Power tool and miter gauge assembly for table saw

A technology for positioning components and power tools, which is applied in the direction of sawing components, manufacturing tools, positioning devices, etc., and can solve problems such as difficult storage and bulky table saws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

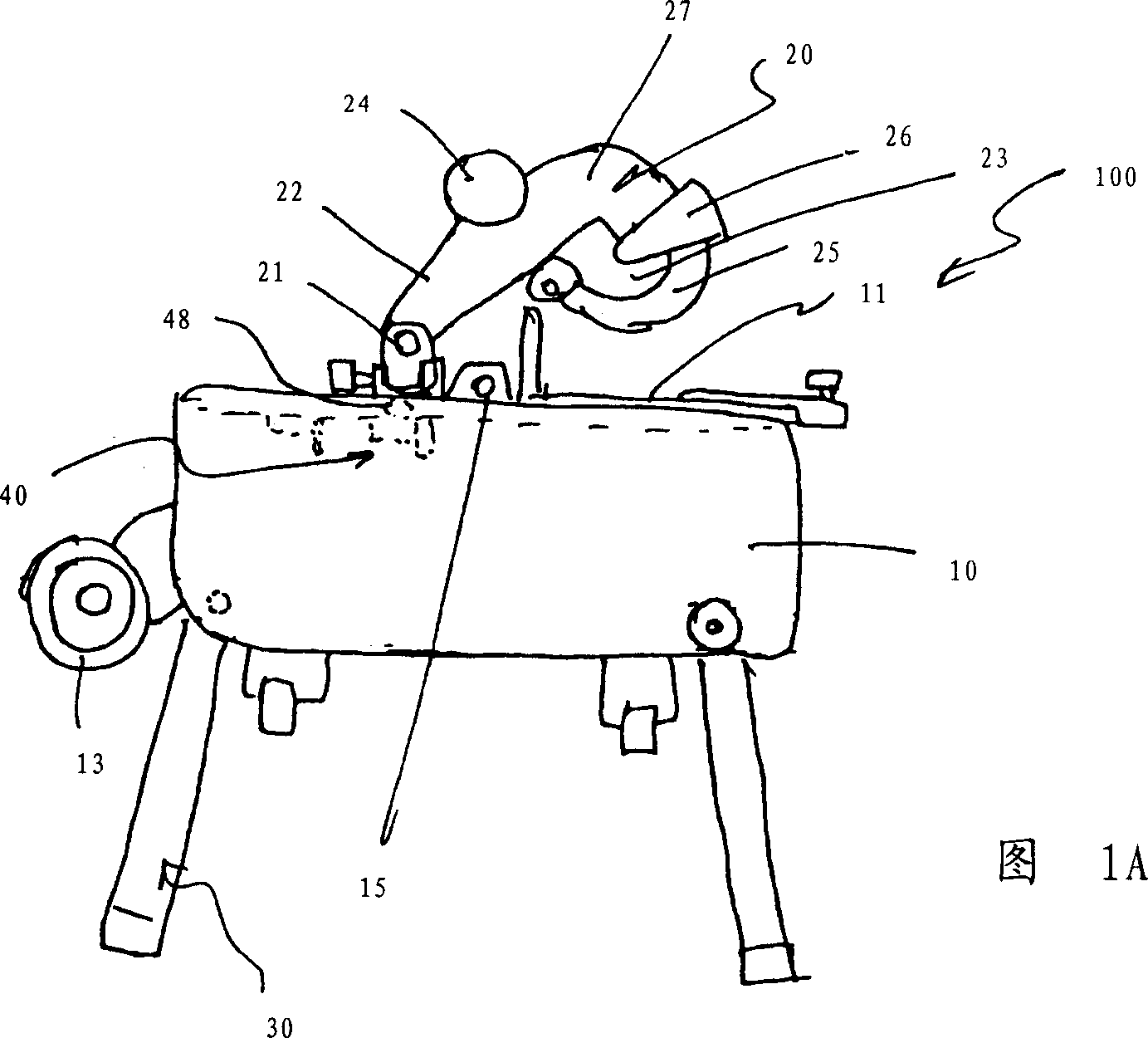

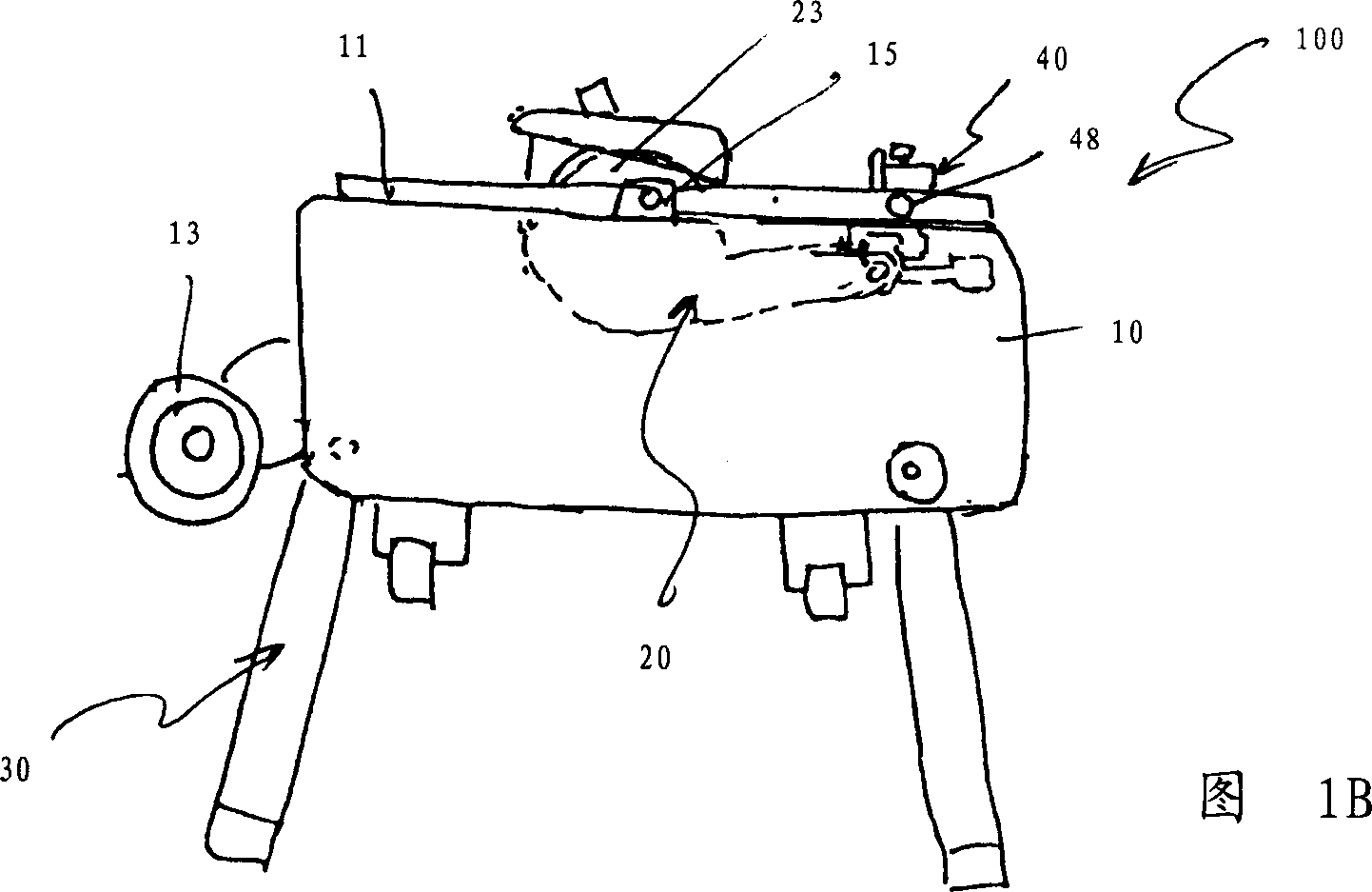

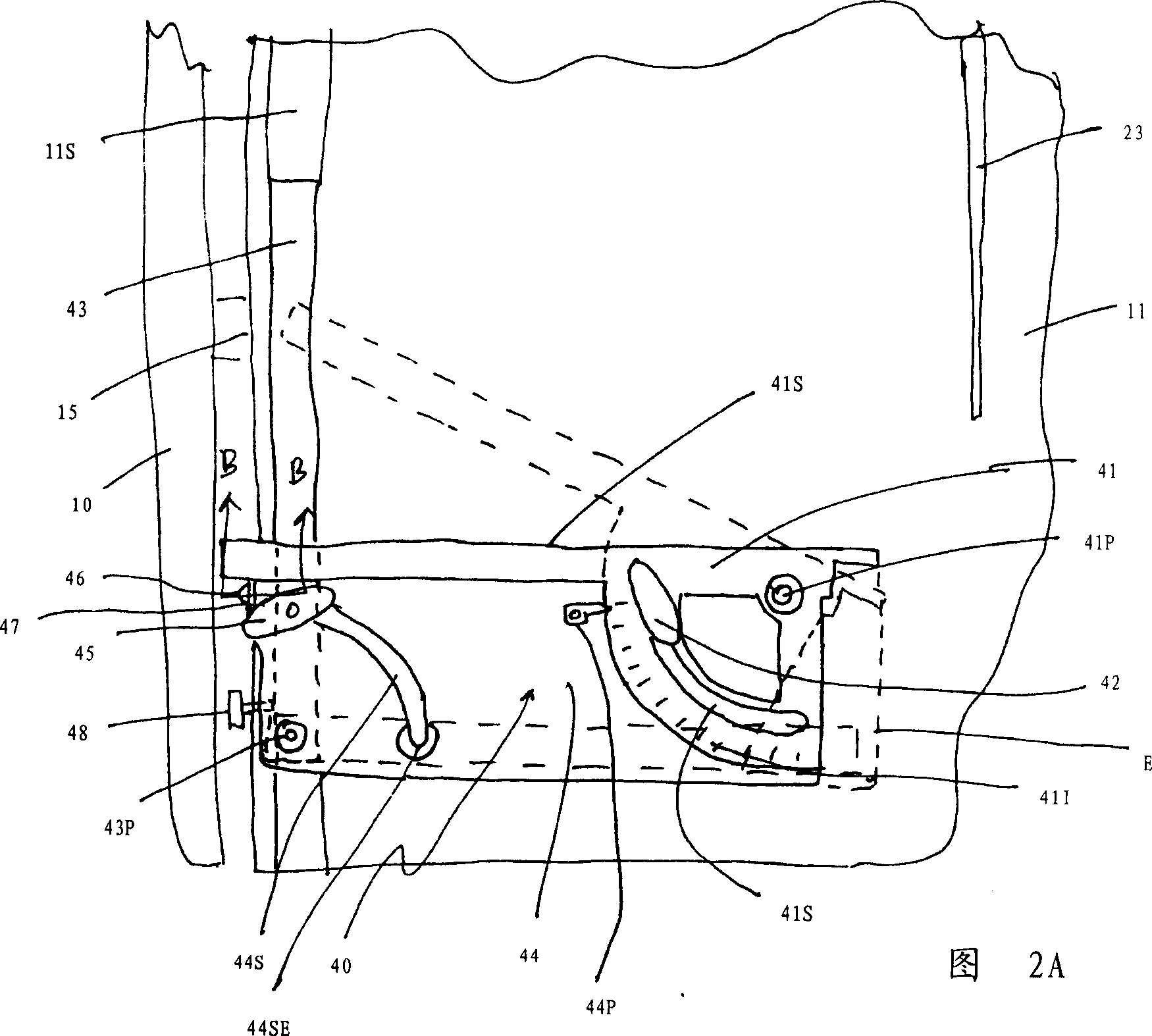

[0009] The invention will now be described with reference to the drawings, wherein like reference numerals refer to like parts. Referring to FIG. 1 , a bench / miter combination saw 100 may include a base assembly 10 , a table assembly 11 supported by the base assembly 10 , and a saw assembly 20 supported by the table assembly 11 . The saw assembly 20 may include a shaft assembly 21 disposed on the table assembly 11 , a pivotable arm 22 pivotably attached to the shaft assembly 21 , and a motor 24 supported by the arm 22 and driving a saw blade 23 . The arm 22 also supports an upper blade guard 27 that covers the upper portion of the saw blade 23 . The lower blade guard 25 is pivotally attached to the upper blade guard 27 . Auxiliary blade guard 26 may be pivotally connected to lower blade guard 25 .

[0010] Preferably, table assembly 11 is pivotally attached to base assembly 10 via joint 15 such that saw assembly 20 can be used as a miter saw when table assembly 11 is in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com