Patents

Literature

299results about How to "Achieve fixed position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

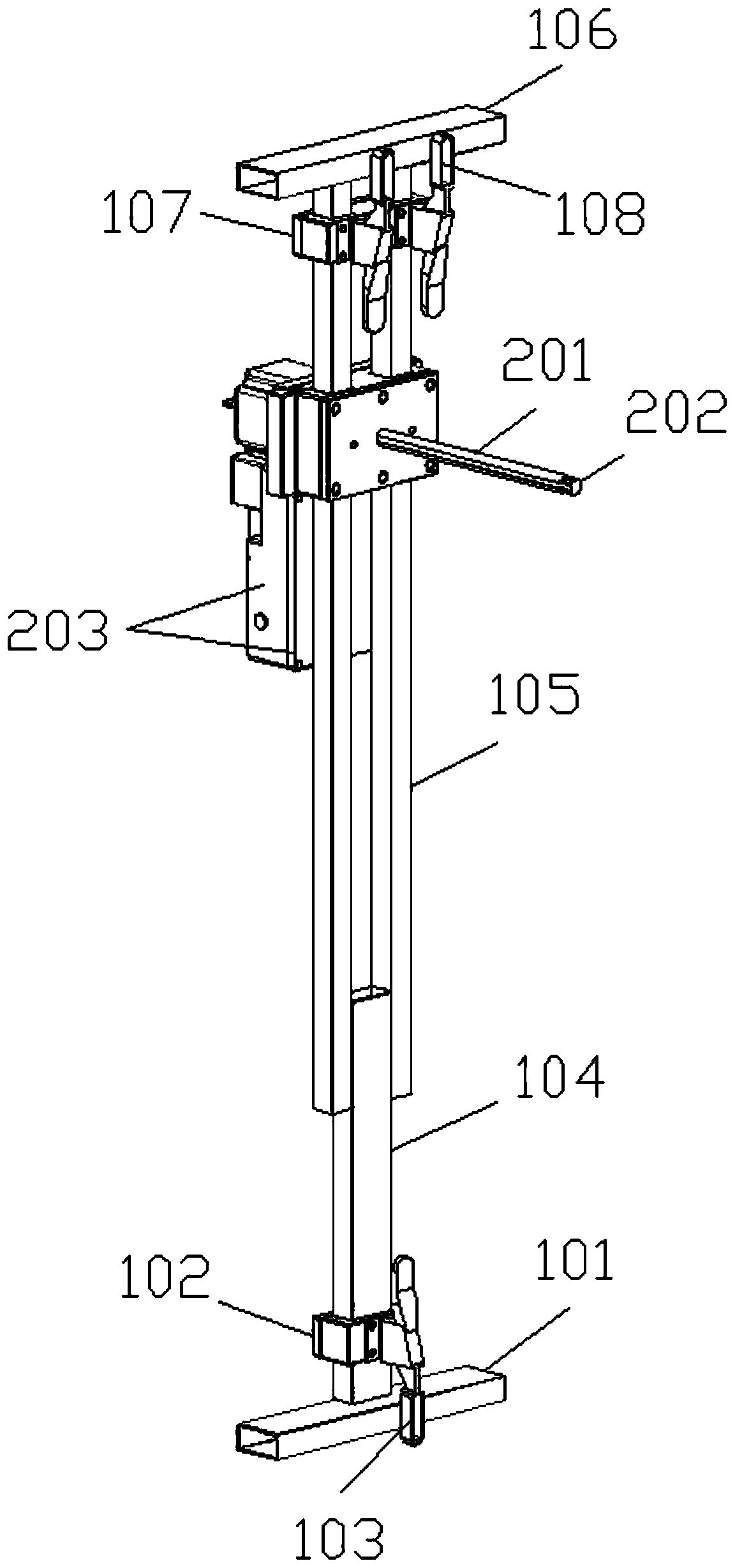

Full-automatic winding production line and processing method thereof

PendingCN109436951ASimple structureIncrease flexibilityFilament handlingProduction lineWinding machine

The invention discloses a full-automatic winding production line and a processing method thereof. The full-automatic winding production line comprises at least one automatic feeding machine, at leastone winding machine and an automatic winding disc feeding and discharging robot, wherein the automatic feeding machine is used for supplying a filament-shaped body; the winding machine is used for fixing a winding disc and driving the winding disc to rotate; and the automatic winding disc feeding and discharging machine can move the winding disc onto the winding machine and taking the winding discdown from the winding machine, and the position of the filament-shaped body can be determined visually when the filament-shaped body is grabbed and cut off. According to the scheme, the automatic winding disc feeding and discharging robot cooperates with the automatic feeding machine and the winding machine, so that the whole process of feeding, winding and discharging is achieved automatically,and the novel full-automatic winding production line which is simple in structure and capable of controlling the winding process easily is provided; in addition, the visual positioning technique can effectively and accurately determine the position of the filament-shaped body, so that automatic grabbing and shearing are made possible; and the visual positioning technique is good in flexibility andhigh in accuracy and efficiency, so that the winding efficiency is improved.

Owner:WUXI MINGONG TECH

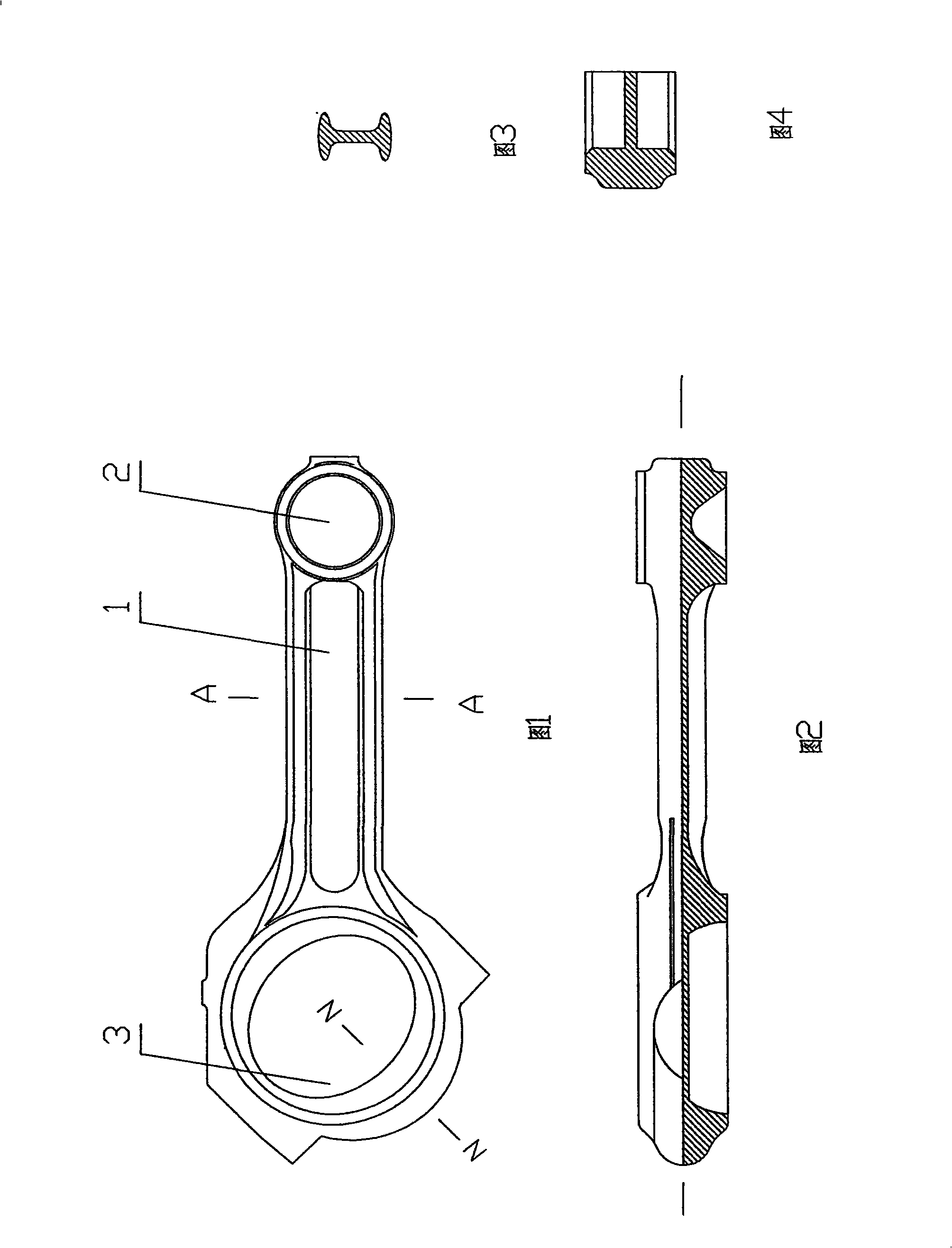

IC link rod manufacture process

InactiveCN101260903AAchieve fixed positionRealize installation positioningConnecting rodsEllipseEngineering

The invention relates to a process for manufacturing an internal-combustion engine connecting rod. The steps of the process are: forging, by a forging die, an integral blank of a connecting rod having a big end ad a small end, with the small end of the blank provided with opposite circular pits, the big end of the blank provided with opposite pits or a through hole, the edges of the pits or the hole on the big end being elliptical, the difference between a major axis and a minor axis being from 5 to 8mm, and the major axis superposing on the axis of the connecting rod or forming an included angle of 45 degrees with the axis of the connecting rod; subjecting the integral blank to blasting shot, flaw detection and phosphorization, then roughly milling two planes of the integral blank of the connecting rod, and machining an mounting hole for a piston pin on the small end; incising along the minor axis of the ellipse of the big end of the integral blank to form a blank of a connecting rod body and a blank of a connecting rod cover board, milling the incising junction surfaces; merging the junction surfaces, synchronously drilling the mounting jump-holes on the connecting rod body and the connecting rod cover board, and machining a crank mounting hole corresponding to the piston pin mounting hole on the big end; threading through the mount jump-holes on the connecting rod body, and machining a gap block position-limiting grooves in the connecting rod body and the connecting rod cover board; and removing burrs, and setting a positioning fixed bolt.

Owner:常州久弘金属材料有限公司

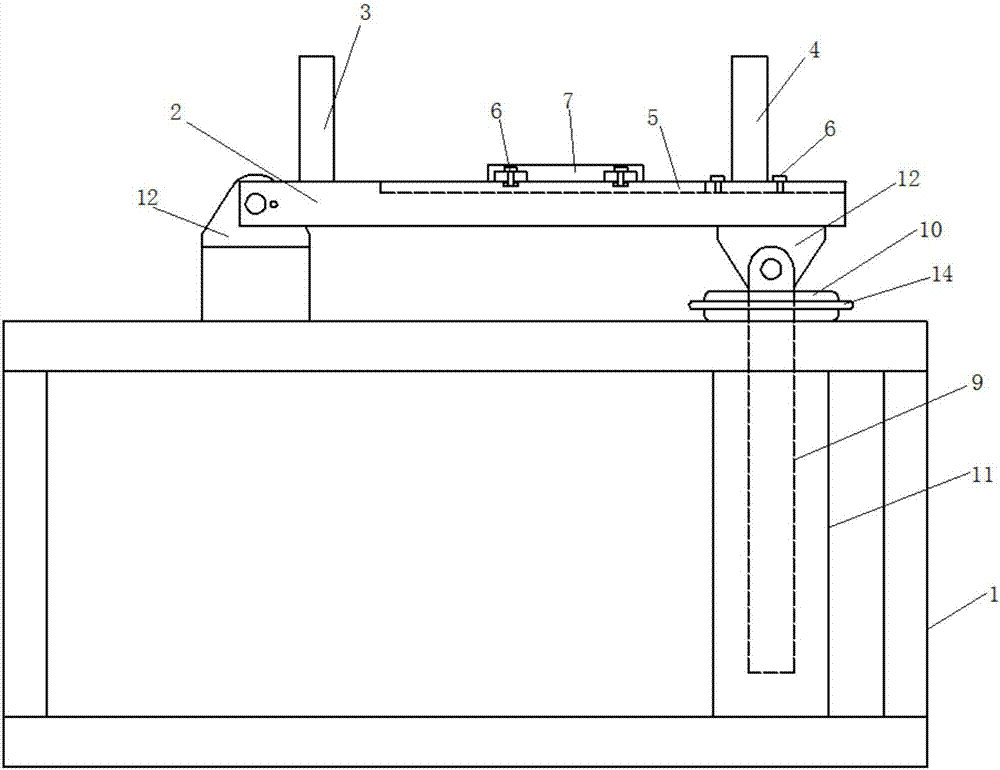

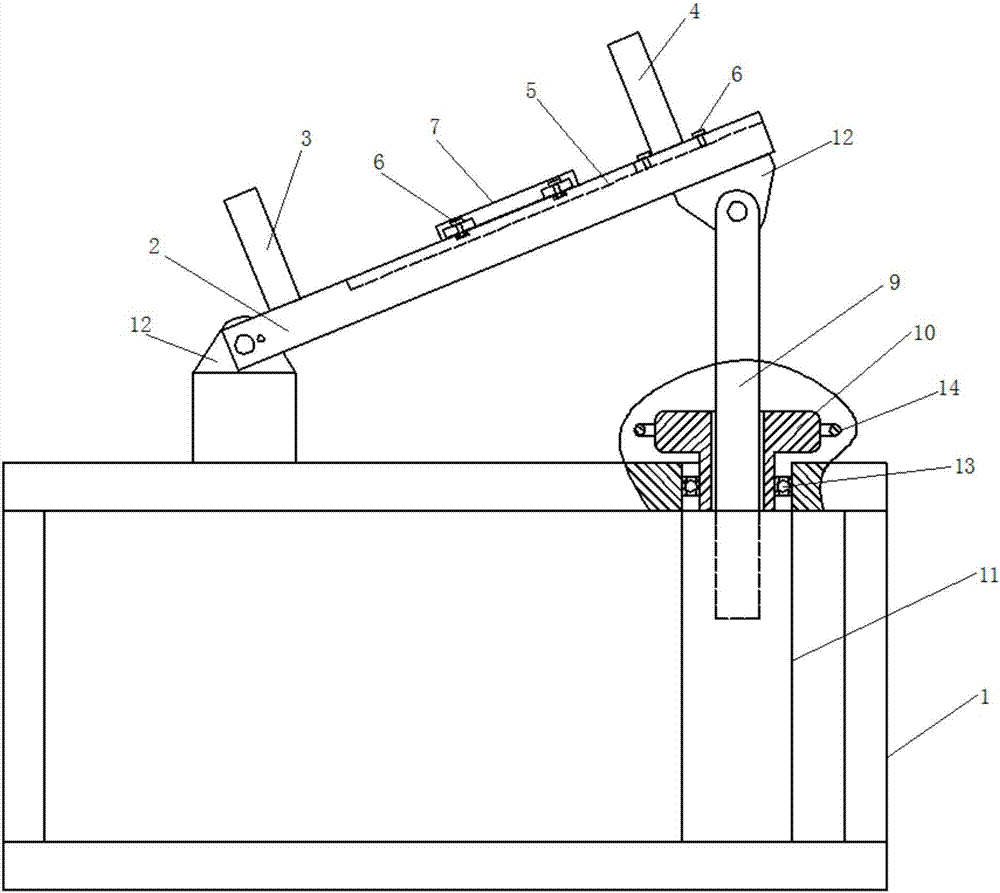

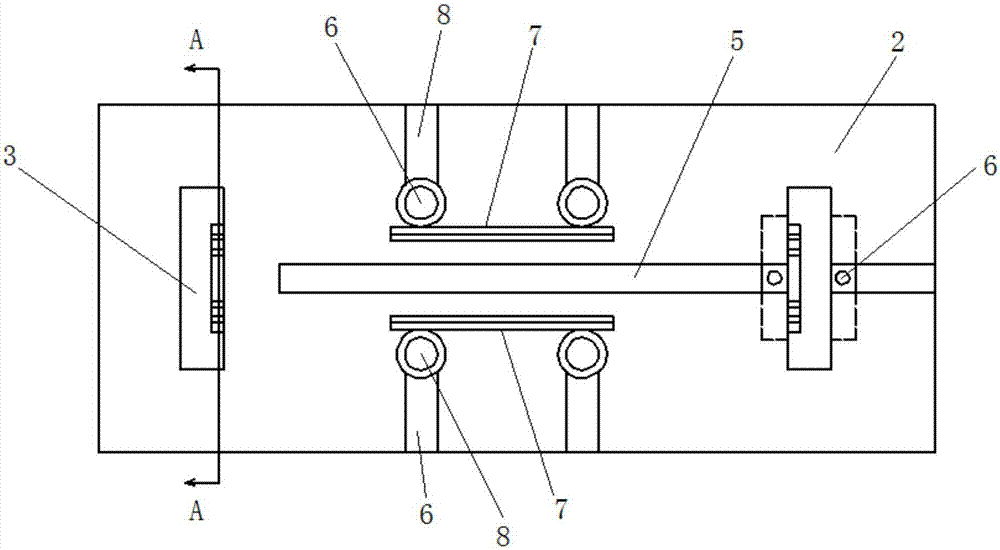

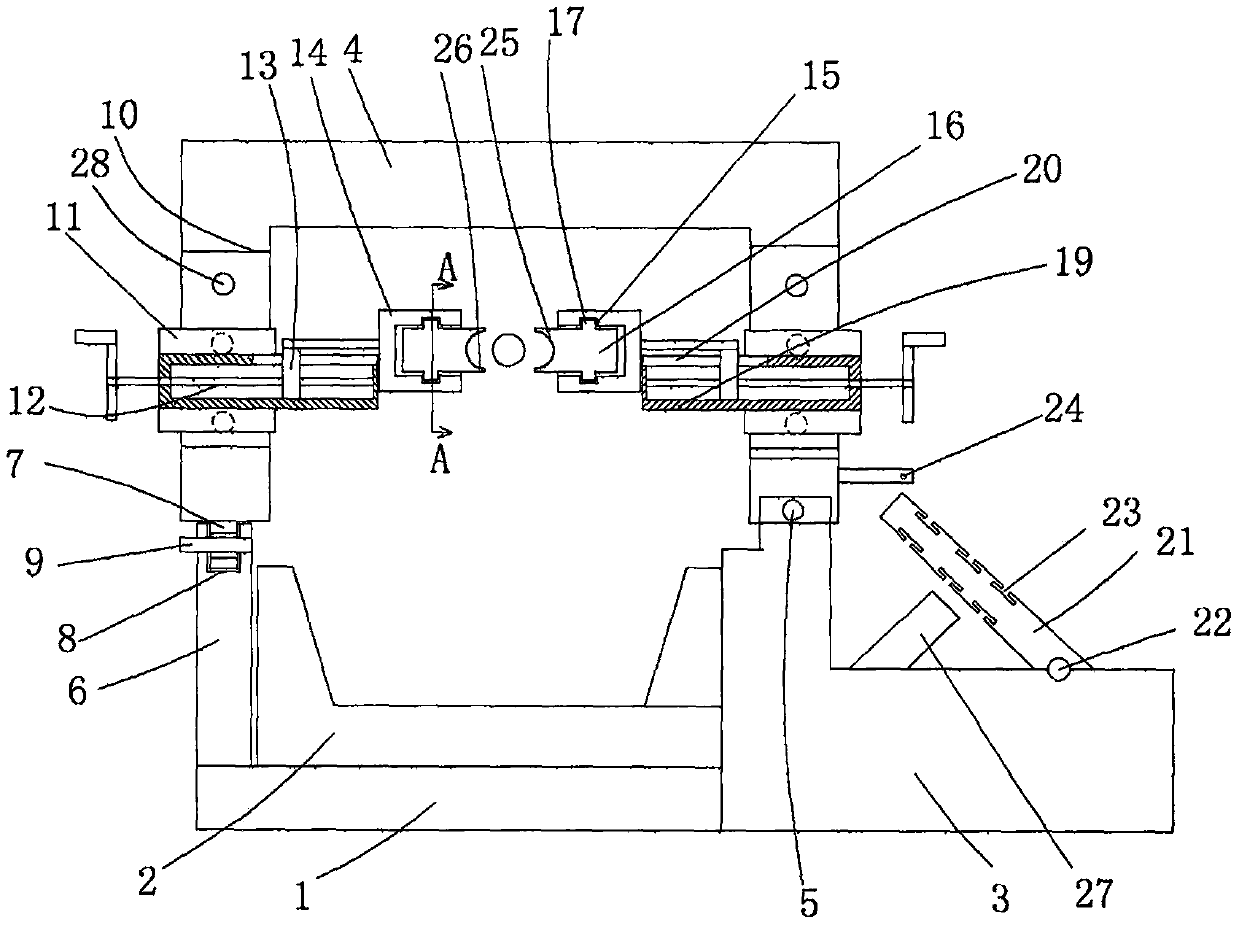

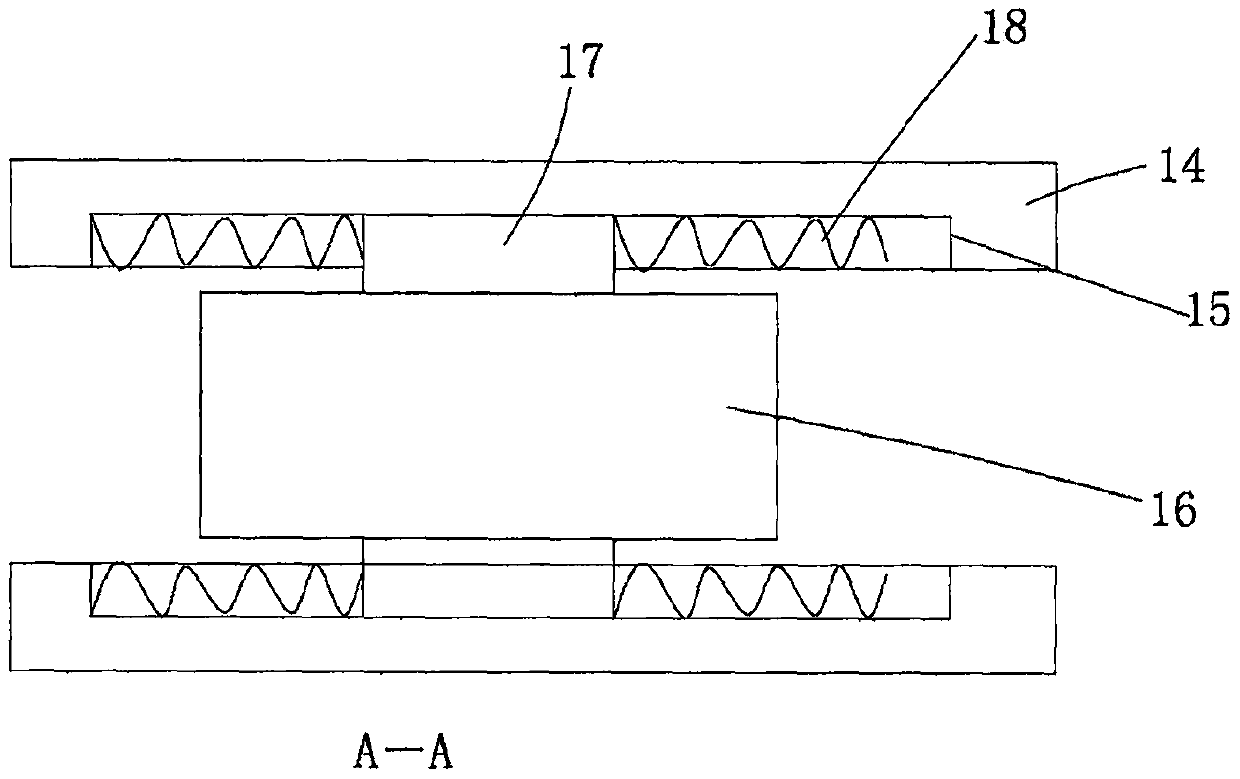

Angle-adjustable tool for inclined hole machining of parts

InactiveCN107160211AAchieve fixed positionWide range of anglesPositioning apparatusMetal-working holdersPunchingBar stock

The invention provides an angle-adjustable tool for inclined hole machining of parts. The tool is provided with a bottom frame, and a clamping platform is arranged at the upper end of the bottom frame; one end of the clamping platform is hinged to one end of the bottom frame, and the other end of the clamping platform and a lifting device arranged at the other end of the bottom frame are integrally hinged; the parts are fixed to the clamping platform; and after the inclined hole angles of the parts are well adjusted through the lifting device, punching is conducted through drilling equipment located above the parts and perpendicular to the bottom frame, and then inclined hole machining of the parts is completed. According to the angle-adjustable tool for inclined hole machining of the parts, the effect that the drilling equipment conducts random inclined hole machining on the parts on the clamping platform is achieved, the structure is simple, design is reasonable, the pre-drilling angle is convenient to adjust, inclined hole machining of plates, bars and pipes is achieved, and the work efficiency and quality of inclined hole machining are improved.

Owner:刘会斌

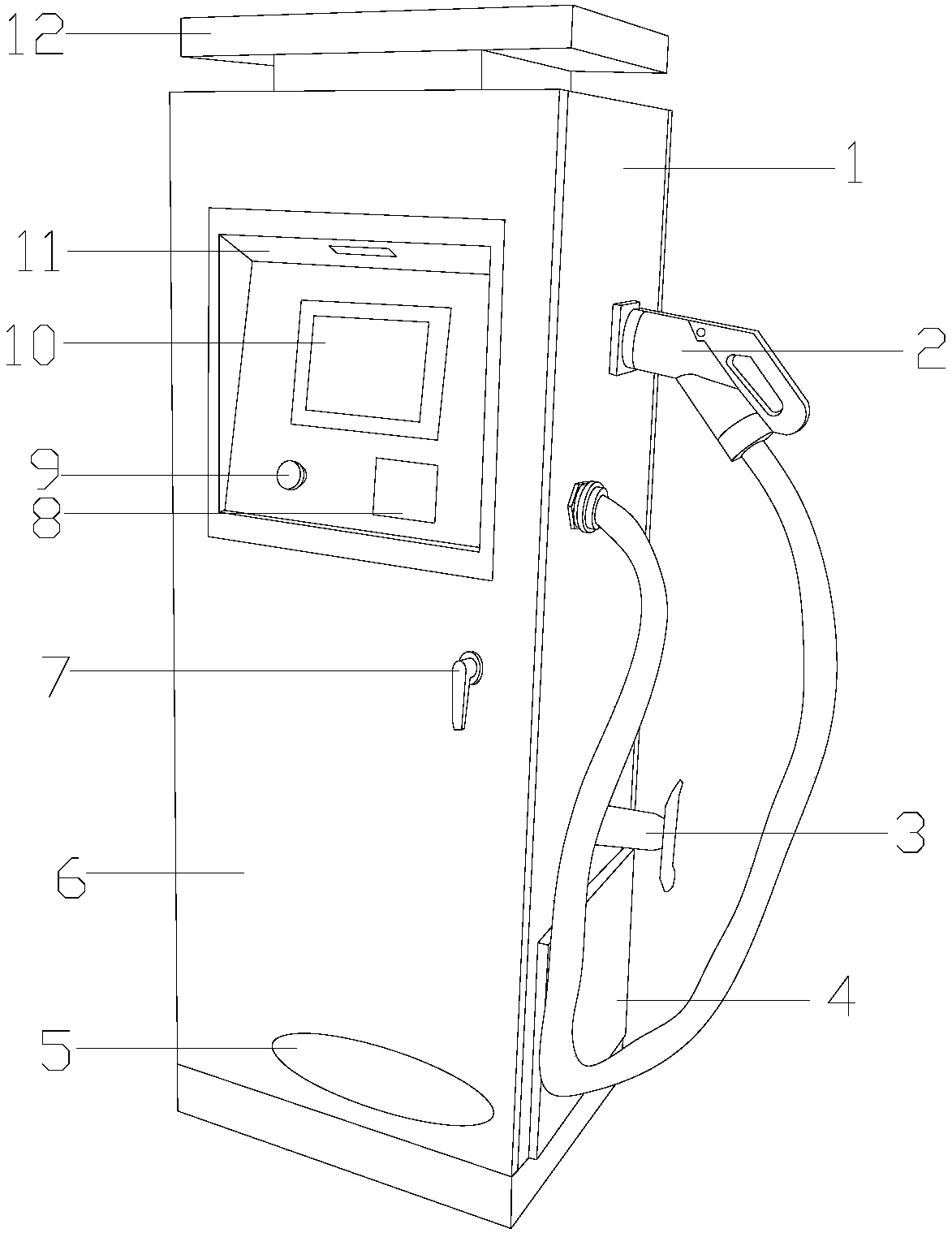

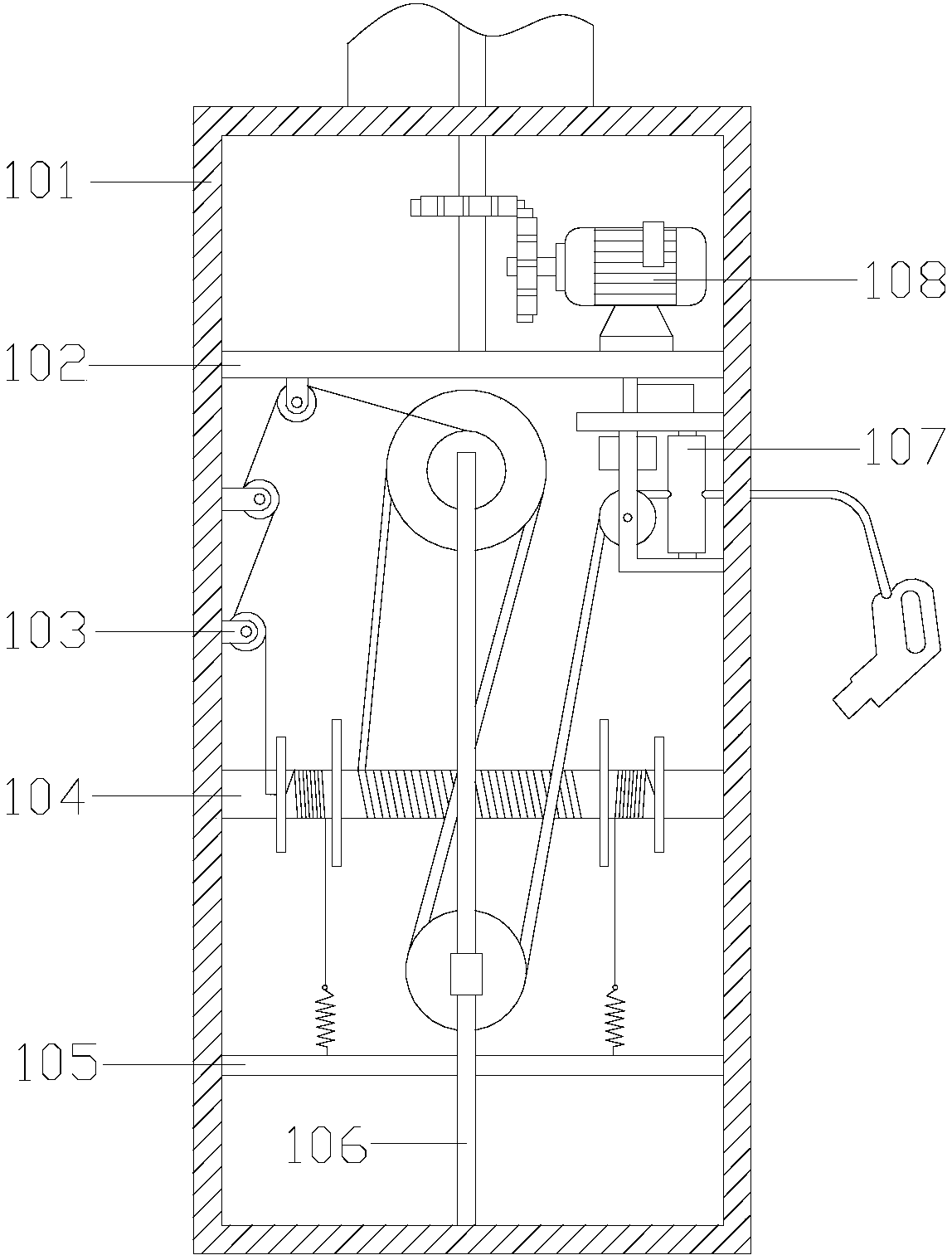

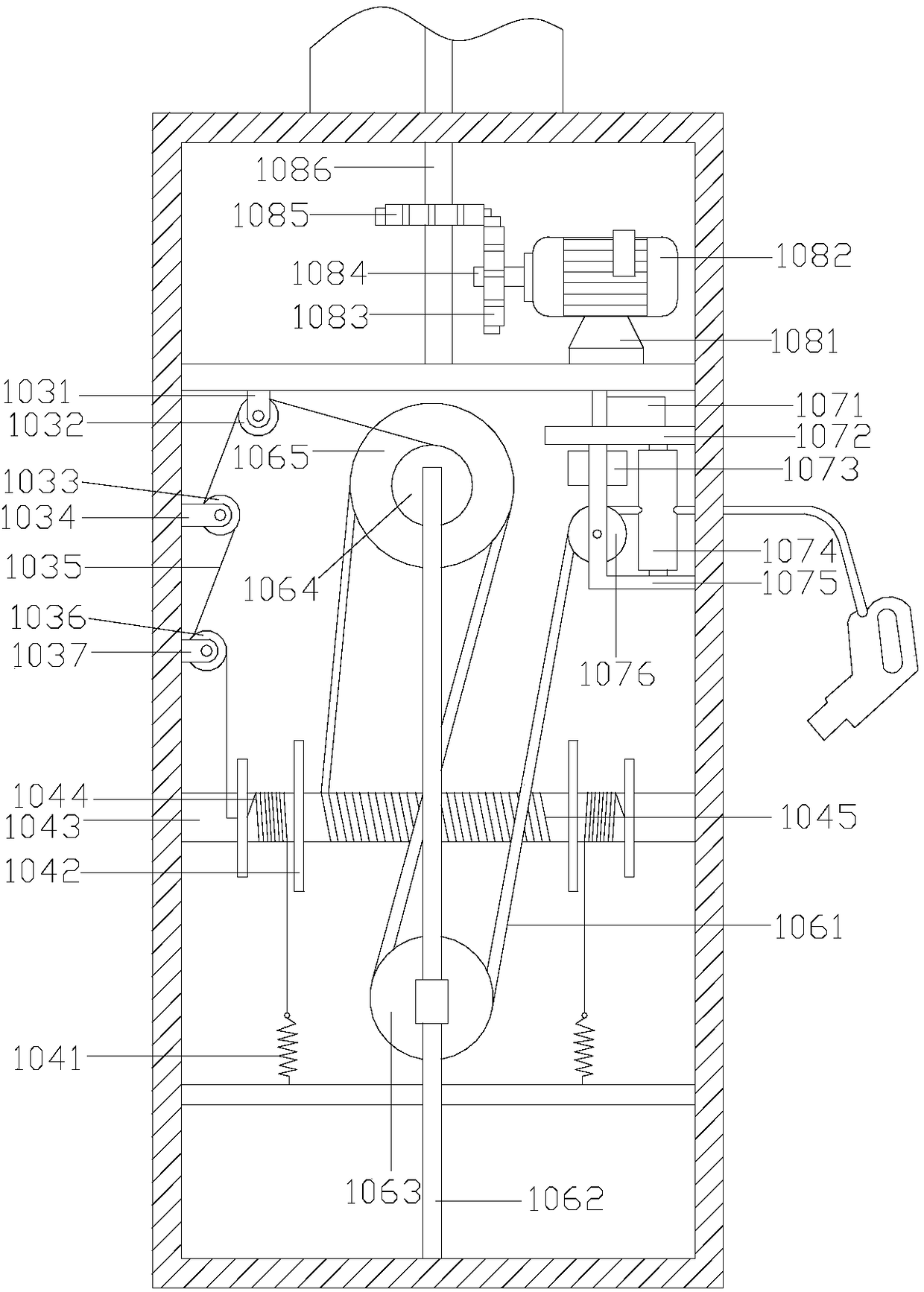

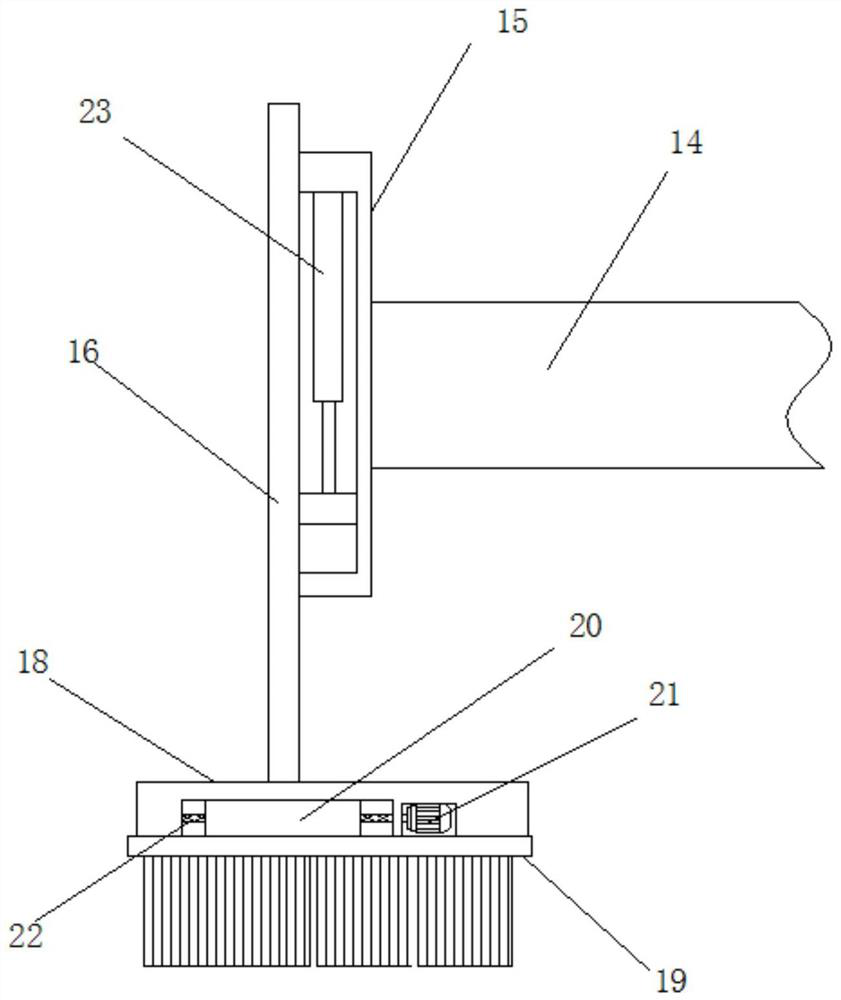

Fixed charging pile for electric vehicle

InactiveCN108297733ARealize automatic windingImprove convenienceCharging stationsElectric vehicle charging technologyEngineeringStops device

The invention discloses a fixed charging pile for an electric vehicle. The fixed charging pile structurally comprises an automatic storage mechanism, a charging gun head, a charging gun head placementseat, a heat dissipation slot, a LOGO, a cabinet door, a door handle, a magnetic card sensing area, an emergency start and stop device, a display screen, an operation platform and a waterproof box. The cabinet door is fixedly arranged at the front end of the automatic storage mechanism and the connection is reinforced by a connecting piece. The waterproof box is fixedly welded to the top end of the automatic storage mechanism and the connection is strengthened by a bolt. According to the invention, under the tension of tension springs, the tension springs pull tension rope winding rollers tounfold, to drive the tension rope winding rollers, a rotating shaft and a cable winding roller to rotate in opposite directions, a charging wire is wound on the cable winding roller, thus automatic winding of the charging wire is realized, the convenience in use of the charging pile is improved, people do not need to manually wind and coil the charging wire on the automatic storage mechanism, andthe charging wire is unlikely to be exposed to sunlight or damaged by foreign objects, and the service life of the charging wire is improved.

Owner:莆田市荔城区任西贸易有限公司

Glue jointing positioning clamp, clamp system for assembling cell core safety component and assembly method

InactiveCN105689950APrevent movementEasy dispensingWelding/cutting auxillary devicesWork holdersEngineeringMechanical engineering

The present invention shows a fixture system for installing safety components of electric cores. The fixture system includes a glued positioning fixture and a welding positioning fixture; the glued positioning fixture includes a base, a front-end positioning mechanism, a rear-end positioning mechanism, two Side positioning mechanism and cell safety component positioning mechanism; the welding positioning fixture includes a cell lug clamping mechanism and a height adjustment mechanism; the setting of the rear positioning mechanism can restrain the cell from moving backward, and can be conveniently used Glue dispensing during the dispensing process; use this fixture to install the safety parts of the battery cell, and the battery cell does not need to be disassembled again. After the glue joint is completed, the glue joint positioning fixture together with the battery cell enters the next link for welding, that is, the entire operation process only It is necessary to load and unload the cells once, which greatly improves the efficiency.

Owner:DONGGUAN AMPEREX TECH

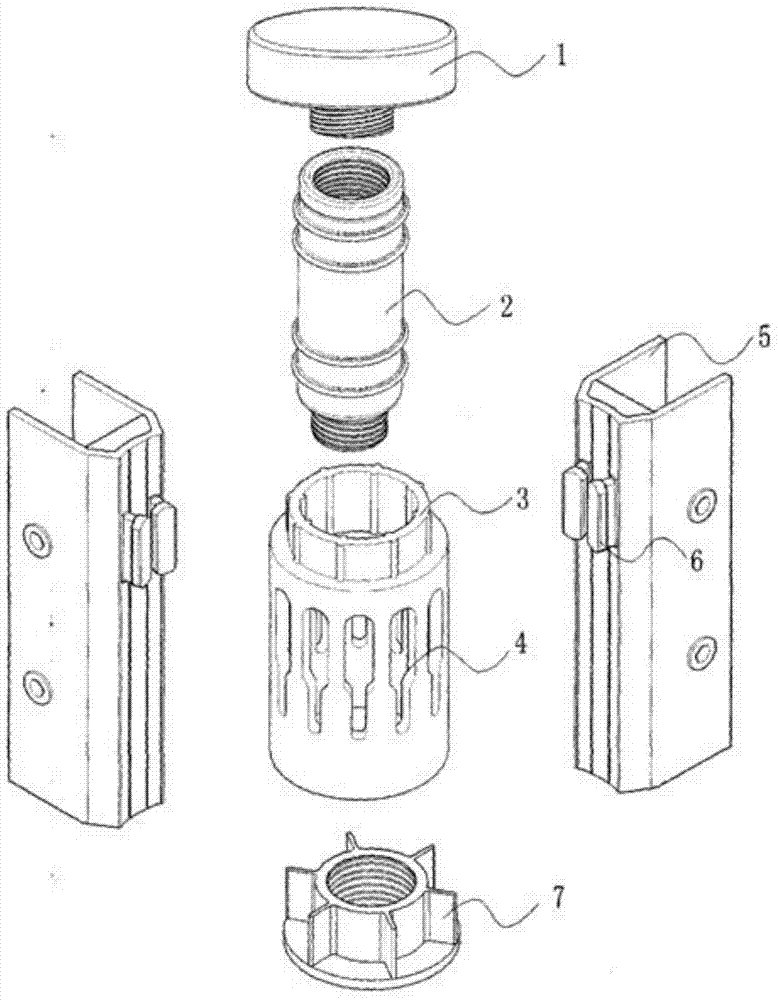

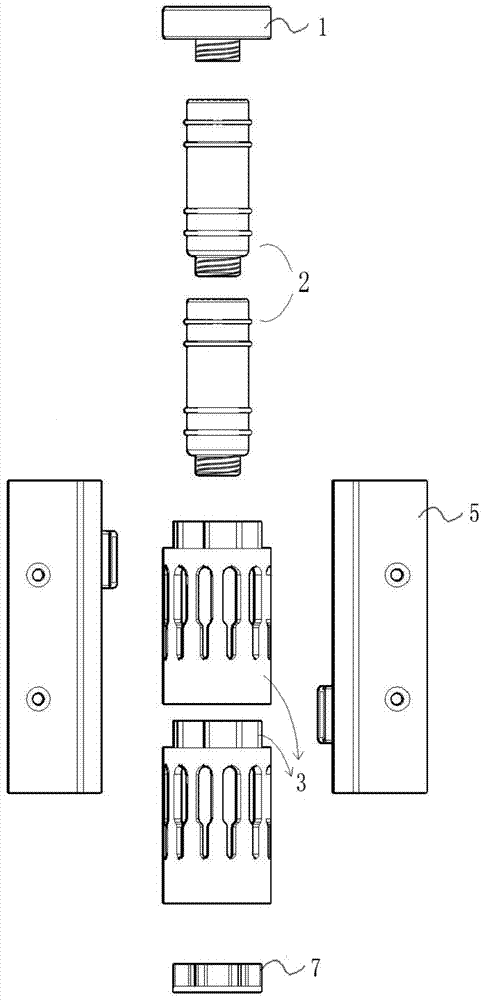

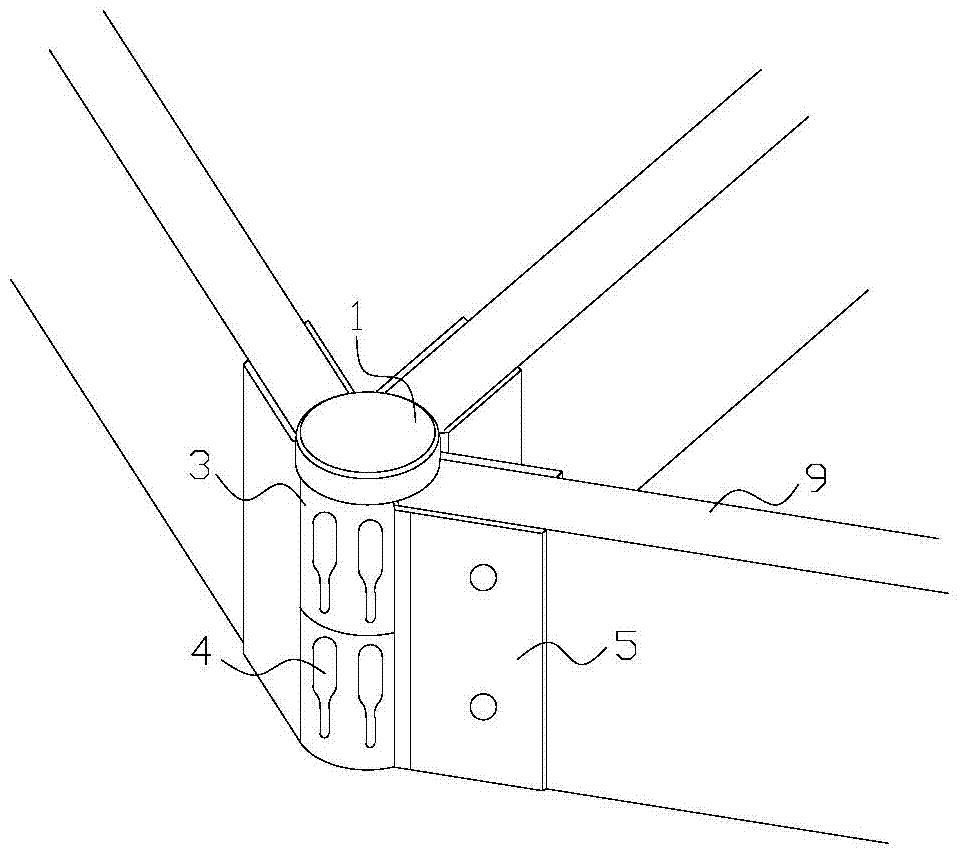

Modularized combined box body and connecting component thereof

ActiveCN103527578AQuick assembly and disassemblyEasy to installRod connectionsSheet joiningModular compositionEngineering

Owner:唐山巍峨能源科技有限公司

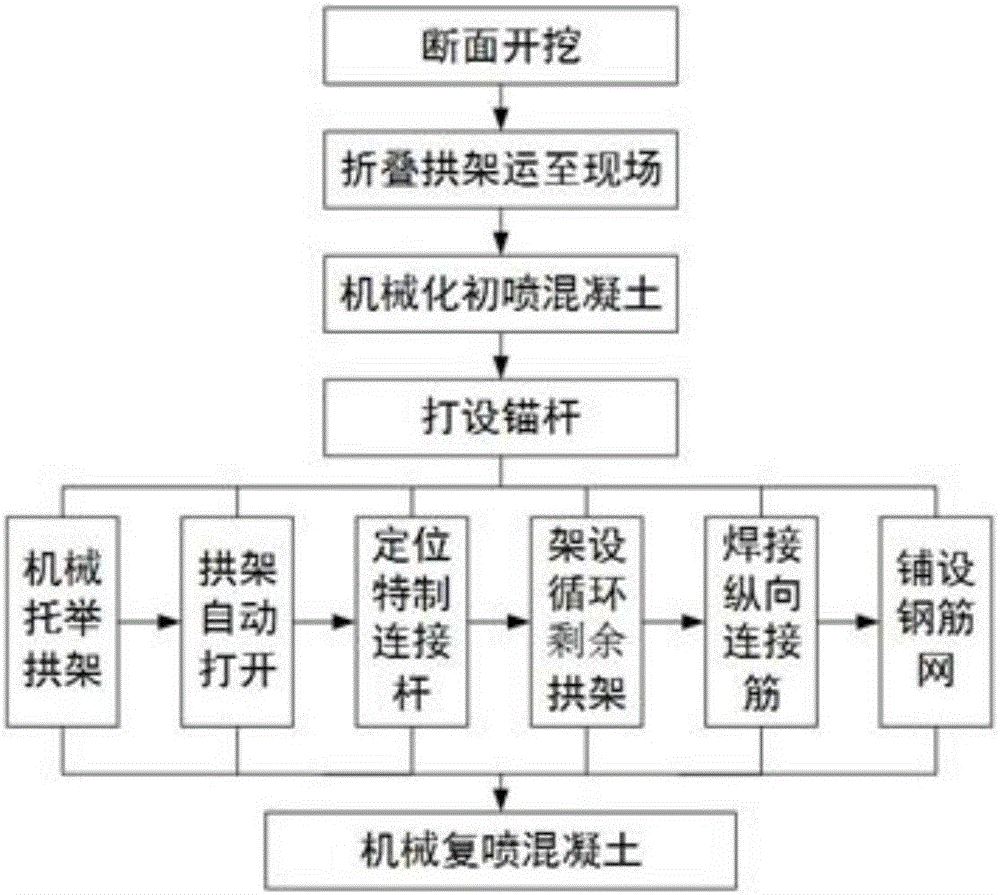

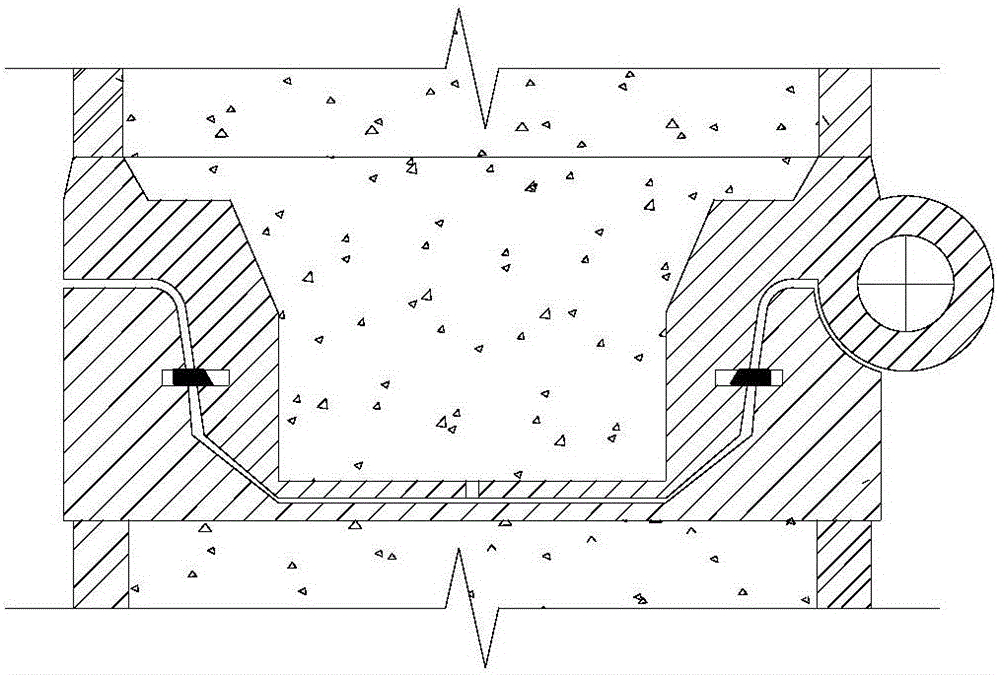

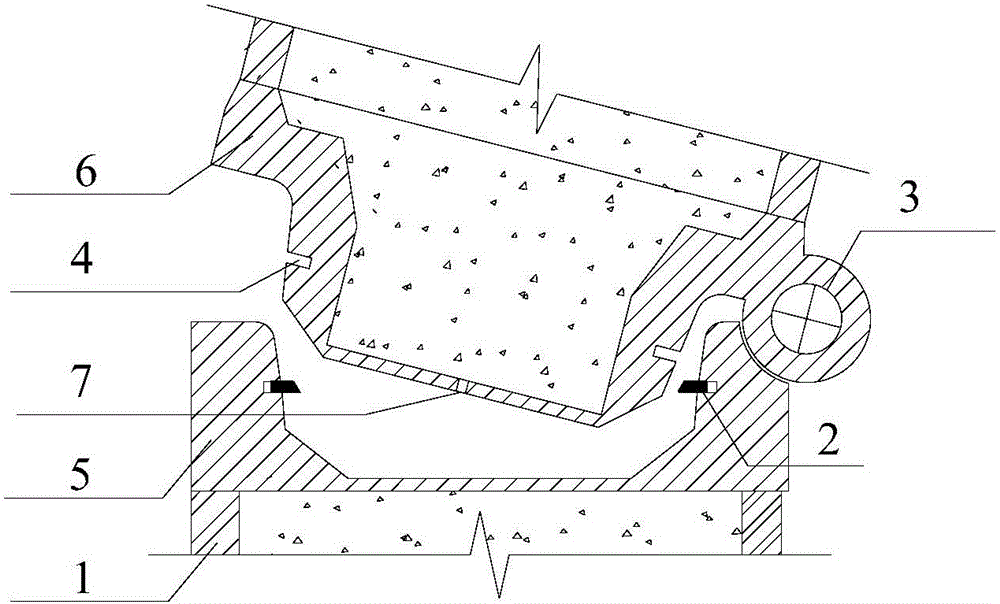

Method for automatically constructing support of confined concrete arch center for underground tunnel

ActiveCN106014453AGuaranteed support strengthImprove mechanical propertiesUnderground chambersTunnel liningConvex structureUnderground tunnel

The invention discloses a method for automatically constructing support of a confined concrete arch center for an underground tunnel. The confined concrete arch center at least comprises two sections, adjacent sections are hinged at joints, the contact surfaces of joints of two adjacent sections are structures matched with each other, the structure of the contact surface of one section is a convex structure, while the structure of the contact surface of the other section is a concave structure matched with the convex structure, a structure is arranged between the convex structure and the concave structure and is used for engaging and fixing the two structures when the two structures are in a matched state, and each section is of a composite structure of which square steel or round steel is filled with concrete. The arch center adopting a foldable mode can be automatically unfolded in the constructing process, does not need manual field splicing, and is safe and efficient; and the concave structure and the convex structure which are matched with each other are arranged on contact surfaces of the joints, and the engaging structures are arranged, so that the confined concrete arch center is automatically engaged when being extended, construction is facilitated, and the support strength of the confined concrete arch center is guaranteed.

Owner:SHANDONG UNIV

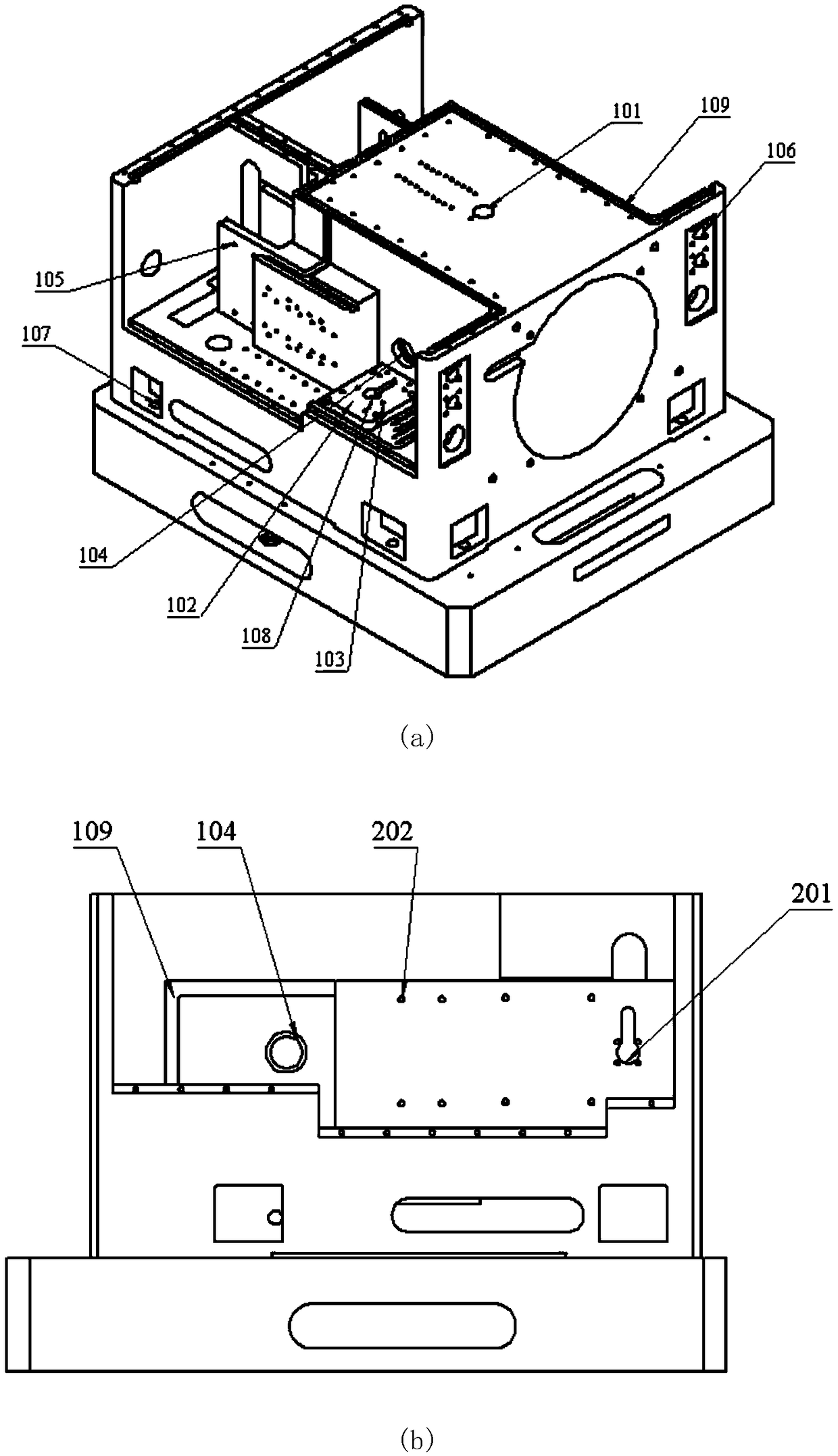

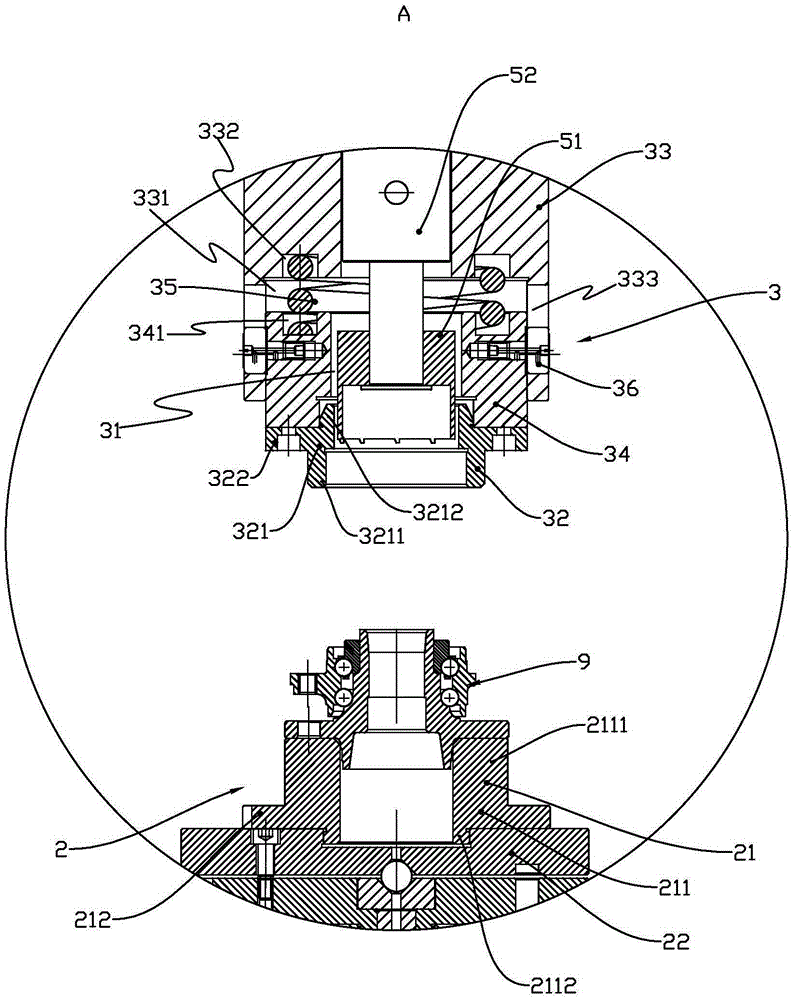

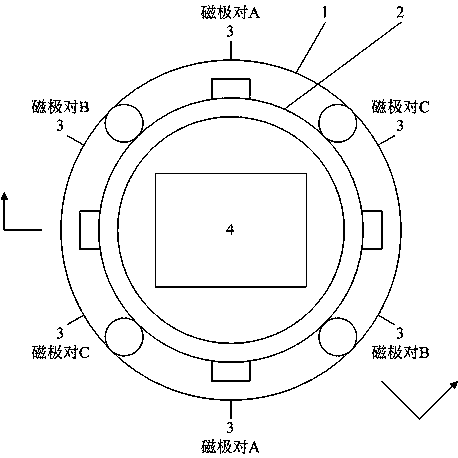

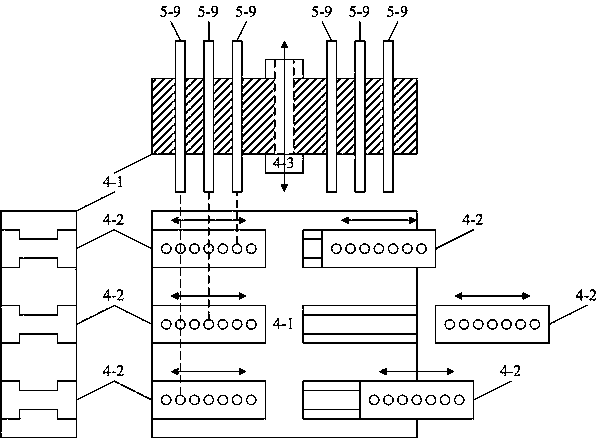

Portable spin-free exchange relaxation atomic gyroscope structure

ActiveCN109186579AReduce size and weightAvoid mutual interferenceTurn-sensitive devicesElectric heatingAlkali metal

The invention discloses a portable spin-free exchange relaxation atomic gyroscope structure. The portable spin-free exchange relaxation atomic gyroscope structure comprises an alkali metal gas chamberfixing seat, a non-magnetic electric heating base, a magnetic field compensation coil framework, a magnetic shielding cylinder, a detecting laser base, a detecting light splitting assembly, a pumpinglaser base, a pumping light beam expanding assembly, a pumping light stabilization light intensity assembly, a main structure, a positioning tool, and a supporting base. The alkali metal gas chamberfixing seat is used for fixing an alkali metal gas chamber. The non-magnetic electric heating base is used for clamping the oven. The detecting light splitting assembly adopts a connection fixing structure of the BS and the Glan prism. The pumping light beam expanding assembly is embedded in the ribs of the main structure. The pumping light stabilization light intensity assembly adopts a connection fixing structure of the PBS and the liquid crystal phase retarder. The main structure adopts a split cavity design combining a sinking type and a hanging type. The supporting base is used for fixingthe main structure and provides an installation reference for the gyroscope. The portable spin-free exchange relaxation atomic gyroscope structure is compact and symmetrical in structure, small in size and light in weight, and the optical assembly connection fixing structure is adopted, so that the optical performance stability is enhanced.

Owner:BEIHANG UNIV

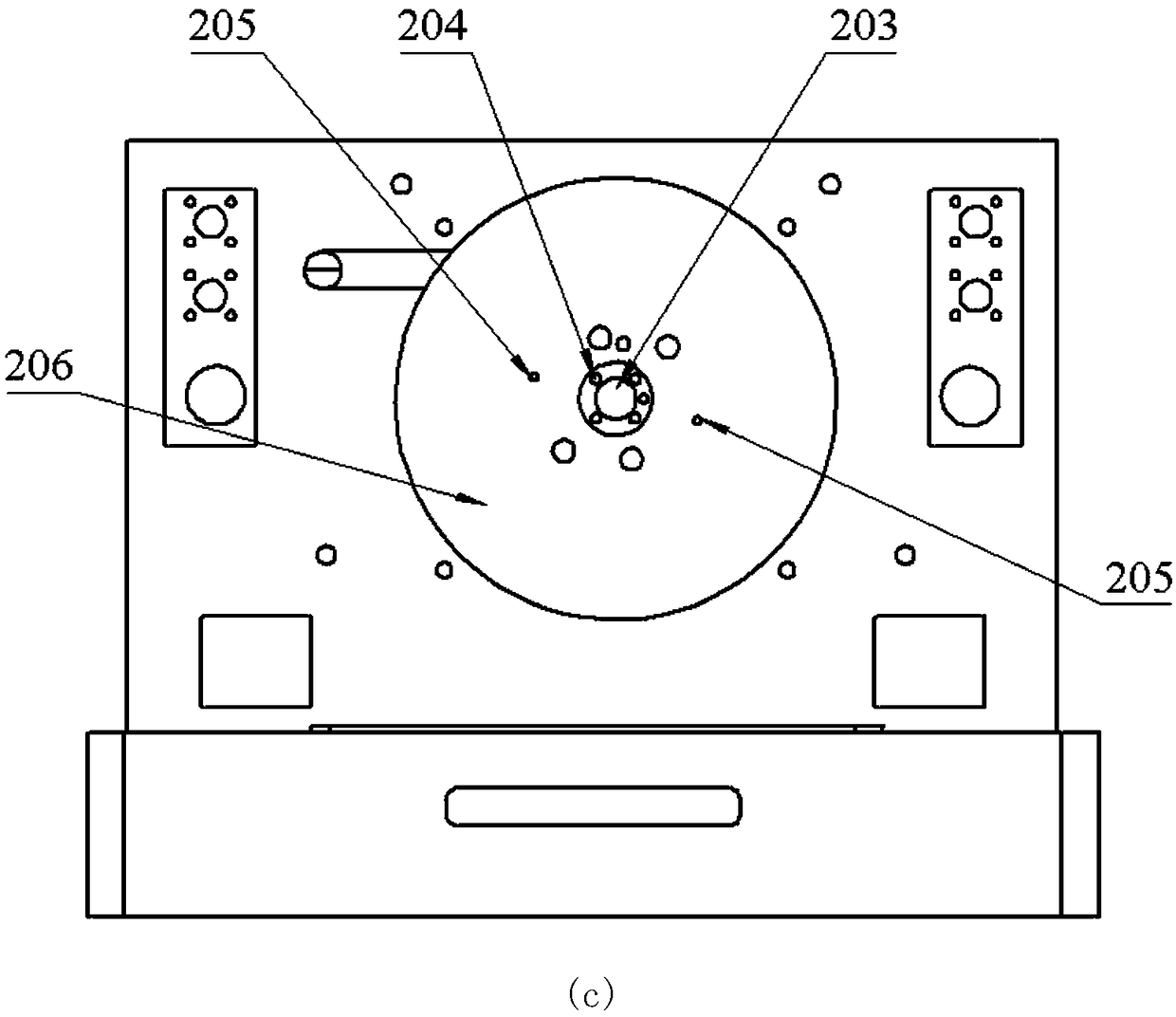

Hub bearing negative windage detection method

InactiveCN105588494AEasy to operateImprove detection stabilityMechanical clearance measurementsAxial pressureSteel ball

The present invention relates to a hub bearing negative windage detection method. A torque loading device applies a rated torque P of 5-15 N. m to the steel ball assembly of a hub bearing; a bearing axial pressure device applies axial load to the hub bearing to allow the hub bearing to tend to release the negative windage; the bearing axial pressure device comprise a mandrel bearing tool and an outer ring positioning tool, and the mandrel bearing tool and the outer ring positioning tool are oppositely arranged and are apart from / close to each other in the axial direction; there is provided a axially telescoping holding space between the outer ring positioning tool and the mandrel bearing tool, an axially extending abdicating through hole is arranged in the outer ring positioning tool, and the steel ball shift fork of the torque loading device is disposed in the abdicating through hole; and the bearing axial pressure device applies load bearing to the hub bearing in a gradually increasing load value mode, and axial load is applied to the torque loading device to stir the steel ball assembly of the hub bearing and drive the rotation of the steel ball assembly larger than 90 degrees, so that the negative windage is obtained. The operation is simple, and the stability and the reliability of the detection are good.

Owner:C&U CO LTD

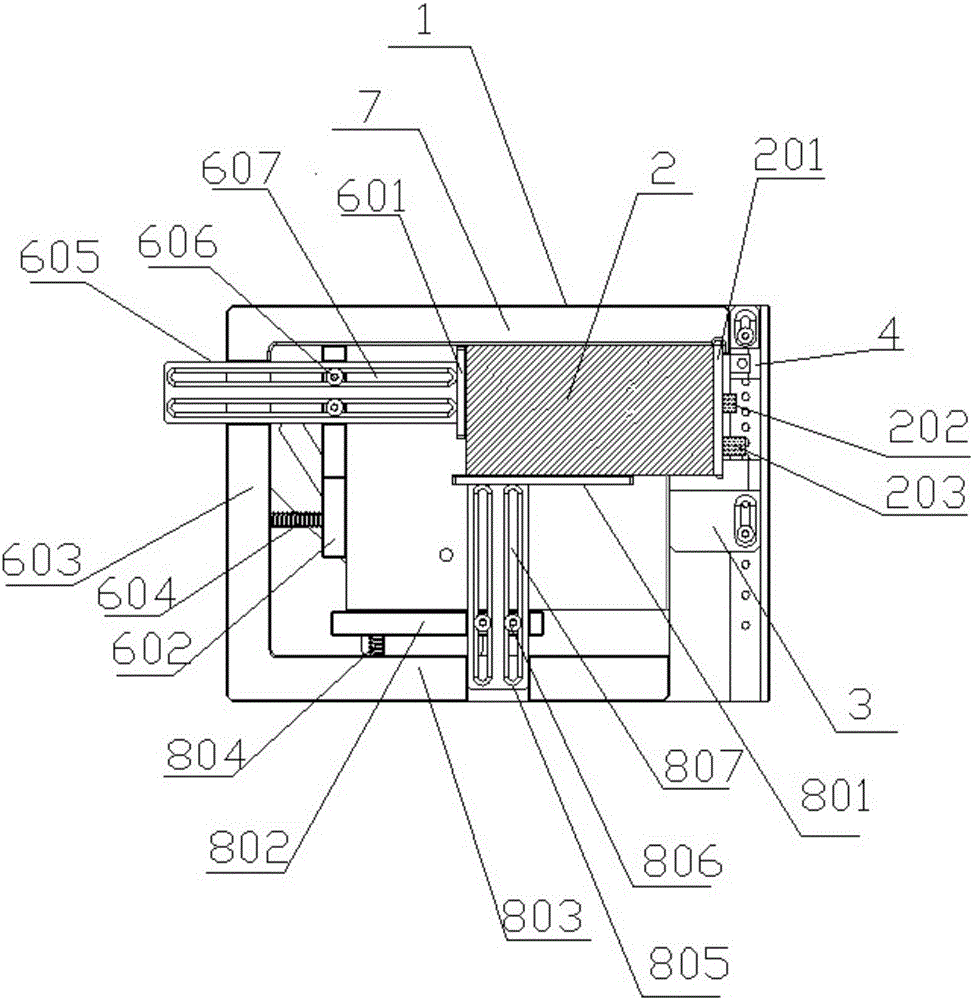

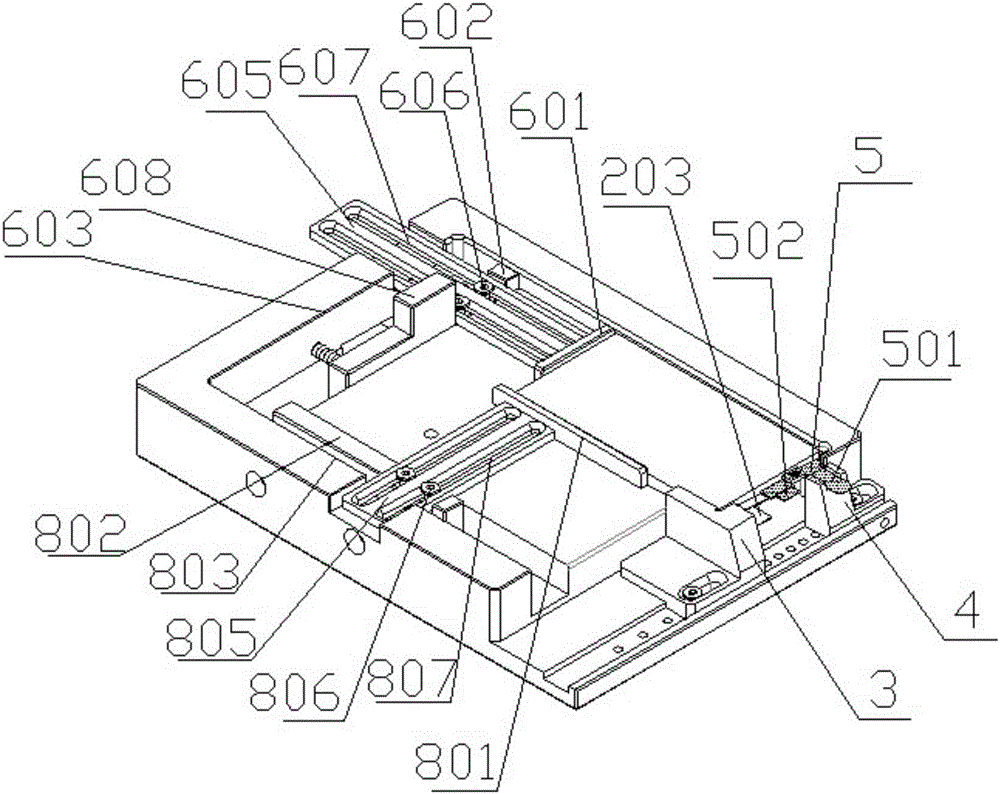

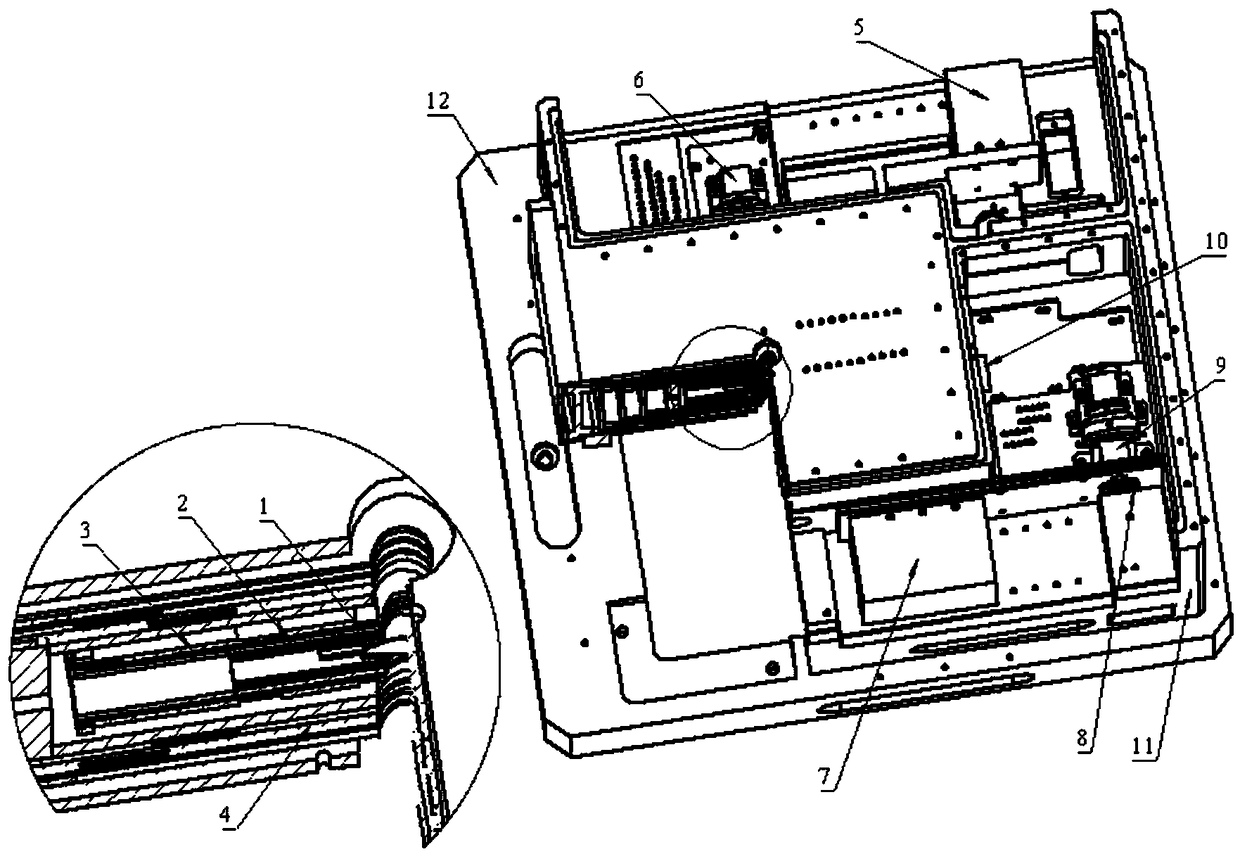

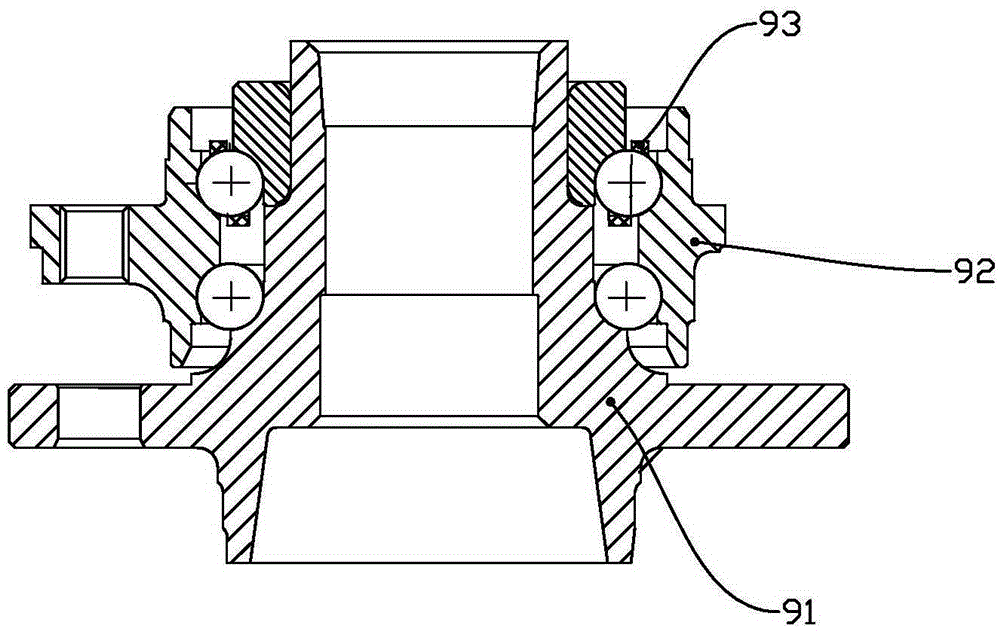

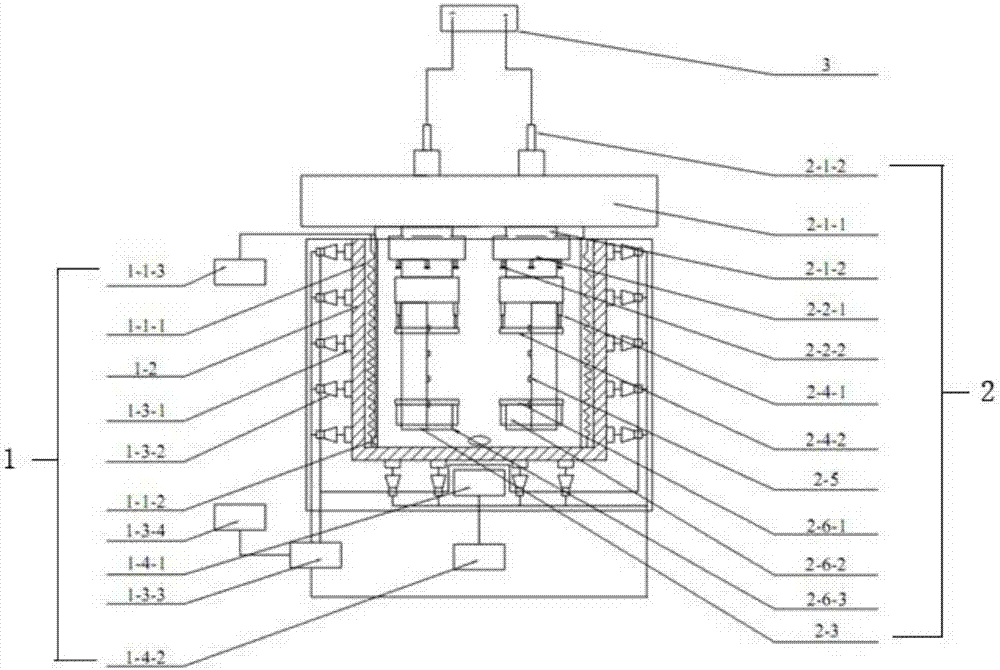

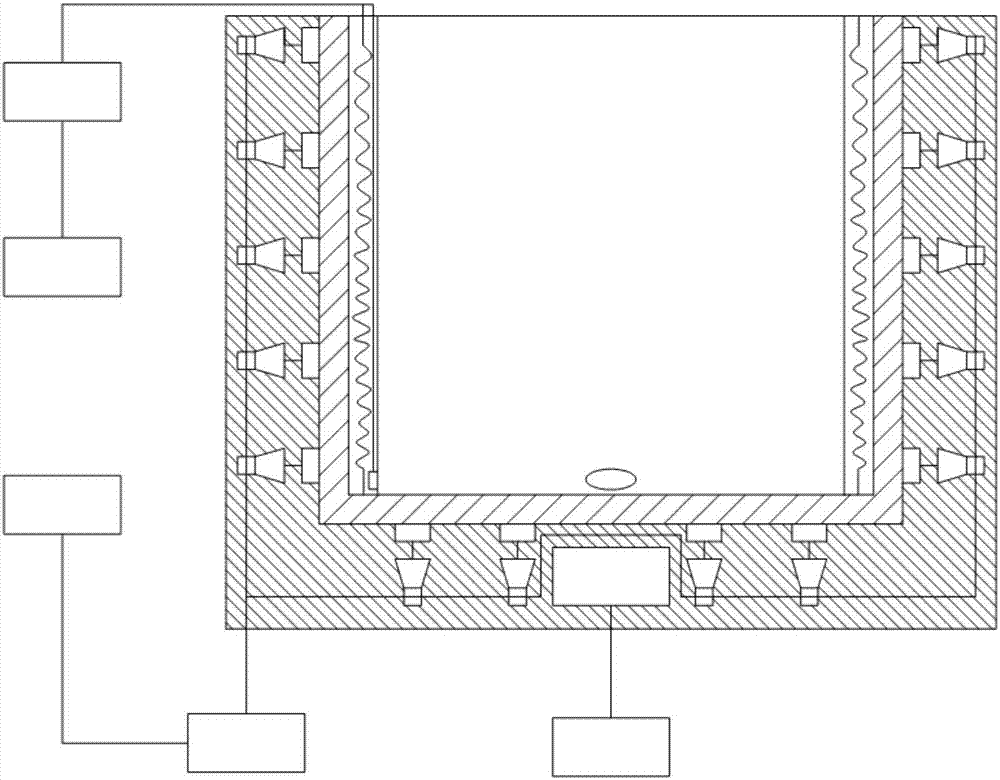

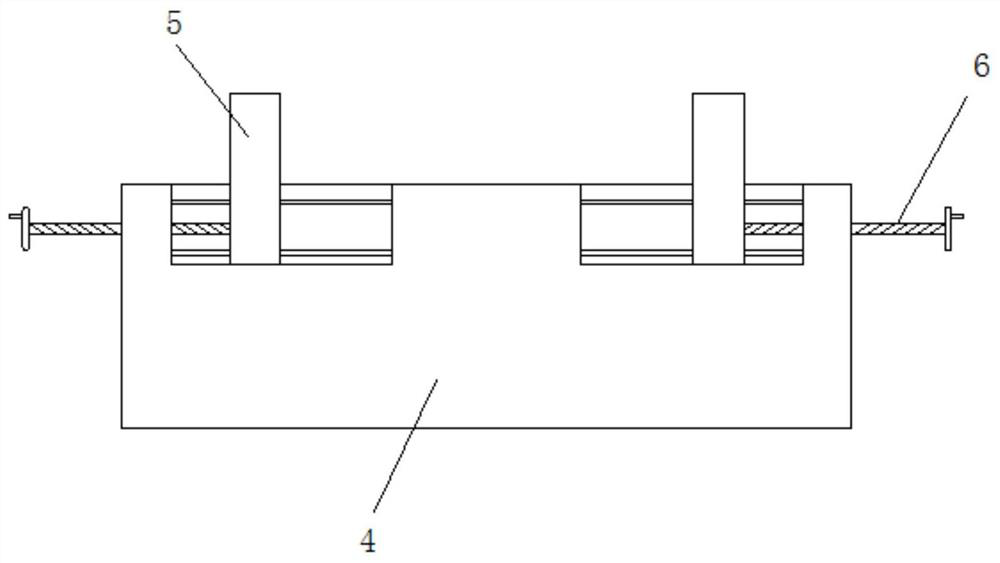

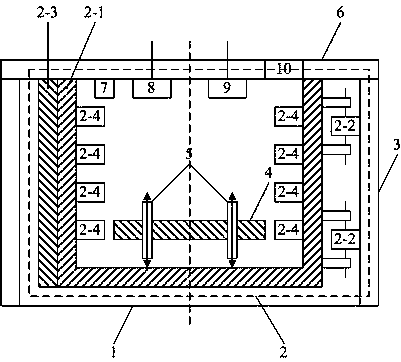

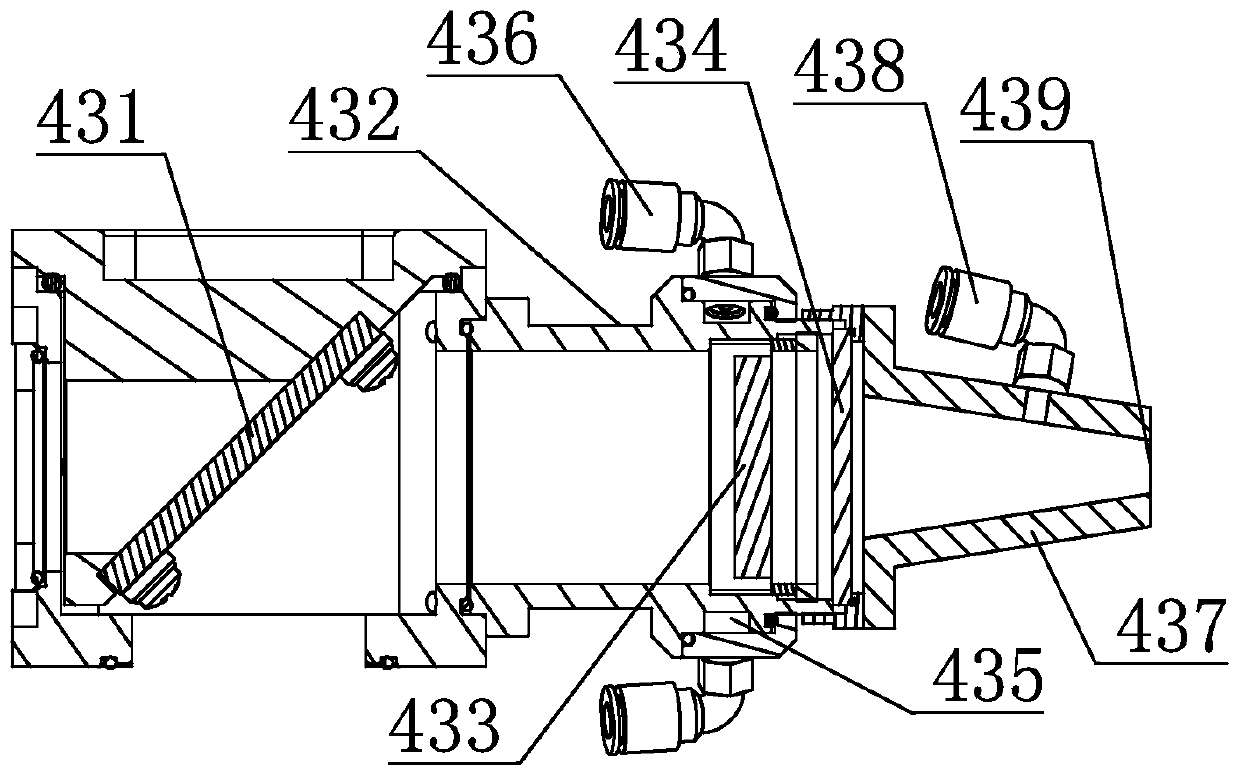

Ultrasonic assistance supercritical electro-deposition device

ActiveCN106906501AHeatingWith ultrasound assistanceCellsCurrent conducting devicesElectricityLocking mechanism

The invention relates to an electrochemical machining technology, in particular to an ultrasonic assistance supercritical electro-deposition device. According to the ultrasonic assistance supercritical electro-deposition device, supercritical carbon dioxide fluid serves as a carrier, ultrasonic waves serve as an assistance, and therefore different mechanisms can act at the same time, superposition, cooperating and complementary effects are generated, the surface quality, the mechanical property and other properties of a composite coating are effectively improved. The ultrasonic assistance supercritical electro-deposition device comprises a reaction still (1) and an electro-deposition clamp (2), and the reaction still (1) is provided with a heating assembly, an ultrasonic wave assembly and a magnetic stirring assembly; and the electro-deposition clamp (2) comprises a flange end cap, a guide rail assembly, an electrode clamping plate assembly and a locking mechanism assembly. The ultrasonic assistance supercritical electro-deposition device is reasonable and simple in structure, the reaction still has the heating, ultrasonic assistance and magnetic stirring functions at the same time, ultrasonic assistance supercritical electro-deposition can be achieved, and the electro-deposition efficiency and the coating quality are improved.

Owner:JIANGSU UNIV OF TECH

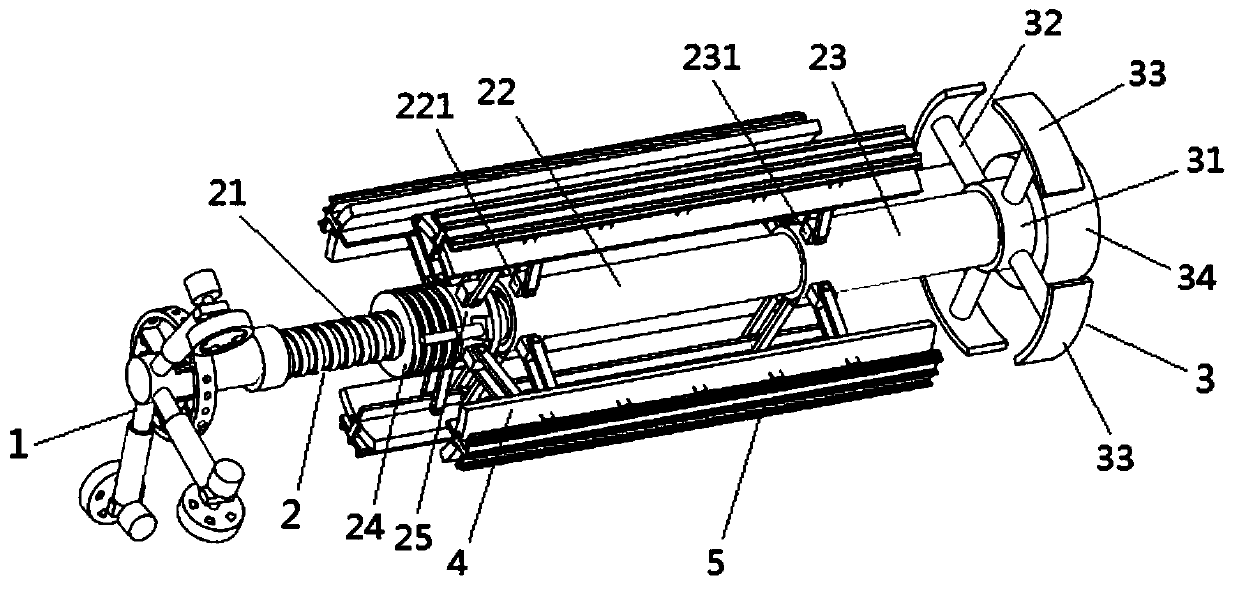

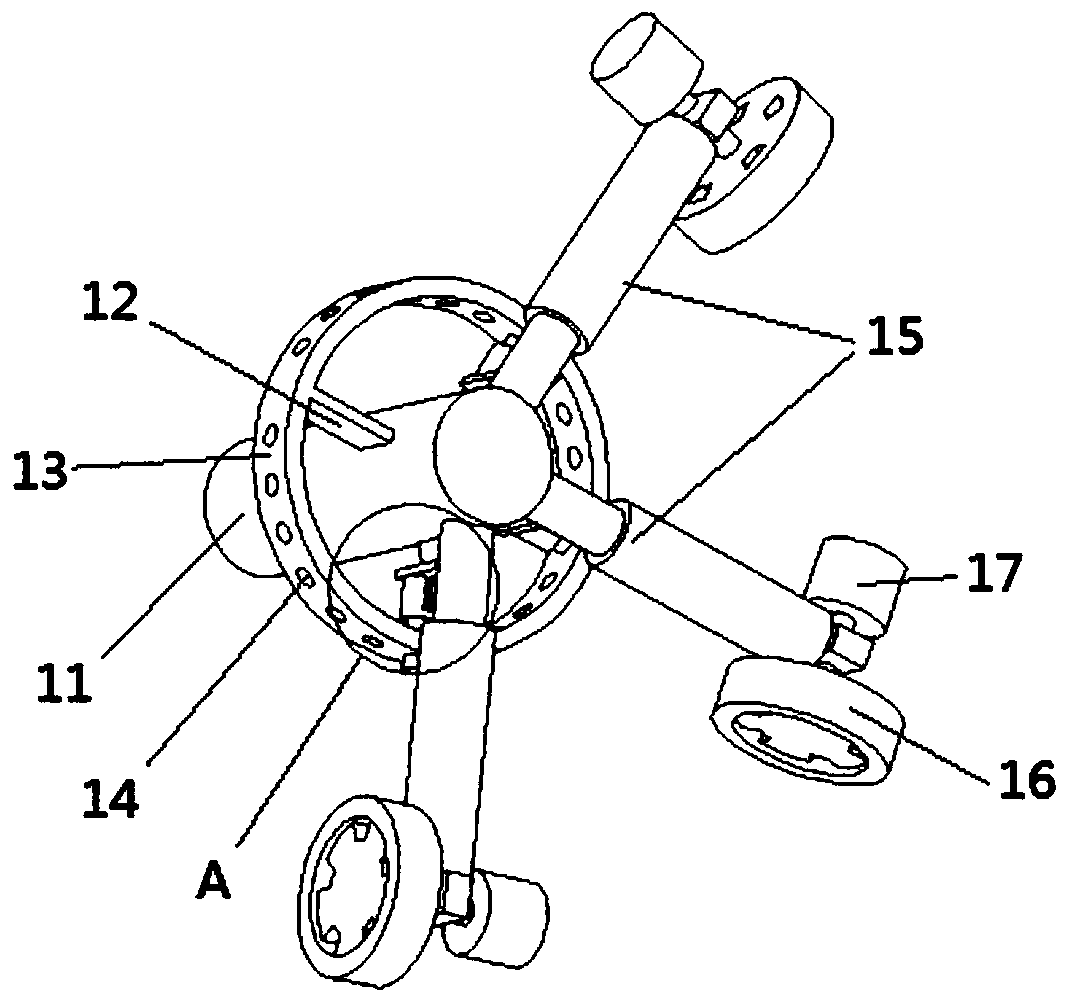

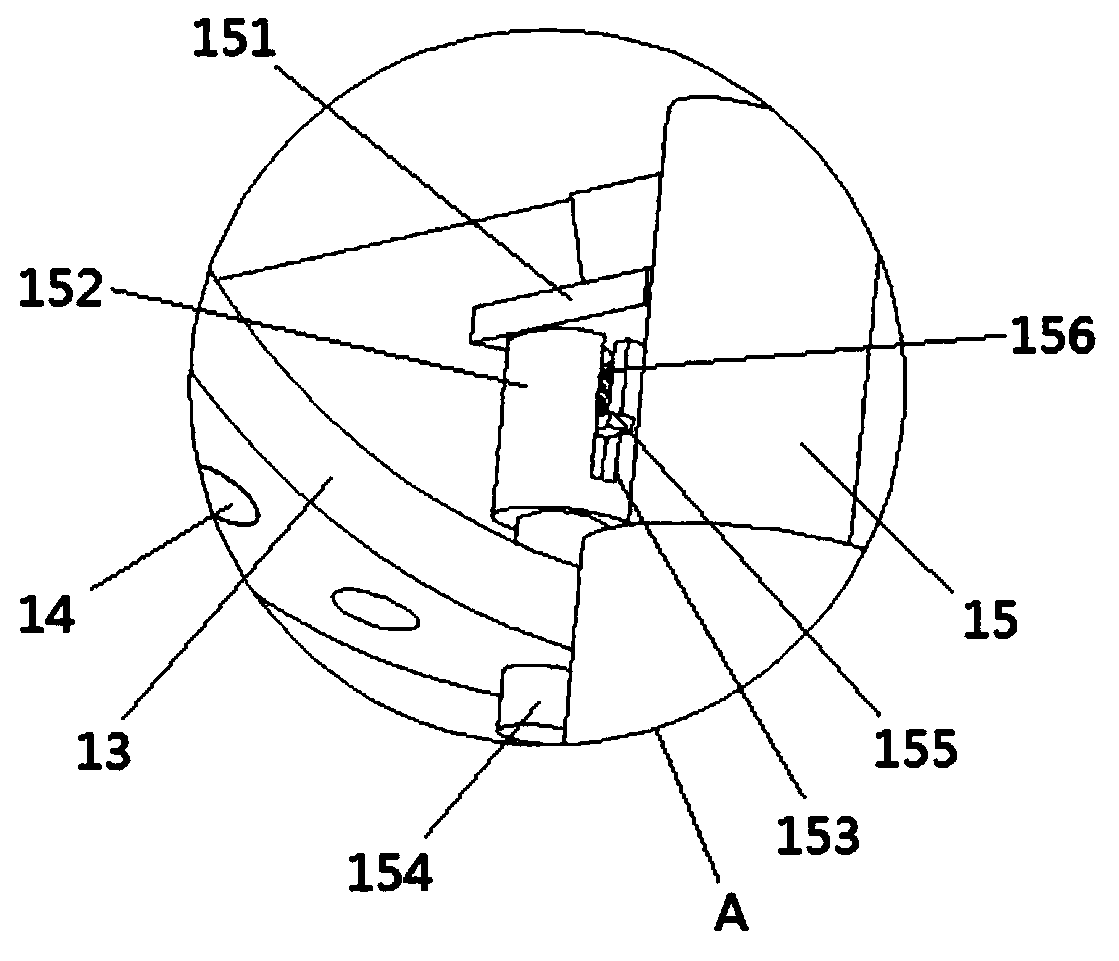

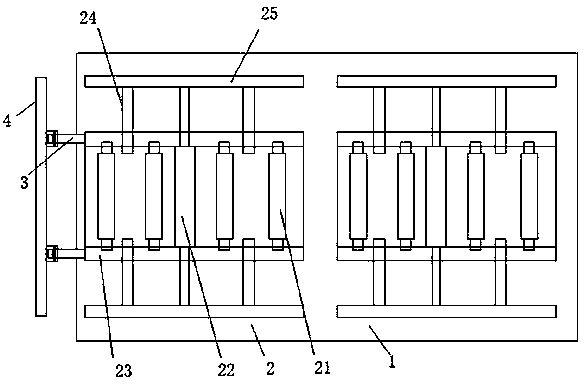

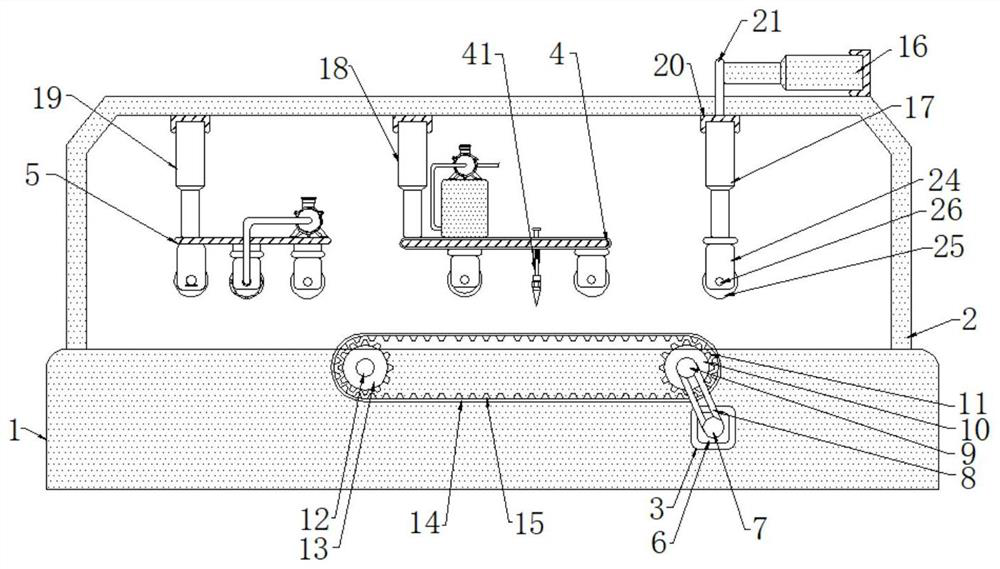

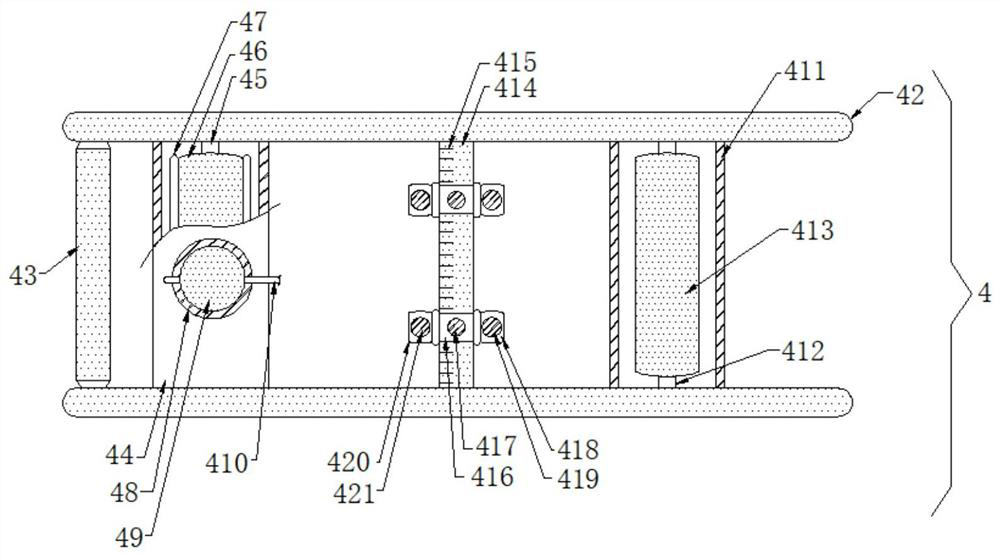

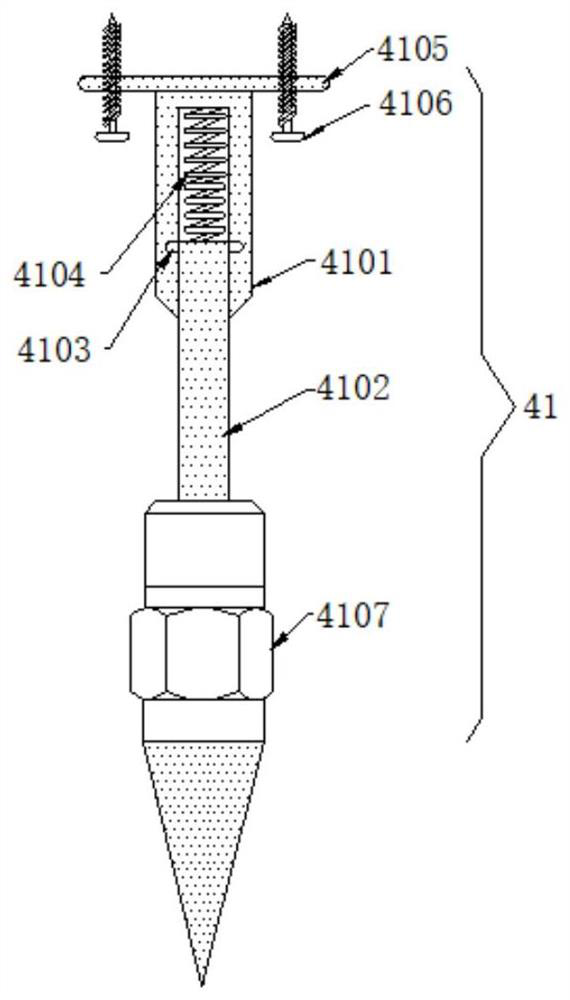

Intelligent decontamination robot for water supply pipeline

ActiveCN111578042AAvoid cleaningAvoid wasting manpowerHollow article cleaningPigs/molesProcess engineeringMaterial resources

The invention discloses an intelligent decontamination robot for a water supply pipeline. The intelligent decontamination robot comprises a traction mechanism, a transmission conveying mechanism, a stable power mechanism, a support adjusting mechanism and a dirt cleaning mechanism; the traction mechanism and the stable power mechanism are distributed and fixed to the two ends of the transmission conveying mechanism; the support adjusting mechanism is hinged to the transmission conveying mechanism; and the dirt cleaning mechanism is installed on the support adjusting mechanism. According to theintelligent decontamination robot for the water supply pipeline, the position of a reducing execution adjusting component relative to a first transmission part can be adjusted through a reducing feeding component, then the reducing execution adjusting component drives the distance between the support adjusting mechanism and the transmission conveying mechanism, so that the requirement for cleaning the inner sizes of different pipelines is met; the stable power mechanism drives the transmission conveying mechanism to rotate, so that the inner wall of the pipeline is rotationally cleaned, and the cleaning efficiency of the inner wall of the pipeline is improved; and the structure is simple, the practicability is high, manpower and material resources are reduced, and the cleaning speed of the inner wall of the pipeline is increased.

Owner:温州思鸣达工业产品设计有限公司

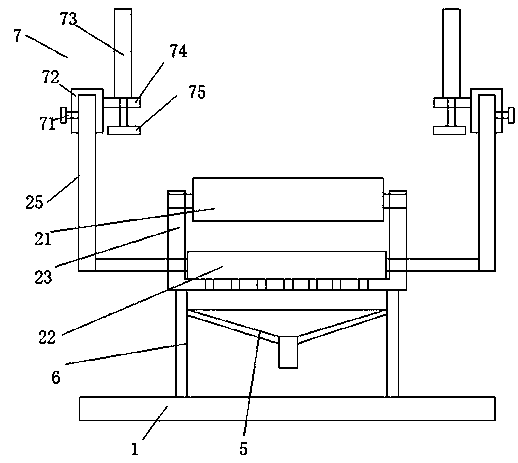

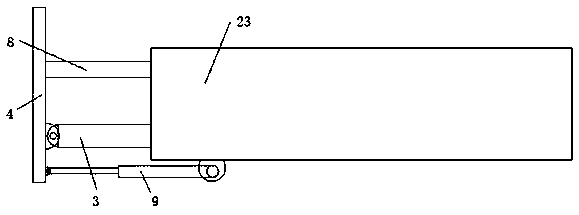

Panel machining and positioning device for furniture manufacturing

InactiveCN109623966AEasy to processImprove processing stabilityProfiling/shaping machinesEngineeringWood cutting

The invention belongs to the field of furniture manufacturing, and particularly relates to a panel machining and positioning device for furniture manufacturing. For the problems that manual positioning is needed during existing wood cutting, the machining efficiency is low, and the machining stability is poor, the following scheme is provided at present, the panel machining and positioning devicecomprises a bottom plate and at least one conveying clamping mechanism located on the bottom plate; supporting frames are arranged on the two sides of the bottom end of each conveying clamping mechanism, the bottom ends of the supporting frames are fixed to the bottom plate, and a plurality of auxiliary fixing mechanisms are arranged on the two side walls of each conveying clamping mechanism; twofixing columns are welded to the side wall of one conveying clamping mechanism, wherein a limiting plate is rotationally connected to one ends of the fixing columns, a second telescopic rod is hingedto the bottom end of the conveying clamping mechanism, and an output shaft of the second telescopic rod is hinged to the side wall of the limiting plate. By means of the panel machining and positioning device, panel conveying, positioning and fixing can be achieved, subsequent machining is convenient, the machining stability is high, automatic positioning can be achieved, and the panel machining efficiency is improved.

Owner:安徽喜聚美家居有限公司

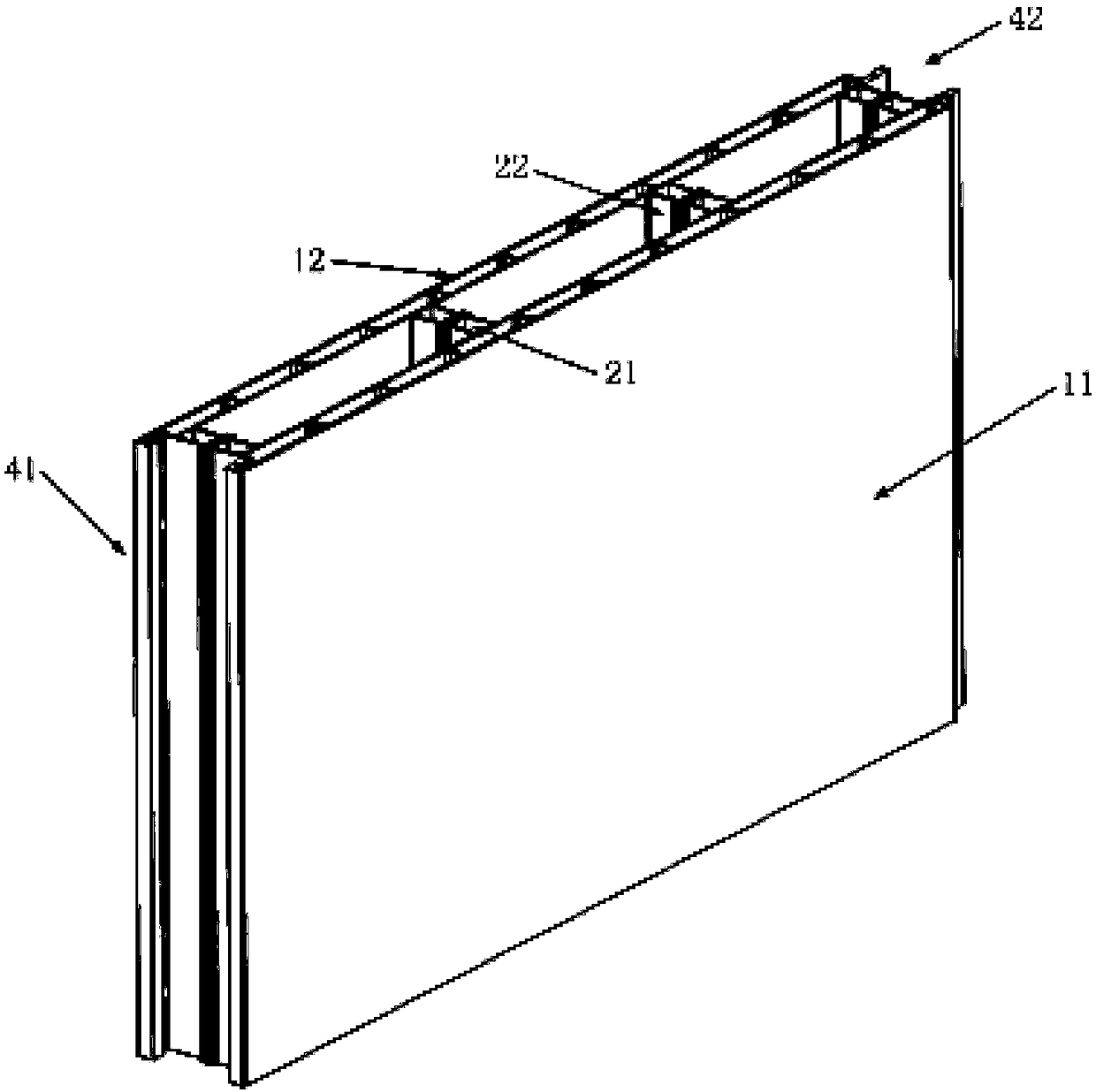

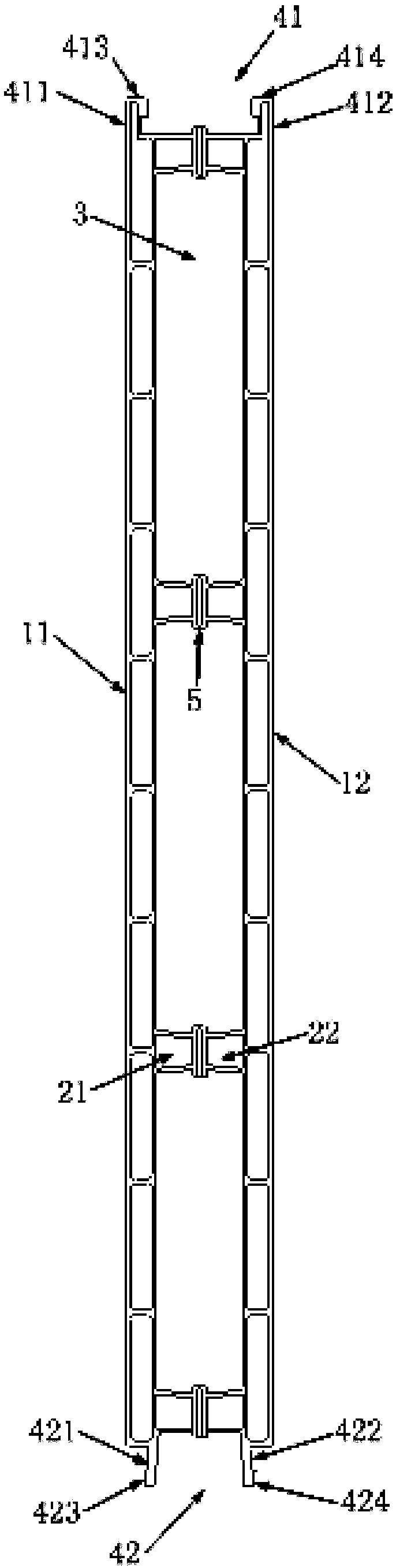

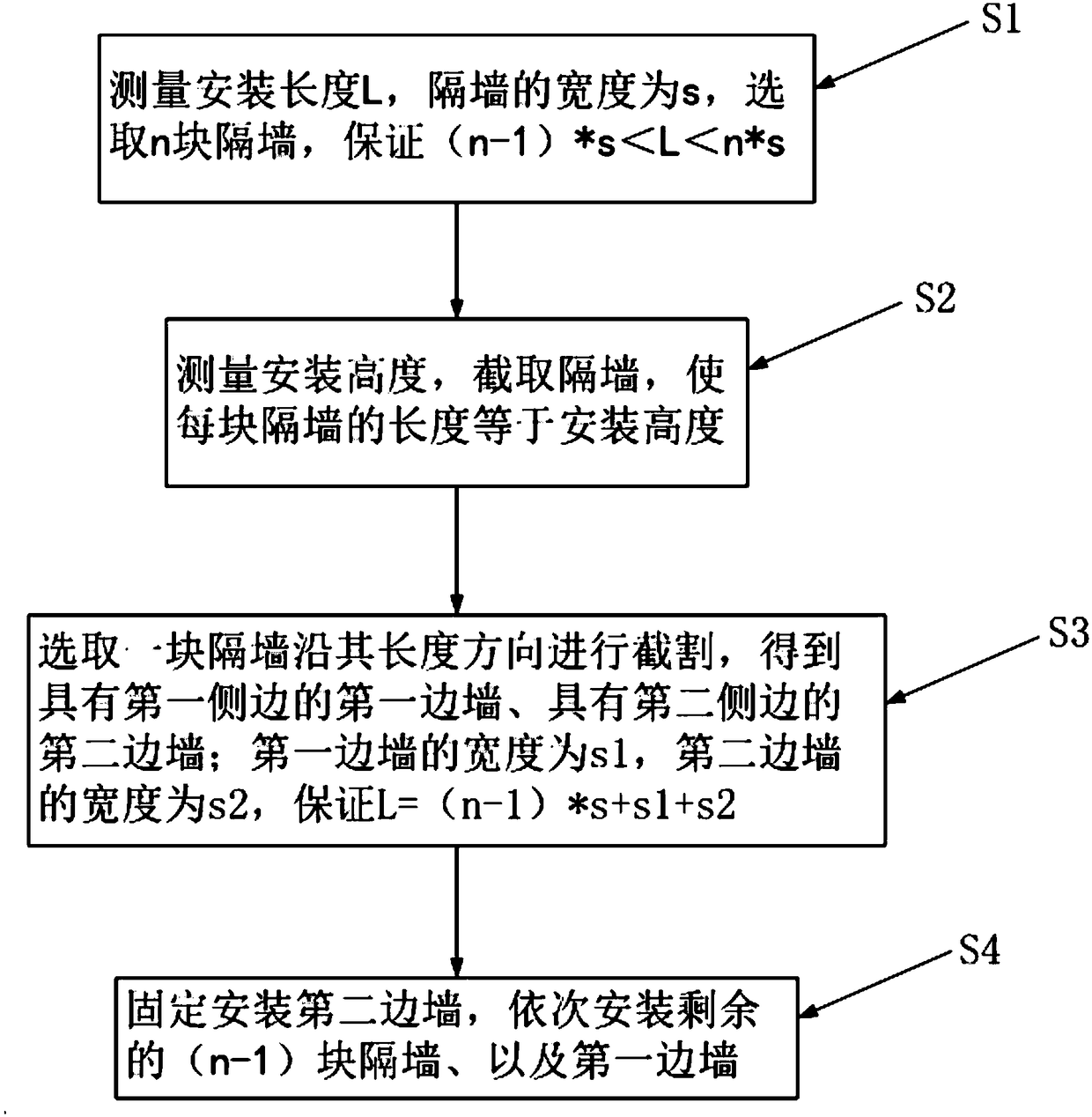

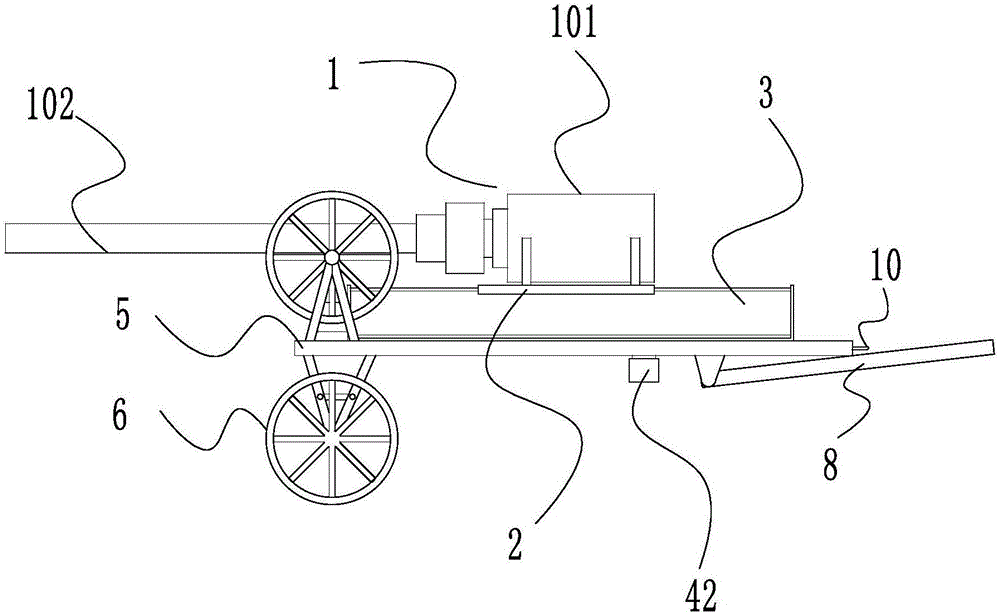

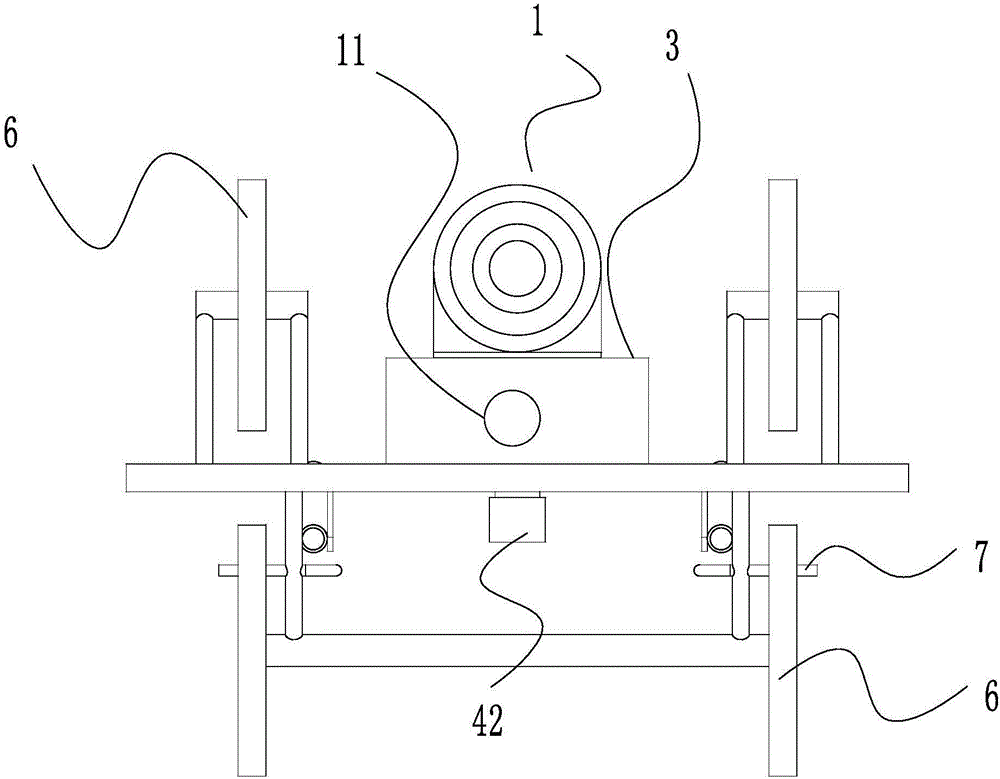

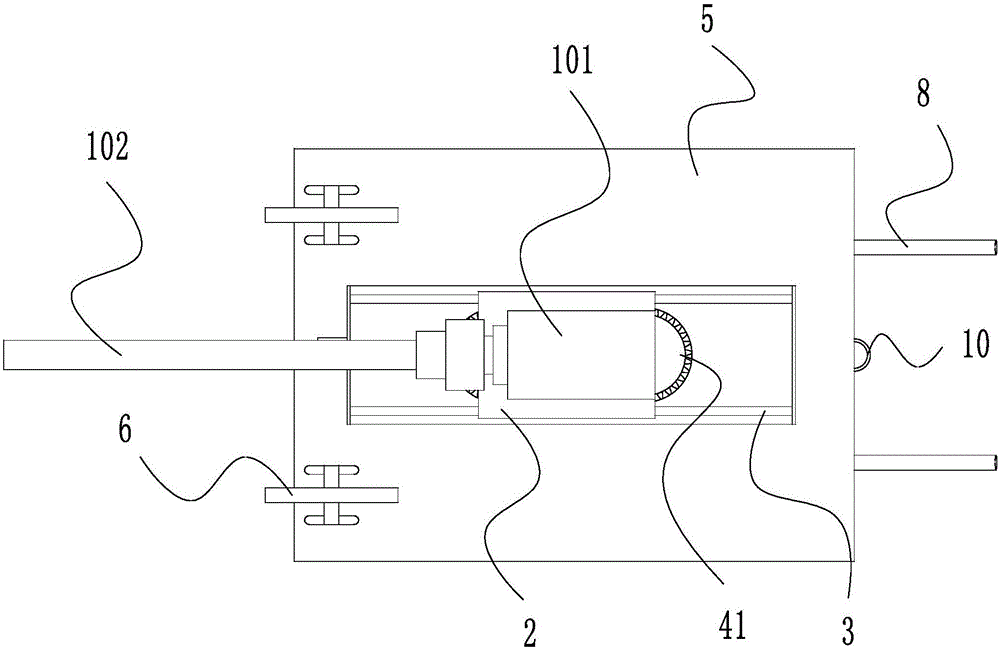

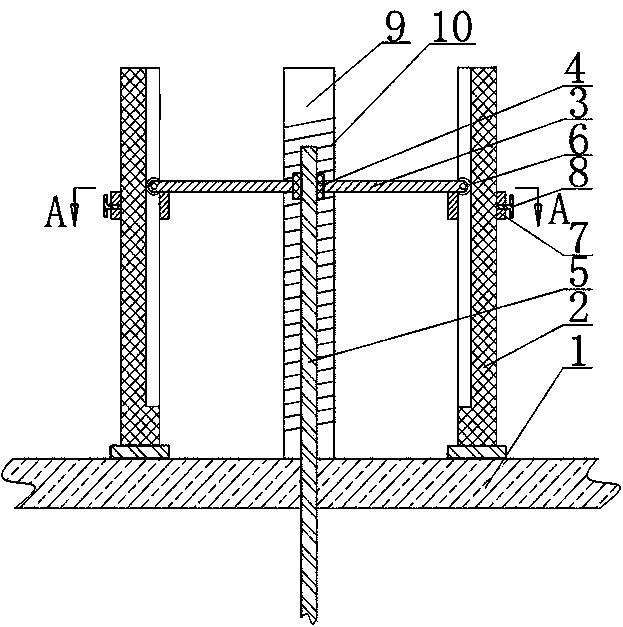

Partition wall, partition structure and mounting method of partition structure

The invention discloses a partition wall, a partition structure and a mounting method of the partition structure. The partition wall comprises a first wallboard and a second wallboard which are oppositely arranged. The first wallboard is provided with a plurality of first supports, and the second wallboard is provided with a plurality of second supports. The multiple second supports and the multiple first supports correspond in position in a one-to-one mode. A wall body is provided with a first side edge and a second side edge which are the same in extending direction. A first clamping-fit piece is arrange at the first side edge, and a second clamping-fit piece capable of being matched with the first clamping-fit piece is arrange at the second side edge. The partition structure is formed by splicing the multiple partition walls. The mounting method of the partition structure is used for mounting the partition structure. By adopting the mounting method, mounting is simple, the site construction noise is small, wet work is avoided, the application range is wide, and meanwhile, the partition structure has the good impact-resistant property.

Owner:ZHEJIANG YASHA DECORATION

Mobile sliding rail pushing type automatic side slope drilling device

InactiveCN106522835AEasy verticalHigh precisionDerricks/mastsDirectional drillingSlide plateMaterial Perforation

The invention discloses a mobile sliding rail pushing type automatic side slope drilling device which comprises a drilling machine, wherein the drilling machine drives a drilling rod to rotate through a drilling motor to realize perforation; the drilling motor is fixedly mounted on a sliding plate; the sliding plate is a flat plate with a sliding chute; the sliding plate is mounted on a rail plate vertically arranged on the lower side; the rail plate is formed by welding four vertical flat plates distributed in a rectangular manner; sliding rails matched with the sliding plate are arranged on the rail plate; the sliding plate is connected with a pushing mechanism; the pushing mechanism can push the sliding plate to slide left and right along the rail plate; the lower end of the rail plate is fixed on a platform; two wheels are respectively arranged on the upper and lower sides of the left end of the platform; the wheels are mounted on the platform through rotating shafts and bearings. When a side slope is drilled, the drilling machine can be conveniently perpendicular to the side slope and positions can be changed freely, so that the waste of resources due to operation via installation of a scaffold is avoided.

Owner:中交二公局第四工程有限公司

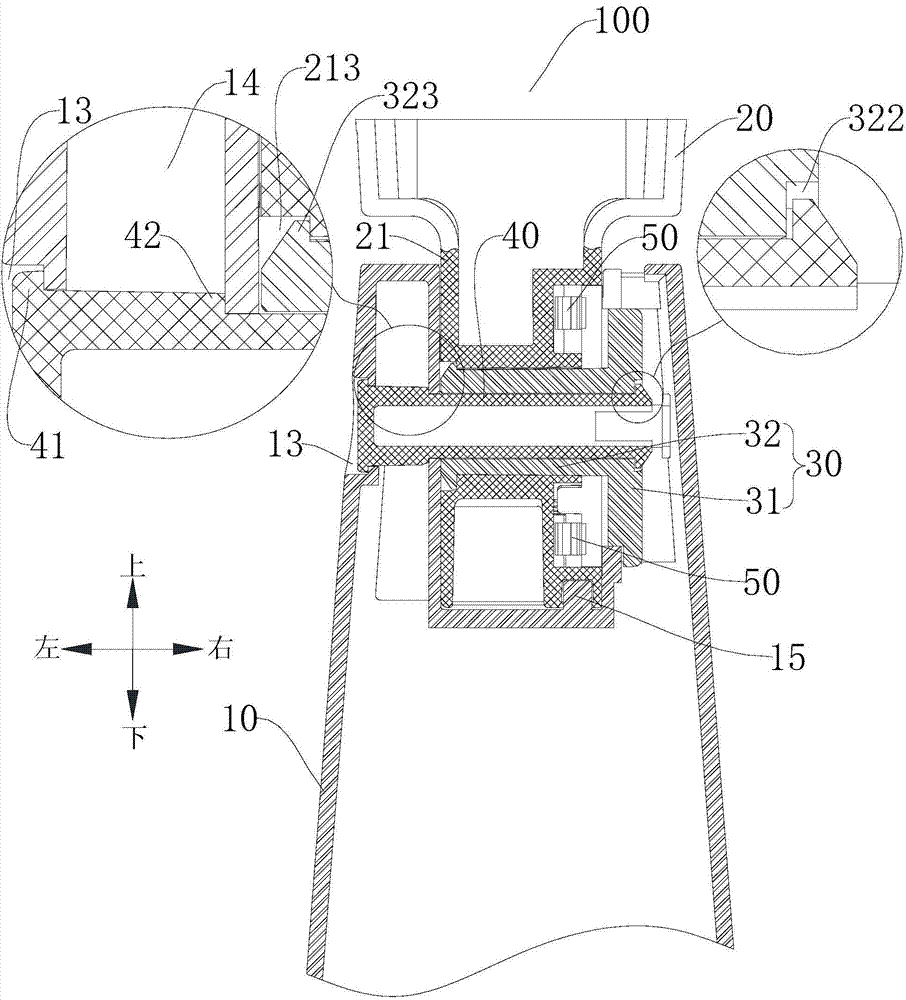

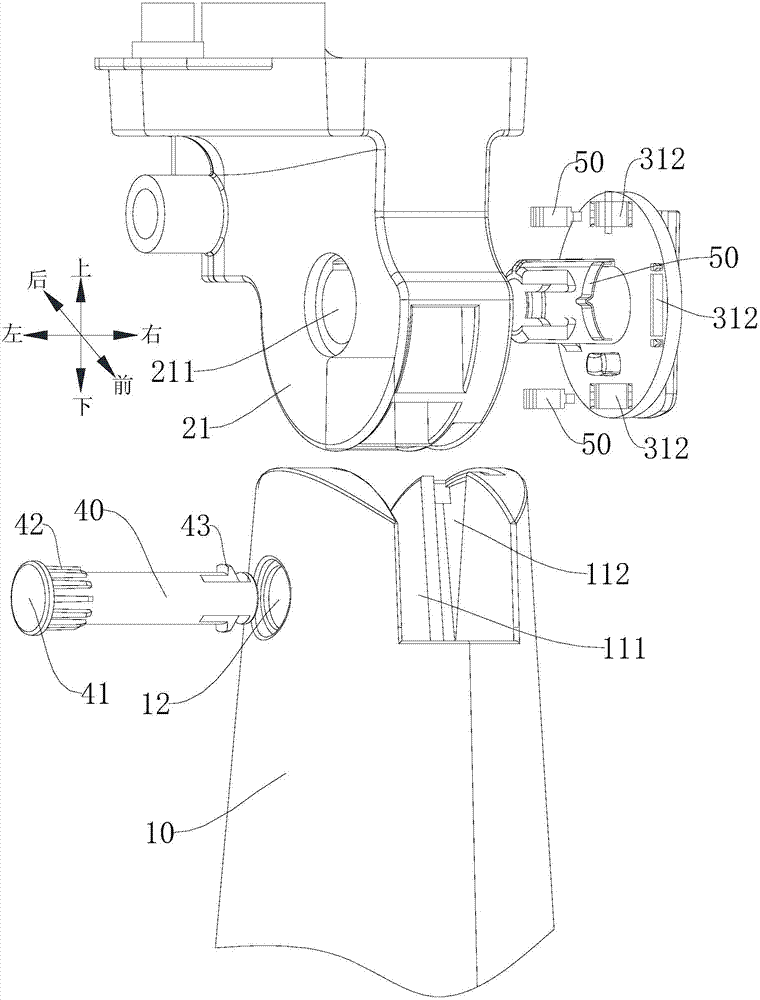

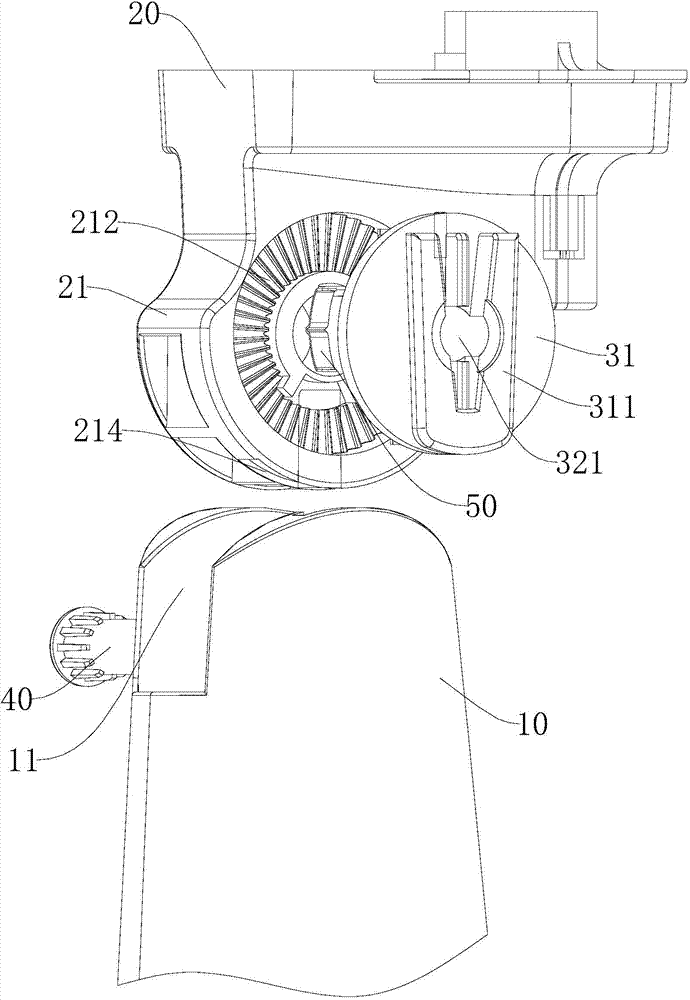

Electric fan connector assembly and electric fan thereof

ActiveCN104776063AImprove assembly efficiencyAchieve fixed positionPump componentsPumpsEngineeringElectric cooling fan

The invention discloses an electric fan connector assembly and an electric fan thereof. The electric fan connector assembly comprises a stand, a connecting elbow, a positioning cover and a positioning pin, wherein the stand is provided with an installation groove and a through hole; the connecting elbow is provided with a pivot part, the pivot part is arranged in the installation groove in a pivoting manner, a pivoting hole is formed in the pivot part, and a circle of a corrugated clamping groove is formed in one end, opposite to the through hole, of the pivot part; the positioning cover is arranged in the installation groove, the positioning cover is provided with a positioning clamping spring, the positioning clamping spring is clamped in the corrugated clamping groove, the position of the positioning clamping spring can be exchanged, one part of the positioning part is inserted and clamped into the pivoting hole, and a pin hole is formed in the positioning cover; the positioning pin penetrates through and is locked in the through hole and the pin hole. According to the electric fan connector assembly of the embodiment, the clamping pressing structure is used for substituting the traditional bolt connecting structure, the connecting structure is simplified, convenience and rapidness in assembling can be realized, a pitching angle of an electric fan head is convenient to adjust, the assembling efficiency is high, the production cost is low, the integral appearance is attractive, and the service life is long.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

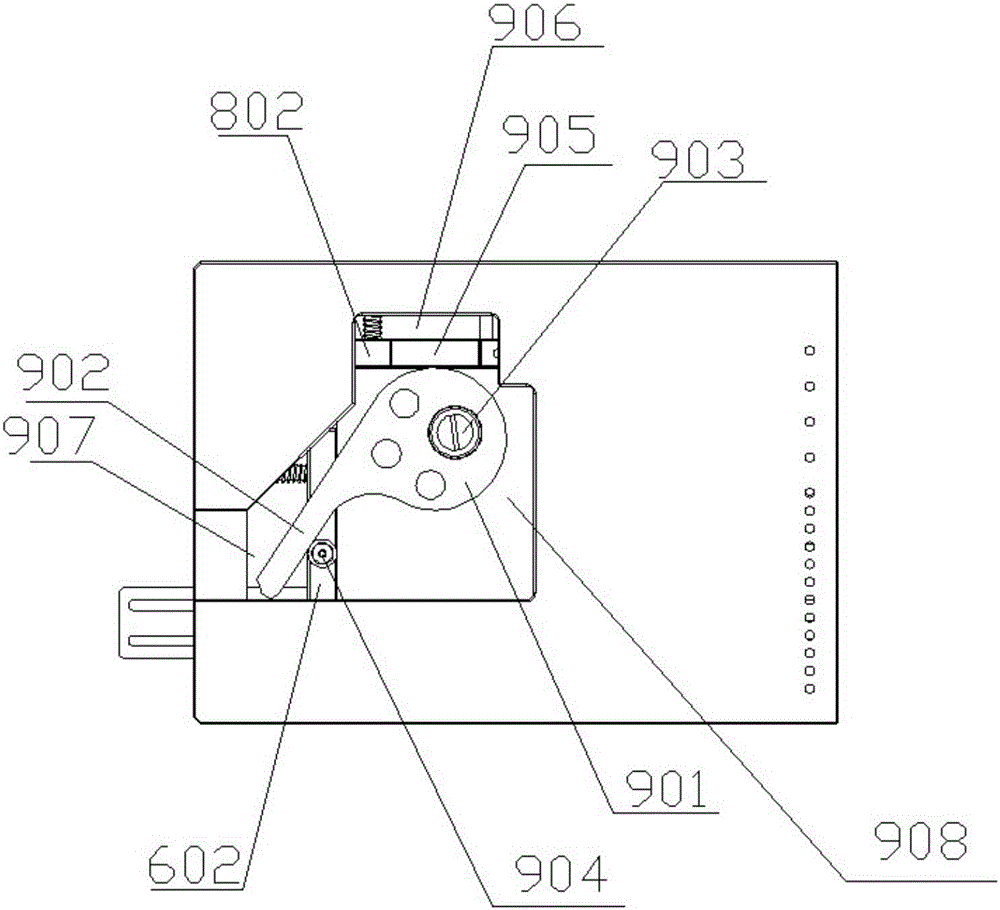

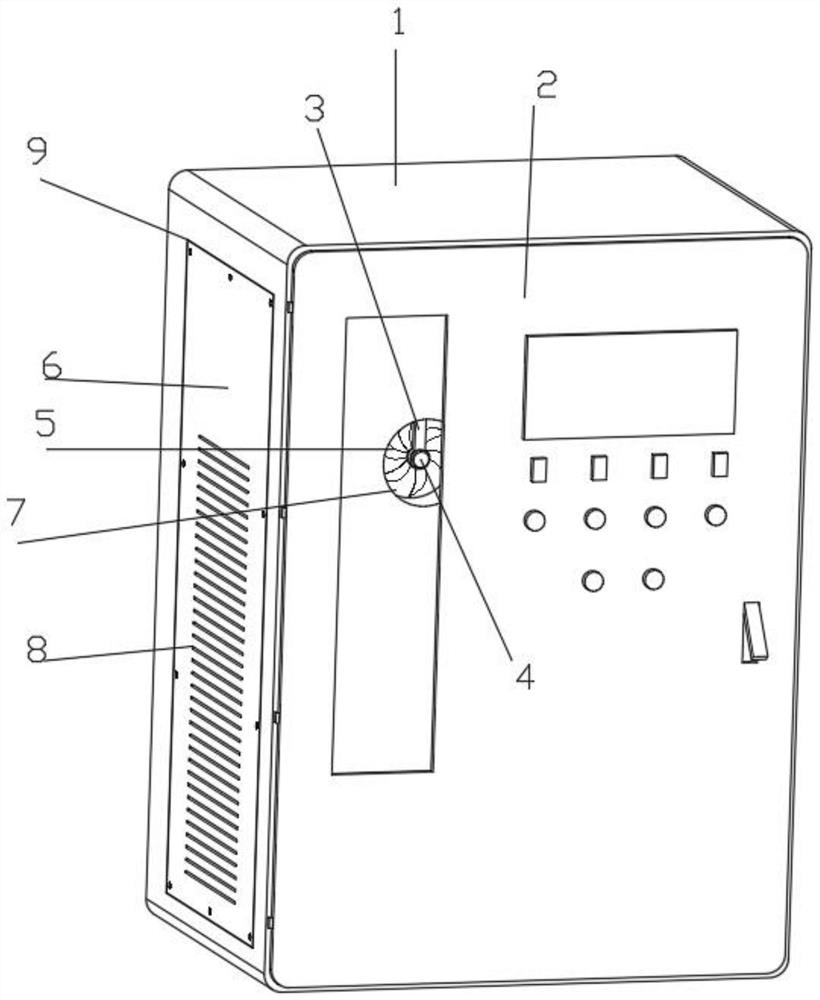

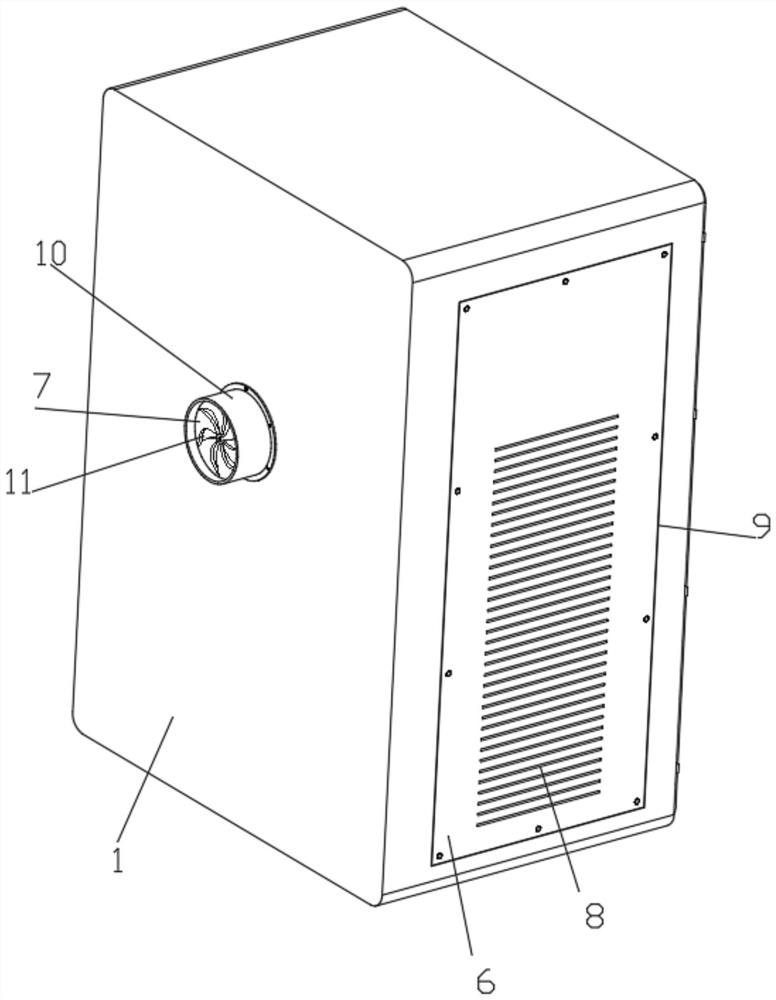

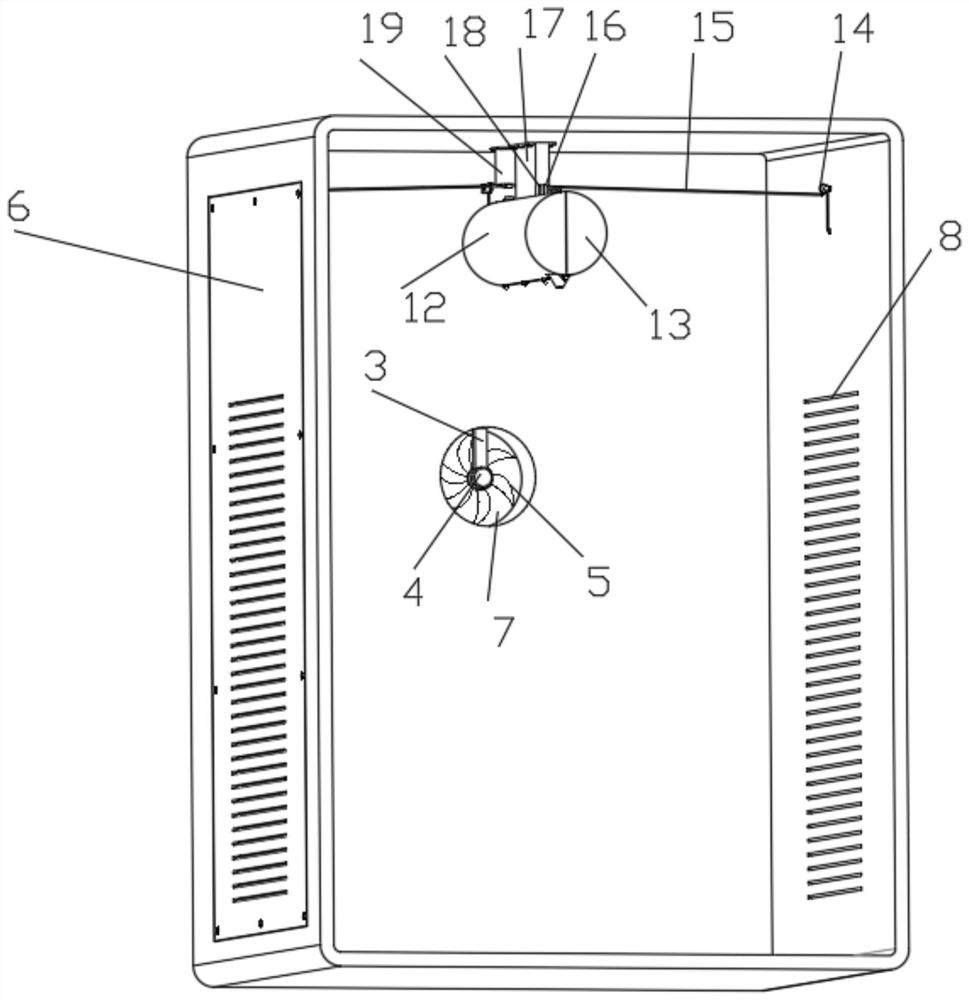

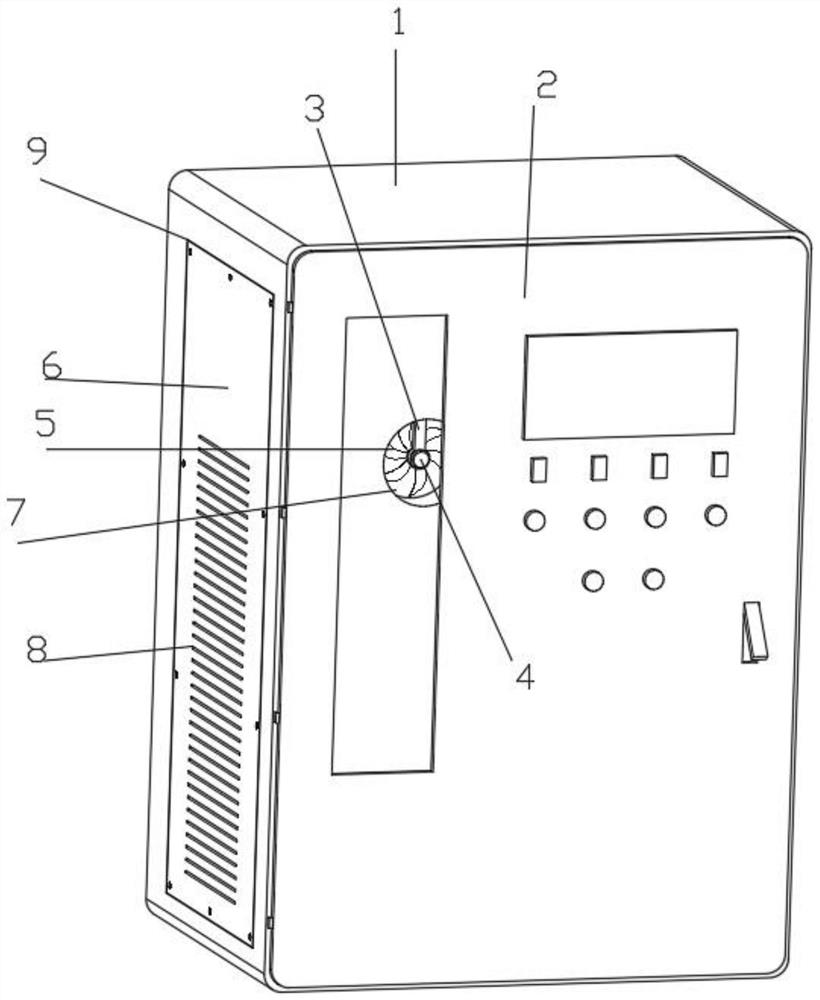

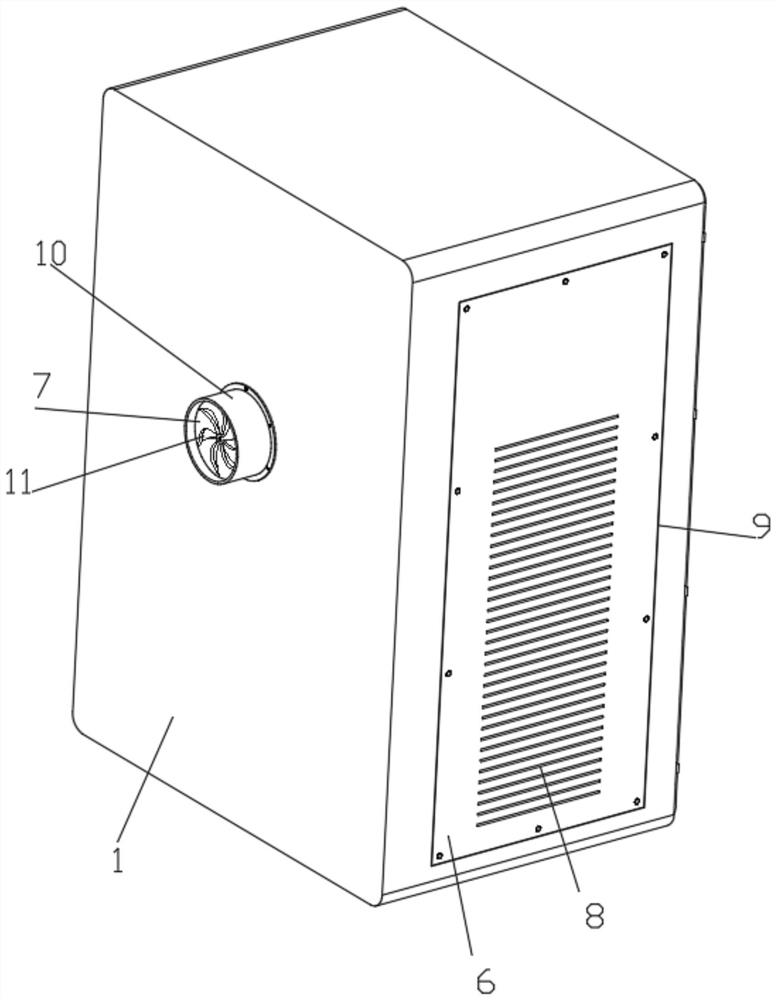

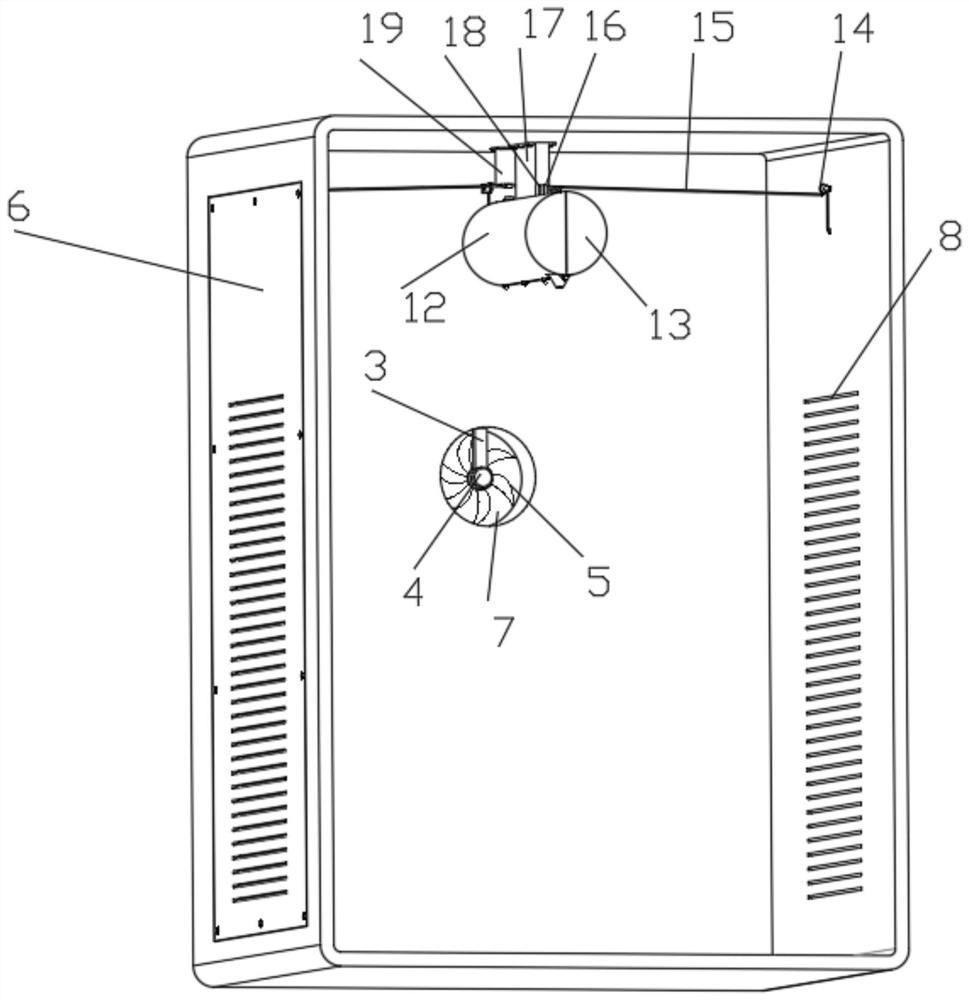

Intelligent power distribution cabinet with remote monitoring function

InactiveCN112909768AImprove protectionFire controlSubstation/switching arrangement casingsFire rescueEngineeringFire extinguisher

The invention discloses an intelligent power distribution cabinet with a remote monitoring function, and relates to the technical field of power distribution cabinets. The intelligent power distribution cabinet comprises an intelligent power distribution cabinet body, grooves are formed in the two outer walls of the intelligent power distribution cabinet body, and side plates are fixedly connected in the grooves through bolts; the side plate and the side wall of the intelligent power distribution cabinet body are uniformly provided with first air inlet inclined holes used for air inlet. The middle end of the inner top of the intelligent power distribution cabinet body is fixedly connected with a movable mounting structure for mounting an aerosol fire extinguisher, and the intelligent power distribution cabinet body is provided with a starting structure for starting the aerosol fire extinguisher at the rear side of the mounting top plate; and the starting structure comprises a mounting cylinder, a second steel rope, a second fixed pulley, a third fixed pulley, an electromagnet, a third spring, a T-shaped iron rod and a hook. According to the invention, the fire behavior is controlled in time, and the intelligent power distribution cabinet is comprehensively protected.

Owner:丁翠芳

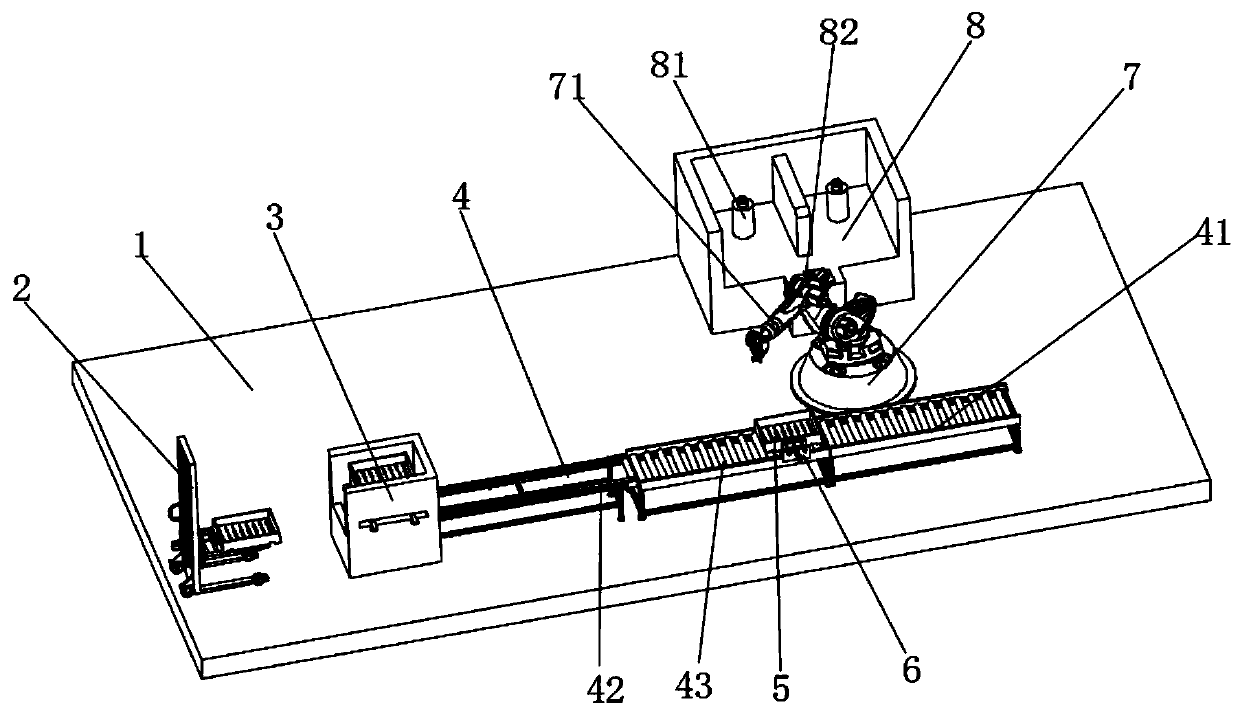

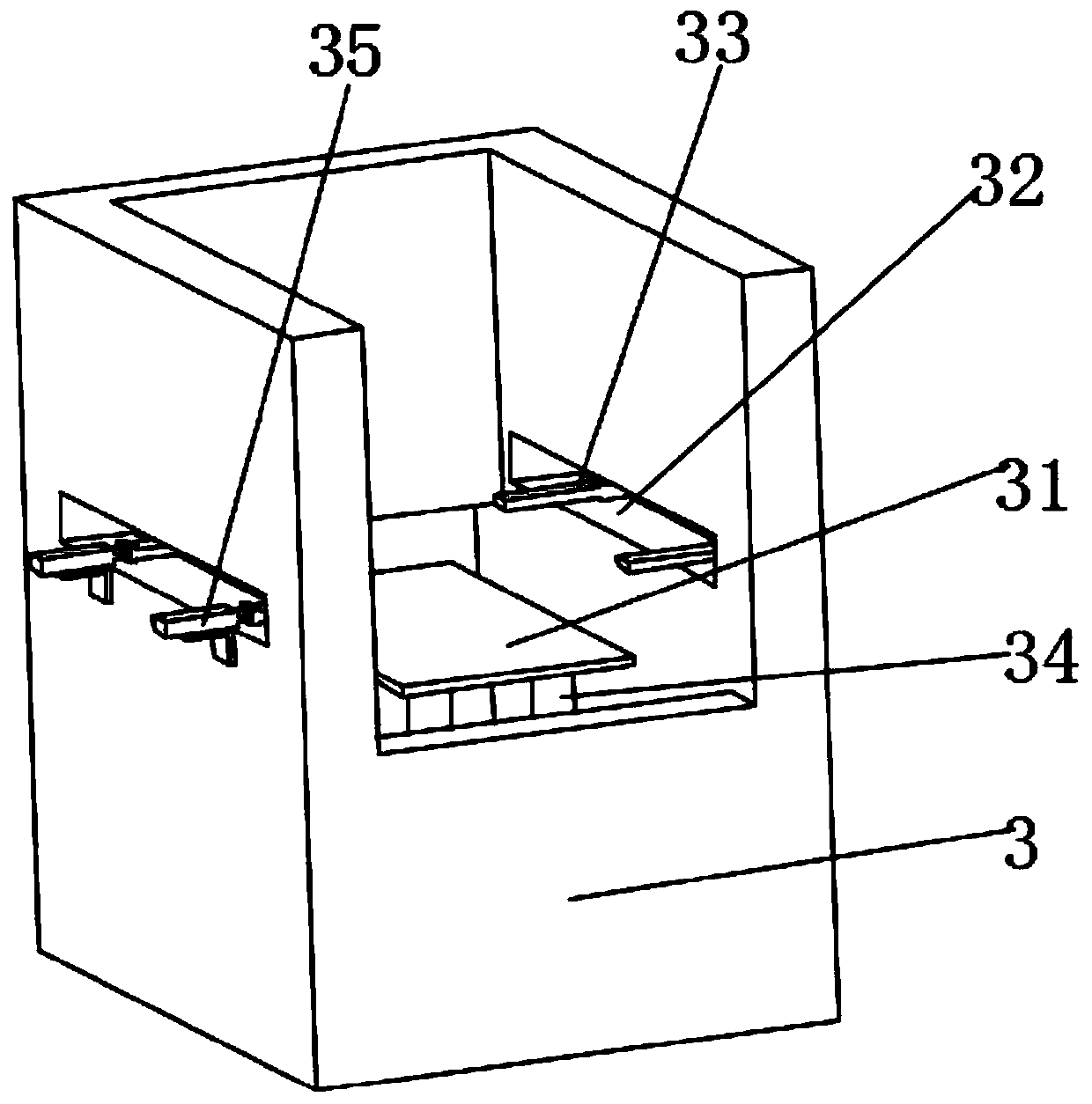

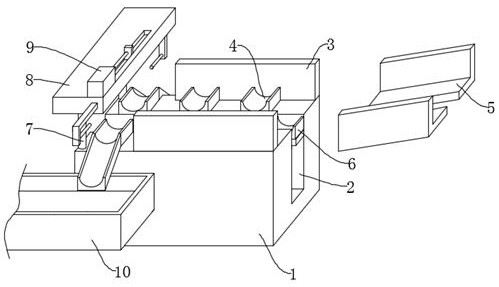

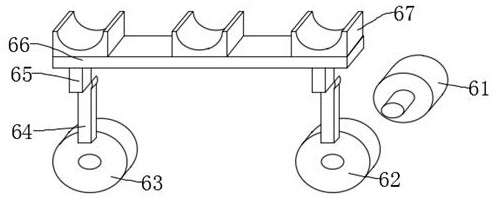

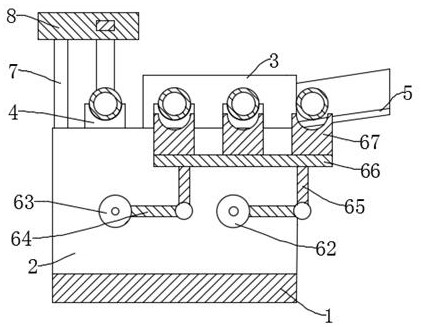

Feeding device for processing ball pin

ActiveCN110497310AReduce labor intensityImprove processing efficiencyGrinding feedersGrinding work supportsFeed processingEngineering

The invention discloses a feeding device for processing a ball pin. The feeding device for processing the ball pin comprises a workshop base, a first conveying rack, a second conveying rack, a feedingforklift, a pickup robot, a processing table and a pressing and positioning mechanism, wherein the first conveying rack, the second conveying rack, the feeding forklift, the pickup robot and the processing table are all arranged on the same horizontal plane, the processing table is positioned behind the pickup robot, the second conveying rack is positioned in front of the pickup robot, the pressing and positioning mechanism is positioned on the outer surface of the second conveying rack, the first conveying rack is positioned on the outer surface of one side of the second conveying rack, andthe outer surface of one side, far away from the second conveying rack, of the first conveying rack, is fixedly provided with a tray library. The feeding device for processing the ball pin can realizefull-automatic feeding in the ball pin processing process and positioning and fixing in the processing and feeding processes, the labor intensity of workers is reduced, and meanwhile, the feeding device for processing the ball pin forms a complete feeding processing line, and greatly improves the processing efficiency of the ball pin.

Owner:马鞍山市安工大智能装备技术研究院有限公司 +1

Conveying mechanism for can processing

InactiveCN111960063AEasy to sieveRealize automatic adjustmentConveyorsConveyor partsStructural engineeringBottle

The invention discloses a conveying mechanism for can processing. The conveying mechanism comprises a base, wherein a mounting groove is formed in the middle of the base, multiple positioning seats are mounted in the positions, located at the top of the base, of two sides of the mounting groove, guide plates are mounted on the base, chutes are mounted in the positions, located on the side walls ofthe base, of two sides of the mounting groove, each chute is connected with one end of the corresponding guide plate, a positioning mechanism is mounted between inner walls of the mounting groove, astand column is fixedly mounted at the top of the end, away from the chutes, of the base, a top plate is fixedly mounted at the top of the stand column, a shunting mechanism is mounted on the top plate and directly faces the positioning seats away from the chutes, and conveying belts are mounted on the outer wall of the end, away from the chutes, of the base. According to the conveying mechanism for can processing, canned bottles are conveyed to the chutes through the conveying belts in a unified manner and slide to the side walls of the base along the chutes, the canned bottles are placed onthe positioning seats one by one by the positioning mechanism, positioning for the canned bottles is realized, the canned bottles on the positioning seats away from the chutes are pushed to the conveying belts on the two sides of the base by the shunting mechanism, so that the opening direction of the canned bottles on each conveying belt are consistent, the canned bottles are automatically adjusted and conveyed, and subsequent processing and production are facilitated.

Owner:宿州皇冠食品有限公司

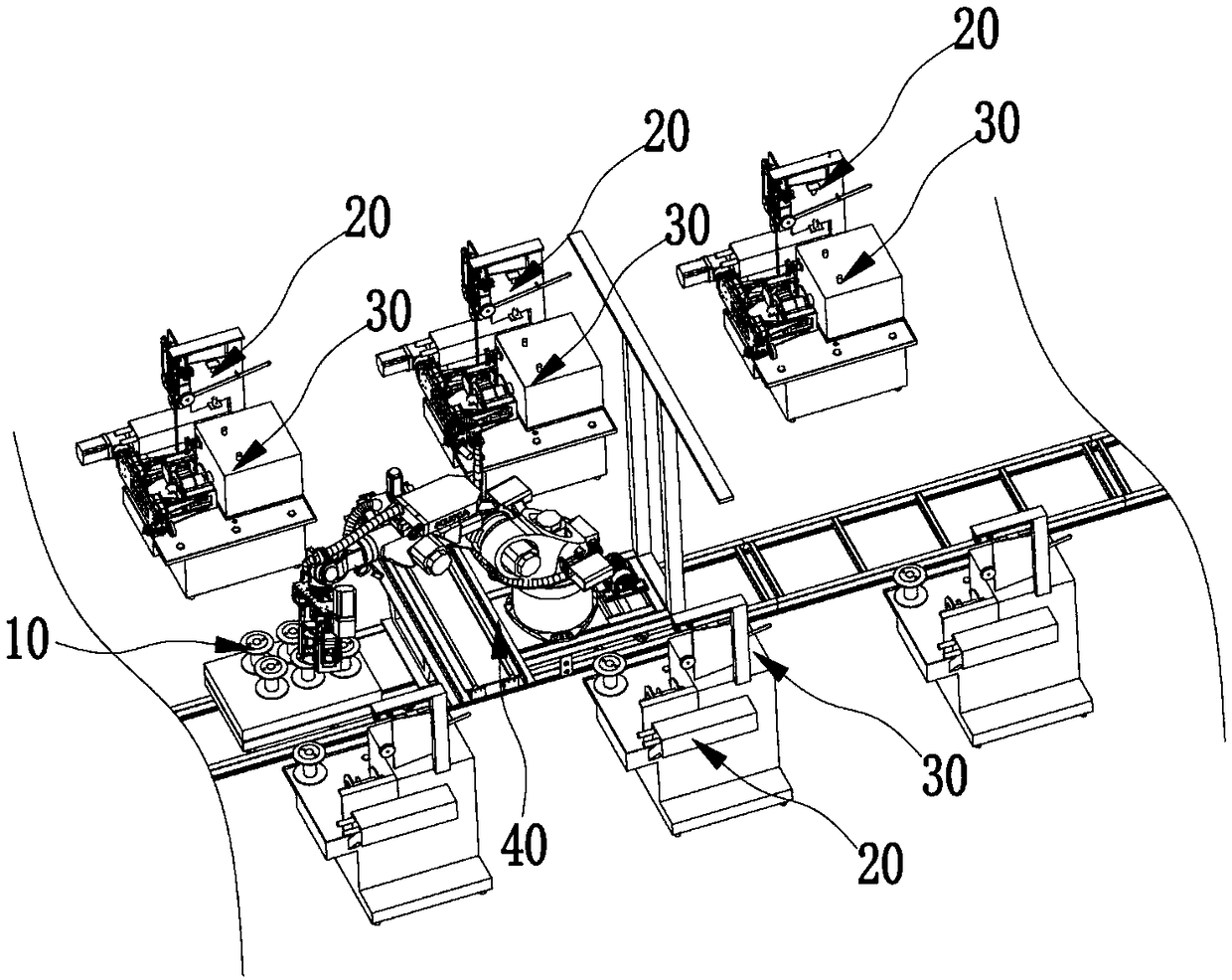

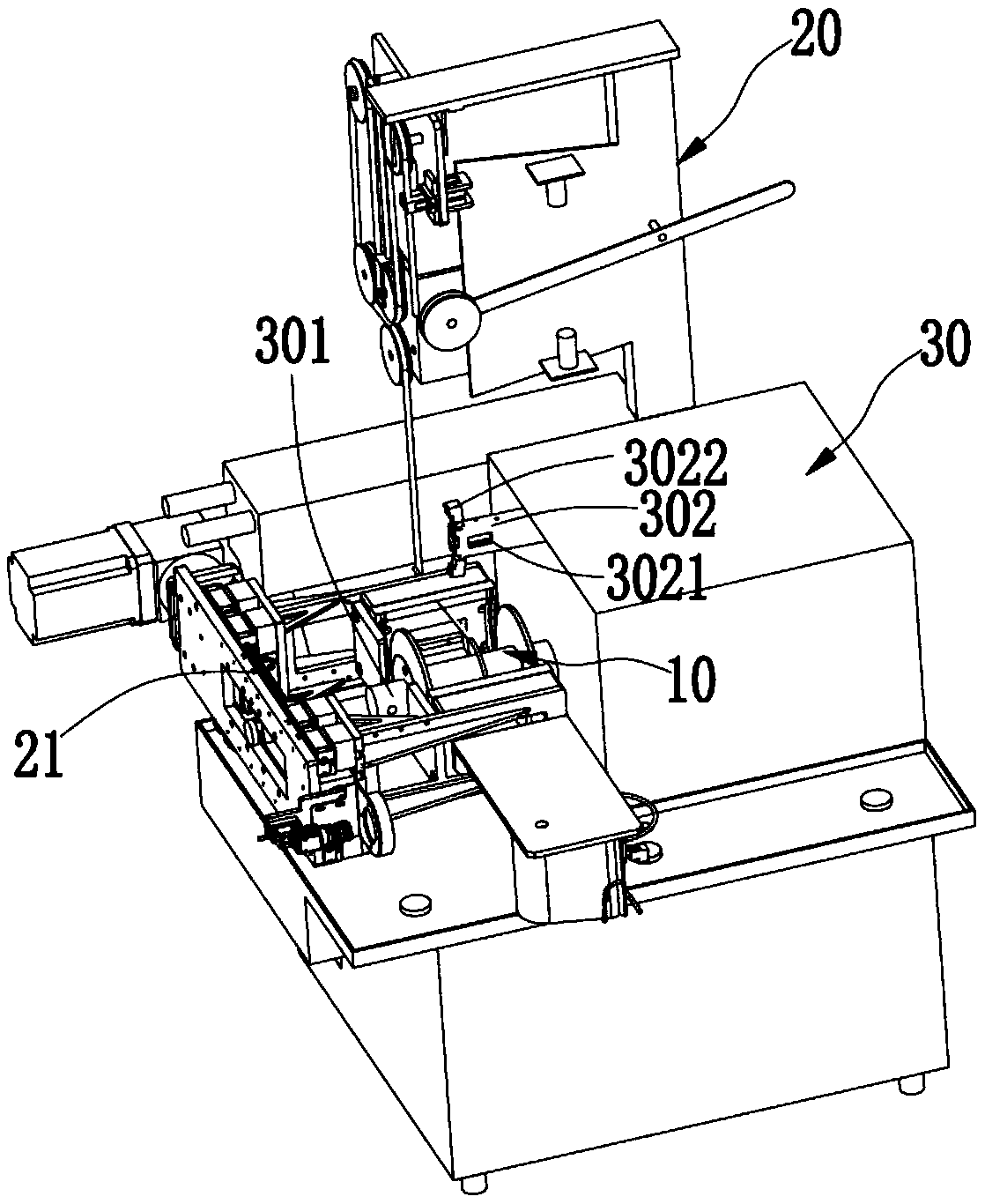

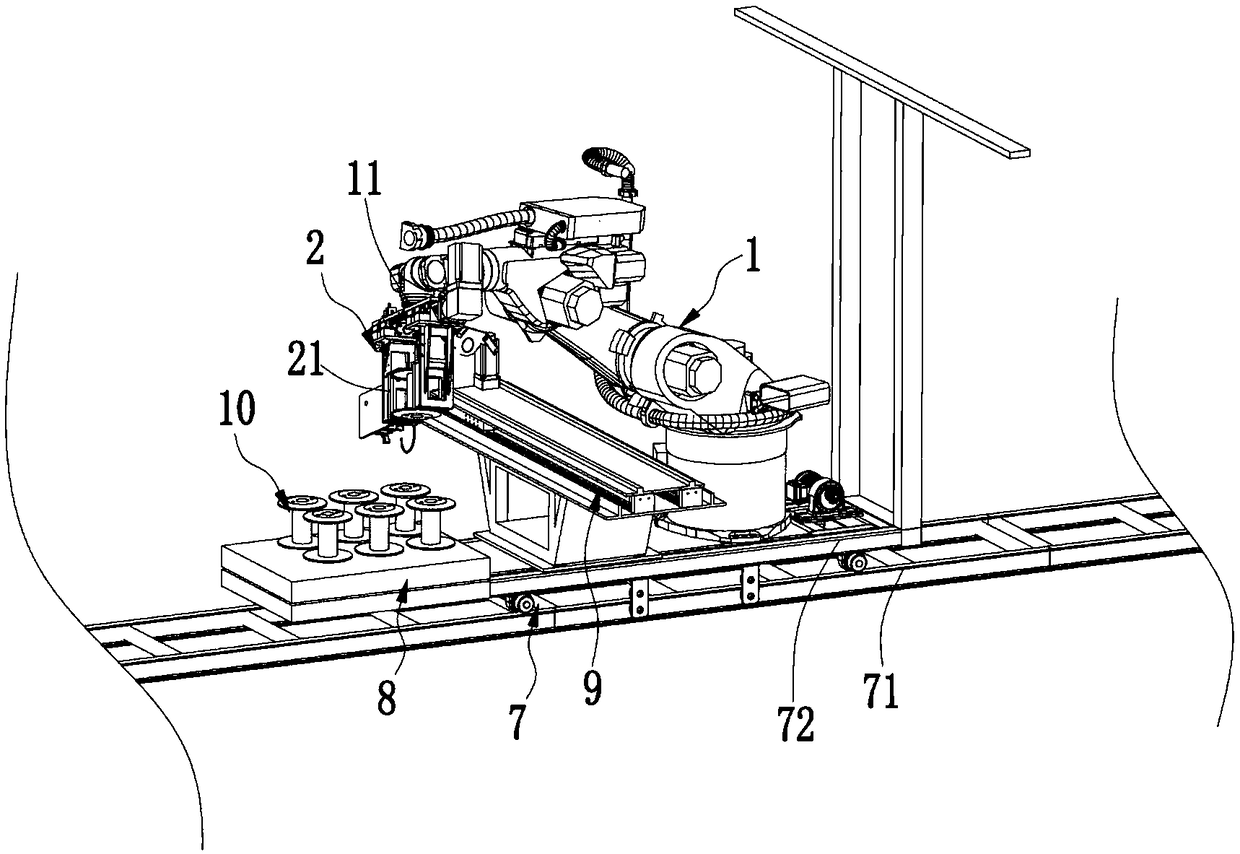

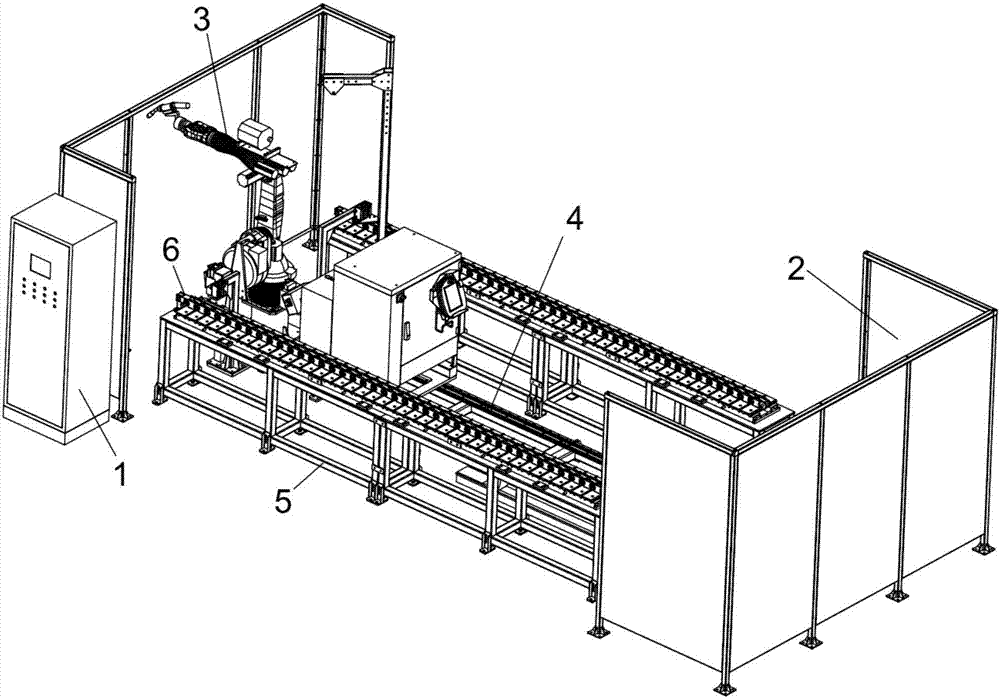

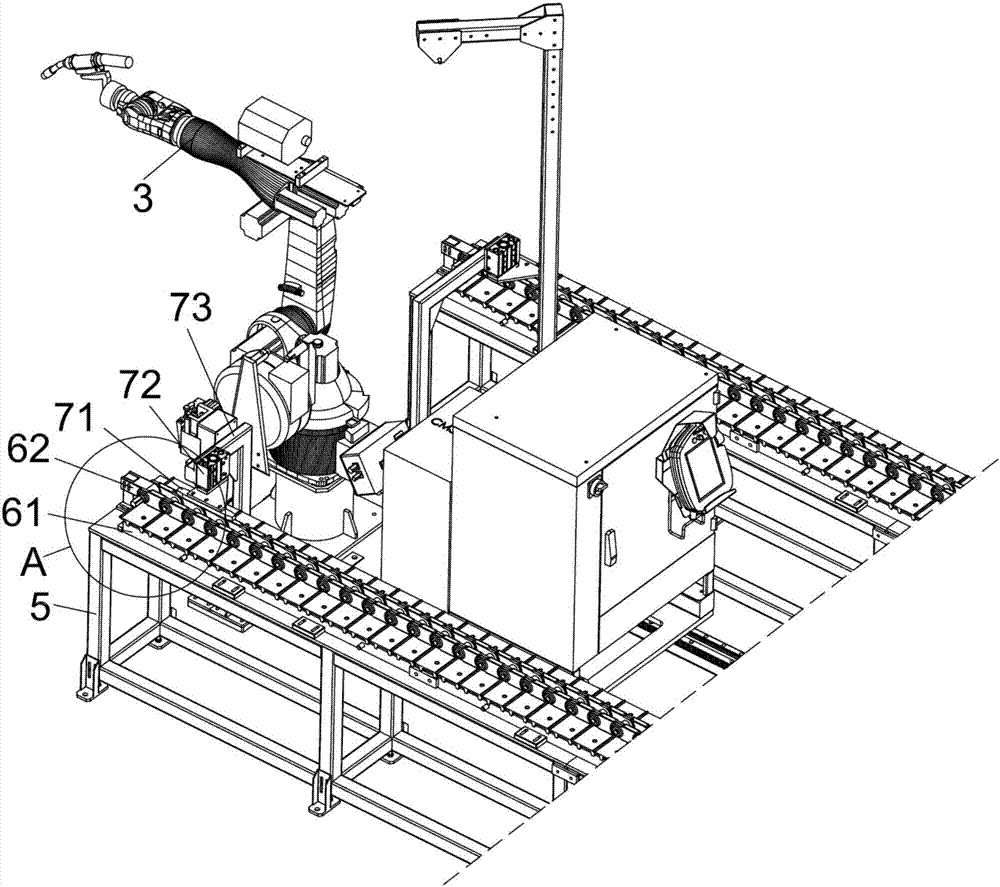

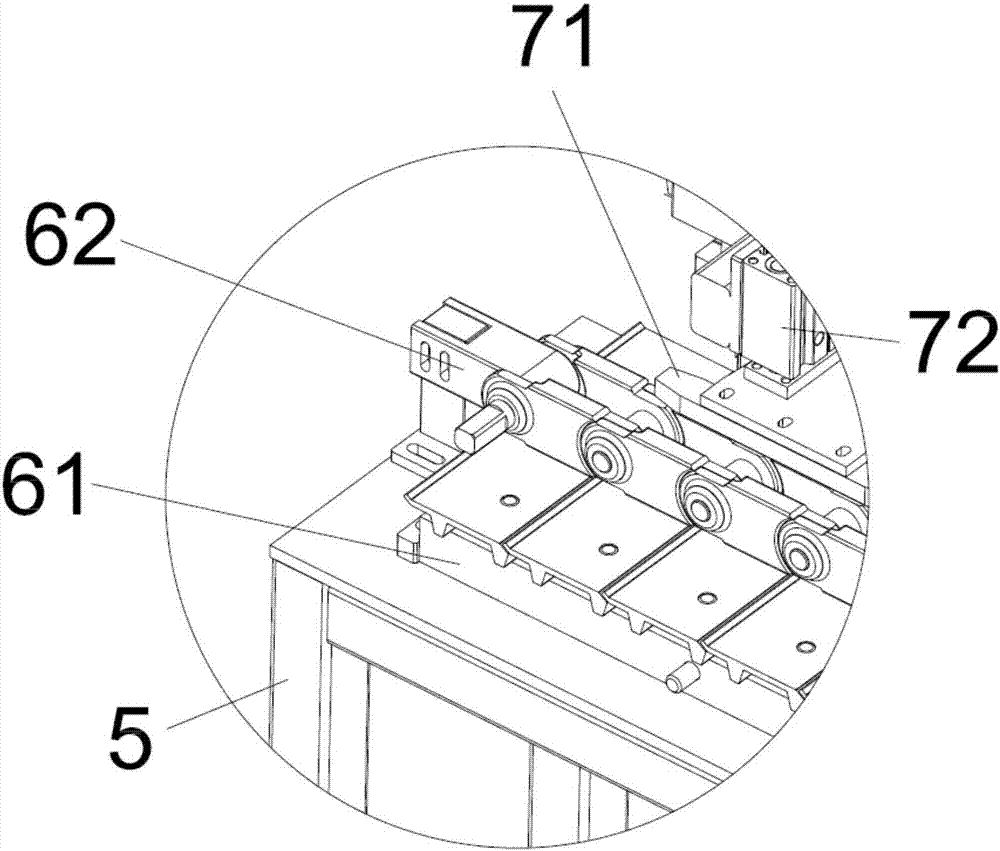

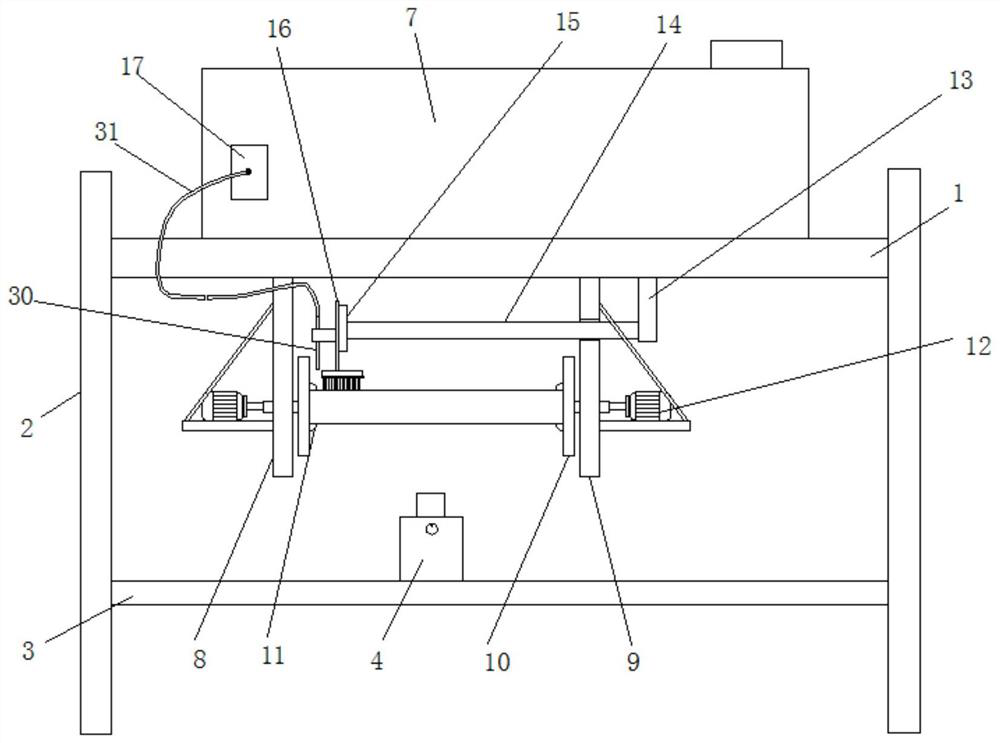

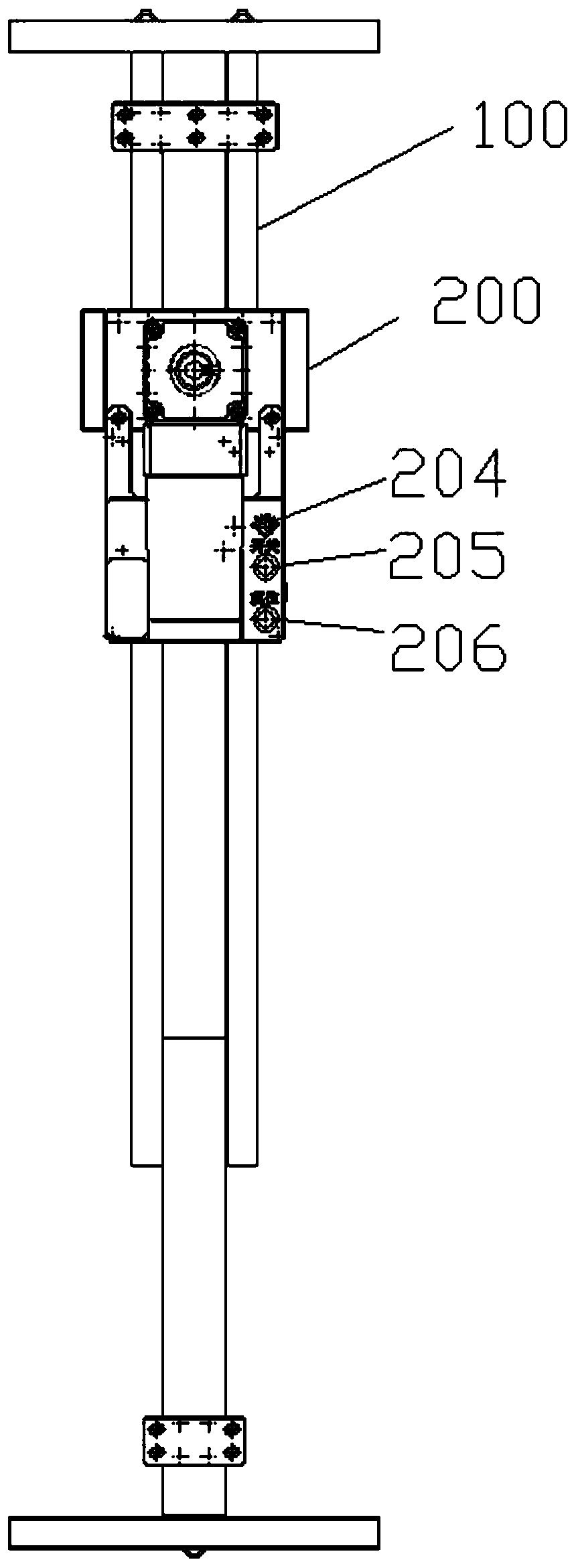

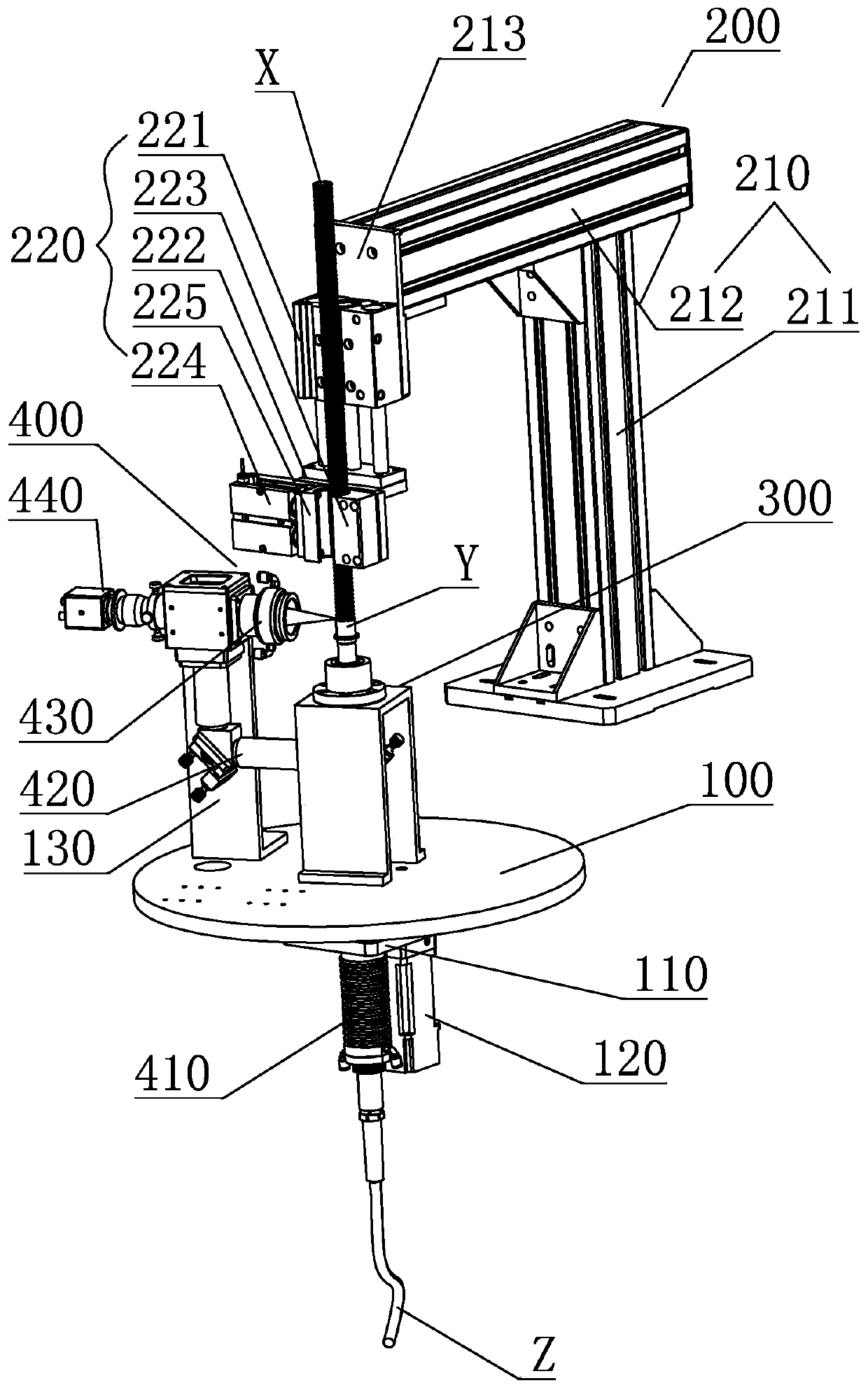

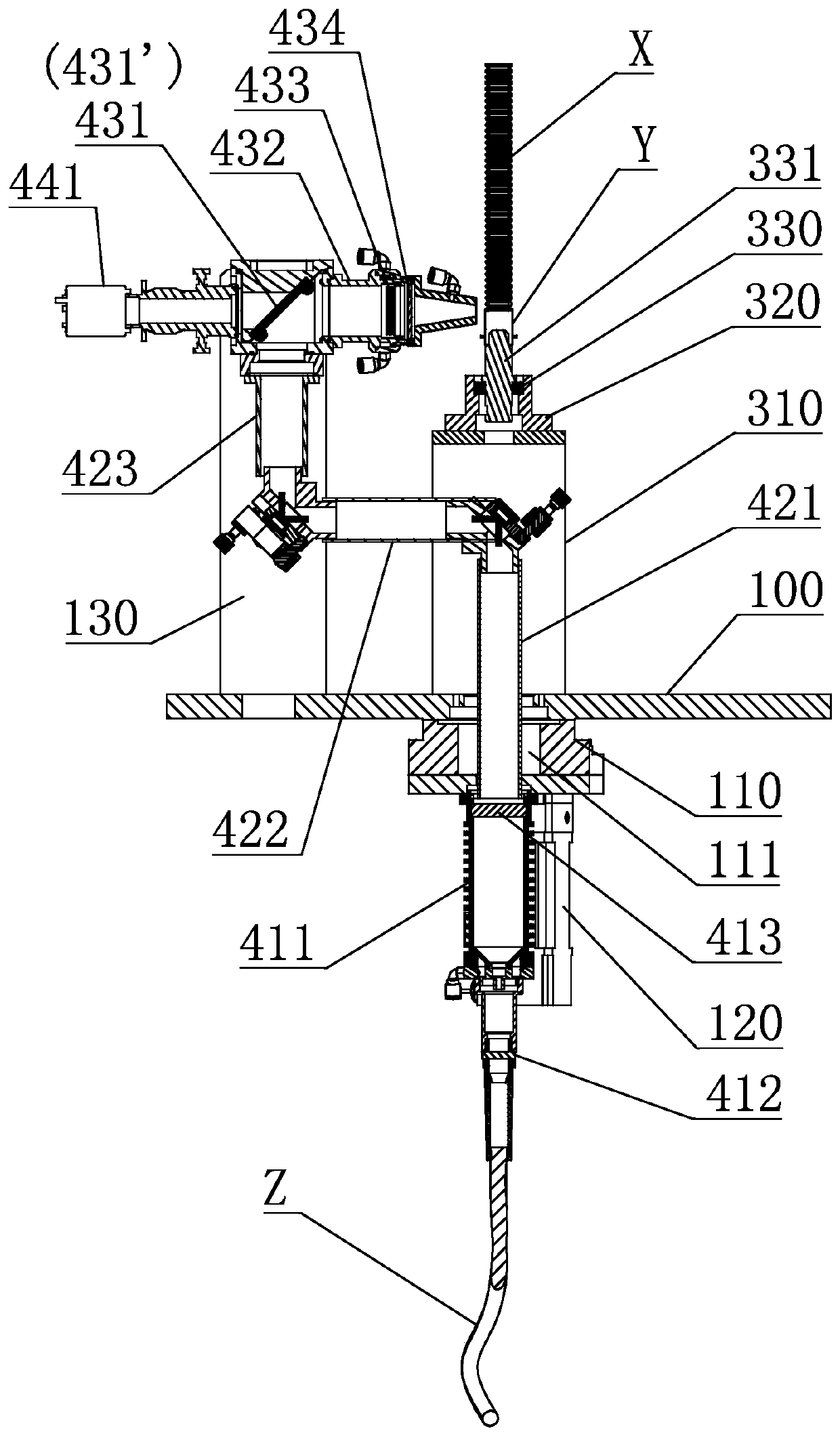

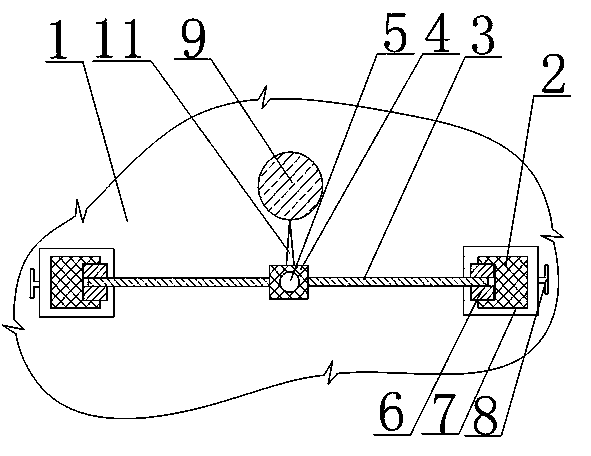

Robot welding equipment for crawler welding

InactiveCN107052649AImprove welding efficiencyAchieve fixed positionWelding/cutting auxillary devicesAuxillary welding devicesDrive motorAutomation

The invention discloses robot welding equipment for crawler welding. The welding equipment for the crawler welded robot comprises a robot moving mechanism, a welding robot is arranged on the robot moving mechanism, tool platforms for holding crawlers are arranged on two sides of the robot moving mechanism correspondingly, and positioning tools for positioning the crawlers are arranged on the tool platforms; and the robot moving mechanism comprises a base, a pair of linear guide rails and a spur rack are laid on the base, a sliding table which can slide along the linear guide rails is arranged on the linear guide rails, a driving motor is arranged on the sliding table, driving gear meshing with the spur rack is arranged on the output shaft end of the driving motor, and the welding robot is arranged on the sliding table. The welding equipment for the crawler welded robot is high in degree of automation and welding efficiency.

Owner:四川纽赛特工业机器人制造有限公司

Efficient washing equipment for aluminum material processing

InactiveCN112871789AAchieve fixed positionEasy loadingCleaning using toolsCleaning using liquidsElectric machineryStructural engineering

The invention belongs to the technical field of aluminum material processing, and particularly relates to efficient washing equipment for aluminum material processing. The efficient washing equipment for aluminum material processing comprises a transverse plate, vertically arranged vertical plates are fixedly mounted at two ends of the transverse plate, a horizontally arranged lifting plate is slidably mounted between the two vertical plates, vertically arranged push rod motors are arranged on the vertical plate, push rods of the push rod motors are in transmission connection with the lifting plate, a feeding plate is fixedly installed at the top of the lifting plate, two clamping plates are slidably installed at the top of the feeding plate, a movable plate is slidably installed at the bottom of the transverse plate, a fixed plate is fixedly installed at the bottom of the transverse plate, and a positioning plate is rotatably installed on the opposite sides of the movable plate and the fixed plate. According to the efficient washing equipment for aluminum material processing, position fixing of aluminum materials is achieved, the aluminum materials with different lengths can be clamped and fixed, feeding of the aluminum materials is facilitated, labor is greatly saved, all-directional electric scrubbing is achieved, labor is greatly saved, the machining efficiency is improved, and popularization is easy.

Owner:上饶市广利装饰材料有限公司

Device fixing rail

PendingCN110165561AAchieve fixed positionPracticalSubstation/switching arrangement detailsEngineering

Owner:GUANGDONG POWER GRID CO LTD +1

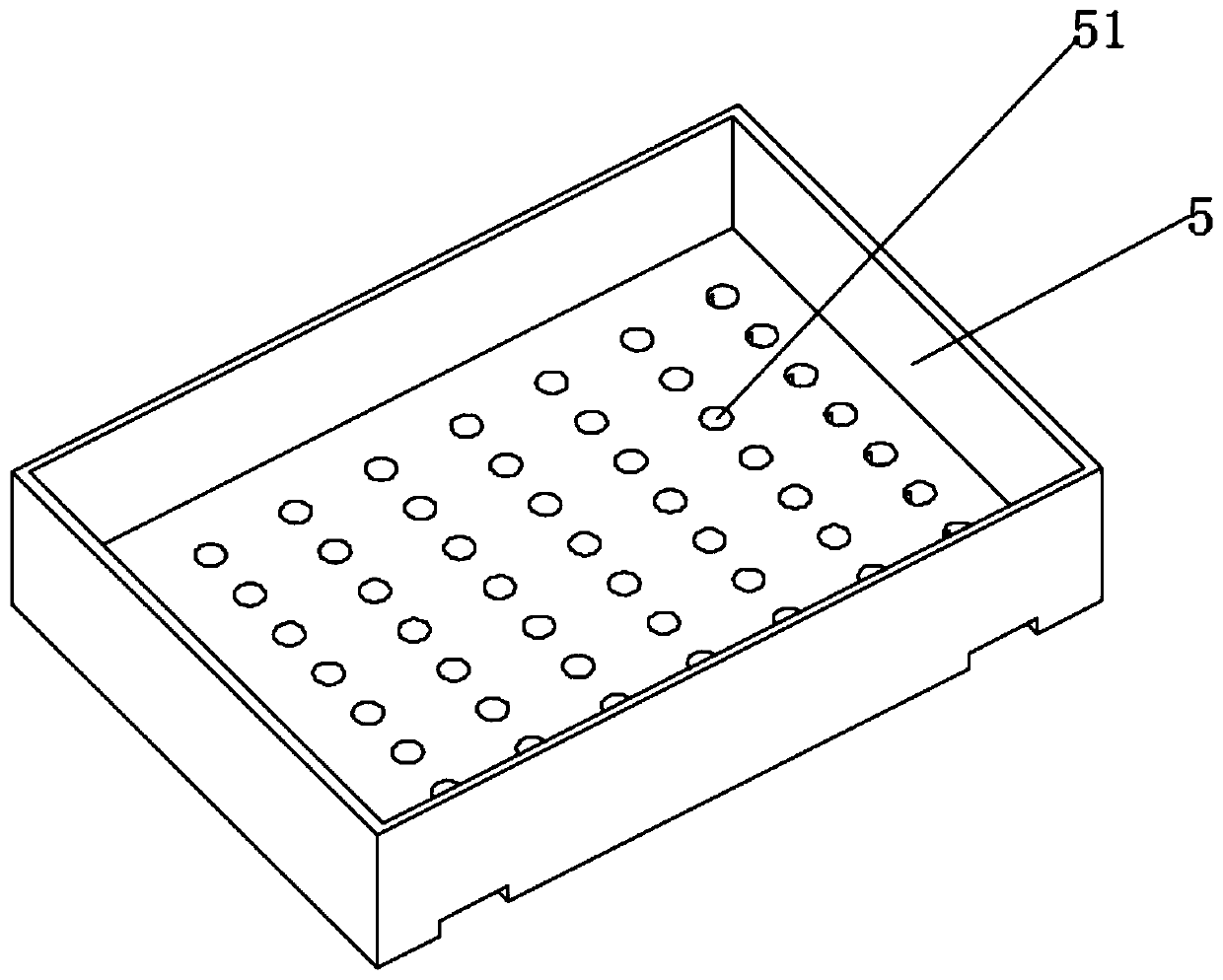

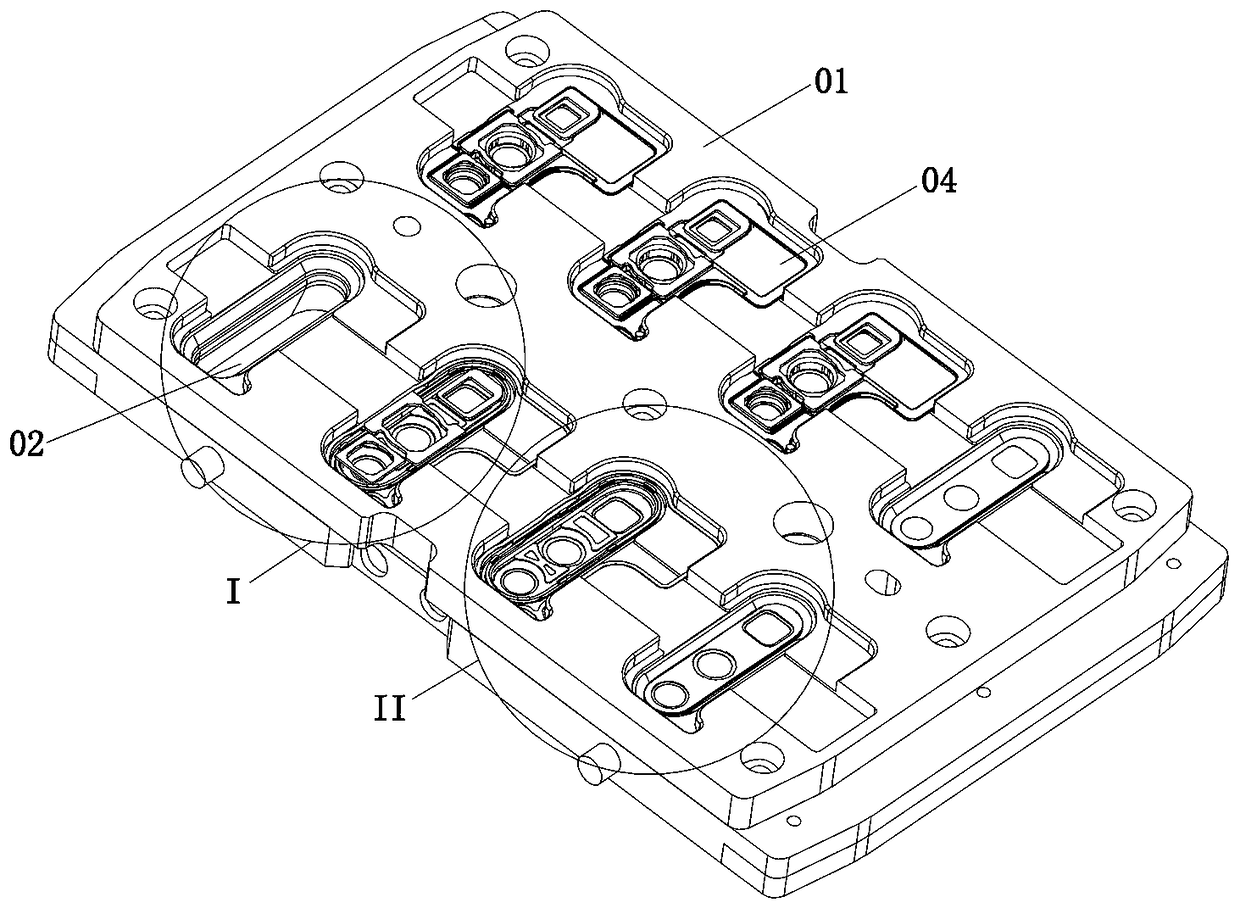

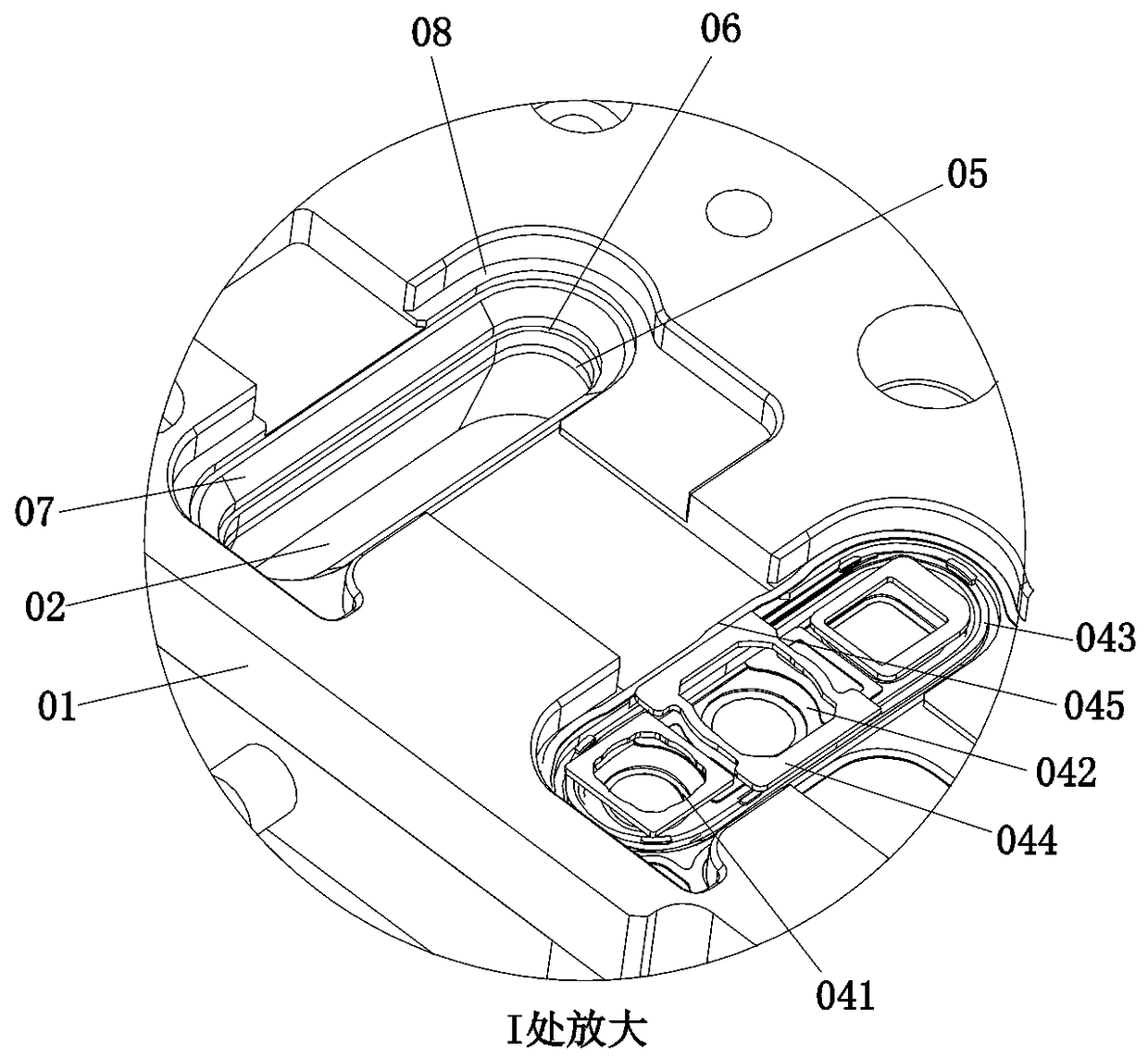

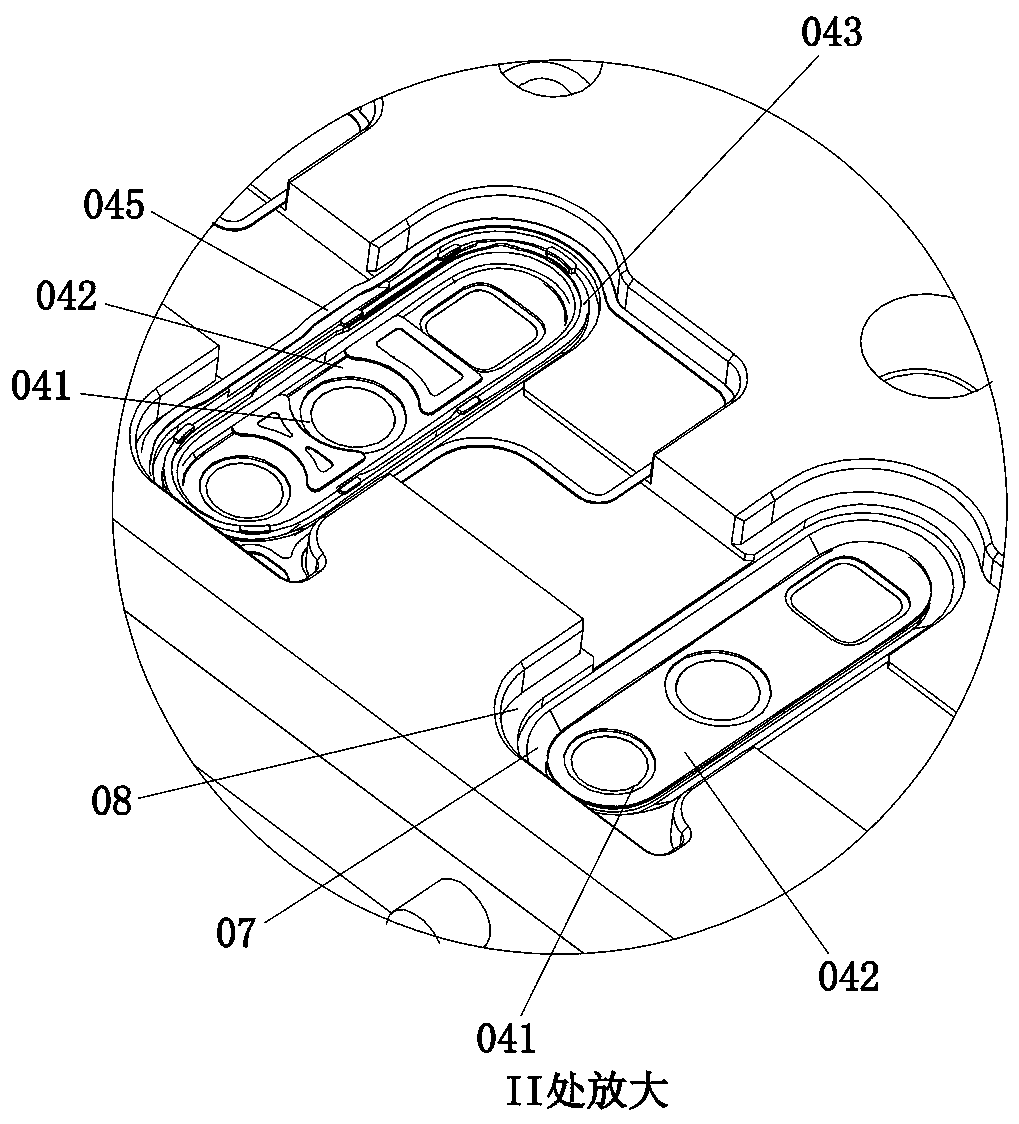

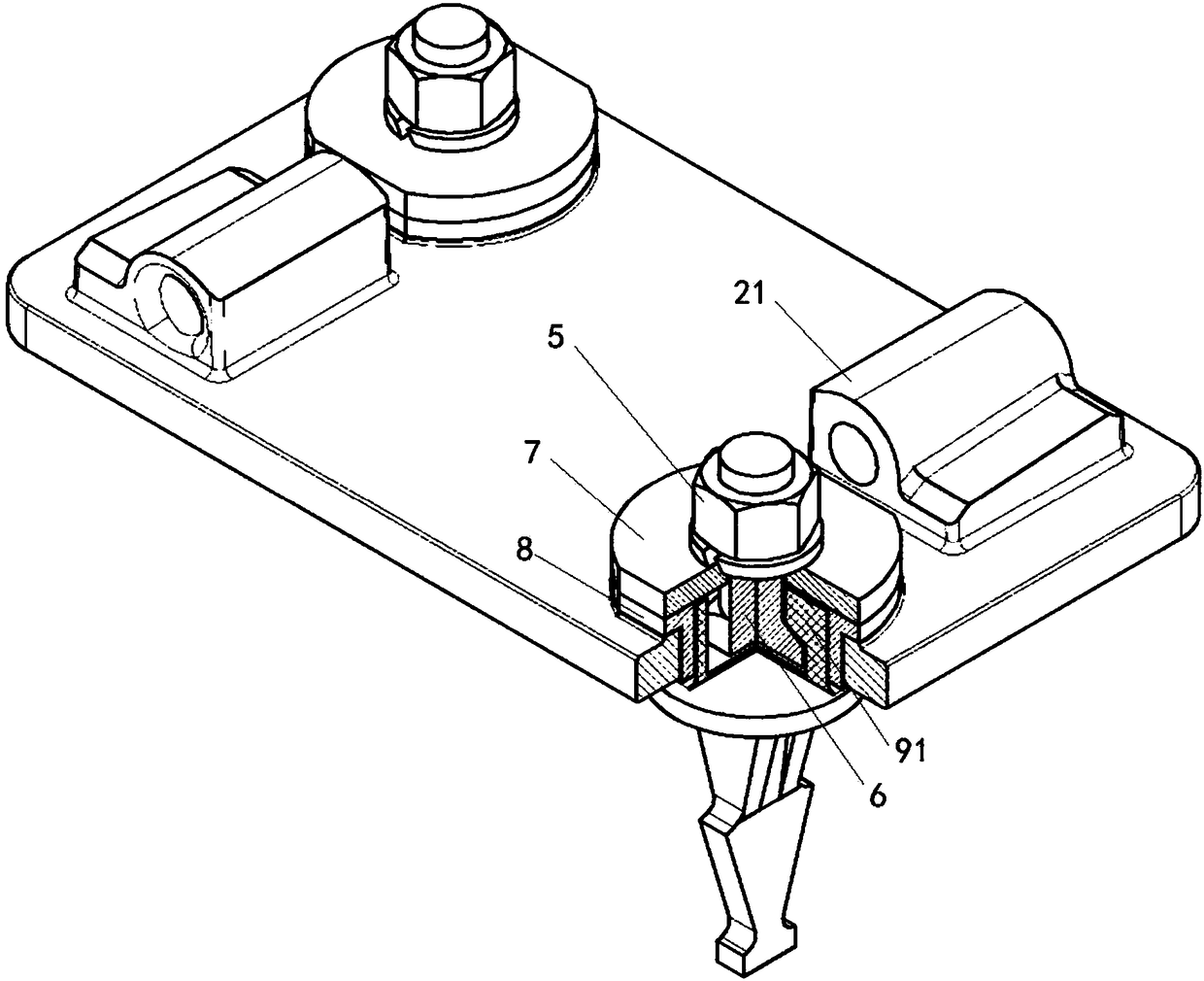

Mobile phone accessory automatic assembly positioning and adsorption supporting device and jig thereof

PendingCN109290988AImprove versatilityImprove assembly capacityMaterial gluingWork holdersEngineeringMobile phone

The invention discloses a mobile phone accessory automatic assembly positioning and adsorption supporting device and a jig for the mobile phone accessory automatic assembly positioning and adsorptionsupporting device. The positioning and adsorption supporting device comprises a support plate, a positioning component, adsorption supporting components and a guiding component, wherein the support plate is horizontally arranged below a material belt of an auxiliary material assembling machine, the positioning component is arranged on the support plate, the adsorption supporting components comprise two sets, the two adsorption supporting components are located on two sides of the positioning component correspondingly, the guiding component comprises a first guiding assembly and a second guiding assembly, the first guiding assembly is connected with the positioning component, and the second guiding assembly is connected with the adsorption supporting components. The jig comprises a jig seat, straight slots and positioning holes, and each straight slot is internally provided with at least two layers of step supporting faces to support all accessories of products. By means of the mobile phone accessory automatic assembly positioning and adsorption supporting device and the jig for the mobile phone accessory automatic assembly positioning and adsorption supporting device, automation assembly of the products at all assembly stations is realized in an assisted manner, the component universality is effectively improved, and the accessory assembly production capacity and quality are greatly improved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

Shearing equipment with wrinkle removing function for non-woven fabric processing and method

ActiveCN111979750AAvoid displacementReduce cut qualityMechanical cleaningPressure cleaningStructural engineeringNonwoven fabric

The invention discloses shearing equipment with the wrinkle removing function for non-woven fabric processing, and belongs to the technical field of non-woven fabric processing equipment. The shearingequipment comprises a workbench, a fixing frame is arranged at the top of the workbench, a second electric telescopic rod, an electric hydraulic rod and a third electric telescopic rod are arranged in an inner cavity of the fixing frame from right to left, top bases are arranged at the tops of the second electric telescopic rod, the electric hydraulic rod and the third electric telescopic rod, afirst U-shaped frame is arranged at the bottom of the second electric telescopic rod, a winding roller is arranged in an inner cavity of the first U-shaped frame, the first U-shaped frame is rotationally connected with the winding roller through a first rotating shaft, a shearing assembly is arranged at the bottom of the electric hydraulic rod, a winding assembly is arranged at the bottom of the third electric telescopic rod, and the periphery of a right shaft is sleeved with a driving roller. The shearing device for non-woven fabric processing can conduct fixed-width shearing on non-woven fabric and can iron and remove wrinkles of the non-woven fabric after shearing so as to guarantee the processing quality of the non-woven fabric.

Owner:瑞安市兴源塑料制品有限公司

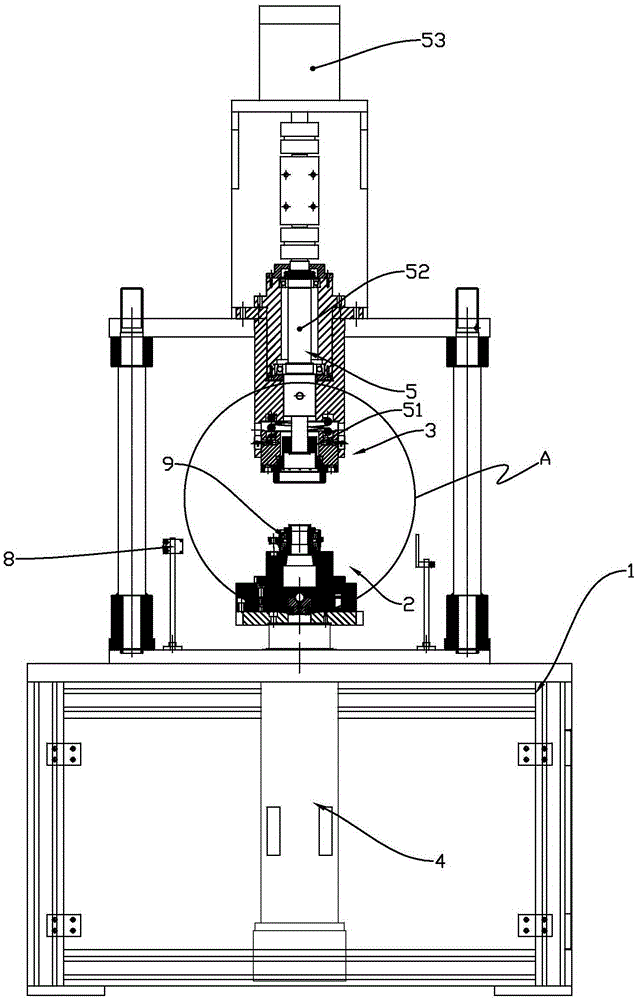

MEMS palladium alloy probe testing method and probe loading method thereof

ActiveCN111504767AFit closelySmooth rotationMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesProbe cardSprayer

The invention discloses an MEMS palladium alloy probe testing method and a probe loading method thereof, belongs to the field of IC manufacturing industry, and particularly relates to a device and method for testing the performance of a palladium alloy probe in an MEMS probe card and a related key technology. The method comprises the following steps of firstly, loading a to-be-tested probe, including a to-be-tested probe loading method for testing the tensile property and a to-be-tested probe loading method for testing the bending property; then setting the test temperature and humidity, namely through the sensor monitoring and the cooperation of a sprayer, a heater and a fan, adjusting the temperature and humidity, wherein in the adjustment process, a disturbance main body rotates under the action of an electromagnetic pole to ensure that the temperature and the humidity in a test environment are uniform; and finally testing. The tensile property and bending property of the to-be-tested probes with different parameters can be tested by only needing the symmetrical bending test structure to work. According to the method, the tensile property and the bending property of the probe onthe MEMS probe card can be tested.

Owner:强一半导体(苏州)股份有限公司

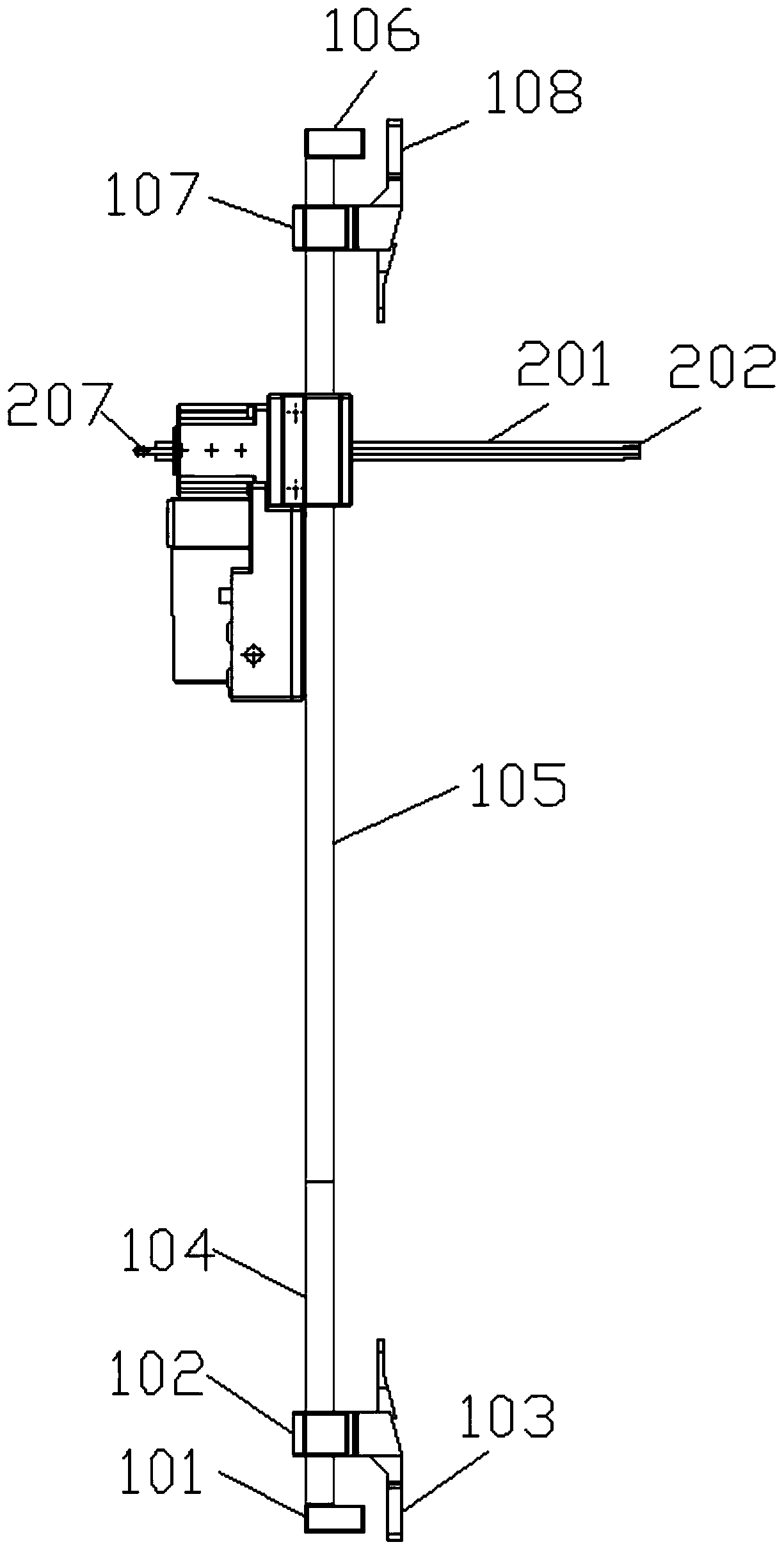

Pipeline laser welding machine

PendingCN110026681APrevent rotationSolve fatigue damageLaser beam welding apparatusEngineeringMechanical engineering

The invention discloses a pipeline laser welding machine. The pipeline laser welding machine comprises a motor rotary table arranged on a machine base and a clamping and locating device. The clampingand locating device comprises a locating frame and a pipeline clamping mechanism arranged above the center of the electric rotary table. A pipe joint locating device is arranged in the position, belowthe pipeline clamping mechanism, of the electric rotary table. The electric rotary table is provided with a laser welding device. The laser welding device comprises a laser alignment assembly connected with a laser generator, a light path guide assembly and a laser focusing assembly. The laser alignment assembly is fixed to the position, below the center of the electric rotary table, of the machine base. The light path guide assembly is fixedly mounted on the electric rotary table. One end of the light path guide assembly corresponds to the laser alignment assembly, and the other end of the light path guide assembly is connected with the laser focusing assembly. The laser focusing assembly points towards the location between the pipeline clamping mechanism and the pipe joint locating device. Accordingly, the problem that an optical fiber is twined onto equipment easily and fatigue failure is caused is effectively solved, and bending deformation is caused to gas pipe to be welded due to swing can be effectively prevented.

Owner:广东聚金激光技术有限公司

Device for measuring long crystal bar of ingot furnace

InactiveCN103409797AReduced chance of lateral breakageSolve large errorPolycrystalline material growthSingle crystal growth detailsStaying timeMechanical engineering

The invention discloses a device for measuring a long crystal bar of an ingot furnace. The device comprises two slide grooves which are vertically formed in the top of the ingot furnace, and a measuring system for the height of the long crystal bar, wherein openings of the slide grooves are opposite; the two slide grooves are internally provided with a slide frame which can move freely up and down; a clamp for clamping the long crystal bar is arranged in the middle of the slide frame. The device disclosed by the invention is provided with the measuring system for the height of the long crystal bar, so that the height of the long crystal bar can be rapidly read and recorded and the problem in the prior art that an error is great due to a read angle is solved; meanwhile, as the measurement can be carried out in time, measurement time is shortened, staying time of the long crystal bar in silicon liquid is shortened and the use risk of the long crystal bar is reduced; the long crystal bar is prevented from being stuck in a silicon ingot for growing a crystal and the finished-product rate of the silicon ingot is improved.

Owner:TIANWEI NEW ENERGY HLDG

Intelligent power distribution cabinet with remote monitoring function

InactiveCN112909767AImprove protectionFire controlFire rescueSubstation/switching arrangement casingsFan bladeServo

The invention discloses an intelligent power distribution cabinet with a remote monitoring function, and relates to the technical field of power distribution cabinets. The intelligent power distribution cabinet comprises an intelligent power distribution cabinet body, grooves are formed in the two outer walls of the intelligent power distribution cabinet body, and side plates are fixedly connected in the grooves through bolts; the side plate and the side wall of the intelligent power distribution cabinet body are uniformly provided with first air inlet inclined holes used for air inlet. The air outlet structure comprises an installation straight plate (3), a servo motor (4), fan blades (5) and an air outlet pipe (10). The air outlet pipe (10) is fixedly installed at an air outlet hole in the rear side wall of the intelligent power distribution cabinet body (1), the inner top of the air outlet pipe (10) is fixedly connected with the installation straight plate (3), the installation straight plate (3) is fixedly provided with the servo motor (4), and the output end of the servo motor (4) is fixedly connected with the fan blades (5). The fire can be controlled in time, and the intelligent power distribution cabinet is comprehensively protected.

Owner:丁翠芳

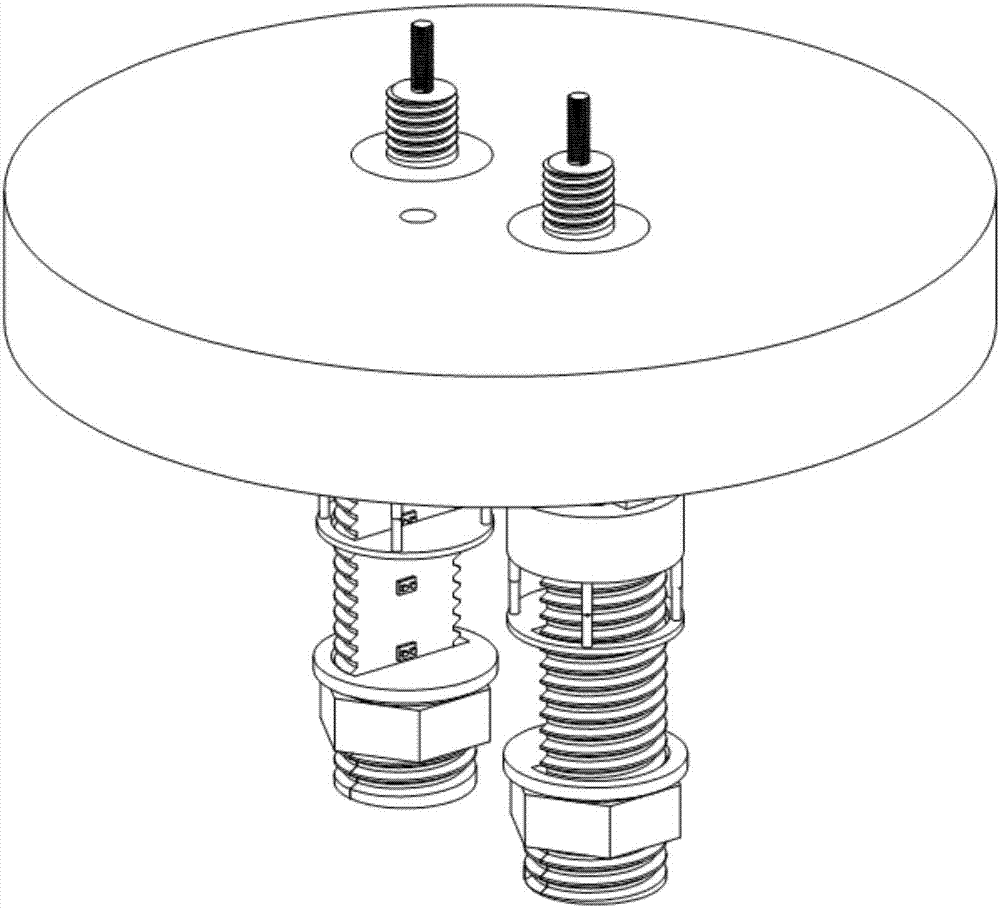

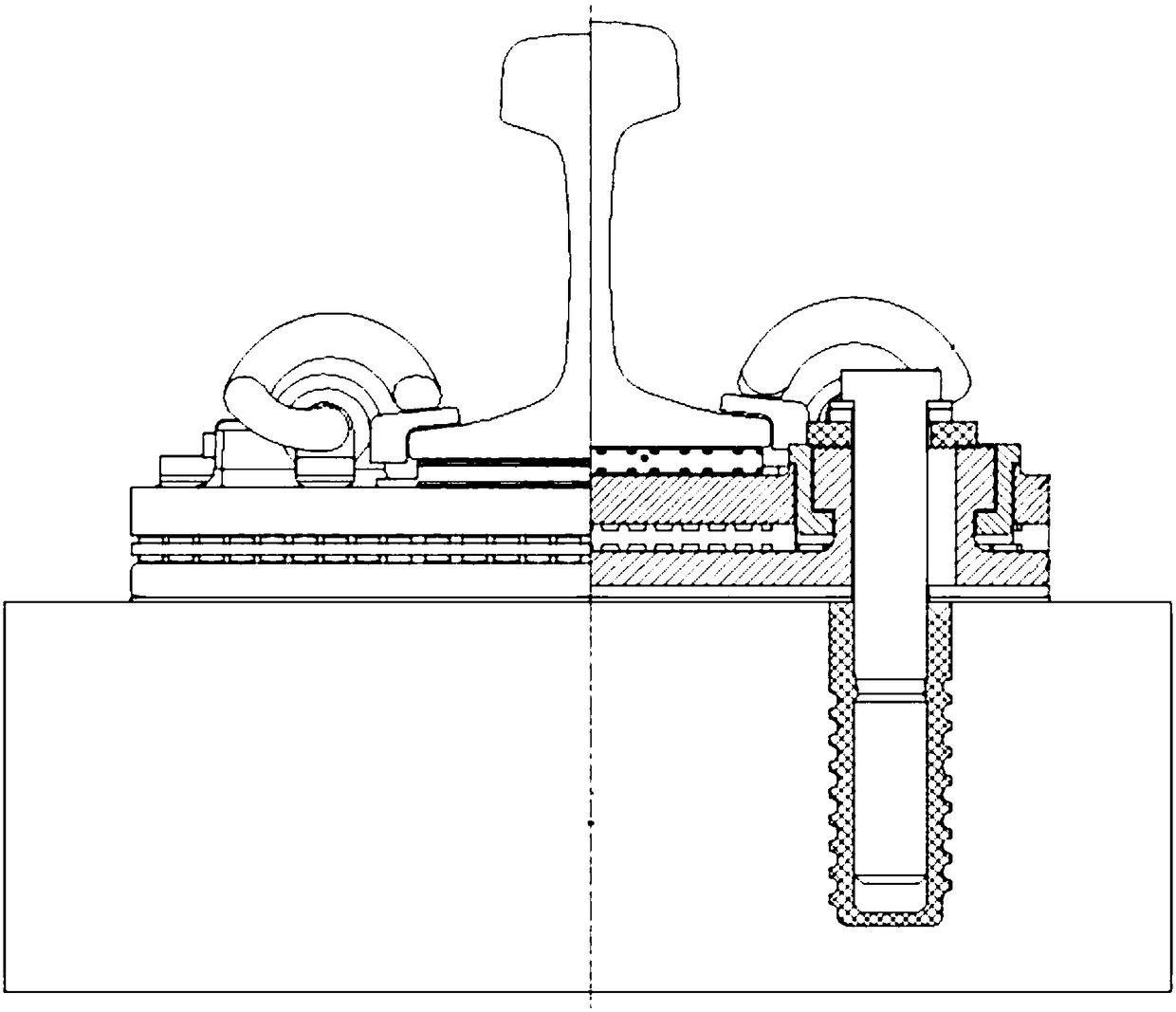

Vibration-reduction fastener system

PendingCN108265571AReduce weightLower installation heightRail fastenersEngineeringUltimate tensile strength

The invention discloses a vibration-reduction fastener system which comprises position-fixing bases, a rail-bearing plate and locking structures, wherein the lower parts of the position-fixing bases are column bodies used for being embedded in a rail foundation; the upper parts of the position-fixing bases are bosses used for being connected to the rail-bearing plate; the rail-bearing plate is provided with elastic bar bases and first through holes through which the bosses penetrate; and the locking structures are used for realizing the locking connection between the rail-bearing plate and theposition-fixing bases. The vibration-reduction fastener system is applicable to the field of rail transit. The vibration-reduction fastener system is capable of effectively overcoming the defects inthe prior art, effectively reducing the cost of the fastener system, effectively improving the overall strength and the service life of a fastener and effectively reducing the installation height of arail, thereby effectively avoiding the increase in tunnel construction cost due to high installation height and effectively improving the transverse stability of the rail at the same time.

Owner:洛阳科博思新材料科技有限公司

Three-dimensional ribbed pipe machining cutter bar positioning device with buffer structure

InactiveCN109866042AAchieve fixed positionGuaranteed fixed effectPositioning apparatusMetal-working holdersMachiningEngineering

The invention discloses a three-dimensional ribbed pipe machining cutter bar positioning device with a buffer structure. The three-dimensional ribbed pipe machining cutter bar positioning device comprises a base and a workpiece bearing frame arranged on the base, a limiting support is arranged on the side face of the base, an n-shaped cutter bar bearing frame is arranged on the base, a position-clamping protruding plate is arranged on the base, a clamping groove with the open top face is formed in the position-clamping protruding plate, a transverse pin rod is arranged on the position-clampingprotruding plate, a positioning clamping ring is inserted into the clamping groove and positioned through the transverse pin rod, vertical adjusting grooves are formed in two vertical rods of the n-shaped cutter bar bearing frame correspondingly, lifting sliding blocks are arranged in the vertical adjusting grooves, transmission lead screws are transversely arranged in the middles of the liftingsliding blocks, transmission sliding blocks are arranged on the transmission lead screws, and C-shaped clamping blocks are arranged on the transmission sliding blocks. The three-dimensional ribbed pipe machining cutter bar positioning device is reasonable in structural arrangement, the using demands under different situations can be met, the machining efficiency is ensured advantageously, using isstable and reliable, and the three-dimensional ribbed pipe machining cutter bar positioning device is high in applicability and good in practicability.

Owner:重庆市融亚换热器科技有限公司

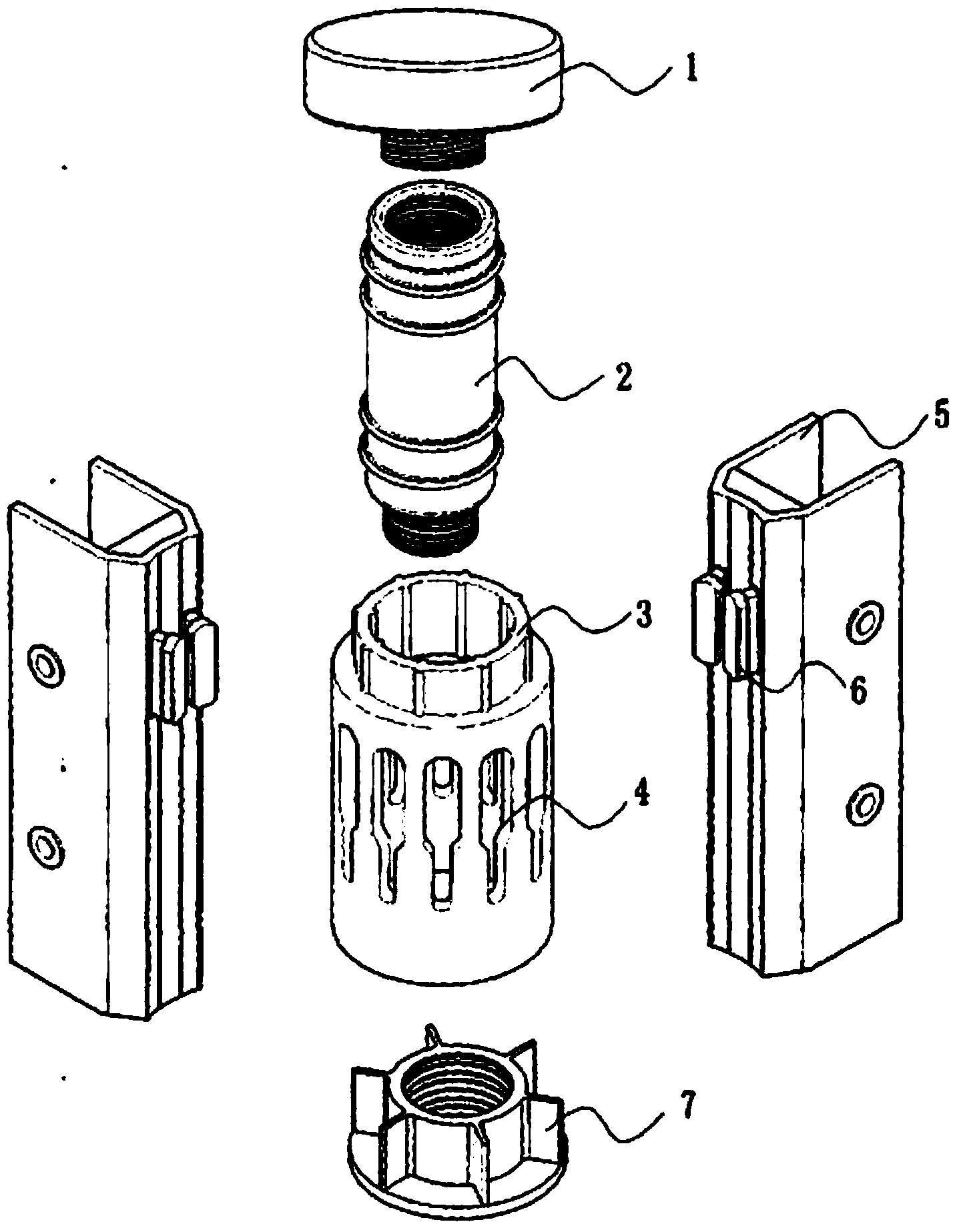

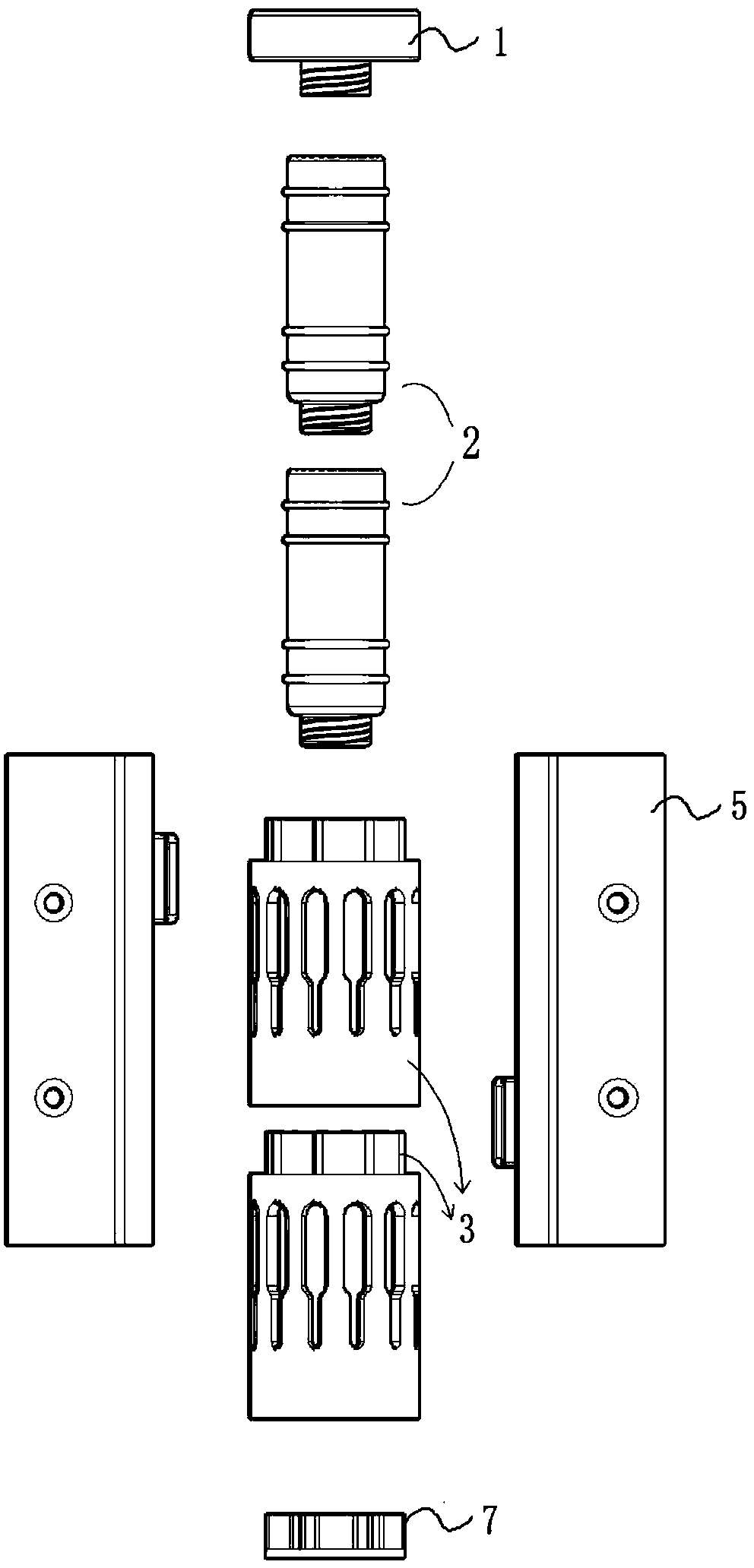

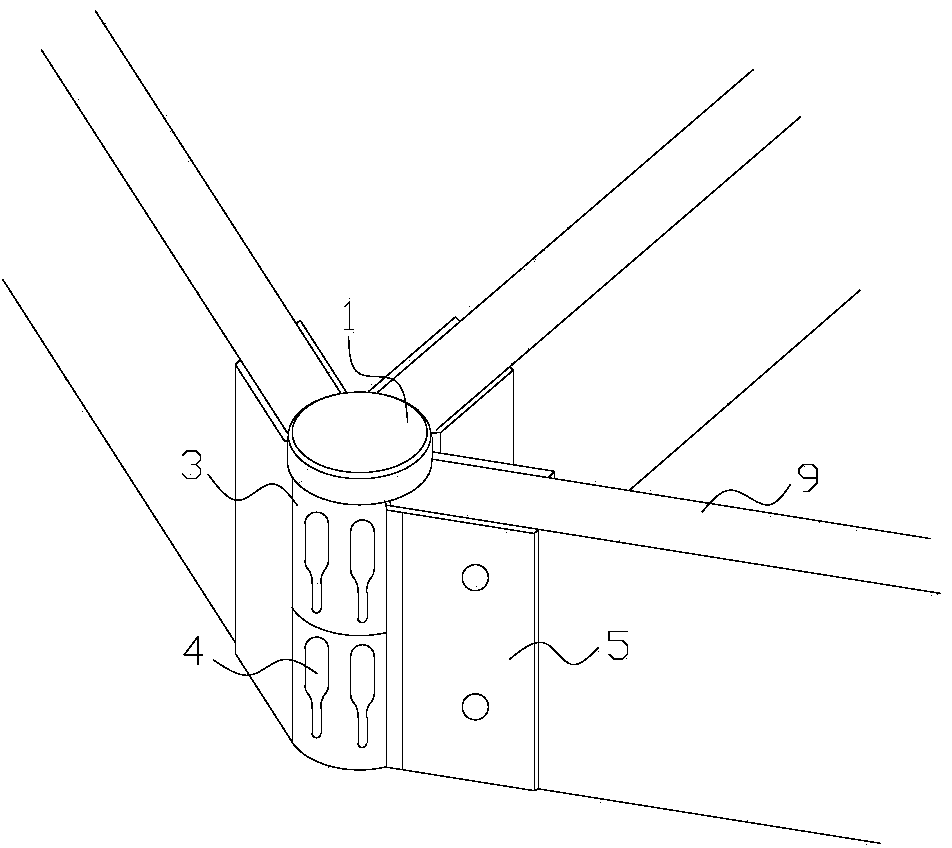

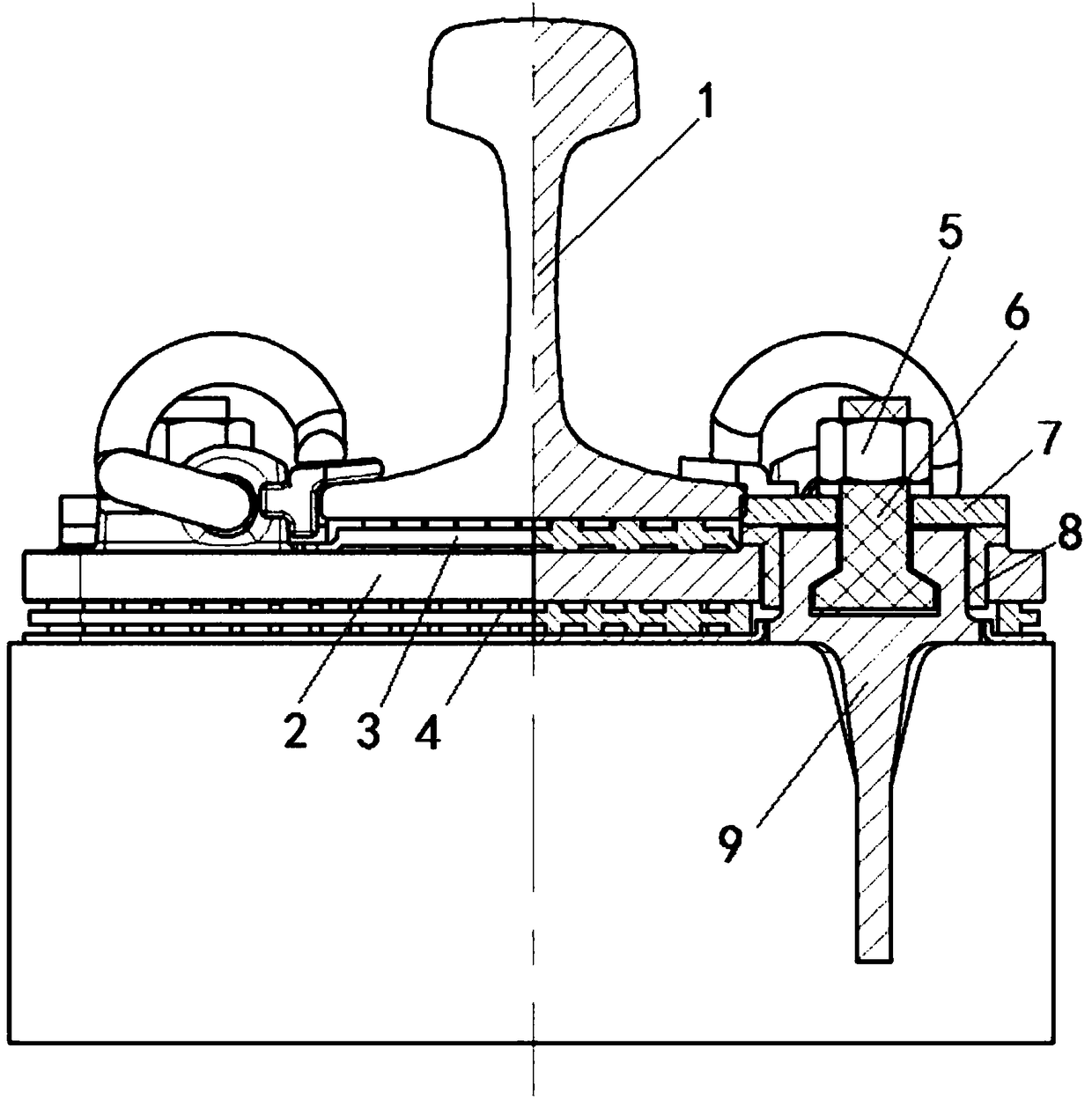

A modular combination box and its connecting components

ActiveCN103527578BQuick assembly and disassemblyEasy to installRod connectionsSheet joiningModular compositionEngineering

A connection assembly of a modular box, comprising a top cover, a sleeve, a mandrel, and a jacket, the sleeve is sleeved on the outside of the mandrel; the sleeve is provided with at least one engaging portion, The jacket is provided with at least one clamping part, and the at least one clamping part is connected with the at least one clamping part, so that the position of the jacket in the circumferential direction of the sleeve is fixed; A cover is connected to the upper end of the mandrel, thereby compressing the sleeve and the jacket to fix the axial positions of the sleeve and the jacket.

Owner:唐山巍峨能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com