Patents

Literature

229 results about "Blast effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

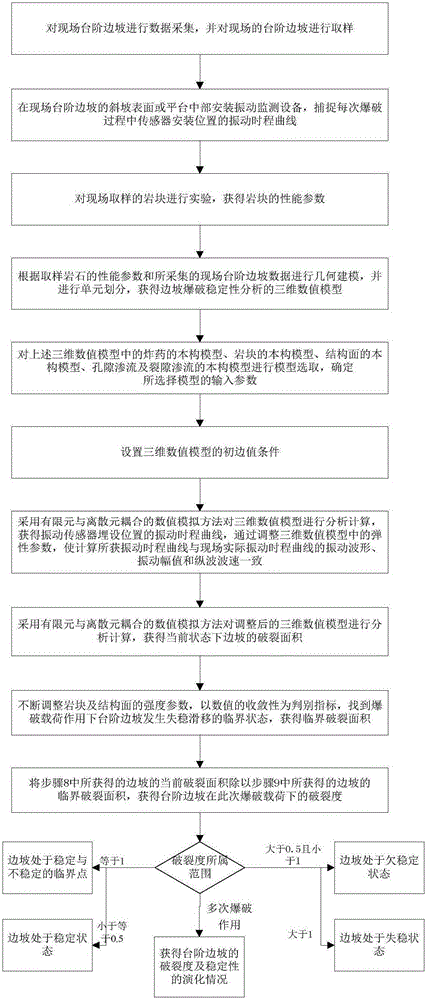

Method for analyzing bench slope stability under blasting effect

ActiveCN105224742ADirectly reflect the damage and ruptureEnter parameters accuratelySpecial data processing applicationsBlast loadOpen-pit mining

The invention provides a method for analyzing bench slope stability under blasting effect, and belongs to the technical field of open-pit mining. Compared with a conventional method, the method combines numerical simulation with vibration monitoring, and uses vibration information of a slop body to correct material parameters of the slop body, and provides more accurate input parameters for numerical simulation. A numerical simulation method coupling finite elements with discrete elements is used to perform mechanical analysis, and progressive failure process of the slope under blast load effect is completely depicted. A calculation result is more accurate. Rupture degree is used to evaluate slope stability, and internal damage and rupture conditions of a slope body can be directly reflected, and an evaluation index is more reasonable.

Owner:ANSTEEL GRP MINING CO LTD

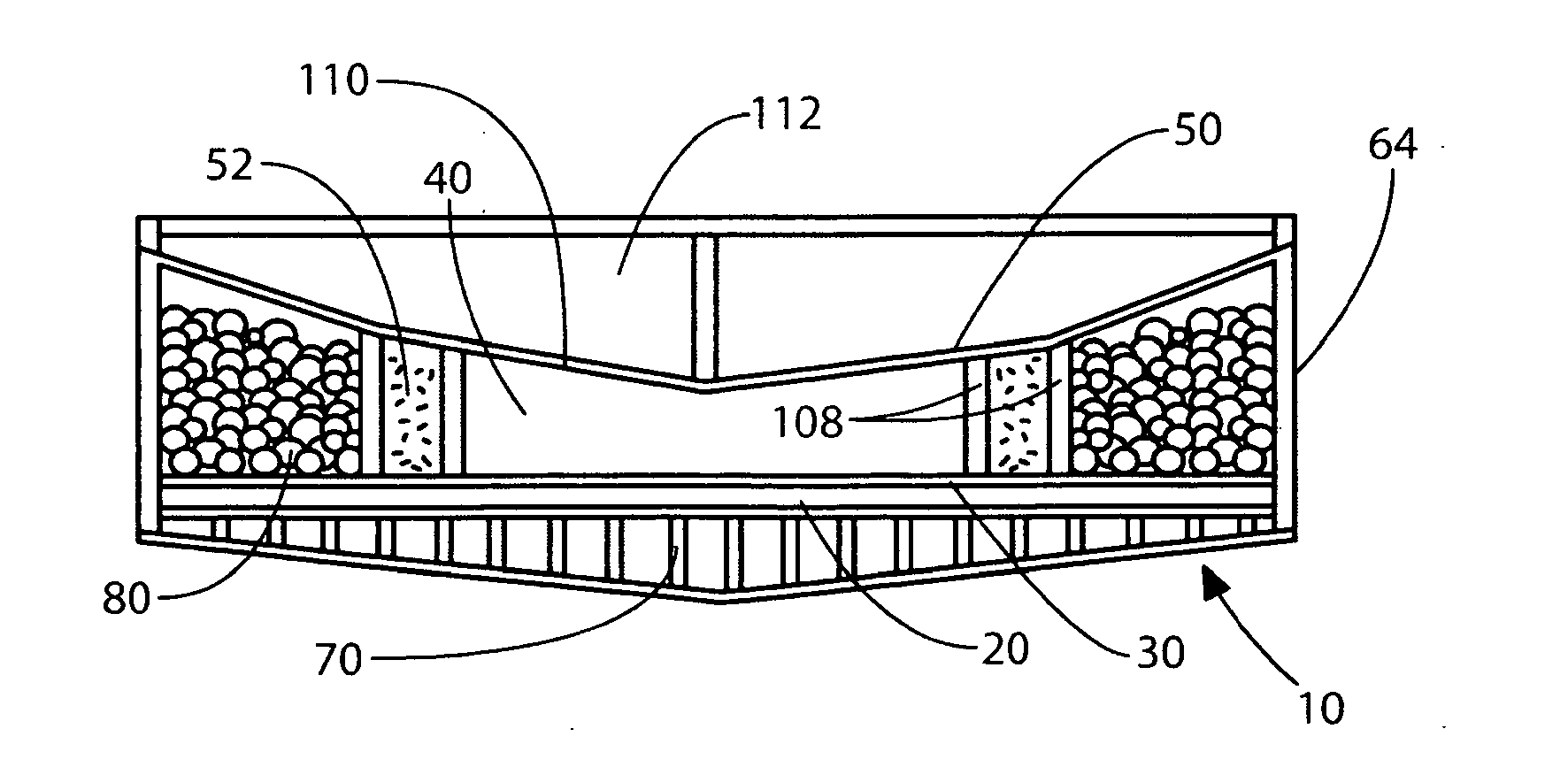

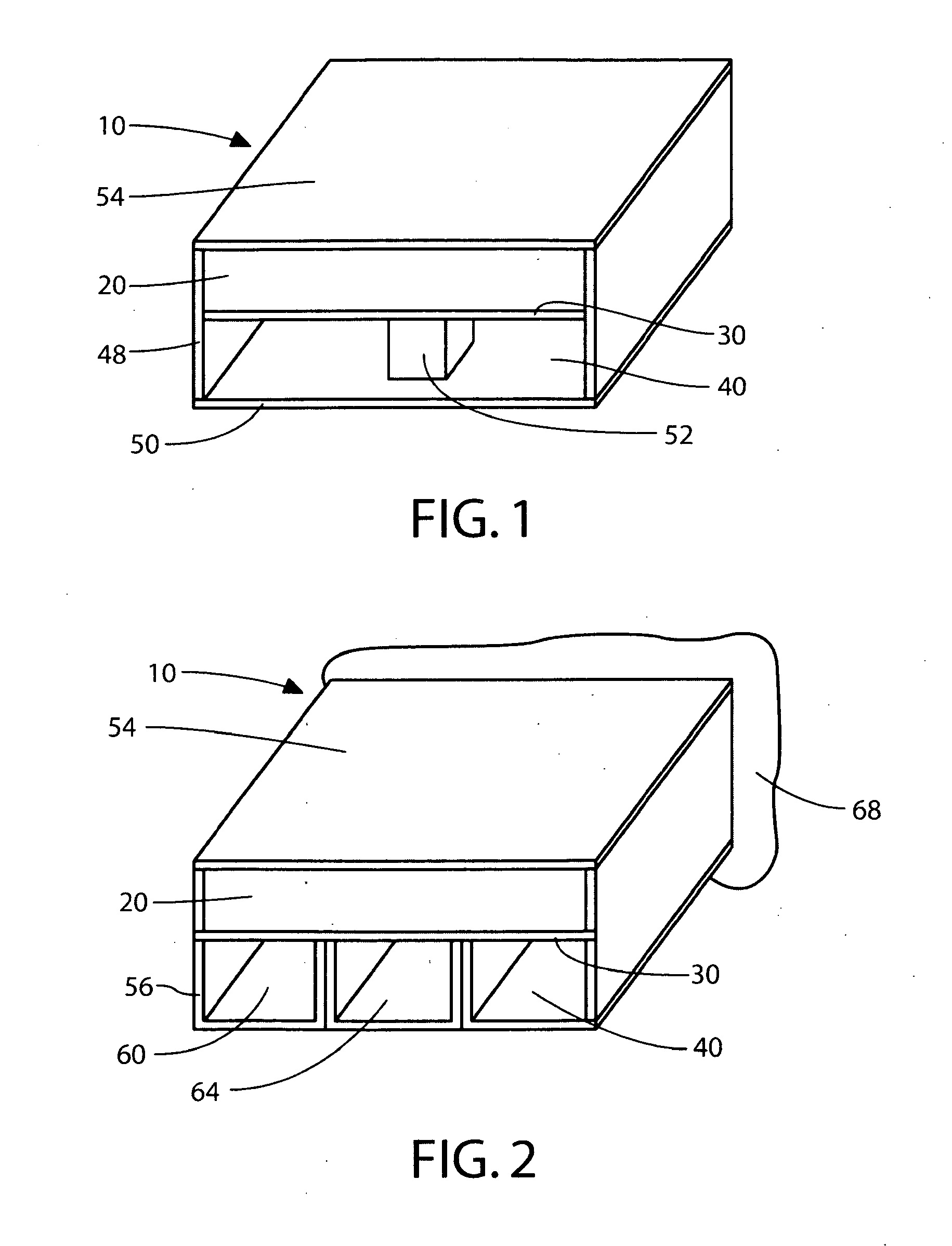

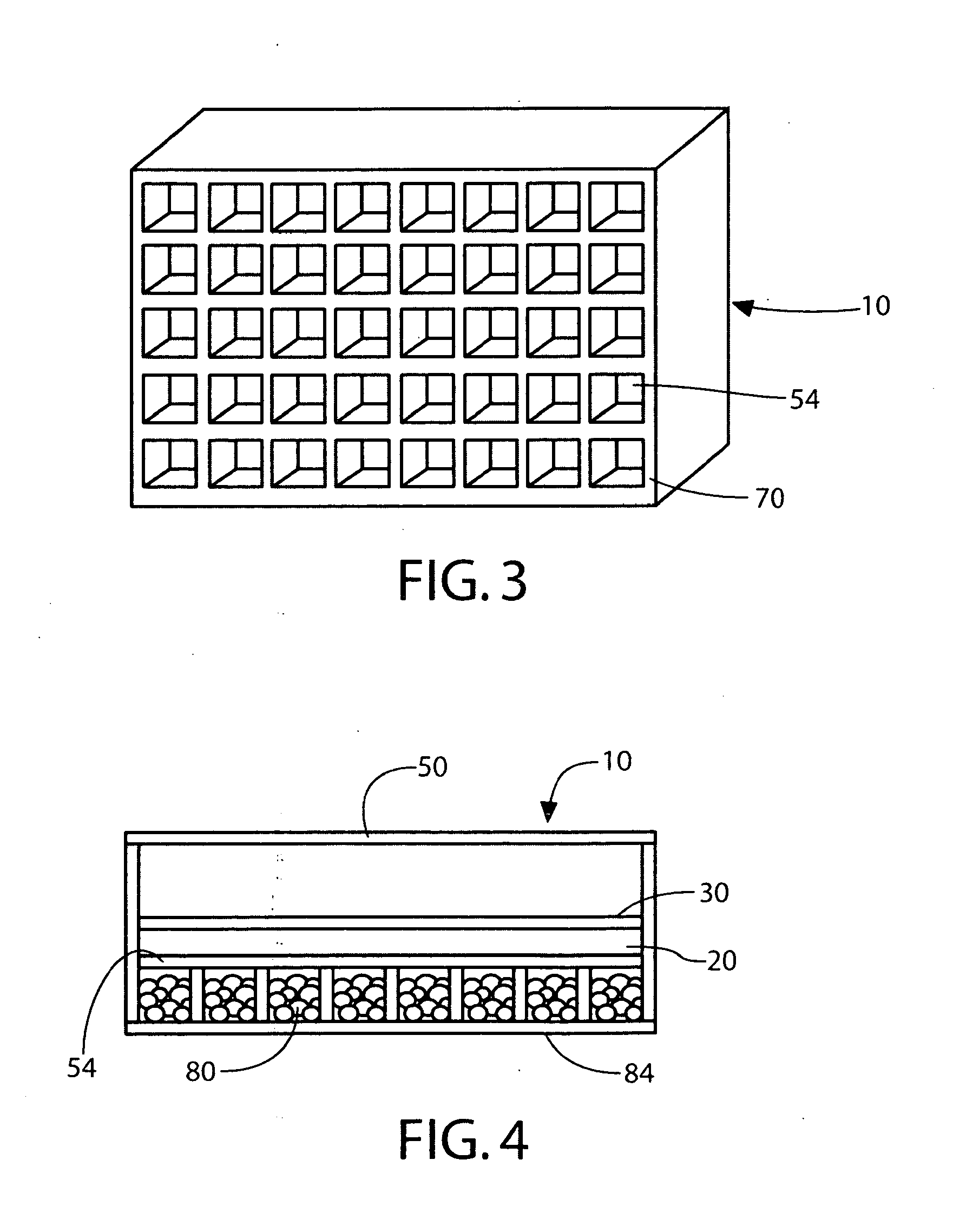

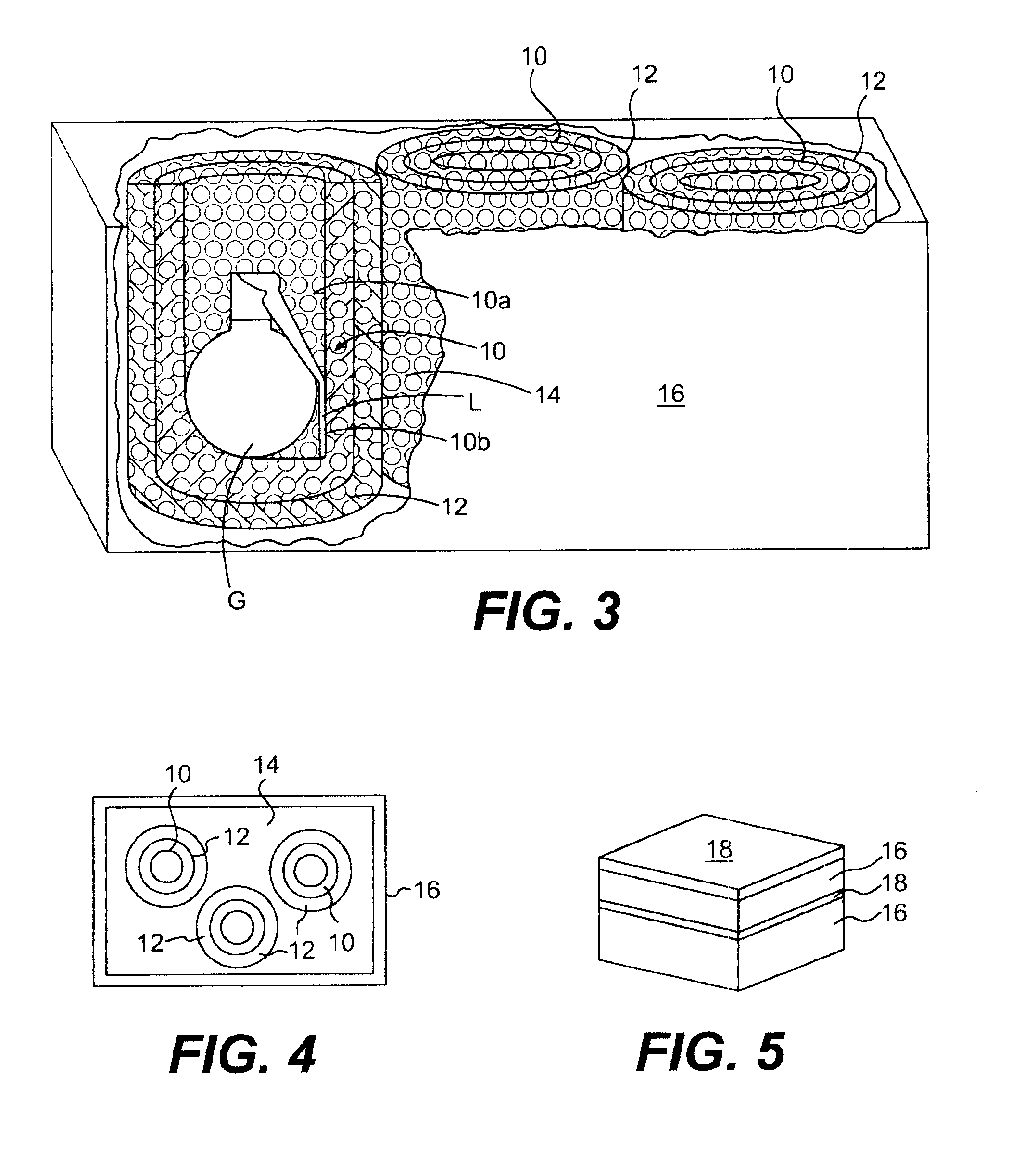

Blast effect mitigating assemble using aerogels

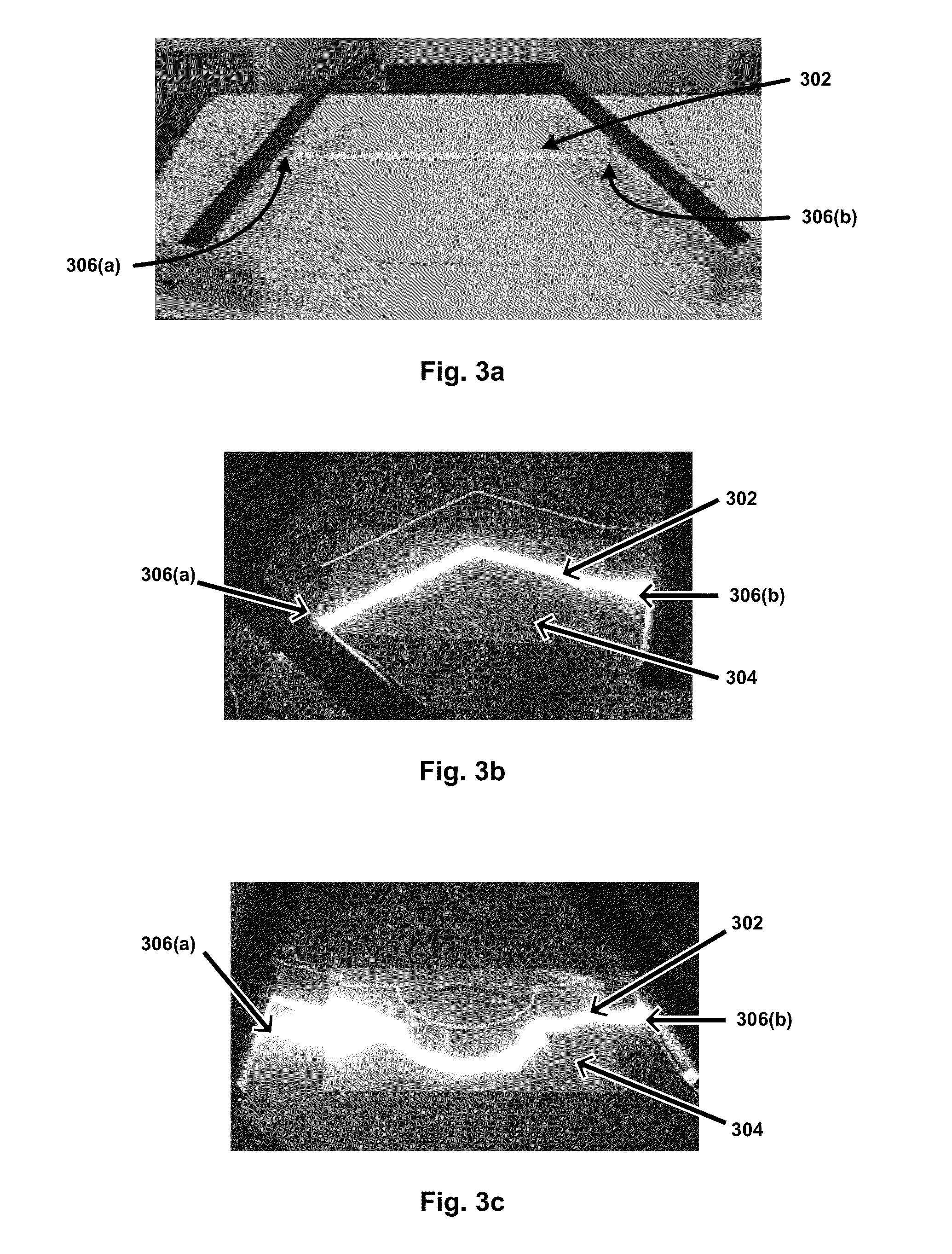

ActiveUS20100307327A1Reducing blast wave pressureReduce the average velocityArmoured vehiclesAmmunitionGratingBlast effects

An assembly for protecting against explosions and explosive devices is formed with aerogels and frangible components. The basic configuration forms a space between an object to be protected by an aerogel having a frangible backing layer. Such assemblies may be mounted on vehicles and structures, and alternatively used as barriers without attachment to other objects. Different geometries for the rear surface of the assemblies enhance the ability of deflecting gas produced by explosions away from objects to be protected. Flowable attenuating media may be introduced into the space behind the aerogel and in gratings placed in the front of assemblies in order to increase blast energy dissipation in intense blast conditions. Armor components may be added to the rear surface to protect against fragments and projectiles. Aerogels, metal foams, and dense ceramic beads may be incorporated to enhance protection against explosively-formed penetrators and other projectiles.

Owner:HYBRID COMPONENTS & COATINGS

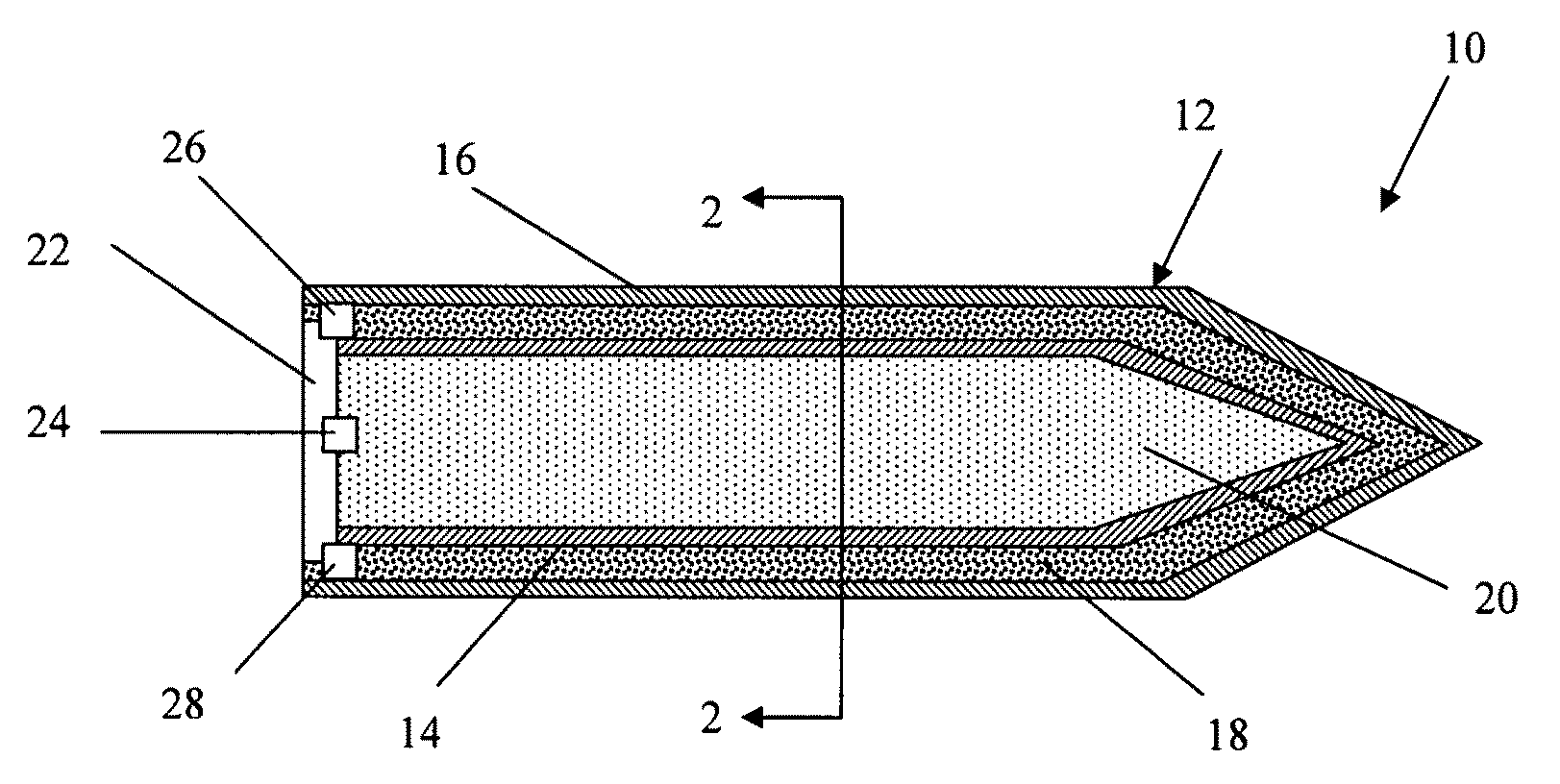

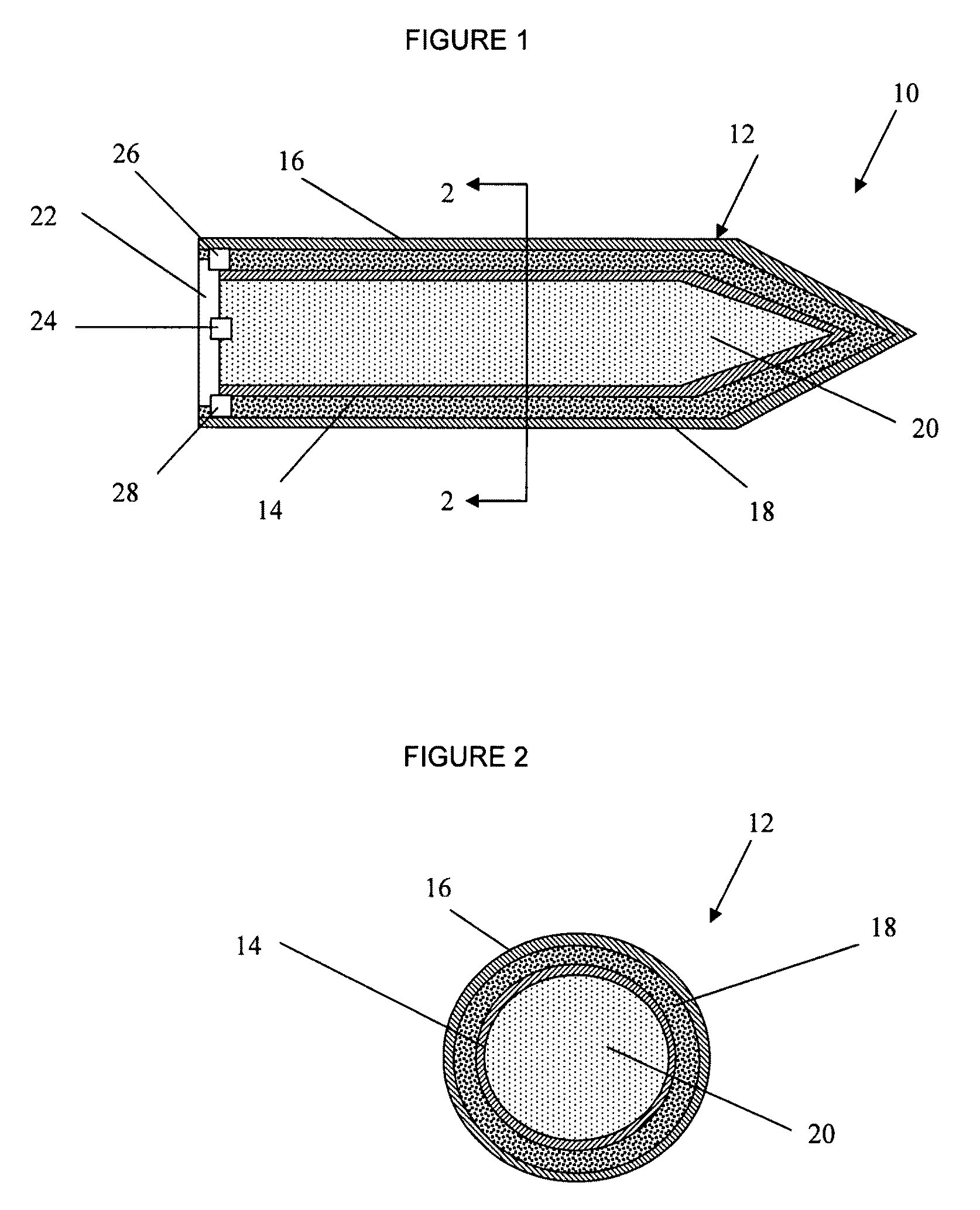

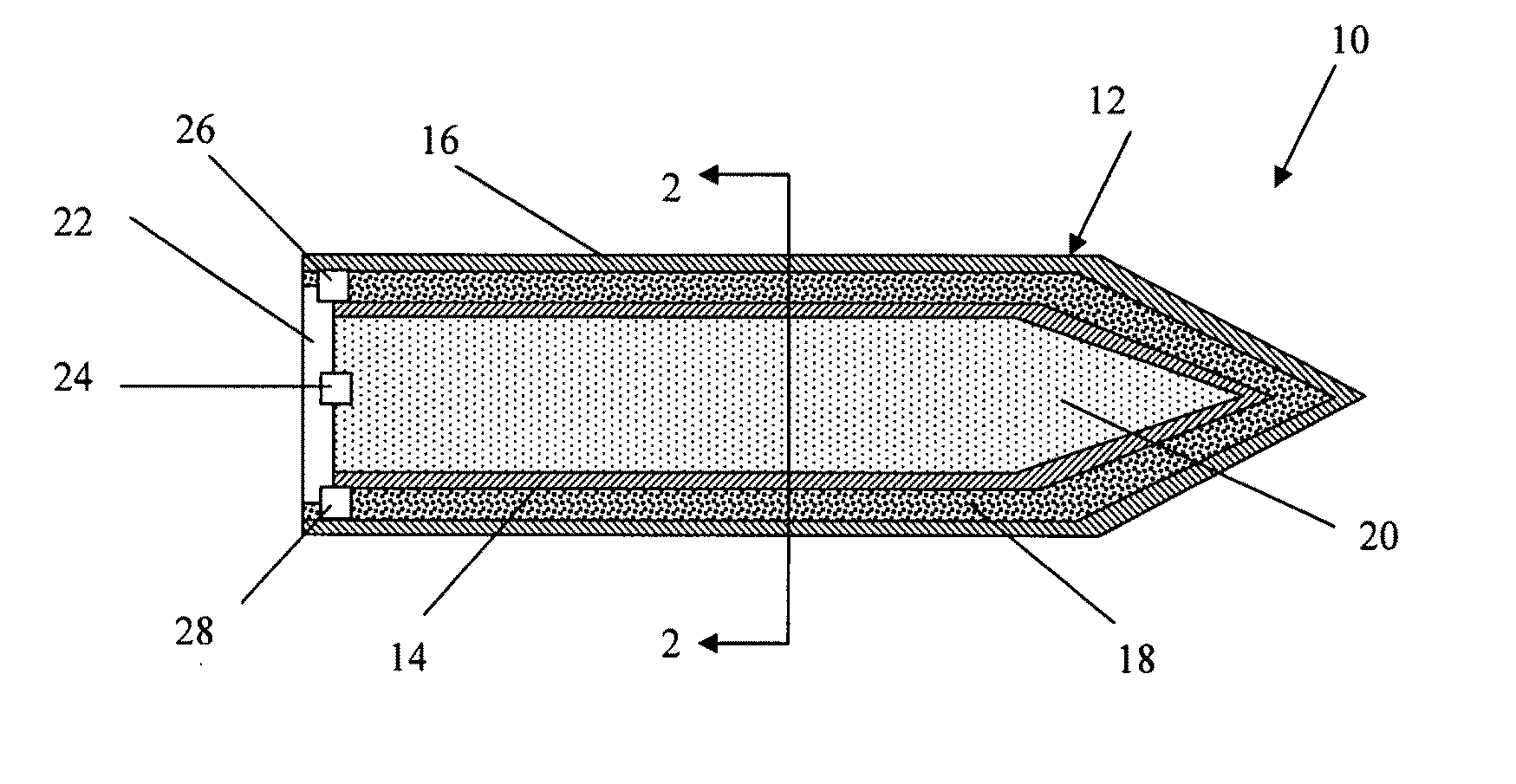

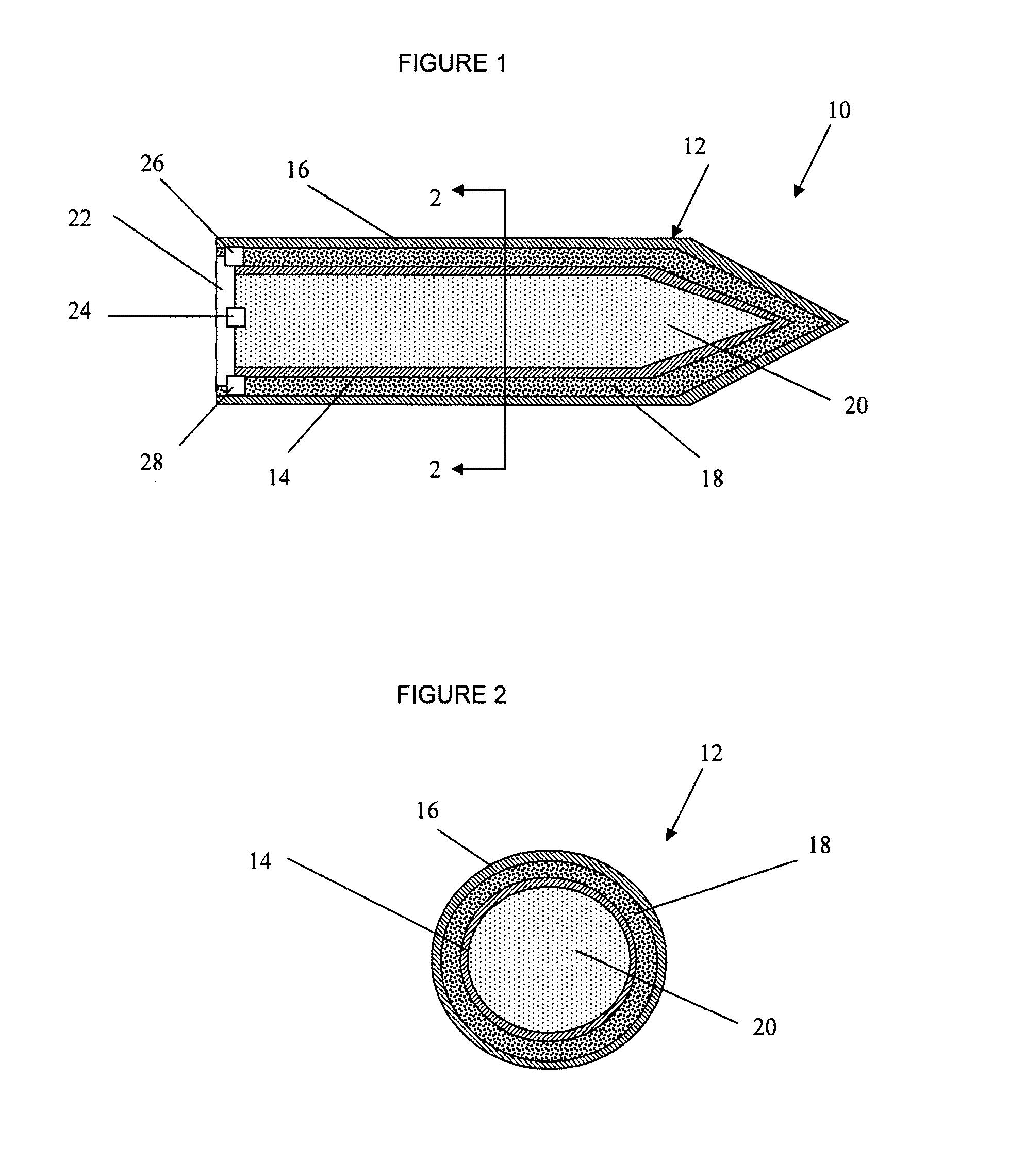

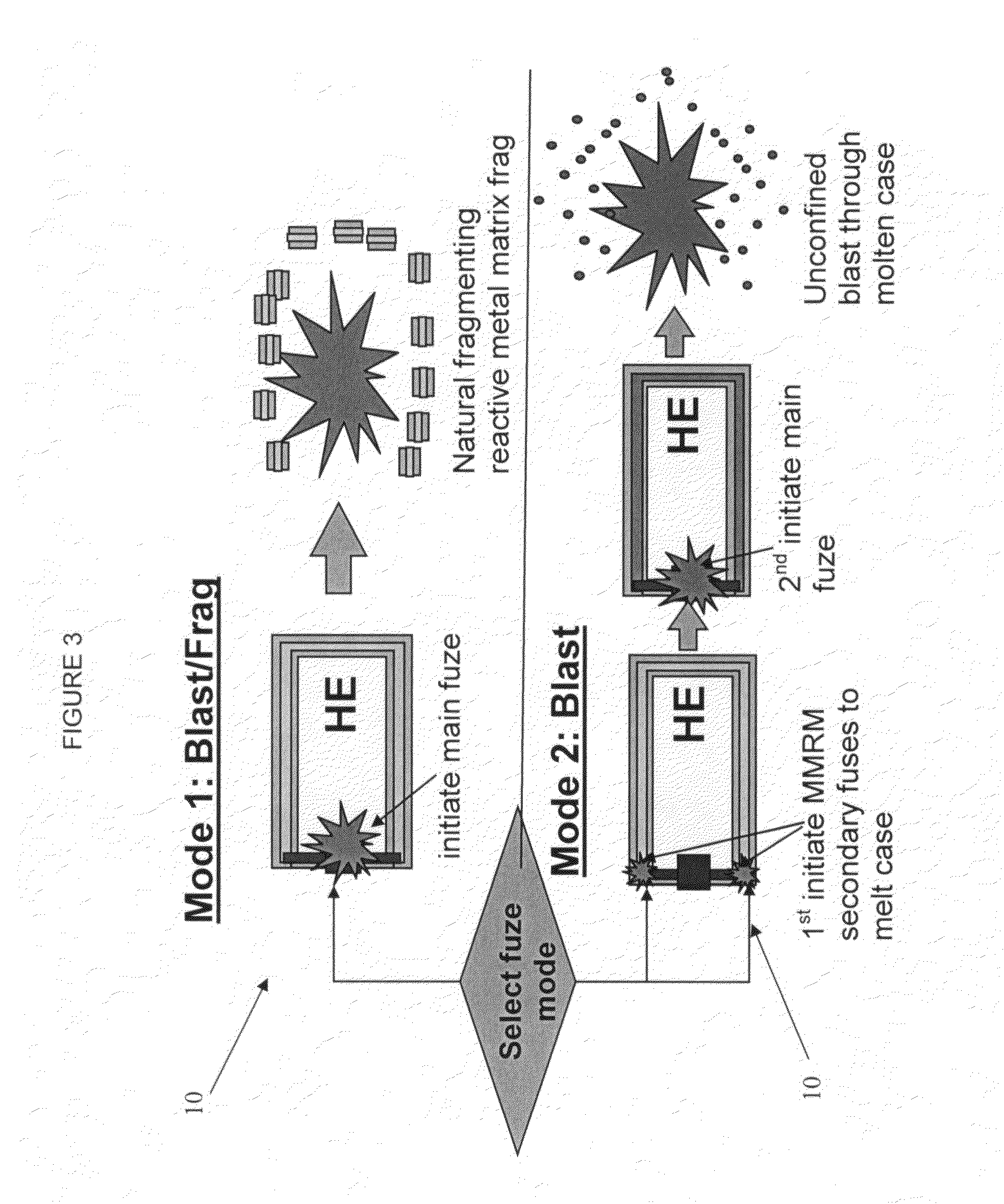

Selectable effect warhead

ActiveUS7845282B2Reduce impactSelectively eliminatedAmmunition projectilesProjectilesBlast effectsOperation mode

A munition includes a casing, the casing formed at least in part from a material comprising (i) a meltable or phase-changing material, and (ii) an energetic material; an explosive payload contained within the casing; and a fuze arrangement, the fuze arrangement comprising a main fuze configured and arranged to ignite the high explosive, and at least one secondary fuze configured and arranged to cause the casing material to melt or undergo a phase change. A method of selectively altering the mode of operation of a munition includes: forming a casing, the casing comprising a material comprising (i) a meltable or phase-changing material, and (ii) an energetic material; introducing an explosive payload into the casing; providing a fuze arrangement comprising a main fuse and at least one secondary fuze configured and arranged to cause the casing material to melt or undergo a phase change; and selectively activating the main fuze and the at least one secondary fuze in a manner that provided at least a first and a second mode of operation, the first mode of operation comprising blast coupled with fragmentation effects, and the second mode of operation comprising mainly blast effects.

Owner:LOCKHEED MARTIN CORP

Selectable effect warhead

ActiveUS20100282115A1Reduce impactSelectively eliminatedAmmunition projectilesProjectilesExplosive AgentsBlast effects

A munition includes a casing, the casing formed at least in part from a material comprising (i) a meltable or phase-changing material, and (ii) an energetic material; an explosive payload contained within the casing; and a fuze arrangement, the fuze arrangement comprising a main fuze configured and arranged to ignite the high explosive, and at least one secondary fuze configured and arranged to cause the casing material to melt or undergo a phase change. A method of selectively altering the mode of operation of a munition includes: forming a casing, the casing comprising a material comprising (i) a meltable or phase-changing material, and (ii) an energetic material; introducing an explosive payload into the casing; providing a fuze arrangement comprising a main fuse and at least one secondary fuze configured and arranged to cause the casing material to melt or undergo a phase change; and selectively activating the main fuze and the at least one secondary fuze in a manner that provided at least a first and a second mode of operation, the first mode of operation comprising blast coupled with fragmentation effects, and the second mode of operation comprising mainly blast effects.

Owner:LOCKHEED MARTIN CORP

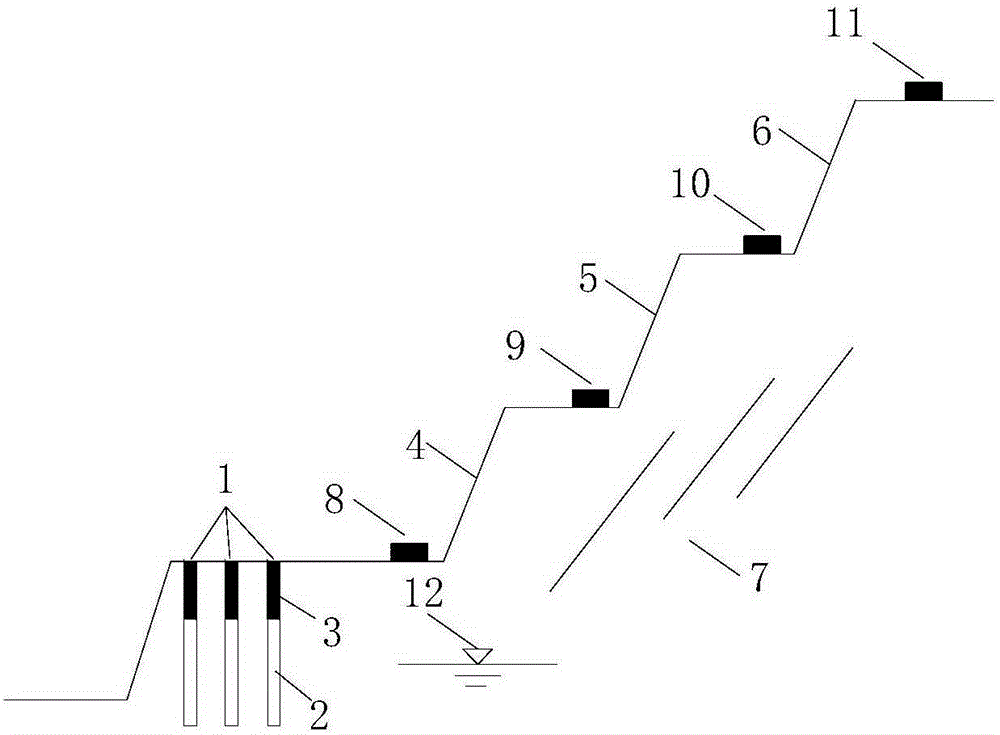

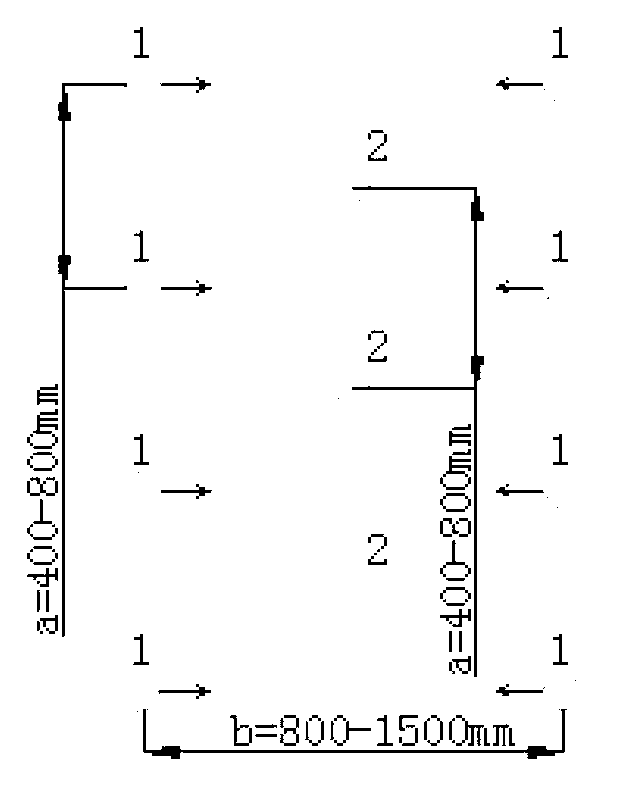

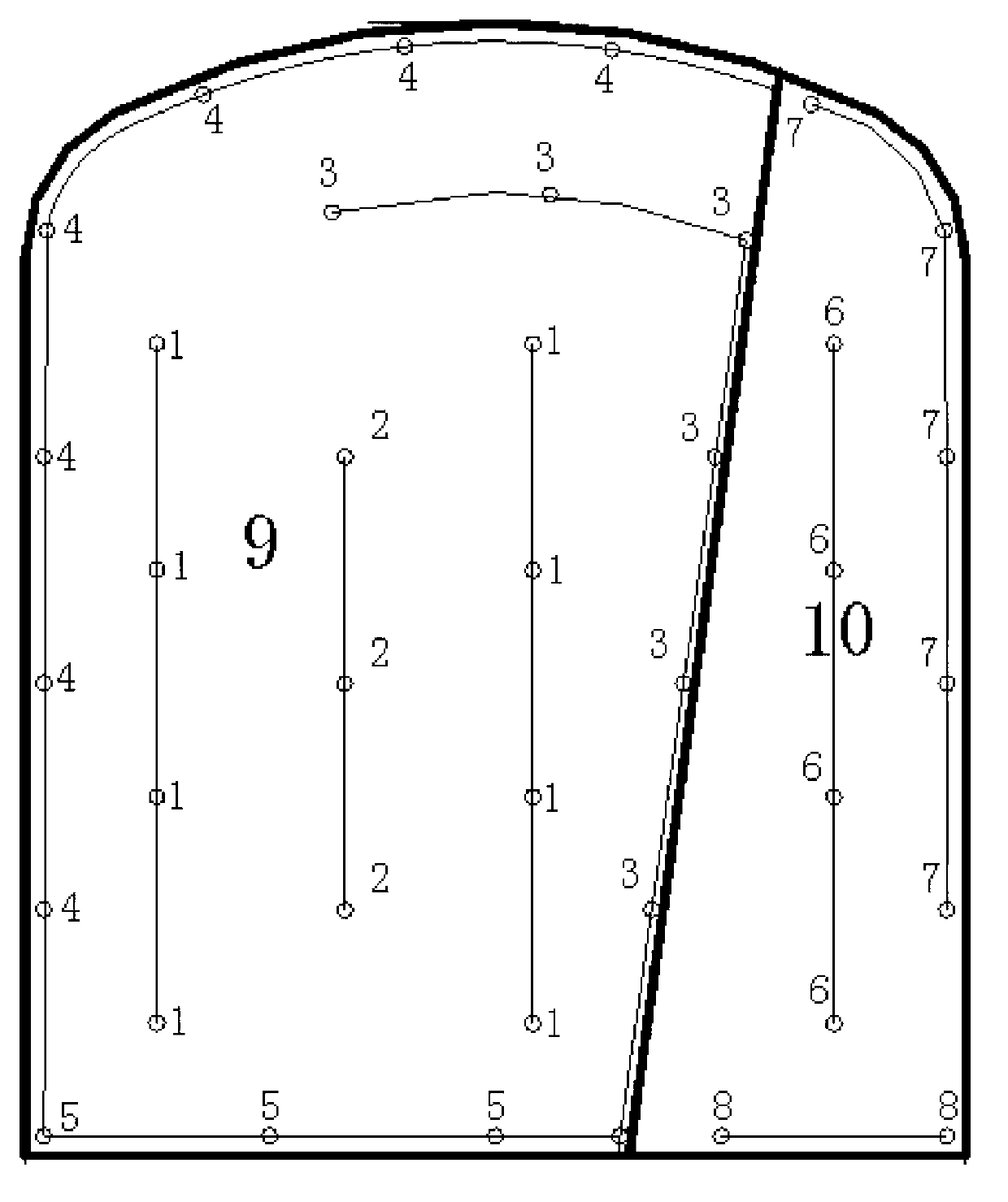

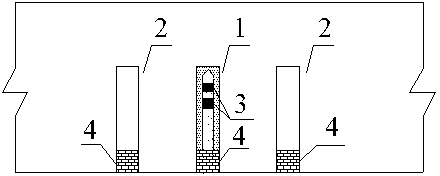

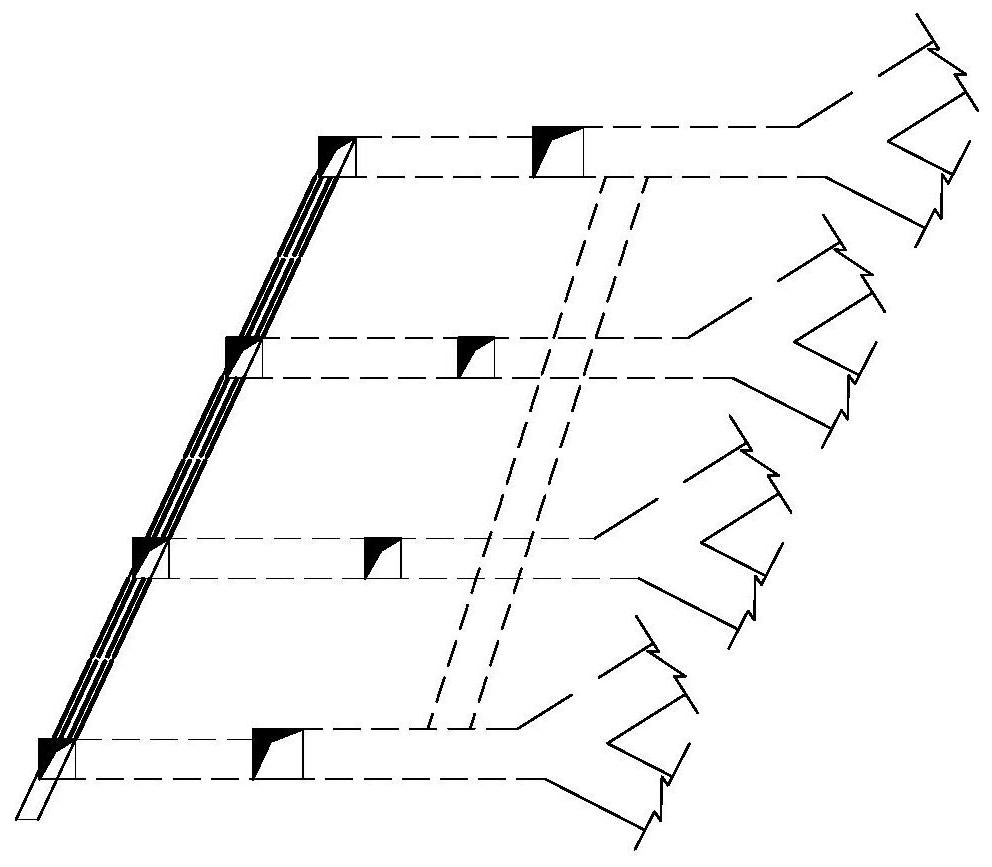

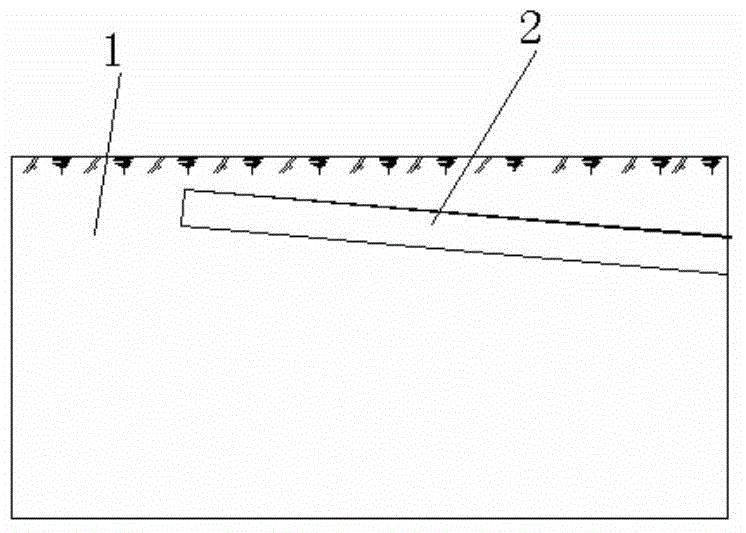

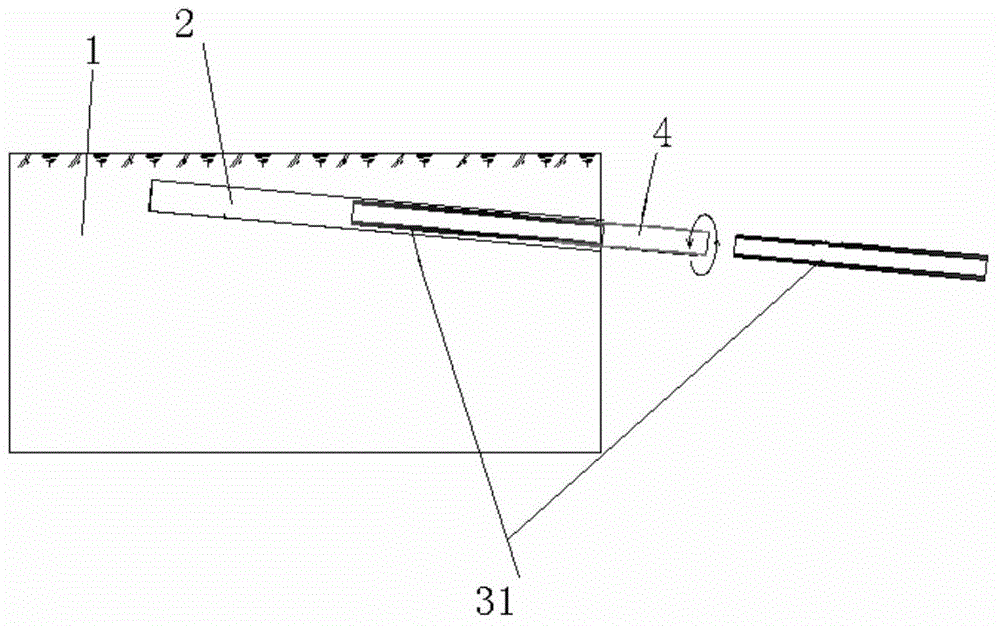

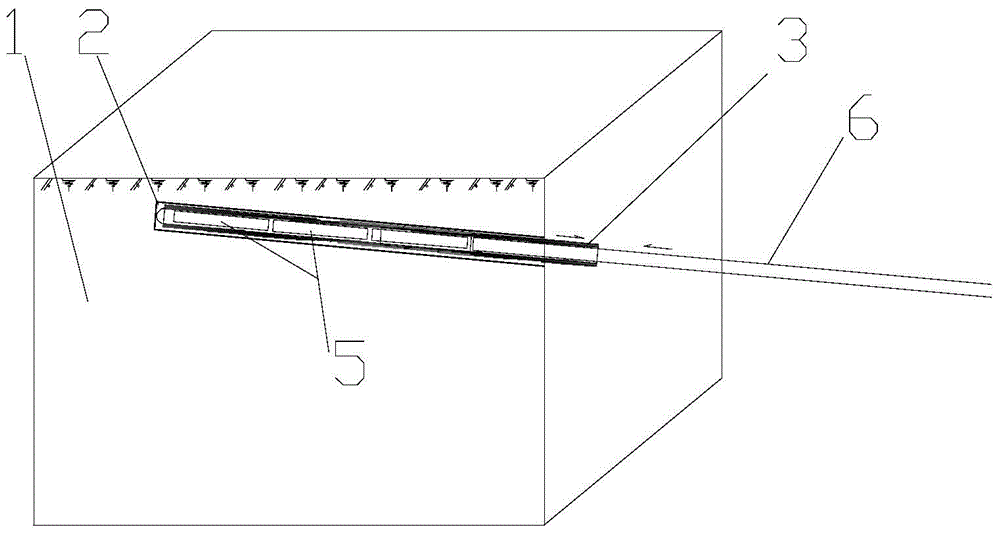

Method for blasting inclined thin ore body by dividing ores and rocks in area in drift driving

The invention provides a technology for blasting an inclined thin ore body by dividing ores and rocks in area in drift driving, belonging to the field of mining engineering. A design process comprises the steps of: 1, dividing a waste rock area (9) and an ore area (10) according to an ore body and a rock distribution condition of a tunnel cross section; 2, arranging a main easer (1) and a secondary easer (2) at the lower part in the waste rock area; 3, arranging an auxiliary hole (3) in the waste rock area according to the size of the cross section; 4, arranging a breaking hole (6) in the ore area according to an inclination angle of the ore body and the size of the cross section; 5, arranging rim holes (4 and 7) and bottom holes (5 and 8) in the circumference edge and the bottom edge of a tunnel; 6, charging each blast hole; 7, sequentially initiating the blast holes; and 8, clearing slag after blasting, and respectively transporting the ores and the waste rocks. With the adoption of the technology provided by the invention, the quantity of the blast holes can be reduced, the use ratio of the blast holes can be improved, a blast effect can be enhanced, the driving efficiency and the ore and rock transportation efficiency can be improved, the dilution rate of the byproduct ores and the engineering cost can be reduced, and the economical benefits of a mine can be improved.

Owner:QINGHAI SHANJIN MINING

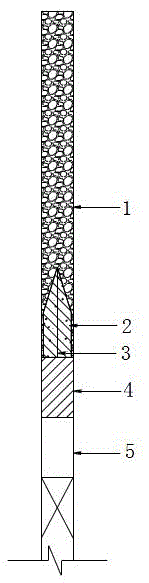

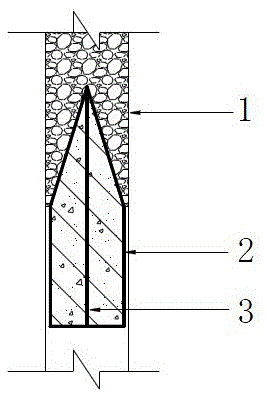

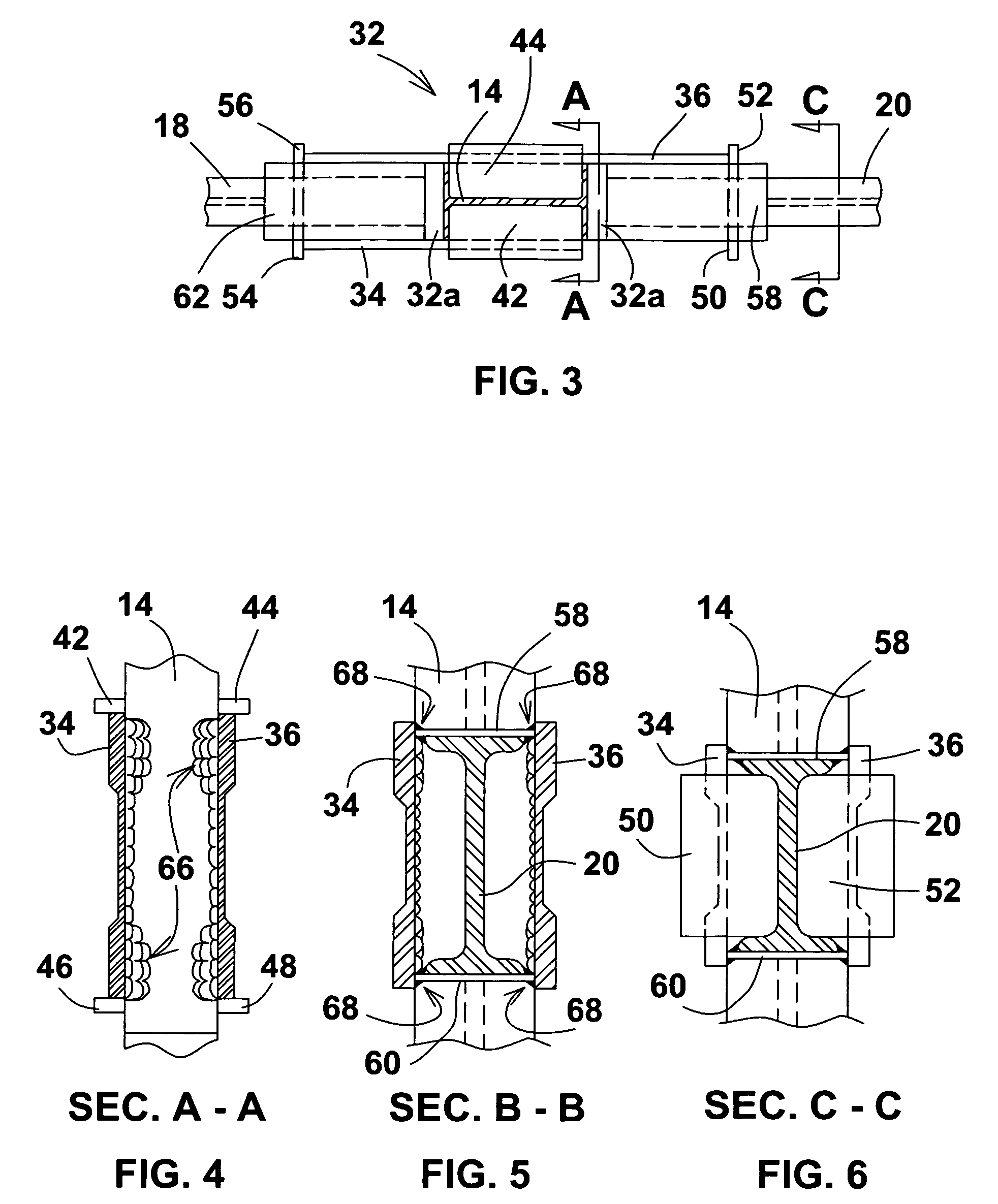

Construction method of blasthole stemming structure for drilling blasting and concrete block structure for method

The invention relates to a construction method of a blasthole stemming structure for drilling blasting and a concrete block structure for the method. The blasthole stemming structure comprises a cylindrical-conical reinforcement built-in concrete block structure, a buffer section and a rock ballast filling body meeting certain grain size requirements, wherein one end of the cylindrical-conical reinforcement built-in concrete block structure is conical while the other end is cylindrical. After shock waves formed after explosion of a blasting cartridge pass the buffer section, concrete blocks on the blocking section generate velocity of movement towards the orifice direction under the action of the buffer section, the rock ballast filling body is squeezed and generates dislocation due to the wedging effect of the upper cone during movement so as to be squeezed and compacted, and bonding power and friction force among particles increase sharply. Meanwhile, the rock ballast filling body generates lateral expansion, however, the squeezed and compacted rock ballast blocks the cylindrical-conical reinforcement built-in concrete block from rushing outwards due to the constraint effect of the hole wall, so that detonation gas is effectively prevented from escaping from the blasthole, acting time of the detonation gas on rock is prolonged, explosive energy is fully utilized, and blasting effect is enhanced.

Owner:WUHAN UNIV

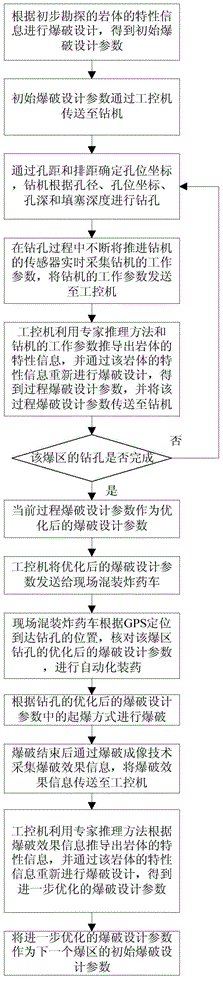

Digitized surface blasting operation method

ActiveCN104596371AEliminate the problem that the blasting quality cannot be guaranteedLow costBlastingBlast effectsEngineering

The invention relates to a digitized surface blasting operation method. The digitized surface blasting operation method includes the following step that according to preliminarily explored rock mass characteristic information, a blasting design is conducted, and an initial blasting design parameter is obtained; according to the initial blasting design parameter, drilling is conducted, during the drilling process, working parameters of a driller are constantly collected, and an industrial personal computer utilizes a specialist inference method and the working parameters of the driller to deduce rock mass characteristic information; according to the rock mass characteristic information, blasting is redesigned, and a process blasting design parameter is obtained; according to the process blasting design parameter, the drilling continues to be conducted, and the processes are repeated until the drilling is finished; according to an optimized blasting design parameter, blasting is conducted, blasting effect information is collected through a blasting imaging technology after the blasting is finished, the industrial personal computer utilizes the specialist inference method to deduce rock mass characteristic information based on the blasting effect information, the blasting is redesigned, and a further optimized blasting design parameter is obtained and taken as an initial blasting design parameter of a next blasting area.

Owner:SHANXI JIANGYANG ENG BLASTING CO LTD

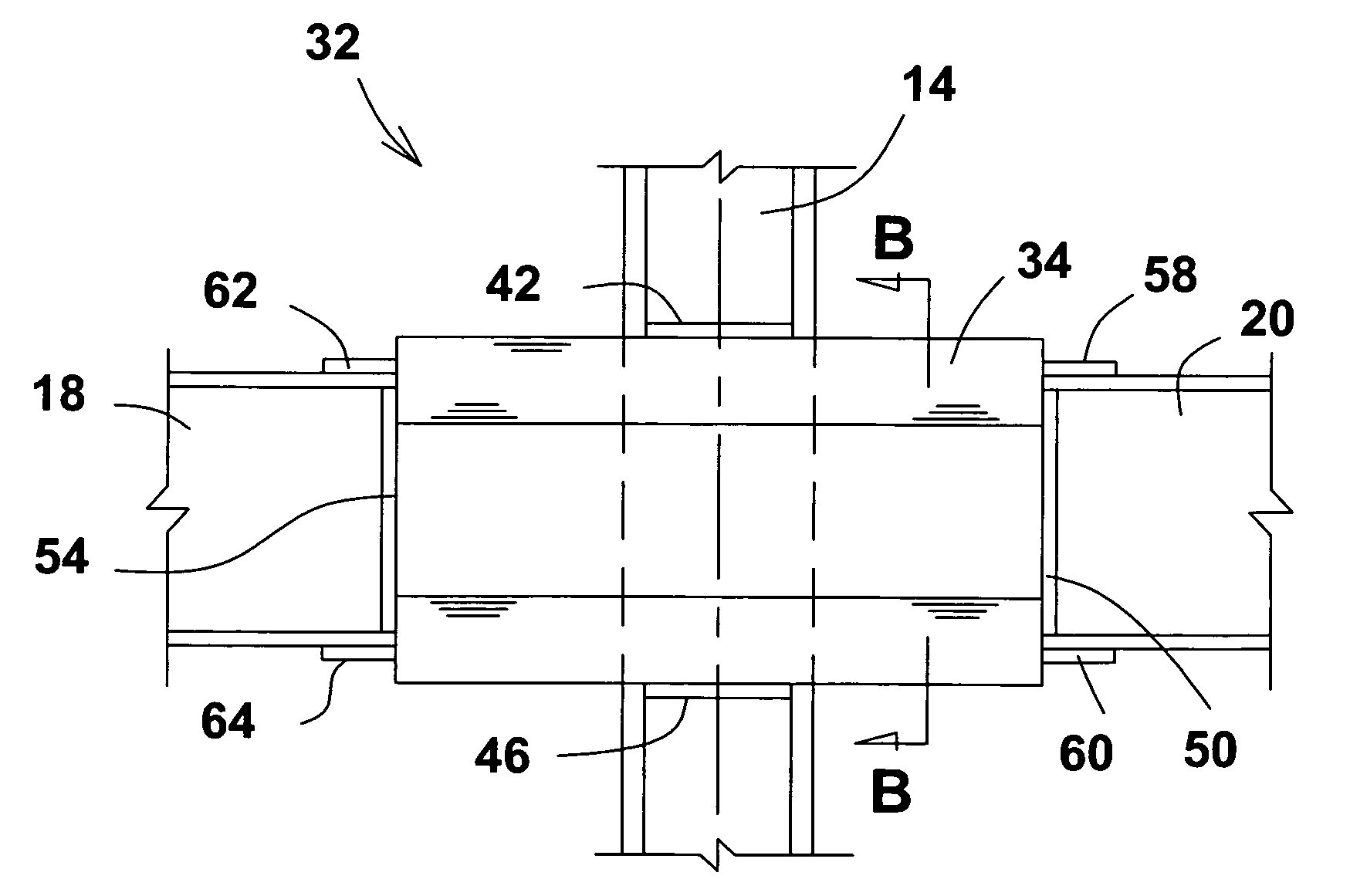

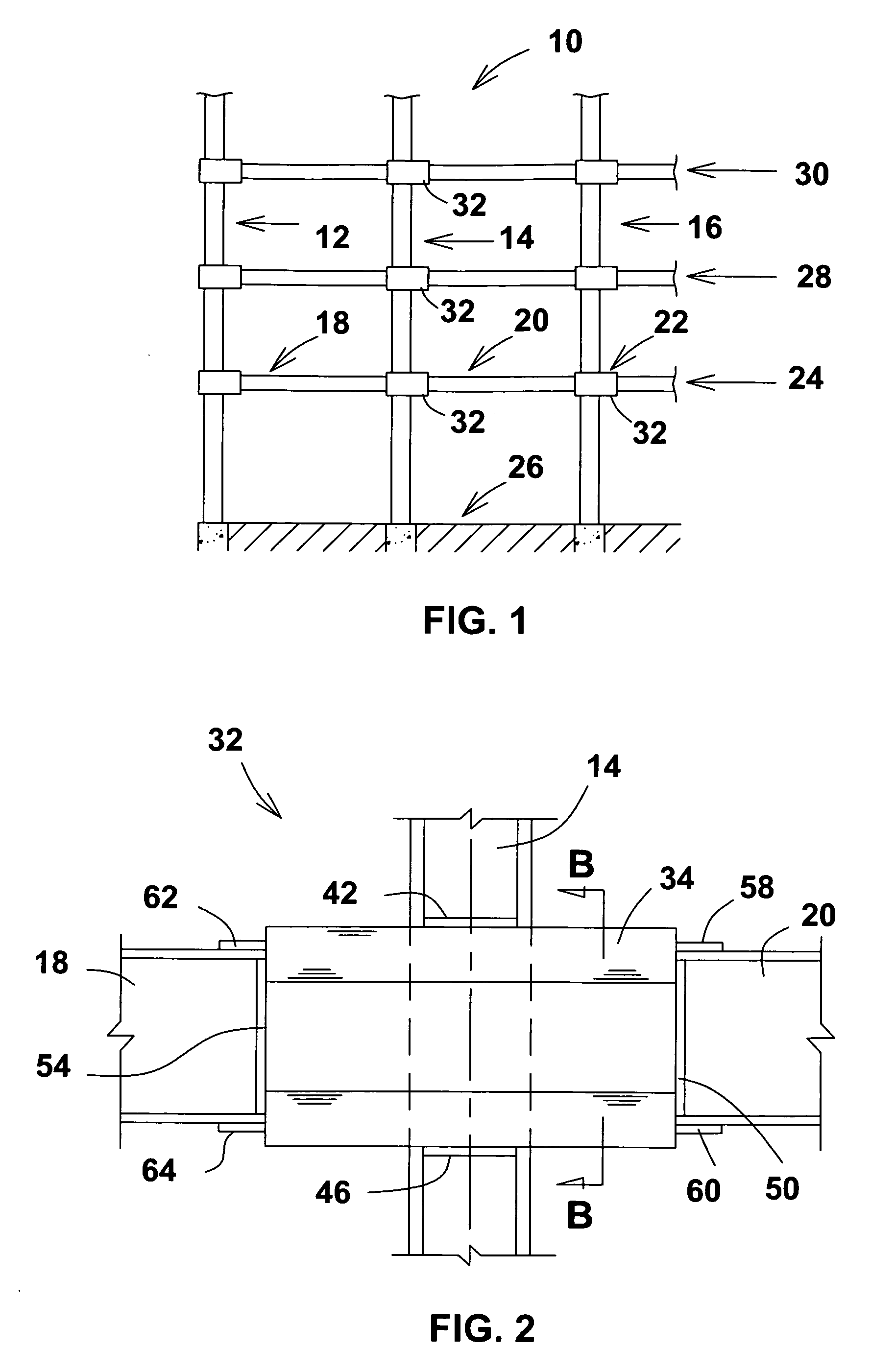

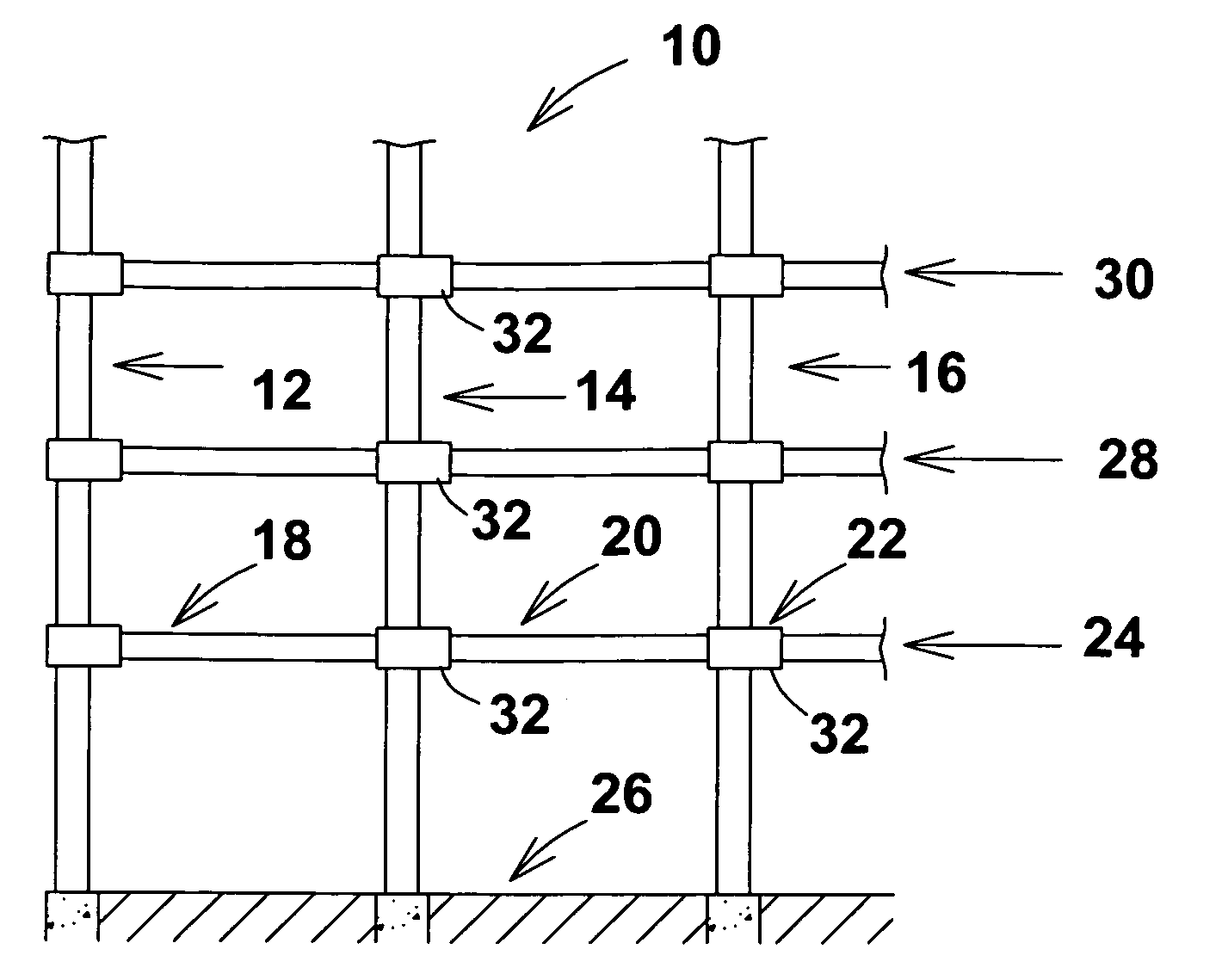

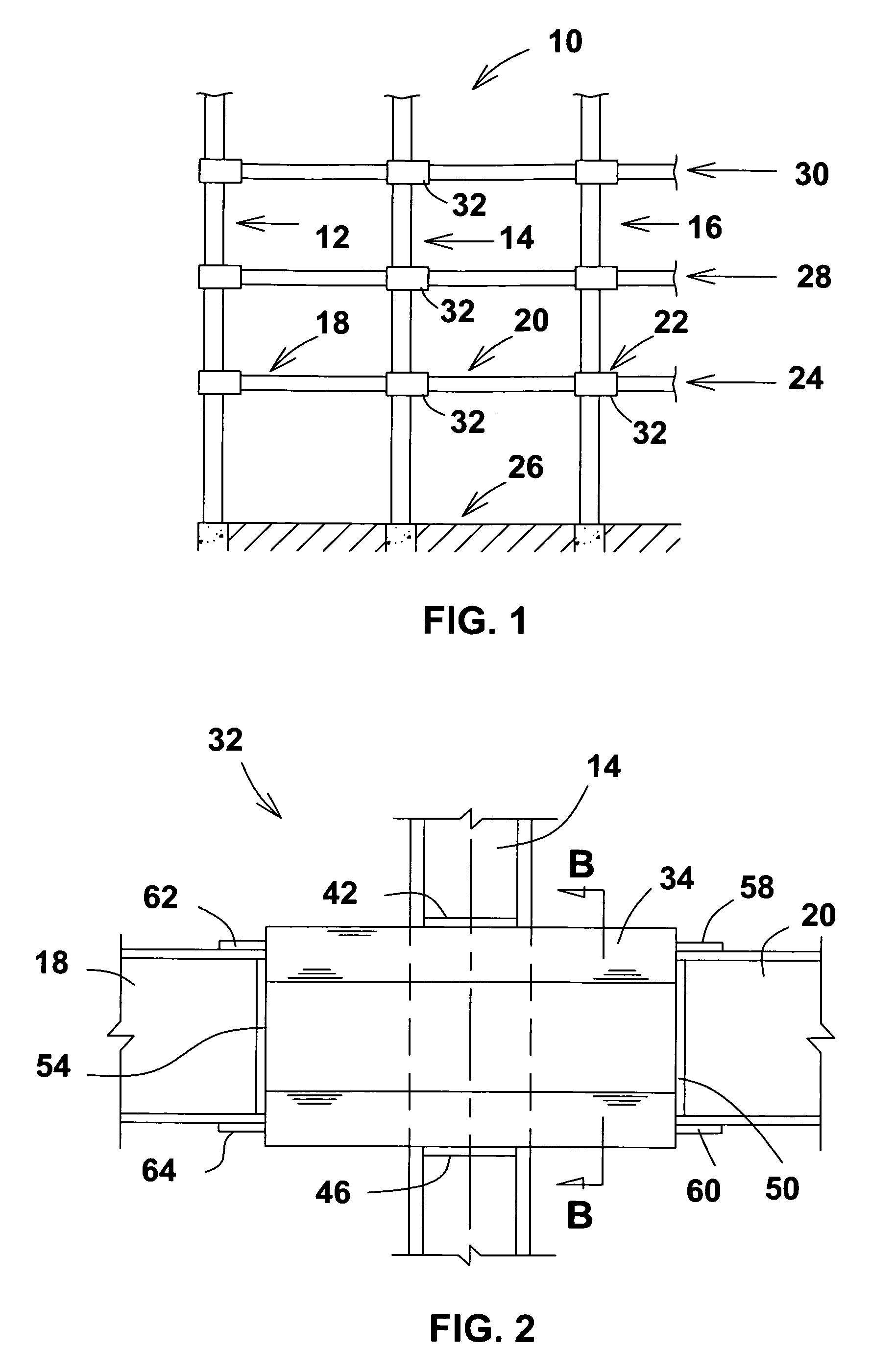

Steel-frame building and method of making

ActiveUS20100043316A1Reduce harmMoment-resisting connectionHuman health protectionLoad-supporting elementsBlast effectsEngineering

An improved building structure and method for making steel frame buildings includes a beam-to-column or beams-to-column joint or connection which is most preferably shop fabricated (as opposed to on-site fabrication) and which offers a considerable savings in both steel requirements (i.e., material savings) and labor to make the joint connection. Also, because material utilization is improved in the connection, the new structure is more resistant to damage by seismic events (i.e., earthquake), by severe weather, and to damage from blast effects (i.e., terrorist attack or accident), than was the prior technology. The improved building structure also mitigates against progressive collapse of the building.

Owner:MITEK HLDG INC

Gas-liquid-solid three-phase coupling blasting weakening rock burst and permeability increasing method

ActiveCN103161493AChange the physical and mechanical propertiesImprove breathabilityFluid removalGas removalStress concentrationBlast effects

Provided is a gas-liquid-solid three-phase coupling blasting weakening rock burst and permeability increasing method. By coal seam water injection and changing of a powder charge structure of traditional blasting, common gas-solid two-phase blasting is converted into gas-liquid-solid three-phase blasting. Blast wave in water, jet flow, secondary pressure wave and other effects are generated by water pressure blasting to enhance blasting effect, after drilled holes are formed, coal bodies are wetted through water injection firstly, physical and mechanical properties around the drilled holes are changed, the gas-solid two-phase coal bodies are converted into gas-liquid-solid three-phase media, a stress concentrating zone is pushed to the deep parts of the coal bodies, stress concentration is lowered; coal seam fractures around blasting holes and in an influence zone are stretched and developed, the fractures are communicated with each other, a facture network is formed, stress concentration is removed, channels are provided for coal seam pressure relief gas flow, and accordingly the purpose that rock burst and gas outburst are prevented is achieved.

Owner:CHINA UNIV OF MINING & TECH

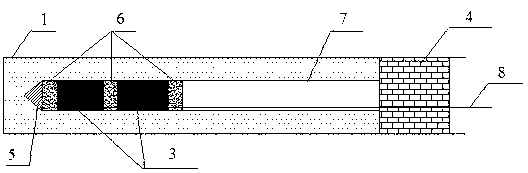

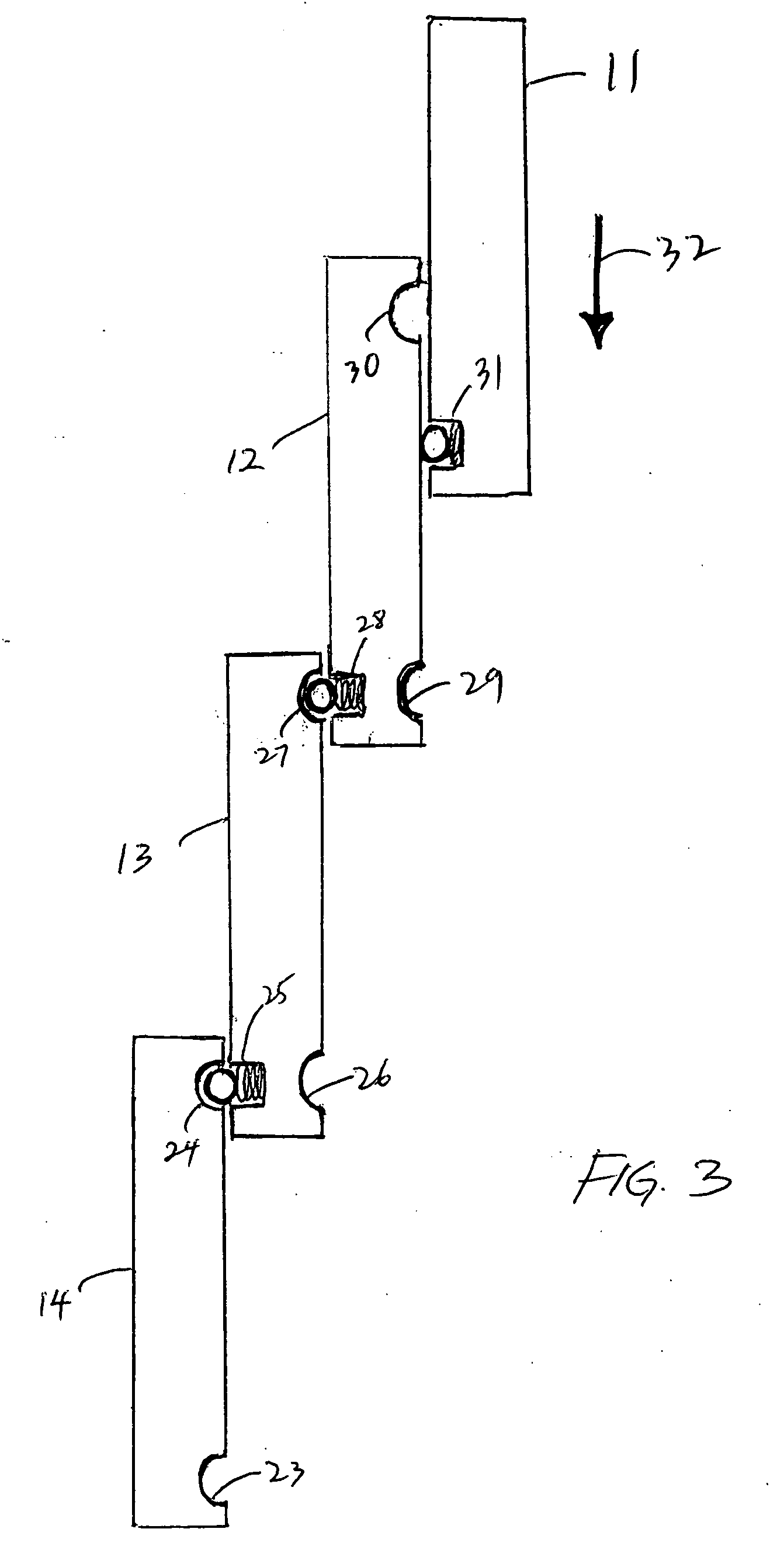

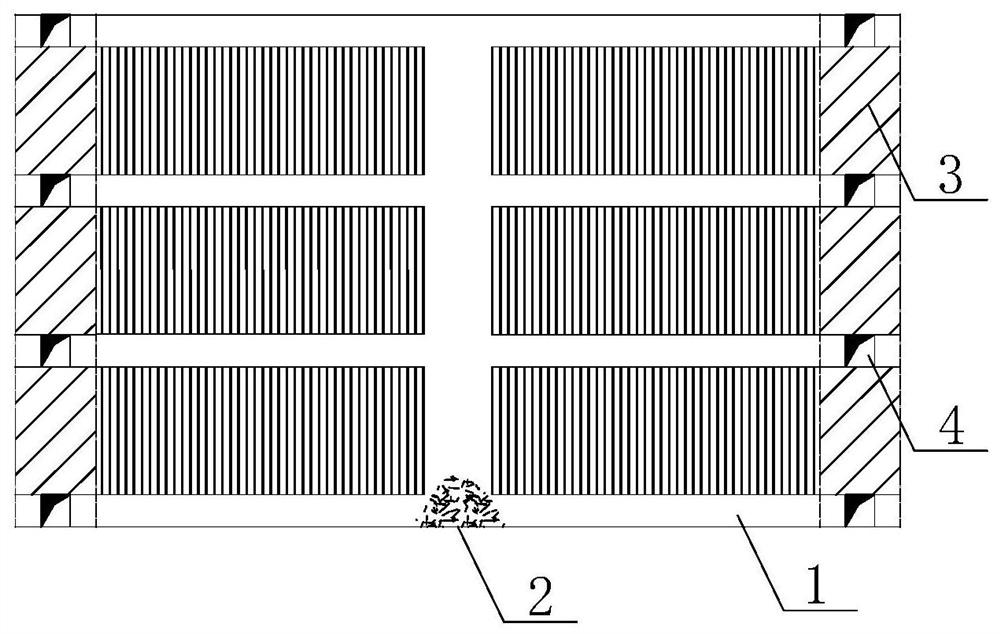

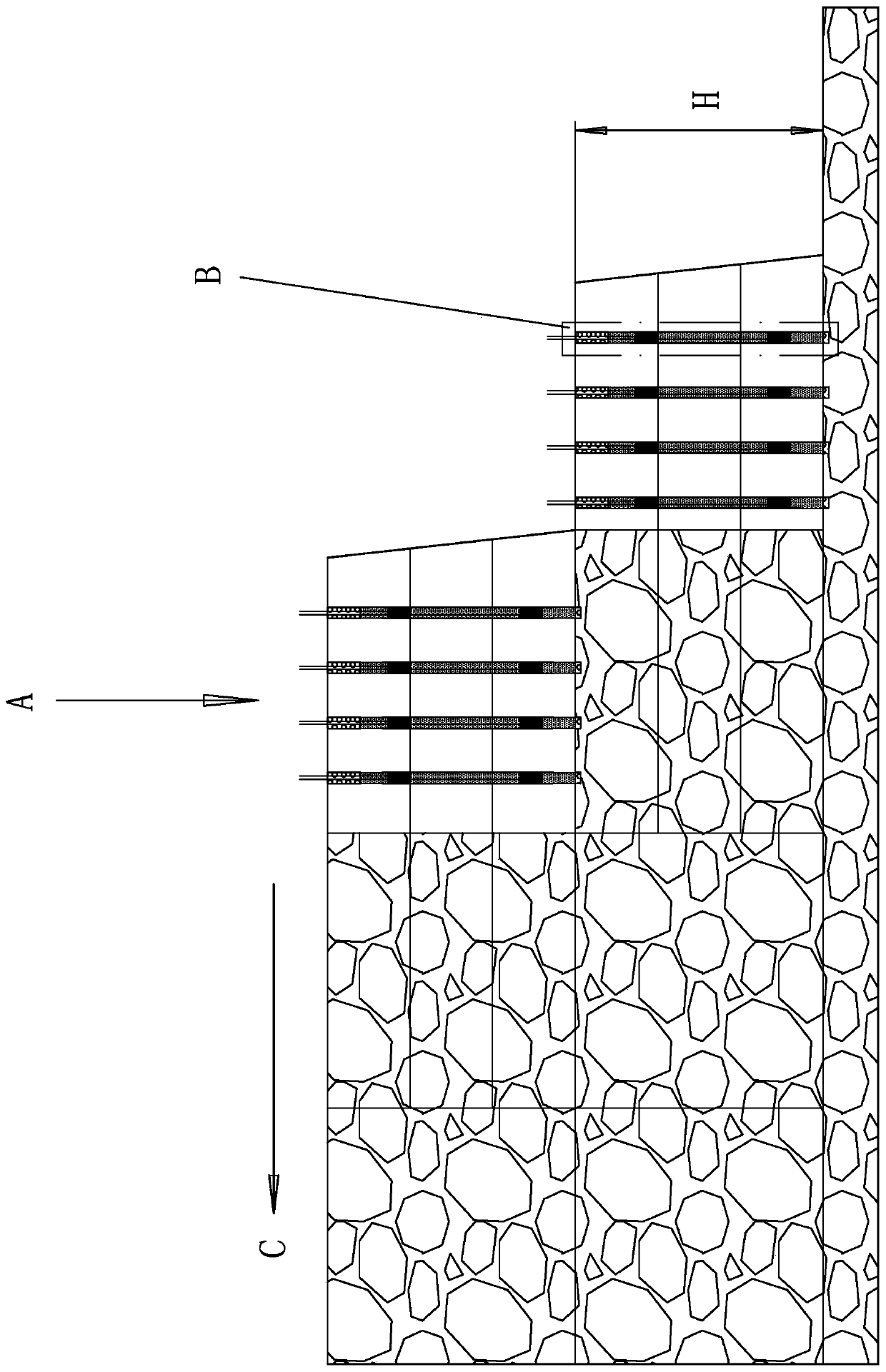

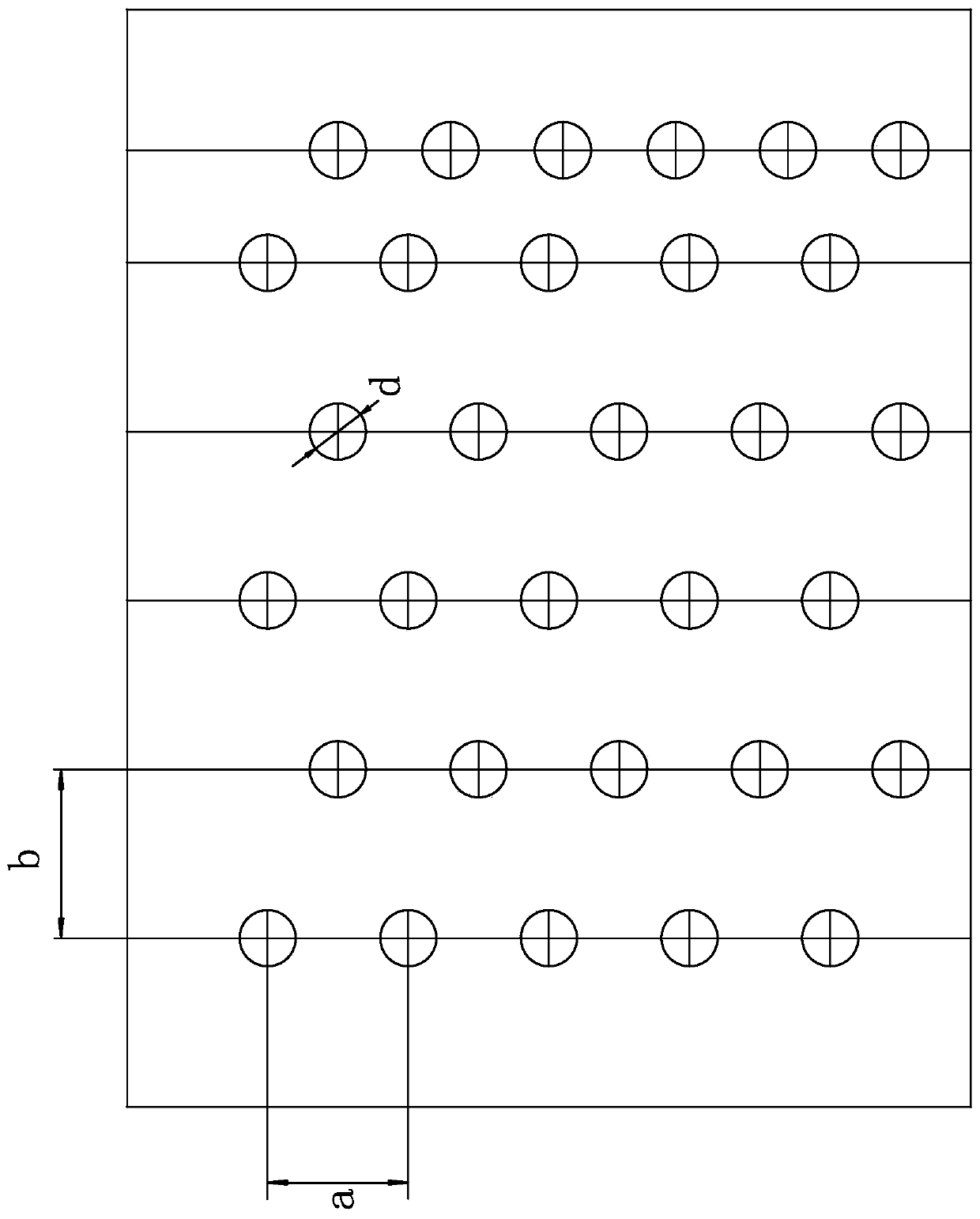

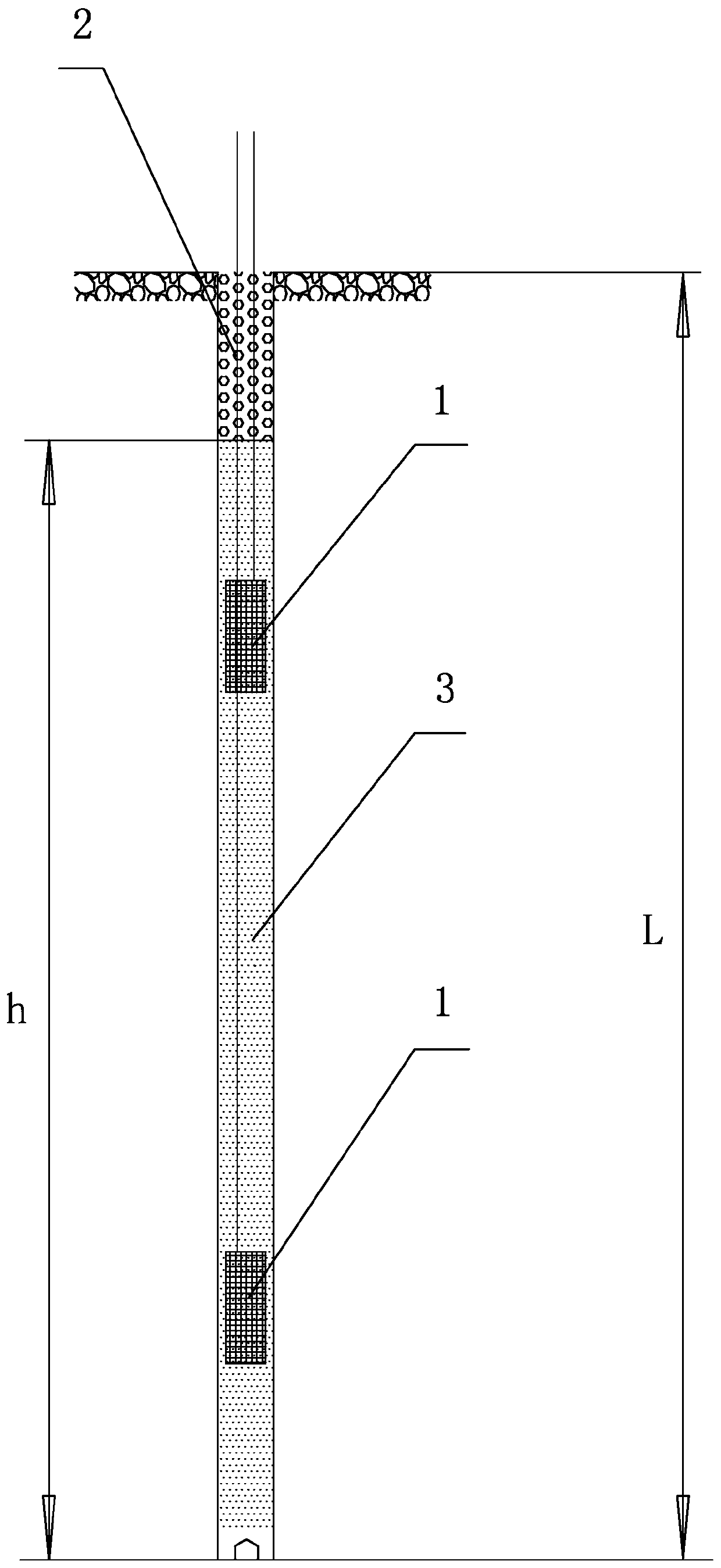

Blast hole charging structure and method for deep-hole bench blasting of layered rock mass mixed up with soft rock strata and hard rock strata

The invention provides a blast hole charging structure and method for deep-hole bench blasting of layered rock mass mixed up with soft rock strata and hard rock strata. The layered rock mass comprises the multiple hard rock strata and the multiple soft rock strata, and the hard rock strata and the soft rock strata are distributed from top to bottom stratum by stratum alternately; the relative positions in the hard rock strata are provided with charging sections, and the charging sections are filled with explosives; a filling section is arranged between every adjacent charging sections and filled with stemming, and the two ends of each filling section are arranged in the adjacent hard rock strata; and the hard rock stratum on the lowermost layer is provided with a hole bottom filling section. The blast hole charging structure is good in blasting effect and low in blasting cost.

Owner:广东锡源爆破科技股份有限公司

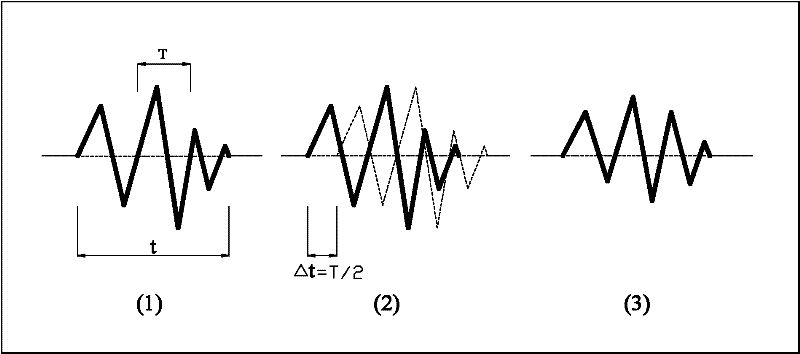

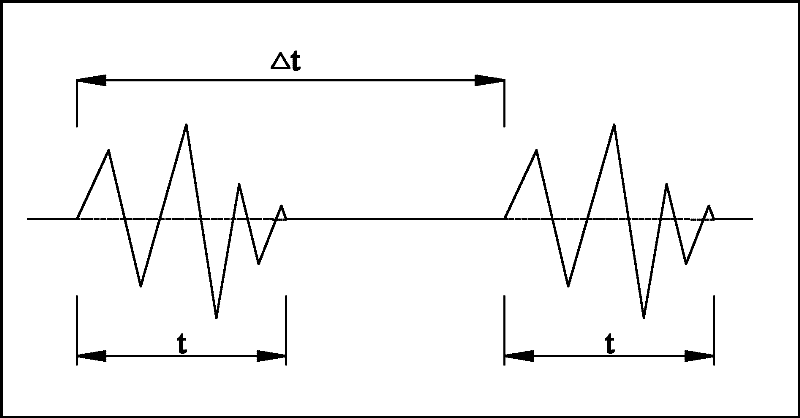

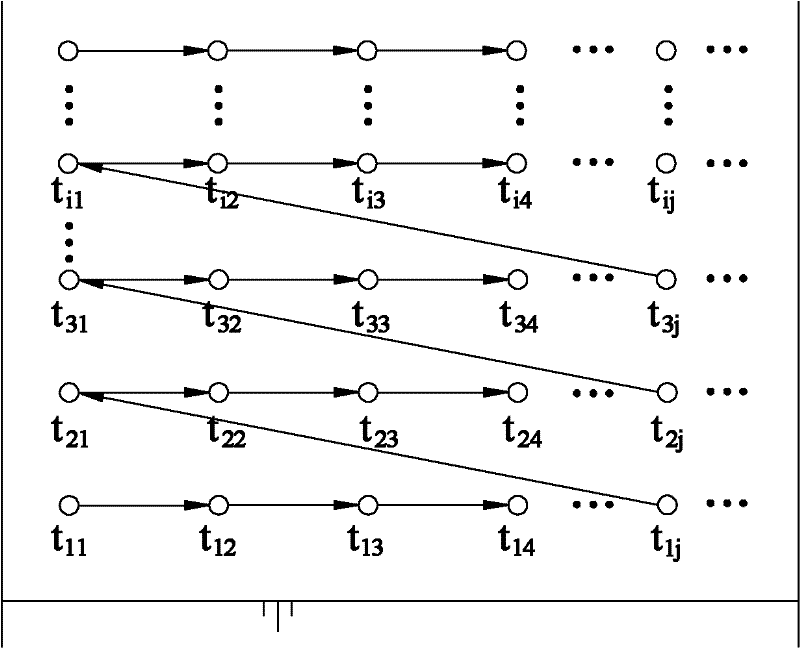

Initiation Control Method for Reducing Blasting Vibration Effect

InactiveCN102269553AEnsure safetyReduce the impact of blasting vibrationBlastingDetonatorVibration control

The invention discloses a detonation control method for reducing blasting vibration effect, which uses digital electronic detonators to reduce blasting vibration effects by controlling the number of each detonator section. One is: the selection of the number of detonator segments adopts the principle of mutual interference between blasting vibration peaks and troughs to reduce vibration, specifically: the delay time between the holes of each row of blast holes adjacent to the detonator detonator ΔTi = T / 2-1000*a / c, where T is the main vibration period of the blasting vibration, in milliseconds; ΔTi is the delay time between adjacent blastholes for sequential detonation, in milliseconds; a is the distance between blastholes, in meters; c is the propagation velocity of seismic waves in rocks, The unit is m / s; the inter-row delay between adjacent rows: ΔTj=nΔTi, ΔTj is the inter-row delay time, and the unit is millisecond; n is the number of adjacent front row detonator segments. The second method is: the selection of the number of each detonator section adopts the principle that the blasting vibration waves are independent of each other and vibration does not superimpose, that is, the inter-hole delay ΔTi=(1.0~1.5)t of sequentially detonating adjacent detonators.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

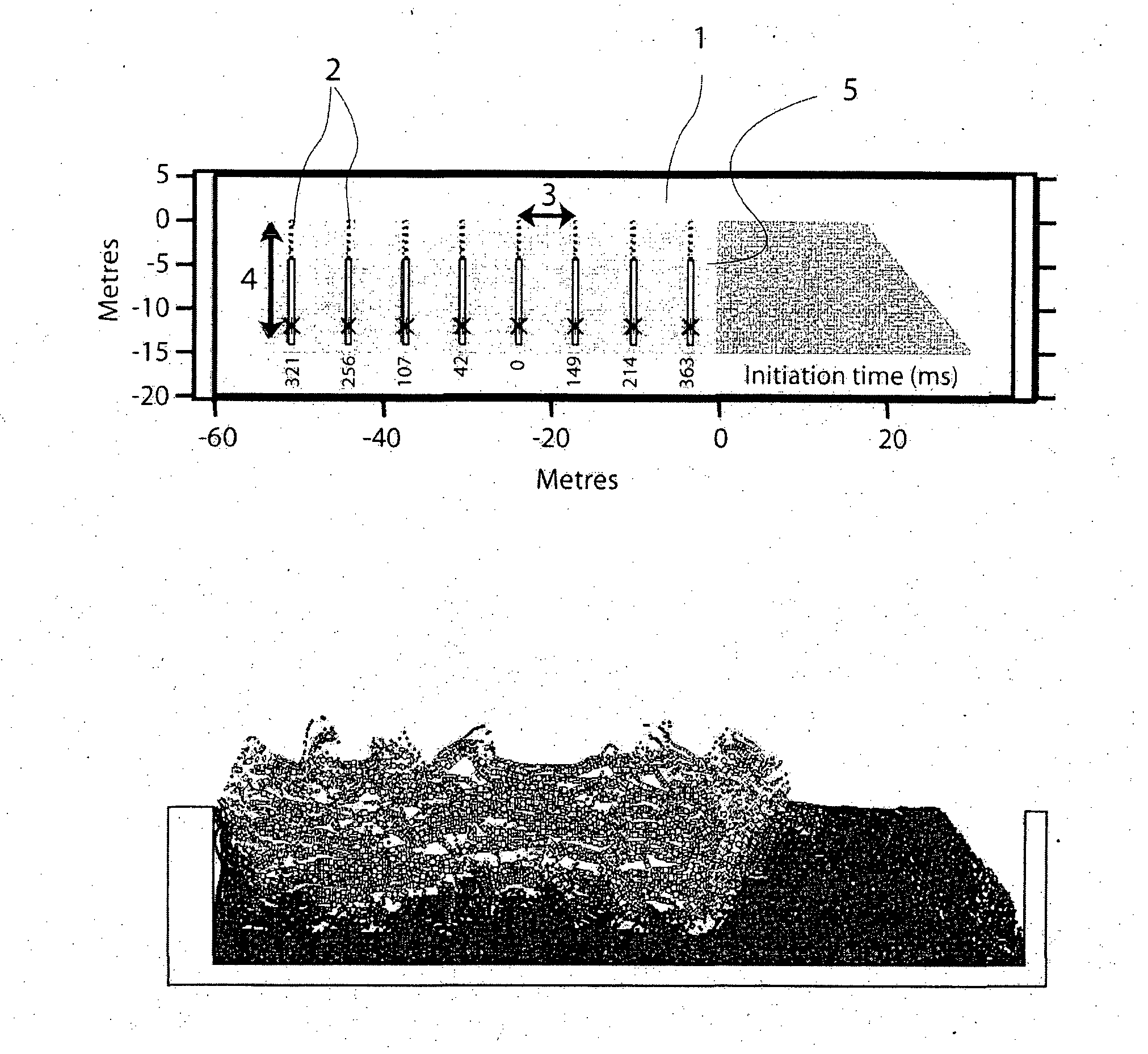

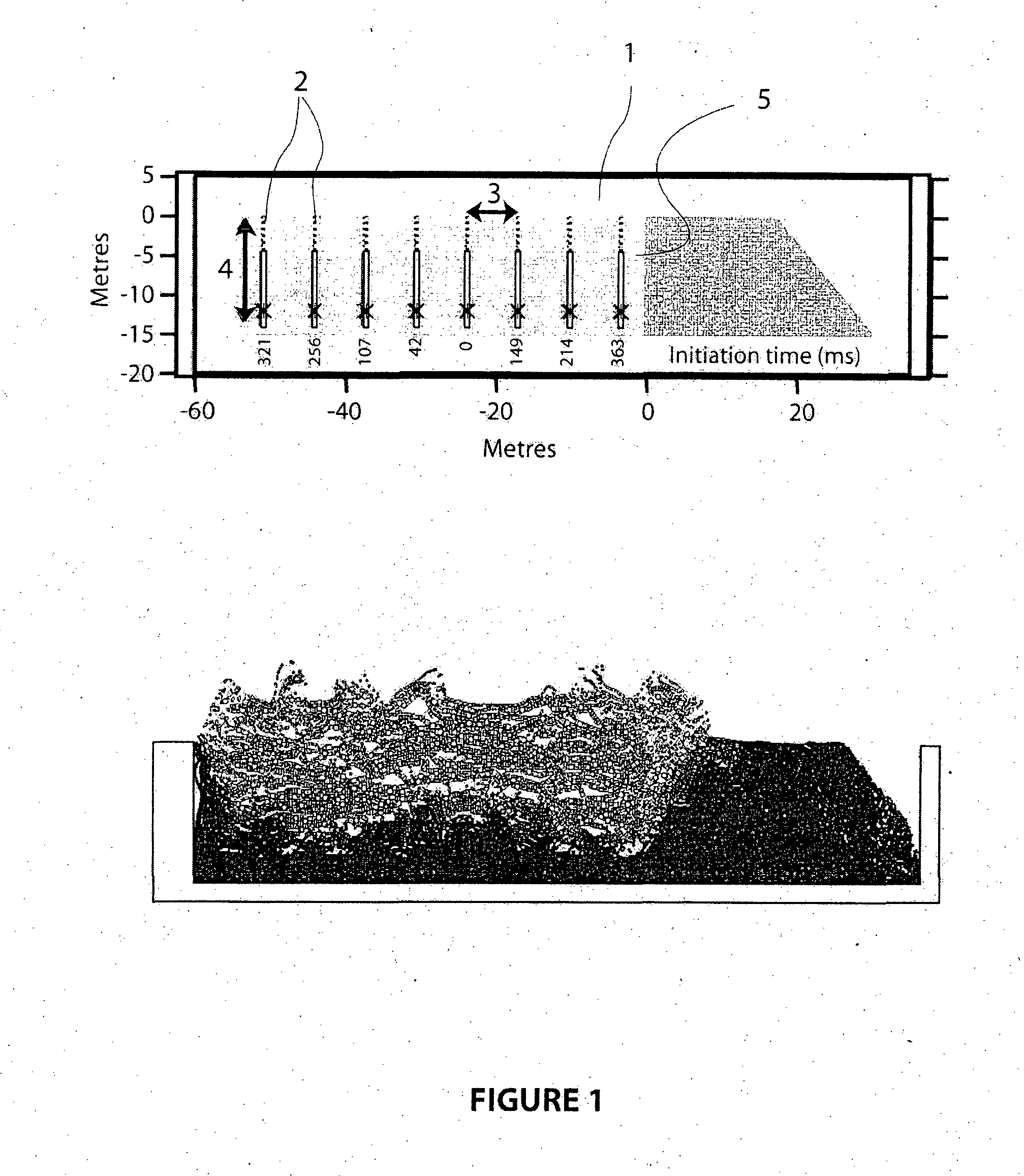

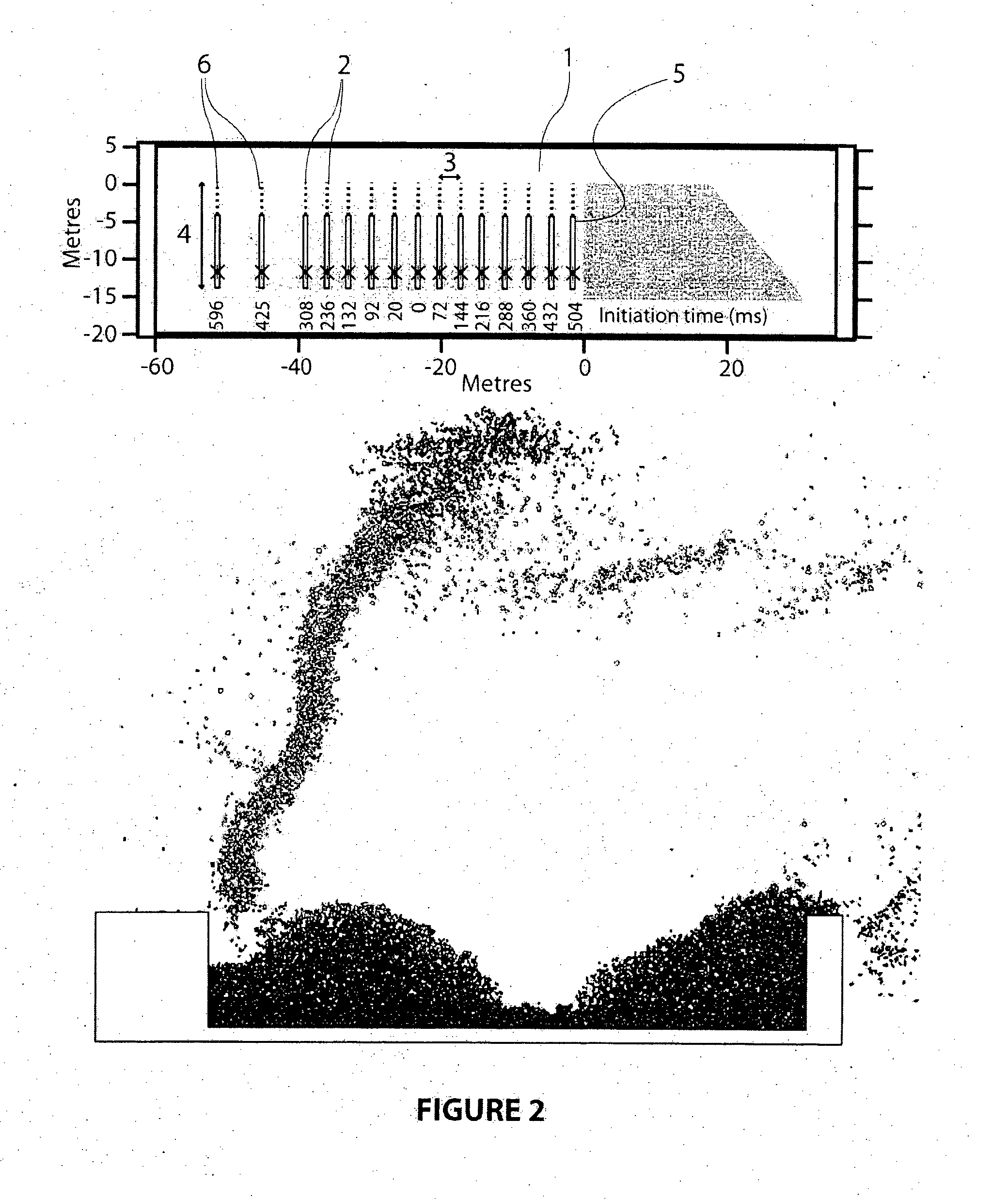

High energy blasting

ActiveUS20130152812A1Higher powder factorsHigh energy concentrationBlasting cartridgesBlastingBlast effectsHigh energy

A method of blasting rock, in mining for recoverable material, comprising drilling blastholes in a blast zone loading the blastholes with explosives and then firing the explosives in the blastholes in a single cycle of drilling, loading and blasting. The blast zone comprises a high energy blast zone in which blastholes are partially loaded with a first explosive to provide a high energy layer of the high energy blast zone having a powder factor of at least 1.75 kg of explosive per cubic metre of unblasted rock in the high energy layer and in which at least some of those blastholes are also loaded with a second explosive to provide a low energy layer of the high energy blast zone between the high energy layer and the adjacent end of those blastholes, said low energy layer having a powder factor that is at least a factor of two lower than the powder factor of said high energy layer. The high energy blasting method provides improved rock fragmentation through increased explosive energy concentration while simultaneously alleviating deleterious environment blast effects.

Owner:ORICA INT PTE LTD

Portable convertible blast effects shield

A rapidly deployable portable convertible blast effects shield / ballistic shield includes a set two or more telescoping cylindrical rings operably connected to each other to convert between a telescopically-collapsed configuration for storage and transport, and a telescopically-extended upright configuration forming an expanded inner volume. In a first embodiment, the upright configuration provides blast effects shielding, such as against blast pressures, shrapnel, and / or fire balls. And in a second embodiment, the upright configuration provides ballistic shielding, such as against incoming weapons fire, shrapnel, etc. Each ring has a high-strength material construction, such as a composite fiber and matrix material, capable of substantially inhibiting blast effects and impinging projectiles from passing through the shield. And the set of rings are releasably securable to each other in the telescopically-extended upright configuration, such as by click locks.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

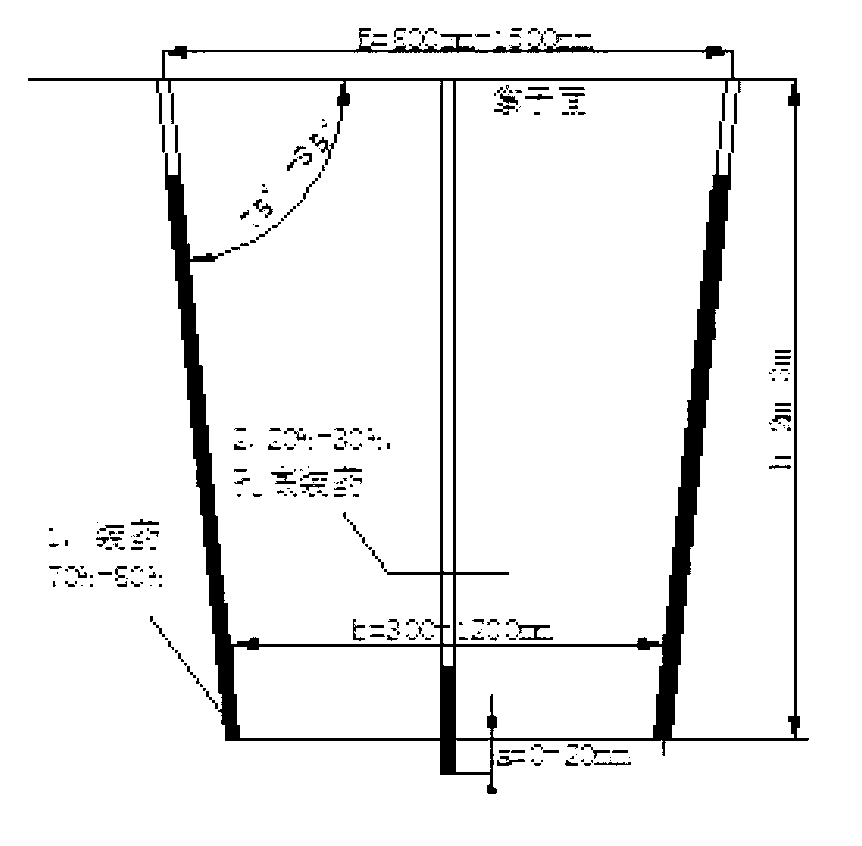

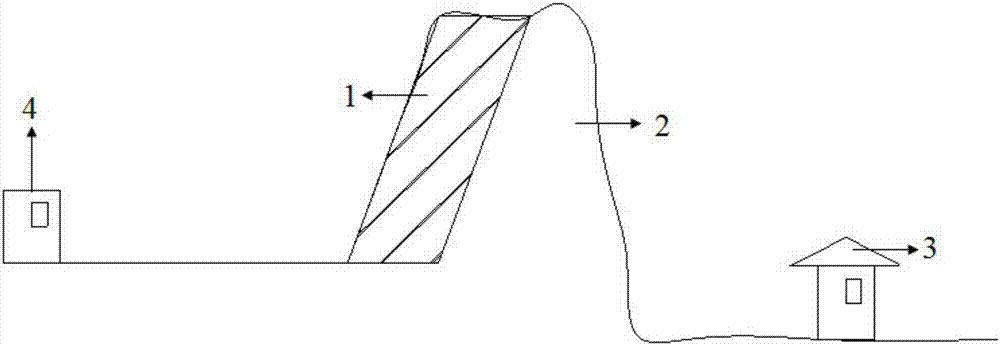

Deep hole blasting construction method for high slope under complicated environment

The invention discloses a construction method for deep hole blasting on a high slope in a complex environment, which comprises the following steps: 1) drafting an overall blasting construction plan, 2) calculating the maximum amount of charge in a section, 3) reasonably determining blasting technical parameters, 4) Drilling, 5) charge and blockage, 6) connection to the detonation network and detonation, 7) blasting effect check and vibration test; adopt "layering in the hole, slight difference inside and outside the hole, multiple sounds in one hole, and charge the air column at intervals" "blasting method, the blasting technical parameters include blasting hole diameter, hole depth, hole spacing, row spacing, explosive unit consumption and single hole charge, the drilling equipment is a self-propelled medium and deep hole drilling rig, and the charge structure is an air column spacer medicine. The invention adopts the shock absorption measures of the air column spaced at the bottom of the hole and the uncoupled charge structure to control the blasting vibration, monitors the blasting vibration for each blasting, and optimizes the blasting parameters in time, effectively guiding the complex environment such as adjacent buildings and residential areas. Under blasting construction.

Owner:HOHAI UNIV

Method for mining inclined or steeply inclined hard thin ore body

PendingCN112177611AChange in stabilityControl mining boundariesUnderground miningSurface miningMining engineeringBlast effects

The invention discloses a method for mining an inclined or steeply inclined hard thin ore body. As for the hard and stable inclined / steeply inclined hard thin ore body, stopes and studs are divided along the trend of the ore body, the height of a stope stage is 15-60 m, and the height of a subsection is 5-20 m. Mining from a middle section of each stope to the two ends or from one end to the otherend according to the overall stoping sequence of the stopes is carried out. Upward or downward medium-length holes are constructed in a rock drilling roadway, the medium-length holes in ore rock boundaries achieve ore rock presplitting, and the medium-length holes in the middle achieve ore breaking after presplitting. Pre-splitting blast holes are blasted by one step pitch before rock breaking blast holes, and the width of the step pitch is 3-5 m. Blasting of the pre-splitting blast holes is advanced to form pre-cracks through communication of the blast holes, and the effects of ore-rock boundary separation and blasting effect blocking are achieved. The rock breaking blast holes are formed in the middles of the stopes, so that the stability condition of the ore body is changed, and natural caving is generated. After stope mining is finished, goafs are filled with tailings or sealed by sealing facilities.

Owner:ANHUI TONGGUAN (LUJIANG) MINING CO LTD +1

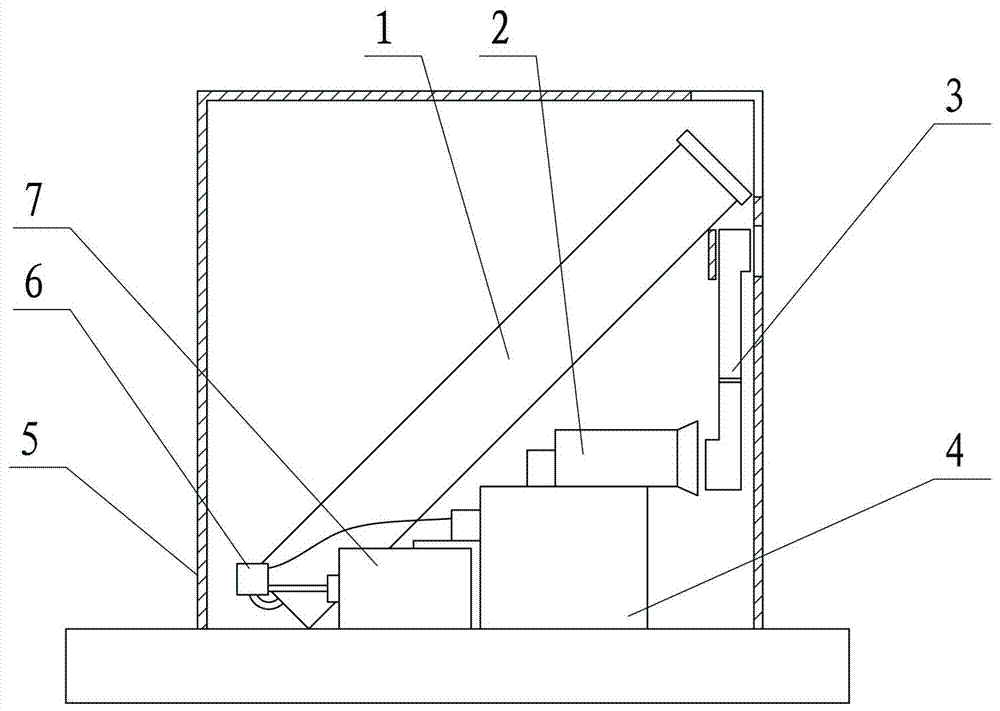

Automatic simulated dummy projectile launching system

ActiveCN107084640AEasy to useLong-term useAmmunition projectilesTraining ammunitionBlast effectsStructural engineering

The invention provides an automatic simulated dummy projectile launching system. The problems that in the conventional simulation actual combat training process, the blast effect of blasting ammunition in the close combat is difficultly simulated in a vivid manner, and the death cannot be avoided are solved, and the problem that the non-gunpowder means is adopted to motivate a fuse so that the simulated dummy projectile is launched is solved; according to the technical scheme, the automatic simulated dummy projectile launching system comprises a canister launcher, a canister launcher control device and the simulated dummy projectile used for being loaded in the canister launcher; the simulated dummy projectile comprises a bomb body shell, a bomb core and a fuse structure at the bottom of a projectile body; the side wall of a canister launcher air cylinder is provided with an air guide hole used for communicating an air cylinder inner cavity with a canister launcher inner cavity, the lower portion of the air cylinder is connected with a high-pressure air storage tank through an air guide pipe and a normally-closed electromagnetic valve, through automatic identification of a target, cooperative control over launching of the percussion fuse is achieved, the projectile body is launched, exploding is simulated, in the launching process, the dangerous hidden dangers brought by gunpowder launching are completely avoided, operation is easy, and the system is safe, reliable, simple in structure and suitable for civil production manufacturing.

Owner:SHENYANG DANGLANG TECH DEV CO LTD

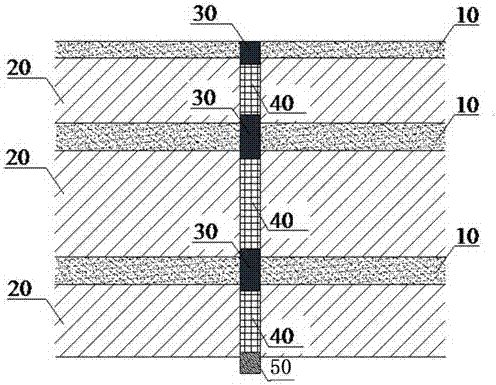

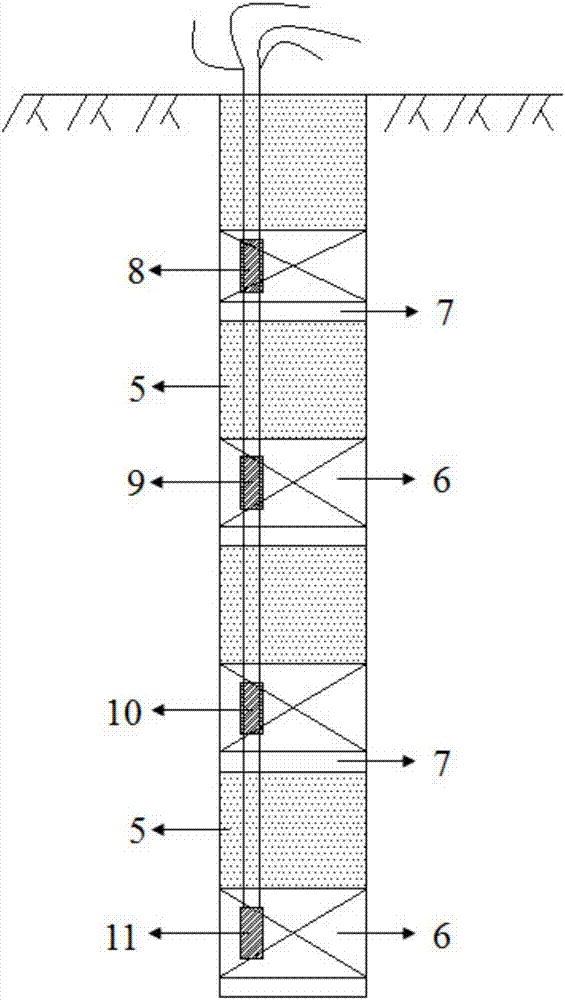

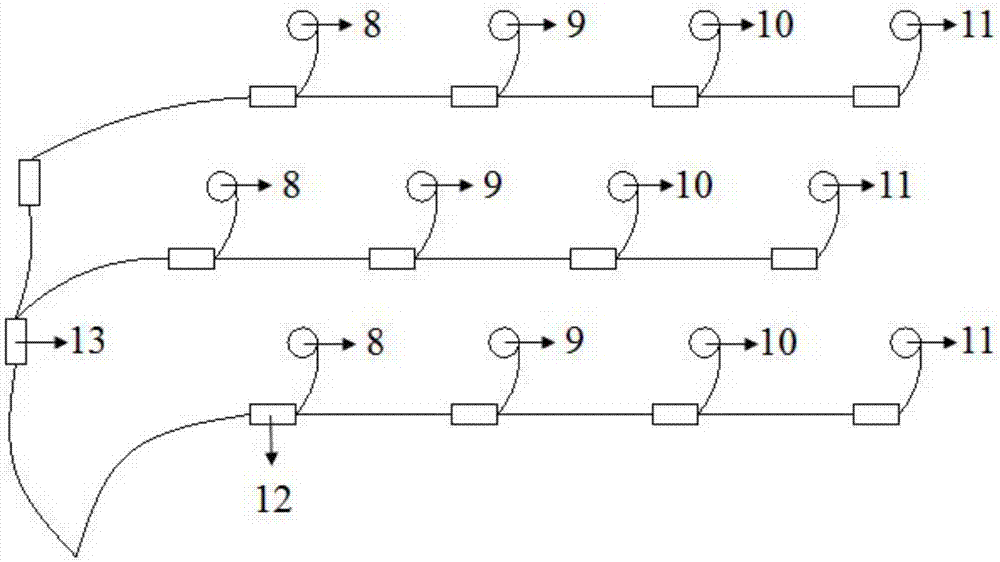

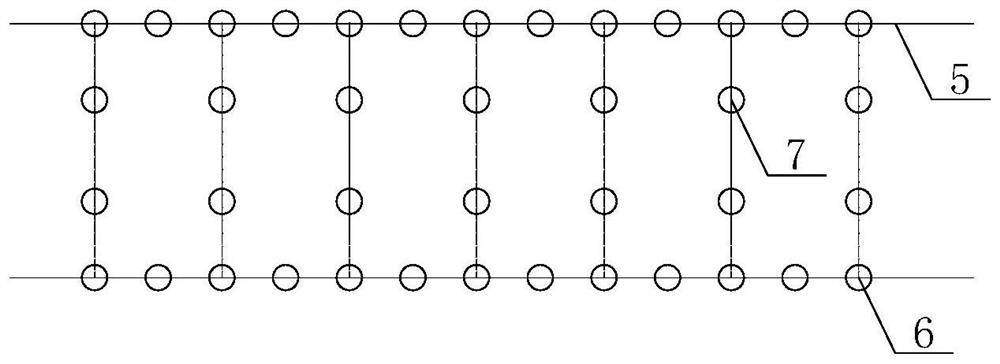

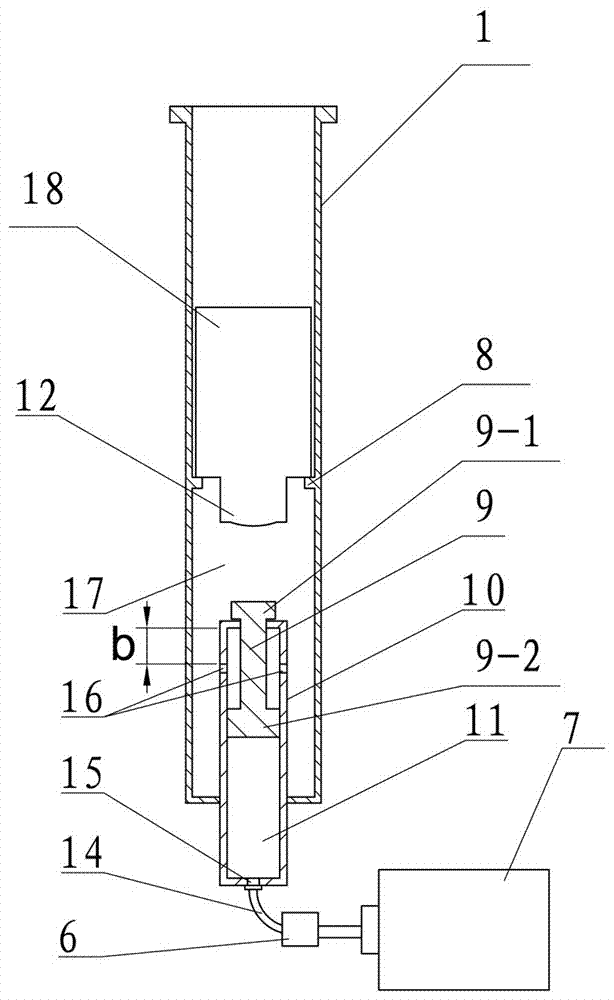

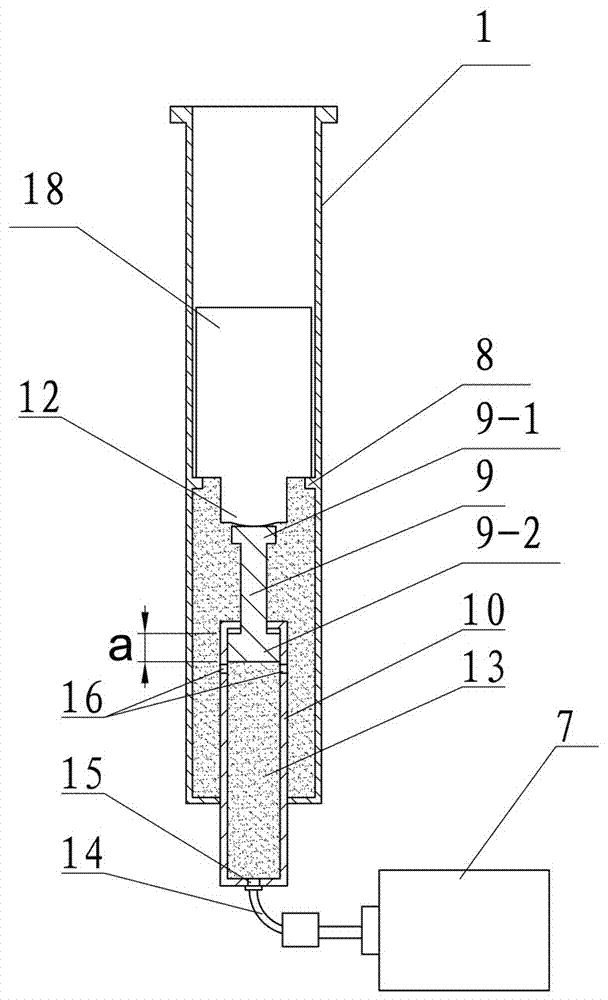

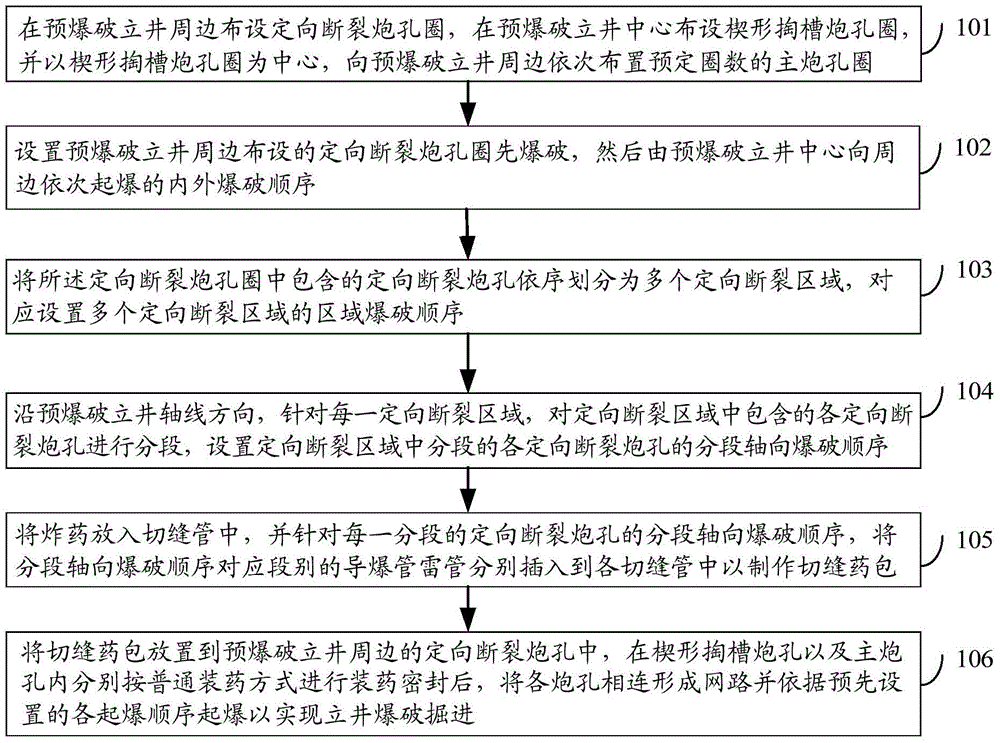

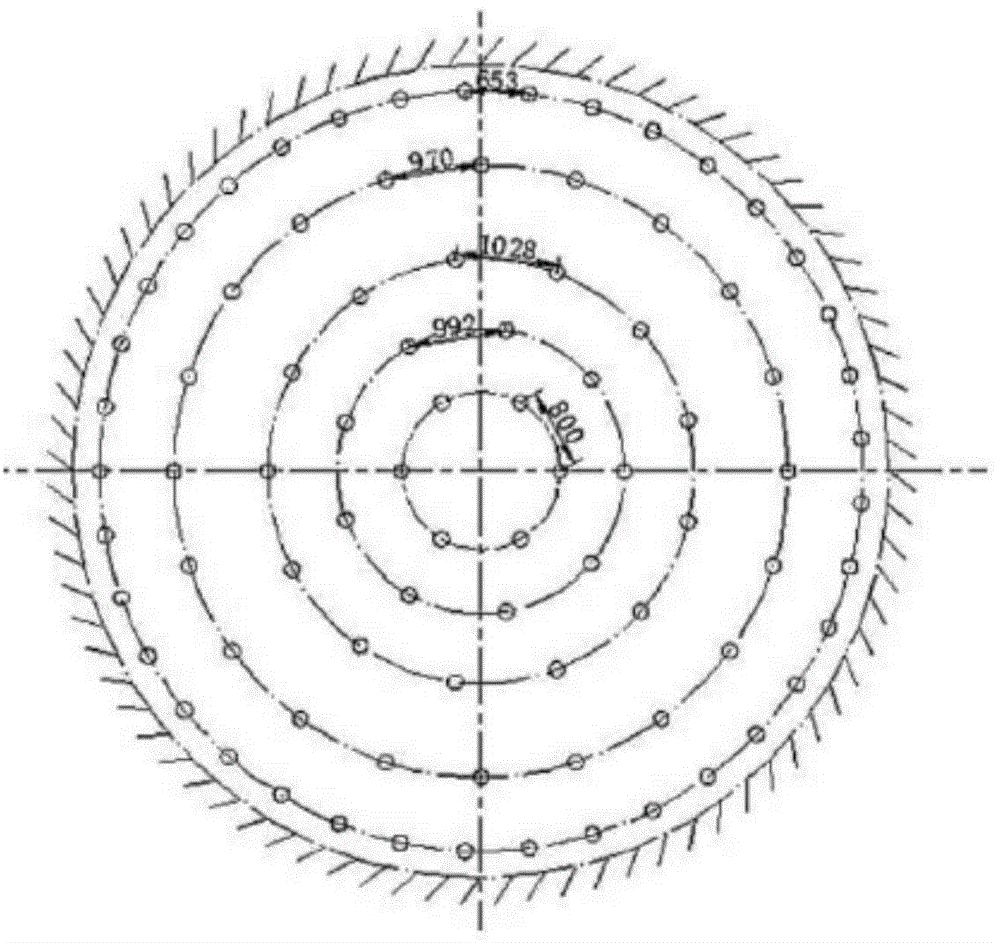

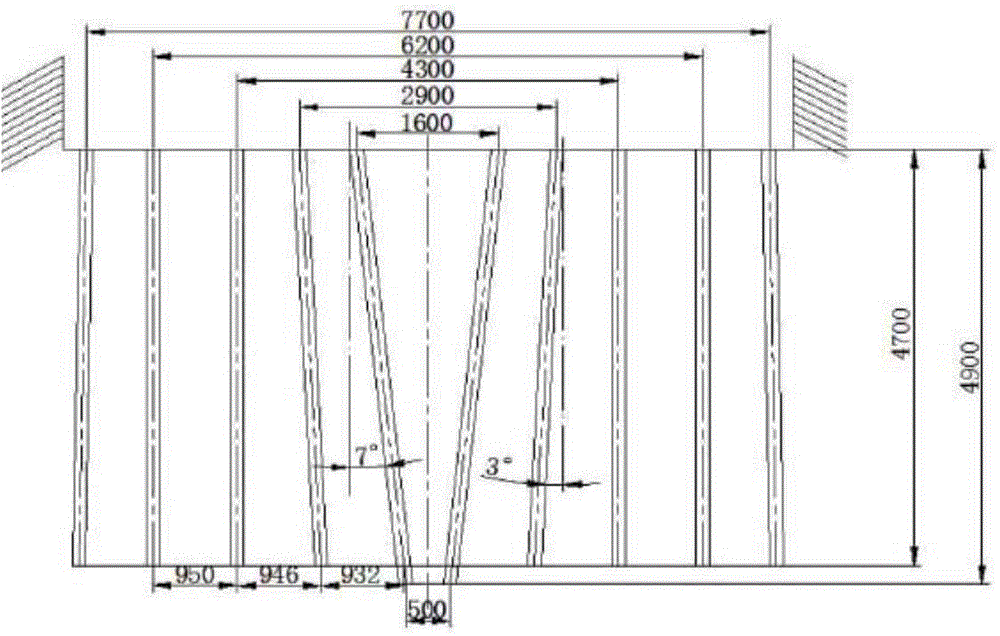

Gradient pre-splitting blasting method and device of lancing cartridges around vertical shaft

An embodiment of the invention discloses a gradient pre-splitting blasting method and device of lancing cartridges around a vertical shaft. The method includes distributing directional-breaking blasthole rings around the vertical shaft, distributing wedge-cut blasthole rings in the center and distributing main blasthole rings with preset ring number from the center to outside; setting a blasting sequence that the directional-breaking blasthole rings blast first, and the blasthole rings from the center to outside blast sequentially; sequentially dividing the directional-breaking blasthole rings into a plurality of directional-breaking areas and setting the corresponding area blasting sequence; subjecting the directional-breaking areas to segmentation and setting the corresponding segmental axial blasting sequence; putting explosive into lancing tubes and inserting nonel detonators corresponding to the segmental axial blasting sequence into the lancing tubes to make lancing cartridges; placing the lancing cartridges in directional-breaking blastholes around the vertical shaft, filling and sealing the wedge-cut blastholes and the main blastholes, and connecting the blastholes to form a detonating network. By the use of the gradient pre-splitting blasting method and device, blasting damage is reduced during the blasting, and blasting effect is improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Fireworks and crackers blasting-agent composition

The invention discloses a fireworks and crackers blasting-agent composition. Agents in the fireworks and crackers blasting-agent composition include, by weight, 40%-60% of potassium perchlorate, 15%-30% of potassium acid phthalate, 10%-20% of a metal-filled multi-walled carbon nanotube, 5%-10% of metal oxide and 3%-5% of black powder, the multi-walled carbon nanotube is filled with one or more combinations of metals of aluminum, silver, iron, nickel, potassium, magnesium, lithium, sodium and the like, and the metal oxide is one or more combinations of ferroferric oxide, iron sesquioxide, copper oxide, manganese oxide, zinc oxide, cobalt oxide and aluminum oxide. The fireworks and crackers blasting composition agents free from metal powder are obviously improved in security coefficient, the explosion dynamics of the agents is high, burning rate of bright points is high, shelf life is long and blasting effect is good.

Owner:WANZAI JIANKUN CHEM

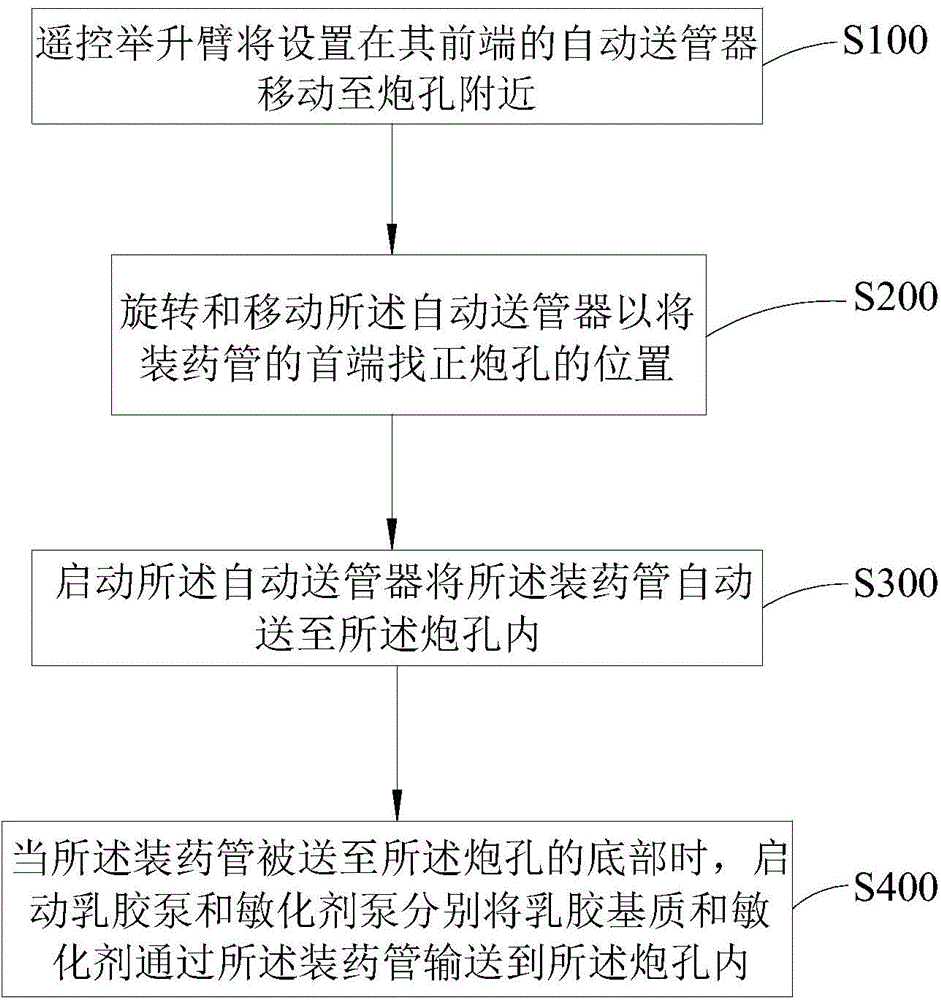

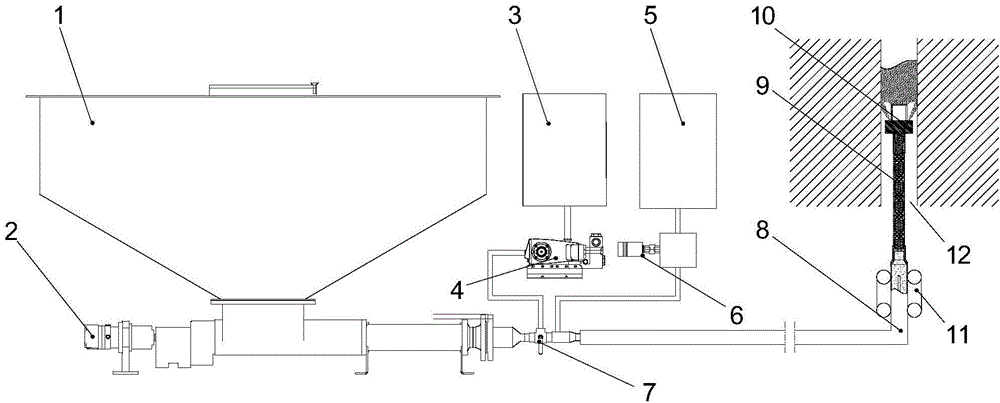

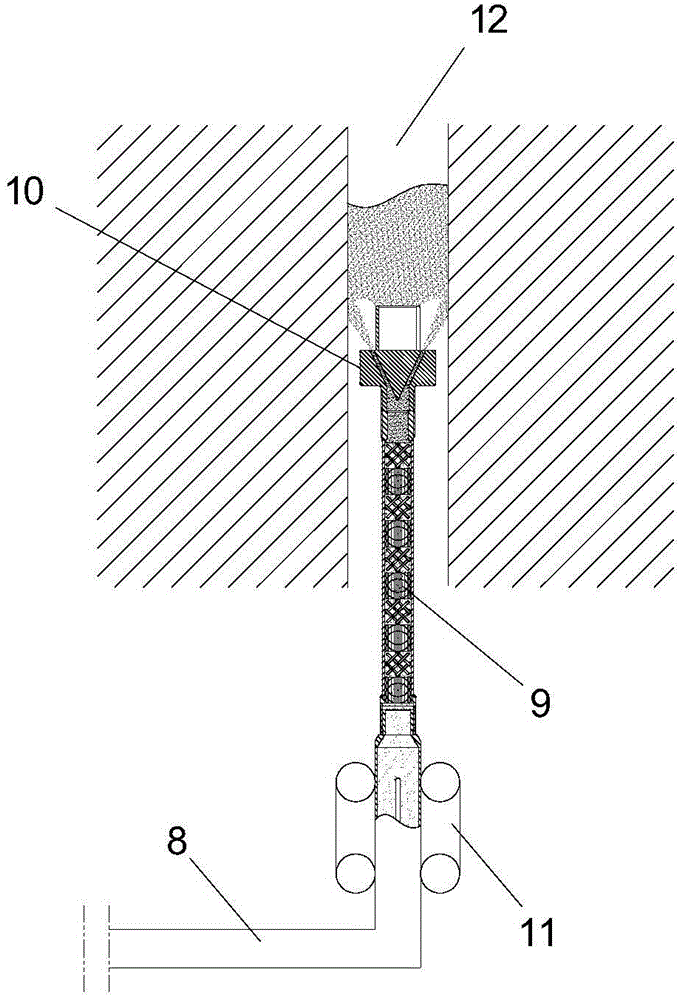

Method for loading explosive in fields in mixed manner on basis of underground explosive loading trucks

The invention relates to the technical field of underground mine blasting explosive loading operation, and discloses a method for loading explosive in fields in a mixed manner on the basis of underground explosive loading trucks. The method includes steps of enabling lift arms to shift automatic tube conveying machines to places near blast holes under remote control; turning and shifting the automatic tube conveying machines to align the head ends of explosive loading tubes with the blast holes; starting the automatic tube conveying machines to automatically convey the explosive loading tubes into the blast holes; starting emulsion pumps and sensitizer pumps when the explosive loading tubes are conveyed to the bottoms of the blast holes, and respectively delivering emulsion substrates and sensitizers into the blast holes via the explosive loading tubes. The automatic tube conveying machines are arranged at the front ends of the lift arms. The method for loading the explosive in the fields in the mixed manner on the basis of the underground explosive loading trucks in an embodiment of the invention has the advantages that emulsion explosive mixed loading operation in the fields is automated, accordingly, the explosive loading efficiency can be improved, the labor intensity can be relieved, the safety of operators can be guaranteed, and blast effects further can be enhanced.

Owner:SHENZHEN KING EXPLORER SCI & TECH CORP

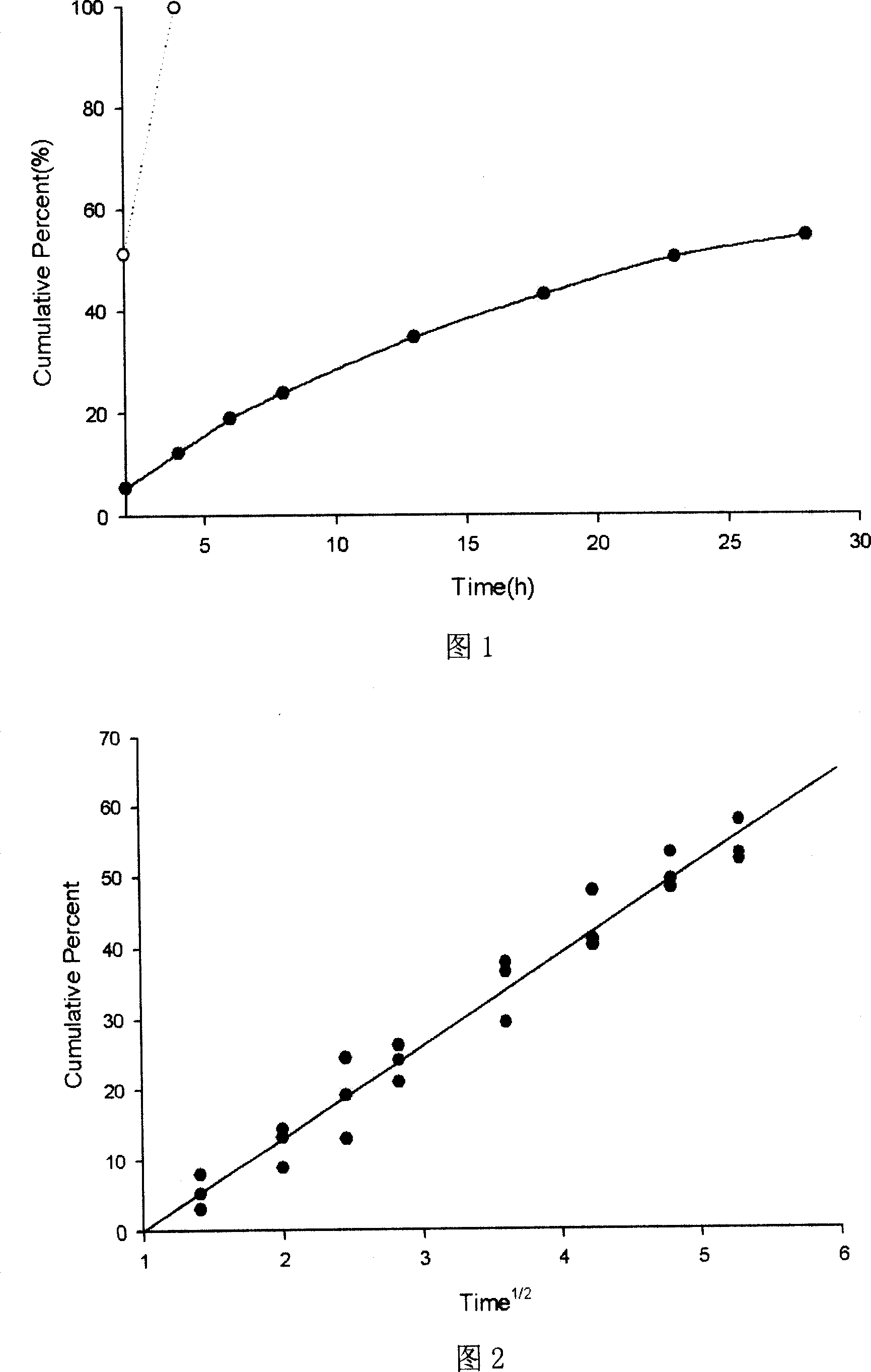

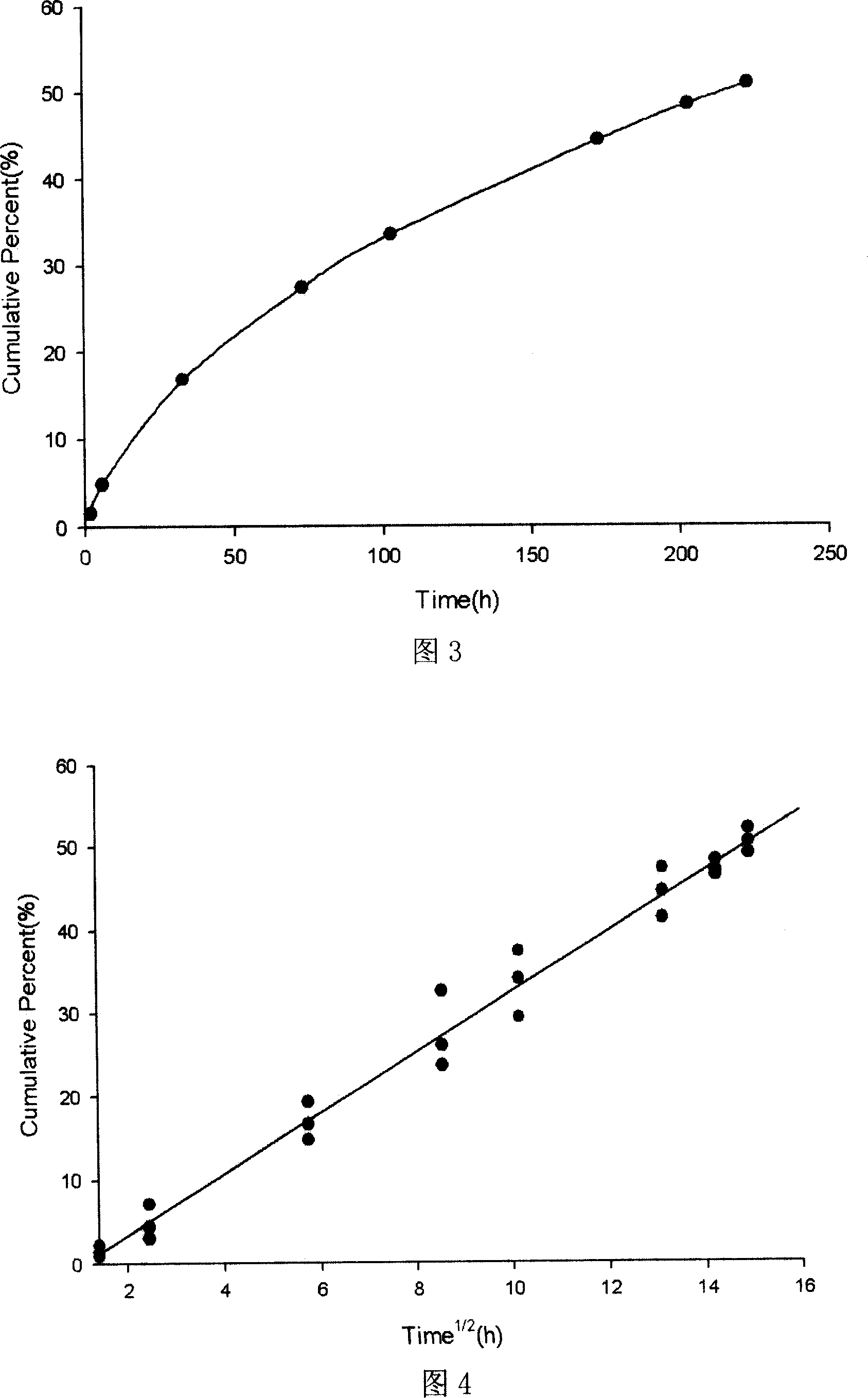

Medicament-carrying complex calcium phosphate bone cement for spinal column reconstruction during tumour operation

The invention relates to drug carrier micro ball composite calcium phosphate skeleton cement used in the rebuilding construction of spine tumor surgery. The invention uses micro balls as carrier to be combined with the anti-tumor drug to obtain the carrier micro ball, then to be mixed with calcium phosphate skeleton cement, therefore, the invention can avoid blasting effect after transplantation to support releasing the anti-tumor drug and holding stable density, and support growing fresh skeleton. The invention can be used to replace CPC carrier.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

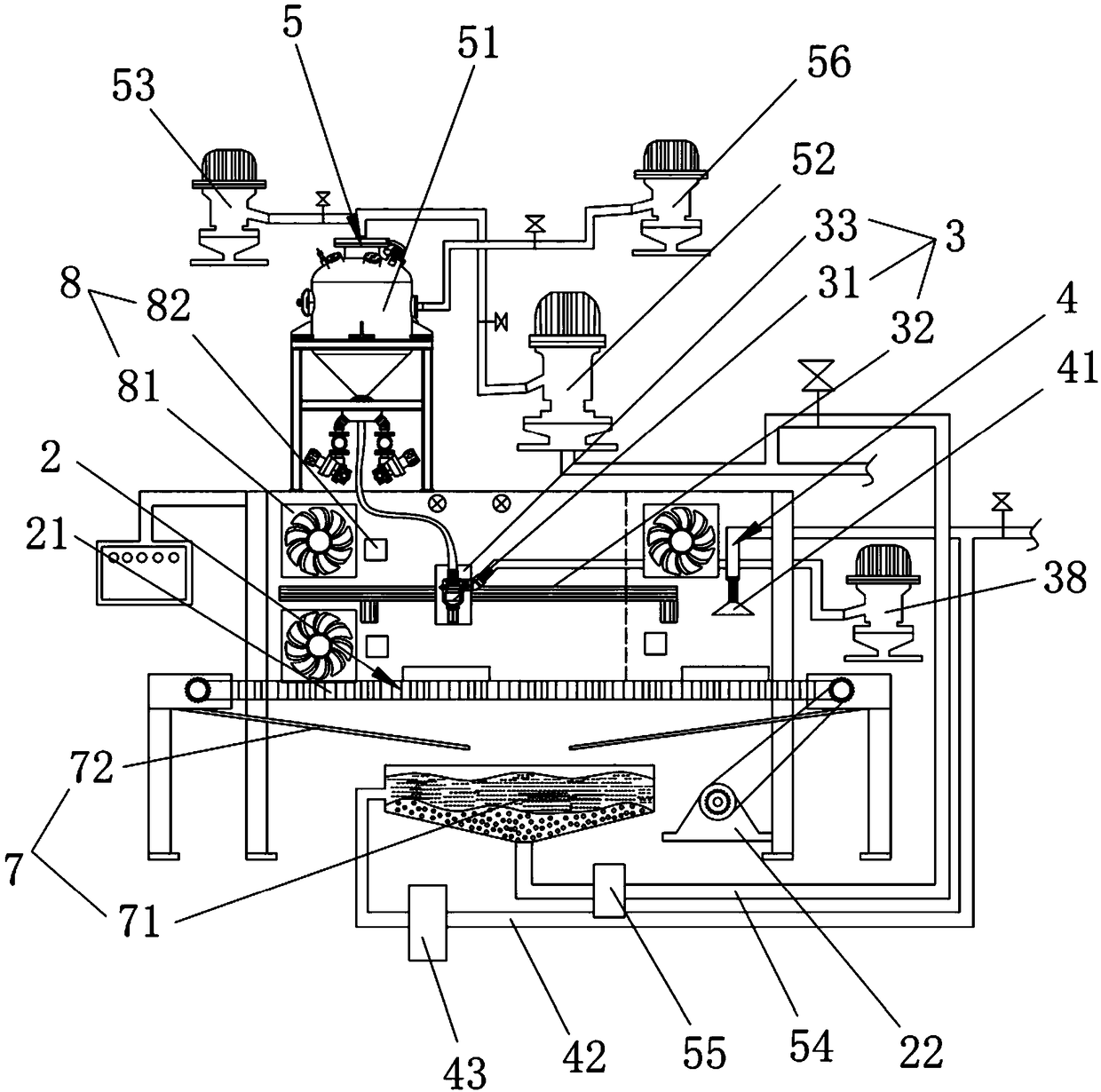

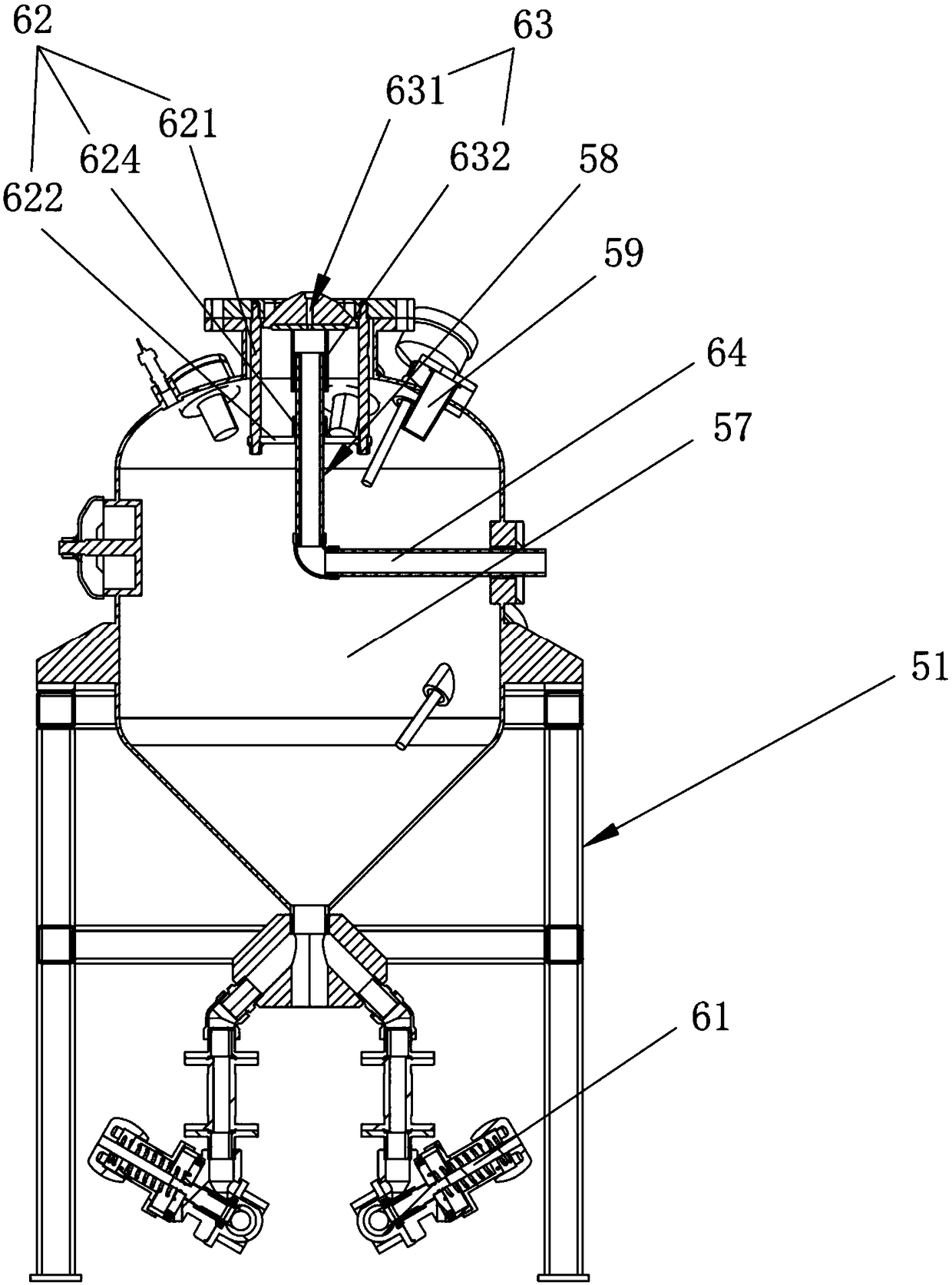

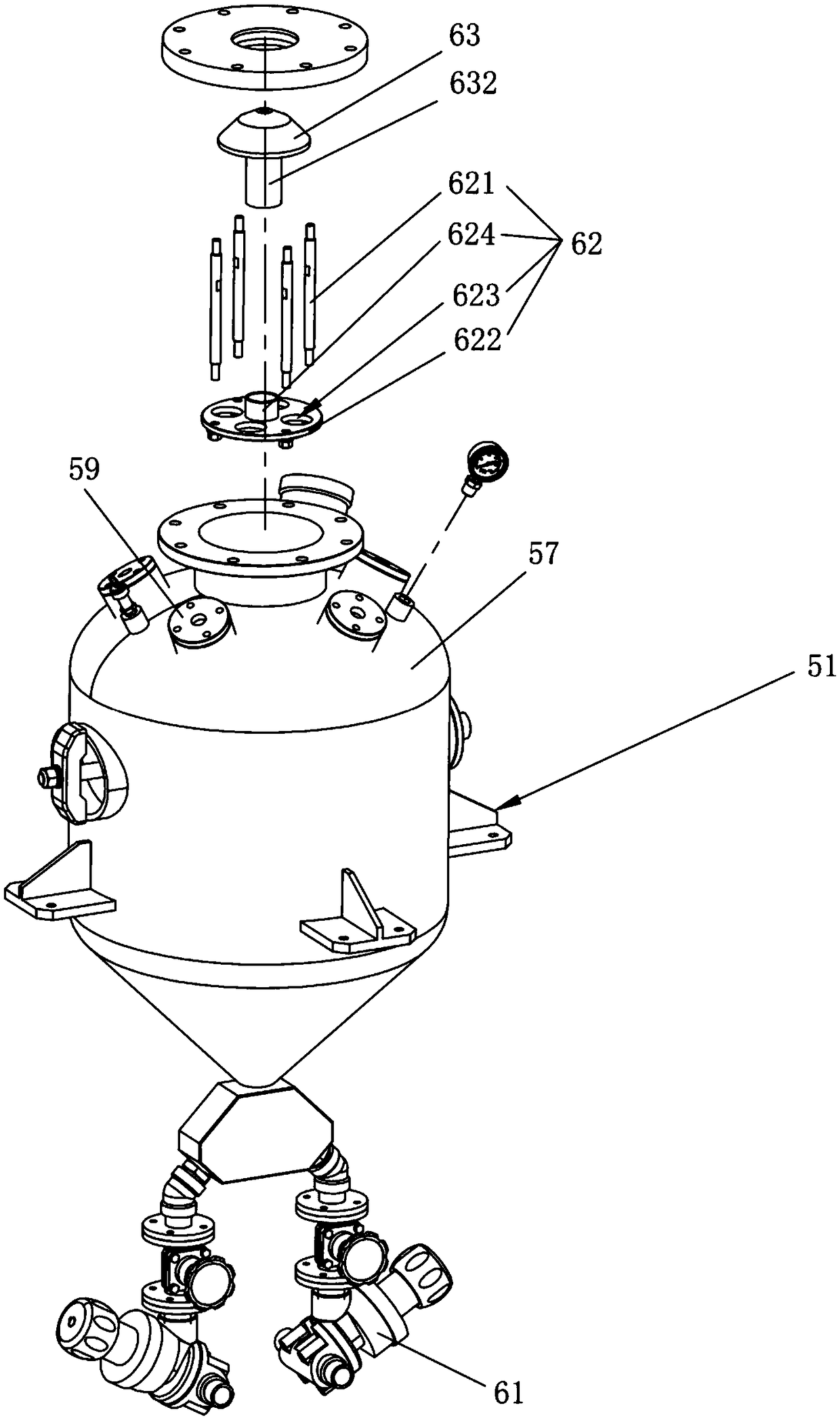

Automatic conveyor-type wet sand blasting equipment

PendingCN109483411AImprove processing efficiencySand blasting effect is goodBlast gunsAbrasive feedersBlast effectsSand blasting

The present invention relates to the technical field of sand blasting and particularly relates to automatic conveyor-type wet sand blasting equipment; the equipment comprises an engine cover, a conveying mechanism, a sand blasting mechanism, a cleaning mechanism, a feeding mechanism for feeding grinding liquid into the sand blasting mechanism, a grinding liquid collecting mechanism for collectingthe grinding liquid and a mist removing mechanism for removing water mist in the engine cover, wherein the feeding mechanism and the cleaning mechanism respectively communicate with the grinding liquid collecting mechanism. Multiple sand blasting mechanisms of the equipment can simultaneously conduct sand blasting to workpieces from multiple sand blasting directions, and thus the equipment is suitable for sand blasting of outer surfaces of various workpieces; dirt and other sundries on the outer surfaces of the workpieces are removed to reach the matte finish effect; the equipment has the advantages that the sand blasting efficiency is high, the sand blasting effect is good, the grinding liquid can be can recycled so as to reduce the loss and no floating dust presents during sand blasting,thereby greatly improving environmental pollution and hazards of worker health resulted from the dust.

Owner:东莞吉川机械科技股份有限公司

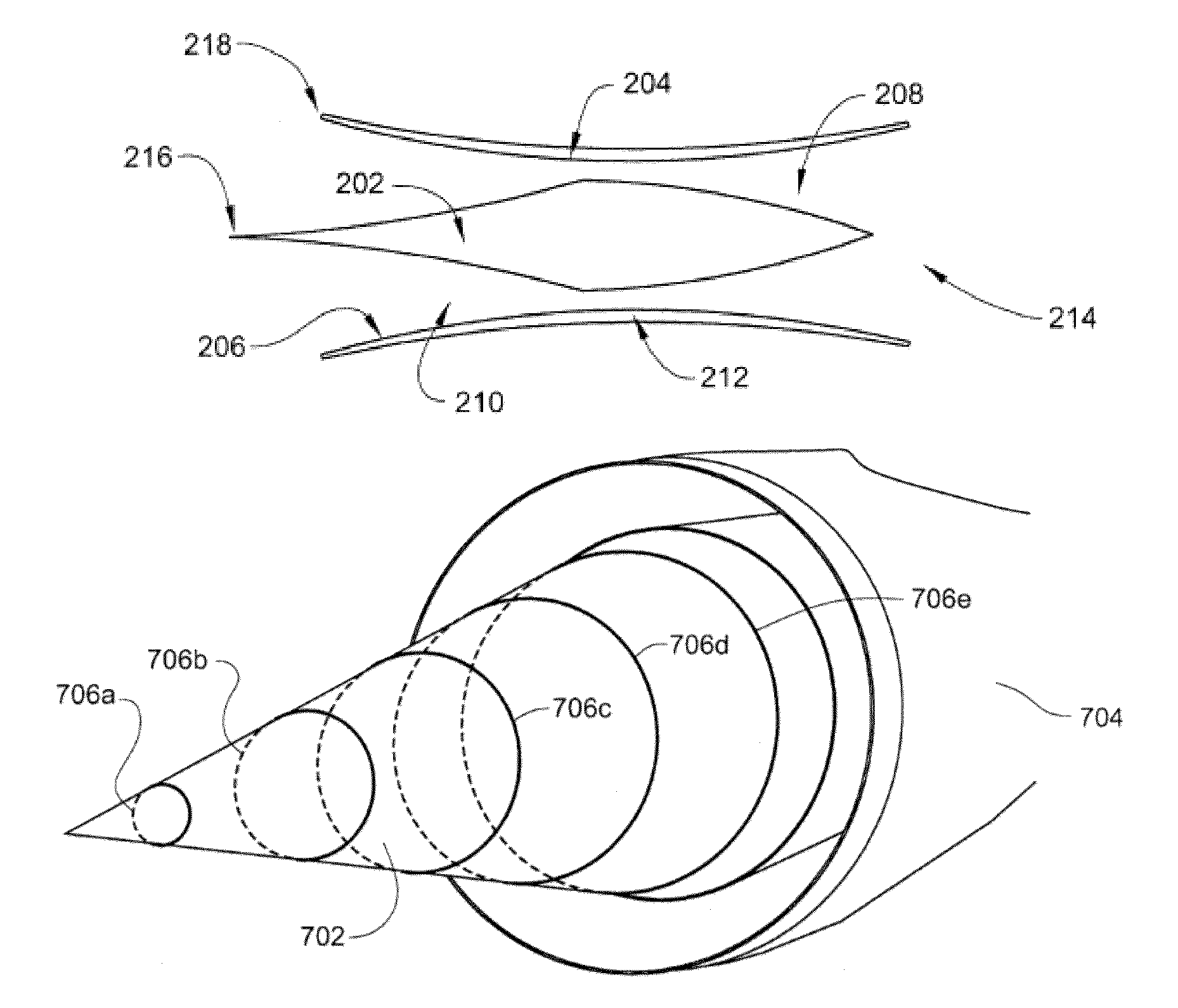

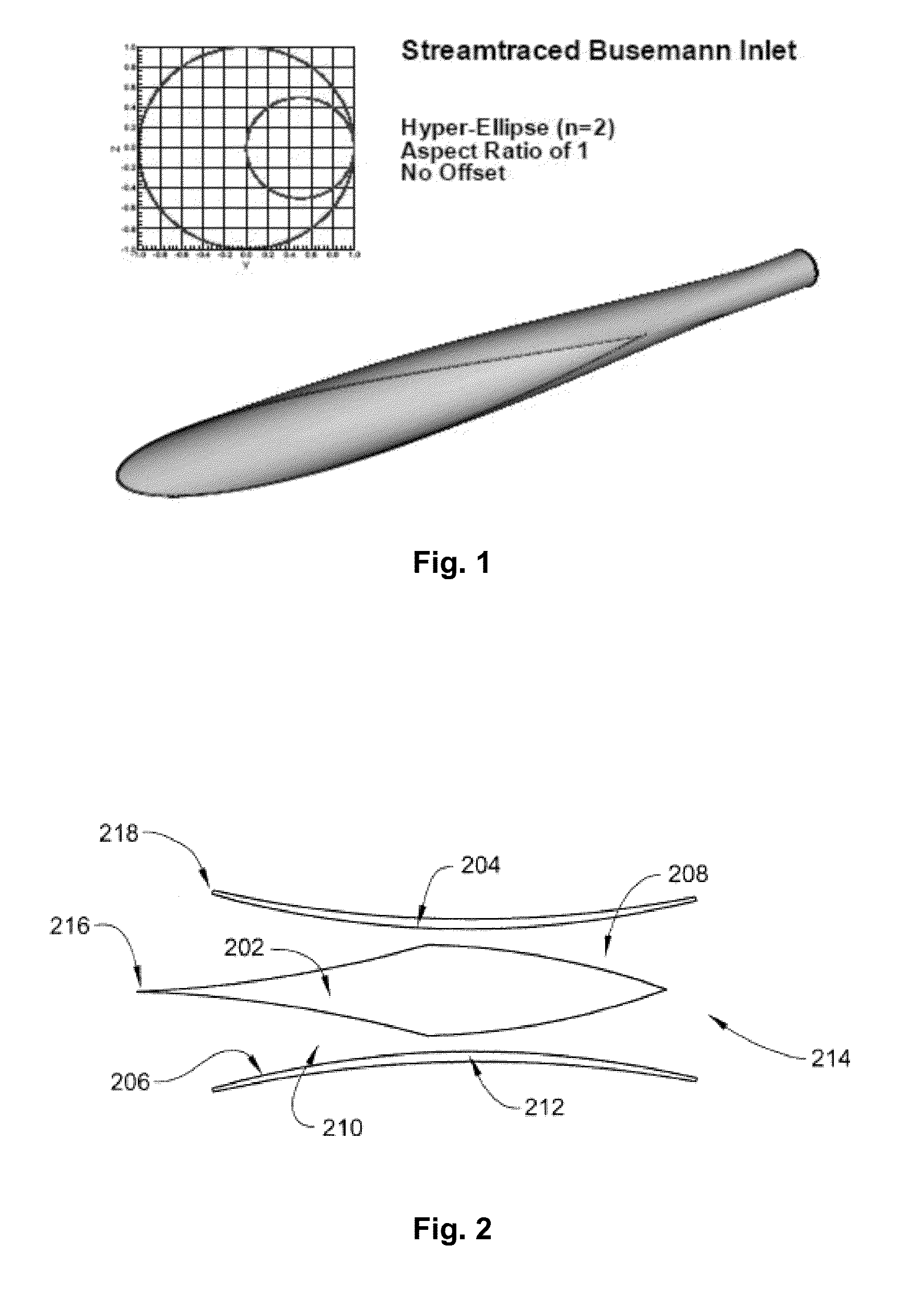

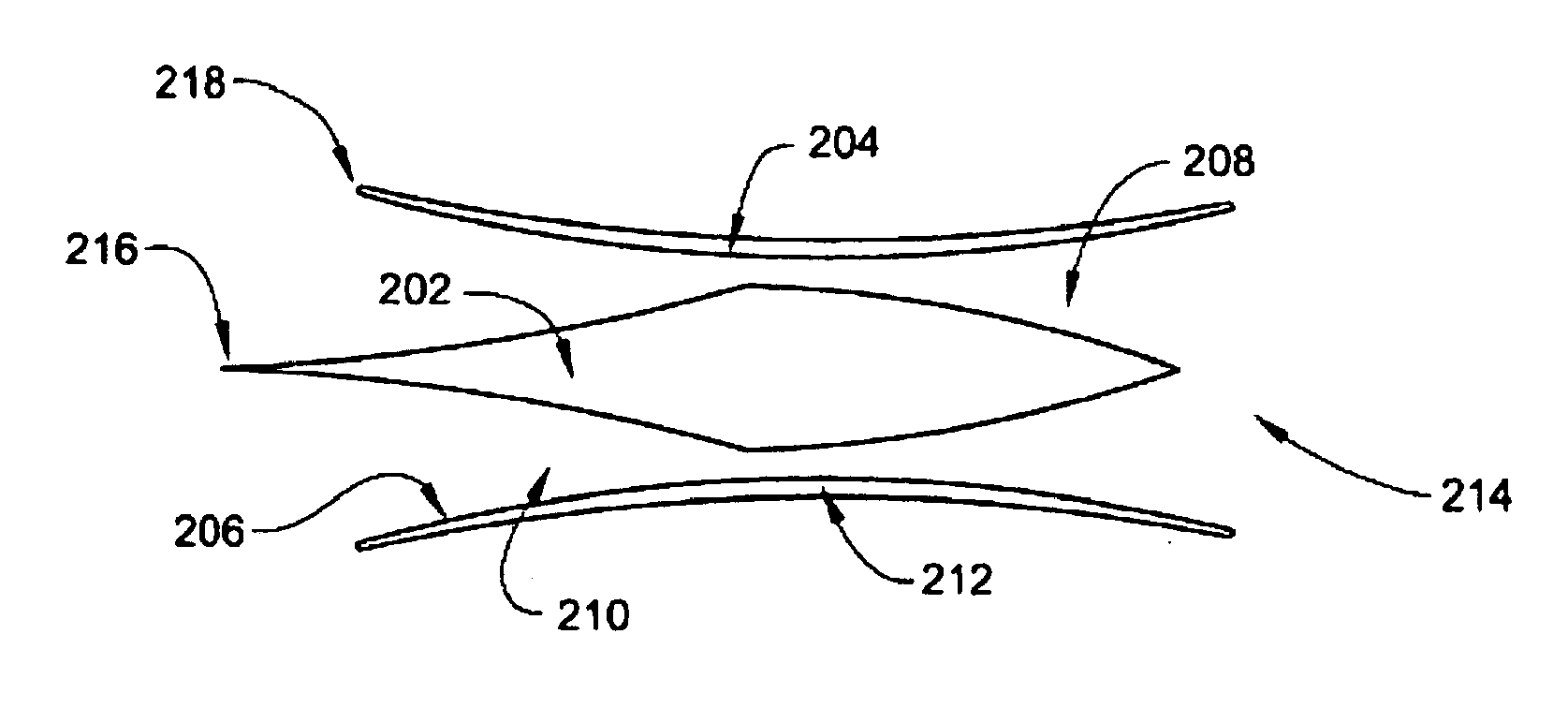

Energy-deposition systems, equipment and method for modifying and controlling shock waves and supersonic flow

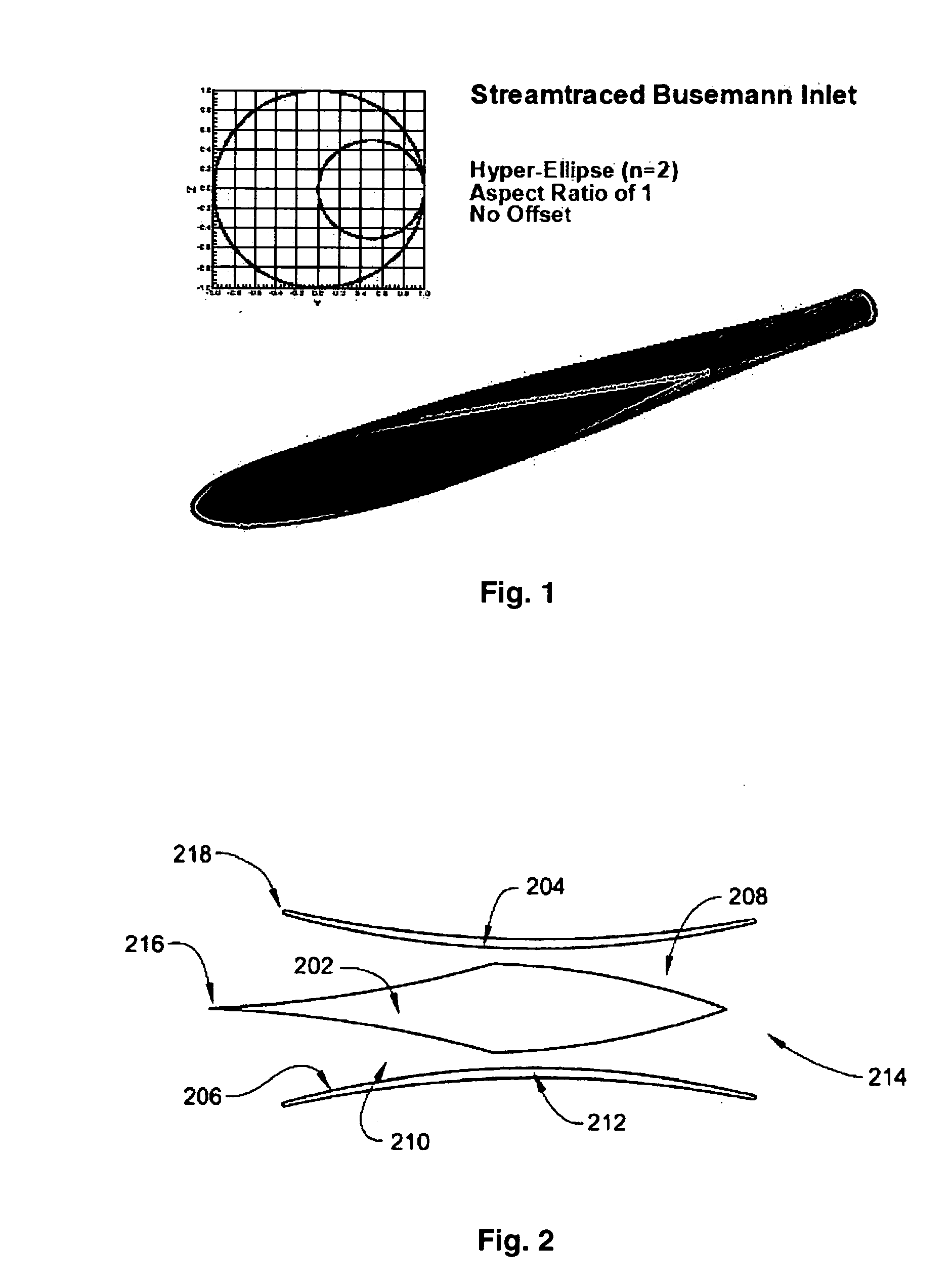

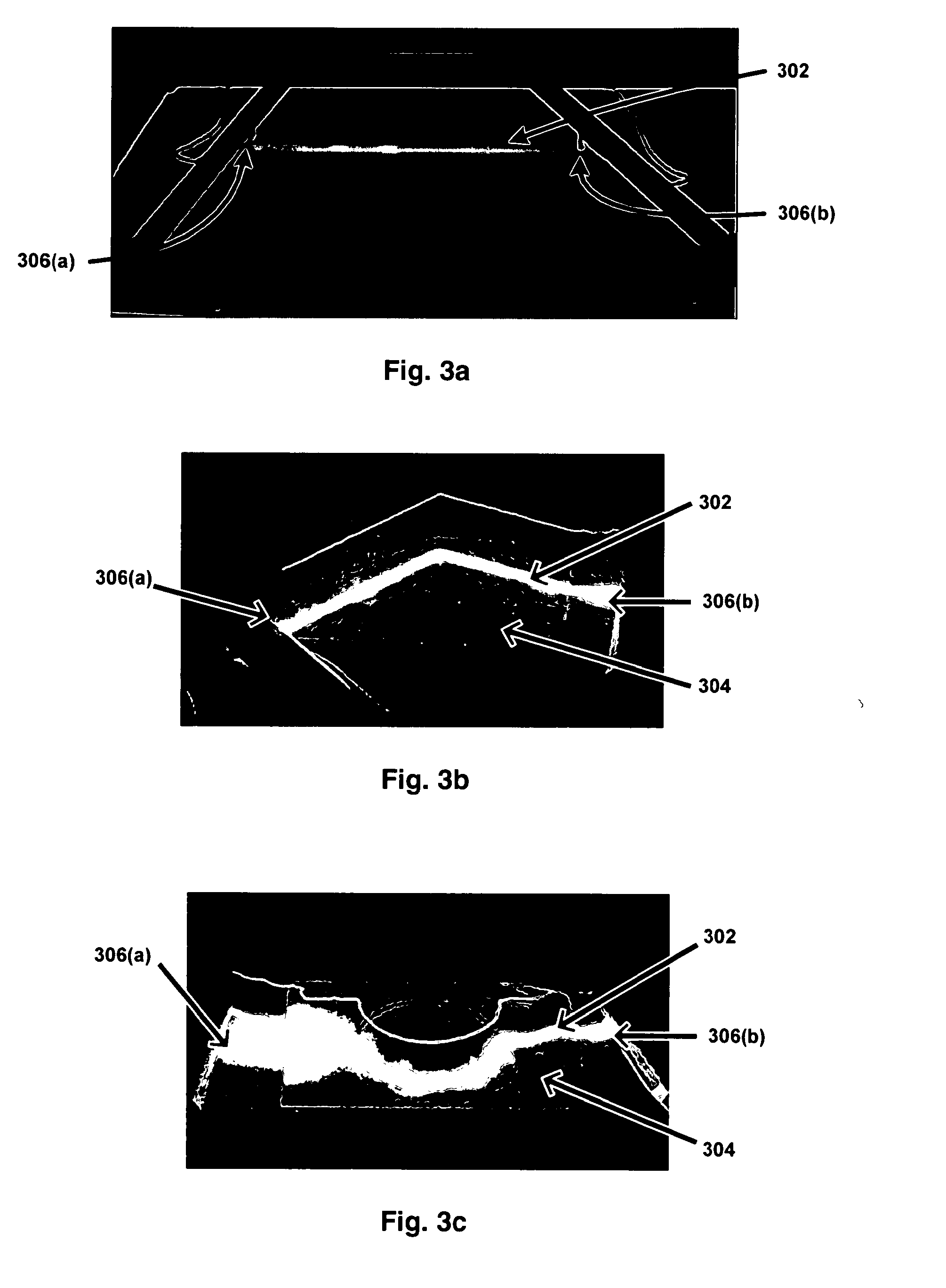

ActiveUS8960596B2Minimize impactMinimizing of buildEngine manufactureAerodynamic testingShock waveThroat

Systems, equipment, and methods to deposit energy to modify and control shock waves and hypersonic or supersonic fluid flow, including systems for controlling, mitigating, and / or effecting air flow in relation to air vehicles, wind tunnels, or other assets, or the like, as well as systems, equipment, and methods for disrupting the shock structure at the inlet for the engine of an air vehicle traveling at supersonic or hypersonic speed; mitigating blast effects on vehicles; mitigating heating of throats in supersonic and hypersonic wind tunnels, as well as control the flow parameters and Mach number in their test sections.

Owner:KREMEYER KEVIN

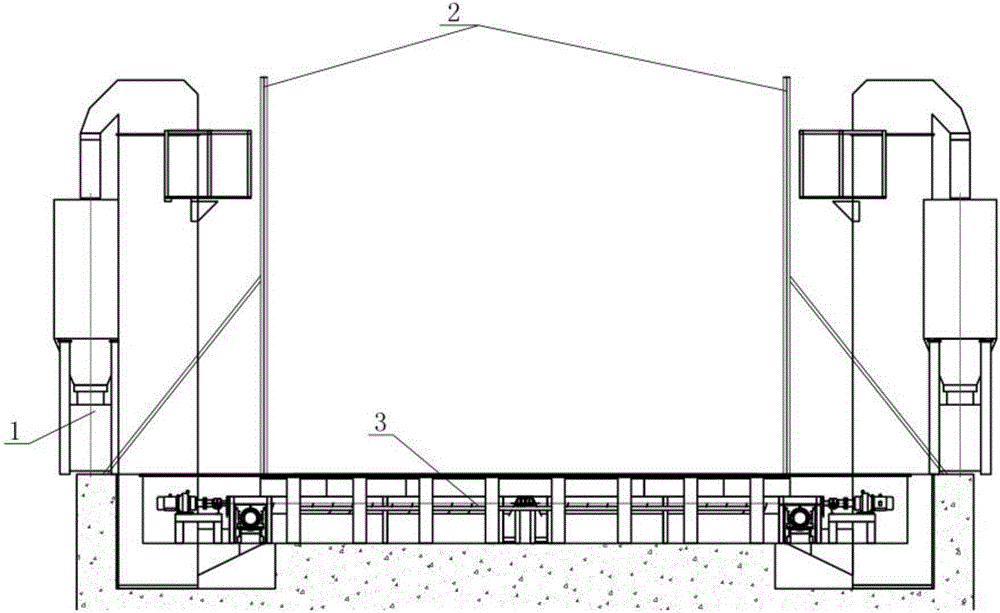

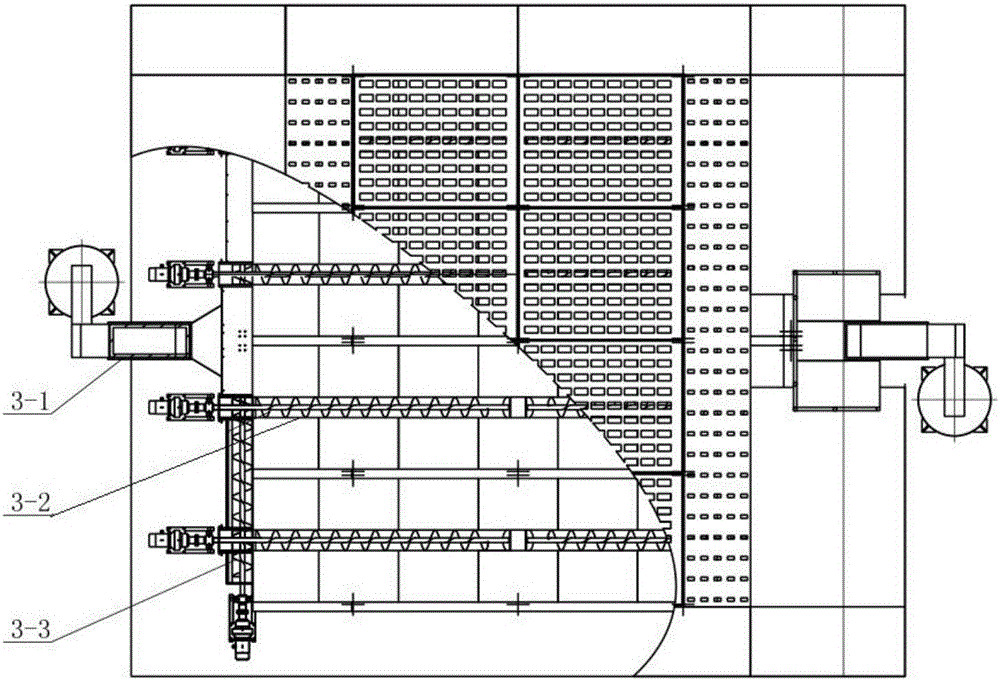

Sand blasting device for wind blade surface and sand blasting method thereof

ActiveCN106312830AReasonable structural designEasy to operateAbrasive machine appurtenancesAbrasive blasting machinesBlast effectsSand blasting

The invention discloses a sand blasting device for a wind blade surface and a sand blasting method thereof. The sand blasting device comprises two symmetric sand blasting mechanisms (1), a de-dusting mechanism (2), a sand recycling mechanism (3) and blade traveling mechanisms, wherein the de-dusting mechanism (2) is arranged between the two symmetrical sand blasting mechanisms (1); the sand recycling mechanism (3) is arranged at the bottom of a middle area of the two symmetrical sand blasting mechanisms (1); the blade traveling mechanisms are arranged on the two sides of the sand recycling mechanism (3). The sand blasting device has the advantages of reasonable structure design, convenience in operation, low cost, excellent sand blasting effect, no damage to fan blades, capability of greatly increasing the processing efficiency and greatly saving manpower, less environmental pollution and wide application in sand blasting for the large-size wind blade surface. The sand blasting method for the wind blade surface provided by the invention has the advantages of reasonable technical design, high maneuverability, high working efficiency, low cost, high quality of the wind blade surface subjected to sand blasting and capability of increasing the overall performance of the wind blade.

Owner:LIANYUNGANG ZHONGFU LIANZHONG COMPOSITES GRP

Energy- deposition sytems,eguipment and method for modifying and controling shock waves and supersonic flow

ActiveUS20110030379A1Minimizing of abrasionMinimizing effect of heatEngine manufactureAerodynamic testingShock waveBlast effects

Systems, equipment, and methods to deposit energy to modify and control shock waves and hypersonic or supersonic fluid flow, including systems for controlling, mitigating, and / or effecting air flow in relation to air vehicles, wind tunnels, or other assets, or the like, as well as systems, equipment, and methods for disrupting the shock structure at the inlet for the engine of an air vehicle traveling at supersonic or hypersonic speed; mitigating blast effects on vehicles; mitigating heating of throats in supersonic and hypersonic wind tunnels, as well as control the flow parameters and Mach number in their test sections.

Owner:KREMEYER KEVIN

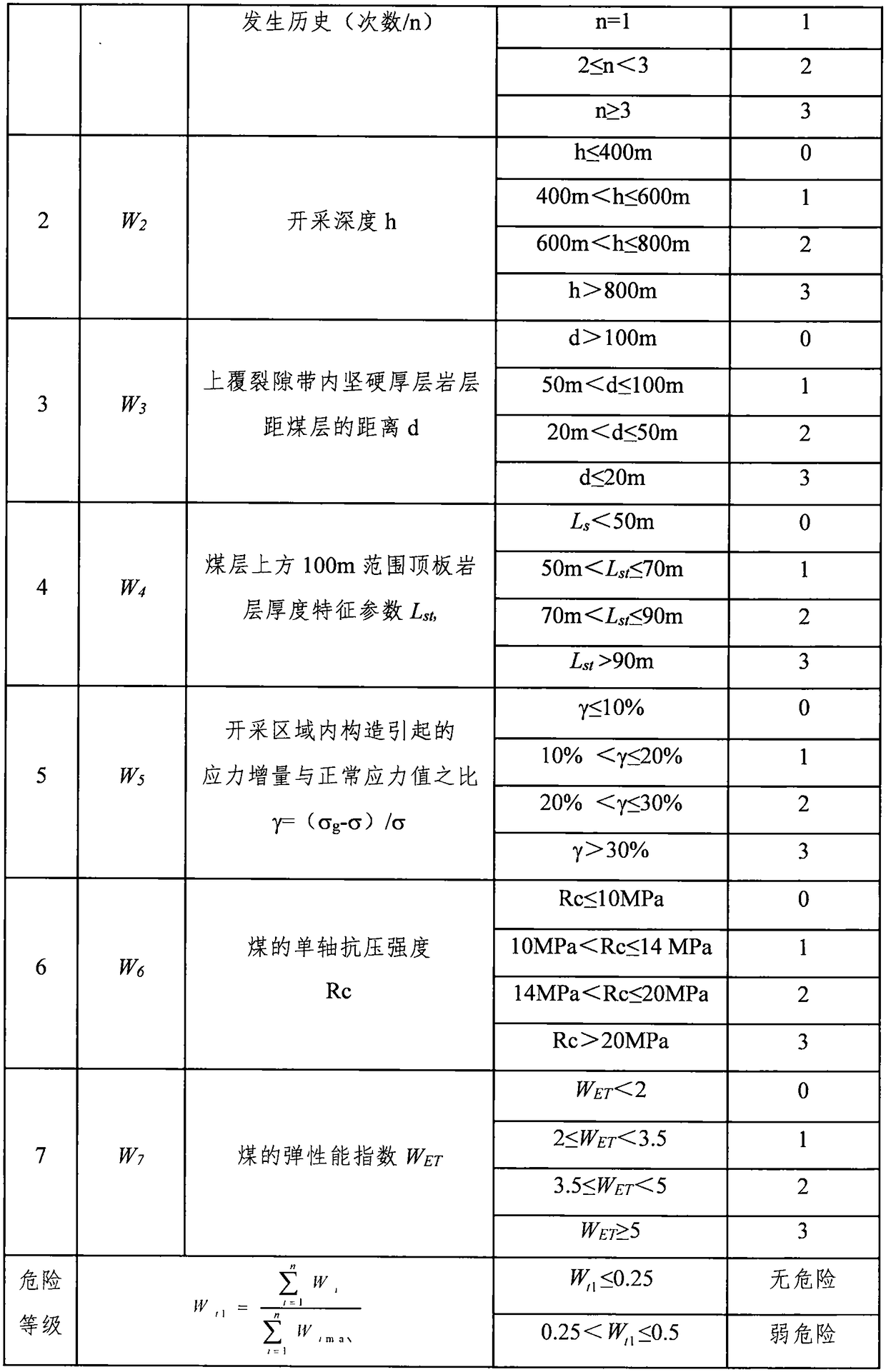

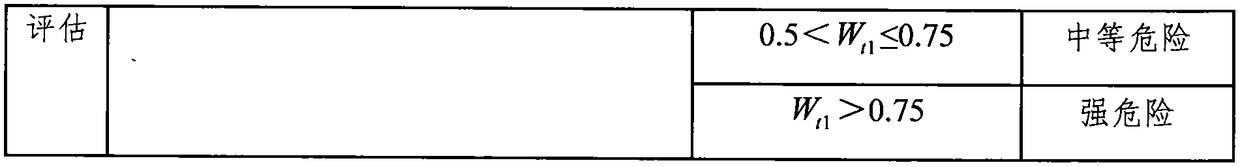

Coal seam blasting pressure relief effect assessment method

A coal seam blasting pressure relief effect assessment method includes steps of arrangement of microseismic sensors, calculation of blast hole microseismic event energy, determination of judgment criteria and the like. The coal seam blasting pressure relief effect assessment method is high in operability and precision and reliable in result, and the problem of difficulty in quantitative assessmentof blasting effects is solved.

Owner:CCTEG COAL MINING RES INST

Urban deep foundation pit shallow layer loosening control blasting construction method

The invention discloses an urban deep foundation pit shallow layer loosening control blasting construction method. The control blasting construction method is characterize in that a blasting investigation scheme comprises the steps of construction early-stage preparation, measurement positioning and trial blasting, a blasting design scheme comprises the steps of blasting mode control through adopting step loosening of deep holes and shallow holes, drilling design, blasting explosive unit consumption calculation and detonation network design, and a blasting construction scheme comprises the steps of drilling and acceptance, hole depth measurement and blast loading, line connection and blast hole blockage, blasting warning and blasting effect inspection. According to the urban deep foundation pit shallow layer loosening control blasting construction method, blasting vibration effects can be effectively reduced, flying stones are controlled, and meanwhile the influence of blasting air shock waves on the surrounding environment is reduced, and the problems of foundation pit slope collapse, super explosion, blind shot, hurt to people by flying stones, difficulty in excavation and the like are solved; and therefore the method has high safety and economic efficiency, is easy to popularize and can be suitable for foundation pit rock stratum loosening blasting in low hilly areas.

Owner:CHINA 19TH METALLURGICAL FANGCHENGGANG DEVICE STRUCTURES

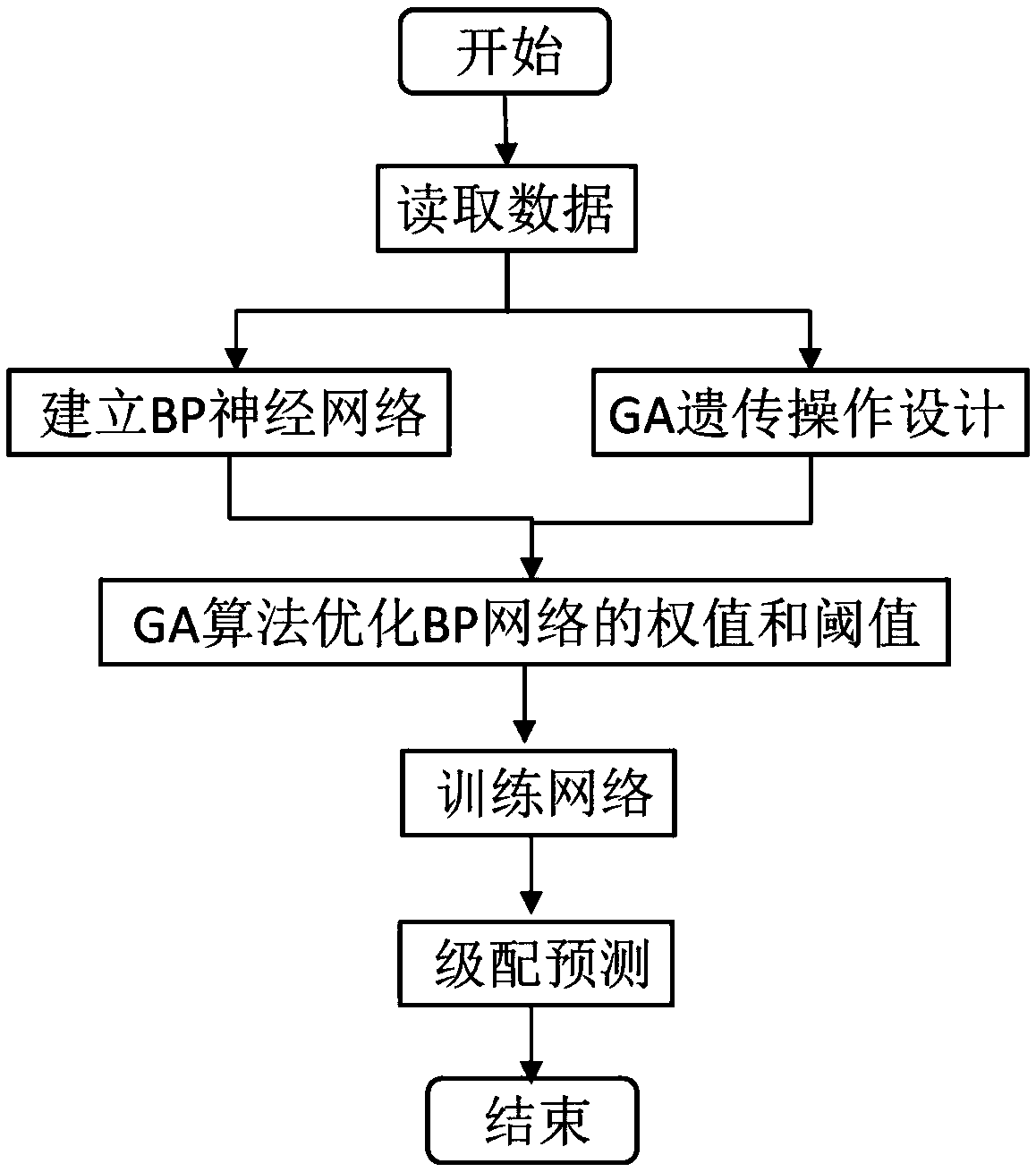

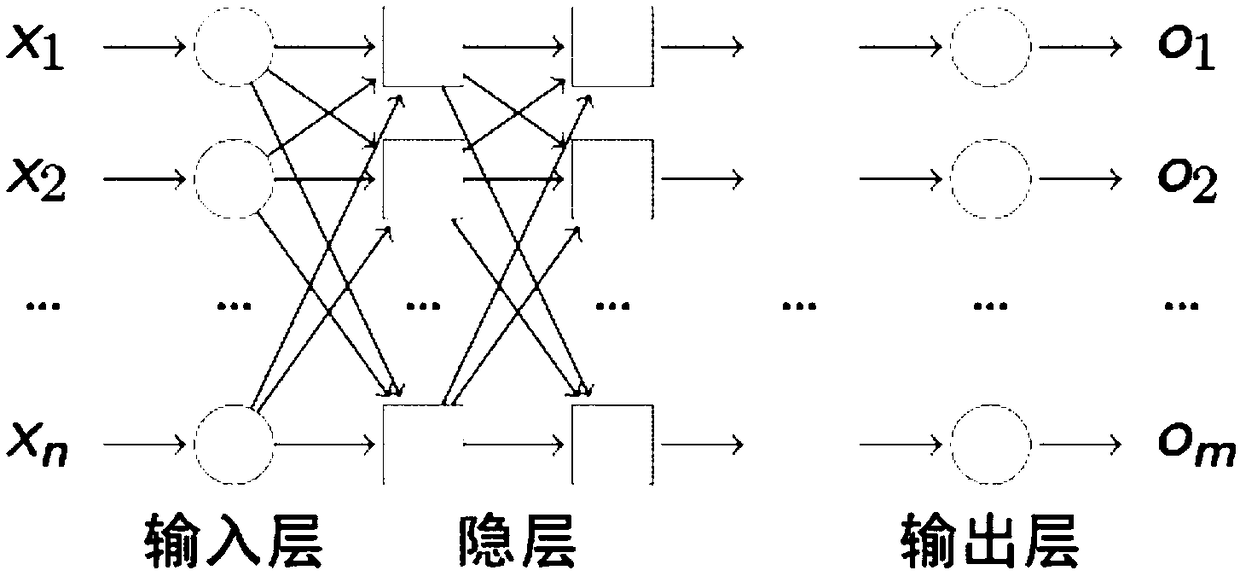

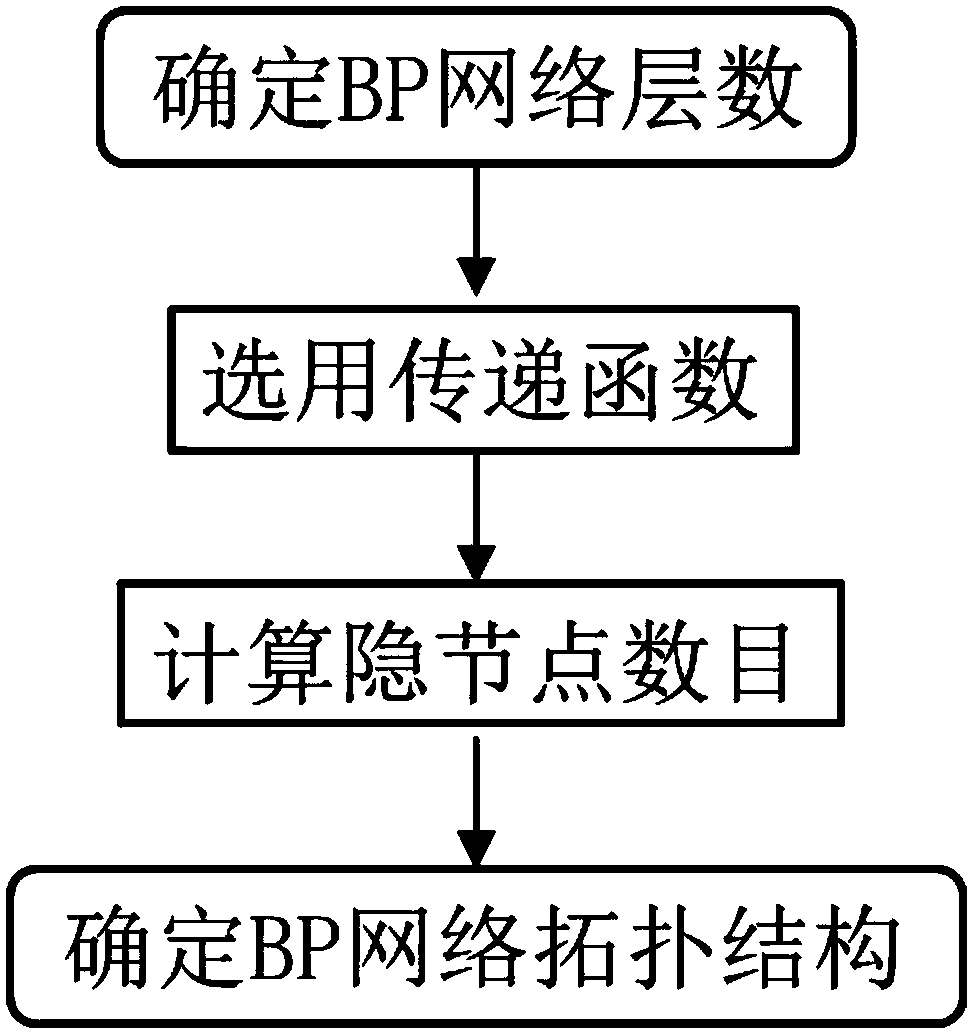

A method for predicting blasting grade distribution in block stone mining

InactiveCN109102109AGlobalImprove performanceForecastingNeural learning methodsBlast effectsGenetic algorithm

A method for predicting blasting gradation in block stone mine includes such steps as: 1, obtaining influence factors of blasting effect as input parameters, taking a distribution index of blasting gradation as an output parameter, and establishing sample database, obtaining blasting effect influence factor as input parameter, taking blasting gradation distribution index as output parameter, and setting up blasting gradation index as output parameter. 2, establishing a BP neural network; 3, optimizing a BP neural network through a genetic algorithm to form a GA-BP model; 4: through the sampledatabase of Step 1, performing GA-BP model training; 5, adopting the model obtained in the step 4 to predict the blasting grade distribution of the block stone material mining. The invention integrates the advantages of the two algorithms to recombine the blasting gradation prediction model, and establishes the GA-BP model for the blasting gradation prediction, thereby improving the Prediction Model of Blasting Grading and its Performance and Precision. The algorithm itself has the function of self-learning and self-adjusting, and has strong adaptability to the model, which can meet the engineering application requirements of gradation prediction in block stone blasting mining.

Owner:SICHUAN UNIV +1

Method of smooth powder charge for preventing blast hole from collapsing

The invention relates to the technical field of mining, in particular to a method of smooth powder charge for preventing a blast hole from collapsing. According to the method of the smooth powder charge for preventing the blast hole from collapsing, the blast hole is filled with a sleeve, so as to realize the smooth powder charge; a sleeve taking rod is inserted into the sleeve, so as to resist an explosive roll, the sleeve is retracted, explosives are left in the blast hole, then a detonator is put in, the blast hole is blocked by adopting stemming, and detonation is waited; thus, the blast hole is supported in advance, so as to prevent the blast hole from collapsing. Compared with a method of unblocking the blast hole by adopting a hole unblocking device, energy consumption for secondary treatment is reduced, high dust pollution is avoided, repeated recycling of the sleeve is realized, and the blasting cost is reduced; a bamboo chip is pressed to the bottom of the blast hole, so as to prevent slag at the bottom of the blast hole from entering the sleeve, wherein the size of the slag is close to the inner diameter of the sleeve, and the appropriate arrangement and blasting effects of the explosives are further guaranteed.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Steel-frame building and method of making

Owner:MITEK HLDG INC

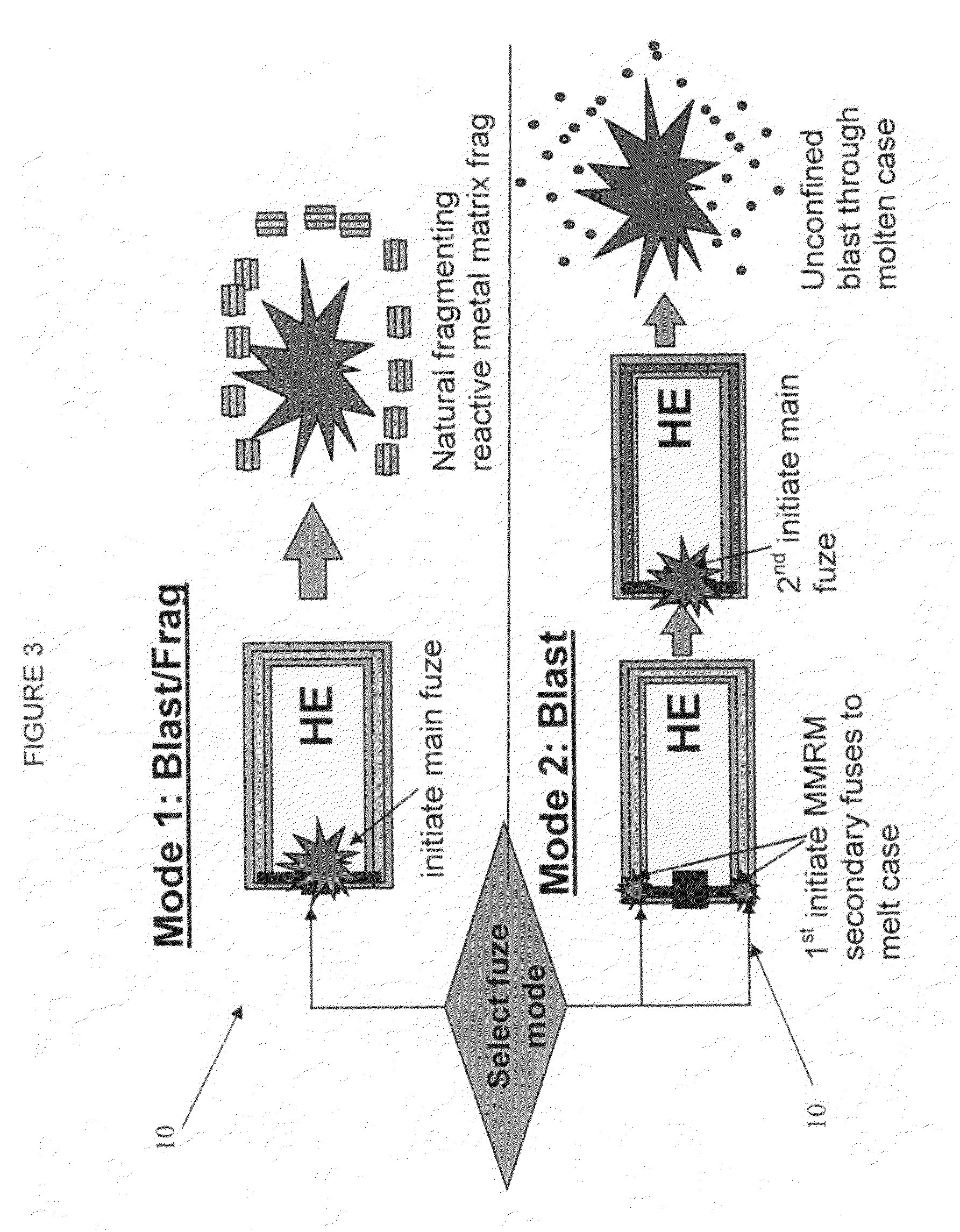

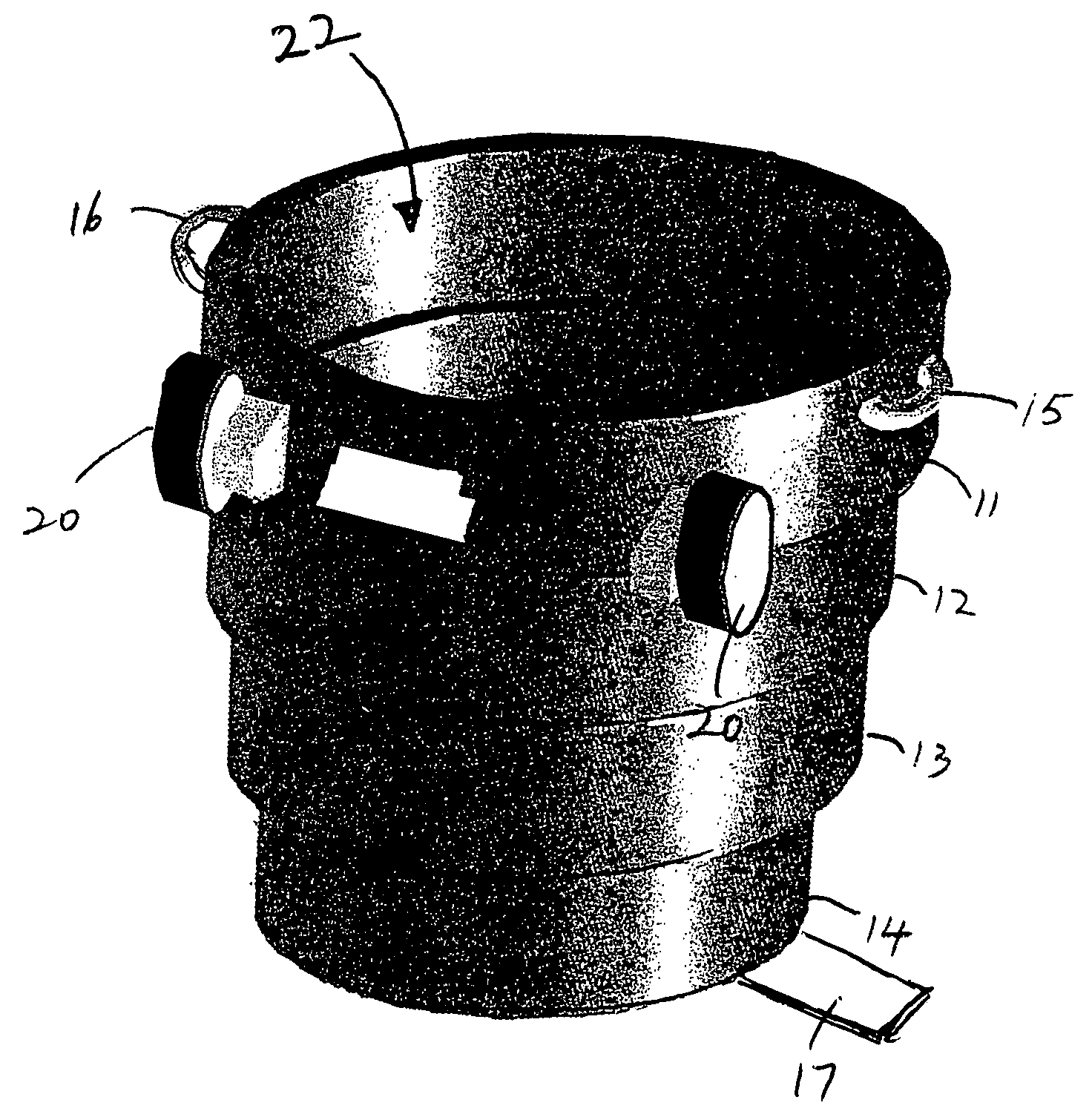

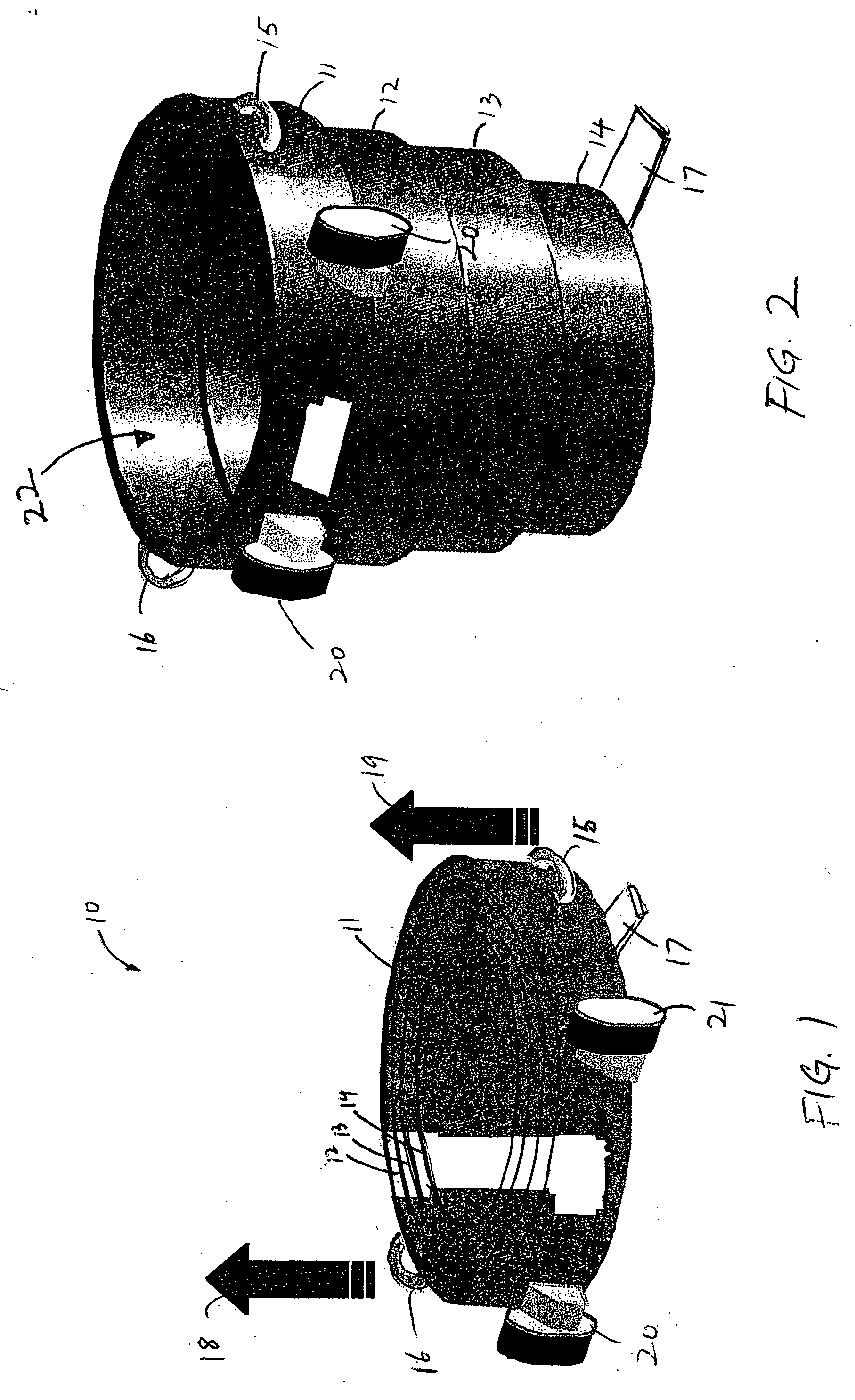

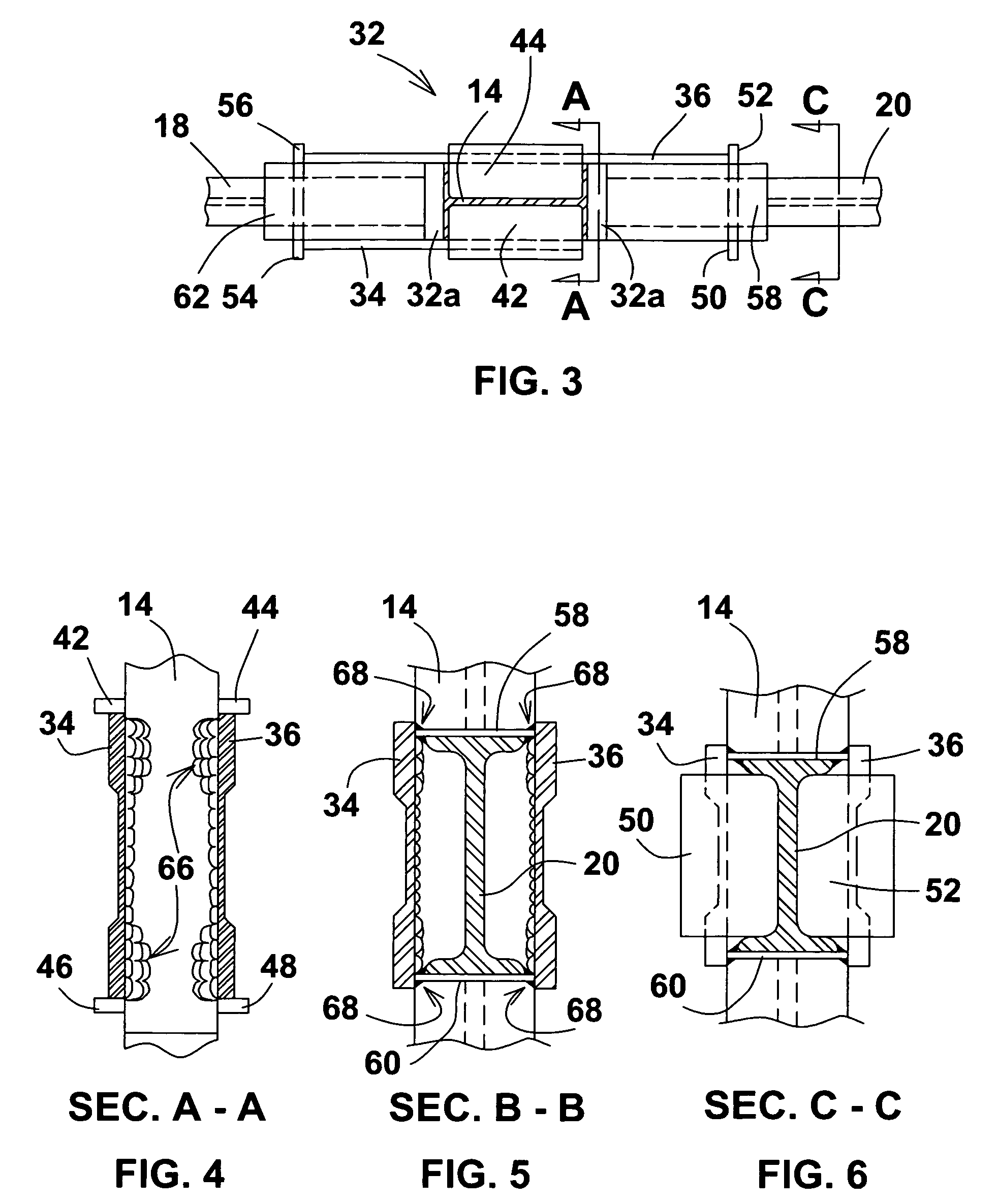

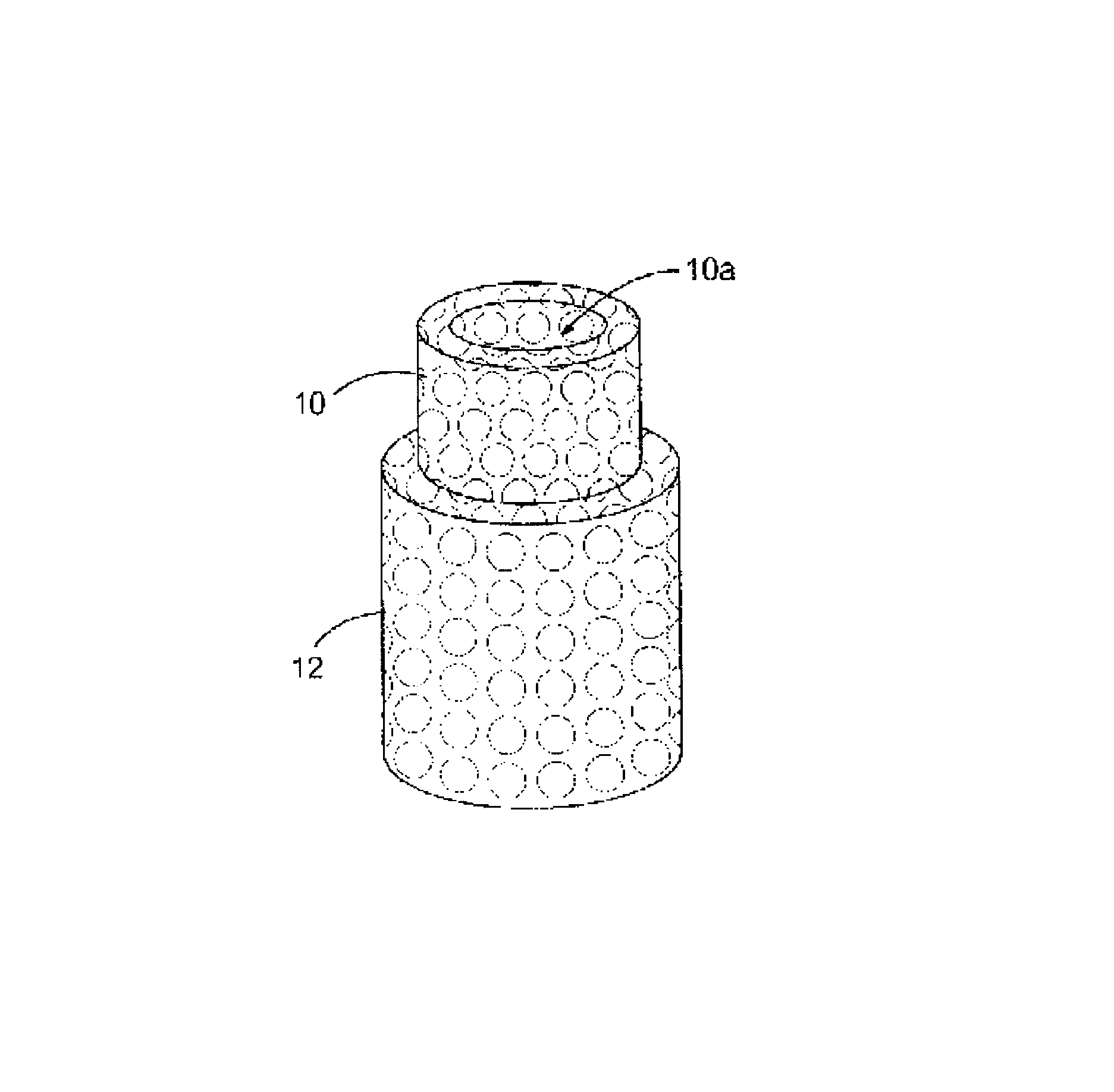

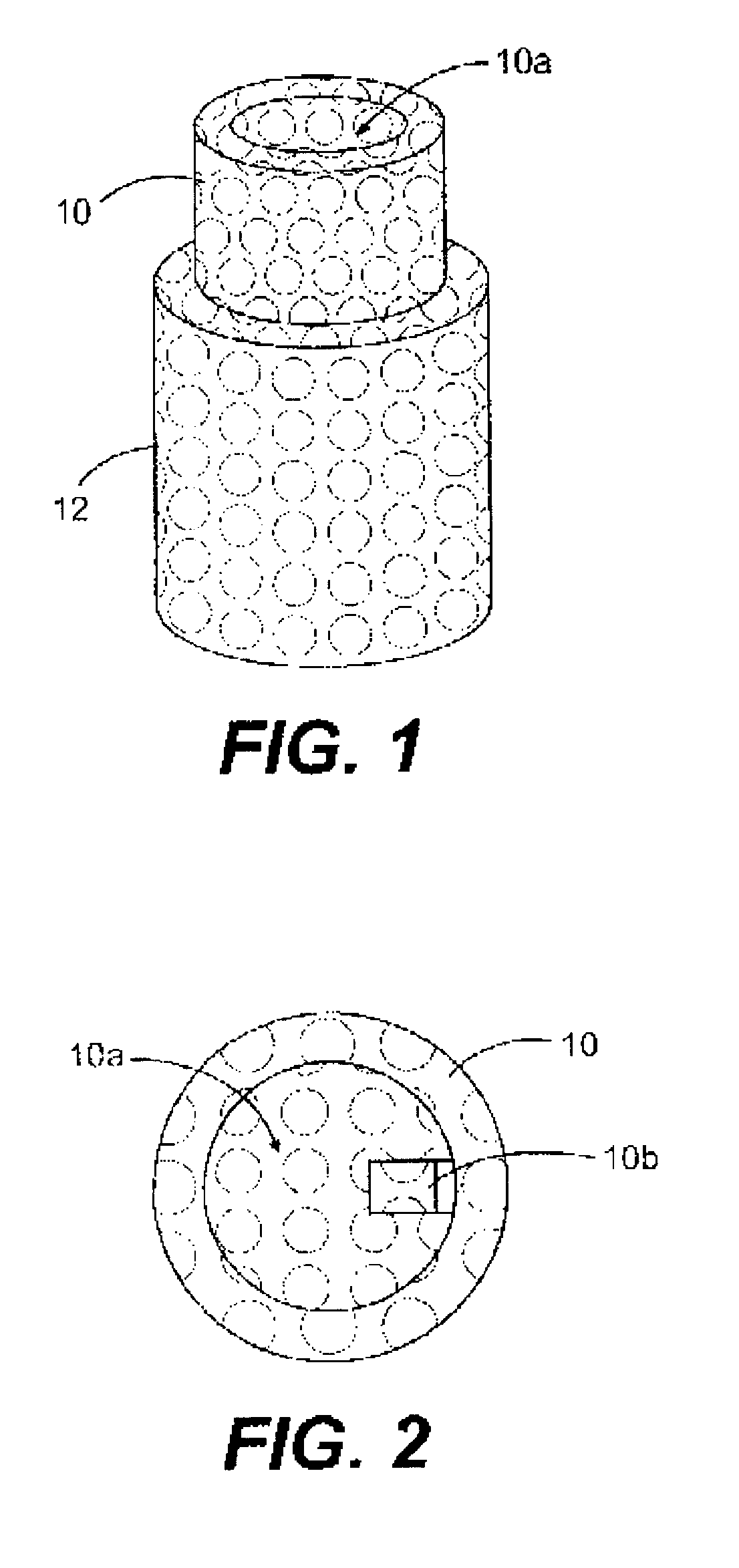

Protective packaging device for blast and fragmentation mitigation

InactiveUS6865977B1Decreases hazard classificationAvoid destructionDoor/window protective devicesAmmunition storageControlled releaseCushioning

A protective packaging device provides mitigation of the blast effect and fragmentation of a hand grenade when the grenade is detonated. The device includes at least one protective housing assembly, formed by inner and outer nested housing members, in which the hand grenade is received, and which, in response to detonation of the grenade, retains fragments of the grenade while providing controlled release, through the mesh material, of gases formed upon detonation. A cushioning container includes a cushioning material having a plurality of open compartments therein in which a corresponding plurality of the protective housing assemblies are received.

Owner:THE US GOVERNMENT AS REPRESENTED BY THE SEC OF THE ARMY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com