Oblique decorative sheet feeding device

A technology for supplying devices and decorative sheets, applied to auxiliary devices, embroidery machine mechanisms, embroidery machines, etc., can solve the problems of feeding deviation, movement adjustment, and difficult installation of decorative sheets, so as to overcome easy damage and prevent left and right swings , Reduce the effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

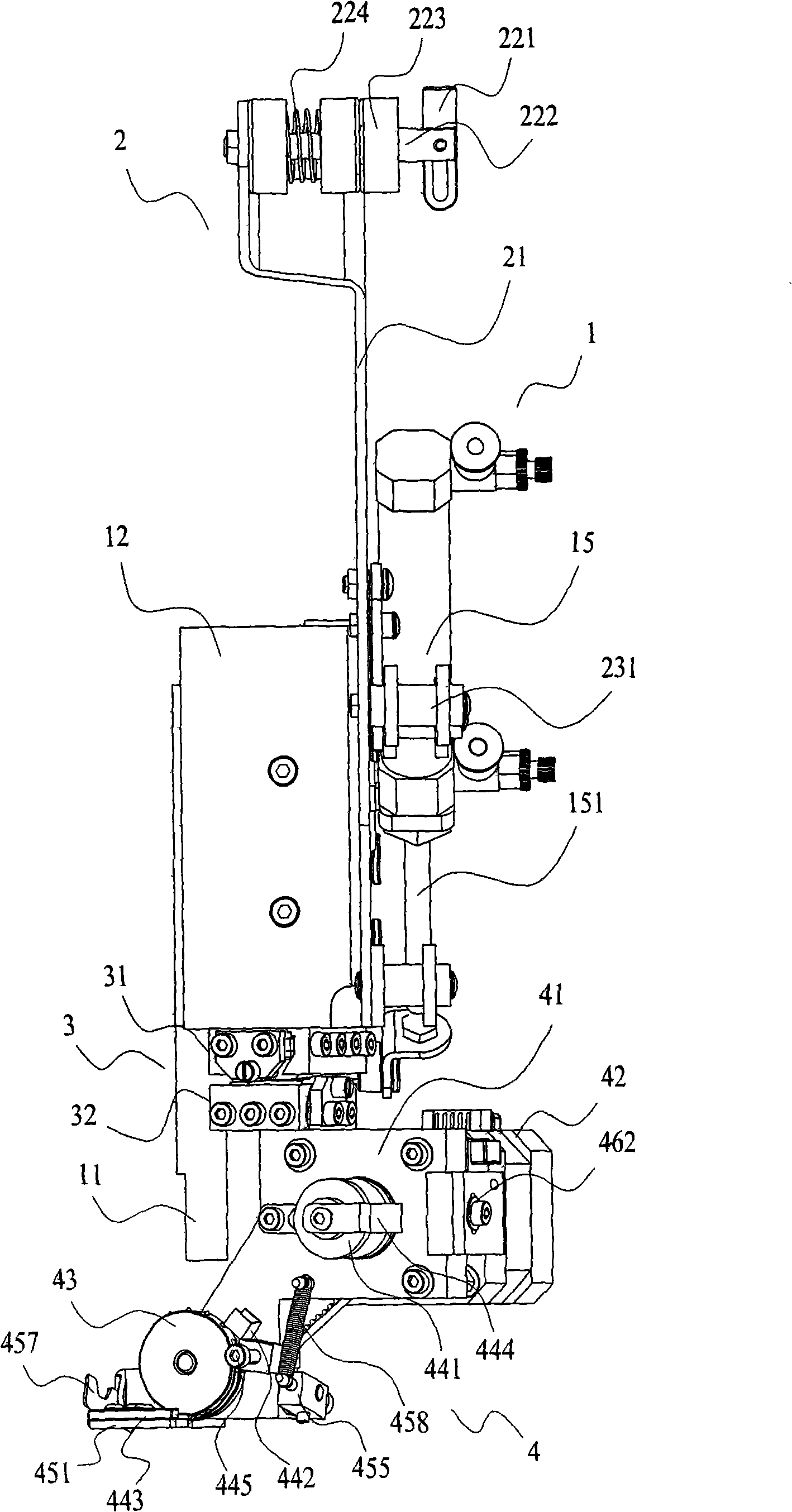

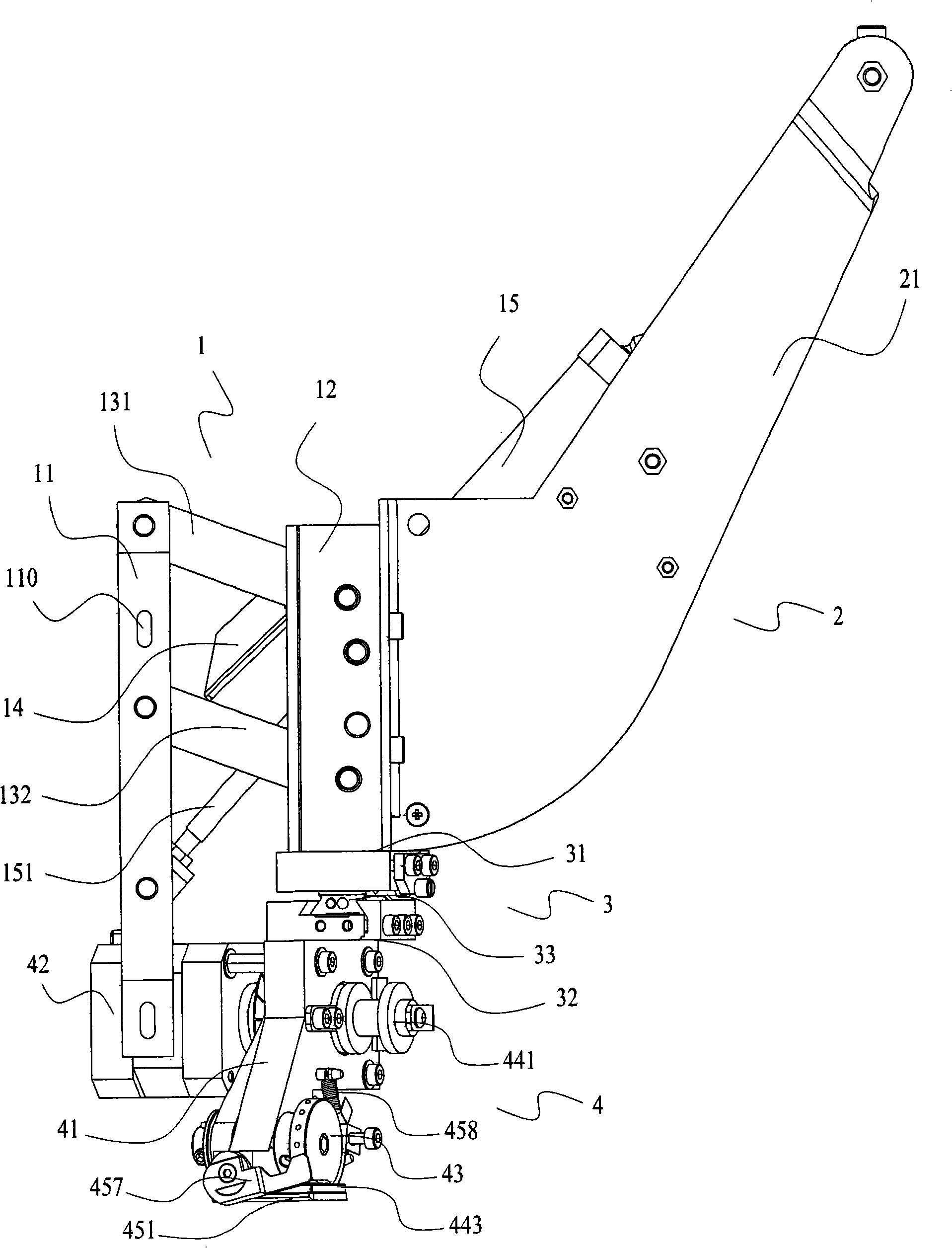

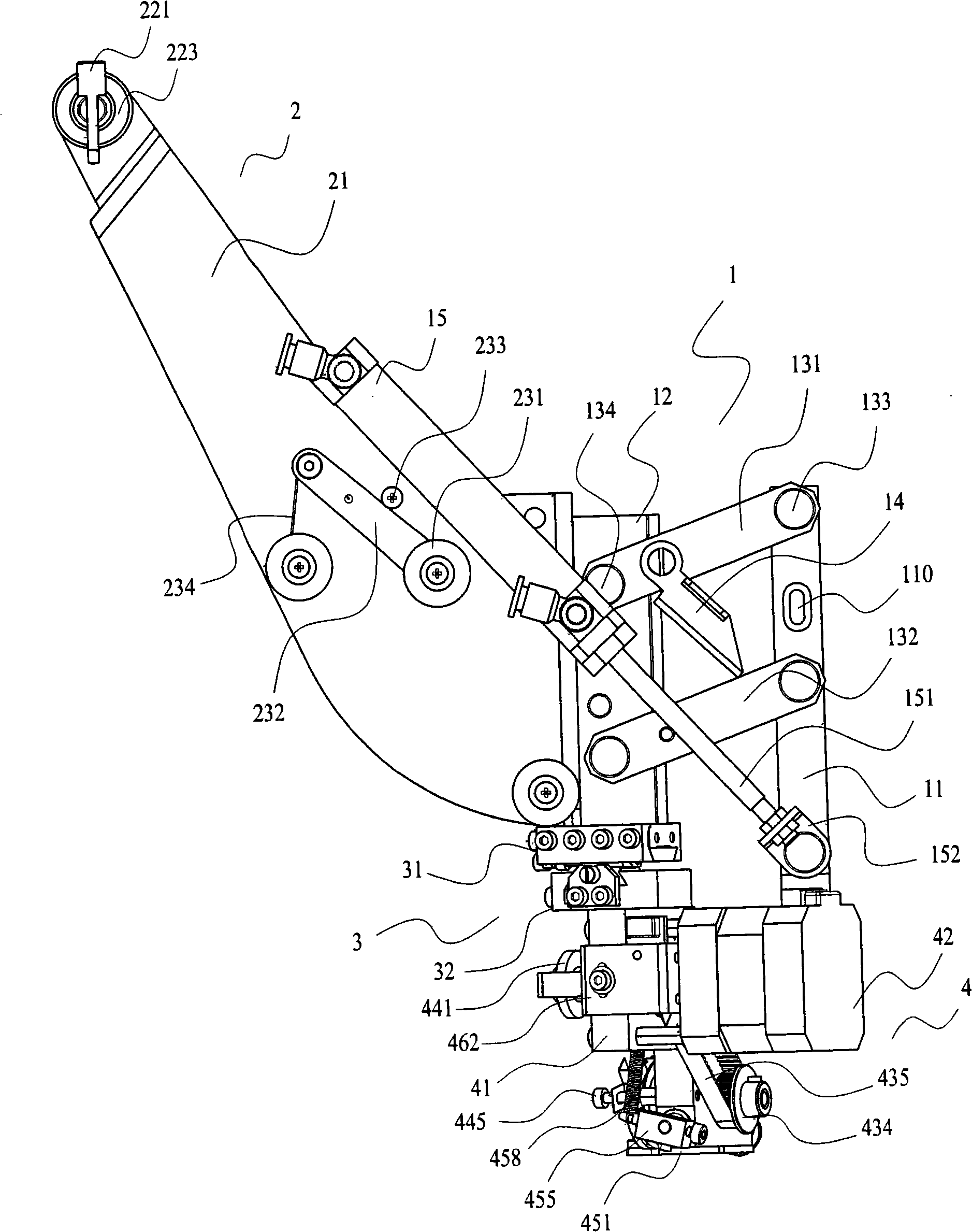

[0047] refer to Figure 1 to Figure 5 , The oblique decorative sheet supply device provided by the present invention includes: a lifting mechanism 1 , a feeding mechanism 2 , an adjusting and locking mechanism 3 , and a feeding mechanism 4 . Referring to Fig. 13, the oblique type decorative sheet supply device is installed on the front of the needle bar case 5 of the embroidery machine by its lifting mechanism 1. Needle bar case 5 is vertically installed on the horizontal beam (not shown in the figure) of machine head, and needle bar mechanism 6 is vertically installed on needle bar case, forms sewing working surface below needle bar mechanism 6.

[0048] Referring to FIGS. 6 and 13 , the lifting mechanism 1 includes a fixed bracket 11 , a movable bracket 12 , a connecting rod 131 , a lower connecting rod 132 , a locking plate 14 and a cylinder 15 . The fixing bracket 11 has a mounting hole 110, and can be fixed to the front of the needle bar case 5 by fasteners. Movable sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com