Patents

Literature

492 results about "Product value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An assessment of the worth of a good or service. The product value assessed by a business when setting a price for a particular product can depend on its productioncosts, its overall market value and the value of the product as perceived by a targeted group of consumers.

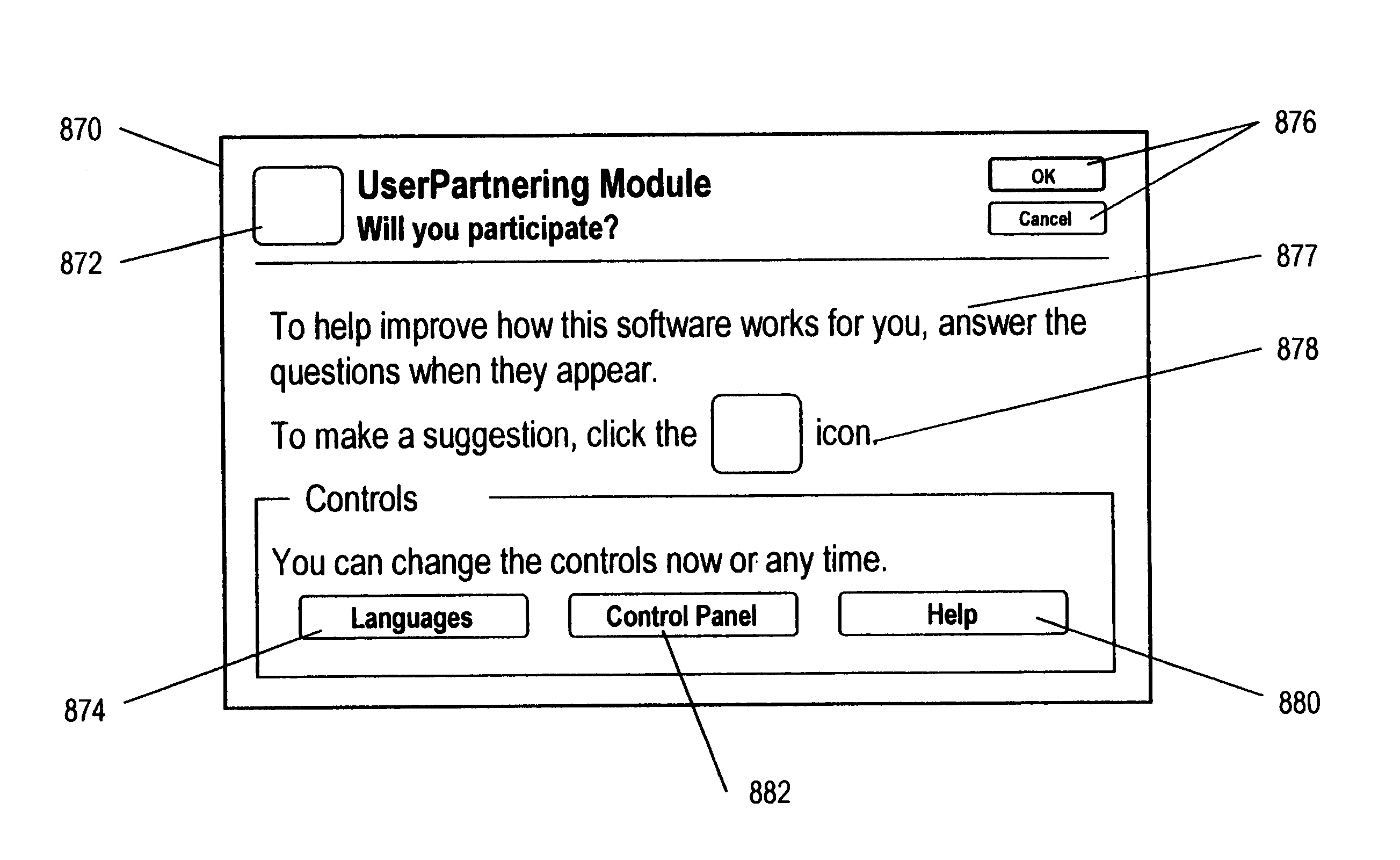

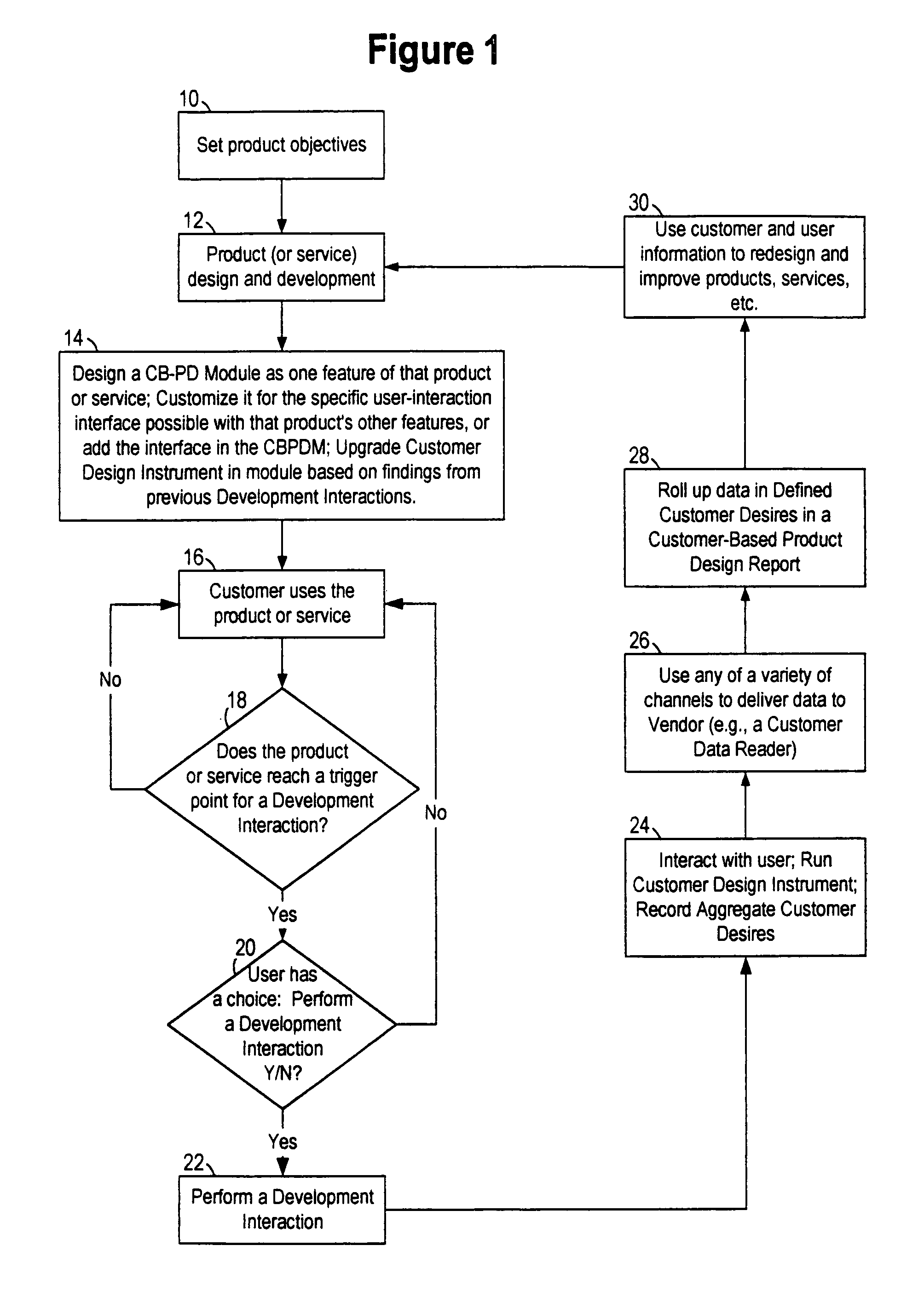

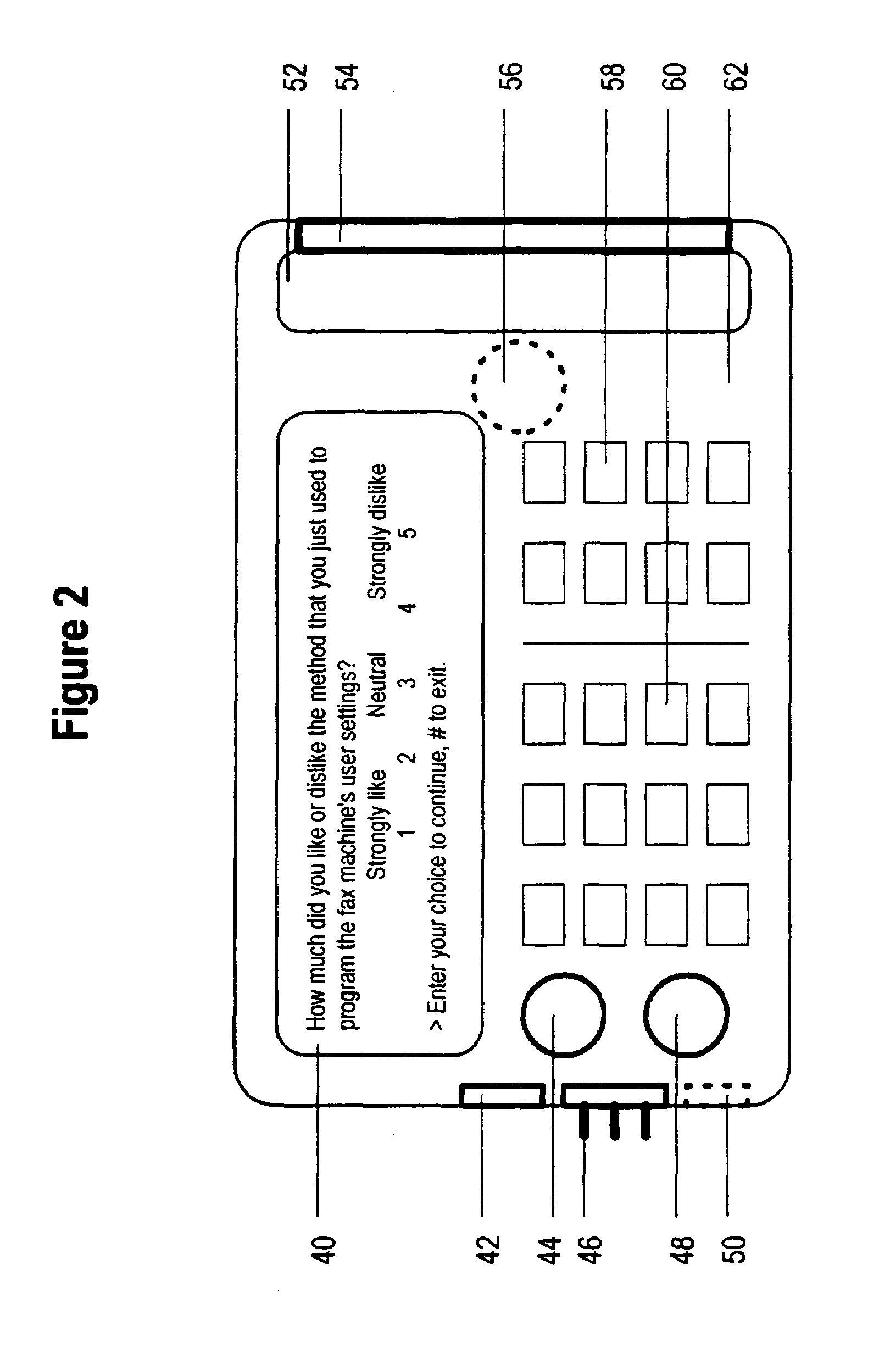

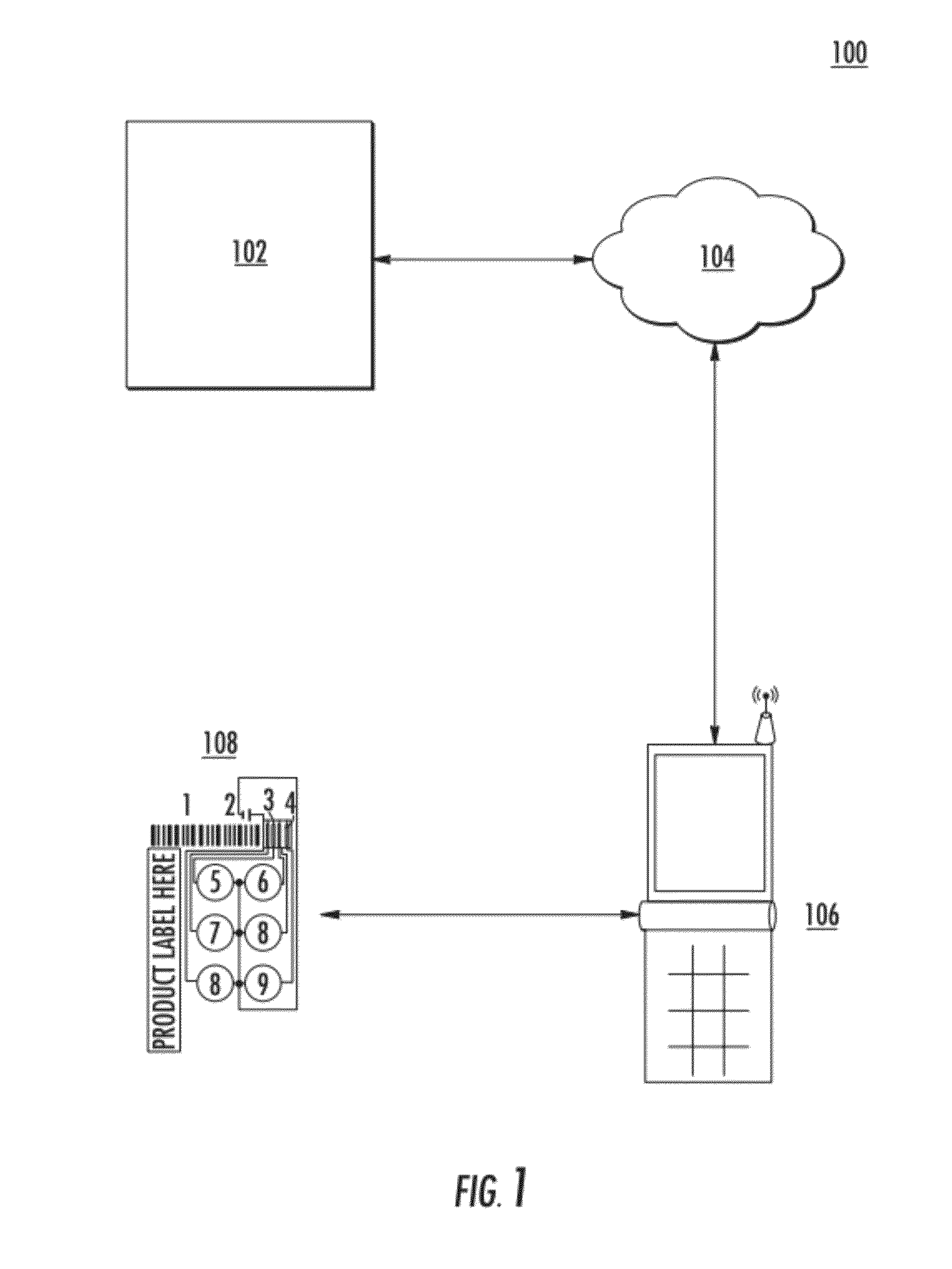

Product value information interchange server

InactiveUS7133834B1Improve recognitionImprove market shareMarket predictionsClient-sideService information

An electronically accessible server receives, stores, and sends value information from customers. The server or other digital medium stores the value information generated by independent users. Triggers or interactions can be used to determine when value information would be useful for a user of a client system. The value information can include customer assessments, usage frequency, navigational pointers, executable program code, instructions, product information, and service information. A digital medium is used to store value information generated by independent users. The medium can be coupled to an electronic communication network to allow for interchange of information.

Owner:LODSYS GRP

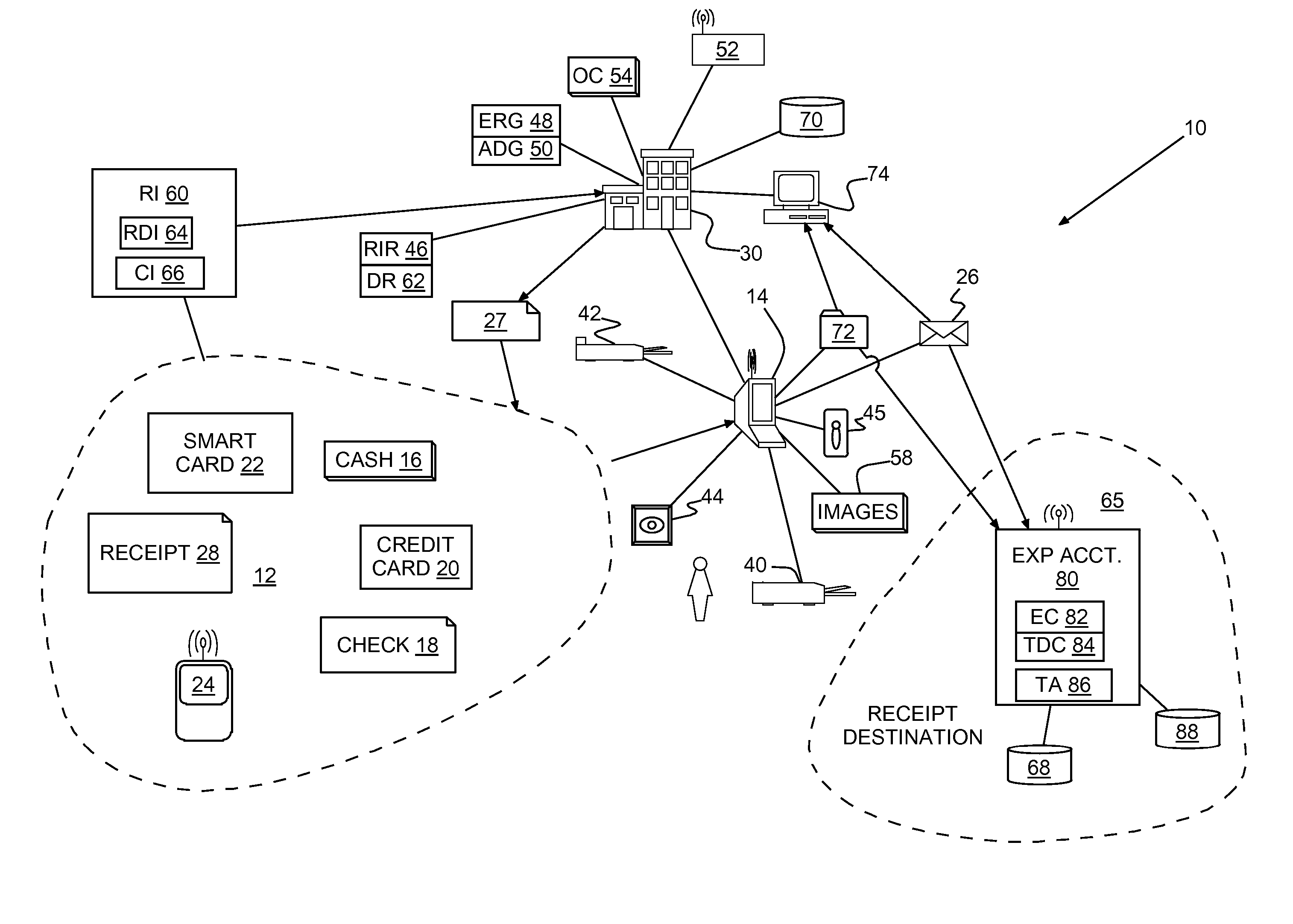

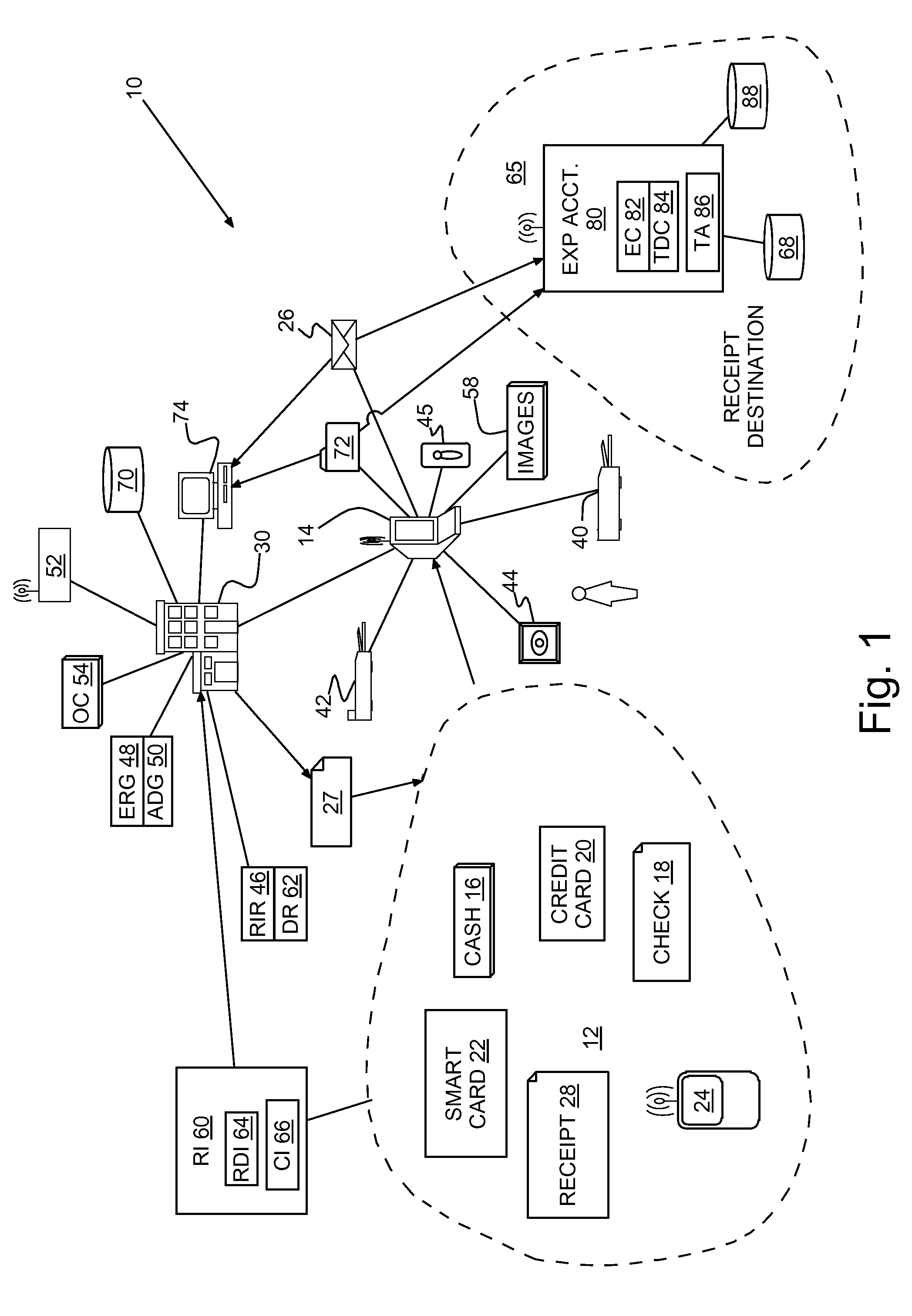

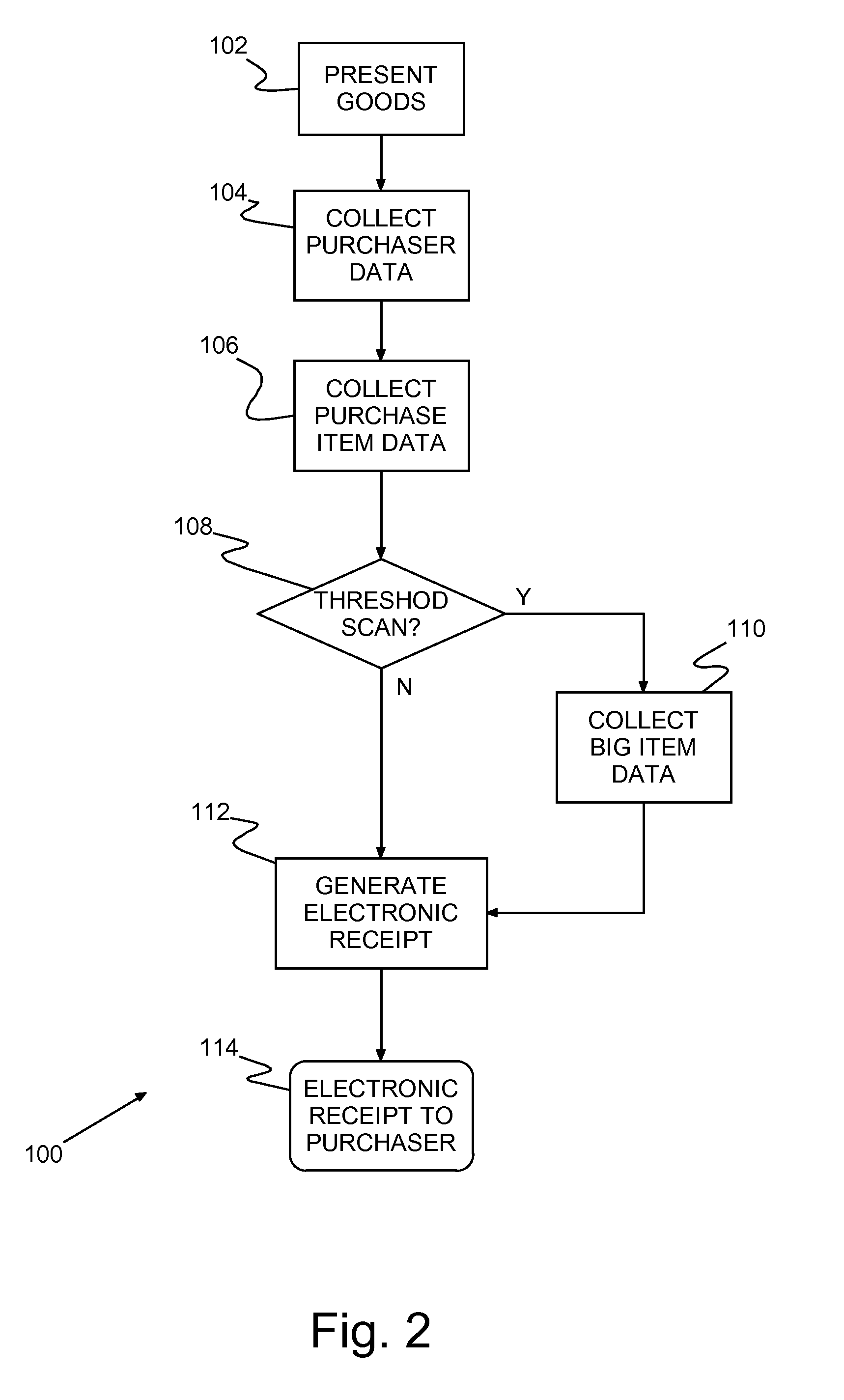

System and method of directly providing electronic receipts

InactiveUS20070094088A1Eliminate needReduce morbidityFinanceCash registersBiometric dataFeature data

A method and program product for providing paperless receipts for conducting business transactions. Biometric data and product specific identification information is collected with each purchase and included with an electronic receipt generated for each purchase. The collected product specific information may include product serial numbers for some products, all products or product valued above a minimum threshold cost. The biometric data may include a digital image of each purchaser. The electronic receipt may be passed directly to the customer.

Owner:IBM CORP

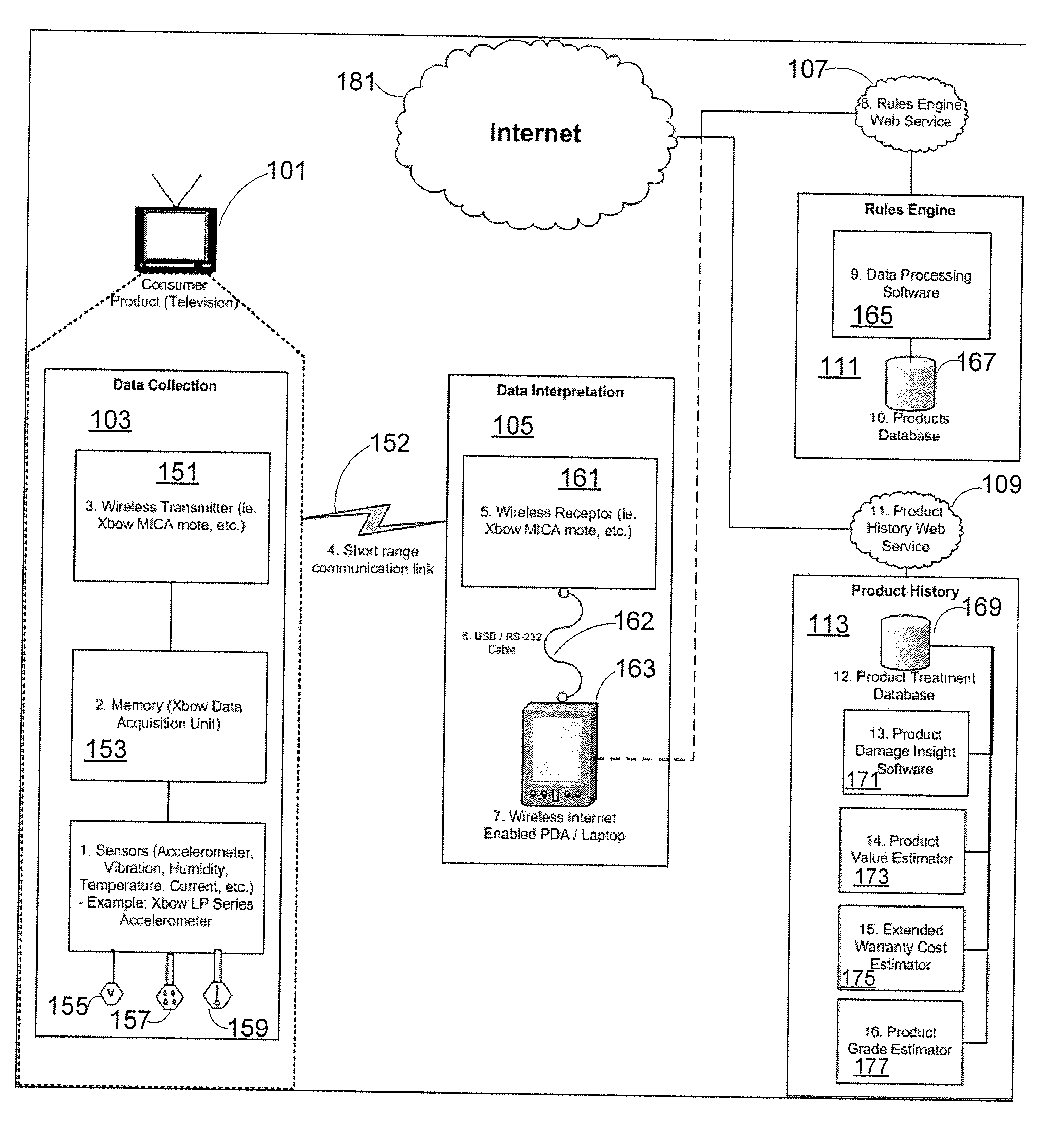

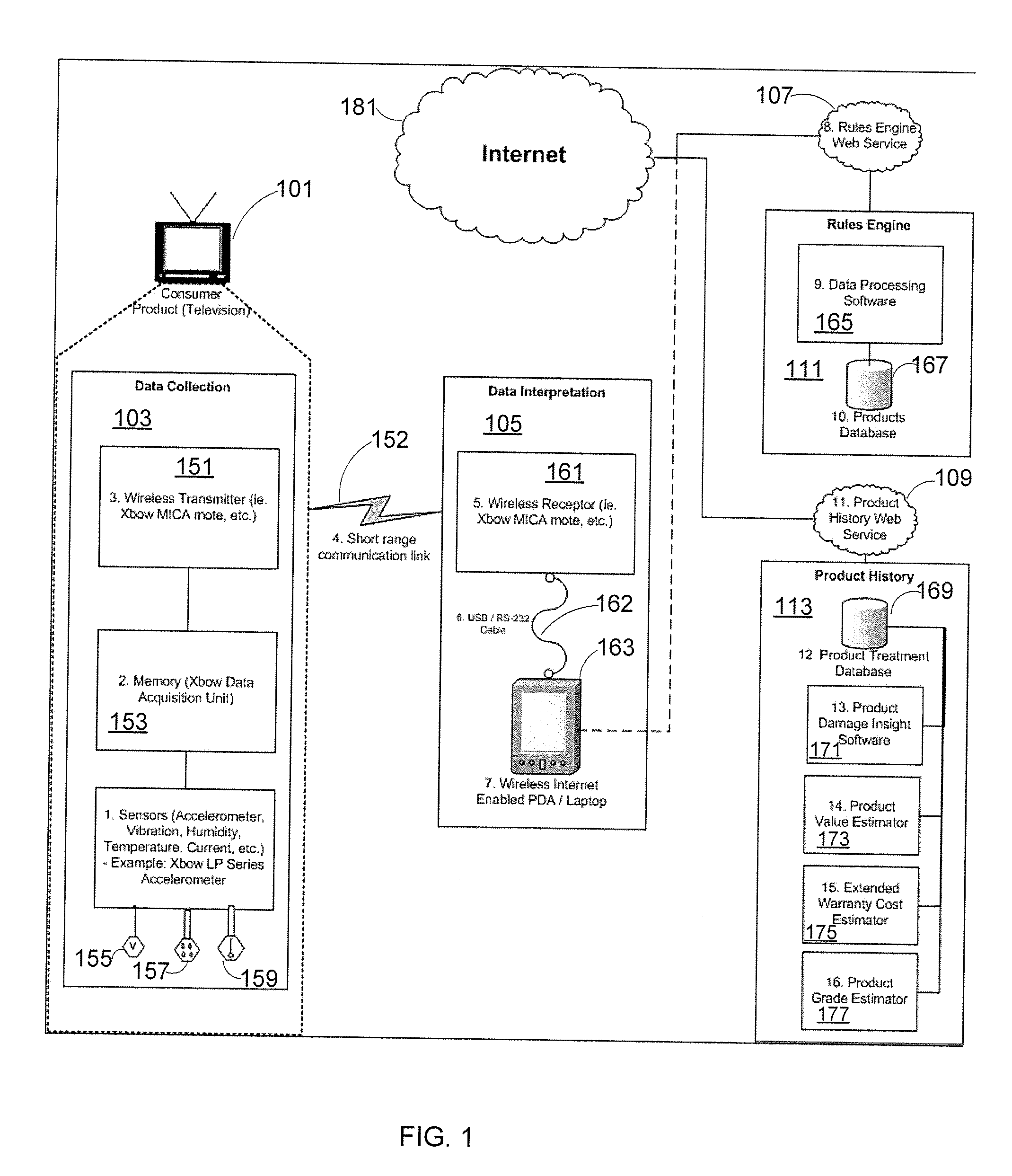

Embedded warranty management

Methods and systems for obtaining and analyzing data from embedded sensors in electronic products for warranty management. A data collection unit in an electronic product collects and reports data about environmental factors that is relevant about a warranty agreement and transmits the data over a communications link to a data interpretation unit. The data interpretation unit may obtain warranty information from an electronic product and query a database to determine if the electronic product has been exposed to environmental factors outside the ranges that are specified in the warranty agreement. The data interpretation unit may query a database to determine the product grade of the electronic product based on the sensor data and to determine an estimated product value. The data interpretation unit may query a database to determine an estimated warranty cost of an extended warranty based on the condition of the electronic product and historical warranty value.

Owner:ACCENTURE GLOBAL SERVICES LTD

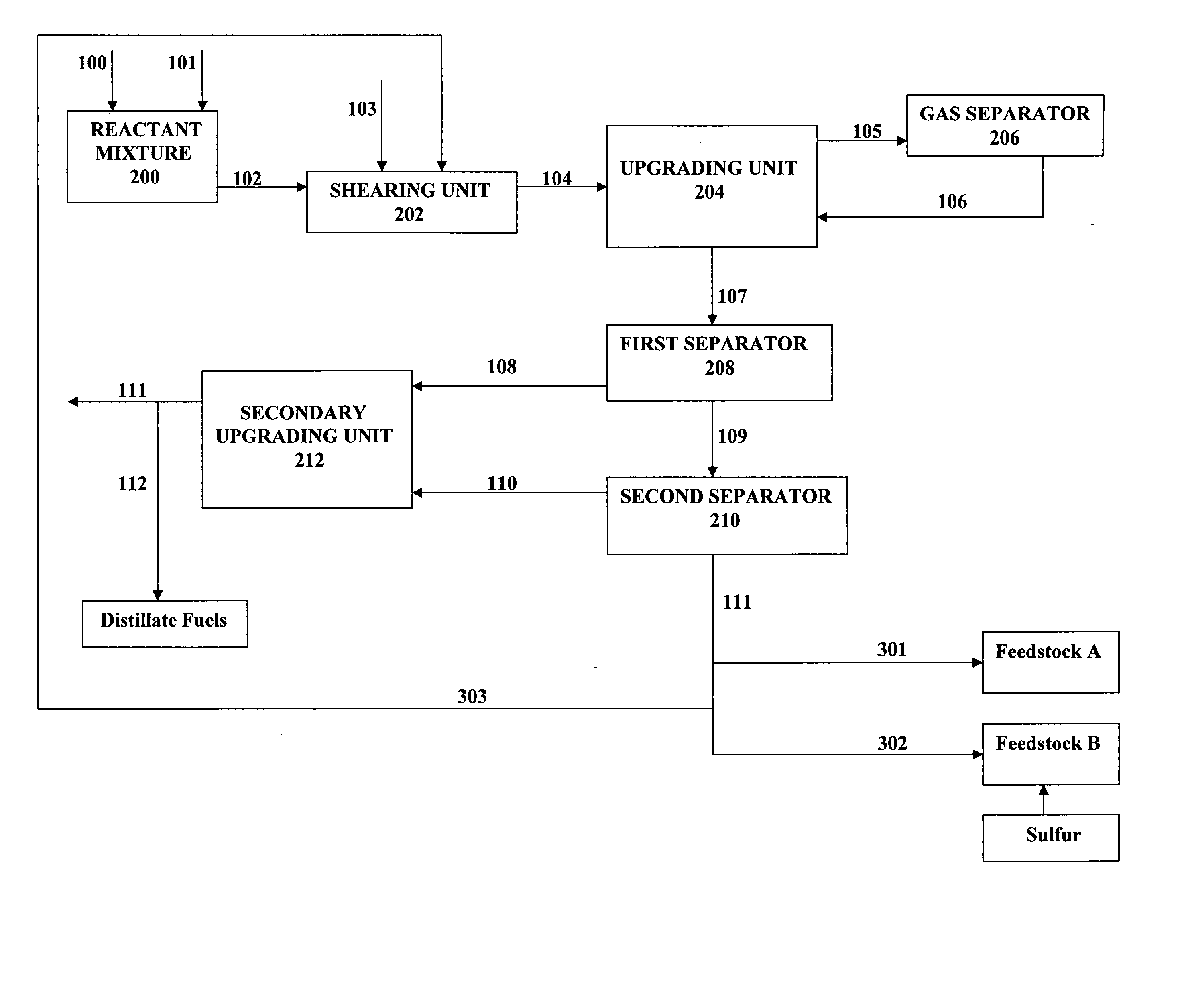

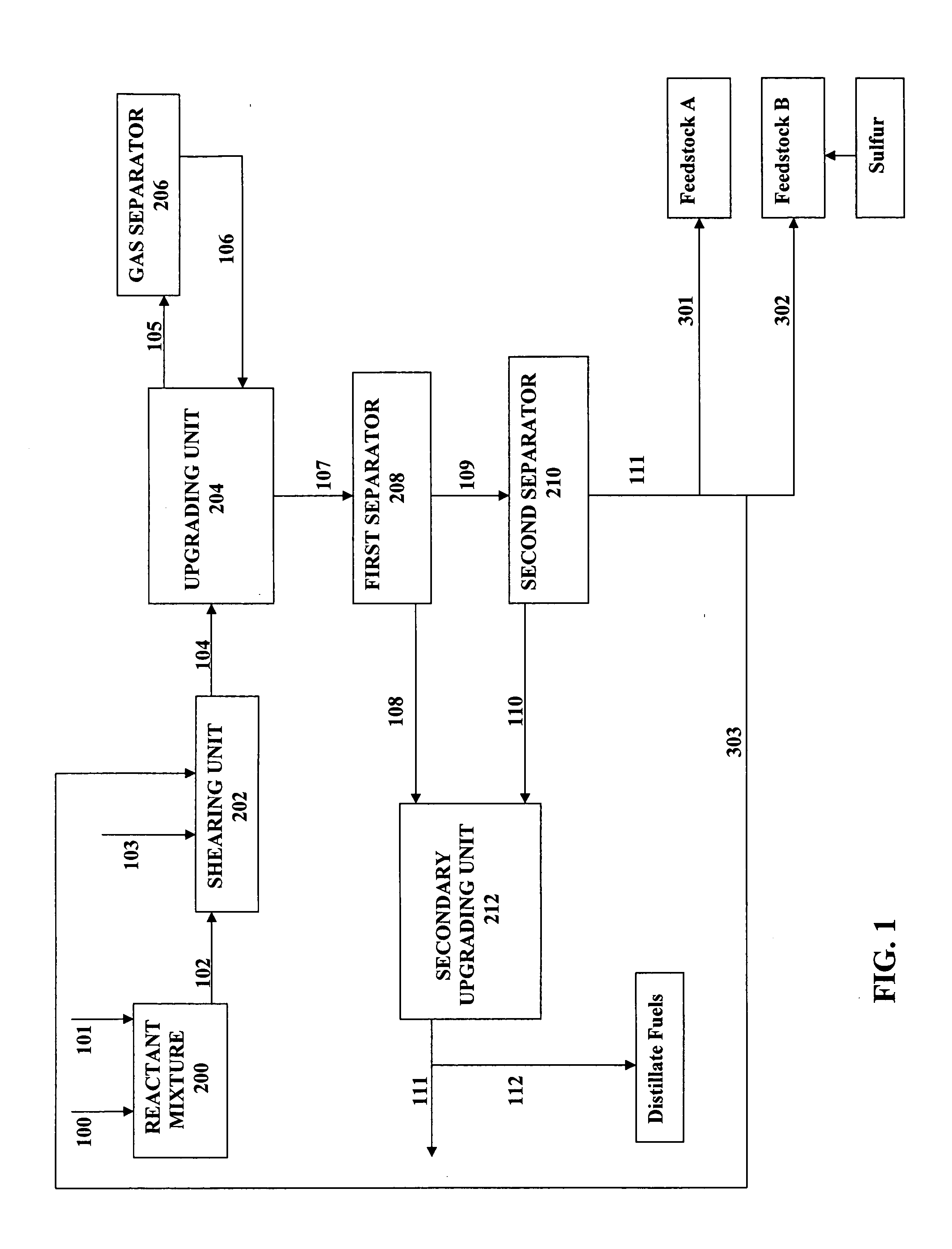

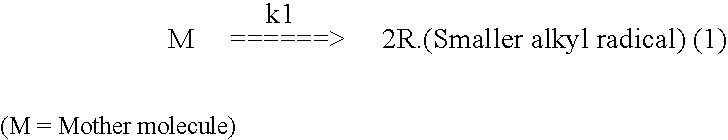

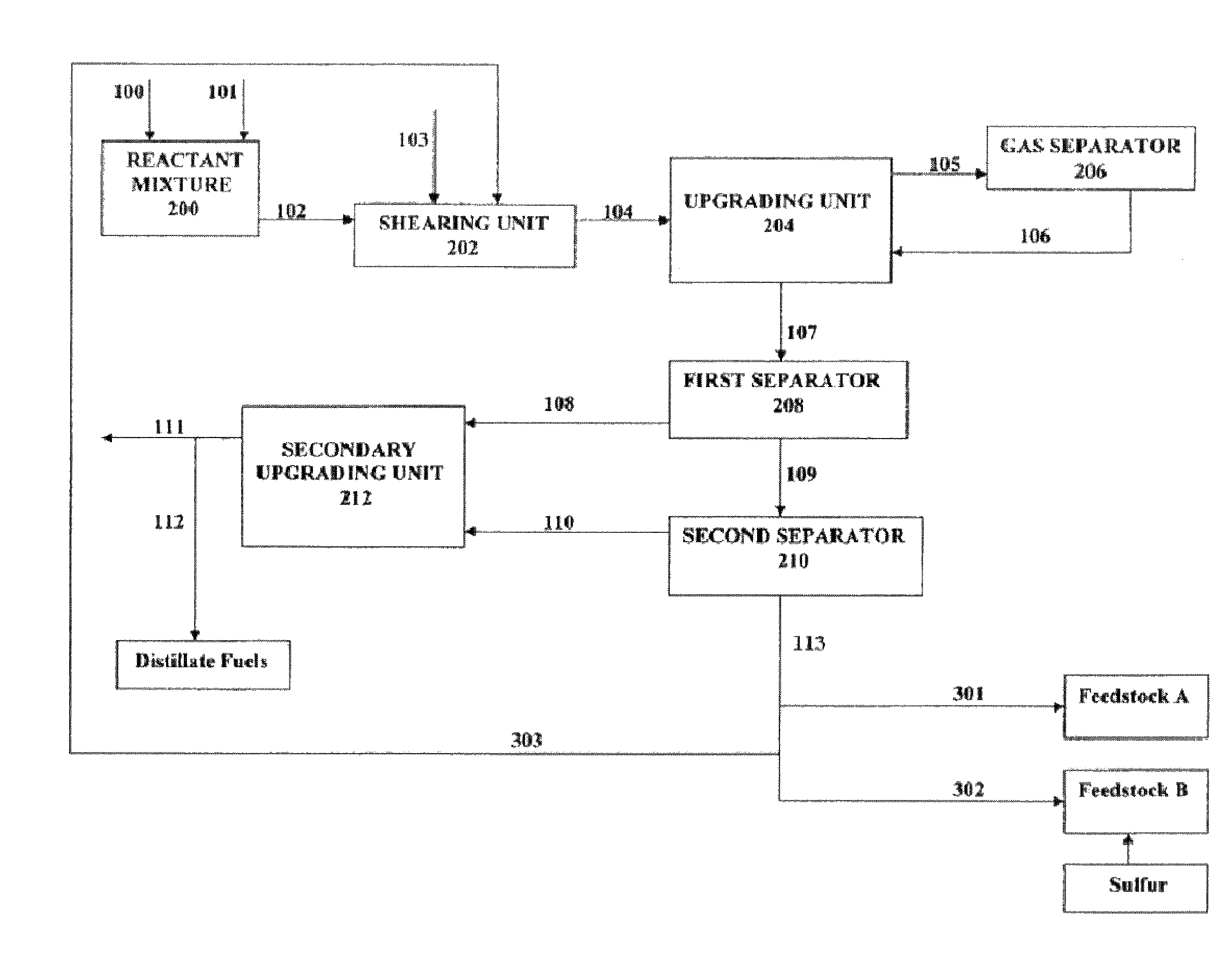

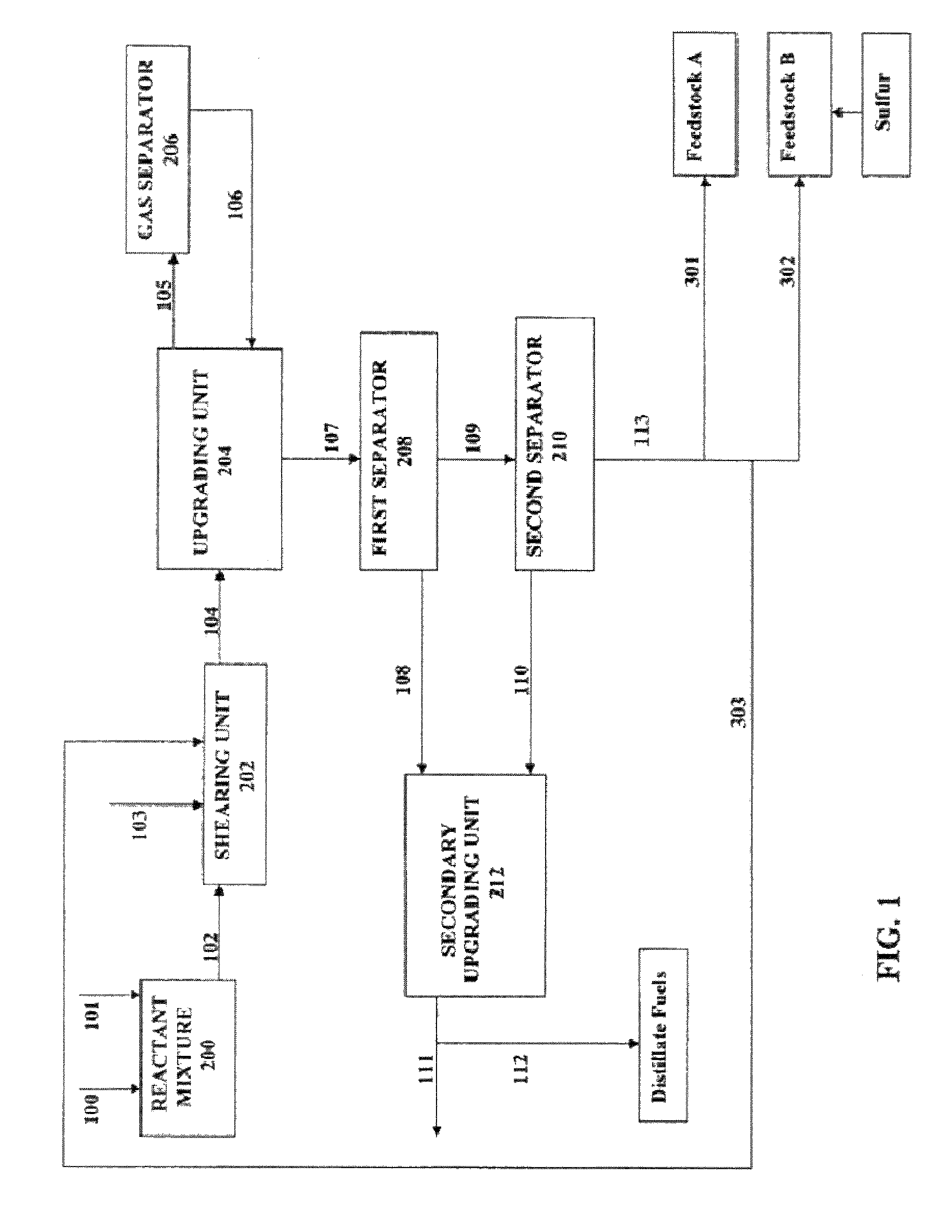

Methods for making higher value products from sulfur containing crude oil

ActiveUS20060254956A1High purityLow operating pressureHydrocarbon oil crackingTreatment with hydrotreatment processesFiberHydrogen

A process for upgrading, or refining, high sulfur containing heavy hydrocarbon crude oil to a lighter oil having a lower sulfur concentration and, hence a higher value product, is disclosed. The process includes reacting the high sulfur heavy hydrocarbon crude oil in the presence of a catalyst and low pressure hydrogen to produce a reaction product stream from which the light oil is recovered. Part of the reaction product is separated and subjected to further upgrading to produce a lower sulfur oil product for application as distillate fuels. The upgrading process also produces residual oil that is suitable for making olefins, carbon fiber or road asphalt. Catalysts utilized in the processes of the invention can include a transition metal containing compound, the metal being selected from Group V, Group VI, and Group VIII of the Periodic Table, and mixtures of these metals.

Owner:SAUDI ARABIAN OIL CO

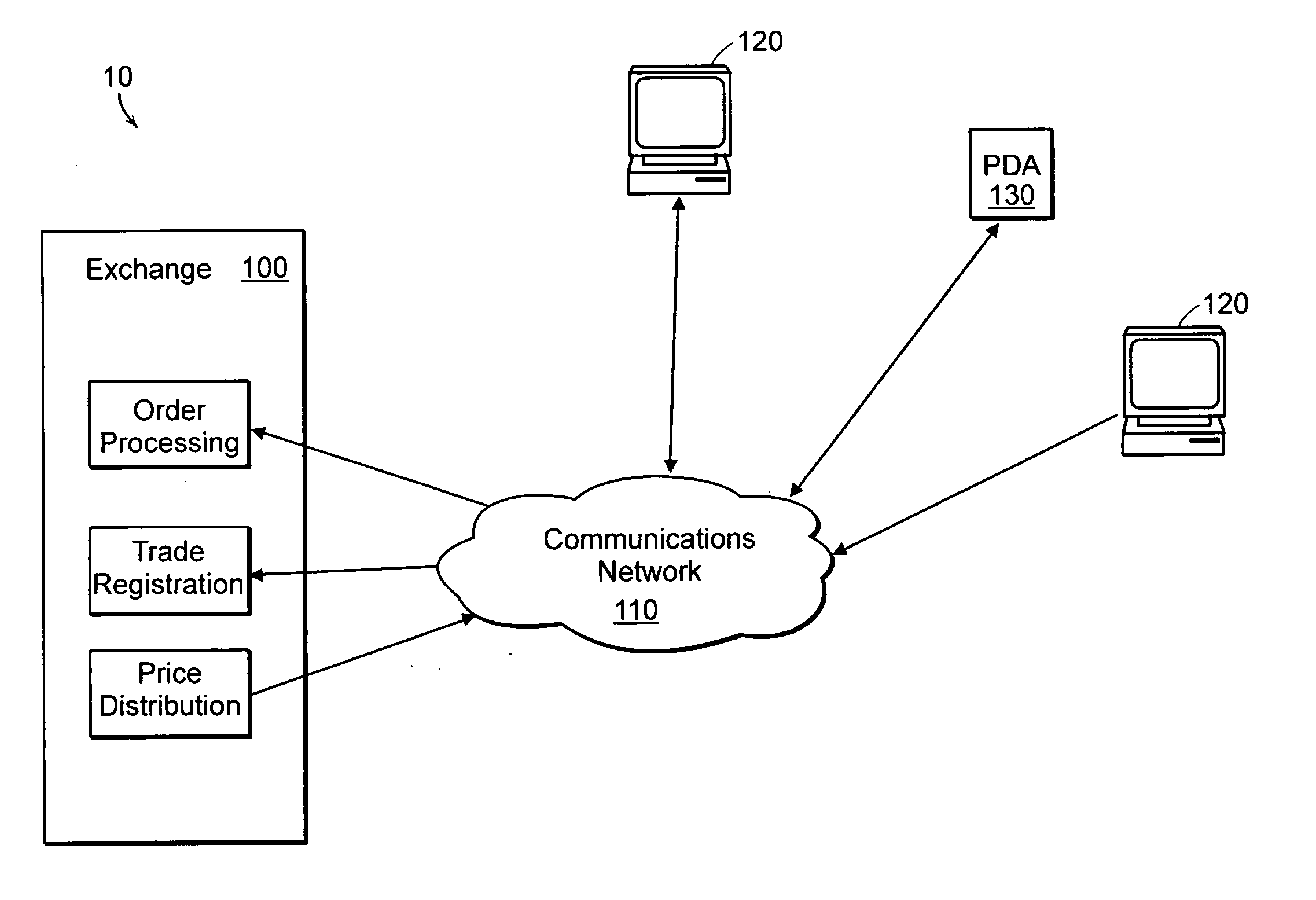

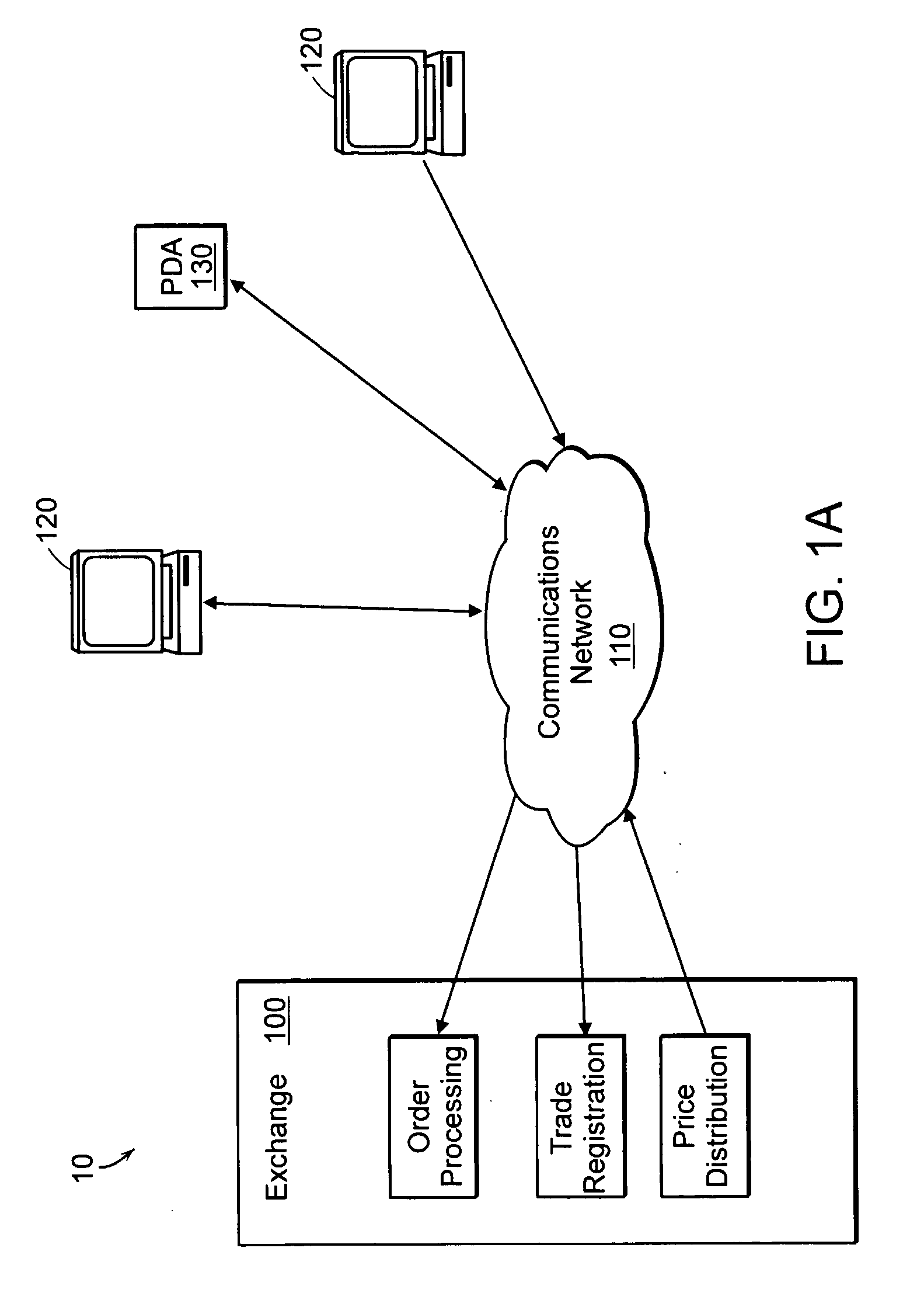

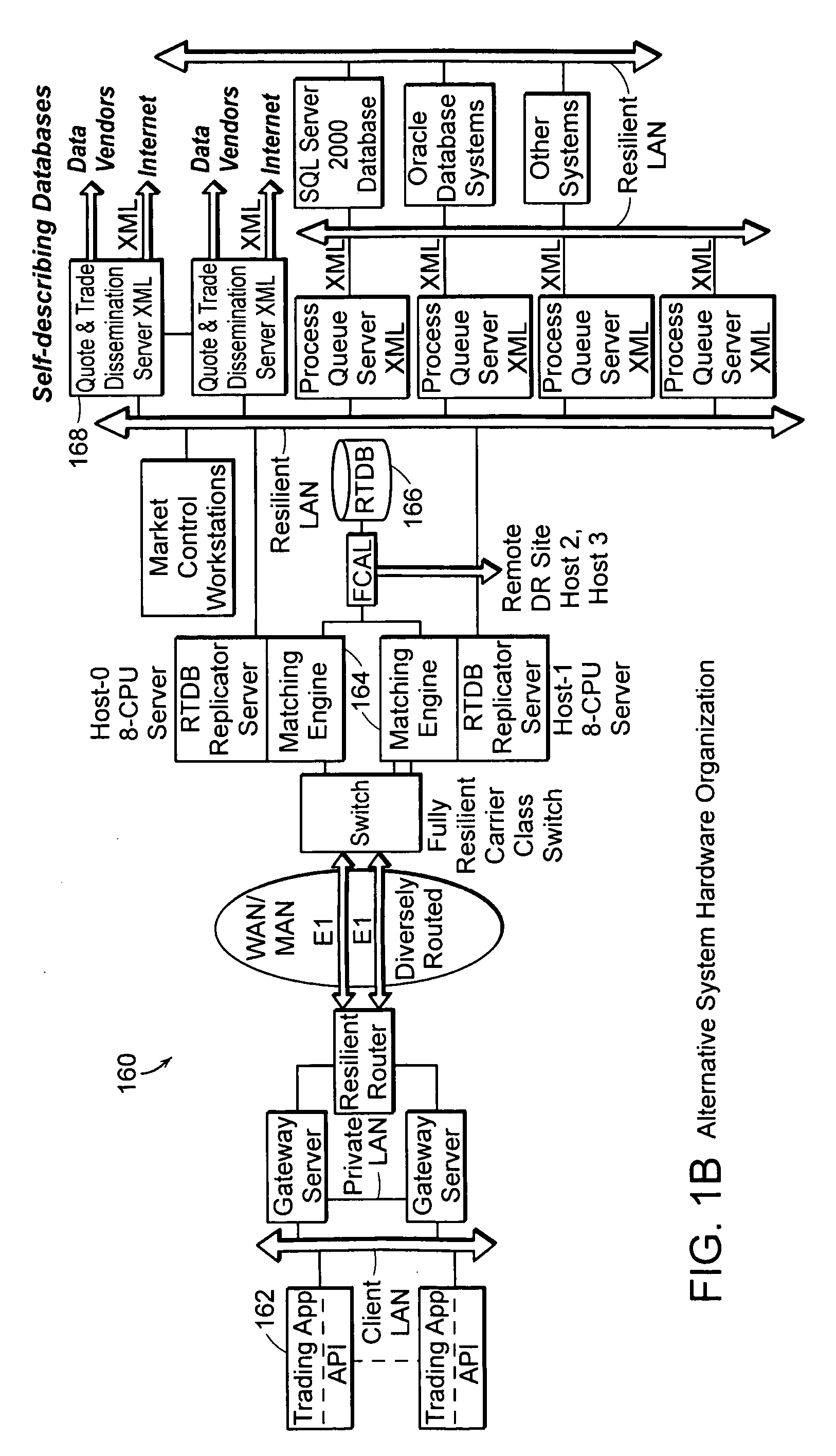

Method for trading securities

A method for trading securities including options. A trader generates a variable derivative product order that identifies at least a derivative product, an underlying financial product or instrument, a pricing formula, and values of price determination variables needed by the pricing formula to establish a price for the derivative. The variable product order is transmitted electronically to an exchange. The exchange calculates the offered price of the derivative using a value of the underlying product and publishes offers to potential traders. The offered price is recalculated as the value of the underlying products changes and republished to potential traders. Trades may then be executed based on the offered prices. Hedging trades may be executed in combination with trades made based on the variable derivative product orders.

Owner:COMMUNICATING

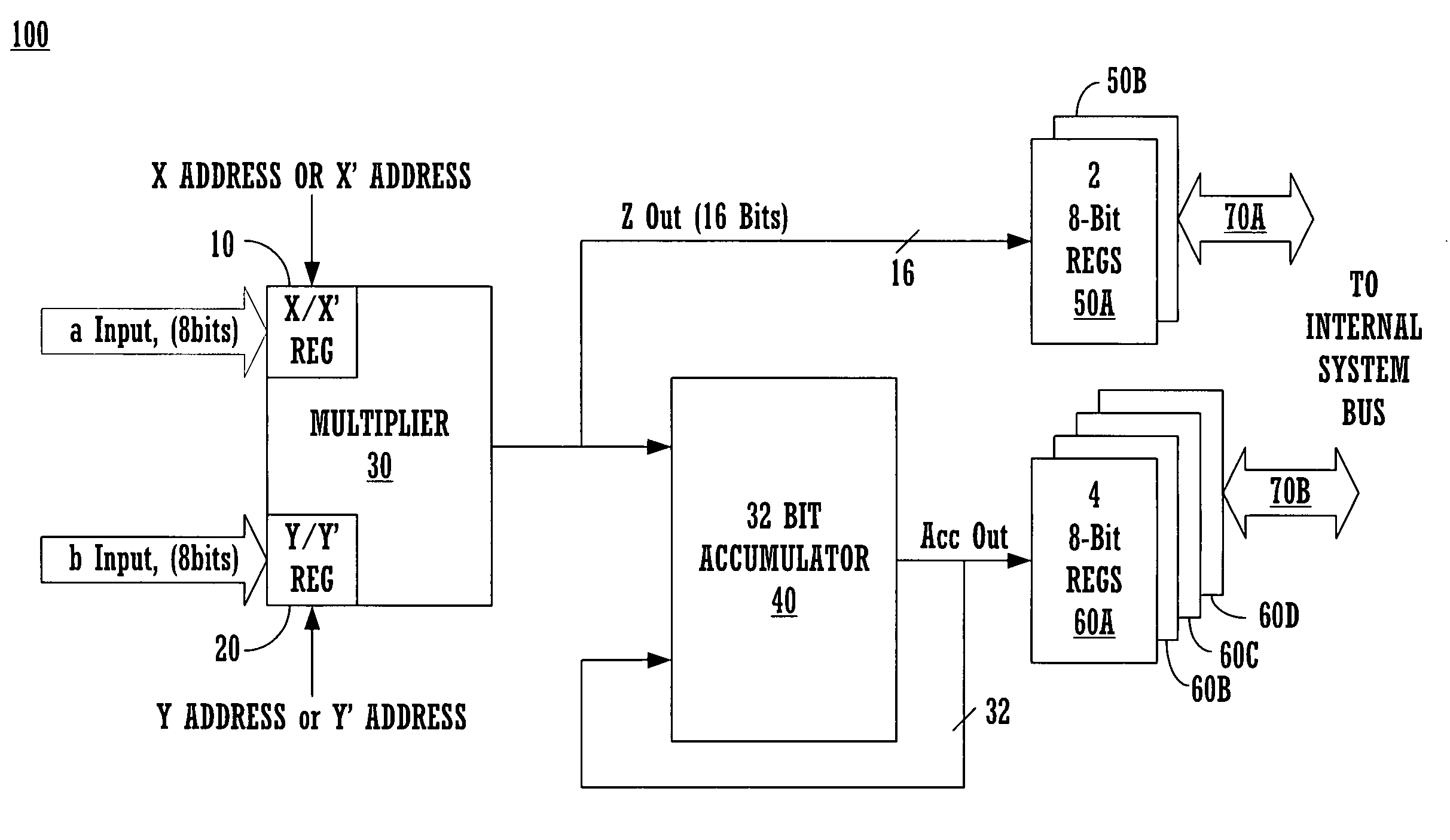

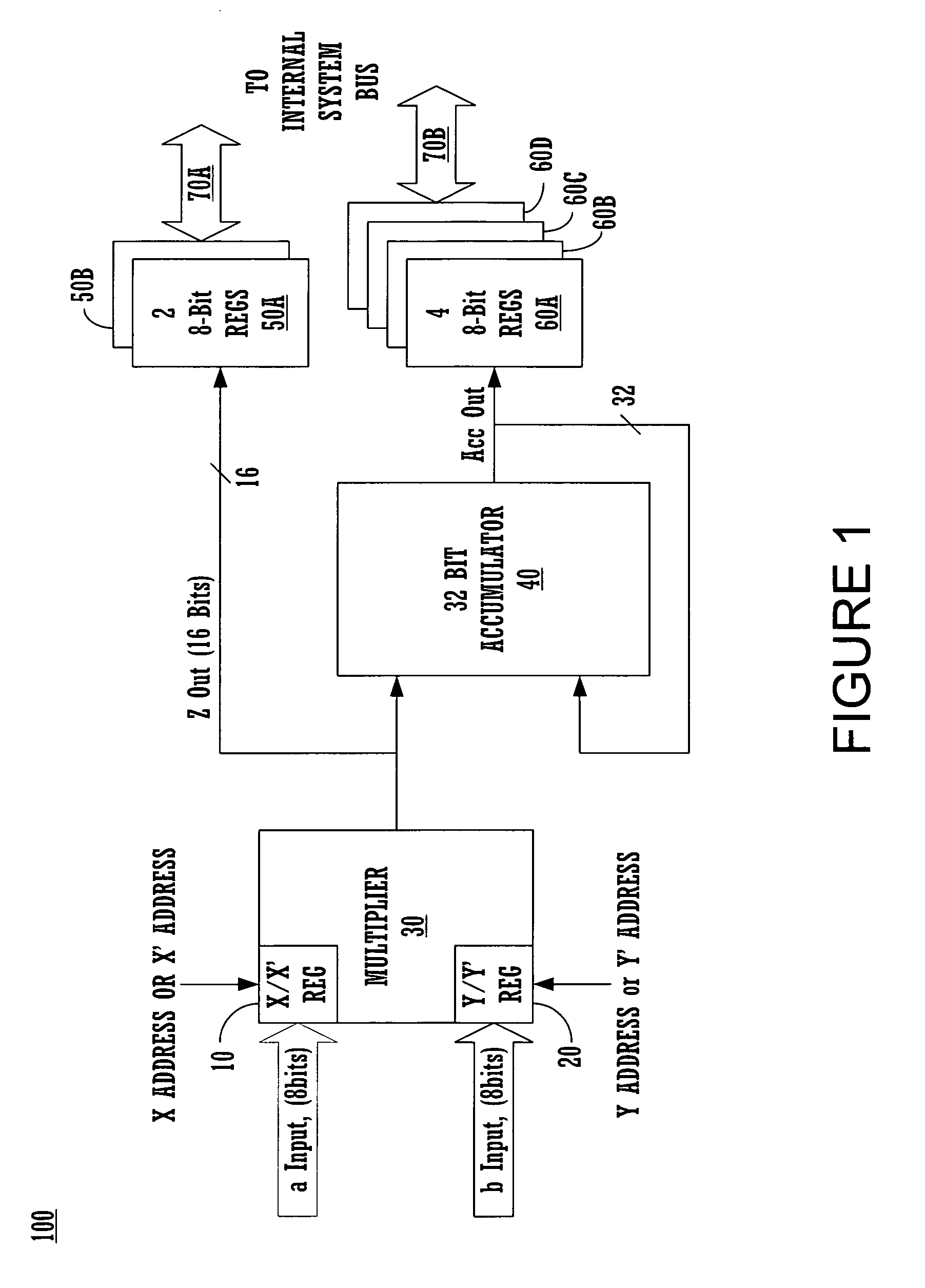

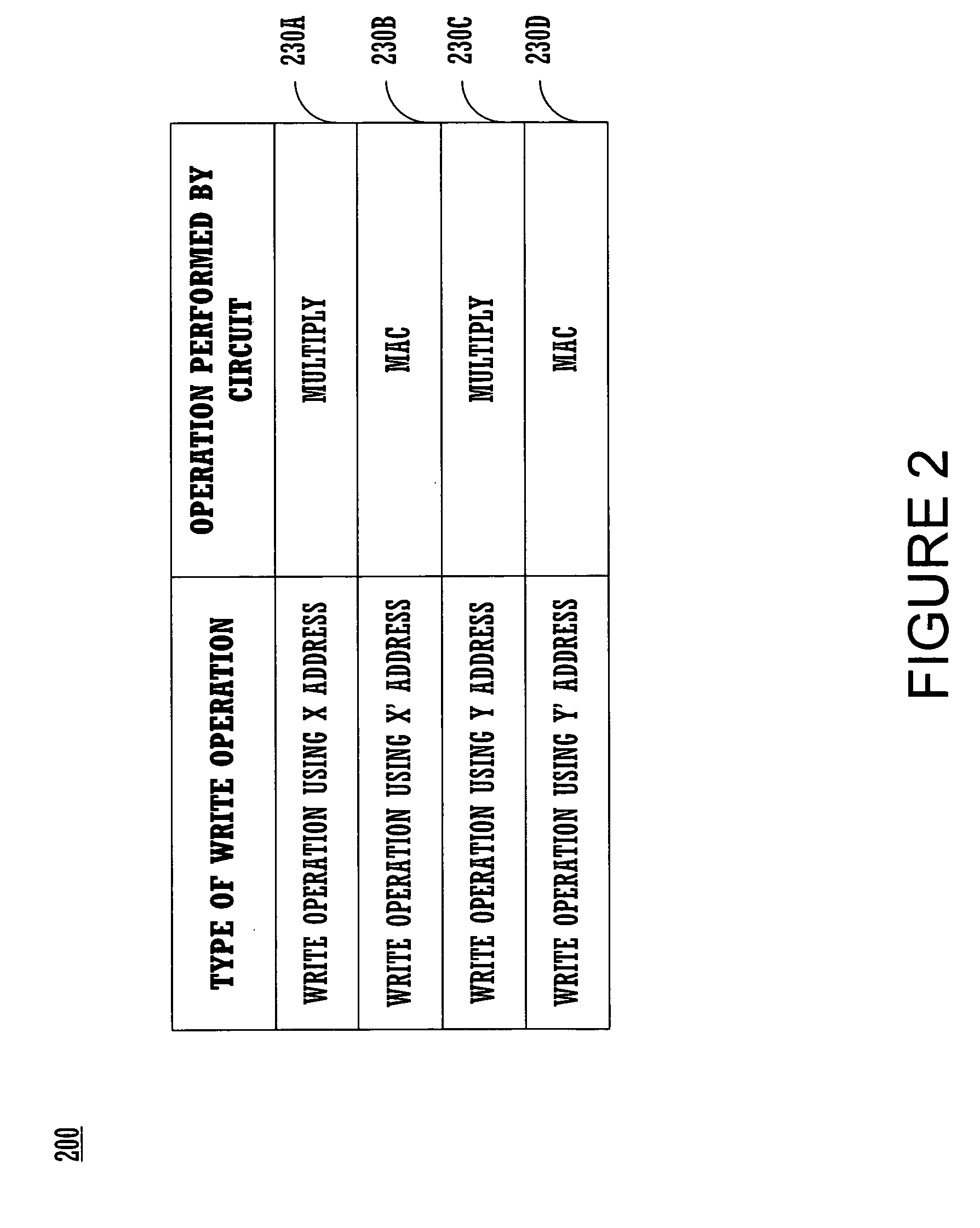

Noninterfering multiply-MAC (multiply accumulate) circuit

InactiveUS6957242B1Computation using denominational number representationProcessor registerProduct value

A noninterfering multiply-MAC (multiply accumulate) circuit is described. The circuit is operational to perform a MAC (multiply accumulate) operation and to perform a multiply operation without interfering with the accumulate value of the MAC operation. The circuit includes a first register, a second register, a multiplier circuit, and an accumulate circuit. The first register is addressable using either a primary first address or an alias first address. Moreover, the second register is addressable using either a primary second address or an alias second address. The multiplier circuit performs a multiply operation to generate a product value based on the data in the first and second registers after a write operation to either the first register or the second register. The accumulate circuit performs an accumulate operation to generate an accumulate value if either the alias first address or the alias second address is used in the write operation.

Owner:CYPRESS SEMICON CORP

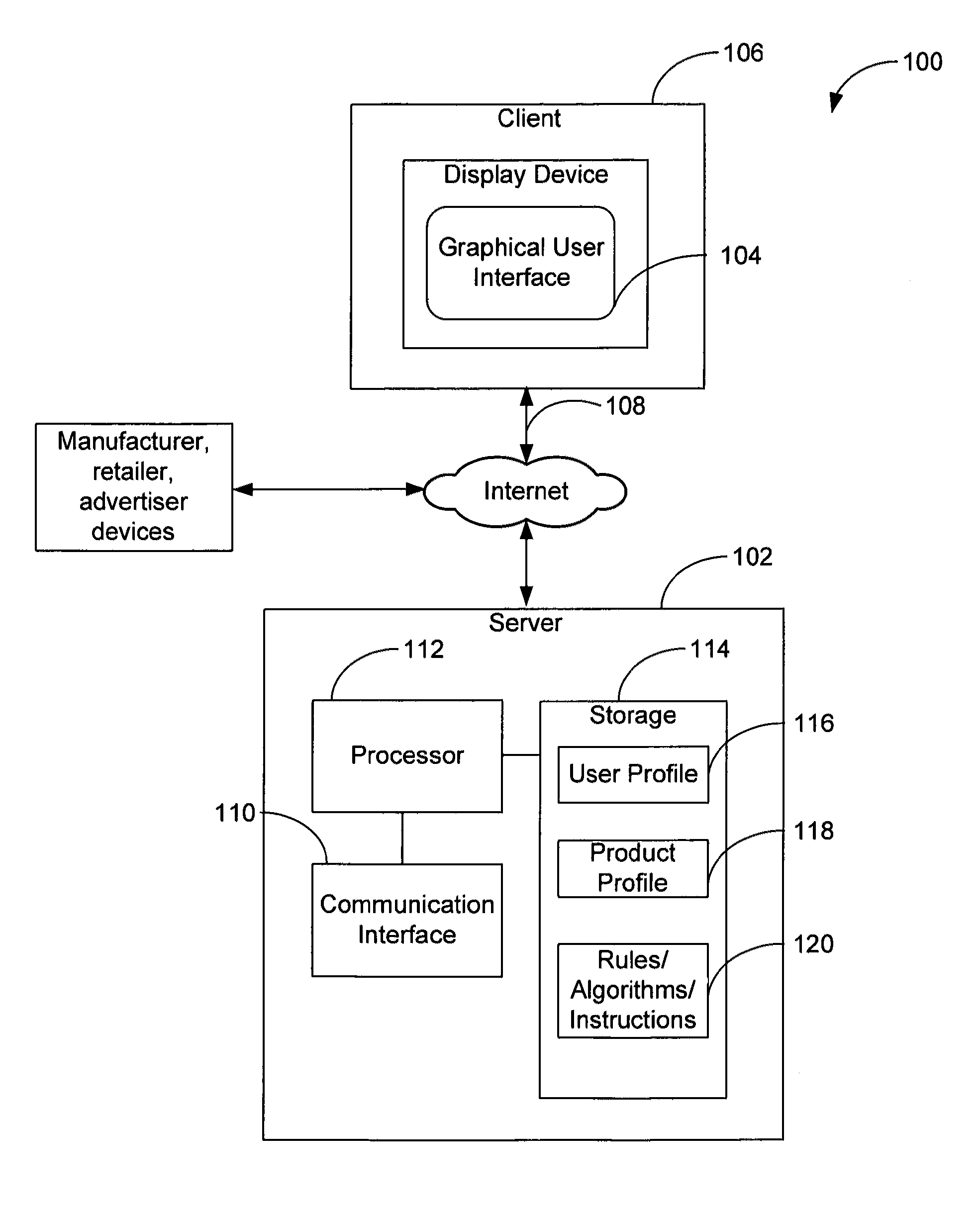

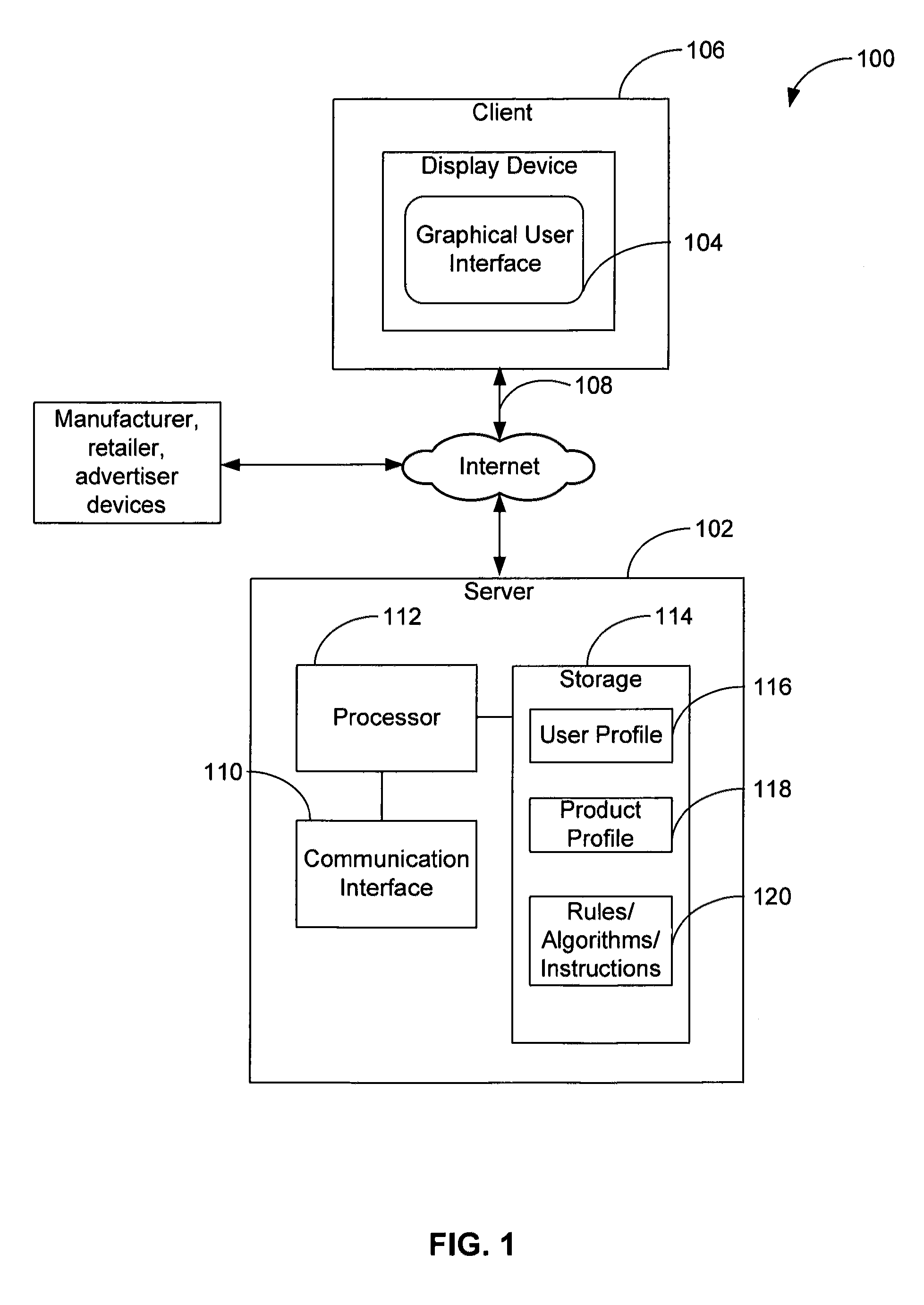

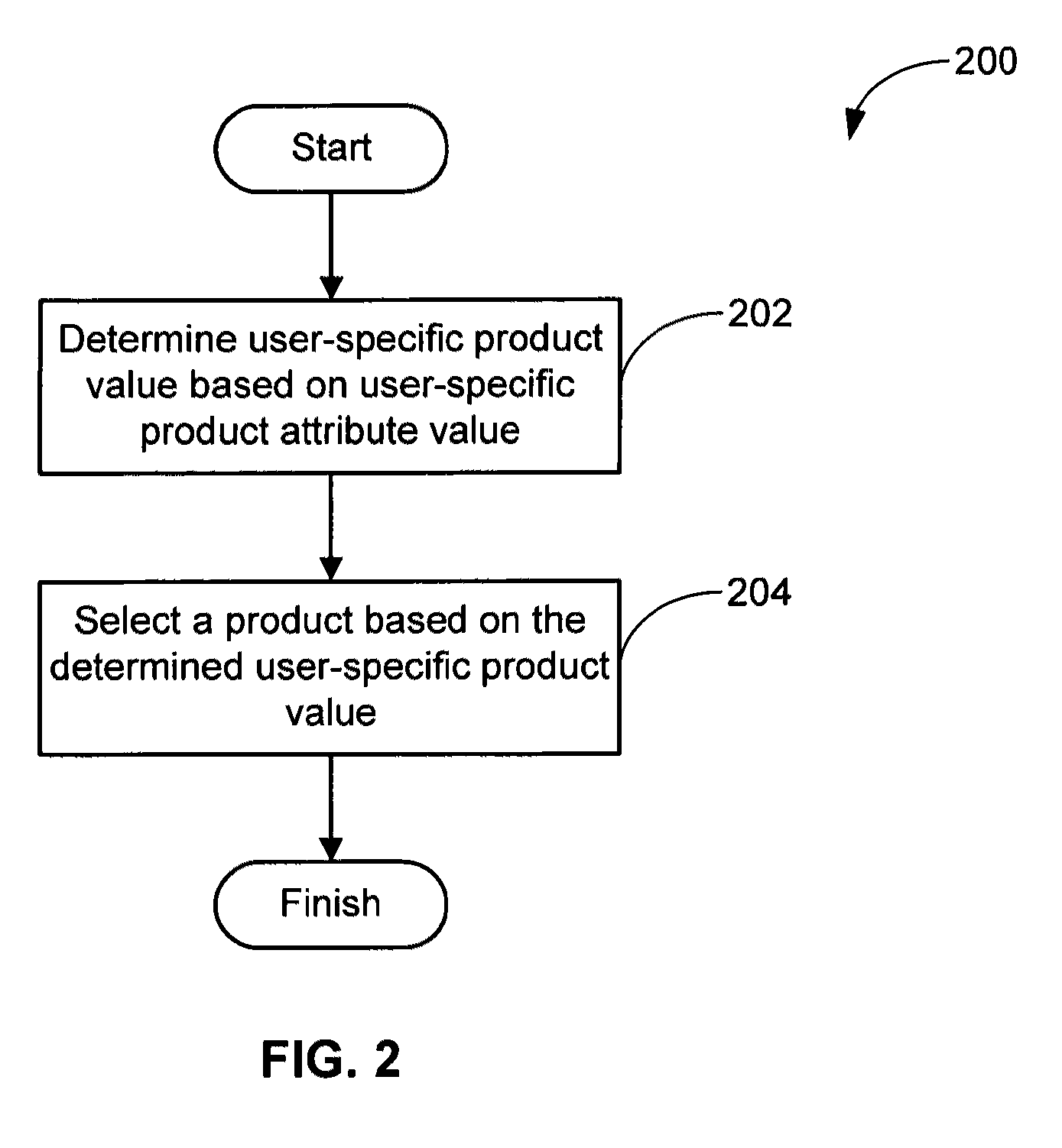

Techniques for product selection

Techniques for selecting a product are disclosed. A user-specific product value specific to a user is determined for each of at least a subset of a set of a plurality of products. The user-specific product value is based at least in part on a user-specific product attribute value associated with a product attribute specific to the user. A product is selected from the set of a plurality of products, the selection is based at least in part on the determined user-specific product values.

Owner:MY WORLD INC

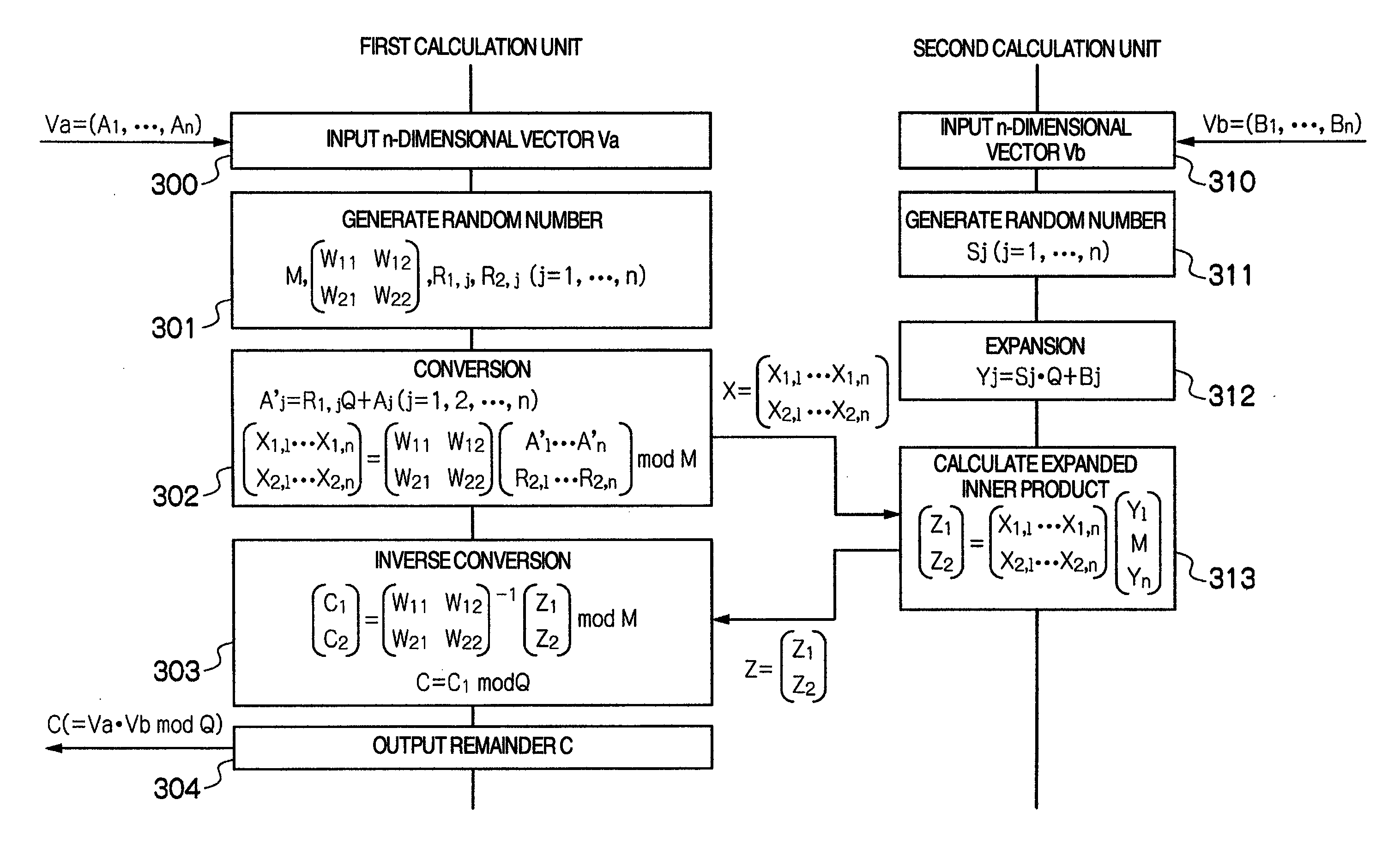

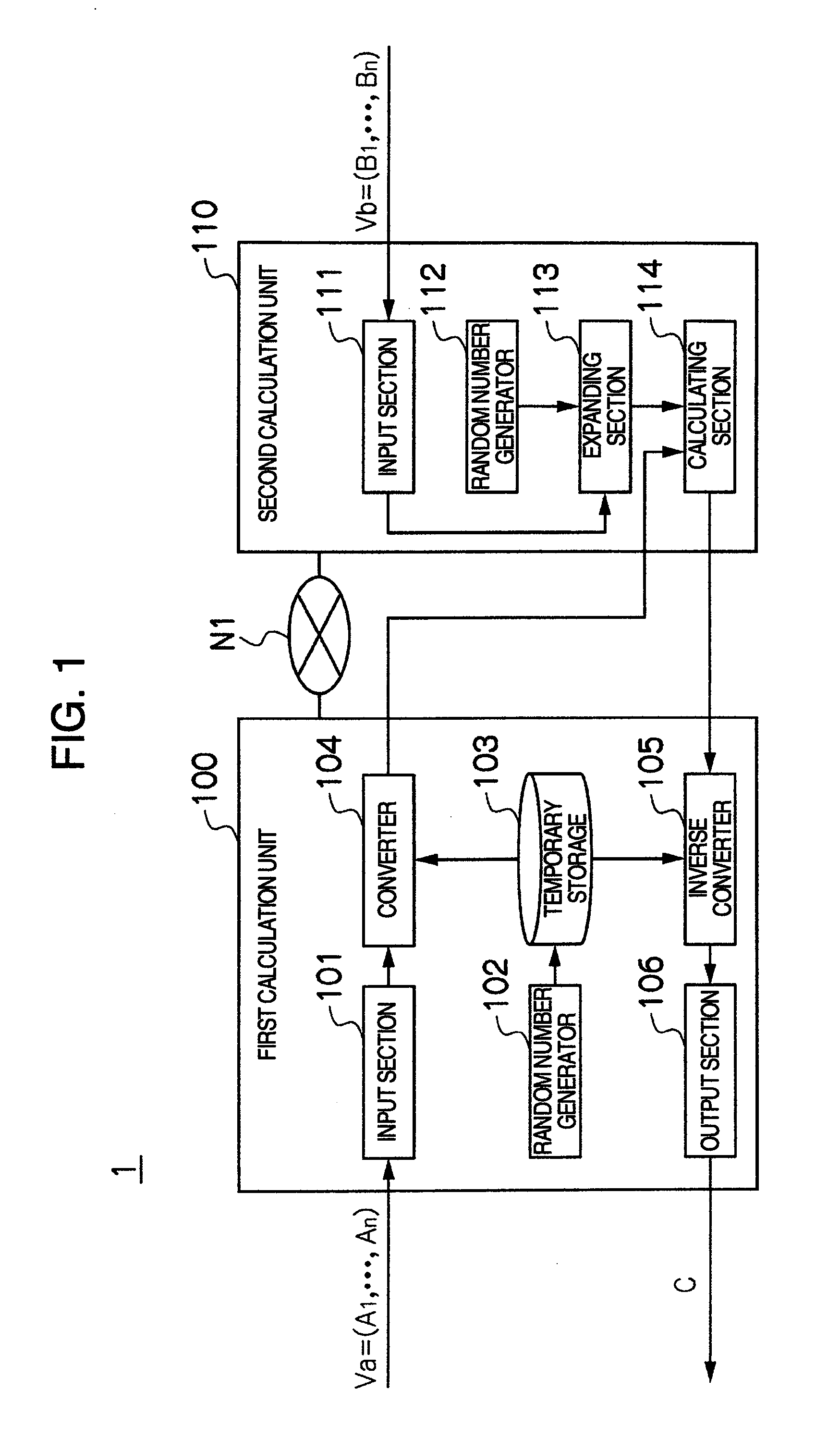

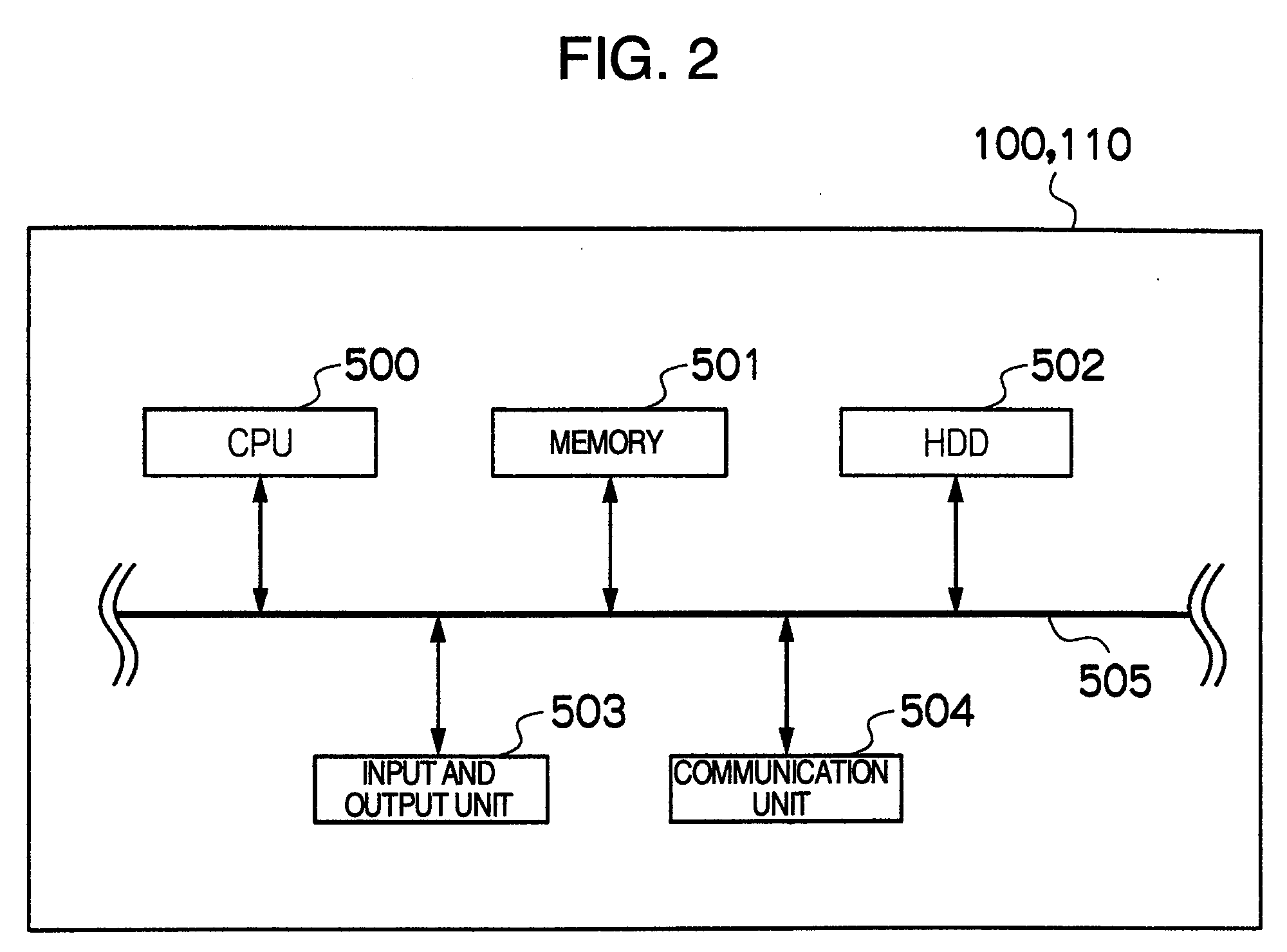

Privacy-preserving scalar product calculation system, privacy-preserving scalar product calculation method and cryptographic key sharing system

InactiveUS20090279694A1Calculation cost is highReduce computing costKey distribution for secure communicationRandom number generatorsScalar ValuePrivacy preserving

A privacy-preserving scalar product calculation system is provided. A first unit linearly transforms an n-dimensional vector Va into an n-dimensional vector based on a scalar value based on a random number Wi and a random number Rj to calculate a remainder by dividing each element of the linearly transformed n-dimensional vector by a random number Mi, and transmits an n-dimensional converted vector X including each of the remainders as its element to the second unit, the second unit calculates an inner product value Z based on the received n-dimensional converted vector X and an n-dimensional vector Vb, and transmits the inner product value Z to the first unit, and the first unit further calculates, based on a reciprocal of the scalar value and the receive inner product value, a scalar value and which calculates a remainder by dividing the scalar value by the random number Mi.

Owner:HITACHI LTD

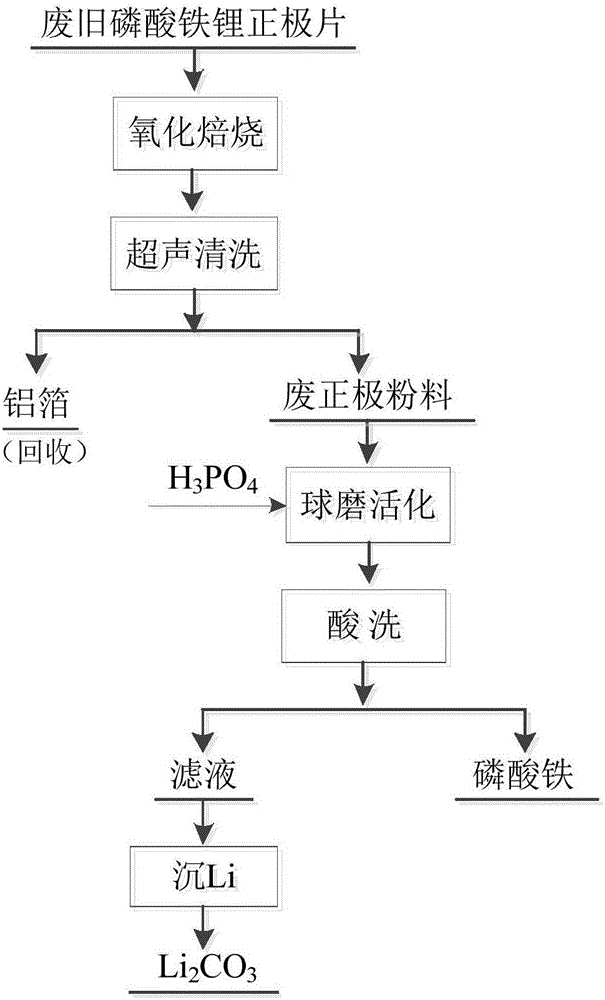

Method for recycling iron phosphate and lithium carbonate from lithium iron phosphate waste

ActiveCN106450547AAdaptableNothing producedWaste accumulators reclaimingBattery recyclingPhosphoric acidIndustrial scale

The invention discloses a method for recycling iron phosphate and lithium carbonate from lithium iron phosphate waste. The method comprises the following specific steps: (I) oxidizing roasting; (II) carrying out pole piece cleaning; (III) adding phosphoric acid and performing ball-milling activation; (IV) performing acid pickling to separate FePO4; and (V) precipitating lithium of the filtrate to obtain a target object Li2CO3. The method disclosed by the invention has the following advantages: the P, Fe and Li resources in the lithium iron phosphate waste can be fully utilized to prepare iron phosphate and lithium carbonate products with high added value, no waste of Fe is generated, the resource recycling rate is high, the technological process is short, the reaction system is simple, a few raw materials are consumed, the cost is low, the product value is high, and the method is very suitable for industrial scale production.

Owner:JINGMEN GEM NEW MATERIAL

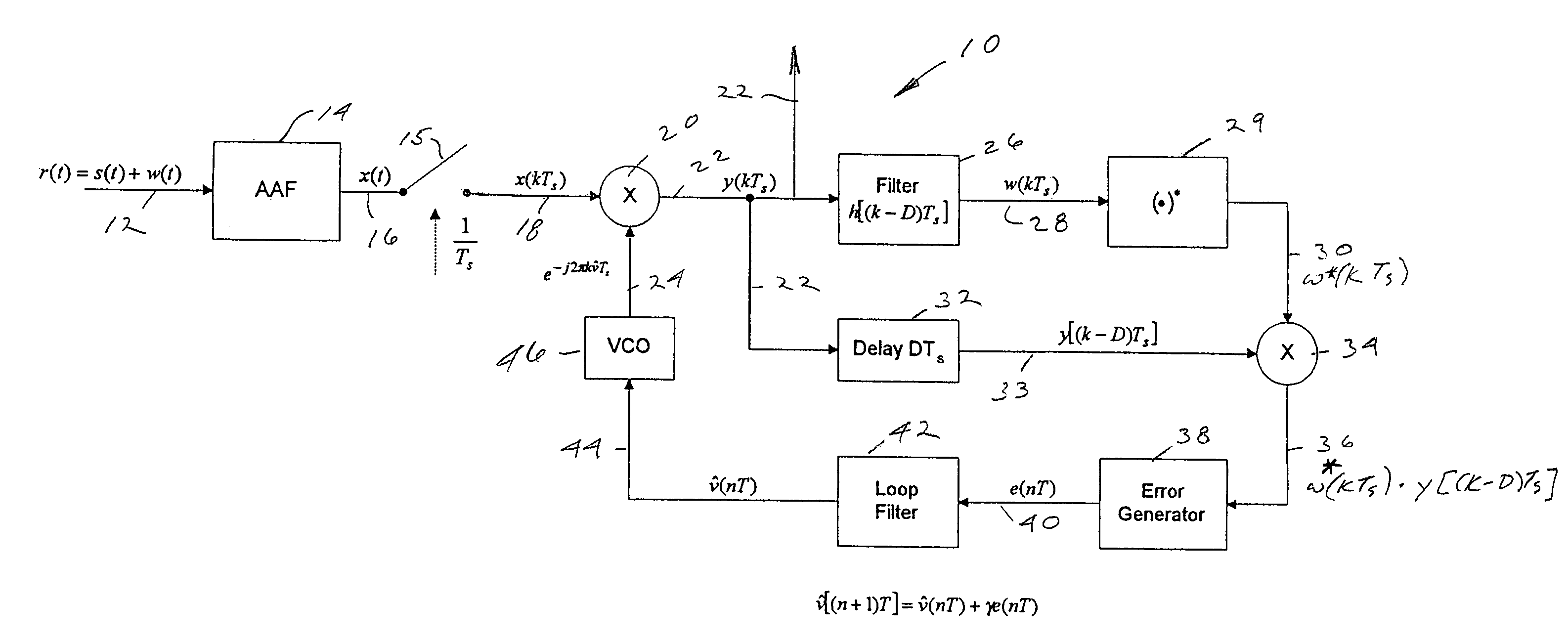

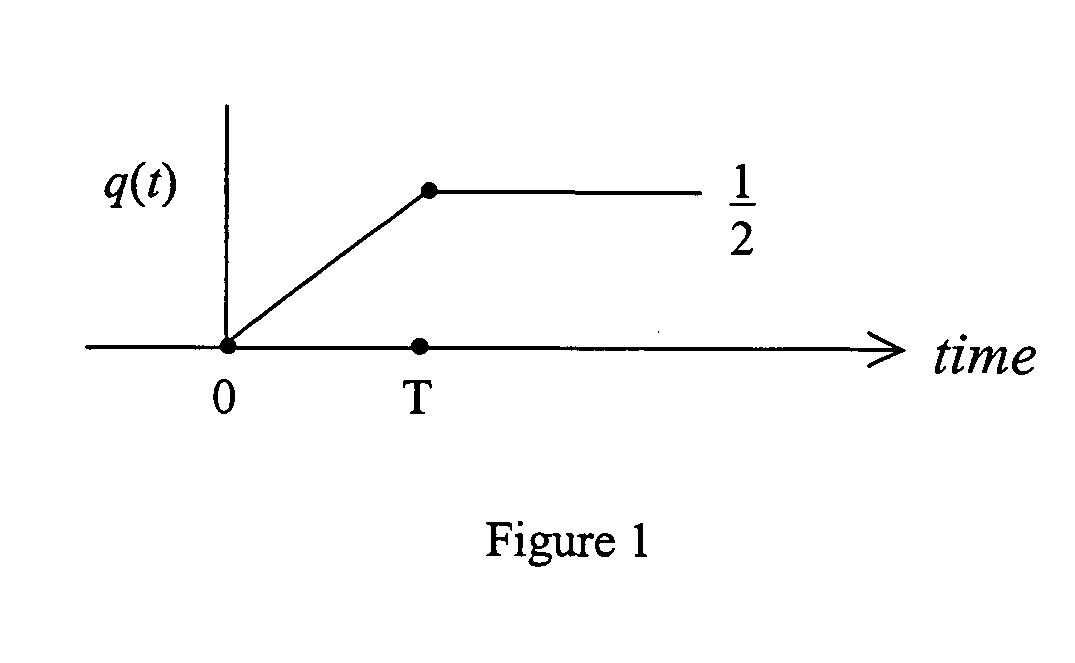

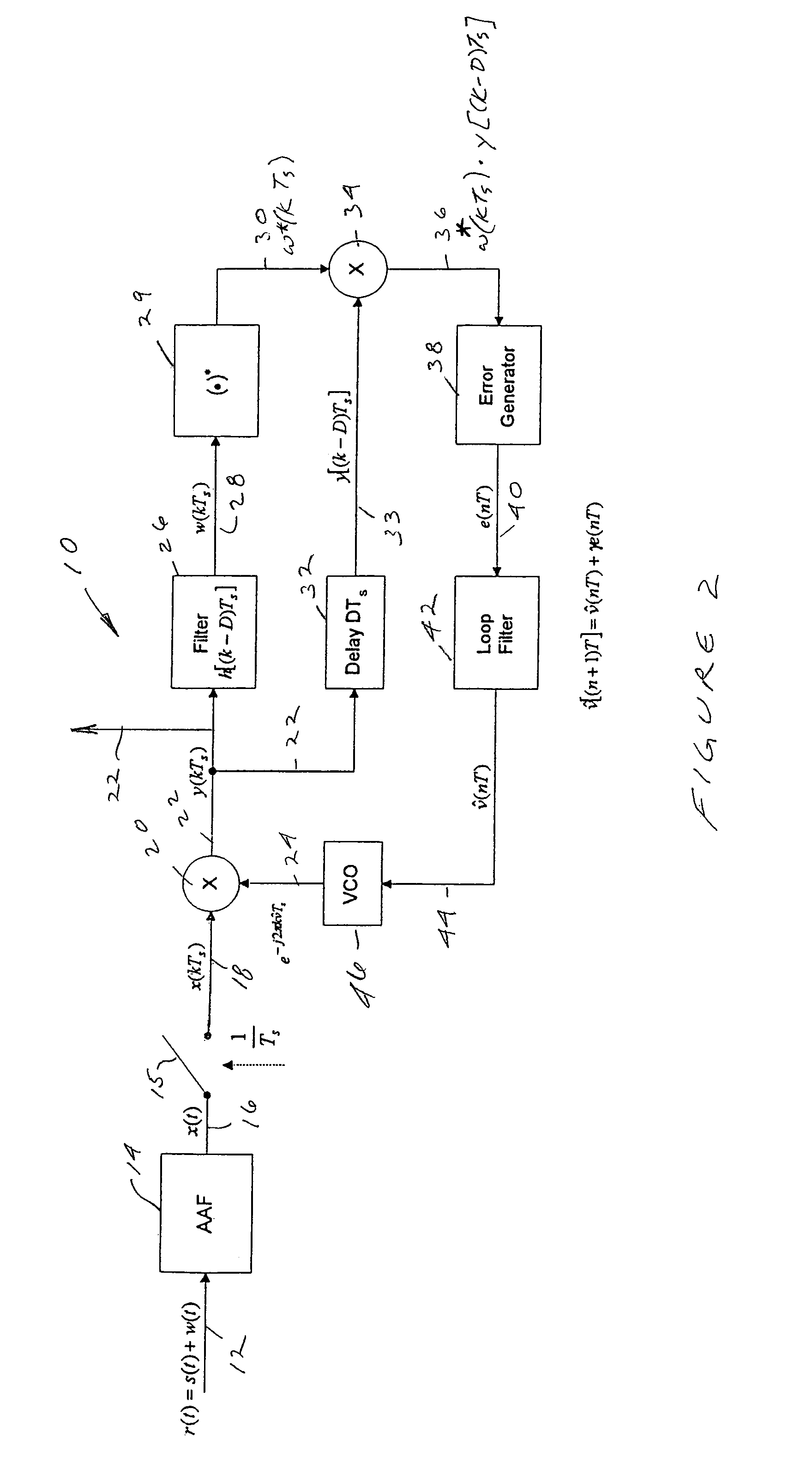

Frequency synchronizer

InactiveUS6947504B1Apparent advantageHigh bandwidthAmplitude-modulated carrier systemsAmplitude demodulationCarrier signalErrors and residuals

A frequency synchronizer system is based on the maximum likelihood criterion from estimation theory and that can achieve both frequency acquisition and frequency tracking without requiring knowledge at the receiver of the carrier's phase angle, baud timing, or a preamble consisting of known signal symbols. The synchronizer includes a processor for executing the following sequence of operations: a) initializing an estimated frequency correction factor; b) determining a corrected frequency offset value from a first product of a sample signal and the estimated frequency correction factor; c) filtering a first sample of the corrected frequency offset value to obtain a filtered corrected frequency offset value; d) imparting a delay to a second sample of the corrected frequency offset value to obtain a delayed corrected frequency offset value; e) determining a conjugate product value from a second product of the filtered corrected frequency offset value and a conjugate of the filtered corrected frequency offset value; f) determining a delay conjugate value from a third product of the delayed corrected frequency offset value and the conjugate product value; g) determining an error signal from the delay conjugate value; h) determining a frequency offset value from the error signal; and i) determining an updated value of the estimated frequency correction factor from the frequency offset value.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

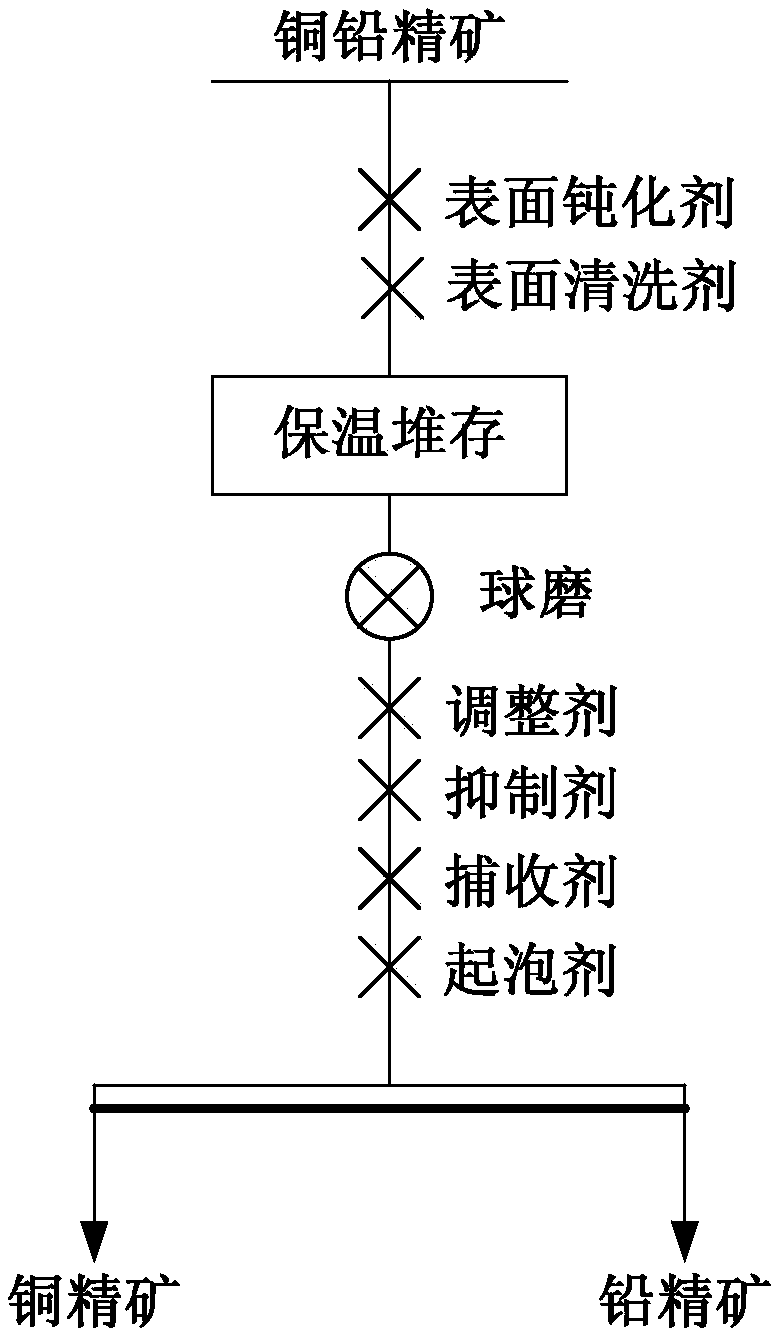

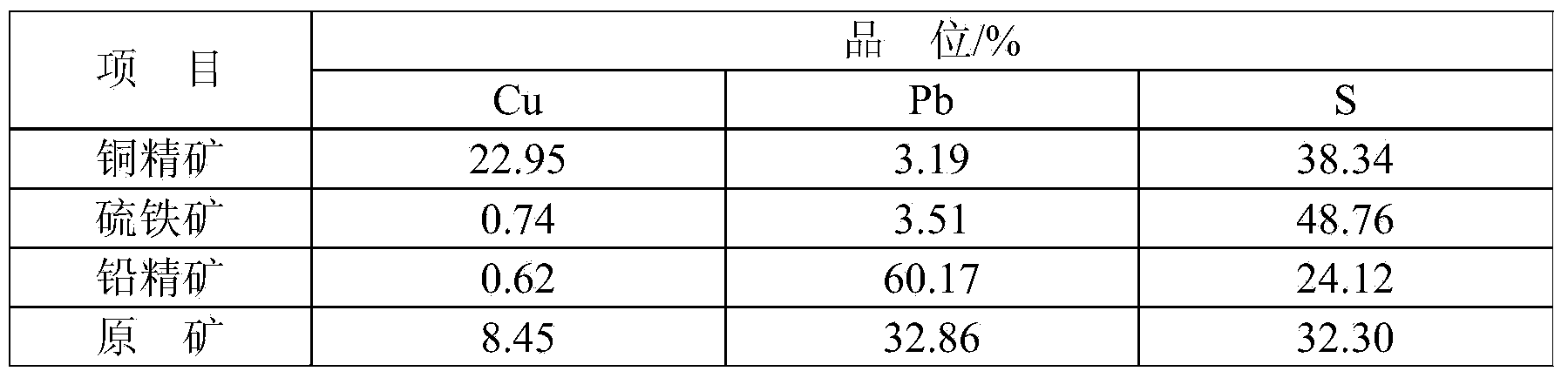

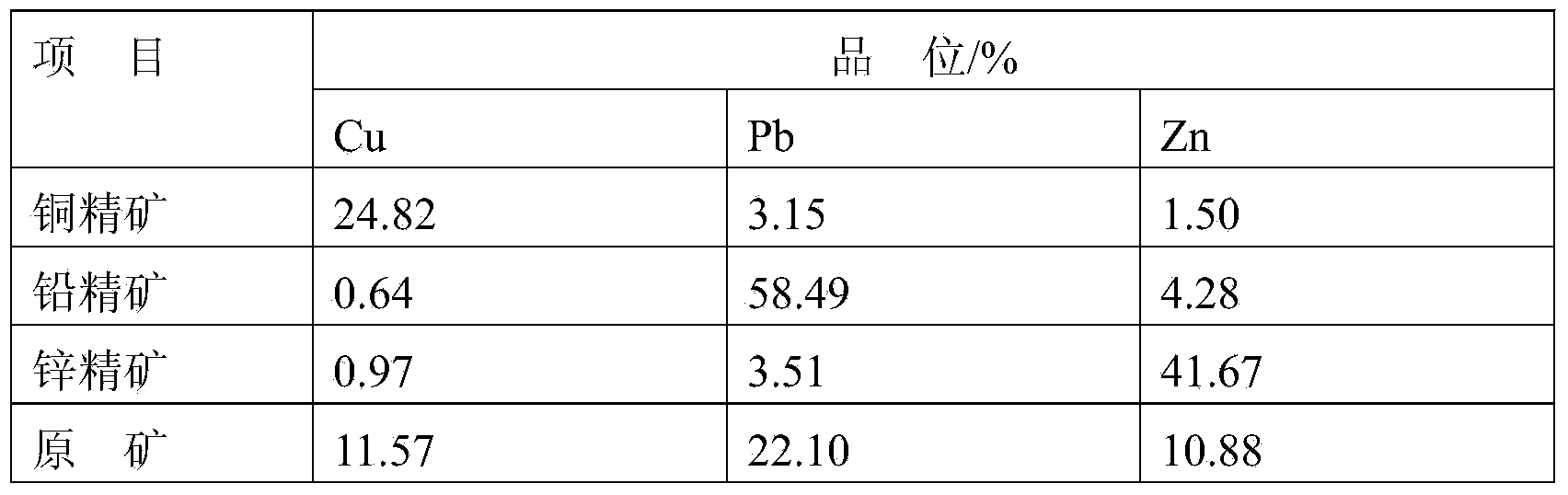

Method for flotation separation of copper sulfide and lead concentrate processed through pre-oxidation

ActiveCN103861740ASlow down the rate of corrosion oxidationImprove flotation effectFlotationSurface cleaningCleansing Agents

The invention discloses a method for flotation separation of copper sulfide and lead concentrate processed through pre-oxidation. A new pretreatment flotation technology comprises the steps that pre-oxidation treatment is carried out on the copper sulfide and lead concentrate by using surface passivator, surface cleaning agents and a certain heat-preservation stockpiling method, wherein the copper sulfide and lead concentrate is obtained through flotation; ball milling is carried out on the preprocessed copper sulfide and lead concentrate; a certain number of floatation reagents including regulators, inhibitors, collecting agents and foaming agents are added, and a foam product, namely copper concentrate and tailings, namely lead concentrate are obtained through flotation separation. According to the new pretreatment flotation technology, the used reagents cannot pollute the environment, and energy consumption of production is reduced; compared with economic value of copper sulfide and lead bulk concentrate, the value of products obtained through separation is greatly improved; the content of heavy metal ions in water is low in the production process, the technology is environmentally friendly, equipment operation and technological process operation are easy, and economy and high efficiency are achieved.

Owner:CENT SOUTH UNIV

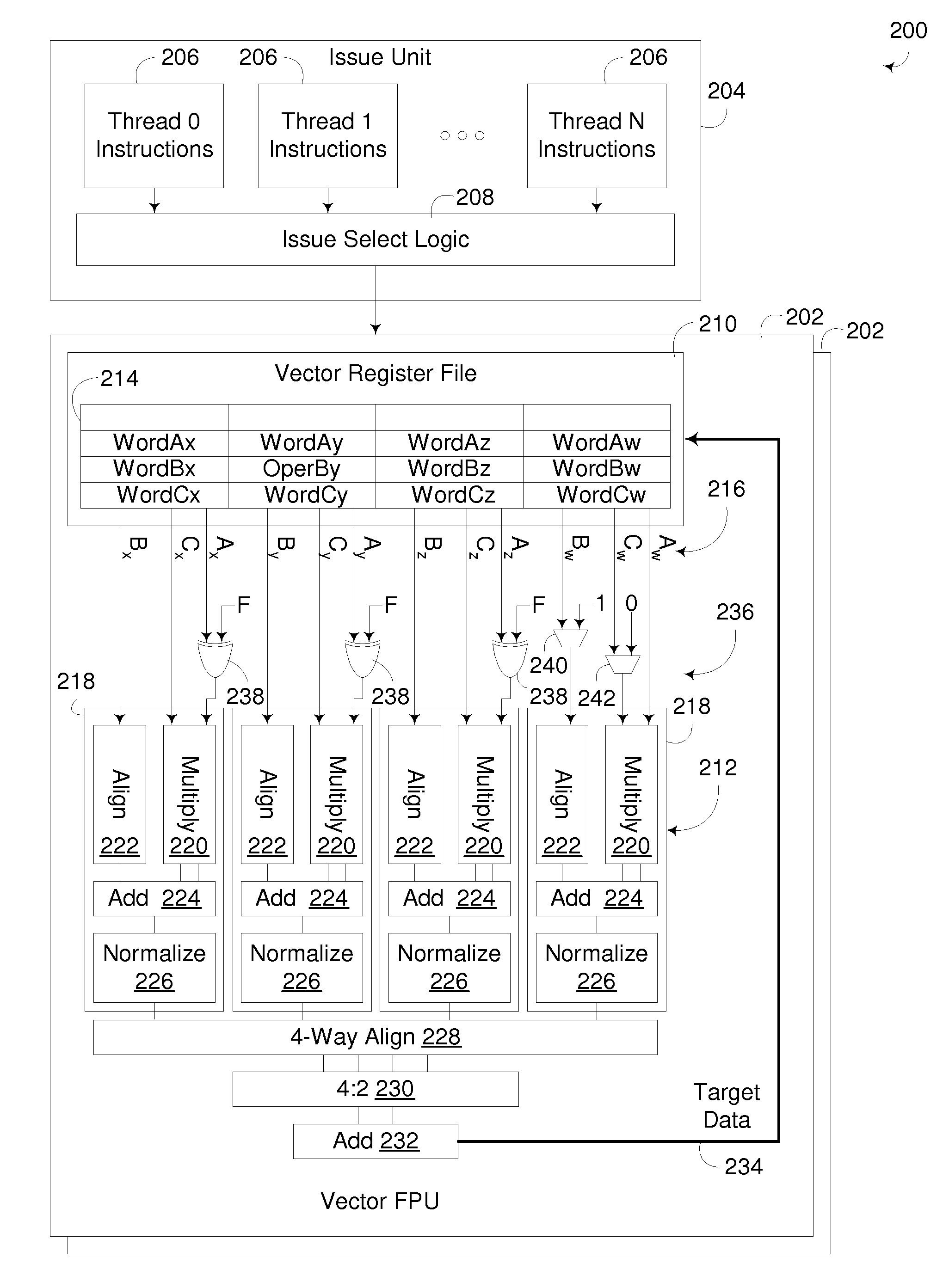

Floating Point Execution Unit for Calculating a One Minus Dot Product Value in a Single Pass

InactiveUS20100031009A1Addressing slow performanceReduce performanceDigital computer detailsSpecific program execution arrangementsProduct valueSingle pass

A floating point execution unit calculates a one minus dot product value in a single pass. As such, the dependency that otherwise would be required to perform the calculations is eliminated, resulting in a substantially faster performance of such calculations. The floating point execution unit may be used, for example, to accelerate pixel shading algorithms such as Fresnel and electron microscope effects.

Owner:IBM CORP

Methods for making higher value products from sulfur containing crude oil

ActiveUS7790018B2High purityLow operating pressureHydrocarbon oil crackingTreatment with hydrotreatment processesFiberHydrogen

A process for upgrading, or refining, high sulfur containing heavy hydrocarbon crude oil to a lighter oil having a lower sulfur concentration and, hence a higher value product, is disclosed. The process includes reacting the high sulfur heavy hydrocarbon crude oil in the presence of a catalyst and low pressure hydrogen to produce a reaction product stream from which the light oil is recovered. Part of the reaction product is separated and subjected to further upgrading to produce a lower sulfur oil product for application as distillate fuels. The upgrading process also produces residual oil that is suitable for making olefins, carbon fiber or road asphalt. Catalysts utilized in the processes of the invention can include a transition metal containing compound, the metal being selected from Group V, Group VI, and Group VIII of the Periodic Table, and mixtures of these metals.

Owner:SAUDI ARABIAN OIL CO

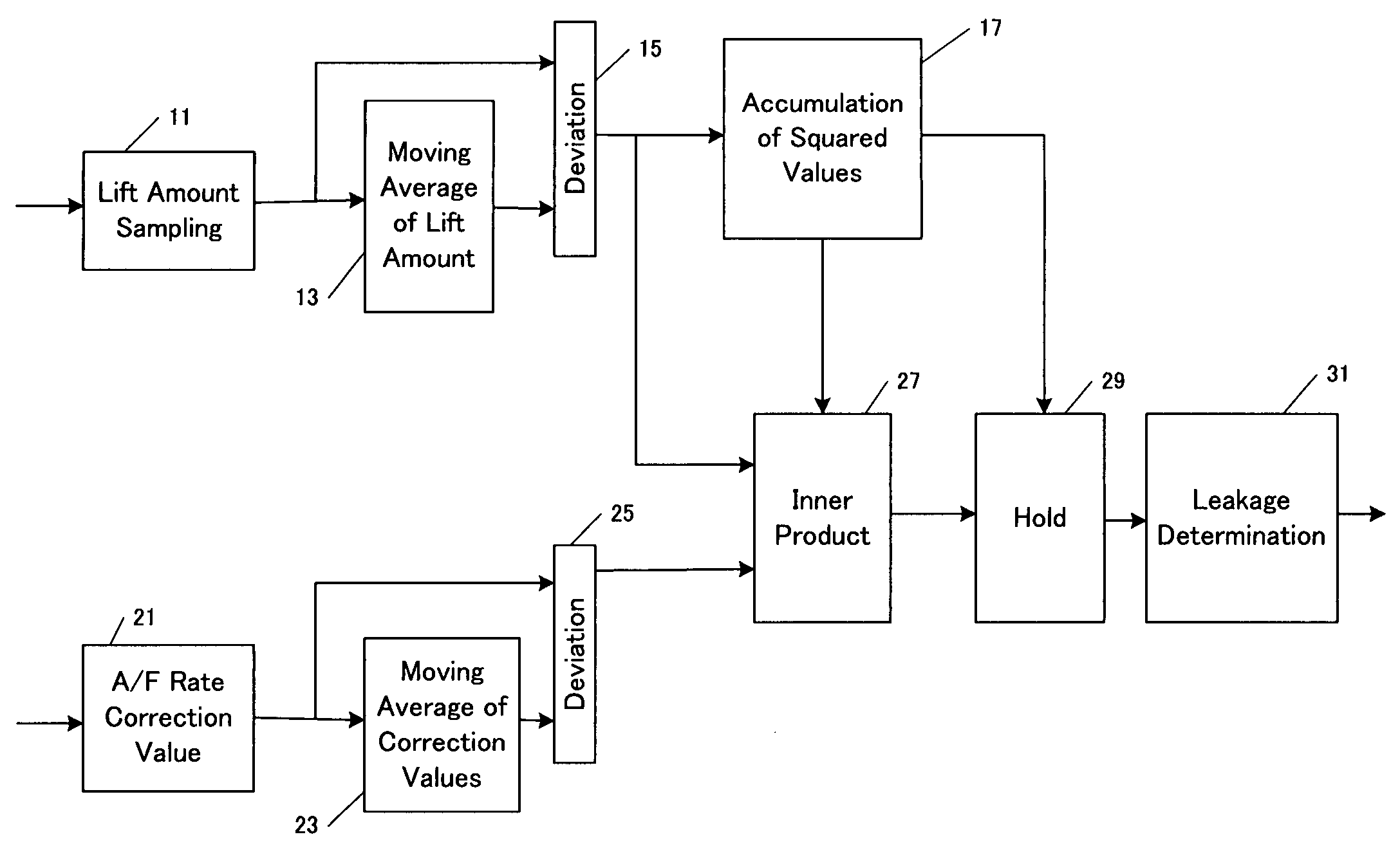

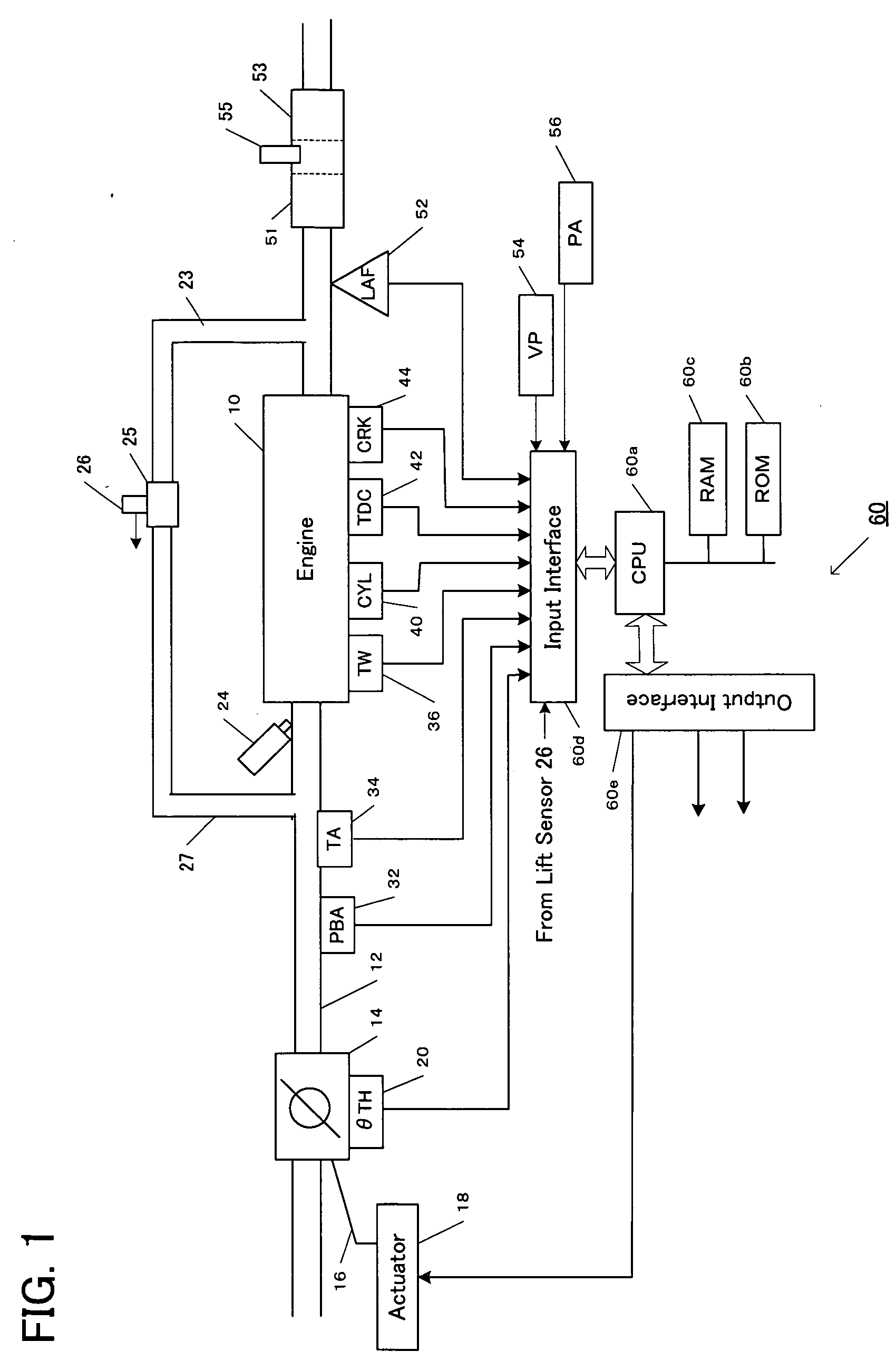

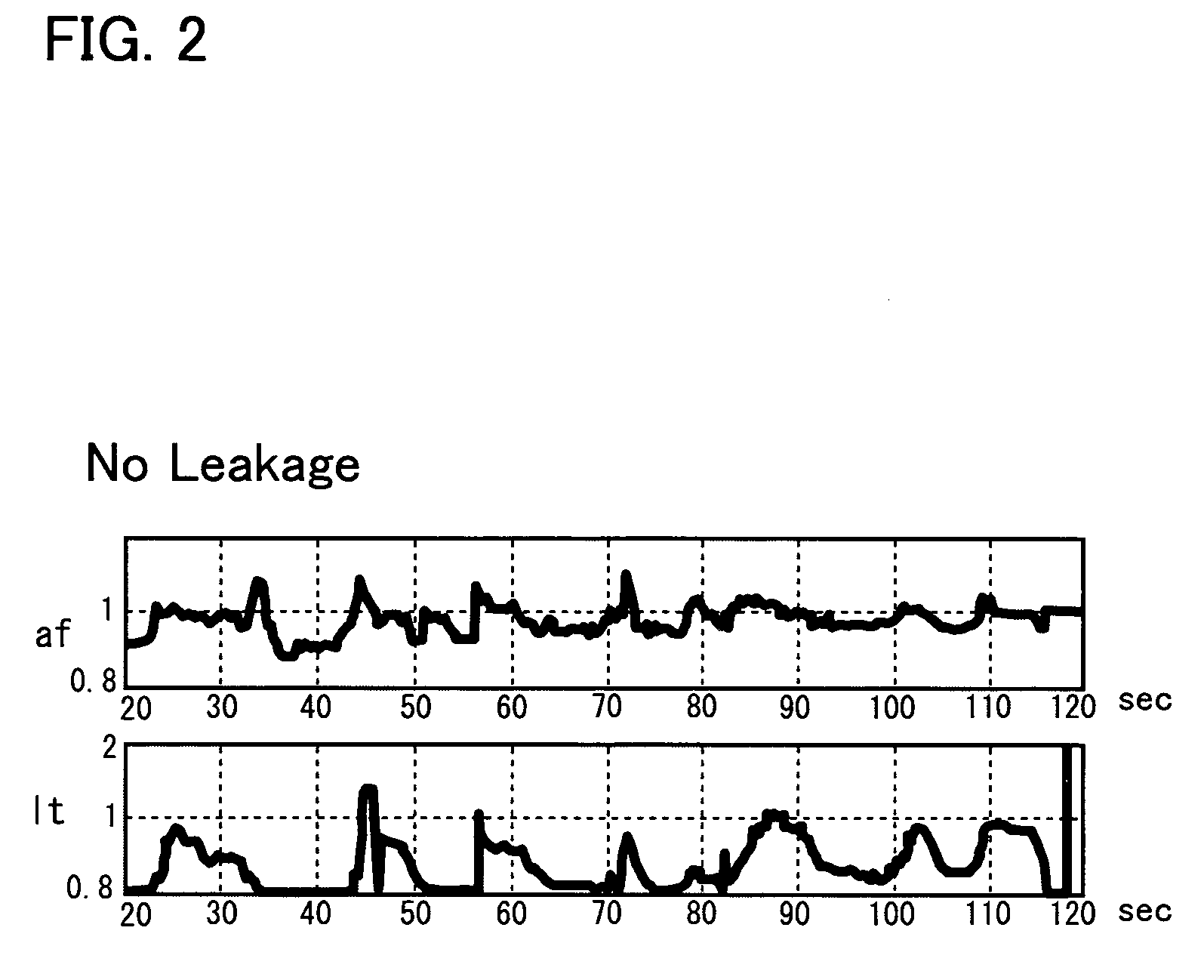

Leakage detecting apparatus for an exhaust gas re-circulating system of an engine

InactiveUS20050161029A1Detection of fluid at leakage pointElectrical controlMoving averageEngineering

A leakage detecting apparatus includes a re-circulating passage for re-circulating an exhaust gas from an exhaust system to an air intake system in the engine, a re-circulating valve disposed in the re-circulating passage to control a flow rate of the re-circulating exhaust gas, and an A / F ratio sensor for detecting an A / F ratio of the exhaust system. An electronic control unit detects an operation amount of the re-circulating valve and calculates correlation between the operation amount and output of the A / F ratio sensor to determine a leakage in the re-circulating passage. The correlation is obtained by an inner product calculation of a vector of deviations of a time-sequence vector of the operation amount relative to a moving average and a vector of deviations of a time-sequence vector of the output of the A / F ratio sensor relative to a moving average. Leakage in the re-circulating passage is detected when an accumulated value of the inner product values over a predetermined period exceeds a threshold value.

Owner:HONDA MOTOR CO LTD

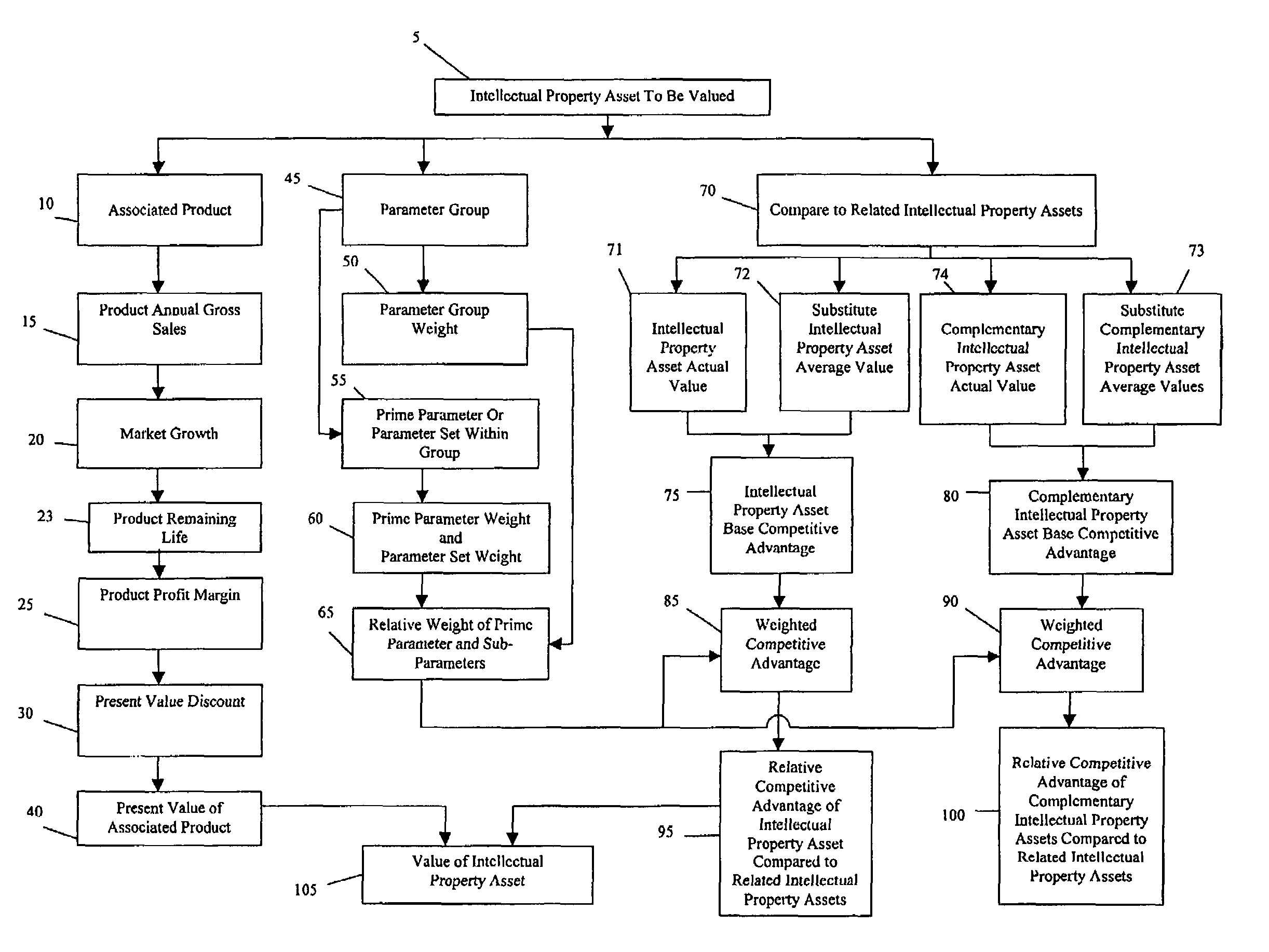

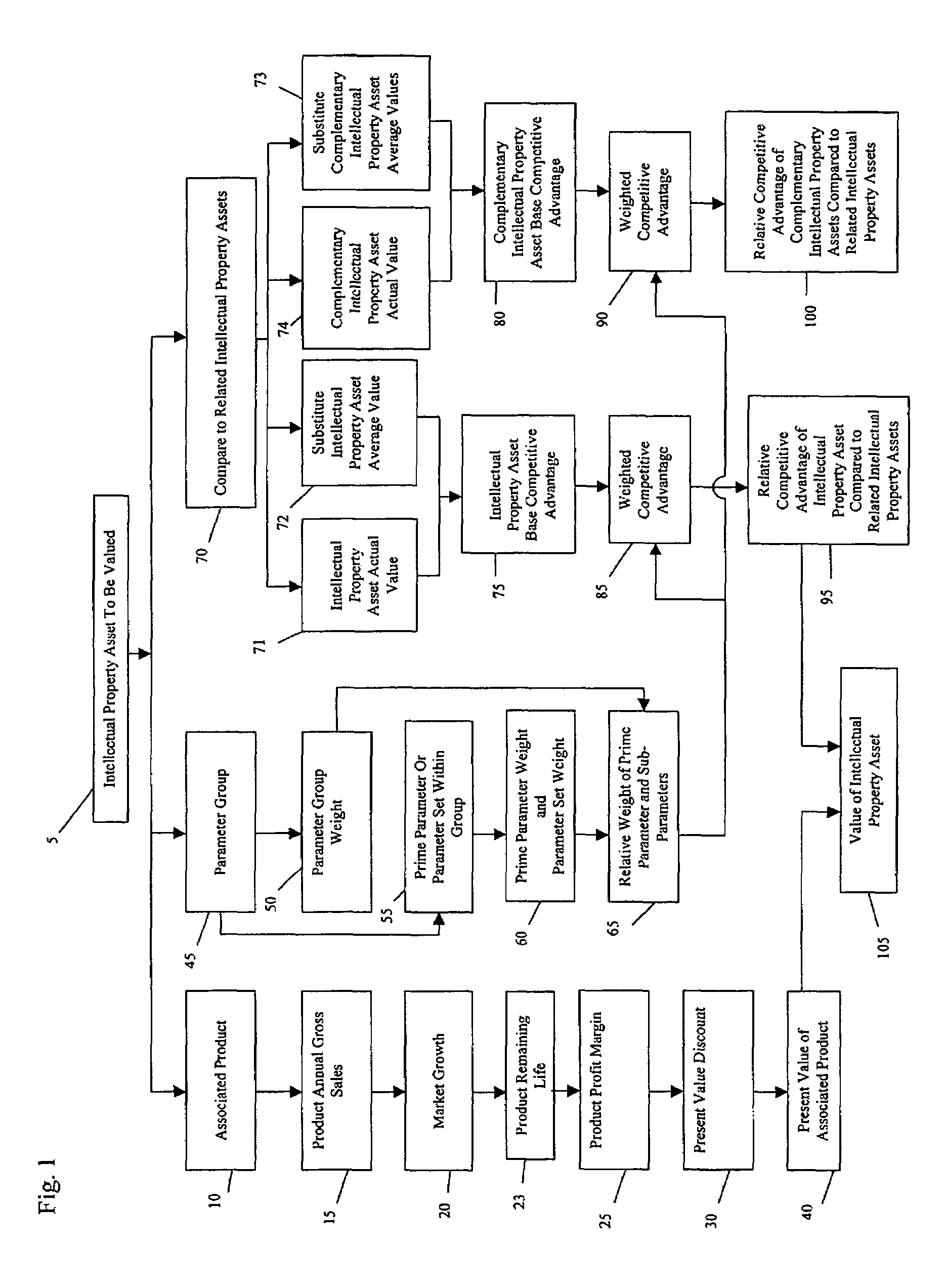

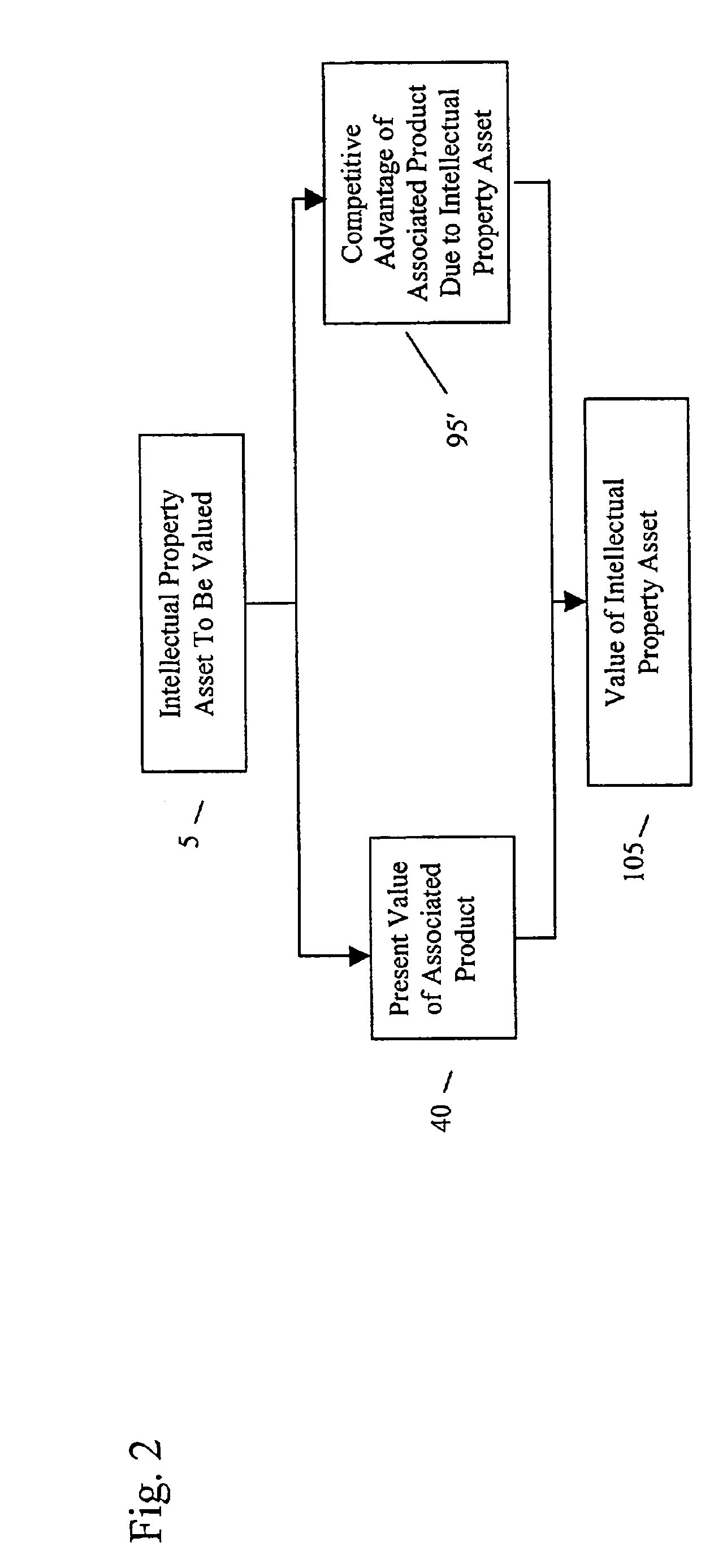

Method for valuing intellectual property

InactiveUS7493262B2Different typeDifferent from valueFinanceMarketingIntellectual propertyComputer science

A computer based system and method for calculating the value of a license for an intellectual property asset between a licensor and a licensee based on the licensor and licensee investment in the license, as well as the predicted increase in product value due to the change in competitive advantage afforded by the intellectual property asset that is the subject of the license. The value of the license may be discounted to adjust for various risks or adjusted based on whether the license is exclusive, limited exclusive, or non-exclusive. The system and method calculates an equal return payment which represents the value of either a one-time, lump-sum payment or the present value of a royalty stream distributed over the lifetime of the intellectual property asset, the system and method of the present invention can place a discrete monetary value on an intellectual property asset.

Owner:SYRACUSE UNIVERSITY

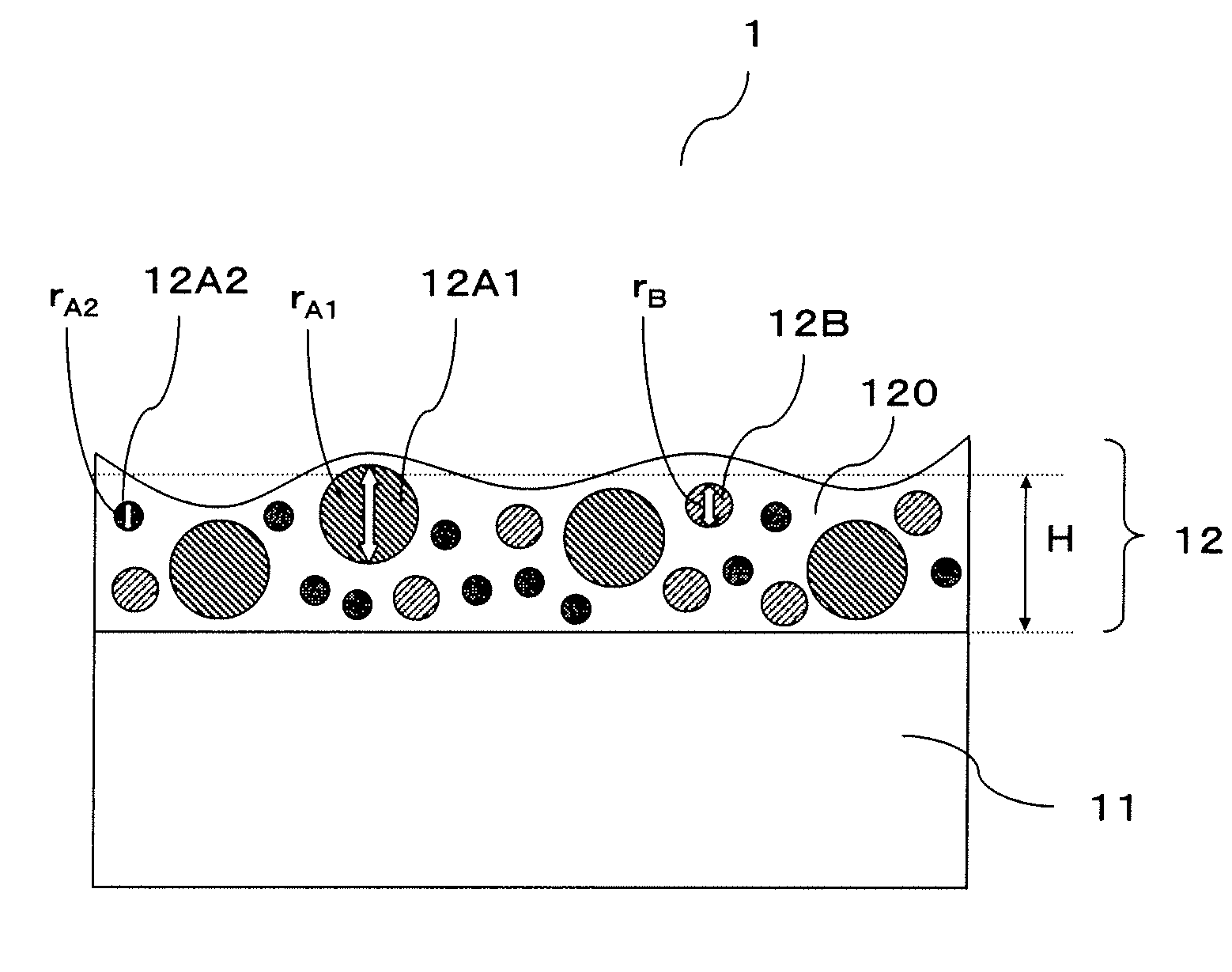

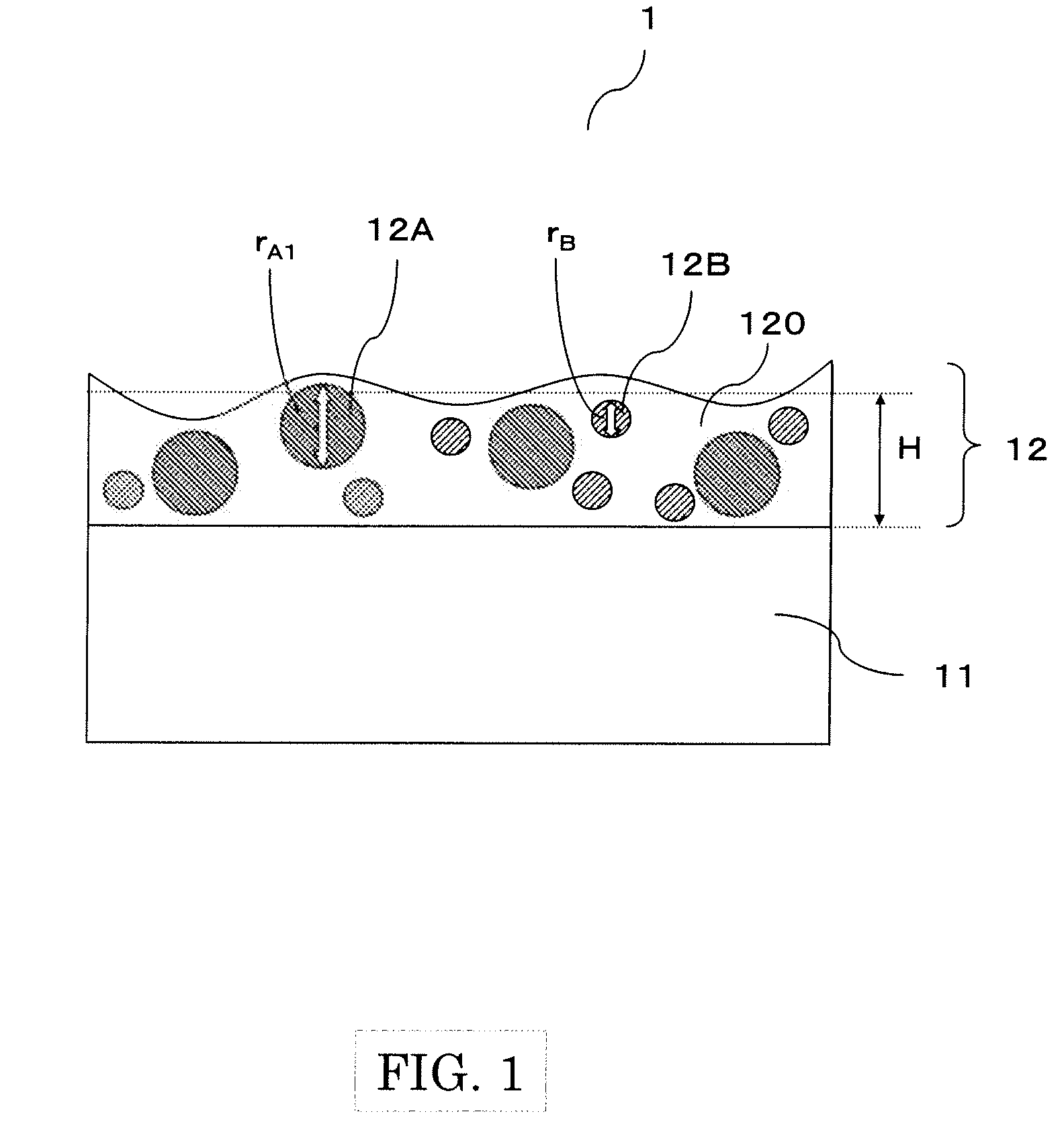

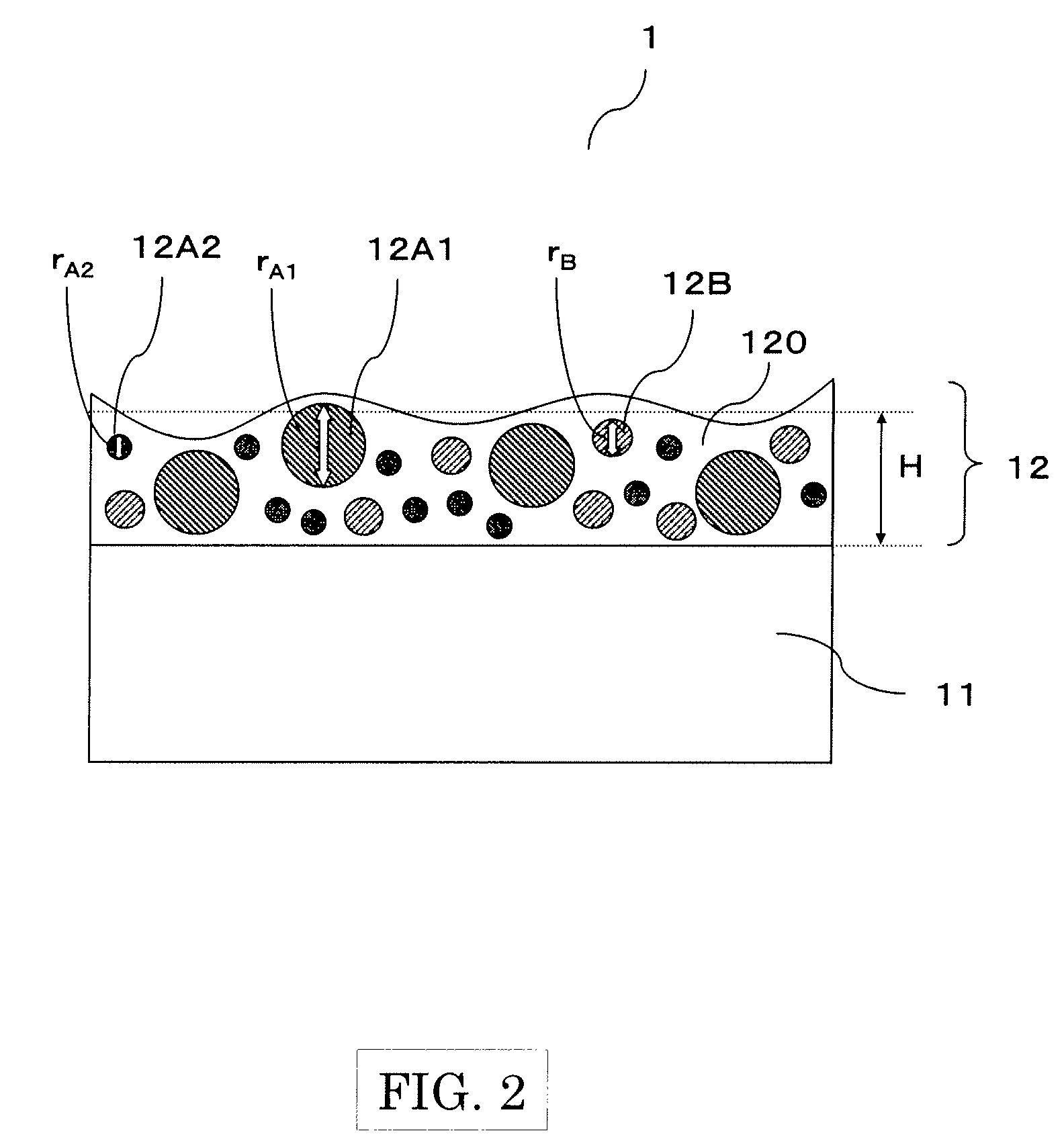

Antiglare Film

An embodiment of the present invention is an antiglare film which includes an antiglare layer having particles A, particles B, and a binder matrix on a transparent substrate. A difference in refractive index between the particles A and the binder matrix (|nA−nM|) is 0.060 or less. A difference in refractive index between the particles B and the binder matrix (|nB−nM|) is in the 0.080-0.300 range. An average diameter (unit: μm) of the particles B (rB) is in the 0.5-5.0 μm range. The product value |nB−nM|wBH, which is obtained by multiplying a difference in refractive index between said particles B and said binder matrix (|nB−nM|) by a content (part by weight) of said particles B as against 100 parts by weight of said binder matrix (wB) and an average thickness (unit: μm) of said antiglare layer (H) is in the 10.0-15.0 range.

Owner:TOPPAN PRINTING CO LTD

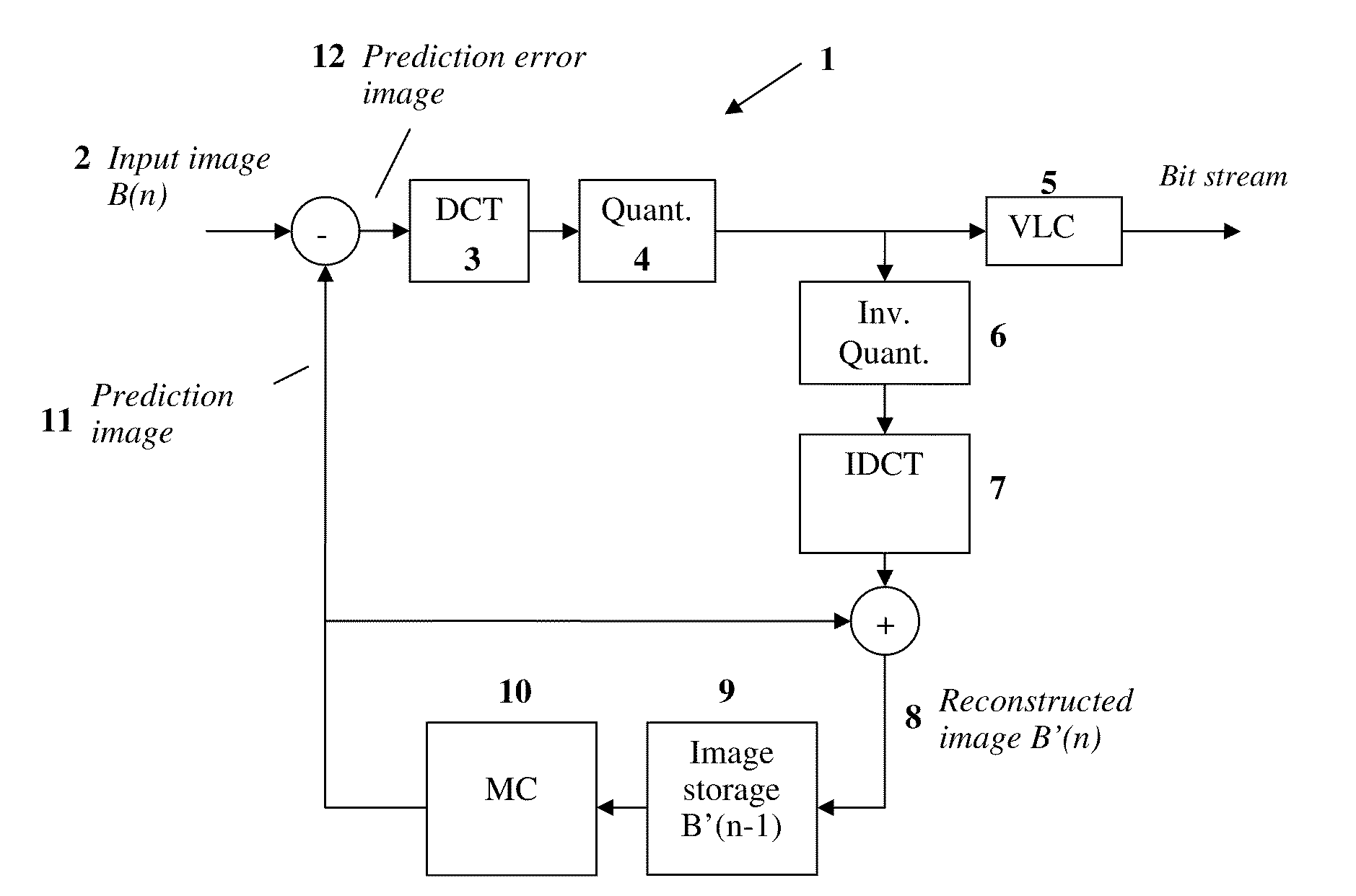

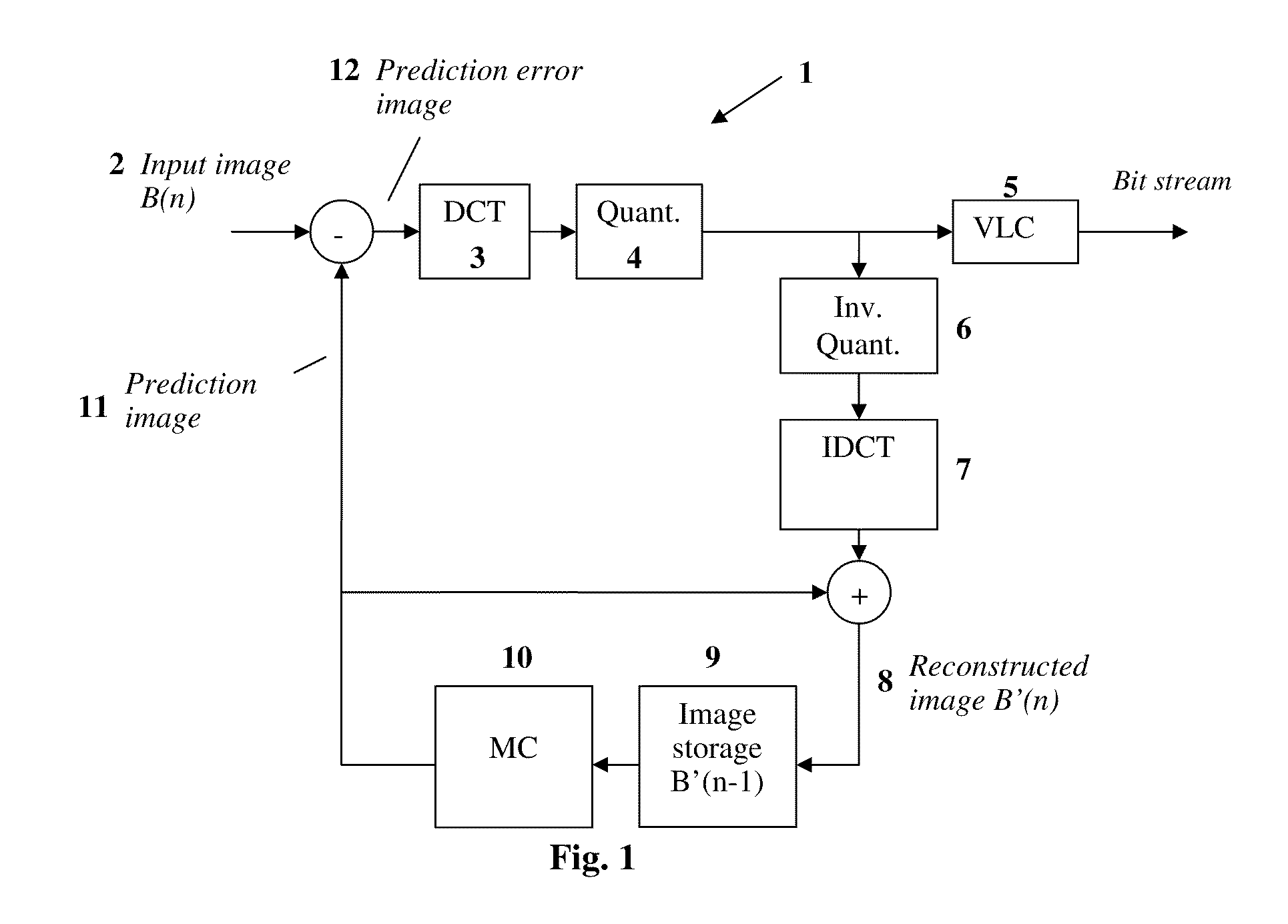

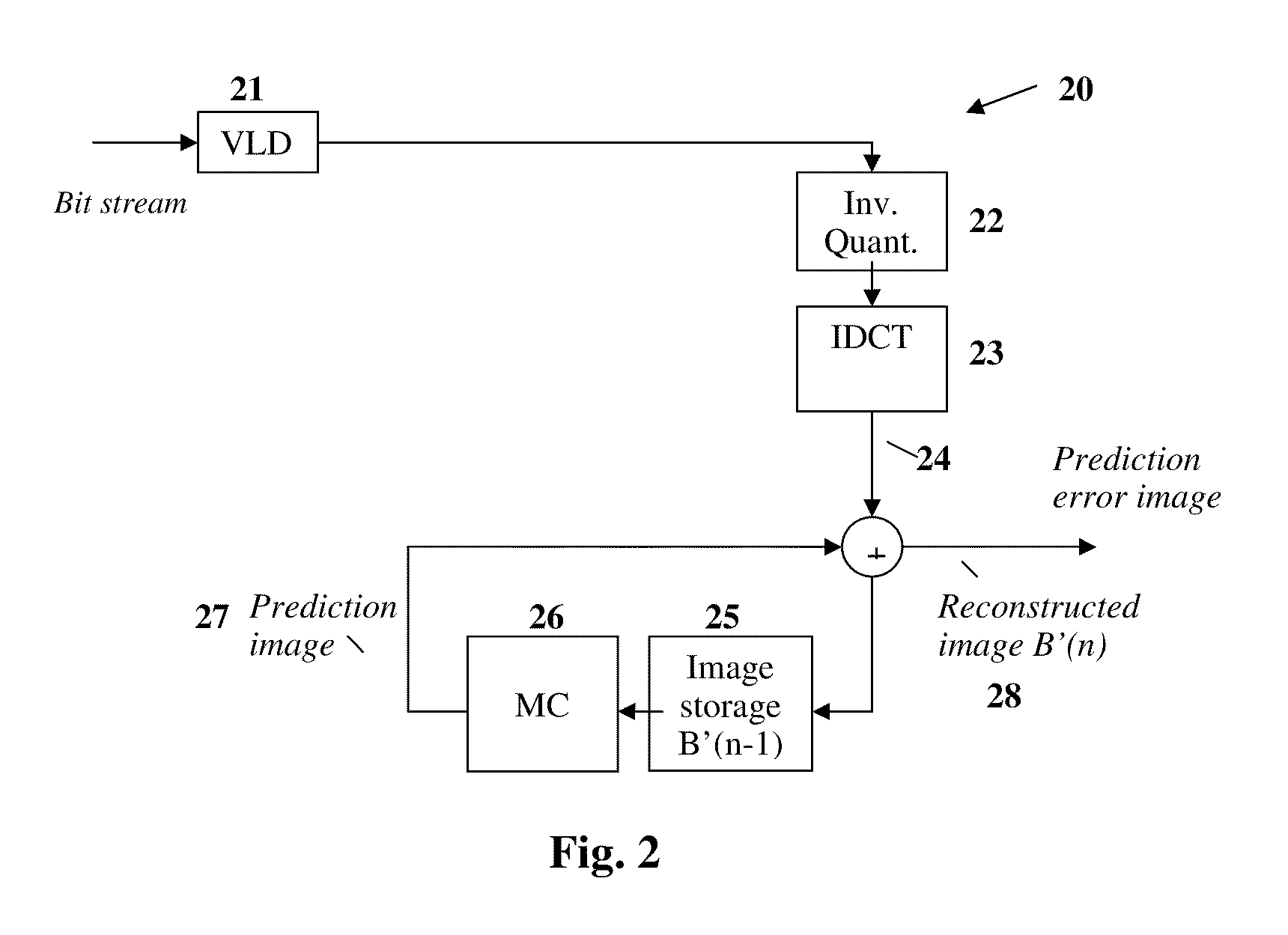

Method and device for avoiding rounding errors after performing an inverse discrete orthogonal transformation

InactiveUS20100208807A1Avoiding rounding errorColor television with pulse code modulationColor television with bandwidth reductionComputer graphics (images)Errors and residuals

The present invention provides a method for avoiding rounding errors during rounding of values after performing an inverse discrete orthogonal transformation. In a first step, a block of coefficients (F′[u][v]) is transformed into a block of image pixel values (f′[y][x]) by means of an inverse discrete orthogonal transformation, wherein each image pixel comprises an image pixel value. In a second step, a product of the block of image pixel values (f′[y][x]) with a first pixel pattern (A[y][x]) is calculated. In a third step, the product values of the second step are summed up to a first sum (Sum1′). In a fourth step, it is determined whether the first sum (Sum1′) is even or odd. In a fifth step, if the first sum (Sum1′) is even, a block of manipulation values (C[y][x]) is added to or subtracted from the block of image pixel values (f′[y][x]) for generating a manipulated block of image pixel values (f[y][x]), wherein the block of manipulation values (C[y][x]) is formed in such a way that rounding errors are avoided in a subsequent rounding operation.

Owner:ECODISC TECH +1

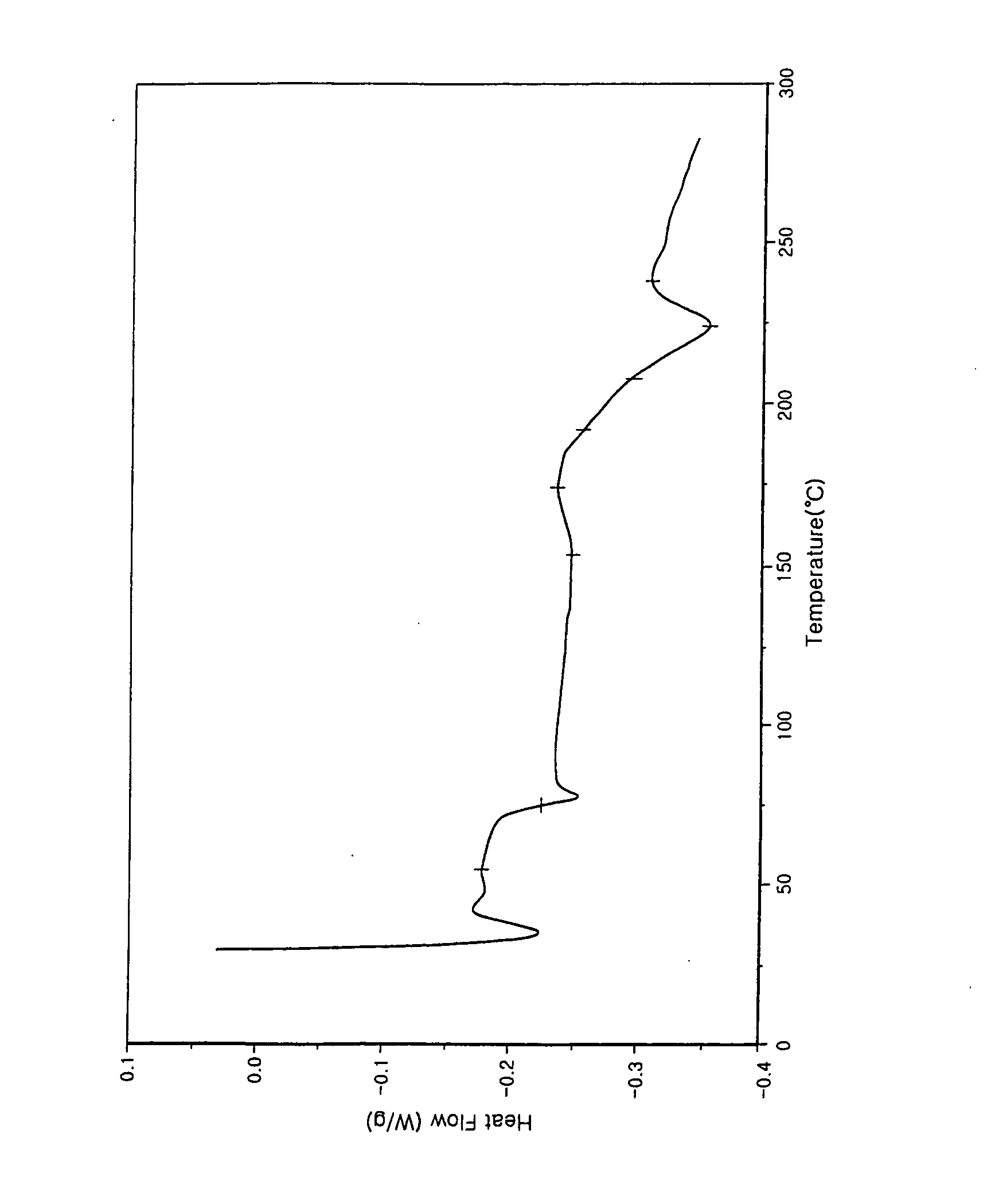

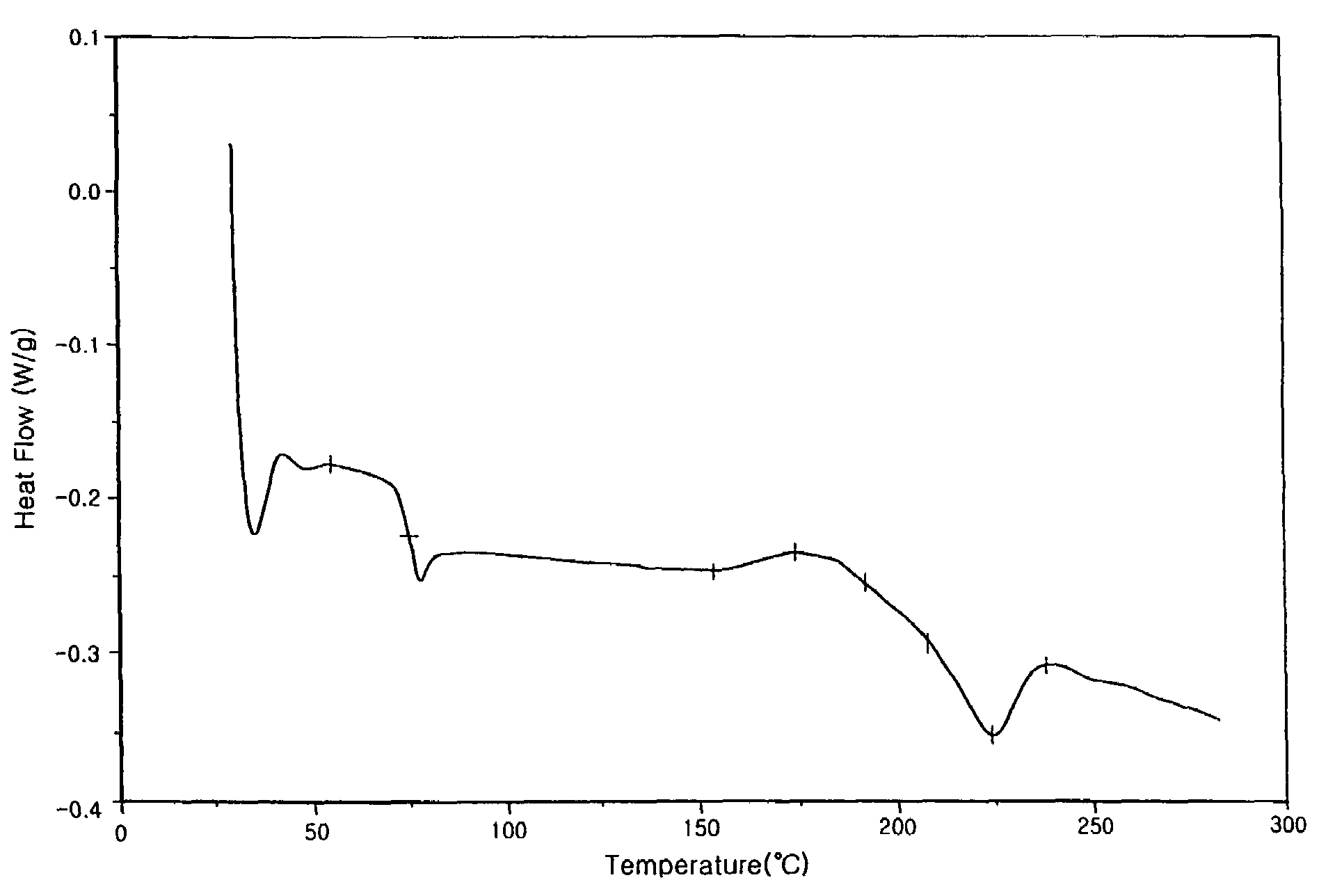

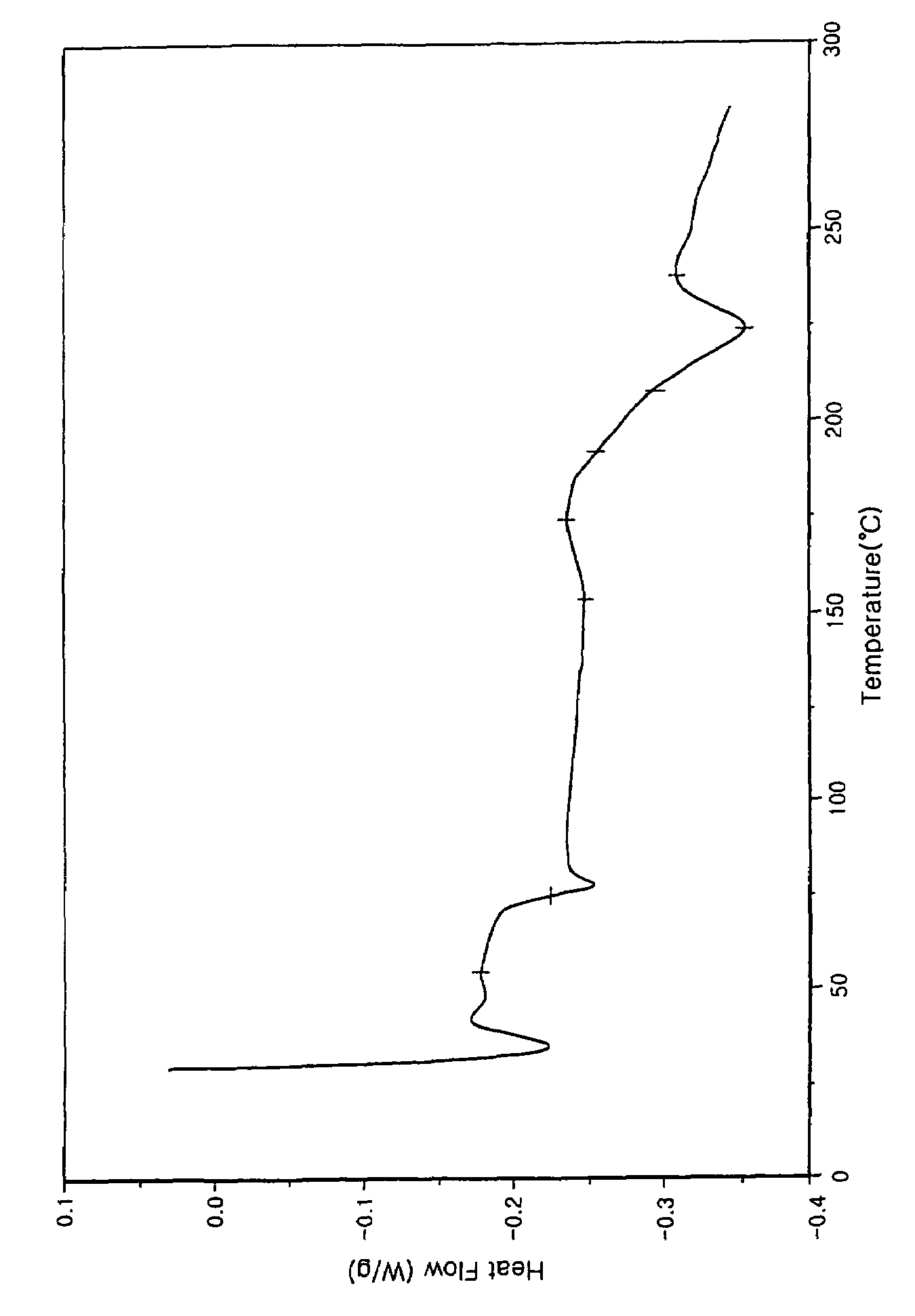

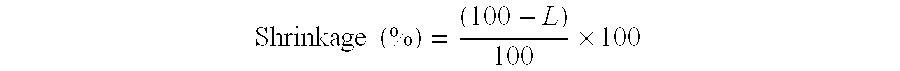

Heat-shrinkable polyester film having excellent crystallinity

InactiveUS20050010018A1Low shrinkageAnimal housingThin material handlingCyclohexanedimethanolCrystallization temperature

Disclosed herein is a heat-shrinkable co-polyester film having terephthalic acid and ethylene glycol as main components and containing 1,4-cyclohexanedimethanol at the amount of 3-40 mol %. The heat-shrinkable co-polyester film has a crystallization temperature of 80-220° C., a heat shrinkage (%) higher than 30% in at least one direction of longitudinal and transverse directions in 90° C. hot water, and a maximum shrinkage stress lower than 3 kg / mm2. The film is suitable for use as various wrapping materials, such as covering, binding and casing materials. Particularly, the film is used to cover a cap, body and shoulder, etc. of various vessels and rod-shaped molded articles and thus to provide labeling, protection, binding or an improvement in product value. Also, the film can be used for multi-package.

Owner:TORAY SAEHAN

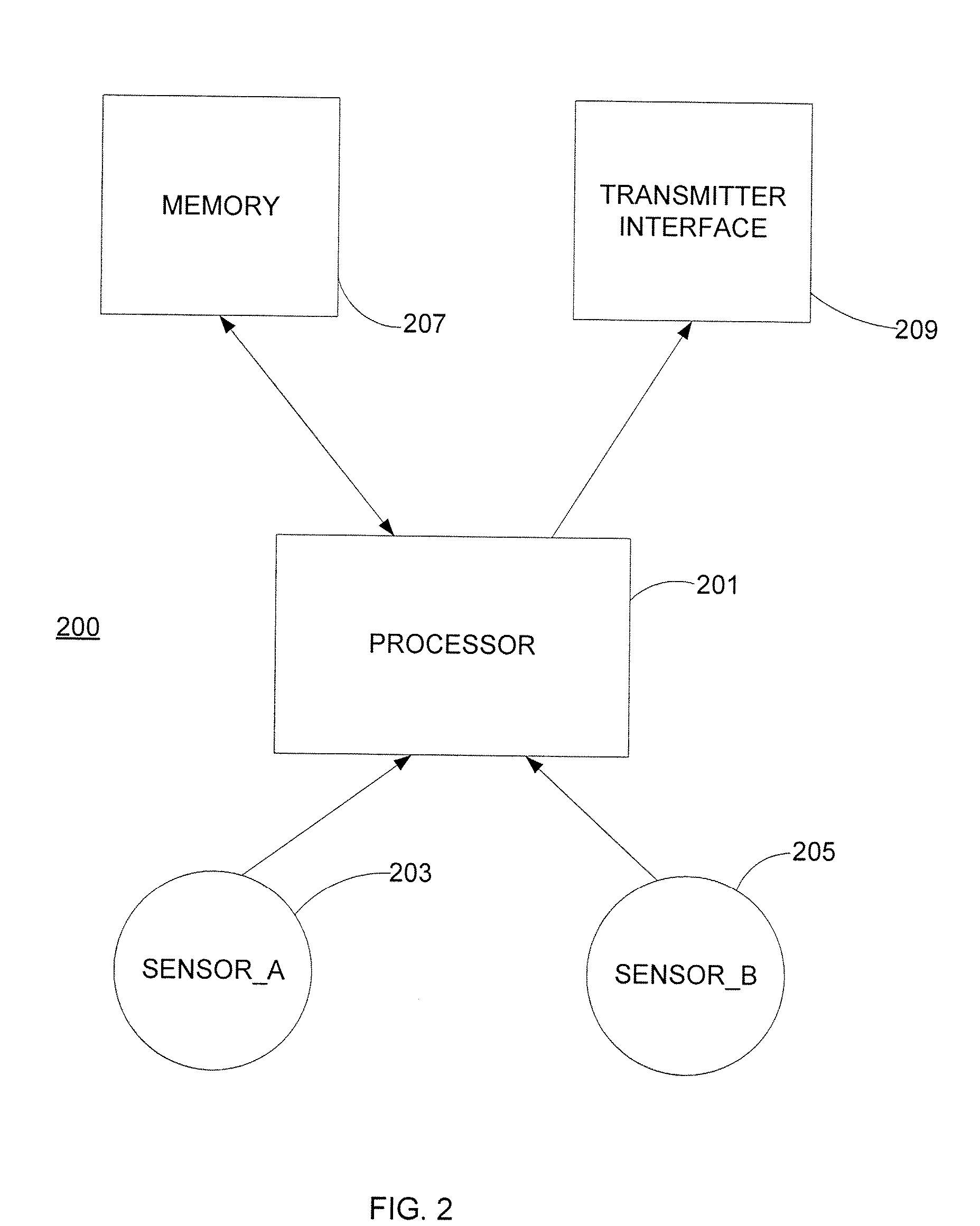

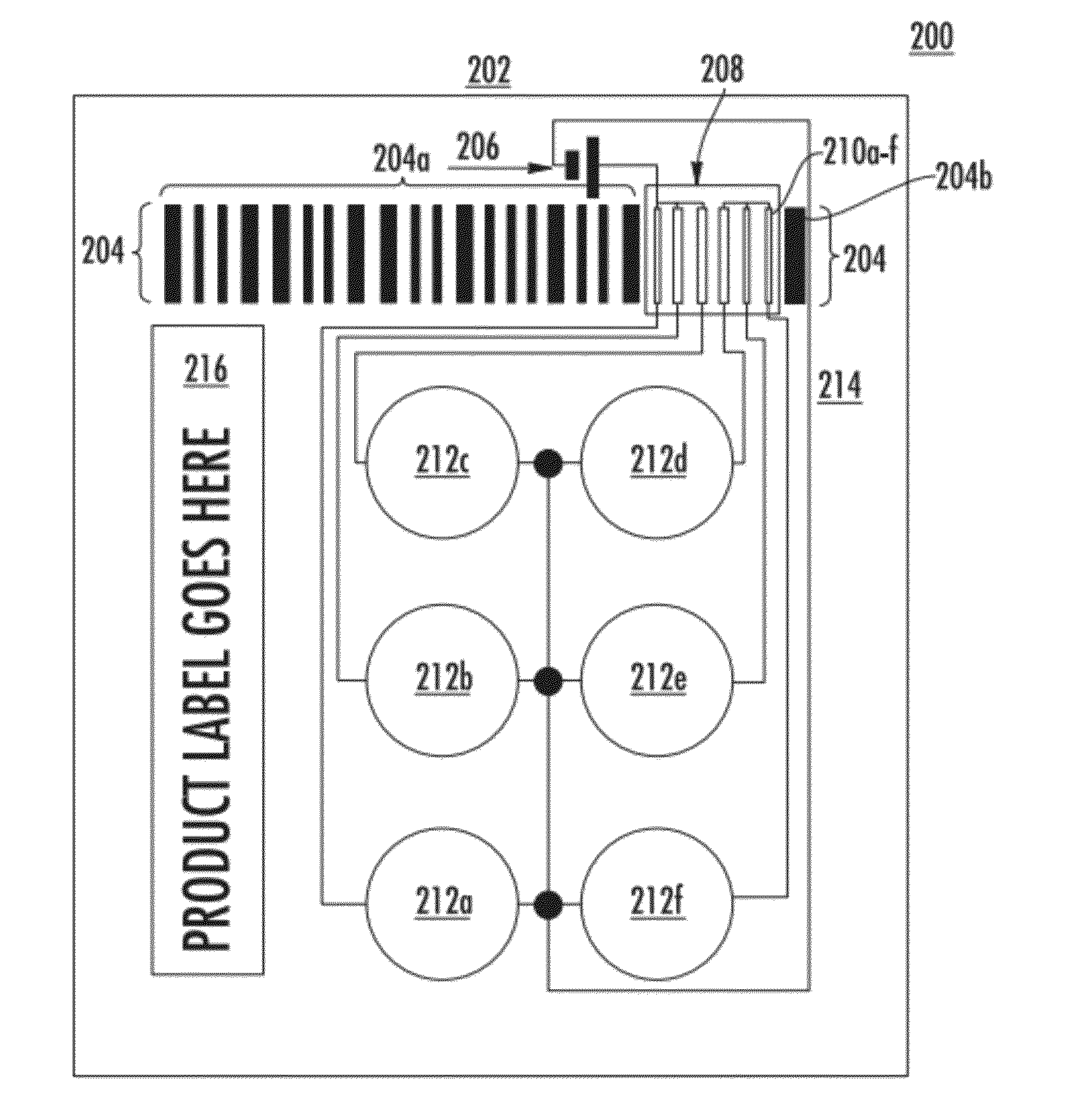

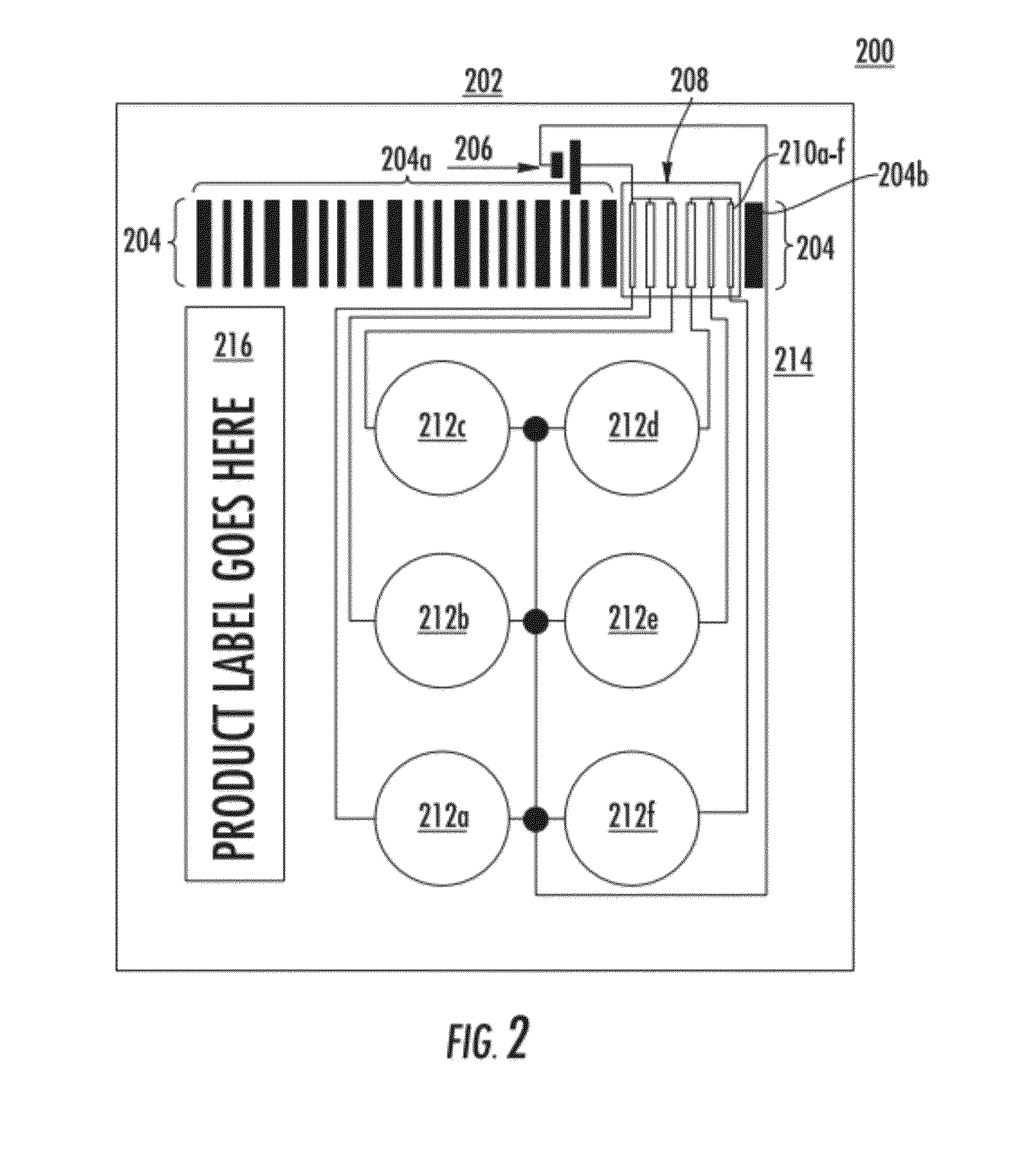

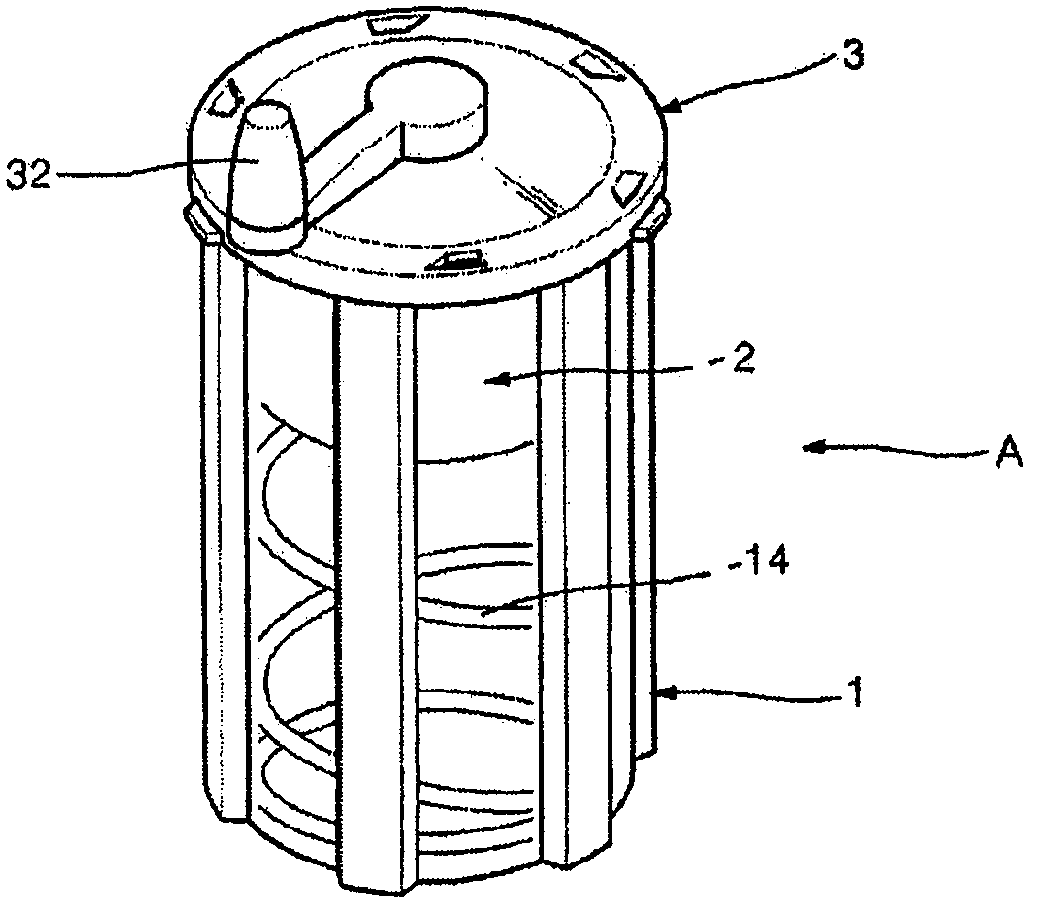

System and method for automating and verifying product value, usage, and suitability for use or sale

ActiveUS20120125994A1Local control/monitoringDrug and medicationsMedication informationComputer science

A computer-based system for monitoring product usage, value, and suitability for use or sale. The system can include one or more processors configured to process and manage data. Additionally, the system can also include product packaging comprising a machine-readable medium. Notably, the machine-readable medium can comprise product information among other types of information. The one or more processors can be configured for receiving the product information of the machine-readable medium. The machine-readable medium and corresponding medication information can be adjusted based automated signals or interactive signals, where the signals are generated based on current or historical data regarding the product or the packaging.

Owner:GUILLAMA NOEL J

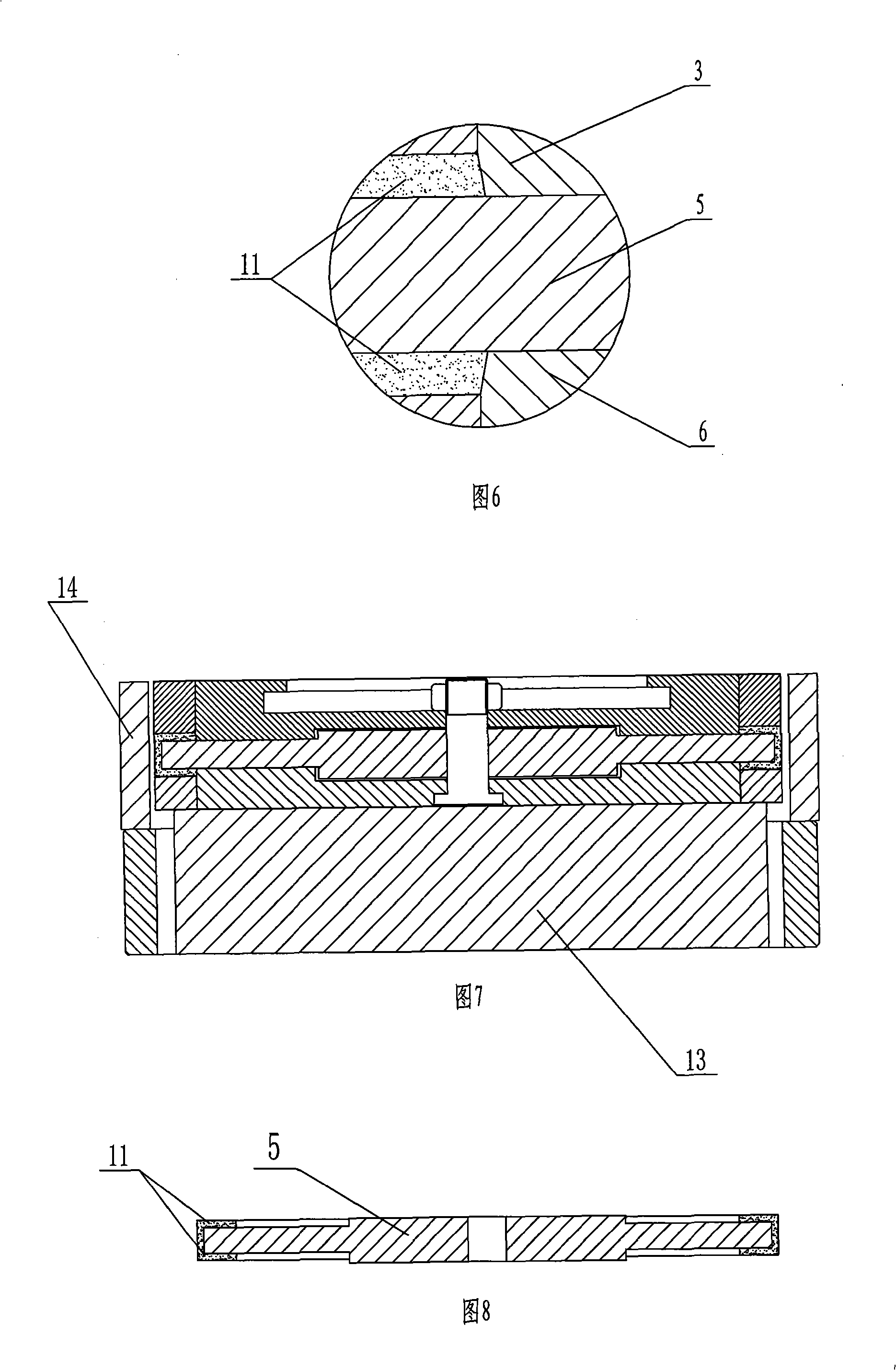

Resin cement cubic boron nitride grinding wheel and preparation method thereof

ActiveCN101332587AExtend your lifeIncrease grinding ratioBonded abrasive wheelsMetal working apparatusPass rateBoron nitride

The invention relates to a resinoid wedding agent cubic boron nitride grinding wheel and a manufacturing method thereof, the resinoid wedding agent cubic boron nitride grinding wheel comprises a grinding wheel matrix and a grinding layer, the grinding layer is arranged on the external wall of the grinding wheel matrix and peripheries of an upper end face and a lower end face; the grinding layer includes 12-40% of cubic boron nitride (nickel plating), 25-50% of Dialok939p resin, 1-10% of villaumite grinding aid, 1-10% of a solid lubricant filler, 10-30% of a powder filler with high thermal conductivity and 1-15% of oxide filler by volume percentage of the grinding layer. A specially designed hot pressing dies and separately batch feeding method are adopted, which causes the pressed products to have homogeneous structure and consistent density; the formula of the grinding wheel is simple, and the designed die has the advantages of simple and reasonable structure, easy die filling and die release, the product obtained has high once-pass rate, homogeneous structure and consistent density; the grinding wheel has good grinding performance and long service life, can perform peripheral grinding and end face grinding, and is equivalent to three grinding wheels with the same specification, the matrix and making cost are saved, production cost is reduced, the product value is improved.

Owner:广东奔朗新材料股份有限公司

Heat-shrinkable polyester film having excellent crystallinity

InactiveUS7128863B2Low shrinkageAnimal housingThin material handlingCyclohexanedimethanolPolymer science

Disclosed herein is a heat-shrinkable co-polyester film having terephthalic acid and ethylene glycol as main components and containing 1,4-cyclohexanedimethanol at the amount of 3–40 mol %. The heat-shrinkable co-polyester film has a crystallization temperature of 80–220° C., a heat shrinkage (%) higher than 30% in at least one direction of longitudinal and transverse directions in 90° C. hot water, and a maximum shrinkage stress lower than 3 kg / mm2. The film is suitable for use as various wrapping materials, such as covering, binding and casing materials. Particularly, the film is used to cover a cap, body and shoulder, etc. of various vessels and rod-shaped molded articles and thus to provide labeling, protection, binding or an improvement in product value. Also, the film can be used for multi-package.

Owner:TORAY SAEHAN

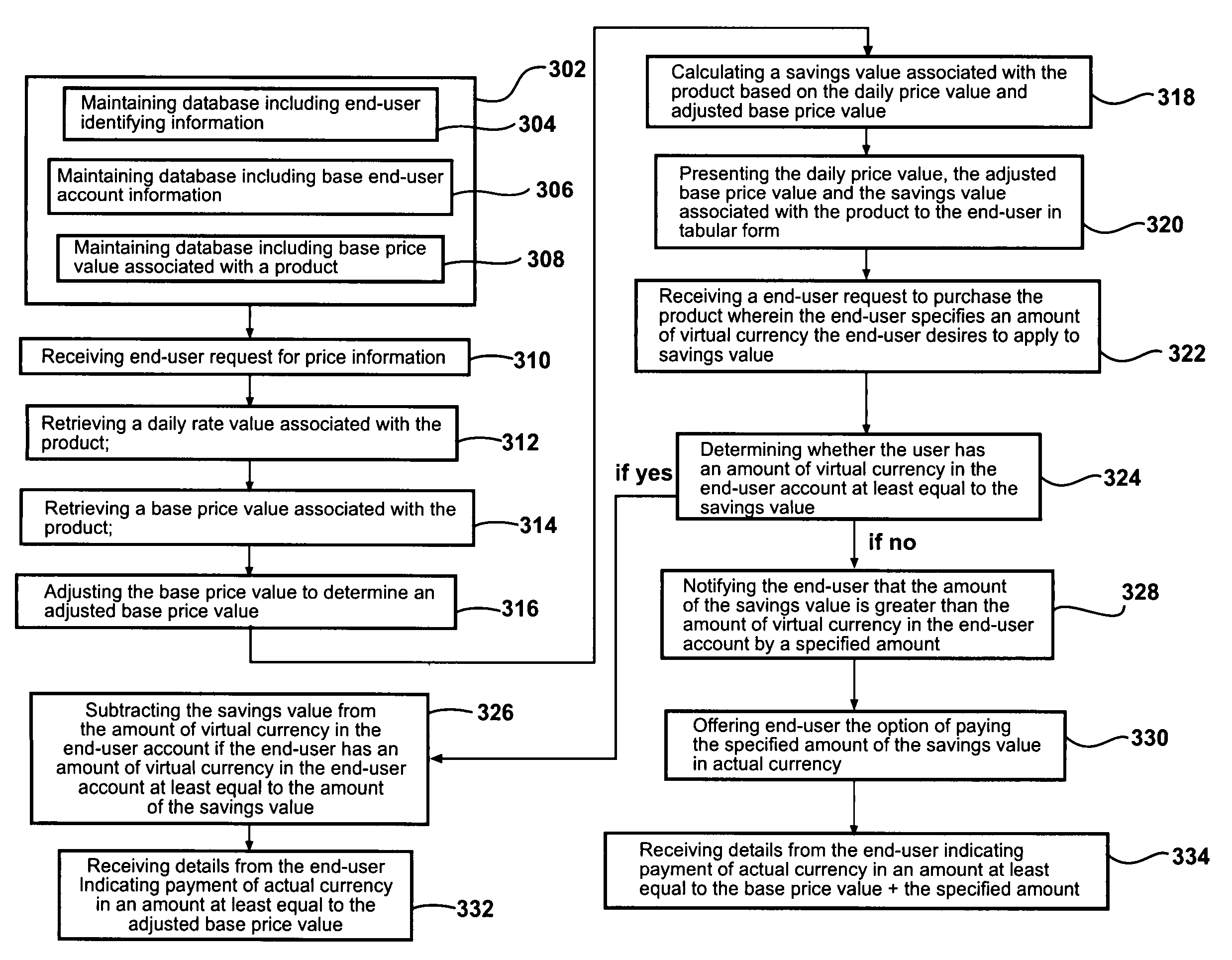

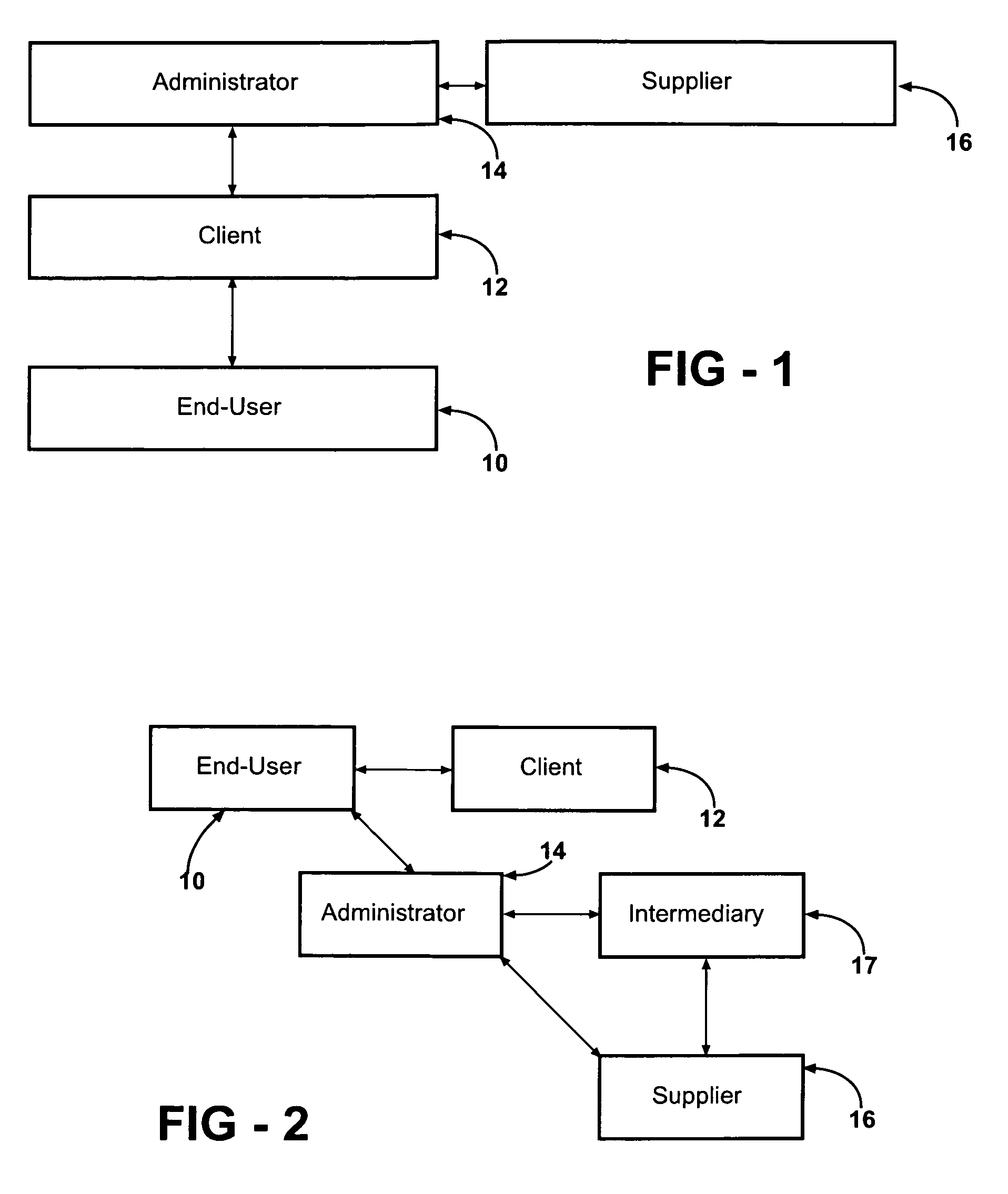

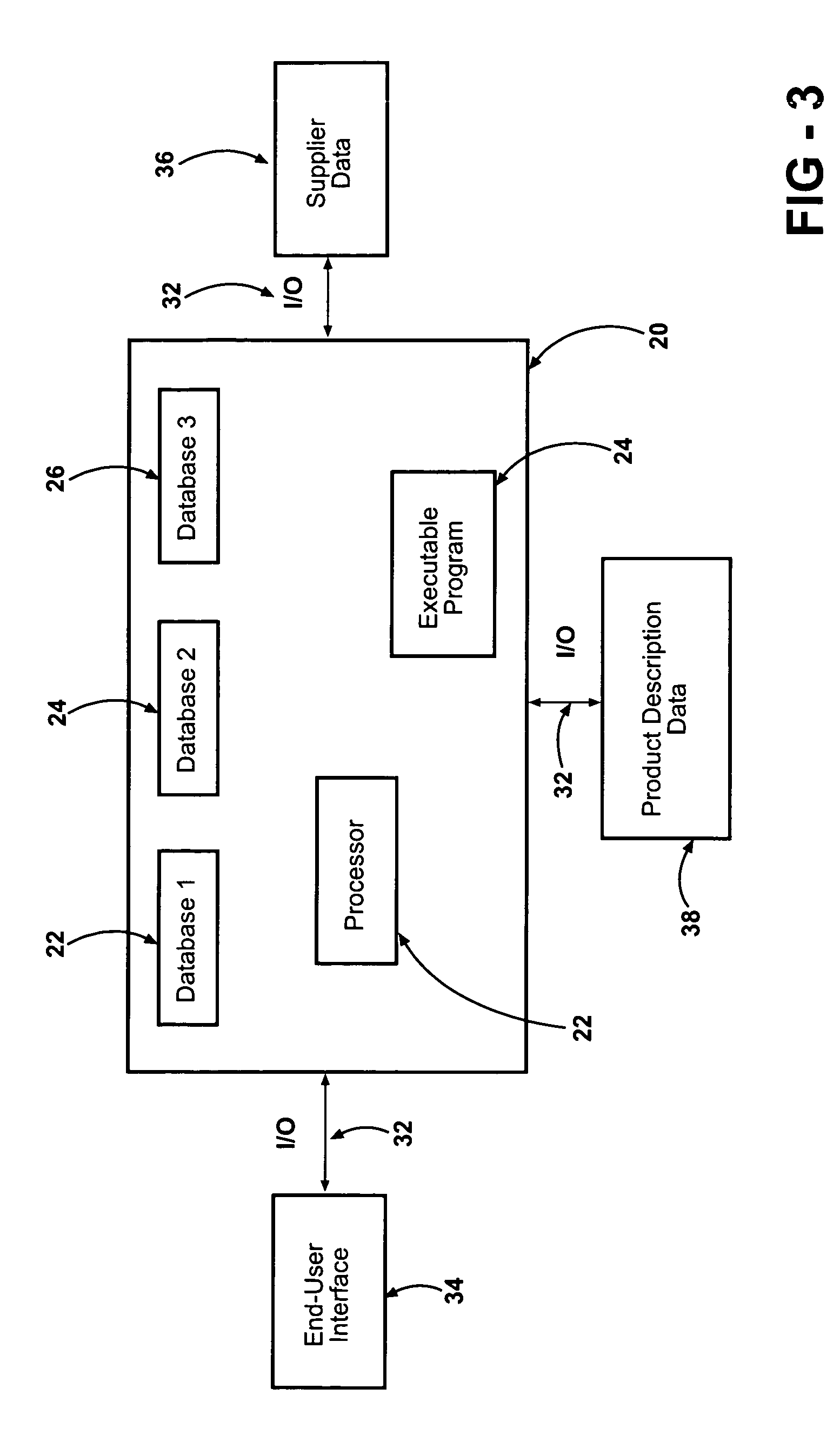

System and method for providing a discount

In particular, systems and methods are provided for delivering a discount using a virtual currency. Inventive systems and methods offer a high perceived savings value to an end-user while maintaining the perception of product value. Further, systems and methods for providing a discount are described which impose little or no cost on the service or product provider. An embodiment of an inventive method includes presenting a display of a price paid by a consumer without access to the virtual currency along with a display of an amount payable by the end-user in actual currency in combination with an amount payable in virtual currency by an end-user of an inventive system. The end-user perceives a benefit to using the virtual currency since the price paid in actual currency is less than the displayed price to be paid by a consumer without access to the virtual currency.

Owner:INTRIDE LOYALTY LLC

Pitaya peel lactic acid fermented beverage and preparation method thereof

InactiveCN105167095ABright colorStrong fragranceFood ingredient functionsAdditive ingredientBULK ACTIVE INGREDIENT

The invention discloses a pitaya peel lactic acid fermented beverage, which is prepared by taking pitaya peel as a main raw material and using lactobacillus fermentation and a preparation method of the beverage, and belongs to the technical field of agricultural and sideline product value-added exploitation new nutrition and health care product development. The preparation method of the pitaya peel lactic acid fermented beverage comprises the steps of adding a certain amount of granulated sugar and milk sugar after carrying out washing, pulping and color protecting on the pitaya peel; carrying out fermentation by adding lactobacillus after sterilization cooling. The pitaya peel lactic acid fermented beverage disclosed by the invention is bright in color, rich in fragrance and unique in flavor, contains abundant nutrient substances and active ingredients and has multiple healthcare effects of promoting metabolism of a human body, enhancing the immunity, resisting the tumor, resisting oxidation and the like; a nutrition additional value of pitaya is increased by comprehensively utilizing a processed by-product, i.e., the pitaya peel, of the pitaya; the pitaya peel lactic acid fermented beverage is directly prepared by utilizing lactobacillus, does not contain an additive, is simple in processing procedures and easy to realize, and has a good economic benefit and a good environment protection benefit.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI +1

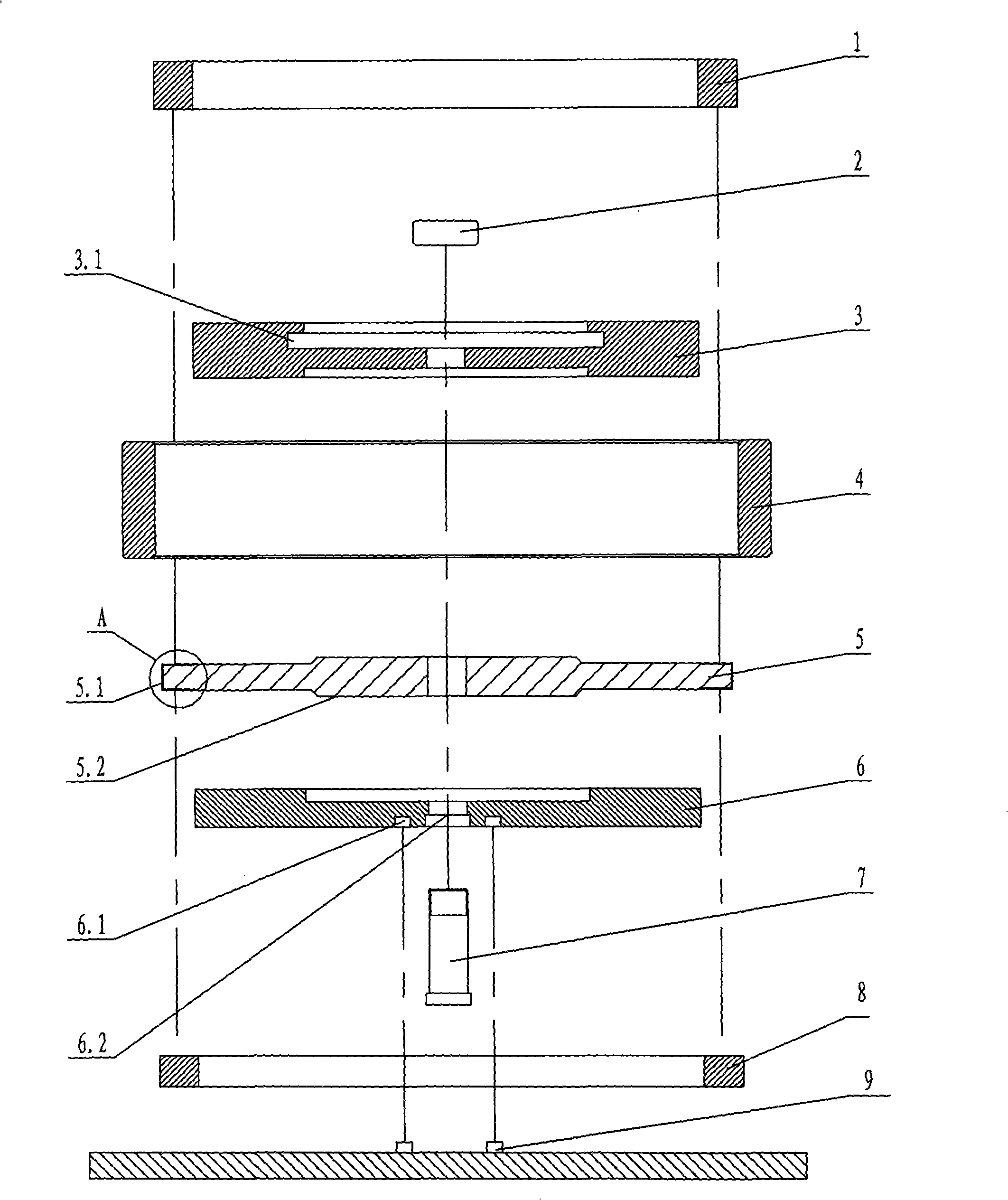

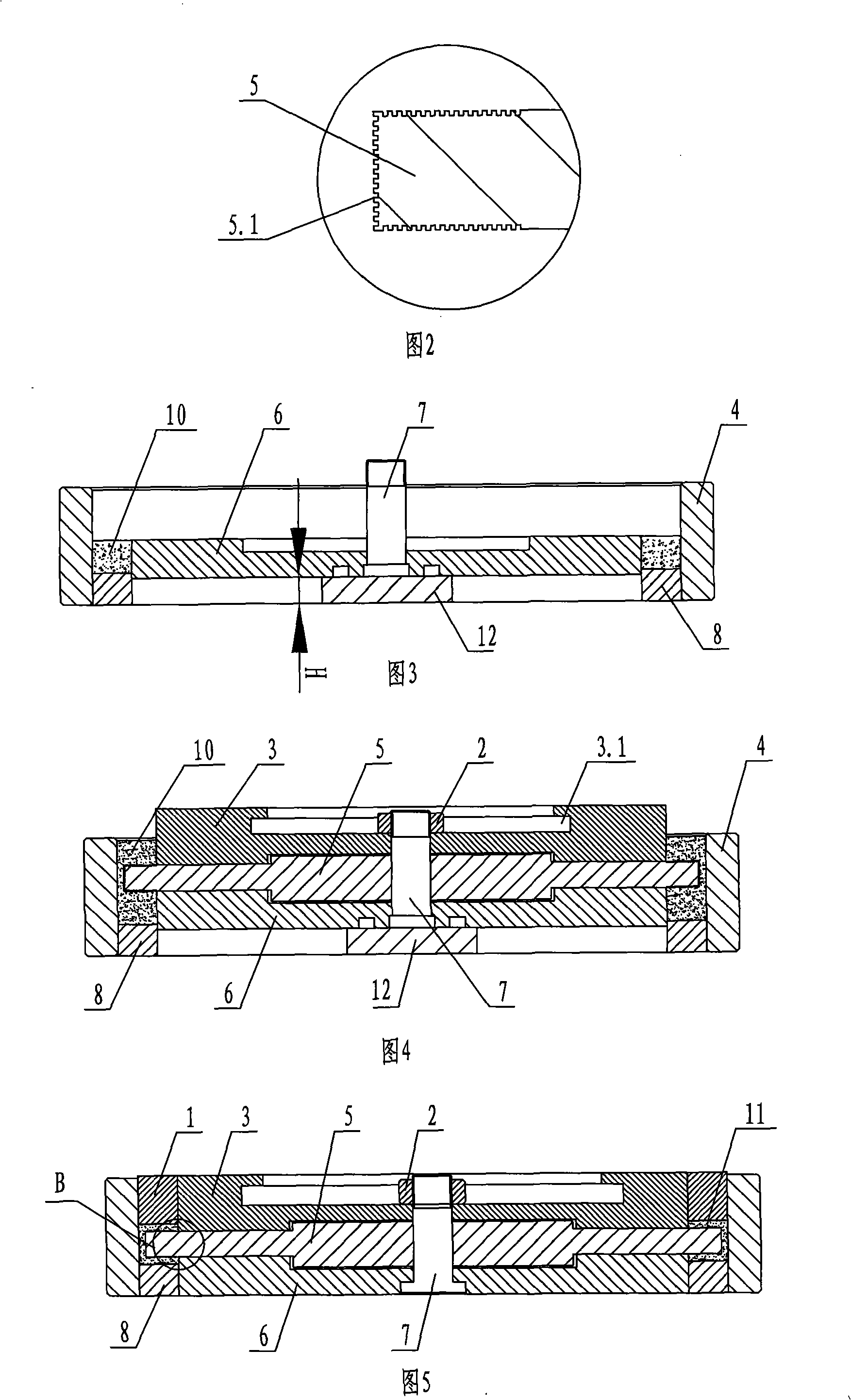

Shaping apparatus for fruits and root and tuberous vegetables

ActiveUS20080307980A1Increase valueEasy to implementFruit stoningGang saw millsEngineeringPlant Tubers

An apparatus is disclosed which can shape fruits and root and tuberous vegetables. The shaping apparatus is operated in such a manner that: when root and tuberous vegetable or fruit is placed in a cutting blade case and rotated, the object is spirally tracked and the spirally tracked object is removed from the lower side of the cutting blade case, so that the spirally tracked object is picked up by an additional stick and then ornamented into various forms. The shaping apparatus allows fruits and root and tuberous vegetables to be easily treated in a variety of ways, as per the second process, thereby enhancing the product value of processed foodstuffs produced from the first process.

Owner:LEE BONG GU +6

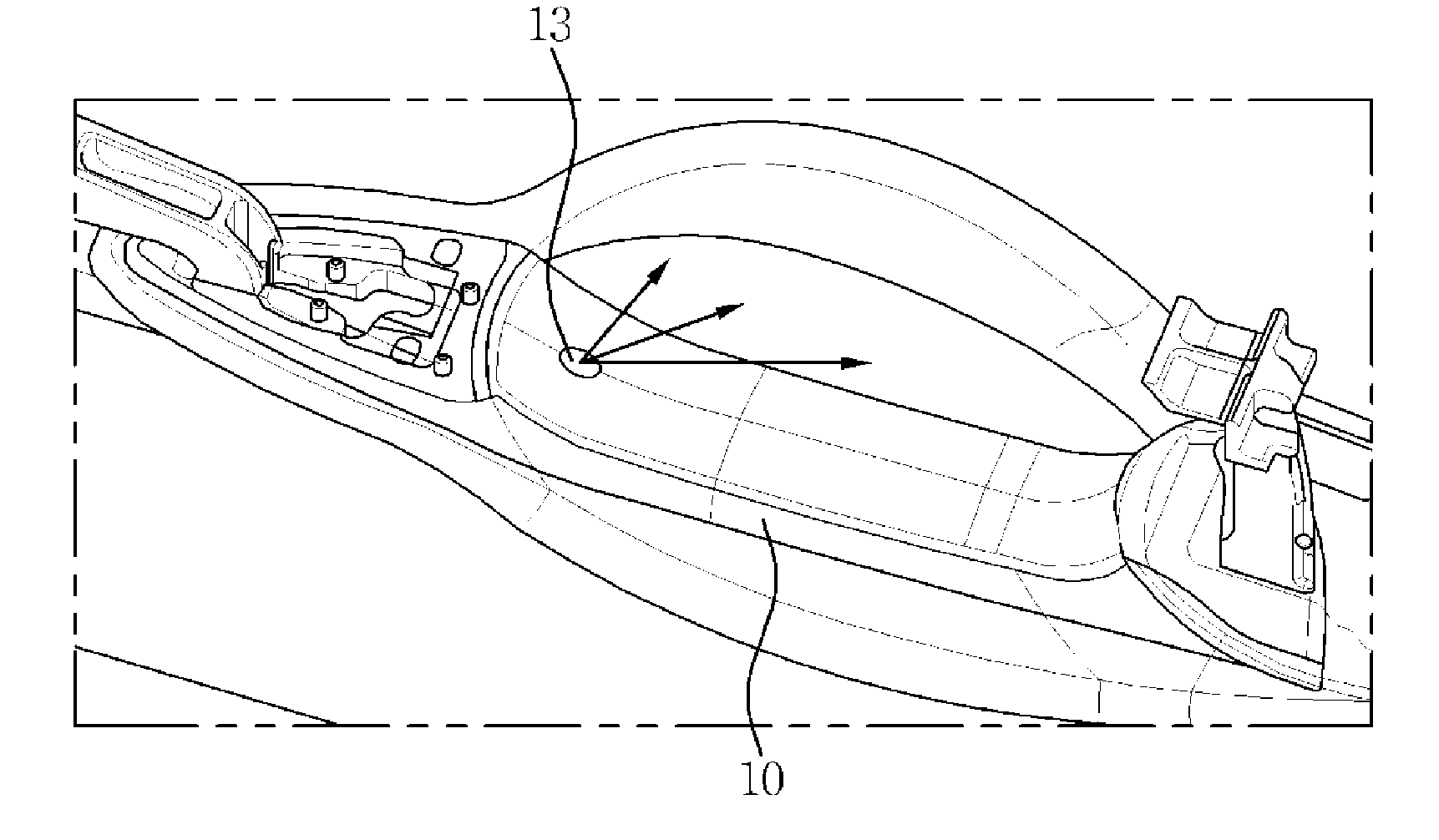

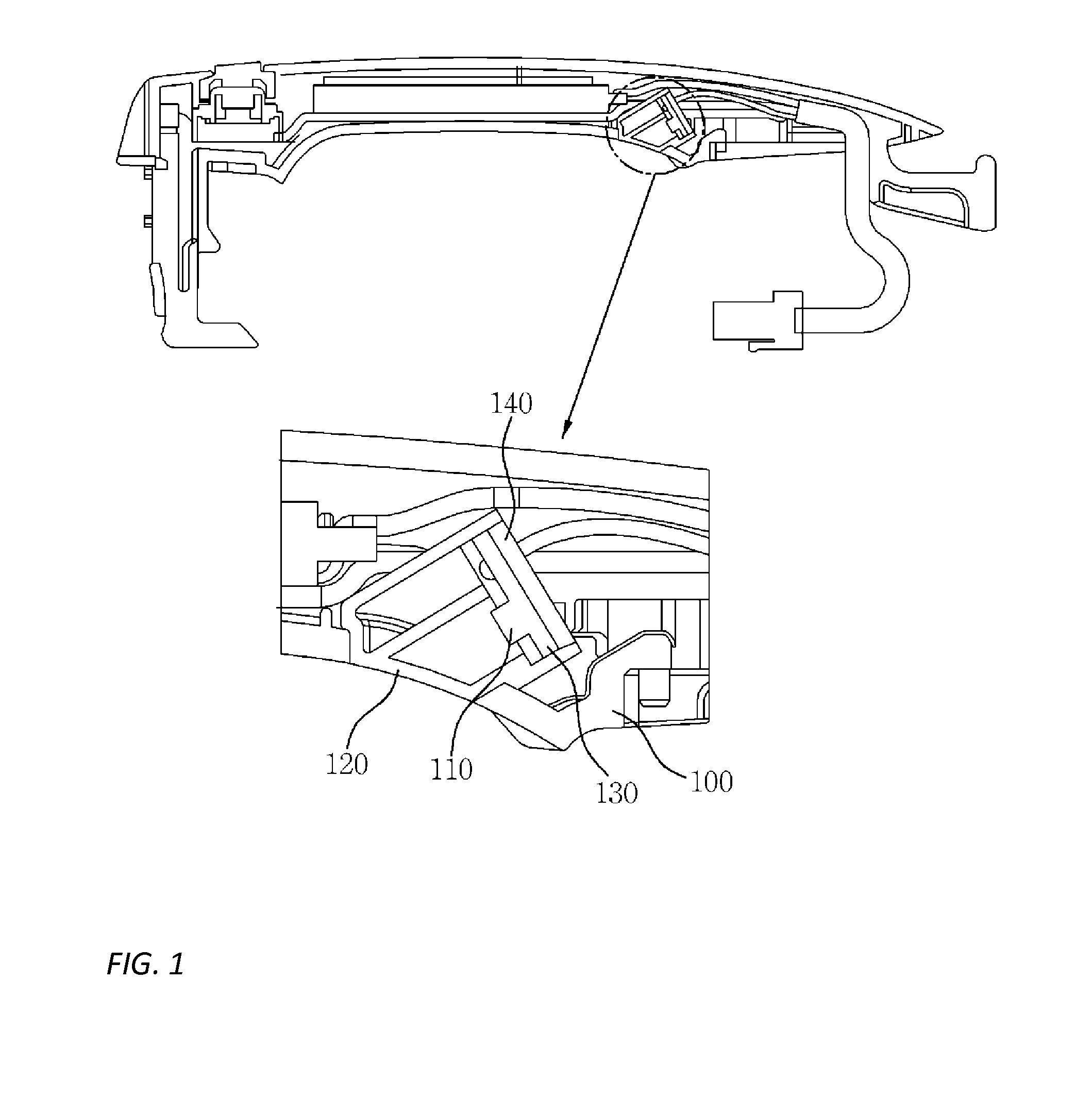

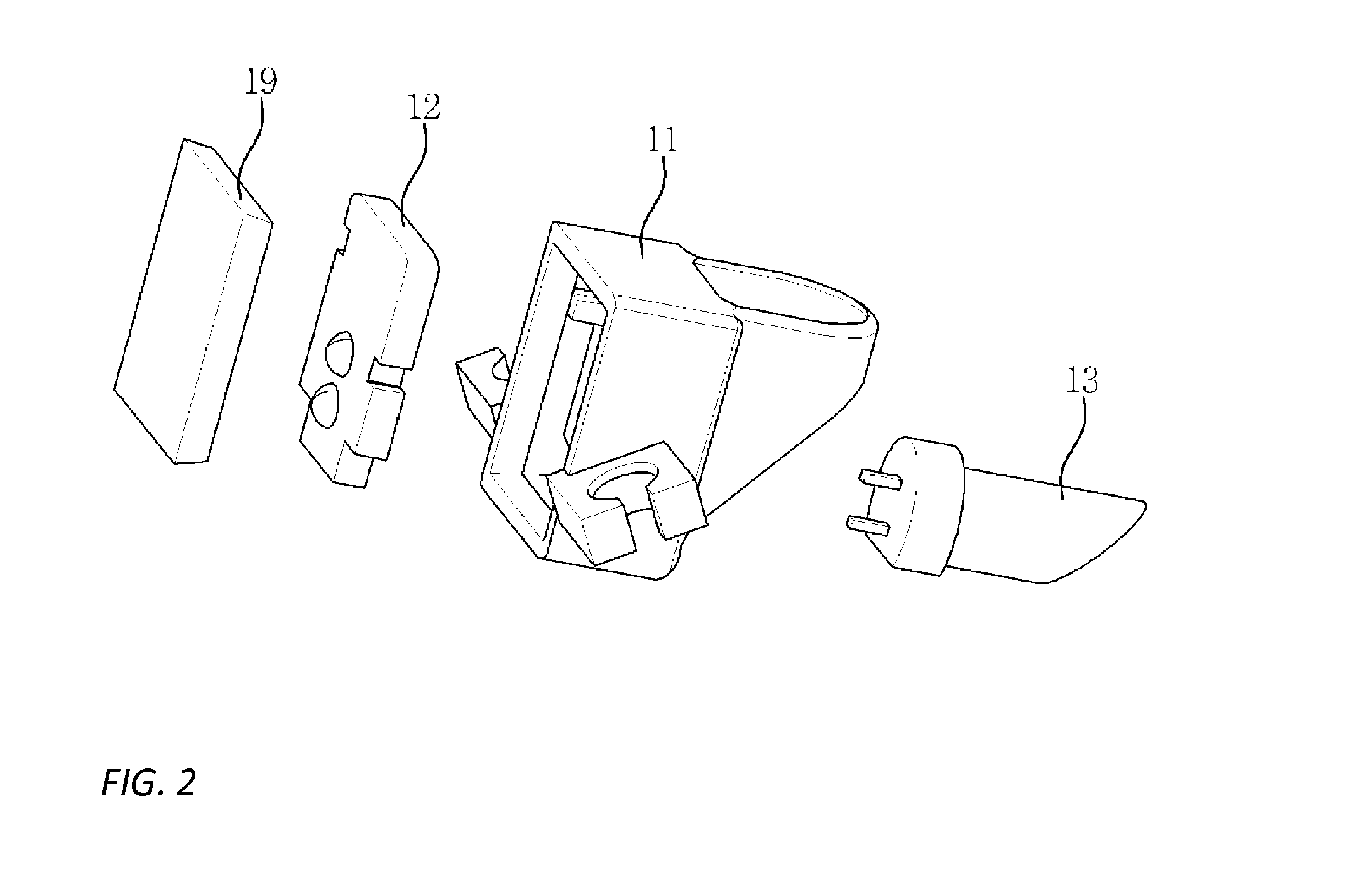

Illuminator of door outside handle for vehicle

ActiveUS20120127746A1Reduce manufacturing costSpace utilizationVehicle locksLighting and heating apparatusLight guideEngineering

An illuminator of a door outside handle for a vehicle may perform both a function of a light source and a light guiding function. The illuminator may further employ a light guide having a mood lamp function on an inner surface of the door outside handle and a top LED combined with the light guide to illuminate the outer panel together with the illuminator, making it possible to enhance a product value due to realization of various illumination effects. The illuminator of a door outside handle for a vehicle can be turned on or off through various operation logics by employing multiple different illumination methods where lights of different colors can be realized according to the operation condition, making it possible to enhance product value.

Owner:HYUNDAI MOTOR CO LTD

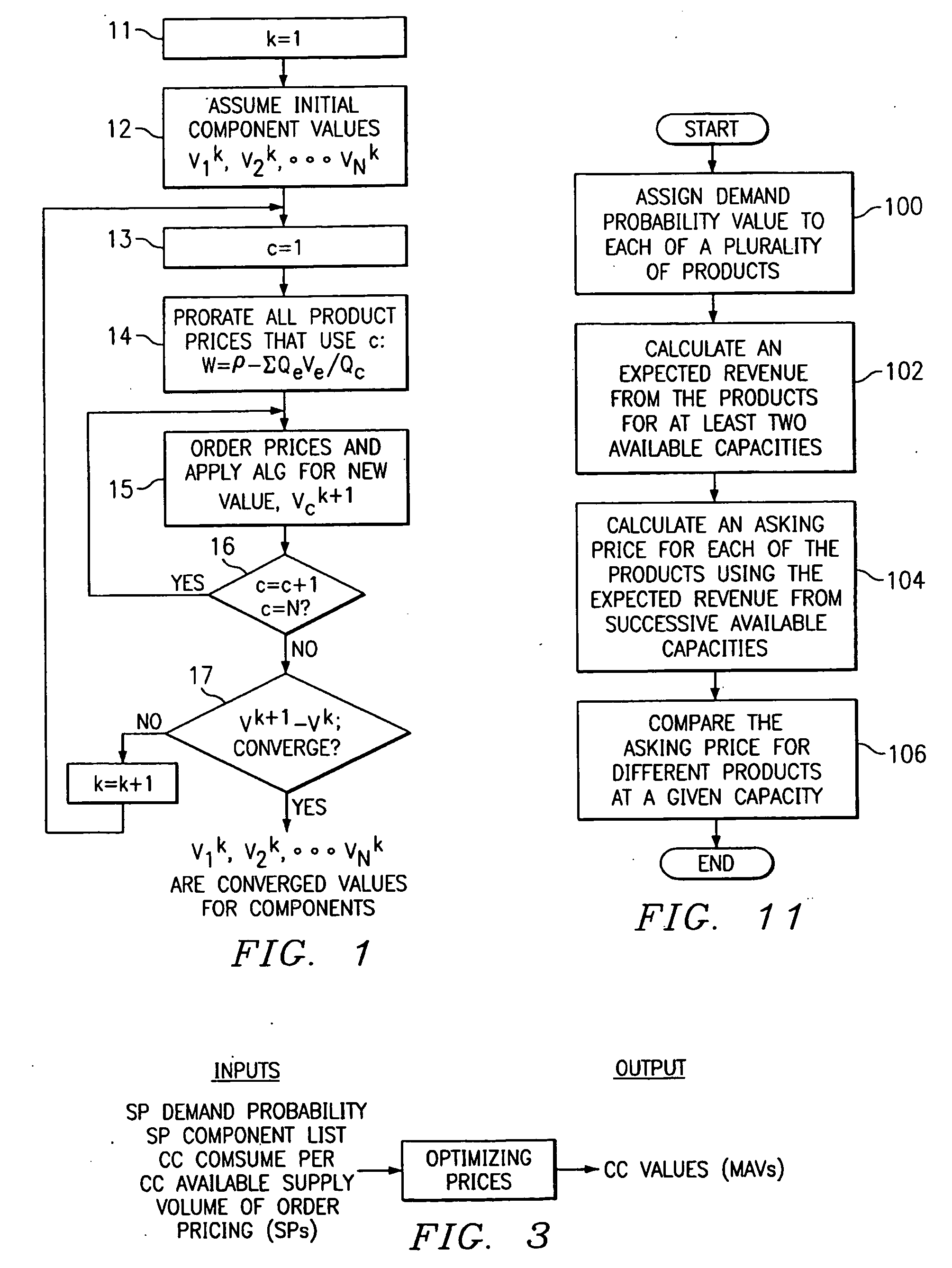

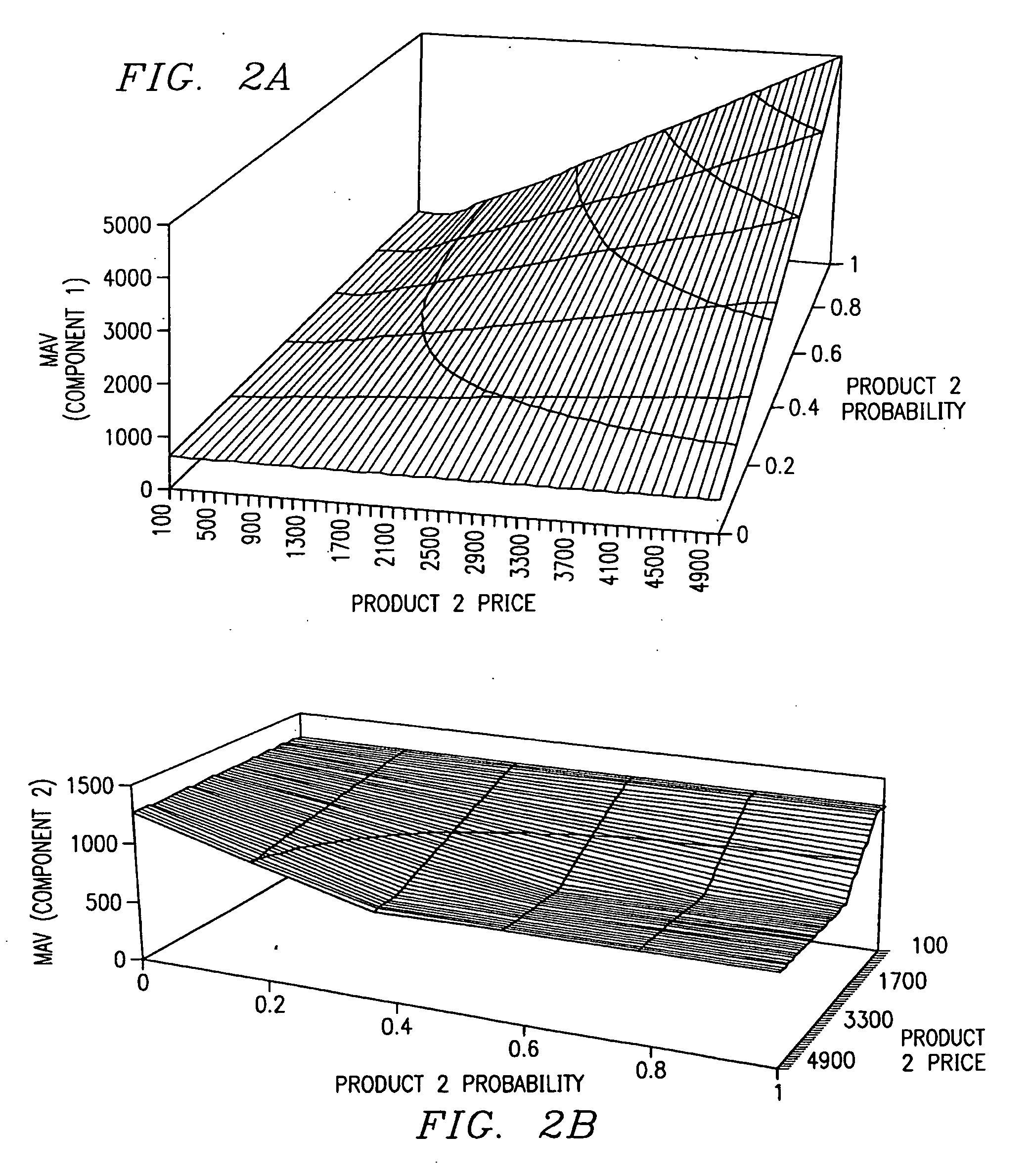

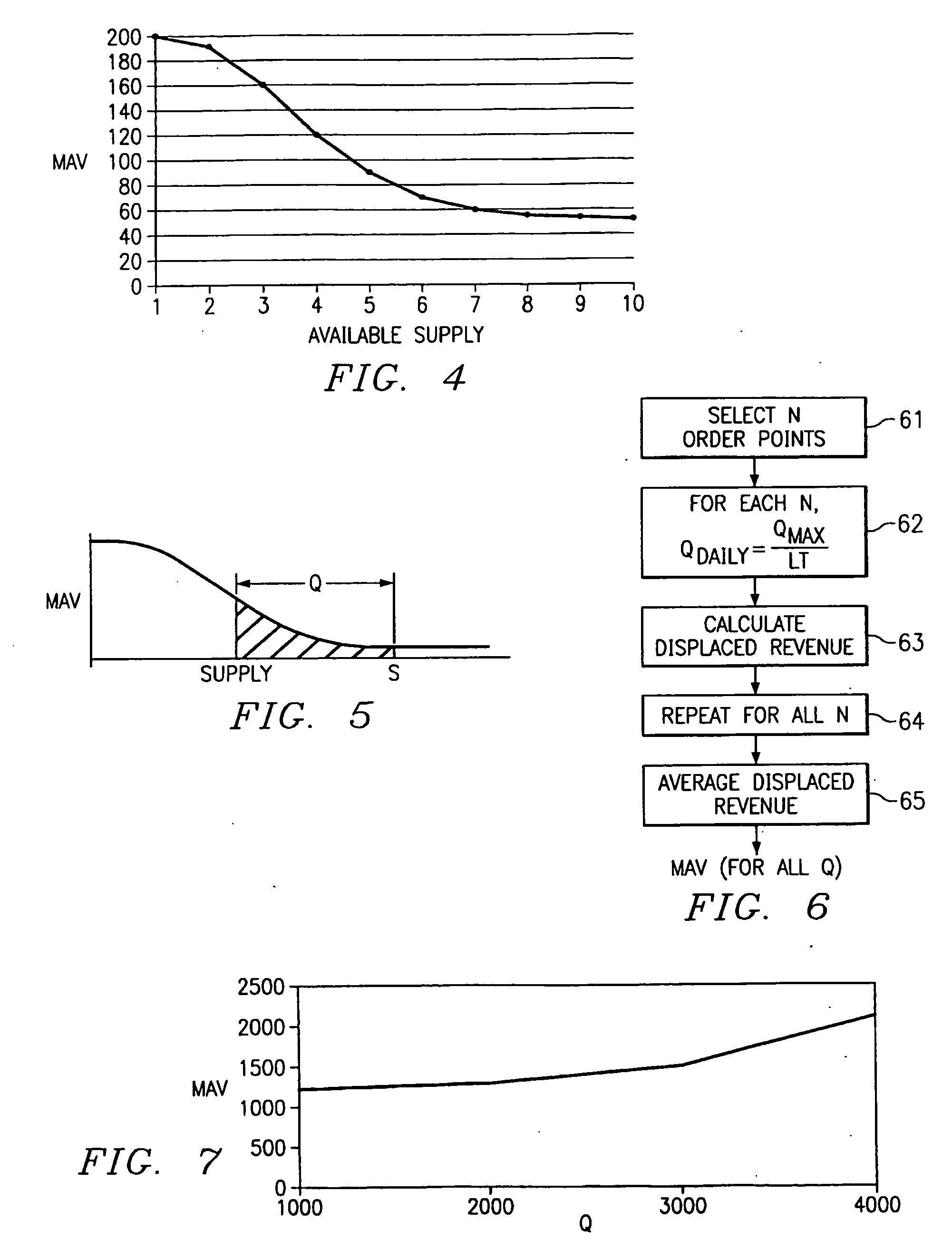

Computer-implemented product valuation tool

A method of valuing products based on demand probabilities. Products are designed by identifying product components, and combining the components in various combinations to provide standard and non-standard products. Components are valued using an algorithm that considers demand probability as well as known prices of standard products. The component values are added to determine product values and may be used to make pricing and order fulfillment decisions.

Owner:JDA SOFTWARE GROUP

Method for preparing iron powder and recovering nonferrous metal from blast furnace iron making smoke dust

InactiveCN102703714ASimple processSimple and fast operationProcess efficiency improvementSlagReducing agent

The invention relates to a method for preparing iron powder and recovering nonferrous metal from blast furnace iron making smoke dust. The method comprises steps as follows: the blast furnace iron making smoke dust is mixed with reducing agent fuel; the mixture is added into a rotary kiln for high temperature reduction reaction, so that nonferrous metal therein is enabled to volatilize into the smoke dust; the smoke dust is collected and used for extracting the nonferrous metal, while iron is reduced to metallic iron which is discharged along with kiln slag; the kiln slag is cooled, crushed, and ground to form ore pulp with the particle size smaller than 100 meshes, and iron ore concentrate with Fe content more than 65% is magnetic-separated; the iron ore concentrate is subjected to second stage grinding, and then metallic iron powder and secondary iron concentrate are separated on a table concentrator; metallic iron powder is dried to obtain commodity reduction iron powder, with particle size smaller than 120 meshes, MFe more than or equal to 85% and TFe more than or equal to 92%; and further, reduced metallic iron powder is reduced by a hydrogen reduction electric furnace and then is discharged, ground and screened to produce commodity metallic iron powder with MFe more than or equal to 98%. The method has simple technology, is mature and reliable, is simple and convenient to operate and low in cost, is high in product value and excellent in comprehensive utilization, has wide population and application values, and provides a new route for solid waste recycling utilization and low cost iron powder preparation.

Owner:GREENNOVO ENVIRONMENTAL TECH CO LTD

Method for selectively extracting lithium from lithium iron phosphate waste materials

ActiveCN109554545AHigh recovery ratePromoting Recycling DevelopmentWaste accumulators reclaimingProcess efficiency improvementElectrical batterySlag

The invention discloses a method for selectively extracting lithium from lithium iron phosphate waste materials. The method comprises the following steps that water is added into the lithium iron phosphate waste material for slurry, then acid is added, and the temperature is heated to 40-100 DEG C, the pH value of the system is adjusted to 2-4, the temperature and the pH value range are kept, reacting is carried out for 1-10 hours, and filtering and separating are carried out on the reacted slurry so as to obtain a lithium solution and phosphorus iron slag; and the acid is one of concentratedhydrochloric acid, concentrated sulfuric acid or concentrated nitric acid. According to the method, the lithium in the waste lithium iron phosphate material is recycled, the lithium recovery rate is up to 98% or above, and the purity of the further prepared lithium carbonate reaches 99.0% or above; the method is simple in process, and low in energy consumption; and the selective extraction of thelithium in the waste lithium iron phosphate material is realized, the product value is high, considerable economic benefits are achieved, and the recovery and development of lithium iron phosphate waste batteries are facilitated.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

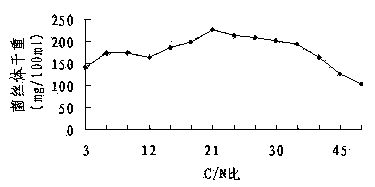

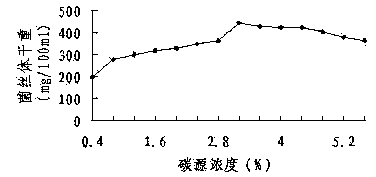

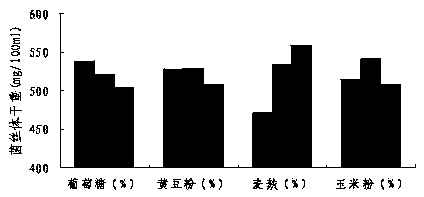

Grifola frondosa liquid culture cultivating and high-yield cultivating method

Owner:LUDONG UNIVERSITY

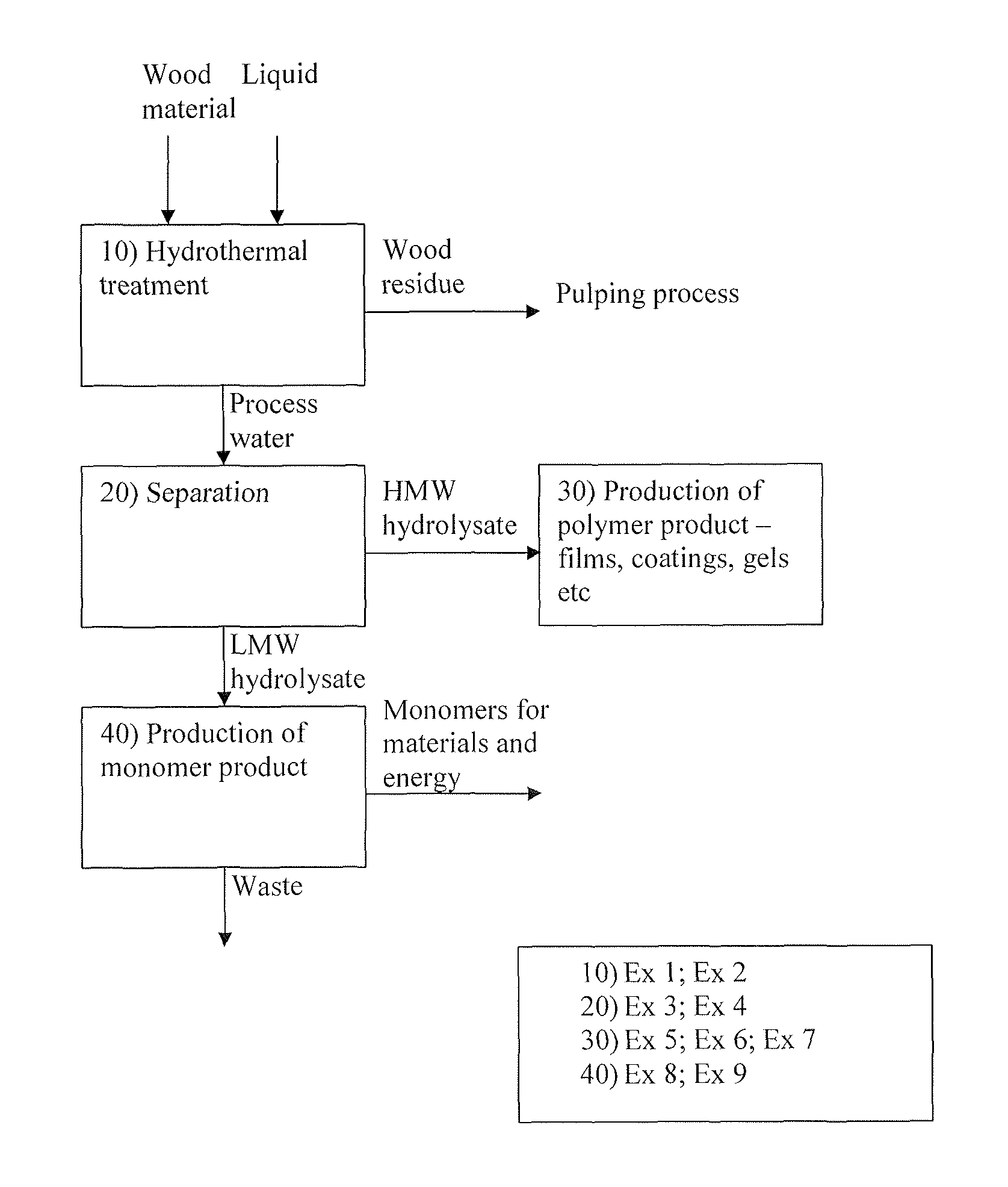

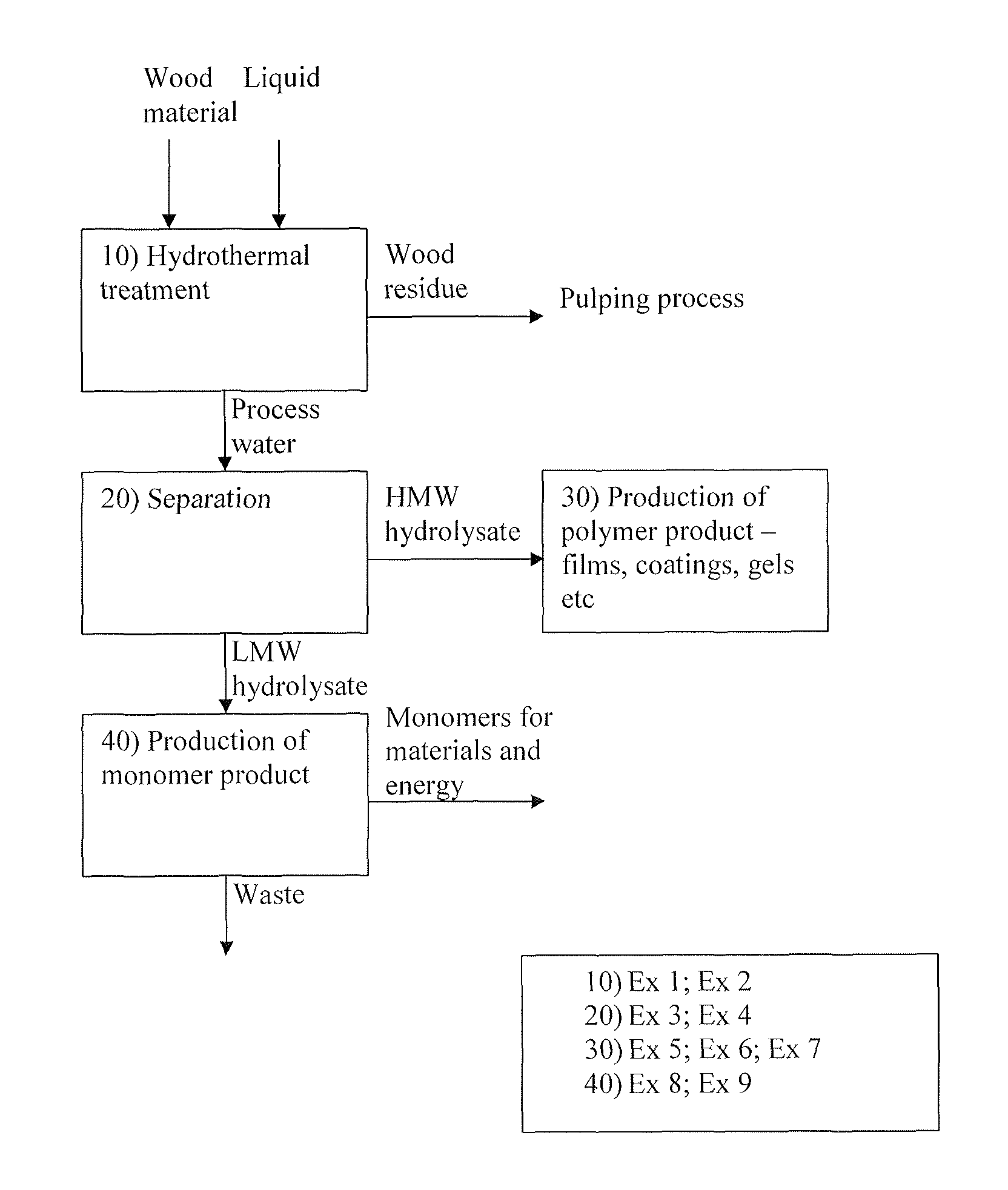

Utilization of a wood hydrolysate

InactiveUS20110028672A1Cost efficientIncrease valuePretreatment with water/steamCellulose material pulpingHydrolysateThermal treatment

The present invention relates to a method for utilizing a wood hydrolysate obtained from a hydrothermal treatment of a wood material method comprises the steps of providing a wood material, treating the wood material by means of an aqueous hydrothermal treatment so that a wood hydrolysate and a wood residue is formed. The wood hydrolysate comprises oligo- and polysaccharides as the main component of dry matter. The method further comprises the steps of; separating the wood hydrolysate into at least a first and a second fraction and using at least one of the at least first and second fractions for production of an intermediate or end product. Such end product may be e.g. a film, coating, package or a gel. The present invention also relates to a polymer product such as a film, a coating or a gel and its applications. The present invention provides for biodegradable and renewable polymer products and a method which utilizes and extracts a very high product value from a process.

Owner:INNVENTIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com