Small-size led packaging structure for enhancing light emitting angle

A technology of light-emitting diodes and improved structures, applied in electrical components, electric solid-state devices, circuits, etc., can solve the problems of reduced LED applicability, poor molding, and difficulty in subsequent use, and achieves reduction of packaging process costs, color performance, and color performance. The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

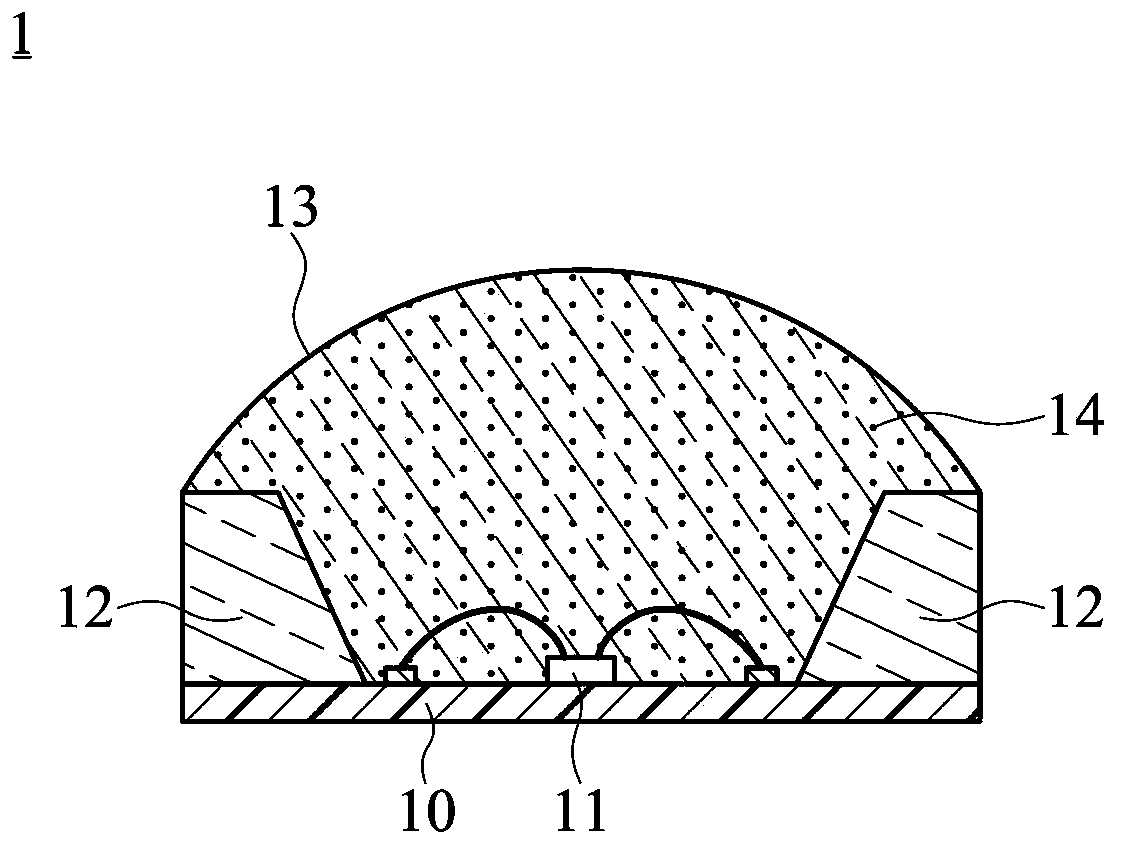

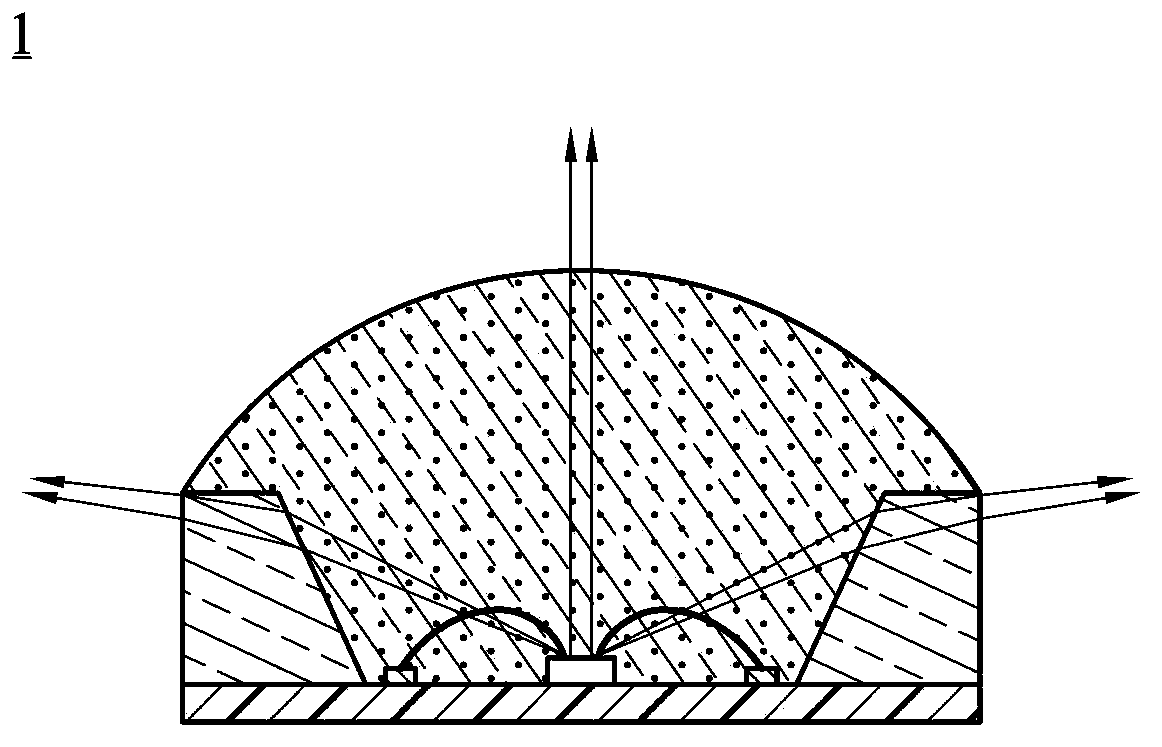

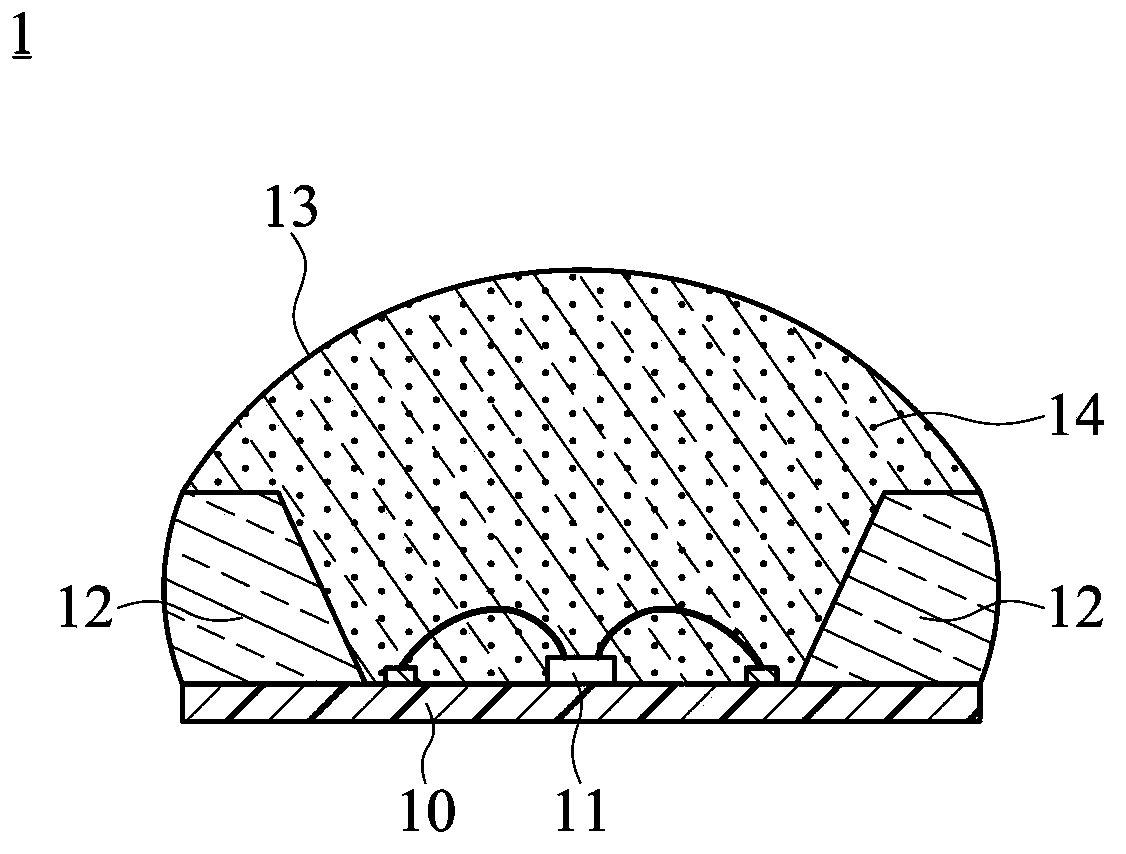

[0017] see figure 1 , figure 2 , are respectively the cross-sectional view and the schematic diagram of the optical path of the first embodiment of the preferred embodiment of the present invention. As shown in the figure, the small-sized light-emitting diode package improvement structure 1 is suitable for lighting devices such as direct-lit backlights or bulb lamps, and has an opaque base 10 and at least one light-emitting chip 11. The light-emitting chip 11 can be yellow light, Red light, blue light or green light LED chips, and the opaque base 10 is surrounded by a transparent side wall 12 to form a concave cup space. The light-emitting chip 11 is disposed on the opaque base 10 and accommodated in the concave cup space, and the light-emitting chip 11 is electrically connected to the positive and nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com