Patents

Literature

100results about How to "Solve handling problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for identity authentication of person and identity card based on face recognition

InactiveCN106778607AImprove authentication efficiencyImprove accuracySpoof detectionFeature vectorValidation methods

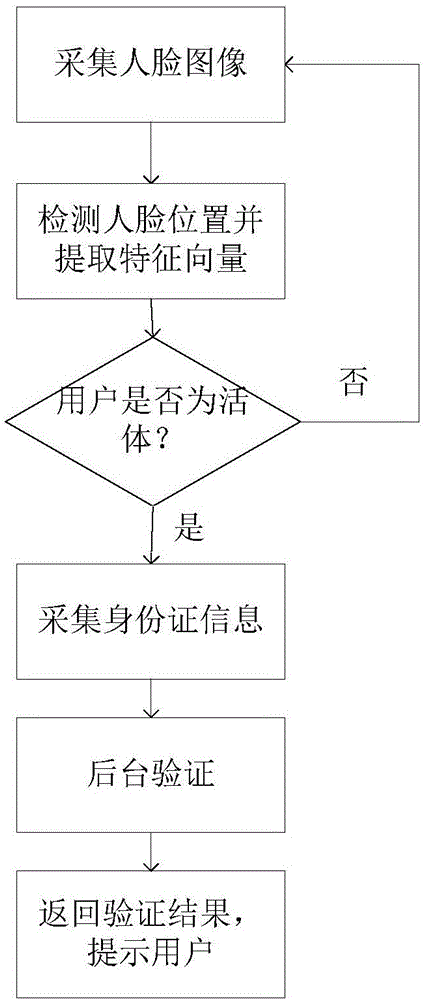

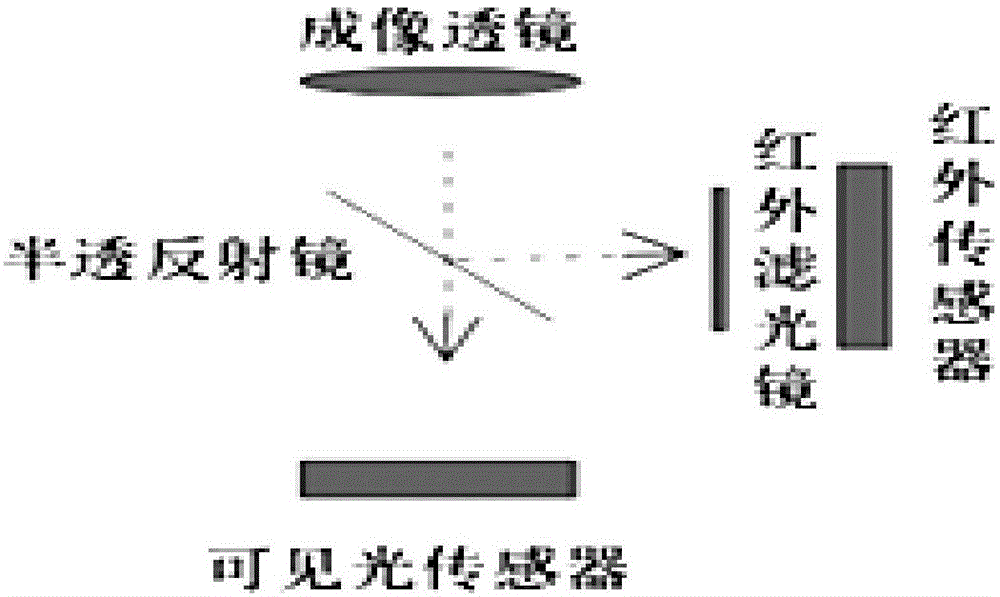

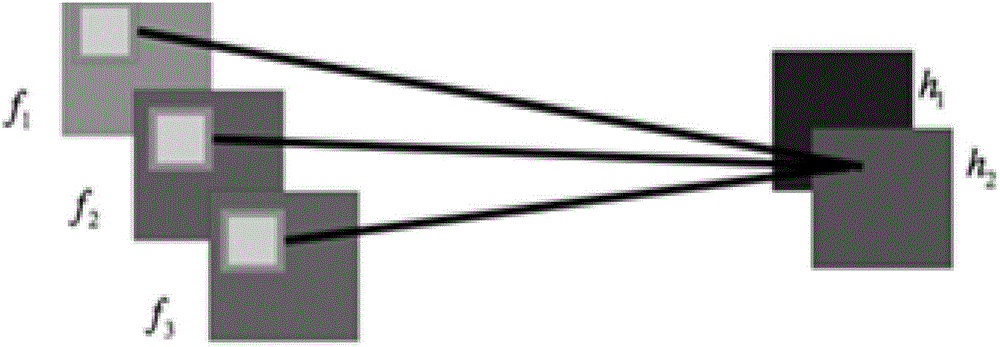

The invention discloses a method and device for identity authentication of a person and an identity card based on face recognition. The method for identity authentication of a person and an identity card based on face recognition comprises the following steps: collecting the face image; detecting the position of the face and extracting the feature vectors according to the face image; confirming whether the user is a live object or not, if not, returning and collecting the face image again; if so, collecting the identity card information; transmitting the extracted feature vectors and the identity card information to the background for authentication; returning the authentication results and prompting the user, which are performed by the background; if authentication is passed, updating the local and remote databases. According to the invention, the authentication efficiency of the ''witness the same'' is improved. The method for identity authentication of a person and an identity card based on face recognition is convenient for large-scale application in various occasions, and can solve the technical problems that the authentication is inaccurate caused by the slight change of the face due to the passage of time, the authentication to the person without carrying the identity card is difficult, and the like.

Owner:BEIJING GZT NETWORK TECH

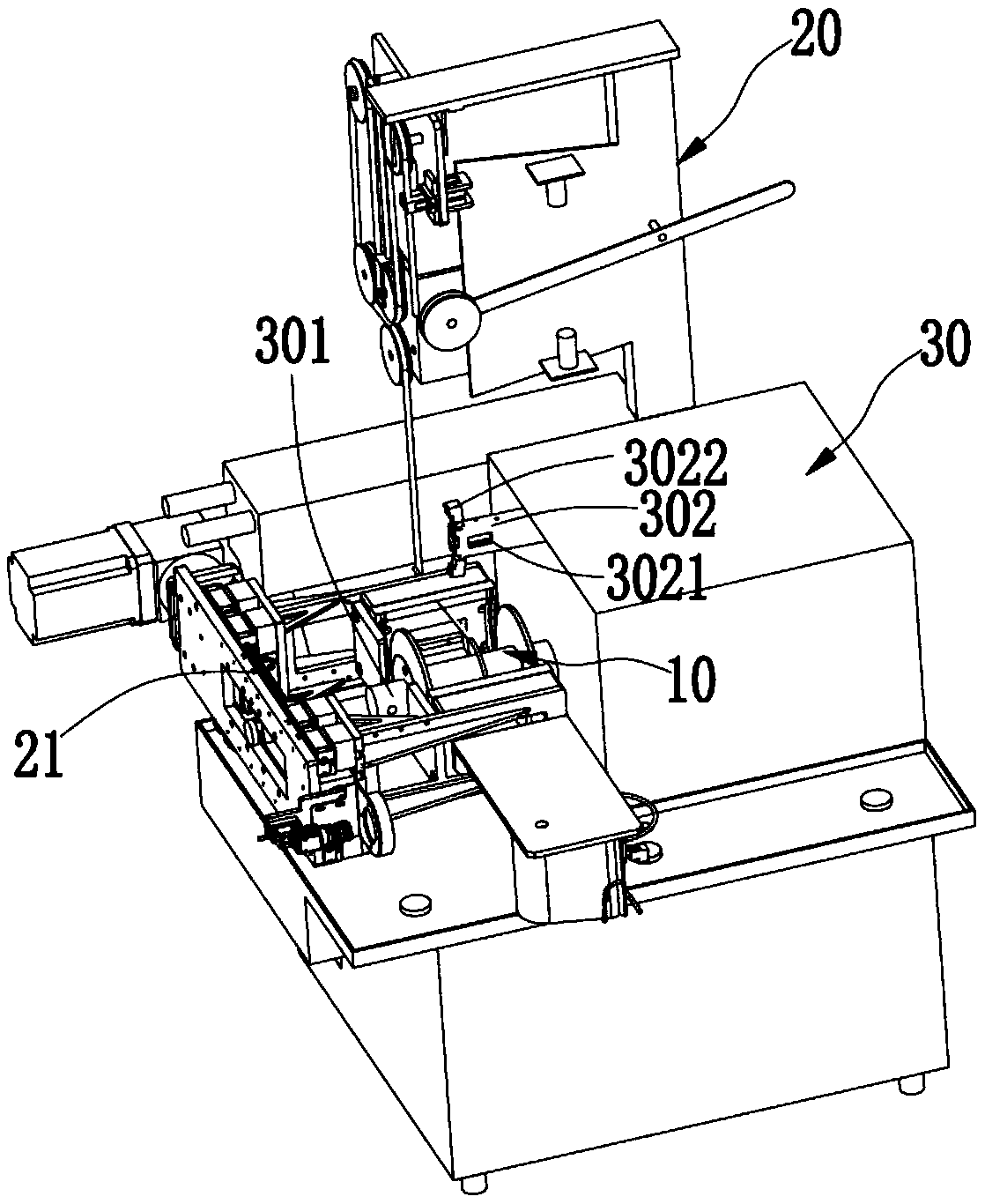

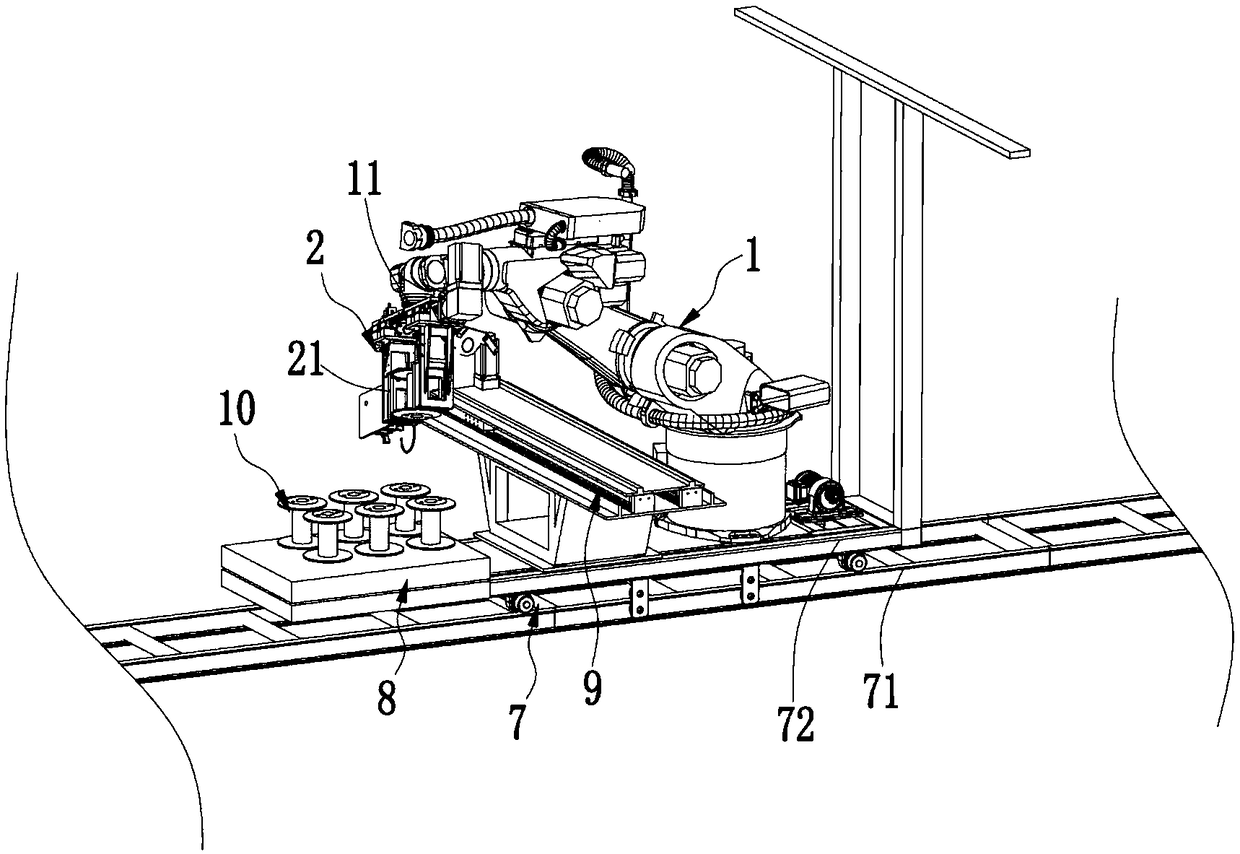

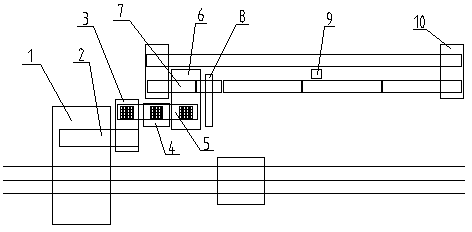

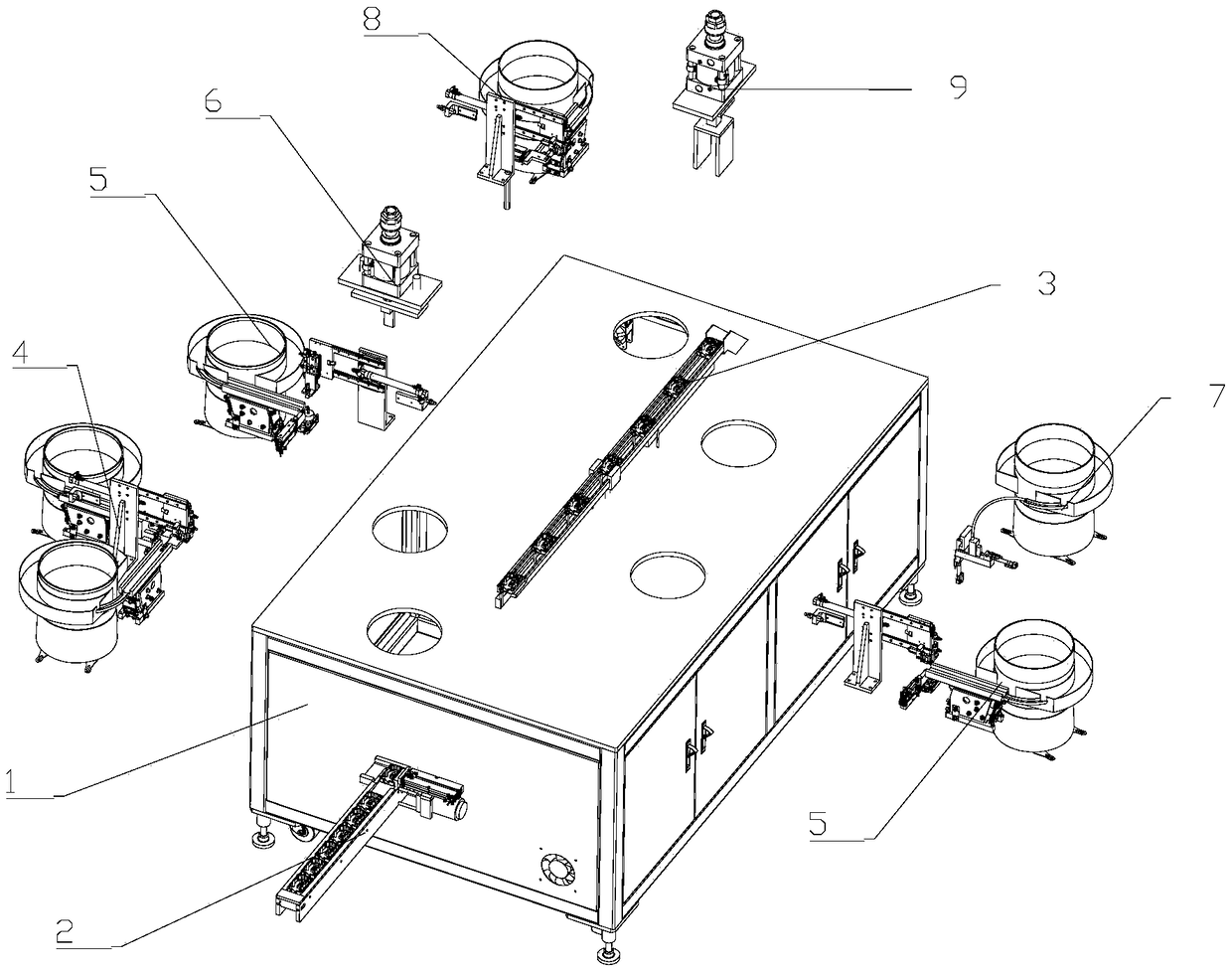

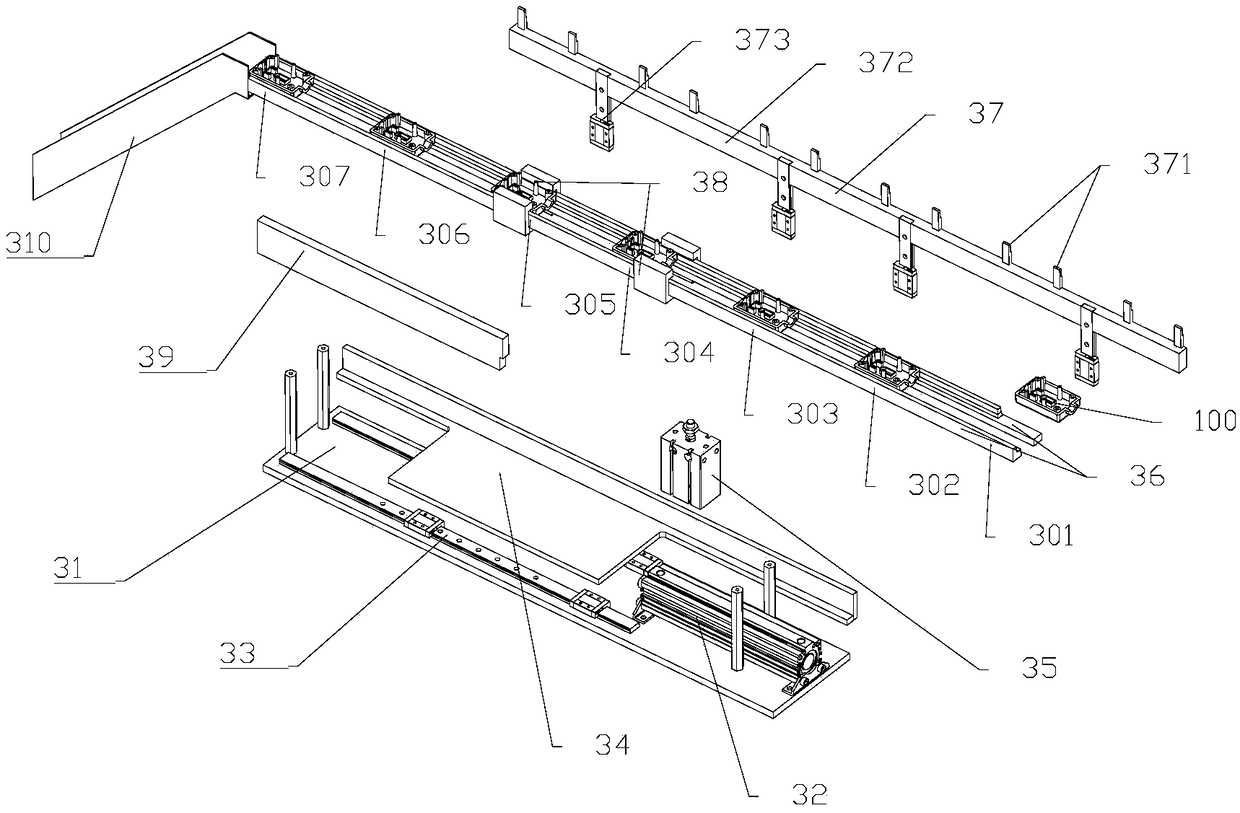

Full-automatic winding production line and processing method thereof

PendingCN109436951ASimple structureIncrease flexibilityFilament handlingProduction lineWinding machine

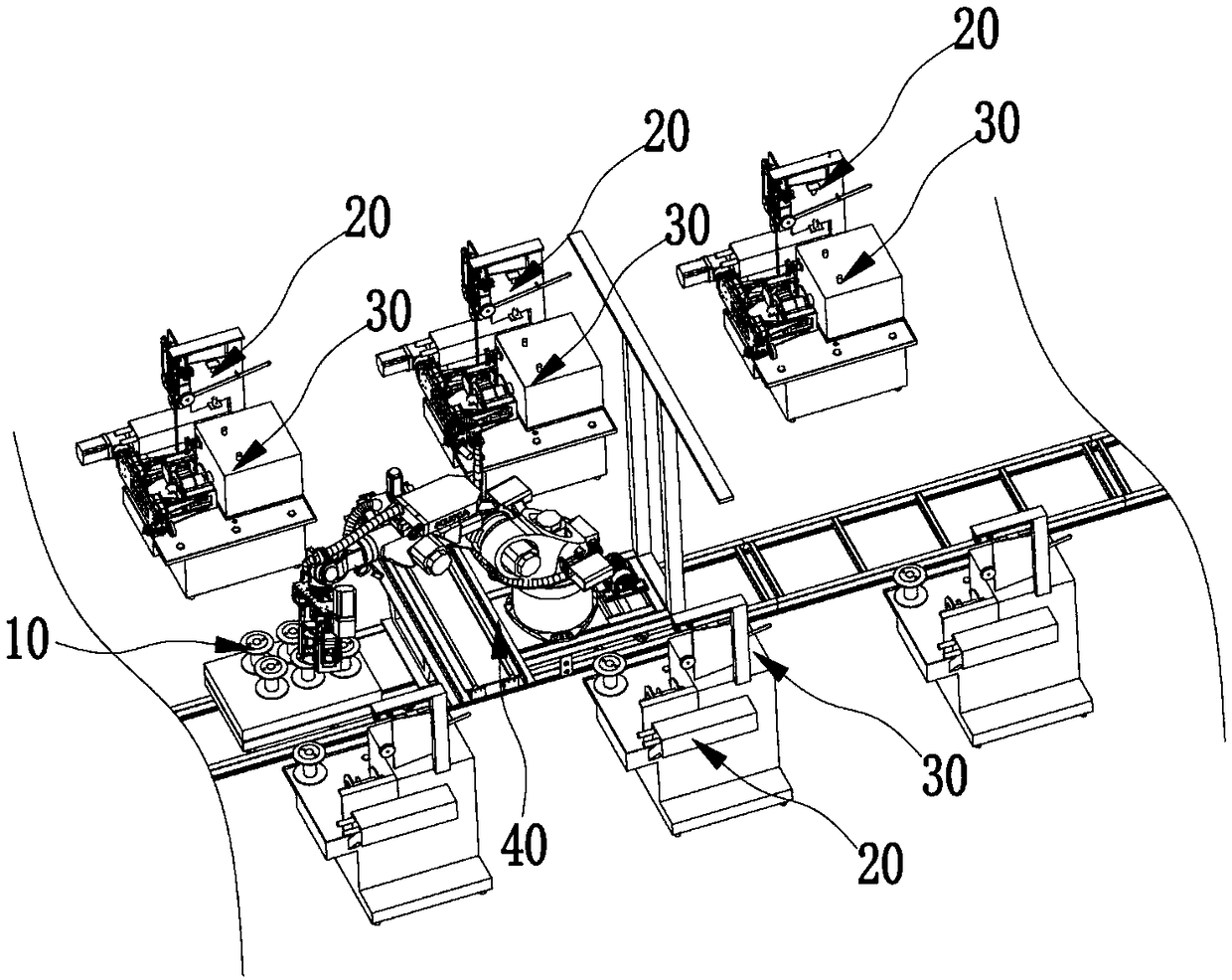

The invention discloses a full-automatic winding production line and a processing method thereof. The full-automatic winding production line comprises at least one automatic feeding machine, at leastone winding machine and an automatic winding disc feeding and discharging robot, wherein the automatic feeding machine is used for supplying a filament-shaped body; the winding machine is used for fixing a winding disc and driving the winding disc to rotate; and the automatic winding disc feeding and discharging machine can move the winding disc onto the winding machine and taking the winding discdown from the winding machine, and the position of the filament-shaped body can be determined visually when the filament-shaped body is grabbed and cut off. According to the scheme, the automatic winding disc feeding and discharging robot cooperates with the automatic feeding machine and the winding machine, so that the whole process of feeding, winding and discharging is achieved automatically,and the novel full-automatic winding production line which is simple in structure and capable of controlling the winding process easily is provided; in addition, the visual positioning technique can effectively and accurately determine the position of the filament-shaped body, so that automatic grabbing and shearing are made possible; and the visual positioning technique is good in flexibility andhigh in accuracy and efficiency, so that the winding efficiency is improved.

Owner:WUXI MINGONG TECH

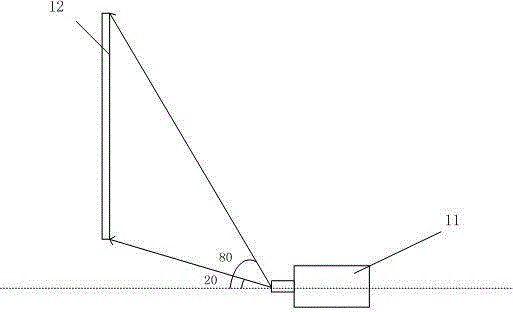

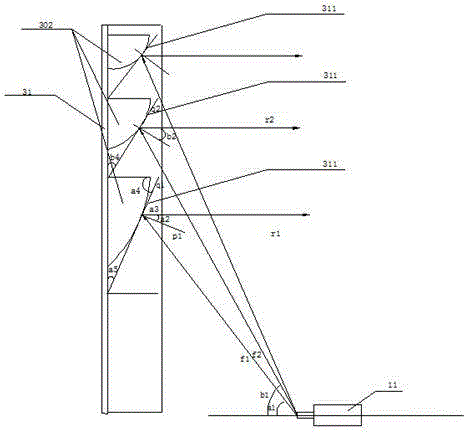

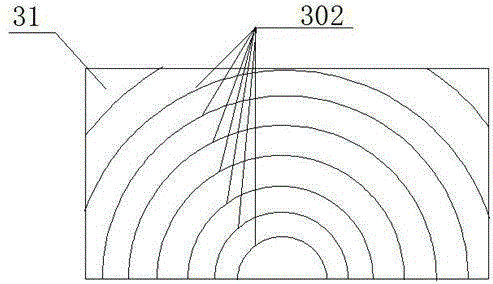

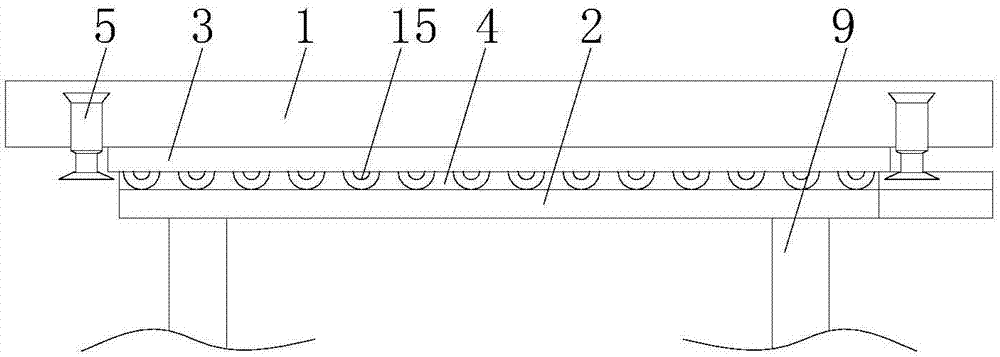

Super short-throw laser projection display screen and super short-throw laser projection device

ActiveCN105785703ASmall brightness lossAchieve normal displayProjectorsReflex reflectorsCamera lensAcute angle

The invention discloses a super short-throw laser projection display screen and a super short-throw laser projection device, and solves the technical problem of inconvenience in carrying and installation of a projection display screen matched with the existing super short-throw laser projection device. The super short-throw laser projection display screen comprises a reflection layer, wherein the reflection layer comprises a plurality of arc micro-protrude structure units, each micro-protrude structure unit is sequentially arranged to form an upper half round pattern, and from the circle center of the upper half round shaft to the outside, acute angles between tangent planes of incident light receiving surfaces of the micro-protrude structures and the reflection layer are gradually increased, so that light emitted from a super short-throw lens is incident to the reflection layer and is then reflected in parallel or in an approximately parallel way. With the application of the projection display screen provided by the invention, the received incident light in a wide angle range is reflected in parallel or in the approximately parallel way, the reflection layer can be sprayed and formed in an arbitrary installation plane in a spraying way, so that the super short-throw laser projection display screen is simple and practical to transport and install.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

Fully-automatic brick packing and unloading method for sintered bricks

InactiveCN103407794AOvercoming deformationOvercoming problems such as lack of bricksStacking articlesDe-stacking articlesBrickConveyor belt

The invention discloses a fully-automatic brick packing and unloading method for sintered bricks. The method comprises the following steps that firstly, the sintered bricks piled in a sintering kiln are transferred from a kiln cart to a conveyor belt I by an unloading clamp according to layers and moved into a transportation clamp, the transportation clamp is used for clamping a certain amount of sintered bricks each time to form a horizontal piling layer, the horizontal piling layer is transported onto a conveyor belt II and conveyed into a horizontal packing machine along the conveyor belt II so as to carry out packing in a horizontal direction, secondly, a piling clamp is used for transferring the horizontal piling layer onto a pallet on a conveyor belt III, the piling of horizontal piling layers in a height on the pallet is completed, thirdly, the packing of sintered brick piles in a longitudinal height is carried out in a horizontal packing machine, after the completion of packing, the sintered brick piles are unloaded from the pallet through a brick holding machine, and the brick packing and unloading of the sintered bricks is finished. According to the method, the problem of moving sintered bricks due to a blanking piling gap is solved, actions of brick unloading, sequencing, packing, piling, unloading, transporting on the pallet and the like are carried out in a separating way, and continuous automation of brick unloading as well as high-efficient production is realized.

Owner:何仕杰

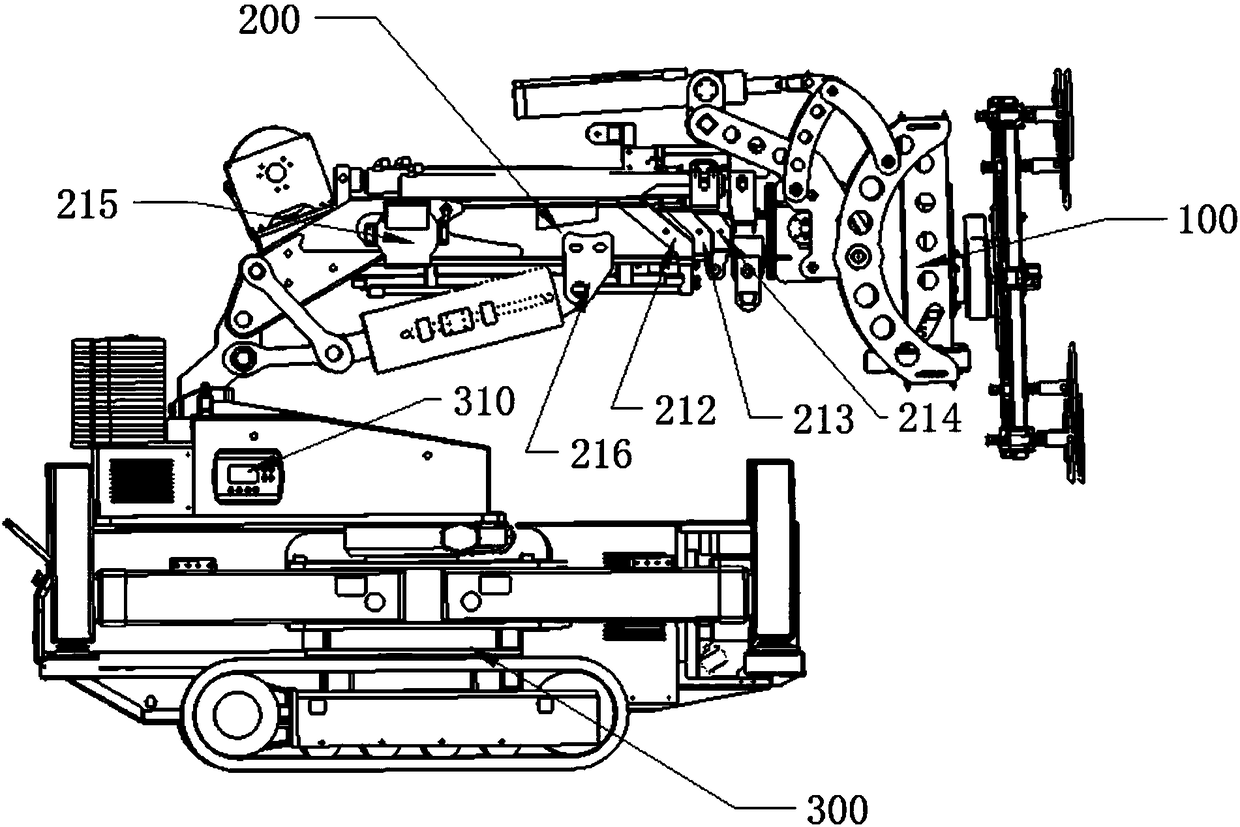

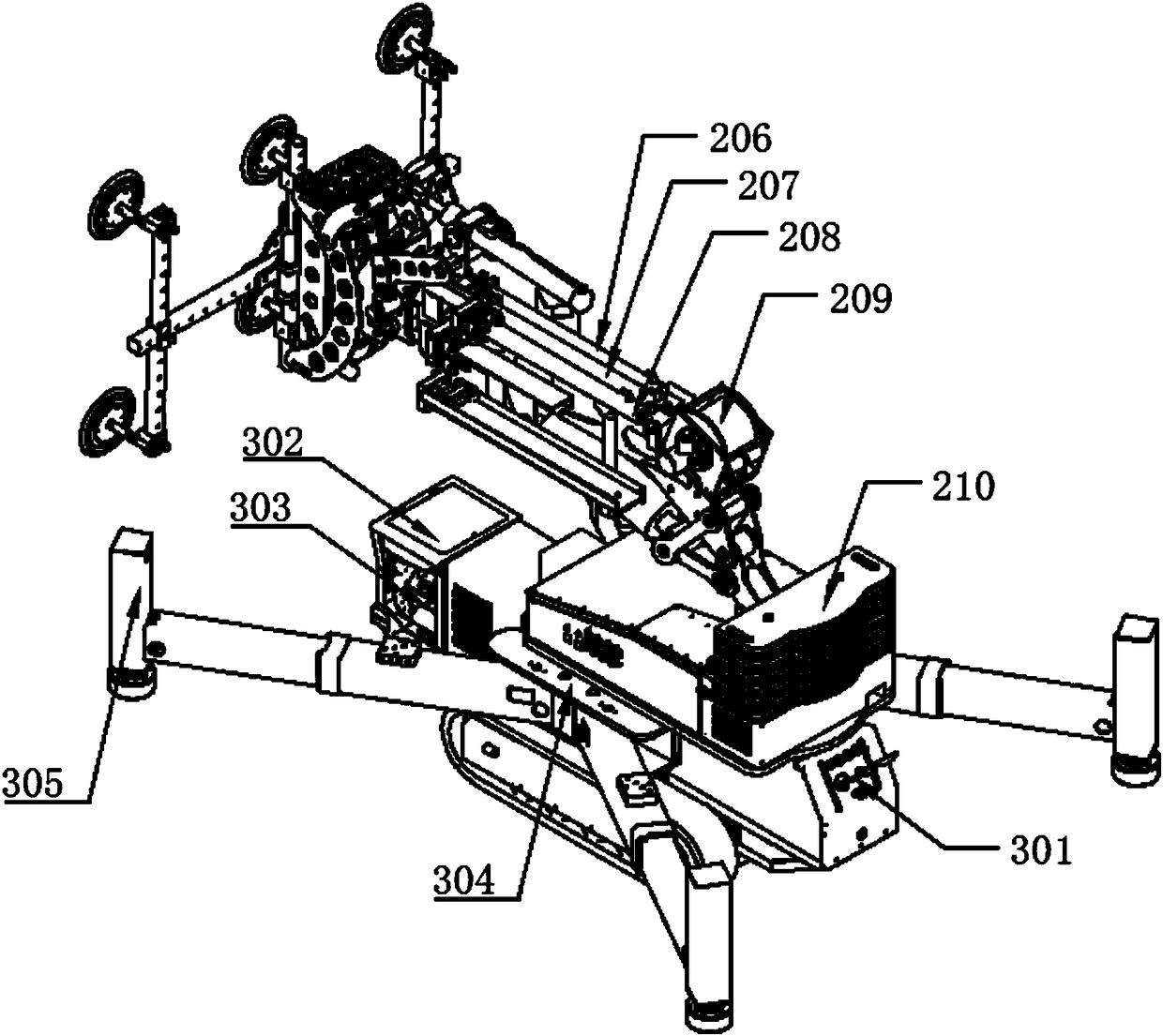

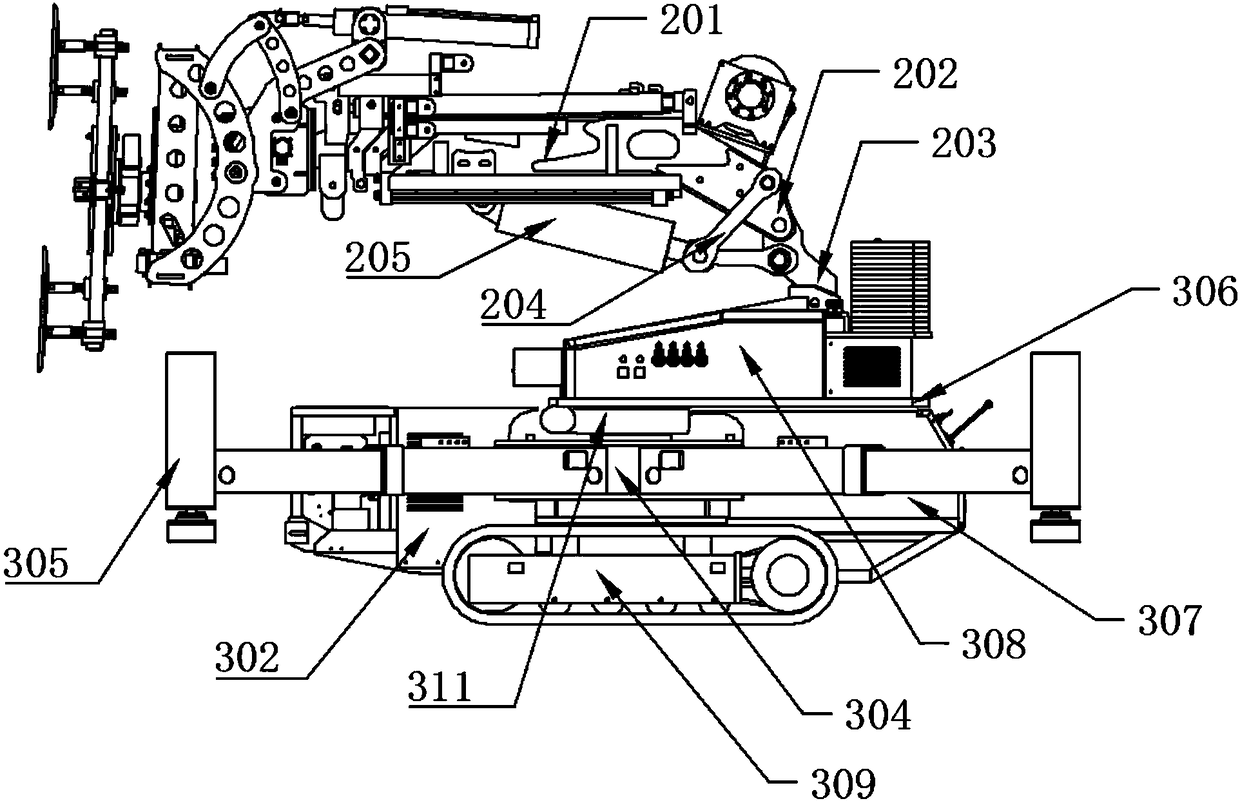

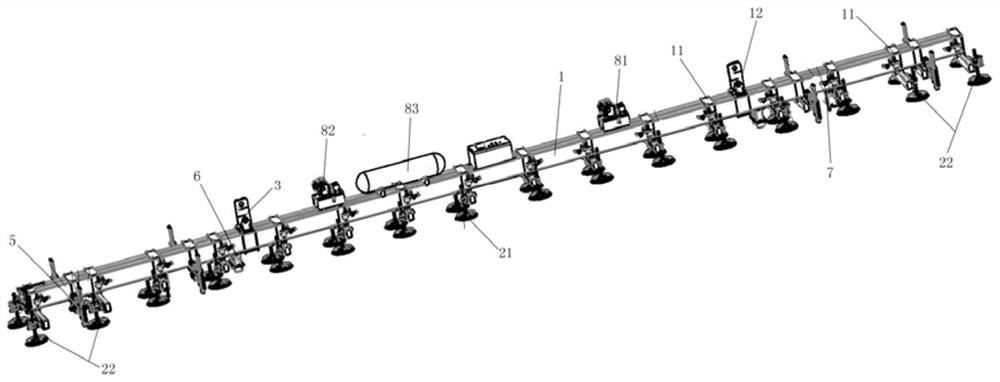

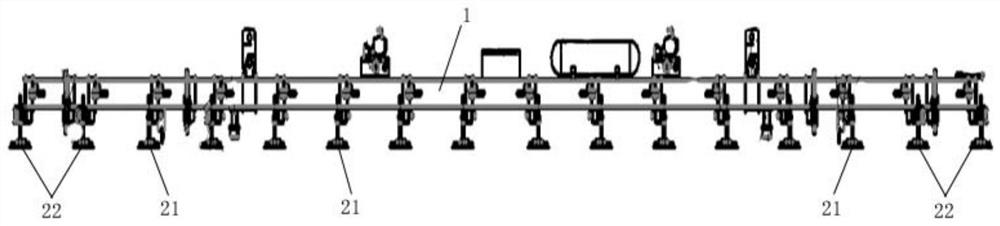

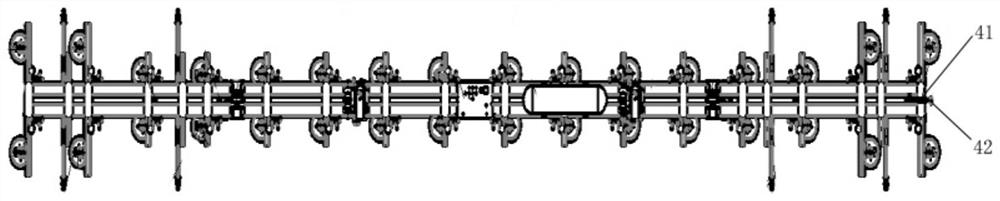

Multi-dimensional glass mounting robot

PendingCN108453697AIncrease productivityImprove production efficiencyProgramme-controlled manipulatorGripping headsEngineeringMulti dimensional

The invention discloses a multi-dimensional glass mounting robot which comprises a multi-dimensional mounting head, a telescopic mechanical arm and a rotary walking chassis, wherein the multi-dimensional mounting head is mounted on the telescopic mechanical arm; the telescopic mechanical arm is mounted on the rotary walking chassis; the multi-dimensional mounting head comprises an up-down slidingunit, a left-right rotating unit, an overturning unit, a rotary unit and a translation unit. The multi-dimensional glass mounting robot is scientific and reasonable in design and compact in structure,at least can achieve movement in eight directions, solves the problems of multi-dimensional and multi-angle mounting and carrying, and achieves the effects of efficiently and flexibly mounting and carrying by coarse and fine adjustment. The multi-dimensional glass mounting robot disclosed by the invention achieves mechanical and auxiliary automatic operations of grabbing, carrying and mounting large glass panels, so that the large panel mounting quality, the production efficiency and the benefit are improved, a lot of labor forces are saved, the labor intensity is reduced, and the construction cost is lowered.

Owner:GUANGZHOU COWEST MACHINERY EQUIP CO LTD

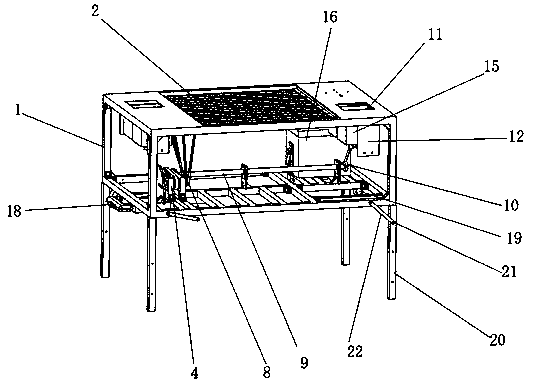

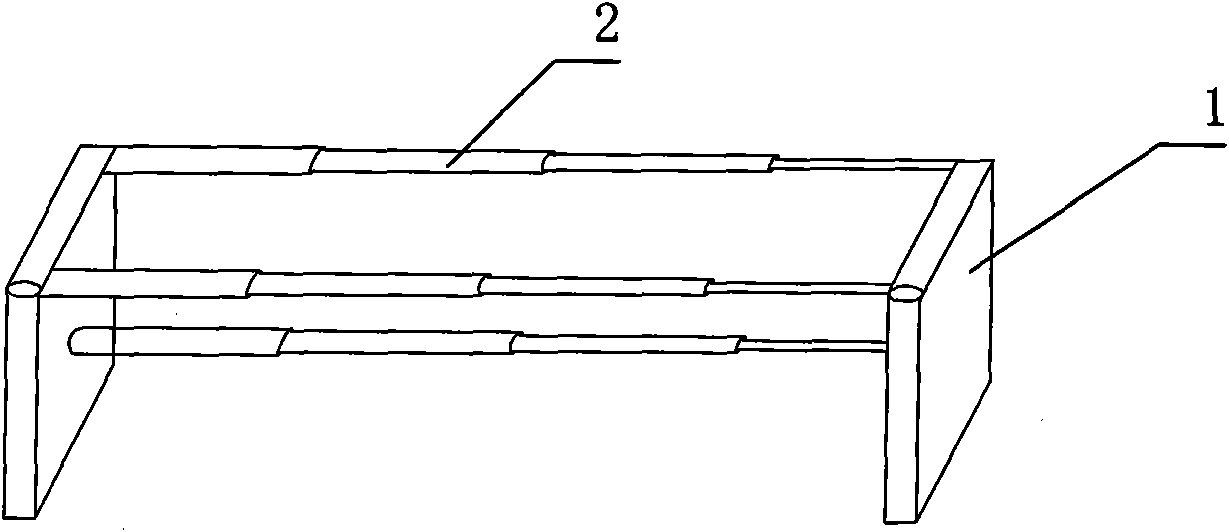

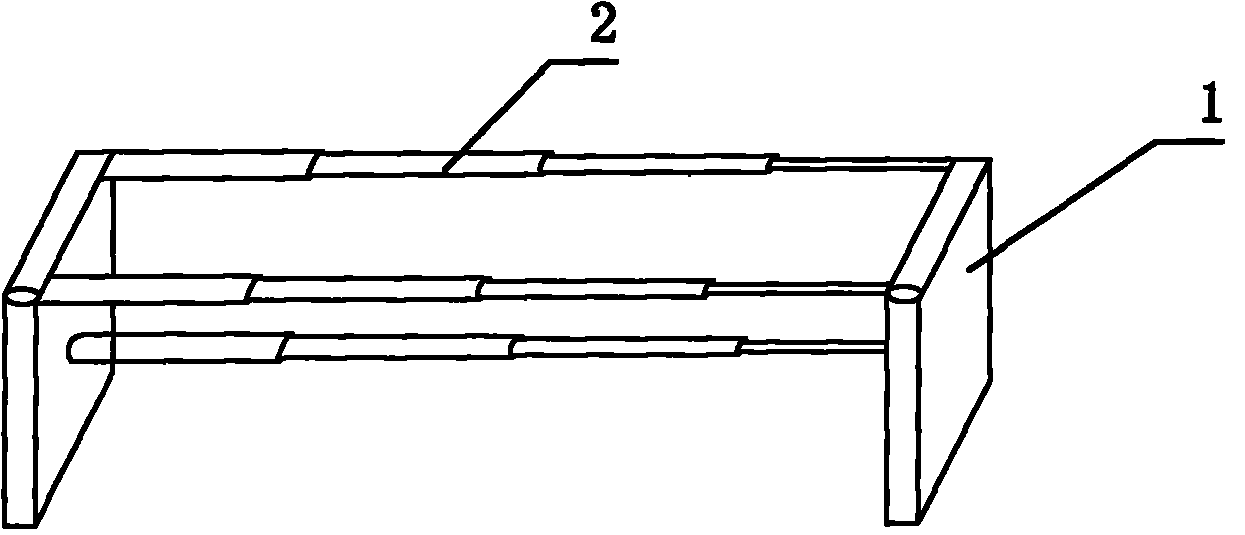

Multifunctional chess table

The invention discloses a multifunctional chess table. The multifunctional chess table comprises a table frame, multiple turnover plates combined to form a chess board surface are arranged on the upper surface of the table frame, and driven turnover belt wheels are arranged on the side faces of the turnover plates. A belt wheel mounting frame is fixedly arranged in the table frame, and a driving belt wheel and a driven belt wheel are arrange din the belt wheel mounting frame. One end of a center shaft of the driving belt wheel is connected with a rocking handle, and a driving turnover belt wheel is arranged at the other end of the center shaft. A center shaft of the driven belt wheel is rigidly connected with a linkage shaft, and crank-link mechanisms are arranged at the two ends of the linkage shaft. Chess box openings located in the two sides of the turnover plates are formed in the upper surface of the table frame. Fixed plates are arranged at the positions, located on the two sidesof the lower portions of the chess box openings, of the table frame, sliding rails are mounted at the lower ends of the fixed plates, crank blocks connected with the crank-link mechanisms are arranged on the sliding rails, chess boxes formed by multiple cavities are arranged on the crank blocks, and openings of the chess boxes coincide with the chess box openings. According to the multifunctionalchess table, the function of playing multiple kinds of chesses on one chess table can be achieved, and the needs of different chess fans are met.

Owner:WENZHOU UNIVERSITY

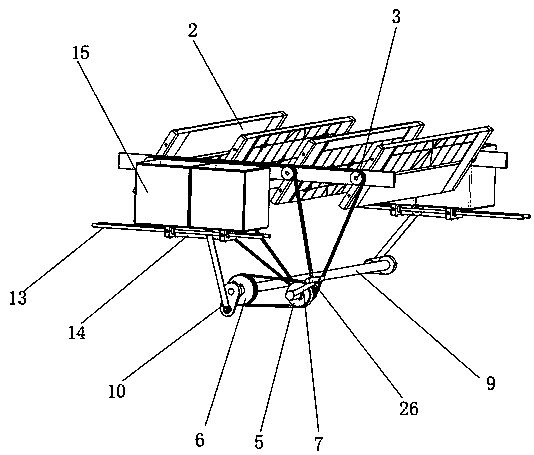

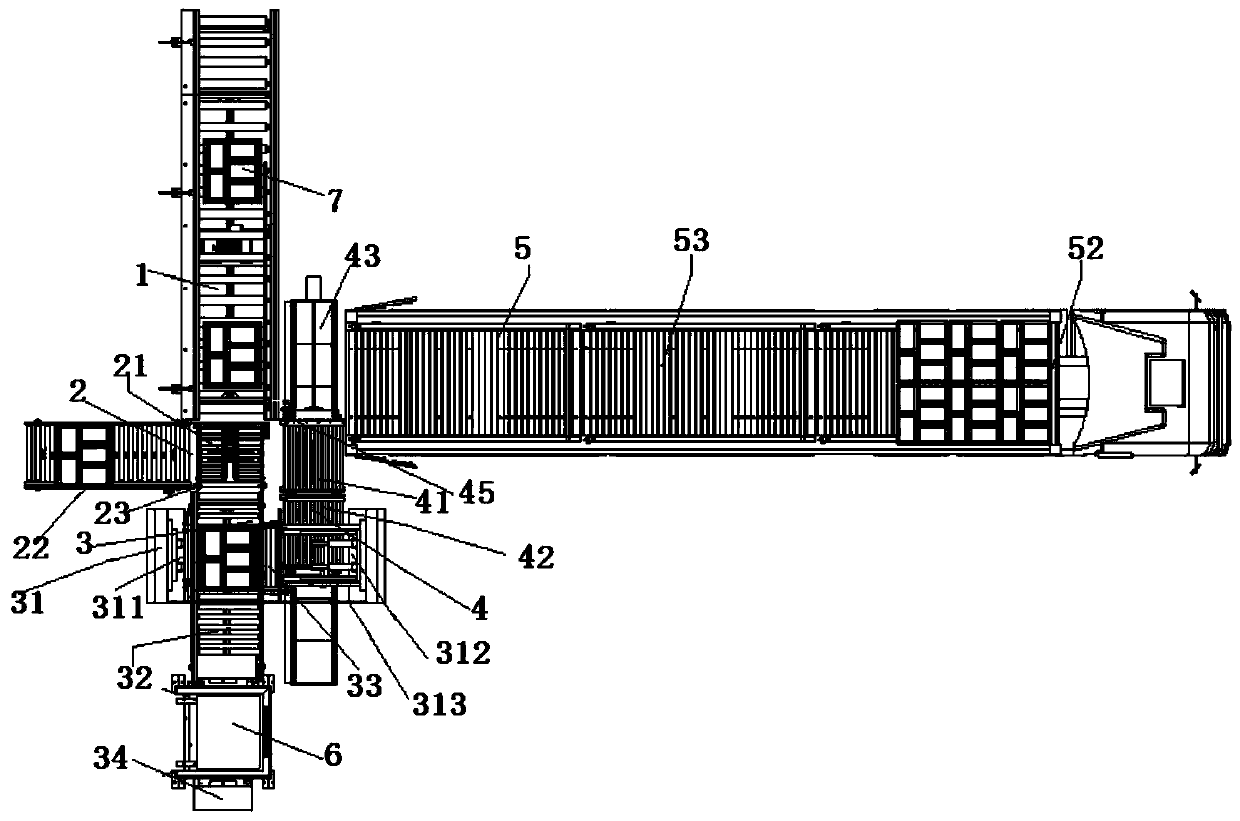

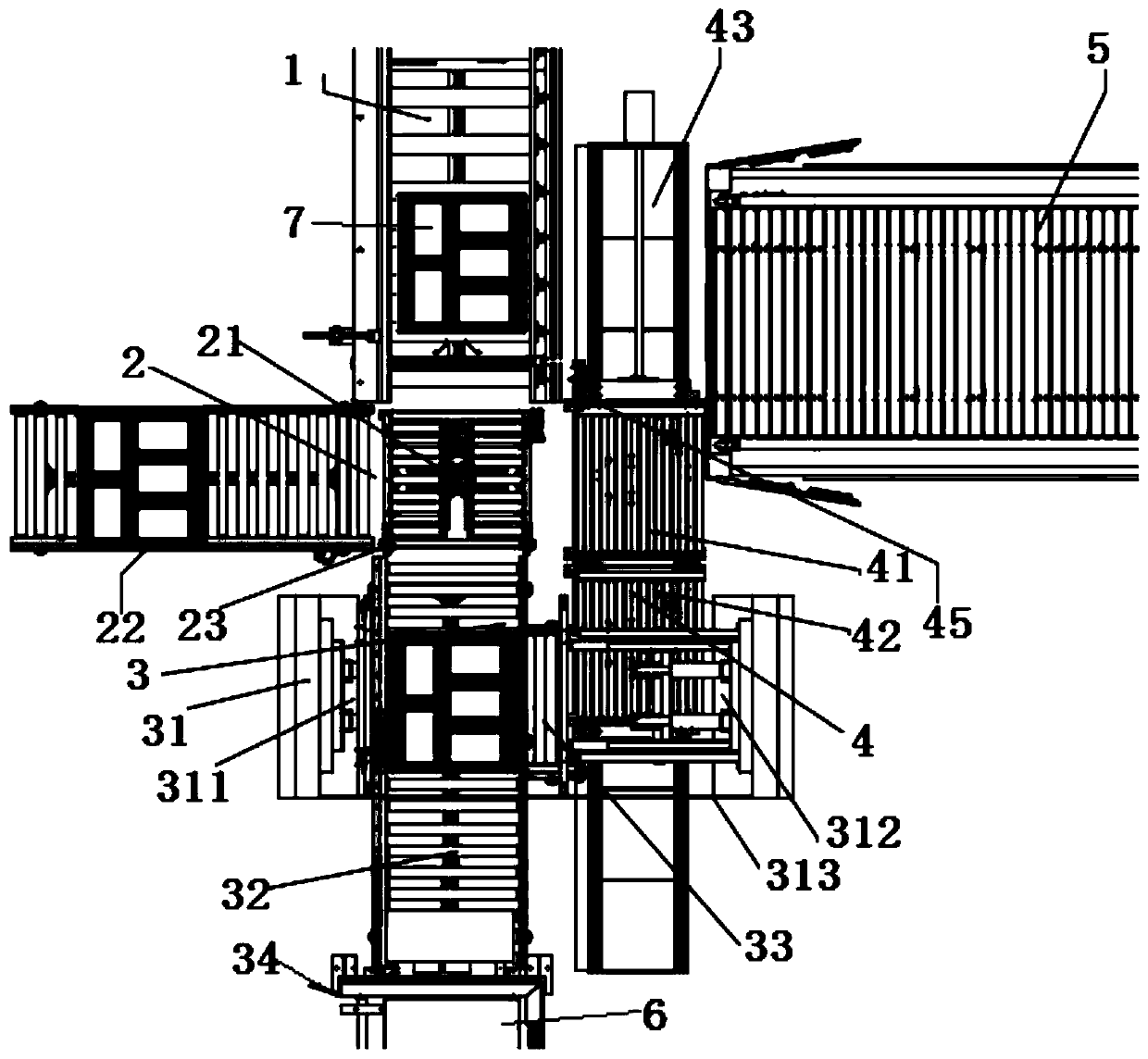

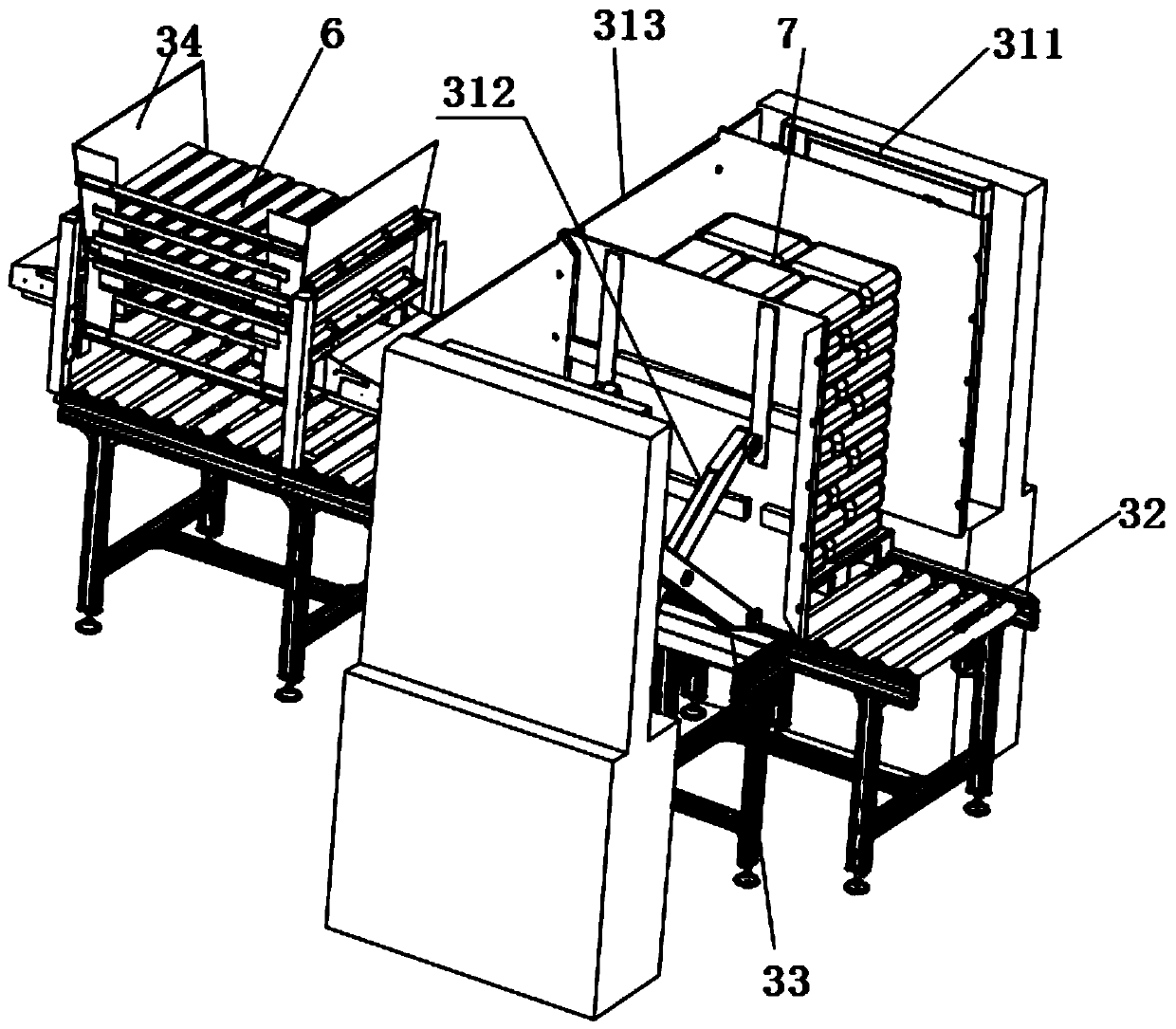

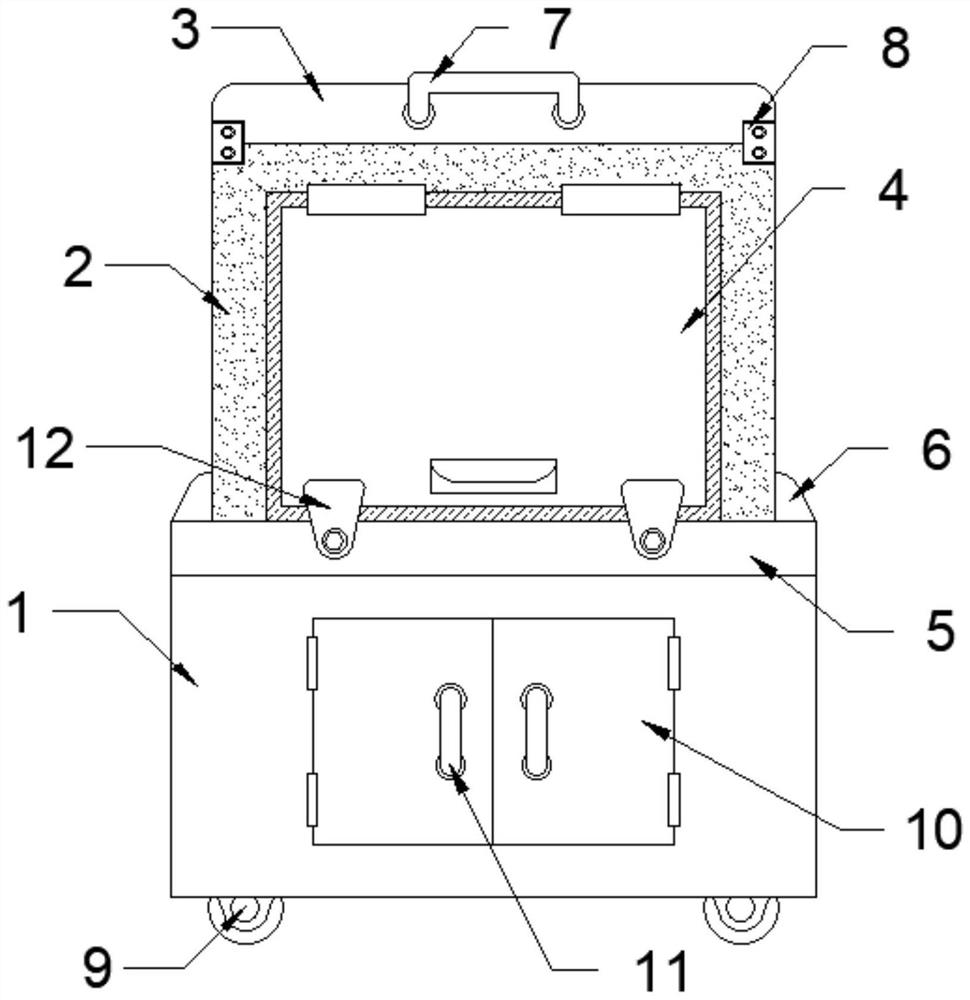

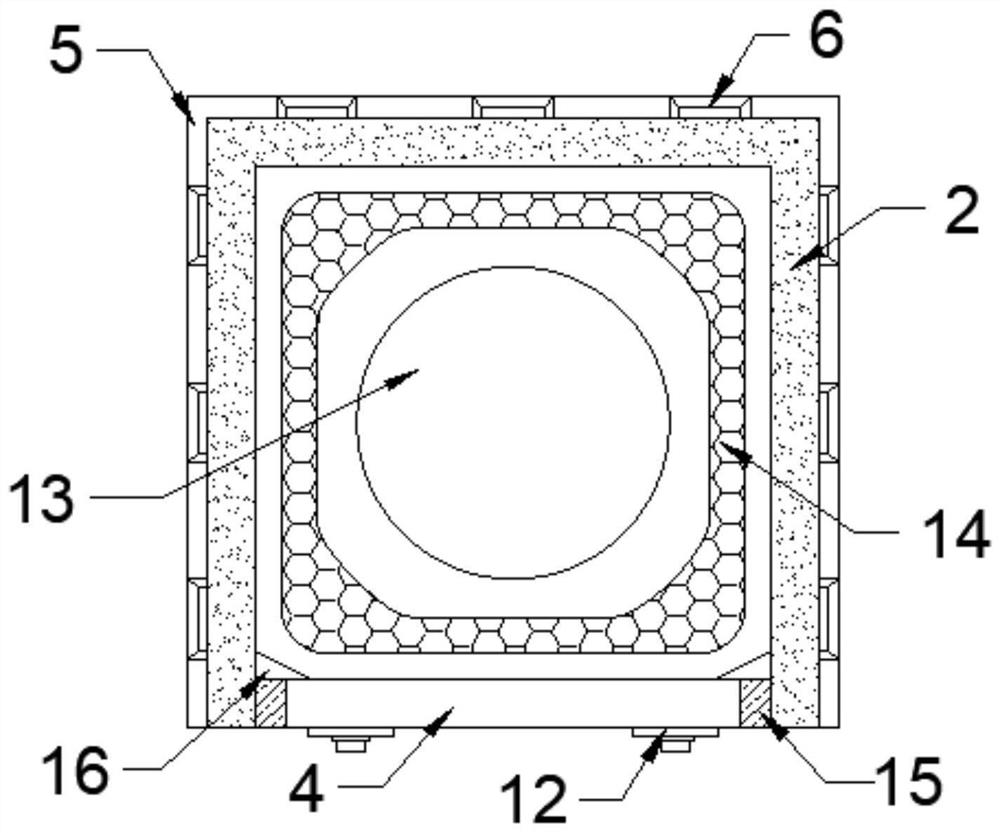

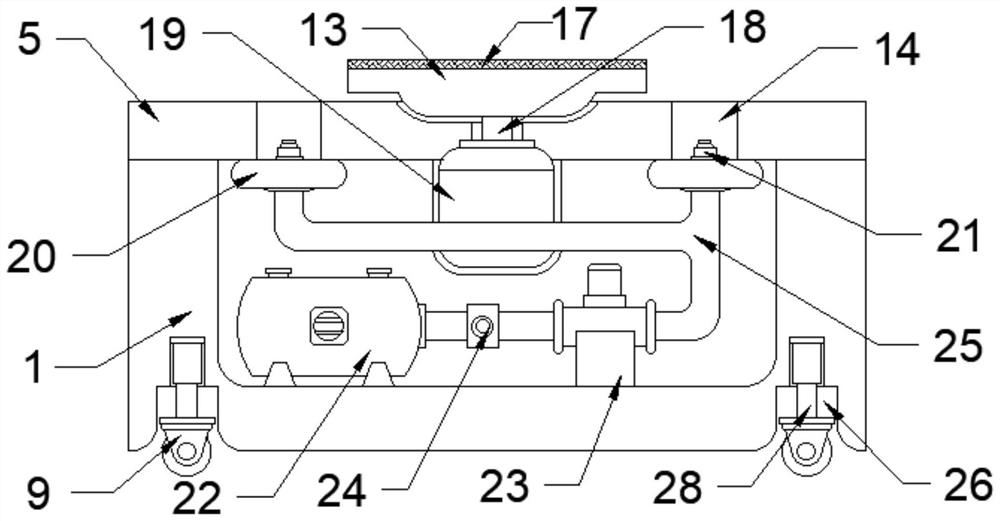

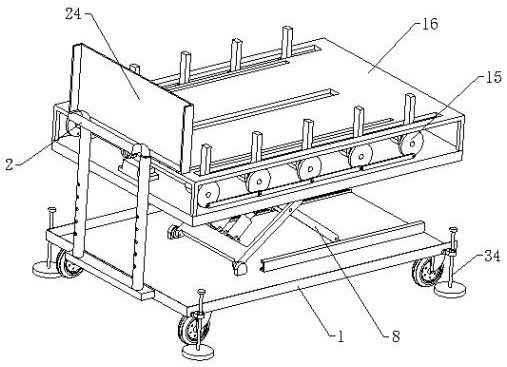

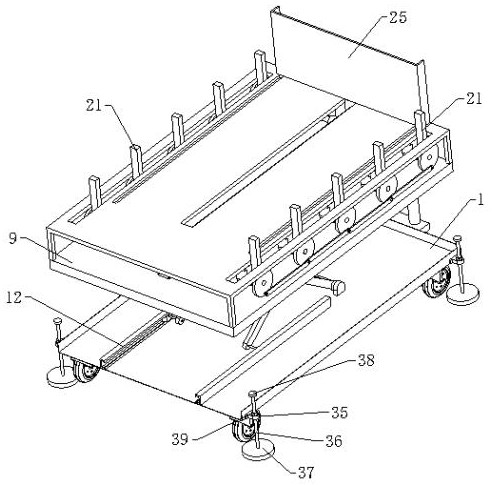

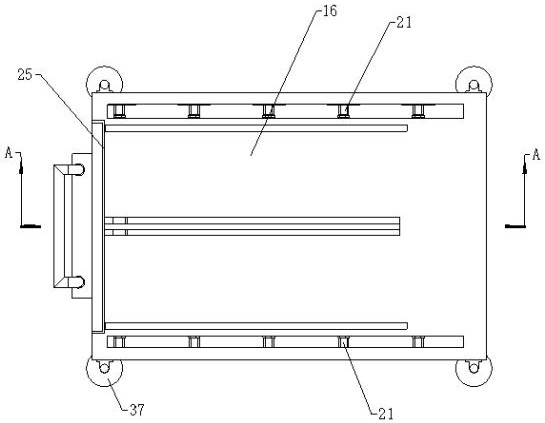

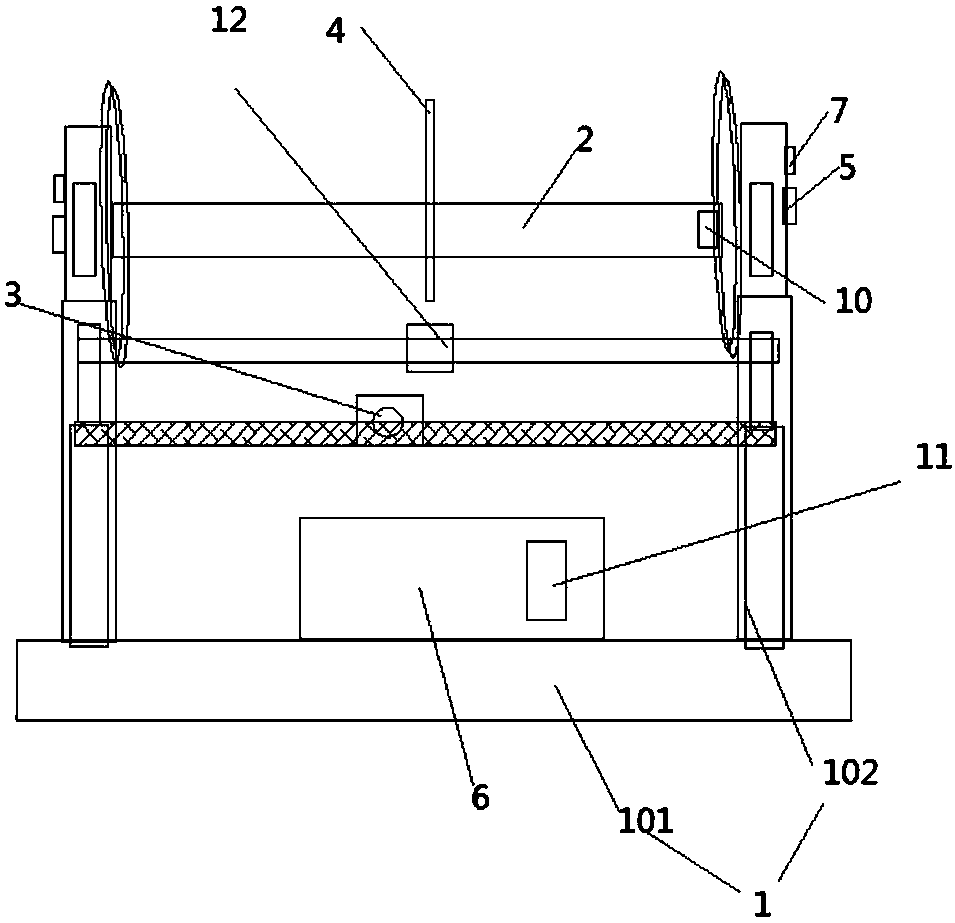

Intelligent logistics loading and unloading system for pallet-free transportation

ActiveCN110723449ASolve handling problemsImprove loading and unloading efficiencyControl devices for conveyorsSupporting framesIn vehicleChain conveyor

The invention discloses an intelligent logistics loading and unloading system for pallet-free transportation. A vehicle-mounted conveying mechanism and a loading and unloading platform are used. The problem of carrying of cargos in a compartment is solved. Manual cost is saved, the cargo loading and unloading efficiency is improved, the use number of loading and unloading platforms, forklifts andtrucks can be reduced, and buffer stock is reduced. The problem that cargos with pallets are transported to a compartment from a common warehouse and a three-dimensional intelligent warehouse, or during online direct loading, automatic pallet removal is carried out is solved, the problem that cargos without pallets are automatically loaded with the pallets during the process from the compartment to the common warehouse and the three-dimensional intelligent warehouse is solved, pallet-free transportation of the cargos with the pallets can be achieved, transportation space is saved, high cost ofpallet recycling and circulation can be reduced, and transport safety is improved. A single-face reciprocating type plate chain conveyor is used, the chain plate self weight is effectively reduced, the system is high in adaptation and compatible with compartment type, breast board type and other types of common trucks and platforms, meanwhile, pallets of different heights are considered, the system is suitable for intelligent loading and unloading of various bagged and box cargos, and the logistics industry needs are met.

Owner:张明 +1

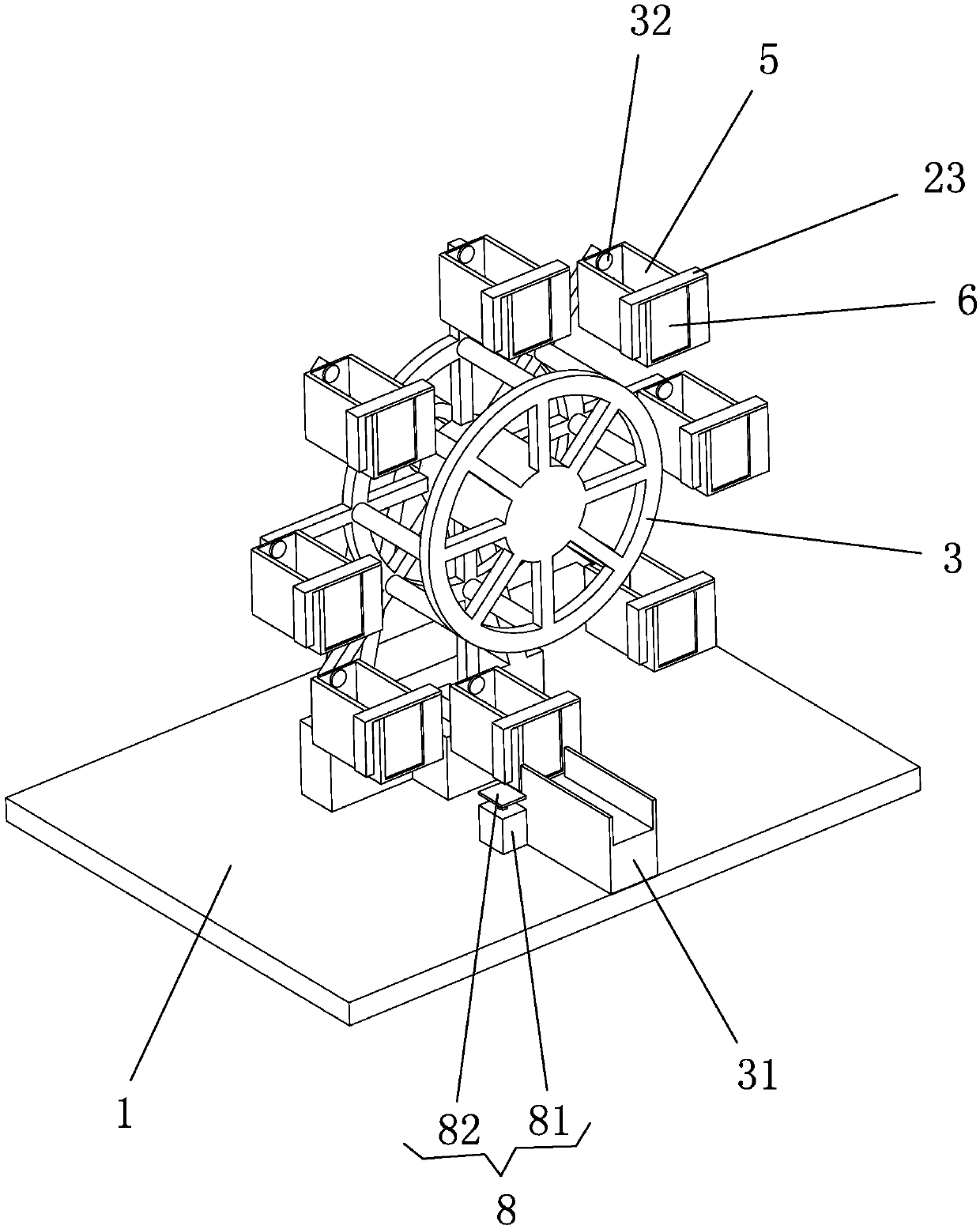

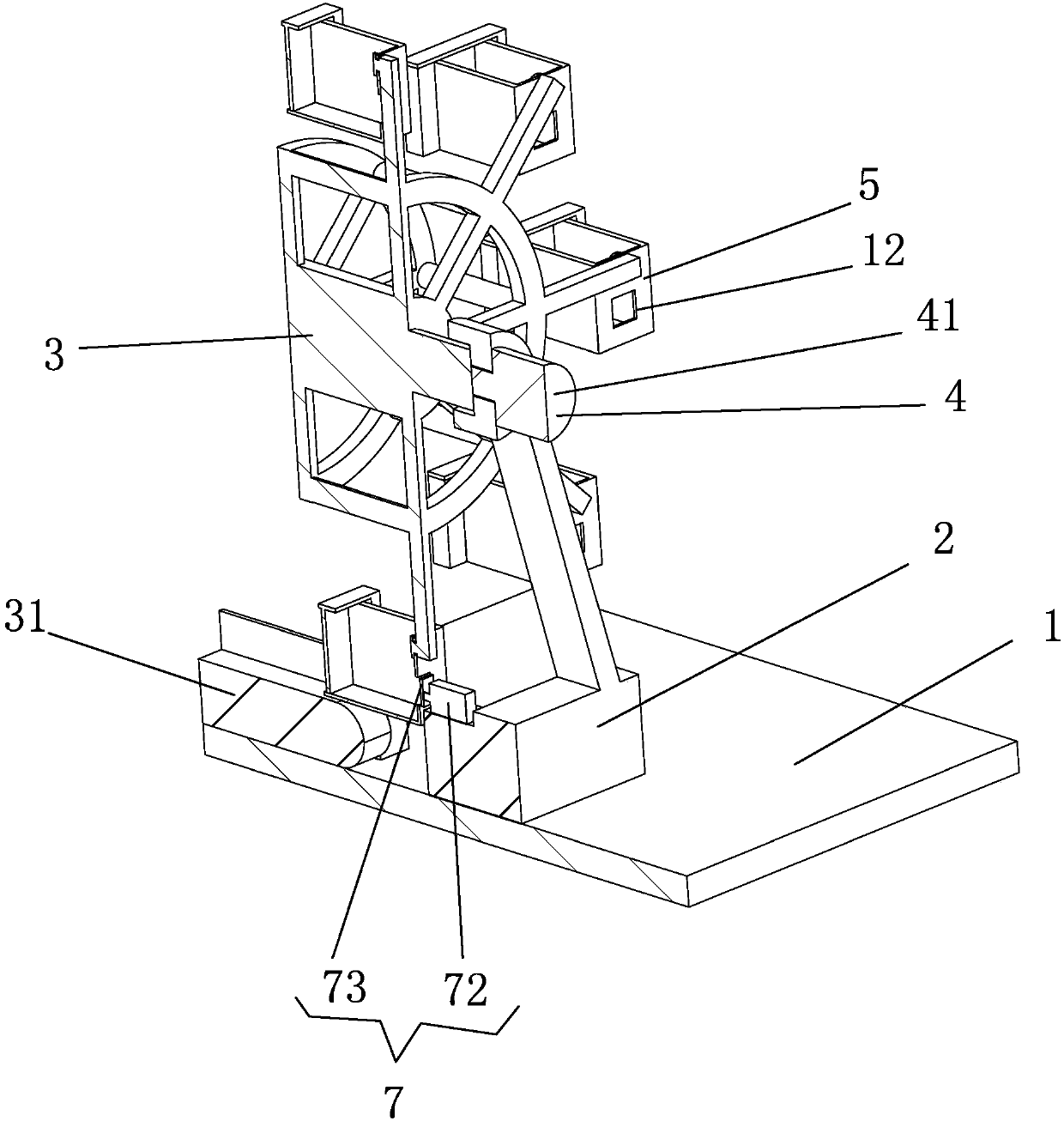

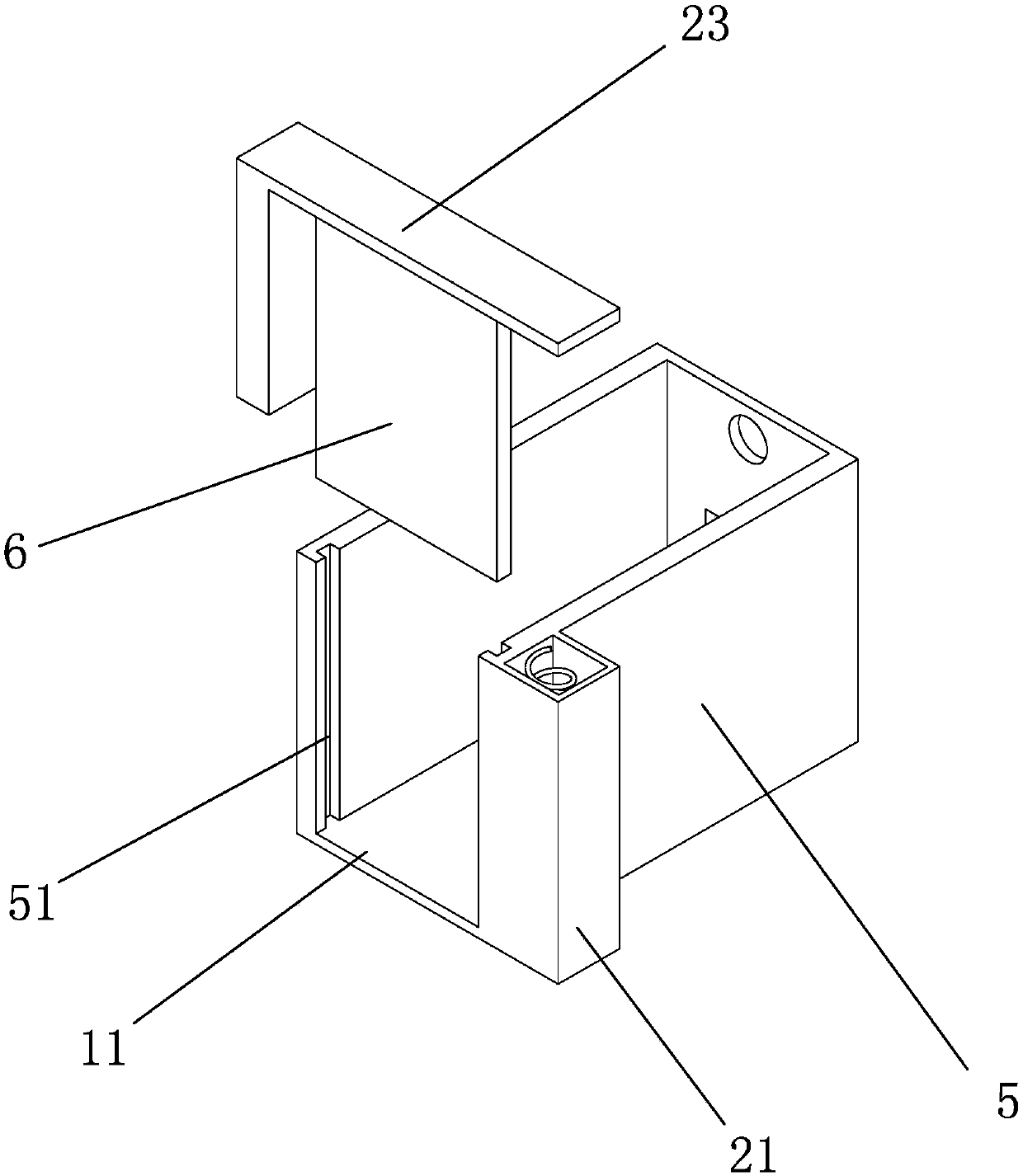

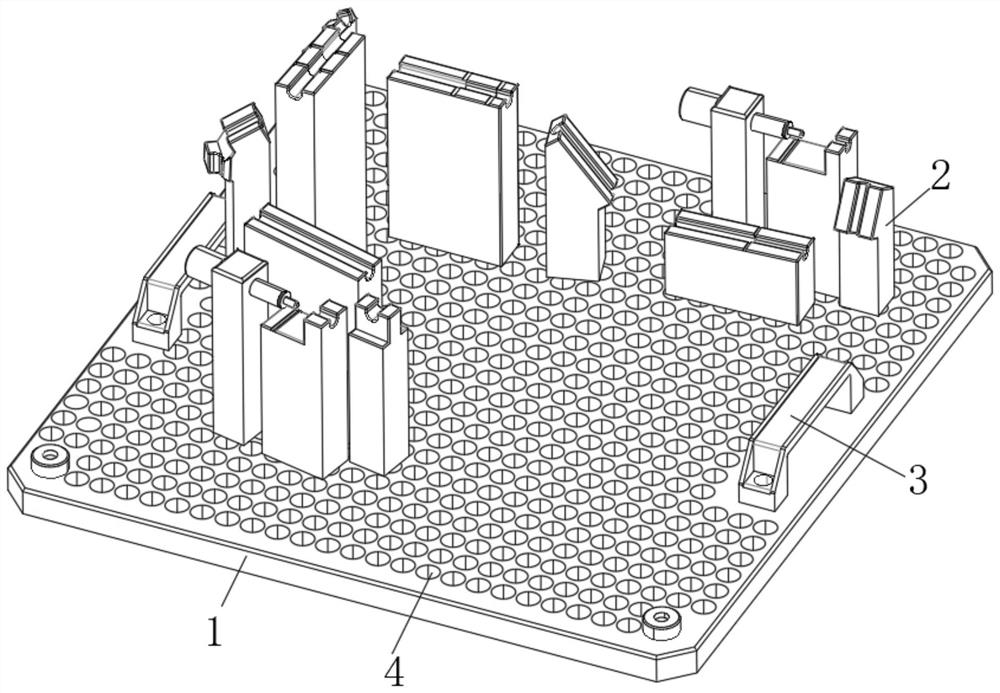

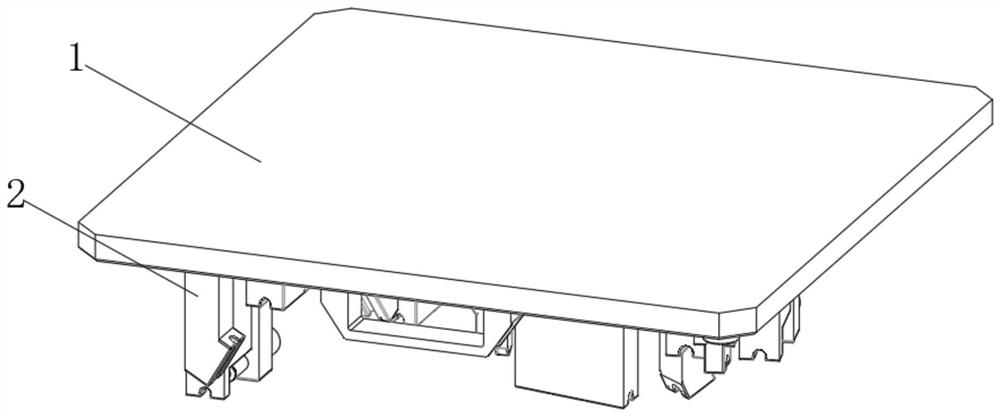

Novel rotating mold base

ActiveCN107825379ASolve handling problemsSimple structureWork tools storageMechanical engineeringEngineering

The invention discloses a novel rotating mold base which comprises a bottom plate. A supporting frame is arranged above the bottom plate. A rotating frame is arranged in front of the supporting frame.A rotating mechanism is arranged behind the supporting frame. A plurality of loading boxes are circumferentially distributed on the rotating frame at intervals through corresponding rotating shafts.Through grooves are formed in the front ends of the loading boxes and are further provided with corresponding baffles. A lifting mechanism is arranged on the bottom plate and located below the rotating frame. Notches are formed in the rear end wall surfaces of the loading boxes. A pushing-out mechanism is arranged below the supporting frame and corresponds to the notch of the loading box at the bottommost position. The novel rotating mold base is simple in structure and convenient to use, and the rotating frame can be driven to rotate through the rotating mechanism. The loading boxes are affected by gravity when being filled with molds, and thus can be kept to move horizontally all the time, the loading boxes of the required molds can be horizontally rotated to the position of the pushing-out mechanism, and the lifting mechanism is controlled to push out the molds after the baffles are jacked up. In this way, the problem of manpower or forklift carrying is effectively solved, the dangerousness is greatly reduced and the safety guarantee is brought about to mechanical workers.

Owner:MEIBAN TECH ZHONGSHAN CO LTD

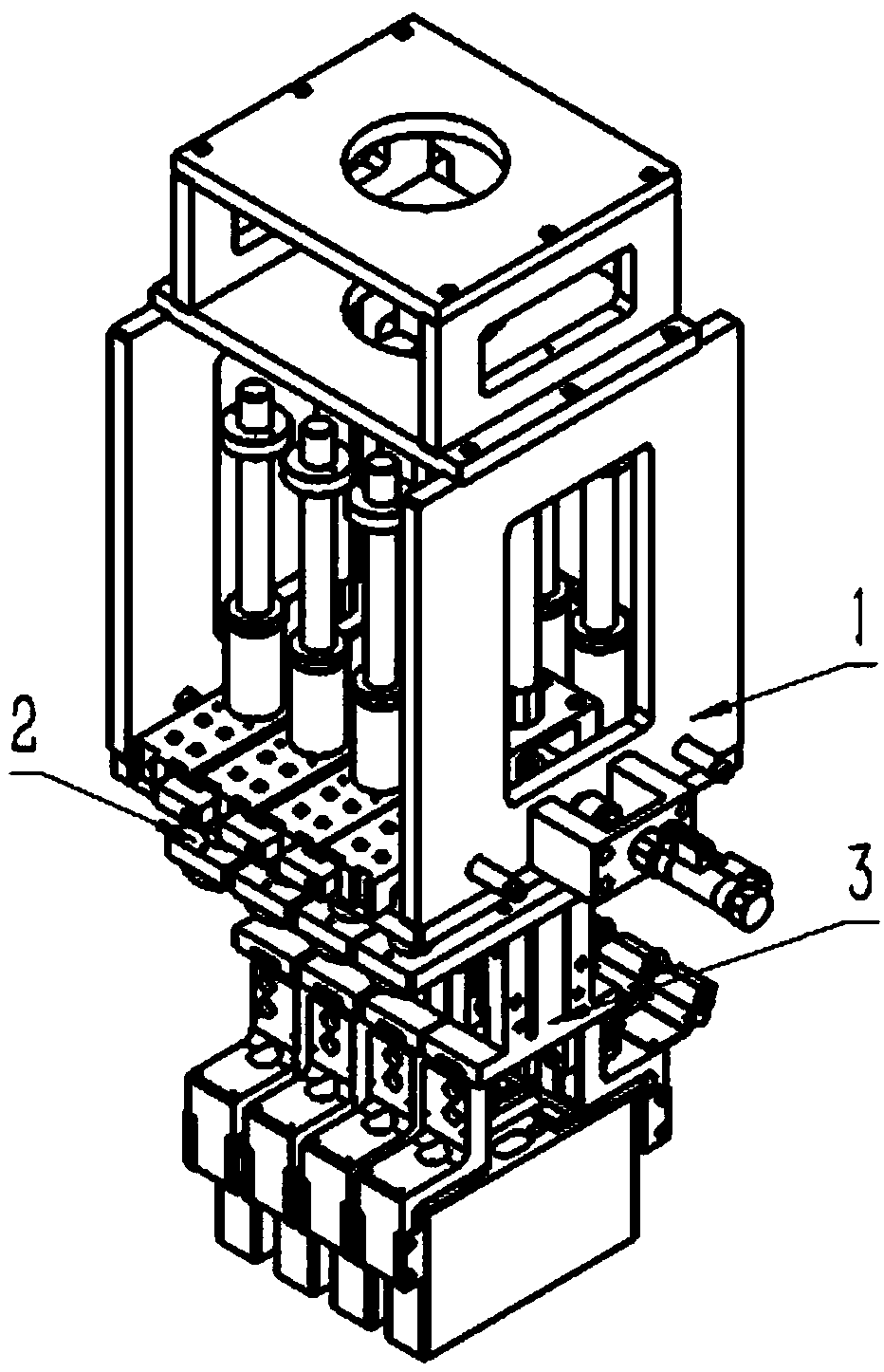

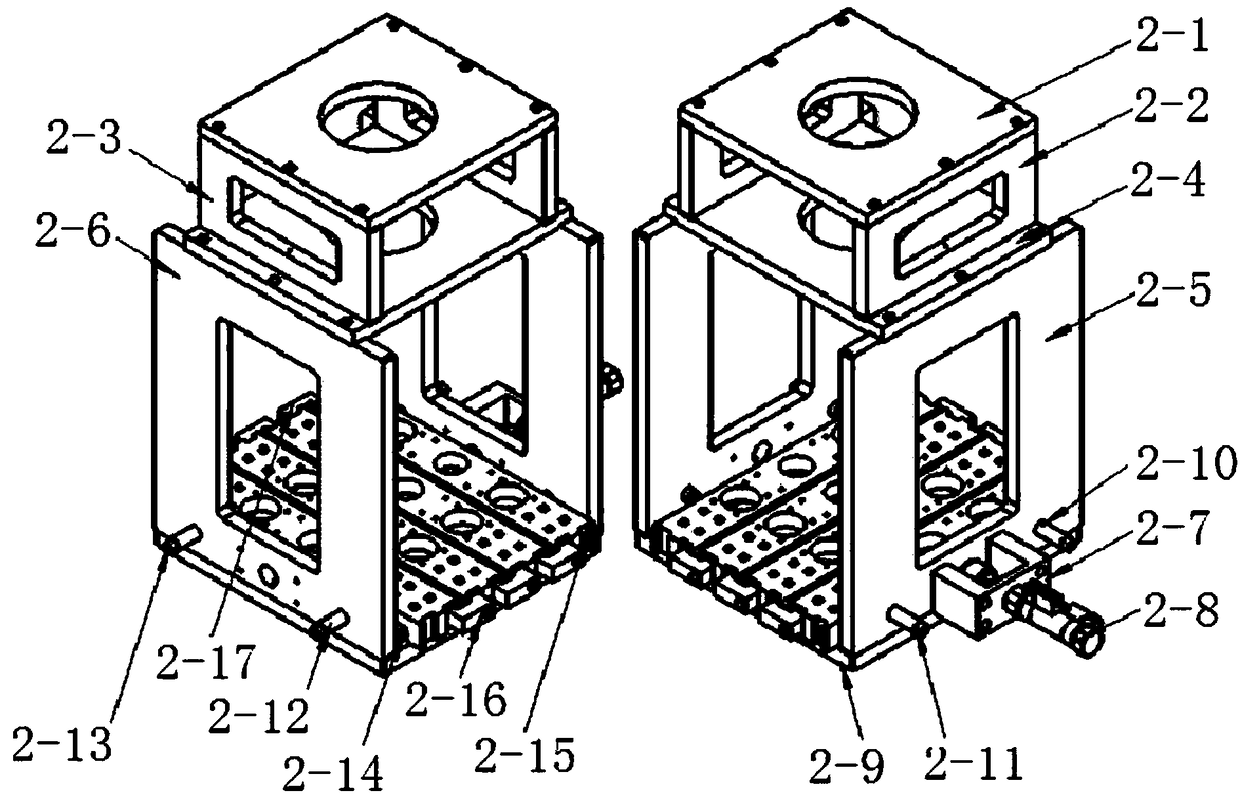

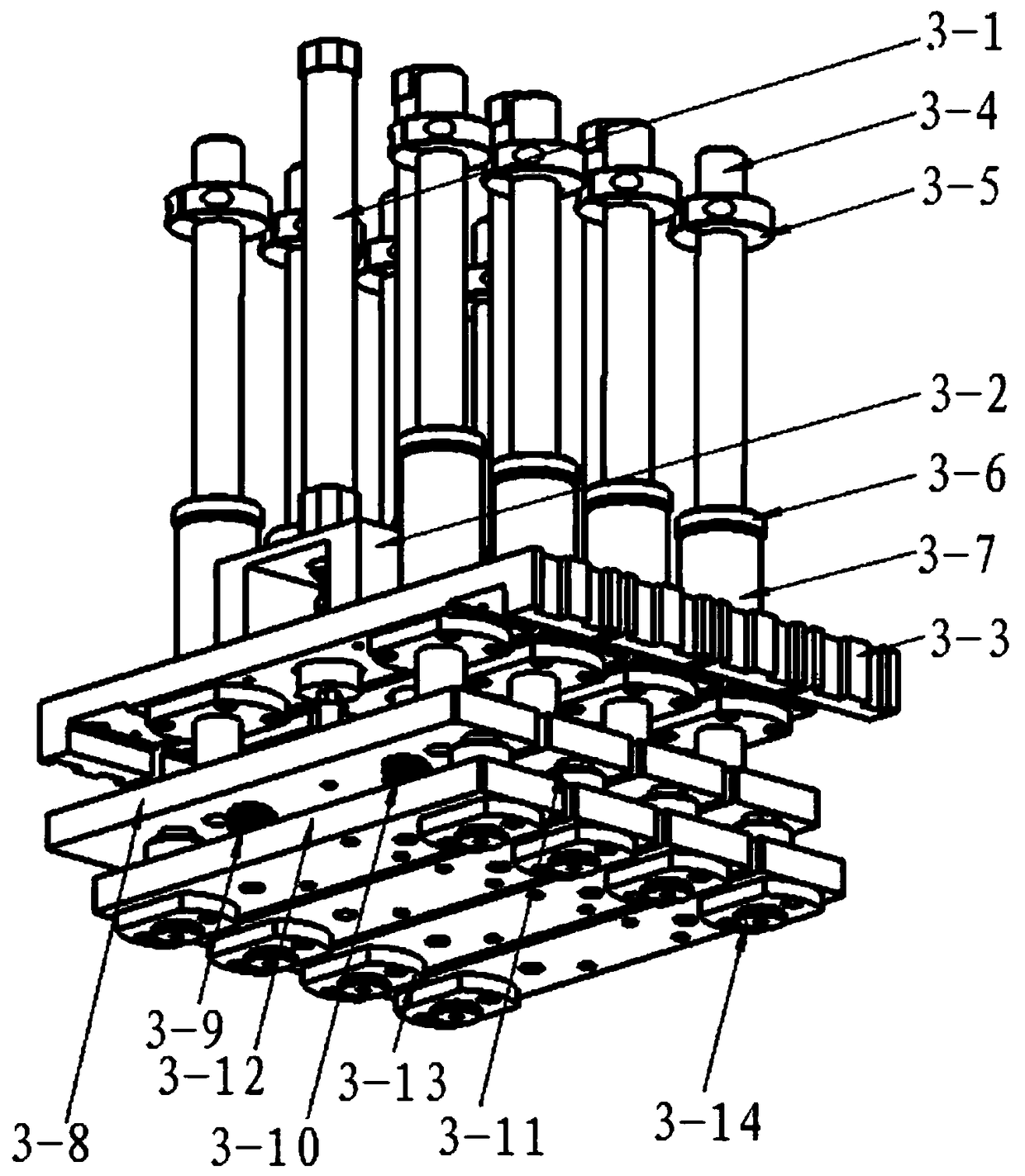

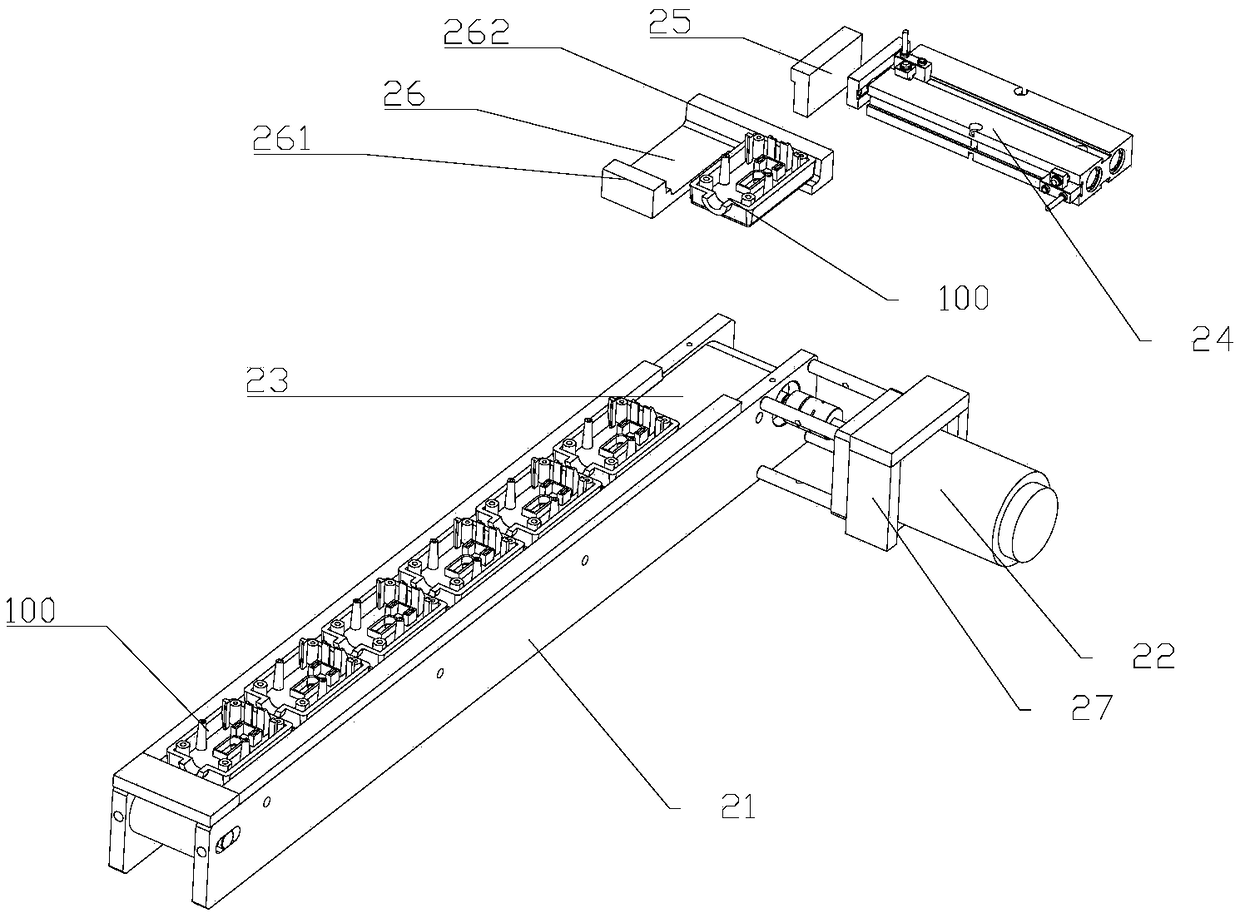

Pitch-variable carrying device for square shell lithium battery

PendingCN108569555ASolve variable pitch feedingSolve handling problemsConveyorsControl devices for conveyorsElectrical and Electronics engineeringLithium battery

The invention relates to a pitch-variable carrying device for a square shell lithium battery. By virtue of cooperation among a pitch-variable structural assembly, a lifting-buffering structural assembly and a clamp claw structural assembly, when a square shell battery is put in place, a pitch-variable mechanism moves to change the pitches of four clamp claws until an electric core is just clamped,the square shell battery is grabbed by the clamp claws, the clamp claws are lifted in place under the effect of an air cylinder, and the pitches of the four clamp claws are changed again until the square shell battery can be just put into a restraining tray. According to the pitch-variable carrying device, the problem of pitch-variable loading or carrying of the square shell lithium battery is solved, and the pitch-variable carrying of the square shell lithium battery can be realized.

Owner:湖南阿提斯智能装备有限公司

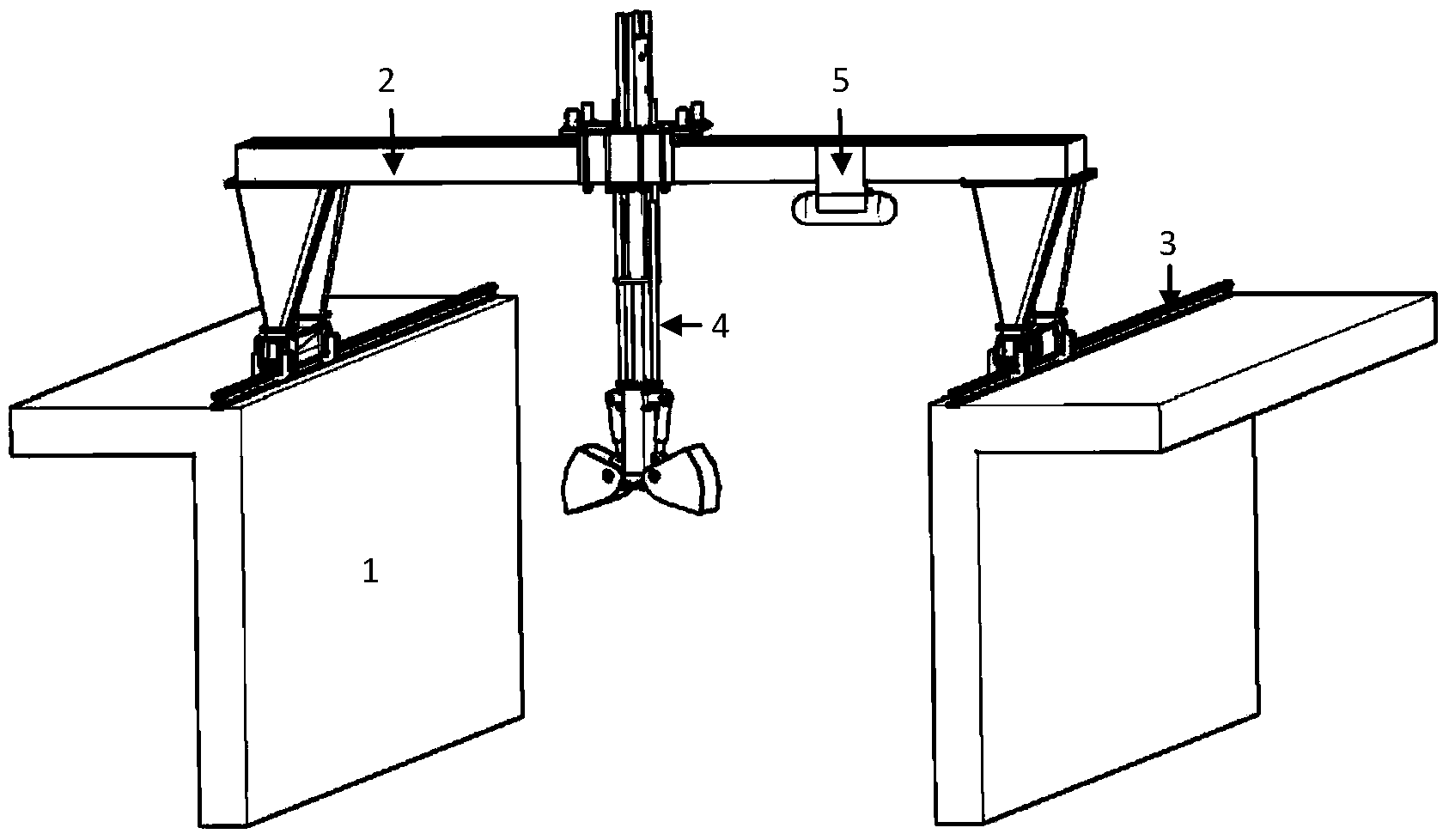

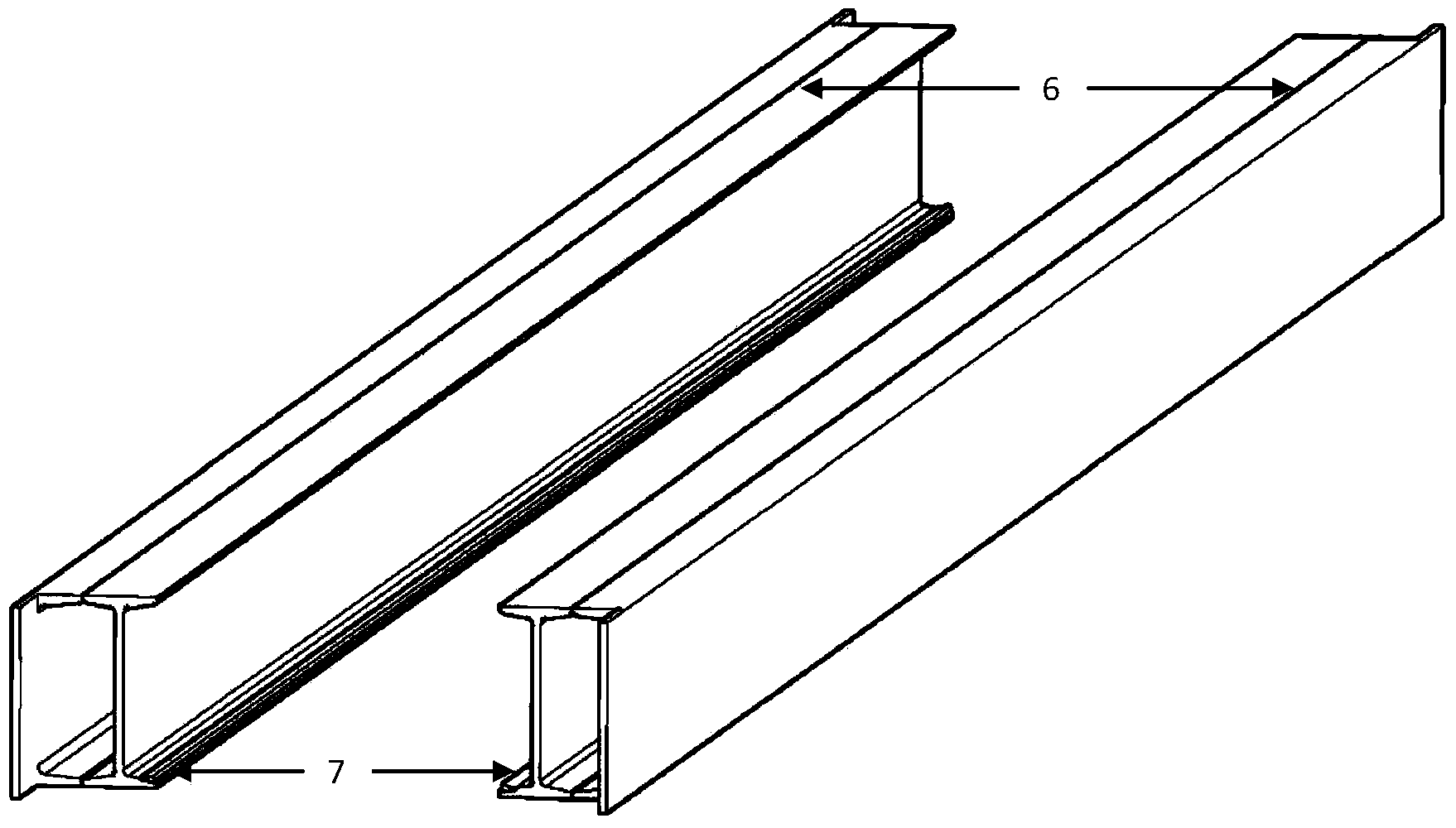

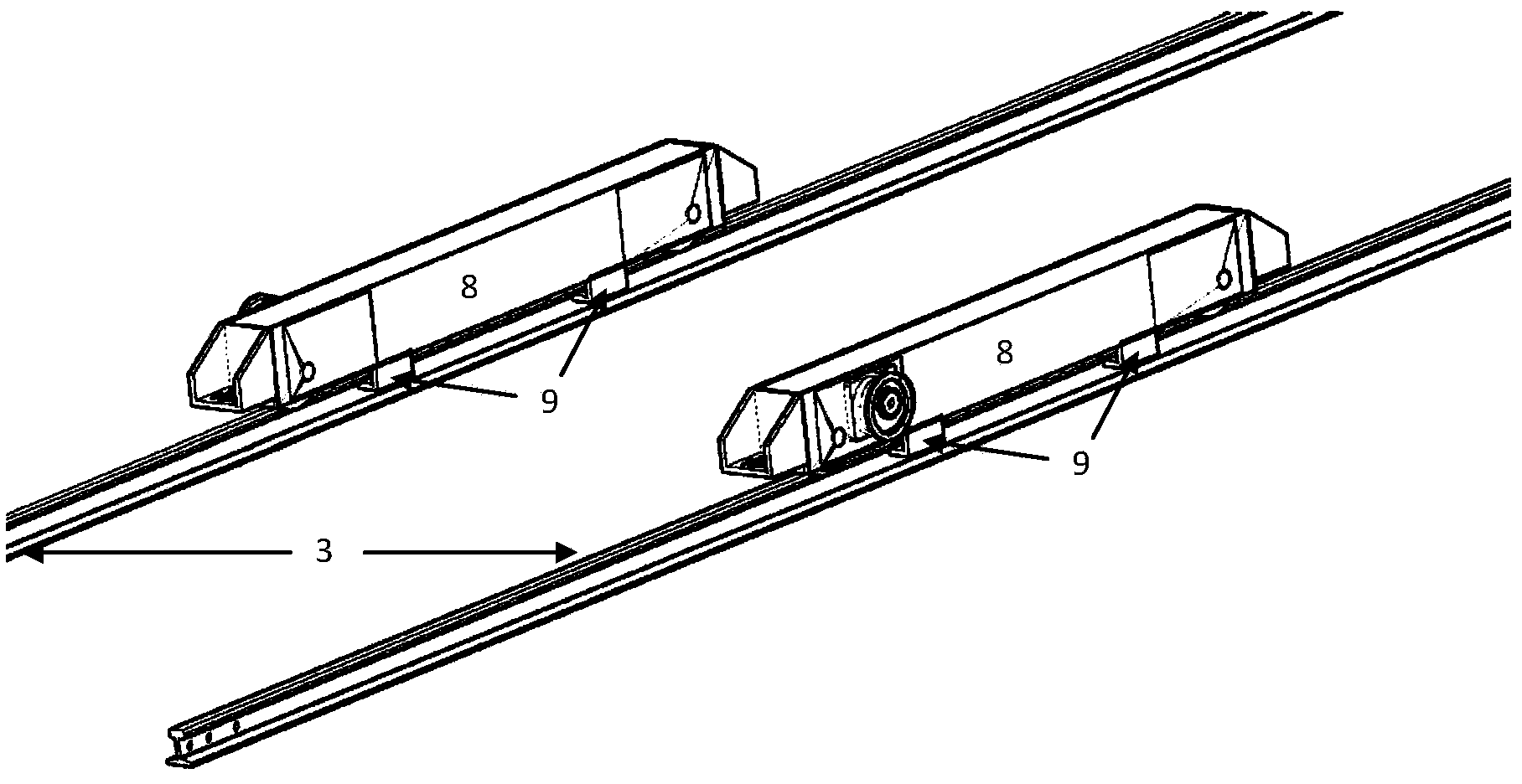

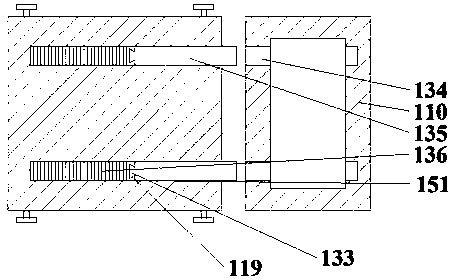

Numerical control automated construction device for large-scale geophysical prospecting test

ActiveCN103711155APrecise Positioning Mining TechnologyAvoid a single patternMechanical machines/dredgersNumerical controlSUSPENDING VEHICLE

The invention discloses a numerical control automated construction device for a large-scale geophysical prospecting test. The numerical control automated construction device comprises a horizontal guide rail which is fixed at the top end of a model test side wall, a double-beam gantry crane which moves on the horizontal guide rail in the direction of the guide rail, a 360-degree rotatable soil taking device, an anomalous body carrying device, and an integrated numerical control operation system which is used for achieving the functions of distance measurement, feedback and real-time display, wherein the 360-degree rotatable soil taking device and the anomalous body carrying device are mounted on the double-beam gantry crane. The double-beam gantry crane moves along the horizontal guide rail, and the 360-degree rotatable soil taking device moves along the double-beam gantry crane or moves vertically downwards. The numerical control automated construction device achieves the full-automatic quick three-dimensional accurate positioning excavation technology in soil of the large-scale geophysical prospecting test, replacing and repeating of materials and geologic abnormal bodies in the model test are achieved, and the advantages of being small in energy consumption, high in efficiency, high in operability, high in safety and the like are achieved.

Owner:SHANDONG UNIV

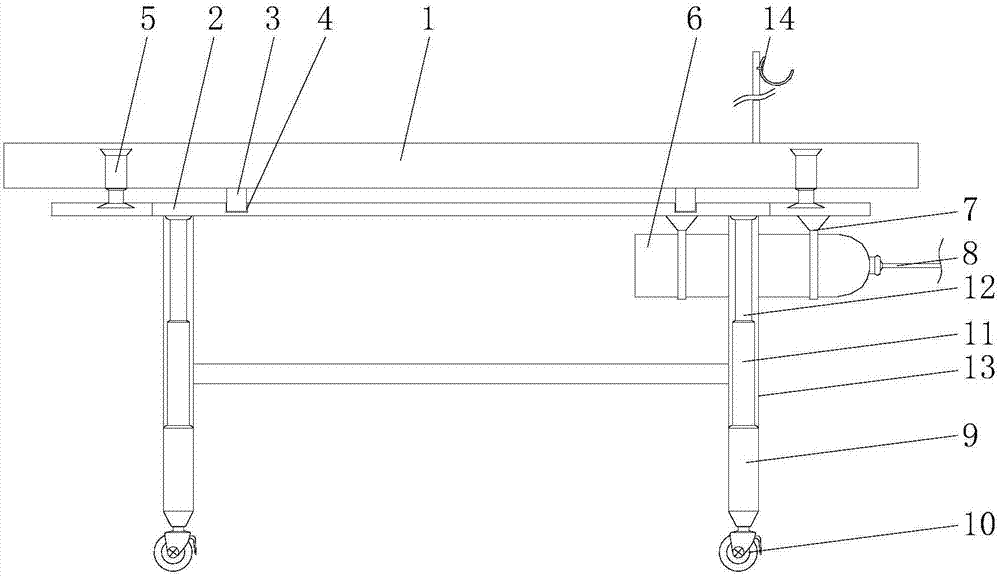

Intelligent medical transfer bed used for transferring patients

InactiveCN107874925ACause secondary damageSolve handling problemsStretcherHydraulic cylinderOxygen tank

The invention discloses an intelligent medical transfer bed for patient transfer, comprising a bed board, a bottom support board, a chute, an oxygen tank, a hydraulic cylinder and a sliding wheel. The lower part of the bed is provided with a mounting seat, and the lower part of the mounting seat is equipped with sliding wheels evenly distributed at equal intervals. An electric telescopic rod is installed inside, an oxygen tank is installed on the lower part of the bottom support plate, and an air outlet pipe is arranged on the air outlet on the right side of the oxygen tank. The present invention provides an intelligent medical transfer bed used for patient transfer. By arranging a bed plate, a bottom support plate, a chute, an oxygen tank, a hydraulic cylinder and a sliding wheel, the still need between the transfer bed and the inspection table is solved. Manual handling and oxygen pillows cannot continuously provide effective oxygen supply to patients.

Owner:谷新运

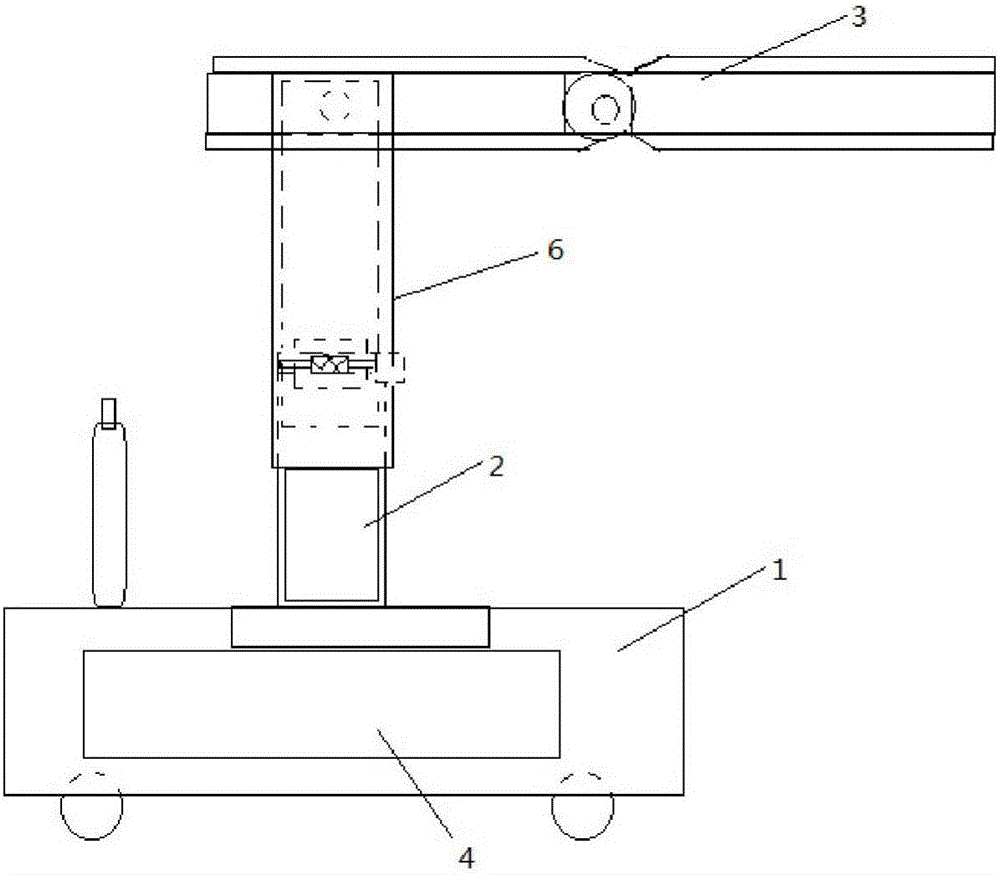

Intelligent mechanical arm convenient to move and working method thereof

The invention discloses an intelligent mechanical arm convenient to move. The intelligent mechanical arm convenient to move comprises a base, a stand column, shaft joints, a control device and a remote controller; a storage box is arranged on one side of the stand column; the shaft joints are rotationally connected pairwise; an extension control mechanism is arranged in the connecting place of two shaft joints; the remote controller and the control device are in wireless communicating connection; a driving control module, an actuation control module, an extension control module, a warning control module, a remote controller control module and a central control module are arranged in the control device; the remote controller control module is connected with the remote controller; and the driving control module, the actuation control module, the extension control module, the warning control module and the remote controller control module are all connected with the central control module. The intelligent mechanical arm convenient to move realizes one-key control through the remote controller, in particular, controls extension of the shaft joints through the remote controller, and is provided with the extension control mechanism between two shaft joints for realizing a shrinkage function of the shaft joints to conveniently carry and move the mechanical arm.

Owner:深圳立专技术转移中心有限公司

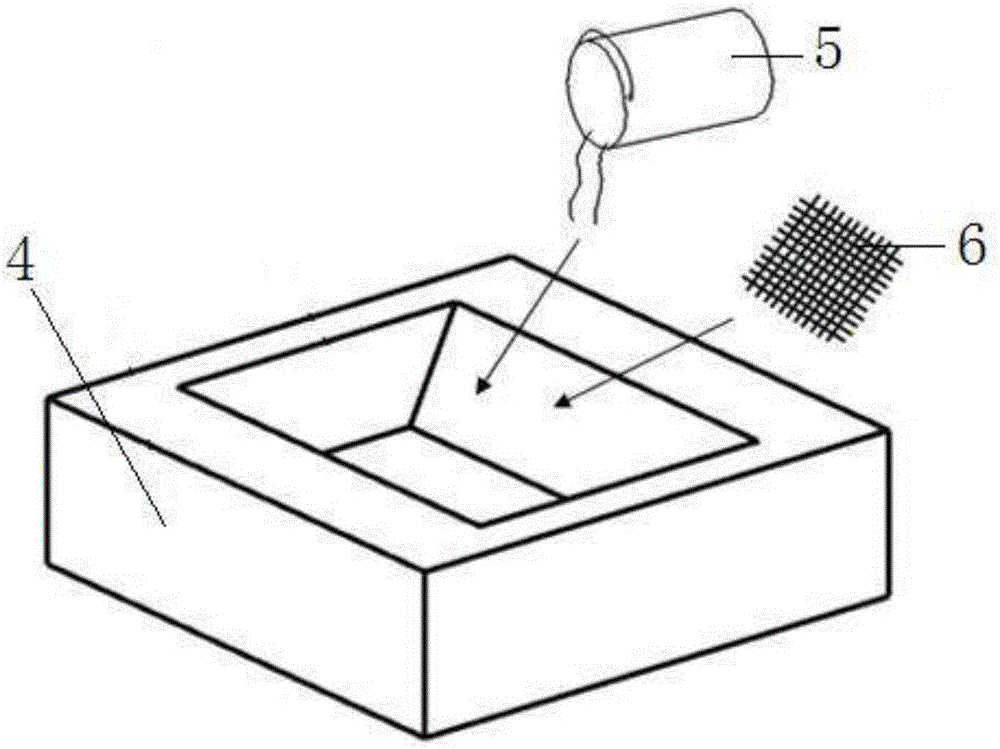

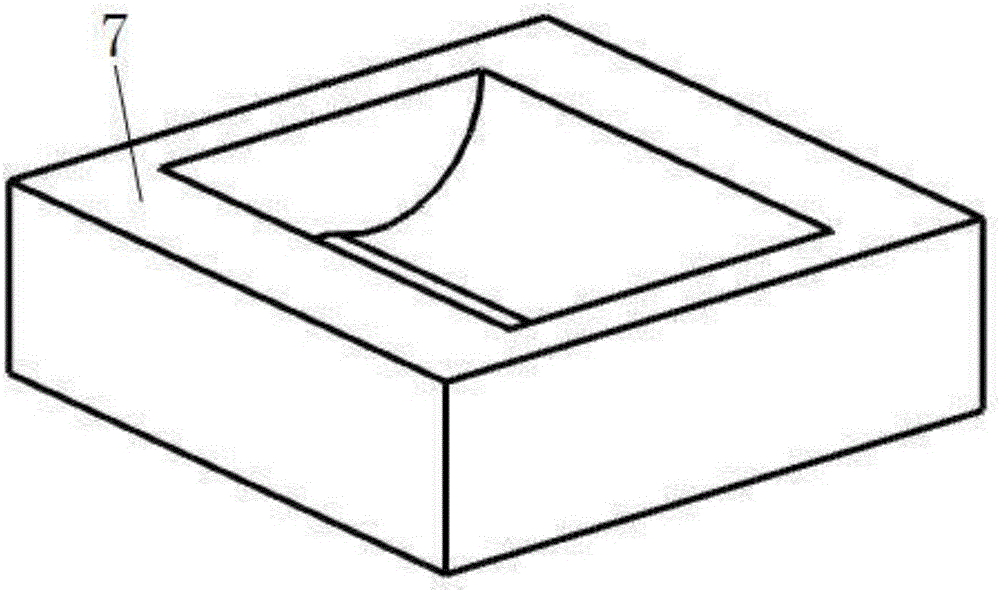

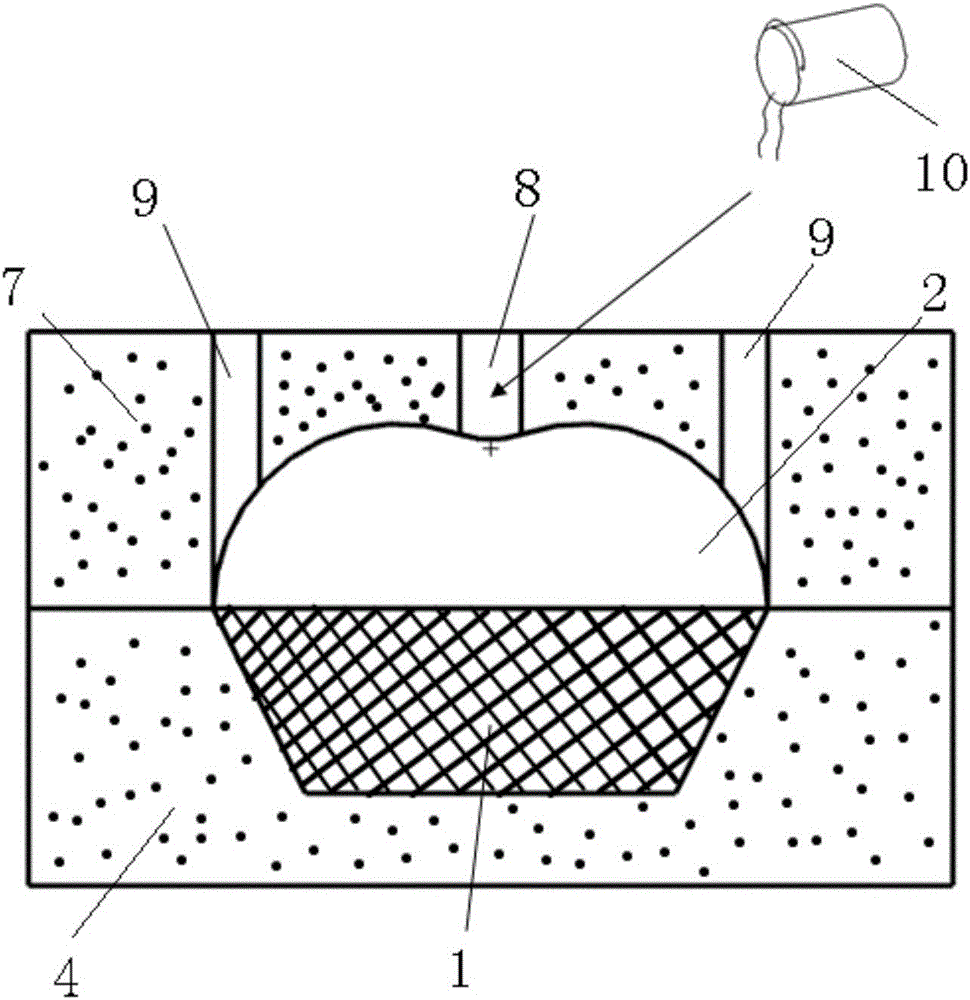

Manufacturing method for airplane part stretch-forming mold made of resin matrix composite

ActiveCN105945159AWith self-lubricating functionUniform surface hardnessShaping toolsNumerical controlResin matrix

The invention discloses a manufacturing method for an airplane part stretch-forming mold made of a resin matrix composite and mainly aims to solve the problems that existing molds are large in manufacturing difficulty, hard to store and large in weight and cannot be repaired. The provided manufacturing method for the airplane part stretch-forming mold made of the resin matrix composite comprises the steps that a matrix and a surface are manufactured with the resin matrix composite; and then the airplane part stretch-forming mold is machined and manufactured through a numerical control machine tool. By means of the manufacturing method, the mold using rate is increased, especially, the part productivity is improved, the mold manufacturing cost is reduced, and the mold manufacturing period is shortened.

Owner:SHENYANG CHINA AVIATION MERITT IND CO LTD

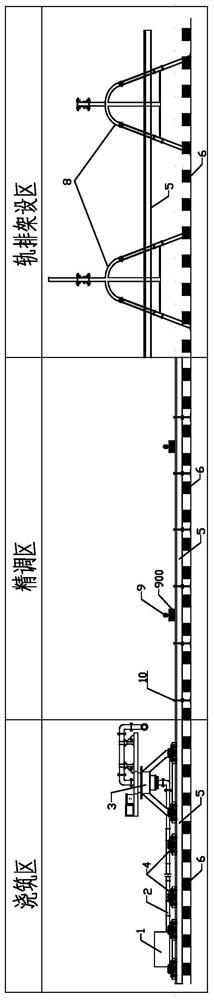

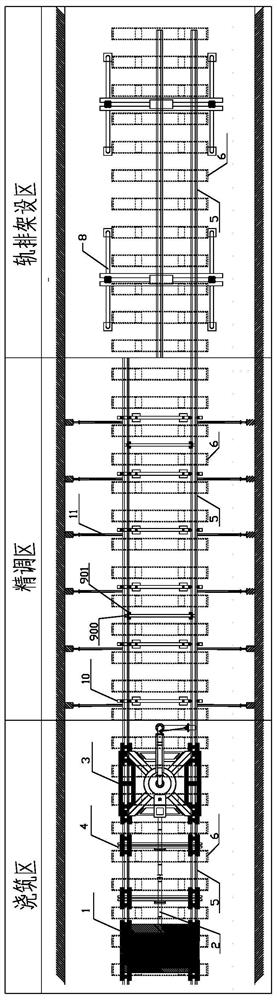

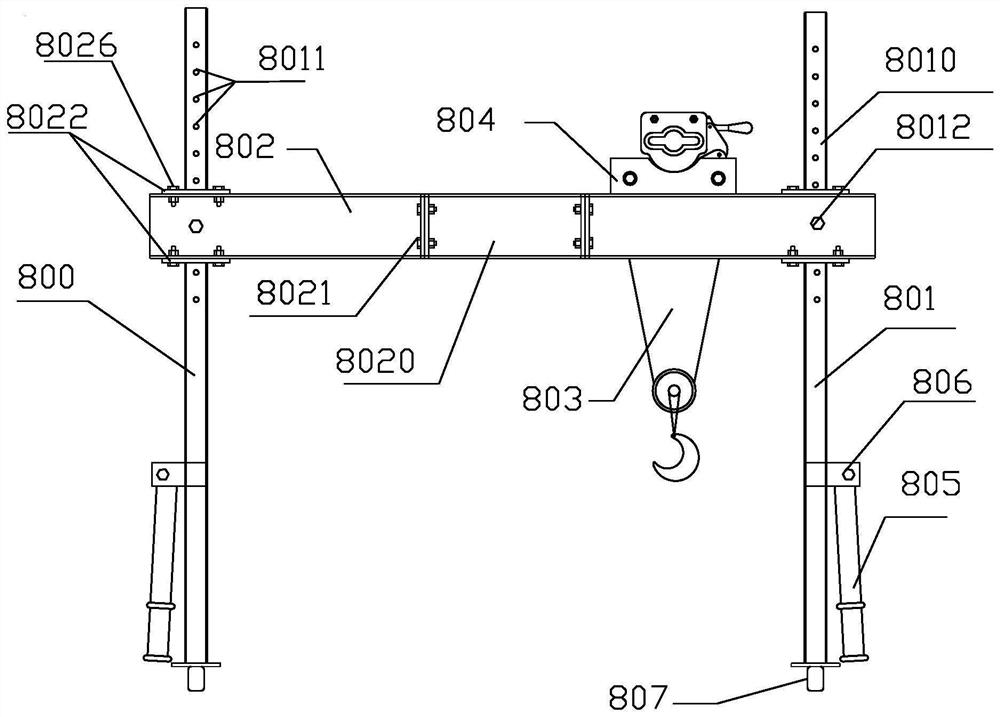

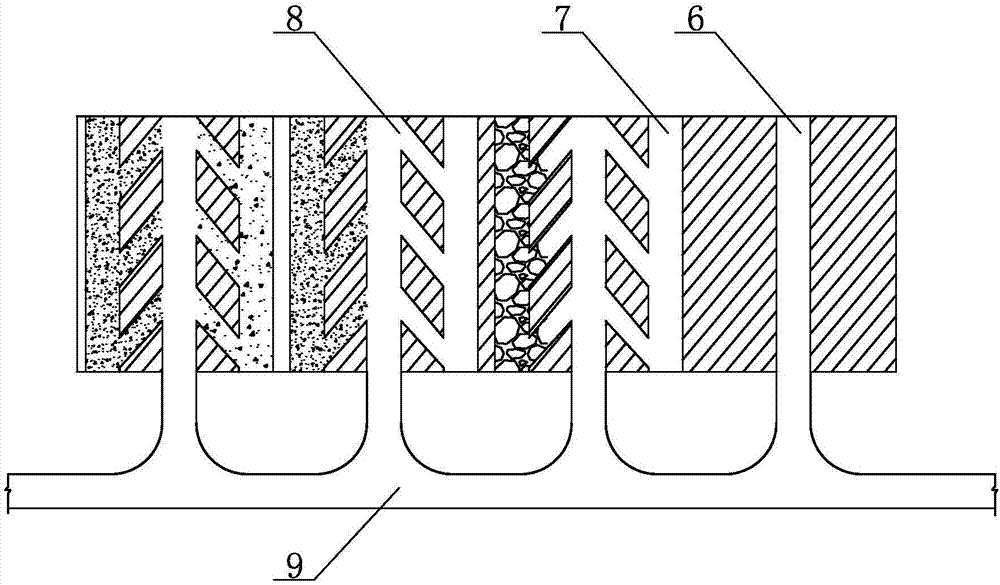

Construction method of cast-in-place ballastless track monolithic track bed in tunnel and used construction equipment

The invention provides a construction method of a cast-in-place ballastless track monolithic track bed in a tunnel and used construction equipment. The construction equipment comprises a hoisting portal frame, rail fine adjustment equipment, a movable concrete pumping machine, a pump pipe, a movable concrete pouring device and a plurality of pump pipe pushing trolleys. The hoisting portal frame issmall and exquisite in structure and can be used for rail material transportation in a narrow space area. In the invention, the concrete pumping machine, the concrete pouring device and the pump pipecan move along a steel rail; a problem of long-distance accurate pouring of concrete in a track transit interval can be solved; and the concrete pouring device can reduce a concrete pumping speed, and 360-degree dead-corner-free material distribution is achieved. Material distribution precision is improved, concrete pollution is avoided, construction efficiency and flexibility of a ballastless track are improved, and the method and the equipment can be applied to special environments such as tunnels with a limited space and complex terrains to carry out ballastless track construction.

Owner:CHINA RAILWAY 11TH BUREAU GRP

Chicken farm egg warehousing system based on Internet of Things

InactiveCN107265035ASolve automated storageSolve sortingConveyorsStorage devicesThe InternetNavigation system

The invention discloses a chicken farm egg warehousing system based on the Internet of Things. The warehousing system is characterized in that the warehousing system comprises an upper computer, an AGV, a positioning indicator and a ground navigation system; the upper computer is used for coordinated control of the AGV, the positioning indicator and the ground navigation system and enabling goods in an ex-warehouse lift to be conveyed from goods shelves to a sorting station; the positioning indicator is used for determining the corresponding goods shelves and positions of the goods in the ex-warehouse lift in storage data according to the upper computer and indicating the specific positions of the goods; and the ground navigation system is used for conducting path planning according to the position of the AGV, the specific positions of the goods in the goods shelves and the position of the sorting station and finding the shortest path.

Owner:合肥裕亿农业技术开发有限公司

Cultural relic display cabinet with nitrogen constant-humidity function and using method thereof

PendingCN112167894ASolve the problem of having nitrogen constant humidity functionAchieve constant humidity environmentShow cabinetsShow shelvesEngineeringNitrogen gas

The invention discloses a cultural relic display cabinet with a nitrogen constant-humidity function and a using method thereof, relates to the technical field of cultural relic display cabinets, and aims to solve the problem that moisture entering the display cabinet is not easy to release again, so that the moisture content in the display cabinet is gradually increased, and as the moisture content in the display cabinet is too high, internal cultural relics can be damaged, and storage of the cultural relics is not facilitated. A display table is arranged above the cabinet body, a glass frameis arranged above the display table, a cover plate is arranged above the glass frame, a moisture sensor is arranged in the center of the lower portion of the cover plate, a nitrogen outlet annular groove is formed in the display table, and a gas disc is arranged below the nitrogen outlet annular groove. A nitrogen tank is arranged in the cabinet body, a vacuum pump is arranged on one side of the nitrogen tank, gas guide pipes are arranged on the two sides of the vacuum pump, and electromagnetic valves are arranged outside the gas guide pipes.

Owner:郑州凌智陈列设备制造有限公司

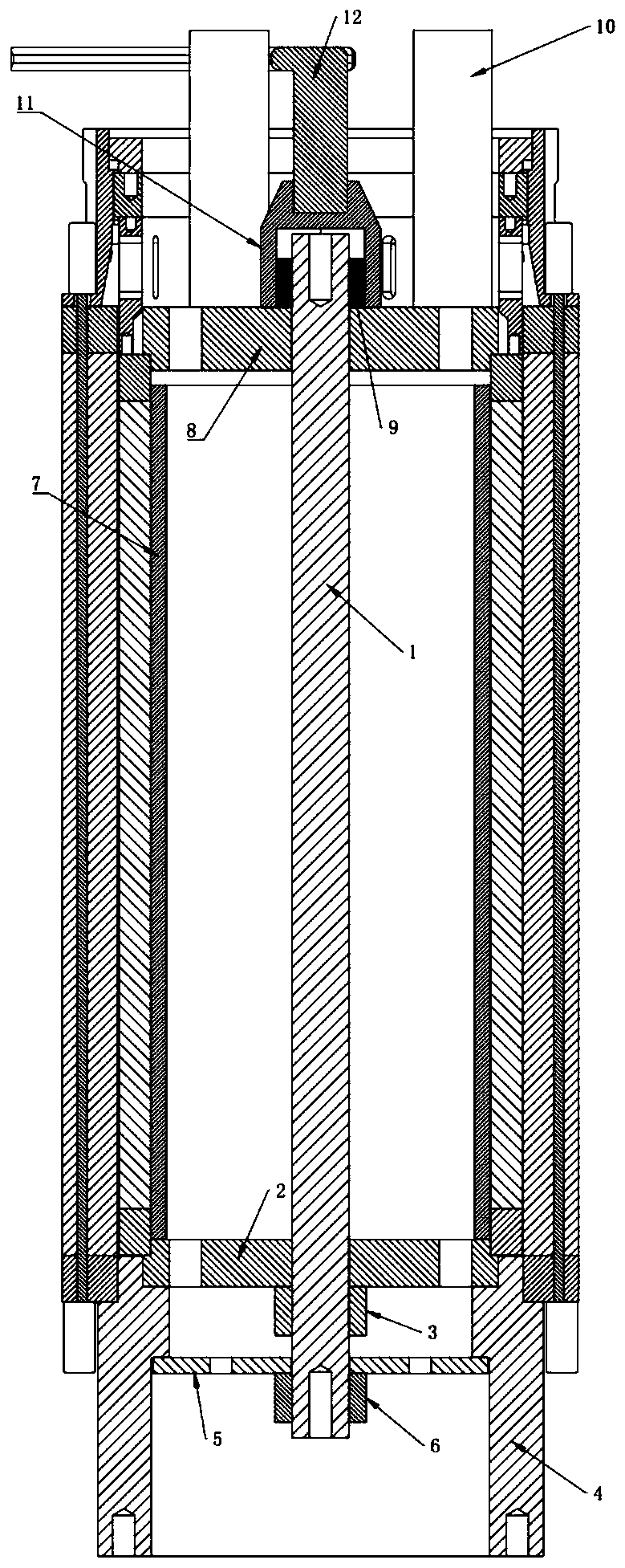

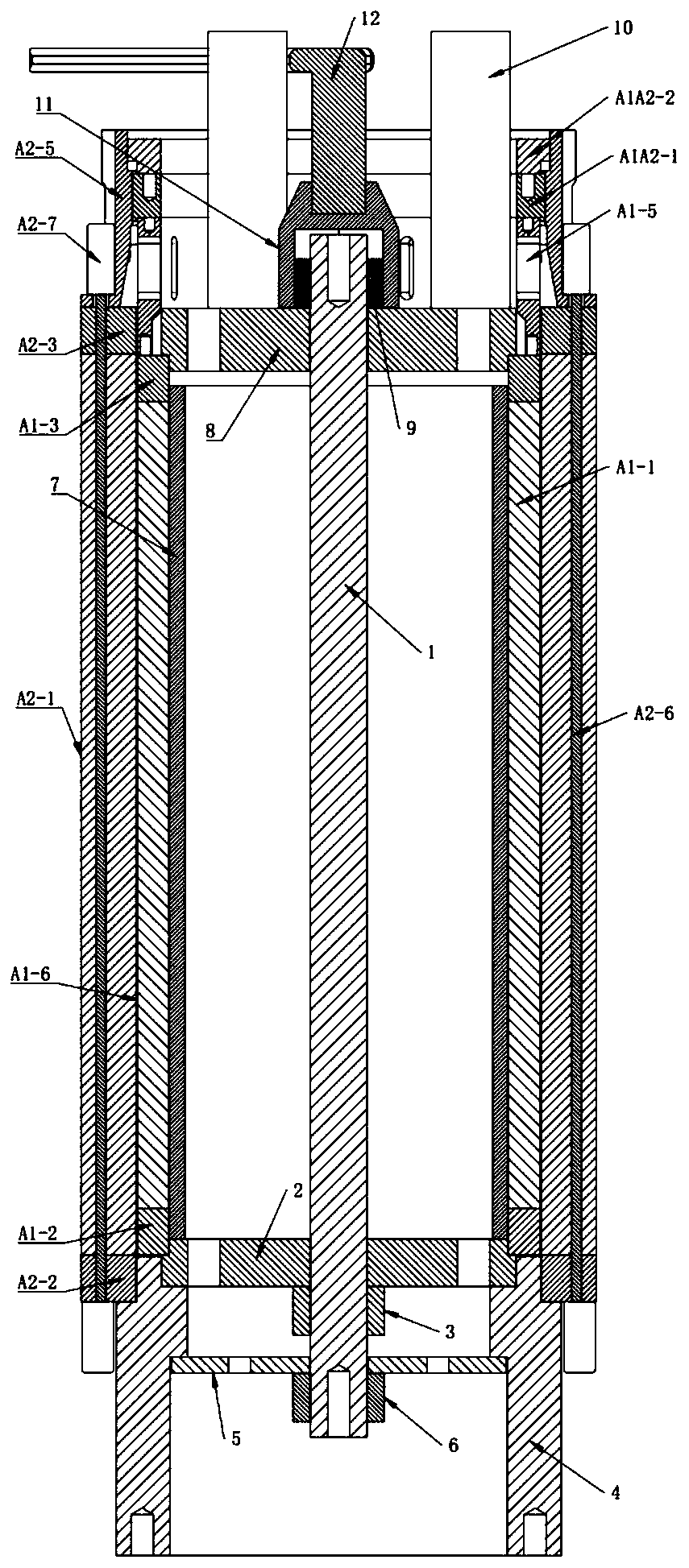

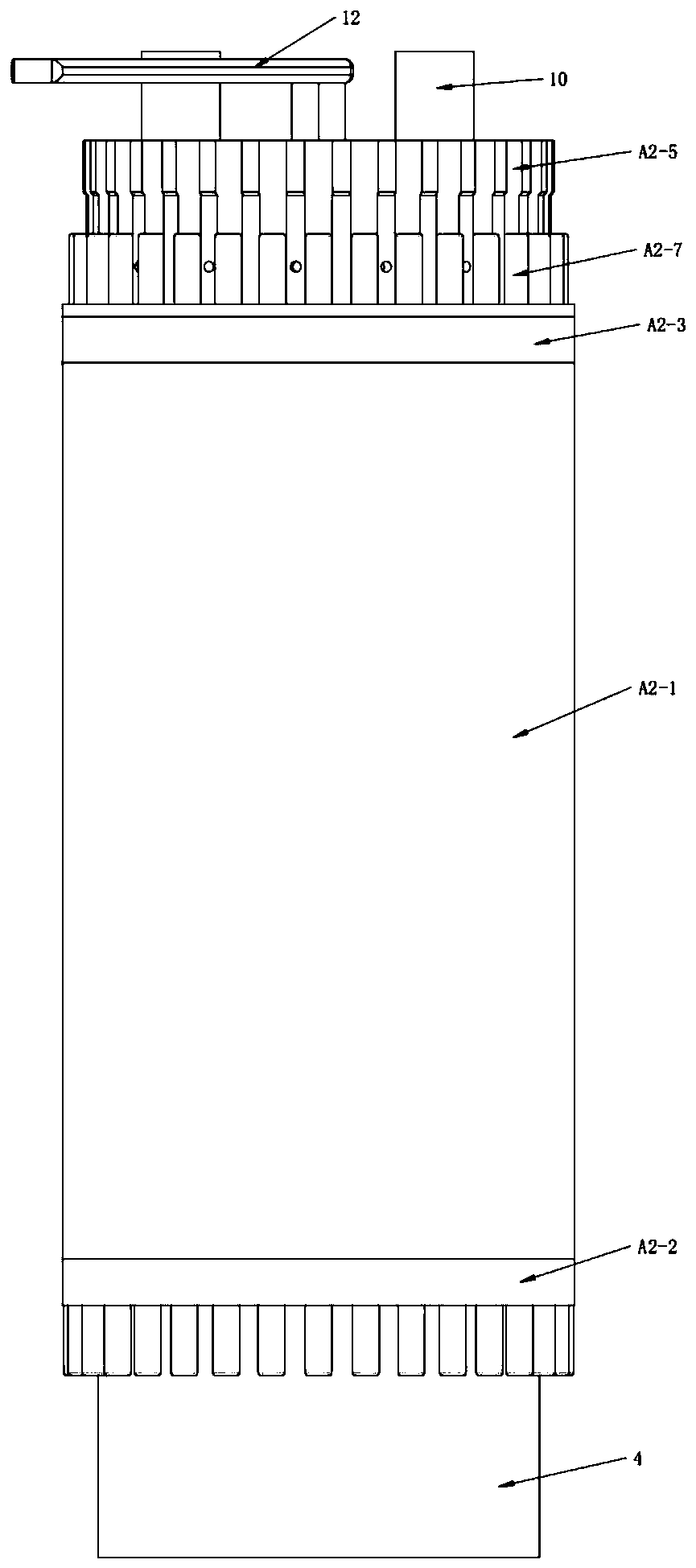

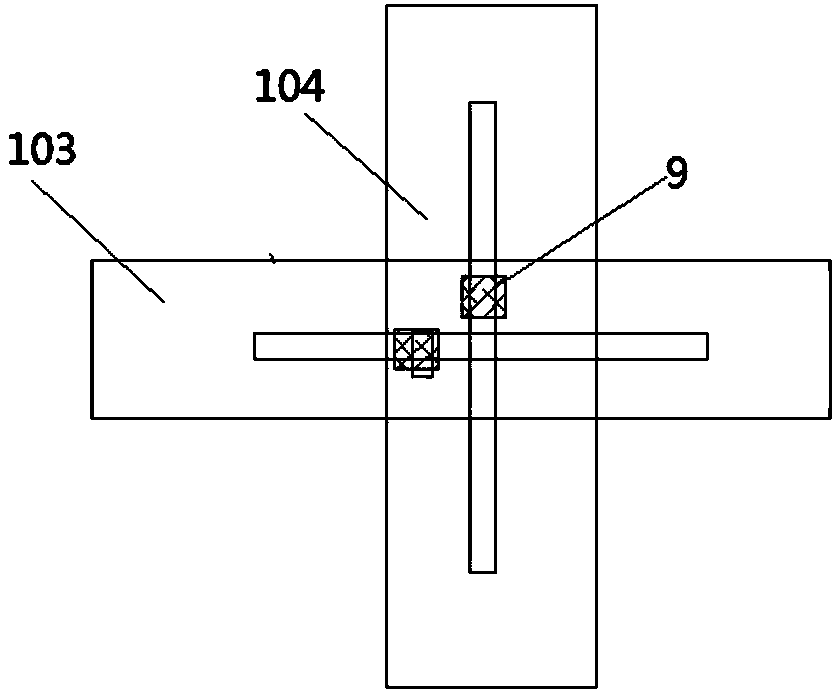

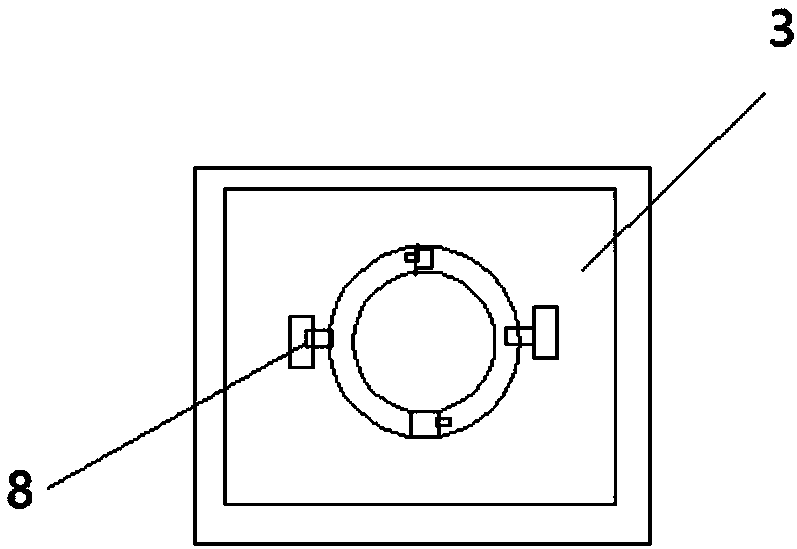

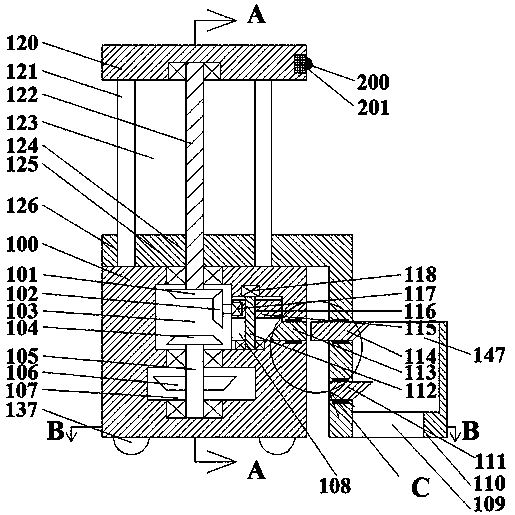

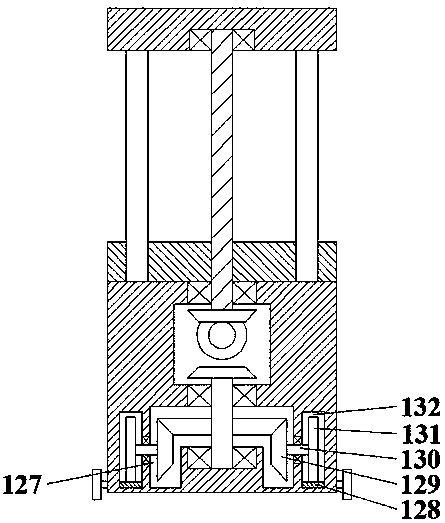

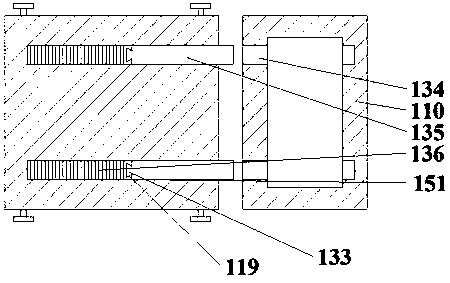

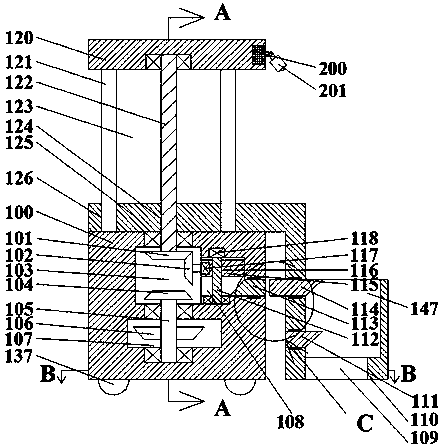

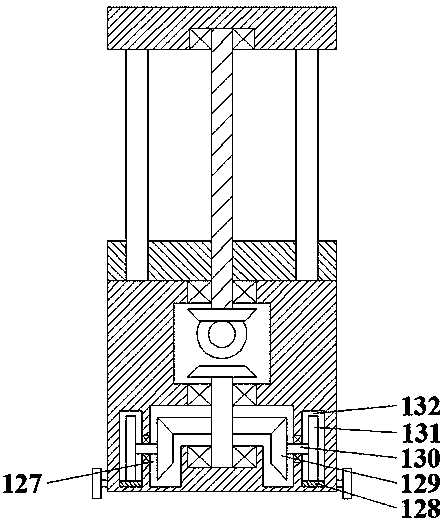

Water cooling magnet parallel coil assembling fixture and parallel coil assembling process

PendingCN110170945APress smoothlyFastened smoothlyAssembly machinesWork holdersArchitectural engineeringWater cooling

The invention discloses a water cooling magnet parallel coil assembling fixture. The fixture comprises a center rod, wherein the lower end of the center rod is in threaded connection with a lower positioning disc, the center rod under the lower positioning disc is sleeved with a lower nut, and the outer circle of the lower positioning disc is connected with a base in a matched mode, the inner circle of the base is connected with an A1A2 positioning disc, the A1A2 positioning disc is in threaded connection with the center rod, the center rod under the A1A2 positioning disc is sleeved with a positioning nut, and one end, far away from the lower positioning disc, of the center rod is in threaded connection with an upper positioning disc. According to the water cooling magnet parallel coil assembling fixture, through the structure design of the fixture, in the installation process of the water cooling magnet, the feasibility of orderly assembling, carrying, performance testing and fixtureoperation during pressing of a magnet in the installation process is achieved, and the feasibility of an orderly using process of the tool is further achieved; and through the obtained water cooling magnet WM3 through the installation process assembling and the fixture, two coils are connected in parallel, a fixed rod is not arranged in an inner coil, so that the magnetic field can be improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

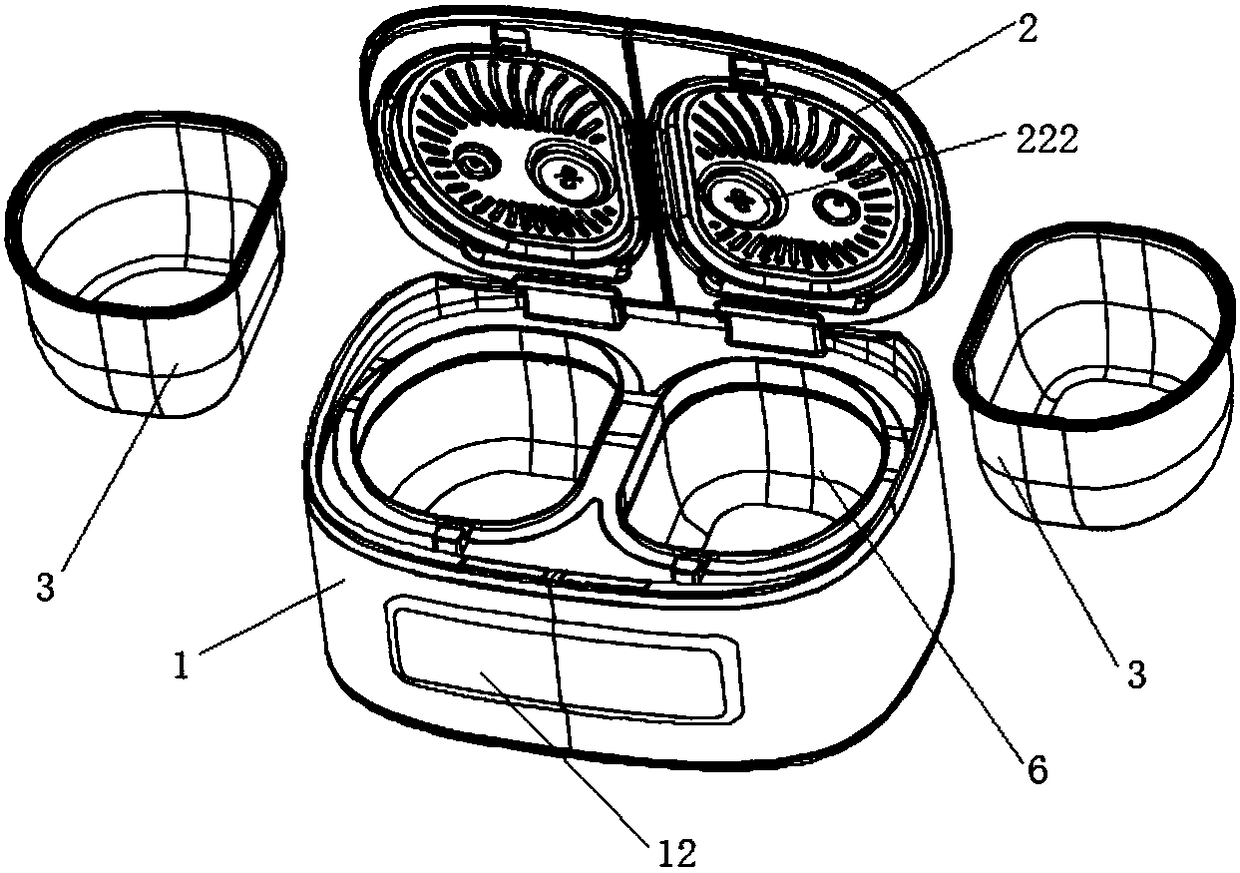

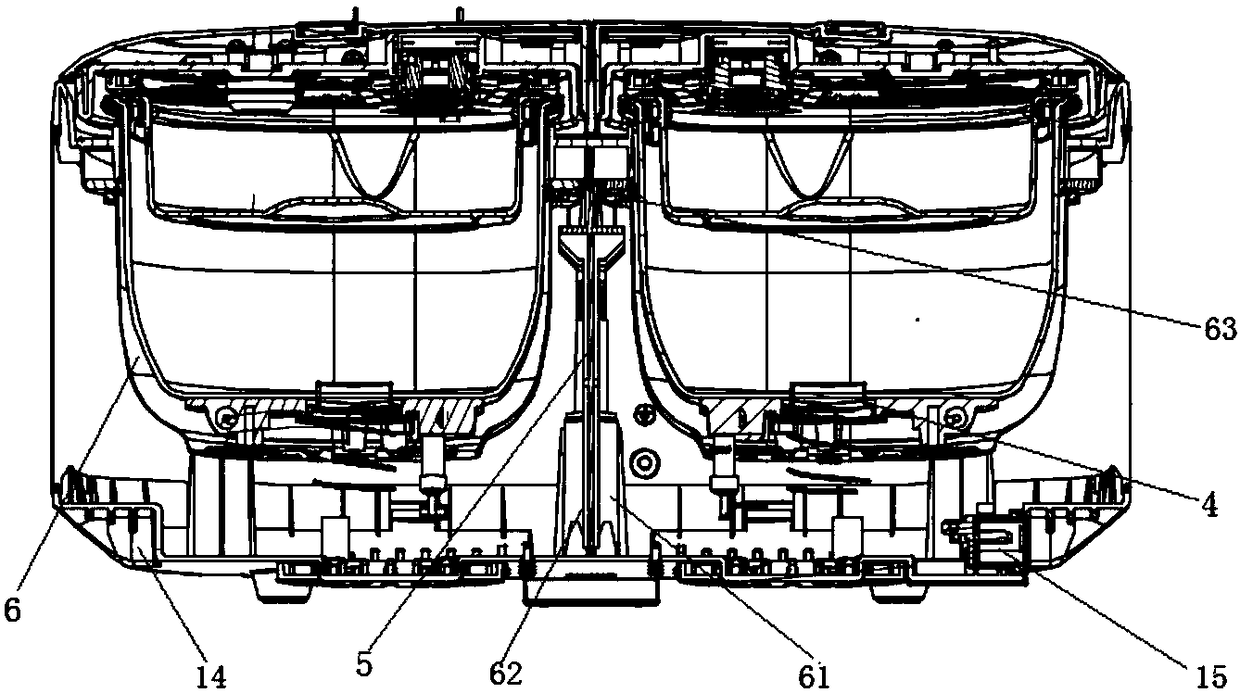

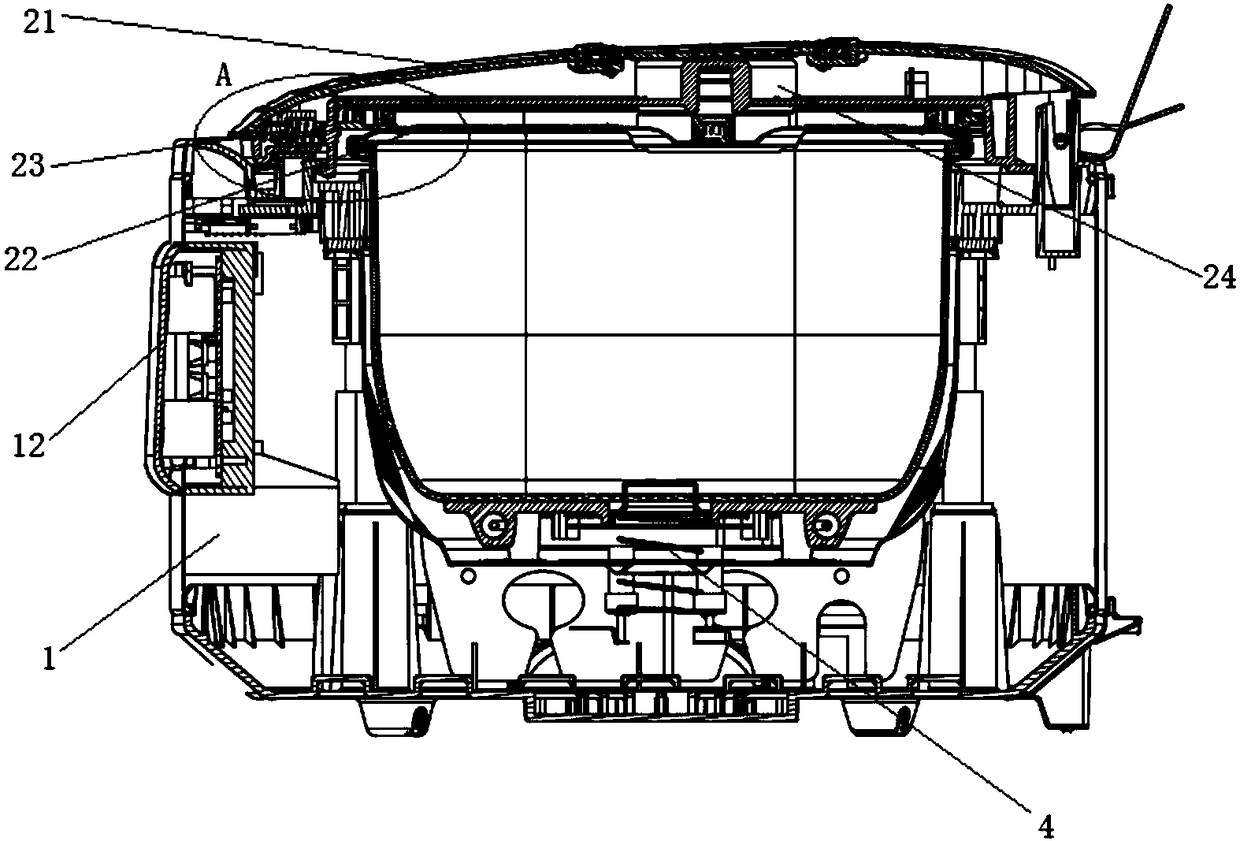

Double-container electric cooker

PendingCN108451353AGood sealing effectPrevent overflowCooking-vessel lids/coversMultiple-unit cooking vesselsCookerEngineering

The invention relates to the technical field of cookers, in particular to a double-container electric cooker. In order to solve the problems that an existing double-container electric cooker is poor in sealing effect and two containers are likely to be tainted by other odor, the double-container electric cooker is provided. The electric cooker comprises a pot body, two pot covers, two inner containers, two heating assemblies and a heat insulation plate; each pot cover comprises an upper cover and a cover plate in the upper cover, the front end of each upper cover is connected with an elastic assembly, one end of each cover plate is connected with the corresponding elastic assembly, and the other end of each cover plate is connected with the rear end of the corresponding upper cover; the elastic assemblies can be clamped with the pot body after being compressed by the cover plates so that the pot covers can be closed. According to the double-container electric cooker, the elastic assemblies are compressed through the cover plates so that the upper covers and the pot body can be in clamped connection, and the pot covers are closed; the pot covers provided with the cover plates have agood sealing effect and can prevent moisture or steam overflow in the cooking process; meanwhile, the two inner containers are isolated through the cover plates, and the phenomenon that the two innercontainers are tainted by other odor is prevented.

Owner:STENTGUANGZHOU IND CO LTD

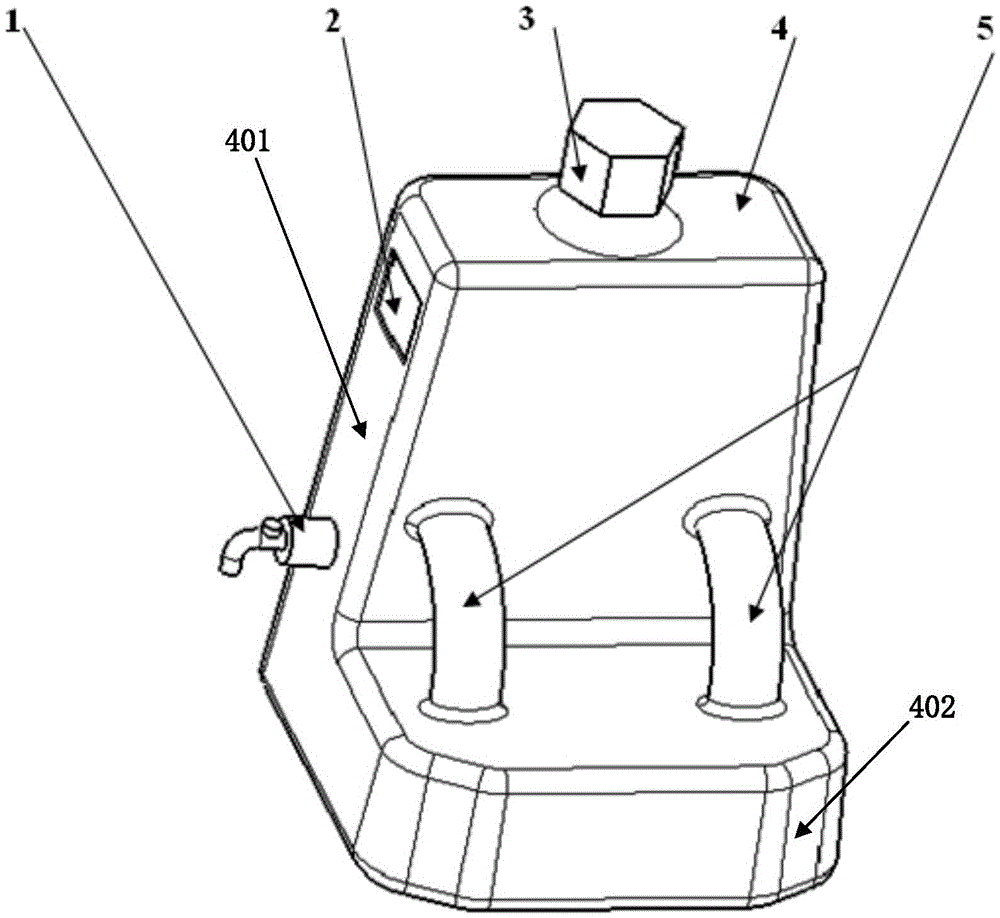

Balance morph

InactiveCN105606377AAccurately grasp the weight qualitySolve handling problemsVehicle testingDisplay deviceEngineering

The invention provides a balance morph, relates to the technical field of vehicle test, and solves the problems that the existing balance morph is difficult to carry and drain and the balance mass is unknown. The balance morph comprises a body, a display, a mass measuring device, a drain valve and a water injection port, wherein the body is a hollow container and is used for adding water for balancing; the display is arranged on the body; the mass measuring device is used for detecting the mass of the balance morph and arranged on the body; the display is connected with the mass measuring device and used for displaying the reading of the mass of the balance morph detected by the mass measuring device; the drain valve is arranged at the lower part of the body, communicated with the interior of the body and used for draining water in the body; and the water injection port is arranged on the body. The balance morph can accurately measure and display self mass, and a user can accurately control the balance morph; and the drain valve is added to drain the water out of the vehicle in time after the balance morph accomplishes balancing, so that the user can carry the morph and the physical exertion of the user is reduced.

Owner:BEIJING AUTOMOBILE RES GENERAL INST

Multifunctional carrier for building construction

InactiveCN112850557APrevent slippingSolve handling problemsLifting framesArchitectural engineeringEngineering

The invention relates to the technical field of building construction, in particular to a multifunctional carrier for building construction. The multifunctional carrier comprises: a flat car; a handrail arranged on one side of the flat car and used for manually driving the flat car to move; a lifting mechanism arranged at the top of the flat car; a bearing plate horizontally erected at the working end of the lifting mechanism and used for bearing a workpiece; a side material blocking mechanism arranged between the lifting mechanism and the bearing plate and used for blocking the workpiece on the bearing plate and preventing the workpiece from sliding off from the two sides of the bearing plate; and a discharging mechanism arranged on the bearing plate and used for executing the automatic discharging process of the workpiece on the bearing plate. According to the technical scheme, the problem of building construction workpiece carrying is solved, the equipment can prevent pipes from falling off when the pipes are carried, the safety is improved, and the carrying efficiency is improved.

Owner:李青

Efficient intelligent winder and working method thereof

The invention discloses a working method of an efficient intelligent winder. The efficient intelligent winder comprises a machine frame, at least one group of wire winding rollers, a group of wire feeders and a control device; a separation plate is arranged on each wire winding roller, a driving mechanism used for driving the wire winding rollers and a control mechanism are arranged in the controldevice, the wire winding rollers are arranged on the machine frame, and the wire feeders are arranged on the machine frame; a wire feeding hole is formed in each wire feeder, and the wire winding rollers, the wire feeders and the driving mechanism are all connected with the control mechanism. According to the working method of the efficient intelligent winder, a plurality of the wire winding rollers can be combined to be used and the separation plates can also be arranged on the wire winding rollers so that the winding requirements of a variety of electric wires and cables can be met at the same time, the effect that one wire winding roller is wound with the various wires can be realized, a lot of convenience is brought to construction and production, and the carrying problem of a plurality of the wire winding rollers is well solved.

Owner:TAICANG LINYUAN CABLES & CORDS CO LTD

Novel vacuum suction cup lifting appliance

PendingCN113501406AImprove handling efficiencyGood for smooth adsorptionLoad-engaging elementsEngineeringElectrical and Electronics engineering

Owner:湖南天桥嘉成智能科技有限公司

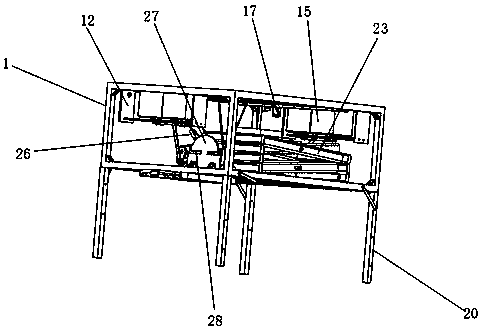

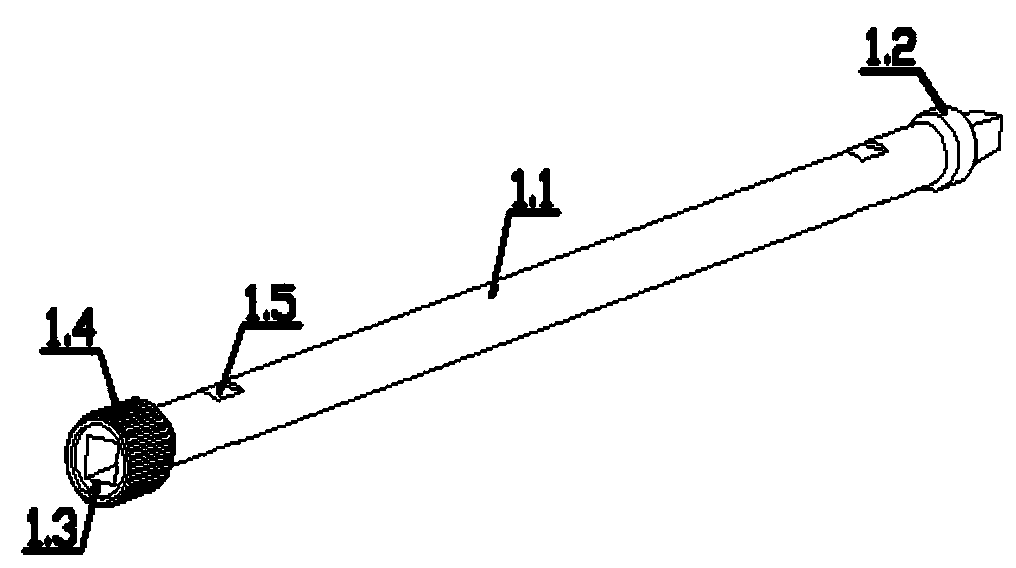

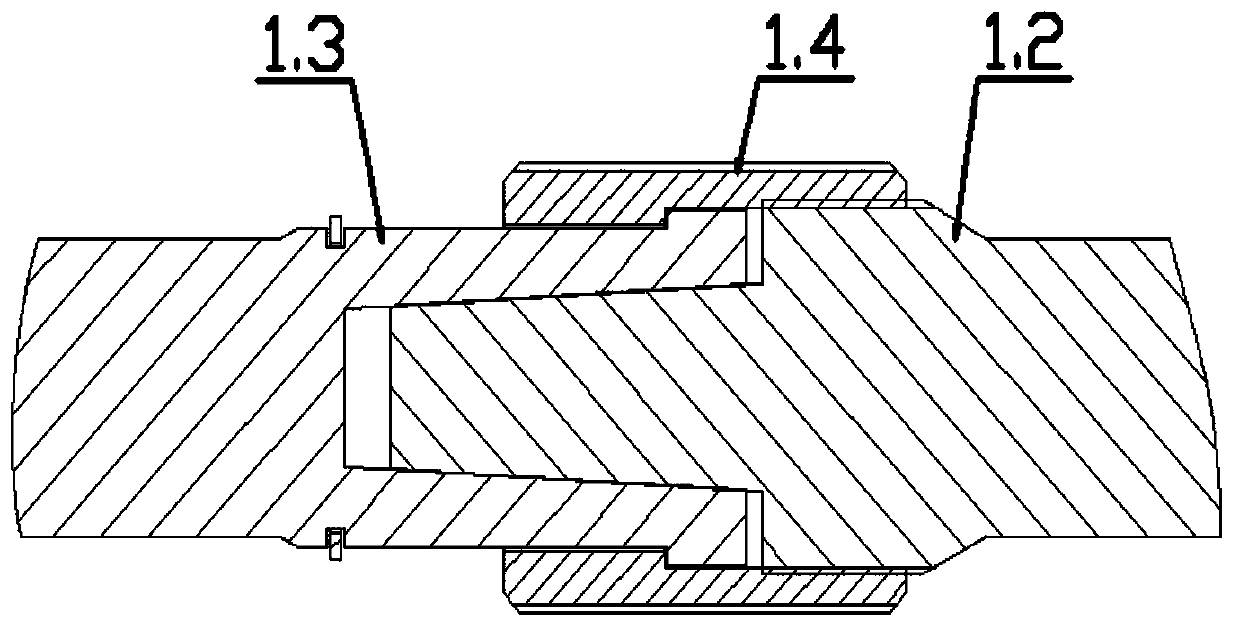

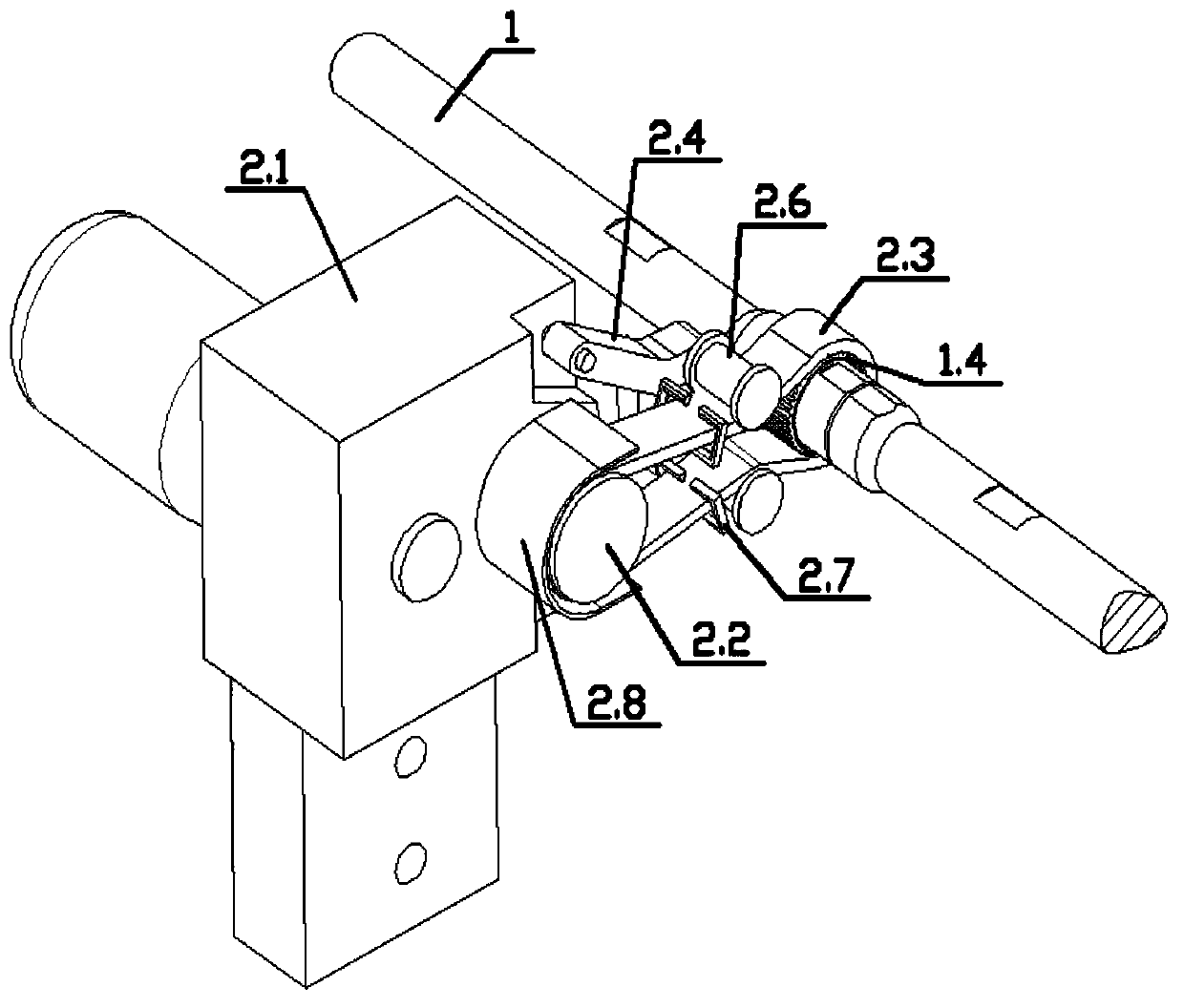

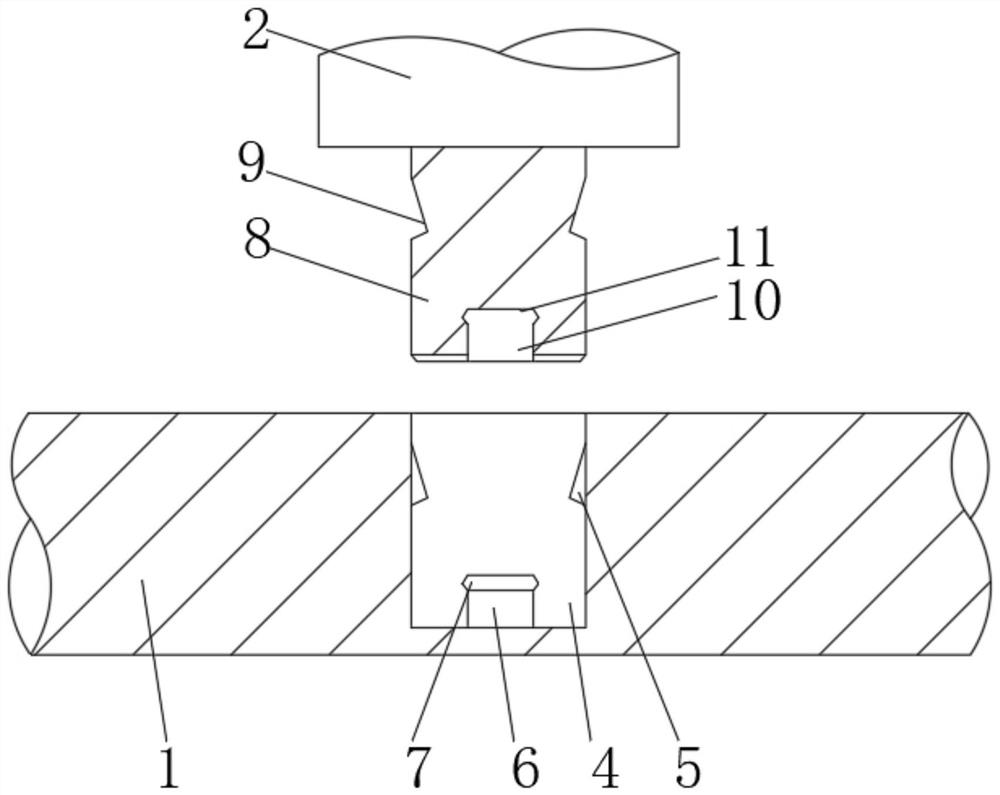

Easy-to-disassemble drill rod and drill rod automatic assembling and disassembling equipment applied to same

PendingCN110552640AQuick installationQuick releaseDrilling rodsDrilling casingsControl systemUltimate tensile strength

The invention discloses an easy-to-disassemble drill rod. The easy-to-disassemble drill rod comprises a rod body, a connecting head, a connecting tail and a connecting nut, wherein the connecting headand the connecting tail are connected to the two ends of the rod body, the connecting head is provided with an axial rectangular pyramid table, the connecting tail is provided with a rectangular pyramid hollow, and a synchronous pulley is arranged on the outer circle surface of the connecting nut. Through coaxial matching of the rectangular pyramid table and the rectangular pyramid hollow, the drill rod can be rapidly assembled and disassembled, and the advantages of being large in bearing torque, long in service life, easy to disassemble, low in cost and the like are achieved. Drilling rod automatic assembling and disassembling equipment applied to the easy-to-disassemble drill rod is arranged on one side of a drilling machine, and comprises a connecting nut assembling and disassemblingmechanism, a drill rod assembling and disassembling mechanism and a control system. The connecting nut assembling and disassembling mechanism can quickly assemble and disassemble the connecting nut, so that manual operation is replaced by mechanical action; the drill rod assembling and disassembling mechanism is high in automation degree, automatic assembling and disassembling of the drill rod arerealized, the labor intensity of operators is greatly reduced, and the working efficiency is improved; and a drill rod circulation box of the drilling rod automatic assembling and disassembling equipment is large in capacity, and the problems of placing, carrying and transporting of the drill rod are solved at the same time.

Owner:洛阳风动工具有限公司

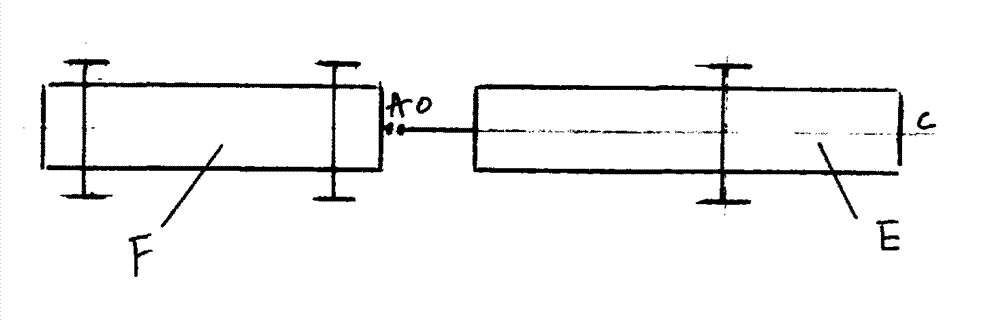

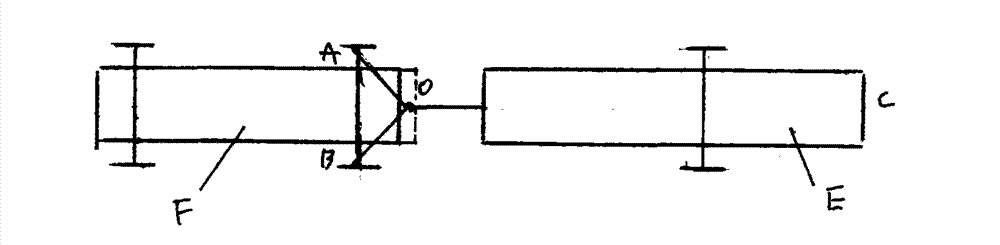

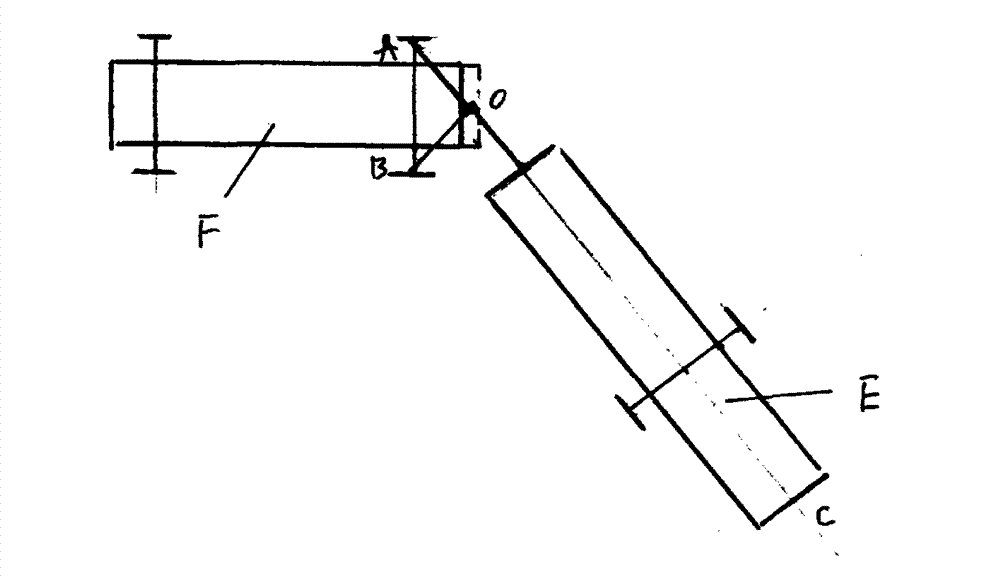

Method for connecting motor vehicle and center shaft trailer

InactiveCN103042889ASolve the handling problemFlexible turningTowing devicesMotor vehicle partTractor

The invention relates to a method for connecting a motor vehicle (automobile, tractor) and a center shaft trailer in the filed of communications and transportation, comprising the following steps: transversely moving a horizontal link point forwards; and effectively connecting the motor vehicle (automobile, tractor) and the center shaft trailer with traction method in isosceles triangle form. The method has the beneficial effect that the problem that the central shaft trailer influences main vehicle controllability after semitrailer connection is solved through the application of the method for connecting a locomotive crew, so that the locomotive crew has the loading effect that the heavier the smoother the locomotive crew is.

Owner:冉恒印

Electric leakage switch automatic assembly device

InactiveCN109300721AHigh degree of automationHigh precisionAssembly machinesElectric switchesEngineeringSmart manufacturing

The invention relates to the field of circuit element intelligent manufacturing. The invention relates to an electric leakage switch automatic assembly device, and the device comprises a frame, a feeding device, a multi-position turnover device, a plastic assembly device, a binding post assembly device, a pressing device, a bottom binding post assembly, a bottom wiring piece assembly device and ariveting device, wherein the feeding device, the multi-position turnover device, the plastic assembly device, the binding post assembly device, the pressing device, the bottom binding post assembly, the bottom wiring piece assembly device and the riveting device are disposed on the frame. The device is high in automation degree, is high in work efficiency, and is high in qualified rate of finishedproducts.

Owner:练国瑛

High-efficiency workpiece handling device

Owner:YUHUAN HANXIN MACHINERY TECH CO LTD

Clothes hanger

InactiveCN102400303ASolve handling problemsSimple structureOther drying apparatusTextiles and paperClothes hangerSpace requirements

The invention discloses a clothes hanger aiming at the problems of inconvenience in conveying and incapability of changing length according to space requirements existing in the present clothes hanger, and provides the clothes hanger. The clothes hanger comprises supporting bodies and a drying rod, wherein the drying rod is used for connecting the supporting bodies at two ends; and the drying rod has a telescopic structure. The telescopic structure is formed by connecting hollow pipes with different diameters. Through the clothes hanger, the problem of conveying is solved well, the length can be adjusted according to the space requirements and the number of clothes; and the clothes hanger has a simple structure, is convenient to manufacture and use and low in cost and contributes to promotion and application.

Owner:章士洲

Automated workpiece carrying equipment

InactiveCN108820824ARealize handlingSolve handling problemsConveyor partsMechanical conveyorsEngineeringFuselage

The invention discloses automated workpiece carrying equipment. The automated workpiece carrying equipment comprises an equipment body and a fixing plate arranged at the top of the equipment body, a first sliding cavity is formed between the equipment body and the fixing plate, and a first sliding block can slide up and down in the first sliding cavity; a lifting device is fixedly installed at thetail end of the right side of the first sliding block, first through holes which are vertically through are symmetrically formed in the first sliding block in the front-back and left-right directions, optical rods which extend up and down are slidably and cooperatively connected to the interiors of the first through holes, the tail ends of the two sides of each optical rod are fixedly arranged inthe upper and lower end walls of the first sliding cavity, and a first threaded hole which is vertically through is formed in the middle of the first sliding block. The automated workpiece carrying equipment is simple in structure and convenient to operate; the same power source is adopted for driving the equipment to fork and lift workpieces, the purpose of carrying workpieces without fork holesor hoisting holes is achieved, all working procedures mutually cooperate with one another and are not influenced, the efficiency of carrying specific workpieces is improved, and the practicability ofthe equipment is improved.

Owner:YUHUAN HANXIN MACHINERY TECH CO LTD

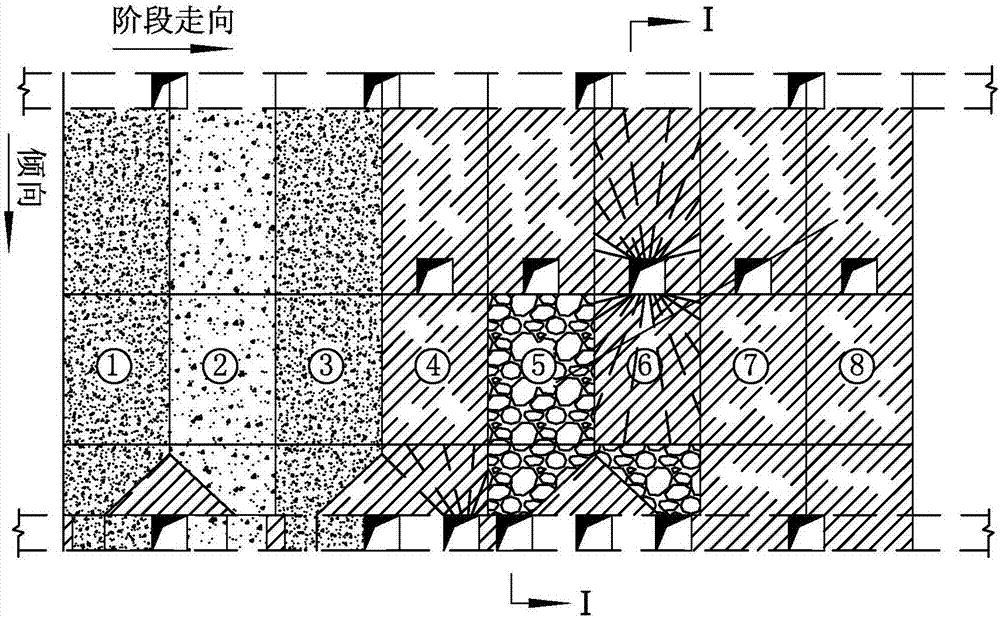

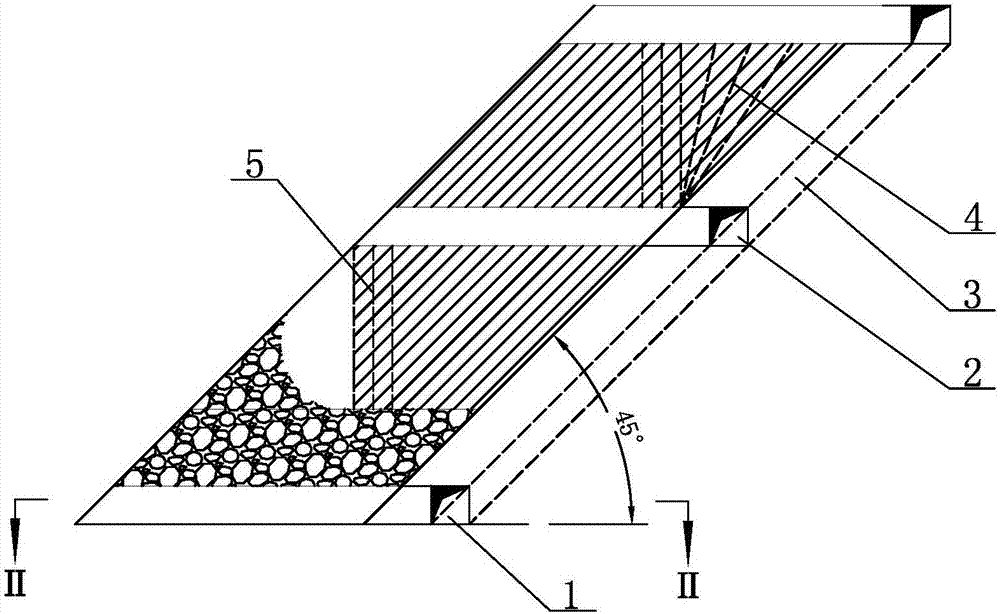

Collaborative mining method of rock-drilling stage and filling after inclined medium-thick ore body

ActiveCN106223958BReduce the amount of mining and cuttingLower filling costsUnderground miningSurface miningMineralogyCave

The invention belongs to the mining field and particularly relates to an ore-blast backfill synergetic mining method for a partitioned rock drilling stage of an inclined medium-thick ore body. According to the mining method, the partitioned rock drilling of fan-shaped blast holes of a trench ore section, annular blast holes of a non-triangular jamb and beam-shaped blast holes of triangular jamb in a rock drilling cave is realized based on different ore bodies and rock drilling conditions, the problem of blasting of a hanging side triangular jamb is solved, and the blasting effect of the annular blast holes in the rock drilling cave is improved; by comprehensively utilizing the dead load and the blasting-power handling of the ore body, the concentrated ore gathering of ores in ore gathering tunnels of trenches of different partitioned mining sections and the concentrated ore removal of ore removal lands and ore removal approach roads in the stage are realized, and the centralized working scale and efficiency of mining are improved; and by virtue of interval recovery, subsequent cementing and non-cementing synergetic backfilling on ore chambers and jambs, the continuity of the mining process among different mining sections is realized, and an efficient, safe and low-cost continuous mining method is provided for the inclined medium-thick ore bodies with medium stability and higher stability.

Owner:SHANDONG HUALIAN MINING +1

Flexible detection tool and detection method

PendingCN113188780AIncrease randomnessSolve storage problemsMachine part testingAdditive manufacturing apparatusEngineeringStructural engineering

The invention discloses a flexible detection tool and a detection method. The flexible detection tool comprises a bearing platform and a detection sample block, a handle is fixedly installed at the center of the upper part of the bearing platform close to one side, an installation hole is formed in the upper surface of the bearing platform, and an installation column is fixedly installed at the bottom of the detection sample block. A connecting structure is arranged between the installation hole and the installation column and comprises a clamping block, a stand column, a clamping head, a clamping groove, a blind hole and a groove head, the clamping block is fixedly mounted in the position, close to the top, of the interior of the installation hole, the stand column is fixedly mounted in the middle of the bottom of the interior of the installation hole, and the clamping head is fixedly connected to the top end of the stand column; the clamping groove is formed in the position, close to the top, of the outer surface of the installation column. According to the flexible detection tool, the split type design is adopted, the production and processing cost of the detection tool can be effectively saved, the detection tool can be assembled, the randomness is high, the space storage problem and the carrying problem are solved, meanwhile, the assembling stability is high, and use is facilitated.

Owner:陕西非凡士三维科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com