Panel machining and positioning device for furniture manufacturing

A plate processing and positioning device technology, applied in the field of furniture manufacturing, can solve the problems of low processing efficiency, manual positioning, and poor processing stability, and achieve the effects of high processing stability, convenient processing, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

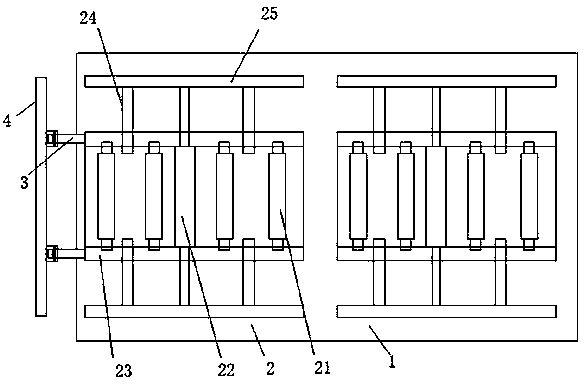

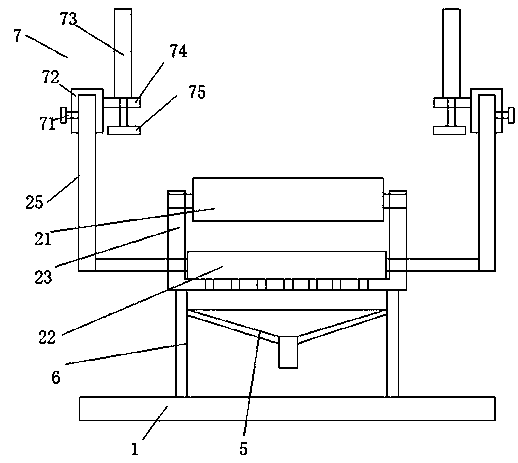

[0027] Embodiment: two conveying and clamping mechanisms 21 are set, and the plate is placed above the conveying roller 21 during use;

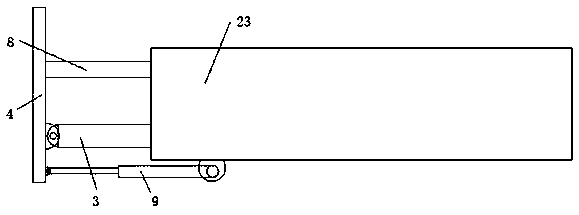

[0028] The driving motor drives the transmission roller 21 to rotate, and drives the plate to move to one side of the limit plate 4 on the transmission roller 21, and the limit plate 4 rotates around the fixed column 3 under the drive of the second telescopic rod 9, so that the limit plate 4 is in a vertical position. state, the plate moves to the limit plate 4 and is limited, and then the two piston rods of the double-headed cylinder 22 are controlled by the control button to drive the side plate 25 to move, and the two sides of the plate are clamped and fixed. After fixing, the The first telescopic rod 73 on the auxiliary fixing mechanism 7 on the side plate drives the pressing plate 75 to move downwards, presses and holds the plate clamped by the limit, and fixes it again. After fixing, the plate is cut or drilled. Holes and other operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com