Blast hole charging structure and method for deep-hole bench blasting of layered rock mass mixed up with soft rock strata and hard rock strata

A technology of step blasting and blast hole charging, which is applied in the field of blasting, can solve the problems of high blasting cost and poor blasting effect, and achieve the effects of less difficult work, lower loading and transportation costs, and reduced blasting workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

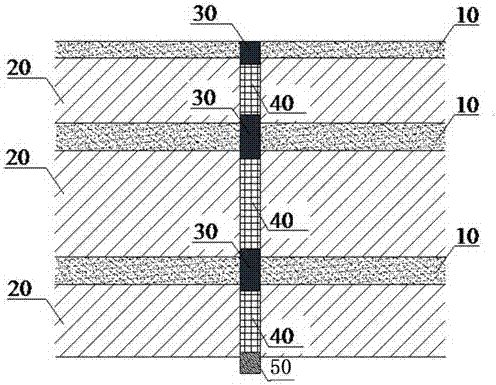

[0030] Such as figure 1 As shown, the present embodiment provides a blasting structure of a deep hole step in a soft and hard interlayered rock mass, including multi-layer hard rock formations 20 and multi-layer soft interlayers 10, and the hard rock formations 20 and weak interlayers 10 are layered from top to bottom. Alternately distributed; each hard rock formation 20 is provided with a charge section 40 at a relative position, and the charge section 40 is filled with gunpowder; adjacent charge sections 40 are provided with a packing section 30, and the packing section 30 is filled with gun mud. Both ends of the filling section 30 enter the corresponding hard rock formation 20 , and the bottom hard rock formation 20 is provided with a hole bottom filling section 50 .

[0031] By setting the charge section 40 on the hard rock formation 20, the high-pressure gas generated when the charge section 40 is detonated is limited to the hard rock formation 20, preventing the high-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com