Patents

Literature

1376results about "Gang saw mills" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wire saw

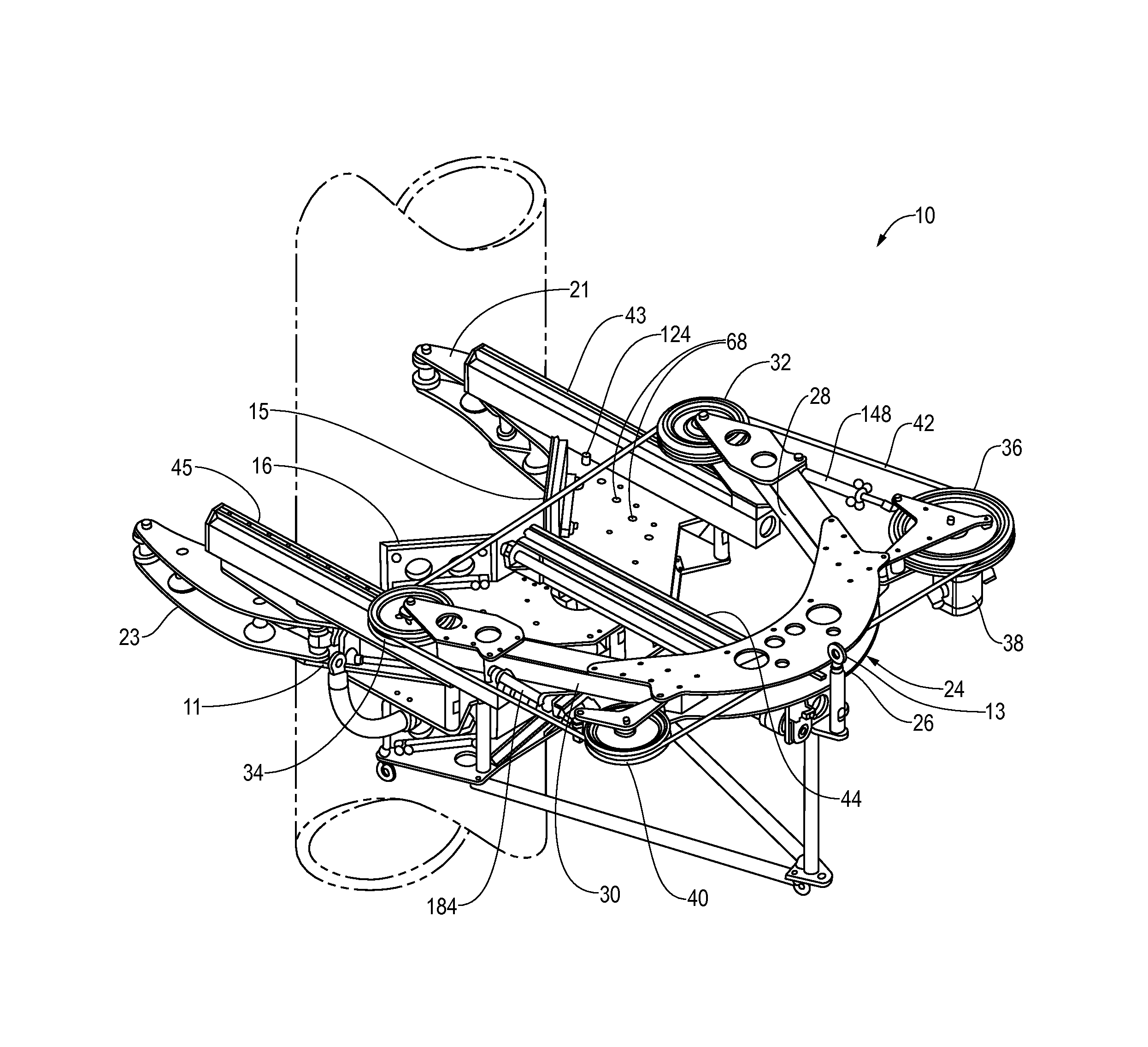

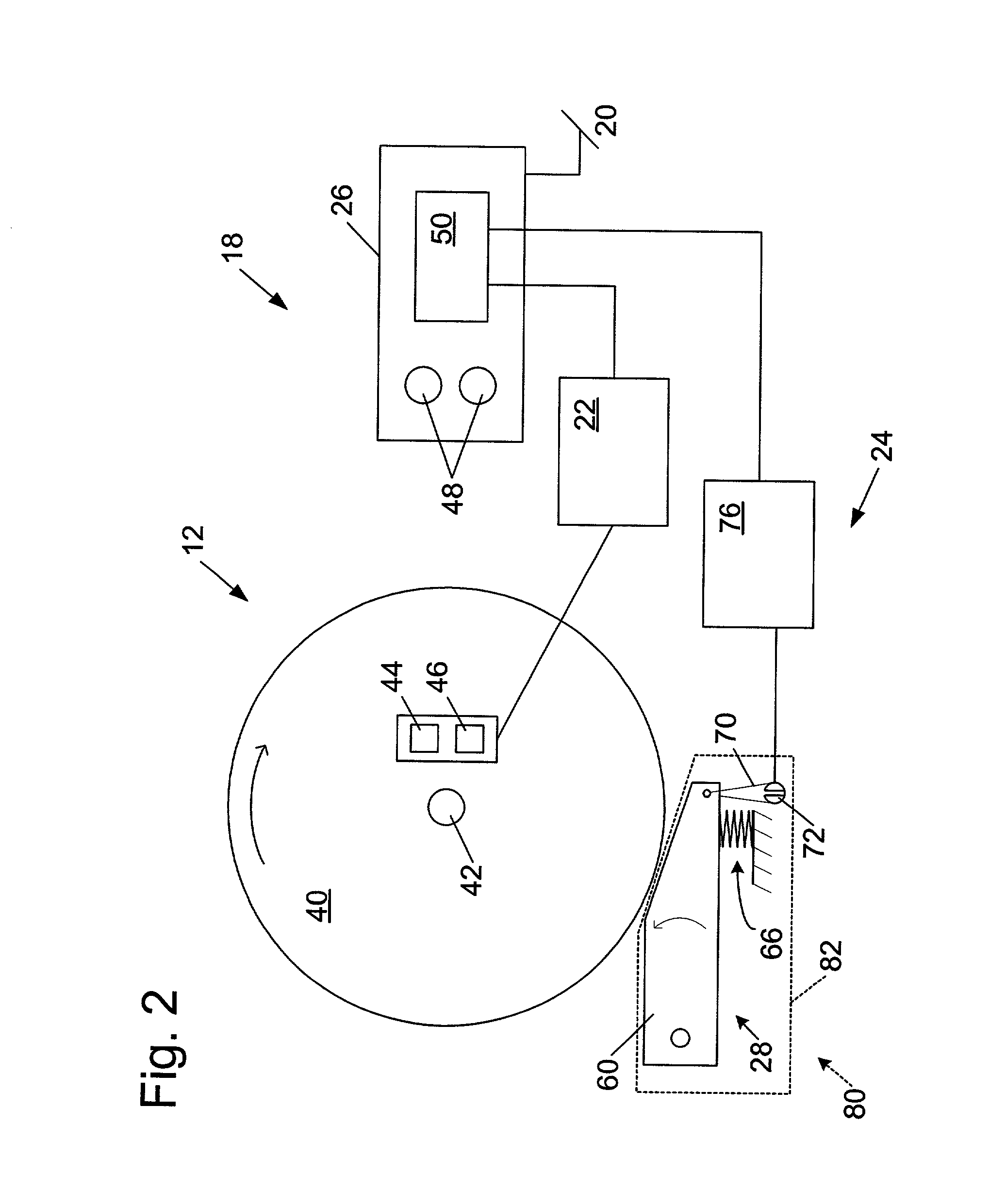

A device for cutting a length of pipe includes a clamp portion for clamping around a length of pipe and a bow moveable with respect to the clamp portion that retains a loop of diamond embedded wire. The device further includes a feed for driving the bow with respect to the clamp portion and a detector for detecting bending of the wire and a control responsive to the detector for controlling feed rates. The device is made of modular parts and has synchronizing arms for clamping around a length of pipe. In one embodiment, the wheels are retained in enclosures with slots through which the cutting wire passes.

Owner:ILLINOIS TOOL WORKS INC

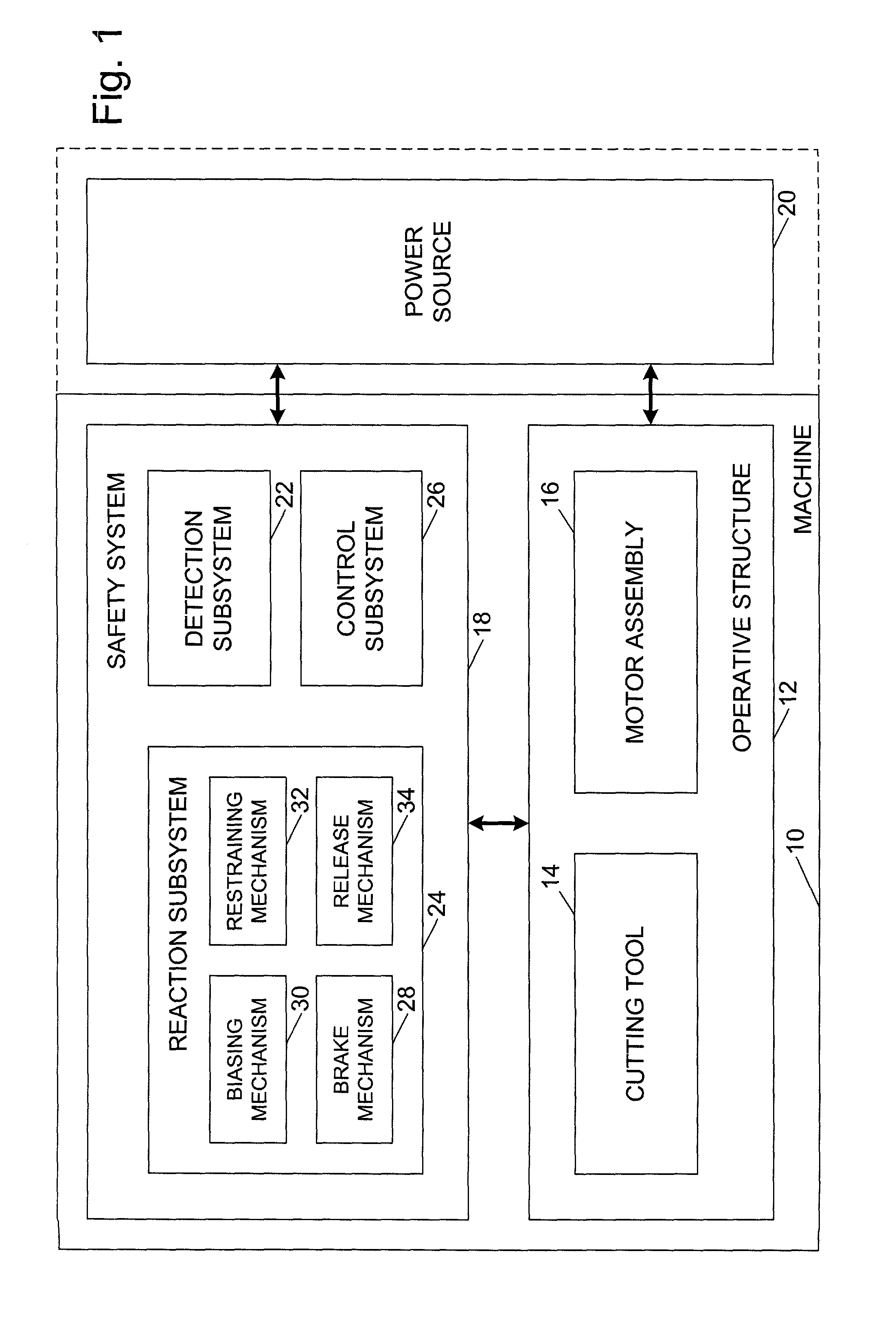

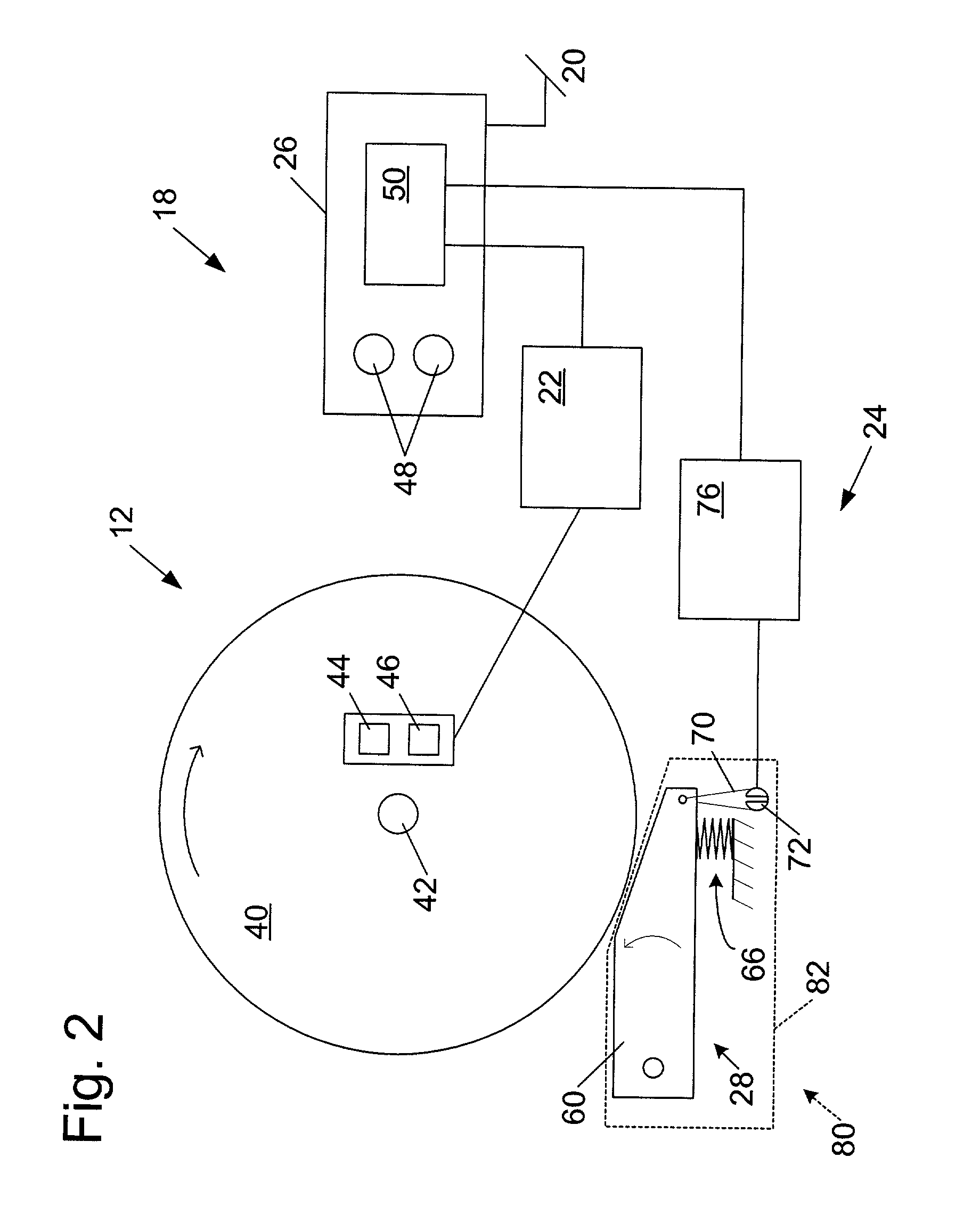

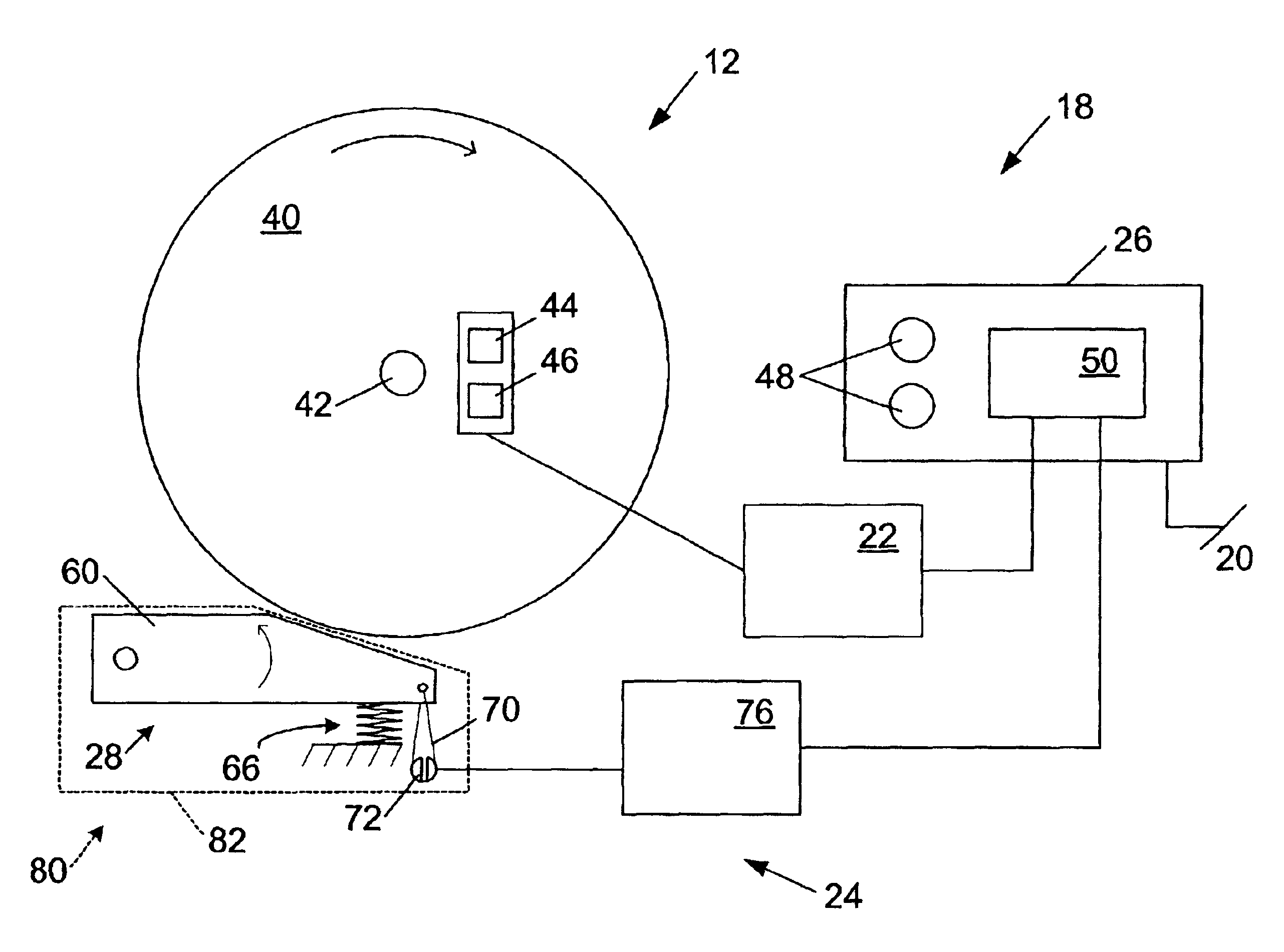

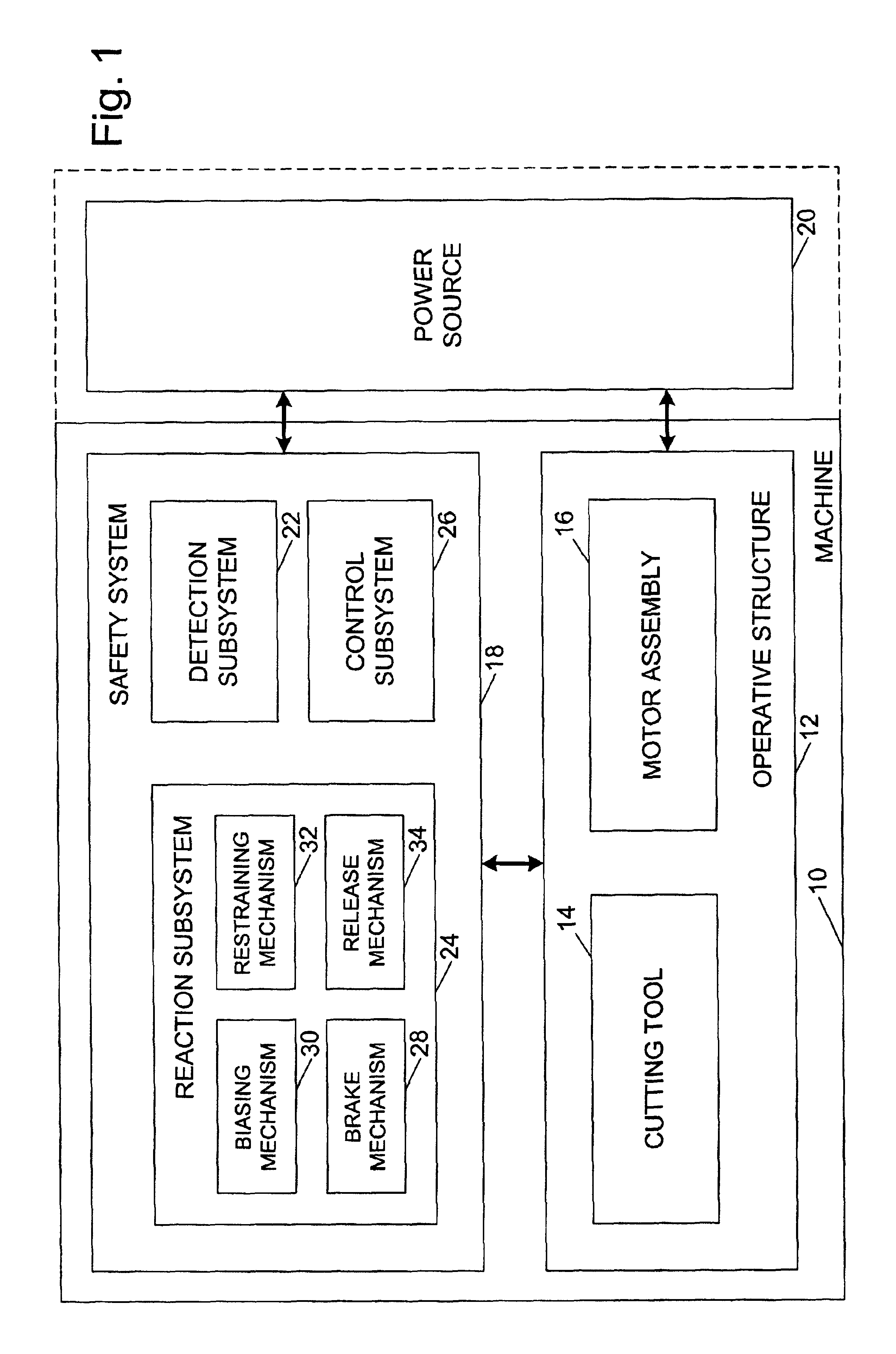

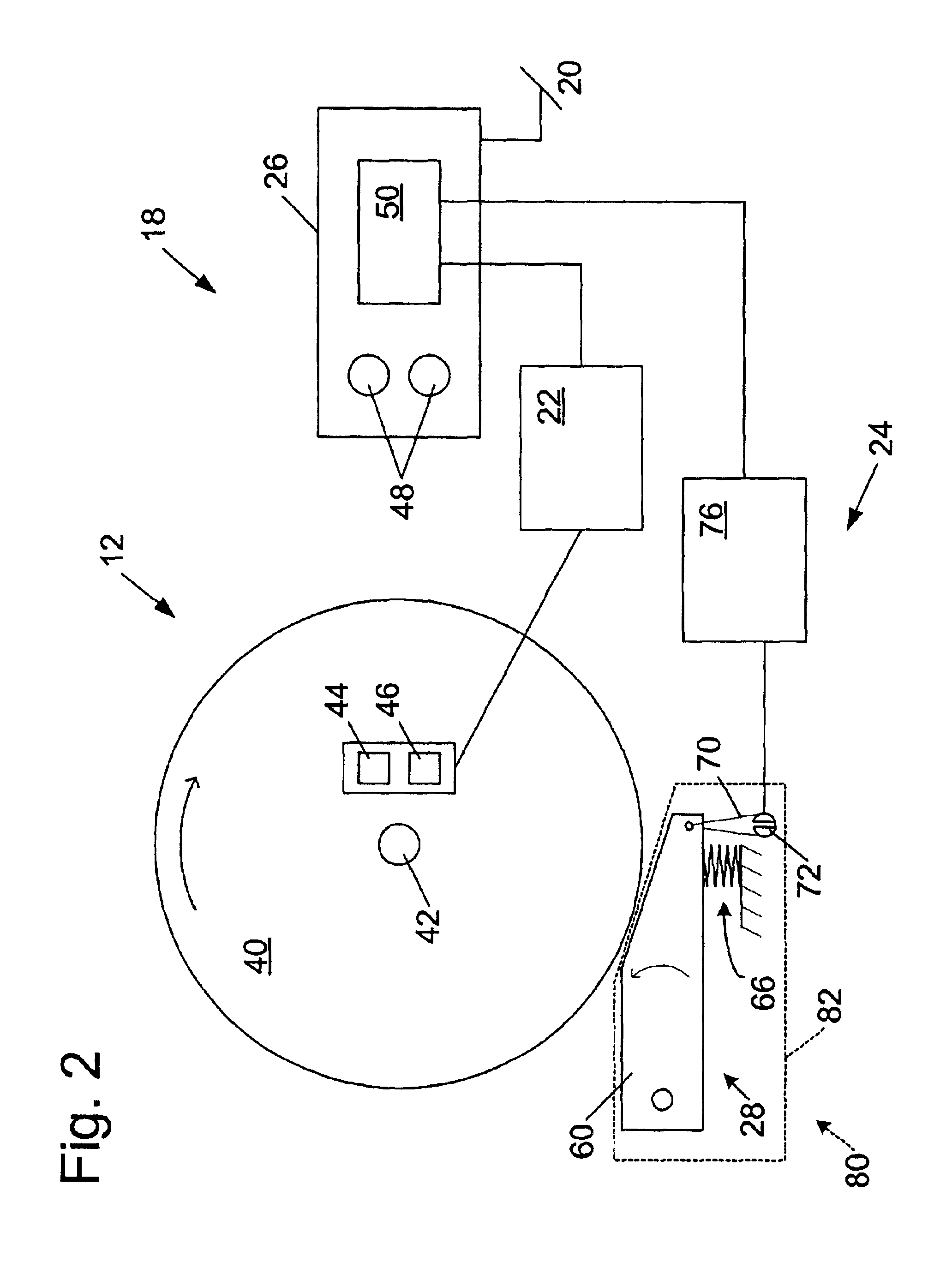

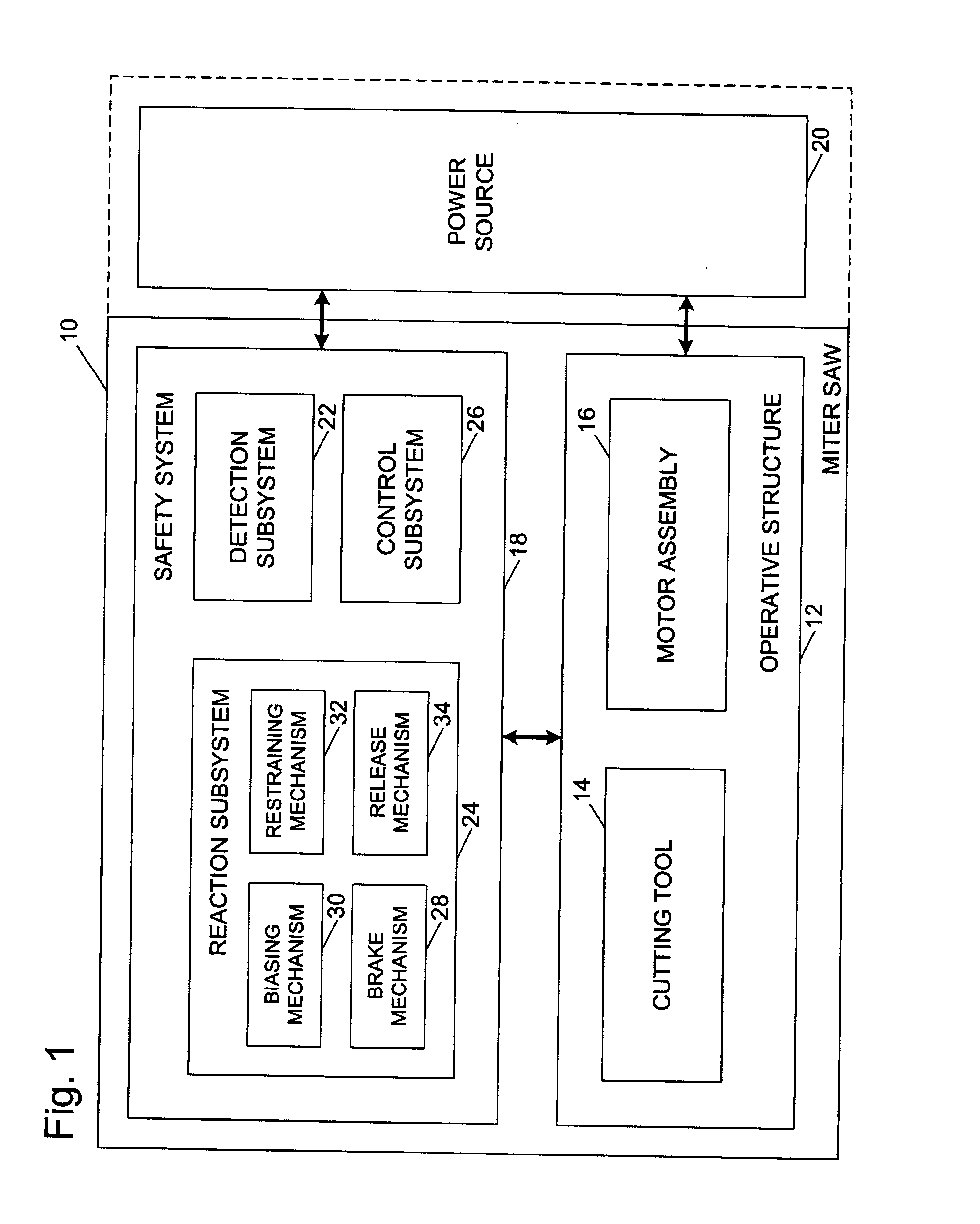

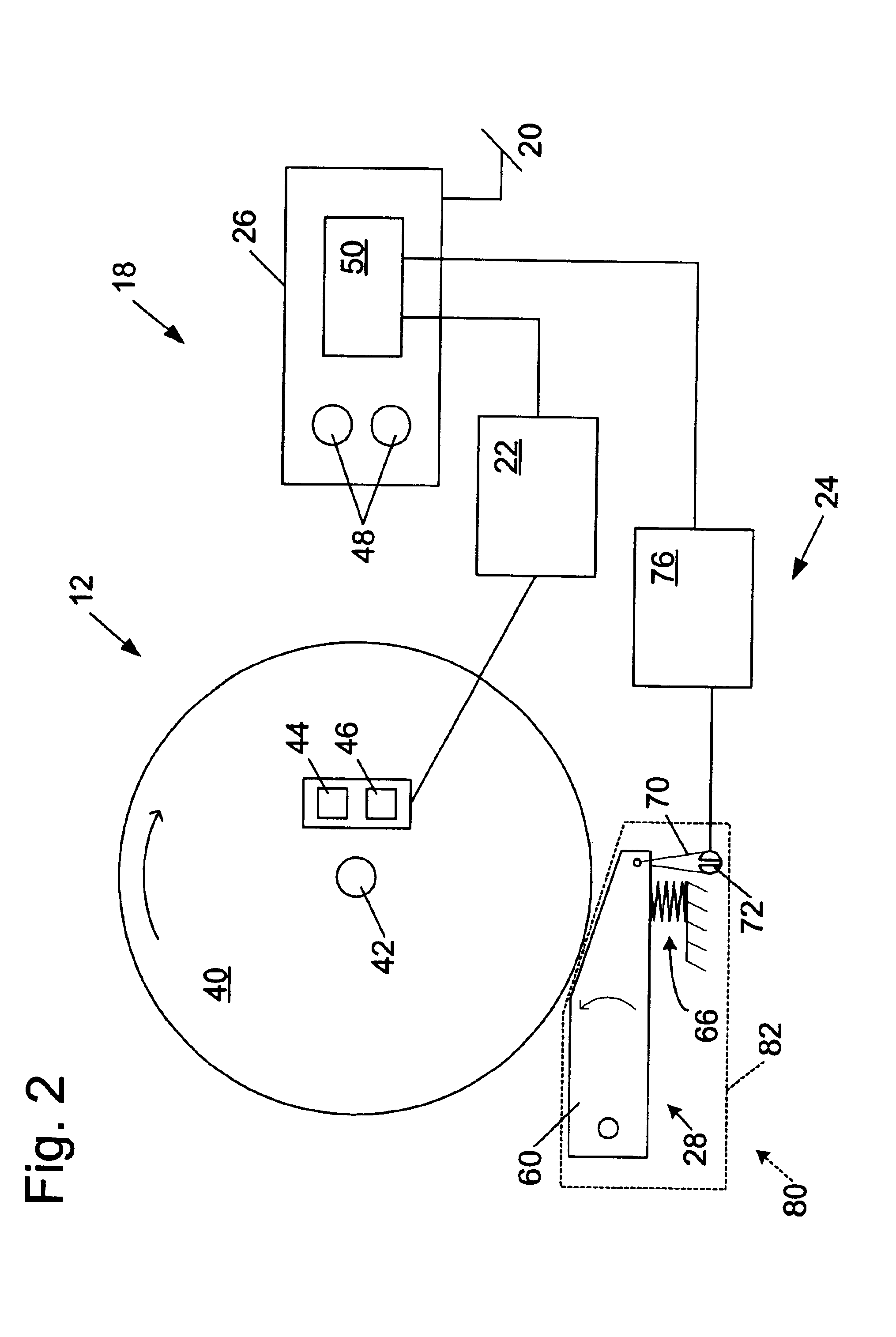

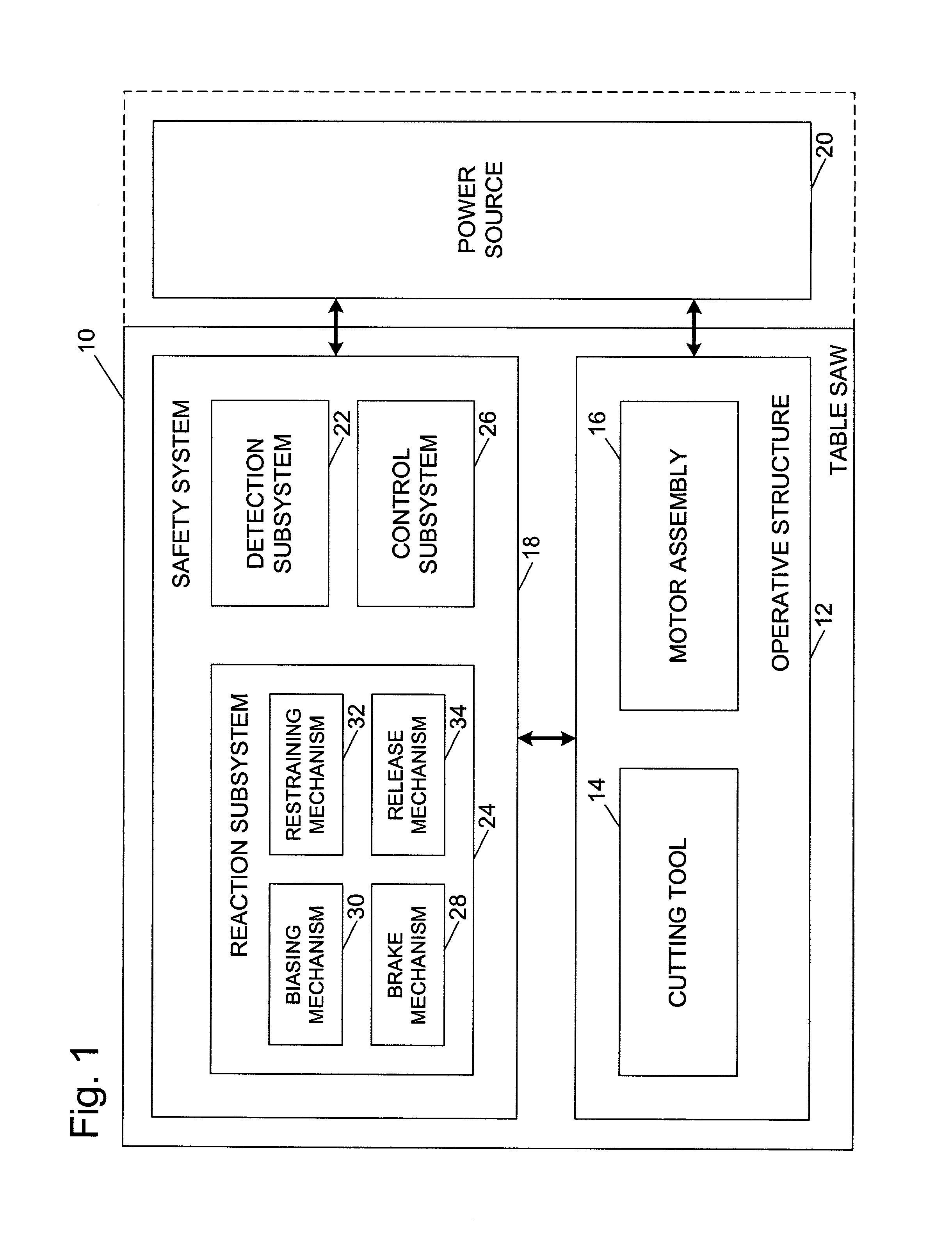

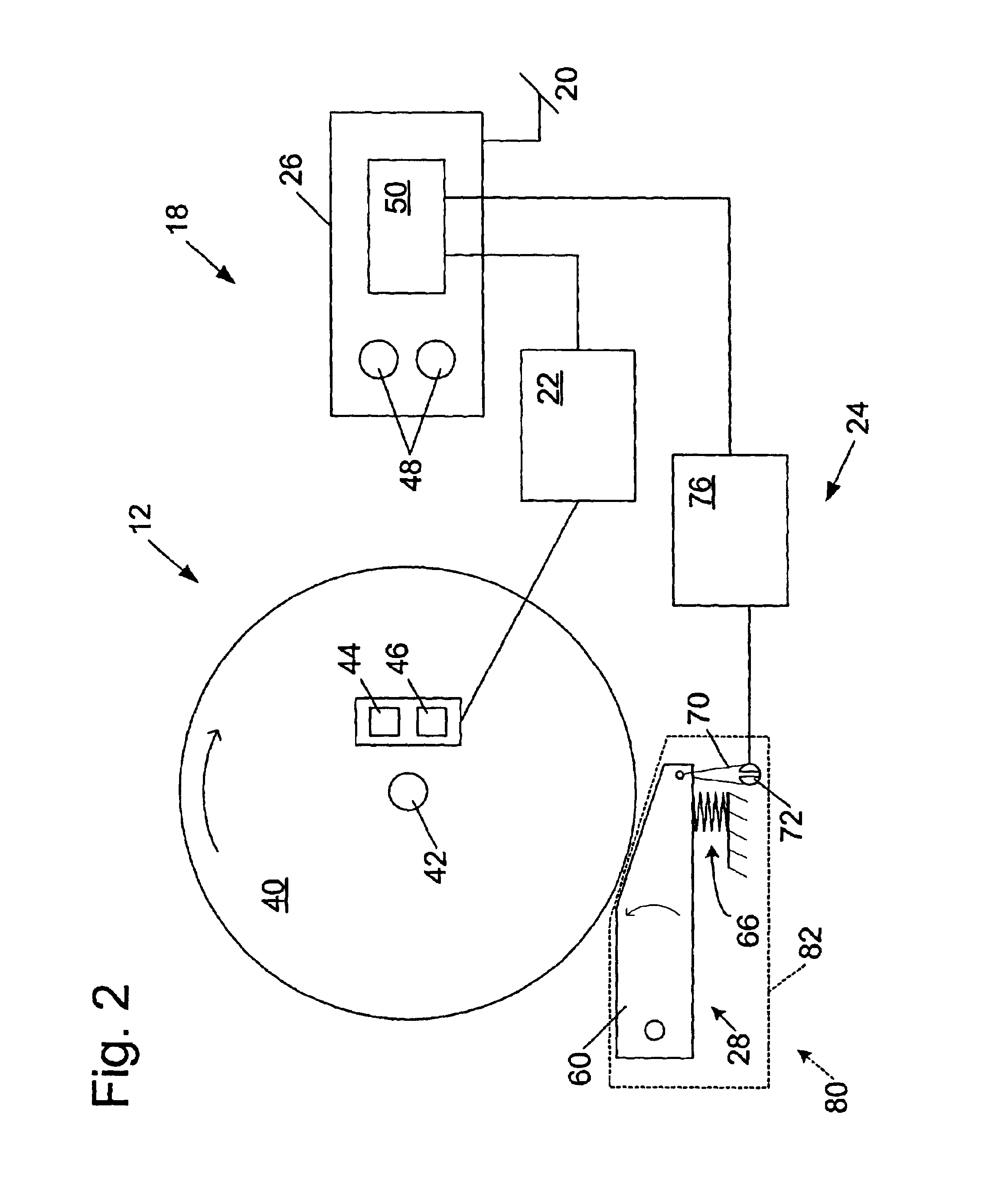

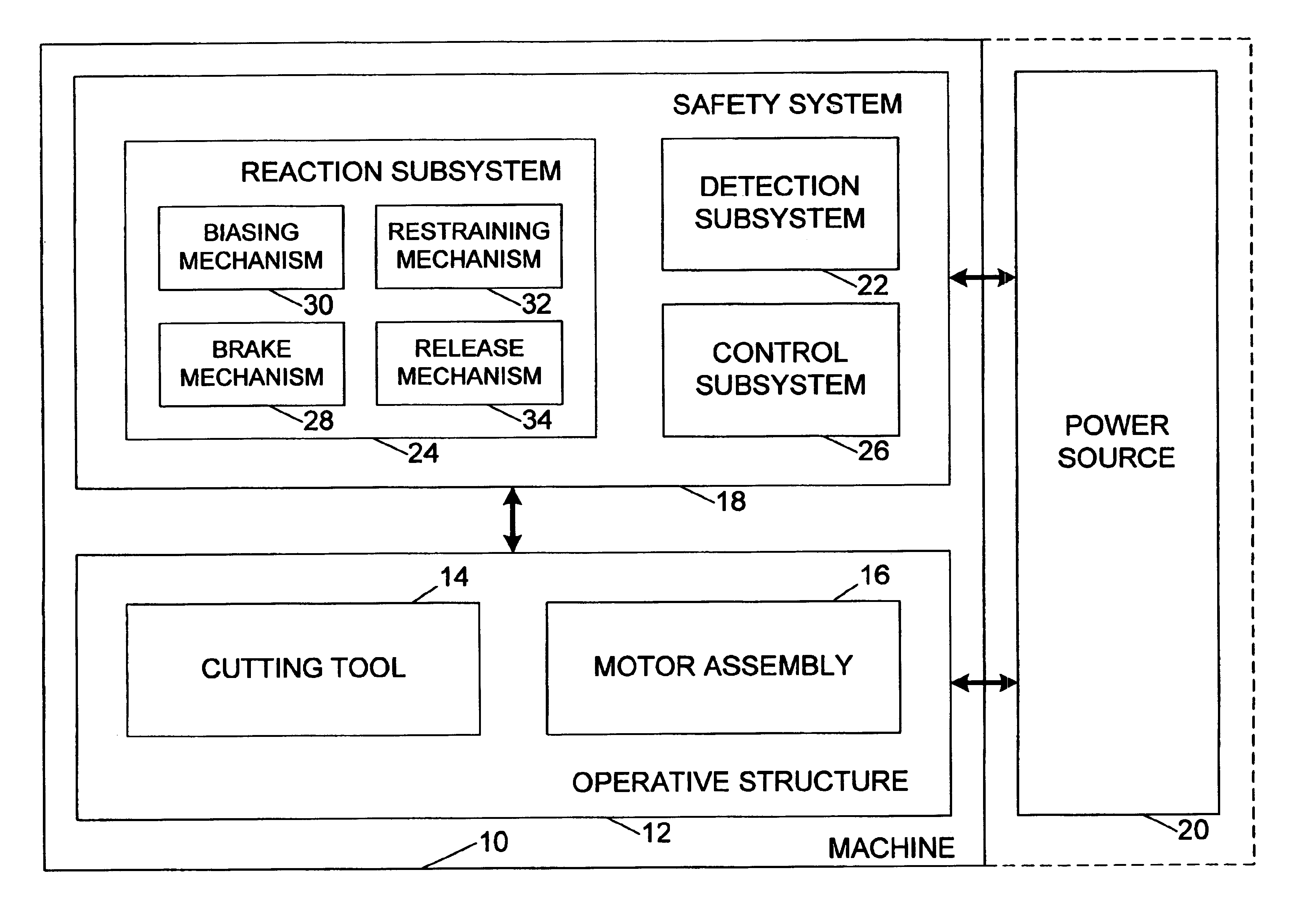

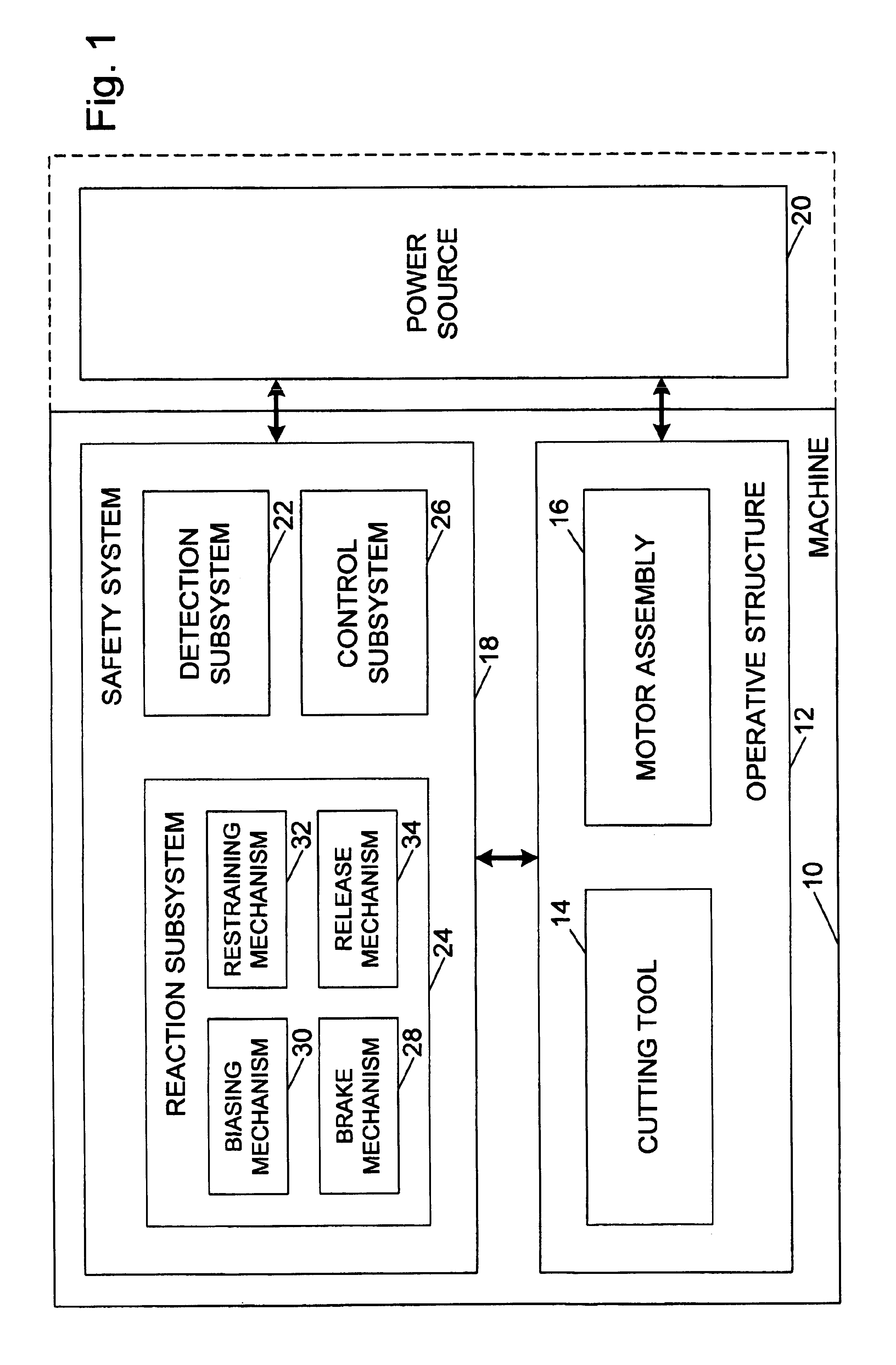

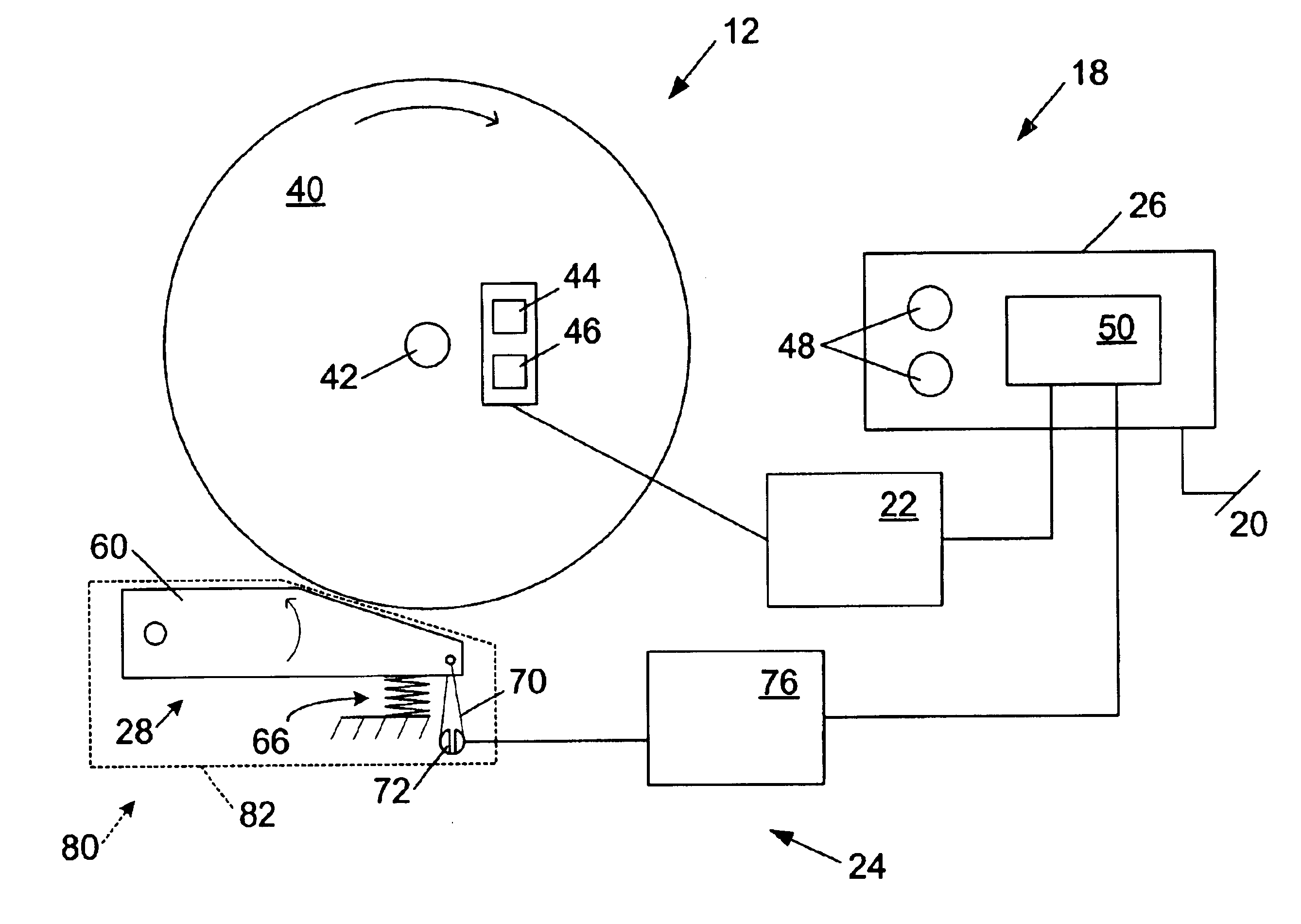

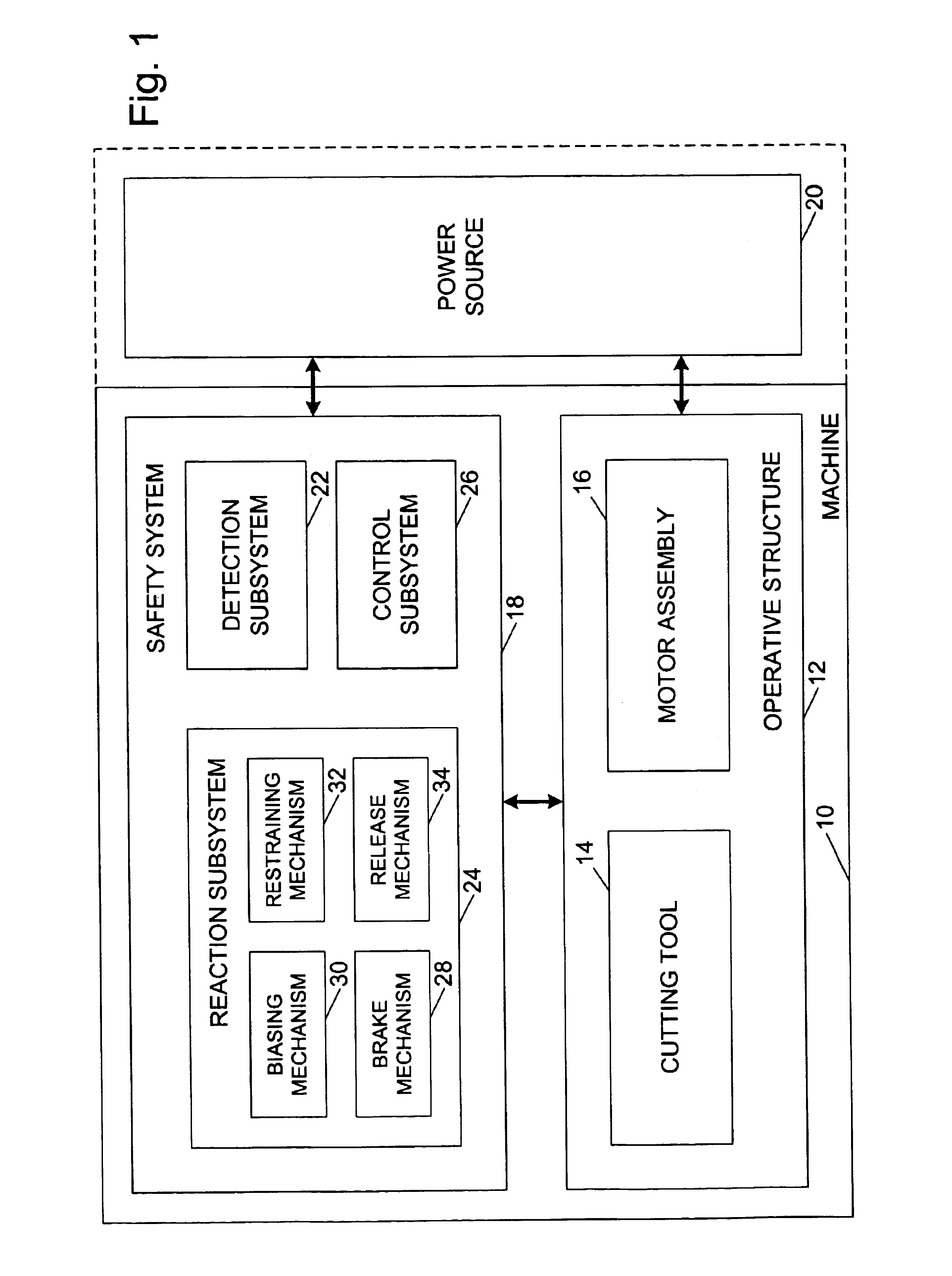

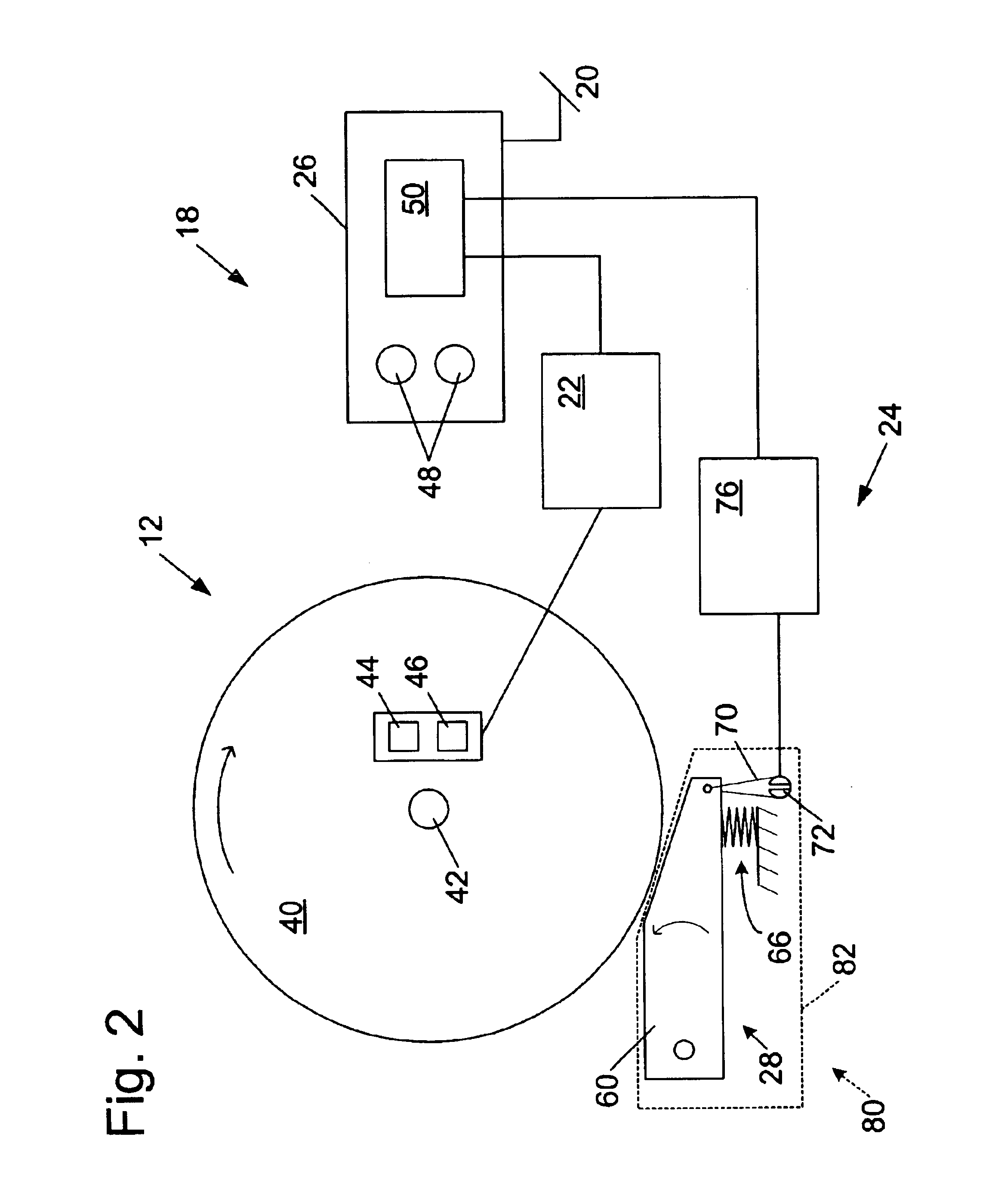

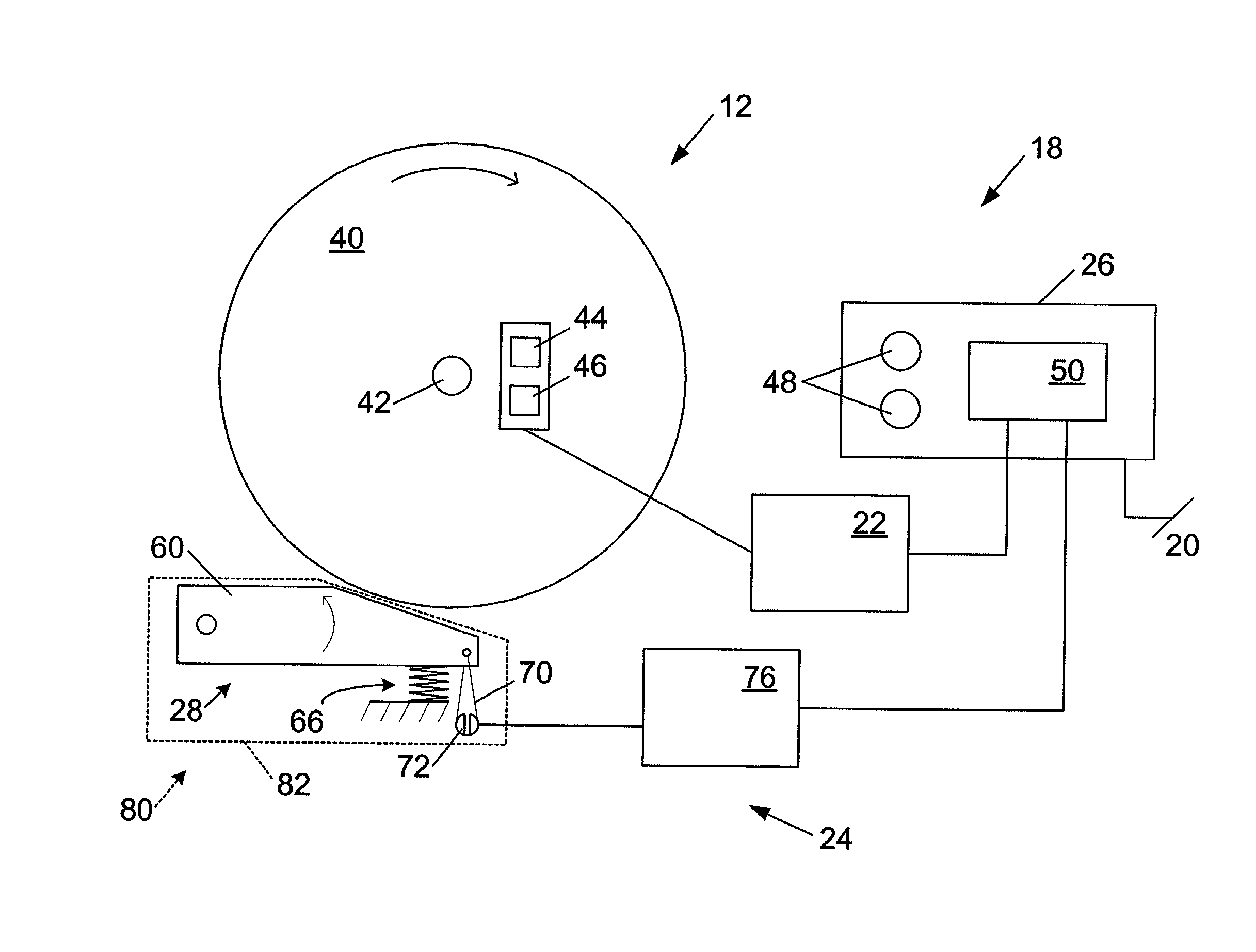

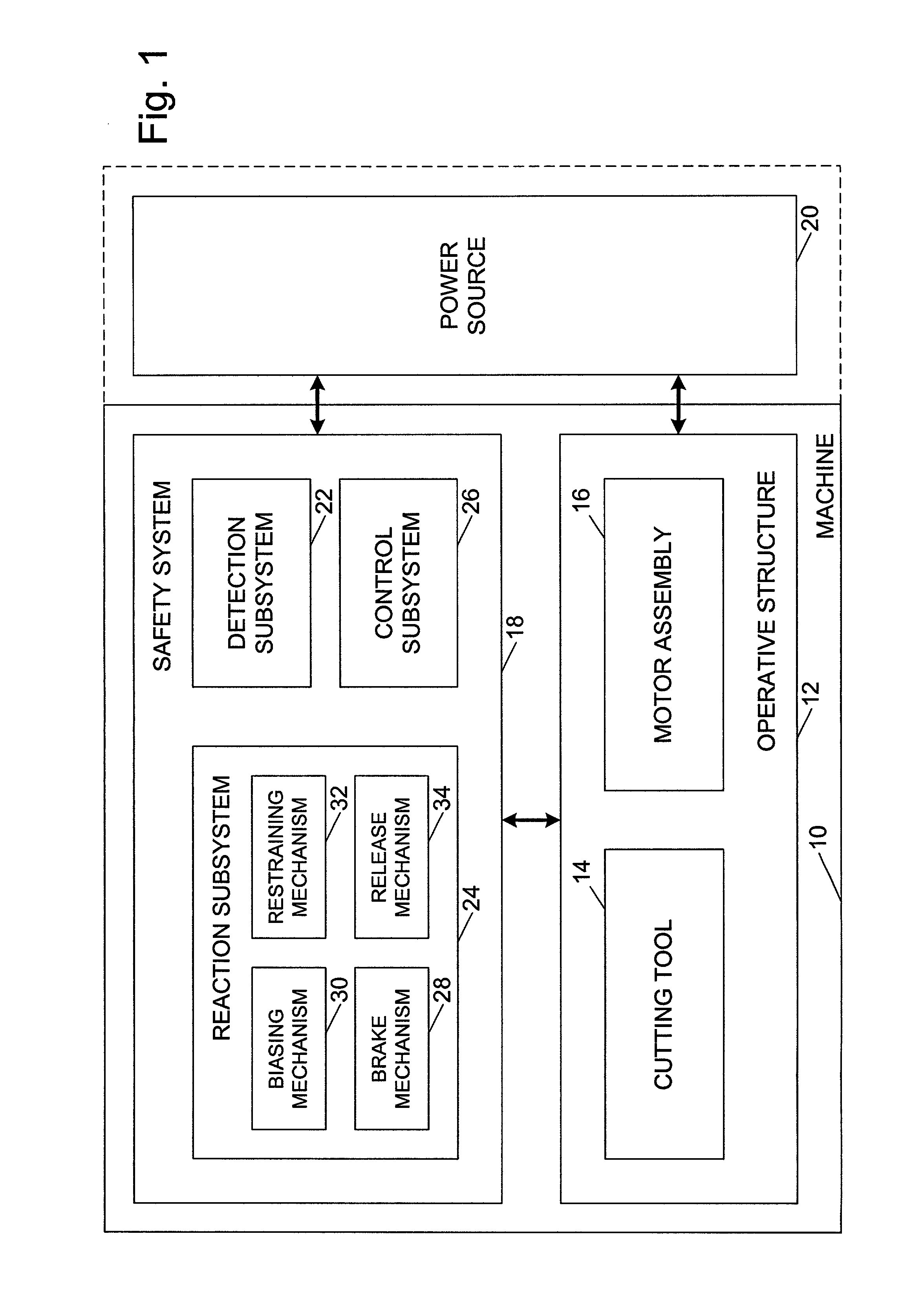

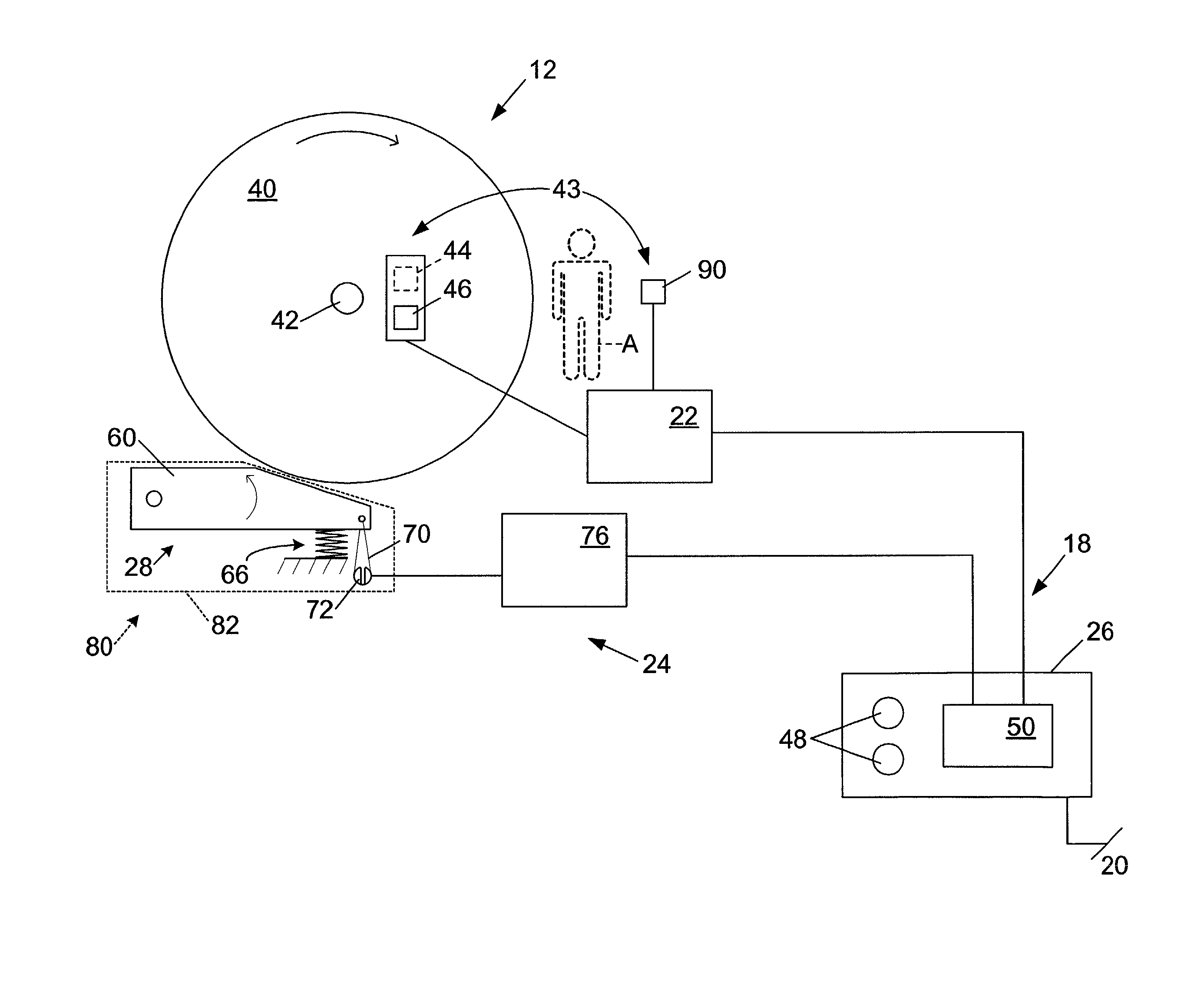

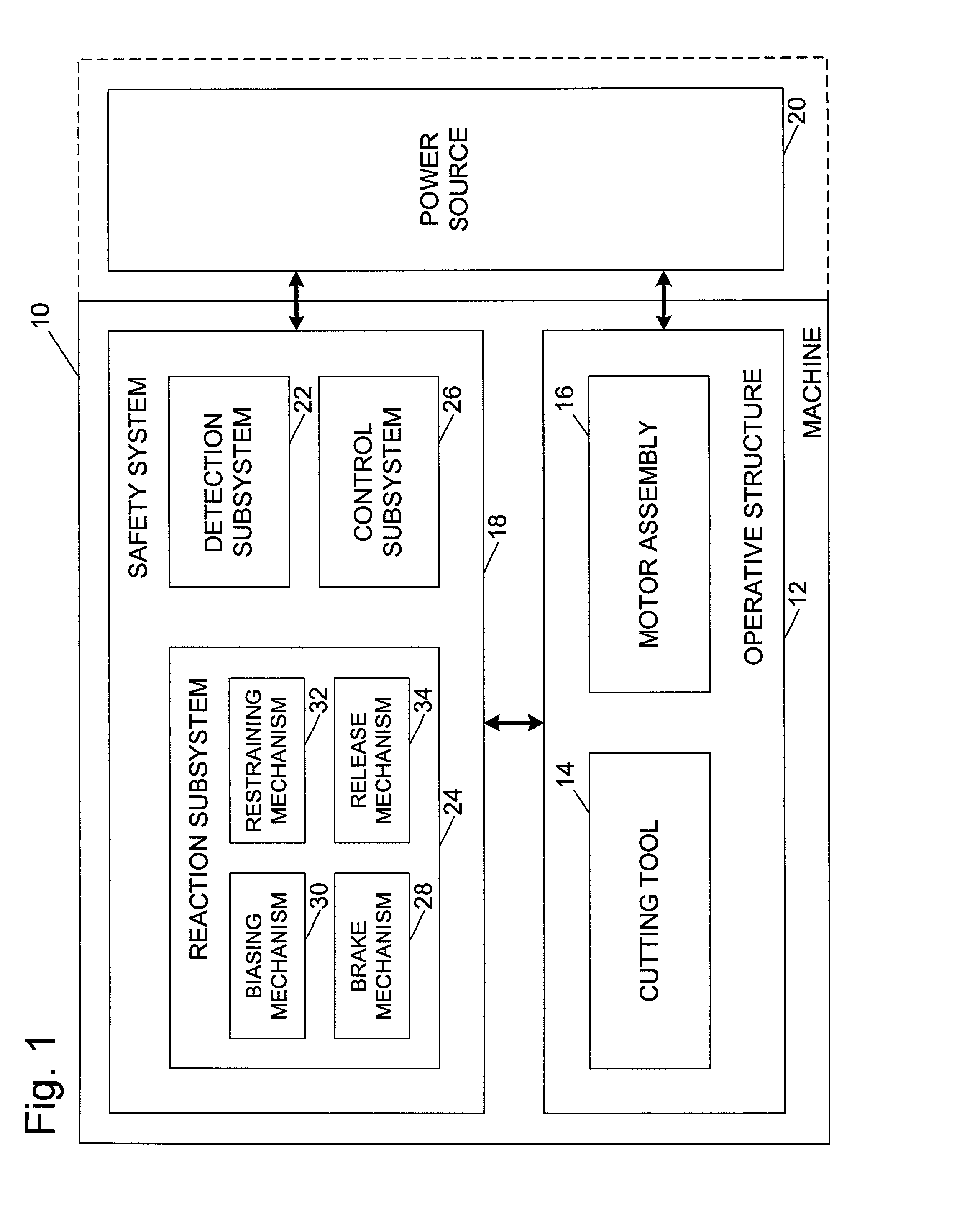

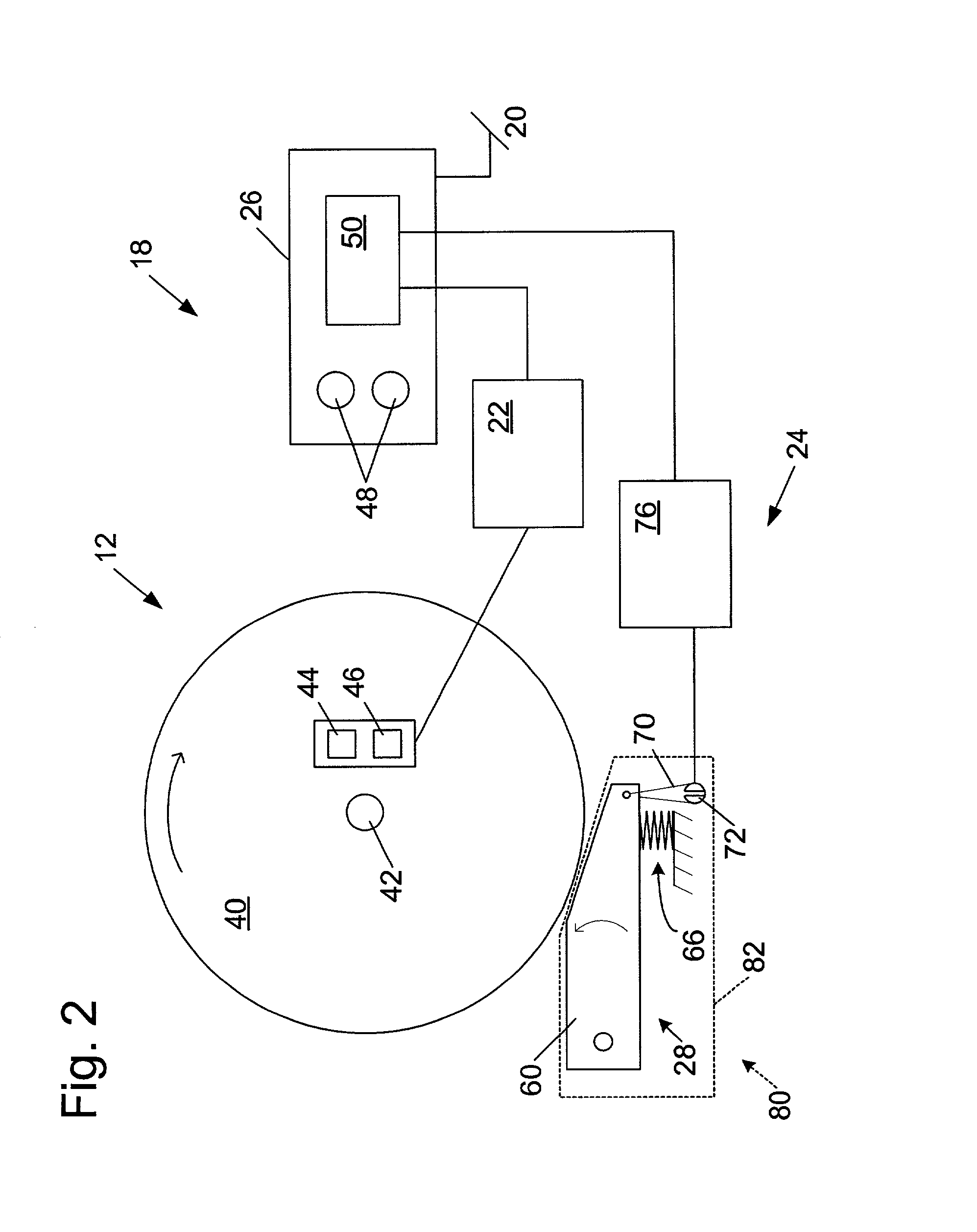

Safety systems for power equipment

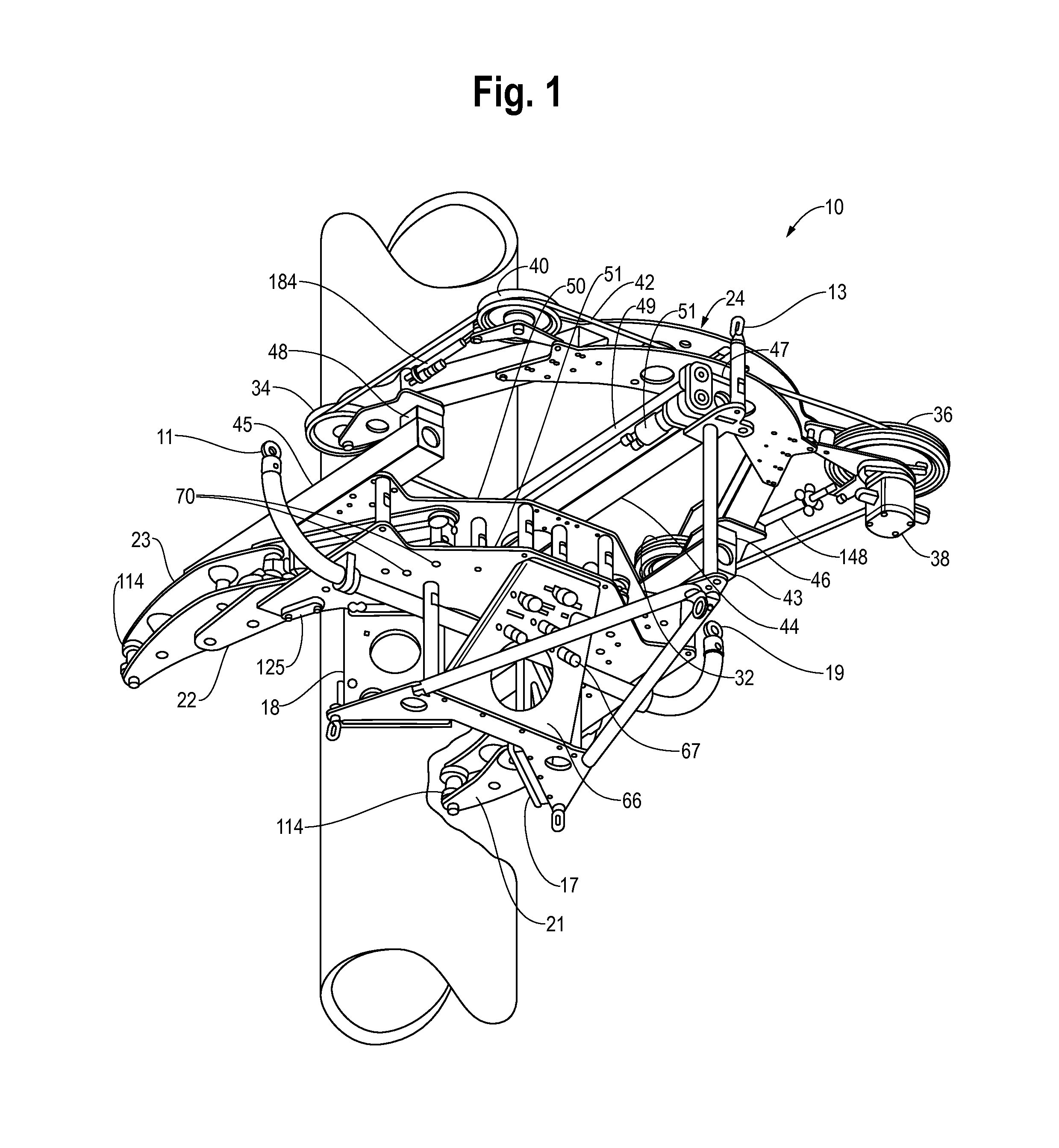

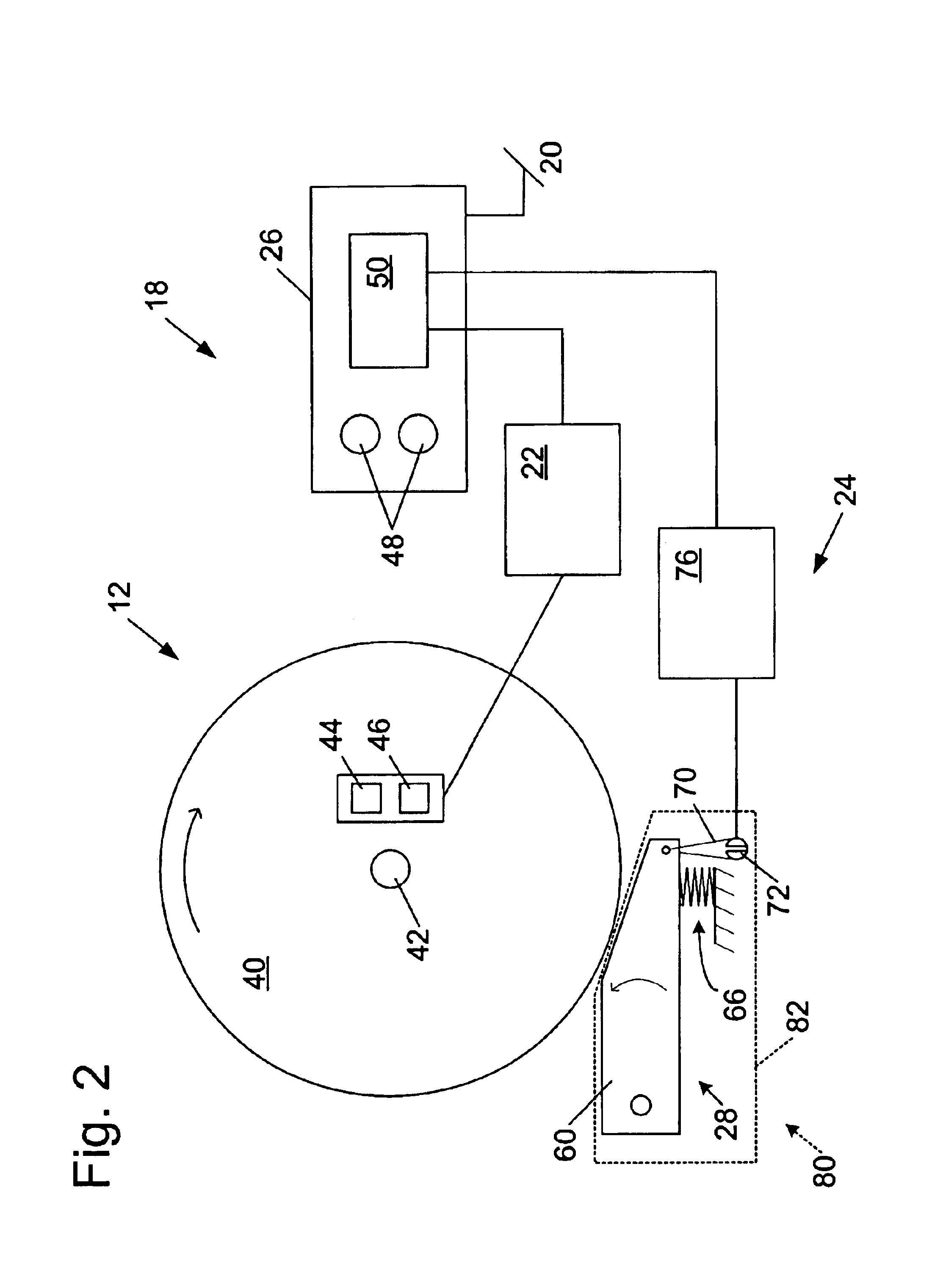

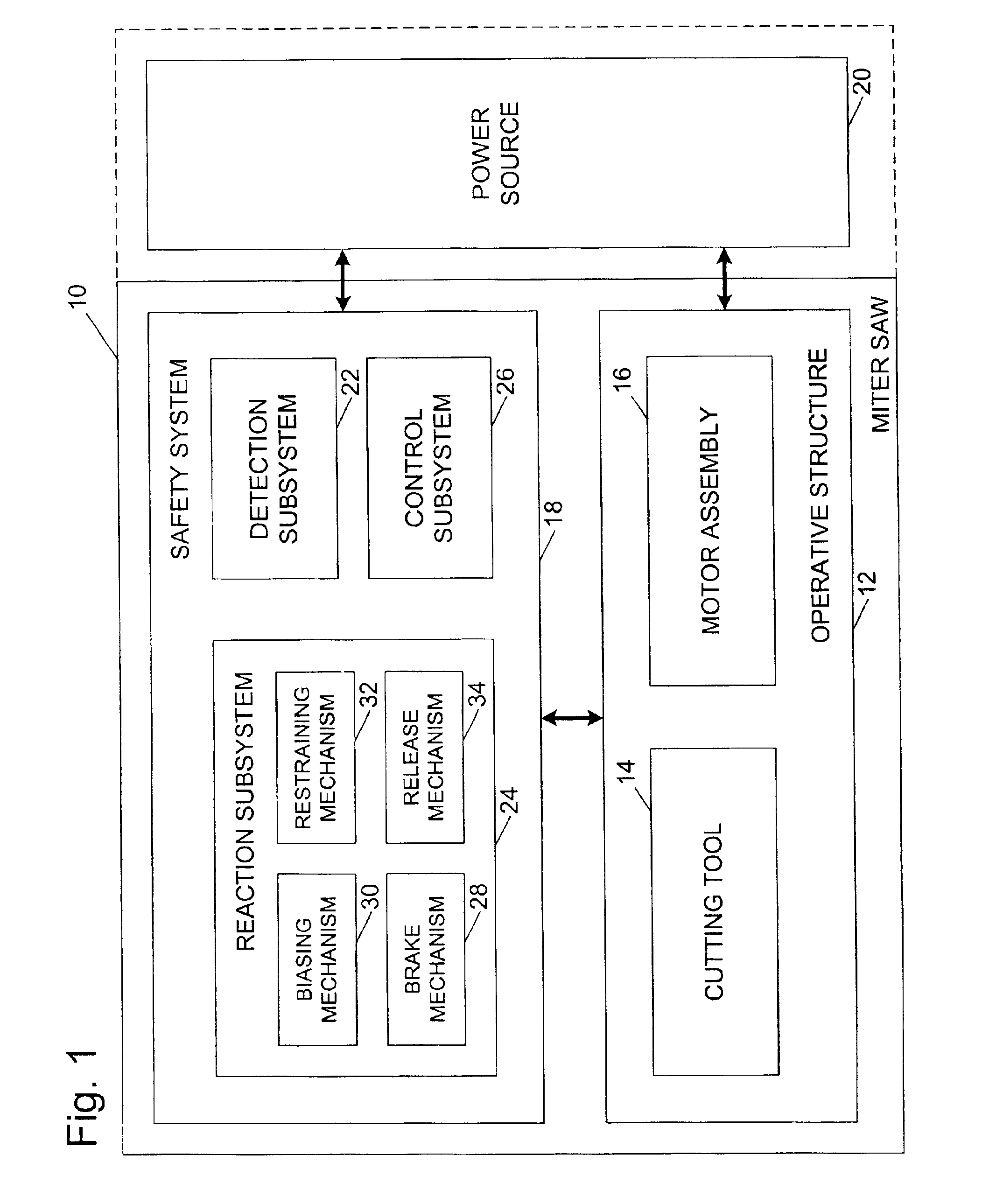

Machines with safety systems are disclosed. The machine may take the form of woodworking machines including table saws, band saws, miter saws, hand-held circular saws, pneumatic chop saws, radial-arm saws, jointers, planars, routers and shapers. The machines may include an operative structure configured to perform a task, where the operative structure includes a cutting tool adapted to move in at least one motion, and a safety system adapted to detect the occurrence of an unsafe condition between a person and the cutting tool and for mitigating the unsafe condition. The safety system may include a detection subsystem and a reaction subsystem.

Owner:SAWSTOP HLDG LLC

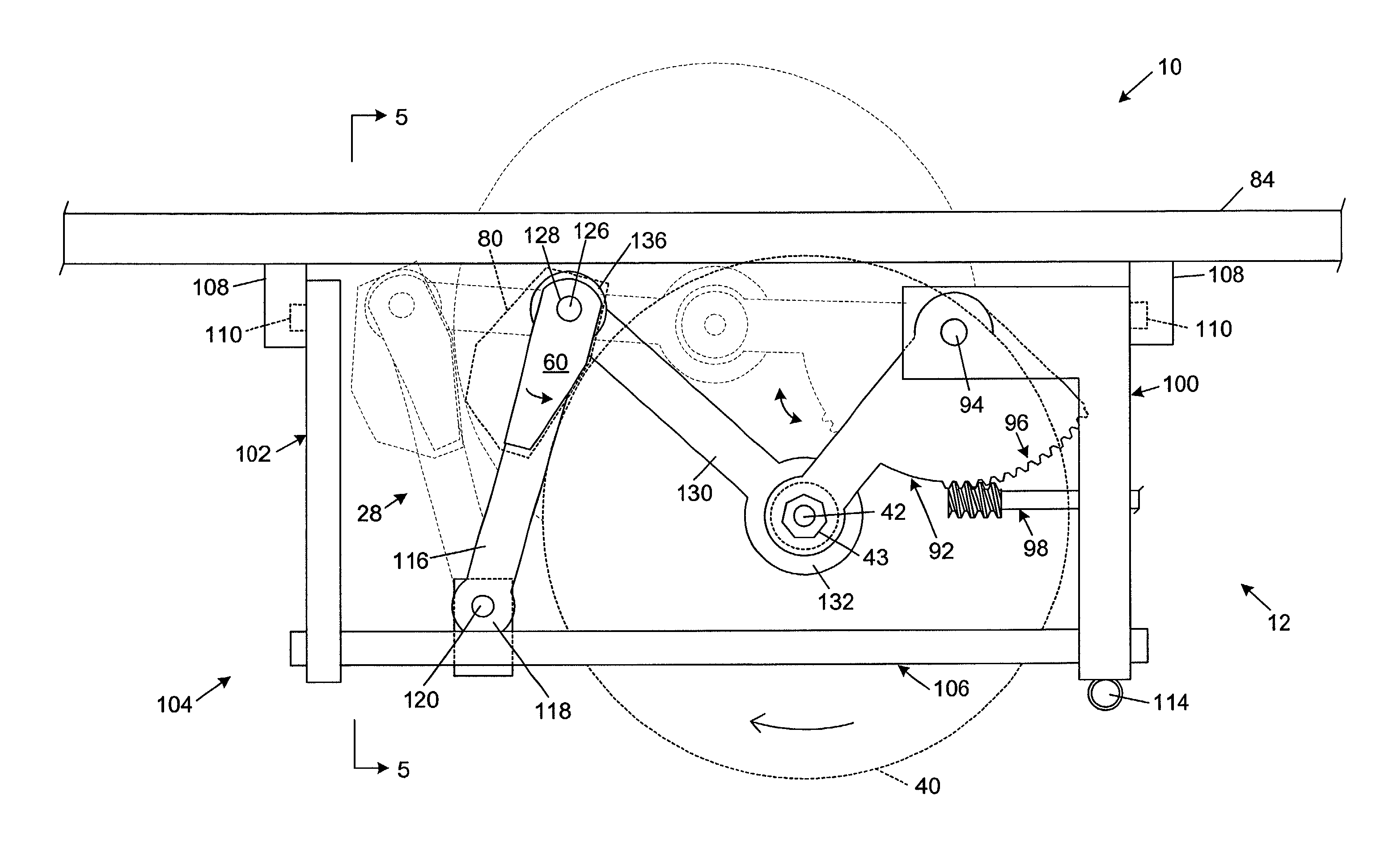

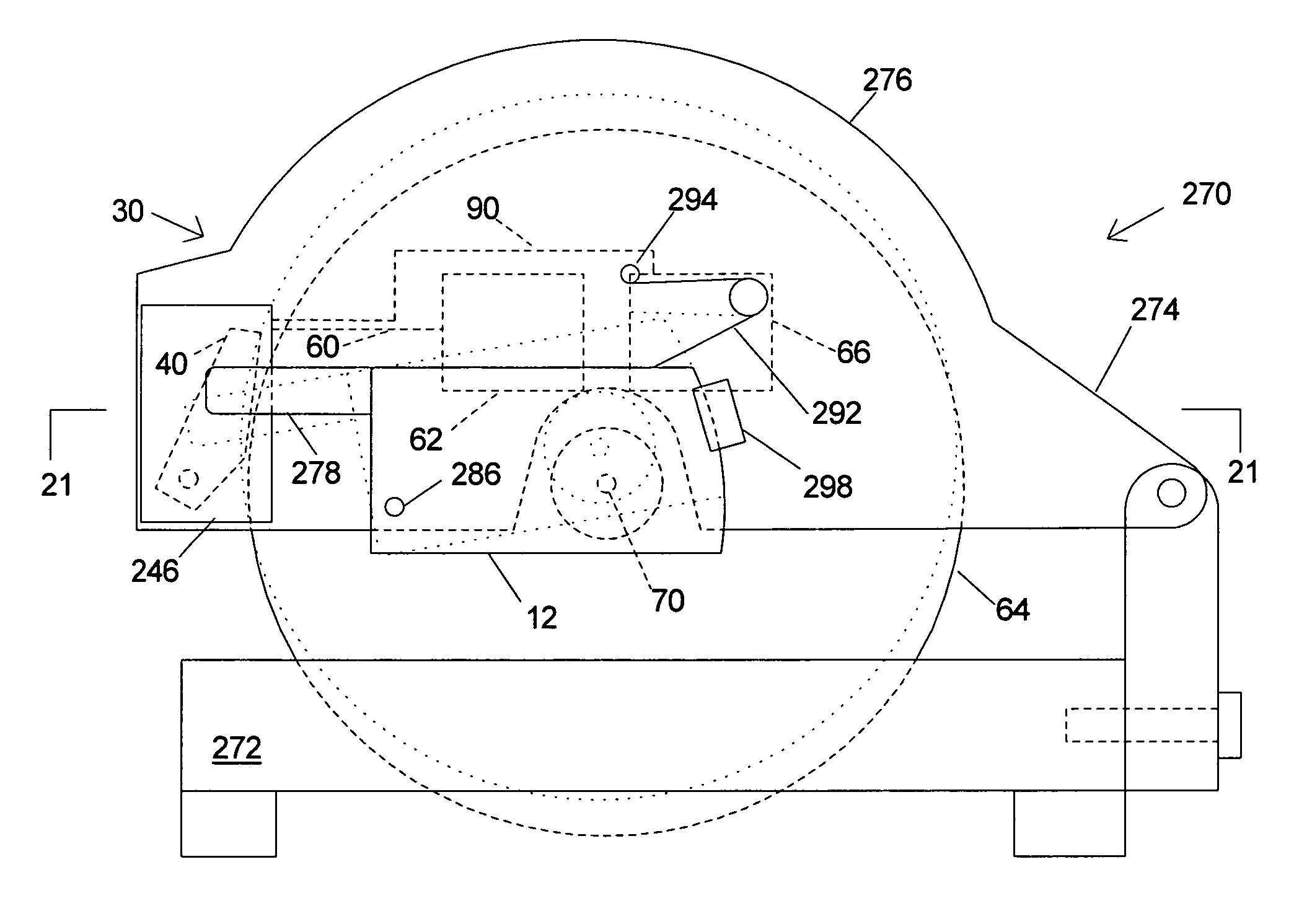

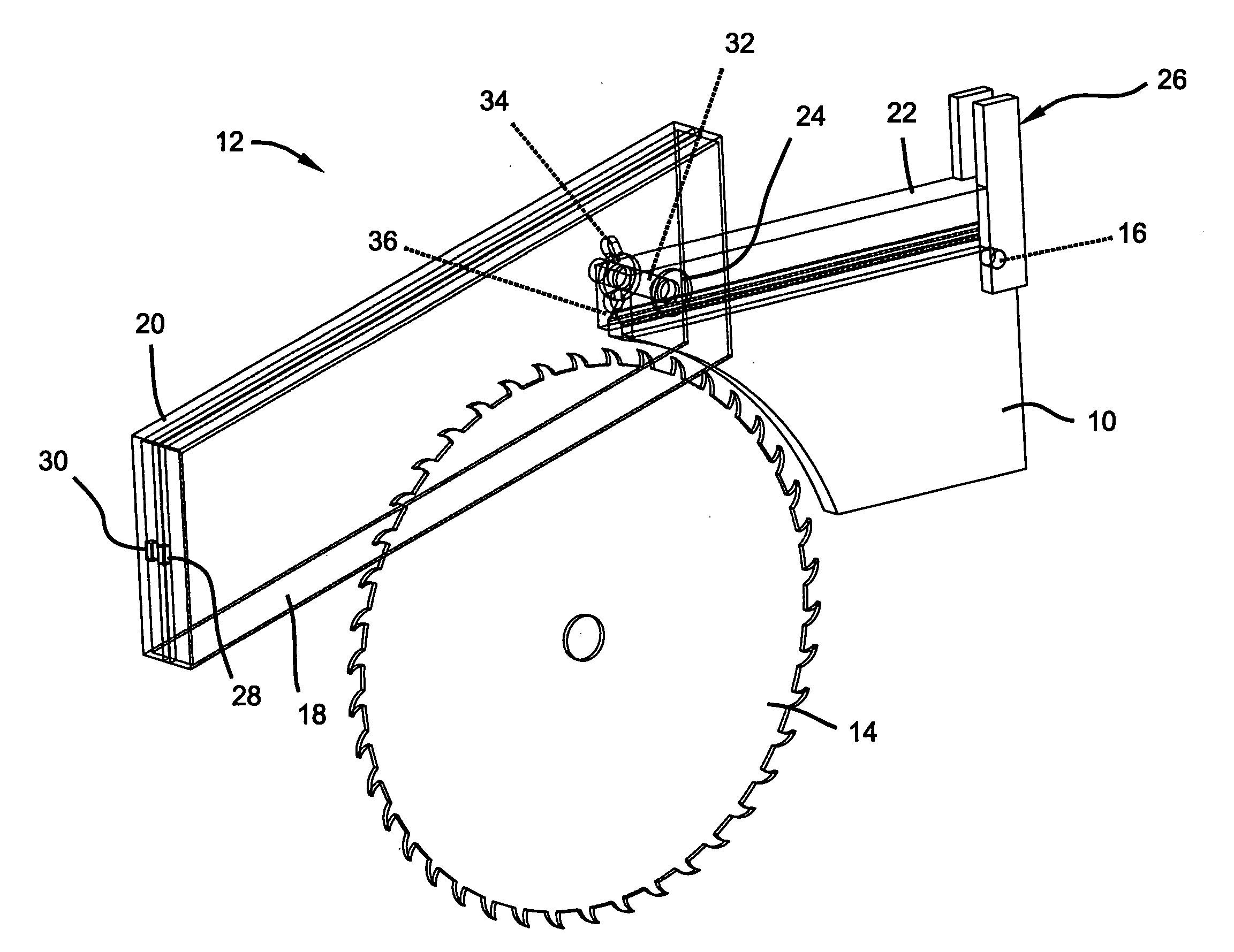

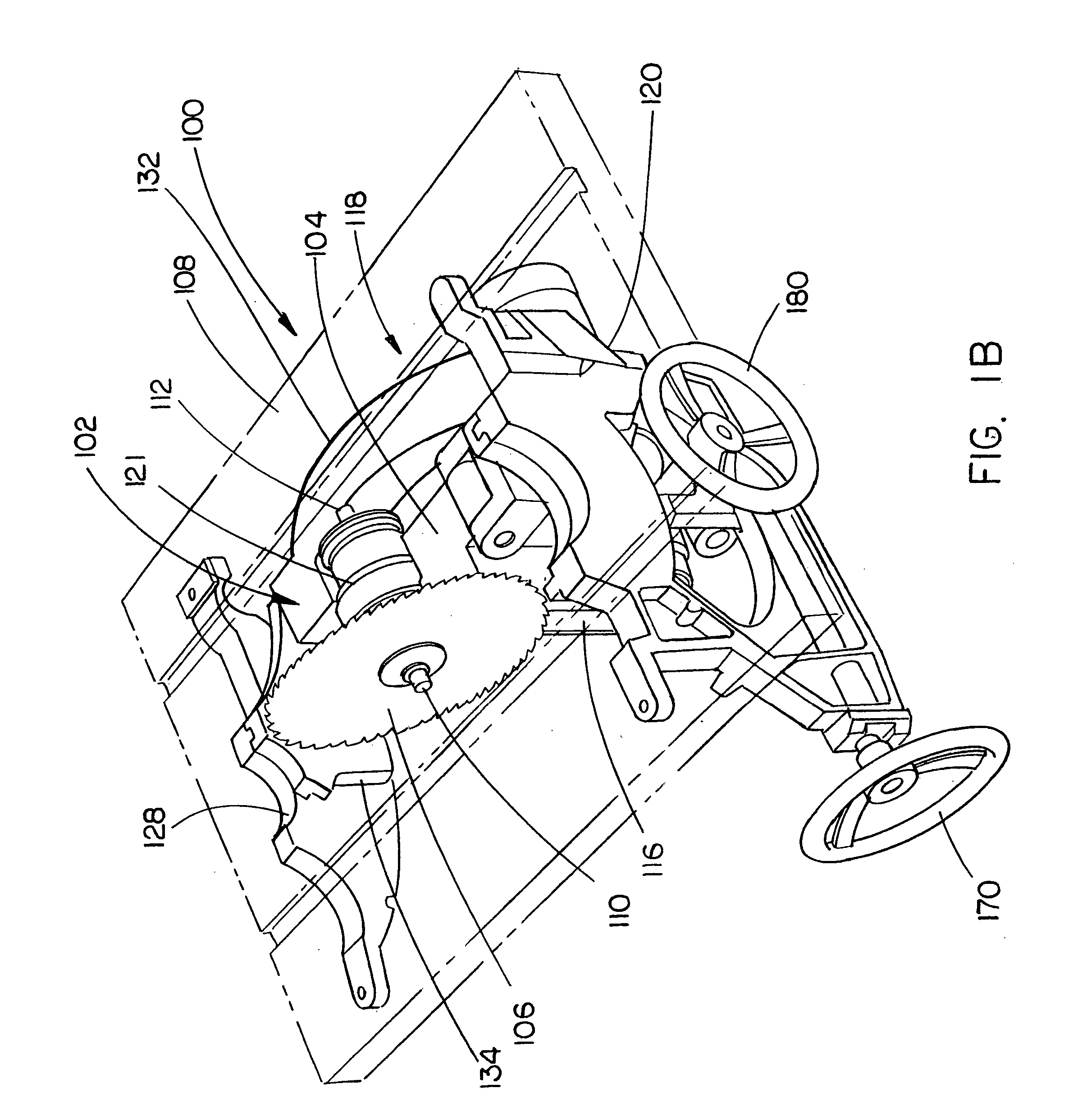

Brake positioning system

InactiveUS6857345B2Multi-purpose machinesEngineering safety devicesEngineeringMechanical engineering

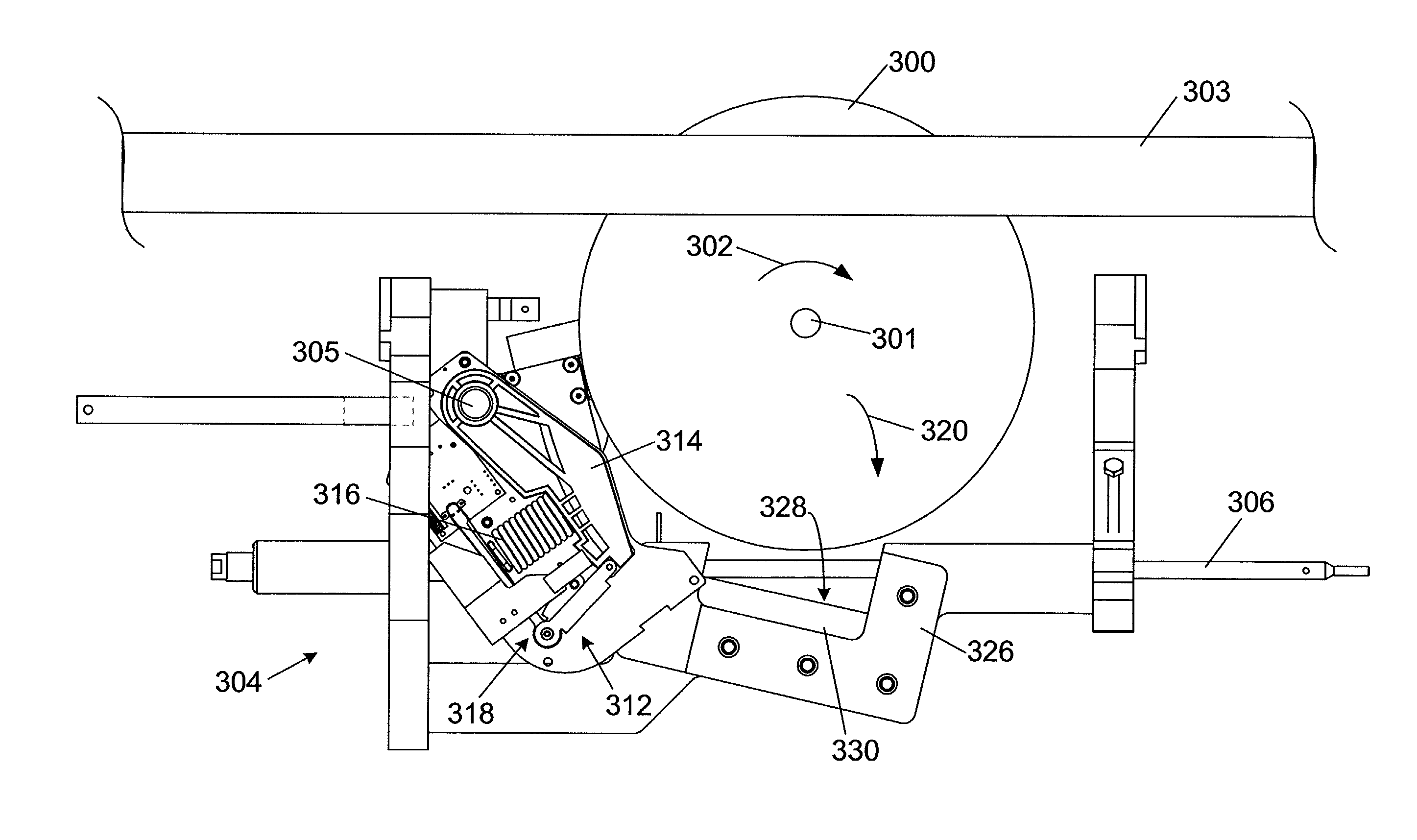

A saw is disclosed having a detection system adapted to detect a dangerous condition between a person and a saw blade, and a brake adapted to stop the saw blade in response to detection of the dangerous condition. The saw further includes a brake positioning system that allows the brake to be positioned in at least two different operable positions to accommodate at least two different blade diameters. The saw may include a system to detect brake-to-blade spacing.

Owner:SAWSTOP HLDG LLC

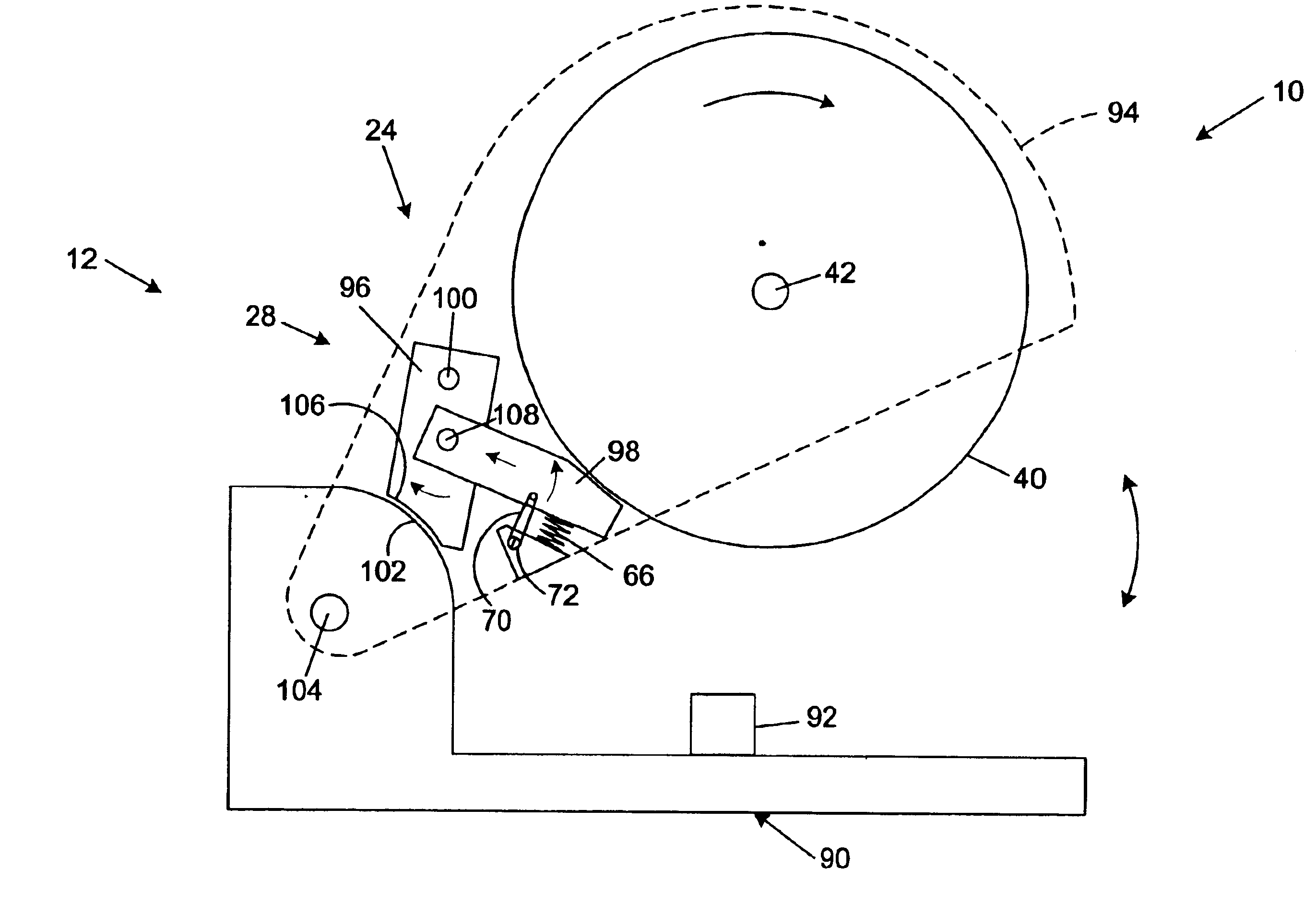

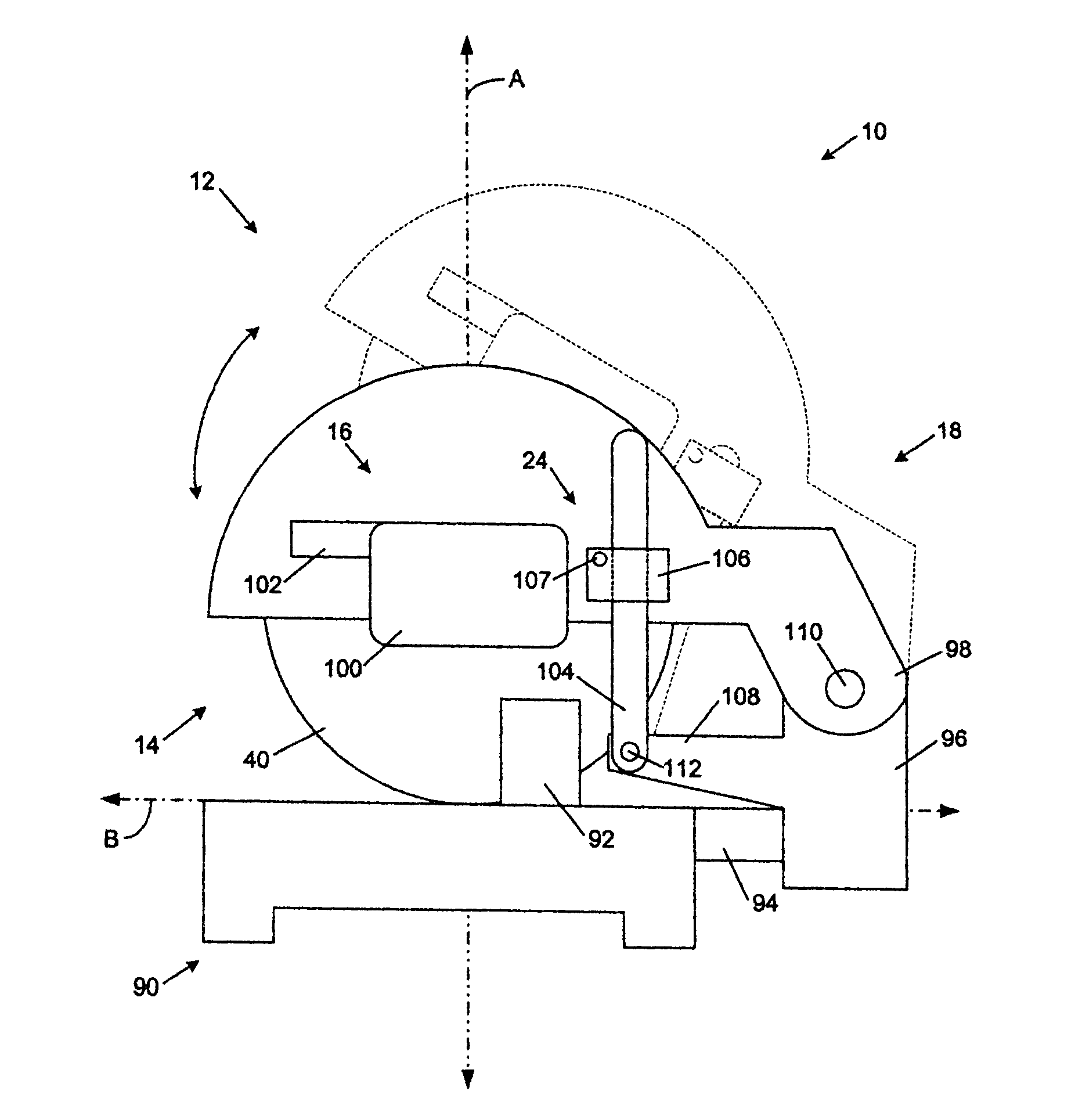

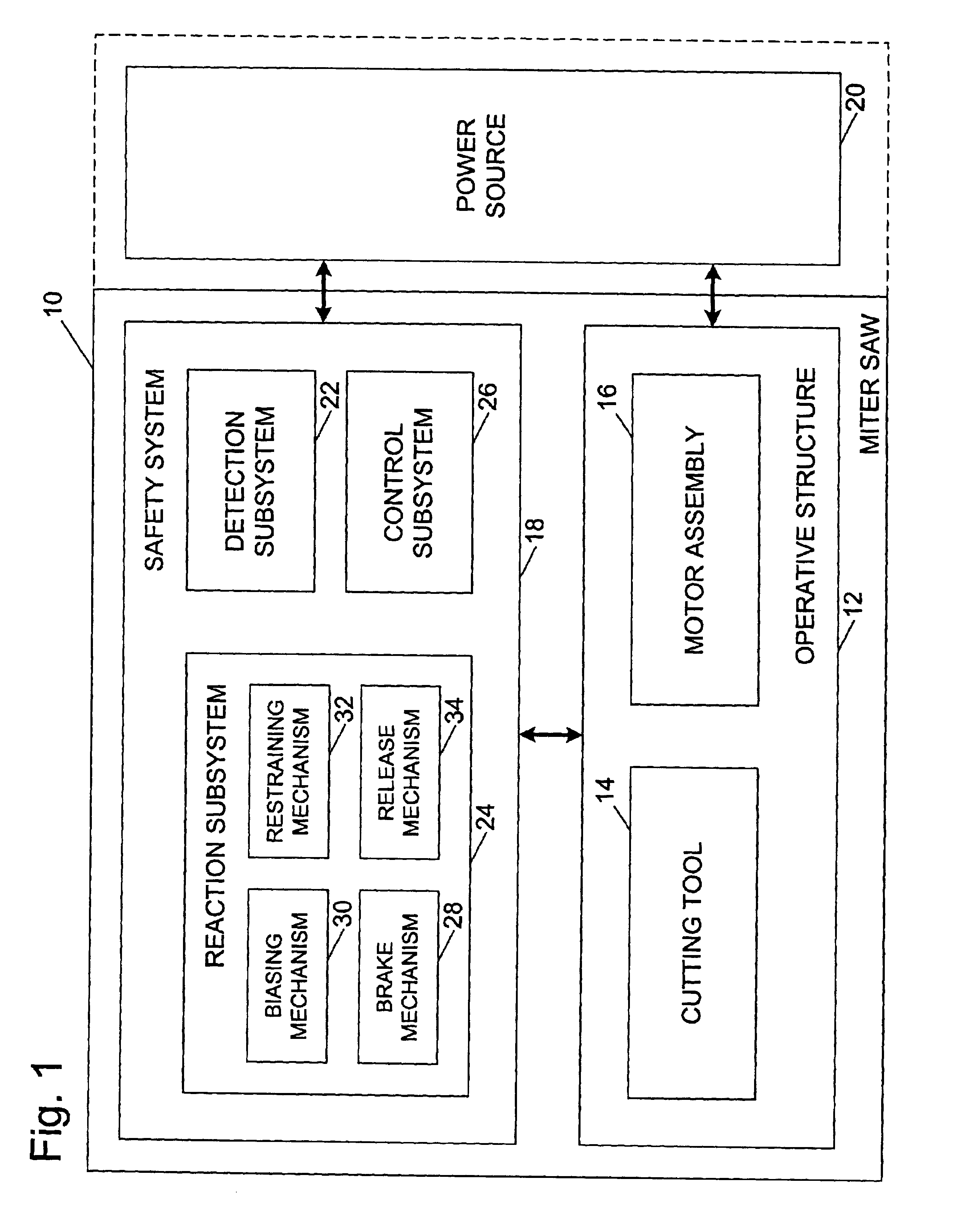

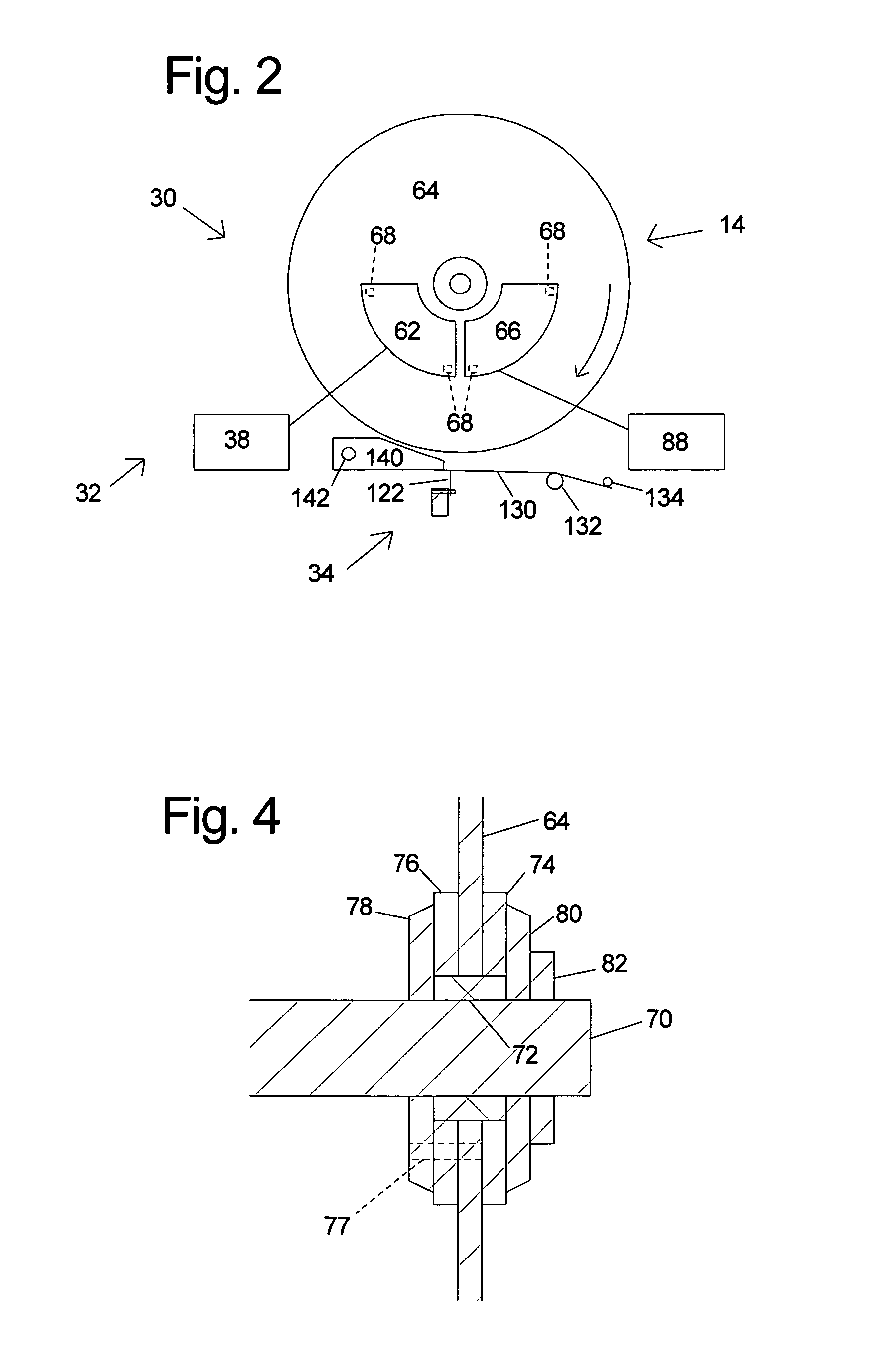

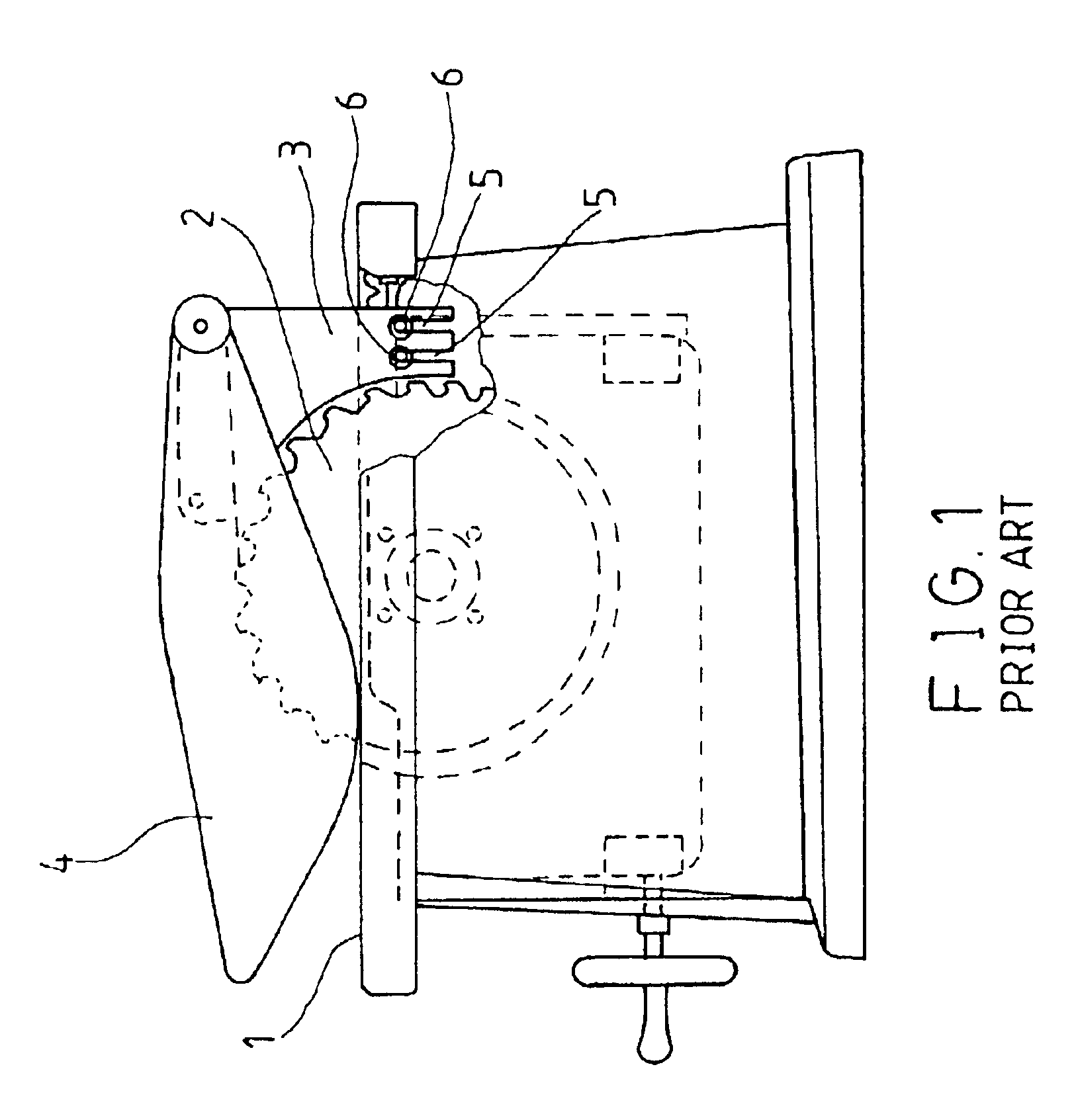

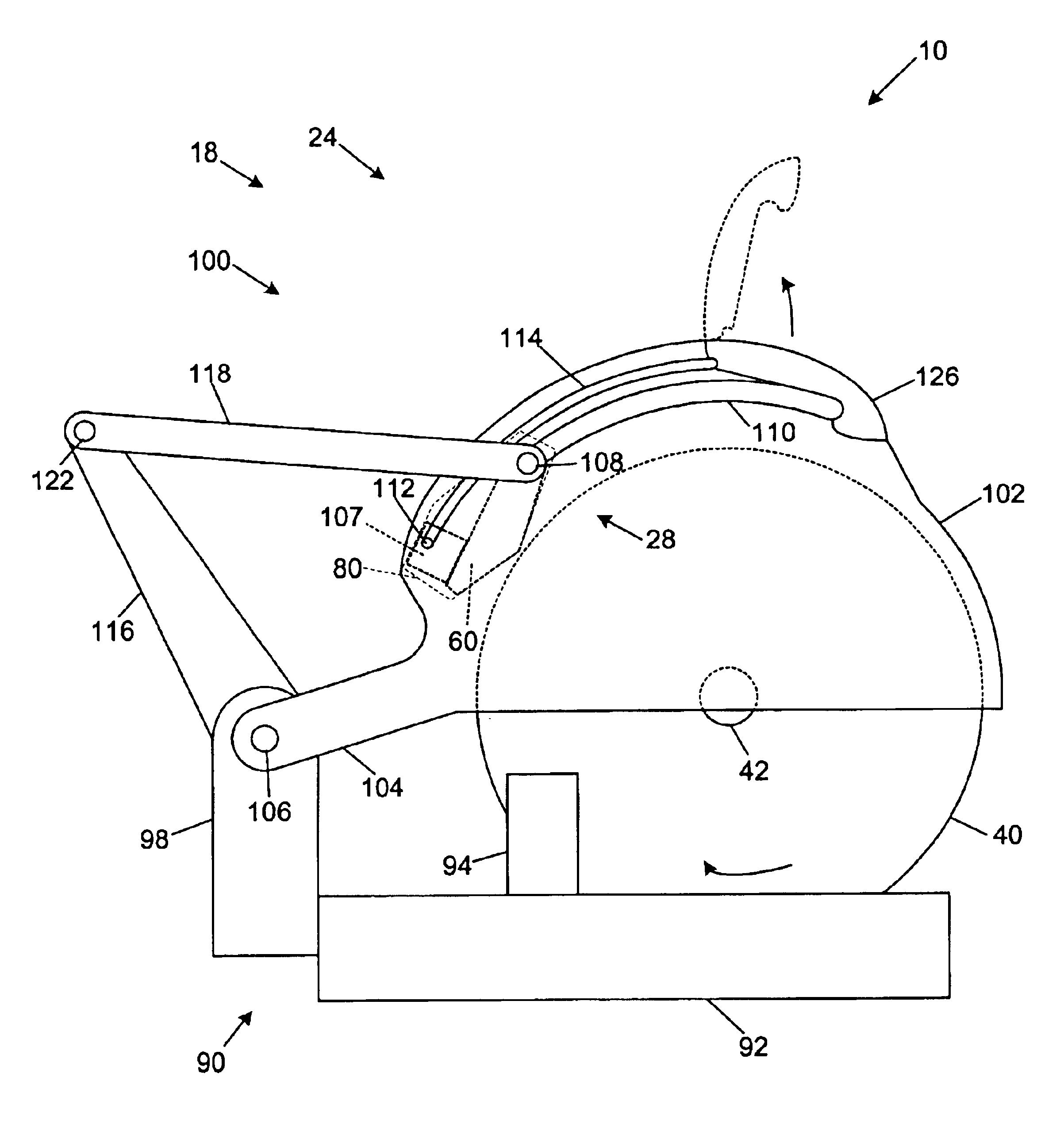

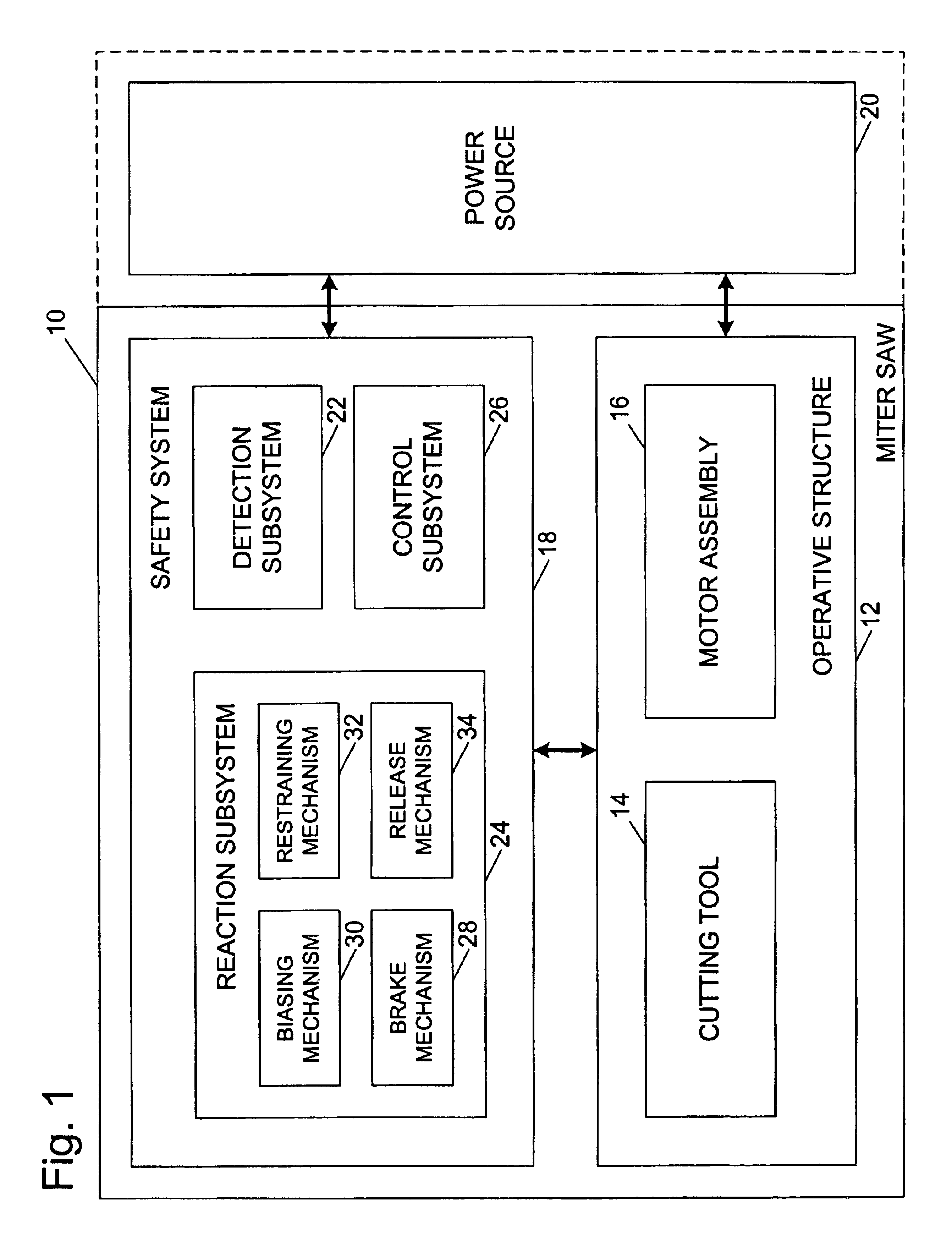

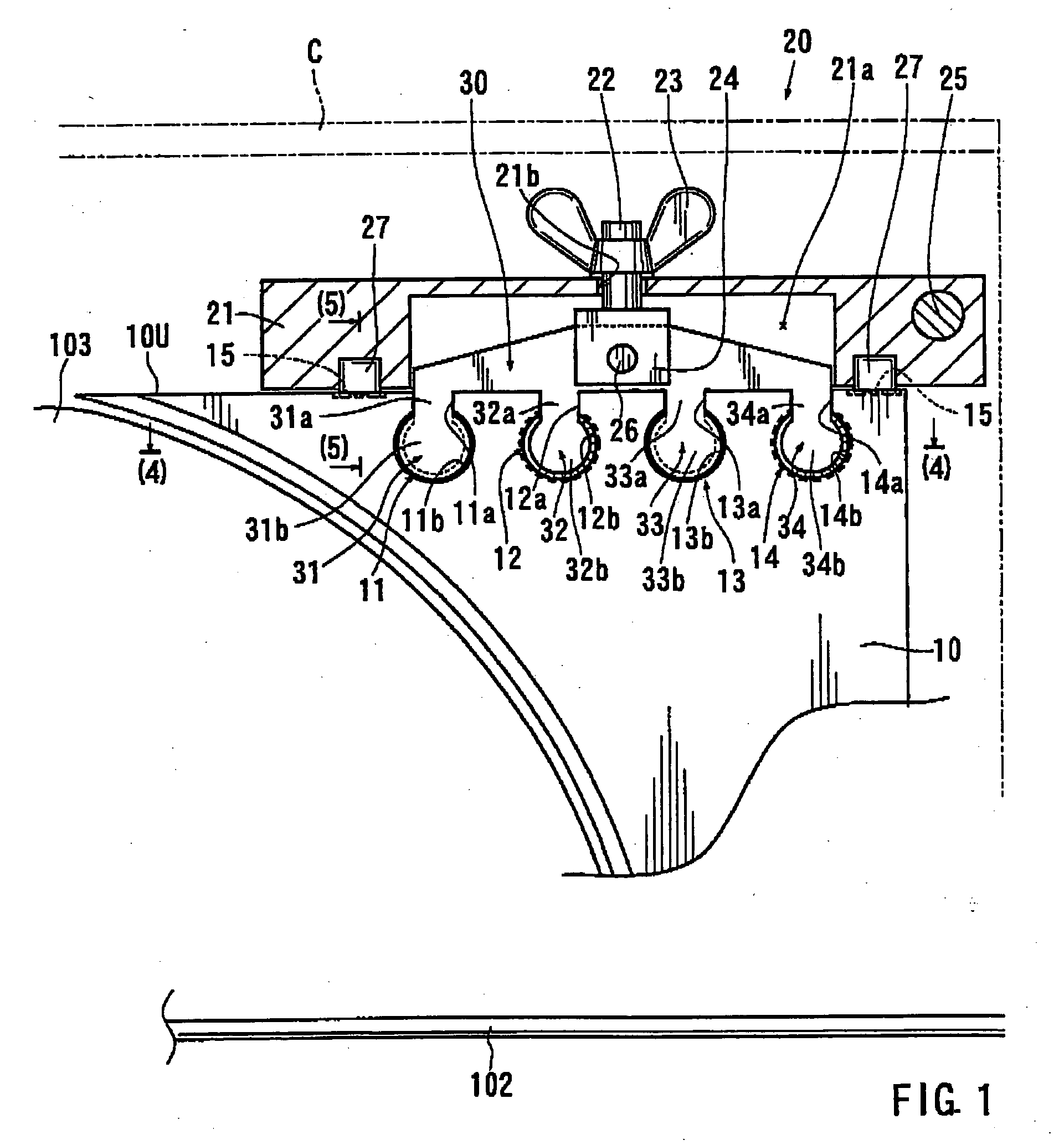

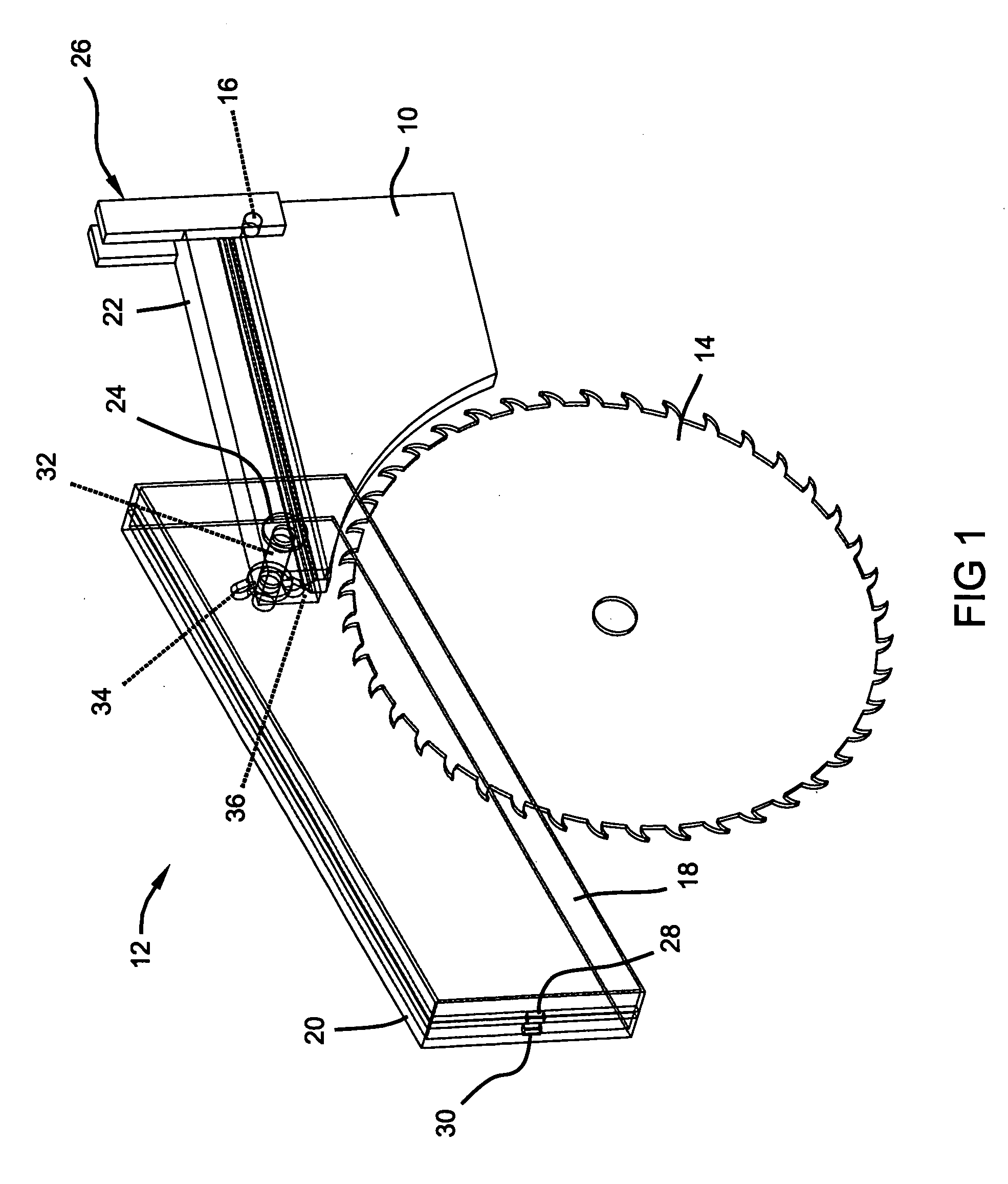

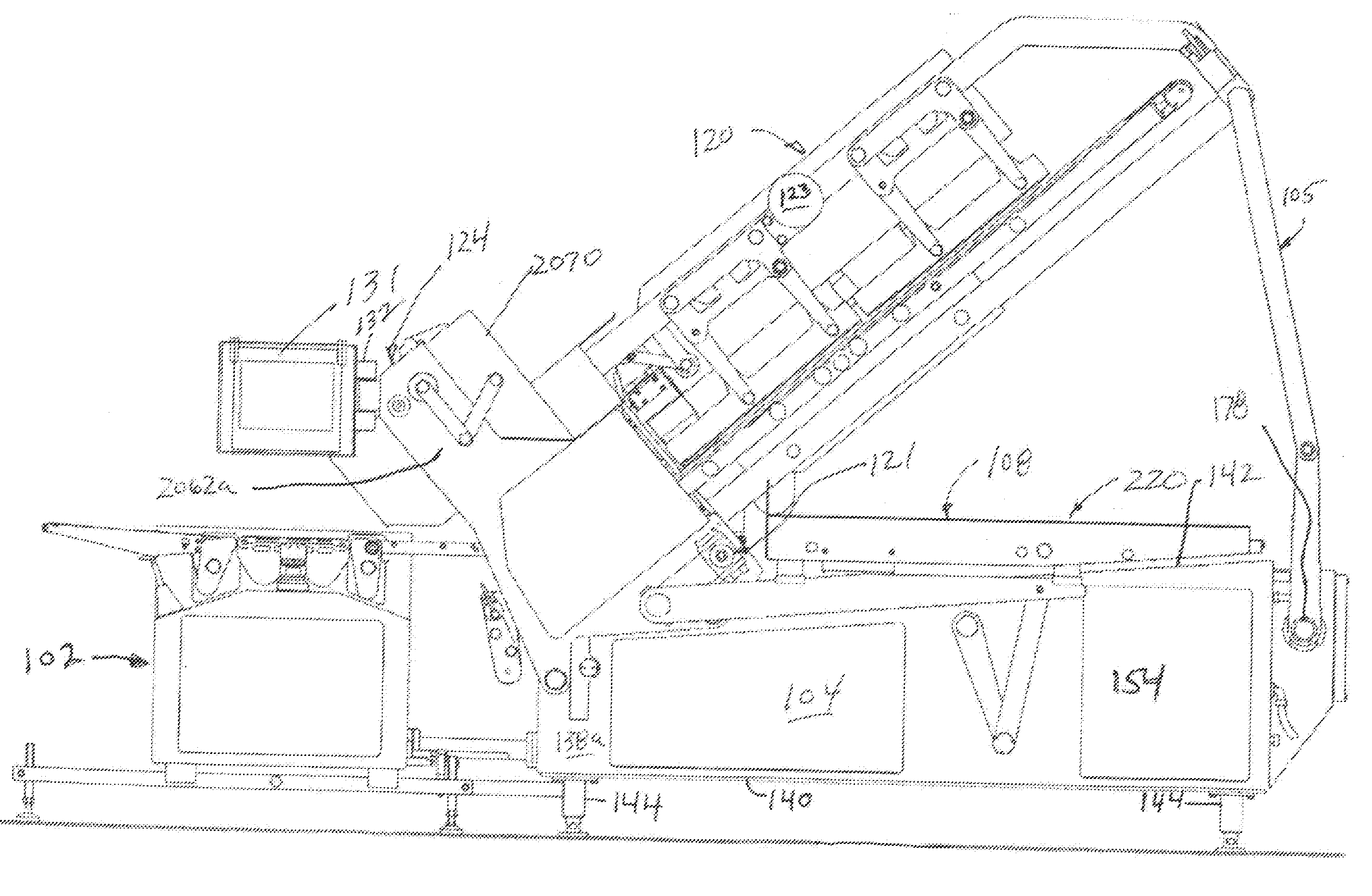

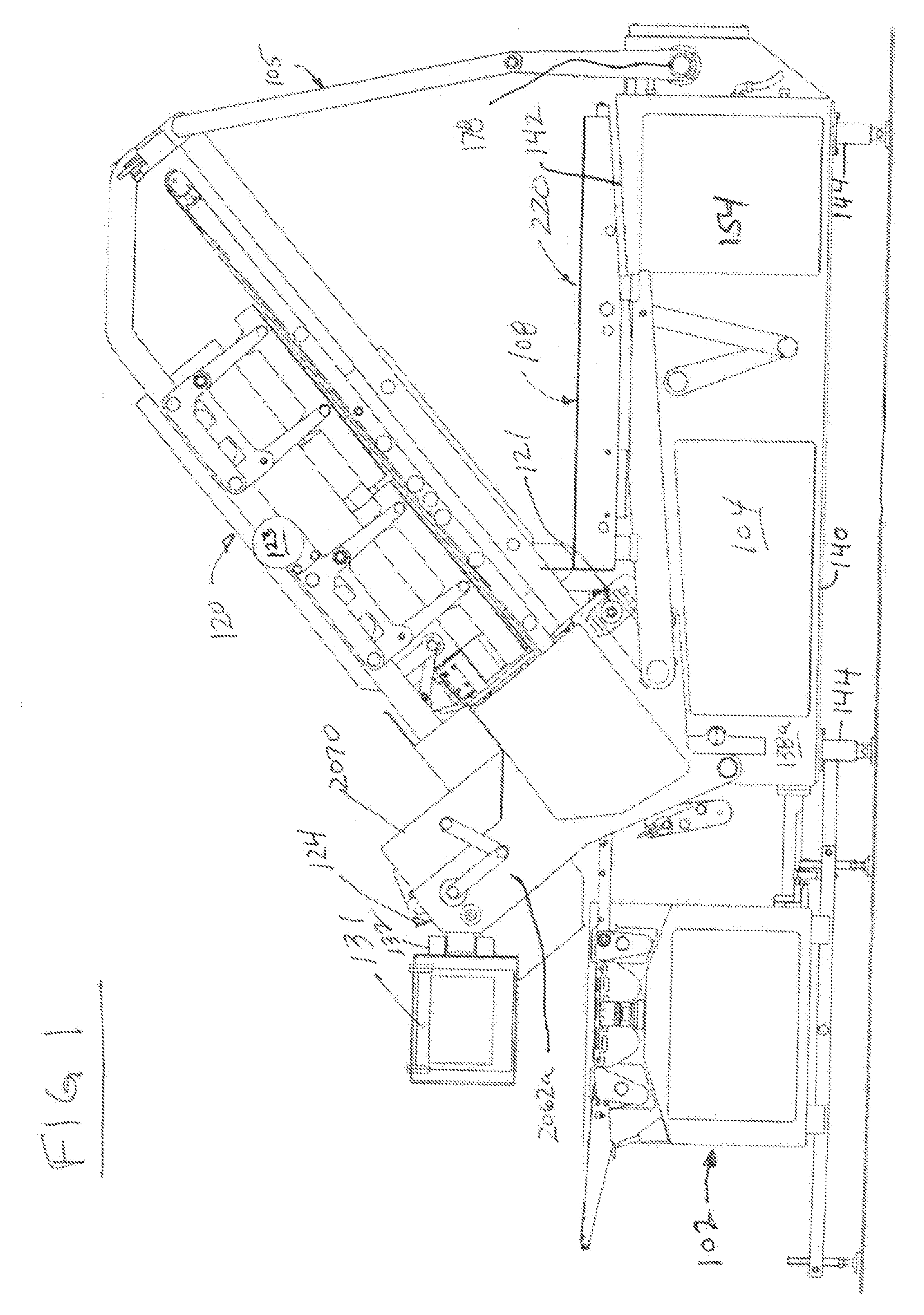

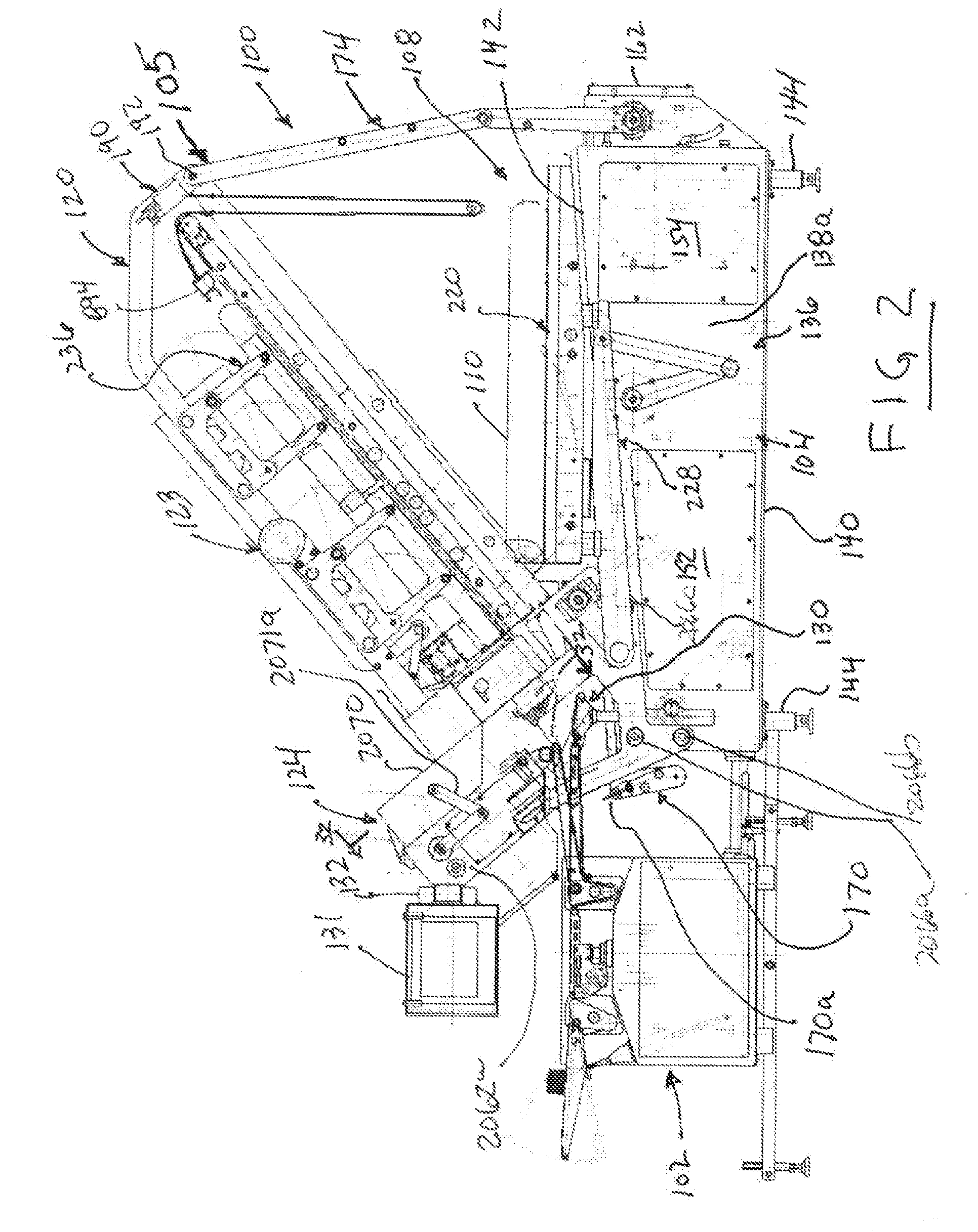

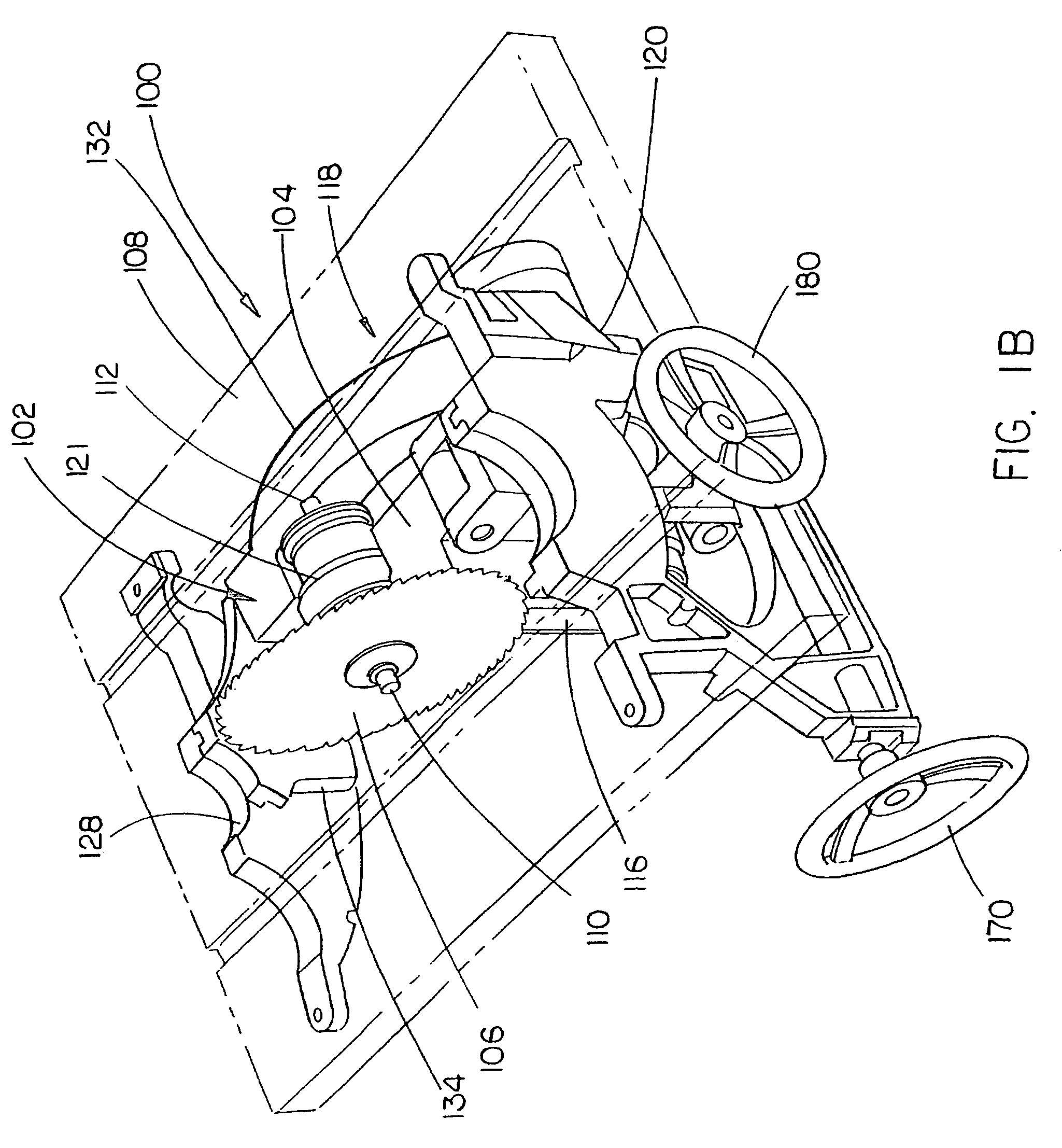

Miter saw with improved safety system

InactiveUS6826988B2Increase opportunitiesLimit and even prevent injuryEmergency protective circuit arrangementsEngineering safety devicesEngineeringWoodworking machine

A woodworking machine is disclosed having a base, a blade, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating and / or to stop movement of the blade toward the cutting zone.

Owner:SAWSTOP HLDG LLC

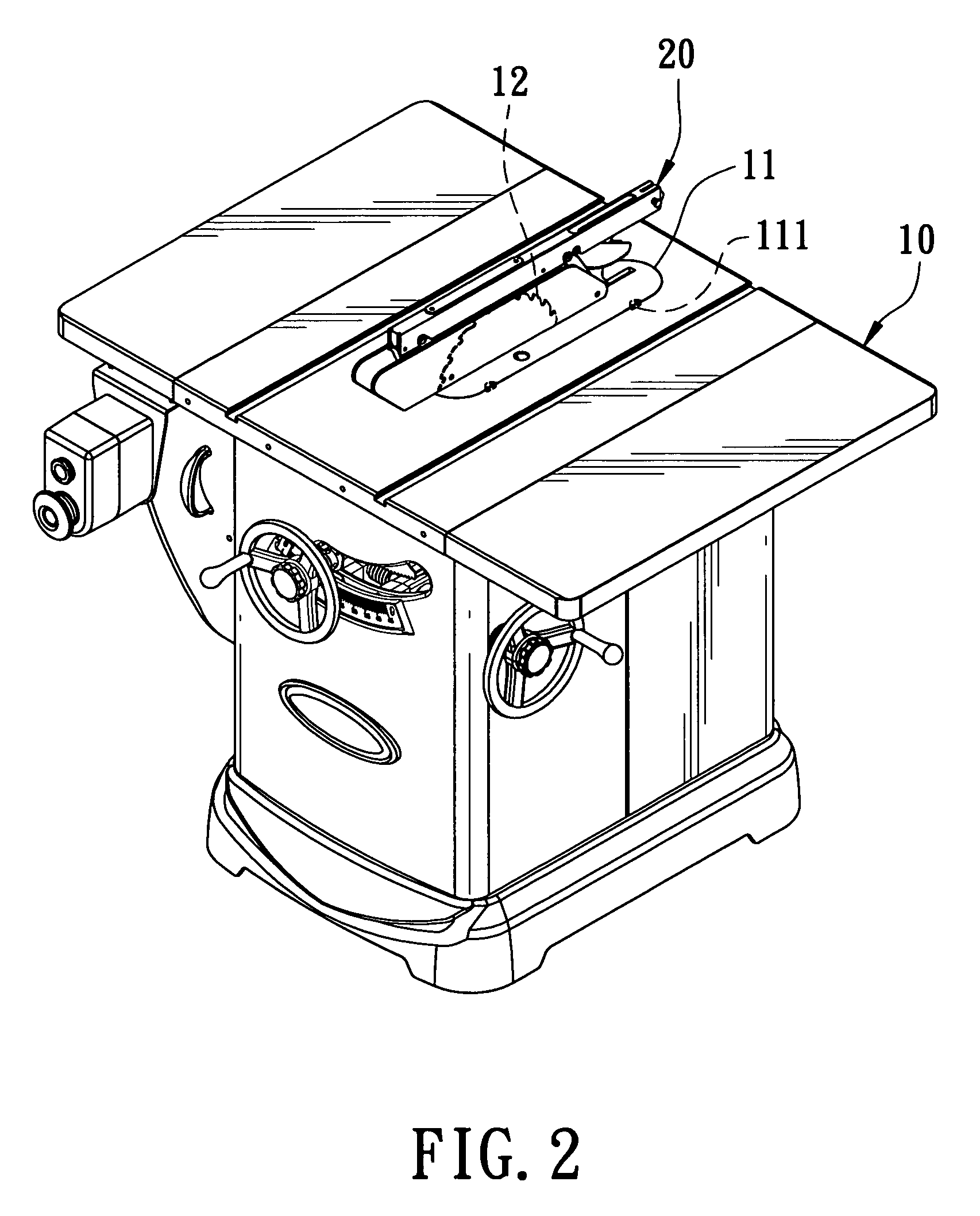

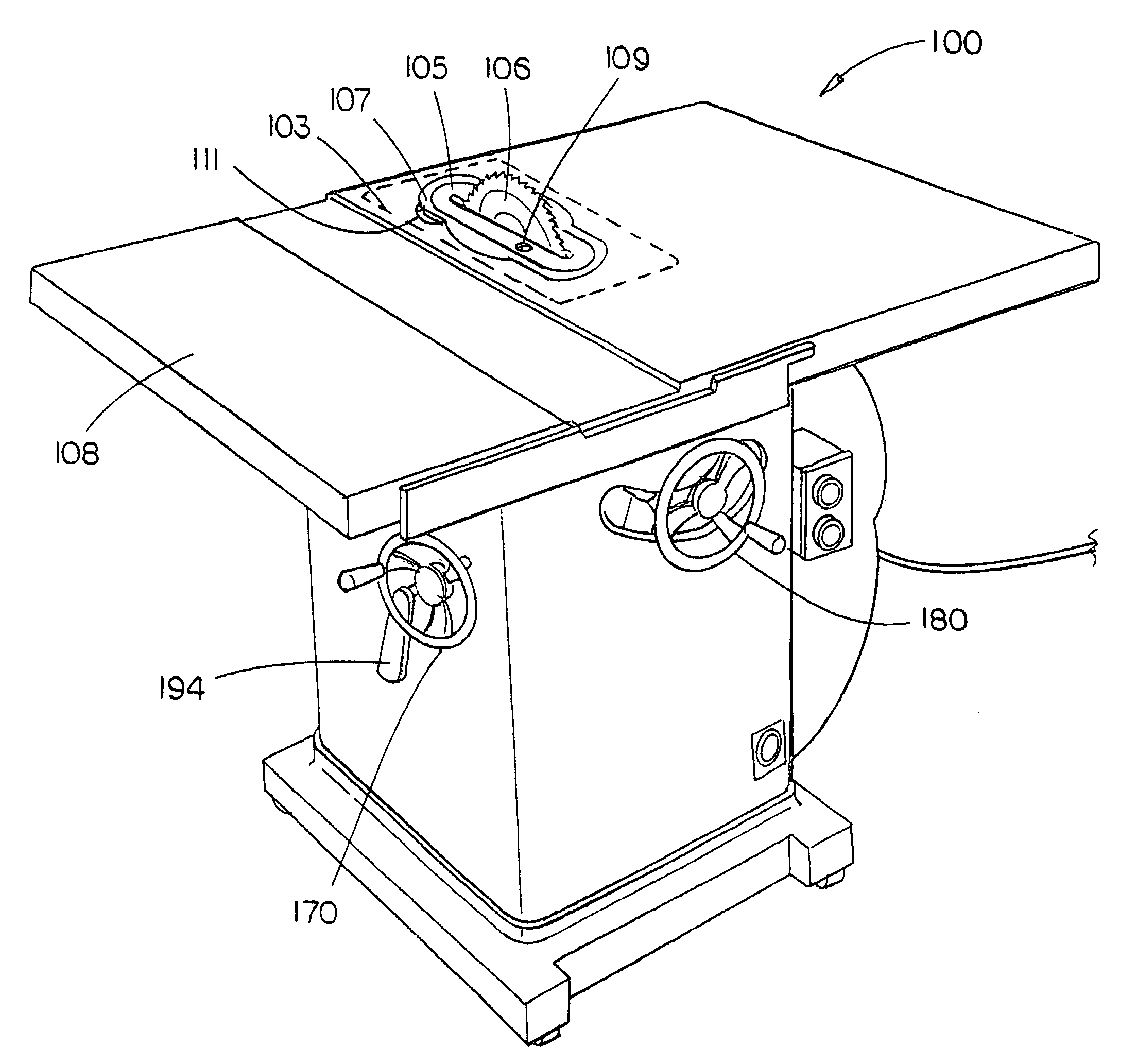

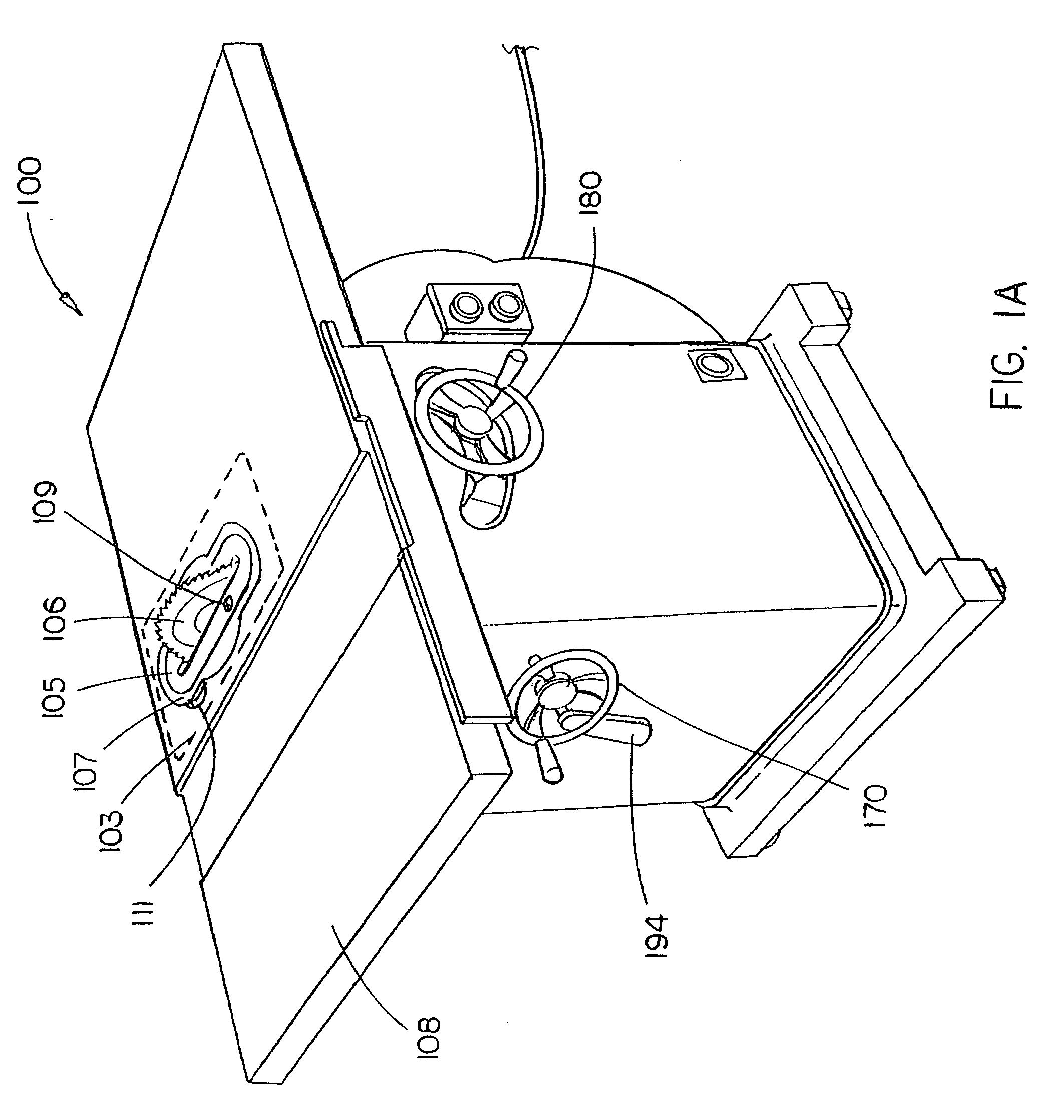

Table saw with improved safety system

InactiveUS6994004B2Metal sawing devicesMetal sawing accessoriesMechanical engineeringPositioning system

A table saw having a brake mechanism configured to engage and stop a blade is disclosed. The table saw includes a brake positioning system configured to adjust the position of the brake mechanism to maintain the brake mechanism in an operative position relative to the blade as the blade is raised and lowered.

Owner:SAWSTOP HLDG LLC

Miter saw with improved safety system

InactiveUS6880440B2Limit and even prevent injuryImprove the security systemEmergency protective circuit arrangementsEngineering safety devicesEngineeringMechanical engineering

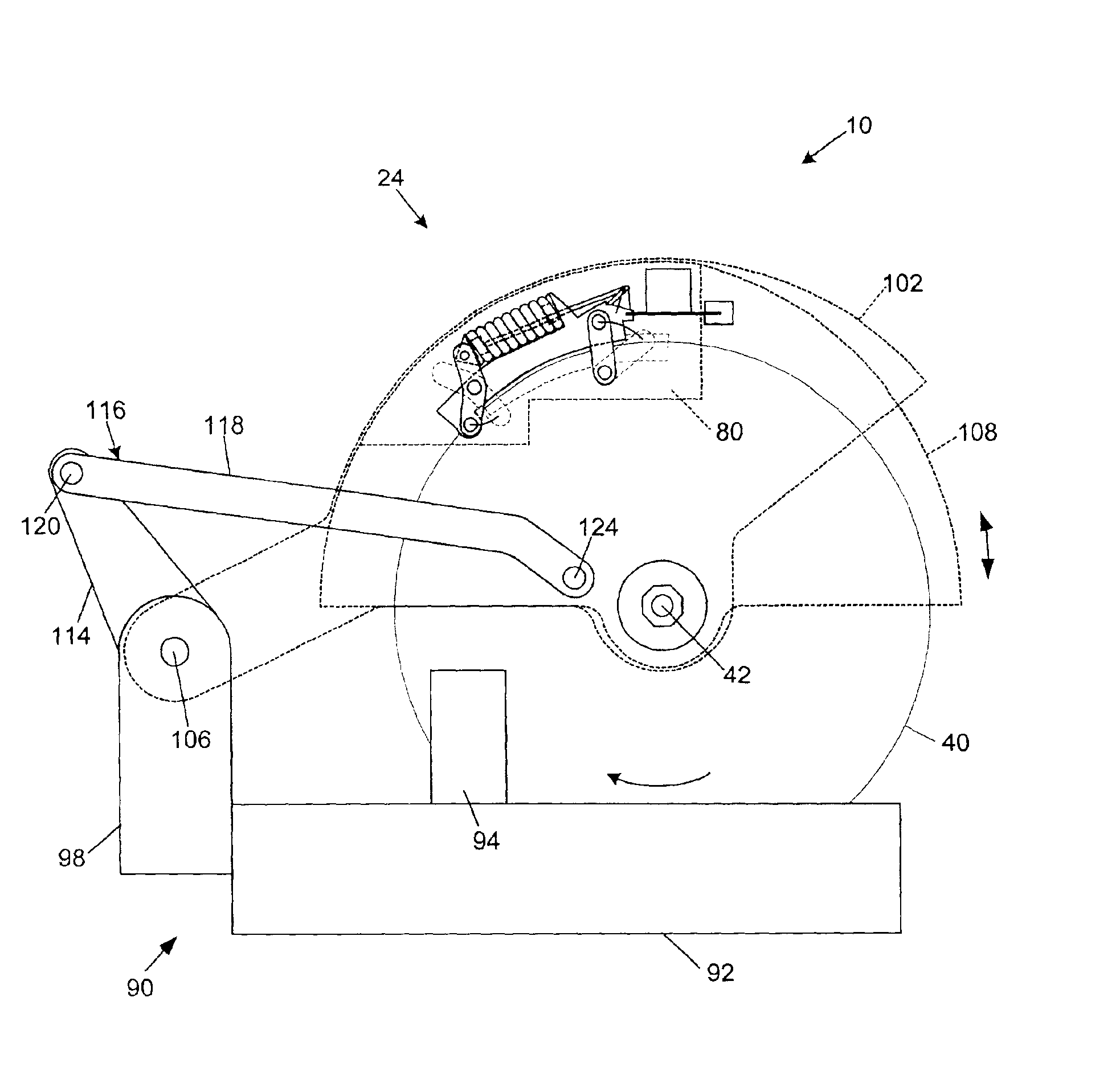

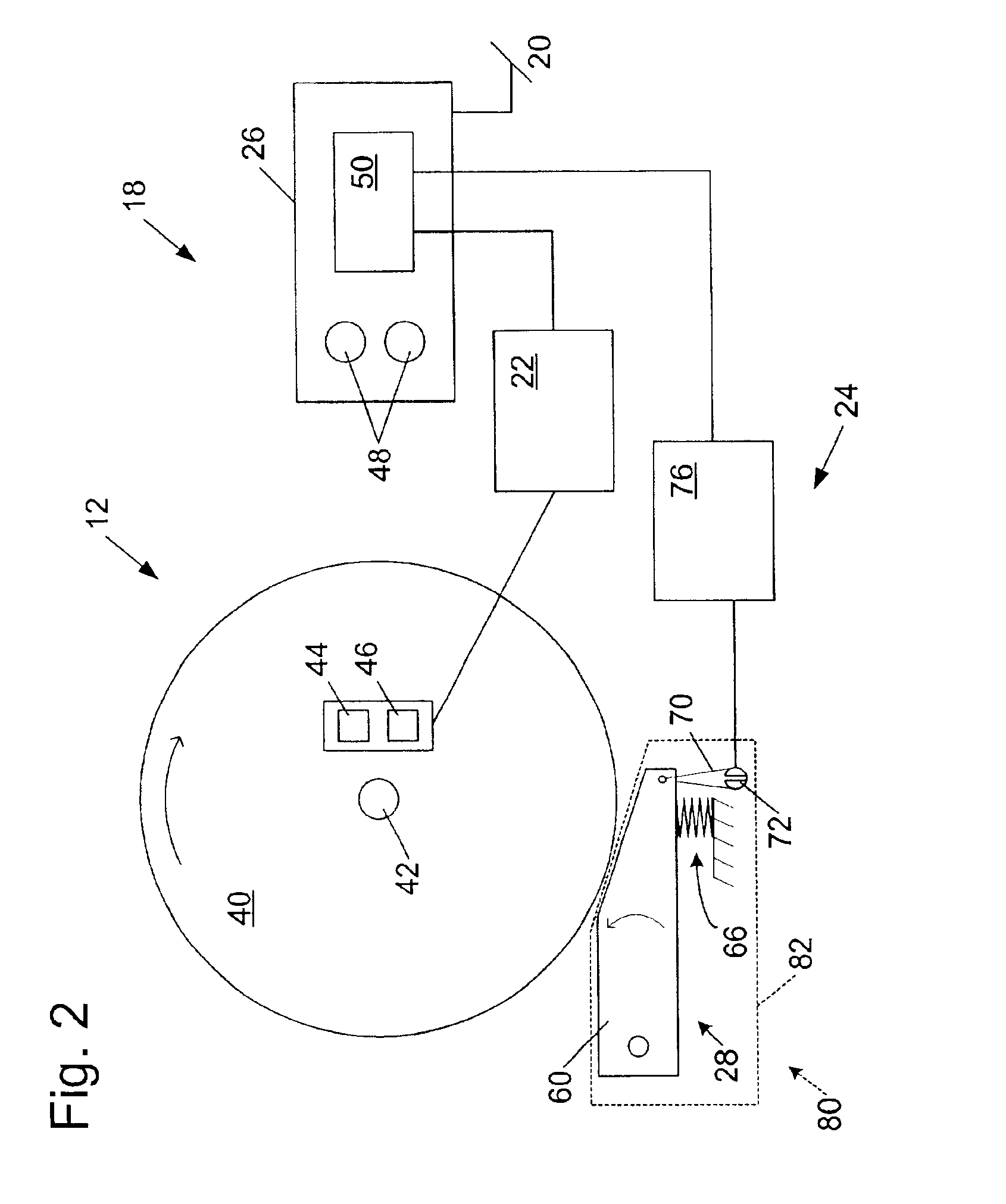

A miter saw having a base and an arm that pivots toward the base is disclosed. A blade is supported by the arm, and is designed to cut workpieces resting on the base when the arm and blade pivot downward. The saw includes a detection system configured to detect one or more dangerous conditions between a person and the blade, such as when a person accidentally touches the spinning blade, and the saw includes a reaction system to stop the downward movement of the blade and arm when the dangerous condition is detected.

Owner:SAWSTOP HLDG LLC

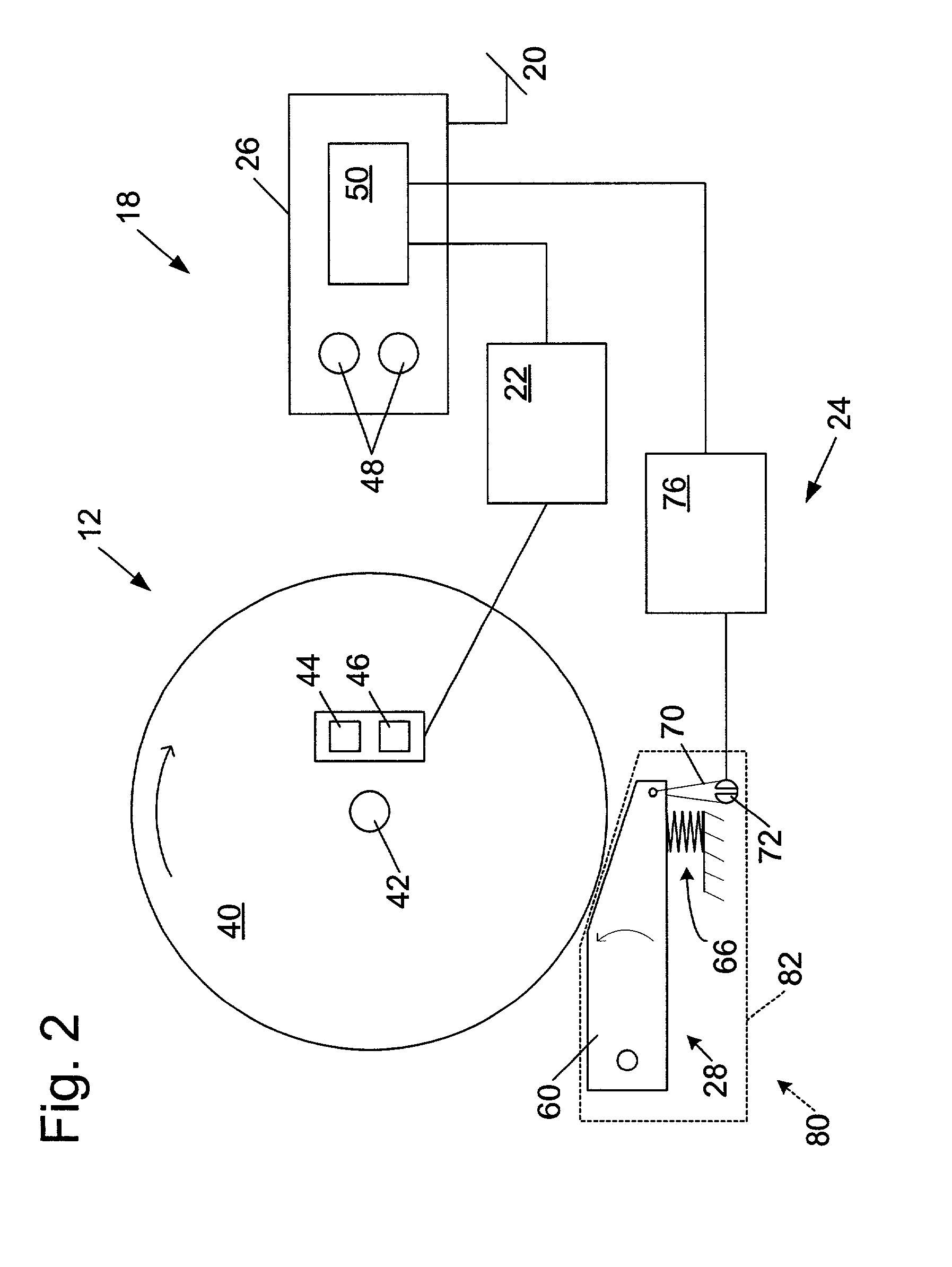

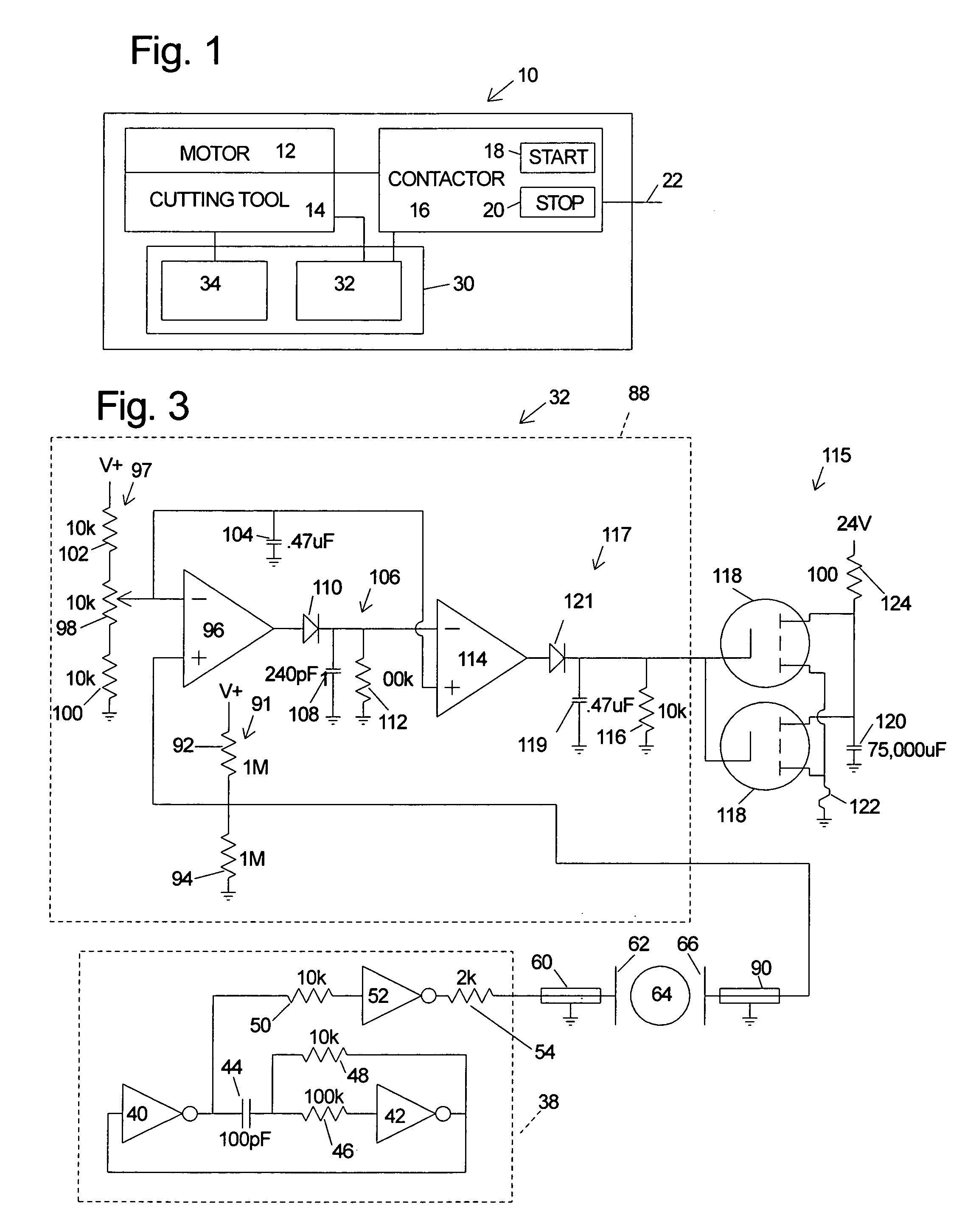

Safety system for power equipment

Safety systems for power equipment are disclosed. The safety systems include a detection system adapted to detect contact between a person and a working portion of a machine, where the detection system is adapted to capacitively impart an electric charge on the working portion and to detect when that charge drops; and a reaction system associated with the detection system to cause a predetermined action to take place relative to the working portion upon detection of contact between the person and the working portion by the detection system. Machines equipped with safety systems are also disclosed, such as saws, jointers, etc. The machines include a working portion, such as a cutter or blade, a detection system adapted to detect a dangerous condition between a person and the working portion, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition, such as a brake system to stop the working portion, a retraction system to retract the working portion, or a system to cover the working portion. The machines may include a control system adapted to control the operability of one or more of the working portion, the detection system and the reaction system.

Owner:SAWSTOP HLDG LLC

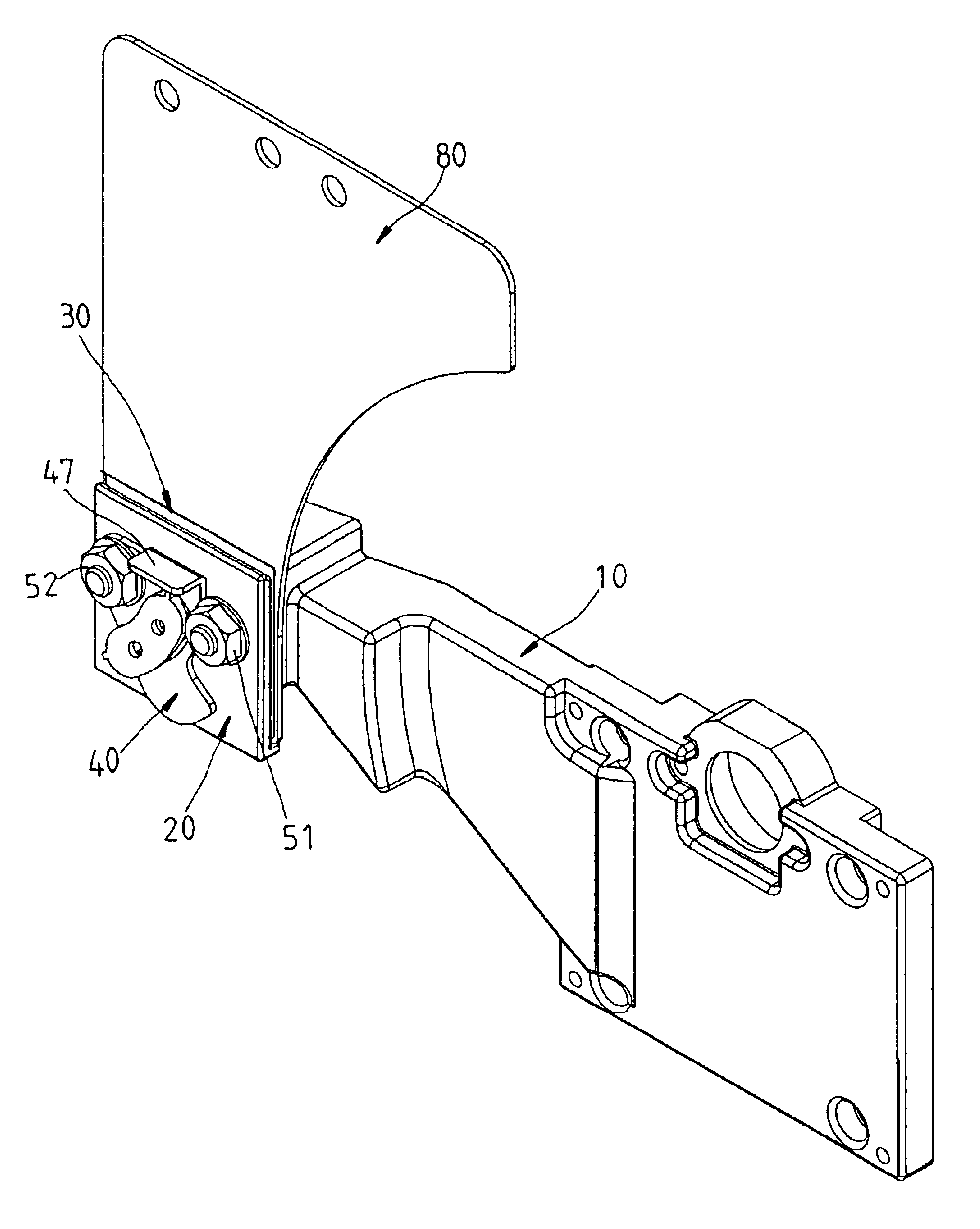

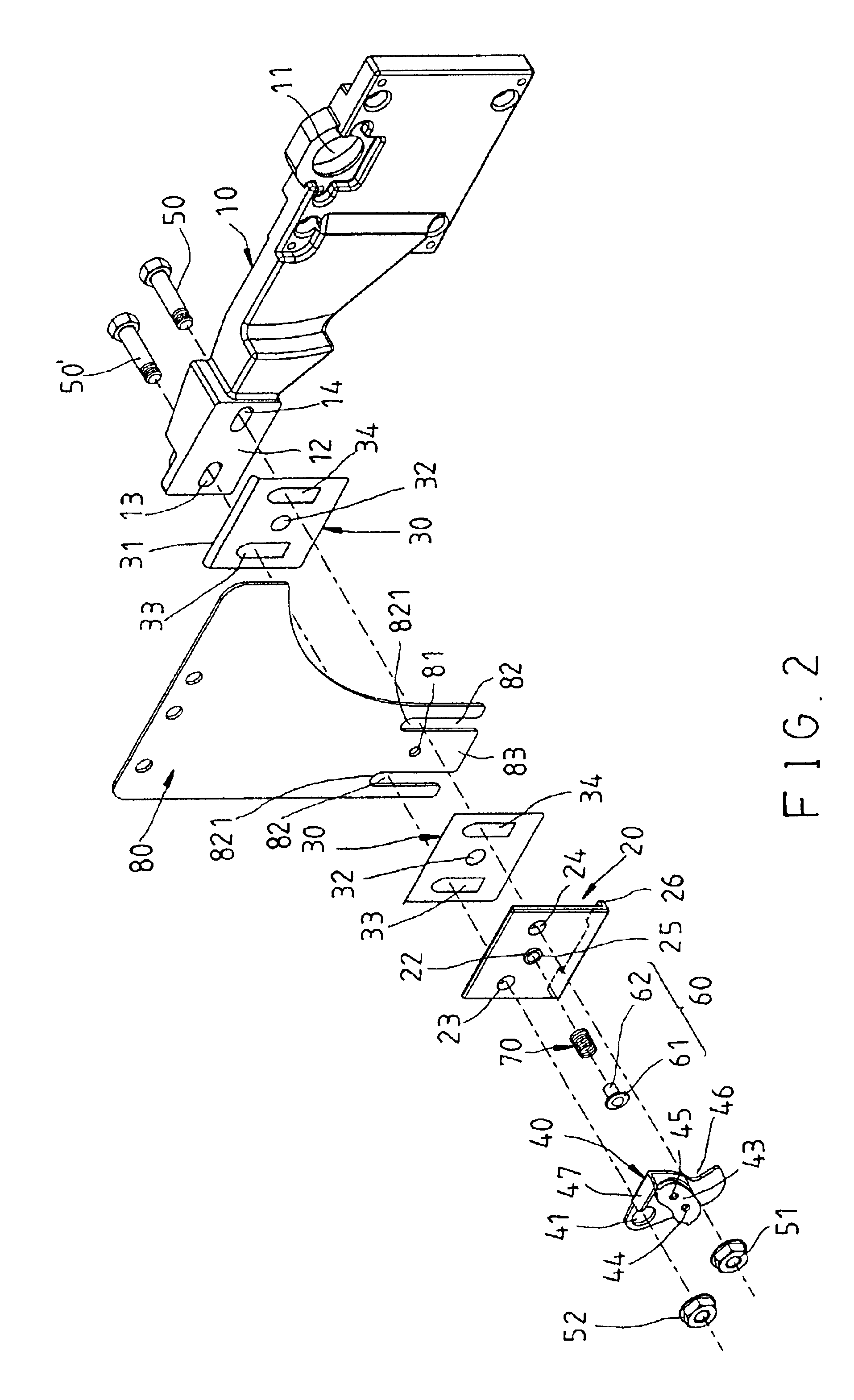

Quick-detachable blade guard mounting structure

Owner:DURQ MACHINERY

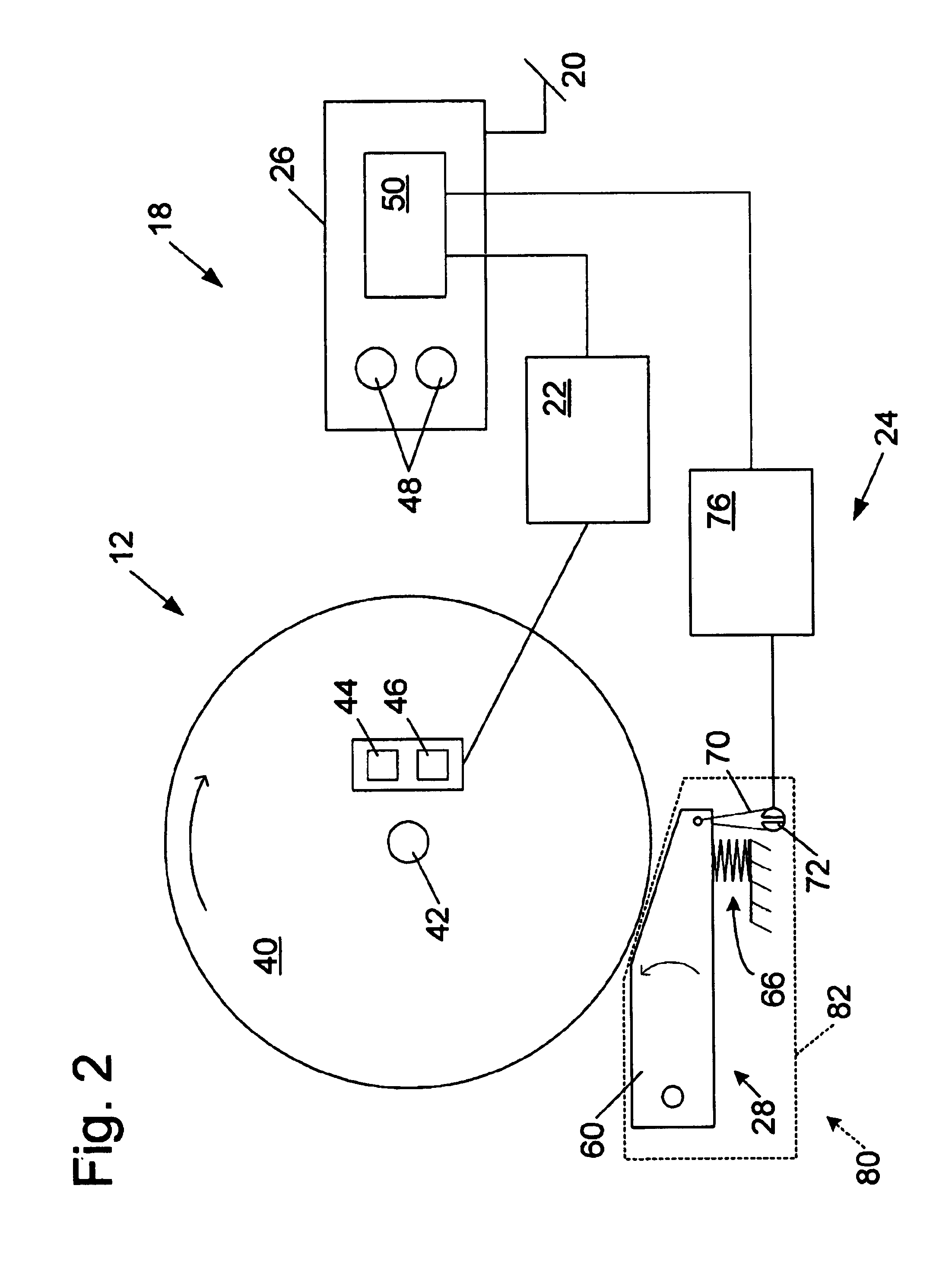

Actuators for use in fast-acting safety systems

Cutting machines with high-speed safety systems, and actuators used in high-speed safety systems, are disclosed. The cutting machines may include a detection system adapted to detect a dangerous condition between a cutting tool and a person. A reaction system performs a specified action, such as stopping the cutting tool, upon detection of the dangerous condition. An actuator may be used to trigger the reaction system to perform the specified action.

Owner:SAWSTOP HLDG LLC

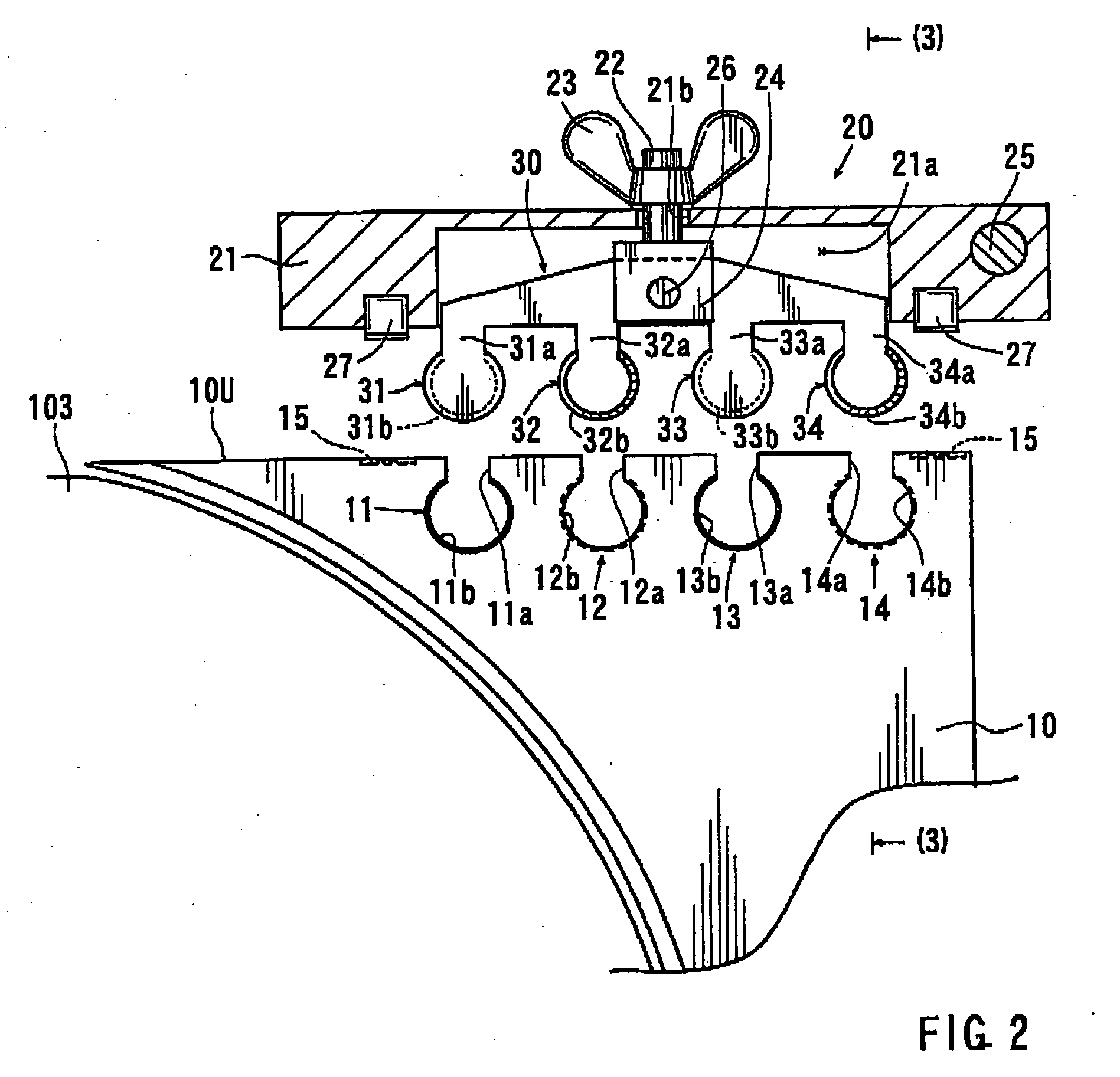

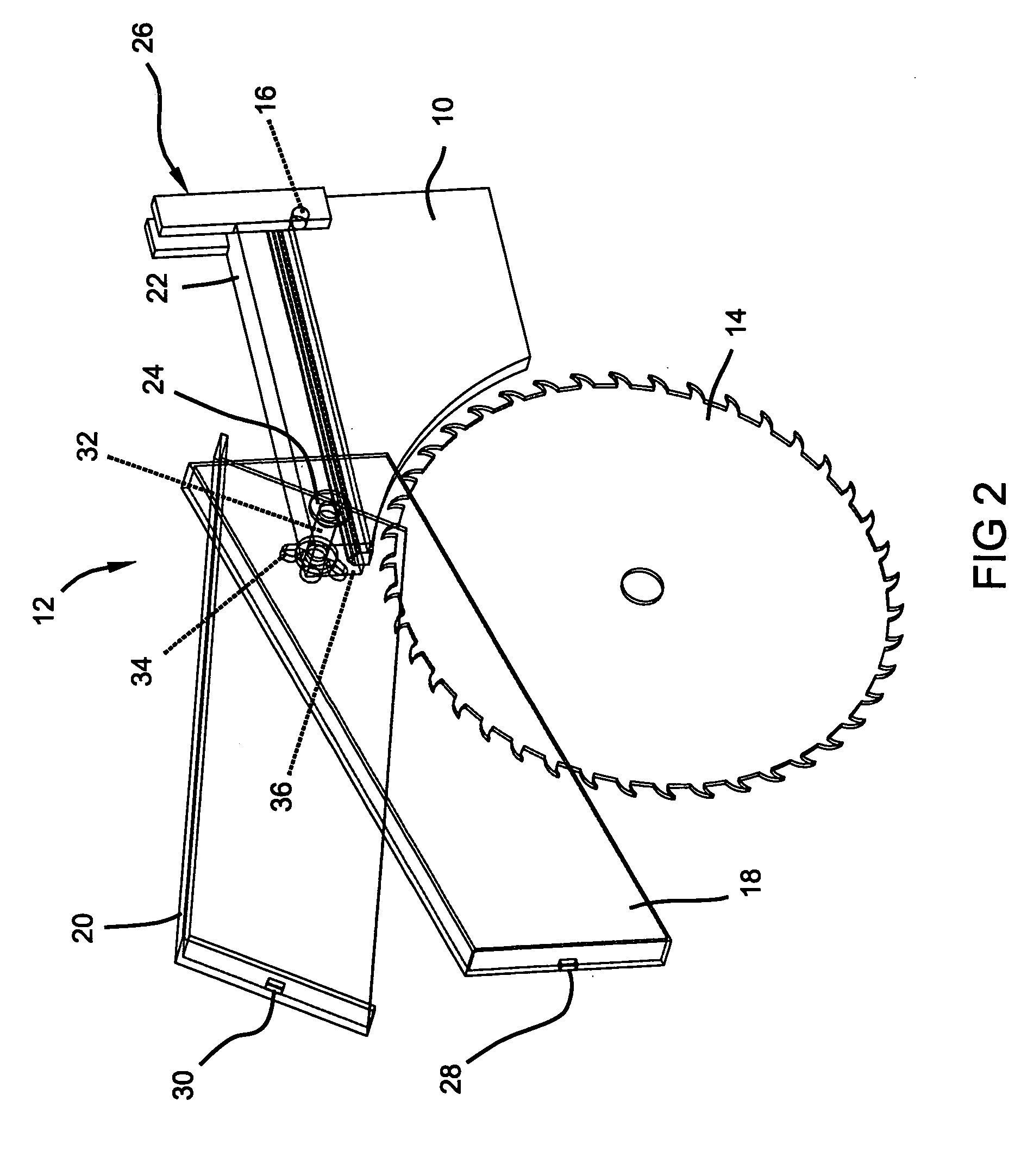

Miter saw with improved safety system

InactiveUS6945148B2Increase opportunitiesLimit and even prevent injuryOther plywood/veneer working apparatusMechanically actuated brakesEngineeringMechanical engineering

A miter saw is disclosed having a base, a blade supported by the base, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating, to create an impulse against movement of the blade into the cutting zone, or to cause the blade to move away from the cutting zone.

Owner:SAWSTOP HLDG LLC

Miter saw with improved safety system

InactiveUS6877410B2Increase opportunitiesLimit and even prevent injuryOther plywood/veneer working apparatusMetal sawing devicesMechanical engineeringReaction system

A miter saw is disclosed having a base, a blade supported by the base, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating, to create an impulse against movement of the blade into the cutting zone, or to cause the blade to move away from the cutting zone.

Owner:SAWSTOP HLDG LLC

Safety systems for power equipment

A saw with a safety system is disclosed. The safety system includes a detection system adapted to detect contact between a person and a blade while the blade is moving. The safety system further includes a brake system adapted to engage the blade and to stop the blade when the detection system detects contact between the person and the blade.

Owner:SAWSTOP HLDG LLC

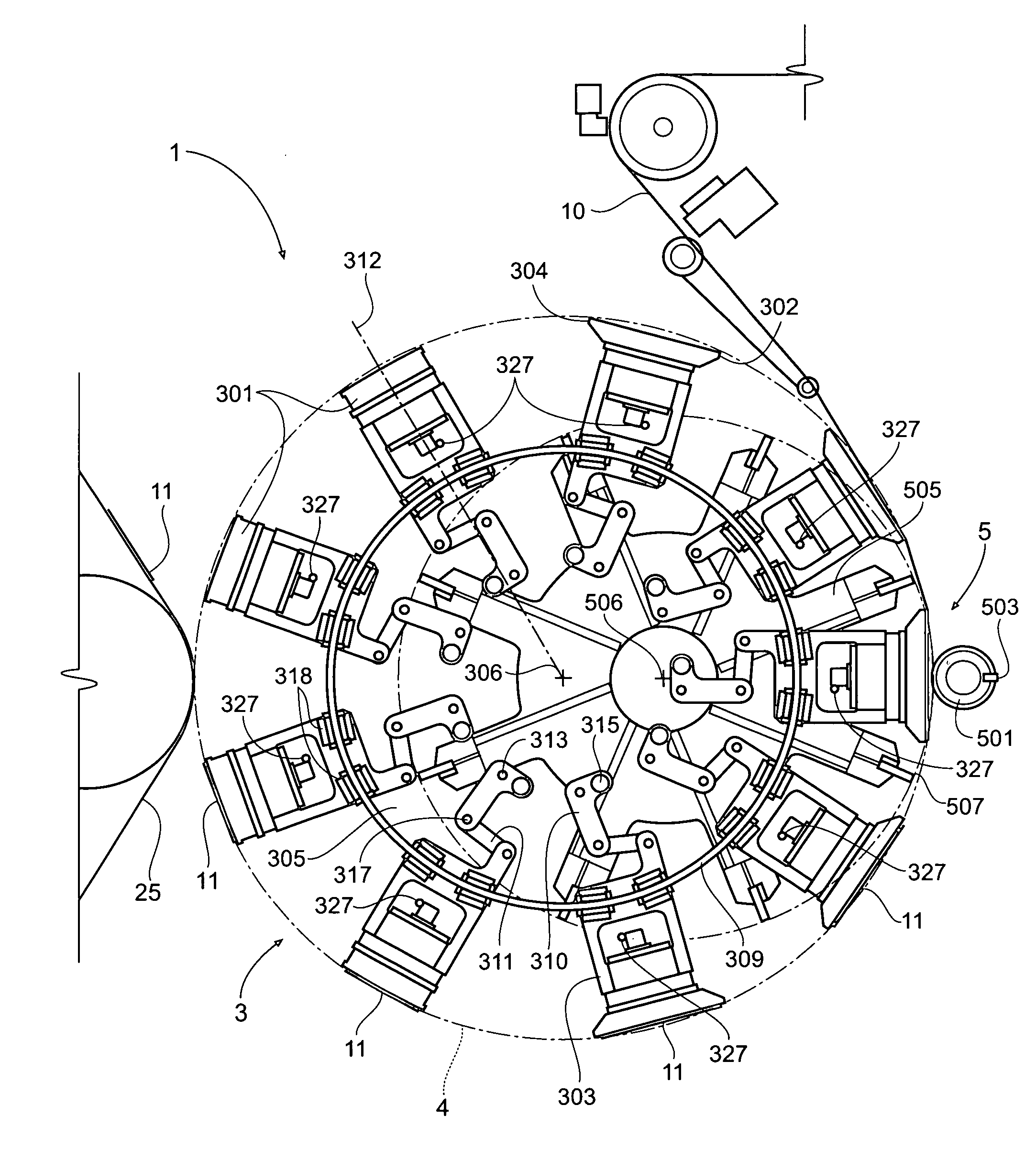

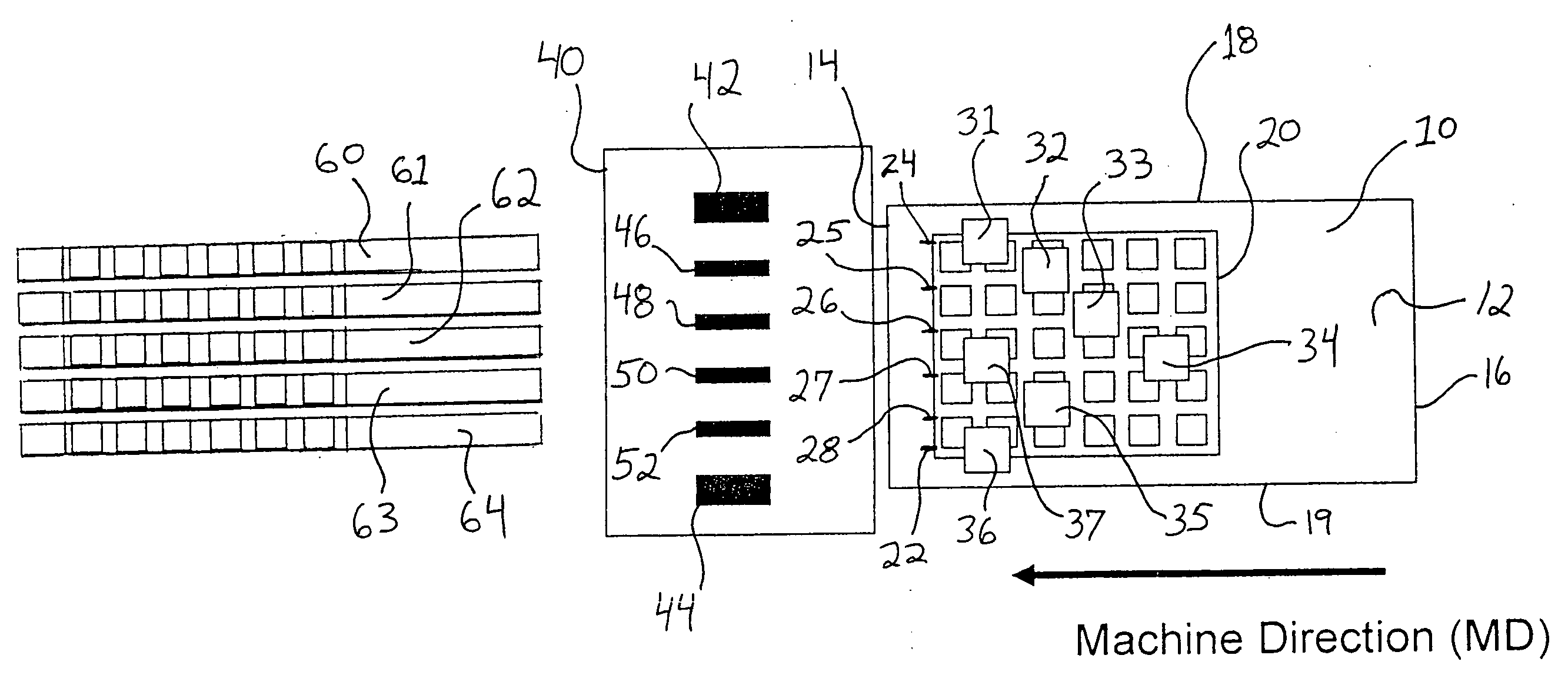

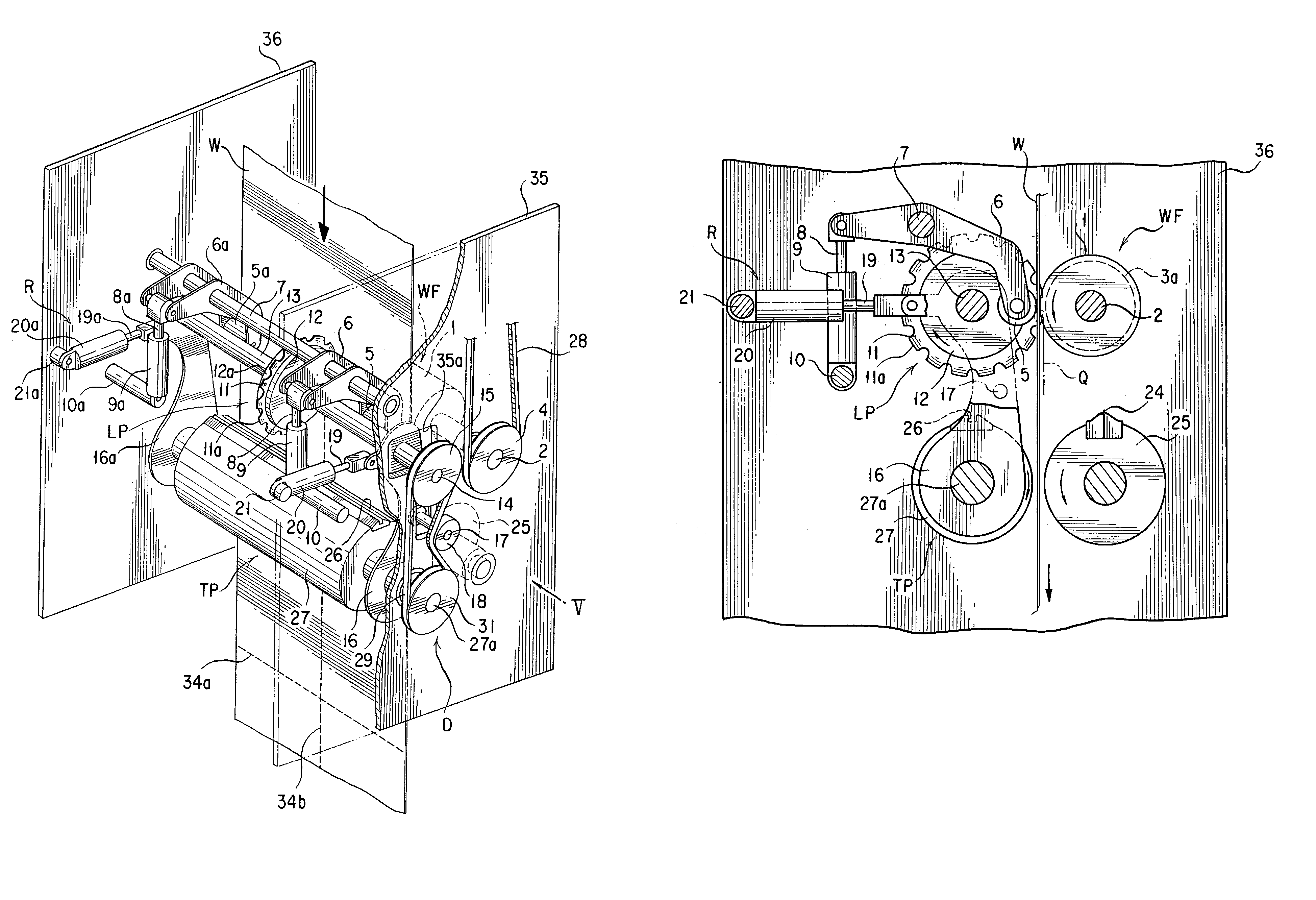

Single transfer insert placement method and apparatus

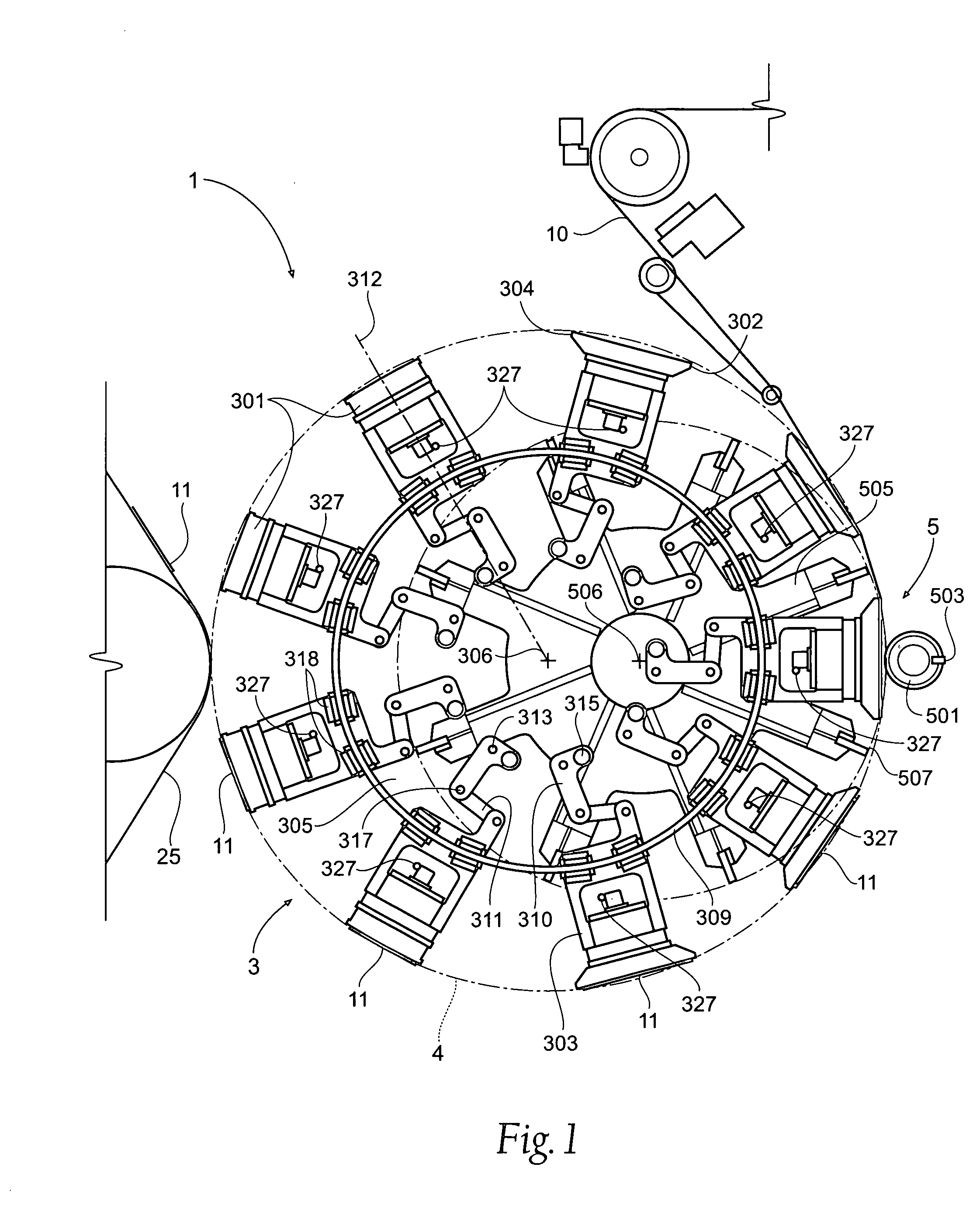

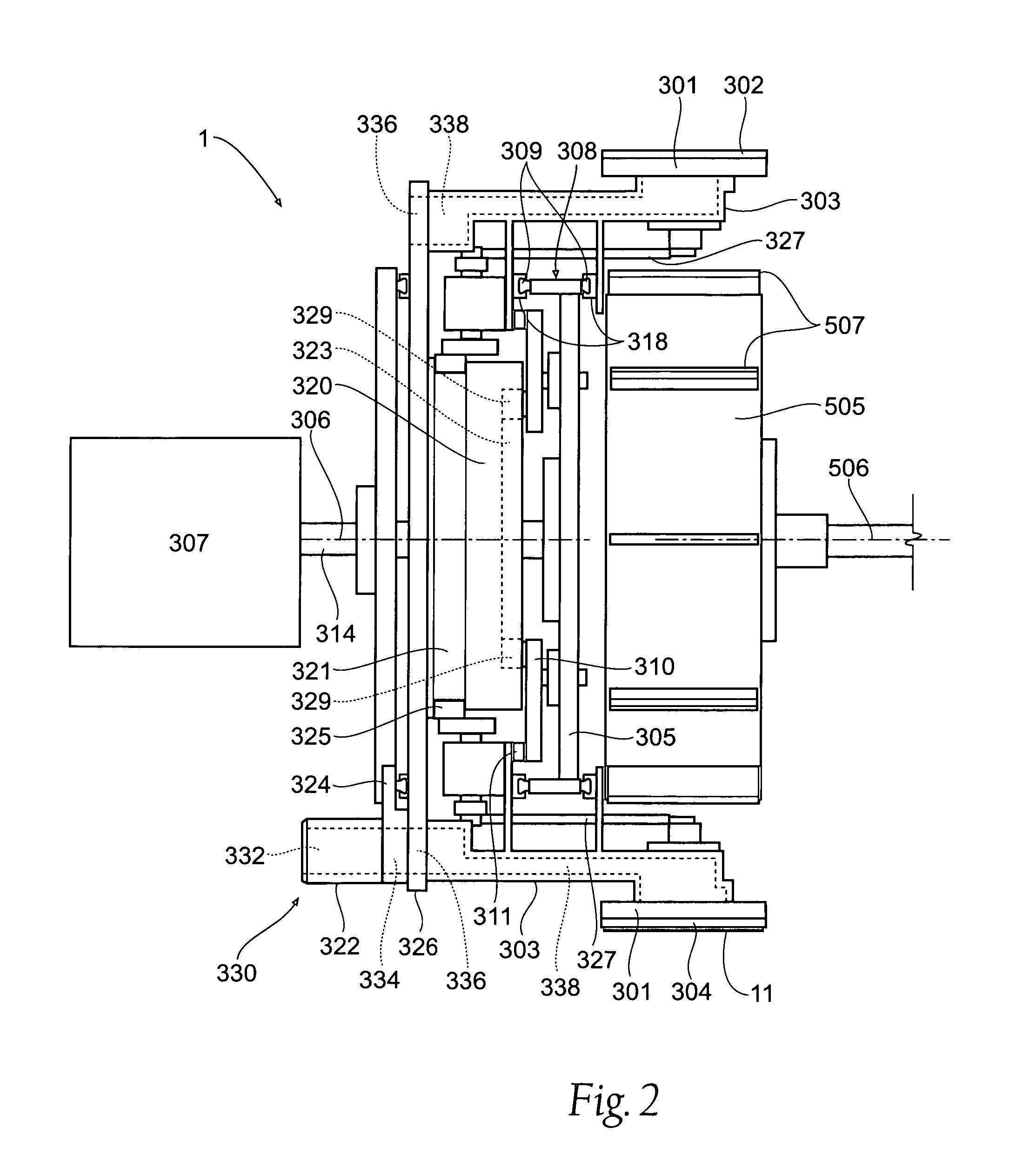

ActiveUS20080196564A1Cam-followersWrapper folding/bending apparatusMechanical engineeringPlacement method

Owner:CURT G JOA

Detection system for power equipment

Woodworking machines including conductive cutters adapted to cut workpieces, and motors adapted to drive the cutters are disclosed. The machines also include a contact detection system adapted to detect contact between a person and the cutter, and to distinguish contact between the person and the cutter from contact between the workpiece and the cutter. The machines further include a reaction system adapted to cause a predetermined action to take place upon detection of contact between the person and the cutter by the contact detection system.

Owner:SAWSTOP HLDG LLC

Mountings for riving knives of table saws

ActiveUS20050211034A1Easy to implementEasy to operateMetal sawing devicesGuide fencesSingle plateEngineering

A device for mounting a cover of a cutting blade to a riving knife may have an engaging member for releasably engaging at least a part of the riving knife from both sides, in a direction of thickness of the riving knife. The engaging member is manually operable without any additional tools. A device for mounting a riving knife to a table saw may include a manually operable lock member and a biasing member. The biasing member is arranged and constructed to normally bias the lock member towards a lock position. The riving knife may be divided into a first knife portion and a second knife portion. A positioning device may position the first knife portion and the second knife portion substantially within a single plate.

Owner:MAKITA CORP

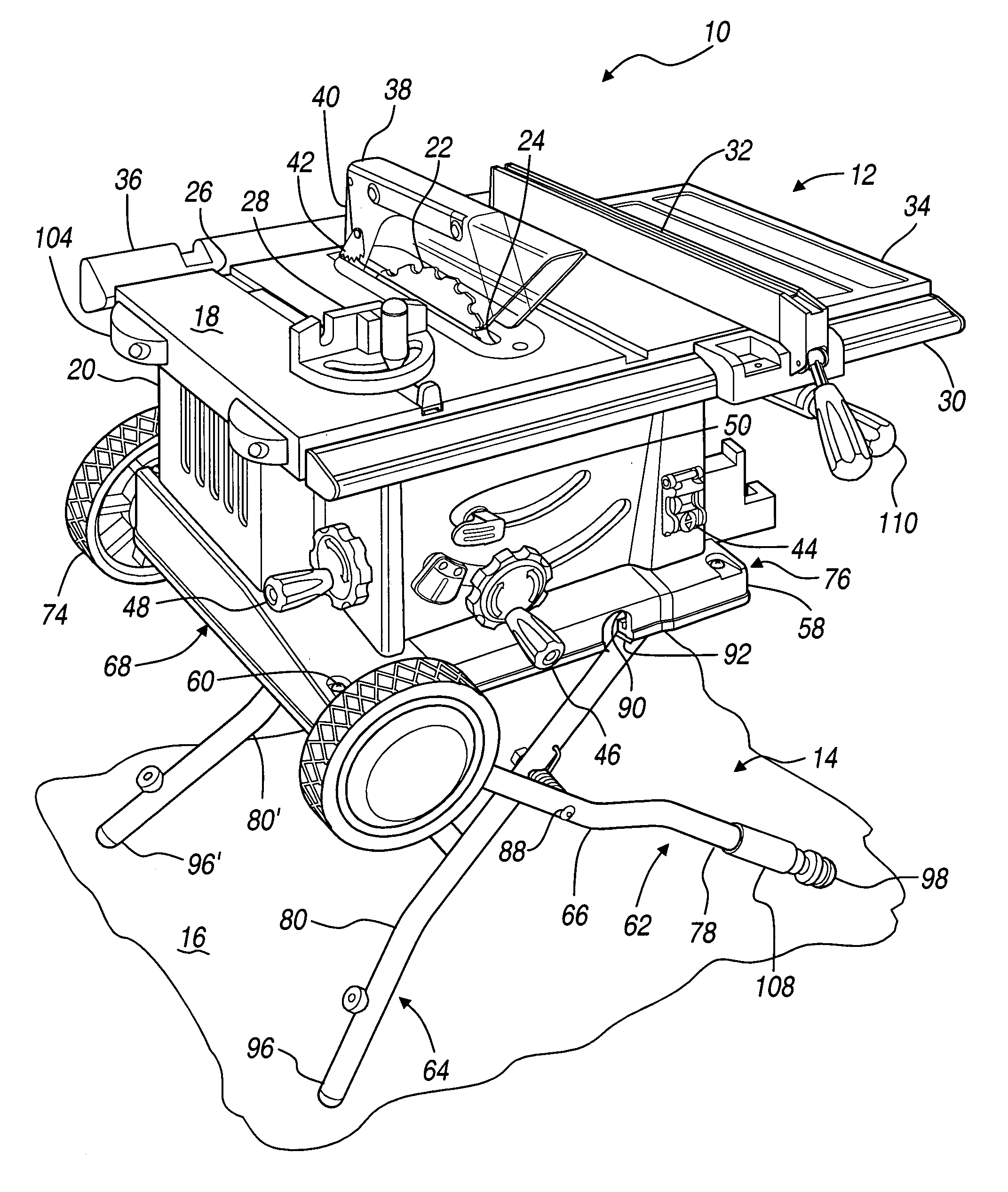

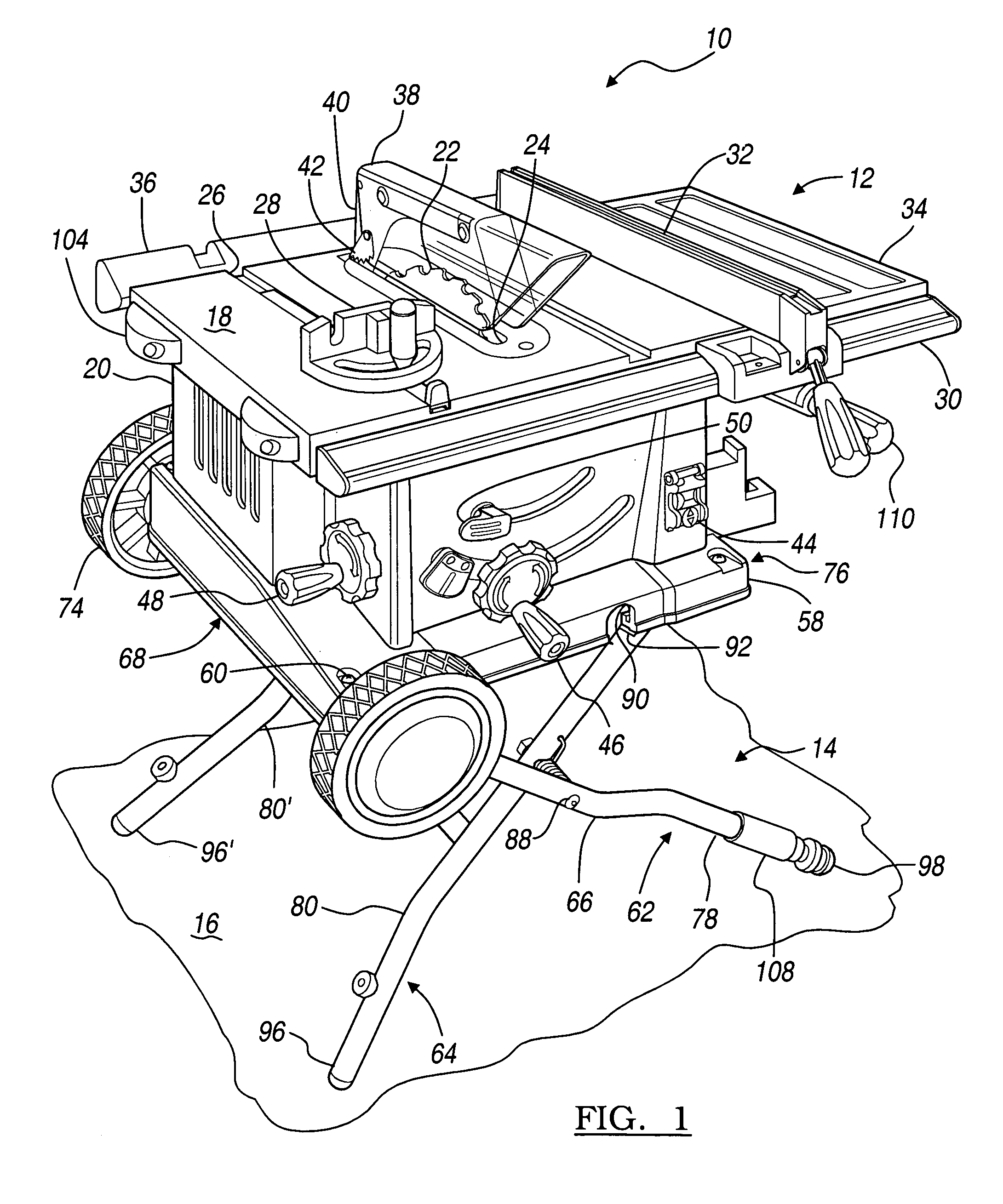

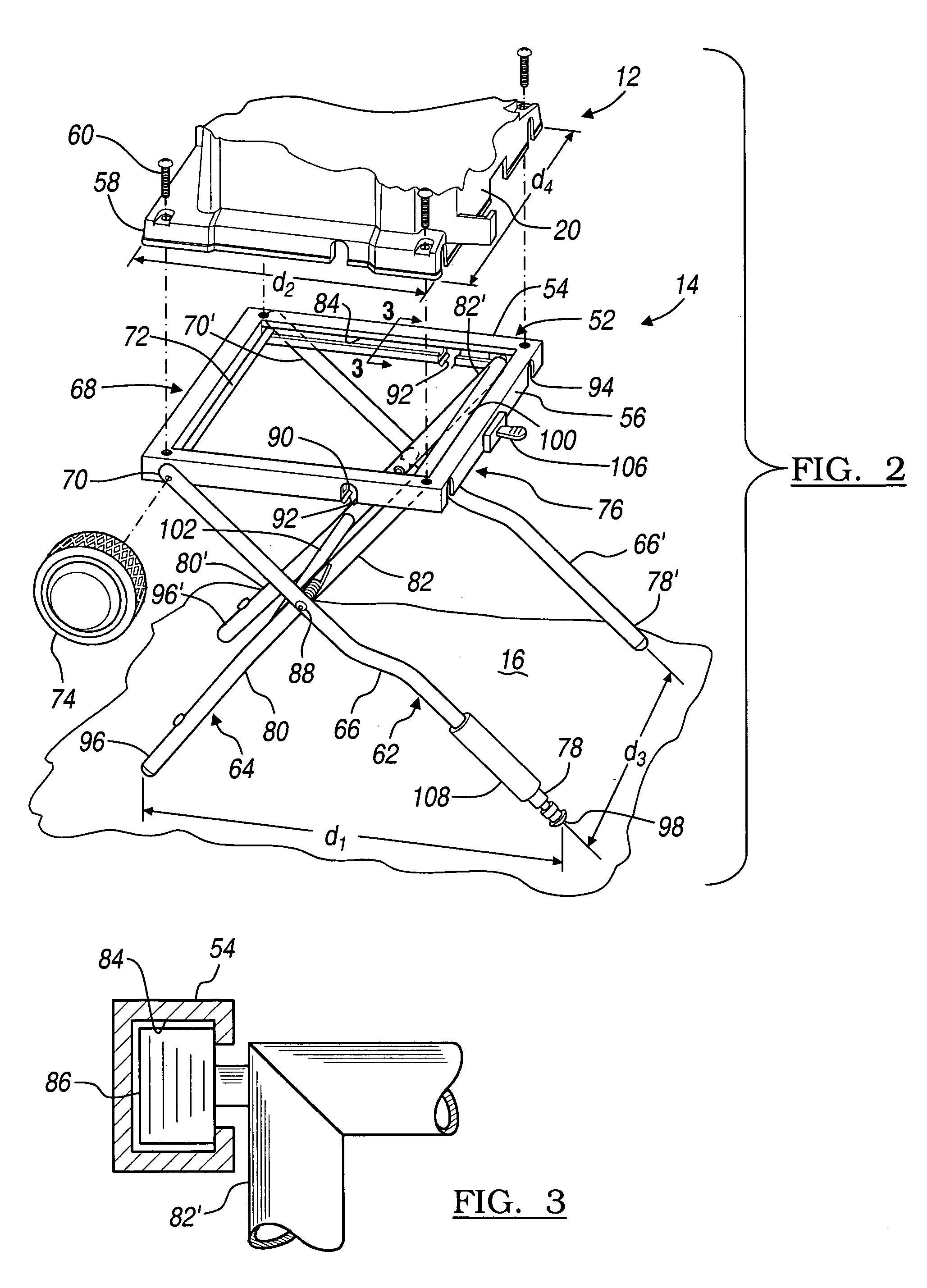

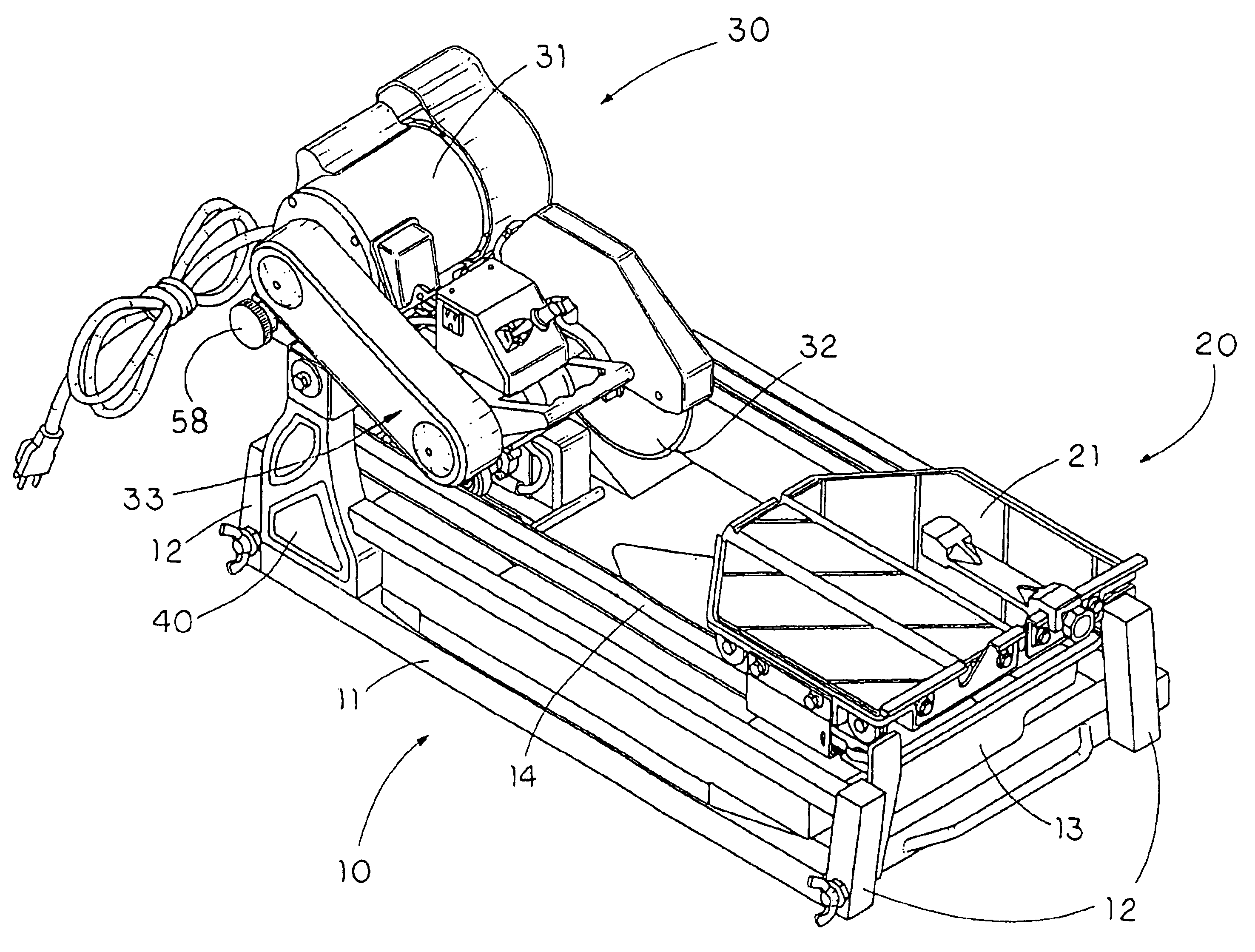

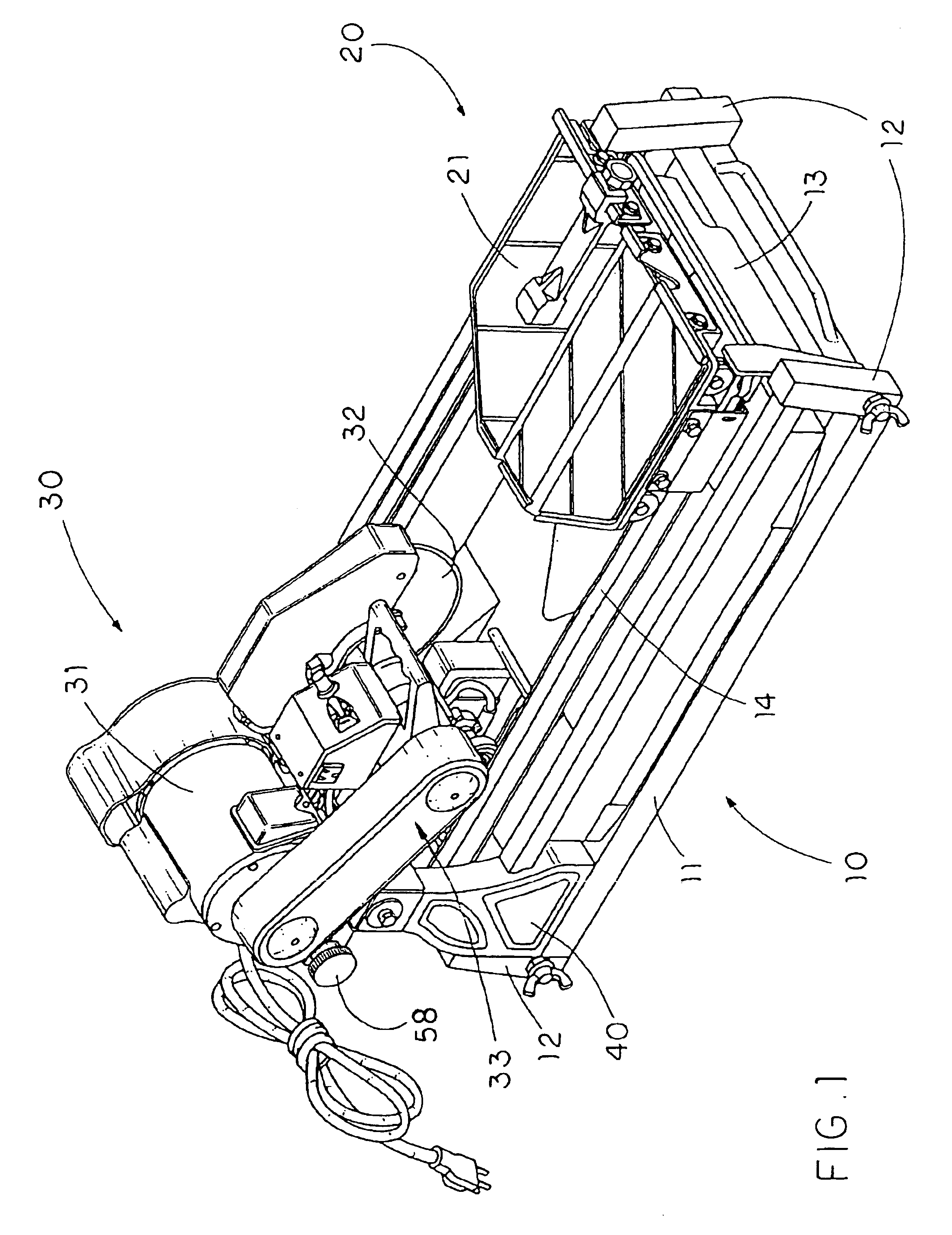

Collapsible stand for a bench-top power tool

InactiveUS6942229B2Facilitating sliding engagementUnderstructuresShearing machinesLocking mechanismPower tool

The present invention discloses a collapsible stand for a bench-top power tool and methods therefore. The stand includes a structural member pivotally secured to a lower peripheral region of a base of a power tool. A slidable member is slidably and pivotally connected to the lower peripheral region and is pivotally connected to the pivotal structural member. Lower distal ends of both the pivotal and slidable structural members provide feet for supporting the associated power tool in an expanded orientation thereof. As the stand is collapsed, a top end of the slidable structural member slides towards a top end of the pivotal structural member. Both structural members may be pivoted to an orientation generally parallel with the lower peripheral region and may be locked thereto by a locking mechanism. A pair of wheels are rotatably connected to the base for transporting the stand and power tool thereupon.

Owner:ONE WORLD TECH

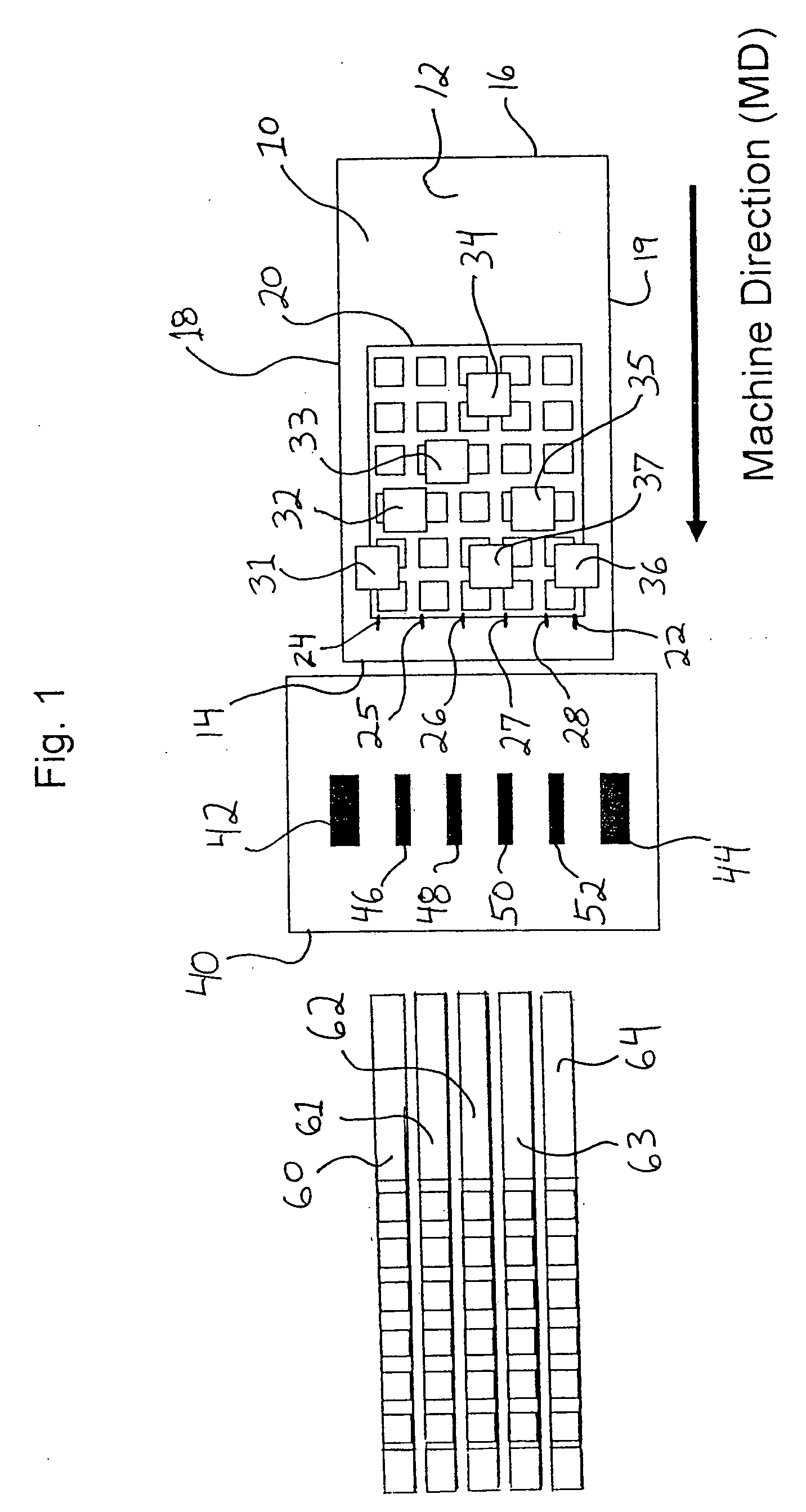

Process and system for sub-dividing a laminated flooring substrate

ActiveUS20070209736A1Good for healthAvoid mistakesMulti-purpose machinesAdjusting equipmentEngineeringControl unit

A process for sub-dividing a laminated flooring substrate into a plurality of laminated flooring planks and a system therefore are described. The process can include providing a laminated flooring substrate having a decorative pattern on a core wherein the decorative pattern can include a plurality of indicators, and independently detecting the indicators with a plurality of detecting devices, each assigned a respective indicator. The detecting devices can individually obtain the position of the detected indicators and a control unit can align a separate saw blade per each position detected. The system includes a cutting unit with individually adjustable saws or an alignment device configured to align the laminated flooring substrate with the saws, to cut the laminated flooring substrate along positions relative to the detected indicators, for example, in the center thereof or off-set therefrom.

Owner:MANNINGTON MILLS

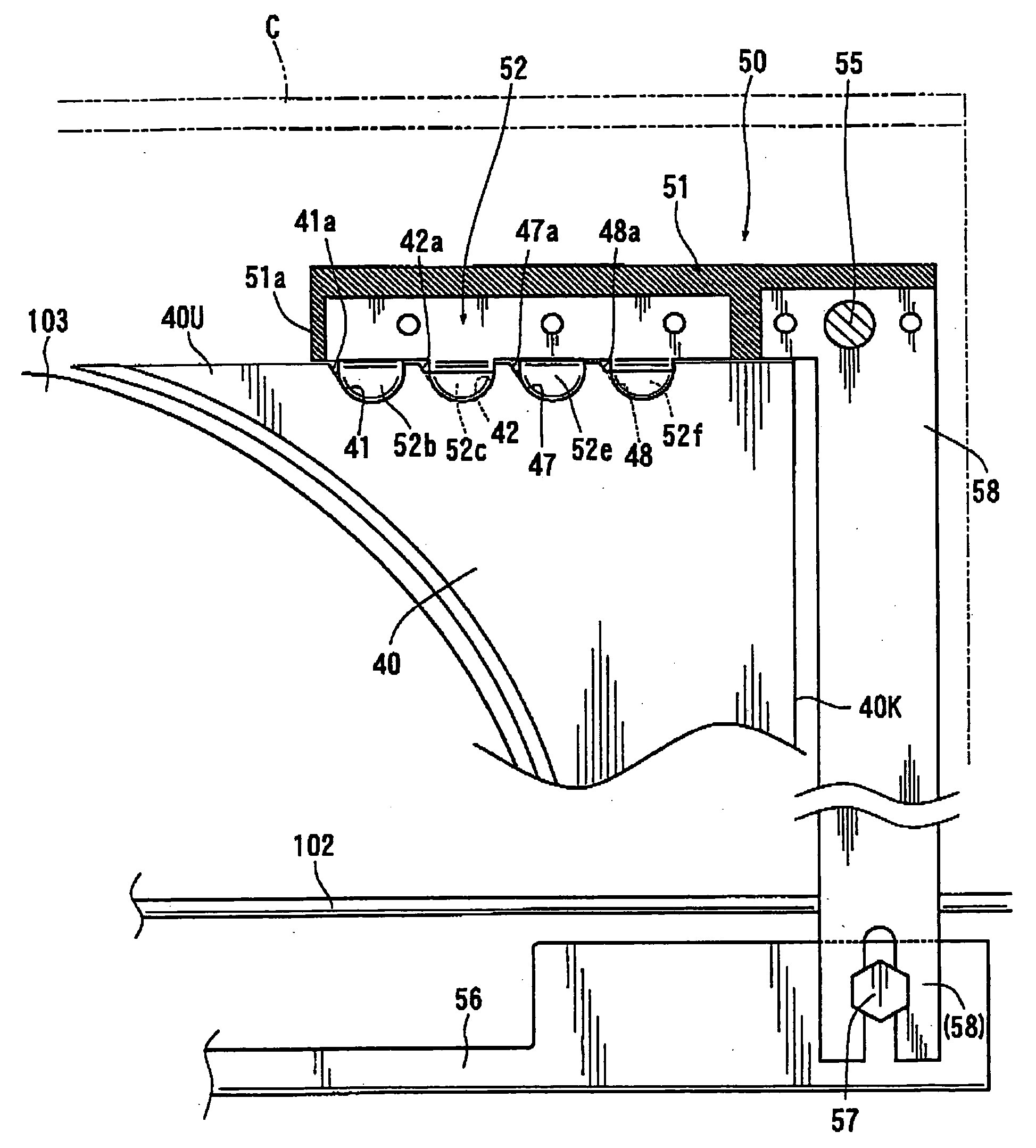

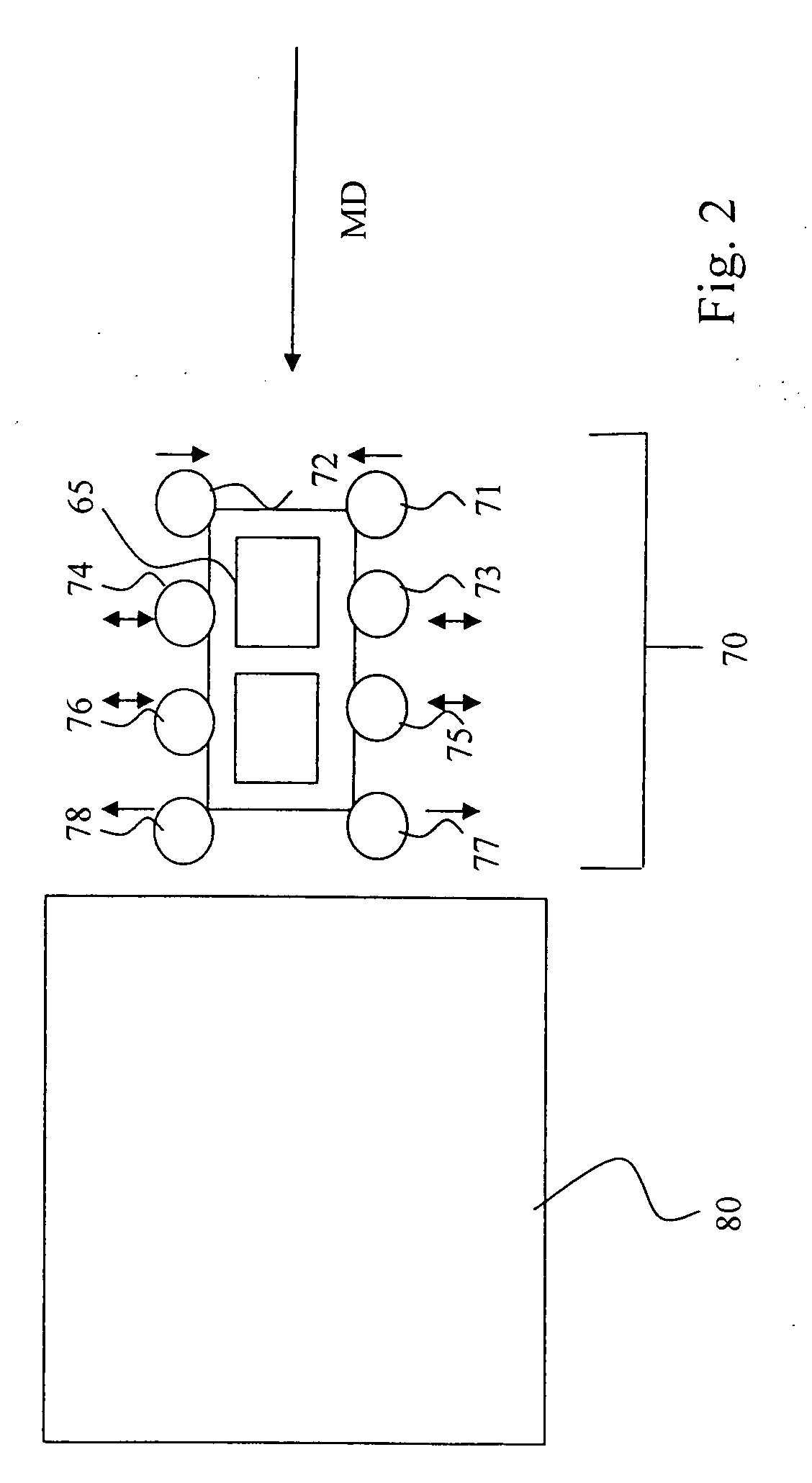

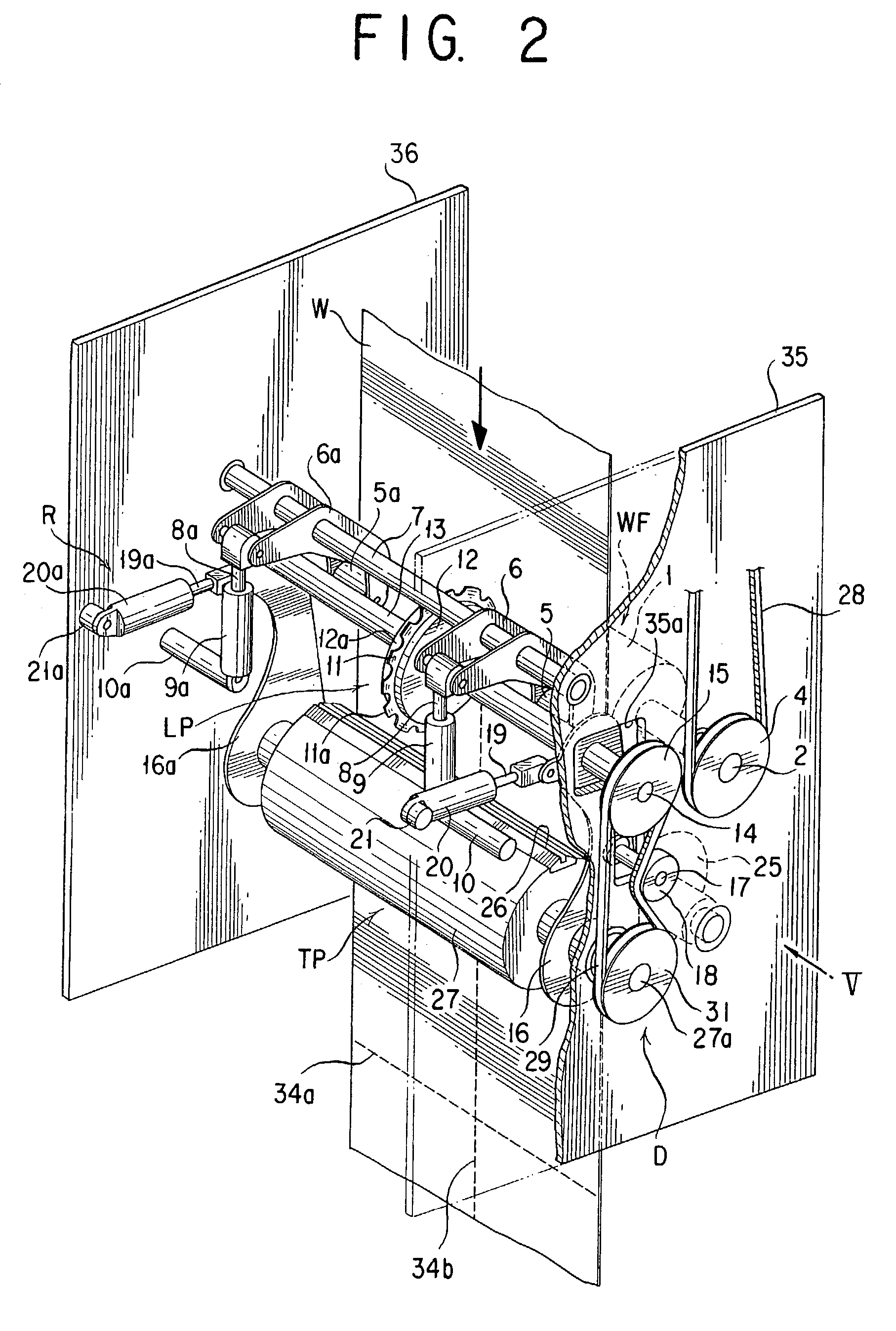

Apparatus for longitudinally perforating a web of paper in a rotary printing press

A rotary printing press has a folding station where the printed web is perforated both transversely and longitudinally in order to expedite subsequent folding thereof into signatures. In order to incorporate a longitudinal perforator into the folding station without adding to its size, a longitudinally perforating blade similar to a circular saw is mounted to a blade carrier shaft which is rotatably supported opposite a feed roller by which the web is frictionally fed into and through the folding station. An annular, longitudinally grooved anvil is formed circumferentially on the feed roller for engaging the longitudinally perforating blade via the web being thereby perforated. The longitudinally perforating blade is movable with the blade carrier shaft into and out of perforating engagement with the anvil on the feed roller.

Owner:TOKYO KIKAI SEISAKUCHI LTD

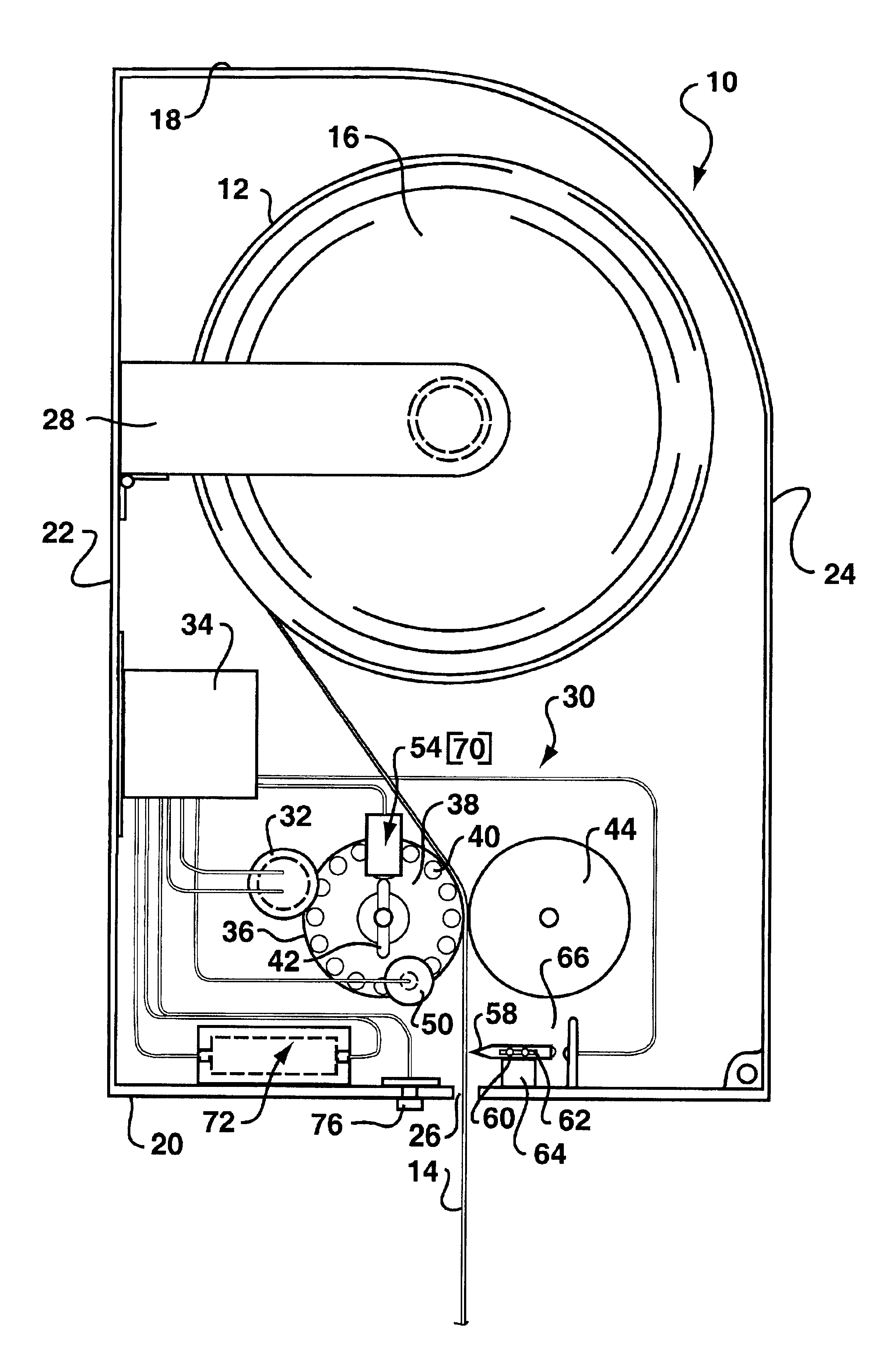

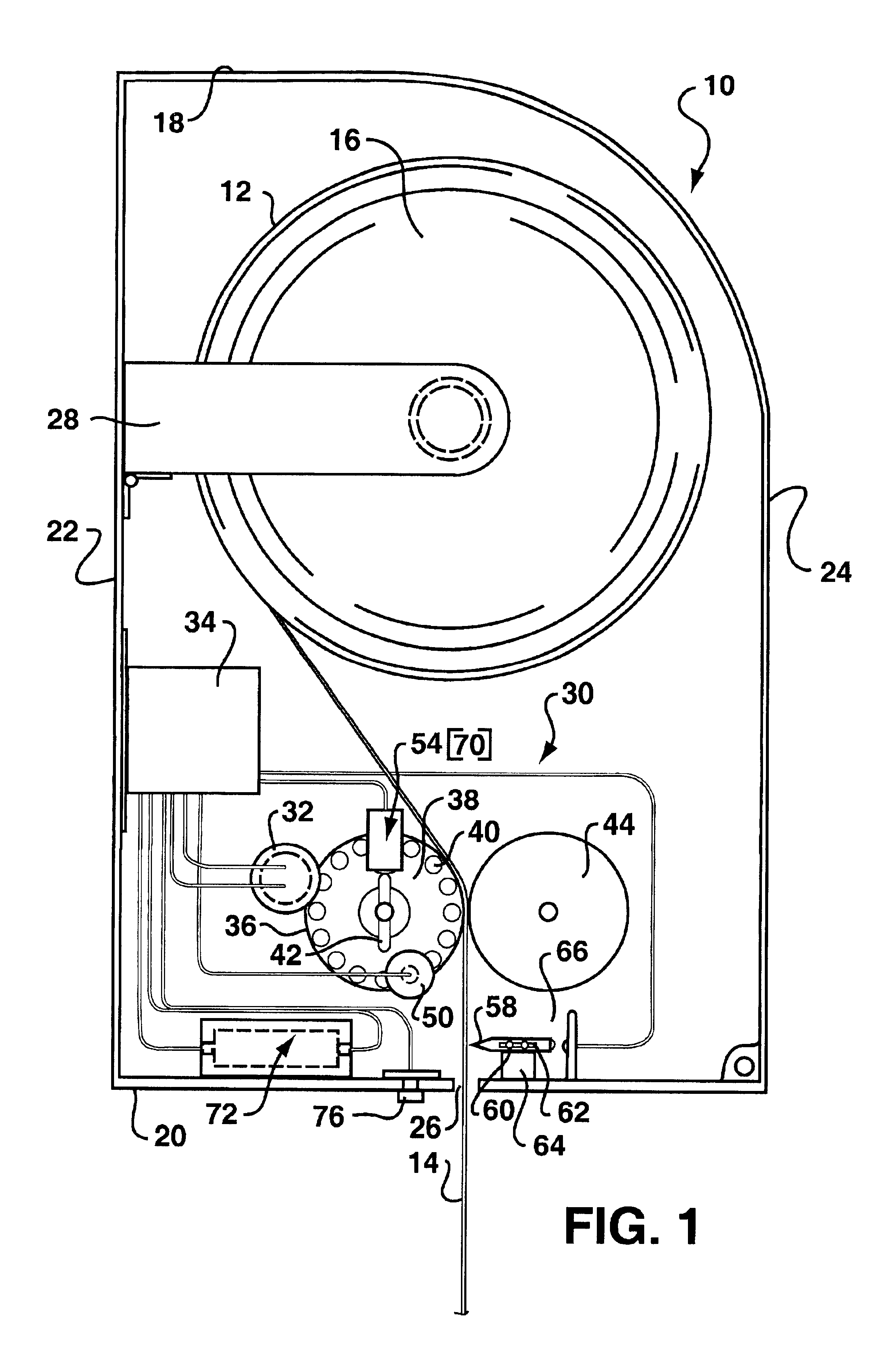

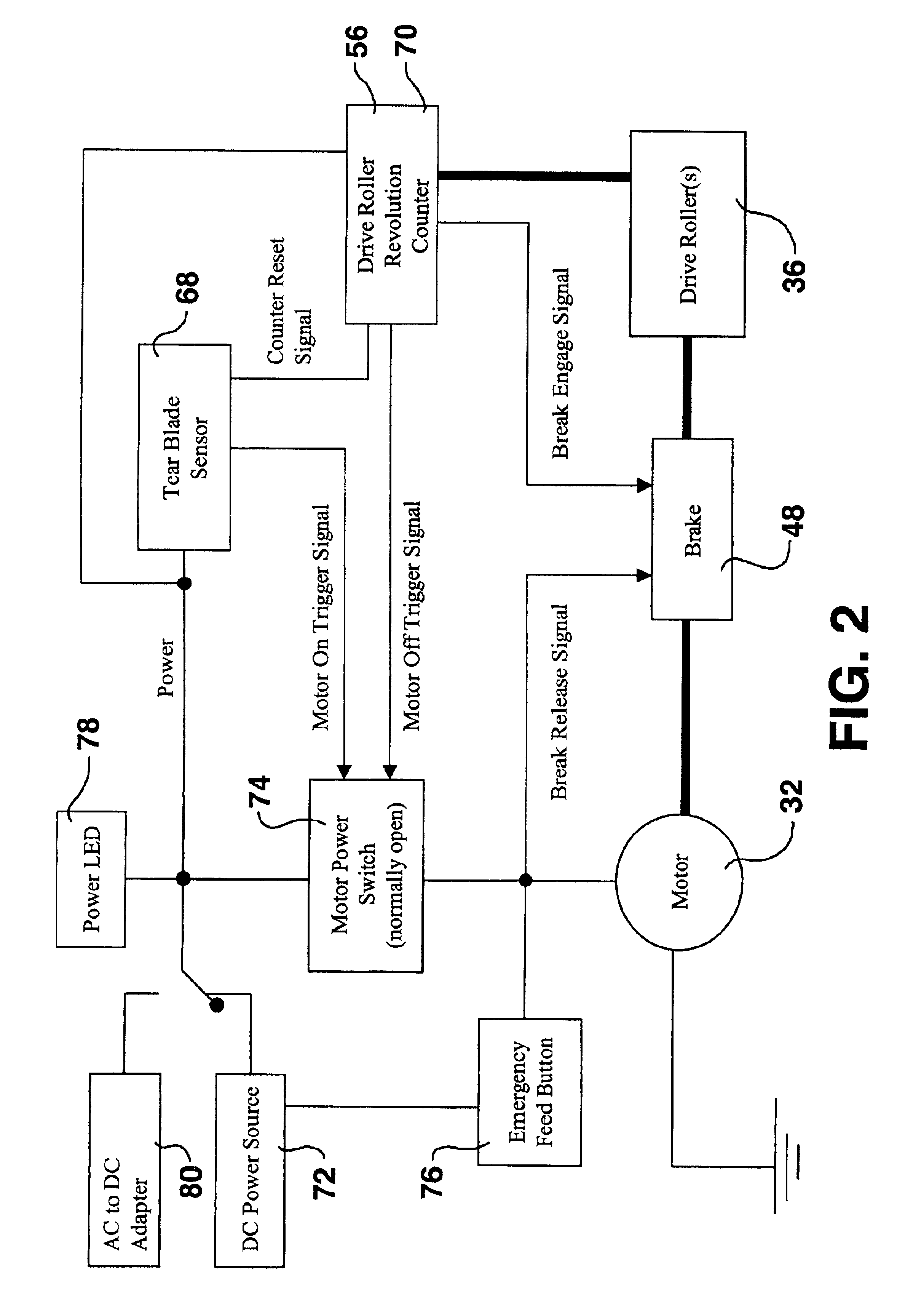

Electro-mechanical roll product dispenser

InactiveUS6892620B2Prevent further rotationFilament handlingGripping devicesFacial tissuePaper sheet

An electro-mechanical roll towel dispenser includes a housing with a roll carrier disposed therein to rotationally support a roll of towel material. An electro-mechanical feed mechanism is disposed in the housing to dispense measured sheets of the towel material. The feed mechanism operates in a first mechanical operational mode wherein the towel sheets are dispensed by a user grasping and pulling on a tail of the towel material extending from the housing, and a second electrical operational mode wherein a measured length of a next sheet is automatically and electrically fed out of the housing to define the tail for the next user.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Cutting machine with built-in miter cutting feature

A miter cutting arrangement for a cutting machine is provided to accommodate cutting work at an angle or a bevel for precisely cutting on a work piece. It includes a platform support arm longitudinally mounting to a cutting head support bracket, a platform pivot arm transversely extended from the platform support arm, a head platform pivotally connected with the platform pivot arm to support a motor, a miter supporting unit, and a locker device for selectively locking the cutting head at the normal position and the slanted position. The miter supporting unit includes a miter support provided at an outer side of the head platform and a miter stopper provided at an outer end of the platform pivot arm to block the miter support when the head platform is rotated at the slanted position.

Owner:LEE WY PERON

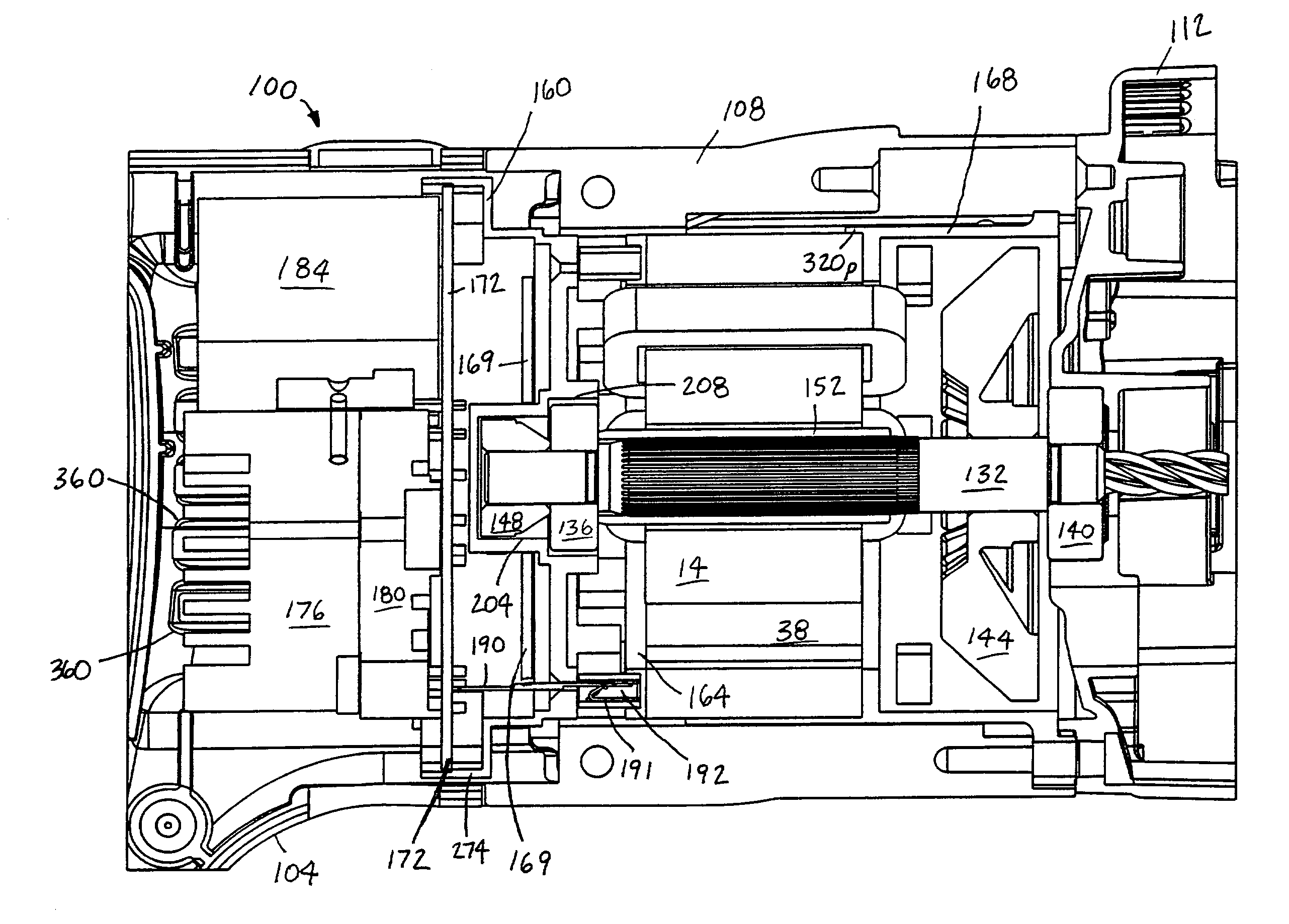

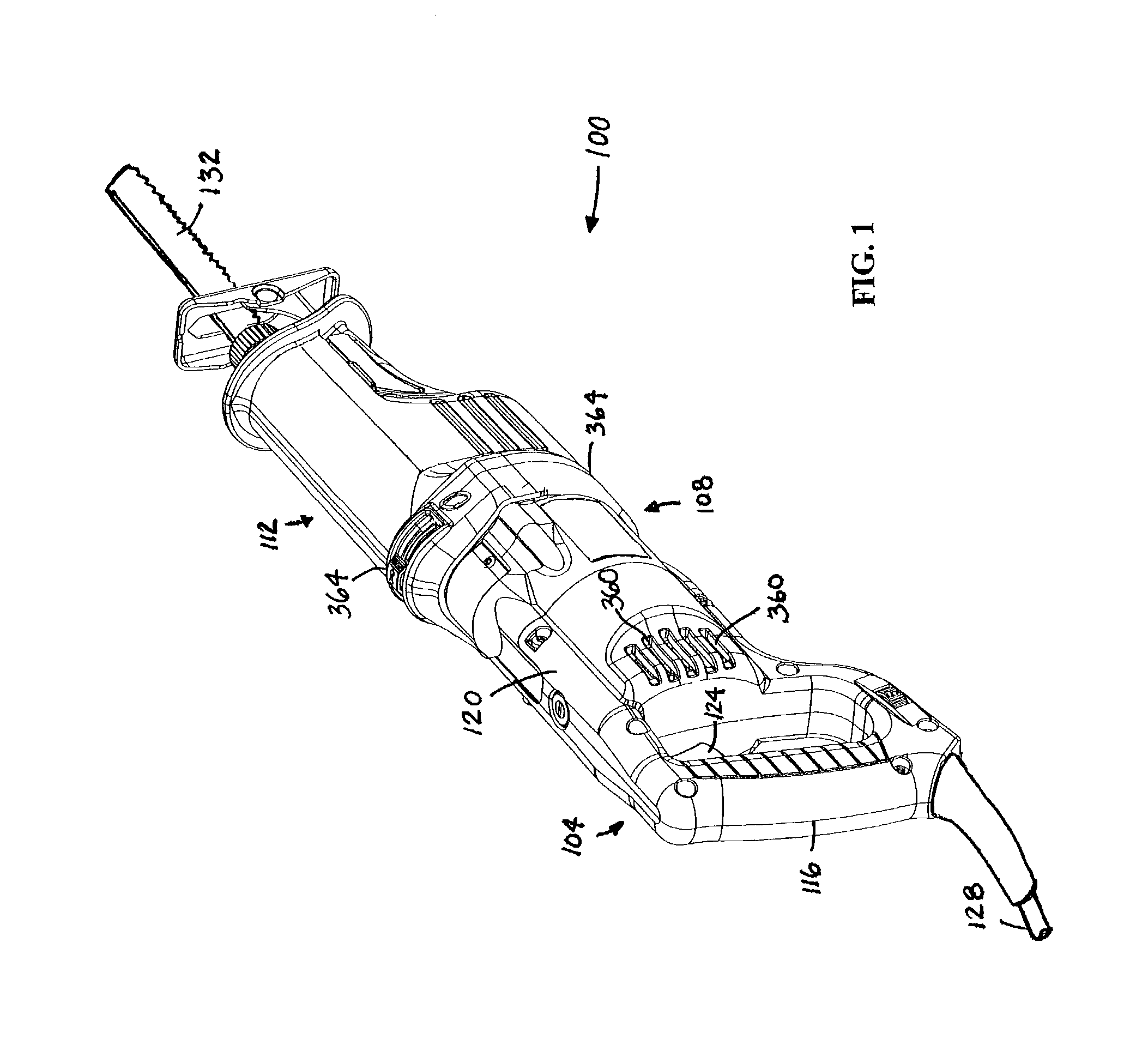

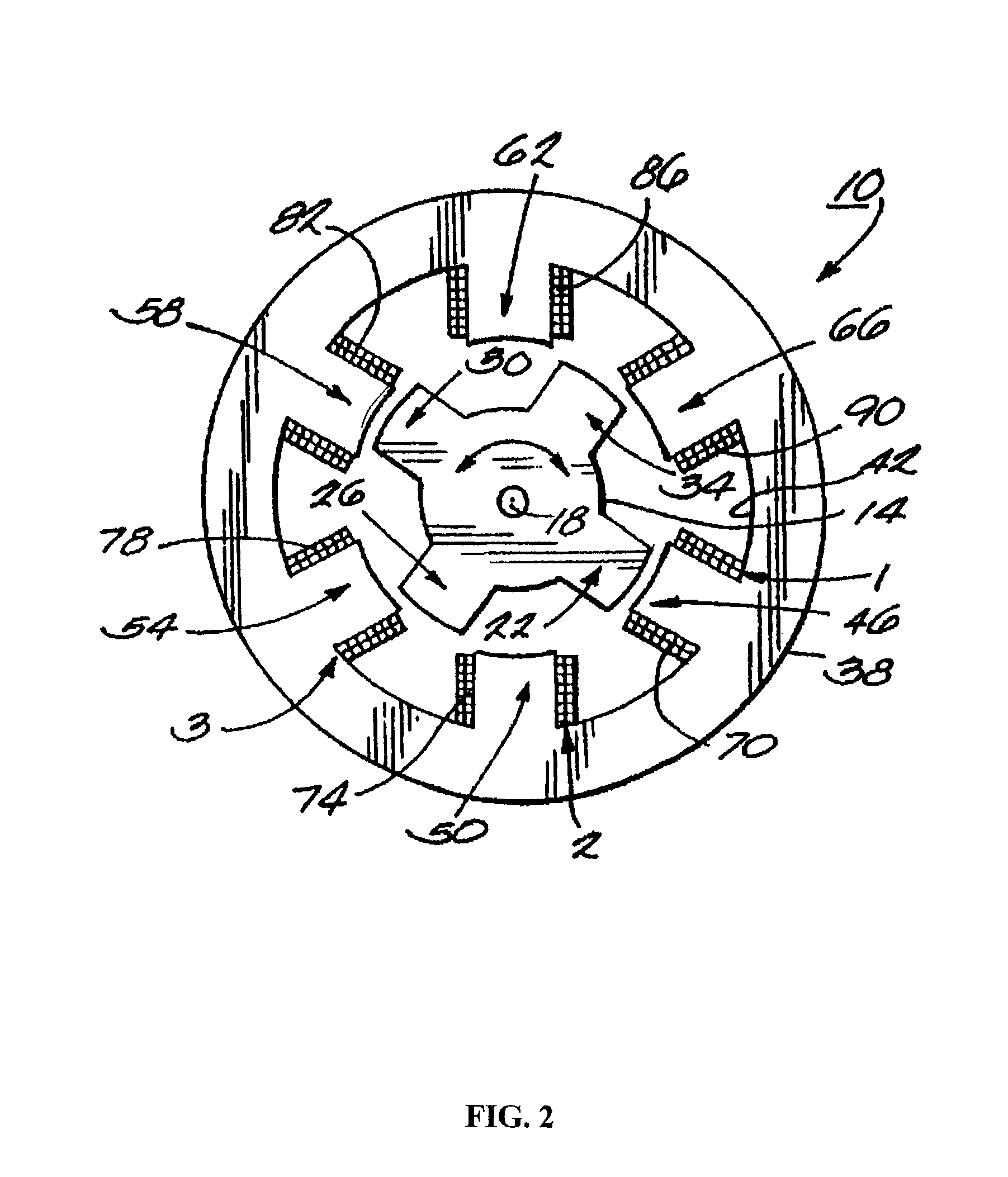

Power tools with switched reluctance motor

InactiveUS7064462B2Reduce Tolerance StackupImprove cooling effectAC motor controlWindingsHand heldMotor control

A method of assembling a power tool, a power tool, a method of assembling an electrical device, and an electrical device includes a switched reluctance motor. The electrical device is preferably a hand-held power tool, however, any type of electrical device that includes a switched reluctance motor may benefit from any number of aspects of the invention. In one independent aspect, the invention provides a construction that reduces tolerance stack-up. In another independent aspect, the invention provides a self-contained electronics package that plugs into a switched reluctance motor to provide control operation of the switched reluctance motor. In another independent aspect, the invention provides enhanced cooling that increases the efficiency of the electrical device using a switched reluctance motor. In another independent aspect, the invention provides an encapsulated magnet that allows for contaminant free motor control over the life of the SR motor. In another independent aspect, the invention provides an apparatus and a method for aligning magnets of a magnet hub with respect to the rotor poles the magnet poles represent.

Owner:MILWAUKEE ELECTRIC TOOL CORP

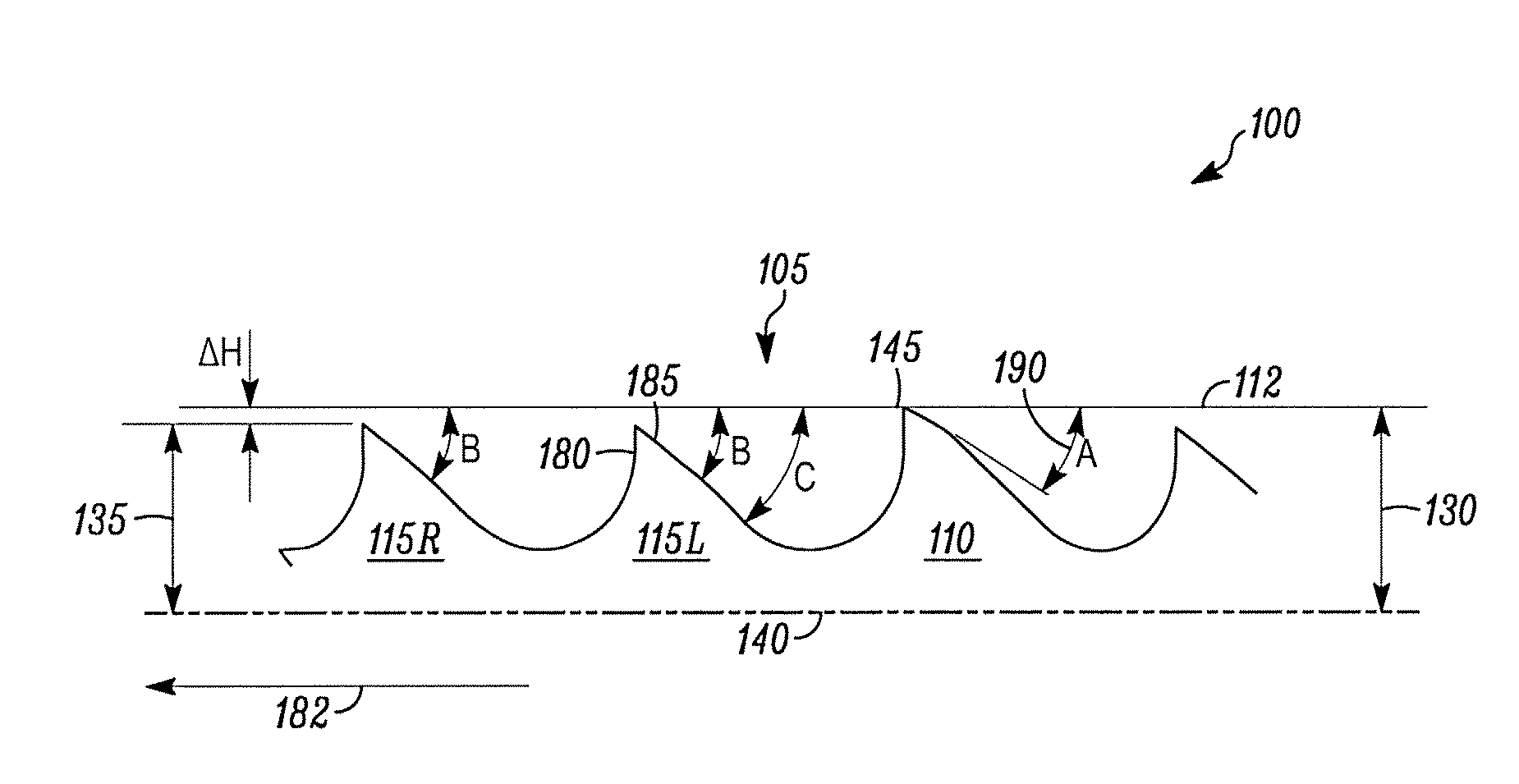

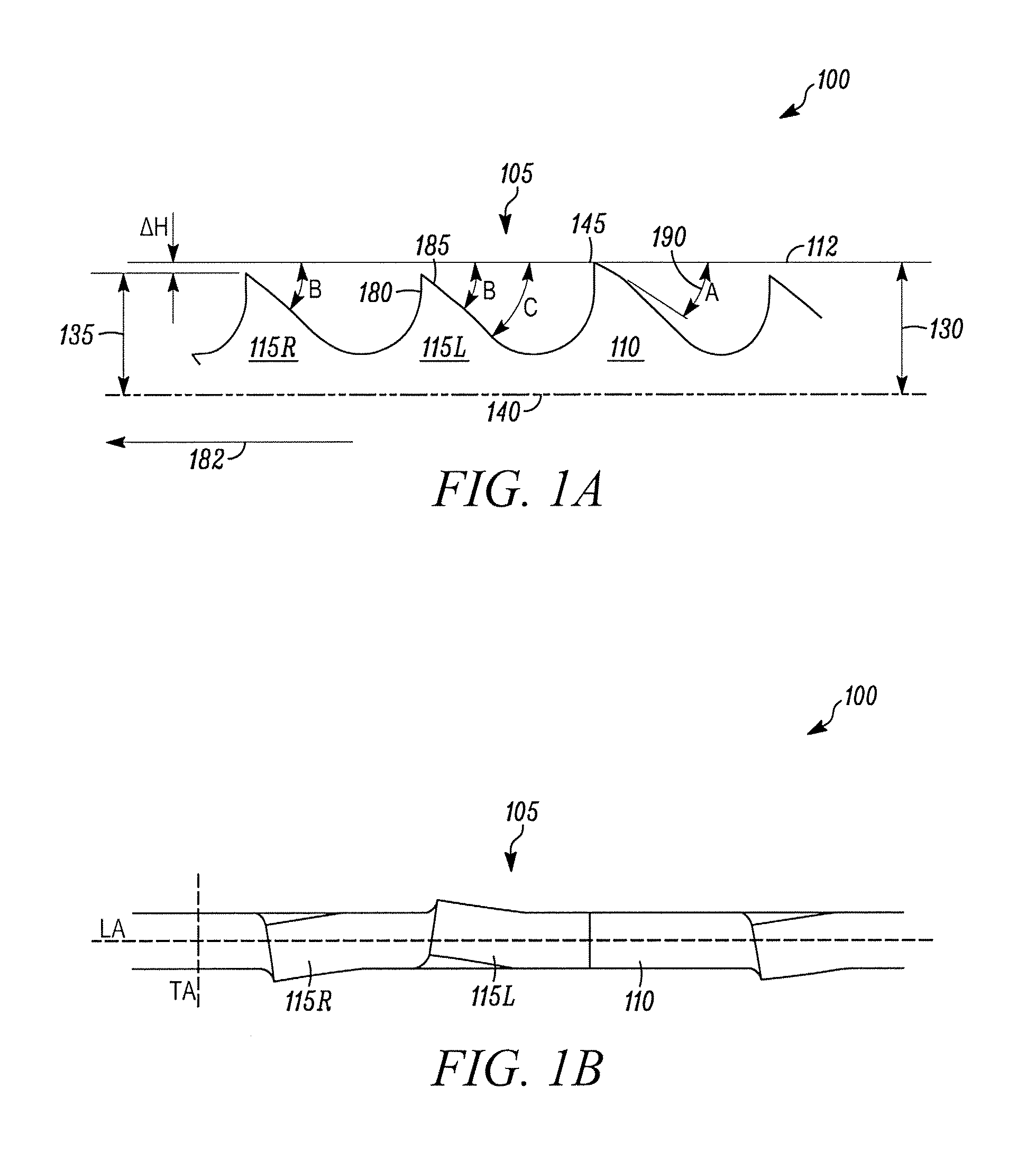

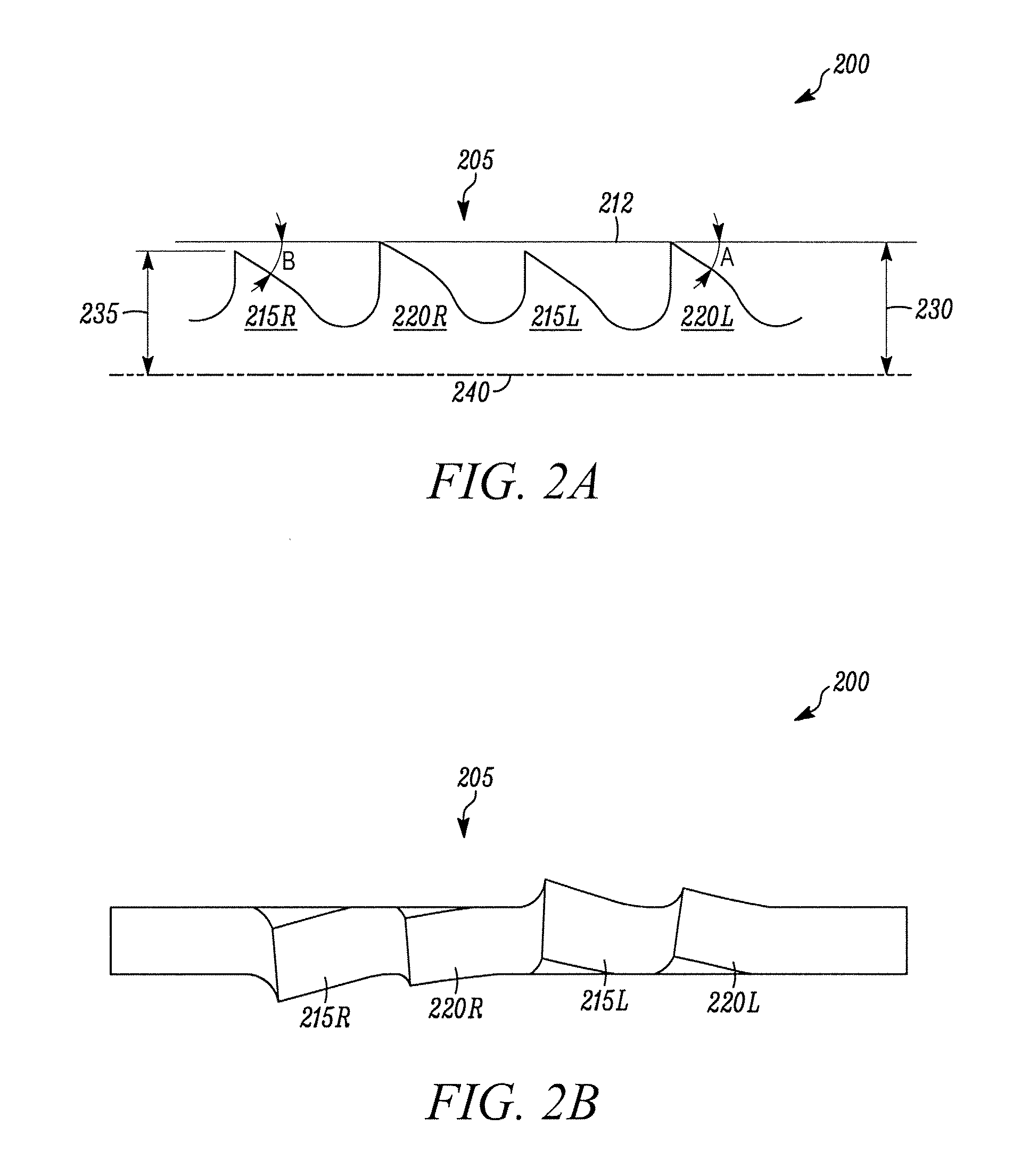

Reciprocating Saw Blade Having Variable-Height Teeth and Related Method

ActiveUS20080307936A1Improve performanceIncrease cutting forceMetal sawing devicesMetal sawing toolsPortable powerEngineering

A reciprocating saw blade, for use in a portable power reciprocating saw including a chuck for releasably engaging the saw blade, includes a tang having an elongated axis and being engageable with the chuck for attaching the saw blade to the reciprocating saw. The saw further includes a blade portion having a cutting edge that defines a plurality of cutting teeth. The cutting teeth define a repeating pattern of successive groups of teeth. Each group of teeth is less than about a half inch in length, and includes a plurality of laterally offset teeth, at least one relatively high first tooth and at least one relatively low second tooth. Prior to tooth set, the at least one relatively high first tooth is at least about 0.002 inch higher than the at least one relatively low second tooth.

Owner:BLACK & DECKER INC

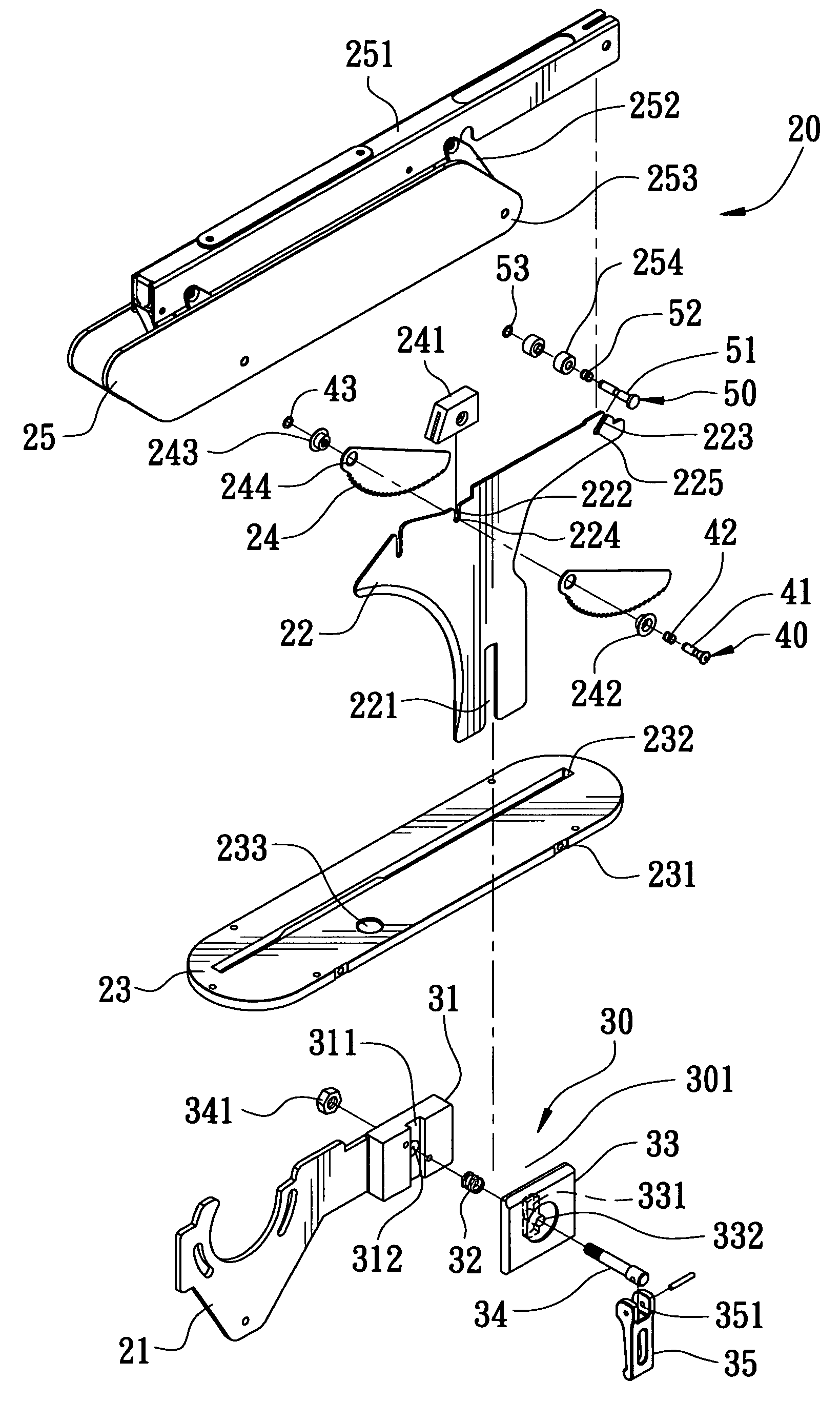

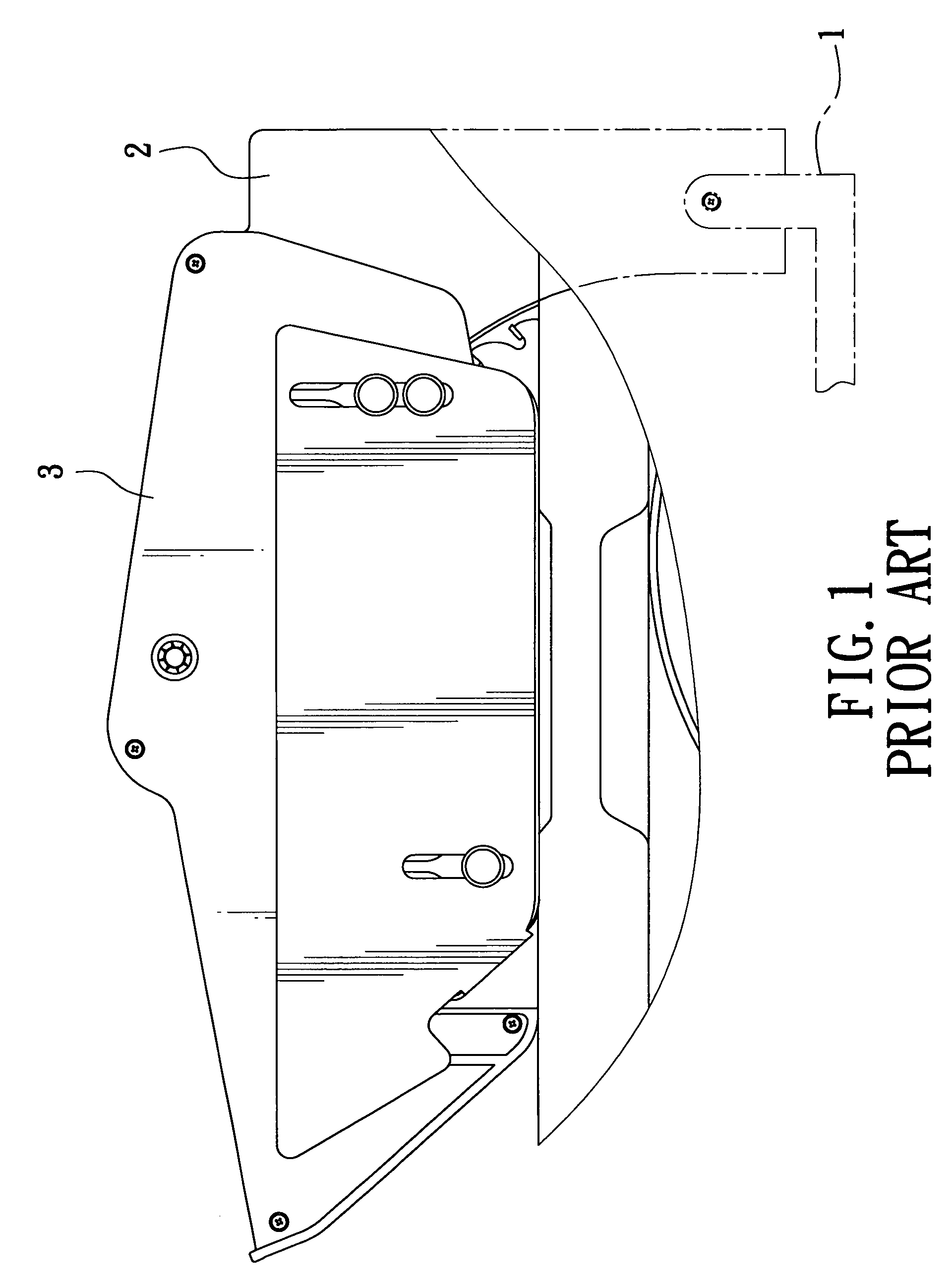

Quickly detachable protective cover unit of a table sawing machine

InactiveUS7210386B1Rapid positioningLess timeMetal sawing devicesGuide fencesEngineeringMechanical engineering

The quickly-detachable protective cover unit of a table sawing machine includes a protective cover, a non-return plate, a protective plate, a combining plate and an extending plate. The extending plate positioned at one side of the saw blade of a table sawing machine has its inner end fixed with a quickly-detachable handle unit for positioning the combining plate thereon. The protective plate is inserted through the saw blade and the combining plate, positioned on the table-sawing machine. The non-return plate and the protective cover are respectively provided with a quickly detachable device to fit in the positioning hole of the combining plate. The components of the quickly detachable protective cover unit are combined by quickly detachable mechanism so they can be disassembled or assembled quickly, needing no tool for carrying out disassembling work.

Owner:KINGSAND MACHINERY

Table saw guard

A table saw guard assembly for guarding a blade on a table saw is provided. The table saw guard assembly includes a support structure and a hood assembly including at least one of a front curtain, first side curtain, second side curtain and top curtain, wherein each of said curtains are independently moveable and / or removable from the hood assembly. Furthermore, a table saw guard assembly is provided including a quick release mechanism for connecting the hood assembly to the support structure.

Owner:BLACK & DECKER INC

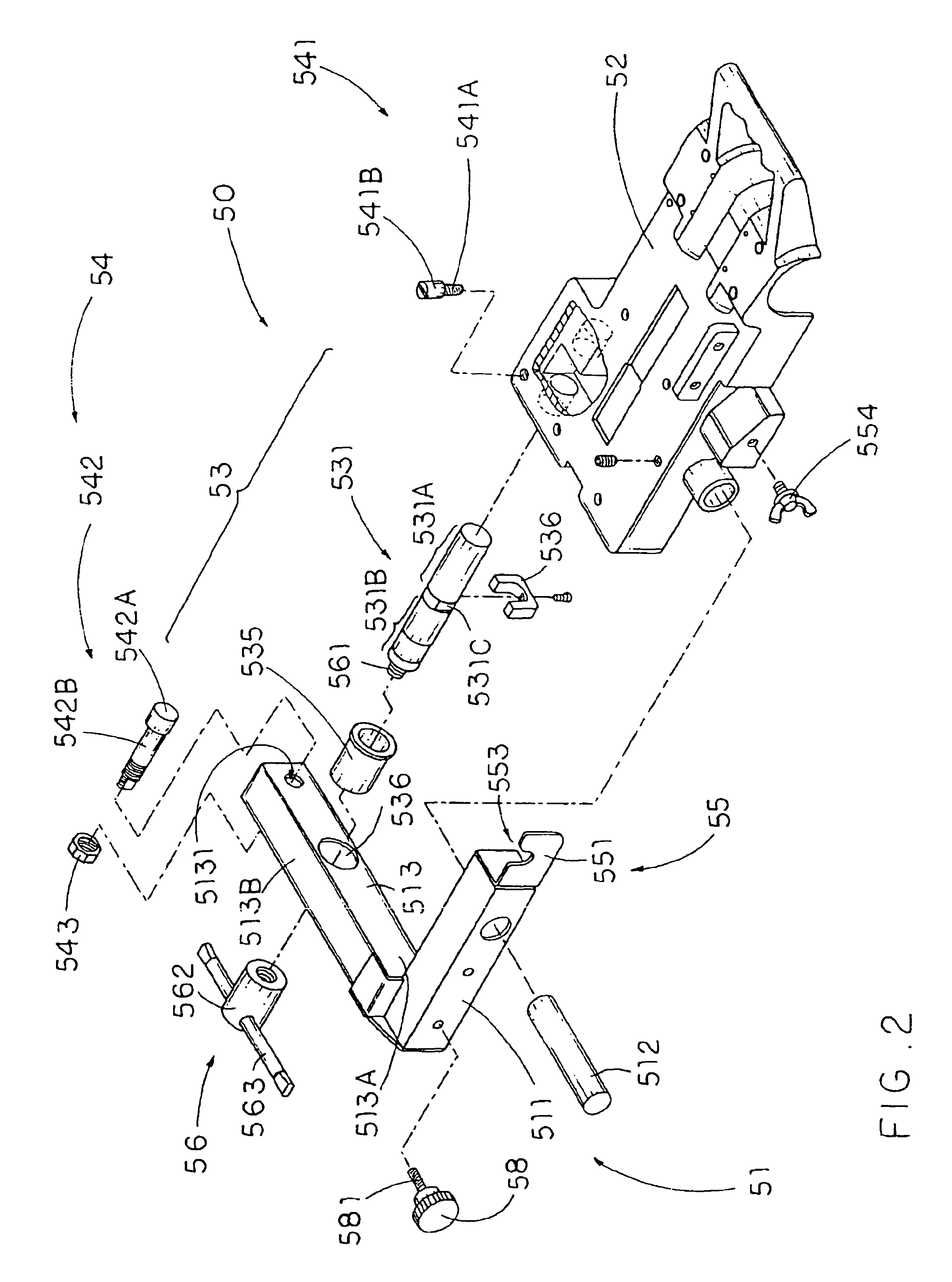

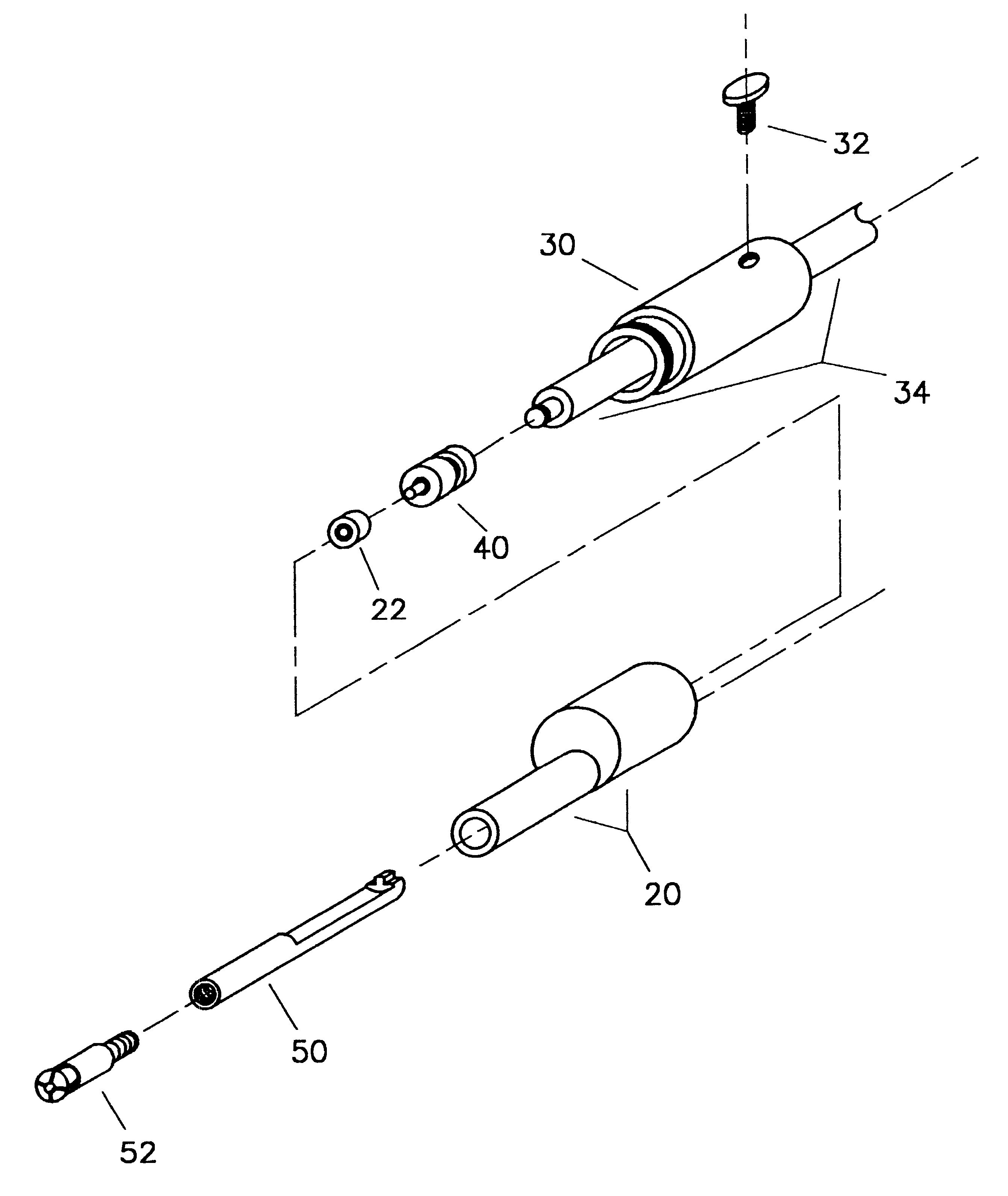

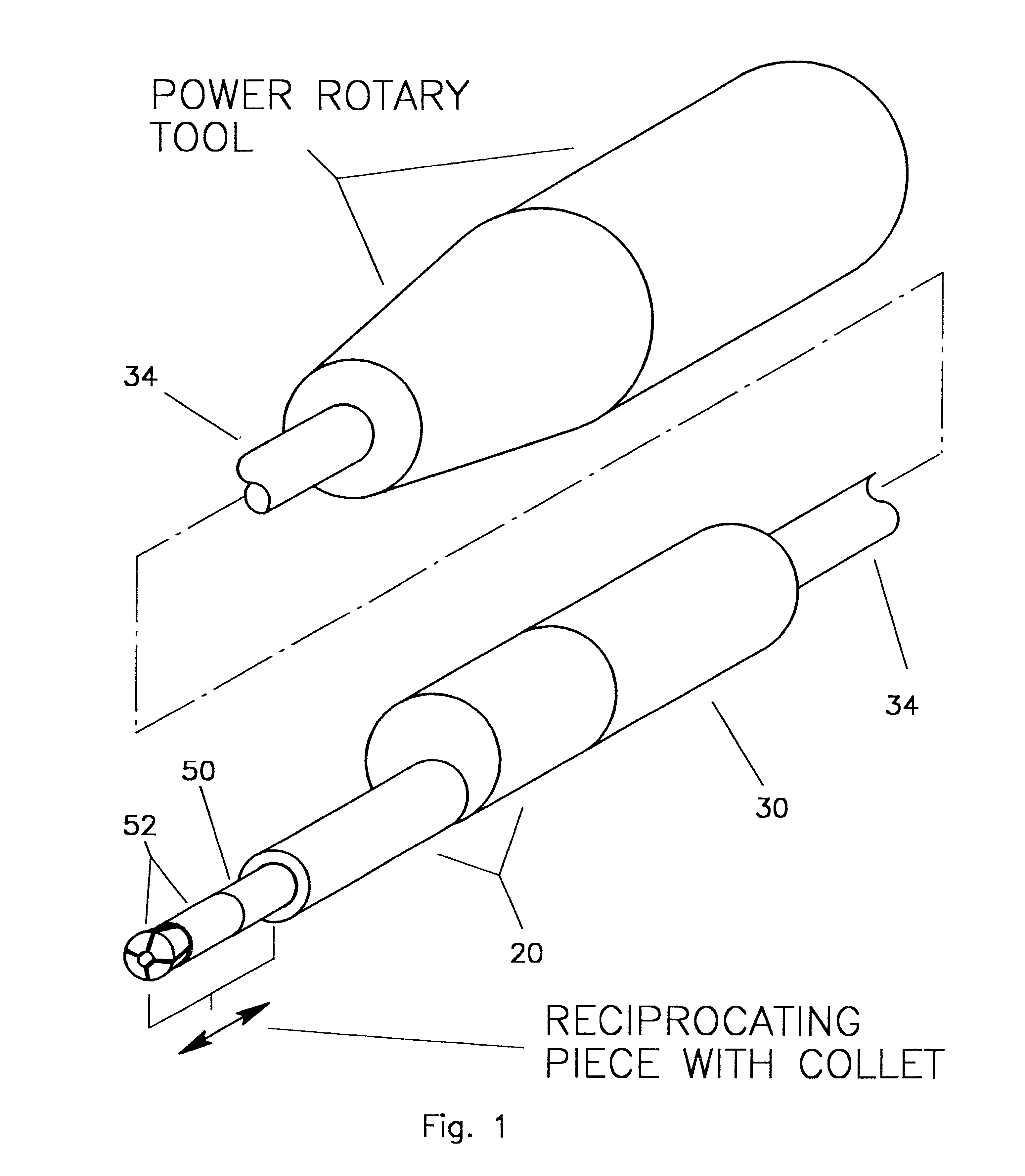

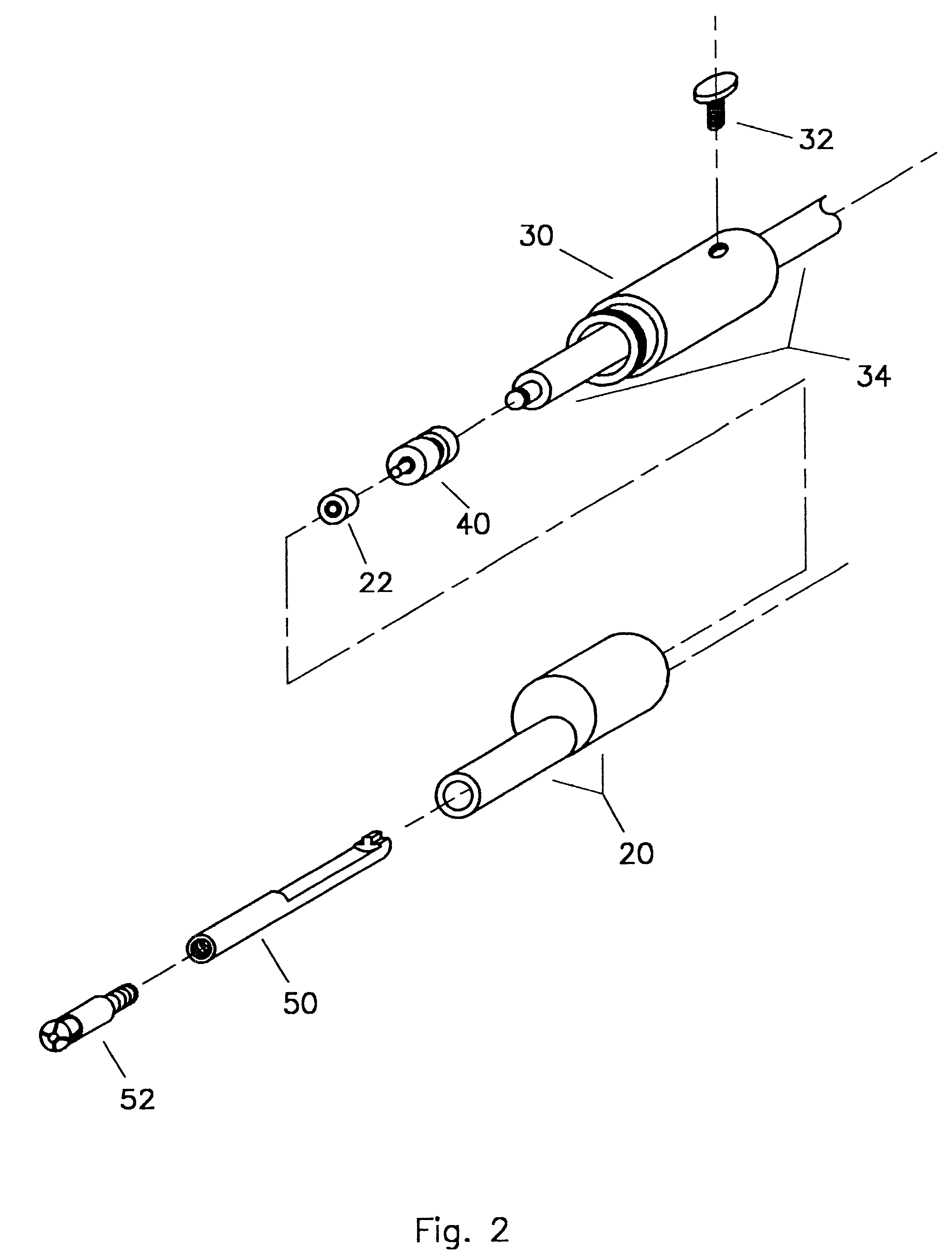

High-speed, hand-held reciprocating method for cutting, carving, sawing, chiseling, filing, sanding, and engraving

A high-speed, hand-held attachment for flex rotor shafts of power rotary tools, and also for direct attachment to power rotary tools without flex rotor shafts, that converts rotary motion to reciprocating motion for precision control of cutting, carving, sawing, chiseling, filing, sanding, and engraving on delicate work pieces. The attachment is one assembly comprising a one-piece front one-piece enclosure (20), a rear one-piece enclosure (30), a high-speed bearing (22), a one-piece rotating piece (40) with integral cam groove, a one-piece reciprocating piece (50) with an integral cam follower on one end and with its other, exposed end accomodating the attachment of a chuck or collet and with geometry to prevent rotation, and a thumbscrew (32). Rotating piece (40) attaches directly to the rotary power source and provides the cam action drive to reciprocating piece (50). Bearing (22) provides rotative support for the other end of rotating piece (40). Reciprocating piece (50) slidably mounts in front one-piece enclosure (20). Front one-piece enclosure (20) and rear one-piece enclosure (30) are attached to each other and maintain proper alignment for rotating piece (40), bearing (22), and reciprocating piece (50). Thumbscrew (32) secures the attachment to the flex rotor shaft of a power rotary tool. A tool holder / collet is attached to the exposed end of reciprocating piece (50) whereby numerous types of cutting tools may be utilized. Alternative versions of the rear one-piece enclosure, (30A) and (30B), described herein, allow for attachment directly to power rotary tools without flex rotor shafts. Alternative versions of the reciprocating piece, (50A), (50B), and (50C), and of the rotating piece, (40A), are also described herein.

Owner:JONES WILLIAM RANDOLPH

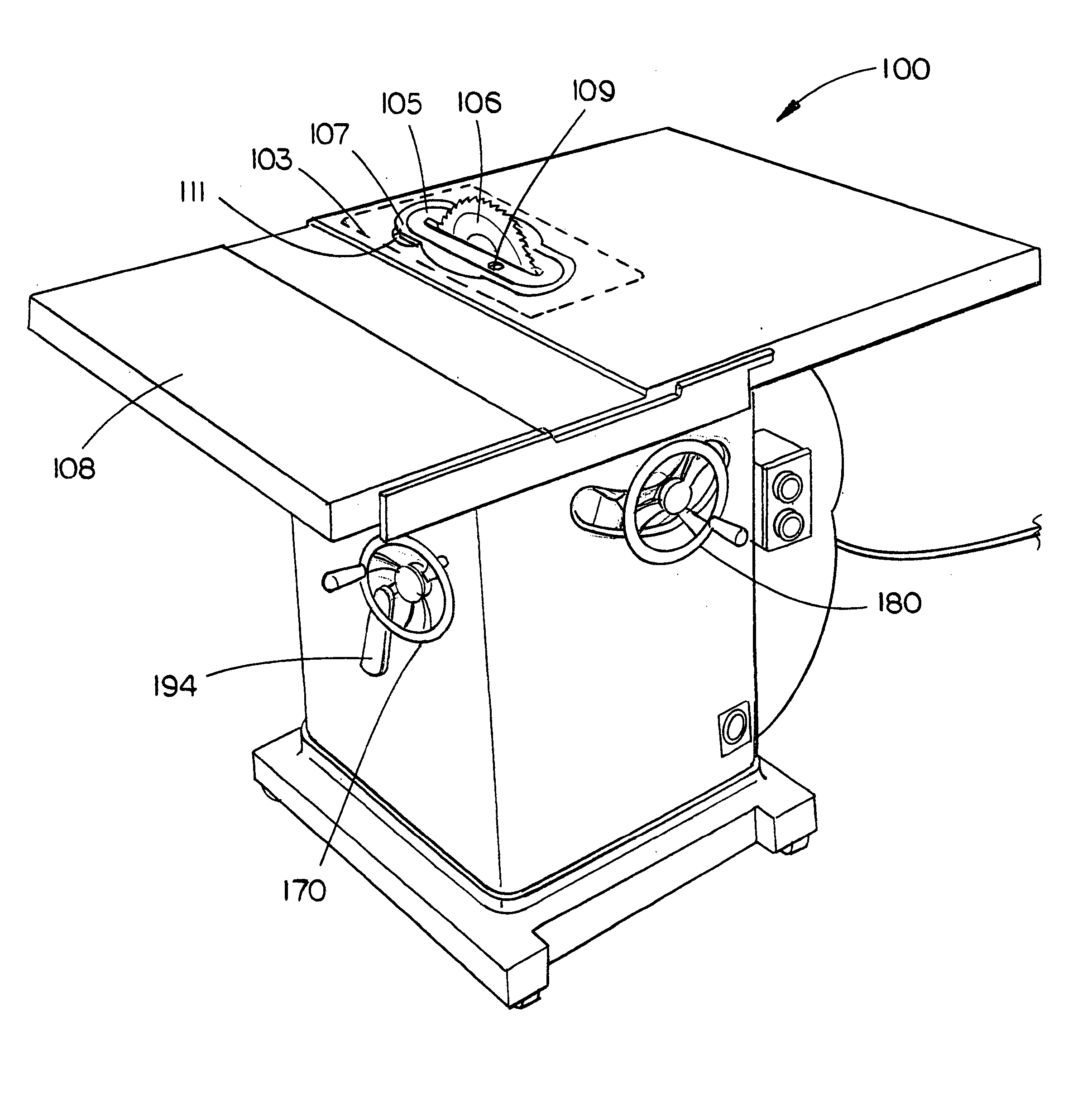

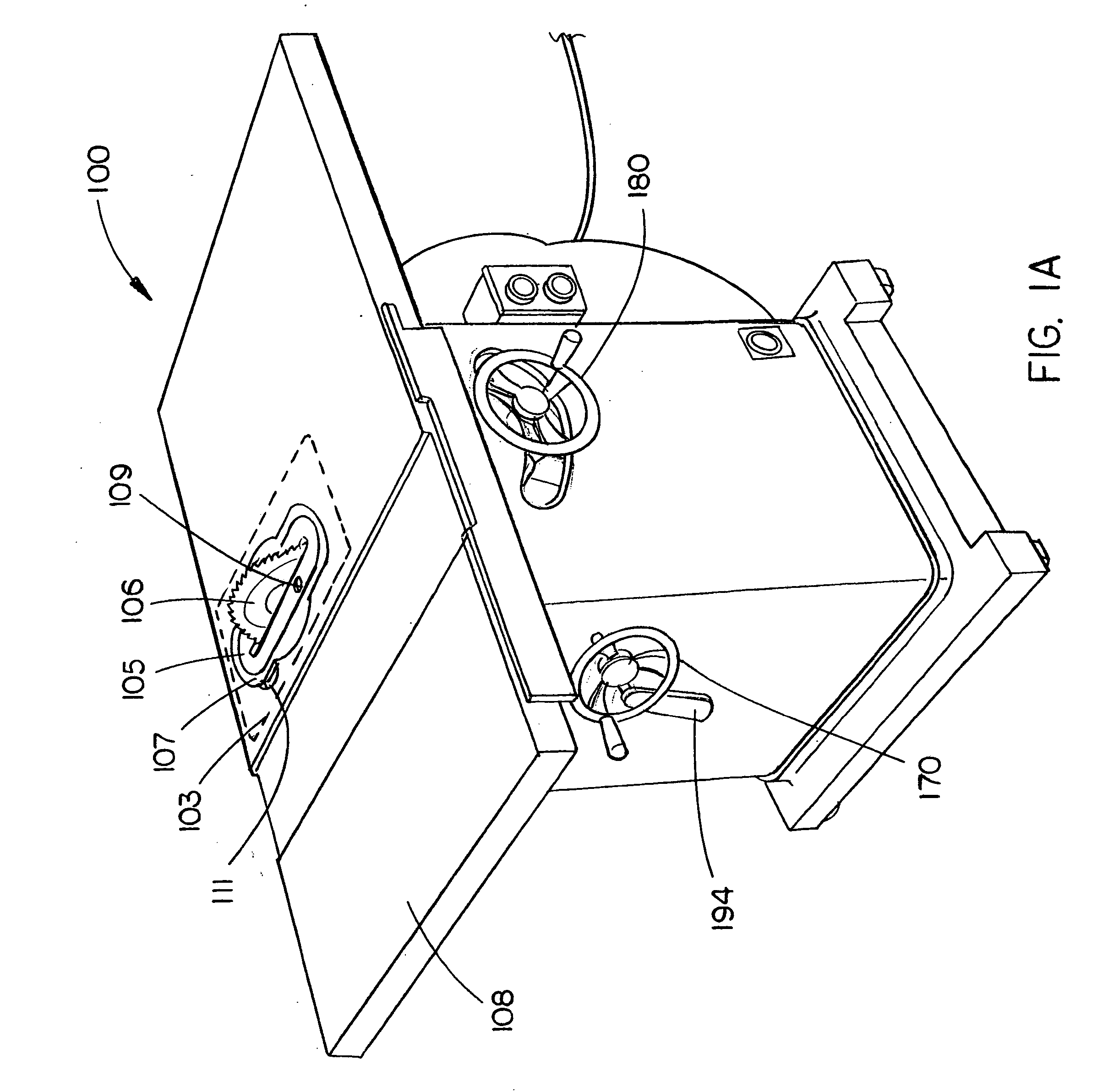

Dual bevel table saw

InactiveUS20040118261A1Efficient use ofMaximizing functional capabilityMetal sawing devicesGuide fencesEngineeringMechanical engineering

A dual bevel table saw provides a table saw enabled with a dual sided arbor assembly and a bi-directional bevel assembly. The dual sided arbor assembly coupled with the bevel assembly further provides for the positioning of a motor and a saw blade to allow for the full range of angular adjustment to be enabled without having to sacrifice any of the cutting features of the saw blade such as depth of cut. The dual bevel table saw may further include a companion saw assembly to provide increased functionality provided by the dual bevel table saw.

Owner:BLACK & DECKER INC

Food Article Feed Apparatus for a Food Article Slicing Machine

ActiveUS20090120256A1Easy to controlHigh yieldMeat packaging/handling/transportingEngineering safety devicesConveyor beltIngested food

A food article feed apparatus for a food article slicing machine. The apparatus has conveyor with a drive belt for connecting a drive source to a drive roller, and a conveyor belt. The drive roller is for driving the conveyor. The drive roller has an outer diameter and a recessed diameter where the drive belt is connected around the recessed diameter and the conveyor belt is connected around the outer diameter. The drive belt operates within an area defined by the first conveyor belt.

Owner:PROVISUR TECHNOLOGIES INC

Contact detection system for power equipment

InactiveUS7377199B2Risk minimizationReduce riskMetal sawing devicesMetal sawing accessoriesPower equipmentEngineering

A woodworking machine having one or more dangerous portions of the machine is disclosed. The machine also includes a safety system configured to detect accidental contact between a person and at least one of the dangerous portions by electrically coupling a signal to the person's body, and detecting if the signal becomes coupled to the dangerous portion.

Owner:SAWSTOP HLDG LLC

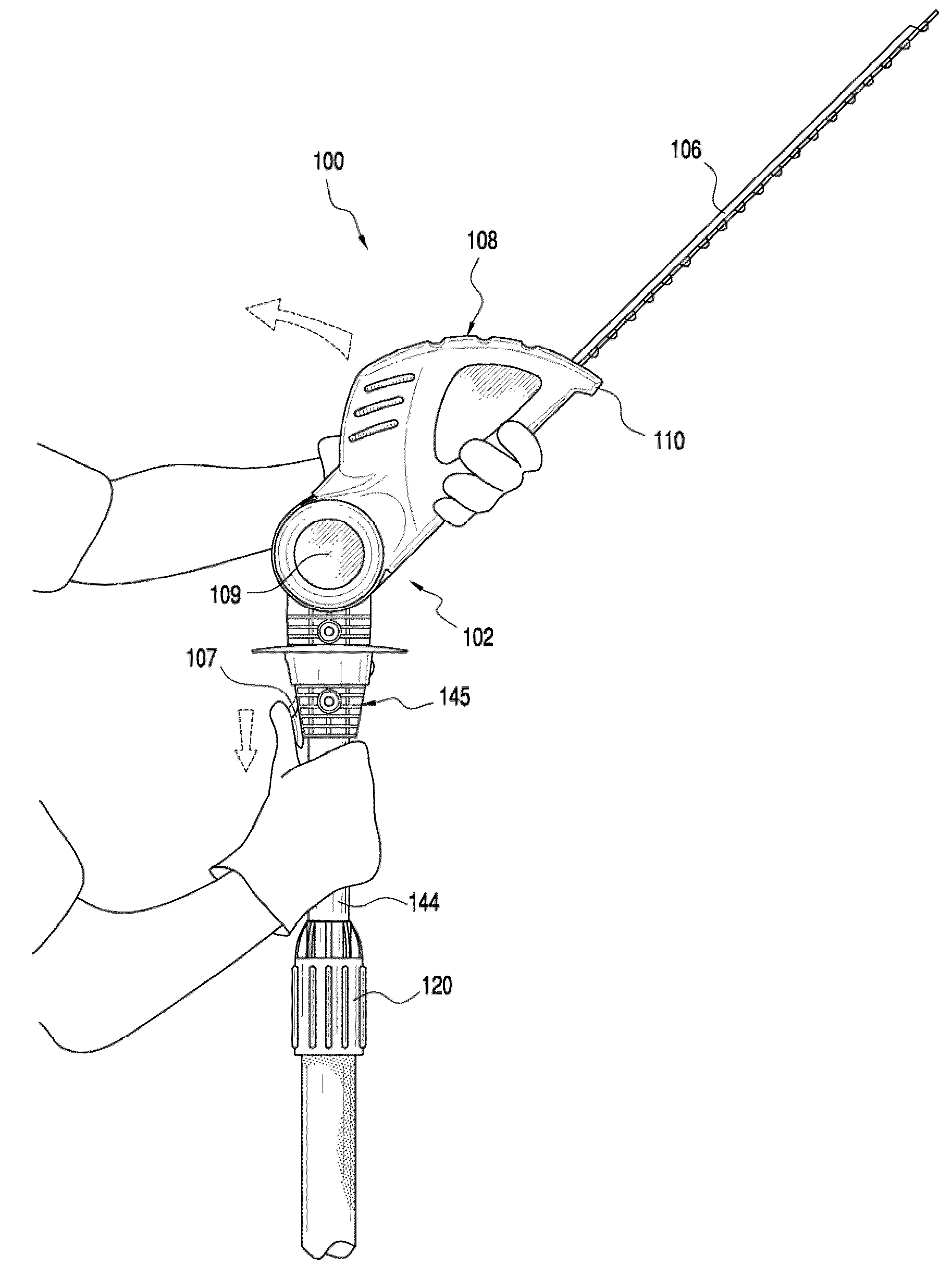

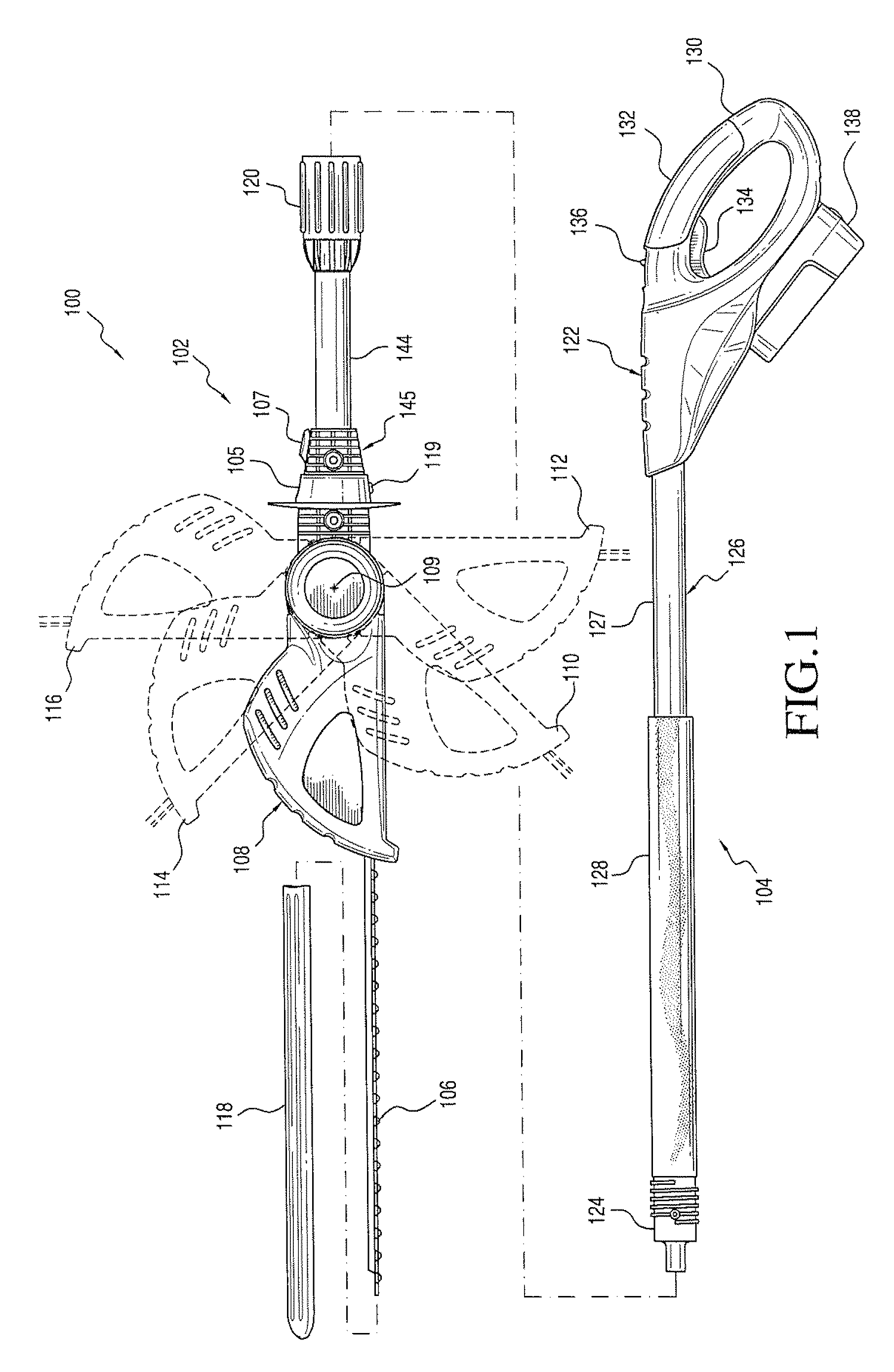

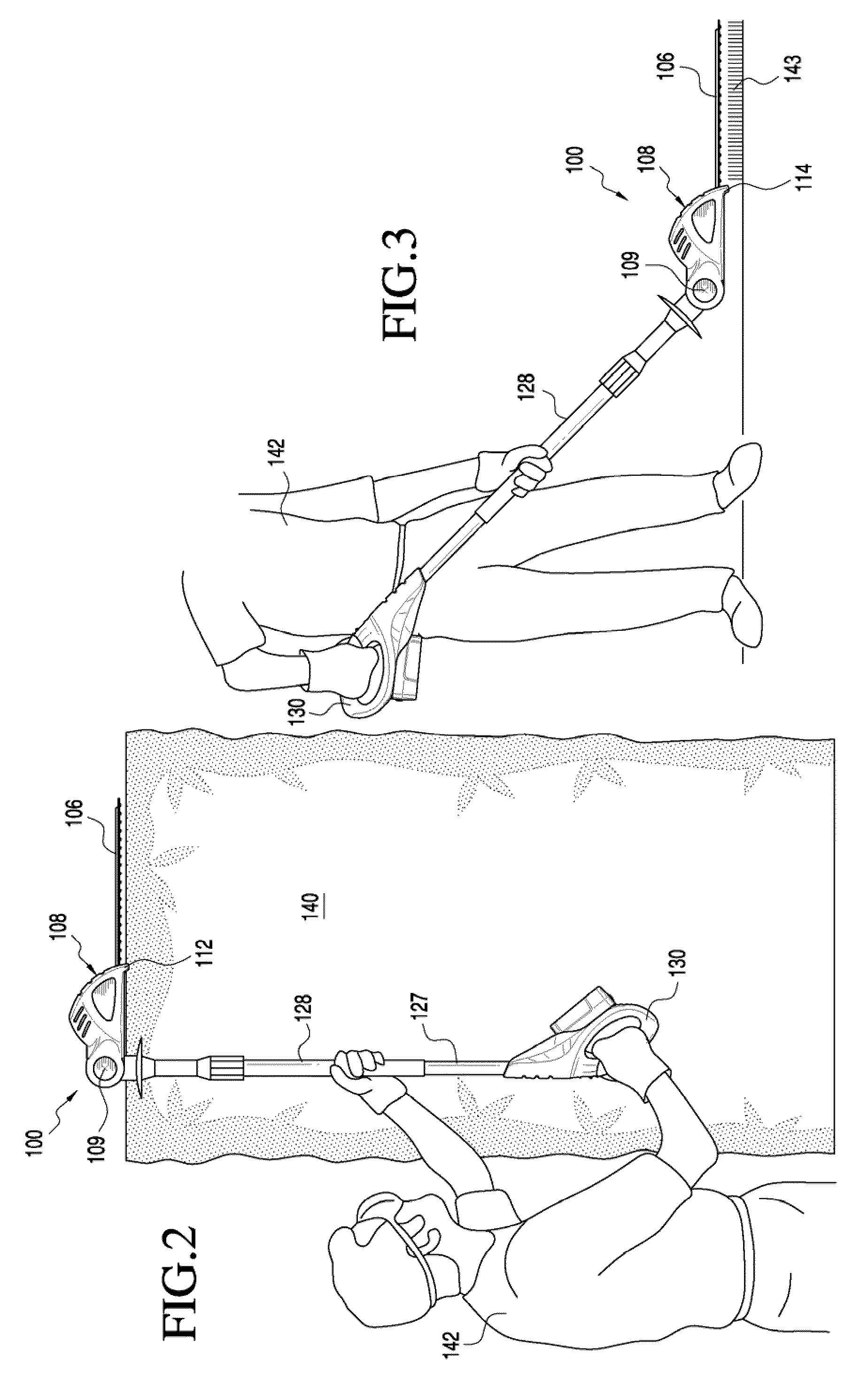

Portable trimmer having rotatable power head

A portable, hand-operated trimmer has a head module that is removably connected to a power control module. The head module has a power head enclosing an electric motor that is operatively connected to a trimming blade. The power head is selectably settable in a plurality of angular positions with respect to a head support, including a neutral position representing 0 degree rotation, 45 degree flexion and dorsiflexion positions, and 90 degree flexion and dorsiflexion positions. The power head also encloses a stator cartridge that is connected to the housing of the power head by a plurality of fastening members. The head support rotates about the stator cartridge and is engaged by way of a movable engagement pin that is received within a selected recess defined in the stator cartridge. The power head housing and stator cartridge further define molded sockets to receive corresponding pivot arms of the head support. An O-ring is disposed about one of the pivot arms to dampen free rotation. The power control module provides power to the power head through a removable rechargeable battery or through direct connection to conventional household power.

Owner:BLACK & DECKER INC

Riving knife assembly for a dual bevel table saw

ActiveUS20050188806A1Efficient use ofFunction maximizationMetal sawing devicesGuide fencesMechanical engineering

An embodiment of the present invention is directed to a riving knife assembly for a dual bevel table saw, comprising: a first armature configured for coupling with a beveling member; a second armature adjustably and rotatably coupled with the first armature; a first mounting member coupled with the second armature; a first riving bracket coupled with the second armature and configured for adjustably coupling with a bearing retaining nut of a dual arbor assembly; a second riving bracket coupled with the first mounting member and configured for adjustably coupling with the inside of a first bore of a first height bracket; a quick release handle disposed upon the first mounting member; an eccentric shaft coupled with the quick release handle; a locking pin having a locking pin body, a second mounting member, a head member coupled with a sheathing member, and a spring loaded assembly, the locking pin operationally coupled with the eccentric shaft; and, a riving knife configured with an engagement assembly for engaging with the locking pin; wherein the spring loaded assembly enables the head member and a circular engagement member disposed on the locking pin body proximal to the head member of the locking pin to be set in a locked position and a release position relative to the second mounting member, the sheathing member and the riving knife; wherein the locked and release positions are established by manipulation of the quick release handle.

Owner:BLACK & DECKER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com