Patents

Literature

132results about "Mitre joint working devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

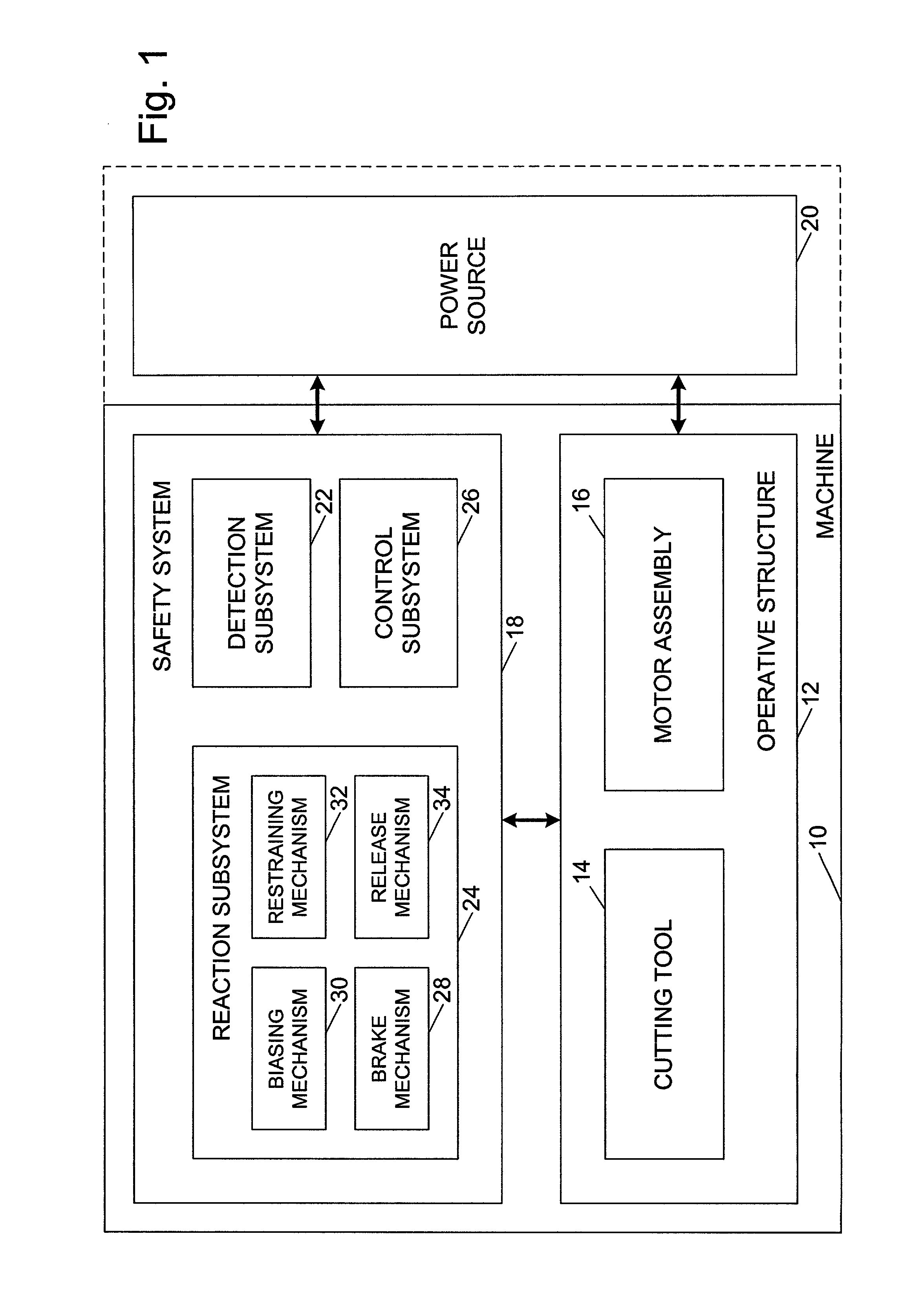

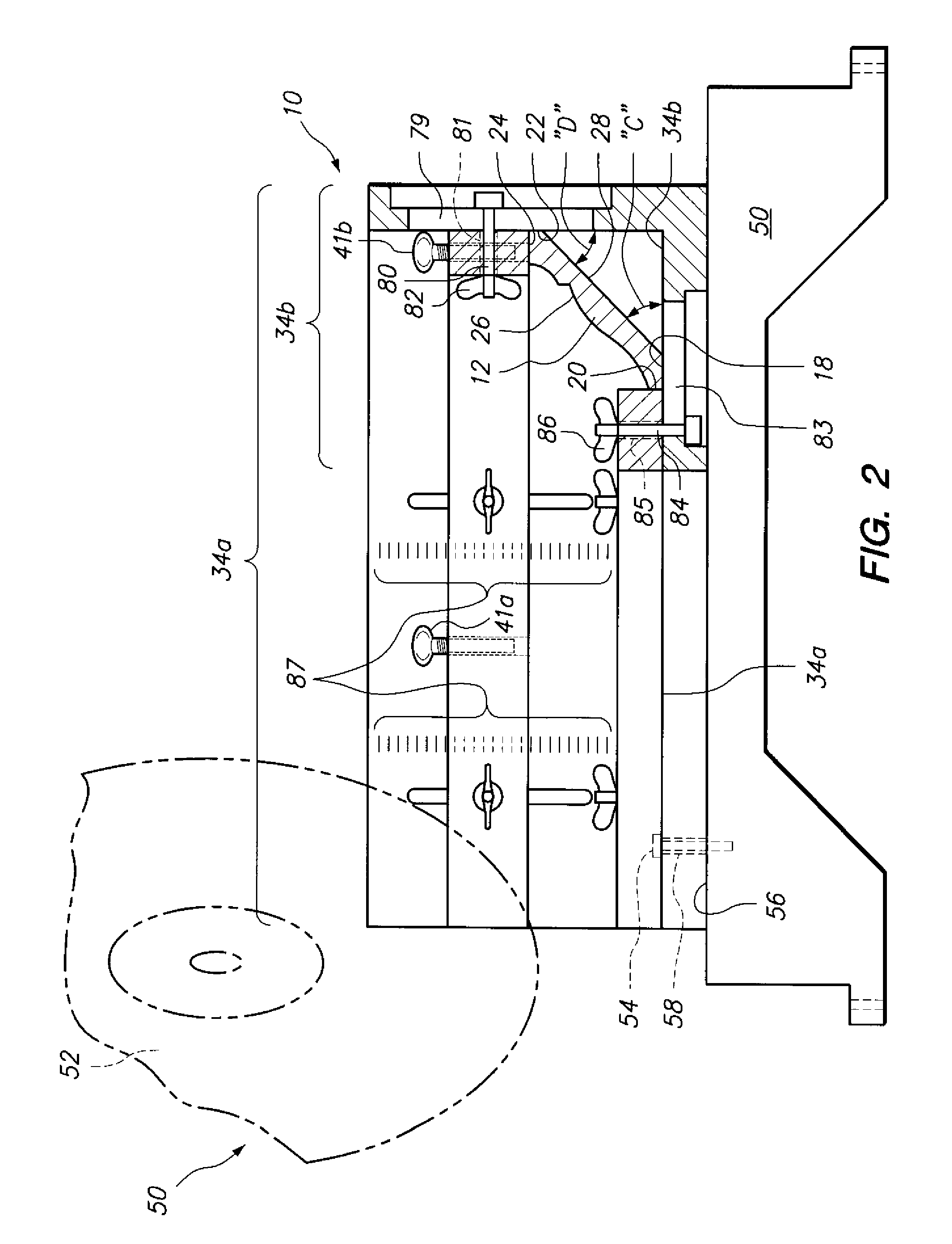

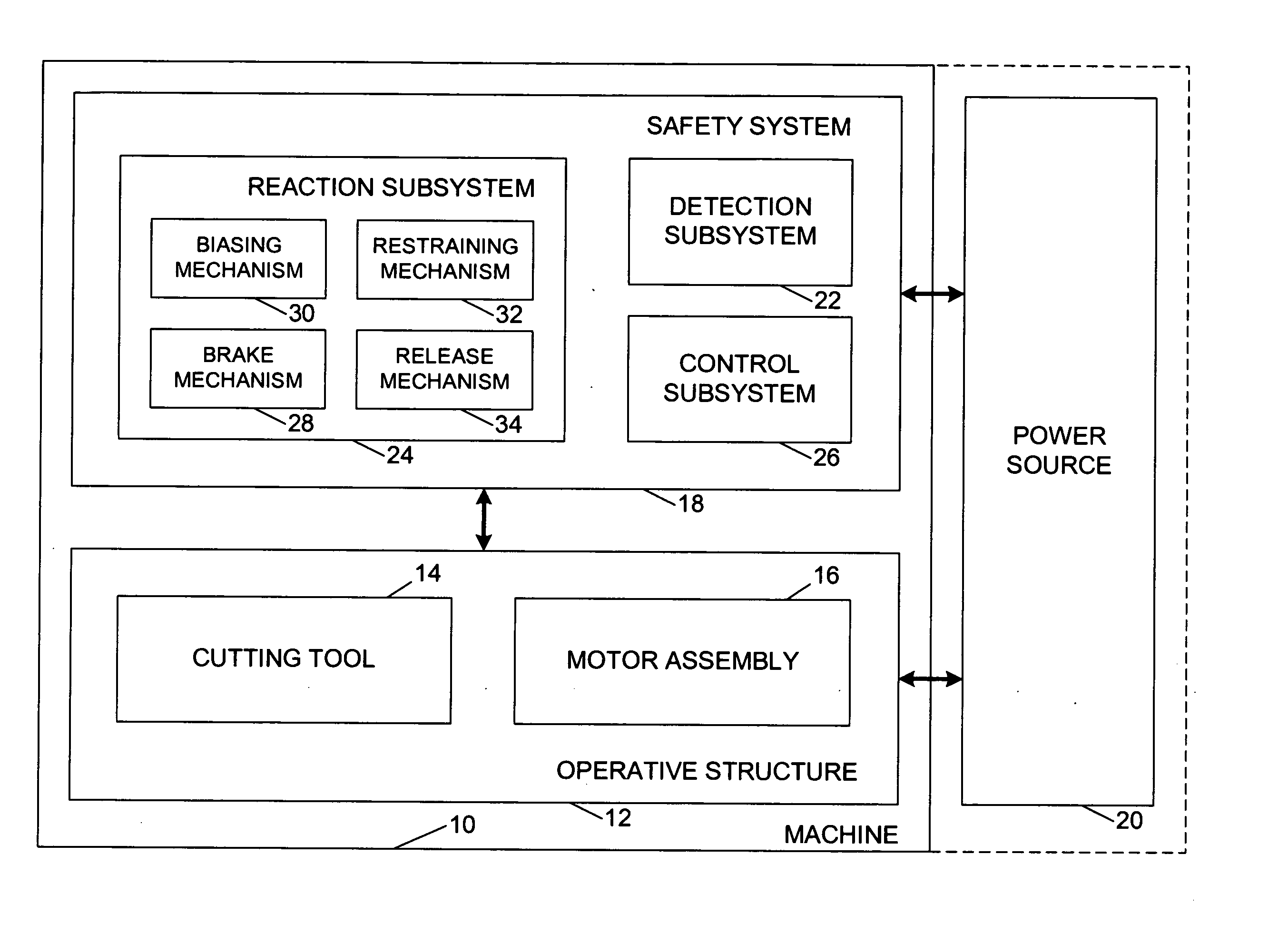

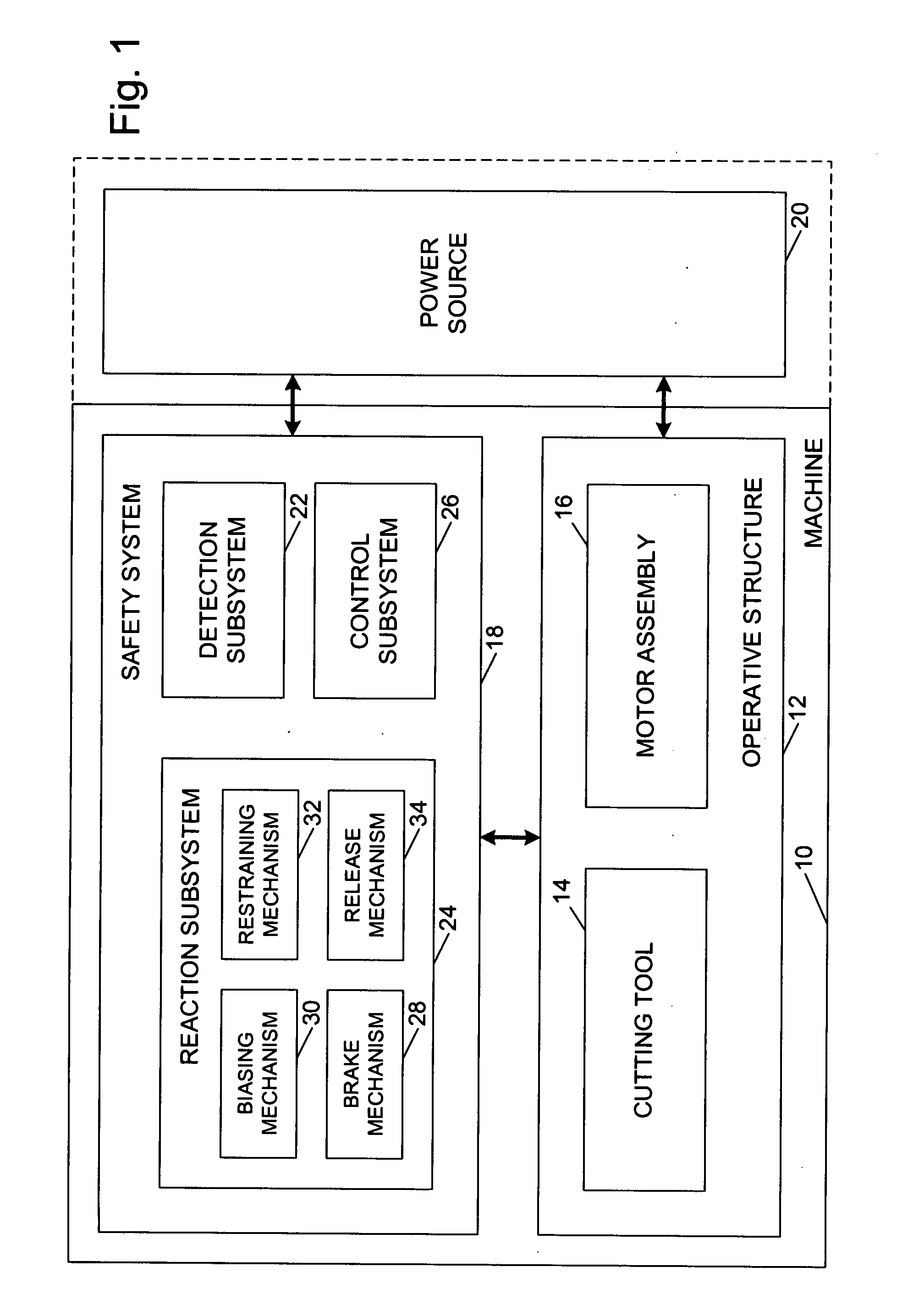

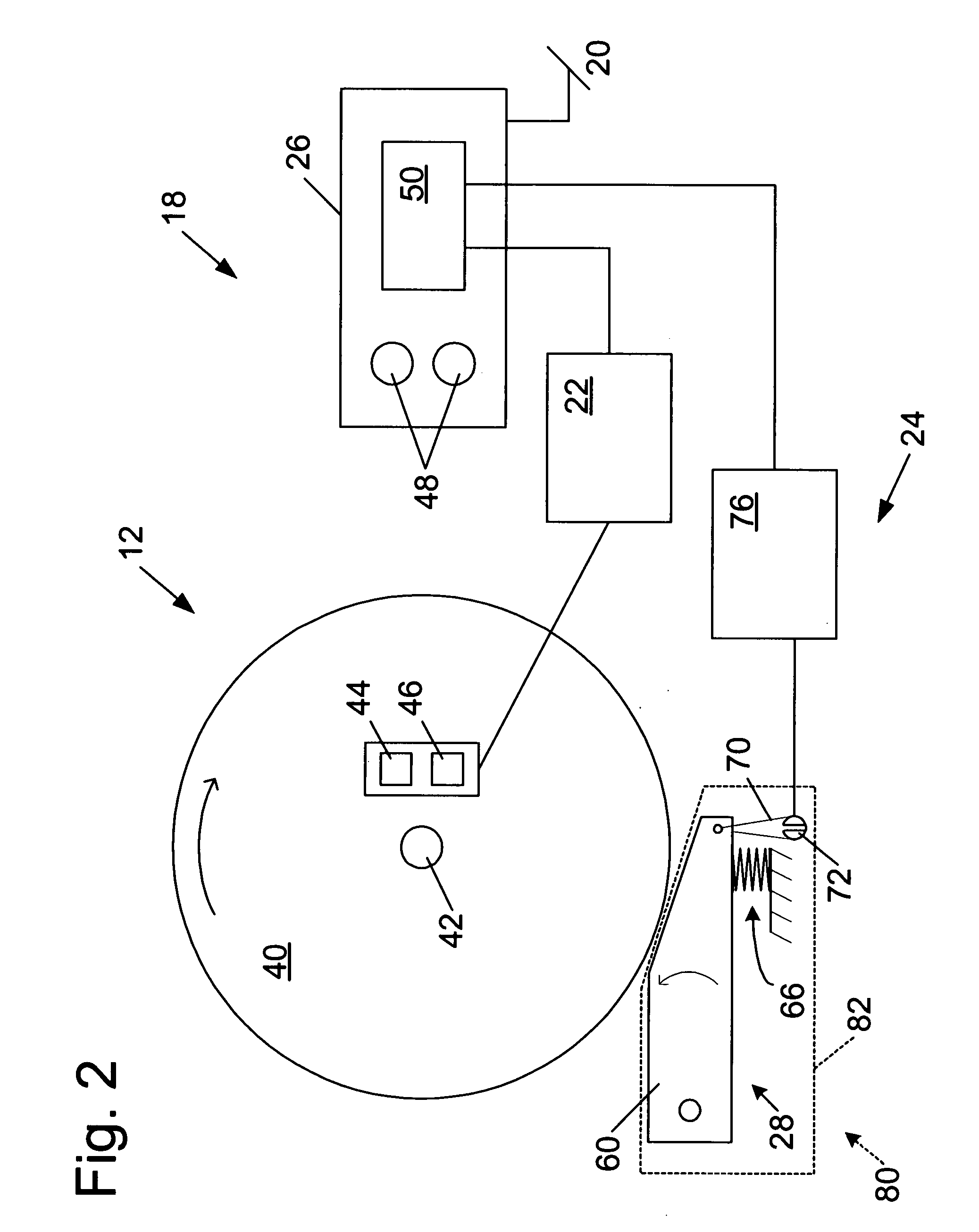

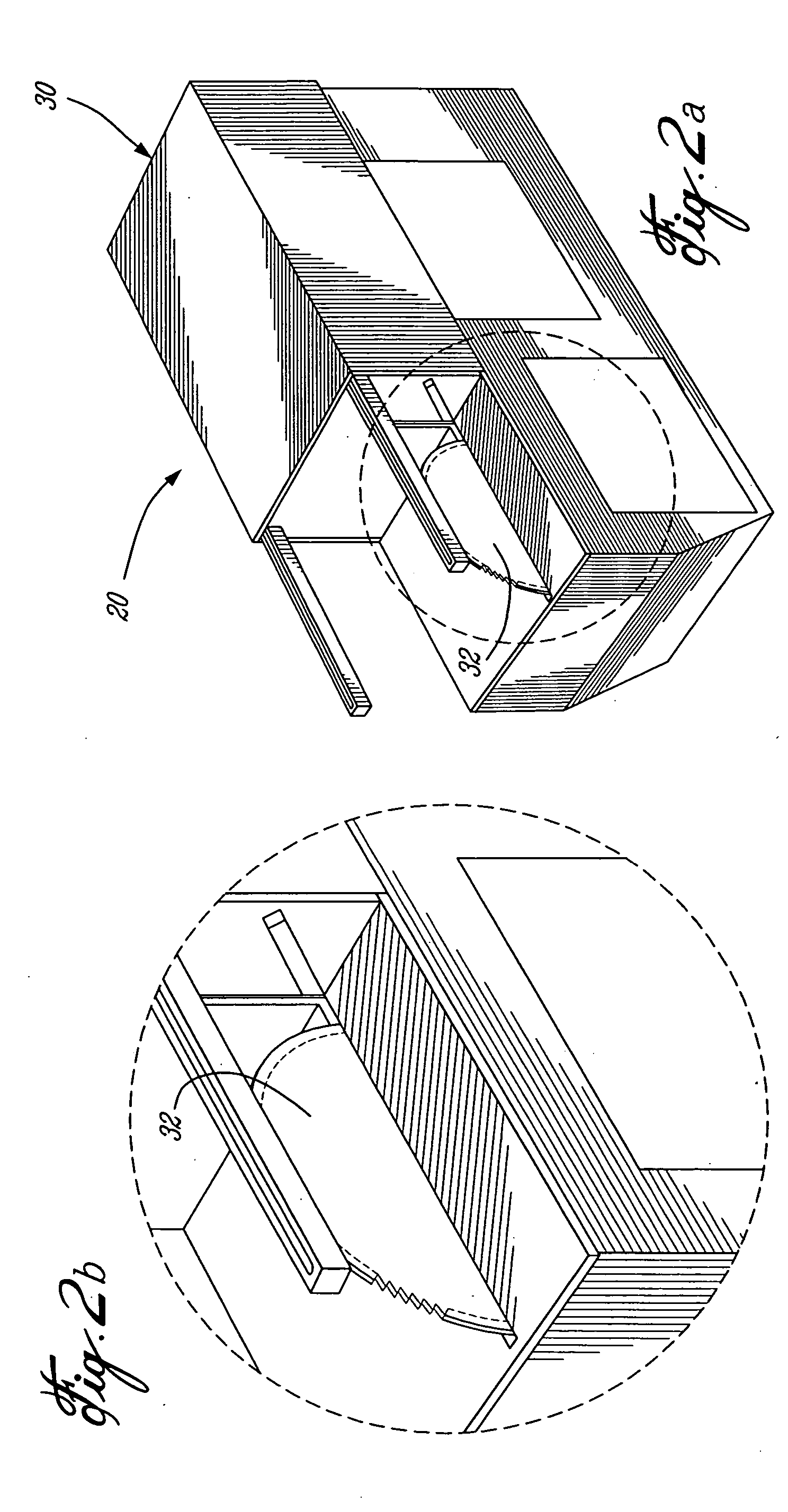

Detection system for power equipment

Woodworking machines including conductive cutters adapted to cut workpieces, and motors adapted to drive the cutters are disclosed. The machines also include a contact detection system adapted to detect contact between a person and the cutter, and to distinguish contact between the person and the cutter from contact between the workpiece and the cutter. The machines further include a reaction system adapted to cause a predetermined action to take place upon detection of contact between the person and the cutter by the contact detection system.

Owner:SAWSTOP HLDG LLC

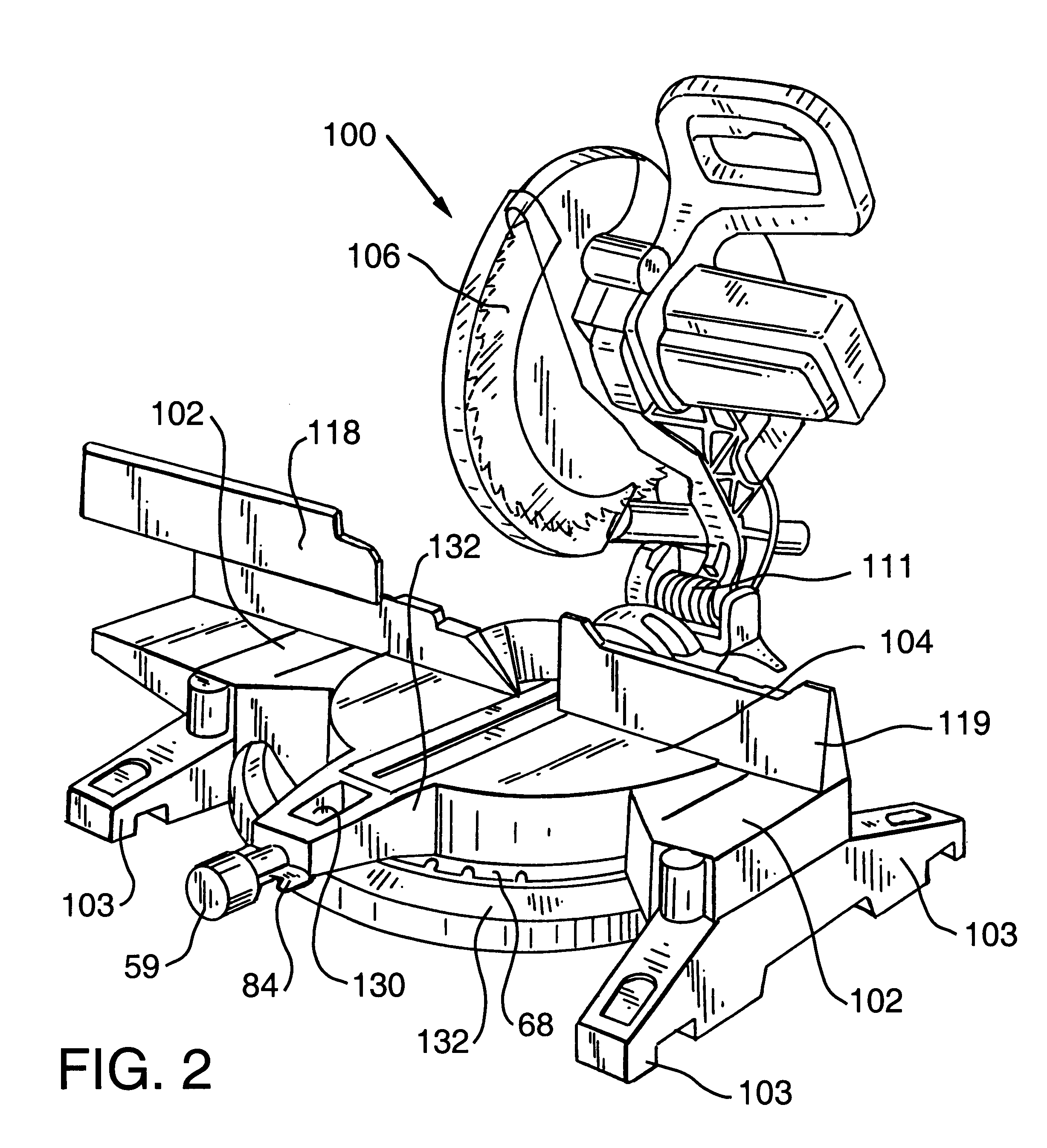

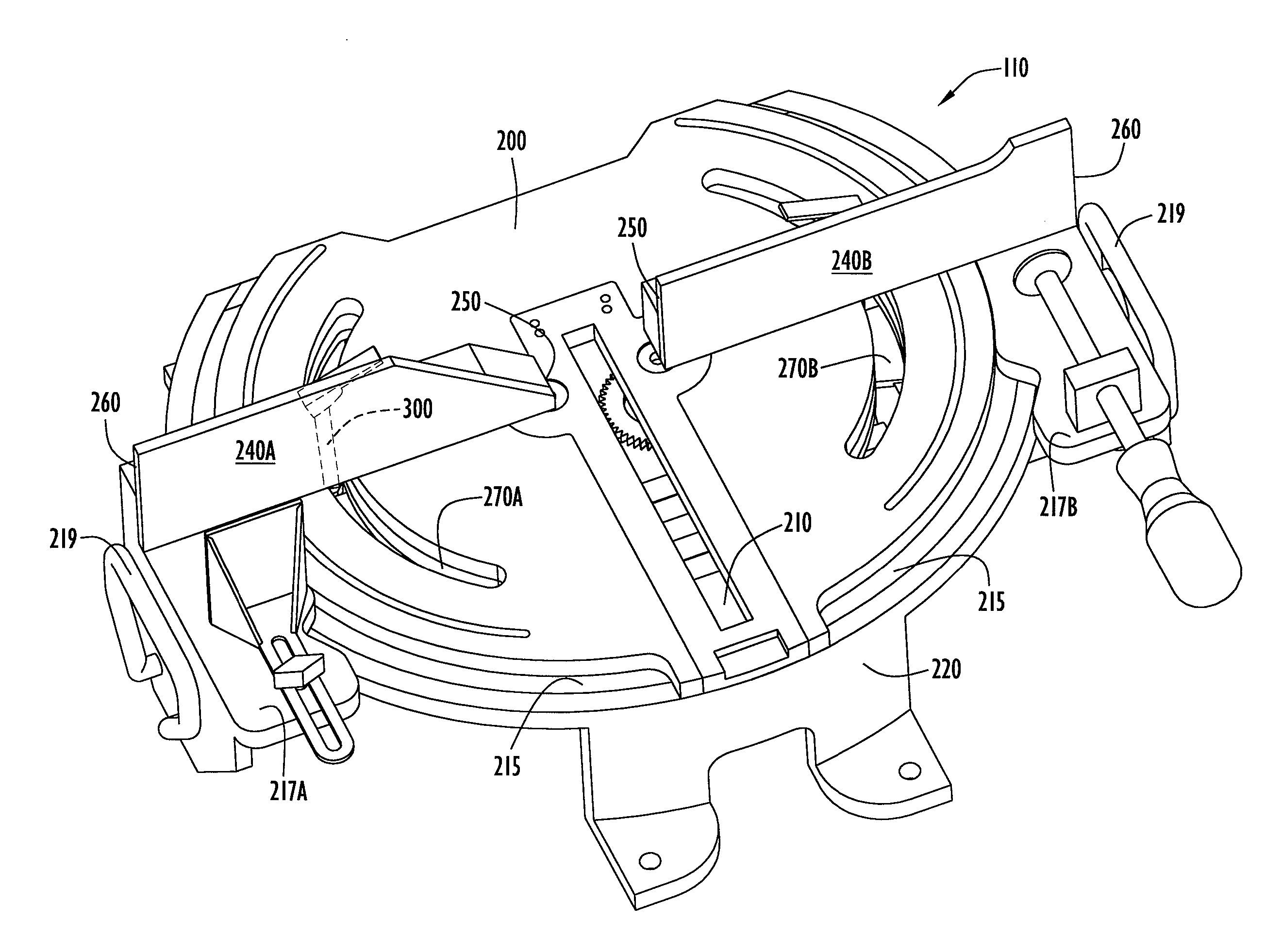

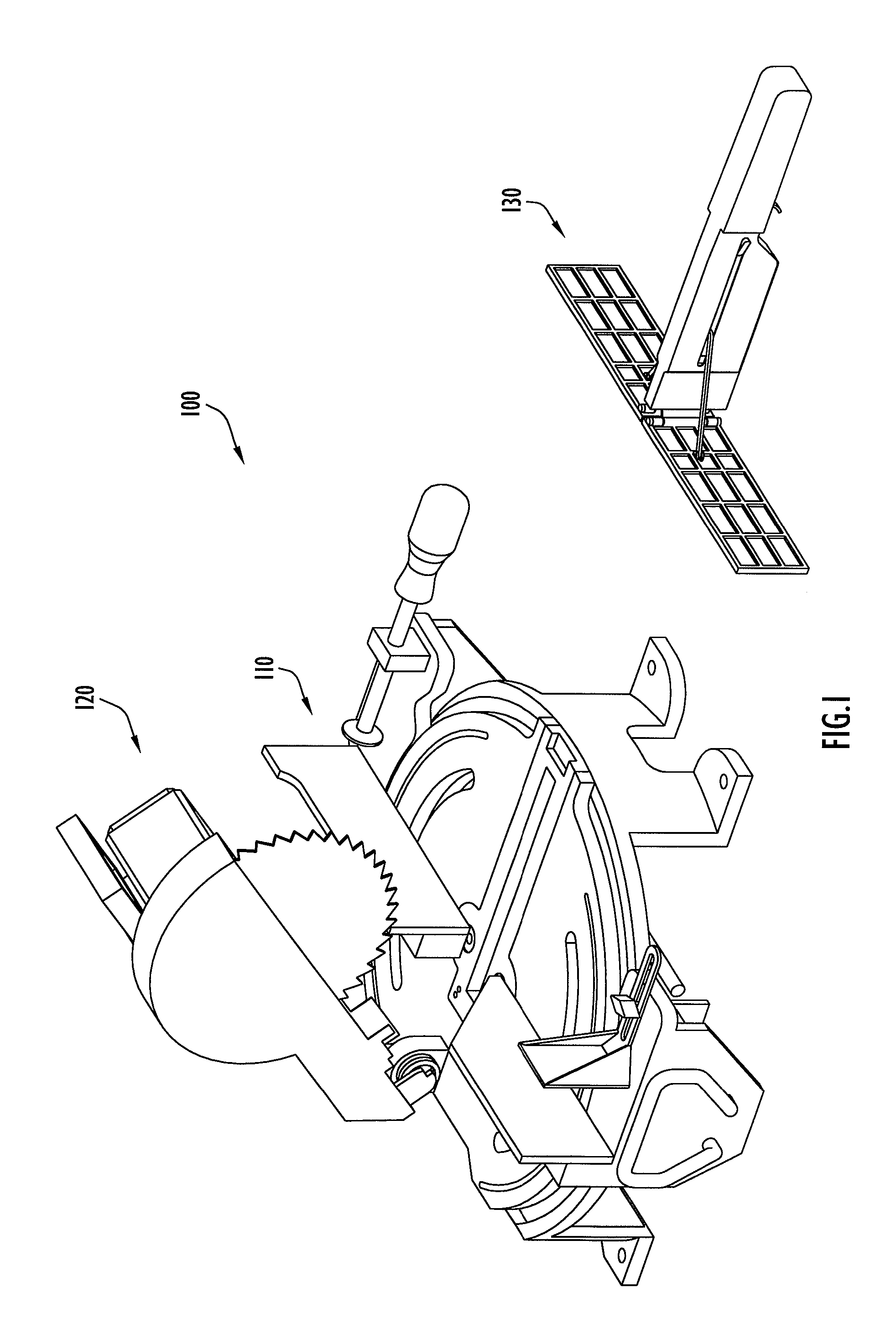

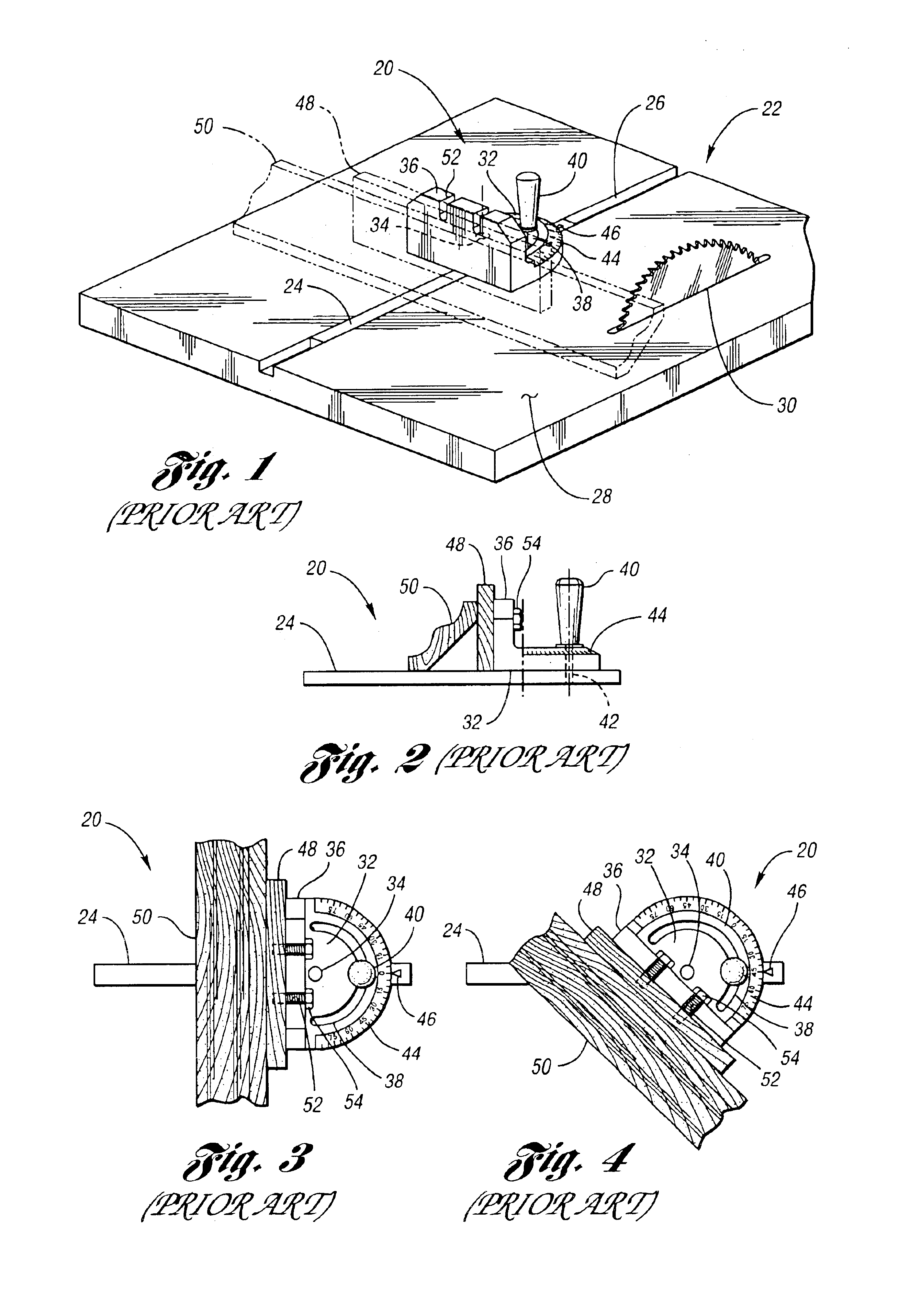

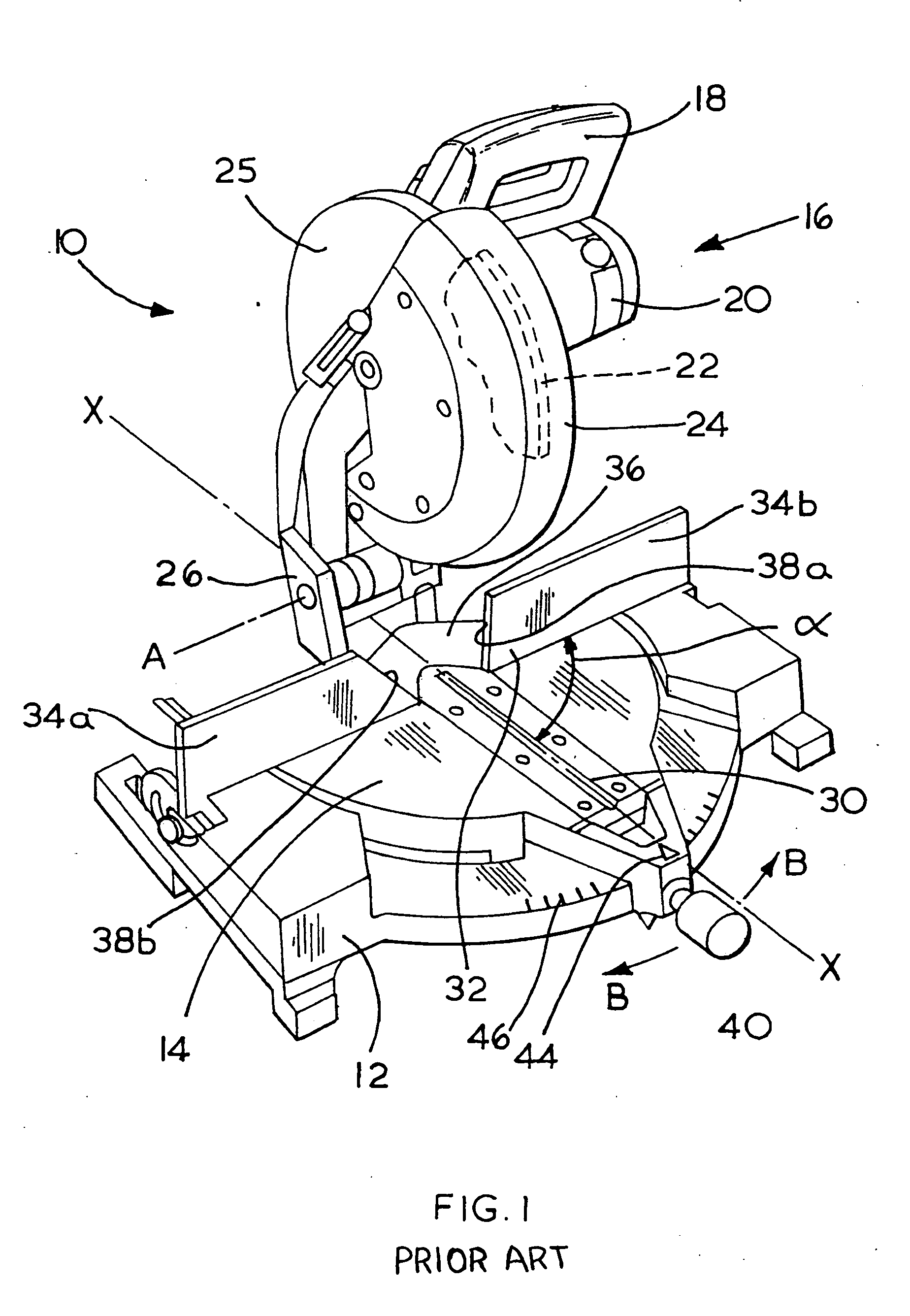

Adjustment mechanism

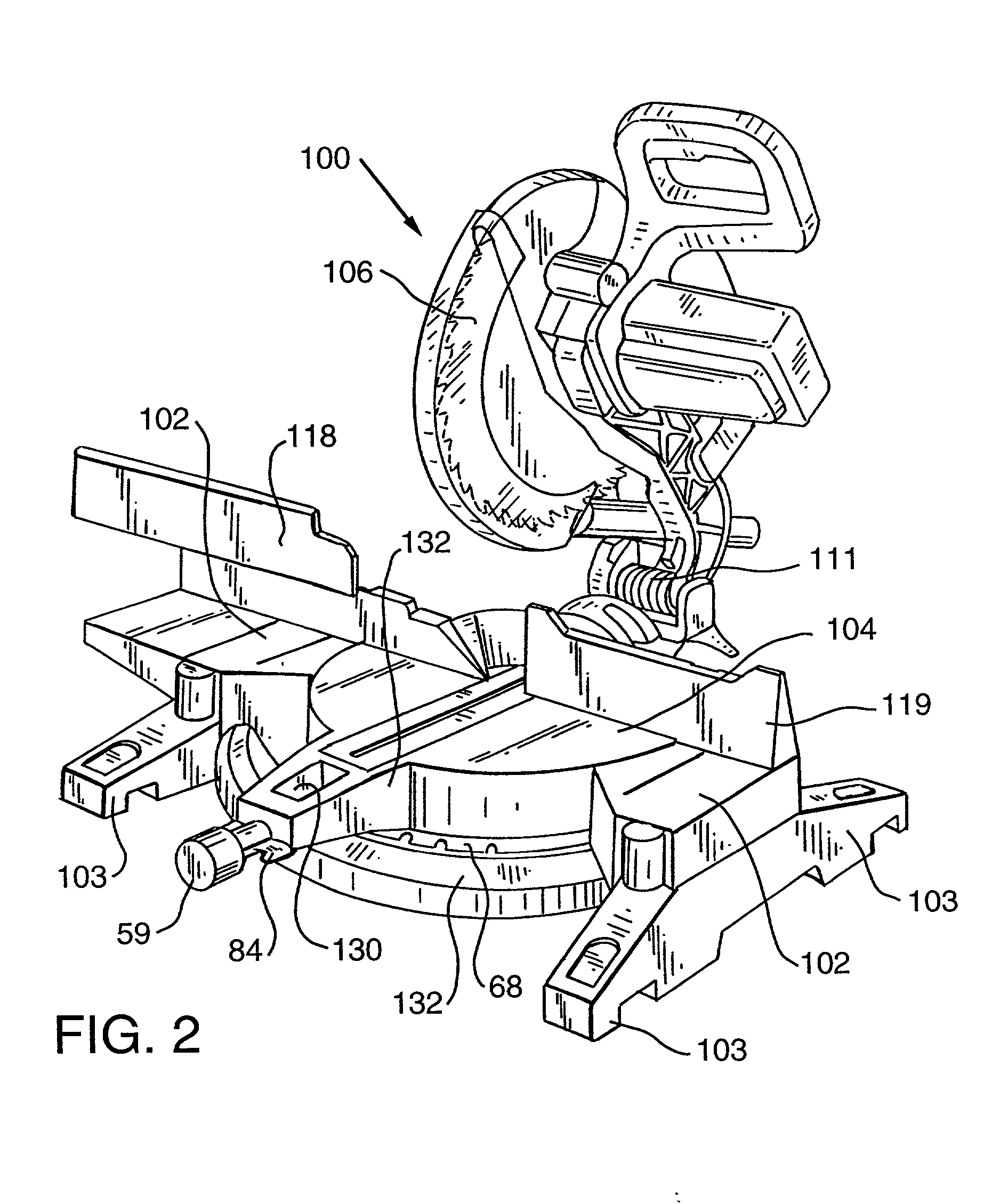

InactiveUS6513412B2Quick and accurate adjustmentSimple designMetal sawing devicesGuide fencesLocking mechanismDetent

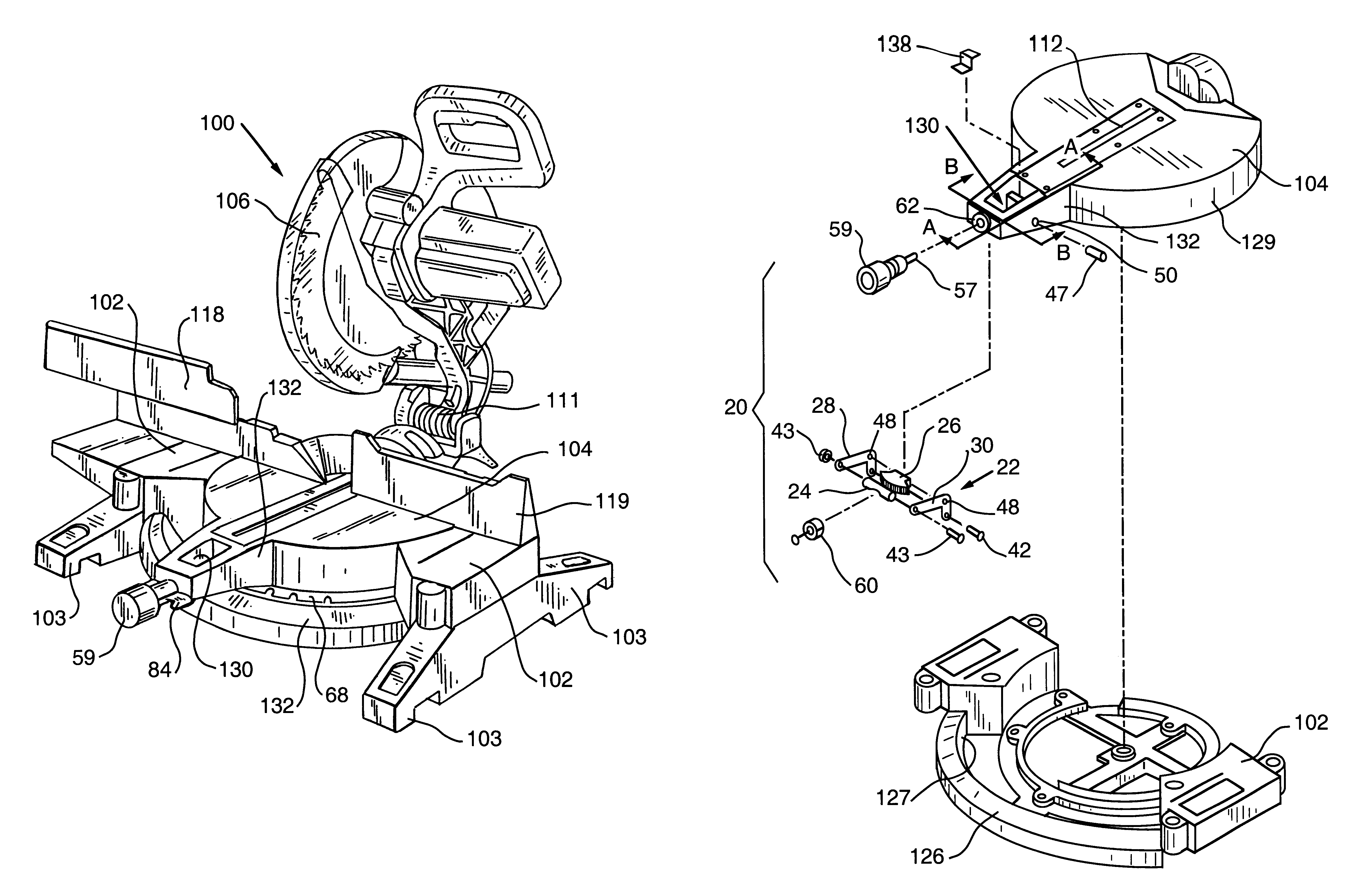

Apparatus for releasably adjusting a position of a first portion of a device relative to a second portion of the device. The first portion includes a first surface, and the second portion includes a second surface. A workpiece support surface is defined by the first and second surfaces, and the first surface is rotatable relative to the second surface. A locking mechanism is provided to selectively restrain rotation of the first surface relative to the second surface. An indexing mechanism optionally is provided including a detent mechanism which selectively restrains rotation of the first surface relative to the second surface in one of a plurality of predetermined positions.

Owner:BLACK & DECKER INC

Adjustment mechanism

InactiveUS20020088327A1Simple designQuick and accurate adjustmentMetal sawing devicesGuide fencesLocking mechanismDetent

Owner:BLACK & DECKER INC

Woodworking machinery stop and track system

Owner:KREG ENTERPRISES

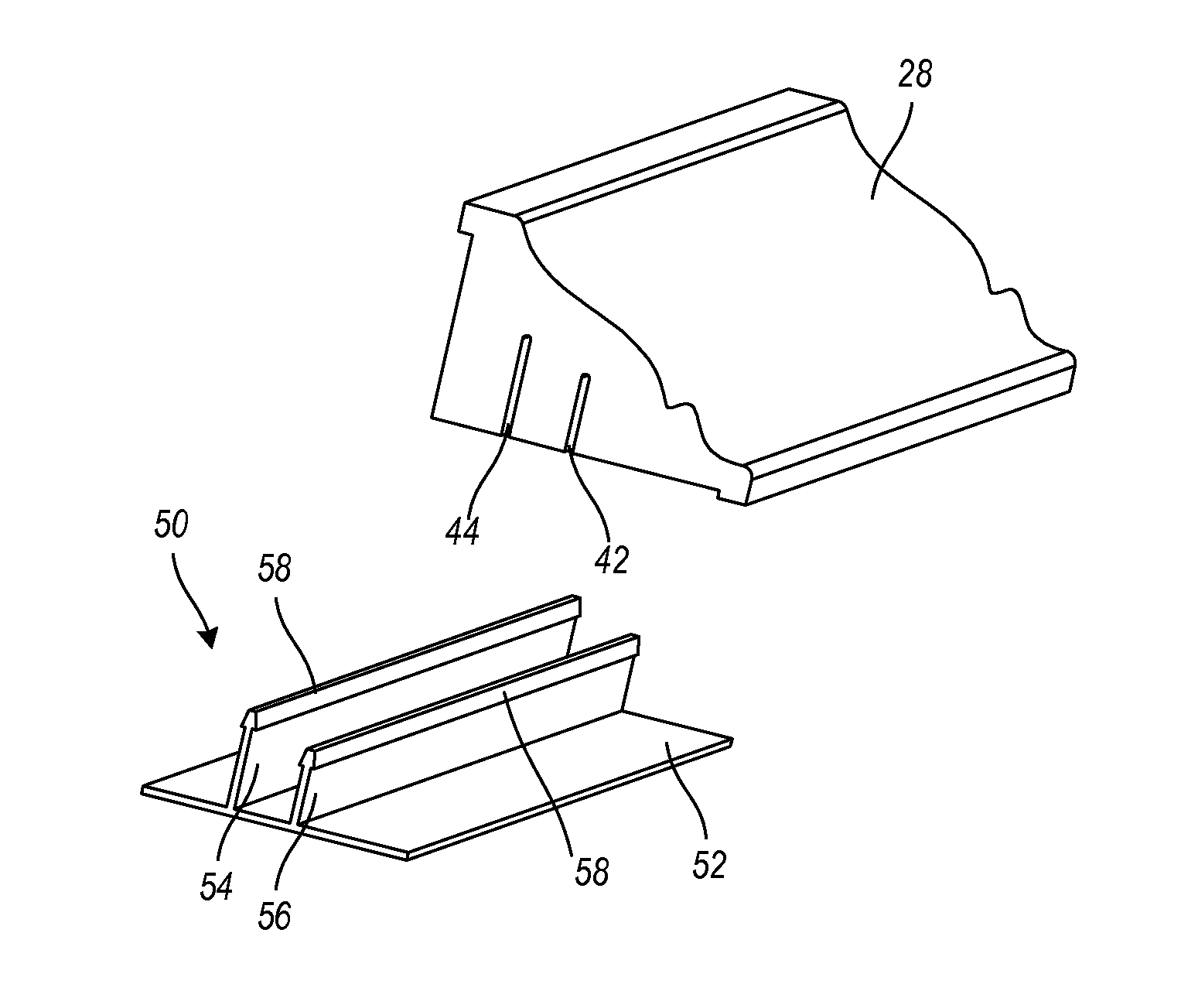

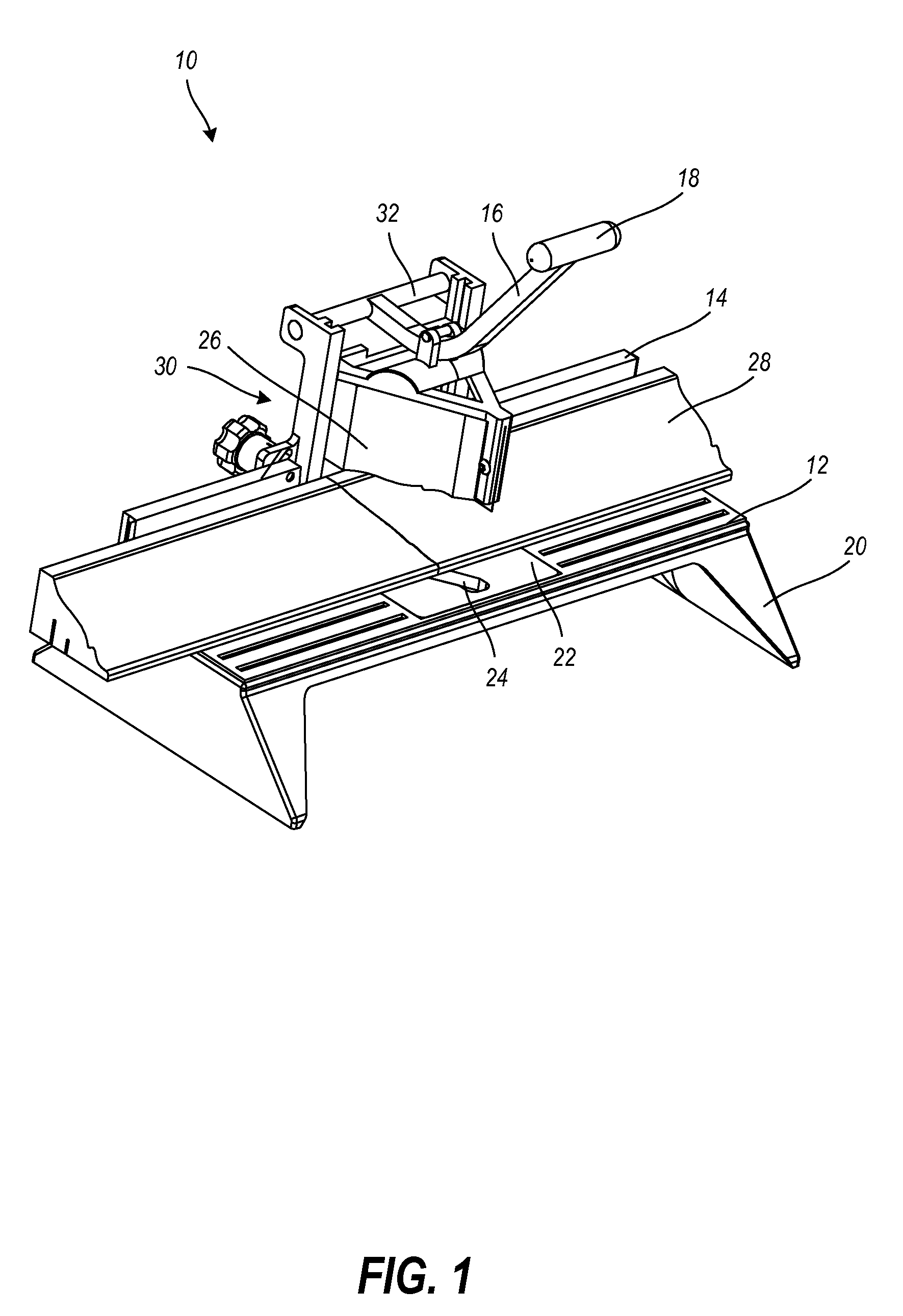

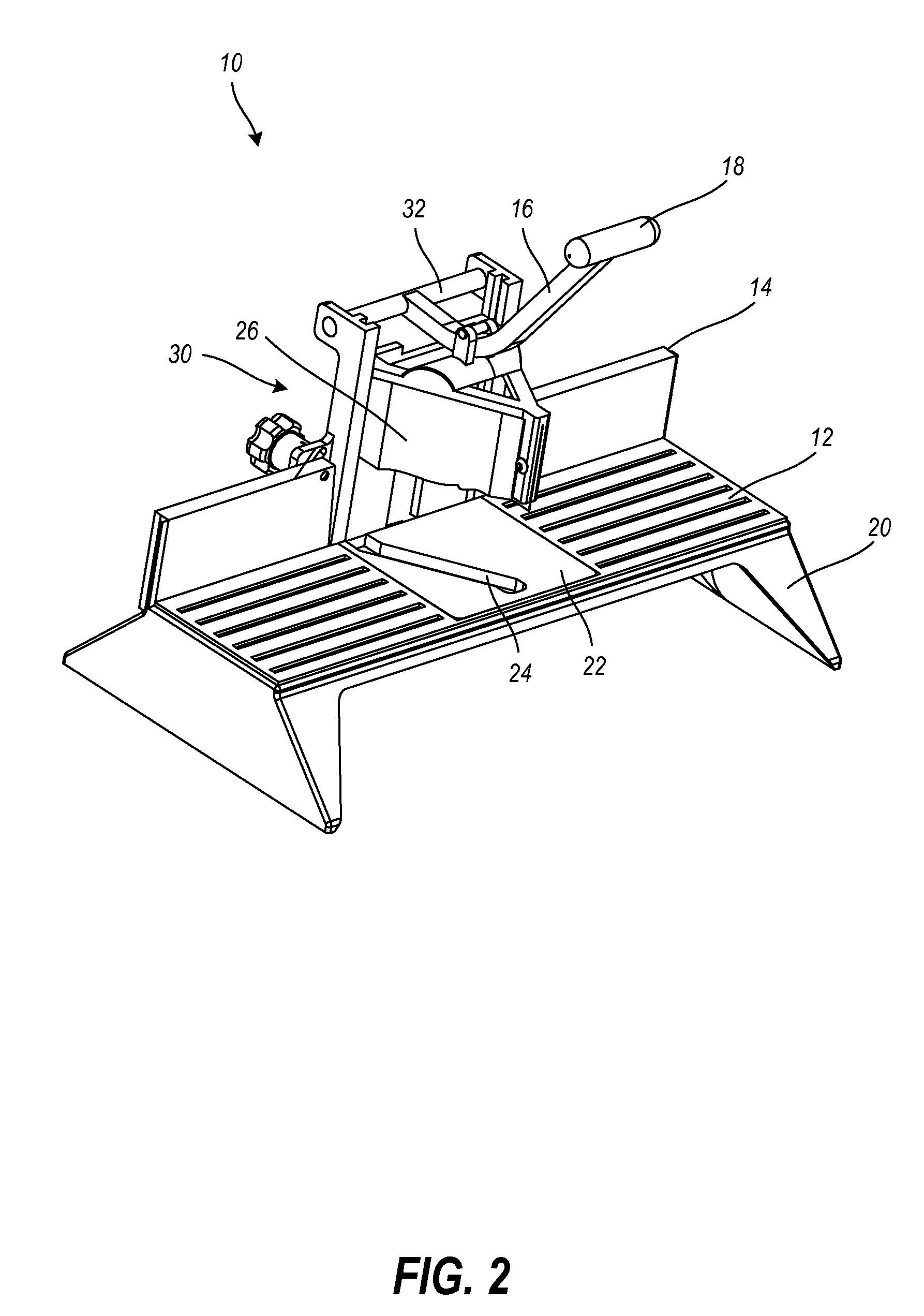

Assembly for coping and mounting trim molding

An assembly for coping and mounting trim molding is provided. A trim holding device for mounting a finish trim molding and a coping device are provided. The coping device includes a platform, having a back, into which to place a finish trim molding for coping and cutting, and a blade assembly having a cutter blade and configured to be manually actuated by a lever. The blade assembly is adjustable and is configured to rotate. The cutter blade is configured specifically to a size and a shape of the finish trim molding to be cut and coped. The mounting device includes a bracket, having a pair of mounting flanges, configured for placement along a wall. The bracket and flanges form generally an “F” shape trim holding device. The flanges are configured to securely hold a finish trim molding without the use of nails, glues, and adhesives.

Owner:ARMACOST GREGORY SCOTT

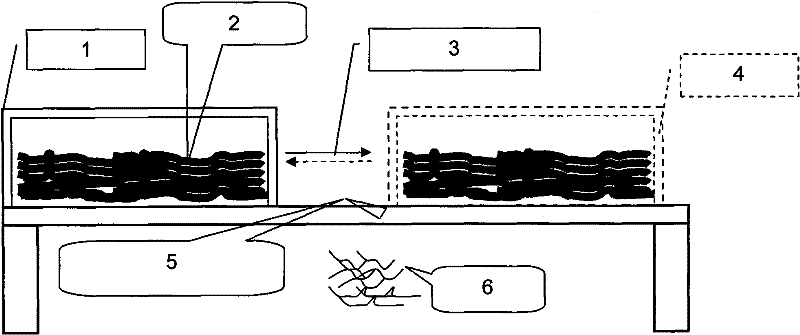

Method for producing high-density recombined wood

InactiveCN102172940AHigh static bending strengthHigh surface hardnessWood compressionVeneer manufactureHigh densityEngineering

The invention relates to a method for producing high-density recombined wood, which is used for manufacturing plates and recombined module timber by the following steps of planning, processing by high-temperature steam, drying, dipping glue, draining glue, drying after draining glue, tidying or weaving, balancing for nourishing, pressing to shape, solidifying at a high temperature and the like. The density of the high-density recombined wood can reach 0.7-1.2kg / cm<3>; the high-density recombined wood has the characteristics of peculiar texture, fine grain, excellent performance, small possibility of cracking and deforming and the like, does not need to prevent insects, prevent mildew, prevent corrosion, prevent from cracking and the like, and can be directly used for the fields of floor, furniture, building and the like. The method disclosed by the invention has simple working procedures, and abandoned secondarily secondary small fuel wood and secondary small wood are utilized to produce plates and module wood, thereby changing waste materials into things of value, and greatly saving forest resource. The wood is an ideal log substitute.

Owner:浙江仕强竹业有限公司

Crown molding and door installation tools

A crown molding jig may have a first guide and a second guide. Each of the guides may be sized and configured to receive a crown molding. A saw guide may be disposed between the first and second guides for guiding a saw blade and cutting a compound angle cut in the crown molding. A crown molding holder may have a base member for engaging the crown molding and an extension pole pivotally attached to the base member such that the crown molding holder may be wedged between the crown molding disposed at the ceiling and the floor. A door installation jig may have a U-shaped member sized and configured to receive a door and an inflatable tube for lifting the door to position adjacent a door frame.

Owner:KHAN VIKTOR

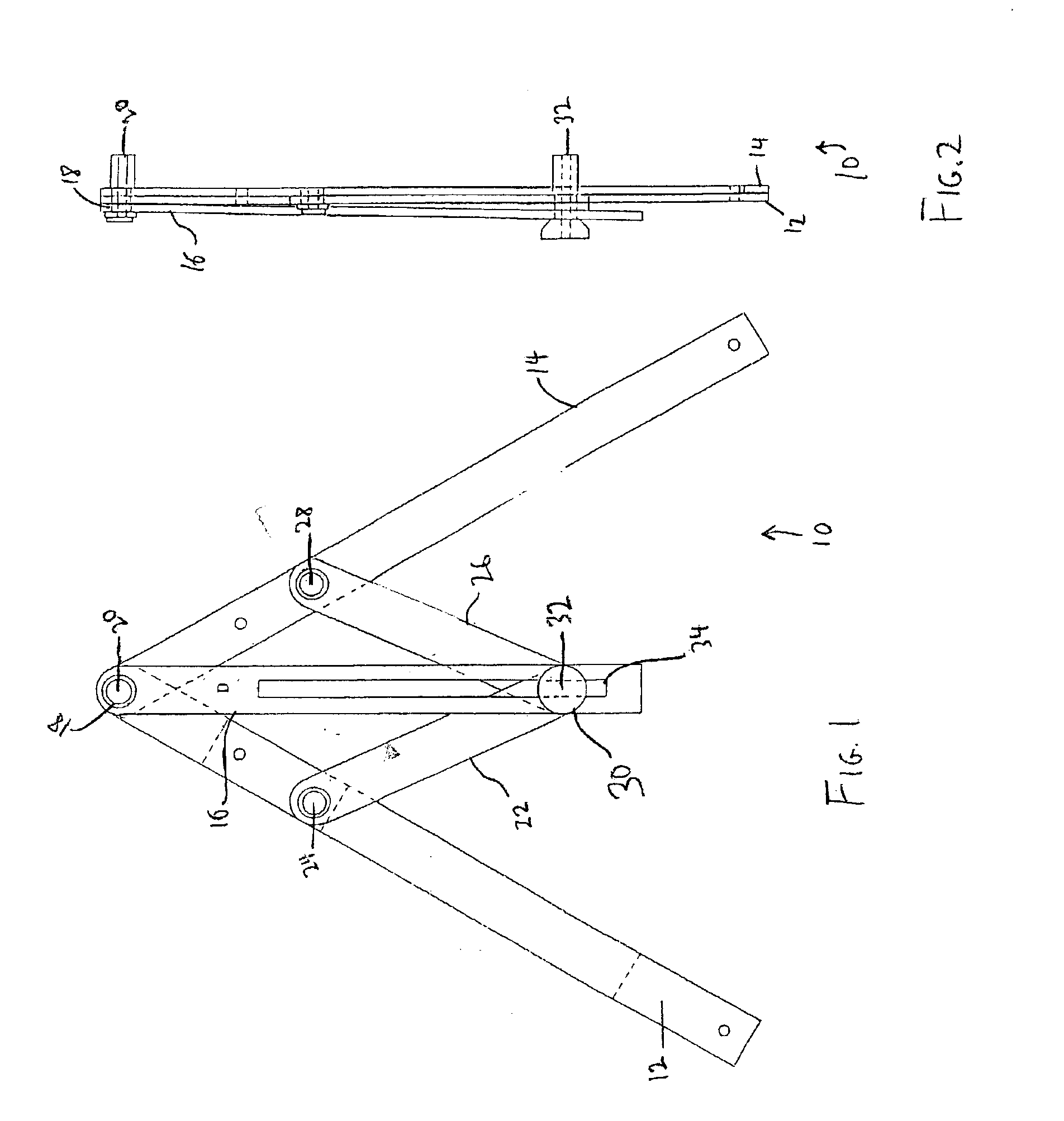

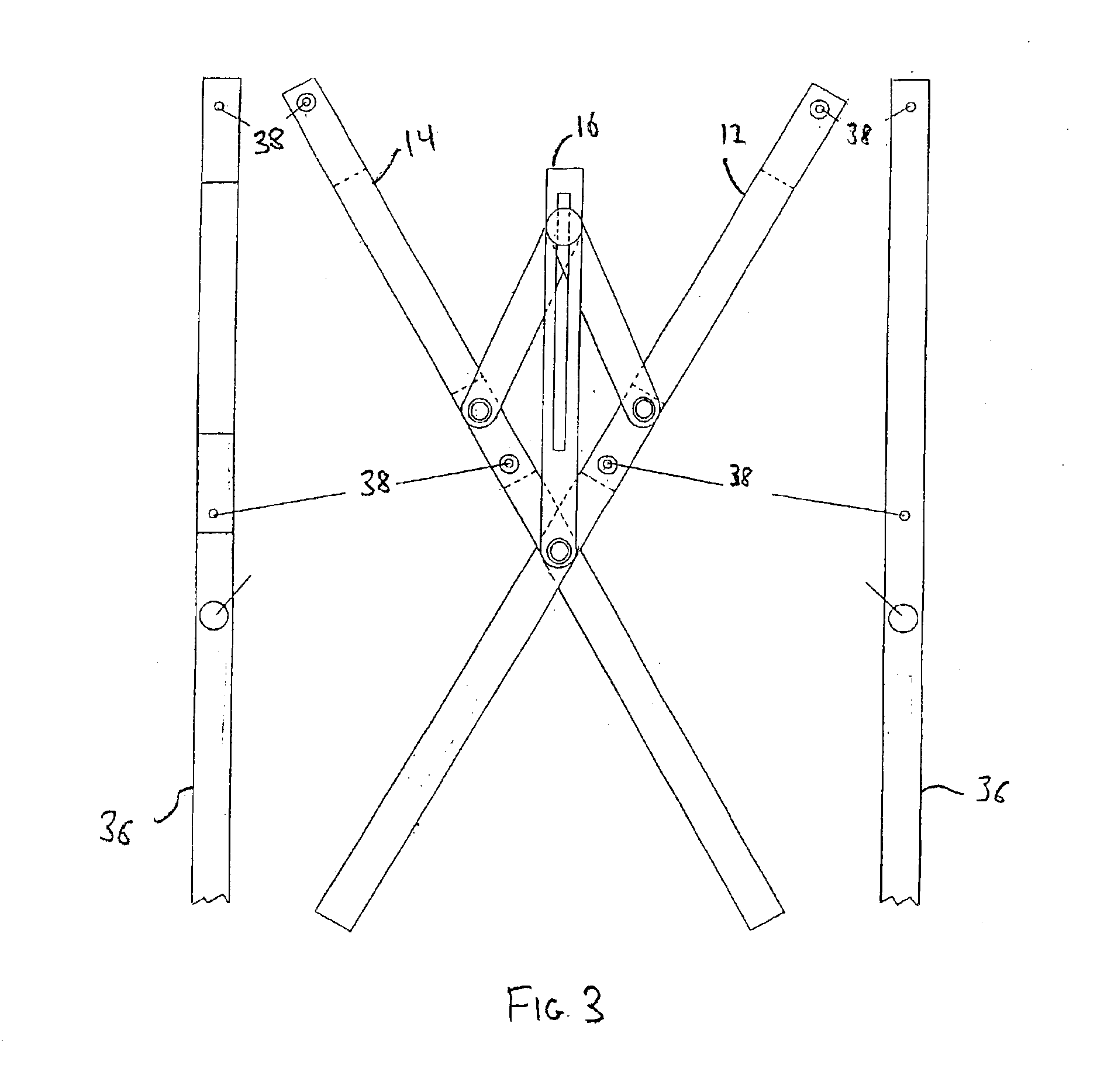

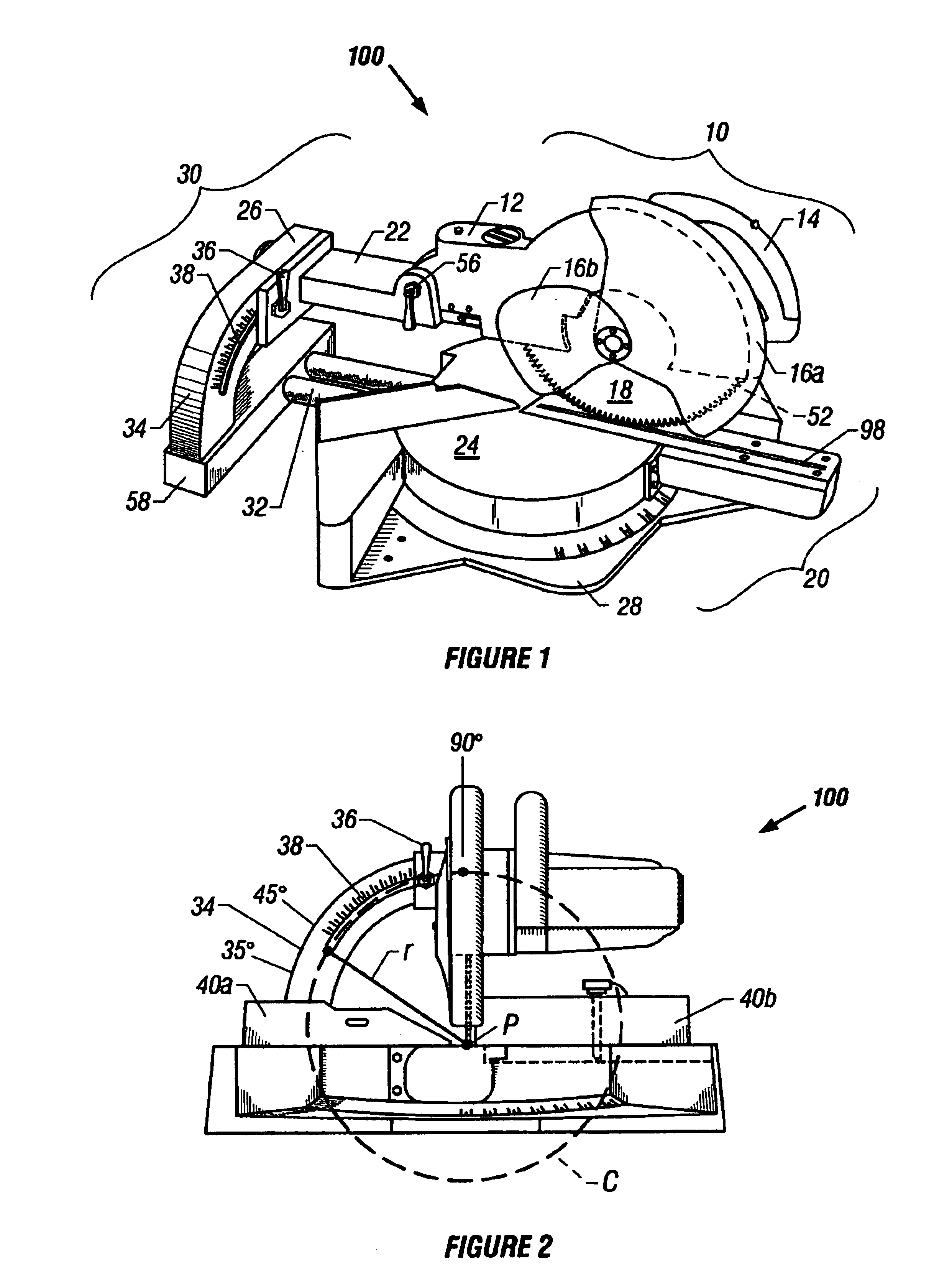

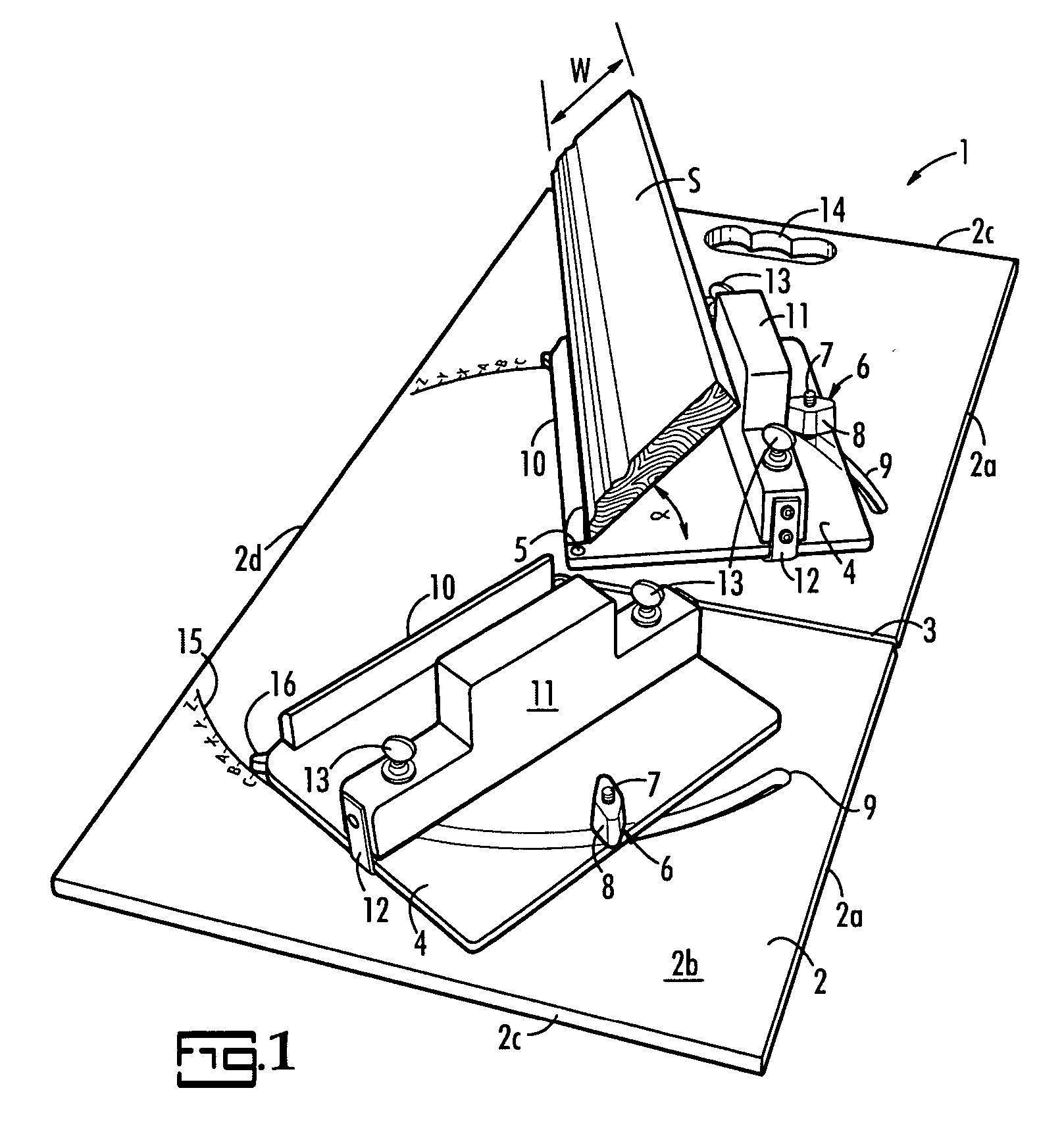

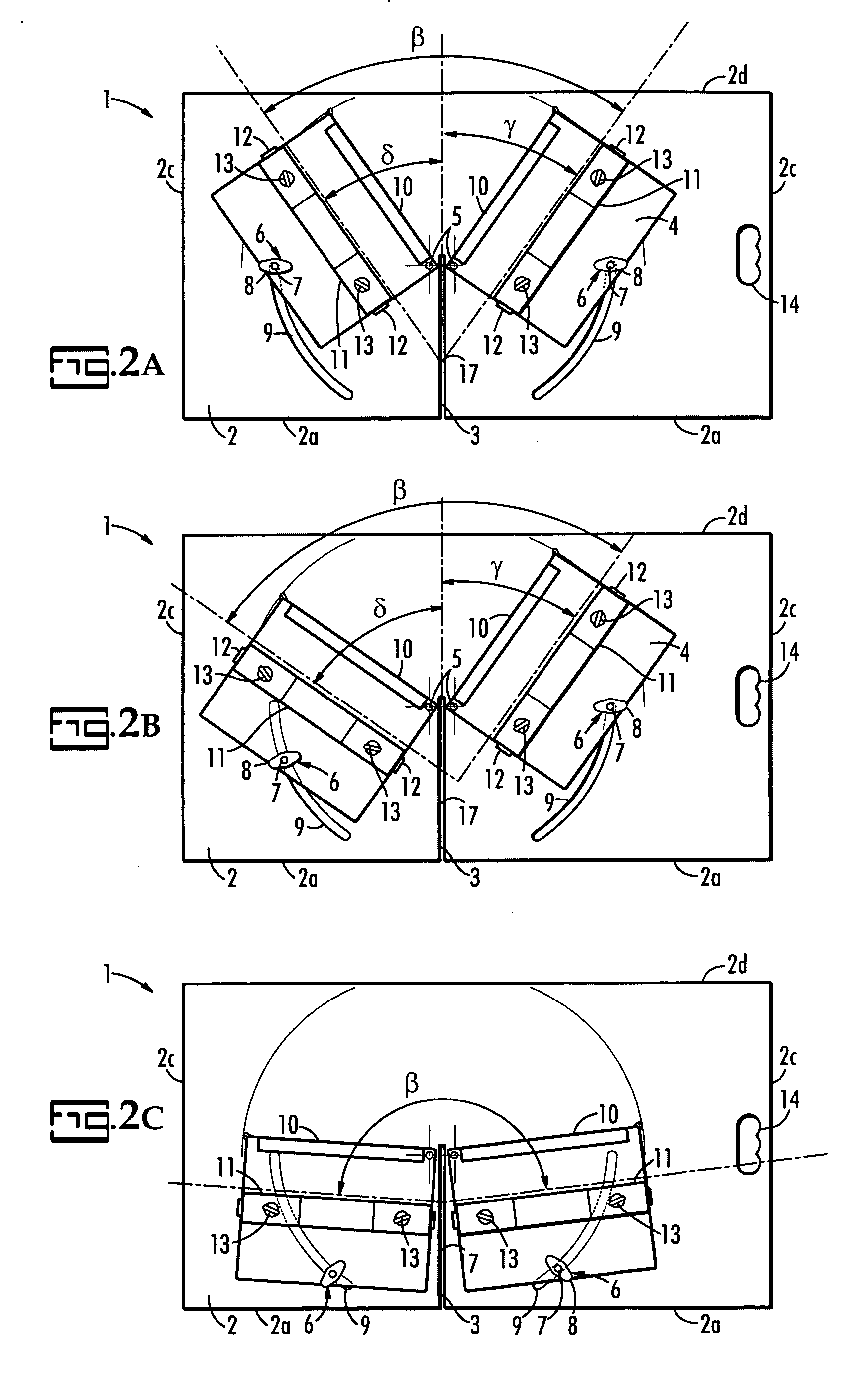

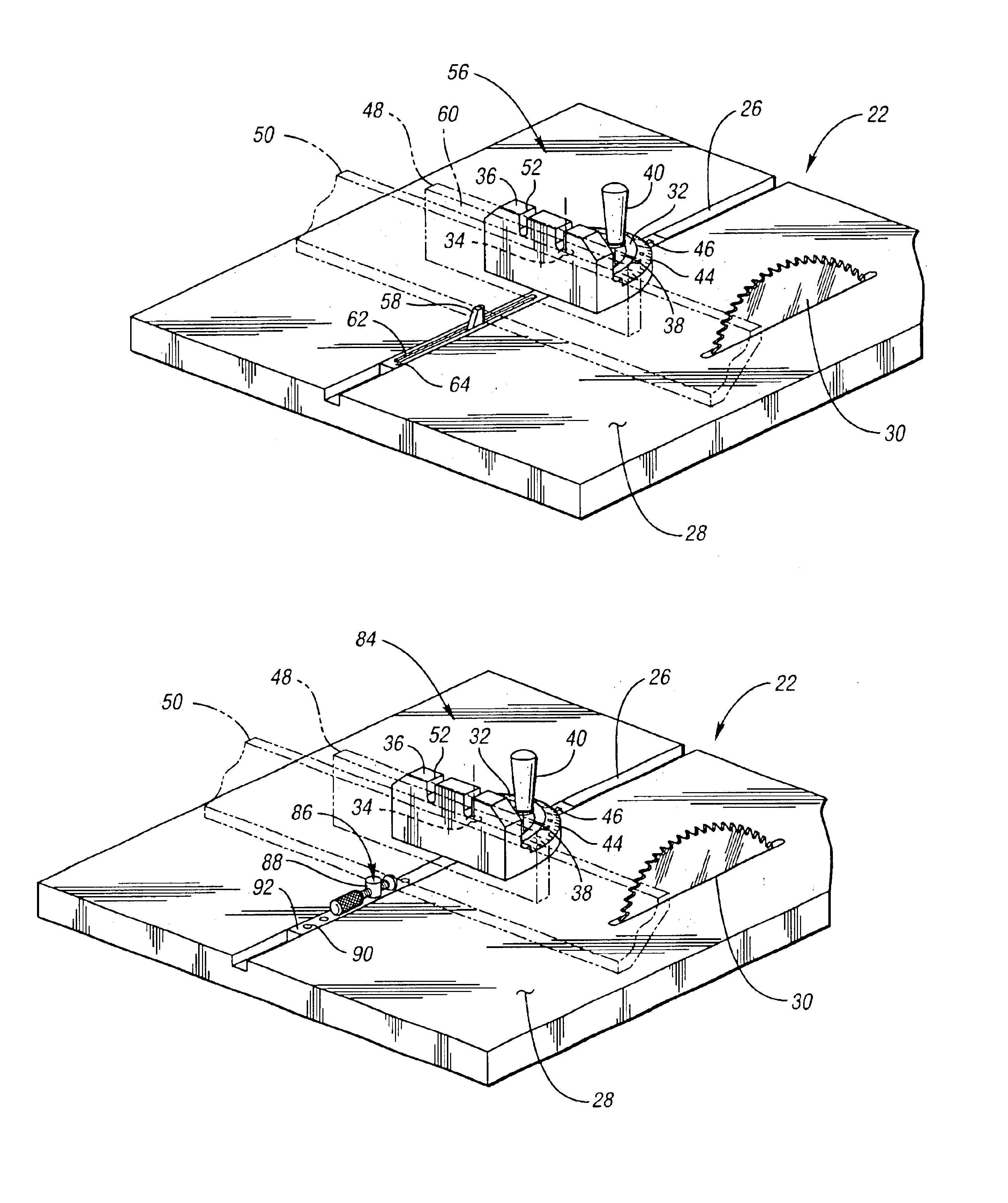

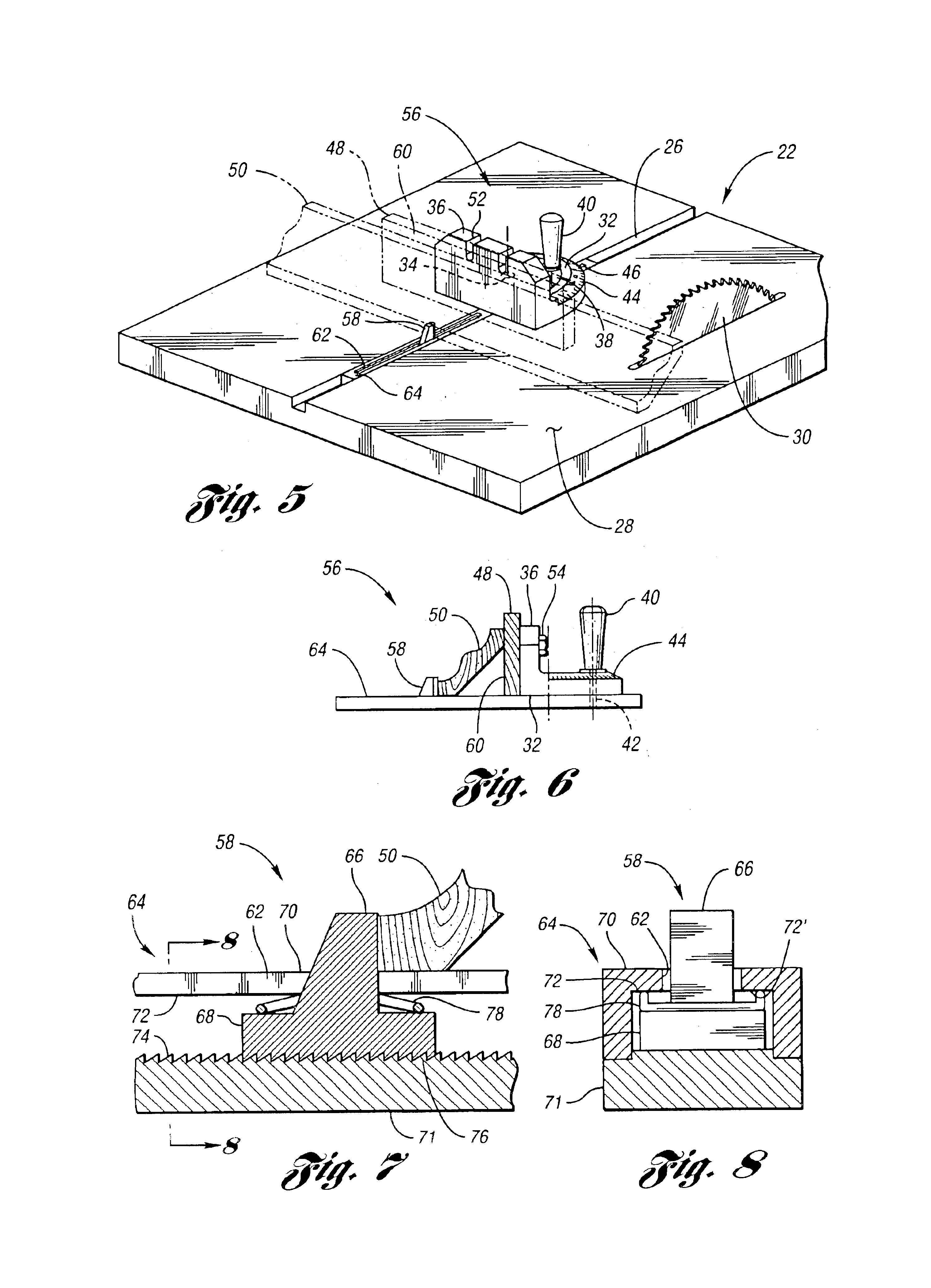

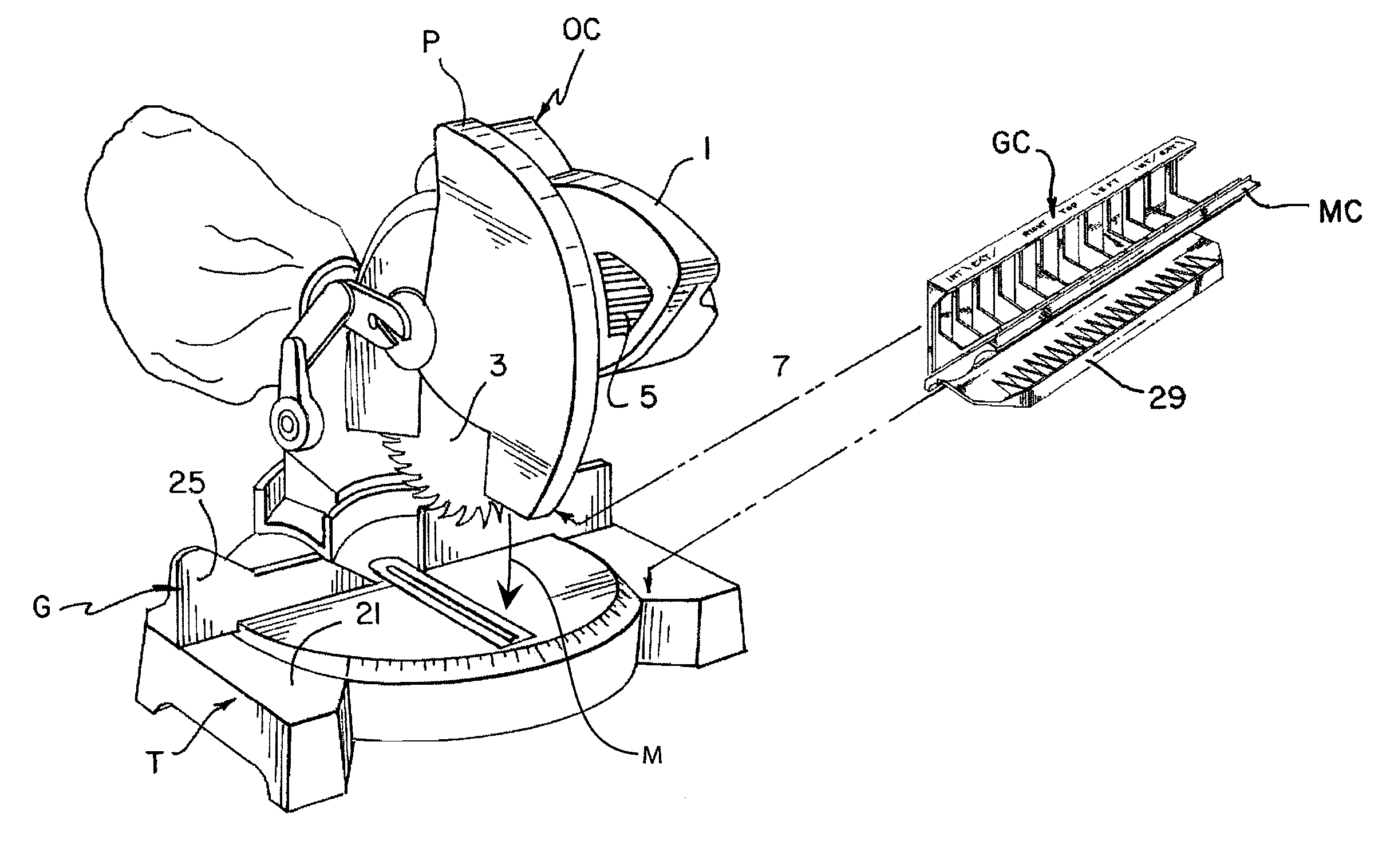

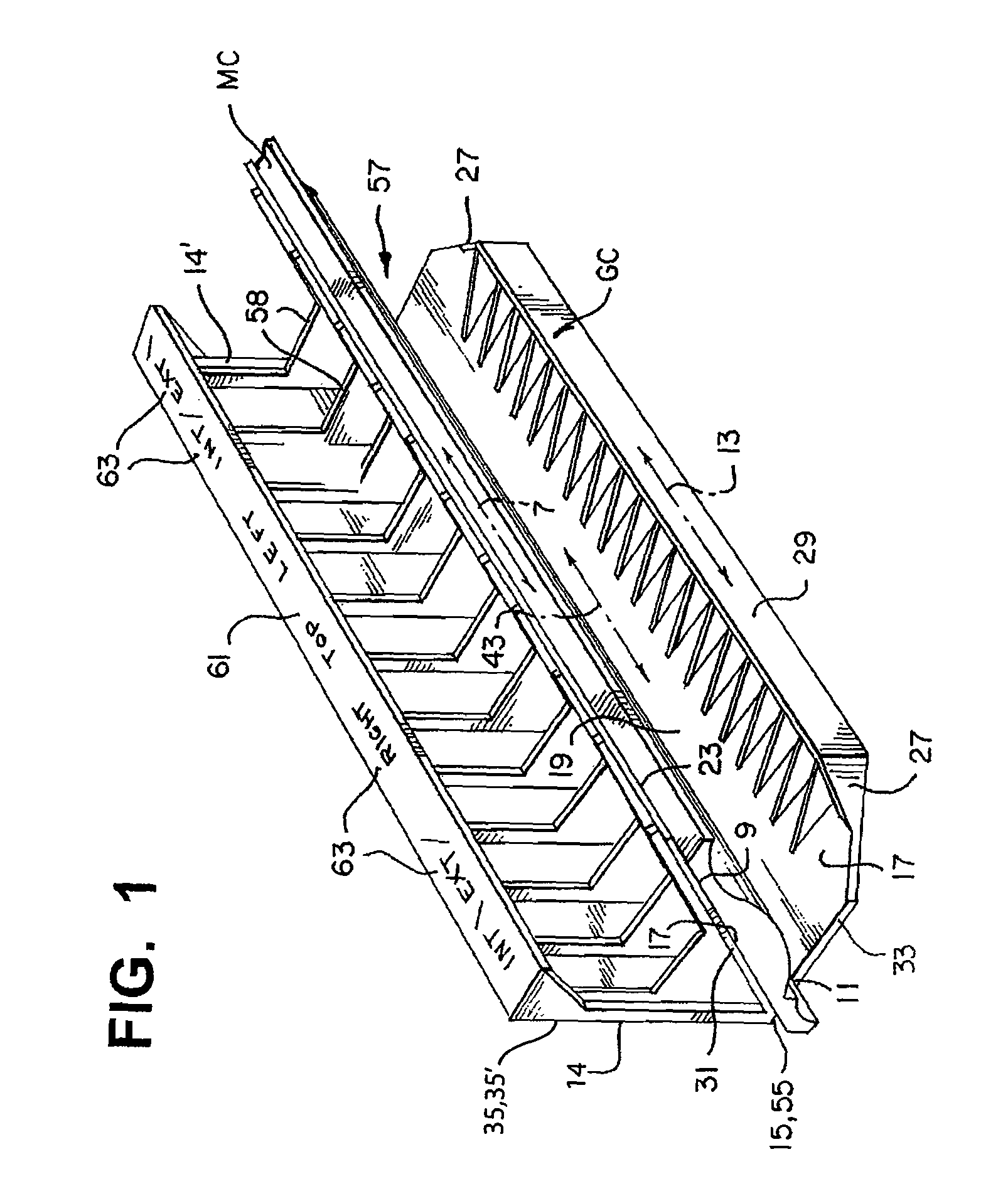

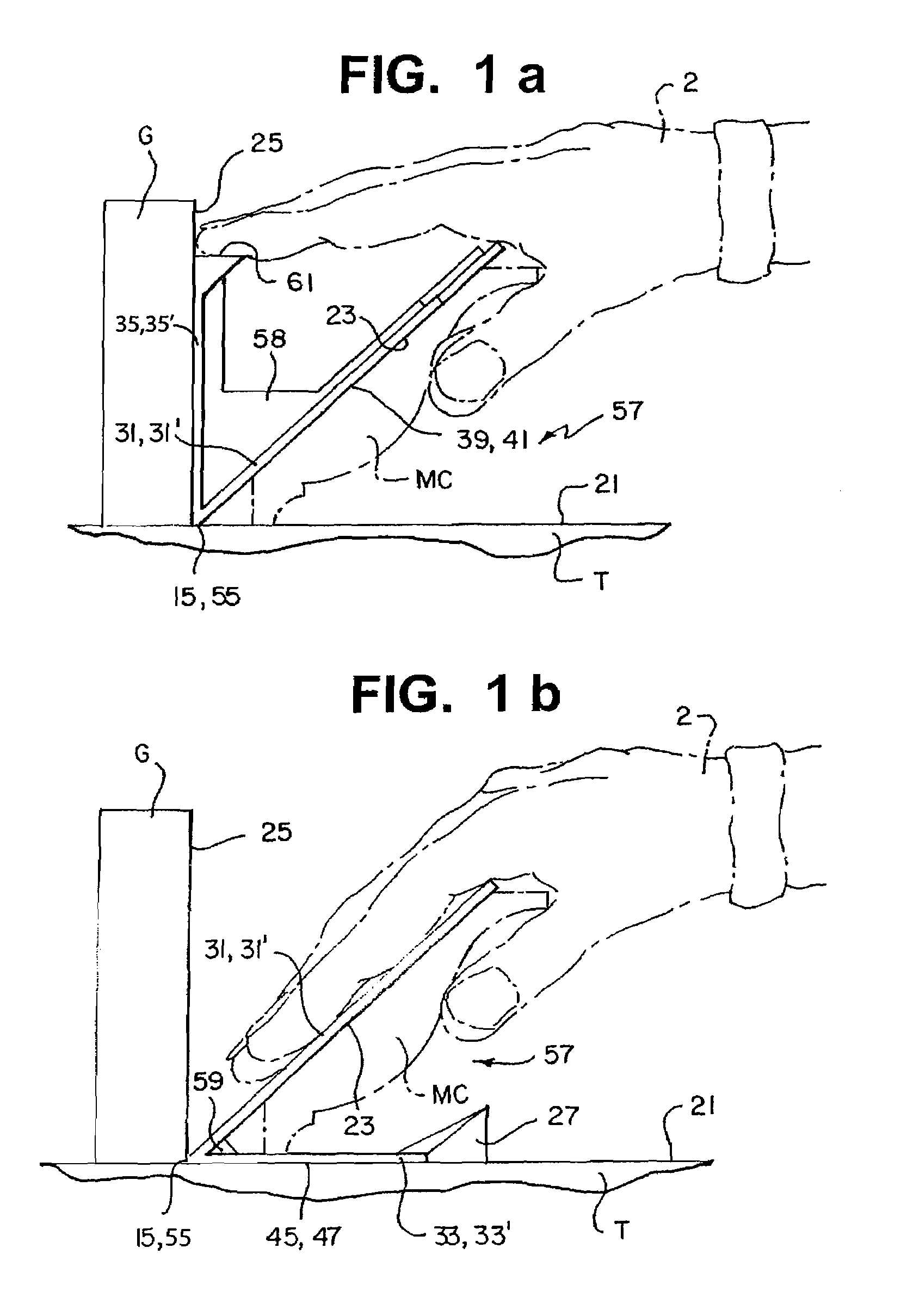

System for precision miter cutting

InactiveUS6877238B2Easy to cutMetal sawing accessoriesBuilding constructionsEngineeringMechanical engineering

A system for modeling a recessed or protruding angle formed by convergent surfaces and transferring that modeled angle directly to a miter saw for facilitating the cutting of workpieces in conformance with the bisection of that modeled angle. This system may be manufactured with, or retrofitted onto a standard miter saw or used with a hand miter saw designed to accommodate the system.

Owner:KANAGA LAWRENCE W

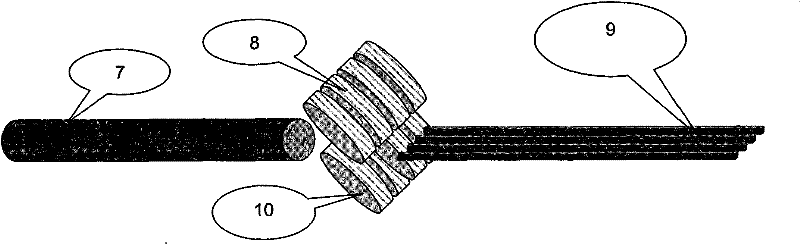

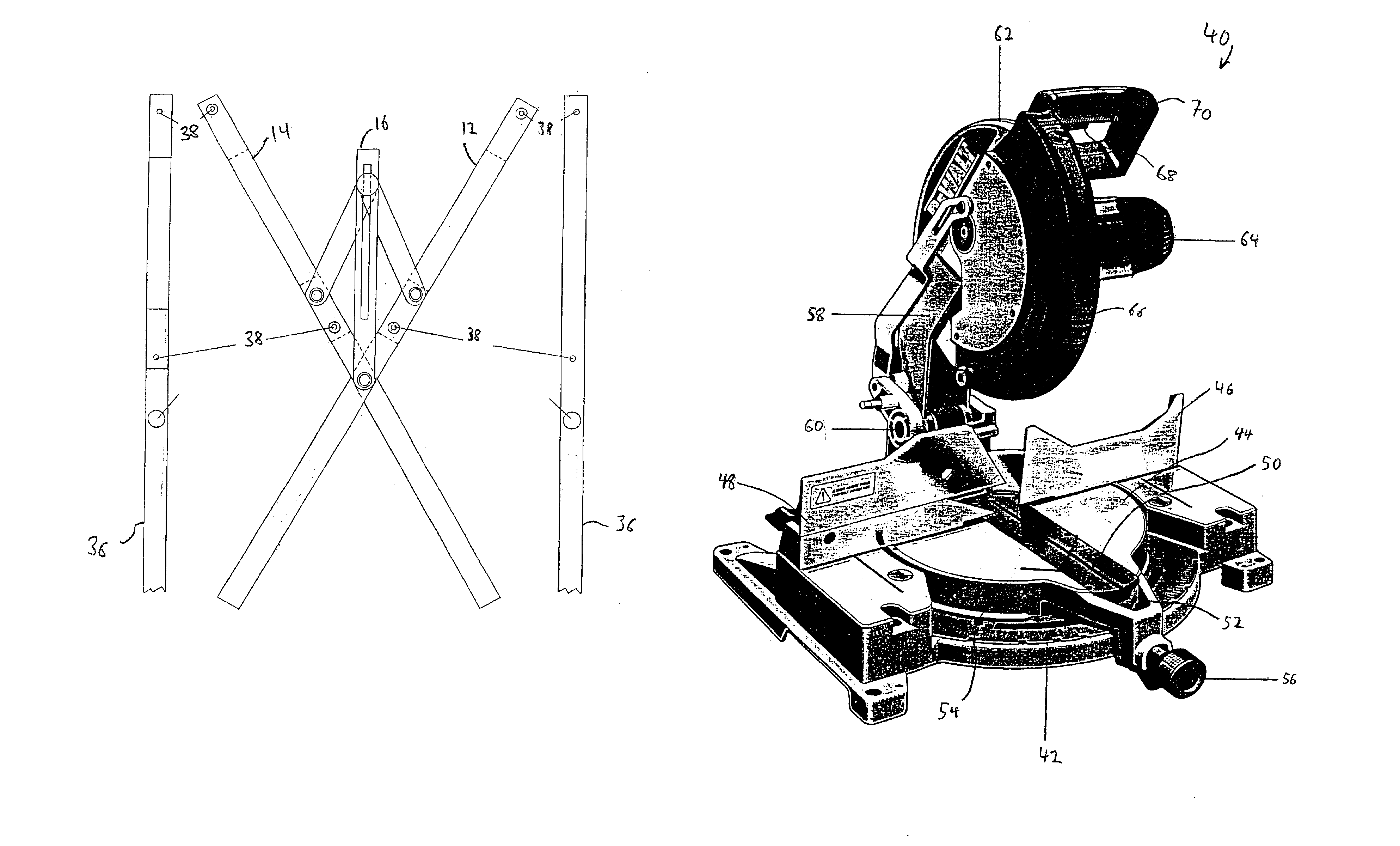

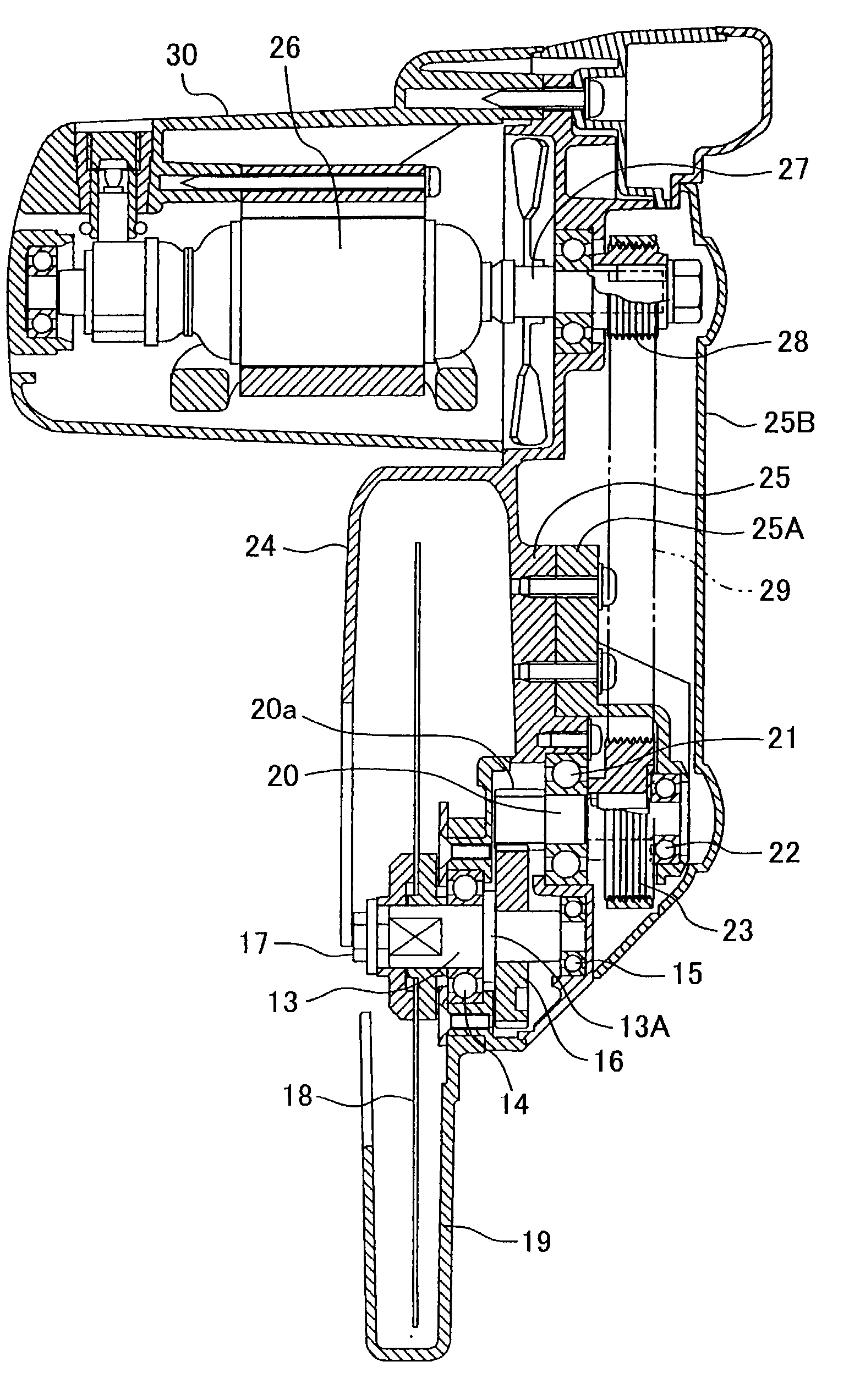

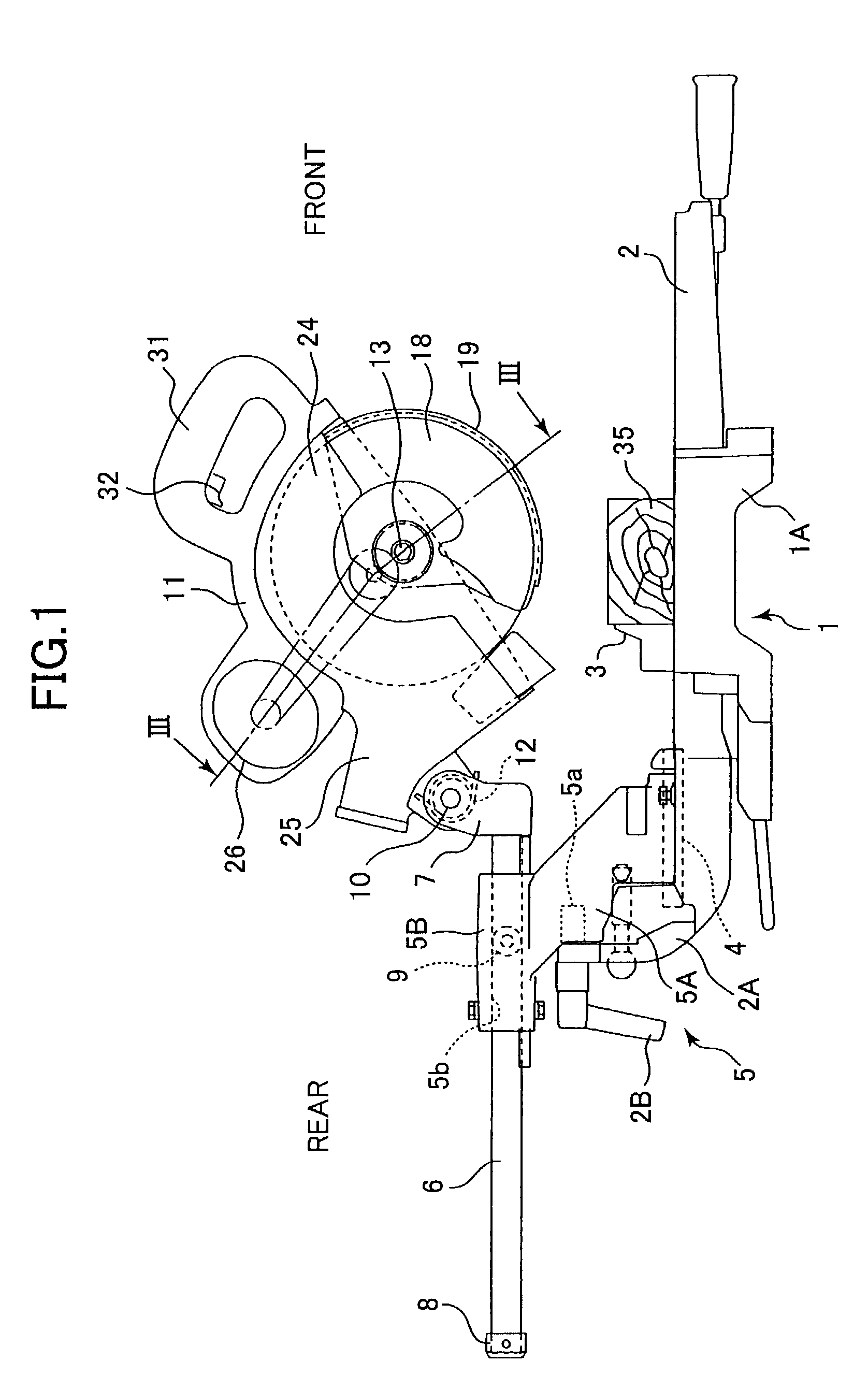

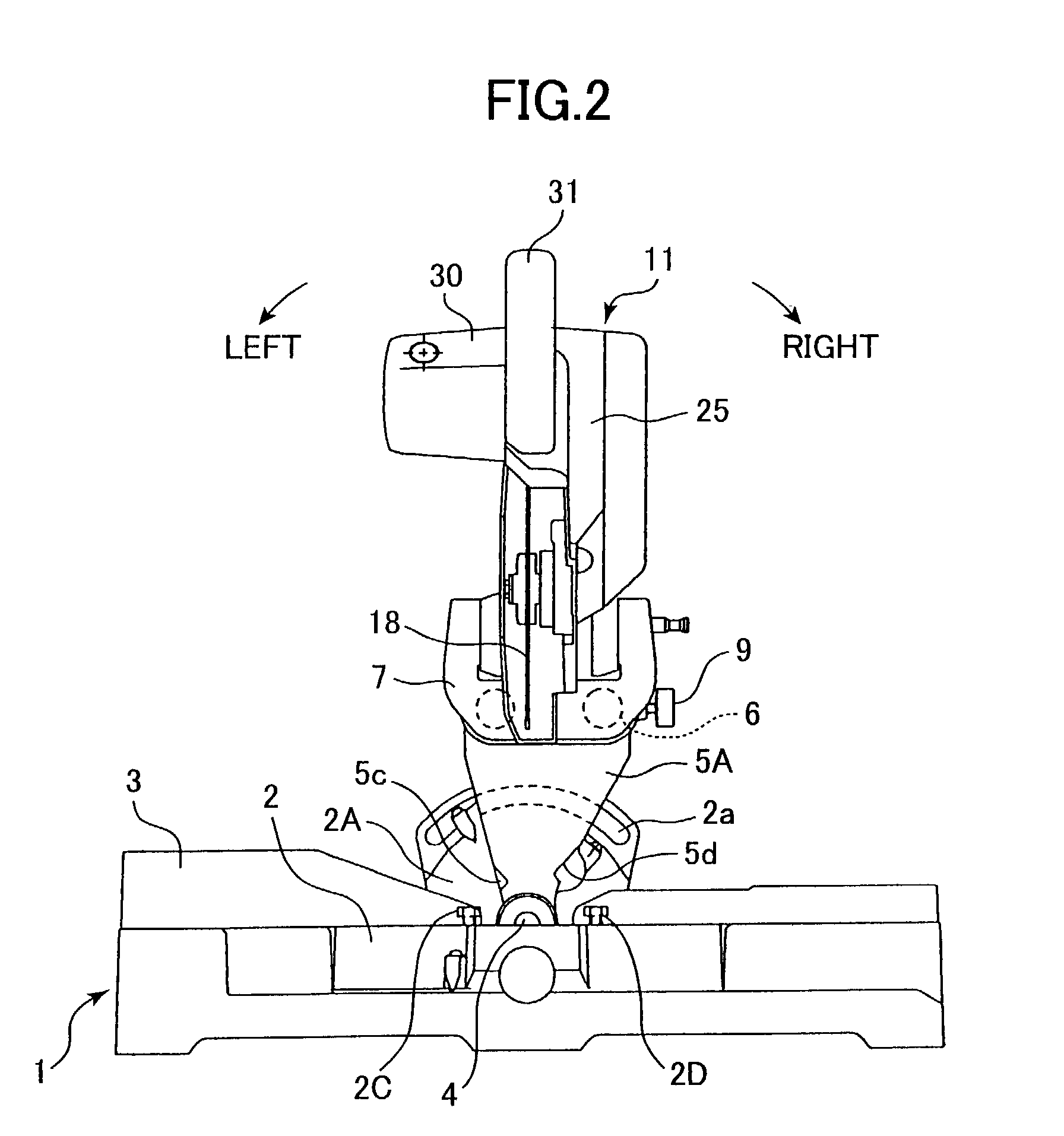

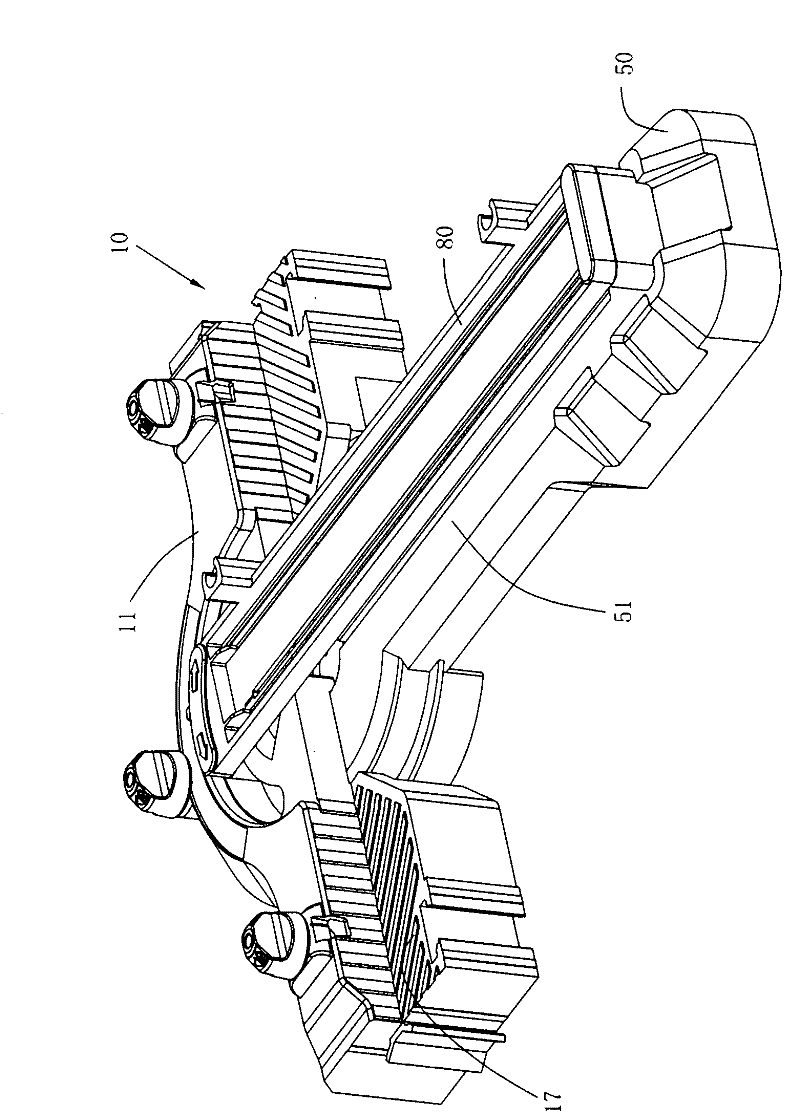

Miter saw with laterally tiltable circular saw blade

InactiveUS6971298B2Reduce axial thicknessIncrease effective cutting lengthMetal sawing devicesMetal sawing accessoriesGear wheelMedial axis

A miter saw including a base portion and a main body portion laterally tiltable and vertically pivotable. The main body portion includes a circular saw blade whose one side is provided with a power transmission mechanism. The mechanism includes a motor shaft pulley fixed to a motor shaft of a motor, a saw blade shaft extending in parallel with the motor shaft and an intermediate shaft extending in parallel with the saw blade shaft and positioned between the motor shaft and the saw blade shaft. On the saw blade shaft, a first saw blade shaft bearing, a flanged abutment portion, a gear and a second saw blade shaft bearing are arrayed in an order from the circular saw blade. On the intermediate shaft, a pinion meshedly engaged with the gear, a first intermediate shaft bearing in alignment with the second saw blade shaft bearing, an intermediate shaft pulley in alignment with the motor shaft pulley and a second intermediate shaft bearing are arrayed in this order from the circular saw blade. The gear and the pinion are positioned closest to the circular saw blade, which permits an axial thickness of the abutment portion to be reduced for reducing entire axial thickness of the power transmission mechanism.

Owner:HITACHI KOKI CO LTD

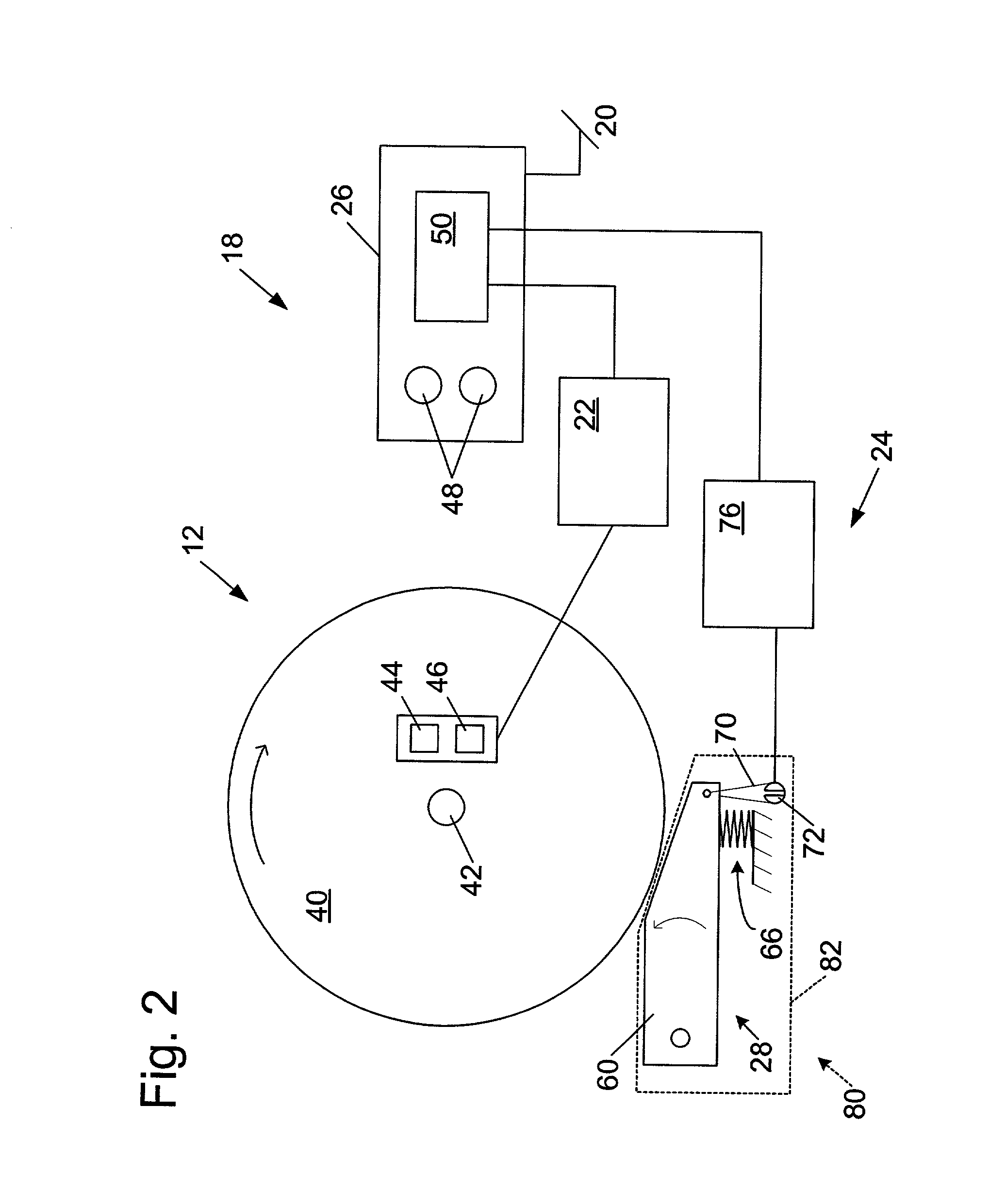

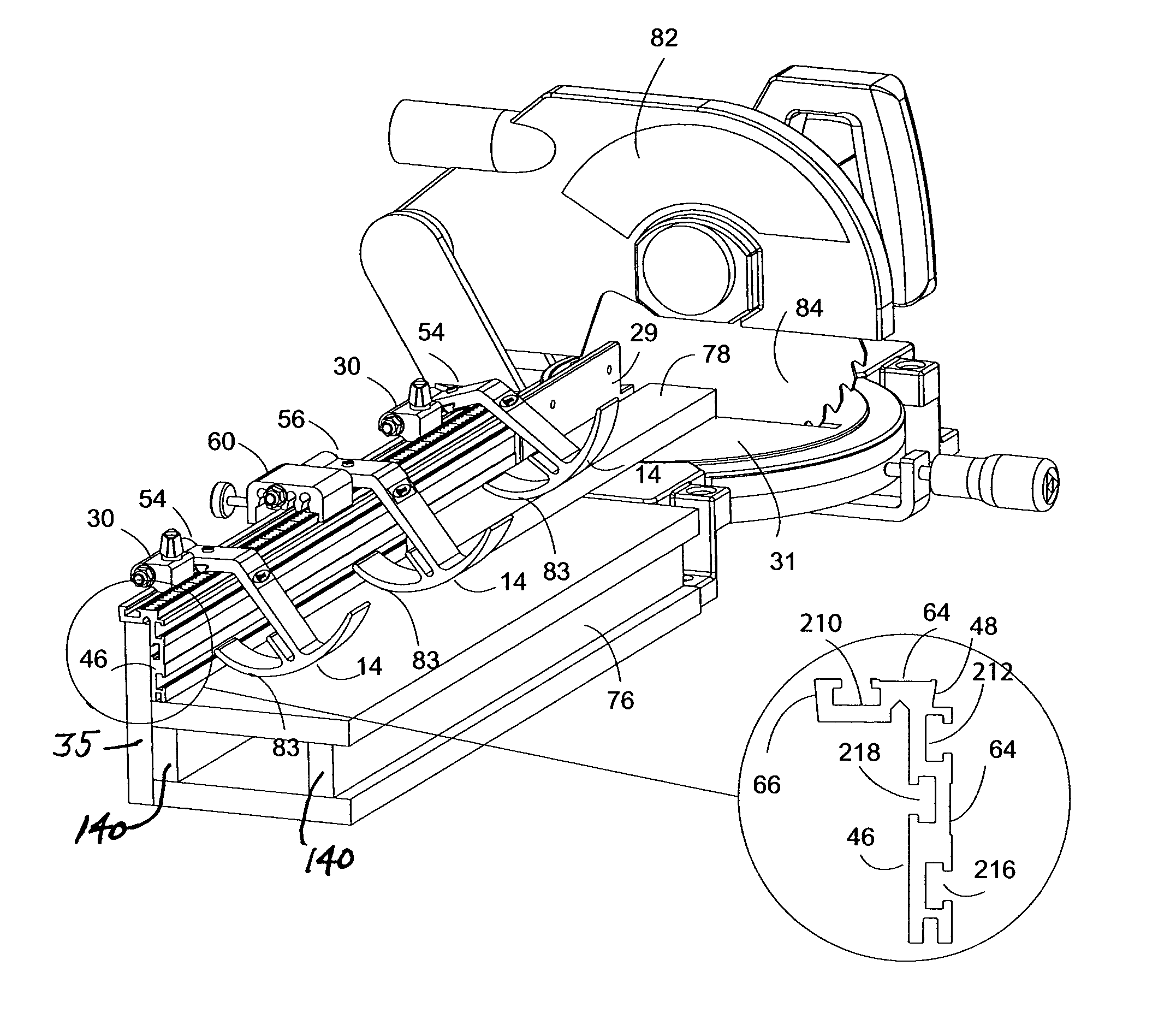

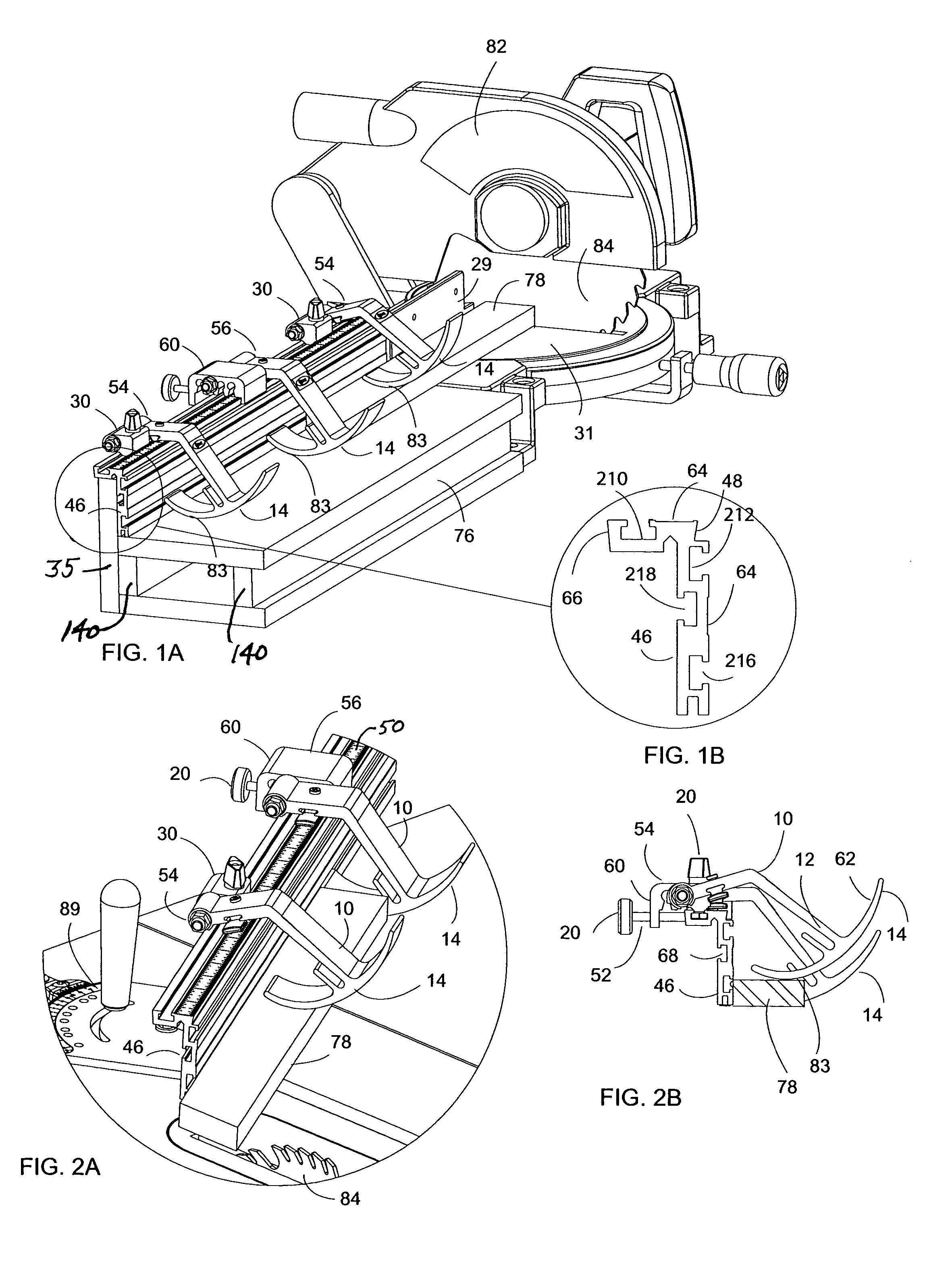

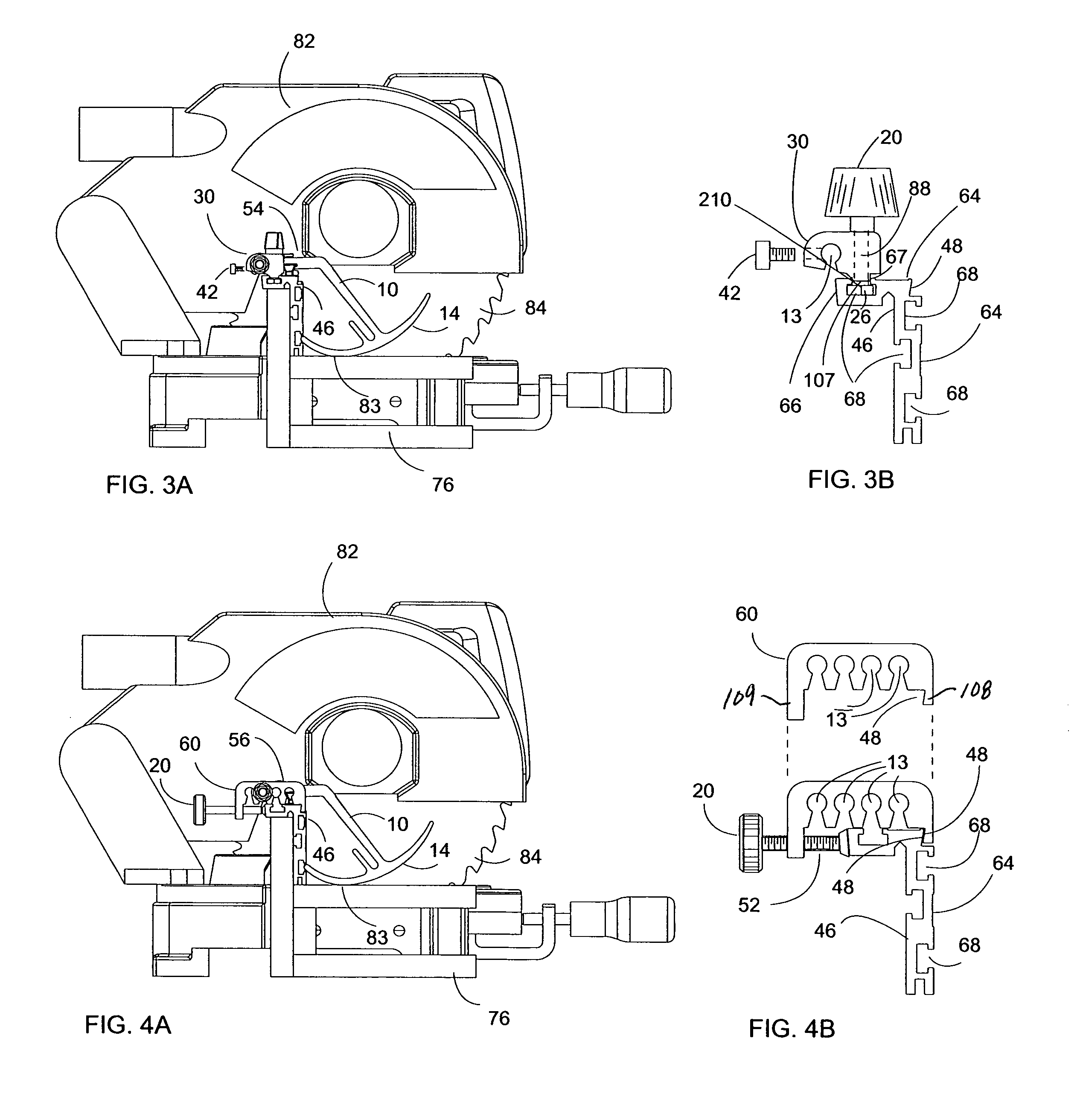

Detection system for power equipment

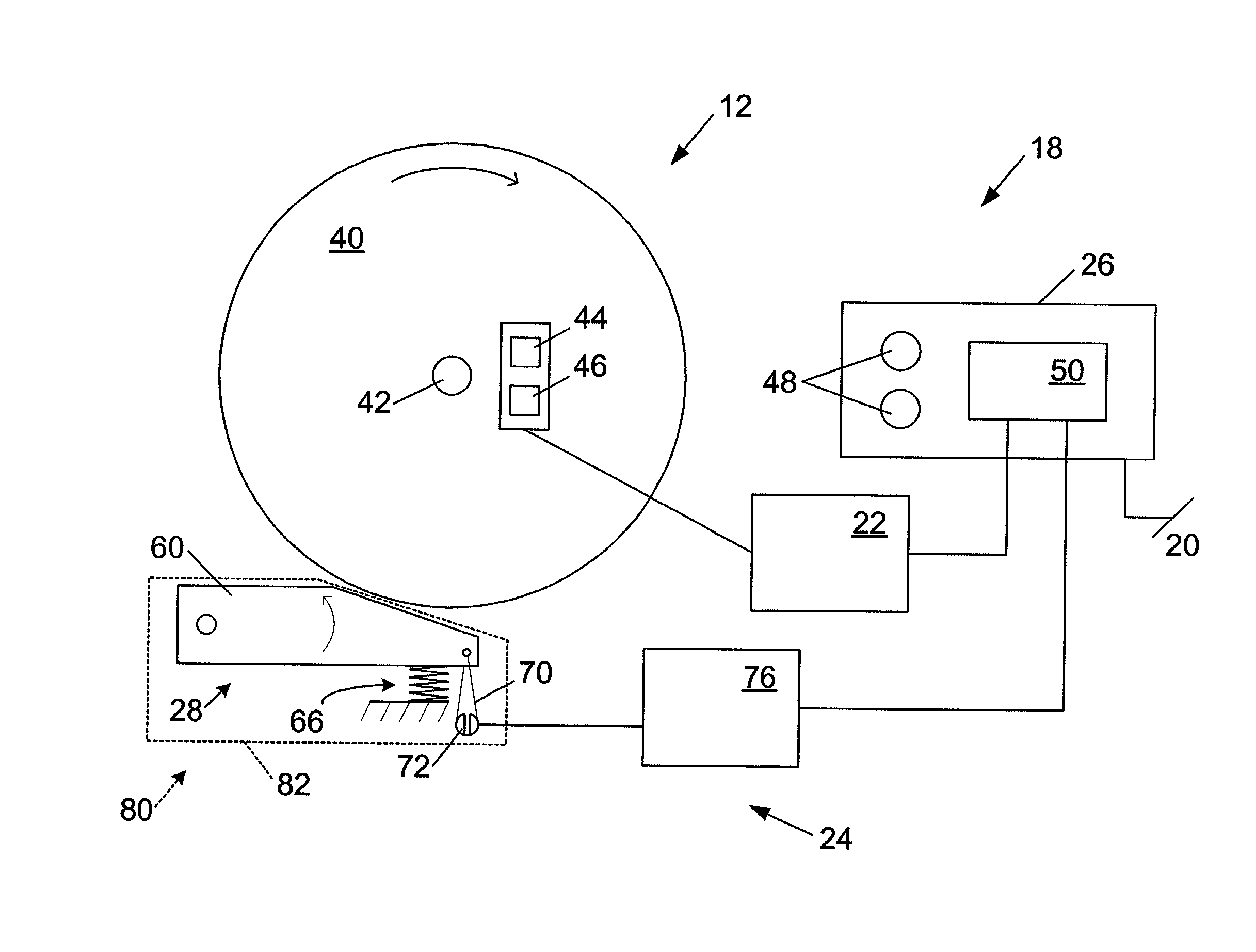

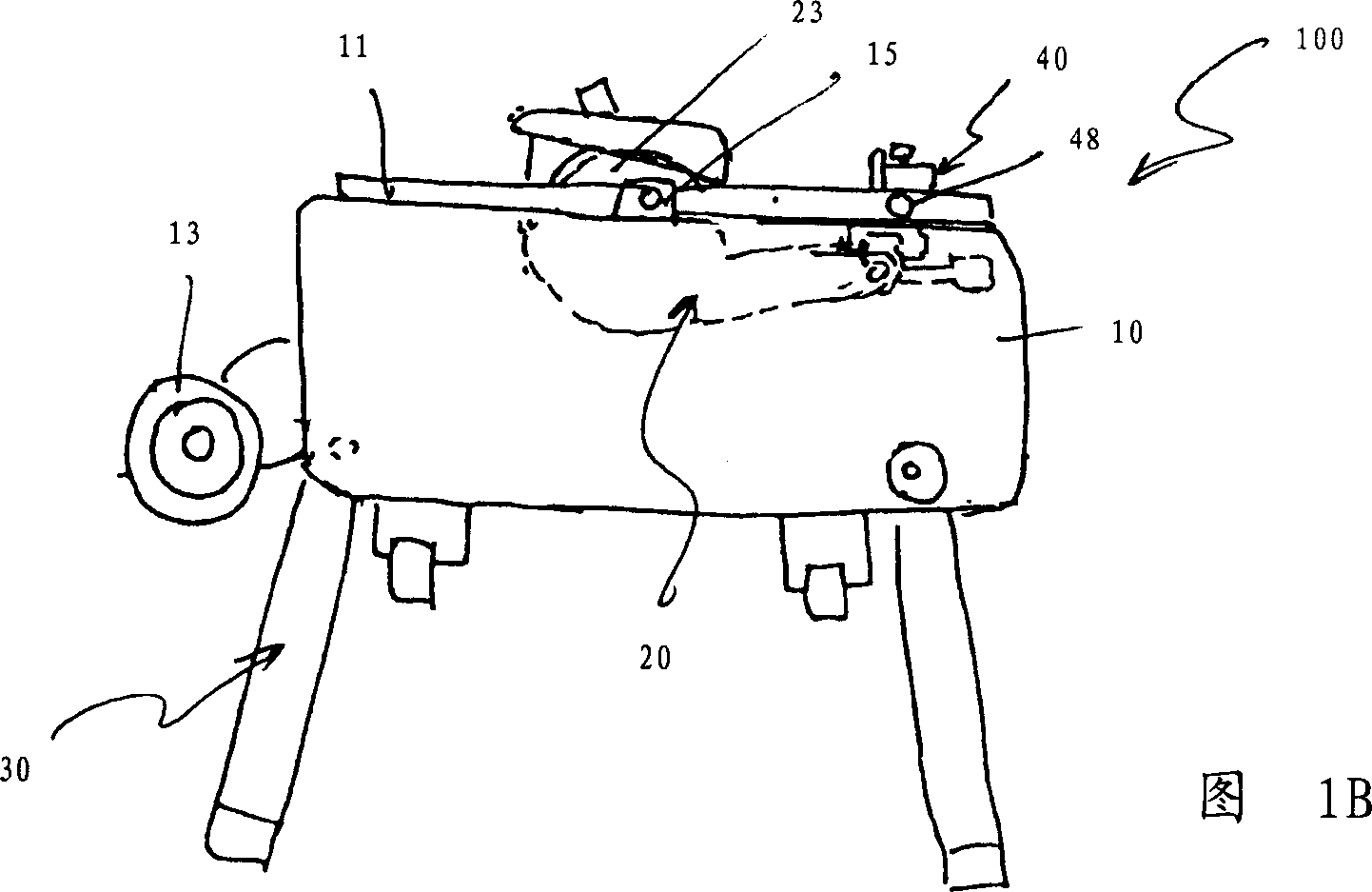

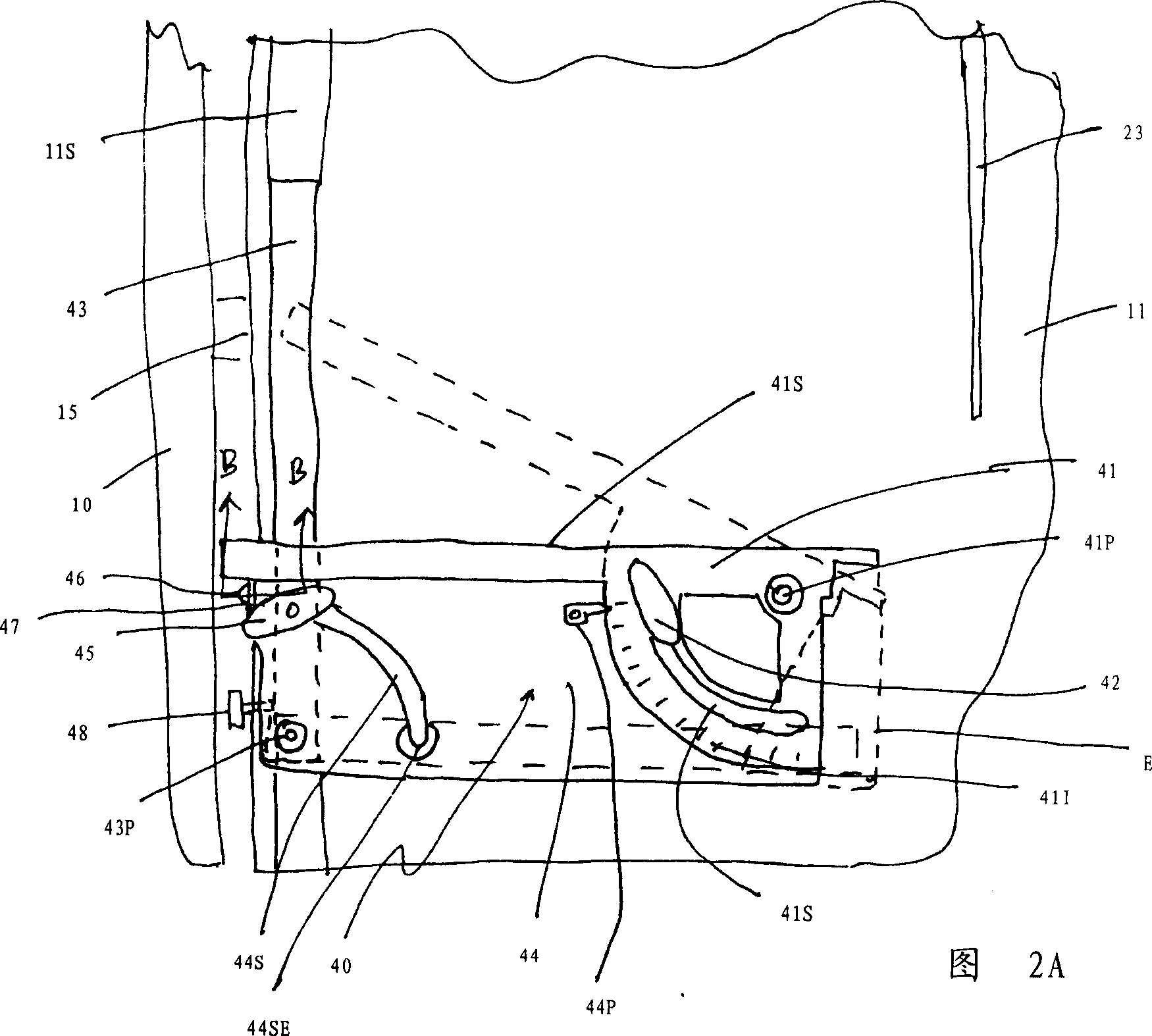

InactiveUS20070199622A1Engineering safety devicesMitre joint working devicesEngineeringPower equipment

Woodworking machines including conductive cutters adapted to cut workpieces, and motors adapted to drive the cutters are disclosed. The machines also include a contact detection system adapted to detect contact between a person and the cutter, and to distinguish contact between the person and the cutter from contact between the workpiece and the cutter. The machines further include a reaction system adapted to cause a predetermined action to take place upon detection of contact between the person and the cutter by the contact detection system.

Owner:SAWSTOP HLDG LLC

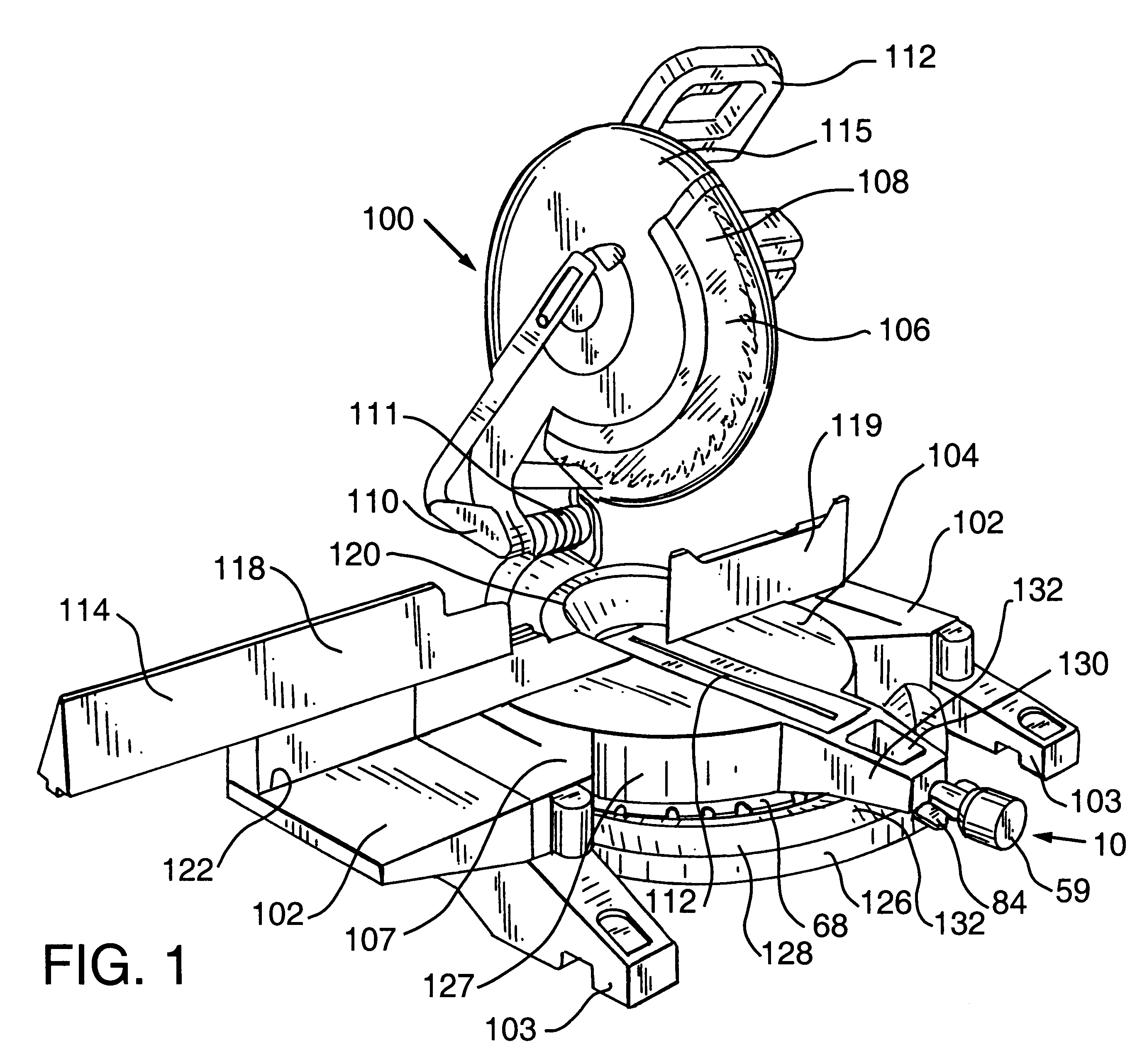

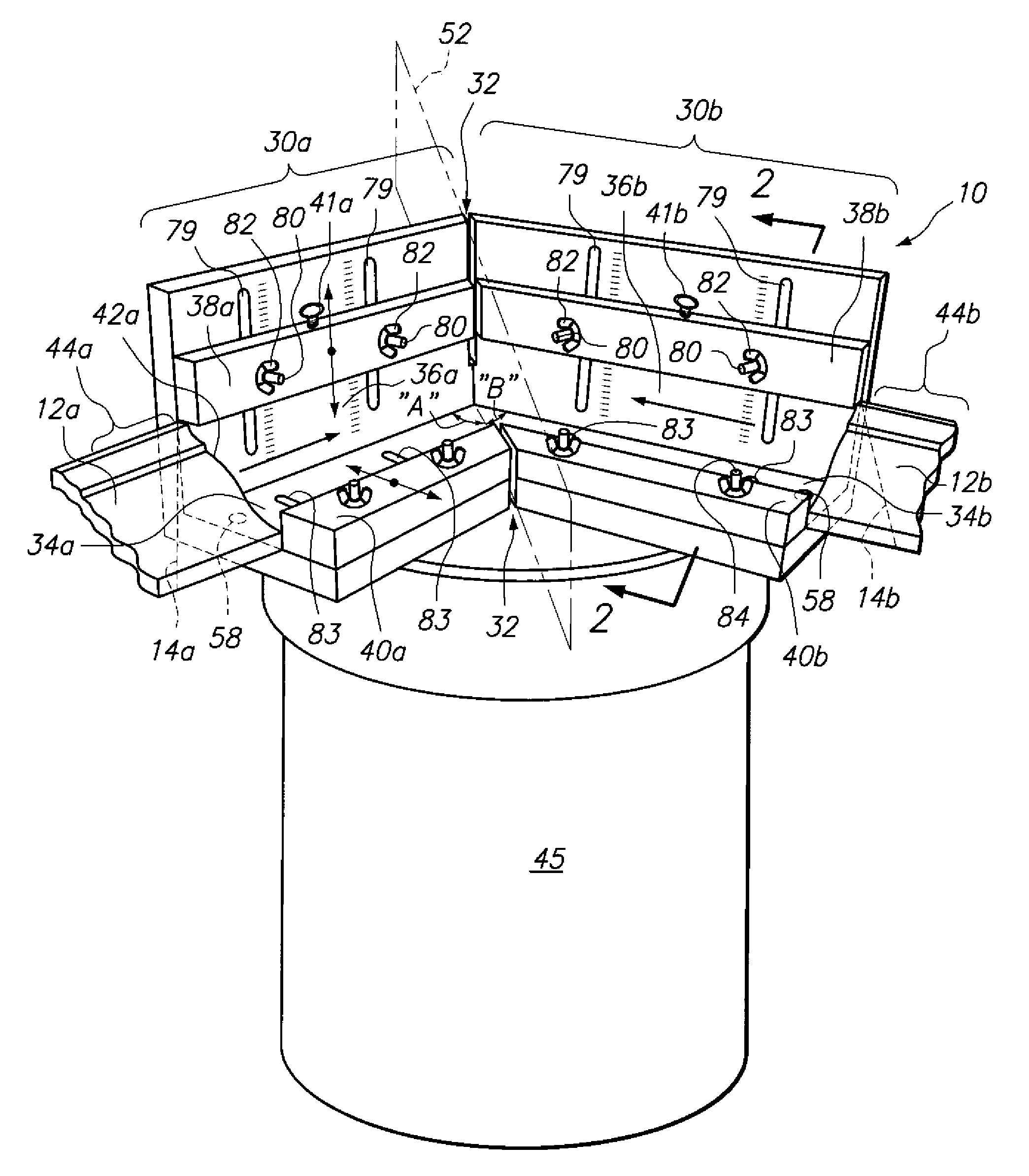

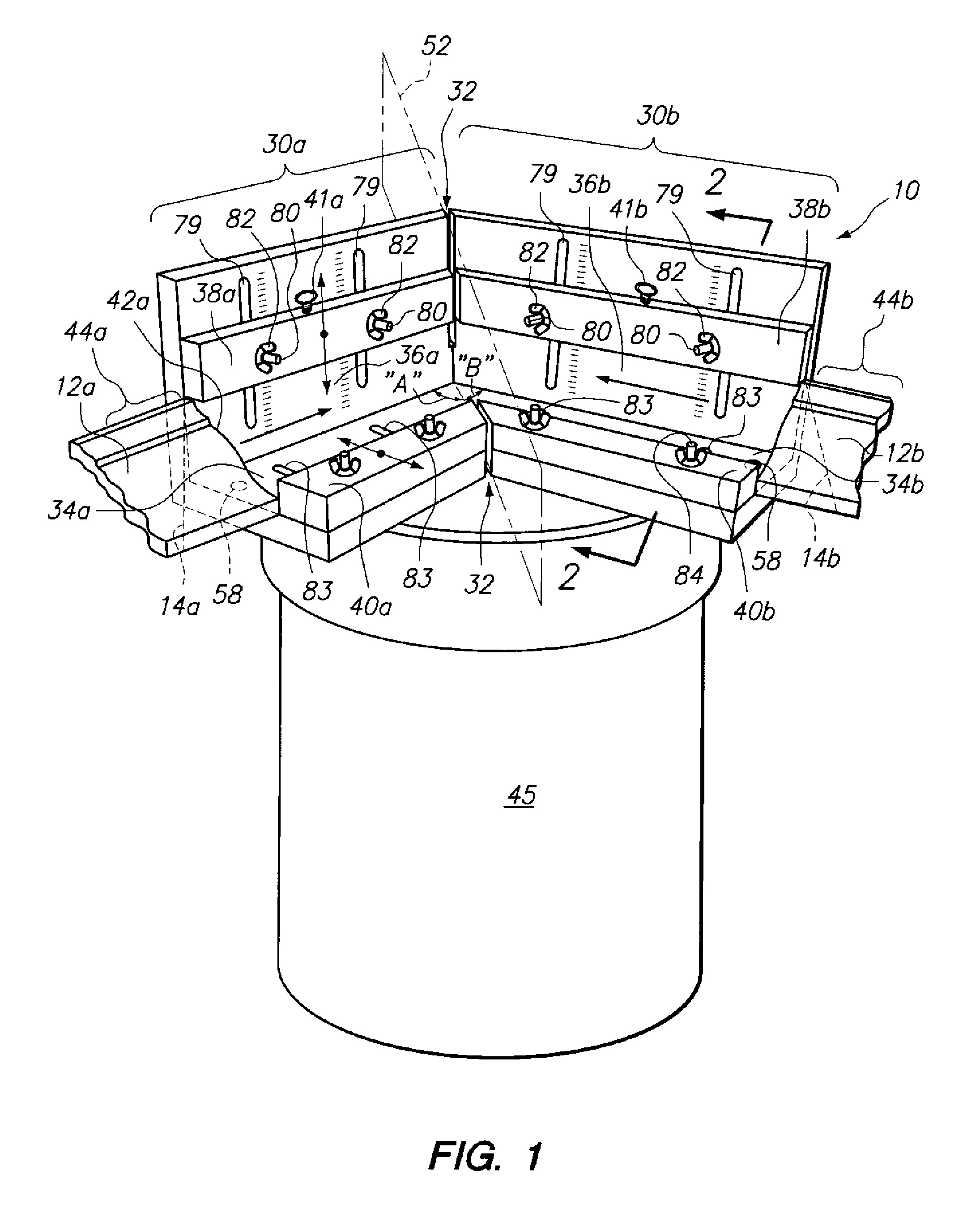

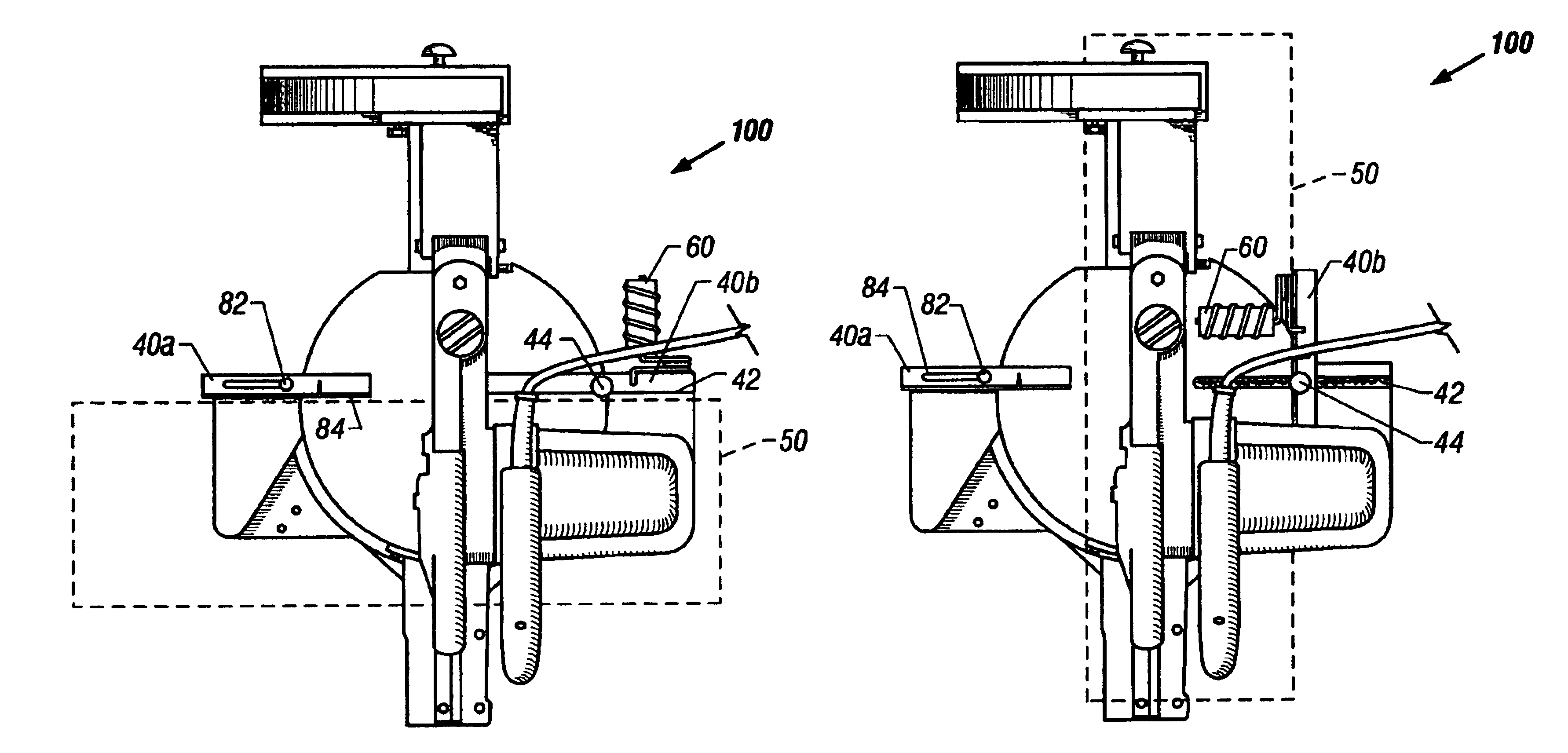

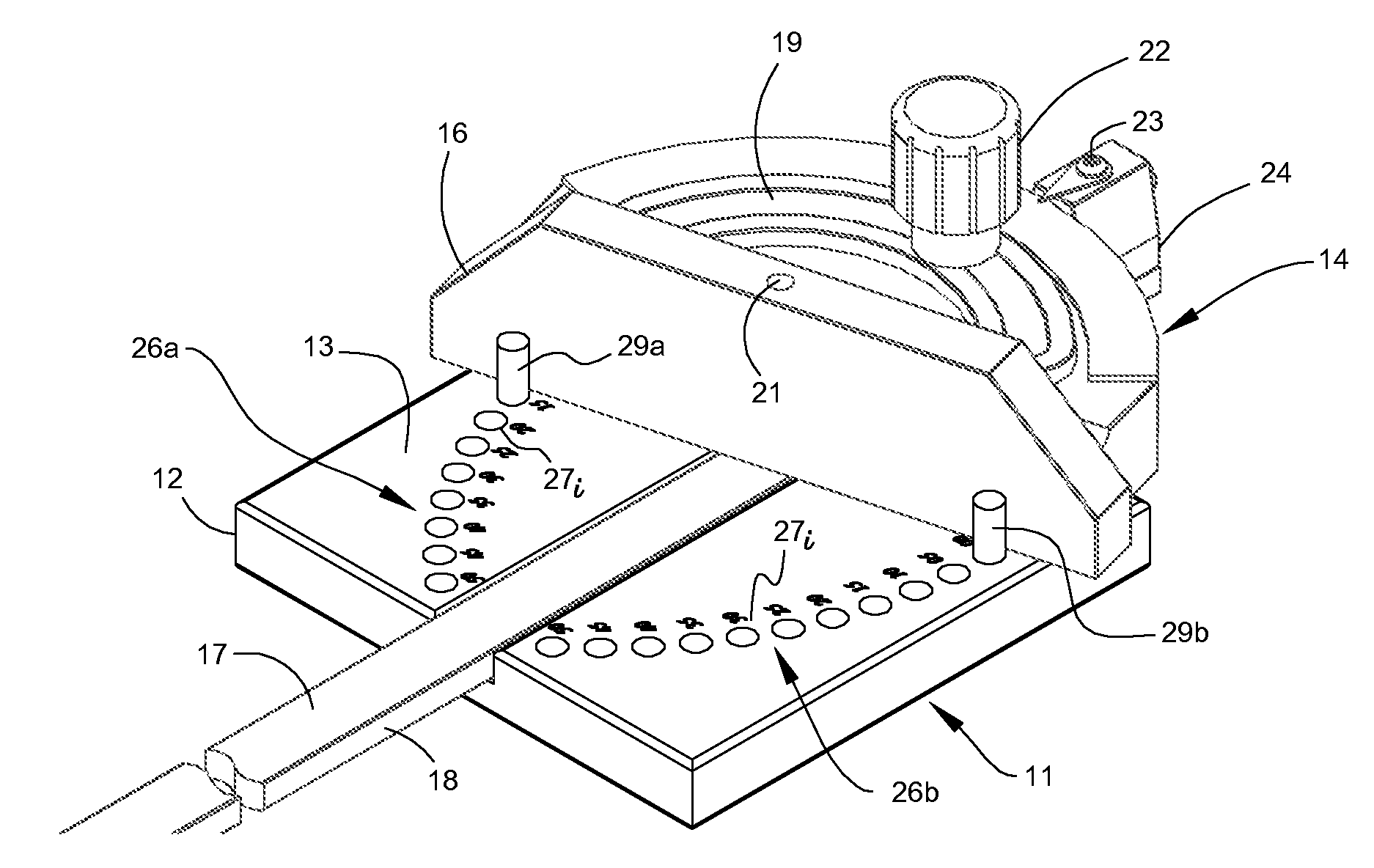

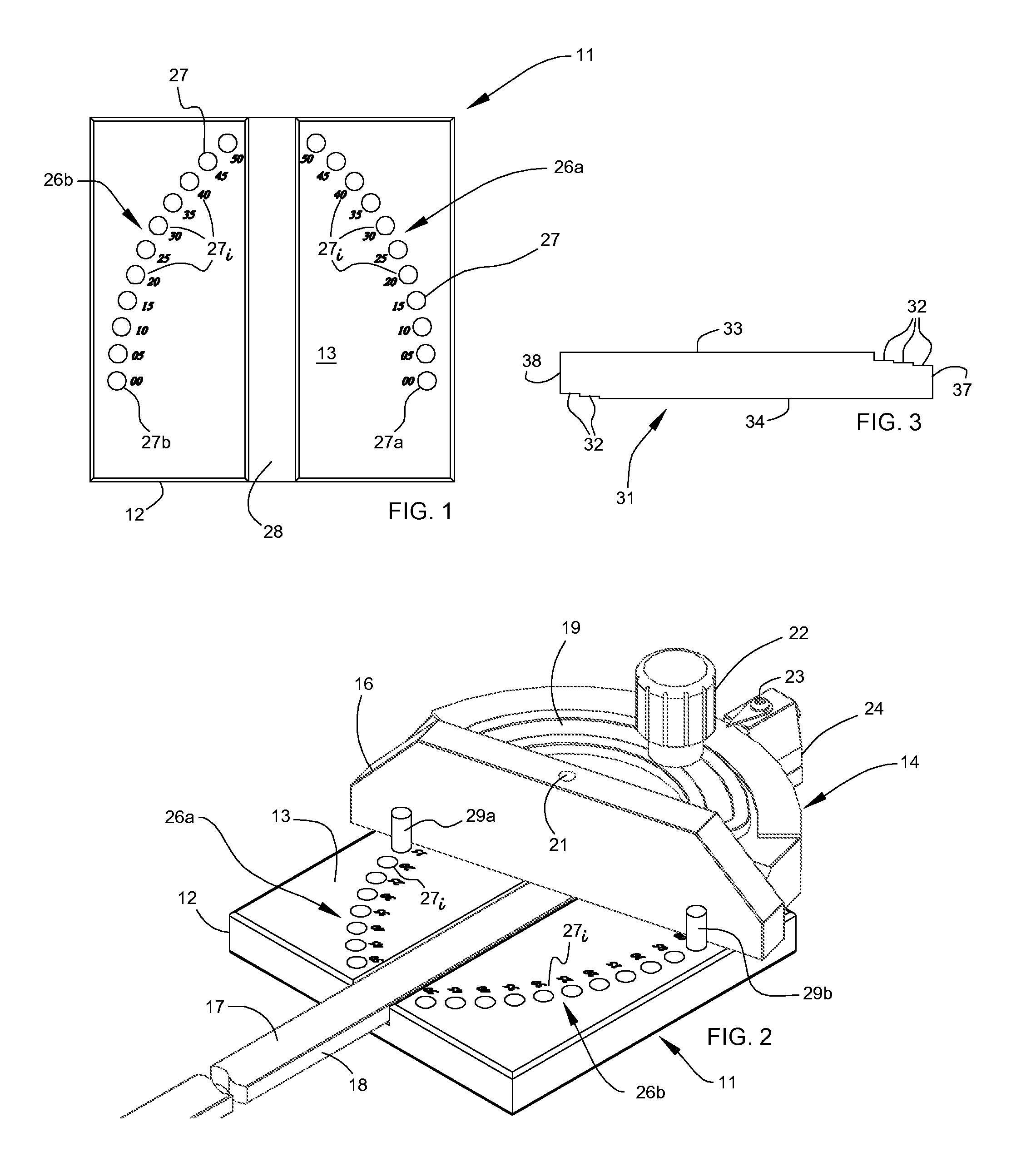

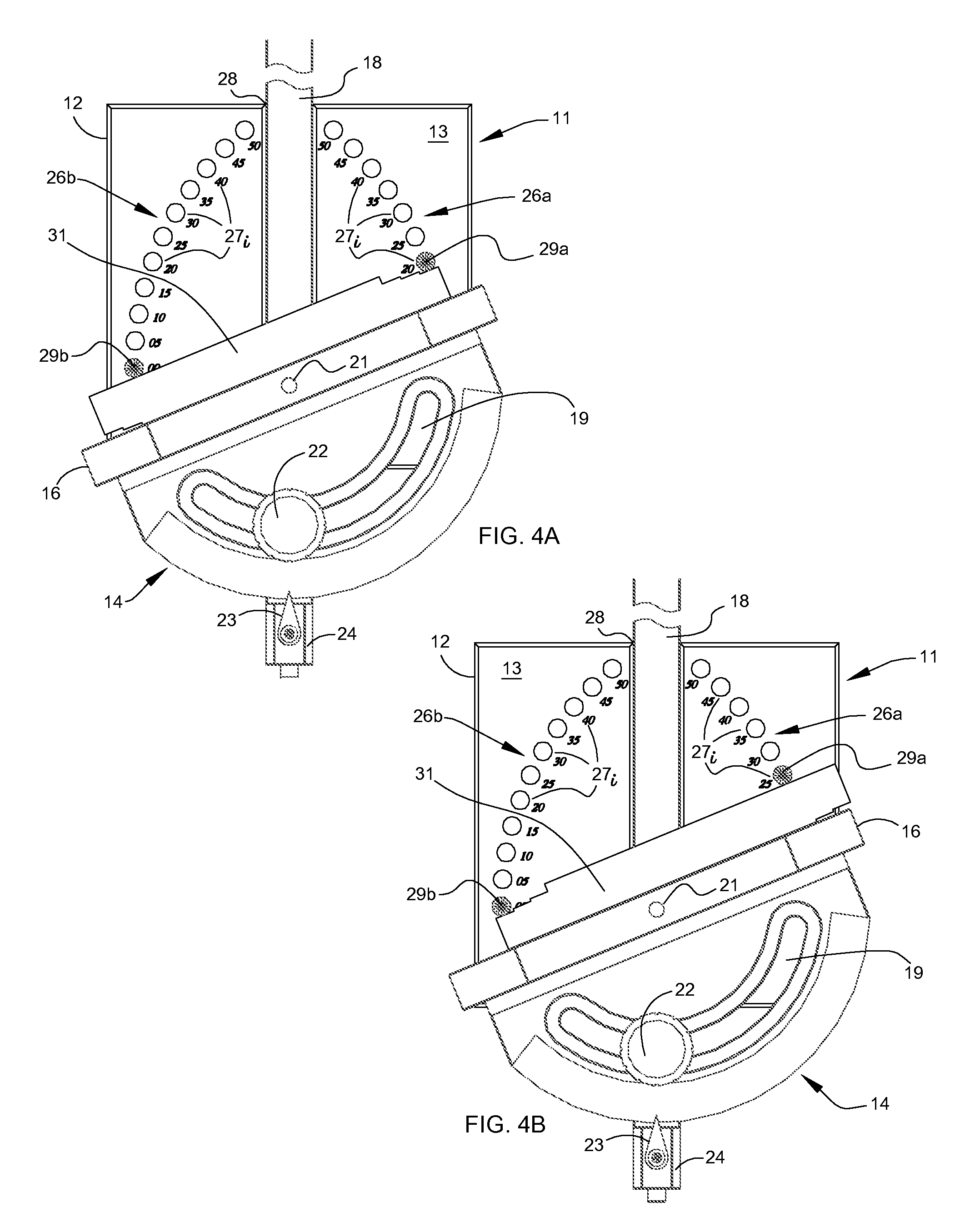

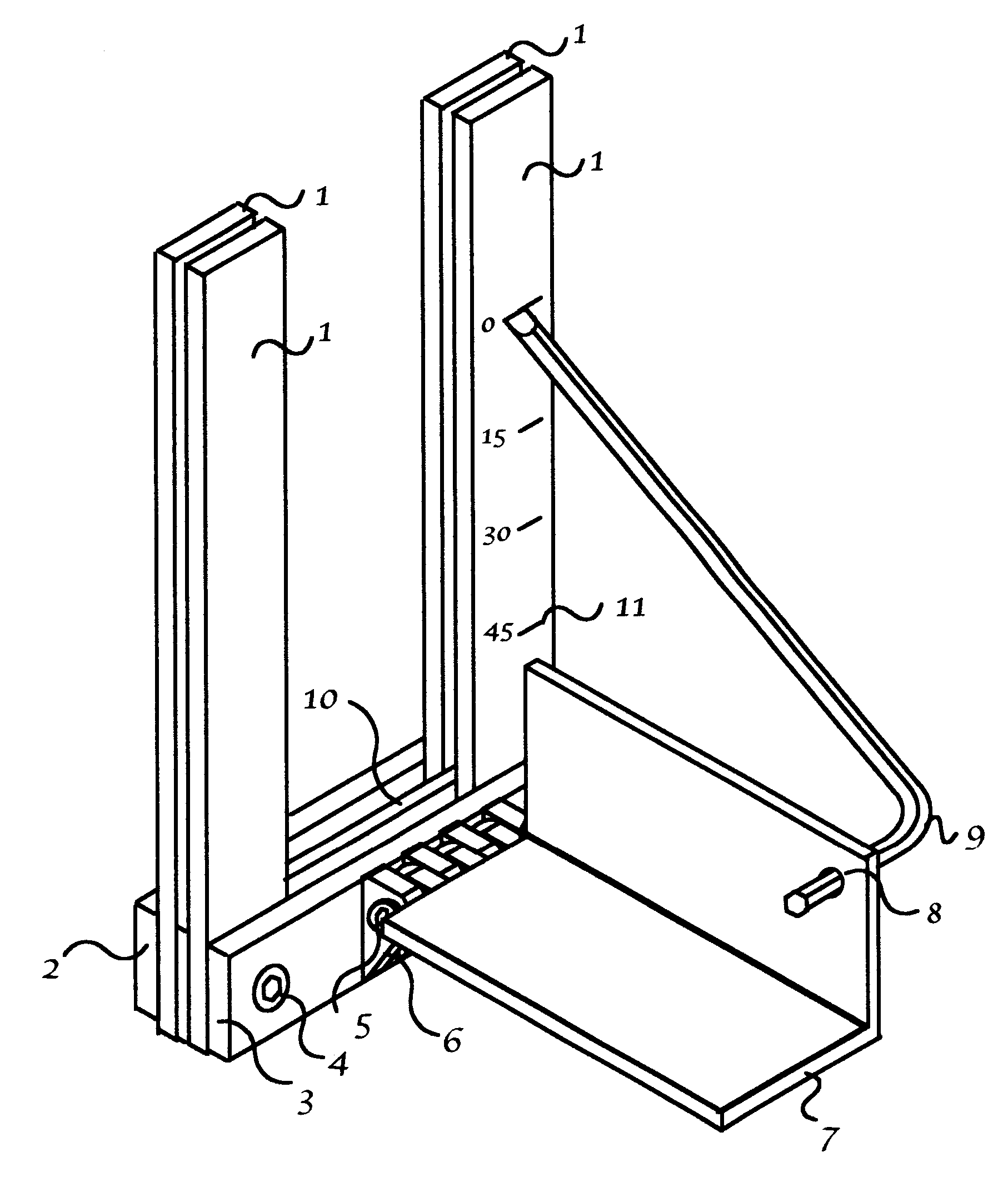

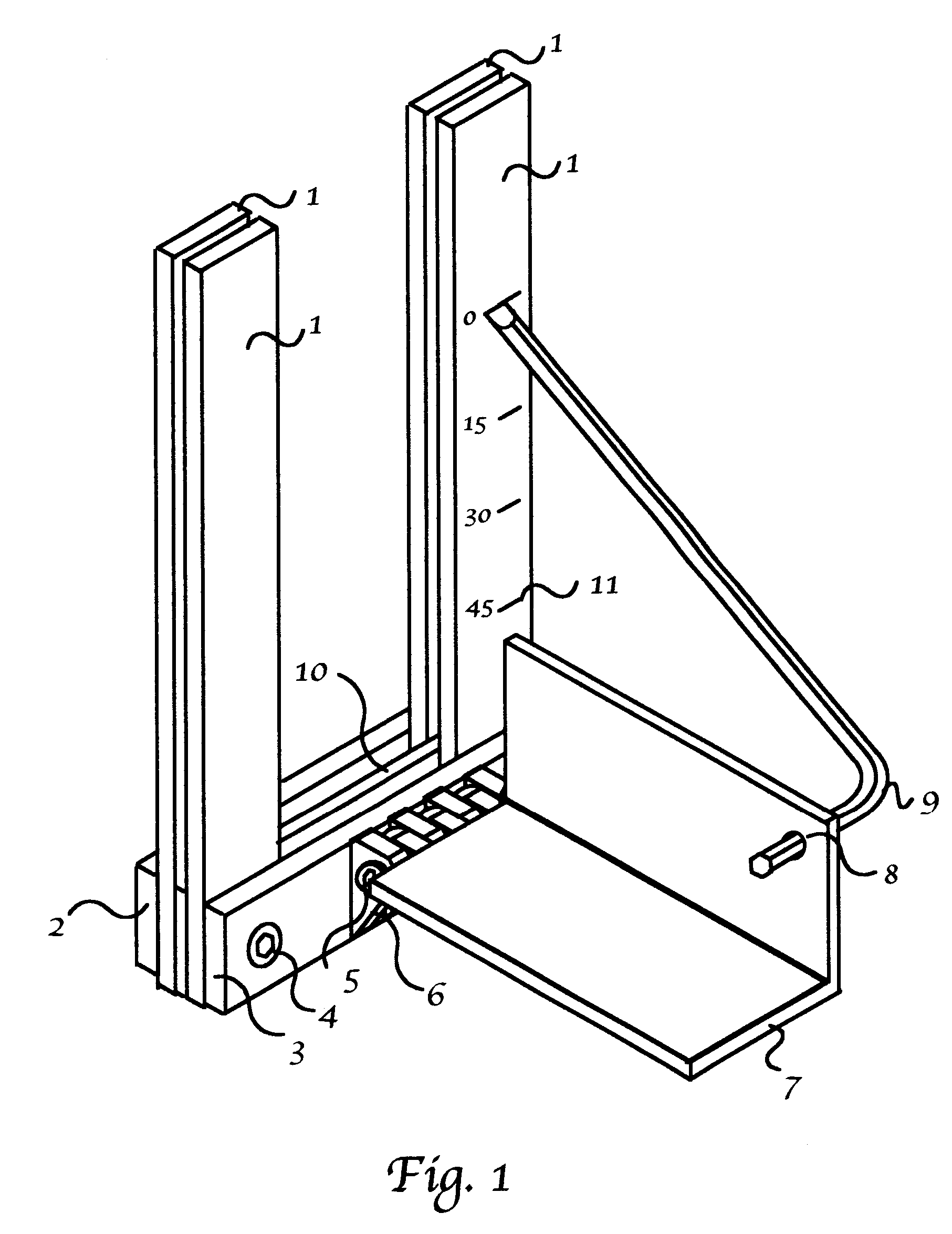

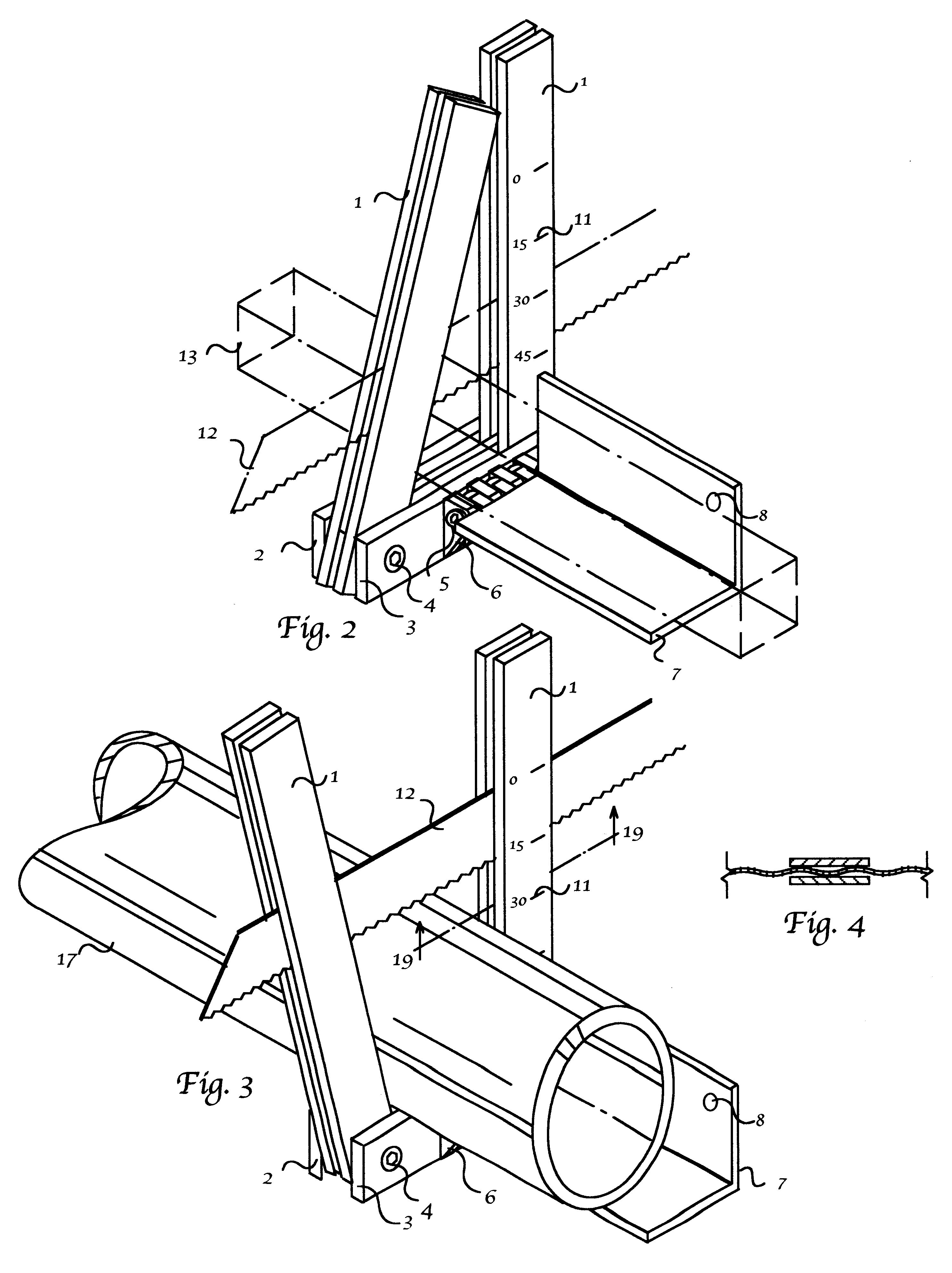

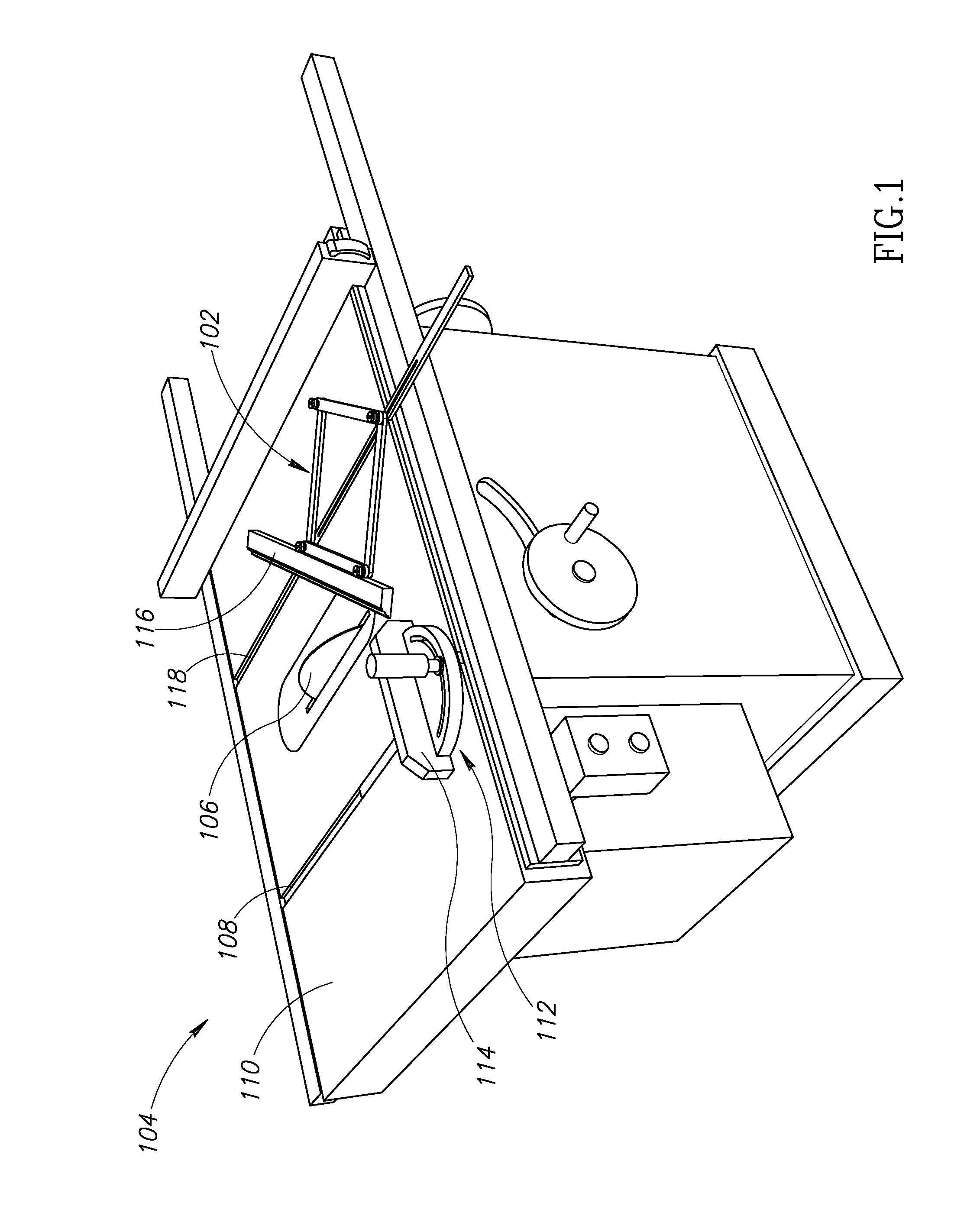

System for Forming a Miter Joint

The present invention is directed toward a system for forming miter joints including a miter saw and an angle gauge. The miter saw includes a platform with a kerf slot and a pair of arcuate slots. Each arcuate slot includes an associated rail located on the underside of the platform. A fence is coupled to each of the rails such that the fence may be pivoted with respect to the platform. The angle measurement tool is a one-handed tool including spring loaded paddles that measure the angle between intersecting surfaces. The angle measurement tool connects to the miter saw to permit the transfer of the measured angle to the fences.

Owner:BLACK & DECKER

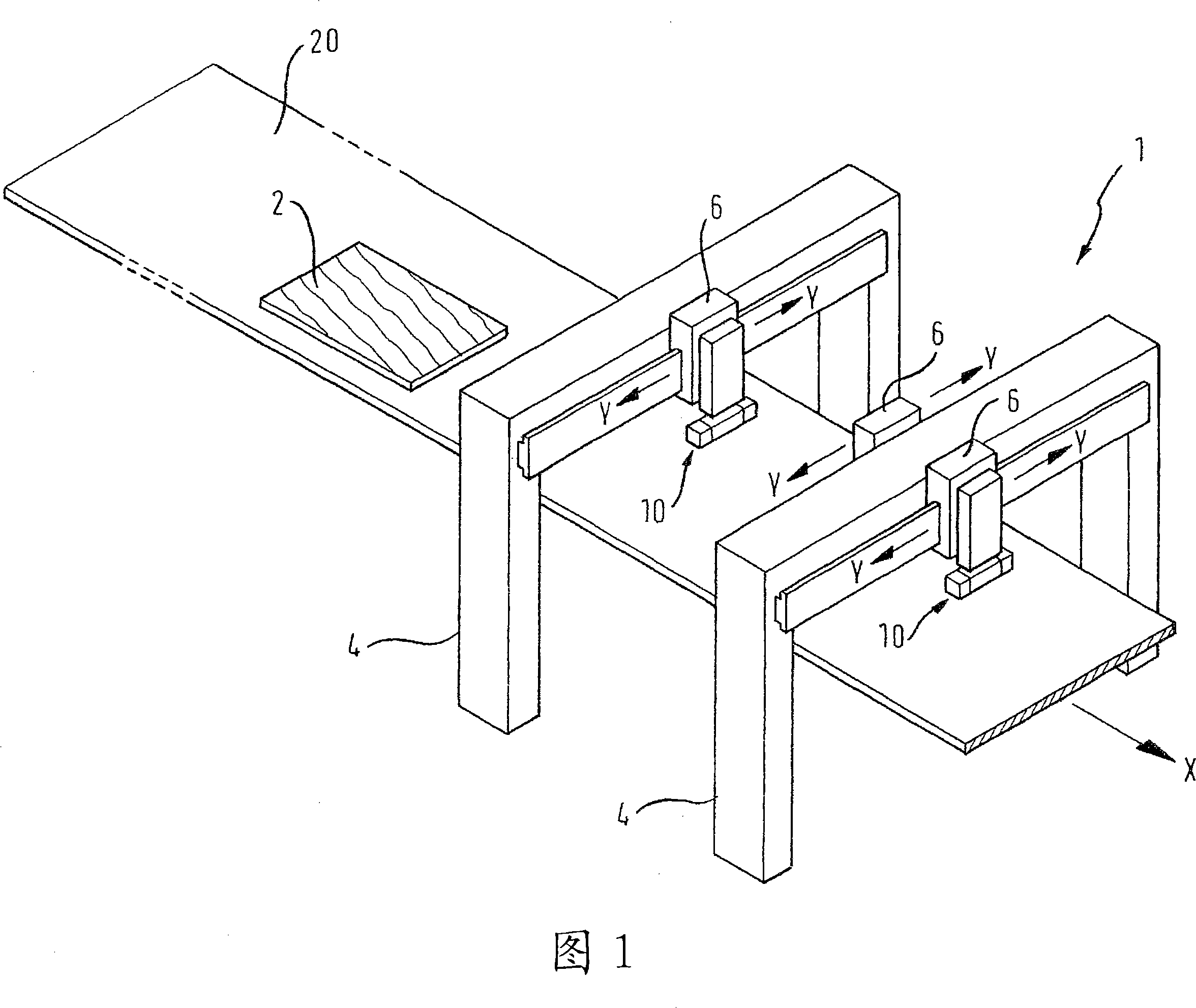

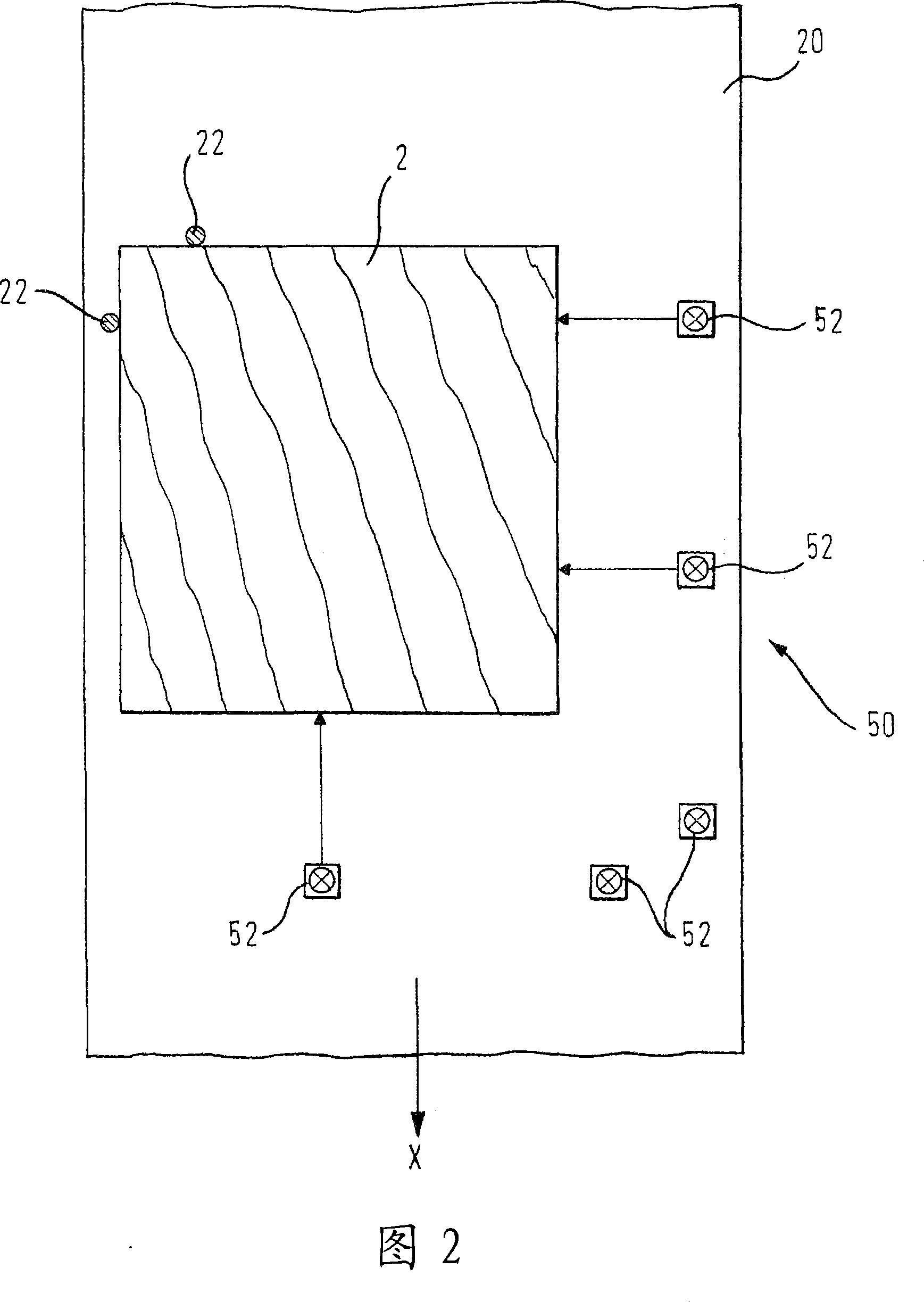

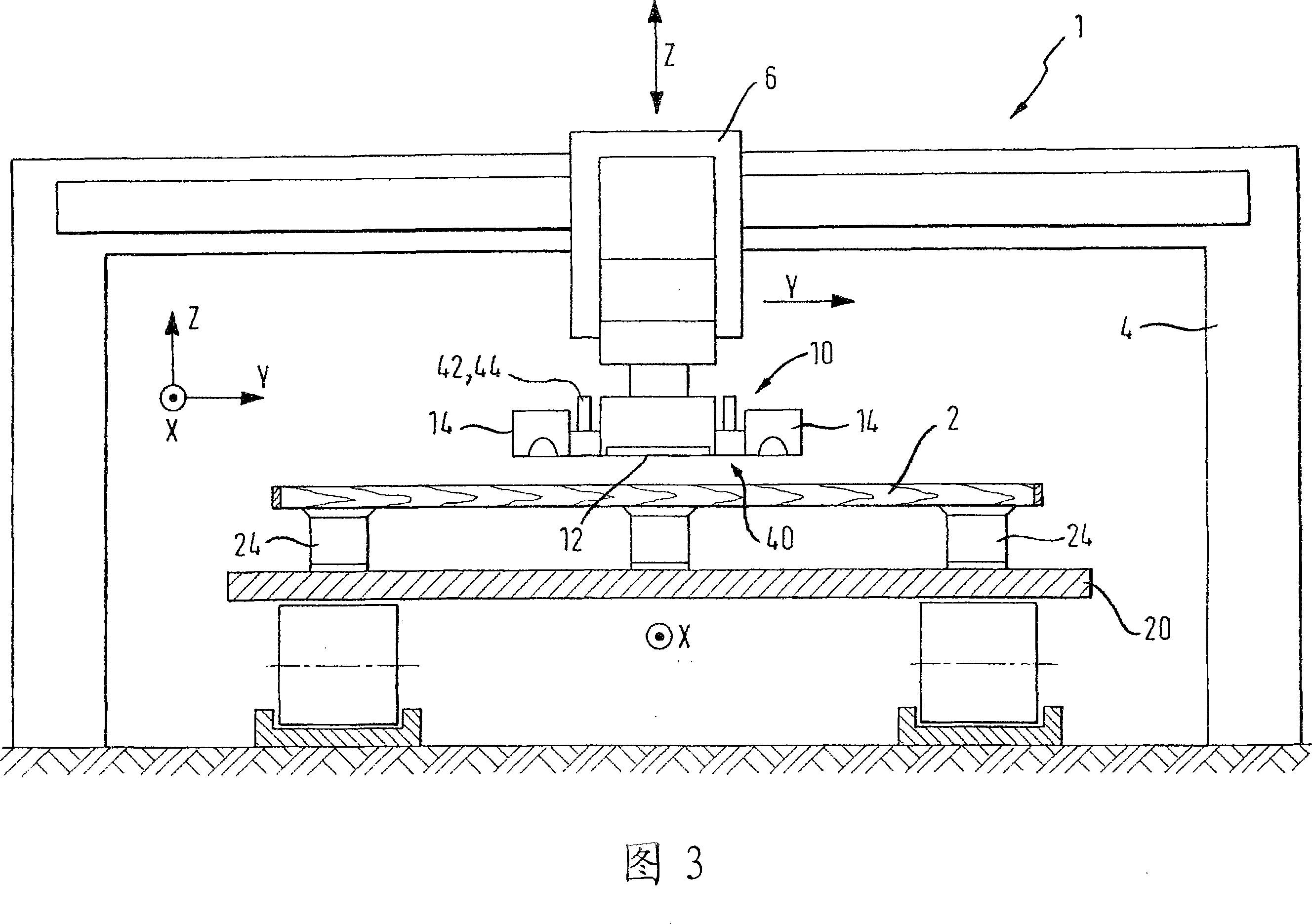

Device for patterning workpieces

ActiveCN101130312AChange operationHigh precisionOther plywood/veneer working apparatusSpraying apparatusRelative motionNozzle

Owner:HOMAG GMBH

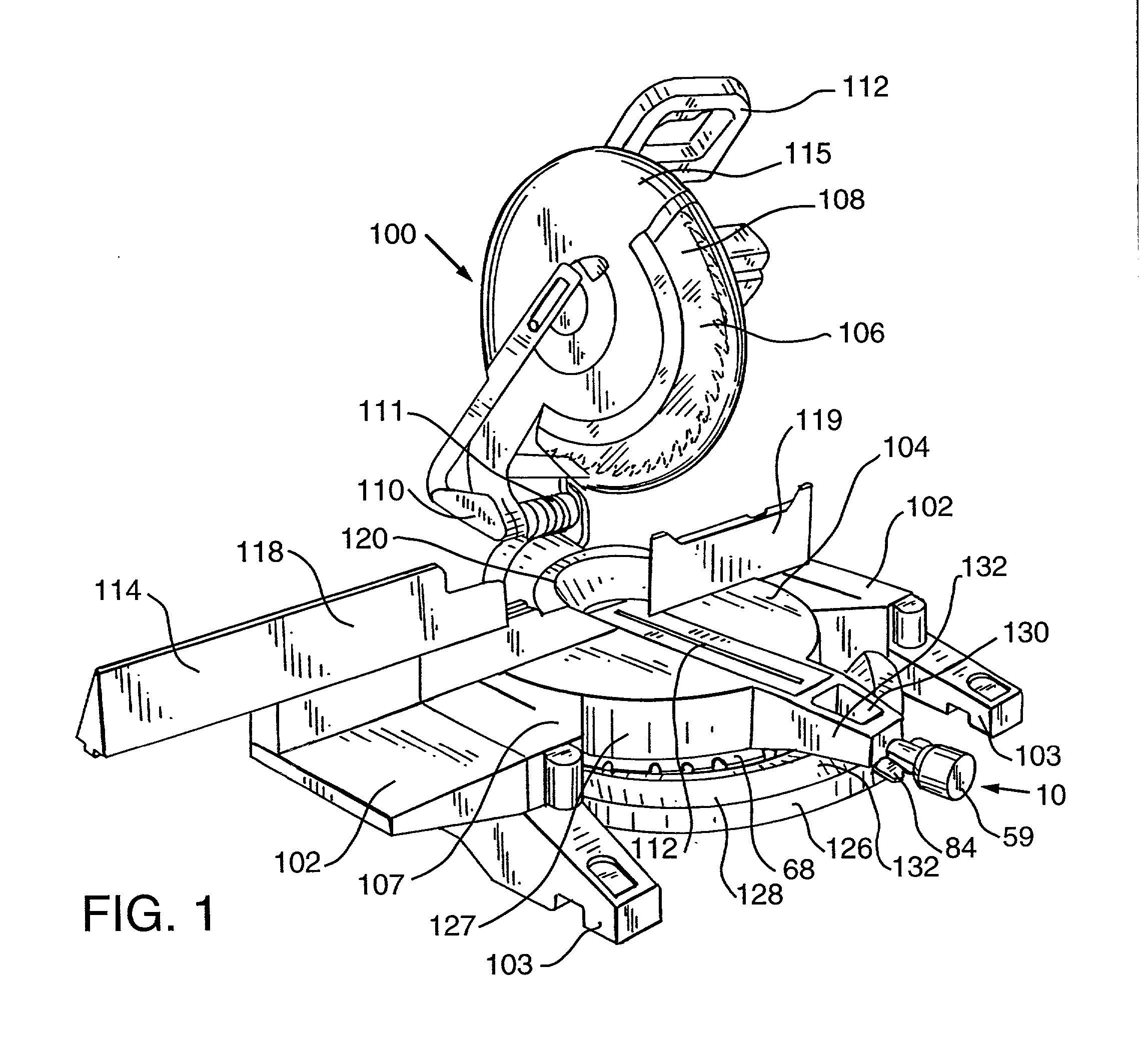

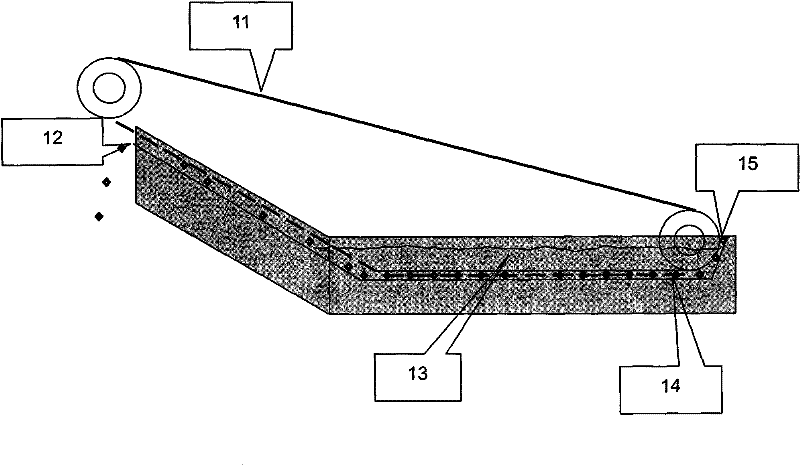

Enhanced miter saw

A miter saw is adapted for performing lengthwise, or rip, operations on a work piece such as wood. A back support arm is positioned off-center such that the work piece can be inserted under the miter saw substantially parallel to the blade. An arcuate aperture in the back support arm ensures that bevel adjustment properly aligns the blade with the blade slot during bevel cuts. An adjustable rail enables the work piece to be positioned in either a normal position, for crosswise cuts, or an orthogonal position, for lengthwise cuts. A toggle switch overrides the on / off switch on the handle, useful when the work piece is fed from behind. Two separate sleeves cover the blade, assuring safety during operation for both lengthwise and crosswise cuts. A tensioning board feed roller holds the work piece in place during lengthwise cutting.

Owner:ANTHONY WILLIAM JEFFERSON

Variable angle miter box

InactiveUS20060053992A1Exact copyMinimal effortShearing machinesGang saw millsMechanical engineeringVariable angle

Owner:UNIWILL COMPUTAR +1

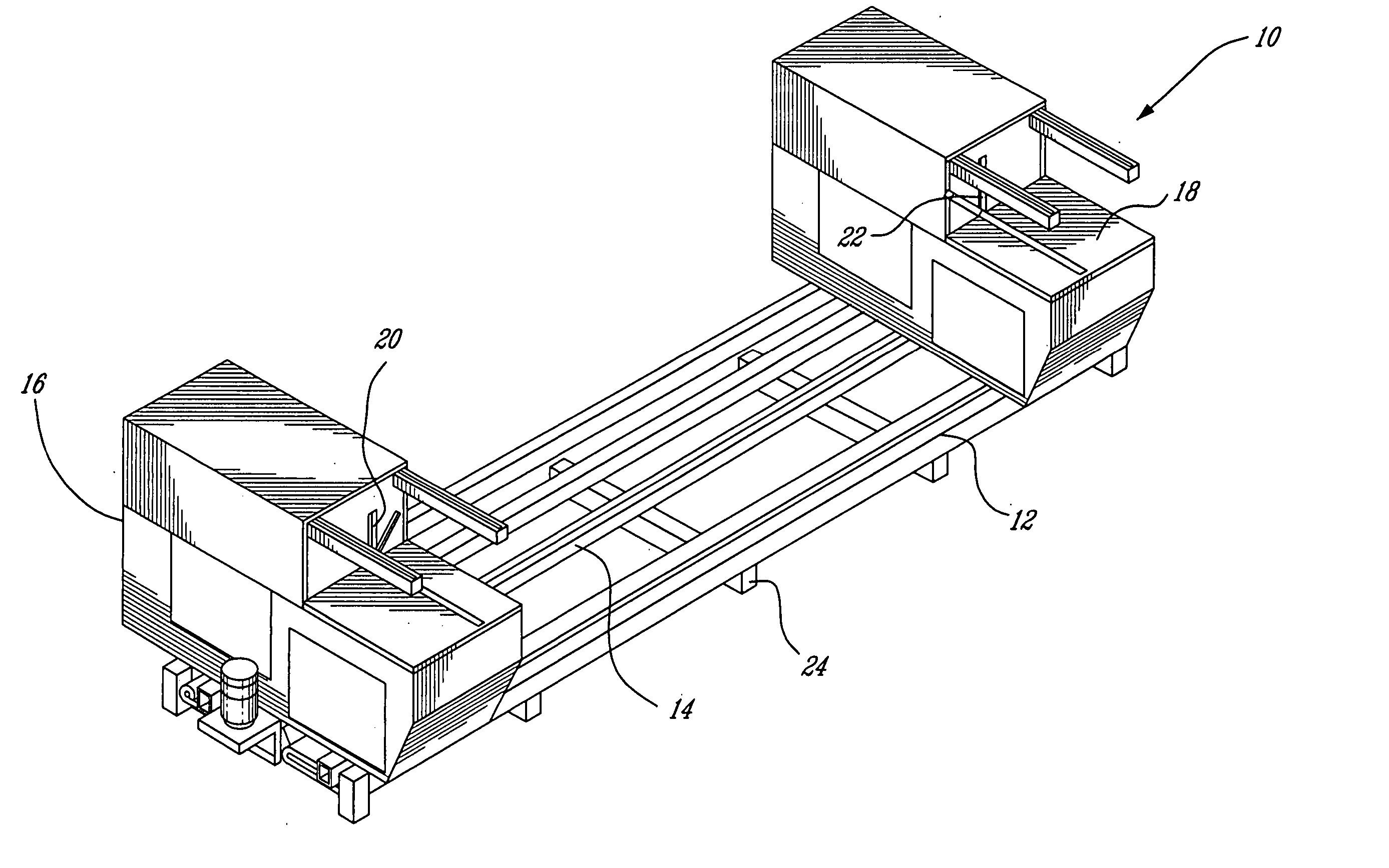

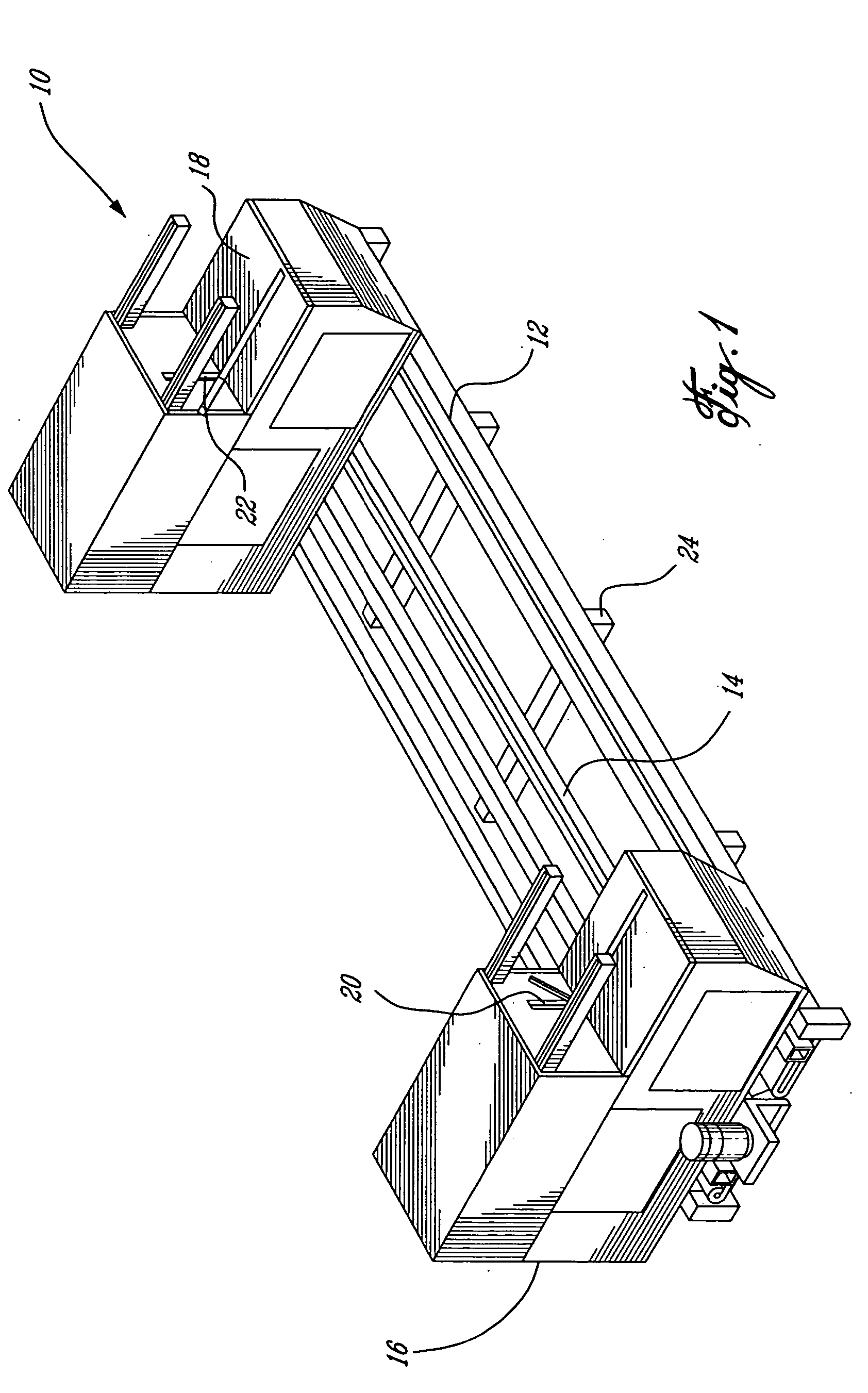

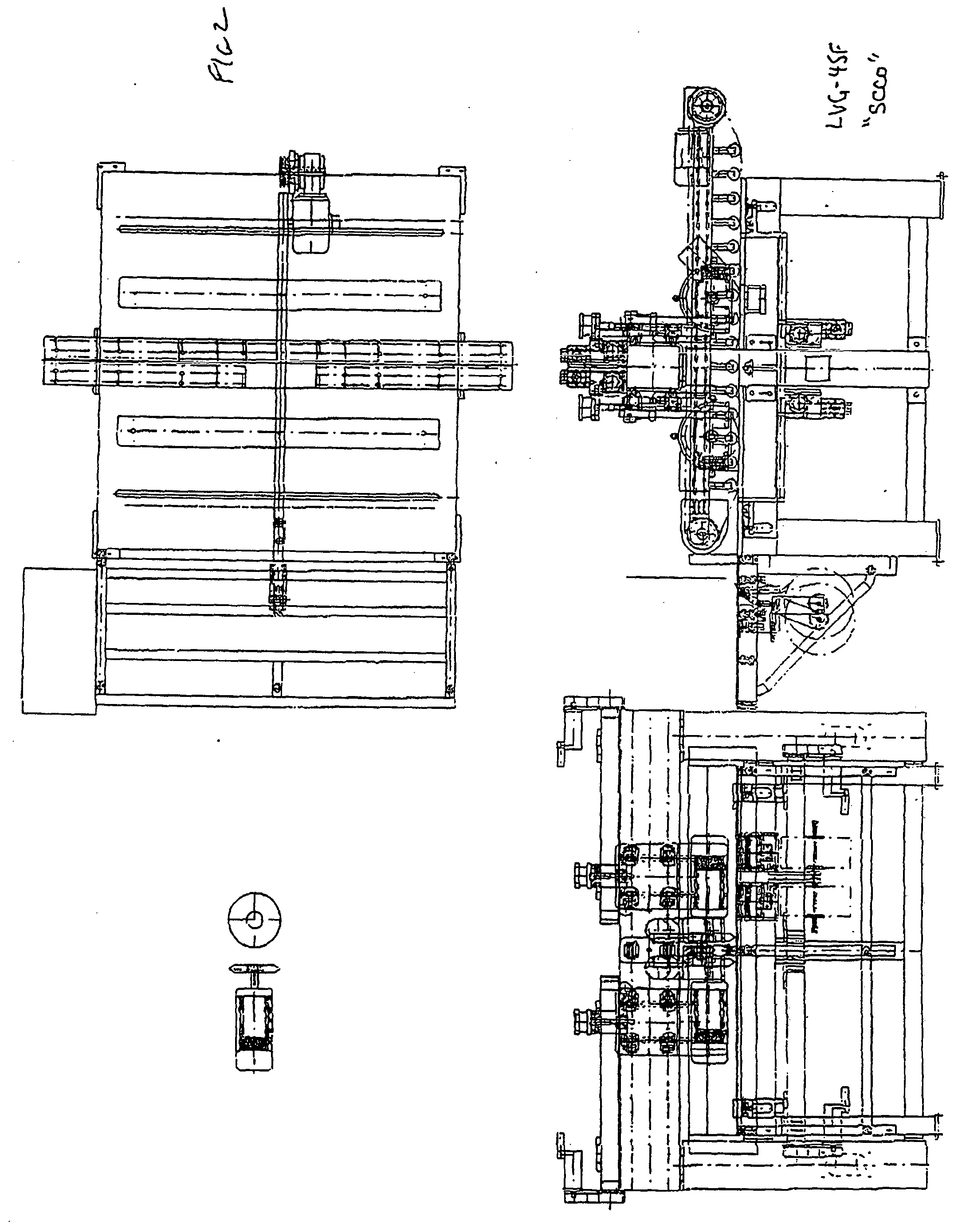

Automated double saw

A saw has a first saw head and a second saw head and is provided with an optimized structure of the saw heads by reducing a number and dimensions of components thereof, thereby allowing to strike an optimized balance between the cutting path, the cutting height and the dimensions of the cutting bench of the saw. Moreover, the saw of the present invention includes a rear movement mechanism allowing a movement of the blade from the rear end of the saw, which permits to accommodate a blade of an increased diameter, and a crosscut indexation mechanism.

Owner:PROTOMACH

Stock stop miter gauge

The present invention discloses an improved miter gauge for retaining and adjustably positioning a workpiece. The miter gauge includes a fence frame pivotally mounted to a base member for adjusting the workpiece to be cut at a user selected angle. The fence frame includes a fence surface for positioning the workpiece. The fence surface is opposed by a quick-adjusting stopping unit mountable to the base member for clamping the workpiece therebetween.

Owner:ONE WORLD TECH

Miter box for guiding a circular saw

InactiveUS7159498B2Improve stabilityCross-cut reciprocating sawsGang saw millsCircular sawFriction reducing

The invention relates to an improved miter box for guiding a handheld portable circular saw. The miter box facilitates several conventional workpiece trim cuts using a handheld portable circular saw, including 45 degree and 90 degree straightcuts, as well as 45 and 90 degree straightcuts with a 45 degree undercut. The invention includes an I-beam that is formed from a rigid base plate having opposing first and second base plate edges disposed along its elongated length. A first and second flange can be respectively attached to the opposing first and second base plate edges. Each of the flanges can include a pair of opposing support faces. One or more transverse guide members can extend either 45, 135, or 90 degrees from one support face of the first flange to another support face of the second flange. The transverse guide member(s) and the support faces provide a friction reduced medium by which the bottom of a handheld portable circular saw's shoe can glide with greater ease and stability.

Owner:STEWART DENHAM RAY

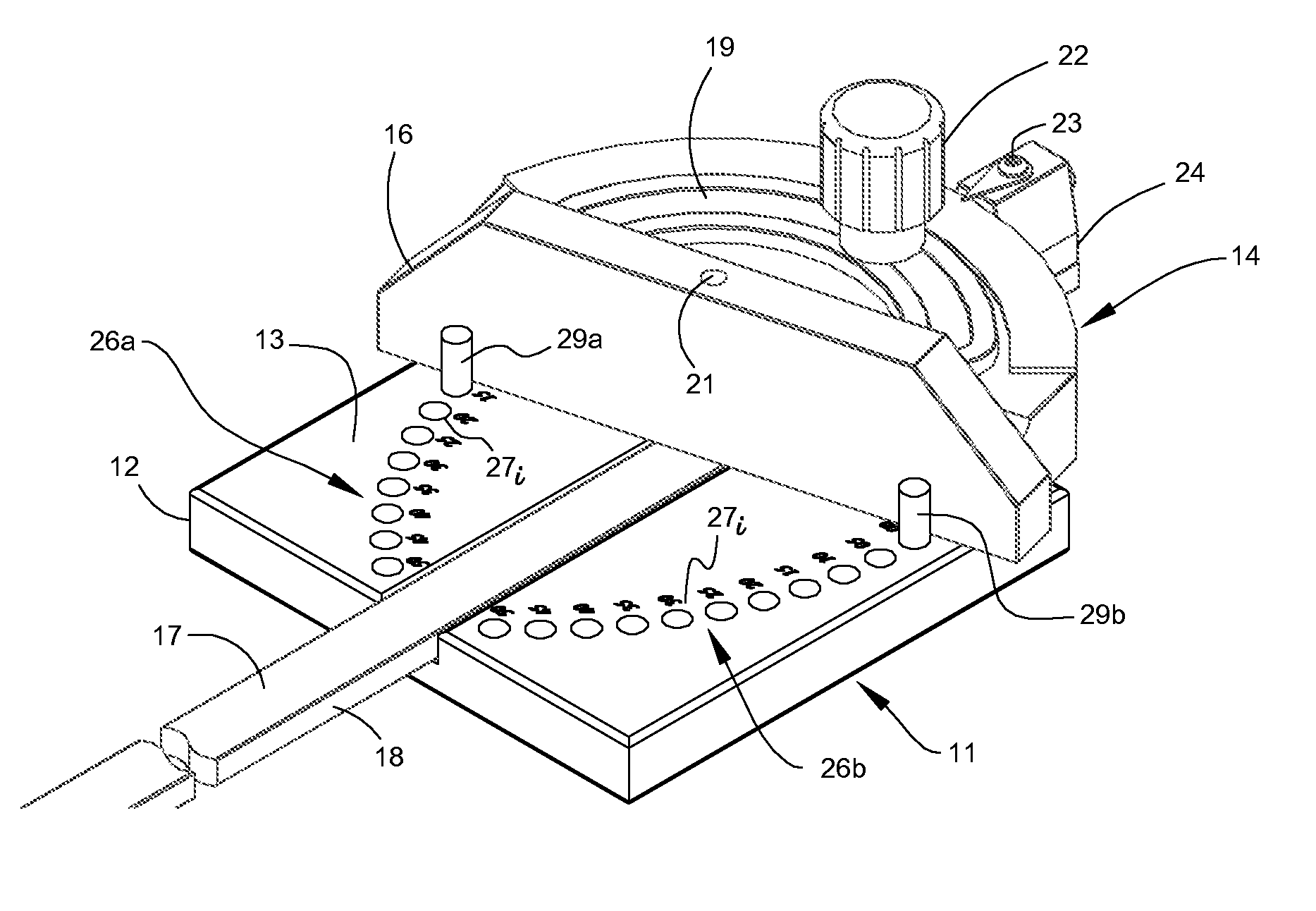

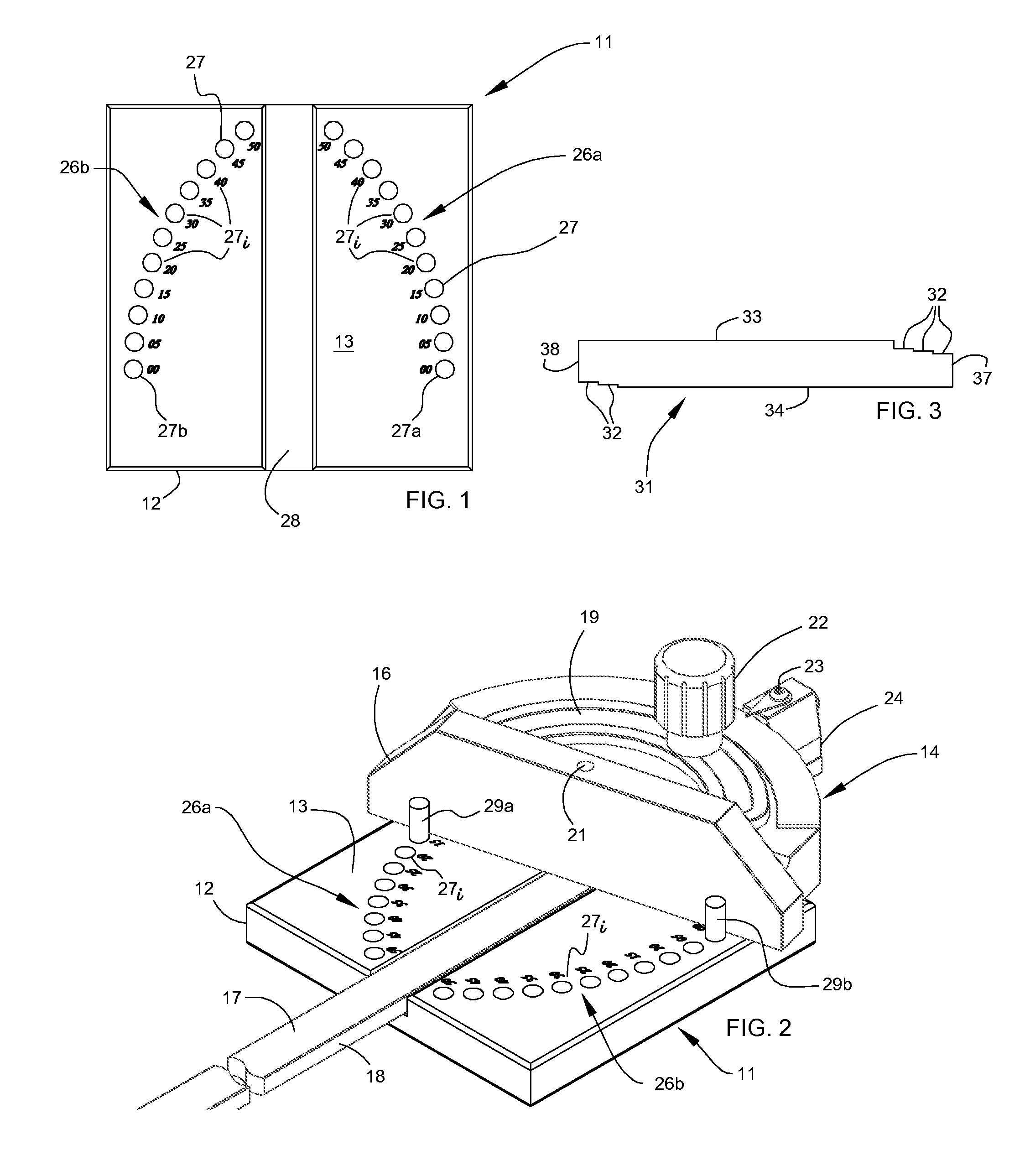

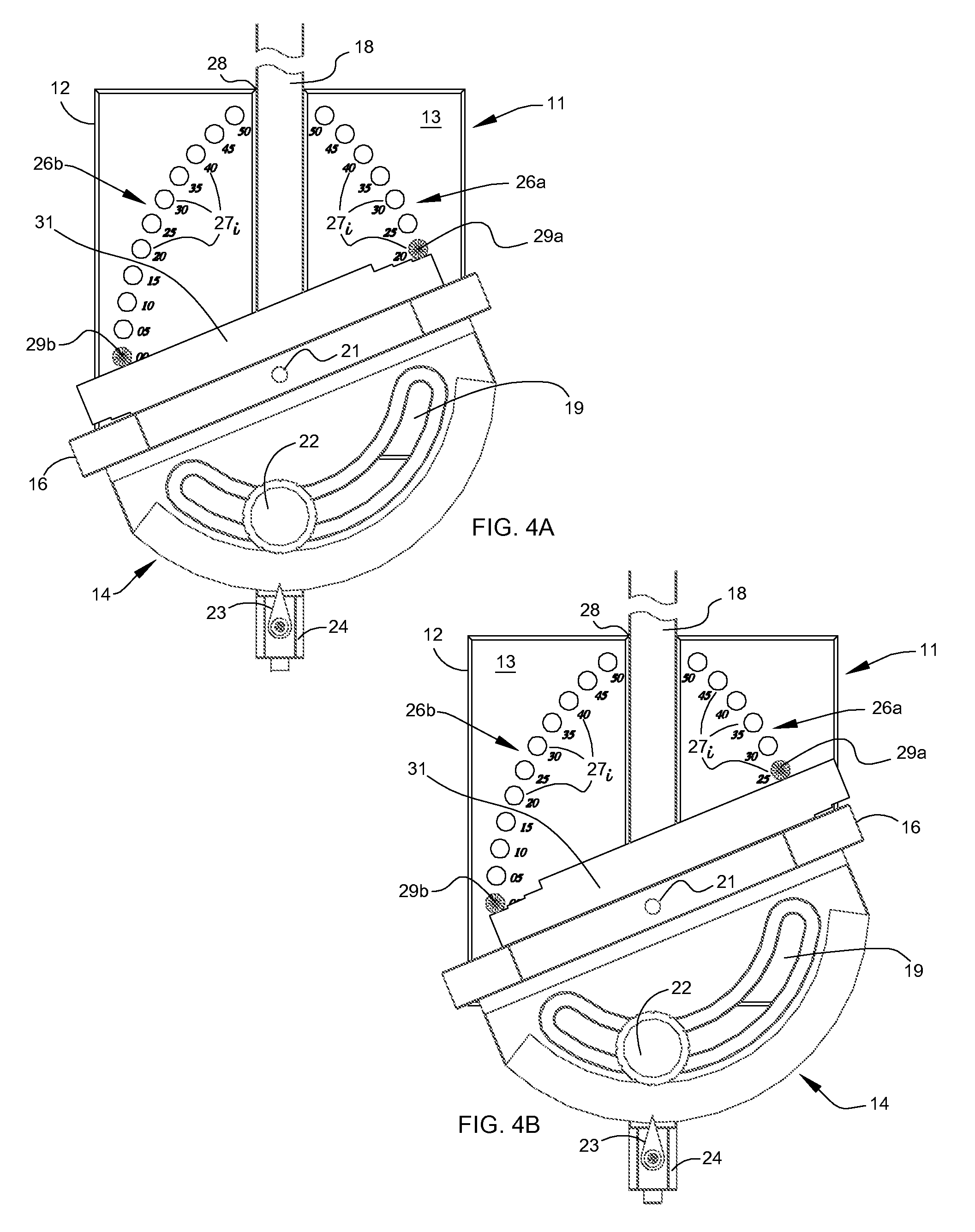

Precision miter gauge setting fixture

ActiveUS7421798B2Drilling/boring measurement devicesMeasurement/indication equipmentsDetentEngineering

A precision miter gauge setting fixture system is described that includes a horizontal surface with a miter bar channel that bisects at least one pair of symmetrical arcs of angularly spaced, position receptacles drilled into the surface, where each angular position receptacle of a paired set of arcs, radially centers on a base position receptacle of the other symmetrically paired arc of angularly space, position receptacles. A pair of position posts, one snugly seated in the base position receptacle of one of the paired symmetrical arcs of angularly spaced, position receptacles, the other snugly seated in one of the angularly spaced, position receptacles of the other symmetrically paired arc define the desired angle for setting the angle of a miter fence head relative to the miter bar of a miter gauge received and sliding in the miter bar channel.The described precision miter gauge setting fixture system further includes one or more straight edged, accessory, detent step bars each having a length sufficient to span the radial distance between a base position receptacle of one of a pair of symmetrical arcs of angularly spaced, position receptacles and each of the angularly spaced, position receptacles of the other arc of the pair. Each straight edged, accessory, detent step bar also has one or more step detents, each detent incrementally increasing in depth, cut into one or both of its opposite longitudinal straight side edges proximate one or both of its ends for incrementally adding to and subtracting from the angle defined by the respectively seated, position posts, where the angle of the miter fence head of the miter gauge is determined by the angle of the longitudinal straight edge of the step dent bar opposite a particular step detent abutting against one or the other of the respectively seated position posts.

Owner:PATTEE RICHARD

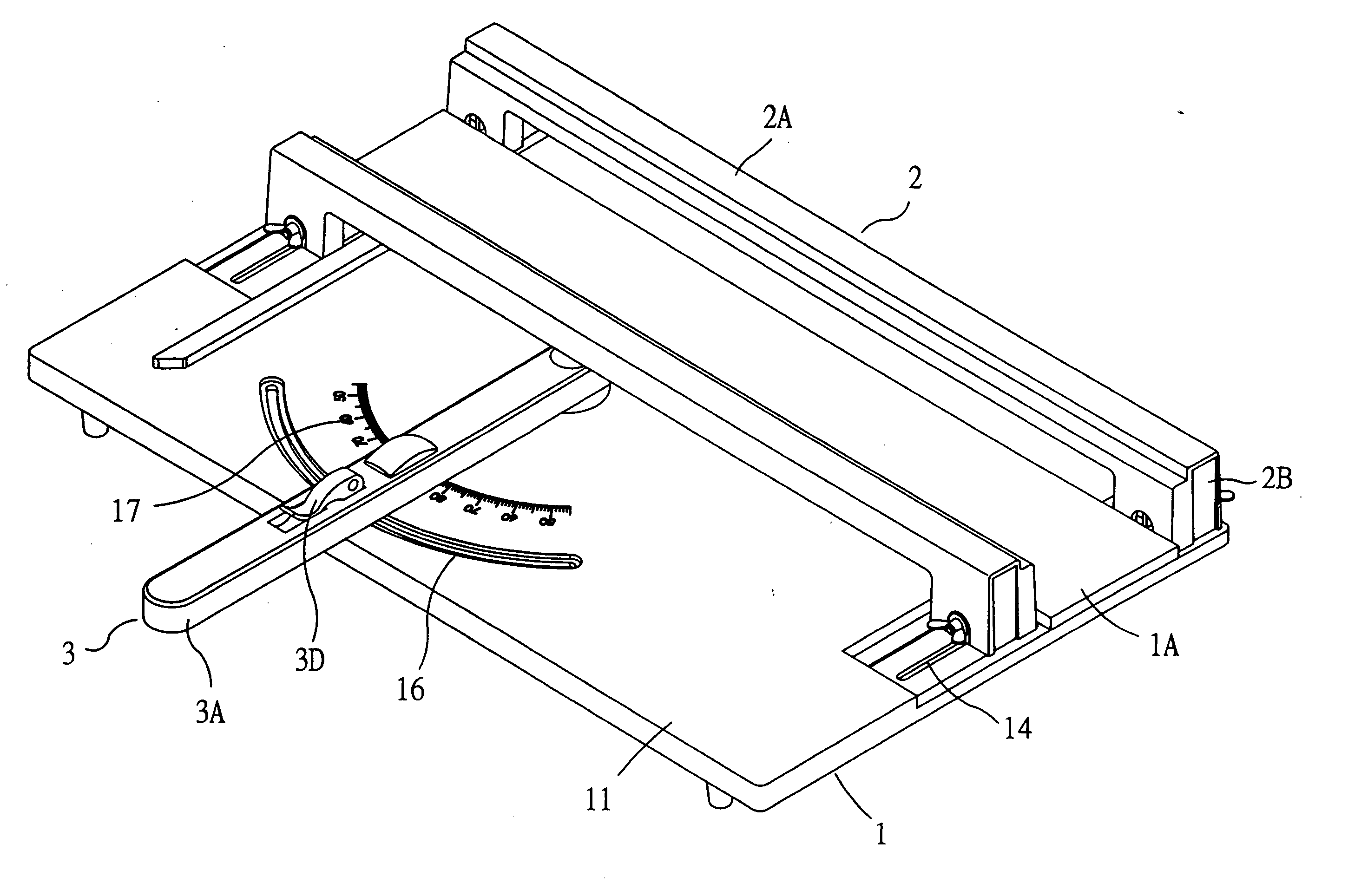

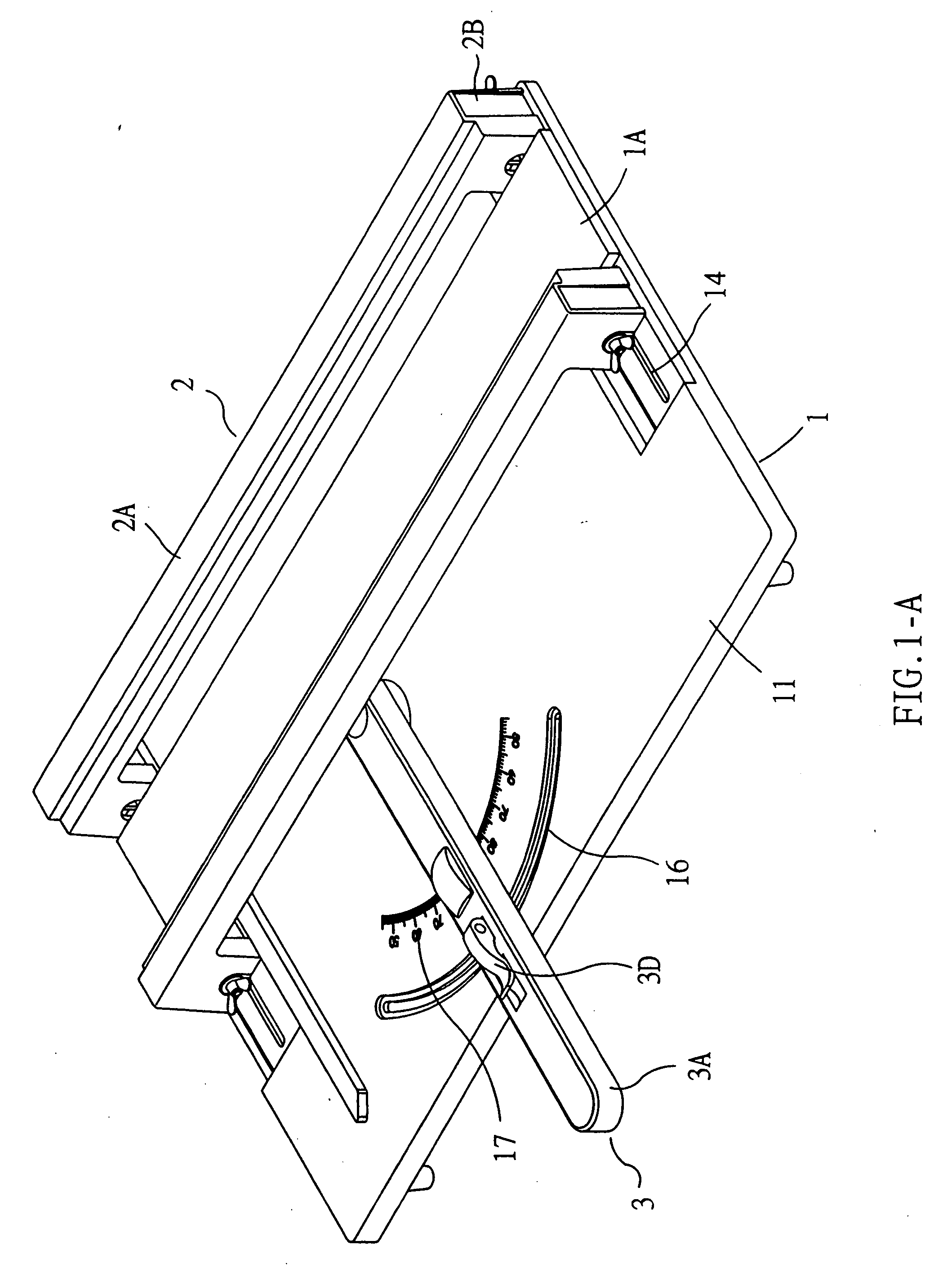

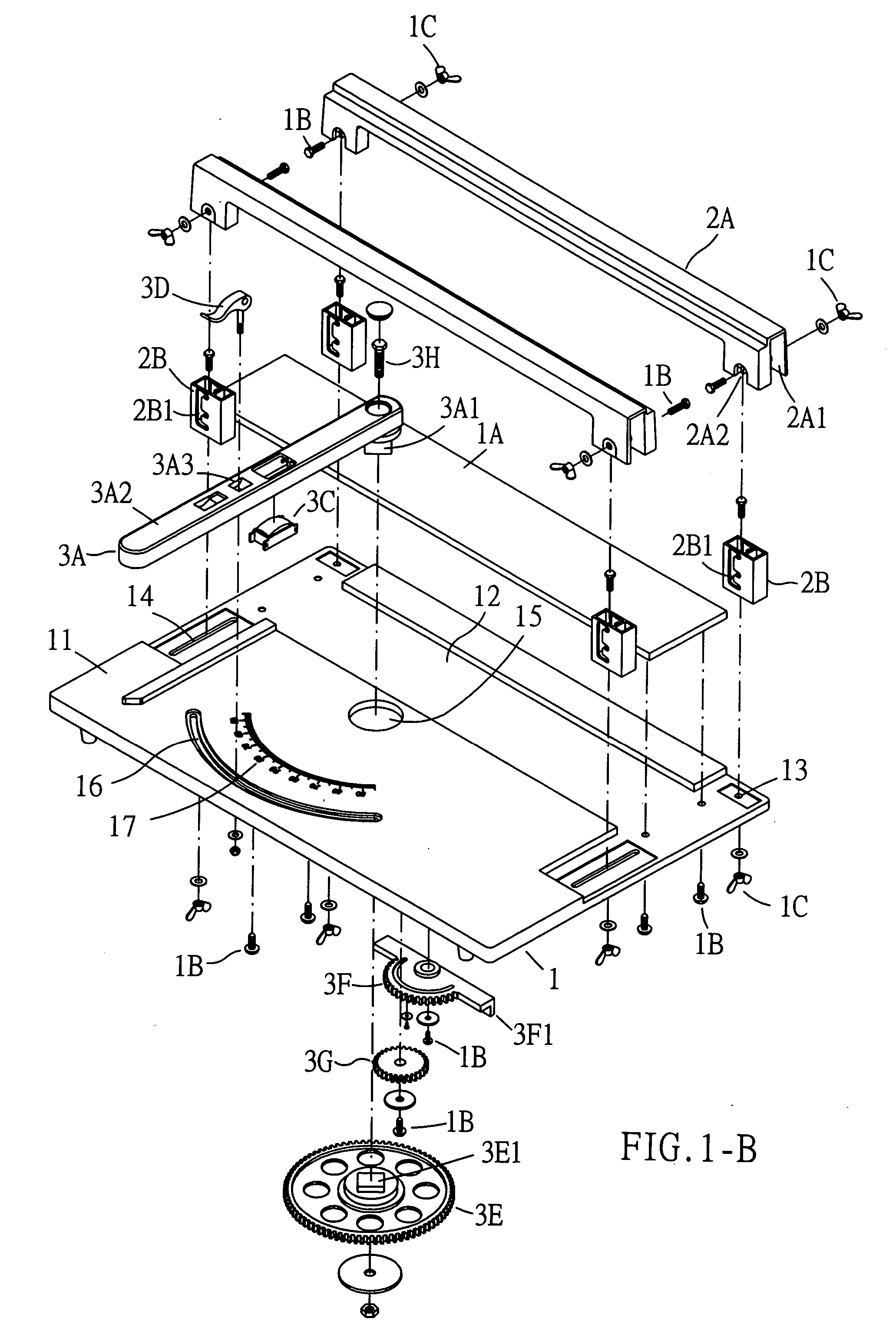

Angle adjustable sawing table

InactiveUS20060027289A1Save effortEasy to installGuide fencesShearing machinesTime efficientCircular saw

An angle adjustable sawing table allowing interchange of displacement among measurement members on the table to compromise the installation of the circular saw; the wood material being place at pre-set geometric angle; one end of the gage being placed on the table, and another of the gage flushed against the measurement member for adjustment to meet the present angle for easier cutting and time-saving.

Owner:QUALIPRO ENTERPRISE +2

Sliding table for workbench

The sliding table is used in conjunction with a workbench and includes a panel slidable along a path which is disposed normal to the longitudinal axis of the workbench. The panel has stop points in front and behind the workbench. At each stop point, the panel has an outwardly extending portion which is cantilevered from an outer support and an inwardly extending portion which is prevented from rising by an inner support. Both supports are beneath the panel and are spaced apart from one another.

Owner:SMITH DARRIN EUGENE

Cutting guide and method of using the same

ActiveUS7360476B2Easy to operateImprove stabilityMetal sawing devicesGuide fencesEngineeringCutting guide

Owner:BERTHIAUME RAYMOND

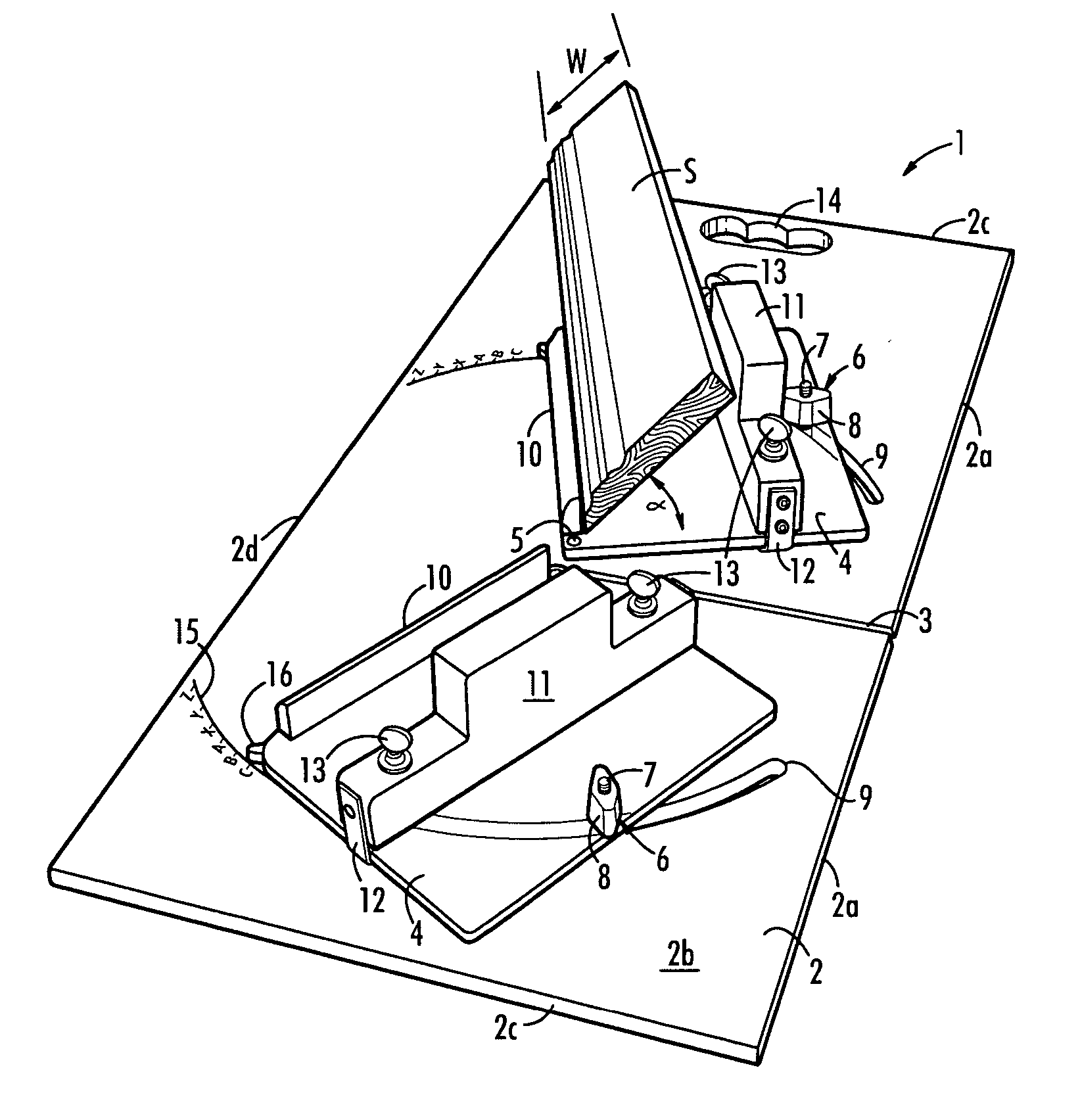

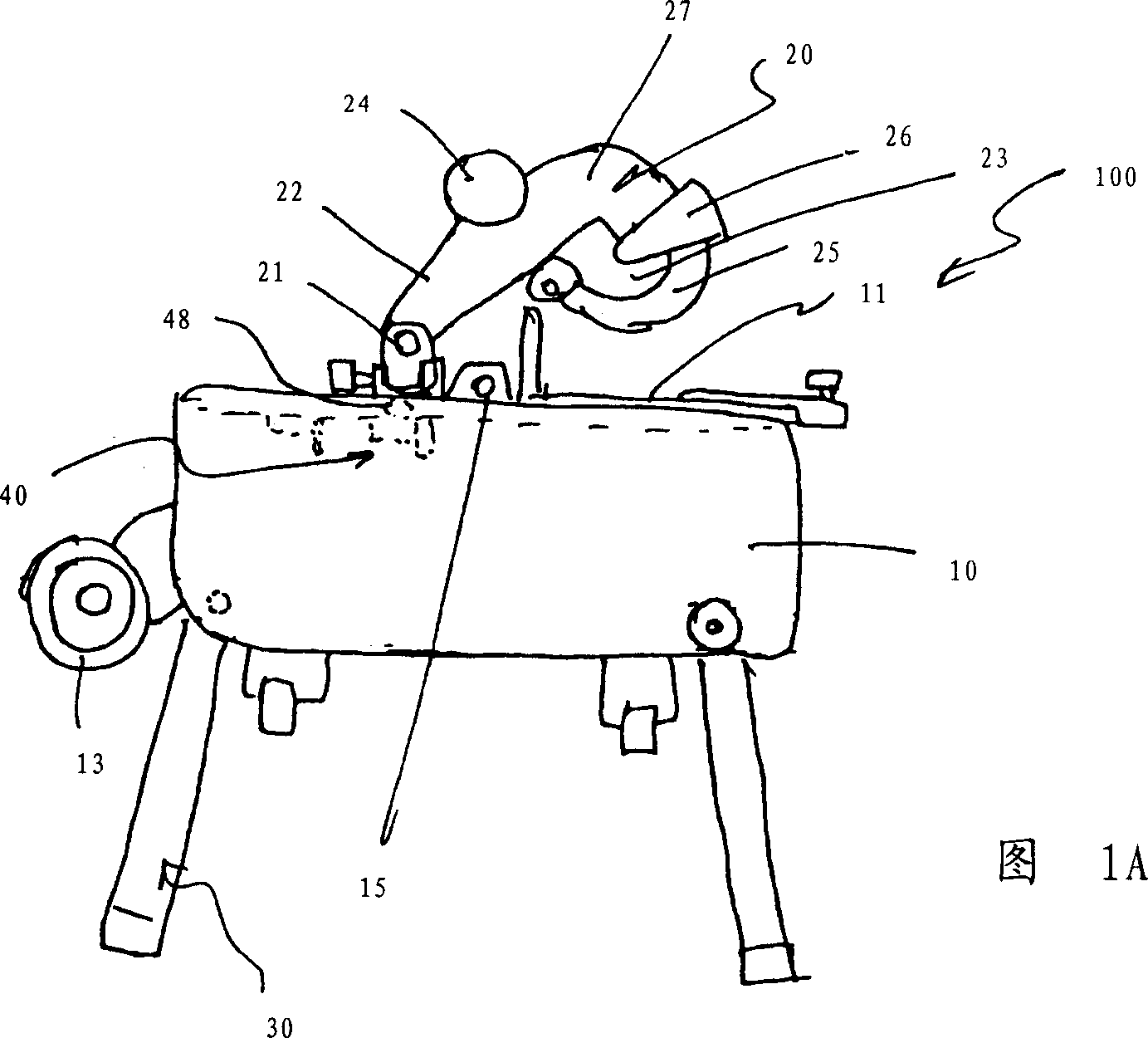

Workbench

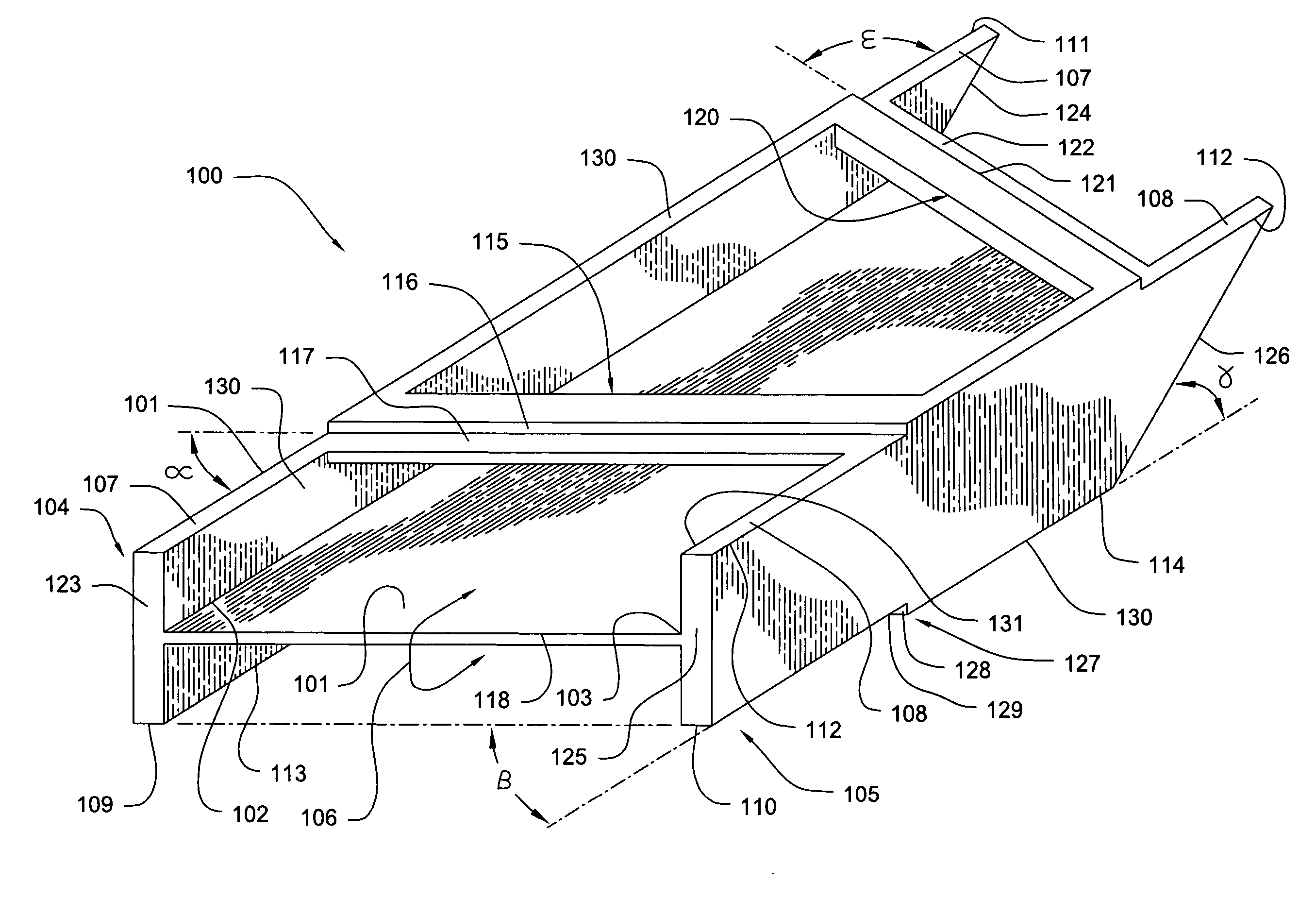

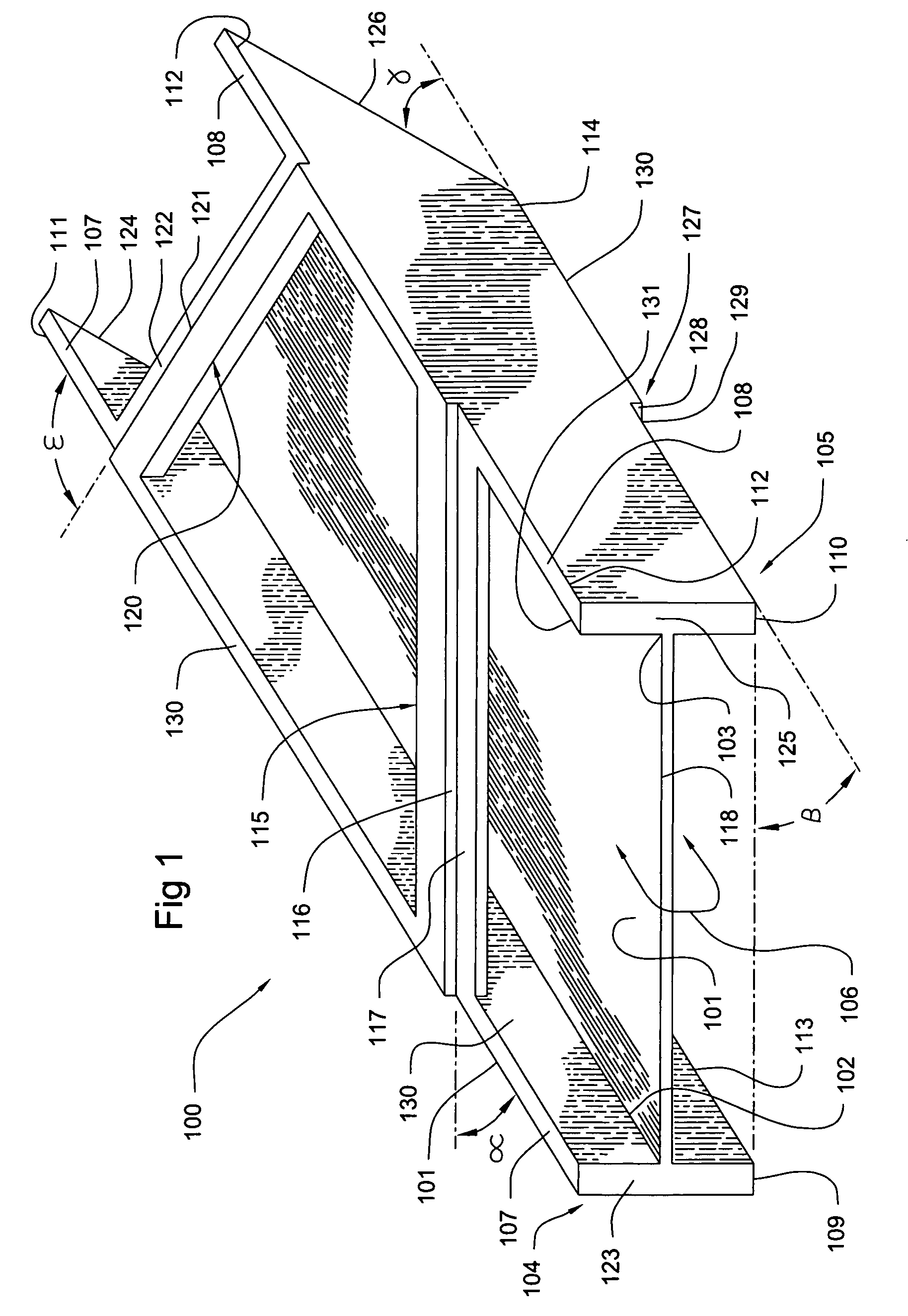

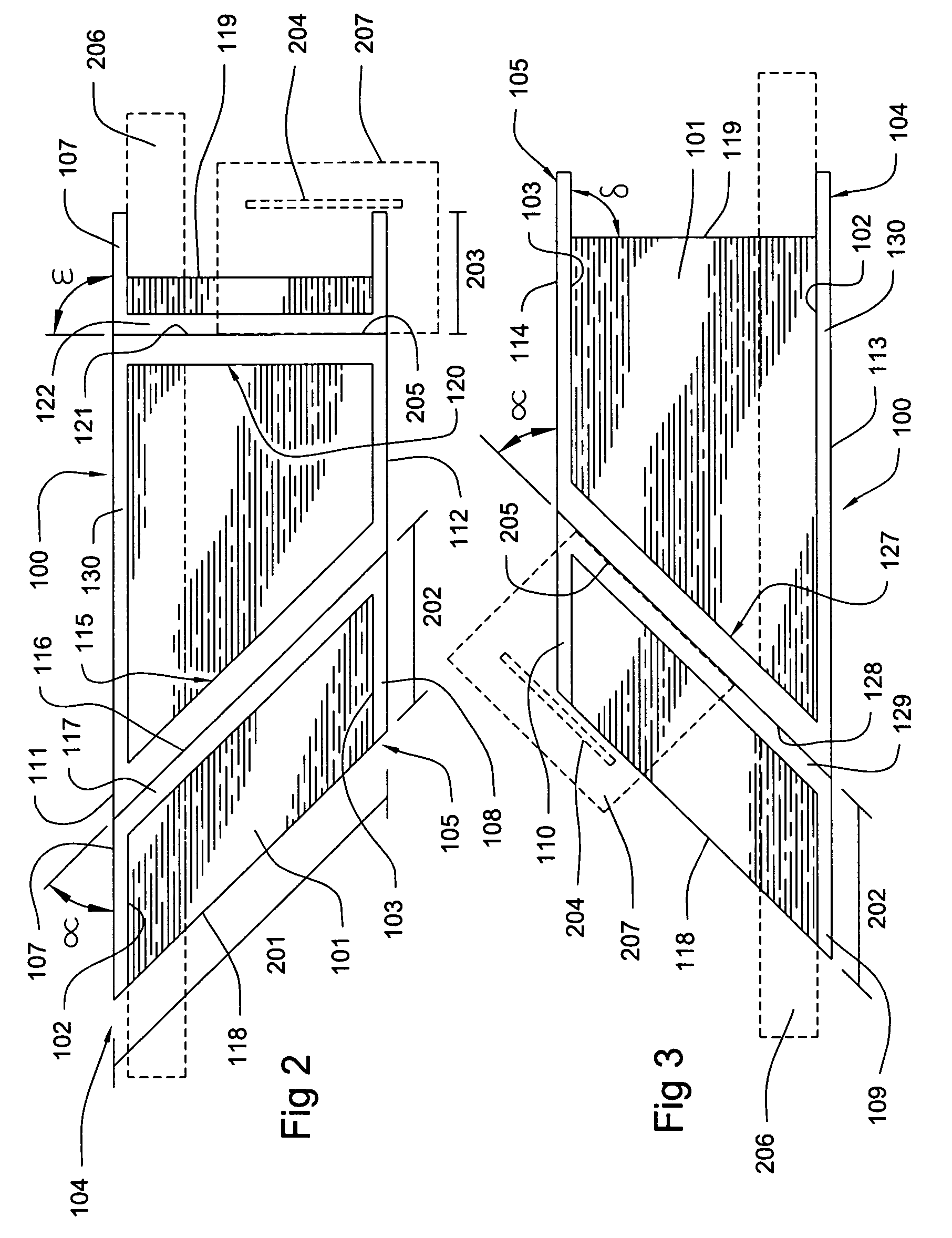

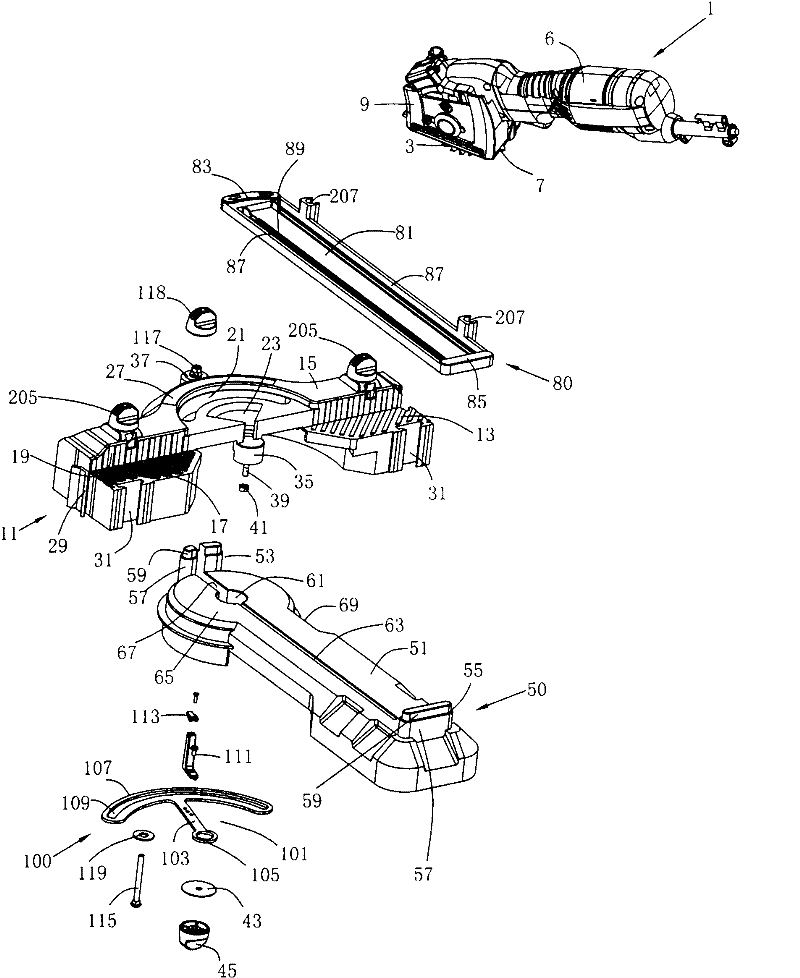

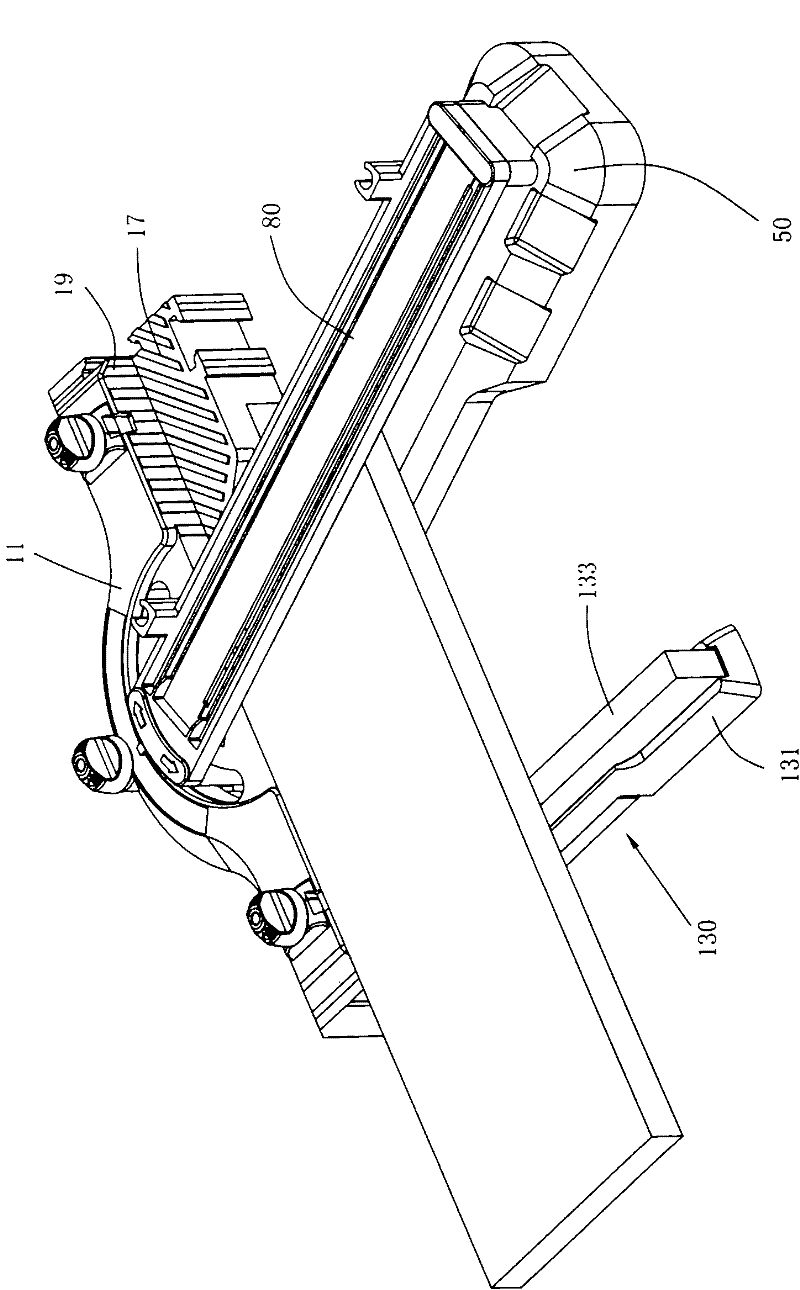

ActiveCN102126155AEasy to installEasy to adjustMetal sawing devicesMitre joint working devicesHand heldEngineering

The invention relates to a workbench which is used for guiding a handheld cutter. The handheld cutter comprises a working head; the workbench comprises a base, a rotary arm and a guide rail, wherein the base extends along the longitudinal length direction; the rotary arm is pivotally connected with the base; the guide rail is detachably mounted on the rotary arm; on a first position, the guide rail is connected with the rotary arm and used for guiding the handheld cutter, and the distance between a contact surface of the guide rail and a second support plane of the base is constant; and on a second position, the guide rail and the rotary arm are disconnected. As the guide rail and the rotary arm can be disconnected, a workpiece is relatively conveniently to mount and adjust; and moreover,as the distance between the contact surface of the guide rail and the second support plane of the rotary arm is constant, the distance between the guide rail and the rotary arm does not need to be regulated according to the thickness of the workpiece when in work, thus the operation is convenient, the structure of the entire workbench is relatively simple, and the cost is relatively low.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

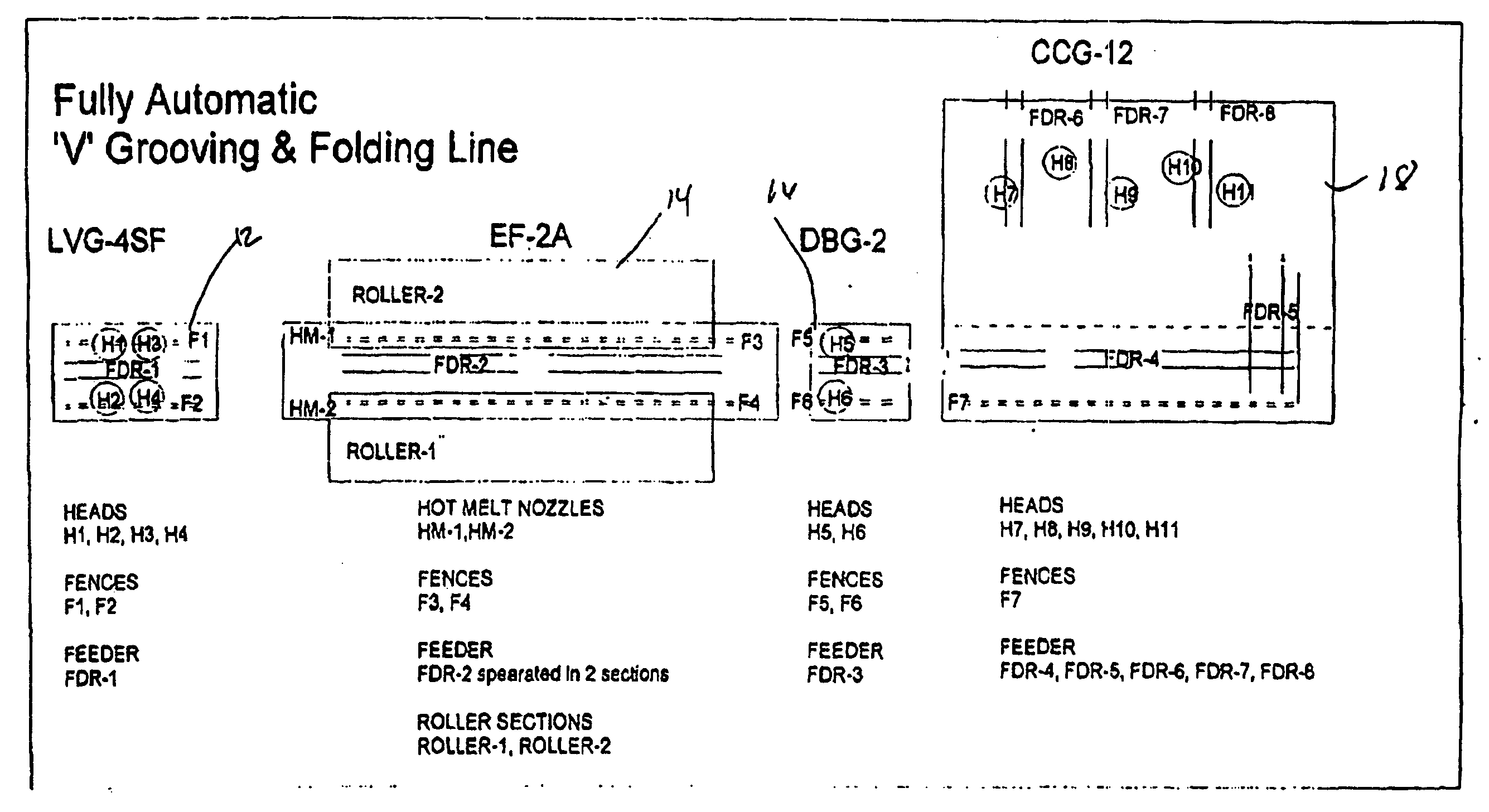

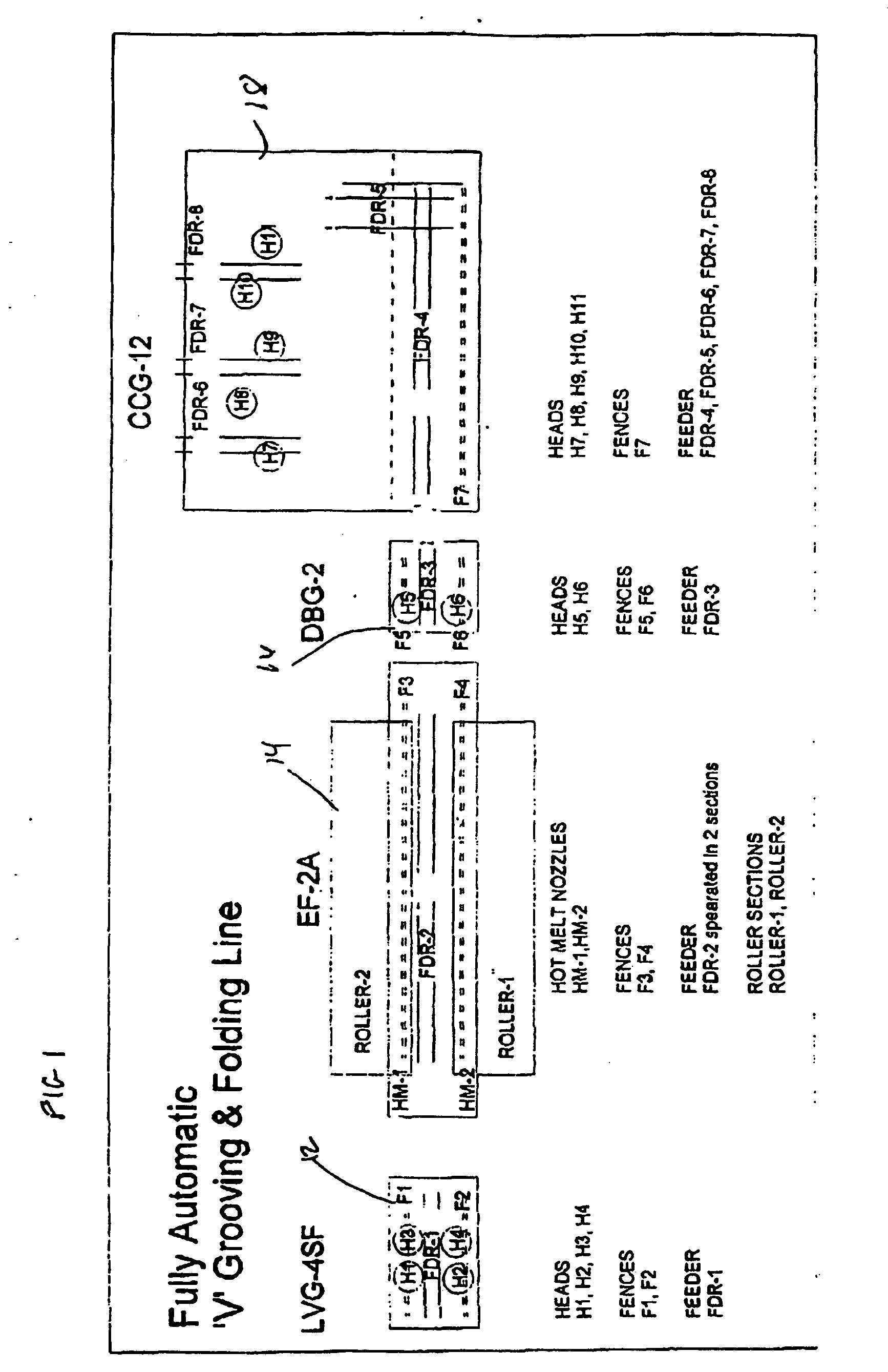

Automated manufacturing line for boxgoods

The present invention is directed to an automated manufacturing line for production of boxlike structures and components therefor from laminated or solid flat material by V grooving, folding and gluing to form the boxlike structure or component. The automated line includes two or more machines selected from lineal V groovers, continuous cross V groovers, edge folding and gluing machines and multiple scoring machines. Each of the machines is provided with fences and feeders for automatically guiding the workpiece through the automated line. The positioning of fences, feeders, cutting heads and applicators of each of the machines is fully adjustable by providing drive means to position the fence, feeder, cutting head and applicator according to a predetermined position required for the production of a particular boxlike structure or component. The drive means is controled by a programmed controller having the parameters of the boxlike structure or component and having a means to cause the drive means to be activated to position the fence, feeder, cutting head or applicator in the correct position for the production of the desired boxlike structure or component.

Owner:BENYOVITS TED

Miter box

Owner:RYAN RICHARD P

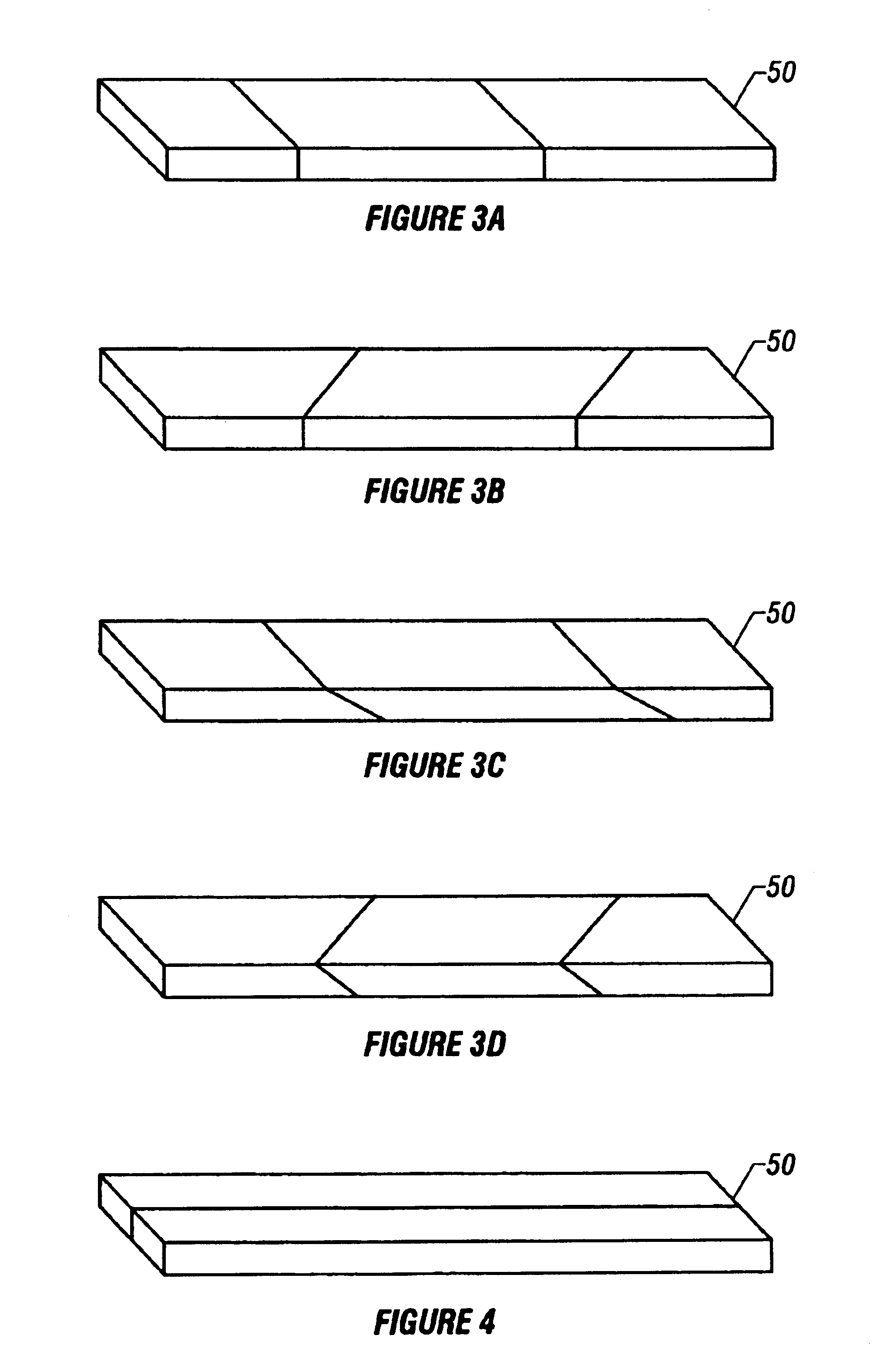

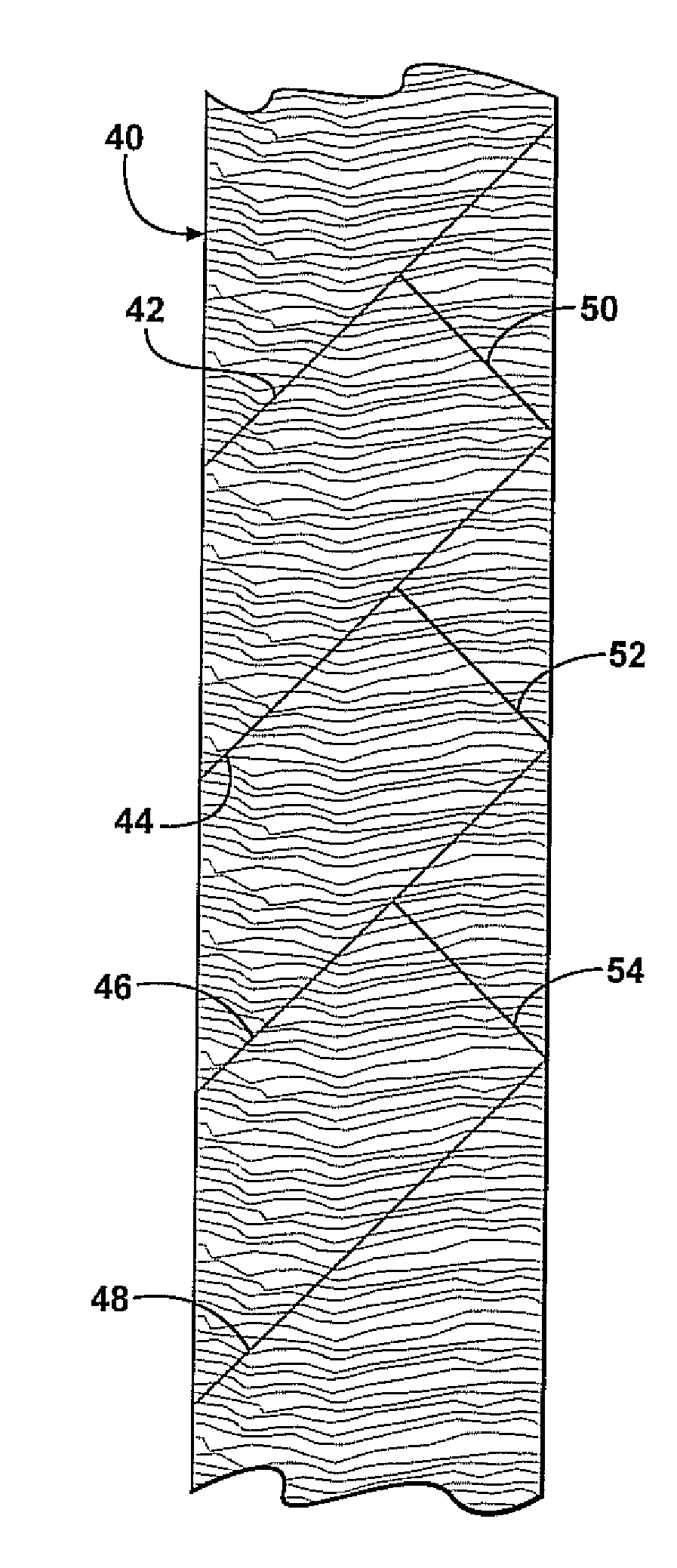

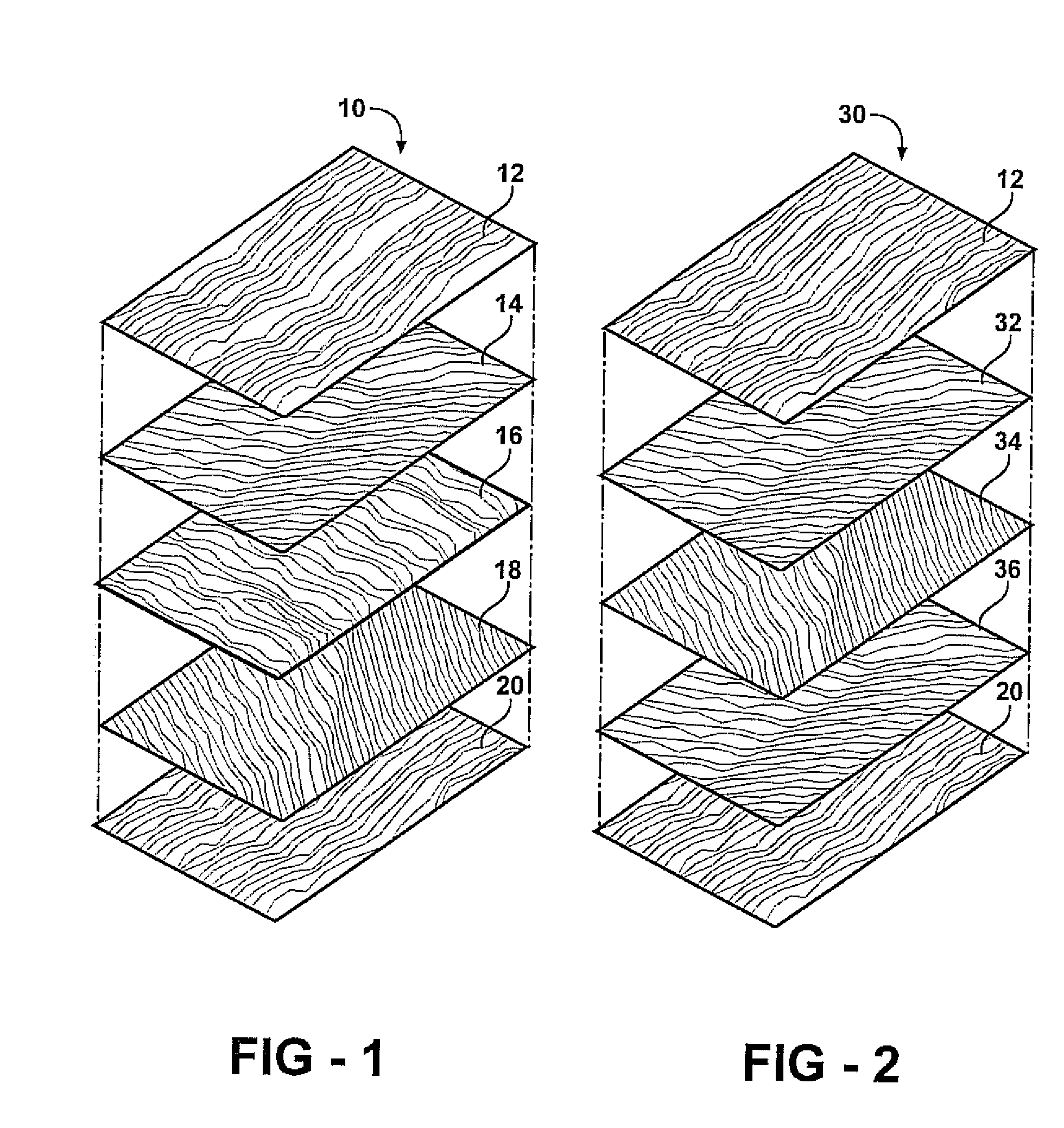

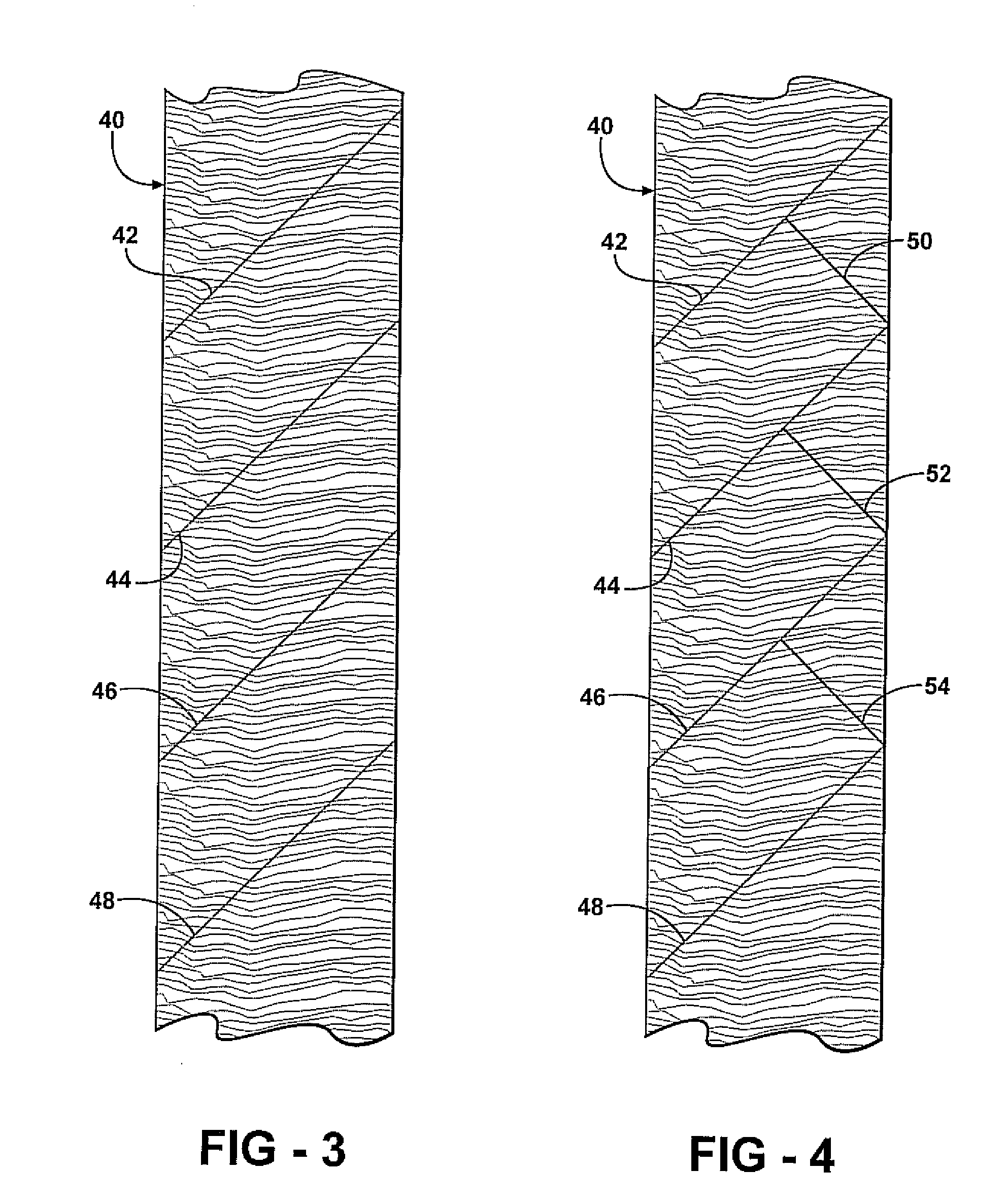

Plywood having omnidirectional strength, and methods for its manufacture

InactiveUS20090053452A1Other plywood/veneer working apparatusWood veneer joiningOmnidirectional antennaDiagonal

Omnidirectional strength plywood includes at least one ply disposed so that its grain runs diagonal to the length and width of the plywood sheet, and as such its grain diagonally intersects the grain of at least one other ply of the sheet. In some instances, two diagonal plies are disposed so that their grains intersect at approximate right angles and both run diagonal to the length and the width of the sheet. Further disclosed is a method for the manufacture of the diagonal grain plies.

Owner:TAKAHASHI NOBUO

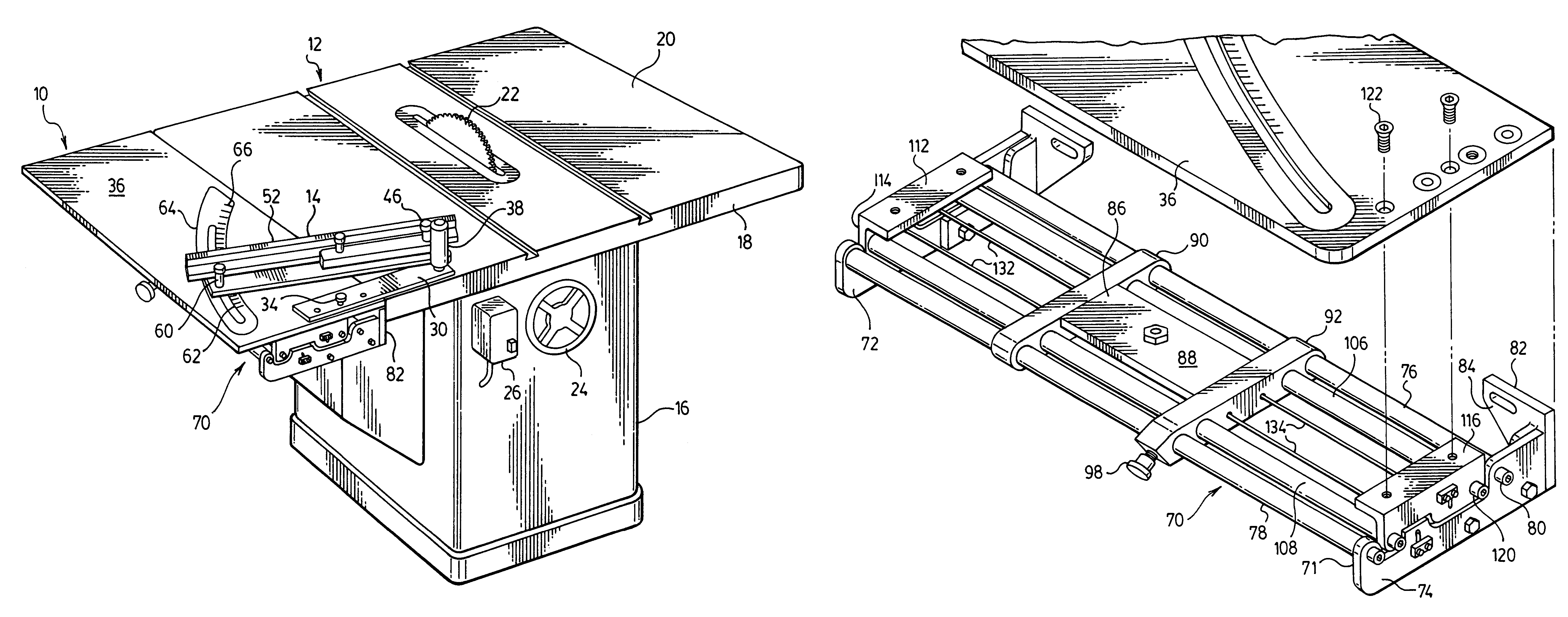

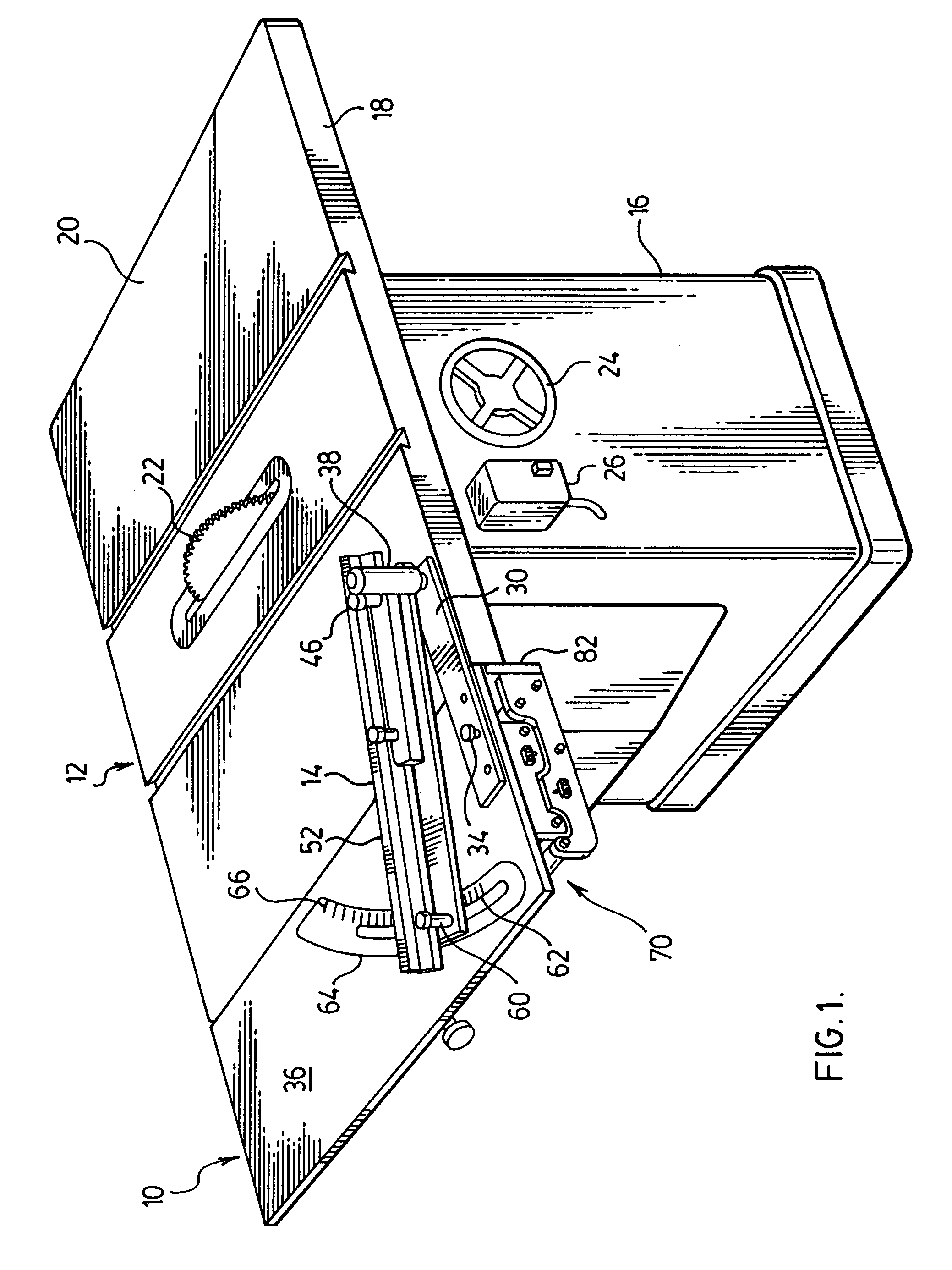

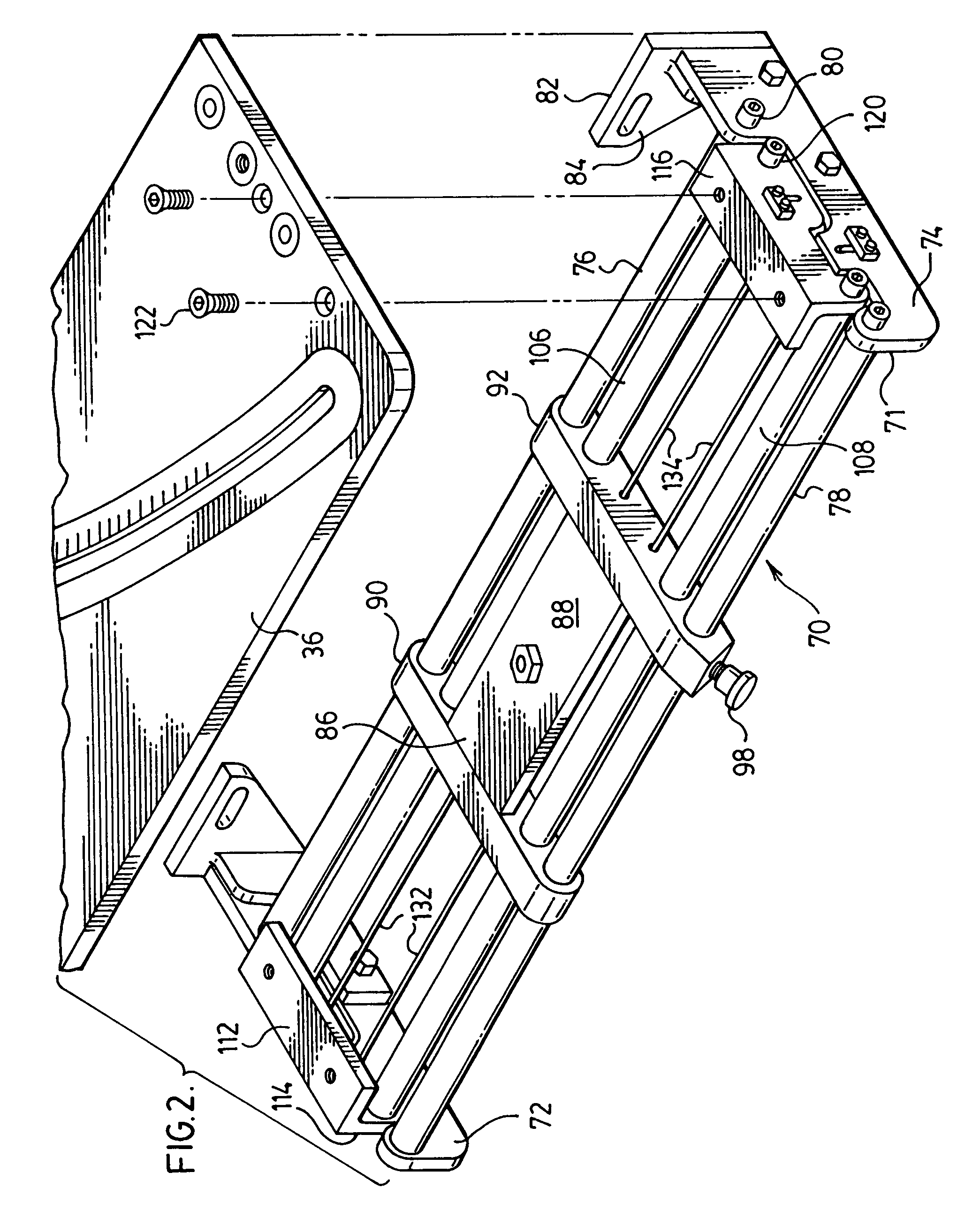

Power tool and miter gauge assembly for table saw

The present invention provides a power tool with a base assembly and a table supported by the base assembly. The table has a slot. A saw assembly is pivotably supported by the table, and includes a motor, and a blade driven by the motor. A miter gauge assembly is disposable on the slot. The miter gauge assembly has a body, a fence pivotably attached to the body, and a bar pivotably attached to the body, where the bar is disposable in the slot.

Owner:BLACK & DECKER INC

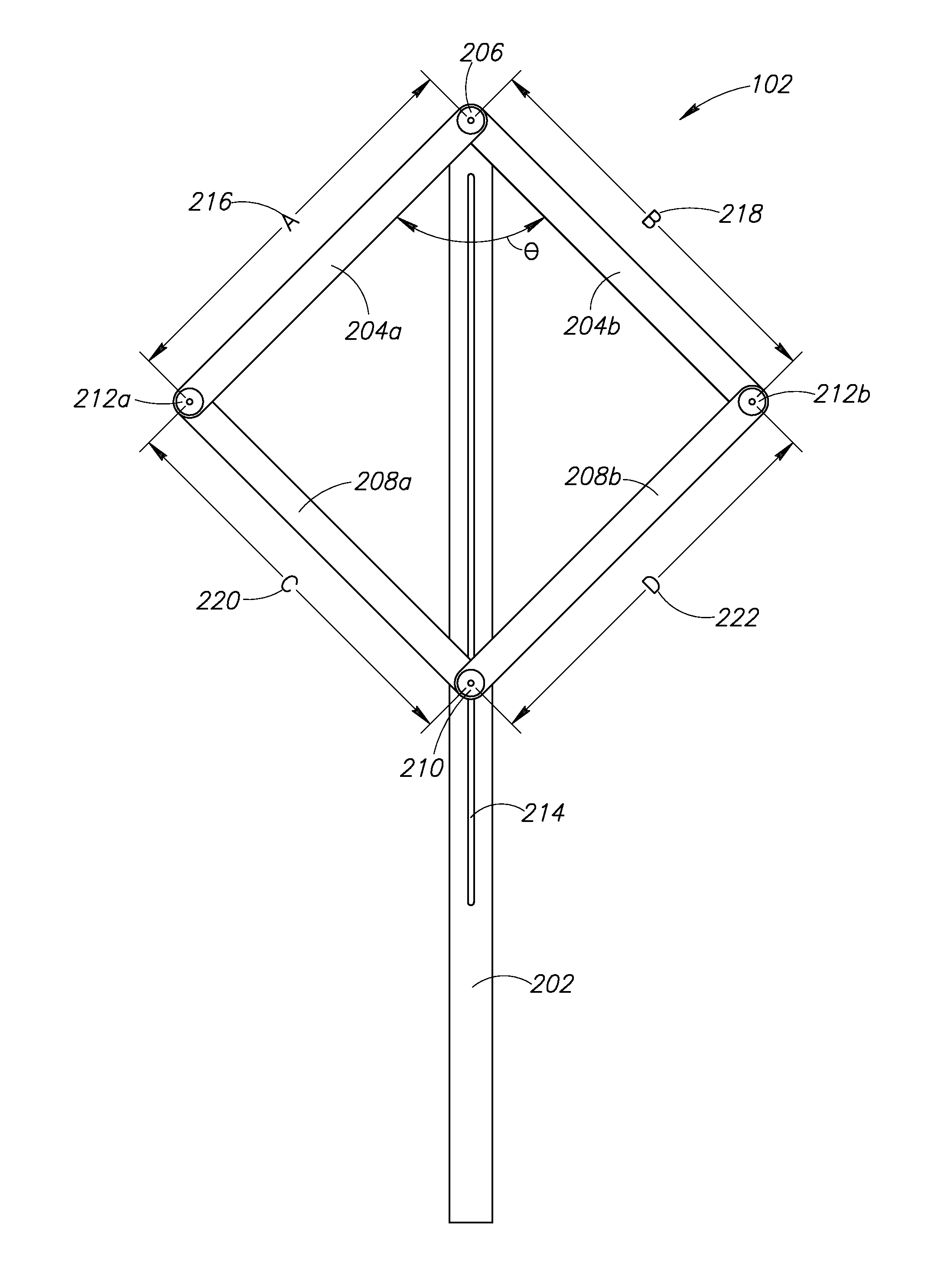

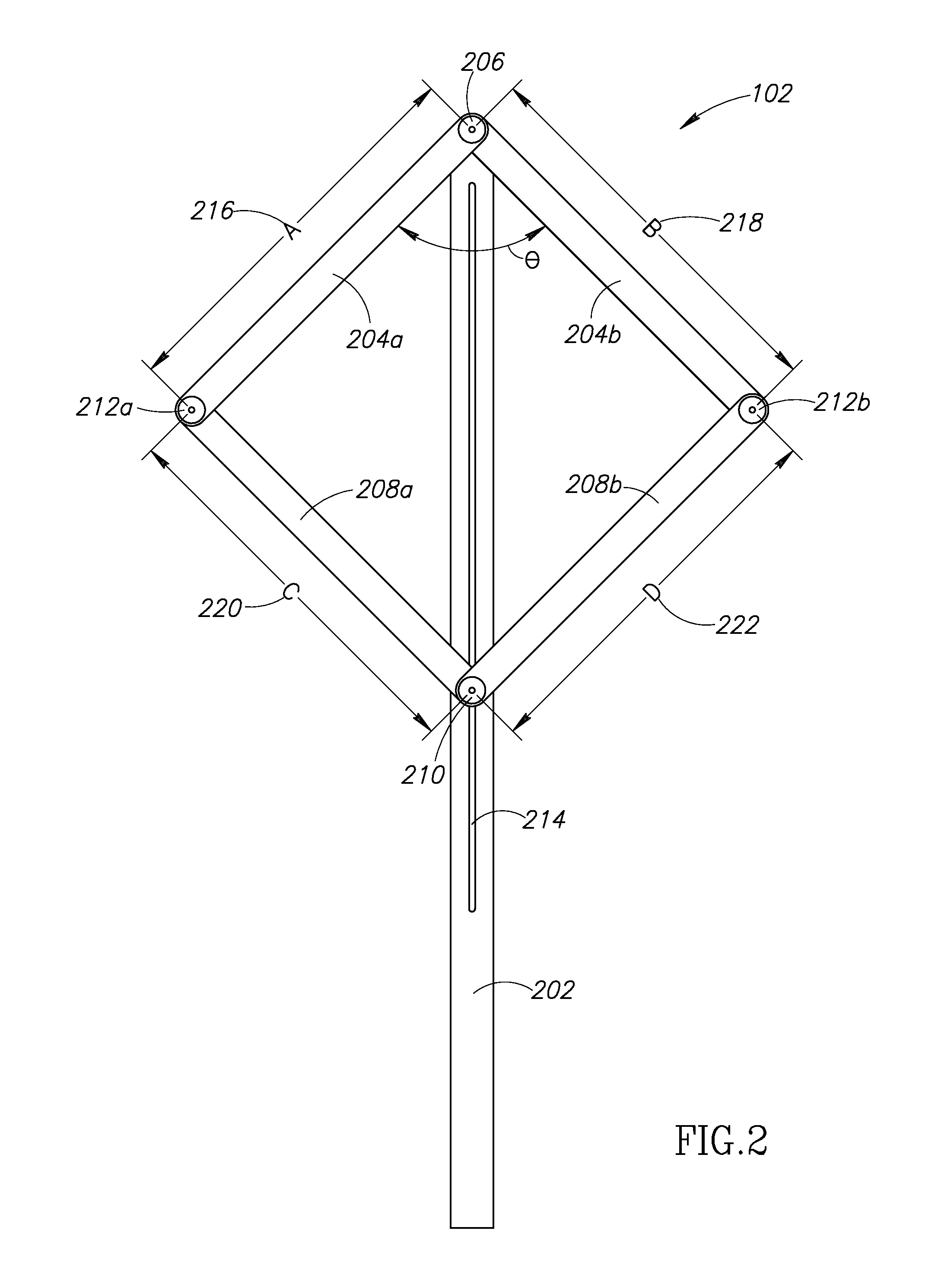

Angle bisector gauge

InactiveUS20160363429A1Prevent slidingGuide fencesMitre joint working devicesAxis of symmetryDiagonal

An angle measuring gauge incorporates four arms pivotally connected to form a quadrilateral. The arms are connected to a guide bar that attaches to the quadrilateral along a diagonal and forms an axis of symmetry. A first corner of the quadrilateral is pivotally attached to the guide bar and the opposite corner of the quadrilateral is pivotally connected and is slidable along the guide bar to adjust the angles of the quadrilateral. In practice, the first corner of the quadrilateral is adjusted to conform to a desired angle, and the guide bar bisects the angle formed by the first corner and can be used to either ride in a miter slot of a cutting tool, or adjust a miter gauge of a cutting tool to cut accurate miters.

Owner:CLERC GREGORY A

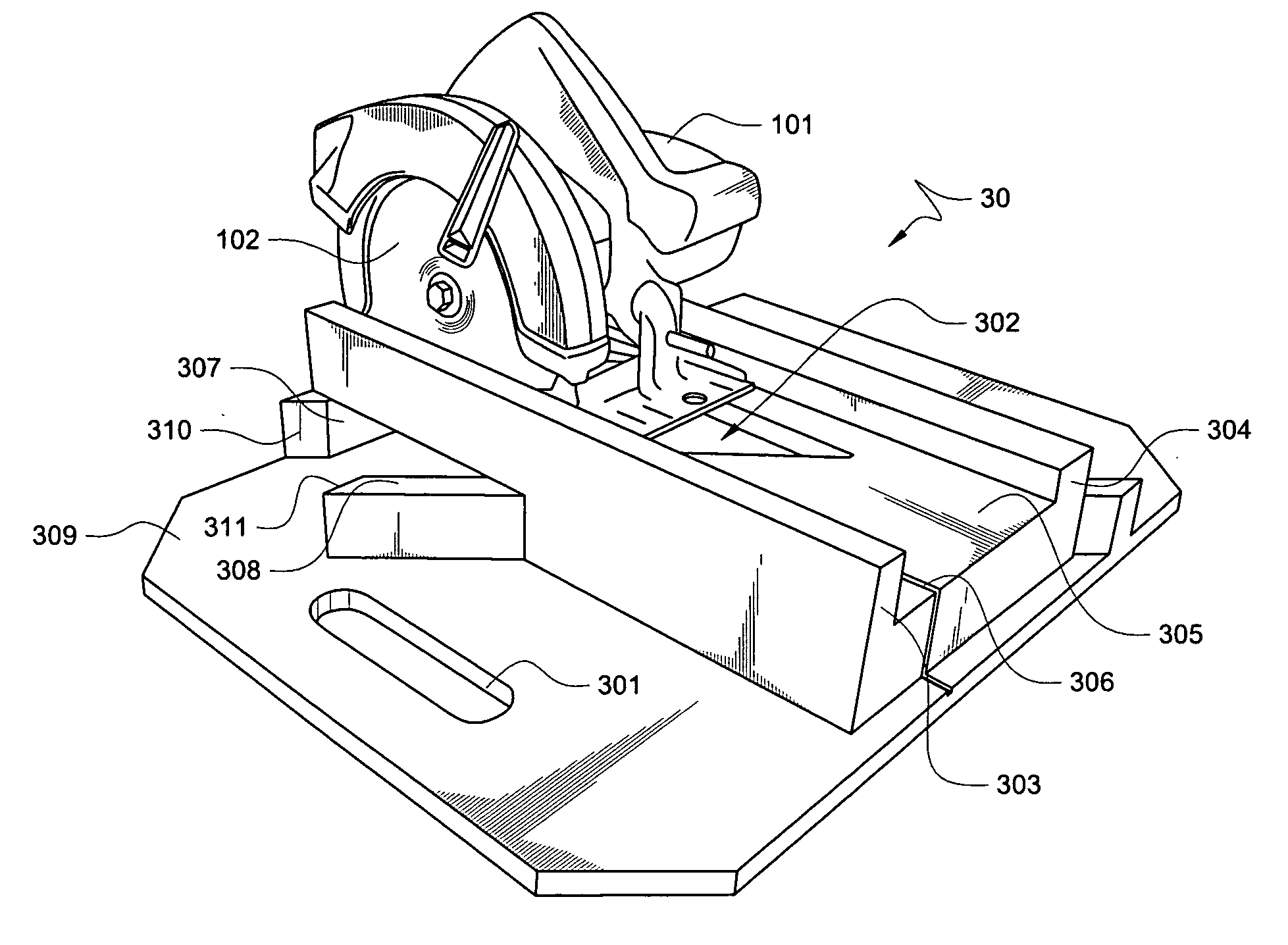

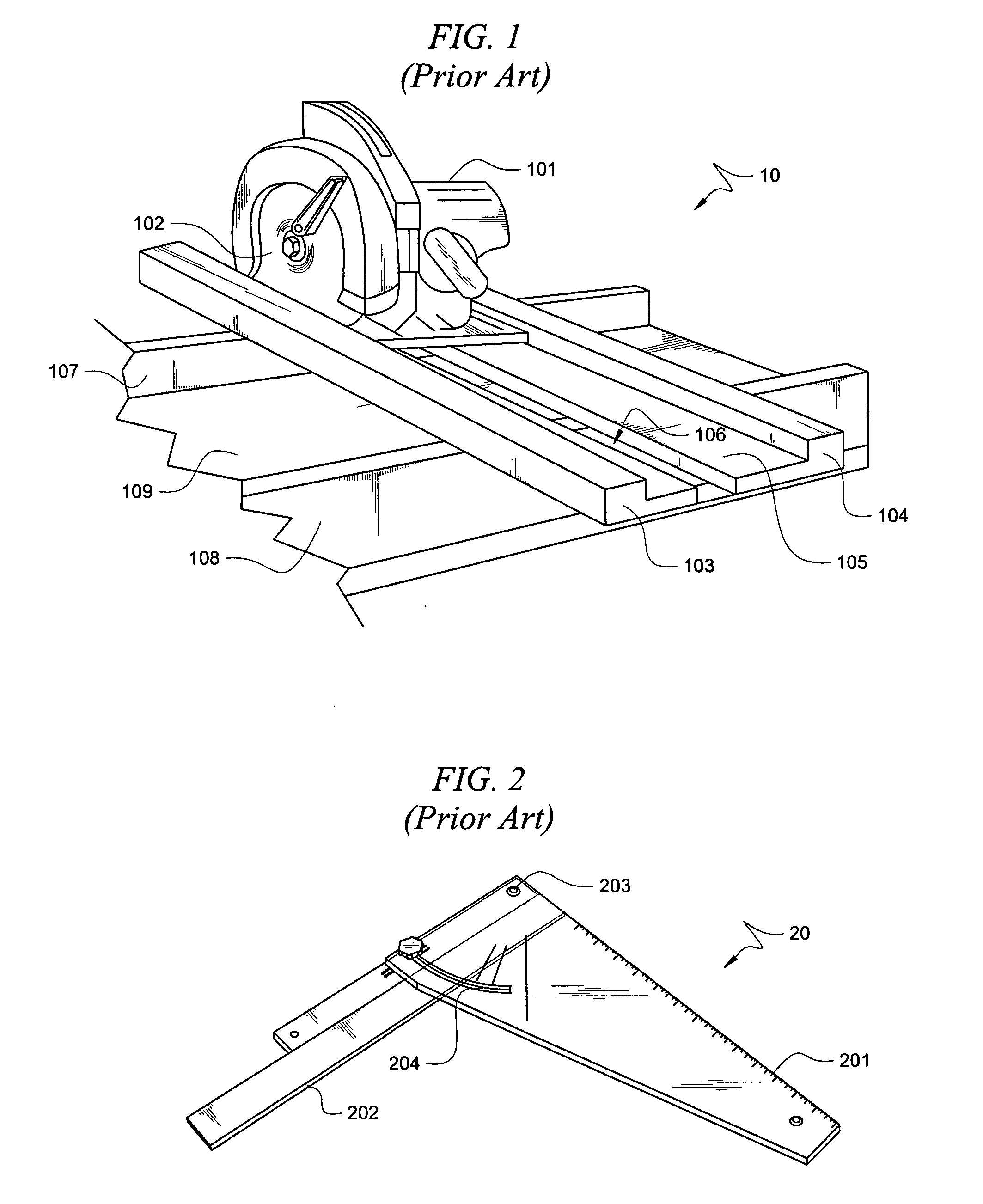

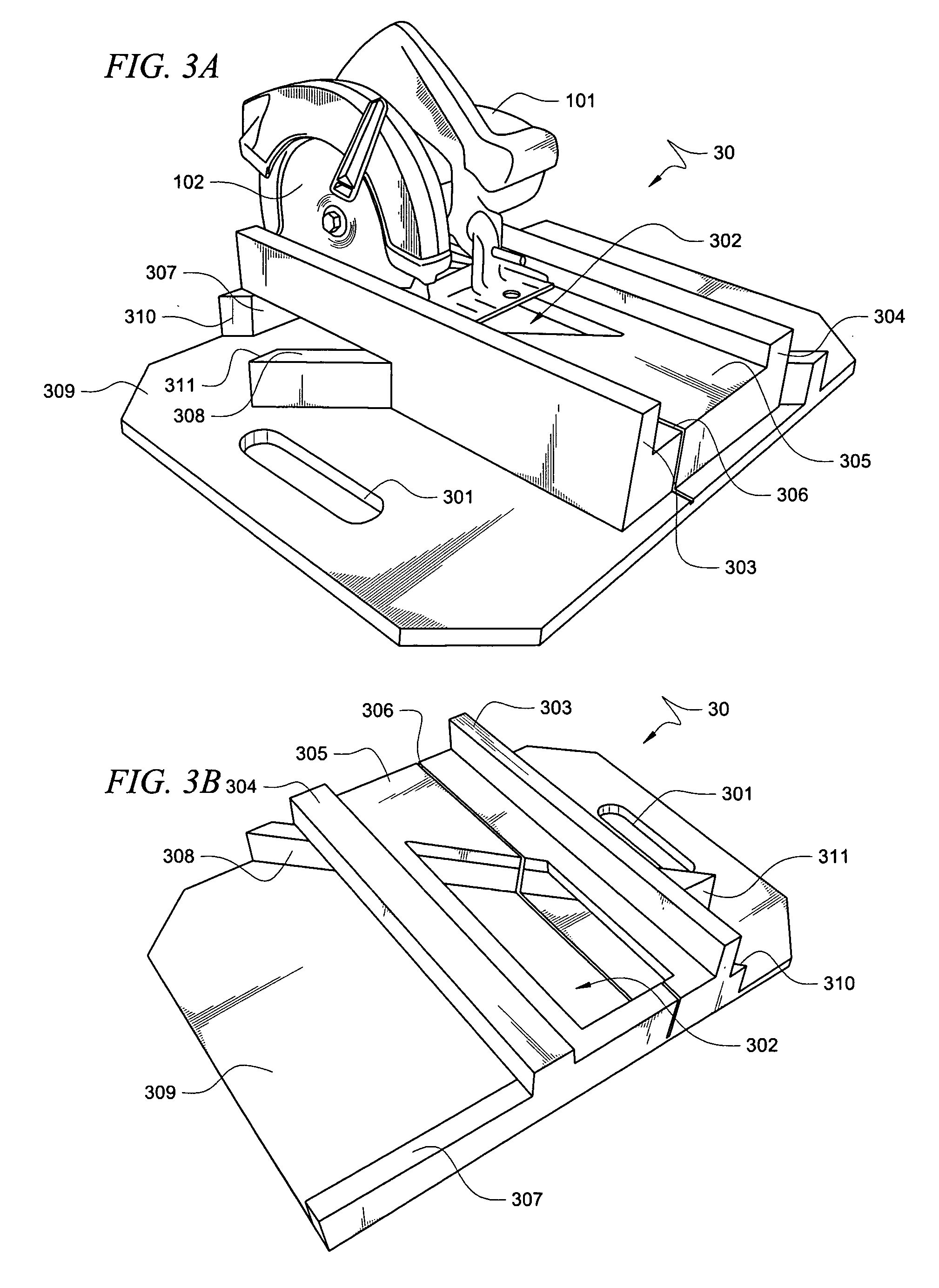

Power saw miter guide

InactiveUS20080127790A1Precise cuttingSecurely holdMetal sawing devicesGuide fencesEngineeringStraight path

Operating a power saw between a pair of parallel guide rails, which engage opposing sides of saw base plate to constrain the motion of the saw to a straight path, allows for precise cuts. A set of two or more fences allows for multiple cutting options. In some embodiments, non-parallel fences coupled to the guide rails allow for precise cuts at more than just a single angle. In some embodiments, two fences may engage opposing sides of the object to be cut simultaneously, holding the object more securely with respect to the guide rails than would a single fence. A possible clamping force holding the two fences against the object allows the miter guide to remain fixed relative to the object so that the user's hand may be freed for another task, such as holding the saw with both hands.

Owner:WILSON KELCE S

Precision Miter Gauge Setting Fixture

ActiveUS20080178486A1Avoid insufficient lengthDrilling/boring measurement devicesMeasurement/indication equipmentsDetentEngineering

A precision miter gauge setting fixture system is described that includes a horizontal surface with a miter bar channel that bisects at least one pair of symmetrical arcs of angularly spaced, position receptacles drilled into the surface, where each angular position receptacle of a paired set of arcs, radially centers on a base position receptacle of the other symmetrically paired arc of angularly space, position receptacles. A pair of position posts, one snugly seated in the base position receptacle of one of the paired symmetrical arcs of angularly spaced, position receptacles, the other snugly seated in one of the angularly spaced, position receptacles of the other symmetrically paired arc define the desired angle for setting the angle of a miter fence head relative to the miter bar of a miter gauge received and sliding in the miter bar channel.The described precision miter gauge setting fixture system further includes one or more straight edged, accessory, detent step bars each having a length sufficient to span the radial distance between a base position receptacle of one of a pair of symmetrical arcs of angularly spaced, position receptacles and each of the angularly spaced, position receptacles of the other arc of the pair Each straight edged, accessory, detent step bar also has one or more step detents, each detent incrementally increasing in depth, cut into one or both of its opposite longitudinal straight side edges proximate one or both of its ends for incrementally adding to and subtracting from the angle defined by the respectively seated, position posts, where the angle of the miter fence head of the miter gauge is determined by the angle of the longitudinal straight edge of the step dent bar opposite a particular step detent abutting against one or the other of the respectively seated position posts.

Owner:PATTEE RICHARD

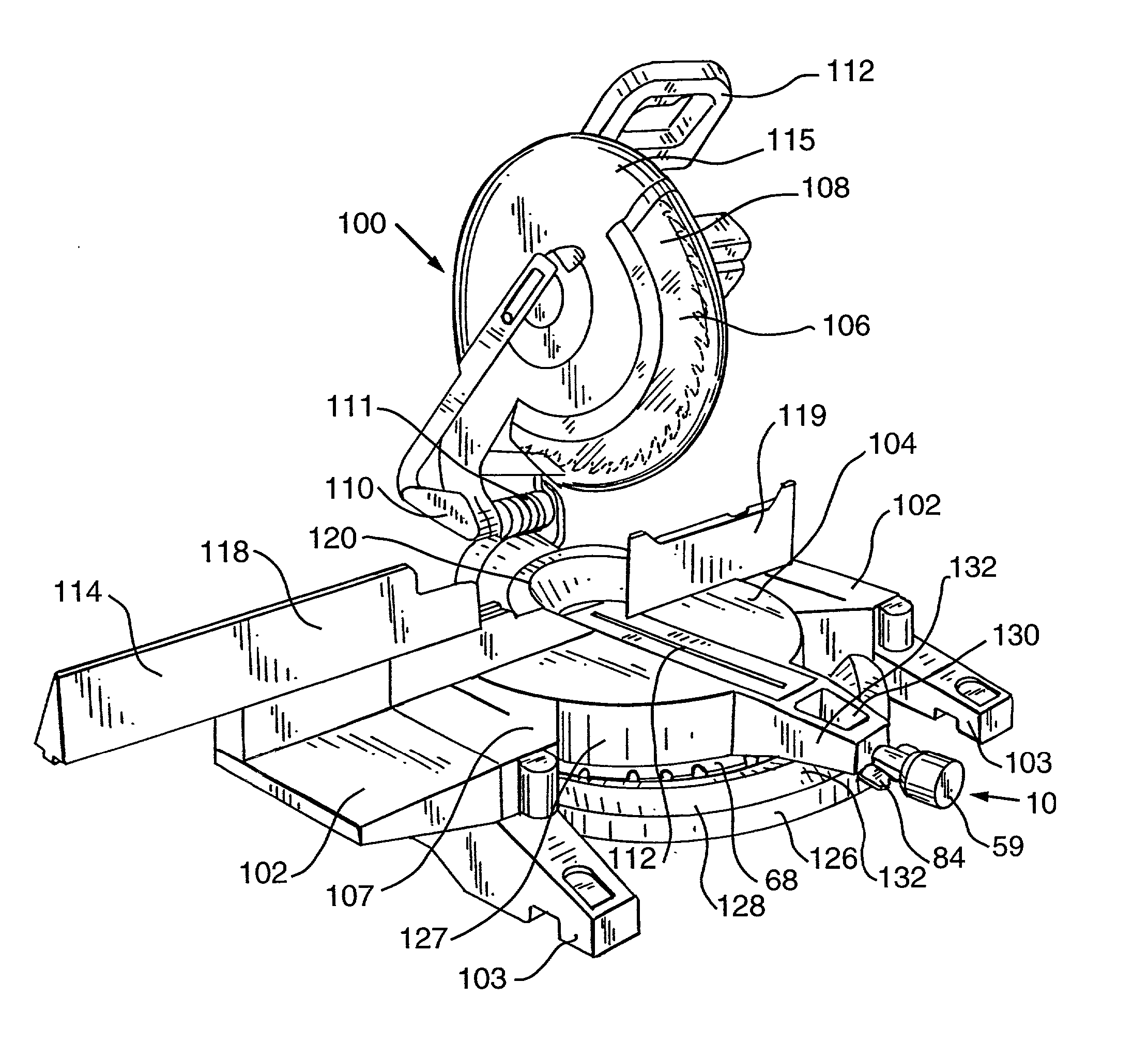

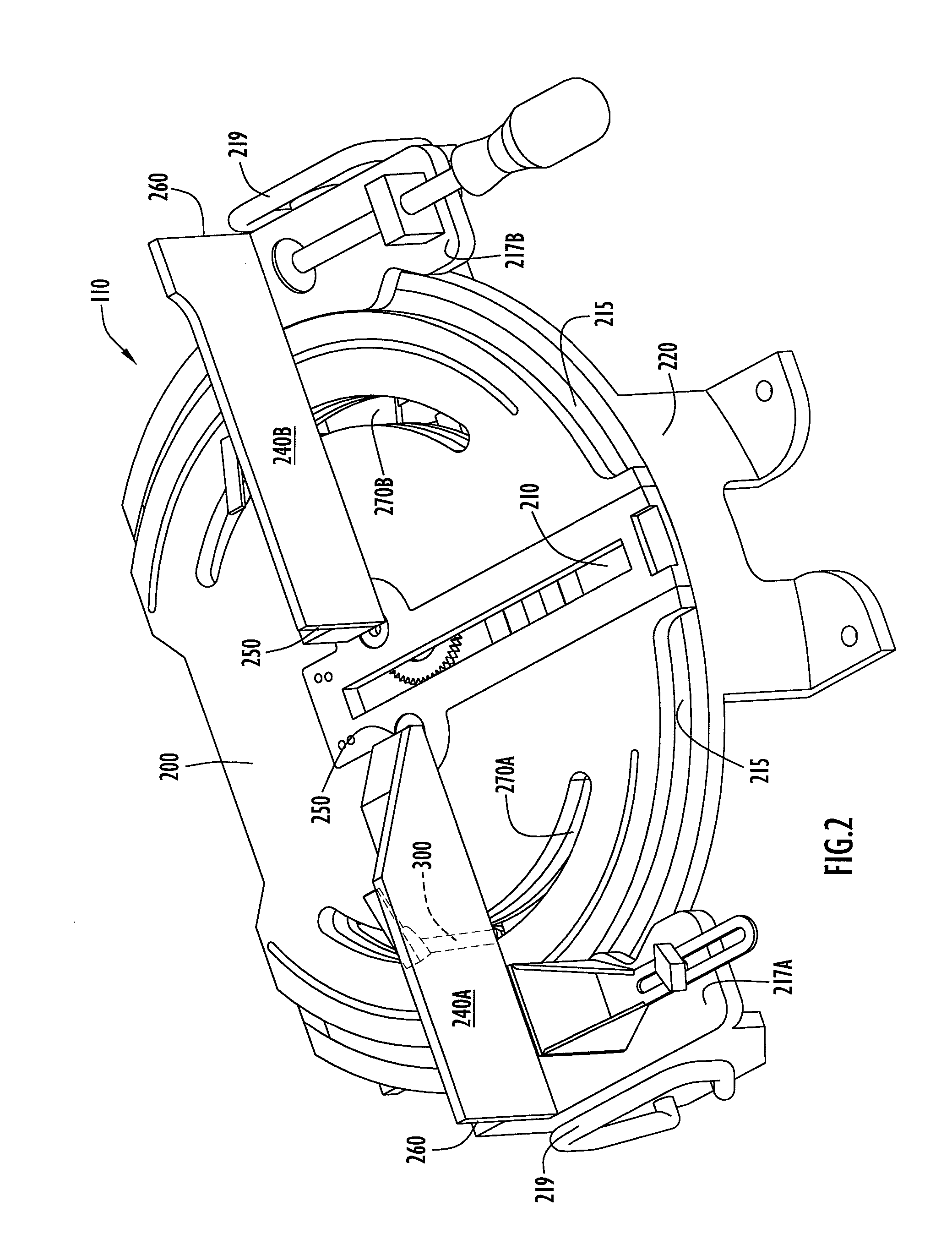

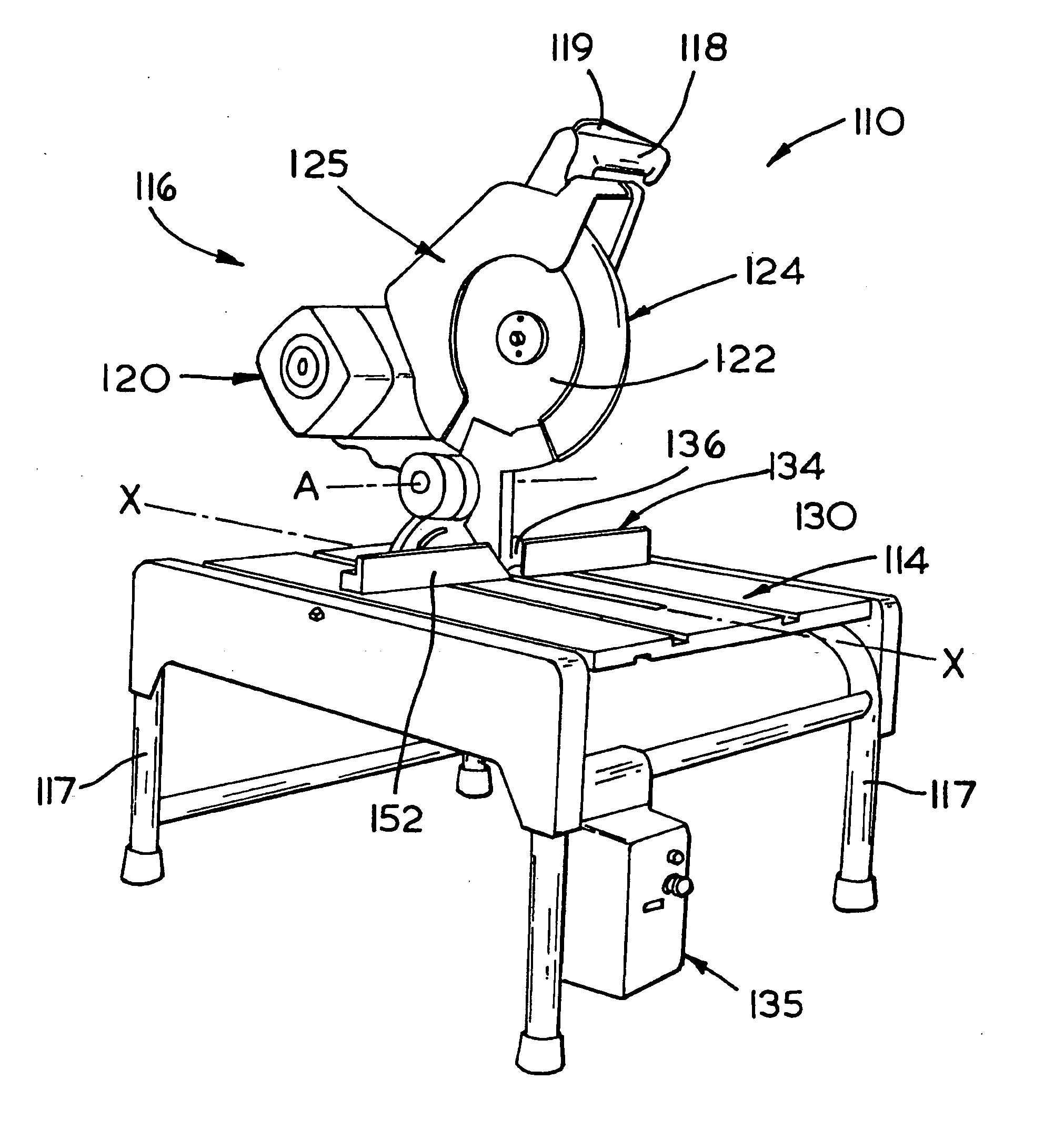

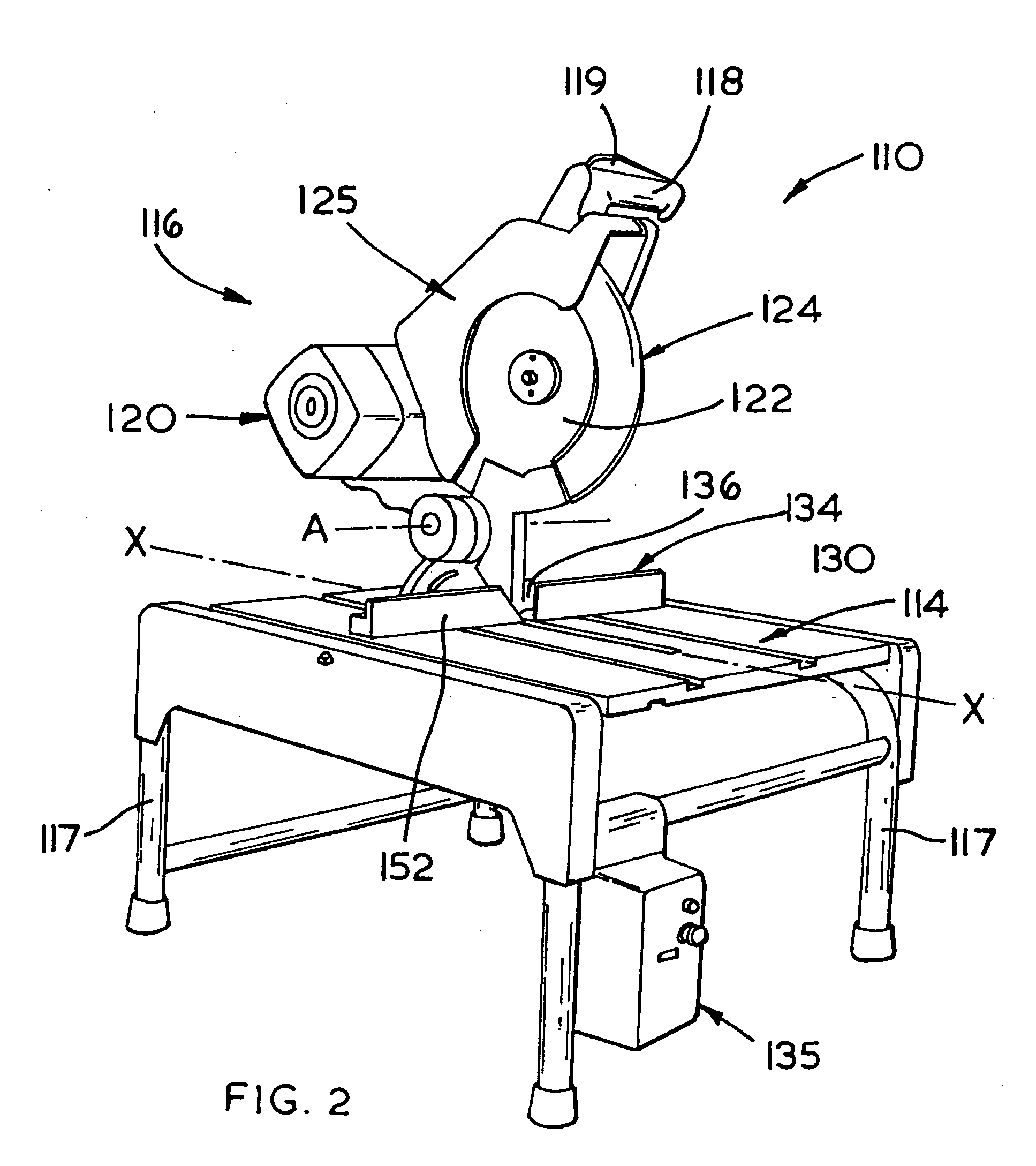

Mitre saw with adjustable fence

InactiveUS20060011033A1Facilitate appropriate angular inclinationEasy to adjust the angleGuide fencesShearing machinesEngineeringMechanical engineering

A miter saw 110 having an operable cutting blade 122 pivotally supported relative to a working surface 114 and displaceable in a first cutting plane which intersects the work surface 114 along a first cutting line X-X. The miter saw has an adjustable elongated fence 134 angularly displaceable relative to the first cutting line X-X. The fence 134 is adjustably mounted on and supported by the working surface 114.

Owner:BLACK & DECKER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com