Novel vacuum suction cup lifting appliance

A vacuum suction cup and suction cup technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problem that the suction cup cannot perform automatic height and width adjustment material handling, cannot effectively divide the material to be handled, and has no mechanical anti-drop setting. , to achieve efficient and fast handling process, improve handling efficiency, and facilitate stable adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

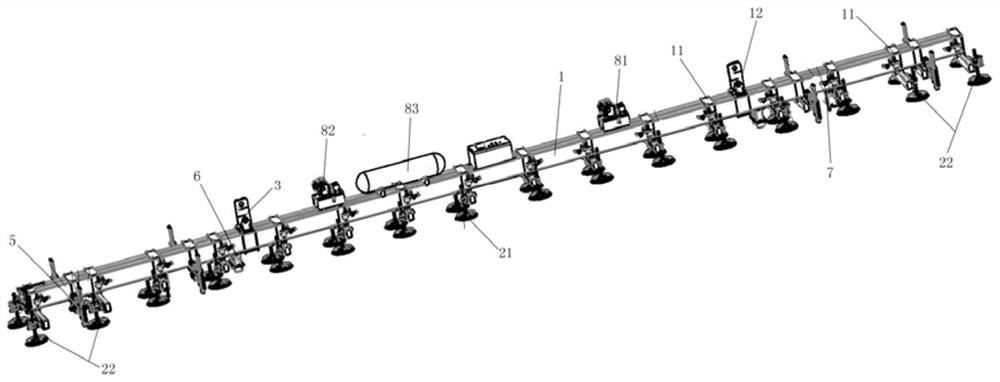

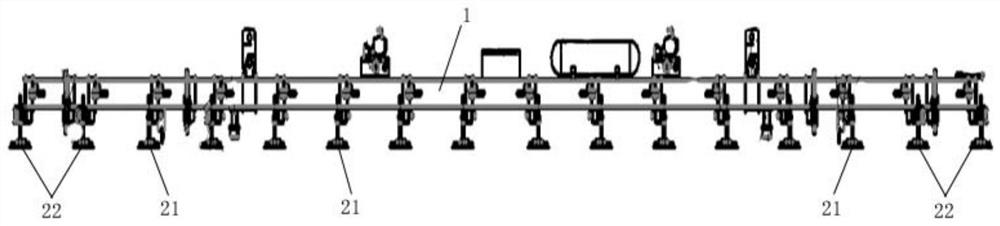

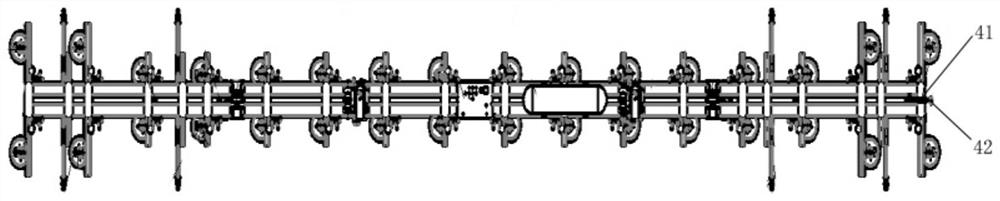

[0035] a kind of like figure 1 The new vacuum suction cup spreader shown is used in metallurgy and heavy industry to carry heavy plates. It is used in conjunction with the crown block, including the frame connected to the crown block. The frame includes the main beam 1, and the length direction of the main beam is A plurality of sets of vacuum suction cup devices 21 and four sets of expansion suction cup devices 22 are arranged through the beam hanger 11. Each of the four sets of expansion suction cup devices 22 is distributed at both ends of the main beam 1 in the length direction, and the vacuum suction cup devices 21 are located at both ends of the main beam. Between the splitting suction cup devices 21 at the end; the splitting suction cup device 22 is mainly used for splitting the sheets, and also for suction and lifting, and the vacuum suction cup device 21 realizes the adsorption and lifting of the sheets. The quantity arrangement on the top is selected according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com