Nanofluid minimum quantity lubrication experimental system and method for ultrasonic vibration auxiliary grinding

A nano-fluid, micro-lubrication technology, applied in the field of grinding processing, can solve the problems of inability to detect the grinding force and grinding temperature online, inability to guarantee the stability of the system, delaying the processing cycle of the workpiece, etc., so as to improve the surface quality of the workpiece and reduce the The effect of small energy loss and improved grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

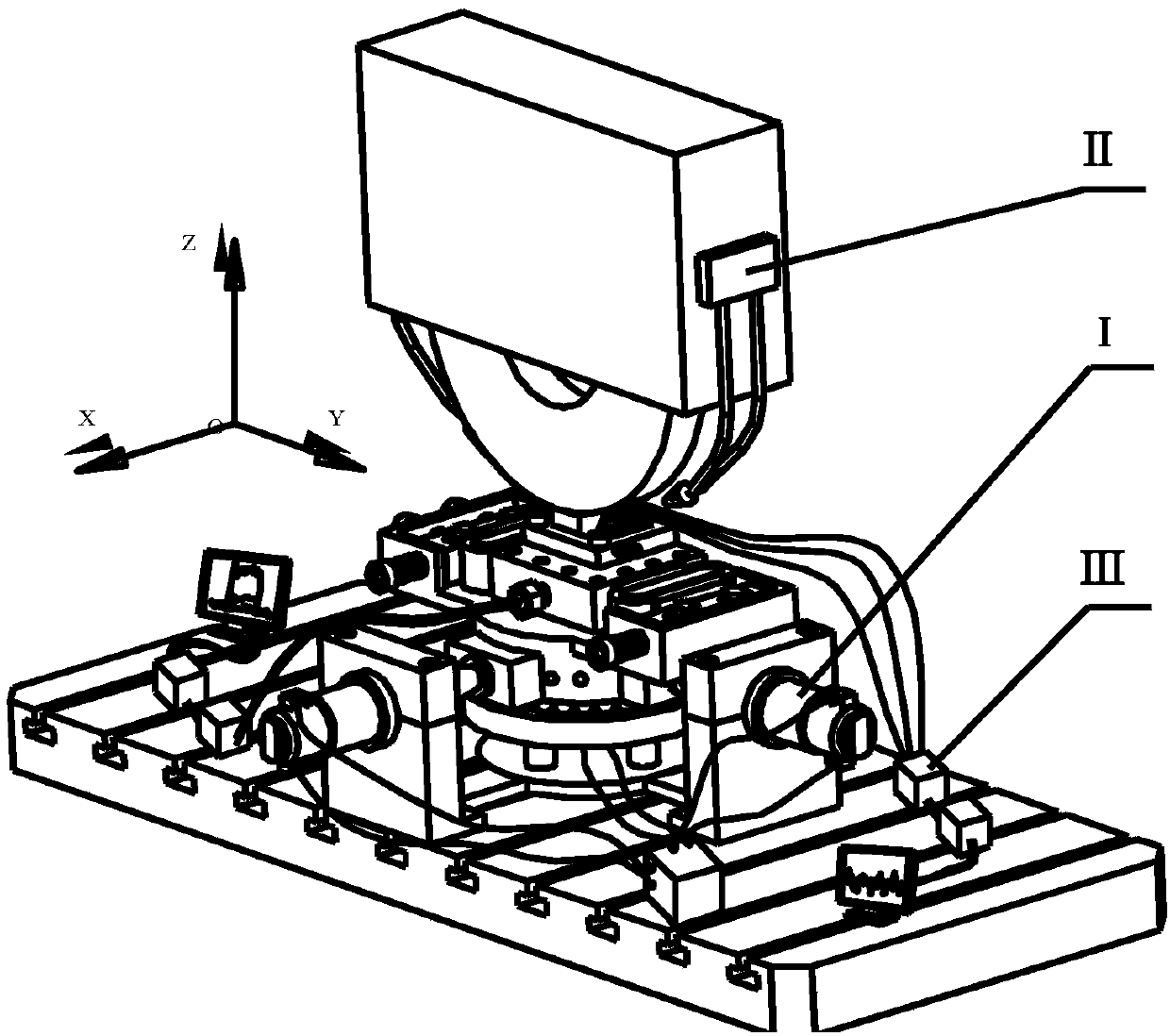

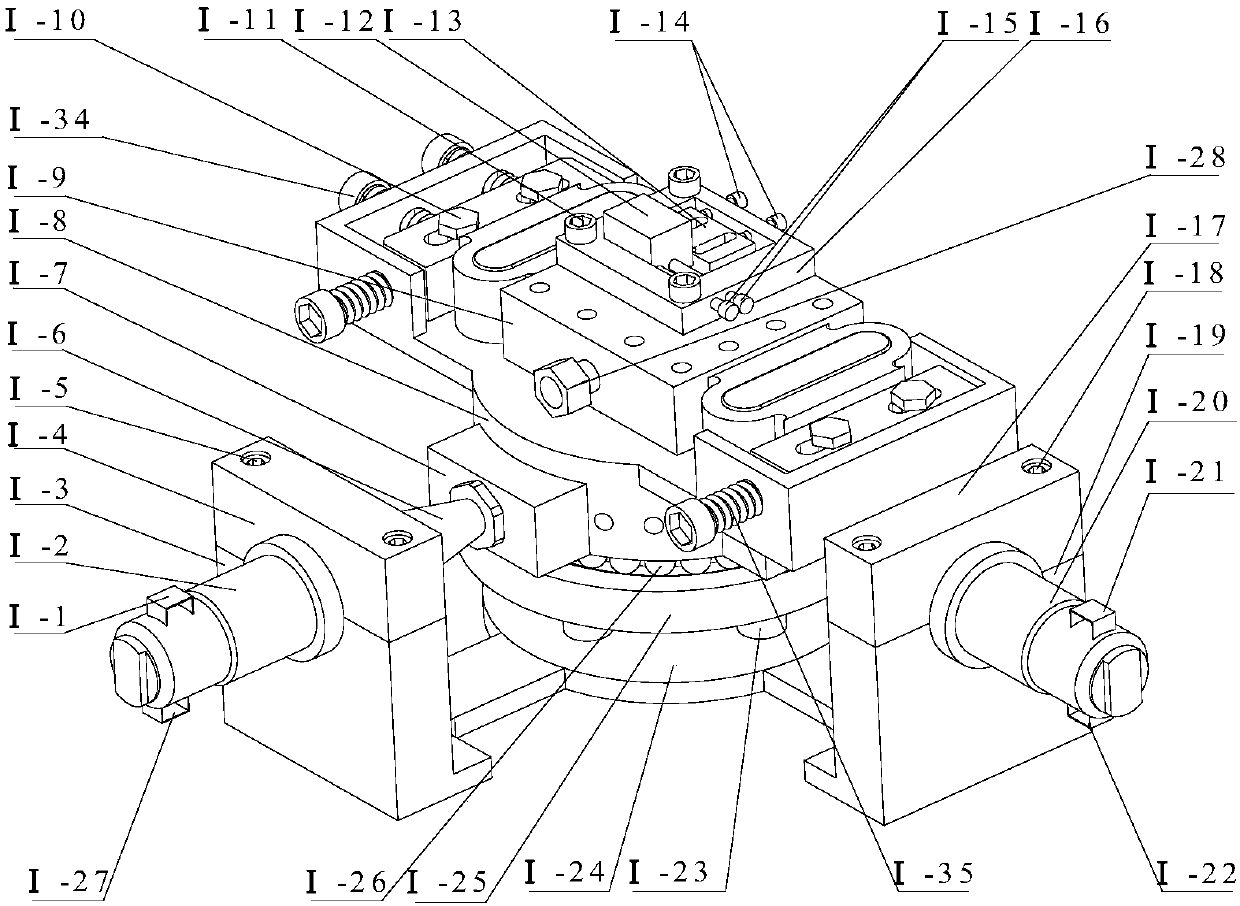

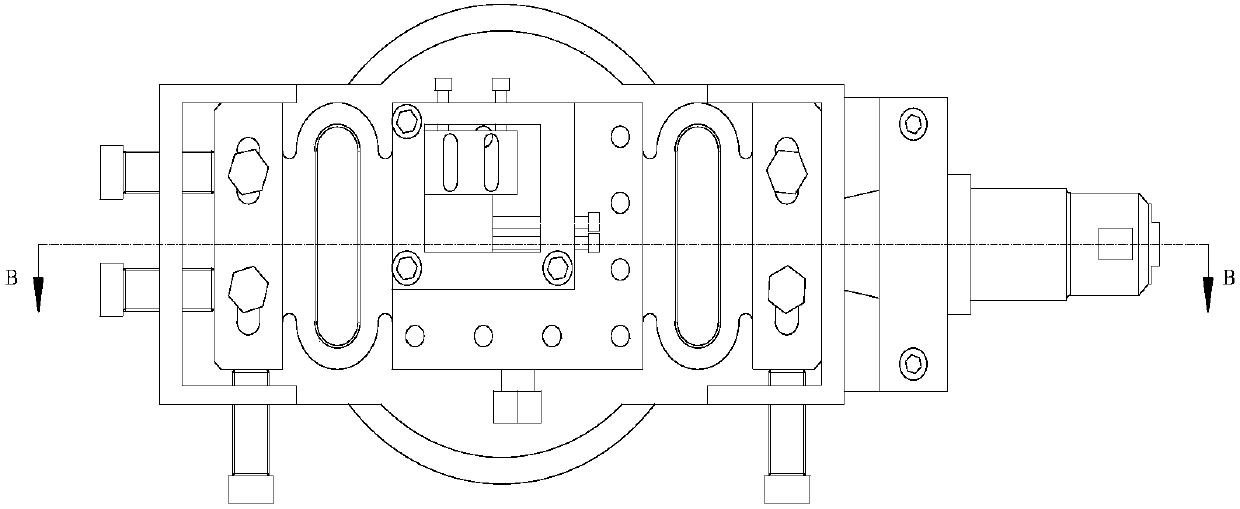

[0079] The first embodiment of the present invention is Figures 1 to 2 , Figures 9 to 17 , Figure 18(a) and Figure 18(b) and Figure 19 As shown, it is about the tangential direction parallel to the grinding direction and the axial coupling ultrasonic vibration assisted nanofluid micro-lubrication grinding device and its grinding force and grinding temperature measurement device.

[0080] Such as figure 1 As shown, the nanofluid minimal quantity lubrication experimental system for ultrasonic vibration assisted grinding consists of three parts: ultrasonic vibration device Ⅰ, nanofluid microlubrication grinding device Ⅱ, and grinding force and grinding temperature measurement device Ⅲ.

[0081] Such as figure 2 As shown, the tangential support Ⅰ-19 and the axially adjustable support Ⅰ-3 are directly placed on the magnetic workbench Ⅱ-7; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com