Hub bearing negative windage detection method

A technology of wheel hub bearing and detection method, applied in the direction of mechanical clearance measurement, etc., can solve the problems of easy looseness, vibration, unfavorable working life of bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

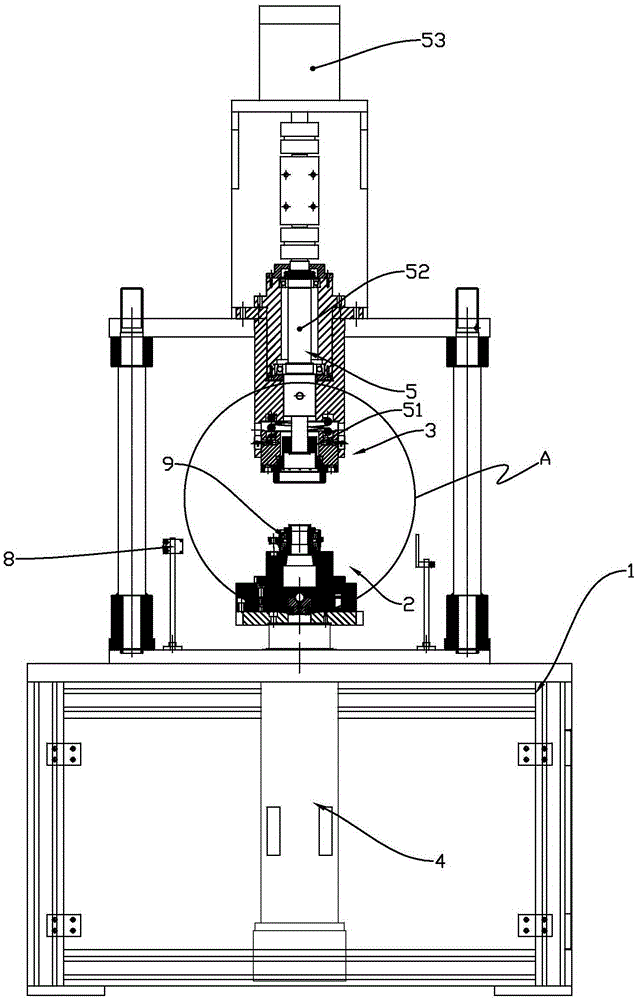

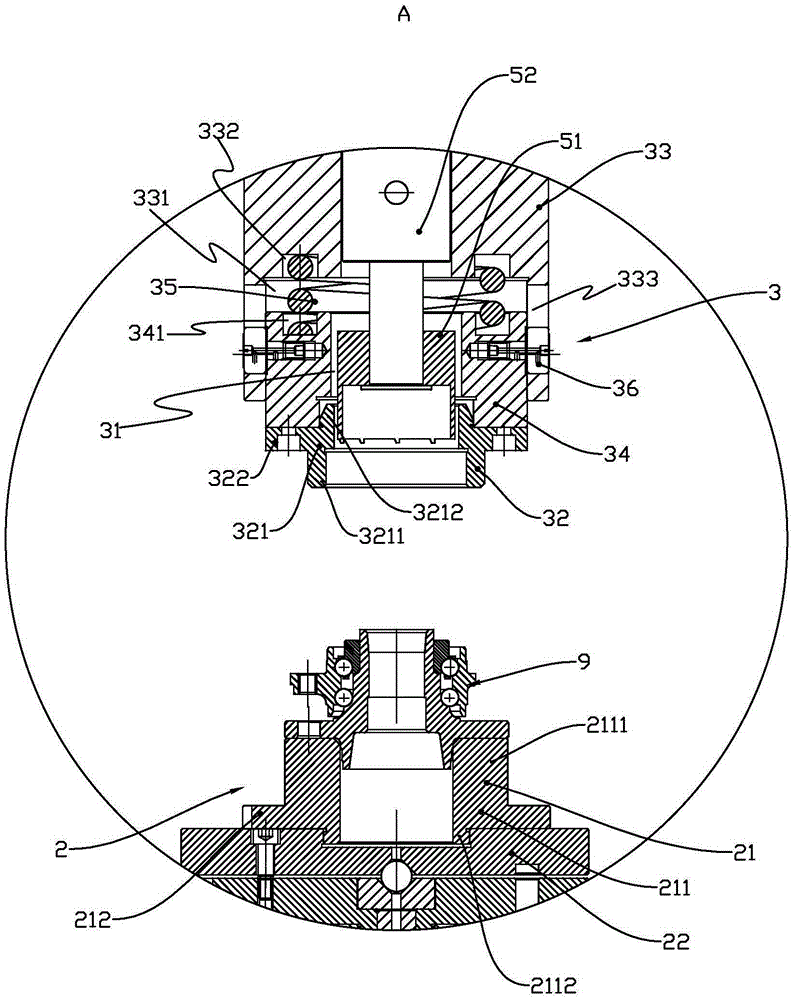

[0024] see figure 2 with image 3 , a wheel hub bearing negative clearance detection method disclosed in the present invention is carried out according to the following procedures:

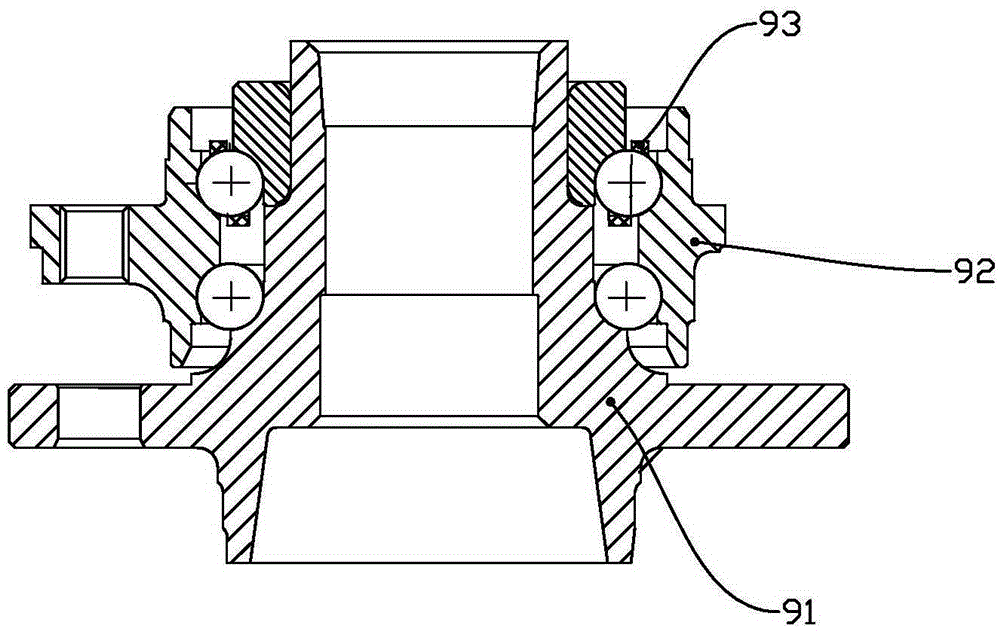

[0025] The rated torque P is applied to the inner column steel ball assembly of the hub bearing through the torque loading device, and the rated torque P is 5 to 15 N.m. The torque loading device 5 includes a steel ball fork 51 and drives the rotation of the steel ball fork Loading the driving mechanism, the steel ball shift fork 51 can be used to directly cooperate with the steel ball to realize the toggle steel ball assembly, and can also be used to cooperate with the cage to realize the toggle steel ball assembly, and the cage is preferred; the bearing is pressed axially The device presses the mandrel of the hub bearing and the outer ring of the bearing to apply an axial load to the hub bearing so that the hub bearing tends to release the negative clearance. The bearing axial pressing device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com