Fuzzy control system and control method for gear tooth type crusher

A fuzzy control system and fuzzy controller technology, applied in grain processing, etc., can solve the problems of slow movement of movable rollers, lack of flexibility and intelligence, failure of main motor of crusher, etc., to reduce operating current and voltage and The effect of iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

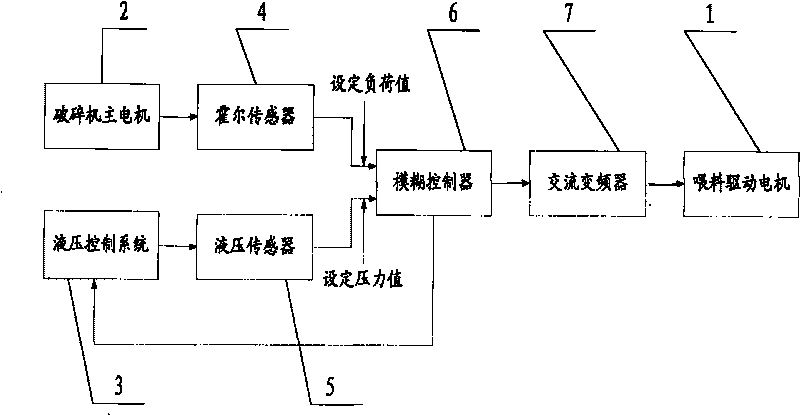

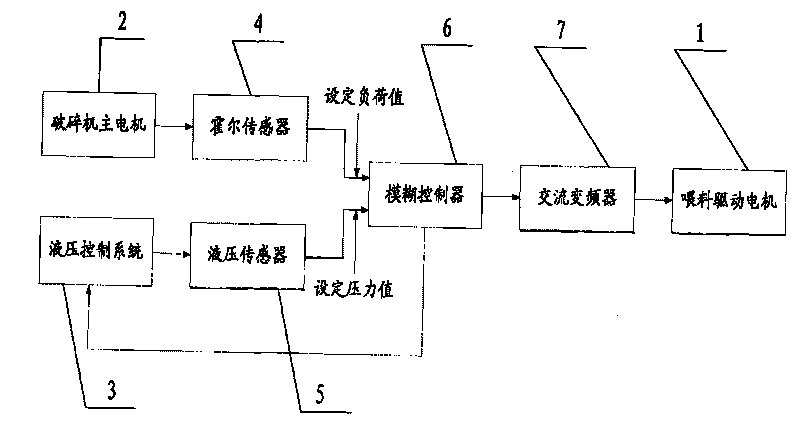

[0015] see figure 1 , the fuzzy control system for gear-tooth crusher of the present invention comprises a feeding drive motor 1, two main motors 2, a hydraulic control system 3, a Hall sensor 4, a hydraulic sensor 5, a fuzzy controller 6 and an AC frequency conversion 7, wherein the two main motors 2 are respectively used to drive a pair of roller shafts for relative rotation; the hydraulic control system is used to adjust the gap between the pair of roller shafts;

[0016] The Hall sensor 4 is used to monitor the instantaneous load of the crusher in real time;

[0017] The hydraulic sensor 4 is used to monitor the instantaneous pressure of the working oil in the hydraulic cylinder in the hydraulic control system 3 in real time;

[0018] The fuzzy controller 6 is used to recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com