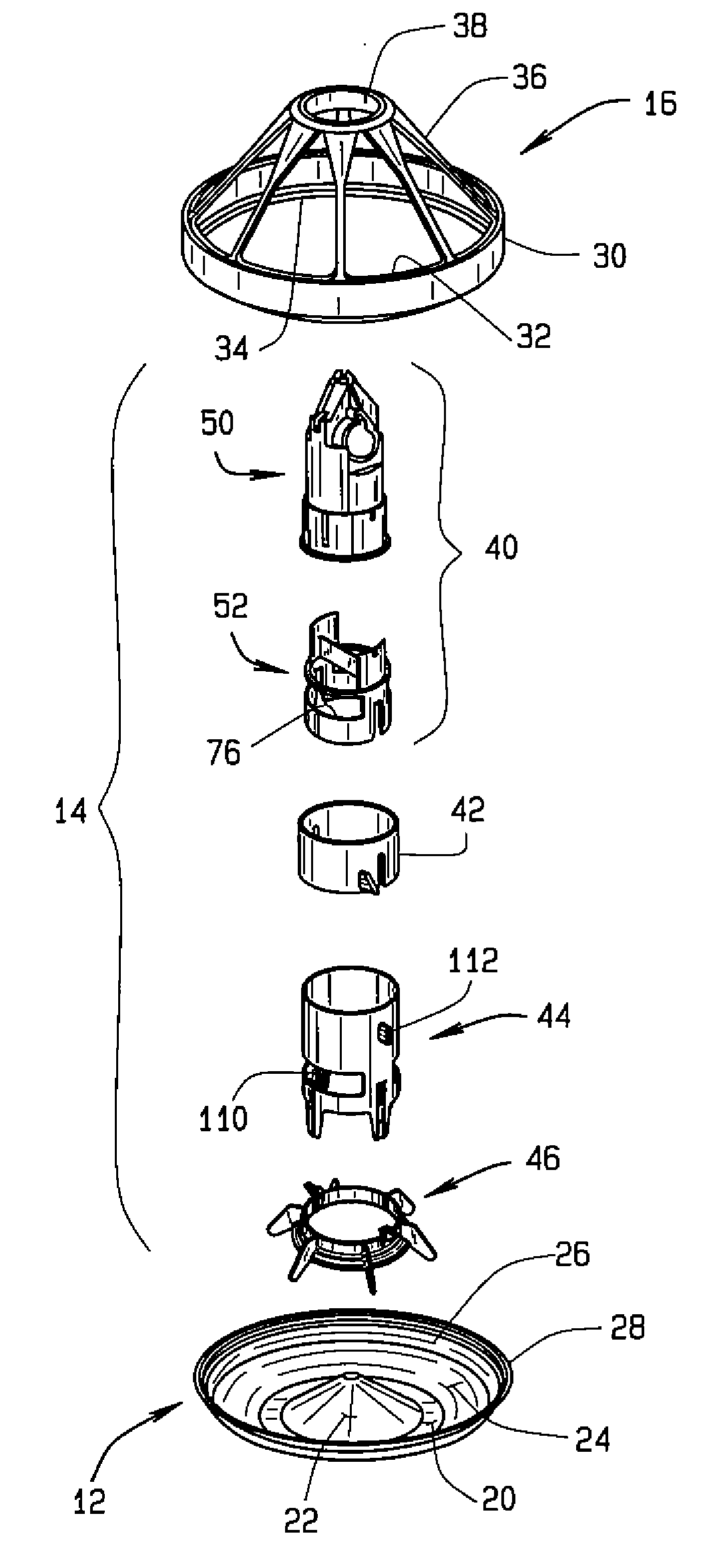

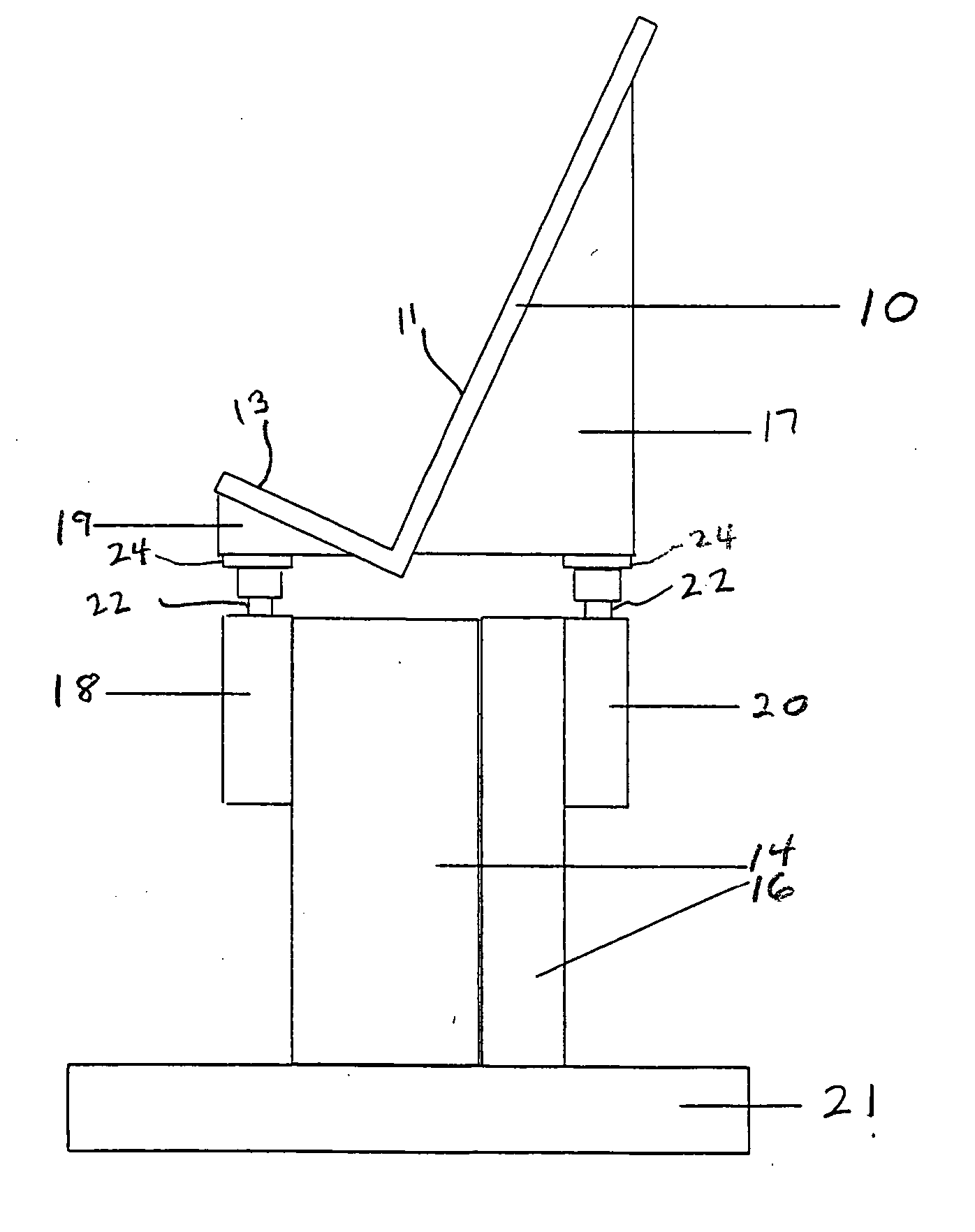

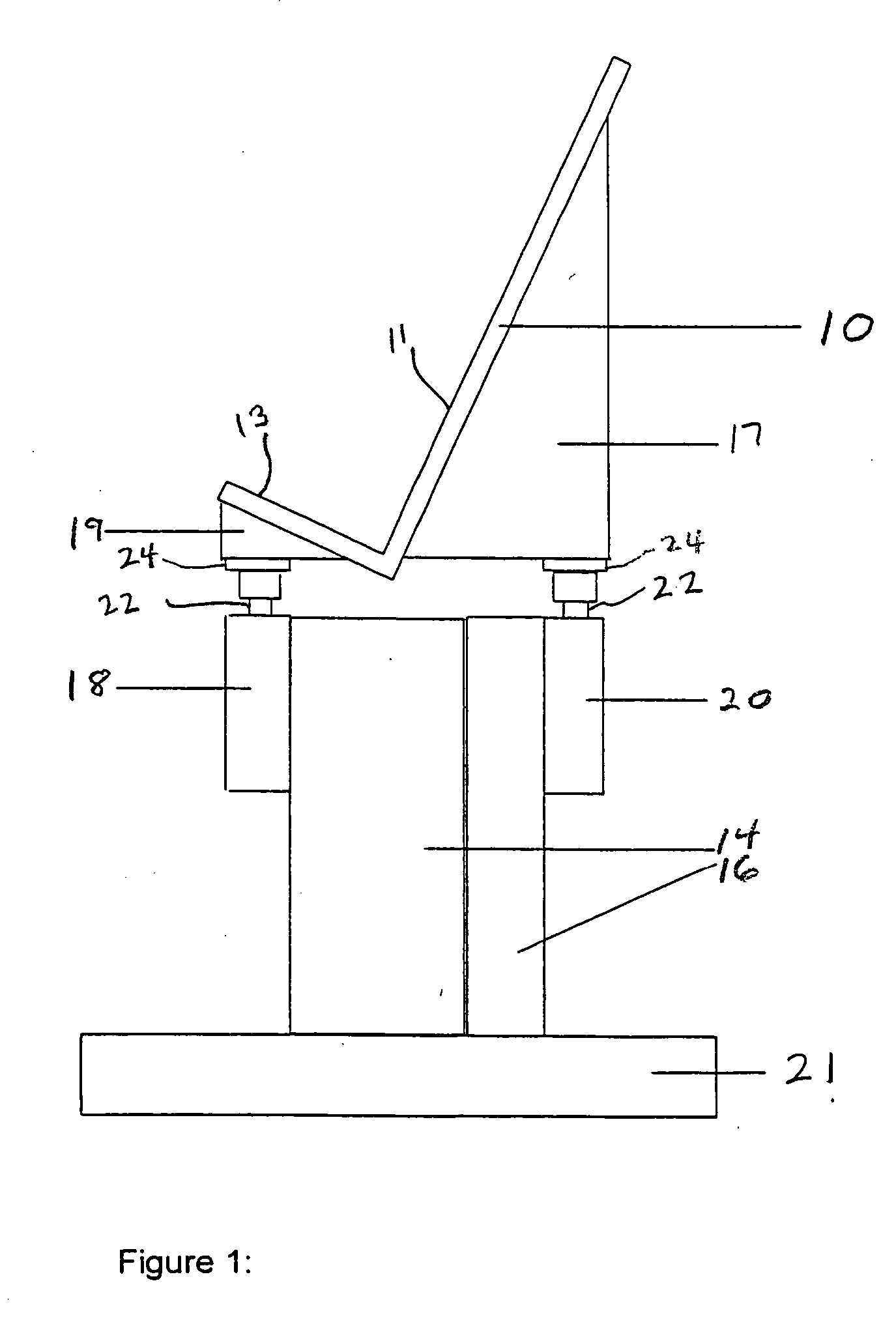

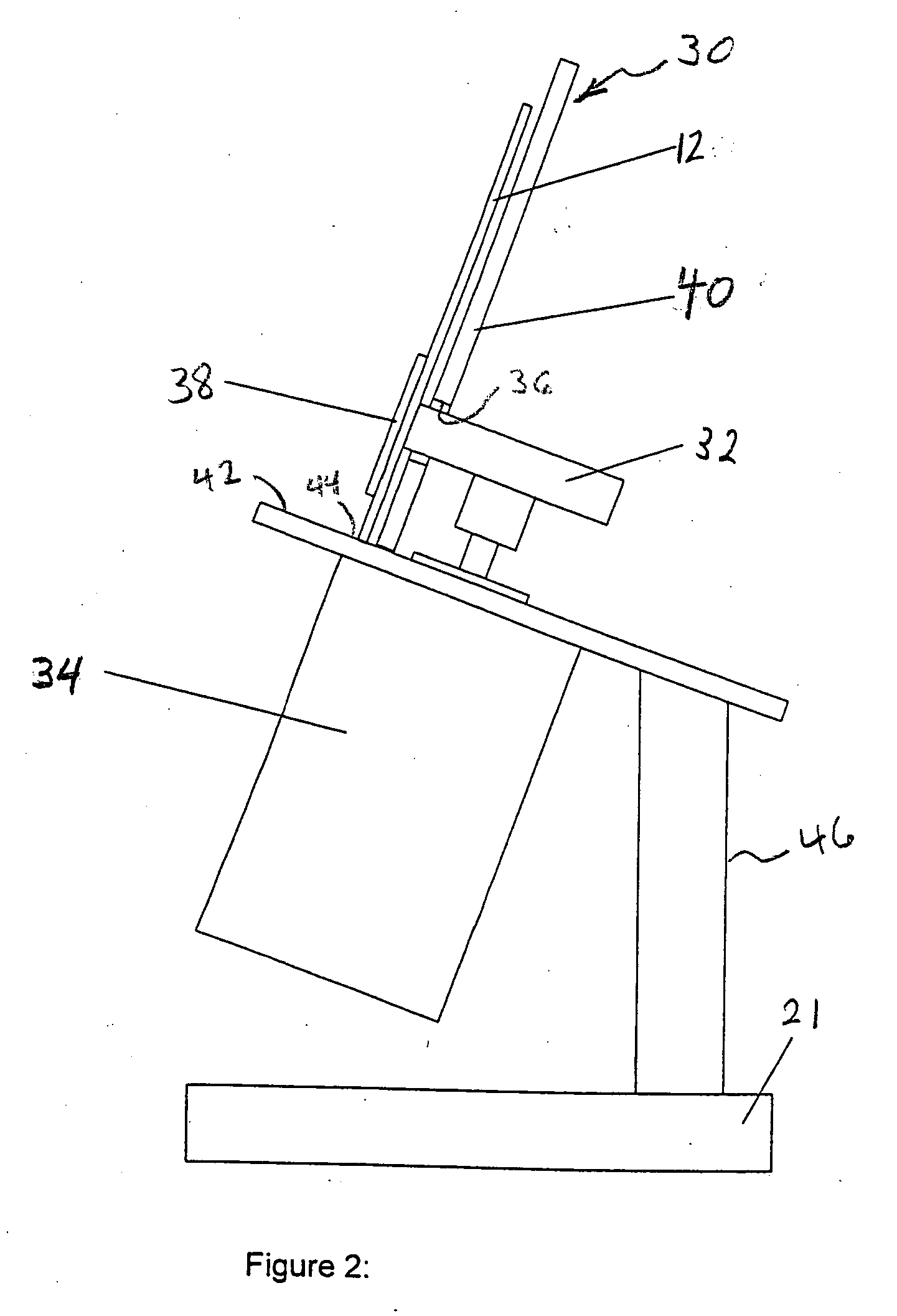

Poultry feeder

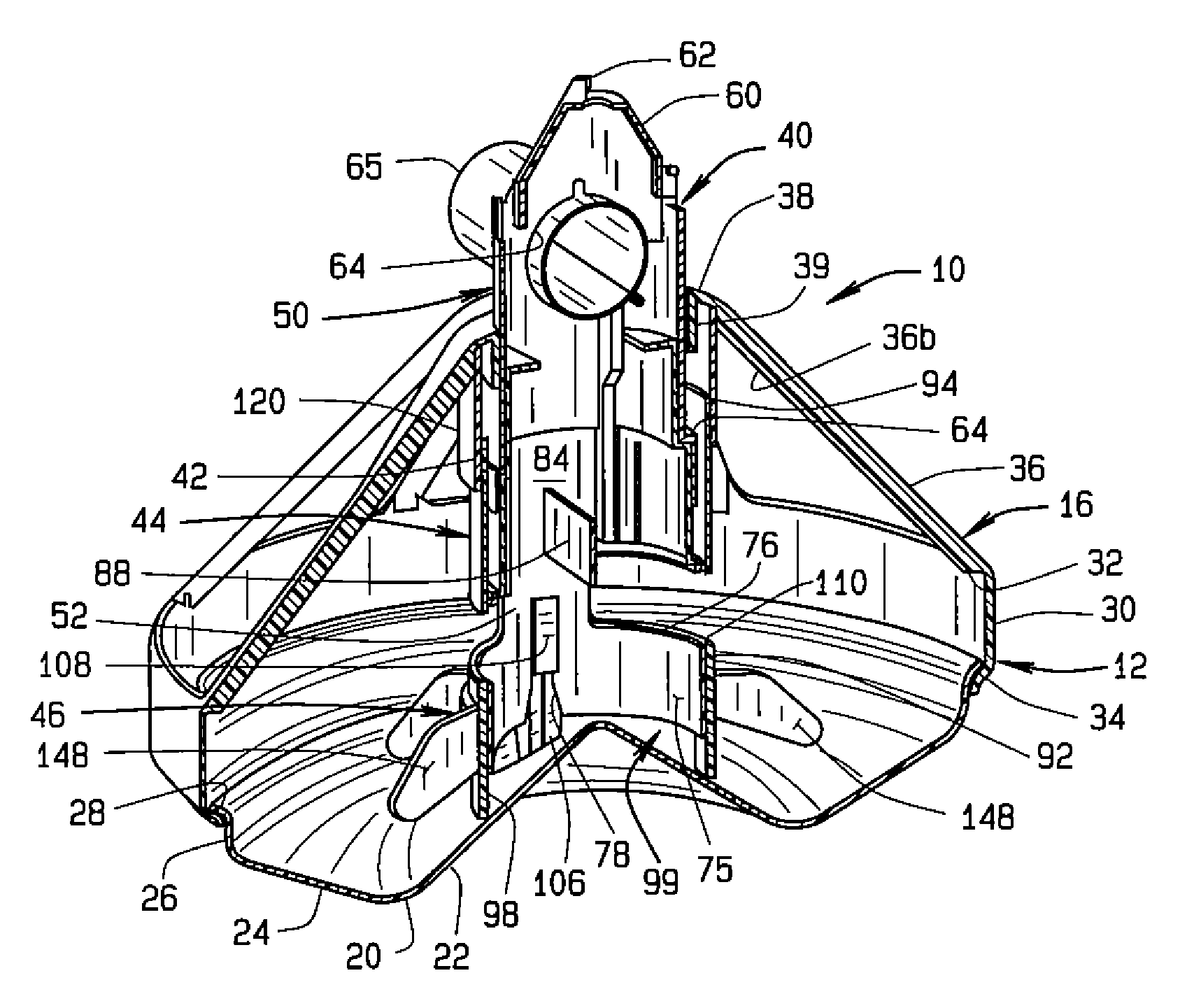

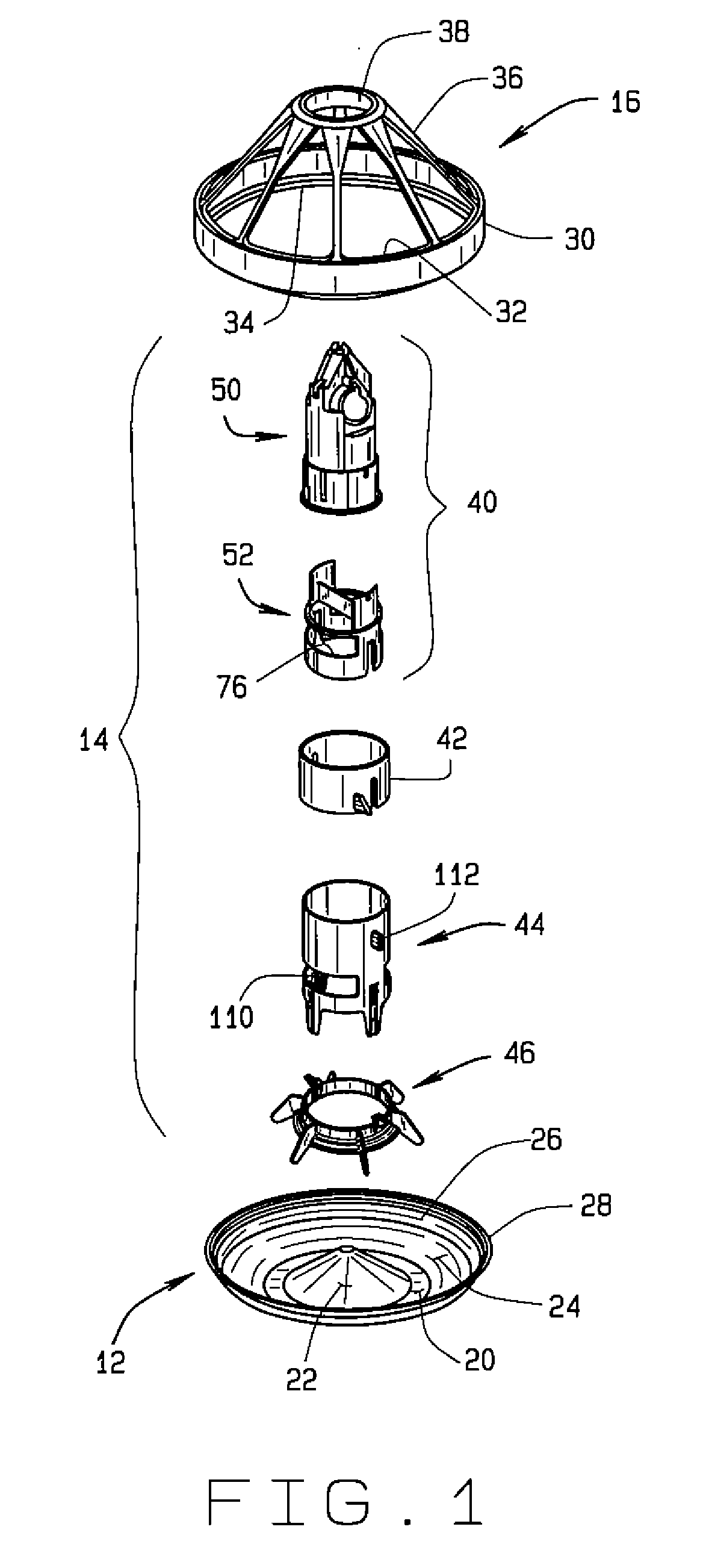

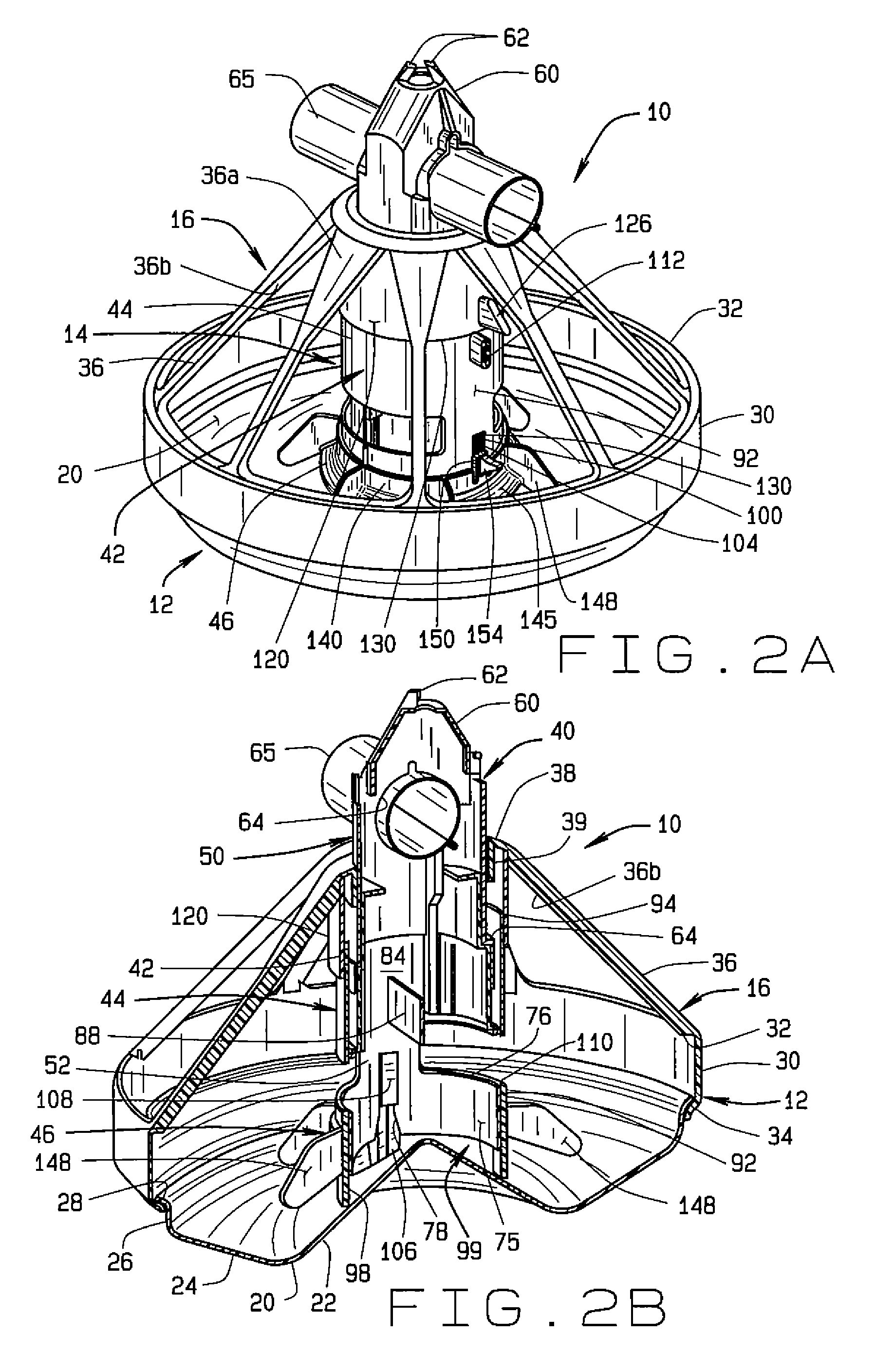

ActiveUS7647888B2Extended range of motionPrecise positioningAnimal feeding devicesAnimal housingEffective heightEngineering

A poultry feeder is provided which can be selectively switched between a mode in which it operates as a flood-type feeder and a mode in which it operates as a shallow-fill type feeder with adjustable height pan walls. The feeder includes a feed tube assembly comprising a drop tube and a feed flooding tube. The drop tube is movable axially relative to the feed flooding tube, which rests on the feed pan. The drop tube and feed flooding tube have windows which are brought into and out of alignment by raising and lowering the drop tube. When the feed flooding tube window is opened, the feeder operates in a flood mode and when the feed flooding tube is closed, the feeder operates in a shallow-fill mode. In this second mode, the effective height of the pan wall can be adjusted to allow chicks and chickens access to the feed.

Owner:THE GSI GRP LLC

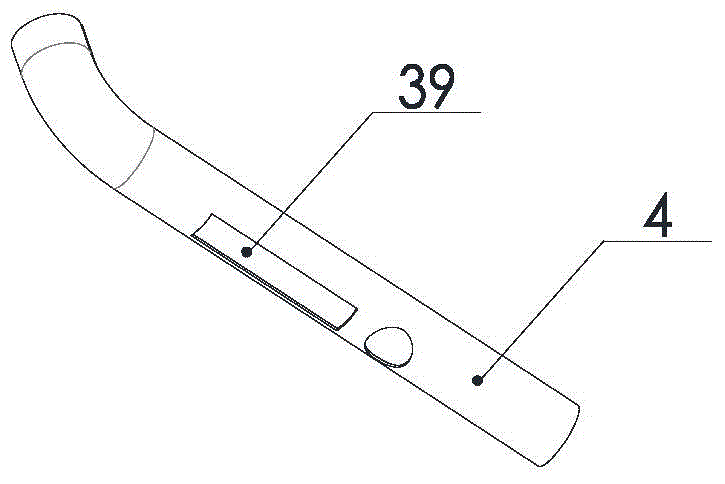

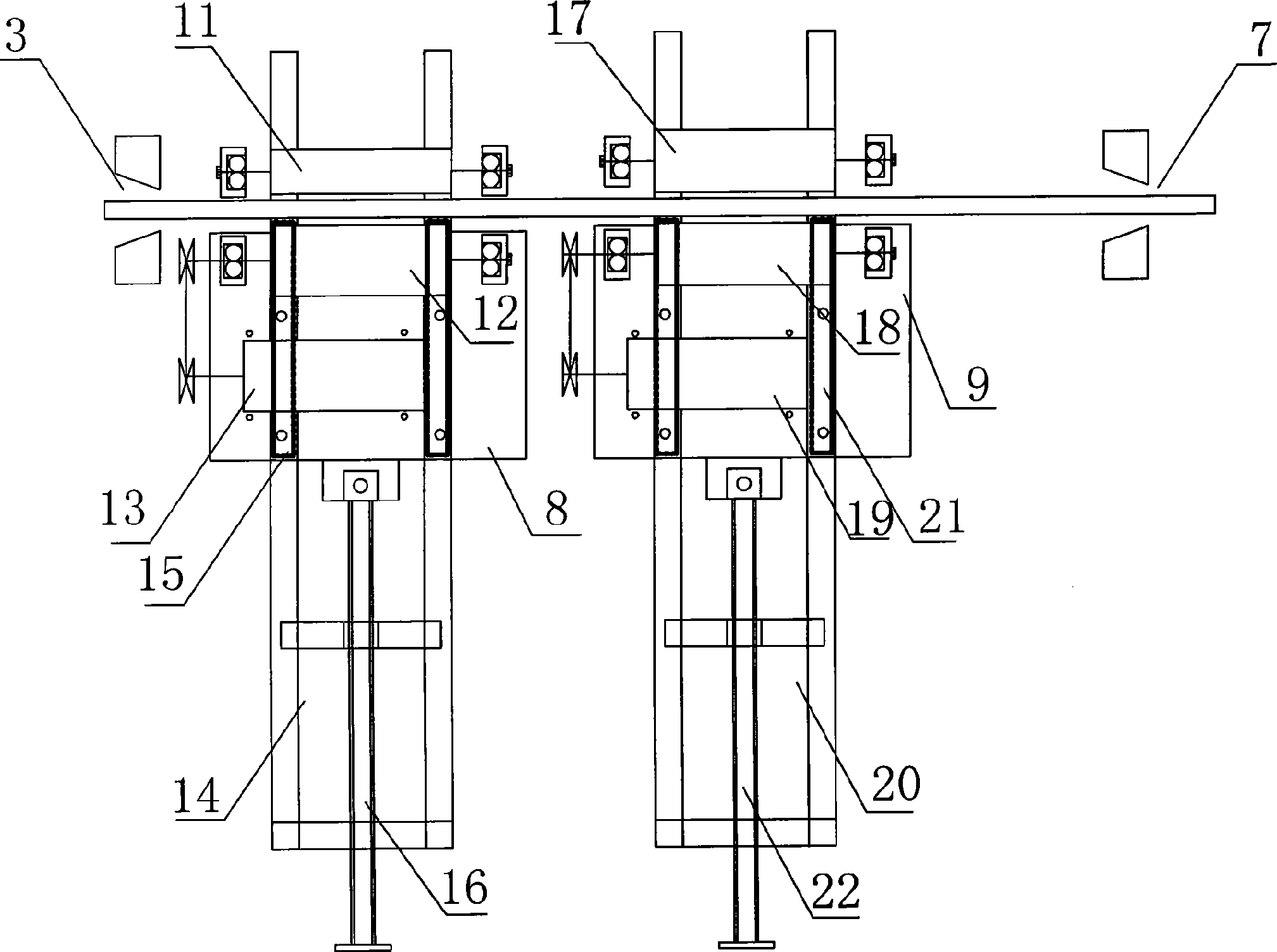

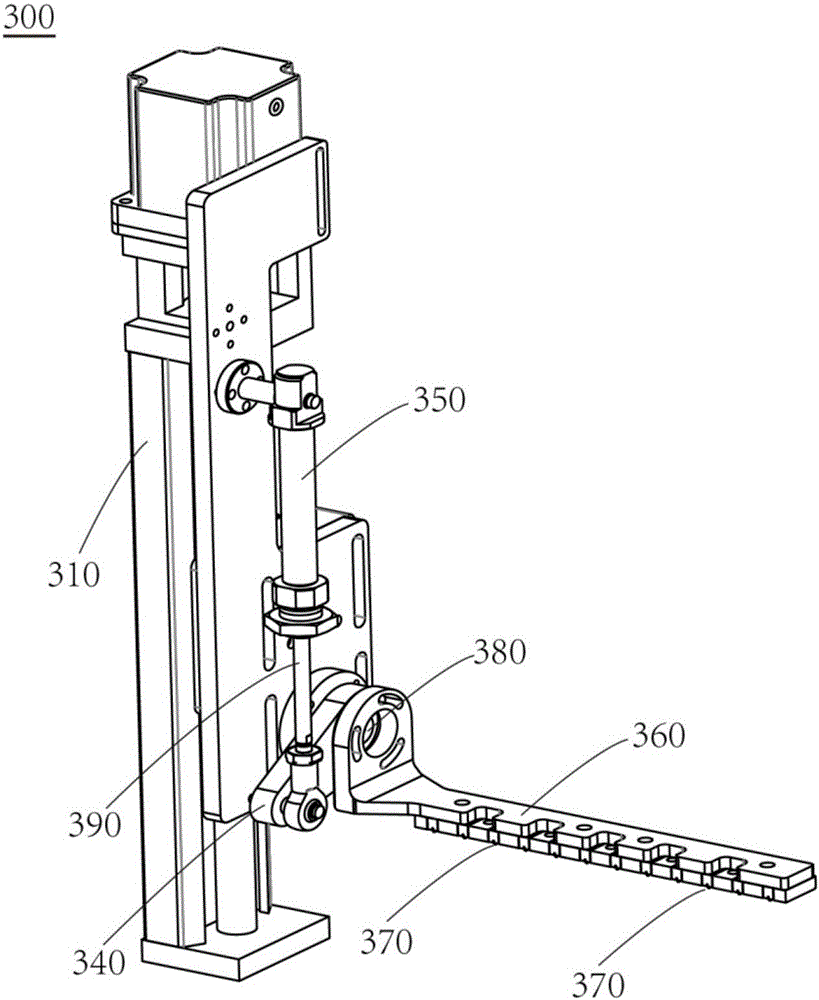

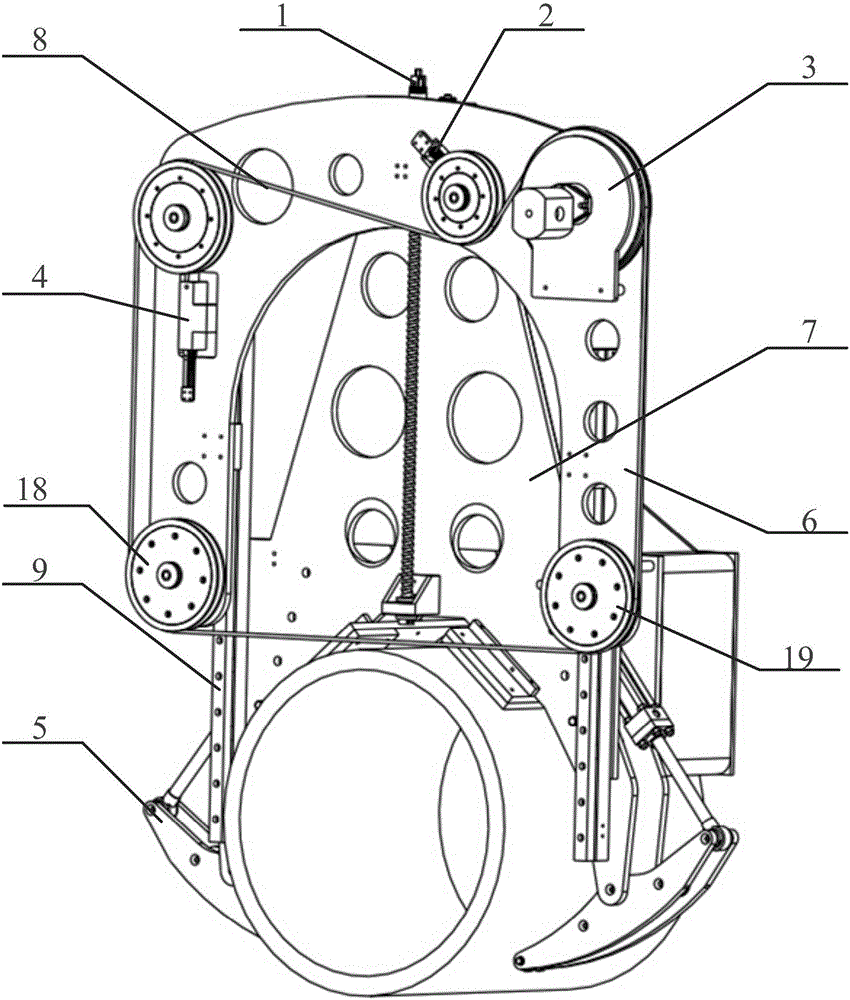

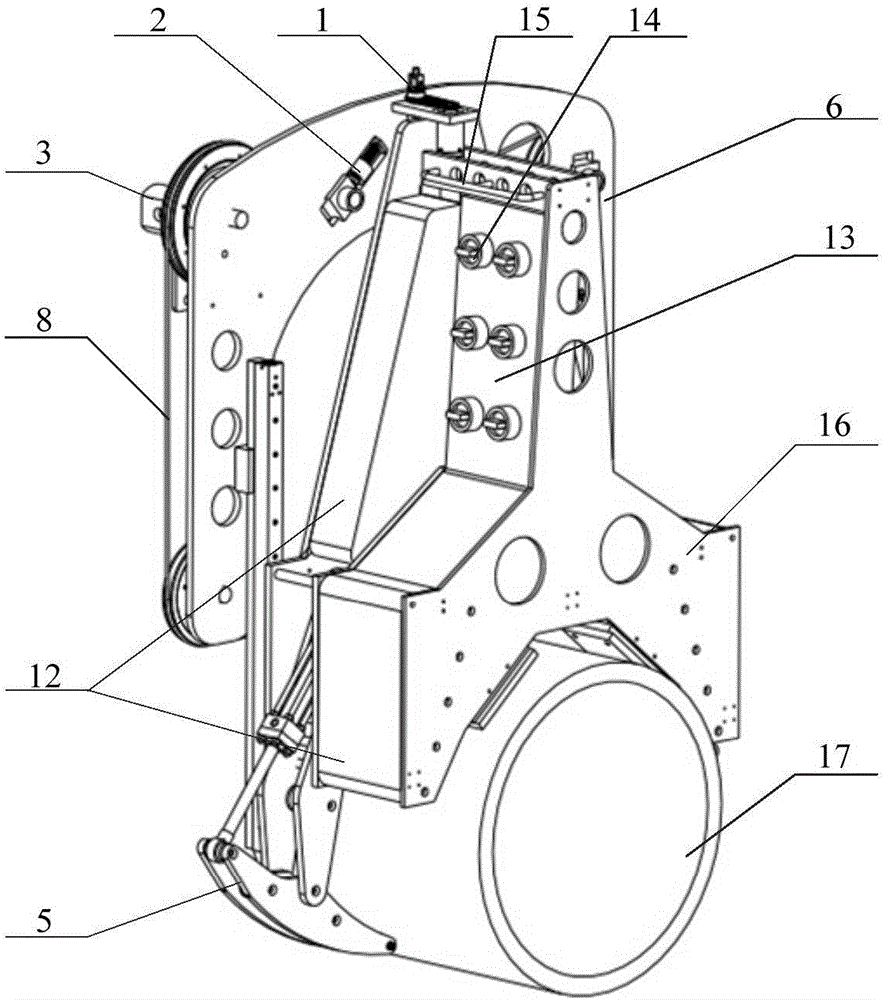

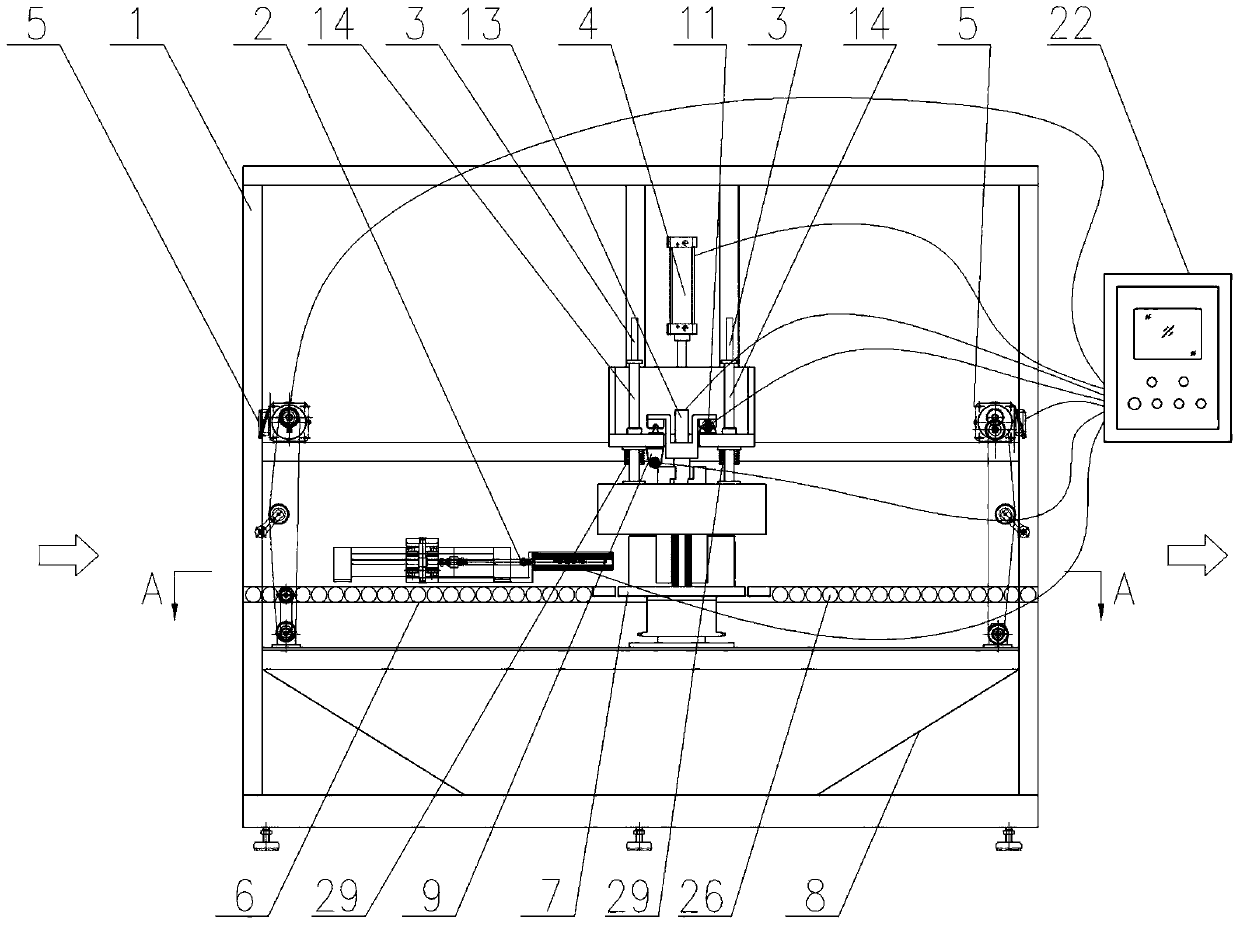

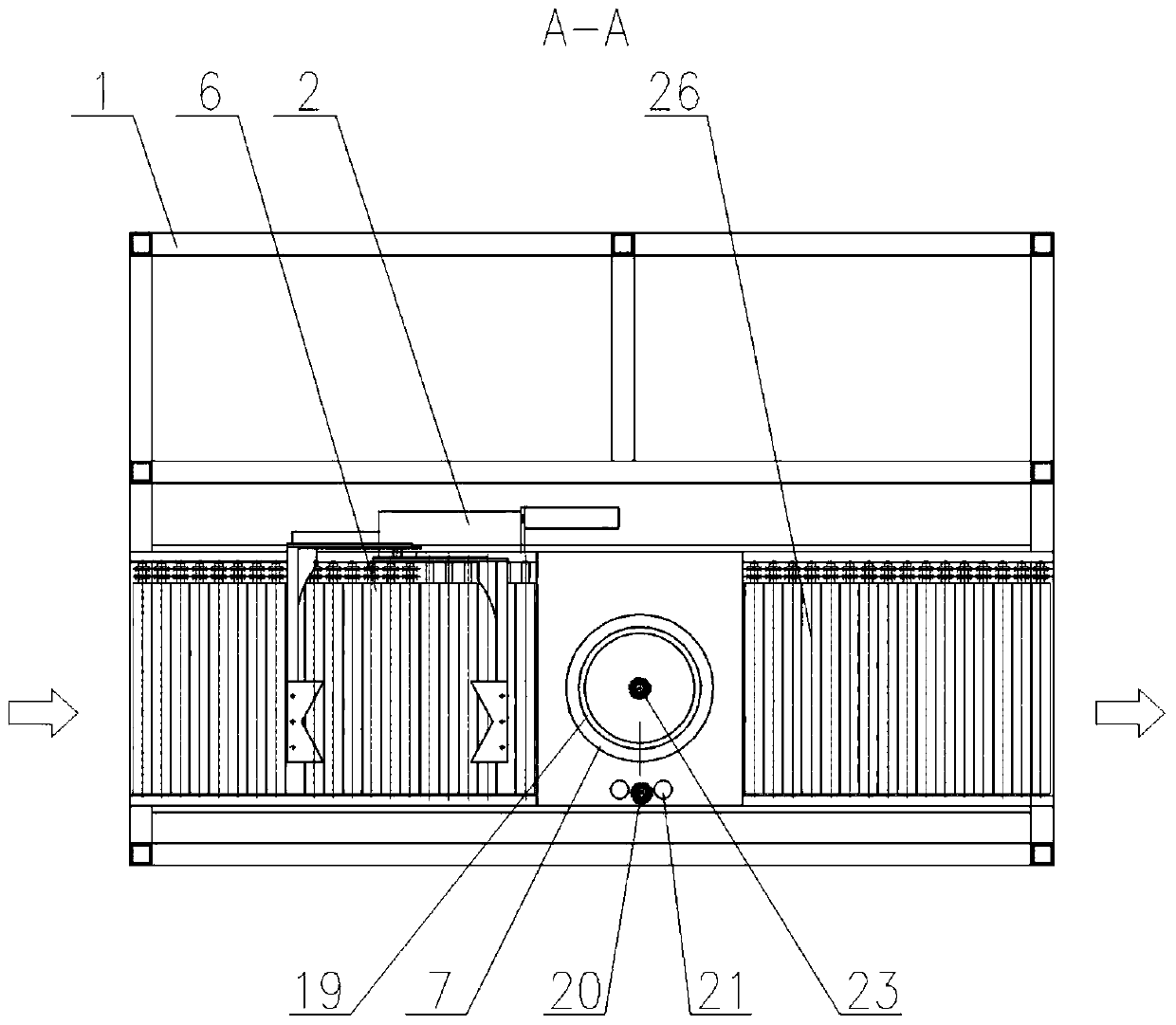

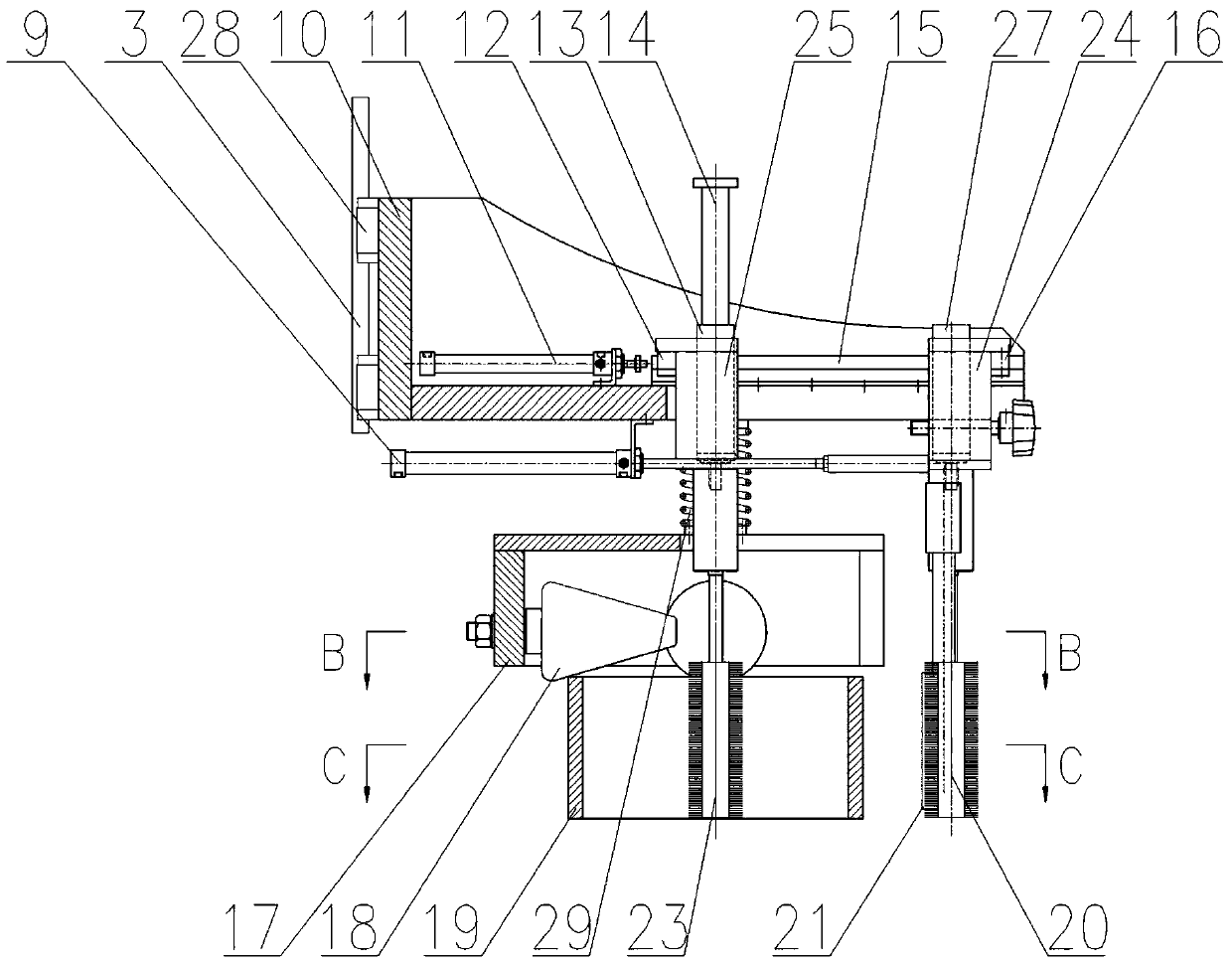

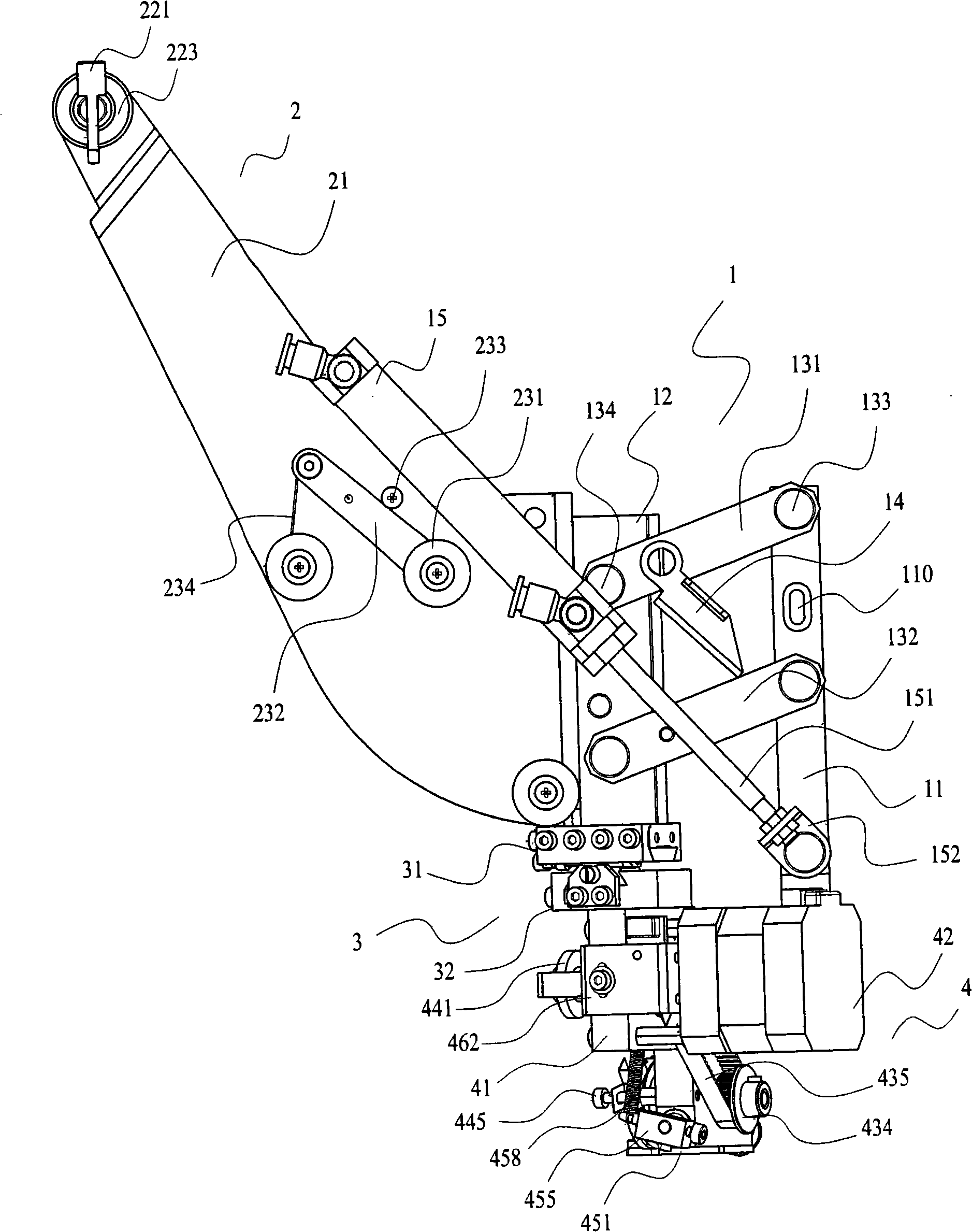

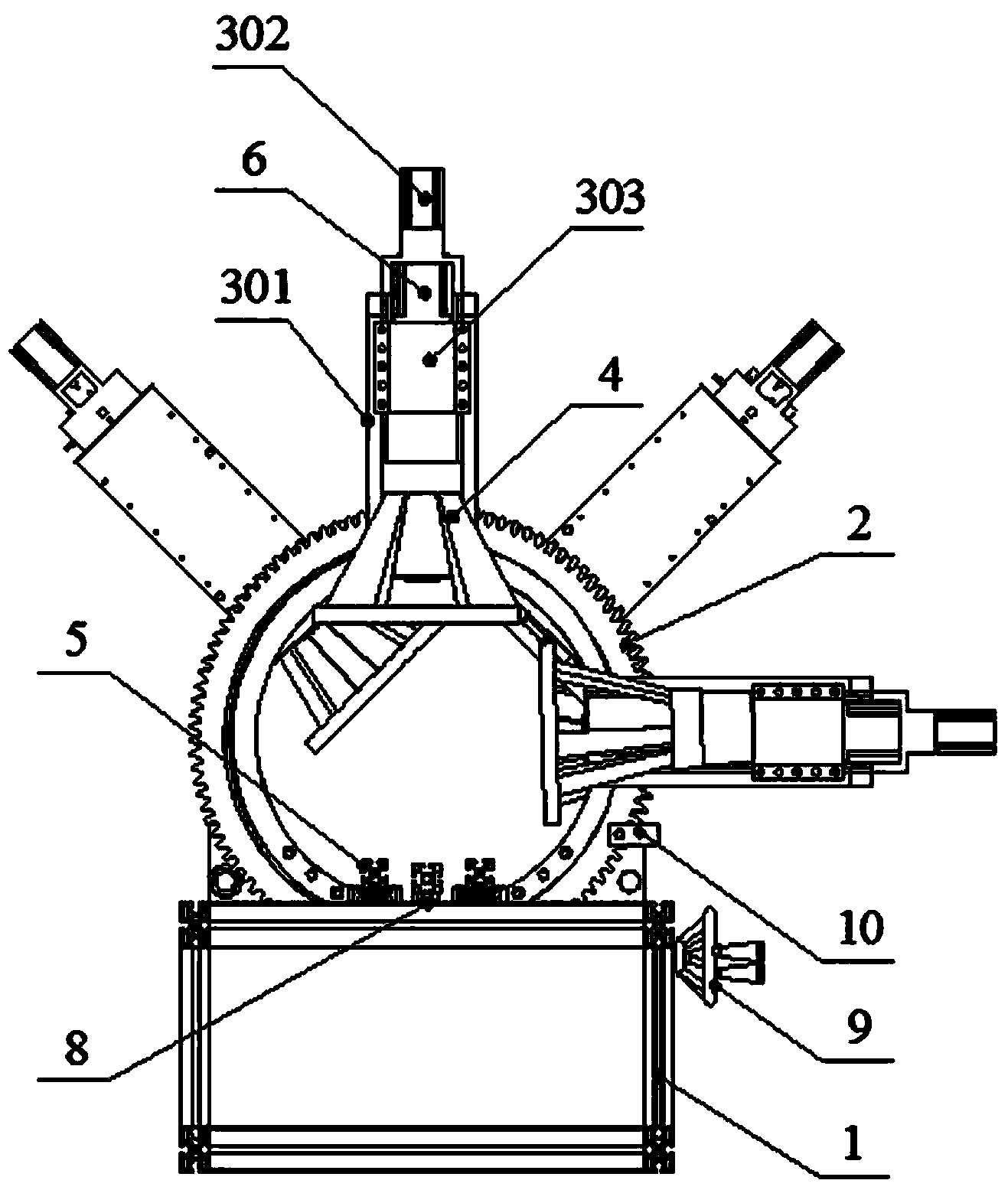

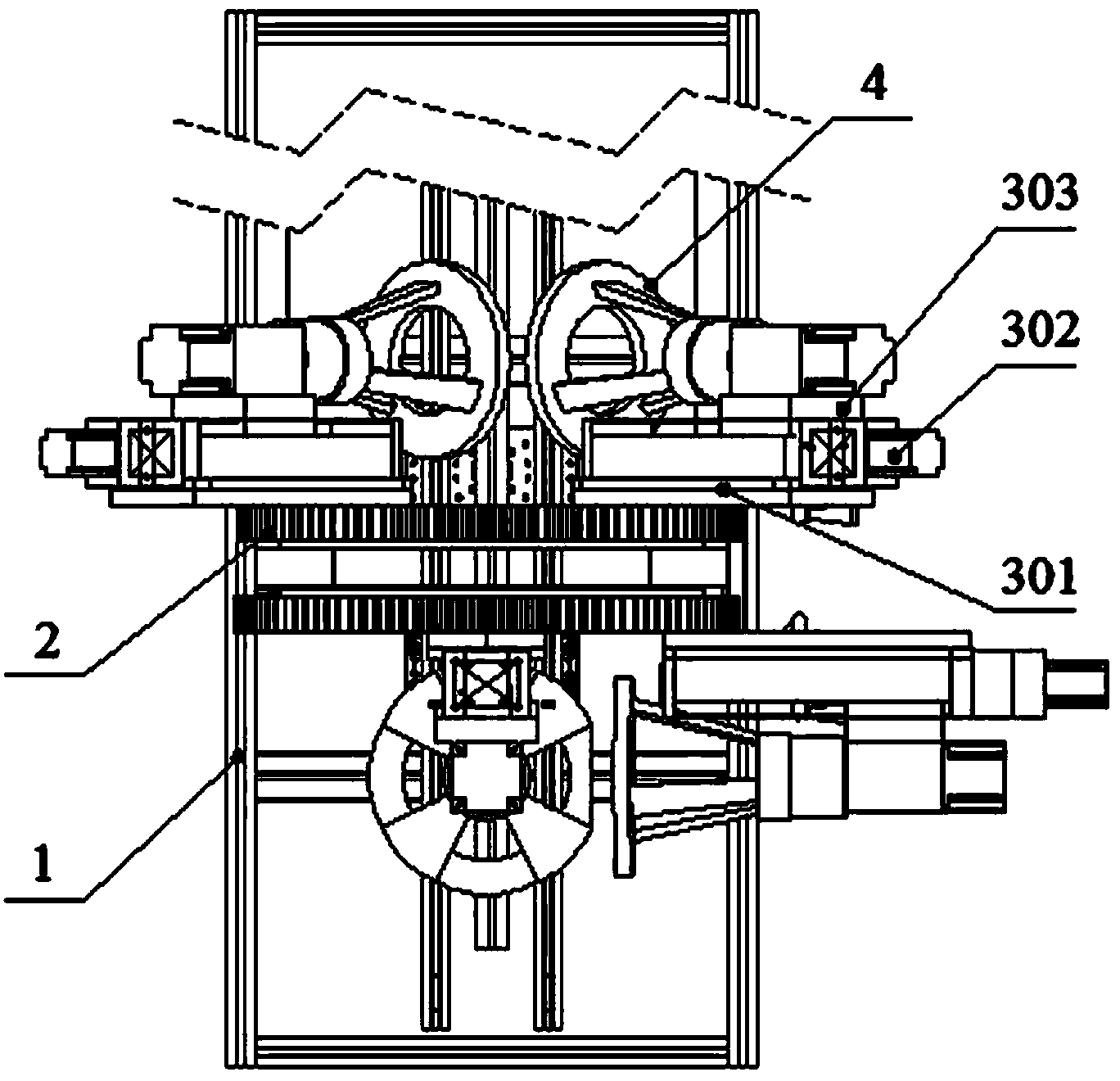

Deepwater diamond wire sawing machine

ActiveCN106141304AConvenient for underwater workGuaranteed lifeMetal sawing devicesMetal sawing accessoriesDiamond wire sawEngineering

The invention provides a deepwater diamond wire sawing machine which is majorly composed of a cutting drive mechanism, a feeding drive mechanism, a feeding speed regulating mechanism, a string bead wire tensioning mechanism and clamping mechanisms, and used for completing cutting repair of underwater structures. The feeding speed regulating mechanism is adopted for the deepwater diamond wire sawing machine, the feeding speed can be regulated along with the change of tension of a string bead wire in the operating process, and the service life of the string bead wire, the cutting efficiency of the machine and the reliability of cutting operation are effectively guaranteed. The feeding drive mechanism can promote transmission separation of a feeding motor and a lead screw, so that overload protection for the feeding drive mechanism is achieved; and meanwhile, under the condition that the machine does not have power, a handle can be rotated for feeding, and integrally automatic and manual drive feeding is achieved. A strong spring, a nut and a screw are adopted for tensioning of the string bead wire tensioning mechanism, and vibration of the string bead wire in the cutting process can be effectively reduced accordingly. The deepwater diamond wire sawing machine is provided with buoyancy materials and a deepwater valve box and suitable for deepwater environment operation.

Owner:HARBIN ENG UNIV

Rotary scrubbing control device capable of cleaning bearings with different sizes

InactiveCN103624017AEasy to useOvercome the problems of low conversion efficiency and complicated adjustment for each conversionCleaning using toolsFeed driveEngineering

Owner:DALIAN UNIV OF TECH

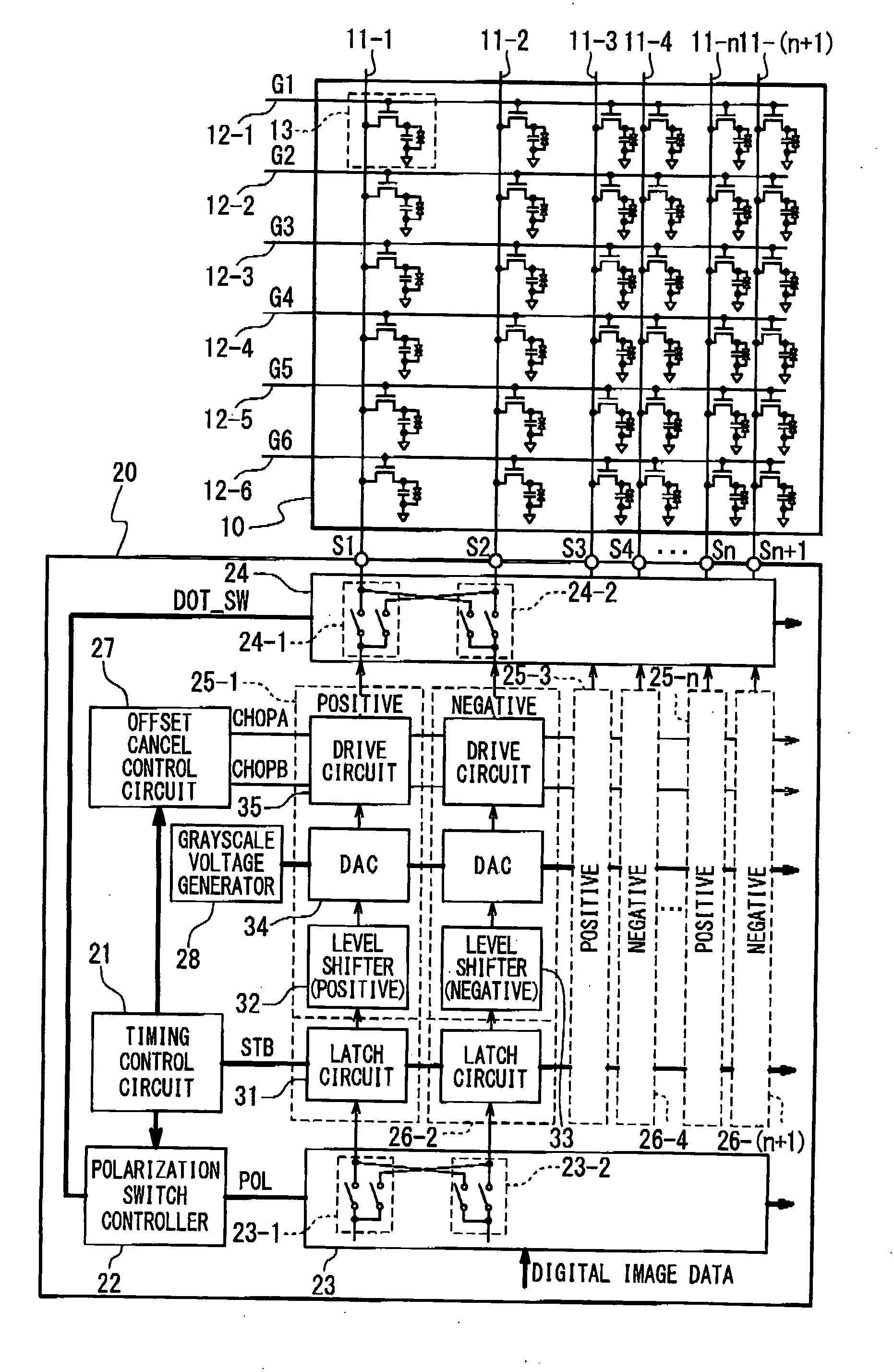

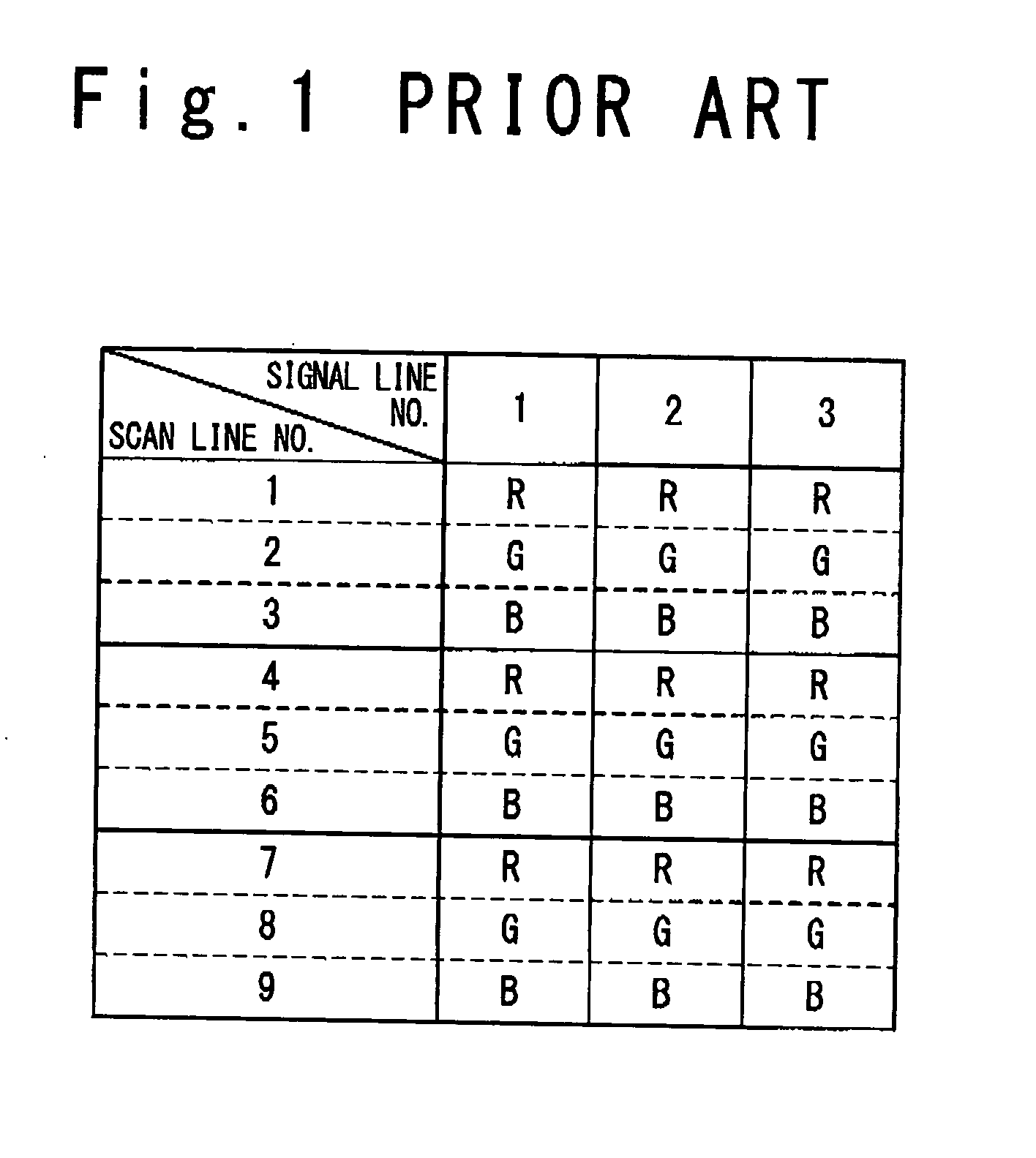

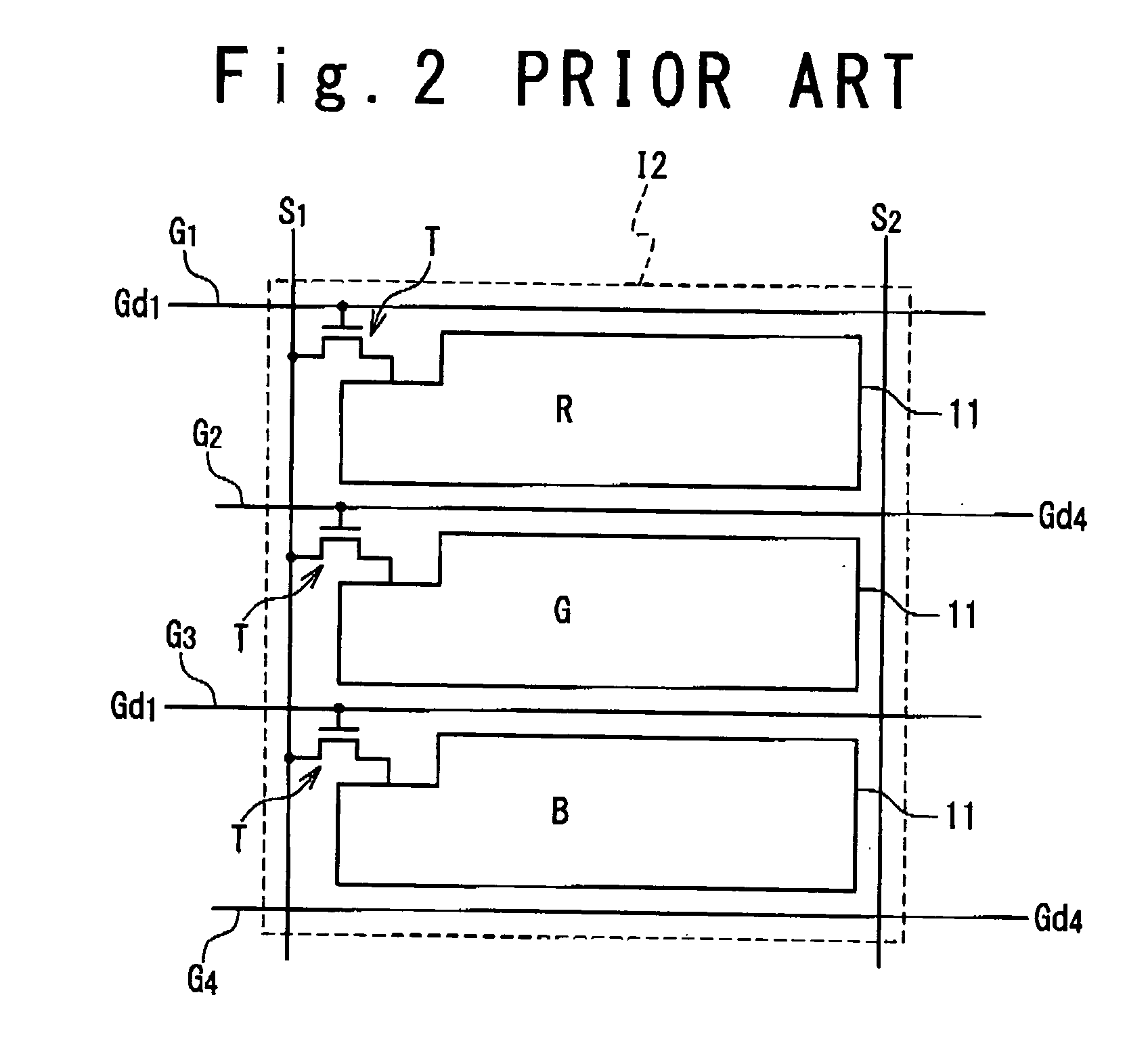

Method for driving liquid crystal display panel with triple gate arrangement

InactiveUS20090102777A1Static indicating devicesNon-linear opticsAudio power amplifierLiquid-crystal display

A method is provided for driving a liquid crystal display panel in which each pixel includes a plurality of sub-pixels arranged in a specific direction, the method including feeding drive voltages to sub-pixels within the liquid crystal display panel by using operational amplifiers. The polarities of the drive voltages fed to each of the sub-pixels are inverted between two adjacent frame periods. The offset polarities of the operational amplifiers are inverted for every a predetermined number of successive sub-pixels. The number of the sub-pixels within each pixel is coprime to the predetermined number of successive sub-pixels.

Owner:RENESAS ELECTRONICS CORP

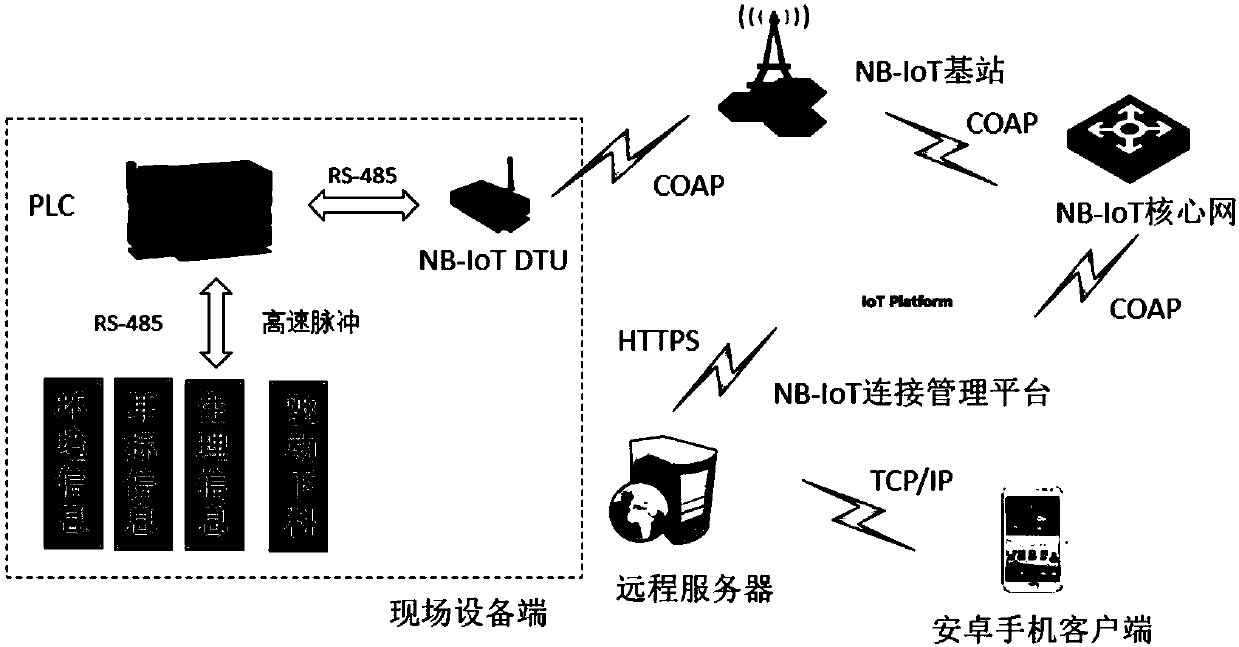

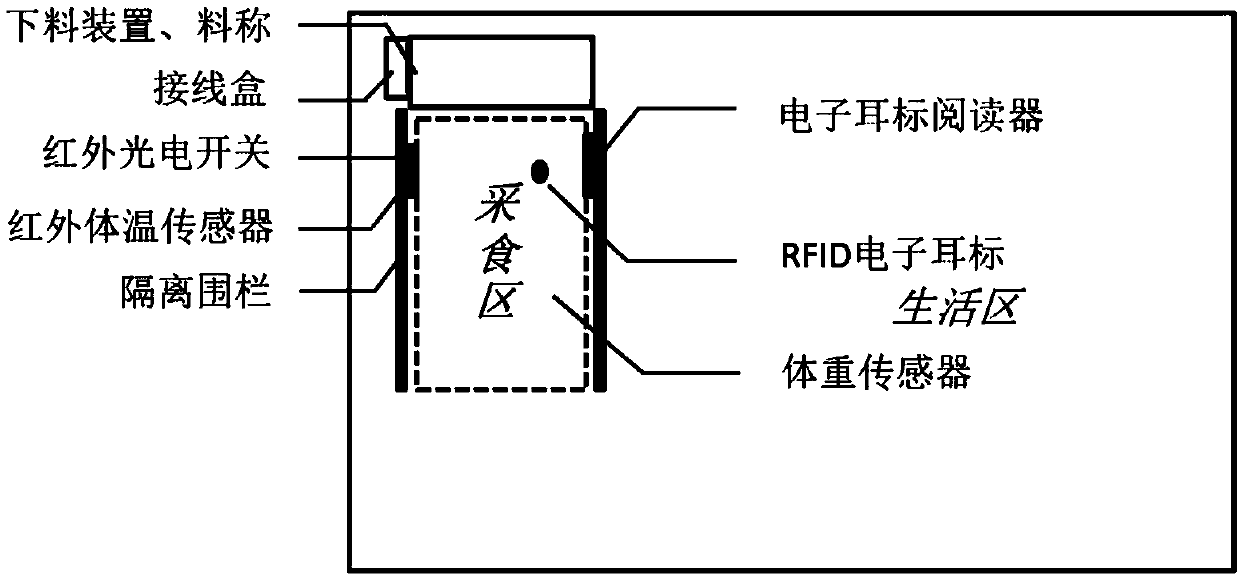

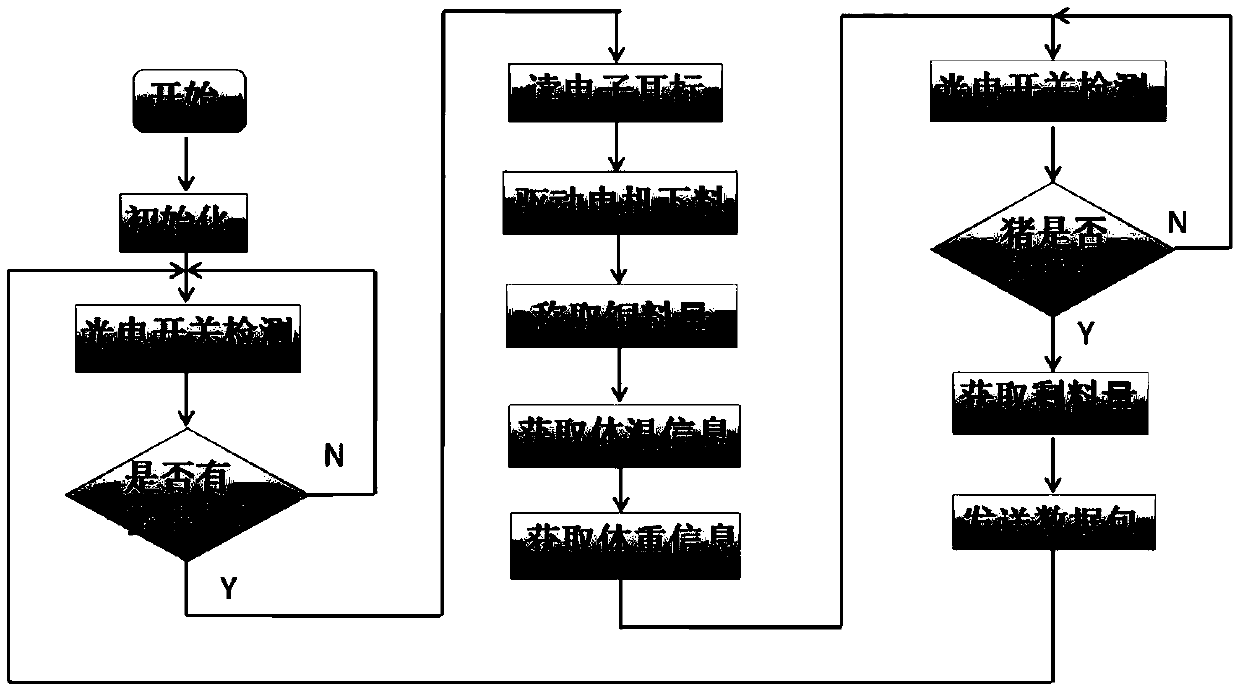

Monitoring system and method for key parameters of pig growth based on NB-IoT

ActiveCN109644891AAdapt to the harsh field environmentReduce failure rateMeasurement devicesOther apparatusGrowth parameterMonitoring system

The invention discloses a monitoring system and method for key parameters of pig growth based on NB-IoT. The monitoring system includes a field device side, a remote server and a mobile client. The field device side comprises an information identification module, a PLC, a parameter acquisition module, a feeding drive module and a feeding device, which can realize automatic feeding and automatic acquisition of pig weight, body temperature, feed intake, feeding frequency and field temperature and humidity information. The collected data are uploaded to the NB-IoT connection management platform through NB-IoT, and the data are parsed and pushed to the remote server by the platform. The remote server processes the data collected in the field and determines whether an exception has occurred. The mobile client comprises a login module, a monitoring node management module, an early warning module, an information monitoring module, and a historical curve analysis module. The monitoring systemand method for key parameters of pig growth based on NB-IoT can effectively obtain the growth parameters of the pigs, and monitor the body temperature and the feeding information which have a great relationship with the health of the pigs throughout the day, and the breeders can timely find the pigs with abnormal health and obtain the early warning information through the mobile phone.

Owner:河北正农牧业有限公司

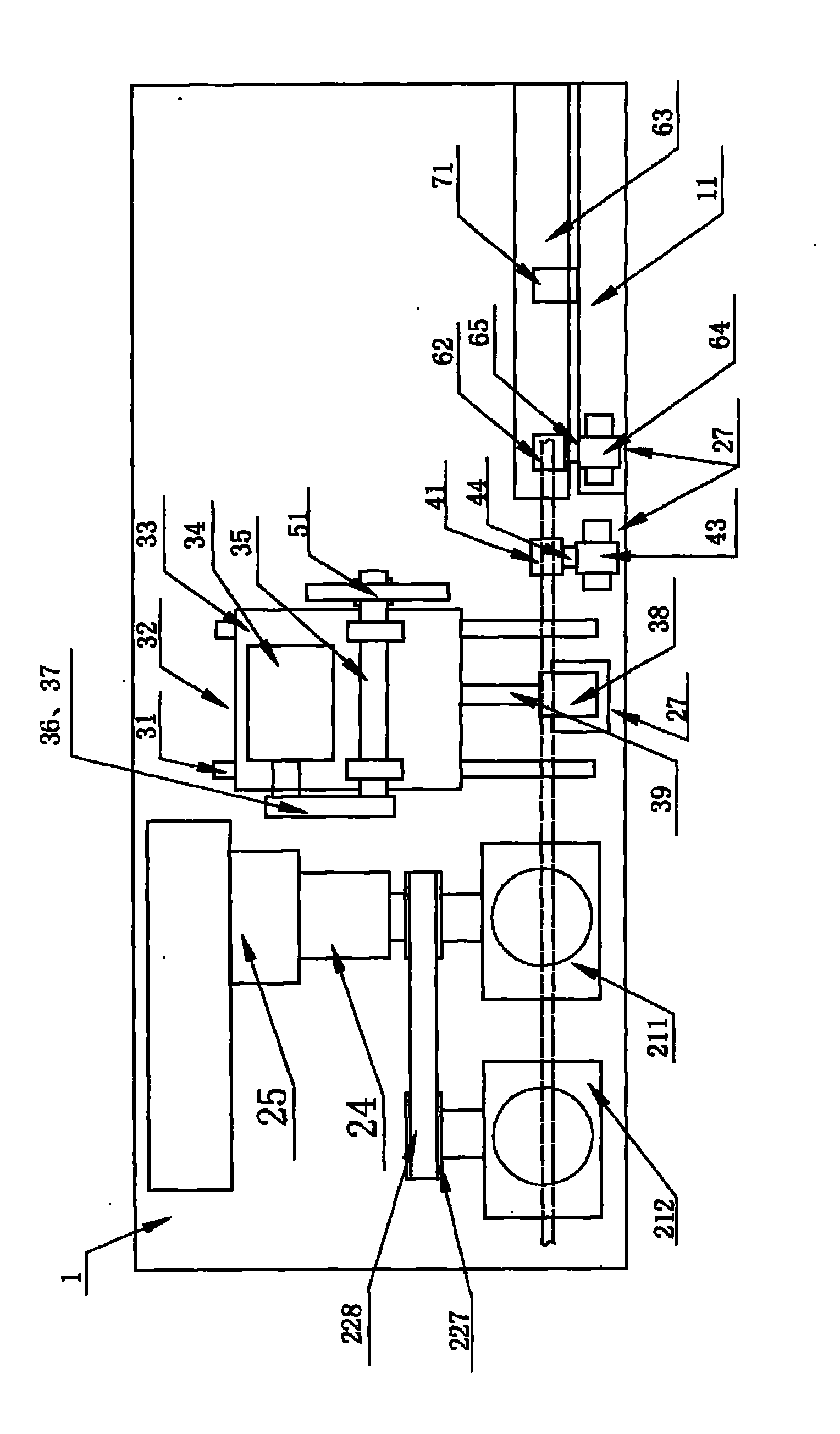

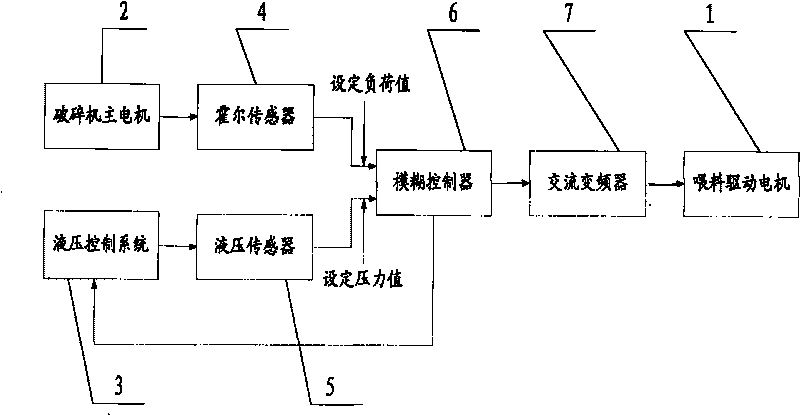

Fuzzy control system and control method for gear tooth type crusher

InactiveCN101745457AReduce the risk of failureReduce performanceGrain treatmentsHydraulic cylinderFeed drive

The invention discloses a fuzzy control system and a control method for a gear tooth type crusher, wherein the control system comprises a feeding drive motor, two main motors, a hydraulic control system, a Hall sensor, a hydraulic sensor, a fuzzy controller and an alternating-current frequency converter, wherein the two main motors are respectively used for driving a pair of roll shafts to relatively rotate; the hydraulic control system is used for regulating a distance between the pair of roll shafts; the Hall sensor is used for monitoring instantaneous load of the crusher in real time; the hydraulic sensor is used for monitoring instantaneous pressure of working oil in a hydraulic cylinder in the hydraulic control system in real time; and the fuzzy controller is used for receiving signals of the Hall sensor, comparing the instantaneous load of the crusher with a preset load, logically controlling the alternating-current frequency converter according to a comparison result, also receiving signals of the hydraulic sensor, comparing the instantaneous pressure of the working oil in the hydraulic cylinder with preset pressure of the working oil and logically controlling the hydraulic control system according to the comparison result.

Owner:SHANGHAI JIANSHE LUQIAO MASCH CO LTD

Method for breeding rice field eels at high density in flowing water under controlled-temperature condition

InactiveCN101933468AFresh waterRich dissolved oxygenClimate change adaptationAnimal feeding stuffFisheries scienceDisease

The invention relates to a method for breeding rice field eels at high density in flowing water under controlled-temperature condition, which belongs to the technical field of fishery science application, and is characterized in that: a flowing water culture pool is built in a fully-closed greenhouse, and strong rice field eel fry are selected; fry are added according to a density of 5 to 6kg / m<2>; the fed feed is the mixture of commercial rice field eel compound feed and fresh silver carp flesh; the daily additive amount of feed is 4 to 6 percent based on the weight of the rice field eels; and micro flowing water is kept in the flowing water culture pool, the flow rate is kept between 0.05 and 0.10m<3> / h, and the water temperature of the flowing water culture pool is kept between 25 and 28 DEG C. In the invention, the large-scale soilless flowing water culture pool is built, an in-greenhouse controlled-temperature culture mode has the advantages of fresh culture water with rich dissolved oxygen, high culture density, and high feeding drive and growth speed and few diseases of the rice field eels and is an industrial culture mode; and compared with the prior pool net cage culture mode, the culture mode has higher per unit area yield and greater economic benefit.

Owner:YANGTZE UNIVERSITY

Mechanical arm clamp feeding and ejecting device

InactiveCN105312955ACenter positioning is accuratePrecise positioningMetal working apparatusEngineeringManipulator

The invention provides a mechanical arm clamp feeding and ejecting device which comprises a feeding mechanism and a main shaft ejecting mechanism. The feeding mechanism comprises a rack, a feeding drive device, a grabbing drive device and a pushing drive device. The main shaft ejecting mechanism comprises a device base, an air cylinder, a material rack and a linear guide rail assembly. The rack is provided with a feeding clamp. A baffle is arranged in the feeding clamp. A conveyor belt assembly is arranged at one side of the baffle, and a trough is formed in the other side of the baffle. A discharge V-shaped groove is formed above the baffle. A telescopic rod is arranged at the upper end of the feeding drive device. A feeding ejector rod is arranged at one side of the baffle. A feeding part is arranged above the feeding ejector rod and located in the trough. The feeding part makes contact with the baffle. A slope is arranged at one side, making contact with the baffle, of the top end of the feeding part. An included angle is formed between the slope and the baffle. The material rack is provided with a left V-shaped groove and a right V-shaped groove which are used for placing blanks. The device can solve the problems that excessive blanks are conveyed at a time and can not be conveyed in place.

Owner:宁波宫铁智能科技有限公司

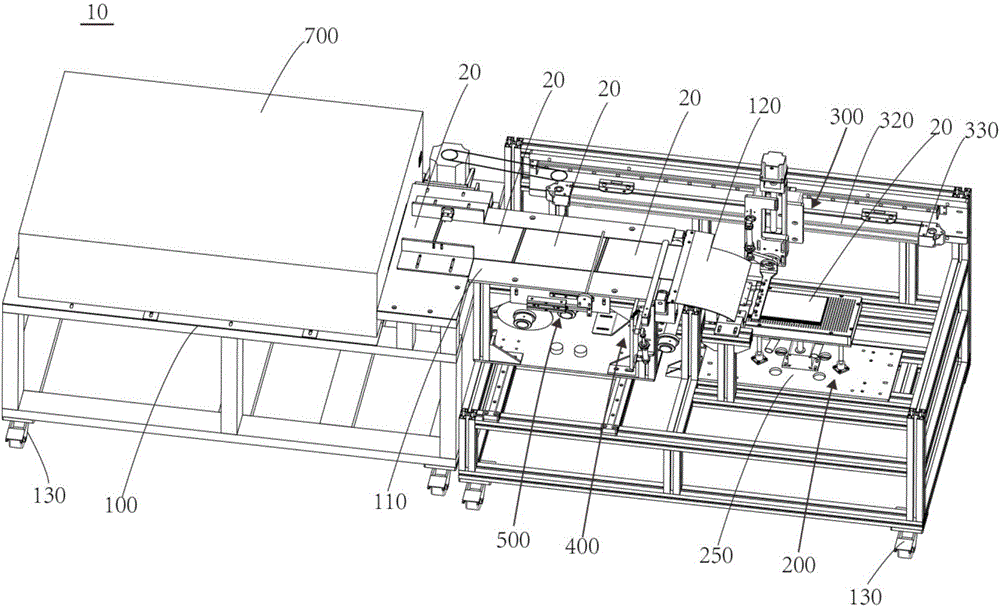

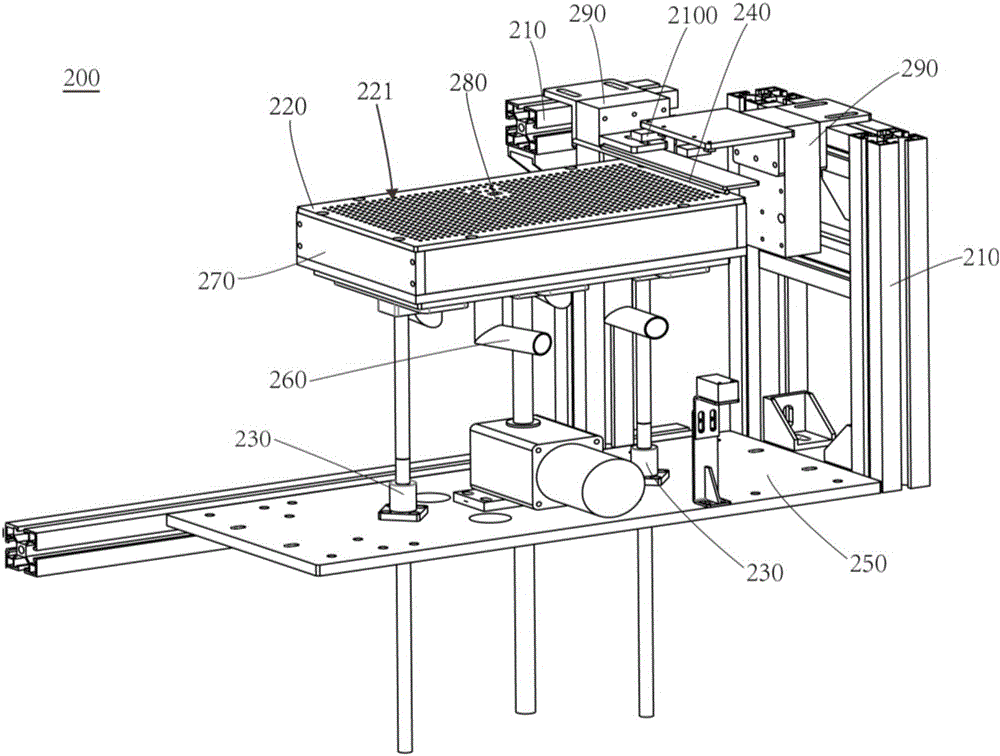

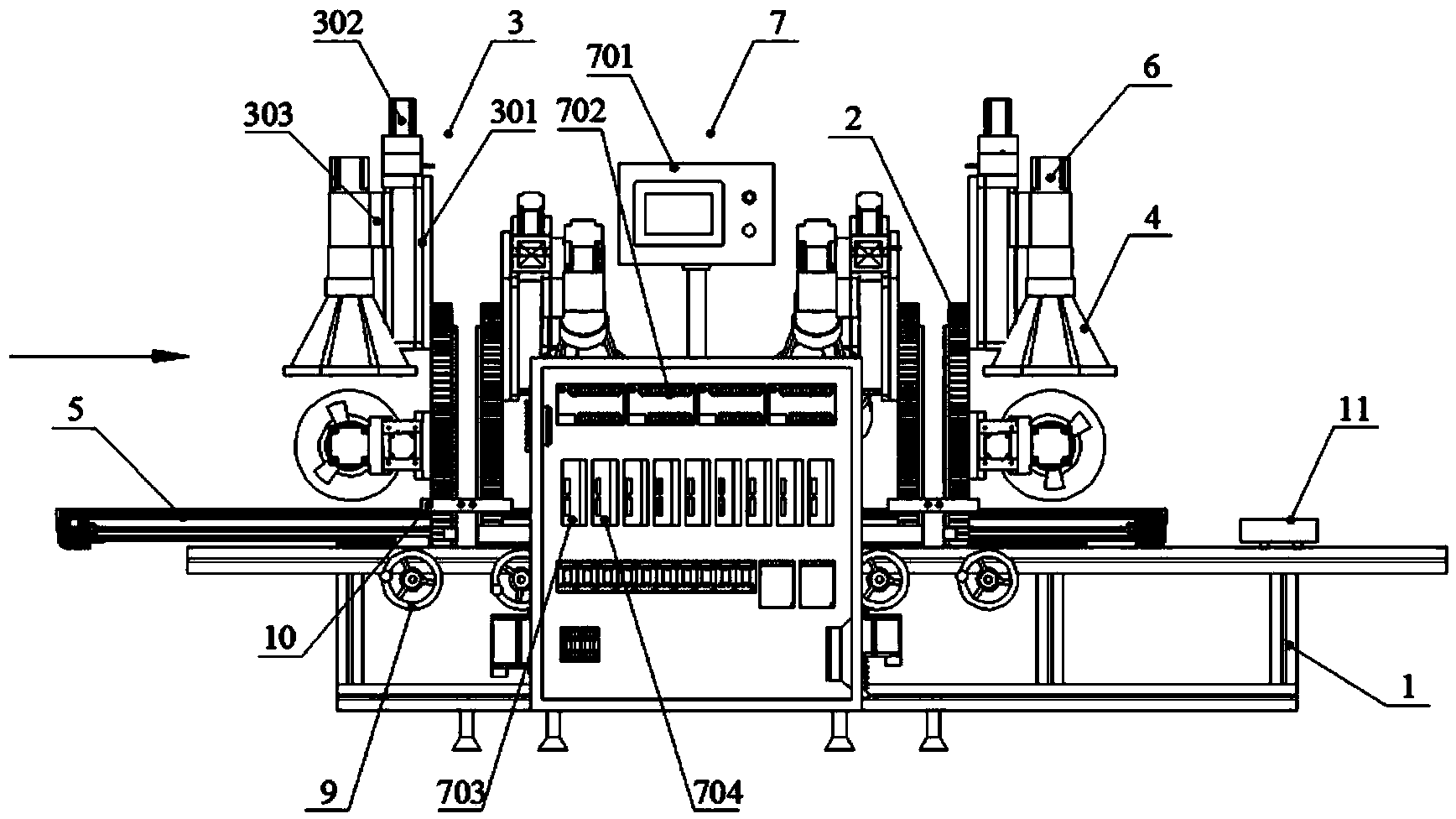

Automatic stitching, buttonholing and buttoning system and method

ActiveCN105019155AAutomate operationSave human effortWork-feeding meansWork-collecting devicesEngineeringAutomatic testing

The invention discloses an automatic stitching, buttonholing and buttoning system and method. The automatic stitching, buttonholing and buttoning system comprises a workbench, a stitching device, a feeding device, a positioning device, a buttonholing device, a buttoning device and a clamping device. The stitching device is arranged on the workbench for stitching cut pieces. The feeding device is provided with a bonding component for bonding the cut pieces and a feeding drive component for driving the bonding component to move. The positioning device is provided with a positioning table facet and a blowing component. The positioning table fact is arranged on the workbench. The blowing component is provided with a plurality of blowing nozzles. The blowing nozzles are fixed to the positioning table fact. The buttonholing device is arranged on the workbench and used for conducting buttonholing on the cut pieces. The buttoning device is arranged on the workbench and used for conducting buttoning on the cut pieces. The clamping device is arranged on the workbench and used for clamping the cut pieces to the buttonholing device and the buttoning device from the positioning table facet. By means of the automatic stitching, buttonholing and buttoning system, the production quality is guaranteed, and production efficiency is high.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

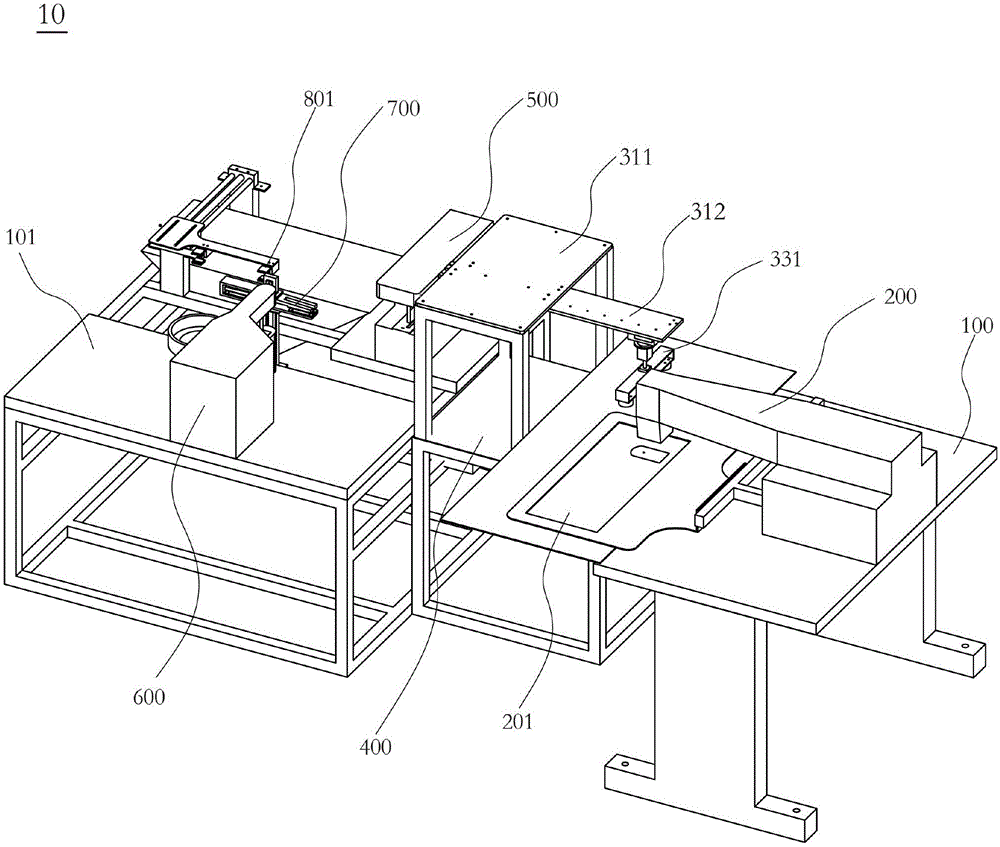

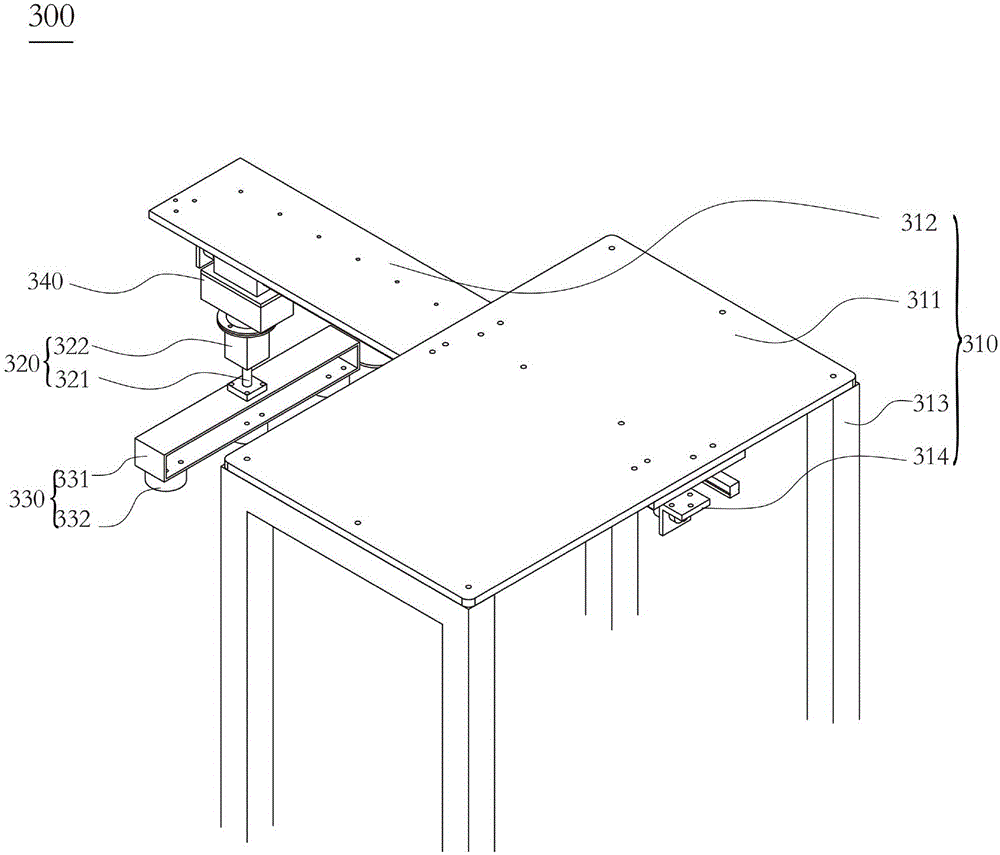

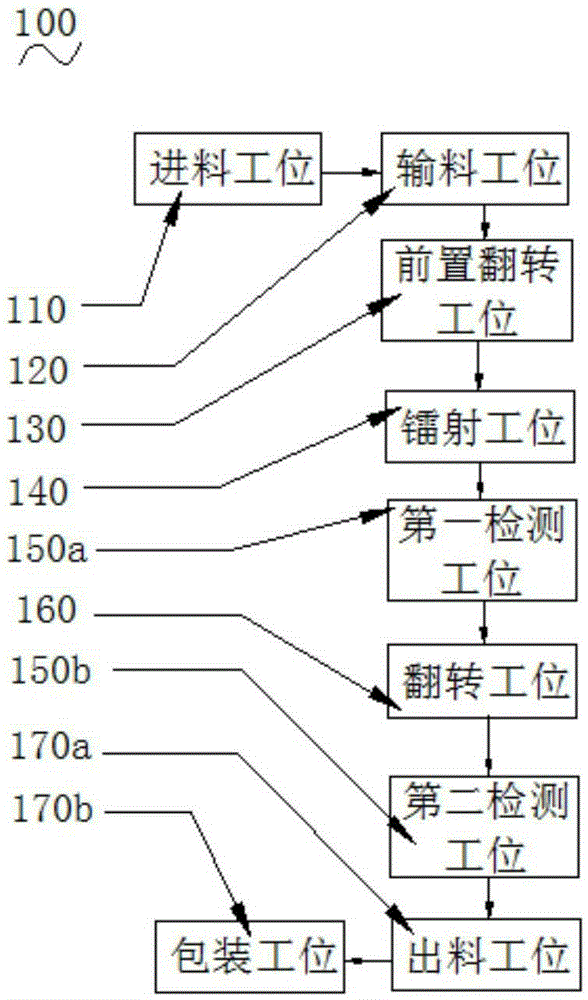

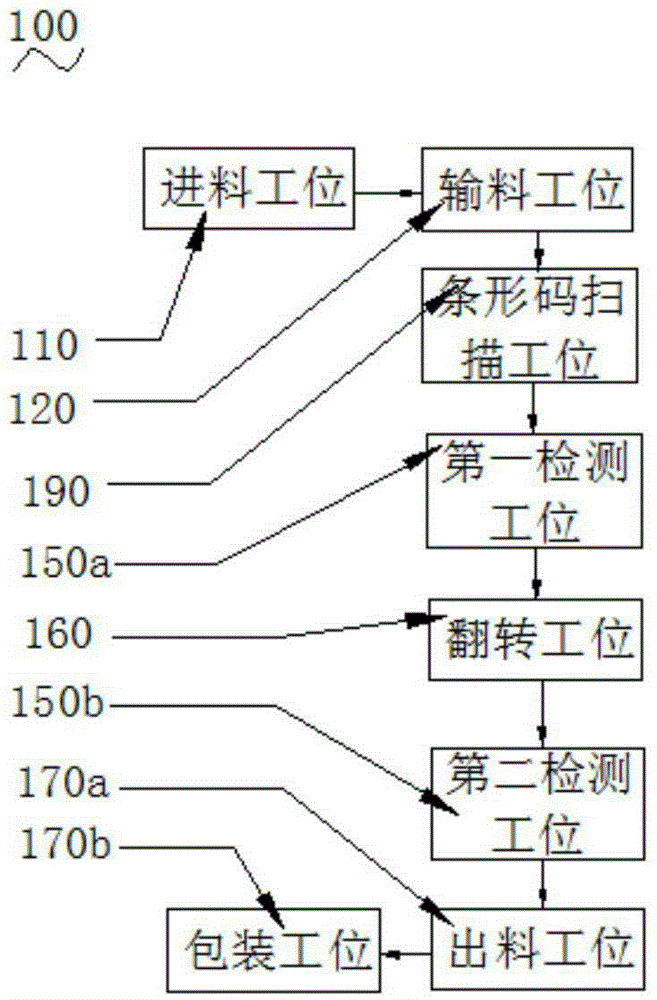

Automatic detecting system for saw blade

InactiveCN105346767AHigh degree of automationImprove work efficiencyPackaging automatic controlSortingFeed driveEngineering

The invention relates to the field of saw blade detecting, in particular to an automatic detecting system for a saw blade. The automatic detecting system for the saw blade comprises a material feeding workstation. The material feeding workstation comprises a material feeding plate, a first positioning assembly, a conveyor belt and a material feeding driving assembly, wherein the material feeding plate is used for placing the saw blade, the first positioning assembly is located in front of the material feeding plate and is used for conducting left-and-right positioning on the saw blade, the conveyor belt is used for conveying the material feeding plate with the saw blade placed, and the material feeding driving assembly is used for driving the conveyor belt to move. A counter is arranged on the material feeding plate. The first positioning assembly comprises a material receiving frame, a plurality of first positioning blocks, material grooves, an upper pressing roller, a lower pressing roller and a positioning driving assembly, wherein the multiple first positioning blocks are all arranged on the material receiving frame, the material grooves are formed between the two adjacent first positioning blocks and are used for placing the saw blade, the upper pressing roller and the lower pressing roller are used for pressing the saw blade to enable the saw blade to be disengaged from a fixture and are both located at the output end of the material receiving frame, and the positioning driving assembly is used for driving the upper pressing roller and the lower pressing roller to move relatively. The upper pressing roller is located above the lower pressing roller, and a gap matched with the thickness of the saw blade is reserved between the upper pressing roller and the lower pressing roller. The automatic detecting system for the saw blade is high in automation degree, high in working efficiency, high in detecting precision and wide in application range.

Owner:DONGGUAN XINTENG ROBOT TECH

Multi-material 3D printer

InactiveCN105538713ARealize seamless switchingReduce weightAdditive manufacturing apparatusTypewritersMulti materialSpray nozzle

The invention discloses a multi-material 3D printer. The multi-material 3D printer comprises a housing. A base, a worktable, spray nozzles, a three-dimensional movement mechanism, a feeding unit and a storing unit. The multi-material 3D printer is connected with a controller. A power supply is arranged below the base, and is connected with the controller. The three-dimensional movement mechanism is driven by a servo motor. The servo motor is electrically connected with the controller. The three-dimensional movement mechanism comprises an X-axis movement mechanism, a Y-axis movement mechanism and a Z-axis movement mechanism. Feeding driving devices are arranged on the spray nozzles, and are electrically connected with the controller. The feeding unit comprises a plurality of guiding pipes. One end of each guiding pipe is connected with the corresponding spray nozzle, and the other end of each guiding pipe is connected with the feeding unit. Valve controllers are arranged on the guiding pipes, and are electrically connected with the controller. The worktable is positioned on the base.

Owner:BONA YUNZHI TIANJIN TECH

Poultry feeder

ActiveUS20080257270A1Extended range of motionPrecise positioningAnimal feeding devicesAnimal housingEffective heightEngineering

A poultry feeder is provided which can be selectively switched between a mode in which it operates as a flood-type feeder and a mode in which it operates as a shallow-fill type feeder with adjustable height pan walls. The feeder includes a feed tube assembly comprising a drop tube and a feed flooding tube. The drop tube is movable axially relative to the feed flooding tube, which rests on the feed pan. The drop tube and feed flooding tube have windows which are brought into and out of alignment by raising and lowering the drop tube. When the feed flooding tube window is opened, the feeder operates in a flood mode and when the feed flooding tube is closed, the feeder operates in a shallow-fill mode. In this second mode, the effective height of the pan wall can be adjusted to allow chicks and chickens access to the feed.

Owner:THE GSI GRP LLC

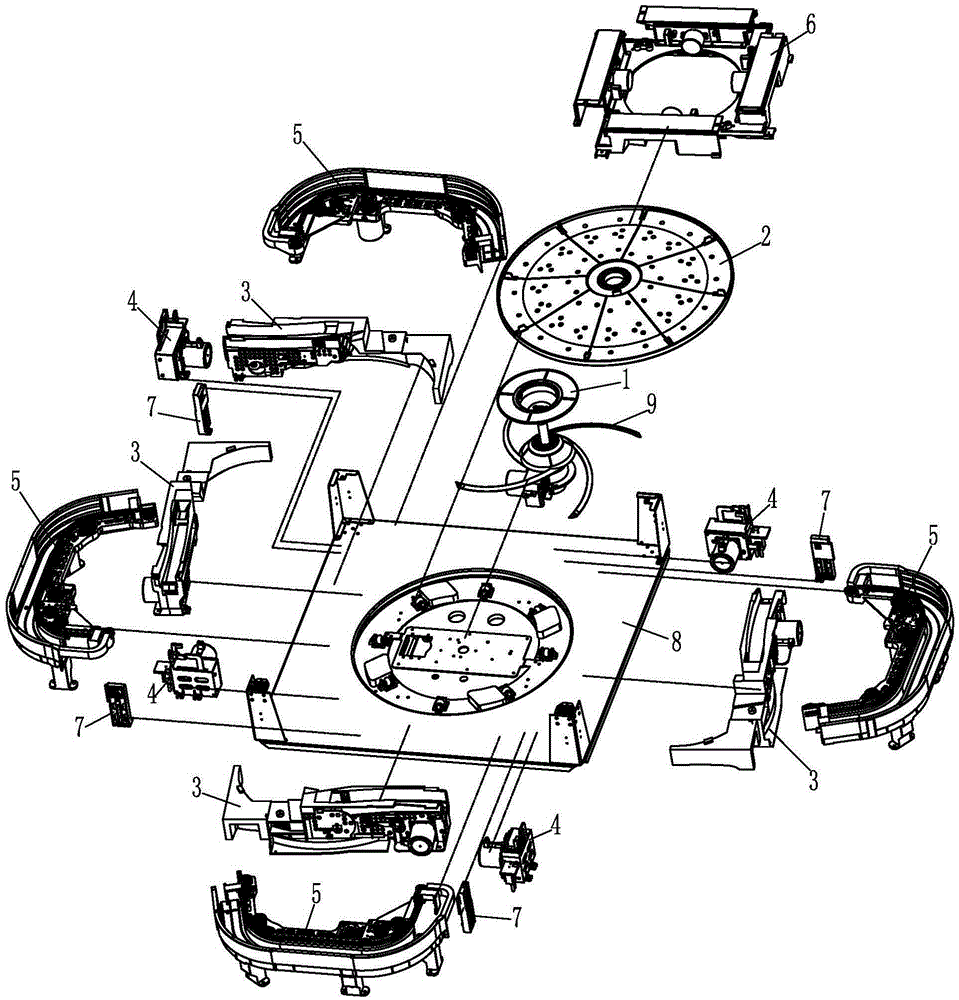

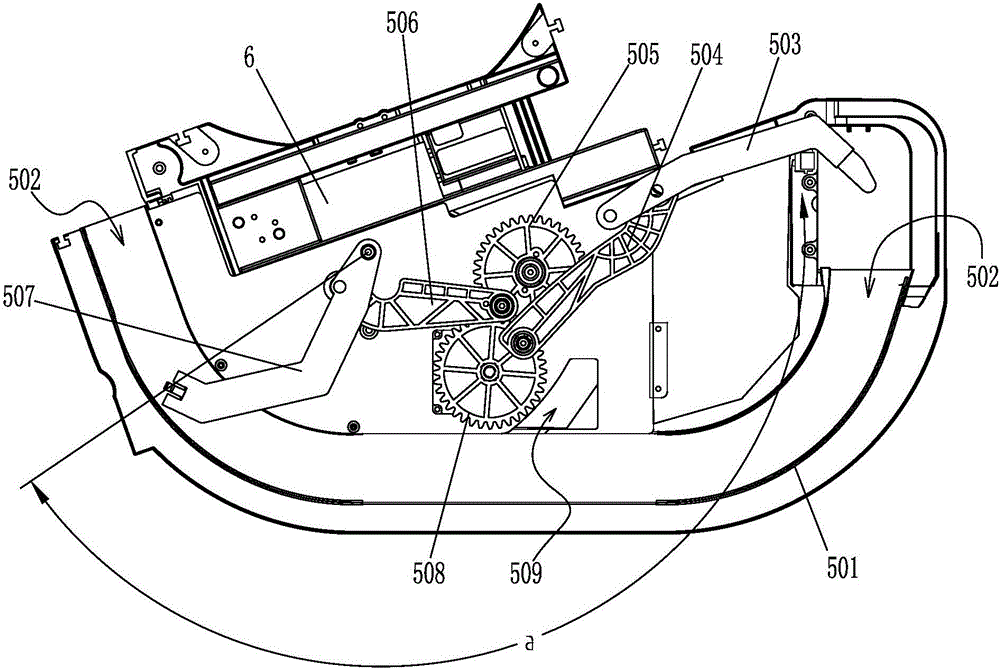

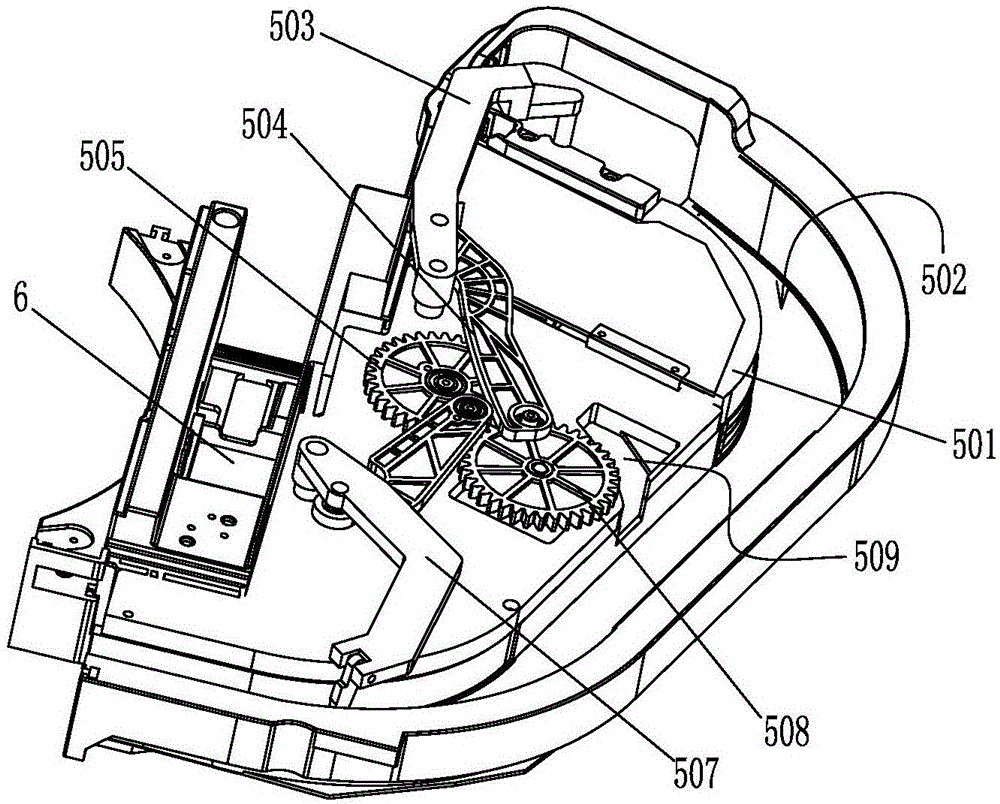

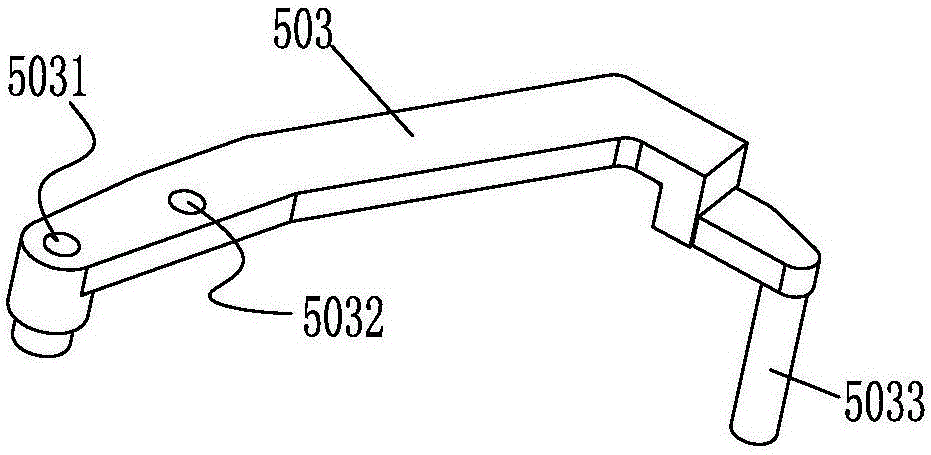

Mahjong machine and slope mahjong tile releasing device of same

The invention provides a mahjong machine and a slope mahjong tile releasing device of the same. The slope mahjong tile releasing device comprises a mahjong tile feeding assembly and a mahjong lifting assembly, wherein the mahjong tile feeding assembly comprises a mahjong tile feeding support; the mahjong tile feeding support is equipped with a mahjong tile storage groove, a first mahjong tile feeding push head and a second mahjong tile feeding push head; a gap is formed in the inner wall of the middle part of the mahjong tile storage groove; the mahjong tile storage groove communicates with a reversing groove by the gap; the first mahjong tile feeding push head is driven by a mahjong tile feeding drive mechanism to move from the outside of a mahjong tile inlet of the mahjong tile storage groove to a location around the gap and then return; the second mahjong tile feeding push head is driven by the mahjong tile feeding drive mechanism to move from a mahjong tile outlet of the mahjong tile storage groove into the reversing and then return; the mahjong tile feeding drive mechanism comprises a first mahjong tile feeding push rod and a second mahjong tile feeding push rod which conduct separate reciprocating motion and cooperate with each other; the first mahjong tile feeding push head is disposed on the first mahjong tile feeding push rod; and the second mahjong tile feeding push head is disposed on the second mahjong tile feeding push rod. The scheme is characterized in that the two mahjong tile feeding push rods push mahjong tiles in succession, so that defects in the prior art that resistance force between the mahjong tile feeding push heads and a guiderail is large, chain working noise is large and the like can be completely avoided.

Owner:ZHEJIANG CHAOSHENG ELECTROMECHANICAL TECH CO LTD

Tile feeding assembly, slope tile playing device and mahjong machine

The invention discloses a tile feeding assembly, a slope tile playing device and a mahjong machine. The tile feeding assembly of the mahjong machine comprises a tile feeding bracket, the tile feeding bracket is provided with a tile storage groove for storing multiple mahjong tiles, the inner side wall of the tile storage groove is provided with a tile feeding guide rail, the tile feeding guide rail is slidably provided with a tile feeding pushing head, and the tile feeding pushing head is driven by a tile feeding drive mechanism to slide along the tile feeding guide rail. A major part of the tile storage groove is horizontal, and a tile playing slope for lifting the mahjong tiles is arranged at the position, close to a tile playing opening, of the tile storage groove. According to the scheme, a tile inlet and a tile outlet are reasonably adjusted and designed through a tile conveying device, and a tile conveying channel is bent in an arc shape, so that the mahjong tiles sent to a tile bearing block of a tile pushing device by the tile conveying device and the mahjong tiles pushed out by the tile pushing device are neat and smaller in resistance.

Owner:ZHEJIANG CHAOSHENG ELECTROMECHANICAL TECH CO LTD

Paper feeding mechanism of paper vessel molding machine

ActiveCN101602265ASolve misalignmentSolve problems such as overturningContainer making machineryMolding machineFeed drive

The invention discloses a paper feeding mechanism of a paper vessel molding machine. The front end of a stand is provided with a feeding drive wheel; the rear end of the stand is provided with a feeding driven wheel; a feeding belt is sleeved on the feeding drive wheel and the feeding driven wheel; a vacuum rack is arranged between the feeding drive wheel and the feeding driven wheel; the feeding belt is supported against an upper panel of the vacuum rack; a plurality of air holes of the feeding belt are communicated with a vacuum cavity of the vacuum rack; a shaft on the feeding drive wheel is provided with a push pawl; the front end of the feeding drive wheel in the paper feeding direction is provided with a positioning rack; the upside of the feeding belt close to the end of the feeding driven wheel is provided with a suction nozzle rack; and the suction nozzle rack is driven by a drive mechanism at the shaft end to periodically swing to the feeding belt. The paper feeding mechanism utilizes external atmospheric pressure and friction force of the paper to transport paper to a pressing idler wheel above the feeding drive wheel, continuously pushes the paper forwards to enter the positioning rack and subsequently adjusts the position of the paper by swinging the push pawl forwards to complete the feeding action.

Owner:ZHEJIANG SEE MACHINERY

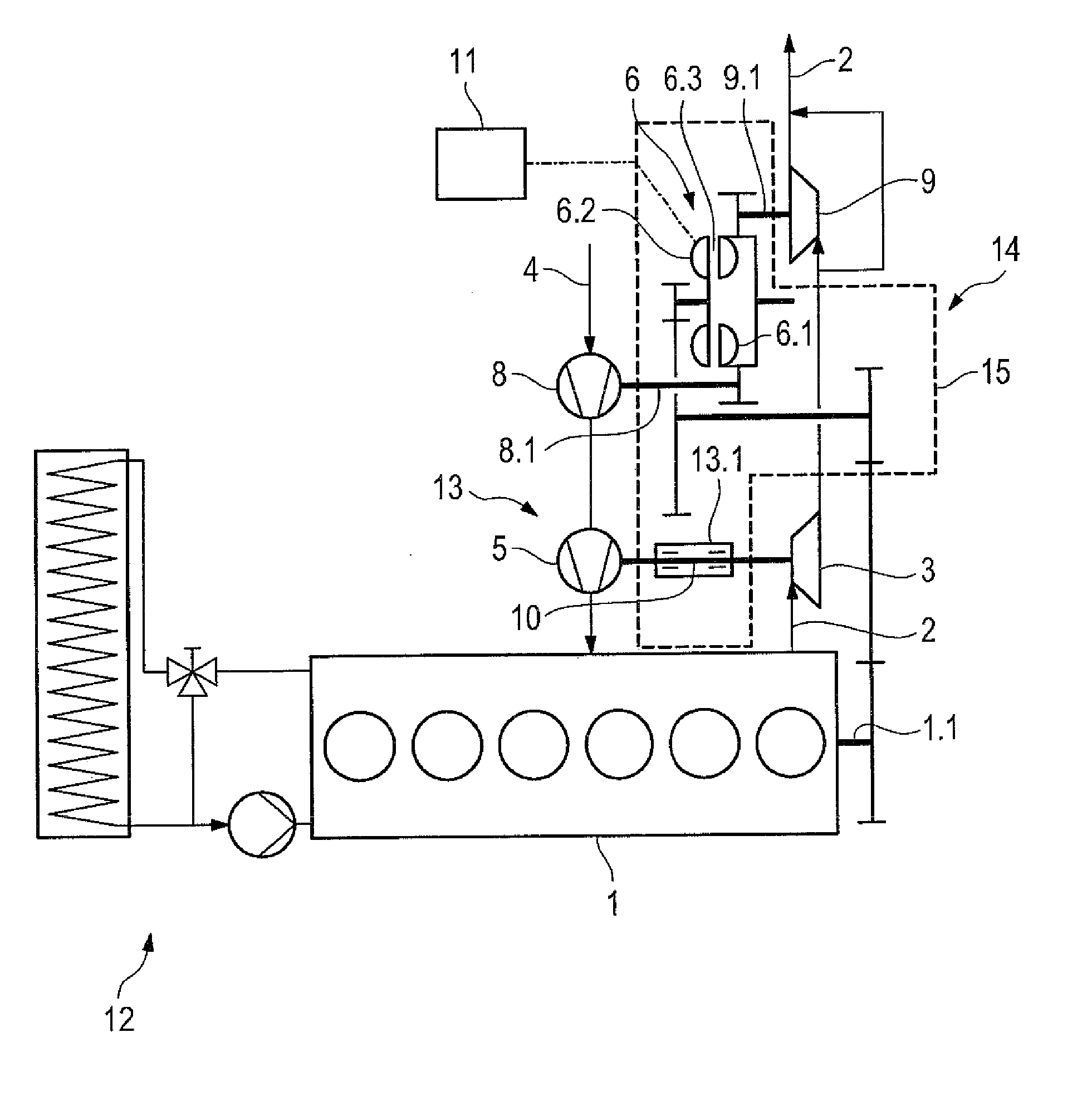

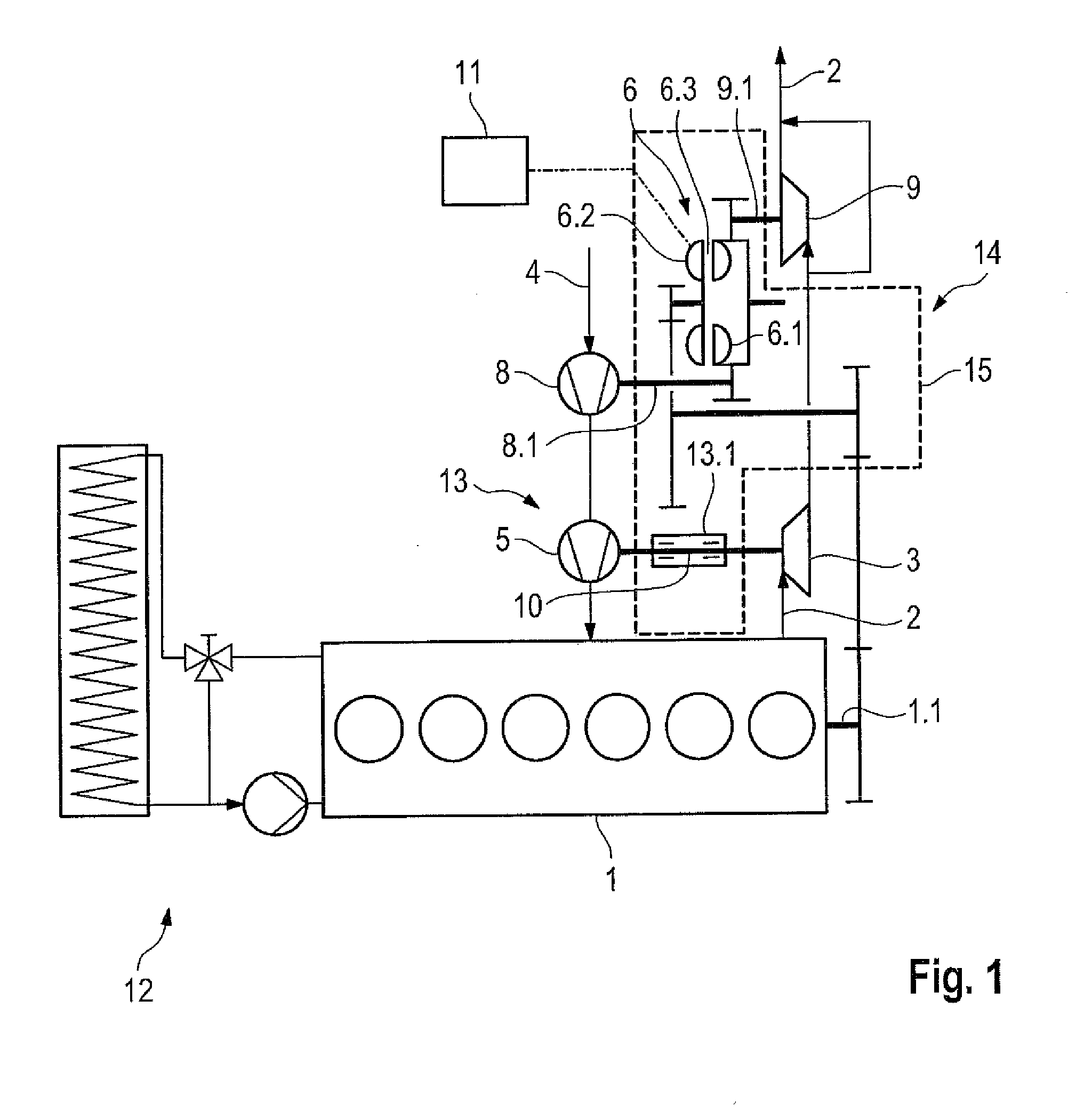

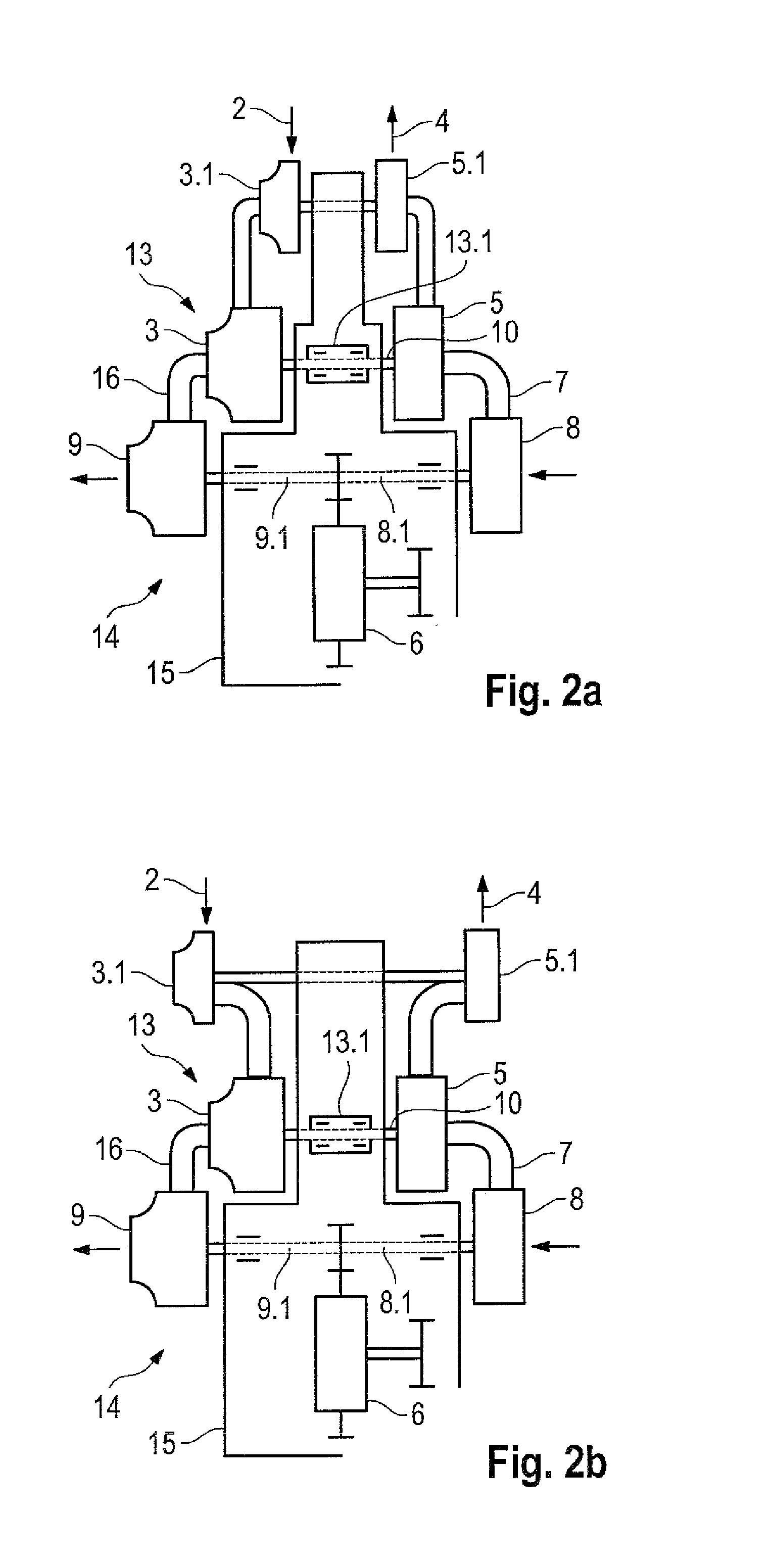

Drive train, in particular vehicle drive train

InactiveUS20140116043A1Reduce traffic lossImprove efficiencyInternal combustion piston enginesEngine componentsTurbochargerInternal combustion engine

A drive train having an internal combustion engine which includes an output shaft feeding drive power into the drive train. A first turbo charger includes a first exhaust-gas turbine arranged in an exhaust-gas flow and mounted rotatably in a turbine housing that drives a first fresh-air compressor via a first turbine shaft. A turbo-compound system includes a power turbine arranged in the exhaust-gas flow and can be drive connected via a power turbine shaft to the output shaft, with the power turbine shaft mounted rotatably in a power turbine housing and extending parallel to the turbine shaft. The turbine housing and power turbine housing can be supported in or on or integrated into a transmission housing. The first turbocharger is arranged radially outside the turbo-compound system. The first turbocharger and turbo-compound system are arranged on a common side or on different and adjoining or opposite sides of the transmission housing.

Owner:VOITH PATENT GMBH

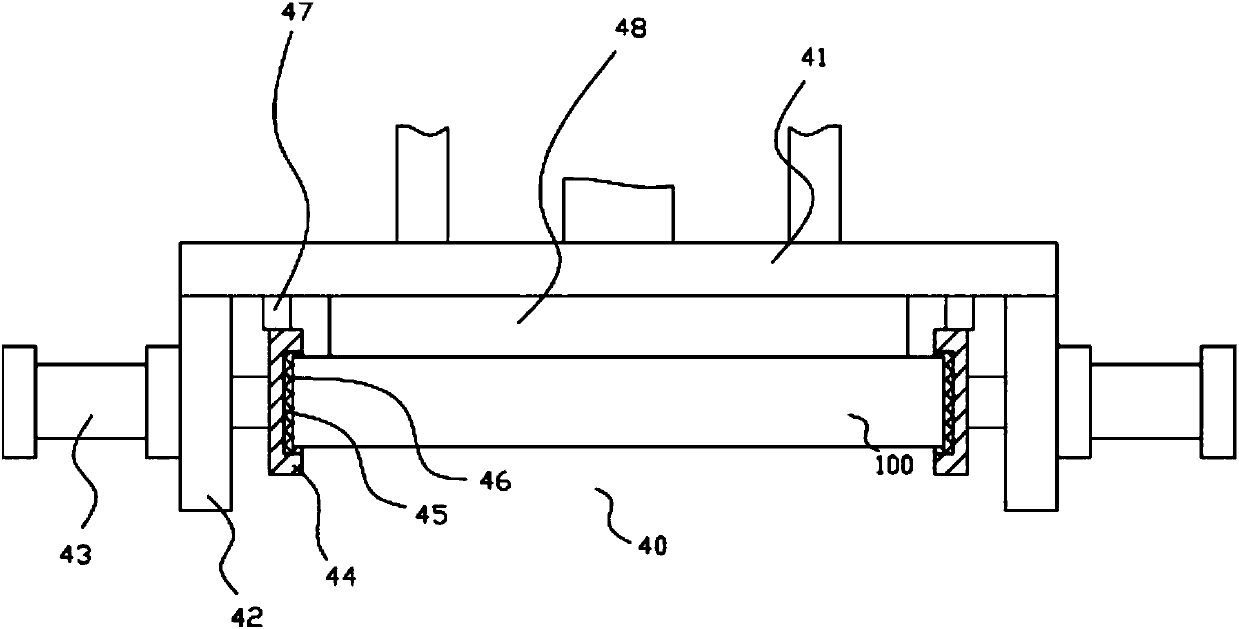

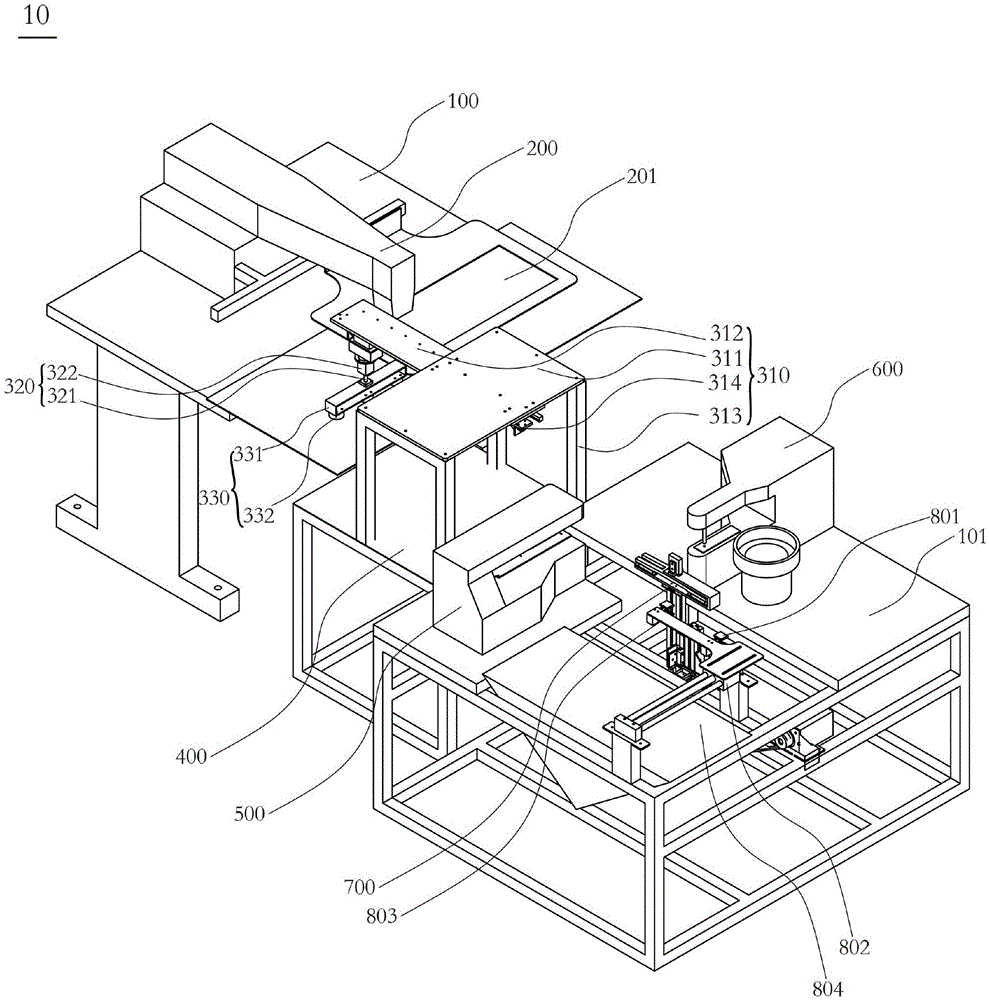

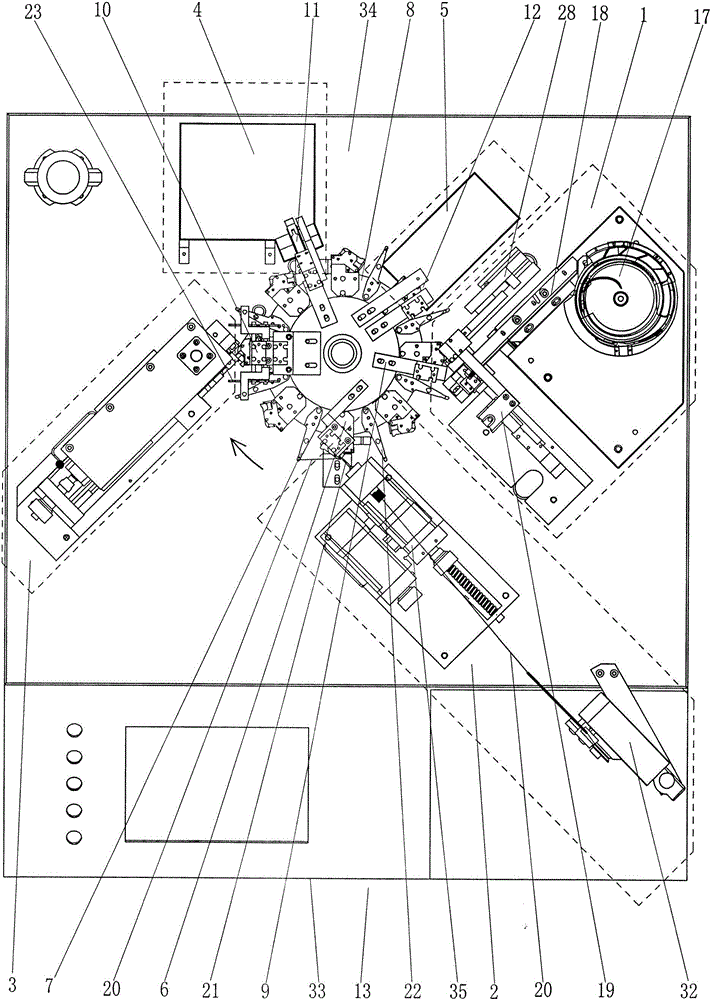

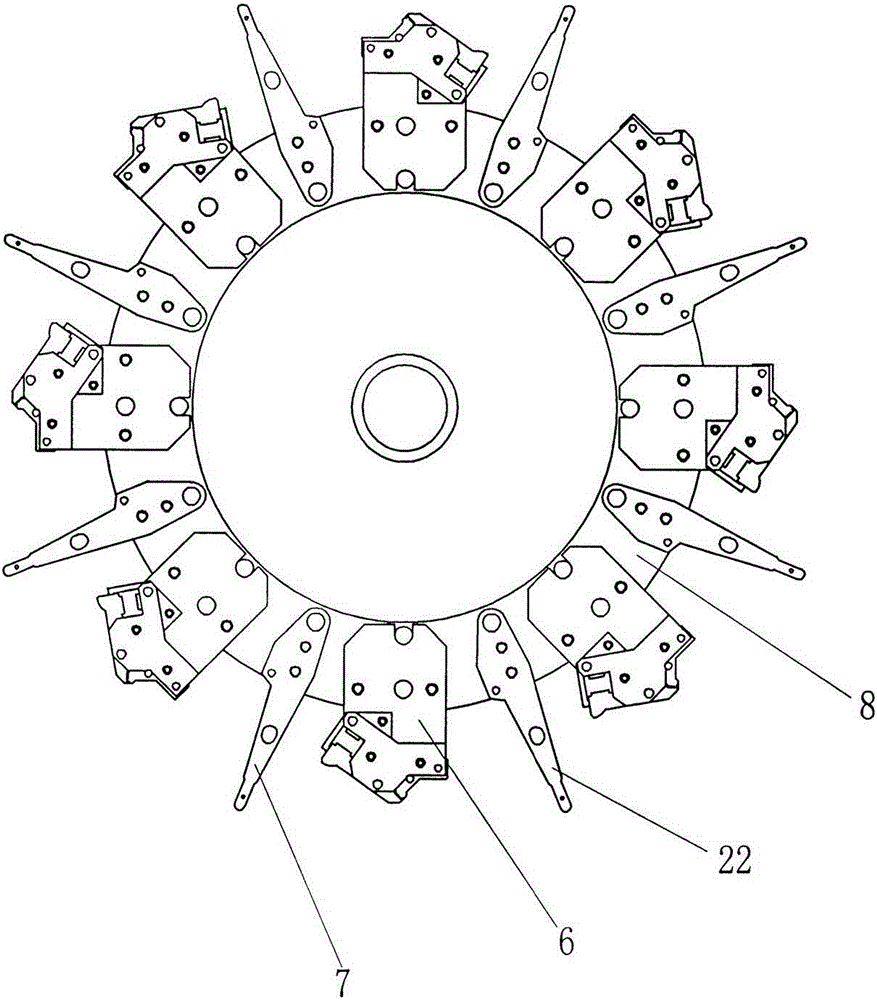

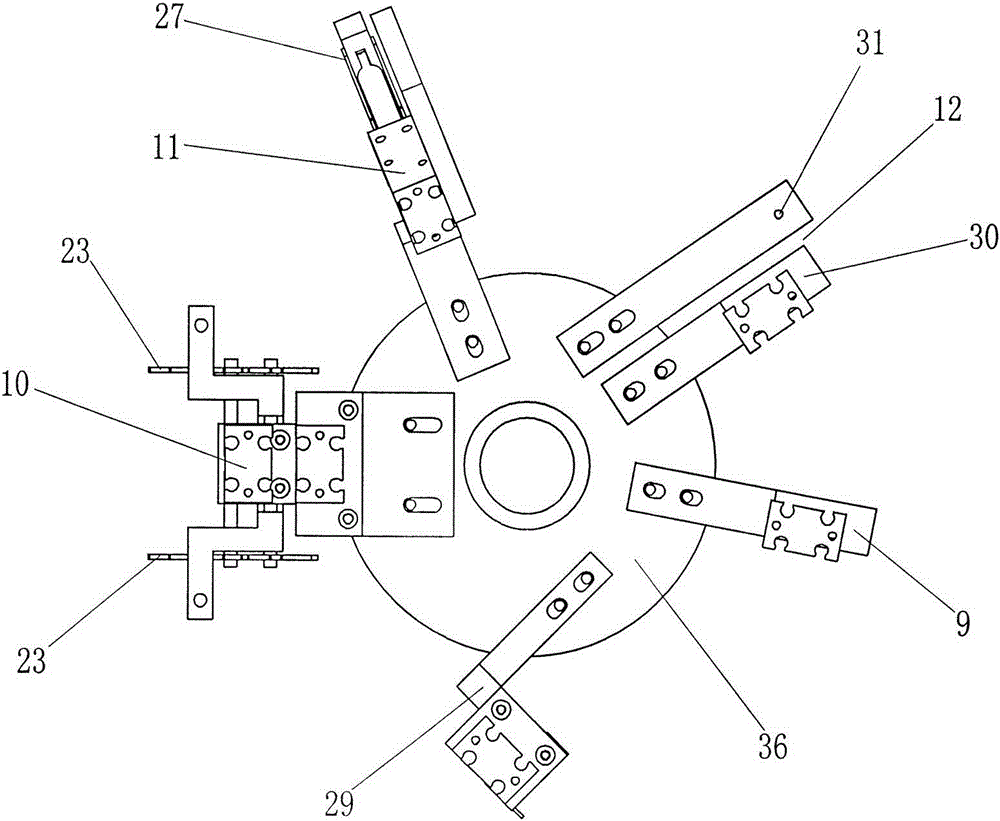

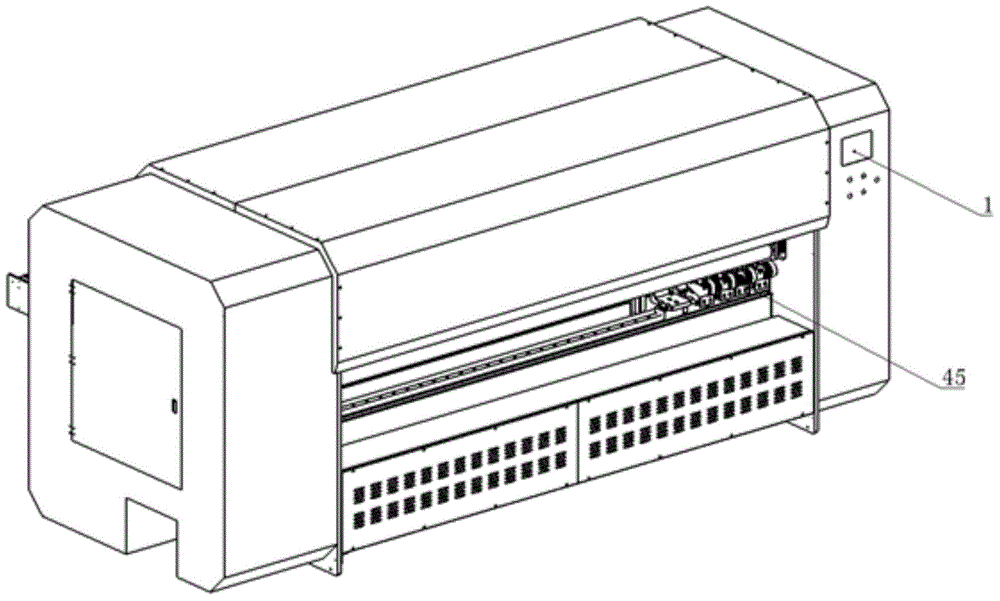

Full-automatic manufacturing method for chip winding inductors and equipment employing full-automatic manufacturing method

The invention discloses a full-automatic manufacturing method for chip winding inductors and equipment employing the full-automatic manufacturing method, and aims at overcoming the defects of low working efficiency, complicated mechanism, large overall dimension, high cost and the like in the prior art due to the facts that a lot of lost motions are generated by reciprocating cycle operations and the time for waiting for feeding on various stations is long. According to the main points of the technical scheme, the full-automatic manufacturing method is characterized by comprising the steps as follows: a feed mechanism, a line feeding and winding mechanism, a welding mechanism, a garbage collection container and a finished product collection container are arranged on the periphery of a conveyor rotating plate with a plurality of clamping devices and a plurality of lead frames, which are alternately arranged; clamping device feeding drive mechanisms, a line pressing mechanism, a line arranging mechanism and a discharging mechanism are arranged on full-automatic equipment above the conveyor rotating plate; and specific operation processes of conveying, feeding, clamping, fixing, winding, welding, line arranging, discharging and automatic manufacturing of the chip winding inductors on ceramic cores are finished on the full-automatic equipment.

Owner:东莞市复纳电子有限公司

Corrugated board slotting machine

ActiveCN106493996AUnlimited heightControl inputBox making operationsPaper-makingCardboardEngineering

The invention discloses a corrugated board slotting machine. The corrugated board slotting machine comprises a device body. The feeding end of the device body is sequentially provided with a feeding sliding roller A, a feeding sliding roller B and a feeding belt. The feeding belt is arranged between feeding paper supporting platforms and arranged on a feeding drive roller and a feeding driven roller. One end of the feeding drive roller is connected with a feeding motor. A feeding front paper baffle is arranged above the feeding paper supporting platforms. The output end of the feeding belt is sequentially provided with a height measuring drive roller and a rear drive roller. The height measuring drive roller is provided with a height measuring press roller, and a rear pressing roller is arranged on the rear drive roller. An end face slotting lifting plate, a middle slotting upgrading plate A, a middle slotting upgrading plate B, a middle slotting upgrading plate C and a trimming lifting plate are arranged at the output end of the rear drive roller in parallel.

Owner:深圳市万德数字科技有限公司

Oblique decorative sheet feeding device

InactiveCN101338500AExtended service lifeAvoid swingingWork-feeding meansAutomatic machinesFeed driveActuator

An oblique decorative plate feeding device comprises a lifting mechanism, which is provided with a fixed bracket fixed on the needle bar box of an embroidering machine and a movable bracket movably connected with the fixed bracket and driven by an actuator to lift; a feeding mechanism, which is provided with a bearing base connected with the movable bracket, a stepping motor arranged on the bearing base, a feeding drive mechanism driven by the stepping motor, a feeding guide mechanism and a cutting mechanism. The feeding mechanism arranged in the oblique front of the needle bar box can lift between a standby position and a work position; when the feeding mechanism lifts to the work position, the feeding guide mechanism points to the decorative plate stitching position from the oblique front of the needle bar box. The present invention overcomes the shortcomings of the prior horizontal or front devices, thus not hindering the threading operation of the embroidering machine and not occupying the lateral space of the head, which is suitable for the embroidering machine with small head distance. In addition, the feeding device is also provided with a regulation fastening mechanism and a photoelectric automatic aligning device.

Owner:FUJIAN YONGXIN NUMERICAL CONTROL TECH

System for high-speed automatic weighing of items in a mail stream

InactiveUS20070050315A1Reduced settling timeWeighing apparatus detailsFranking apparatusLeading edgeControl system

An apparatus for weighing mail pieces being advanced across a transport path including a weighing module having load cells, an in-feed drive module and a takeaway module. The scale platform is mounted independently of the in-feed drive module and the takeaway module, and the scale platform comprises an uninterrupted mail piece support surface. A control system is provided that acquires a mail piece weight signal when the lead edge of a mail piece reaches a sensor at the exit of the weighing module. Sensors also calculate the velocity of a mail piece as it leaves the weighing module, whereby speed of each mail piece is accelerated to its original speed and position in the mail transport path. Mail weighing throughput rates of up to 10 mail pieces per second are achieved.

Owner:RABINDRAN K GEORGE

Screw conveyor

The invention relates to a screw conveyor and belongs to the technical field of screw installation. According to the screw conveyor, structures are installed compactly, mechanisms can be tightly matched with one another, screws can be discharged in order, the situation that the screws are clamped is avoided, and therefore the conveying efficiency of the screws is improved, and the installation rhythm of the screws is improved. By means of the switching mechanism, the switching efficiency of the switching mechanism is improved, the situations that in the prior art, the switching precision is low and the switching efficiency is low due to the fact that the structure of a screw switching mechanism is complex are avoided, and the precision requirement of the screw switching mechanism during screw switching is guaranteed. By means of a material channel of the feeding drive mechanism, the sequence of discharging of the screws is guaranteed, and the occurrence of the clamping situation is avoided.

Owner:SHANGHAI JINGZHI IND CO LTD

Numerical-control multi-station automatic drilling-tapping machine

InactiveCN103894834AReduce usageSimple structureAutomatic control devicesFeeding apparatusNumerical controlHuman–machine interface

The invention discloses a numerical-control multi-station automatic drilling-tapping machine. The numerical-control multi-station automatic drilling-tapping machine comprises a frame, a plurality of slewing bearings, a feeding linear module, a drilling-tapping assembly, a conveying linear module, and a numerical control mechanism; the slewing bearings are disposed on the frame; the feeding linear module is disposed on the slewing bearings; the drilling-tapping assembly is mounted on the feeding linear module; the conveying linear module penetrating inner holes of the slewing bearings axially slides on the frame along the slewing bearings; the numerical control mechanism controls the feeding linear module and the drilling-tapping assembly to operate. The feeding linear module comprises a module support, a drive motor and a slider; the drilling-tapping assembly is mounted on the slider and driven a drilling-tapping drive motor; both a drilling, tapping and feeding drive motor and the drilling-tapping drive motor are controlled by the numerical control mechanism. The numerical-control multi-station automatic drilling-tapping machine has the advantages that the slewing bearings are simple in structure and flexible to use, equipment adaptability is greatly improved, usage of fixtures is greatly reduced by the use of reciprocated conveying of the conveying linear module, and operation with a man-machine interface is more facilitated.

Owner:黎德智

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com