Numerical-control multi-station automatic drilling-tapping machine

A tapping machine, multi-station technology, applied in automatic control devices, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of fixed processing stations, low production flexibility, and high production costs, and achieve flexible use and improved production. Adaptive and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

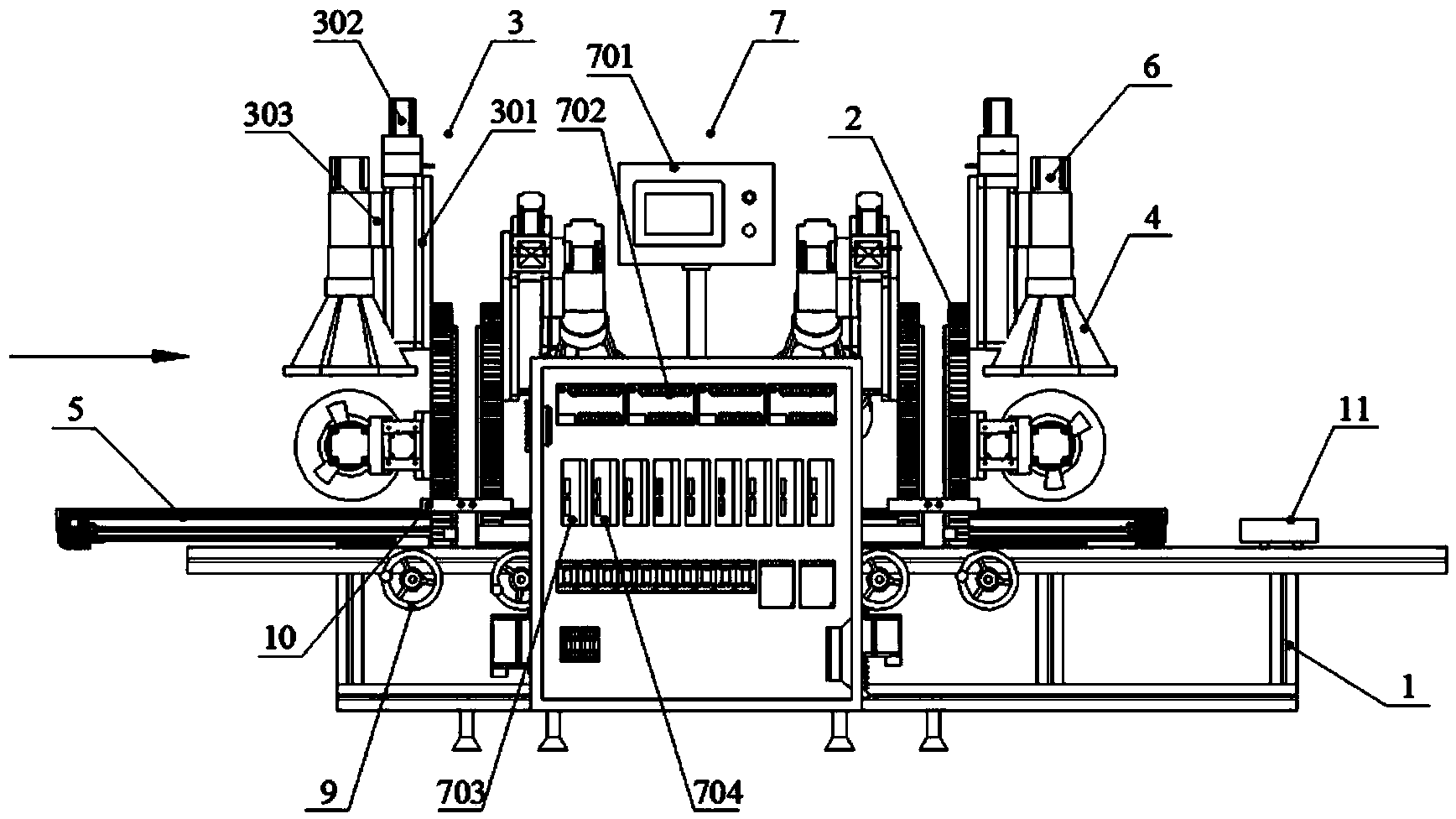

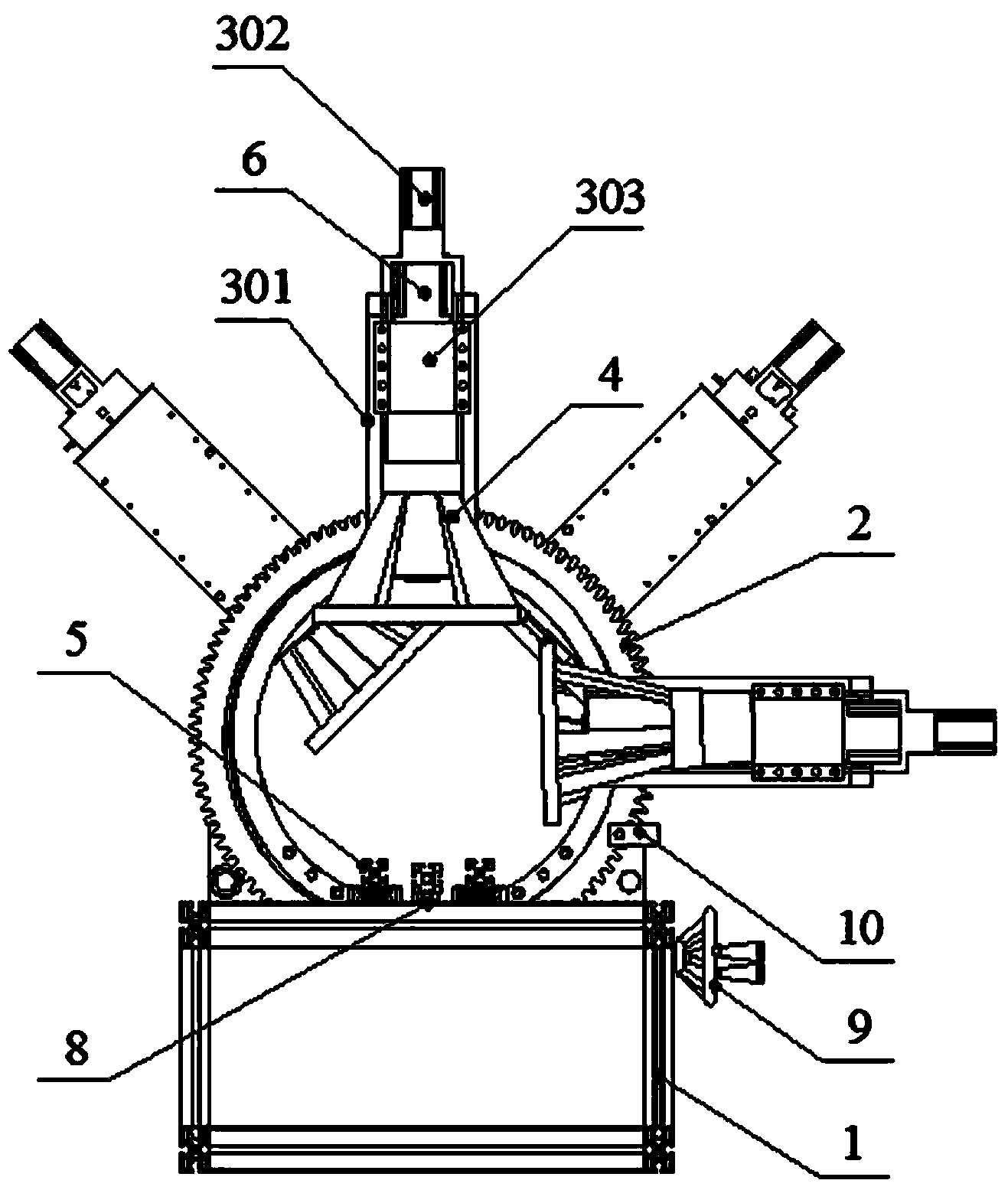

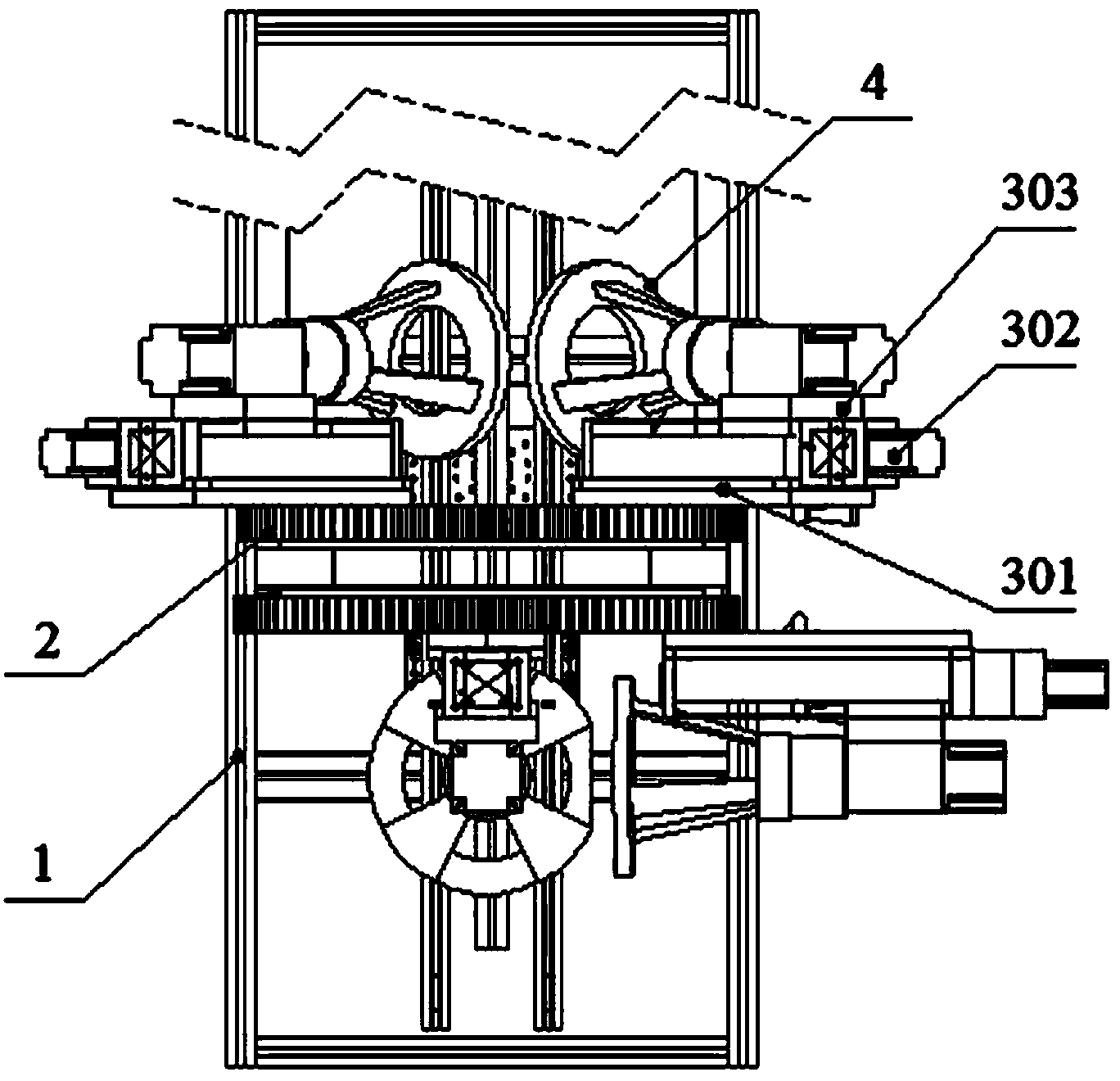

[0019] refer to figure 1 , figure 2 and image 3 , the numerically controlled multi-station automatic drilling and tapping machine of the present invention comprises: a frame 1, a plurality of rotatable and circular slewing bearings 2 arranged on the frame 1, a feed feeder arranged on the slewing Linear module 3, the drilling and tapping assembly 4 installed on the feed linear module 3, the feeding linear module that passes through the inner hole of the slewing support 2 and slides on the frame 1 along the axial direction of the slewing support 2 5, and the CNC mechanism 7 that controls the work of the feed linear module 3 and the drilling and tapping assembly 4. Wherein, the feed linear module 3 includes: a module bracket 301 fixed on the slewing bearing 2, a drilling and tapping feeding drive motor 302 installed on the module bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com