Patents

Literature

2470results about How to "Easy to adjust the angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

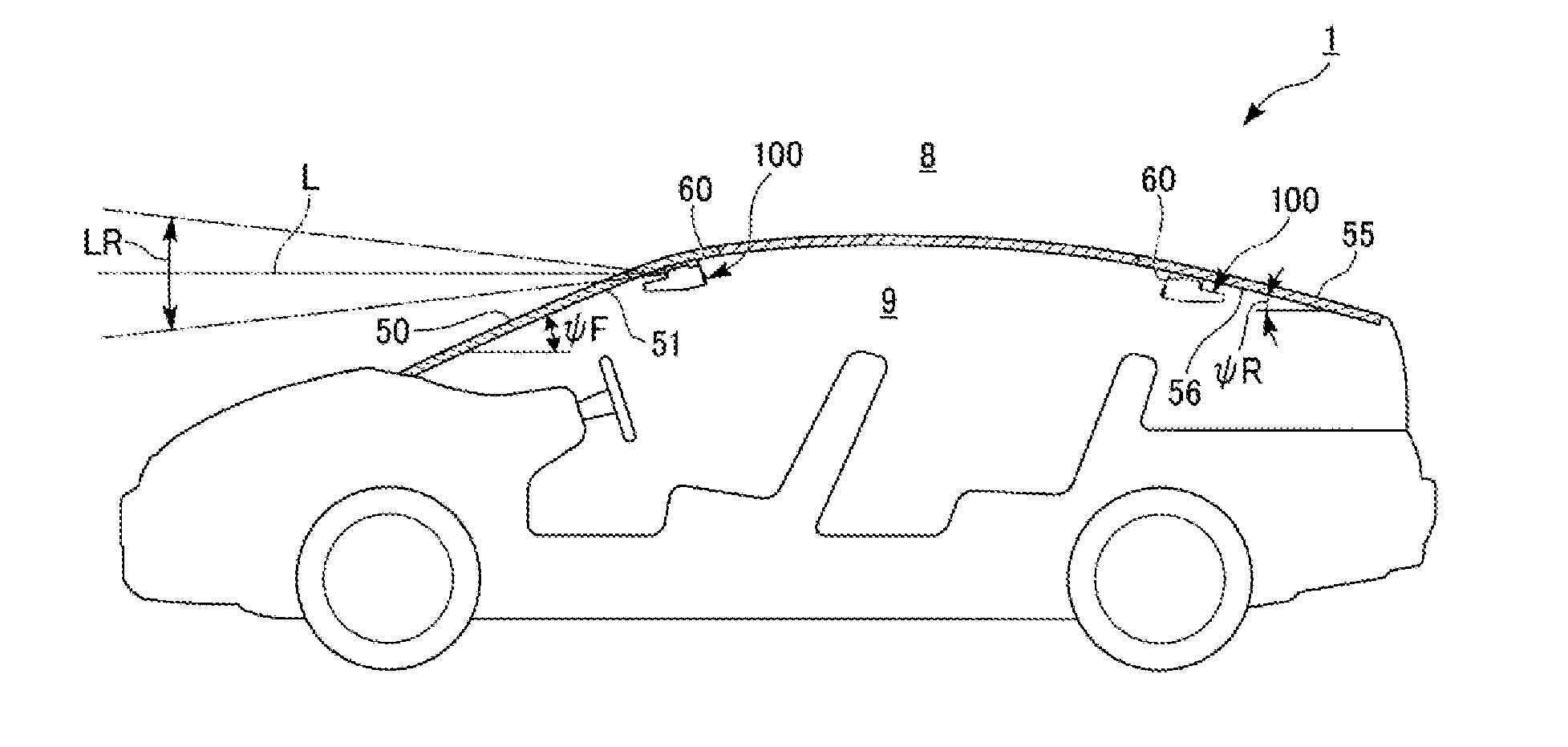

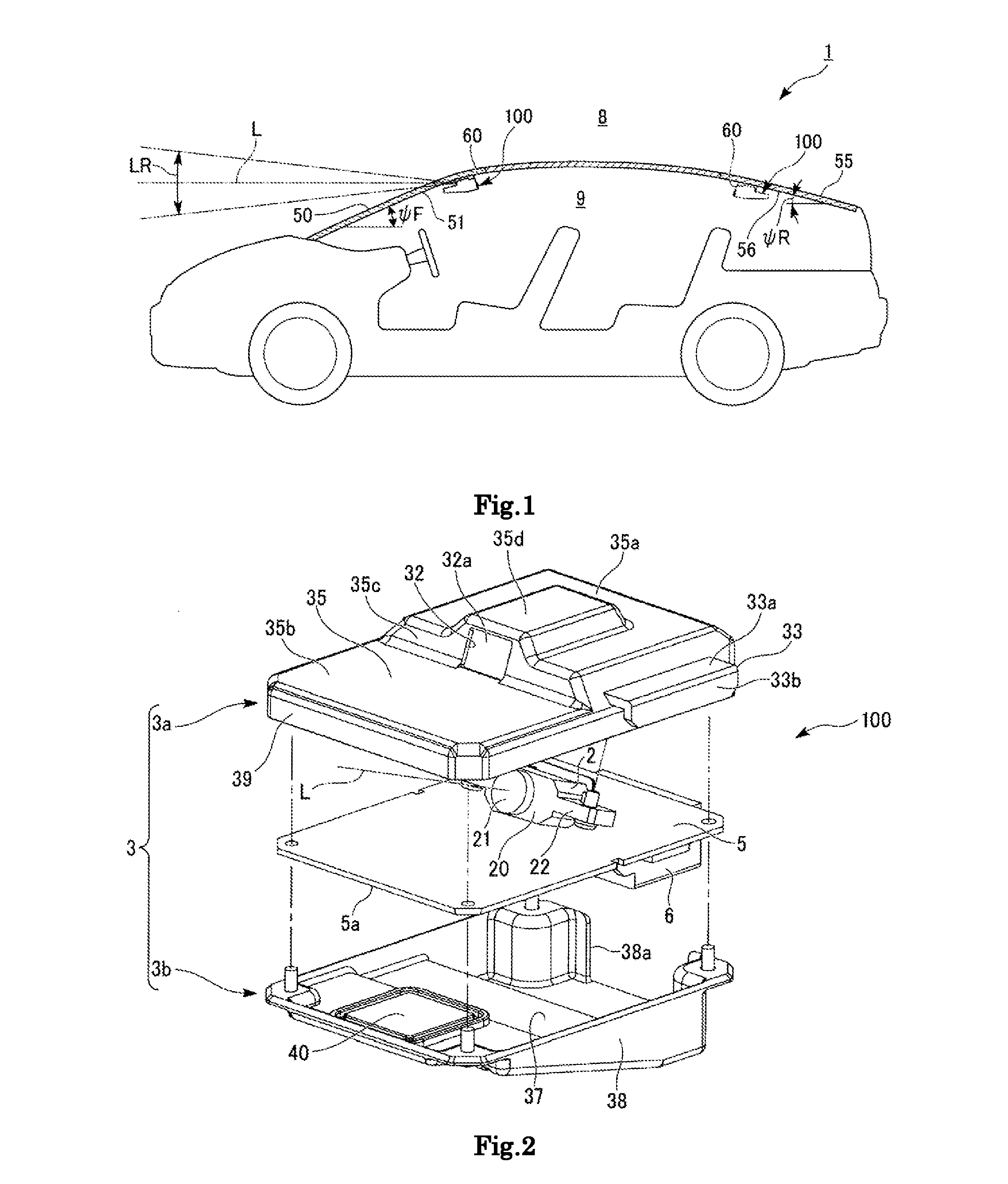

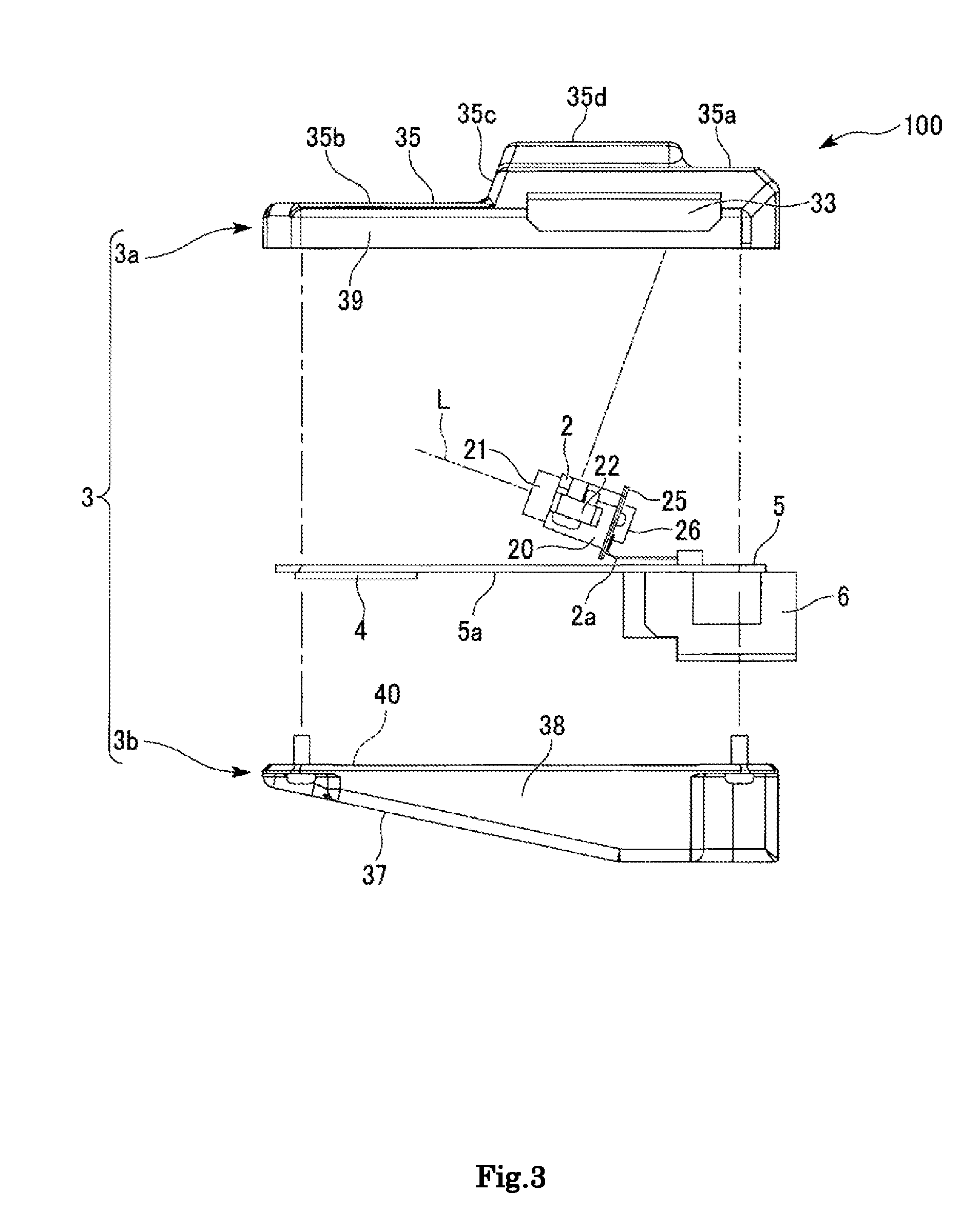

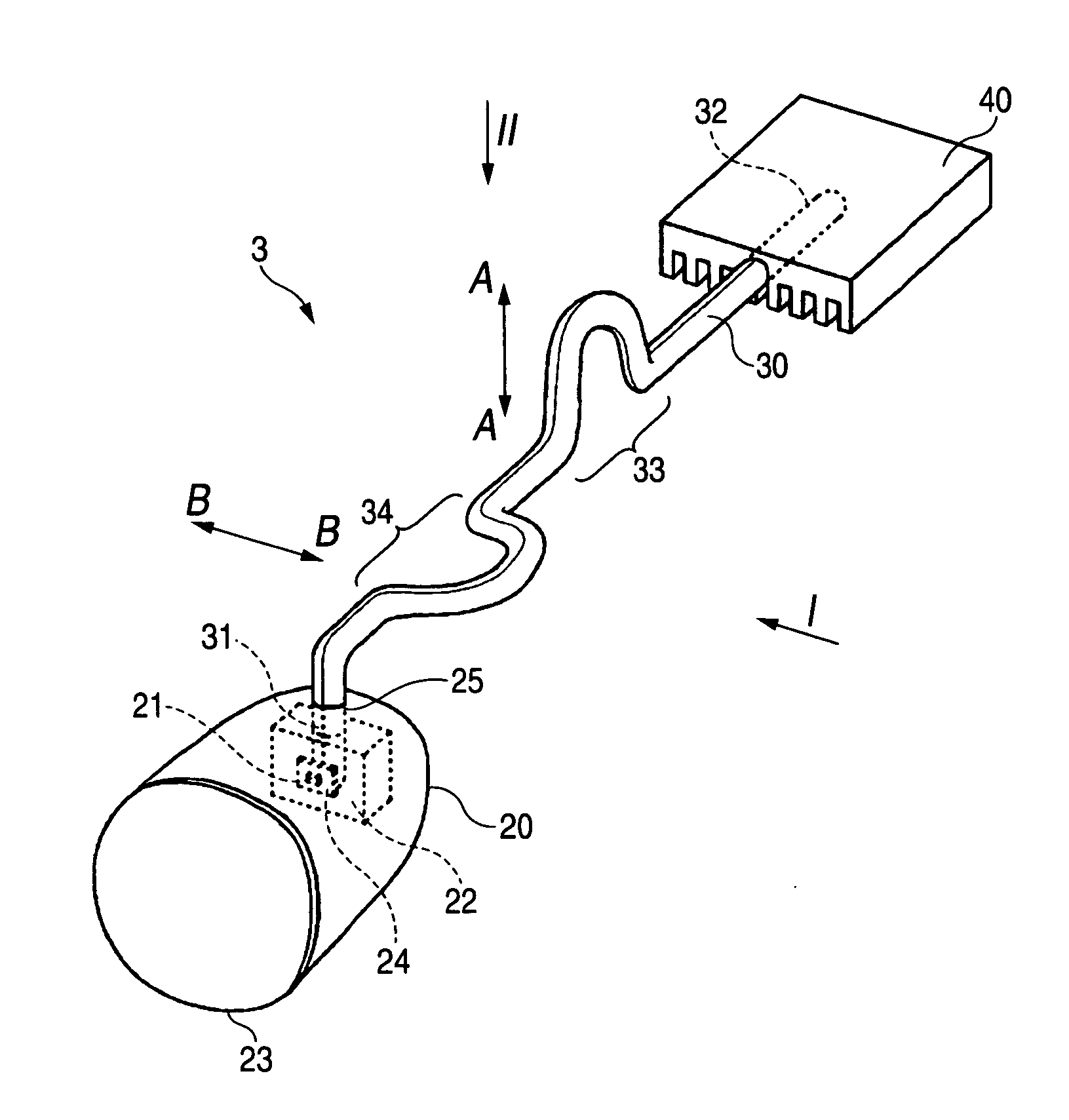

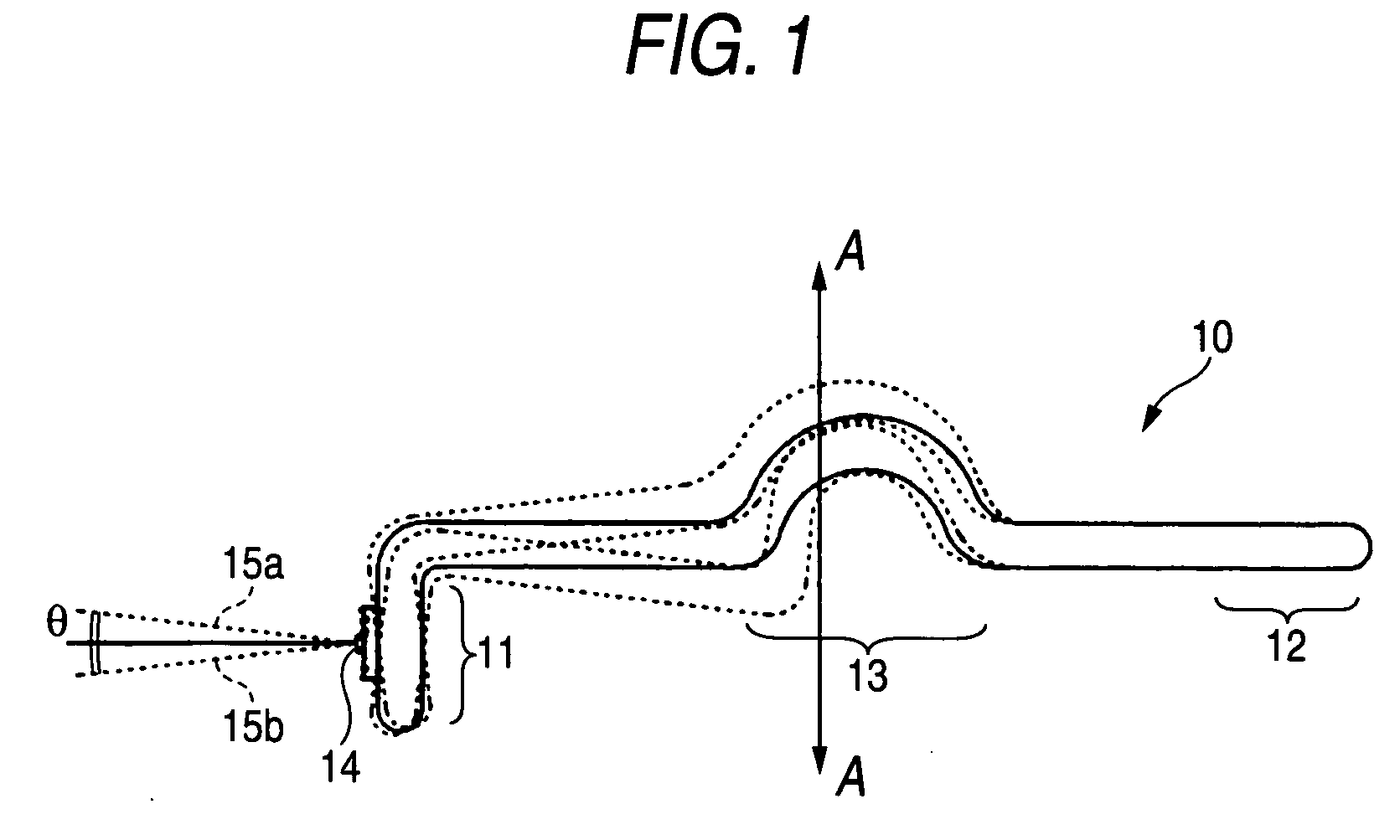

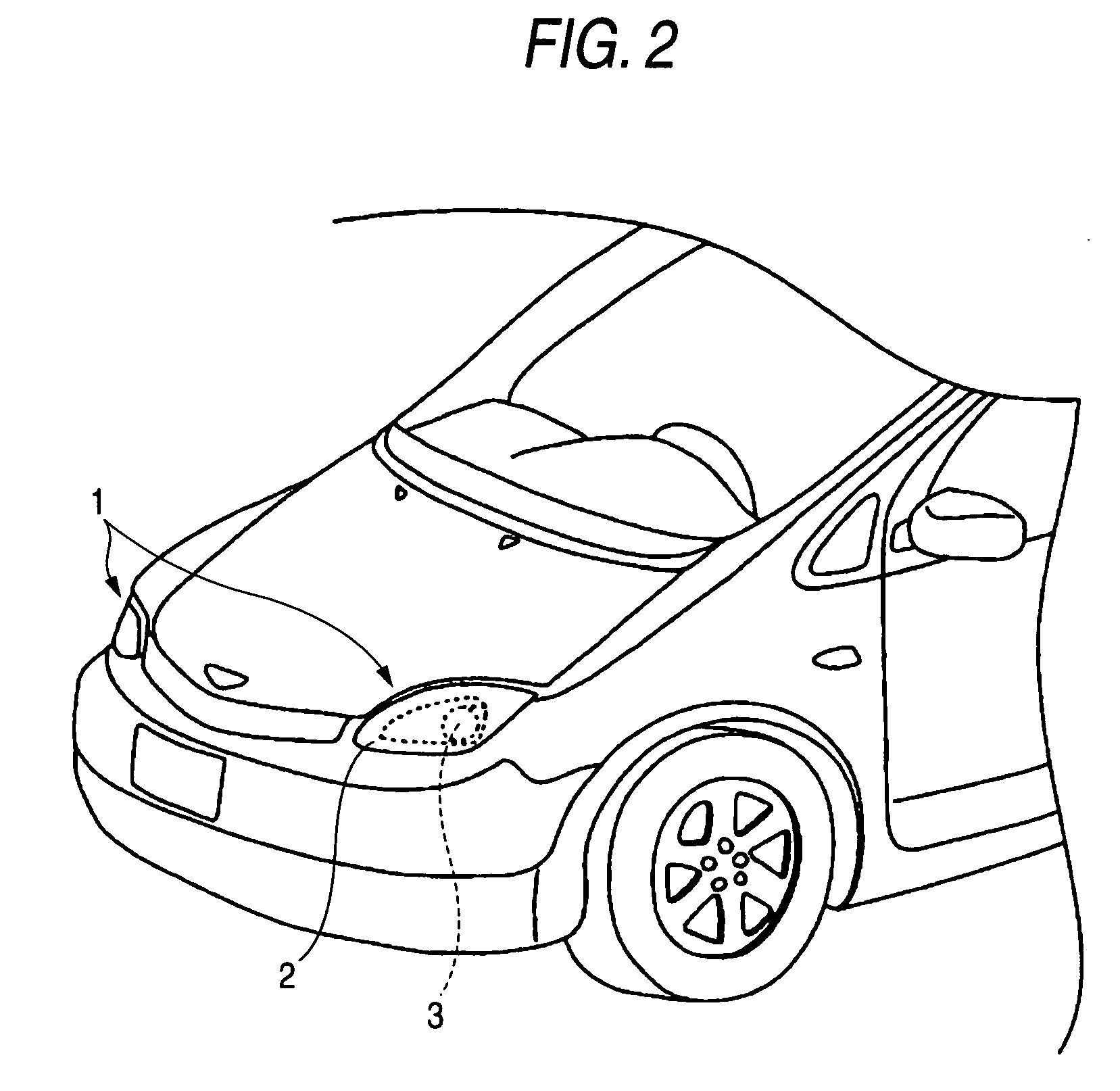

Method of attaching vehicle-mounted camera

InactiveUS20170057421A1Low costEasy to adjust the angleTelevision system detailsColor television detailsPosition angleComputer science

Owner:NIDEC ELESYS

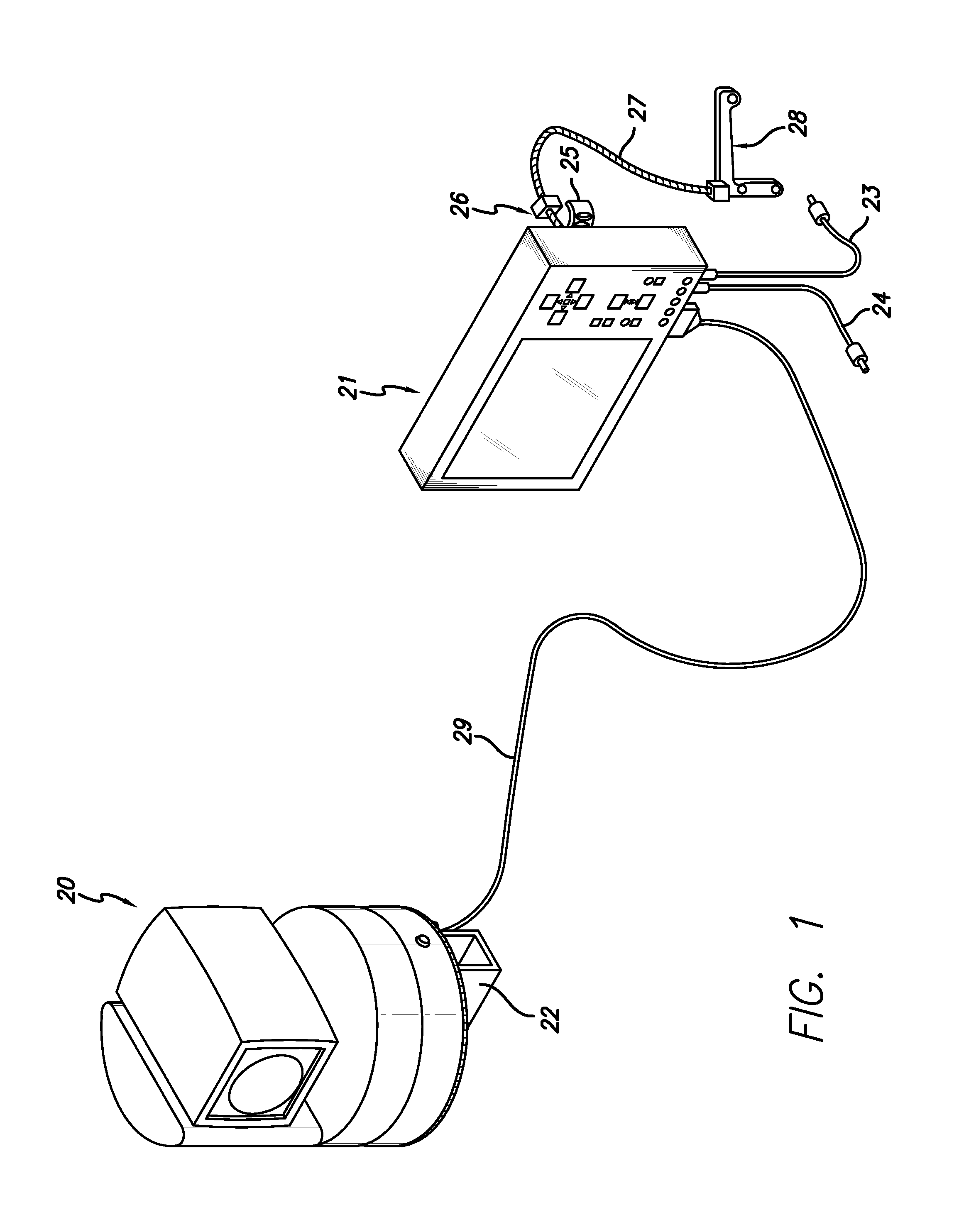

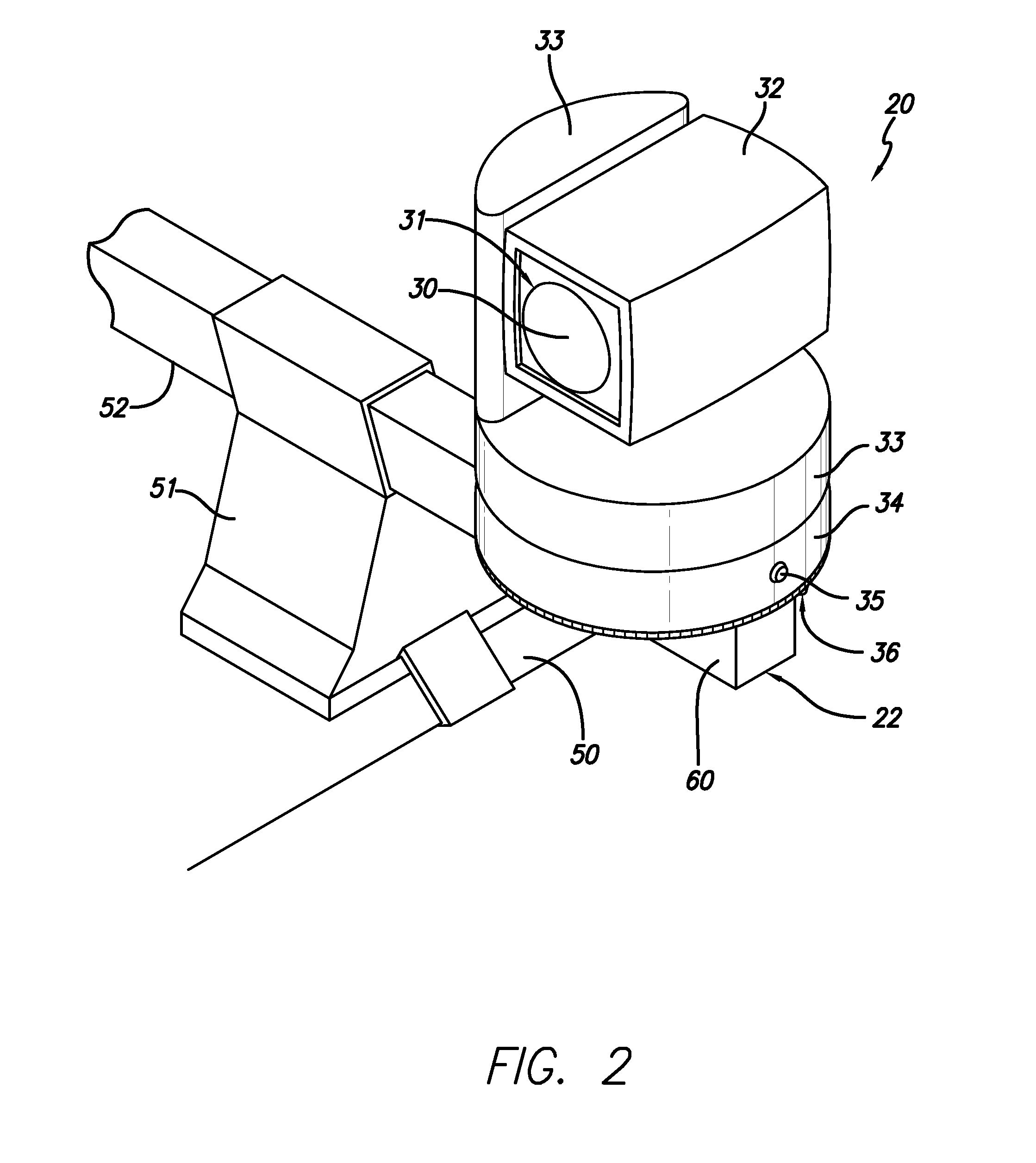

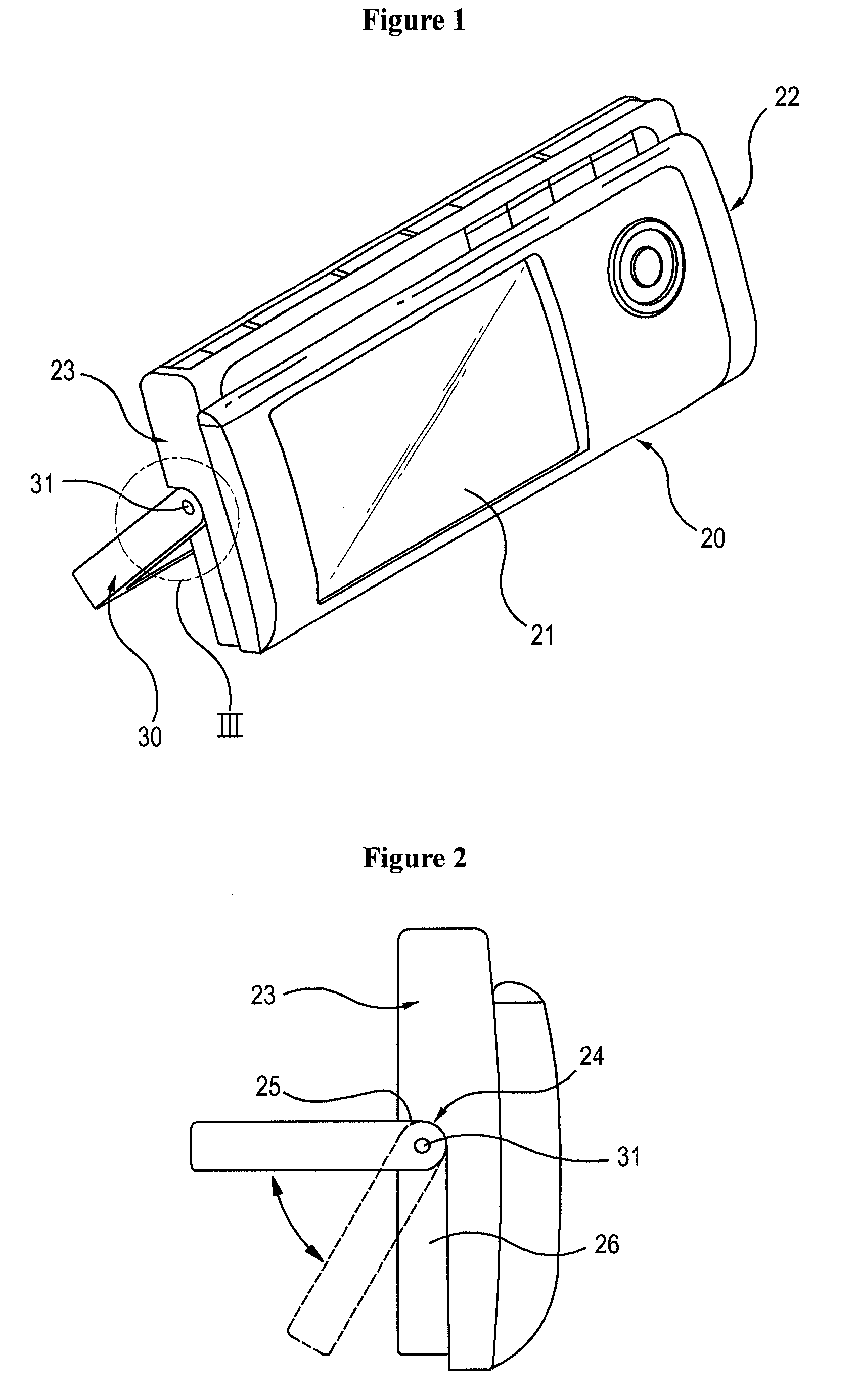

Mobile Surveillance System

InactiveUS20100110192A1Simple and safe operationEasy to adjust the angleTelevision system detailsColor television detailsLocking mechanismRadio frequency

A mobile pan and tilt camera and display-control apparatus comprising a fully rotatable camera mounted to a vehicle for capturing images, a display-control box having an image display screen and control buttons for controlling said camera and its movement attached to an adjustable mount in said vehicle within an operator's view and reach, an image capture box for storage on various recording media or for transmission of said captured mobile images, said captured mobile images are sent by radio frequency transmission to a data storage server for a consumer to access. A preferred embodiment includes further comprising a mount that incorporates a quick disconnect mechanism along with a locking mechanical base and an electronic signal connector for easy camera installation and removal. A preferred embodiment includes further comprising a double locking mechanism where one mechanism is a security fastener.

Owner:JOHNSTON GREGORY E +1

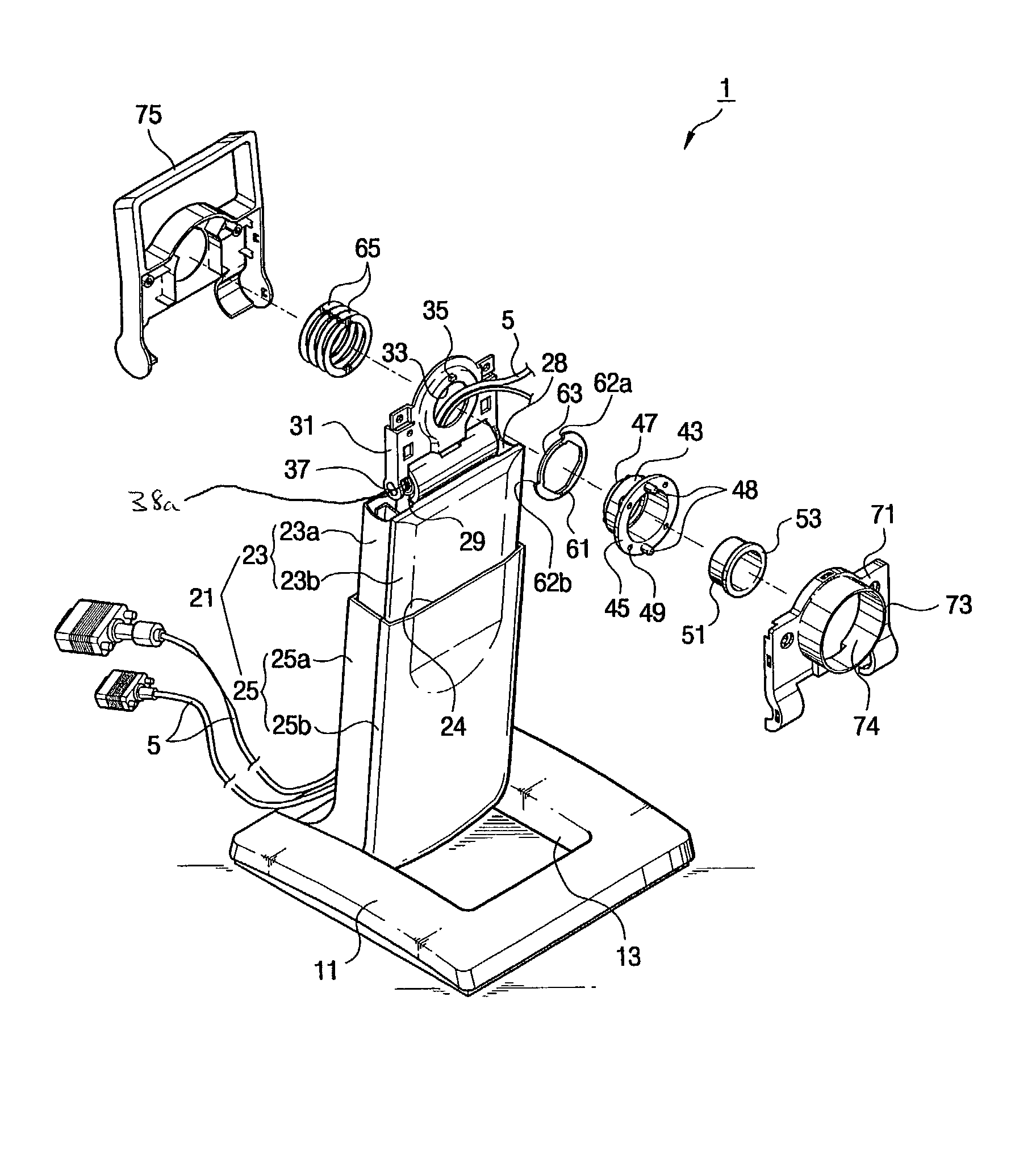

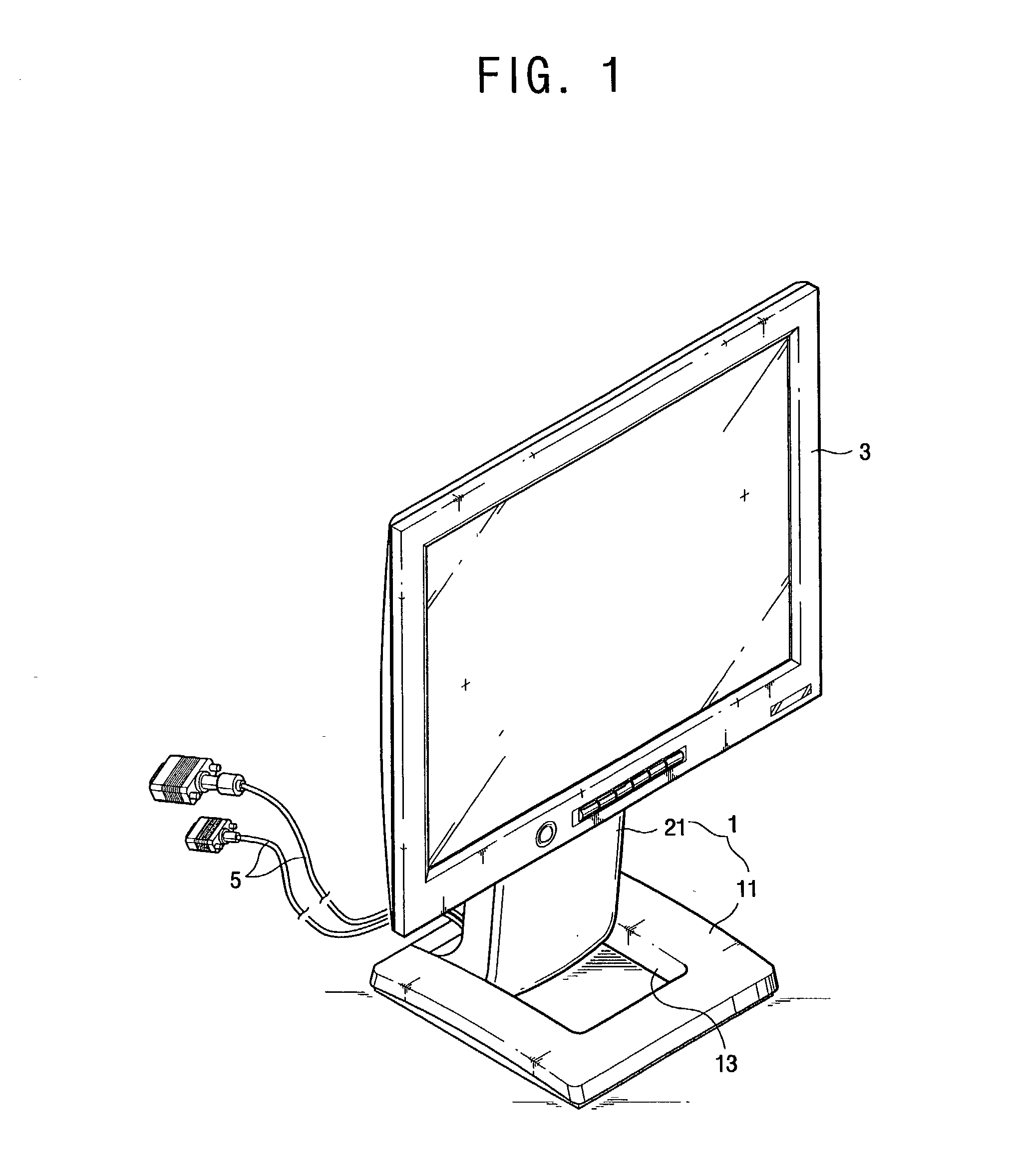

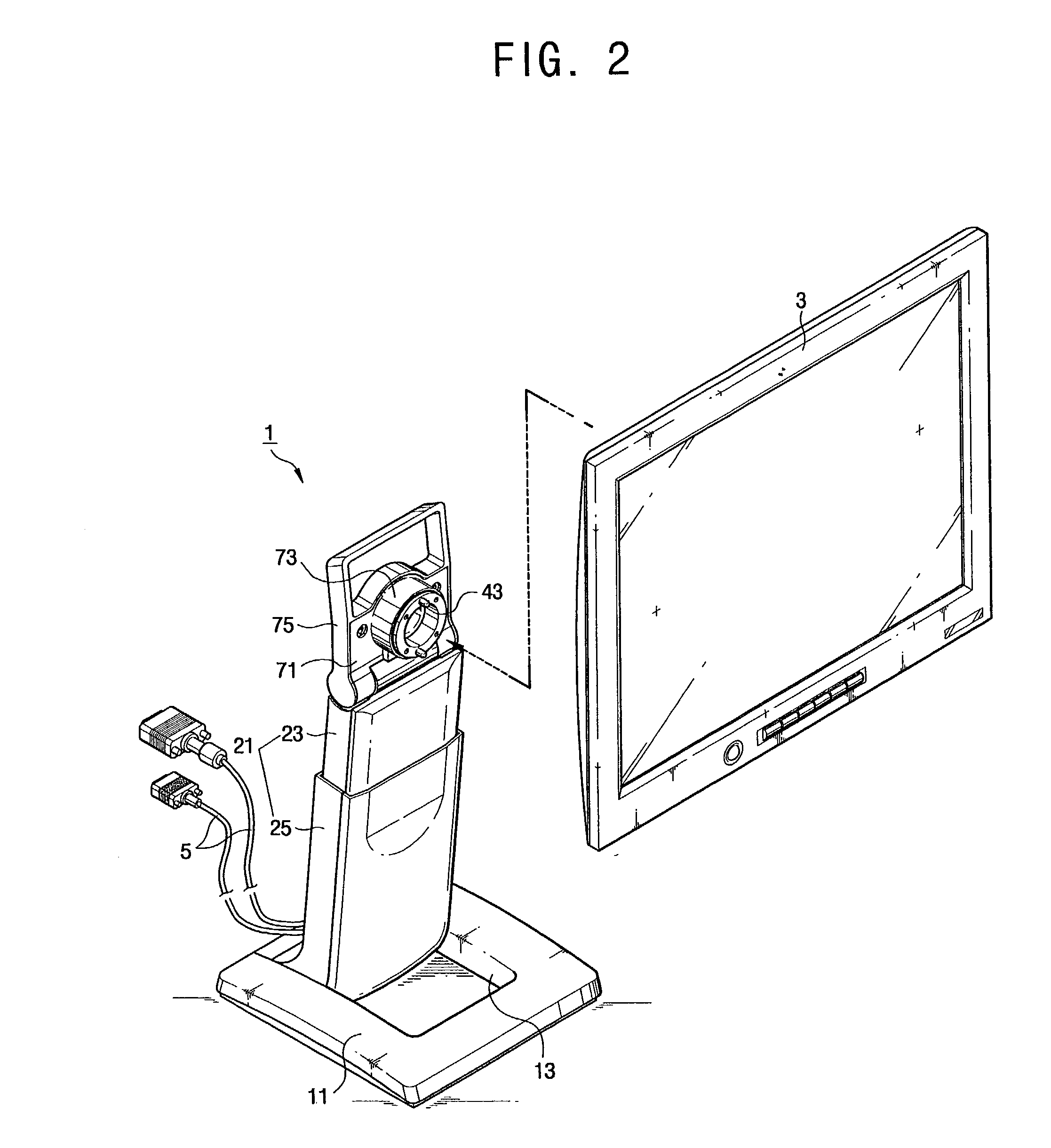

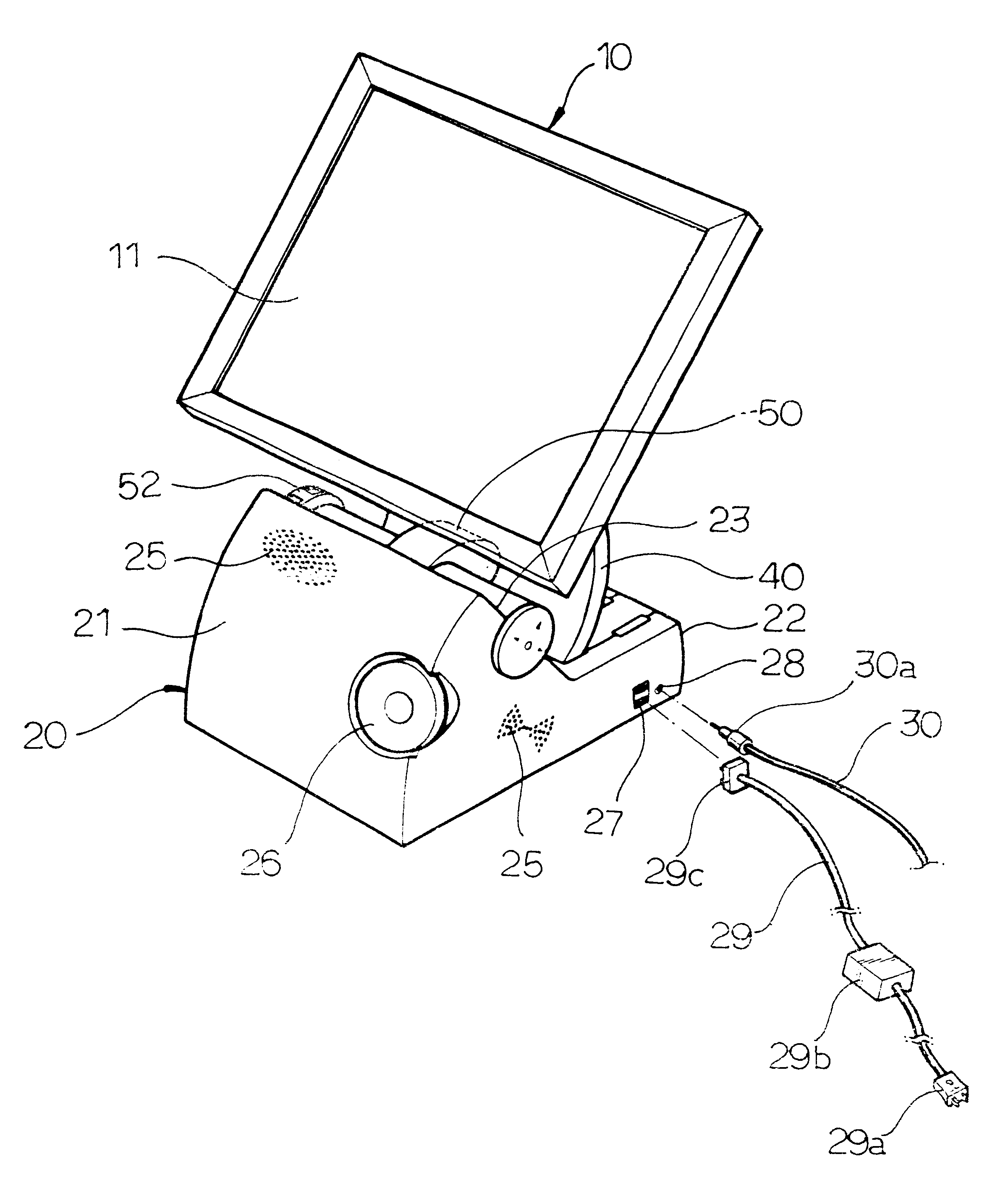

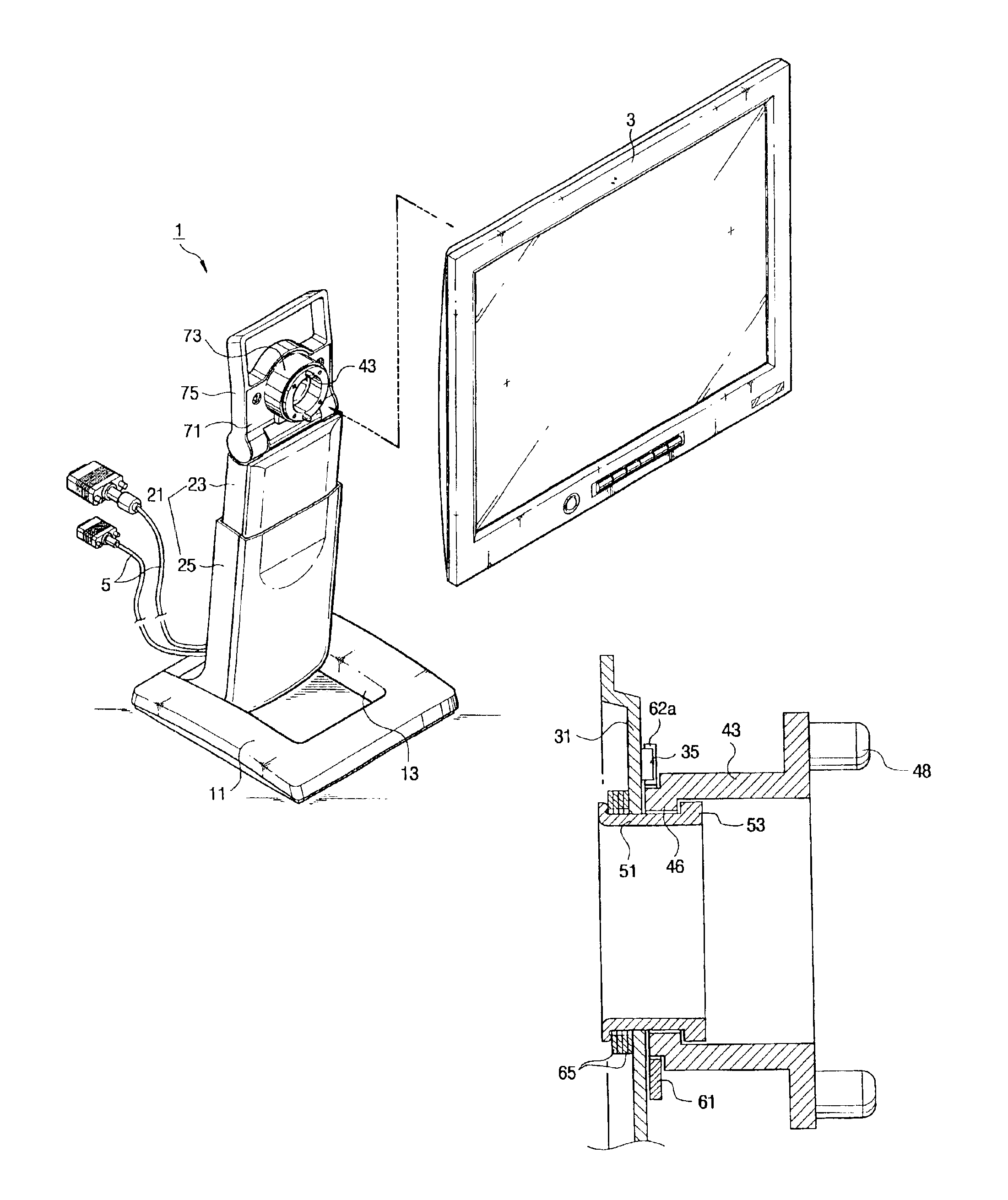

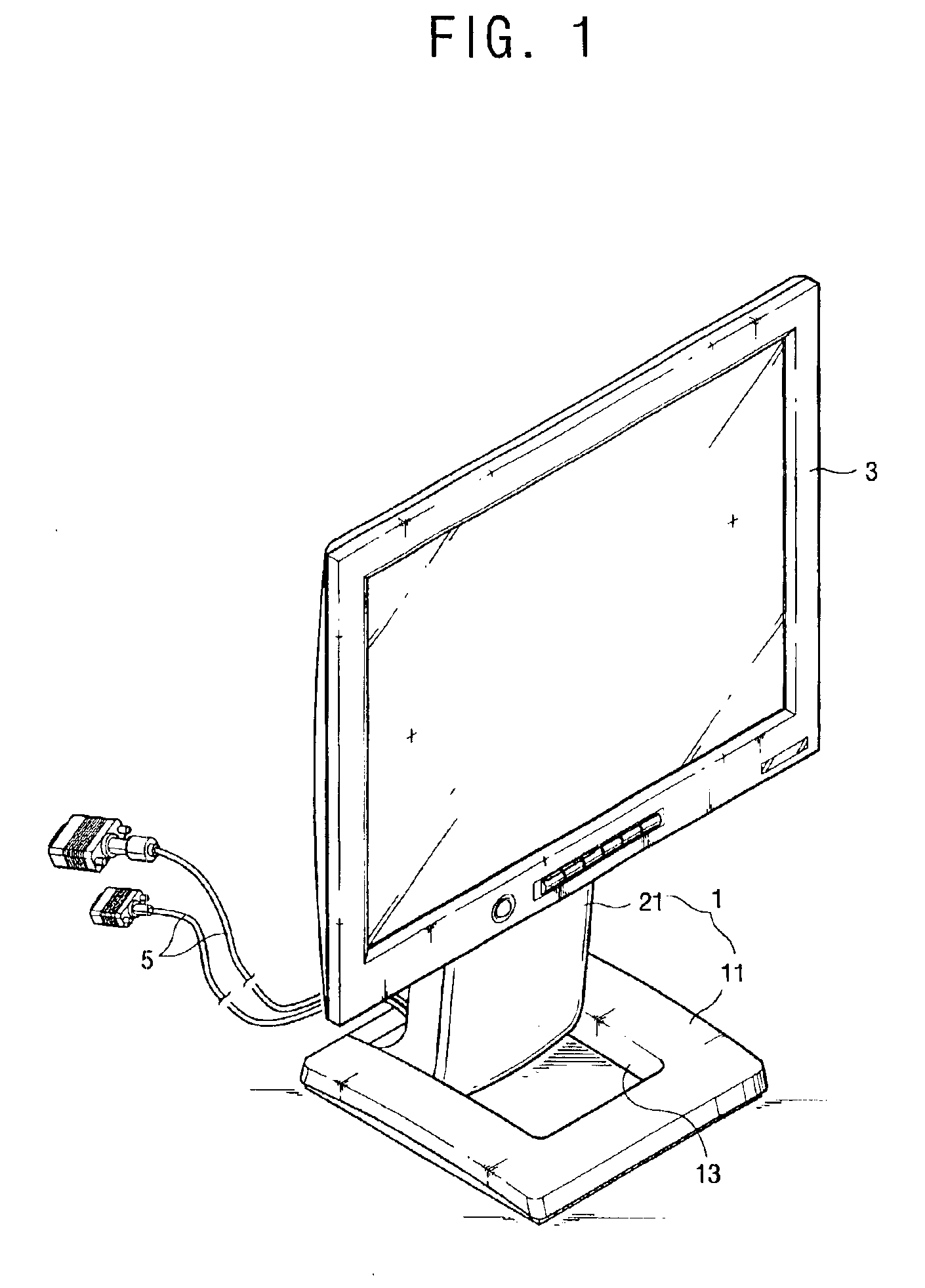

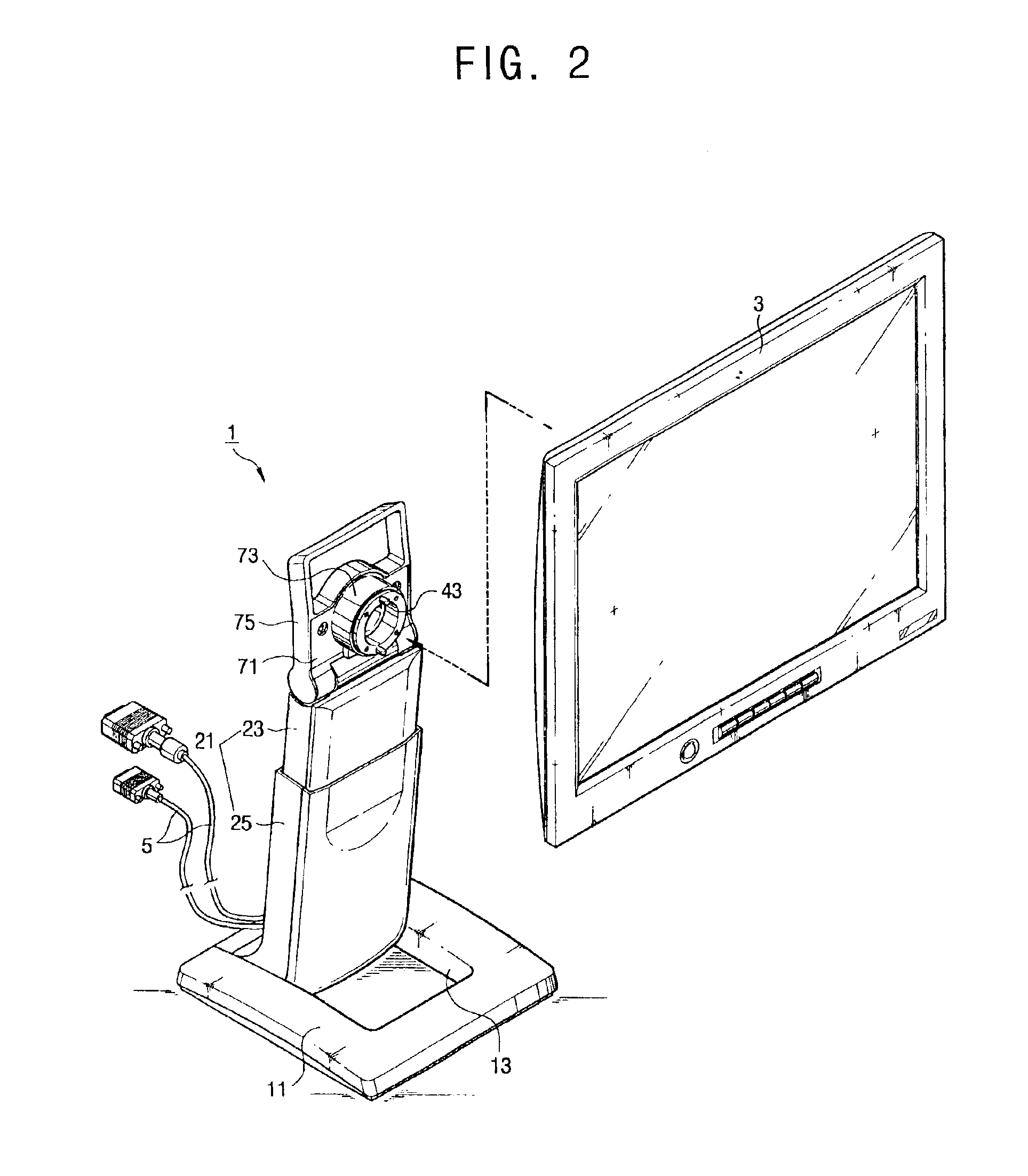

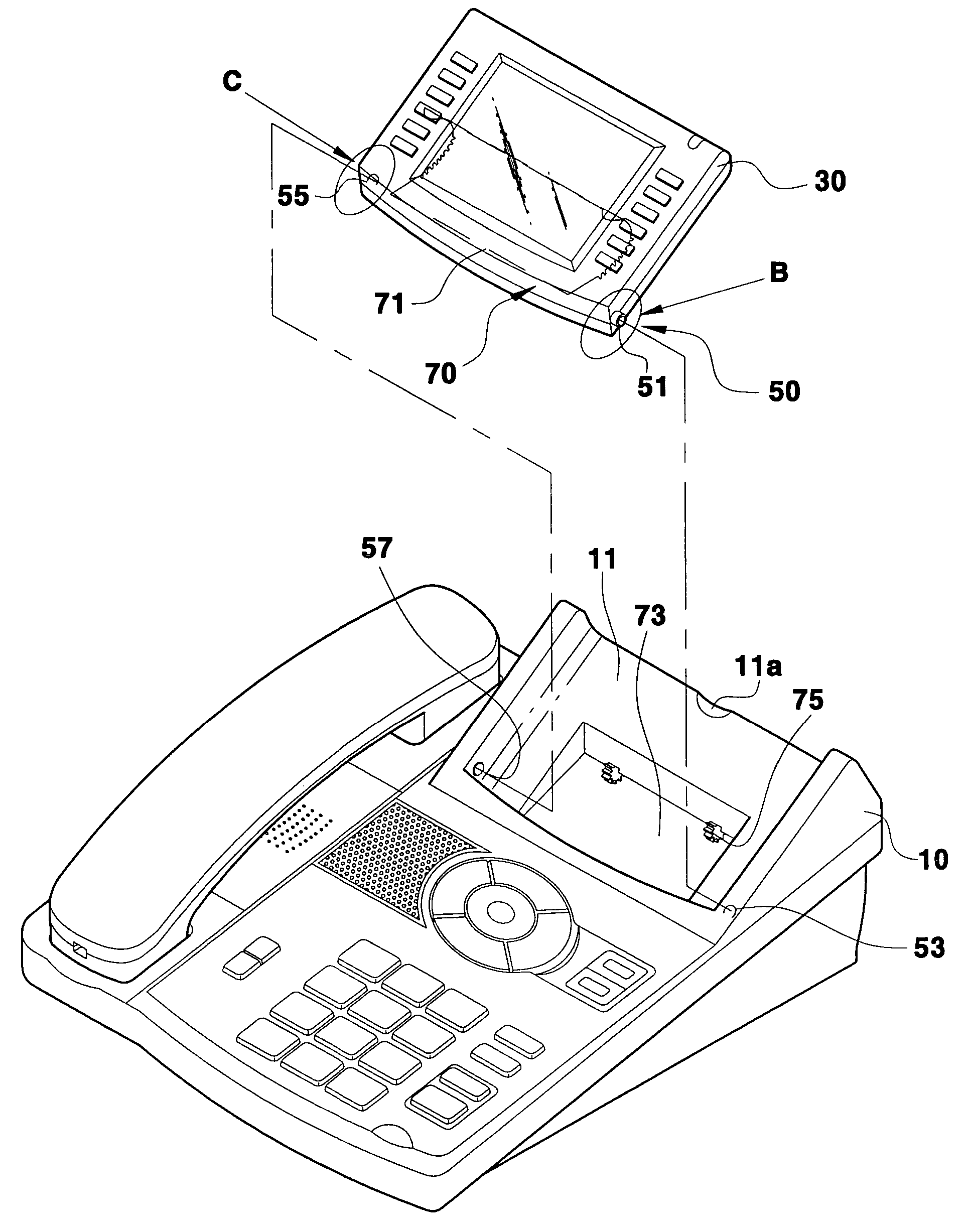

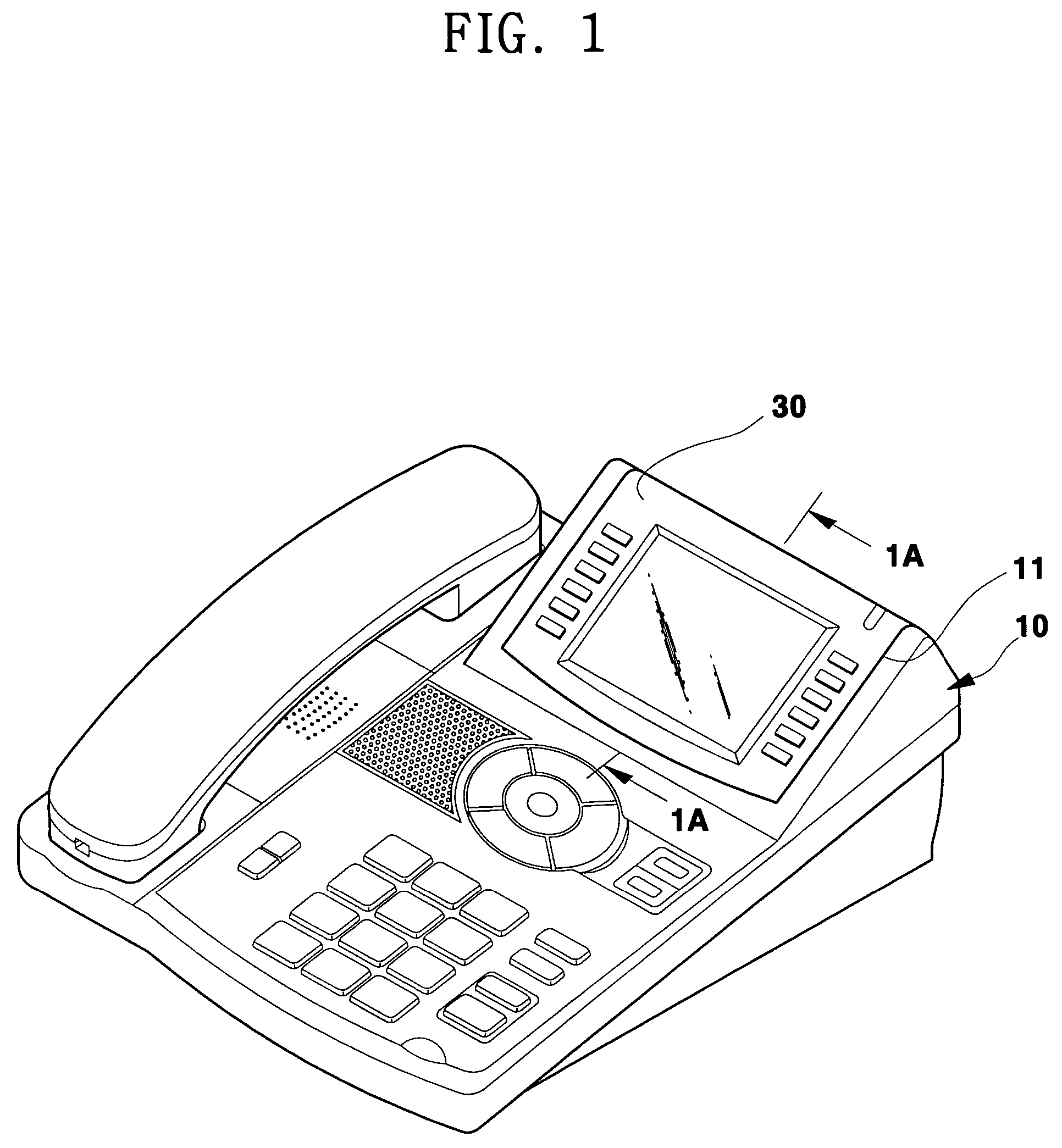

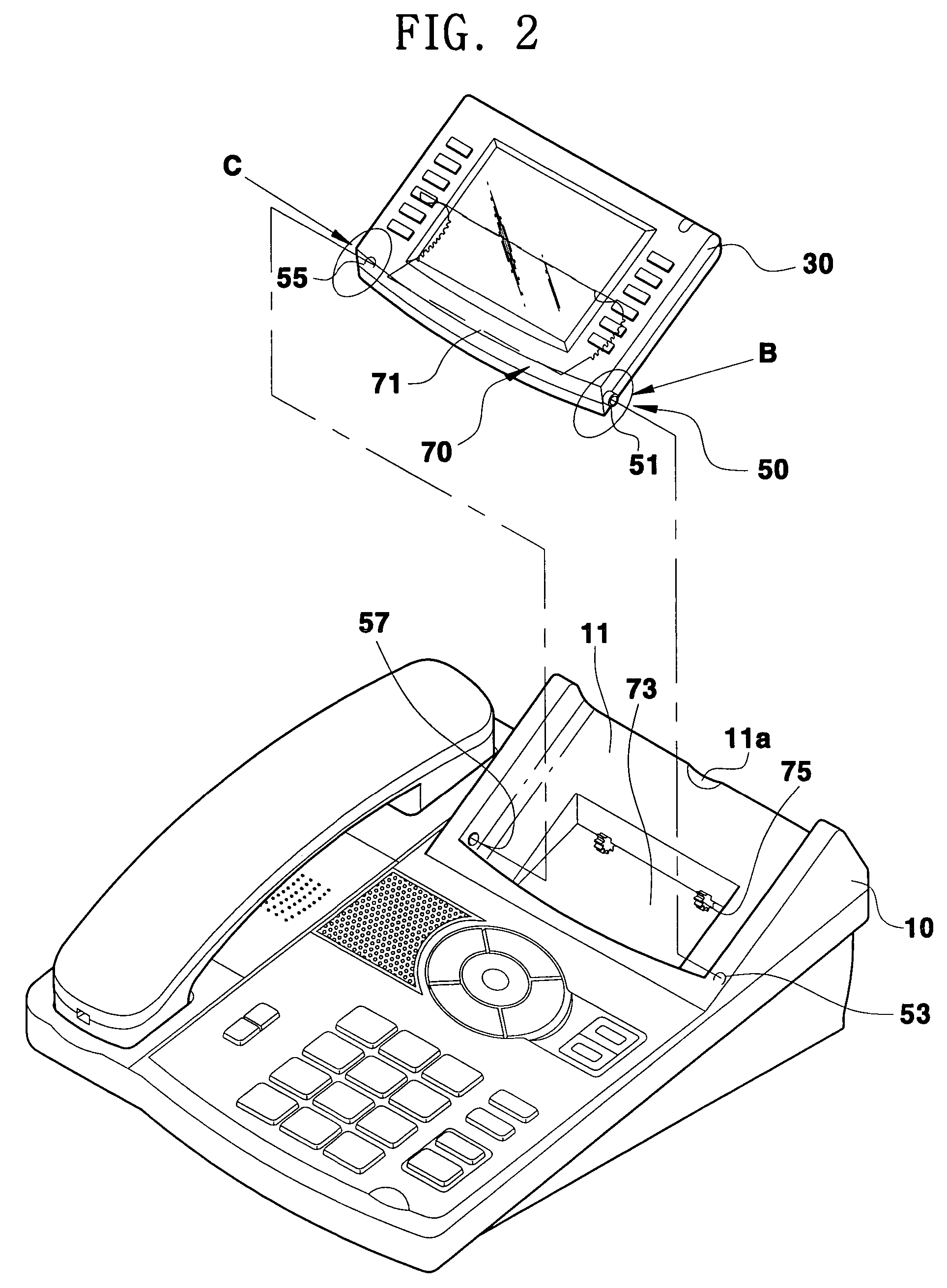

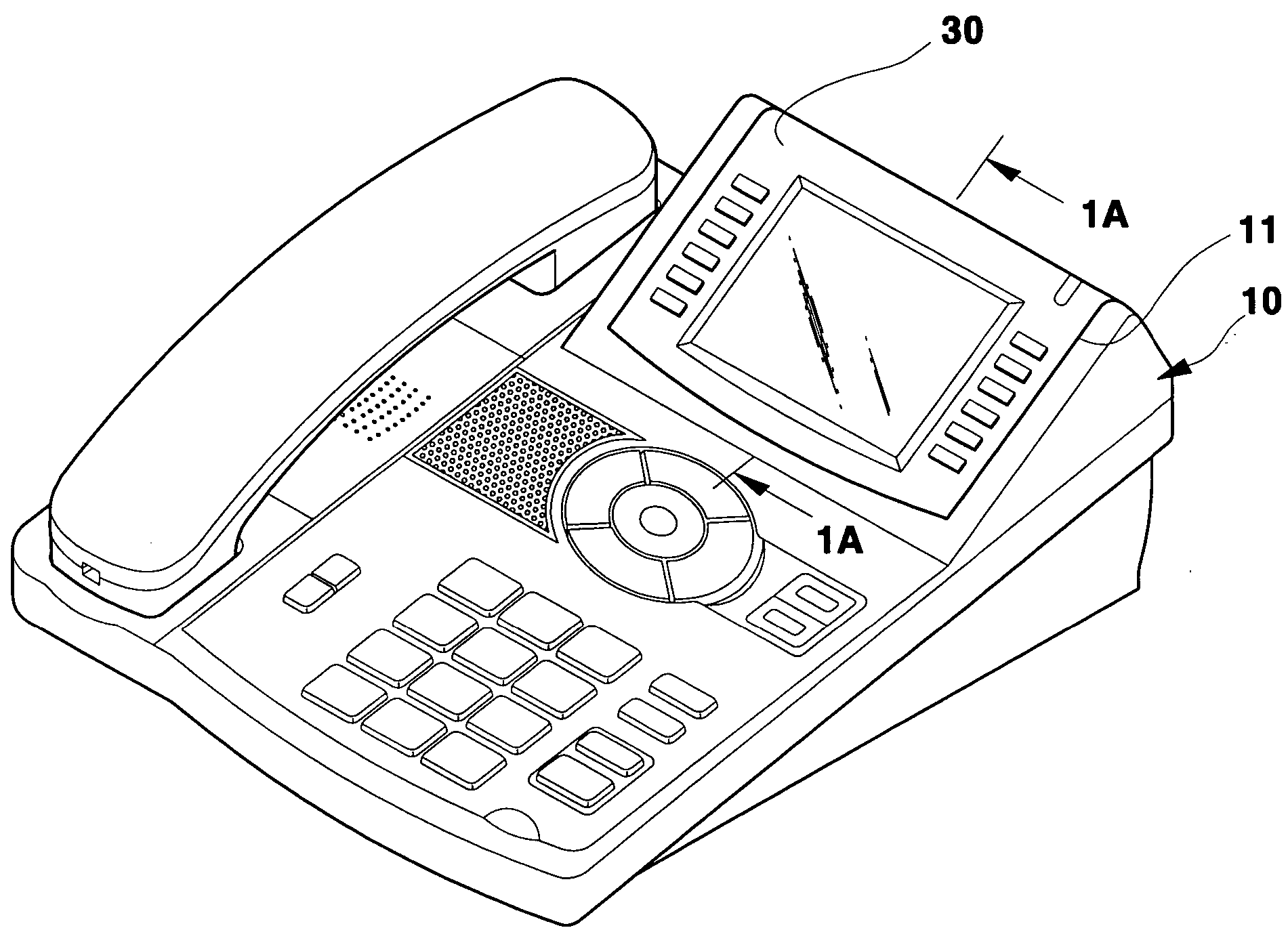

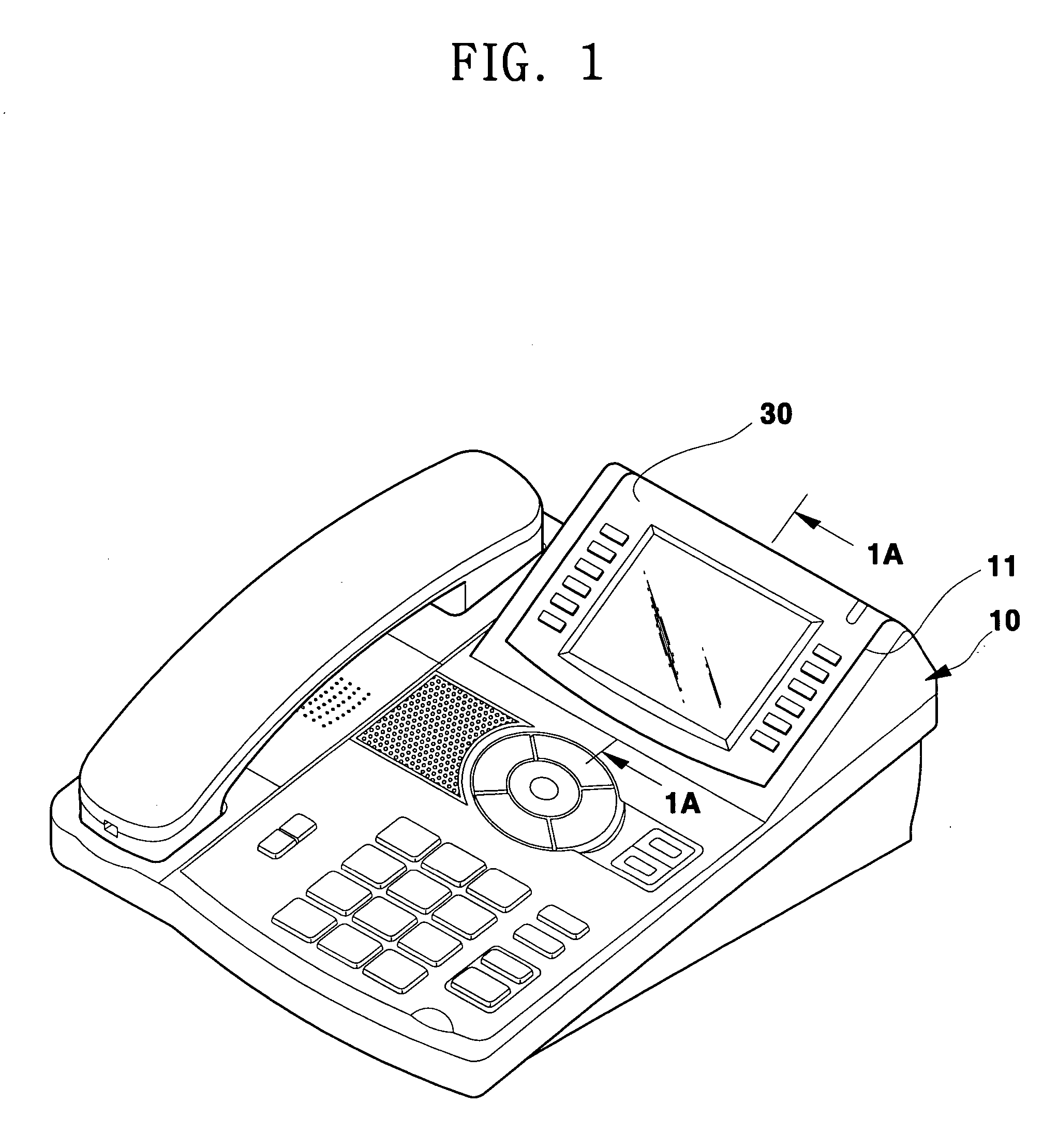

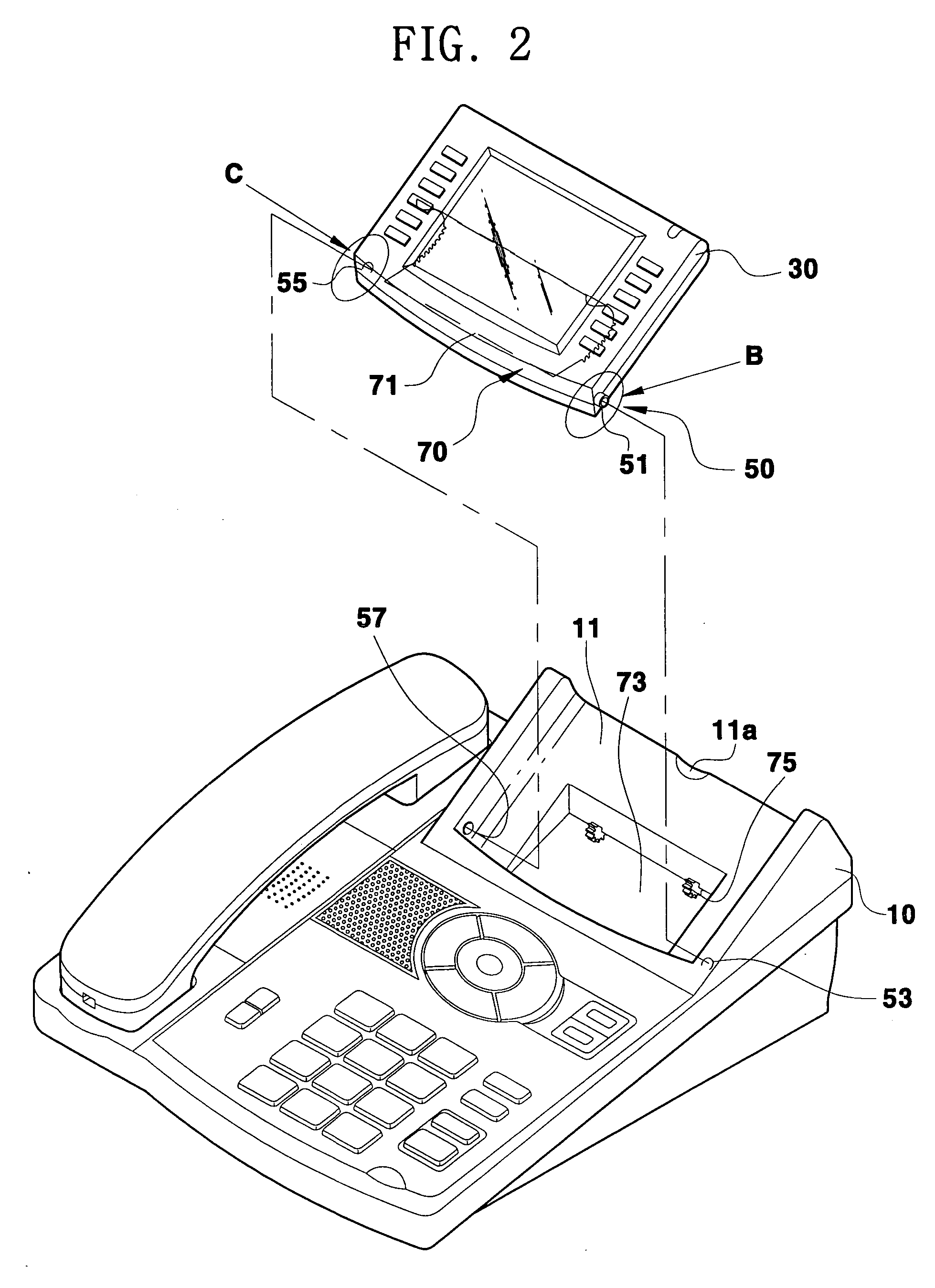

LCD monitor stand

InactiveUS20030075649A1Simple pivoting and tiltingEasy to adjust the angleDigital data processing detailsStands/trestlesLiquid-crystal displayEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

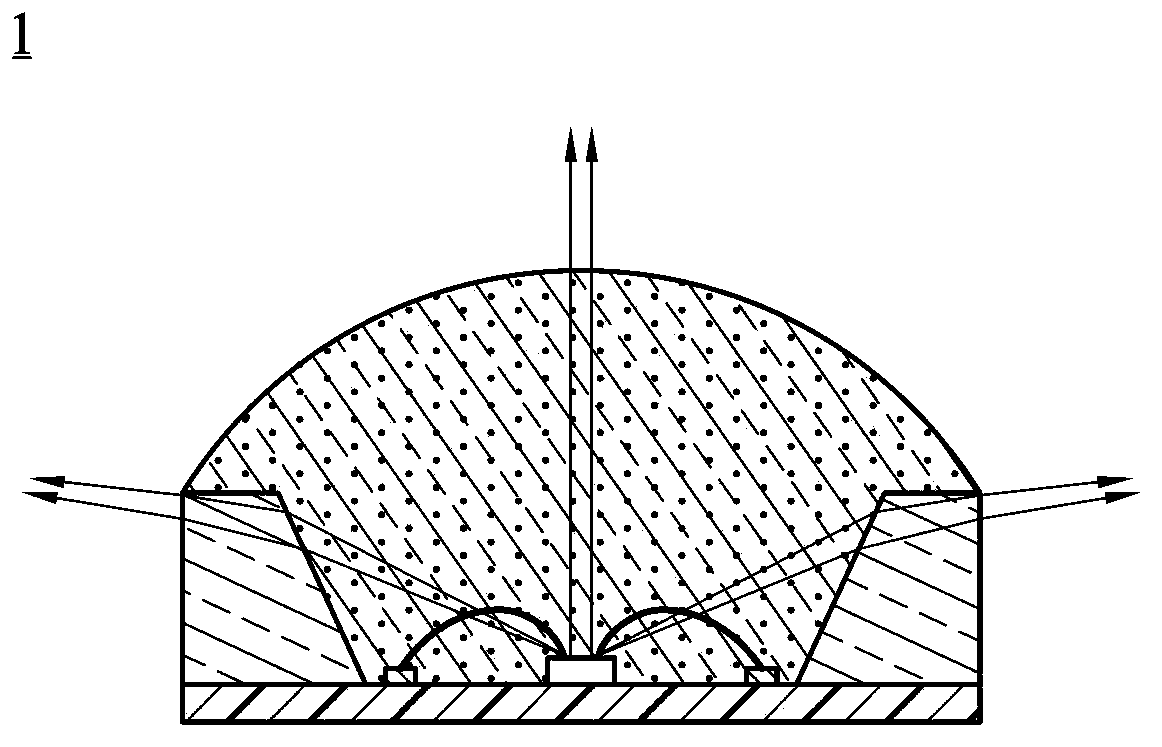

Luminescent device

InactiveUS20080247177A1Efficient disseminationLarge heat capacityVehicle headlampsPoint-like light sourceOptical axisEngineering

A luminescent device includes: a light source; a housing for accommodating the light source, a heat discharging member including a heat transfer portion and a heat dissipation portion and passed through the housing, the heat transfer portion being mounted on the light source and the heat dissipation portion being located outside the housing; a seal portion for sealing a gap between the heat discharging member and the housing; and optical axis adjusting device for adjusting an optical axis of the light source, wherein the heat transfer portion or the seal portion is deformed so as to follow an angular change of the optical axis of the light source by the optical axis adjusting device.

Owner:TOYODA GOSEI CO LTD

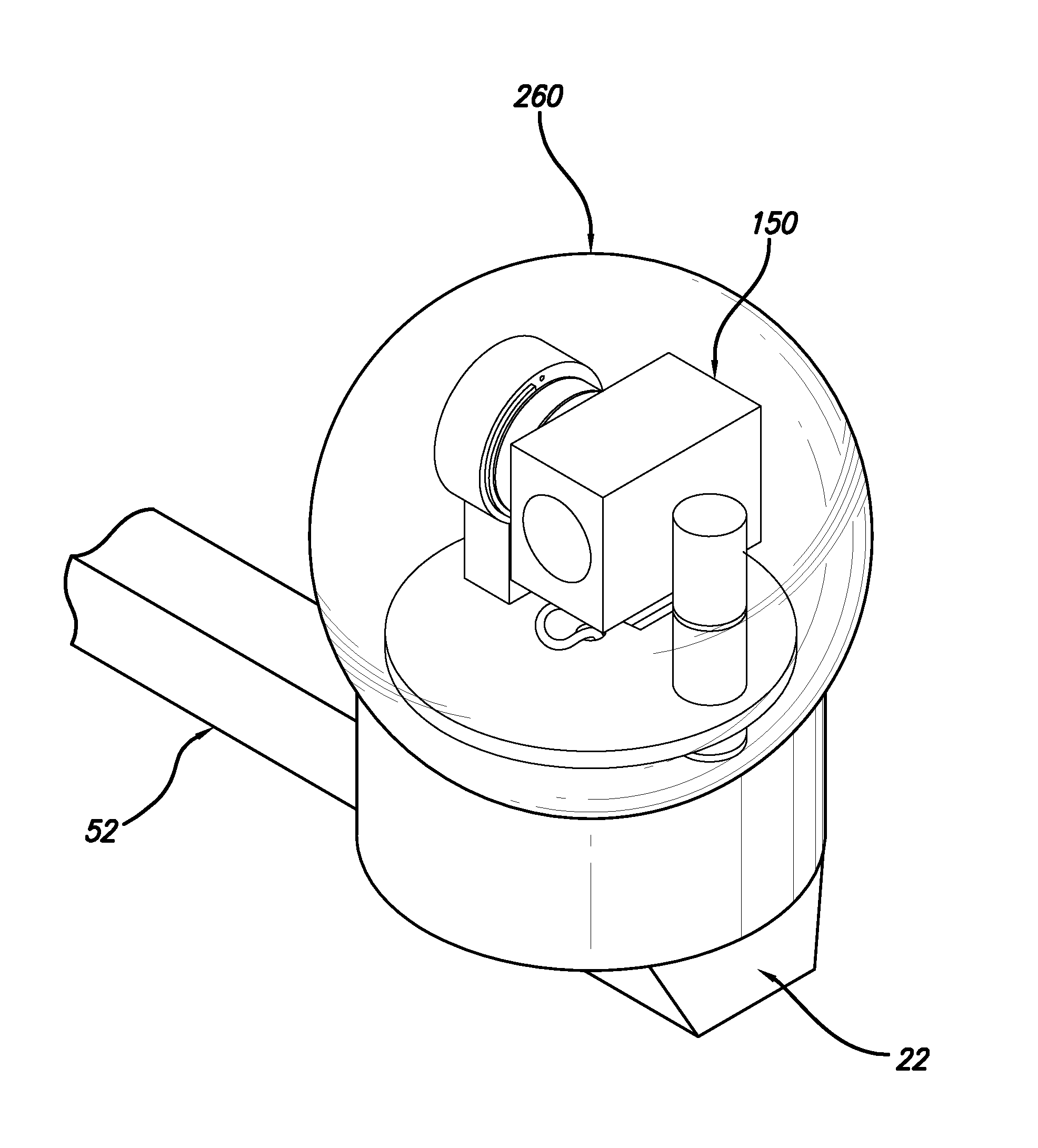

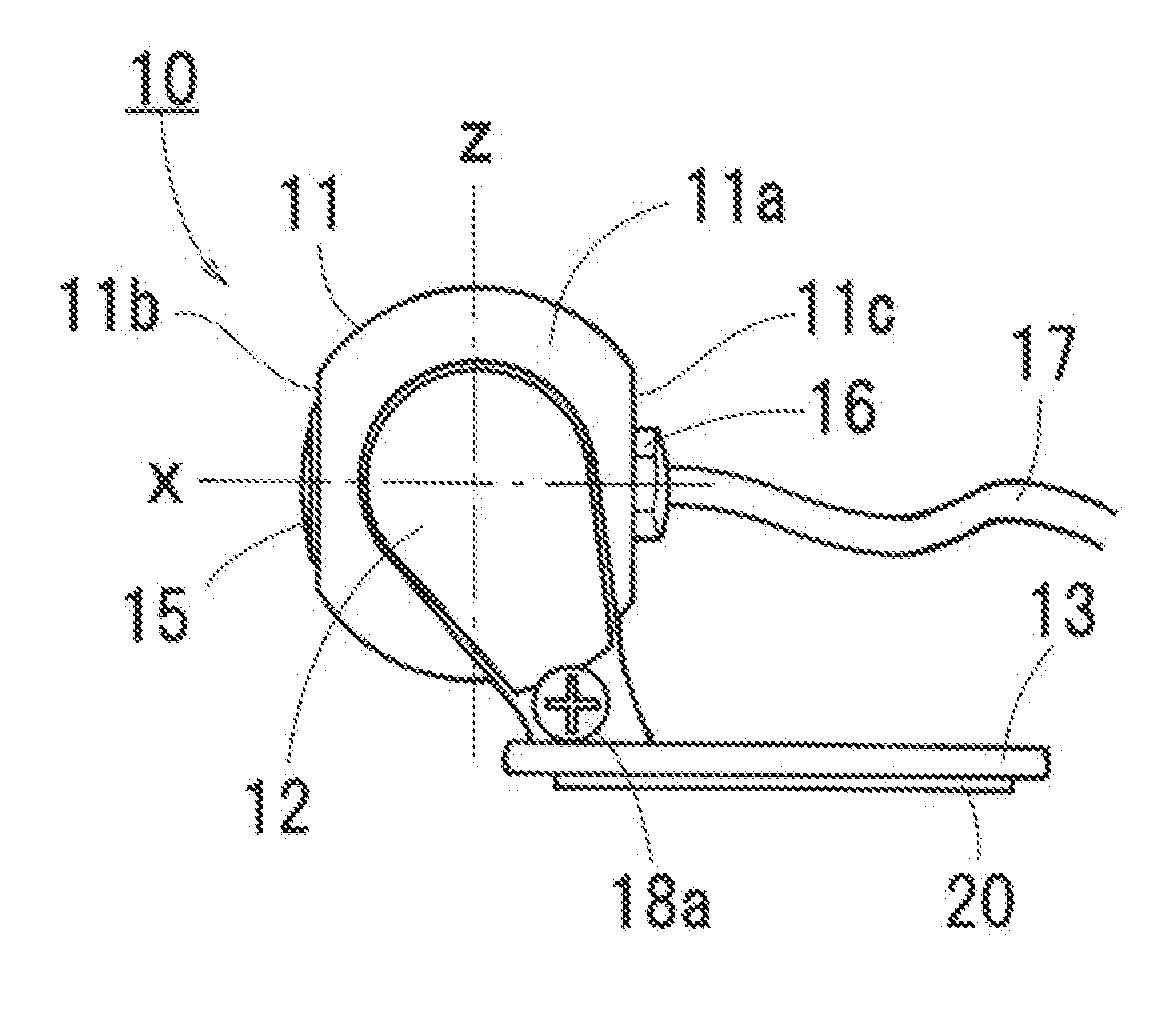

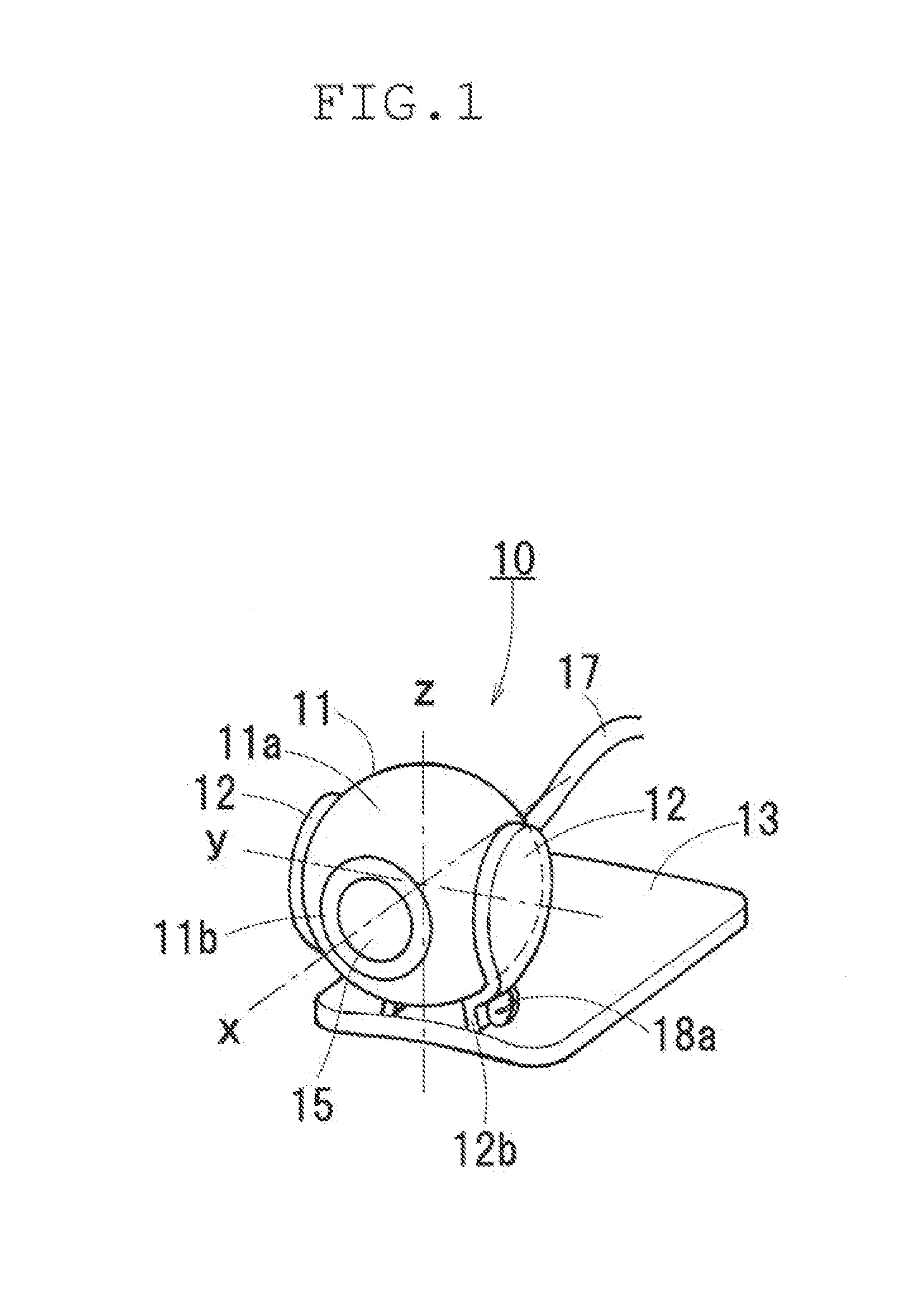

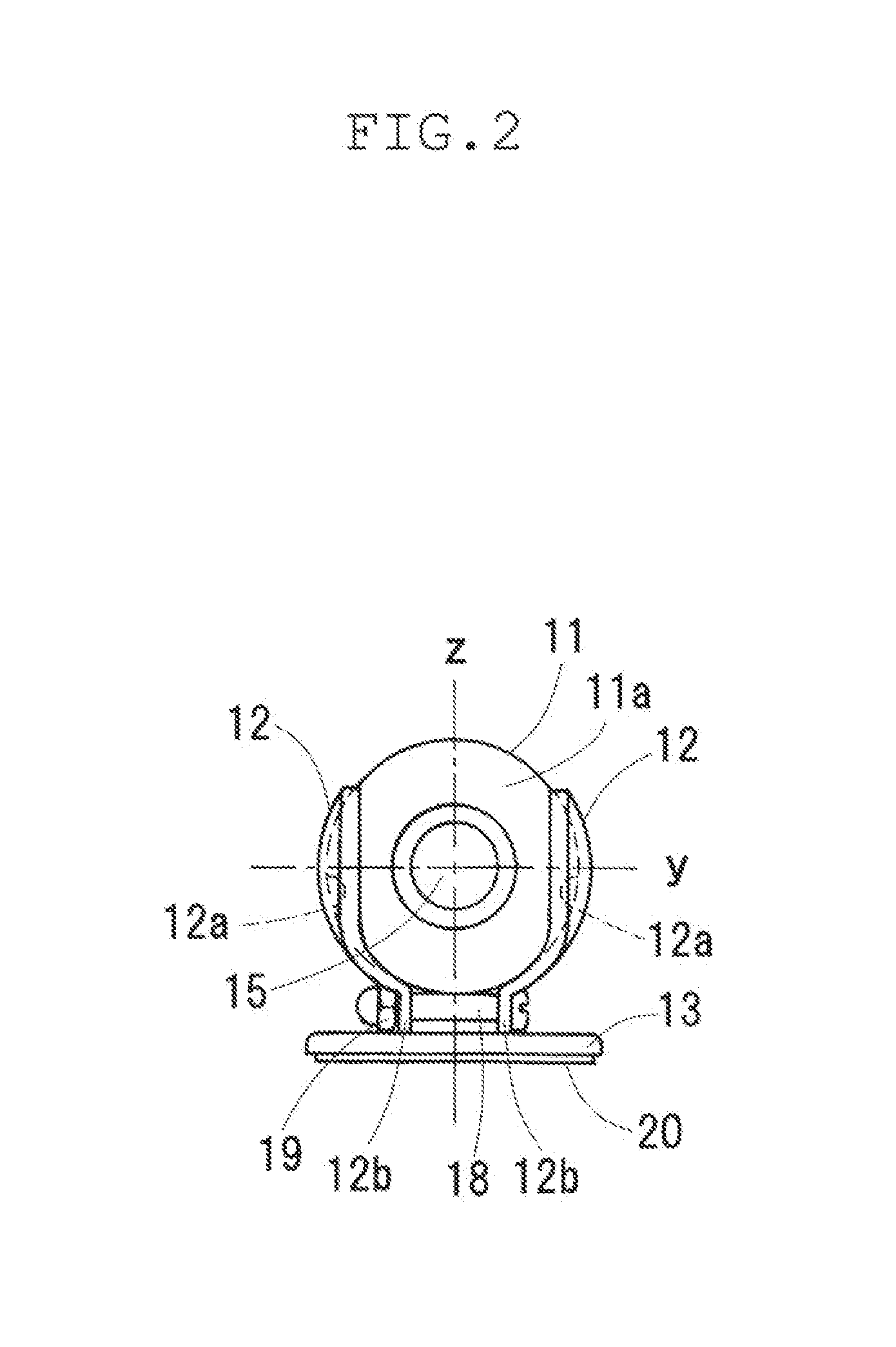

Camera device with reduced size

InactiveUS20120263450A1Easy to adjustEasy to adjust the angleColor television detailsClosed circuit television systemsLeft directionOptical axis

A camera device includes a camera body including a camera housing which is formed into a substantially spherical shape, a bracket fixable to a vehicle, and a socket provided on the bracket into which a spherical portion of the camera housing is fittable. The camera body includes an imaging lens which is exposed from the socket. The spherical portion of the camera housing is fitted into the socket so that the imaging lens has an optical axis a direction of which is adjustable in a vertical direction and in a right-left direction relative to the socket.

Owner:BEAT SONIC

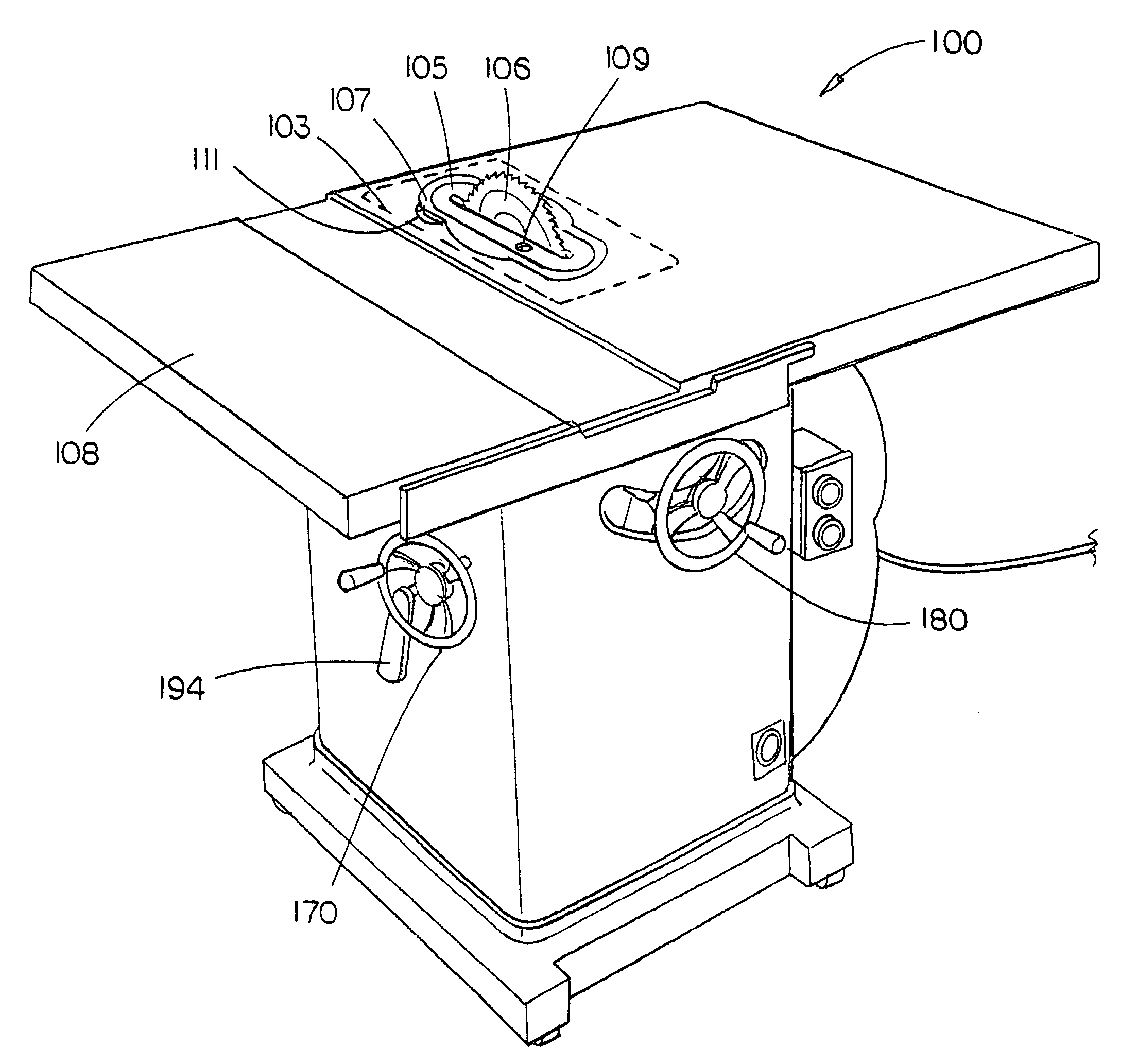

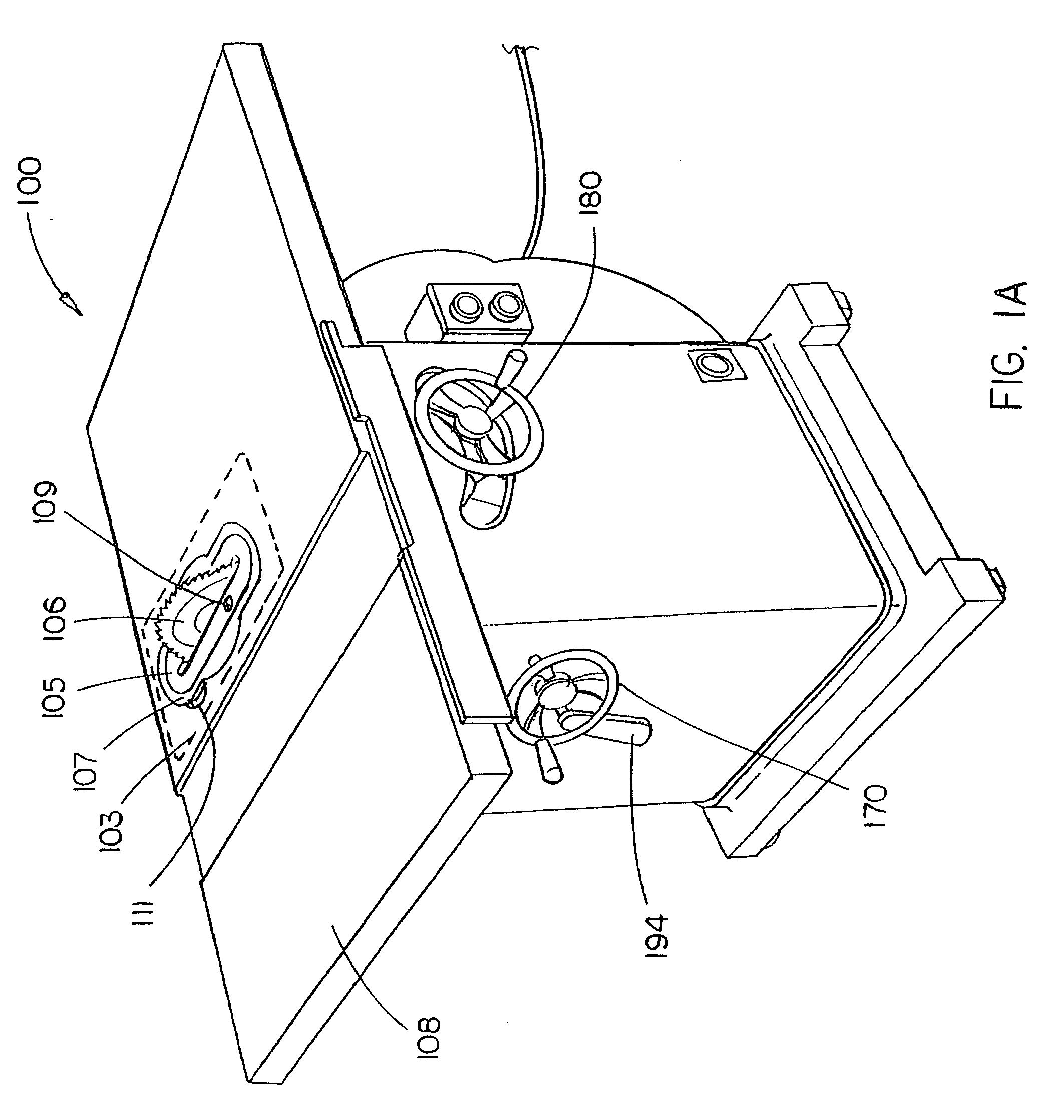

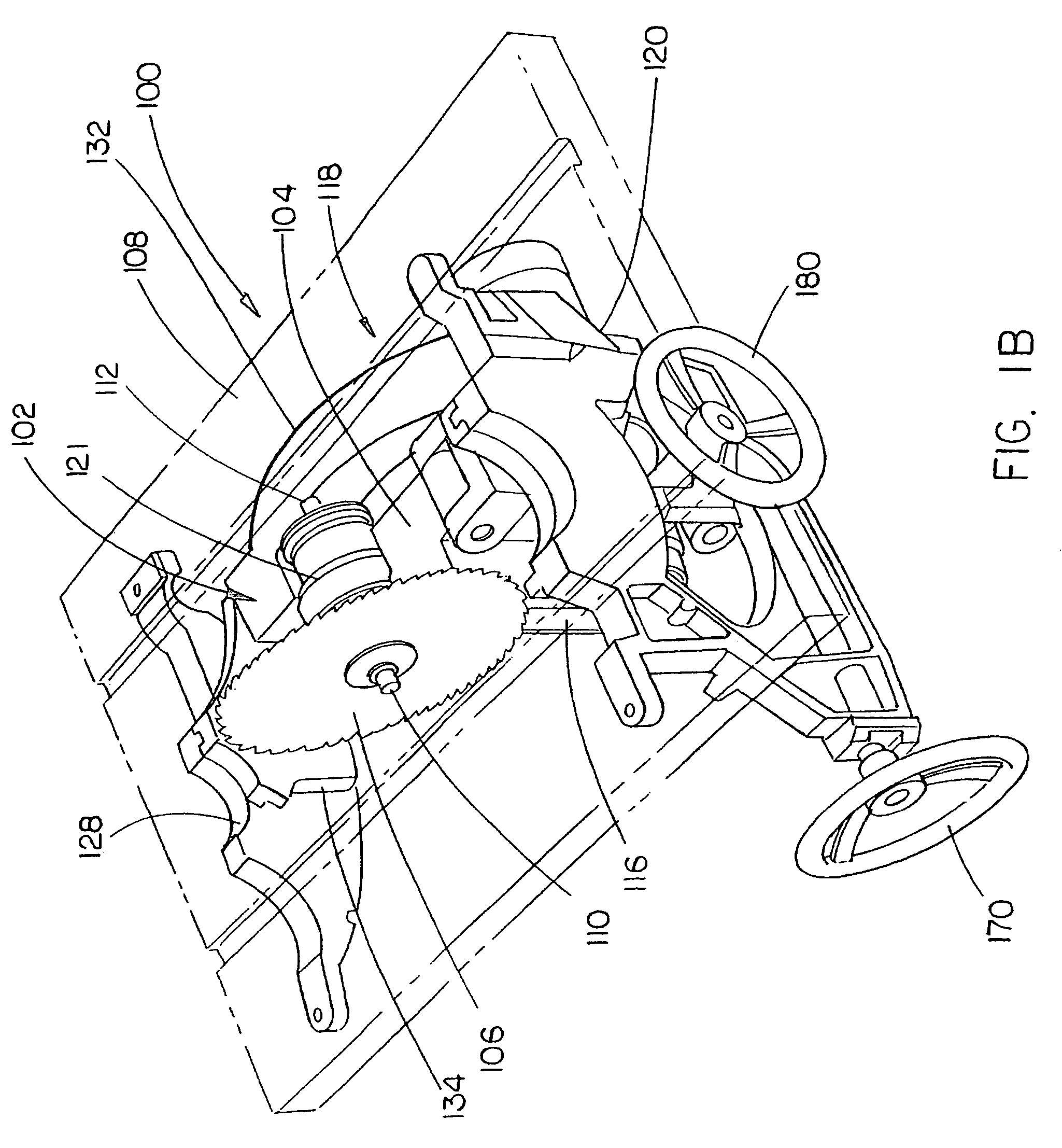

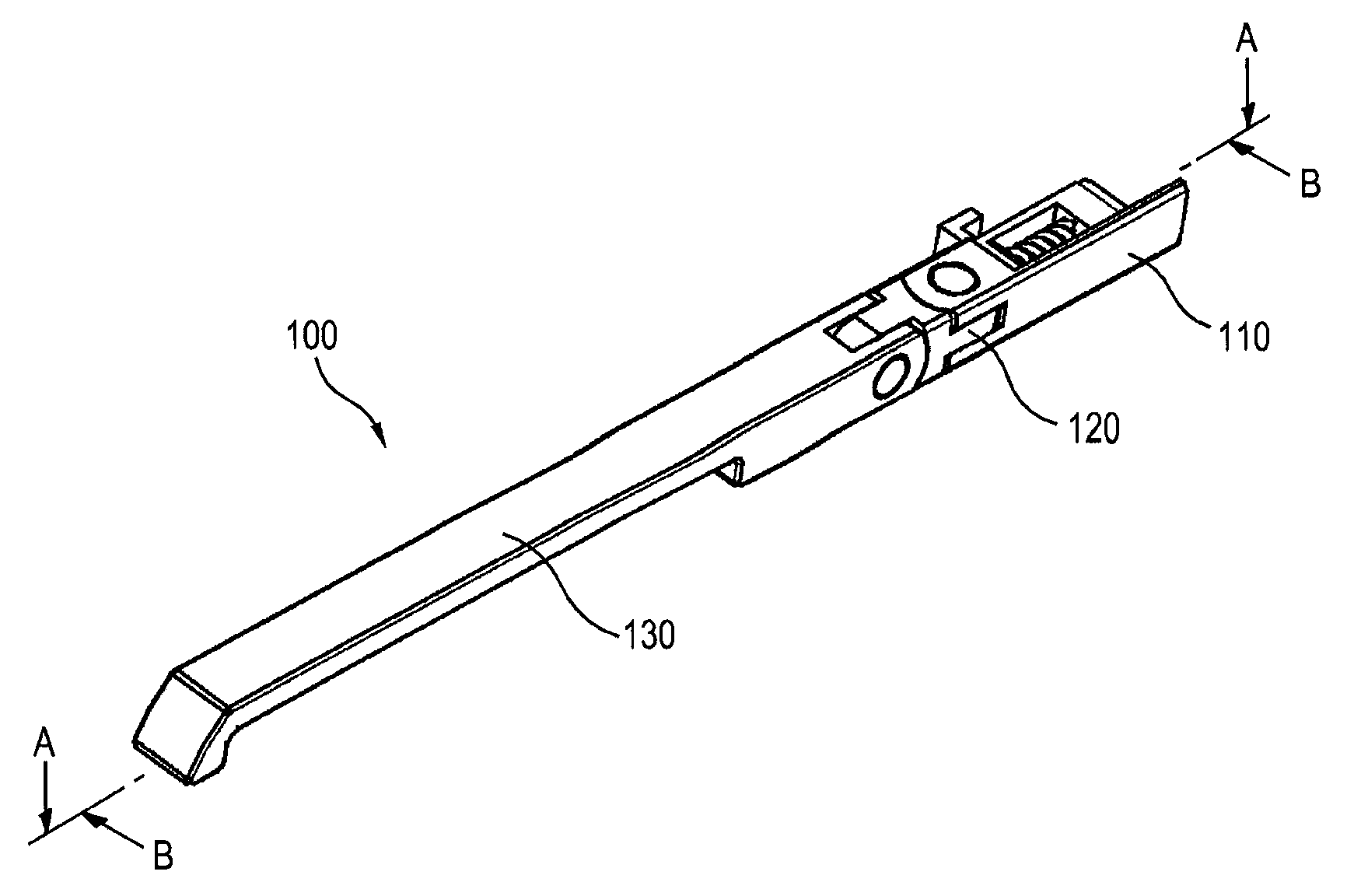

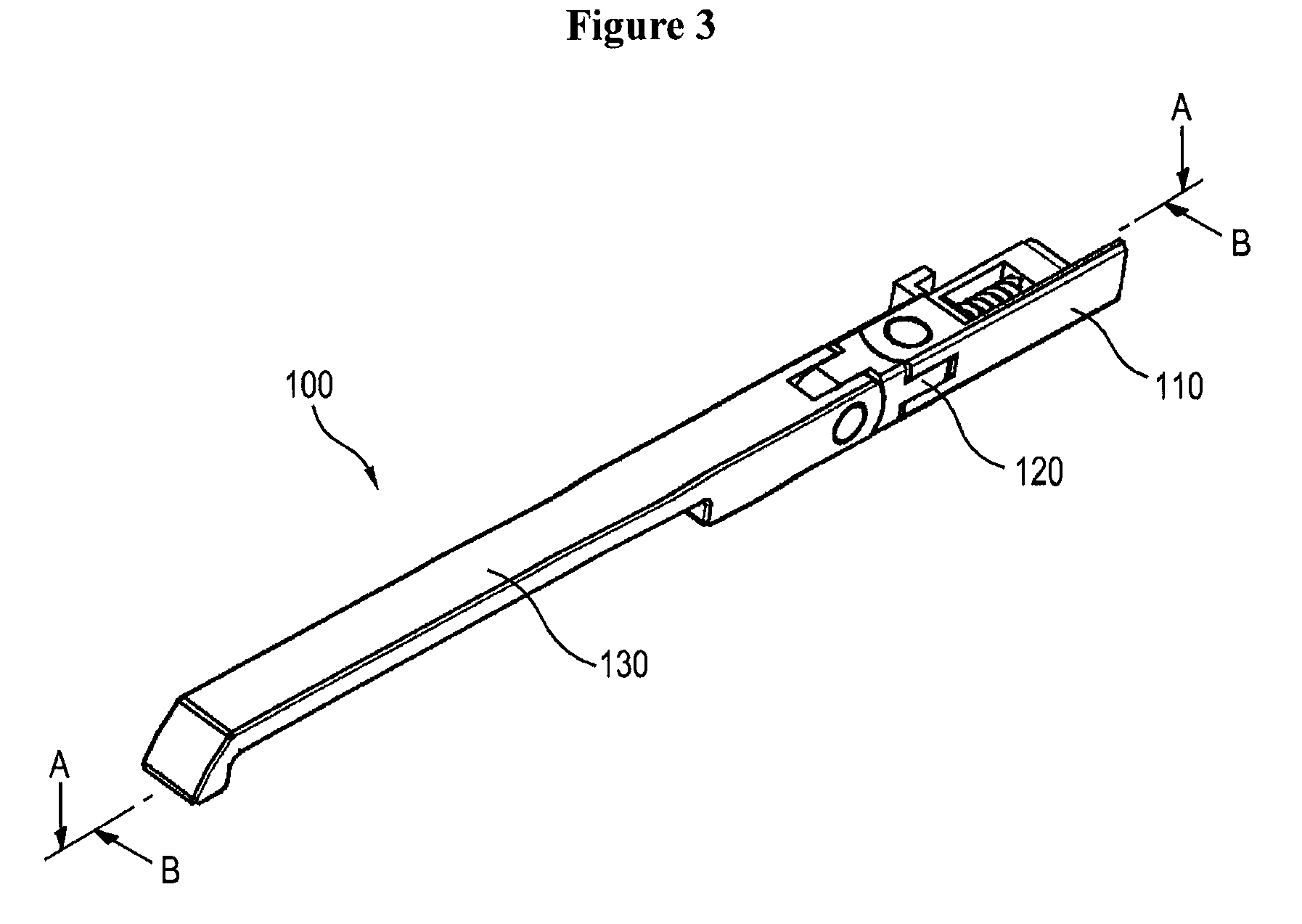

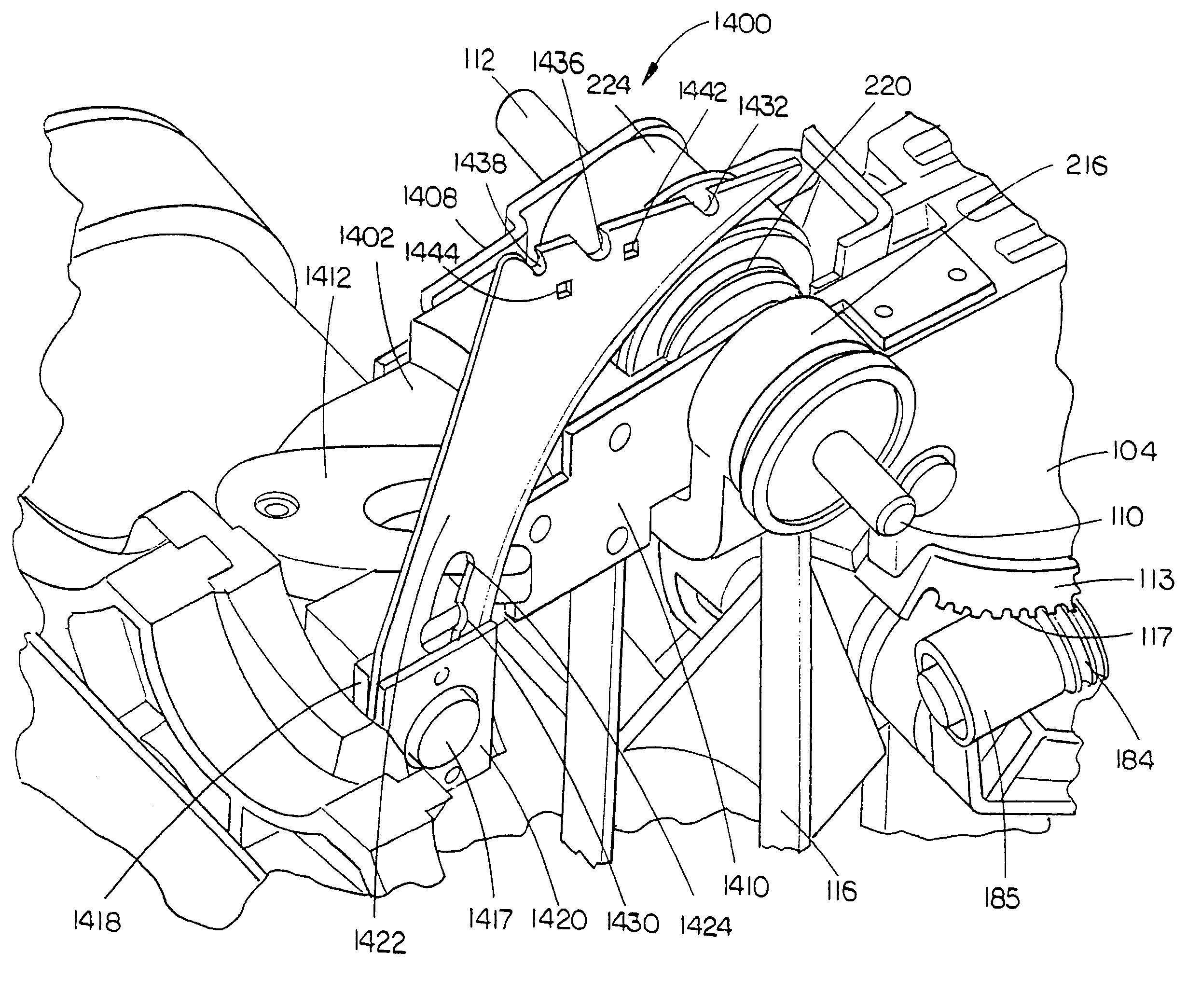

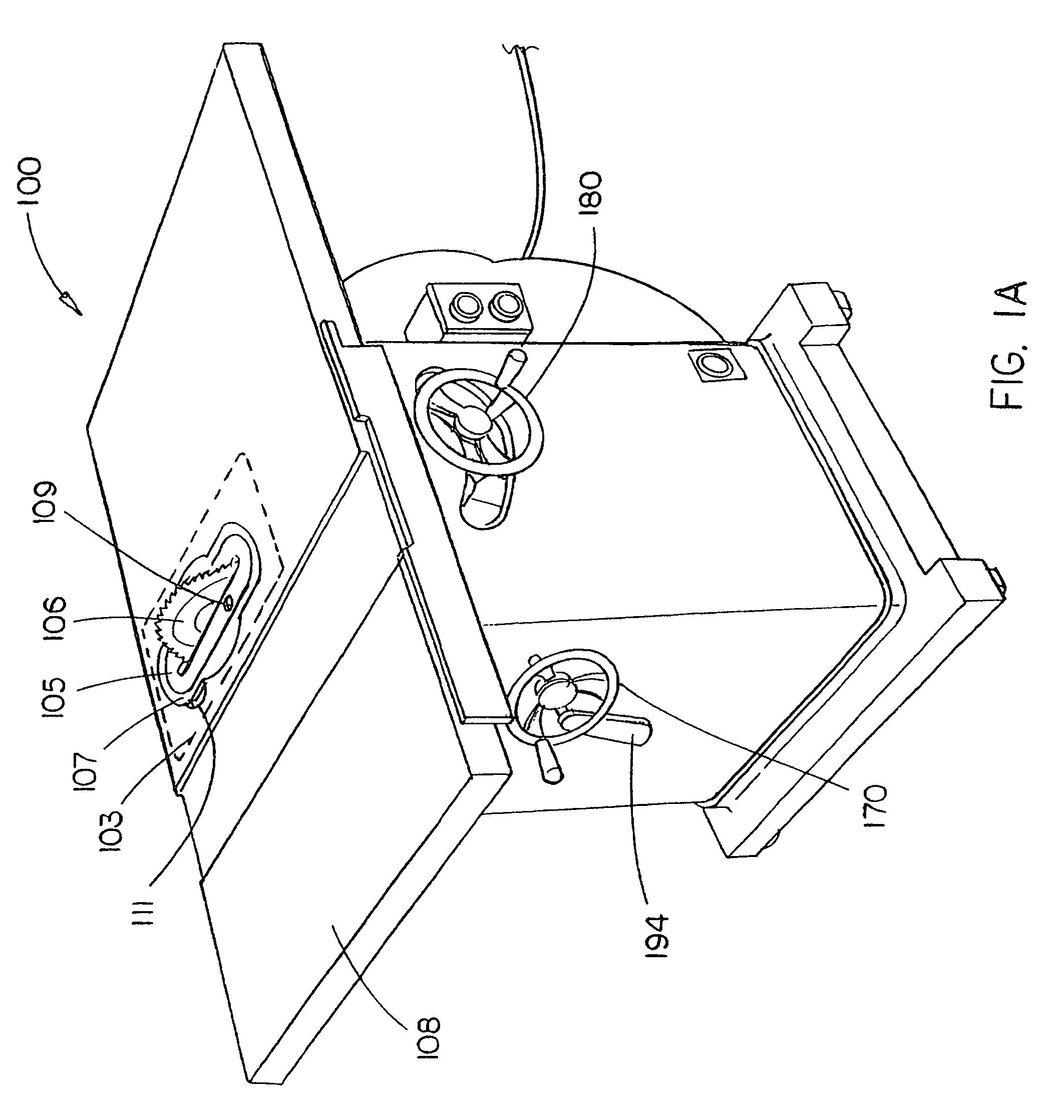

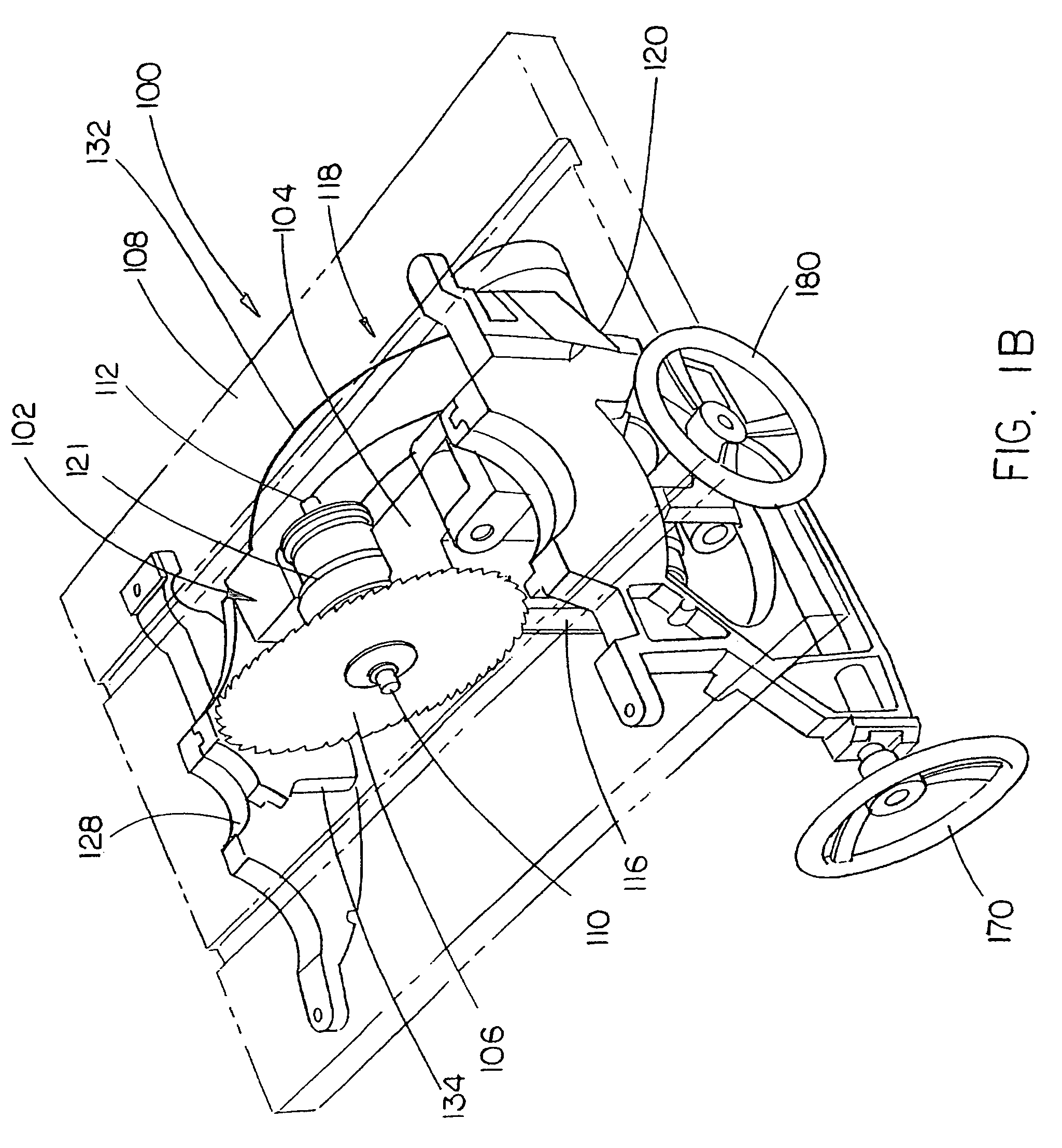

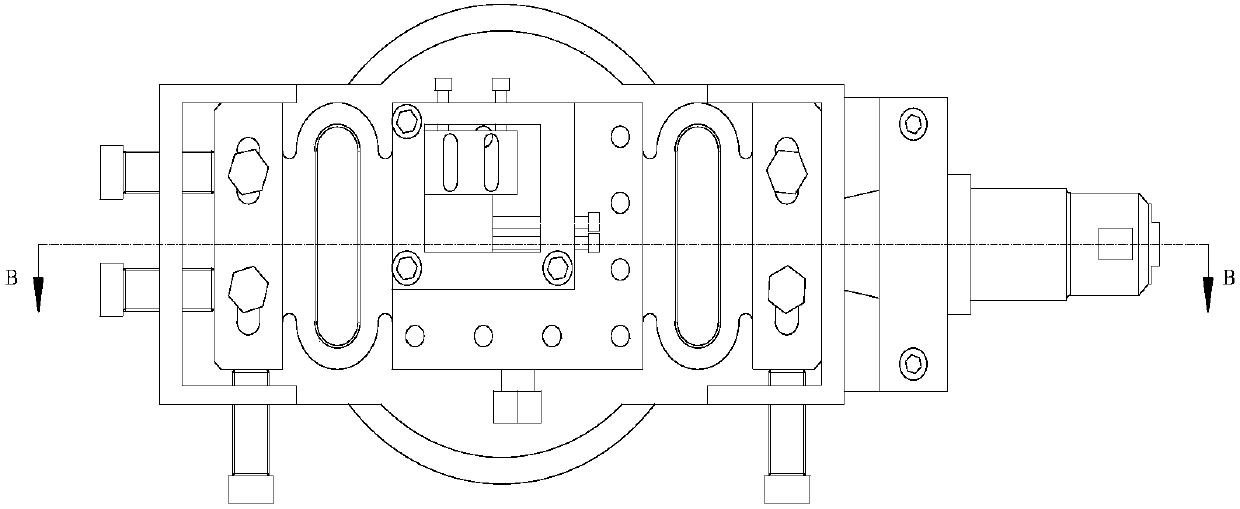

Riving knife assembly for a dual bevel table saw

ActiveUS20050188806A1Efficient use ofFunction maximizationMetal sawing devicesGuide fencesMechanical engineering

An embodiment of the present invention is directed to a riving knife assembly for a dual bevel table saw, comprising: a first armature configured for coupling with a beveling member; a second armature adjustably and rotatably coupled with the first armature; a first mounting member coupled with the second armature; a first riving bracket coupled with the second armature and configured for adjustably coupling with a bearing retaining nut of a dual arbor assembly; a second riving bracket coupled with the first mounting member and configured for adjustably coupling with the inside of a first bore of a first height bracket; a quick release handle disposed upon the first mounting member; an eccentric shaft coupled with the quick release handle; a locking pin having a locking pin body, a second mounting member, a head member coupled with a sheathing member, and a spring loaded assembly, the locking pin operationally coupled with the eccentric shaft; and, a riving knife configured with an engagement assembly for engaging with the locking pin; wherein the spring loaded assembly enables the head member and a circular engagement member disposed on the locking pin body proximal to the head member of the locking pin to be set in a locked position and a release position relative to the second mounting member, the sheathing member and the riving knife; wherein the locked and release positions are established by manipulation of the quick release handle.

Owner:BLACK & DECKER INC

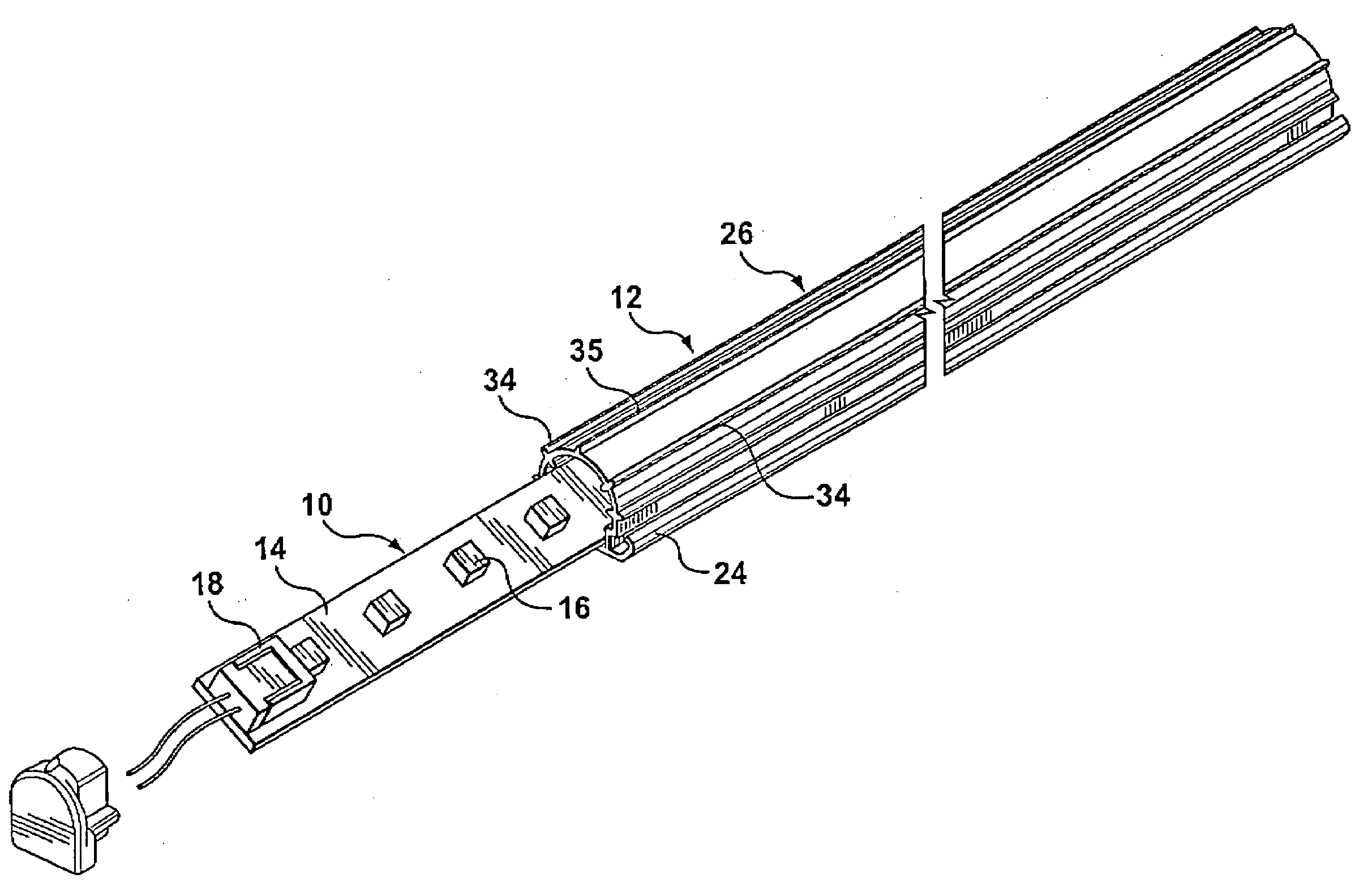

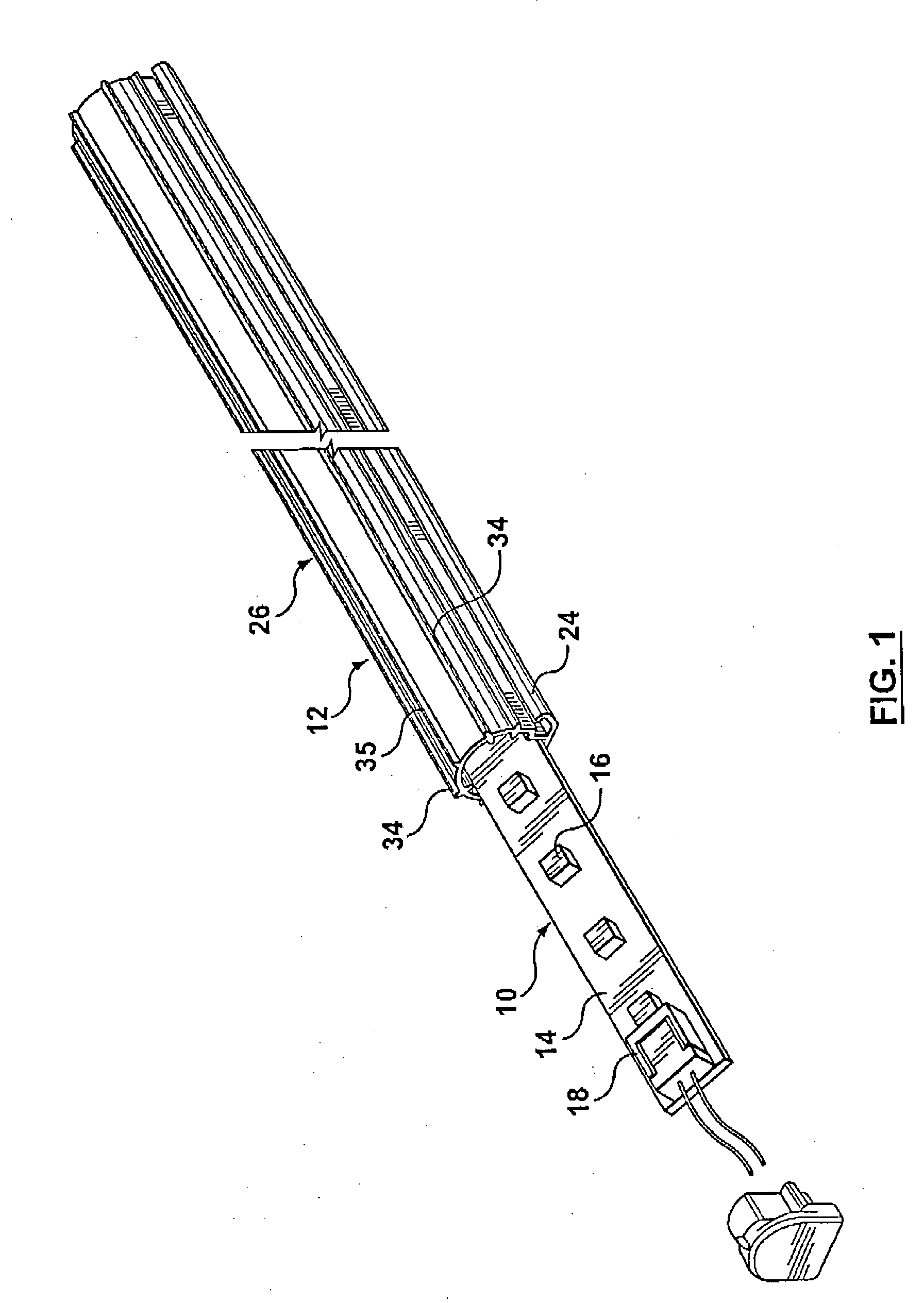

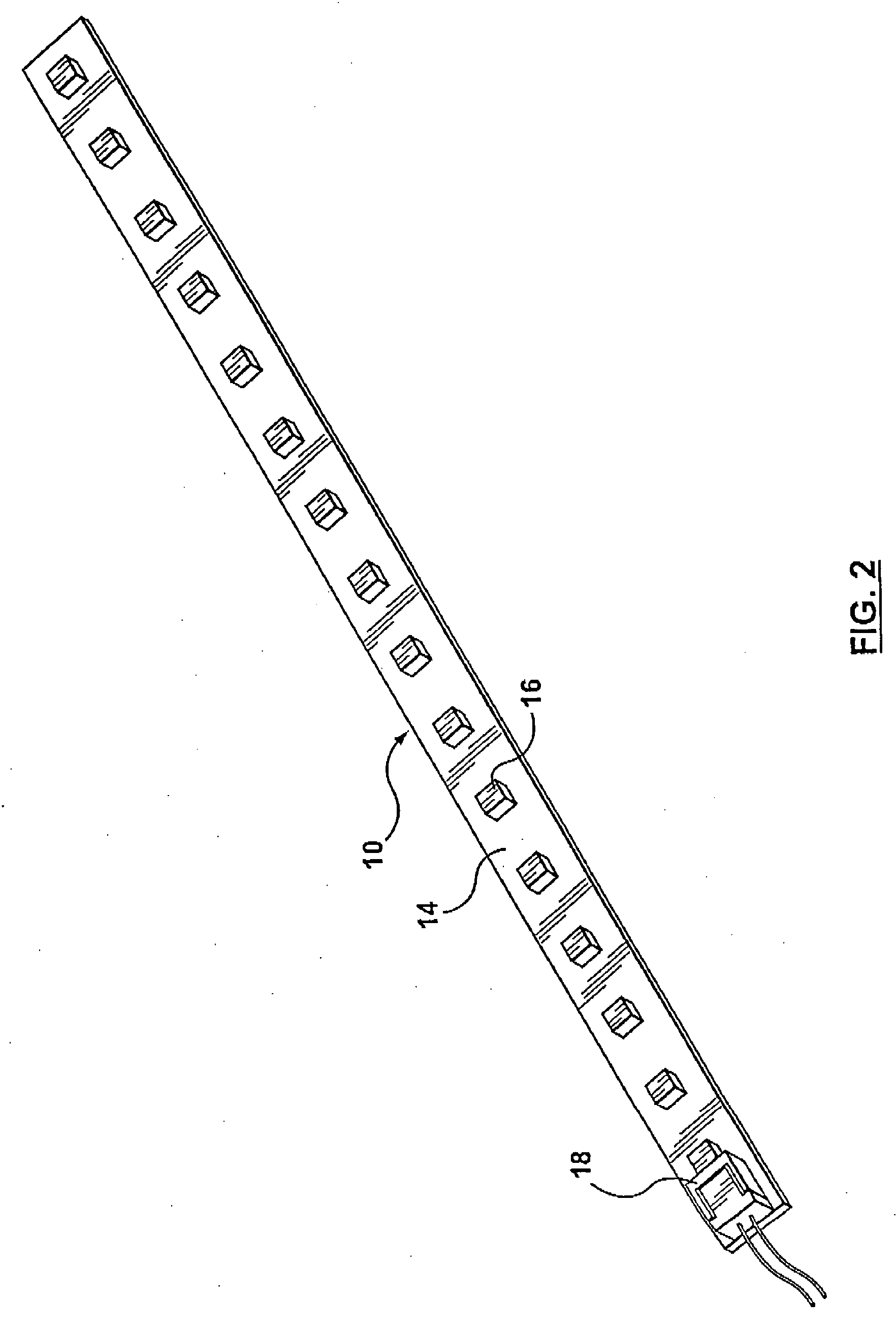

Strip lighting assembly

InactiveUS20080285264A1Easy to adjust the anglePoint-like light sourceElongate light sourcesEffect lightEngineering

A strip light assembly including an elongated light carrying member with a series of lights extending along the length thereof, and an elongated translucent tubular cover member in which the light carrying member is removably slidably mounted, the interior of the cover member having radially spaced internal projections positioned to receive the light carrying member therebetween to maintain the light carrying member in selectable different angular orientations in the cover member.

Owner:AMDOR

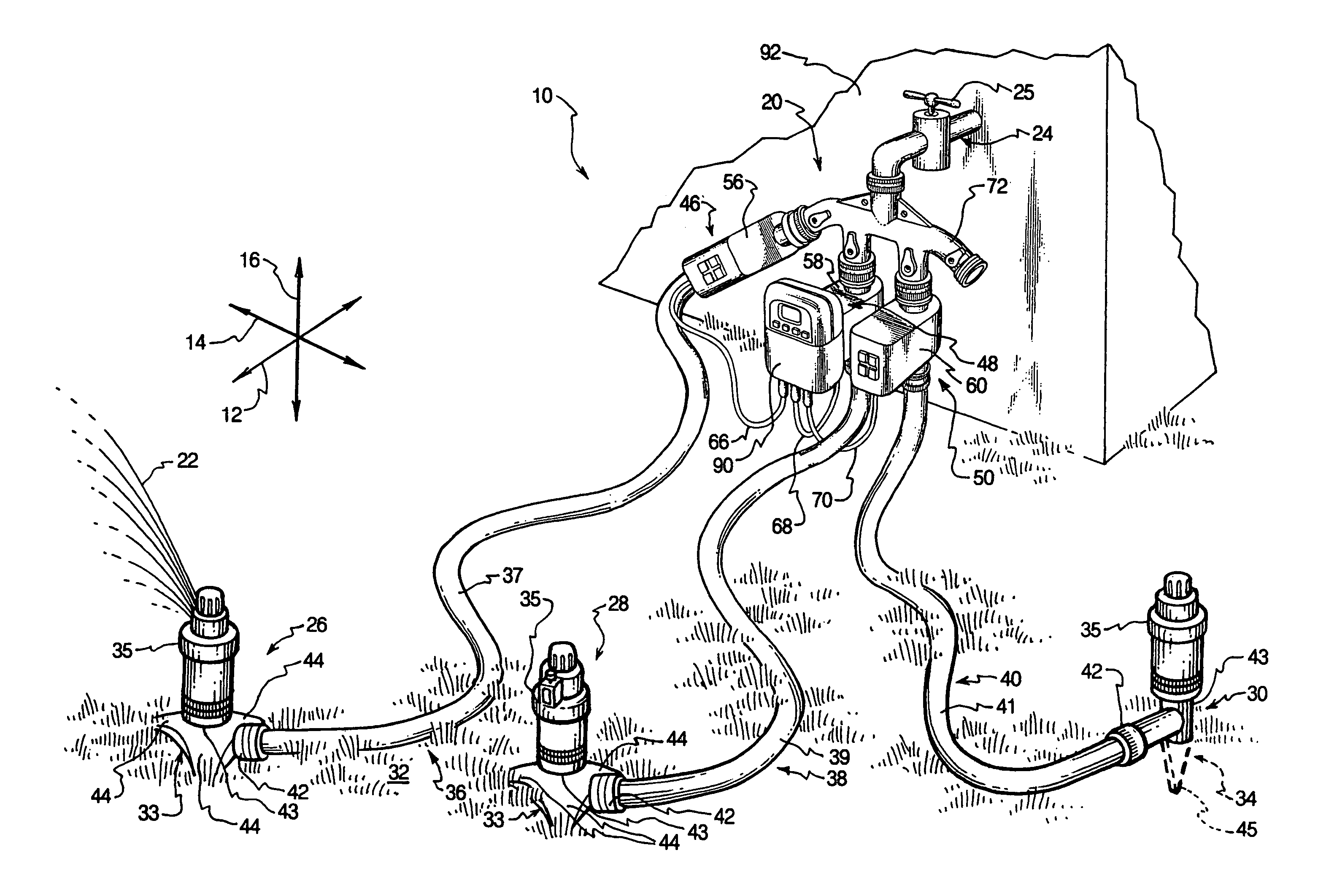

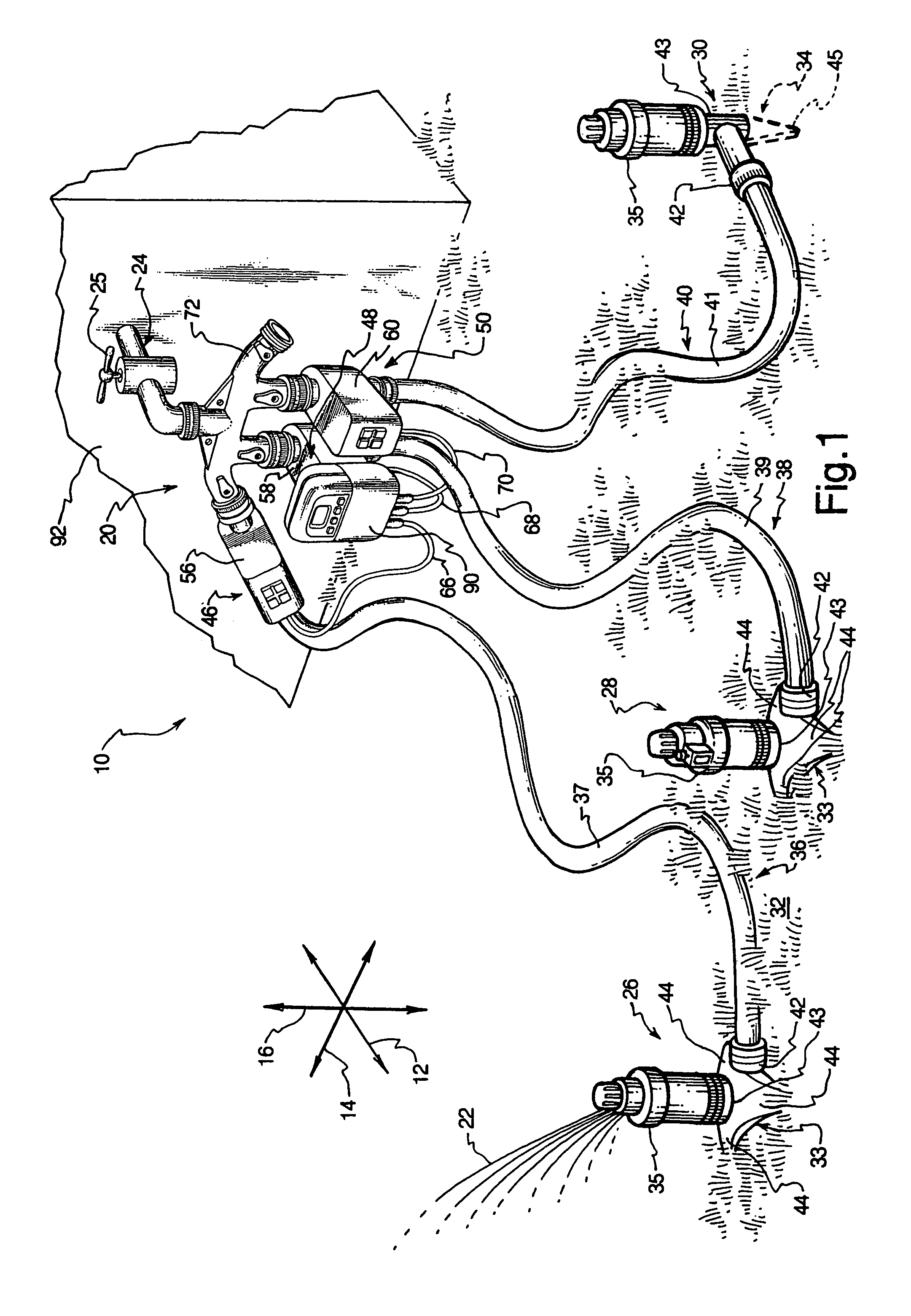

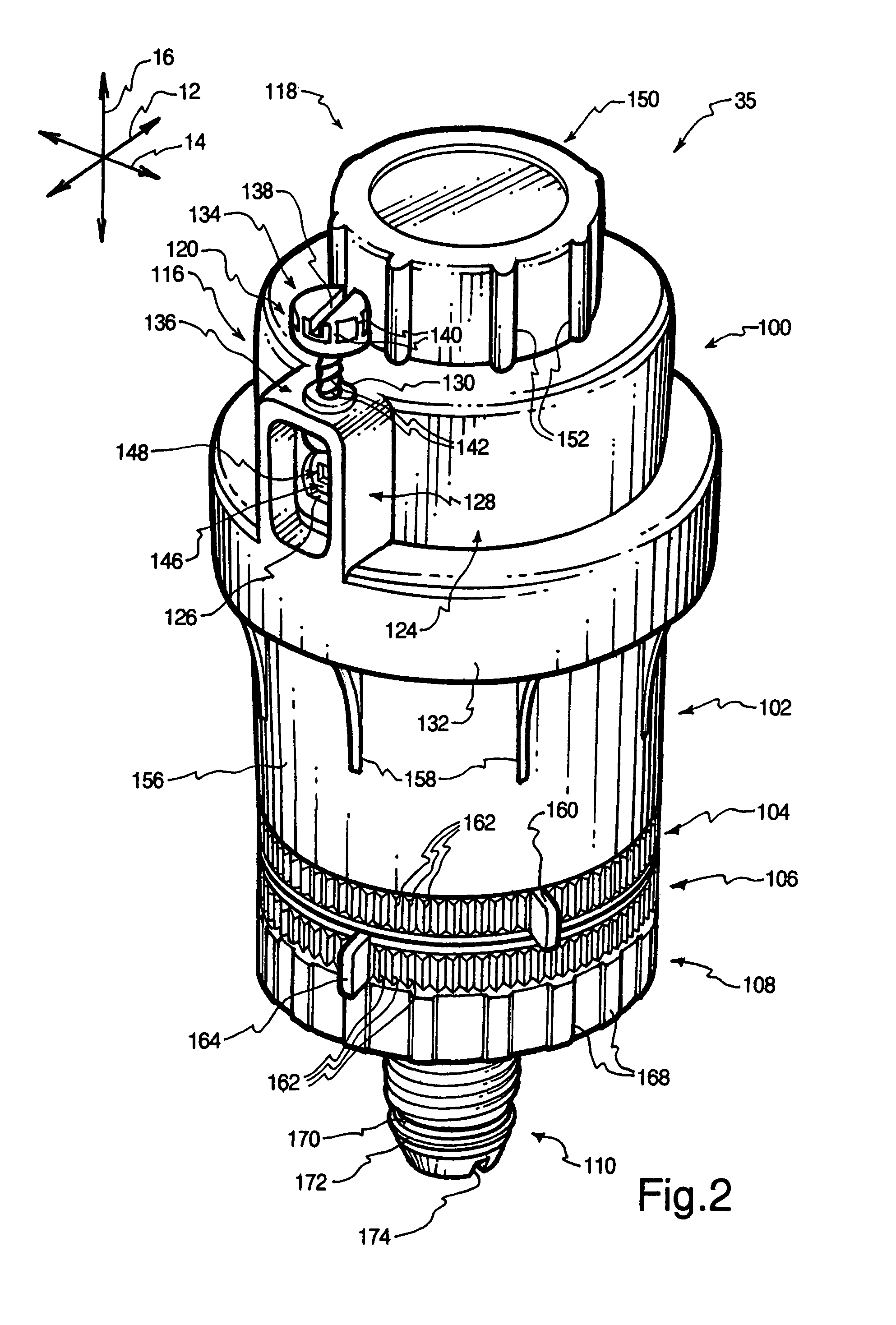

Above-ground adjustable spray pattern sprinkler

ActiveUS7090146B1Improve ease of useIncrease flexibilityWatering devicesMovable spraying apparatusGear driveAbove ground

An above-ground sprinkler may have a head that rotates about an angle determined by the relative angles between a pair of arc adjustment rings. Rotation of the head may be driven by a drive mechanism with a rotor rotationally driven by fluid flowing to the head. The drive mechanism may have a valve disposable in two positions to control flow to the rotor to determine the direction in which the rotor rotates. A reduction gear drive may transmit torque from the rotor to the head to cause the head to rotate. The head may have a cover with an outlet aperture and a flow control member that rotates within the cover to dispose any of a plurality of nozzles in alignment with the outlet aperture. A deflection screw or a slider with a plurality of deflectors may be used to provide variable deflection of water sprayed from the outlet aperture.

Owner:HUSQVARNA AB

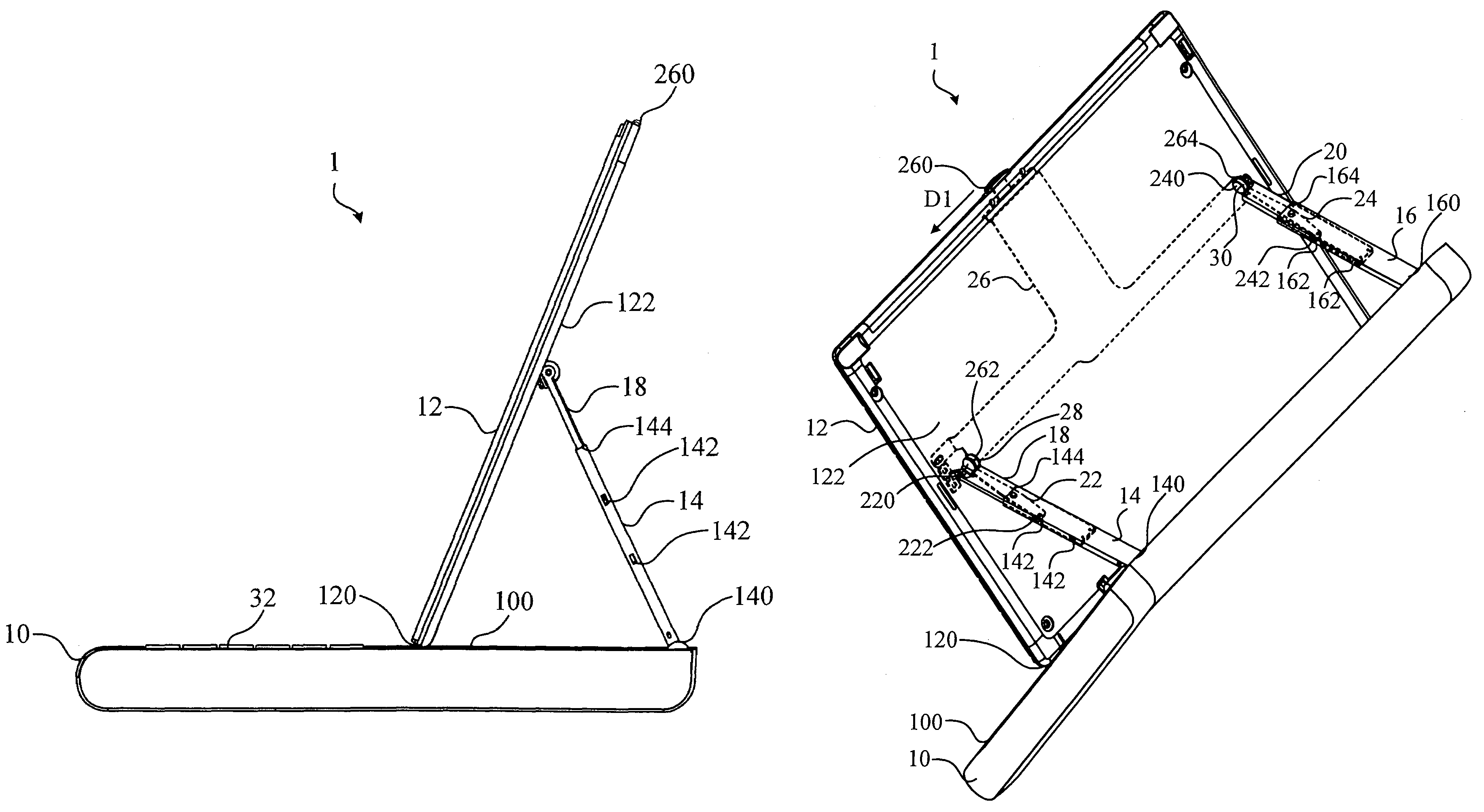

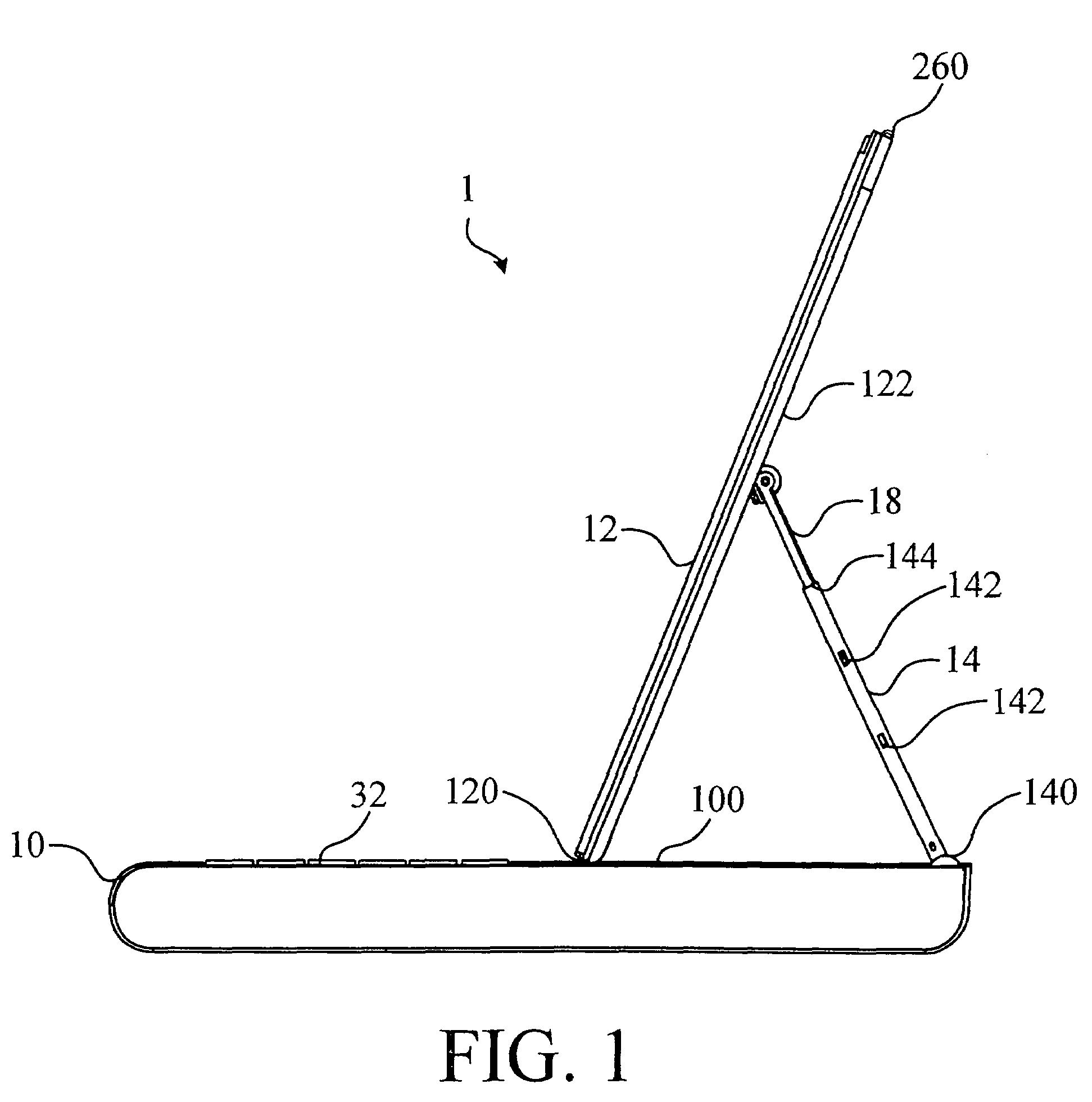

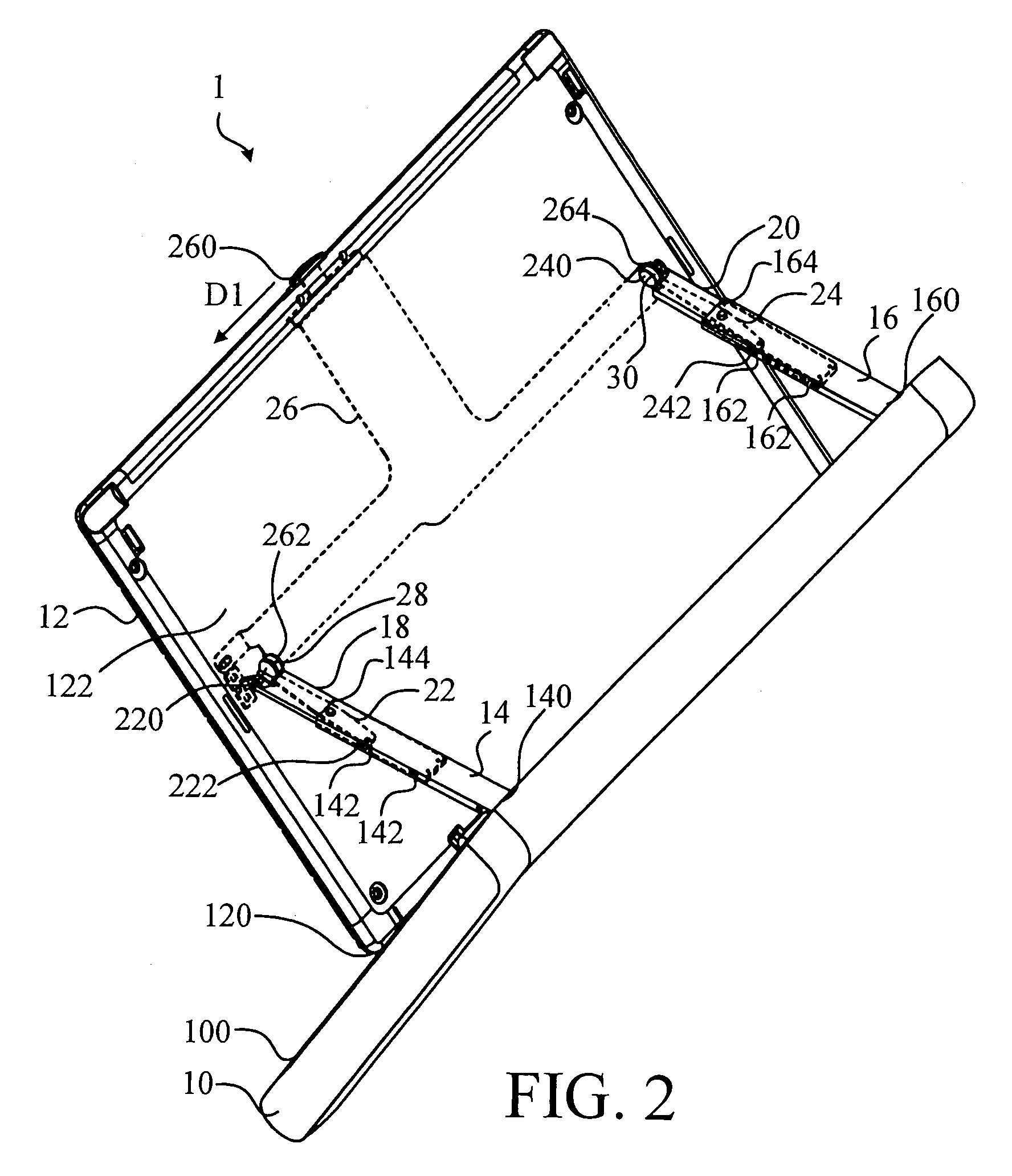

Stand hinge for an electronic device and an electronic device with same

InactiveUS20100259876A1Easy to adjust the angleEasy to usePipe supportsWing accessoriesElectronic equipmentElectrical and Electronics engineering

Owner:LAIRD TECH KOREA YH

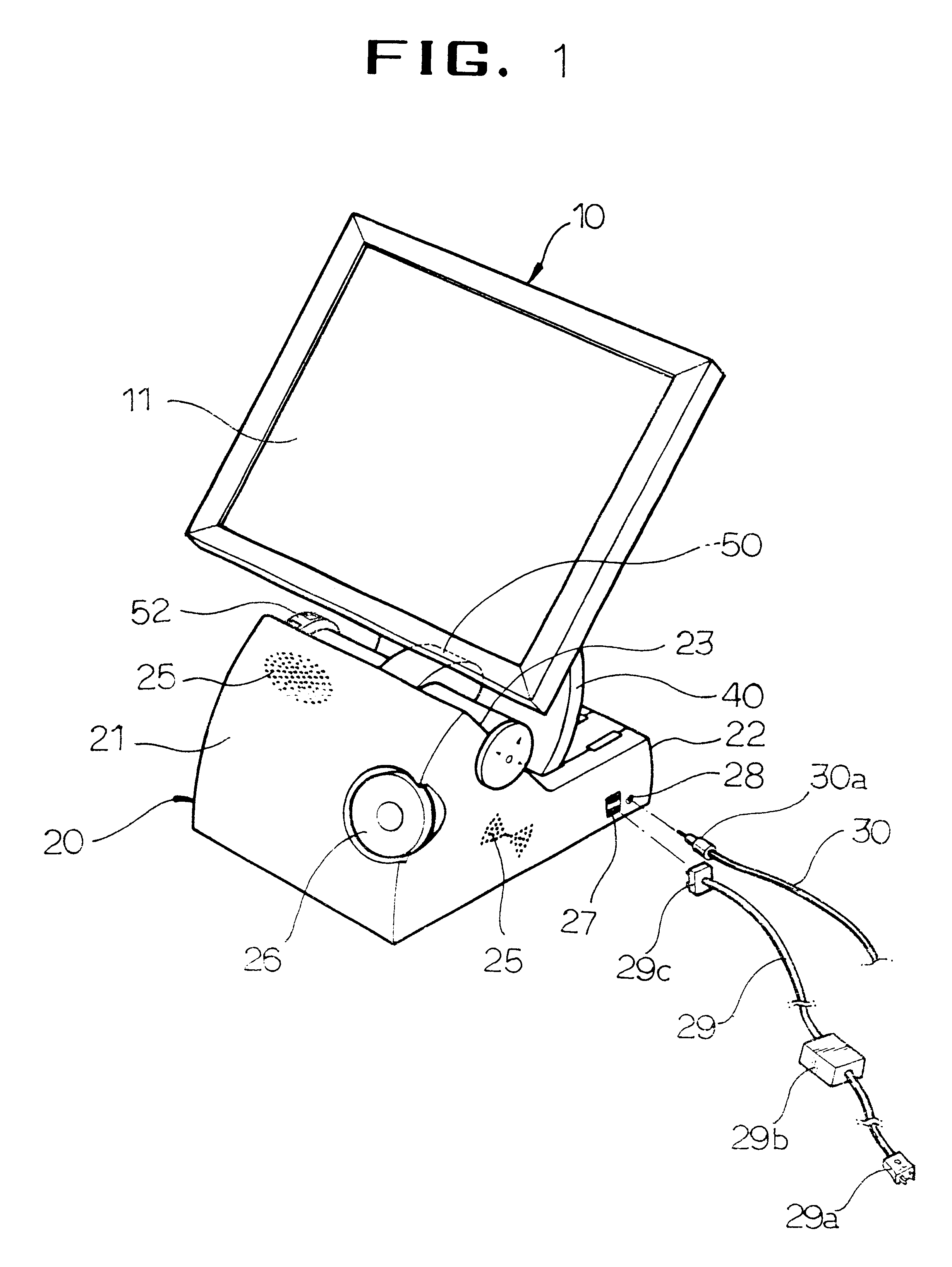

Liquid crystal display

InactiveUS6411271B1Less expensiveEasy to adjust the angleStatic indicating devicesDigital data processing detailsLiquid-crystal displayEngineering

A liquid crystal display including many speakers within a stand and having a display unit, a display angle of which can be adjusted by a cam in order that a user can conveniently see it. The stand supports the display unit through a support and has an inclined part between a front part and a rear part. In addition, a speaker for outputting a high-pitched sound is installed within the front part of the stand and speakers for outputting a middle-low pitched sound are installed within the both sides of the stand. The support is rotatably connected to the display unit and the stand by a driving of the cam and contacted with the cam provided to toe inclined part of the stand and the angle of the support is adjusted by a rotation of the cam and so an angle of the display unit is adjusted.

Owner:SAMSUNG ELECTRONICS CO LTD

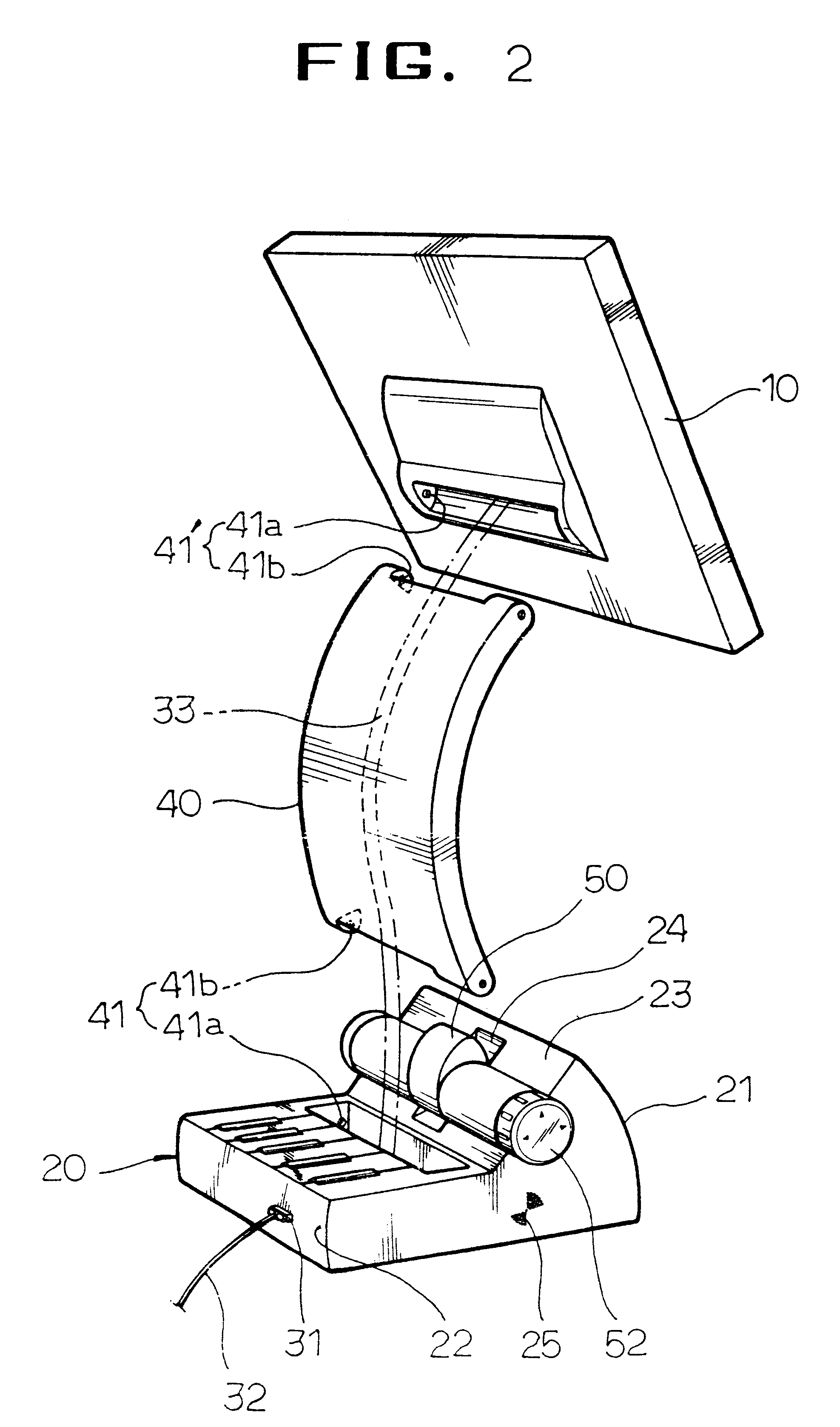

LCD monitor stand

InactiveUS7014154B2Simple pivotingSimple tiltingDigital data processing detailsStands/trestlesLiquid-crystal displayEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

Riving knife assembly for a dual bevel table saw

ActiveUS7137327B2Efficient use ofFunction maximizationMetal sawing devicesGuide fencesEngineeringRivet

An embodiment of the present invention is directed to a riving knife assembly for a dual bevel table saw, comprising: a first armature configured for coupling with a beveling member; a second armature adjustably and rotatably coupled with the first armature; a first mounting member coupled with the second armature; a first riving bracket coupled with the second armature and configured for adjustably coupling with a bearing retaining nut of a dual arbor assembly; a second riving bracket coupled with the first mounting member and configured for adjustably coupling with the inside of a first bore of a first height bracket; a quick release handle disposed upon the first mounting member; an eccentric shaft coupled with the quick release handle; and a riving knife configured with an engaging assembly for engaging with a locking pin or a guard assembly or a kickback finger system.

Owner:BLACK & DECKER INC

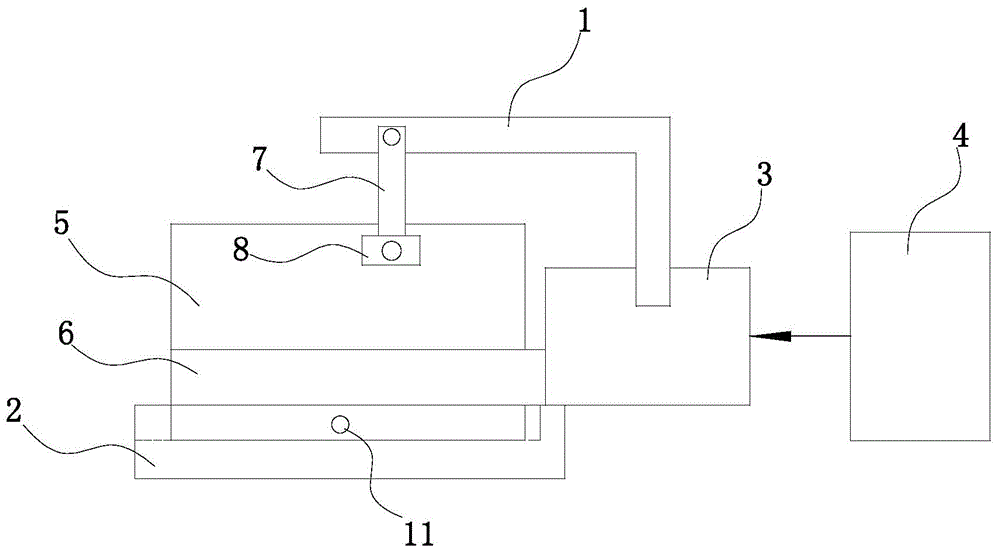

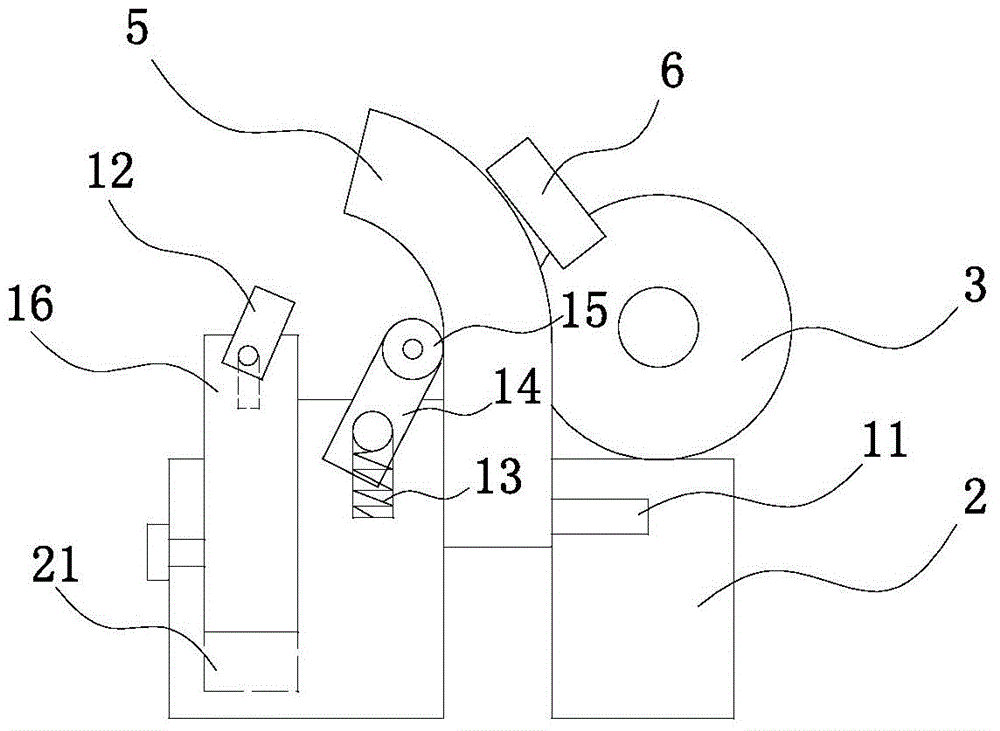

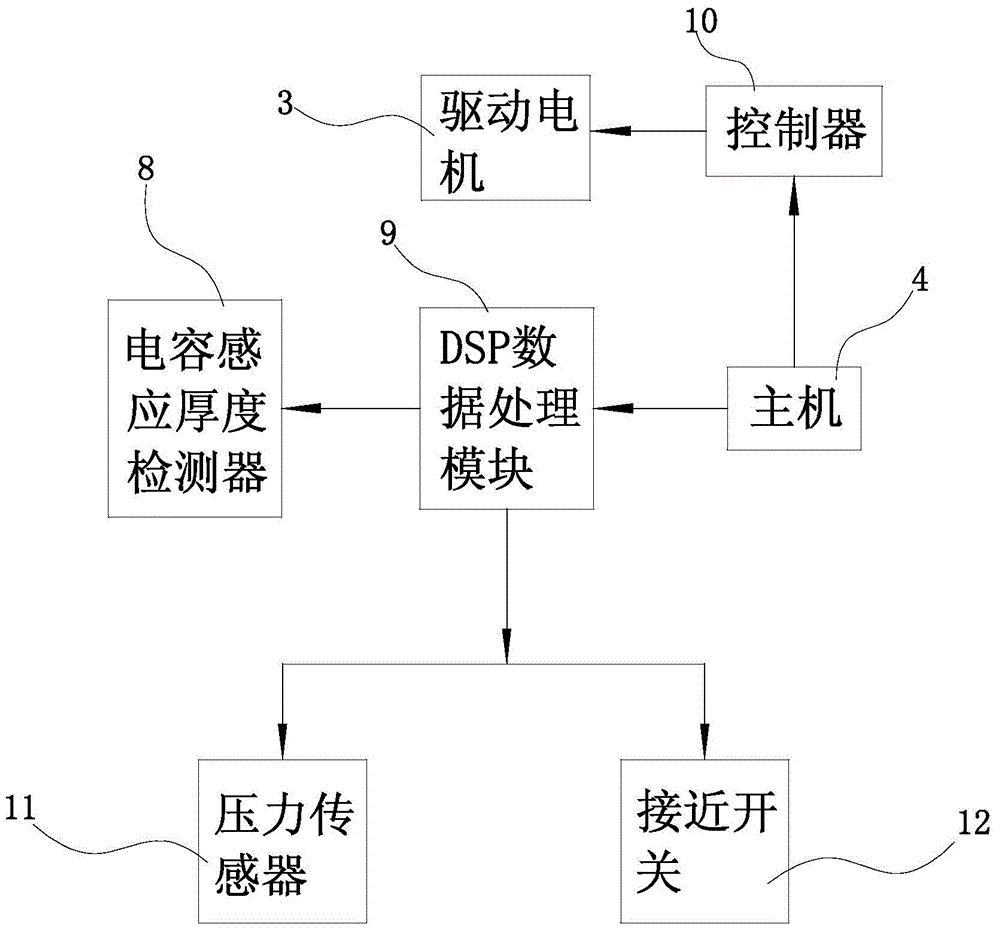

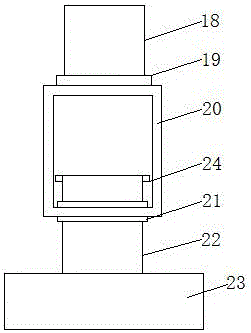

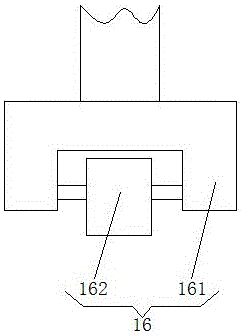

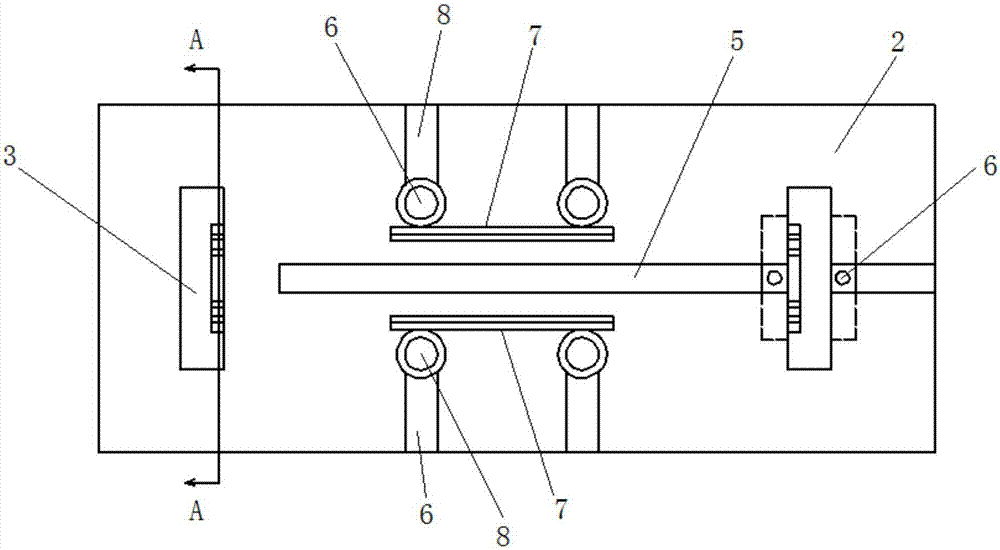

Bending machine controlling torque adjustment and roll bending through PLC and method

InactiveCN104624737APrevent looseningPrevent excessive deformationMetal-working feeding devicesMetal working apparatusCapacitanceAutomatic control

The invention relates to a bending machine controlling torque adjustment and roll bending through a PLC and a method. The bending machine comprises a driving motor, a clamping-fixing seat and a PLC mainframe, wherein the driving motor, the clamping-fixing seat and the PLC mainframe are arranged on a machine frame, a bending shaft is installed on the driving motor, and a machined part is arranged on the clamping-fixing seat. The bending machine further comprises a capacitive sensing thickness detector installed on the machine frame through a support, a proximity switch installed on the clamping-fixing seat, a pressure sensor and a rolling shaft, wherein the rolling shaft is connected to the upper end face of an adjusting plate, and the lower end face of the adjusting plate is installed in an installing groove formed in the clamping-fixing seat by means of a rotary shaft and a spring. The bending machine adopts the pressure sensor to control clamping force, and excessive deformation and looseness of boards are avoided. Bending is performed by utilizing most suitable torque, and machining quality is improved. The bending machine automatically controls a bending angle through the arranged proximity switch and prevents excessive bending. The inner concave face of the machined part is rolled through the rolling shaft, and cracks and burrs at the position of the concave face are decreased.

Owner:DONGGUAN ZHENGQIANG HARDWARE ELECTRONICS

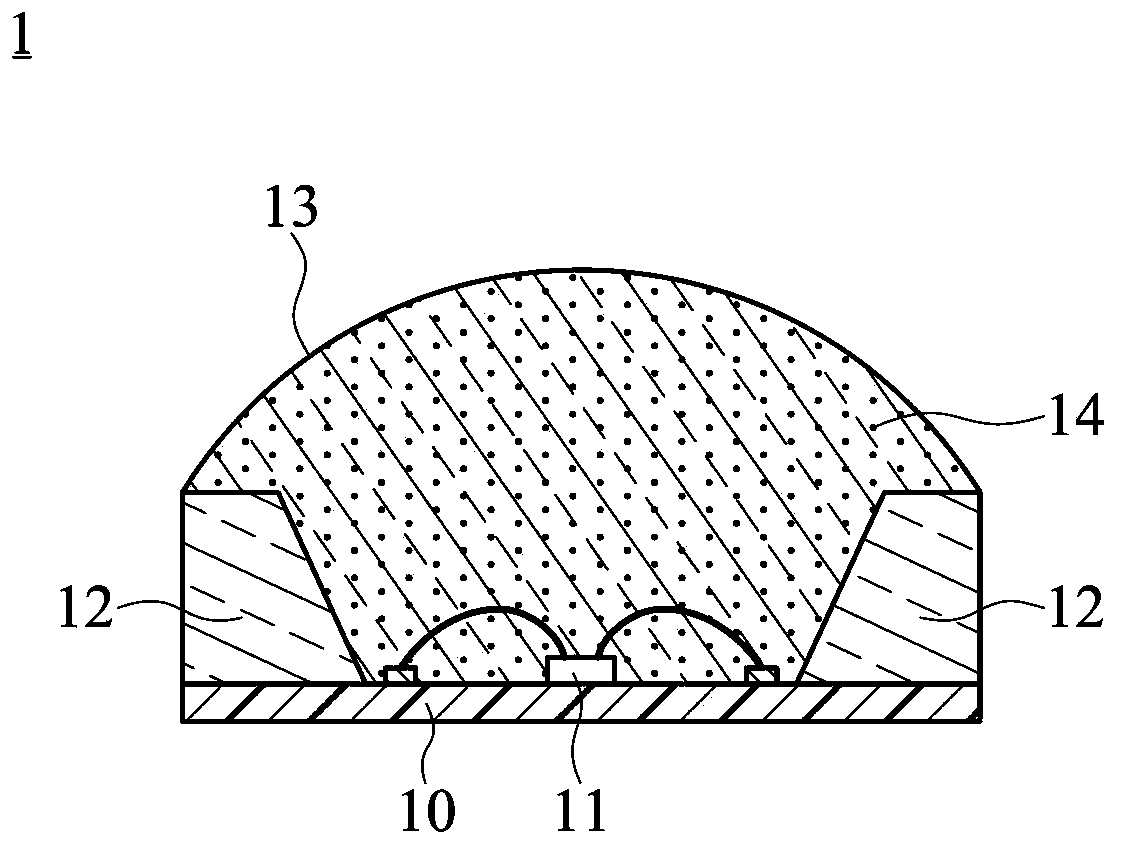

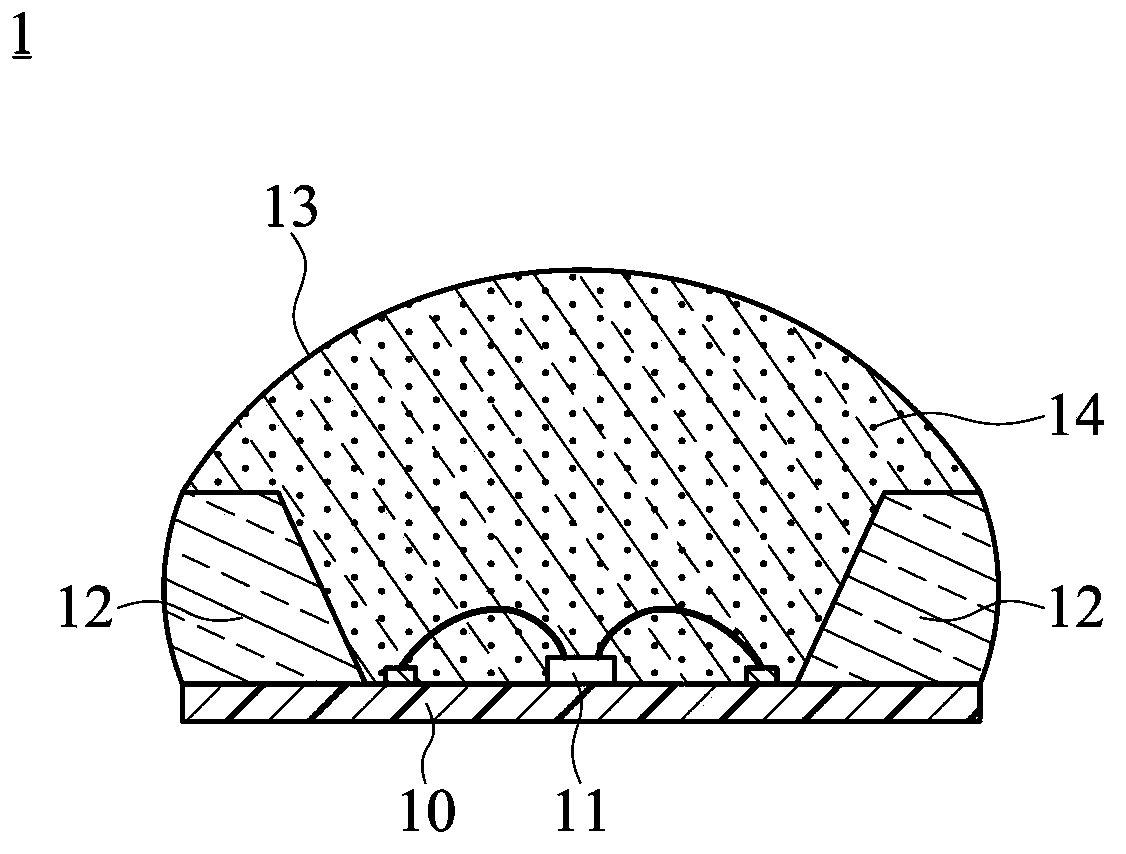

Small-size led packaging structure for enhancing light emitting angle

InactiveCN103489986AImprove applicabilityImprove coloring performanceSolid-state devicesSemiconductor devicesGamutFluorescence

A small-size LED packaging structure for enhancing a Sight emitting angle includes an opaque base and at least one light emitting chip. The light emitting chip is installed on the opaque base, and the opaque base includes a transparent sidewall disposed around the base and a concave-cup space, and the transparent sidewall is formed by a molding method, and the concave-cup space is filled with a packaging gel by a dispensing method, and the packaging gel is doped with at least one phosphor powder. Therefore, the transparent sidewall can increase the light emitting angle to 140°~180° and reduce the amount of internal reflected light significantly to avoid the occurrence of a yellow ring phenomenon, and the phosphor powder can enhance the color manifestation and the color gamut.

Owner:UNITY OPTO TECH CO LTD

Hinge assembly and housing

InactiveUS7216401B2Simplified angle adjustment structureEasy to adjust the angleDigital data processing detailsWing accessoriesEngineeringPinion

Owner:SAMSUNG ELECTRONICS CO LTD

Portable electronic apparatus with adjustable display panel

ActiveUS7586743B2Increase profitEasy to operateDetails for portable computersElectrical apparatus contructional detailsEngineeringOperational behavior

The invention discloses a portable electronic apparatus with an adjustable display panel. The portable electronic apparatus uses a retained portion cooperated with a plurality of retaining portions (like a recess) to support the display panel. Thereby, the display panel of the portable electronic apparatus can be adjusted to a plurality of angles so as to adapt to real conditions, such as angles of light source, operational behaviors of users and the like, which further enhances the utility of the portable electronic apparatus. Furthermore, because the supporting force offered by the retained portion cooperated with the retaining portions is greater than a pressing force generated as a user operates the display panel, the display panel can remain steady when the user operates the display panel.

Owner:QUANTA COMPUTER INC

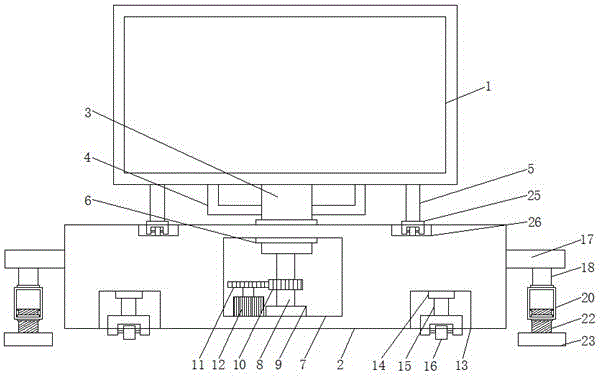

A New Multifunctional Computer Display

ActiveCN109144178AReduce morbidityEasy to operateDigital data processing detailsStands/trestlesCervical spondylosisDisplay device

The invention relates to a novel multifunction computer display. By adjusting the rack to drive the planetary gear train to rotate, the planetary gear is driven by the power transmission of the worm gear and the screw threaded with the third worm to complete the feeding in the left and right directions, the two sets of screws are identical to the cylinders, a four-bar linkage mechanism composed ofa display and a connecting rod adjusts the upper and lower angles of the display, you can also move the drive handle up and down selectively, whether the cylinder is adjusted reciprocally or not is realized, and a clever reversing device is introduced at the same time, while dissipating heat, selective angular adjustment is performed in the anterior and posterior directions, when the angle adjustment is carried out before and after, because the third worm is symmetrically arranged, the upper and lower angle adjustments are not affected. The invention utilizes the power output of heat dissipation to carry out angle adjustment, reasonably utilizes resources, is simple and convenient to operate, has ideal angle adjustment effect, and can reduce the incidence probability of cervical spondylosis, and has ingenious structure and strong practicability.

Owner:湖南鑫源链科技有限公司

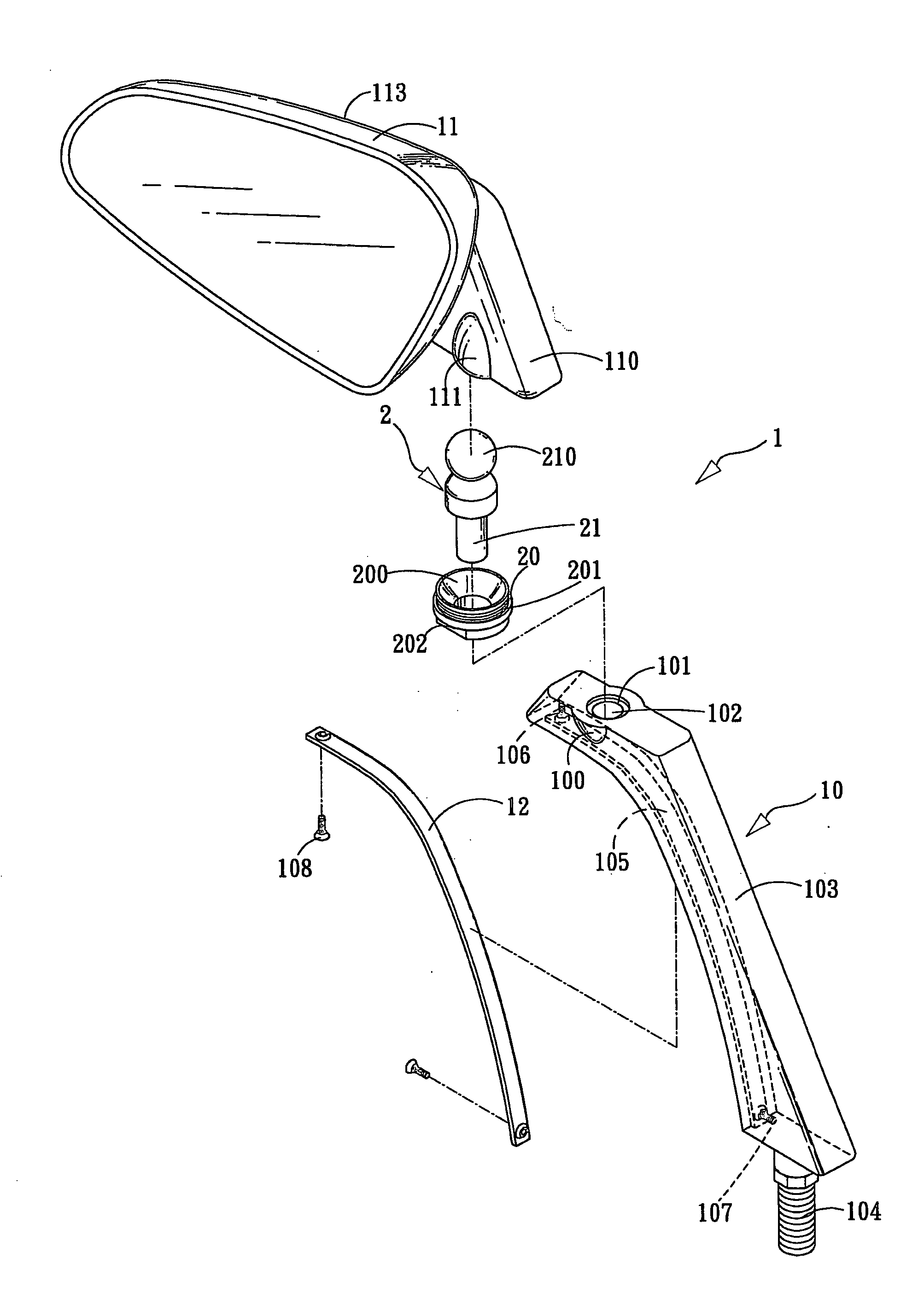

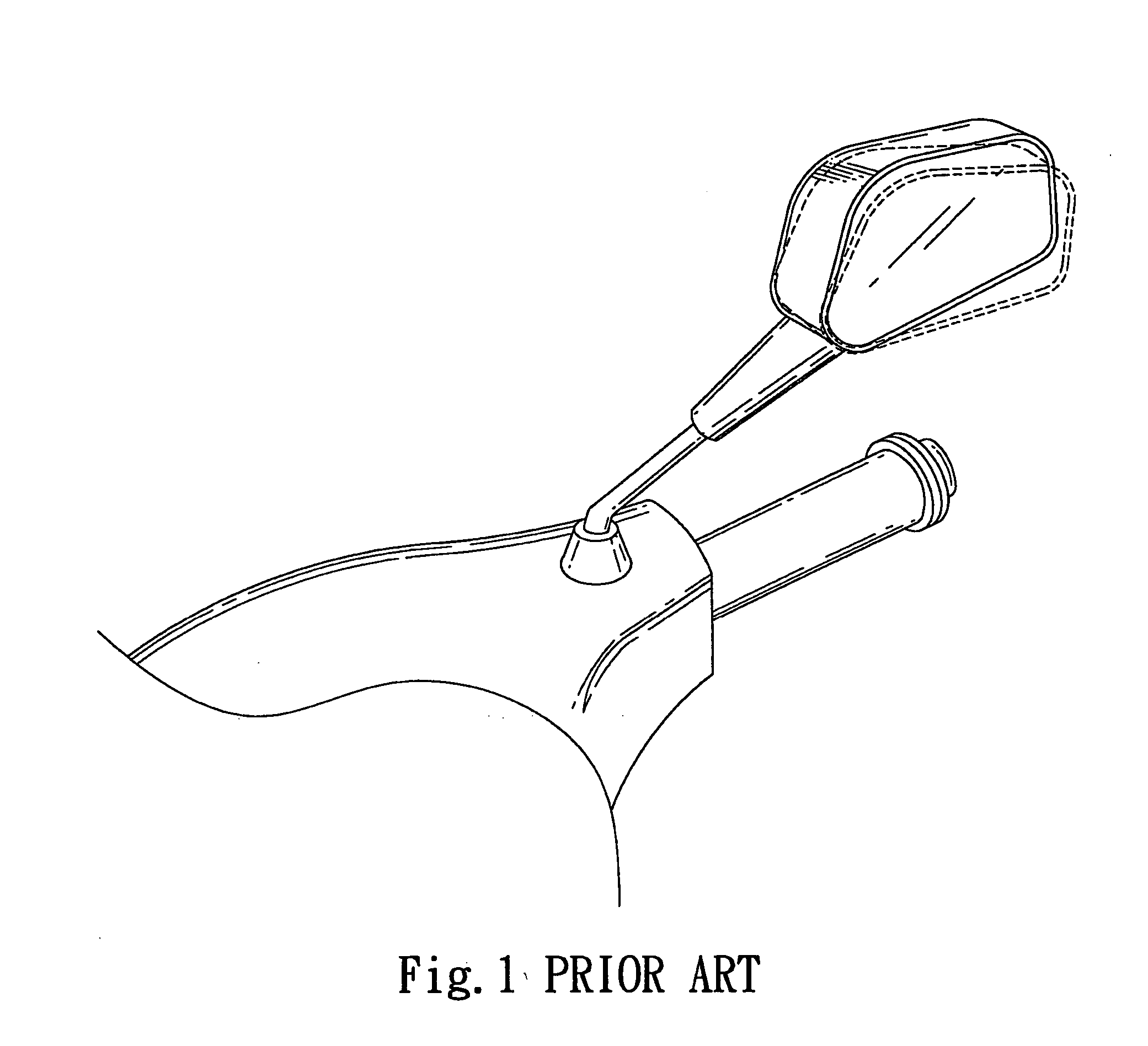

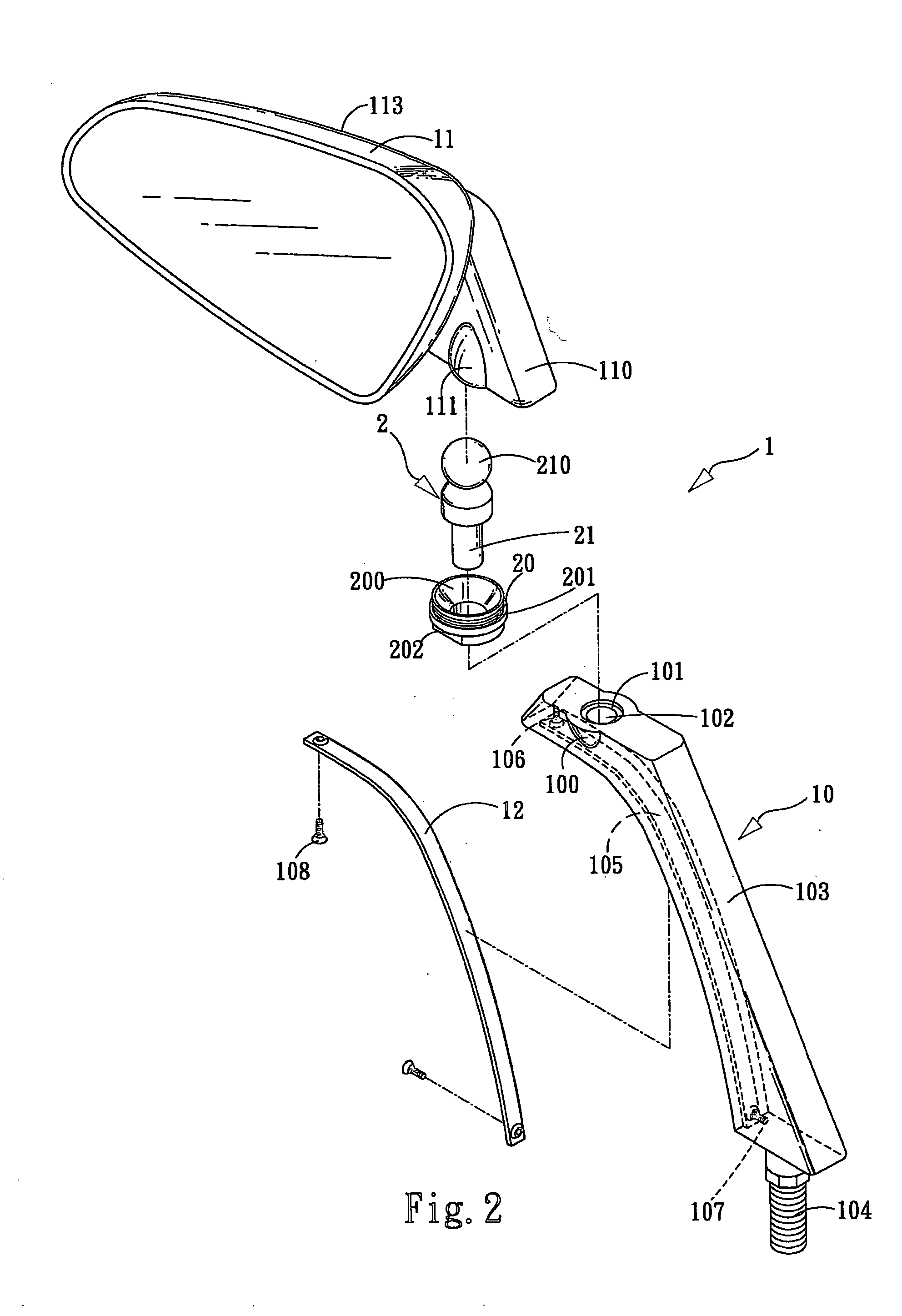

Mirror of motorcycle with swivel mount

InactiveUS20050237643A1Making safeDirection is limitedCycle mirrorsMountingsVertical planeUniversal joint

A mirror assembly of motorcycle is disclosed. The assembly comprises an arm mechanism including an arm secured to a handlebar, and a bore on the top end; a mirror mechanism including a threaded hole on a bottom of a connecting member thereof; and a universal joint mechanism including a ring-shaped seat secured to the threaded hole, and a post having a top ball, the ball being substantially enclosed by the mirror mechanism and the seat and pivotably supported on the seat when the post is inserted through the seat into the bore for fastening. The mirror mechanism is operative to either turn freely about the ball on a horizontal plane or turn about the ball on a vertical plane in a limited angle.

Owner:WU HSIU LI

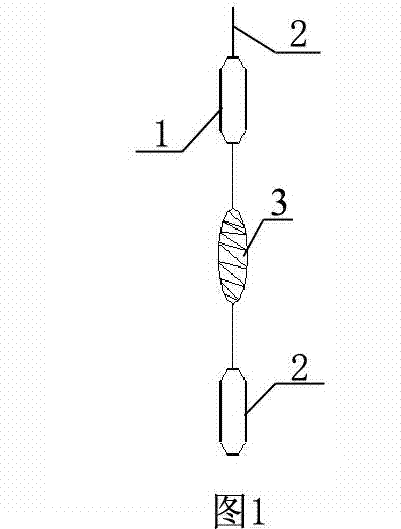

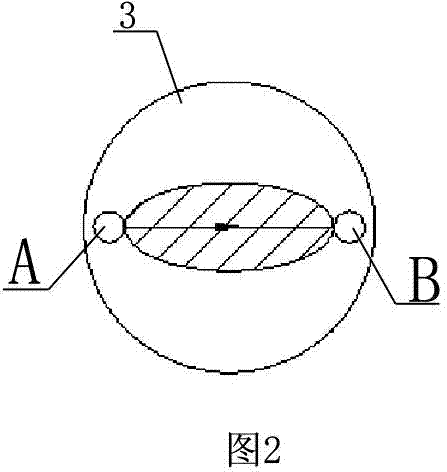

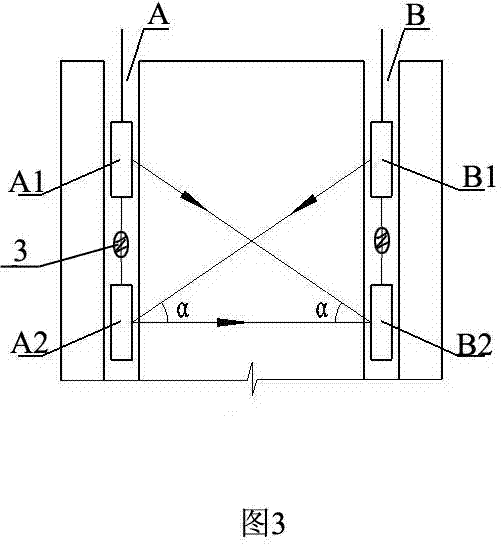

Apparatus for detecting integrity of foundation pile by using acoustic transmission method and detection method used therein

ActiveCN102313778AImprove test efficiencyEasy to adjust the angleAnalysing solids using sonic/ultrasonic/infrasonic wavesAcoustic transmissionSpatial positioning

The invention relates to an apparatus for detecting integrity of foundation piles by using the acoustic transmission method and a detection method used therein, belonging to the technical field of acoustic detection of foundation piles. According to the invention, simultaneous detection of measuring lines at a plurality of directions in the process of one full elevation lifting detection of a profile is realized by arranging at least two tandem radial energy transducers at cable terminals; the method has the advantages of simplified detection procedures and improved detection efficiency, is more favorable for spatial positioning of a defect part and can be extensively used in detection of integrity of foundation piles by using the transmission method.

Owner:北京市康科瑞工程检测技术有限责任公司 +2

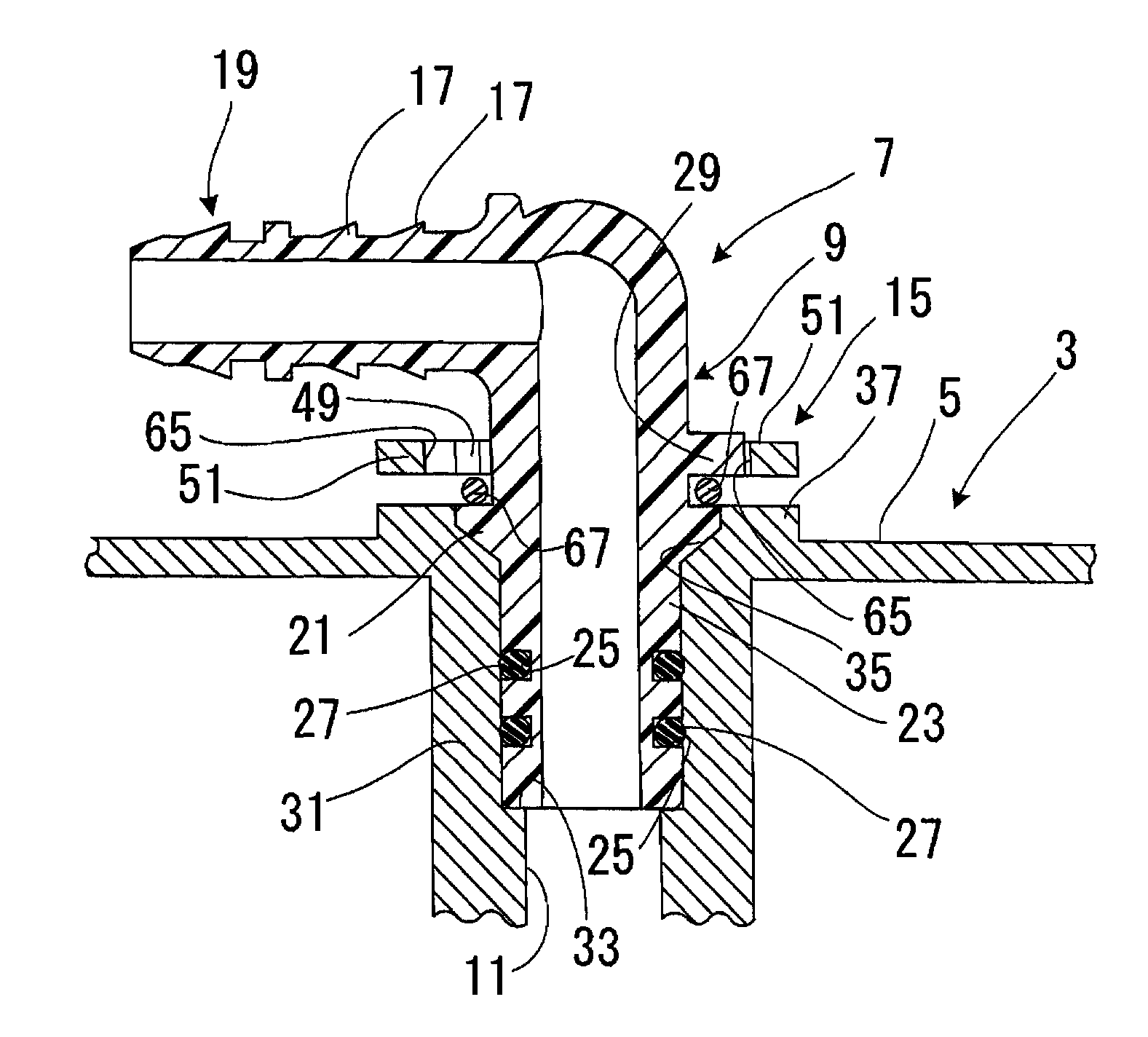

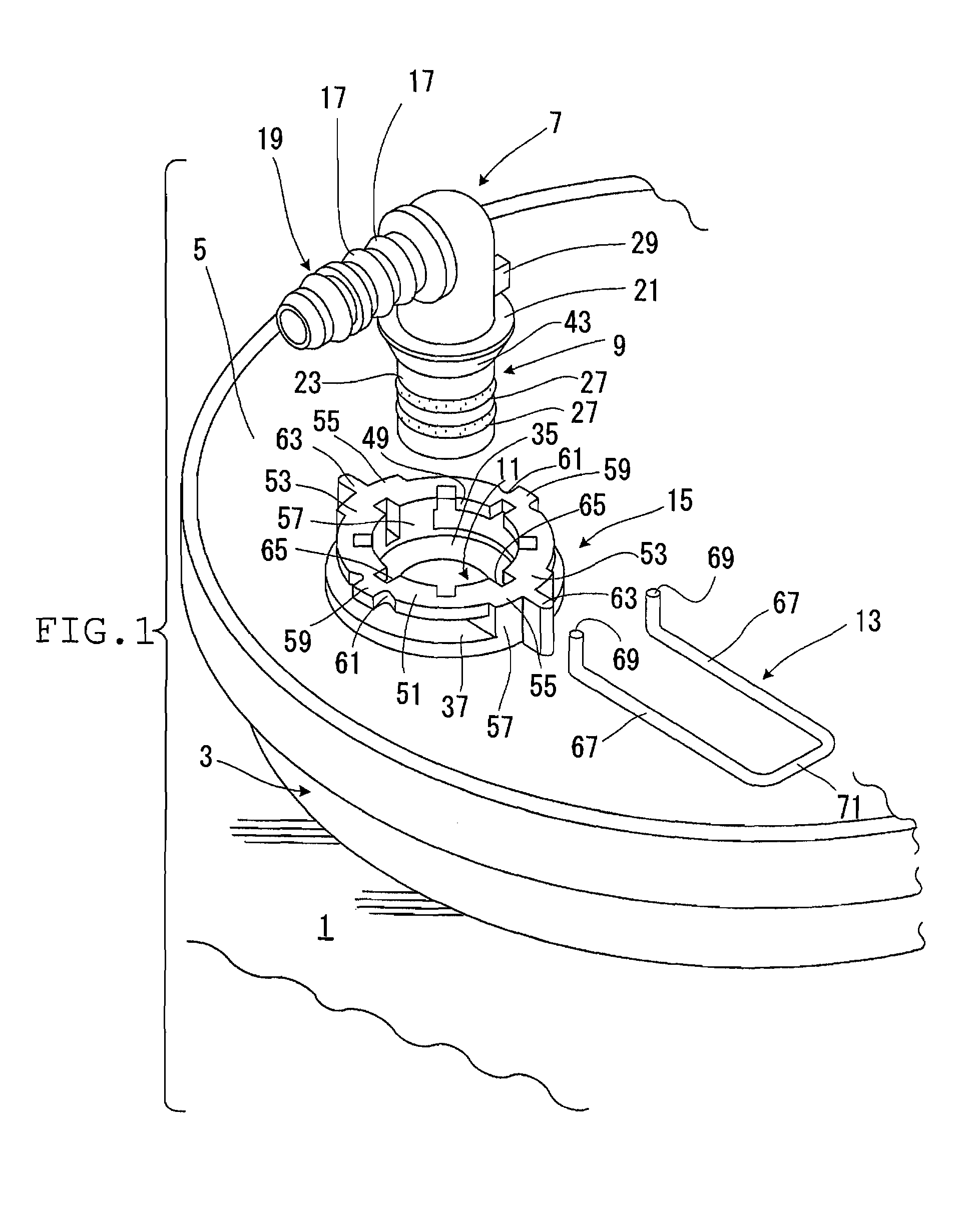

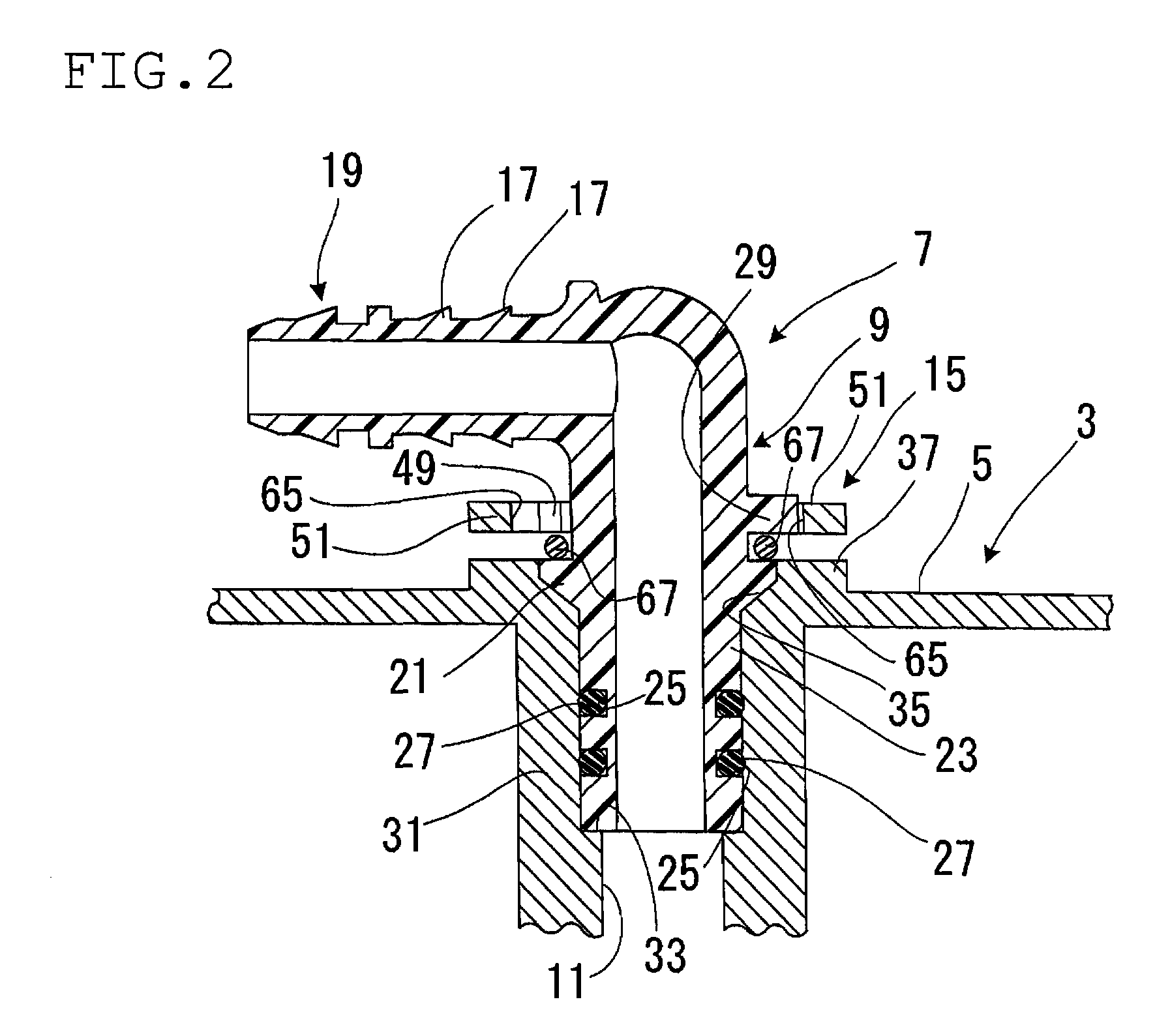

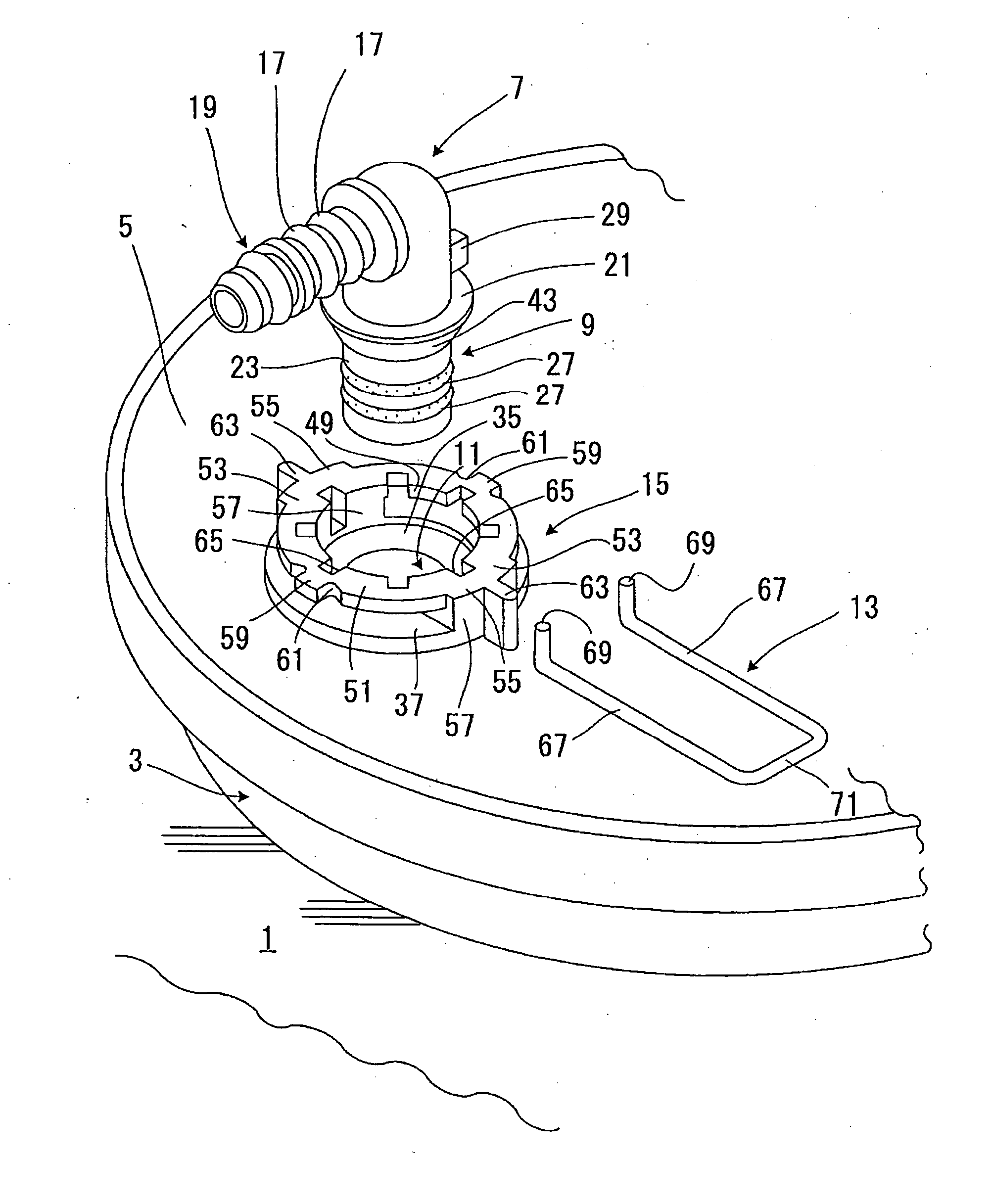

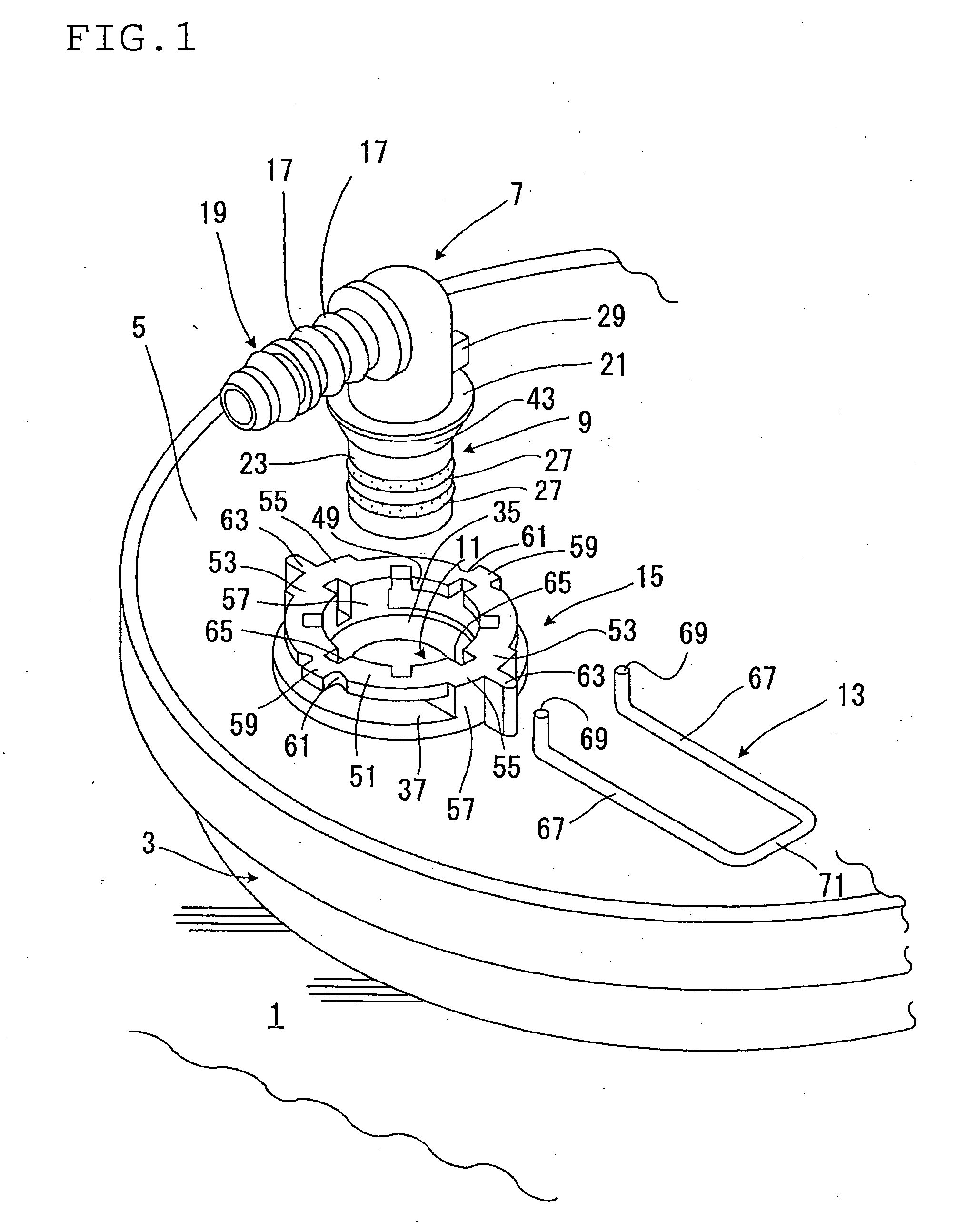

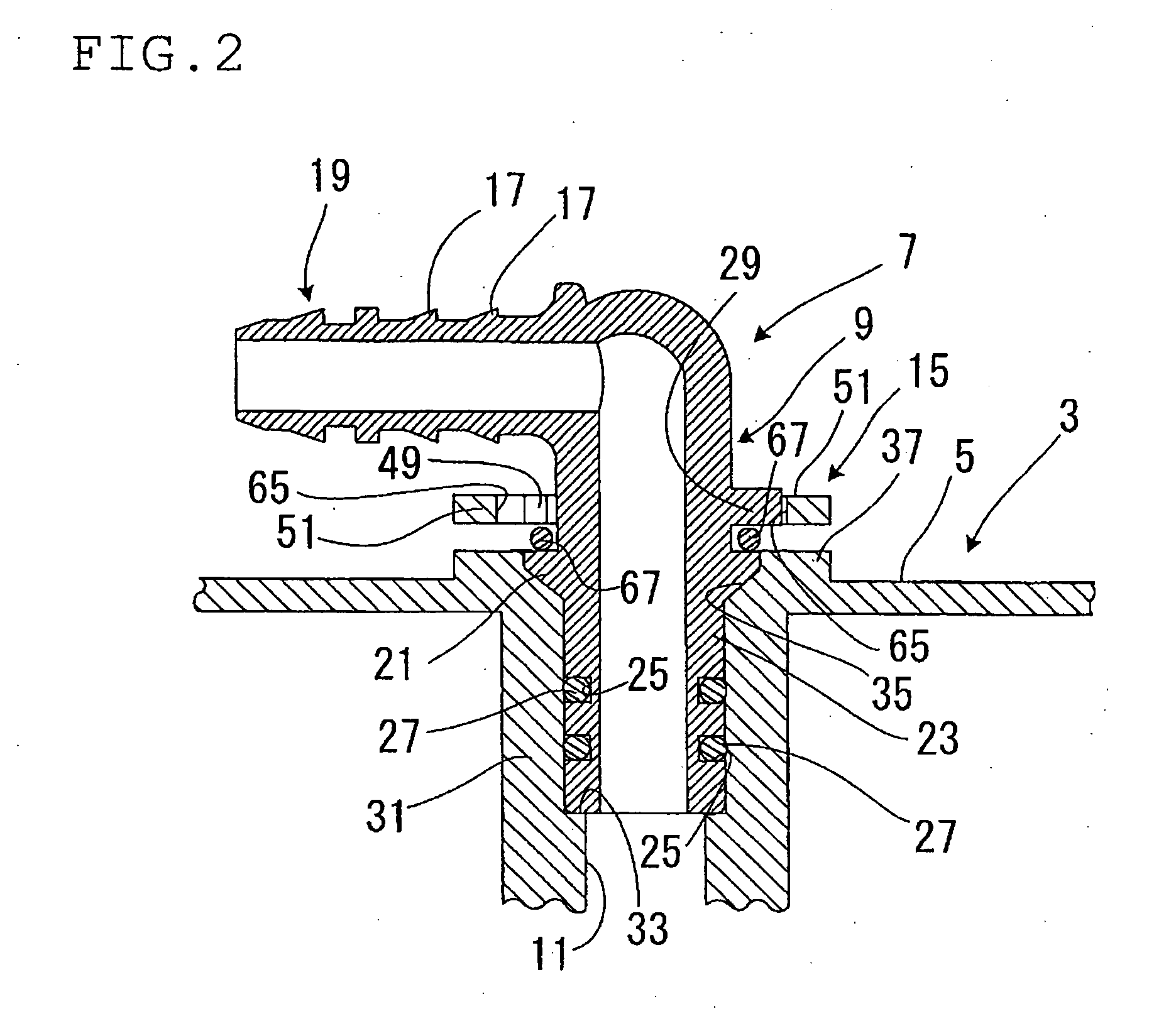

Connector mounting structure

ActiveUS7401820B2Large diameterIncrease intervalSleeve/socket jointsFluid pressure sealed jointsEngineeringDrop out

A connector is inserted into a connection hole provided on a fluid piping equipment, and the connector is prevented from dropping out via a retainer held by a retainer holding portion. The connector has a connecting portion including a flange stop portion, and a positioning means is disposed between the connecting portion and the fluid piping equipment. This positioning means is to position the connecting portion in a circumferential direction so as not to rotate relative to the connection hole and has a mounting angle adjusting function capable of positioning the connecting portion in the circumferential direction selectively at any one of a number of mounting angular positions relative to the connection hole. An annular surface on the other end in the axial direction of the stop portion is formed in a taper shape tapered toward the other end in the axial direction.

Owner:SUMITOMO RIKO CO LTD

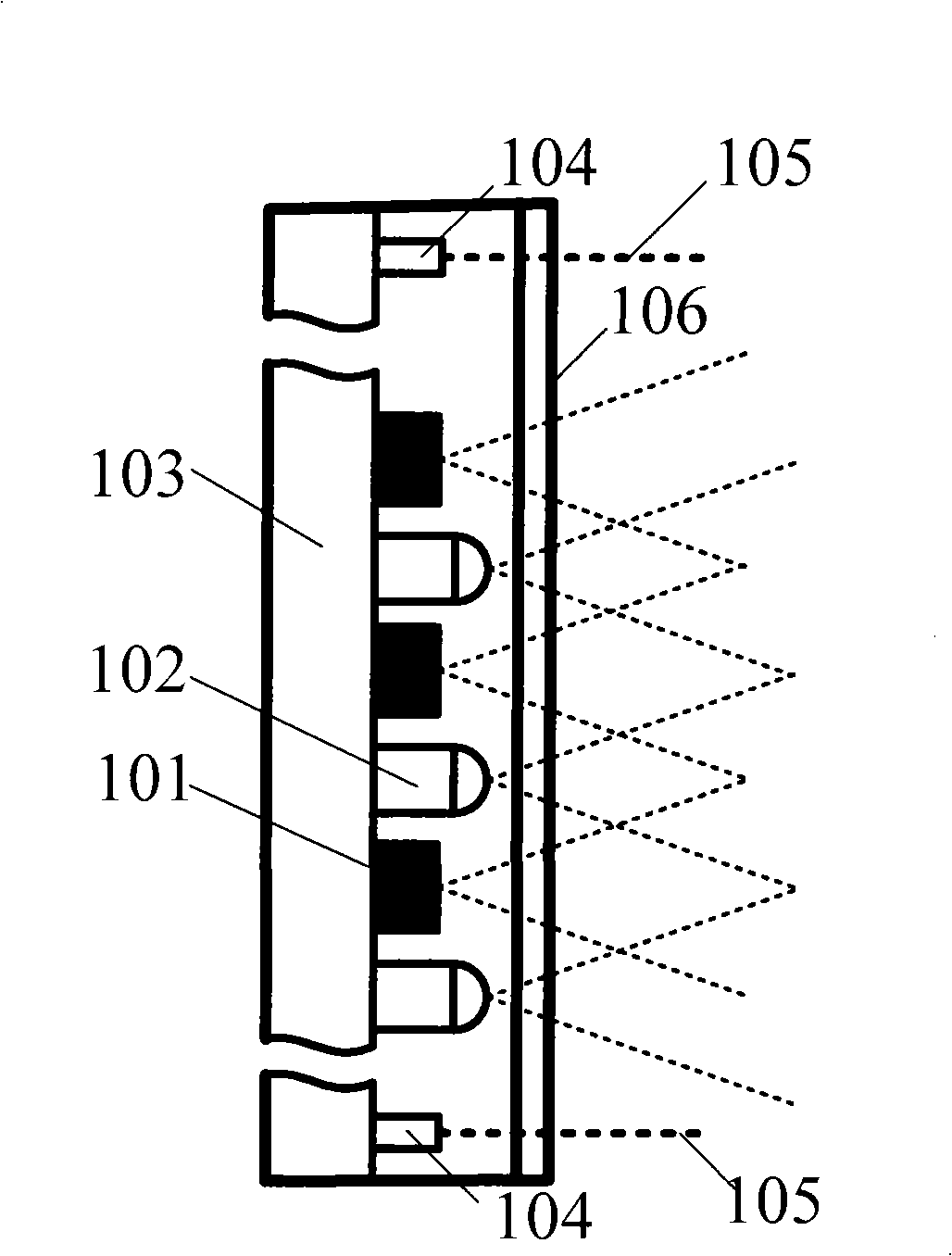

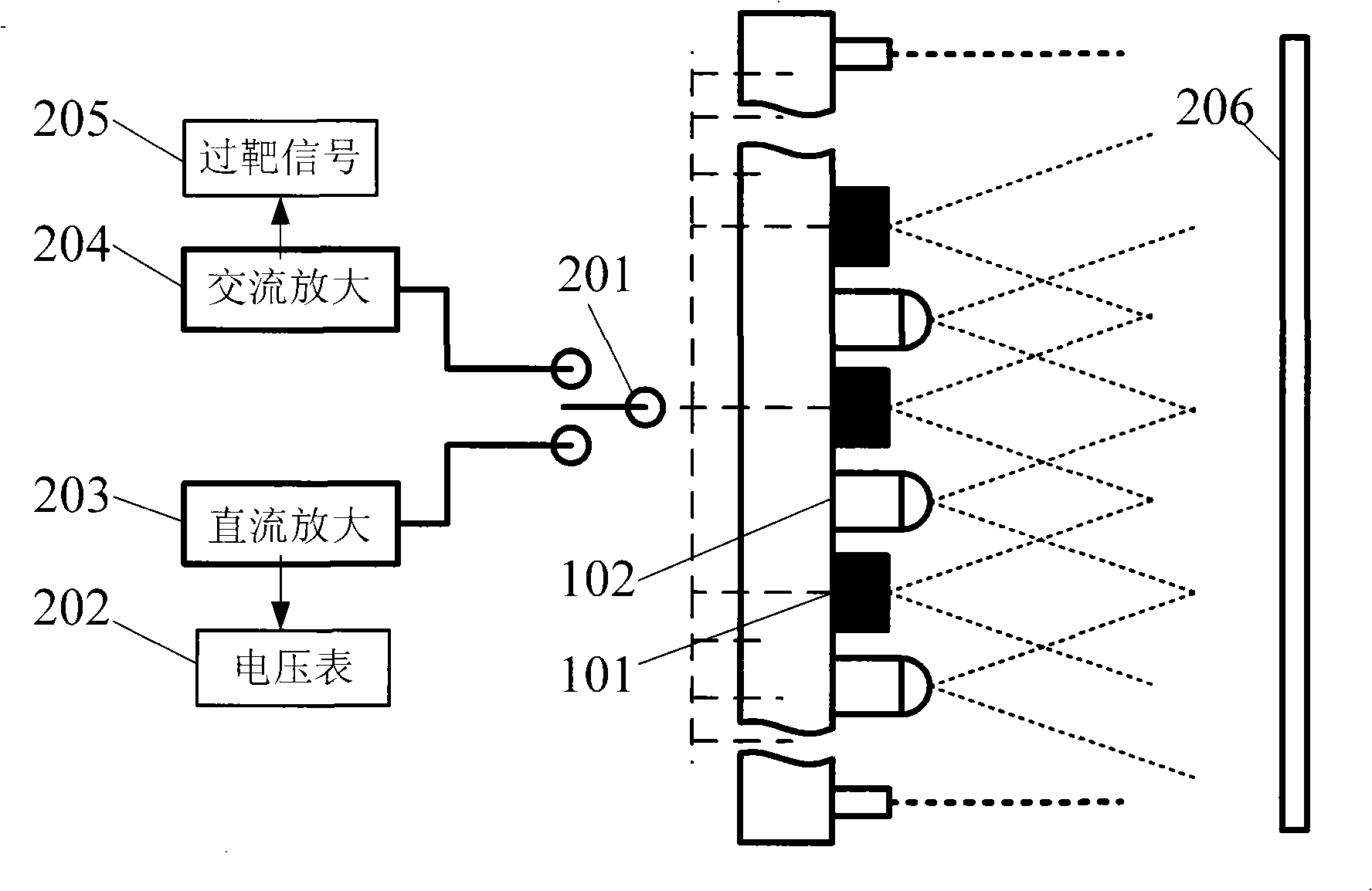

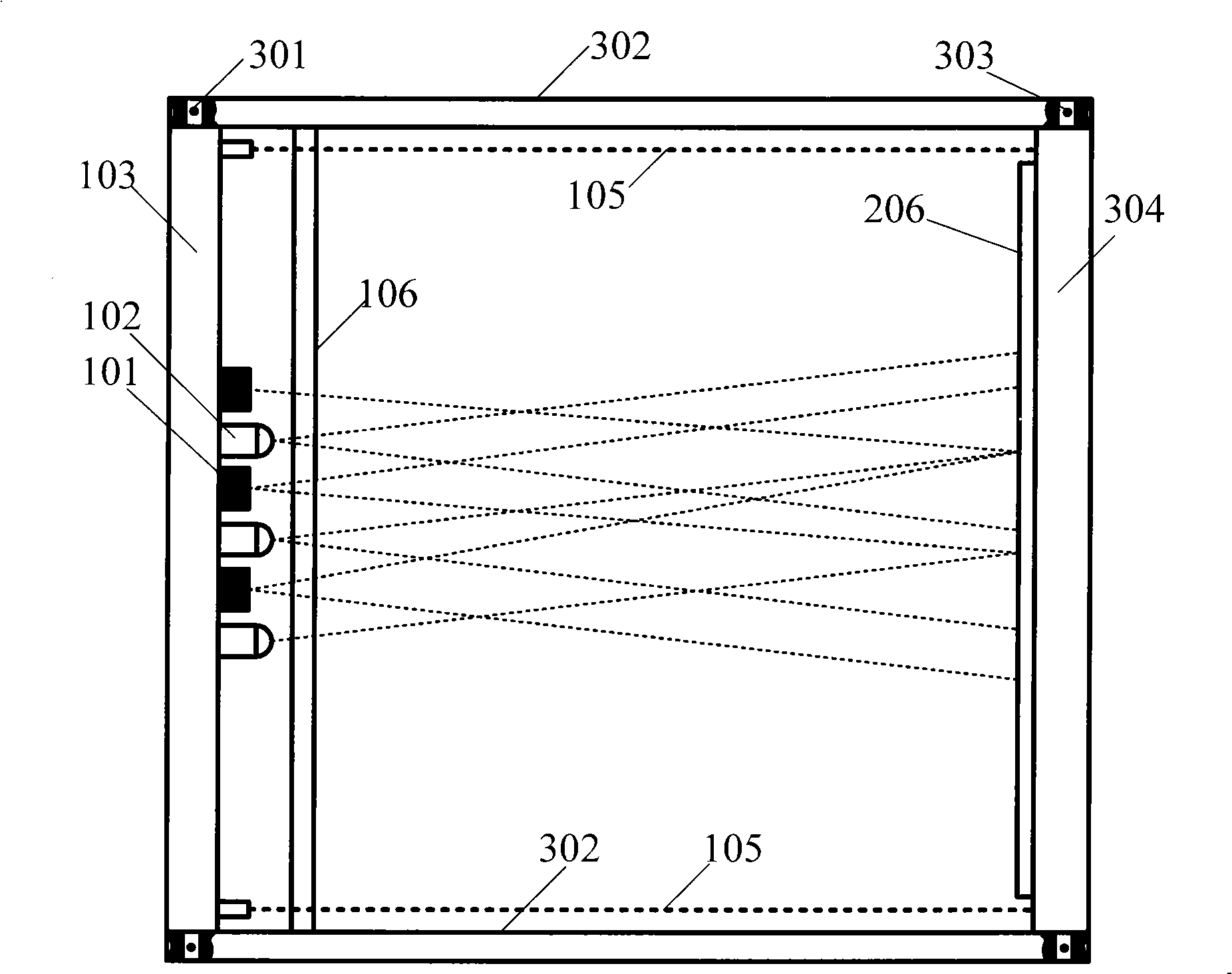

Transmitting-receiving integrated light screen target apparatus and its test method

InactiveCN101403592AImplementation of speed measurementEliminate geometric angle errorsAmmunition testingAiming meansLight emitting deviceMeasurement precision

The invention discloses a light screen device with sending and receiving functions and a test method of the light screen. A light source and a receiving light device are installed on a circuit board to form a detection device main body with sending and receiving functions, and the light is reflected by an illuminator to form a detection screen. The detection device and the reflecting device are both provided with angle regulatory mechanisms with the same structure, the angle regulatory mechanism can adjust the angle of an incidence screen and a reflecting screen to ensure the angle between two screens by cooperating with the light screen. The main light axis of the light-emitting device is ensured to be at the same plane with the main light axis of the receiving device. The light screen device has the advantages of simple structure, fewer links, small cumulative error, high measurement precision, and convenient assembling; the light screen device not only can be used for measuring the speed of a pellet, but also used for carrying out the denseness degree test and the measurement of pellet flying angle and direction; and the light screen device broadens the measurement scope of the pellet.

Owner:XIAN TECHNOLOGICAL UNIV

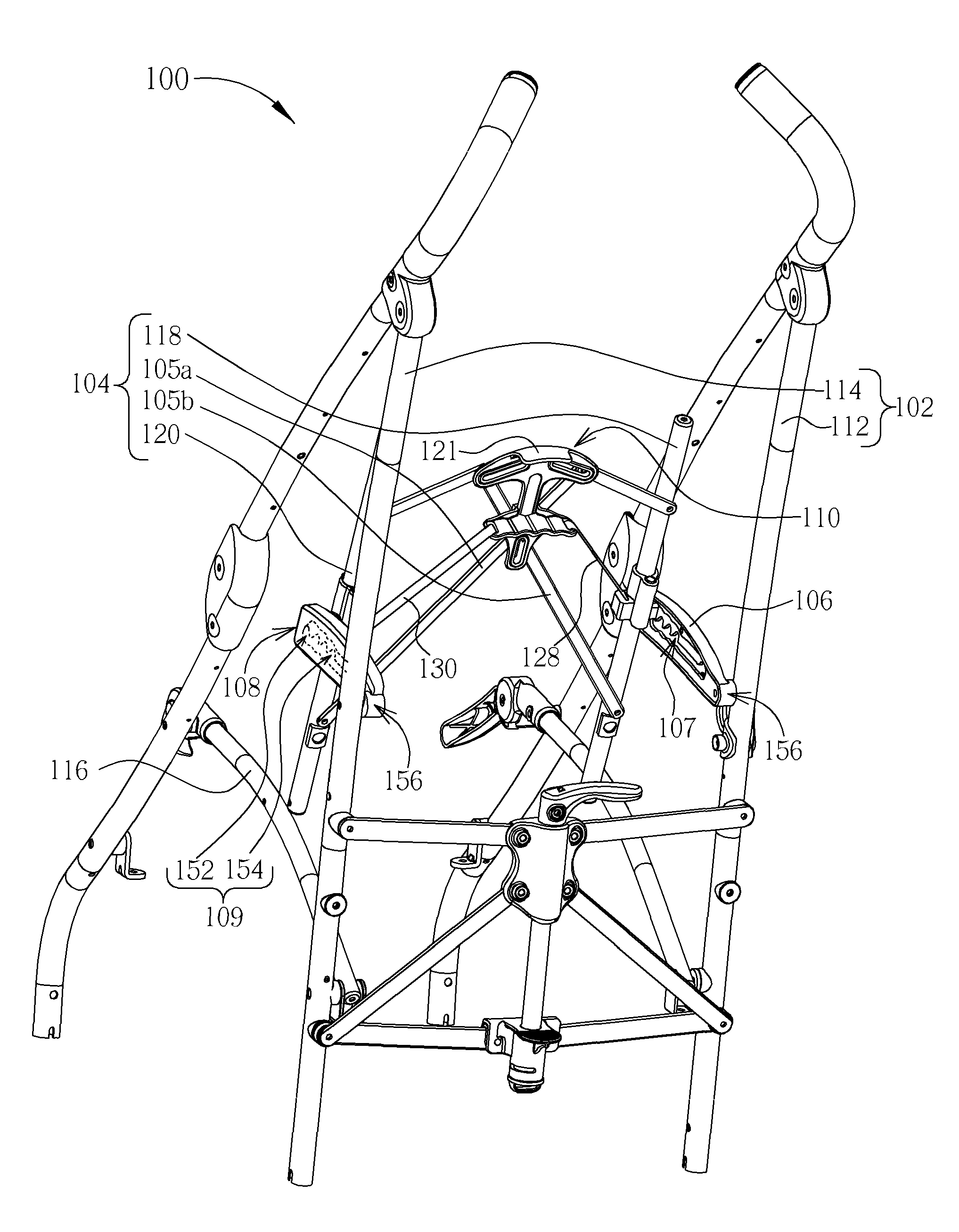

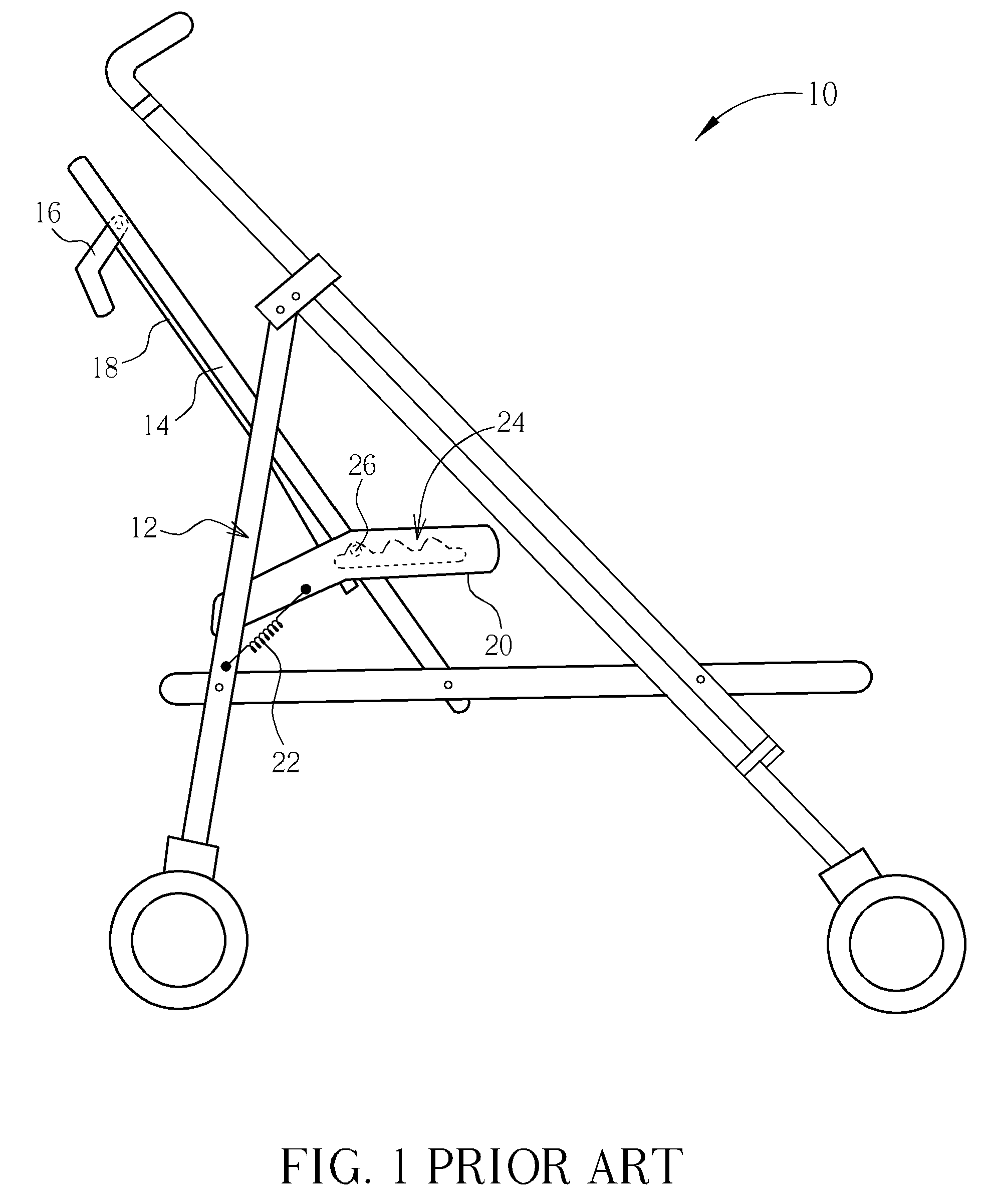

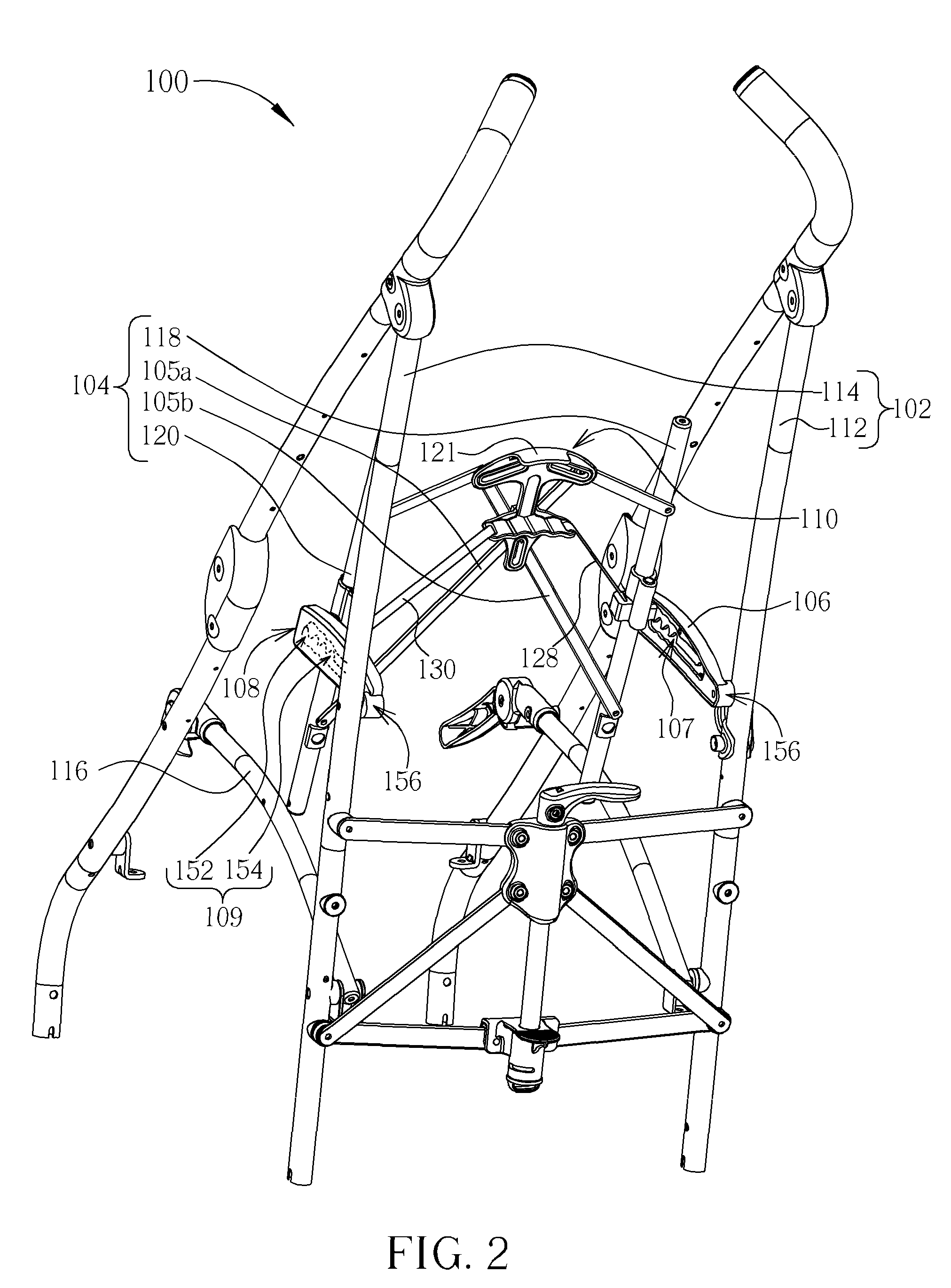

Stroller and backrest recline device thereof

ActiveUS7832744B2Improve convenienceSimple structural designCarriage/perambulator accessoriesSledgesBraced frameEngineering

A stroller includes a main frame, a backrest, a backrest adjustor, and a linkage device. There is a guide rail formed inside the backrest adjustor. A positioning part of the backrest engages with the guide rail. When a handle of the linkage device is moved upward, a connecting component of the linkage device drives a pushing component of the linkage device to move upward along a supporting rod of the backrest. Accordingly, a protruding portion of the pushing component drives the backrest adjustor to rotate relative to a supporting frame of the main frame so as to release the positioning part from the guide rail.

Owner:WONDERLAND NURSERYGOODS CO LTD

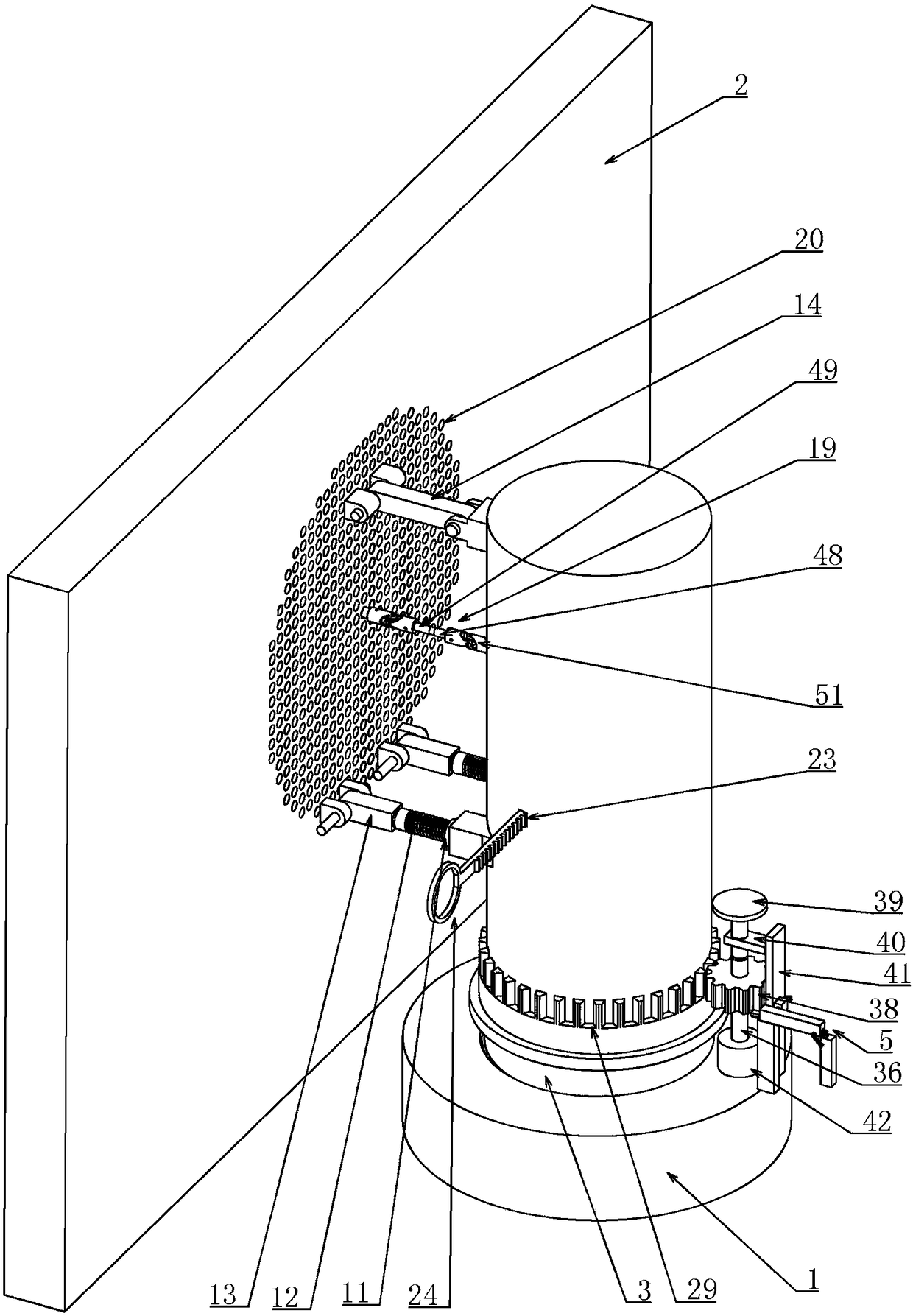

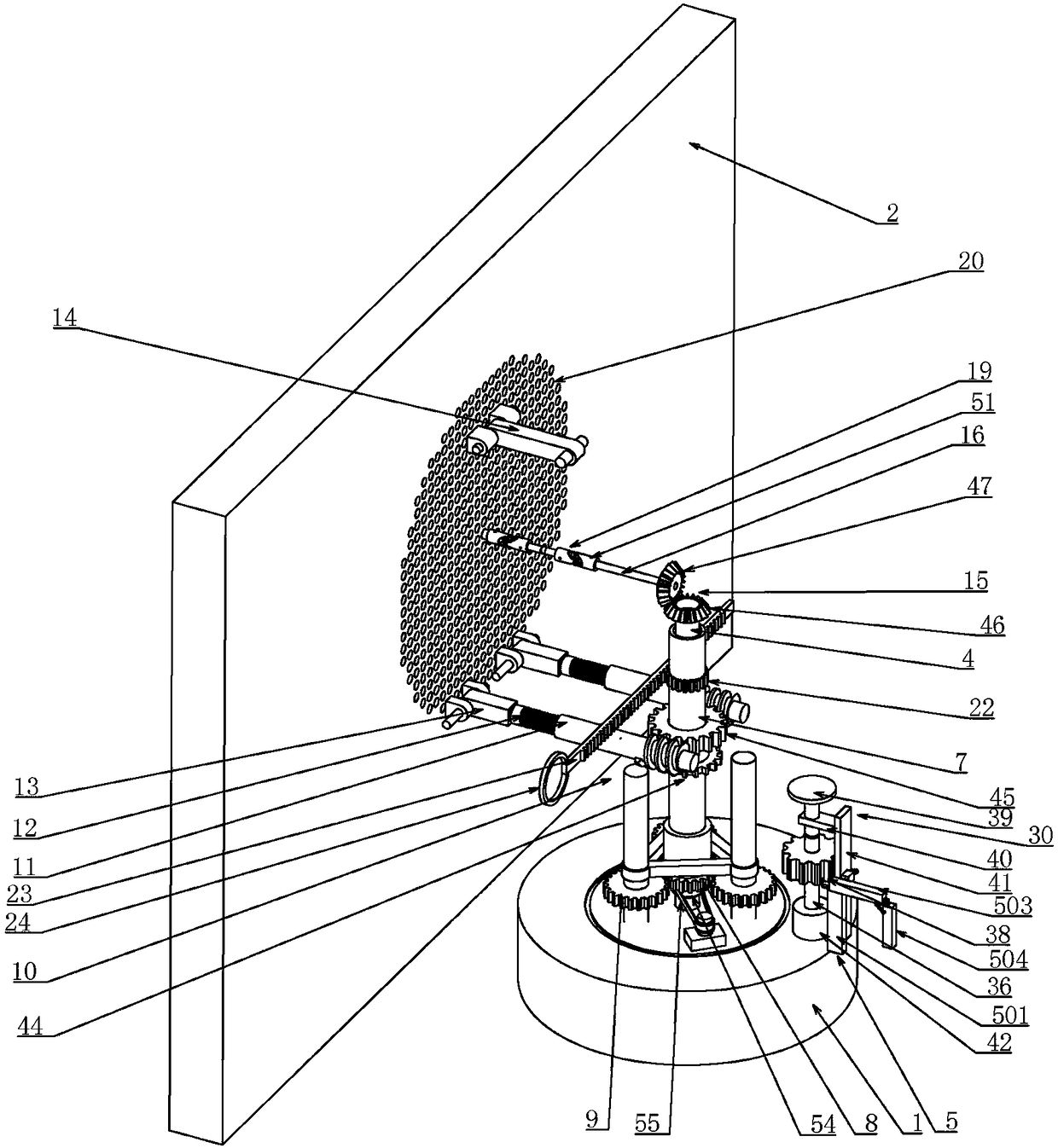

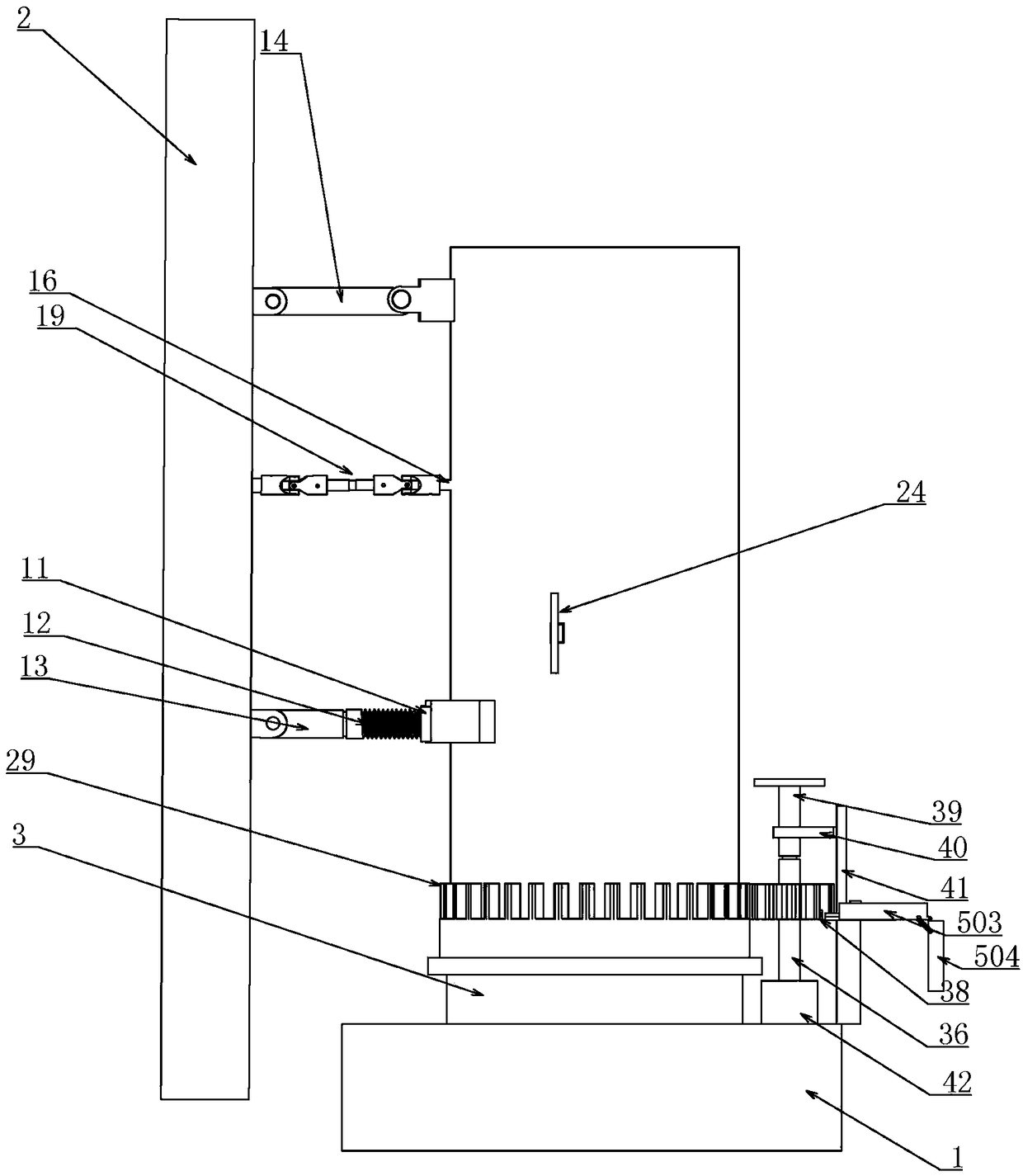

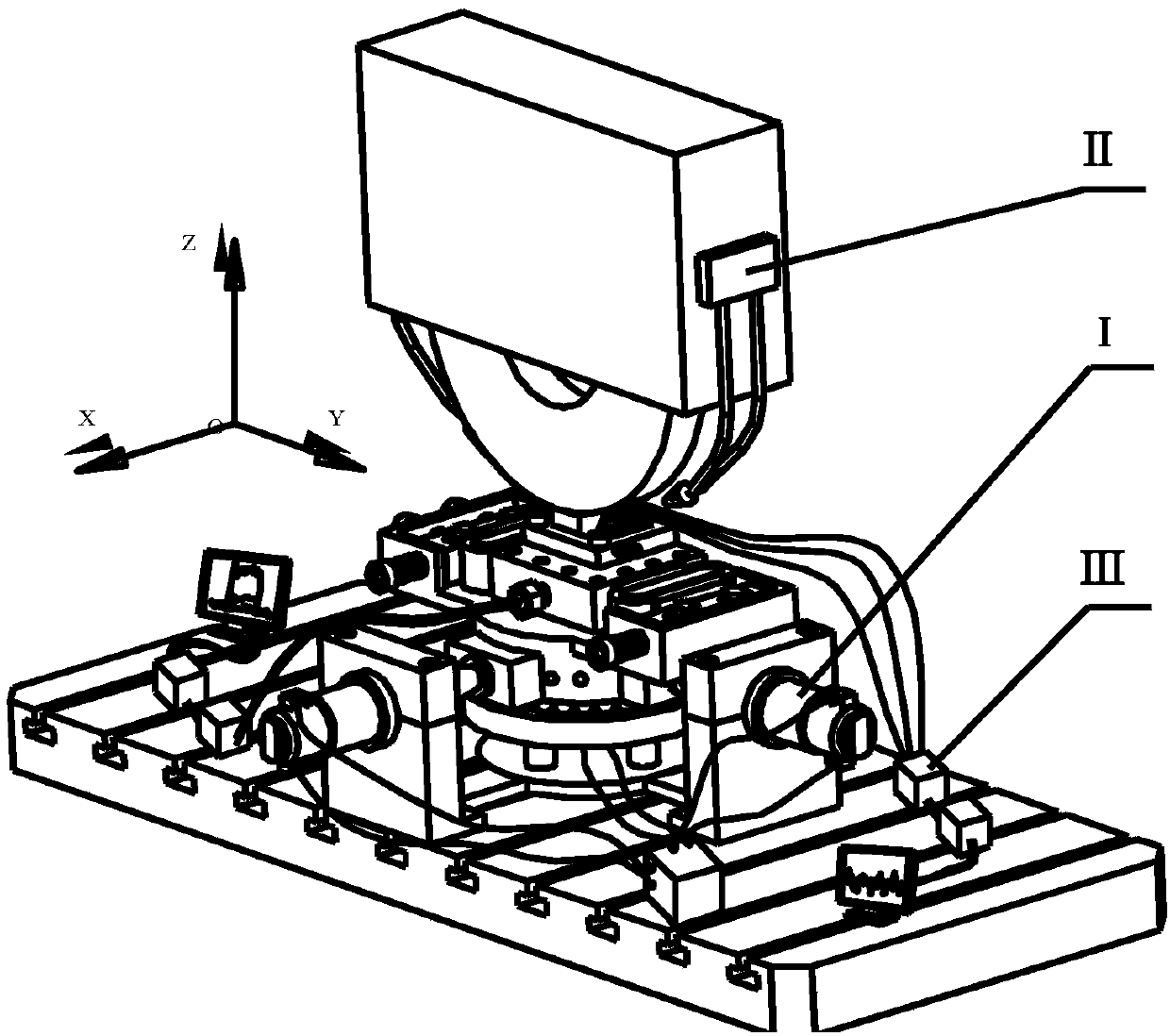

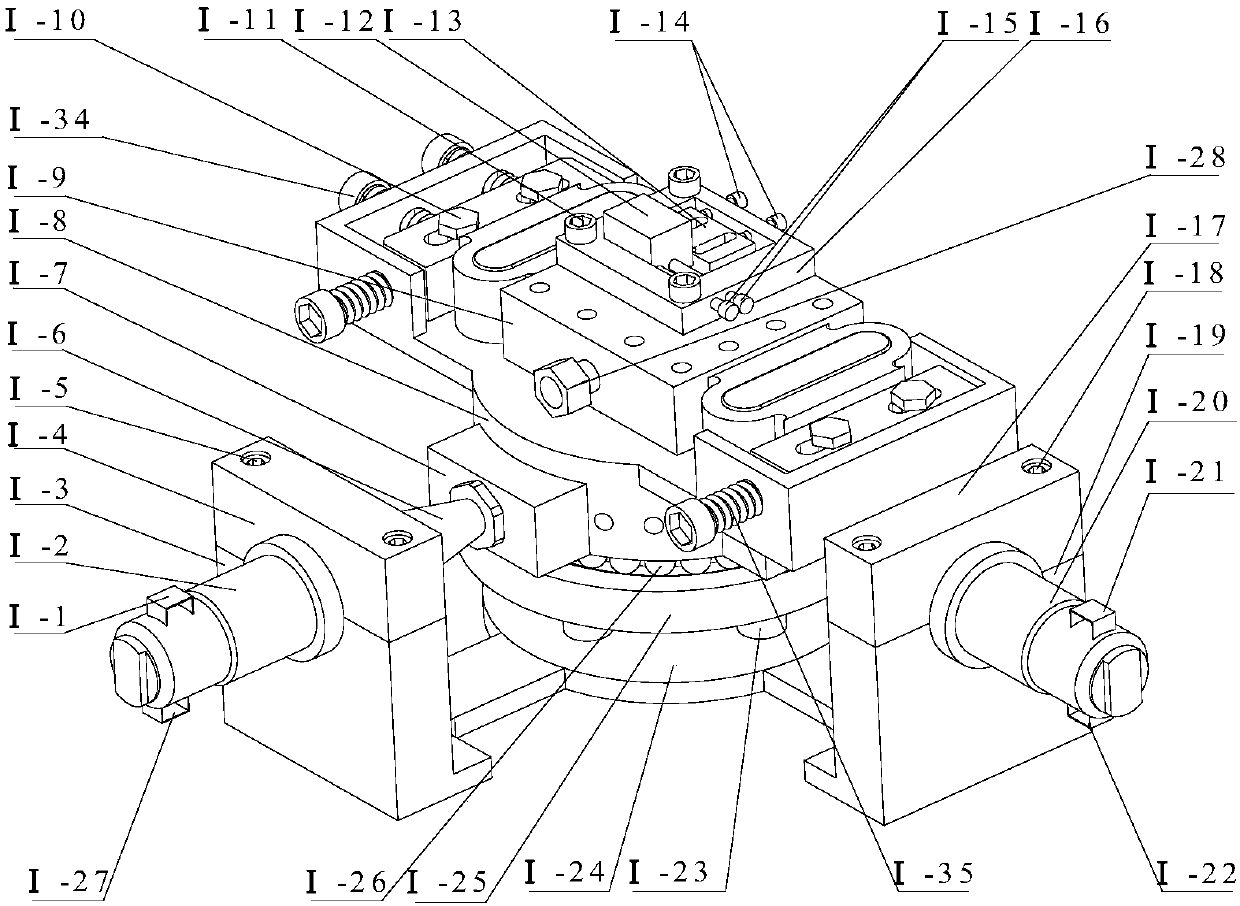

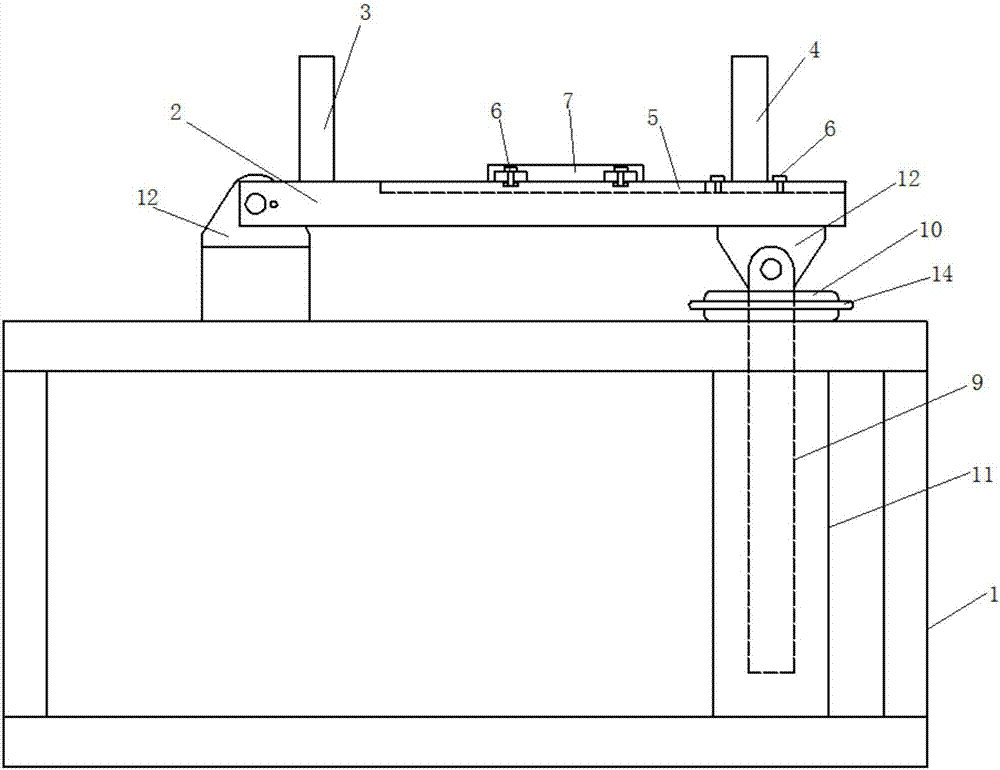

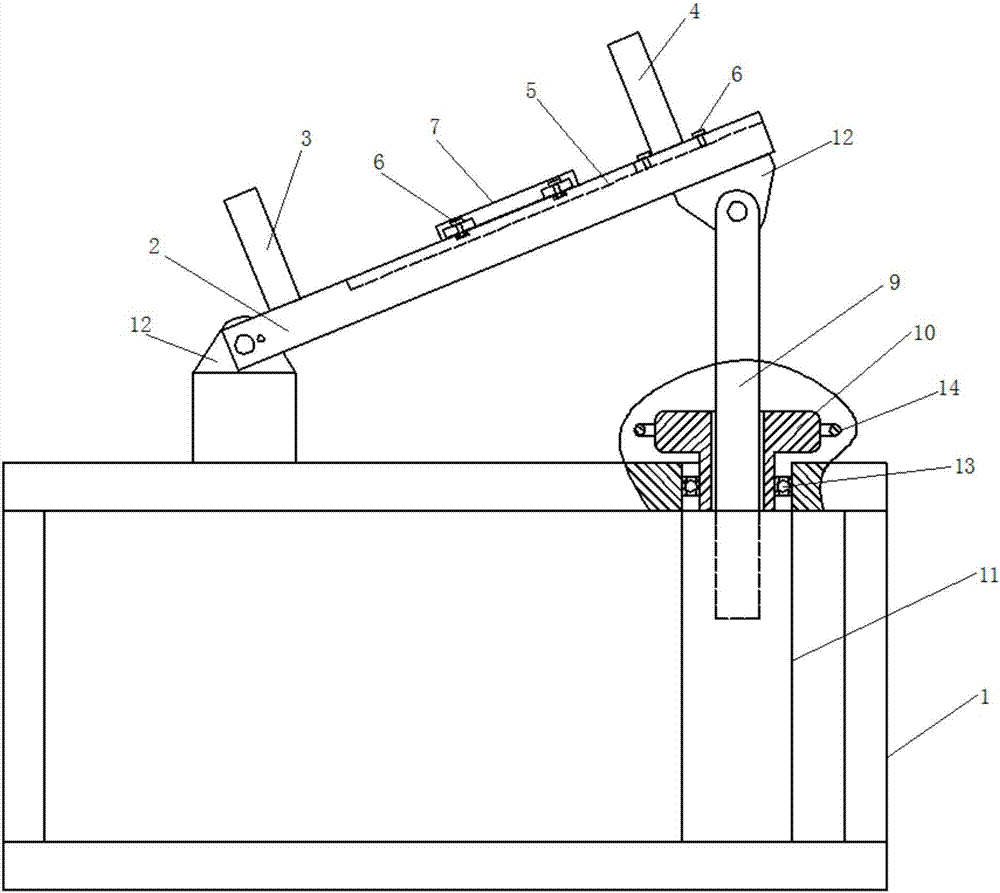

Nanofluid minimum quantity lubrication experimental system and method for ultrasonic vibration auxiliary grinding

InactiveCN107336086AImprove surface qualityDifferent grinding effectsUltrasonic vibrationLubrication

The invention discloses a nanofluid minimum quantity lubrication experimental system and method for ultrasonic vibration auxiliary grinding. The system comprises a magnetism worktable, a workpiece clamp, a measuring cell and an ultrasonic vibration device; the ultrasonic vibration device comprises a tangential ultrasonic vibration device, an axial ultrasonic vibration device, a vibrating base and radial piezoelectric ceramic pieces fixed on the vibrating base; the tangential ultrasonic vibration device and the axial ultrasonic vibration device are respectively fixed on the vibrating base and meanwhile, are respectively fixed on the magnetism worktable by supports, the measuring cell is fixed on the vibrating base and the workpiece clamp is fixed on the measuring cell. The nanofluid minimum quantity lubrication experimental system and method for ultrasonic vibration auxiliary grinding have the advantages that simultaneous online detection of a grinding force and a grinding temperature are realized, time is saved, and the machining errors caused by assembling for multiple times are also avoided.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

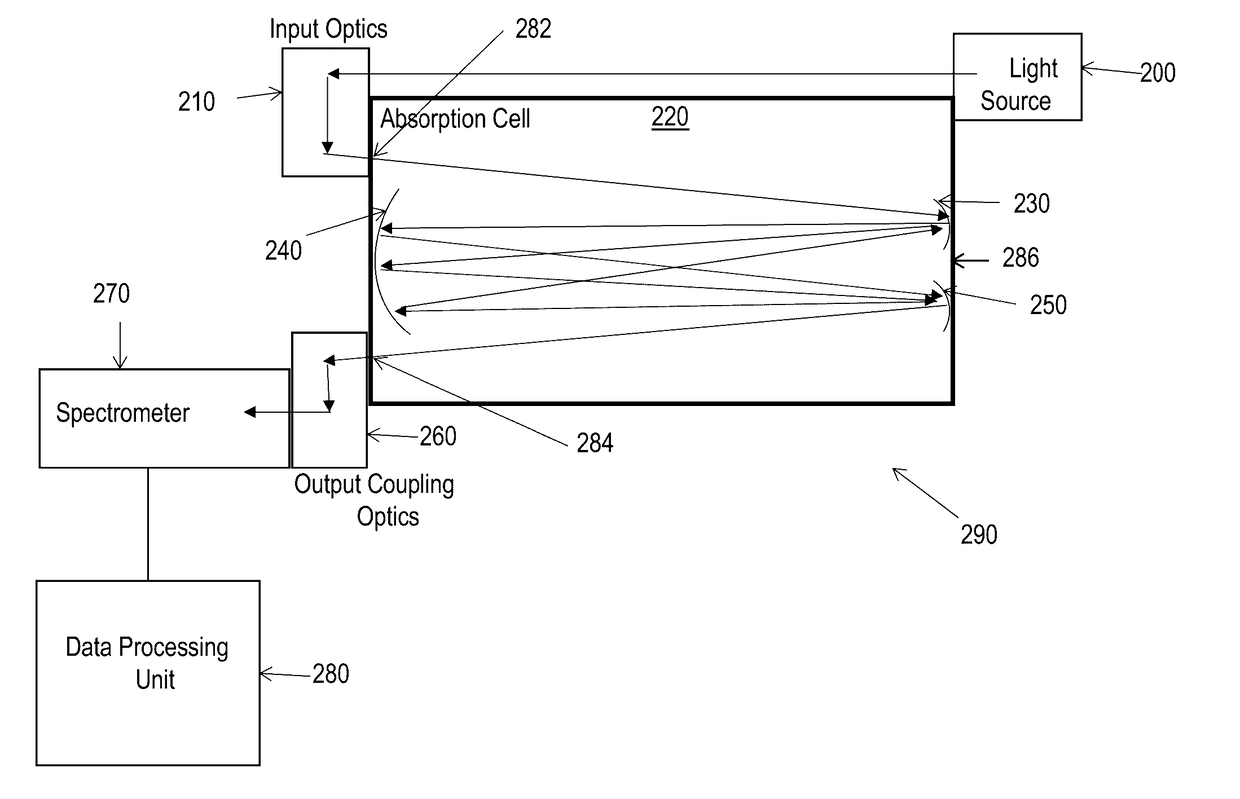

Optical alignment apparatuses and methods for optics used in absorption cell spectrometers

ActiveUS20170139182A1Increase luminous fluxExact numberRadiation pyrometryMirrorsAbsorption cellLaser light

Systems and methods of the present disclosure are directed to optics used in absorption cell spectrometers. The absorption cell includes a plurality of mirrors arranged in a manner such that a detection light traverses multiple passes through the fluid within the absorption cell. In some implementations, the detection light is reflected by the plurality of mirrors to form optical paths in more than one plane. In some implementations, the orientation of the mirrors are aligned with specific orientations to provide the desired optical path to the detection light. In one or more embodiments, an alignment apparatus can be used to pre-align the mirrors before they are placed within the absorption cell. The alignment apparatus includes an aperture plate and an adjustable mount to mount one or more mirrors. The mirrors are aligned based on reflected images on the aperture plate laser light incident on the mirrors.

Owner:DUVAS TECH

Hinge assembly and housing

InactiveUS20050078818A1Simple structure for angle adjustmentSimplified angle adjustment structureInterconnection arrangementsDigital data processing detailsGear wheelEngineering

A hinge assembly adapted for a housing having a main body and a sub-body rotatably positioned on the main body, the hinge assembly including: a first hinge portion adapted to rotatably support both lower sides of the sub-body; and a second hinge portion adapted to rotatably support a rear surface of the sub-body with a surface contact and to maintain a rotated angle of the sub-body. The first hinge portion includes: a hinge protrusion arranged on one side surface of the sub-body; a hinge protrusion inserting-hole arranged on one side surface of a sub-body rotational space and adapted to receive the hinge protrusion; a hinge-hole arranged on the other side surface of the sub-body; a through-hole arranged on the other side surface of a sub-body rotational space to correspond to the hinge-hole; and a hinge locker passing through the through-hole and the hinge-hole. The second hinge portion includes: a curved portion protruding from a bottom surface of the sub-body and having a gear groove arranged on the surface thereof; a window arranged on the sub-body rotational space of the main body and passing through the curved portion; and a pinion rotatably positioned at a predetermined position, the pinion arranged to be rotated together with the sub-body upon the sub-body being rotated in engagement with the gear groove.

Owner:SAMSUNG ELECTRONICS CO LTD

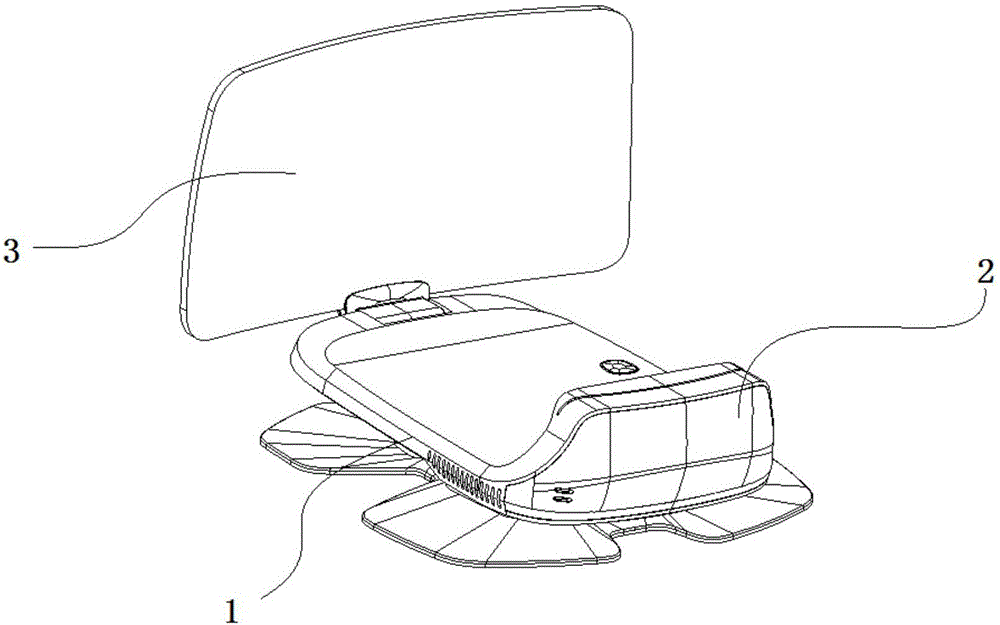

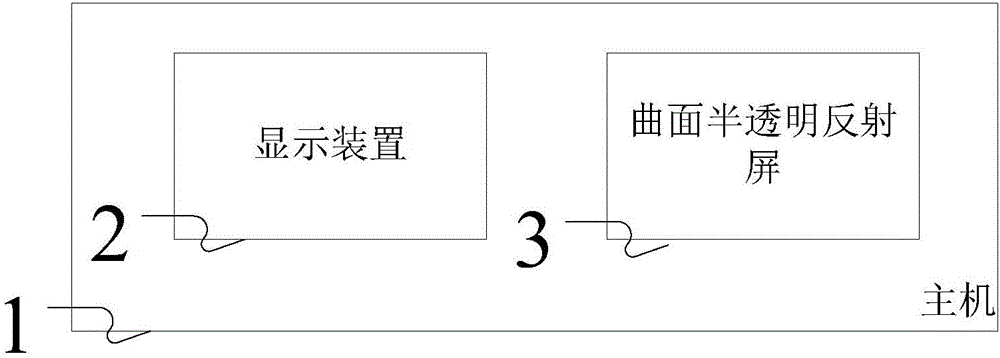

Augmented reality (AR) display screen convenient to use and method for conveniently using AR display screen

InactiveCN106764302AEasy to adjust the angleMove wellDigital data processing detailsStands/trestlesAugmented realityComputer science

The invention relates to the technical field of augmented reality (AR), and discloses an augmented reality (AR) display screen convenient to use. The AR display screen convenient to use comprises a display screen body and a base, wherein the center shaft position at the bottom of the display screen body is fixedly connected with one end of a supporting rod, the surface of the supporting rod is fixedly connected with one end of a balance rod, the other end of the balance rod is fixedly connected with the bottom of the display screen body, the bottom, away from the balance rod, of the display screen body is fixedly connected with one end of each supporting sliding rod, the other end of each supporting rod penetrates through a lantern ring and stretches to the inside of an empty groove, and the lantern ring is embedded in the base. According to the AR display screen convenient to use, because the supporting ring, the lantern ring, the empty groove, a rotating rod, a first bearing, a first gear, a second gear and a motor are arranged, the angle of the AR display screen can be adjusted more conveniently in use, the problem that in the prior art, an AR display screen can just be fixed to one position in use without angle adjustment is solved, and the AR display screen convenient to use can be more convenient to use.

Owner:杨仲辉

Angle-adjustable tool for inclined hole machining of parts

InactiveCN107160211AAchieve fixed positionWide range of anglesPositioning apparatusMetal-working holdersPunchingBar stock

The invention provides an angle-adjustable tool for inclined hole machining of parts. The tool is provided with a bottom frame, and a clamping platform is arranged at the upper end of the bottom frame; one end of the clamping platform is hinged to one end of the bottom frame, and the other end of the clamping platform and a lifting device arranged at the other end of the bottom frame are integrally hinged; the parts are fixed to the clamping platform; and after the inclined hole angles of the parts are well adjusted through the lifting device, punching is conducted through drilling equipment located above the parts and perpendicular to the bottom frame, and then inclined hole machining of the parts is completed. According to the angle-adjustable tool for inclined hole machining of the parts, the effect that the drilling equipment conducts random inclined hole machining on the parts on the clamping platform is achieved, the structure is simple, design is reasonable, the pre-drilling angle is convenient to adjust, inclined hole machining of plates, bars and pipes is achieved, and the work efficiency and quality of inclined hole machining are improved.

Owner:刘会斌

Connector mounting structure

ActiveUS20080007052A1Large diameterIncrease intervalSleeve/socket jointsFluid pressure sealed jointsDrop outFlange

A connector is inserted into a connection hole provided on a fluid piping equipment, and the connector is prevented from dropping out via a retainer held by a retainer holding portion. The connector has a connecting portion including a flange stop portion, and a positioning means is disposed between the connecting portion and the fluid piping equipment. This positioning means is to position the connecting portion in a circumferential direction so as not to rotate relative to the connection hole and has a mounting angle adjusting function capable of positioning the connecting portion in the circumferential direction selectively at any one of a number of mounting angular positions relative to the connection hole. An annular surface on the other end in the axial direction of the stop portion is formed in a taper shape tapered toward the other end in the axial direction.

Owner:TOKAI RUBBER IND LTD

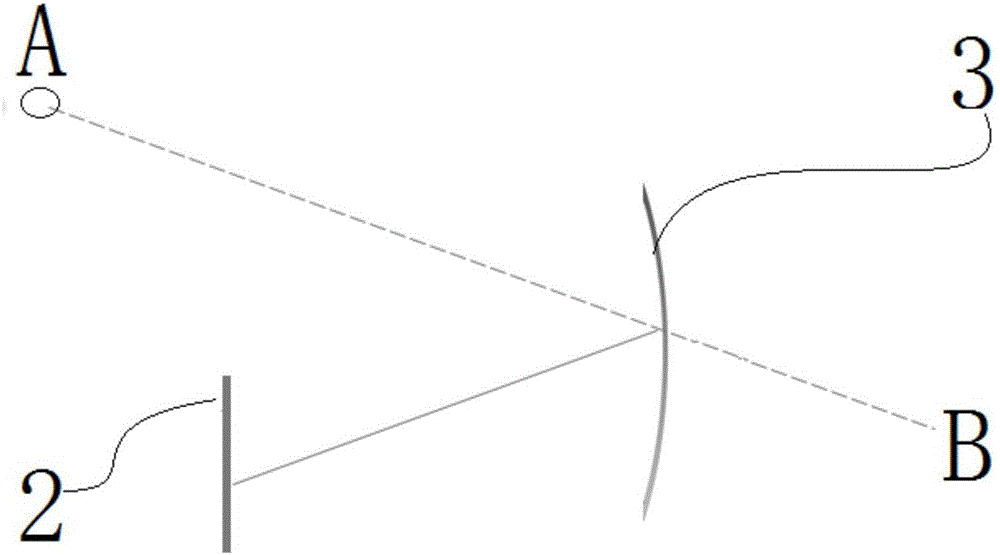

Head-up display device

ActiveCN106226905AEnsure driving safetyOvercome the deficiency of projection principle imagingCharacter and pattern recognitionElectric/fluid circuitHead-up displayDriver/operator

The invention discloses a head-up display device. The head-up display device comprises a host machine, a display device, a curved-surface semi-transparent reflecting screen, a voice interaction unit and a driver detection device, wherein the host machine is used for transmitting an image signal to the display device, the display device is arranged at one side of the host machine and used for displaying the image signal, the curved-surface semi-transparent reflecting screen is used for receiving an image displayed by the display device and displaying the image after ghosting is removed, the image is displayed at the other side by penetrating the semi-transparent reflecting screen at one side of the host machine, the voice interaction unit is arranged in the host machine in advance, and the driver detection device is arranged in the host machine. The invention provides an intelligent vehicle-mounted device which supports whole-course voice interaction, monitors a driver in real time, gives an alarming in advance and has a good display effect, and the defects that a head-up display device is lack of voice interaction operation, is inconvenient to be placed in a vehicle and is lack of special driving emotion analysis in the prior art are overcome.

Owner:BEIJING ILEJA TECH CO LTD

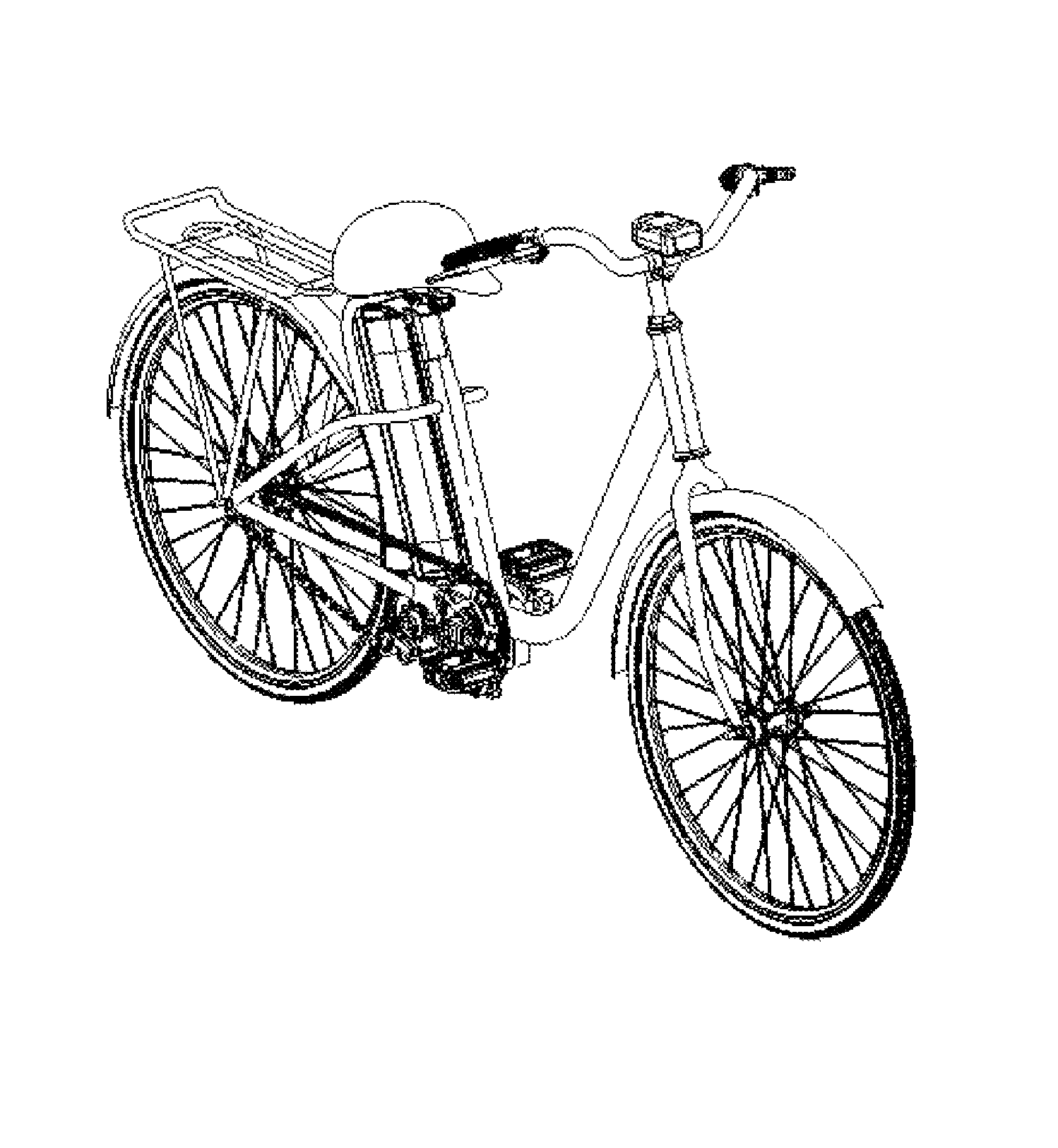

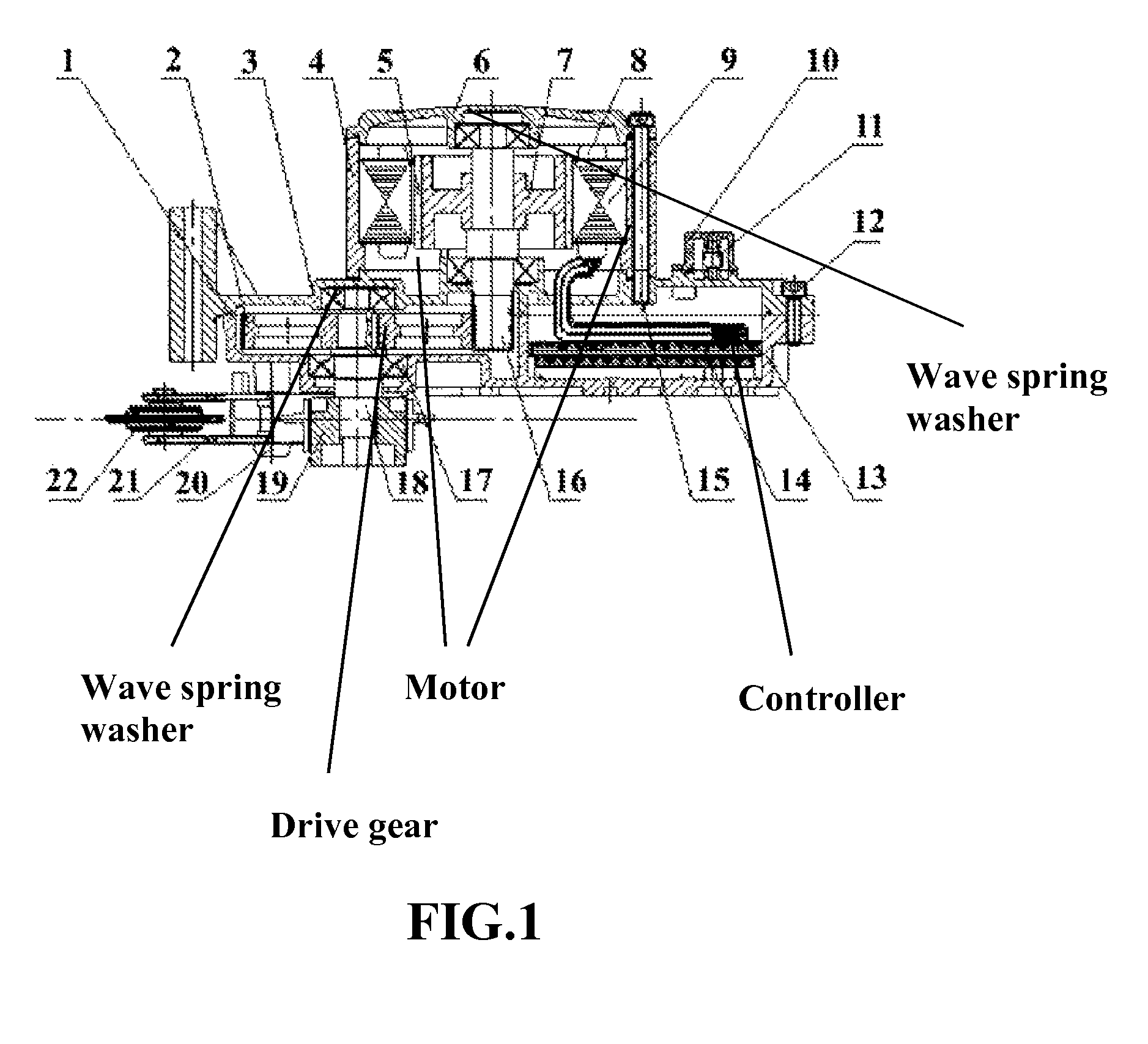

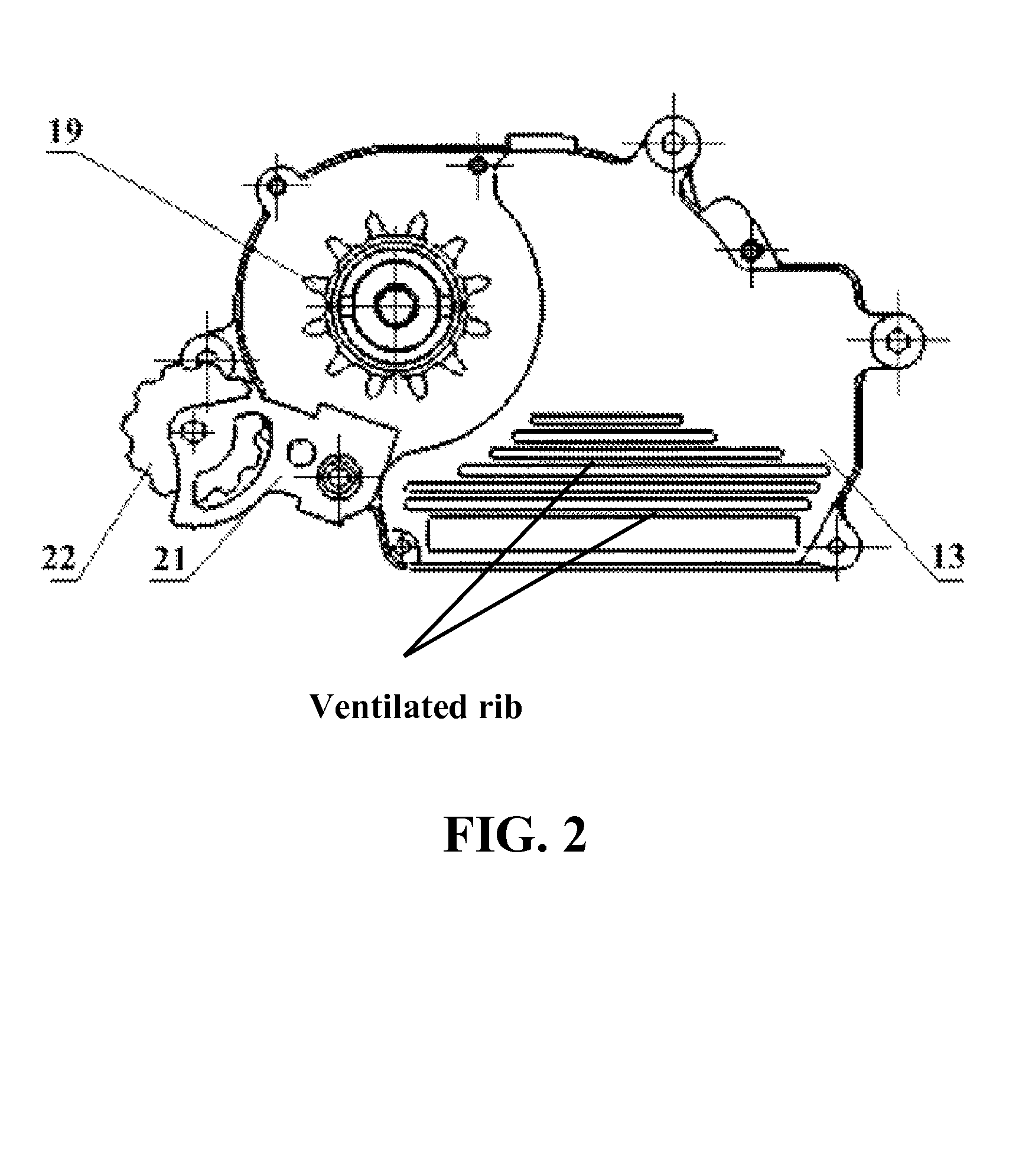

Middle electric motor drive unit for electric bicycle

InactiveUS8205705B2Compact and reasonable structureConvenience to workSpeed controllerPropulsion by humans/animalsReducerControl theory

A middle electric motor drive unit for an electric bicycle, including a motor, a controller, a sensor, a gear reducer, a one-way clutch, a chain tightener, and a housing. The middle electric motor drive unit is disposed below a frame of the electric bicycle, and in the vicinity of a pedal shaft thereof. The middle electric motor drive unit is independent from the pedal shaft with respect to functions and structure. The motor is an internal rotor and permanent magnet DC motor. The motor shaft of the motor is parallel to a gear shaft and the pedal shaft. The controller is built-in, and disposed in or on the housing. The sensor is an internal sensor or an external pedal shaft sensor.

Owner:TIANJIN MINGDU TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com